Adjustable smoke equidistant inker

An equidistant and adjustable technology, applied in transplanting machinery, agriculture, application, etc., can solve problems such as difficult to ensure three-point seedling setting, difficult to operate triangular seedling setting, and time constraints in fixed-point link, achieving good consistency, simple structure, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

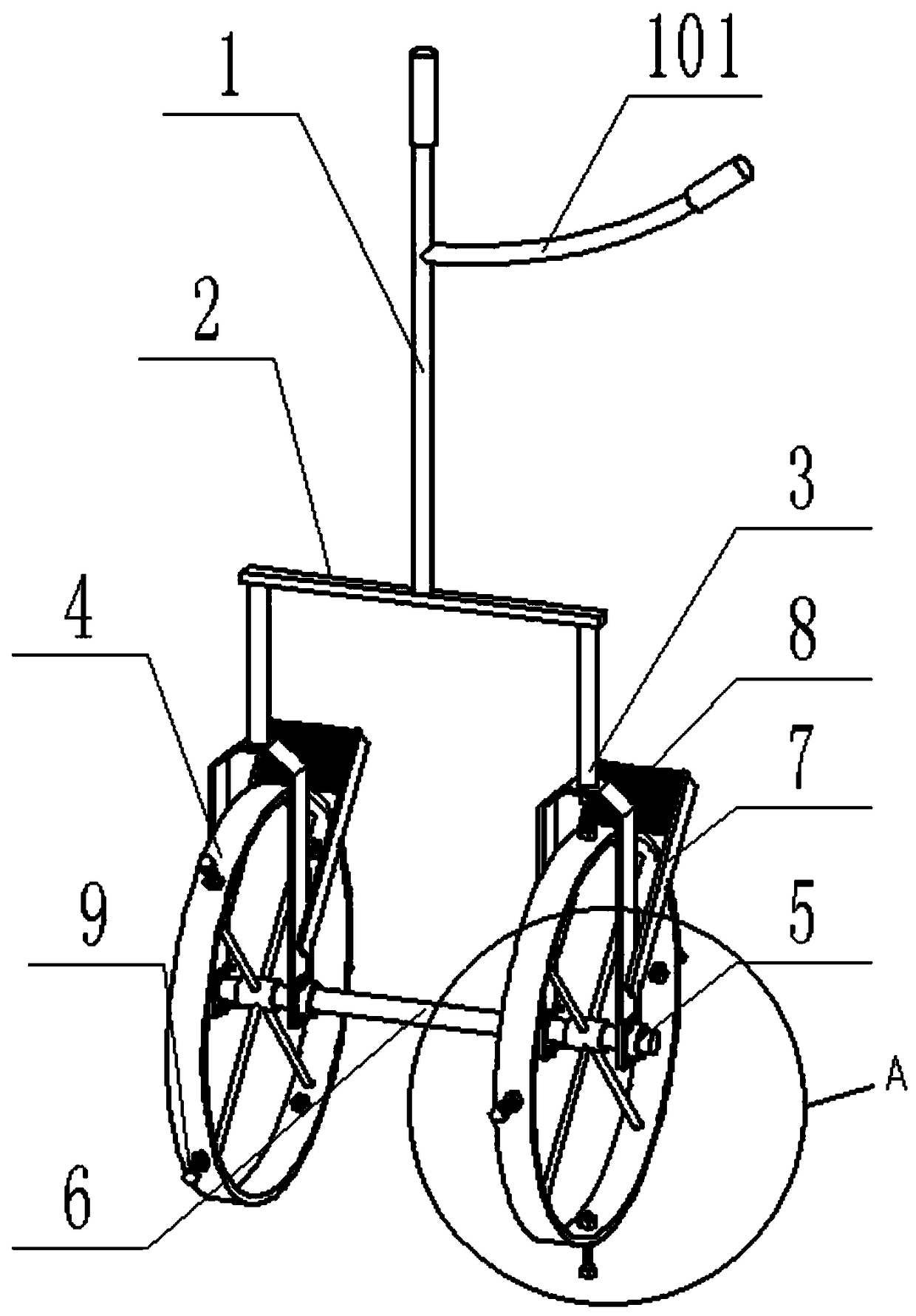

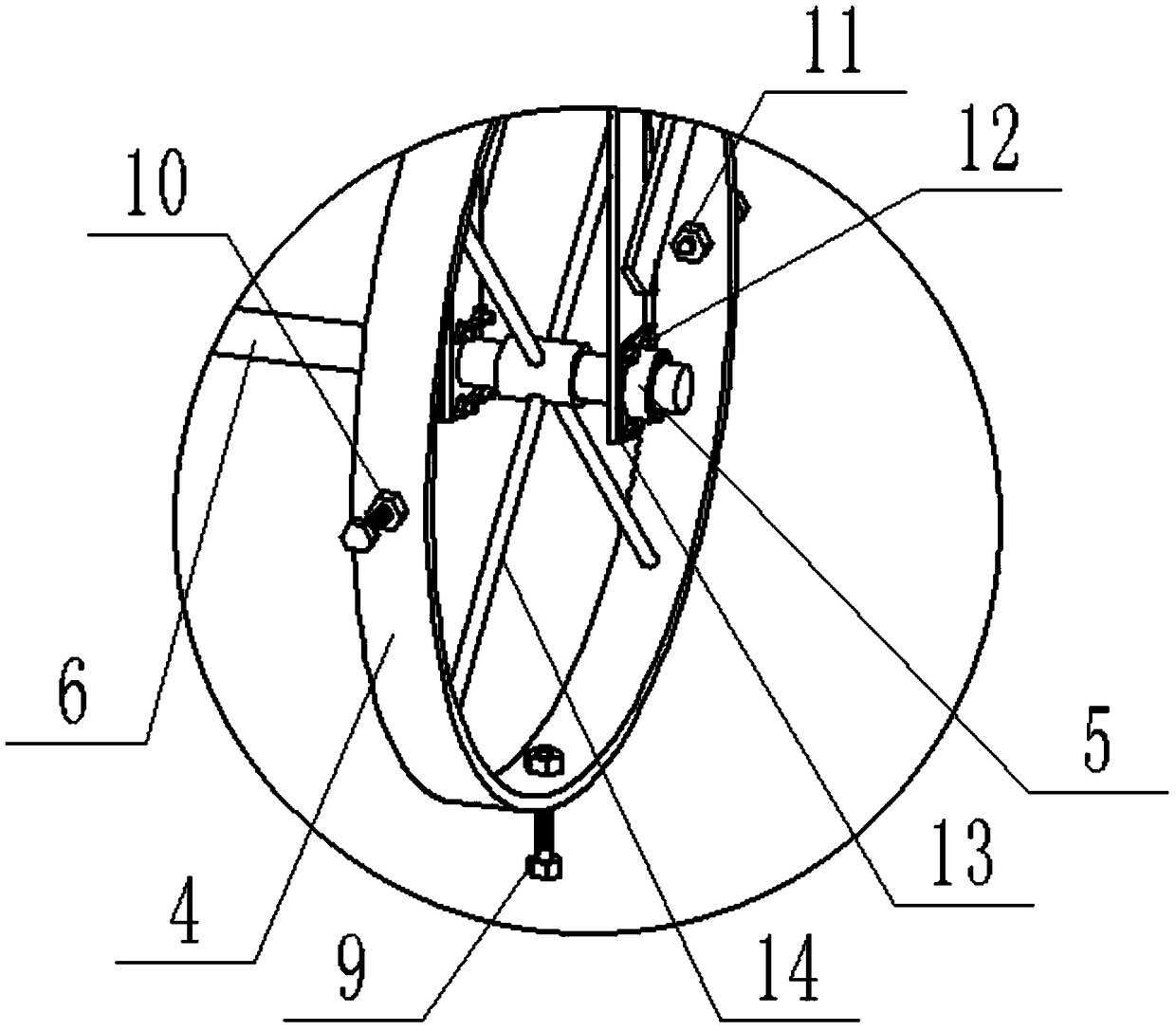

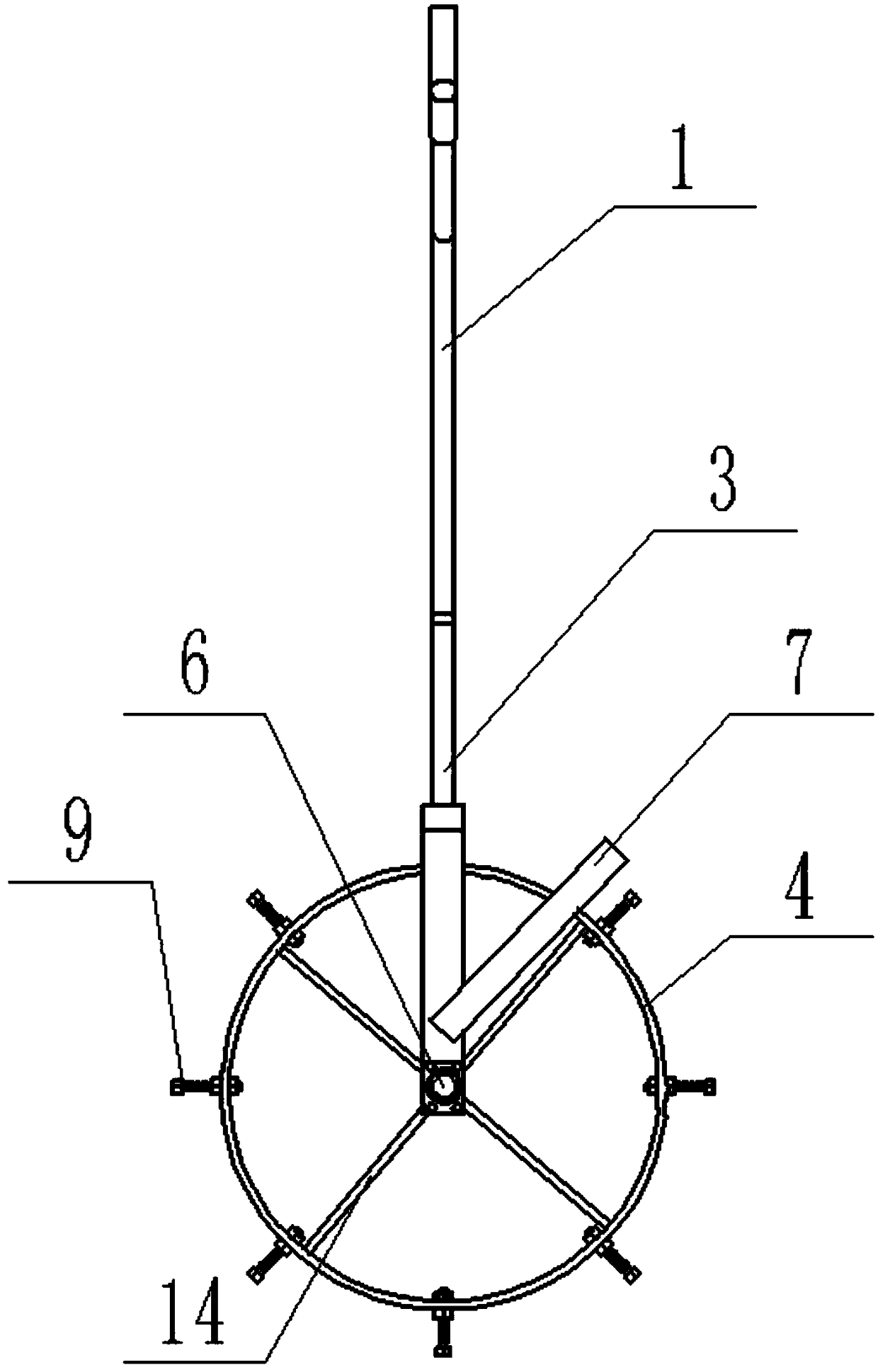

[0021] according to Figure 1 to Figure 4 As shown, an adjustable tobacco plant equidistant inker includes a handle 1, a support frame 3 and a roller 7, a crossbeam 2 is provided between the lower end surface of the handle 1 and the upper end surface of the support frame 3, and the lower end surface of the handle 1 It is connected with the upper end surface of the crossbeam 2 by welding. The middle position of the handle 1 is provided with a handle 101. The handle 101 is convenient for the operator to exert force during the dotting process. The support frame 3 is located on the lower side of the left and right ends of the crossbeam 2. The support frame 3 is provided with one on the left and right sides, and one on the left and right sides of the support frame, which can realize two grooves at one time and improve efficiency. The upper end surface of the support frame 3 is connected with the lower end surface of the beam 2 by welding. The frame 3 is in an inverted Y shape, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com