Patents

Literature

73results about How to "Orderly production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

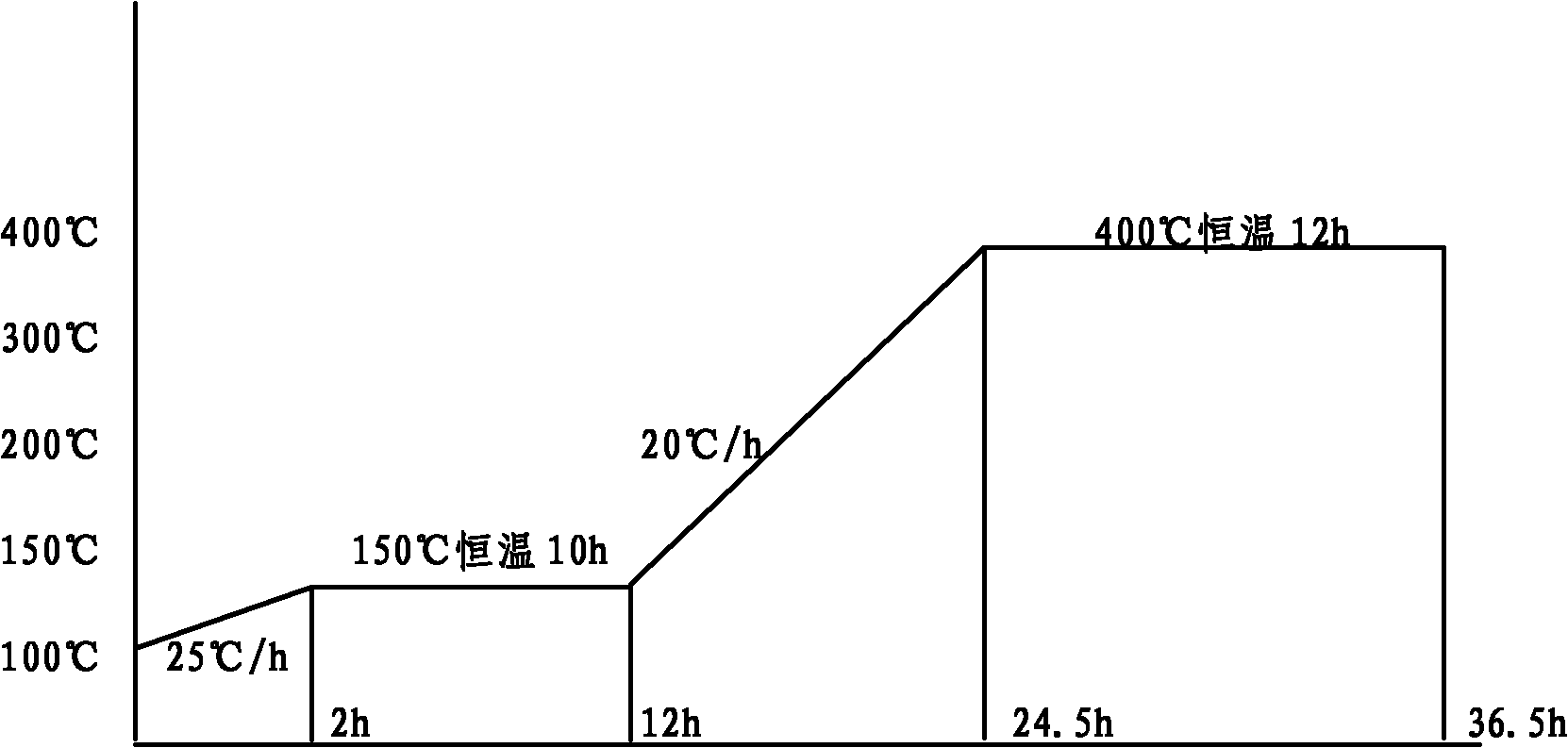

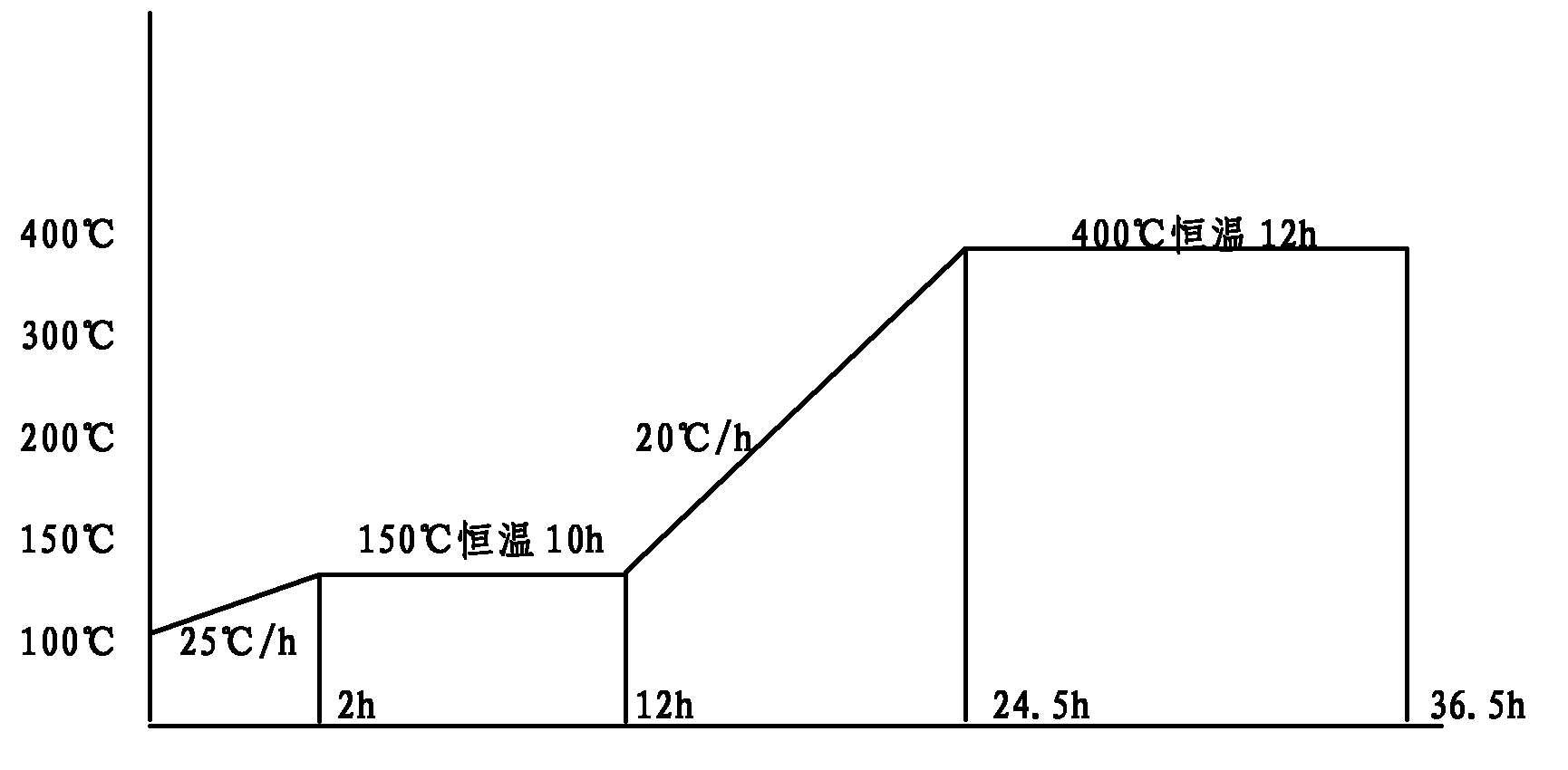

Method capable of rapidly reaching yield after small and medium maintenance of blast furnace

InactiveCN101818221ADischarge in timeOpen the furnace smoothlyBlast furnace componentsBlast furnace detailsSlagEconomic benefits

The invention relates to a method capable of rapidly reaching a yield after the small and medium maintenance of a blast furnace, mainly comprising the steps of adjusting a furnace condition before stopping the furnace, selecting relevant technological parameters in the process of running the furnace, and the like. The invention discharges iron slag in time and realizes the purpose of smooth furnace running and rapid yield reaching of the blast furnace through establishing a scientific furnace running scheme and sufficient preparation and adopting a reasonable air supply and loading system, and the yield reaching schedule achieves a satisfactory purpose. The whole production process of the invention is safe, sequential, scientific and high-efficient, the utilization factor of the blast furnace can achieve 2.253t / m3.d within 5 days, and in the whole process of furnace-running yield reaching, the blast furnace has the advantages of favorable iron slag fluidity, satisfactory quality of molten iron and less unplanned blast stoppage, greatly saves manpower and physical resources and obtains favorable effects and economic benefits.

Owner:CHONGQING IRON & STEEL CO LTD

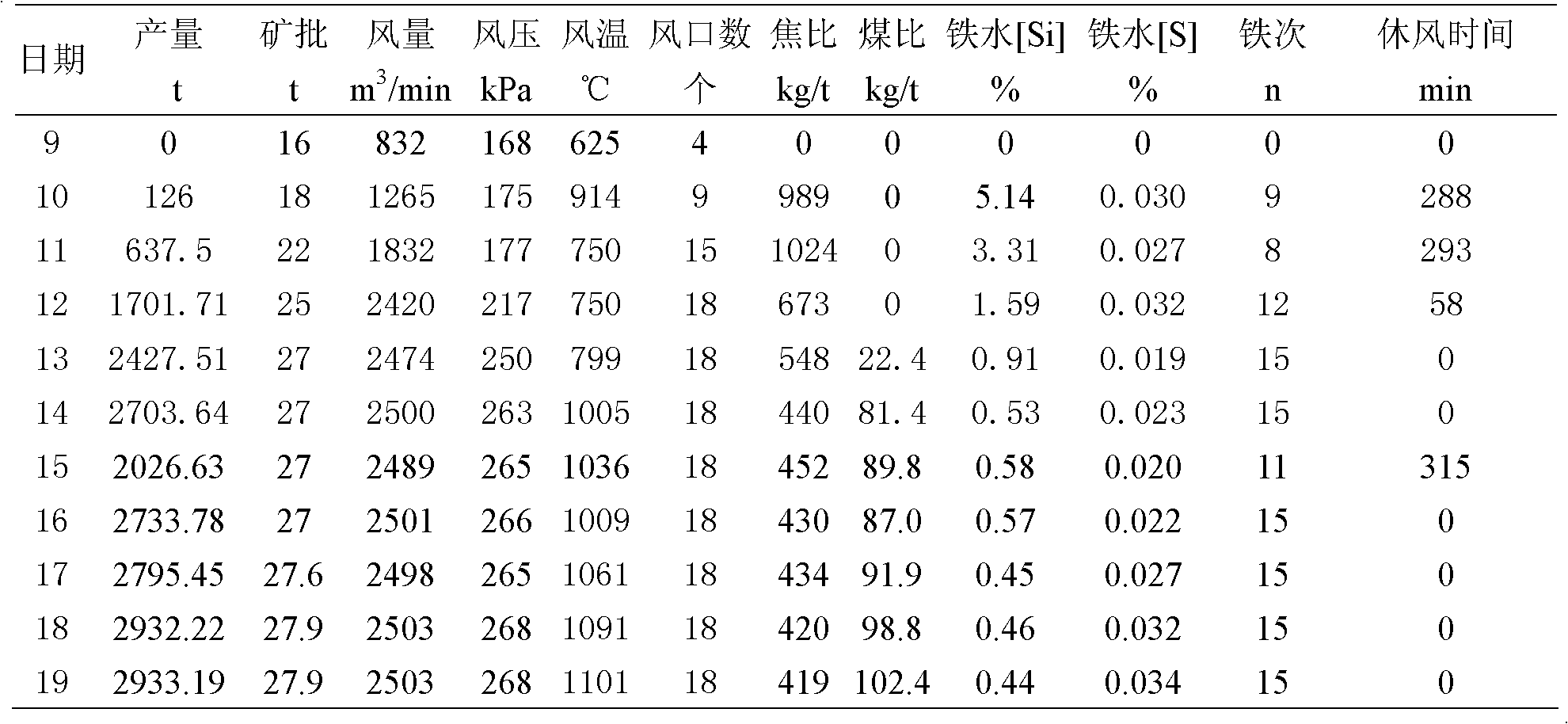

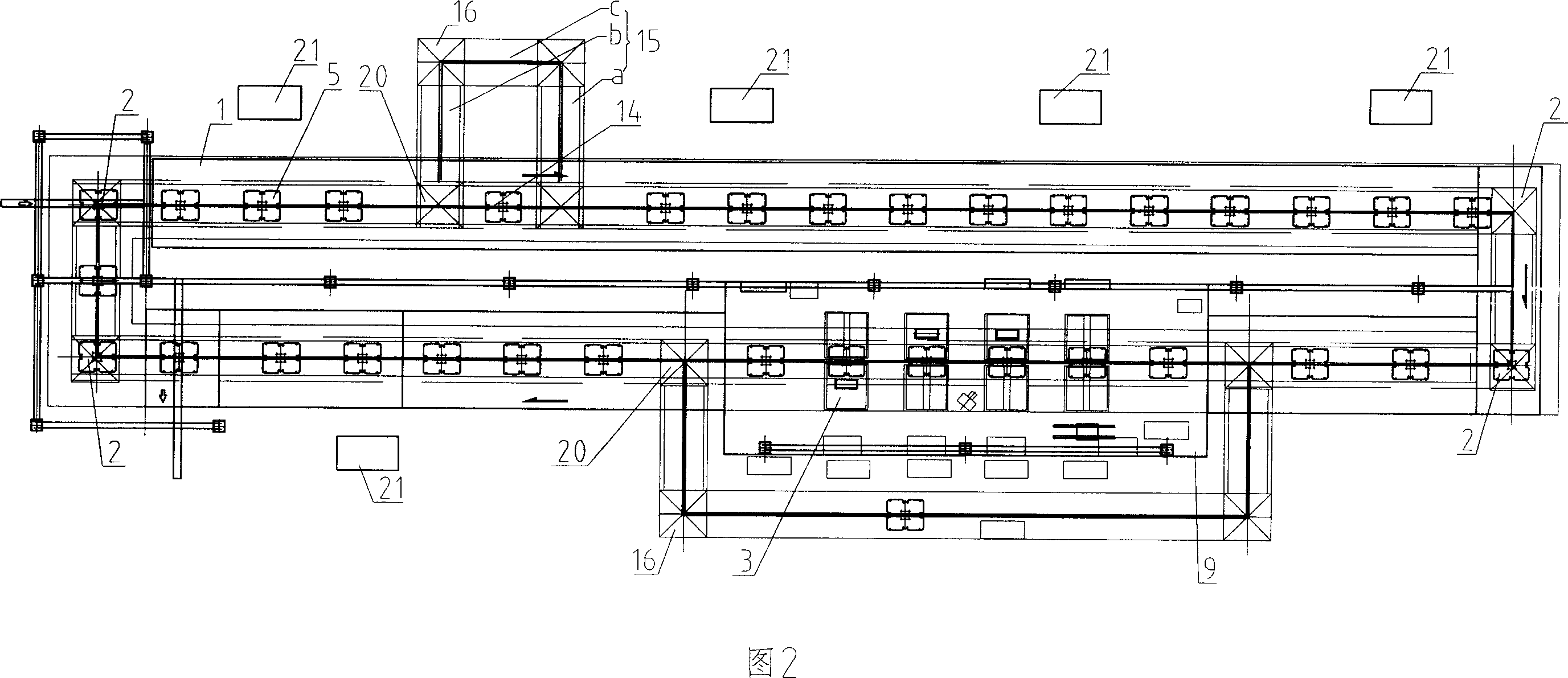

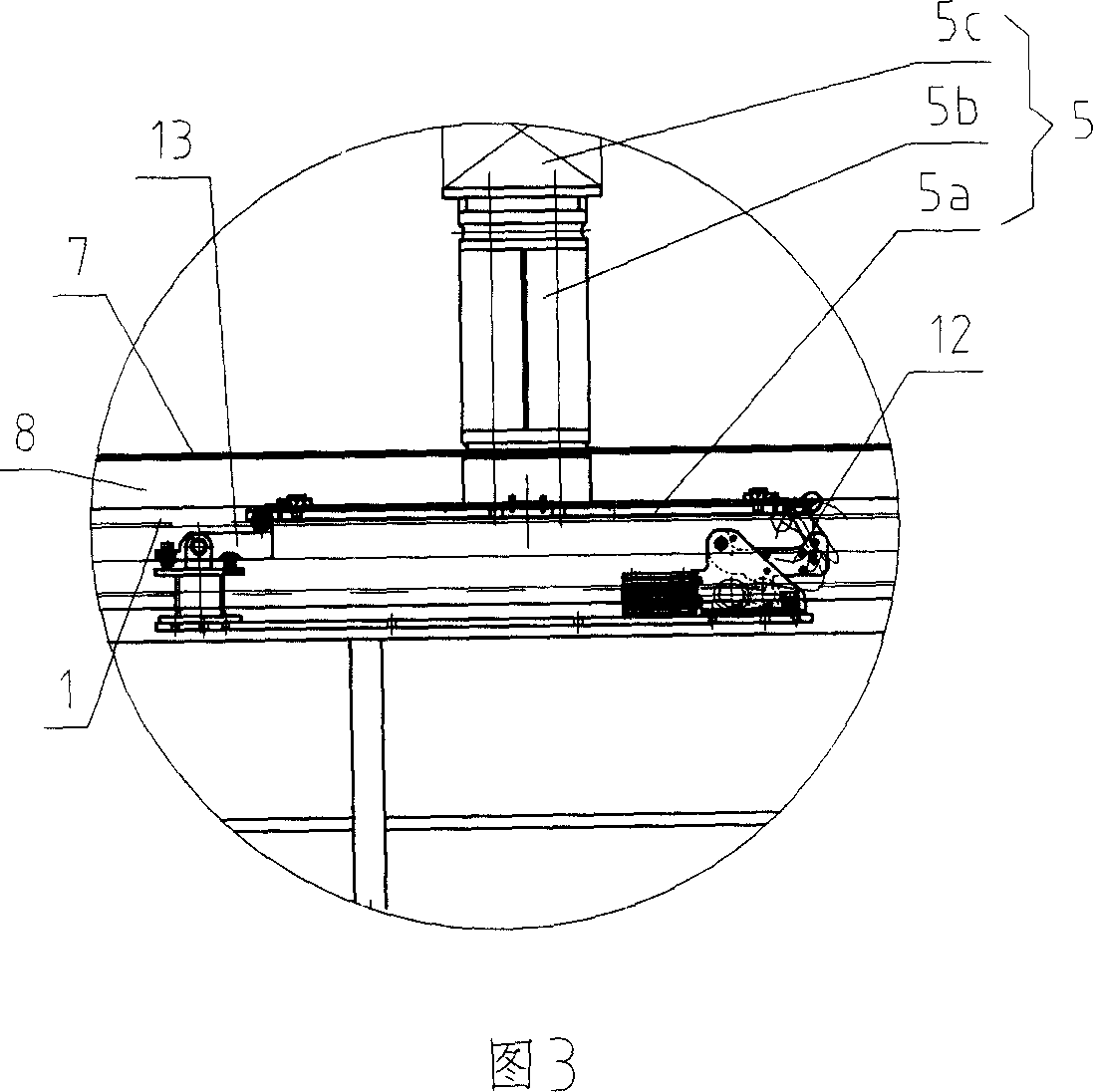

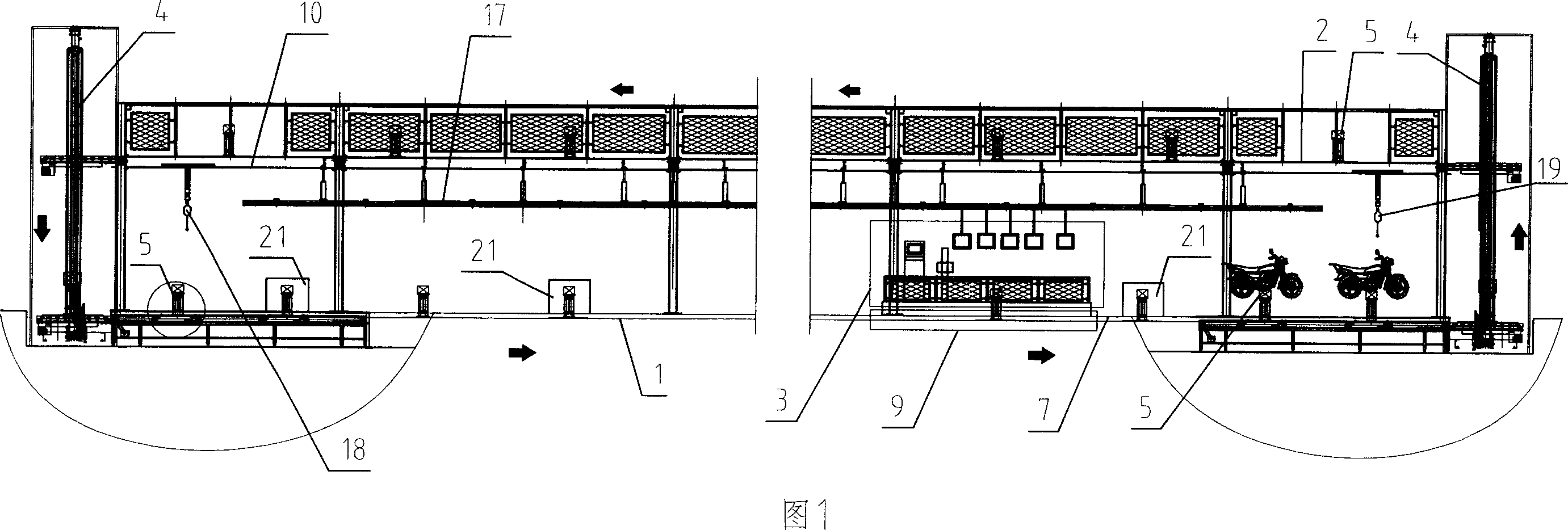

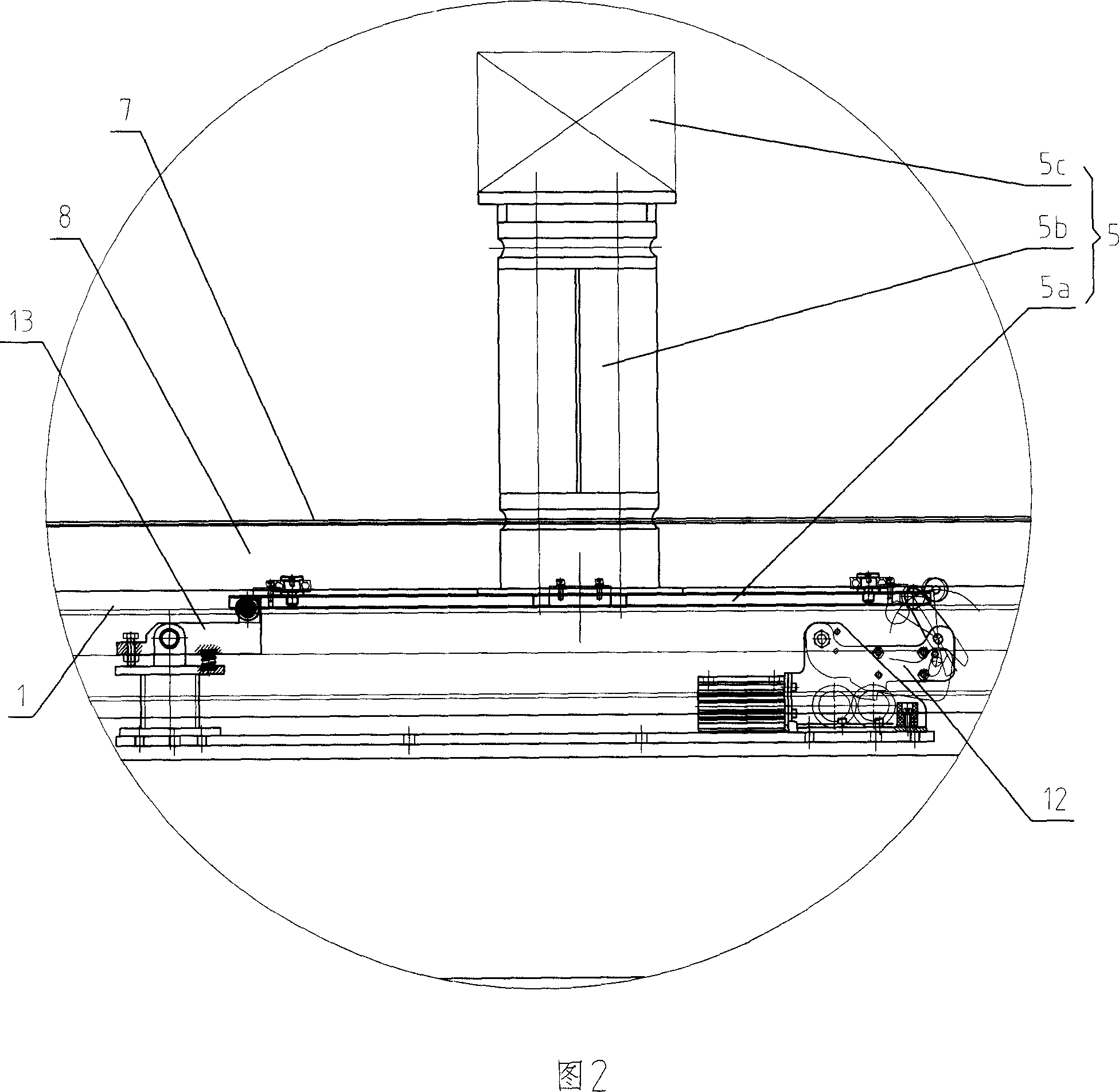

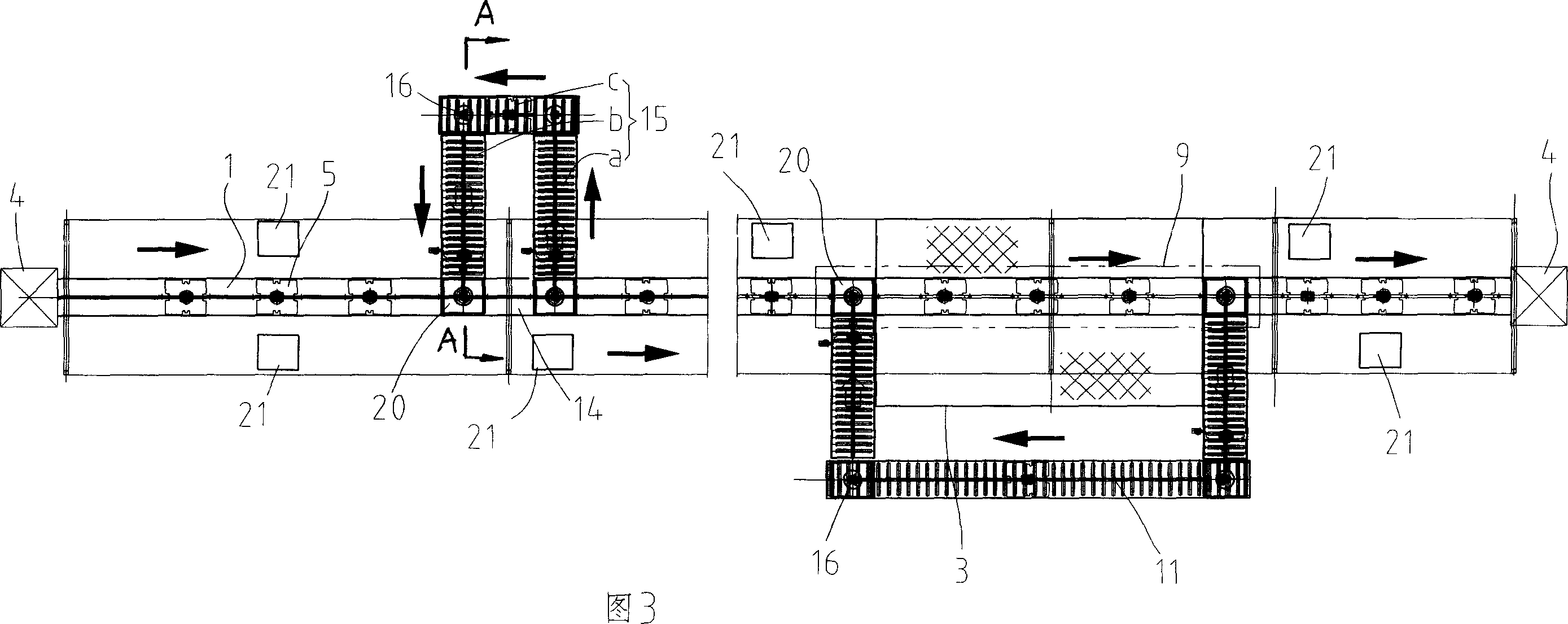

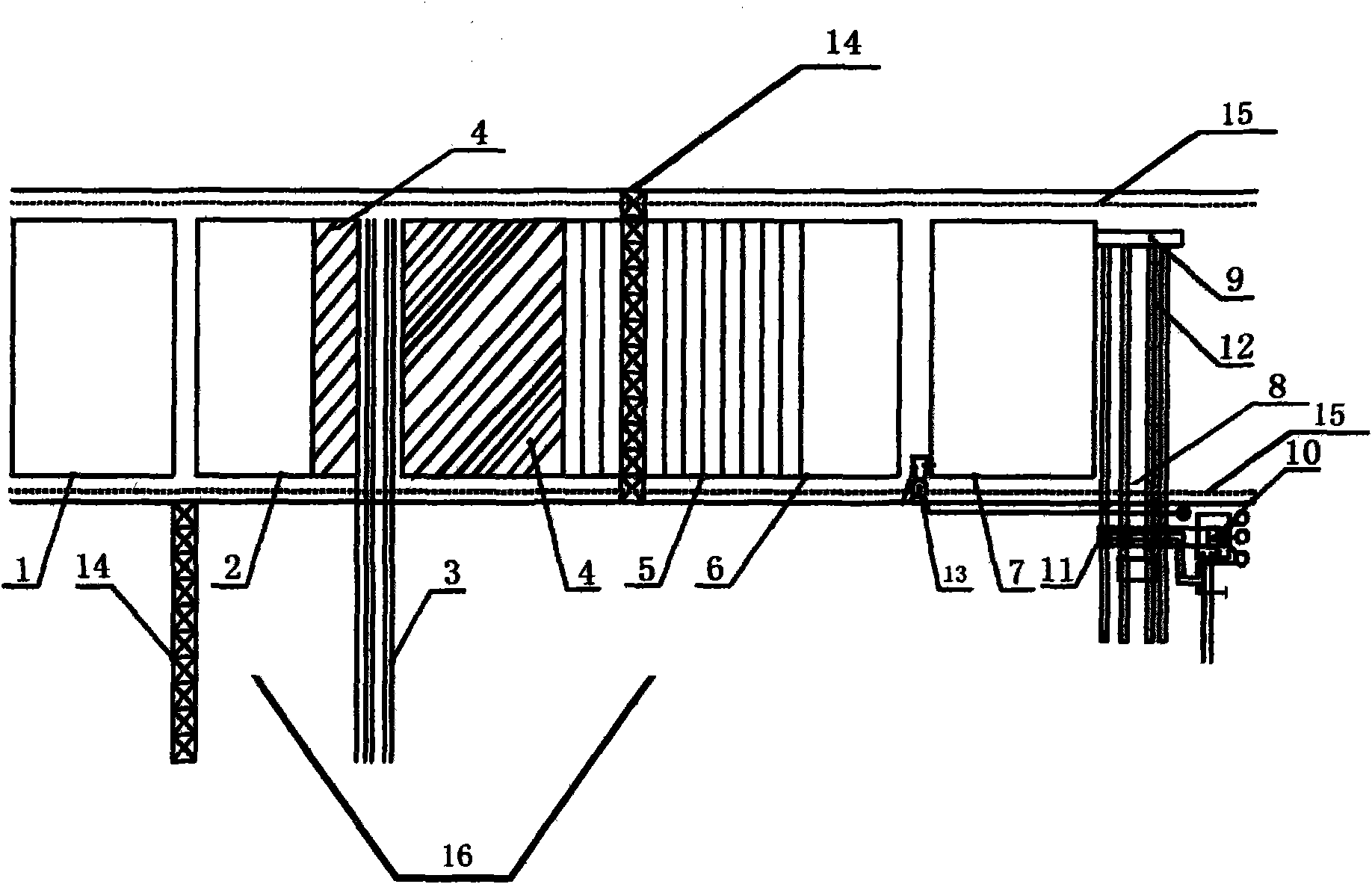

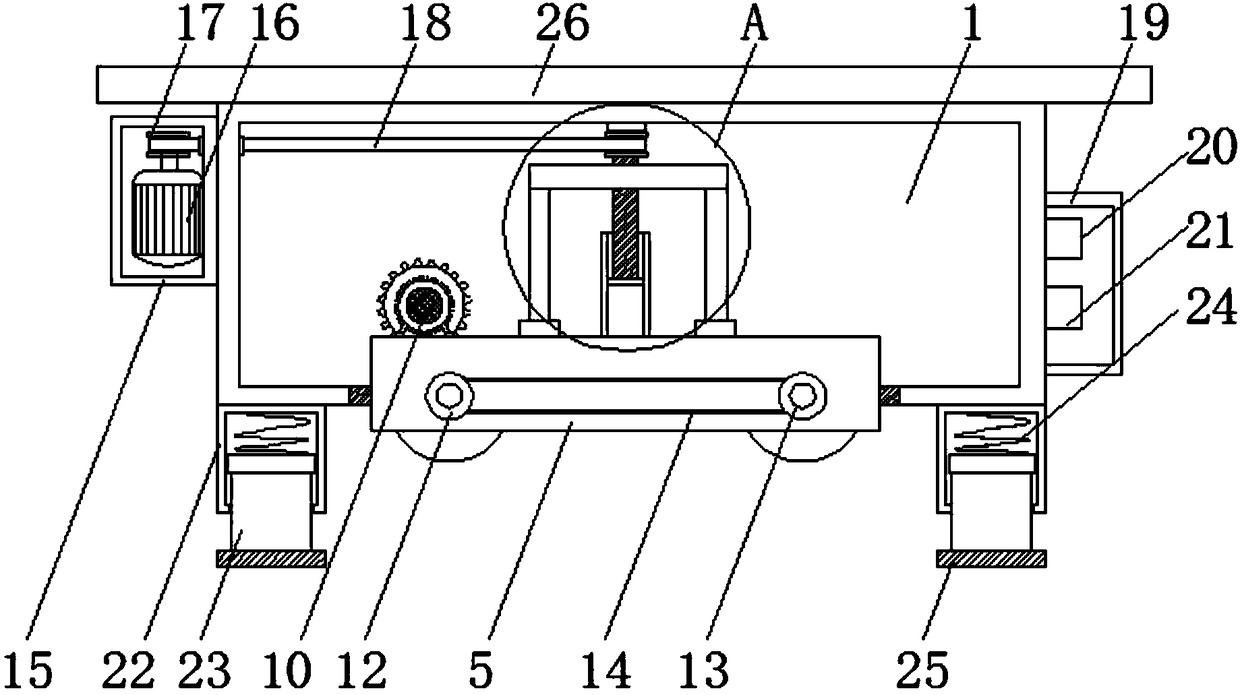

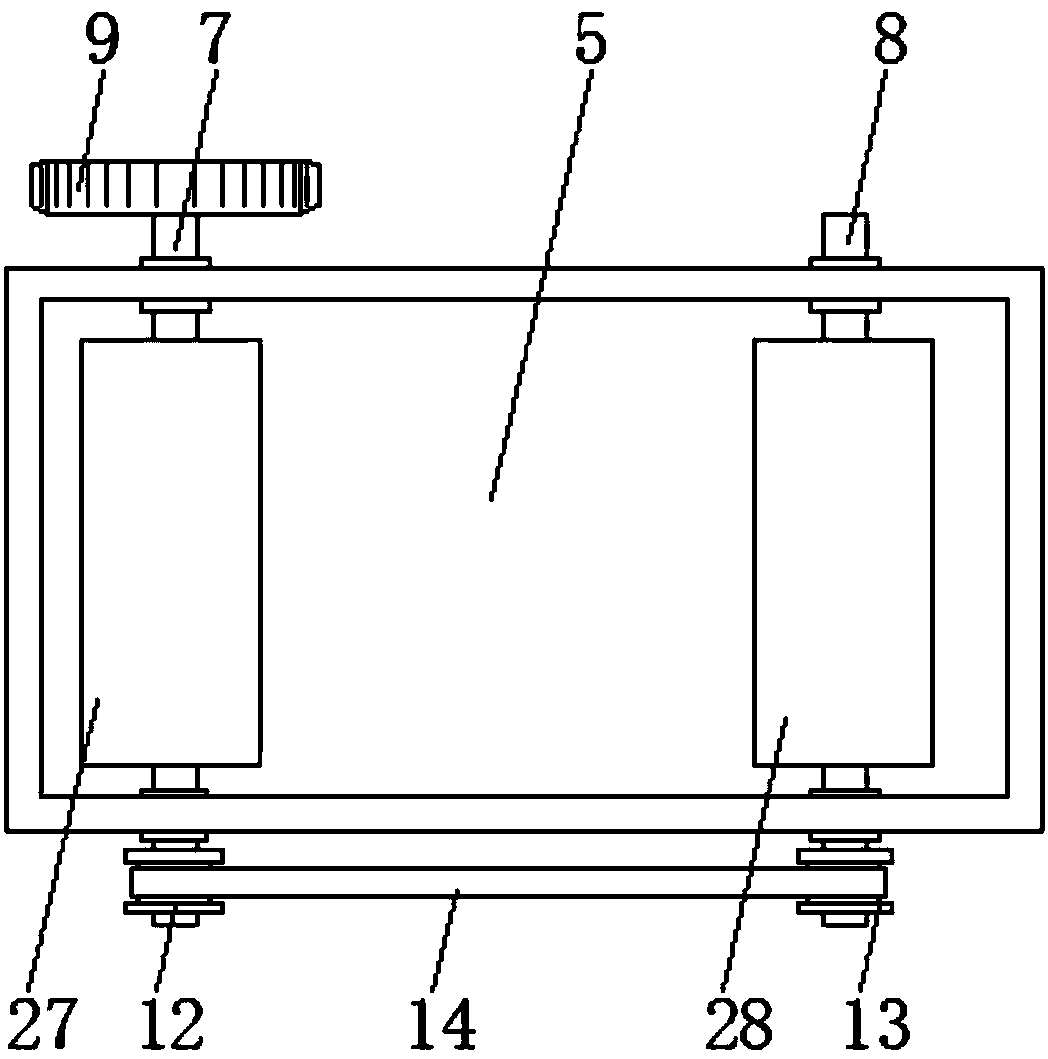

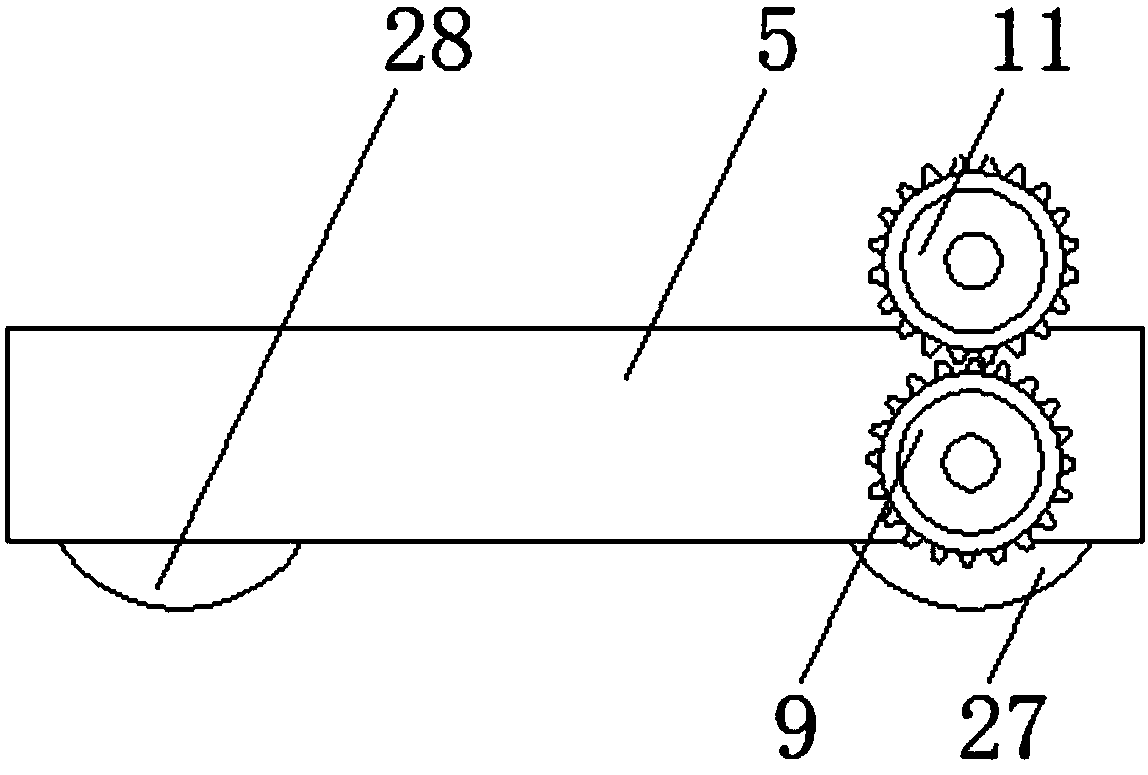

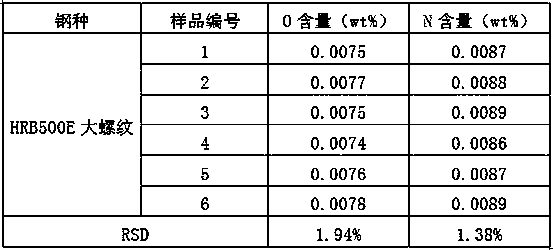

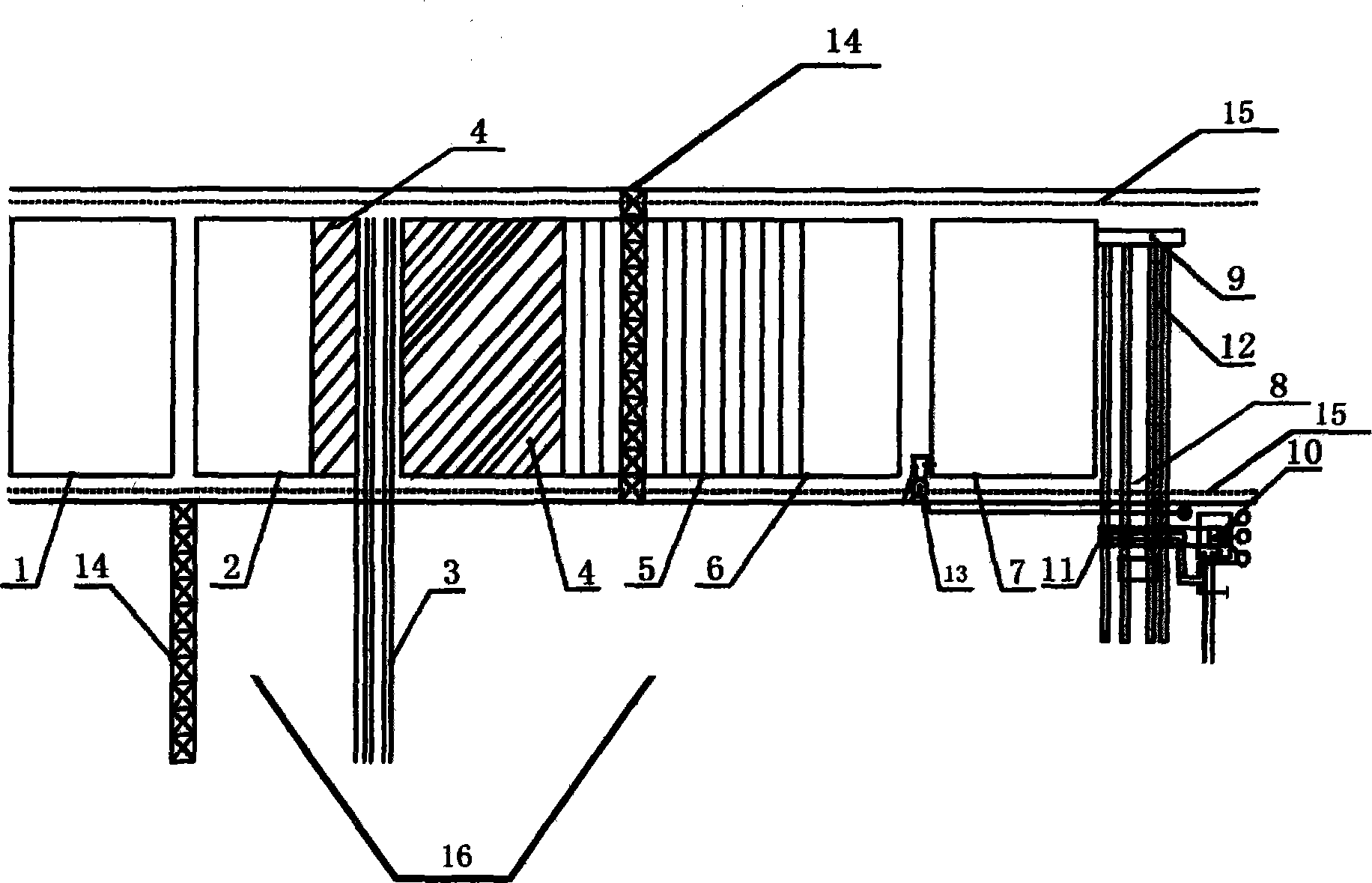

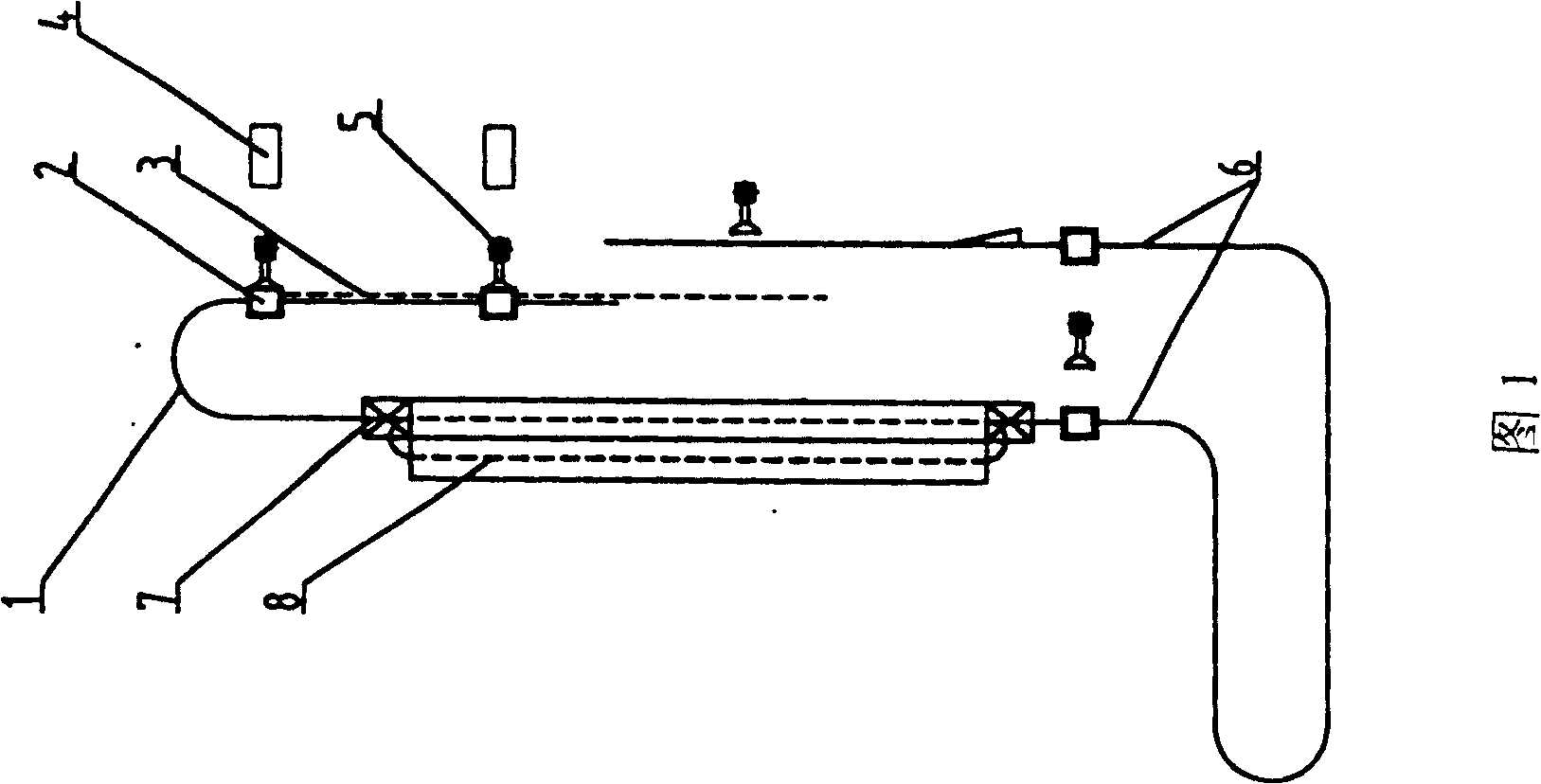

Integrative ground horizontal circular flexible production line for assembling and checking out motorcycle

ActiveCN101003292AFlexible and convenient operationReduce labor intensityVehiclesProduction lineRoller chain

A motorcycle assembling and testing integrated flexible production line circulating horizontally on the ground is composed of an endless master roller-chain conveyer line arranged horizontally underground, the assembling workstations at the side of said master conveyer, the flat base plates of assembling fixture on said roller-chain, performance test position, performance test system, and returning-repairing line.

Owner:ฉงชิ่ง จงเซิน มอเตอร์ไซเคิล อินดัสเทรียล แมนูแฟคเจอร์ โค แอลทีดี

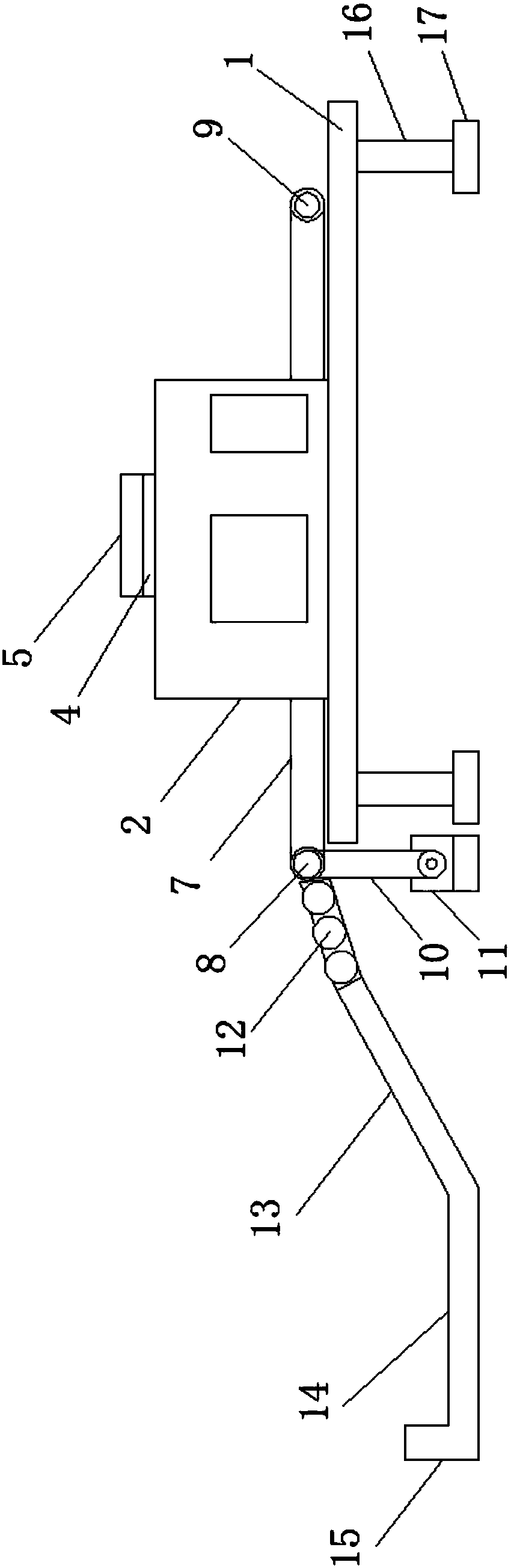

Integrative aerial 3D circular flexible production line for assembling and checking out motorcycle

ActiveCN101003293AFlexible and convenient operationReduce labor intensityVehiclesProduction lineRoller chain

A motorcycle assembling and testing integrated flexible production line circulating over head is composed of an endless master roller-chain conveyer line arranged on the ground, a fixture returning back conveyer arranged over head, the assembling workstations at the side of said master conveyer, the flat base plates of assembling fixture on said roller-chain, performance test position, performance test system, and returning-repairing line.

Owner:ฉงชิ่ง จงเซิน มอเตอร์ไซเคิล อินดัสเทรียล แมนูแฟคเจอร์ โค แอลทีดี

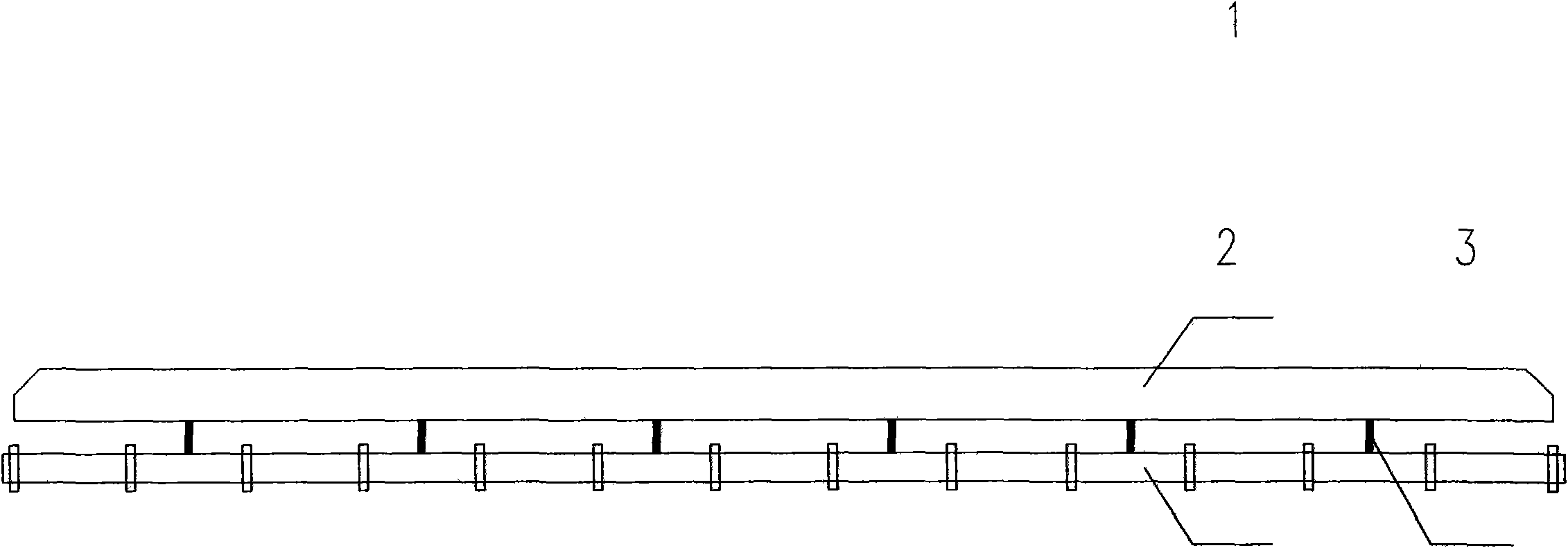

Method for producing precast concrete piles

The invention relates to a method for producing precast concrete piles, which comprises the following main steps of: manufacturing a reinforcement cage; placing the reinforcement cage into a die; pouring concrete into the die; centrifugally rotating; and carrying out steam curing. The method is characterized in that the die with the length of over 20 meters is adopted in the method; two or a plurality of precast concrete piles can be simultaneously produced by one die; upper and lower half dies of the die have a transporting mode of transversely moving in parallel in the direction vertical to the axis of a crane beam of a plant in the production process; and centrifugal equipment and a curing tank are transversely arranged in parallel in the direction vertical to the axis of the crane beam of the plant. Due to the adoption of the transverse flow production scheme of the long die, the production effect can be multiplied, the space occupied by the plant is greatly reduced, a great amount of lands are saved, the working efficiency is improved, and the production quality can be ensured.

Owner:NINGBO YIZHONG CONCRETE PILE +2

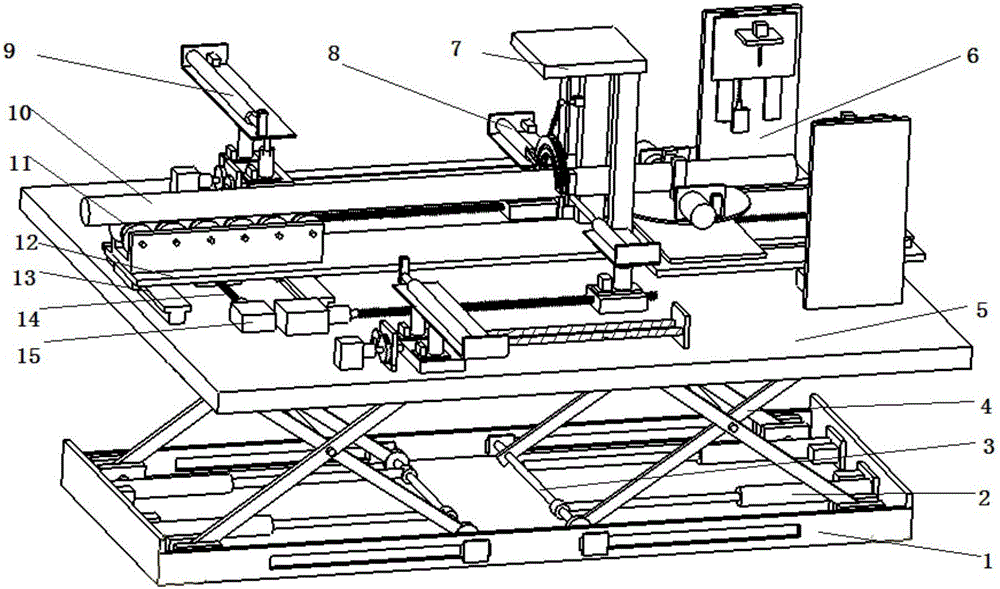

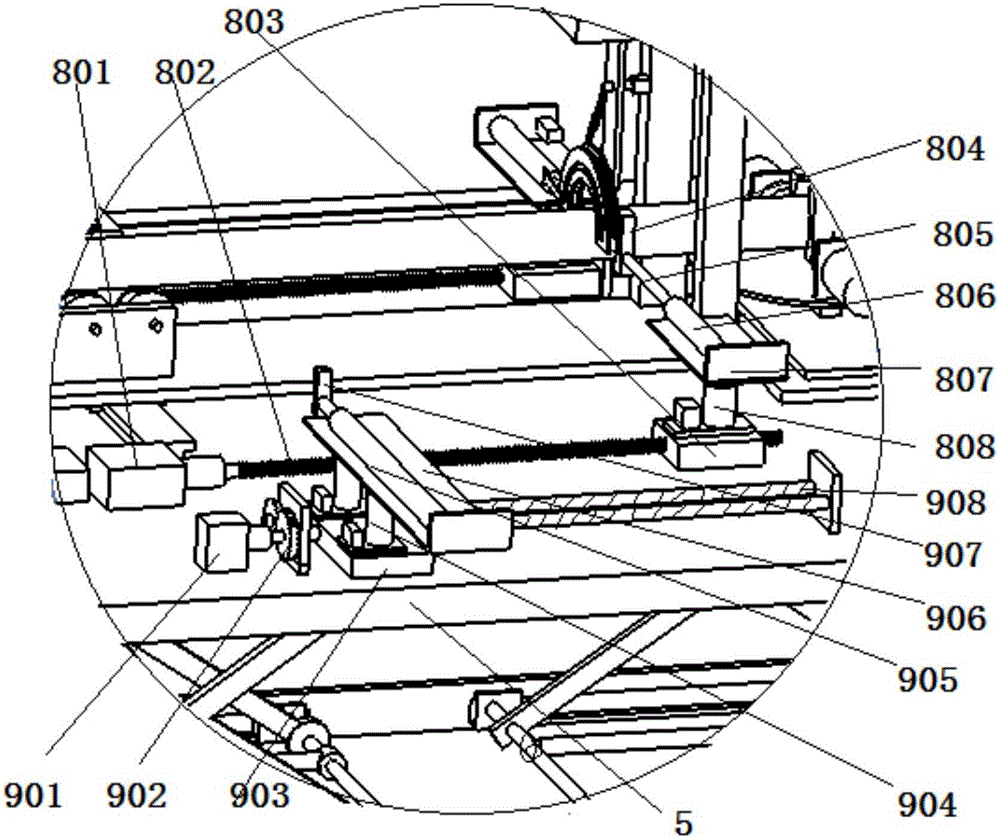

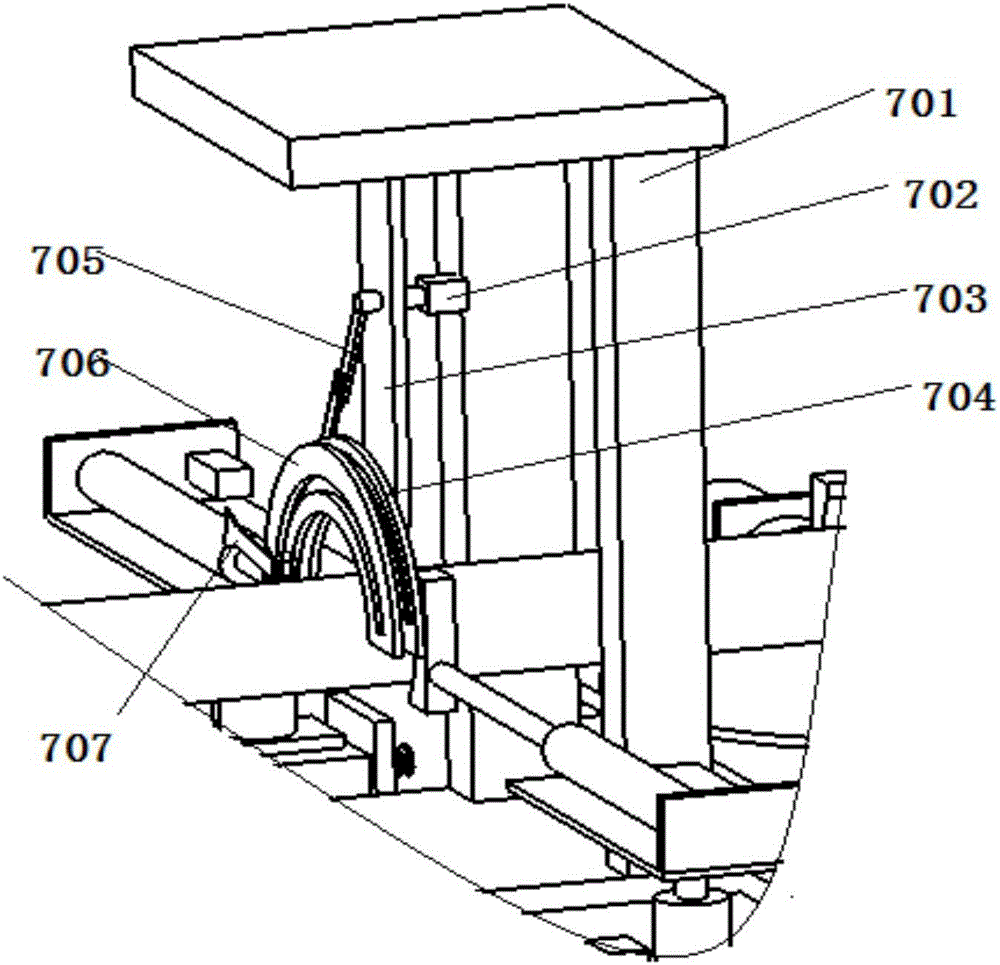

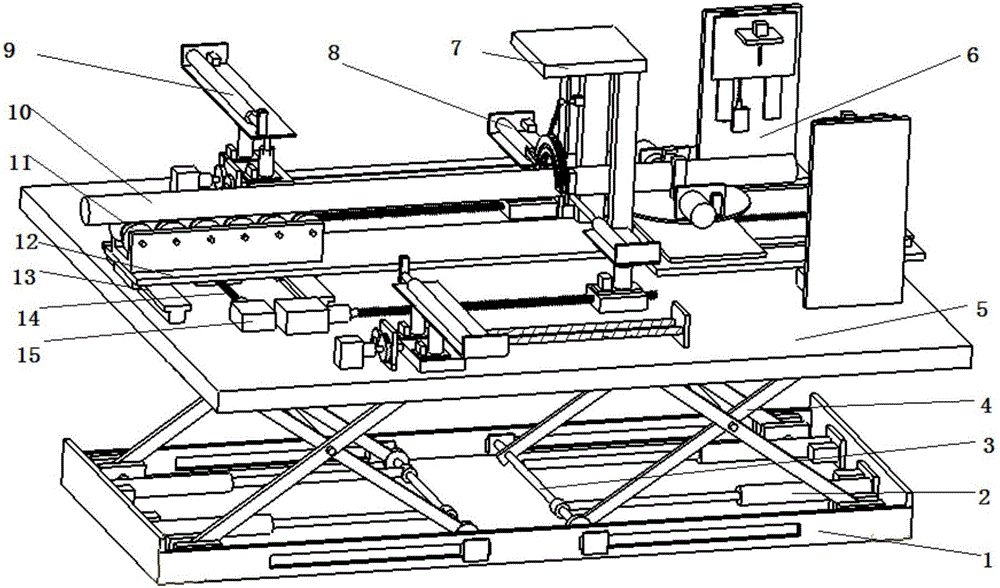

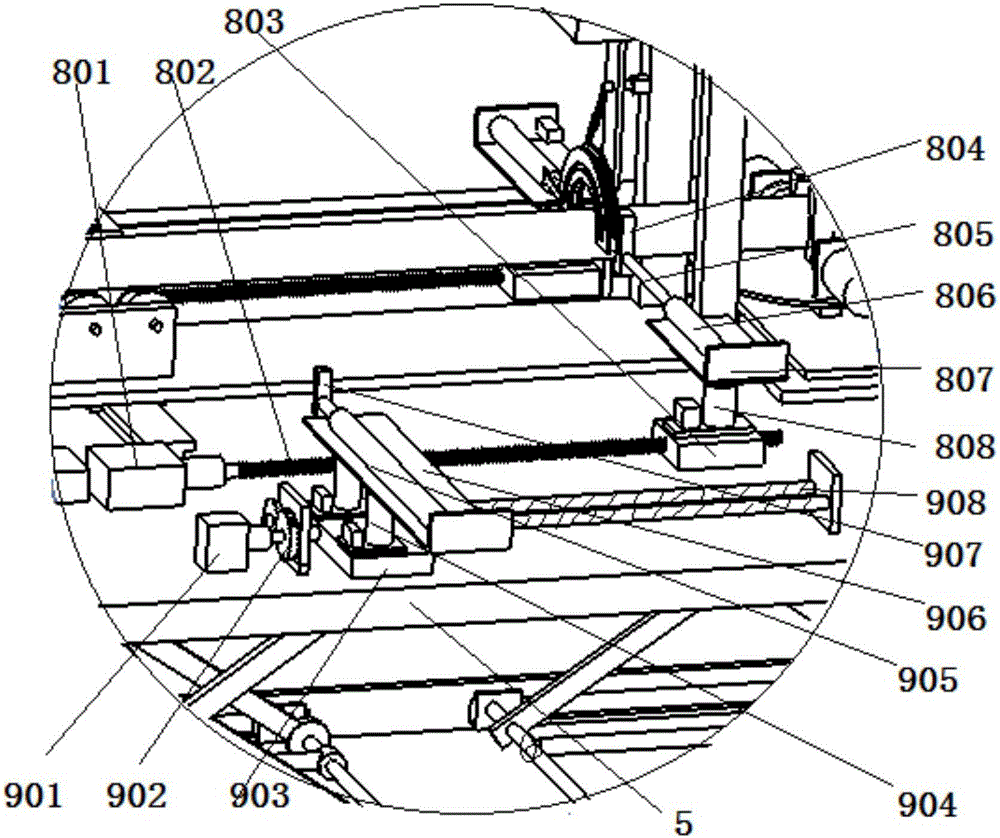

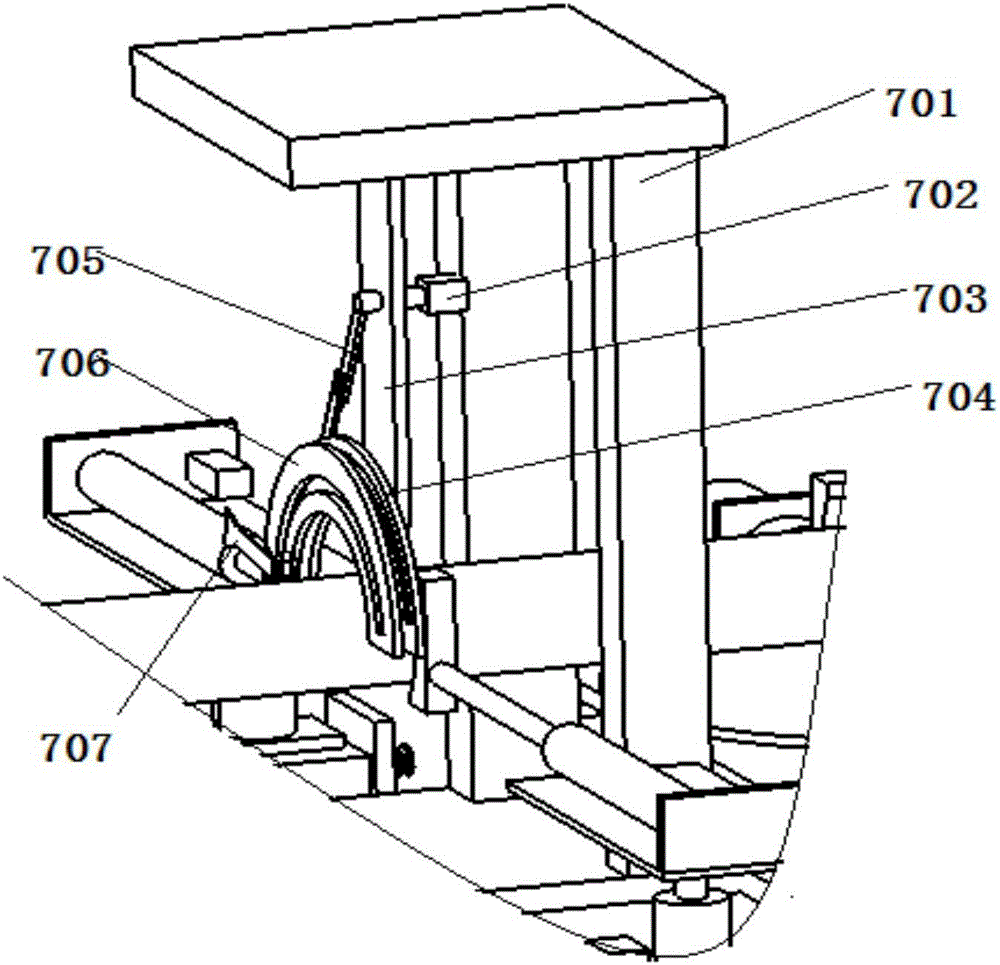

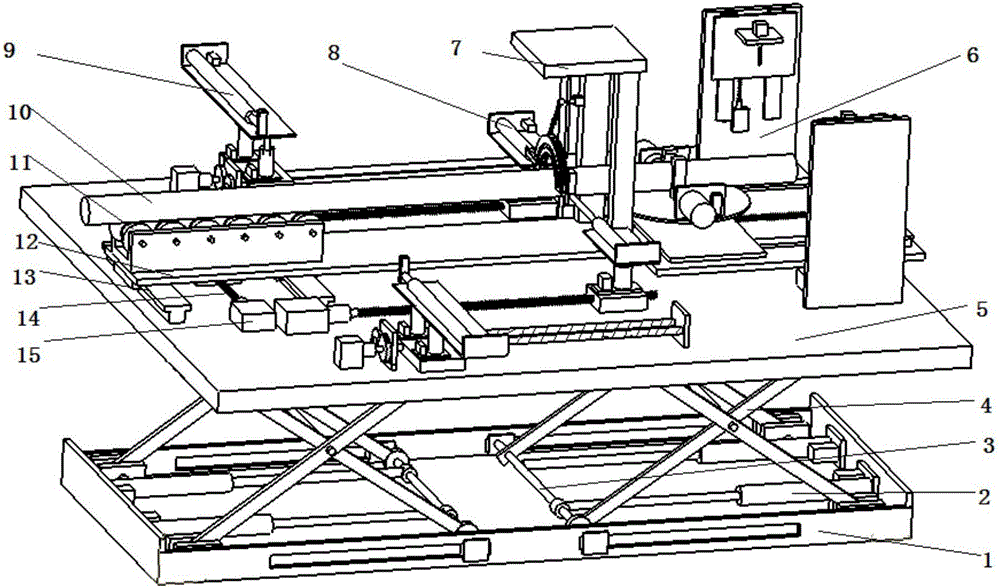

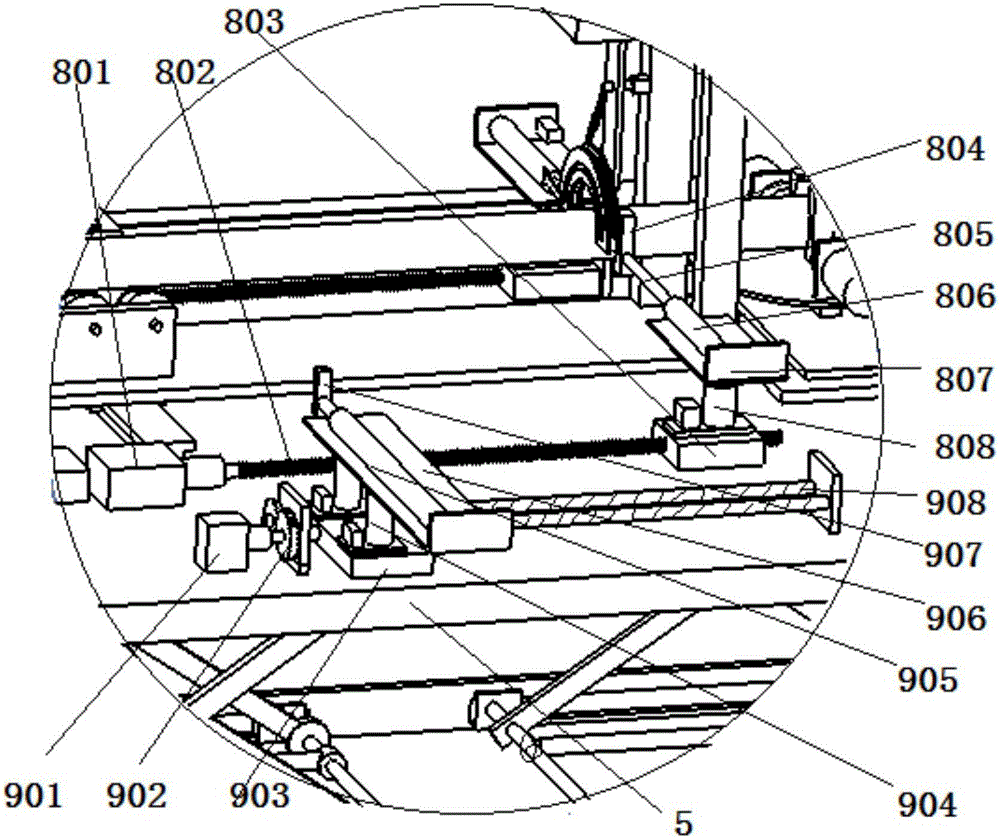

Equal-length glass tube batch production cutting device

InactiveCN106495457AReduce workloadReduce time for step-by-step processingEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides an equal-length glass tube batch production cutting device which comprises a base and a lift plate. A pad plate is slidably connected to the lift plate, rollers are arranged on the pad plate, a clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism, the first clamping mechanism comprises a first motor and a first transmission rod, the cutting mechanism comprises a support and a cutter arranged on the support, a first arc connection plate and a second arc connection plate are arranged on the support, the milling mechanism comprises a side wall and a milling cutter slidably connected with the side wall, and a sliding plate is slidably connected to the pad plate. By using the equal-length glass tube batch production cutting device, cutting and milling of equal-length glass tubes can be completely efficiently, staff's manual operation during the entire process is omitted, potential safety hazards of staff are reduced, production efficiency is improved, and machining cost is reduced.

Owner:天津南玻节能玻璃有限公司

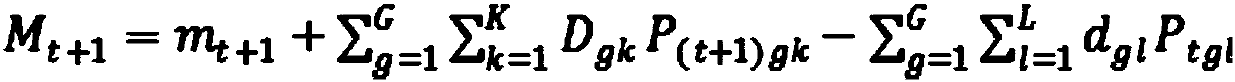

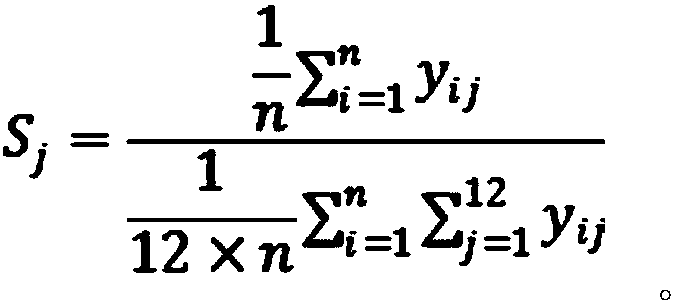

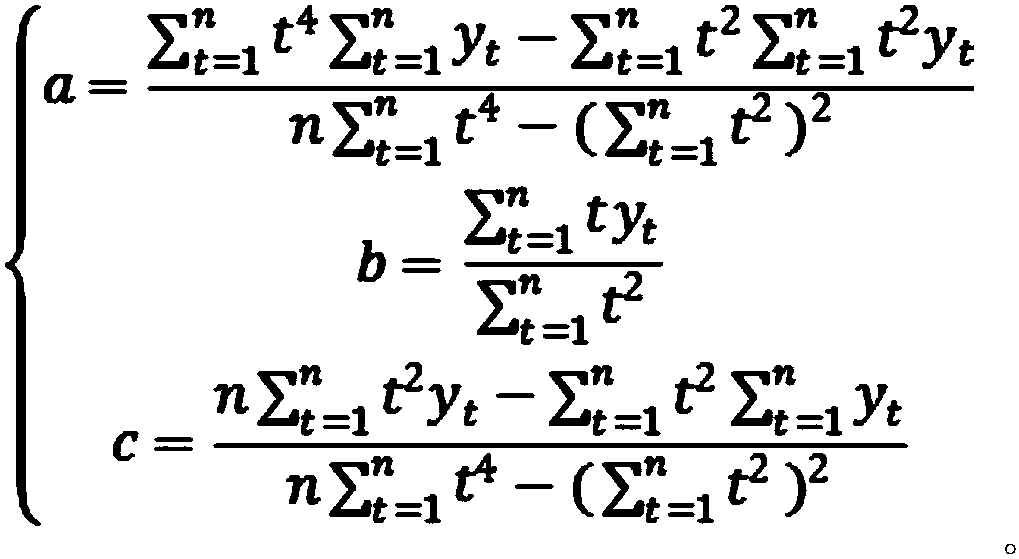

Electric energy meter ordered replacement method based on grid line operation error remote calibration

InactiveCN107590561AImprove automationImprove inventory turnoverForecastingResourcesConditional probabilityElectric energy

The present invention relates to an electric energy meter ordered replacement method based on grid line operation error remote calibration. The method comprises the steps of when the demand predictionis carried out on the metering devices of the business expansion projects, firstly determining the types of the metering devices, and when the demand prediction is adjusted, subdividing the businesstypes; gathering and calculating the samples of the historical data to obtain the demand generation probability of the metering devices of different business subclasses, or calculating the demand generation condition probability by the Bayes theorem. By applying the method of the present invention, the whole production process is more ordered, the automatic, intelligent and fine management levelsof the production management are improved, the inventory turnover rate is improved effectively, and the safe stock and cost are reduced.

Owner:TIANJIN ELECTRIC POWER TECH DEV CO LTD

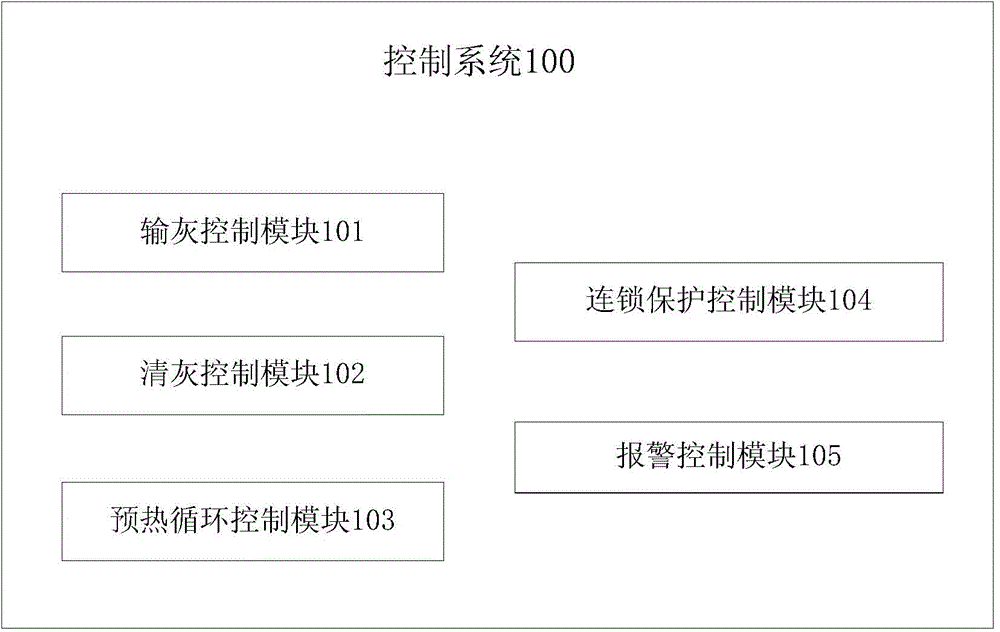

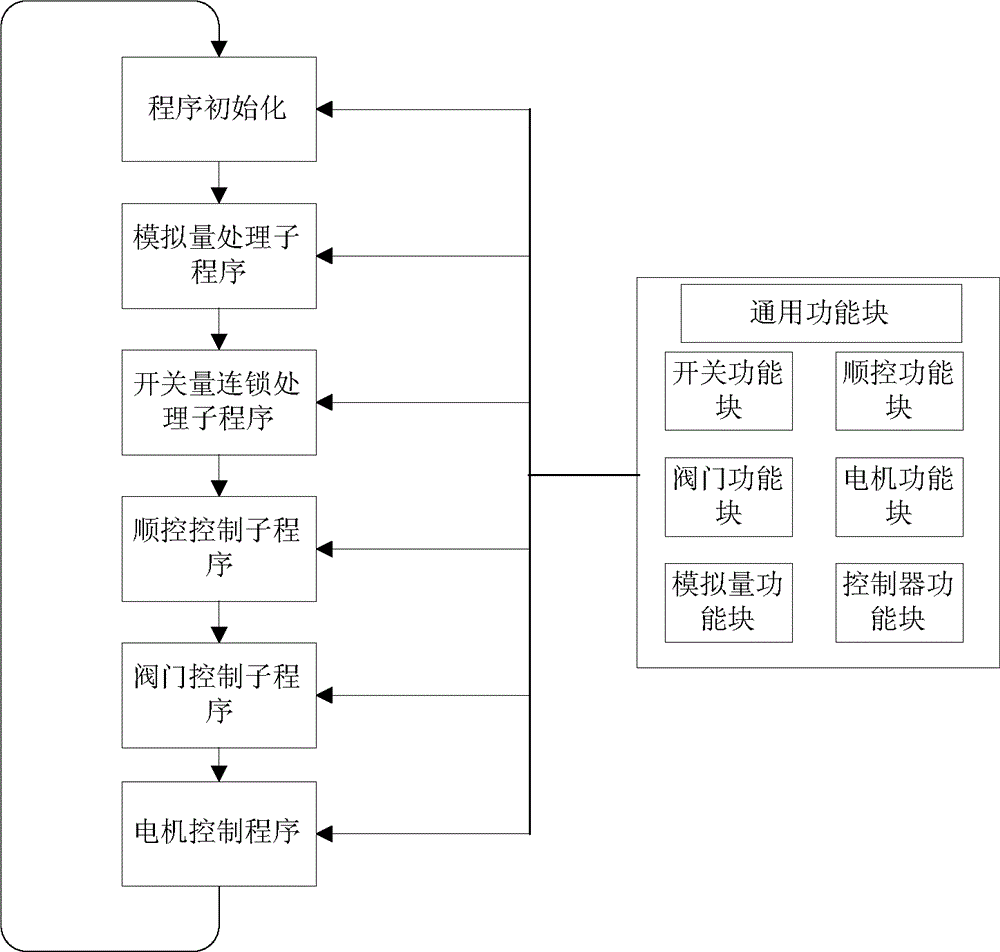

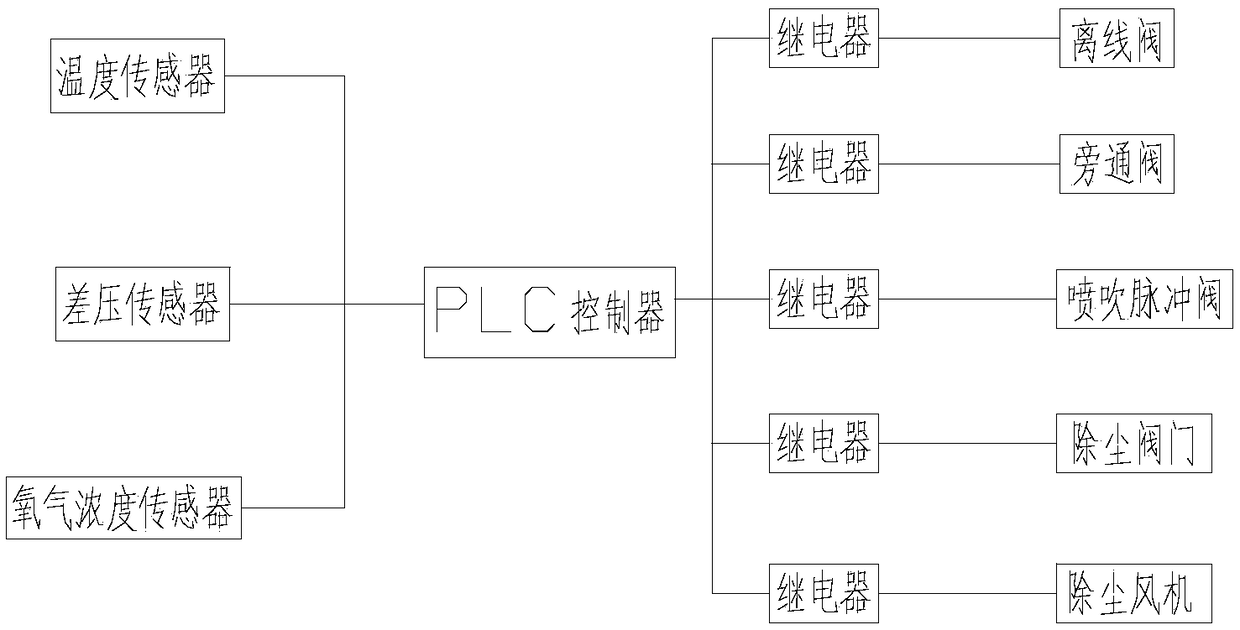

Control method and control system for bag-type dust collector

ActiveCN104147874AAccelerate emissionsOrderly productionDispersed particle filtrationCycle controlControl system

The invention provides a control method and a control system for a bag-type dust collector. The control system comprises a dust conveying control module, a dust cleaning control module and a preheating cycle control module, wherein the dust conveying control module is used for controlling the dust conveying based on the selected dust conveying mode; the dust cleaning control module is used for controlling dust cleaning sequentially in small rooms based on the selected dust cleaning mode and the selected small rooms; the preheating cycle control module is used for controlling a heater to be started and to run until the temperatures of all the small rooms reach the preset temperatures. The control method and the control system of the bag-type dust collector are stable and reliable, so that the whole production is normally carried out in sequence, and the flue gas emission status is good.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA

Production technology of precast reinforced concrete piles

The invention discloses a production technology of precast reinforced concrete piles. The technology comprises the following steps: making a steel reinforcement cage, putting the steel reinforcement cage in a precast concrete pile die, injecting concrete to the die, arranging the die in a centrifuge device, carrying out centrifugal rotation, carrying out steam curing in a curing pool, demolding, taking out, and molding. The precast concrete pile die is an elongated die with the length of above 25m, and a plurality of precast concrete piles can be simultaneously produced through one die; and the above concrete is prepared from the following raw materials, by weight, 80-100 parts of a gelling material, 20-30 parts of fine aggregate, 30-100 parts of coarse aggregate, 5-10 parts of a water reducer and 100-200 parts of water. The elongated steel die adopted in the invention allows a plurality of centrifugal concrete piles with the length of above 10m to be made, the concrete formula is reasonable, and the centrifugal concentrate piles made in the invention have high strength and good quality.

Owner:青岛昊河水泥制品有限责任公司

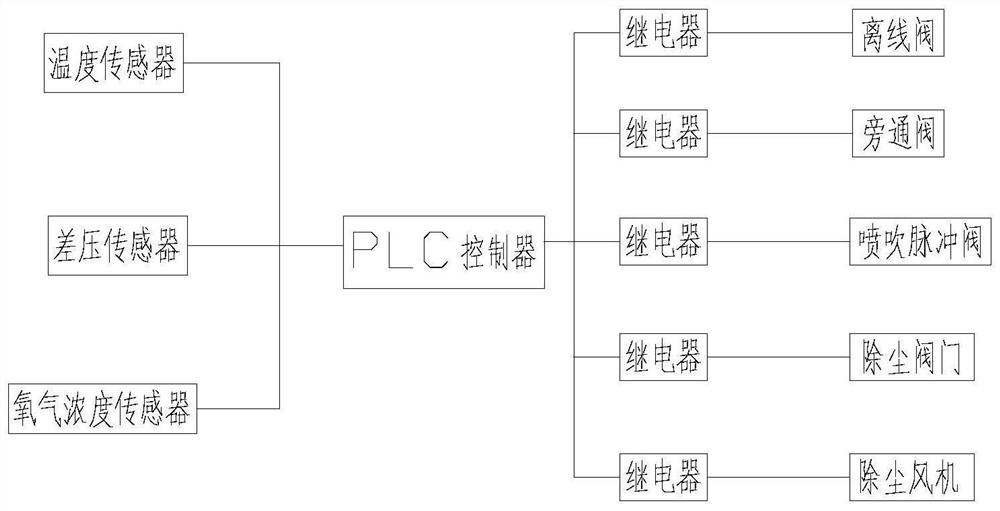

Control system and control method of bag-type dust remover

ActiveCN108379968AImprove cleaning efficiencyExtended service lifeGas treatmentDispersed particle filtrationAutomatic controlControl system

The invention discloses a control system and a control method of a bag-type dust remover. The system comprises a temperature sensor, a differential pressure sensor, an oxygen concentration sensor anda PLC (programmable logic controller); the temperature sensor is arranged in an inlet air flue and is in signal connection with the input end of the PLC; the differential pressure sensor is arranged at the top of the bag-type dust remover and is in signal connection with the input end of the PLC; the oxygen concentration sensor is arranged in a steel-making converter and is in signal connection with the input end of the PLC; and the output port of the PLC is connected with an offline valve, a bypass valve, a blowing pulse valve and a dust-removing fan of the bag-type dust remover as well as adust-removing valve arranged at the flue gas outlet of the steel-making converter. The system has the advantages of automatic detection and automatic control and can guarantee that the production is conducted normally and orderly; furthermore, the flue gas discharge situation is good.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Board detecting mechanism for wood packing box

InactiveCN107537786AQuick checkImprove detection efficiencyCounting objects on conveyorsSortingCrateConveyor belt

The invention relates to a wooden board sorting mechanism for wooden packaging boxes, which belongs to the field of wooden packaging box production. It includes a frame and a conveyor belt, the conveyor belt is connected with a stepping motor, a first detection mechanism is provided on one side of the conveyor belt, and the detection mechanism is fixed on the machine side along the direction of the conveyor belt. The first pushing device on the frame, the first pushing device is provided with a receiving device at a symmetrical position along the conveyor belt, and the first pushing device is provided with a second detection device along one side of the conveyor belt direction, so One side of the second detection device is provided with a second pushing device. The advantage of the present invention is that it can realize rapid detection of wooden packing boxes, improve the detection efficiency and detection accuracy, and complete the sorting of different types of wooden boards at the same time as the detection, which is convenient for the subsequent process and is automated. The degree is high; it is equipped with a counter, which can automatically count qualified products, making the whole production process more orderly.

Owner:苏州卫刚木包装制品有限公司

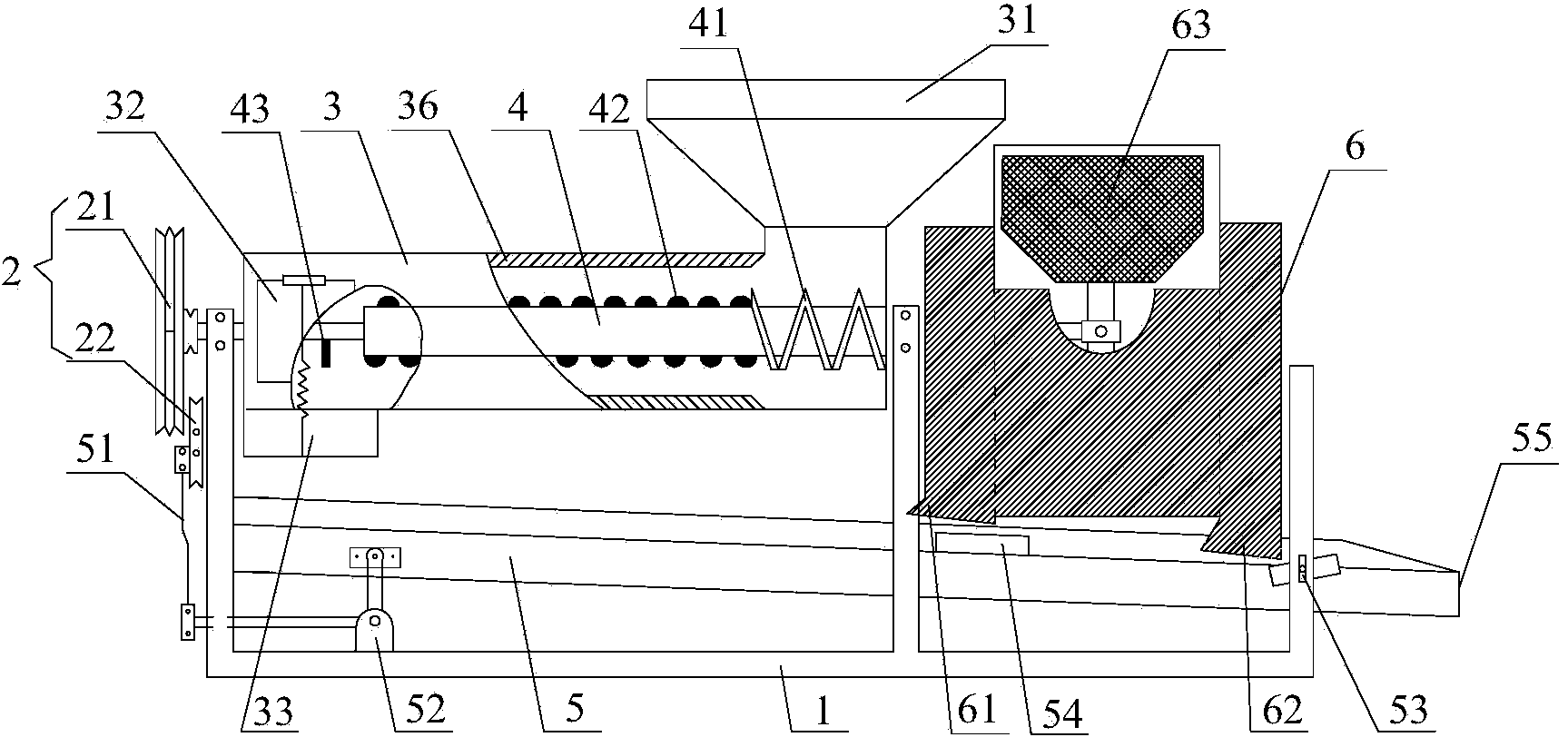

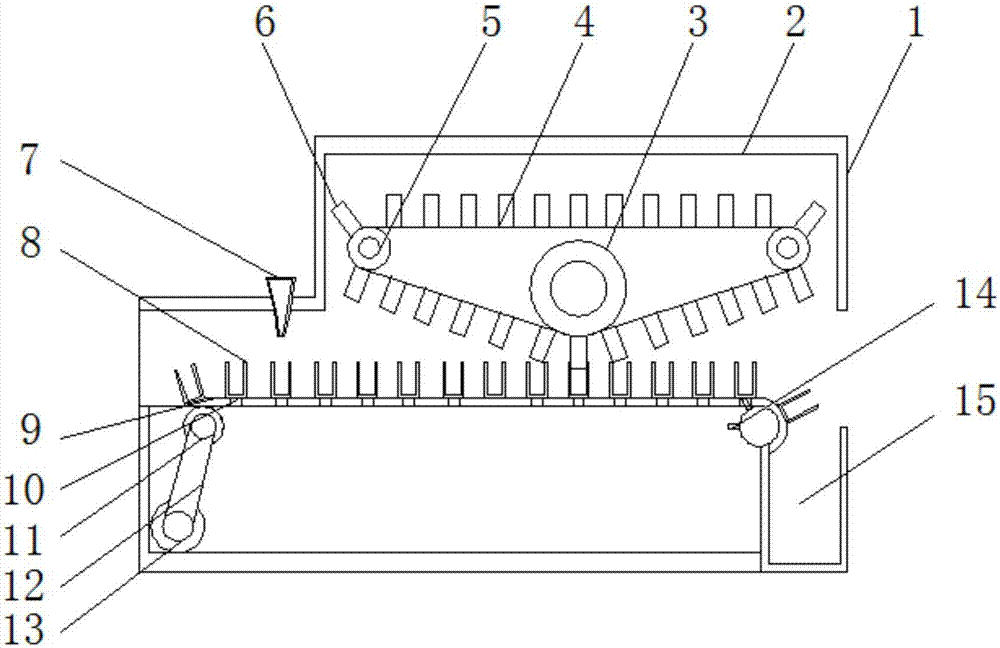

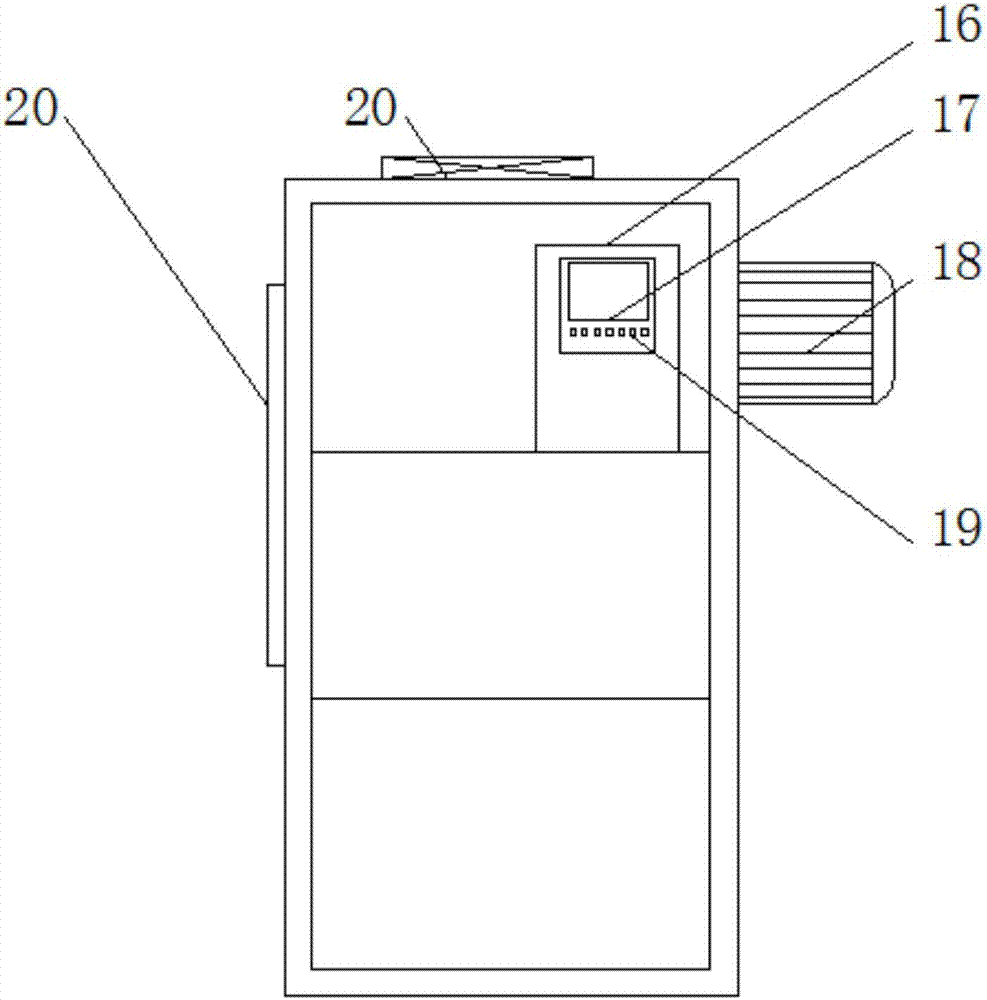

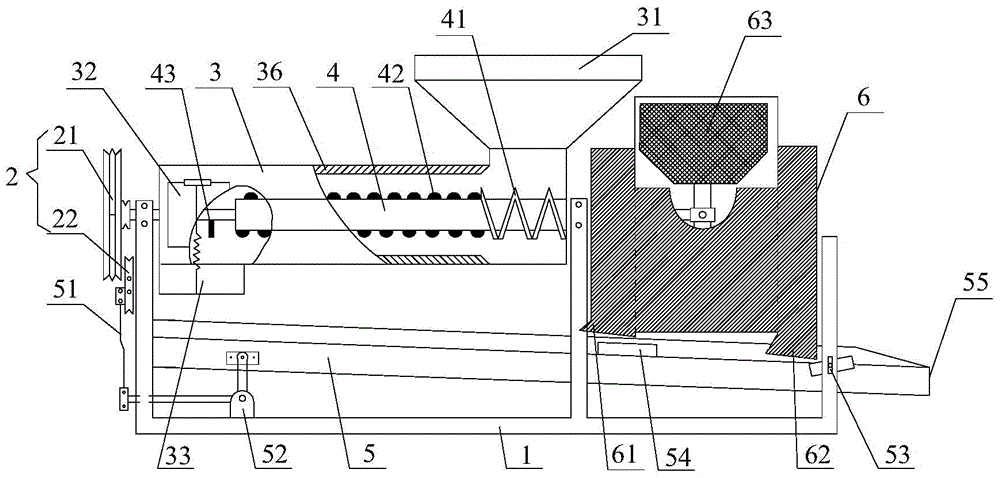

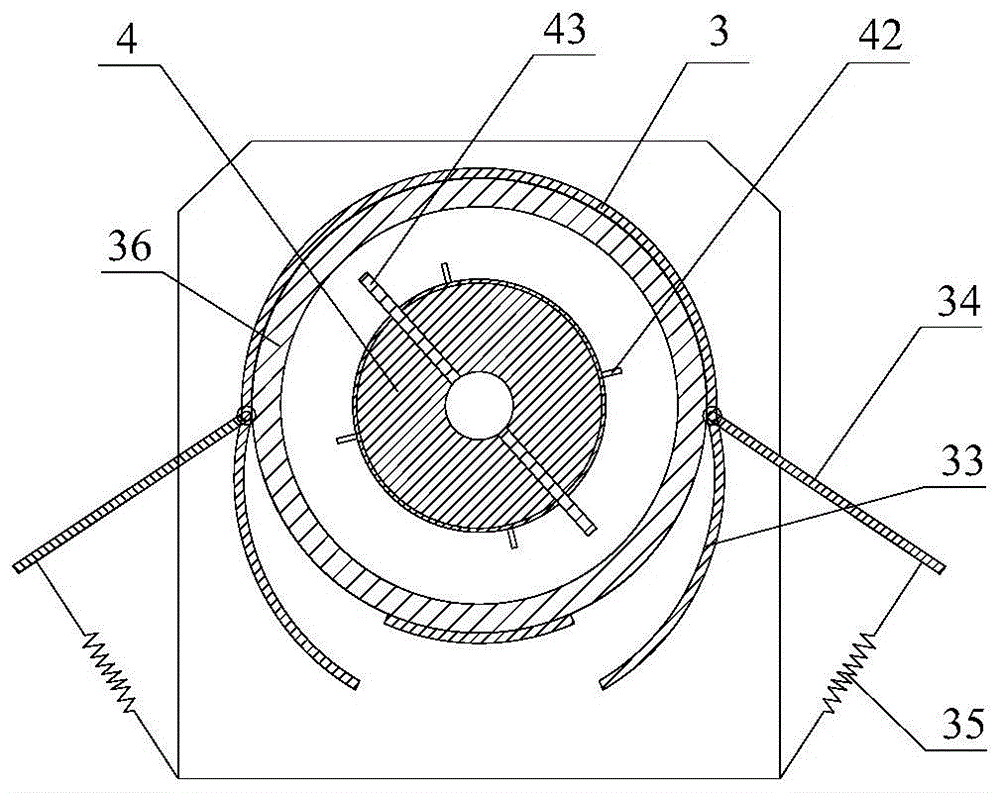

Hazelnut huller

The invention discloses a hazelnut huller, which relates to the field of crop hulling machines. A barrel body is provided with a feeding hole and discharging holes; a main shaft penetrates through the barrel body; a driving mechanism and a blower box are arranged at the two ends of the barrel body respectively; a sieve layer is arranged below the barrel body; the driving mechanism is connected with the main shaft and the sieve layer respectively; the sieve layer is provided with a lower layer outlet; a spiral propeller is arranged at a position on the main shaft corresponding to the feeding hole; chamfered teeth are arranged on the main shaft; the inner wall of the barrel body is provided with slats; the two discharging holes are formed in two sides of one end, which is far away from the feeding hole, of the barrel body respectively; a position, which corresponds to the discharging holes, of the barrel body is connected with a discharge door; a discharge door lever is connected with the barrel body through a lever and a spring; the sieve layer consists of double layers of sieves; and the blower box is a dual-suction air box. The invention aims to provide a hazelnut huller which is used for realizing rapid hulling of a large quantity of hazelnuts instead of labor force, is easy to operate, and contributes to increasing the hazelnut hulling efficiency.

Owner:佟成伟

Pepper baking oven

ActiveCN110522055AHeating evenly and quicklyAvoid Grinding SituationsFood treatmentCooking & bakingHot peppers

The invention relates to the technical field of chili processing, and concretely relates to a pepper baking oven, the pepper baking oven comprises an oven body internally provided with a baking cavity, an opening is formed in the front side of the oven body, an oven door is arranged at the opening, a heating mechanism is arranged in the oven body, a plurality of placing grooves are formed in the baking cavity, trays containing peppers can be placed in the placing grooves, and each tray is correspondingly provided with a stirring mechanism comprising a stirring part; a driving mechanism for driving the stirring mechanism to stir chilies is arranged in the baking cavity; a sensing mechanism for sensing the tray is arranged in the placing groove, and when the tray is placed in the placing groove, the sensing mechanism automatically pushes a stirring part into the chili from the side surface of the tray. According to the pepper baking oven, when hot peppers are baked, the stirring mechanism is used for automatically stirring the hot peppers, so that the hot peppers are uniformly heated, and the problem that large-batch hot peppers cannot be quickly dried in the prior art is solved.

Owner:重庆市长寿区可又可食品有限公司

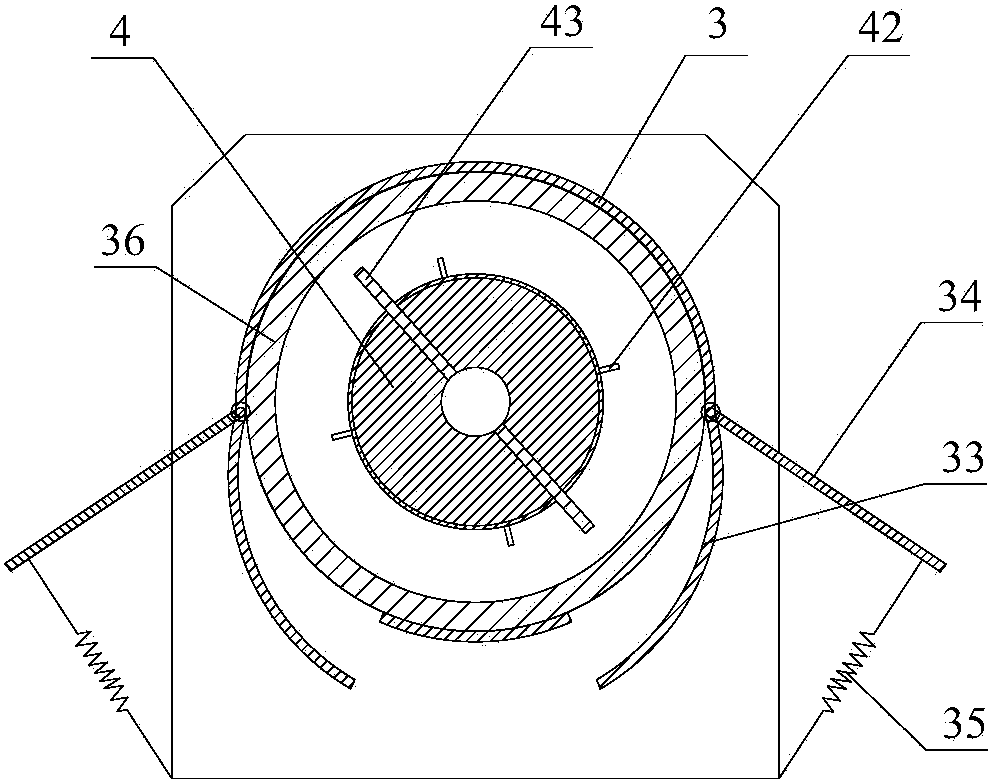

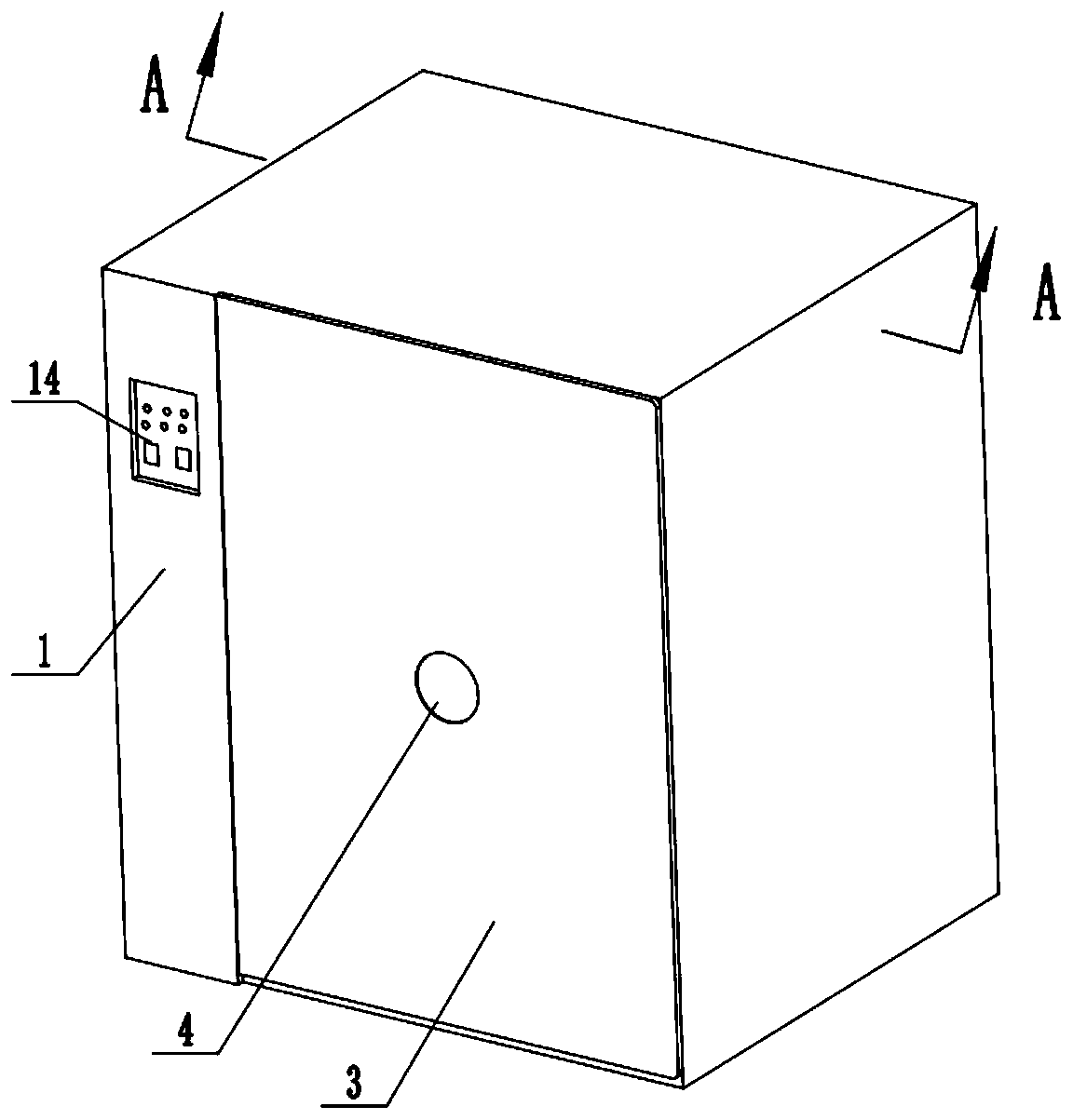

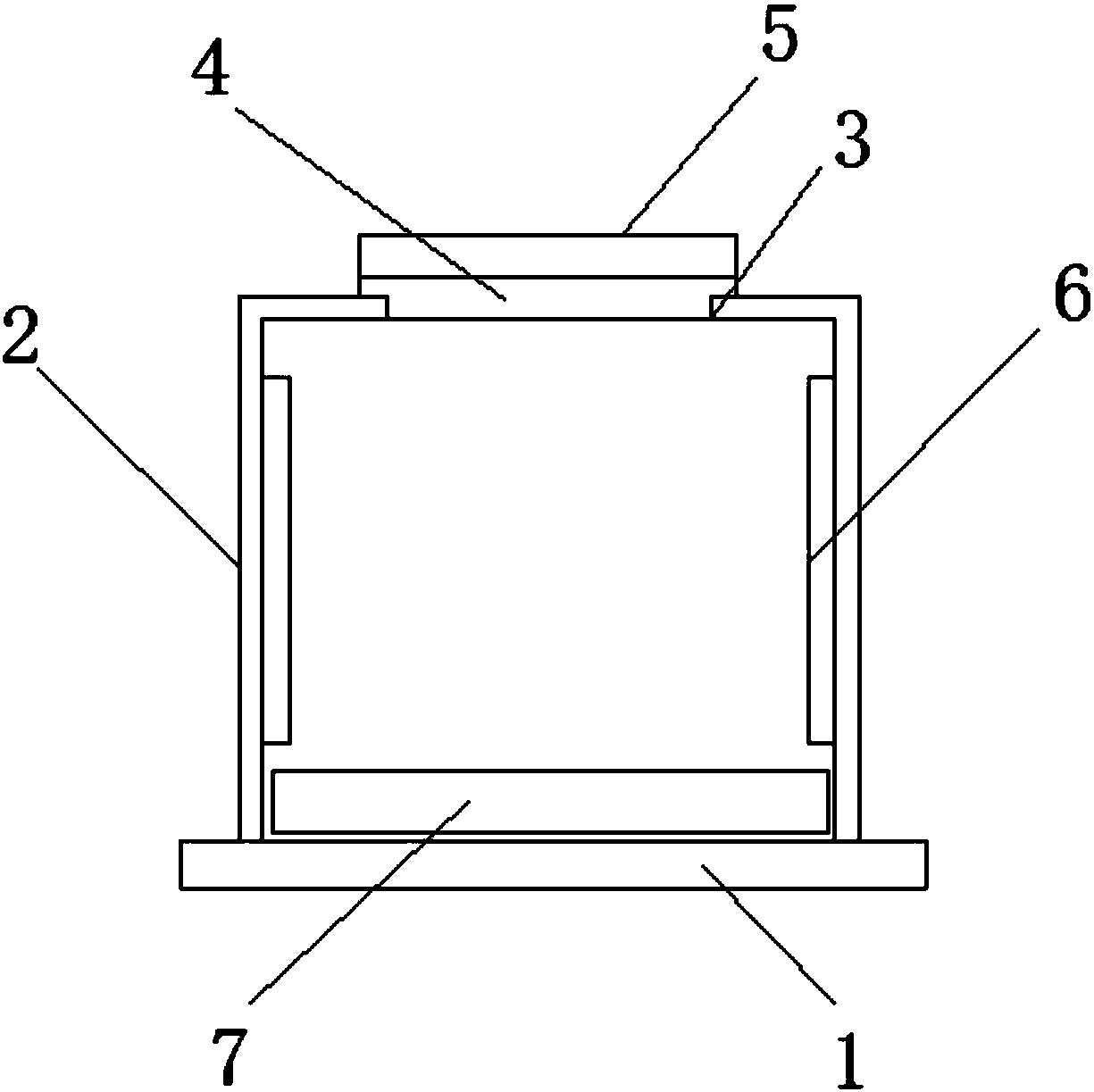

Stable automatic control equipment base convenient to move

PendingCN108591769AEasy to moveRealization of mobile and stable automatic controlNon-rotating vibration suppressionStands/trestlesAutomatic controlControl engineering

The invention discloses a stable automatic control equipment base convenient to move and relates to the technical field of equipment bases. The stable automatic control equipment base convenient to move comprises a box body; the top of an inner chamber of the box body is rotationally connected with a threaded rod; the surface of the threaded rod is in threaded connection with a threaded plate in asleeving manner; a connecting rod is fixedly installed at the bottom of the threaded plate; the bottom end of the connecting rod is fixedly connected with a lifting box; the bottom of the lifting boxpenetrates through a base plate of the box body and extends to the place below the box body; a limiting cylinder is fixedly installed at the top of the lifting box; a first rotating shaft and a second rotating shaft are arranged at the rear side of the lifting box; a second switch is used for controlling a second rotating motor; the second rotating motor is used for rotationally driving the lifting box to life up and down so that a rolling wheel makes contact with the ground; a first switch is used for controlling a first rotating motor to rotate to make the rolling wheel rotate so as to drive the sable automatic control equipment base to move; and the design realizes automatic control and reduces manpower consumption when the stable automatic control equipment base moves.

Owner:浙江两山信息科技有限公司

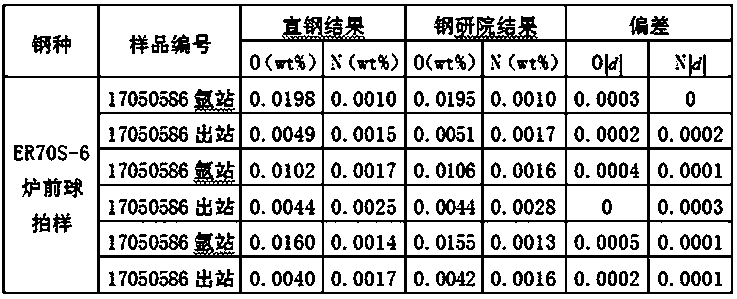

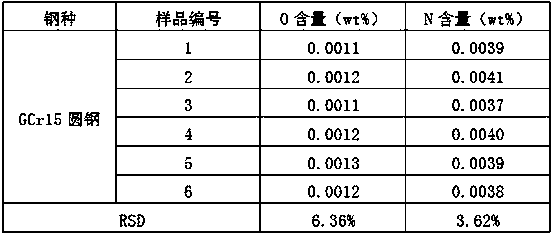

Sampling method and analyzing method for oxygen and nitrogen analysis samples

InactiveCN107817141AEasy to prepareEasy to polishPreparing sample for investigationInvestigating phase/state changeNitrogenSurface roughness

The invention discloses a sampling method and analyzing method for oxygen and nitrogen analysis samples, wherein a flaky sample is cut from the cross section of a sample of above phi20mm, and after polishing, the flaky sample is stamped into a caky analysis sample. The sampling method aims at samples such as round steel of various specifications, large-specification screw-tread steel and racket samples, a rodlike sample is replaced by the flaky sample, and the original sampling process of linear cutting of rodlike sample and peeling is changed to the sampling process of slicing, polishing andstamping; the surface of the flaky sample is easier for polishing, the surface roughness Ra completely meets the requirement specified by standard, and observation for the sample surface is more intuitive; sample preparation is convenient and quick, and the efficiency is increased by about 3-4 times. The sampling method is anhydrous and greaseless in the whole process, and compared with the original linear cutting rodlike samples, sampling speed is greatly increased, judgement for the quality of the sample surface is more intuitive and better to control, and therefore, powerful guarantee is provided for subsequent oxygen and nitrogen analysis accuracy and oxygen and nitrogen analysis precision and accuracy are increased.

Owner:宣化钢铁集团有限责任公司

Drying device for printing packaging

InactiveCN107776192AImprove heating efficiencyFast dryingOther printing apparatusPrinting press partsMicrowaveDrive shaft

The invention discloses a drying device for printing packaging. The drying device comprises a workbench, wherein the upper surface of the workbench is fixedly connected with a drying box; a through hole is formed in the top of the drying box; a filtering layer is arranged in the through hole; an exhaust fan is fixedly mounted on one side, away from the workbench of the filtering layer; microwave dryers are fixedly mounted on two sides of the inner wall of the drying box respectively; a conveying belt penetrates in one end, close to the workbench of the drying box; one end of the conveying beltis in sleeve joint with a first transmission shaft; one end, away from the first transmission shaft of the conveying belt, is in sleeve joint with a second transmission shaft; the outer surface of one end of the first transmission shaft is in sleeve joint with a belt. The drying device for printing packaging has the advantages of fast drying, high efficiency, convenience in operation, satisfaction of requirements for energy conservation and environmental protection and the like, and solves the problems of low production efficiency, high energy consumption and unsatisfactory product quality oftraditional infrared curing technology.

Owner:陈雪峰

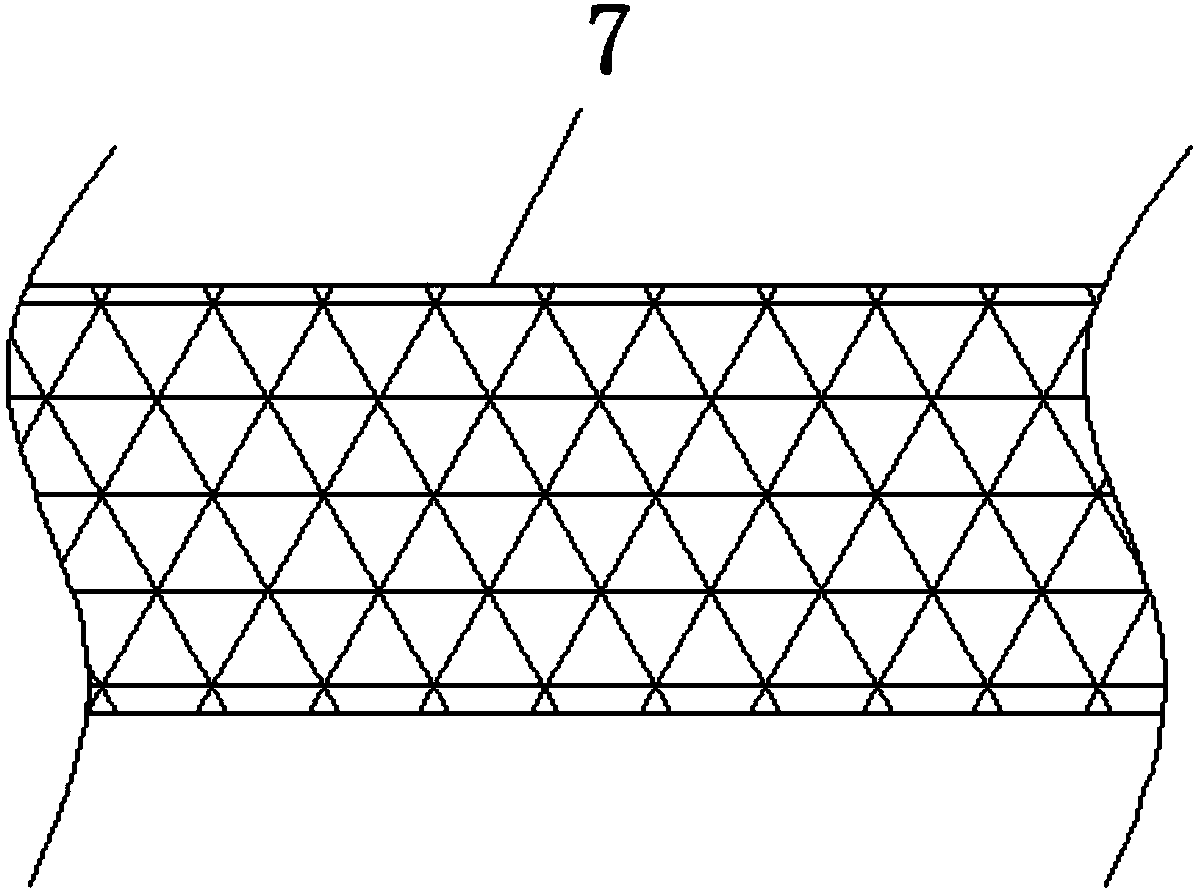

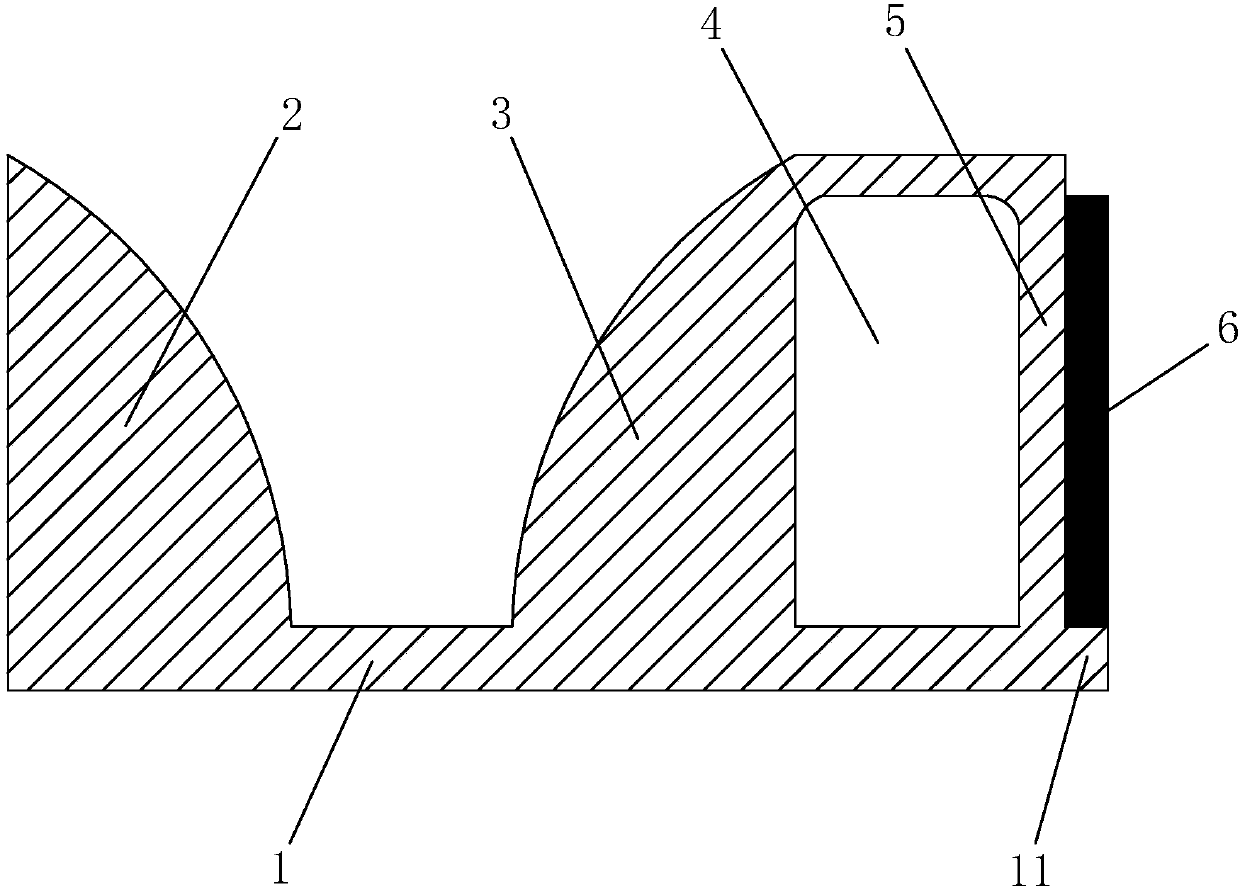

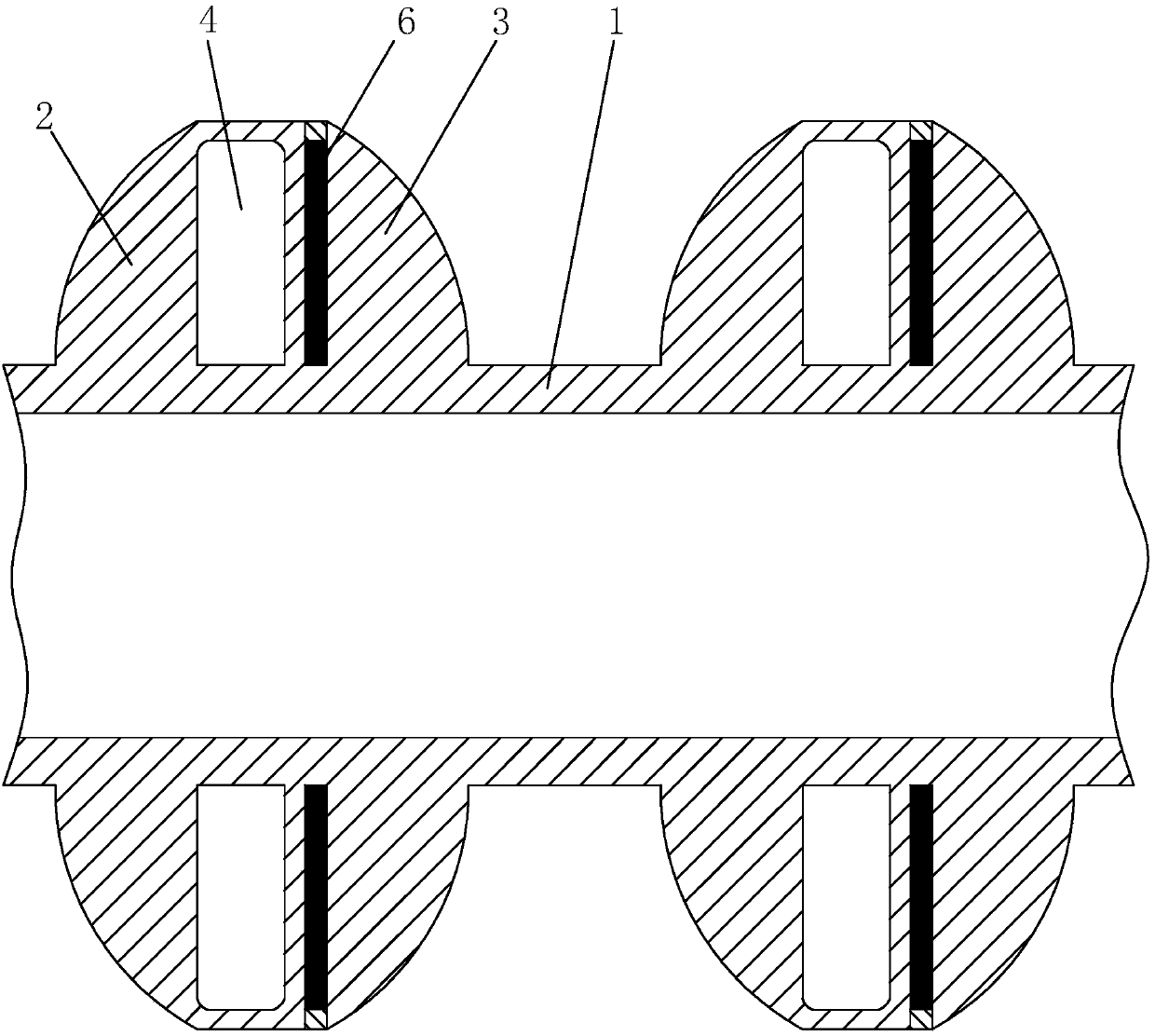

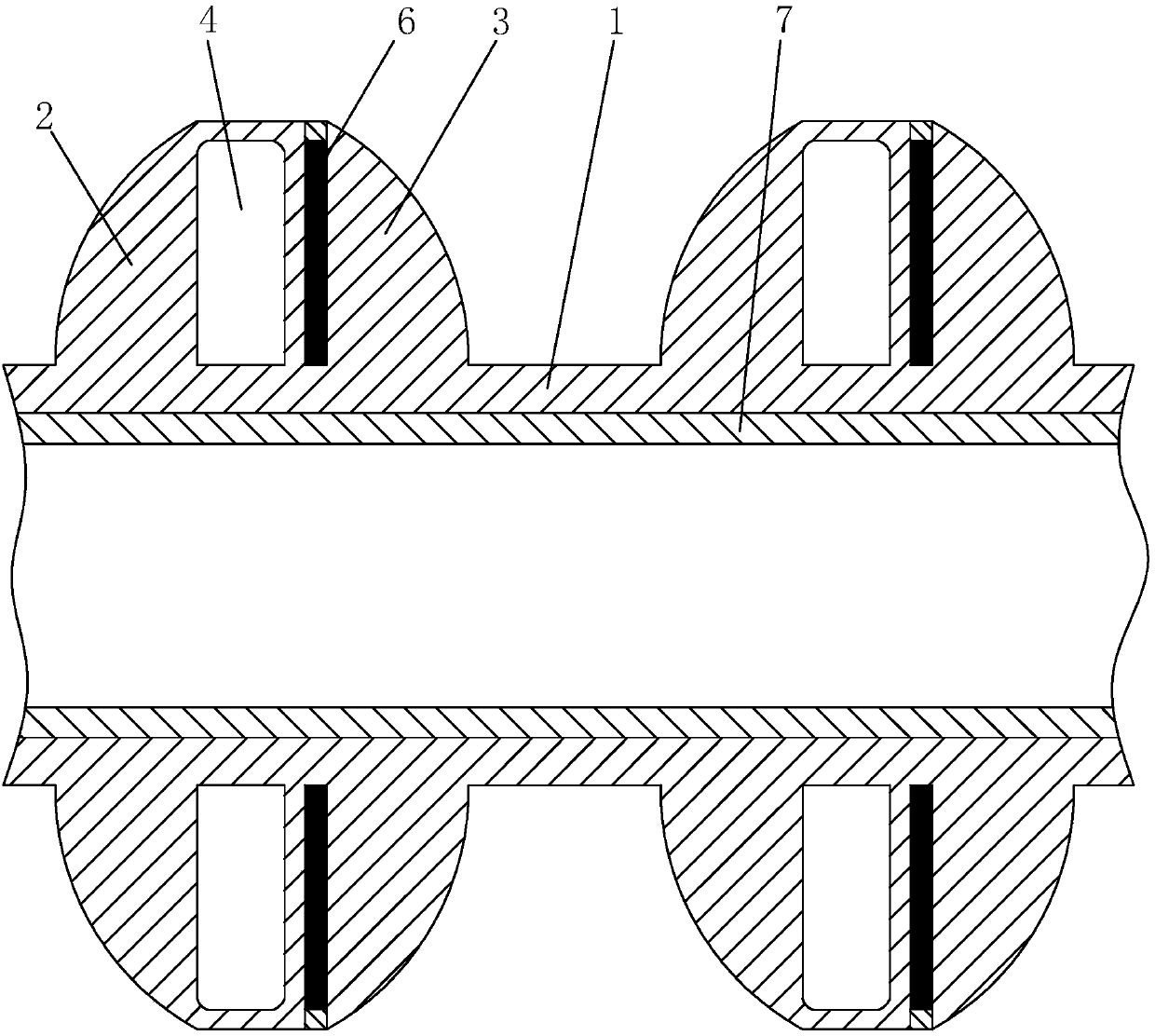

Corrugated tubular material with winding structure and strip material thereof

InactiveCN107588317AIncreased ring stiffnessReduce production processElongated constructional elementsRigid pipesEngineeringUltimate tensile strength

The invention discloses a corrugated tubular material with a winding structure and a strip material thereof. According to the technical scheme of the invention, the corrugated tubular material is characterized by comprising a bottom sheet, wherein a left solid protrusion is arranged on one side of the bottom sheet, a right solid protrusion is arranged on the other side of the bottom sheet, the right solid protrusion is connected with a supporting rib perpendicular to the bottom sheet, a cavity is defined by the supporting rib, the bottom sheet and the right solid protrusion, and the section, protruding out of the supporting rib, of the bottom sheet forms an extending portion. The problem is solved that an existing corrugated tube is insufficient in strength and accordingly collapse is likely to occur when the tube is used.

Owner:北京华宇中天环境工程有限公司

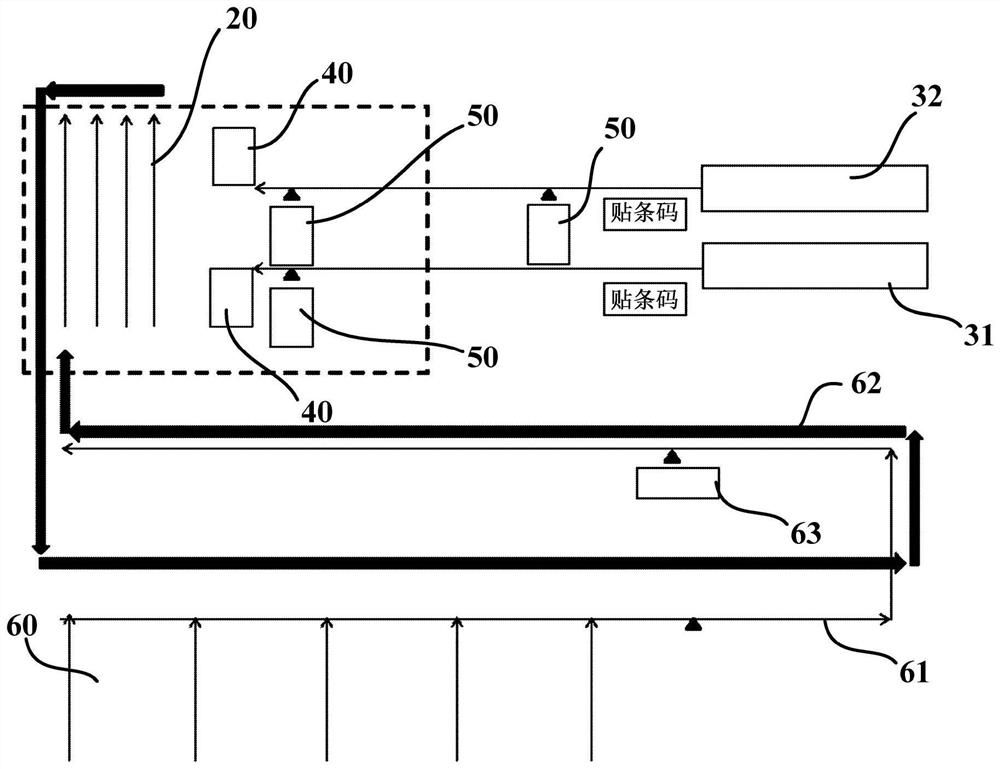

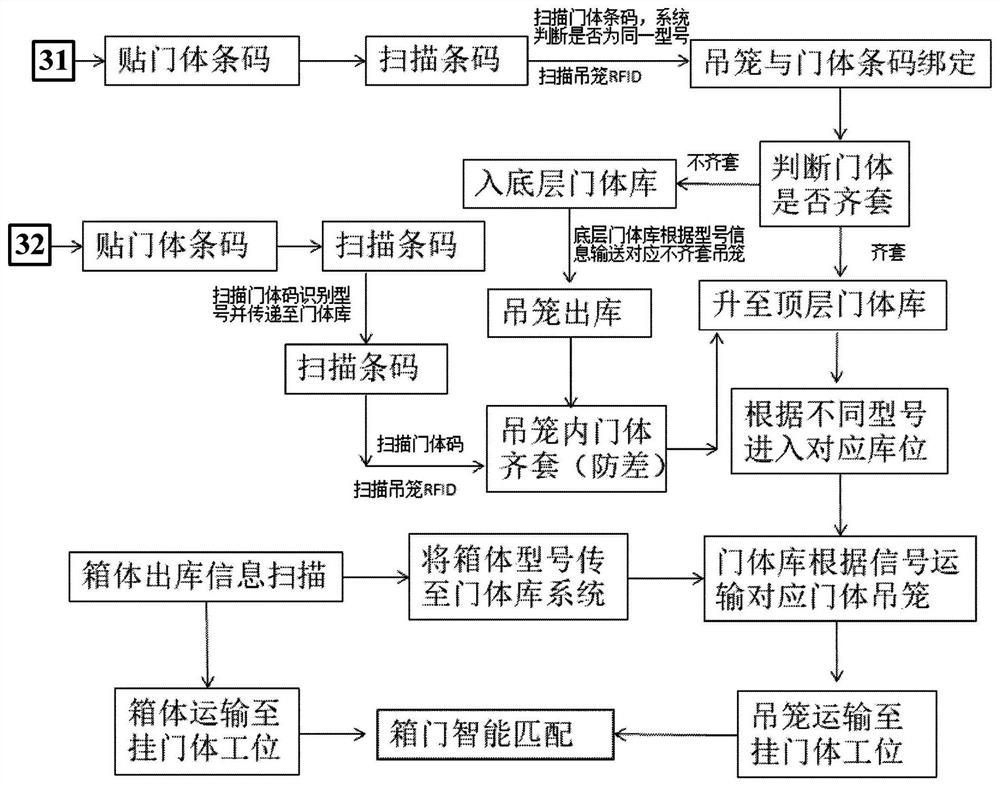

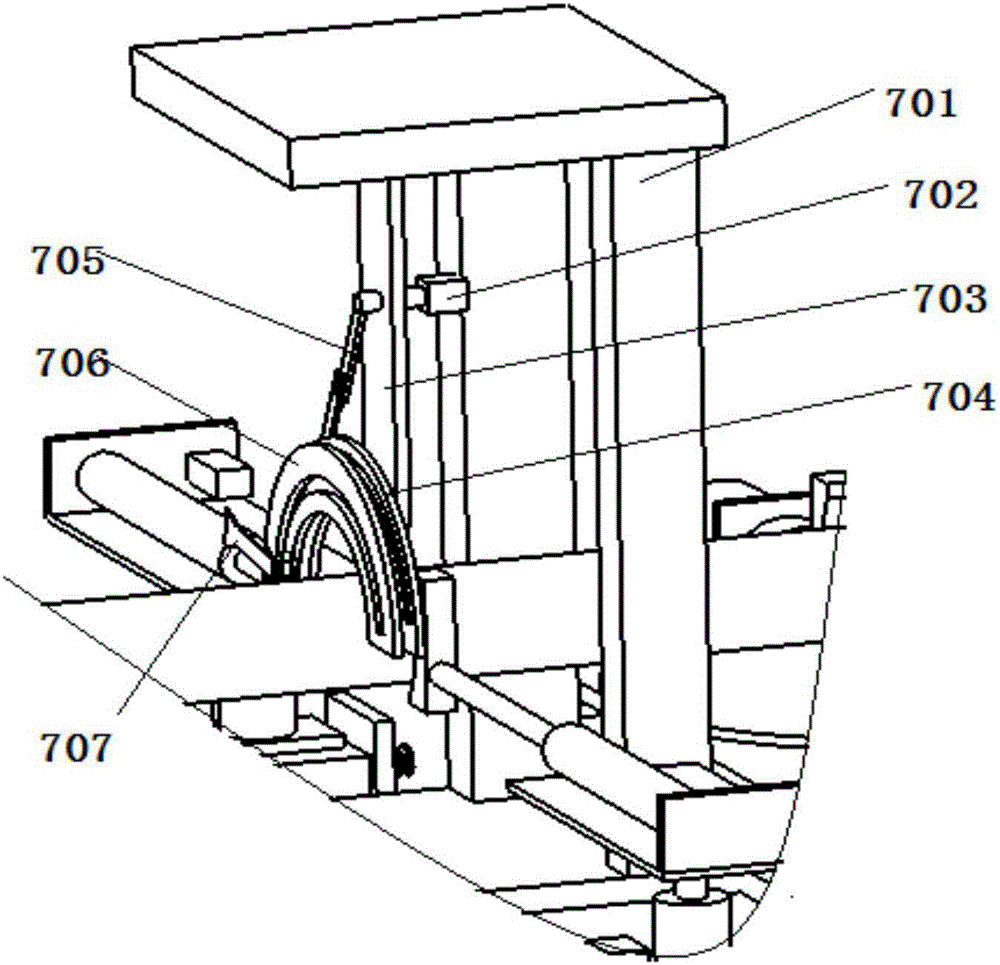

Door production system and method and refrigerator door matching system of refrigerator production line

The invention provides a door production system and method and a refrigerator door matching system of a refrigerator production line. The door production system comprises a first depositing space, a second depositing space, a first door production station, a second door production station and a hoisting cage system. The first door production station is configured to produce first doors. The seconddoor production station is configured to produce second doors. The hoisting cage system is provided with a hoisting cage and a transportation system for driving the hoisting cage to move. The transportation system is configured to transport the hoisting cage to the first door production station to receive a first set of doors and transport the hoisting cage and the first set of doors in the hoisting cage to the first depositing space; and the hoisting cage is transported to the first door production station to receive the first door of a second set of doors, the hoisting cage and the first door in the hoisting cage are transported to the second depositing space, then the hoisting cage and the first door in the hoisting cage are transported to the second door production station from the second depositing space to receive the second door of the second set of doors, and then the hoisting cage and the second set of doors in the hoisting cage are transported to the first depositing space.

Owner:QINGDAO HAIER SPECIAL REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

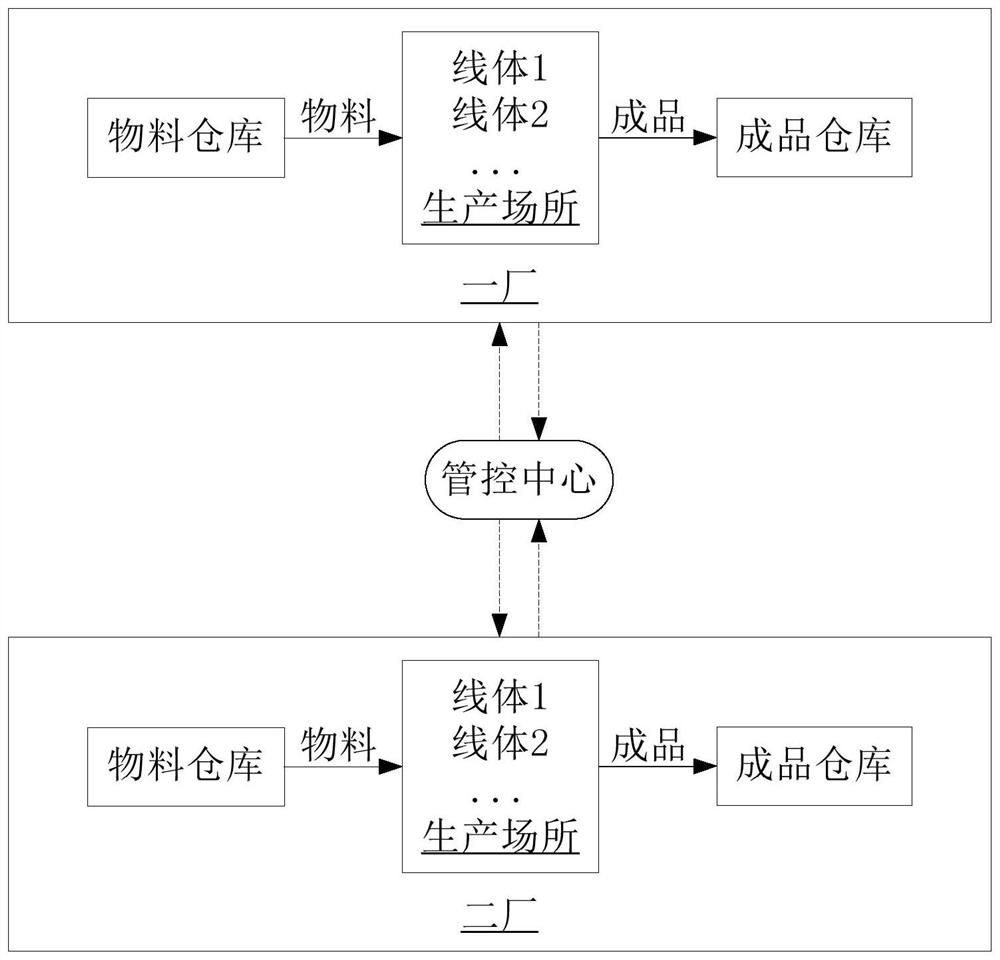

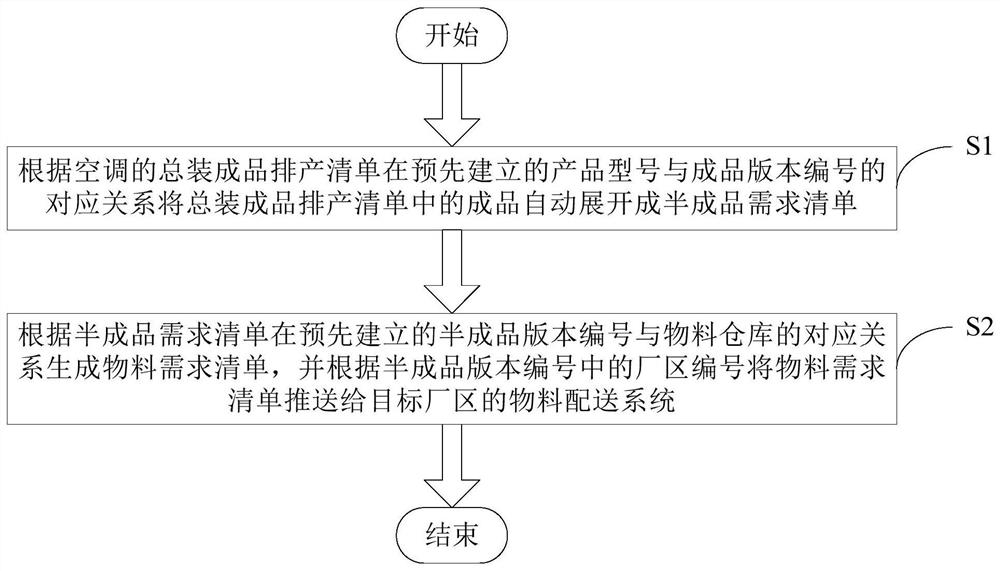

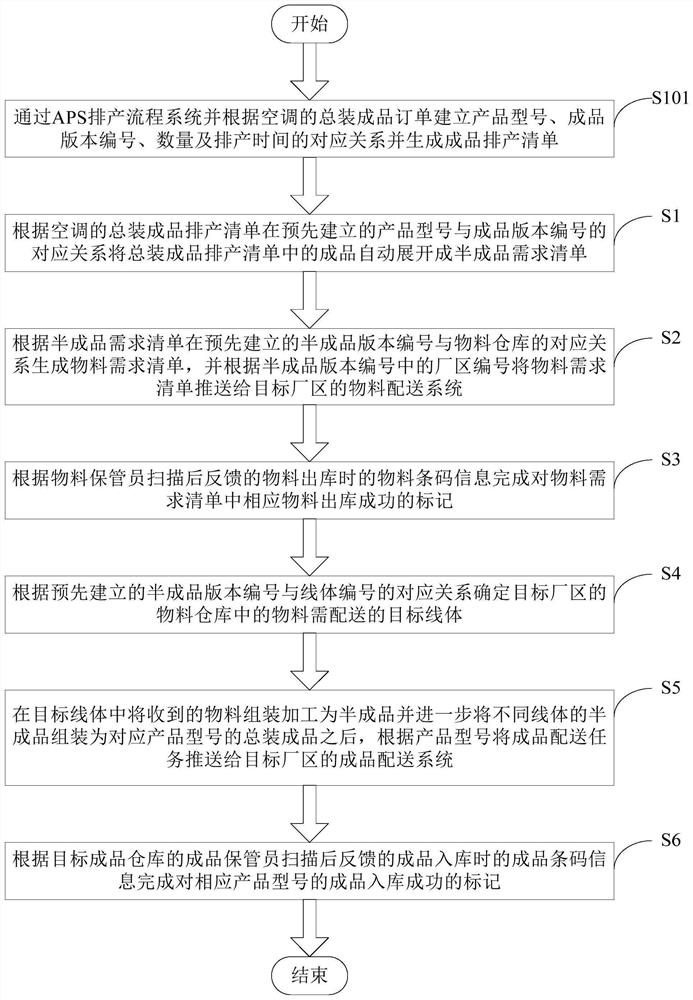

Air conditioner production management and control method and system and readable storage medium

PendingCN112434910AAvoid delivery errorsOrderly productionResourcesLogisticsControl systemProcess engineering

The invention belongs to the technical field of air conditioners, and particularly relates to an air conditioner production management and control method and system, and a readable storage medium. Theinvention aims to solve the problem that an existing air conditioner management and control system cannot realize unified management and control of different air conditioner factories under the condition that the number of the air conditioner factories is large. For the purpose, when air conditioner production in multiple factories is managed and controlled, finished products in a final assemblyfinished product scheduling list can be automatically unfolded into a semi-finished product demand list and a material demand list according to a pre-established corresponding relation between productmodels and finished product version numbers of the final assembly finished product scheduling list of the air conditioners, and the material demand list is pushed to a material distribution system ofthe target factory according to the factory number in the semi-finished product version number. In this way, material distribution errors can be prevented through the finished product version numbersand the factory numbers contained in the semi-finished product version numbers, and it is guaranteed that orderly and efficient production scheduling can be conducted in the air conditioner production process.

Owner:QINGDAO HAIER JIAOZHOU AIR CONDITIONER

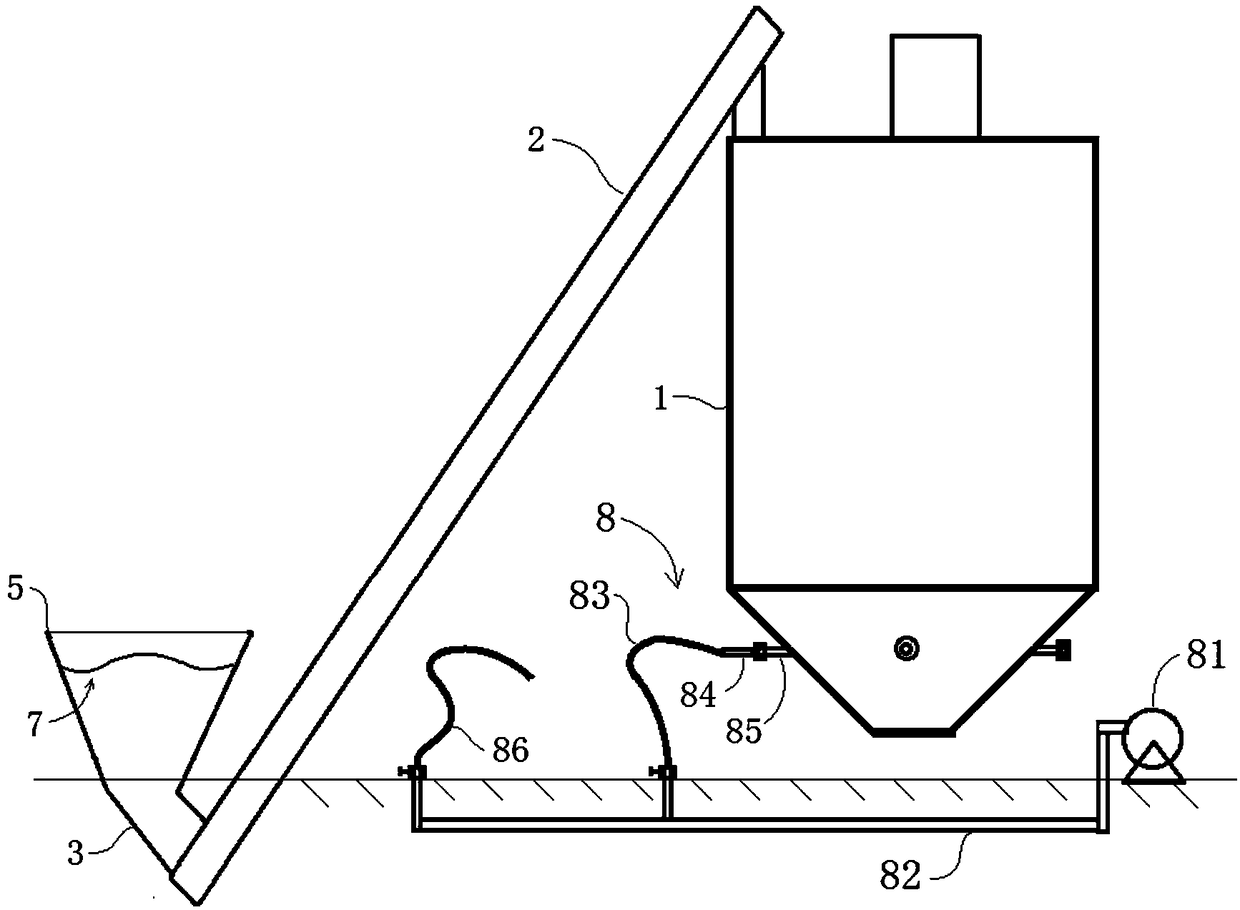

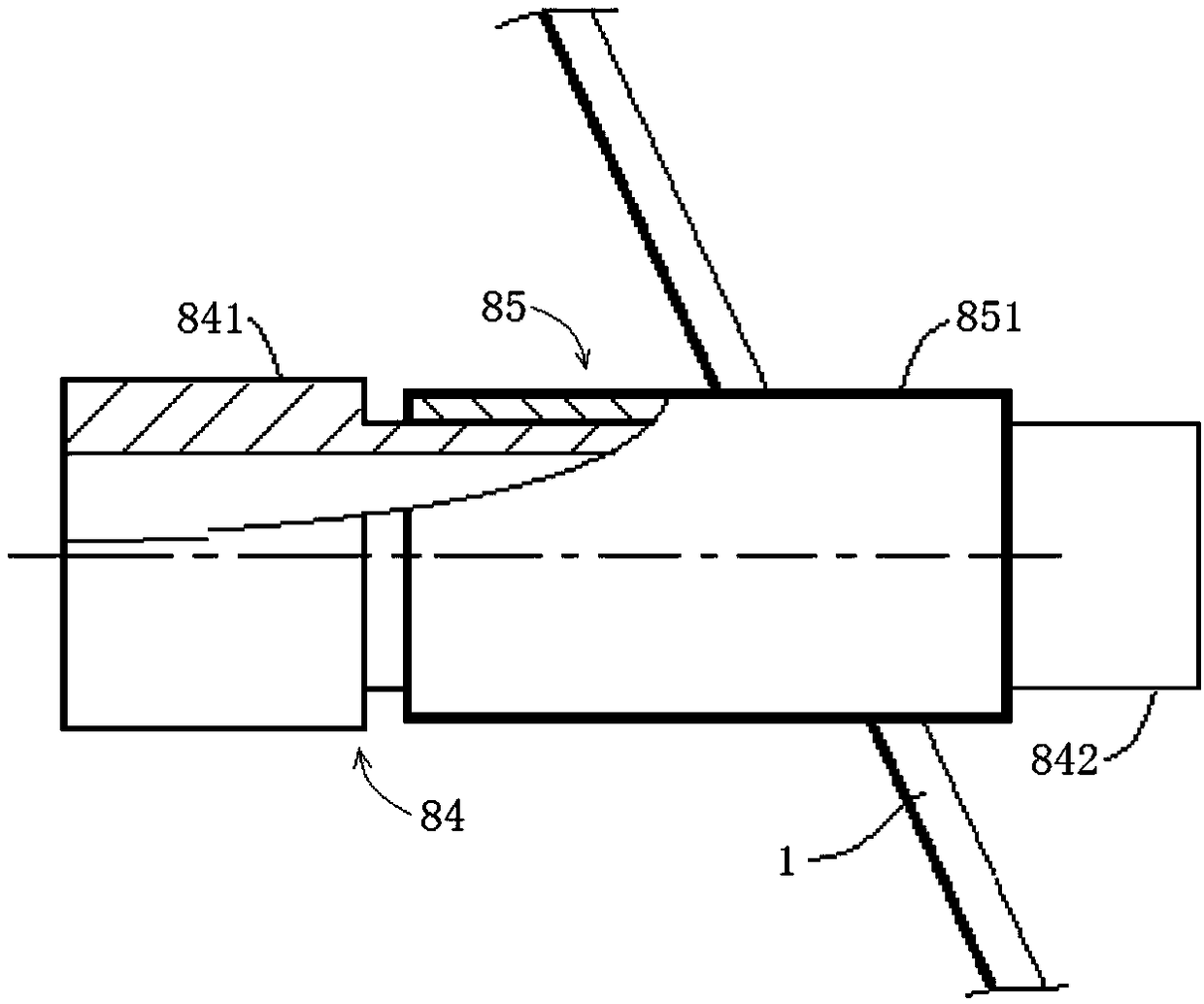

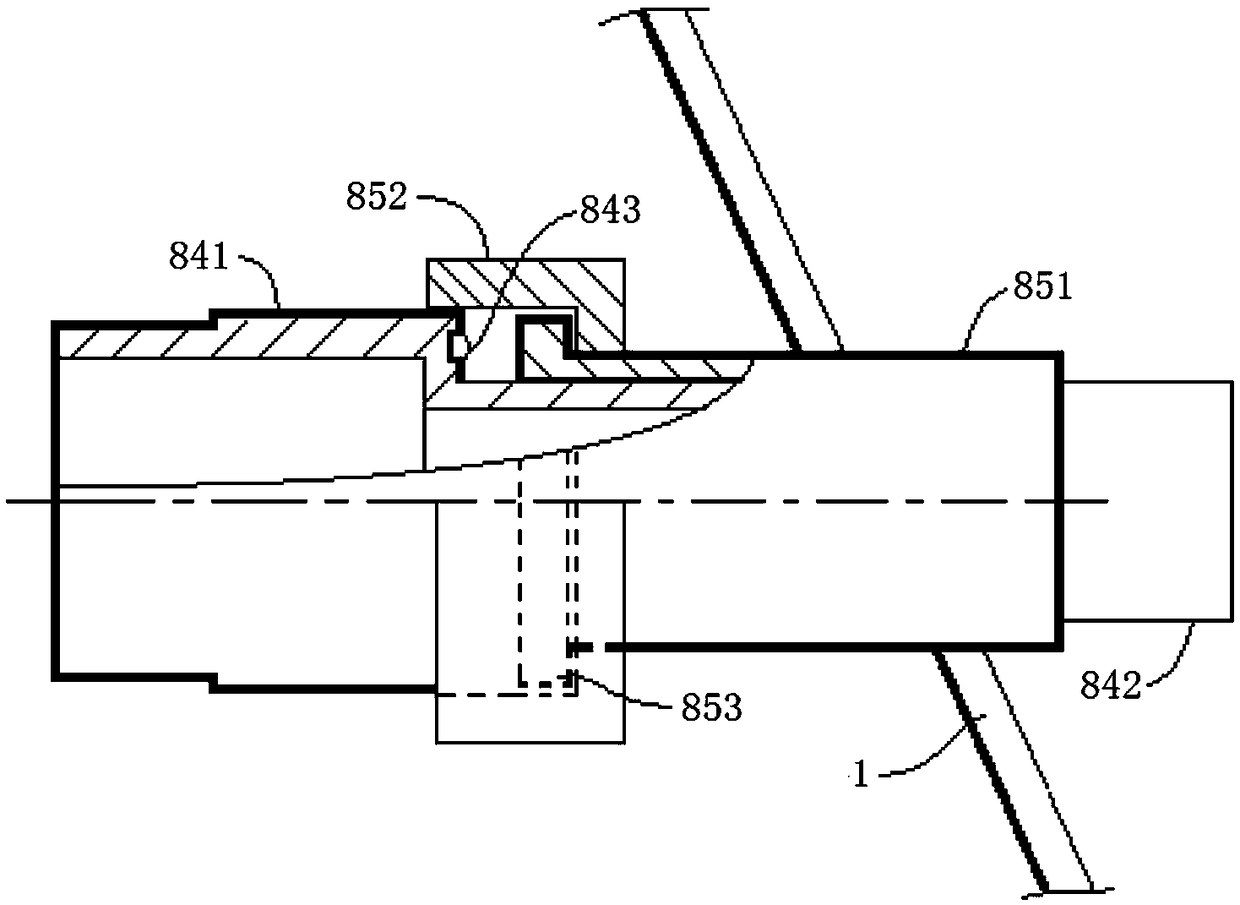

Curing agent production system based on air-jet disturbance

PendingCN108726024AOrderly productionPrevent looseningLarge containersLoading/unloadingEngineeringAir compressor

The invention discloses a curing agent production system based on air-jet disturbance, belonging to the field of curing agent processing. The curing agent production system comprises a material tank,a spiral feed delivery pipe and a hopper, wherein the bottom of the hopper is communicated with one end of the spiral feed delivery pipe by means of a connecting sleeve, and the other end of the spiral feed delivery pipe is communicated with the material tank; a blowing mechanism is arranged at the lower end of the material tank; the blowing mechanism comprises an air compressor, a gas conveying pipe, a blowing pipe, a pipe joint and a pipe connector seat which are sequentially connected, wherein the pipe connector seat is arranged on the material tank; the pipe connector seat comprises a flange pipe; the flange pipe is internally provided with threaded hole; one end of the pipe joint is connected with the threaded hole by means of threads, and protrudes from the inner end of the flange pipe; the other end of the pipe joint is used for connecting the blowing pipe; a gas transmission cavity is arranged in the center of the pipe joint. The curing agent production system not only can accelerate the blanking speed of the material tank, but also can avoid the situation of material accumulation in the hopper, thus accelerating the material transmission speed and improving the productivity.

Owner:ANHUI GUWEITE MATERIAL TECH CO LTD

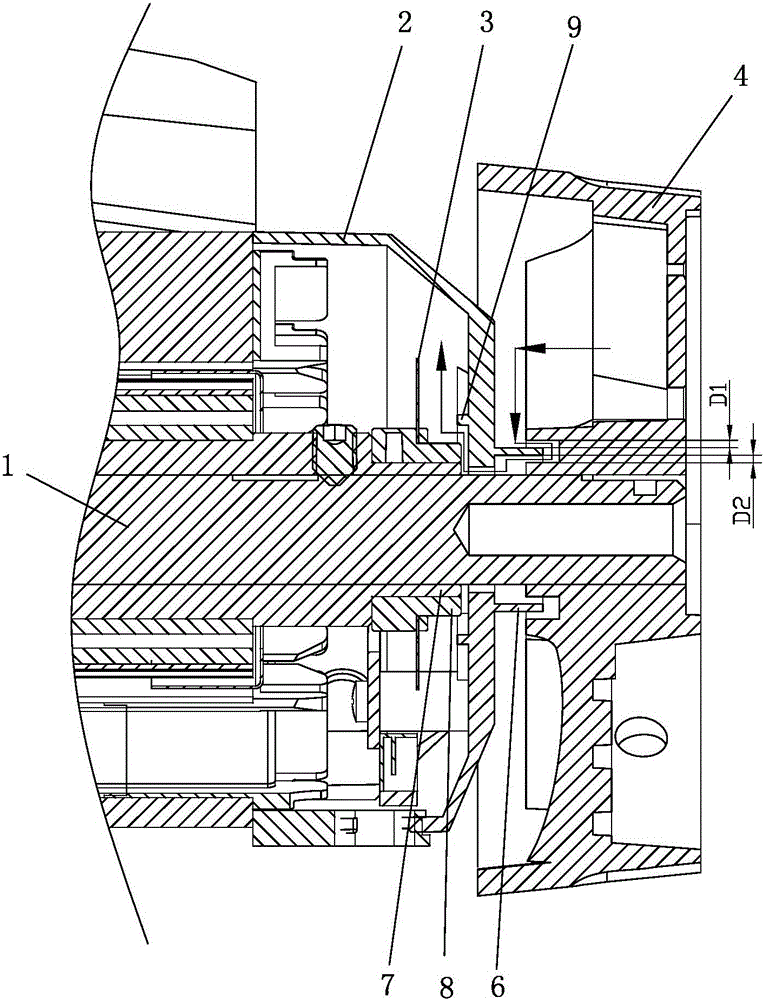

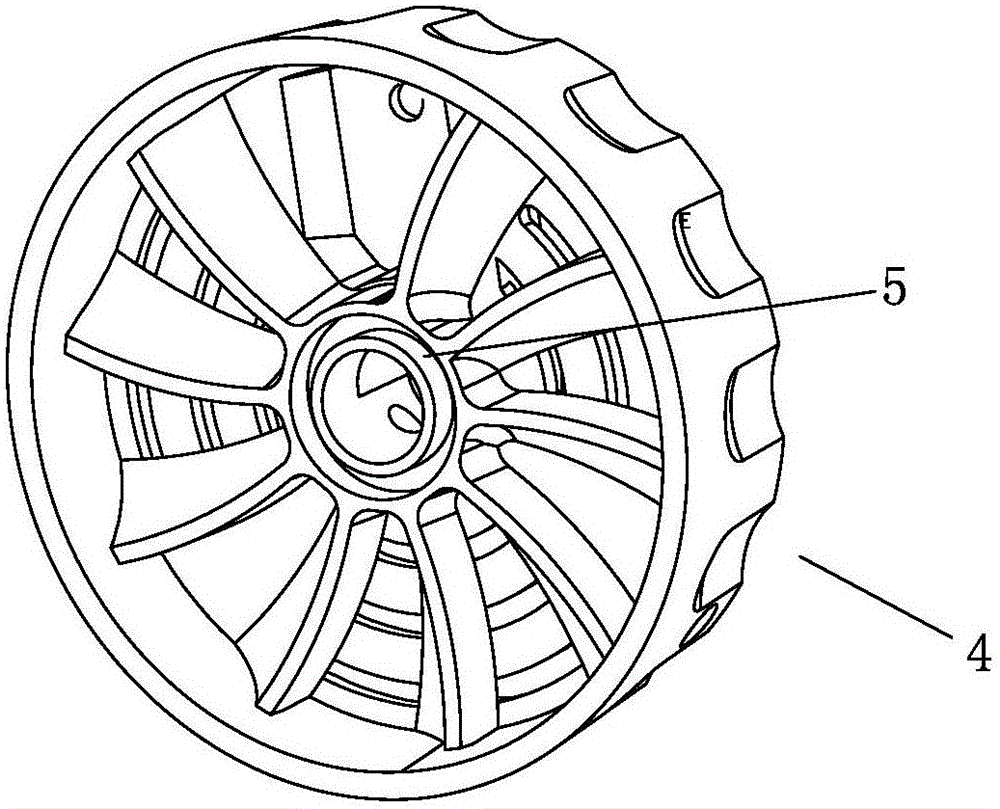

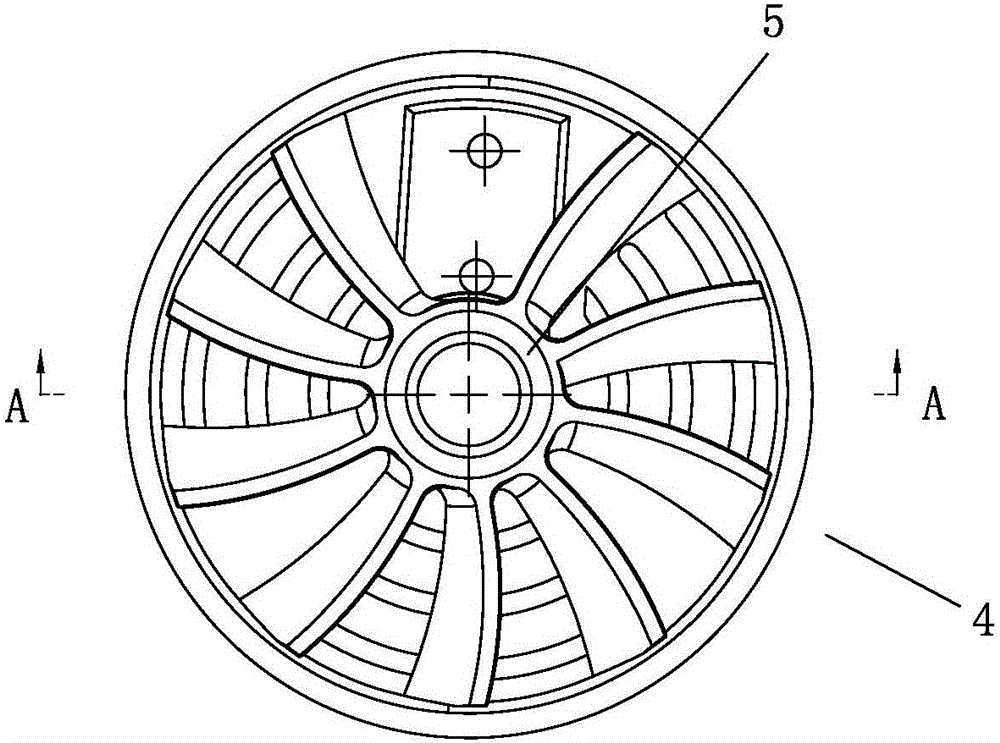

Dustproof structure of sewing machine housing

The invention belongs to the technical field of sewing machines and particularly provides a dustproof structure of a sewing machine housing. The dustproof structure comprises a spindle, wherein a protective cover for covering a motor assembly is arranged on the spindle, a hand wheel is arranged on the spindle outside the protective cover, and a dustproof structure body for preventing outside dust from falling into the protective cover is arranged on the hand wheel or between the hand wheel and the protective cover. The dustproof structure can effectively prevent dust from falling into the protective cover and affecting components including encoders, gratings and the like, prolong the service life of a motor and ensure orderly production.

Owner:JACK SEWING MASCH CO LTD

Milling and grinding mechanism for mass production cutting device of equal-length glass tubes

InactiveCN106514447AReduce workloadReduce time for step-by-step processingGrinding carriagesGrinding feed controlCushionPotential risk

The invention provides a milling and grinding mechanism for a mass production cutting device of equal-length glass tubes. The milling and grinding mechanism comprises a base and a lifting plate, wherein a cushion board is slidably connected to the lifting plate; a plurality of rollers which are uniformly distributed in a single rank are arranged on the cushion board; a clamping mechanism is arranged on the lifting plate; a cutting mechanism is arranged on the cushion board; a milling and grinding mechanism body, comprising a sidewall and a milling tool which is in slide connection with the sidewall, is arranged on the lifting plate; a slide plate is in slide connection with the cushion board; a circular plate is rotatably connected to the slide plate; fifth hydraulic cylinders are symmetrically arranged on the circular plate; third clamping claws are arranged at top boards of fifth hydraulic rods of the fifth hydraulic cylinders. According to the milling and grinding mechanism for the mass production cutting device of the equal-length glass tubes, two sides of each glass tube are milled and grinded once after cutting, so that the processing steps are simplified; moreover, a small space is used; the processing time can be saved; the glass tubes do not need to be manually grinded by workers, so that the potential risk in work is reduced, and the processing quality is improved.

Owner:天津南玻节能玻璃有限公司

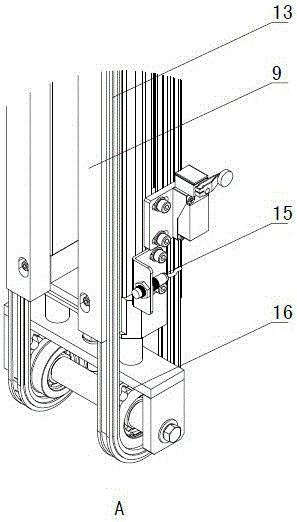

Clamping mechanism for equal-length glass tube batch production cutting devices

InactiveCN106495456AReduce workloadHigh precisionWorking accessoriesGlass severing apparatusMachiningGlass tube

The invention provides a clamping mechanism for equal-length glass tube batch production cutting devices. The clamping mechanism comprises a base and a lift plate arranged thereon, a pad plate is slidably connected to the lift plate, a plurality of rollers evenly arrayed in single row are arranged on the pad plate, the clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism which are respectively and symmetrically arranged, the first clamping mechanism comprises a first motor and a first transmission rod, and the second clamping mechanism comprises a second motor and a first screw-nut assembly. By using the clamping mechanism, machining efficiency is guaranteed by alternative operation of the first and second clamping mechanisms, the clamping mechanism is suitable for batch production and machining of glass tubes, time is saved, efficient and highly precise machining is guaranteed, and production efficiency is improved.

Owner:天津南玻节能玻璃有限公司

Manufacturing method of large steel box girder

InactiveCN112719795AEffectively control welding deformationAvoid cross assignmentCantileverWelding deformation

The invention relates to a manufacturing method of a large steel box girder. The manufacturing method comprises the following steps of: manufacturing a unit piece, assembling and pre-splicing girder sections, hoisting a steel box girder on a construction site, and performing welding, wherein the step of manufacturing the unit piece comprises: designing a drawing by using AUTOCAD software, performing modeling, determining a theoretical size, and determining welding and processing compensation amounts; and the step of manufacturability analysis comprises: A, welding manufacturability test, B, manufactured bridge actual measurement data and C, part machining requirements. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that a forward mounting method and a reverse mounting method are adopted, namely, bottom plate unit pieces are firstly assembled, then web unit pieces, diaphragm plate unit pieces, panel unit pieces and cantilever unit pieces are sequentially assembled, and the cantilever unit pieces adopt the reverse mounting method. The method has the advantage that most of weld joints are welded in a horizontal or climbing position. During welding, welding deformation is effectively controlled by utilizing the principles of constraint, self-constraint, strong constraint and flexible constraint, so that various geometric dimension deviations of all steel box girders are within a very small range.

Owner:江苏恒睿杰钢结构工程有限公司

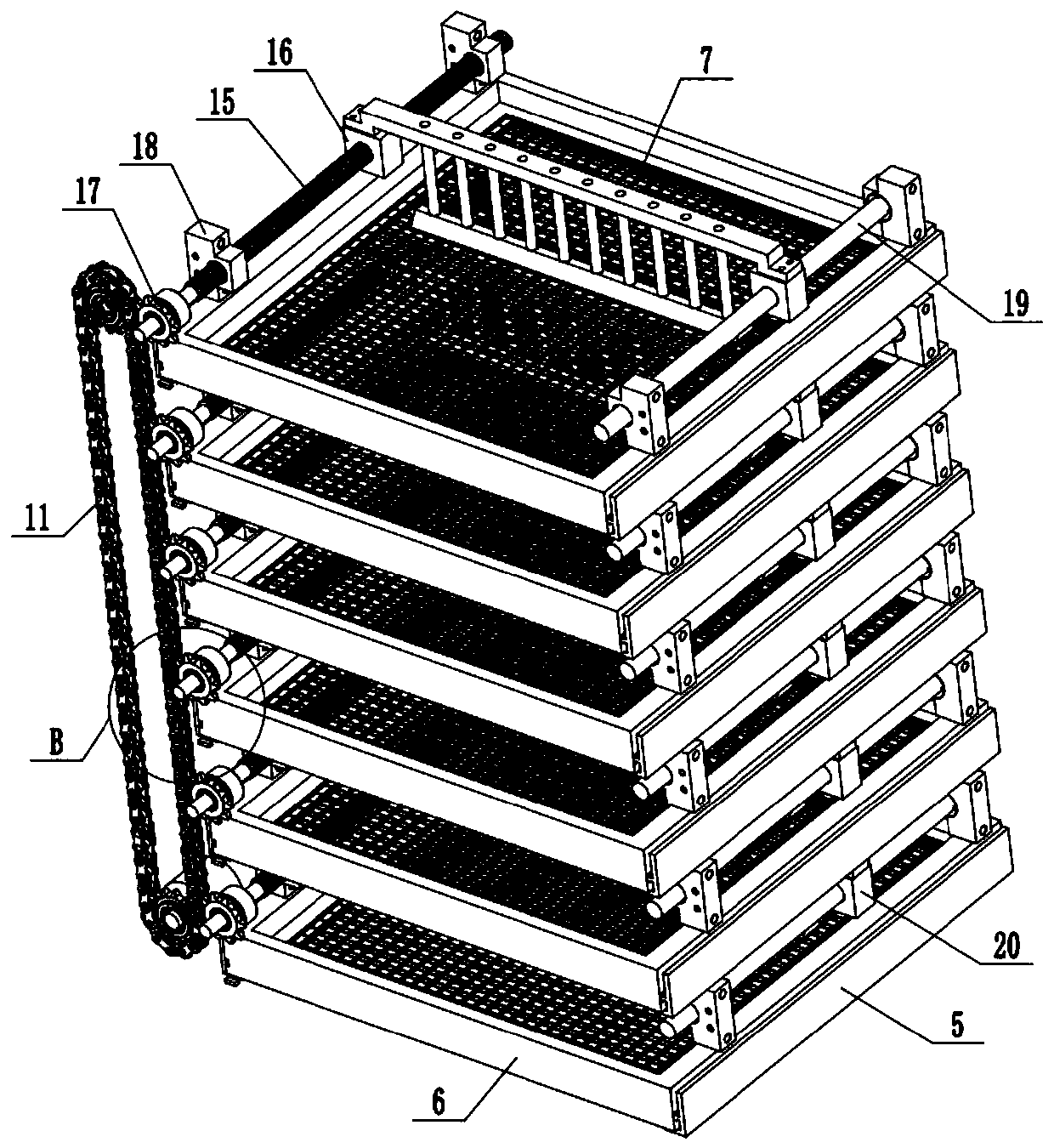

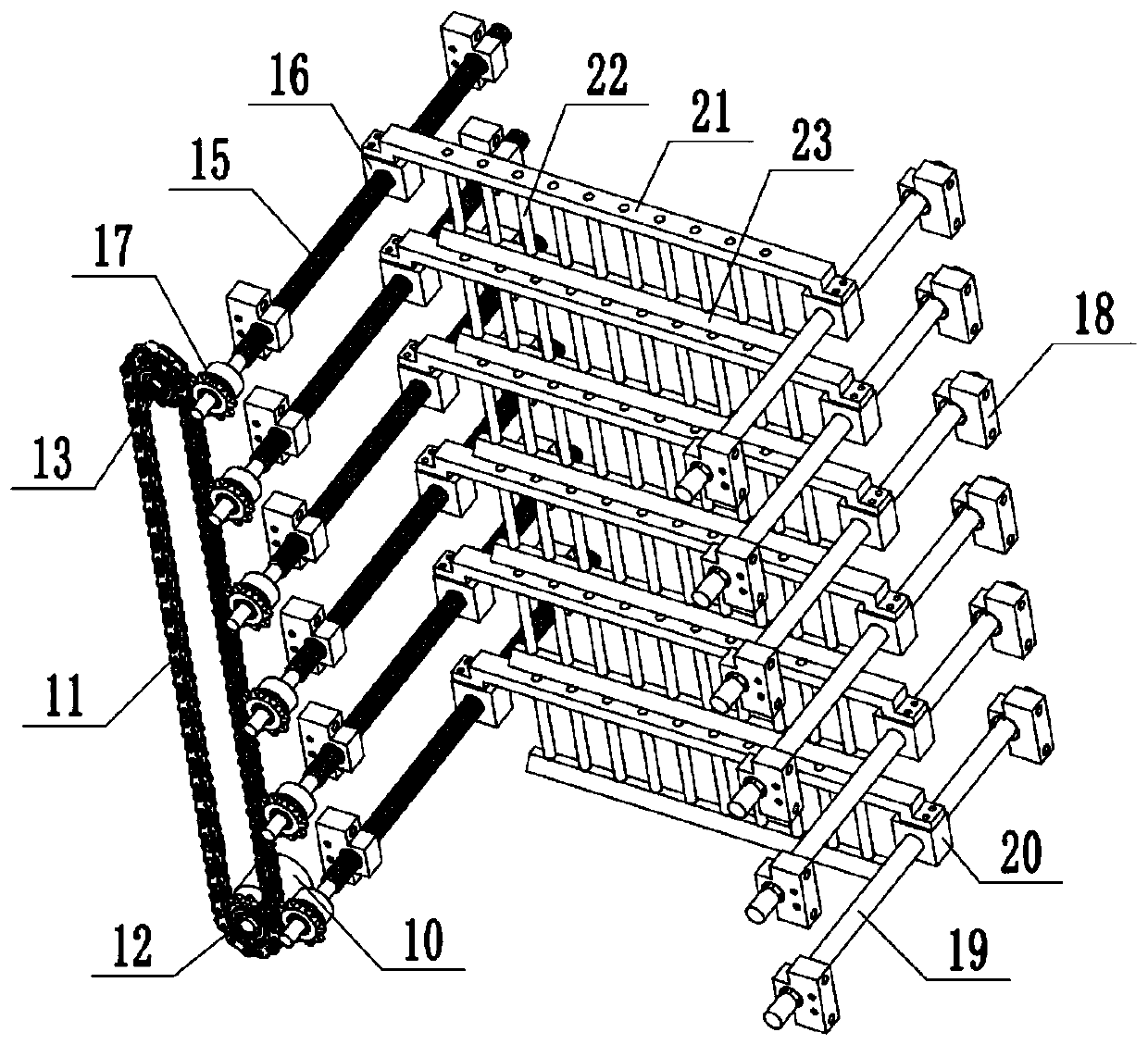

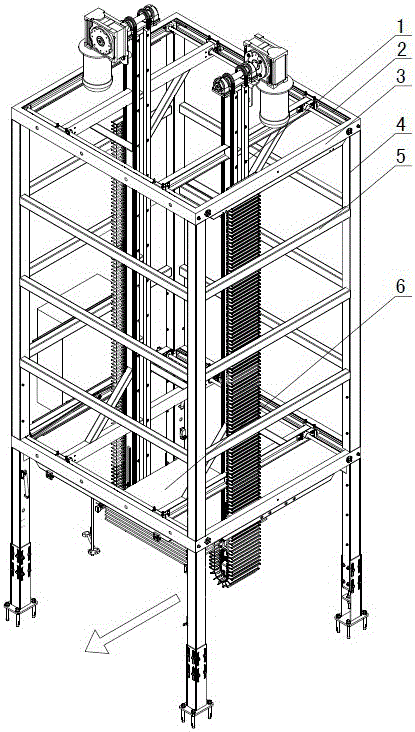

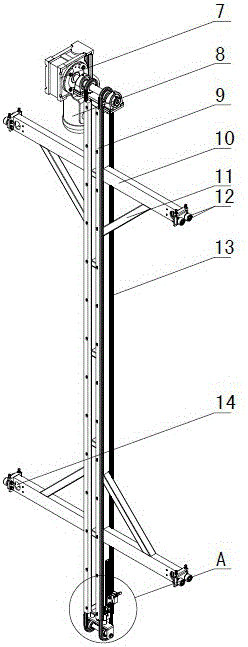

A tile lifting method for a tile temporary storage warehouse of a tile packaging line

The invention discloses a ceramic tile temporary tile storage warehouse of a ceramic tile packaging assembly line and a ceramic tile lifting method, and belongs to the field of ceramic tile packaging equipment. The warehouse is characterized by comprising a tile storage warehouse main frame, two ceramic tile lifting devices (1) are vertically arranged in the tile storage warehouse main frame, power units are arranged in the ceramic tile lifting devices (1), and drive chain lifting units vertically arranged on the ceramic tile lifting devices (1) to run, ceramic tile bearing and supporting mechanisms are arranged on the chain lifting units, ceramic tile bearing and supporting mechanisms on the ceramic tile lifting devices (1) are oppositely arranged and carry out bearing and supporting from two sides of ceramic tiles (6), and lifting or falling of the ceramic tiles (6) is achieved. According to the ceramic tile temporary tile storage warehouse of the ceramic tile packaging assembly line, detained ceramic tiles can be automatically borne, supported and lifted, large-amount detaining of the ceramic tiles in the packaging link can be effectively prevented, and in-order operation of production is ensured.

Owner:山东爱而生智能科技有限公司

Mechanical automation pressing device

ActiveCN106944520AHard textureGood insulation performanceShaping toolsEjection devicesEnergy consumptionAutomation

The invention discloses a mechanical automation pressing device comprising a device body. A first electric motor VEMTE is arranged at the bottom end of the device body and rotatably connected with one of second rotating shafts through a belt. The second rotating shafts are located at the two ends of a conveying device. A plurality of mould grooves are arranged on the upper side of the conveying device at same intervals. A sealing telescopic bottom groove is formed in the bottom end of each mould groove. A material groove is arranged on one side of a shell. A second electric motor VEMTE is installed on one side of the shell. One side of the second electric motor VEMTE is rotatably connected with first rotating shafts. A chain is wound on the outer sides of the first rotating shafts. A plurality of pressing heads are arranged on the outer side of the chain at same intervals. One side of the chain is rotatably connected with a pressing wheel. Operation is easy, mechanism energy consumption is little, and continuous working is carried out. An exhaust fan can pump out hot air inside the device body to cool the device body. Through matching of the first rotating shafts and the second rotating shafts, rapid and ordered production can be carried out, manual operation is not needed, and the risk of the production is reduced.

Owner:常熟市福鑫合金新材料有限公司

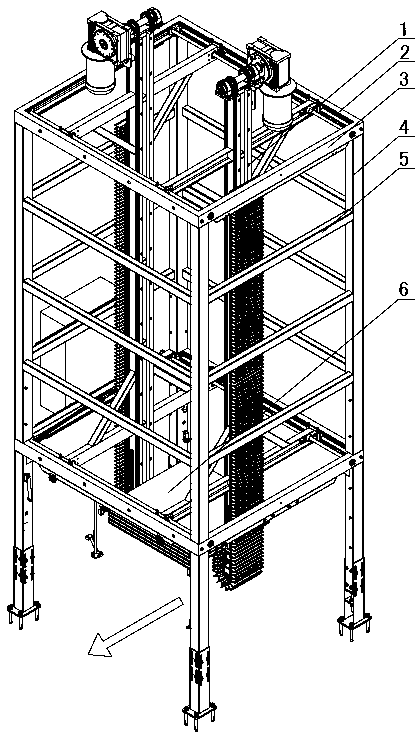

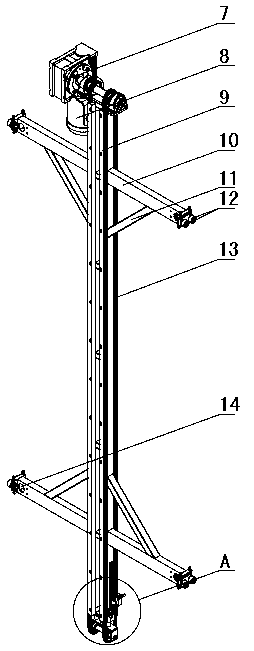

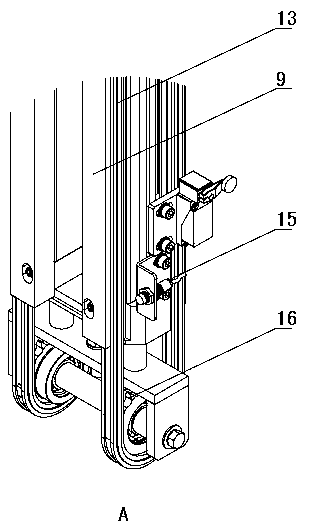

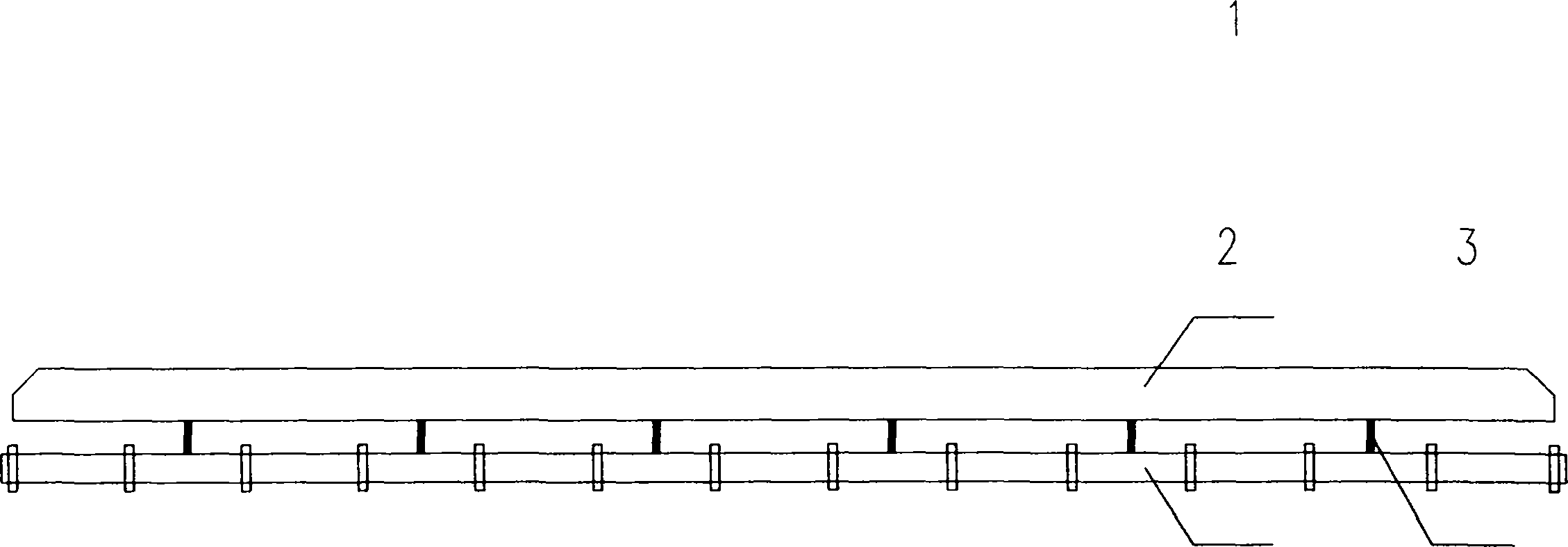

Ceramic tile temporary tile storage warehouse of ceramic tile packaging assembly line and ceramic tile lifting method

The invention discloses a ceramic tile temporary tile storage warehouse of a ceramic tile packaging assembly line and a ceramic tile lifting method, and belongs to the field of ceramic tile packaging equipment. The warehouse is characterized by comprising a tile storage warehouse main frame, two ceramic tile lifting devices (1) are vertically arranged in the tile storage warehouse main frame, power units are arranged in the ceramic tile lifting devices (1), and drive chain lifting units vertically arranged on the ceramic tile lifting devices (1) to run, ceramic tile bearing and supporting mechanisms are arranged on the chain lifting units, ceramic tile bearing and supporting mechanisms on the ceramic tile lifting devices (1) are oppositely arranged and carry out bearing and supporting from two sides of ceramic tiles (6), and lifting or falling of the ceramic tiles (6) is achieved. According to the ceramic tile temporary tile storage warehouse of the ceramic tile packaging assembly line, detained ceramic tiles can be automatically borne, supported and lifted, large-amount detaining of the ceramic tiles in the packaging link can be effectively prevented, and in-order operation of production is ensured.

Owner:山东爱而生智能科技有限公司

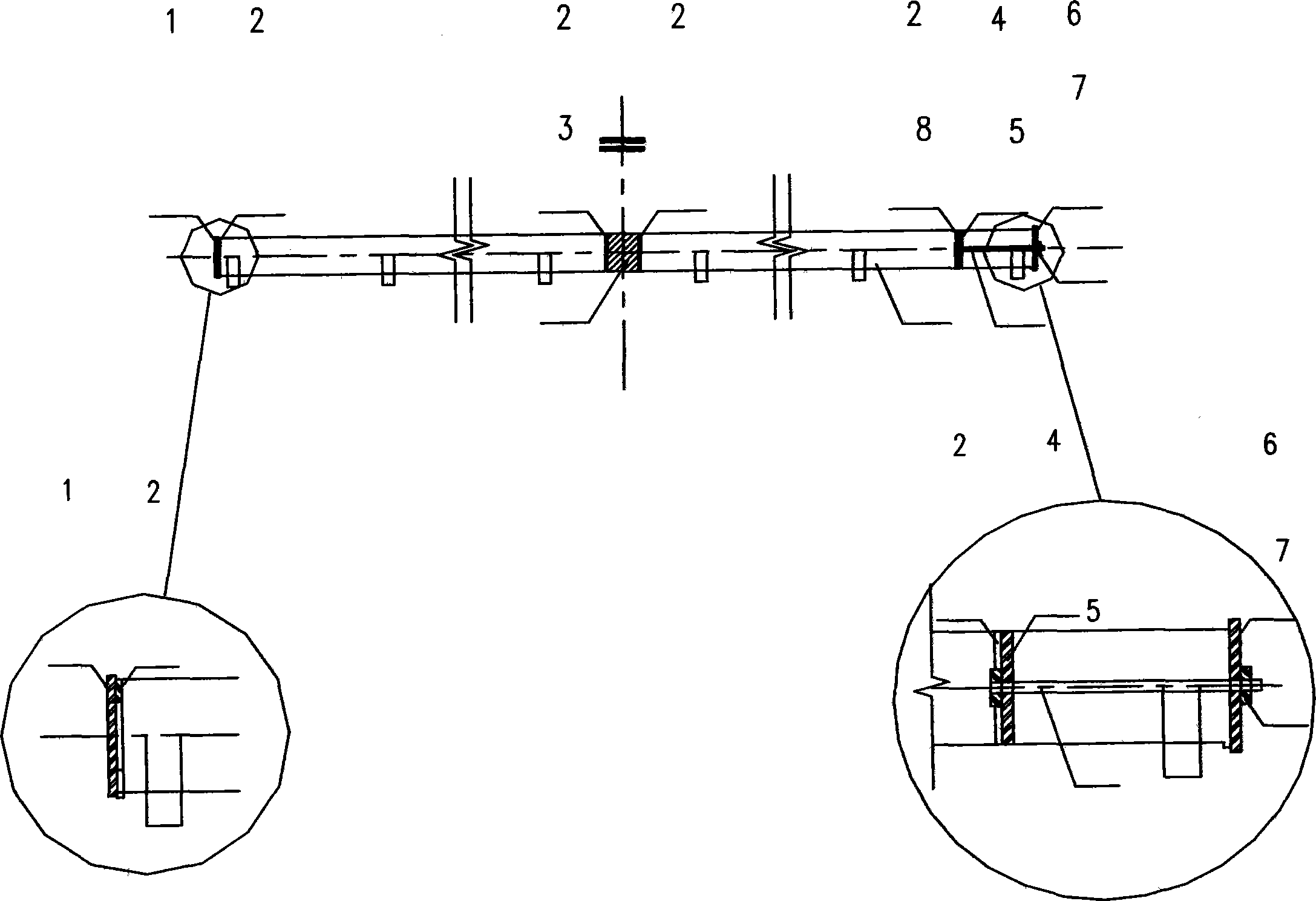

Method for producing precast concrete piles

InactiveCN102398305BSave spaceIncrease productivityMouldsCeramic shaping plantsProduction effectEngineering

The invention relates to a method for producing precast concrete piles, which comprises the following main steps of: manufacturing a reinforcement cage; placing the reinforcement cage into a die; pouring concrete into the die; centrifugally rotating; and carrying out steam curing. The method is characterized in that the die with the length of over 20 meters is adopted in the method; two or a plurality of precast concrete piles can be simultaneously produced by one die; upper and lower half dies of the die have a transporting mode of transversely moving in parallel in the direction vertical to the axis of a crane beam of a plant in the production process; and centrifugal equipment and a curing tank are transversely arranged in parallel in the direction vertical to the axis of the crane beam of the plant. Due to the adoption of the transverse flow production scheme of the long die, the production effect can be multiplied, the space occupied by the plant is greatly reduced, a great amount of lands are saved, the working efficiency is improved, and the production quality can be ensured.

Owner:NINGBO YIZHONG CONCRETE PILE +2

A control system and method for a bag filter

ActiveCN108379968BImprove cleaning efficiencyExtended service lifeGas treatmentDispersed particle filtrationSteelmakingAutomatic control

The invention discloses a control system and a control method of a bag-type dust remover. The system comprises a temperature sensor, a differential pressure sensor, an oxygen concentration sensor anda PLC (programmable logic controller); the temperature sensor is arranged in an inlet air flue and is in signal connection with the input end of the PLC; the differential pressure sensor is arranged at the top of the bag-type dust remover and is in signal connection with the input end of the PLC; the oxygen concentration sensor is arranged in a steel-making converter and is in signal connection with the input end of the PLC; and the output port of the PLC is connected with an offline valve, a bypass valve, a blowing pulse valve and a dust-removing fan of the bag-type dust remover as well as adust-removing valve arranged at the flue gas outlet of the steel-making converter. The system has the advantages of automatic detection and automatic control and can guarantee that the production is conducted normally and orderly; furthermore, the flue gas discharge situation is good.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Hazelnut peeling machine

The invention discloses a hazelnut huller, which relates to the field of crop hulling machines. A barrel body is provided with a feeding hole and discharging holes; a main shaft penetrates through the barrel body; a driving mechanism and a blower box are arranged at the two ends of the barrel body respectively; a sieve layer is arranged below the barrel body; the driving mechanism is connected with the main shaft and the sieve layer respectively; the sieve layer is provided with a lower layer outlet; a spiral propeller is arranged at a position on the main shaft corresponding to the feeding hole; chamfered teeth are arranged on the main shaft; the inner wall of the barrel body is provided with slats; the two discharging holes are formed in two sides of one end, which is far away from the feeding hole, of the barrel body respectively; a position, which corresponds to the discharging holes, of the barrel body is connected with a discharge door; a discharge door lever is connected with the barrel body through a lever and a spring; the sieve layer consists of double layers of sieves; and the blower box is a dual-suction air box. The invention aims to provide a hazelnut huller which is used for realizing rapid hulling of a large quantity of hazelnuts instead of labor force, is easy to operate, and contributes to increasing the hazelnut hulling efficiency.

Owner:佟成伟

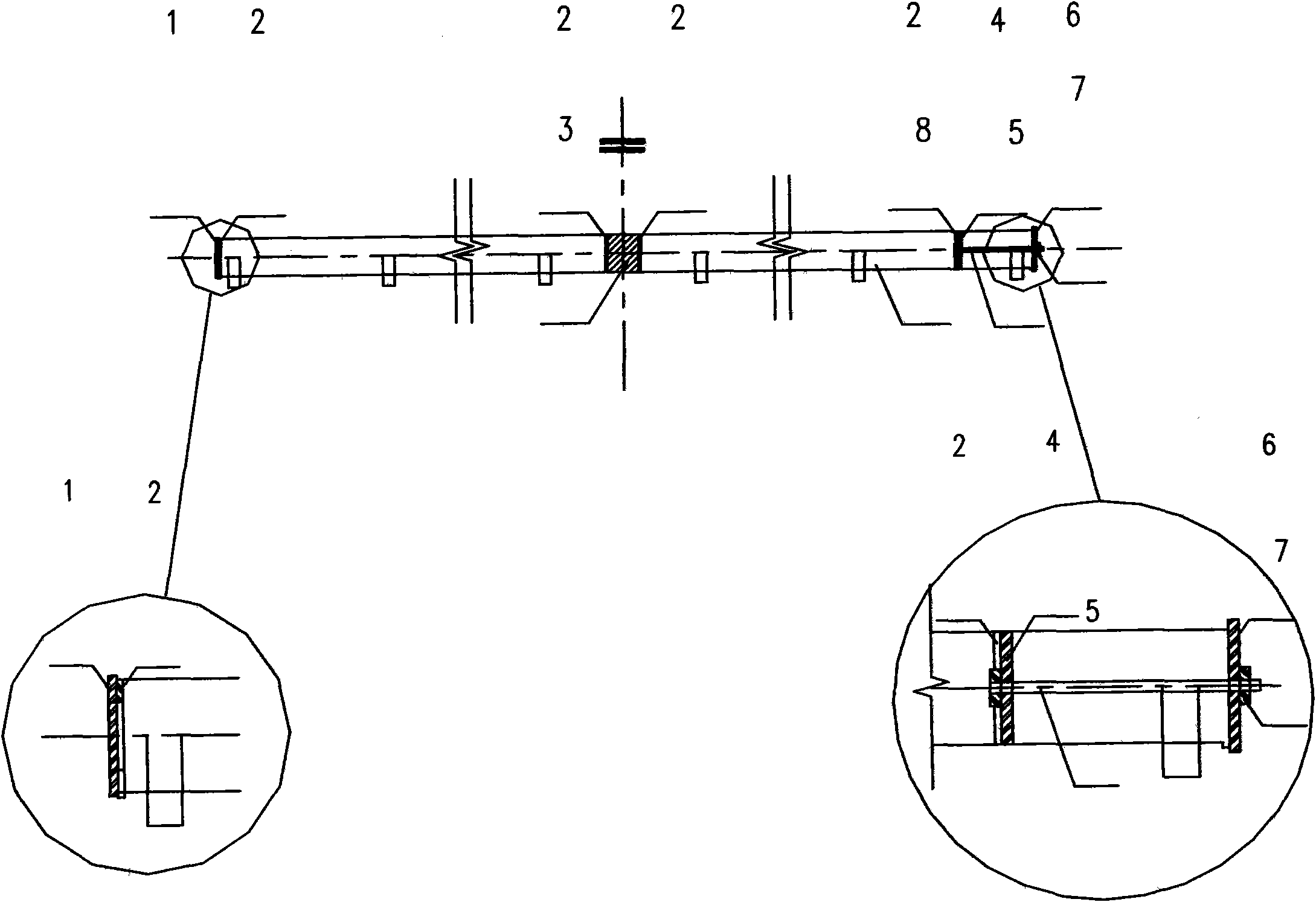

Stereo distribution and storage conveying device for power and free type suspension conveyer

InactiveCN100457583CRealize changing line conveyingRealize one-to-one correspondenceConveyorsBolt connectionTransfer line

The invention relates to an accumulation hanging transmitting machine solid branching and storing device, which is characterized in that: the accumulation hanging transmitting line is welded mounted; the movable rail is mounted at the feeding vehicle of accumulation hanging transmitting line; the upper vertical transmitting line or lower vertical transmitting line is welded connected to the accumulator hanging transmitting line; two parallel lines of parallel hanging transmitting line are individually welded connected to the accumulation hanging transmitting line, and via the bolt between them to mount, lift, rotate and clamp the claw; two end lifters are individually mounted at two ends of multilayer multi-row storage cycle line, to be welded on the steel structure of said line together, to connect the accumulation hanging transmitting line. The invention has the advantages that: solid transmission and storage; the lifting rotating device can clamp the upper and lower lines.

Owner:JIANGSU SUSHENG AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com