Patents

Literature

55results about How to "Reasonable process layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

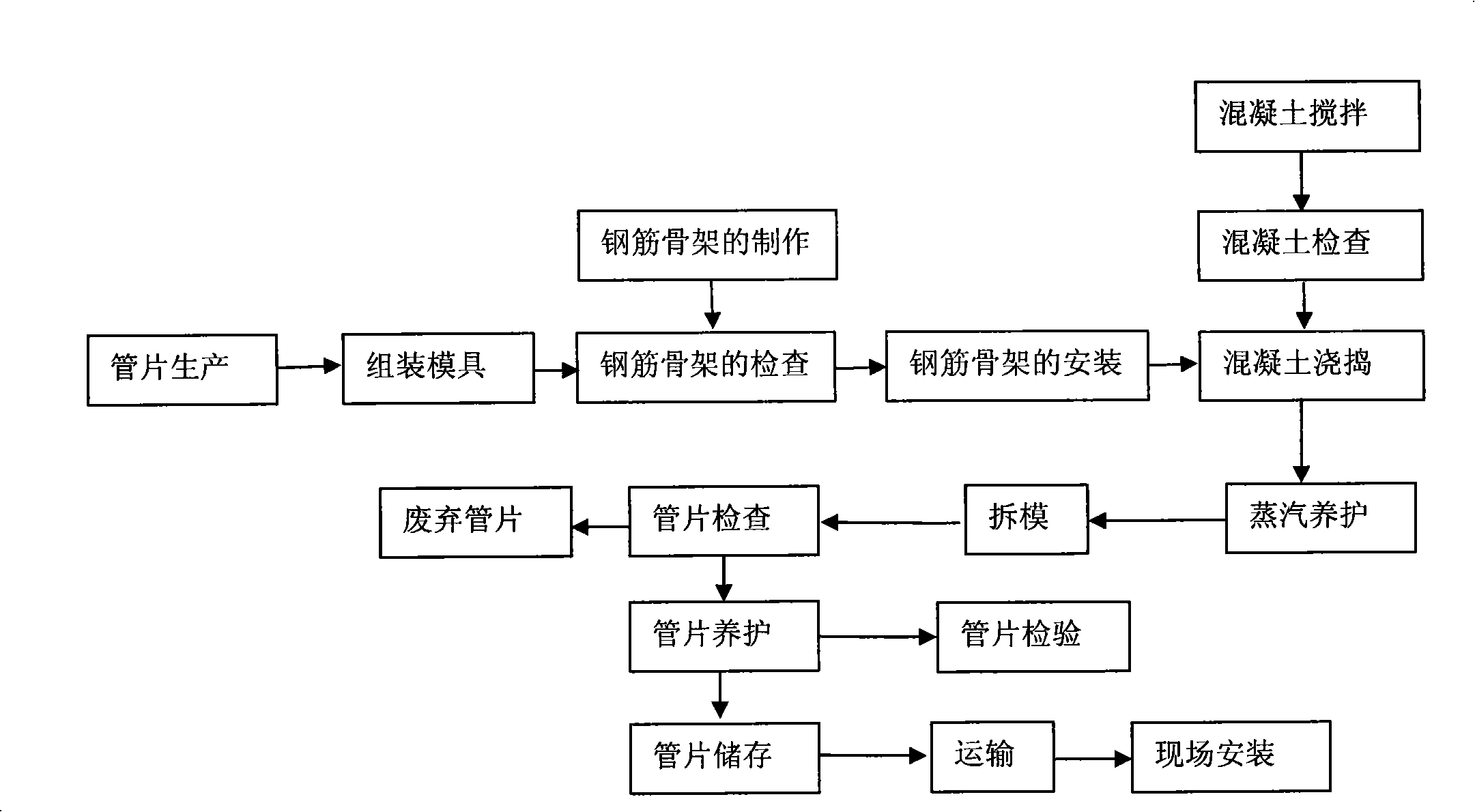

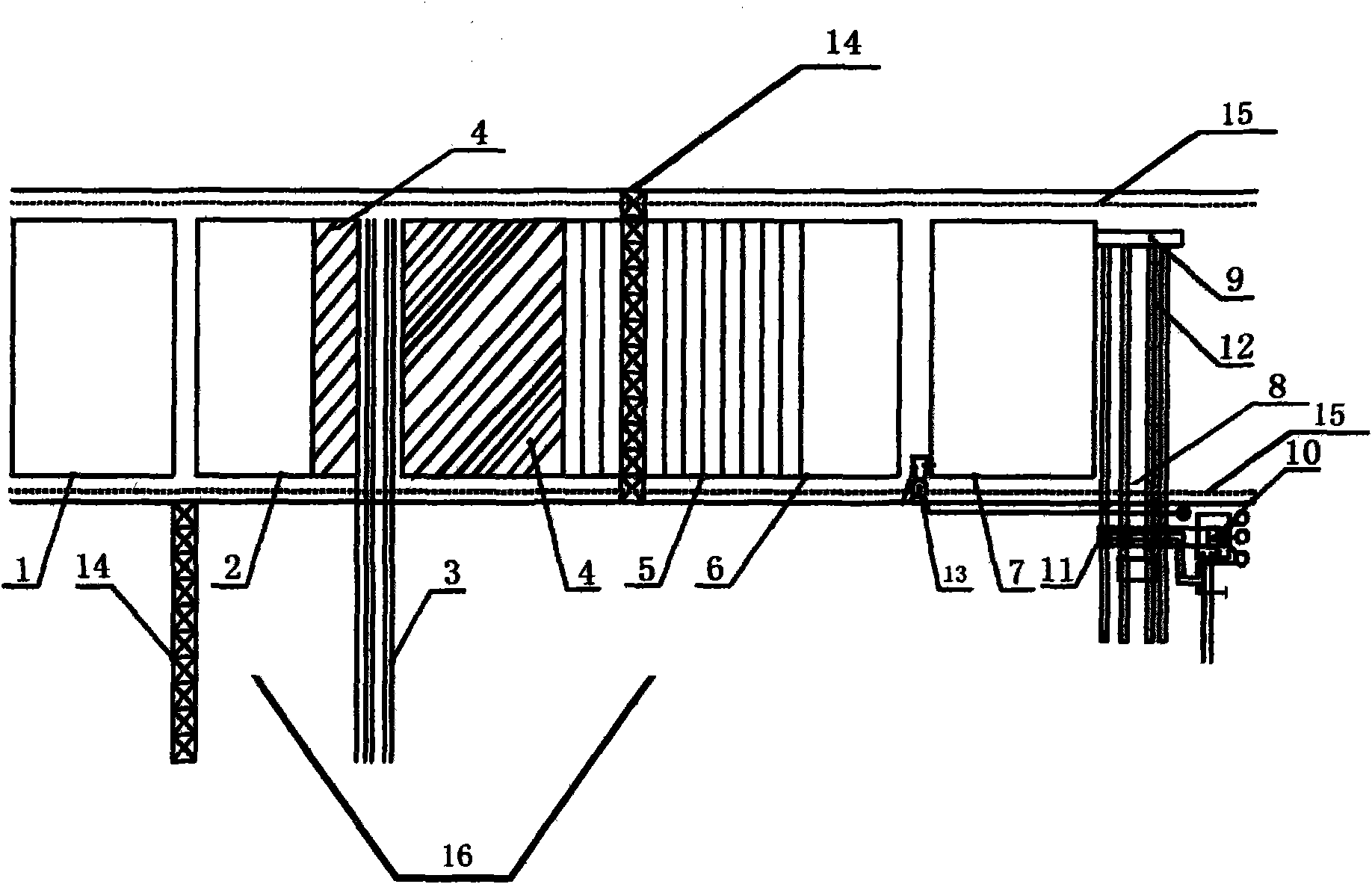

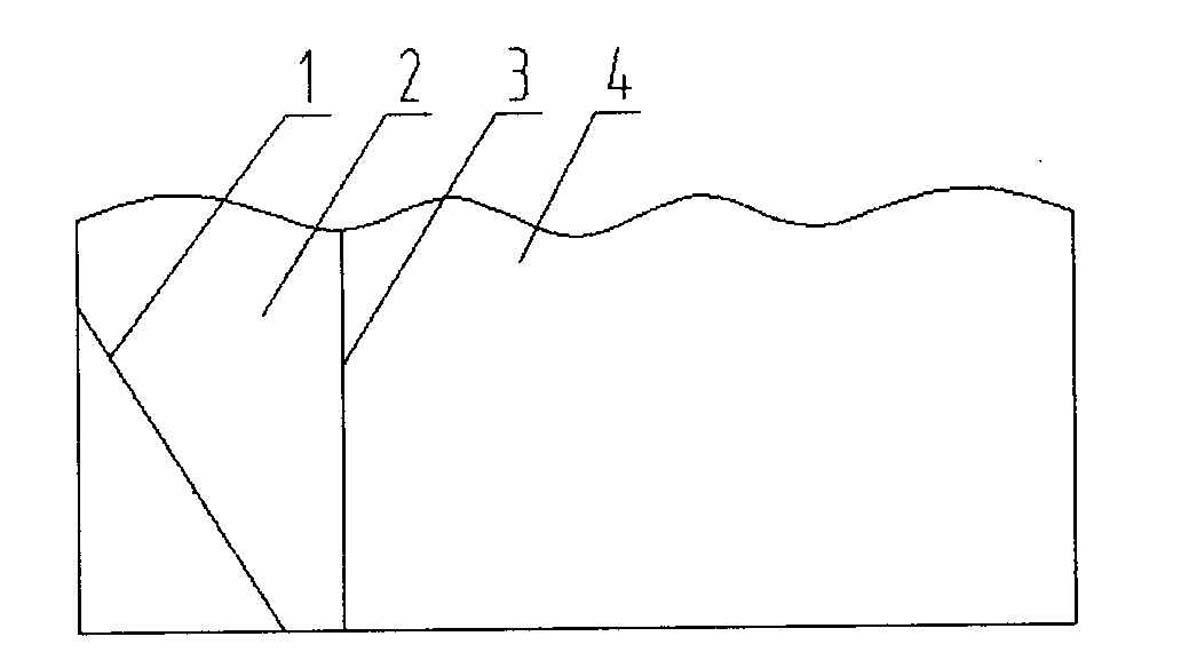

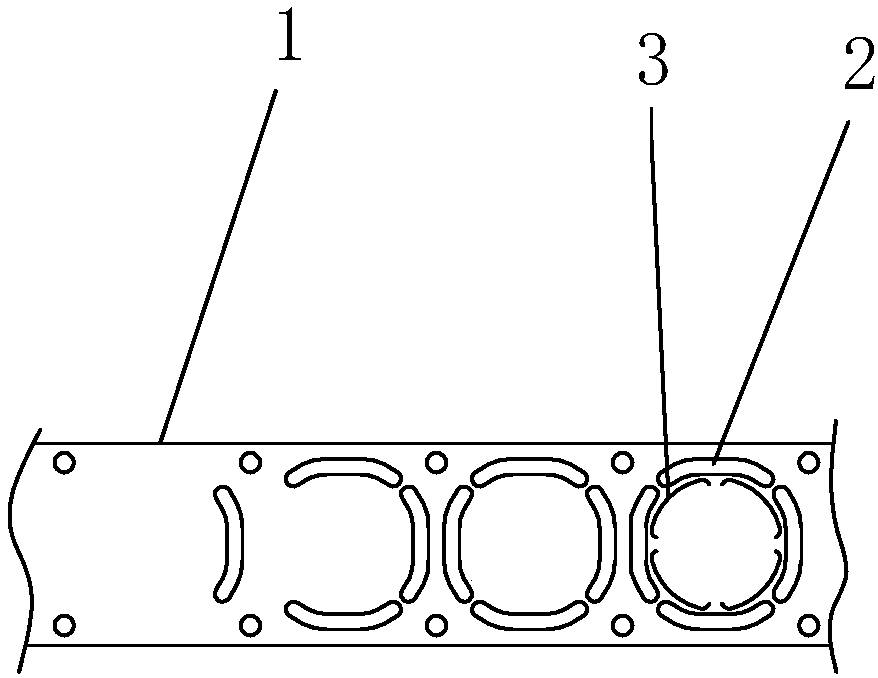

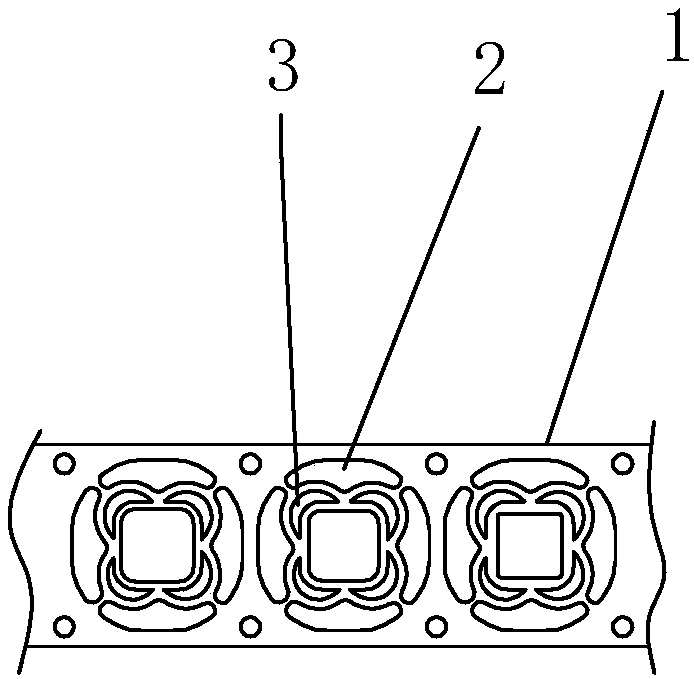

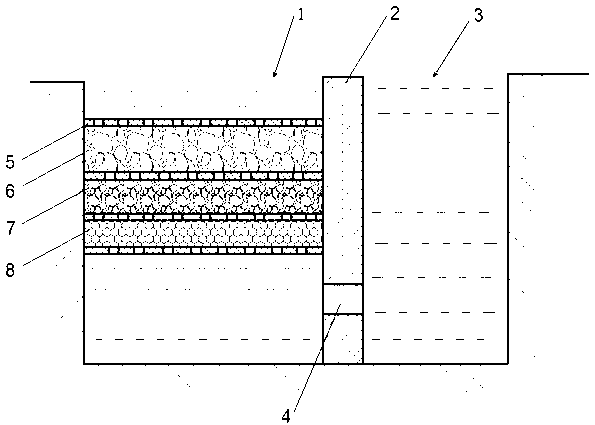

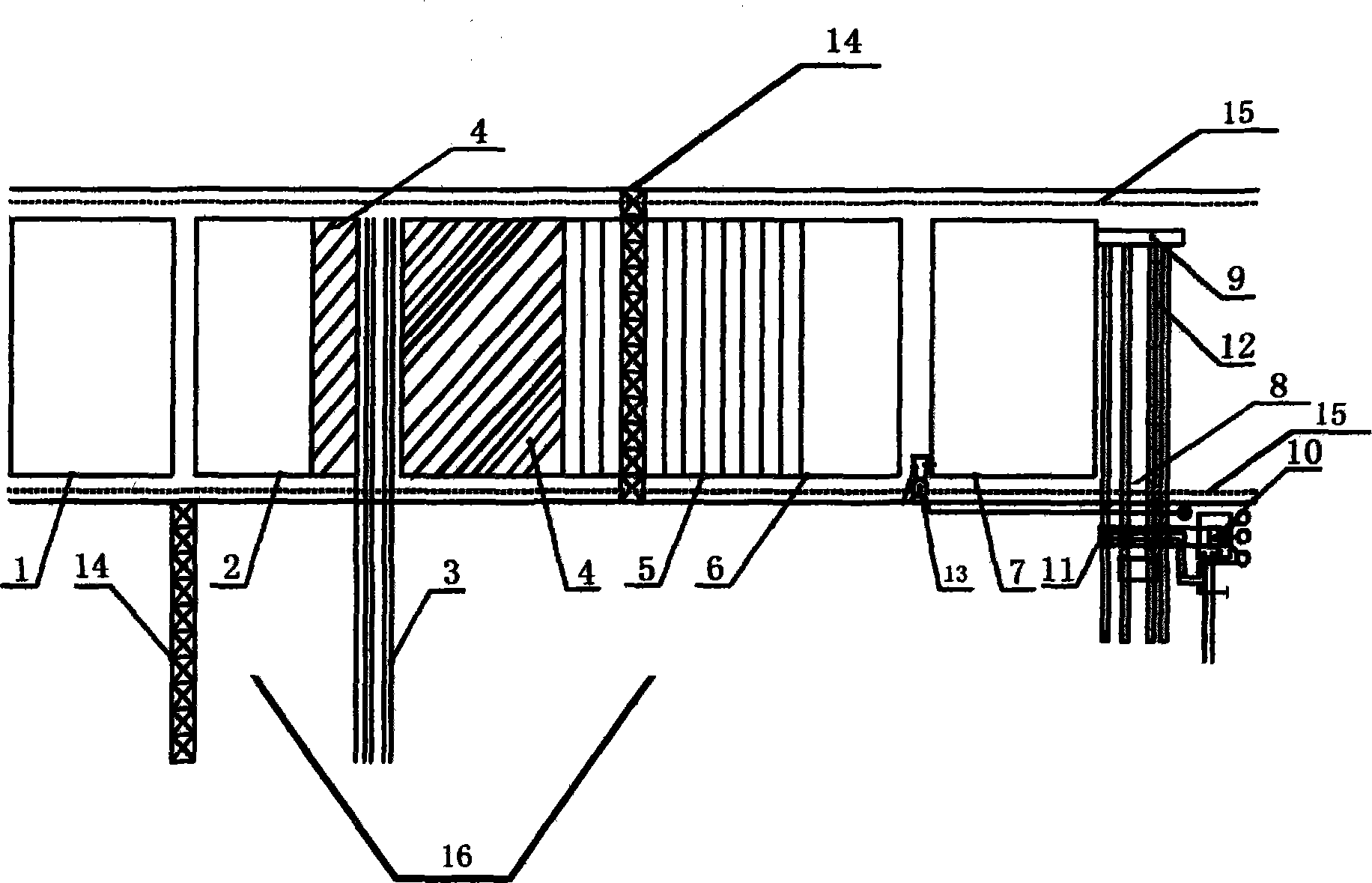

Subway dedicated shield tunneling segment prefabricated construction method

ActiveCN101338682AReasonable process layoutGuaranteed smooth productionUnderground chambersTunnel liningProduction lineEngineering

The present invention relates to a shield segment prefabrication construction method special for subway. The method comprises the steps of manufacturing and installing a reinforcement cage, assembling a mould, stirring, transporting and casting concrete, carring out segment surface, steam maintenance, removing the mould and segment maintenance. The segment is allowed to stand for one hour after the segment surface is finished. Firstly, the segment is covered with a maintaining cover and then is processed for non-pressure steam maintenance. The segment maintenance comprises pool maintenance and spray maintenance. The segment is allowed to stand for 30 to 60 minutes after the mould is removed, the pool maintenance is not less than seven days, and then the segment is transferred to a spray maintenance field. The concrete ring segment prefabrication construction used for an underground large-caliber pipeline shield can also refer to the shield segment prefabrication construction method which has reasonable technical distribution, smooth production, less resource investment, large production capacity, high production efficiency and high automatization degree and is good for forming a segment production line on a large scale.

Owner:GUANGZHOU JISHI CONSTR GRP +1

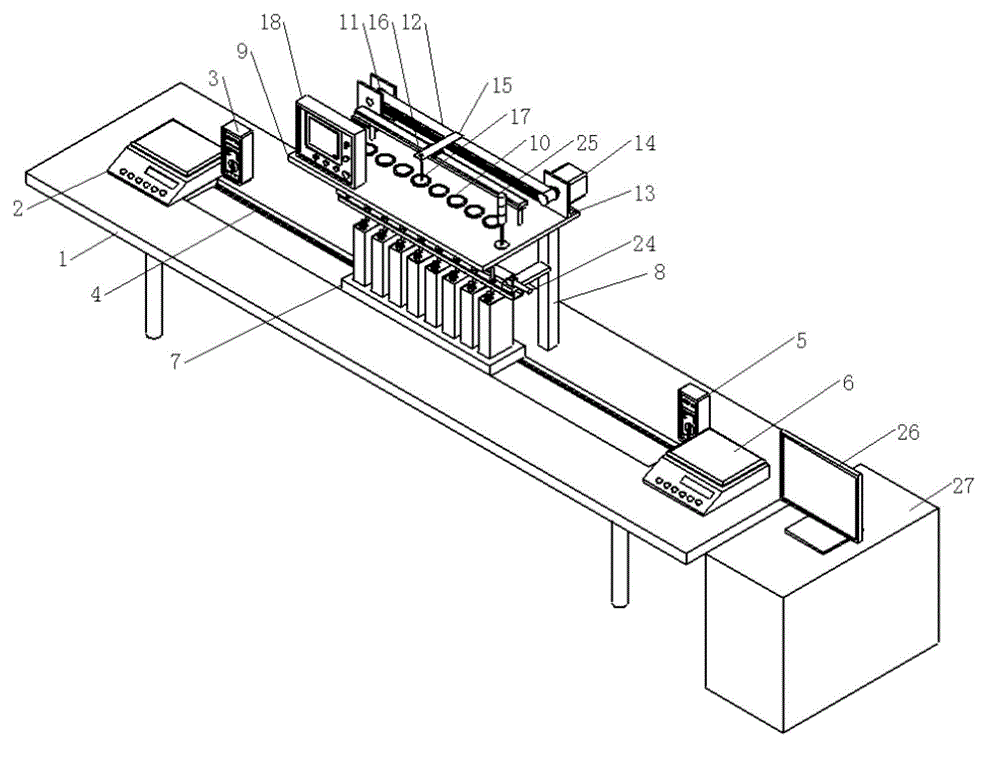

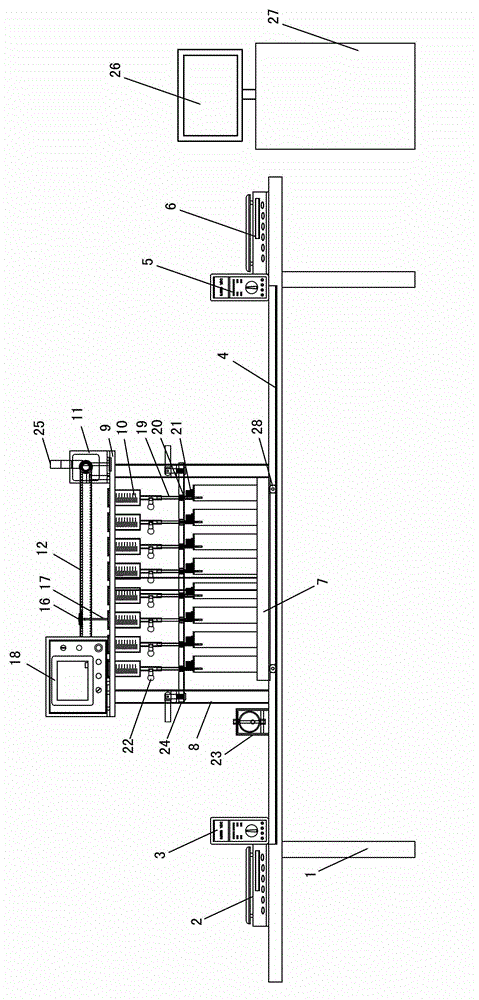

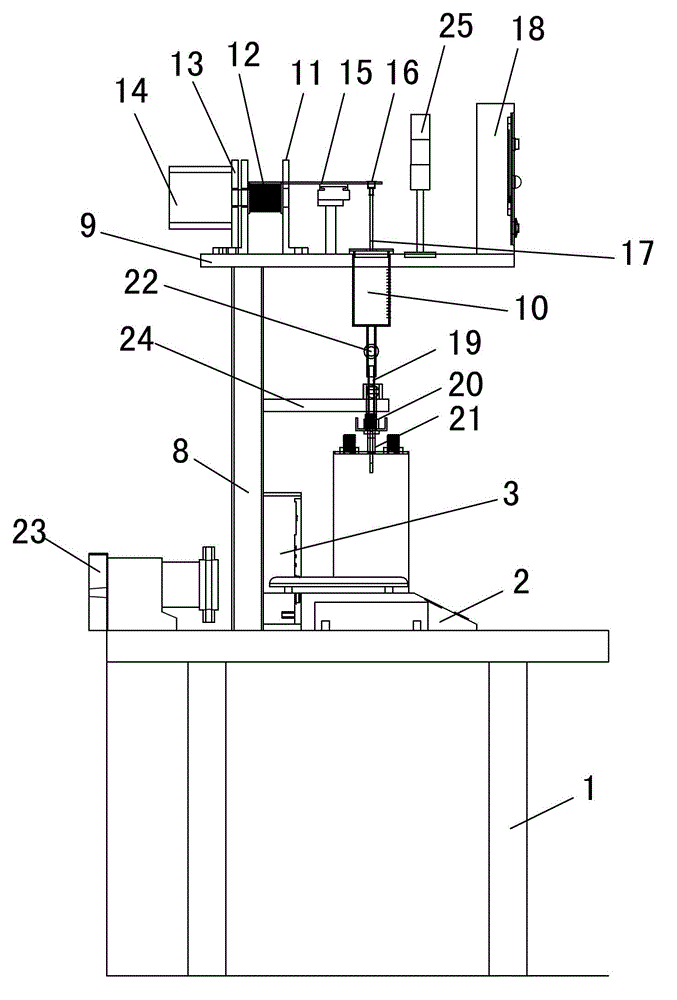

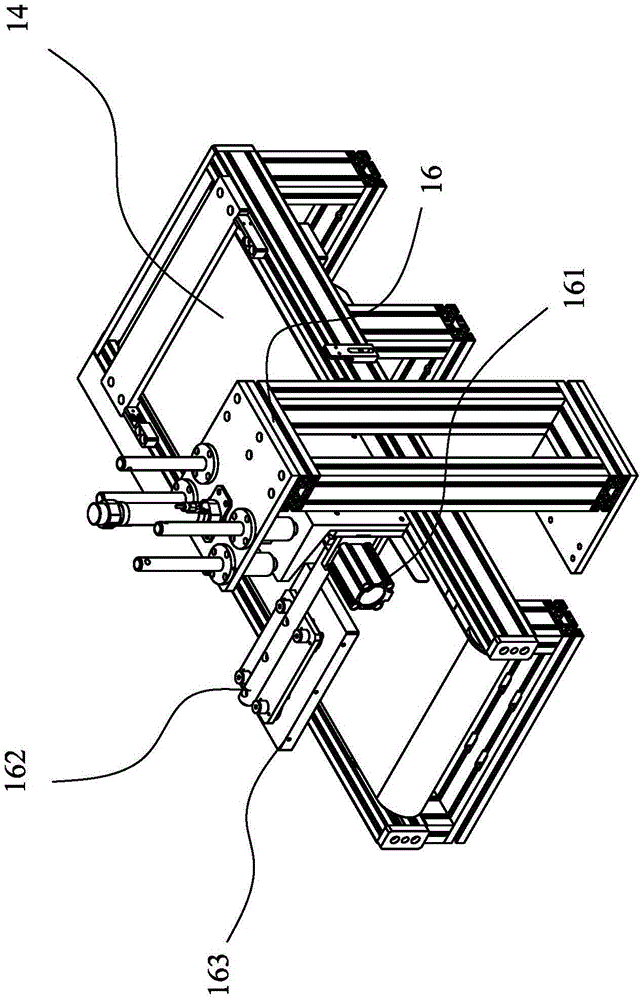

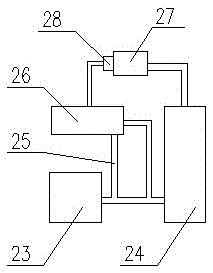

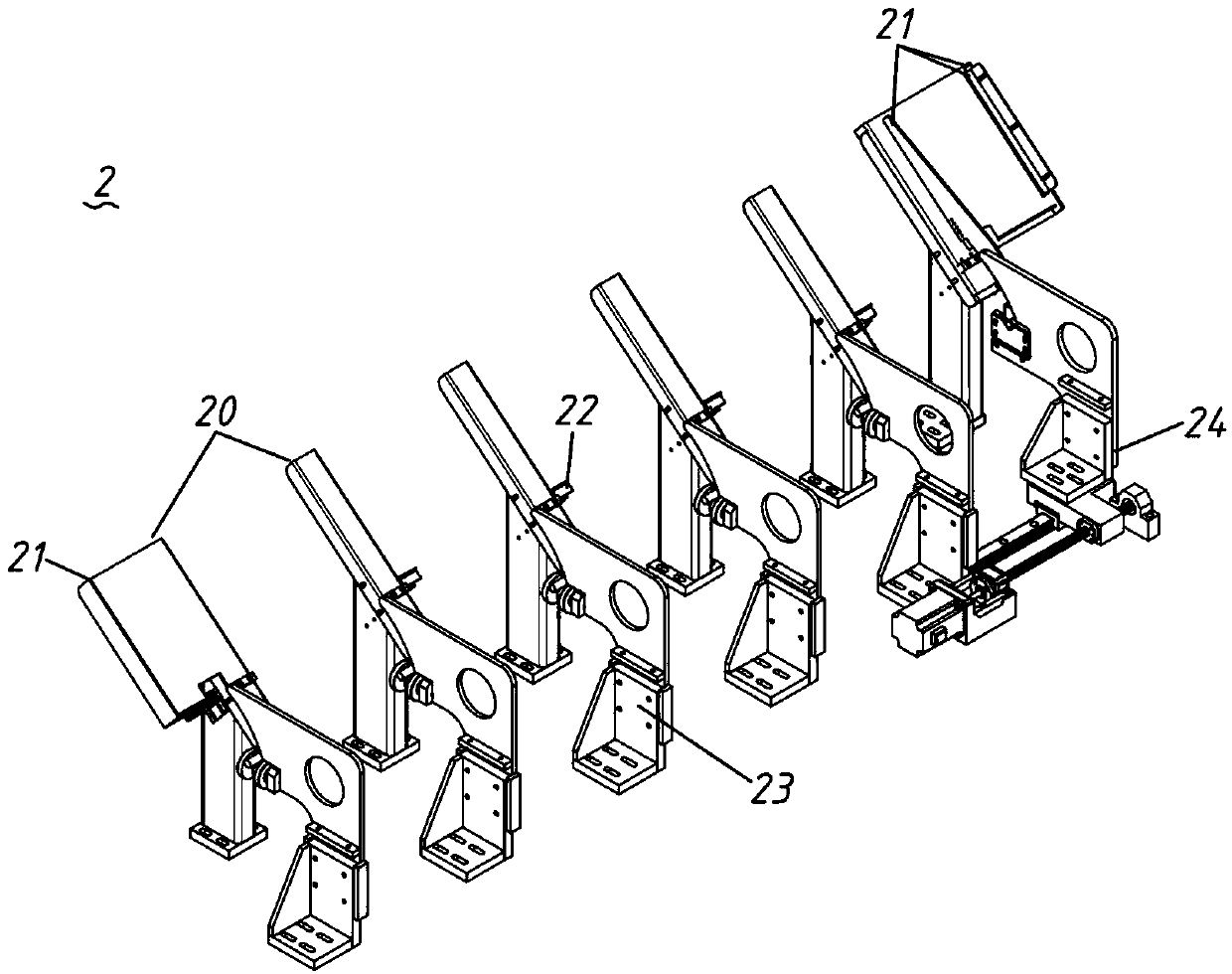

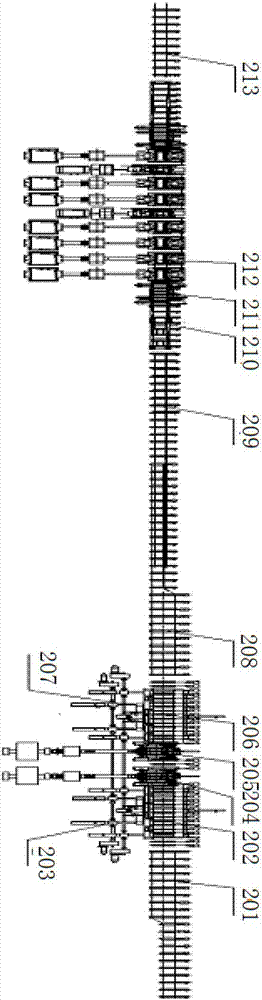

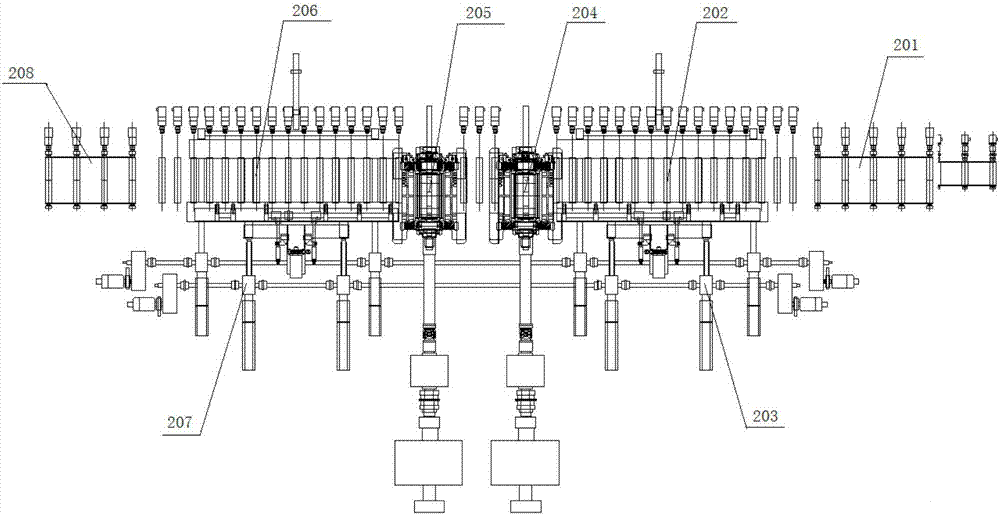

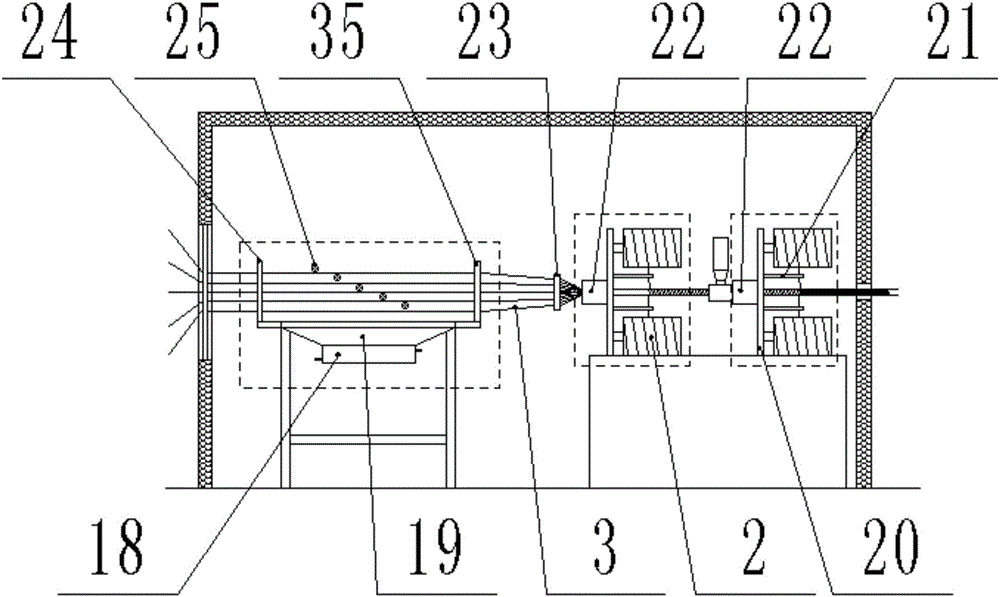

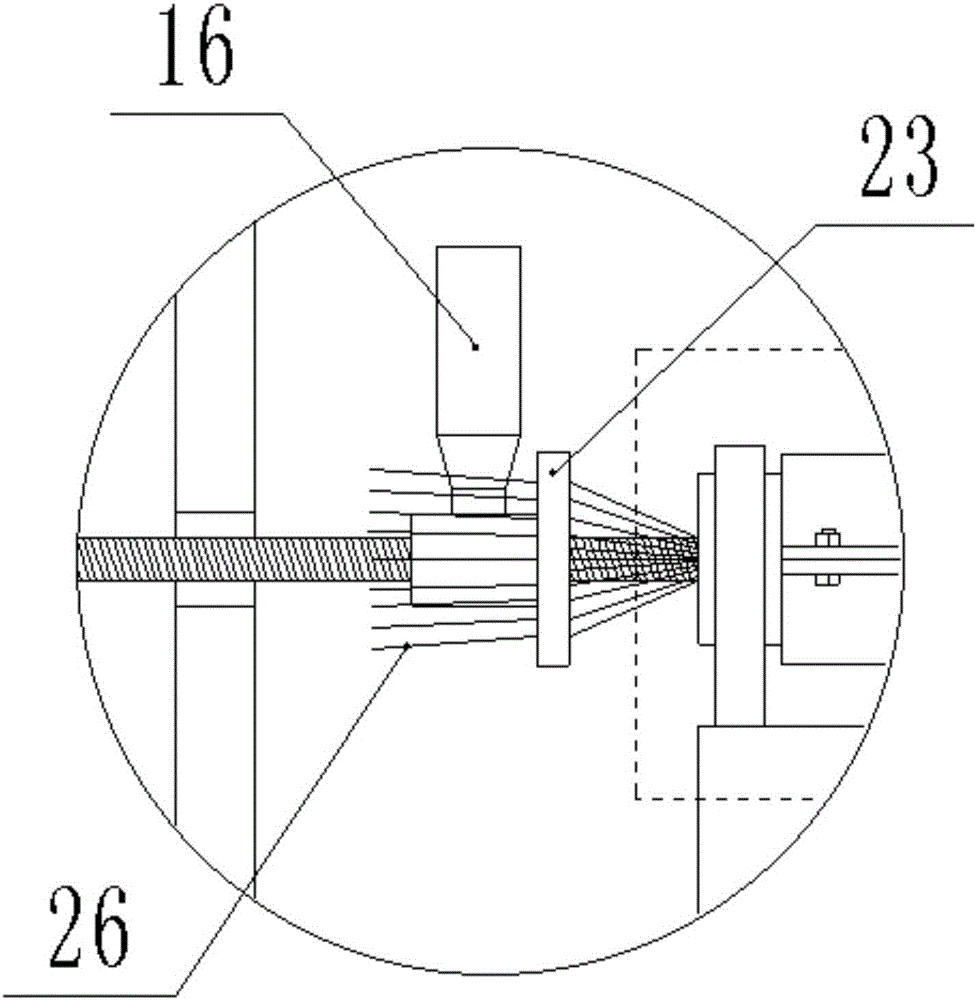

Linear liquid injection machine for capacitance battery and liquid injection method thereof

ActiveCN102945943ASimple designReasonable process layoutCell component detailsCapacitanceMeasurement device

The invention relates to a linear liquid injection machine for a capacitance battery and a liquid injection method thereof. The liquid injection machine comprises a rack, wherein a front weighing device, a front voltage measurement device, a linear guide way, a back voltage measurement device and a back weighing device are sequentially arranged on the rack, a normal-voltage liquid injection device is arranged on the rack arranged at one side of the linear guide way, and a tray is arranged on the linear guide way. The liquid injection method comprises the following steps of: weighing the weight of the battery which is not injected with liquid, and measuring the voltage; putting the battery with normally-tested voltage which is not injected with liquid into the tray, and pushing to the normal-voltage liquid injection device; computing the liquid injection quantity, and sequentially injecting liquid into a liquid injection barrel through a hibar pump till the required liquid injection quantity is reached; carrying out the normal-voltage liquid injection on the battery; weighing the weight of the liquid-injected battery, and measuring the voltage; and pushing the tray back to an initial position through the guide way, and resetting a positioning device to complete the one-time cycle of injected liquid. According to the invention, the whole operation is linear, the invention is high in work efficiency, and the functions of on-line voltage detection, normal-voltage liquid injection and on-line liquid compensation can be realized.

Owner:淄博国利新电源科技有限公司

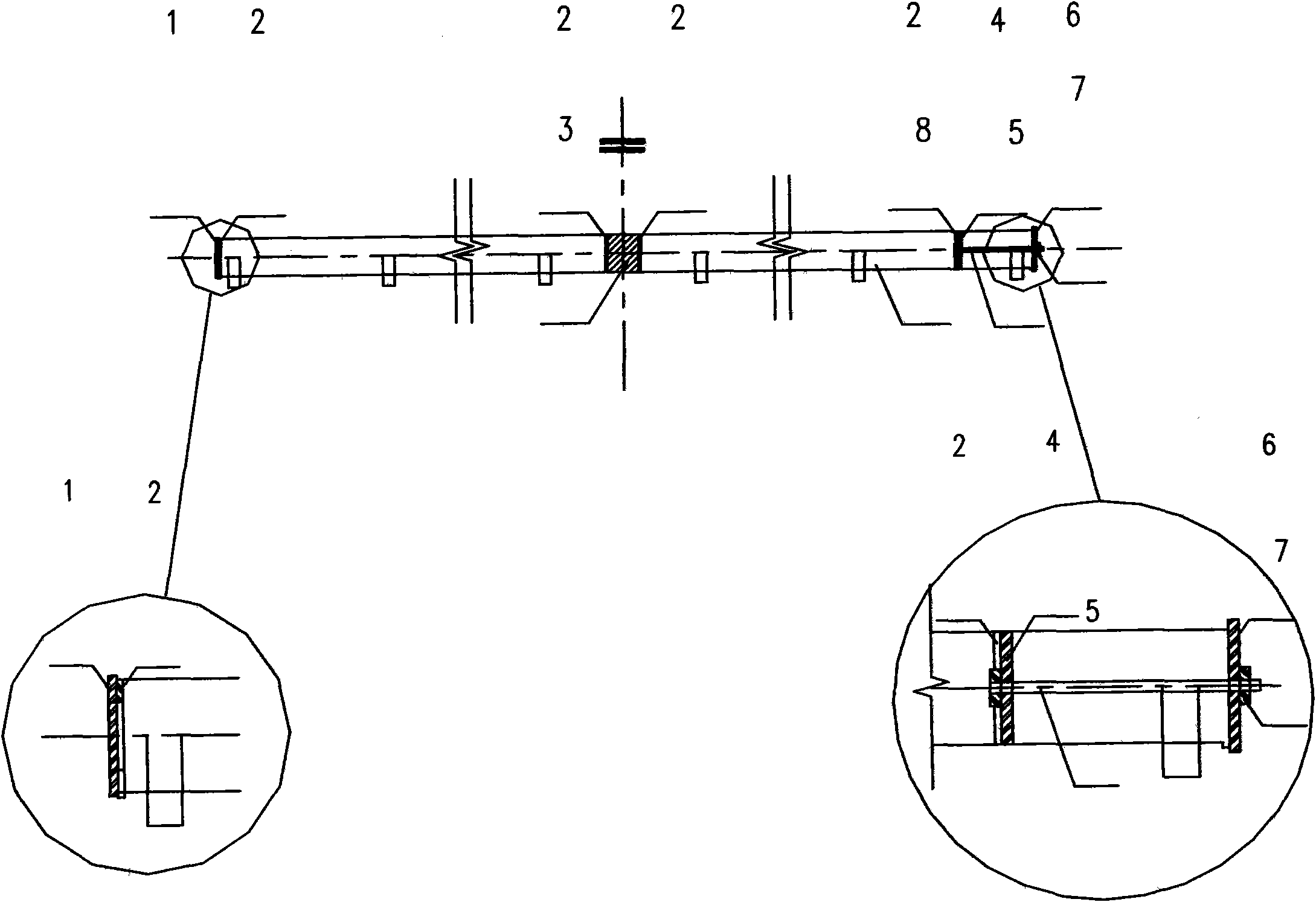

Method for producing precast concrete piles

The invention relates to a method for producing precast concrete piles, which comprises the following main steps of: manufacturing a reinforcement cage; placing the reinforcement cage into a die; pouring concrete into the die; centrifugally rotating; and carrying out steam curing. The method is characterized in that the die with the length of over 20 meters is adopted in the method; two or a plurality of precast concrete piles can be simultaneously produced by one die; upper and lower half dies of the die have a transporting mode of transversely moving in parallel in the direction vertical to the axis of a crane beam of a plant in the production process; and centrifugal equipment and a curing tank are transversely arranged in parallel in the direction vertical to the axis of the crane beam of the plant. Due to the adoption of the transverse flow production scheme of the long die, the production effect can be multiplied, the space occupied by the plant is greatly reduced, a great amount of lands are saved, the working efficiency is improved, and the production quality can be ensured.

Owner:NINGBO YIZHONG CONCRETE PILE +2

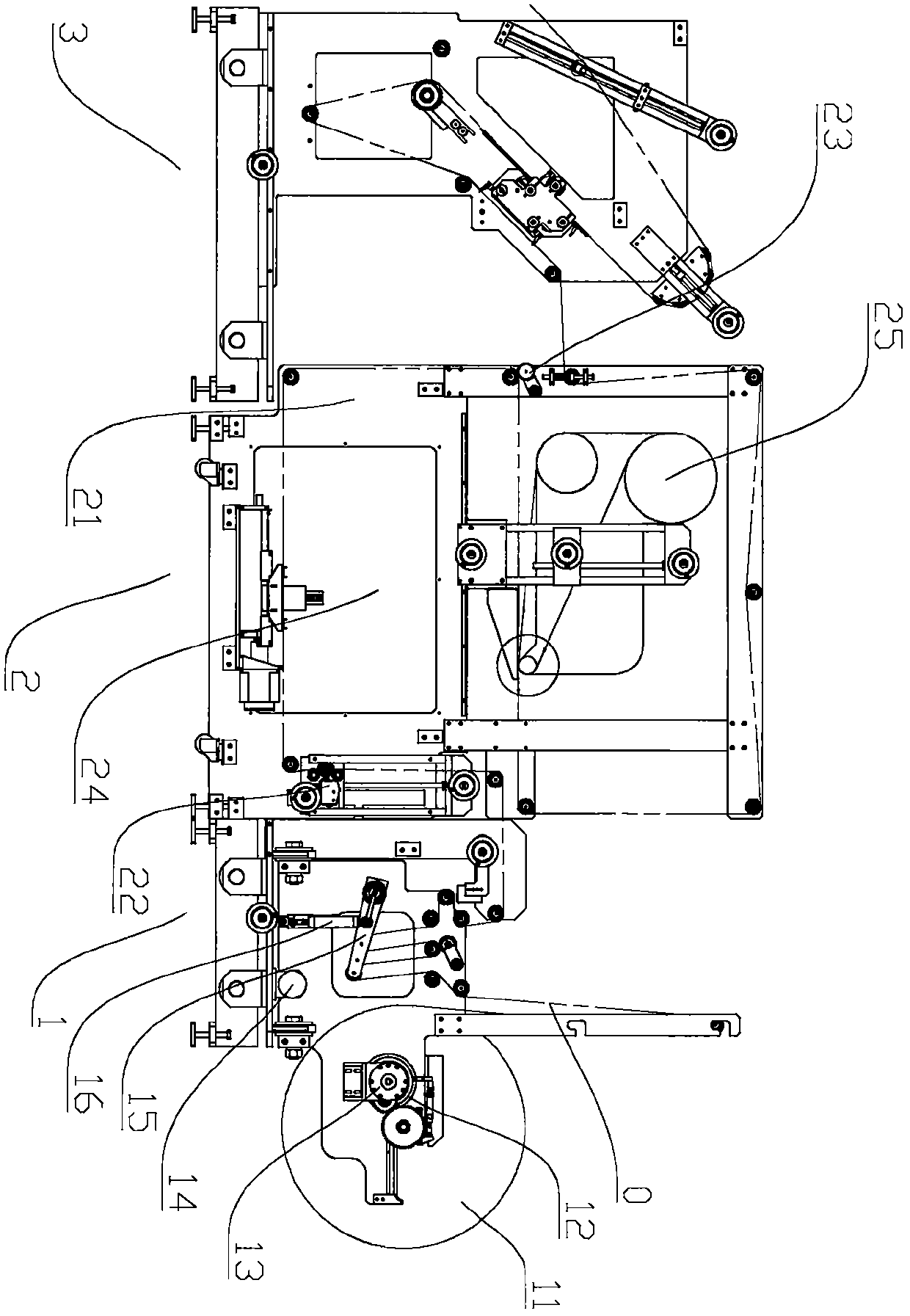

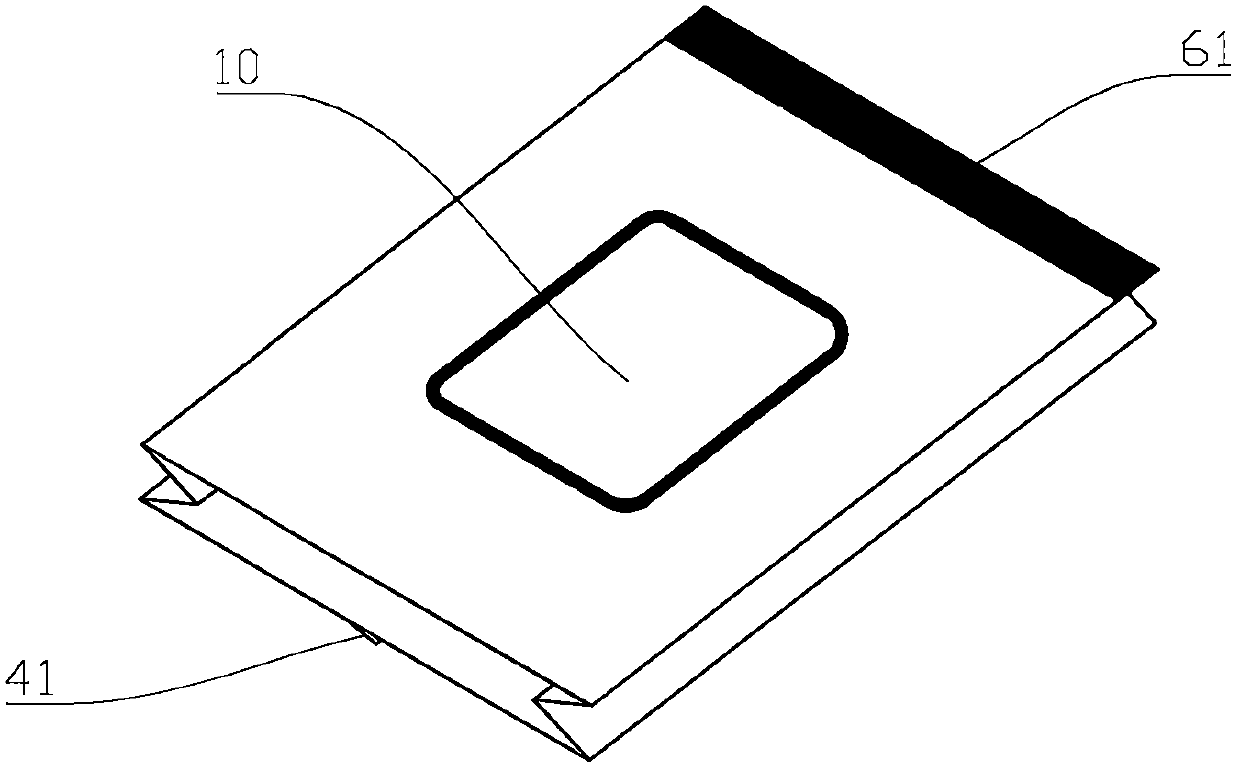

Middle seal labeling bag making machine

InactiveCN107775998AImprove processing efficiencyAvoid time costBag making operationsPaper-makingEngineeringFold-forming

The invention discloses a middle seal labeling bag making machine. In the moving trend of a film, the middle seal labeling bag making machine sequentially includes a discharging frame device, a punching labeling device, a folding forming device, a longitudinal sealing device, an organ forming device, a transverse sealing device, a second traction group and a cutter device, wherein the dischargingframe device is used for continuously and stably providing a film for a follow-up process; the punching labeling device is used for first punching the film conveyed by the discharging frame device andthen performing labeling; the folding forming device is used for performing continuous folding forming on the labeled film, folding the films on the two sides towards the middle and causing the filmsto be in lap joint in the middle positions of the films; the longitudinal sealing device is used for performing longitudinal heat sealing on the folded films at the lap joint position; the organ forming device folds in the edges of the two sides of the films having undergone longitudinal heat sealing towards the middle of the two layers of films; the transverse sealing device is used for performing transverse heat sealing on the films having been processed by a longitudinal sealing forming device; the second traction group is used for providing power for movement of the films; and the cutterdevice is used for slitting the well processed films to form finished products. According to the middle seal labeling bag making machine, automatic labeling treatment can be performed on a middle sealbag while the middle seal bag is processed.

Owner:冯葆如

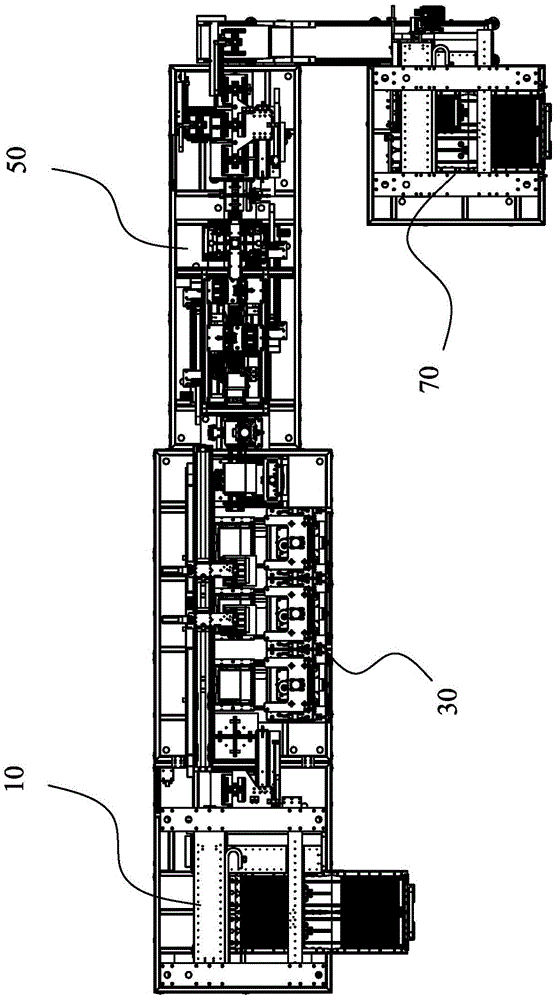

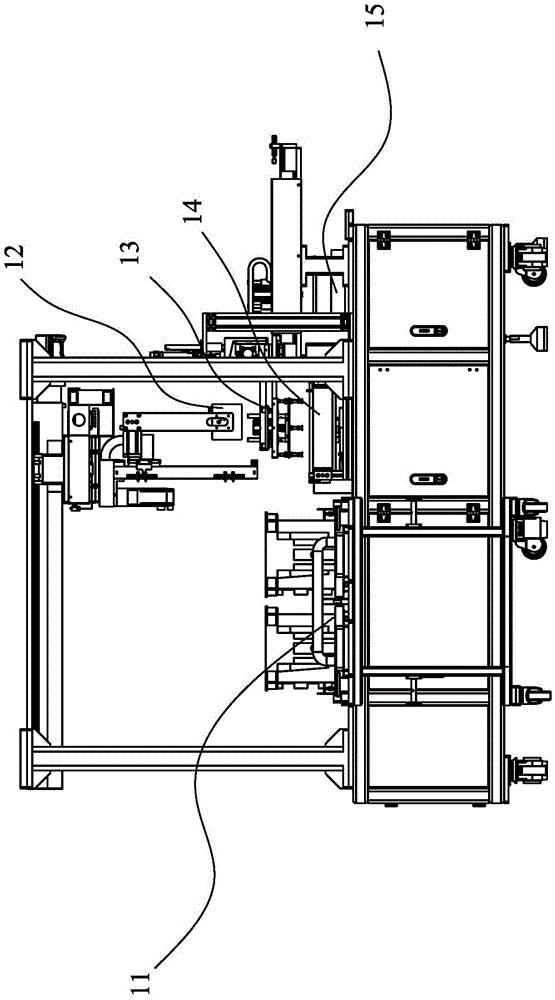

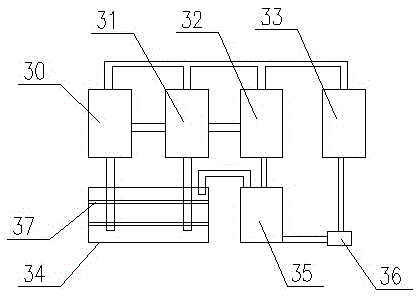

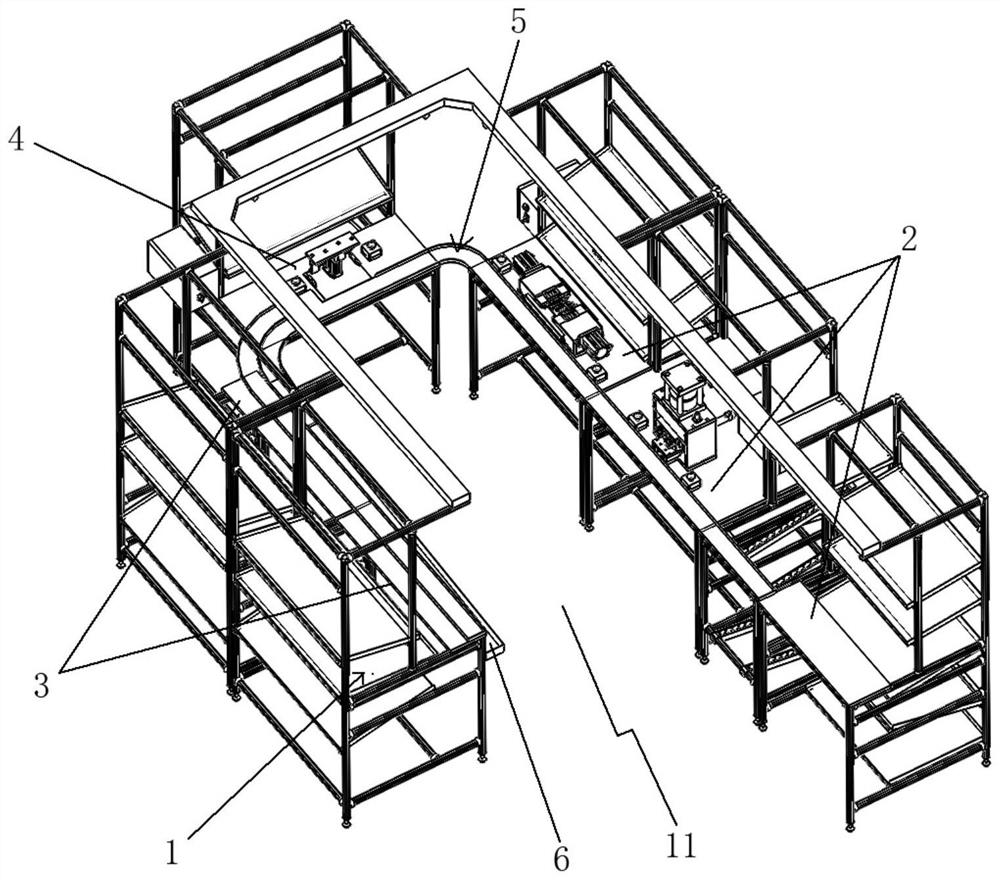

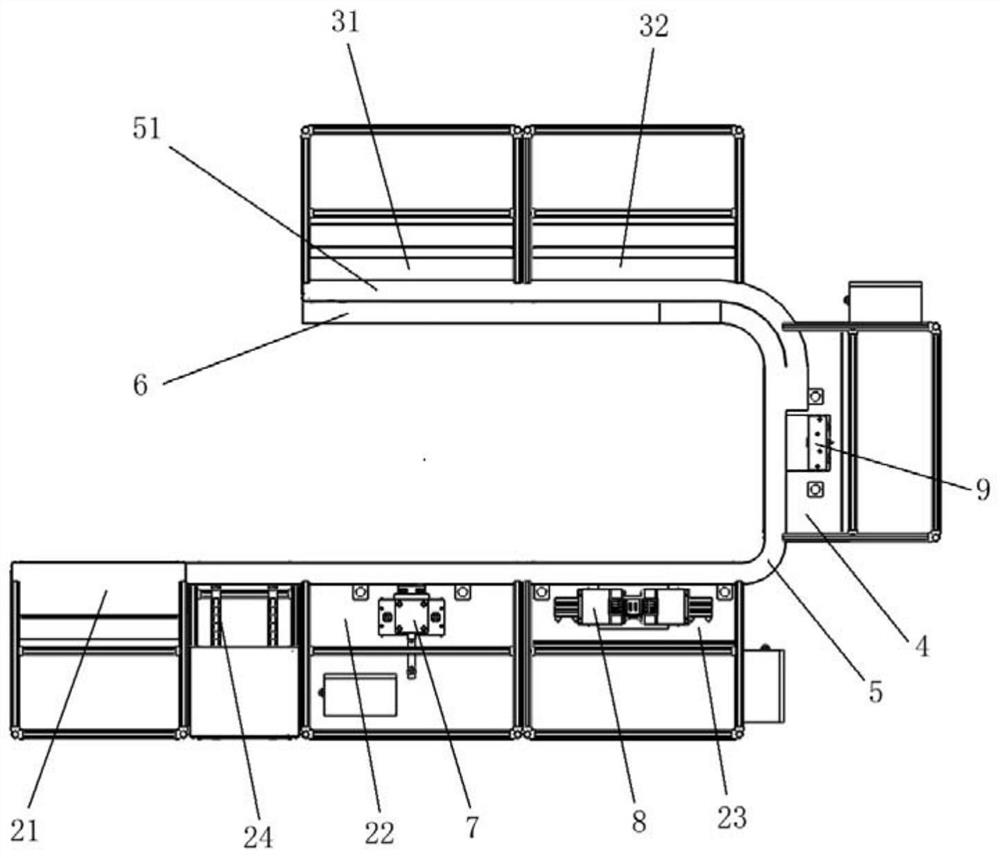

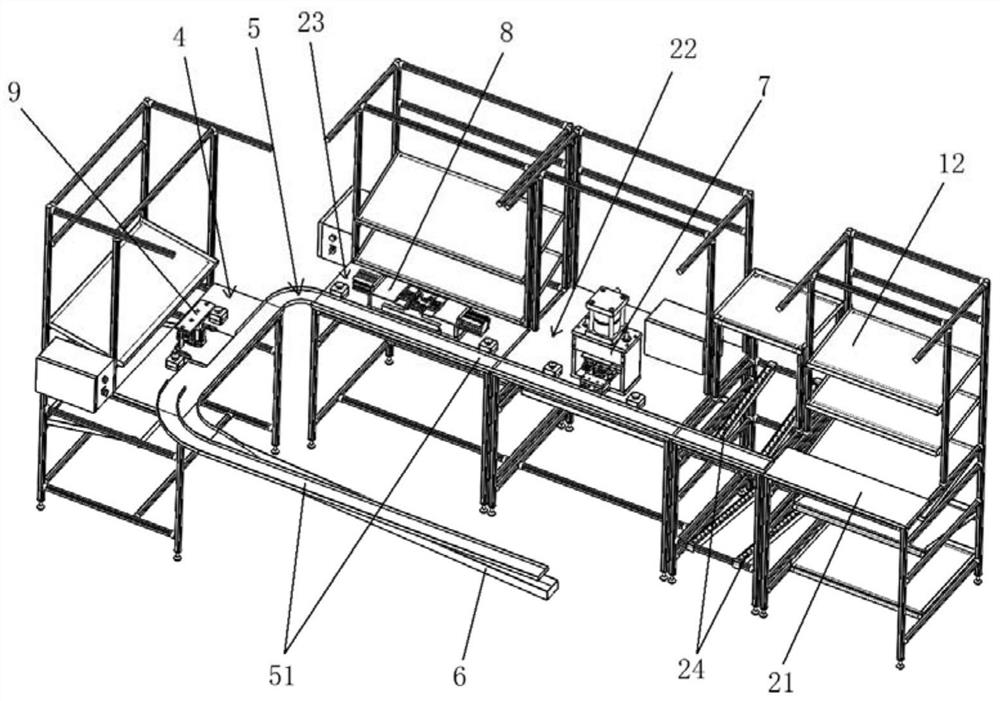

Automatic secondary-packaging molding production line

ActiveCN105633478ARealize fully automatic productionIncrease productivityAssembling battery machinesFinal product manufactureProduction lineEconomic benefits

The invention discloses an automatic secondary-packaging molding production line. The production line comprises a feeding unit, a packaging unit, a molding unit and a discharging unit, wherein the feeding unit comprises a feeding pull band; the packaging unit comprises a primary-packaging station and a primary-cutting station; the primary-packaging station is arranged close to the primary-packaging correction station; an upper packaging cavity, a low packaging cavity and a movable cavity are formed in the primary-packaging station; the primary-cutting station is provided with a primary-cutting mechanism for cutting sealing edges of cells; the molding unit comprises a cell transfer mechanism, and a fine packaging mechanism, a rolling wheel edge-folding mechanism, an adhesive dispensing mechanism, a thermoprint edge-folding mechanism, and a second weighing station arranged on the two sides of the cell transfer mechanism in sequence; and the discharging unit comprises a discharging pull band. According to the automatic secondary-packaging molding production line, the feeding unit, the packaging unit, the molding unit and the discharging unit are integrated on one equipment, so that the fully automatic production of a softly-packaged lithium battery from feeding to discharging can be realized; and therefore, the production efficiency of the lithium battery is improved, the productivity is improved, the production cost is lowered, and the economic benefit is increased.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Production technology of aluminum foil inner liner paper for composite coating packaging

ActiveCN103522723ASimple production processReasonable process layoutLamination ancillary operationsLaminationProcess engineeringSlip sheet

The invention relates to a composite production technology of inner liner paper, and discloses a production technology of aluminum foil inner liner paper for composite coating packaging. The production technology uses a process of unwinding- compositing-protection layer coating-printing-drying-cutting-winding, the production technology is continuous and uninterrupted, is continuously completed in one time, and has the advantages of simple technique, low cost, promoting efficiency, saving labor, stable product quality, and saving energy, in addition, according to the production technology, by double aluminum foil unwinding and cutting at a winding position, a secondary cutting process needed by a half-cut machine can be reduced.

Owner:NANJING JINLING GOLDFOIL CO LTD

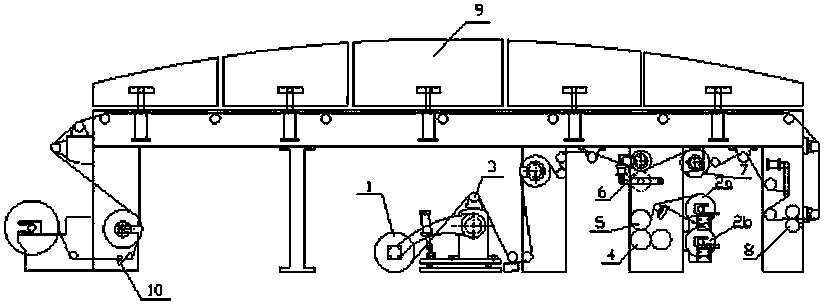

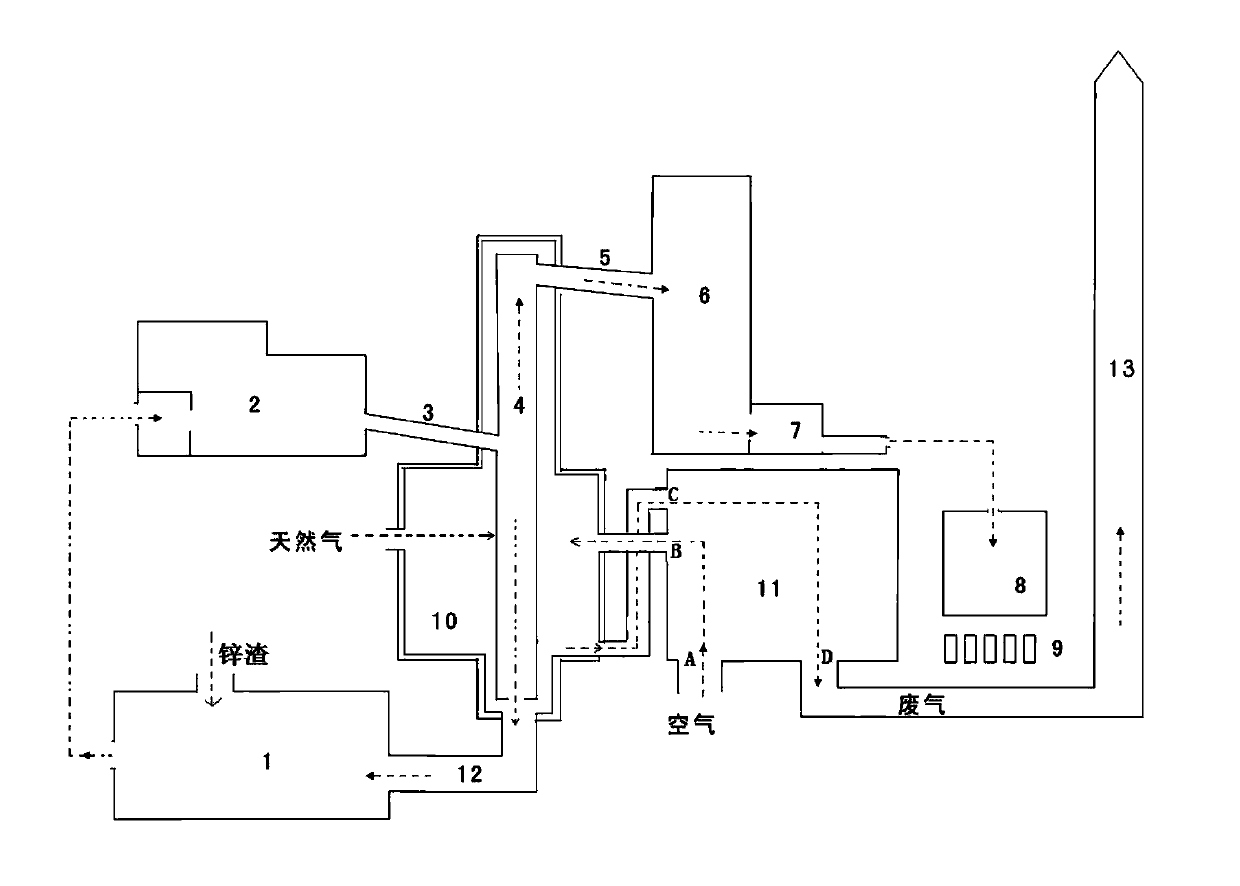

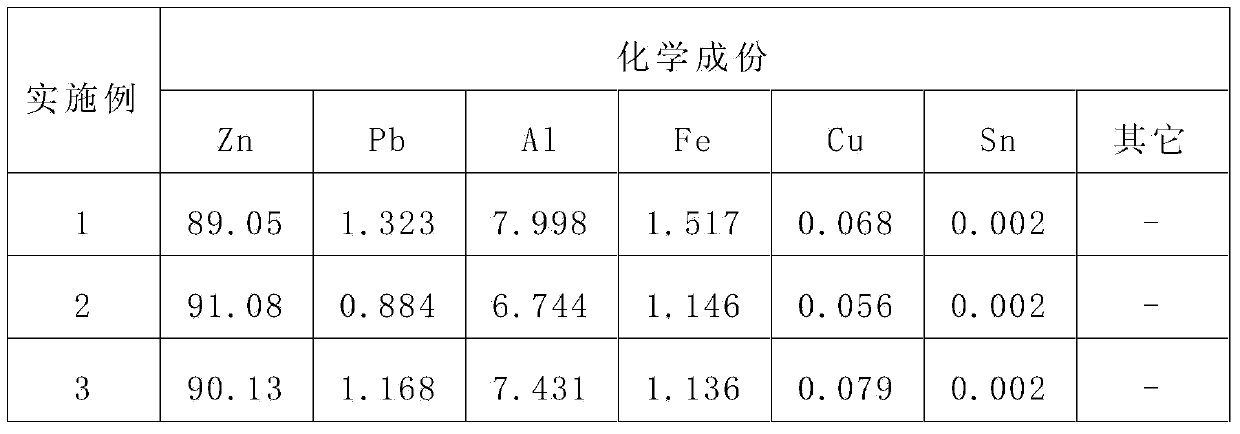

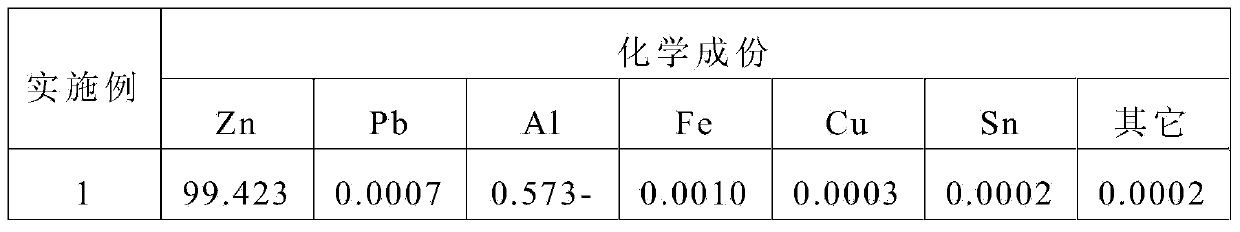

Method and device for producing zinc alloy used for hot dipping by using zinc slag

ActiveCN103602828AReduce consumptionExtended service lifeHot-dipping/immersion processesProcess efficiency improvementSlagZinc alloys

The invention discloses a method and a device for producing a zinc alloy used for hot dipping by using zinc slag. The method comprises the following steps of 1) adding materials for a first time and removing slag for the first time; 2) keeping warm and removing residues; 3) rectifying and heat-exchanging; 4) condensing; 5) re-adding the materials for circulation; 6) preparing the alloy: adding aluminium element in condensed No. 0 zinc liquid according to requirements, and mixing uniformly to cast a alloy ingot. The invention also provides a device for producing the zinc alloy used for hot dipping by using the zinc slag. The method is reasonable in process arrangement and low in production cost, greatly reduces in energy consumption, reduces potential risks, can control the whole production process, and realizes cyclic utilization of resources.

Owner:武汉扬光实业有限公司资源循环科技分公司

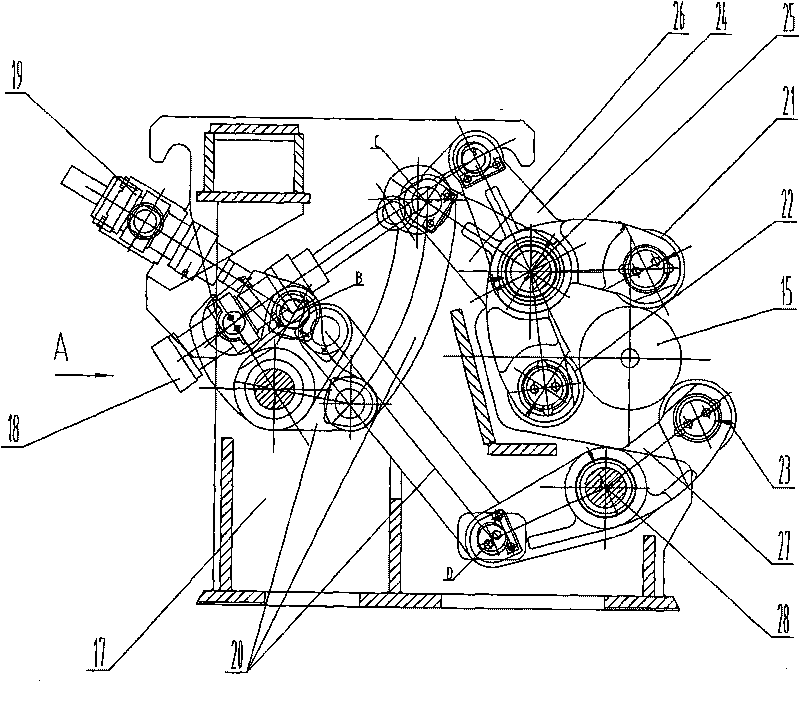

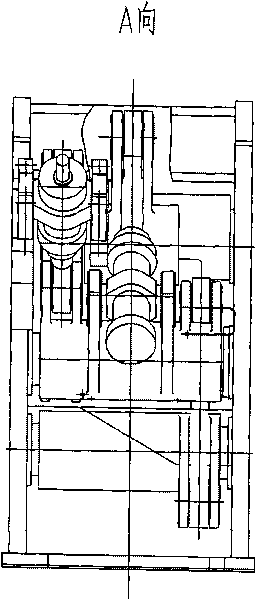

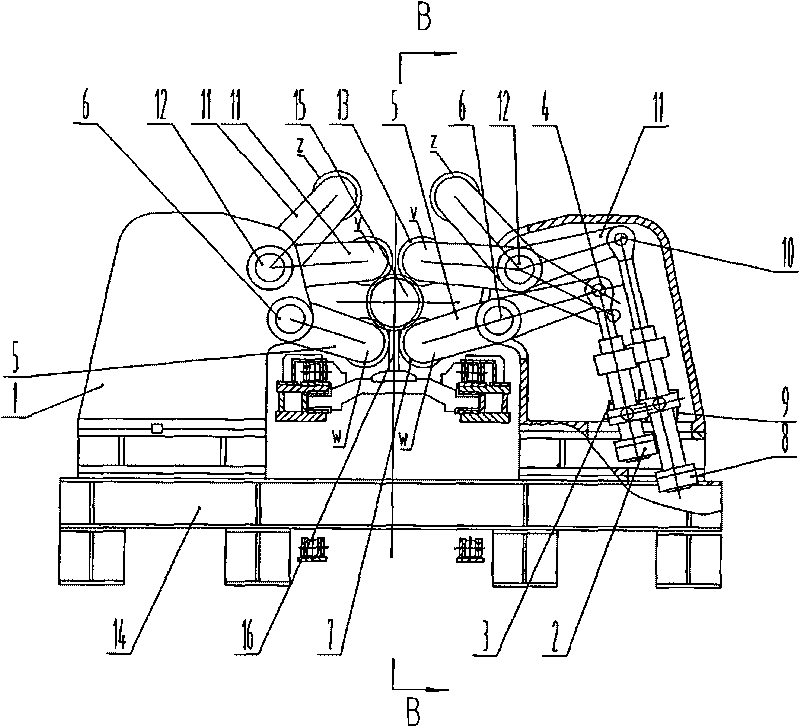

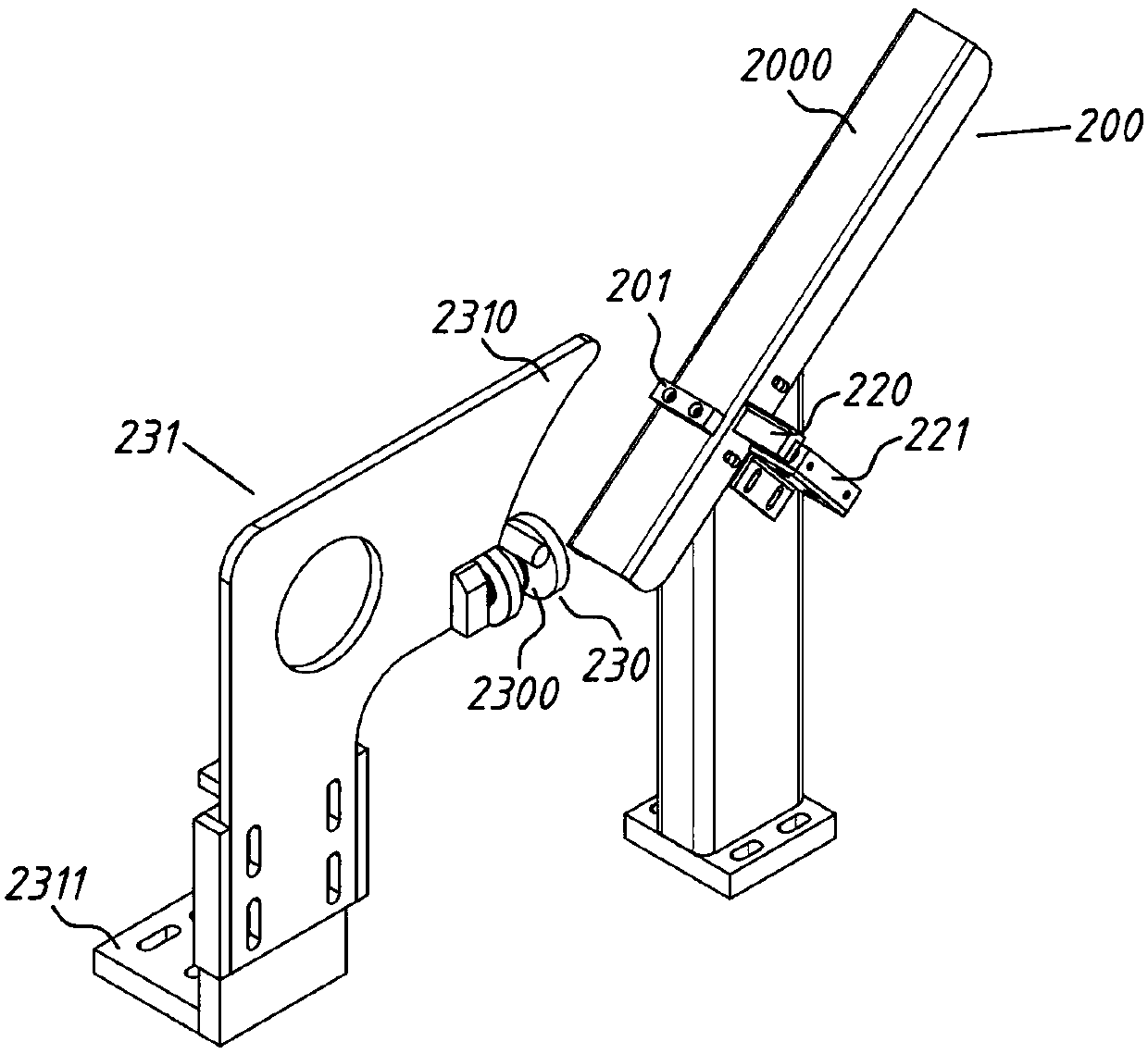

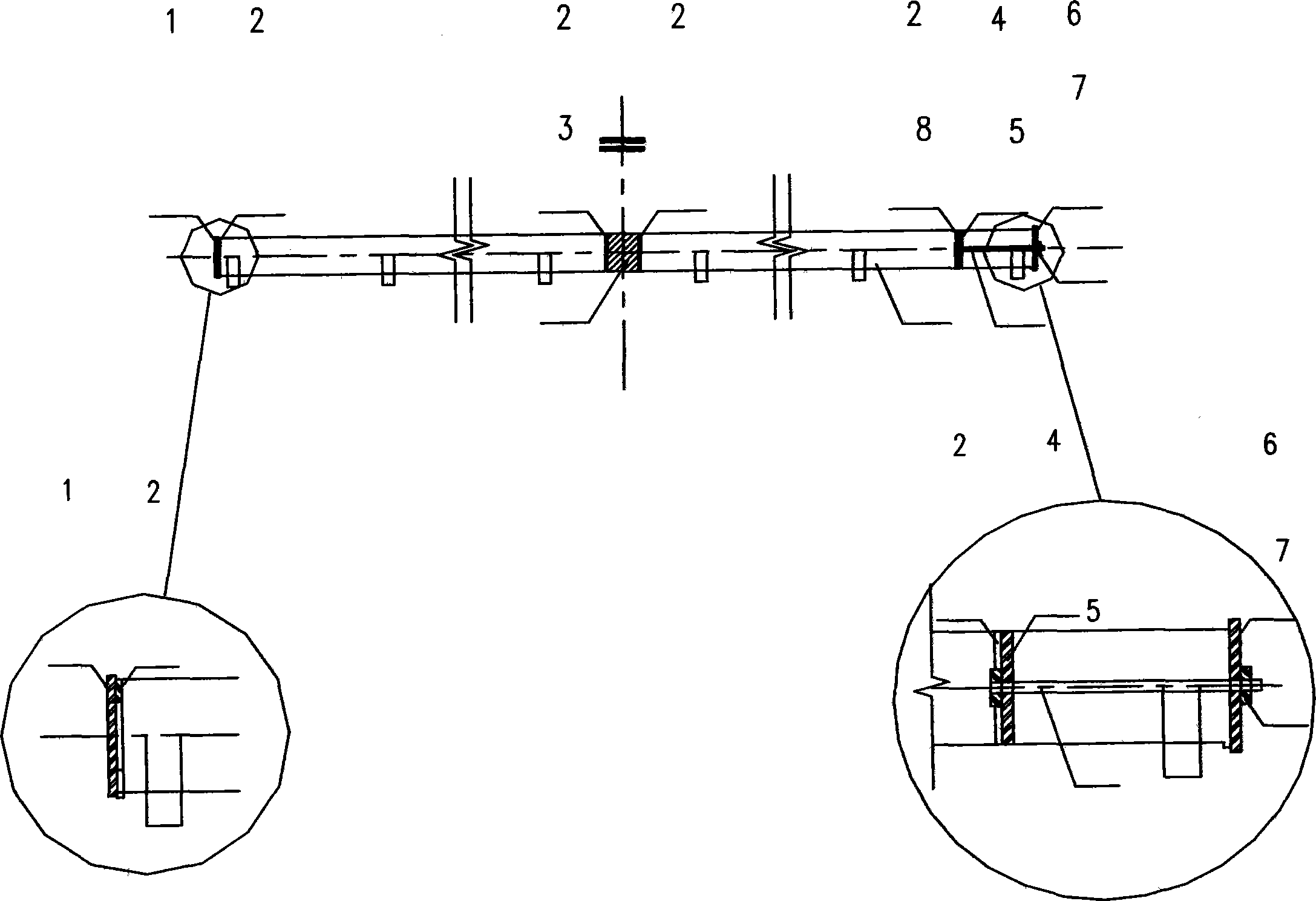

Split type core locking device

ActiveCN101758075AReasonable process layoutImprovement of hot rolling processMandrelsMetal rolling arrangementsSnubberMechanical engineering

The invention provides a split type core locking device, which relates to a lock core device for a perforator and a pipe rolling machine. The invention solves the problems of the existing core locking device that the capillary can not get in and out transversally; the technological layout of the hot rolling equipment is unreasonable. The split type core locking device comprises bases, oil cylinders and snubber rolls, wherein the oil cylinders are connected with the bases; the snubber rolls are connected with the oil cylinders through swinging arms. The split type lock core device is characterized in that the number of the bases is two, and the bases are symmetrically arranged on the large base; the number of the oil cylinders is four, two lower swinging oil cylinders and two upper swinging oil cylinders are respectively symmetrically arranged on the two bases, the two lower swinging oil cylinders are respectively connected with two lower snubber rolls through two lower swinging arms, and the two upper swinging oil cylinders are respectively connected with two upper lock cores through two upper swinging arms. As the four snubber rolls are symmetrically arranged on the large base, the opened split type lock core device is formed, the capillary can get in and out from the upper part, and a pipe pushing trolley can push the capillary into the pipe rolling machine from the middle part, therefore the technological layout of the hot rolling equipment is reasonable.

Owner:TAIYUAN HEAVY IND

Pollution-free isooctane regeneration production line

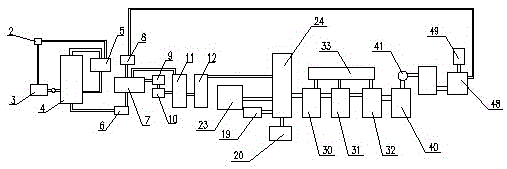

ActiveCN105567359AReasonable process layoutMaximize development and utilizationGaseous fuelsLiquid carbonaceous fuelsProduction lineReflux

Disclosed is a pollution-free isooctane regeneration production line. The pollution-free isooctane regeneration production line is characterized by comprising a coolant pump (2), a raw material buffer tank (3), a depropanizer (4), a depropanizer reflux drum (5), a dehydrater (6), a reactor (7), a sulfuric acid settler (8), an acid pickling settling chamber (9), an alkali cleaning settling chamber (10), a deisobutanizer (11), an n-butane removal tower (12) and a sulfuric acid regeneration production line. The pollution-free isooctane regeneration production line has the advantages that the isooctane regeneration production line with a tail gas regeneration device is rational in process layout, efficient and environment friendly, and raw materials can be developed and utilized to the uttermost degree by recycling of tail gas.

Owner:钦州天恒石化有限公司

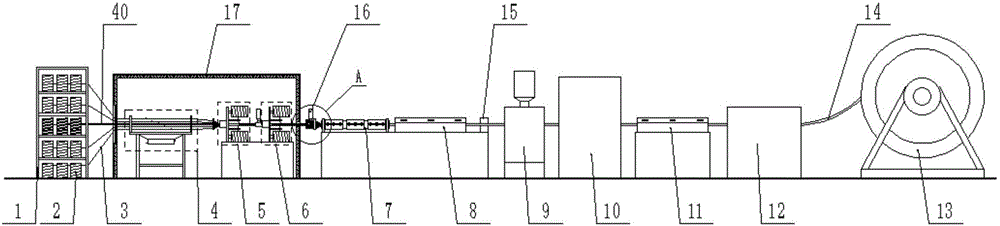

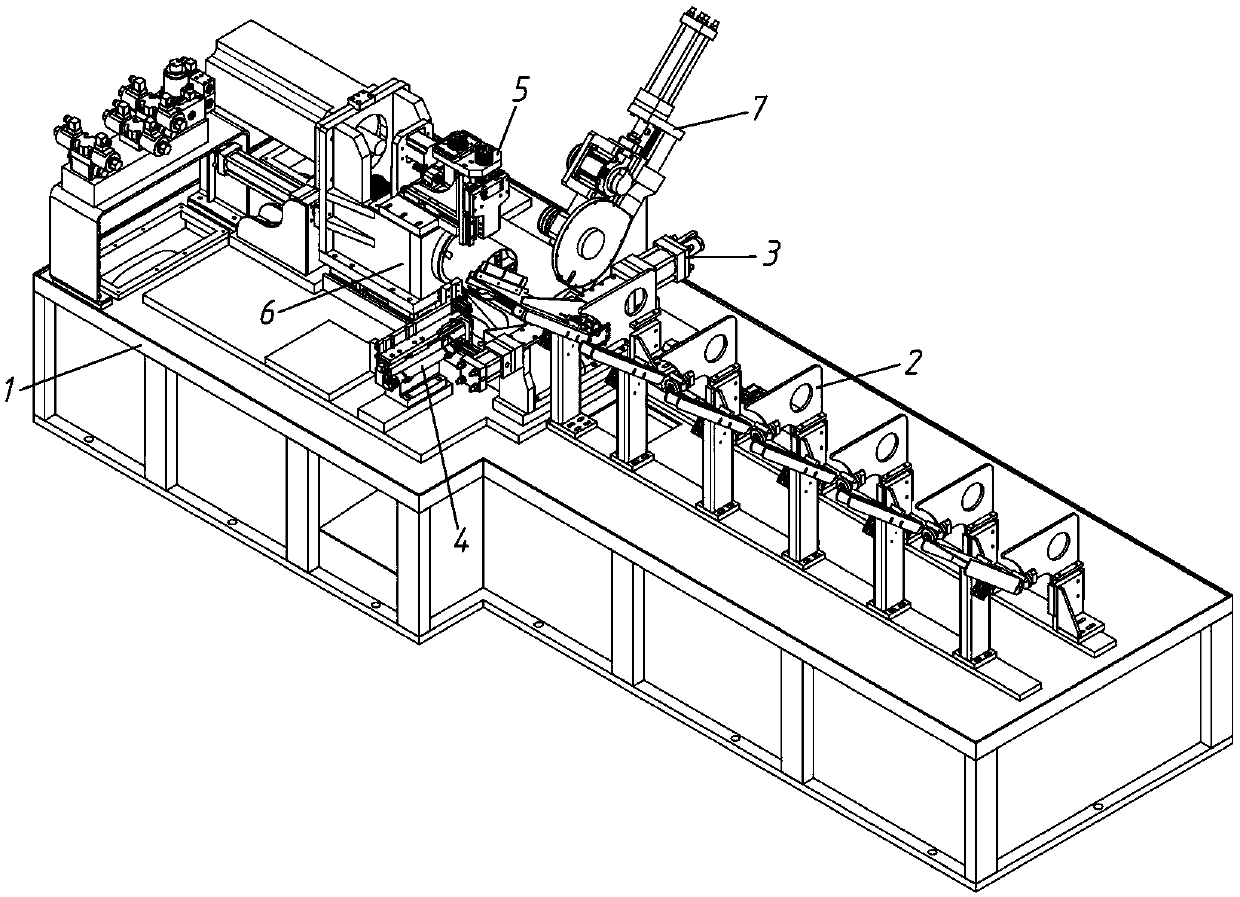

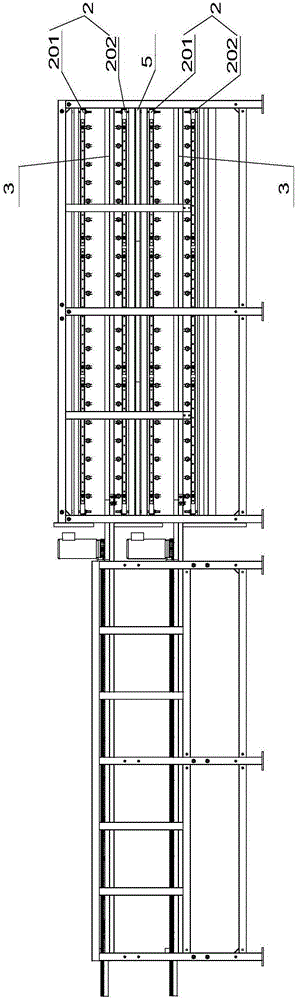

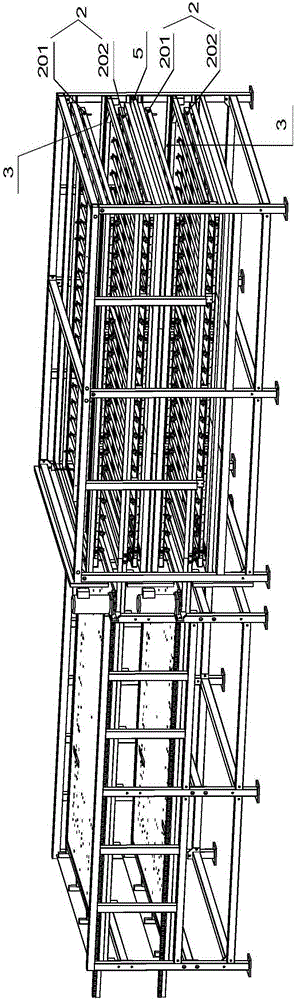

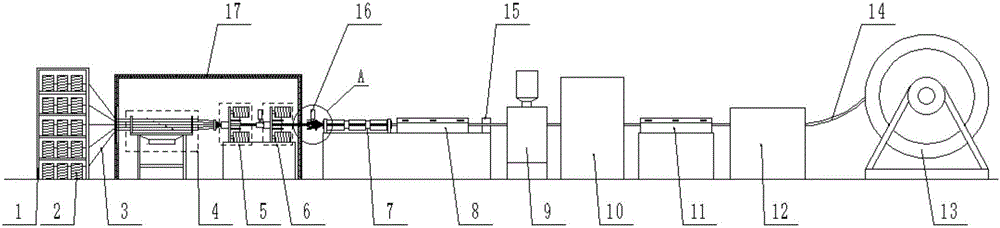

Continuous sucker rod with communication function and preparation device and preparation method thereof

InactiveCN106761447AReduce weightRealize continuous automatic productionDrilling rodsDrilling casingsGlass fiberEpoxy

The invention belongs to the field of oil extraction devices for oil fields and especially relates to a continuous sucker rod with the communication function and a preparation device and a preparation method thereof. The device comprises carbon fiber core body, a glass fiber layer wrapping outside the carbon fiber core body and an epoxy resin layer wrapping outside the glass fiber layer; the center of the carbon fiber core body is provided with a ribbon heater; the carbon fiber core body is made of carbon fiber bundles which are bonded with resin; the glass fiber layer is made of a winding glass fiber layer and a vertical glass fiber layer; the winding glass fiber layer spirally winds outside of the carbon fiber core body; the glass fiber and the carbon fiber forming the vertical glass fiber layer are parallelly arranged. The technology of the invention is simple; the layout is reasonable; by means of the method, a multi-layer antifriction continuous sucker rod can be produced; the sucker rod is provided with thermostatic heating function and can prevent wax precipitation; the sucker rod is light, stands wear and tear and has high twisting strength, shearing strength and tensile strength.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Cleaning process after silicon wafer CMP

ActiveCN109742018AEfficient removalGood removal effectSemiconductor/solid-state device manufacturingHydrofluoric acidSlurry

The invention relates to a cleaning process after silicon wafer CMP, comprising the following steps: step (1), cleaning: removing the polishing slurry on a silicon wafer; step (2), detection: detecting the pre-cleaned silicon wafer by using a detecting machine, proceeding the step (3) if the pre-cleaned silicon wafer meets the requirements, and otherwise, returning to the step (1) to continue thepre-cleaning; and step (3), final cleaning: removing the particles generated by the silicon wafer in the step (2), and further removing SiO2 contained in the polishing slurry on the silicon wafer. Thecleaning process after silicon wafer CMP provided by the invention adds vibration equipment in the pre-cleaning process for cooperation with ozone water to quickly and effectively remove organic matters, SiO2, particles and the protective layer on the surface of the acidified film and facilitate the subsequent removal of the acidified film by hydrofluoric acid, so as to effectively remove organicmatters, SiO2 and particles, and adds alkaline liquid of high temperature state to rinse the silicon wafer in the final cleaning to effectively remove residual SiO2.

Owner:若名芯半导体科技(苏州)有限公司

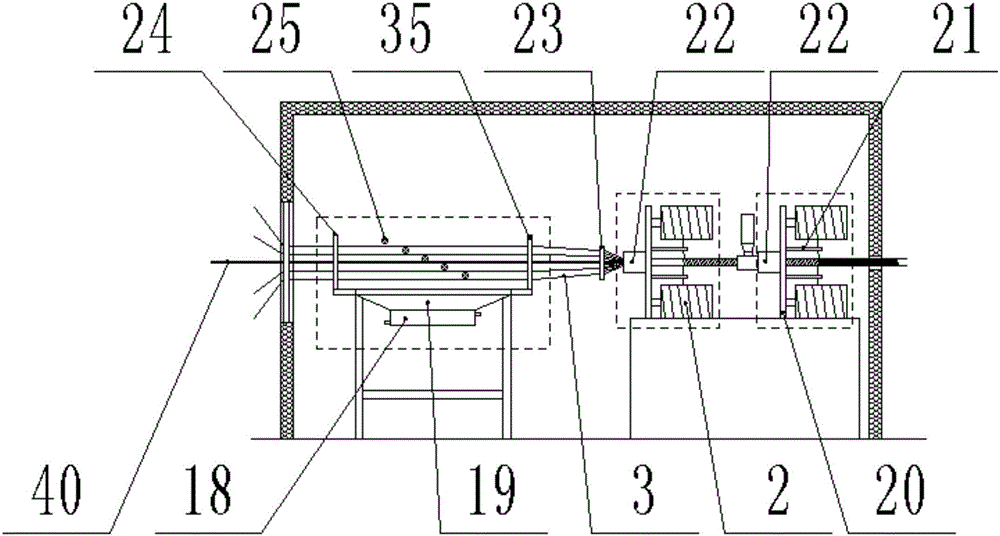

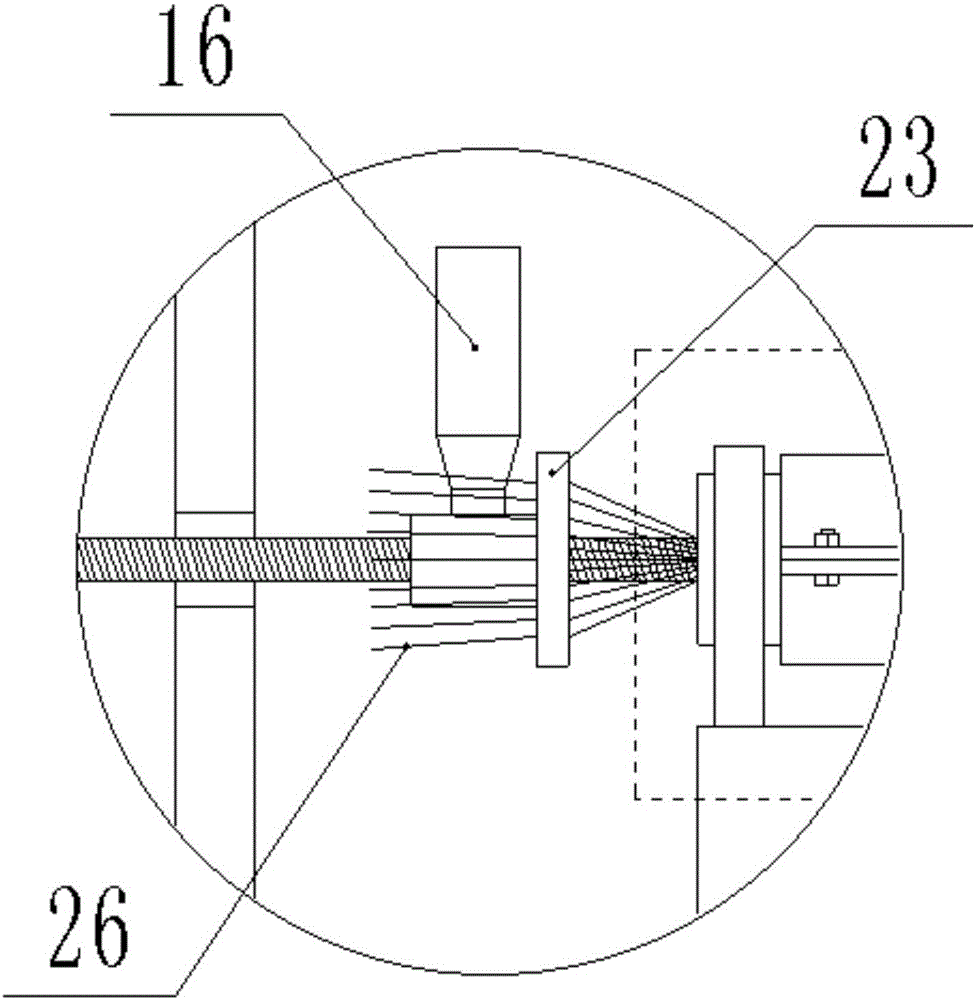

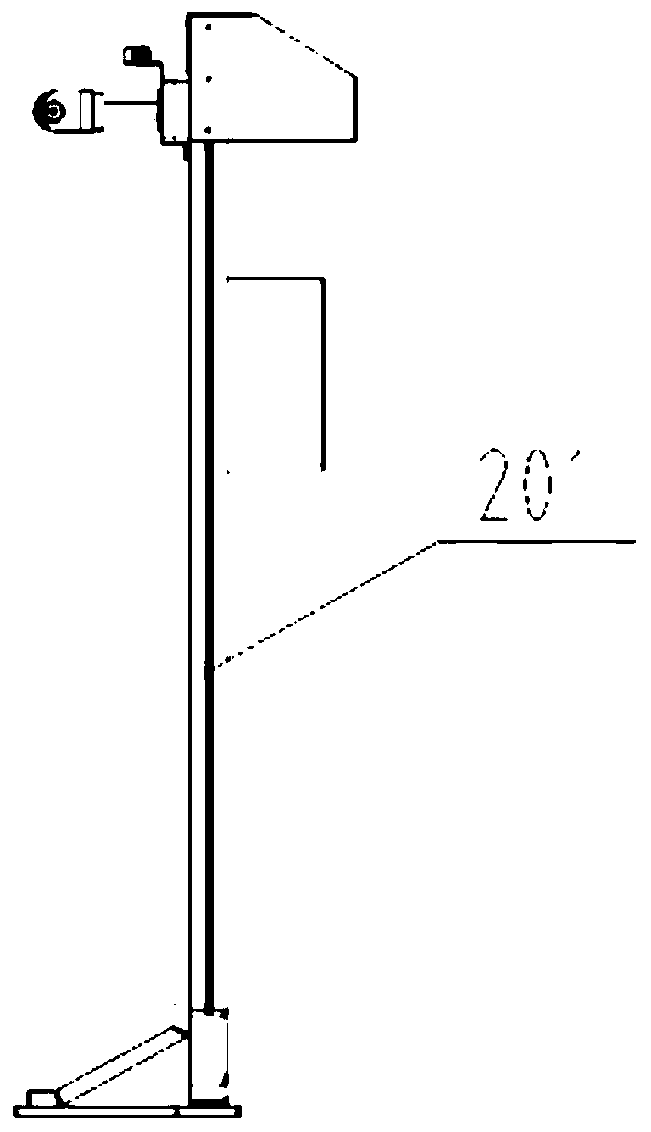

Electrode friction welding equipment

PendingCN111482806AReasonable process layoutCompact structureOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingTool bit

The invention provides electrode friction welding equipment. The electrode friction welding equipment is used for vertically welding a columnar pole to the surface of a flaky pole sheet through friction welding, and the electrode friction welding equipment comprises a pole feeding mechanism, a pole clamping mechanism, a pole sheet feeding mechanism, a cutting mechanism, a rotary handpiece mechanism and a cut-off mechanism. The pole feeding mechanism comprises a supporting rod device, a positioning device, a taking device, a rod receiving device and a rod conveying device. The pole clamping mechanism comprises a clamp and a clamping driving device. The pole sheet feeding mechanism comprises a vibration disc and a positioning and conveying mechanism. The cutting mechanism comprises a mechanical arm and a tool bit. The rotary handpiece comprises a chuck, a rotary driving device and an upsetting driving device. The cut-off mechanism comprises a cut-off wheel device and a slitting driving device. According to the friction welding equipment, production can be automatically completed simply by placing raw materials in the equipment in batches, the procedure layout is reasonable, the structure is compact, and the welding stability and the high efficiency of production can be guaranteed.

Owner:亿迪生精密科技(赣州)有限公司

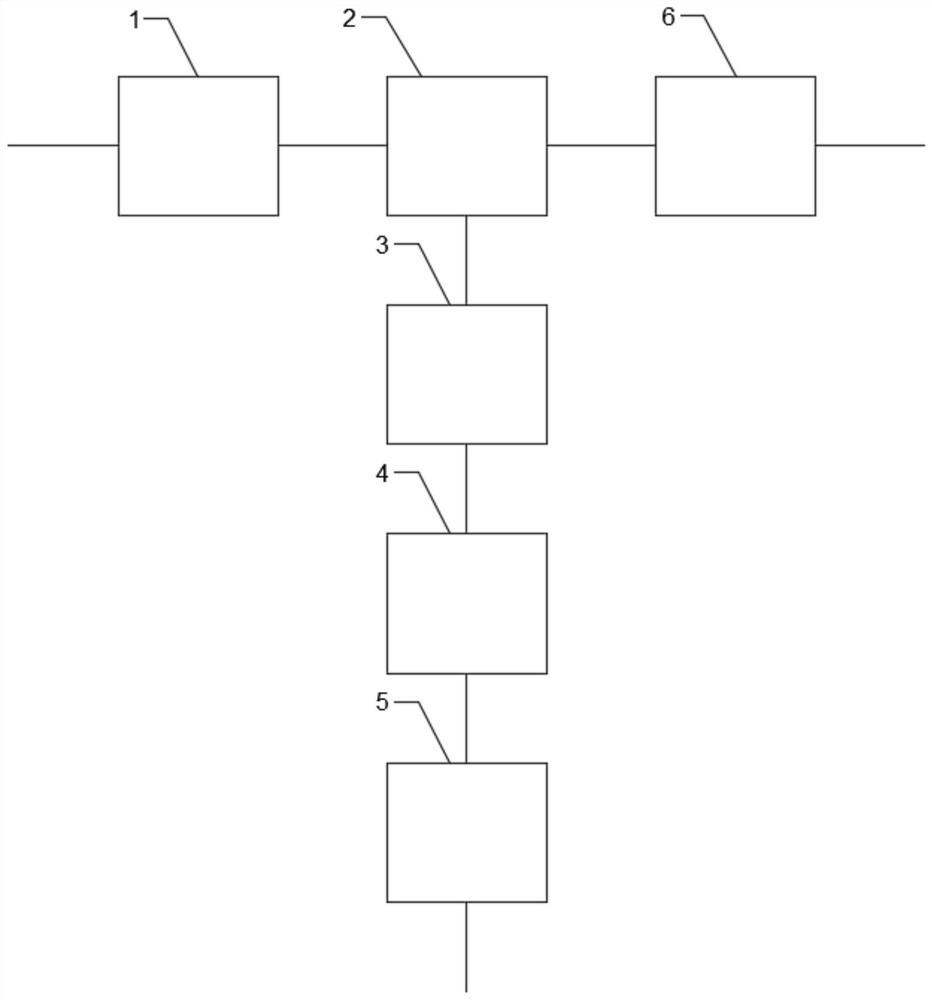

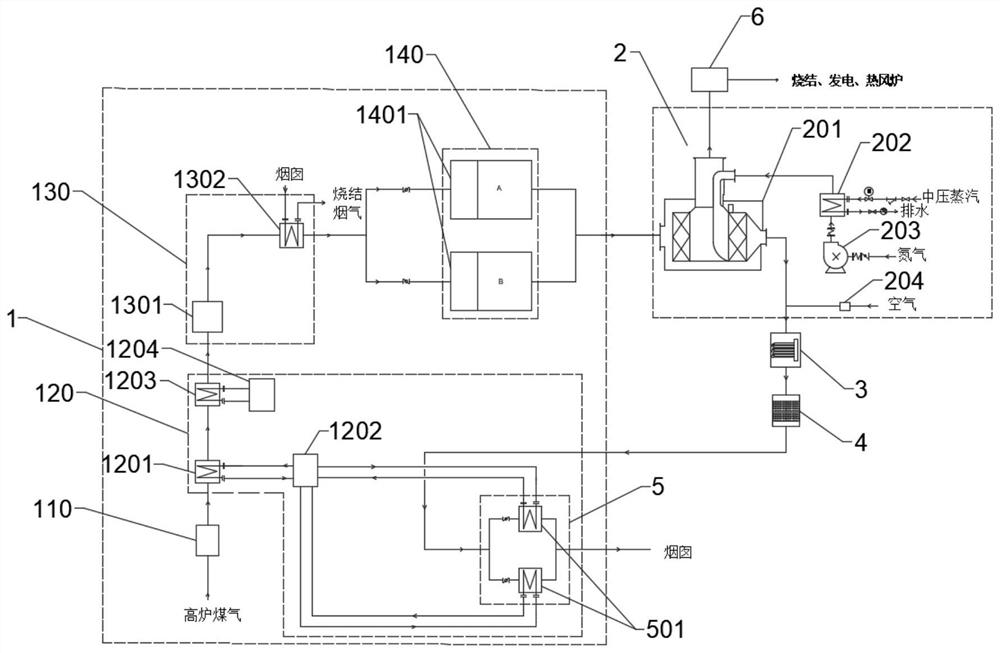

Blast furnace gas sulfur resource utilization device

PendingCN113604255ARealize processingAchieve recyclingGas treatmentChemical industryThermodynamicsProcess engineering

The embodiment of the invention discloses a blast furnace gas sulfur resource utilization device. The blast furnace gas sulfur resource utilization device comprises a pretreatment unit, an adsorption / desorption unit, a conveying unit, a heating unit, a catalysis unit and a condensation recovery unit; an inlet of the pretreatment unit is communicated with to-be-treated blast furnace gas, and the pretreatment unit is used for dechlorinating the to-be-treated blast furnace gas, cooling to remove water, heating to dehumidify and filtering to deoxidize; an inlet of the adsorption / desorption unit is communicated with an outlet of the pretreatment unit, and the adsorption / desorption unit is used for separating sulfur-containing substances of blast furnace gas; and the conveying unit is arranged at an adsorption gas outlet of the adsorption / desorption unit and is used for conveying clean coal gas to a gas using point. According to the blast furnace gas sulfur resource utilization device, low-investment and low-energy-consumption desulfurization of the blast furnace gas can be realized, and sulfur-containing species resources are utilized.

Owner:上海展恒环保科技有限公司

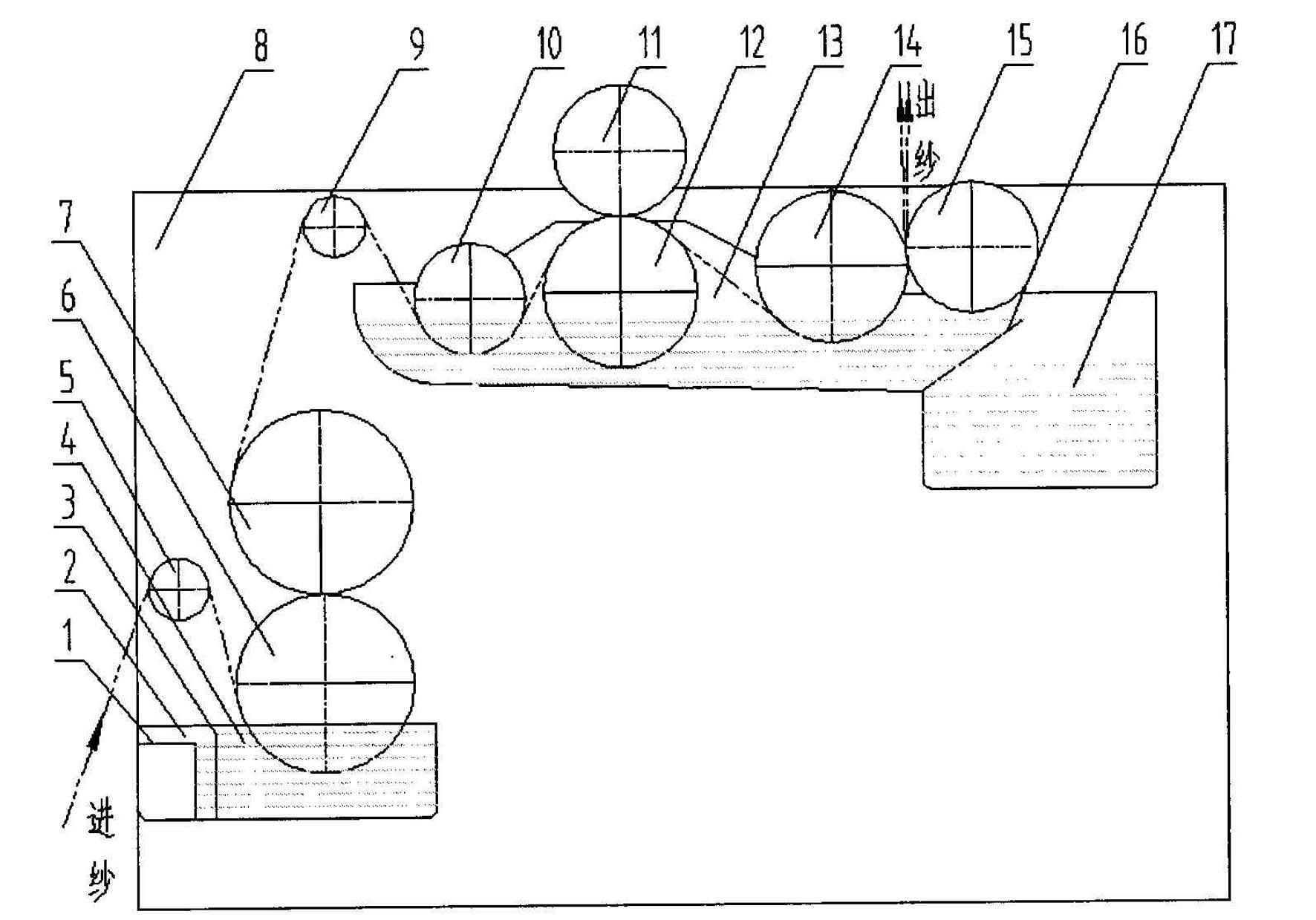

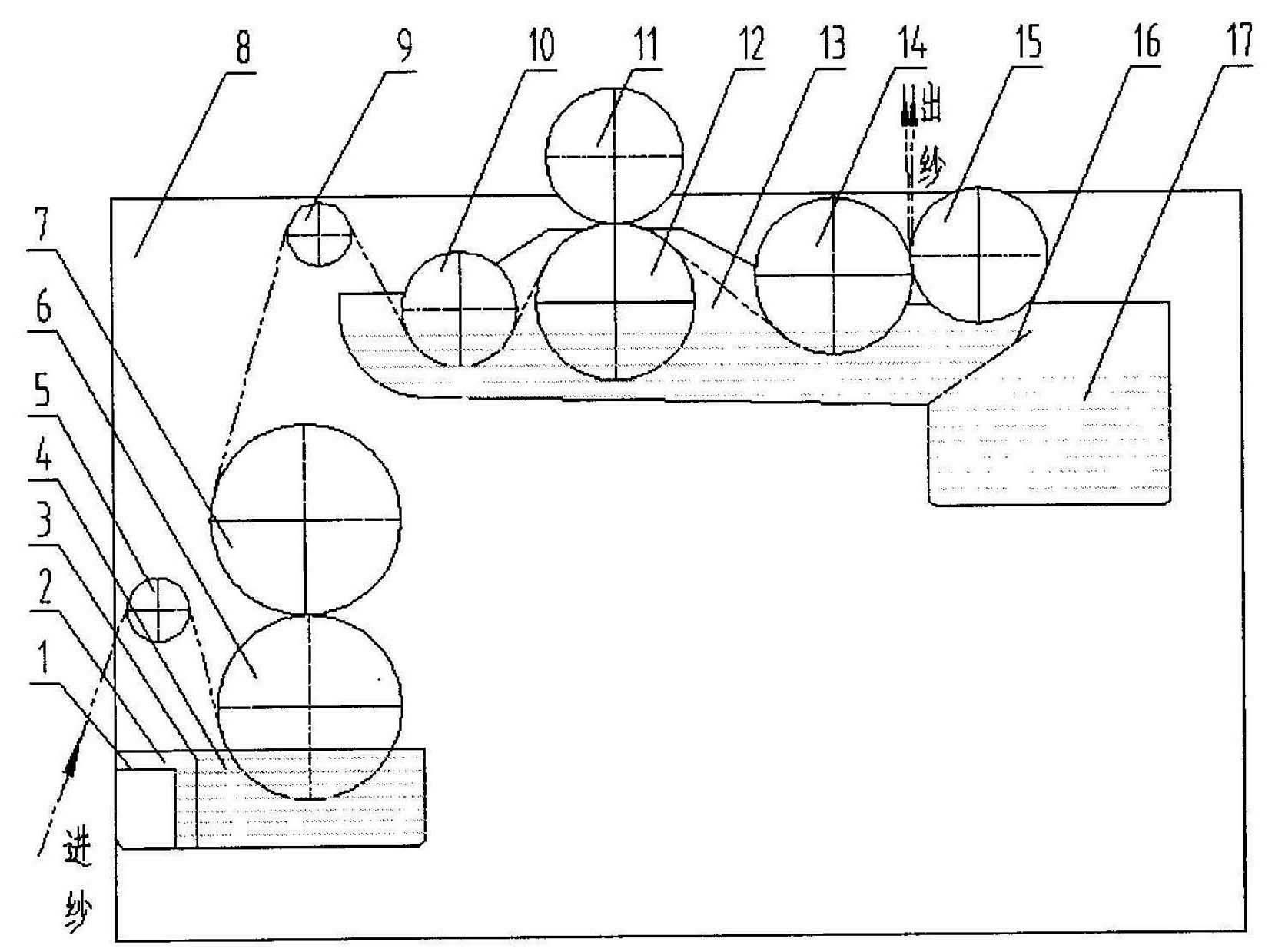

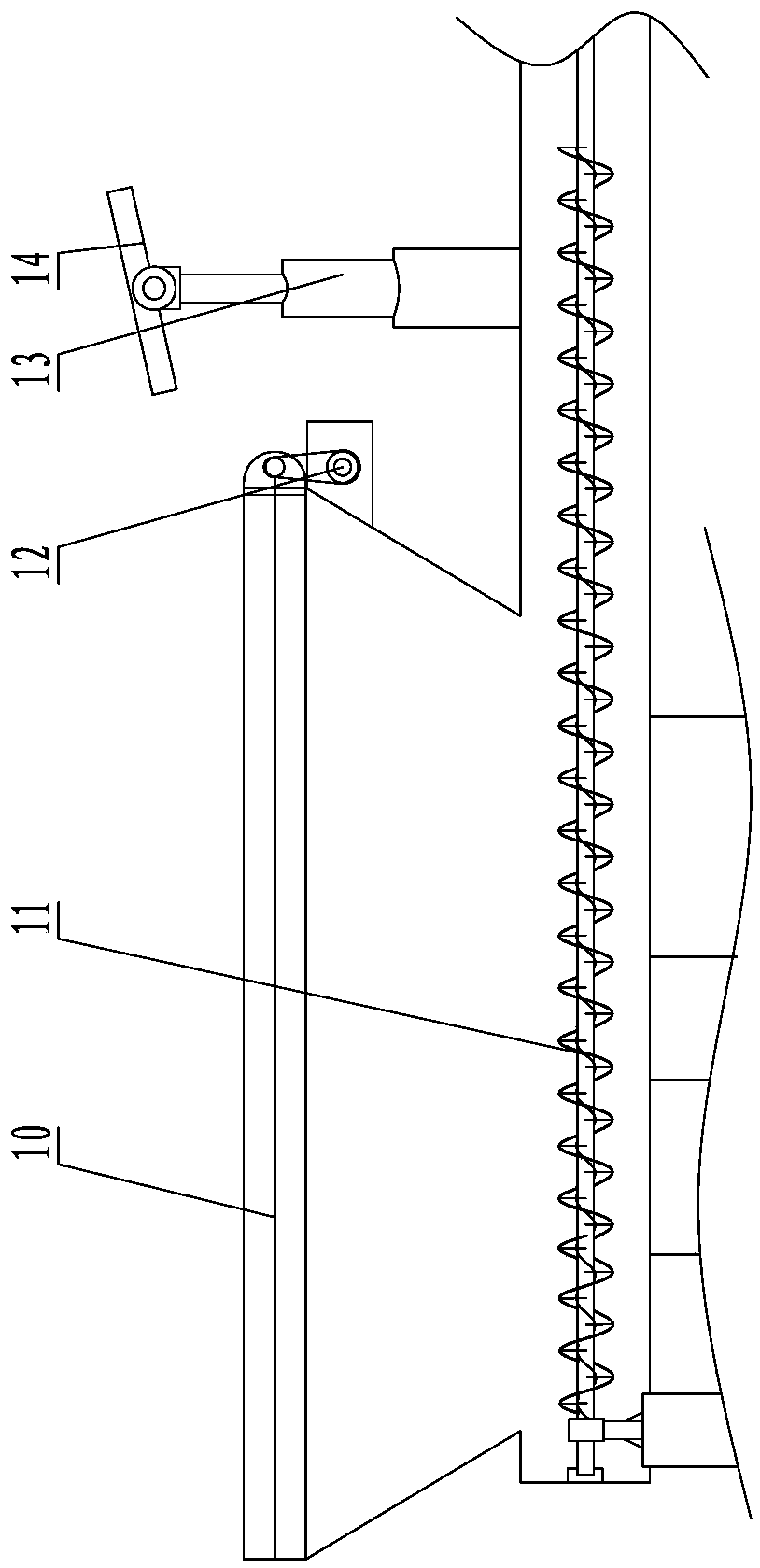

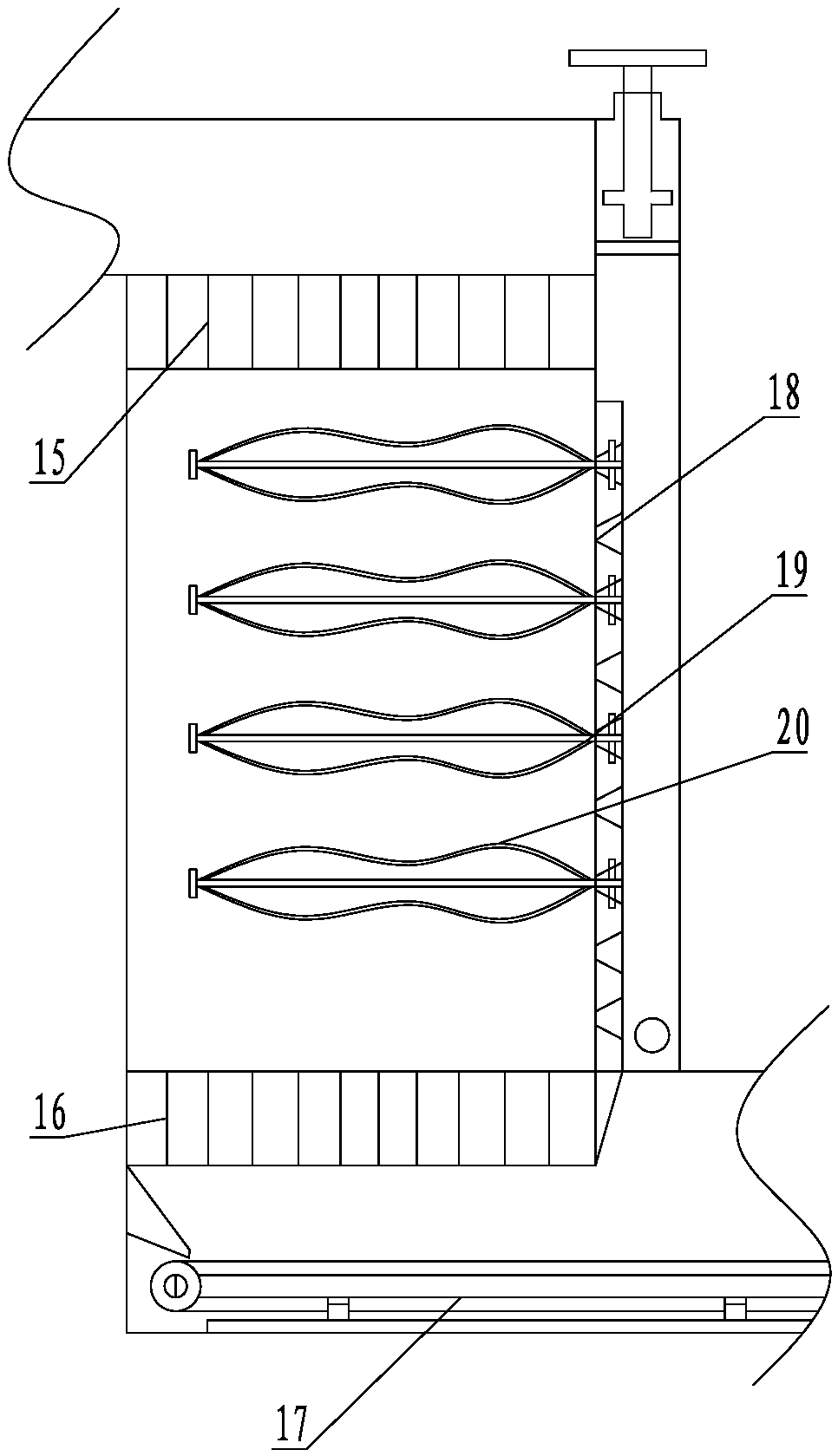

Pre-wetting size vat device of pre-wetting sizing machine

InactiveCN102587062AShorten the lengthImprove work efficiencySucessive textile treatmentsTextile treatment carriersYarnPulp and paper industry

The invention discloses a pre-wetting size vat device of a pre-wetting sizing machine. The pre-wetting size vat device comprises a machine frame, a main size vat, a main water tank, a yarn guide roller, a water charging roller, a water squeezing roller, a yarn guide roller, an immersing roller, a first sizing roller, a second sizing roller, a first size squeezing roller and a second size squeezing roller, wherein the main size vat is arranged at the upper part of the machine frame; the main water tank is arranged on the machine frame which is arranged at the bottom front side of the main size vat; the yarn guide roller, the water charging roller, the water squeezing roller, the yarn guide roller and the immersing roller are arranged along the yarn running direction in sequence; the first size squeezing roller is arranged above the first sizing roller; the second size squeezing roller is arranged at the rear side of the second sizing roller; the yarn guide roller is arranged on the machine frame which is arranged at the top front side of the main size vat; the yarn guide roller, the water charging roller and the water squeezing roller are arranged above the main water and below the yarn guide roller respectively; the lower part of the water charging roller is immersed in the main water tank; the yarn guide roller is arranged above the front side of the water charging roller; the lower parts of the immersing roller, the first sizing roller, the second sizing roller and the second size squeezing roller are all immersed in the horizontally arranged main size vat; a preparatory size vat is arranged at the rear part of the main size vat; and a size vat overflowing plate is arranged between the main size vat and the preparatory size vat.

Owner:CHTC HEAVY IND

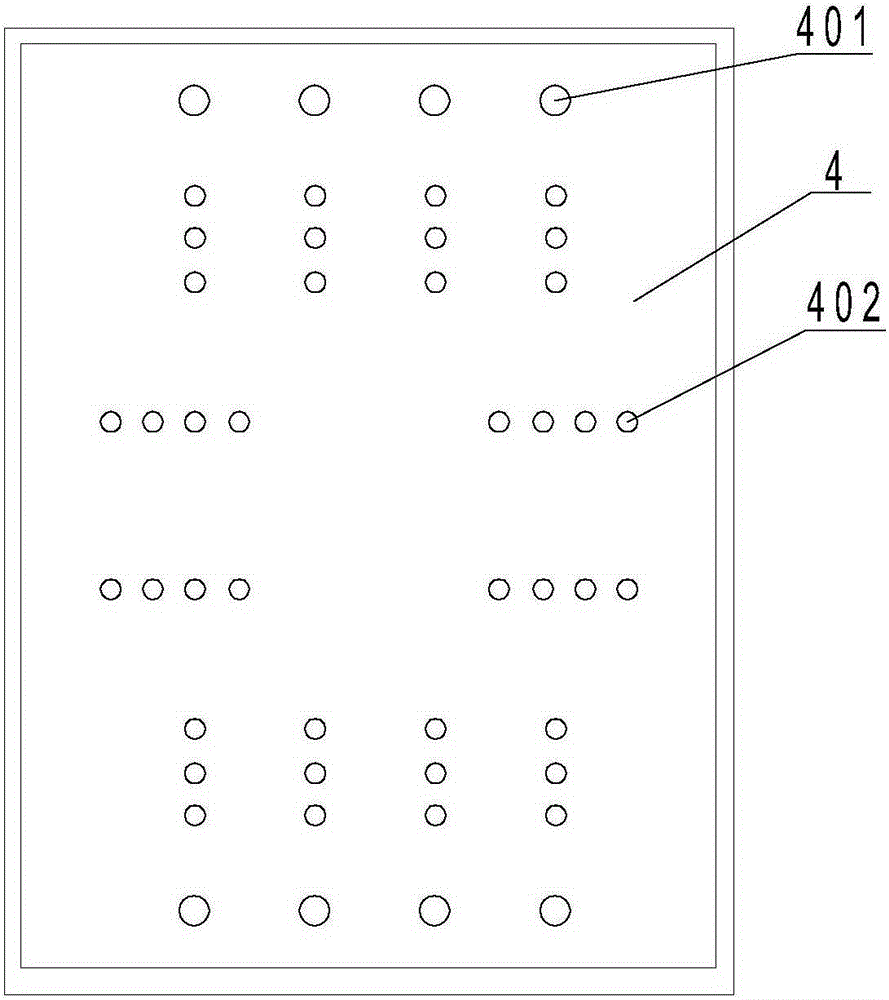

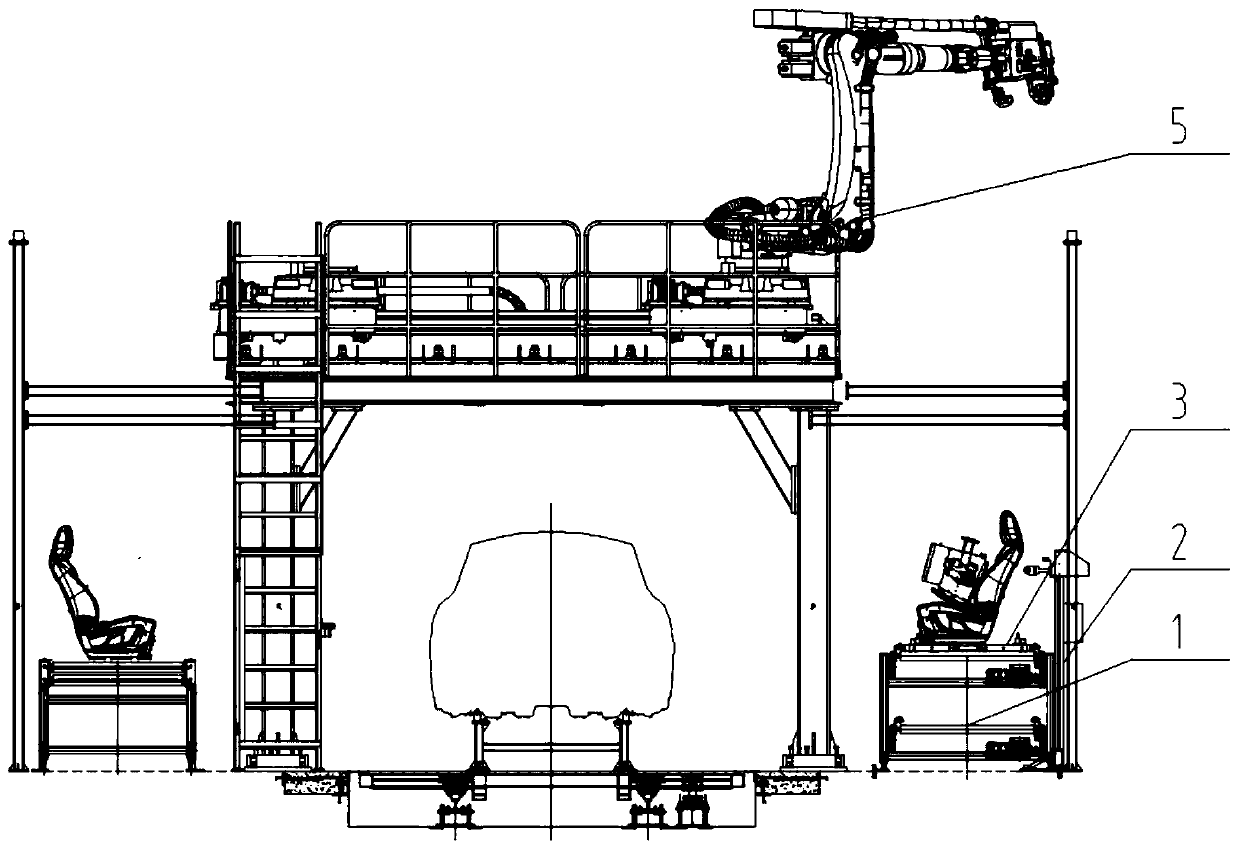

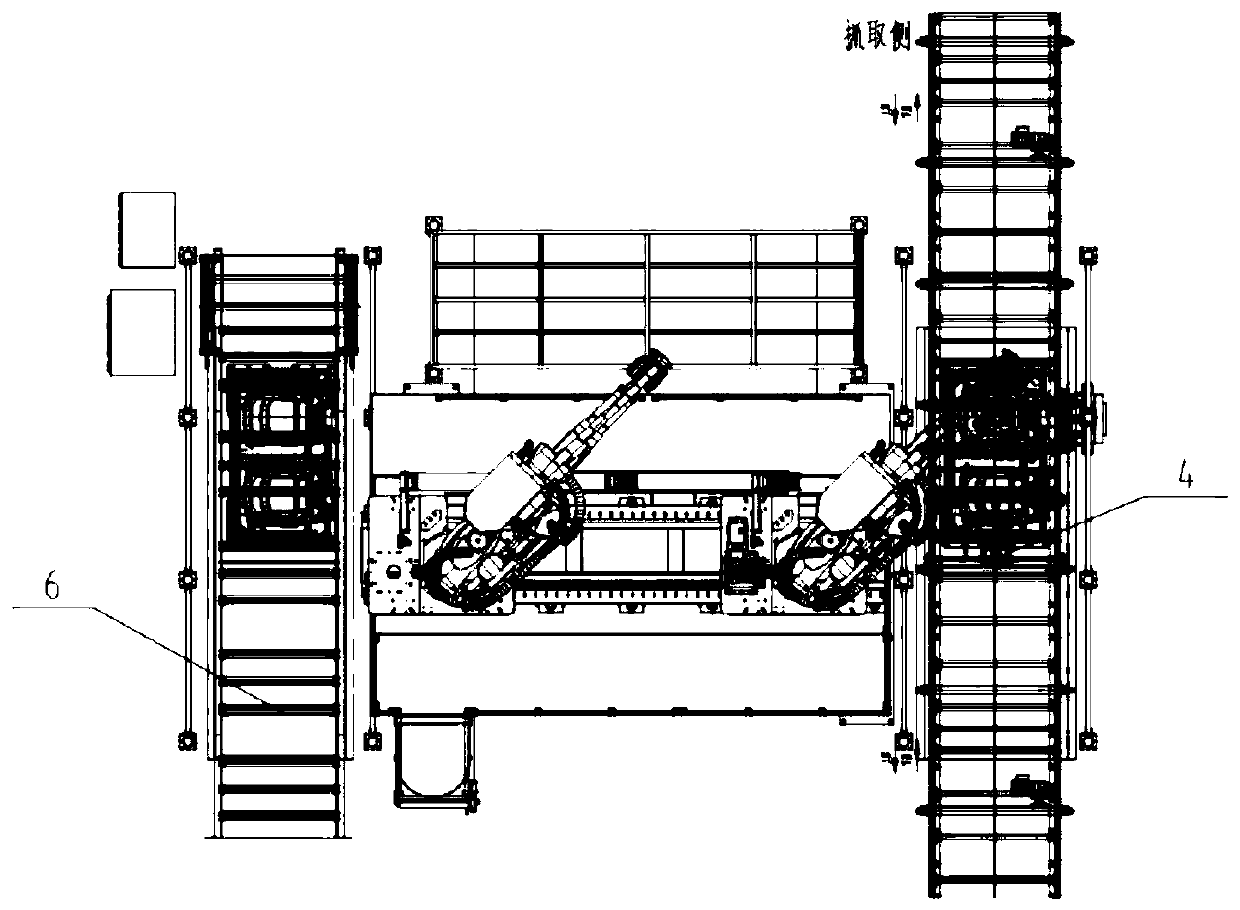

Die pressing automatic molding system for interior trim plate of car roof and process of die pressing automatic molding system

The invention relates to a die pressing automatic molding system and a process thereof, in particular to a die pressing automatic molding system for an interior trim plate of a car roof and a process of the die pressing automatic molding system. The system comprises a pressing die, a press, an automatic fabric clipping device, a robot and an oven. The oven comprises an oven rack, heating devices, rails located in the heating devices, and a grafter arranged on the rails and used for containing a base material. The grafter is provided with multiple positioning holes for positioning the base material and facilitating prick fetching and multiple vent holes. The robot is located between the automatic fabric clipping device and the oven. The process includes the steps of S1, fabric preparation; S2, base material preparation; S3, base material heating; S4, fabric fetching; S5, base material fetching; S6, pressing; S7, pressure maintaining; and S8, die opening and completing of the process. The accuracy of dynamic repeated positioning of the base material can be improved, and the purpose of accurate mobile positioning is achieved; and the system and the process have the beneficial effects of being high in machining efficiency, high in product quality, reasonable in process and convenient to operate, and are easy to use and popularize.

Owner:柳州裕信方盛汽车饰件有限公司

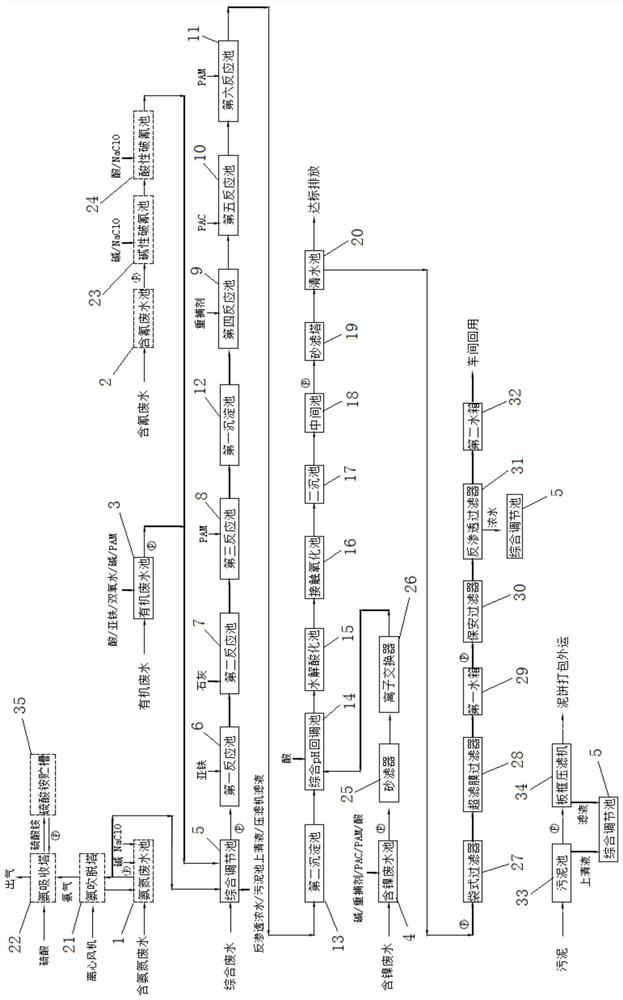

Circuit board production wastewater treatment method

PendingCN112441683AImprove processing efficiencyReduce processing costsWater contaminantsTreatment involving filtrationIon exchangeHydrolysis

The invention discloses a circuit board production wastewater treatment method. A system used in the method comprises an ammonia nitrogen wastewater pool, a cyanide-containing wastewater pool, an organic wastewater pool, a nickel-containing wastewater pool, a comprehensive adjusting pool, a first reaction pool, a second reaction pool, a third reaction pool, a fourth reaction pool, a fifth reactionpool, a sixth reaction pool, a first sedimentation pool, a second sedimentation pool, a comprehensive pH back-regulating pool, a hydrolysis and acidification pool, a contact oxidation pool, a secondary sedimentation pool, an intermediate pool, a sand filter tower, a clean water pool, an ammonia stripping tower, an ammonia absorption tower, an alkaline cyanide breaking pool, an acidic cyanide breaking pool, a sand filter, an ion exchanger and a dosing device capable of preparing an alkaline agent, NaClO, ferrous iron, hydrogen peroxide, PAC and PAM flocculants, recapturing agents and the likeand feeding the prepared reagents into corresponding pools. According to the invention, the quality characteristics of circuit board production wastewater are refined and classified; the process layout of the method is reasonable, and good cooperative treatment effect is realized; the whole treatment system is stable and reliable in operation; wastewater treatment efficiency and a resource reuse rate are greatly improved; wastewater treatment cost is reduced; and effluent quality is improved.

Owner:江门全合精密电子有限公司

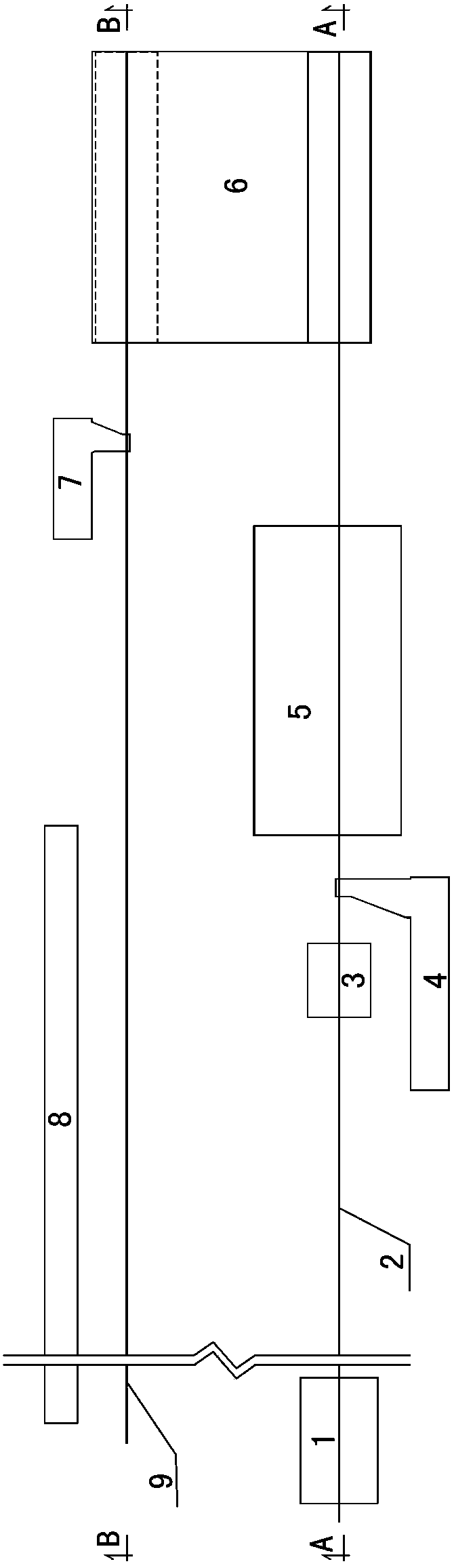

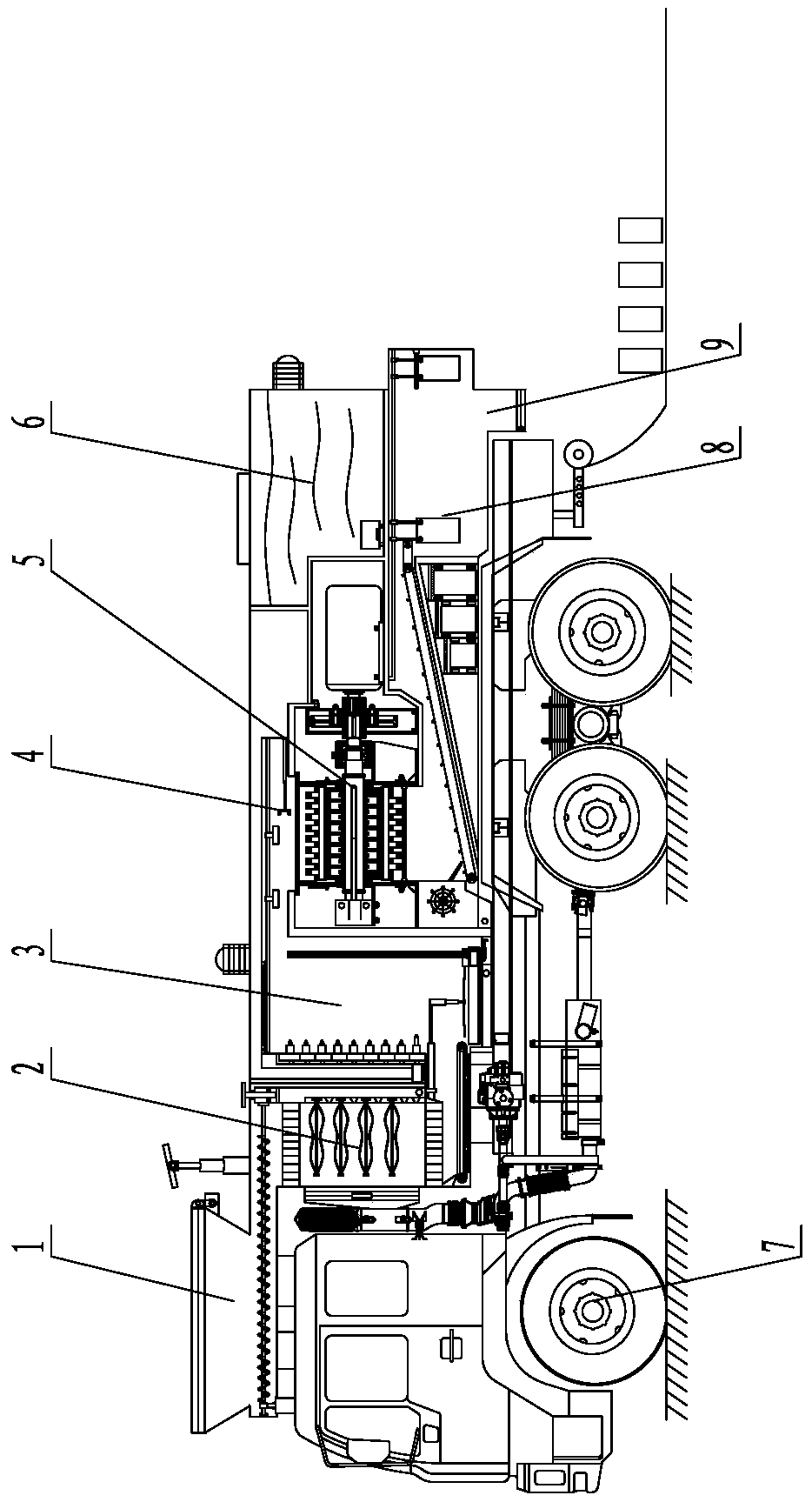

Railway transportation automatic dumping system

The invention relates to a railway transportation automatic dumping system which is characterized in that a heavy train track line and an empty train track line are arranged in parallel, a train dragging platform is vertically arranged between the ends of the heavy train track line and the empty train track line, a loosening machine track is arranged on the outer side of the heavy train track line, a loosening machine is arranged on the loosening machine track, a train shifting machine track is arranged beside the heavy train track line, a heavy train shifting machine is arranged on the train shifting machine track, a wheel clamp is arranged at a train-in end close to a train turning machine, two vibration grate plates are symmetrically arranged at the top of a buffering ore storage bin, two cloth sealing-tape machines are symmetrically arranged between the buffering ore storage bin and a sealing-tape machine, an empty train shifting track is arranged on the outer side of the end of the empty train line, an empty train shifting machine is arranged on the empty train shifting track, a train bottom clearing funnel is arranged on the empty train line, and a bulk cargo sealing-tape machine is arranged below the train bottom clearing funnel. The railway transportation automatic dumping system is reasonable in arrangement and small in occupied space, dumping capacity is added, and the problem of material freezing in winter can be effectively solved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Vehicle agricultural grain packaging apparatus

InactiveCN109110209AReasonable process layoutHigh-quality and efficient processingWrapper twisting/gatheringItem transportation vehiclesWater coolingGrinding teeth

The invention discloses a vehicle agricultural grain packaging apparatus, and belongs to the field of farming machinery and equipment. The vehicle agricultural grain packaging apparatus is characterized in that the apparatus includes a grinding and crushing device and a track travelling packaging device. The grinding and crushing device includes a material grinding inlet, a grinding motor, a grinding rotating shaft, a grinding tooth saw, a grinding chamber, a powder outlet and a water cooling chamber. The material grinding inlet is arranged above the grinding chamber. The powder outlet is arranged under the grinding chamber. The track travelling packaging device includes a power conveyer belt, a packaging hung slide rail, a lifted bag changing device, telescopic lifting arms and a finishedbag discharging device. The power conveyer belt is arranged below a power outlet. A barrier plate is arranged on the power conveyor belt. The other end of the packaging hung slide rail is arranged above the finished bag discharging device. The telescopic lifting arms are arranged on the packaging hung slide rail. A nail plate is arranged on each telescopic lifting arm. The nail plates fix a lifted bag. The vehicle agricultural grain packaging apparatus can crushing, grinding and packaging threshed grain, is intensively designed in structure and reasonable in process layout, and can carry outprocessing with high quality and efficiency.

Owner:ZIBO DACHUANG AUTOMATIC TECH CO LTD

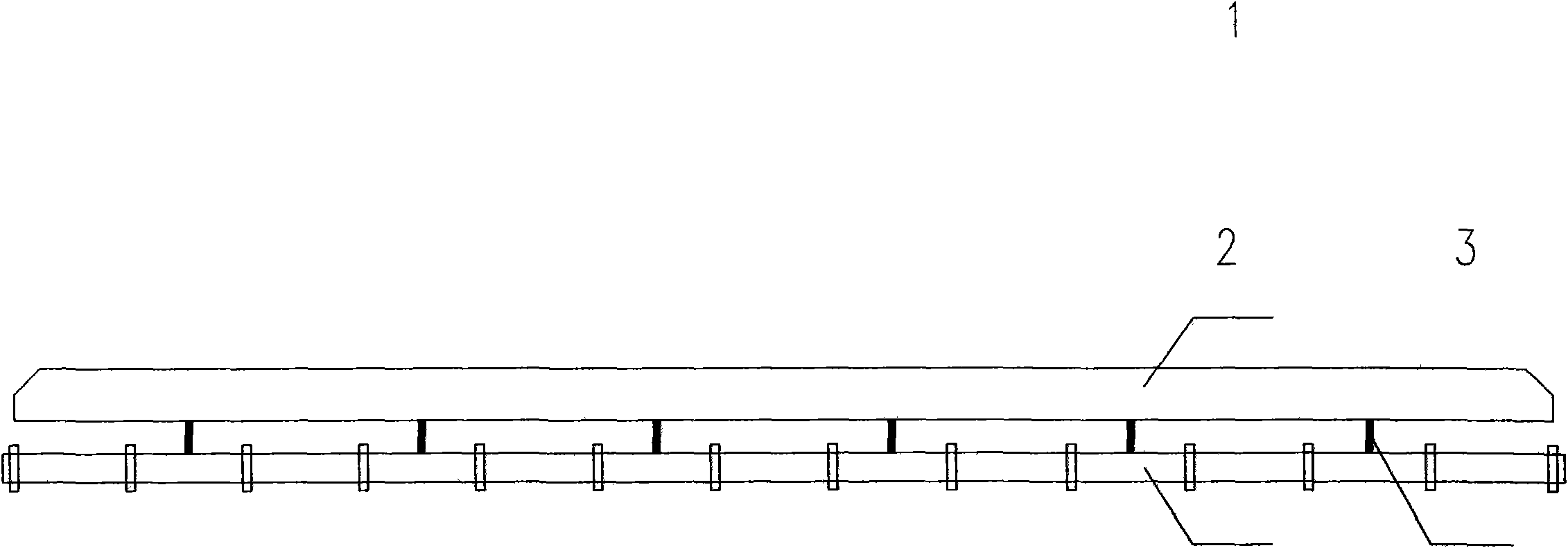

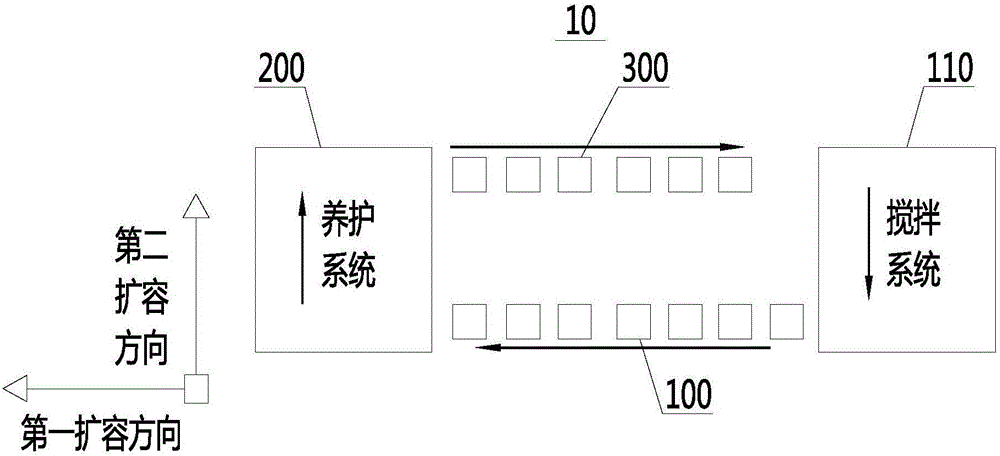

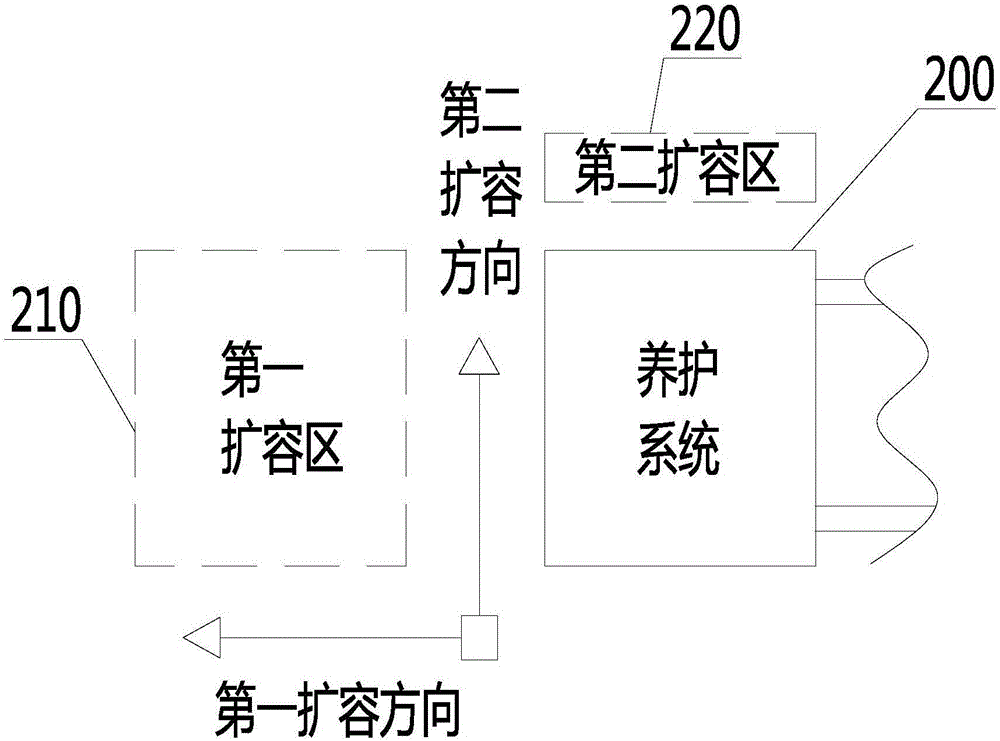

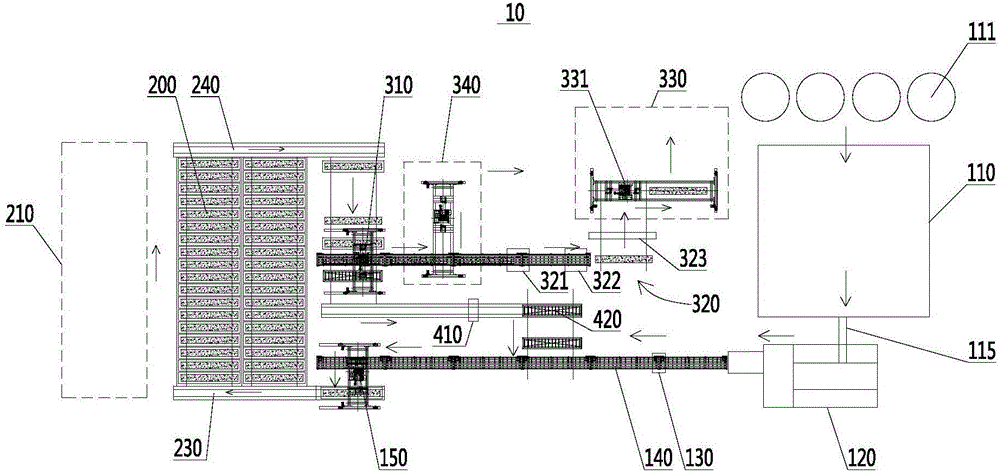

Plate production process and production line thereof

The invention provides a plate production line which comprises maintenance pre-processing equipment, a maintenance system and maintenance post-processing equipment which are connected successively, wherein the maintenance system is located at the end part of one side of the plate production line; and the maintenance pre-processing equipment and the maintenance post-processing equipment are located on the same side of the maintenance system. The plate production line is compact in structure; the area occupied by the plant is greatly reduced; the investment for the plant and the equipment is obviously reduced, and the automation degree is higher; and furthermore, the plate production line is favorable for improving the maintenance efficiency, so that the production efficiency is improved. The invention further provides a plate production process which adopts the plate production line. The plate production process is more reasonable in process layout and higher in maintenance efficiency, and the production efficiency is improved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Forming process of electric wire fixing preformed armor rods

InactiveCN104384405AClosely connectedHigh stranding strengthWire articlesEngineeringForming processes

The invention discloses a forming process of electric wire fixing preformed armor rods. The forming process comprises the steps of forming-head polishing-cleaning-rod selection-twisting-binding-gum dipping-ribbon shearing (ribbons for binding)-marking-sand spreading-combining-bending. The forming process overcomes the defects of the prior art, and is reasonable in layout; steel wire strips of each set of steel wires are connected tightly; each steel wire in each set of the steel wires is specially treated, so that the preservative effect is good; and the preformed armor rods are high in twisting strength, so that the loose phenomenon is not generated in use.

Owner:MINGGUANG RUICHUANG ELECTRIC

Large section steel rolling production system and method

ActiveCN107199242AReduce consumptionReasonable process layoutMetal rolling arrangementsContinuous rollingEnergy consumption

The invention discloses a large section steel rolling production system. The large section steel rolling production system comprises a first horizontal two-roller reversible primary mill system and a second horizontal two-roller reversible primary mill system which are continuously arranged and connected to form a continuous rolling relation. 8-11 continuous rolling units are continuously arranged behind the second horizontal two-roller reversible primary mill system. The defects in the large section steel rolling production technology in the prior art are overcome, the technological layout is reasonable, energy consumption is reduced, environmental protection is achieved, production operation and maintenance are easy, the production cost is reduced, and the product quality is easy to control.

Owner:HUATIAN ENG & TECH CORP MCC +1

Processing method for selected electroplating area of bismuth telluride thermoelectric cooling chip

The invention discloses a processing method for a selected electroplating area of a bismuth telluride thermoelectric cooling chip. The following technical scheme is adopted: a photosensitive emulsion shielding process is adopted, emulsion coating, exposure and development are carried out on an area needing electroplating, and the electroplating is carried out with a medicinal liquid; the other areas are protected by an electroplating-resistant photosensitive emulsion; and the photosensitive emulsion is removed after the electroplating to achieve the purpose of selecting the electroplating area. The process is reasonable and feasible in layout, and capable of saving the losses of nickel, tin and gold, and improving recycling for a cutting powder; and a plating layer on the surface of a product is high in binding force, and the production cost is greatly lowered.

Owner:鹏南科技(厦门)有限公司

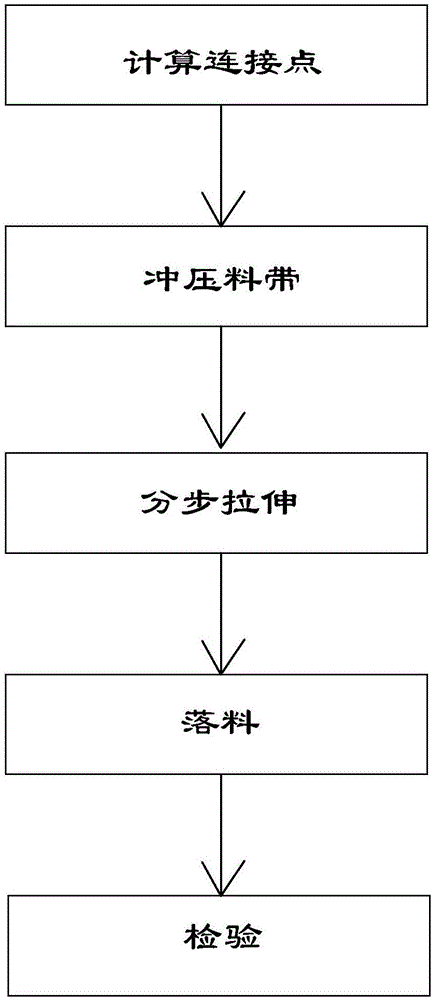

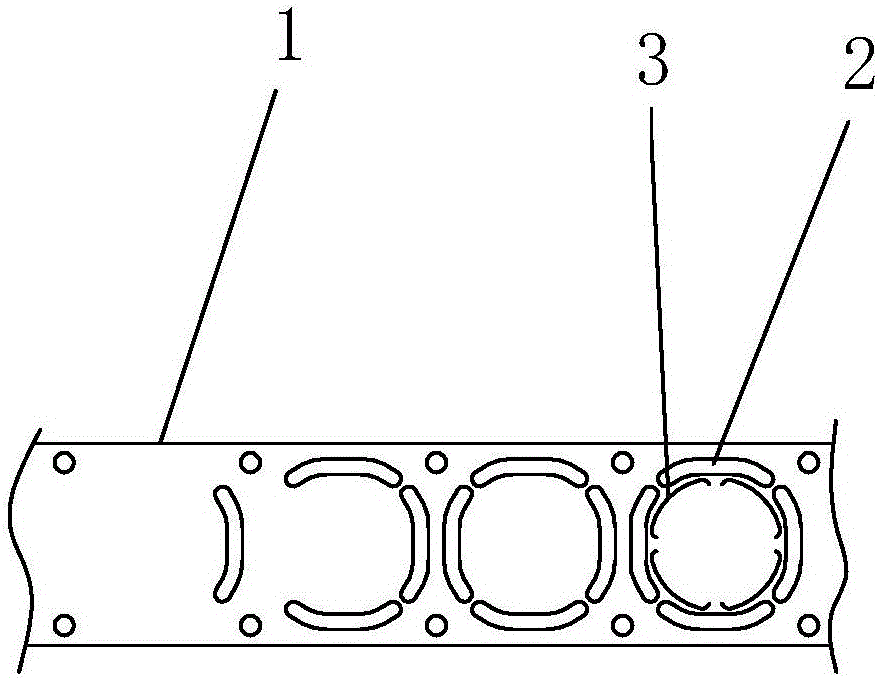

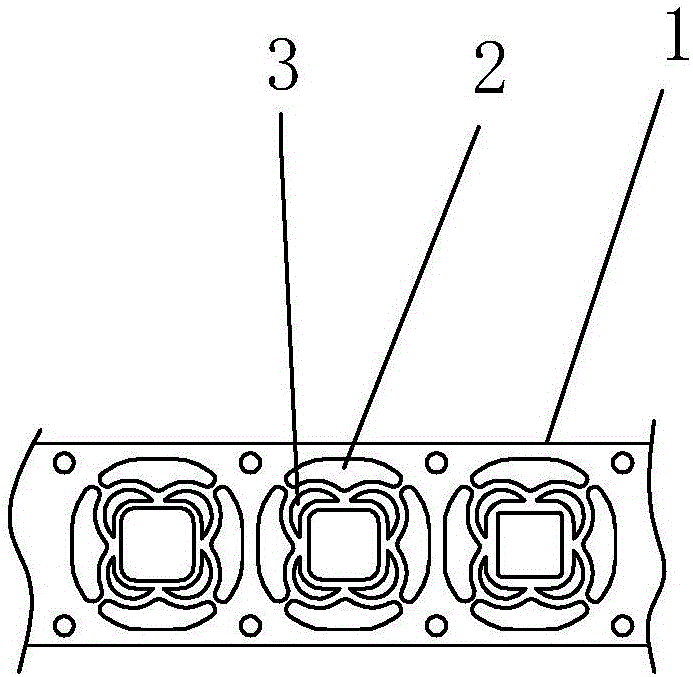

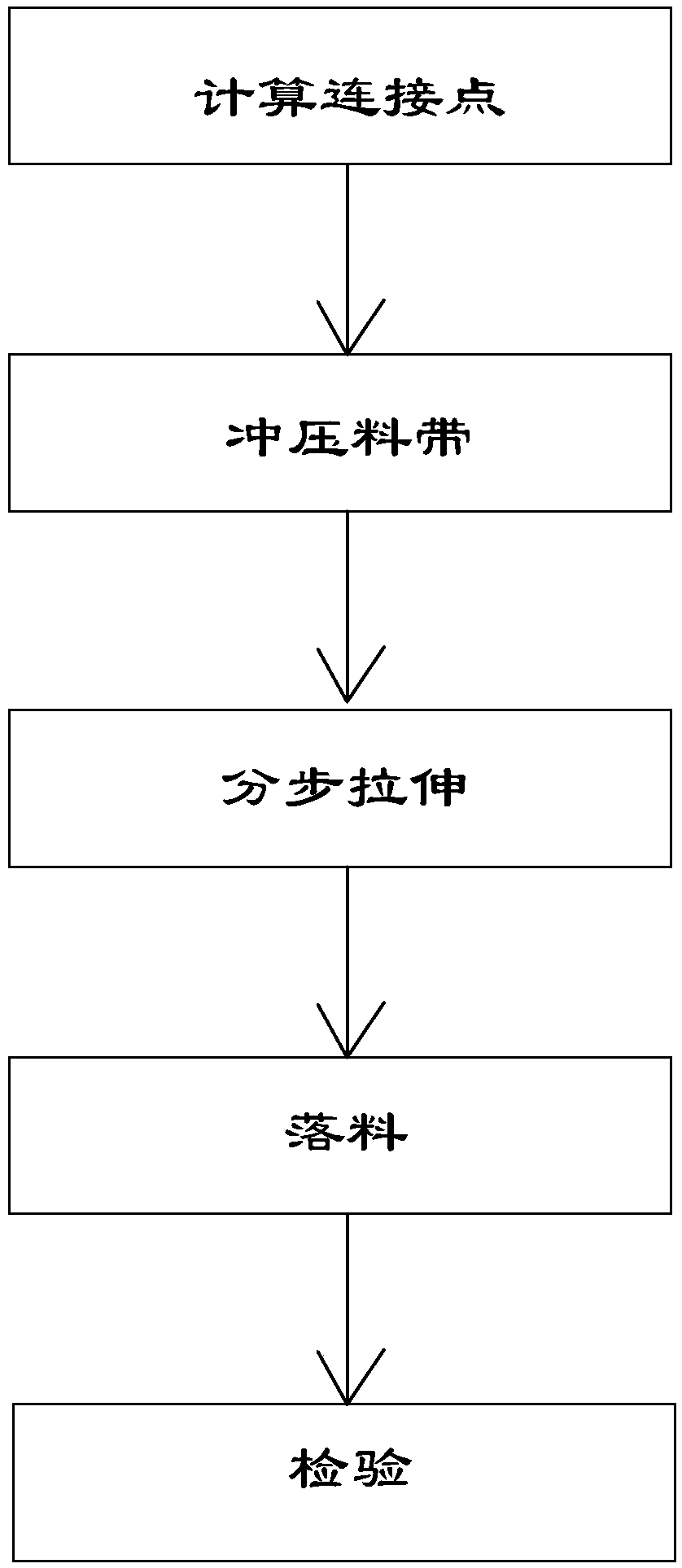

Progressive die cold punching and drawing process of camera support

The invention relates to a progressive die cold punching and drawing process of a camera support. The process comprises the steps that according to the superficial area, size and shape of a product, the positions of connecting points of the product and a material belt are firstly calculated through the plastic deformation tensile strength of a material; four outer ring connecting points are punched on the material belt with the calculated connecting points of the product and the material belt, and four inner ring connecting points are punched on the inner side of the position between every two adjacent outer ring connecting points; reversed tension is provided for the inner parts and the outer parts of the four outer ring connecting points to carry out step-by-step drawing from large to small, plastic deformation of the material is fully utilized, and the depth and boundary dimension needed by the product are obtained through drawing; the drawn product and material belt are vertically arranged in the width direction, the drawn product and material belt waste are separated from the side face, and blanking is achieved; and the finished camera support obtained after blanking is comprehensively inspected. The aims that the product is prevented from being directly punched, the surface of the product has no burrs, and no deformation happens during blanking are achieved.

Owner:JIANGSU ARAINBOW PRECISION METAL TECH CO LTD

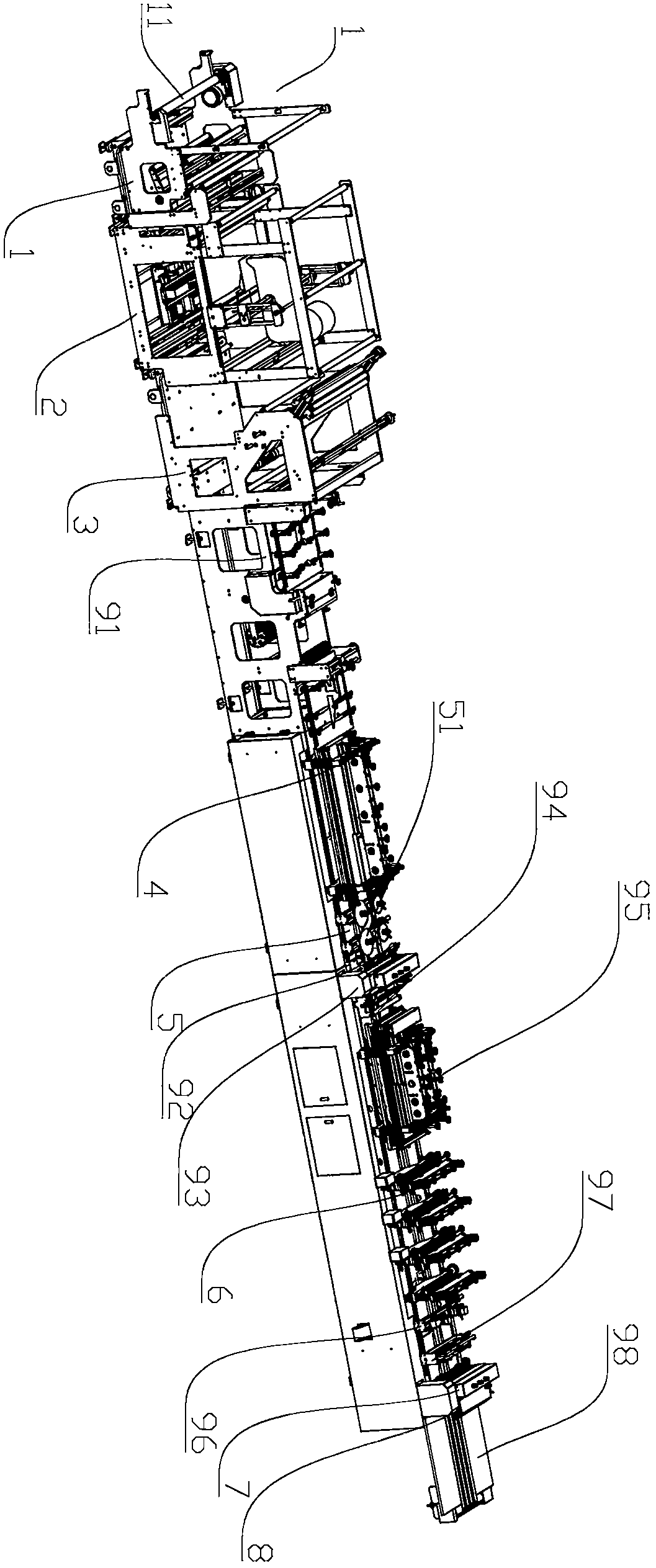

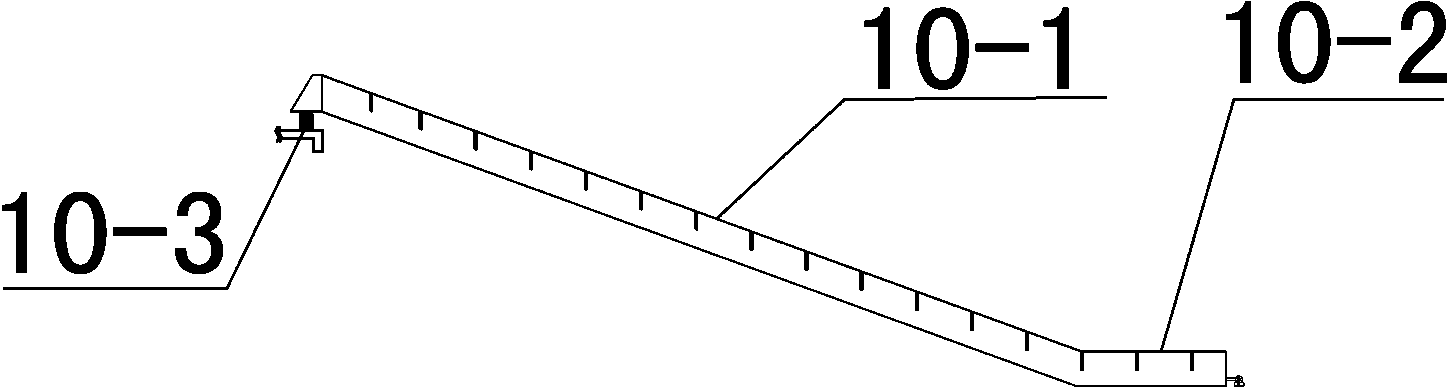

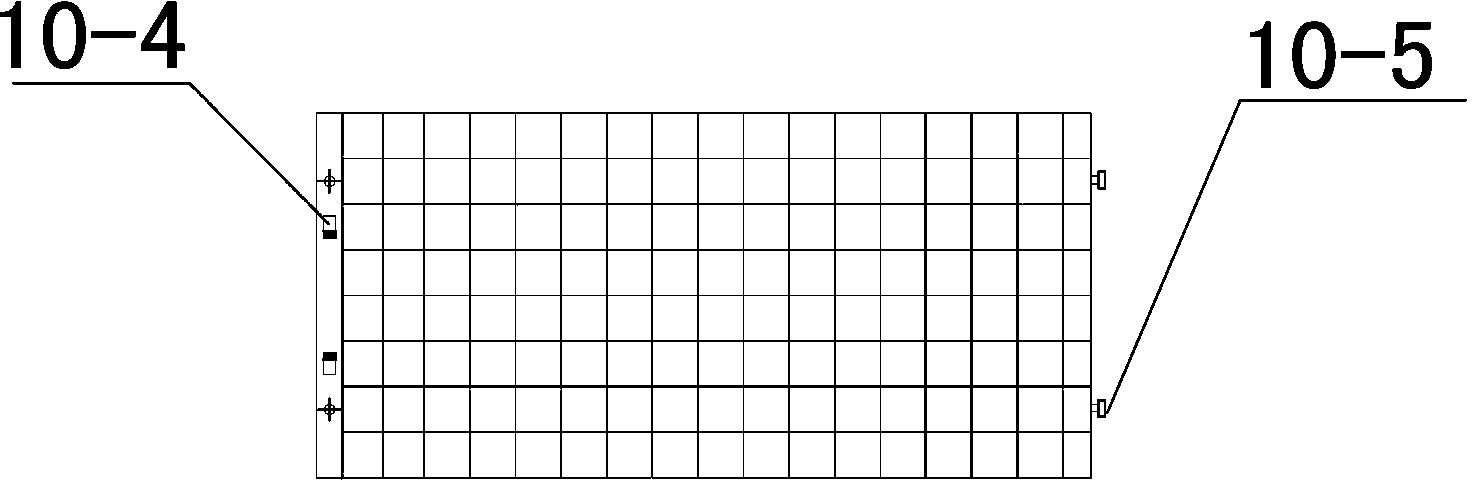

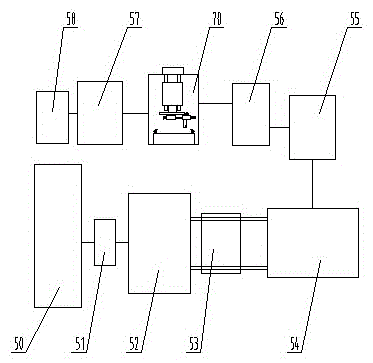

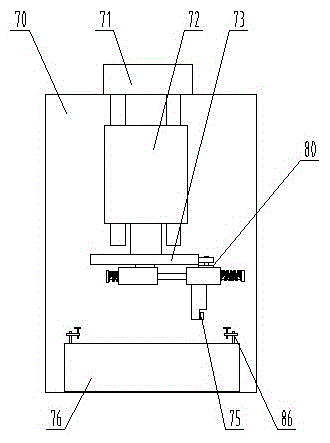

Marble plate production line with marble plate profile tapping machine

InactiveCN106696100AReasonable process layoutIncrease productivityEdge grinding machinesLaminationProduction lineEngineering

Provided is a marble plate production line with a marble plate profile tapping machine. The marble plate production line with the marble plate profile tapping machine comprises a rough marble quarrying system (50), a transportation system (51) used for conveying rough marble to a machining plant area, a rough marble lifting frame saw (52), a plate track transfer trolley (53), a marble plate back mesh automatic bonding line (54), a marble plate polishing and grinding machine (55), a marble plate primary cutter (56), the marble plate profile tapping machine, a marble plate finish cutter (57) and a marble plate edge grinder (58), wherein the transportation system (51) is used for conveying rough marble quarried by the rough marble quarrying system (50) to the machining plant area. The marble plate production line with the marble plate profile tapping machine integrates rough marble quarrying, marble plate primary cutting and finish machining, is reasonable in process layout and high in production efficiency, and has good market promotion value.

Owner:HUBEI JINGSHAN TANG STONE PROD

A continuous die cold stamping and drawing process for a camera bracket

The invention relates to a progressive die cold punching and drawing process of a camera support. The process comprises the steps that according to the superficial area, size and shape of a product, the positions of connecting points of the product and a material belt are firstly calculated through the plastic deformation tensile strength of a material; four outer ring connecting points are punched on the material belt with the calculated connecting points of the product and the material belt, and four inner ring connecting points are punched on the inner side of the position between every two adjacent outer ring connecting points; reversed tension is provided for the inner parts and the outer parts of the four outer ring connecting points to carry out step-by-step drawing from large to small, plastic deformation of the material is fully utilized, and the depth and boundary dimension needed by the product are obtained through drawing; the drawn product and material belt are vertically arranged in the width direction, the drawn product and material belt waste are separated from the side face, and blanking is achieved; and the finished camera support obtained after blanking is comprehensively inspected. The aims that the product is prevented from being directly punched, the surface of the product has no burrs, and no deformation happens during blanking are achieved.

Owner:JIANGSU ARAINBOW PRECISION METAL TECH CO LTD

Device and process for purifying brine

ActiveCN103342374AQuality improvementImprove stabilityLoose filtering material filtersGravity filtersOfficinalFiltration

The invention discloses a device and a process for purifying brine, namely, a starting step raw material for producing officinal sodium chloride. The device comprises a dissolving tank and a brine storage tank, wherein a tank partitioning plate is used for partitioning the device into the dissolving tank and the brine storage tank, the interior of the dissolving tank is partitioned into a primary filtration layer, a middle filtration layer and a refined filtration layer from top to bottom by using four baffle plates, a guide hole is formed in the lower part of the tank partitioning plate, and a plurality of small holes are formed in the baffle plates. The process comprises the following steps of: (a), making refined brine, wherein three stages of filtration are included, namely, (i) primary filtration, (ii) middle filtration and (iii) refined filtration; and c, flowing the made refined brine into the brine storage tank through the guide hole for later use. The refined brine prepared by adopting the device and process is high in quality, good in stability, low in cost, large in brine treatment capability, capable of carrying out continuous operation, and more reasonable in process layout.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

A multi-layer wear-resistant carbon fiber continuous sucker rod and its preparation device and preparation method

ActiveCN106194046BRealize continuous automatic productionReduce weightLamination ancillary operationsDrilling rodsGlass fiberEpoxy

The invention belongs to the field of oil field oil extraction equipment, and particularly relates to a multi-layer abrasion-resistant carbon fiber continuous sucker rod, a making device and a making method. The multi-layer abrasion-resistant carbon fiber continuous sucker rod comprises a carbon fiber core body, a glass fiber layer wrapping the carbon fiber core body and an epoxy resin layer wrapping the glass fiber layer, the carbon fiber core body is composed of carbon fiber beams bonded through resin, the glass fiber layer is composed of a winding glass fiber layer and a longitudinal glass fiber layer, the winding glass fiber layer winds around the outer side of the carbon fiber core body in a spiral mode, and glass fibers and carbon fibers which form the longitudinal glass fiber layer are arranged in parallel. According to the multi-layer abrasion-resistant carbon fiber continuous sucker rod, the making device and the making method, the technology is simple, layout is reasonable, the multi-layer abrasion-resistant carbon fiber continuous sucker rod which has the advantages of being light in weight, resistant to abrasion, high in torsional strength, shear strength and tensile strength and the like can be produced, the sucker rod is applied to oilfield production, the use function is guaranteed, the energy saving and efficiency improvement effects can be achieved simultaneously, and the benefit is significantly increased.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Automatic carrying and conveying system for automobile seats

ActiveCN110745532AImprove the level of intelligenceReduce workloadConveyor partsCar seatControl engineering

The invention discloses an automatic carrying and conveying system for automobile seats. The automatic carrying and conveying system comprises a seat accumulation and placement conveying rail, a seatback pushing mechanism, a carrying robot, a seat tray, a tray stopper and the like, wherein the seat accumulation and placement conveying rail is positioned on one side of the carrying robot, and a seat conveying line is positioned on the other side of the carrying robot; the carrying robot is used for grabbing the seats and placing the seats on the seat conveying line from the seat accumulation and placement conveying rail; the seat accumulation and placement conveying rail is divided into an upper layer and a lower layer, the upper layer is responsible for conveying the seat tray, and the lower layer is responsible for returning an empty pushing disc; the seat tray is mounted on the seat accumulation and placement conveying rail and provides a conveying carrier for seat conveying; the tray stopper is arranged on the side of the seat accumulation and placement conveying rail and used for fixing the position of the seat tray; and the seat back pushing mechanism is arranged on one sideof the seat accumulation and placement conveying rail and used for keeping the stability of the seats of different models.

Owner:MH ROBOT & AUTOMATION

Contactor production line

The invention discloses a contactor production line. The production line comprises a feeding assembly table, and a base part assembly line, a middle assembly line and a base part assembly line which are arranged around a U-shaped section of the feeding assembly table. U-shaped runner structures are arranged among the base part assembly line, the middle assembly line and the base part assembly line in an extending mode, the middle assembly line is used for assembling base semi-finished products of the base part assembly line and base semi-finished products of the base part assembly line into finished products of the contactors, the U-shaped production line design reduces operation sites, the procedure layout is reasonable. The base part assembly line and the base part assembly line independently complete assembly of respective parts, finally, final assembly is completed through the middle assembly line, the waiting time of assembly procedures can be shortened, the overall assembly progress is improved, all the procedures are smoothly connected, the assembly efficiency is high, in addition, the number of workers is remarkably reduced. The labor cost and the management difficulty are reduced, and the competition of contactor products is improved.

Owner:ZHEJIANG PEOPLE ELE APPLIANCE

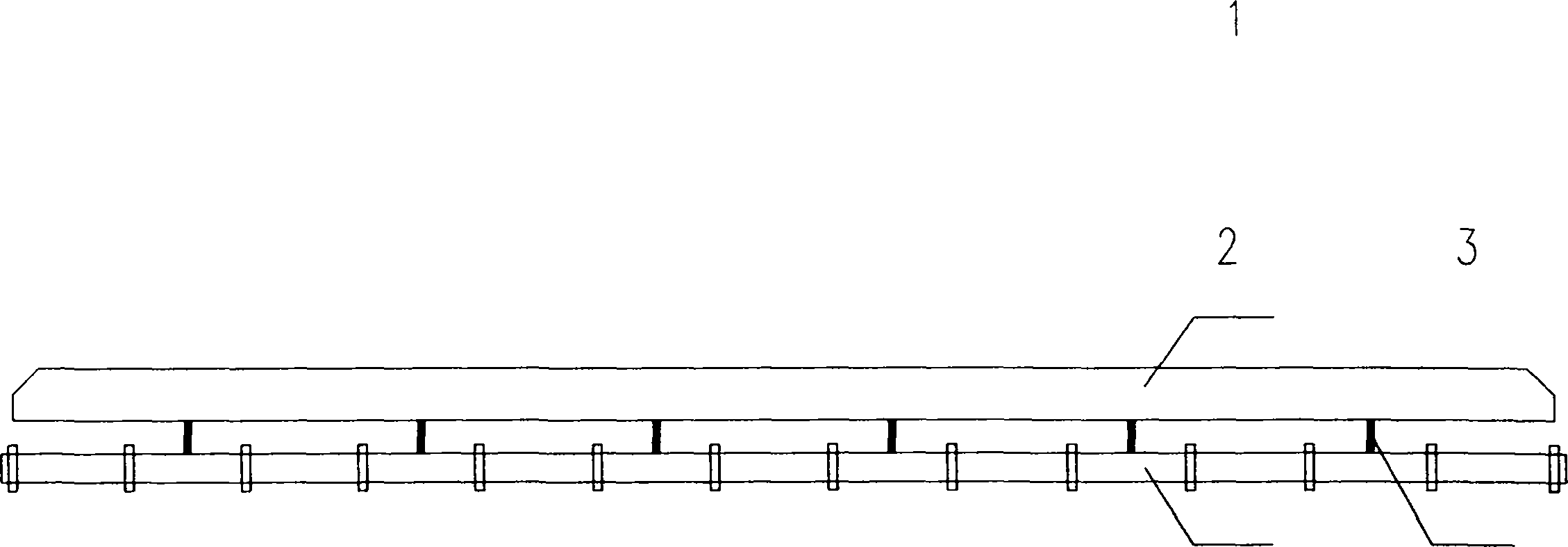

Method for producing precast concrete piles

InactiveCN102398305BSave spaceIncrease productivityMouldsCeramic shaping plantsProduction effectEngineering

The invention relates to a method for producing precast concrete piles, which comprises the following main steps of: manufacturing a reinforcement cage; placing the reinforcement cage into a die; pouring concrete into the die; centrifugally rotating; and carrying out steam curing. The method is characterized in that the die with the length of over 20 meters is adopted in the method; two or a plurality of precast concrete piles can be simultaneously produced by one die; upper and lower half dies of the die have a transporting mode of transversely moving in parallel in the direction vertical to the axis of a crane beam of a plant in the production process; and centrifugal equipment and a curing tank are transversely arranged in parallel in the direction vertical to the axis of the crane beam of the plant. Due to the adoption of the transverse flow production scheme of the long die, the production effect can be multiplied, the space occupied by the plant is greatly reduced, a great amount of lands are saved, the working efficiency is improved, and the production quality can be ensured.

Owner:NINGBO YIZHONG CONCRETE PILE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com