A kind of sound insulation coated cotton and its production process

A production process and film-covering technology, applied in the field of sound-absorbing materials, can solve problems such as environmental pollution, cotton wool and cotton dust flying, and achieve the effects of reducing noise, convenient construction, and protecting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

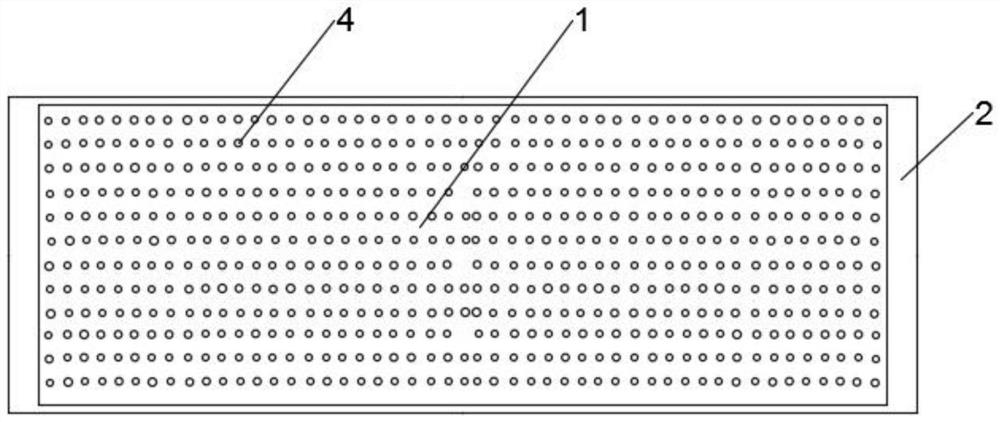

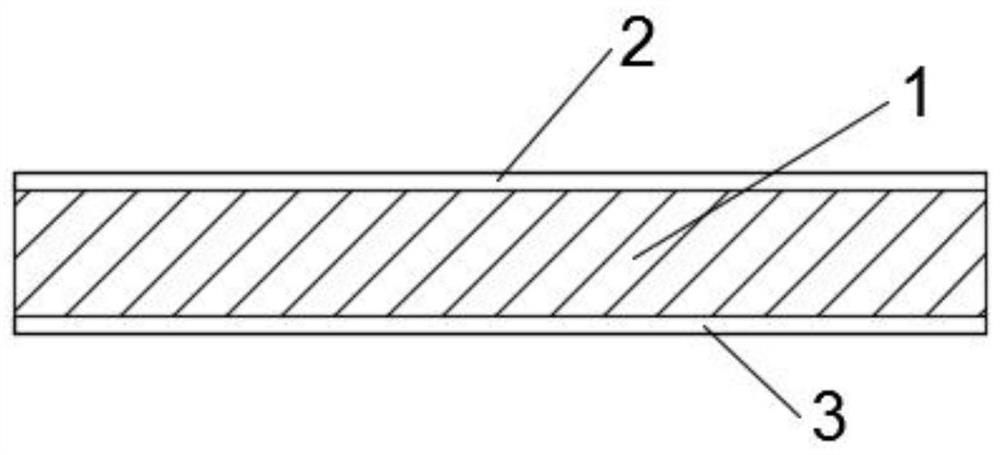

[0024] Such as Figure 1-2 As shown, a sound-insulating film-coated cotton includes glass wool 1, and the top surface and both sides of the glass wool 1 along its length direction are covered with an upper plastic film 2 and extend to the bottom surface. A through hole 4 is provided, and the glass wool can absorb sound by using the through hole. The bottom surface of the glass wool 2 along its length direction is covered with a lower plastic film 3 , and the lower plastic film 3 is covered and connected to the upper plastic film 2 by hot melt adhesive. Both ends of the upper plastic film 2 and the lower plastic film 3 along the length direction are sealed by a hot melt machine. The closed upper plastic film 2 and the lower plastic film 3 are used to block the fly generated by the glass wool during transportation or use, so as to protect the environment.

[0025] A production process of sound-insulating film-coated cotton is characterized in that: its specific steps are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com