Patents

Literature

32results about How to "Prevent flying phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

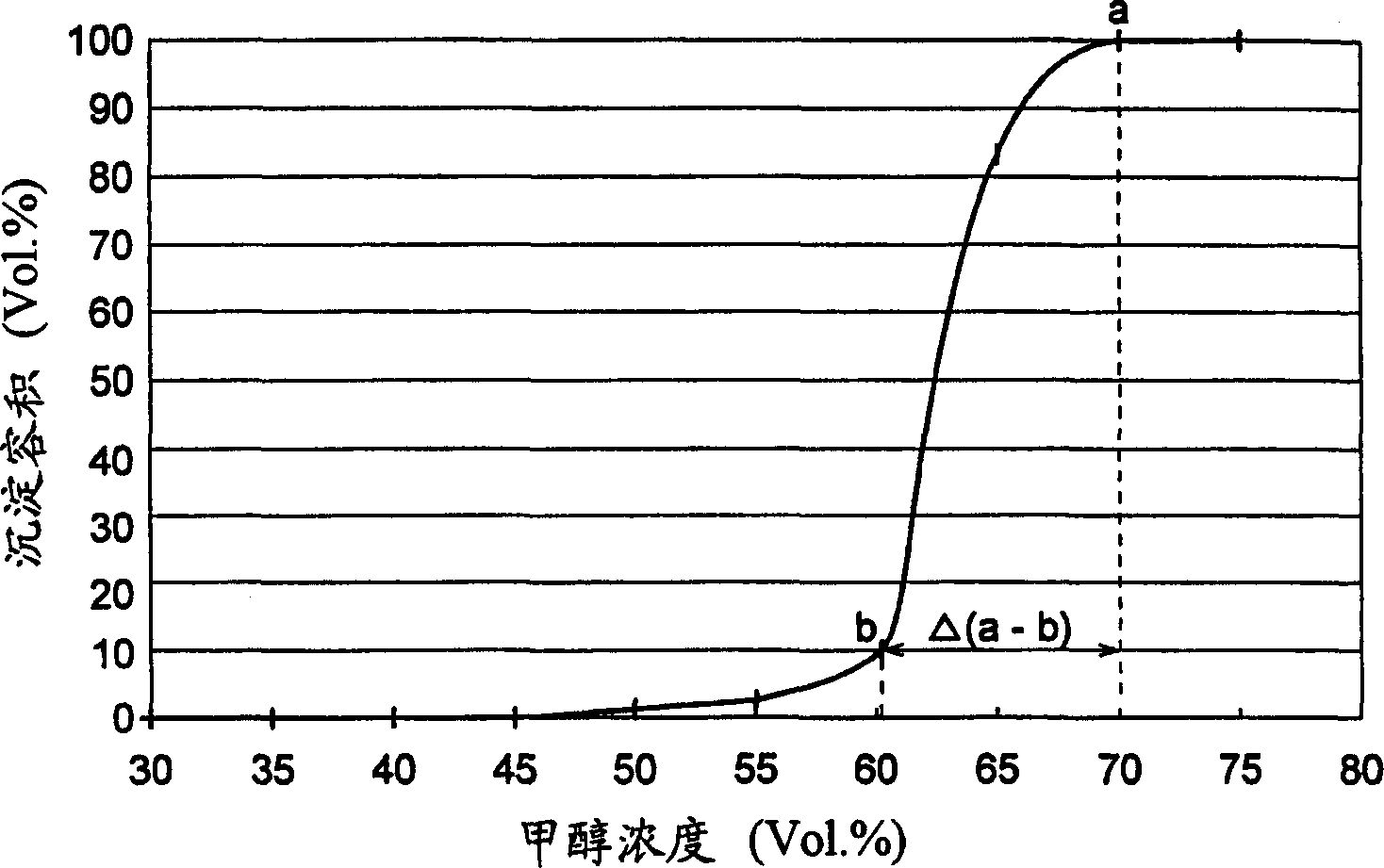

Coal granule flying inhibitor mixture, and preparation method and application method thereof

InactiveCN102719223AEasy to prepareEasy to operateOther chemical processesCelluloseMolecular materials

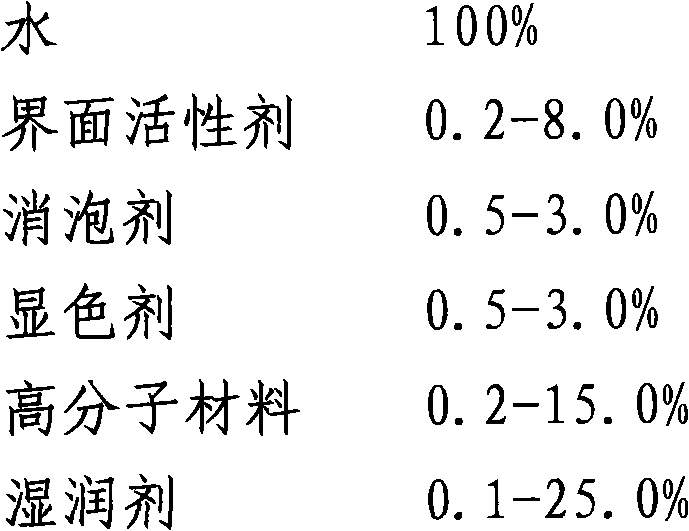

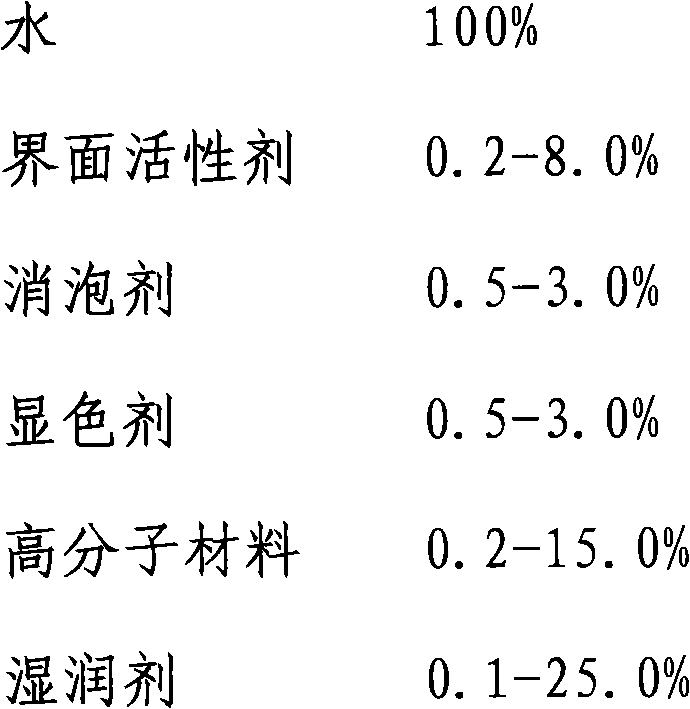

The invention relates to an inhibitor, and in particular relates to an inhibitor mixture for inhibiting coal granule flying and a preparation method of the inhibitor mixture. The coal granule flying inhibitor mixture comprises the following components in mass percent: 100% of water, 0.2%-0.8% of interfacial agent, 0.5%-3.0% of defoamer, 0.5%-3.0% of color-developing agent, 0.2%-15.0% of high molecular materials, and 0.1%-25.0% of wetting agent. According to the invention, the preparation method of the coal granule flying inhibitor mixture has the beneficial effects of being simple and easy to implement; and the coal granule flying inhibitor mixture has the beneficial effects of adopting the high molecular material which is at least one of synthetic cellulose material, hydrophilic synthetic high molecular material and natural high molecular material and is rationally blended with the interfacial agent, thus being capable of effectively absorbing superfine coal granules of 2.5-10 mu m (PM10), preventing flying of the superfine coal granules, and further, achieving the effect of making an operating environment comfortable and protecting the health of nearby residents and operators.

Owner:QINGDAO KAIXI PIER ENVIRONMENTAL PROTECTION TECH CO LTD

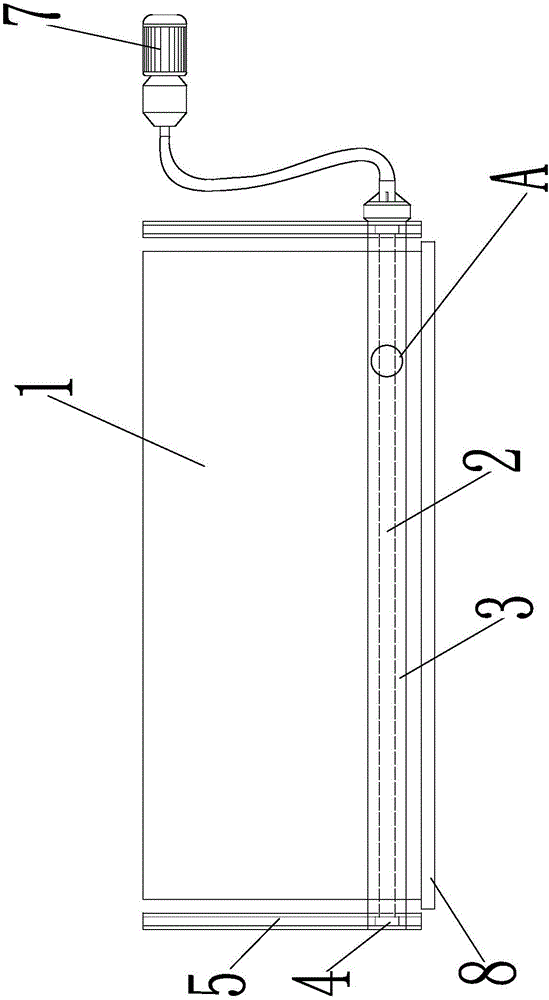

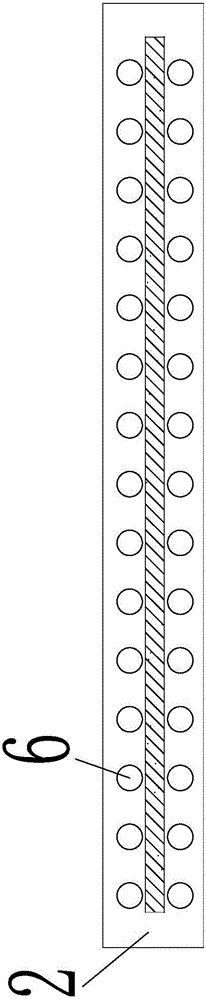

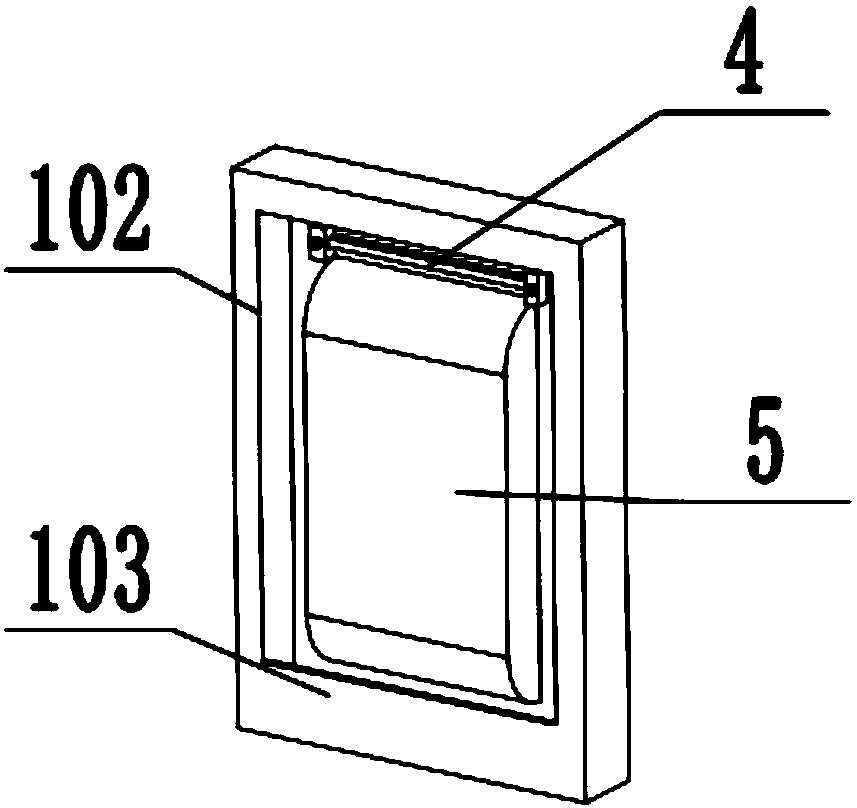

Cyclic utilization device for removing chalk dust by means of washing

InactiveCN105667137APrevent flying phenomenonProtect healthBoard cleaning devicesWriting boardsEngineeringWater spray

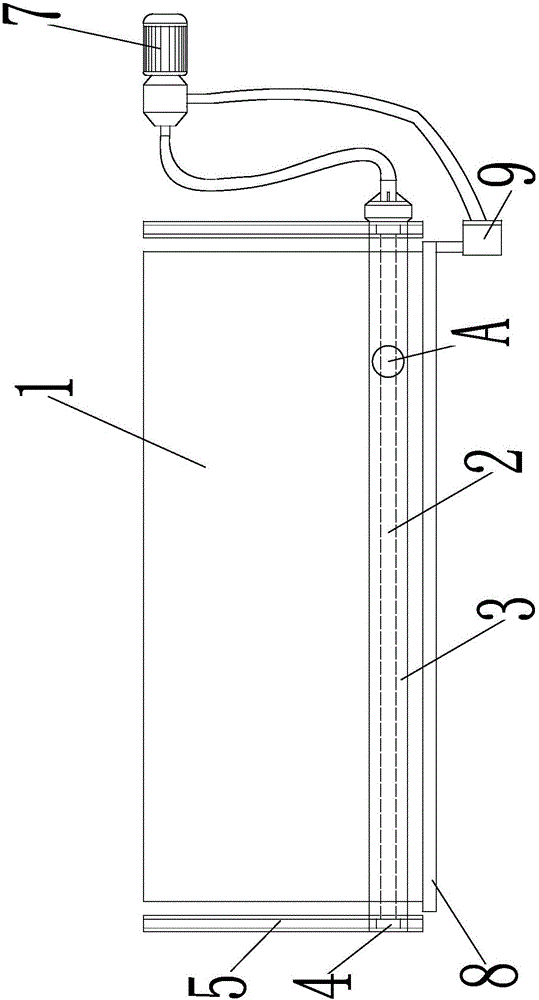

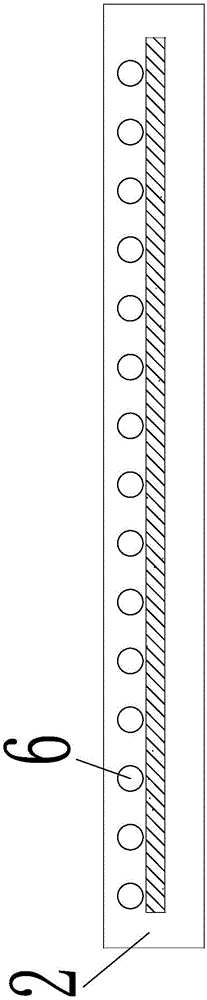

The invention discloses a recycling device for washing and removing chalk dust. The pulley matched with the slide rail, the pipe wiper can move up and down, a row of water spray holes arranged horizontally is arranged on the side of the pipe wiper facing the blackboard, one end of the pipe wiper is connected with the water pump through a pipeline, A hand rest cover is fixed, and a water collection tank is placed under the blackboard, which is connected to one side of the filter device through a pipeline under one side of the water collection tank, and the other side of the filter device is connected to a water pump through a pipeline. The invention has the advantages of simple structure and convenient use, and the powdered chalk is adsorbed in water by washing, which effectively prevents the phenomenon of flying powder and protects the health of teachers and students.

Owner:尹全宝

Washing dustproof chalk dust erasing device

InactiveCN105667150APrevent flying phenomenonHarm reductionBoard cleaning devicesPulleyWaste management

The invention discloses a water-washing dustproof chalk powder erasing device, which comprises a blackboard, a tubular eraser, a casing, a pulley and a slide rail, and is characterized in that slide rails are arranged on both sides of the blackboard, and a water collection tank is arranged at the bottom of the blackboard , there are pulleys matched with the slide rails on the slide rail, the pulleys are fixed on both sides of the case, inside the case there are fixed tube-shaped wipers, and the tube-type wipers are arranged in two rows horizontally towards the side of the blackboard One end of the tube type wiper is connected with the water pump pipeline. The invention is simple in structure and easy to use, effectively prevents the phenomenon of powder flying during the process of erasing chalk powder, reduces the harm to the human body caused by inhaling powder, and the chalk powder adheres to the water and stays in the water collection tank, reducing the need for cleaning chalk. end of trouble.

Owner:尹全宝

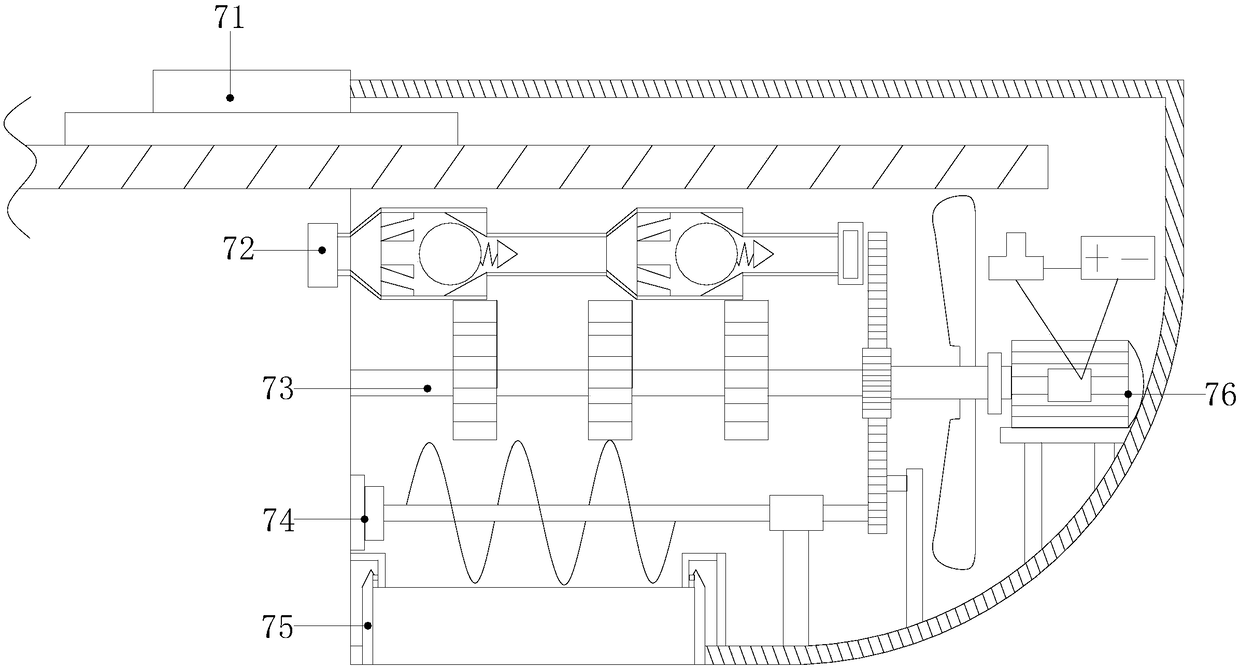

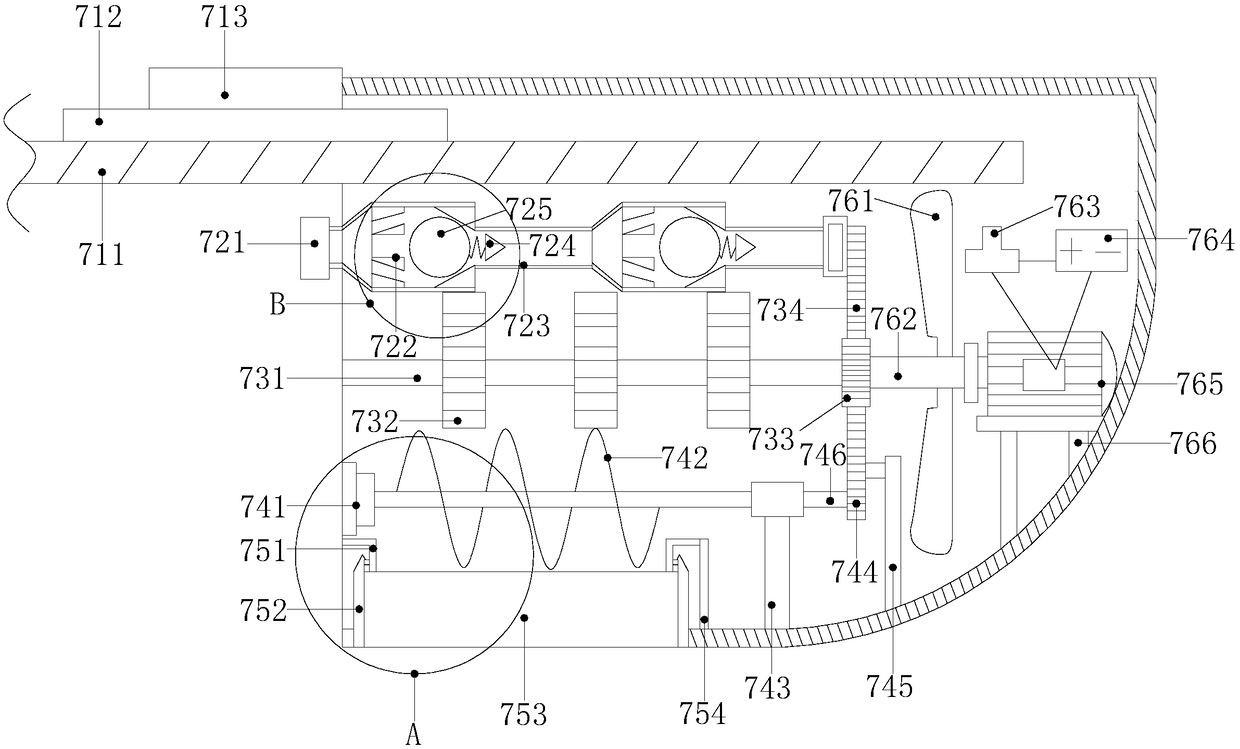

Dust collecting device for electric tool

ActiveCN106975277AAvoid dustyGood water resistance and elasticityCombination devicesDispersed particle filtrationElectrical and Electronics engineeringElectric machine

Owner:柳州市昌泉贸易有限公司

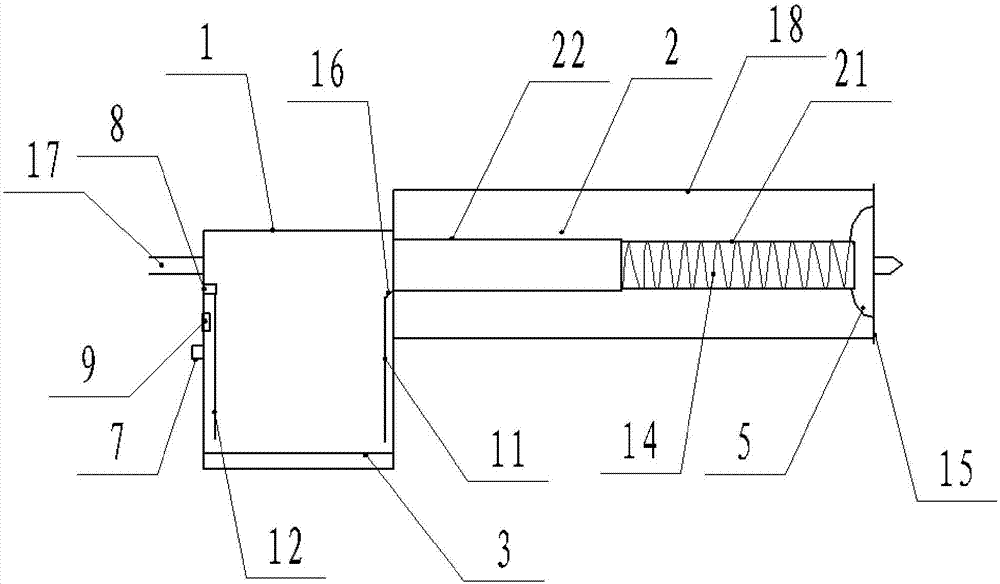

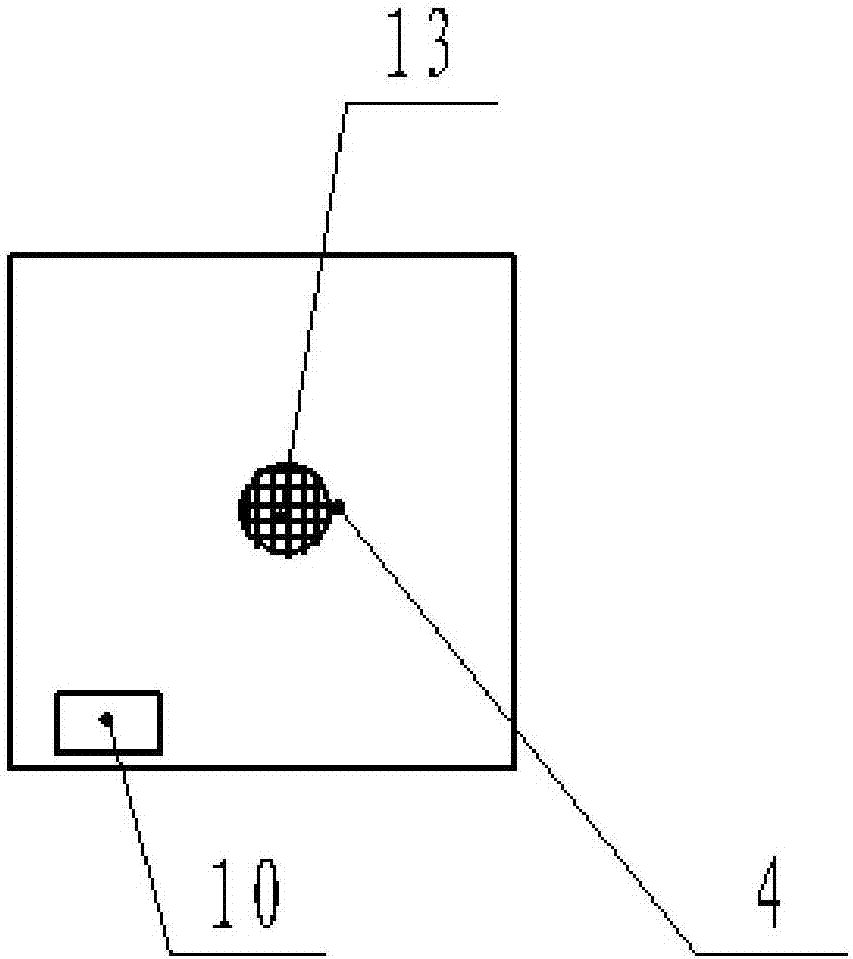

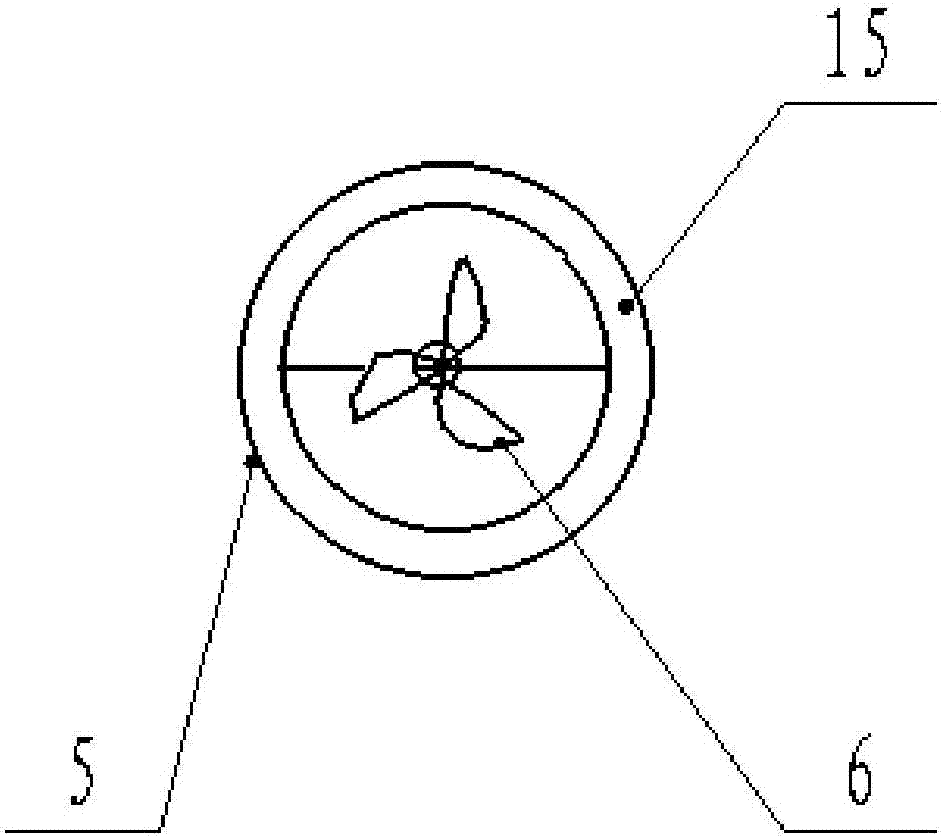

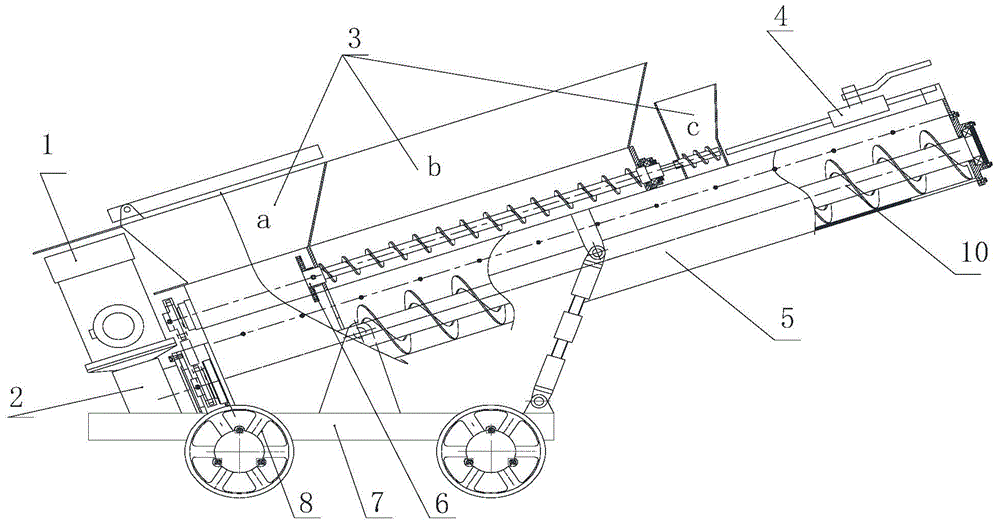

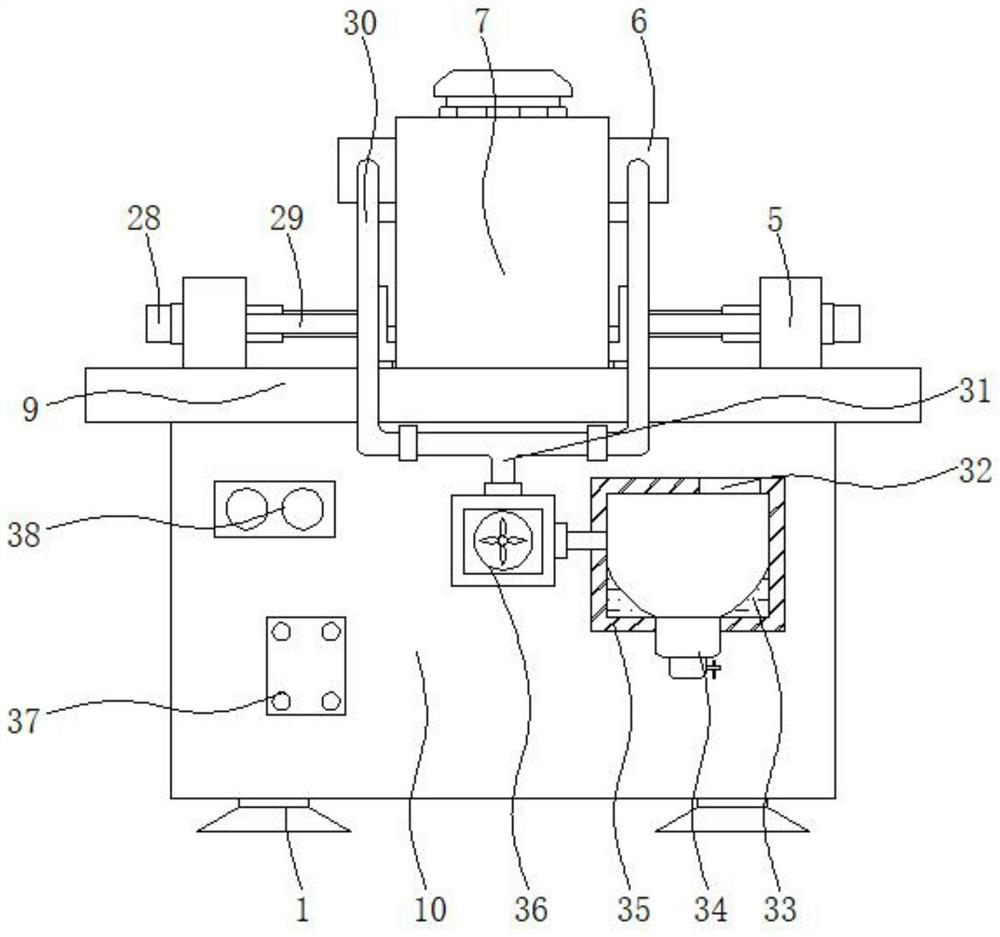

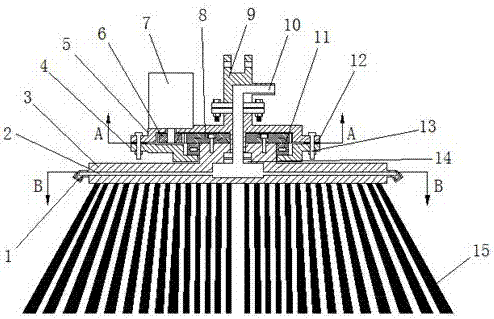

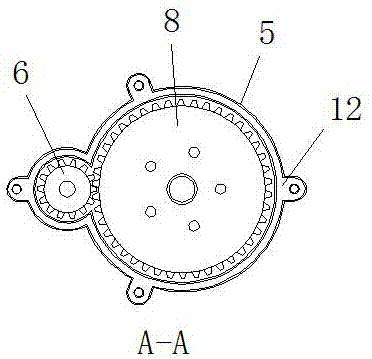

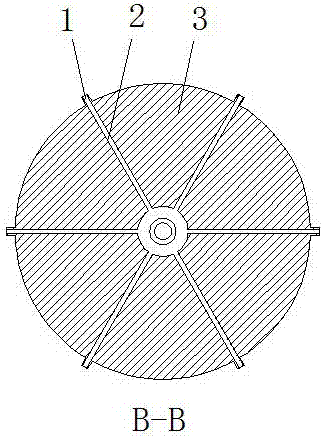

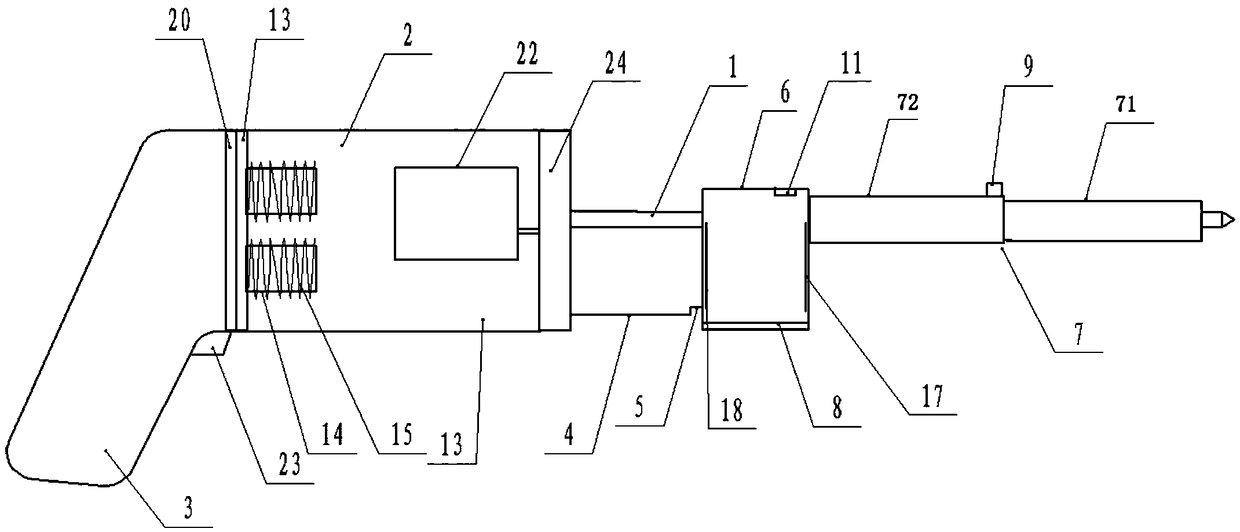

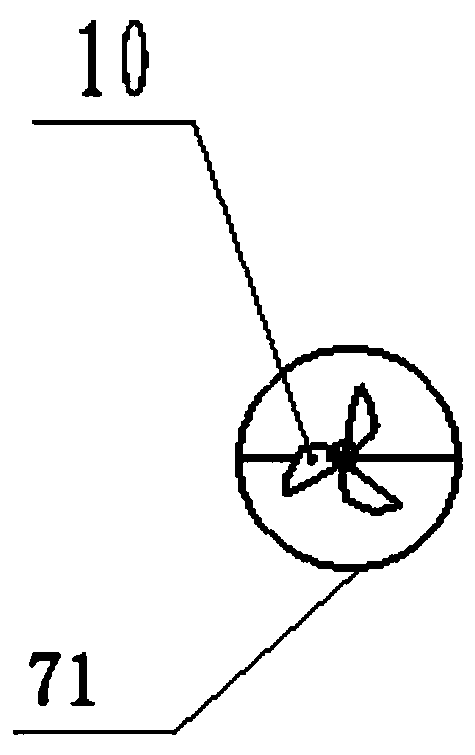

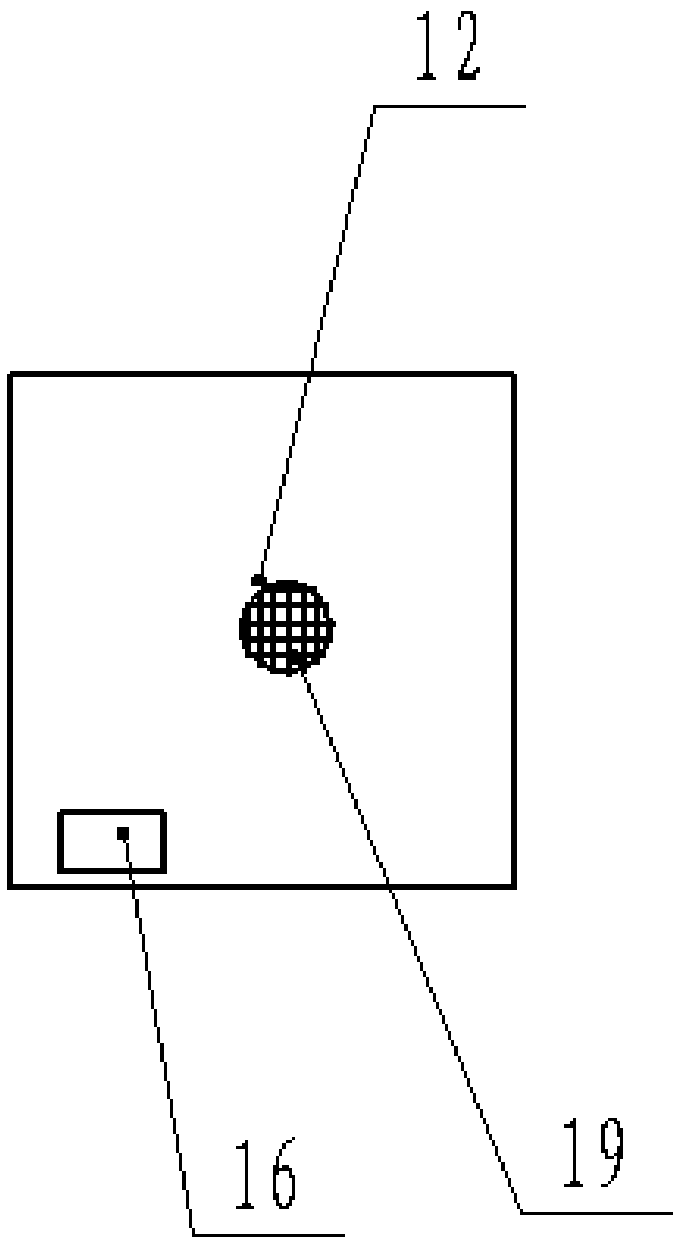

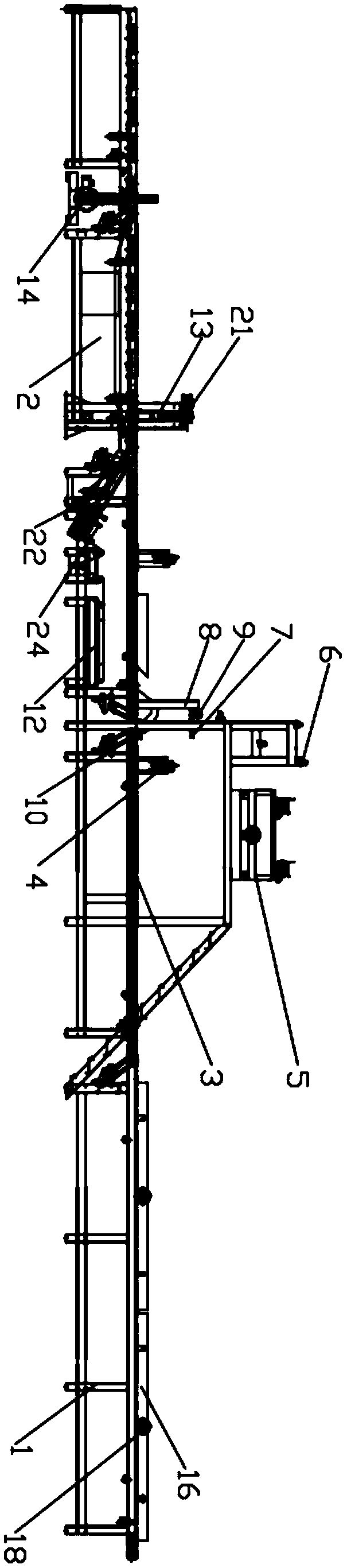

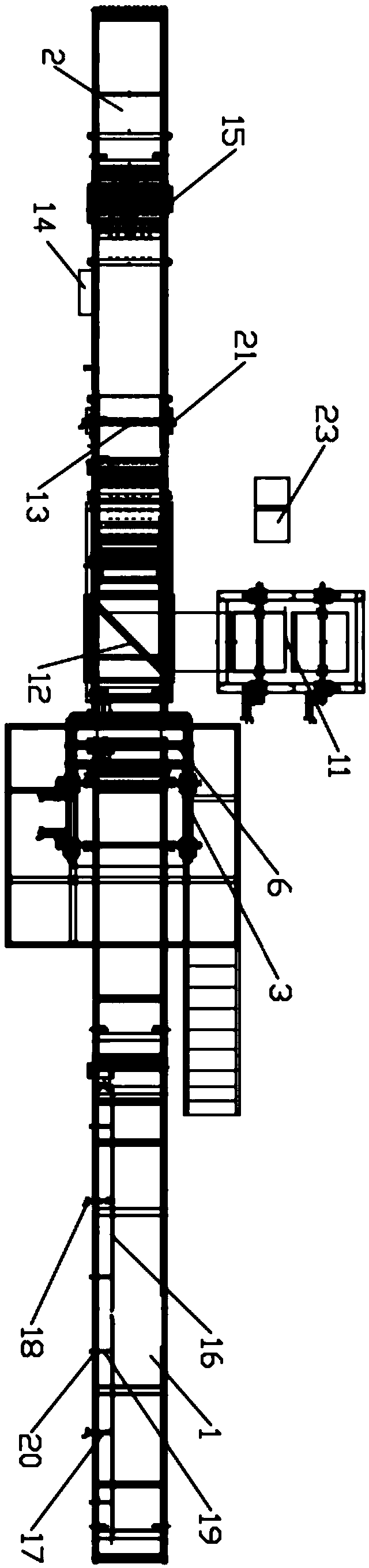

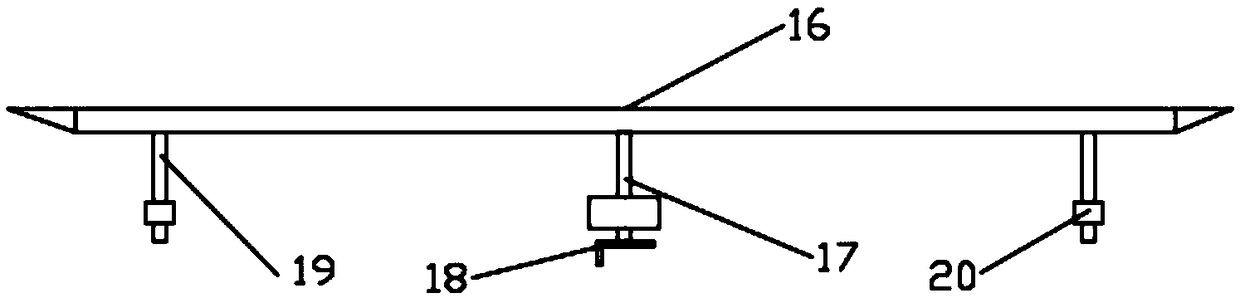

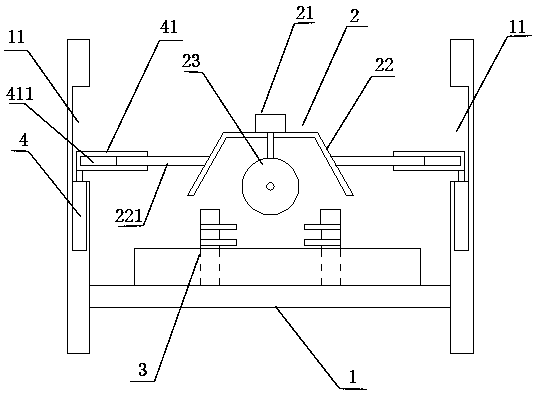

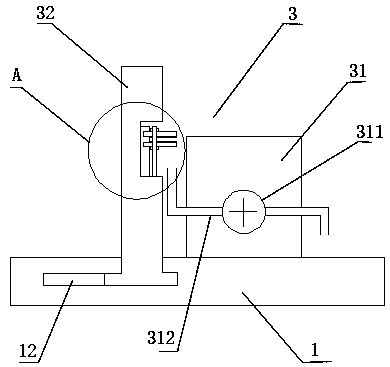

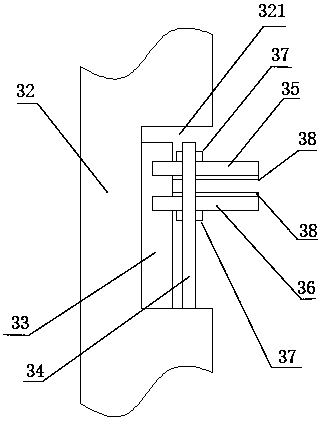

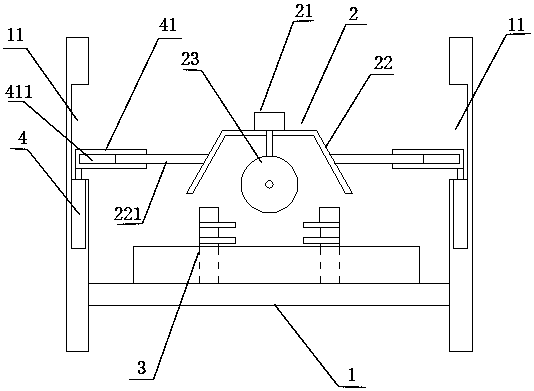

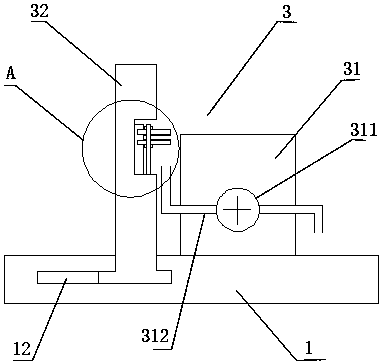

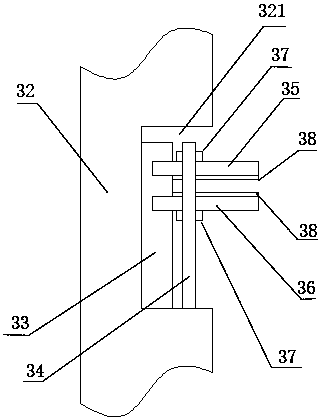

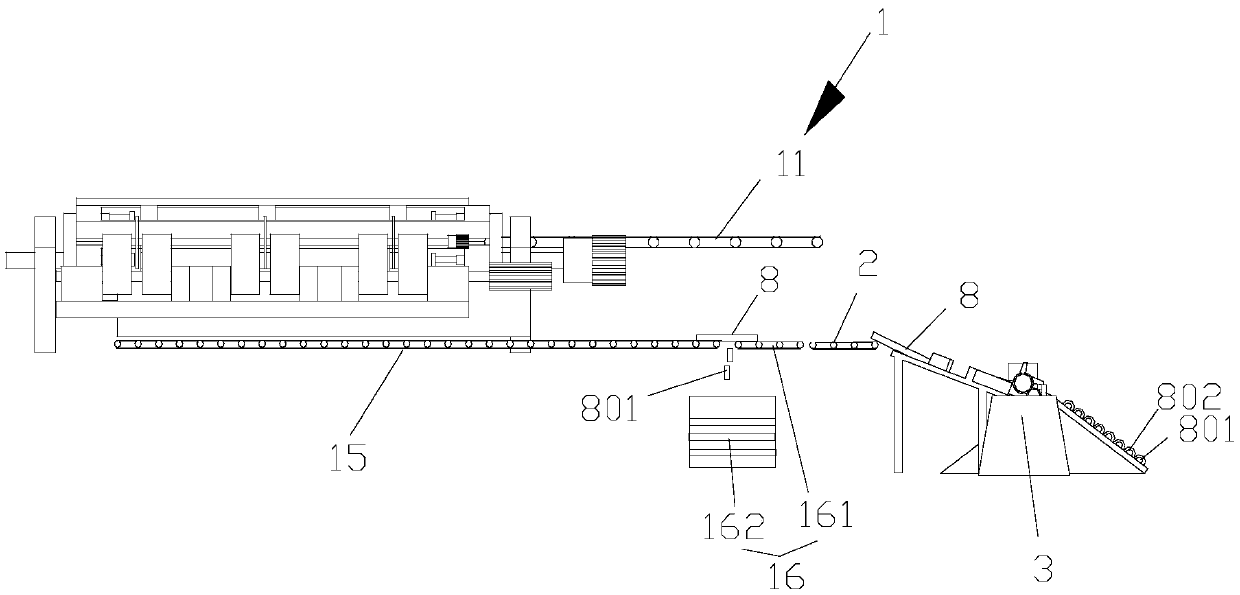

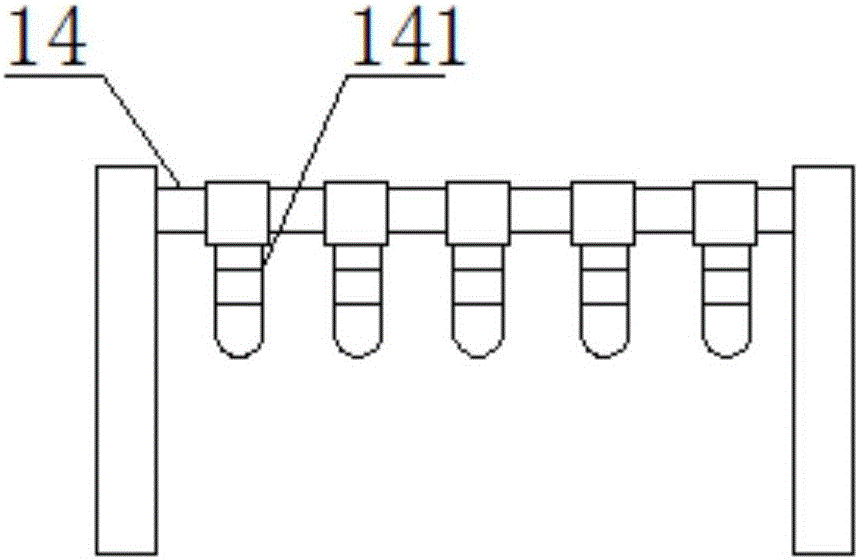

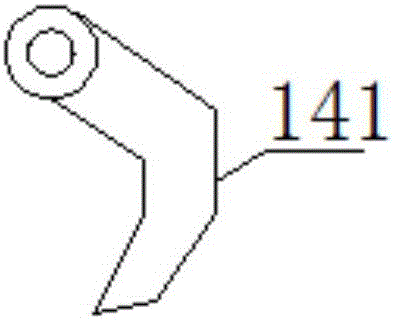

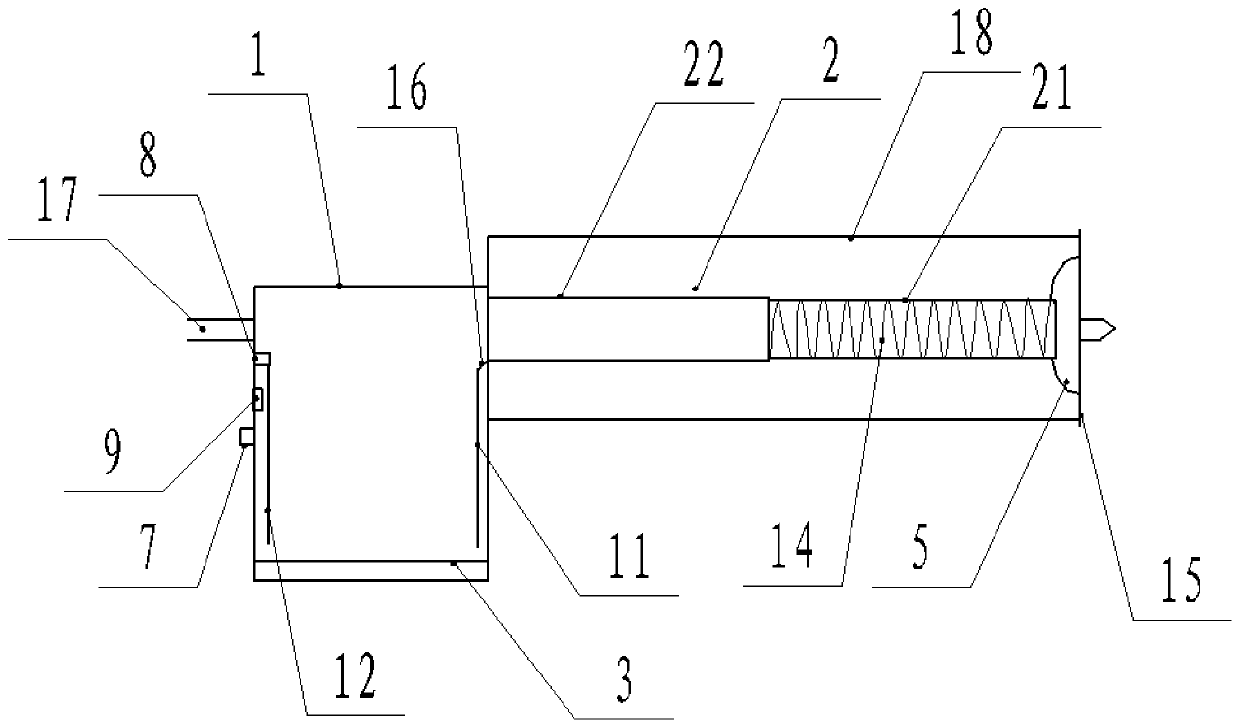

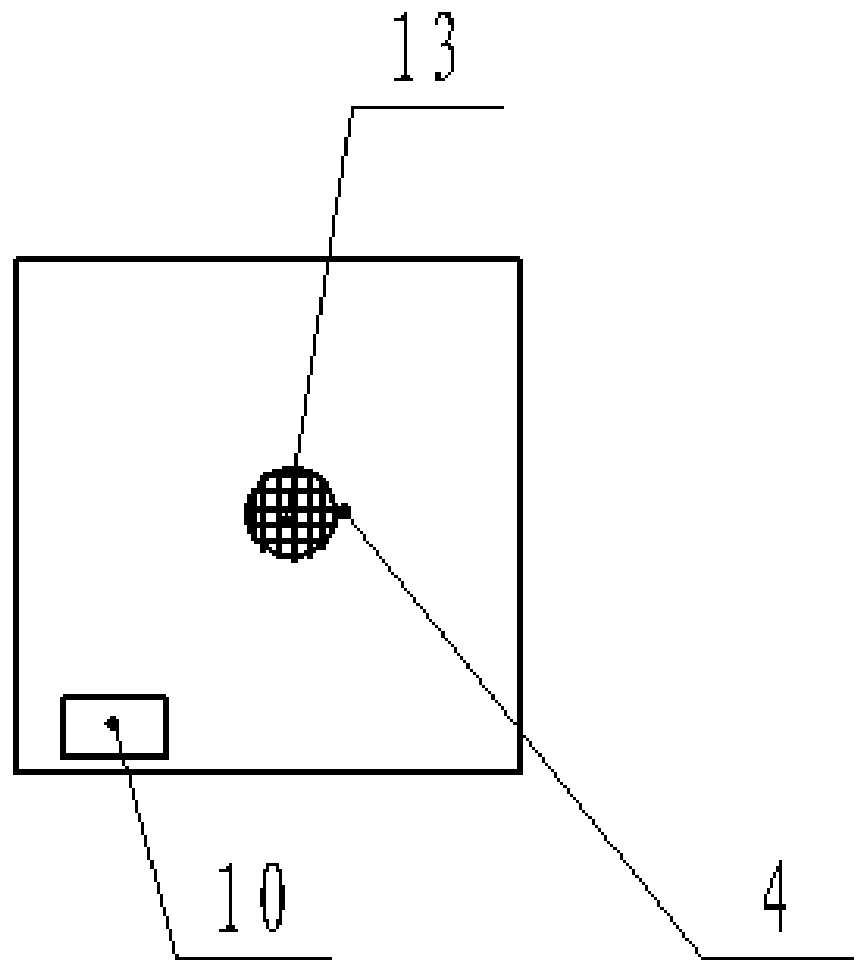

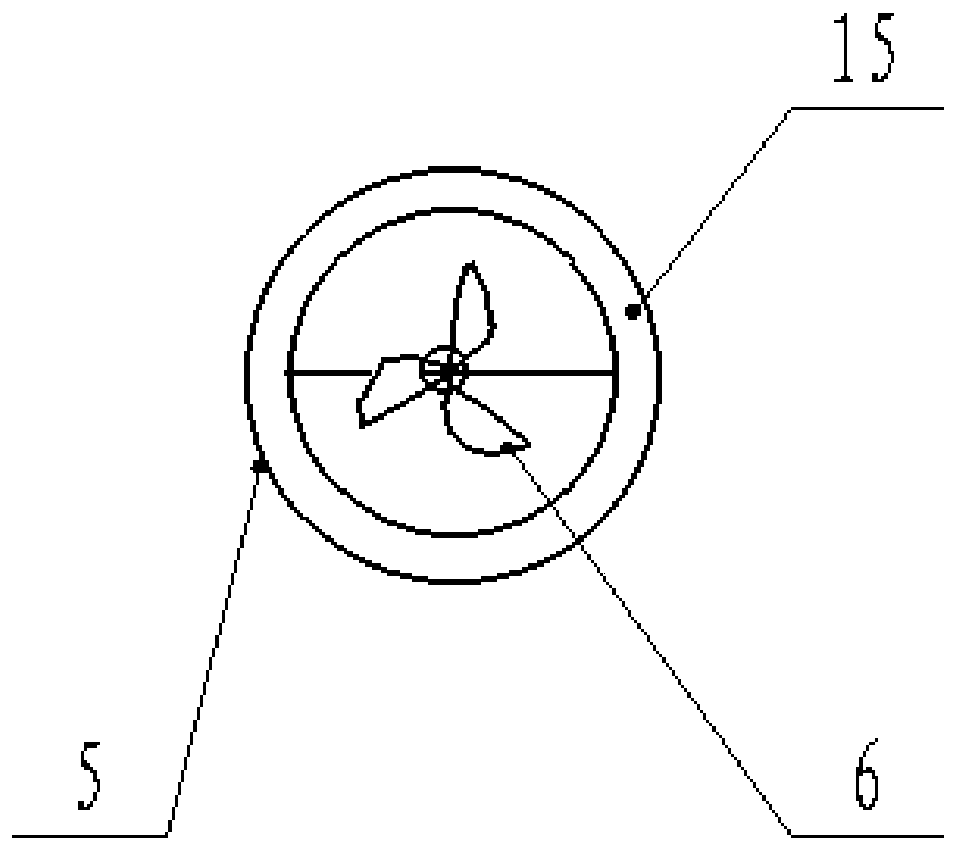

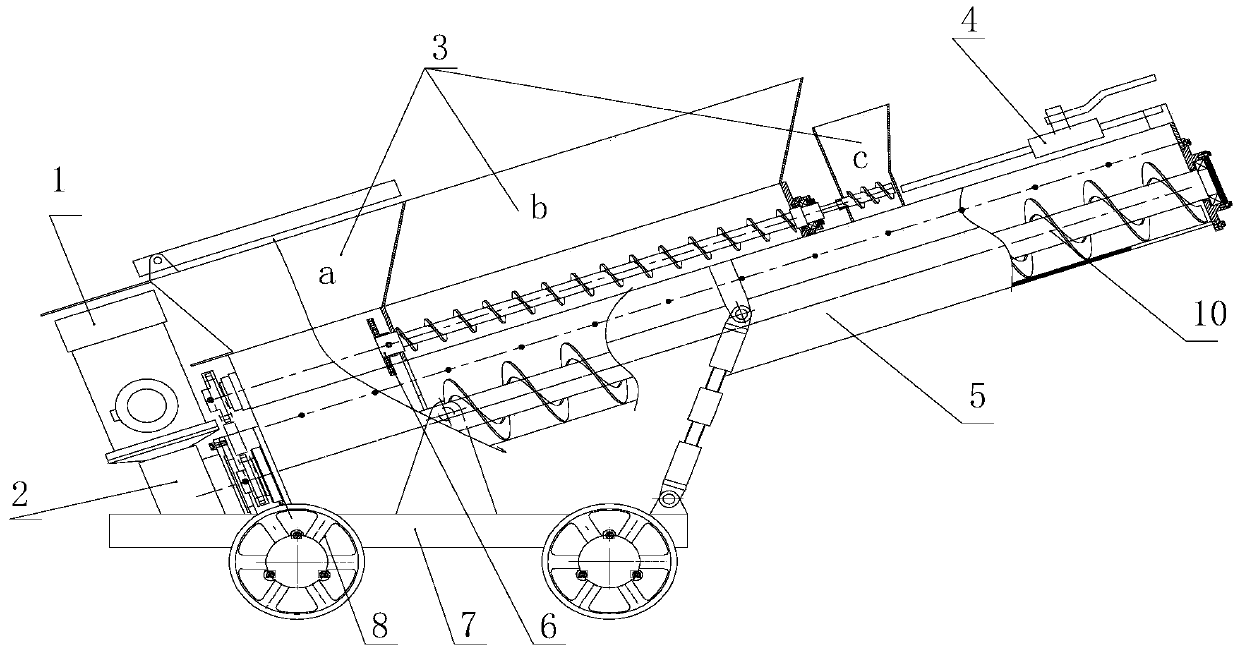

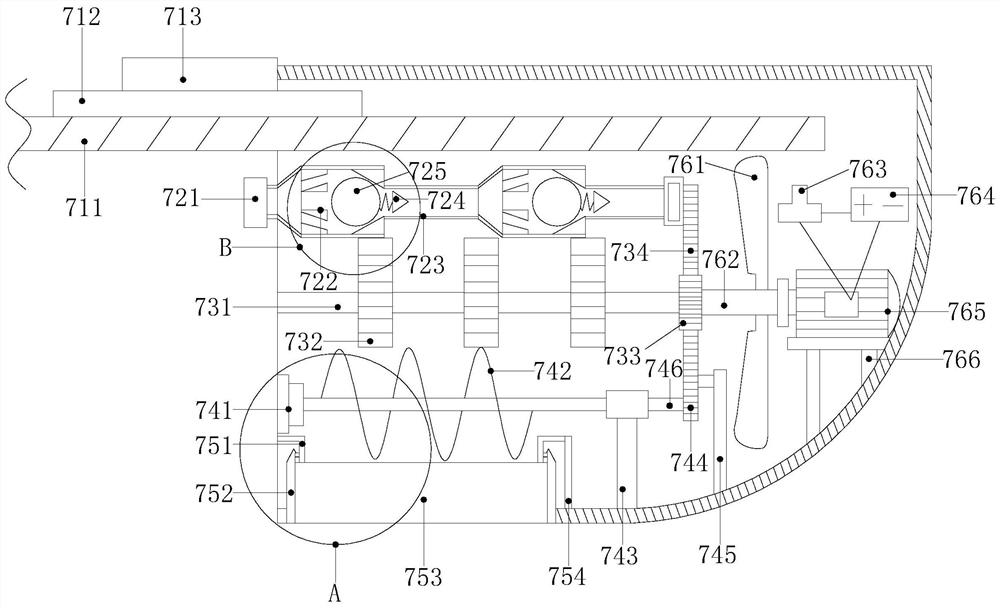

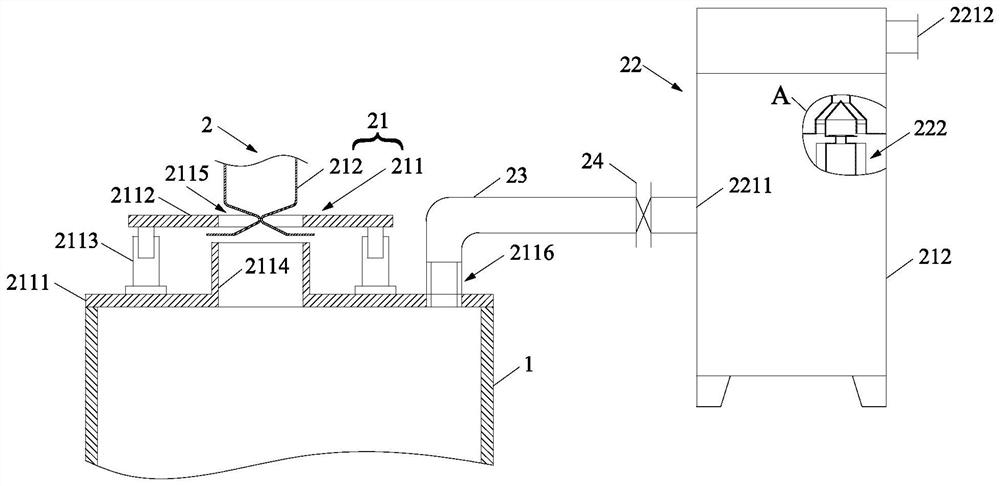

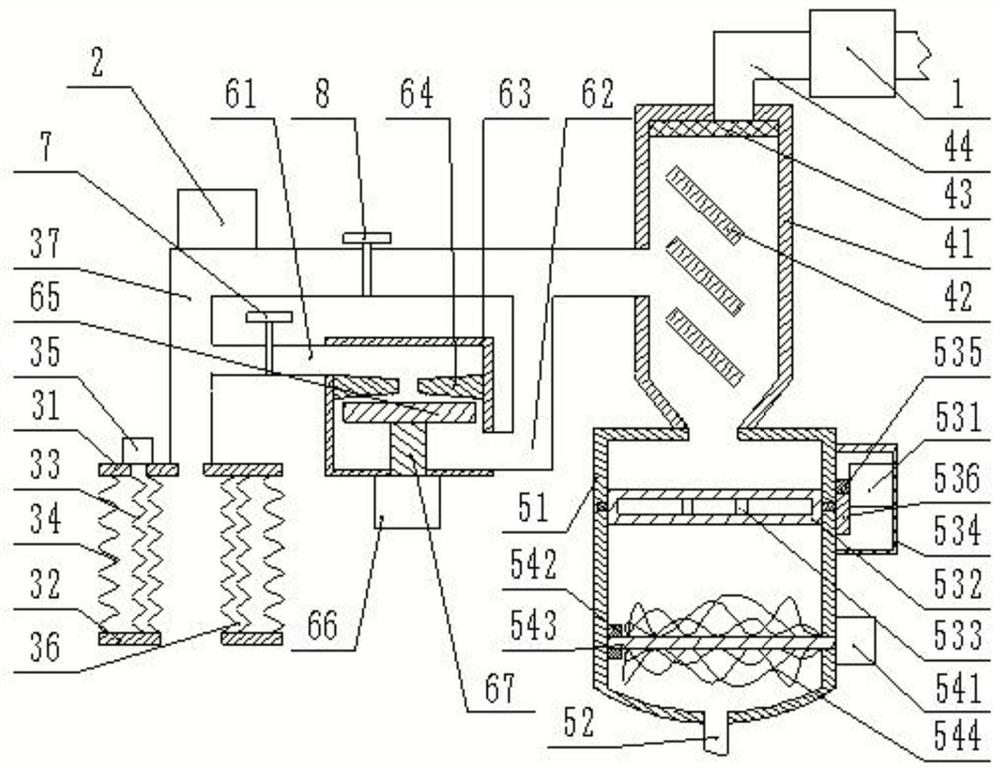

Mining spiral feeder

ActiveCN104819001AGood transportabilityExcellent fill factorUnderground chambersTunnel liningEngineeringCam

The invention discloses a mining spiral feeder. The mining spiral feeder is composed of a body, a frame and wheels; the body is hinged to the frame; the wheels for moving back and forth are symmetrically mounted at the bottom of the frame. The body comprises an explosion-proof motor, a burdening mechanism and a water spraying device, all of which are located on the same inclined surface; the explosion-proof motor is mounted at the bottom end of the body and used for driving a cam vibrating screen mechanism and a stirring conveying trough. The cam vibrating screen mechanism is arranged under the burdening mechanism; the stirring conveying trough is arranged under the cam vibrating screen mechanism; the burdening mechanism is communicated with the stirring conveying trough by use of the cam vibrating screen mechanism. The mining spiral feeder has the advantages of reducing the underground operating personnel, saving the material cost, reducing the labor intensity of workers and improving the field operating environment; meanwhile, the guniting feeding is also even and the guniting quality is improved certainly.

Owner:SHANDONG UNIV OF SCI & TECH

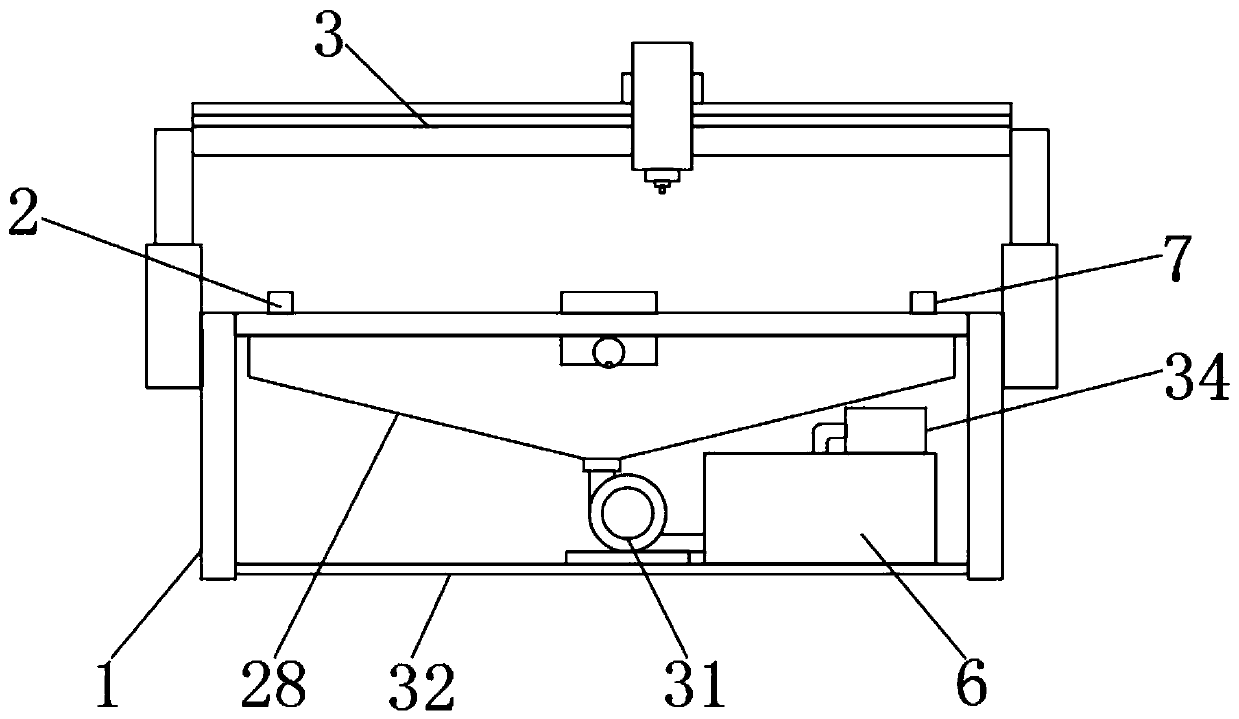

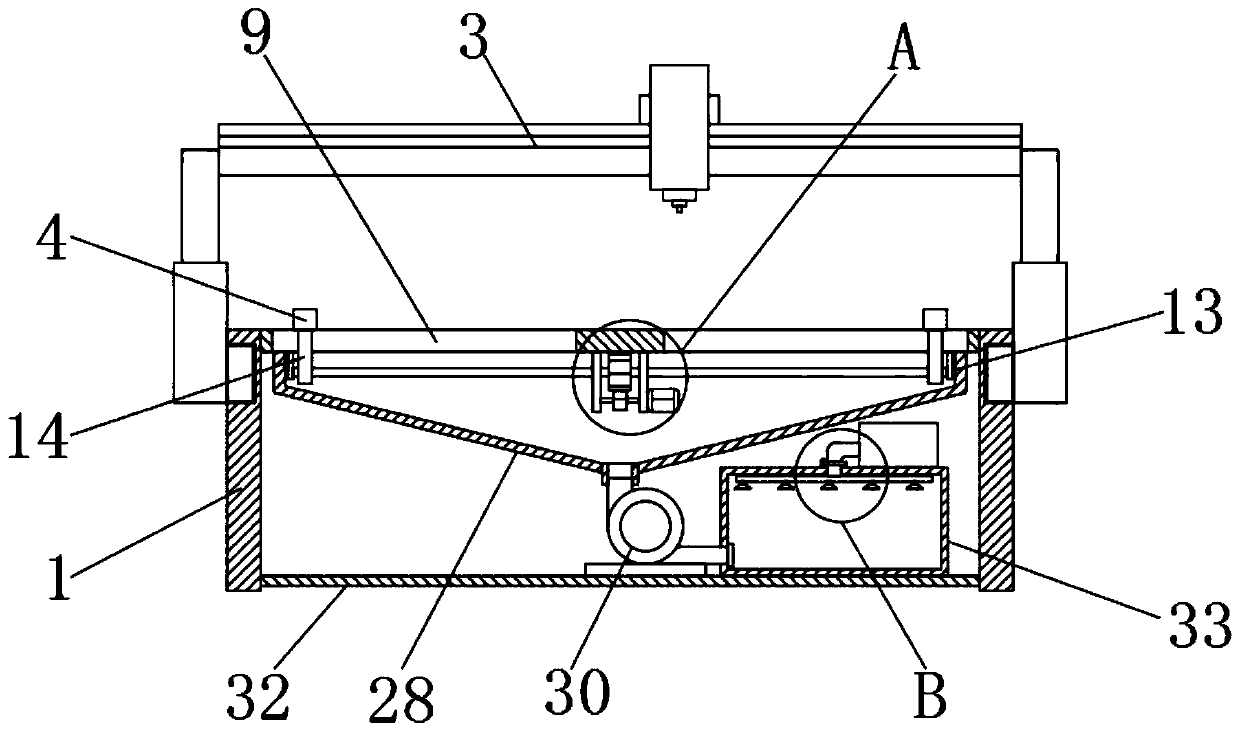

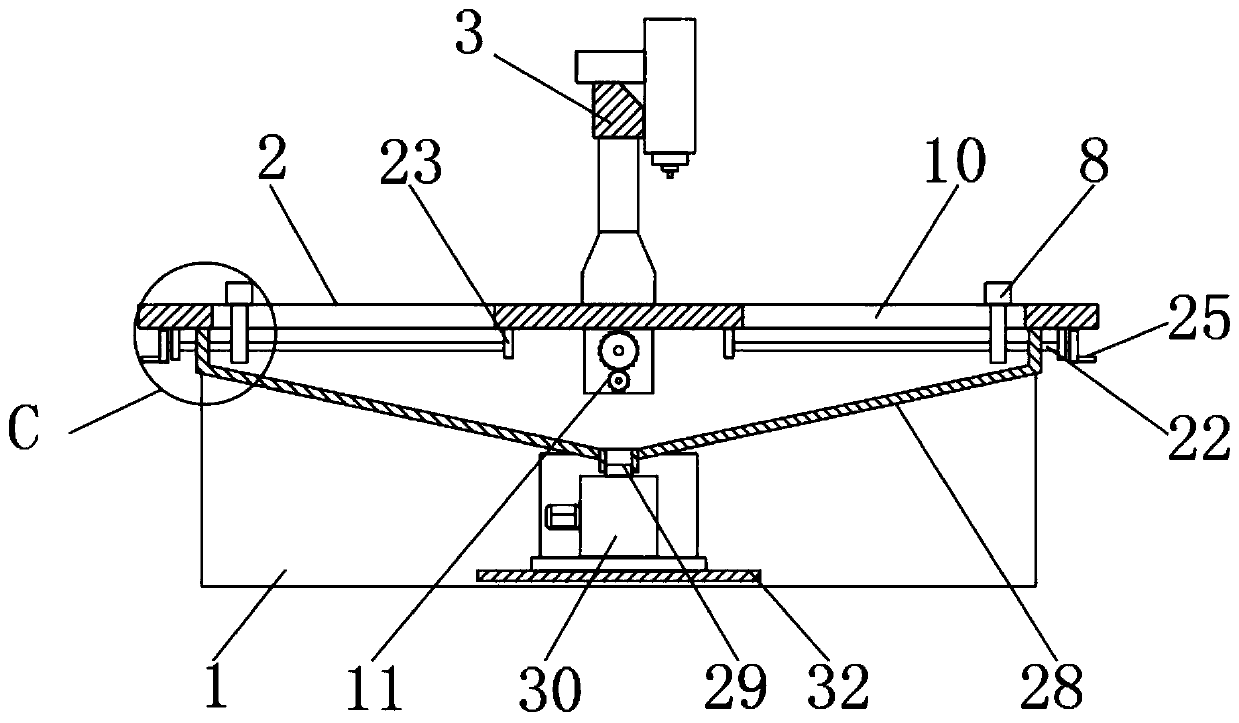

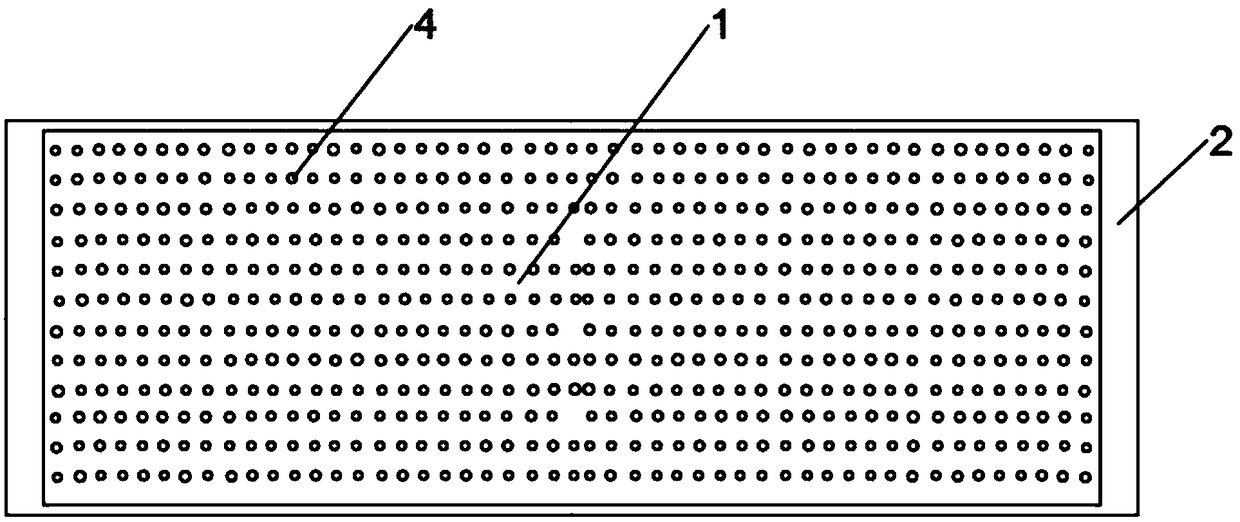

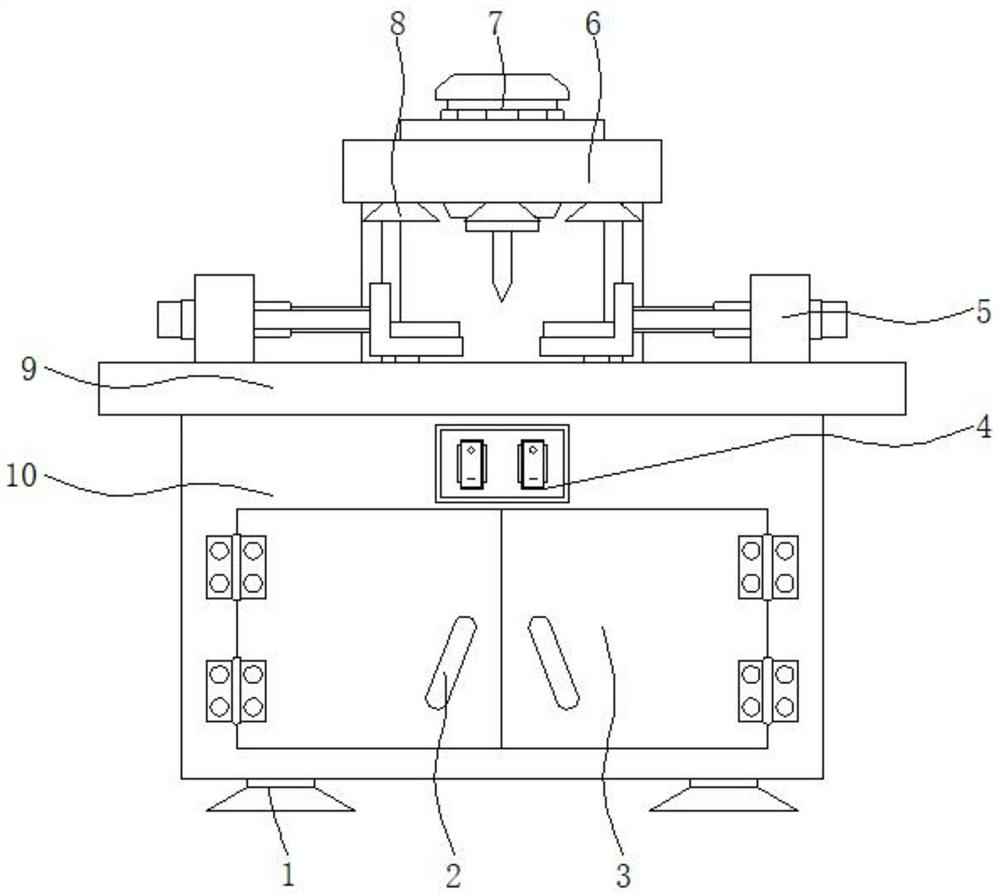

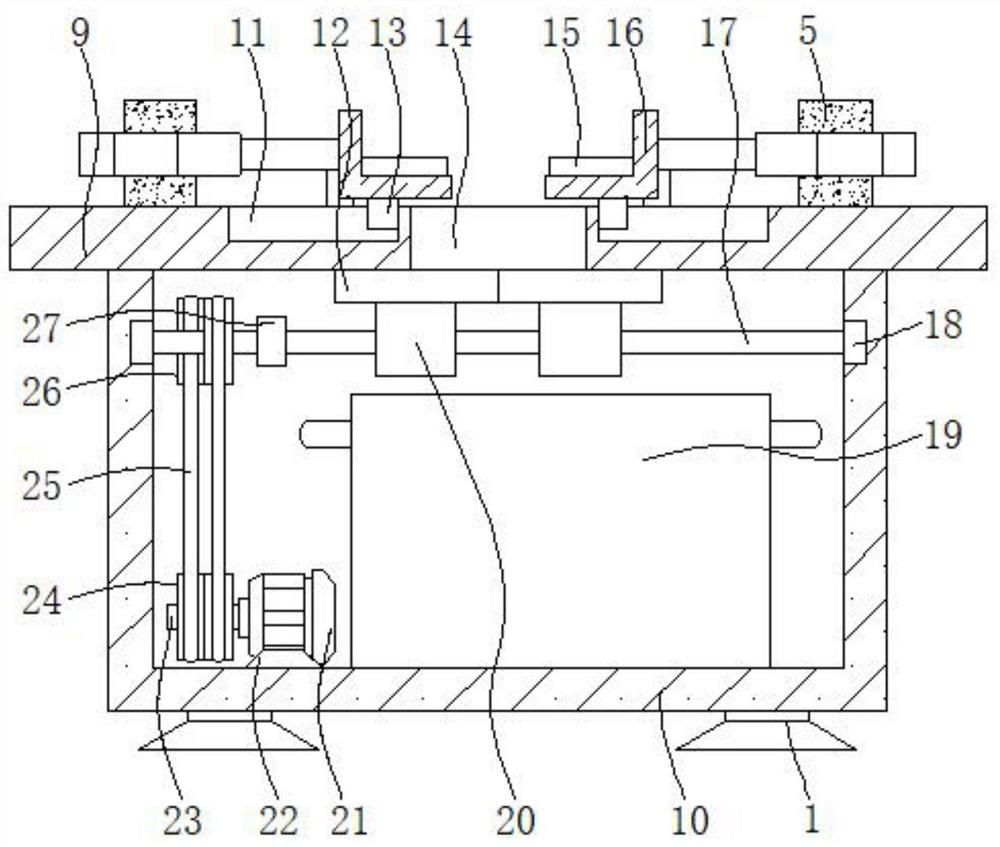

Carving device for wooden door production

InactiveCN110480757AWide range of applicationsQuality improvementProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineering

The invention discloses a carving device for wooden door production. The carving device comprises a supporting frame, a supporting plate and a carving mechanism, wherein the carving mechanism is positioned on the supporting frame; the supporting plate is fixedly connected to the top end of the supporting frame; a driving positioning device is fixedly connected to the supporting plate; a pluralityof openings are formed in the supporting plate; and an adsorption dust removal device is arranged at the bottom ends of the openings and fixedly connected to the bottom end of the supporting frame. According to the carving device for wooden door production, the driving positioning device is arranged on the supporting plate, and wooden doors are rapidly and accurately positioned by the driving positioning device when needing to be carved; and the driving positioning device is used for the wooden doors with different sizes, so that the application range is wide, and the carving quality of the wooden doors is effectively improved.

Owner:百隆智能家居有限公司

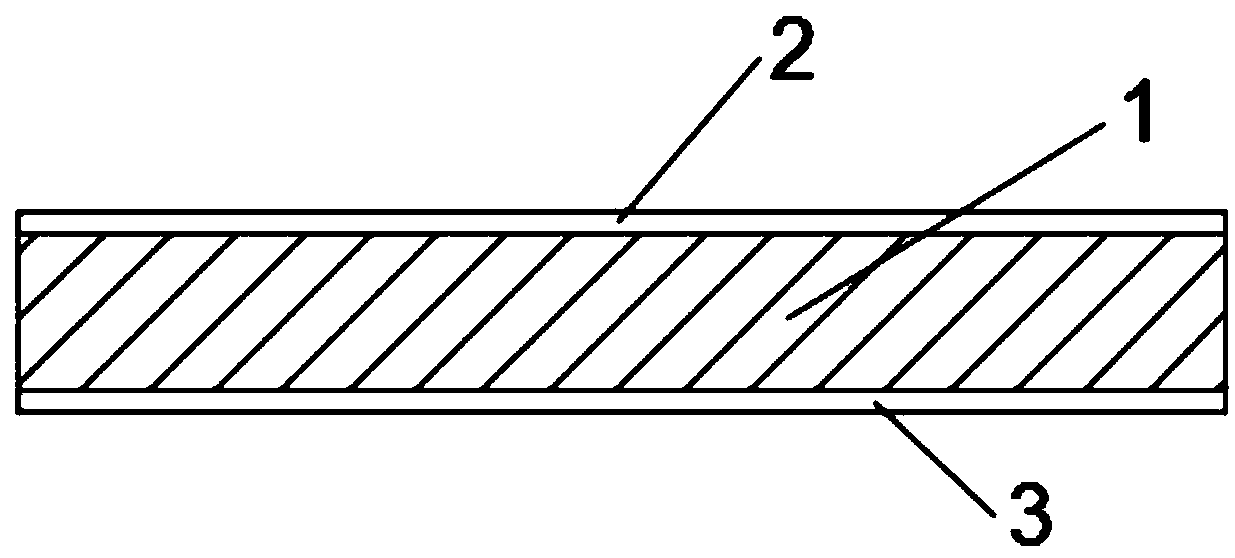

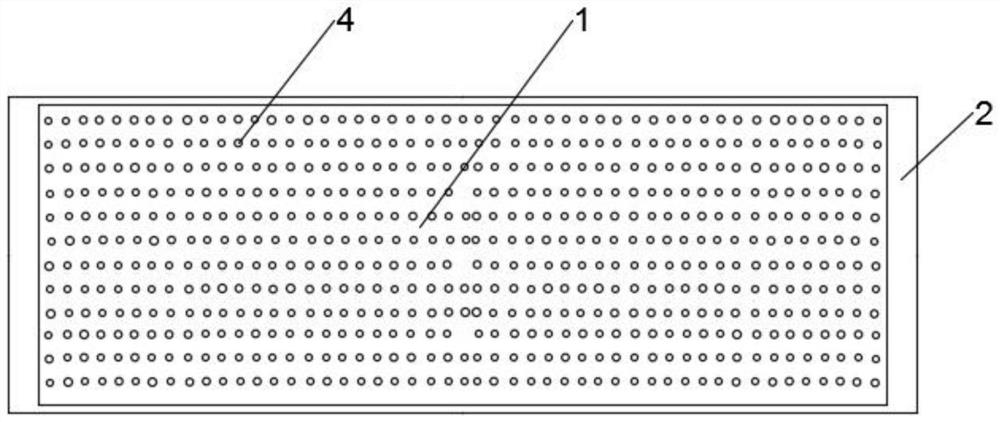

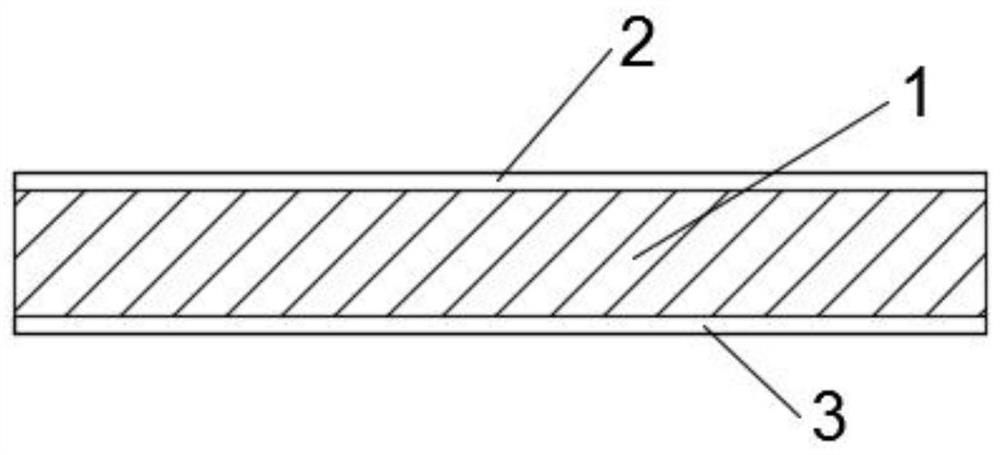

Soundproof laminating cotton and production process thereof

ActiveCN109334169APrevent flying phenomenonAvoid pollutionGlass making apparatusSynthetic resin layered productsFiberEngineering

The invention discloses soundproof laminating cotton which comprises glass wool, wherein upper plastic films are coated on the top surface and two side faces of the glass wool along a length directionof the glass wool and extend to the bottom surface; a lower plastic film is coated on the bottom surface of the glass wool along the length direction of the glass wool; the lower plastic film coversand is connected onto the upper plastic films; two ends of the upper plastic films and the lower plastic film along the length direction are sealed by a fuse machine. According to the soundproof laminating cotton disclosed by the invention, the plastic films are coated on six surfaces of the glass wool and achieve a certain moisture-proof effect, lots of cotton fibers and flocking can be preventedfrom flying during use so as not to pollute the environment, and noise can be absorbed by utilizing pores in the plastic films.

Owner:华美节能科技集团玻璃棉制品有限公司 +1

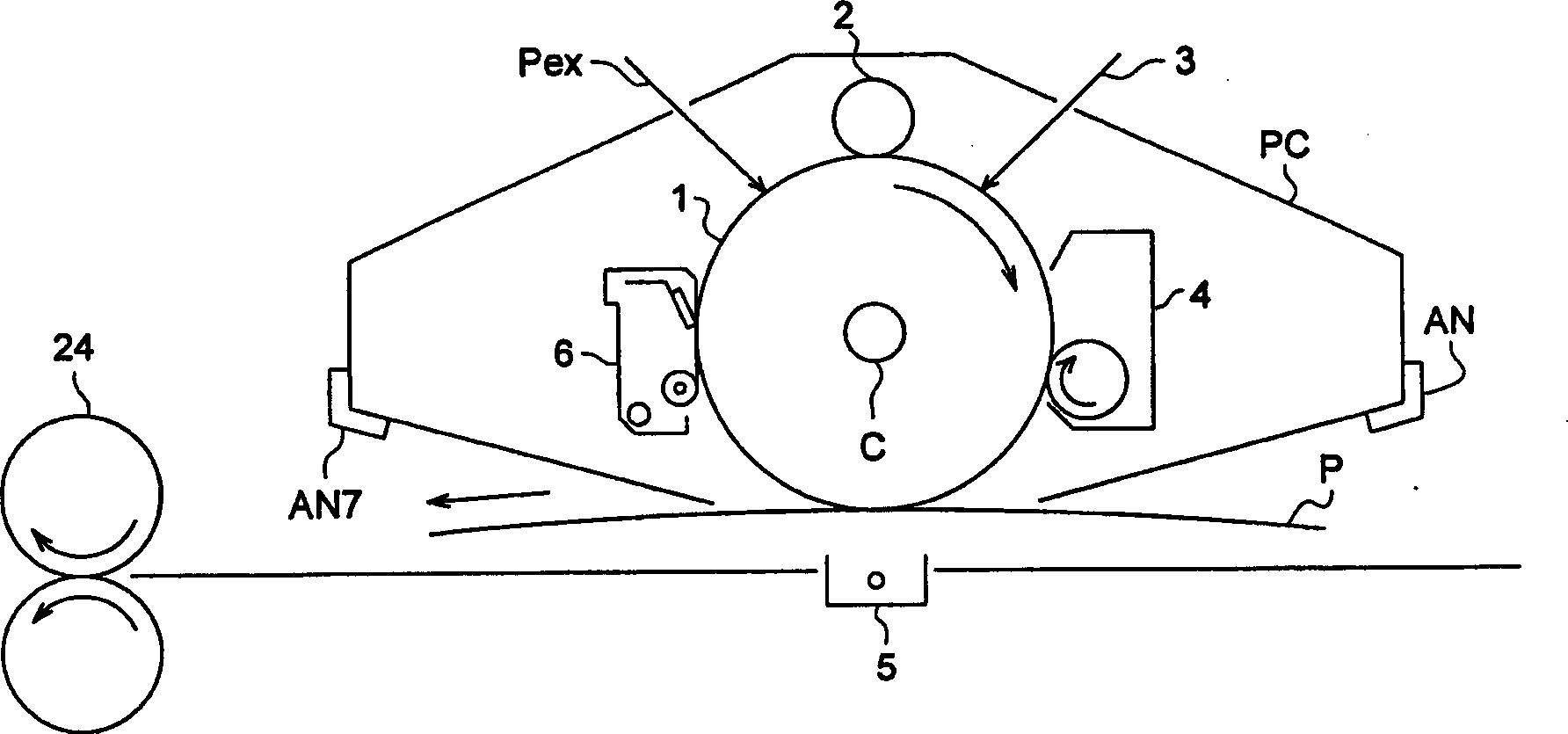

Image forming method and image forming apparatus

ActiveCN1800993APrevent flying phenomenonReduce scatterElectrographic process apparatusElectrographic processes using charge patternLatent imageImage formation

In an image forming apparatus provided with an organic photoreceptor; a developing device to bring a developing brush in contact with the organic photoreceptor so as to visualize an electrostatic latent image to toner image; a transfer device; and an agent supplying device to provide a surface energy lowering agent to the surface of the organic photoreceptor. The electrostatic latent image is visualized to the toner image while the developing sleeve is rotated in a direction counter to that of the organic photoreceptor at the developing section.

Owner:KONICA MINOLTA BUSINESS TECH INC

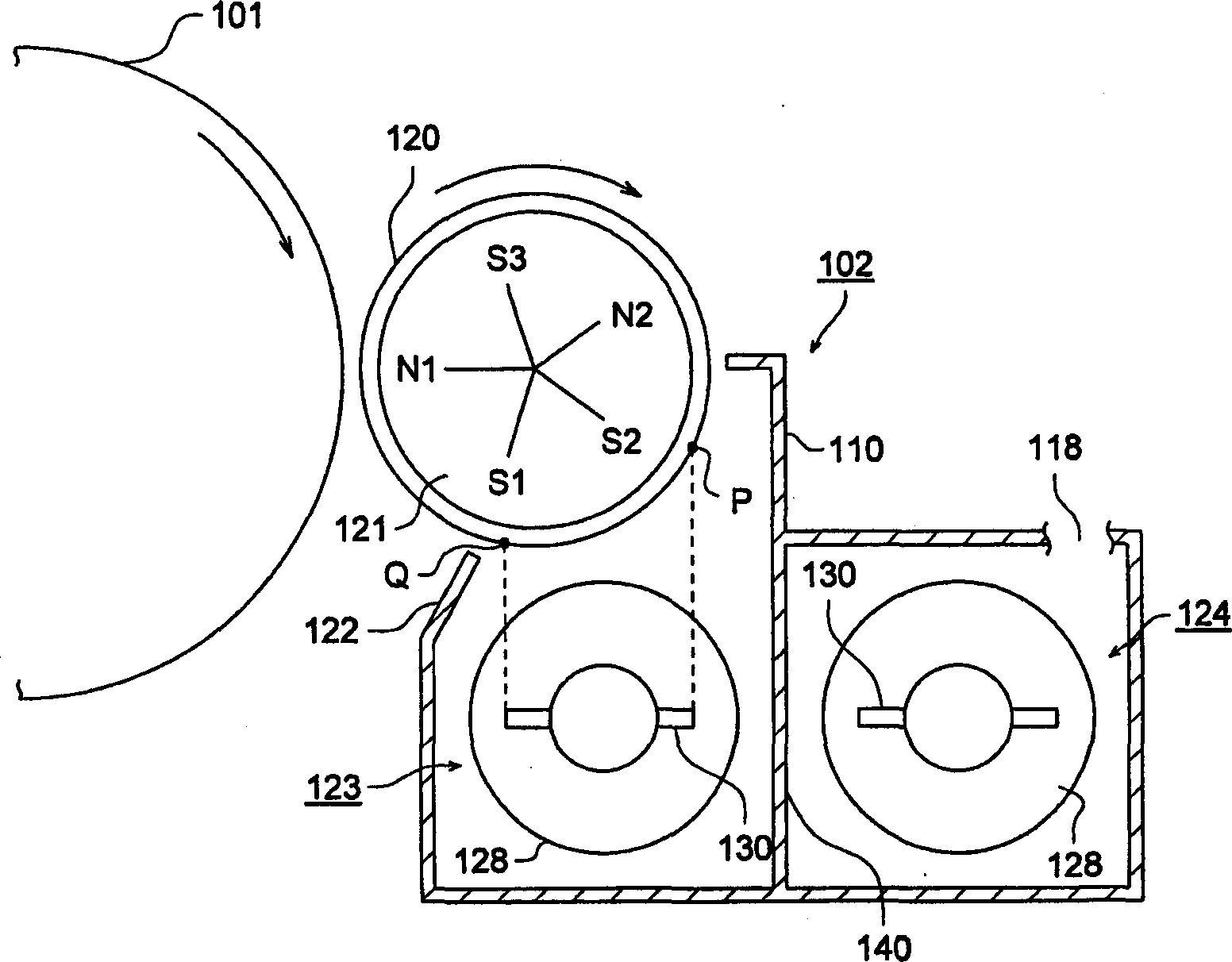

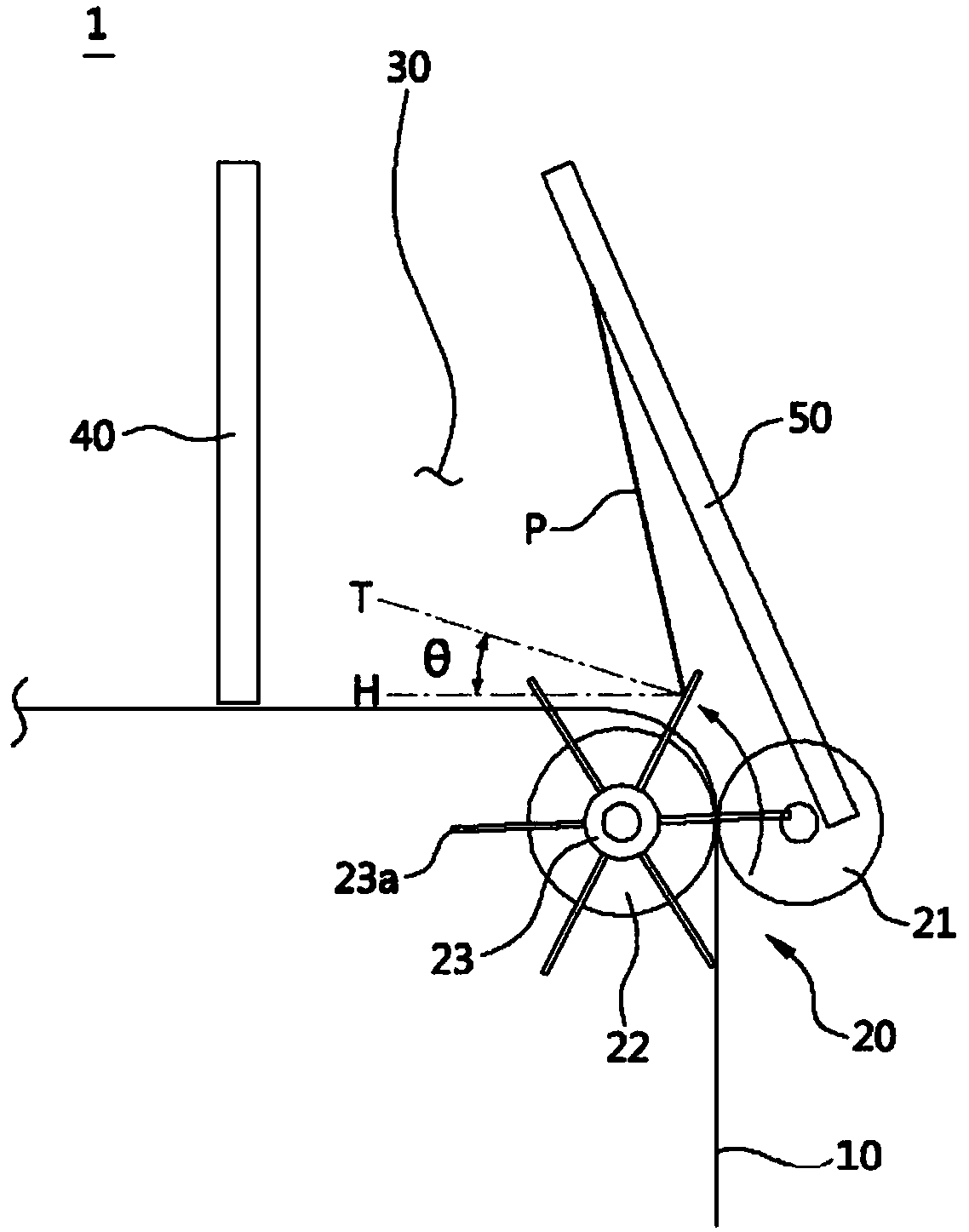

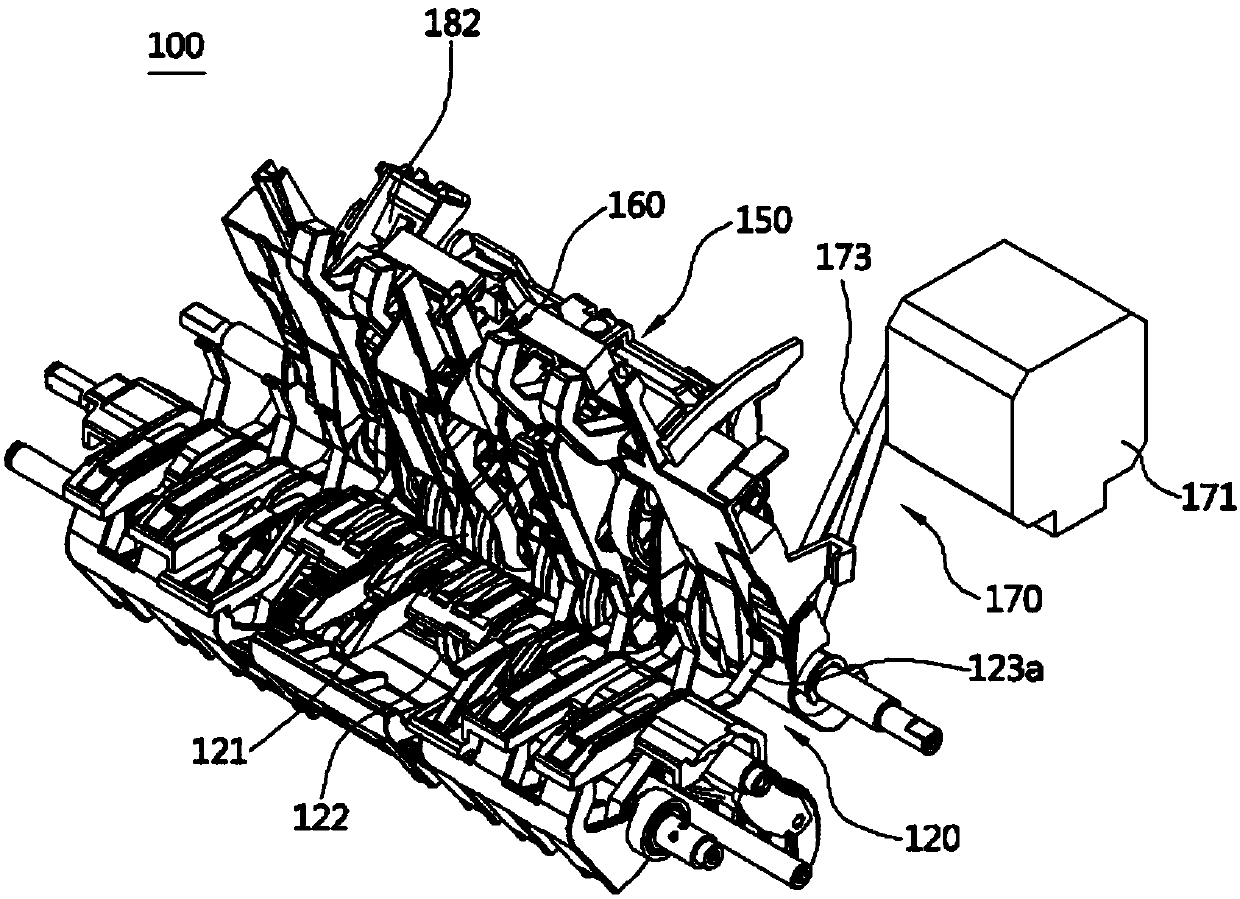

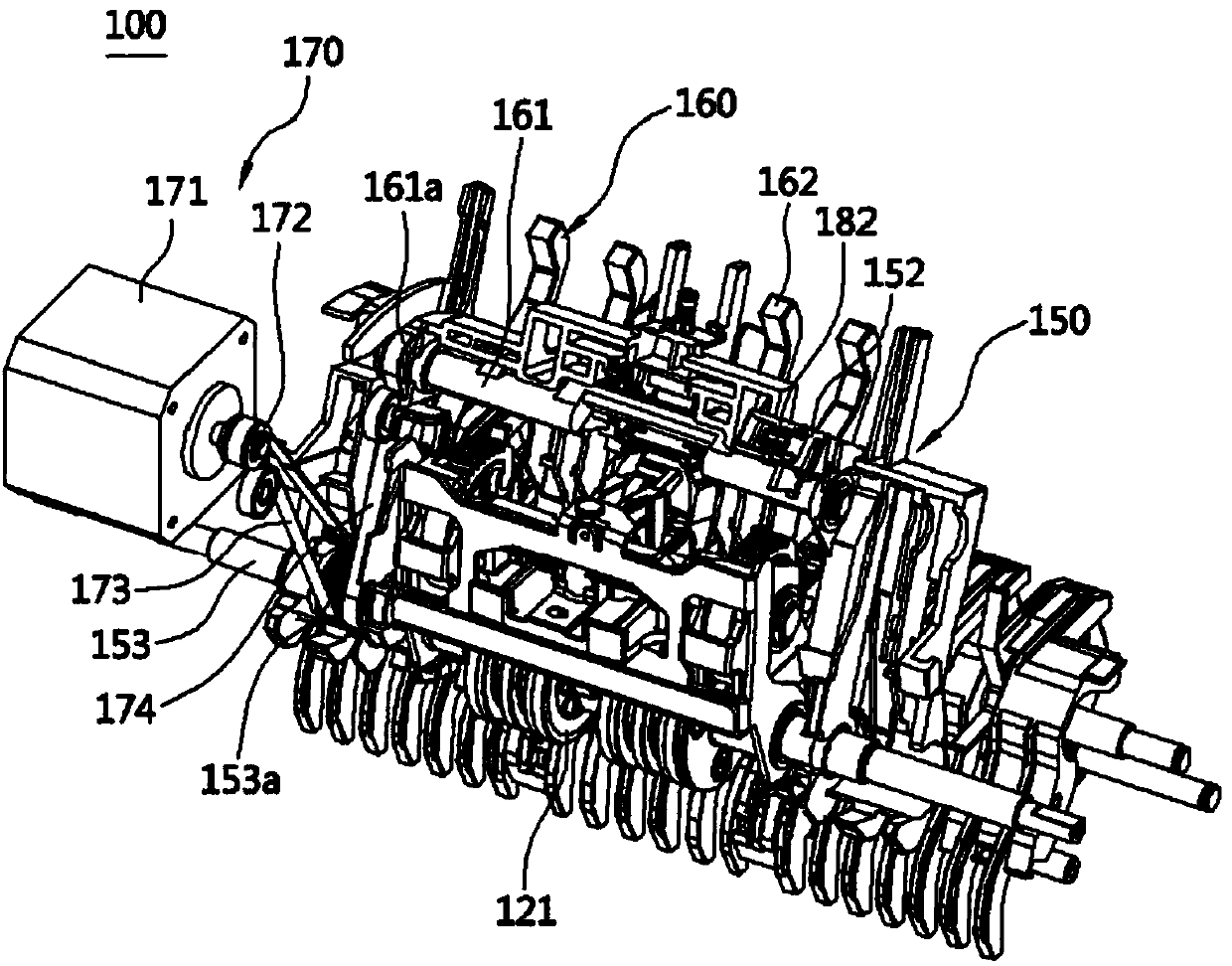

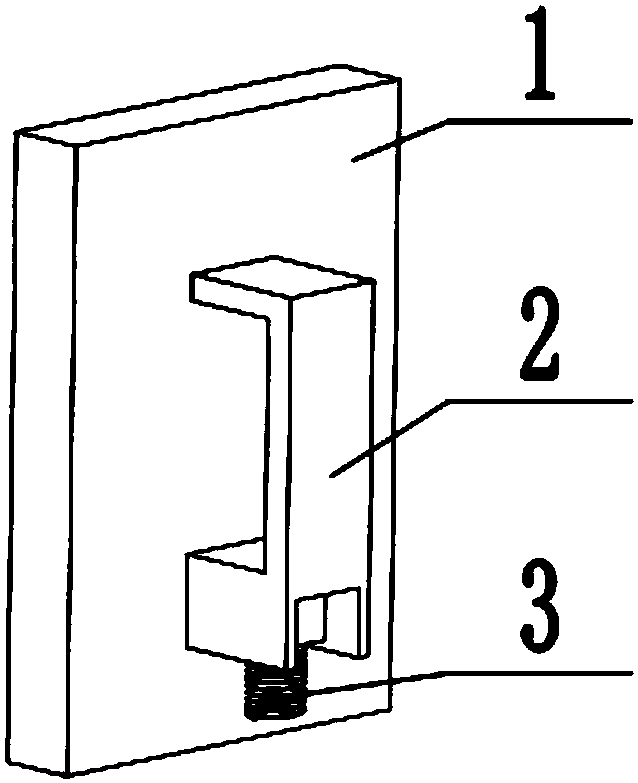

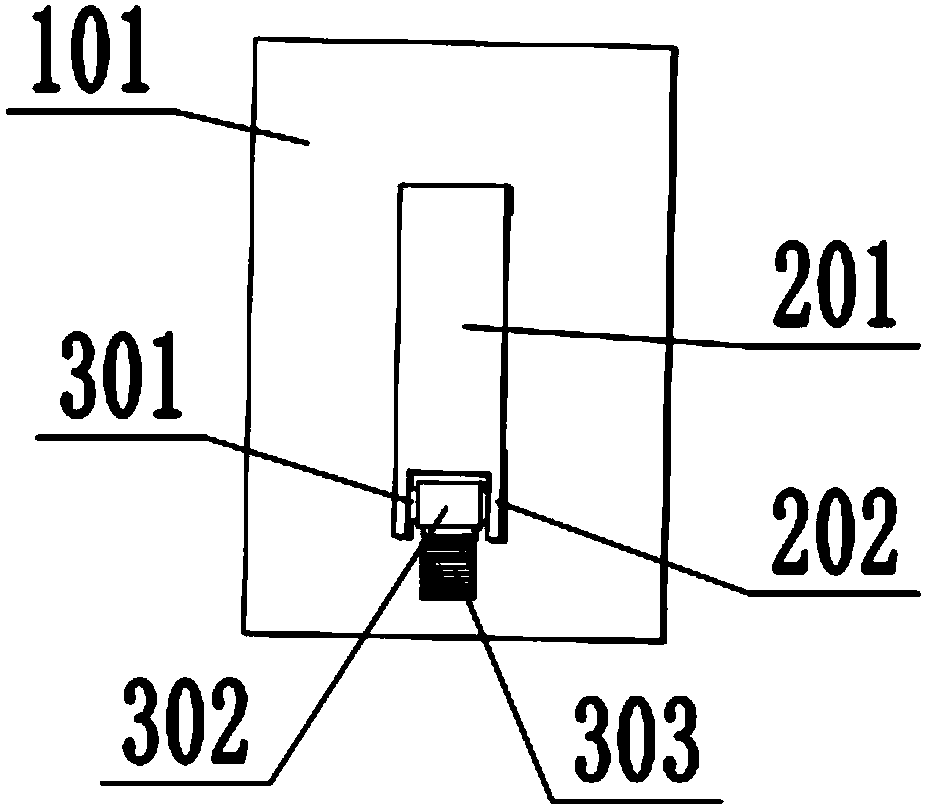

Banknote stacking apparatus

ActiveCN107871357APrevent flying phenomenonStack stableComplete banking machinesCoin/currency accepting devicesStacker

The present invention is directed to providing a banknote stacking apparatus capable of stably stacking banknotes even when various types of banknotes are stacked therein by preventing banknotes stacked in the banknote stacking space from being blown away. The banknote stacking apparatus includes a stacker for stacking banknotes in the banknote stacking space; a push plate provided to support thebanknotes stacked in the banknote stacking space and be movable in a reciprocating direction; a stack guide configured to guide the banknote which passes the stacker to be loaded into the banknote stacking space; a damper configured to press the banknote introduced into one side of the banknote stacking space toward the push plate located on the other side of the banknote stacking space and prevent the banknotes from being blown away; and a damper driver configured to operate the damper to move in a direction toward the banknote stacking space and a direction away from the banknote stacking space.

Owner:HYOSUNG TNS INC

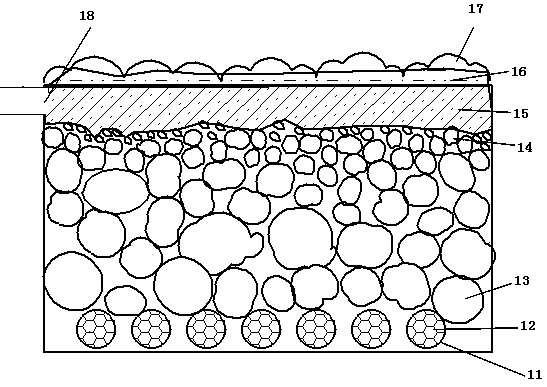

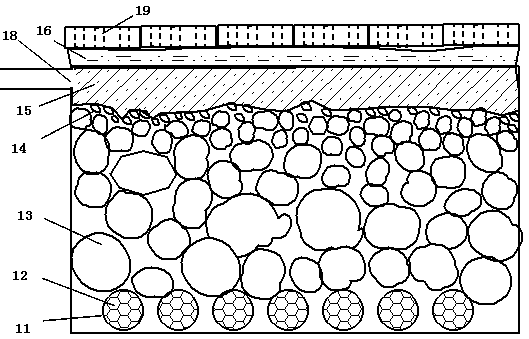

A water seepage structure and reconstruction method of an impermeable road

ActiveCN105507113BReduce floodingGuaranteed cleanlinessPaving gutters/kerbsClimate change adaptationPondingBrick

The invention discloses a water seepage structure of a road with a waterproof road surface and a transformation method, and belongs to the field of municipal engineering. The water seepage structure comprises a plurality of water seepage pipes with water seepage holes in the periphery, a water seepage ditch is arranged at one end of each water seepage pipe, filter nets are arranged on pipe openings and orifices of the water seepage pipes, the water seepage pipes are arranged below a road rammed earth layer, the water seepage ditches are arranged below a green belt or a sidewalk, the bottoms of the water seepage ditches are backfilled with stone or sand, the top layers of the water seepage ditches are provided with green belts or cement bricks, the water seepage ditches are communicated with the curb, overflowing openings are formed in the water seepage ditches, road water overflowing can be relieved by means of the water seepage structure and construction method, disaster caused by unsmooth road accumulated water is avoided, the road water seepage speed and water seepage total quantity are improved, the underground conservation is improved, the modification cost is lowered, and the building cost is saved.

Owner:海南路桥工程有限公司

Recovery device for perforating machining based on bristle plate

The invention is applicable to the technical field of brushes, and provides a recovery device for perforating machining based on a bristle plate. The recovery device comprises a box body, the upper surface of the box body is fixedly connected to a workbench, the upper surface of the workbench is fixedly connected to a perforating mechanism, the upper surface of the workbench is fixedly connected to two fixed plates, an electric push rod is fixedly embedded in the left side face of each fixing plate, two sliding grooves are formed in the upper surface of the workbench, a sliding block matching with the corresponding sliding groove is connected into each sliding groove in a clamped mode, and L-shaped clamping plates are fixedly connected to the ends, close to each other, of the two electric push rods. According to the recovery device for perforating machining based on the bristle plate, by means of suction force provided by an exhaust fan, a dust hood matches with a dust collecting box, a connecting pipe and a T-shaped pipe to suck dust, the exhaust fan is used for discharging the dust into a storage box, the phenomenon that the the dust flies during work can be prevented, and serious pollution of the dust to air is avoided.

Owner:ANHUI ZHEN DA BRUSH IND

Road sweeper brush with dust-setting device

The invention discloses a sweeping brush of a road sweeper with a dust reduction device, which comprises an upper casing, a driving device is fixedly installed on one side of the upper casing, and a driving gear is fixedly installed at the power output end of the driving device. The upper part of the upper casing is fixedly connected with a connecting frame through a flange, one side of the connecting frame is fixedly connected with a water inlet pipe, and the lower side of the upper casing is fixedly installed with a lower casing through fastening screws. A driven gear is installed in the inner cavity of the lower casing through bearing rotation, and the lower side of the driven gear is fixedly connected with the upper part of the turntable through fastening screws, and water outlet pipes are evenly distributed in the inner cavity of the turntable, so A water spray head is fixedly installed at one end of the water outlet pipe, and a rotating joint is fixedly installed at the middle part of the inner chamber of the turntable. The invention has a simple structure, can absorb the dust particles raised by the brush, effectively prevents the phenomenon of flying dust caused by the high-speed rotation of the brush, is convenient for disassembly and assembly, is convenient for maintenance and replacement, and has low production cost.

Owner:宿迁洁丽环保设备制造有限公司

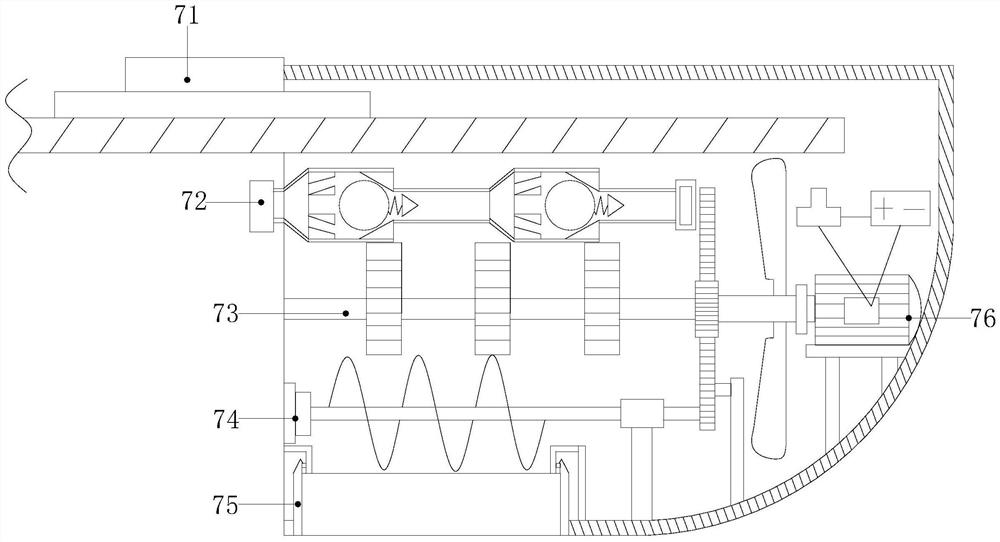

An electric drill capable of dust absorption and shock absorption

ActiveCN106964814BPrevent flying phenomenonAvoid damagePortable drilling machinesElectric machineryEngineering

The invention discloses an electric drill capable of absorbing dust and reducing vibration and belongs to the technical field of electric machinery. The electric drill comprises a drill bit, a drill body, a handle and a dust absorption device which are connected with one another, and the dust absorption device is connected with the drill body. The dust absorption device comprises a dust collection box, a dust absorption pipe connected with an inlet of the dust collection box, a first filtering mesh and a pressure sensor, wherein the first filtering mesh is arranged in the dust collection box and is away from one end of the dust absorption pipe, and the pressure sensor is arranged on the outer surface of the dust absorption pipe; the end, away from the dust collection box, in the dust absorption pipe is provided with a draught fan for sucking dust, and the end, correspondingly provided with the first filtering mesh, of the dust collection box is provided with an outlet; the dust collection box is furthermore internally provided with a cavity with a flip cap, and the cavity is internally provided with a controller connected with the pressure sensor; and the drill body is furthermore internally provided with a vibration reduction mechanism. By means of the electric drill, the phenomenon of flying dust in the work process of the electric drill can be effectively prevented, the dust absorption device in the electric drill can also be controlled intelligently to move along a sliding rail, and thus the situation that the dust absorption pipe in the dust absorption device is excessively pressed by the wall or the ground and damaged is prevented.

Owner:柳州市昌泉贸易有限公司

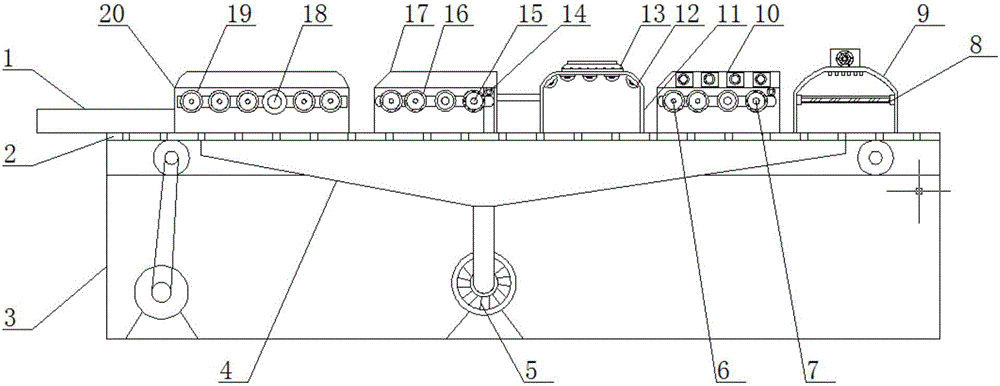

Laminating equipment for sound-proof laminating cotton

PendingCN109080878APrevents lint and lint from flyingProtect human healthPackagingEngineeringPlastic film

The invention discloses laminating equipment for sound-proof laminating cotton. The equipment comprises an input platform, a laminating device and an output platform; the laminating device is installed at an outlet end of the input platform, the laminating device comprises a laminating conveying platform and a guiding device, a film feeding and supplying frame is arranged on the upper portion of the laminating conveying platform, and a plastic film is guided to the film guiding device through the film feeding and supplying frame; by means of the film guiding device, three faces of the sound-proof cotton in the length direction are laminated, by means of cooperation of a film discharging and supplying frame and a glue spraying device, the other face of the sound-proof cotton in the length direction is laminated, the upper film and the lower film are bonded, holes are penetrated in the surfaces of the films, and finally hot melt sealing is conducted. Accordingly, the sound-proof cotton is wrapped by a layer of the plastic film, a certain moisture-proof effect is achieved, the phenomenon that a large amount of batt and cotton flock are generated and fly in use, and then the environment is polluted can be prevented, and by making the holes penetrated in the plastic film, the sound-proof cotton can absorb noise conveniently.

Owner:华美节能科技集团玻璃棉制品有限公司 +1

A kind of sound insulation coated cotton and its production process

ActiveCN109334169BPrevent flying phenomenonAvoid pollutionGlass making apparatusSynthetic resin layered productsPolymer scienceNoise

Owner:华美节能科技集团玻璃棉制品有限公司 +1

A wind power blade flash cutting device

ActiveCN107803861BPrevent flying phenomenonFlexible useSevering textilesMetal working apparatusTurbine bladeDrive motor

The invention discloses a wind turbine blade flash cutting device. The wind turbine blade flash cutting device comprises a U-shaped bracket, a cutting mechanism, a clamping mechanism and telescopic devices. The clamping mechanism is installed at the bottom of the U-shaped bracket. The cutting mechanism is mounted above the clamping mechanism and comprises a dust screen cover, a driving motor and acutting disc. The cutting disc is installed in the dust screen cover. The driving motor is installed at the upper end of the dust screen cover. The driving motor drives the cutting disc to rotate. Mounting grooves are formed in the inner sides of the two edges of the U-shaped bracket correspondingly. The telescopic devices are arranged in the mounting grooves. Connecting rods are arranged on thetwo sides of the dust screen cover. The upper ends of the telescopic devices are fixed to the connecting rods on the two sides of the dust screen cover. The wind turbine blade flash cutting device isprecise in cutting and high in cutting efficiency.

Owner:上海玻璃钢研究院东台有限公司

Dustproof wind turbine blade flash cutting device

ActiveCN107839124APrevent flying phenomenonFlexible useDirt cleaningMetal working apparatusDrive motorPolytetrafluoroethylene

The invention discloses a dustproof wind turbine blade flash cutting device which comprises a U-shaped bracket, a cutting mechanism, clamping mechanisms and telescopic devices, wherein the cutting mechanism comprises a dust hood, a driving motor and a cutting disc; a detachable hood is arranged inside and movably inserted into the dust hood; inserting teeth are arranged inside the dust hood; inserting grooves are formed in the outer side of the detachable hood; the inserting teeth of the dust hood are inserted into the inserting grooves of the detachable hood; and the detachable hood is made of a polytetrafluoroethylene material. According to the dustproof wind turbine blade flash cutting device disclosed by the invention, the detachable hood can be directly detached from the interior of the dust hood for being replaced and cleaned, thereby achieving the convenience and the practicability.

Owner:上海玻璃钢研究院东台有限公司

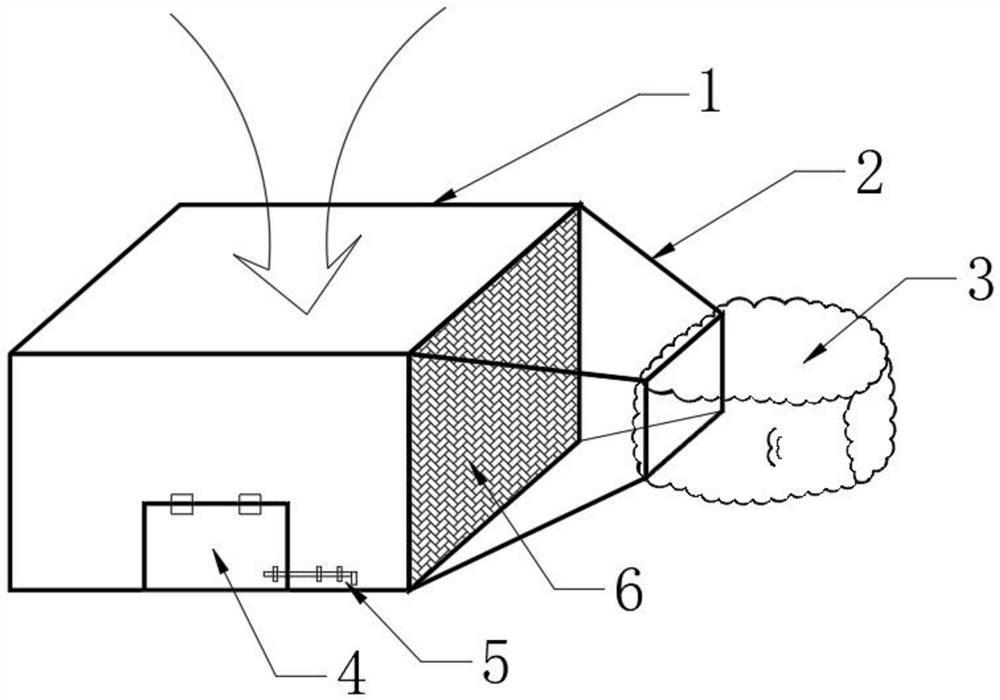

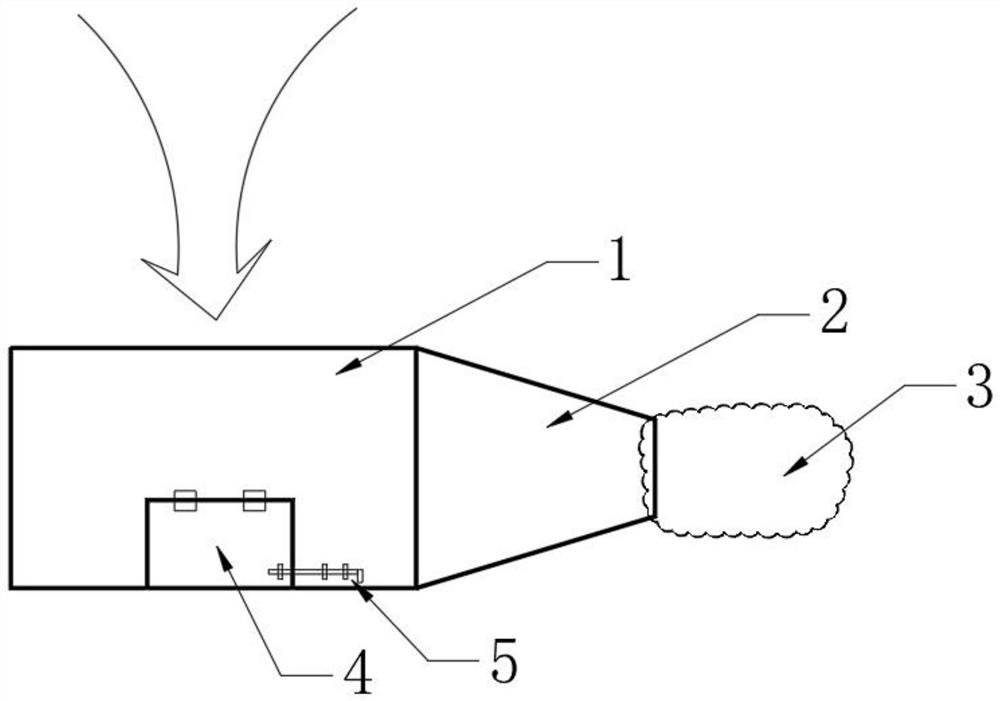

Dust falling device for building block cutting machine

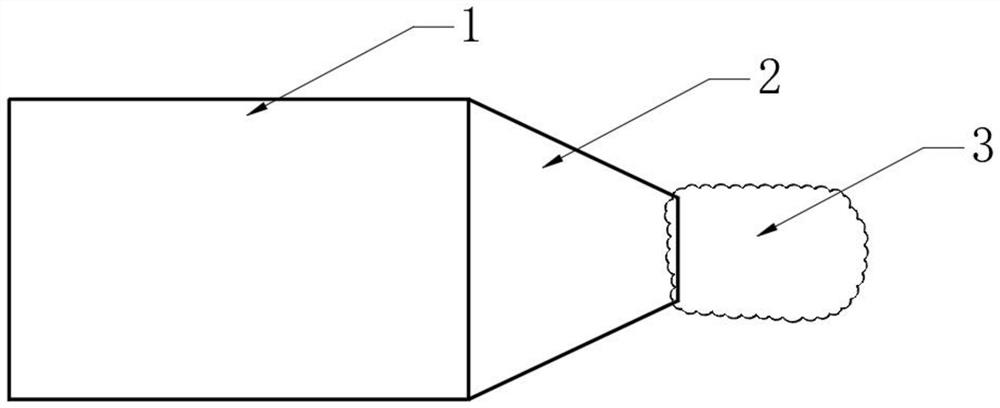

InactiveCN113085026APrevent flying phenomenonEasy to cleanWorking accessoriesStone-like material working toolsArchitectural engineeringMechanical engineering

The invention relates to a dust falling device for a building block cutting machine. The dust falling device comprises a main box body, wherein a dust inlet is formed in the top surface or the side surface of the main box body; a dust outlet is formed in the other side surface of the main box body and is connected with one end of an auxiliary box body; the other end of the auxiliary box body is connected with a dust collecting bag; and the cross section area of the auxiliary box body is gradually reduced from the end connected with the dust outlet to the end connected with the dust collecting bag. The dust falling device for the building block cutting machine can effectively prevent the circumstance of dust flying in a cutting site, and is simple in structure; and the dust inlet can be formed in the top surface of the main box body and can also be formed in the side surface of the main box body, so that the dust falling device can be suitable for building block cutting machines in different types.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP +1

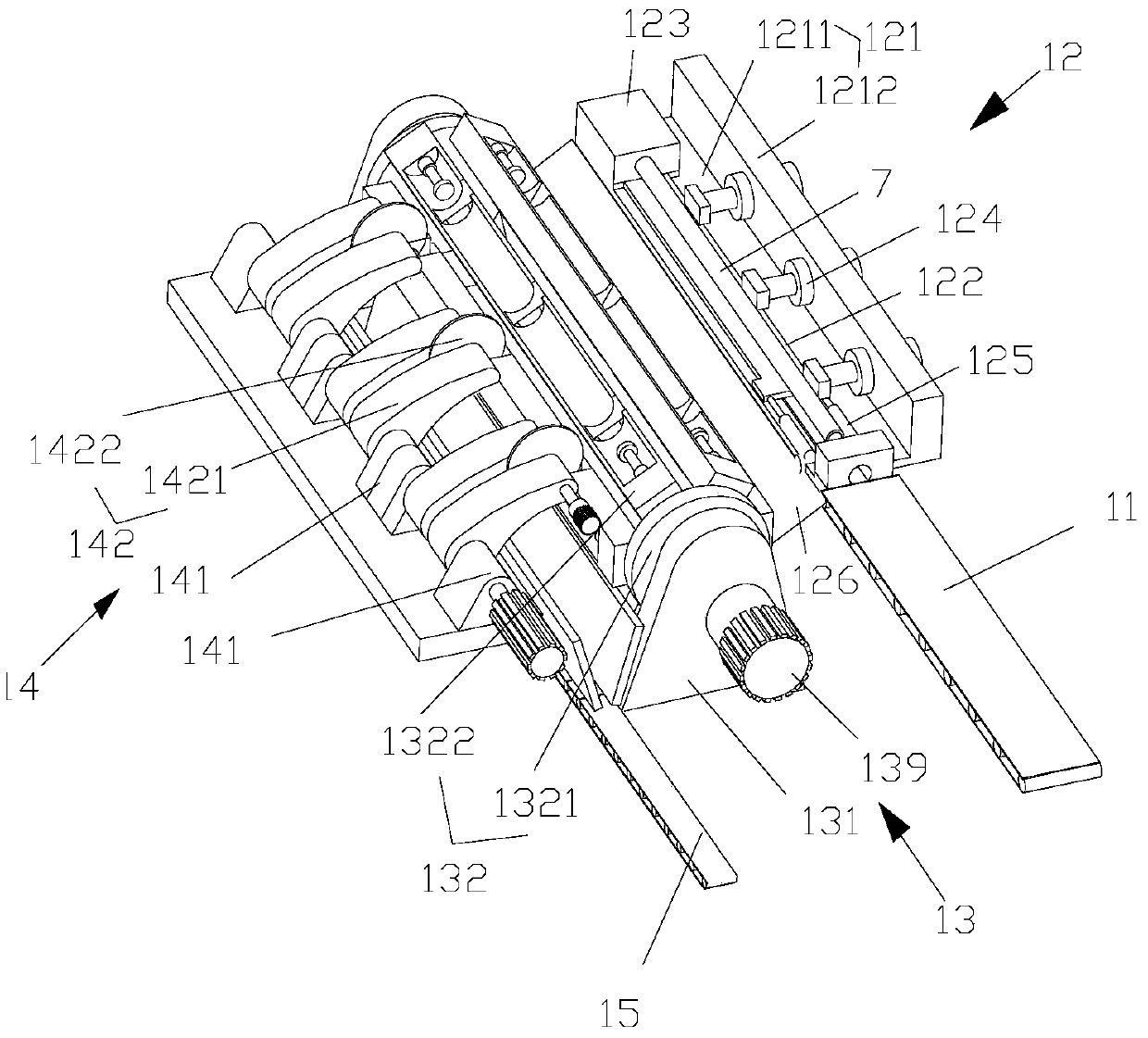

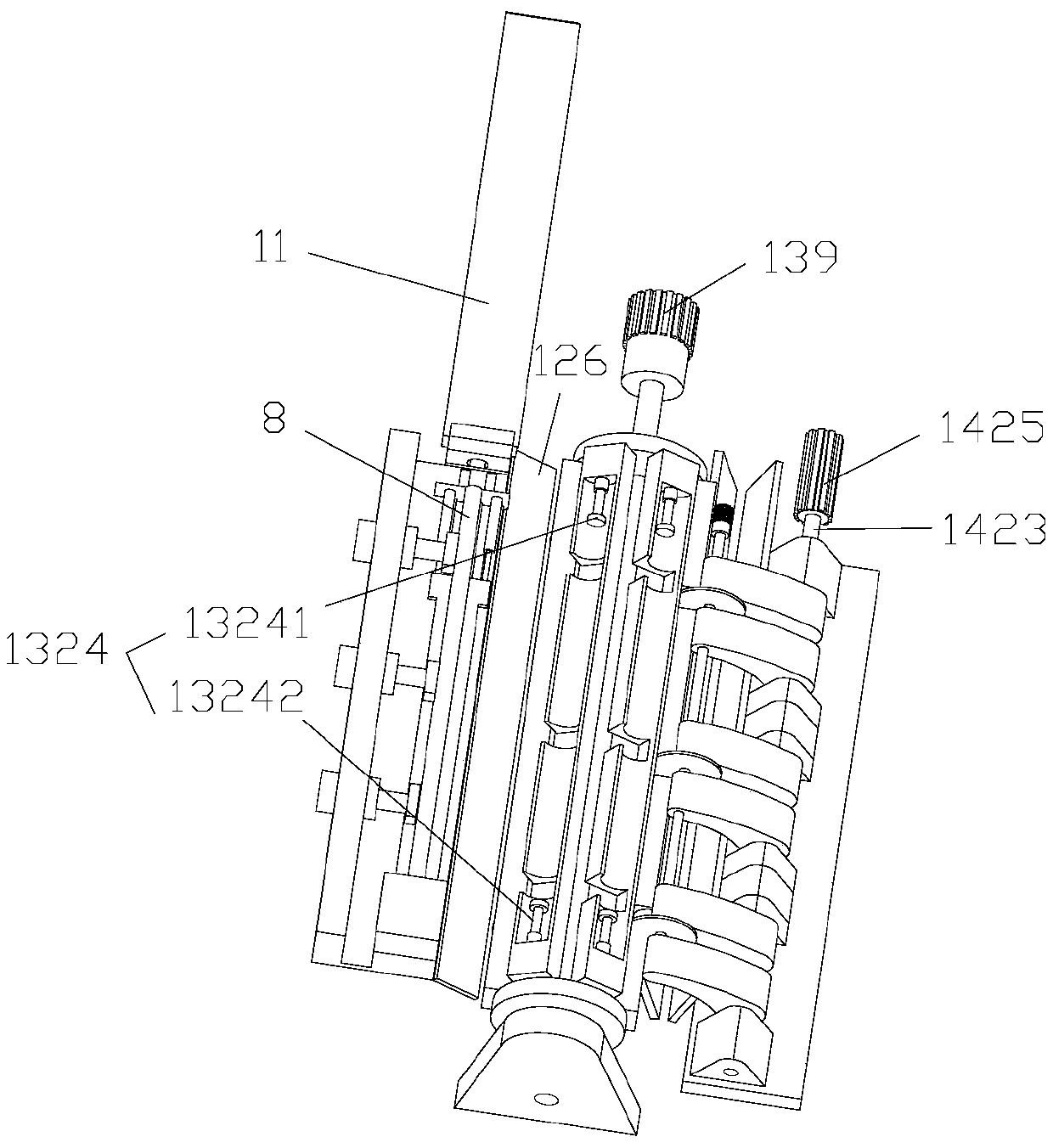

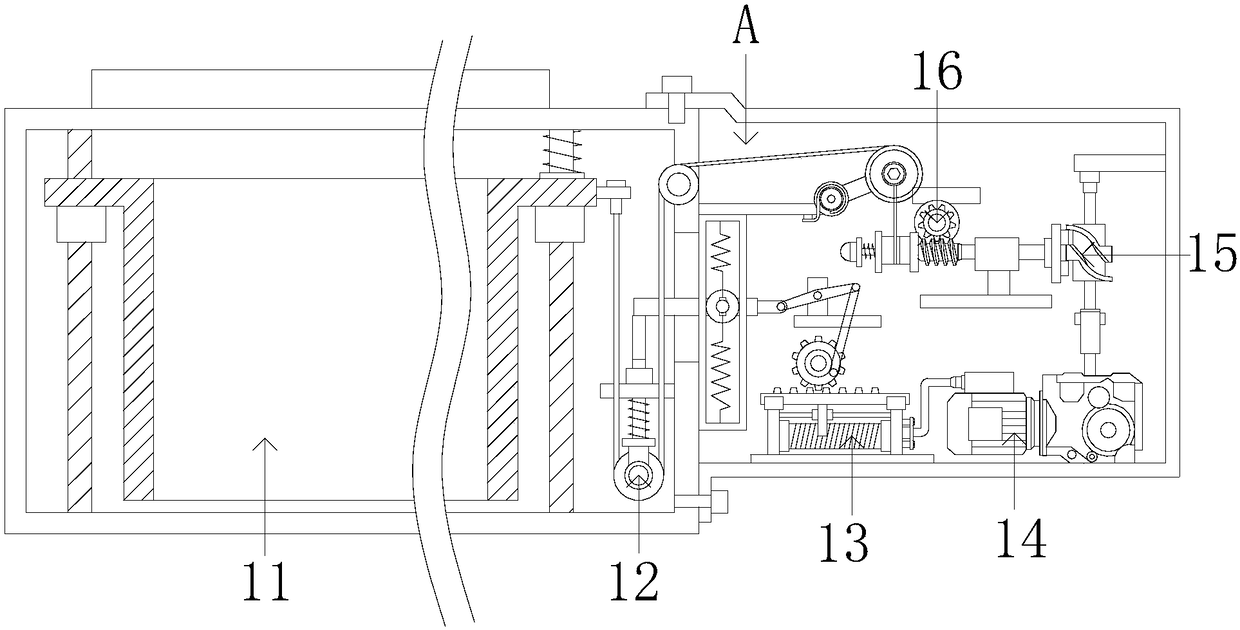

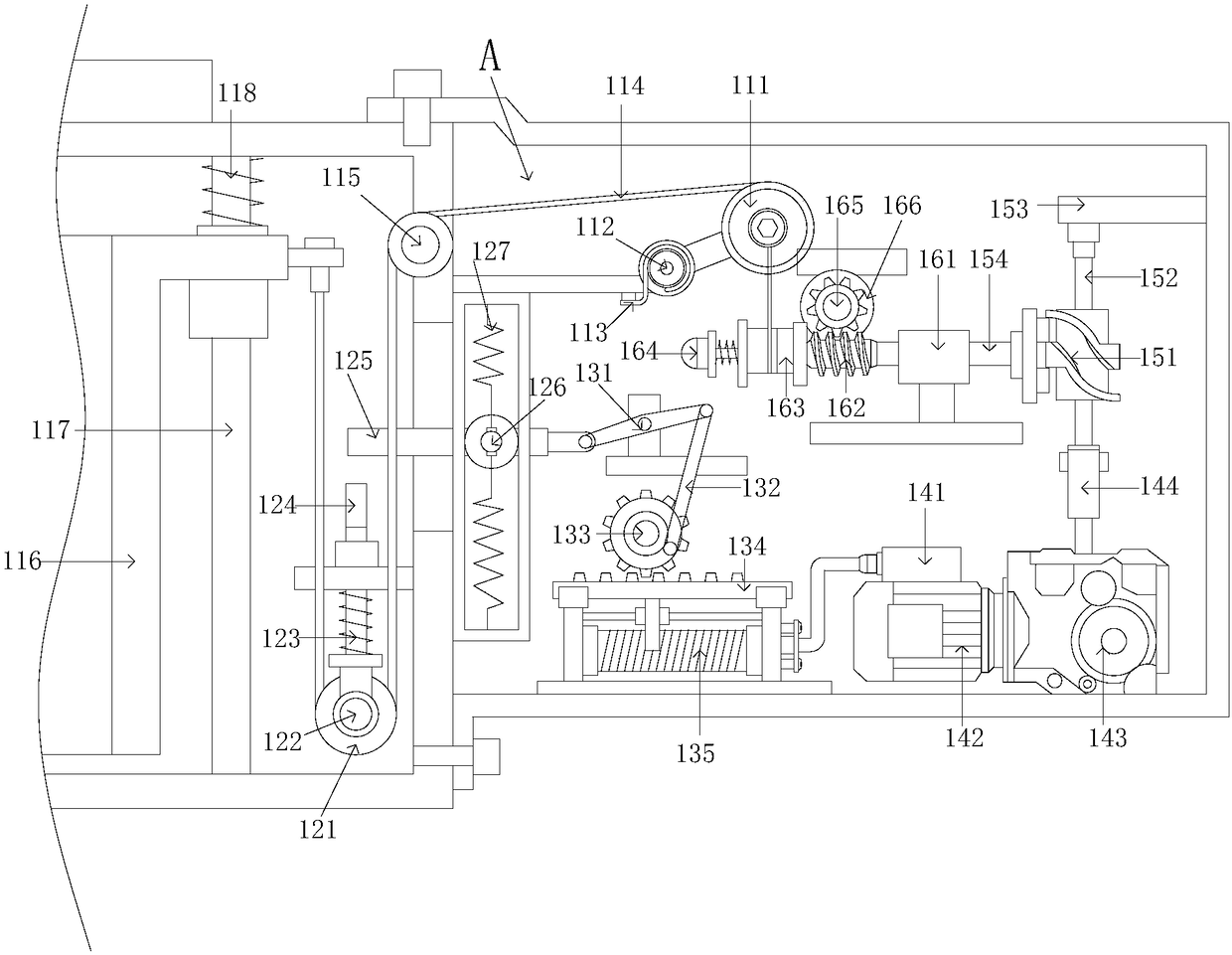

An integrated pipe body cutting and stacking mechanism for automobiles

InactiveCN108555374BAchieving Continuum IntegrationImprove pipe delivery efficiencyTube shearing machinesShearing machine accessoriesTransfer mechanismEngineering

The invention discloses an integral pipe body cutting and stacking mechanism for a car. The integral pipe body cutting and stacking mechanism comprises a cutting mechanism, a transferring mechanism and a stacking mechanism. The cutting mechanism is used for cutting straight pipes to be cut. The transferring mechanism is used for conveying the cut straight pipes to the stacking mechanism to be stacked. The cutting mechanism comprises a first conveying device, a straight pipe aligning and blanking device, a rotary feeding device, a cutting machine, a second conveying device and a leftover material separating device. The invention further discloses a method for using the integral pipe body cutting and stacking mechanism for the car to cut and stack pipe bodies for the car. The integral pipe body cutting and stacking mechanism has the beneficial effects that the cutting efficiency is improved, the cutting precision is high, cut leftover materials can be separated conveniently, and the straight pipes can be stacked conveniently.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

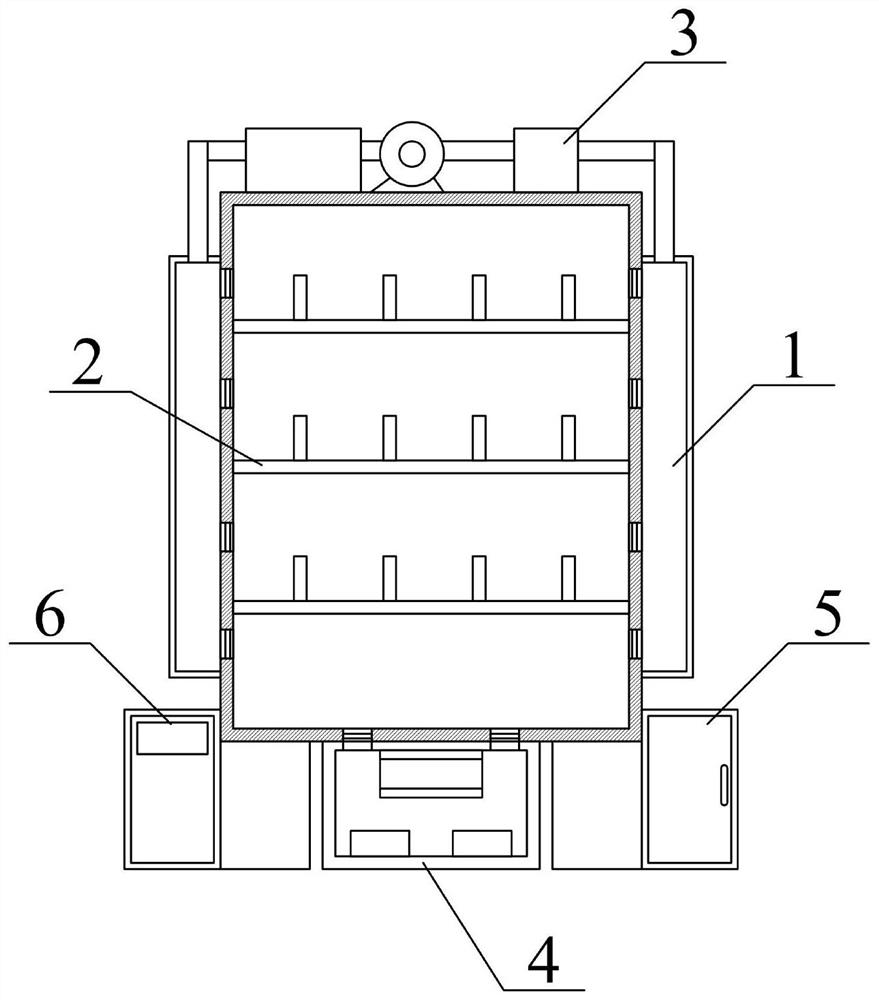

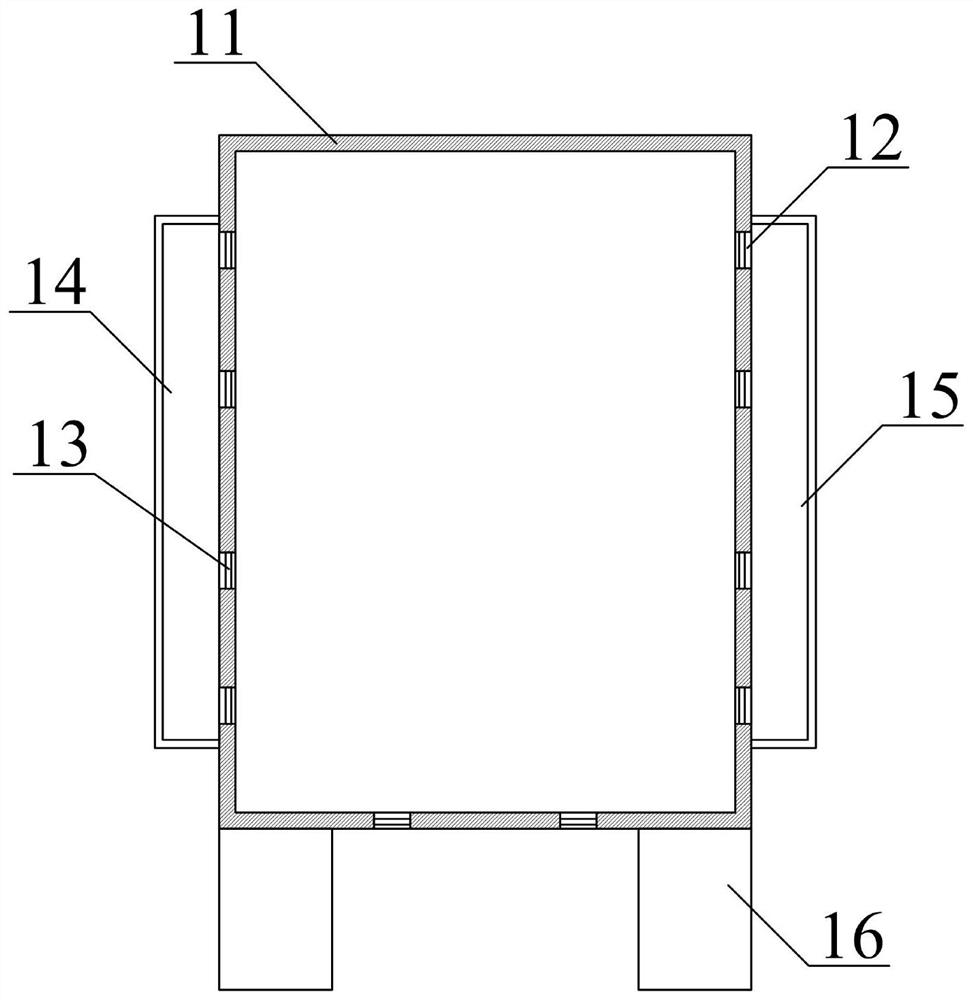

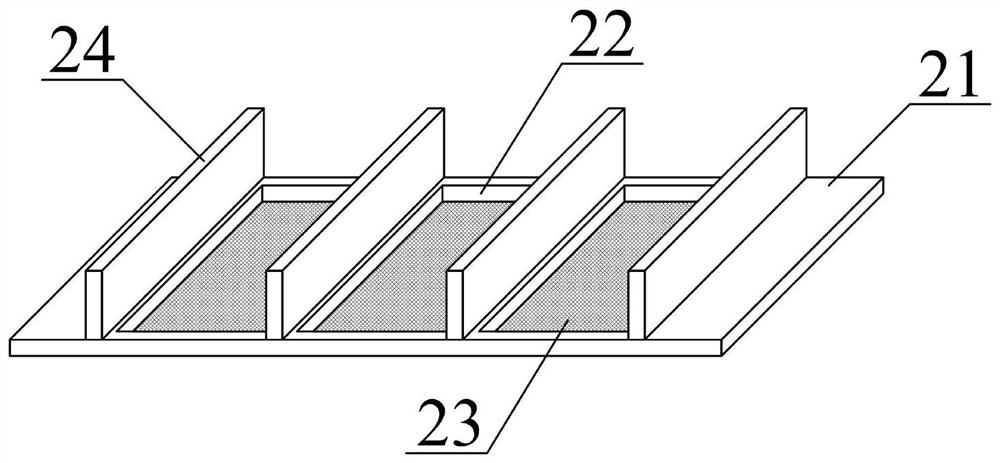

Multi-circulation cooling device for chemical production and use method of multi-circulation cooling device

InactiveCN112762645ARealize multiple circulation coolingImprove cooling effectLighting and heating apparatusDomestic refrigeratorsCold airThermodynamics

The invention discloses a multi-circulation cooling device for chemical production and a use method of the multi-circulation cooling device. The multi-circulation cooling device for chemical production comprises a box body assembly, storing assemblies, a first cooling assembly, a second cooling assembly, an electric control cabinet and a programmable logic controller (PLC).By arranging the first cooling assembly and the second cooling assembly, the PLC controls a first refrigerator, an exhaust fan, a second refrigerator and a draught fan are powered on to operate, materials in a box body are cooled, and multi-circulation cooling of the materials is achieved through an air outlet box, an air inlet box and through grooves. Compared with a natural cooling mode for cooling treatment, the cooling effect of the cooling device is improved; by arranging the storing assemblies, the materials are placed on storing nets, different materials are placed on the different storing nets, the phenomenon of pollution among the materials is avoided, and the utilization rate of the storing assemblies is improved; and baffles play a role in slowing down cold air, the materials are prevented from being blown by the cold air, and the phenomenon that the materials fly is prevented.

Owner:九天起宏(江苏)检测有限公司

Intelligent ultraviolet glazing machine

InactiveCN106541699APrevent flying phenomenonStable deliveryCylinder pressesPlaten pressesUltravioletPulp and paper industry

The invention discloses an intelligent ultraviolet glazing machine comprising a rack; the rack is provided with a paper feeding table, and the top of the rack is provided with a conveying belt; a negative pressure fan is mounted inside the rack; an air suction pipeline is mounted above the negative pressure fan; a powder removal mechanism is arranged above the rack; a powder removal roller is arranged inside the powder removal mechanism, and the side of the powder removal mechanism is provided with a servo motor; and one side of the powder removal mechanism is provided with a primer coating mechanism. According to the intelligent ultraviolet glazing machine, the negative pressure fan is arranged inside equipment, and paper sheets can be adsorbed by the negative pressure fan through an air suction hole, so that a paper sheet flying phenomenon caused by a wind effect in an operation process of the equipment is avoided; and when the paper sheets are adhered to a rubber coating roller, the paper sheets and the rubber coating roller can be separated by a cutting head, the normal conveyance of the paper sheets is ensured, and manual removal by stopping the machine by working staff is not needed, so that the production efficiency is increased, and the stable processing for the paper sheets during processing is ensured.

Owner:重庆乔远环保科技有限公司

A dust collection device for electric tools

ActiveCN106975277BPrevent the dust from being vacuumed normallyPrevent flying phenomenonCombination devicesDispersed particle filtrationEngineeringVacuum cleaner

The invention discloses a dust suction device for an electric tool, which belongs to the technical field of electric machinery. The dust suction device includes a dust collection box, a dust suction pipe connected to the air inlet of the dust collection box, and a first filter screen disposed in the dust collection box and away from one end of the dust collection pipe, and the periphery of the first filter screen abuts against the dust collector. On the inner wall of the dust box, an air outlet is provided at one end of the dust collection box corresponding to the first filter screen; a dust suction hood is also connected to the periphery of the nozzle of the dust suction pipe away from the end of the dust collection box, and the inside of the dust suction hood is far away from the first dust suction. There is a fan at one end of the tube; an alarm is also provided on the outside of the dust collection box, and a sensor and a cavity are arranged in the dust collection box. A controller connected with an alarm, a sensor and a fan is arranged inside; the dust collecting box is connected with the electric tool body. The invention can not only effectively prevent the phenomenon of flying dust during the working process of the electric tool, but also prevent the effect of dust collection from being affected by too much dust in the dust collecting box.

Owner:柳州市昌泉贸易有限公司

A mining screw feeder

ActiveCN104819001BGood transportabilityExcellent fill factorUnderground chambersTunnel liningEngineeringCam

Owner:SHANDONG UNIV OF SCI & TECH

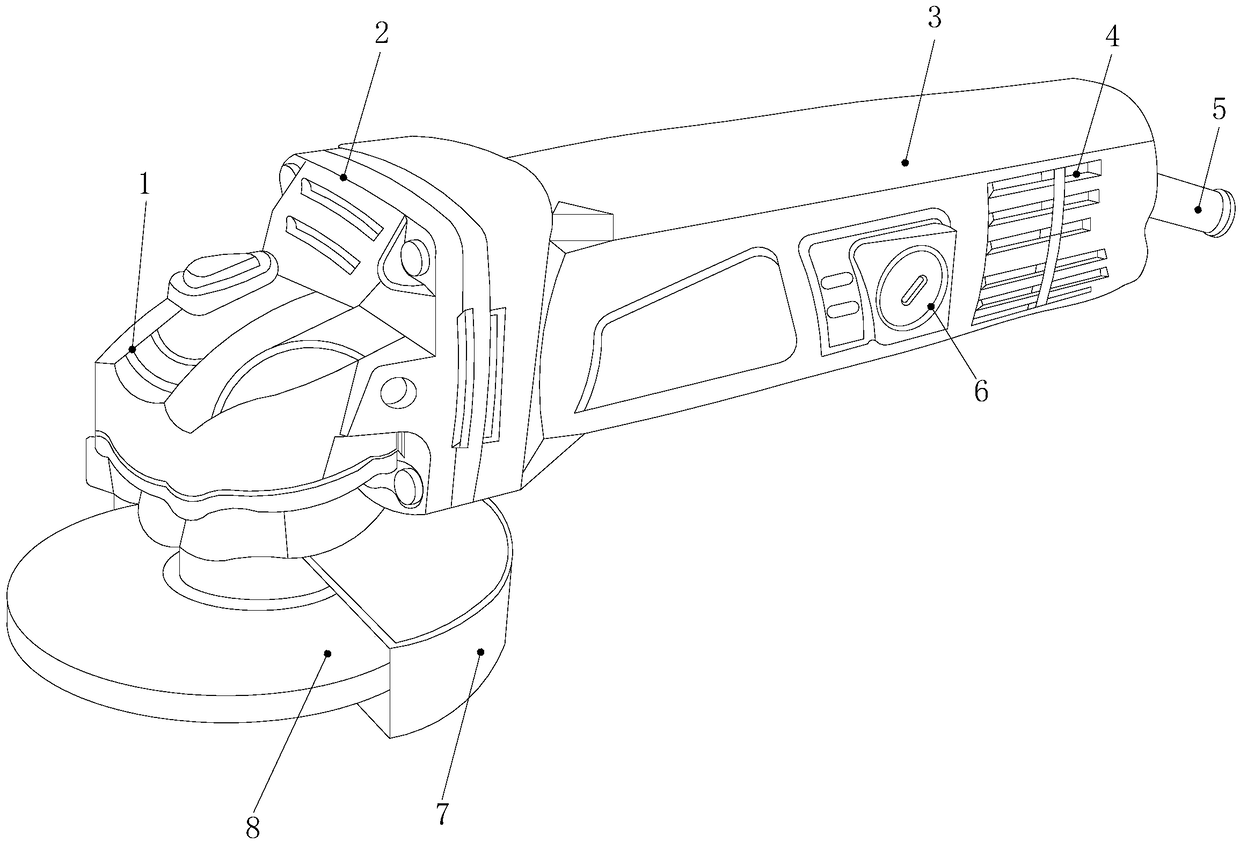

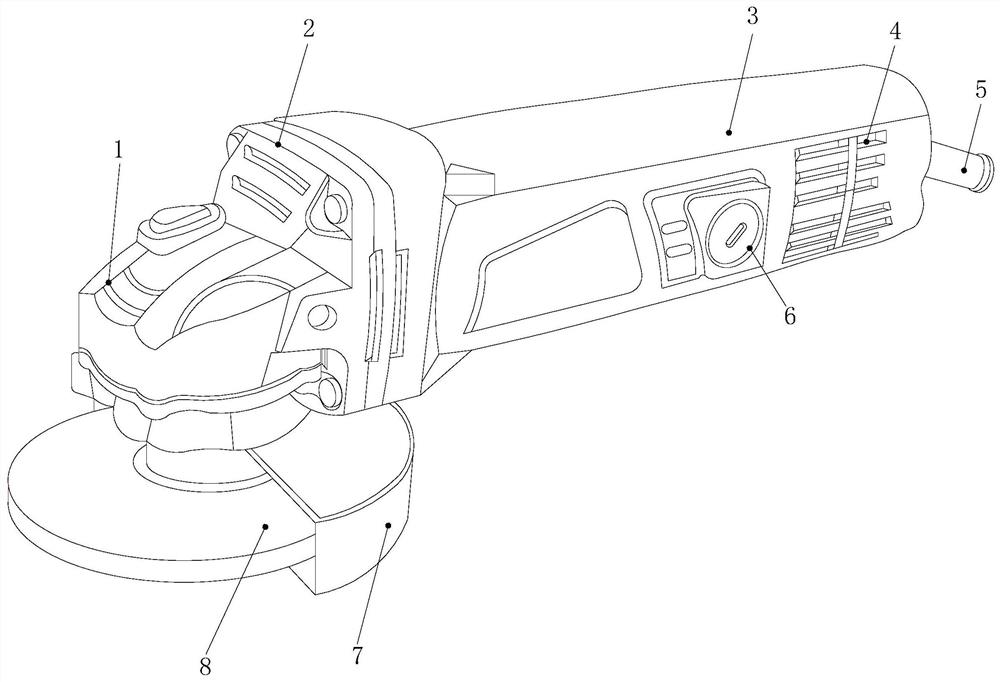

Wood grinding and polishing device assisting in wood painting

ActiveCN109397038AEasy accessCause flying phenomenonPortable grinding machinesGrinding/polishing safety devicesEngineeringRespiratory disease

The invention discloses a wood grinding and polishing device assisting in wood painting. The wood grinding and polishing device structurally comprises a grinding machine head, a connecting disc, a holding handle, heat dissipation holes, an external connecting wire, a speed adjustment device, a protective cover and a grinding disc. The grinding machine head is located at the left side of the connecting disc and fixedly connected with the connecting disc through screws. The connecting disc is fixedly buckled to the left side of the holding handle. The heat dissipation holes and the holding handle are of an integral mechanism component. The external connecting wire penetrates the right side of the holding handle and is connected to an electric system inside the holding handle. The grinding disc is horizontally fixed to the bottom of the grinding machine head and is in transmission connection with the grinding machine head. The protective cover is fixedly welded to the bottom of the grinding machine head, and the protective cover and the grinding disc are mounted on the same horizontal plane. After the device is improved, when the device is used for carrying out the grinding and polishing work, wood chippings and dust generated in the grinding process can be rapidly and effectively collected, and thus, the phenomena that the external wood chippings and dust fly everywhere and enterrespiratory tracts of workers to cause respiratory diseases are prevented.

Owner:日照现代家具有限公司

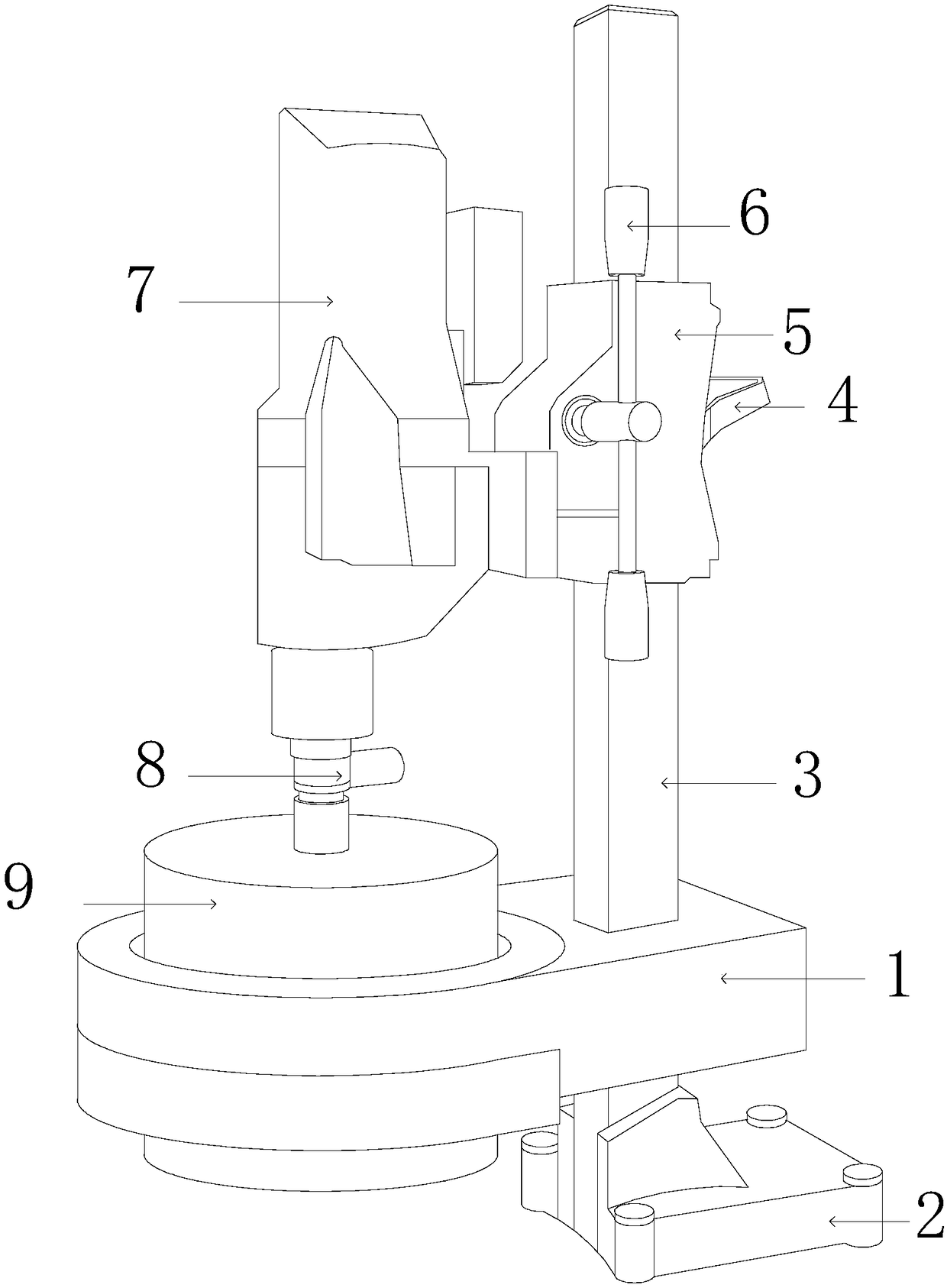

Diamond tapping equipment

The invention discloses diamond tapping equipment. The diamond tapping equipment is characterized by structurally comprising a dust suppression mechanism, a fixed base, a stand column, a handle, a fixed slide sleeve, a limiting handle, a tapping motor, a composite shaft coupler and a drill bit. The improved diamond tapping equipment disclosed by the invention can isolate dust, and is matched withwater injection for cooling and lubricating, so that injected water flows out along with dust; the dust suppression mechanism can block muddy water to prevent splashing, and further can prevent a phenomenon that dust flies around in work as well as the risk of harming eyes by gravel splashing; and meanwhile, the drill bit can be assisted to position, so that smoothness and straightness of holes are guaranteed.

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

Wood grinding and polishing device for assisting wood spraying

ActiveCN109397038BEasy accessCause flying phenomenonPortable grinding machinesGrinding/polishing safety devicesPolishingEngineering

The invention discloses a wood grinding and polishing device assisting in wood painting. The wood grinding and polishing device structurally comprises a grinding machine head, a connecting disc, a holding handle, heat dissipation holes, an external connecting wire, a speed adjustment device, a protective cover and a grinding disc. The grinding machine head is located at the left side of the connecting disc and fixedly connected with the connecting disc through screws. The connecting disc is fixedly buckled to the left side of the holding handle. The heat dissipation holes and the holding handle are of an integral mechanism component. The external connecting wire penetrates the right side of the holding handle and is connected to an electric system inside the holding handle. The grinding disc is horizontally fixed to the bottom of the grinding machine head and is in transmission connection with the grinding machine head. The protective cover is fixedly welded to the bottom of the grinding machine head, and the protective cover and the grinding disc are mounted on the same horizontal plane. After the device is improved, when the device is used for carrying out the grinding and polishing work, wood chippings and dust generated in the grinding process can be rapidly and effectively collected, and thus, the phenomena that the external wood chippings and dust fly everywhere and enterrespiratory tracts of workers to cause respiratory diseases are prevented.

Owner:日照现代家具有限公司

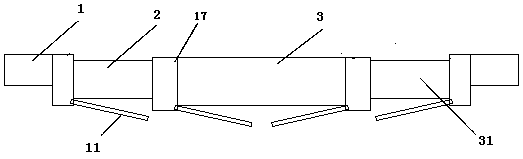

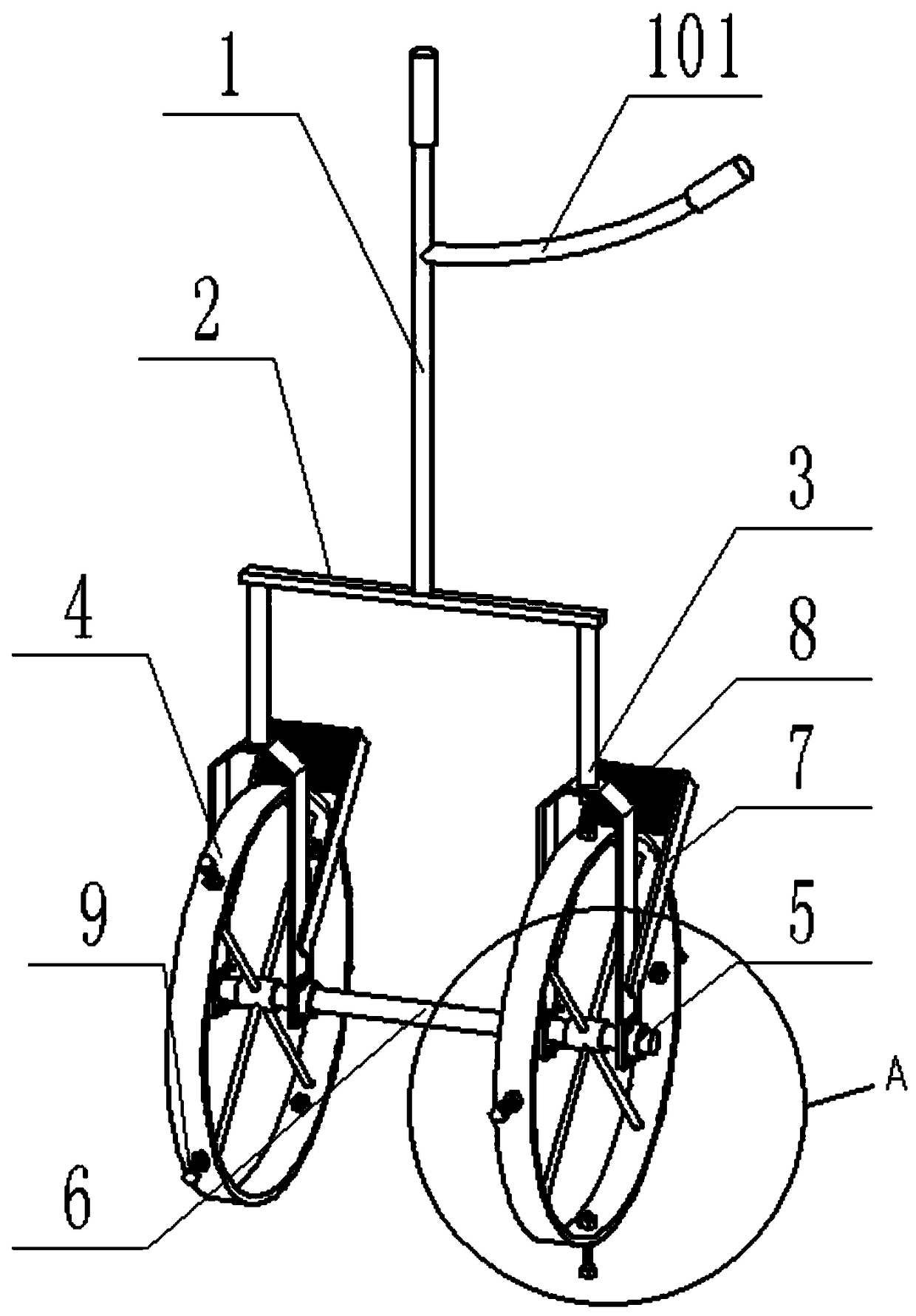

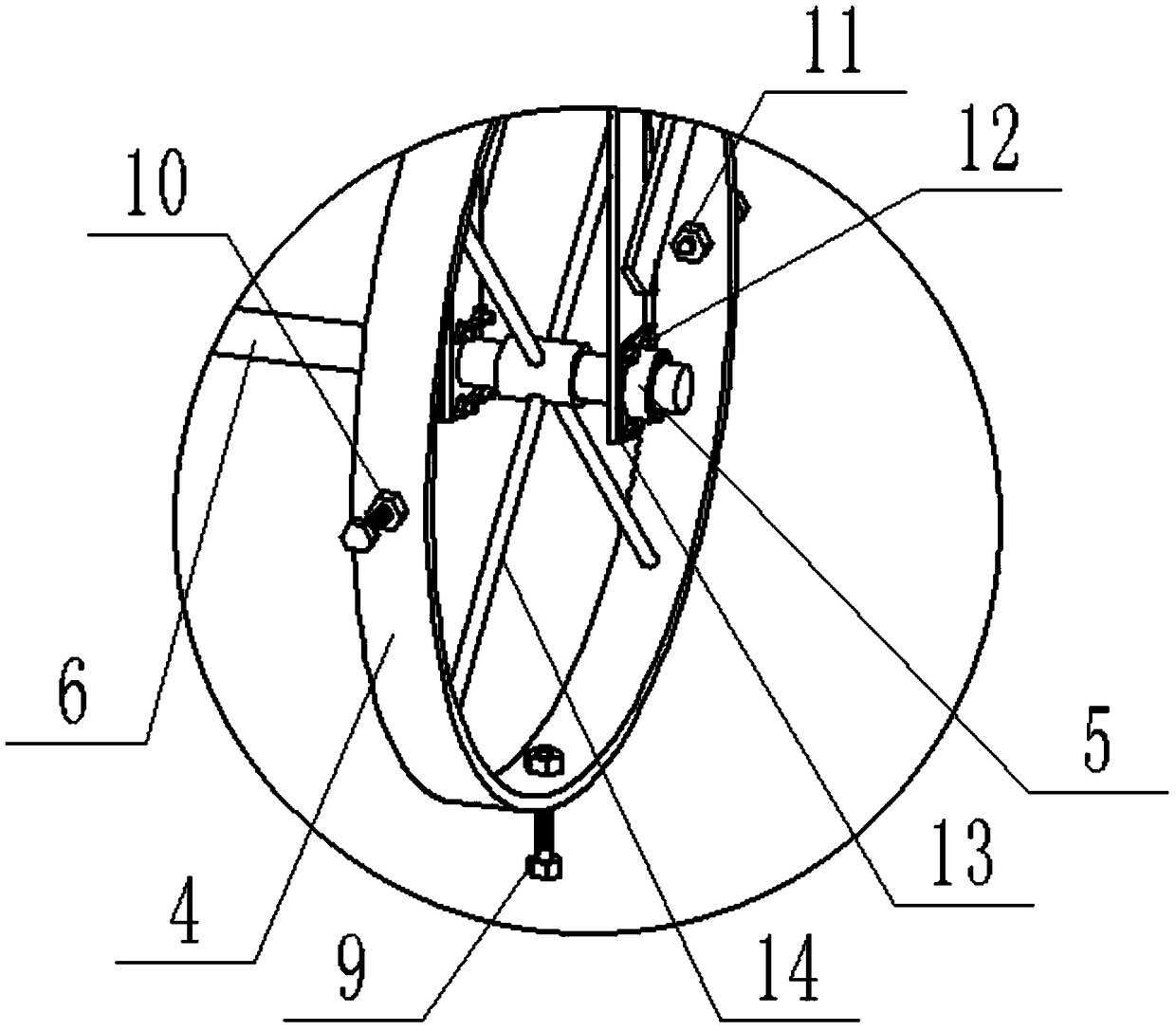

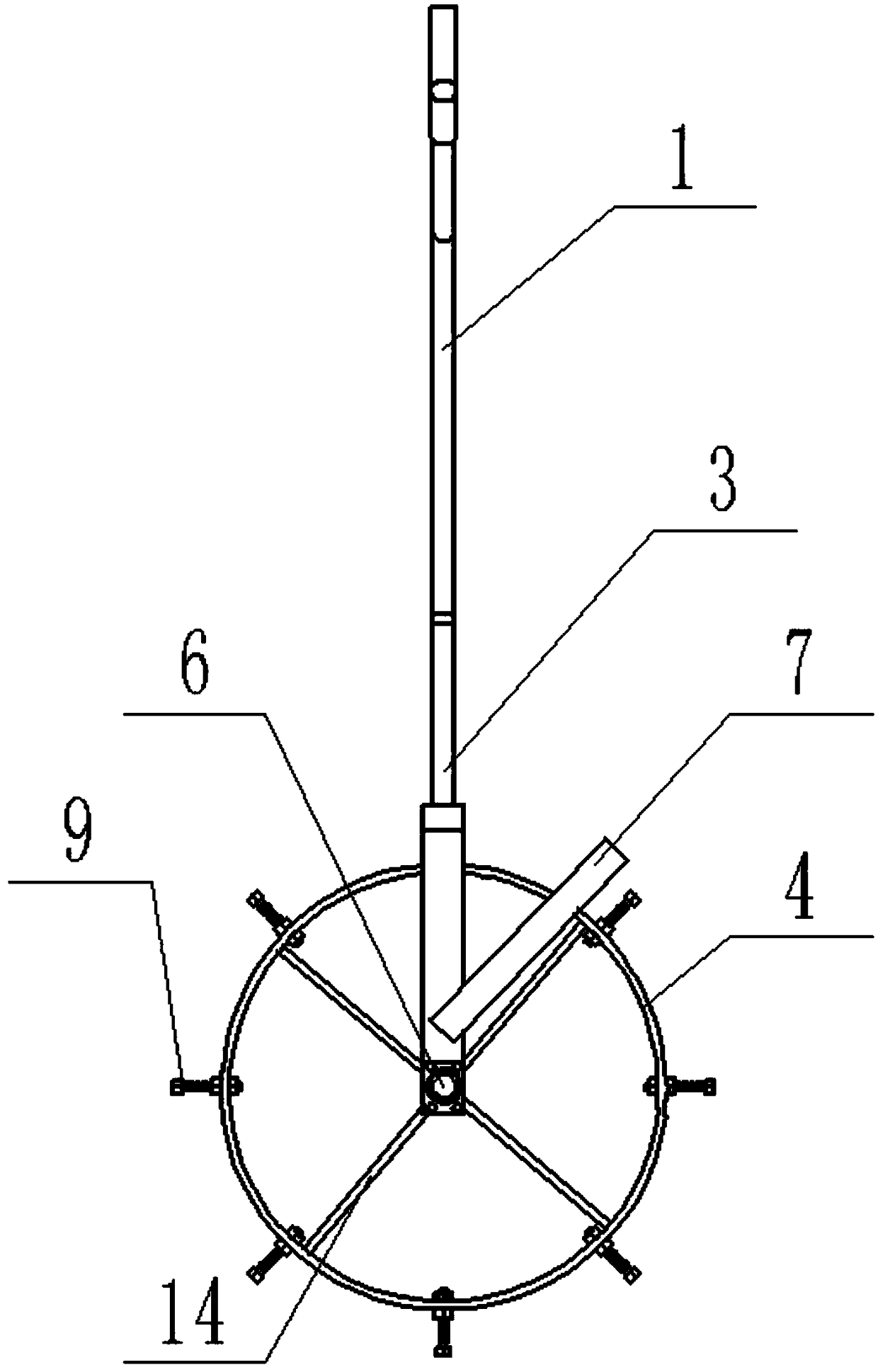

Adjustable smoke equidistant inker

InactiveCN106304916BShort distance between plantsRigid adjustment is accurateTransplantingEngineeringEquidistant

The invention provides an adjustable tobacco equidistant dotting machine including handle, bracket and roller. Beam is set between the handle and bracket, the lower end face of the handle is connected with the upper end face of the beam, the bracket is located at the lower side of both ends of the beam, the upper end surface of the bracket is connected with the lower end face of the beam, a fixing axle is set at the lower end of the bracket, bearings are set at both left and right sides of the bracket on the fixing axle, the roller is located at the lower end of the bracket on the fixing axle, and bolts I are set along the radial direction on the roller evenly. The adjustable tobacco equidistant dotting machine provided by the invention has high accuracy, which can satisfy the principle that tobacco location based on three points with low production cost.

Owner:SHANDONG LINYI TOBACCO

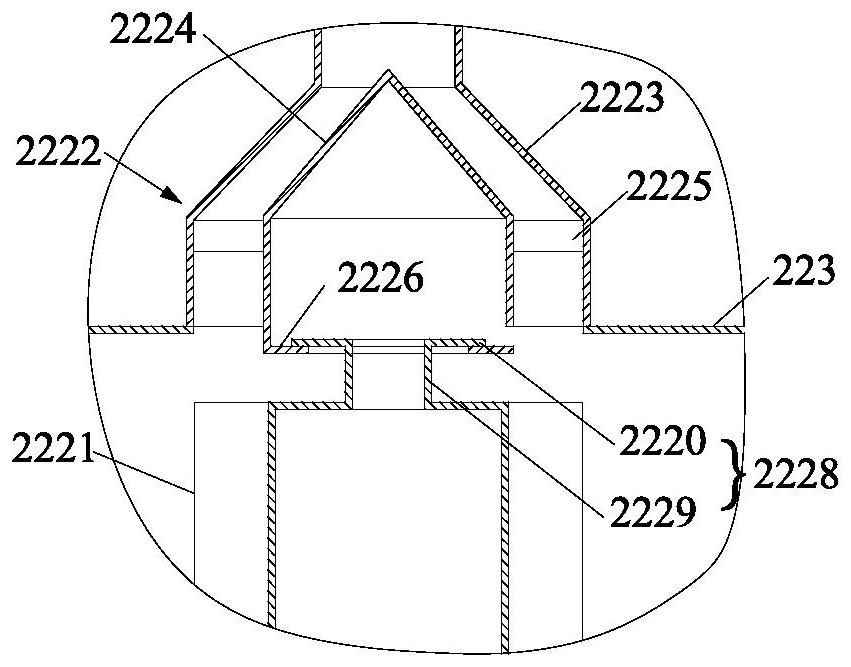

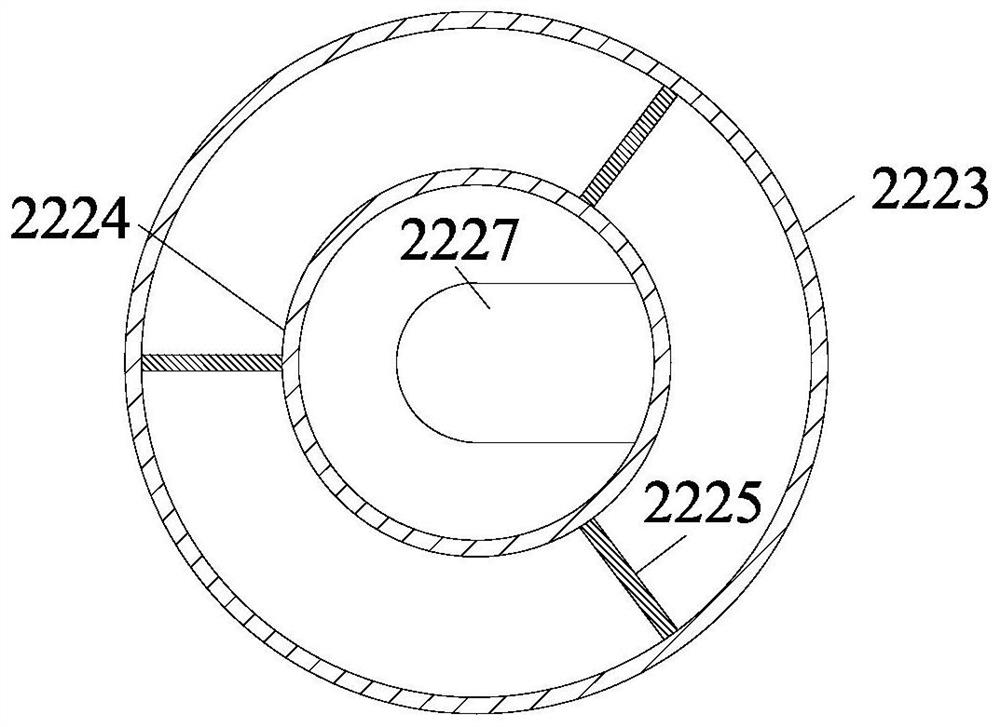

Sealed feeding device and container

PendingCN113978868APrevent flying phenomenonReduce pollutionFlexible bulk container emptying systemsBags openingEngineeringMechanical engineering

The invention relates to a sealed feeding device which comprises a feeding assembly and a dust remover. The feeding assembly comprises a packaging bag and a feeding cover, the feeding cover comprises a base and a top plate, the base is provided with a feeding channel and an air outlet, the top plate is provided with a feeding port, the feeding channel of the base is opposite to the feeding port of the top plate, and the base and the top plate are connected through a telescopic part. The telescopic part can extend or retract in the axial direction of the telescopic part so that the distance between a feeding channel opening of the base and a top plate feeding opening is increased or decreased, a packaging bag can be fixed between a feeding channel of the base and the top plate feeding opening, the dust remover comprises a box body and a filtering assembly, an inlet and an outlet are formed in the box body, and the filtering assembly is arranged in the box body. The air outlet of the base is communicated with the inlet of the box body through a connecting pipeline. According to the invention, the phenomenon of material spilling or dust flying in the feeding process can be prevented, the pollution to the environment and the influence on human health are reduced, the structure is simple, operation is convenient, and the feeding efficiency is improved.

Owner:TAIKANG KITCHEN SCI TECH SUZHOU CITY

Building wall grinding device

InactiveCN108115485APrevent flying phenomenonKeep healthyGrinding wheel securing apparatusGrinding/polishing hand toolsArchitectural engineering

The invention discloses a building wall grinding device. The building wall grinding device is composed of a grinding head and a supporting rod, wherein the grinding head consists of a dustproof device, a handgrip, a connecting device connected with the supporting rod, pressing devices used for pressing abrasive cloth and a pressing table used for placing the abrasive cloth; the dustproof device isarranged at the periphery of the pressing table; the dustproof device consists of a cover plate, baffle plates and a material receiving box; the material receiving box used for receiving dust is arranged on the upper surface of the baffle plate at the upper side; a pressing slot is formed in the surface of the cover plate; pressing teeth for preventing the abrasive cloth from sliding are arrangedin the pressing slot; the two ends of the pressing slot are equipped with supporting blocks; the supporting blocks are fixedly connected with the cover plate; a pressing rod is arranged between slideslots; the pressing rod is in sliding connection with the slide slots; and the lower end of the handgrip is rotatably connected with the supporting rod through the connecting device. The device guarantees health of construction staff, can intensively collect and treat dust, and reduces follow-up workload.

Owner:惠水县凡趣创意科技有限公司

Powdery material conveying system for producing Chinese herbal medicine toothpaste

ActiveCN112407962AReduce work costsImprove work efficiencyCocoaBulk conveyorsProcess engineeringChinese herbs

The invention discloses a powdery material conveying system for producing Chinese herbal medicine toothpaste. The powdery material conveying system for producing the Chinese herbal medicine toothpastecomprises a material mixing device, a gas-powder separation device, a grinding device and a material suction device; the material suction device comprises a telescopic suction head and a material suction pipe; one end of the material suction pipe is communicated with the telescopic suction head; the other end of the material suction pipe is communicated with one side of the gas-powder separationdevice; the bottom of the gas-powder separation device is communicated with the material mixing device; the top of the gas-powder separation device is communicated with an air blower; a granularity sensor is arranged on the material suction pipe; and the material suction pipe is communicated with a grinding device. According to the powdery material conveying system for producing the Chinese herbalmedicine toothpaste, the working cost can be saved, the working efficiency can be improved, the manufacturing cost can be saved, and full automation is achieved; and raw material conveying in a closed environment is adopted, therefore, cleanliness of raw materials is guaranteed, the dust flying phenomenon is prevented, and green production is achieved.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com