A control system and method for a bag filter

A technology of bag dust collector and control system, which is applied in the direction of chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of inability to monitor bag dust removal conditions well, achieve good flue gas emission conditions, improve dust cleaning efficiency, save The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (the bag filter is the structure of two warehouses):

[0028] A control method of a bag filter for a flue gas dust removal system of a steelmaking converter, comprising the following steps:

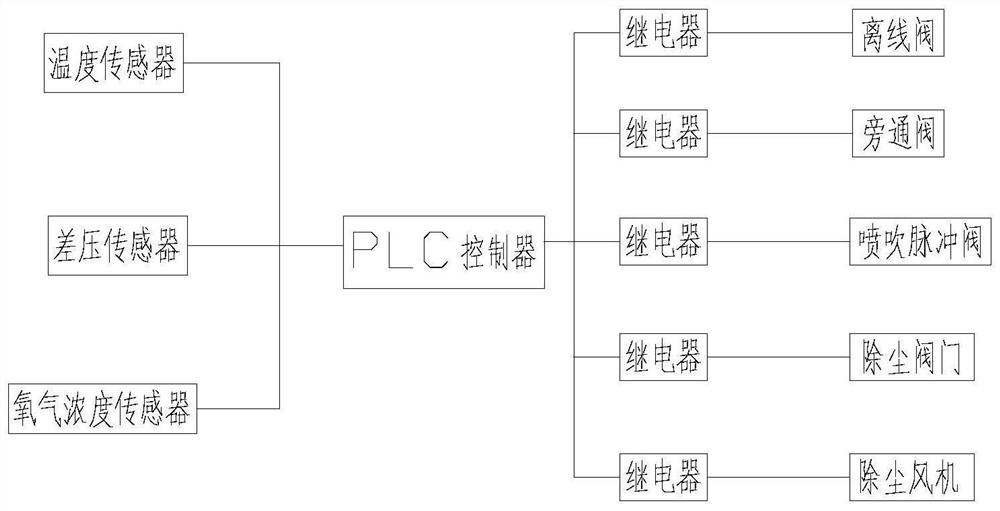

[0029] (1) Signal detection: The temperature sensor detects the temperature of the flue gas entering the bag filter, the differential pressure sensor detects the pressure difference between the inlet and outlet of the bag filter, and the oxygen concentration sensor detects the oxygen concentration in the steelmaking converter;

[0030] (2) Signal comparison: The PLC controller receives the temperature signal of the temperature sensor, the differential pressure signal of the differential pressure sensor and the oxygen concentration signal of the oxygen concentration sensor, and compares it with the set value to see whether it is close to or exceeds the set value;

[0031] (3) Action:

[0032] A. When the temperature exceeds or is lower than the set value, the PLC contr...

Embodiment 2

[0035] Embodiment 2 (the bag filter is the structure of three warehouses):

[0036] A control method of a bag filter for a flue gas dust removal system of a steelmaking converter, comprising the following steps:

[0037] (1) Signal detection: The temperature sensor detects the temperature of the flue gas entering the bag filter, the differential pressure sensor detects the pressure difference between the inlet and outlet of the bag filter, and the oxygen concentration sensor detects the oxygen concentration in the steelmaking converter;

[0038] (2) Signal comparison: The PLC controller receives the temperature signal of the temperature sensor, the differential pressure signal of the differential pressure sensor and the oxygen concentration signal of the oxygen concentration sensor, and compares it with the set value to see whether it is close to or exceeds the set value;

[0039] (3) Action:

[0040] A. When the temperature exceeds or is lower than the set value, the PLC con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com