Patents

Literature

288results about How to "Stable and reliable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

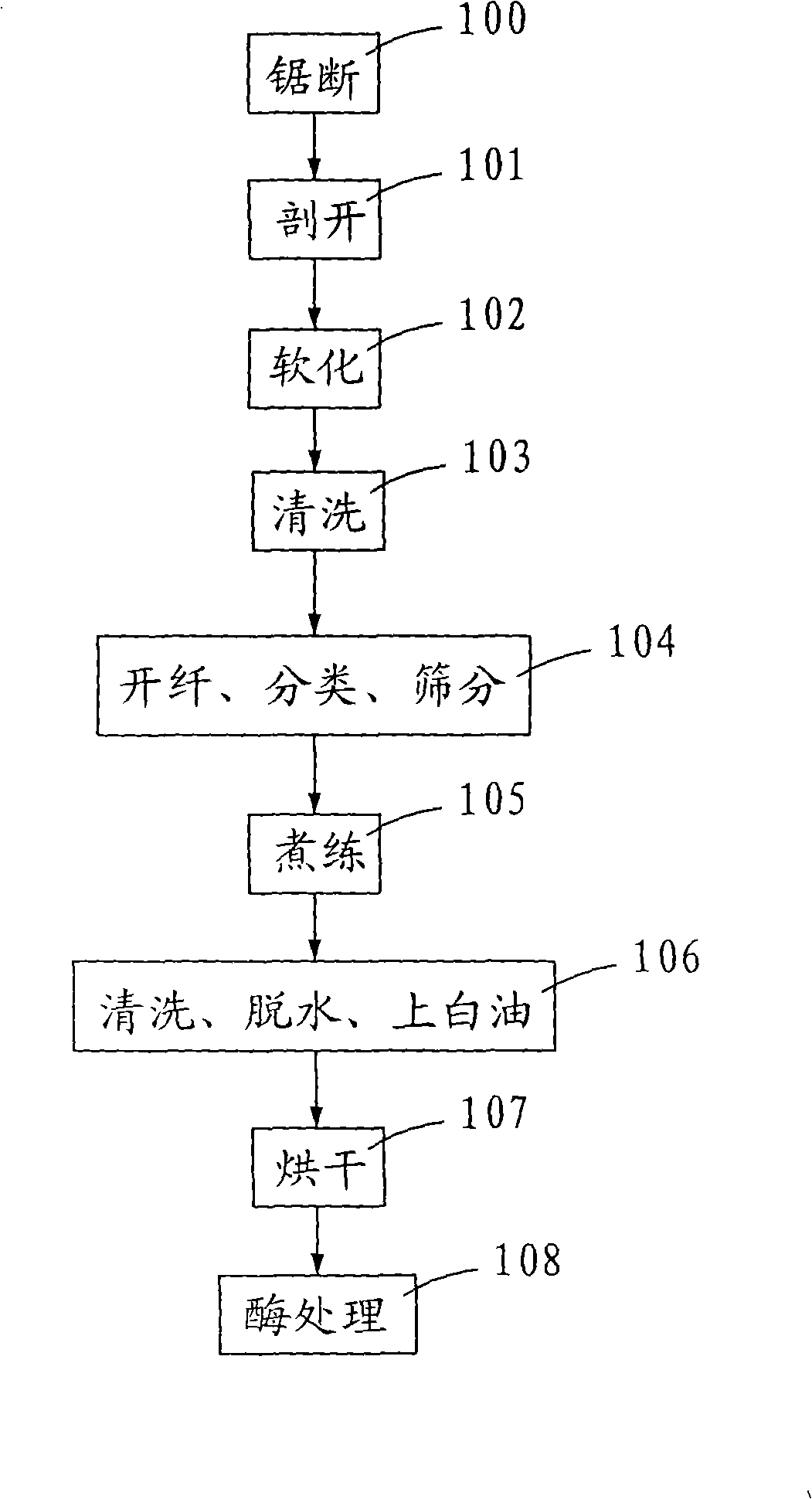

Method for producing bamboo fiber

InactiveCN101538744AEfficient productionThe production process is stable and reliableCane mechanical workingWood working apparatusChemistryEmulsion

The invention provides a method for producing a bamboo fiber, comprising the following steps of sawing off, splitting and softening the bamboo, sending the bamboo material to a bamboo splitting separator to realize combing, splitting separation and airflow classification, thus obtaining the bamboo filament fiber; cooking and drying the bamboo filament fiber, cleaning, dehydrating, oiling and drying the bamboo filament fiber subsequently; and carrying out the enzyme treatment, thus obtaining the coarse bamboo fiber; subsequently carrying out fine treatment, cleaning and dehydrating, bleaching, cleaning, dehydrating, oiling, drying and curing by emulsion, thus obtaining the fine bamboo fiber. The method has high production efficiency, low processing cost and can prepare the bamboo fiber with the diameter within 0.03-0.15mm and the length within 30-300mm.

Owner:FUJIAN DANHAI MATTRESS

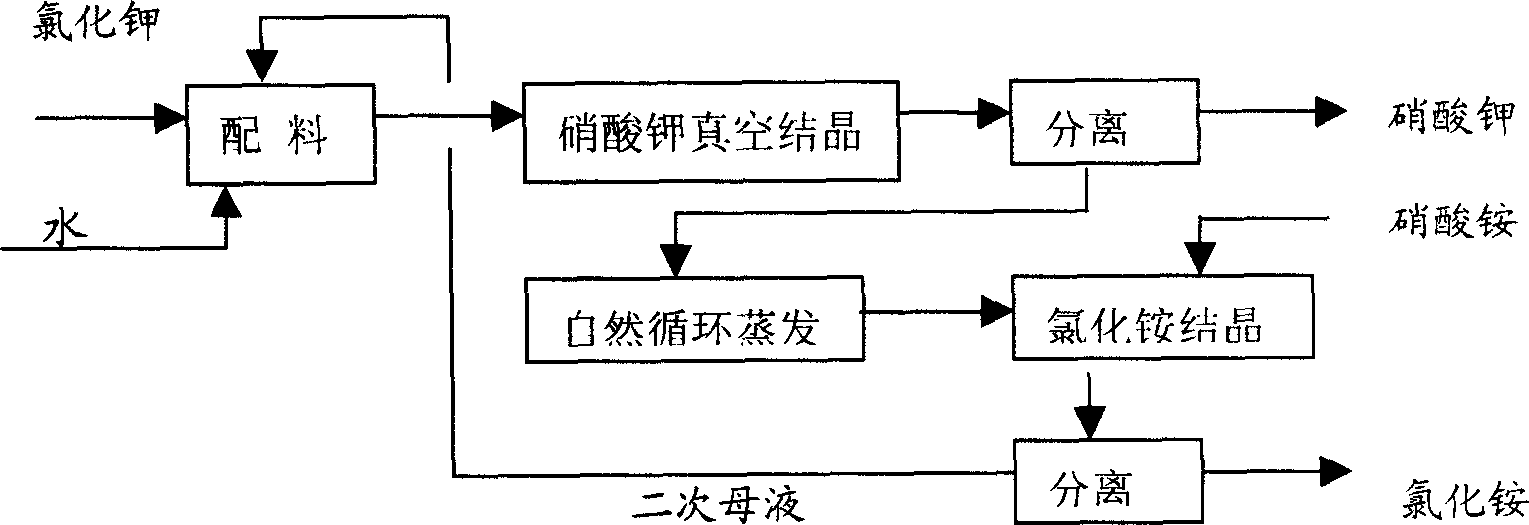

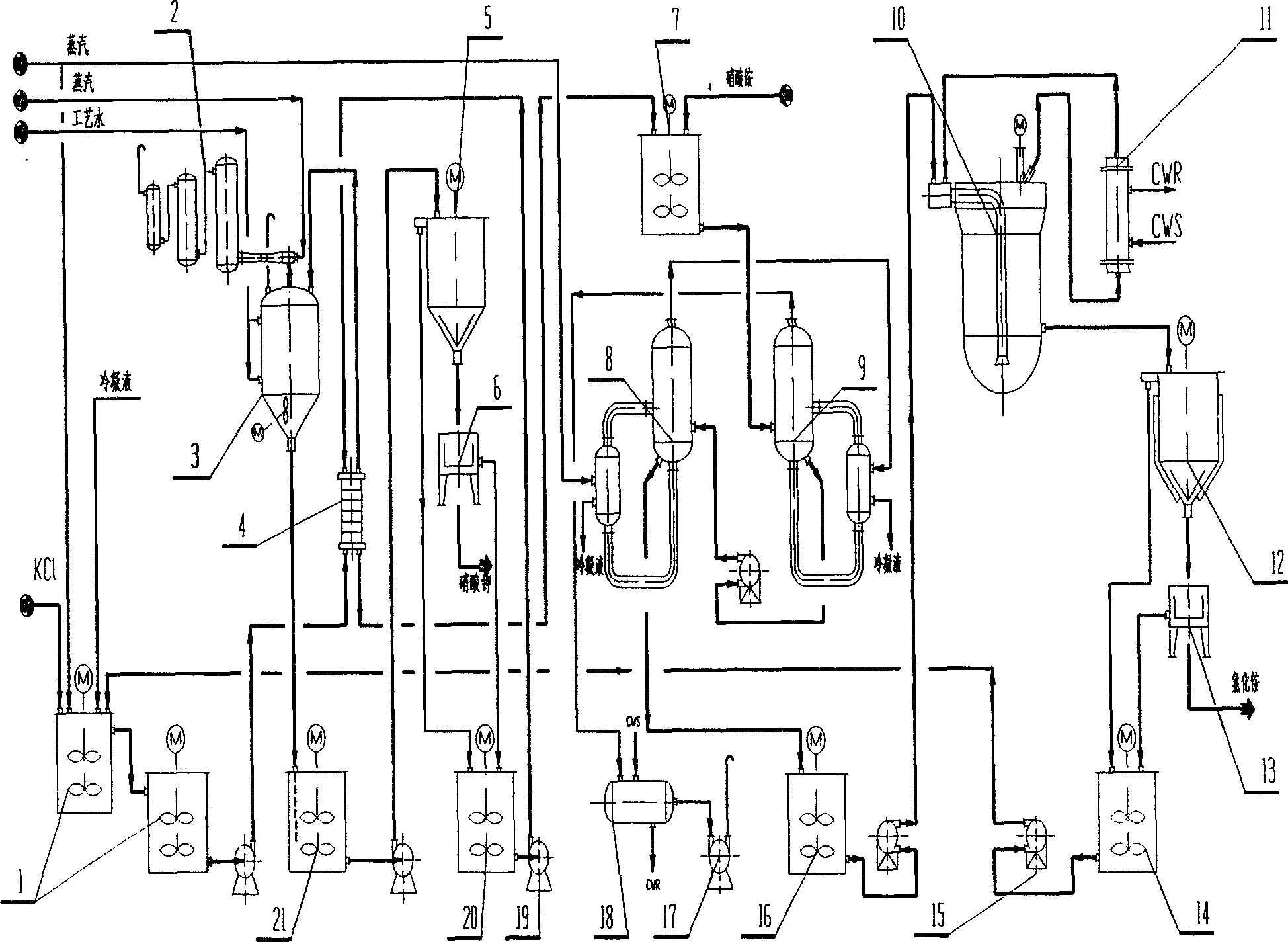

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

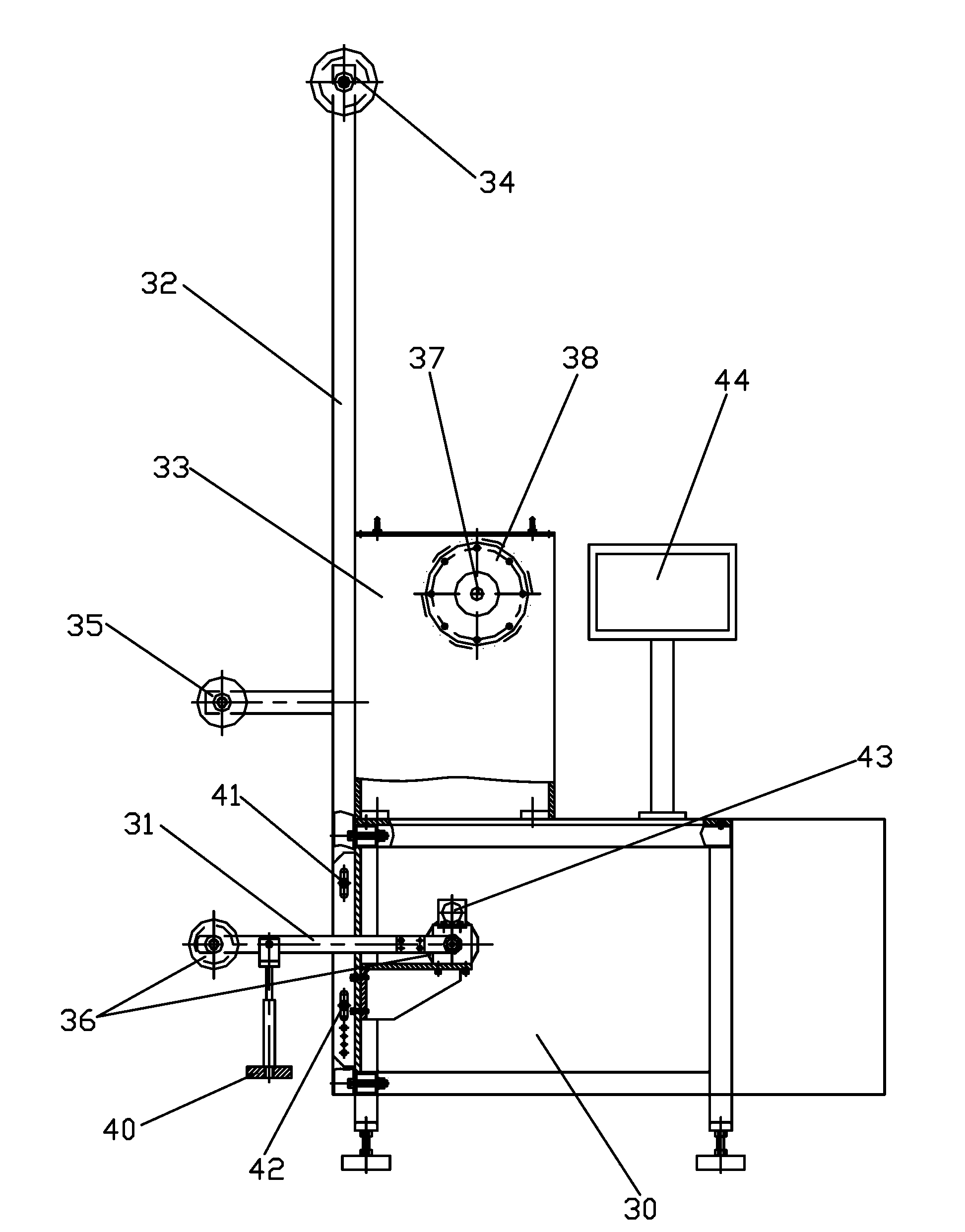

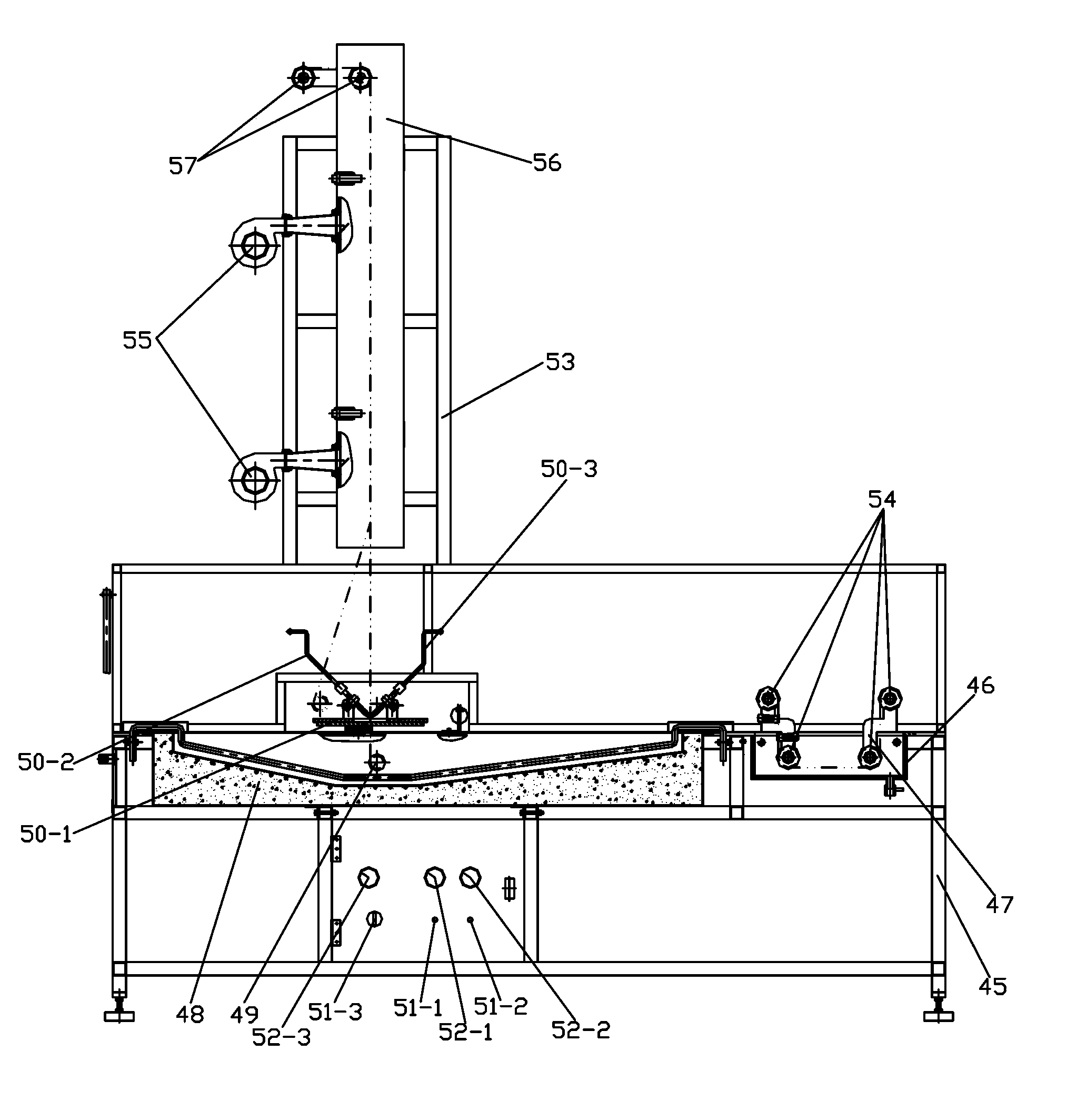

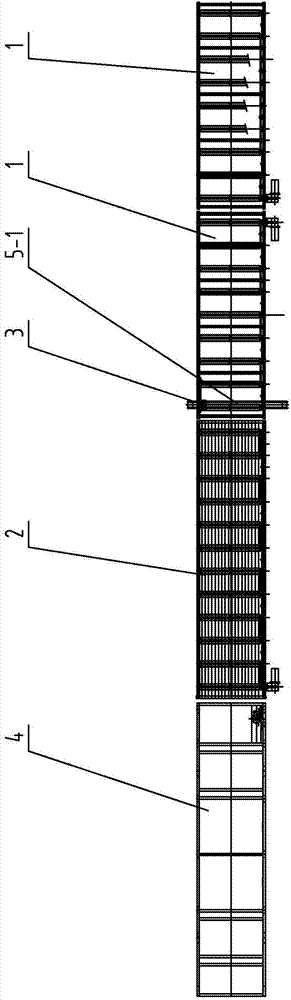

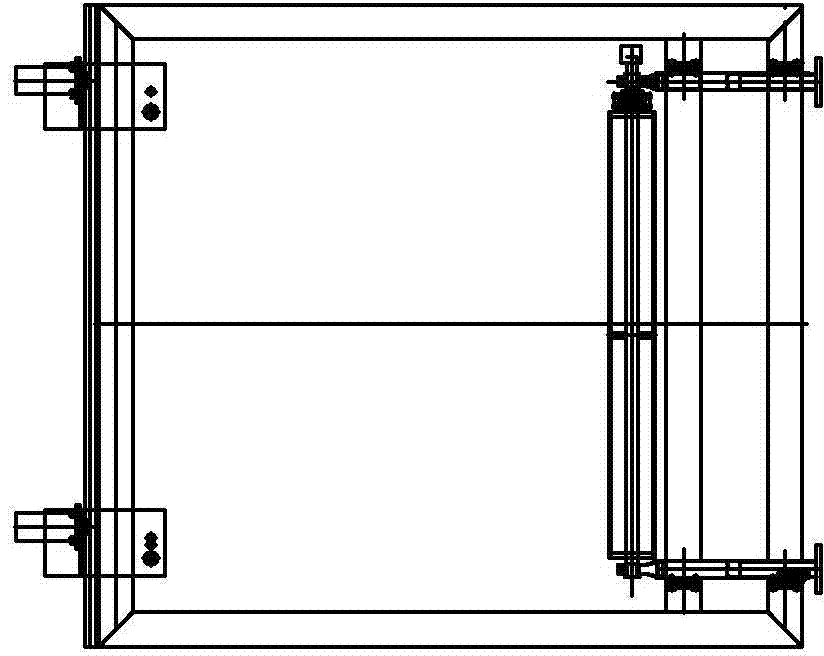

High speed automatic tin-plating machine

InactiveCN103834891ACompact structureNovel and reasonable designHot-dipping/immersion processesControl systemTin plating

The invention discloses a high speed automatic tin-plating machine which comprises an unreeling mechanism, a tin-plating mechanism, a driving and cleaning mechanism, a storage mechanism, a reeling mechanism and a control system sequentially arranged, wherein the unreeling mechanism comprises an unreeling frame, a paying off swing rod, an unreeling transitional wheel, an unreeling belt wheel, a tension adjusting wheel and an unreeling motor; the tin-plating mechanism comprises a tin-plating frame, an acidifying box, an acidifying transitional wheel frame, a solder machine, a pinch roller, a wind knife assembly and an air flue frame; the driving and cleaning mechanism comprises a cleaning frame, a cleaning agent groove, a cleaning transitional wheel bracket, a thickness measuring assembly and a traction assembly; the storage mechanism comprises a storage frame, a fixed wire storage wheel set, a mobile wire storage wheel set and a tension detection mechanism; the reeling mechanism comprises a reeling frame, a reeling guide rail bracket, a vertical wiring device and a horizontal wiring device. The high speed automatic tin-plating machine disclosed by the invention is novel and reasonable in design, ensures the quality and efficient production of tin-plating welding strips, is high in working reliability, better realizes continuous, efficient, high-quality and low-cost tin plating, and is convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

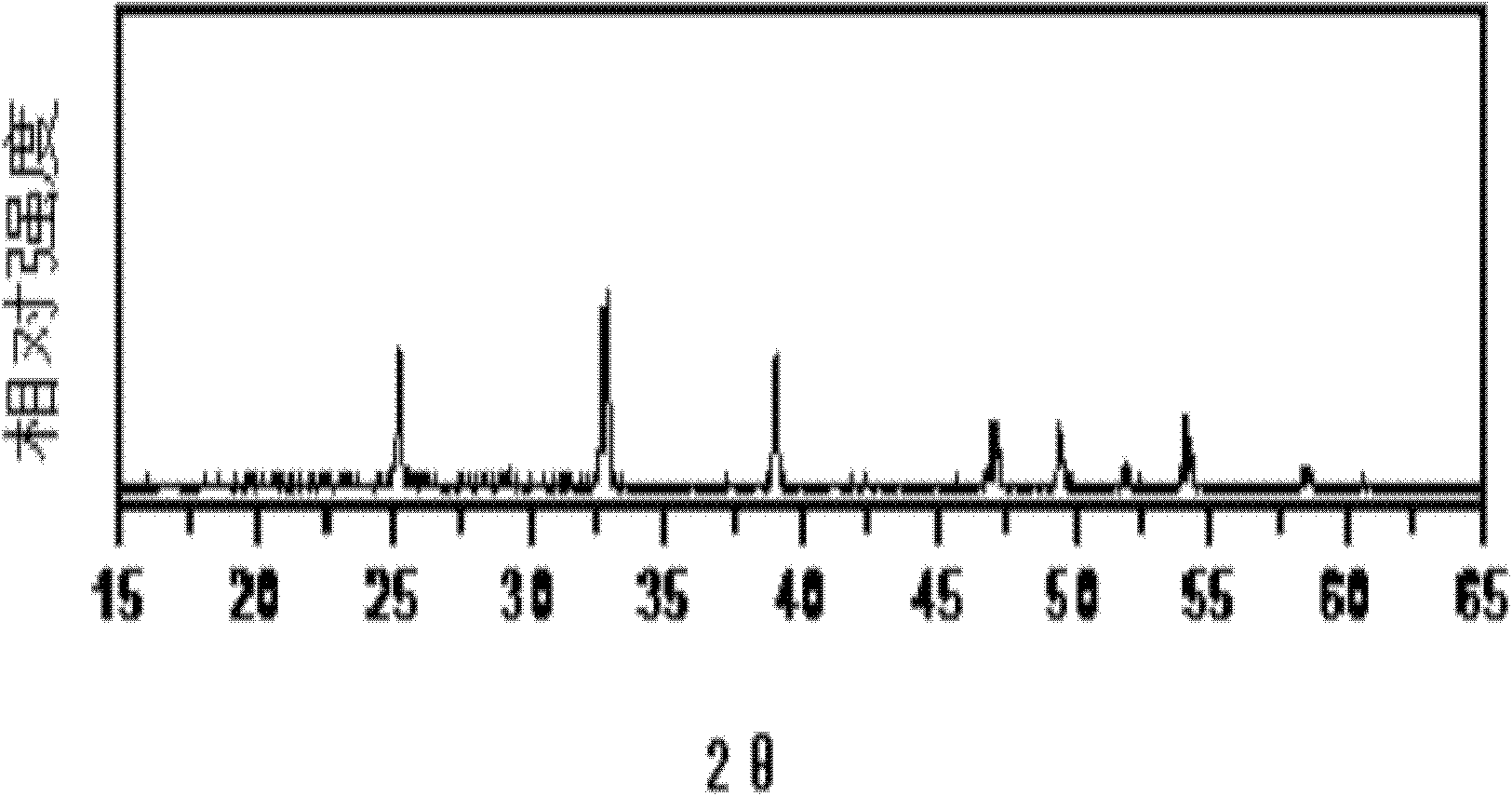

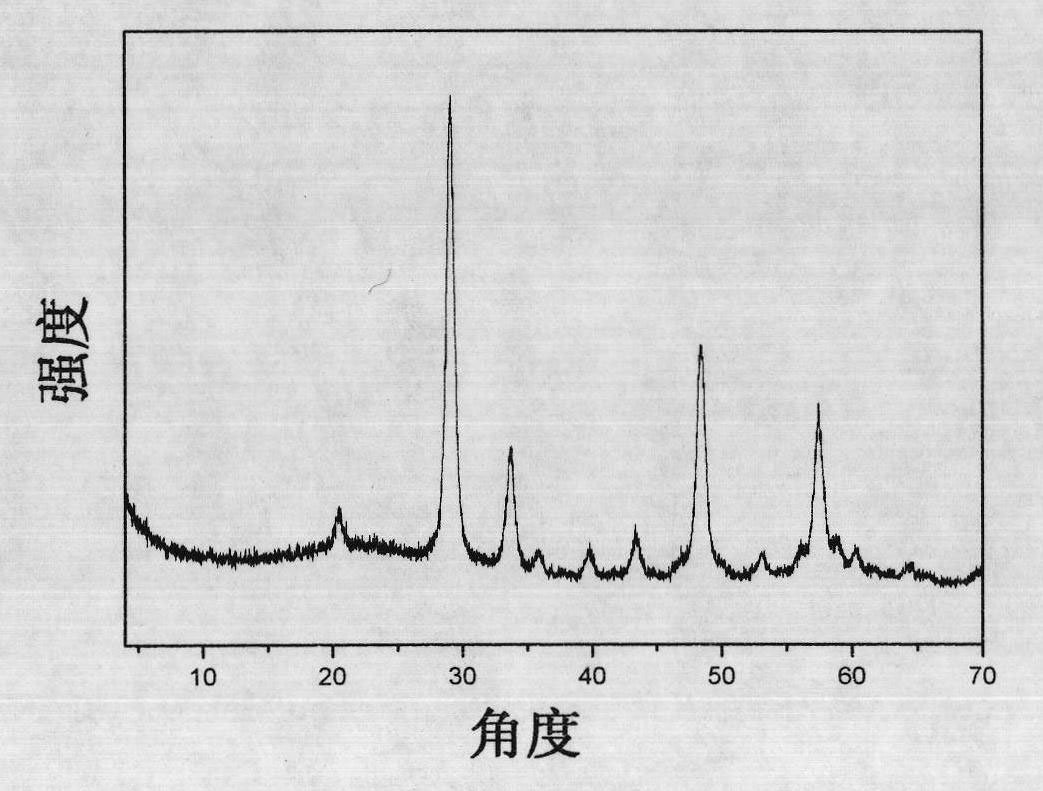

Battery-grade anhydrous iron phosphate and preparation method thereof

The invention relates to a battery grade anhydrous iron phosphate and a preparation method thereof. The battery grade anhydrous iron phosphate is in an orthorhombic type. The preparation method of the battery grade anhydrous iron phosphate is an oxidation precipitation method using air as oxidant and includes steps: adding pH value modifier solution into aqueous solution of mixture of ferrous salt with phosphoric acid or phosphate, feeding air and stirring for reaction to generate a crystalline-state composite containing ammonium, hydroxyl and water of crystallization; and obtaining the battery grade anhydrous iron phosphate after solid-liquid separating, washing, drying and roasting. The battery grade anhydrous iron phosphate is an ideal material for preparation of lithium iron phosphate which is the material of anodes of lithium ion batteries. The preparation method is suitable for large-scale, economical, stable and reliable production of high-quality battery grade anhydrous iron phosphate, and has evident advantages and practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

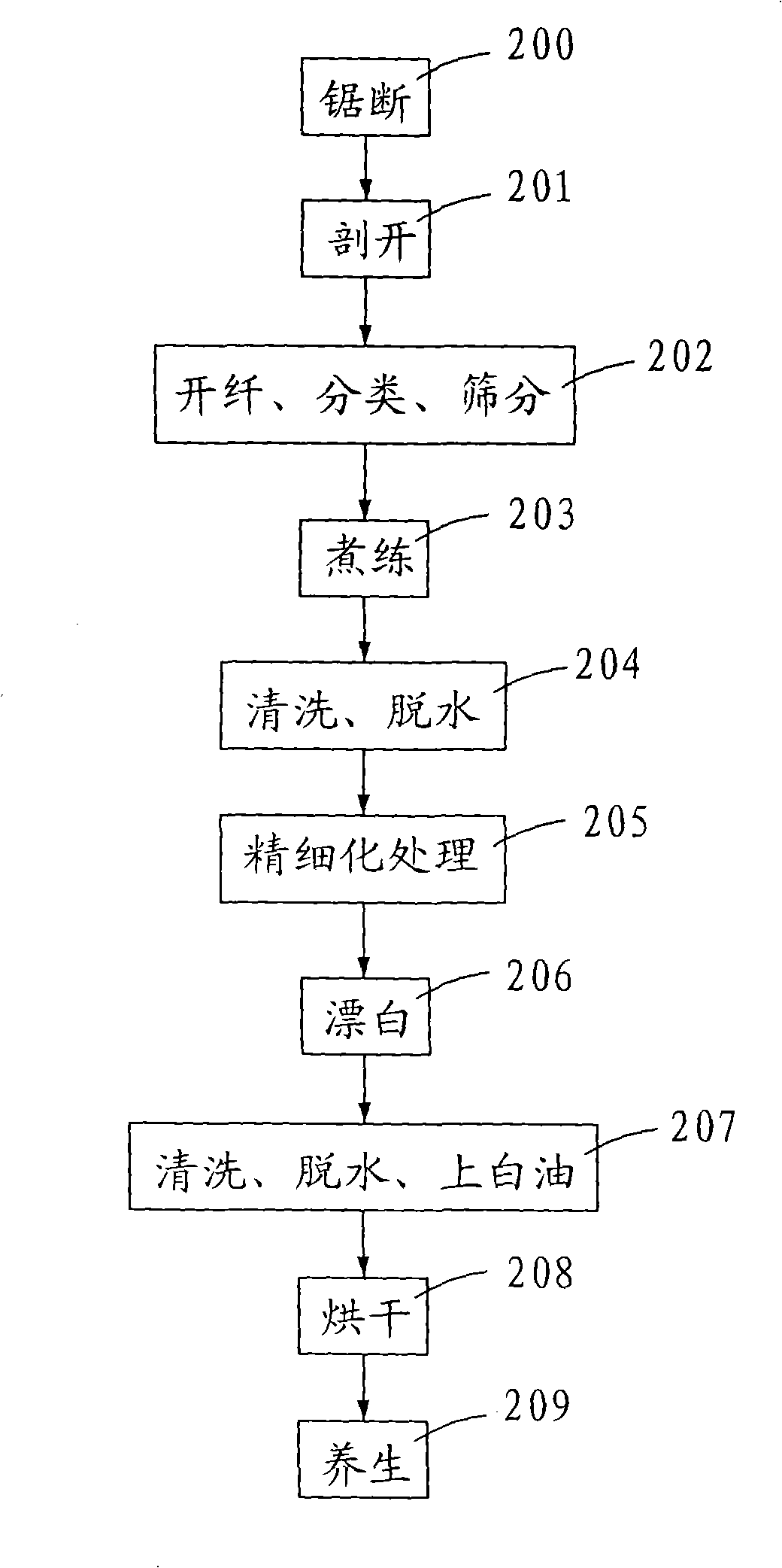

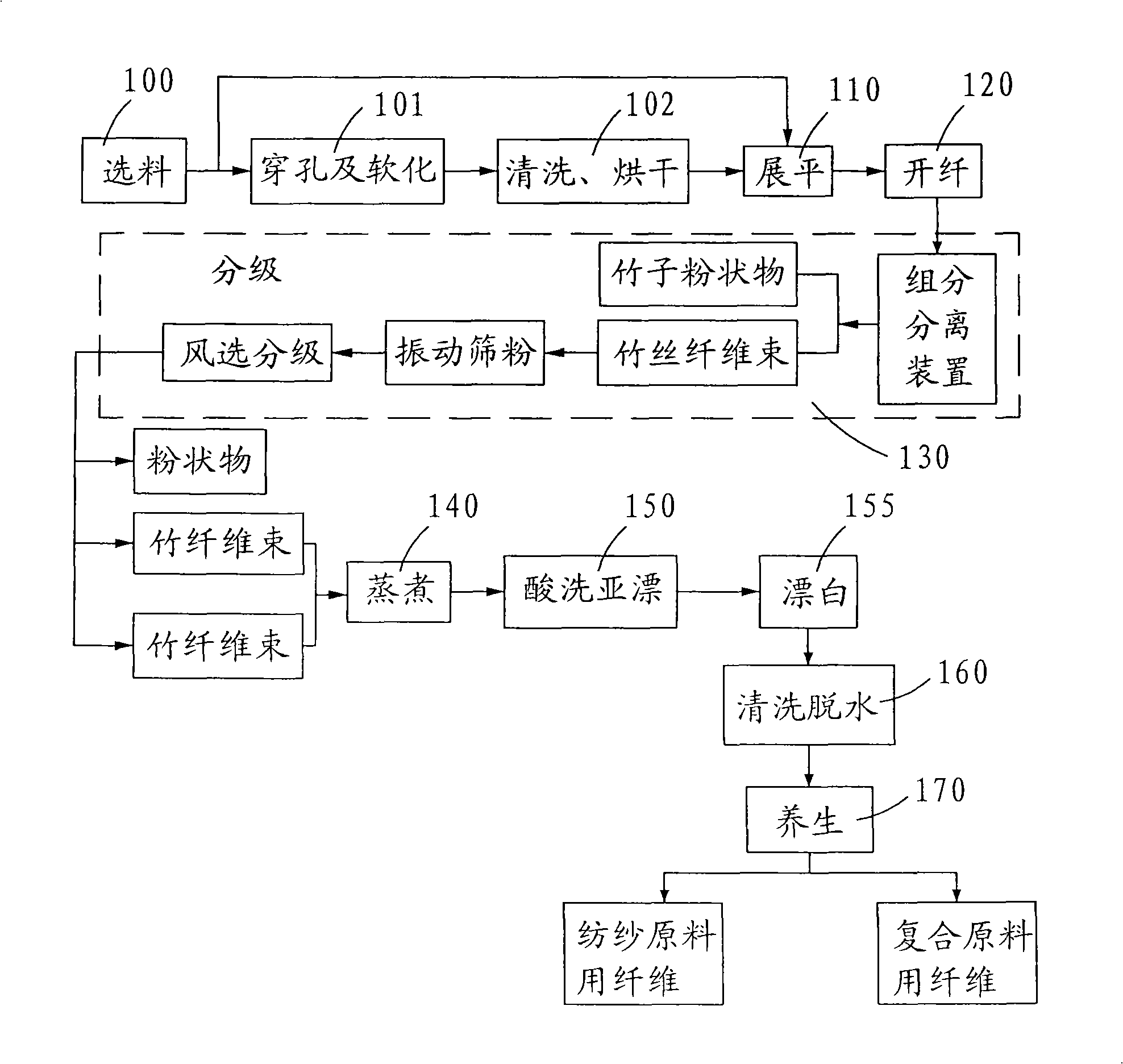

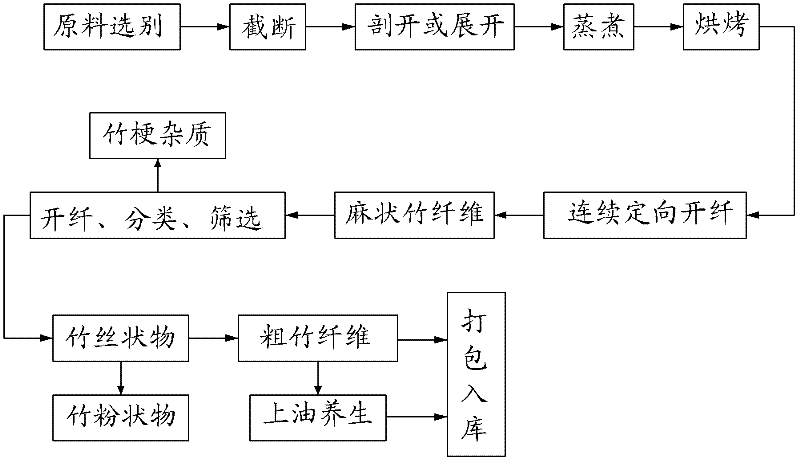

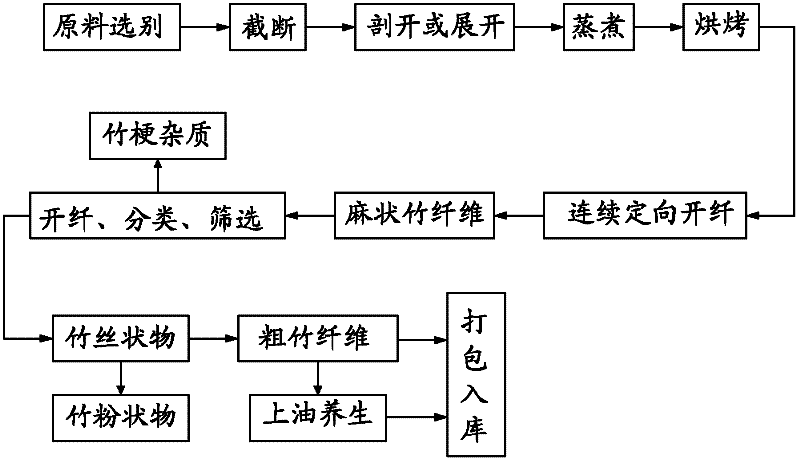

Process for producing bamboo fiber

InactiveCN101537648AReduce processing costsReduce pollutionWood working apparatusVegetable materialResource utilizationChemistry

The invention discloses a process for producing a bamboo fiber, comprising the following steps of selecting raw materials, extending, splitting, classifying, stewing and cooking, pickling, cleaning, dehydrating, curing and the like, thus preparing the bamboo fiber with the fineness of 0.03-0.08mm and the length of 30-80mm. The process can lead a whole bamboo to be extended by a special tool and subsequently and directly processed without being cut; furthermore, the processed bamboo fiber is longer, finer and more uniform, the utilization ratio of the resource is high, the cost is low and the quality of the product is stable.

Owner:FUJIAN DANHAI MATTRESS

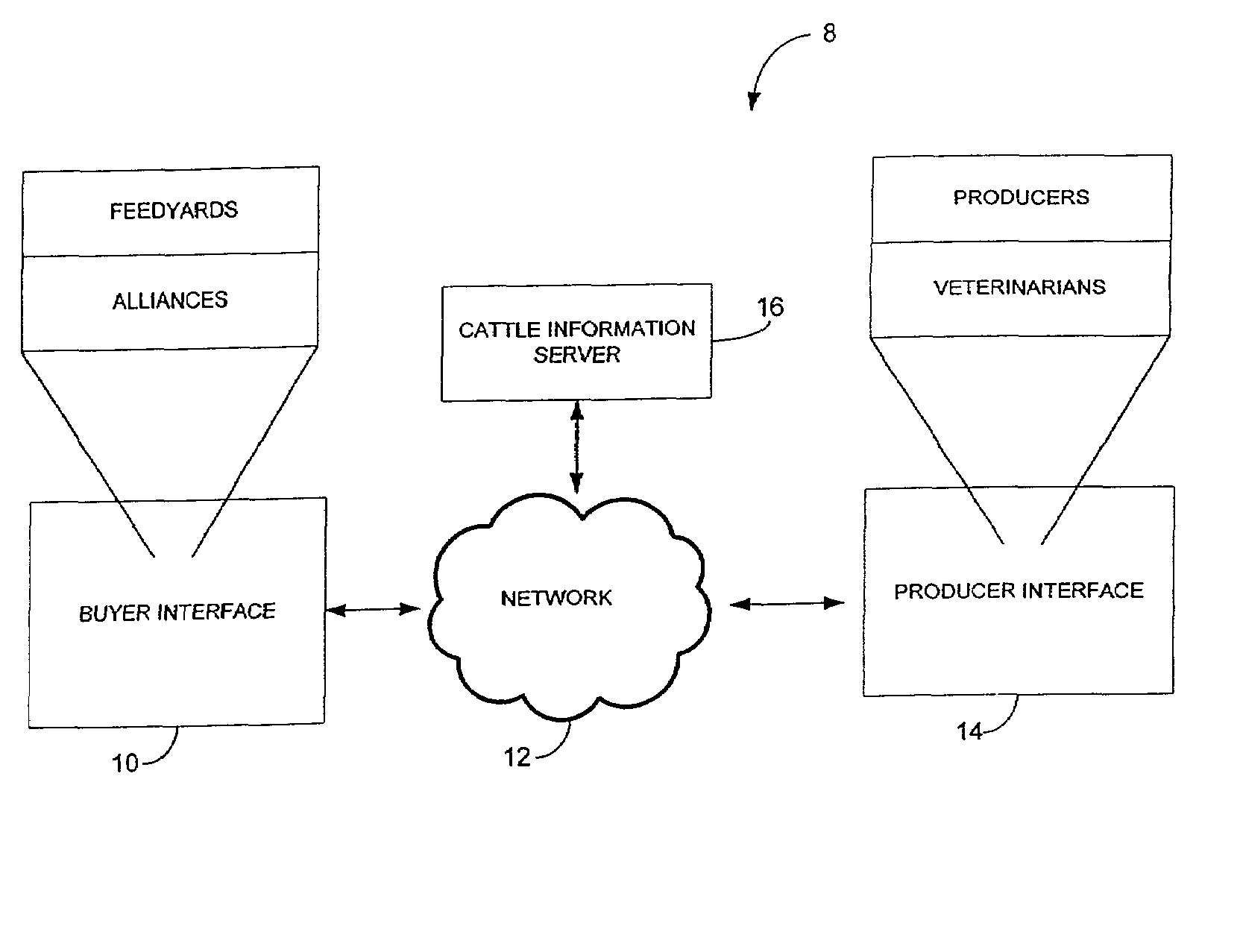

Systems and methods for interactive beef cattle marketplace

InactiveUS7584136B2Facilitates consistentFacilitates reliableFinanceBuying/selling/leasing transactionsPre conditioningComputer science

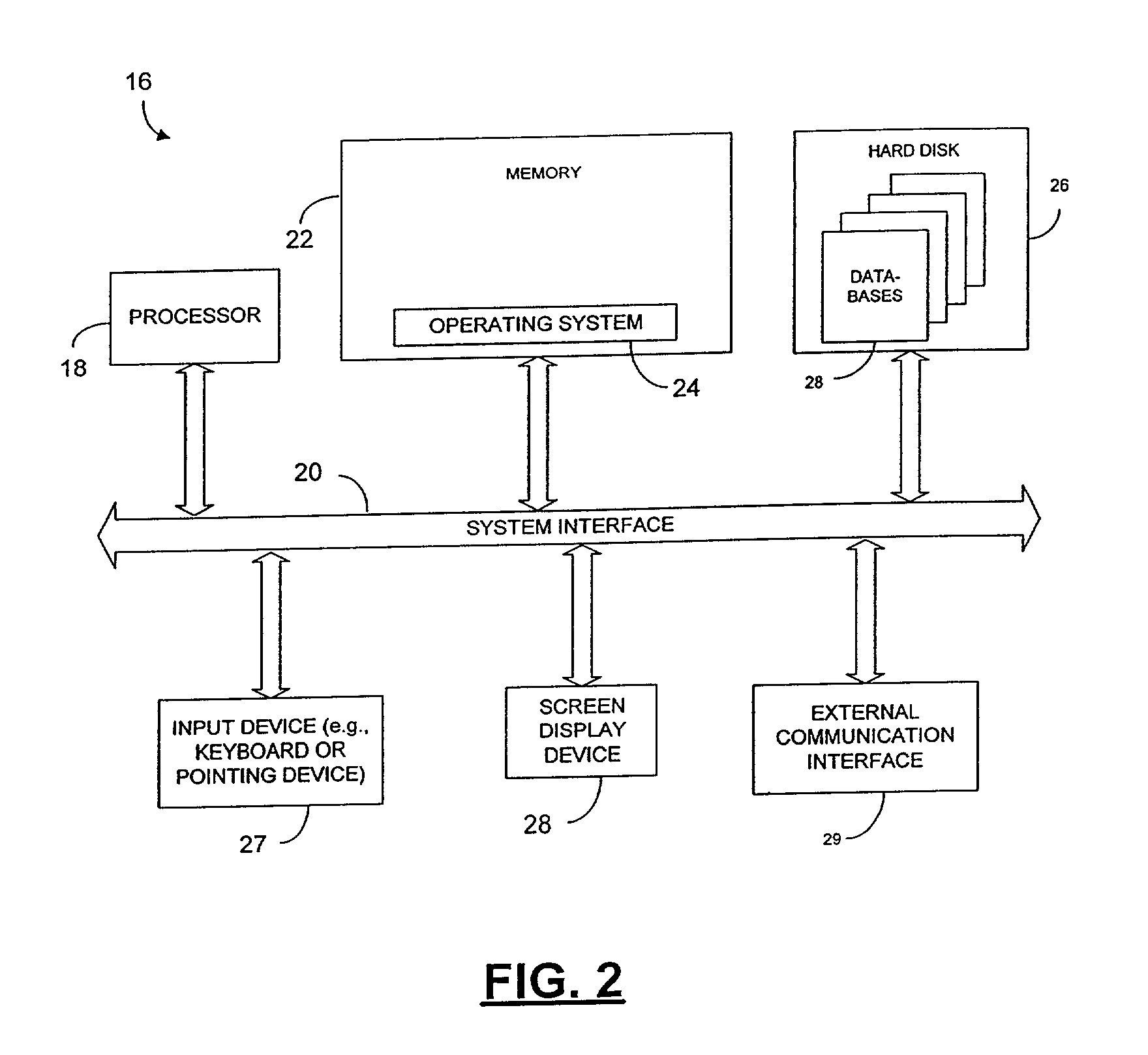

A system and method for dynamically marketing cattle is provided comprising a buyer interface, a producer interface, a network, and an cattle information server. The cattle information server receives information from the buyer interface defining a plurality of demand profiles at least one which contains information specifying a first pre-conditioning program. The cattle information server also receives information from the producer interface defining a supply profile that specifies a second pre-conditioning program and stores the demand profiles and supply profile in a database. The cattle information server searches the database to determine if one or more of the demand profiles match the supply profile based at least in part on a comparison of the first and second pre-conditioning programs and identifies at least one demand profile in response to a match between the supply profile and the demand profile.

Owner:ELI LILLY & CO

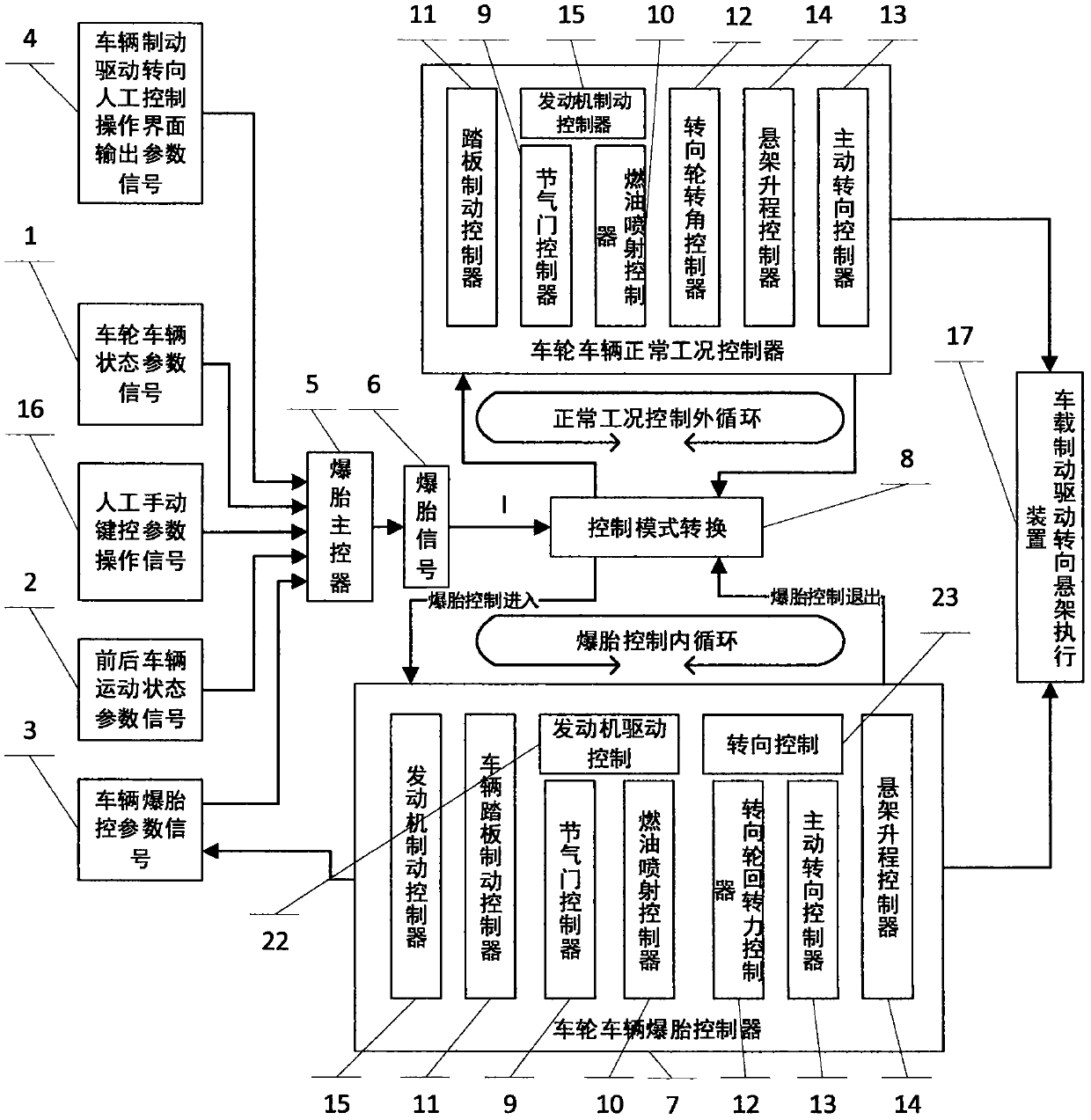

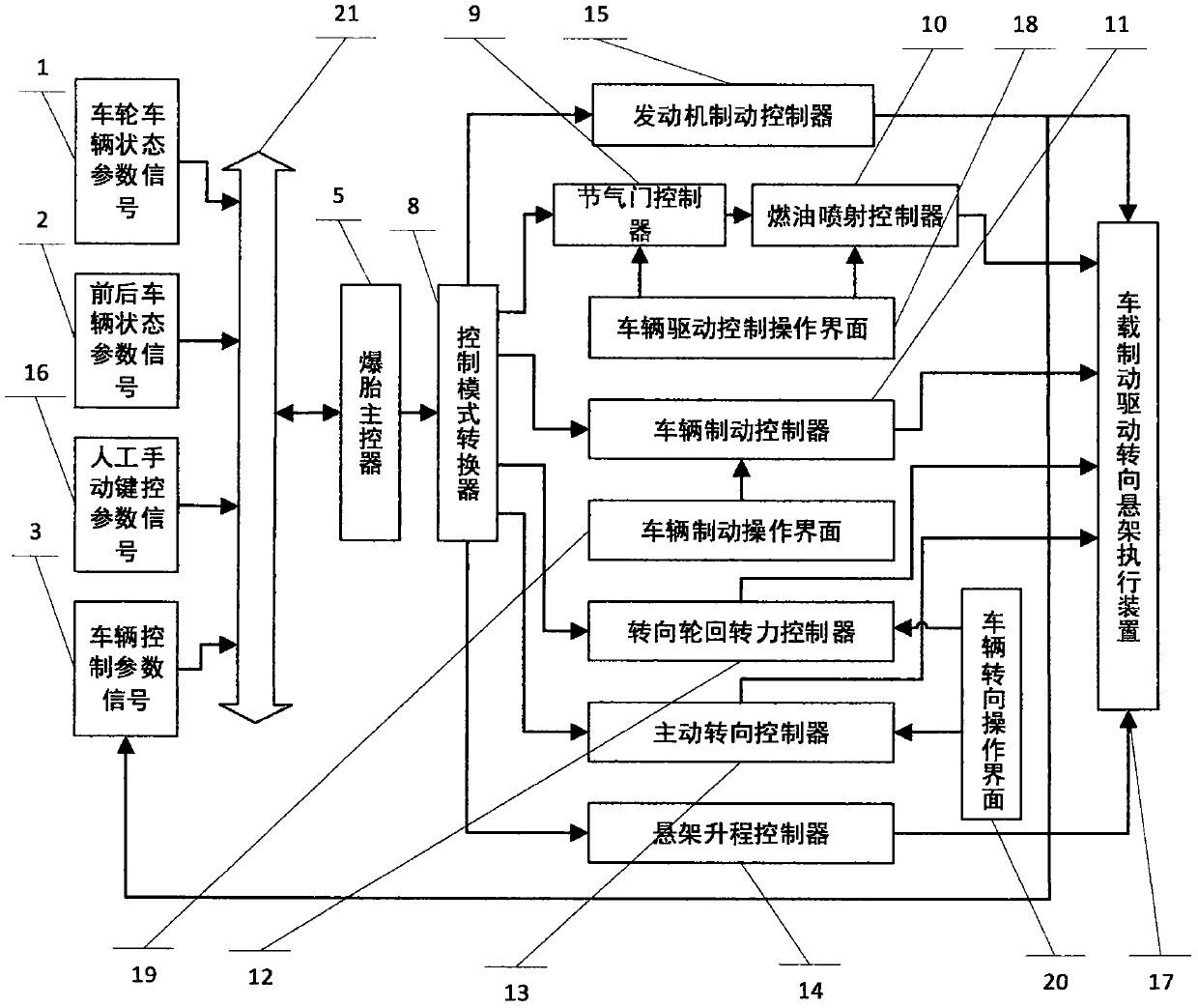

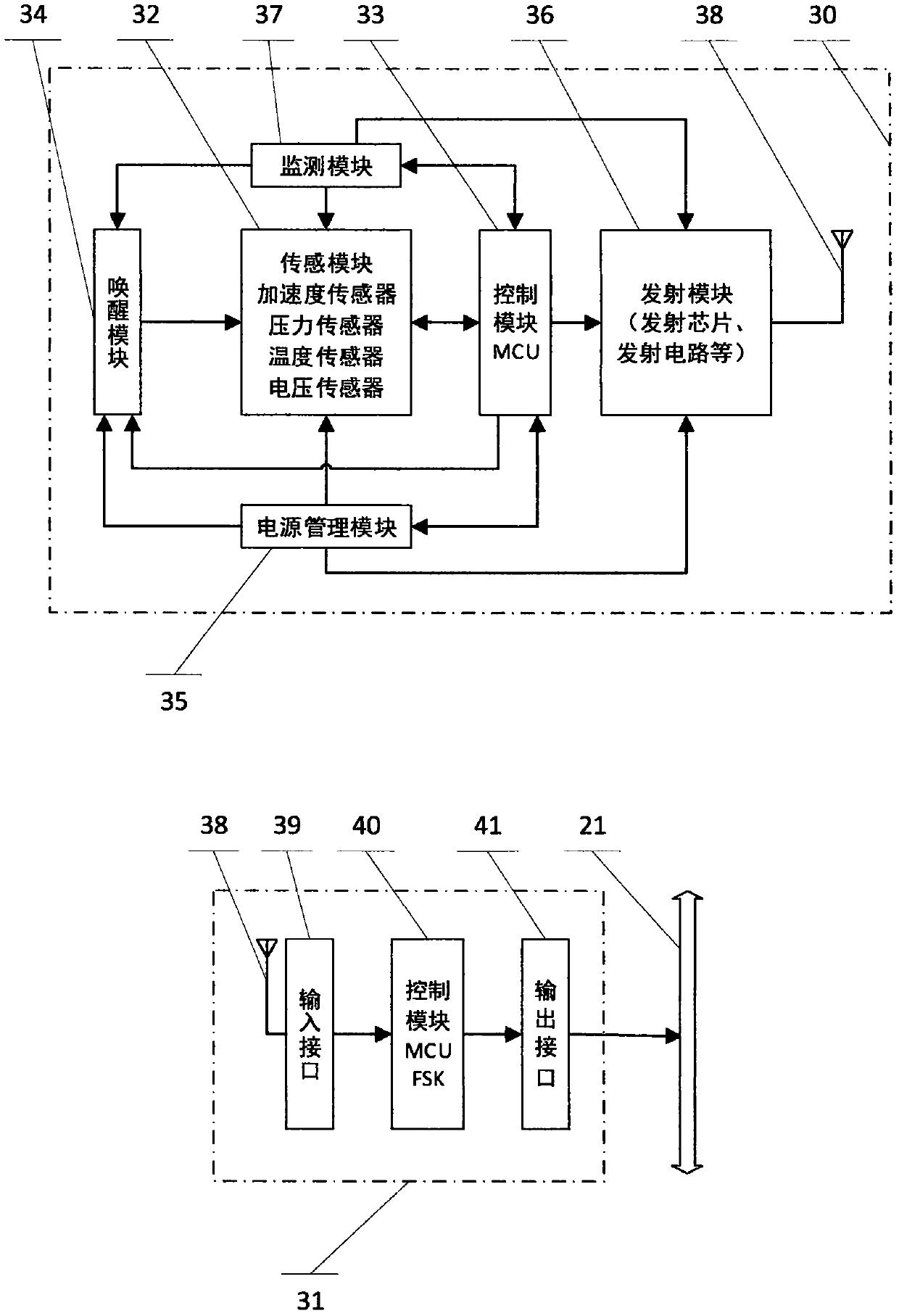

Automobile tire blew-out safety and stability control system

InactiveCN108715163AImplement Stability ControlAdvanced technologyVehicle condition input parametersSteering wheelControl system

The invention discloses an automobile tire blew-out safety and stability control system for manned and unmanned vehicles, is based on vehicle braking, driving, steering and suspension systems, and belongs to the field of automobile tire blew-out safety. The system establishes the tire blew-out determination of tire pressure detection, a state tire pressure and a steering mechanics state mode, andadopts an automobile tire blew-out safety and stability control mode, a model, an algorithm, a control structure and a flow; based on tire blew-out state points, through conversion of tire blew-out control entering and exit and normal and tire blew-out control modes, vehicle braking, driving, steering, steering wheel rotation force and suspension balance control are coordinately conducted, the real or non-real tire blew-out process overlapped tire blew-out control is achieved; under the conditions of rapid changes of the tire blew-out process state and the movement state of blew-out tires andvehicles, technical barriers such as severe instability of the tires and the tire blew-out, the difficulty in controlling the extreme state of the tire blew-out and the like are broken through, and the system solves the major problem which long plagues the automobile tire blew out safety.

Owner:吕杉 +1

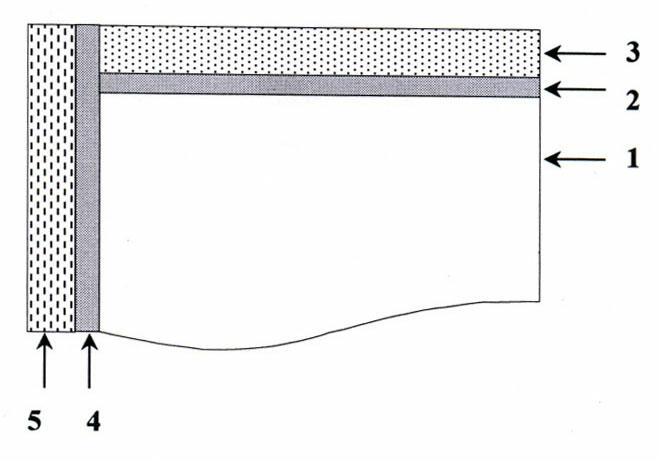

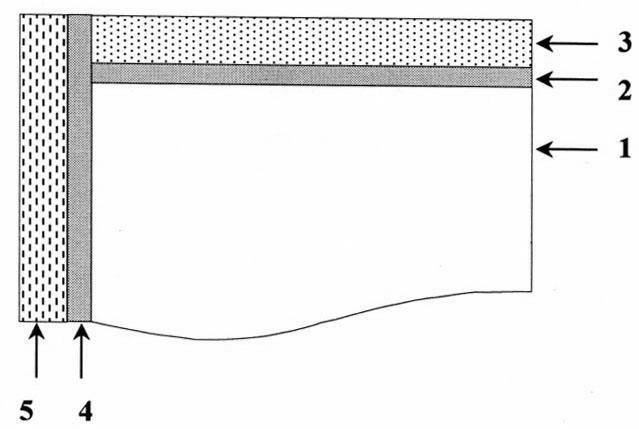

Ti-TiN & Ti-MoS2/Ti double-cutting-surface coated cutting tool and preparation process thereof

ActiveCN102161106AImprove performanceReduce coefficient of frictionVacuum evaporation coatingSputtering coatingHardnessTransition layer

The invention relates to a Ti-TiN & Ti-MoS2 / Ti double-cutting-surface coated cutting tool and a preparation process thereof. The front surface of the cutting tool is an MoS2 / Ti lubricating coating and a Ti front cutting tool surface transition layer is arranged between the MoS2 / Ti lubricating coating and a cutting tool substrate. The rear surface of the cutting tool is a TiN coating with high hardness and a Ti rear cutting tool surface transition layer is arranged between the TiN coating with high hardness and the cutting tool substrate. The preparation process comprises the steps of pre-processing, ion cleaning, depositing the Ti transition layer on the front cutting tool surface, depositing the MoS2 / Ti coating on the front cutting tool surface, sampling, refitting a furnace, ion cleaning, depositing the Ti transition layer on the rear cutting tool surface, depositing the TiN coating on the rear cutting tool surface and post-processing. Advantages of a Ti-TiN coated cutting tool withhigh hardness and a Ti-MoS2 / Ti lubricating coated cutting tool are combined in the present invention of the double-cutting-surface coated cutting tool which has both high hardness and low friction coefficient, so that performance of the coated cutting tool is substantially improved. The preparation process enables the Ti-TiN & Ti-MoS2 / Ti coated cutting tool to be produced conveniently. It is easyto grasp the process and the production process is stable and reliable.

Owner:SHANTUI CONSTR MASCH CO LTD

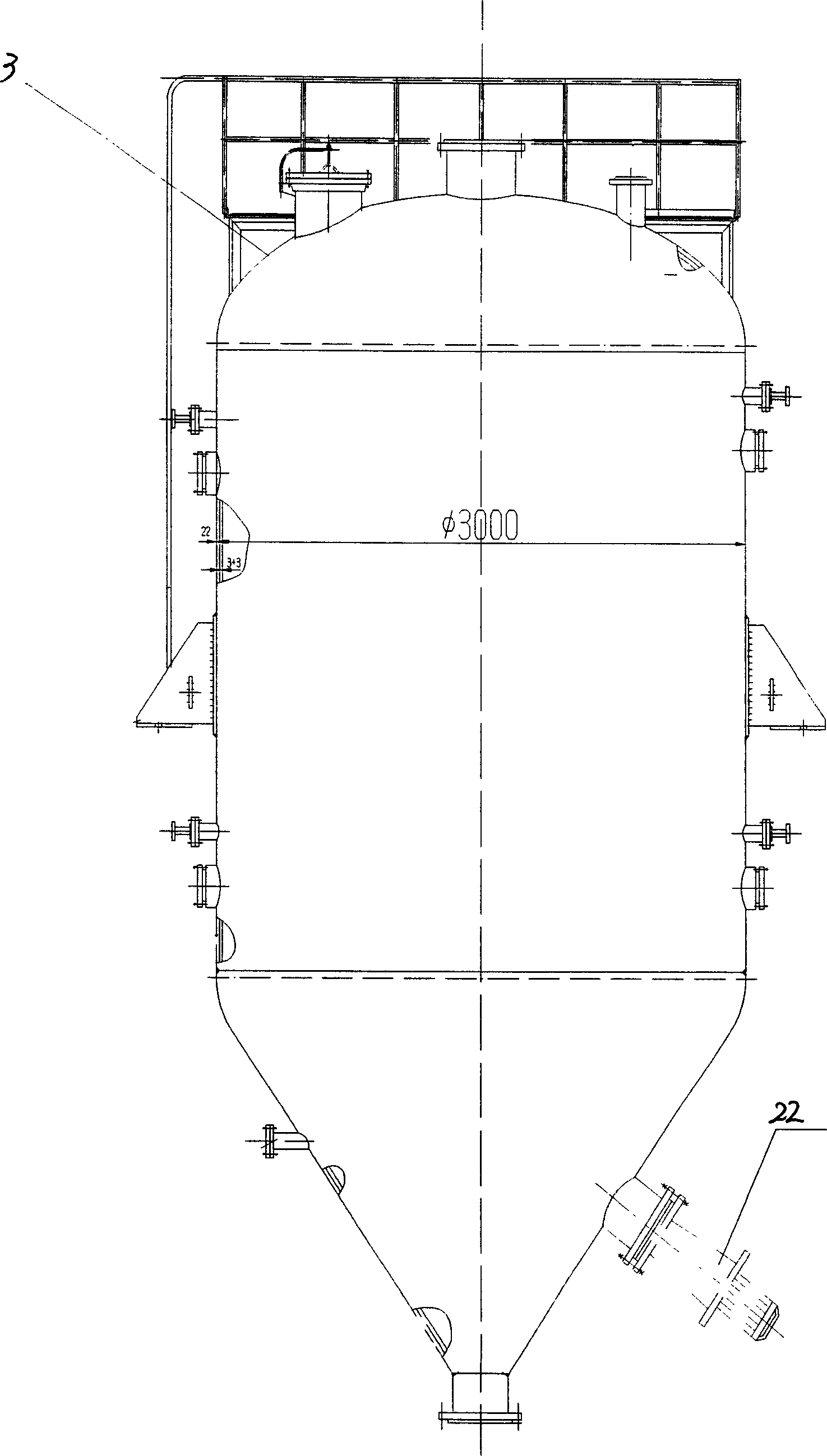

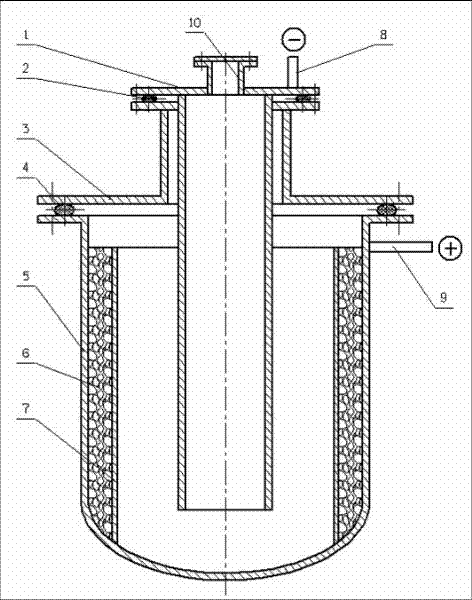

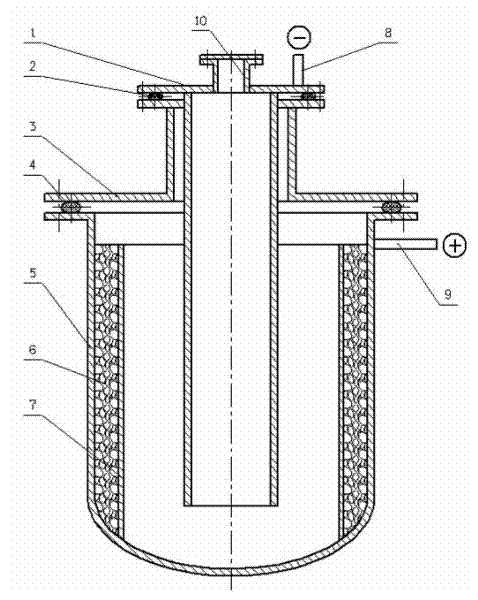

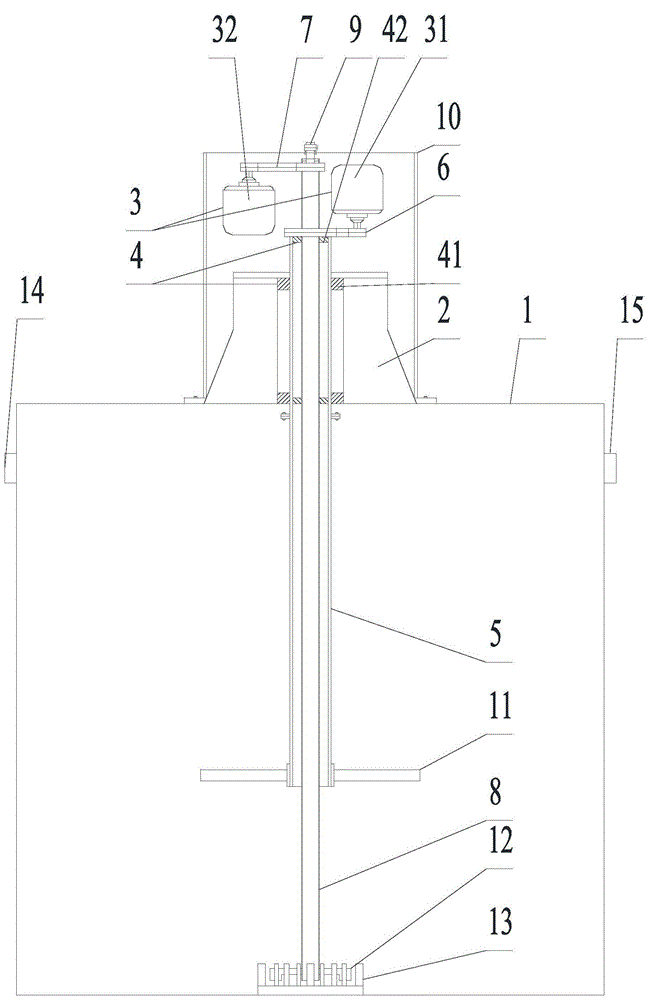

Device for producing high-purity titanium by fused salt electrolysis process

The invention provides a device for producing high purity titanium by a fused salt electrolysis process. The device mainly comprises a big cover (3), a crucible (5) and an anode frame (7), wherein the big cover (3) is connected with the crucible (5) by a sealed insulating pad (4) in a sealed manner; the anode frame (7) is placed in the crucible (5); a cathode (1) is arranged on the big cover (3) and connected with the big cover (3) by a sealing ring (2) in a sealed manner; and the cathode (1) is a cylinder body, the upper part of which is provided with an anode connection terminal (9). According to the device, the crucible is adopted as the anode, and the fused salt can be directly added to the crucible via a fused salt adding hole formed on the cathode; the structure of the equipment is simplified so that the production process is more stable and reliable; and the purity of the product produced by using the device can reach more than 4N5 (99.995%).

Owner:ZUNYI TITANIUM

Method of leaching copper, cobalt and nickel from smelting alloy

A method of leaching copper, cobalt and nickel from smelting alloy comprises the following steps: the smelting alloy containing at least two of copper, cobalt and nickel and iron impurities is molten, and then the molten smelting alloy is atomized into alloy powder by high-pressure gas or high-pressure water; the atomized alloy powder is added into a stir aeration reaction device, a sulfuric acid solution is used as a leaching medium in the stir aeration reaction device, air or oxygen is uniformly brought from a stirring shaft system of the stir aeration reaction device, the brought gas is uniformly dispersed under the shear action of stirring blades in high-speed rotation at the bottom of the stirring shaft system, and under the effects of an oxidizing agent and a catalyst, the alloy powder is subjected to corrosion oxidizing leaching reaction in the stir aeration reaction device; after reaction is completed, most iron impurities enter a leaching residue, and solid-liquid separation is finally carried out to collect and obtain a leaching liquid containing at least two of copper, cobalt and nickel. The method of leaching copper, cobalt and nickel from the smelting alloy has the advantages that the process cost is low; the technology is convenient to control; the production is stable and reliable; the environment pollution is low and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

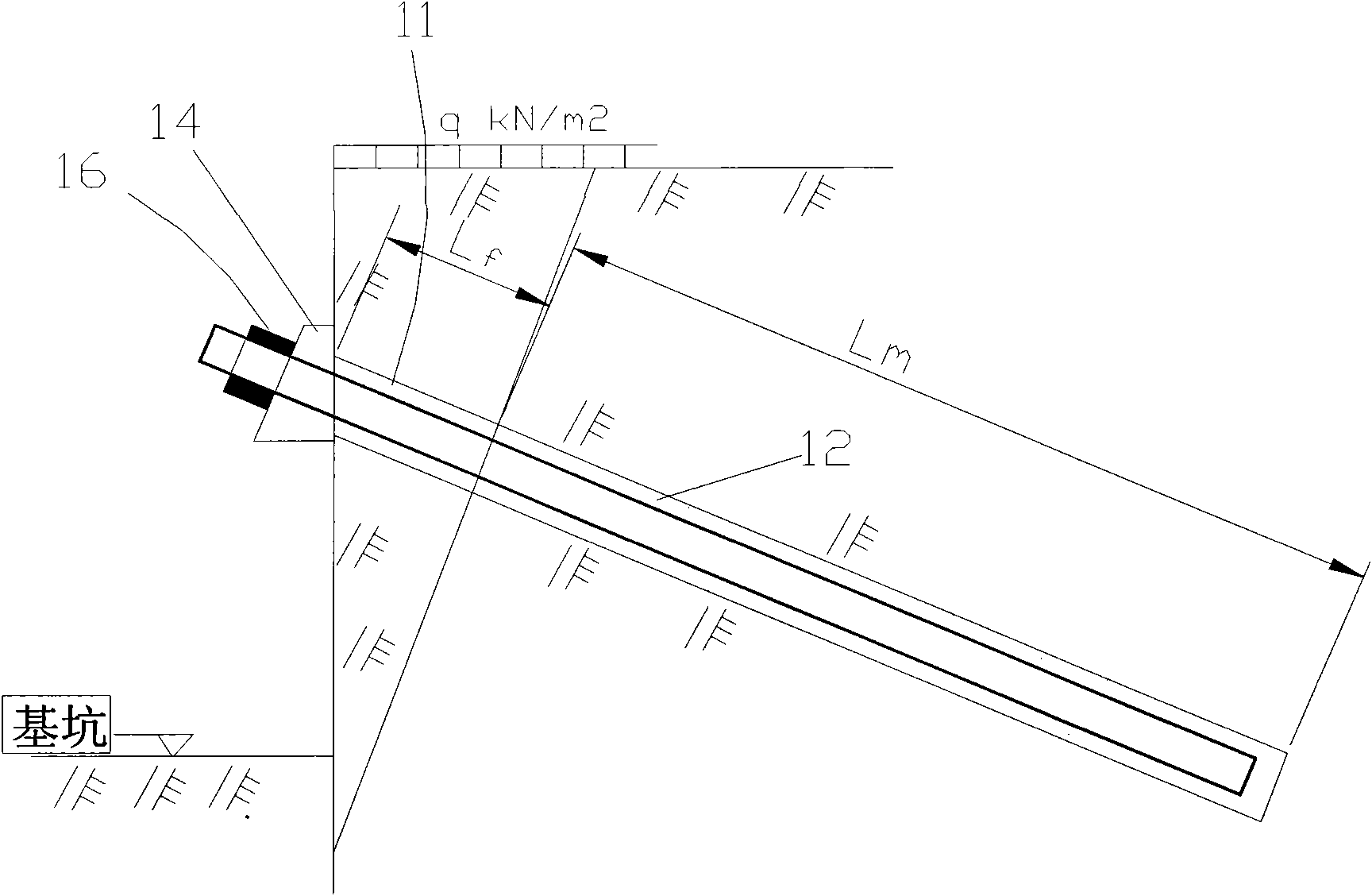

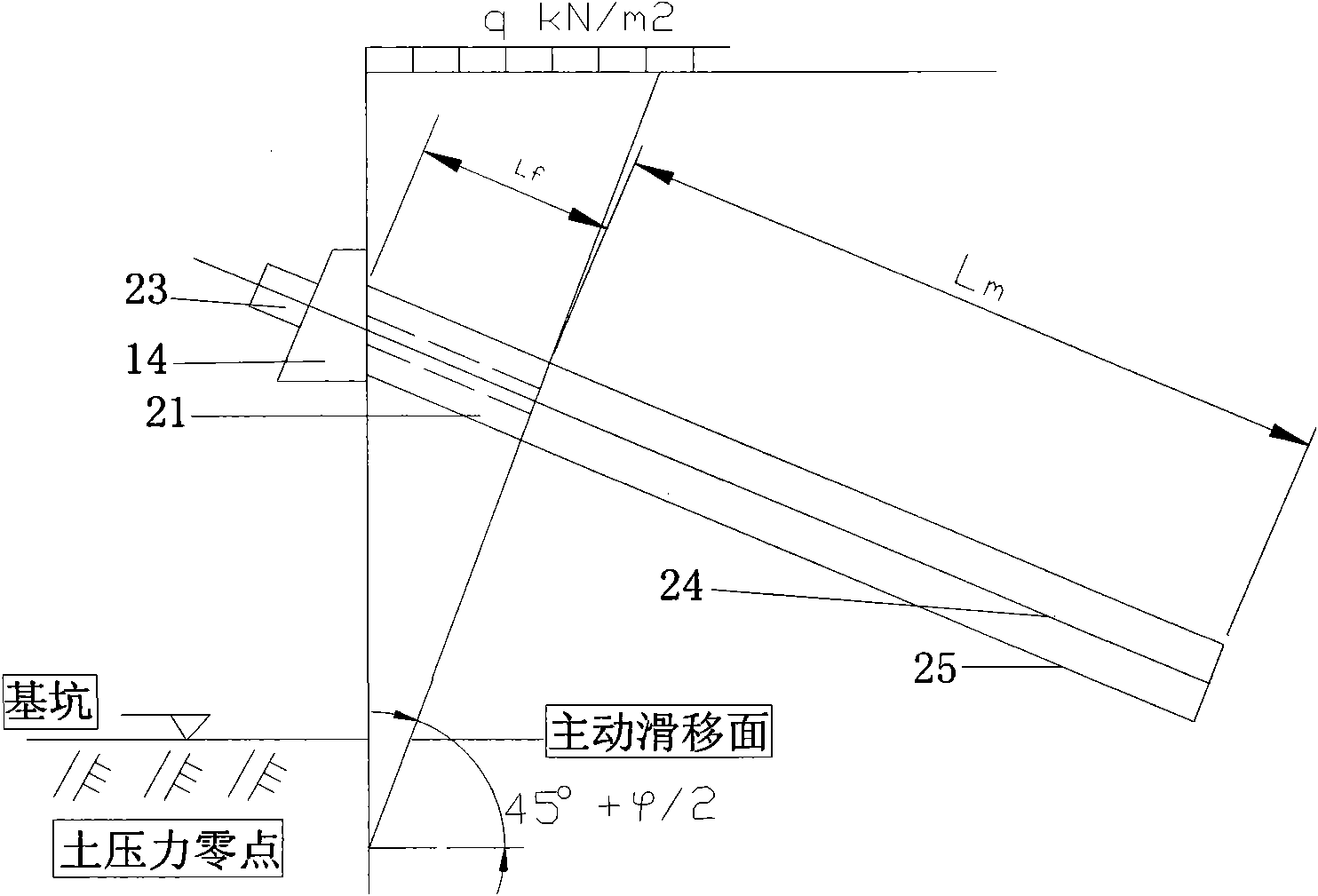

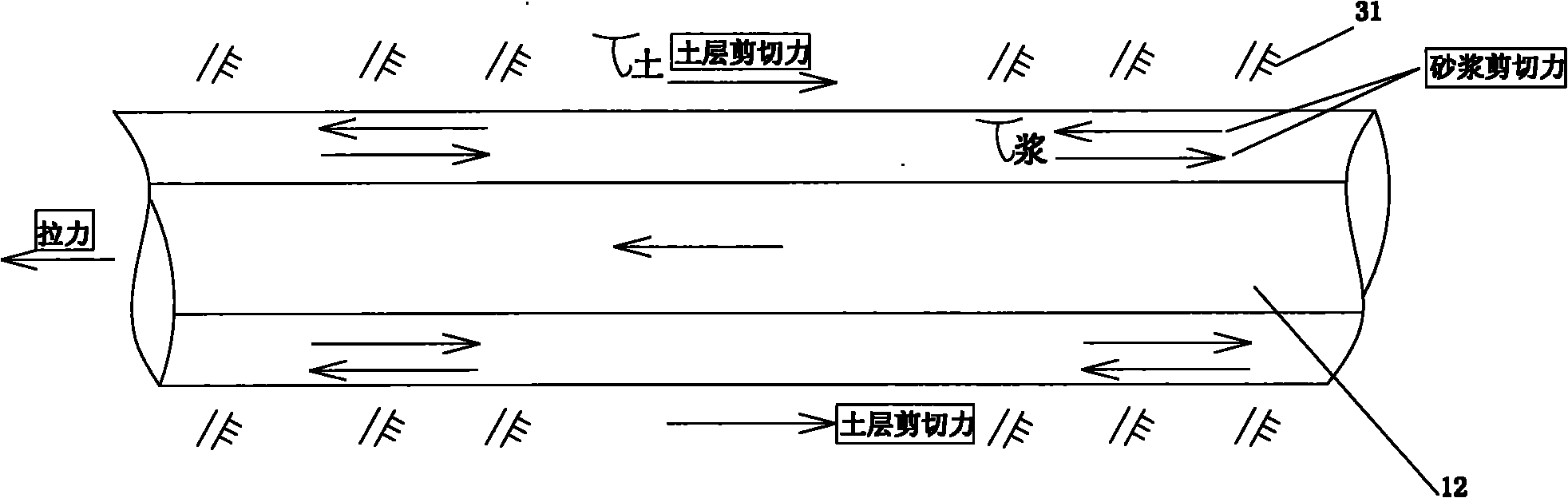

Soil anchor quick construction method and anchor thereof

InactiveCN101768967AIncrease production capacityStable and reliable productionExcavationsBulkheads/pilesSoil horizonRock bolt

The invention relates to an anchor quick construction method using steel tube as the anchor bar. The method includes that a hole is prepared in the soil and the jointed steel tube is inserted into the hole; grout is injected through the steel tube hole and stopped when overflowing the anchor hole or the predetermined position; a waist beam is spanned or the anchor is locked firmly on the waist beam by nuts after short time maintenance. With the method of the invention, the anchor bar is tensioned in resistance of drawing after satisfying the corresponding conditions, thereby the time waiting for the anchor bar construction in the side slopes and foundation ditches supporting process is greatly shortened and the construction period is also shortened.

Owner:郑鸿彰

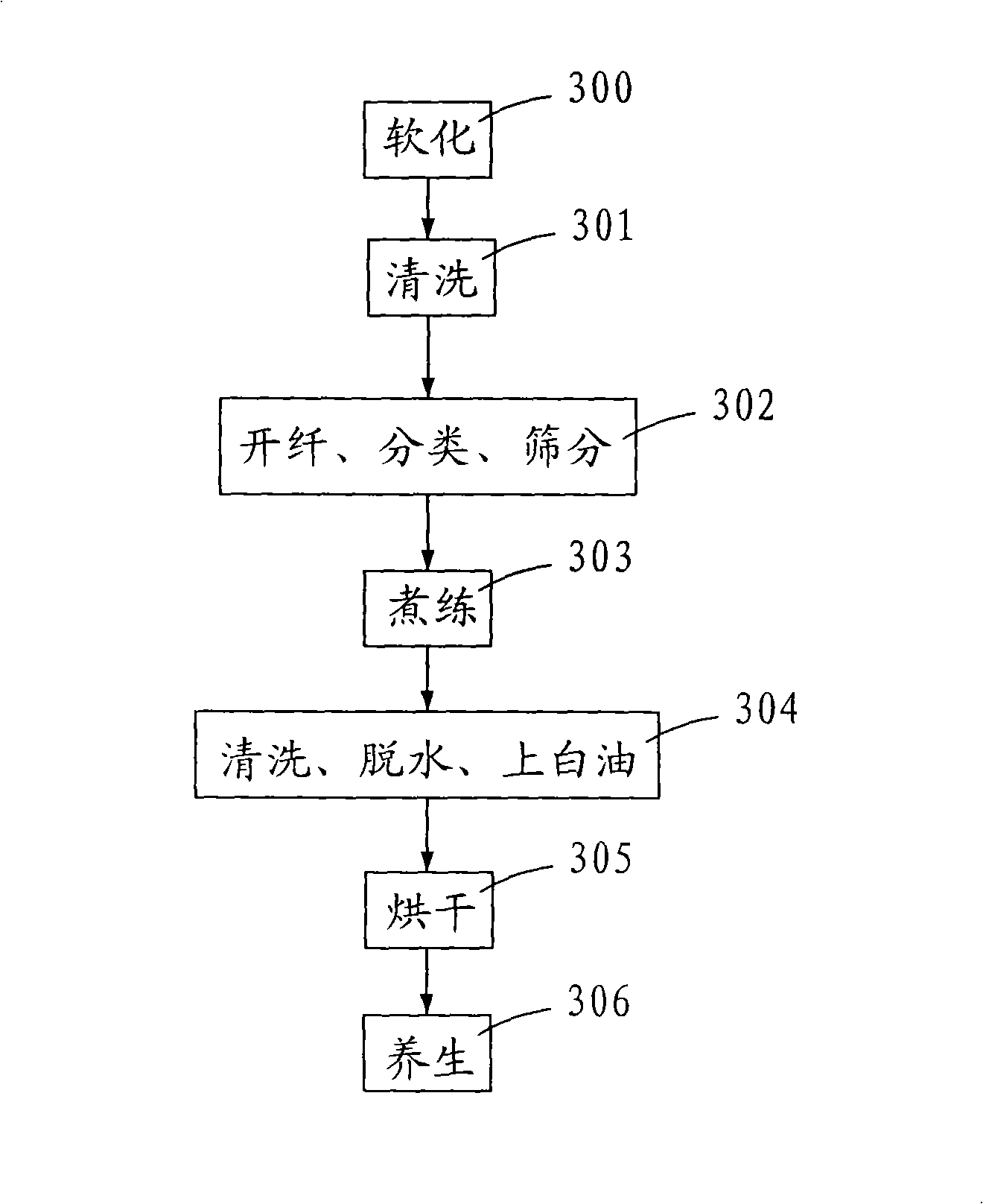

Production method for bamboo fiber

InactiveCN102433594AThe production process is stable and reliableImprove resource utilizationVegetable materialMechanical fibre separationChemistryFineness

The invention relates to a production method for bamboo fiber, which comprises steps of cutting, softening, fiber splitting, scouring, bleaching, cleaning, dewatering, drying, enzyme treatment and the like. An optimal fiber splitting point after bamboo is softened can be fully developed by a fiber splitting separator, machining parameters can be adjusted according to requirement, and different slenderness rates of the fiber are obtained to make the processed bamboo fiber finer and more uniform than original fiber. The production process is reliable, the resource utilization rate is high, the processing cost is low, environmental pollution is low, and the product quality is stable. The fine bamboo pure fiber produced by the invention has the characteristics of uniform length and fineness, high intensity, good flexibility, high moisture absorbing and releasing performance, high air permeability and particularly remarkable bacteria resistance and deodorization, is a new generation natural functional fiber which is cheap and has high quality and superior cost performance, and can be widely applied to fields of textile, building, automobiles and the like.

Owner:常熟市佳懿针纺织品有限公司

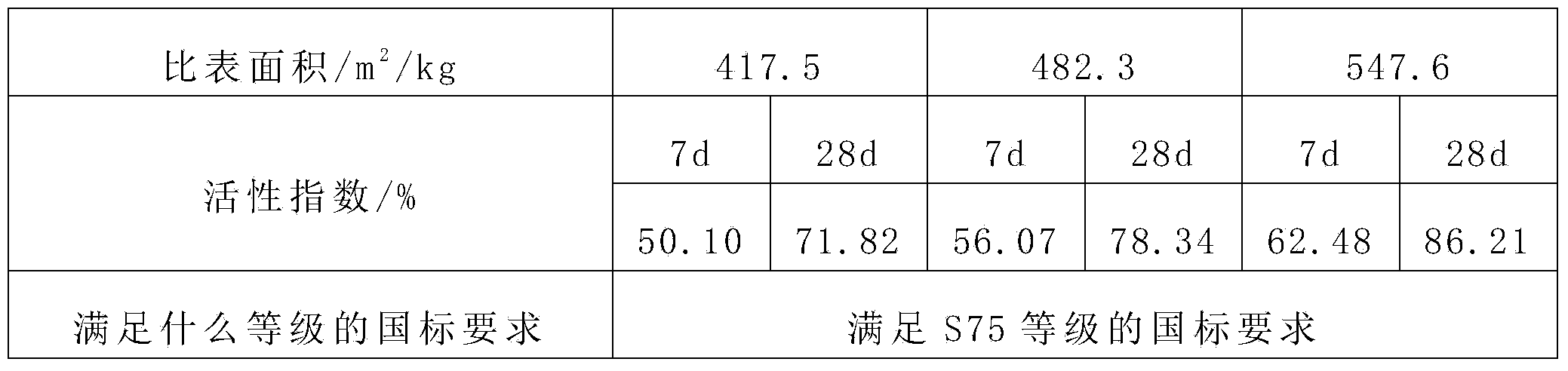

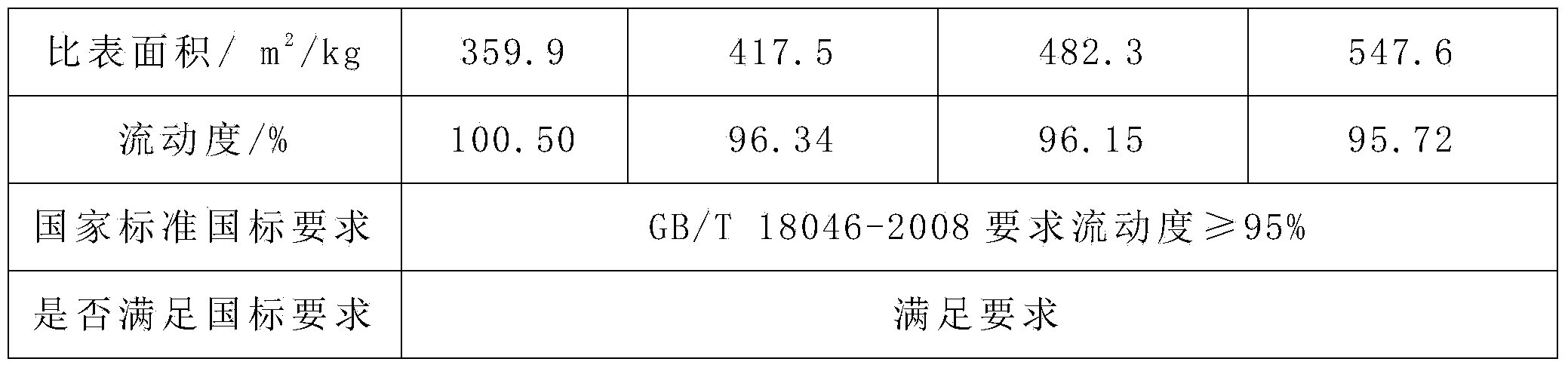

Nickel iron slag micropowder and preparation method thereof

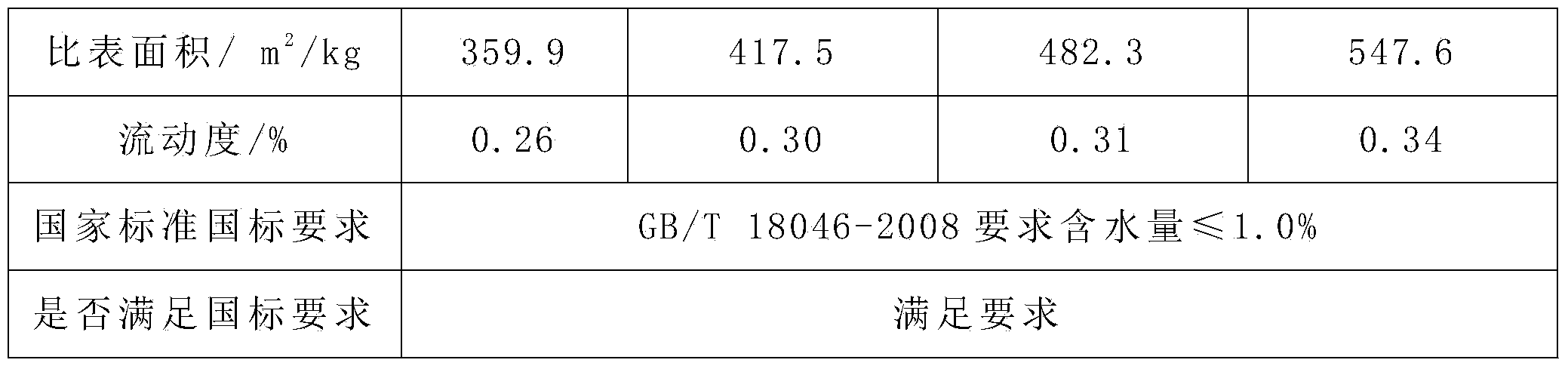

InactiveCN103771739AUniform surface area distributionImprove activity indexSolid waste managementSocial benefitsEcological environment

The invention relates to nickel iron slag micropowder and a preparation method thereof. The method comprises the following steps: performing magnetic separation on nickel iron slag taken as a raw material and grinding the nickel iron slag so as to obtain the nickel iron slag micropowder with the specific surface area being 359.9m<2> / kg to 550m<2> / kg. The specific surface area of the nickel iron slag micropowder is uniformly in distribution; the nickel iron slag micropowder with the certain specific surface area has a good activity index, thereby conforming to the international S75-level standard. In addition, the water content, the ignition loss and the like of the nickel iron slag micropowder all conform to rules in 'Granulated Blast Furnace Slag Powder Used in Cement and Concrete' of GB / T18046-2008. The prepared nickel iron slag micropowder can be taken as a blending stock of the cement and the concrete. Meanwhile, after the nickel iron slag micropowder is prepared from the nickel iron slag, the purposes of recycling wastes and turning wastes into wealth are realized. Thus, pollutions to atmosphere, soil and water, which are caused by the nickel iron slag, are lightened, namely, the ecological environment is optimized; the high added-value is obtained while the cost is low. As a result, the significant economic and social benefits are achieved.

Owner:SHANDONG WEIYE NEW BUILDING MATERIAL

Medicament carrying nano particles and preparation method and application thereof

InactiveCN102370622AGood water dispersibilityImprove solubilityPowder deliveryOrganic active ingredientsGlycolic acidPolyglycolide

The invention discloses medicament carrying polymer nano particles and a preparation method thereof in the technical field of pharmacy. The medicament carrying polymer nano particles contain medicaments and polylactic acid-methoxy polyethylene glycol (PLA-mPEG) or poly (lactic-co-glycolic acid)-methoxy polyethylene glycol (PLGA-mPEG). The molecular weight of the block polylactic acid (PLA) or the poly (lactic-co-glycolic acid) (PLGA) is 10,000 to 60,000, the molecular weight of the block methoxy polyethylene glycol (mPEG) is 2,000 to 5,000, and the block ratio of the PLA or the PLGA to the mPEG is (60:40)-(90:10). The preparation method of the nano particles avoids the defects of low medicament nano particle entrapment rate and serious burst release caused by using the conventional surfactant, complex removing steps and the like; and the medicament carrying polymer nano particles with high quality are synthesized by simplified processes and with relatively low cost.

Owner:ZHEJIANG UNIV

Chicken feed additive for producing selenium-rich eggs and application of chicken feed additive

InactiveCN104171427AImprove qualityImprove antioxidant capacityAnimal feeding stuffBetaineAnimal science

The invention provides a chicken feed additive for producing selenium-rich eggs. The chicken feed additive is characterized by being formed by mixing the following components in percentage by mass: 0.1-0.2 percent of methionine, 0.02-0.05 percent of vitamin E, 0.1-0.3 percent of vitamin C, 1-2 percent of choline, 1-2 percent of menotropins, 1-2 percent of betaine, 50-55 percent of Chinese herbal medicines, 0.2-0.5 percent of bacillus subtilis, 30-35 percent of tea dregs, 0.2-0.5 percent of selenium-enriched yeast and 5-10 percent of zeolite powder, wherein the Chinese herbal medicines are prepared by mixing pericarpium citri reticulatae, hawthorns and chilli according to a mass ratio of 1 to 1 to 1. According to the chicken feed additive for producing the selenium-rich eggs, the quality of the eggs can be obviously improved, and the production cost is lowered; meanwhile, the oxidization resistance, the stress resistance and the organ immunity of laying hens are improved; the chicken feed with the chicken feed additive can safely, stably and reliably produce the selenium-rich eggs.

Owner:WUHAN DINGWO BIOLOGICAL TECH

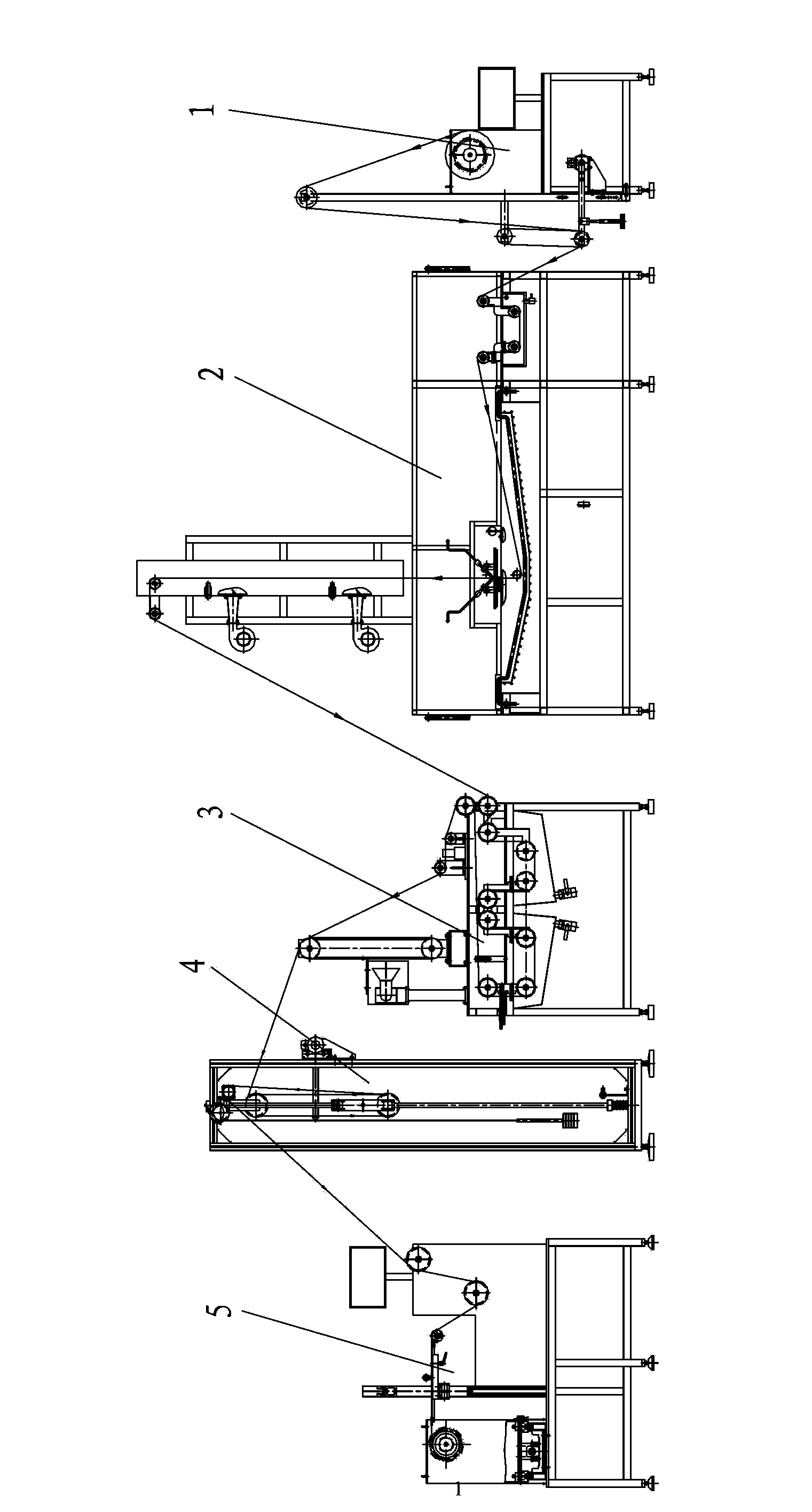

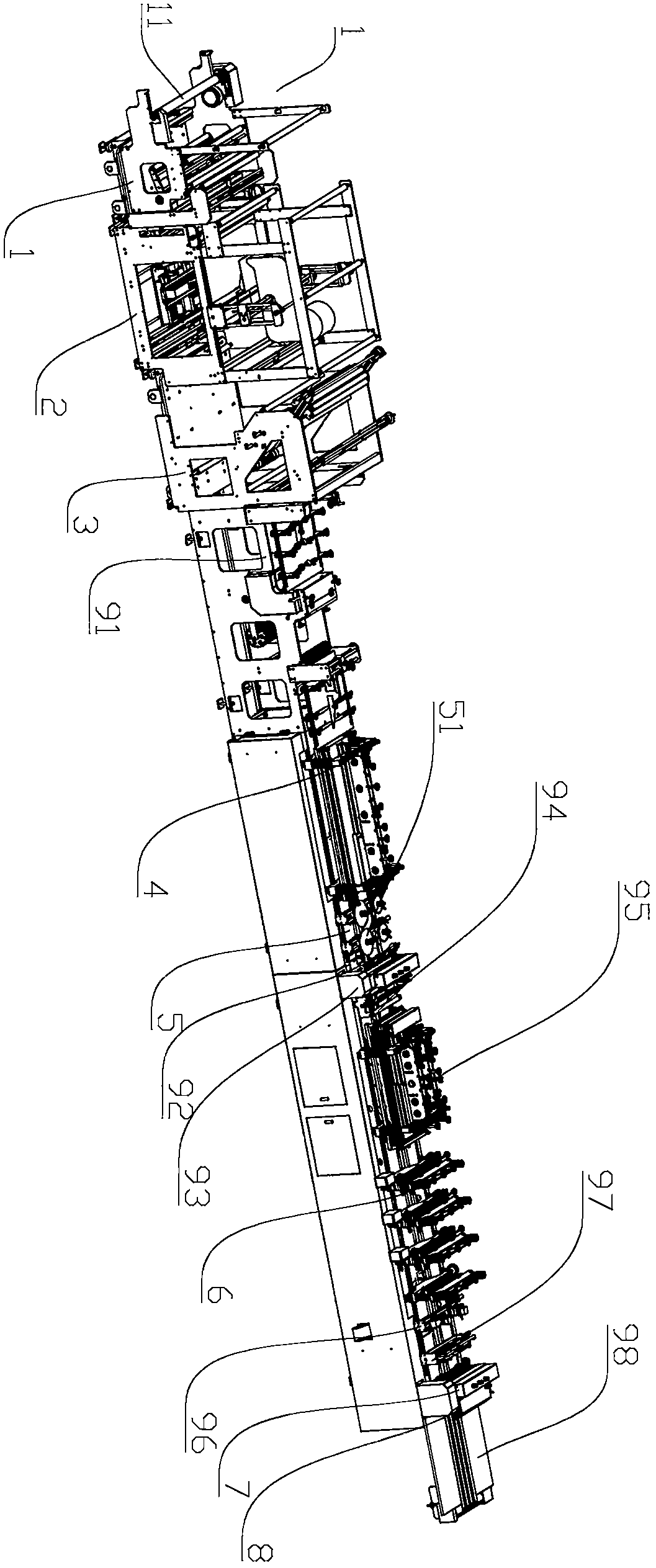

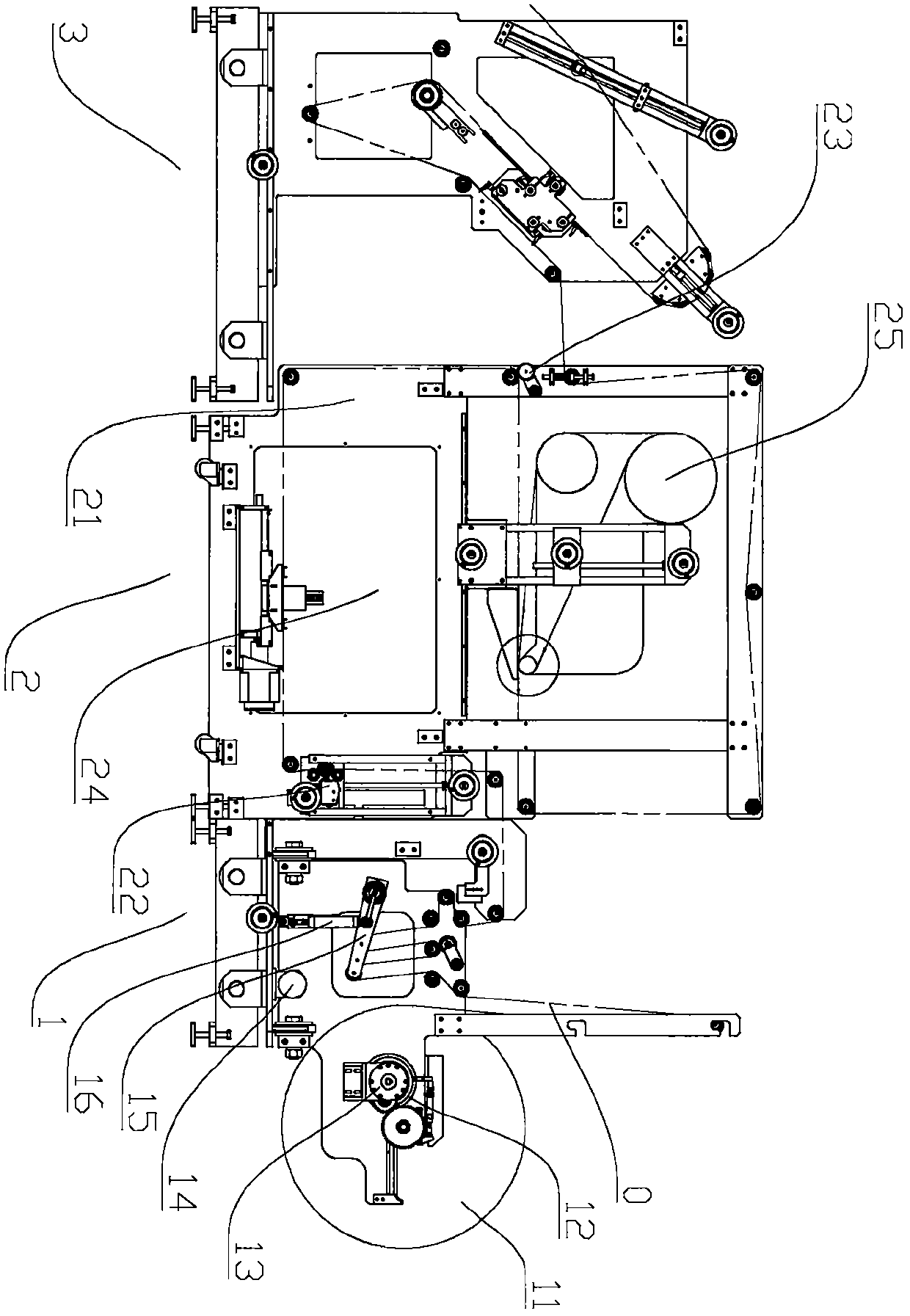

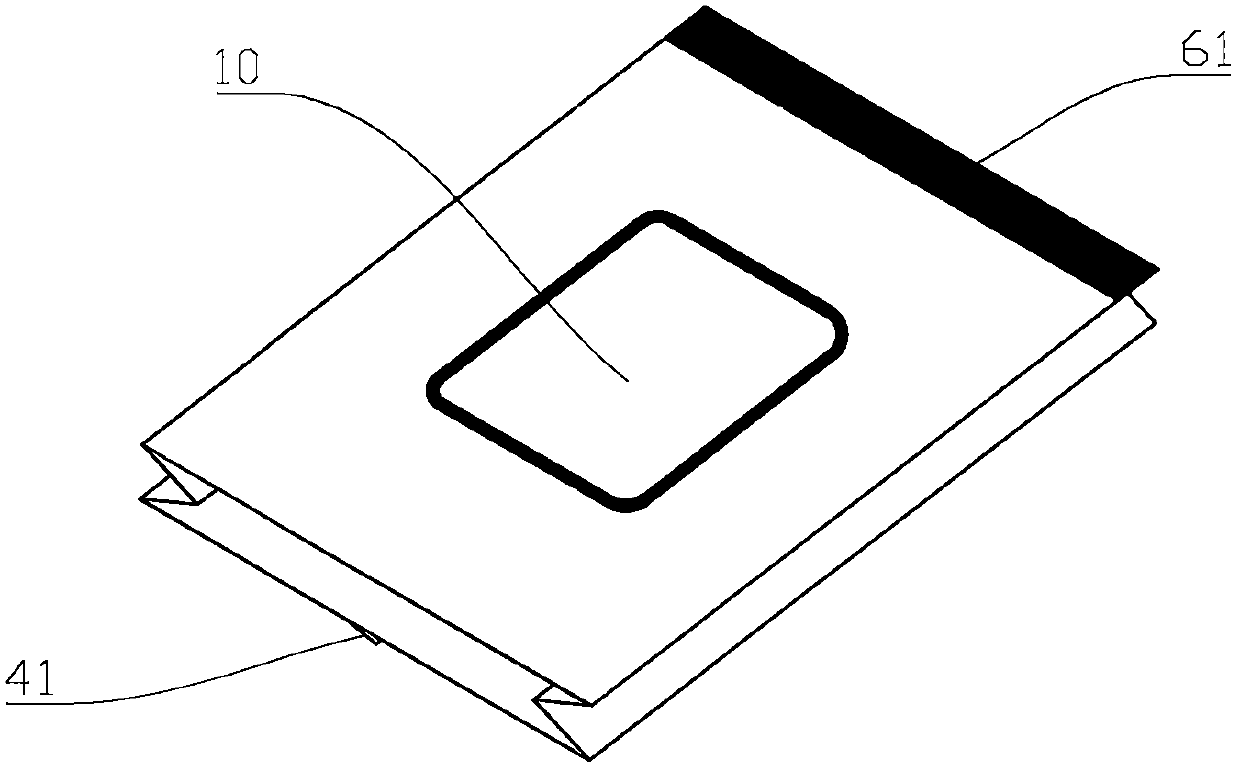

Middle seal labeling bag making machine

InactiveCN107775998AImprove processing efficiencyAvoid time costBag making operationsPaper-makingEngineeringFold-forming

The invention discloses a middle seal labeling bag making machine. In the moving trend of a film, the middle seal labeling bag making machine sequentially includes a discharging frame device, a punching labeling device, a folding forming device, a longitudinal sealing device, an organ forming device, a transverse sealing device, a second traction group and a cutter device, wherein the dischargingframe device is used for continuously and stably providing a film for a follow-up process; the punching labeling device is used for first punching the film conveyed by the discharging frame device andthen performing labeling; the folding forming device is used for performing continuous folding forming on the labeled film, folding the films on the two sides towards the middle and causing the filmsto be in lap joint in the middle positions of the films; the longitudinal sealing device is used for performing longitudinal heat sealing on the folded films at the lap joint position; the organ forming device folds in the edges of the two sides of the films having undergone longitudinal heat sealing towards the middle of the two layers of films; the transverse sealing device is used for performing transverse heat sealing on the films having been processed by a longitudinal sealing forming device; the second traction group is used for providing power for movement of the films; and the cutterdevice is used for slitting the well processed films to form finished products. According to the middle seal labeling bag making machine, automatic labeling treatment can be performed on a middle sealbag while the middle seal bag is processed.

Owner:冯葆如

Preparation method of rare-earth colorant

ActiveCN102120602APromote safe productionStable and reliable productionRare earth metal compoundsSolid carbonRare earth

The embodiment of the invention discloses a preparation method of a rare-earth colorant, comprising the step of subjecting a rare-earth compound, sulphur and solid carbon to reaction in an airtight reactor at 1,000-1,500 DEG C to obtain the rare-earth colorant, wherein the rare-earth compound is rare-earth carbonate or a rare-earth oxide. In the invention, two solid substances of the sulphur and the solid carbon are vulcanizing agent, the sulphur and the solid carbon react at high temperature to generate carbon disulfide, and then the carbon disulfide reacts with the rare-earth carbonate or the rare-earth oxide in an airtight system to generate rare-earth sulfides. Therefore, no hydrogen, hydrogen sulfide or carbon disulfide and other dangerous and toxic gasses are used in the invention to prepare the rare-earth colorant. The preparation method provided by the invention has the characteristics of safety and reliability for production. Meanwhile, because the reaction between the sulphur and the solid carbon is the solid-solid reaction, the preparation method provided by the invention is easy to realize industrial production and has high yield and low cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

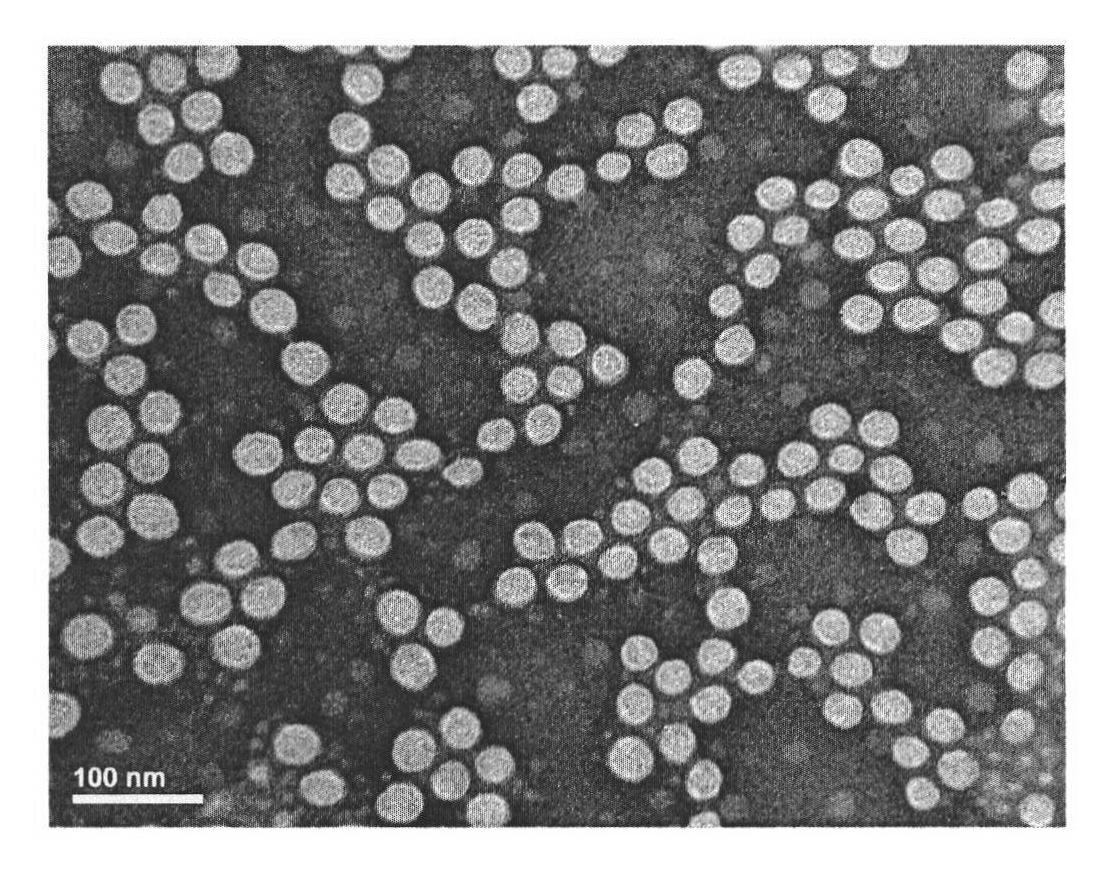

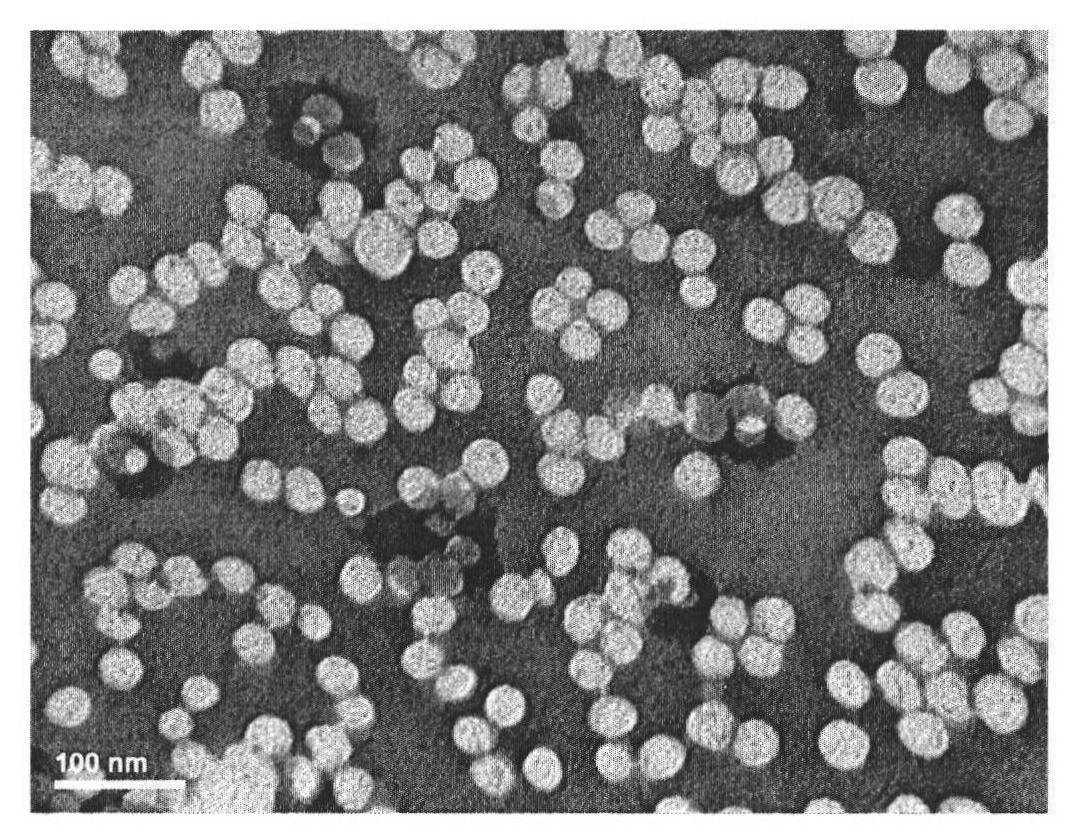

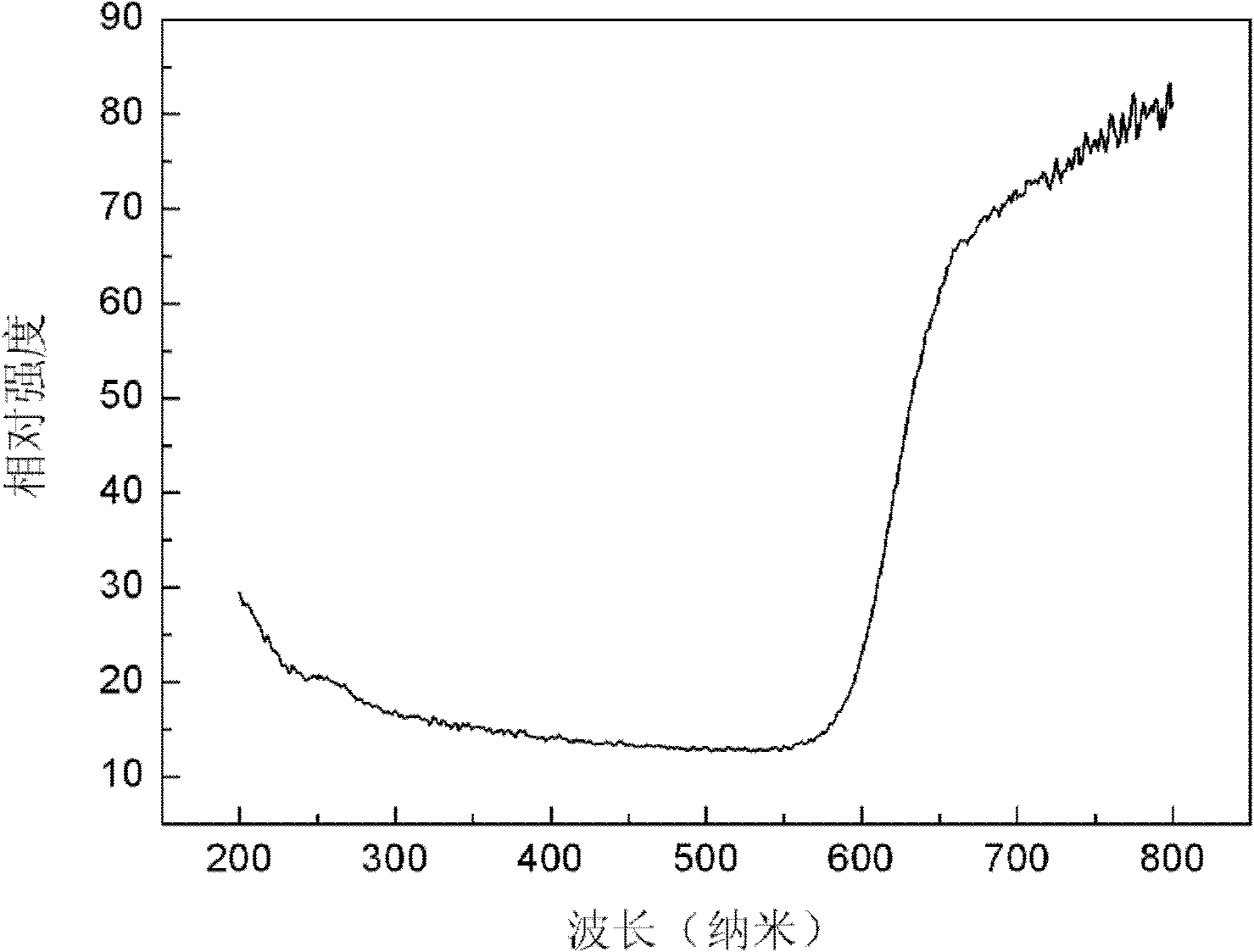

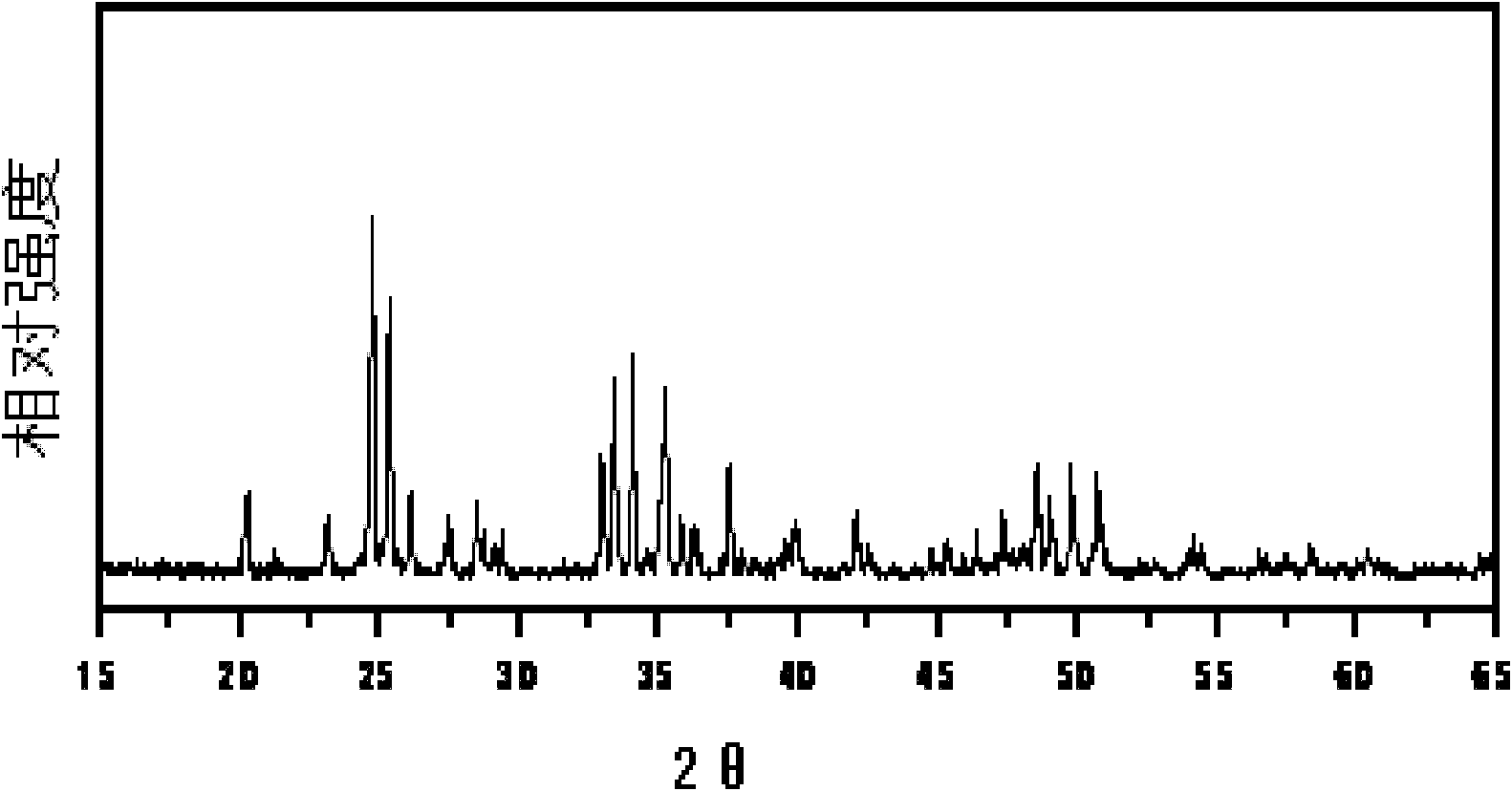

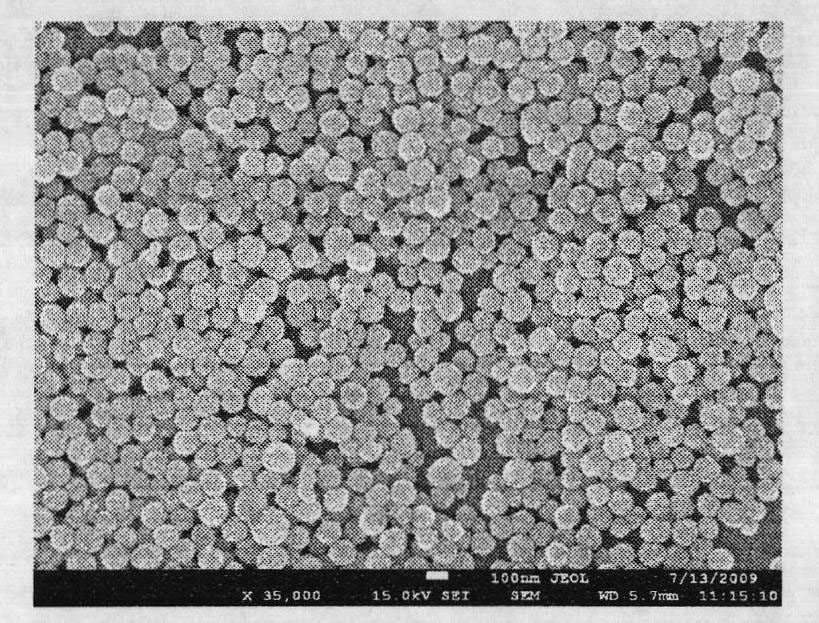

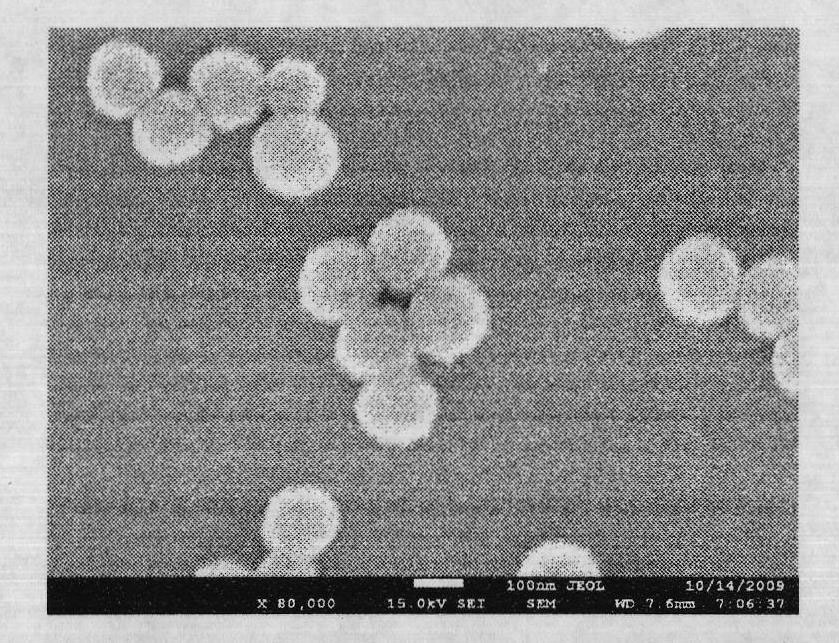

Method for preparing Ln2O3:RE<3+> and Ln2O3:RE<3+>@SiO2 monodisperse rare earth nano particles

InactiveCN101941676ARich energy level structureAchieve multi-color light emissionNanostructure manufactureDecompositionOrganic dye

The invention belongs to the technical field of rare earth materials and in particular relates to a method for preparing Ln2O3:RE<3+> and Ln2O3:RE<3+>@SiO2 monodisperse spherical rare earth oxide (REO) nano particles with uniform size. The Ln2O3:RE<3+> nano particles are in spherical shapes, and a SiO2 shell layer can be coated outside Ln(OH)3:RE<3+> nano sphere through controlling the experimental condition; the thickness of the shell layer can be regulated, and then Ln2O3:RE<3+>SiO2 can be obtained through firing; and the Ln2O3:RE<3+>SiO2 can be dispersed into an aqueous solution to form a stable hydrosol. When the nano particle product is used as a developer, the product has better stability, difficult decomposition and good light stability compared with clinically used organic dyes, is safer than radioactive elements and has attractive prospect in the aspects of biomedical imaging and fluorescent calibration. The invention has the advantages of simple operation, good repeatability, wide scope of application, stable physical and chemical properties of prepared materials, and the like.

Owner:JILIN UNIV

Production process for bamboo fiber

InactiveCN102433593AReduce pollutionImprove folding resistanceVegetable materialMechanical fibre separationFiberPulp and paper industry

The invention relates to a production process for bamboo fiber, which comprises steps of material selection, fiber splitting, classification, digestion, reduction, acid pickling, cleaning, dehydration, curing and the like. According to the production process, the whole piece of bamboo is directly processed after being flatten by a special tool under the condition of no cutting and splitting, a mode of bamboo eaten and fiber spit is realized, the production process is free from the limitation of bamboo varieties, bamboo age, bamboo joint and bamboo diameter, a heat-force-chemical multi-field coupling principle is adopted in a bamboo fiber splitting separator to make the machined bamboo fiber longer, finer and more uniform than original fiber, edges and unprocessed bamboo are a few, and an additive is added, so that a product has high folding resistance and flame retardance. The production process is reliable, the resource utilization rate is high, the processing cost is low, environmental pollution is low, the product quality is stable, and the problem of high-efficiency mass production of fine and long bamboo pure fiber is effectively solved.

Owner:常熟市佳懿针纺织品有限公司

Fire extinguishing agent prepared from grapheme and superfine materials

The invention relates to a fire extinguishing agent prepared from grapheme and superfine materials. The fire extinguishing agent takes water as a carrier, and is prepared from 0.1-8.5 parts of modified grapheme, 0.8-5 parts of additive and surfactant, 8-35 parts of antifreeze agent, 2-15 parts of fire retardant, 1-9 parts of thickener, 0.1-0.5 part of preservative, and 27-88 parts of water. The fire extinguishing agent is pumped or driven with inert gas to be jetted for extinguishing a fire. A large amount of hydrophilic oxygen-containing functional groups are contained on the surface and the edge of the surface of modified grapheme, so that grapheme can be stably dispersed in a water solution, and the hydrophilic oxygen-containing functional groups can enable grapheme to be modified covalently and non-covalently; since grapheme is very large in specific surface area, very high in strength and high in thermal stability, grapheme can be combined with a solution in the fire extinguishing agent to form a superfine and ultra-thin liquid membrane and foam, which cover the fire; and grapheme is a nanomaterial with high lubricating property, and takes the effect of a drag reducer in the fire extinguishing agent. The fire extinguishing agent is high in fire extinguishing efficiency, is harmless to the human body, does not corrode devices, is energy-saving, environmental-friendly and safe.

Owner:胡泽军

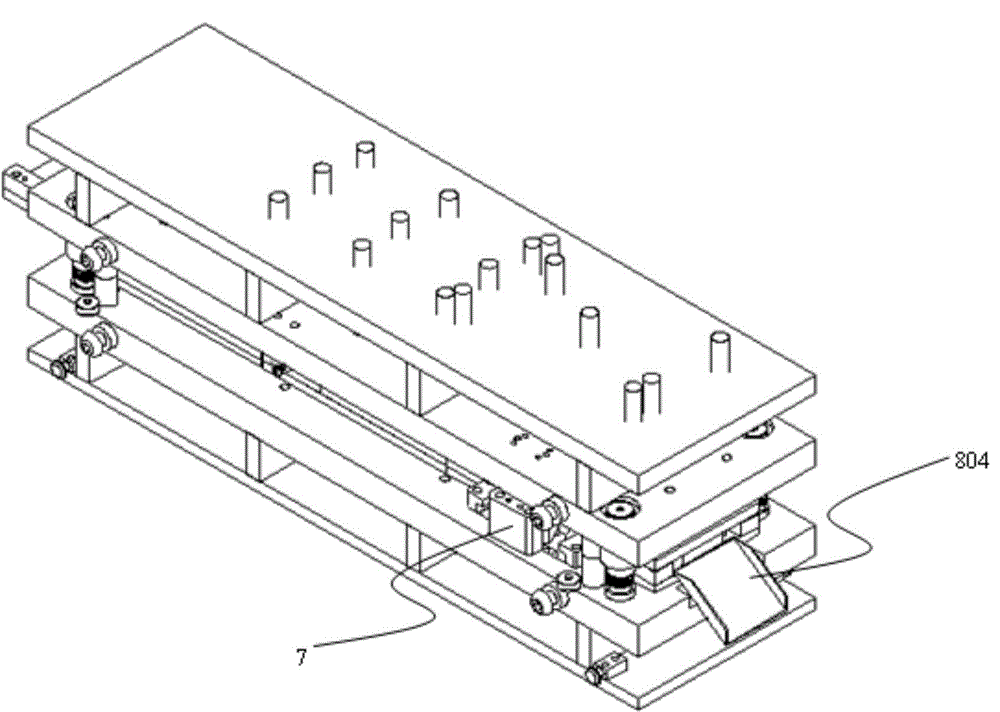

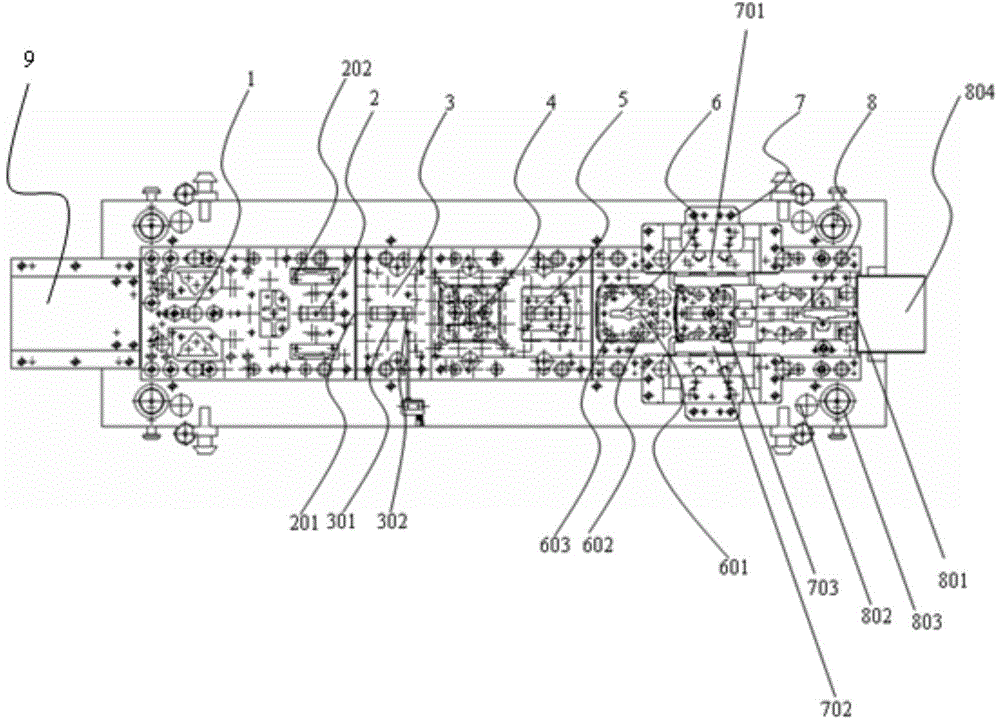

Continuous punching mold of vehicle engine cabin

InactiveCN104889243AExtended service lifeEliminate defective productsShaping toolsMetal-working feeding devicesNacelleEngineering

The invention discloses a continuous punching mold of a vehicle engine cabin. The mold comprises a guide traction lubrication structure, a leveling limiting fixed-length punching structure, a horizontal feeding structure, a hole position primary positioning punching and secondary horizontal positioning pull structure, a continuous punching waste dropping and feeding material detecting structure and a flat cutter discharge structure. A steel strip to be machined is sprayed with lubricant by itself, and is driven by a traction sub-mold to forwards move. Then, the steel strip enters the leveling limiting fixed-length punching structure to finish the striping fixed-width punching, and enters the horizontal feeding structure to perform the hole position primary positioning punching; the secondary horizontal positioning pull structure guarantees the continuous horizontal forward movement of materials; when the steel strip enters the continuous punching waste dropping, the product is basically molded; the steel strip is fed into the material detecting structure to detect the punching aperture and the striping fixed-length size; and finally, the flat cutter discharge structure performs the fixed-length cutting discharge. The six procedures of leveling, striping, feeding, punching, detection and discharge in the engine part machining process are integrated and finished by one set of mold, so that the production flow is shortened, the production efficiency is improved, the production cost is reduced, and the mold is suitable for continuous large-batch production.

Owner:HEFEI HAODONG PRECISION IND CO LTD

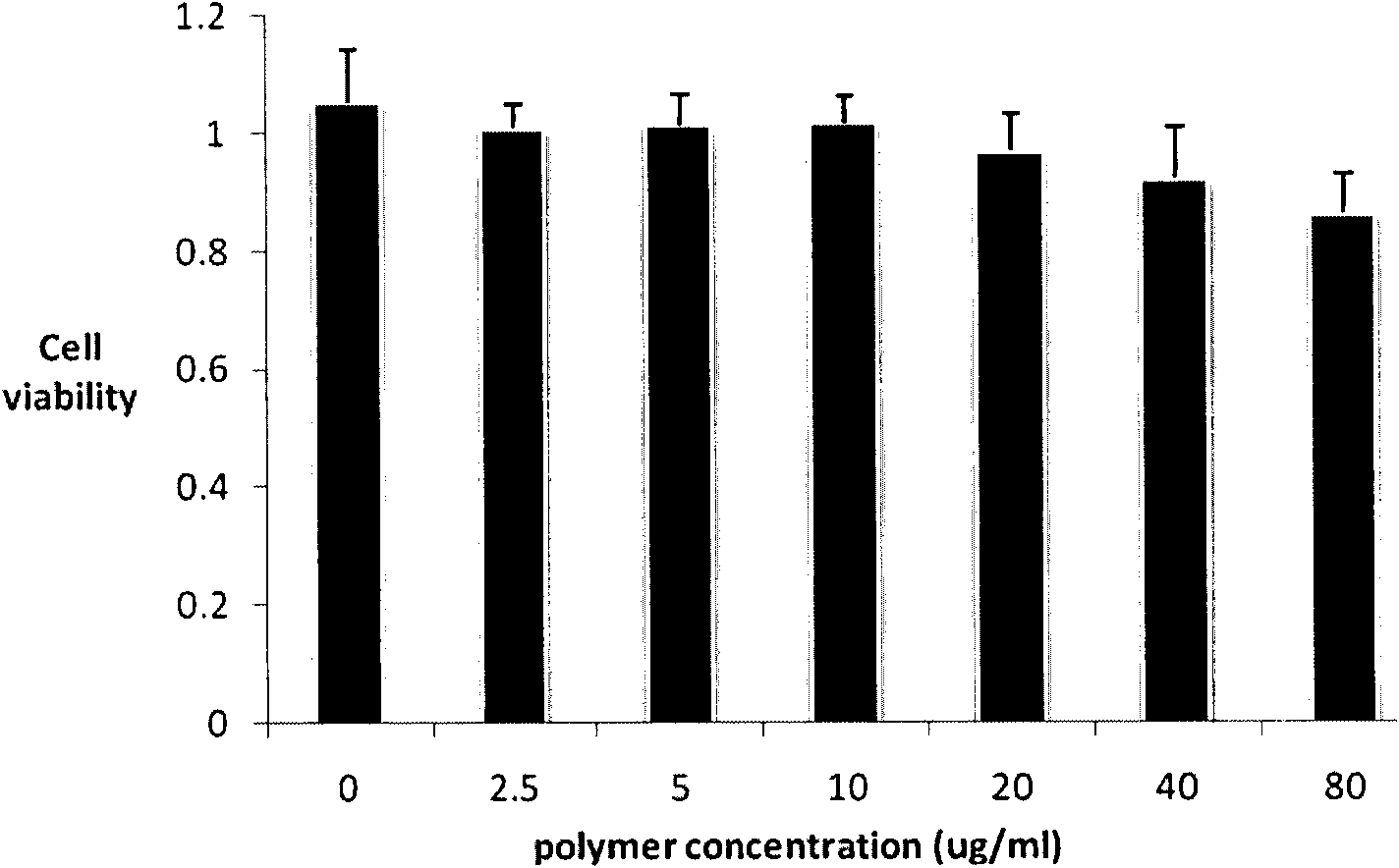

Vibrio harveyi recombined outer-membrane protein Ompk microspheres vaccine and preparation method thereof

InactiveCN101507815AHigh antigen contentLong release timeAntibacterial agentsPharmaceutical non-active ingredientsAntigenSide effect

The invention discloses a microsphere vaccine and a preparation method thereof. The vaccine is the microsphere vaccine which is prepared from recombinant outer-membrane protein Ompk of vibrio harveyi as a common mariculture fish pathogen, as well as biodegradable polymer materials through emulsification and drying. The microsphere vaccine is simple in preparation process, convenient for factory production, stable and reliable in production, safe and convenient to use, and the product yield reaches more than 80 percent. The microsphere vaccine has the advantages of high antigen content, long sustained release time, few toxic-side effects, convenience for large-scale application and the like. The prepared microsphere vaccine which is orally taken for immunization can stimulate an immune system to produce immune response in a long period of time, has high relative protection ratio to tested fishes, and can effectively prevent mariculture fish vibriosis.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

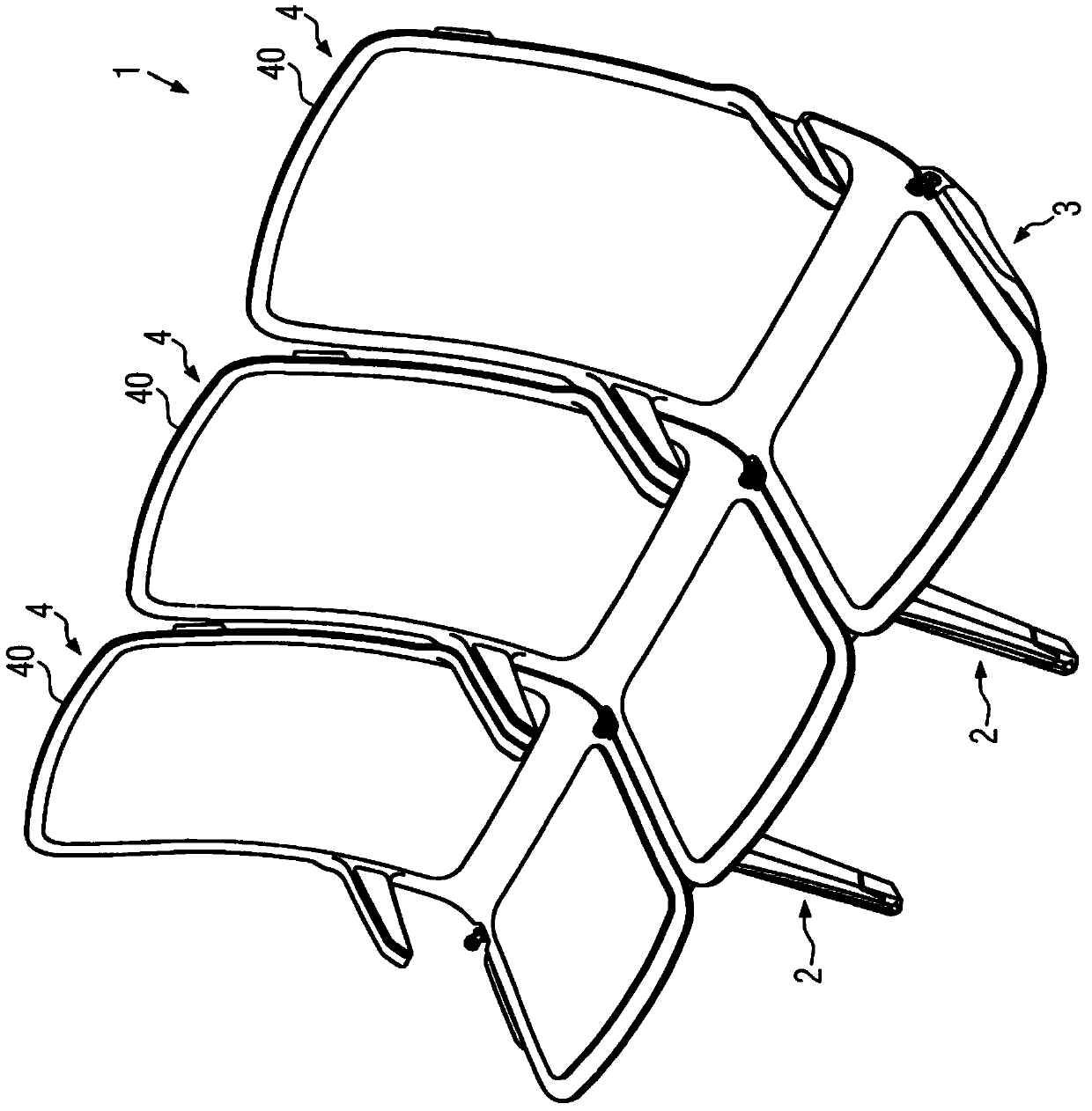

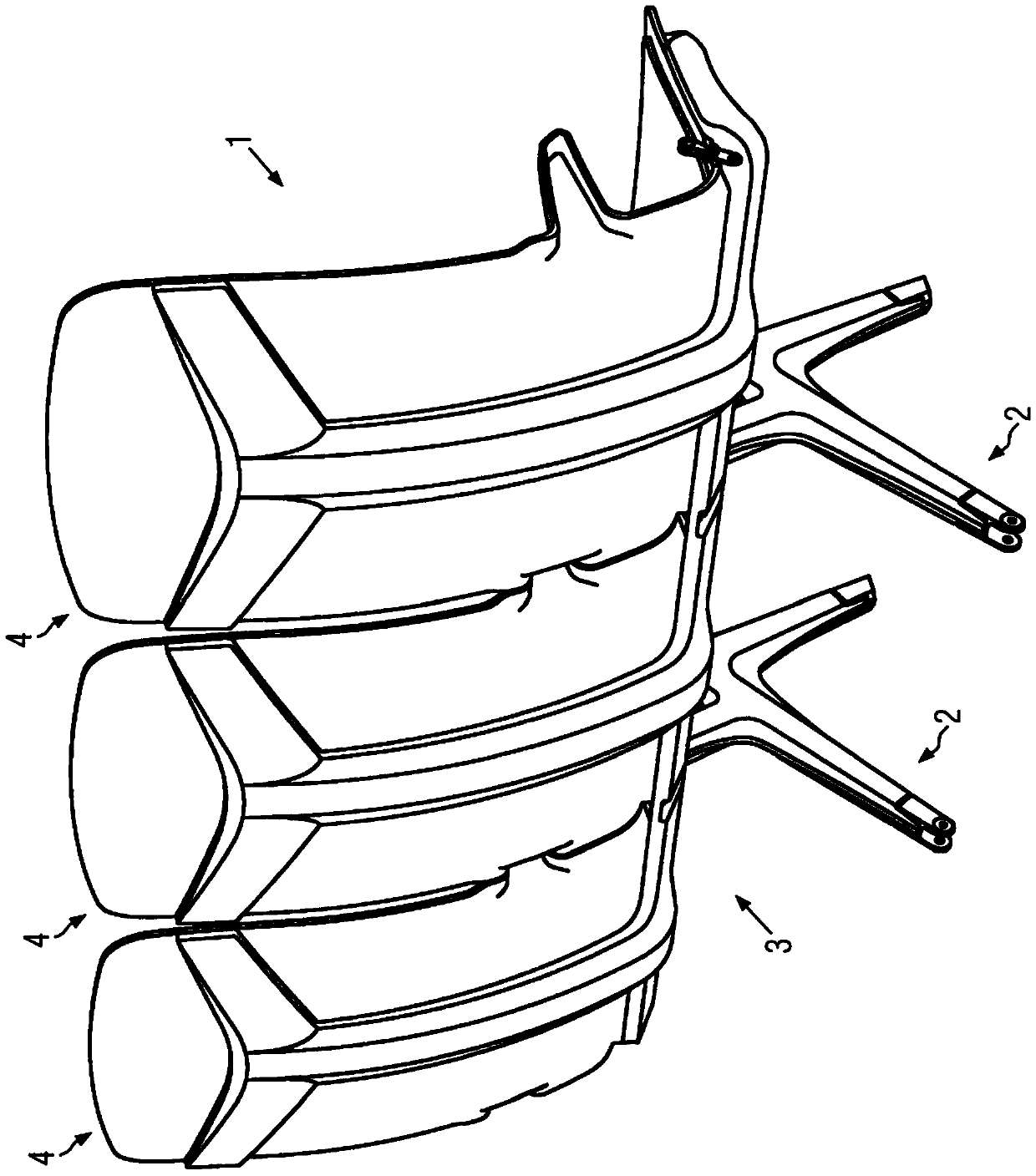

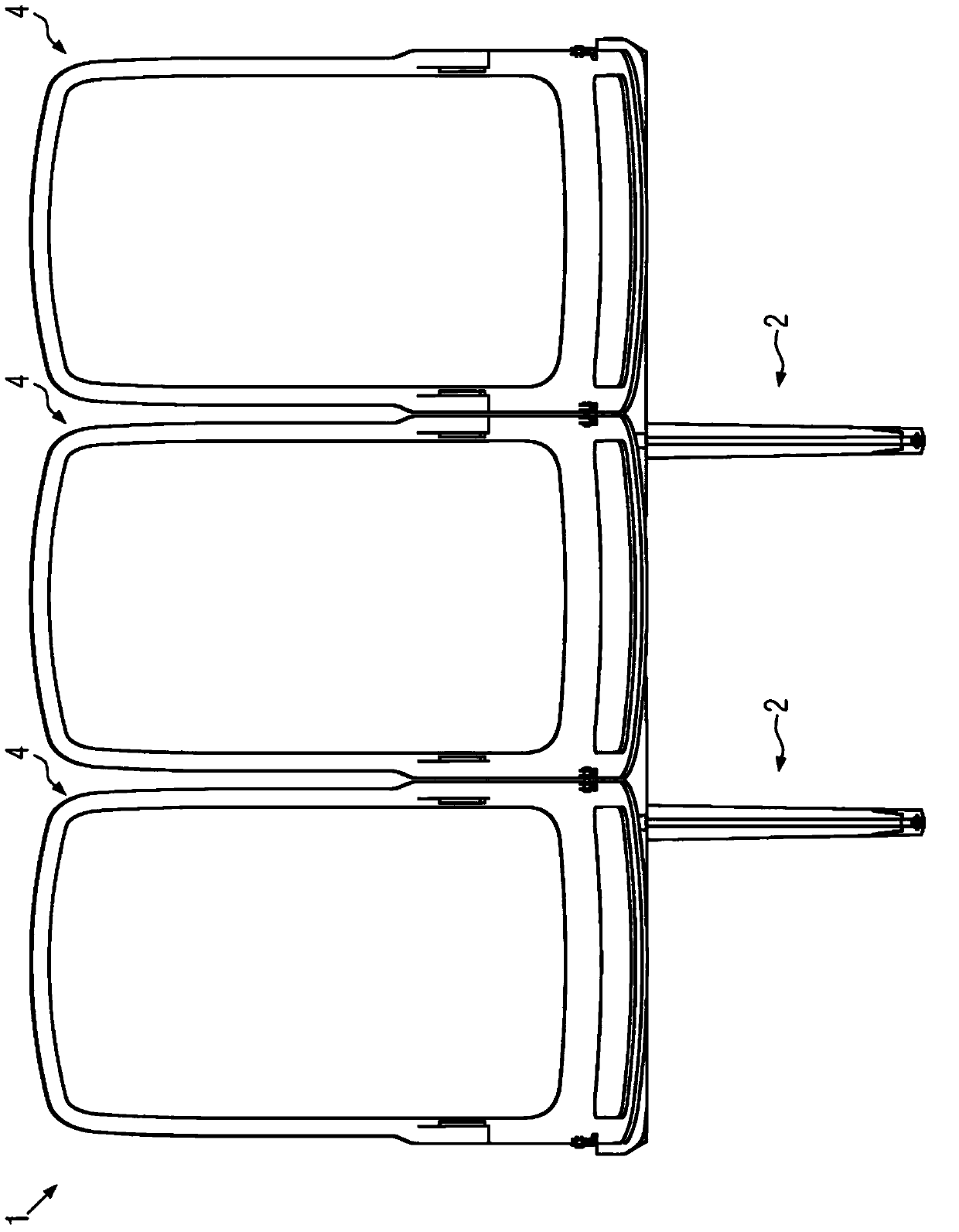

Lightweight aircraft passenger seat assembly

InactiveCN103991550AReduce complexityReduce sizeSeating arrangementsWeight reductionFlight vehicleControl theory

The invention relates to a lightweight aircraft passenger seat assembly, comprising at least one seat portion and at least one supporting portion for supporting the at least one seat portion relative to an aircraft structure. In order to provide an improved lightweight aircraft passenger seat assembly having a reduced weight, size and complexity as compared to conventional lightweight passenger seat designs, the invention provides a lightweight aircraft passenger seat assembly, comprising at least one seat portion with at least one seat shell for an aircraft passenger and at least one supporting portion for supporting the at least one seat portion relative to an aircraft structure, wherein the at least one seat shell and the at least one supporting portion are constructed as lightweight components.

Owner:COMPOSITE DESIGNS EU

Non-pollution production method of bamboo fibers

ActiveCN102517642AEfficient productionNo harmVegetable materialMechanical fibre separationFiberPollution

The invention provides a non-pollution production method of bamboo fibers, wherein the method is used for producing coarse bamboo fibers with lengths of 60-120 mm and diameters of 0.18-0.35 mm. the method comprises the steps of: firstly, selecting the raw materials; and then, cutting the bamboos into regulated lengths; splitting or flattening the bamboos; adding a reusable neutral softening solution in the bamboos to stew and soften the bamboos; roasting the softened bamboos on a drying machine; directionally opening fibers from the roasted bamboos; drying the bamboos, opening fibers for the second time, classifying and sorting to obtain bamboo fibers with stable quality. The method of the invention has the advantages of non waste liquid drainage during the production process, simple technique, high production efficiency, reliable product quality, and capability of greatly improving the fiber yield and reducing the production cost, so that the method is an ideal method for producing bamboo fibers.

Owner:ZHEJIANG FORESTRY UNIVERSITY

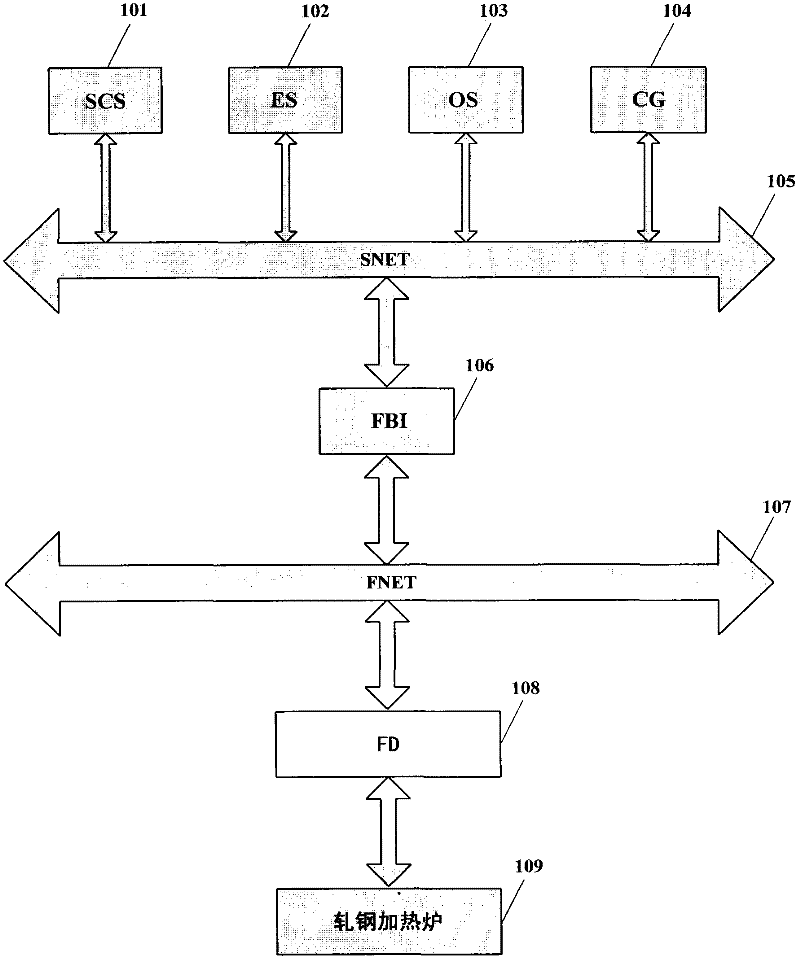

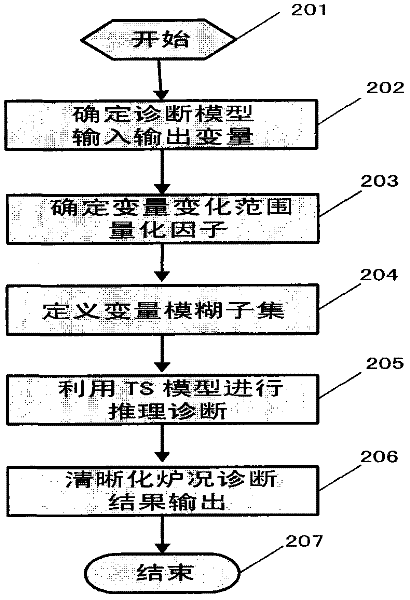

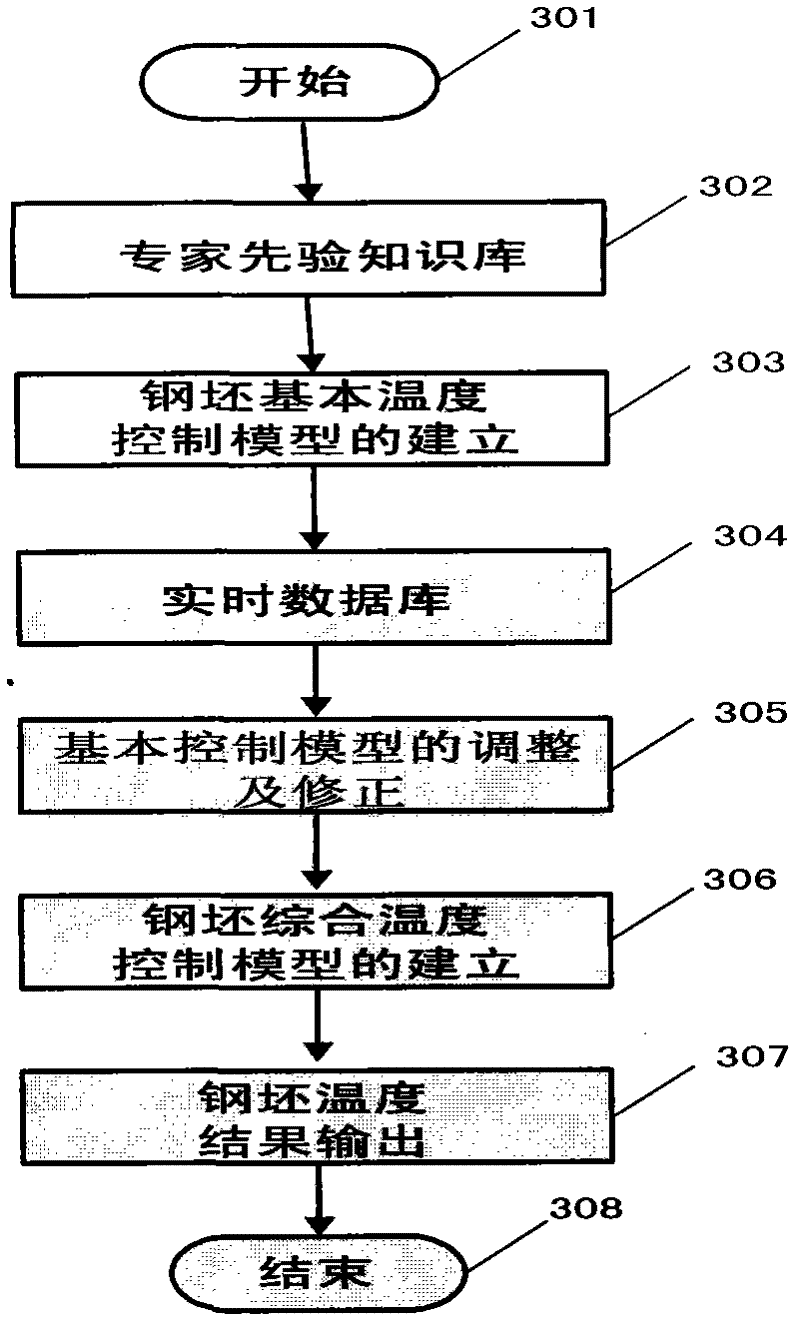

Integrated-type control system of roll steel heating furnace

InactiveCN102637020APrevent signal wave reflectionHighly integratedTotal factory controlProgramme total factory controlTemperature controlFurnace temperature

The invention relates to an integrated-type control system of a roll steel heating furnace. The integrated-type control system of the roll steel heating furnace comprises a control computer system [101], an engineer control machine [102], an operator computer [103], a computer gateway [104], a monitoring network [105], a field bus interface [106], a field bus network [107], a field bus instrument and an auxiliary device [108]; and the integrated-type control system of the roll steel heating furnace is characterized in that the monitoring computer system also comprises a furnace condition diagnosing module, a billet temperature control module and a furnace temperature rising optimal control module, wherein the furnace temperature rising optimal control module is used for realizing the furnace condition diagnosing, the billet temperature control and the furnace temperature rising optimal control during the production process of the roll steel heating furnace, and a control method provided by the monitoring computer system is used for carrying out information fusion by integrating multiple modules, realizing advanced control strategy of the monitoring computer system, carrying out optimization and coordination control, diagnosing, forecasting and analyzing the furnace condition of the heating furnace and ensuring the safe production. According to the integrated-type control system of the roll steel heating furnace, provided by the invention, under a complex condition, the production process of the roll steel heating furnace can be effectively and integrally controlled, the production efficiency and the billet heating quality are increased, the energy consumption is reduced, the safe and stable operation of the heating furnace is ensured, and thus a high-quality, low-consumption and high-yield production target of the roll steel heating furnace and a safe, stable and balanced control standard are achieved.

Owner:WUHAN UNIV OF SCI & TECH

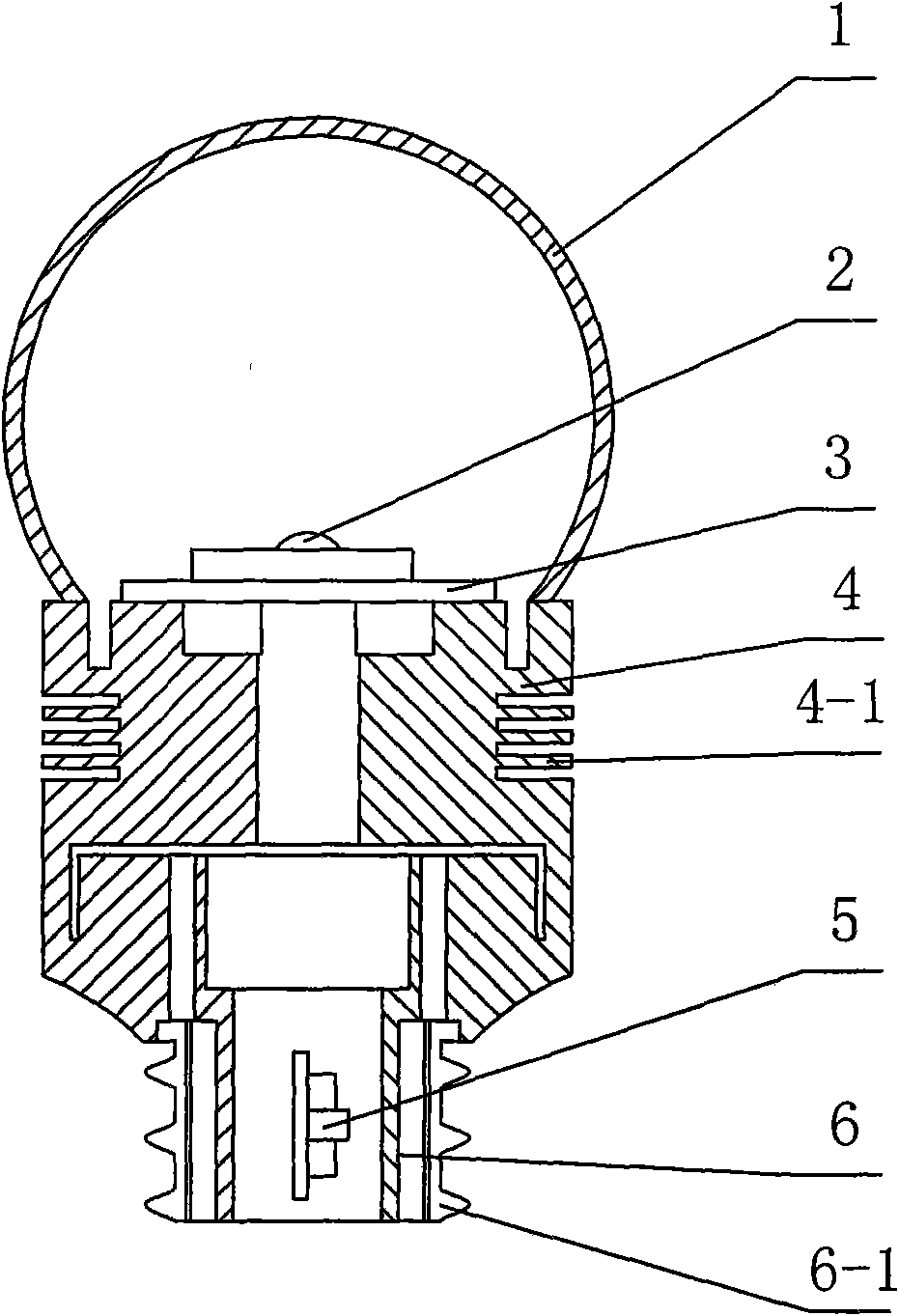

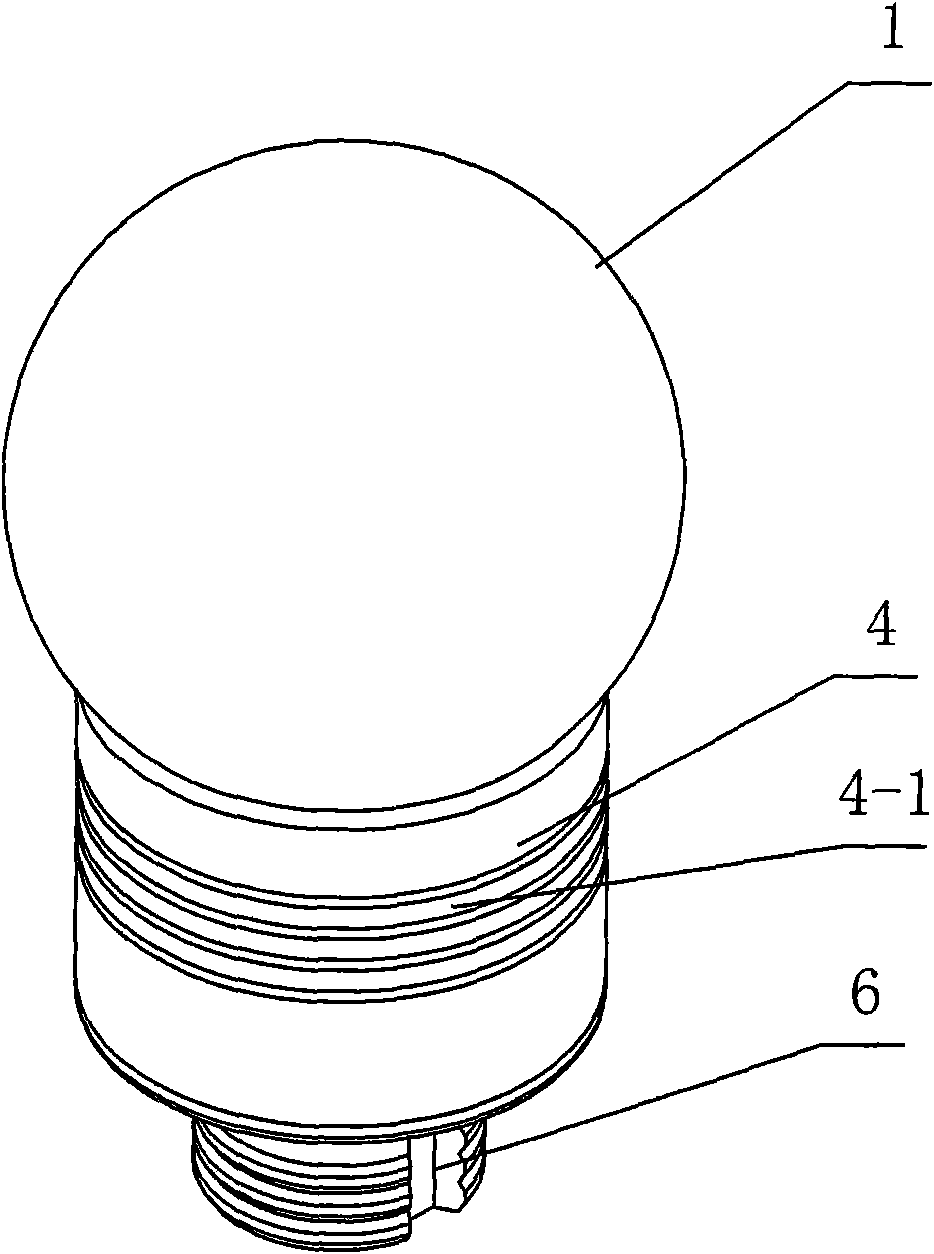

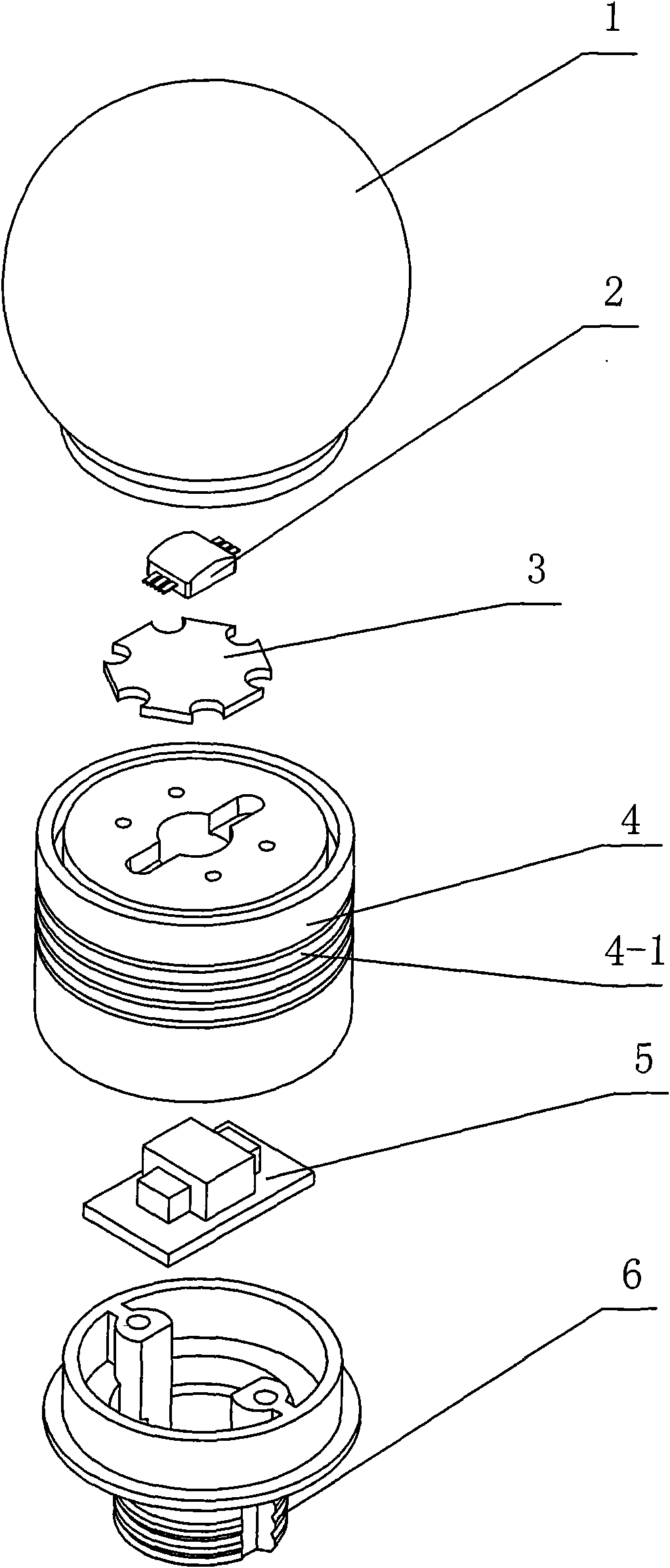

High power LED bulb

InactiveCN101614344AIncrease brightnessImprove performancePoint-like light sourceElectric circuit arrangementsEngineeringConstant current

The invention relates to a high power LED bulb, which comprises a connector for being connected with an illuminating lamp interface, an LED constant-current driving device, a radiator, an LED light source, a bulb cover and a circuit board, wherein the connector is provided with a cavity, and the LED constant-current driving device is fixed in the cavity; the radiator is a ceramic radiator with an annular radiating fin, and the upper part of the connector is fixedly connected with the lower part of the radiator; the circuit board is an aluminum-based circuit board, and the LED light source is fixed on the circuit board; and the circuit board is fixed at the top end of the radiator, the bulb cover is arranged above the radiator, and the lower part of the bulb cover is fixedly connected with the radiator. The high power LED bulb has the advantages of high luminescent efficiency, good heat dissipation effect, low cost, simple production and reliable performance.

Owner:JIANGSU GUOXING ELECTRIC EQUIP

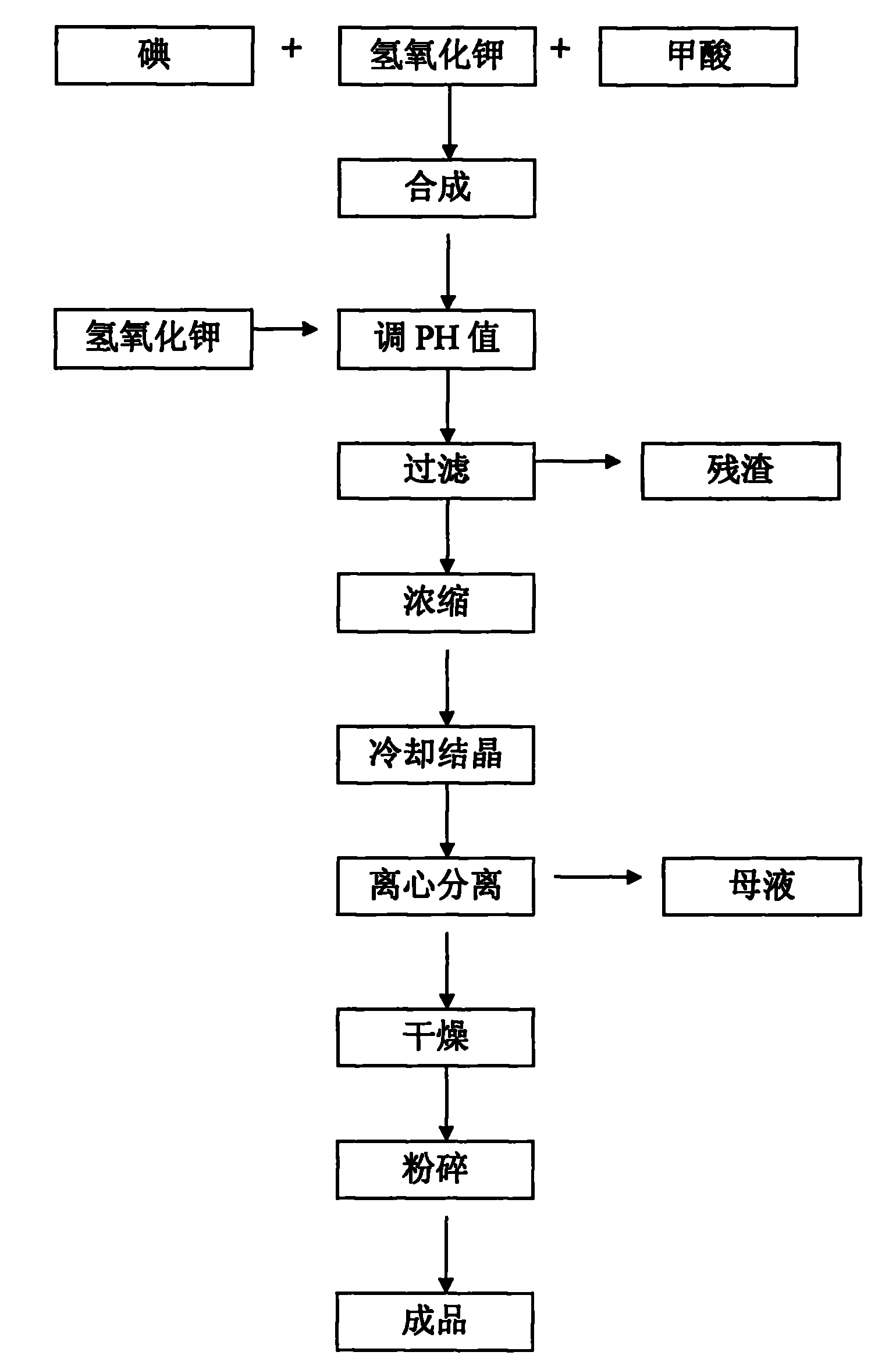

Preparation method of potassium iodide

InactiveCN102101683APromote safe productionEasy to produceAlkali metal iodidesEvaporationPotassium hydroxide

The invention relates to a preparation method of potassium iodide. The preparation method is implemented based on the following technical scheme: (1) adding 765 parts of iodine tablets in a reaction container with a stirrer, then adding distilled water, and stirring; slowly adding 337 parts of potassium hydroxide solution with the relative density of 1.3 under the state of stirring until the reaction is complete, wherein when the solution in the reaction is puce and the pH value of the solution is 5-6, potassium iodate crystals occur in the container; and (2) slowly adding 277 parts of formic acid solution in the solution to reduce the potassium iodate, then adding potassium hydroxide for regulating the pH value to 9-10, introducing steam, carrying out heat preservation for 1-2 hours, standing, filtering to remove undissolved substances so as to obtain a silvery solution, carrying out evaporation concentration until most crystals are separated out, carrying out cooling crystallization and centrifugal separation, and drying, so as to obtain a finished product. According to the preparation method of the potassium iodide, the potassium iodide can be safely, conveniently and reliably produced, and the large-scale production is ensured to be possible, thus the preparation method can be widely applied.

Owner:庄朝晖

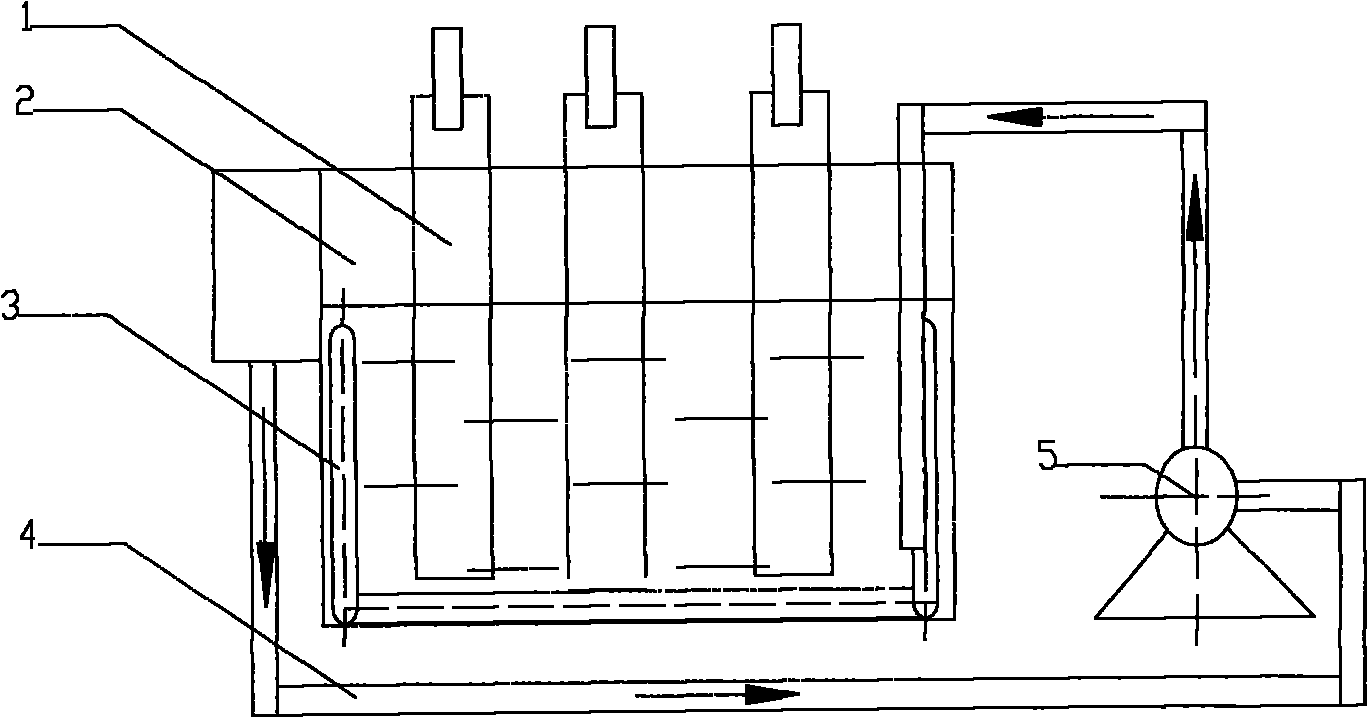

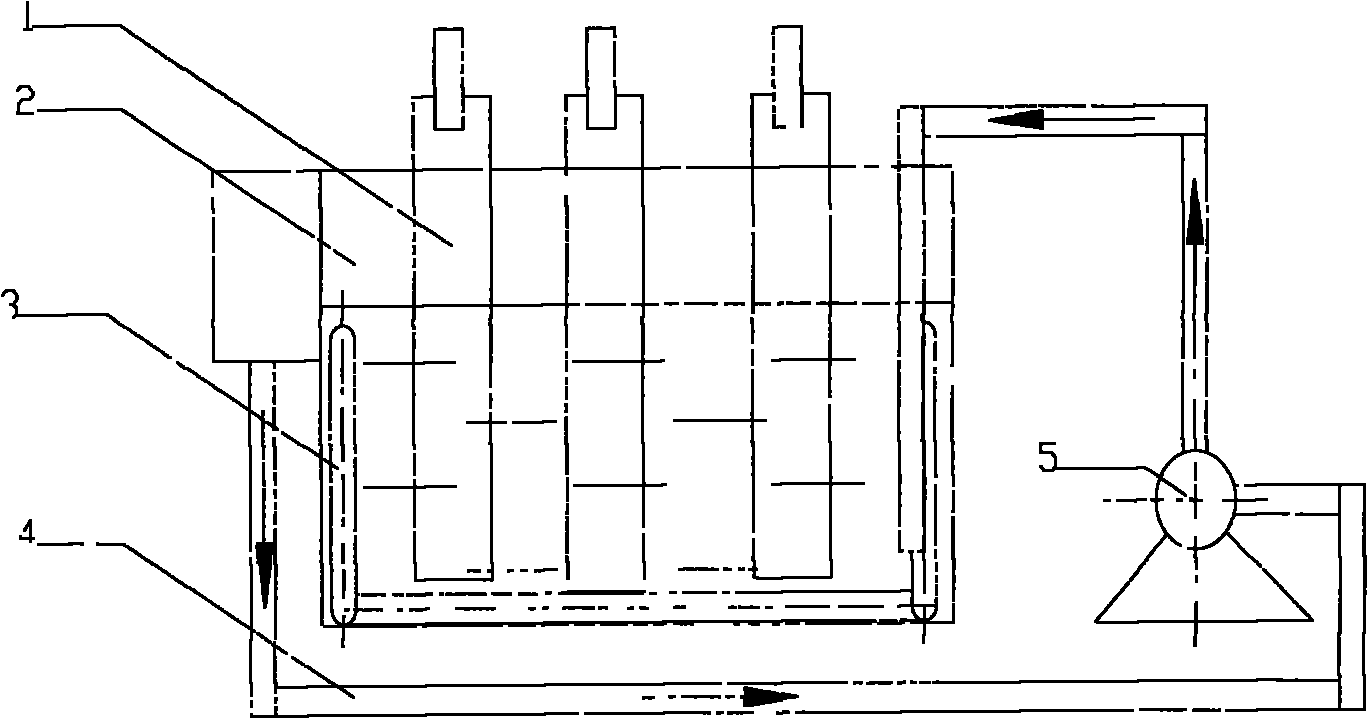

Process and special equipment for plating copper on special steel piece with deep/blind hole

InactiveCN101942682AImprove stabilitySimple and fast operationElectrolysis componentsCopper platingAlcohol

The invention discloses a process for plating copper on a special steel piece with a deep / blind hole, namely render copper. The process comprises the following steps of: chemical deoiling, washing with hot water, electrolytic deoiling, washing with hot water, washing with cold water, acid washing, secondary washing with cold water, neutralizing, washing with cold water, plating copper without cyanide, secondary washing with cold water, plating tin, secondary washing with cold water, neutralizing, washing with hot water, passivating, secondary washing with hot water, washing with hot pure water, dehydrating with alcohol, removing the residual water, drying and inspecting, wherein electroplate liquid used in the step of plating copper without cyanide has the following formula: 400 to 600ml / L of BH-580 non-cyanide alkaline copper cylinder plating bath solution, 1 to 2ml / L of BH-580 non-cyanide alkaline copper brightening agent and 7.5 to 12g / L of metal copper; and the pH value is 9.2 to 9.8. The process has the advantages of good stability of a plating liquid, simple and convenient operation, good dispersibility and good covering capability; the formed plating layer has the advantages of fine and compact crystallization, good adhesive force, stable and reliable production; and the method can effectively protect environment and the physical and psychological health of operators.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

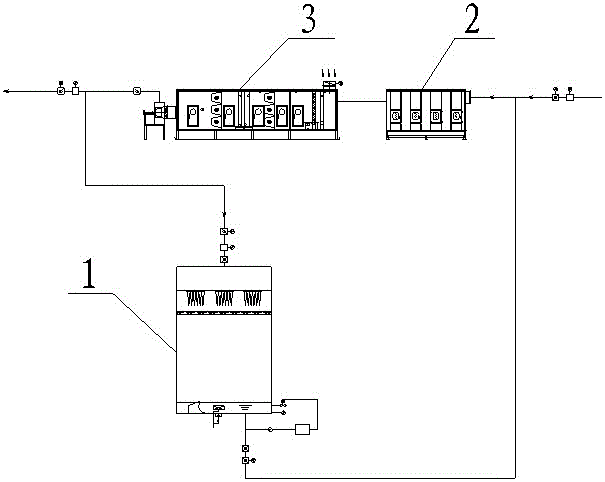

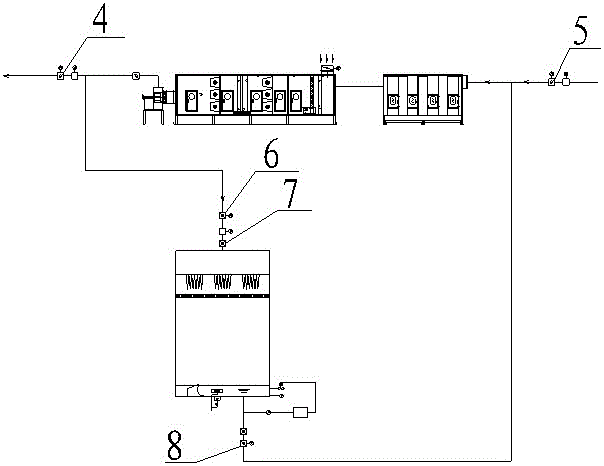

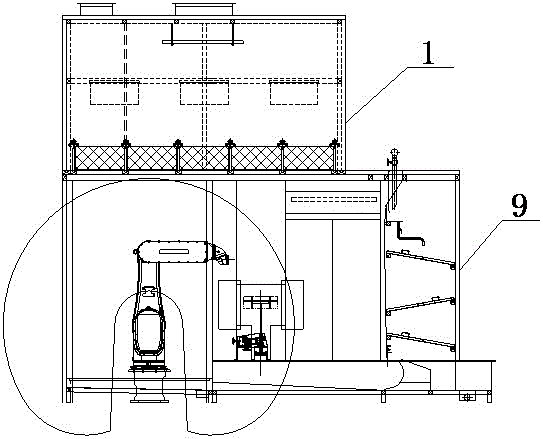

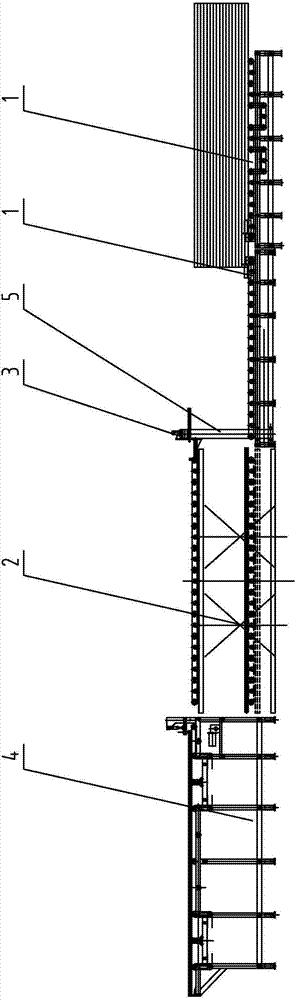

Internal circulation type spraying room

ActiveCN105013651AReduce exhaust emissionsProtect environmental resourcesLiquid surface applicatorsCoatingsFresh airControl system

The invention discloses an internal circulation type spraying room. The internal circulation type spraying room comprises a paint spraying room, a paint mist filtering system, an air conditioning system and a control system, wherein the paint mist filtering system is connected with the paint spraying room and used for filtering paint mists and supplementing fresh air, the air conditioning system is connected with the filtering system and used for exhausting waste gas and supplying air to the paint spraying room according to a certain proportion of fresh air and previous air, and the control system is connected with the paint spraying room, the paint mist filtering system and the air conditioning system and used for adjusting the proportion of fresh air and previous air and supplementing fresh air according to the concentration of the paint mists in the paint spraying room. According to the invention, gas with a certain enthalpy value can be recycled, and therefore the production cost can be saved.

Owner:SHENZHEN LIUXI SCI & TECH DEV CO LTD

Full-automatic wood feeder

InactiveCN104493906AReduce in quantityReduce labor intensityLoading equipmentDe-stacking articlesSolid woodEngineering

The invention relates to the field of wood processing machinery, in particular to a full-automatic wood feeder, and aims to solve the problem that the wood feeding process in the existing solid-wood door / window processing field is not automated, leading to low productivity and high labor intensity for operators. The full-automatic wood feeder comprises a conveying mechanism, a lifting mechanism, a feeding mechanism, a stirring mechanism, a portal frame and a control cabinet; the conveying mechanism, the lifting mechanism and the stirring mechanism are arranged in order along the lengthwise direction; the portal frame is perpendicularly fixed to a joint of the conveying mechanism and the lifting mechanism; the feeding mechanism is disposed on a mounting beam of the portal frame; the conveying mechanism, the lifting mechanism, the feeding mechanism and the stirring mechanism are all connected with the control cabinet through power cords. The full-automatic wood feeder is used for feeding wood materials in the solid-wood door / window processing field.

Owner:HARBIN SAYYAS WINDOWS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com