Patents

Literature

65 results about "Cotton dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

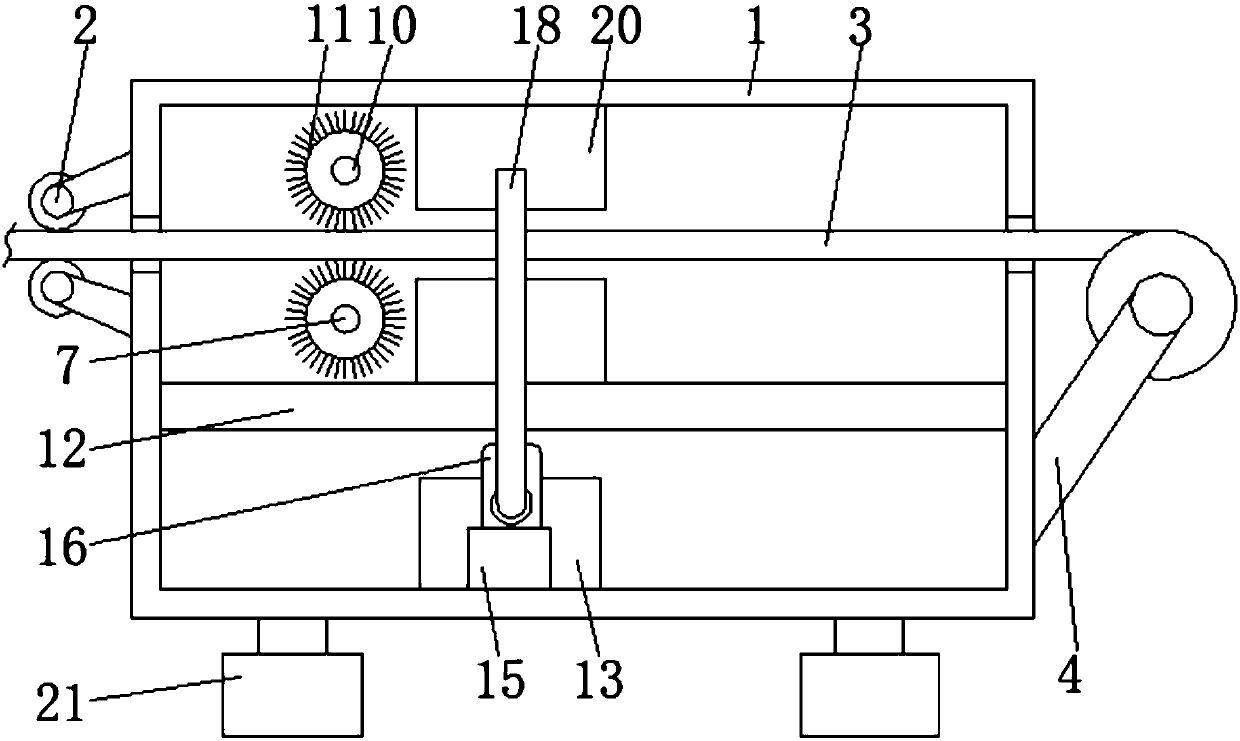

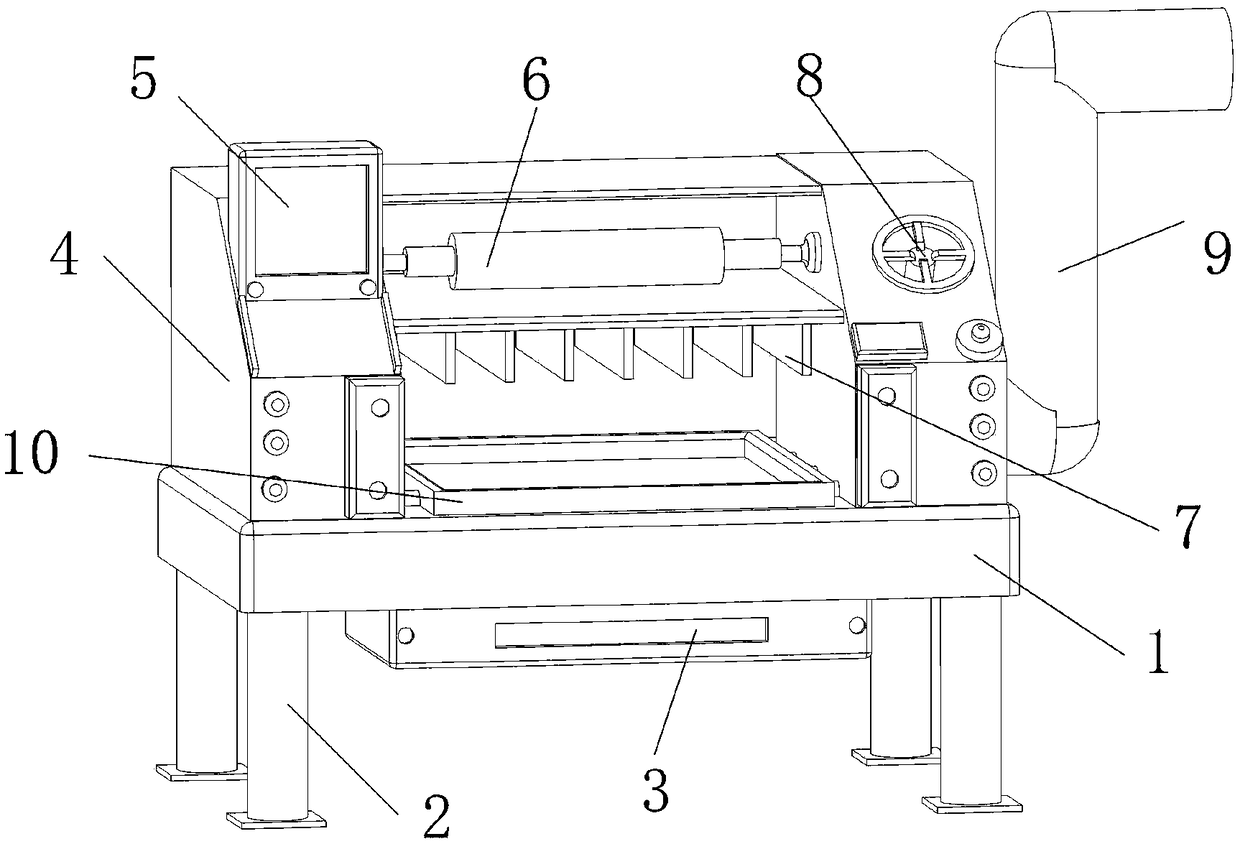

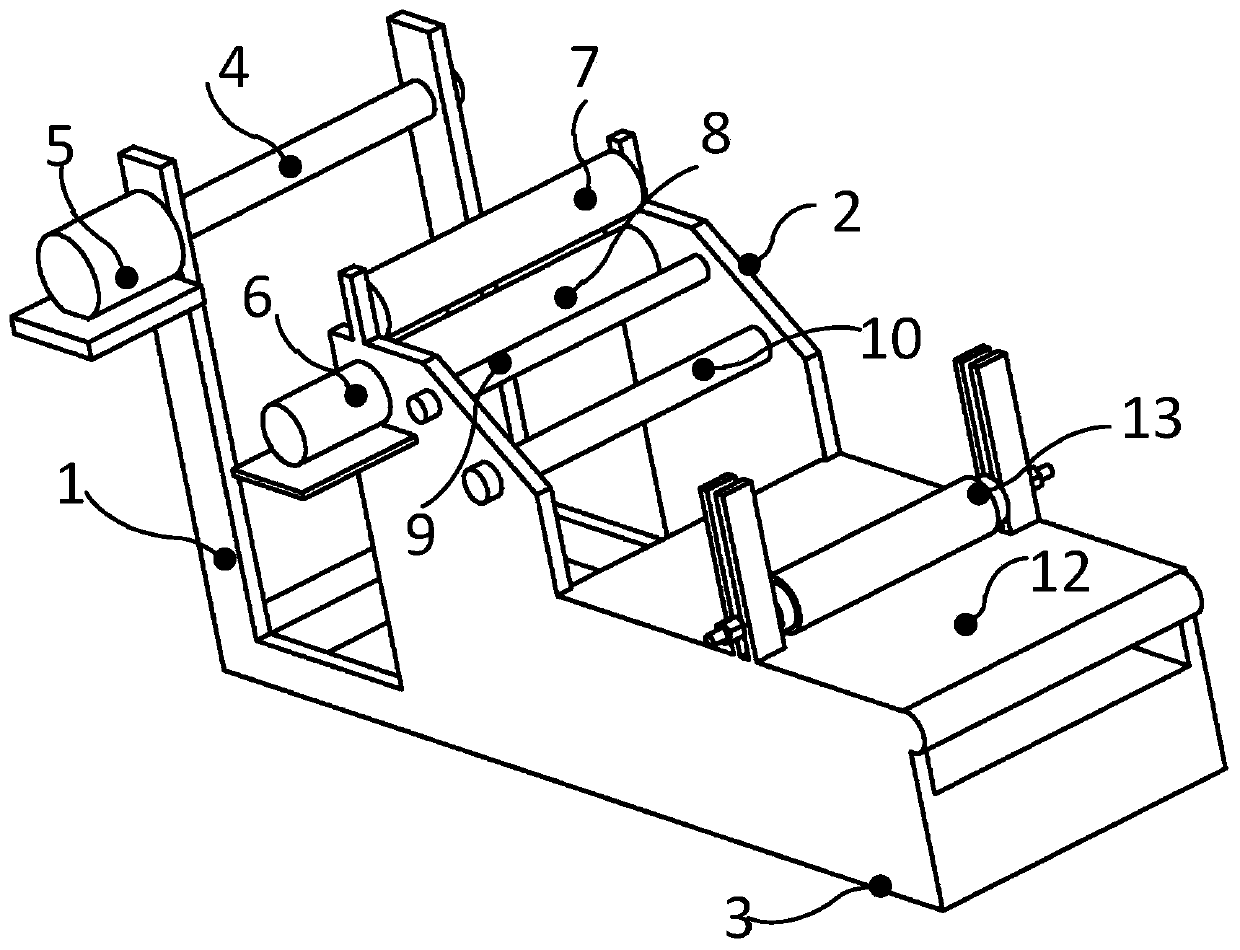

Textile fabric dust removal device

InactiveCN107805931AEfficient removalTo achieve a comprehensive cleaning effectMechanical cleaningPressure cleaningBody rollEngineering

The invention discloses a textile cloth dedusting device, which comprises a device body, openings are opened on both sides of the device body, and two symmetrical rollers are fixedly installed on the left end of the device body, between the two rollers room set with textile fabrics. The textile fabric dedusting equipment can drive the first rotating shaft and the second rotating shaft to rotate through the provided first pulley and the second pulley under the action of the motor, so that the two rolling brushes can simultaneously clean the upper surface and the second rotating shaft of the textile fabric. The lower surface is cleaned to effectively remove the cotton dust, cotton wool and other dust adhering to the textile fabric, achieving a comprehensive cleaning effect. Through the suction pipe set, under the action of the fan, the dust cover can The cotton dust, cotton wool and other dust cleaned by the rolling brush can be effectively absorbed, which prevents the cotton dust, cotton wool and other dust cleaned by the rolling brush from being scattered inside the equipment body, causing re-contamination of the textile fabric, and ensuring the cleaning efficiency.

Owner:SHAOXING HOUDAO AUTOMATION EQUIP CO LTD

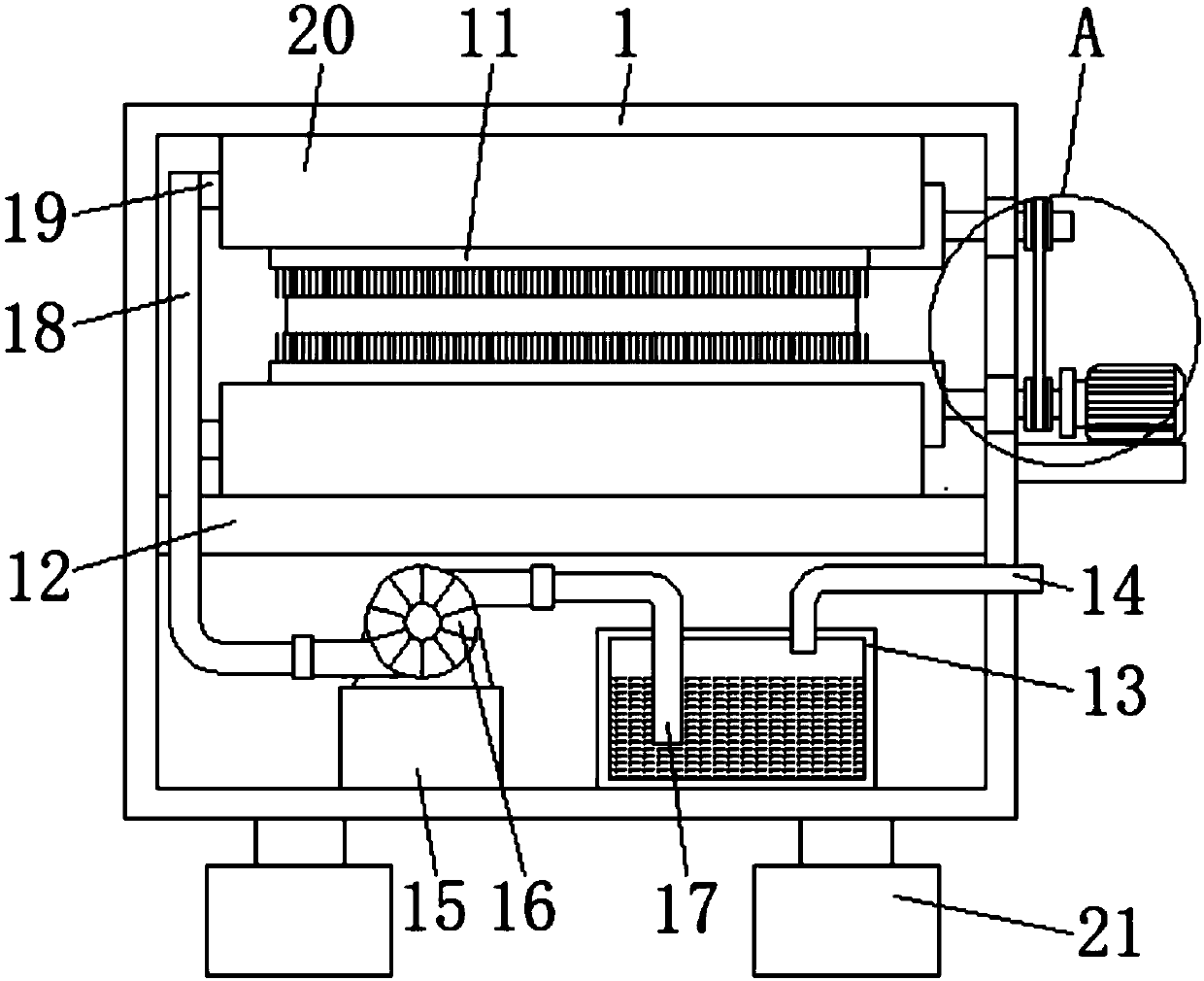

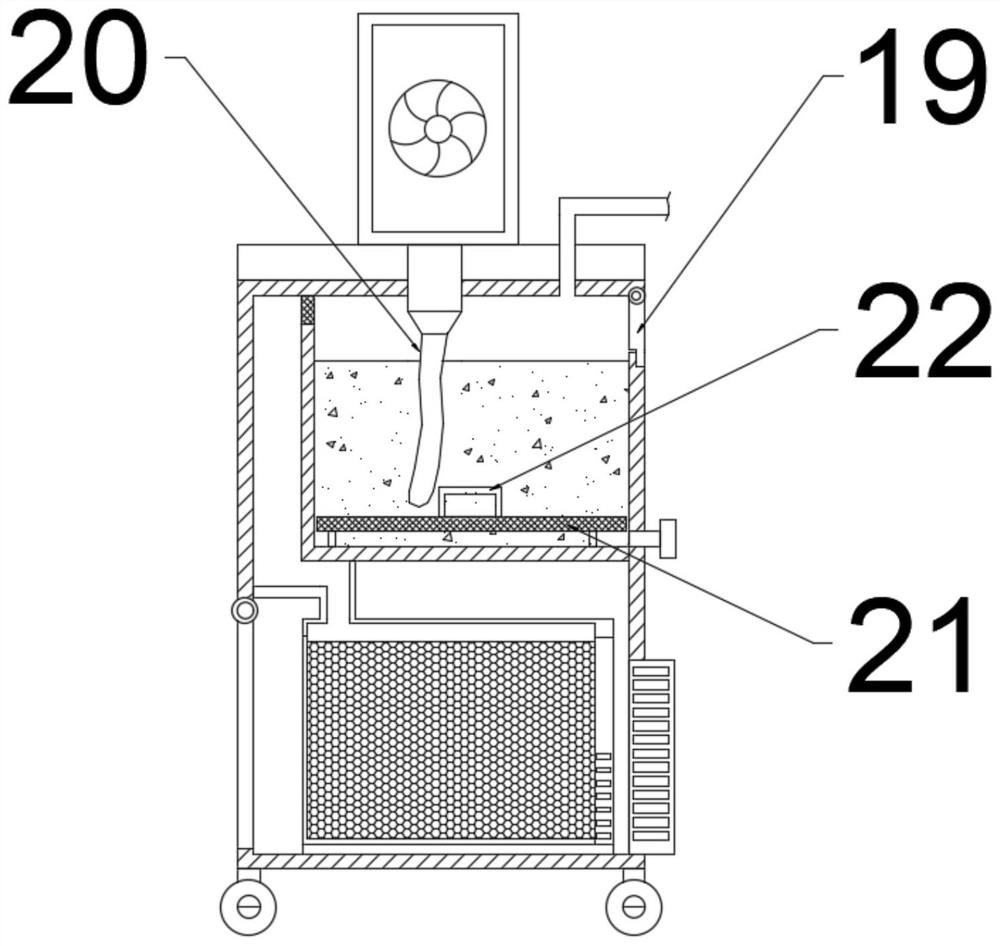

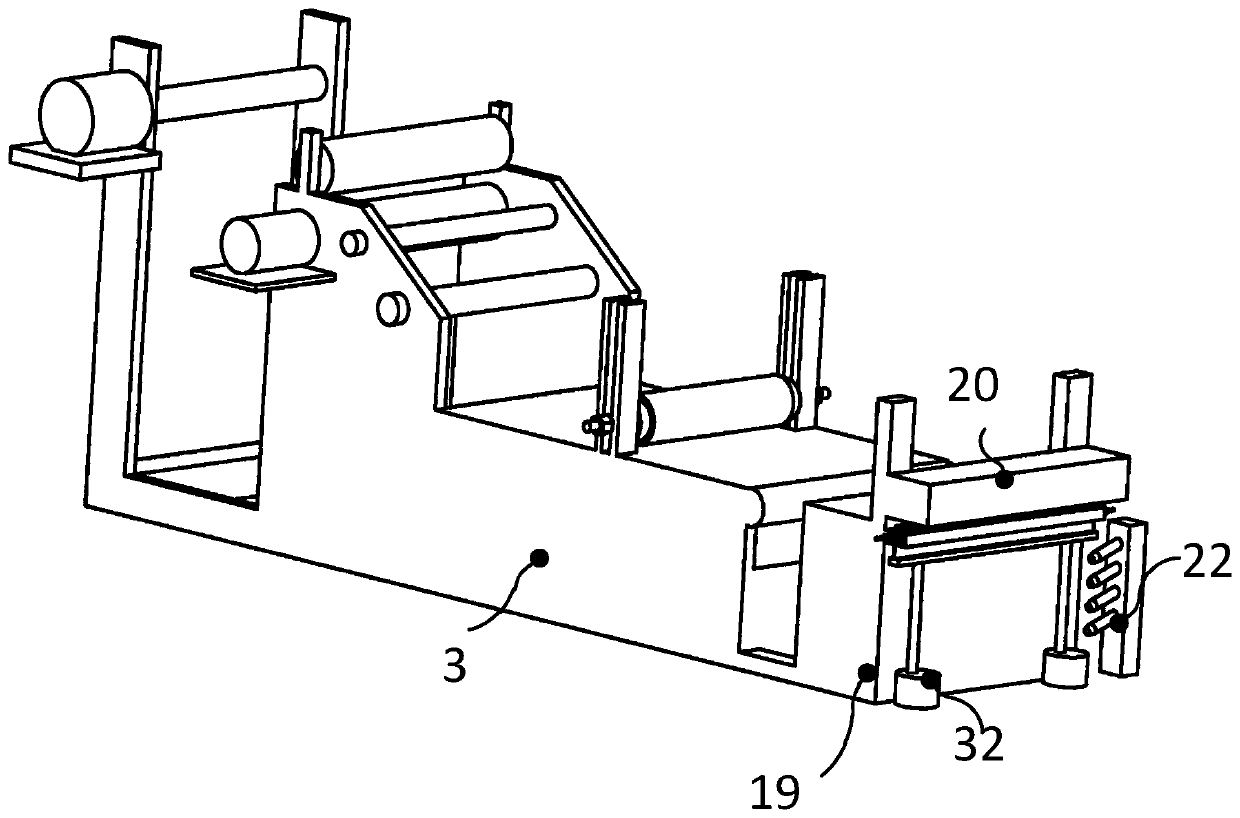

Cotton dust removal recycling equipment for producing colored spun yarns

InactiveCN107245780AWith rotation functionImprove dust removal effectUsing liquid separation agentCarding machinesYarnSuction stress

The invention discloses cotton dust removal recycling equipment for producing colored spun yarns, and relates to the field of technologies for producing colored spun yarns. The cotton dust removal recycling equipment comprises a base tank. A first motor is fixedly connected with the bottom of the inner wall of the base tank, a transmission shaft is fixedly connected with an output shaft of the first motor by a coupling, a first conical gear is fixedly connected with the end, which is far away from the first motor, of the transmission shaft, a second conical gear meshes with the top of the first conical gear, a rotary shaft is fixedly connected with the axis of the second conical gear, a rotary tank is fixedly connected with the top of the rotary shaft, and suction fan blades are fixedly connected with an output shaft of a second motor. The cotton dust removal recycling equipment for producing the colored spun yarns has the advantages that strong suction can be generated by the cotton dust removal recycling equipment, suction of fans can be optimally utilized, cotton dust in contact with water can settle without blocking machines after the cotton dust is sucked into the machines, accordingly, effects of quickly removing the dust can be realized, and the work efficiency of the machines can be greatly improved.

Owner:响水县嘉禾纺织制衣有限公司

Cotton seed separating device

InactiveCN109652862AEasy to separatePrevent flutteringVegetable fibre separation from seedsFiberWood splinter

The invention relates to the field of textile, and discloses a cotton seed separating device which comprises a body. The inside of the body is provided with a feeding port, a feeding pipe, an operation barrel, a pressuring roller and a sliding rail, a screw rod is arranged in the feeding pipe and provided with a chamber, a through hole, a first bevel gear, a steamer and a motor, the first bevel gear is engaged with a second bevel gear, the second bevel gear is coaxially connected with an incomplete gear, a baffle plate is fixedly connected at the tail end of the feeding pipe, a conveying pipeis fixedly connected at the top of the operation barrel and connected with a treatment box, an air feeding plate, a plurality of heating pipes and a fan are arranged in the operation barrel, air outlet holes are densely formed in the air feeding plate, a separating tank is arranged on the operation barrel, a brush is arranged in a separating box, a collecting box is communicated with the bottom ofthe separating box, a rack and a spring are arranged in a guide rail, a pushing rod and a connecting rod mechanism are arranged on the rack, a needle plate is arranged on the pushing rod, iron splinters are densely distributed on the needle plate. By the aid of the technical scheme, the separating device solves the problems of low quality of cotton fibers separated by a ginning machine and more cotton dust in the prior art.

Owner:象山平悦环保科技有限公司

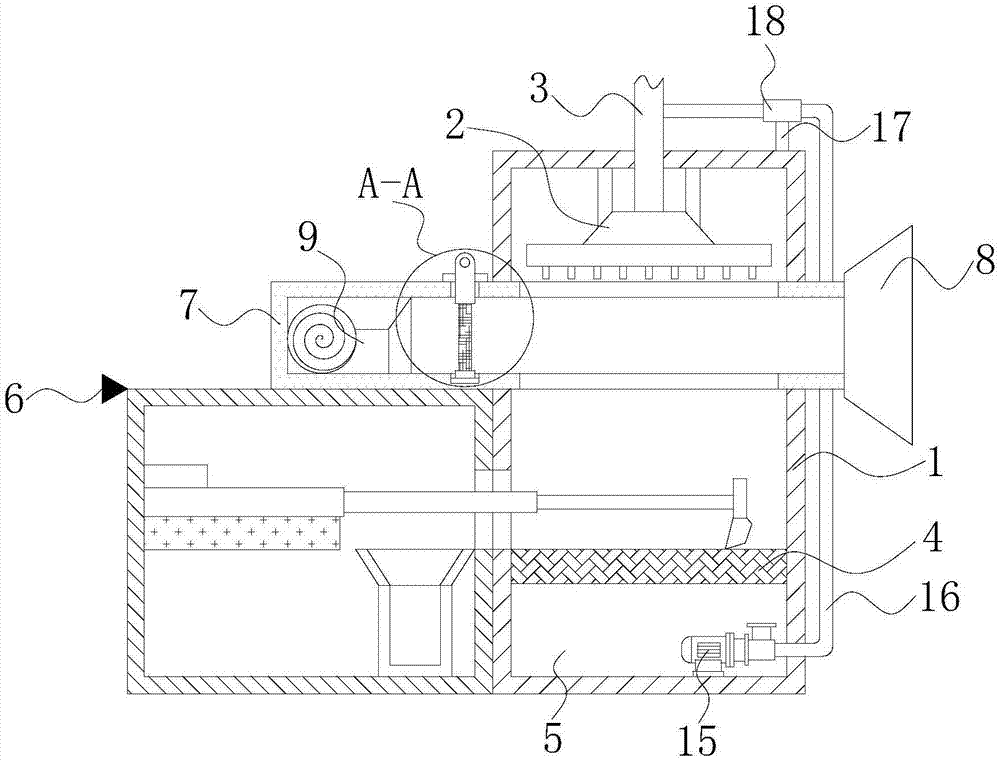

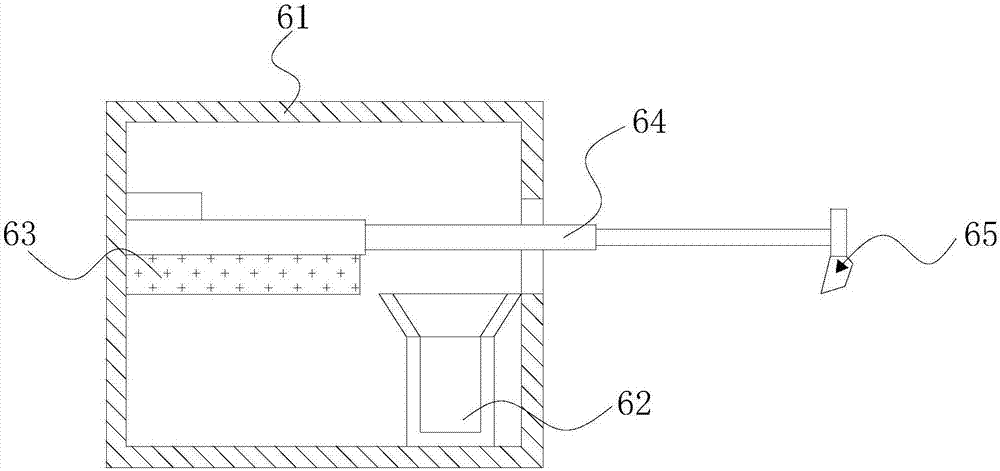

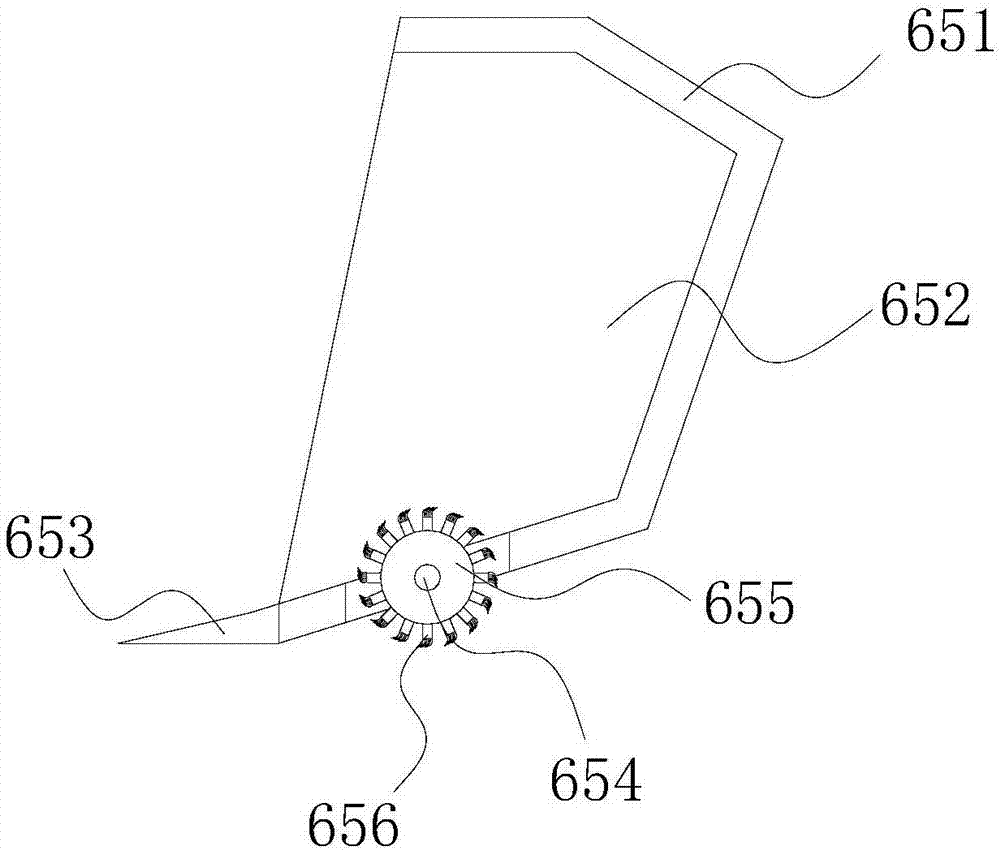

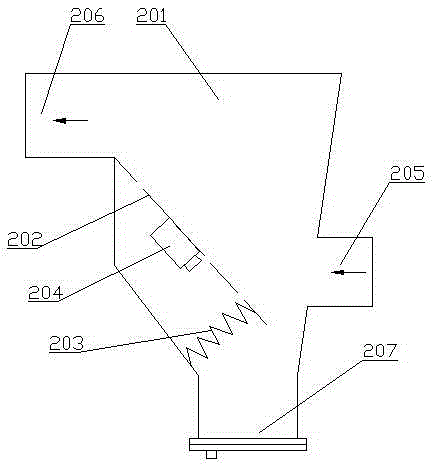

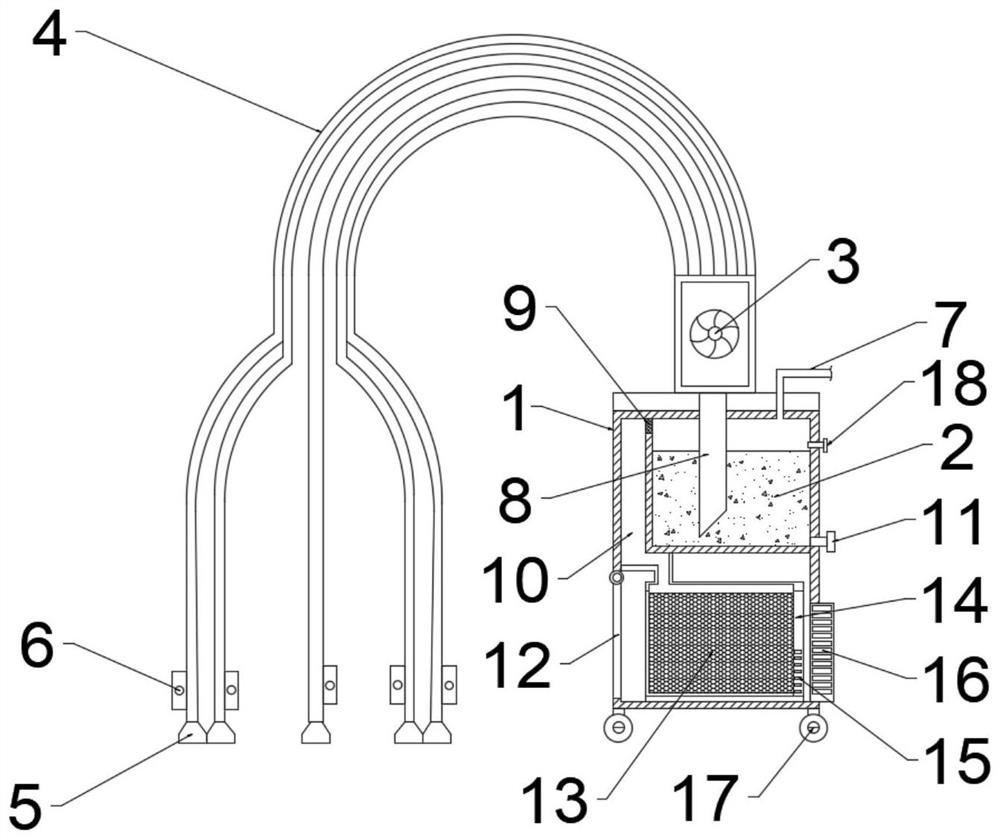

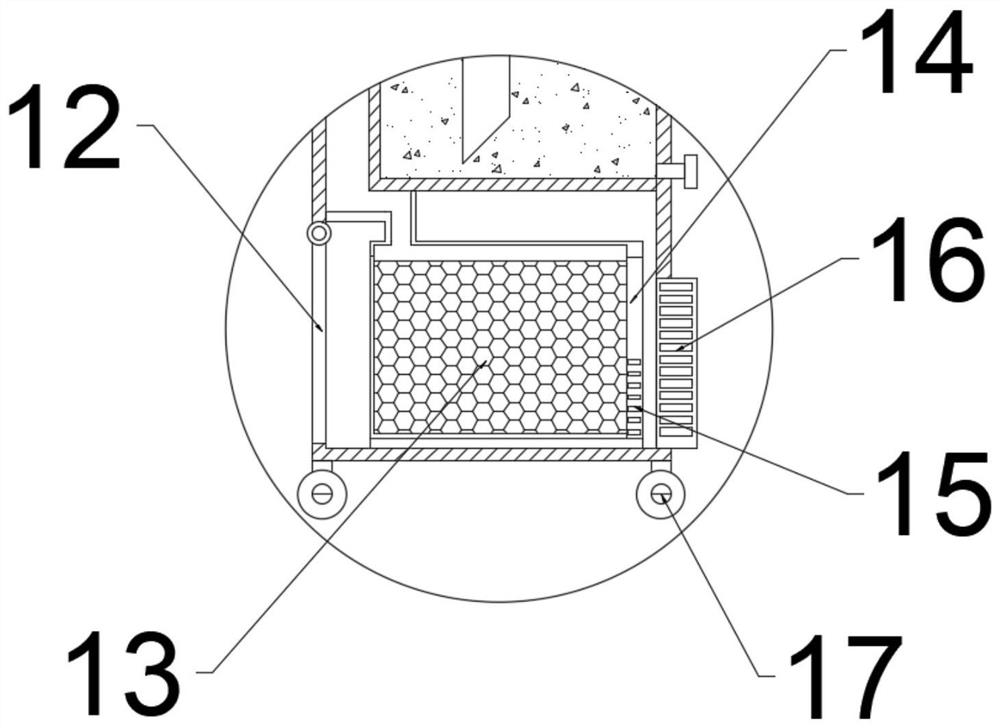

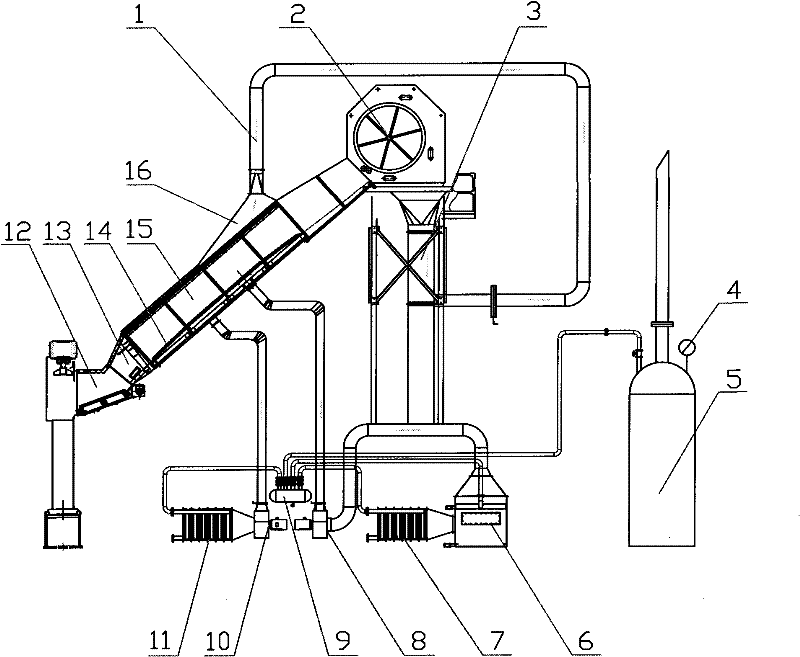

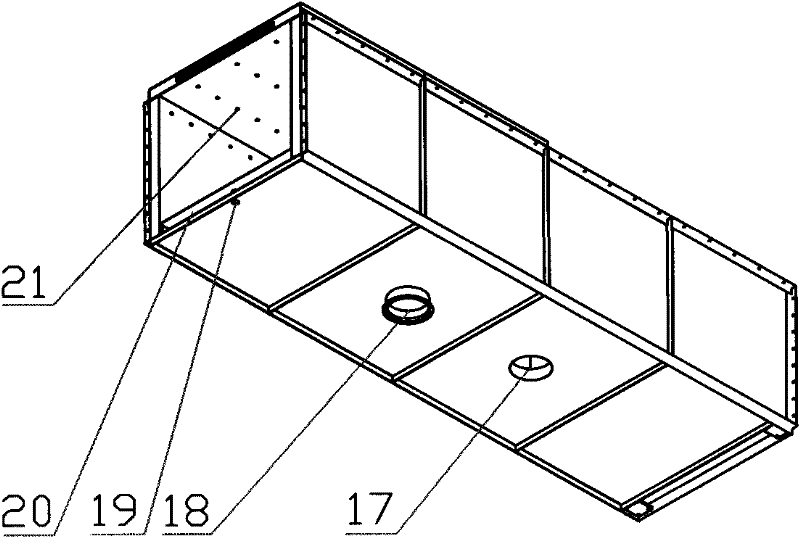

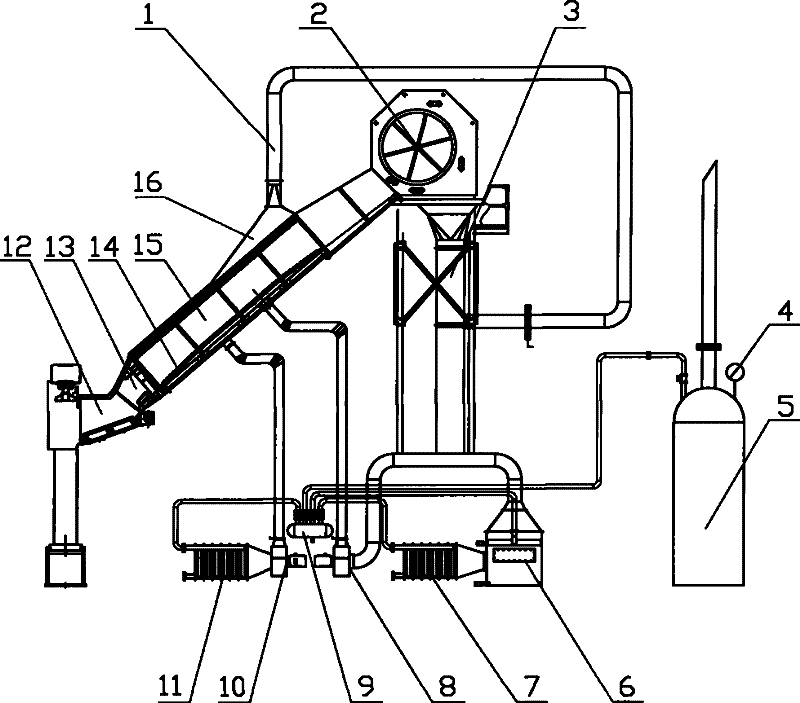

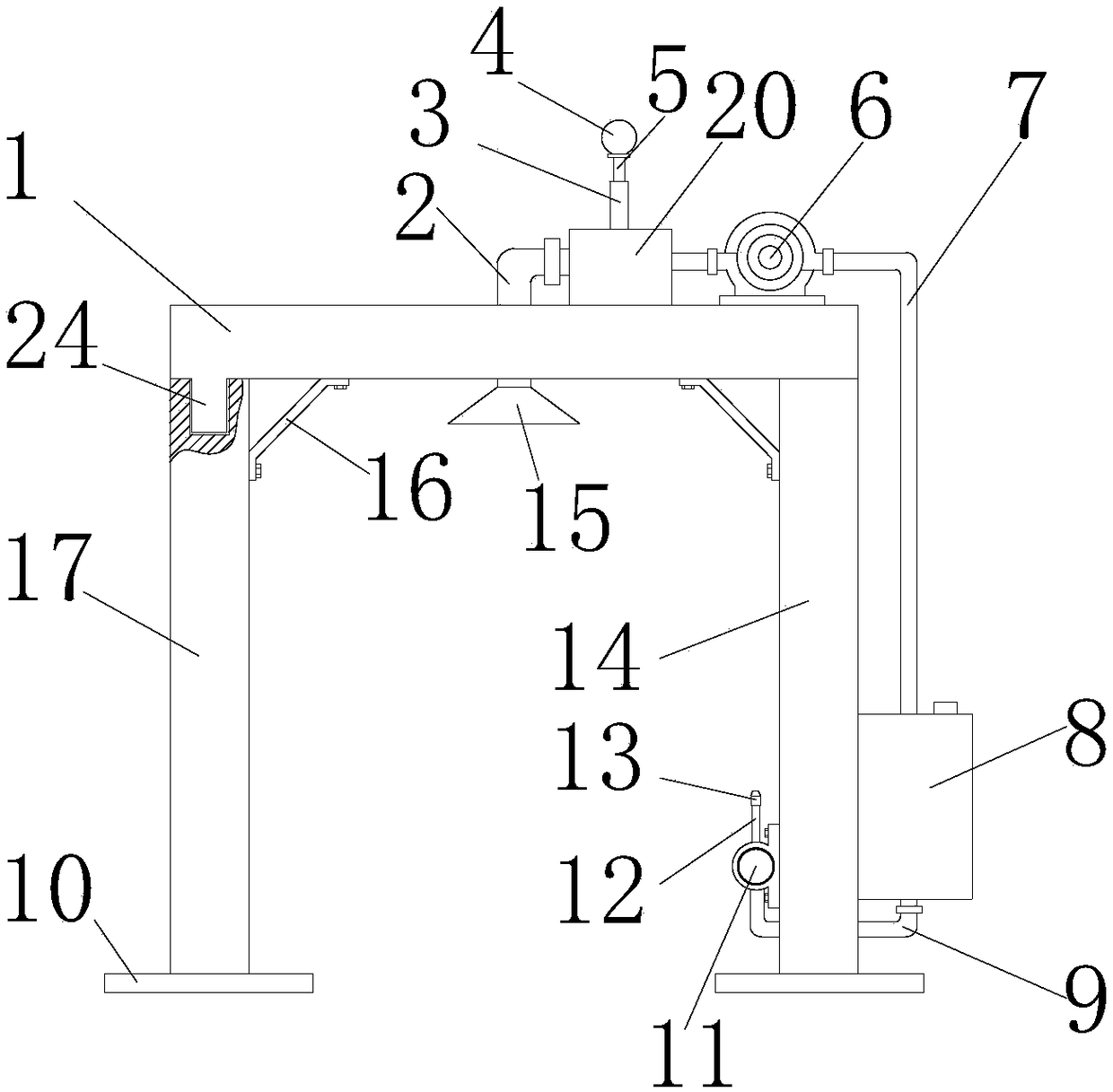

Ginned cotton humidifier

ActiveCN101797987AMoisture regain reachedHigh moisture regainFibre treatmentPackagingGratingEngineering

The invention discloses a ginned cotton humidifier. The ginned cotton humidifier comprises a cotton delivery channel and a humidifying device, wherein the cotton delivery channel is slantingly downwards arranged and connected with a cotton delivery device and a cotton dust collecting cage; and the humidifying device is used for humidifying the ginned cotton passing through the cotton delivery channel and comprises a humidifying grating assembly which is arranged in the cotton delivery channel, and a steaming device which is connected to the humidifying grating assembly through an humidification air blower and a configured pipeline. The ginned cotton humidifier based on the technical scheme of the invention has a better humidifying effect.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Method for preparing cellulose nitrate for explosive from wood pulp

InactiveCN102219861ASolve the costPrice stabilityNitrocellulose explosive compositionsEnvironmental resistanceNitrocellulose

The invention relates to a method for preparing cellulose nitrate for an explosive from wood pulp, in particular relates to a preparation method of cellulose nitrate for an explosive and belongs to the technical field of cellulose preparation. The method is characterized by comprising the following steps: adding 20-30 parts by weight of wood pulp in 500 parts by weight of mixed acid, carrying outmiddle-low temperature nitration reaction and then washing; and then successively carrying out boil washing, shredding and refine washing so as to obtain the cellulose nitrate for the explosive. In the preparation method of the cellulose nitrate, the wood pulp is used as a raw material, which is not a precedent in the field of military cellulose nitrate, thereby broadening the use range of the raw material in nitrated cellulose production, and simultaneously, the wood pulp is cheaper than cotton linter and can be used as the raw material of energy-containing nitrated cotton for production, thereby greatly solving the cost problem of the raw material; and at the same time, the environmental protection pressure problem brought by a large amount of cotton dust, black liquid and acidic wastewater which are generated in the processes of cotton opening, boiling, bleaching and drying refined cotton when a nitrated cotton product is prepared by utilizing the cotton linter as the raw material is solved.

Owner:SICHUAN NITROCELLULOSE CORP

Novel automatic dedusting equipment

InactiveCN106948072AAvoid floating aroundAvoid driftingAuxillary apparatusKnittingEngineeringCotton dust

The invention discloses a new type of automatic dedusting equipment, which comprises a dedusting housing. The top of the inner wall of the dedusting housing is fixedly connected with a sprinkler through a fixed rod. The top of the sprinkler is fixedly connected with a water inlet pipe communicating with it. The top of the water pipe runs through the dust removal housing and extends to the outside to be fixedly connected to the peripheral water tank. The bottom of the sprinkler is equidistantly evenly distributed with nine sprinkler heads, and the lower part of the inner wall of the dust removal housing is fixedly connected to a water filter. By setting sprinklers, water filter nets, dust suction pipes, dust suction hoods and exhaust fans together, the dust can be sucked, avoiding the impact of dust and cotton wool on the health of workers, while protecting the normal operation of the equipment, and through The collected dust and lint are wetted and precipitated to avoid dust and lint from floating around, and the dust and lint are effectively collected and stored, with higher dust removal efficiency and better dust removal effect.

Owner:浙江高派机器人科技有限公司

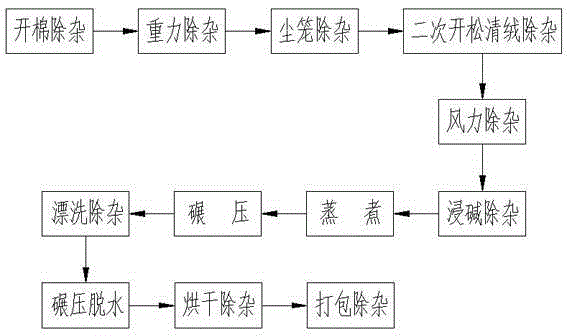

Cleaning system for refined cotton production

InactiveCN106544761AGuaranteed qualityFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberBlack liquor

The invention discloses a cleaning system for refined cotton production. Raw cotton linters are subjected to primary opening via an opening and cleaning device, the cotton linters subjected to the primary opening are cleaned via a gravity cleaning device, a dust cage cleaning device, a secondary opening, fiber-removing and cleaning device and a pneumatic cleaning device sequentially, the cleaned cotton linters are then charged into an alkali soaking cleaning device for alkali soaking, the alkali-soaked cotton linters are cooked via a rotary spherical digester to form cotton pulp, the cotton pulp is subjected to black liquor rolling and primary cleaning via a rolling device, the cotton pulp subjected to the primary cleaning is blanched and washed via a rinsing cleaning device, the washed pulp is then subjected to rolling dewatering and drying cleaning to form a finished product, and the finished product is packaged via a packaging cleaning device. The cleaning system for refined cotton production has the advantages that cleaning control is provided for each of the main steps of refined cotton production, such as opening, alkali soaking, rinsing, drying, and packaging, full-course systematic cleaning is provided, the impurities such as cotton seed hulls, sand, cotton dust and iron dust are removed thoroughly, and the product quality is effectively guaranteed.

Owner:HUBEI JINHANJIANG REFINED COTTON

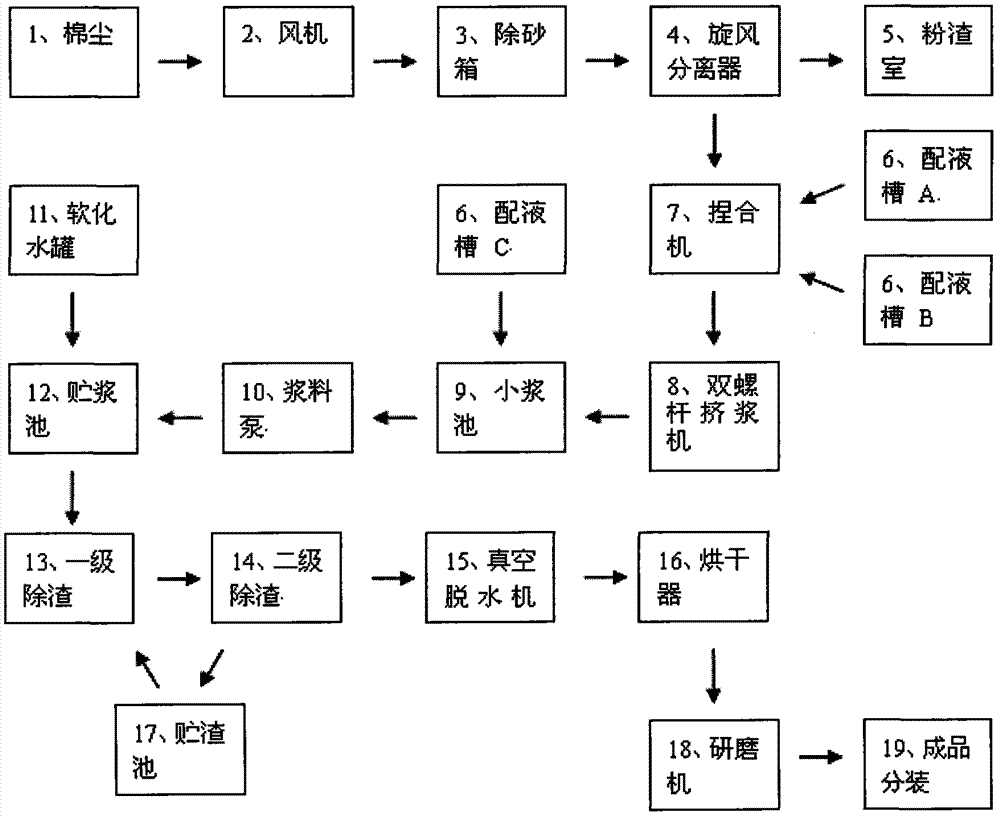

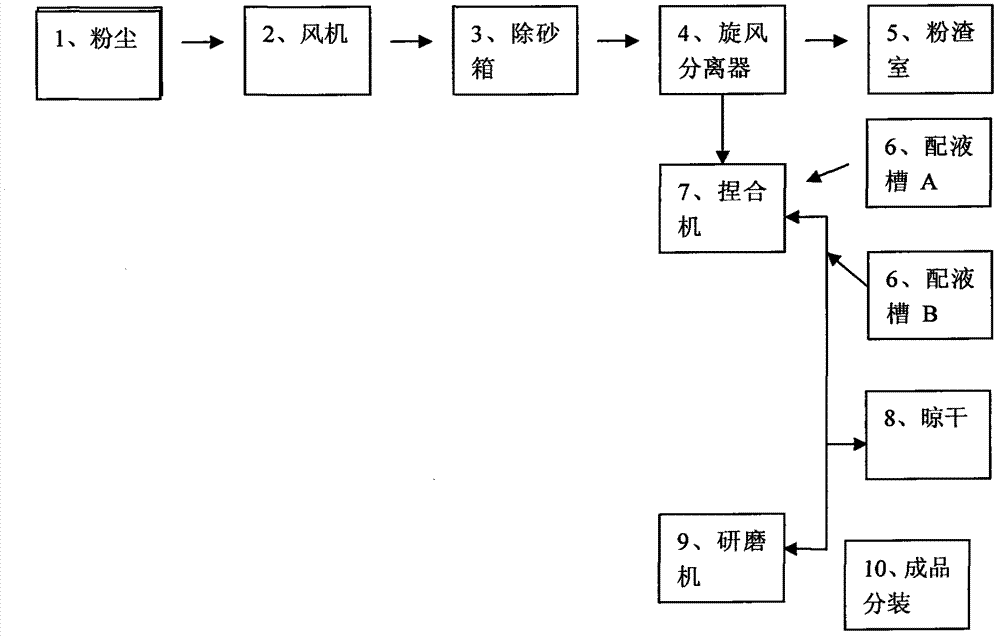

Micro-powder cellulose preparation method

The invention discloses a micro-powder cellulose preparation method, which is characterized in that cotton dust is adopted as a raw material, purity-increase impurity-removing and decoloration degradation are performed, and one of an improved twin-screw slurry extruder, a ball mill, a rod mill and a vibration mill is adopted to carry out a high shear oxidation depolymerization treatment to obtain the micro-powder cellulose, wherein cotton dust can not be used by textile industry. According to the present invention, the characteristic of low polymerization degree of the cotton dust fine fiber is utilized, and the resource is complete, such that large-scale industrial production can be performed, and product stability and purity are high.

Owner:SHANGHAI TONNOR MATERIAL SCI

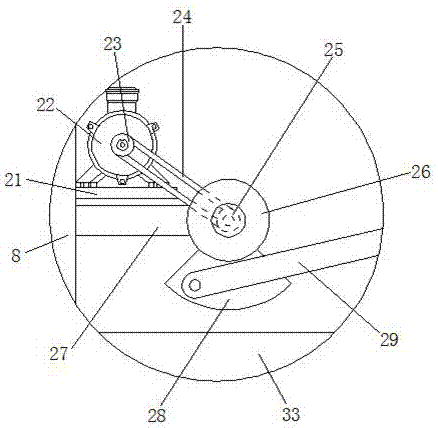

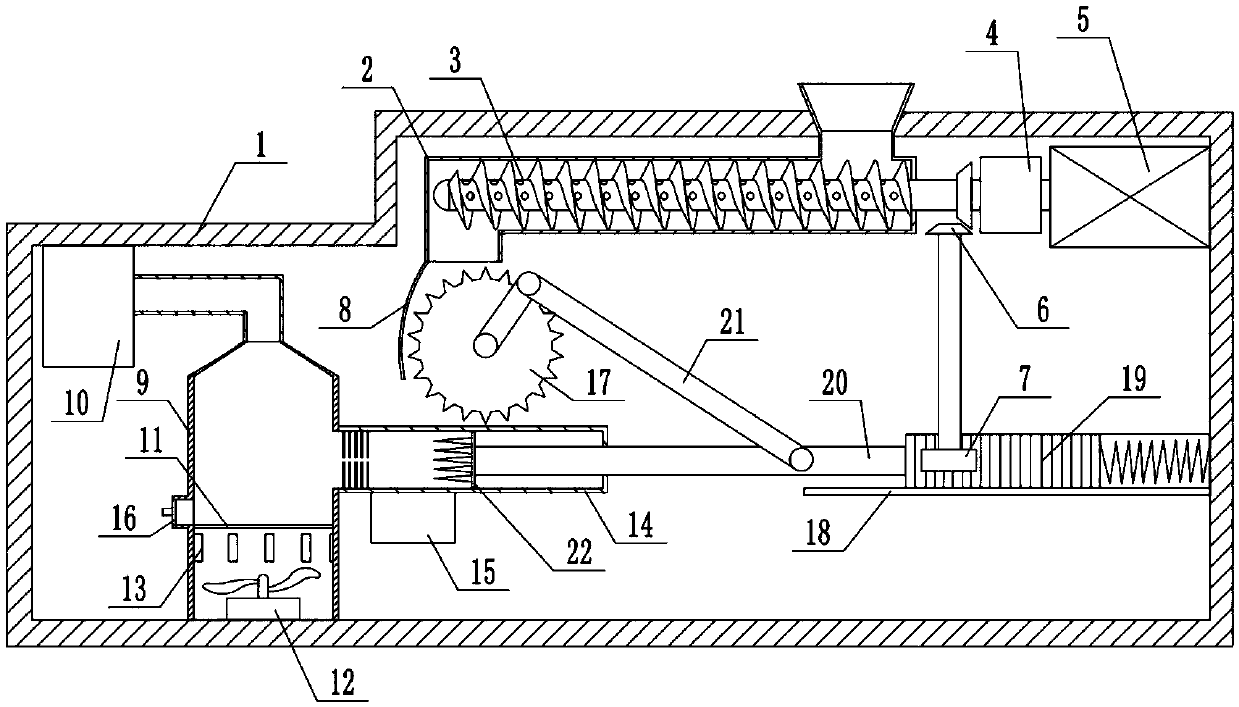

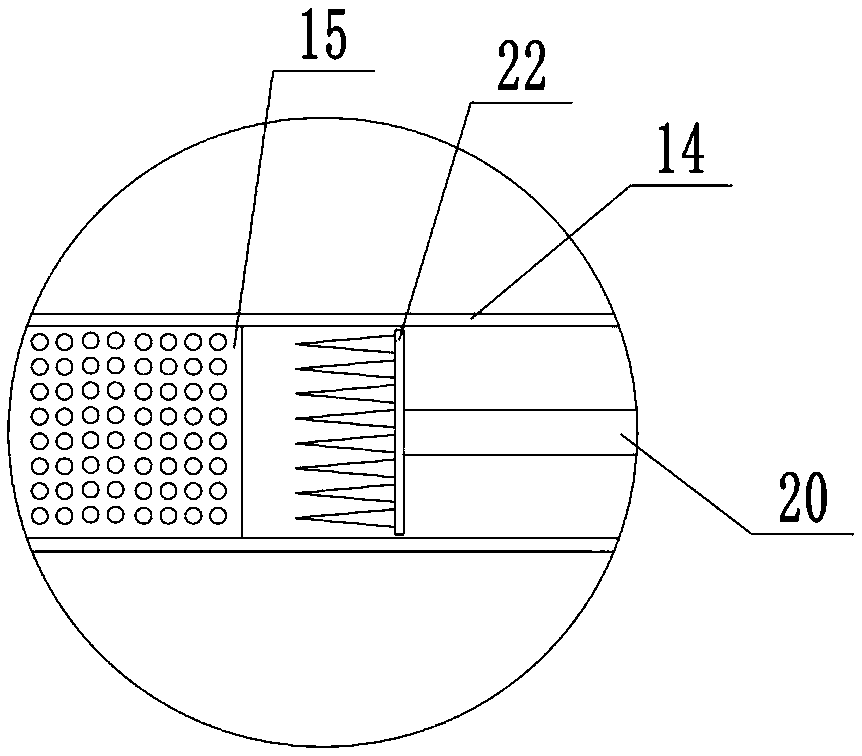

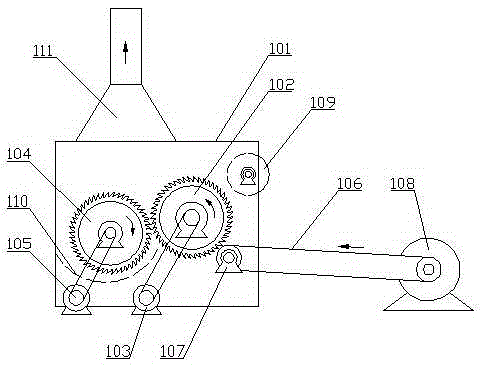

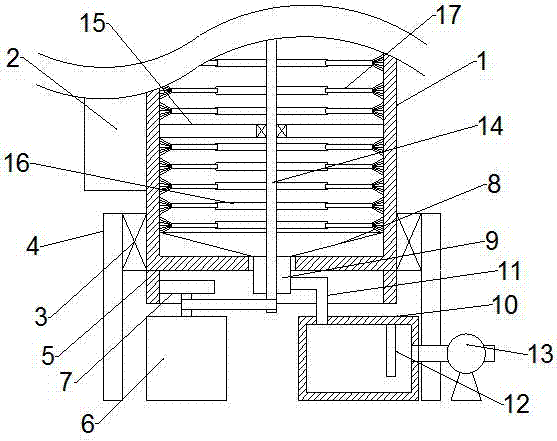

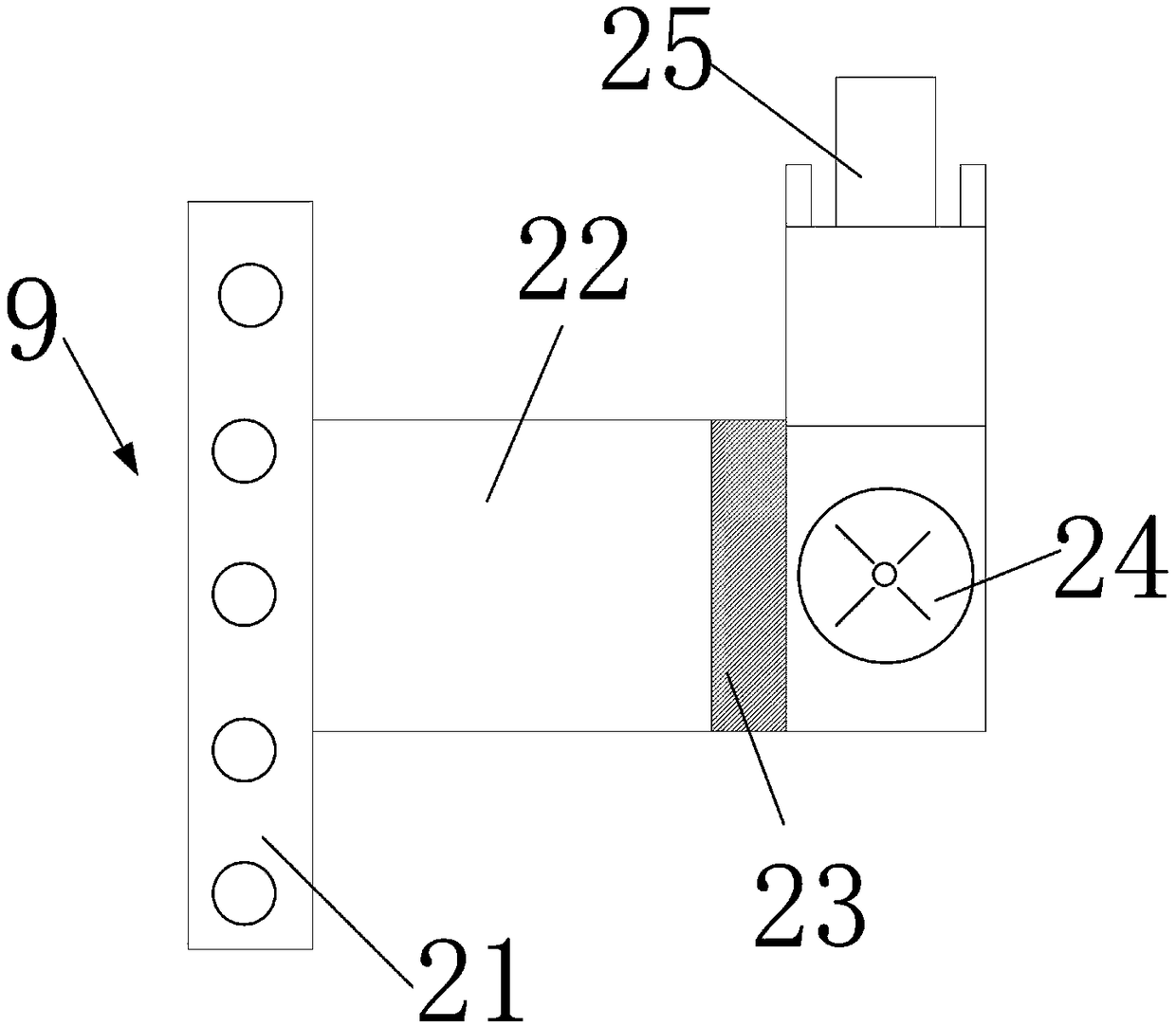

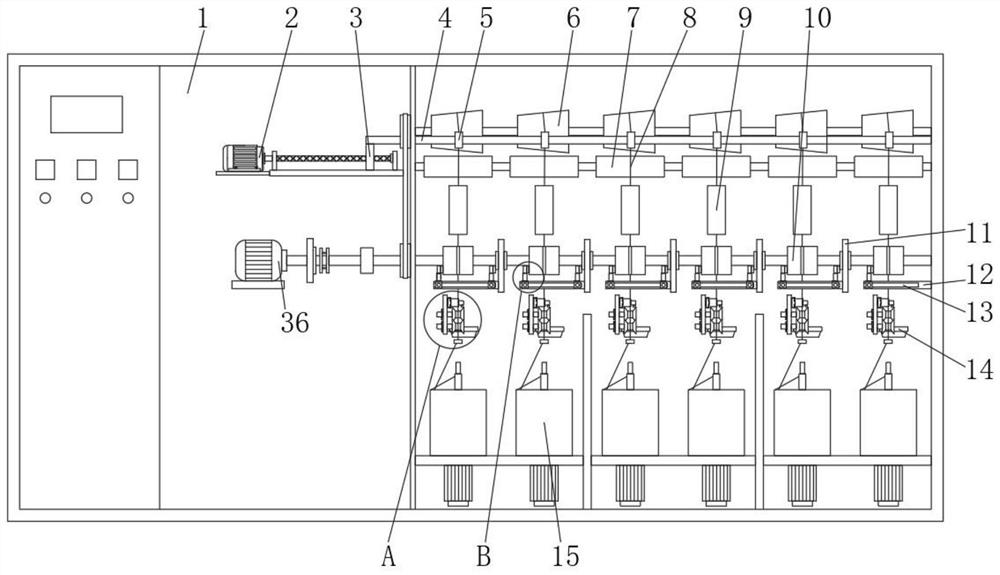

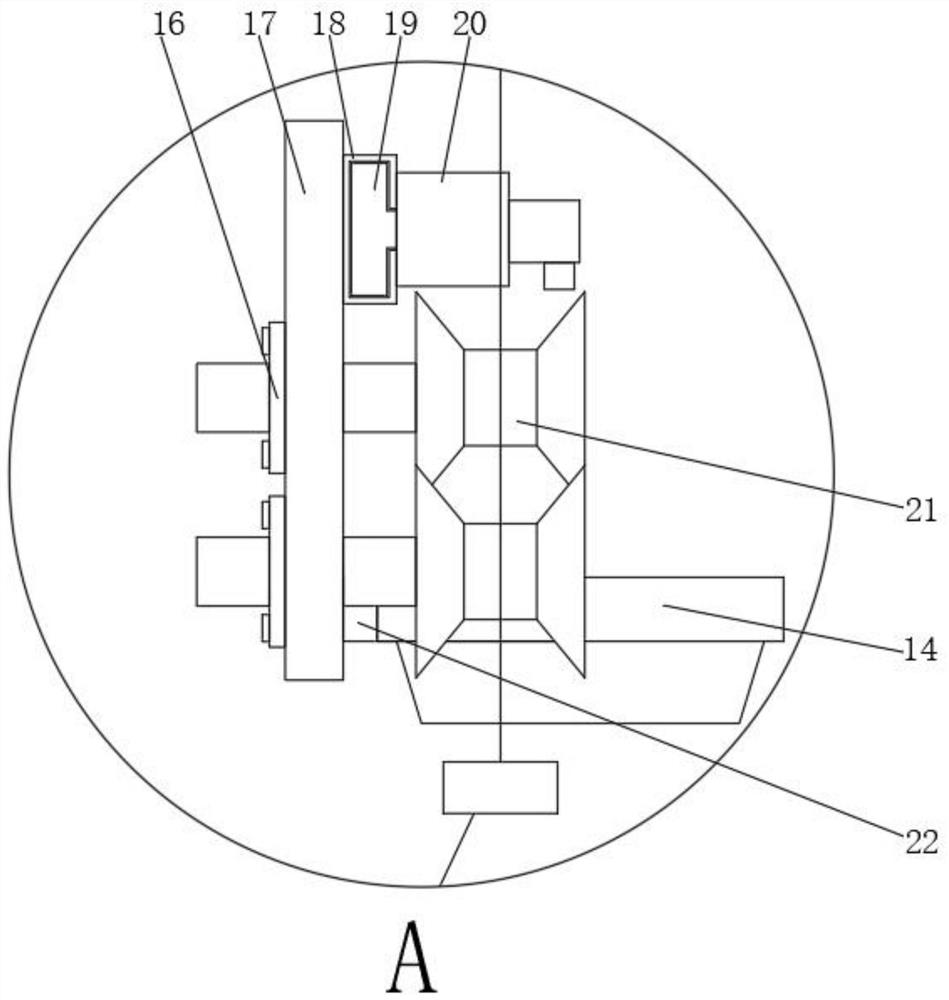

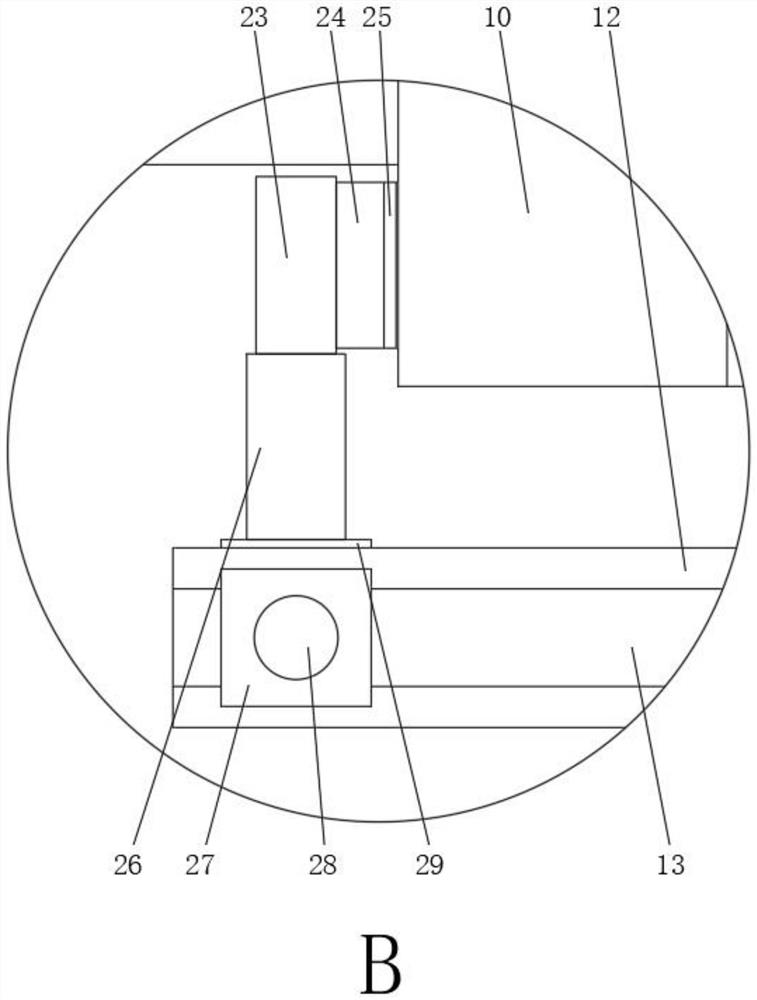

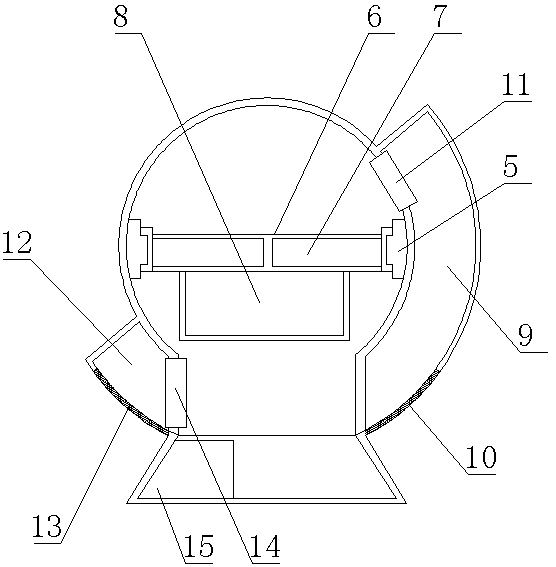

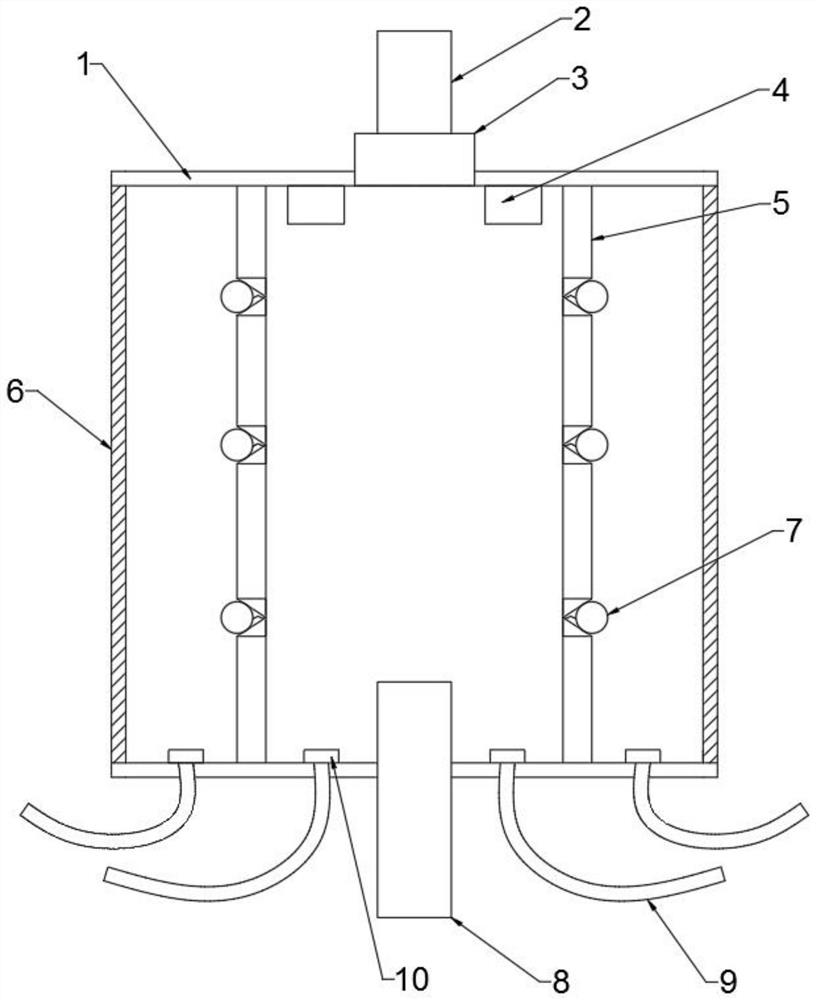

Anti-blocking efficient cotton spinning dust removal and impurity removal device

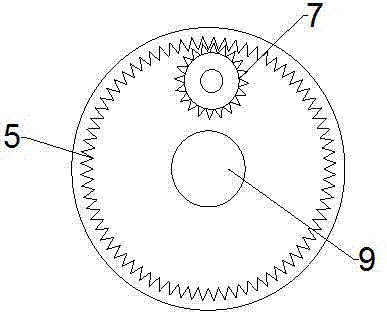

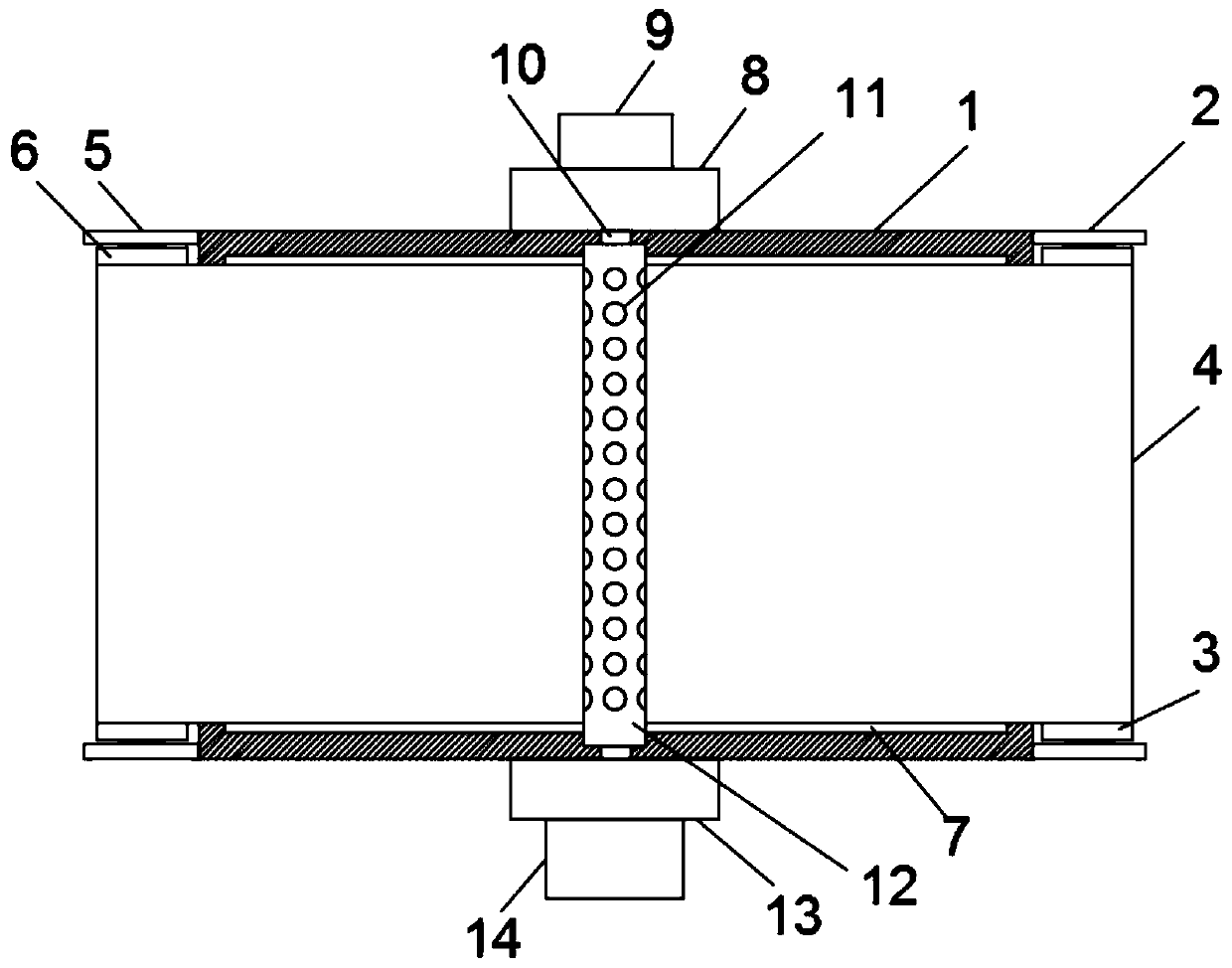

InactiveCN107313132AAvoid cloggingSpeed up entryFibre cleaning/opening by air draught arrangementsCarding machinesMotor driveEngineering

The invention discloses a high-efficiency anti-blocking dust removal and impurity removal device for cotton spinning, which comprises a dust cage, a cotton stripping roller and a dust collection box. The cotton stripping roller is arranged on the left side of the dust cage; a rotating bearing and a bracket are arranged on the periphery of the dust cage; The lower end of the dust cage is equipped with internal gears, motors, driving gears, dust collection boxes, connecting air pipes, baffles and air pumps; the inside of the dust cage is equipped with dust collection covers, dust suction pipes, rotating shafts, support frame plates, fixed rods, swing rods and brush. In the present invention, the driving gear on the motor cooperates with the internal gear at the lower end of the dust cage to drive the dust cage to rotate, and at the same time, the motor drives the rotating shaft to rotate, and the brush can continuously clean the inner wall of the dust cage through the speed difference with the dust cage to avoid blockage; through the action of the air pump , the air enters the dust collection box through the dust suction hood, dust suction pipe and connecting air pipe, so that the dust can be efficiently removed while the gas emission is clean.

Owner:洪飞飞

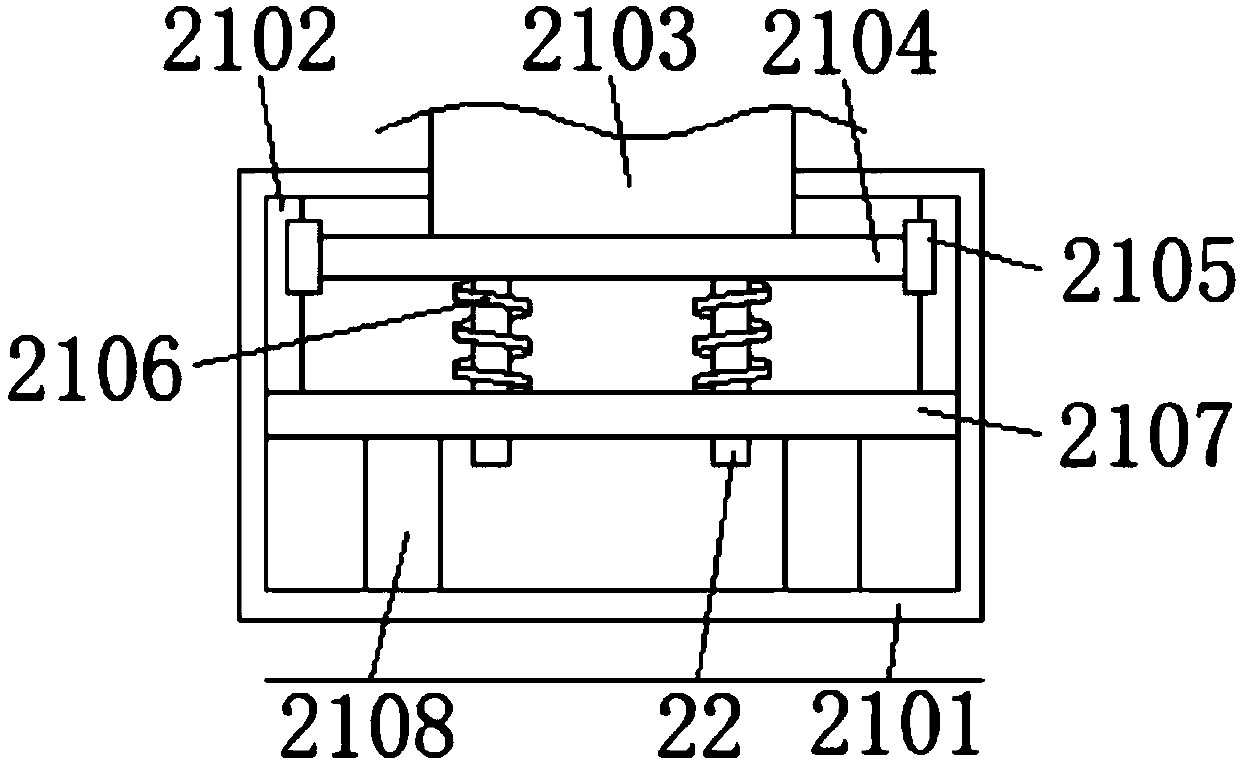

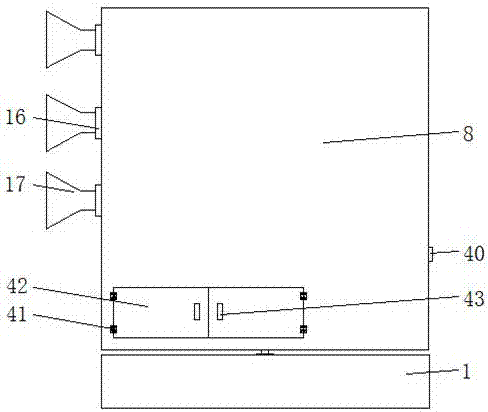

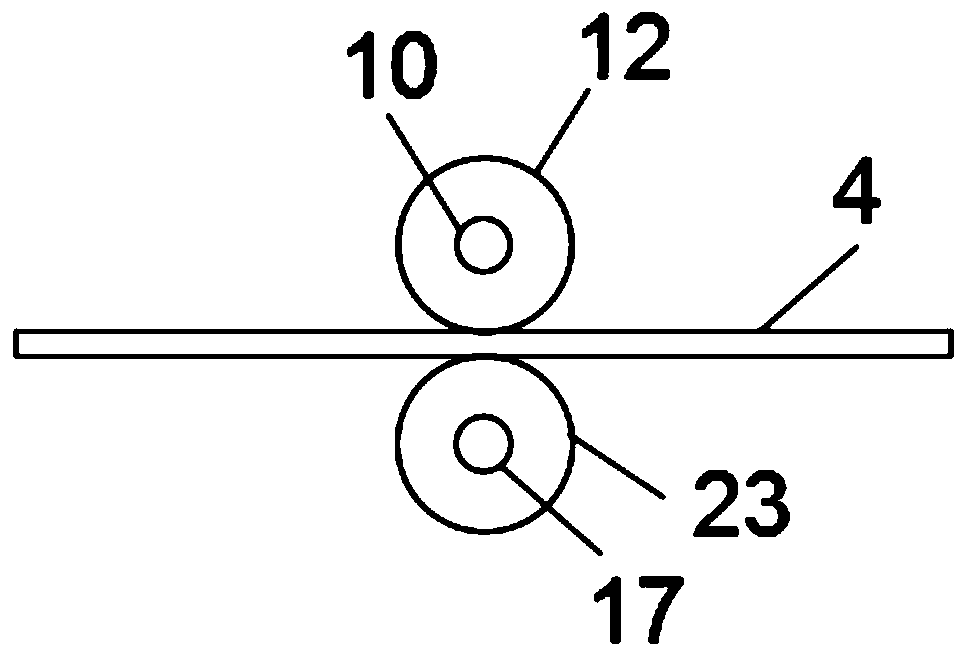

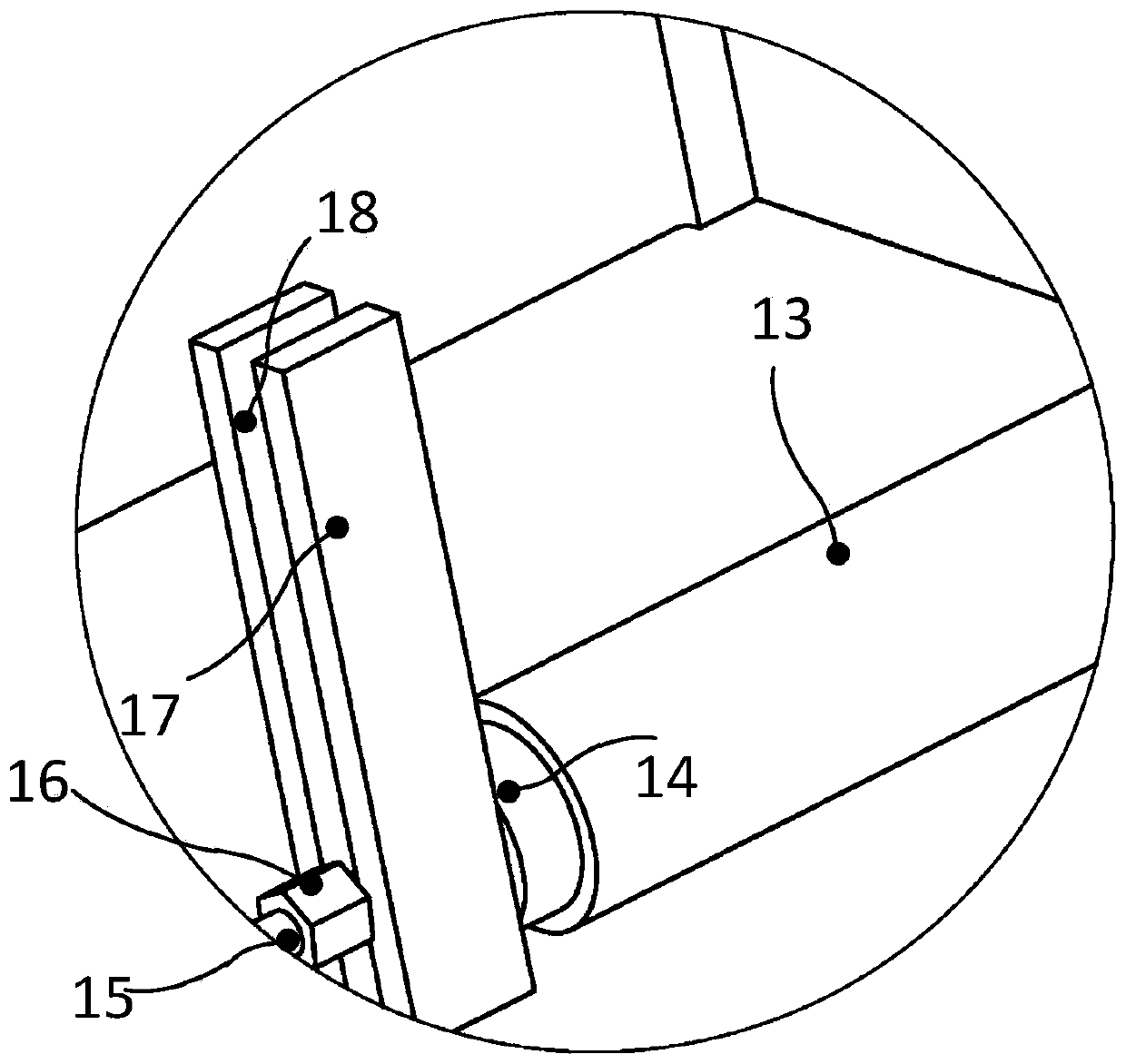

Dust removal equipment for anti-static cotton processing

InactiveCN110106685AImprove dust removal efficiencyDust removal speed is fastMechanical cleaningPressure cleaningEngineeringCotton dust

The invention relates to the technical field of cotton dust removal, in particular to dust removal equipment for anti-static cotton processing. A technical scheme is provided aiming at the problems that after an existing dust removal device collects dust on one side face of cotton, the cotton still needs to be turned over to be subjected to dust removal on the other side face, a lot of time needsto be cost for overall dust removal of the cotton, and the overall dust removal efficiency is low. According to the technical scheme, the dust removal equipment comprises a workbench, openings are formed in the workbench, second mounting racks are fixedly connected with the left side of the workbench, and cotton discharging rollers are rotatably connected with the second mounting racks; first mounting racks are fixedly connected with the right side of the workbench, and cotton collecting rollers are rotatably connected with the first mounting racks. According to the dust removal equipment, negative pressure is generated inside a first dust collection roller and a second dust collection roller to make dust collection holes continually collect dust on the upper surface and the lower surfaceof the cotton, through the mode of conducting dust removal on the upper and lower sides at the same time, the overall dust removal speed of the cotton is greatly increased, and the working efficiencyis improved.

Owner:江苏科沃纺织股份有限公司

Burr-removing and dedusting weaving and printing device for spinning

InactiveCN106004023AKeep shapeQuality improvementCylinder pressesPlaten pressesEngineeringCotton dust

The invention discloses a burr-removing and dedusting weaving and printing device for spinning. The burr-removing and dedusting weaving and printing device is characterized in that a feeding device used for conveying woven cloth is assembled in an arranged first rack; the feeding device comprises woven cloth traction machines used for pulling and moving the woven cloth, and a tensioning mechanism used for enabling the woven cloth to maintain a tensed state during the feeding process, the woven cloth can maintain the tensed and smooth state when moved to a printing mechanism, and the woven cloth can better receive the printing procedure; an arranged second rack and the first rack are arranged in a cross shape, and the operation of the printing mechanism arranged inside the second rack and the changing of accessories are facilitated; and the printing mechanism comprises printing plates connected inside a connecting plate. According to the burr-removing and dedusting weaving and printing device, a drying dedusting component arranged at the lower part of the second rack is used for drying procedure after woven cloth printing and woven cloth dedusting procedure, patterns can stay on the woven cloth relatively quickly through the drying procedure, shapes of the patterns can be maintained, the printing quality is improved, cotton dust on the surface of the woven cloth is conveniently cleaned through the dedusting procedure after the woven cloth is dried, and the woven cloth is guaranteed to be clean.

Owner:WUJIANG HUAYUN TEXTILE

Textile device with automatic dust removing function

InactiveCN109023679AWith automatic dust removal functionSimple structureAuxillary apparatusEngineeringControl valves

The invention discloses a textile device with an automatic dust removing function, which comprises a textile machine table, a textile machine base, a main control cabinet and the like, wherein one endof the textile machine table is connected with the textile machine base; the textile machine base is arranged below the textile machine table; the main control cabinet is arranged below the textile machine table; one end of a textile machine frame is connected with the textile machine table, one end of a control instrument is connected with the textile machine frame, one end of a cloth rolling roller is connected with the textile machine frame, a partition plate is arranged below the cloth rolling roller, a cloth rolling roller control valve is arranged on the right side of the cloth rollingroller, the dust removing device is arranged on the right side of the textile machine frame, a cloth collecting table is arranged below the partition plate, a dust passing pipe is arranged on the right side of a dust collecting plate, a filtering piece is arranged on the right side of the dust collecting pipe, a booster fan is arranged below an air outlet pipe, and one end of the air outlet pipe is connected with the booster fan. The textile device has the advantages of simple structure, reasonable design and good dust removing effect, can thoroughly remove the cotton dust inside the textile machine, improves the cleanliness of the textile machine and prolongs the service life of the textile machine.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

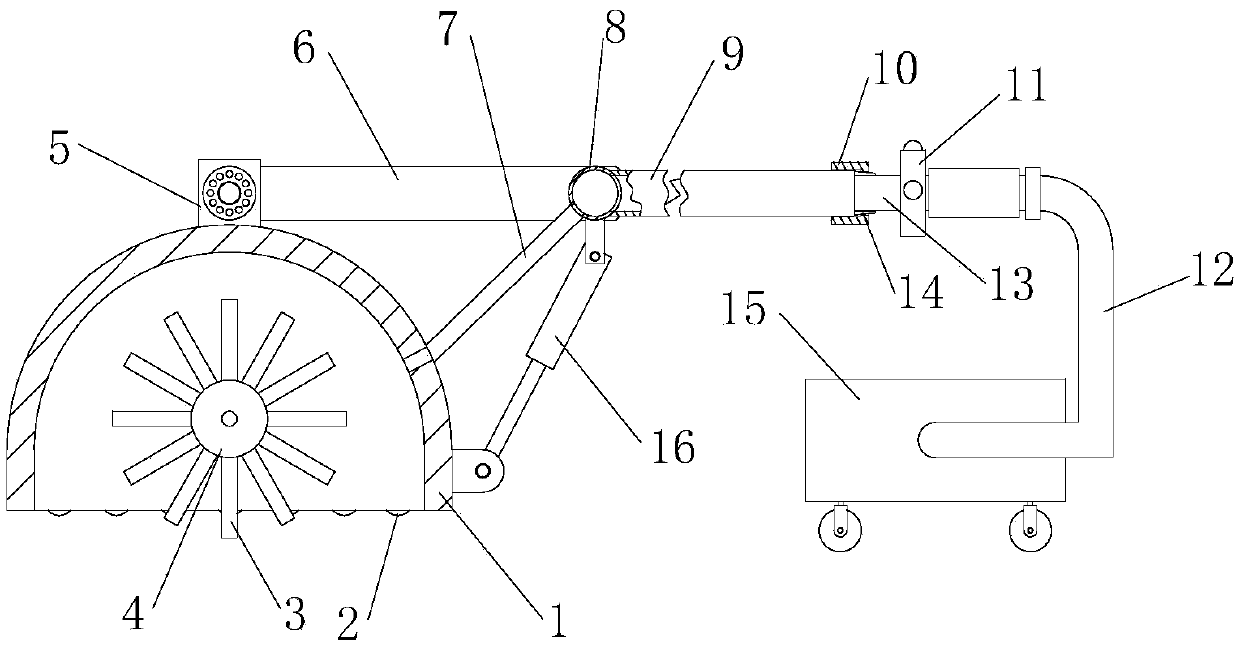

Cleaning device for cotton dust on walls of textile workshop

InactiveCN108670138AEasy to cleanReasonable designCarpet cleanersFloor cleanersElectric machineryEngineering

The invention discloses a cleaning device for cotton dust on walls of a textile workshop. The cleaning device comprises a semi-circular plastic frame, plastic rollers, thin plastic strips, a rotatingrod, a bearing seat, a strip-shaped plate, a first corrugated hose, a fixed steel pipe, a first steel pipe, an internal thread ring hole cover, an operation ring block, a second corrugated hose, a second steel pipe, a clamping and fixing block, a dust collector, an electric push rod and a motor. The cleaning device is reasonable in design, cleaning of the cotton dust stuck and adsorbed in higher positions of the walls of the textile workshop is facilitated, cotton dust impurities raised by cleaning are covered in a controllable space range, and furthermore, the cotton dust impurities are subjected to adsorptive concentrated treatment by the dust collector connected with a pipe; a shade structure convenient to adjust flexibly is added and covers the to-be-cleaned wall surfaces all the timewith movement, so that the quantity of the raised cotton dust impurities scattering into air is reduced.

Owner:苏州秦汉纺织有限公司

Dedusting cotton fluffing device

InactiveCN108998862AImprove cleanlinessEliminate odorDispersed particle filtrationTransportation and packagingWorking environmentEngineering

The invention discloses a dedusting cotton fluffing device, including a rack, a baffle, a transmission band, a base, a dust collection box, a filter device, a transmission pipe, a connecting base, a dust collector, a supporting base, a roll shaft, a cotton dust absorbing cage, a purifying device, and an exhaust pipe. The base is arranged on the bottom of the rack. The baffle and the transmission band are connected with one side of the rack. The baffle is connected with the transmission band. The dust collection box and the filter device are arranged in the rack. The dust collection box is on the lower side of filter device, and the transmission pipe, the connecting base, and the supporting base are connected with the other side of the rack. The transmission pipe is connected with the connecting base through the dust collector. The connecting base is on the upper side of the supporting base. The device can improve air cleanliness, and remove peculiar smell and dust in air, so as to protect working environment.

Owner:SUZHOU BAIBI TEXTILE TECH CO LTD

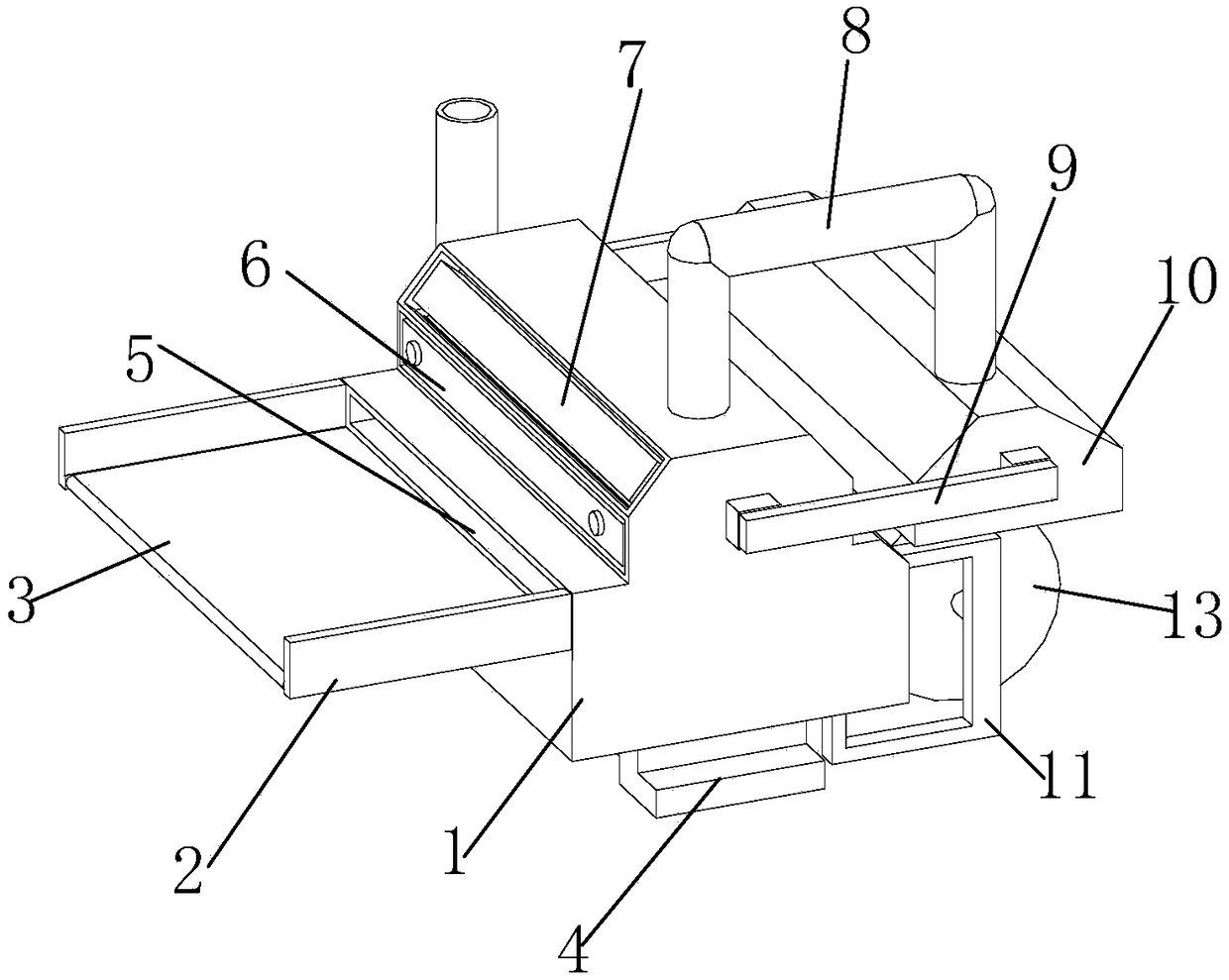

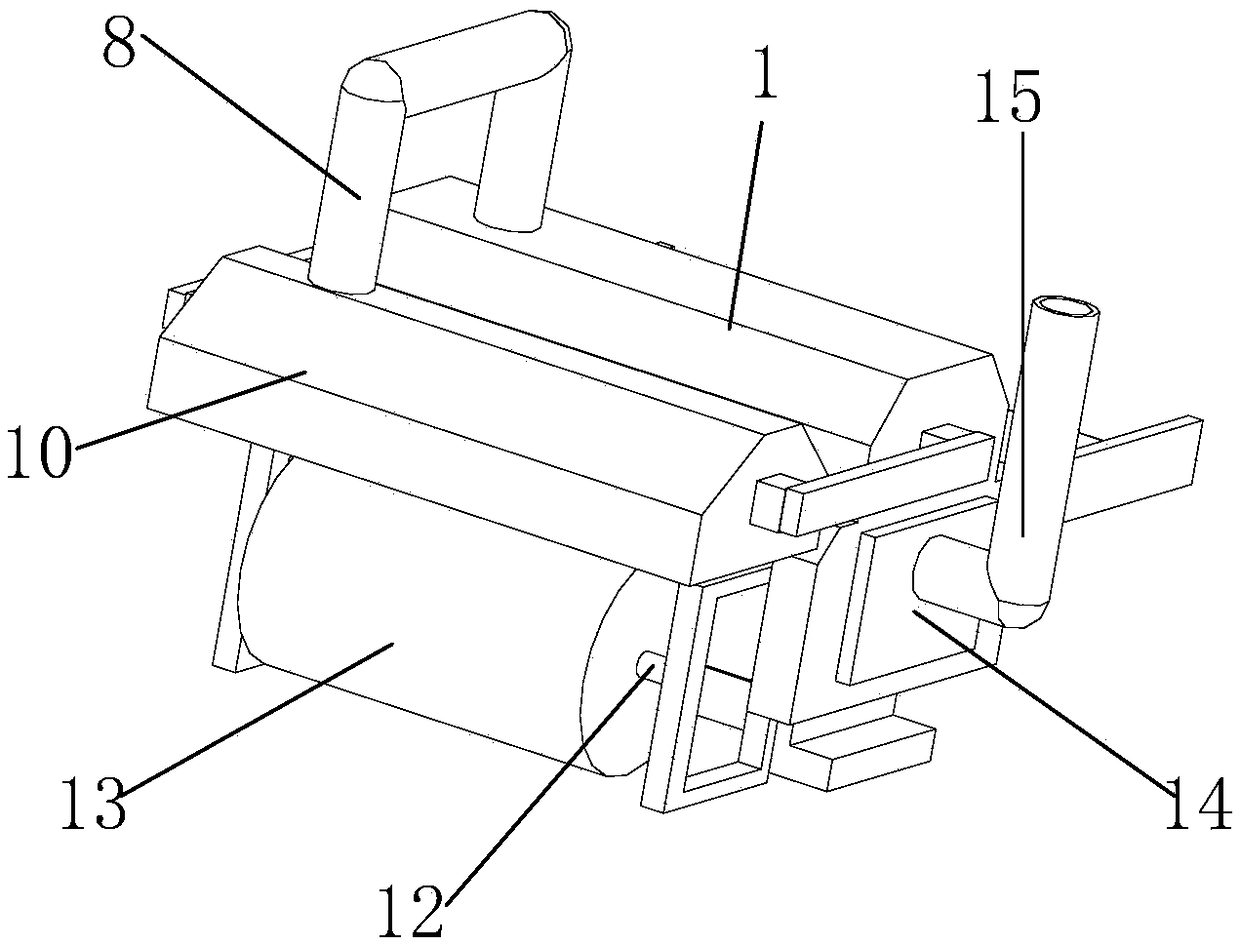

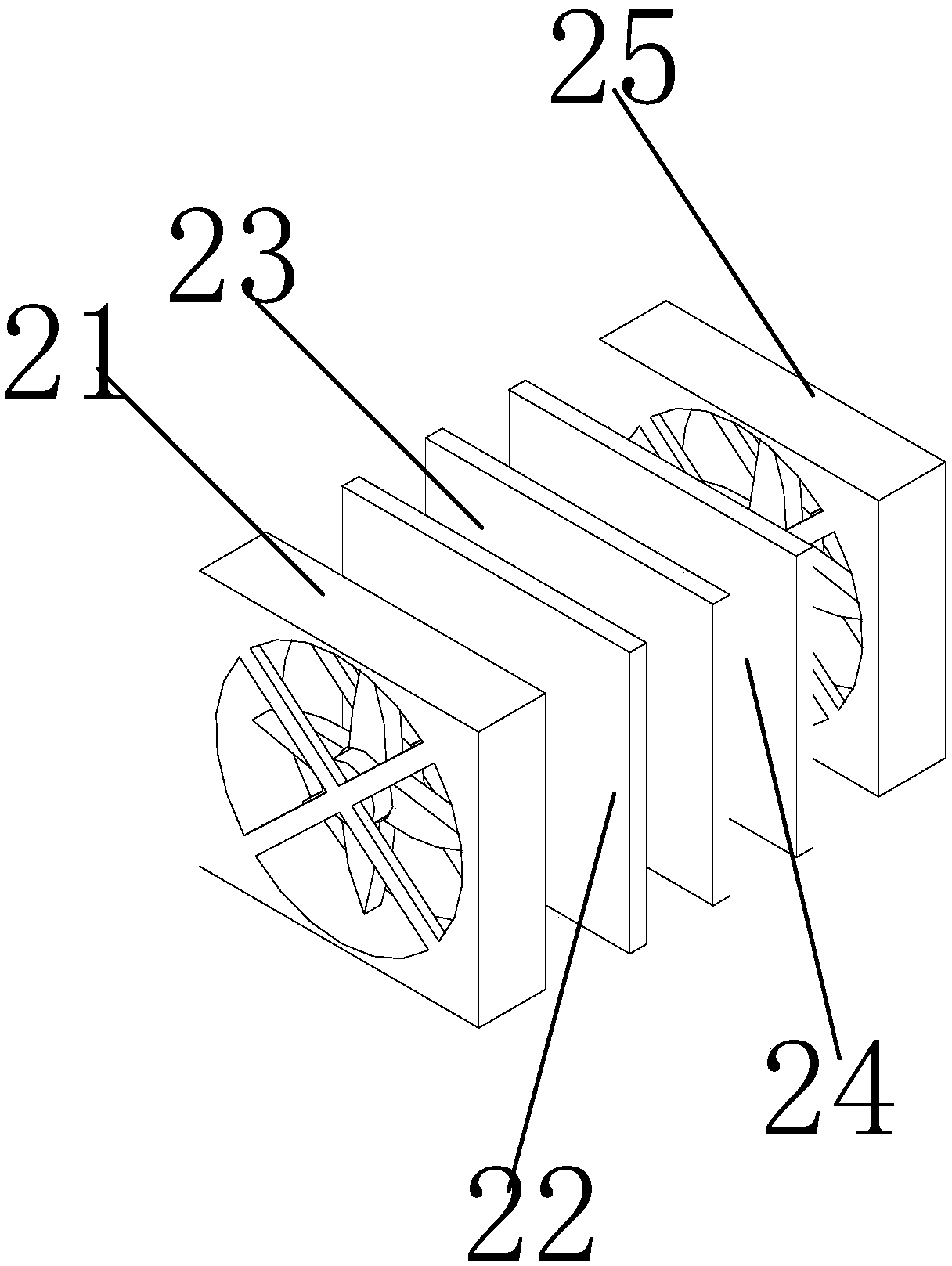

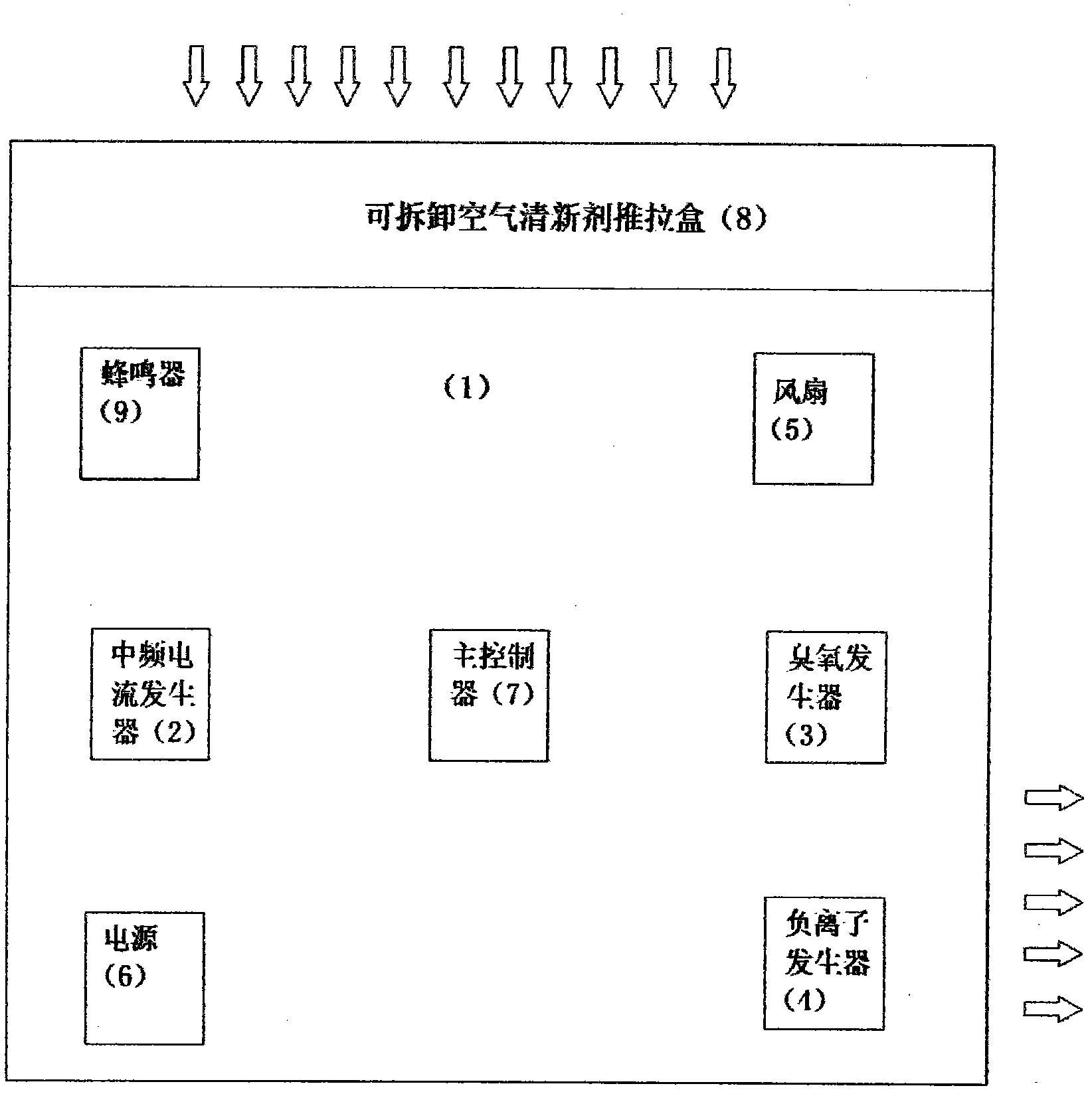

An electronic health instrument

InactiveCN102274578APurifying airSoothing effectElectrotherapyBathing devicesIntermediate frequencyEngineering

The invention discloses an electronic health-preserving instrument, which comprises a health-preserving instrument shell, an intermediate frequency current generator, an ozone generator, an anion generator, PP dust-removing cotton, a fan, a power supply and a main controller. The intermediate frequency current generator, the power supply and the The main controllers are all located in the housing of the health-preserving instrument, the head of the ozone generator and the anion generator are located at the air outlet of the housing of the health-preserving instrument, the fan is located at the air inlet of the housing of the health-preserving instrument, and the intermediate frequency current generator , ozone generator, negative ion generator, fan, and power supply are all connected to the main controller. The intermediate frequency generator of the present invention can generate intermediate frequency current to perform deep treatment on human acupuncture points, skin and bones, etc., and is attached with PP dust removal cotton and negative ion generator, which can also purify the air and relieve nerve effects while performing treatment; The generator can effectively disinfect and sterilize the office and living places in a timely manner, effectively preventing the reproduction of bacteria and the spread of virus infections that directly threaten personal health.

Owner:陈旗

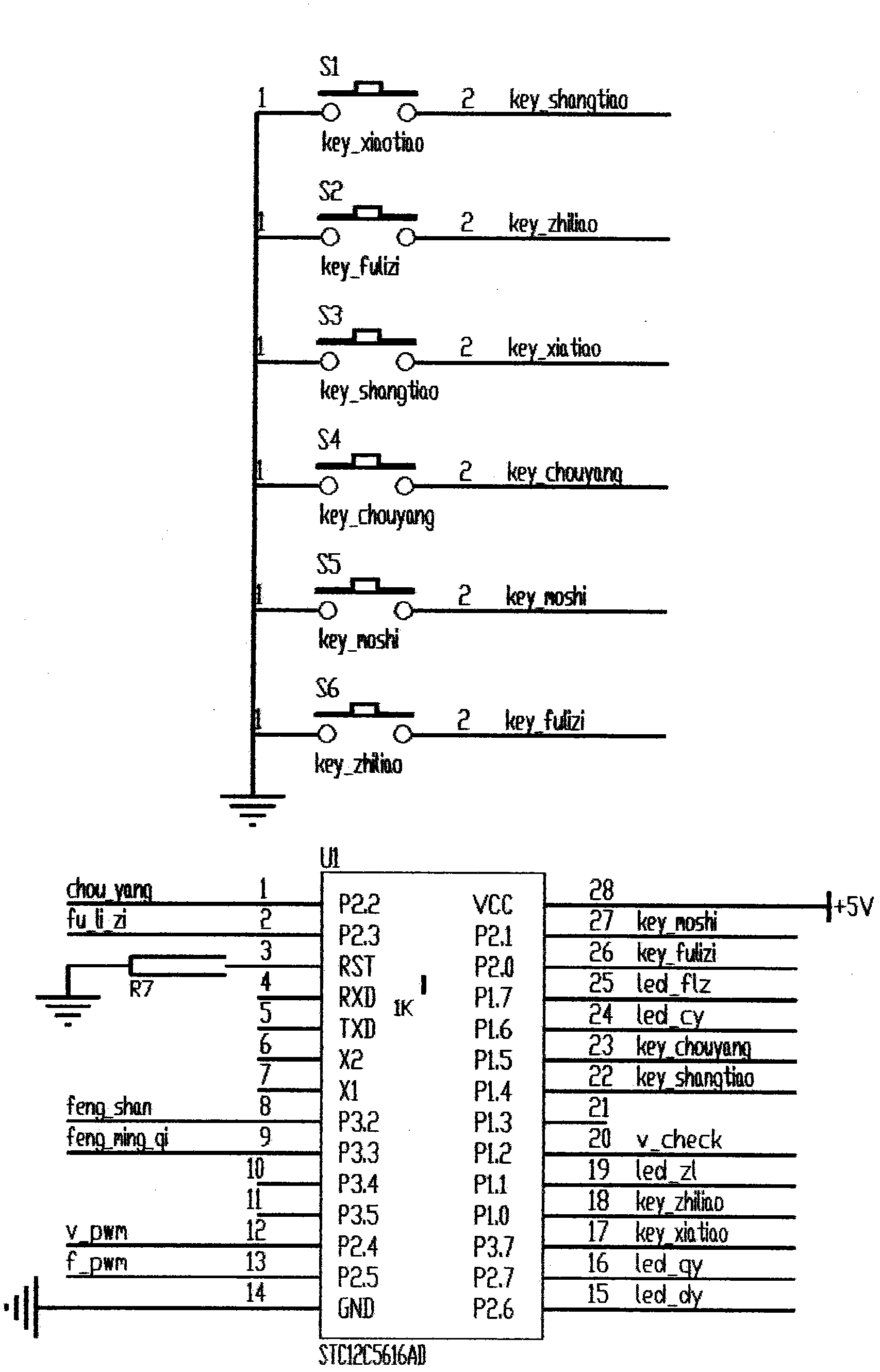

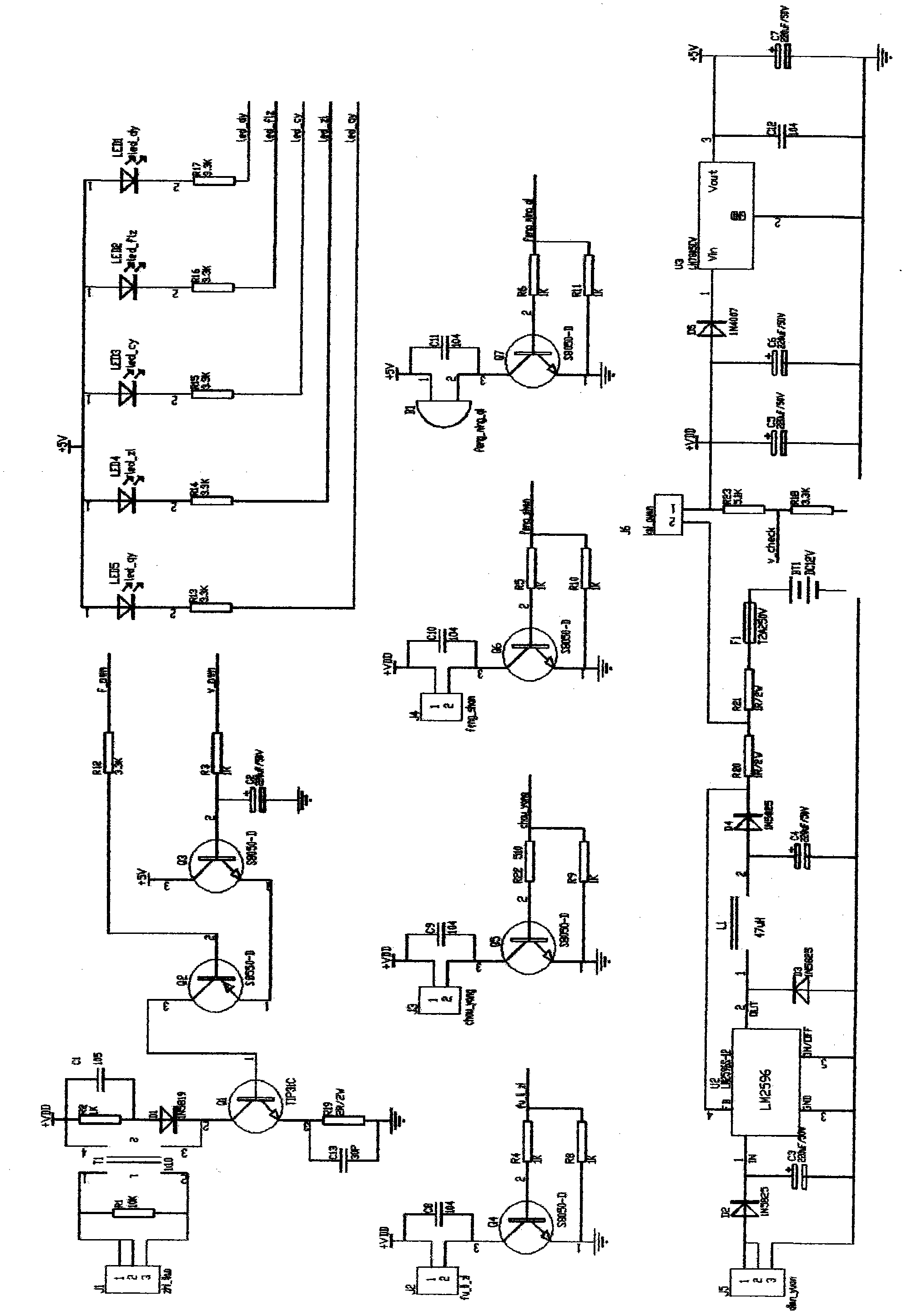

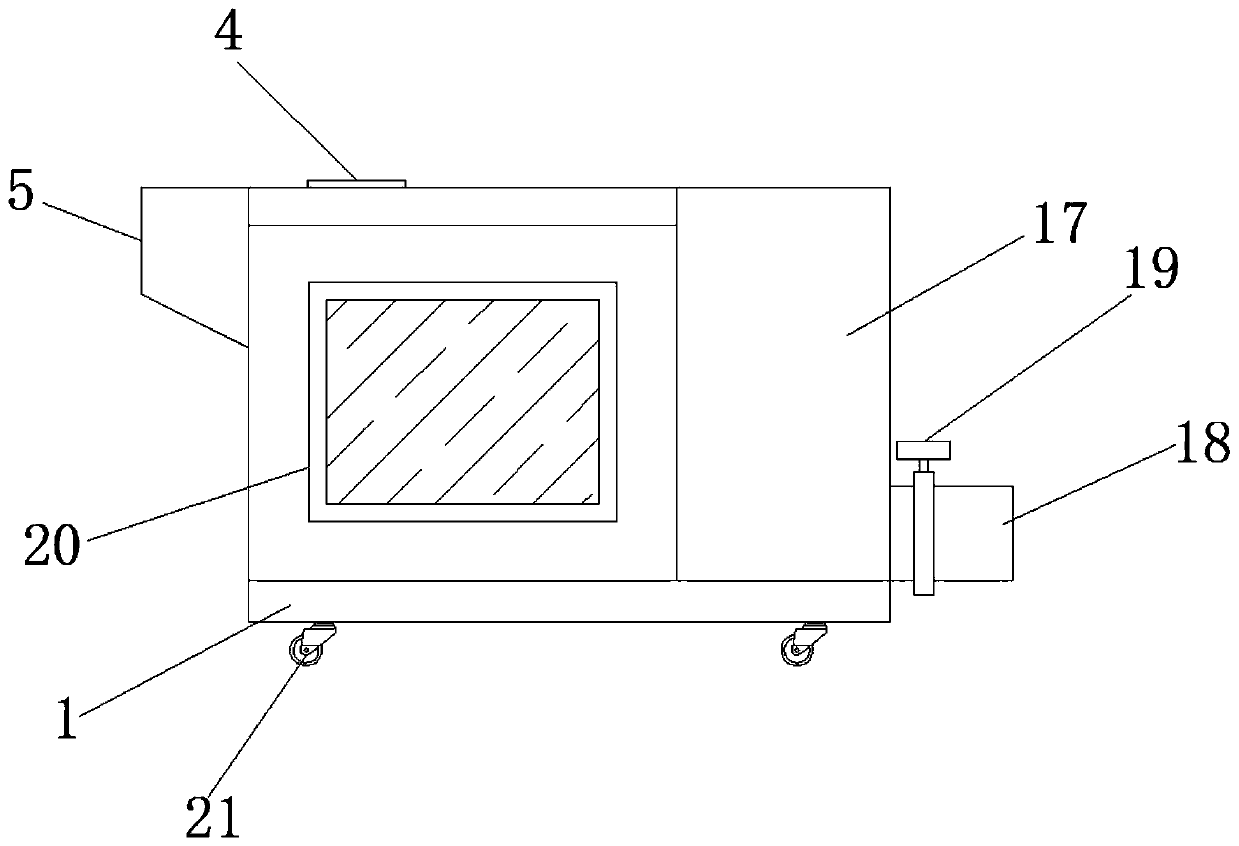

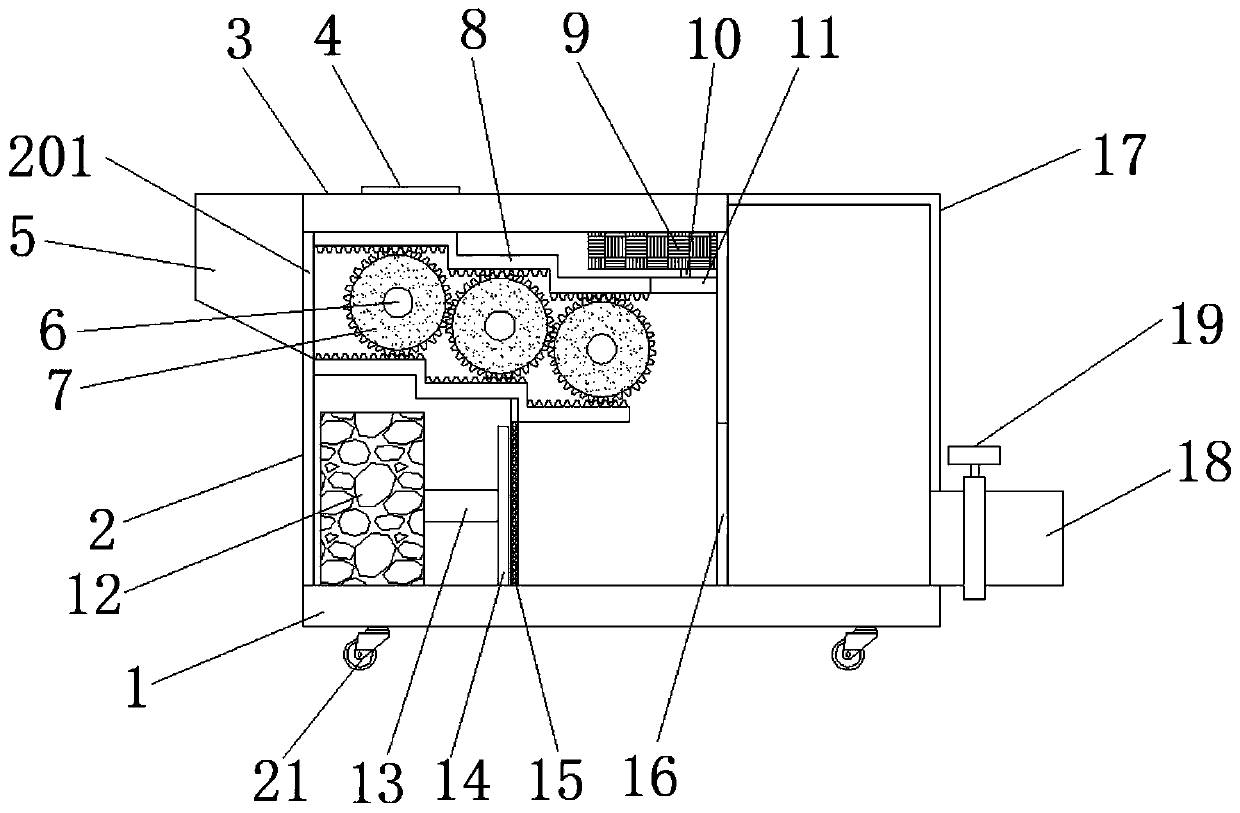

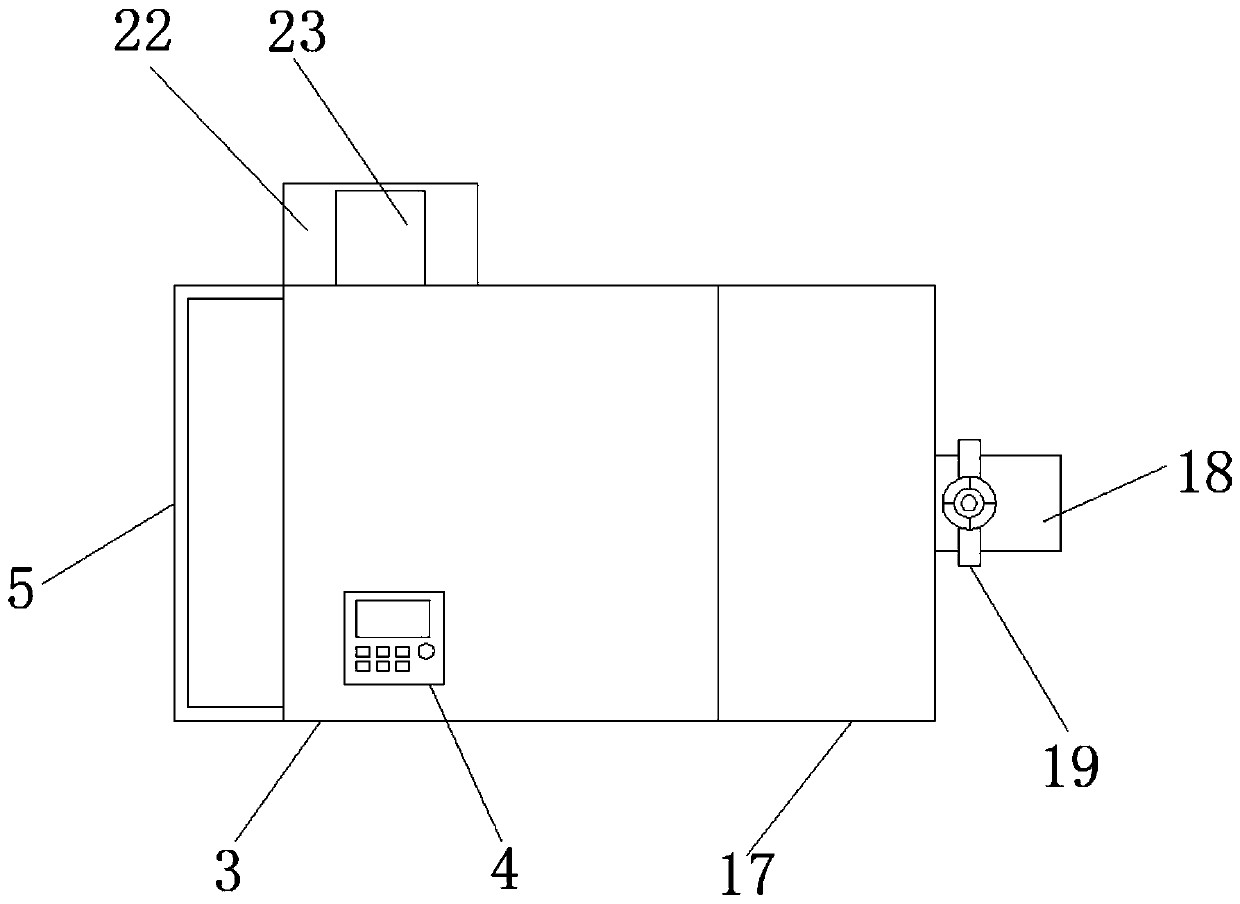

Cotton crusher

InactiveCN111111846AProtect your healthPrevent leakageGrain treatmentsTextile technologyAgricultural science

The invention relates to the technical field of textiles, in particular to a cotton crusher. The cotton crusher comprises a base, a cotton crushing box and a control box, wherein universal wheels arefixedly mounted at the bottom of the base, the cotton crushing box and a cotton collecting box are sequentially and fixedly mounted at the top of the base from left to right, a feeding port is formedin the left side of the cotton crushing box body, a feeding hopper is fixedly installed at the position, close to the outer edge opening of the feeding port, of the left side of the cotton crushing box body, an observation window is formed in the center of the base face of the cotton crushing box body, a motor cover is fixedly installed on the back face of the cotton crushing box body, and a motoris fixedly installed in the motor cover. The cotton crusher has the advantages that the whole device has effects of preventing field workers from inhaling cotton dust and protecting health of workers, the crushing effect is ensured, so that the crushing effect and the crushing efficiency are improved, the automation degree and the practicability of the cotton crusher are improved, the labor forceis reduced, the labor cost is saved, the stability and the practicability are higher, and the cotton crusher has a certain popularization value.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

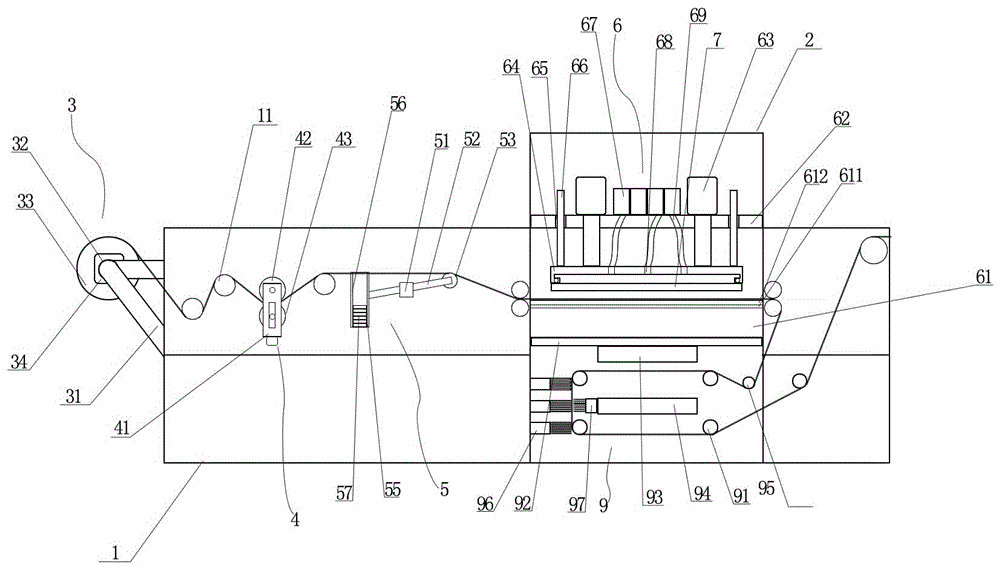

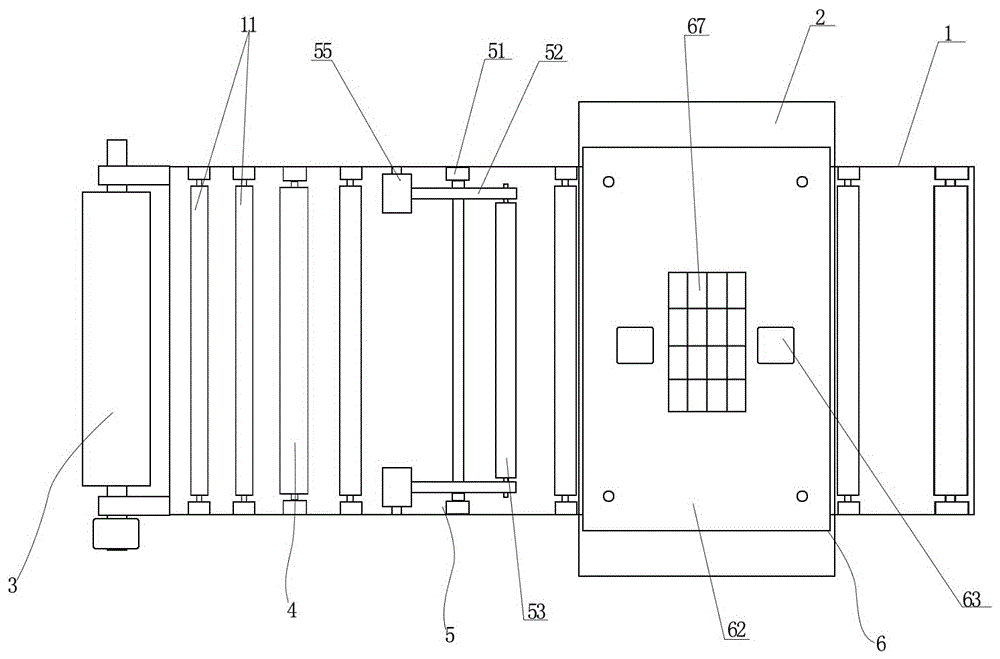

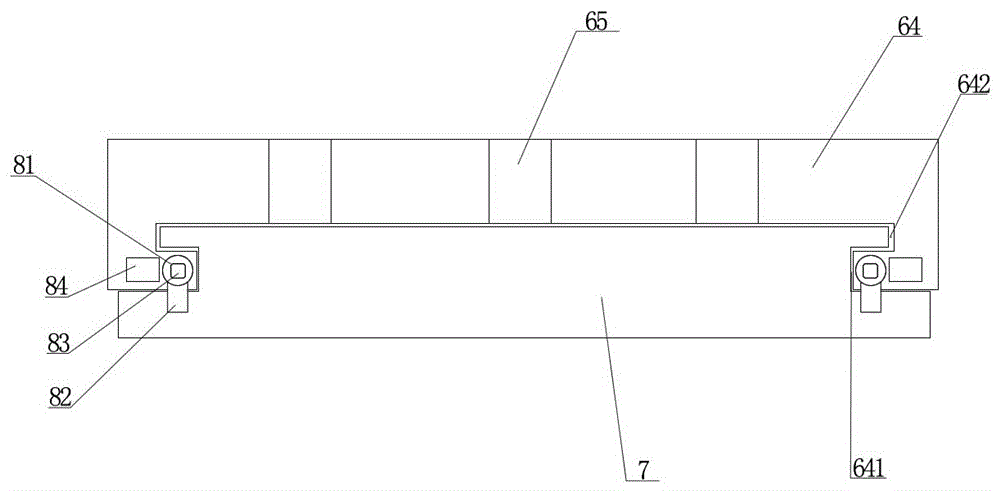

First twist conveying device of novel two-for-one twister and using method of first twist conveying device

InactiveCN112746359AAvoid affecting workEasy to disassembleDrafting machinesContinuous wound-up machinesMechanical engineeringCotton dust

The invention discloses a first twist conveying device of a novel two-for-one twister and a using method of the first twist conveying device, and relates to the technical field of two-for-one twisters. The first twist conveying device comprises a rack and silk threads; the rack is provided with a twisting mechanism used for twisting the silk threads, a conveying mechanism used for conveying the silk threads and a winding mechanism used for winding the silk threads; and the conveying mechanism is provided with an anti-static mechanism, an adjusting mechanism and a scraping mechanism. According to the device, a tensioning wheel can be adjusted through the adjusting mechanism, so that the tightness of silk threads is adjusted; a large amount of static electricity accumulated on the silk threads is eliminated through the anti-static mechanism; fluff and cotton dust on an overfeeding roller and a partition plate are scraped through the scraping mechanism; and therefore, the influence on the normal work of the overfeeding roller due to excessive accumulation of the fluff and the cotton dust is prevented, and certain convenience is brought to the conveying of the silk threads.

Owner:湖北智盛纺织科技有限公司

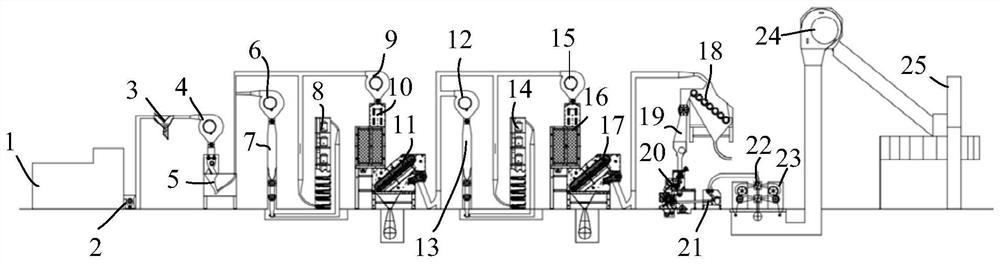

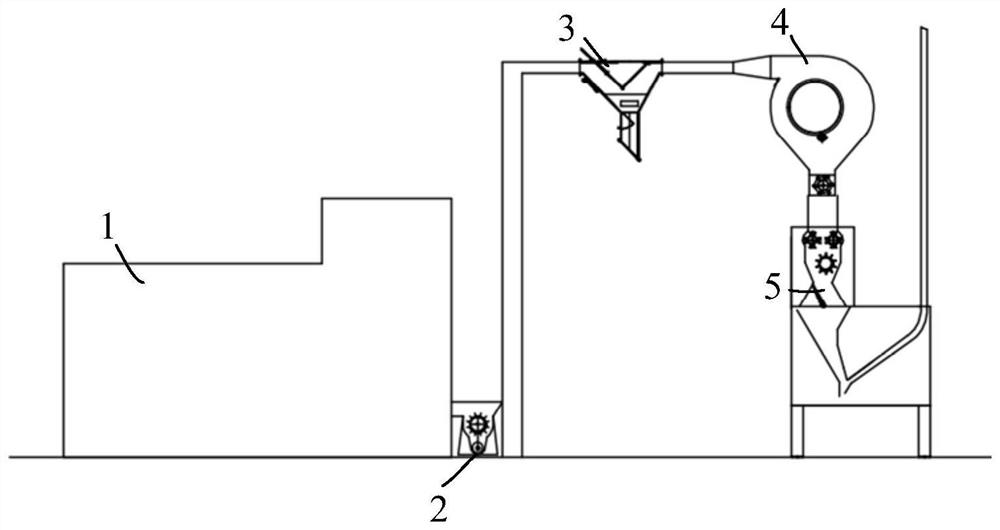

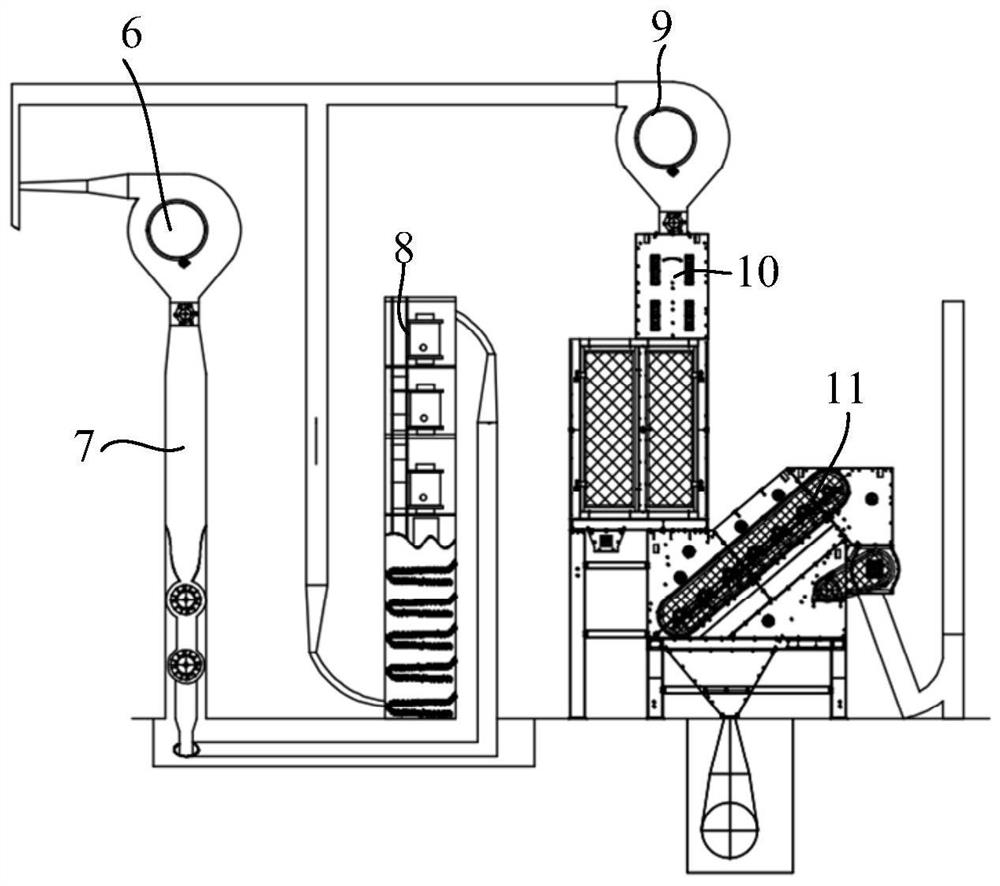

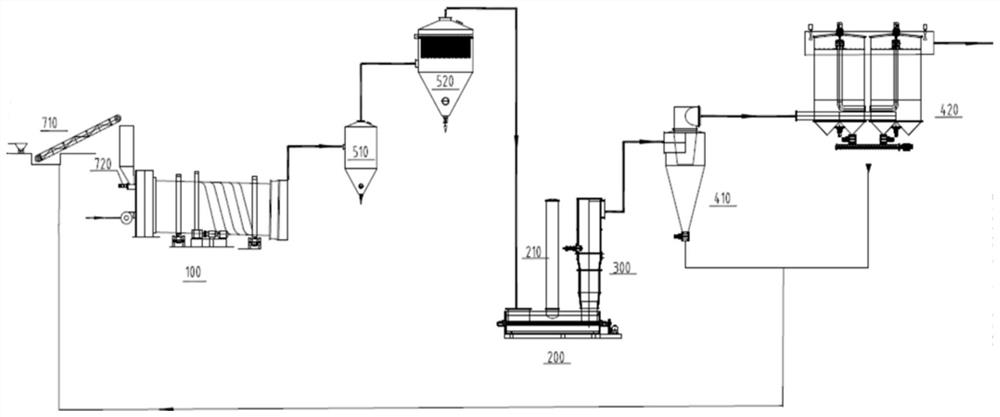

Machine-harvested cotton cleaning process

ActiveCN113403691AShorten the processing flowAvoid multiple damageVegetable fibre separation from seedsAgricultural engineeringProcess engineering

The invention discloses a machine-harvested cotton cleaning process. Machine-harvested cotton sequentially passes through a cotton feeding machine, a seed cotton pre-cleaning machine, a heavy impurity separator, a first unloader, a triangular drawing machine, a first-stage drying system, a first-stage boll cleaning negative pressure combined seed cotton cleaning unit, a second-stage drying system, a second-stage boll cleaning negative pressure combined seed cotton cleaning unit, a lower air suction seed cleaning machine, a cotton assorting auger, a cotton ginning machine, airflow skin cleaning machines, sawtooth skin cleaning machines, a cotton dust collecting auger and a packaging machine for processing. The machine-harvested cotton cleaning process has the technical effects that the key problems of the seed cotton cleaning process and the like are researched, a novel boll cleaning machine, a novel leaf cleaning machine and a combined cleaning machine of the boll cleaning machine and the leaf cleaning machine are provided in combination with the current machine-harvested cotton processing situation, the machine-harvested cotton processing flow is shortened, repeated damage of the machine to the length of seed cotton is avoided, the workload of manually cleaning an impurity discharging port of the machine is reduced, and more economic benefits can be brought to cotton enterprises.

Owner:山东中棉机械有限公司

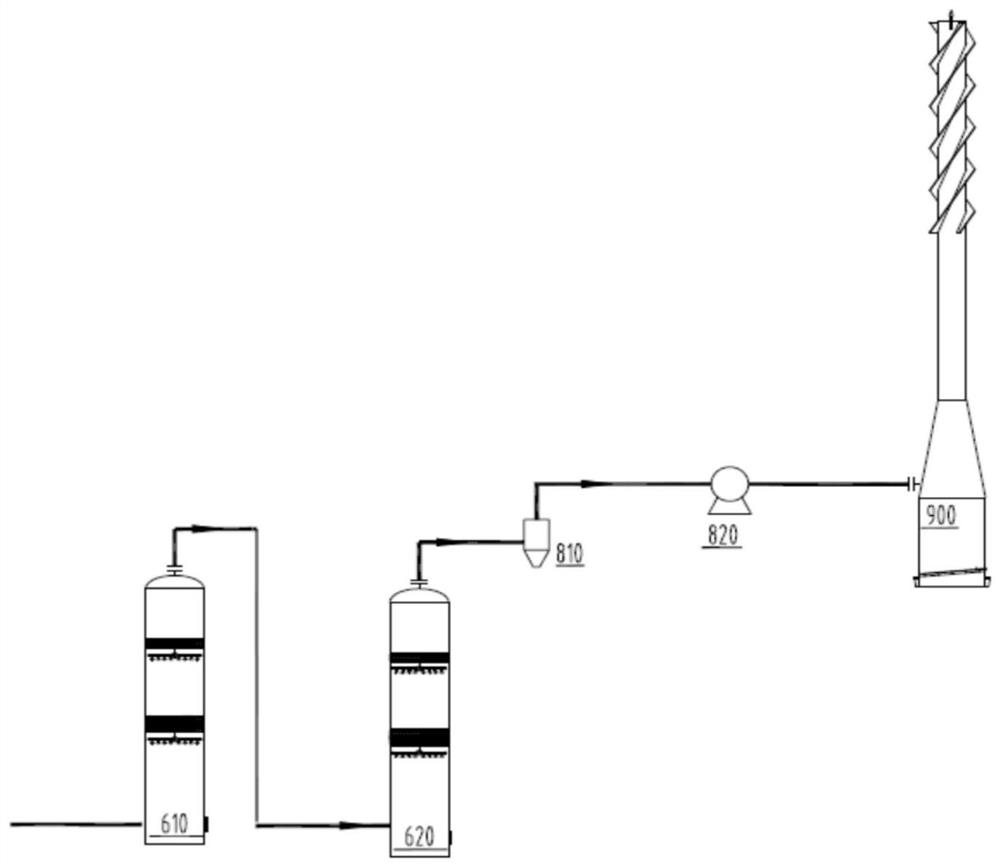

High-salinity wastewater treatment system and method

PendingCN112142148AHigh thermal efficiencyAll-in-one processingDispersed particle separationWater/sewage treatmentPolyesterDust control

The invention discloses a high salinity wastewater treatment system, which comprises an incinerator, a dryer, a drying tower, a flue gas treatment system, a smoke exhaust fan and a discharge cylinder,the incinerator comprises a feed port and a discharge port, one side of the feed port is provided with a cloth belt conveyor and a screw conveyor, the discharge port is sequentially connected with aflue gas dust settling tower and a high temperature polyester cotton dust remover, and the high temperature polyester cotton dust remover is connected with the dryer. the drying machine comprises a high-salinity wastewater feeding hole, a flue gas inlet and a flue gas outlet, one side of the drying tower is connected with the flue gas outlet, one side, far away from the drying machine, of the drying tower is connected with a cyclone dust collector and a bag type dust collector, the bag type dust collector is used for introducing dust-removed gas into the flue gas treatment system, and the fluegas exhaust fan comprises an air inlet and an air outlet. The air inlet is connected with the flue gas treatment system, and the air outlet is connected with the discharge cylinder. According to thehigh-salinity wastewater treatment system, a whole set of circulation is formed, the heat efficiency of high-salinity wastewater drying is greatly improved, integrated treatment of high-salinity wastewater drying, incineration and waste gas is achieved, and regeneration and utilization of high-salinity wastewater are greatly met.

Owner:南通久华环保设备科技有限公司

Odor removing device of textile equipment

PendingCN112246820AEfficient removalAvoid cloggingGas treatmentUsing liquid separation agentActivated carbonAir pump

The invention discloses an odor removing device of textile equipment, and belongs to the technical field of textile. The odor removing device comprises an odor removing box, a dust falling pool, a bent pipe and a drawing box. The dust falling pool used for adsorbing cotton dust is mounted at the upper part of the odor removing box, the bent pipe used for sucking gas is mounted outside the odor removing box, and the drawing box used for containing activated carbon is mounted at the bottom of the odor removing box. A gas pump is arranged at the top of the odor removing box, the upper end of thegas pump is connected with the bent pipe, a gas channel is arranged between the left side of the dust falling pool and the odor removing box, the drawing box is arranged below the gas channel, a movable plate is arranged on the left side of the drawing box and movably connected with the odor removing box through a hinge, meshes are formed in the lower right corner of the drawing box, and an exhaust pipe is arranged on the right side of the drawing box and fixedly mounted at the lower right corner of the odor removing box. The device can be suitable for various types of textile equipment through the bendable bent pipe, high universality is achieved, meanwhile, large-particle dust impurities such as cotton dust contained in peculiar smell gas can be effectively removed through the dust falling pool, and a gas purification pipeline is prevented from being blocked.

Owner:绍兴金诚达纺织股份有限公司

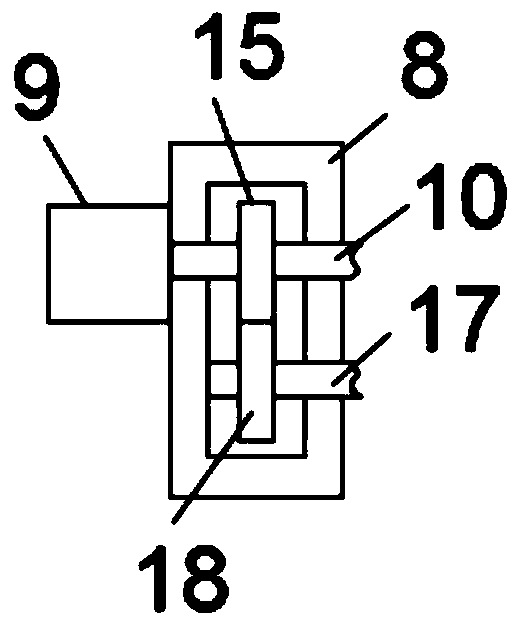

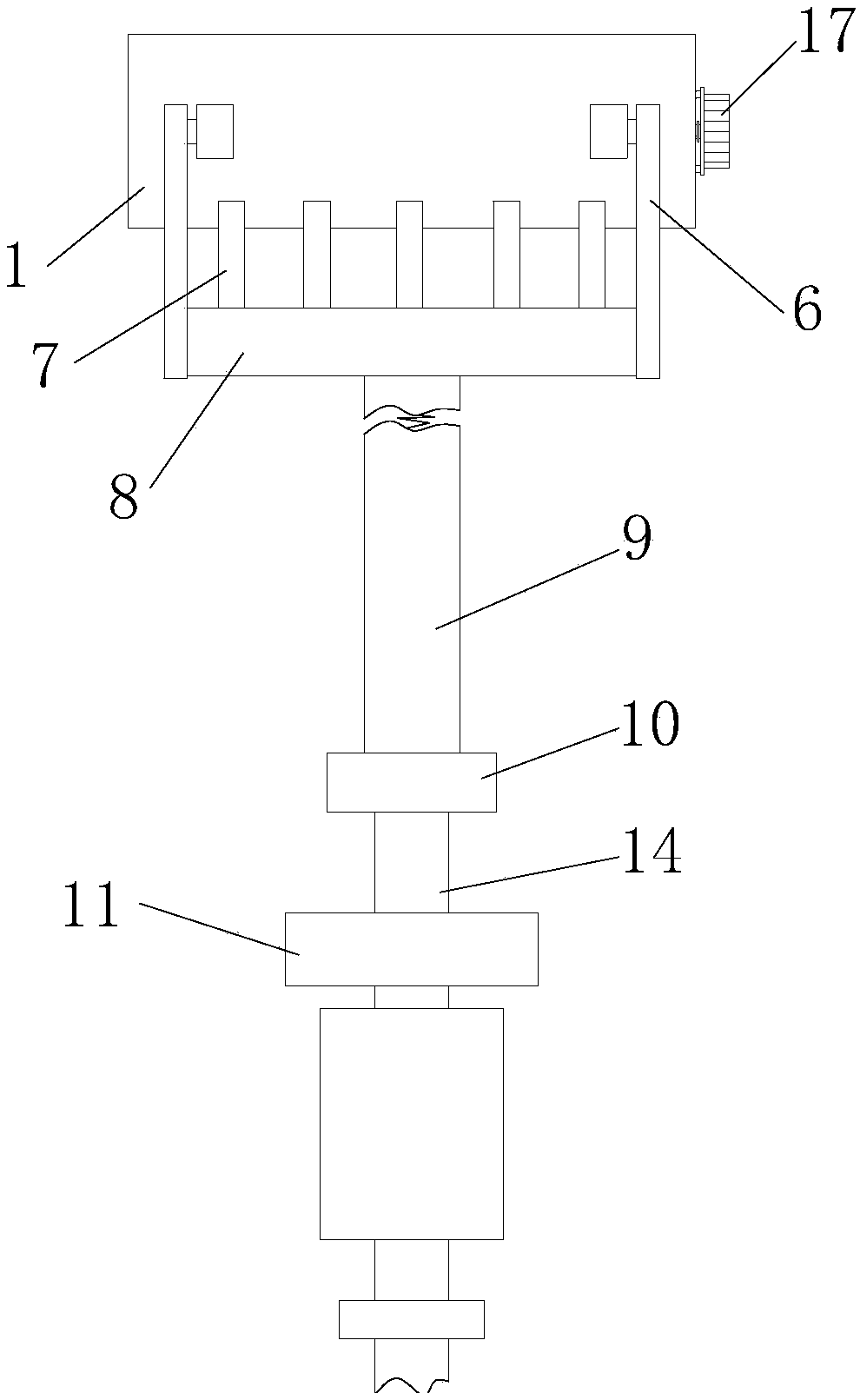

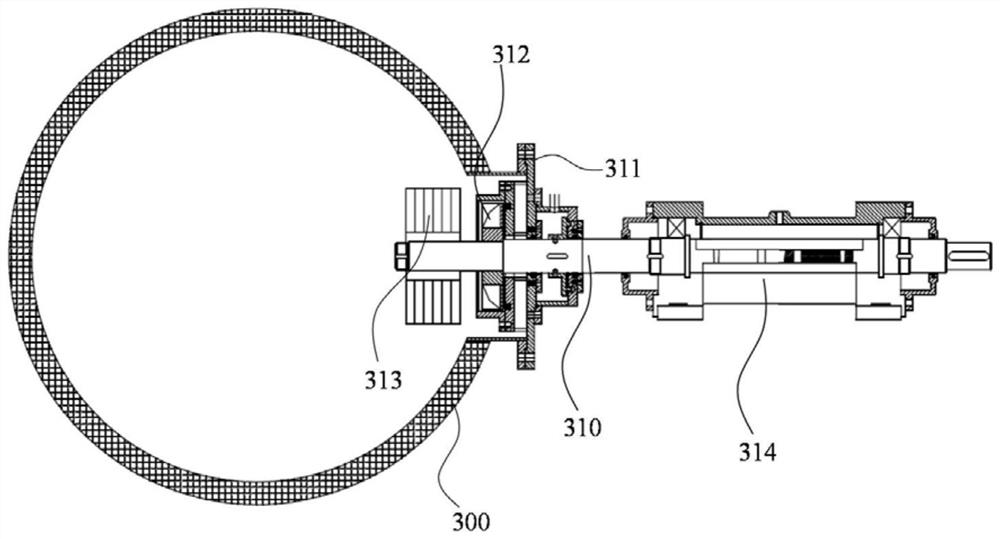

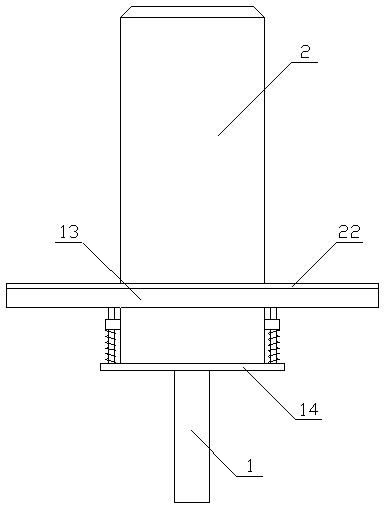

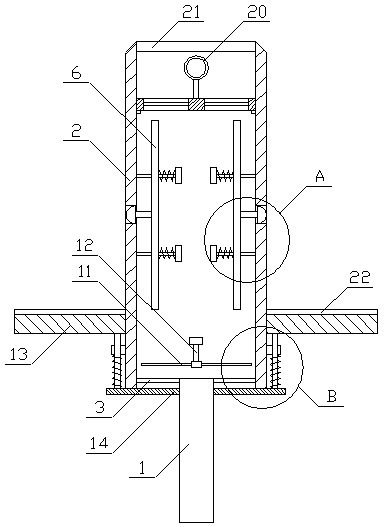

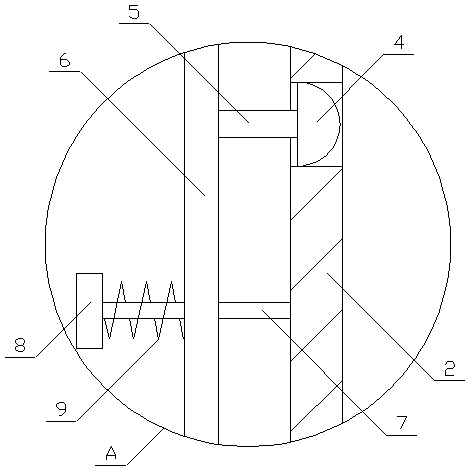

Spinning device with wide application range and dedusting function

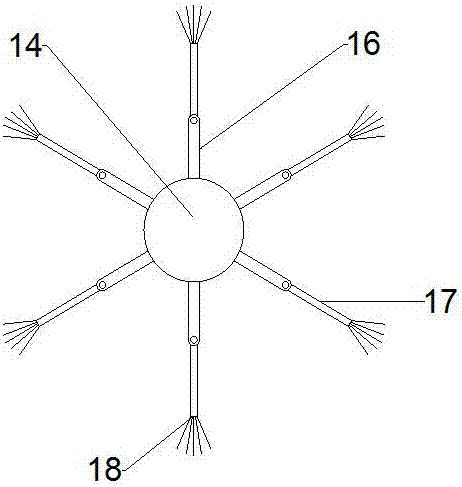

ActiveCN111020761APracticalImprove filtering effectContinuous wound-up machinesDrive shaftDust control

The invention relates to a spinning device with a wide application range and a dedusting function. The device comprises a transmission shaft, a rotating pipe and at least two connecting rods, whereinthe transmission shaft and the rotating pipe are arranged coaxially, the diameter of the transmission shaft is smaller than the inner diameter of the rotating pipe, one end of the transmission shaft is arranged in the rotating pipe, a driving device is arranged at the other end of the transmission shaft, the driving device is in transmission connection with the transmission shaft, the axis of eachconnecting rod and the axis of the transmission shaft are perpendicular and intersect, the connecting rods are uniformly arranged in the rotating pipe in the circumferential direction with the axis of the transmission shaft being a center, the transmission shaft is fixedly connected with the inner wall of the rotating pipe through the connecting rods, an auxiliary mechanism and a dedusting mechanism are arranged in the rotating pipe, and the auxiliary mechanism is arranged at the side, away from the driving device, of the transmission shaft. According to the spinning device with the wide application range and the dedusting function, the application range is expanded through the auxiliary mechanism, and moreover the functions of filtering and collecting cotton dust are further achieved through the dedusting mechanism.

Owner:桐乡乐维新材料有限公司

Ginned cotton humidifier

The invention discloses a ginned cotton humidifier. The ginned cotton humidifier comprises a cotton delivery channel and a humidifying device, wherein the cotton delivery channel is slantingly downwards arranged and connected with a cotton delivery device and a cotton dust collecting cage; and the humidifying device is used for humidifying the ginned cotton passing through the cotton delivery channel and comprises a humidifying grating assembly which is arranged in the cotton delivery channel, and a steaming device which is connected to the humidifying grating assembly through an humidification air blower and a configured pipeline. The ginned cotton humidifier based on the technical scheme of the invention has a better humidifying effect.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Computer case with dustproof effect

InactiveCN107656592AEntry barrierBarrier inhalationDigital processing power distributionEngineeringHeight difference

The invention discloses a computer case with the dustproof effect. The computer case comprises an inner case, an outer case and a base. By arranging the outer case on the outer side of the inner case,the outer case is composed of a gas inlet cavity and a gas outlet cavity, during operation, gas enters the gas inlet cavity through a gas inlet formed in the bottom of the gas inlet cavity and is poured into the inner case under the drive of a gas inlet fan, in the process, due to the height difference between the gas inlet and the gas inlet fan, dust cannot ascend to the height of the gas inletfan, dust can be effectively stopped from being sucked in, gas mixed with micro dust enters the gas inlet cavity from the gas inlet, under the effect of the gas inlet fan, dust in gas collides with the inner wall of the gas inlet cavity, the dust is adsorbed by sound absorbing cotton on the inner wall of the gas inlet cavity, the dustproof effect is further enhanced, after gas enters the inner case, all components installed on a main board installing support are cooled, then sucked out by the gas outlet fan and exhausted by the gas outlet, the gas inlet and the gas outlet are each provided with dustproof cotton, and the dust can be stopped to the maximum extent.

Owner:季正明

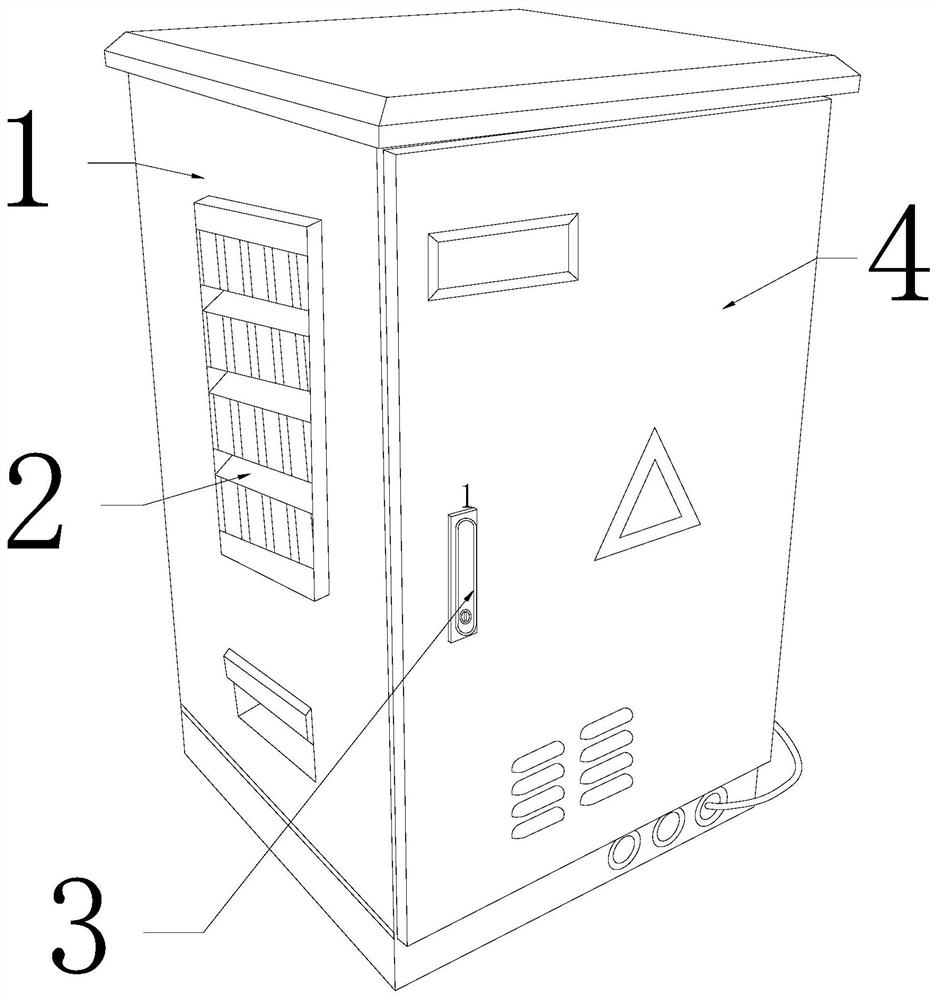

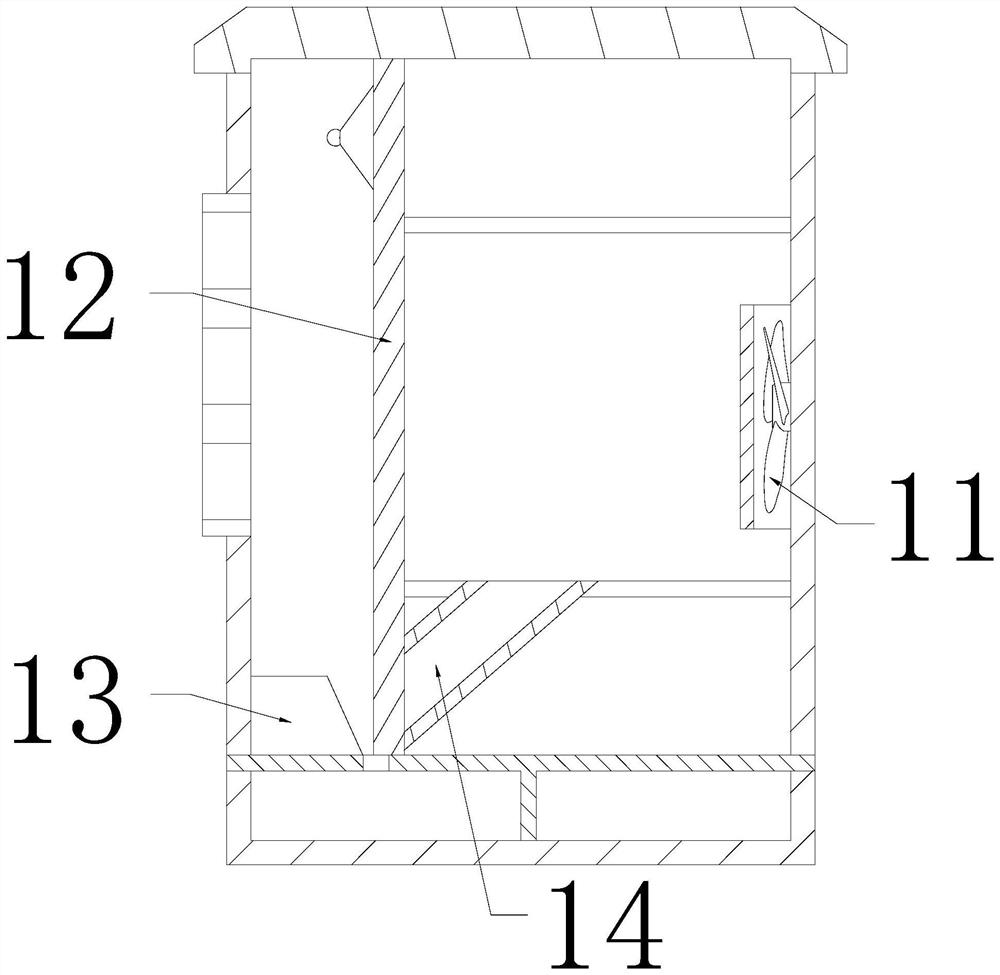

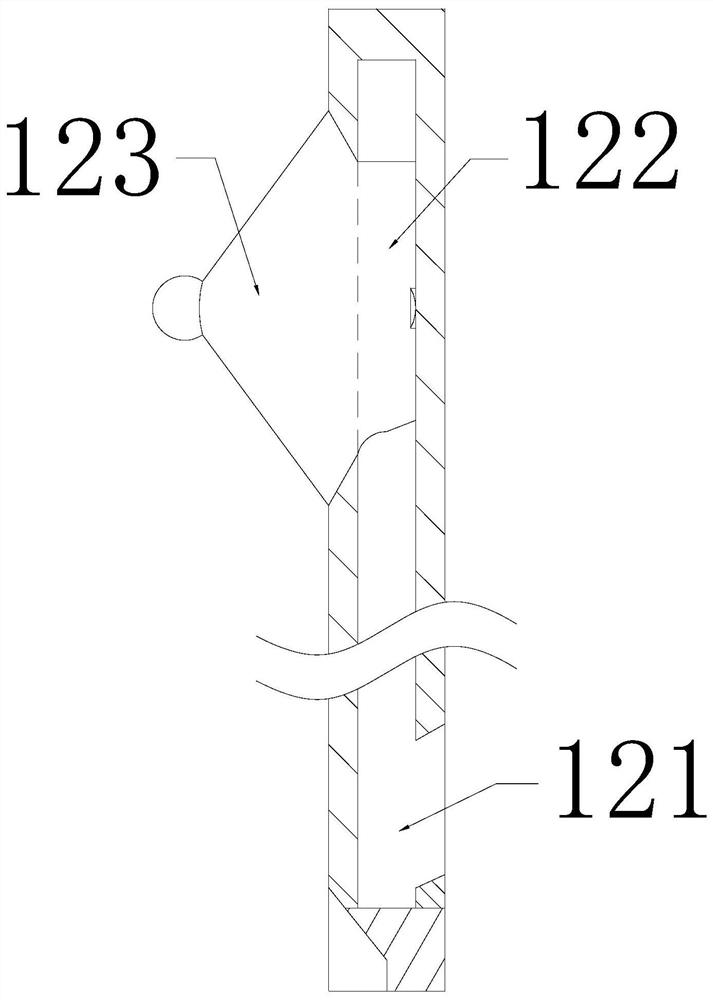

Integrated power supply equipment

PendingCN113020022AImprove cooling effectReduce weightCleaning using toolsScraping - actionCotton dust

The invention provides integrated power supply equipment which structurally comprises a box body, a ventilation plate, a handle and a box door. The ventilation plate is installed at the left side of the box body, the handle is fixedly embedded at the front end of the box door, and the right side of the box door is hinged to the box body. According to the integrated power supply equipment, air flow blown out by a heat dissipation fan is guided into a heat conduction plate through an air guide pipe, so that the air flow pushes a scraping plate upwards, wet cotton dust adsorbed on the heat conduction plate is removed, the problem that the heat dissipation performance of a power supply cabinet is reduced due to the fact that the heat conduction plate is covered by the wet cotton dust layer by layer is avoided, and the operation performance of the power supply cabinet can be effectively played; and the scraping plate falls to the bottom end of the heat conduction plate, a push-pull strip is pressed to push a scrap removing block out through a bearing block, the wet cotton dust left on the top of the scraping plate is removed, scraped objects on the top of the scraping plate can be removed, the weight of the scraping plate is reduced, it is ensured that pushing by the air flow is easier, and the subsequent scraping action of the scraping plate is facilitated.

Owner:邱柔媚

Automatic slicer with tool cleaning mechanism

InactiveCN111304901AGuaranteed cleanlinessDoes not affect slicing jobsSevering textilesMetal working apparatusProcess engineeringNonwoven fabric

The invention relates to an automatic slicer with a tool cleaning mechanism. The automatic slicer with the tool cleaning mechanism is characterized in that the automatic slicer comprises a unwinding device, a guide device, a transmission device and a slicing device; and the slicing device comprises a slicing rack, an upper fixed plate, a moving tool mechanism and a cleaning mechanism. The automatic slicer with the tool cleaning mechanism can thoroughly clean a slicing tool, ensure that non-woven cloth after slicing not sticks to cotton dust, and during the cleaning process, no influence on theslicing operation is caused.

Owner:扬州市凯瑞特医疗用品有限公司

Dust removal device for textile machine

The invention discloses a dust removal device for a textile machine. The dust removal device comprises a top plate, a dust collection pipe, a piston barrel, an extrusion ball, a piston rod, a centrifugal fan, an air outlet pipe, a water tank, a first water pipe, mounting feet, a second water pipe, goosenecks, a spray nozzle, a first side plate, a dust hopper, a reinforcement connecting pipe, a second side plate, an atomizer, a third water pipe, a dust collection box, a piston, a press plate, an air filter element and a convex block. According to the dust removal device for the textile machine,the dust collection box is installed on the top of the machine by means of the top plate, the first side plate and the second side plate, and the dust collection box is close to the machine, so thatmost of batt, cotton dust and the like, which are generated by the textile machine, are collected in the dust collection box, the dust removal effect is obvious, the batt, the cotton dust and the like, which enter the machine, can be reduced, and the service life of the machine is prolonged; furthermore, the dust removal device improves the working environment of workers and reduces the risk of respiratory diseases; the dust collection box directly collects the batt, the cotton dust and the like, thus avoiding the impact on the environment.

Owner:WUJIANG FUAILIANG TEXTILE

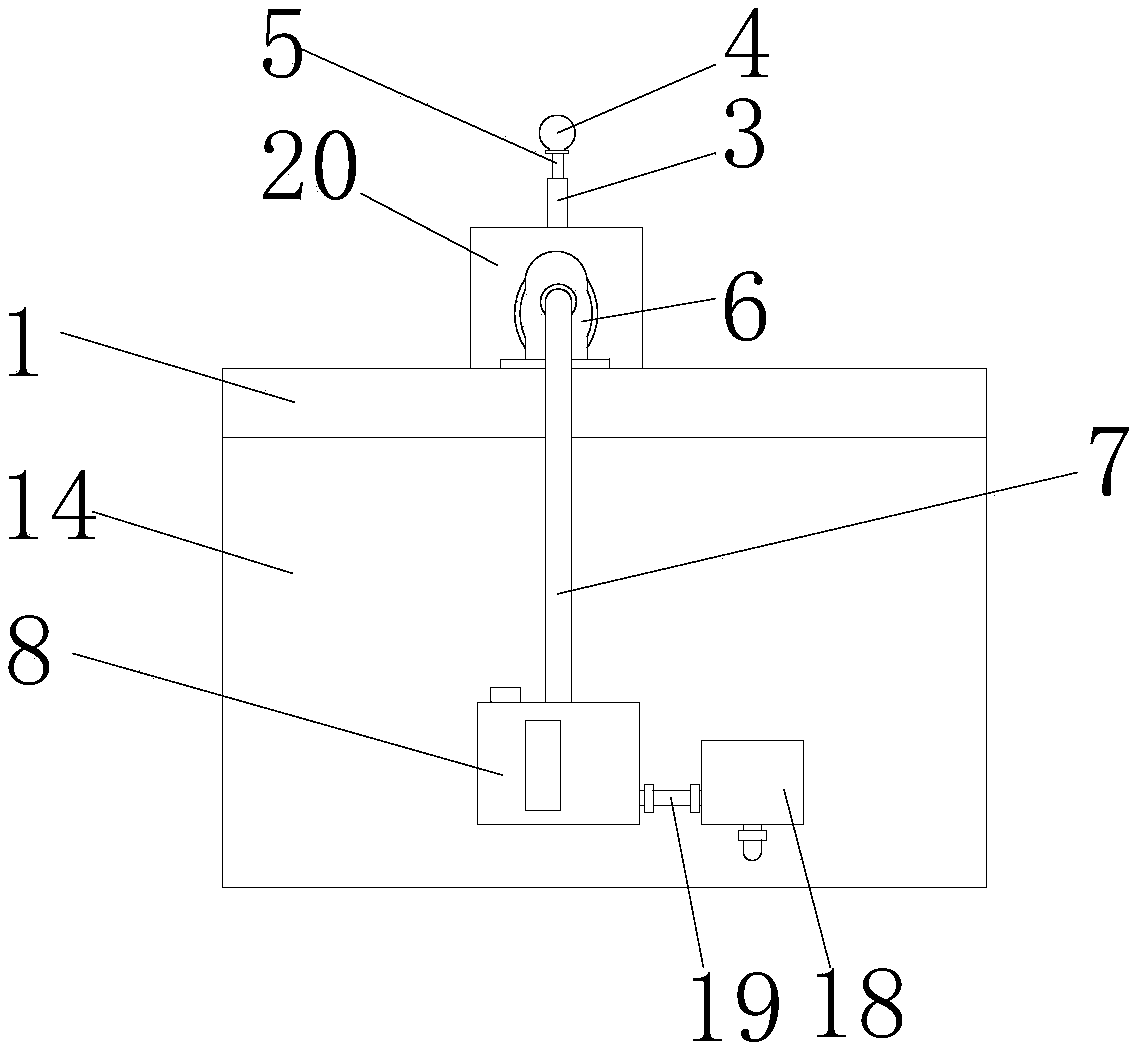

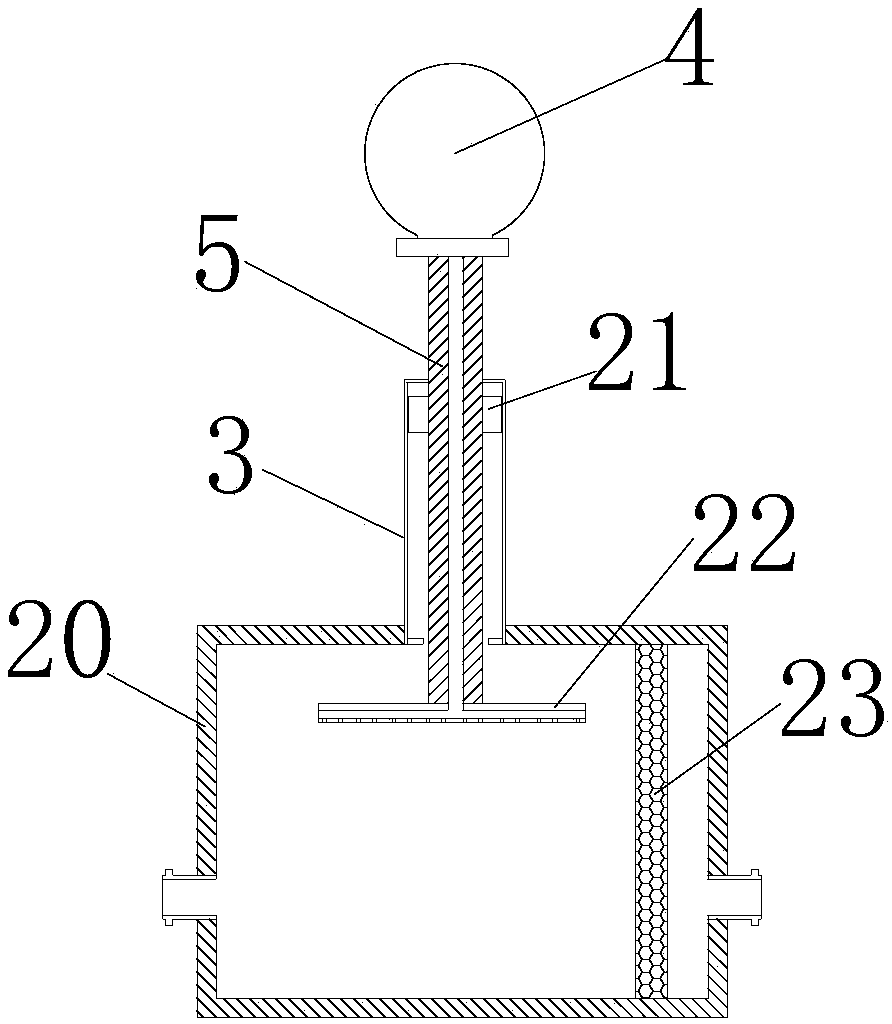

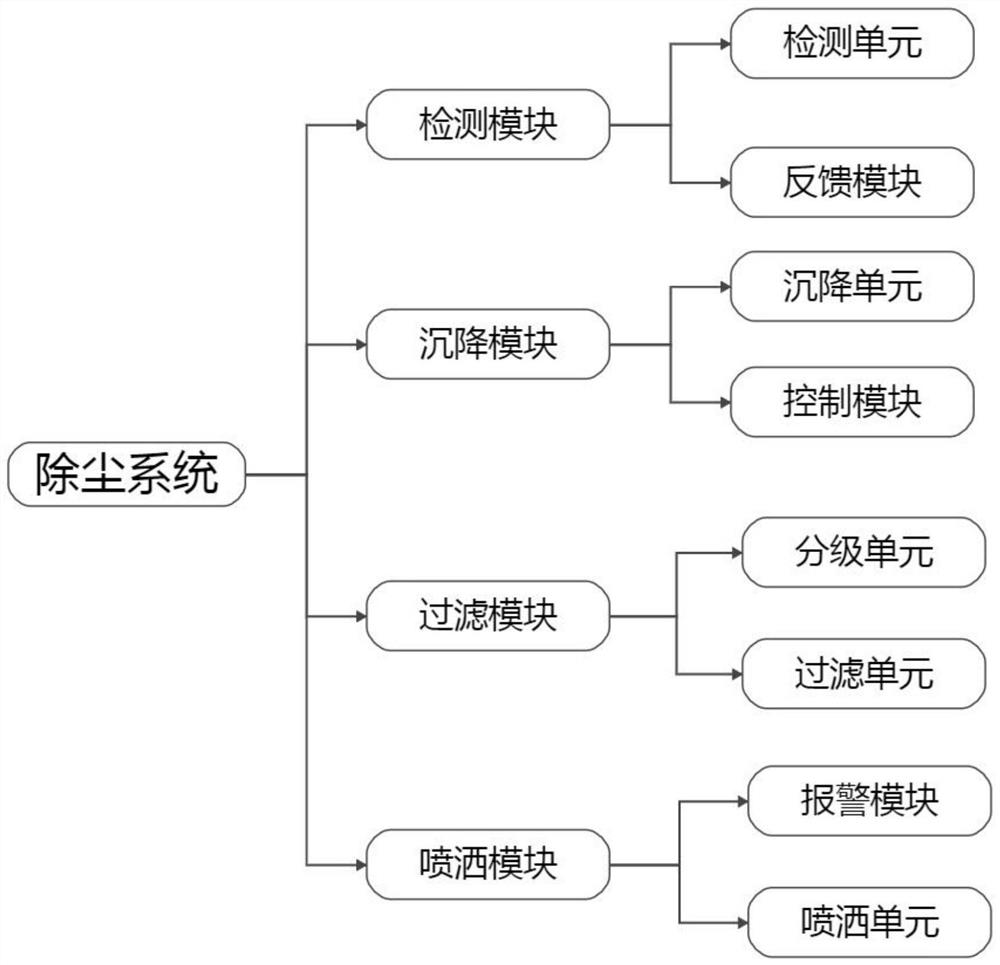

Textile workshop dust removal device and system based on big data

PendingCN114699867AEasy to handleReduce economic costsCombination devicesAlarmsDust controlEnvironmental engineering

The invention discloses a big data-based dust removal device for a textile workshop, which comprises a dust removal cylinder, and is characterized in that a filter screen is arranged on the outer side of the dust removal cylinder, an isolation cylinder is arranged in the dust removal cylinder, a plurality of groups of pressure valves are arranged in the isolation cylinder, an air inlet pipeline is arranged below the dust removal cylinder, and an air outlet pipeline is arranged below the air inlet pipeline. A first valve is arranged above the dust removal cylinder, a discharge pipeline is arranged above the first valve, two humidifiers are arranged in the dust removal cylinder, a group of second valves are arranged on the lower side of the dust removal cylinder, a cleaning pipeline is arranged on one side of the group of second valves, and a dust suction pump is arranged on one side of the cleaning pipeline. The dust removal system comprises a detection module, a sedimentation module, a filtering module and a spraying module, the detection module is electrically connected with the sedimentation module, and the device has the advantage that the treatment means and the treatment intensity can be adjusted in real time according to the cotton dust concentration.

Owner:周珊珊

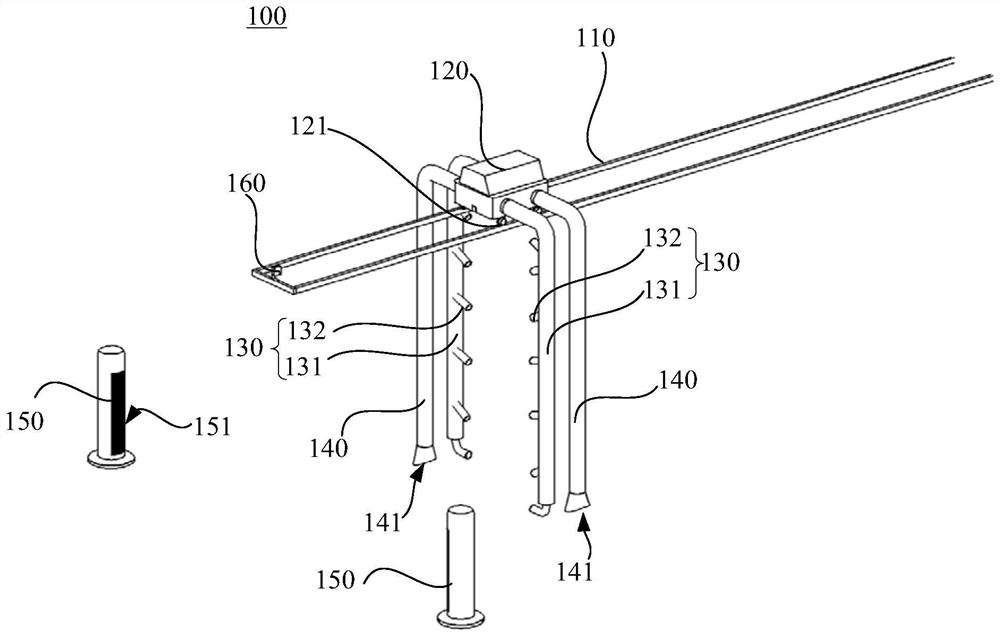

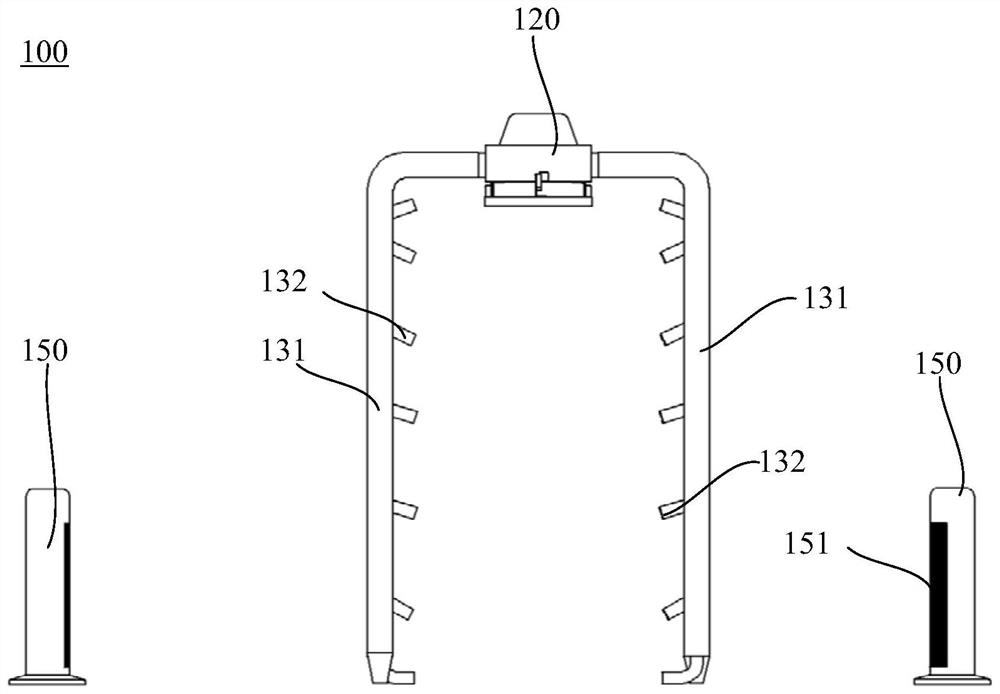

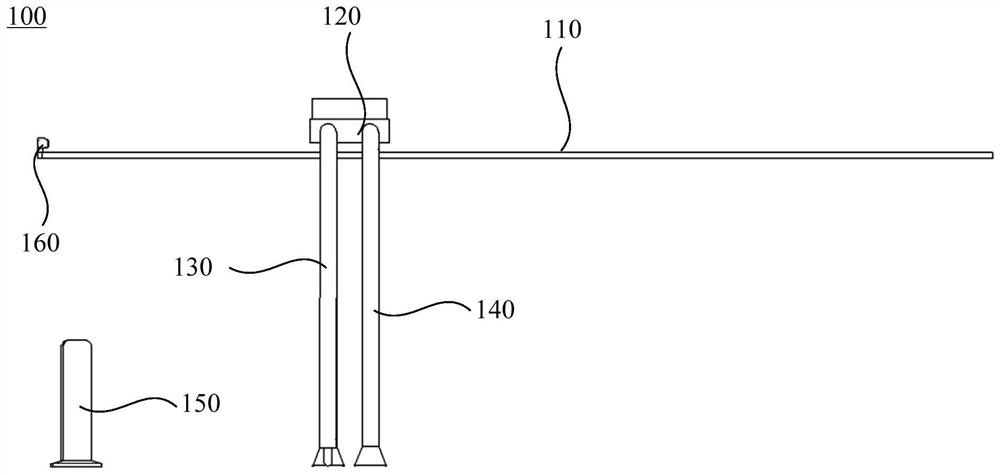

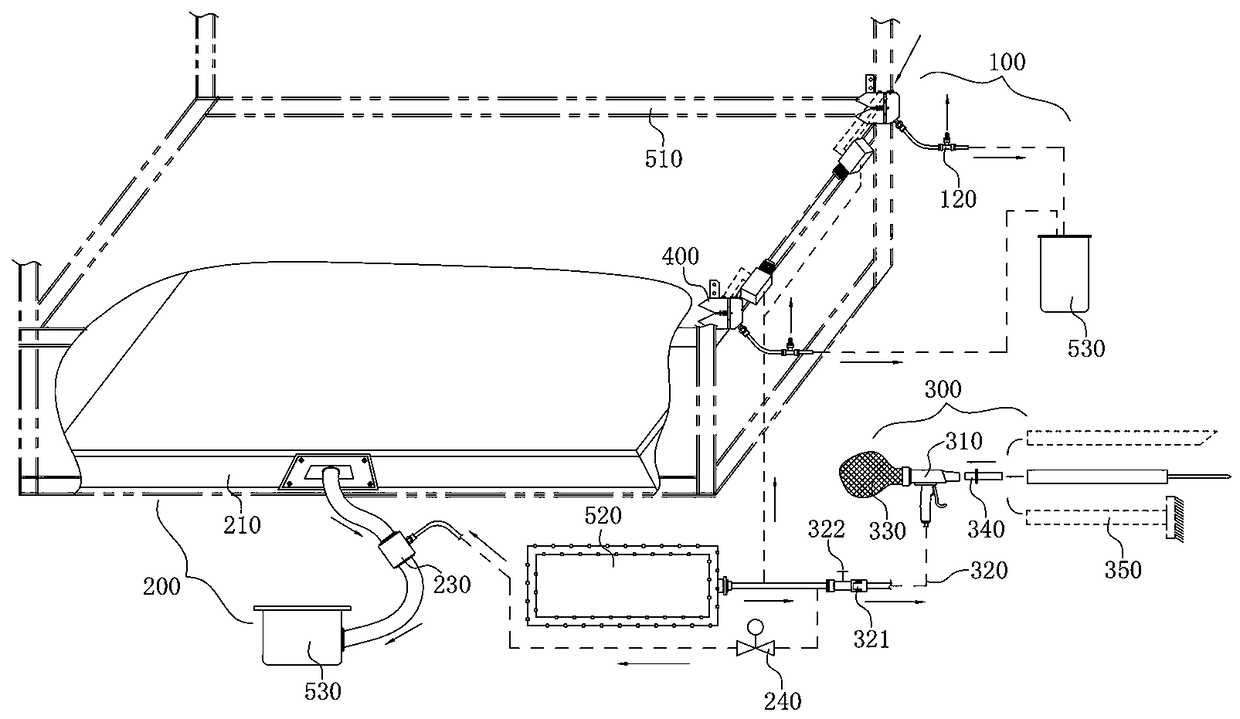

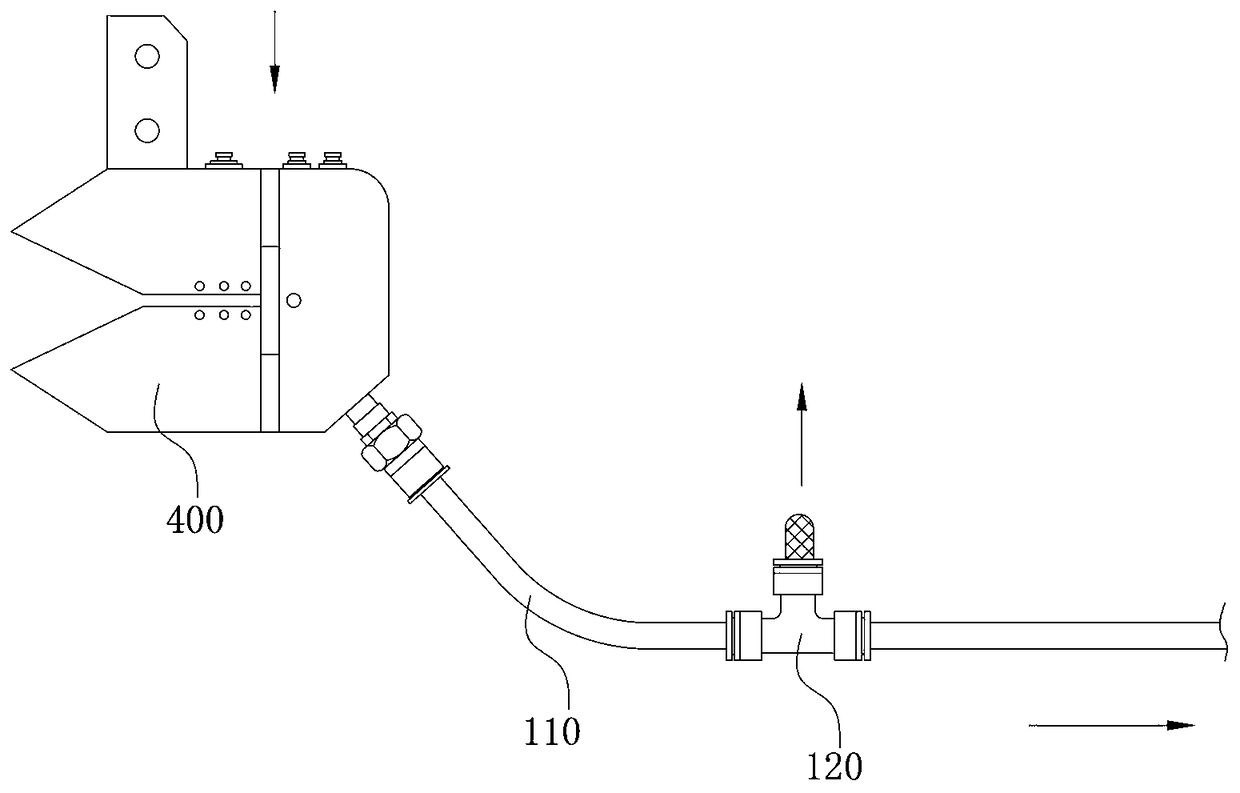

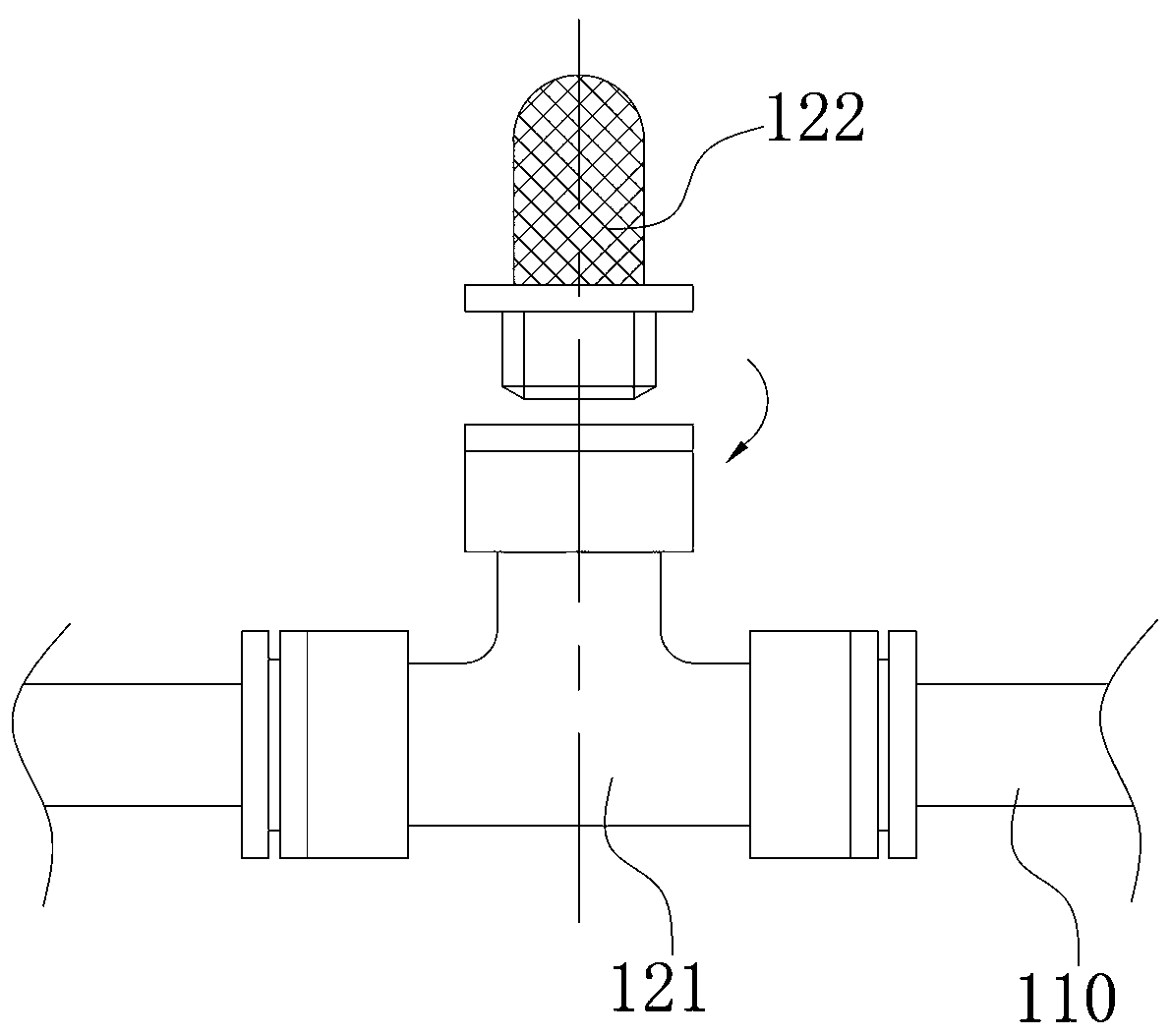

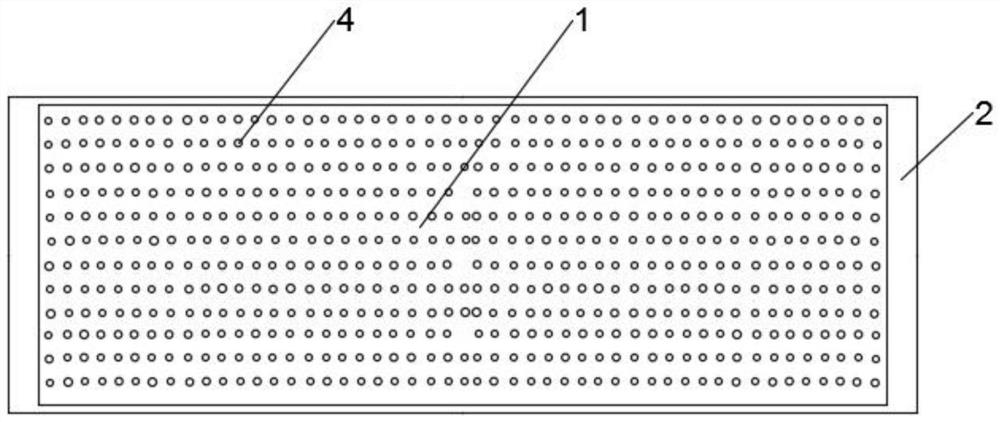

Equipment cleaning device and method and spinning equipment

PendingCN114351303ARealize automatic cleaningSave human effortAuxillary apparatusSpinningCotton dust

The invention relates to an equipment cleaning device and method and spinning equipment. The equipment cleaning device comprises a movable guide rail, a fan, an air blowing pipeline and an air suction pipeline. The movable guide rail is used for being erected above to-be-cleaned equipment, the fan is arranged on the movable guide rail and can move back and forth on the movable guide rail, the air blowing pipeline comprises a main pipeline and a plurality of air outlet nozzles, the main pipeline is communicated with the fan and extends downwards, and the air outlet nozzles are communicated with the main pipeline. The multiple air outlet nozzles are distributed at multiple different height positions, one end of the air suction pipeline communicates with the draught fan and extends downwards, and an air suction opening with a downward opening is formed in the other end of the air suction pipeline. By the adoption of the equipment cleaning device, cotton dust and flyings on equipment can be blown off through the air blowing pipeline, and the cotton dust and the flyings falling on the ground can be sucked through the air suction pipeline. Through reciprocating movement of the fan, automatic cleaning of the whole equipment to be cleaned and the ground is achieved, and manpower is saved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

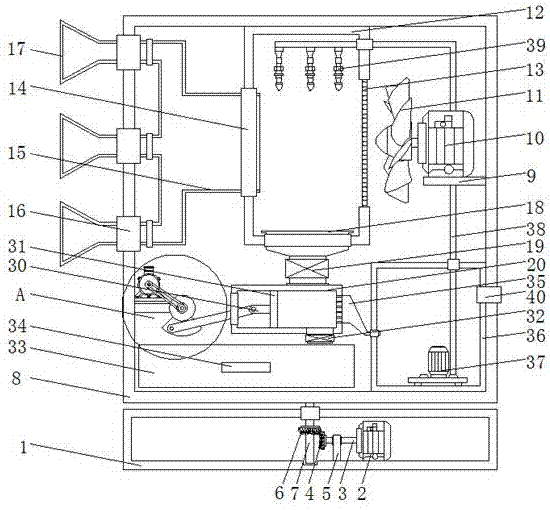

Dust collection system of air jet loom and method

PendingCN108385247AGuarantee Arrangement StructureAvoid the impact of work performanceLoomsAuxillary apparatusAir-jet loomStop time

The invention belongs to the technical field of an air jet loom, and discloses a dust collection system and method of an air jet loom. The dust collection system comprises an upper dust collection assembly, a lower dust collection assembly and a dust collection box, wherein the upper dust collection assembly comprises an exhaust hole formed in a hemmer and an air exhaust pipe which is communicatedwith the air exhaust hole, and a voltage stabilizing assembly is communicated with an air exhaust pipe close to the air exhaust hole; the lower dust collection assembly comprises a dust collection shell which is arranged at the lower portion of the air jet loom, a dust collection suction pipe which is connected to the dust collection shell and a negative pressure sucking unit. By means of the dust collection system and method of the air jet loom, the energy source can be saved, spare parts are saved, the health of staff is guaranteed, the environment of workshops is improved, the dust removaleffect is good, the problem of hidden safety hazards caused by cotton dust when the air jet loom conducts producing is solved fundamentally, the frequency of cleaning and maintaining a loom platformis reduced, the stopping time for cleaning and maintaining the loom platform is shortened, the yield is increased, and the quality is improved; meanwhile, the using period of the spare parts is prolonged, the equipment performance is improved, and the product quality is improved.

Owner:SHEN MA INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com