Mining spiral feeder

A spiral feeding and mine-used technology, which is applied in mining equipment, shaft lining, tunnel lining, etc., can solve the problems of low effective utilization rate of concrete spraying machines, high labor intensity of workers, and inability to continuously supply materials, etc., and achieve environmental improvement , reduce operating personnel, and save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

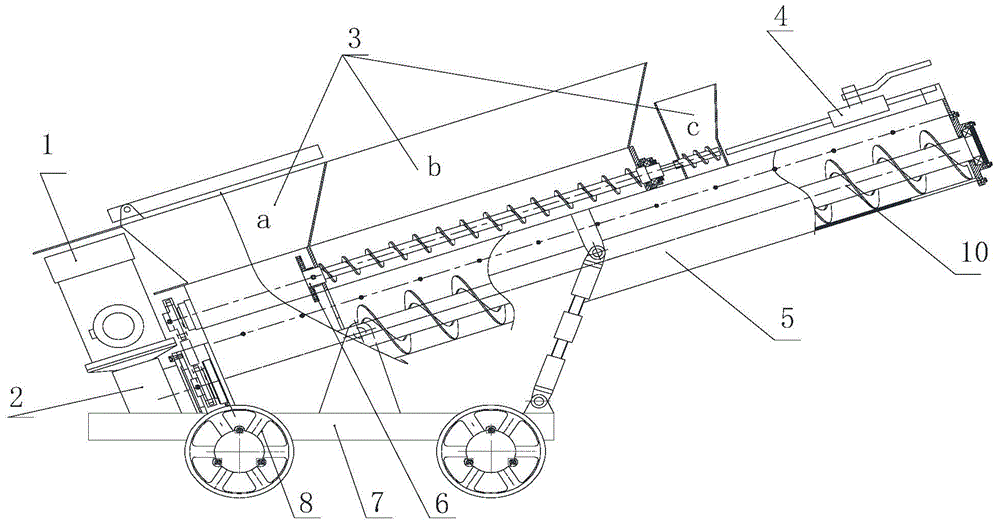

[0026] combined with Figures 1 to 3 The specific embodiment of the present invention is described further:

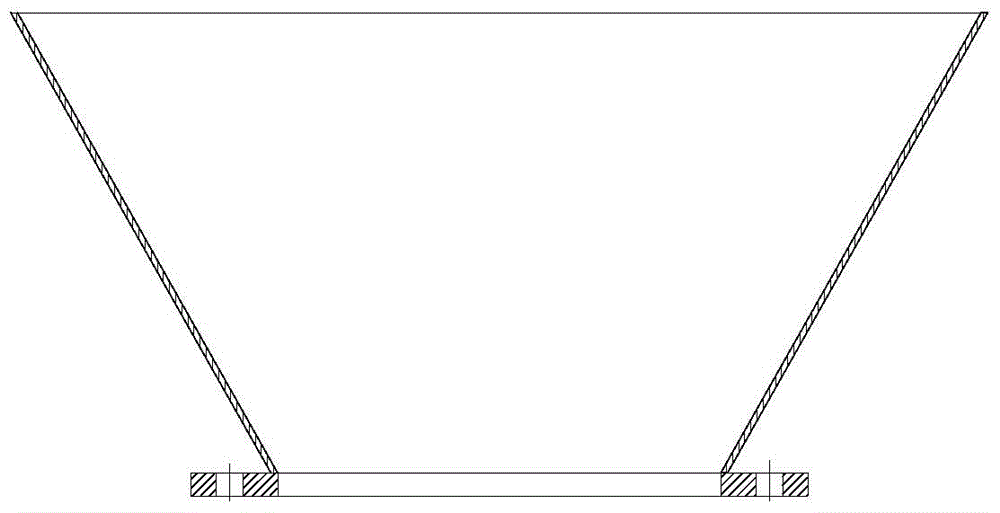

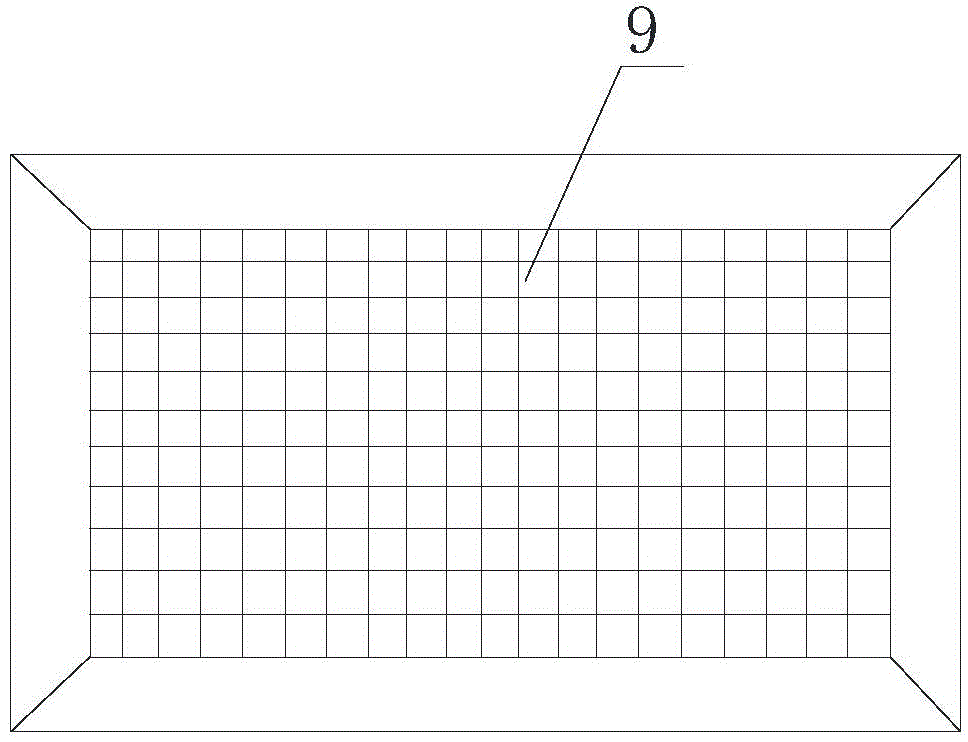

[0027] A mining spiral feeding machine is composed of a fuselage, a vehicle frame 7, and wheels 8. The fuselage is hinged on the vehicle frame 7, and the bottom of the vehicle frame 7 is symmetrically equipped with wheels 8 for advancing and retreating. The fuselage includes an explosion-proof motor 1, a batching mechanism 3, and a water spray device 4 on the same slope. The explosion-proof motor 1 is installed at the bottom of the fuselage. Feeding trough 5. The bottom of the batching mechanism is provided with a cam vibrating screen mechanism 6, and the bottom of the cam vibrating screen mechanism 6 is provided with a stirring and conveying trough 5, and the batching mechanism 3 communicates with the stirring and conveying trough 5 through the cam vibrating mesh mechanism 6. The water spray device 4 is located at the top of the fuselage, and the water spray device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com