Method for producing precast concrete piles

A technology of prefabricated concrete and production methods, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of main reinforcement deviation, insufficient compactness, and high labor intensity of workers, and achieve the effect of uniform and synchronous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

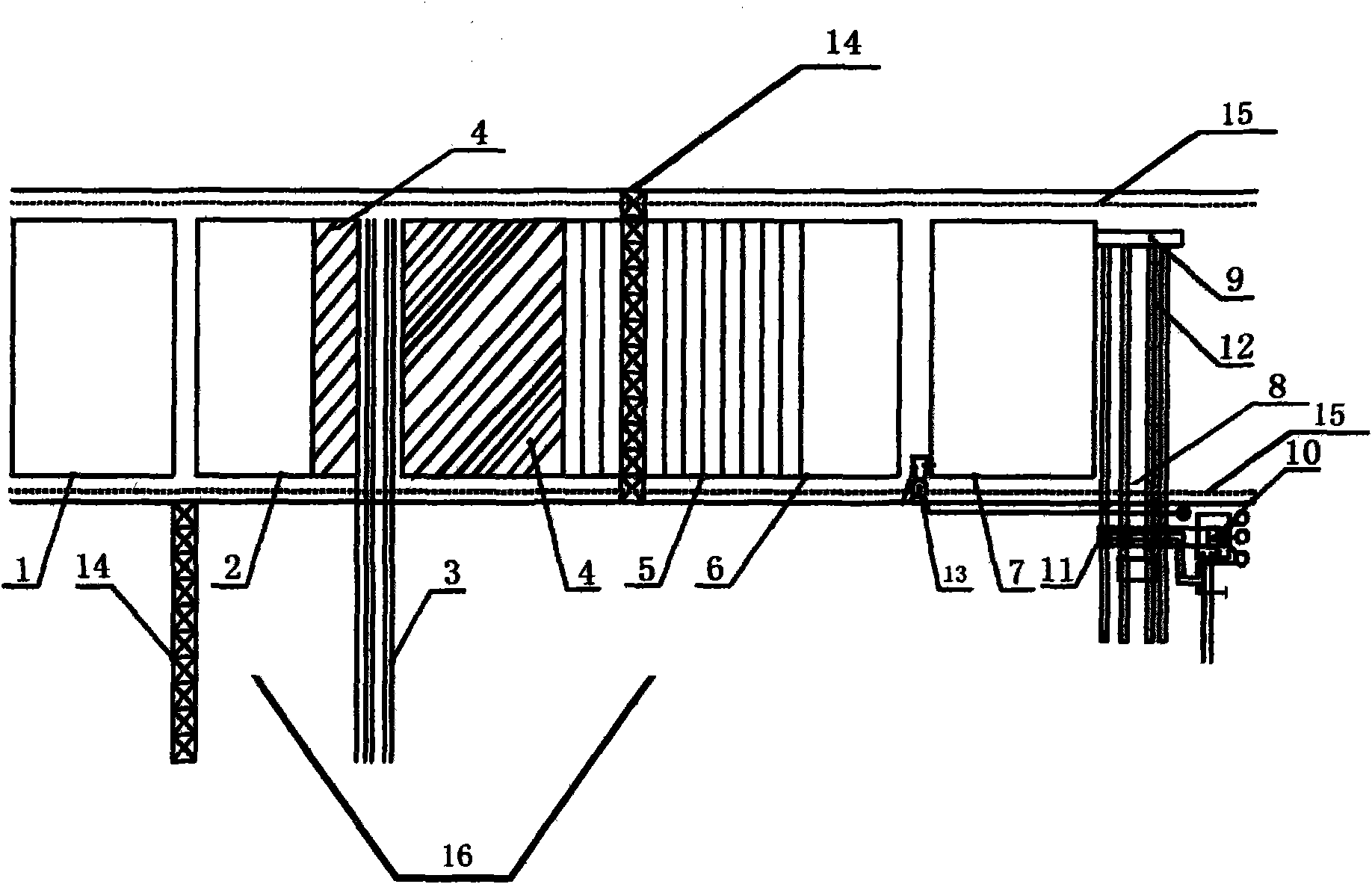

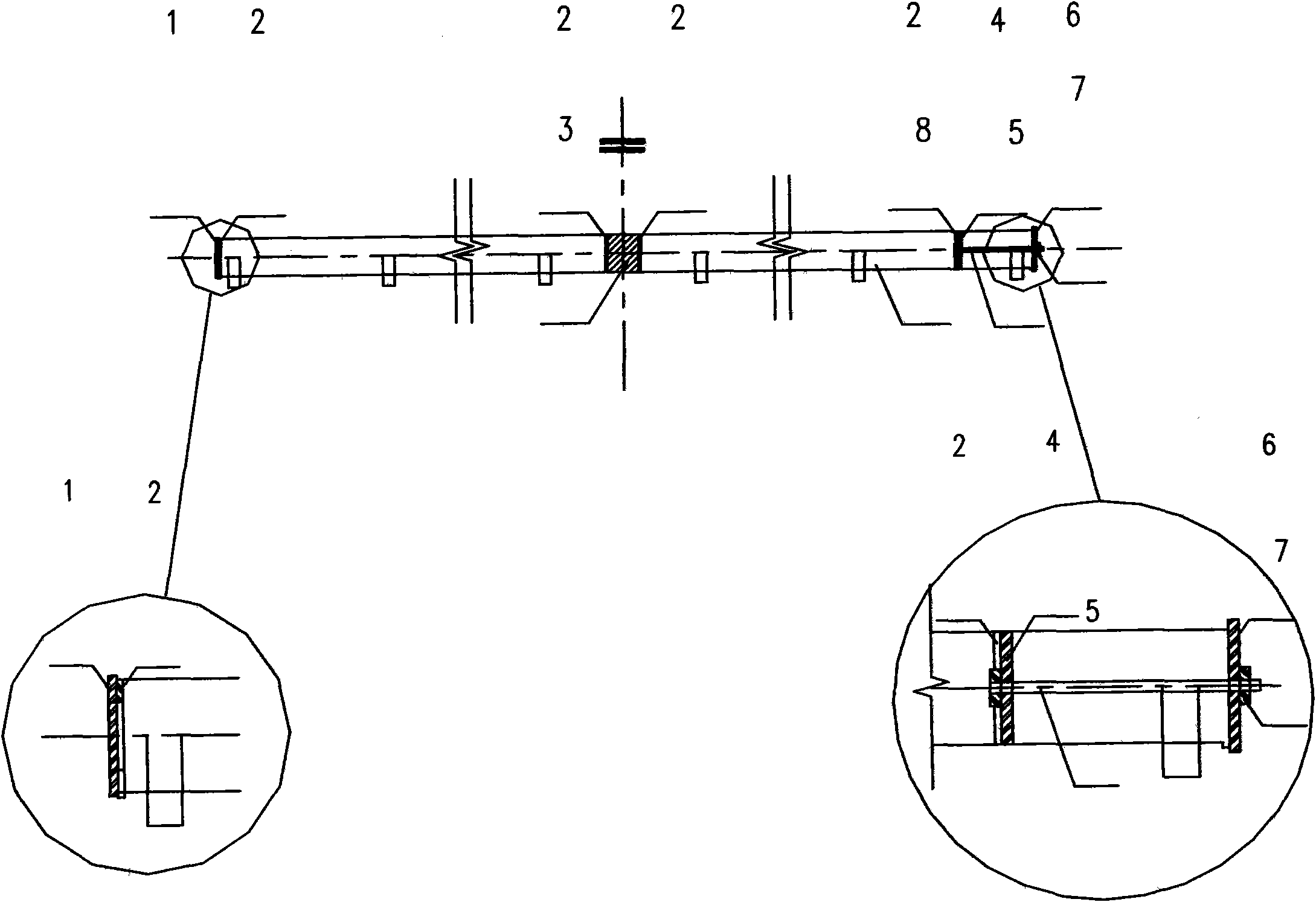

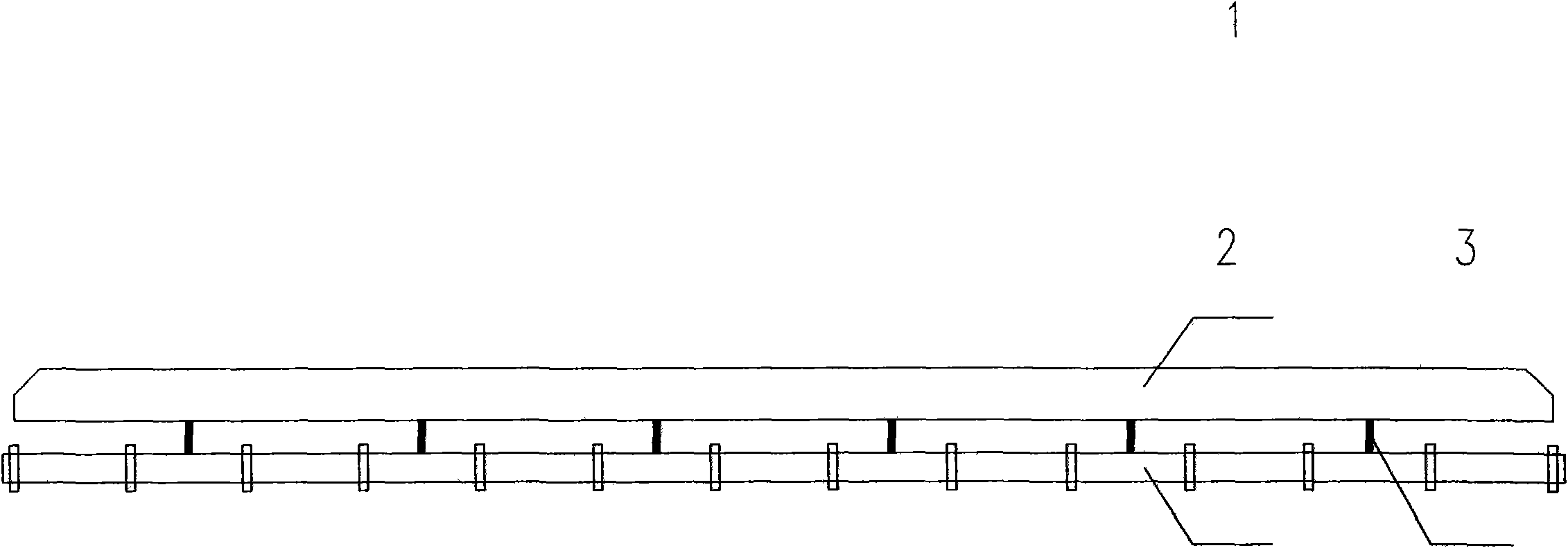

[0026] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail, at first, finish the technological layout in the factory building, comprise reinforcement cage processing area 1 and successively adjacent reinforcement cage storage yard 2, piling driveway 3, pile dismantling area 4. Curing pool 5, upper mold cleaning area 6, centrifugal equipment 7, feeding area 8, tensioning area 9, mixing station 10, concrete ferry transportation system 11, feeding flat lane 12, between the upper mold area and the centrifugal area The residual slurry recovery device 13, the transport operation crane 14, and the precast concrete pile yard 16 connected by the driving beam 15 and the main factory building. Centrifugal equipment 7, curing pool 5, and transport operation crane (14) are arranged horizontally and parallel perpendicular to the axial direction of the driving beam of the factory building. The mold adopts a 26-meter-lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com