Patents

Literature

41results about How to "Affect the effect of dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

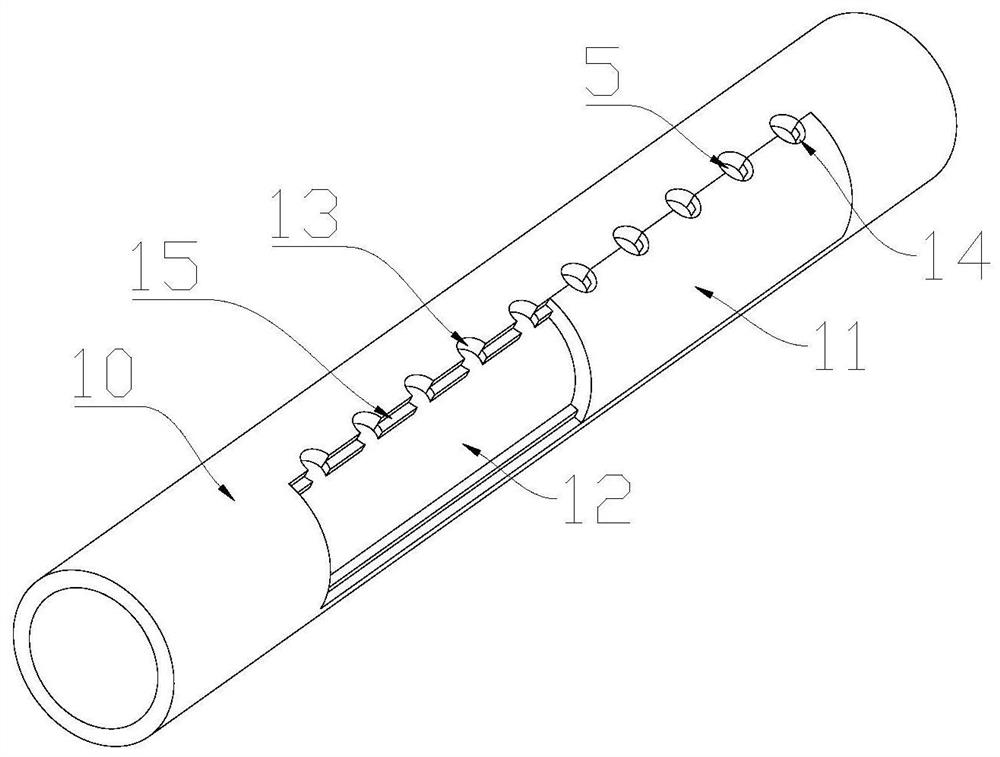

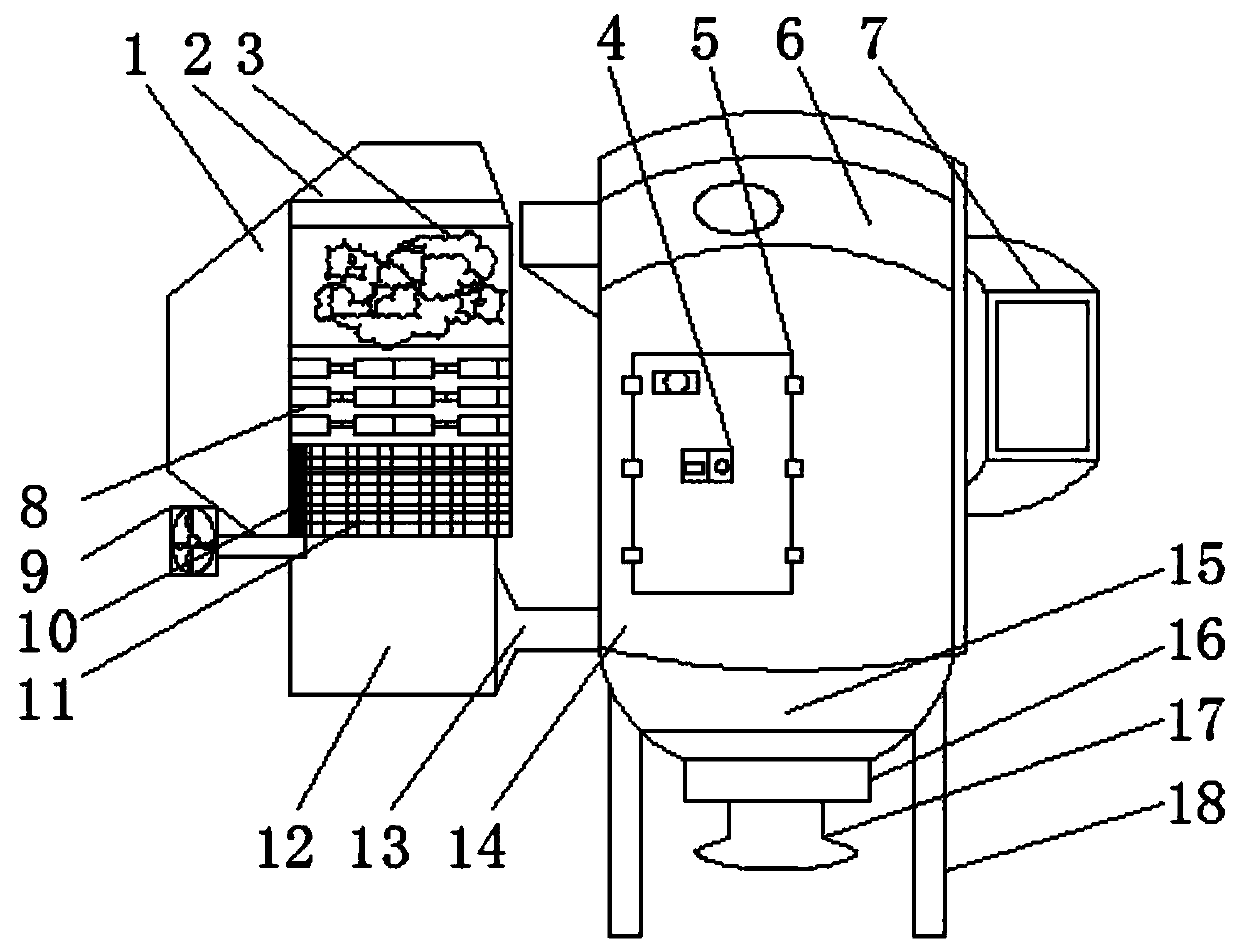

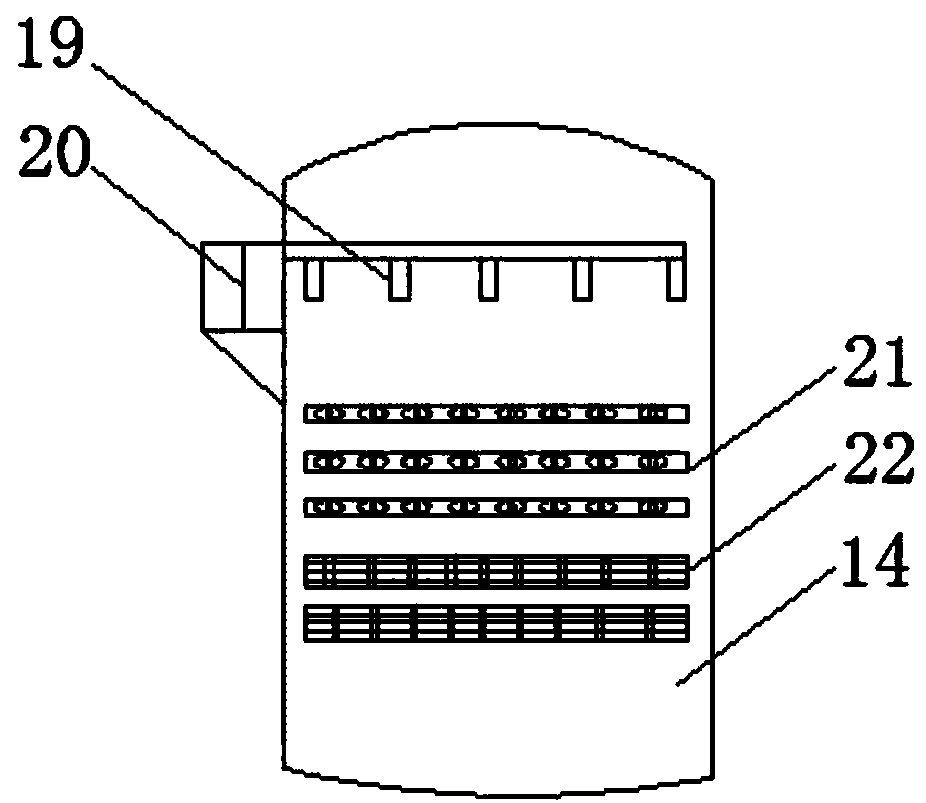

Electric automation dedusting equipment

InactiveCN108311284AAutomatic collectionAffect the effect of dust removalExternal electric electrostatic seperatorElectrodes cleaningActivated carbonMotor drive

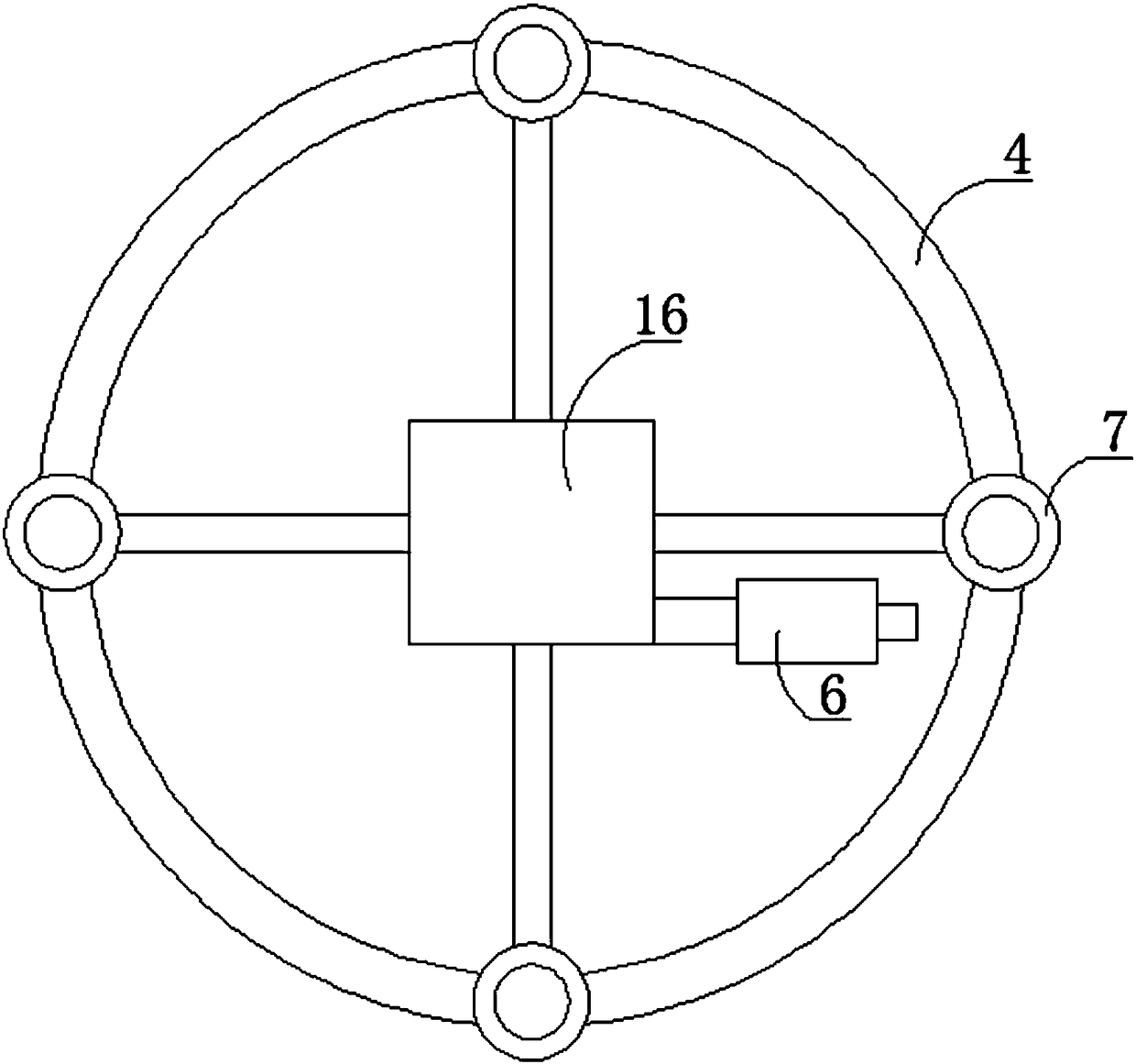

The invention discloses electric automation dedusting equipment. The electric automation dedusting equipment comprises a cylinder, a first fan, a corona electrode, a motor, a dust collection electrode, a conductive piece, a brush, a second fan and an activated carbon plate. The electric automation dedusting equipment has the advantages that by arranging the cylinder, the motor, a power source, thecorona electrode, the conductive piece and the dust collection electrode, an output shaft of the motor drives the dust collection electrode to rotate through a connecting rod; when the dust collection electrode is moved to touch the conductive piece at the right side wall of the cylinder, the dust is moved to the dust collection electrode and is adsorbed to the surface of the dust collection electrode; when the dust collection electrode adsorbing the dust continues to move to the left side of the cylinder and disengage from the conductive piece, the dust collection electrode is deenergized, the dust falls down and falls into a dust collection box through a dust discharge pipe, and the dust is removed by static electricity, so that the purifying efficiency is high, and the gas treatment range is large; the dust on the dust collection electrode is brushed off by the brush, so as to avoid the influence to the dedusting effect and the service life of the equipment due to accumulation of dust on the dust collection electrode along with the dedusting operation of the building; the dust can be automatically collected, and the working efficiency is high.

Owner:重庆峰创科技有限公司

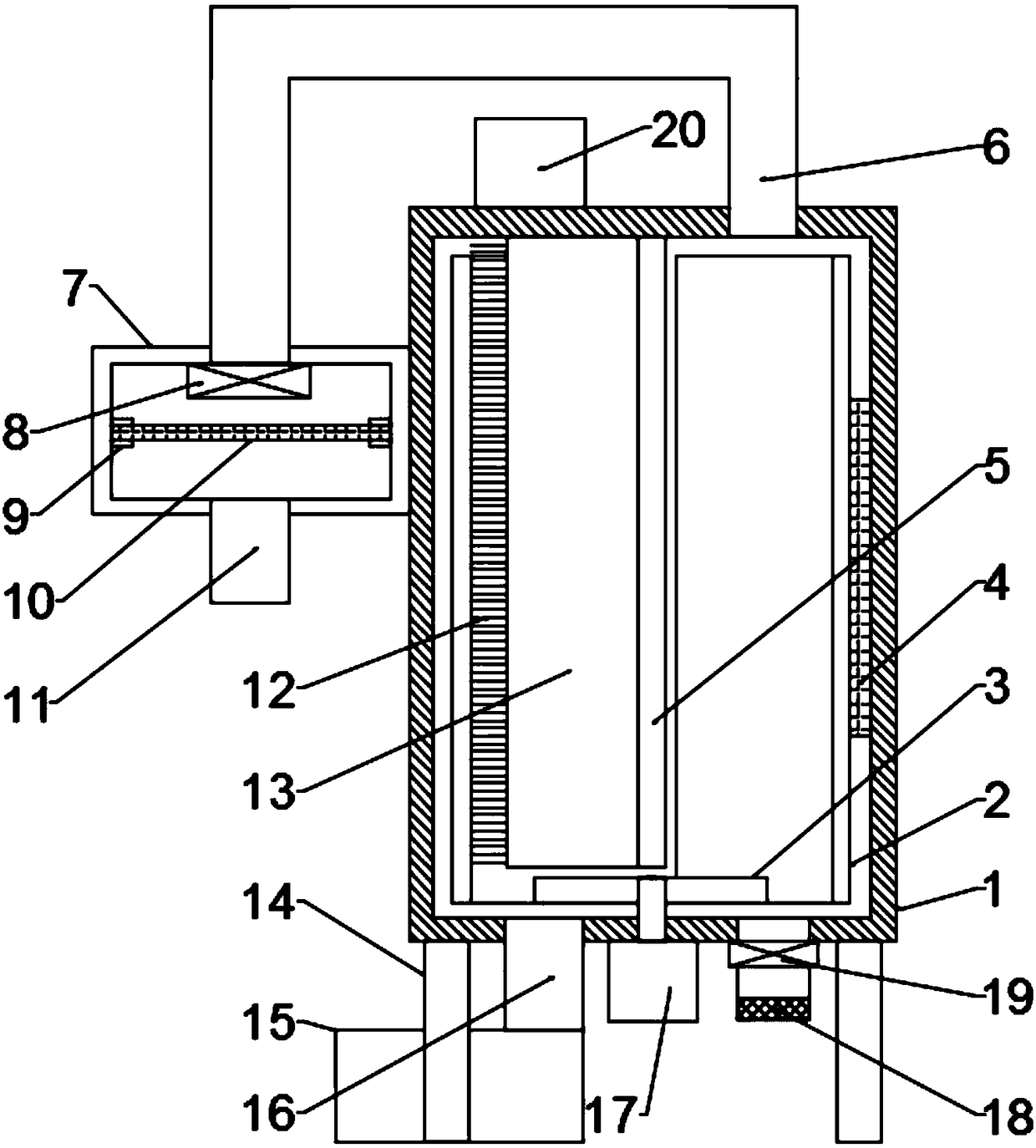

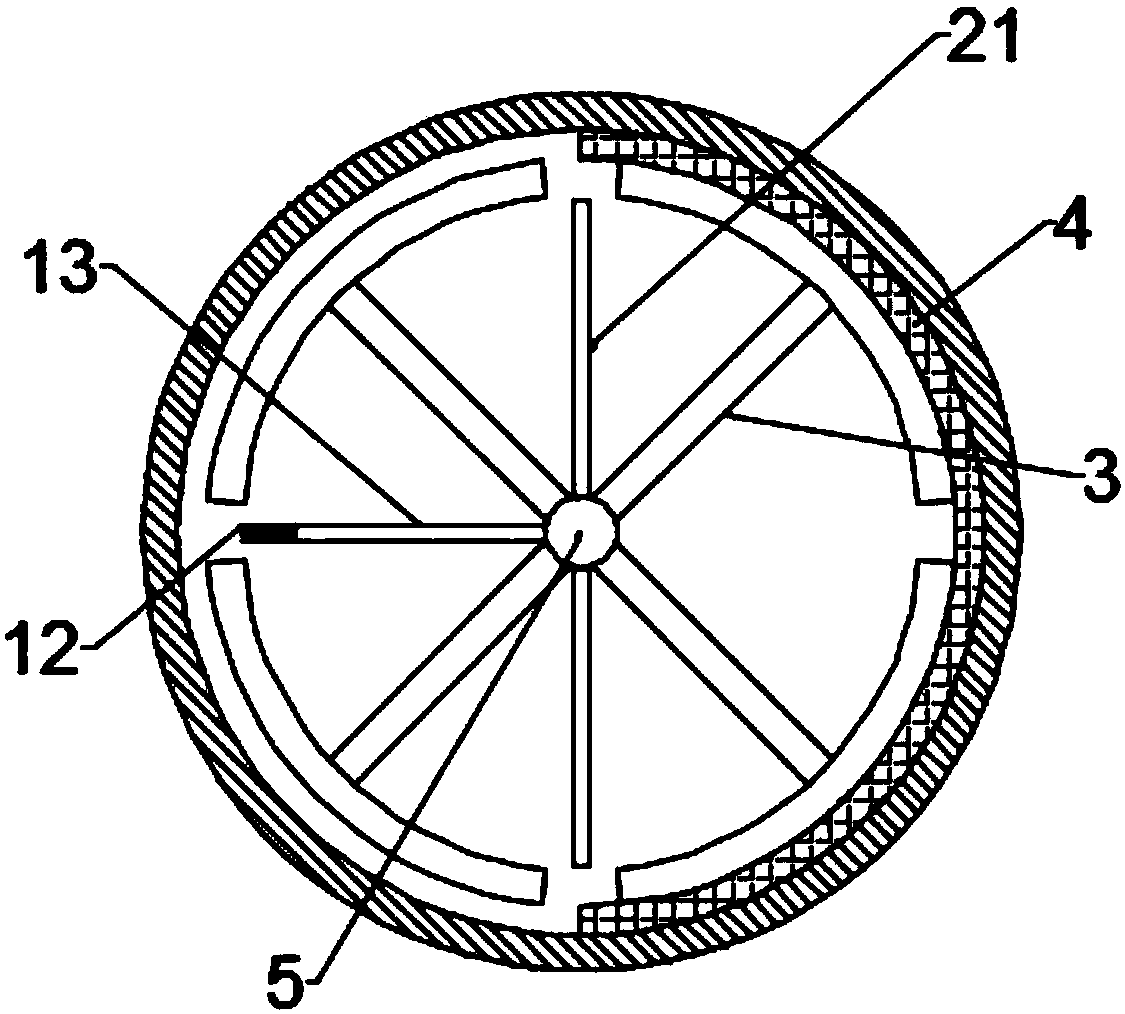

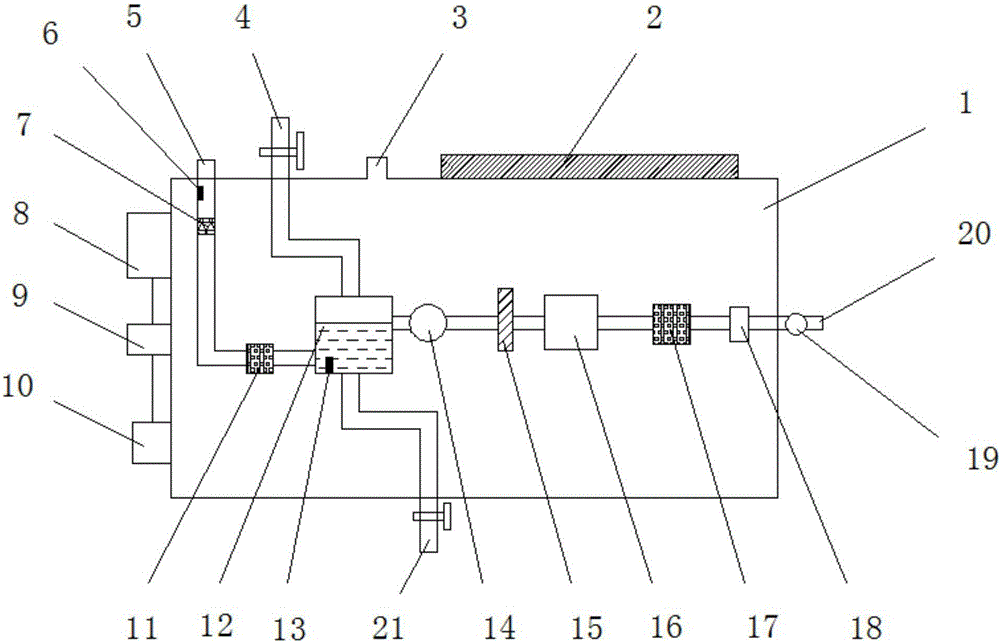

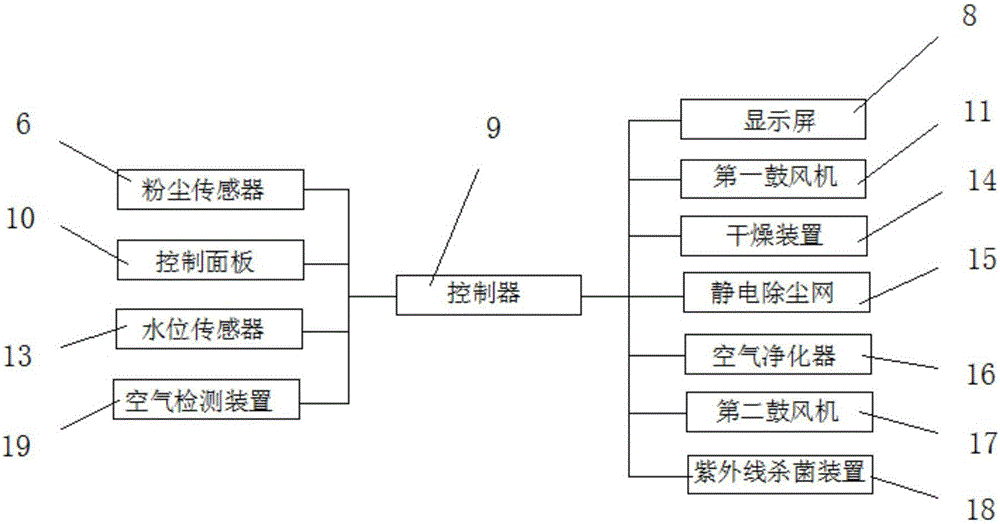

Electrical automation dust removal device

InactiveCN106268151AReasonable designAffect the effect of dust removalCombination devicesRadiationAir purifiersEngineering

The invention discloses an electrical automation dust removal device. The electrical automation dust removal device comprises a shell, an air inlet and an air outlet. The air inlet is formed in the top end of the shell, provided with a dust concentration sensor and a filter screen and connected with a first air blower, a water tank, a drying device, an electrostatic dust removal screen, an air purifier, a second air blower, an ultraviolet sterilization device and the air outlet in sequence through pipelines. The top end of the water tank is communicated with a water inlet through a water pipe, and the bottom end of the water tank is communicated with a water outlet through a water pipe. A display screen, a controller and a control panel are installed on the outer side of the shell. The display screen, the control panel, the dust concentration sensor, the first air blower, the drying device, the electrostatic dust removal screen, the air purifier, the second air blower and the ultraviolet sterilization device are electrically connected with the controller through wires. The electrical automation dust removal device is reasonable in design, high in automation degree and good in dust removal effect and can be widely used and popularized.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

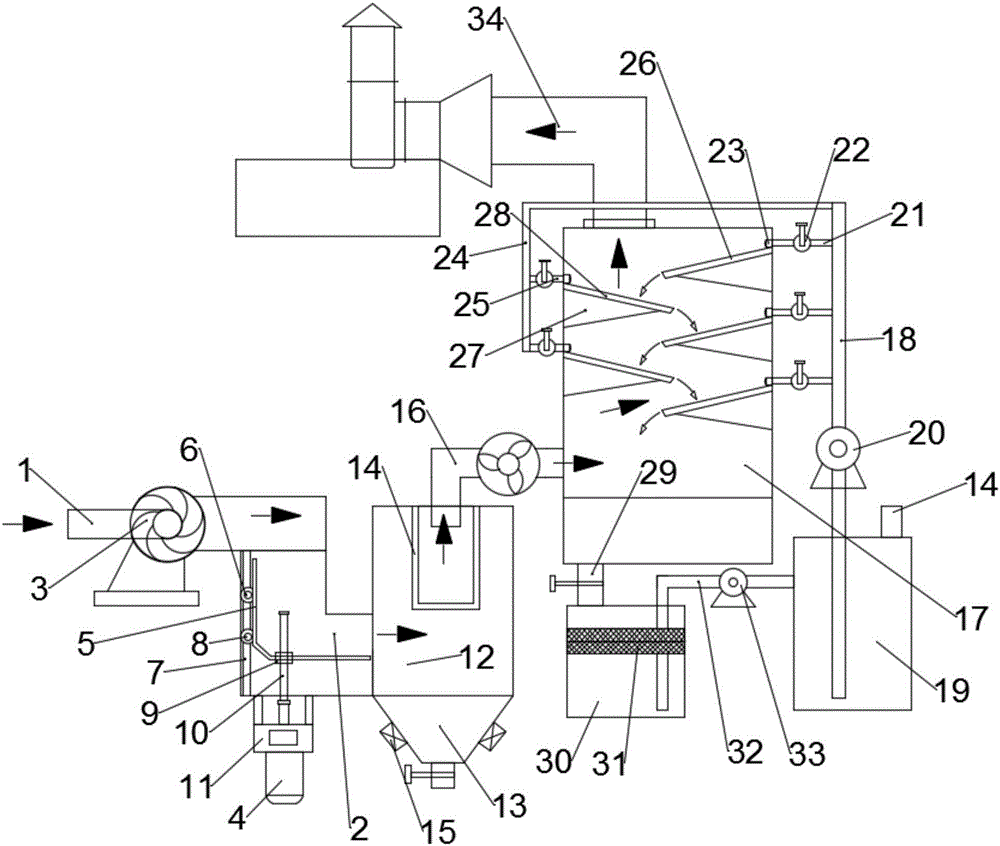

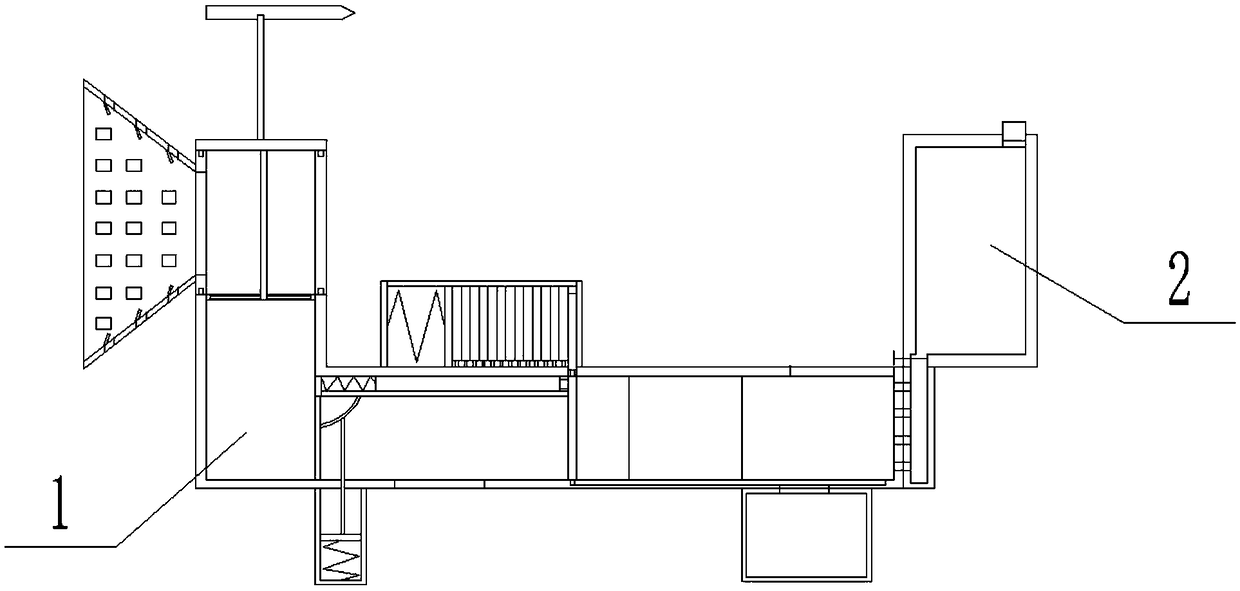

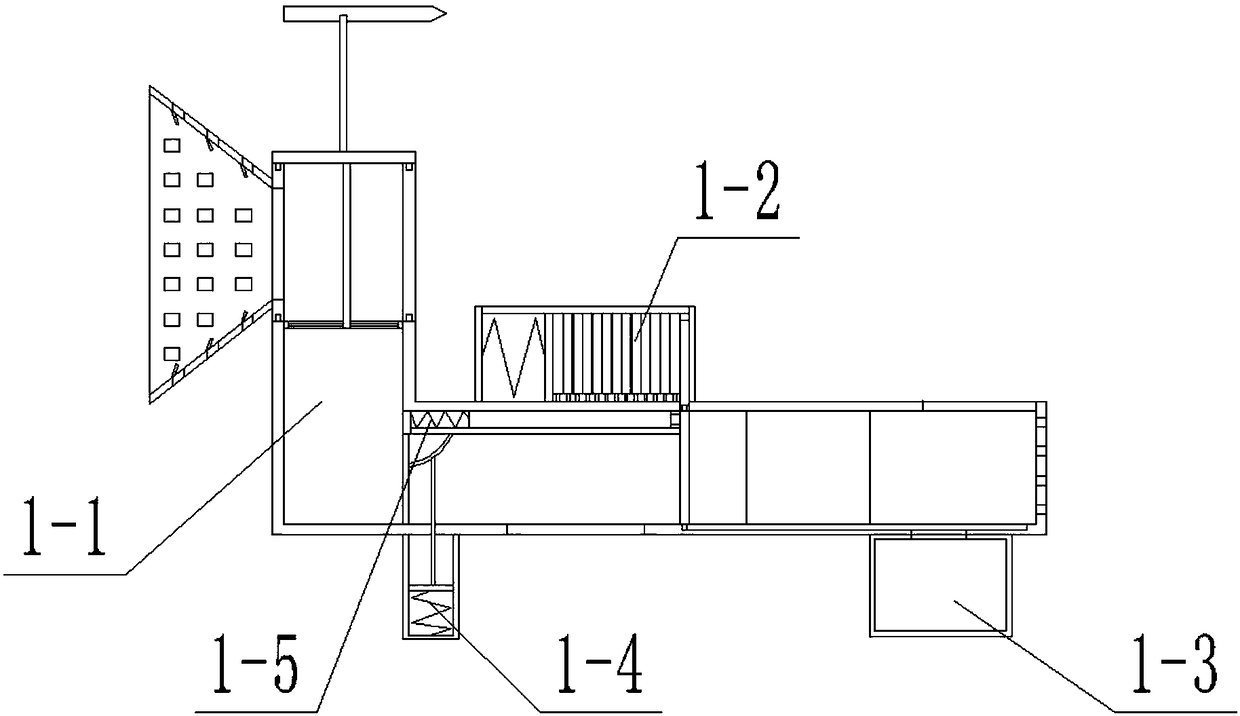

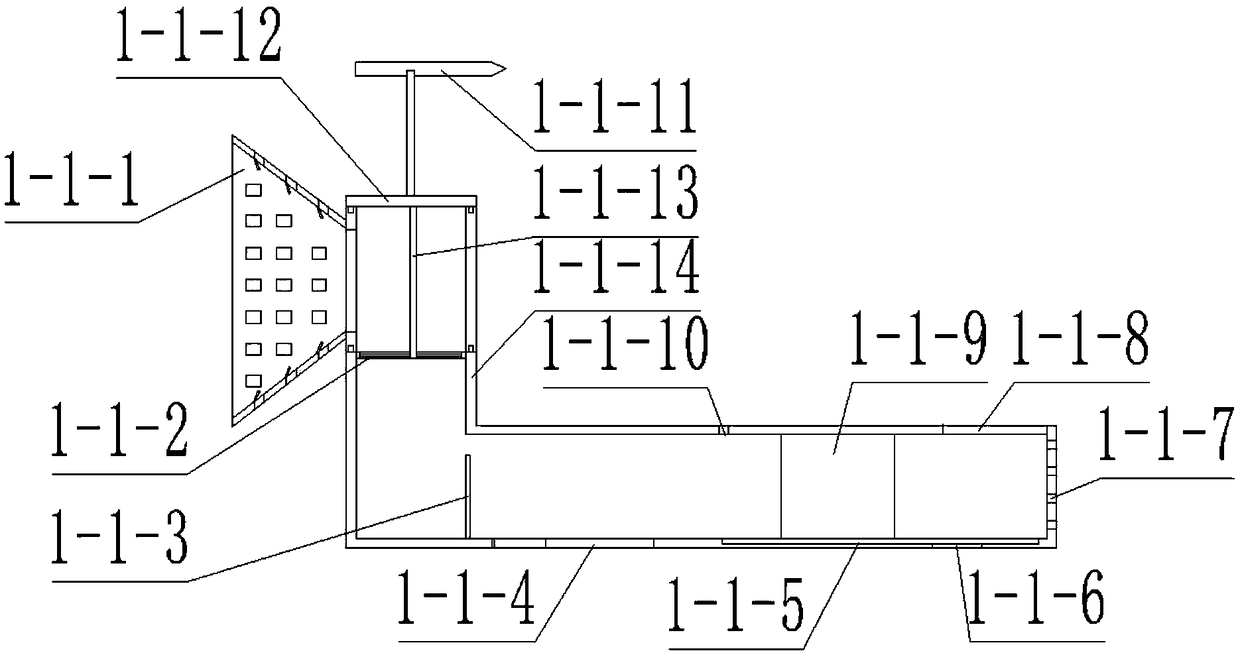

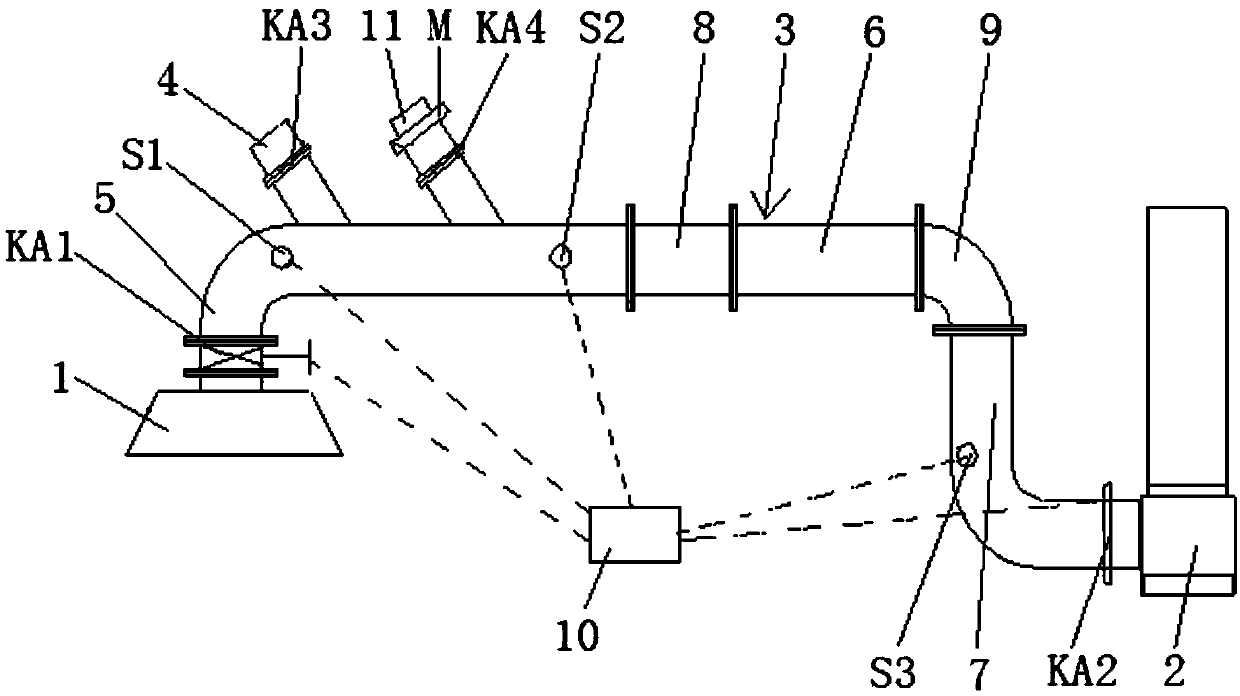

Water curtain check-type super-purification smoke exhaust dedusting and desulfurization system

InactiveCN106693650AAffect the effect of dust removalAffect the purification effectCombination devicesGas treatmentExhaust fumesEngineering

The invention discloses a water curtain check-type super-purification smoke exhaust dedusting and desulfurization system, which comprises a smoke exhaust inlet tube, wherein the end part of the smoke exhaust inlet tube is connected to a flow rate control tube; the left side wall of a tube body of the flow rate control tube is provided with a guide rail; the internal thread of a lifting nut is adaptively provided with a rotating screw rod; two side walls of a conical extrusion cavity are respectively provided with one vibrating motor; the left side wall of the upper side of an inner cavity in a case body of an ultra-clean desulfuration case is provided with first diversion water curtain boards; the two first diversion water curtain boards and three second diversion water curtain boards are staggered; the bottom end of a tube body of a drainage through tube is communicated with a circulating filter box pump. The system is capable of solving the problem of weakened desulfuration effect caused by uncontrollable smoke feeding velocity in a traditional process, ensuring that sulfides in the smoke are fully absorbed and removed and the treated solvent also can be recycled, and further saving the solvent resource.

Owner:合肥图腾龙企业管理事务所(有限合伙)

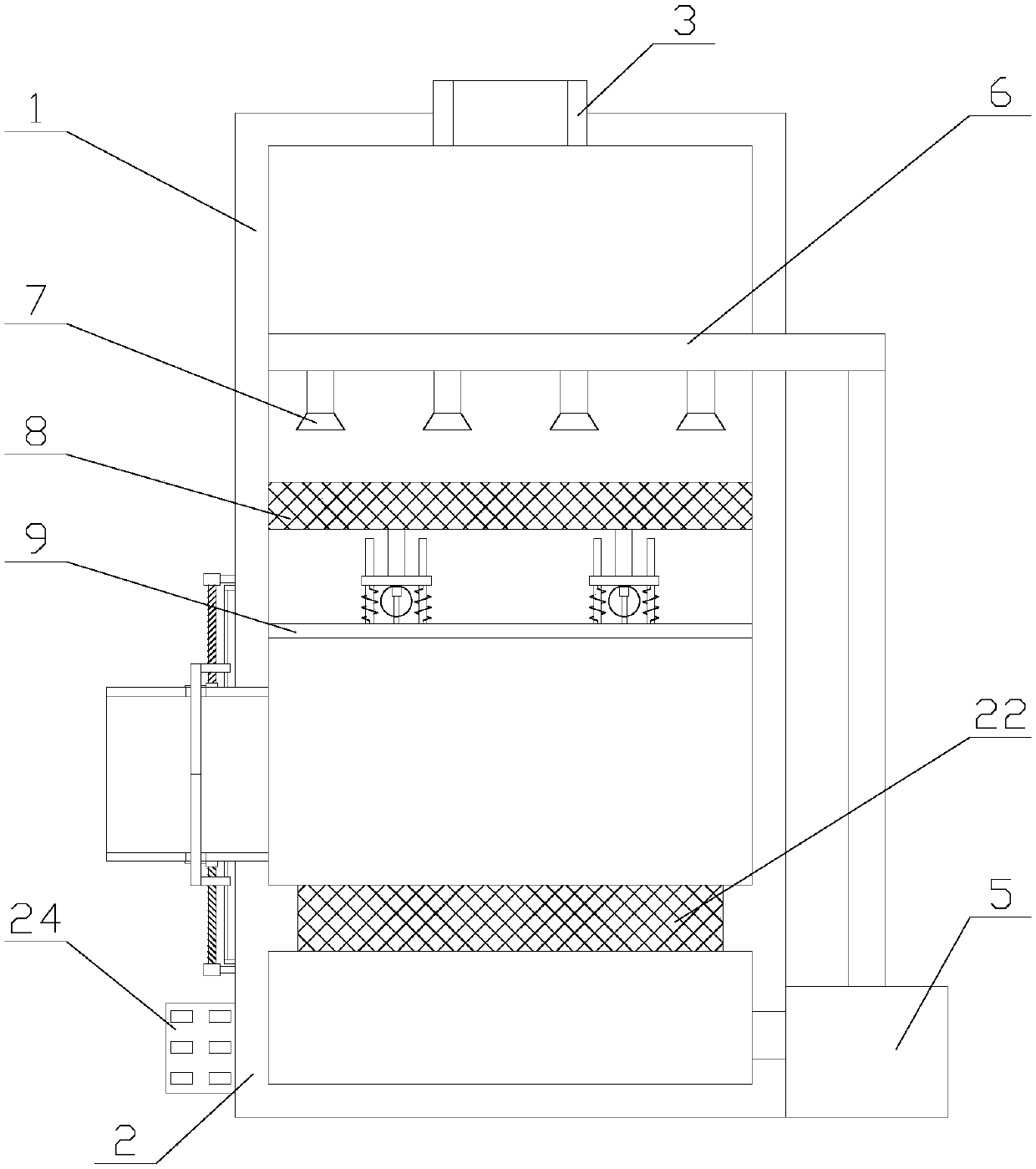

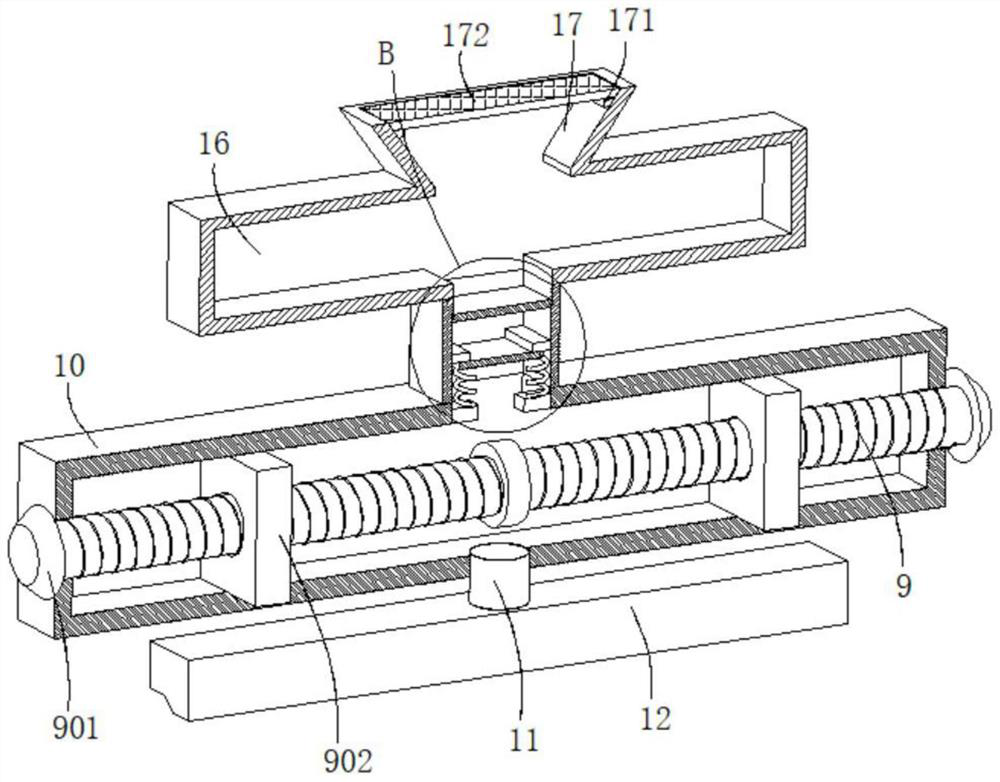

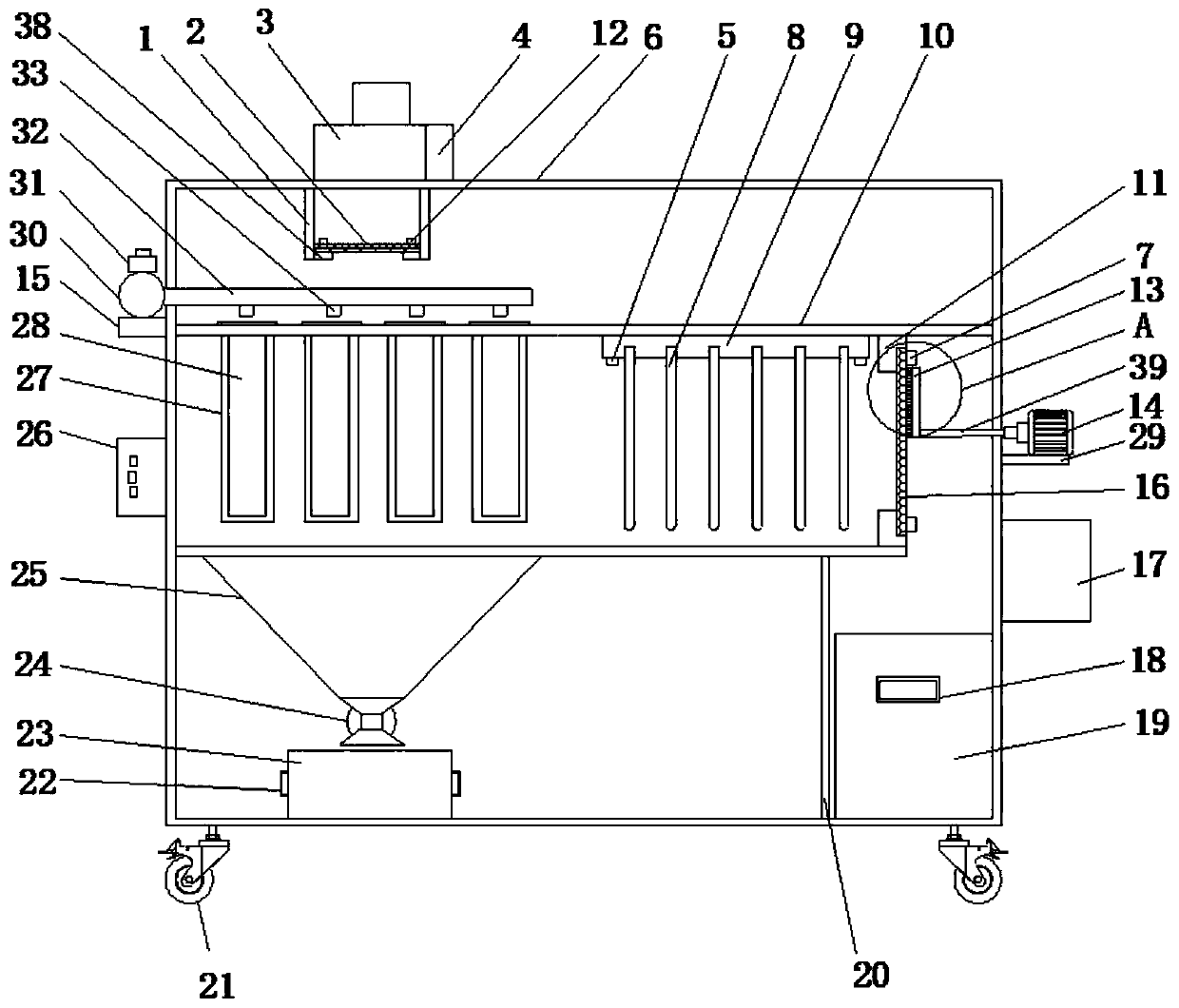

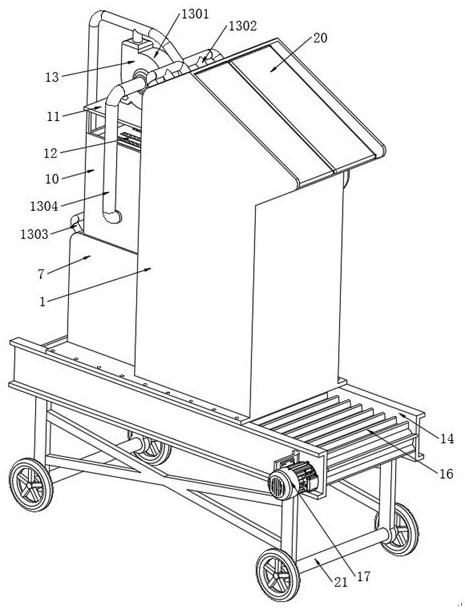

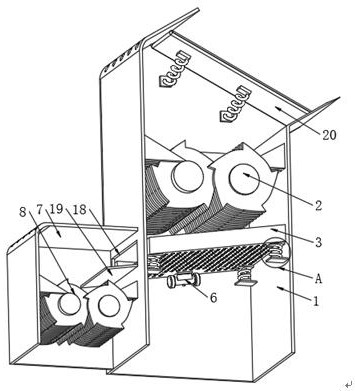

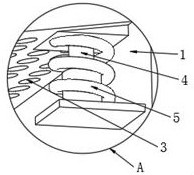

Efficient spraying tower with anti-blocking function for waste gas treatment

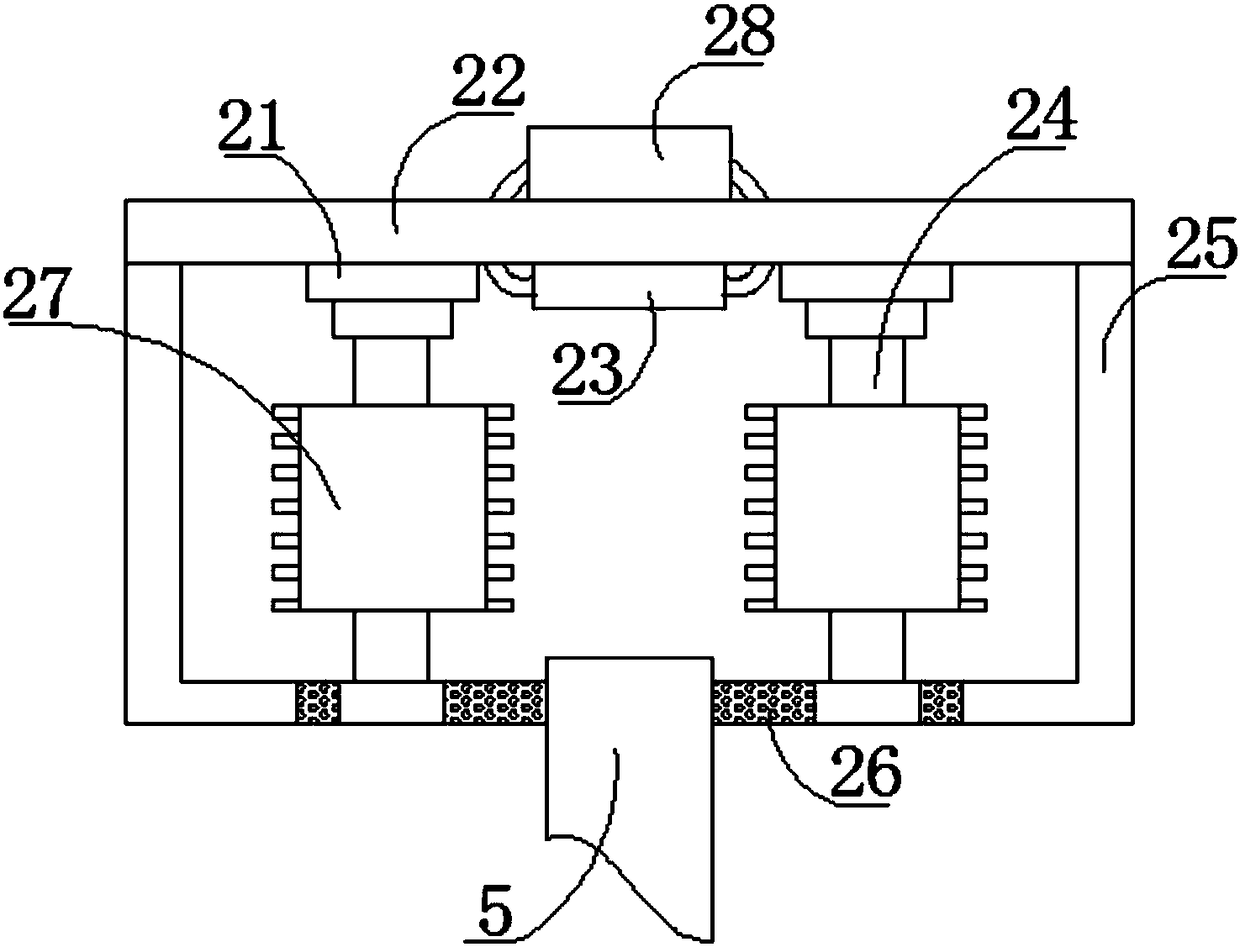

ActiveCN109603373AControl feedAffect the effect of dust removalGas treatmentUsing liquid separation agentSludgeLiquid storage tank

The invention relates to an efficient spraying tower with an anti-blocking function for waste gas treatment. The efficient spraying tower comprises a tower body, an air inlet, an air outlet, a fillerlayer, a spraying mechanism, a controller and a liquid storage tank, and further comprises a dredging mechanism and an adjusting mechanism. The dredging mechanism comprises a supporting rod and two vibrating assemblies; each vibrating assembly comprises a first motor, a supporting rod, an eccentric wheel, a moving plate, a vibrating rod and two springs; the adjusting mechanism comprises two adjusting assemblies, and each adjusting assembly comprises a baffle and a moving unit; each moving unit comprises a second motor, a fixed block, a rotating shaft and a movable block. According to the efficient spraying tower with the anti-blocking function for waste gas treatment, the filler layer can be dredged through the dredging mechanism, the filler layer is prevented from being blocked by sludge,and the dust removal effect is prevented from being affected; through the adjusting mechanism, the amount of waste gas can be controlled so that the waste gas and reagents can be in full contact, andthe dust removal effect is improved.

Owner:蒋宗霞

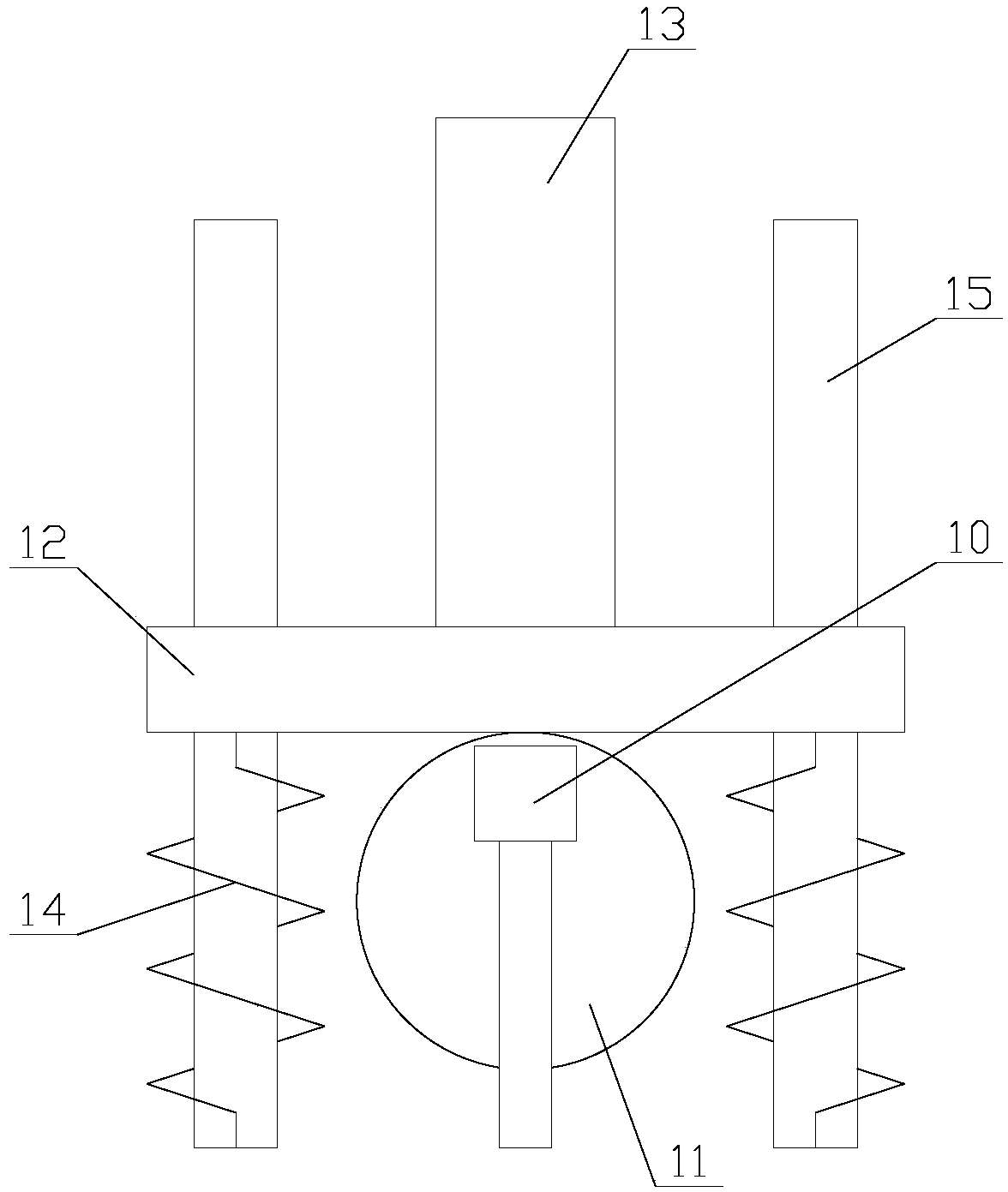

Efficient automatic waste gas treatment method

ActiveCN113019042ATo achieve the purpose of dust removalAffect the effect of dust removalCombination devicesDispersed particle filtrationParticulatesWater source

The invention relates to waste gas treatment, and discloses an efficient automatic waste gas treatment method. The treatment method is based on waste gas treatment equipment. The treatment equipment comprises a water tank, a bottom box is welded to the surface of the water tank, a dust removal mechanism is arranged in the bottom box, a vertical plate is welded in the water tank, a crushing mechanism is arranged on the rear wall of the water tank, a spraying mechanism is arranged on the bottom wall of the water tank and located on the right side of the vertical plate, and the right side of the vertical plate is fixedly connected with the inner wall of the water tank through a transverse plate. According to the waste gas treatment equipment with a dust removal function and the use method thereof, waste gas can be subjected to preliminary dust removal through a water source to reduce the existence rate of dust in the waste gas, then the waste gas is conveyed into the bottom box and a dust removal pipe through an air pump, the waste gas subjected to dust removal through a water adsorption method is filtered again through a filter screen, a filter plate and a filter box, and therefore, particulate matters in the waste gas are reduced again, and the purpose of removing dust from the waste gas is achieved.

Owner:湖南利苍环保科技有限公司

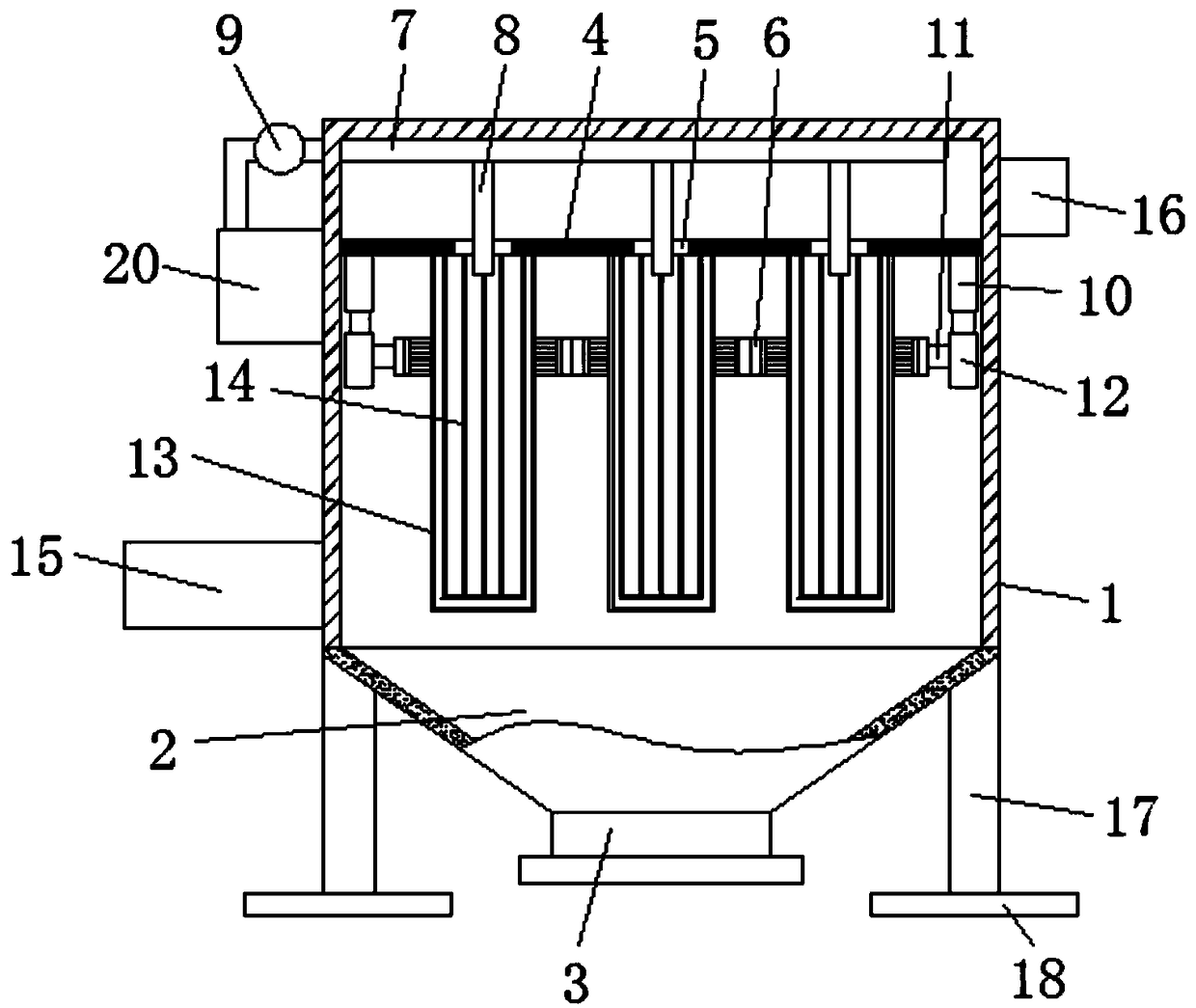

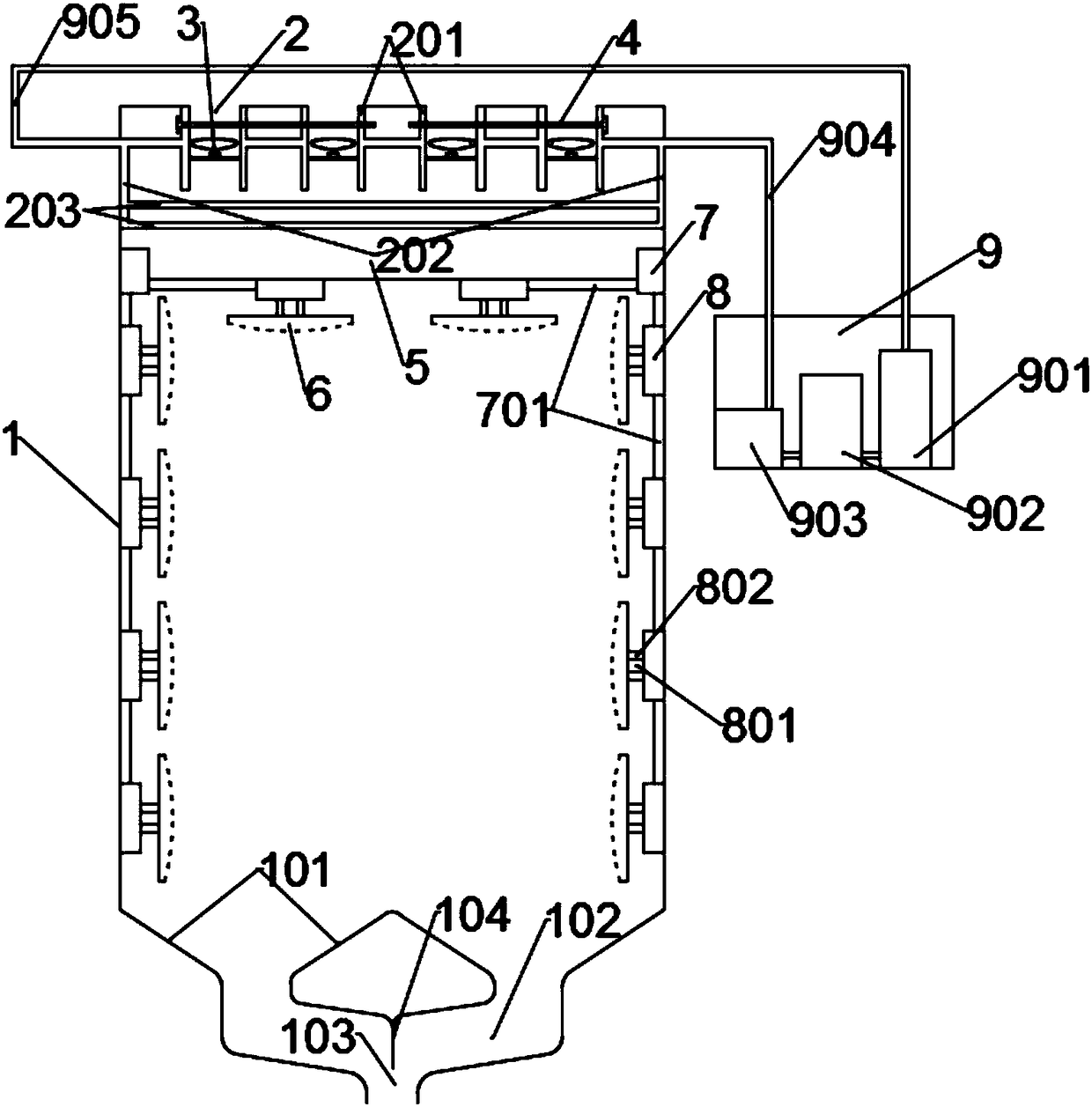

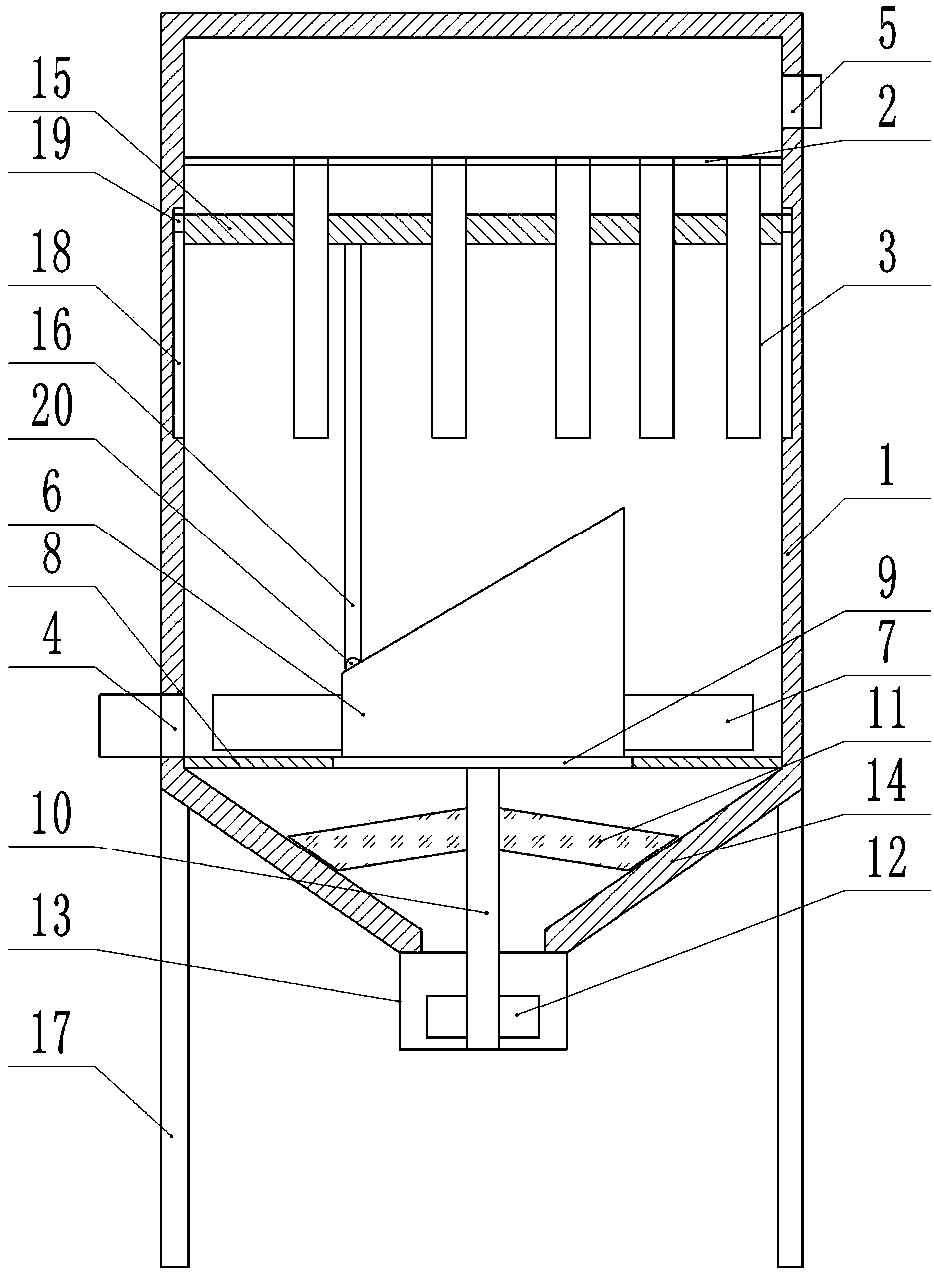

Bag-type dust collector

PendingCN108854299AAffect work efficiencyAffect the effect of dust removalDispersed particle filtrationAir filterBaghouse

The invention relates to the technical field of dust collecting equipment, particularly relates to a bag-type dust collector, which comprises a box body. The bottom wall of the box body is fixedly provided with a dust collecting bin in a penetrating manner, one side, away from the box body, of the dust collecting bin is fixedly provided with a dust discharging opening, the dust collecting bin on two sides of the dust discharging opening is provided with supporting devices, the upper end of the interior of the box body is horizontally and fixedly provided with a separation plate which is used for dividing the interior of the box body into an air filtering chamber and a dust chamber in sequence, the side wall of the box body on one side of the air filtering chamber is provided with a gas discharging pipe in the penetrating manner, the side wall of the box body on one side of the dust chamber is provided with a gas feeding pipe in the penetrating manner, cloth bags are vertically arrangedin the dust chamber at interval. According to the bag-type dust collector, the dust adsorbed on the cloth bags are cleaned, the dust is prevented from adsorbing on the surface of the cloth bag, so that the working efficiency and the dust collecting effect of the bag-type dust collector are improved.

Owner:广东青蓝环保科技有限公司

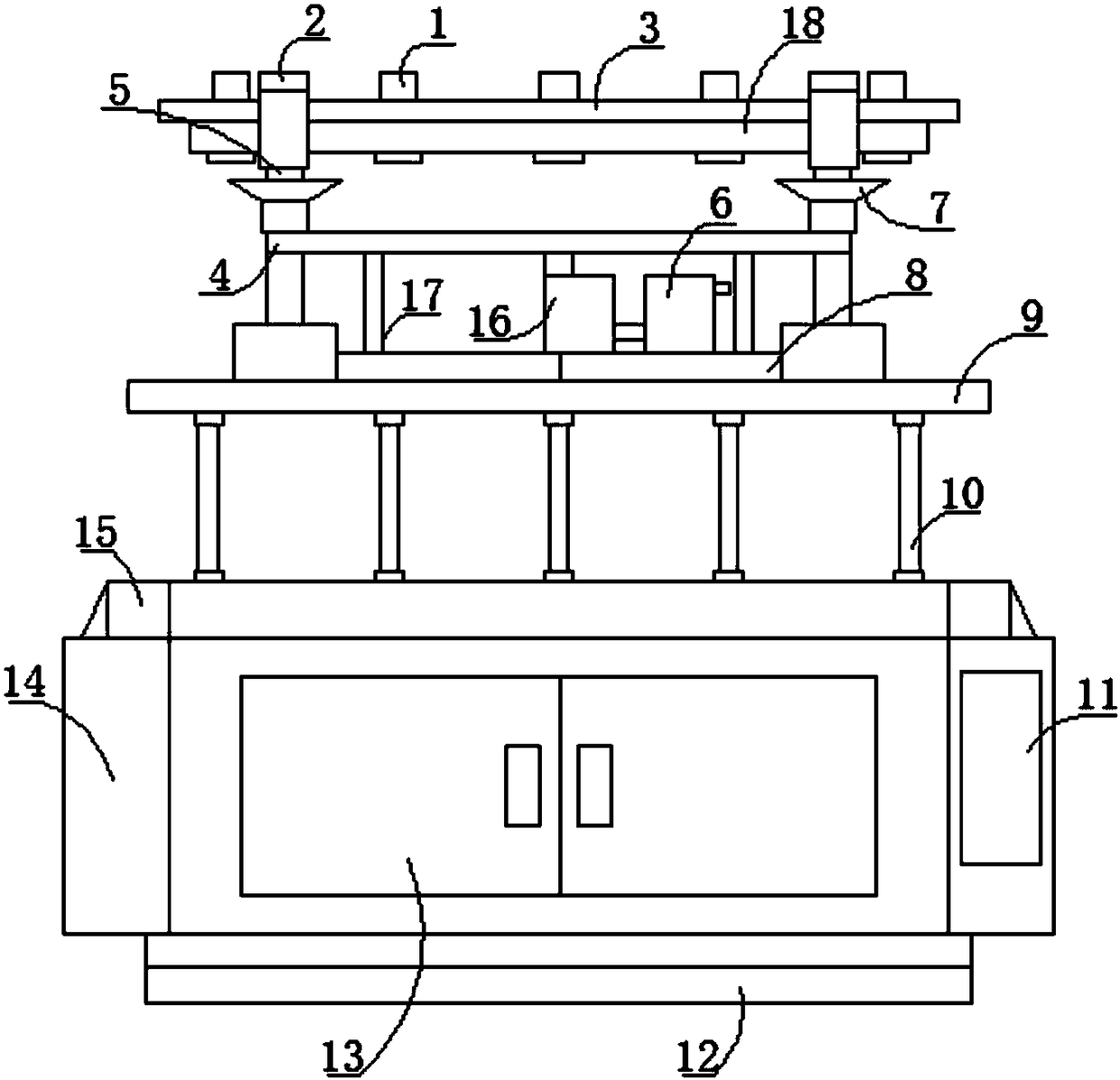

Circular knitting machine with efficient dust removal function

InactiveCN108118443AGood dust removal effectImprove efficiencyKnittingElectrostatic chargesYarnEngineering

The invention discloses a circular knitting machine with an efficient dust removal function. The circular knitting machine comprises a fixed engine base, wherein an electrical cabinet is arranged inside the fixed engine base, a cushion is arranged at the bottom of the fixed engine base, an FK-0301S controller is arranged at one side, close to the electrical cabinet, of the front surface of the fixed engine base, a fixed station is arranged at the top of the fixed engine base, the top of the fixed station is fixedly connected with a supporting frame through a support rod, a supporting seat is arranged at the top of the supporting frame, and the two sides of the top of the supporting seat are respectively fixedly connected with a cross beam by virtue of a communicating rod. The circular knitting machine disclosed by the invention has the advantages that a dust collection bucket is arranged at the bottom of a dust removal device, in a dust removal process of the dust removal device, a dust removal fan works, cotton dust and wool yarn which are produced during dust removal are sucked into the interior of the dust removal bucket through a filter screen on the dust removal device, then enter into the interior of a connecting pipe through the dust collection bucket and finally enter into the interior of a dust storage tank through the connecting pipe, the cotton dust and wool yarn which are produced during the dust removal are prevented from being suspended in the air, and an environment of a workshop is not influenced.

Owner:CHANGXING TIANSUO INTERLINING CO LTD

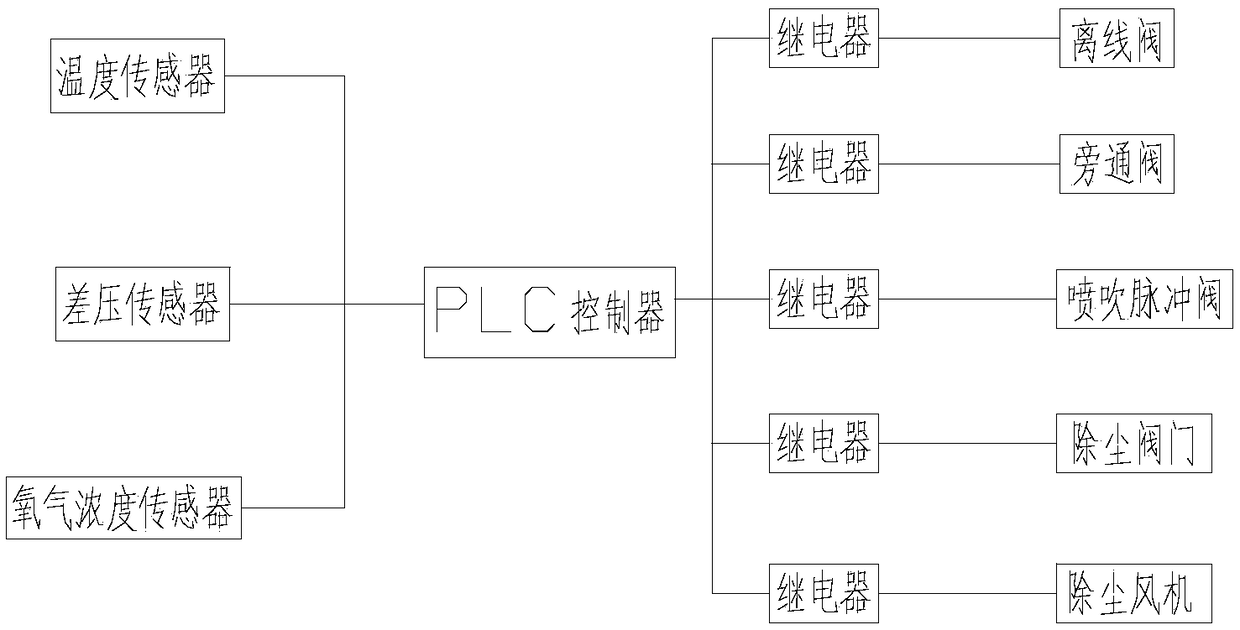

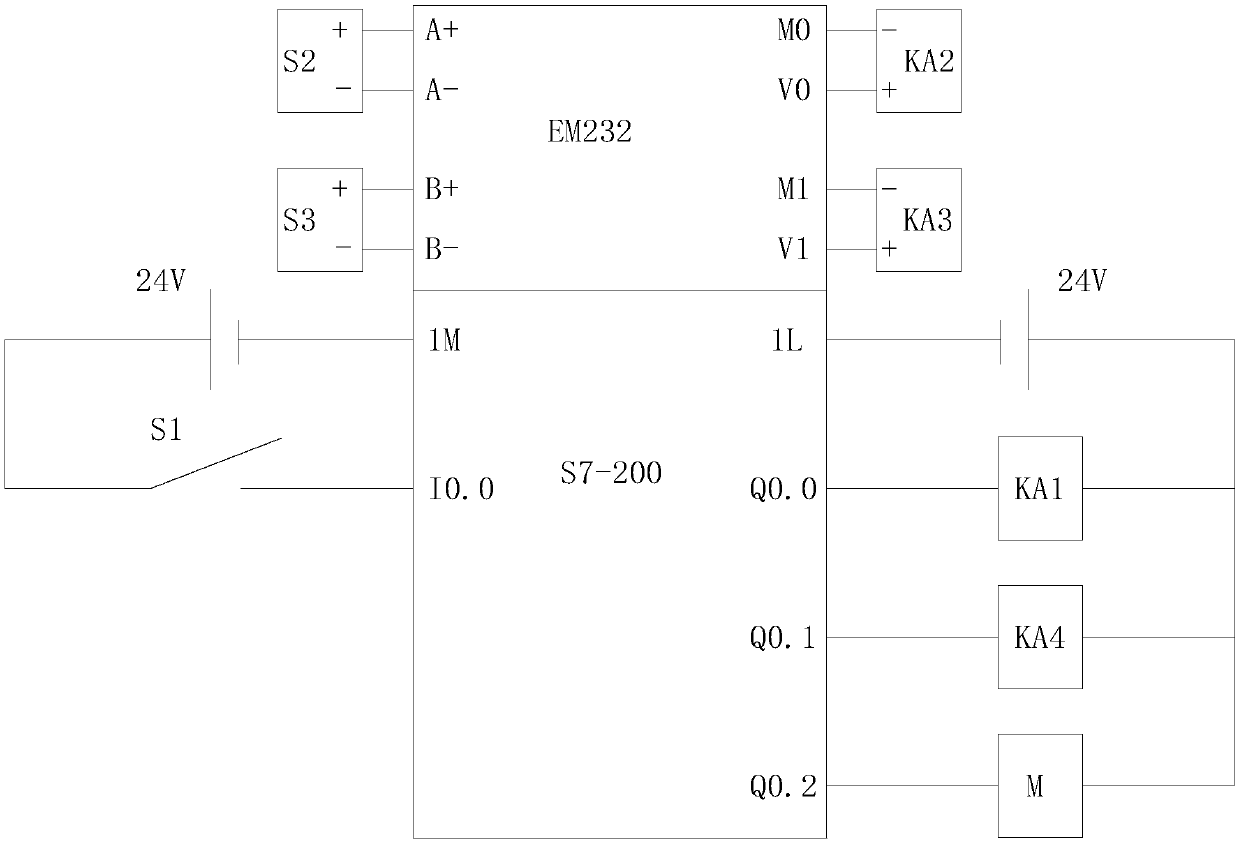

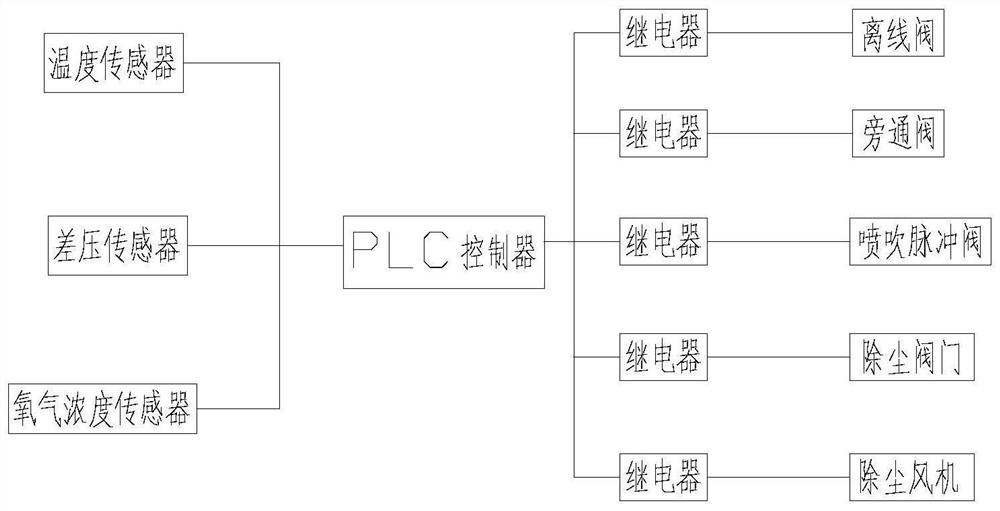

Control system and control method of bag-type dust remover

ActiveCN108379968AImprove cleaning efficiencyExtended service lifeGas treatmentDispersed particle filtrationAutomatic controlControl system

The invention discloses a control system and a control method of a bag-type dust remover. The system comprises a temperature sensor, a differential pressure sensor, an oxygen concentration sensor anda PLC (programmable logic controller); the temperature sensor is arranged in an inlet air flue and is in signal connection with the input end of the PLC; the differential pressure sensor is arranged at the top of the bag-type dust remover and is in signal connection with the input end of the PLC; the oxygen concentration sensor is arranged in a steel-making converter and is in signal connection with the input end of the PLC; and the output port of the PLC is connected with an offline valve, a bypass valve, a blowing pulse valve and a dust-removing fan of the bag-type dust remover as well as adust-removing valve arranged at the flue gas outlet of the steel-making converter. The system has the advantages of automatic detection and automatic control and can guarantee that the production is conducted normally and orderly; furthermore, the flue gas discharge situation is good.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

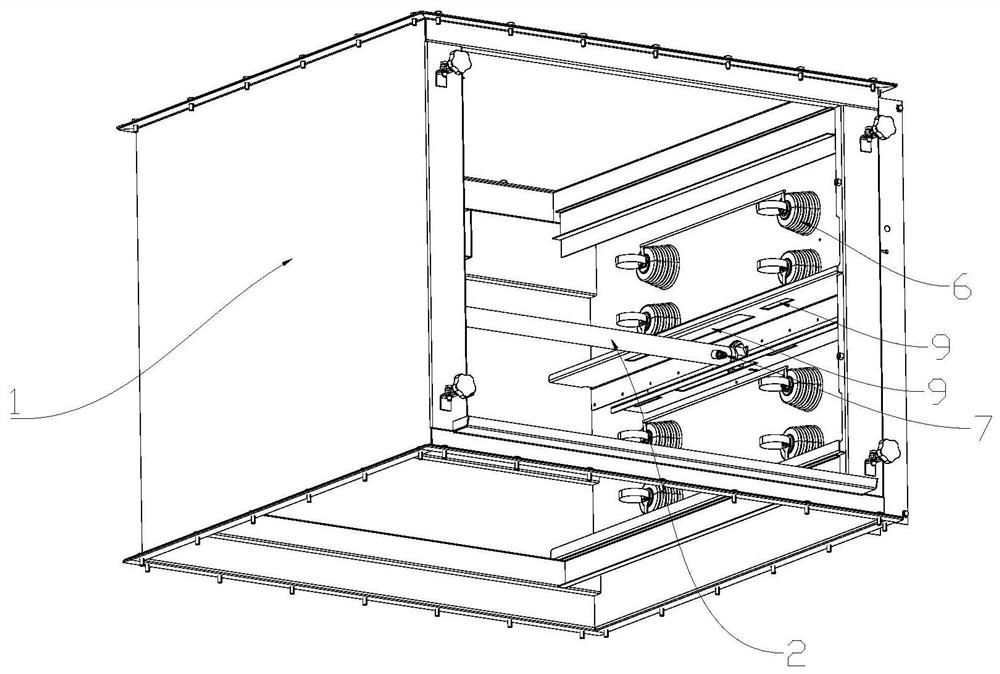

Dedusting and heat-radiating integrated cabinet

InactiveCN108064125AReduce the temperatureReduce internal temperatureCooling/ventilation/heating modificationsInlet channelCooling chamber

The invention discloses a dedusting and heat-radiating integrated cabinet which relates to the technical field of computer equipment. The dedusting and heat-radiating integrated cabinet settles a problem of low dedusting and heat-radiating efficiency in an existing cabinet. The cabinet comprises a cabinet body. An air inlet channel is arranged above the cabinet body. The air inlet channel is internally provided with an air inlet fan. The cabinet is characterized in that the periphery of the air inlet channel is provided with a first cooling wall; a cooling chamber is arranged below the air inlet channel; the periphery of the cooling chamber is provided with a second cooling wall; the cooling chamber is internally provided with a cooling tube; the inner wall at the periphery of the cabinetbody is provided with a mounting table; the mounting table is internally provided with a rotating motor; the rotating motor is connected with a rotating shaft; the rotating shaft is connected with a turntable; the surface of the turntable is provided with air guiding holes and air guiding strips; the periphery of the rotating shaft is provided with second air guiding pipes; and the lower end in the cabinet body is provided with an ash discharging channel. The dedusting and heat-radiating integrated cabinet has advantages of high efficiency, high effect, and no harm to health.

Owner:HENAN YUNLE TECH CO LTD

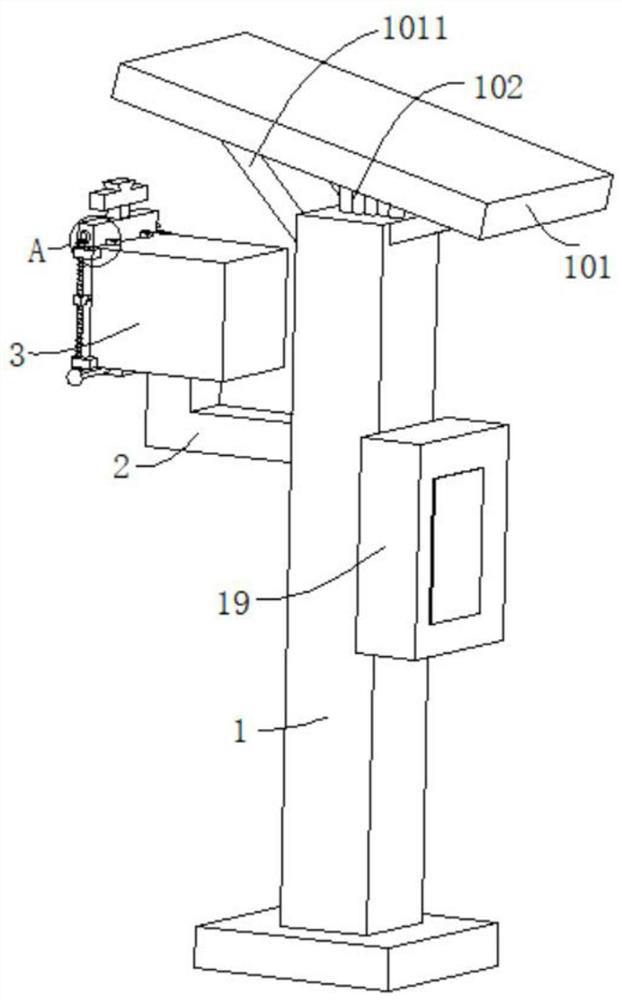

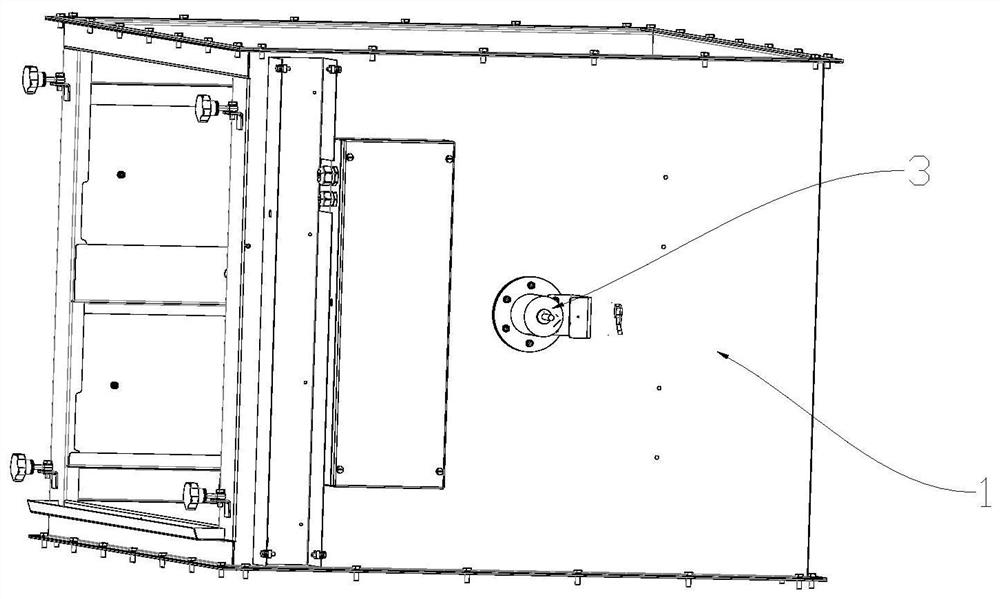

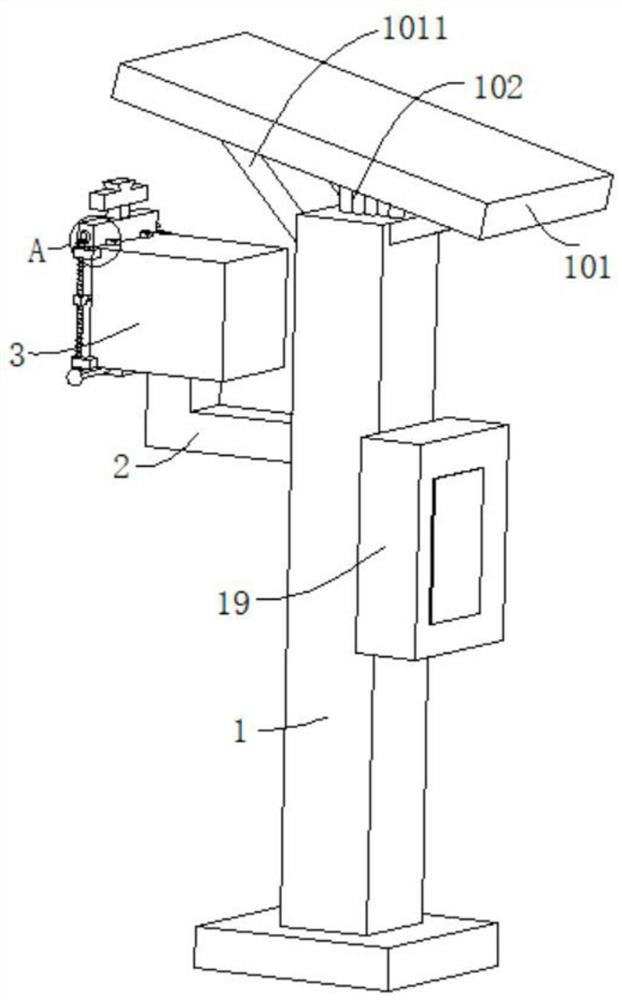

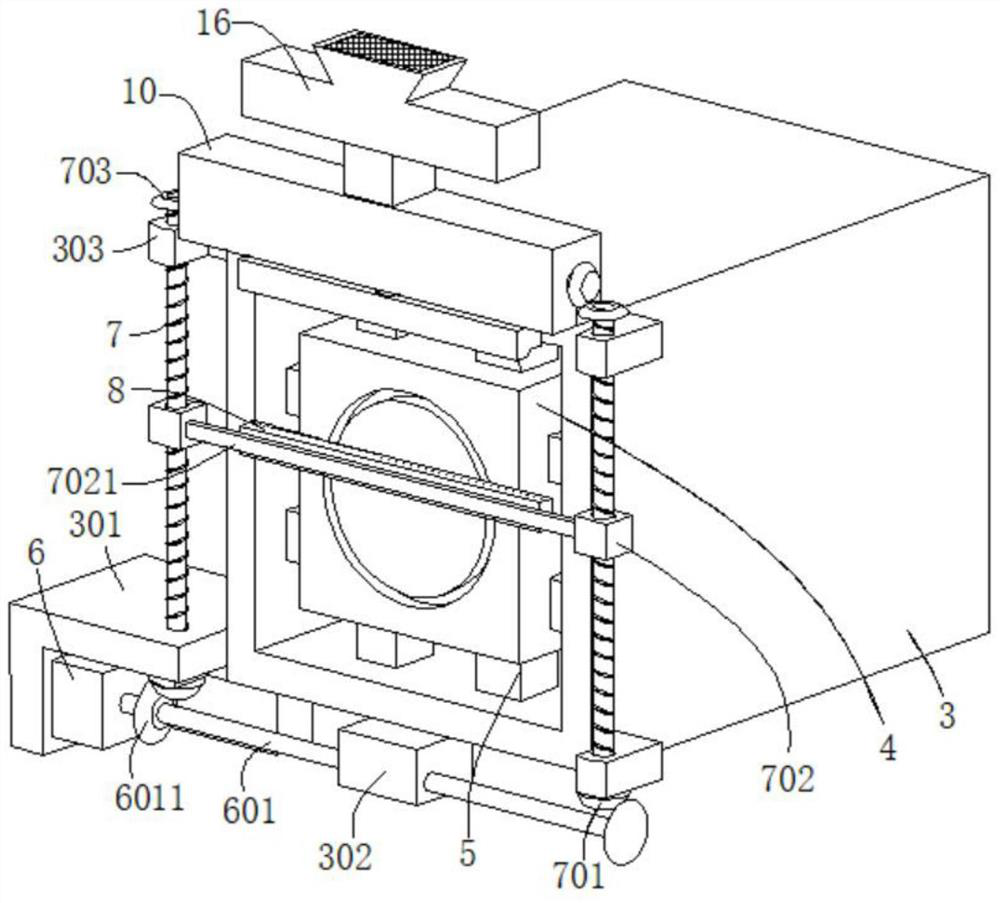

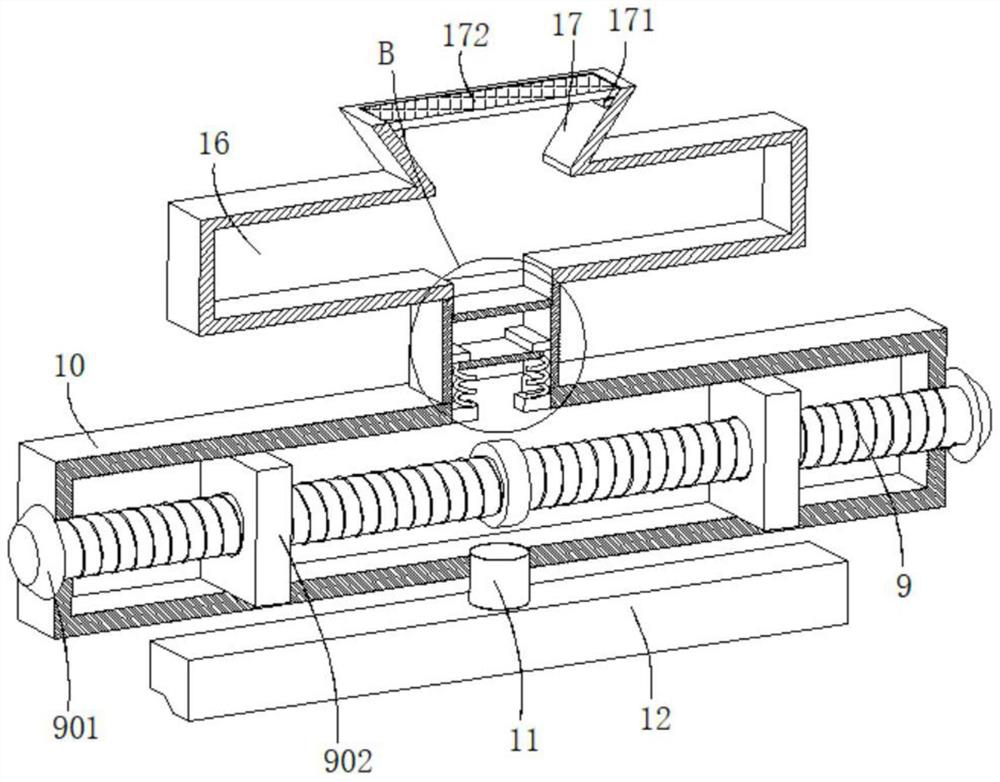

Smart city traffic safety monitoring device and monitoring system

ActiveCN111866469AEasy to cleanAffect the effect of dust removalTelevision system detailsColor television detailsElectric machineryEnvironmental geology

The invention provides a smart city traffic safety monitoring device. The device comprises a stand column, and a control box is connected to the outer wall of the stand column; a connecting rod is connected to the outer wall of the stand column; the end, away from the stand column, of the connecting rod is connected with a shell; a camera is arranged in the shell, a reinforcing part is connected between the shell and the camera, the outer wall of the shell is connected with a mounting seat and a mounting plate, the inner wall of the mounting seat is connected with a motor part, the output endof the motor part is connected with a rotating shaft, the rotating shaft is rotatably connected in the mounting plate, and the outer wall of the rotating shaft is connected with two first bevel gears;when the brush is used for removing dust on the outer side of the camera, clear water can be used for spraying the outer side of the camera, the cleaning effect of the brush is improved, the situation that the outer side of the brush is contaminated by too much dust, and the dust removal effect of the brush is affected is avoided, then it is guaranteed that monitoring images of the camera are clear, and the monitoring effect is improved.

Owner:成都和乐信软件有限公司

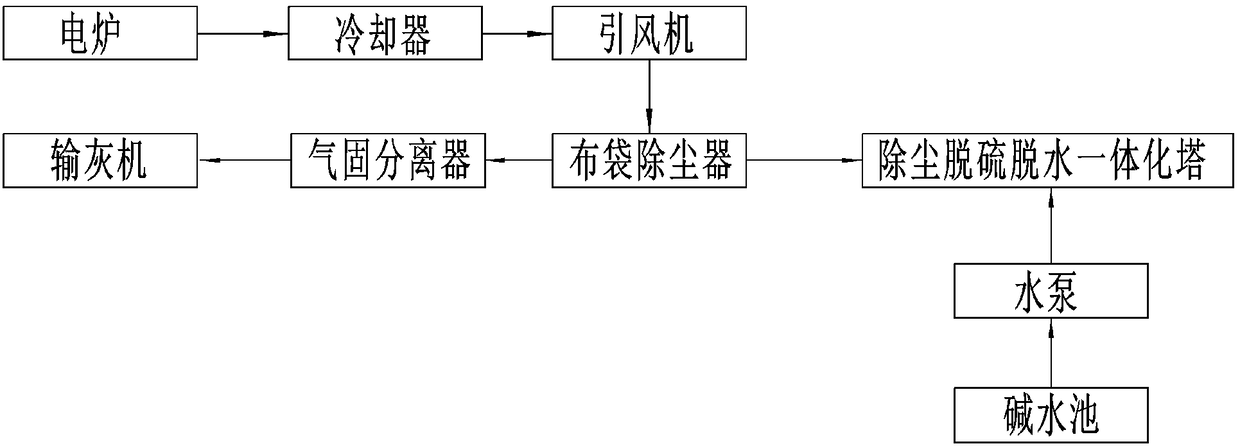

Flue gas dust removal process

InactiveCN108554149AReduce impactImprove dust removal effectGas treatmentDispersed particle filtrationCycloneBaghouse

The invention belongs to the technical field of waste gas treatment process, and particularly discloses a flue gas dust removal process. An alkali pond, a reactor, an electric furnace, a cooler, a double-stage cyclone dust remover, an inducted draft fan, a cloth bag dust remover and a dust removal, desulfurization and dehydrating integrated tower are used in the flue gas dust removal process, andthe electric furnace, the cooler, the double-stage cyclone dust remover, the inducted draft fan, the cloth bag dust remover and the dust removal, desulfurization and dehydrating integrated tower are successively connected; and the cloth bag dust remover is connected with a densifying bin, a gas-solid separator and a pneumatic dust delivering fan which are connected successively, the dust removal,desulfurization and dehydrating integrated tower is connected with the alkali pond through a water pump, and a slurry pond is connected between the reactor and the dust removal, desulfurization and dehydrating integrated tower. The flue gas dust removal process is mainly used for flue gas dust removal, and the problems that in flue gas dust removal, a cloth bag is easily blocked after being used for a long time, and the dust removal effect is poor are solved.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

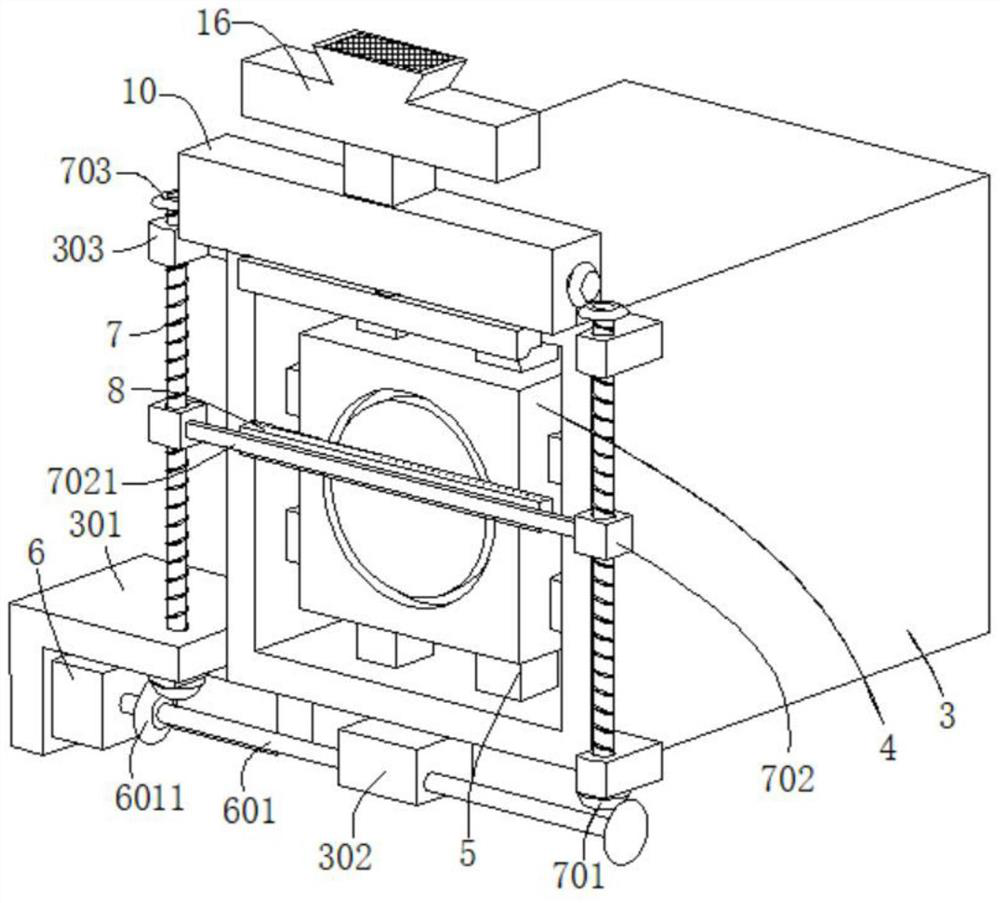

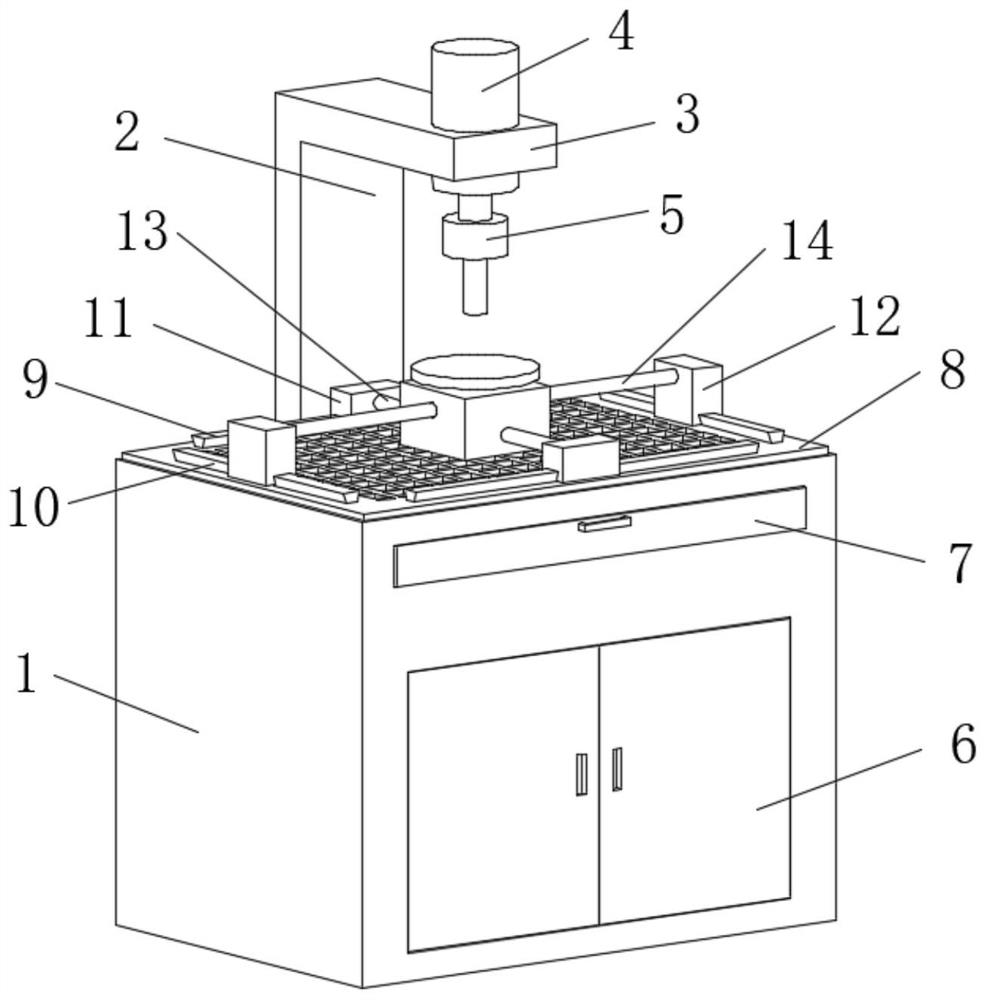

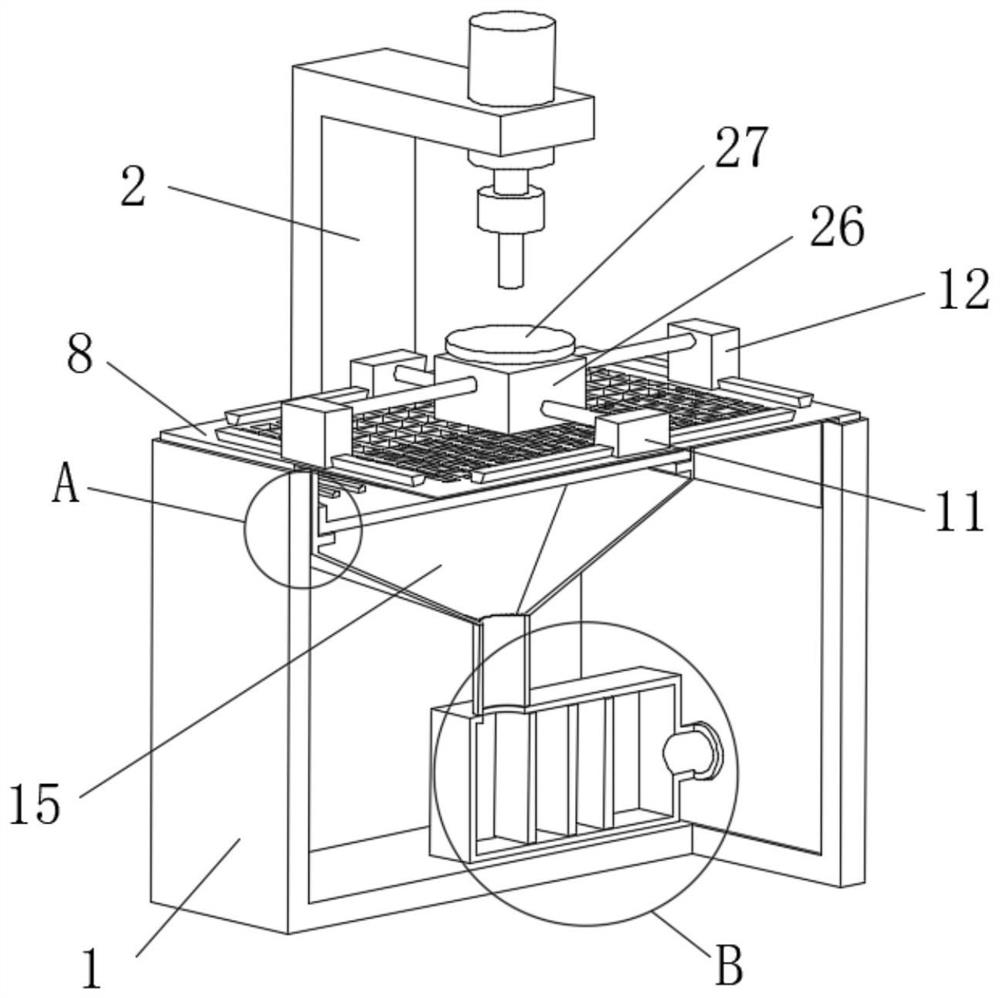

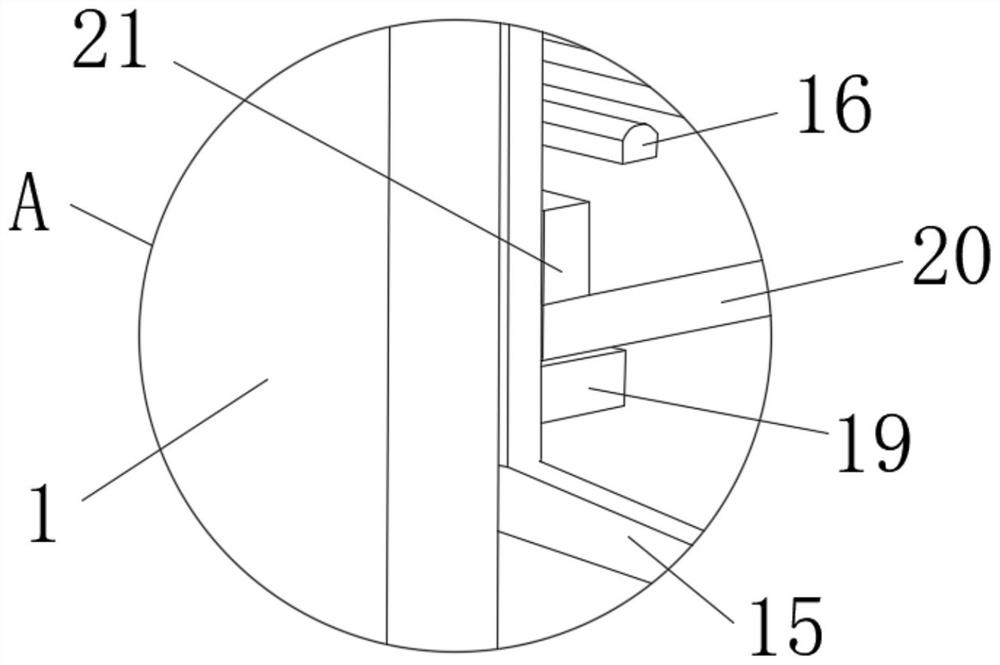

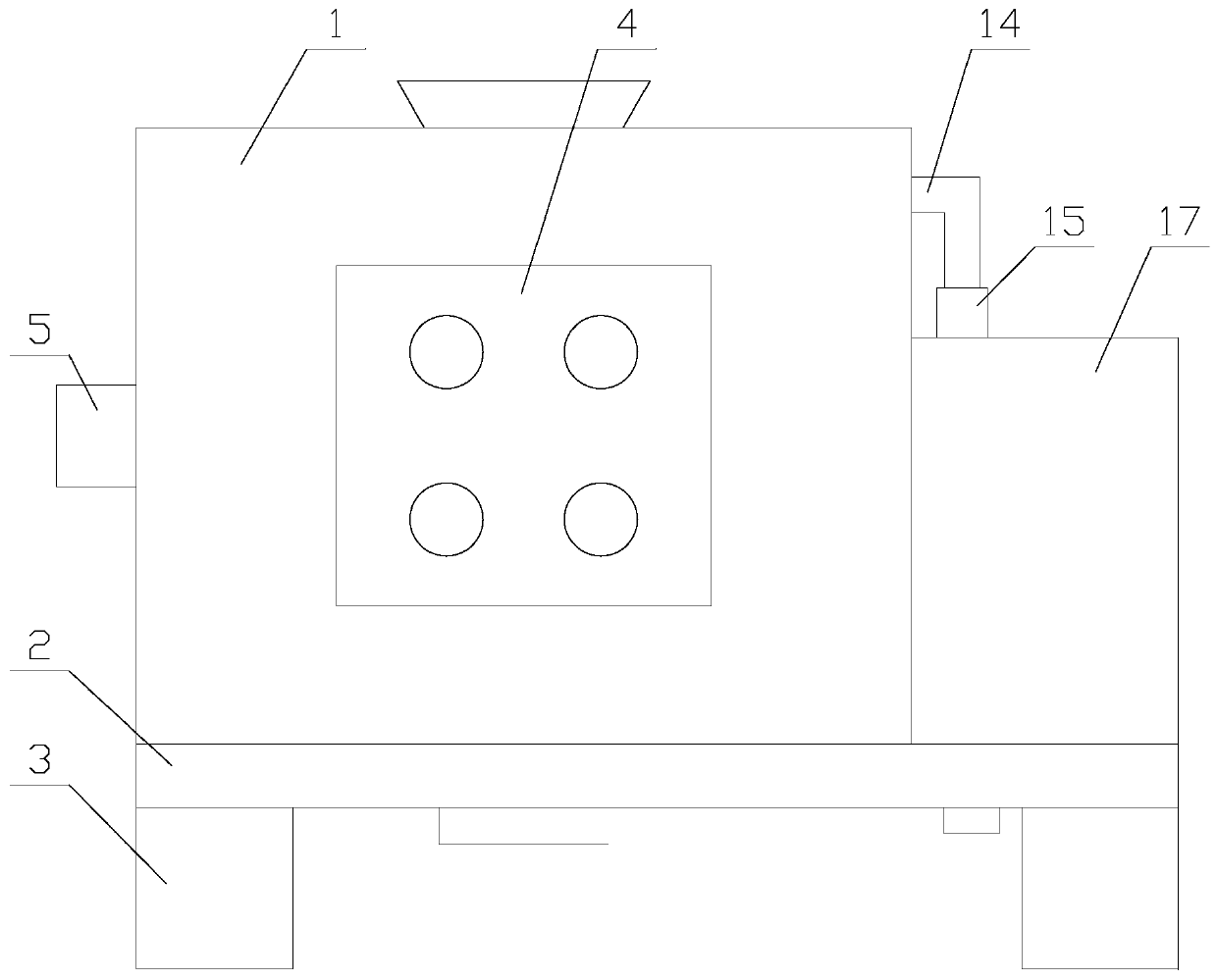

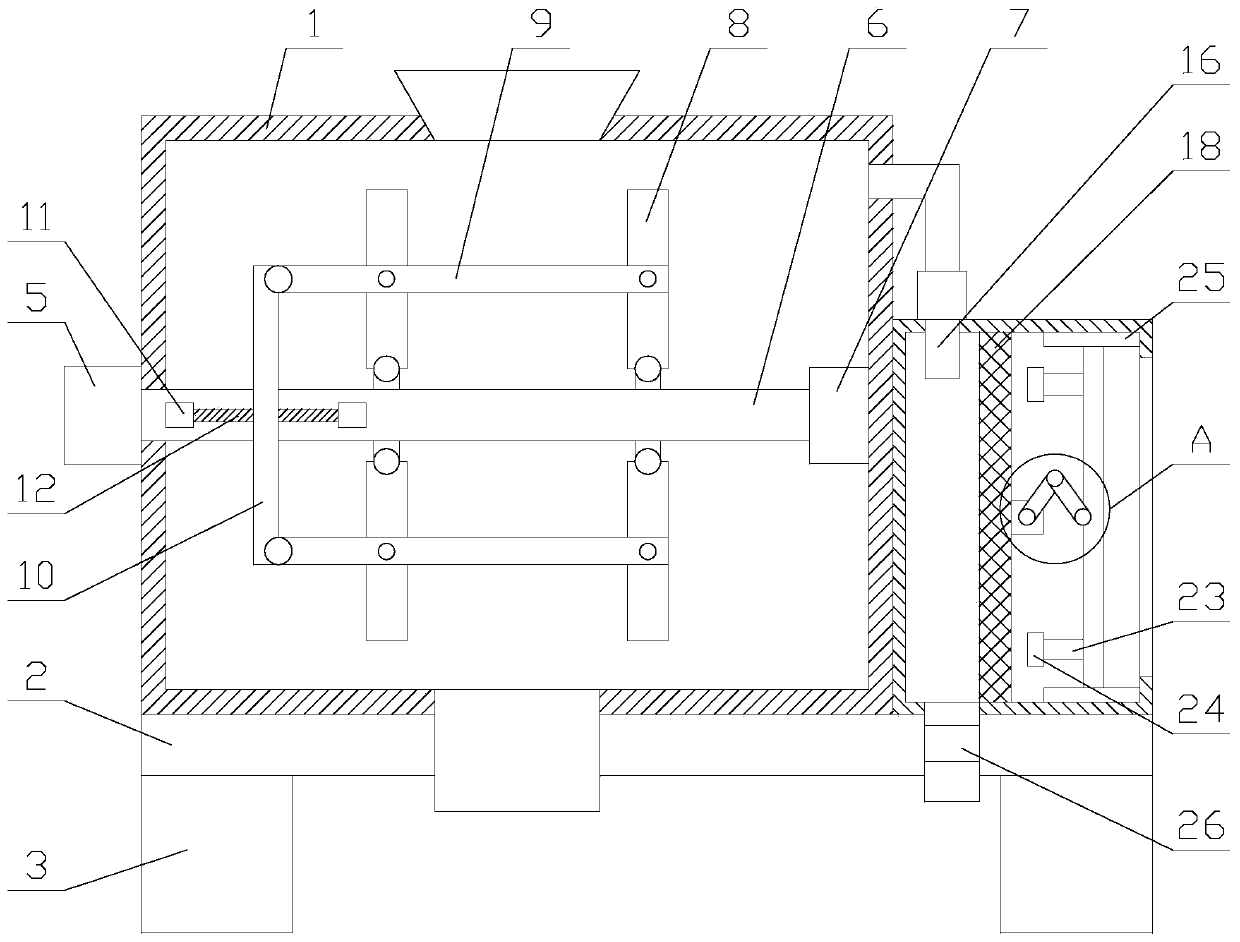

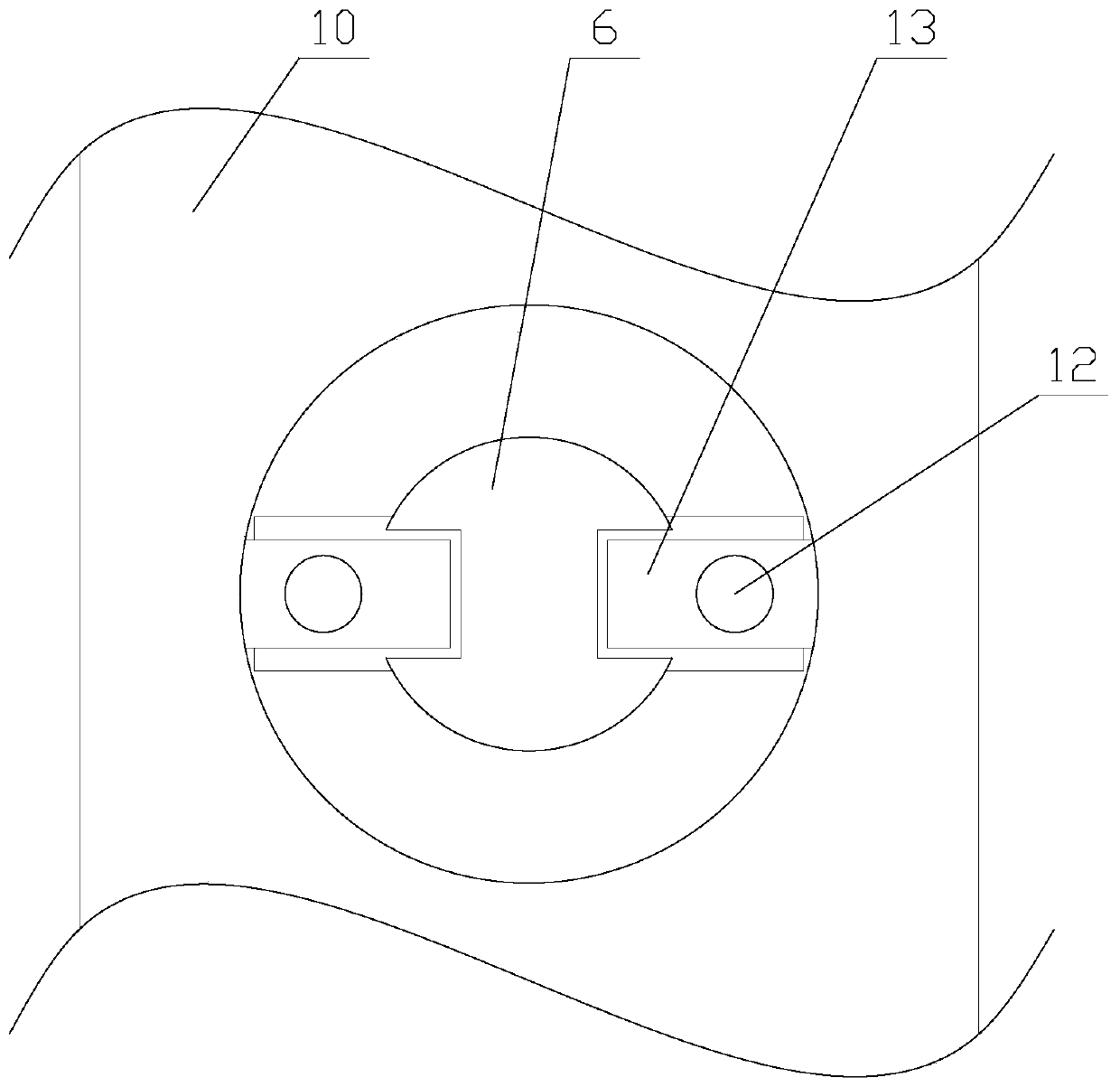

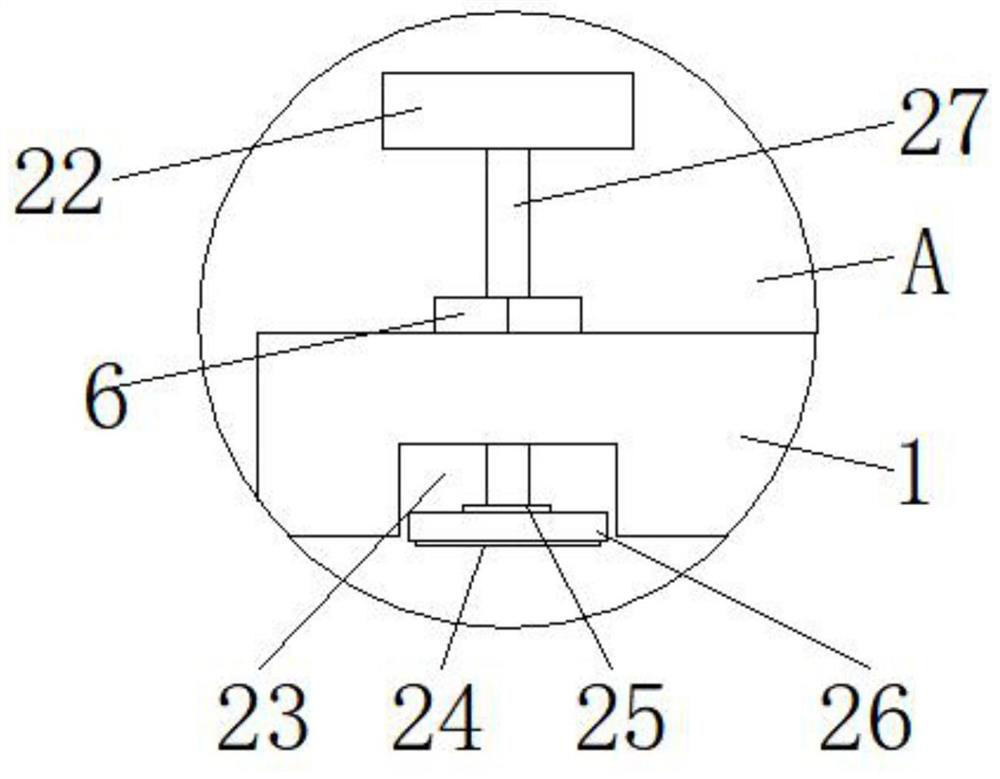

Automobile brake disc drilling center

InactiveCN112518411AAffect healthAffect the effect of dust removalMaintainance and safety accessoriesBoring/drilling machinesAir pumpDust control

The invention discloses an automobile brake disc drilling center. The automobile brake disc drilling center comprises an operation table and a supporting rod arranged on the back face of the operationtable, wherein the operation table is a rectangular box body; a first notch and a second notch are arranged in the front surface of the box body; a box door is arranged in the first notch through a hinge; a sealing plate is rotatably arranged in the second notch through a hinge; handle structures are arranged on the box door and the sealing plate; the upper surface of the operation table is not closed; a mesh plate is erected on the upper surface of the operation table; and mesh structures are evenly arranged in the center of the mesh plate. The mesh plate is arranged on the upper surface ofthe operation table, a waste hopper is arranged at the lower end of the mesh plate, an outlet in the lower end of the waste hopper is connected to an air inlet of a dust removal box, and an exhaust port of the dust removal box is connected to the air inlet end of an air pump through a second air pipe, so that adsorption force is formed on the upper surface of the operation table through the actionof the air pump, and therefore, the situation that the physical health of workers is affected due to random drifting of dust formed by drilling machining is avoided.

Owner:徐保龙

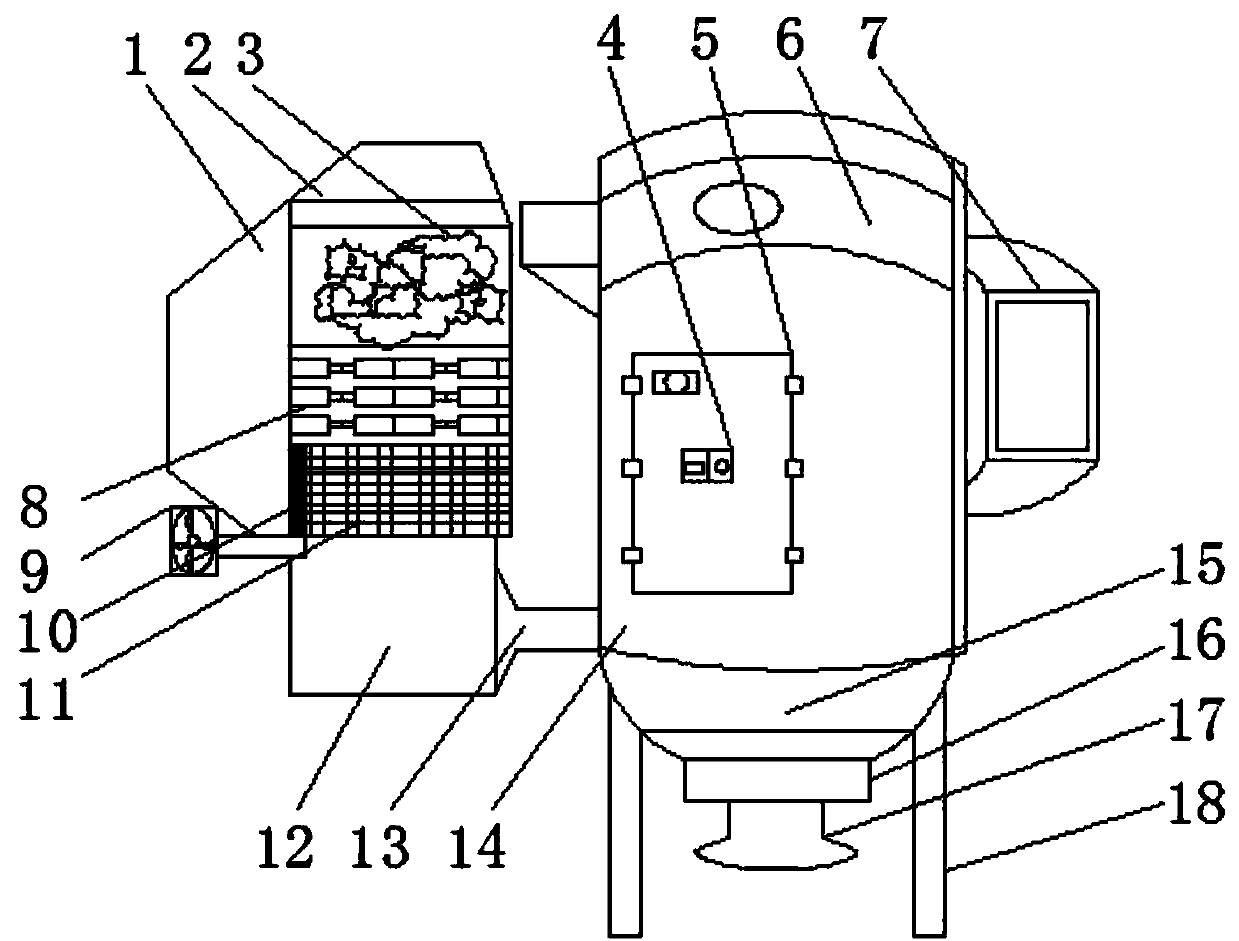

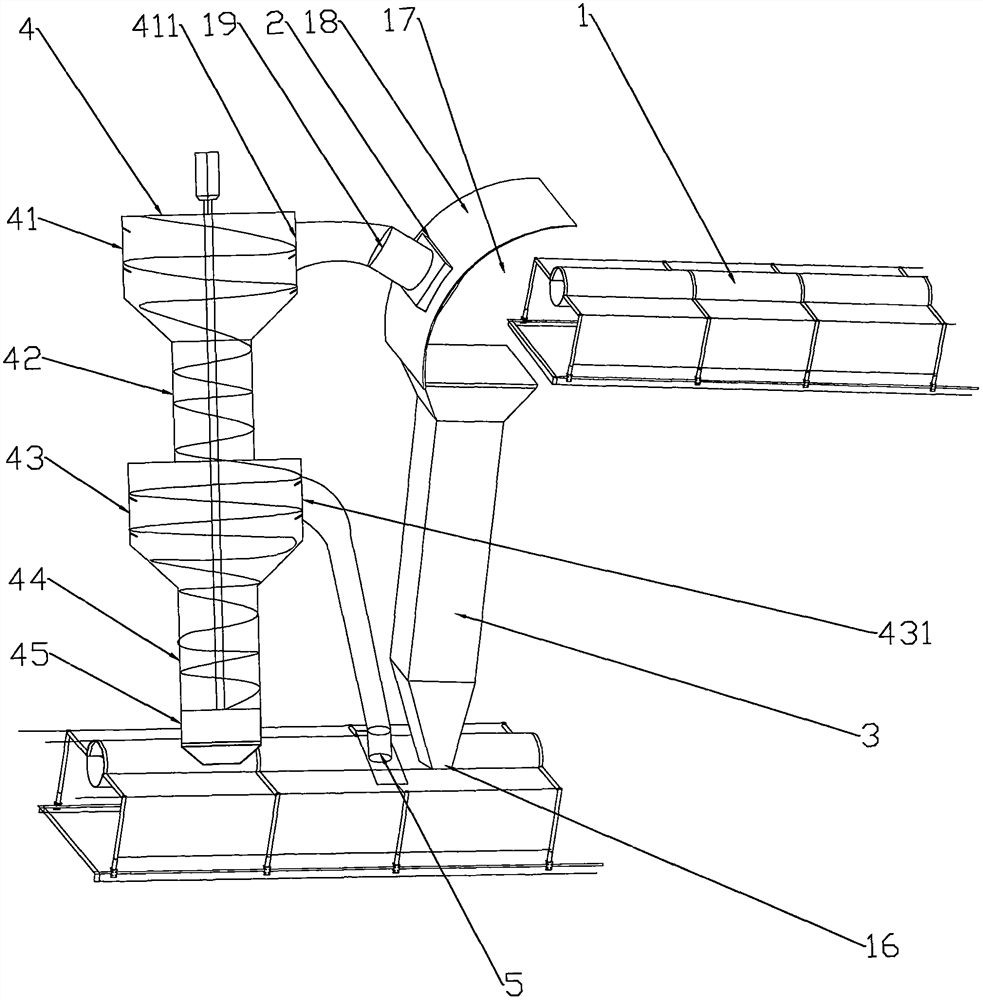

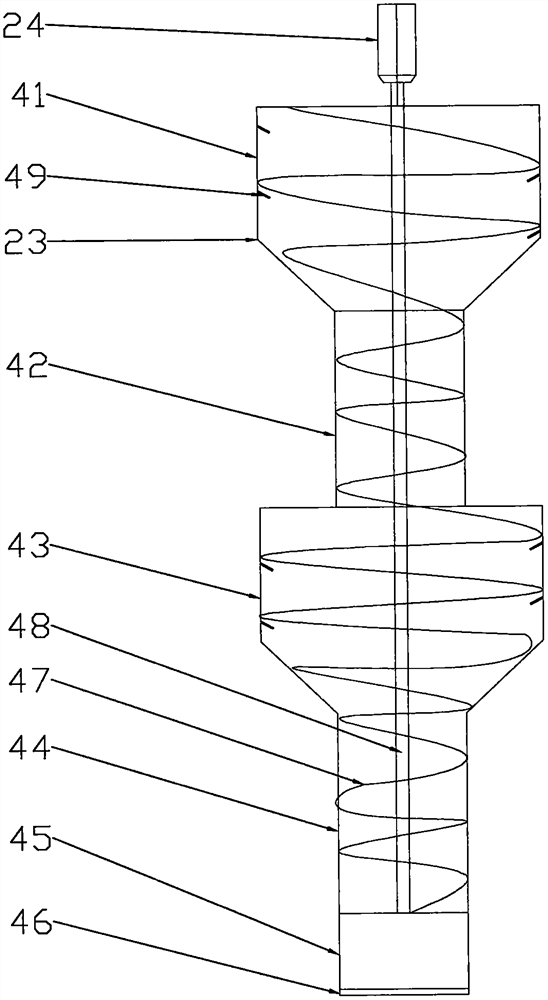

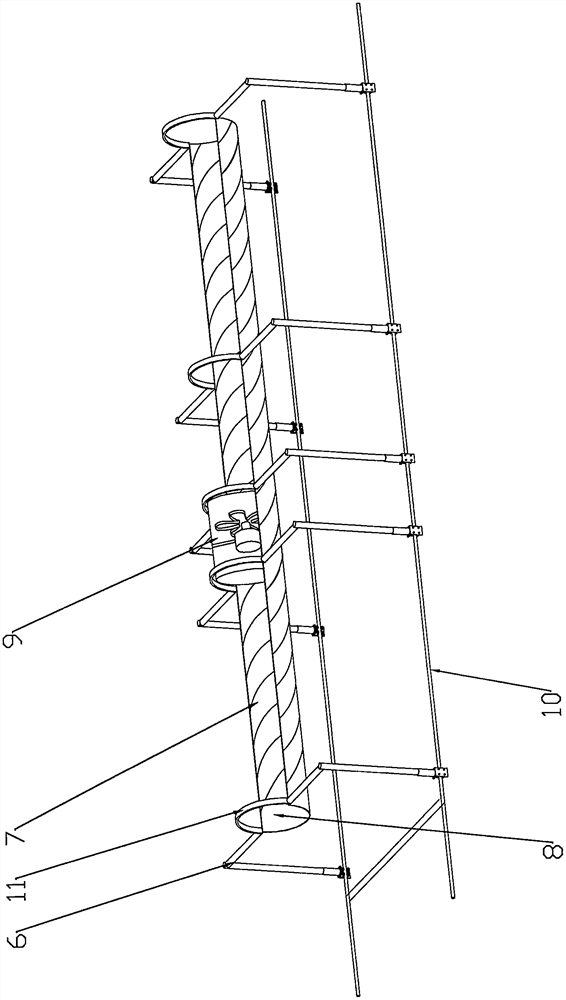

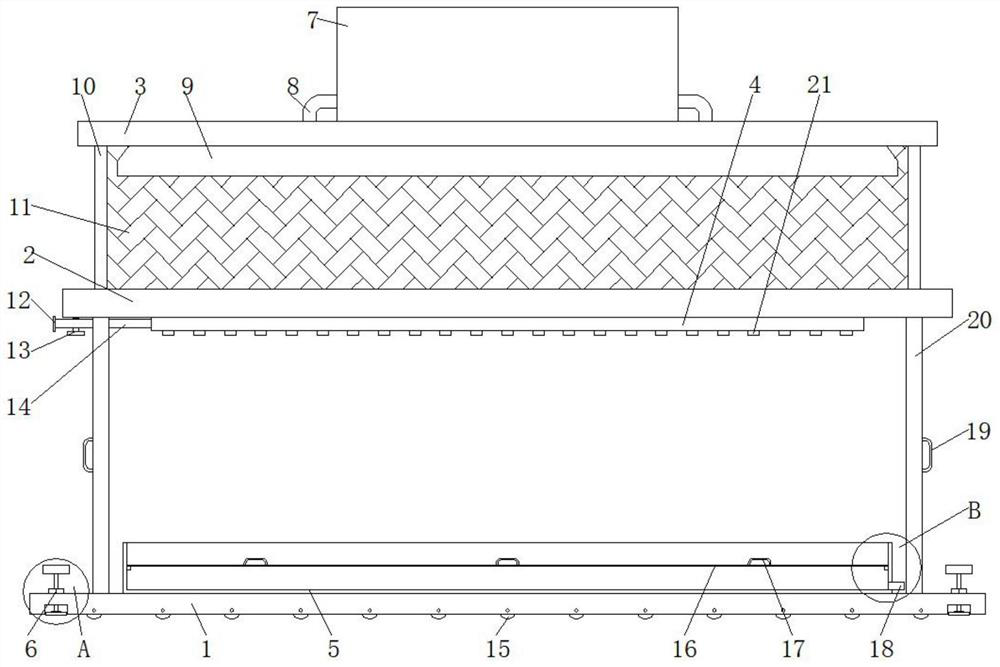

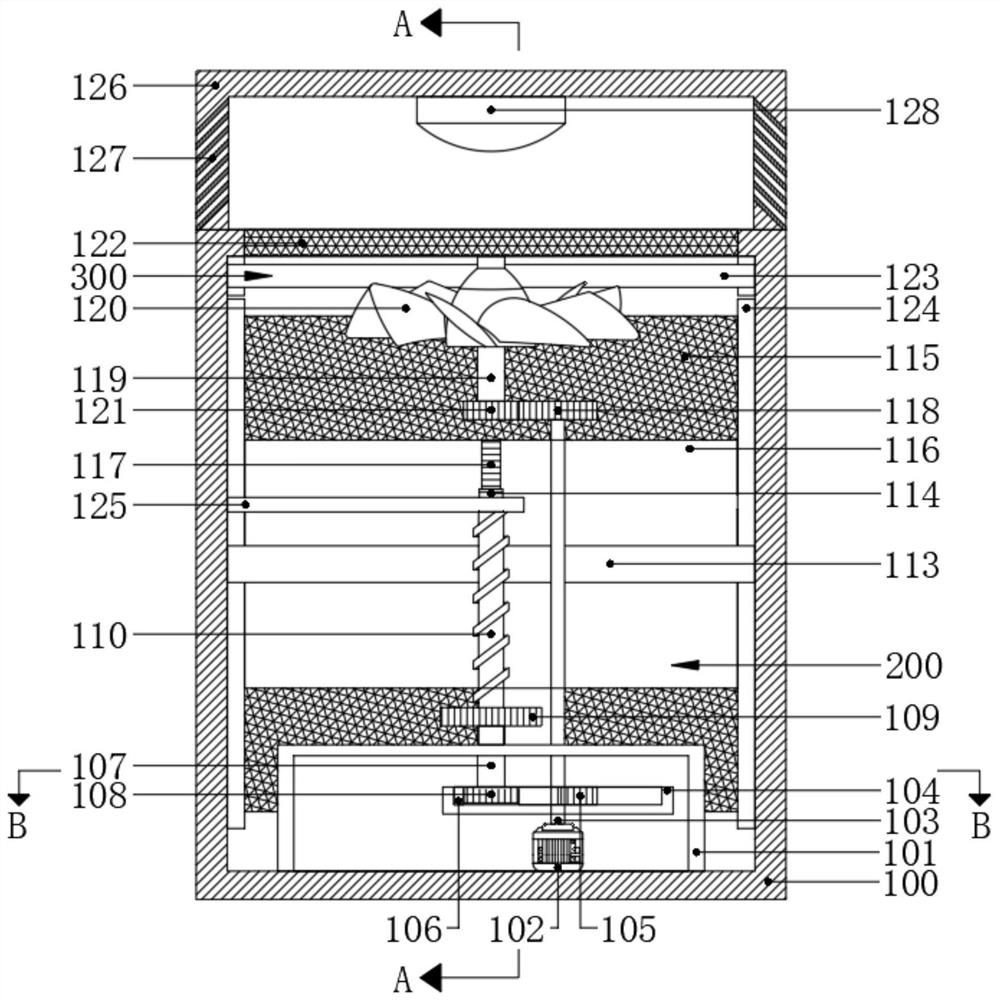

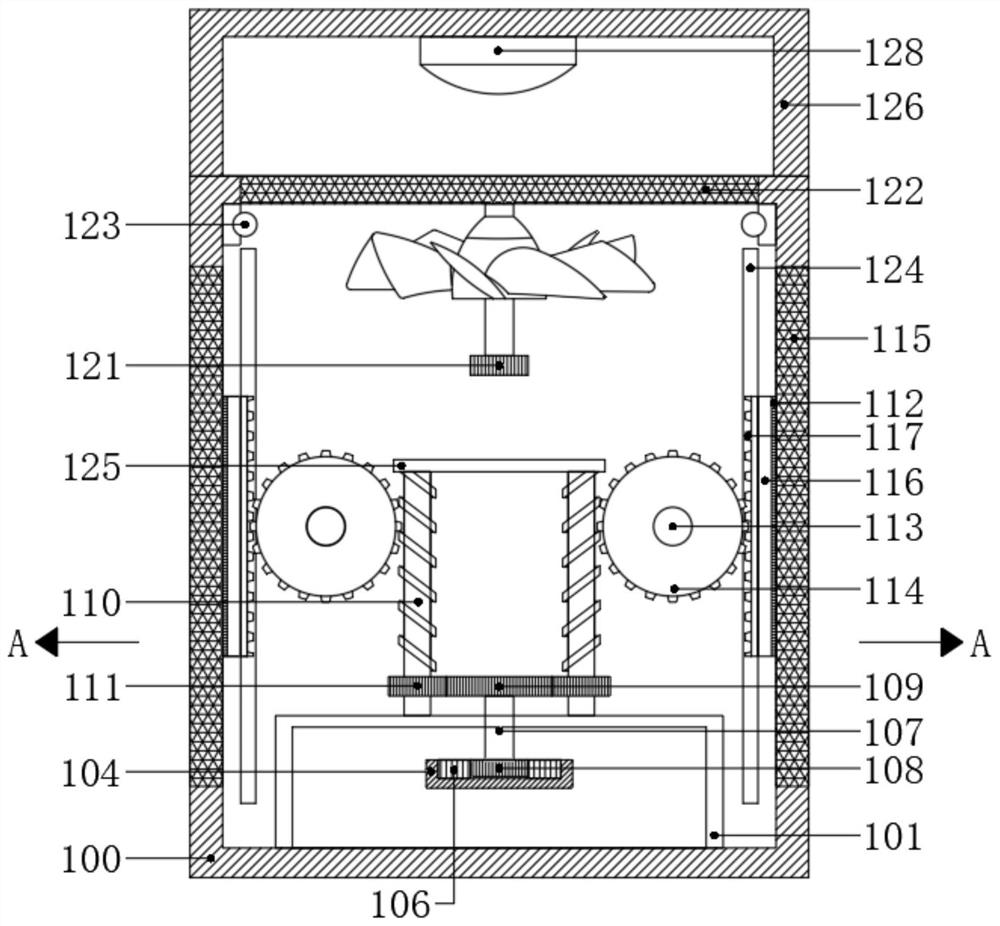

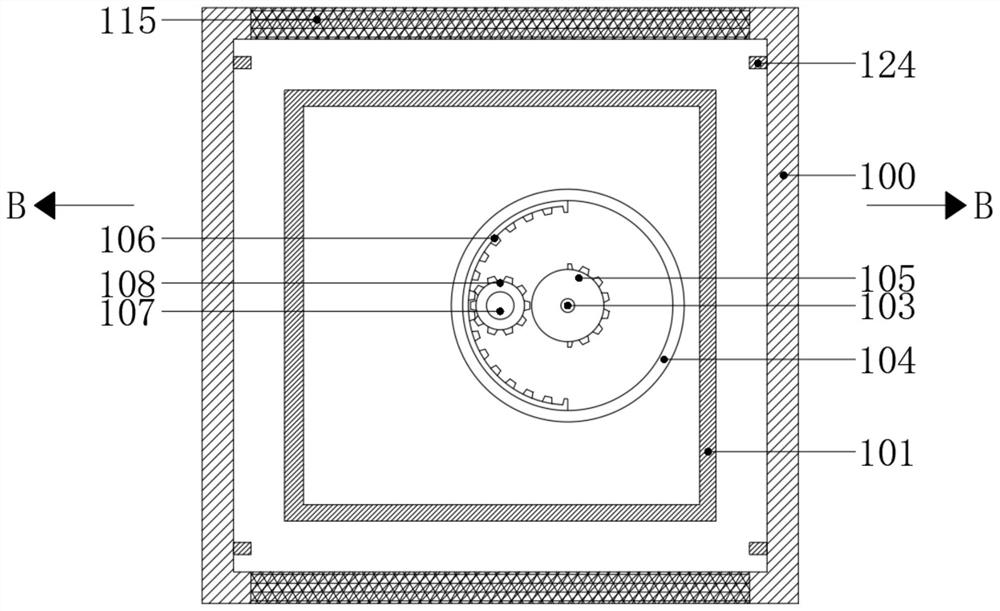

High-efficiency drying facility for coal chemical industry and with dust prevention function

InactiveCN110274456AExpand the mixing rangeAvoid cloggingDrying machines with non-progressive movementsDrying solid materialsAtmospheric airEngineering

The invention relates to a high-efficiency drying facility for the coal chemical industry and with a dust prevention function. The high-efficiency drying facility comprises a body, a supporting plate and four supports, and further comprises a stirring mechanism and a dust preventing mechanism. The stirring mechanism comprises a first motor, a rotating shaft, a moving plate, a bearing, two driving assemblies, multiple connecting rods and multiple stirring assemblies. Each stirring assembly comprises a supporting shaft and a stirring plate. The dust preventing mechanism comprises an air suction assembly, a dust preventing box and a filtering screen. A shaking assembly is arranged inside the dust preventing box and comprises a power unit, a moving rod and two vibrating rods. The high-efficiency drying facility for the coal chemical industry and with the dust prevention function can conduct the stirring work on coal materials in the body through the stirring mechanism, the phenomenon that due to the fact that the coal materials are stacked together, the drying effect is affected is avoided, and the drying efficiency is improved; and the dust removal work can be conducted on the air of the body through the dust preventing mechanism, and the phenomenon that the dust is directly discharged into the atmosphere and affects the air environment is avoided.

Owner:李冉冉

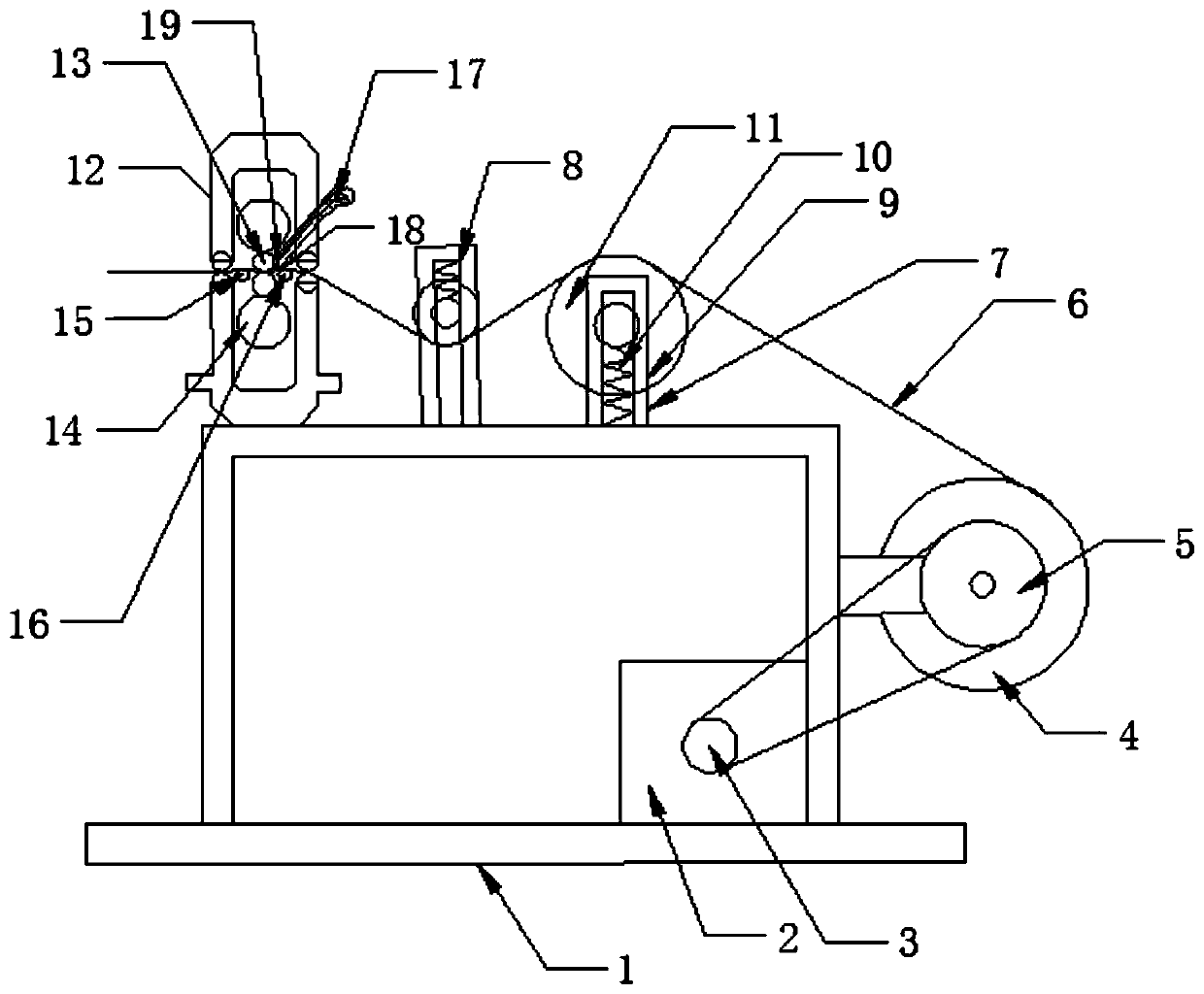

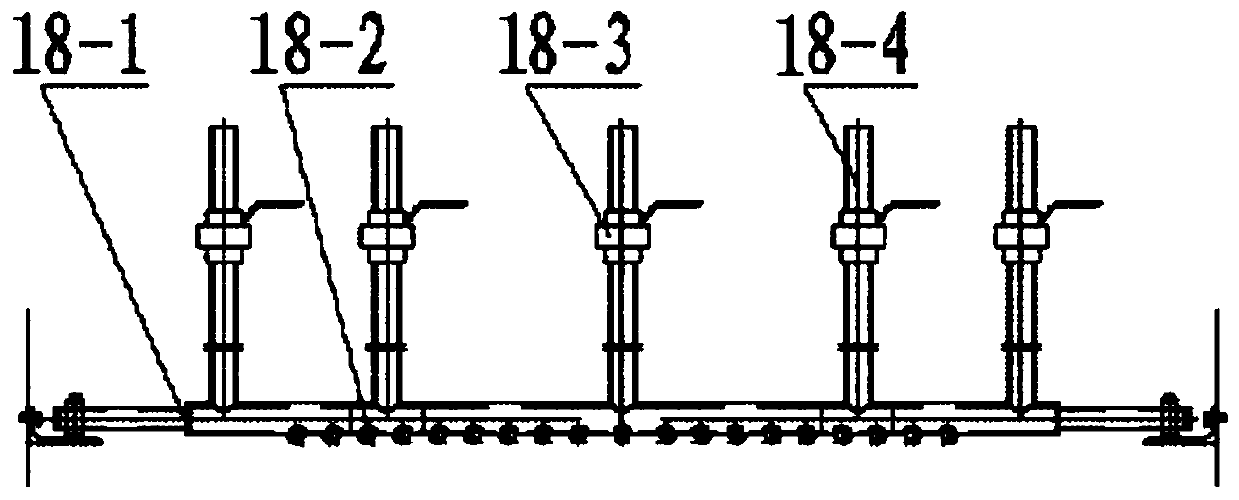

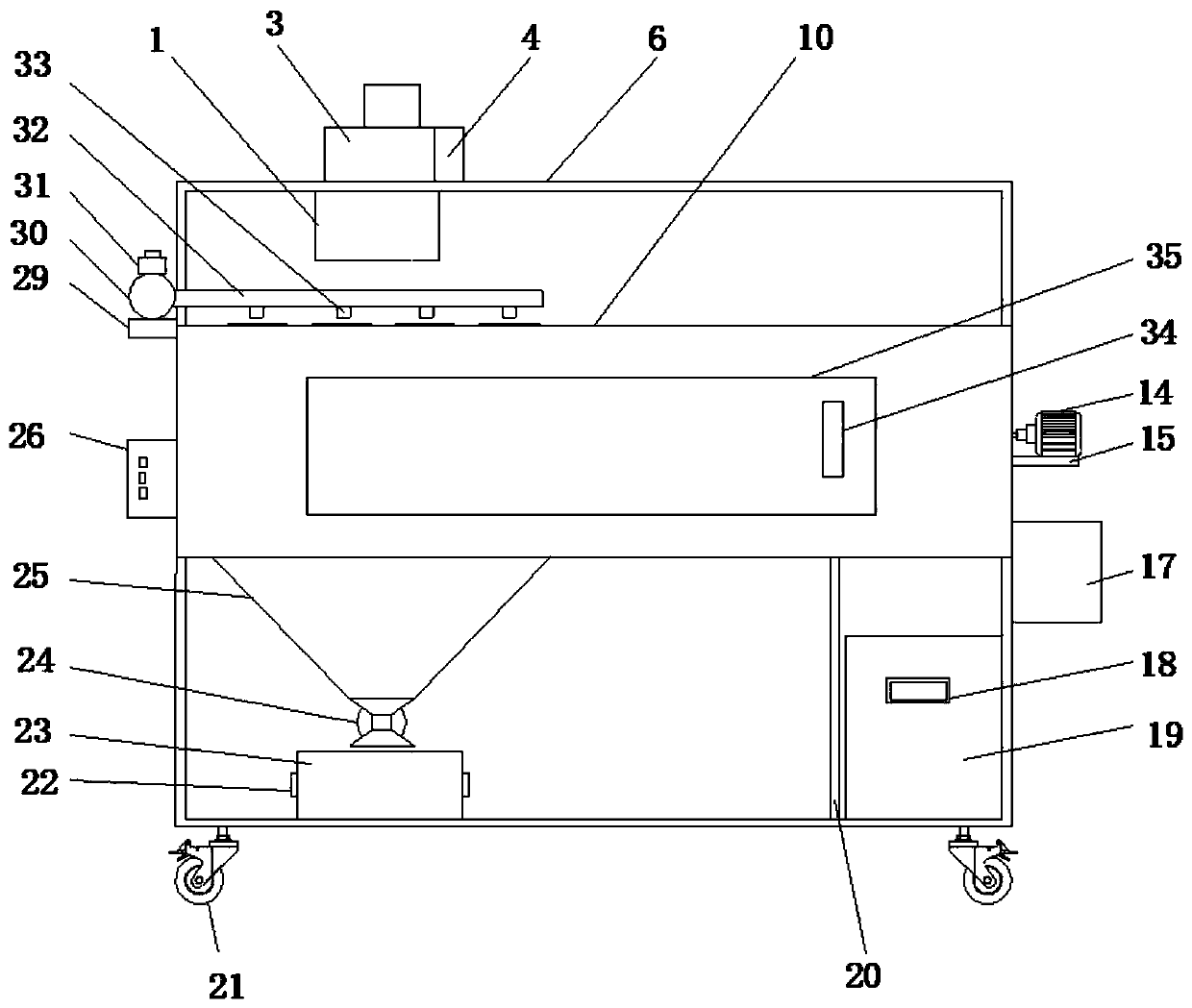

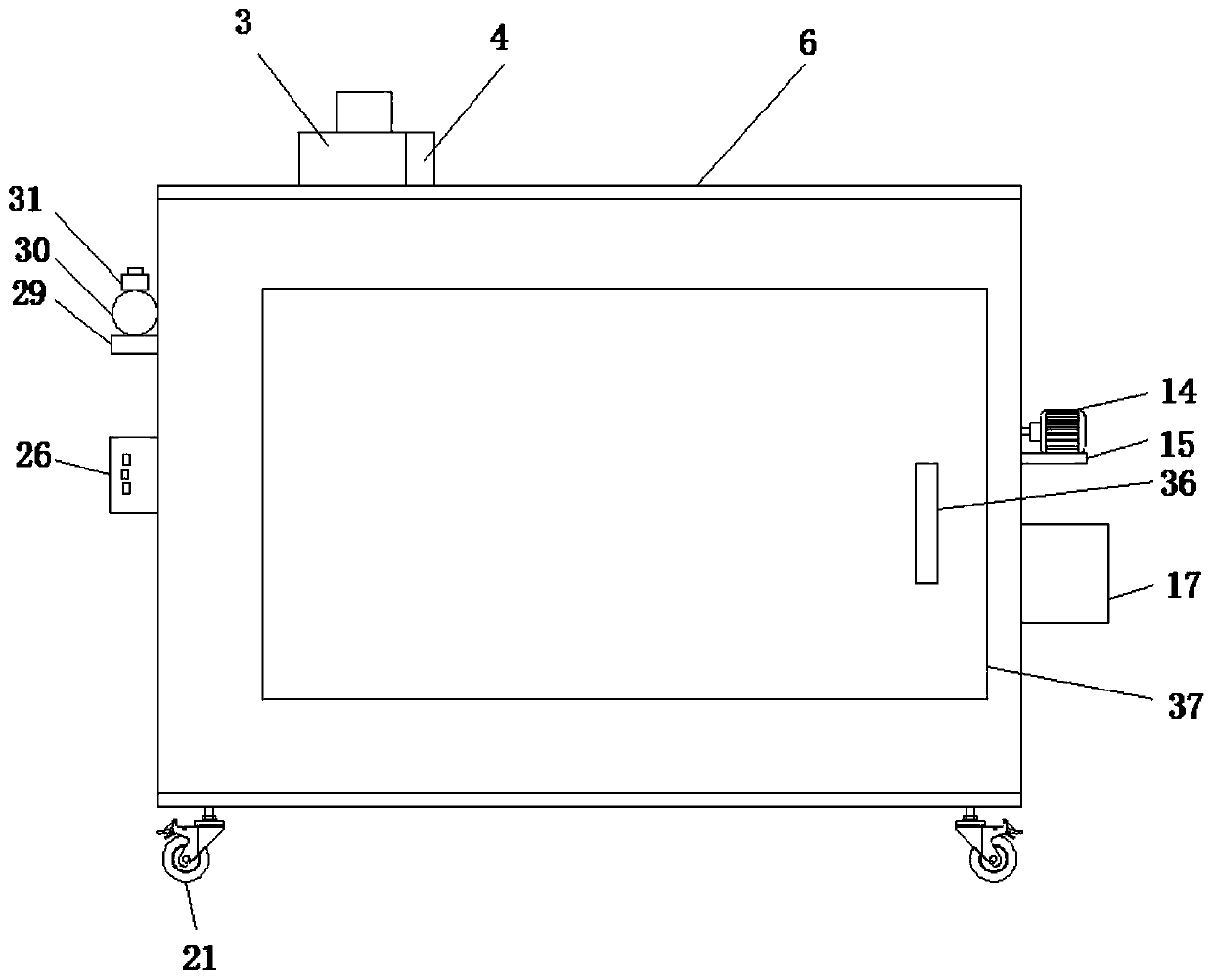

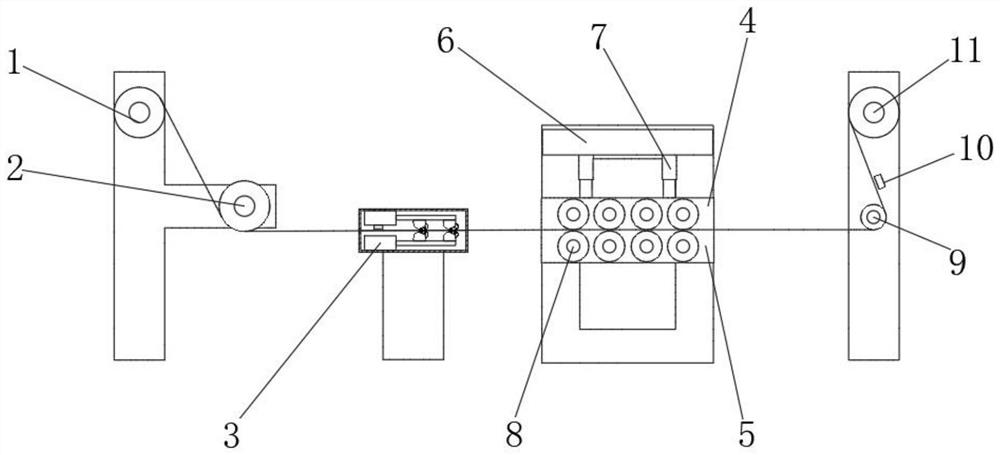

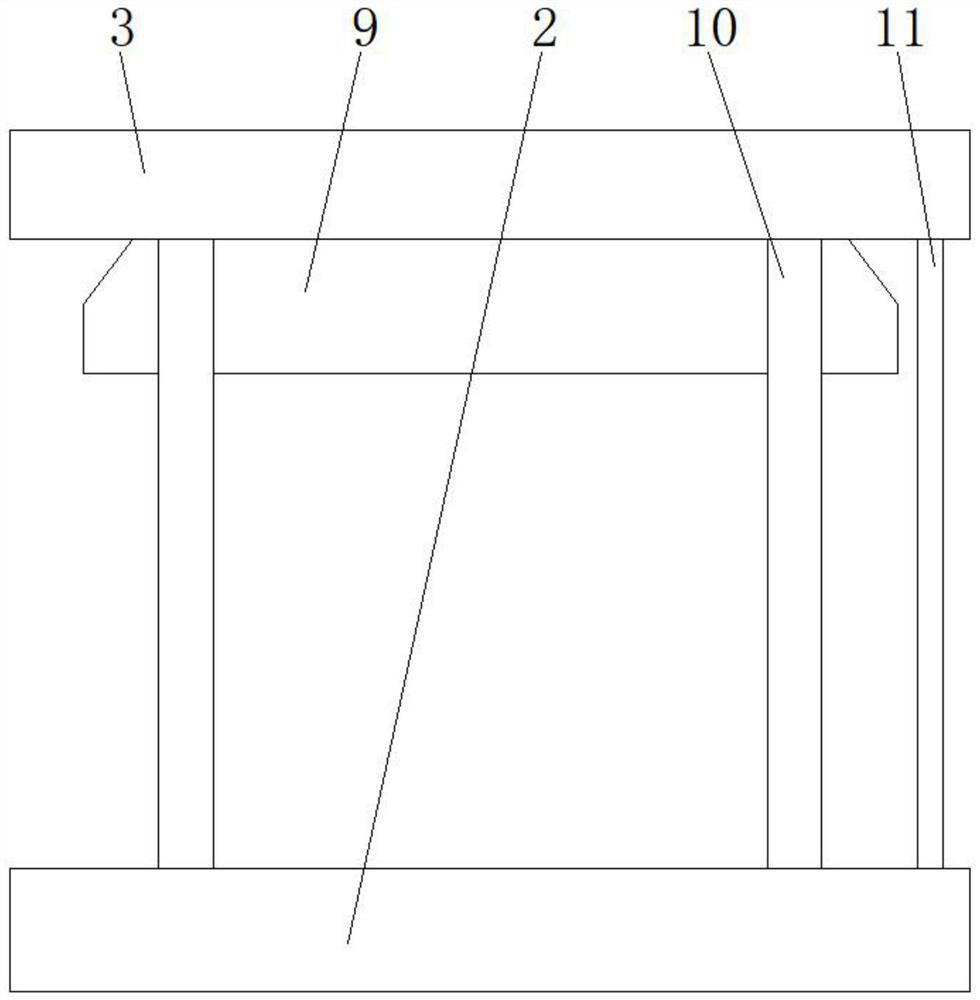

Coiling device for production of non-woven fabric

InactiveCN110127411APrevent fallingEasy to take awayCleaning using gasesWebs handlingDrive wheelDrive motor

The invention discloses a coiling device for production of a non-woven fabric, and mainly relates to the technical field of production equipment for the non-woven fabric. The coiling device comprisesa processing rack; a driving motor is arranged on the horizontal section of the processing rack; the end of the driving motor is connected with a driving wheel; a winding roller is arranged on one side of the machining rack; driven wheels are arranged at two ends of the winding roller; the coiling device is characterized in that a first tensioning device and a second tensioning device are arrangedon the processing rack respectively; and a leveling and dust cleaning device is arranged on one side of the second tensioning device. A relatively-closed area is constructed to limit diffusion of dust, a stable air cushion is formed on the surface of the finished non-woven fabric at an outlet of the leveling and dust cleaning device, the dust is prevented from falling onto the finished non-wovenfabric, meanwhile, impurities produced during leveling are blown up and can be pumped away conveniently by the aid of a negative-pressure pumping device, the non-woven fabric can be tensioned effectively under the action of the first tensioning device and the second tensioning device, continuous production of the non-woven fabric can be guaranteed, the coiling device is convenient to operate, andthe working efficiency is improved.

Owner:JINAN HAOXIN IND

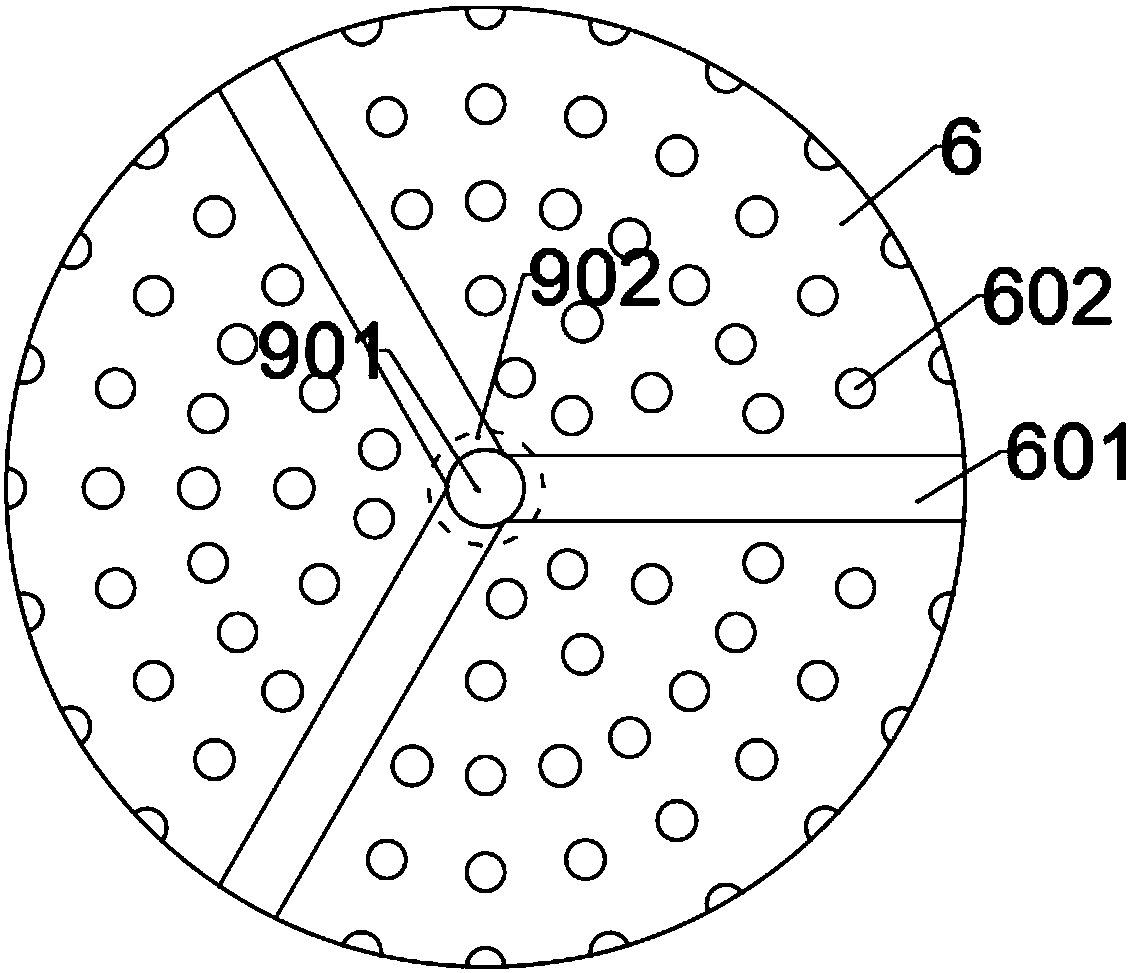

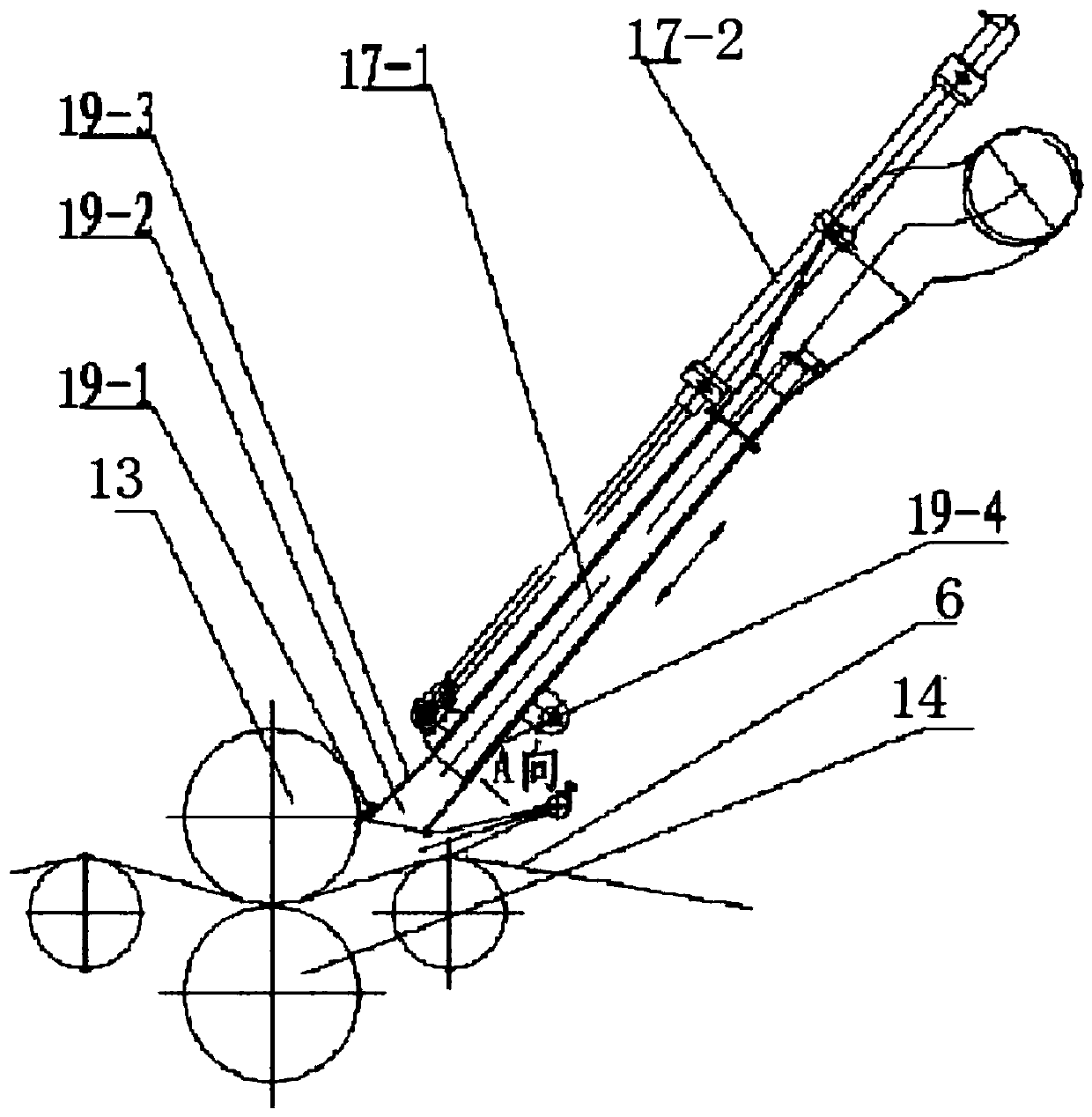

Rotary cleaning device and rotary cleaning method for electrostatic dust collection equipment

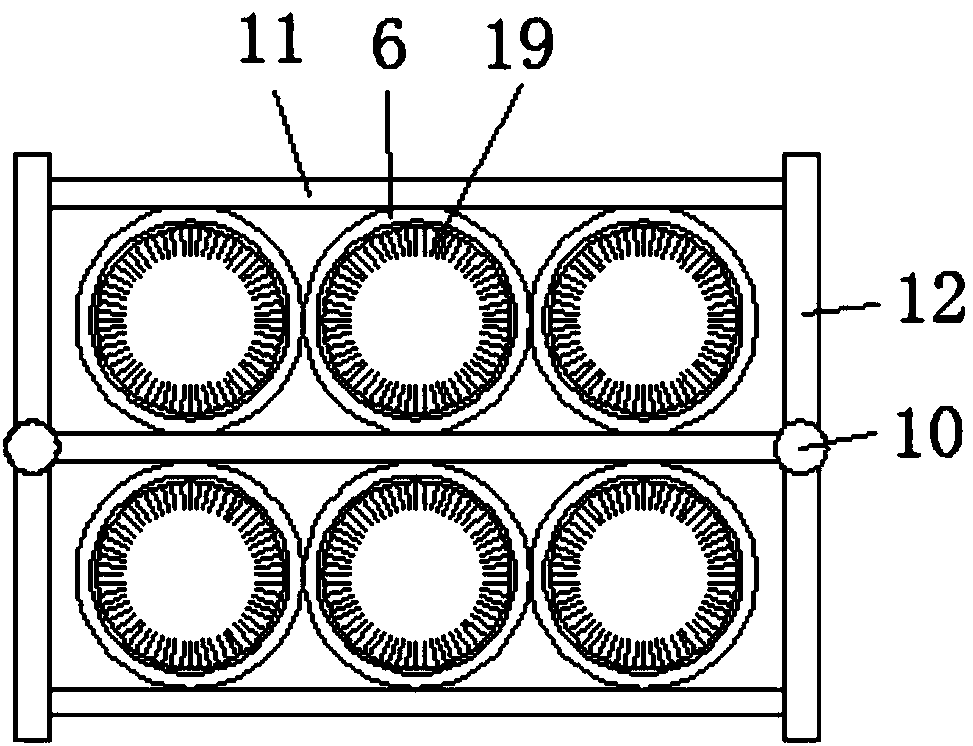

PendingCN113814067AAffect the effect of dust removalGuaranteed dust removal performanceCleaning using liquidsElectrodes cleaningDust controlElectric machinery

The invention discloses a rotary cleaning method of a rotary cleaning device of electrostatic dust collection equipment. The rotary cleaning device comprises a plurality of cleaning pipes, wherein the cleaning pipes are respectively arranged between two adjacent layers of electrostatic dust collection units, two ends of each cleaning pipe are respectively rotatably mounted on a case, one end of each cleaning pipe extends out of the case and is connected with a water supply pipe through a rotary sealing joint, the water supply pipes are connected with a water tank through booster pumps, a plurality of micropores are formed in the pipe walls of the cleaning pipes and communicated with the interior of the cleaning pipes, a motor is installed on the outer side of the case, and the cleaning pipes are driven by the motor to rotate. The rotating cleaning pipes spray high-pressure water to clean an upper electrostatic dust collection unit and a lower electrostatic dust collection unit, and the situation that too much dust is accumulated on the electrostatic dust collection units to affect the dust collection effect of the dust collection equipment is avoided. By adopting the mode of rotating the cleaning pipes, the structure is simpler, and the cost is lower; the cleaning effect can be effectively guaranteed; and the cleaning pipes are very convenient to clean and maintain.

Owner:嘉兴沃非尔环境技术有限公司

Wind energy dust removal equipment

ActiveCN109316862AAutomatic replacementAffect the effect of dust removalDispersed particle filtrationTransportation and packagingWater storage tankEngineering

The invention relates to dust removal equipment, in particular to wind energy dust removal equipment, which not only can be used for removing dust by means of wind energy so as to save electric energy, but also can automatically replace a filter plate so as to prevent a dust removing effect from being affected since the filter plate is blocked by dust. A push device is arranged at the upper end ofa shell; a cleaning device and a water storage tank II are arranged at the lower end of the shell; a blocking device is arranged in the shell; one end of a spring III is fixedly connected with a fixed plate, and the other end of the spring III is fixedly connected with a board; a magnet is arranged at the right end of the board; the fixed plate is fixedly connected with the interior of a main body of the shell, and is positioned at the upper end of a filter plate I; the magnet attracts a filter plate II; a water storage tank I consists of a main body of the water storage tank I, a plug, a valve and a through hole IV; the plug is arranged at the upper end of the main body of the water storage tank I; the valve is arranged on the main body of the water storage tank I; the through hole IV isformed at the left lower left end of the main body of the water storage tank I.

Owner:南京勤丰秸杆科技有限公司

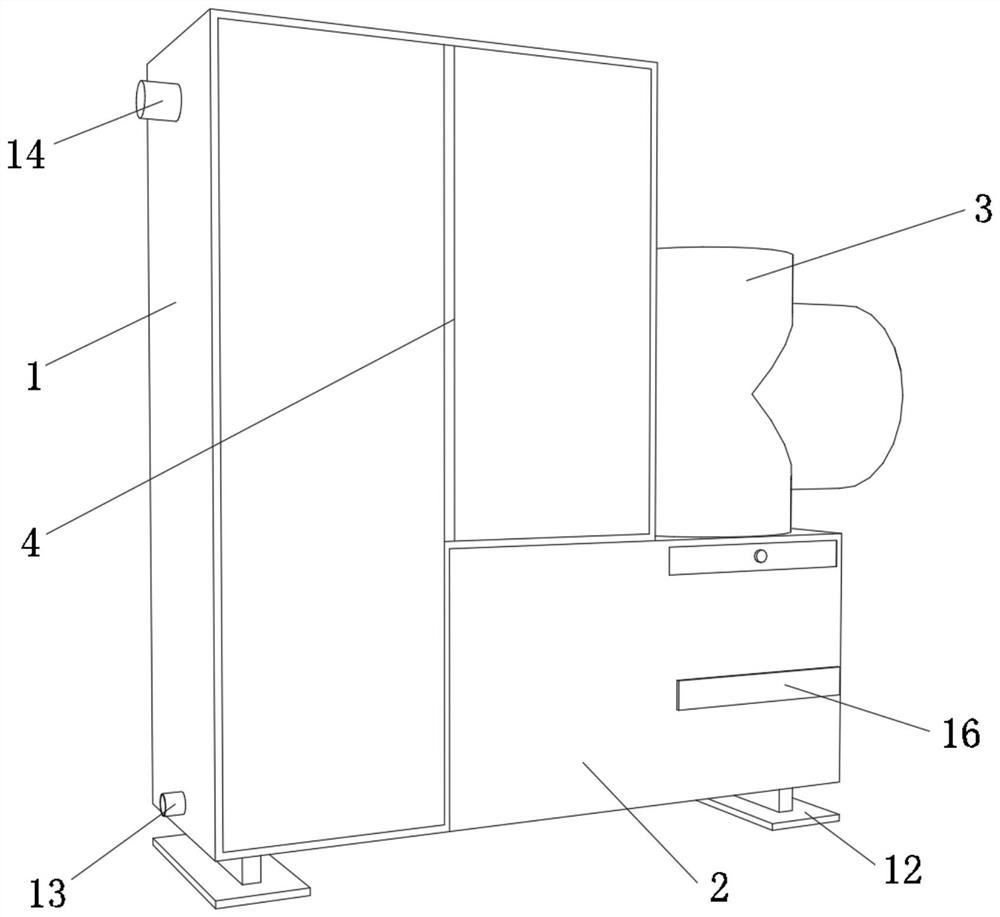

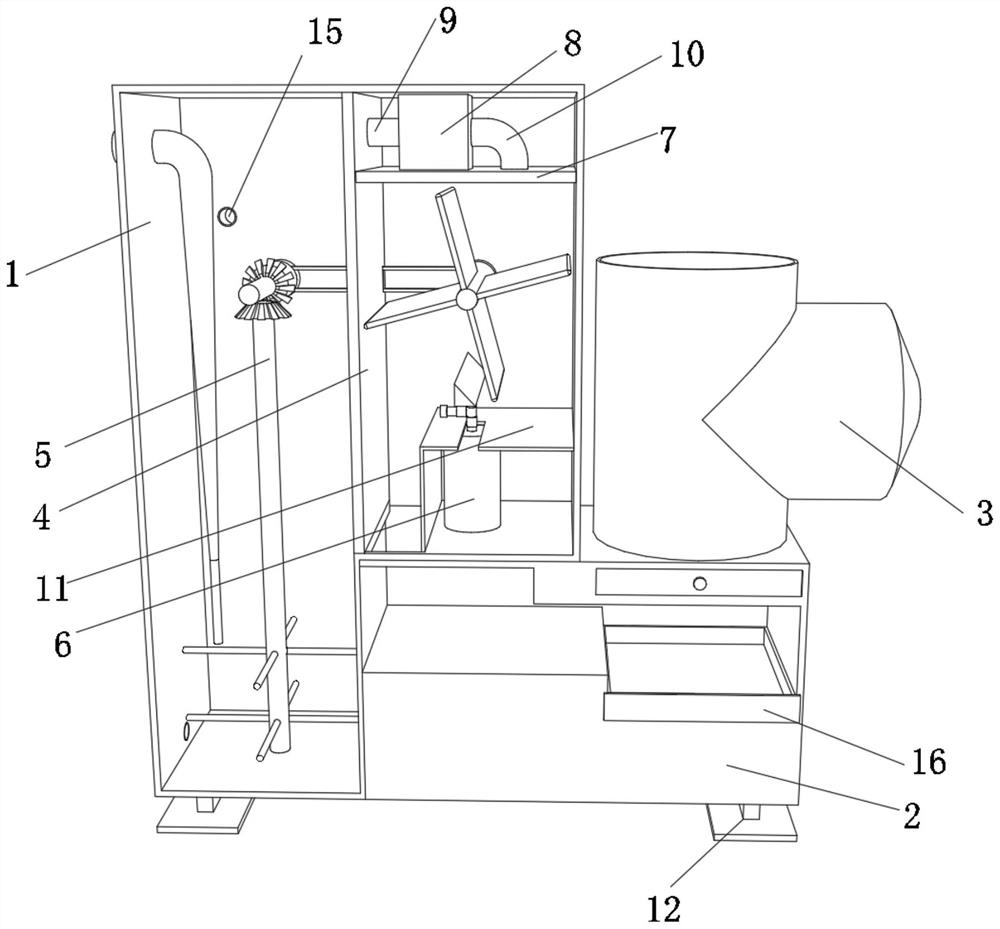

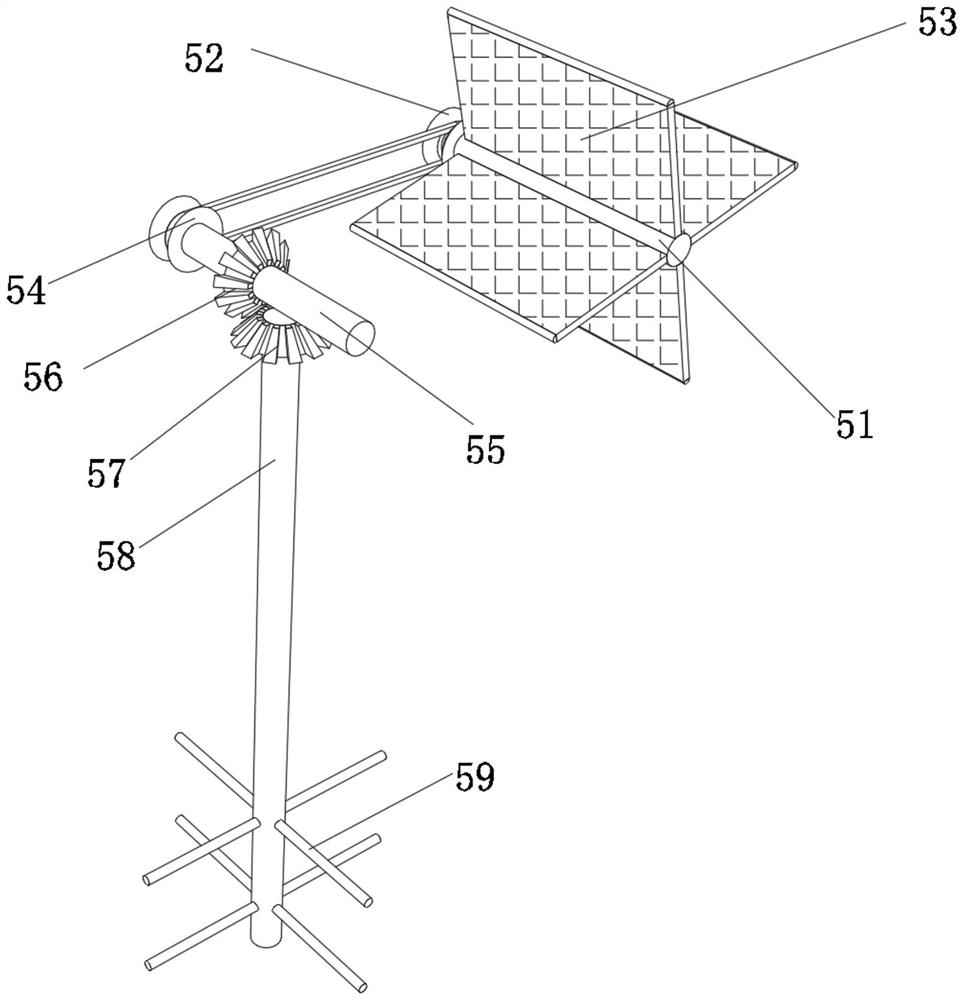

Dust removal device for furniture production

PendingCN111408206ASolve the problem of inability to remove harmful substancesAffect the effect of dust removalDispersed particle filtrationTransportation and packagingThermodynamicsHazardous substance

The invention relates to the technical field of dust removal devices, in particular relates to a dust removal device for furniture production. In order to solve the problem that the dust removal effect of a dust remover is affected due to the fact that a dust removal cloth bag of an existing dust removal device for furniture production is affected with damp and sawdust adheres to the surface of acoarse filter screen, the following scheme is provided: the dust removal device comprises a dust remover box and a dust removal chamber, the top of the dust remover box is fixedly connected with a fan; an air inlet pipe is fixedly connected to the outer part of the dust removal box; a pulse bag-type dust remover body, a heating device, a coarse filter screen and a brush are arranged in the a dustremover box; a connecting rod is fixedly connected to one end of the back face of the brush, the other end of the connecting rod extends out of the dust remover box, a rotating motor is arranged outside the dust removing box, an output shaft of the rotating motor is in transmission connection with the other end of the connecting rod, and a partition plate and an ash hopper are fixedly connected tothe bottom of the dust removal cavity. The problem that the dust removal effect is affected is solved, and the purpose of removing harmful substances volatilized from paint is achieved.

Owner:江苏冠誉办公科技有限公司

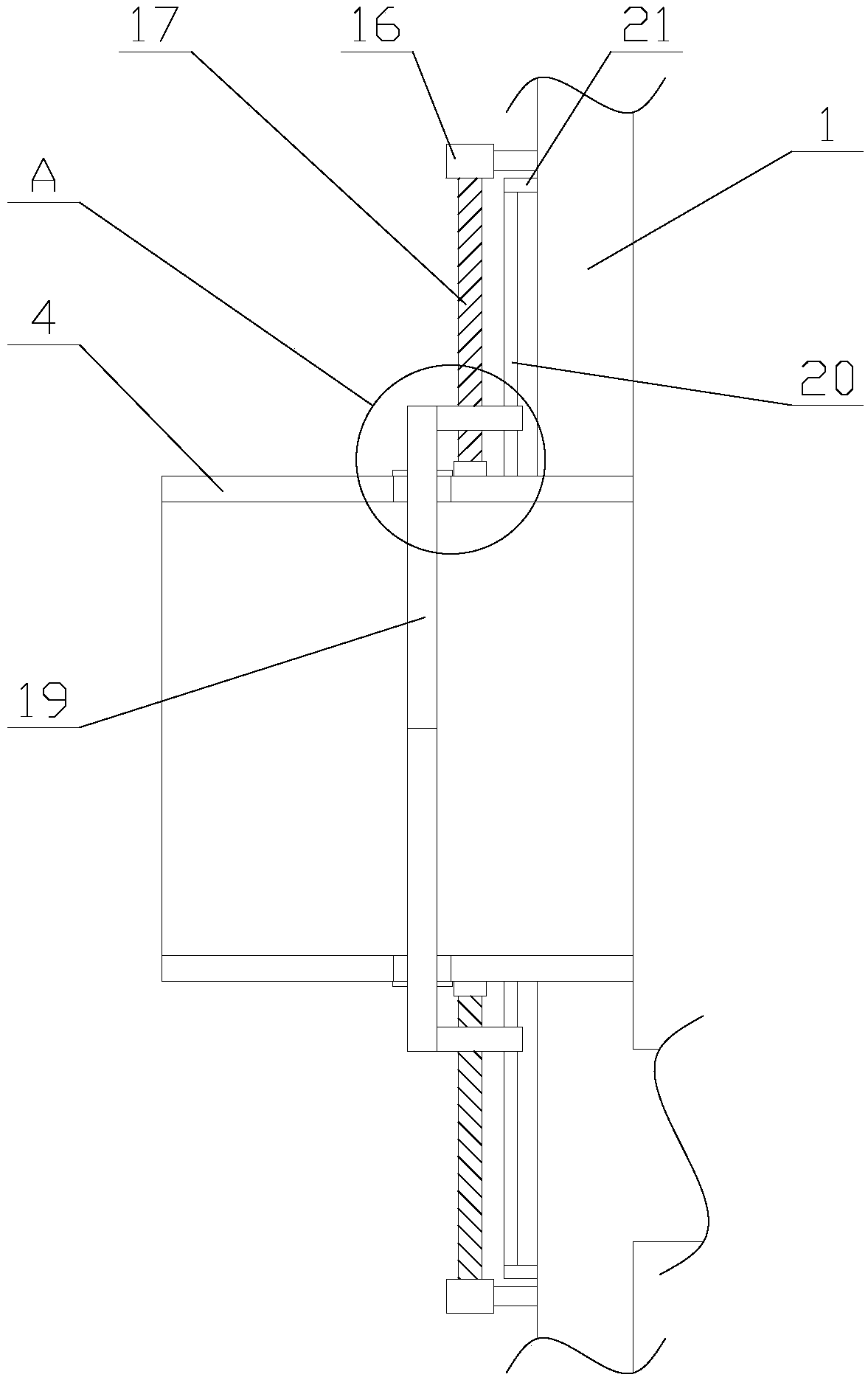

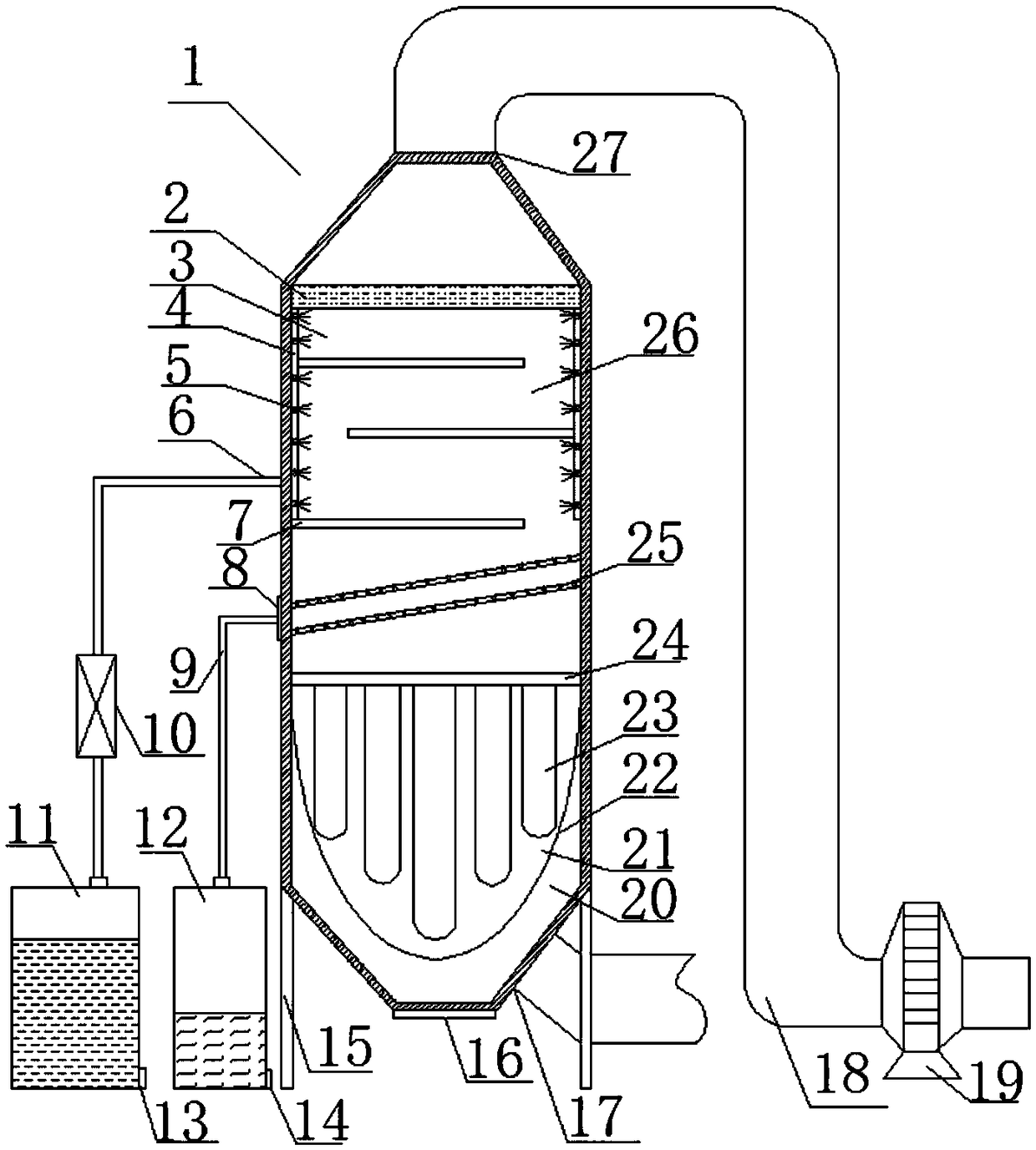

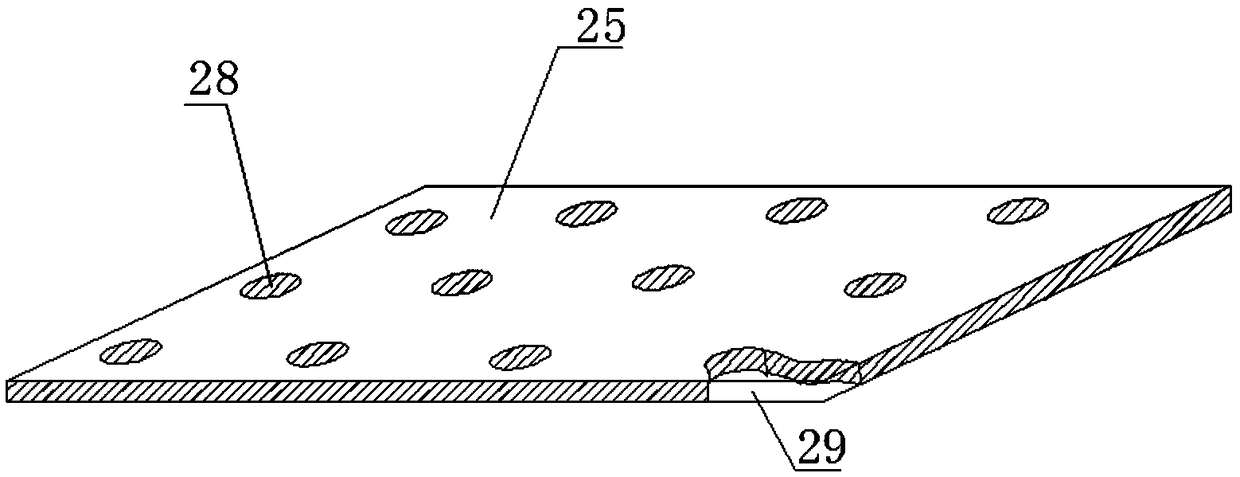

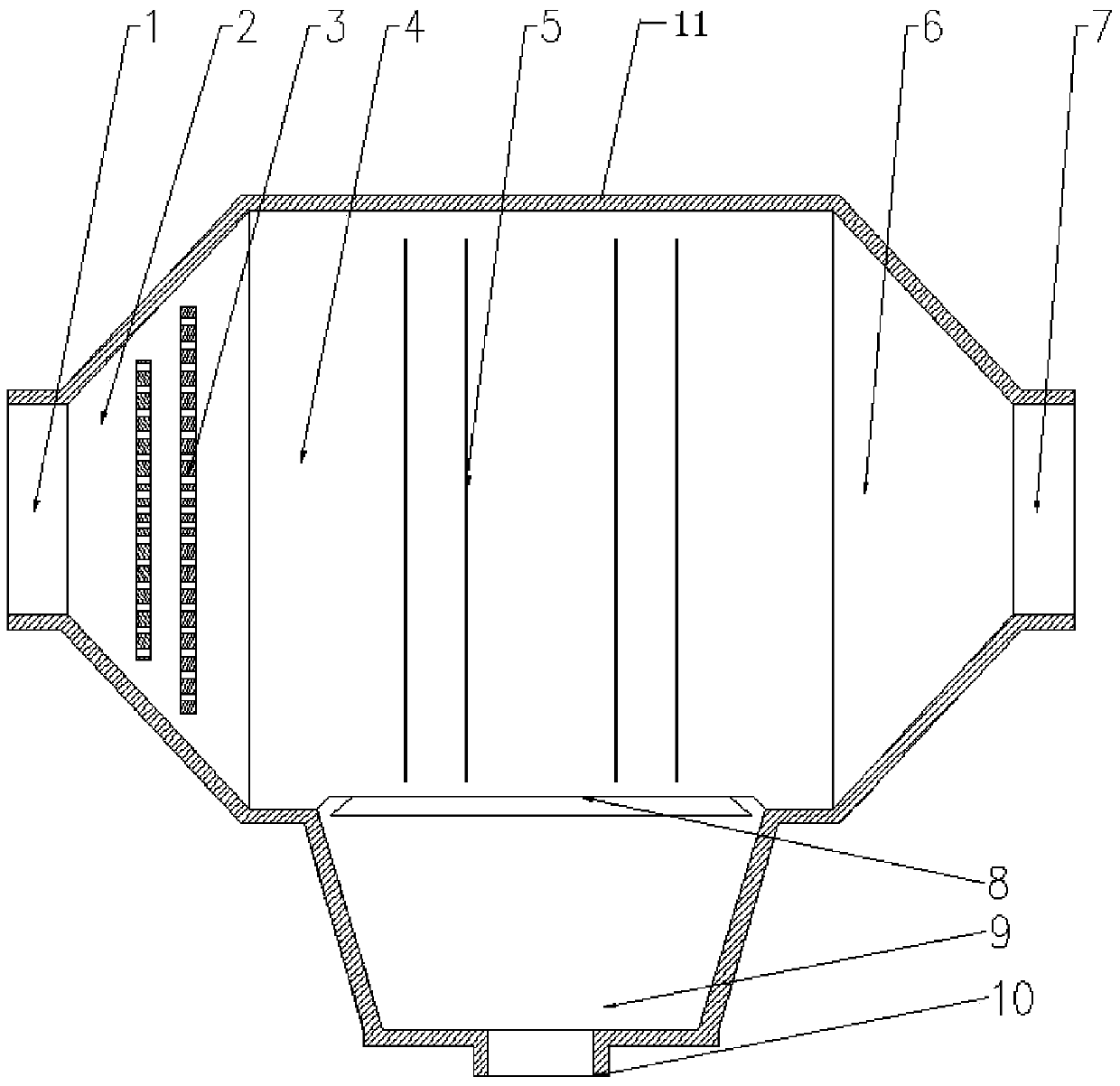

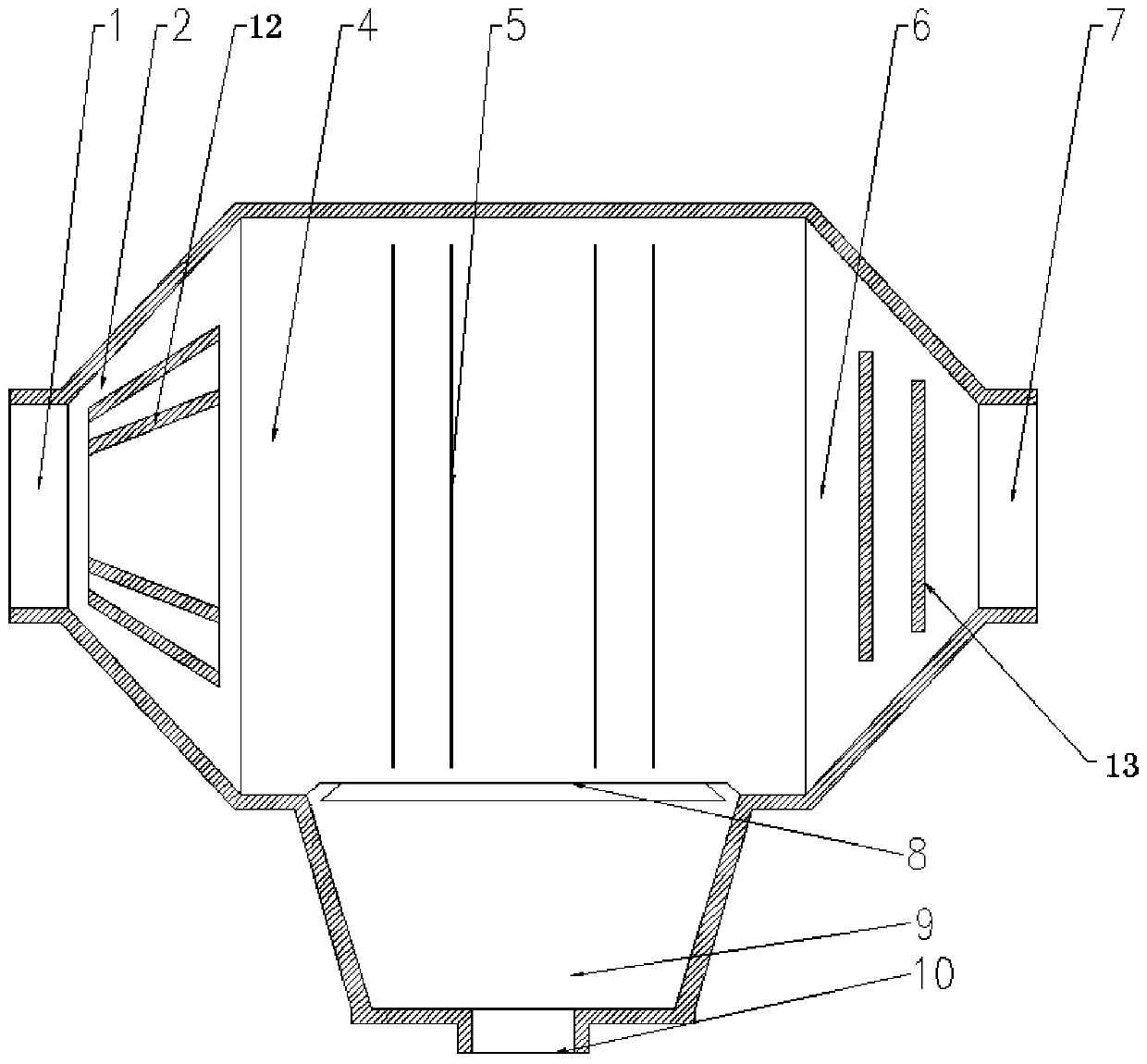

An environmentally friendly efficient desulfuration dust collector

InactiveCN108993076AThorough dust removalGood effectCombination devicesGas treatmentSpray nozzleEngineering

The invention relates to an environmentally friendly efficient desulfuration dust collector. The desulfuration dust collector includes a dust collector main body and a support. The bottom of the dustcollector main body is provided with a gas inlet and a dust outlet, and the top of the main body is provided with a gas outlet connected to a draught fan through a gas pipeline. The main body includesa bag type dust collection chamber, a spraying chamber and a filler layer in order from bottom to top. Inclined permeable plates are disposed between the bag type dust collection chamber and the spraying chamber. A bag filter fixedly mounted to the inner wall of the bag type dust collection chamber is disposed in the bag type dust collection chamber. A plurality of spraying pipes are fixedly mounted to the periphery inner wall of the spraying chamber and are provided with a plurality of spray nozzles. The bag type dust collection chamber, the spraying chamber and the filler layer are disposedin the main body in order so that dry type dust collection and wet dust collection are combined, dust and harmful and toxic substances such as sulfur dioxide in gas can be removed at the same time, and dust is thoroughly removed with good effects.

Owner:河南东贵电子科技有限公司

Dedusting method and device for high-temperature smoke

PendingCN109603334AReduce stressReduce the action on the valveDispersed particle filtrationEngineeringHot Temperature

The invention discloses a dedusting method for high-temperature smoke. The method comprises the steps that a dust collection cover is used for collecting the smoke, the smoke is conveyed to a purification dedusting system through a pipe for dedusting, and the concentration of combustible substances in the pipe is detected in real time; when the concentration exceeds a preset concentration range, first protective gas is supplemented for the interior of the pipe at a preset spraying angle, so that the concentration is restored to the preset concentration range; the temperature in the pipe is detected in real time, and when the temperature exceeds the preset temperature range, second protective gas is supplemented for the interior of the pipe, so that the temperature is restored to a preset temperature range; an expansion assembly is arranged on the pipe for compensating for deformation of the pipe. The invention further discloses a dedusting device for the high-temperature smoke. The device corresponds to the method. According to the method and device, the pipe can be effectively prevented from being damaged, smoke escape is avoided, and the device is safe to use.

Owner:GUANGXI YUCHAI MASCH CO LTD

Efficient multifunctional dust collector

InactiveCN109833675AAffect the effect of dust removalExtended service lifeDispersed particle filtrationElectrostatic separationEngineeringDust collector

The invention discloses an efficient multifunctional dust collector, which comprises an air jet chamber, a filter and a dedusting box. The dedusting box is connected to an exhaust chamber through an air inlet pipe, and the filter is installed on the upper side of the exhaust chamber, a filter bag is installed under the filter, an ash storage bin is installed on the left side of the filter, an electrostatic dust collector is installed on the upper side of the filter, and an air inlet chamber is installed on the electrostatic dust collector, an ash hopper is installed under the dedusting box, and an ash discharge hole is installed under the ash hopper, a bracket is installed under the dedusting box, a pulse valve is installed on the left side of the dedusting box's surface, the air jet chamber is installed on the right side of the pulse valve, an air outlet is mounted on the right side of the air jet chamber, air jet pipes are installed inside the air jet chamber, and a dust collector isinstalled below the air jet pipes. According to the invention, a vibration filter screen is installed inside the dedusting box for vibration of the dust filtered out by the dust collector in the dedusting box, thus accelerating the falling of dust into an deasher, and increasing the dust removal efficiency.

Owner:刘艳

Conveyor belt dust collecting and processing device

PendingCN113877309ADoes not affect operation and maintenanceSimple structureDispersed particle separationDirt cleaningDust controlEngineering

A conveyor belt dust collecting and processing device relates to the technical field of dust removal equipment and comprises a dust collector, a conveyor belt dust removal device, a throwing point dust suction device and a blanking point dust suction device. The conveyor belt dust removal device comprises a dust removal cover, a collection gill and an air duct fan. The dust removal cover is formed by overlapping a plurality of sections of telescopic cover bodies, and a group of supporting frameworks are arranged on each section of cover body at intervals. The collecting gill is formed by sequentially connecting a plurality of gill bodies in a lap joint mode, and a set of air duct fans are arranged in the length direction of the collecting air duct at intervals. The dust collector comprises a shell, a spiral blade and a transmission shaft. The throwing point dust collection device comprises a first dust collection cover and a first dust collection fan, and the blanking point dust collection device comprises a second dust collection cover and a second dust collection fan. The dust removal device is simple in structure, reliable in performance and convenient to install, maintenance of the conveyor belt is not affected, good dust removal and treatment effects can be achieved for particles of different sizes and dust of different humidity and viscosity, and the fault rate is low.

Owner:贾玉彬

A smart city traffic safety monitoring device and monitoring system

ActiveCN111866469BEasy to cleanAffect the effect of dust removalTelevision system detailsColor television detailsDust controlMonitoring system

Owner:成都和乐信软件有限公司

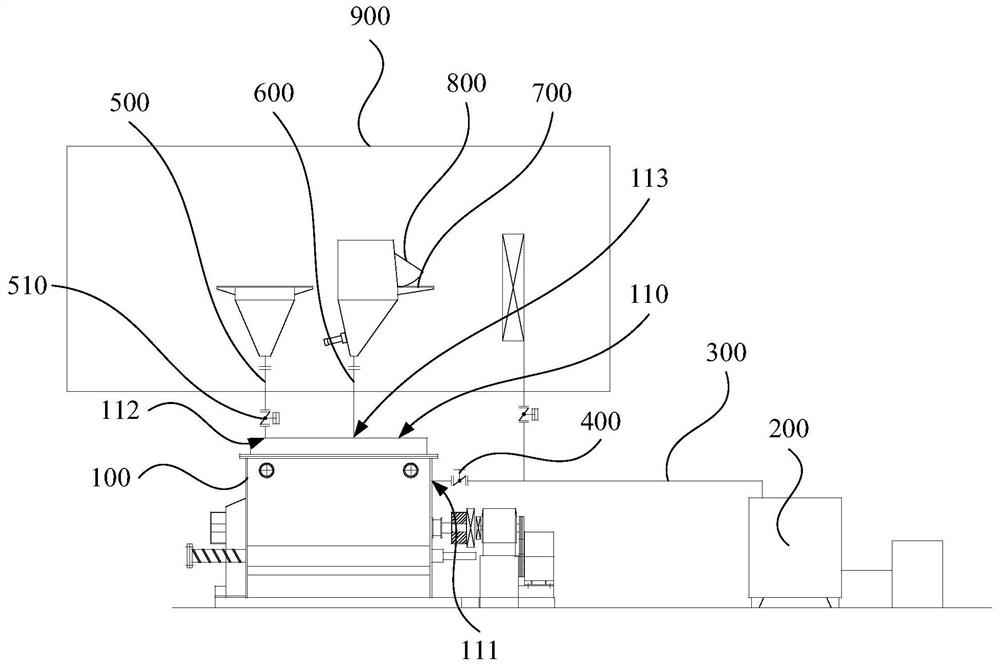

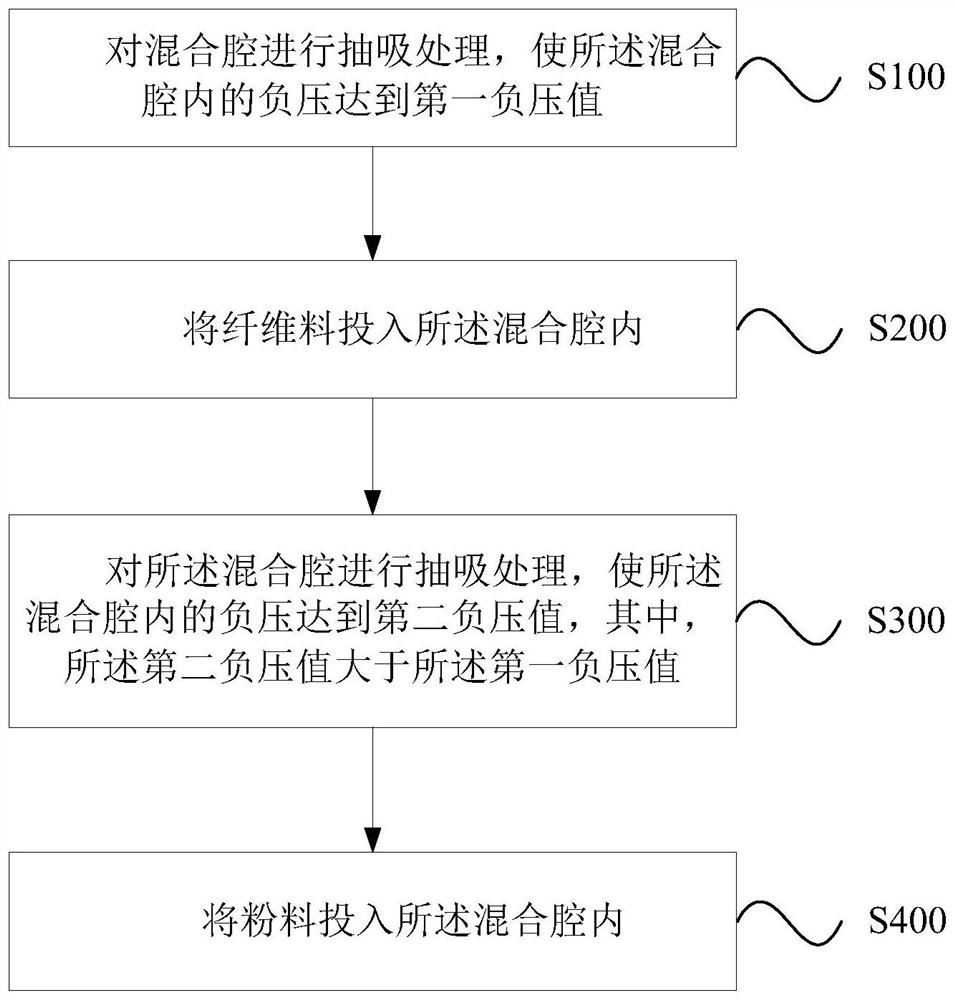

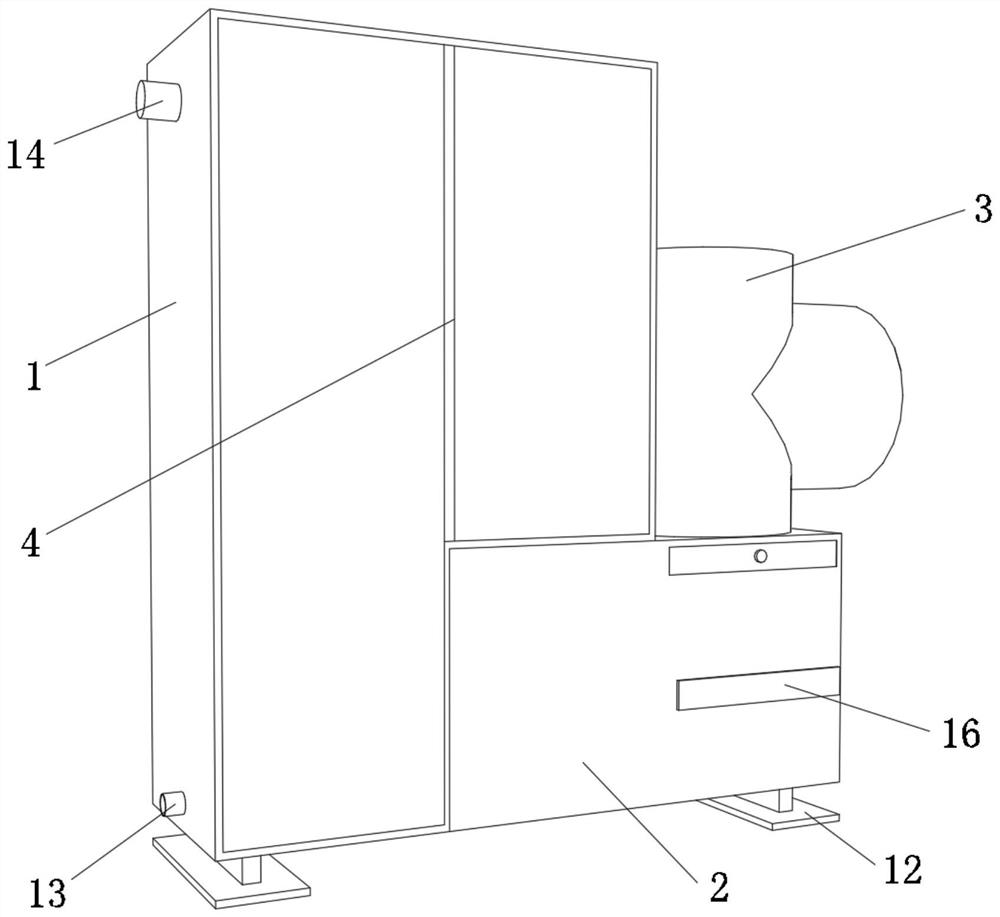

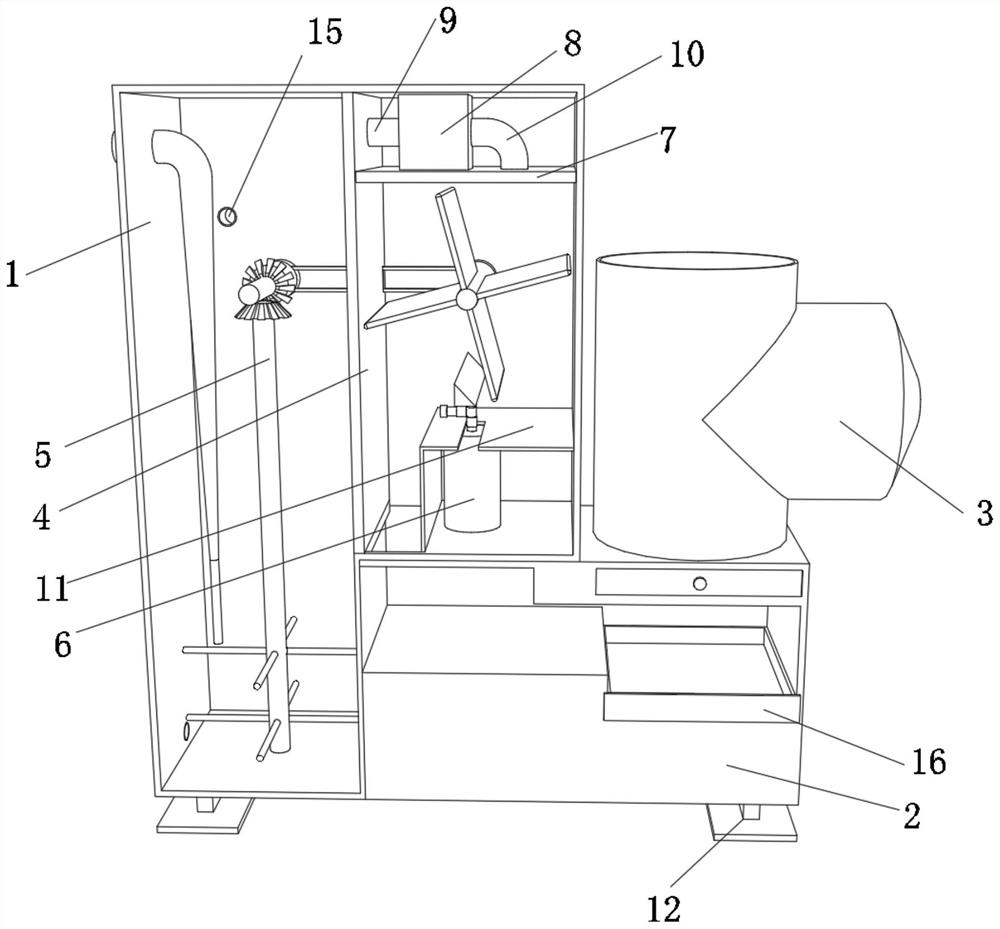

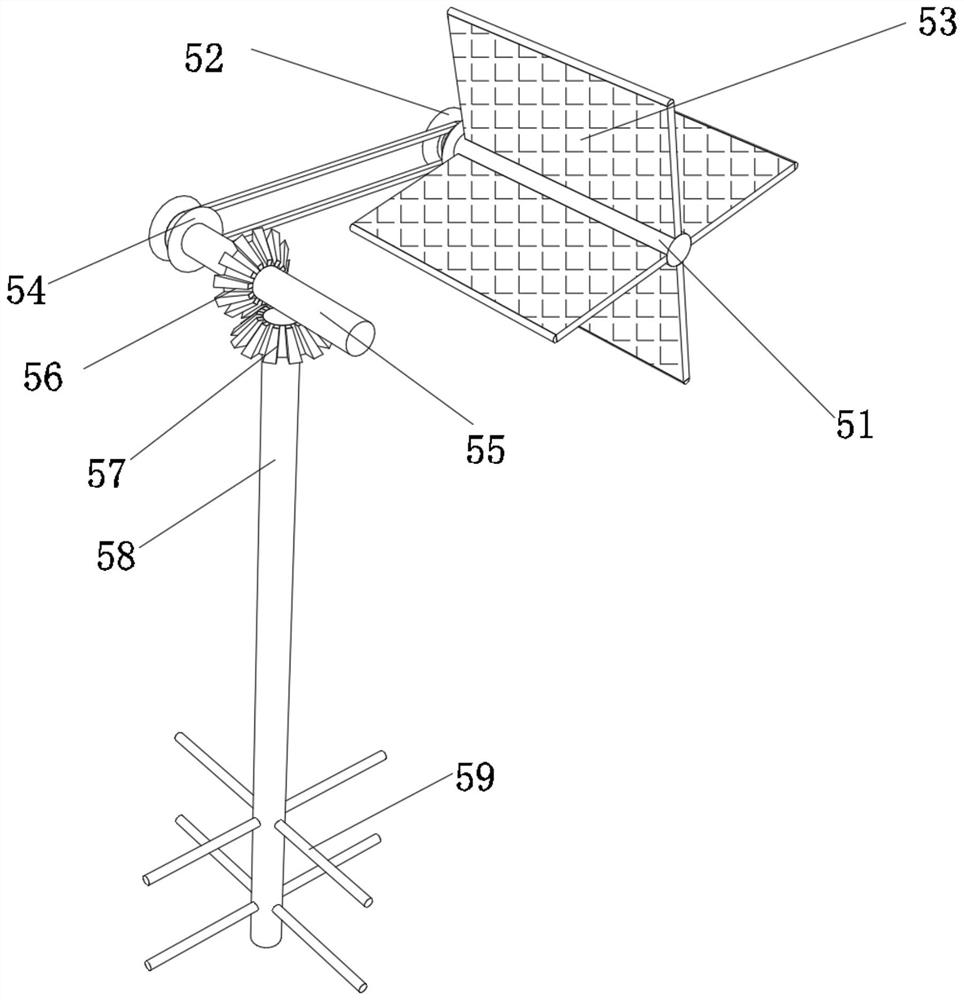

Production device and production method of sealing grease

PendingCN111686622AAffect the effect of dust removalAvoid Spills FlyingTransportation and packagingMixer accessoriesOil and greaseThermodynamics

The invention relates to a production device and a production method of sealing grease. The production device comprises a mixer and a dust removal mechanism, wherein the mixer is provided with a dustremoval port and a mixing cavity for mixing raw materials, the dust removal port is communicated with the mixing cavity; the dust removal mechanism comprises a suction element, an air inlet of the suction element is communicated with the dust removal port, and the suction element can adjust the negative pressure in the mixing cavity. After raw materials are added into the mixing cavity, a large amount of dust can be generated and can be sucked and removed through the suction element, dust is prevented from overflowing and flying, environmental protection is facilitated, and health of field personnel is also facilitated. Meanwhile, the negative pressure in the mixing cavity can be adjusted by the suction element; therefore, the negative pressure in the mixing cavity can be adjusted according to raw materials with different weights, on the premise that the dust removal effect is guaranteed, raw material waste caused by the fact that the raw materials are sucked into the suction element can be avoided, and the situation that the dust removal effect is affected due to the fact that the suction element is blocked by the sucked raw materials can also be avoided.

Owner:中铁建华南建设(广州)高科技产业有限公司

A waste gas treatment equipment with dust removal function

ActiveCN113019043BTo achieve the purpose of dust removalAffect the effect of dust removalCombination devicesParticulatesWater source

The invention relates to waste gas treatment, and discloses waste gas treatment equipment with a dust removal function, comprising a water tank, a bottom box is welded on the surface of the water tank, a dust removal mechanism is arranged inside the bottom box, and a The vertical plate, the rear wall of the water tank is provided with a crushing mechanism, the bottom wall of the water tank is located on the right side of the vertical plate with a spray mechanism, and the right side of the vertical plate is fixedly connected to the inner wall of the water tank through the horizontal plate. The waste gas treatment equipment with dust removal function and its use method can initially remove the waste gas through the water source, reduce the existence rate of dust in the waste gas, and then transport the waste gas to the bottom box and the inside of the dust removal pipe through the air pump, so that the water adsorption method The exhaust gas after dedusting is filtered again by the filter screen, filter plate and filter box, so as to reduce the existence of particulate matter in the exhaust gas again, so as to achieve the purpose of dedusting the exhaust gas and meet the requirements of environmental protection.

Owner:四川中电福溪电力开发有限公司

A control system and method for a bag filter

ActiveCN108379968BImprove cleaning efficiencyExtended service lifeGas treatmentDispersed particle filtrationSteelmakingAutomatic control

The invention discloses a control system and a control method of a bag-type dust remover. The system comprises a temperature sensor, a differential pressure sensor, an oxygen concentration sensor anda PLC (programmable logic controller); the temperature sensor is arranged in an inlet air flue and is in signal connection with the input end of the PLC; the differential pressure sensor is arranged at the top of the bag-type dust remover and is in signal connection with the input end of the PLC; the oxygen concentration sensor is arranged in a steel-making converter and is in signal connection with the input end of the PLC; and the output port of the PLC is connected with an offline valve, a bypass valve, a blowing pulse valve and a dust-removing fan of the bag-type dust remover as well as adust-removing valve arranged at the flue gas outlet of the steel-making converter. The system has the advantages of automatic detection and automatic control and can guarantee that the production is conducted normally and orderly; furthermore, the flue gas discharge situation is good.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

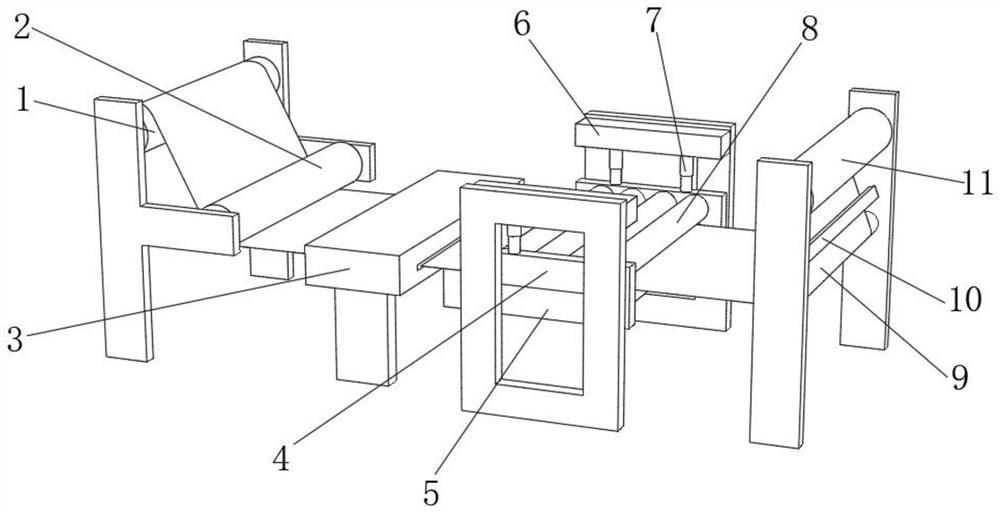

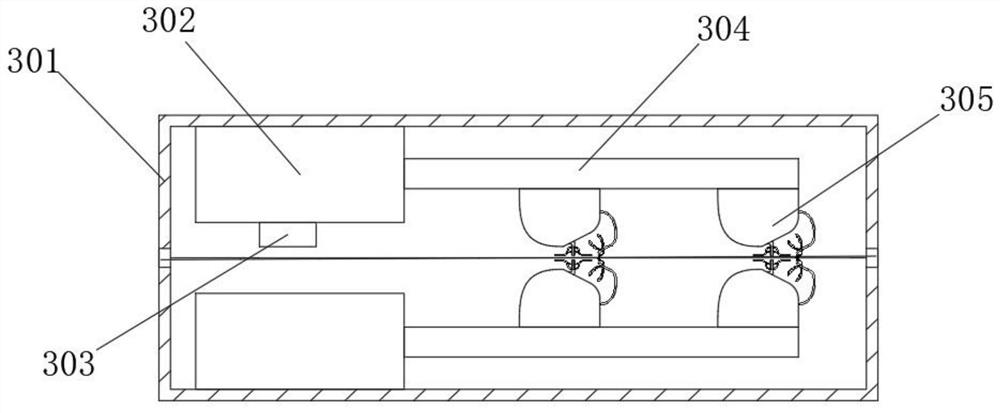

Processing and flattening equipment for automatically producing PVC film and flattening method thereof

ActiveCN113443492AElectrostatic influenceEliminate static electricityCleaning using toolsElectrostatic chargesSuction forceDust control

The invention discloses processing and flattening equipment for automatically producing a PVC film and a flattening method thereof, and relates to the technical field of film processing equipment. The processing and flattening equipment for automatically producing the PVC film comprises an unwinding roller, first supports are rotationally connected to the front end and the rear end of the unwinding roller correspondingly, a first turning roller is rotationally connected to the inner side of the right end of the middle of each first support, a second support is arranged on the right side of each first support, a dust removal box is fixedly connected to the upper end of each second support, and a third support is arranged on the right side of each second support. According to the processing and flattening equipment for automatically producing the PVC film and the flattening method thereof, a second dust removal mechanism can secondarily sweep and intercept dust and sundries, the dust and sundries can be more thoroughly removed in cooperation with a first dust removal mechanism, in addition, the second dust removal mechanism ingeniously utilizes suction force to generate power, the movement effect of second bristles is finally promoted, the cleaning effect on the dust and sundries is greatly enhanced, dust removal is faster, and the effect is better.

Owner:山东立盛装饰材料有限公司

Production equipment applied to environment-friendly nickel pig iron production

PendingCN114425481AImprove the crushing effectAvoid pollutionDispersed particle filtrationDirt cleaningProcess engineeringNickel

The invention belongs to the technical field of nickel pig iron production, and particularly relates to production equipment applied to environment-friendly nickel pig iron production, which comprises a crushing box, two first crushing rollers are rotatably connected in the crushing box through bearings, a screen frame is arranged below the first crushing rollers, and four telescopic sleeves are symmetrically fixed at the bottom of the screen frame; the surfaces of the telescopic sleeves are sleeved with first springs, and the top ends of the first springs are fixed to the bottom of the screen frame. By arranging the driving mechanism, the through opening, the bearing plate, the shell and a second crushing roller, large raw ore which does not pass through screening can be subjected to secondary crushing, the crushing effect on the raw ore is improved, by arranging a dust treatment box, a dust removal mechanism, a conveying mechanism and a baffle, dust-containing gas generated during crushing can be filtered and then discharged, and the dust removal effect is improved. In addition, the dust removal mechanism can be used for treating the detained dust, and the situation that the dust removal effect of the dust removal mechanism is affected due to the fact that much dust is accumulated is avoided.

Owner:扬州一川镍业有限公司

Environment-friendly dust removal equipment for plant

InactiveCN113082906AGuaranteed removal rateAffect the effect of dust removalCombination devicesUsing liquid separation agentDust controlStructural engineering

The invention relates to the technical field of environment-friendly dust removal, and discloses environment-friendly dust removal equipment for a plant. The equipment comprises a base, a transverse plate, a support plate, a spray pipe, a water receiving tank and a nut, the transverse plate is supported and fixed to the upper portion of the base through the supporting columns, the two supporting columns are fixed to the two sides of the lower portion of the transverse plate, the supporting plate is supported and fixed to the upper portion of the transverse plate through the supporting rods, the two supporting rods are fixed to the two sides of the lower portion of the supporting plate, the transverse plate and the supporting plate are both parallel to the base, the supporting columns support the two sides of the surface of the base, and the supporting rods support the two sides of the surface of the transverse plate. By arranging the transverse plate and the supporting plate and fixing the spraying pipe with the multiple spraying heads below the transverse plate, after the device is arranged at a designated position, most of dust generated during work can be cleaned away through water curtains sprayed out of the spraying heads, and then the dust scattered upwards is absorbed by an industrial dust collector through a dust collection cover; the dust removal rate is guaranteed, and meanwhile the dust removal effect of the dust collector is prevented from being affected by excessive dust.

Owner:肖海平

An outdoor dielectrophoresis dust removal equipment

InactiveCN106311471BNon-contactWill not change natureExternal electric electrostatic seperatorVapor flow controlMixed flowEngineering

The invention relates to outdoor dielectrophoresis dust removing equipment. The middle of a box body of the dust removing equipment is provided with a dust removing chamber. The dust removing chamber of the dust removing equipment is provided with parallel electrode groups. Each parallel electrode group comprises a plurality of parallel dielectrophoresis electrodes. The dielectrophoresis electrodes comprise metal profiles. The cross sections of the metal profiles are in the shapes with protrusions. The protrusions form the ridges of the dielectrophoresis electrodes. According to the outdoor dielectrophoresis dust removing equipment, the structural design is scientific and reasonable; a mixed flow control chamber, the dielectrophoresis dust removing chamber and an outlet smoke box are arranged in the equipment, so that airflow steadily and smoothly gets in and out of the dust removing equipment, and the applicability of the dielectrophoresis dust removing equipment under the outdoor environment is improved; and the parallel electrode groups are adopted, the electrodes of the different electrode groups can be connected to the two ends of an alternating current power source, and a dielectrophoresis effect can be formed in a large-scale range.

Owner:王冰

Vehicle-mounted air filtering electric sterilizer

InactiveCN112549917AAvoid affecting intake air filtrationGuaranteed uptimeGas treatmentAir-treating devicesAir filtrationBacterial virus

The invention relates to the technical field of air filtering electric disinfectors, and discloses a vehicle-mounted air filtering electric disinfector. The vehicle-mounted air filtering electric sterilizer comprises a self-cleaning mechanism and a sterilizing mechanism, and the sterilizing mechanism is fixedly connected to the upper side of an inner cavity of the self-cleaning mechanism; the self-cleaning mechanism comprises a plate box, a mounting box is fixedly connected to the bottom wall of an inner cavity of the plate box, and a motor is fixedly mounted on the bottom wall of an inner cavity of the mounting box. According to the vehicle-mounted air filtering electric disinfector, through matching of the plate box, the mounting box, the motor and the like, the device can perform dedusting operation on the inner chamber. Dust is prevented from blocking a filter screen due to long-time air filtration to influence inlet air filtration of the device, and long-time stable operation of the device is facilitated; and through cooperation of a fan rod, fan blades, a fifth gear and other devices, the device can disinfect filtered air, invasion of harmful bacteria and viruses in the air is effectively reduced, and body health of users is facilitated.

Owner:杭州展虹科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com