Dust removal device for furniture production

A dust removal device and furniture technology, applied in transportation and packaging, disperse particle filtration, disperse particle separation, etc., can solve the problems of dust bag damp, sawdust adhesion, and affect the dust removal effect of the dust collector, achieving ingenious design, reasonable structure, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

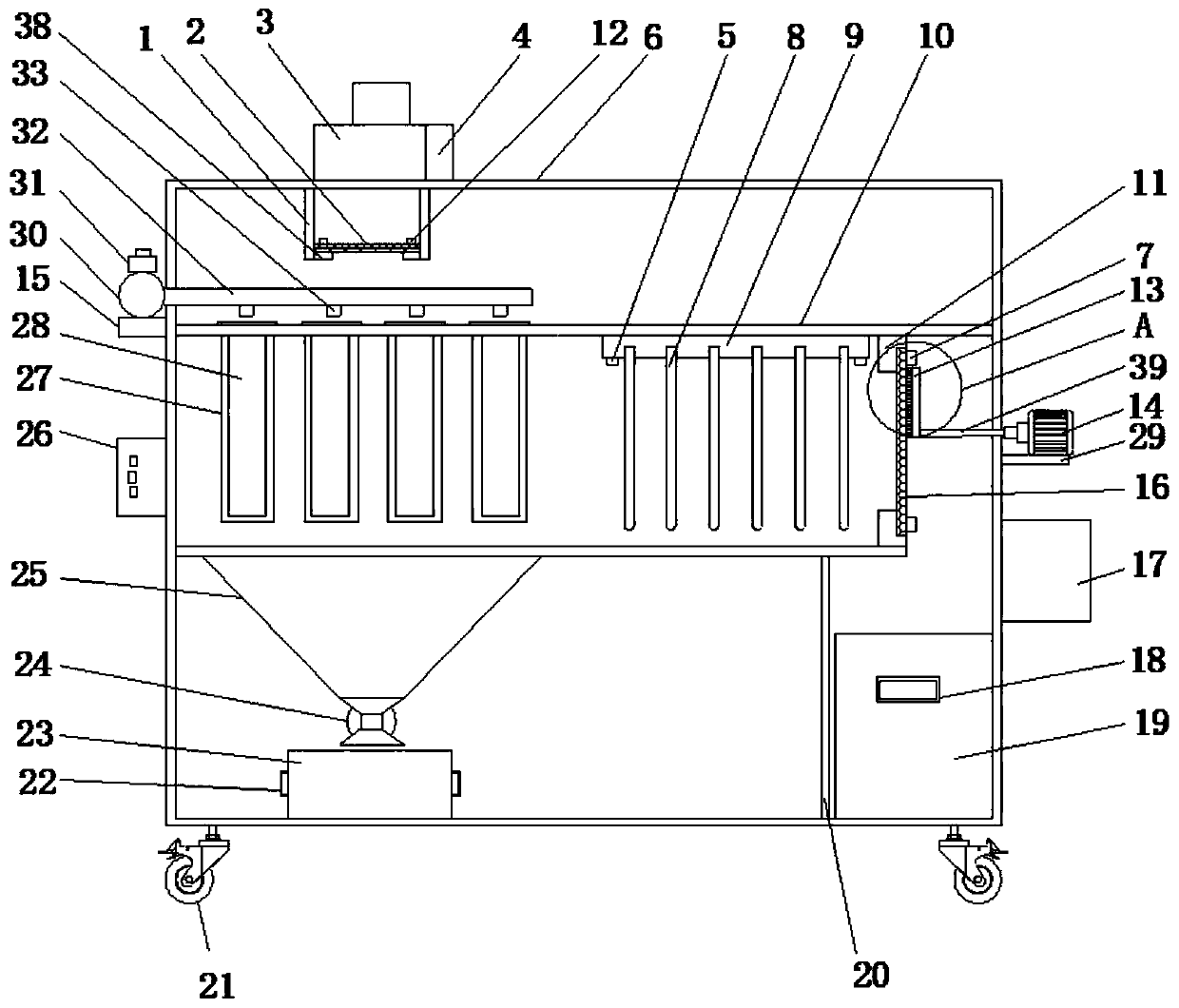

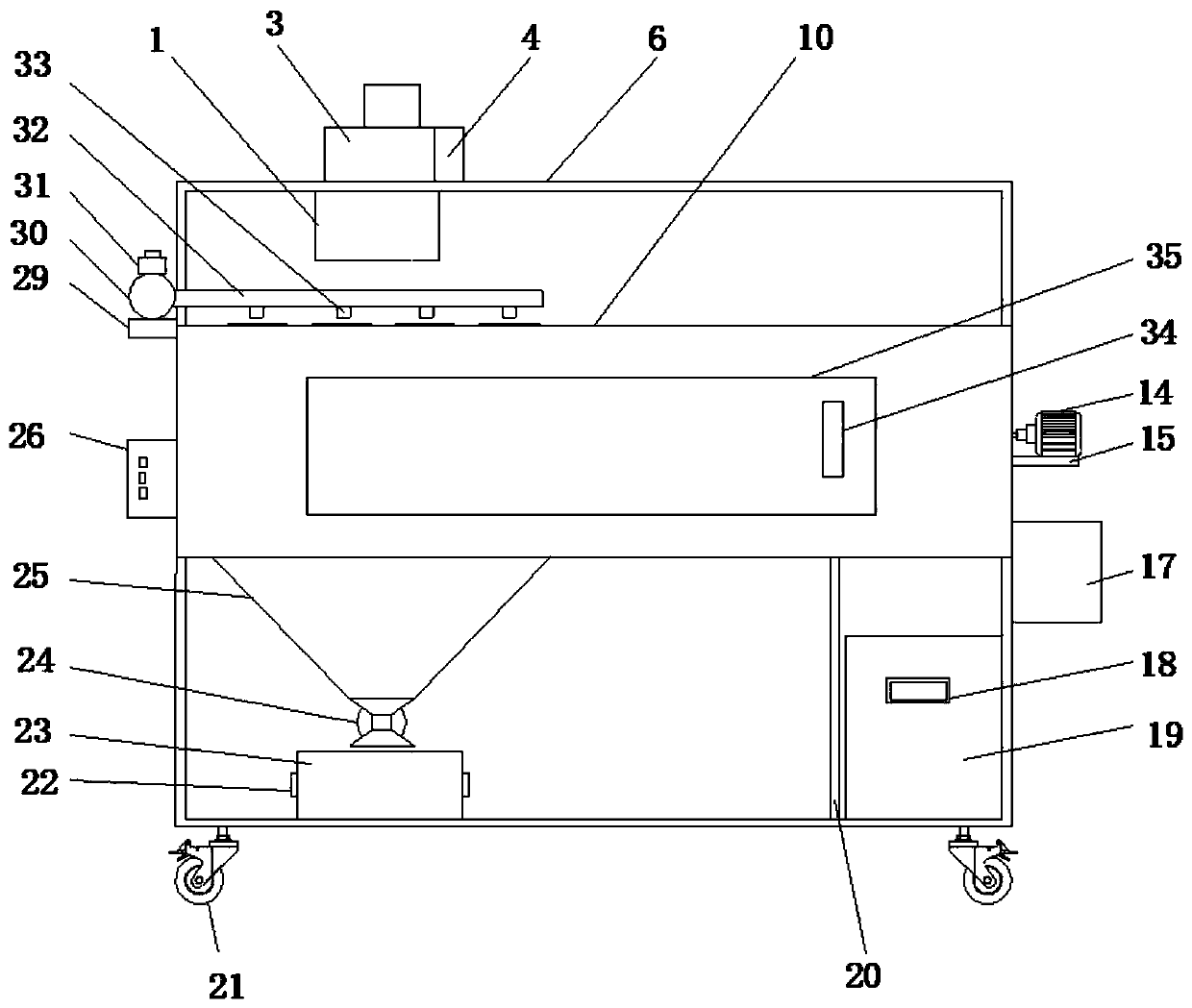

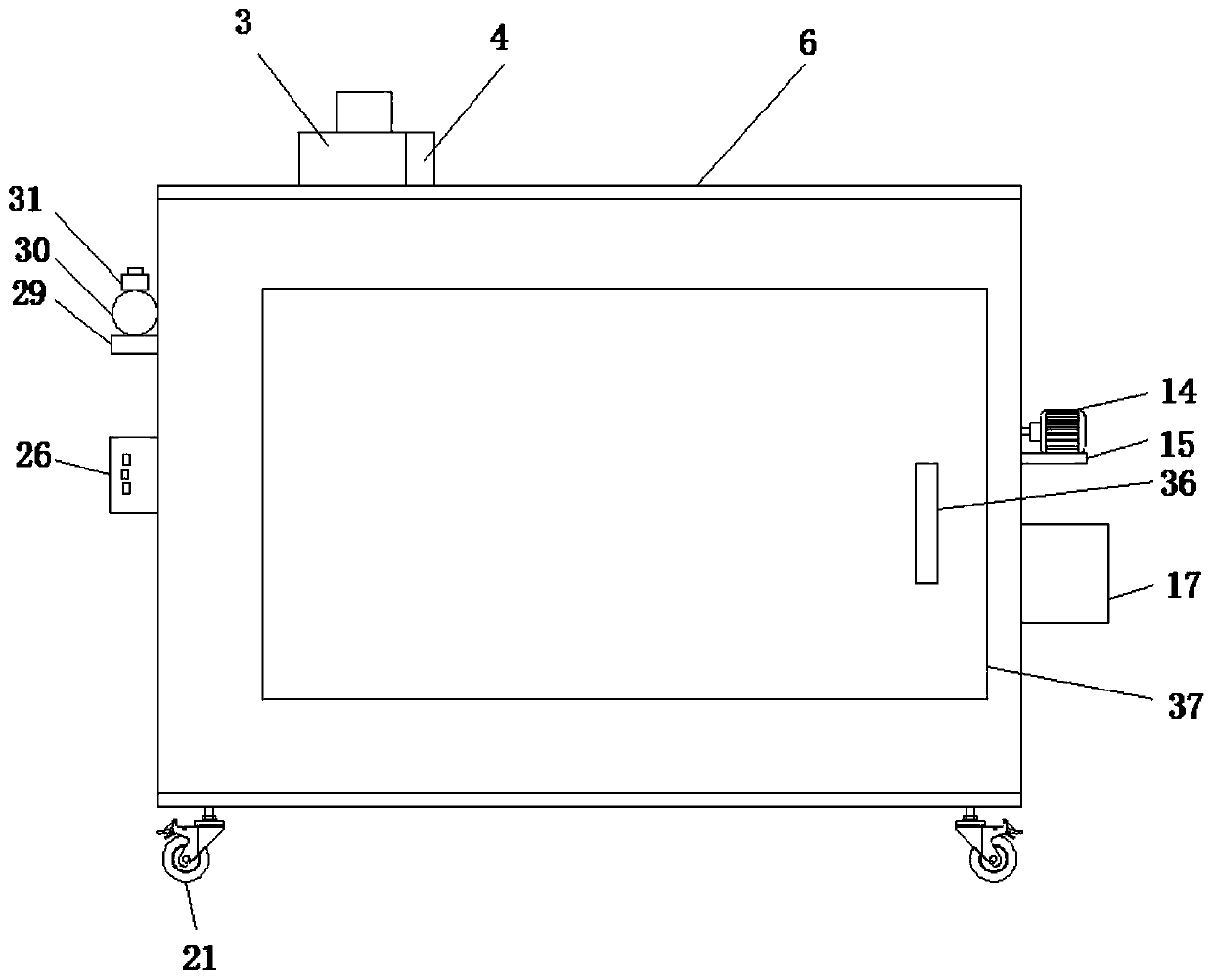

[0023] refer to Figure 1-4 , a dust removal device for furniture production, comprising a dust collector box 6 and a dust removal chamber 10, the bottom surface of the dust collector box 6 is externally fixedly connected with a plurality of universal wheels 21, and the universal wheels 21 include free universal wheels 21 and Universal wheels 21 with brakes are used to facilitate moving and fixing the position of the entire dust removal device. The dust removal chamber 10 is located inside the dust collector box 6, and the top outer wall of the dust collector box 6 is fixedly connected with the fan 3 and the bottom of the fan 3. The air inlet is provided with a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com