Middle seal labeling bag making machine

A bag making machine and labeling technology, which is applied in bag making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of reducing processing efficiency, increasing labor costs, time costs, and reducing the application of middle-sealed bags. Achieve the effects of improving processing efficiency, reducing time and labor costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

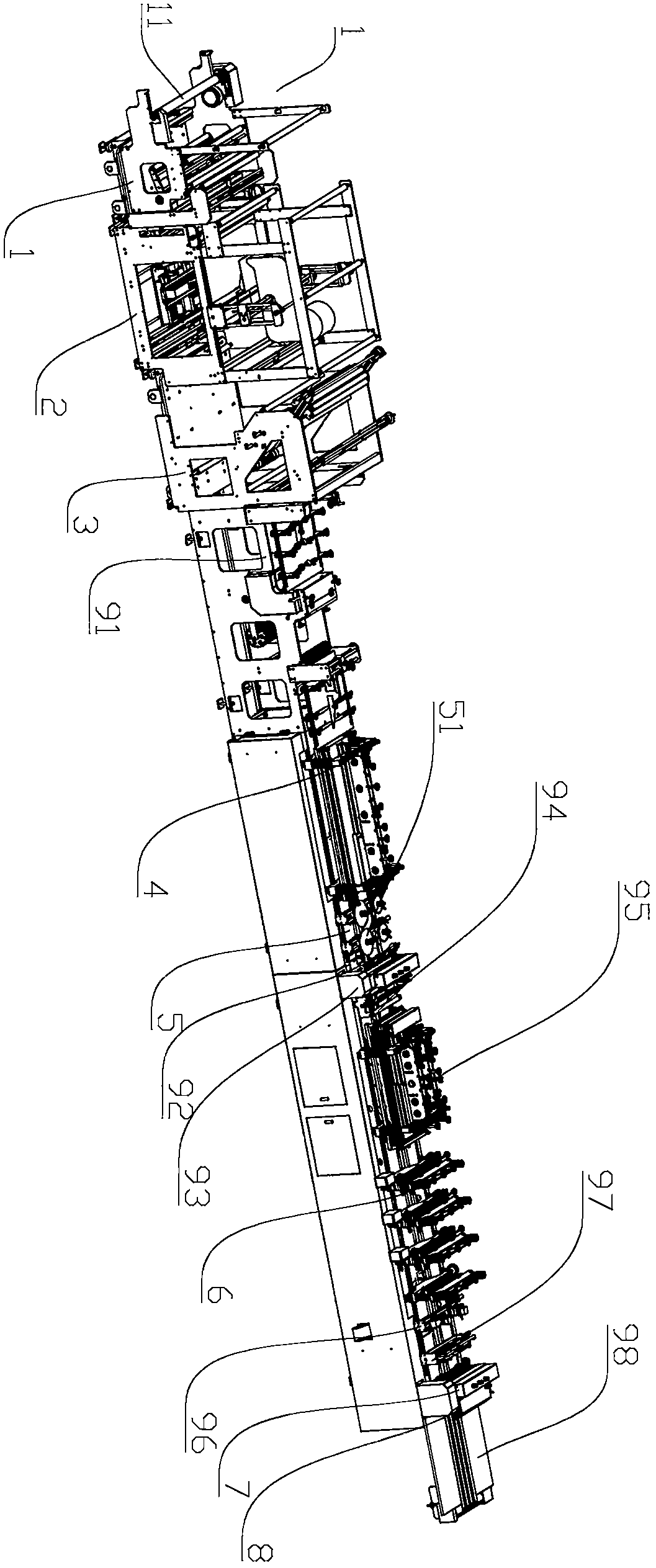

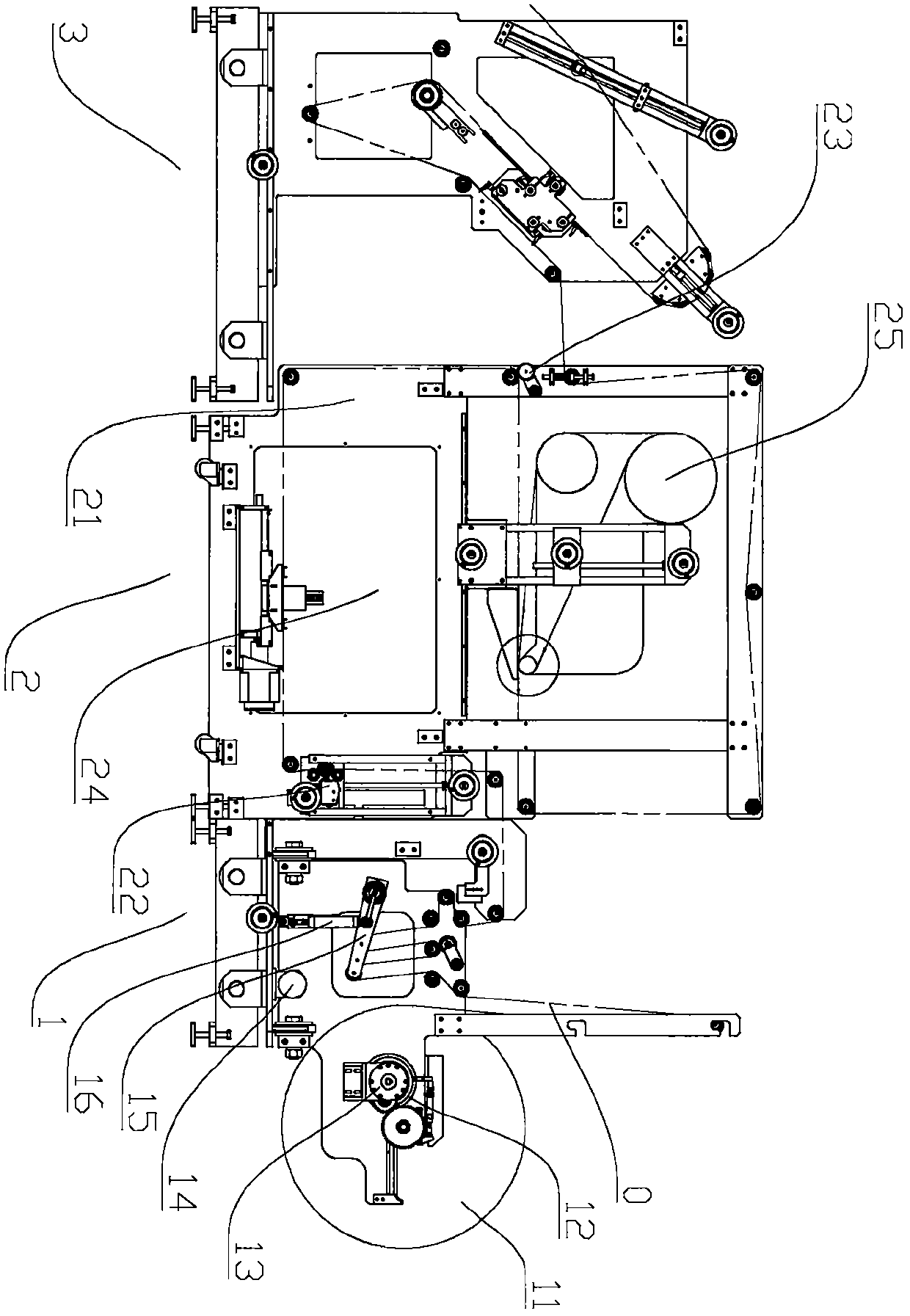

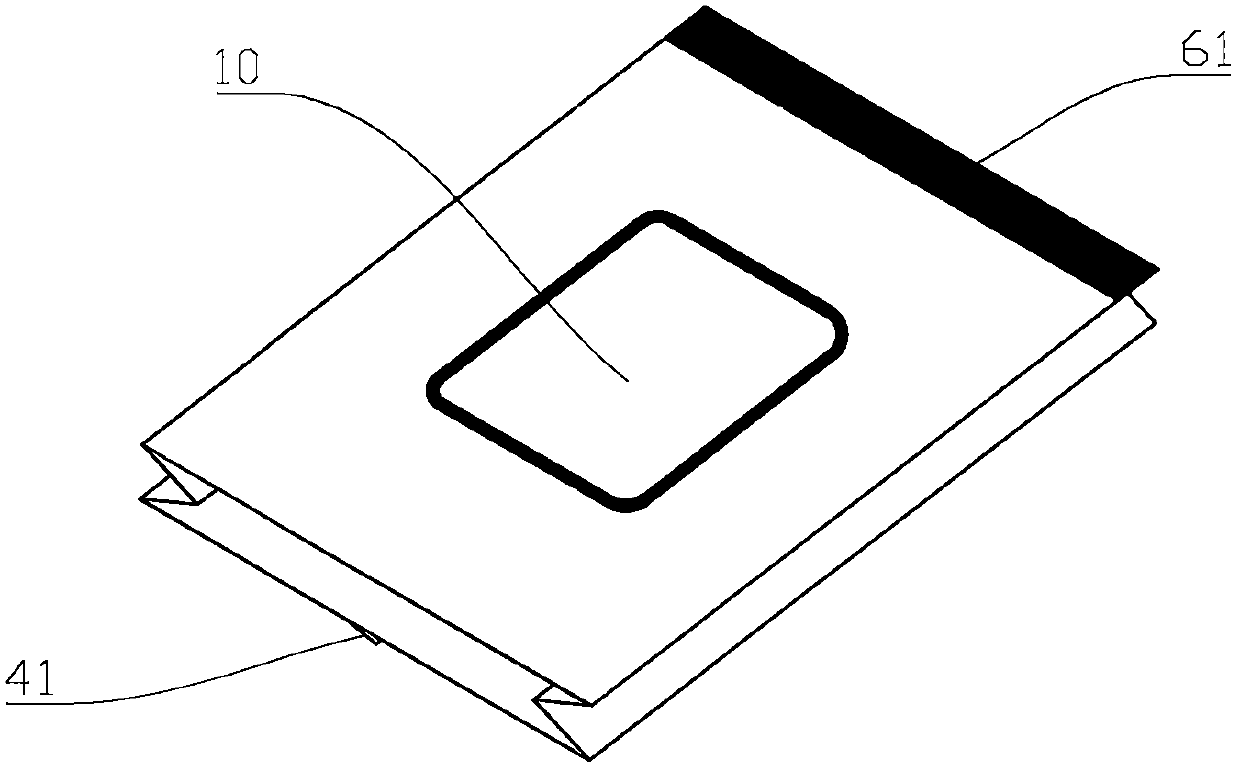

[0034] refer to Figure 1 ~ Figure 3 , the present invention is a middle sealing and labeling bag making machine, which includes:

[0035] The discharge rack device 1 is used to continuously and stably provide the film O to the subsequent process. The discharge rack device 1 may specifically include a discharge roller 11, a magnetic powder brake 12, an electromagnetic brake 13, a deviation correction device 14, a tension pendulum roller 15 and an electric potential Meter 16, tension pendulum roller 15 are used to make the tension on the film O maintain within a certain range, potentiometer 16 is used to measure the displacement of tension pendulum roller 15, and the data is converted into the signal of controlling magnetic powder brake 12, and magnetic powder brake 12 can Control the rotation resistance of the discharge roller 11, and then achieve a closed-loop control of the tension of the film, and the correction device 14 is used to ensure that the film does not deviate fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com