Cleaning system for refined cotton production

A technology for refining cotton and impurities, which is applied in the direction of cleaning with suction devices, fiber cleaning machines, etc., can solve the problems of no systemic formation, difficult separation of impurities and cotton linters, and limited removal of impurities by production equipment. Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

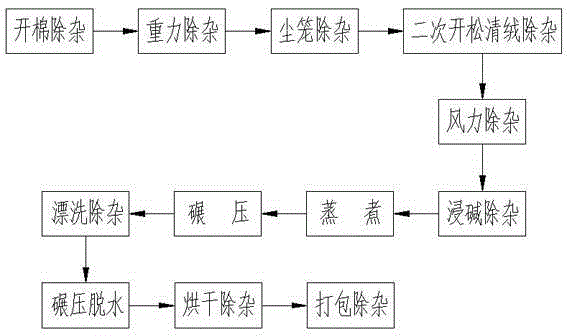

[0026] Depend on figure 1 As shown in the impurity removal system for refined cotton production, the raw cotton linters are firstly opened by the cotton opening and impurity removal device, and then the cotton linters treated by the first cotton opening are passed through the gravity impurity removal device, the dust cage impurity removal device, and the second After being cleaned and removed by the secondary opening and cleaning device and the wind-powered impurity removal device, it is sent to the alkali soaking and impurity removal device for alkali soaking treatment. The cotton linters treated with alkali soaking are steamed into cotton pulp after steaming balls, and the cotton pulp is rolled. After the black pulp is rolled and preliminarily cleaned by the device, it is bleached and washed by the rinsing and removing impurities device, and then rolled, dehydrated, dried and removed to become a product, and finally packed by the packing and removing impurities device.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com