Patents

Literature

271 results about "Weather proofing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

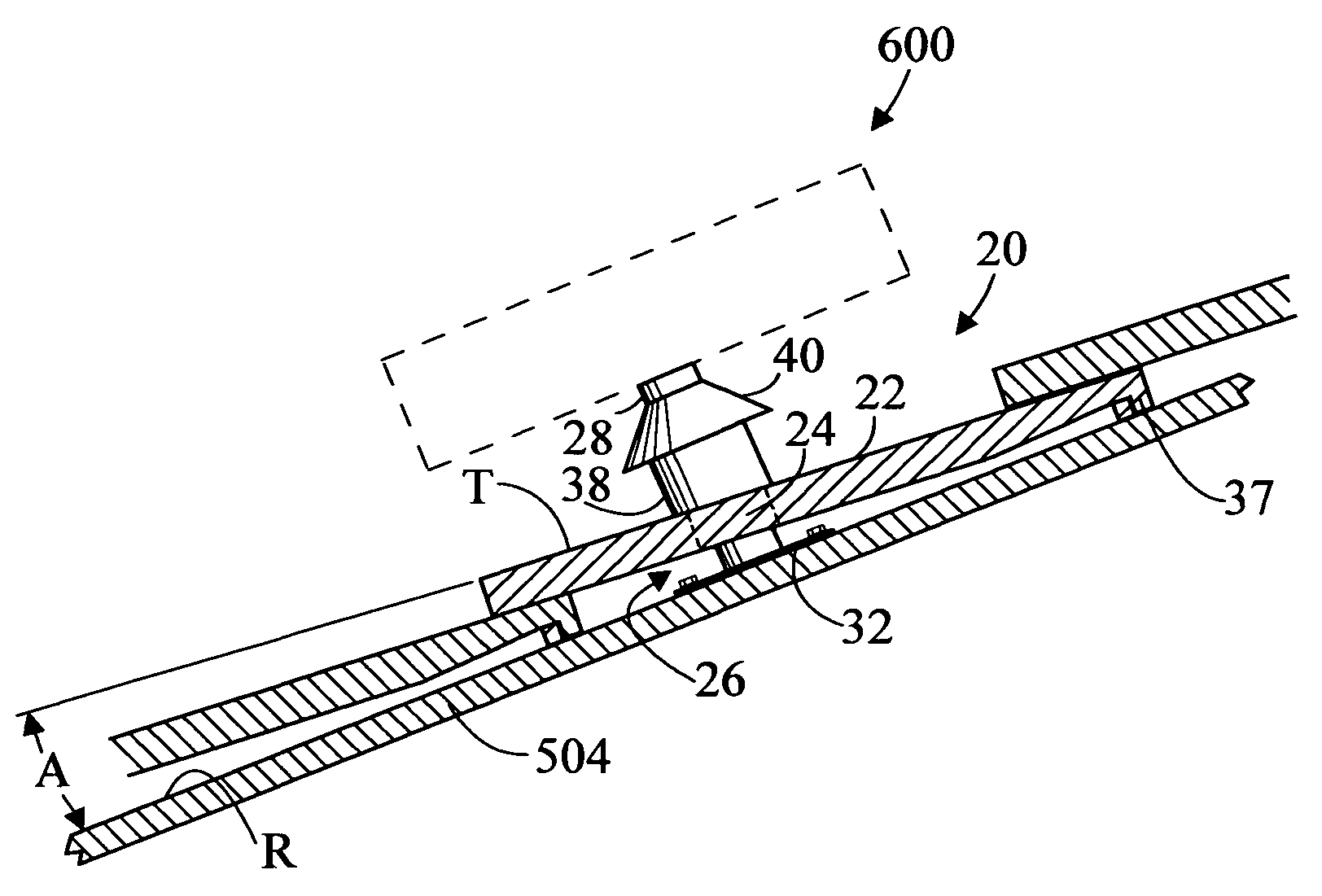

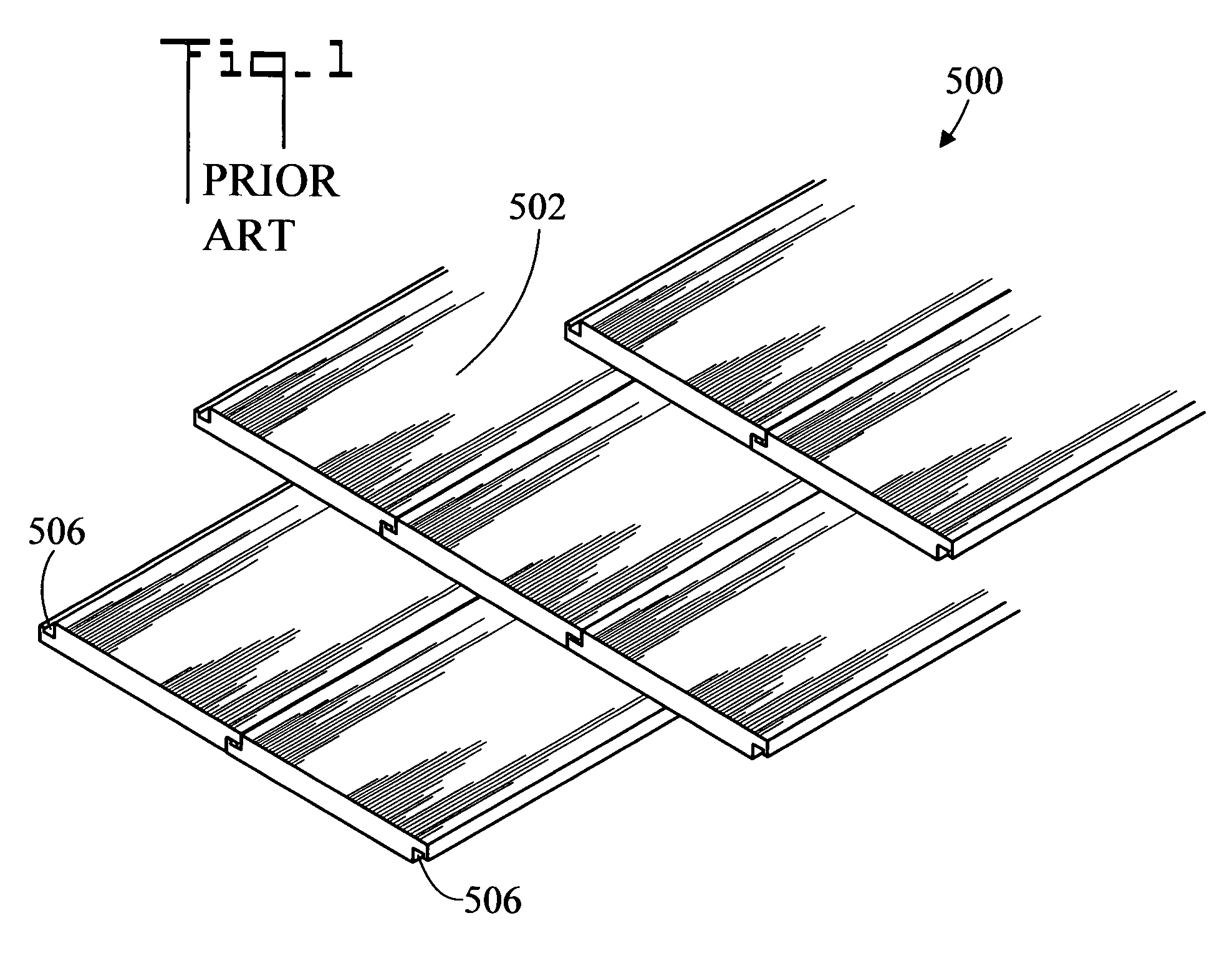

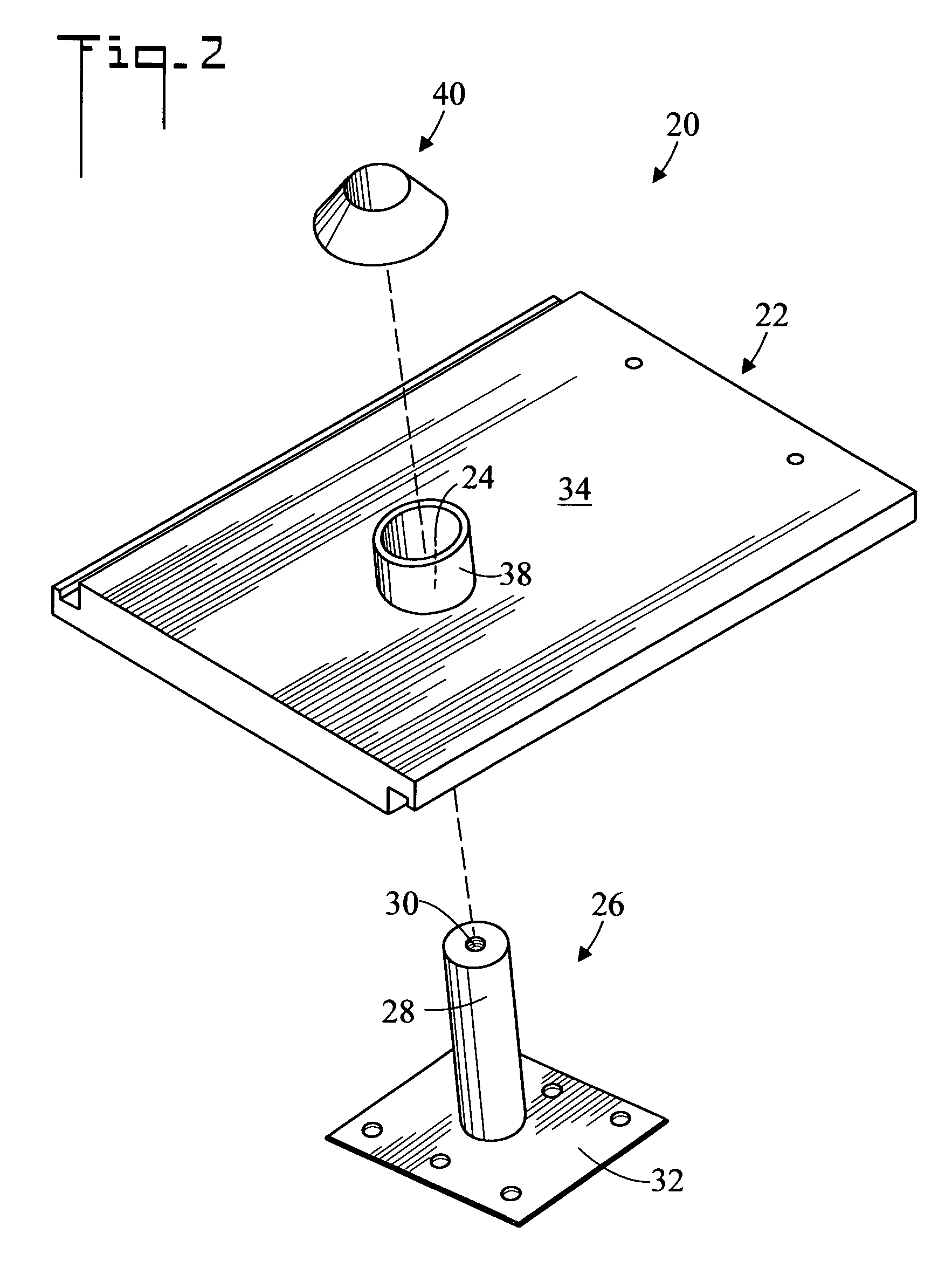

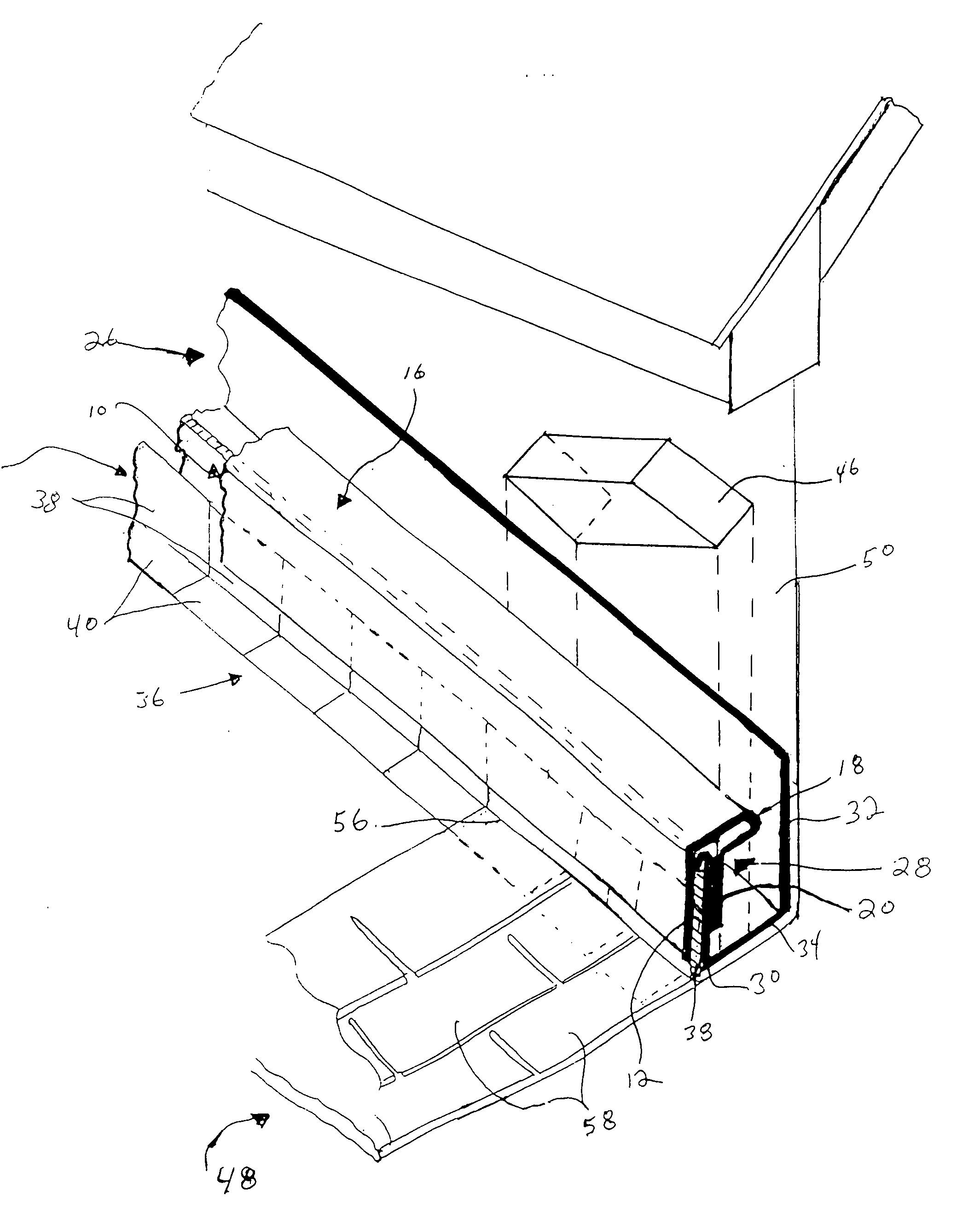

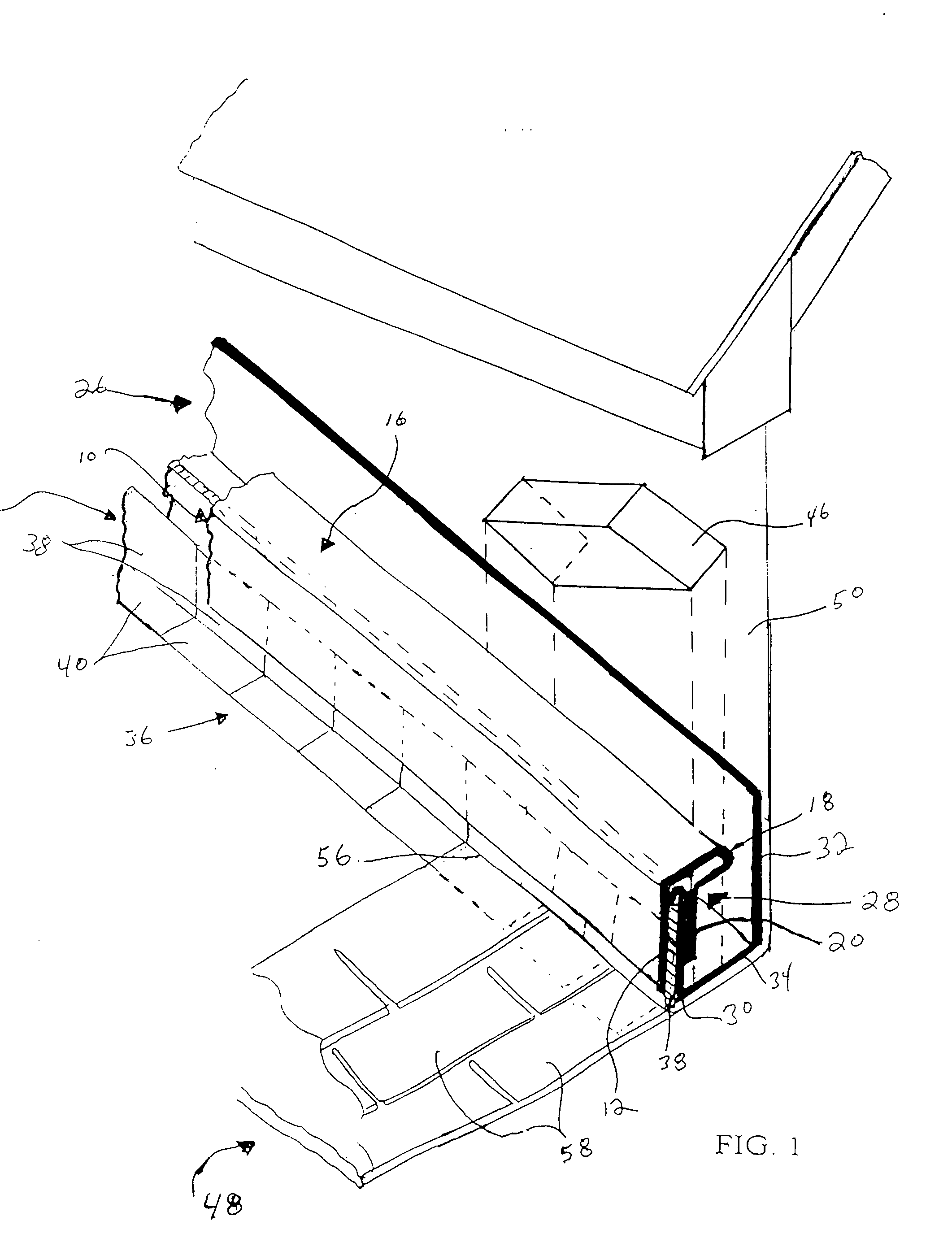

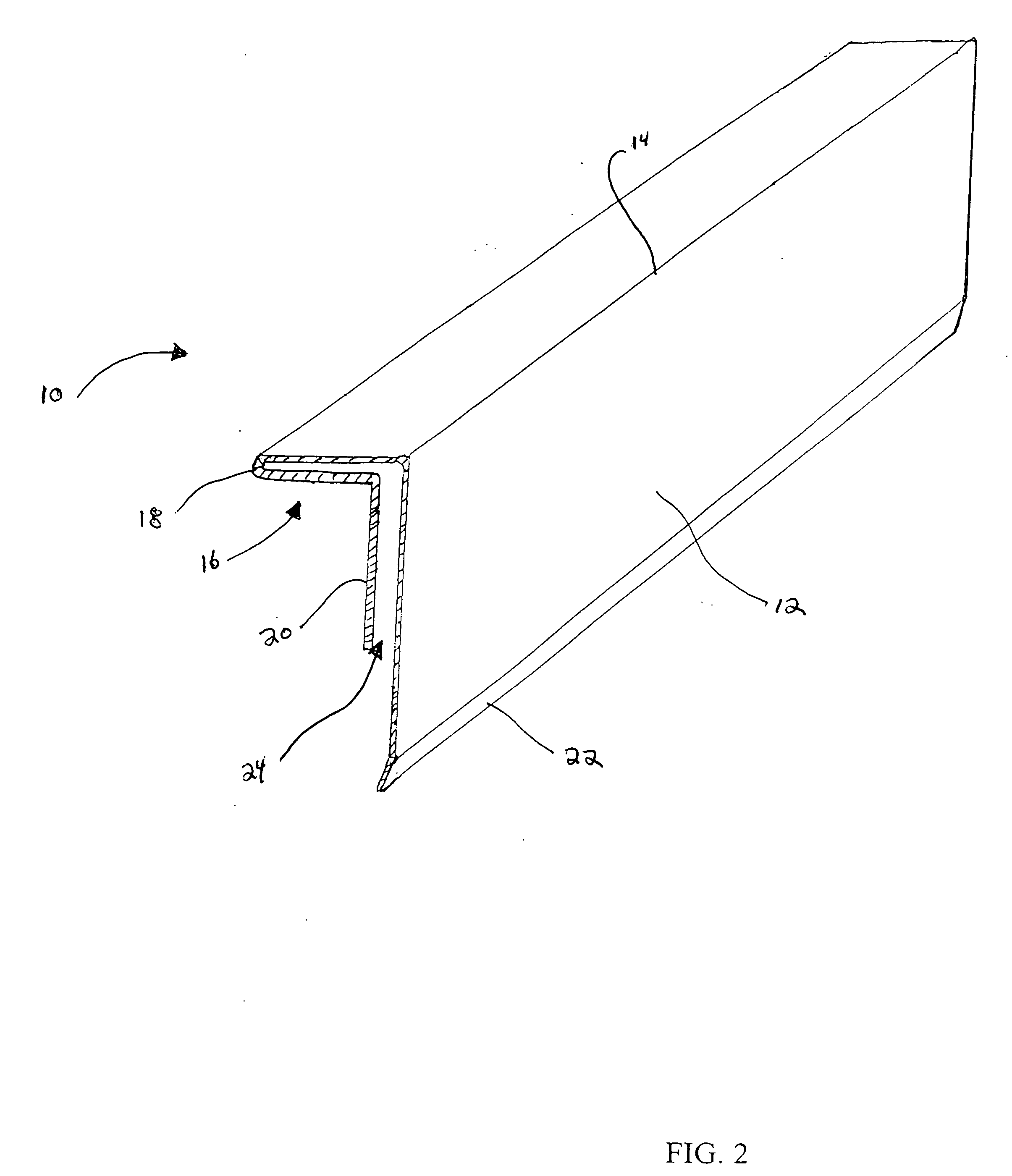

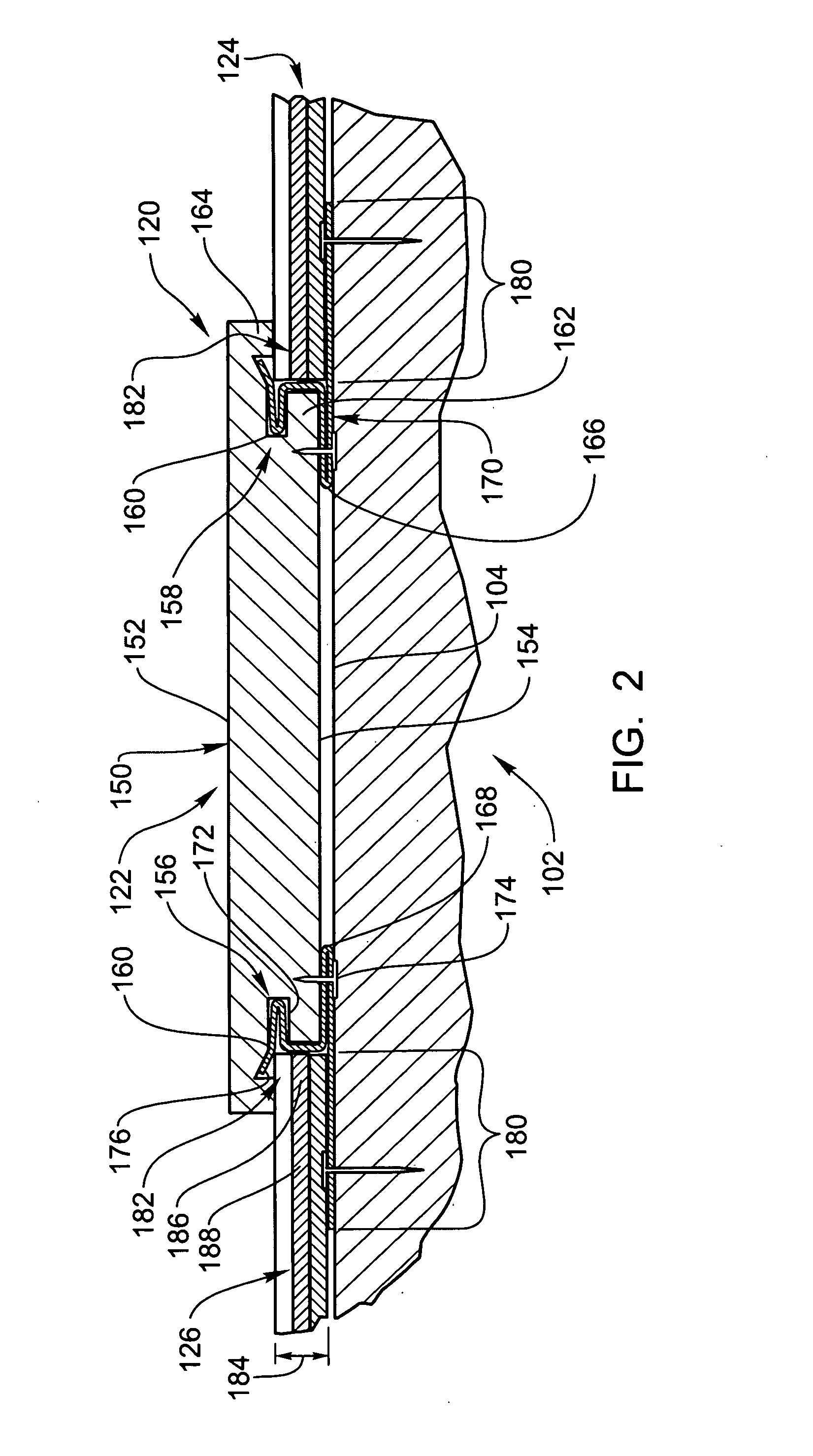

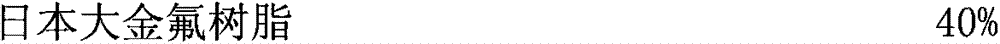

Method for installing a stanchion on a tile roof and system therefor

A method and apparatus for installing a stanchion on a tile roof includes a tile which has an aperture and a stanchion which fits through the aperture. An existing roof tile is removed and the stanchion is connected to the roof sheathing at the place of removal. The tile is then placed over the stanchion so that the stanchion project through the aperture. In an embodiment of the invention, a sleeve surrounds the aperture and a seal provides a weather proof seal between the stanchion and the sleeve.

Owner:WENCON DEV INC

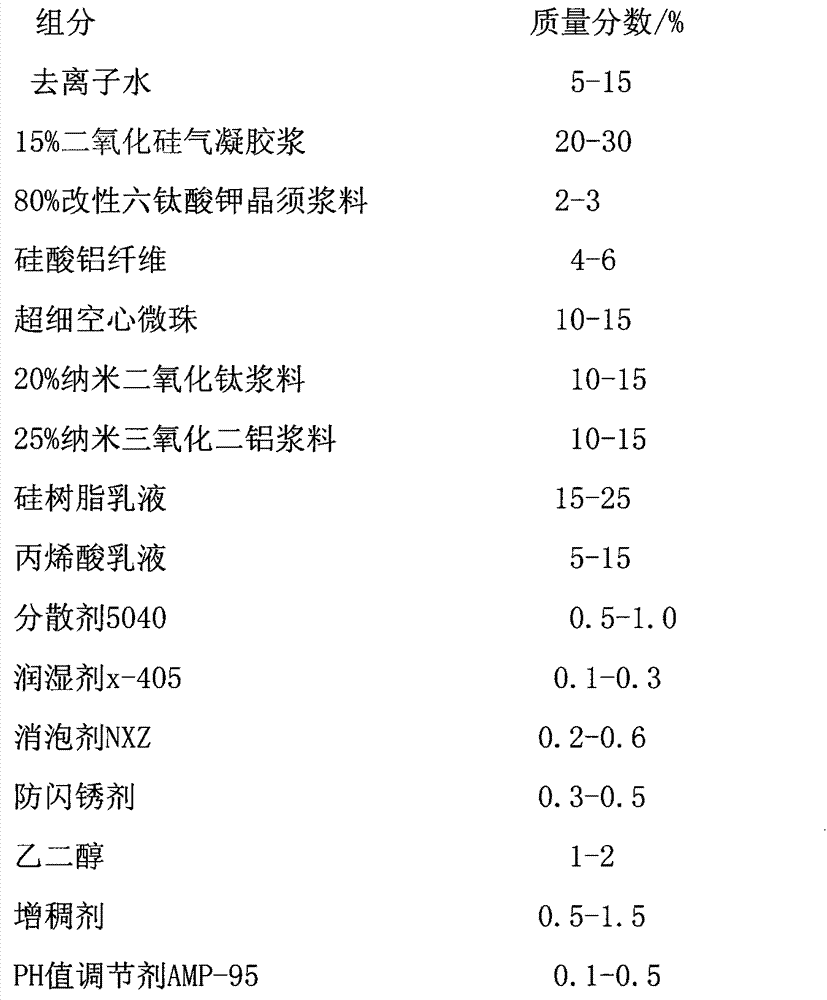

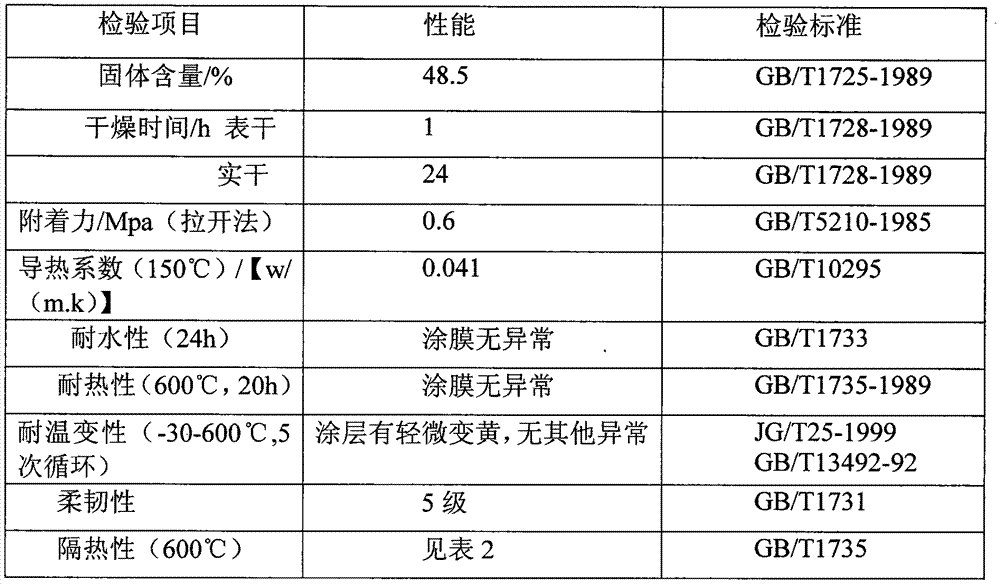

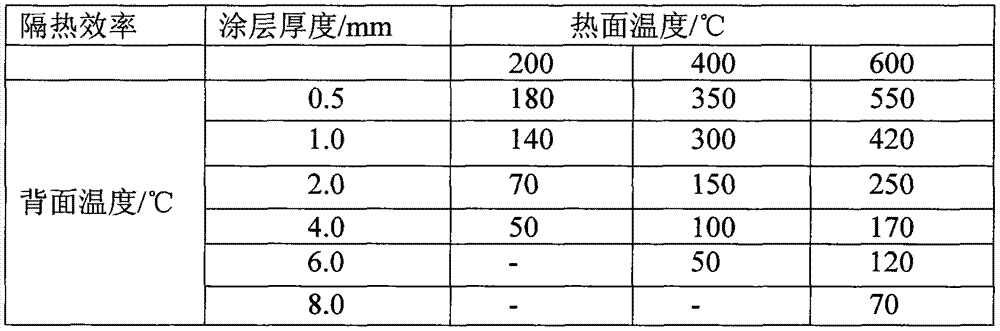

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

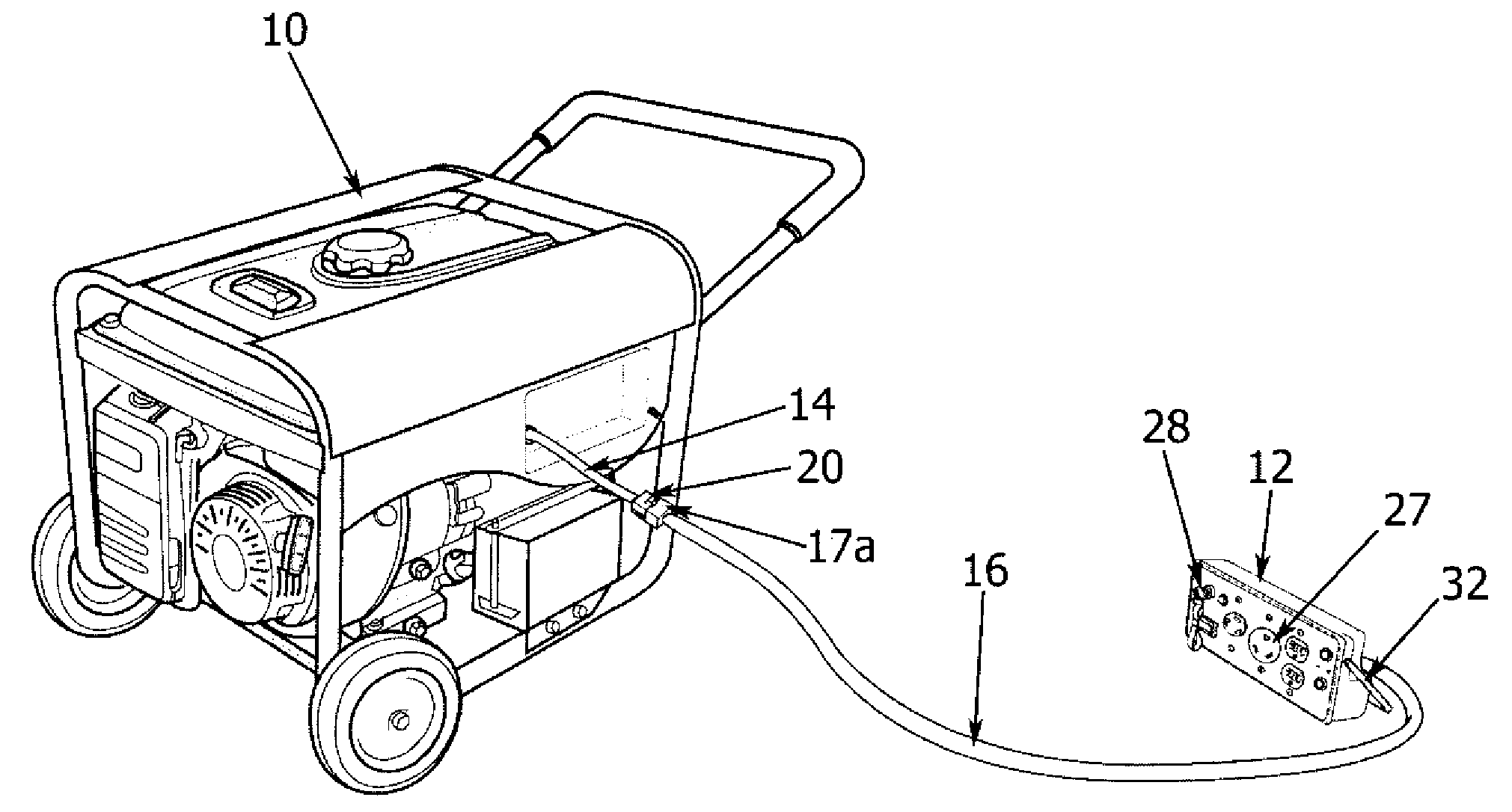

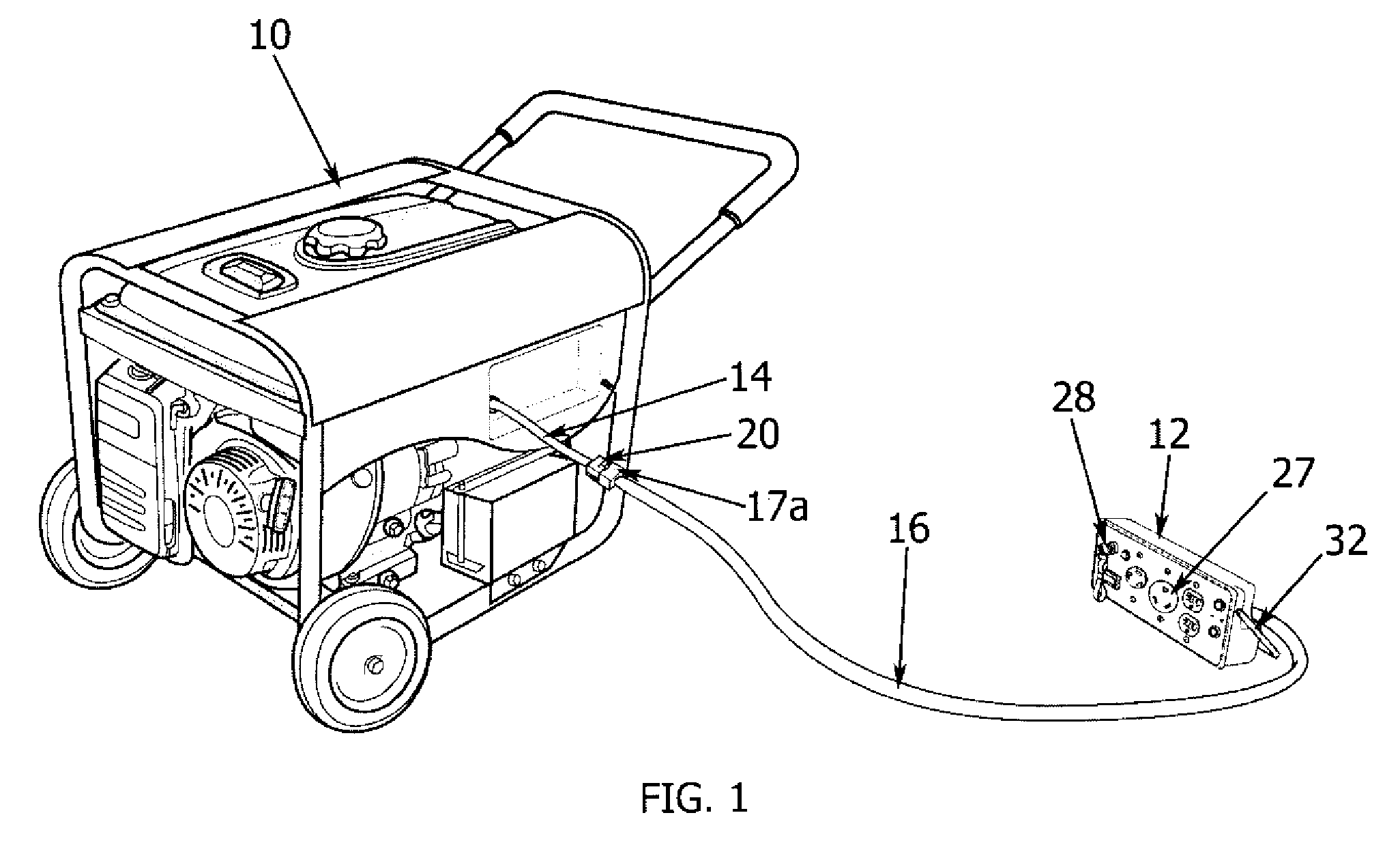

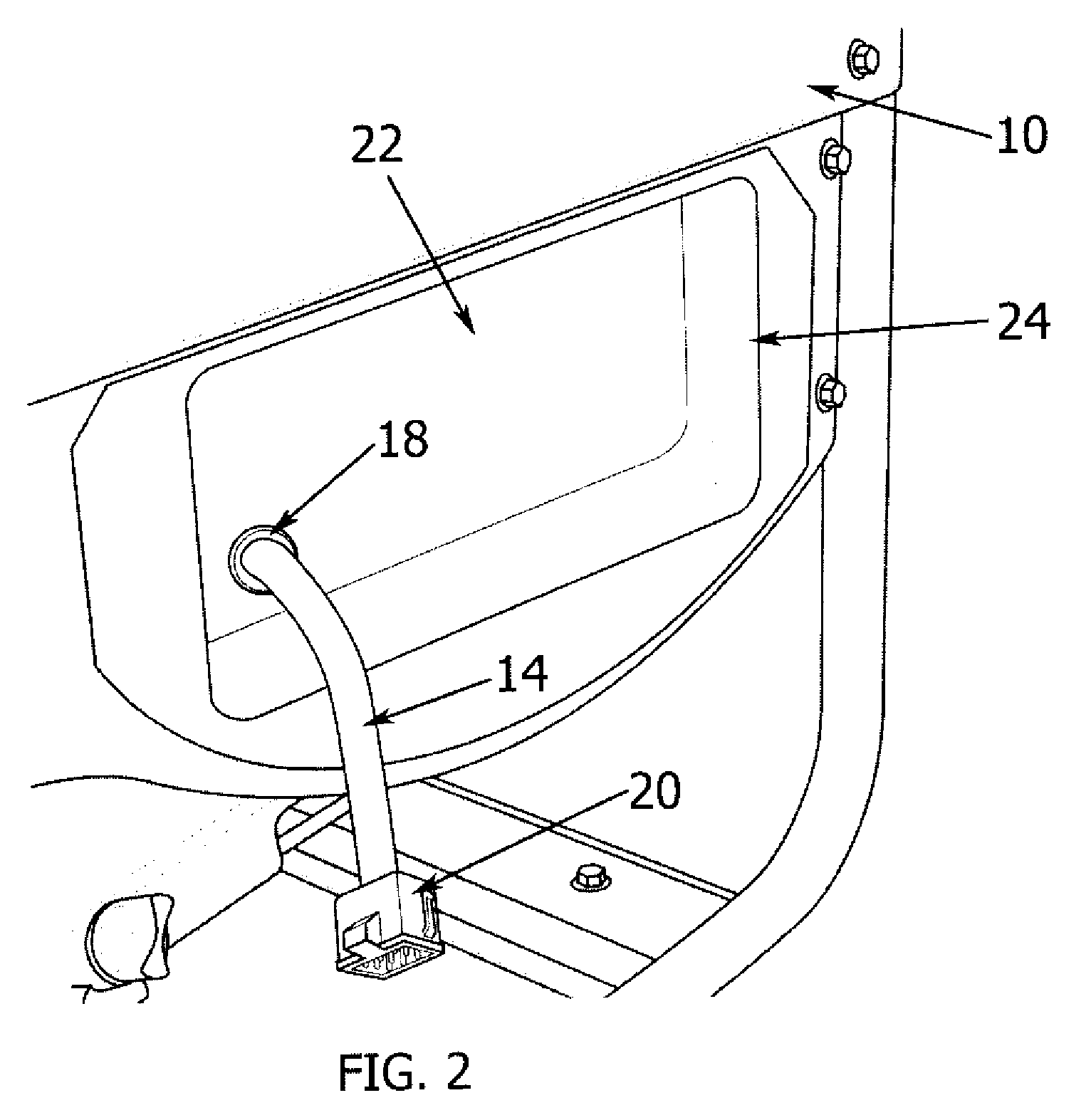

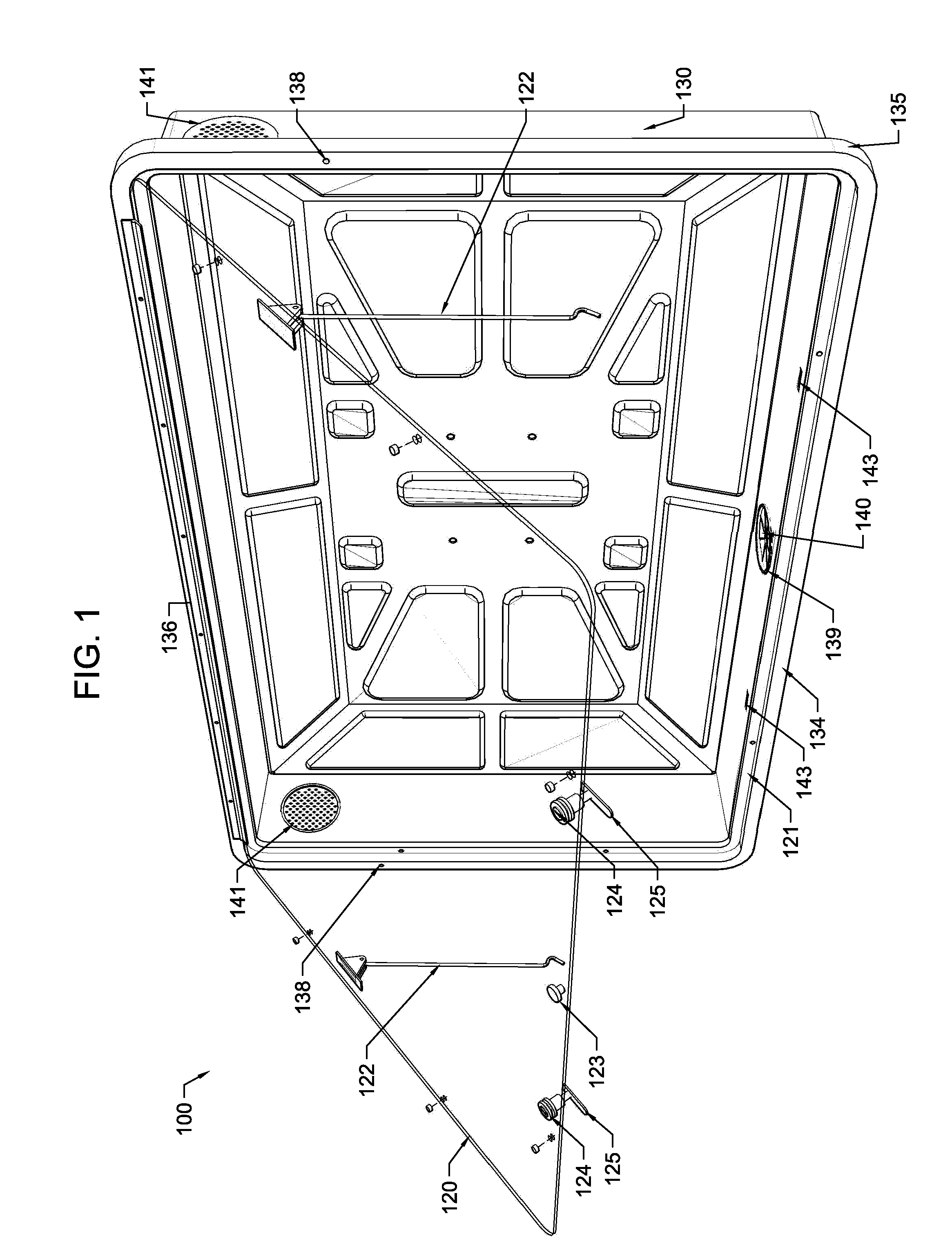

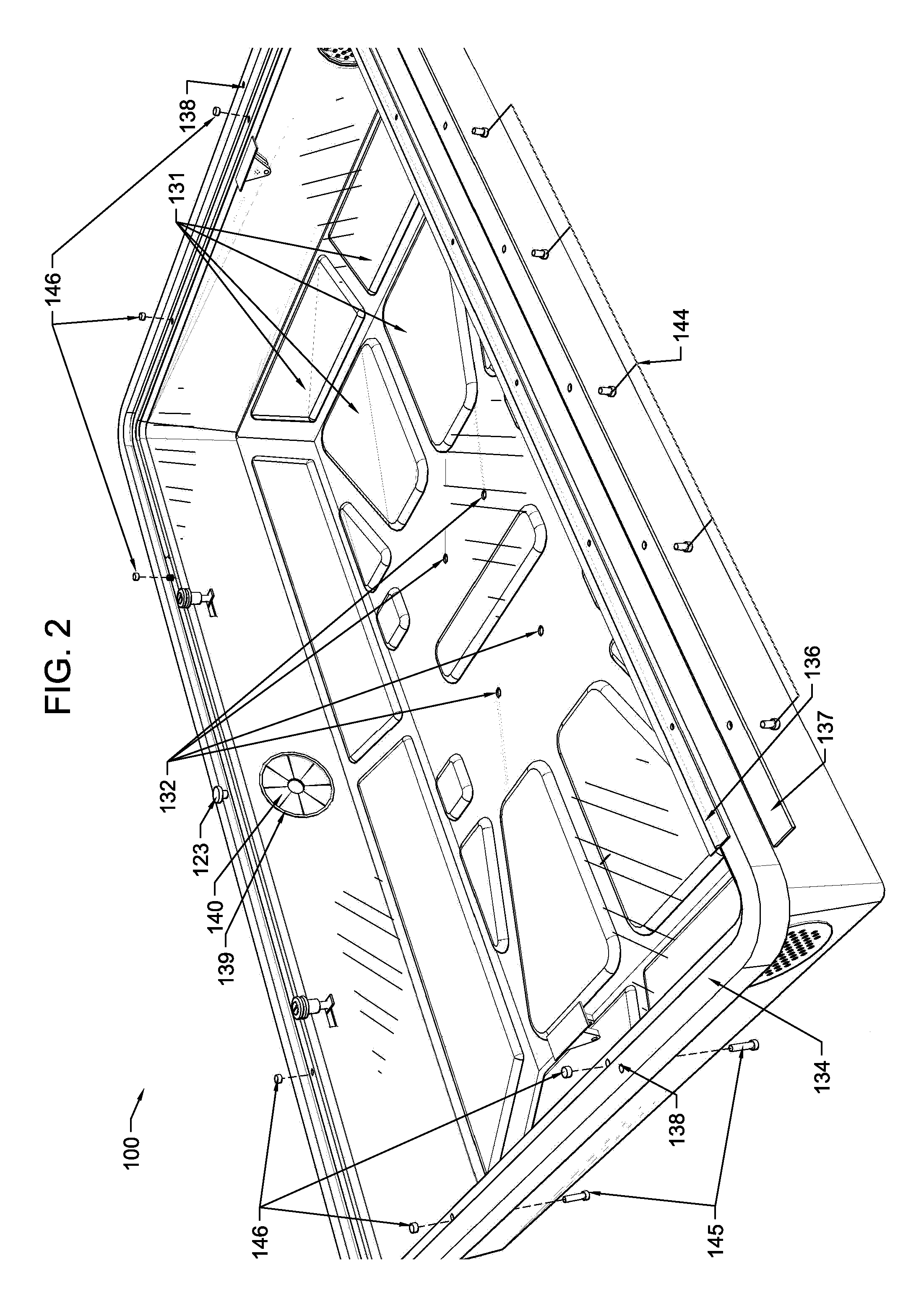

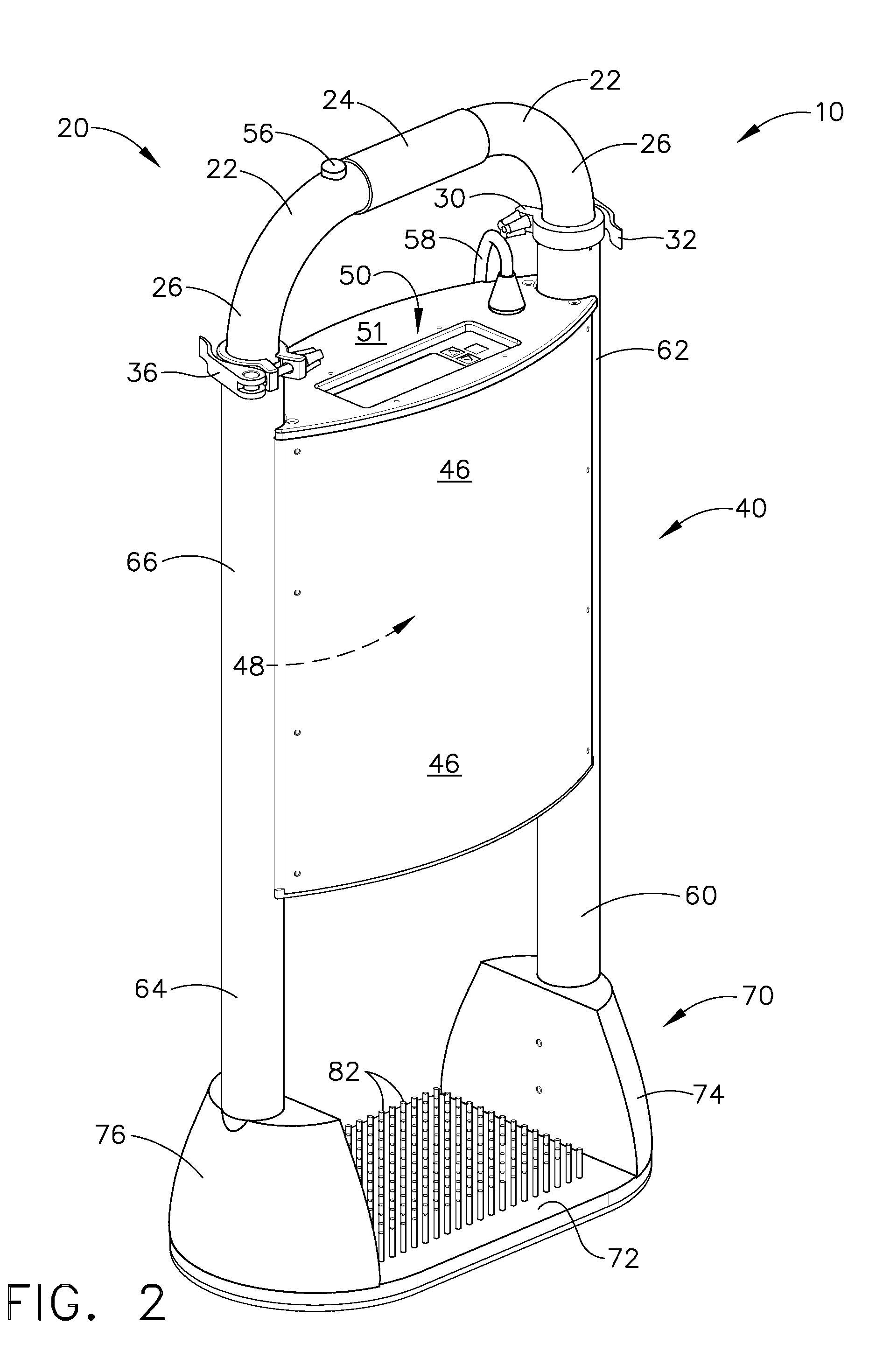

Portable generator having a detachable panel

InactiveUS20100060015A1Secure couplingSolve insufficient storage spaceMachines/enginesMechanical energy handlingElectric power transmissionRemote control

A portable generator is provided with a remote power source connection, and optionally also provided with remote control and / or monitoring features. The portable generator's control panel is partially or entirely removable from the portable generator. A short pigtail with a weatherproof multi-pin connection connects to the generator's wiring harness. The multi-pin connector on the pigtail allows the panel to be removably connected to the pigtail and the generator to be removably connected to an interconnecting cord. A longer interconnecting cord connects the removable panel to the generator, and transmits the power to the remotely locatable panel, along with transmitting any desired control aspects such as on, off, start, or circuit breaker re-set commands, and / or transmitting any desired monitoring information such as voltage, amperage, gas level, oil level, frequency of the generated power, circuit breakers, or operating time. But preferably the removable panel has all the power outlets supplied by all the electrical power generated by the portable generator.

Owner:CHAMPION POWER EQUIP

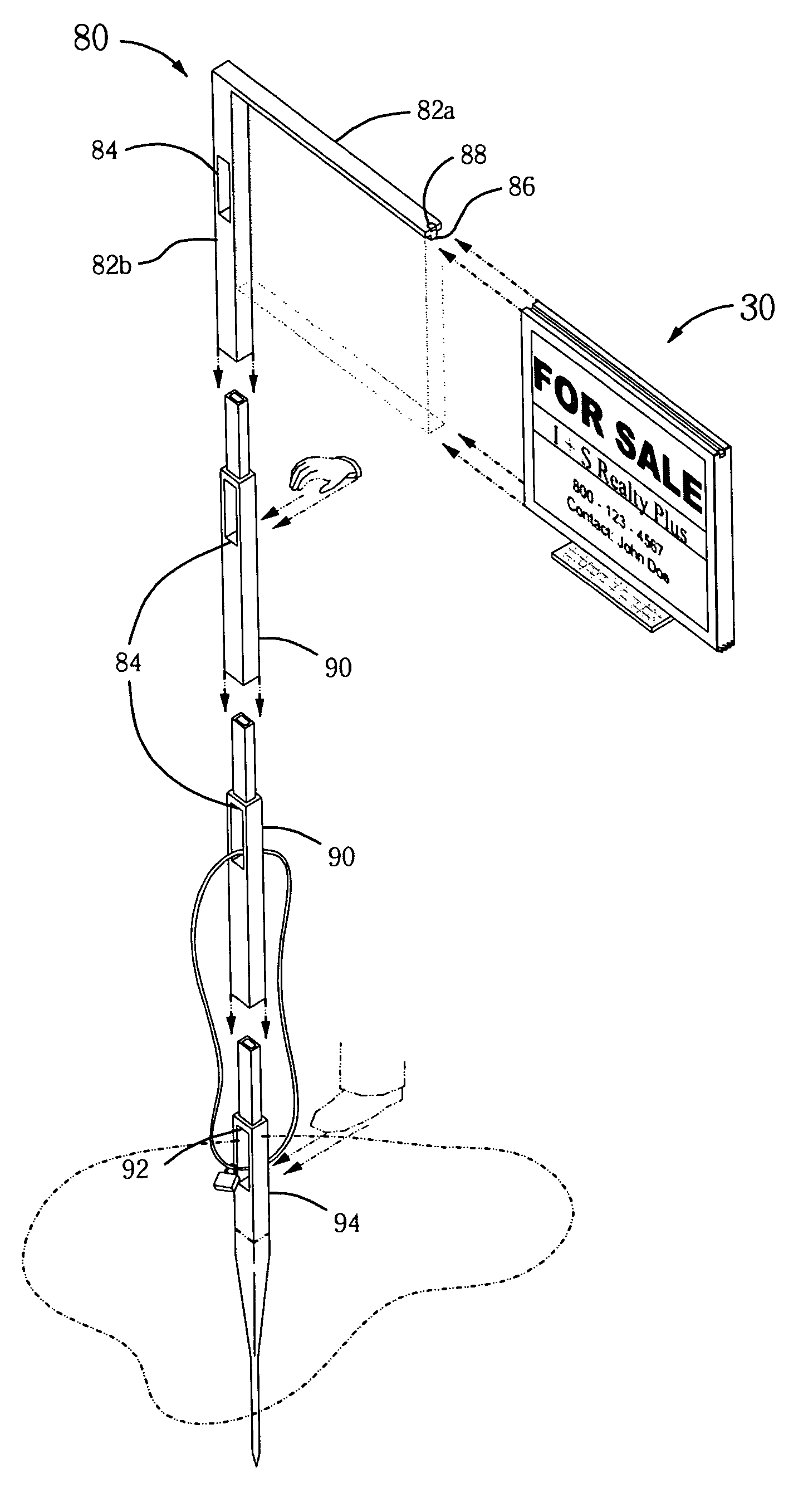

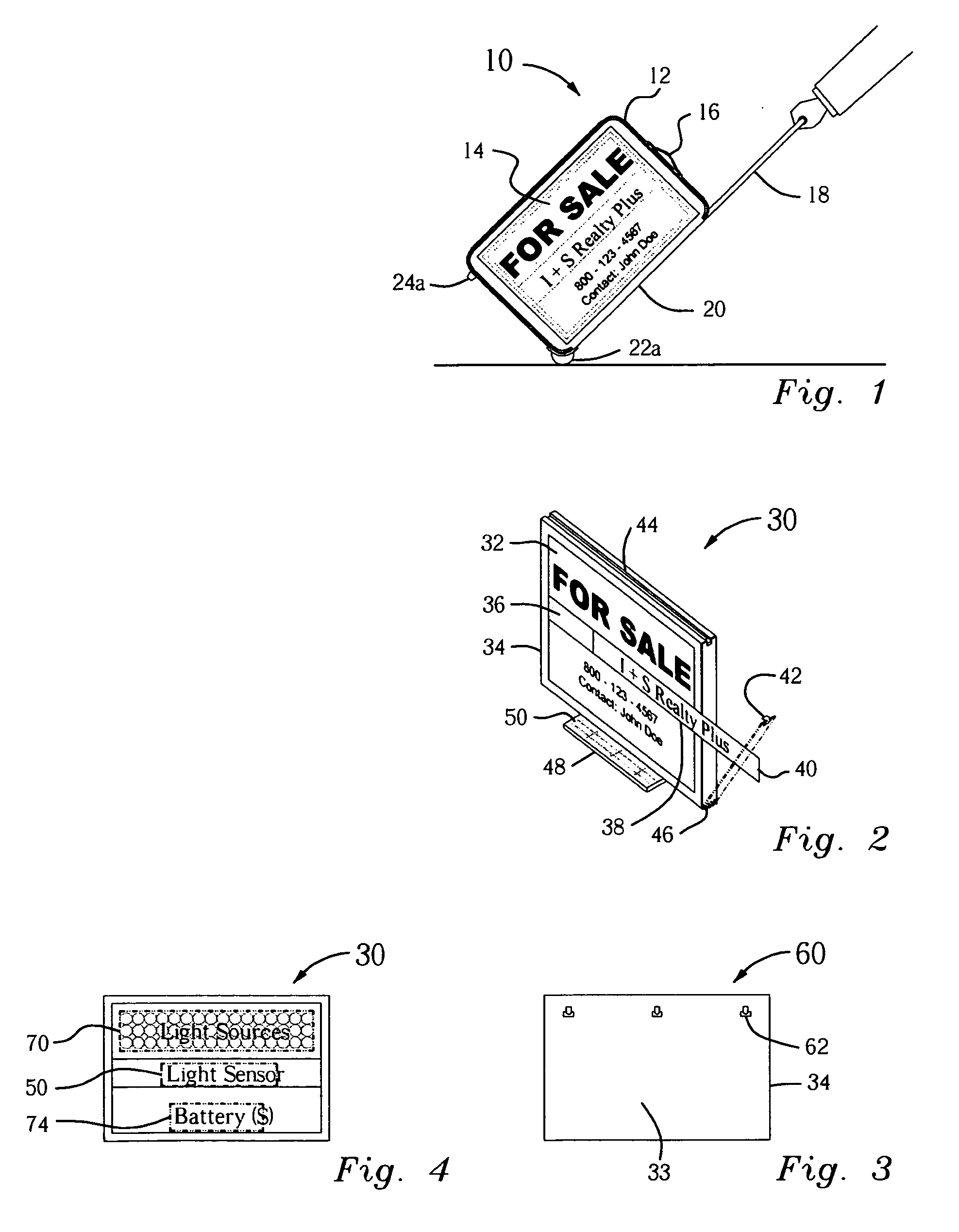

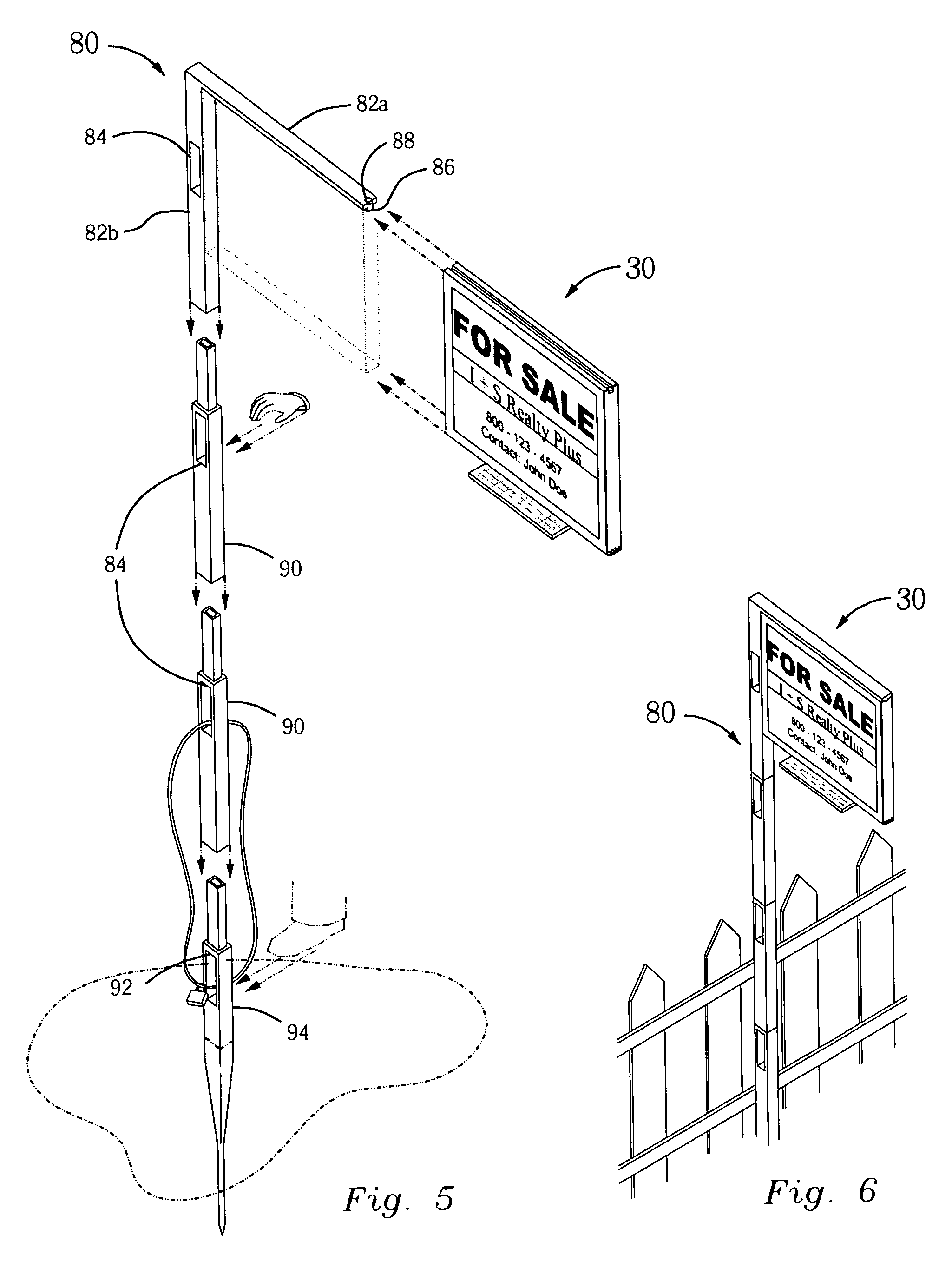

Portable illuminated real estate sign system

InactiveUS20060185203A1Easy to carry and assemble and installReduced vulnerability to and theftAdvertisingIlluminated signsAnti theftLight source

The portable illuminated real estate sign system consists of a carrying case, a sign, and a post. This solar powered illuminated sign is attached to a detachable post that has an anti-theft device. An accompanying bag is used for ease of transport and storage. The sign can be single- or double-sided, having a weatherproof casing, a plastic transparent front and back, and a hinged door to allow signage to be easily changed. Within the sign casing is a solar panel that collects solar energy to charge at least one rechargeable battery, energizing light sources to be turned on by a light sensor from dusk till dawn.

Owner:BITTLE IVY RENE +1

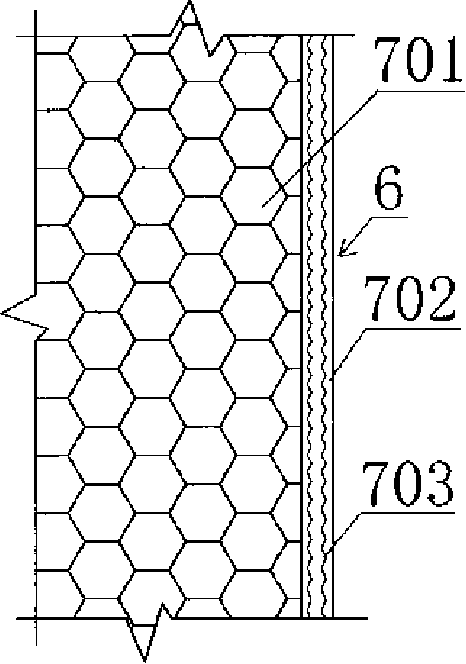

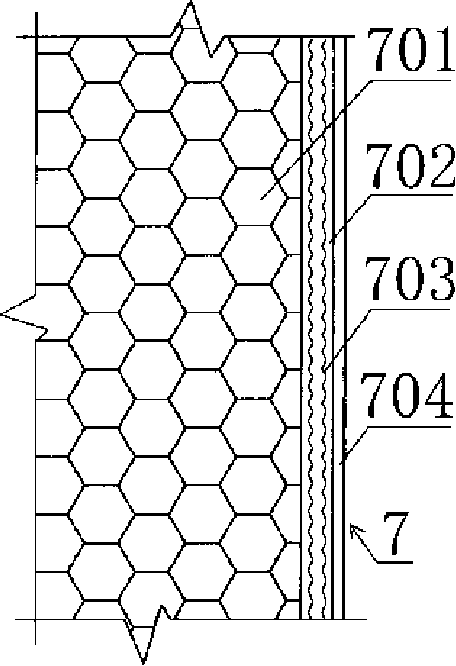

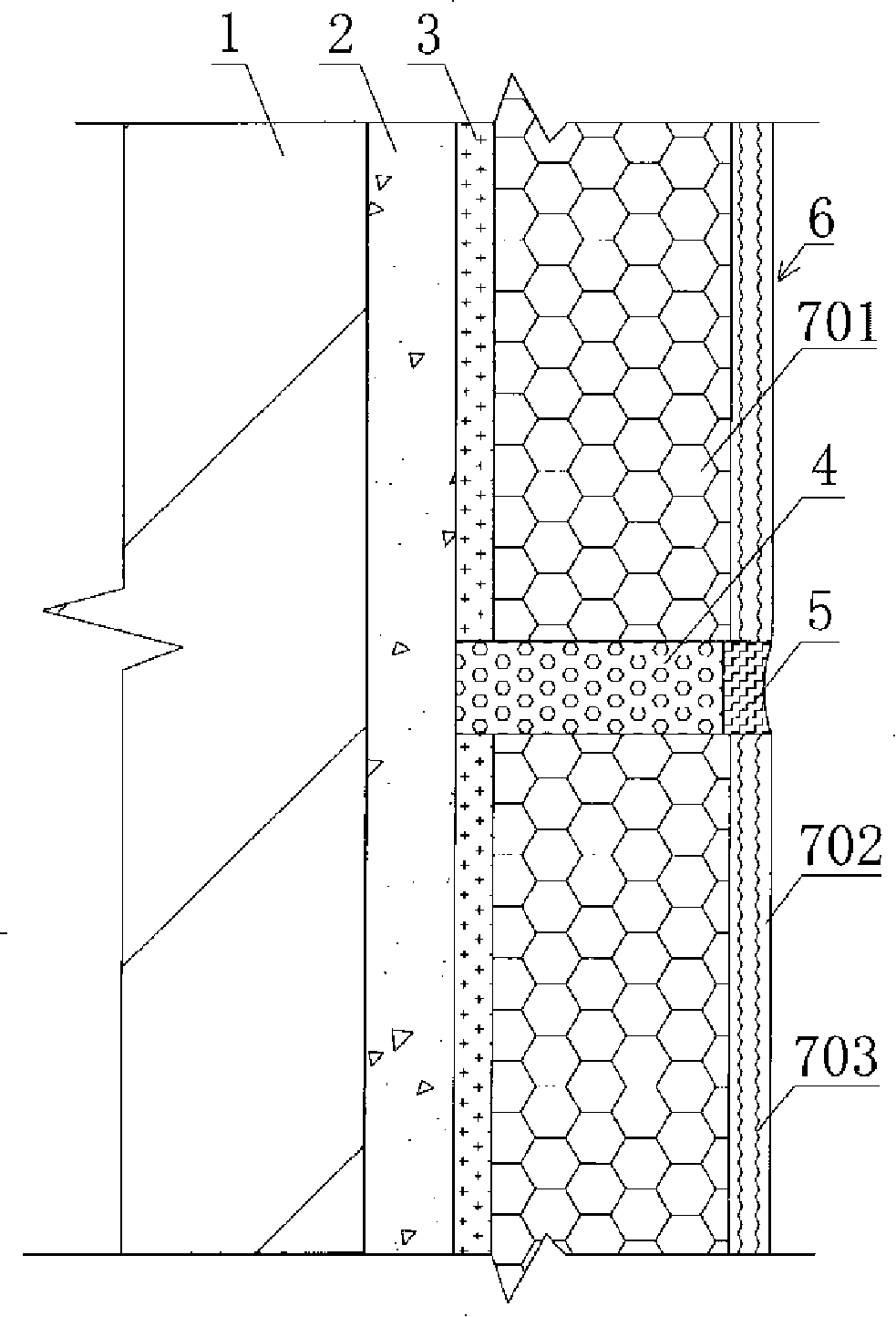

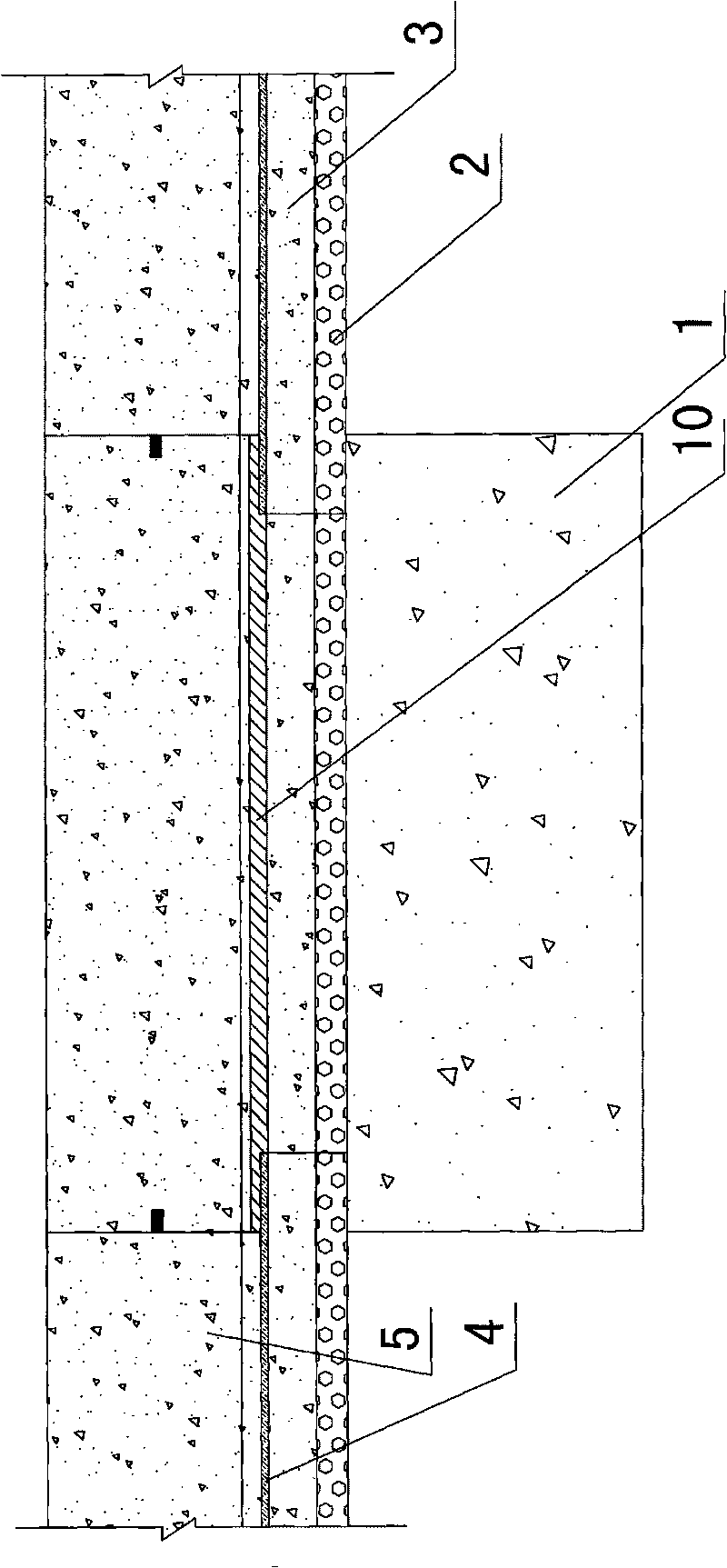

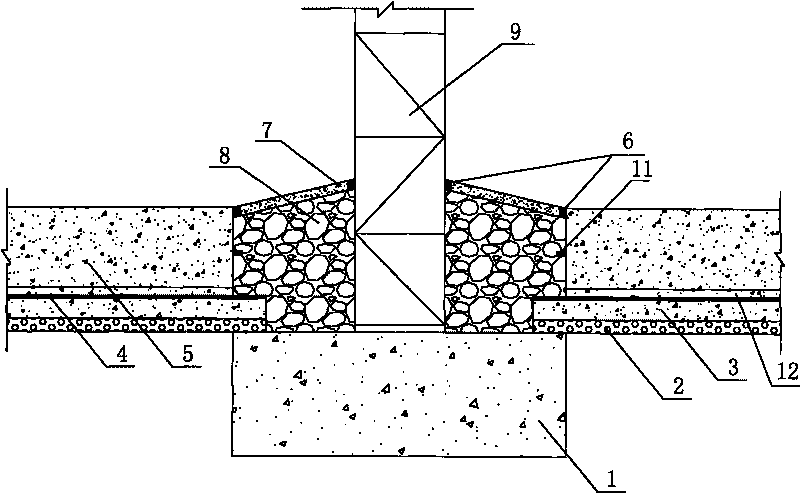

Direct-compress EPS inorganic clad plate and exterior outer-insulating system and construction method thereof

InactiveCN101158213AAvoid field workRapid productionCovering/liningsSolid waste managementComposite plateWeather proofing

The invention discloses an external insulation system and a construction method of a straight compressing EPS inorganic composite plate. The external wall firstly pre-produces the straight compressing EPS inorganic composite plate or a straight compressing EPS inorganic composite decorative board in a factory and compresses an inorganic composite enhancement layer onto a single-side of an expanded EPS plate by using a mechanical method; the outer surfaces of a base course wall of a building all adopt the EPS inorganic composite plate which adheres to a leveling blanket through bonding sands; the slab joint is pointed by jointing material and the outside of the jointing material is sealed again by weather proofing sealant; and a finish is arranged at the lateral of the system. The invention is characterized by the anti-crack, the good durability, the reliability and safety, the low cost and the fast construction.

Owner:余景春

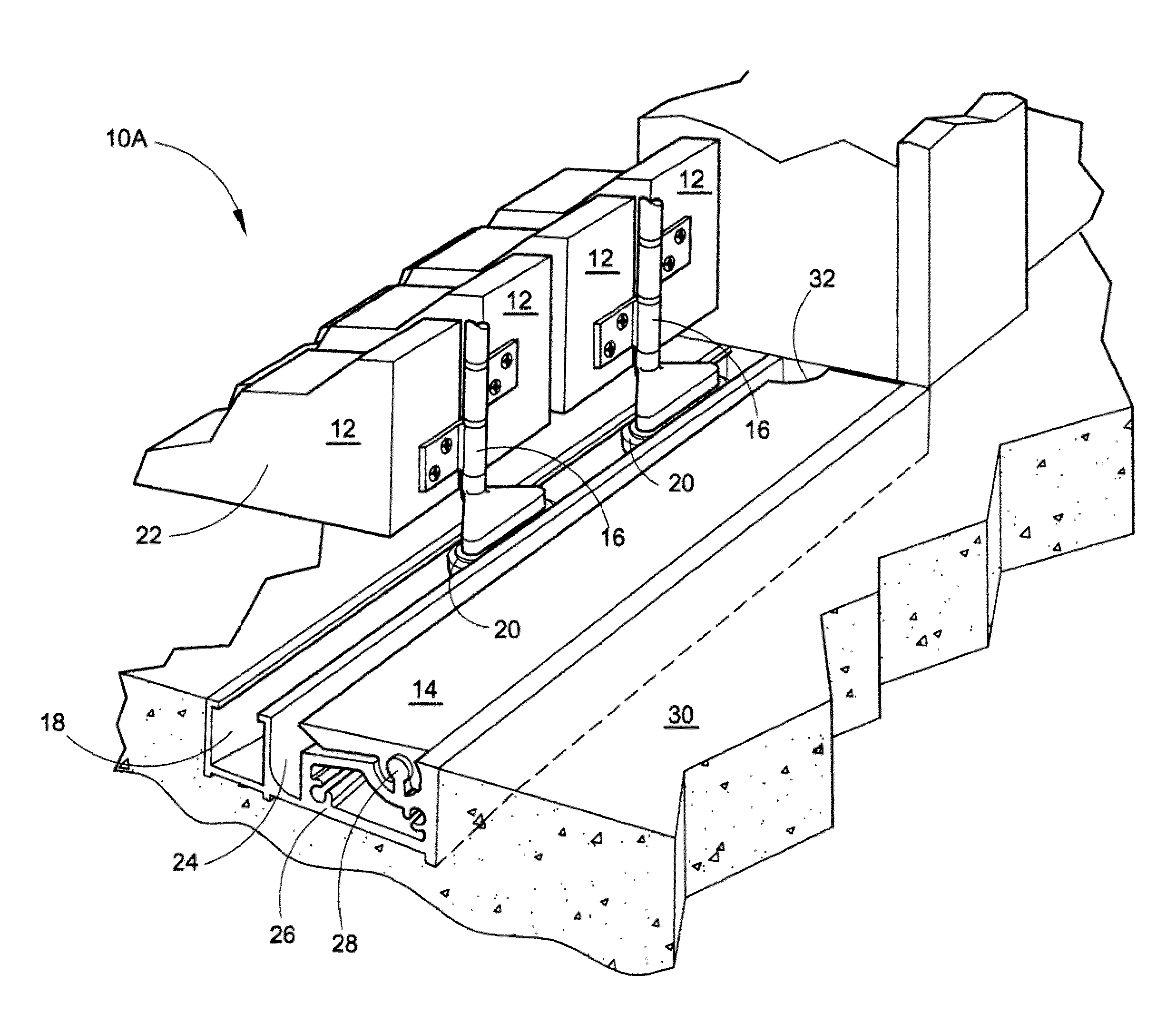

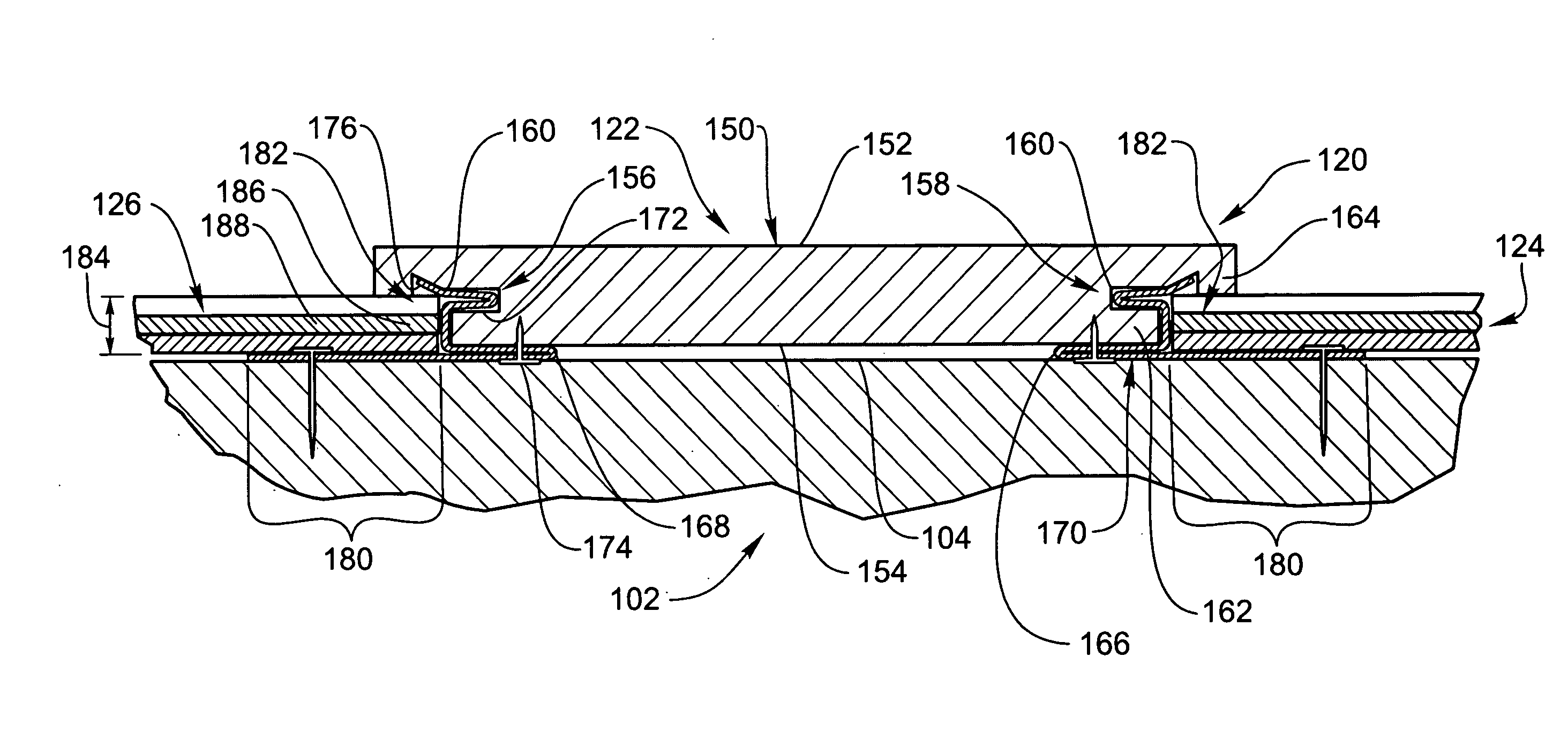

Zero step sill extruded flush threshold door seal system

The present application is directed to a manual or automatic flush threshold door seal system used on folding exterior doors along with an alternate embodiment for conventional exterior entryway doors that will not impede the passage of a wheelchair. A flexible weather seal can be put in a retracted or down position within an aluminum extrusion imbedded within the threshold providing a flush access surface and may be raised up into the upright position providing an adequate weather seal.

Owner:JELD-WEN

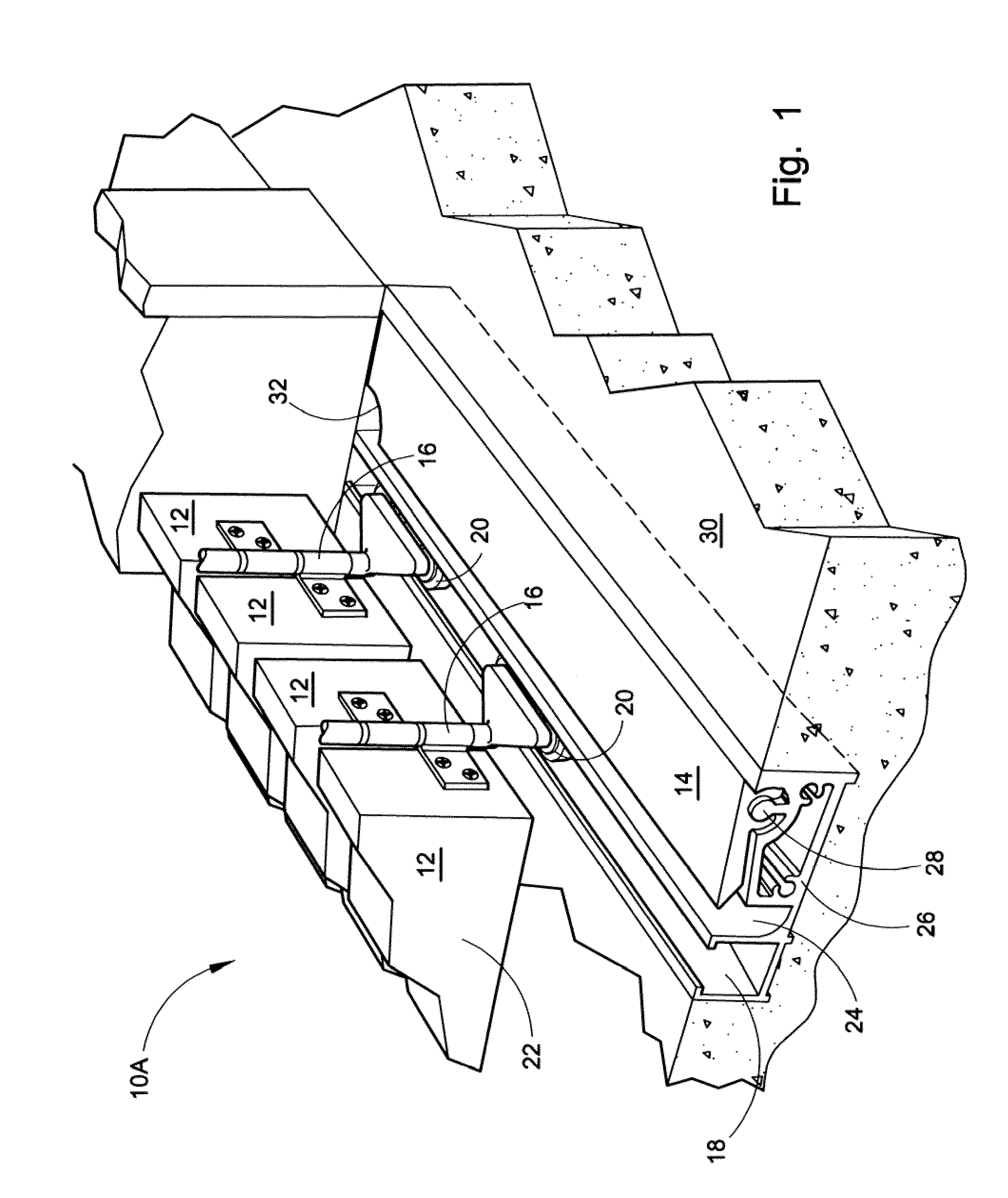

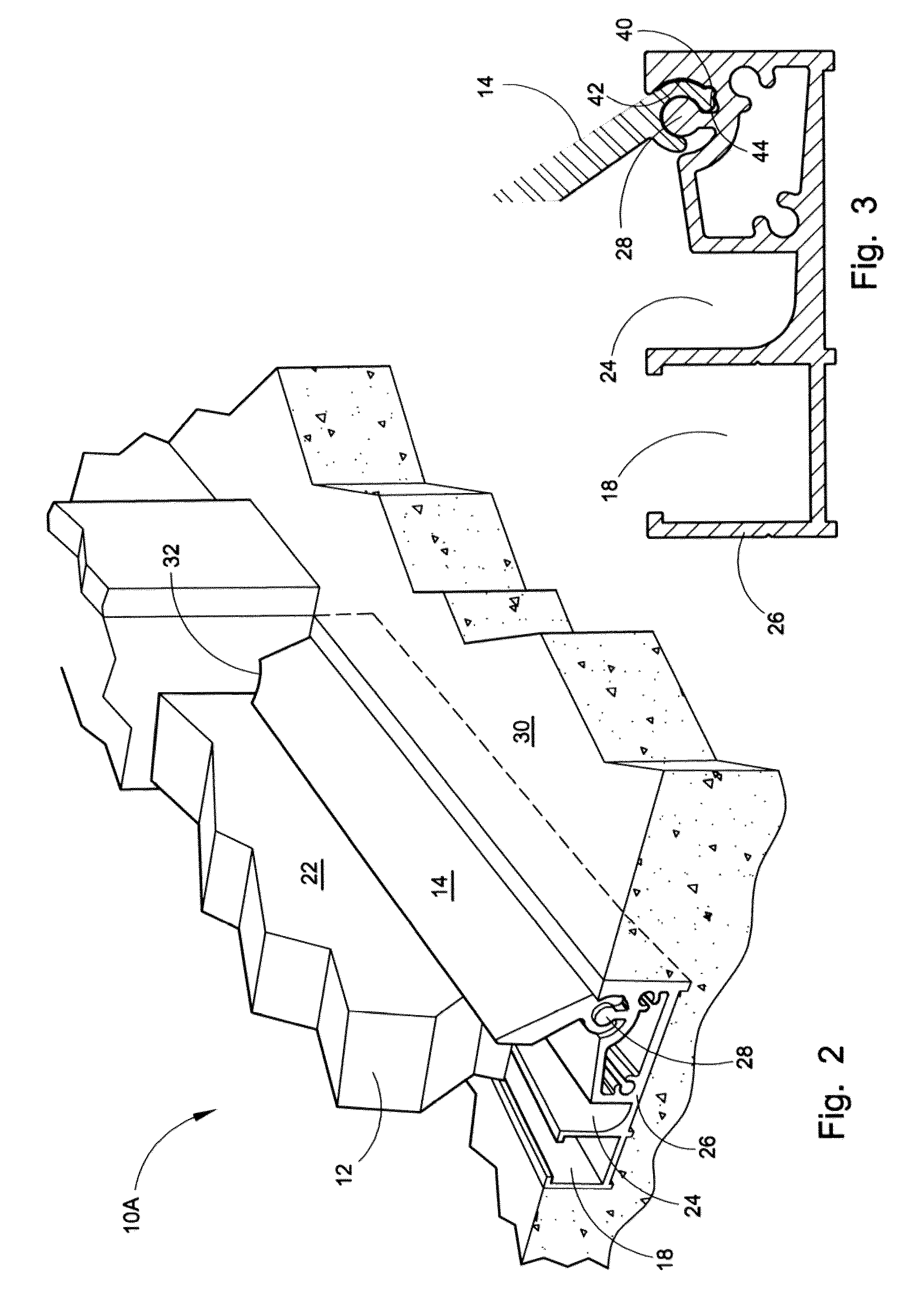

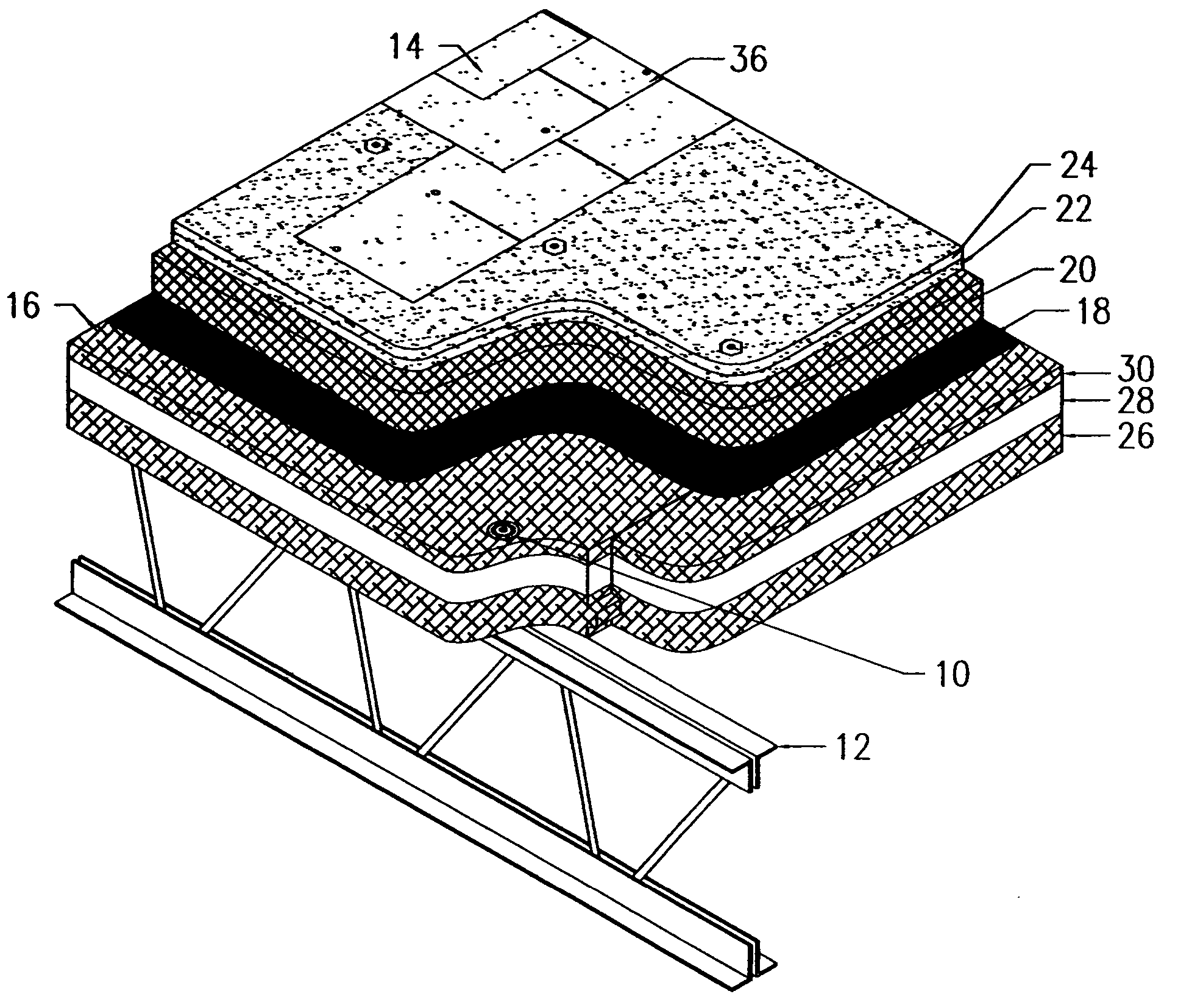

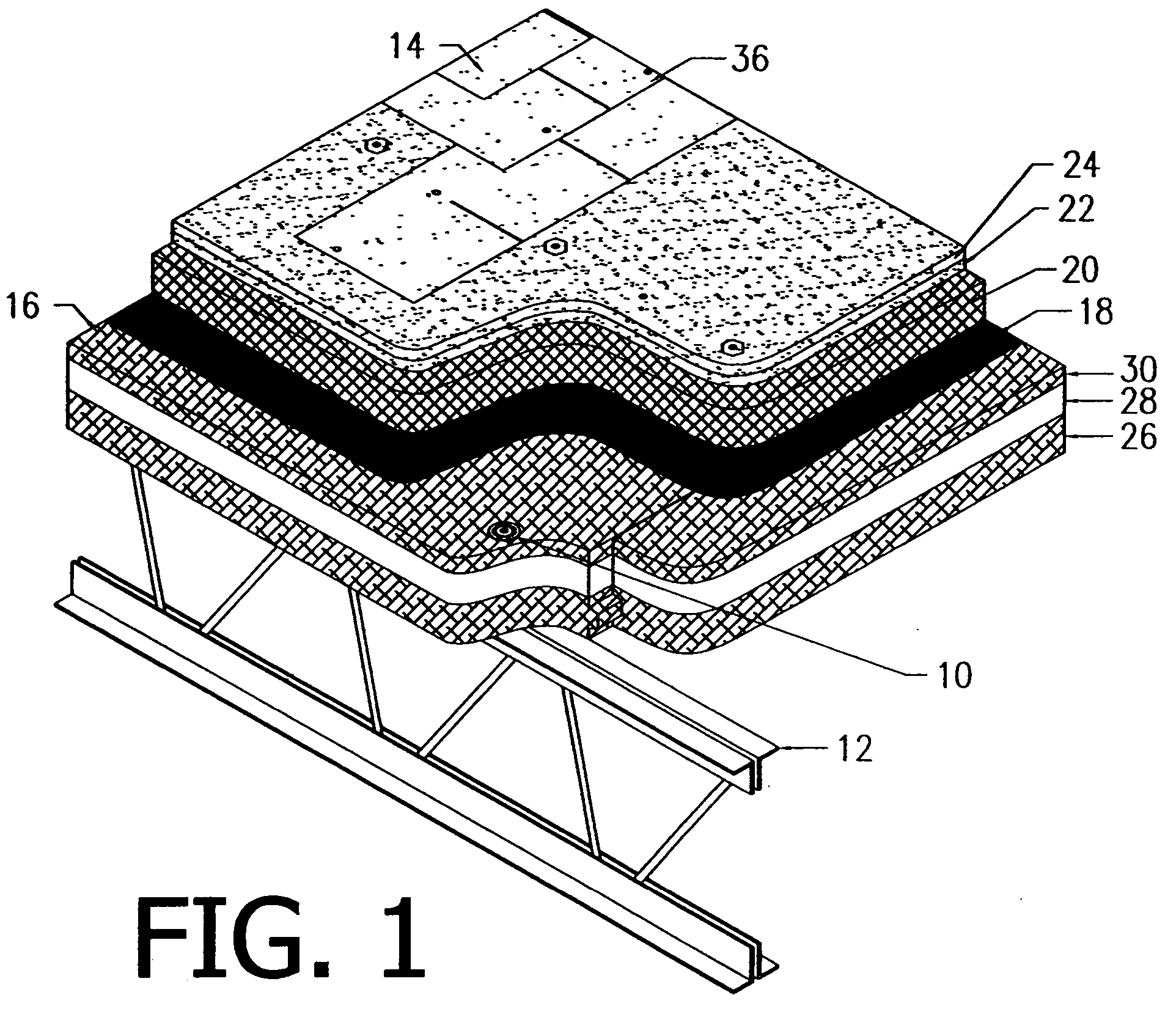

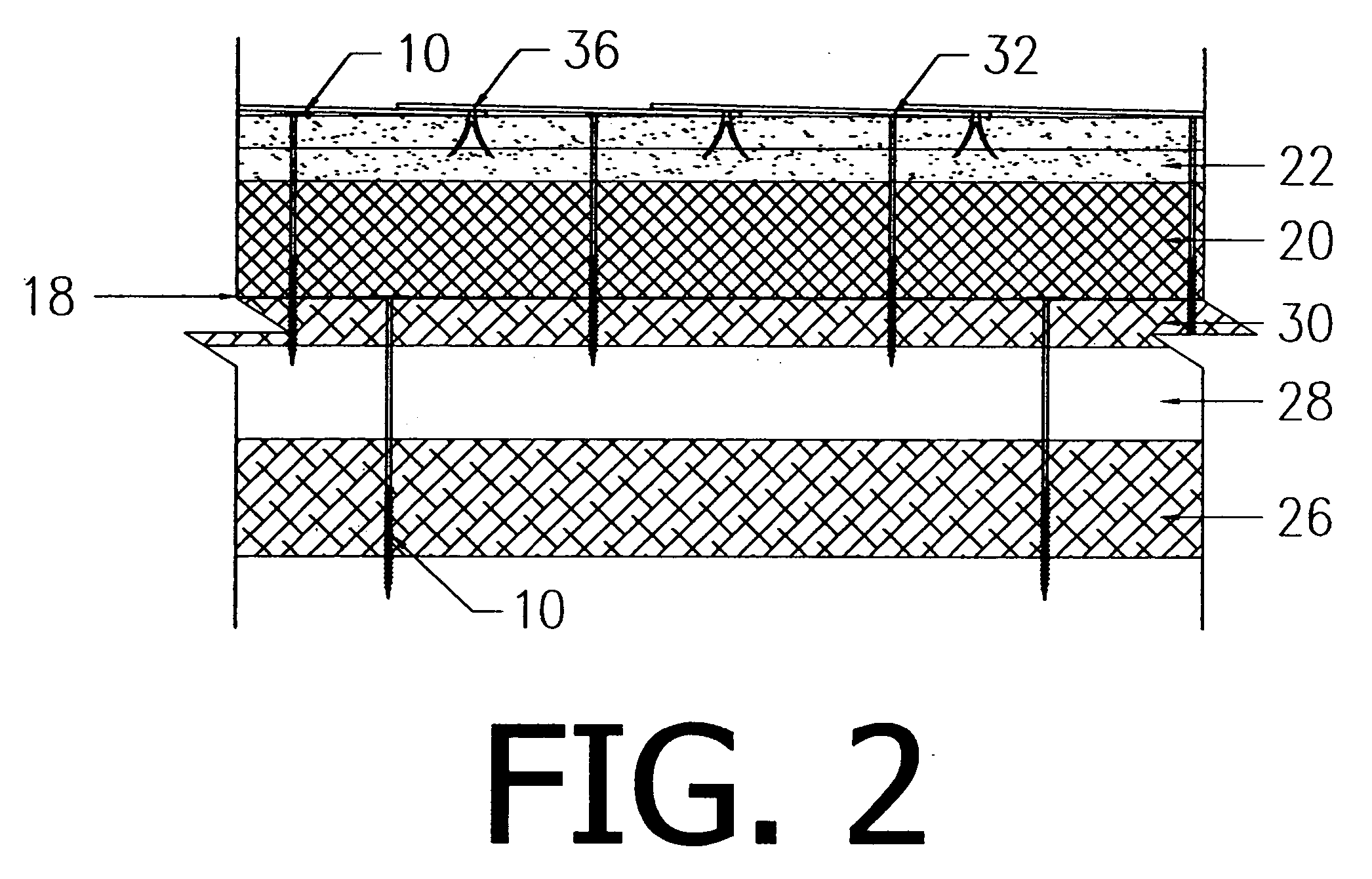

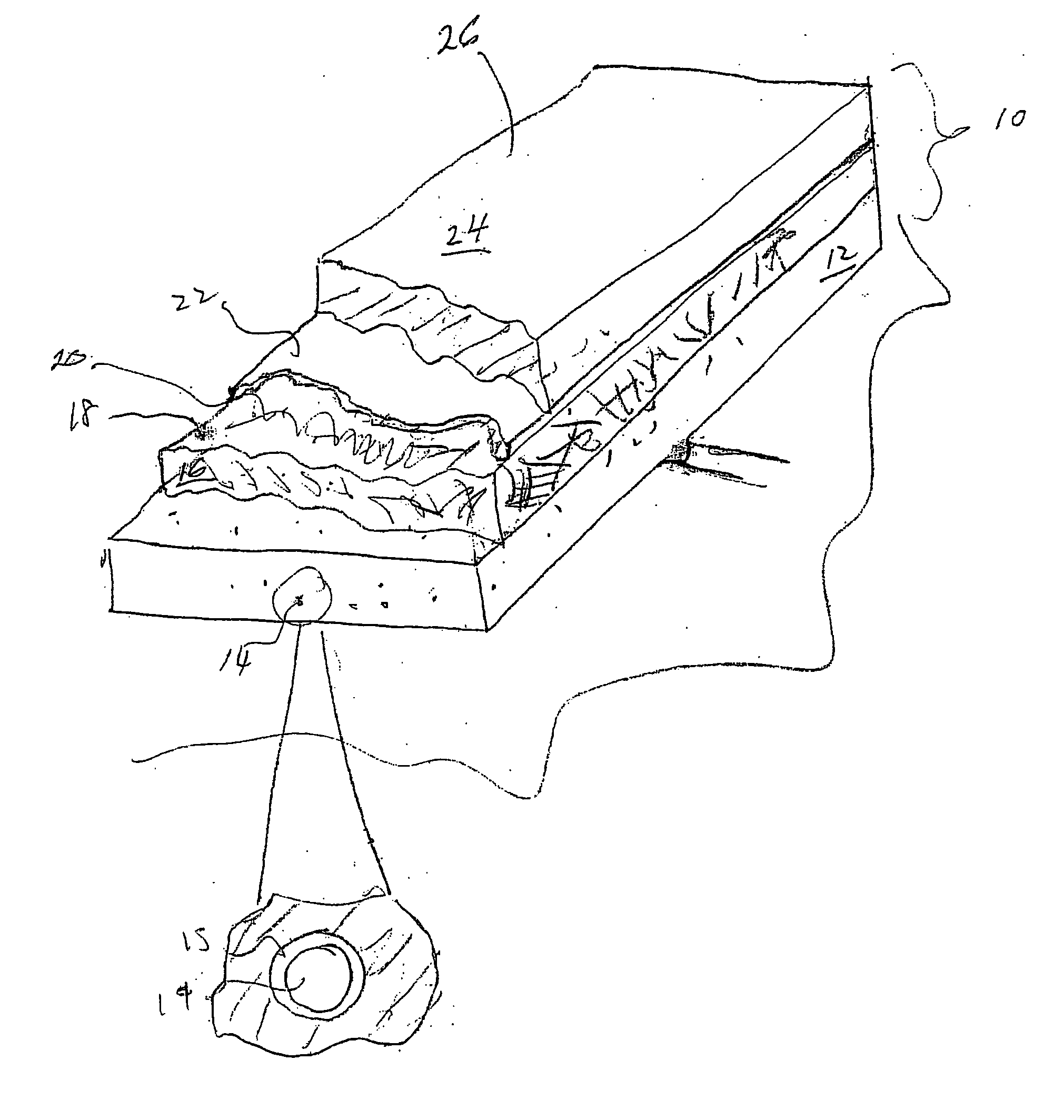

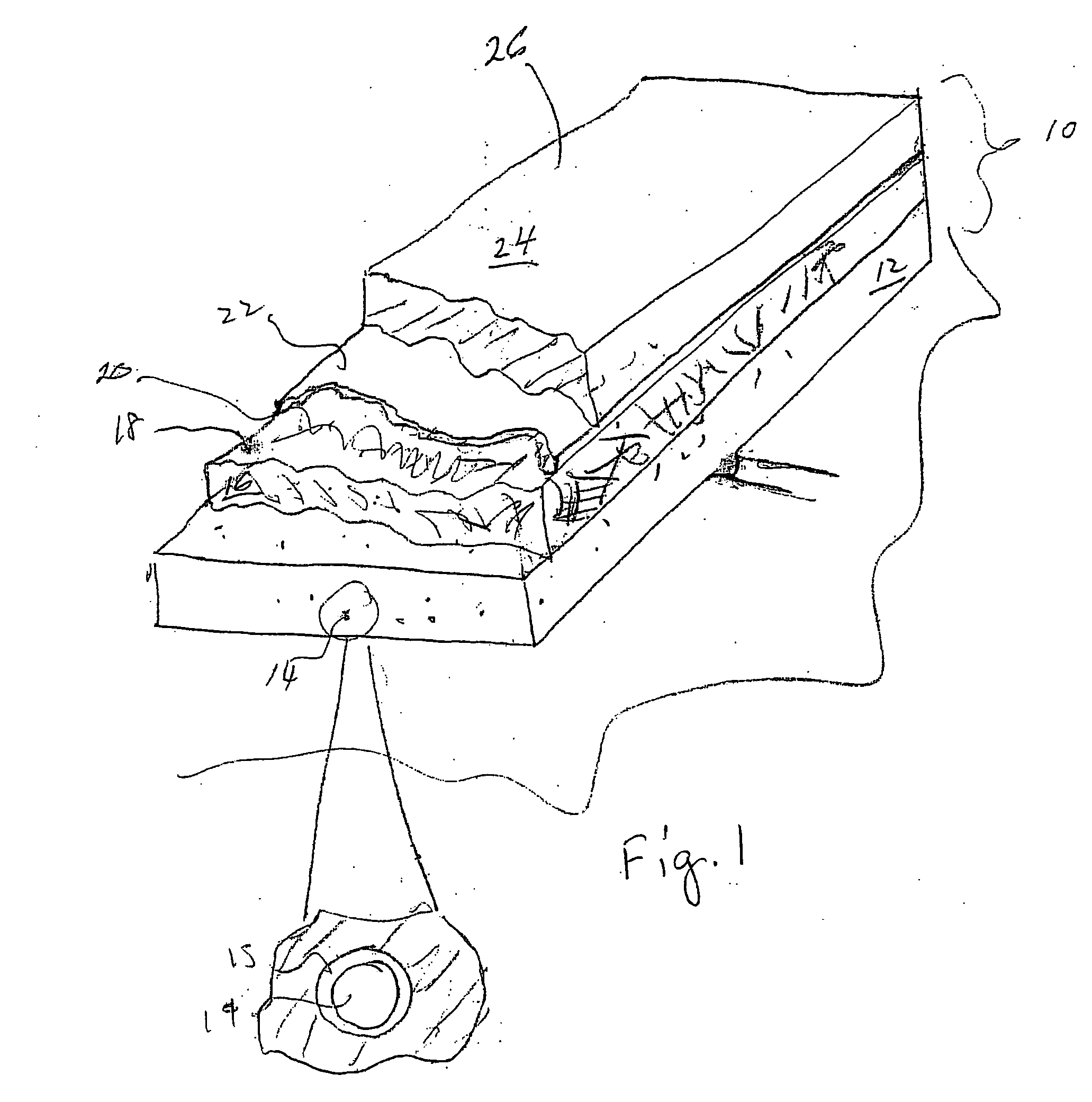

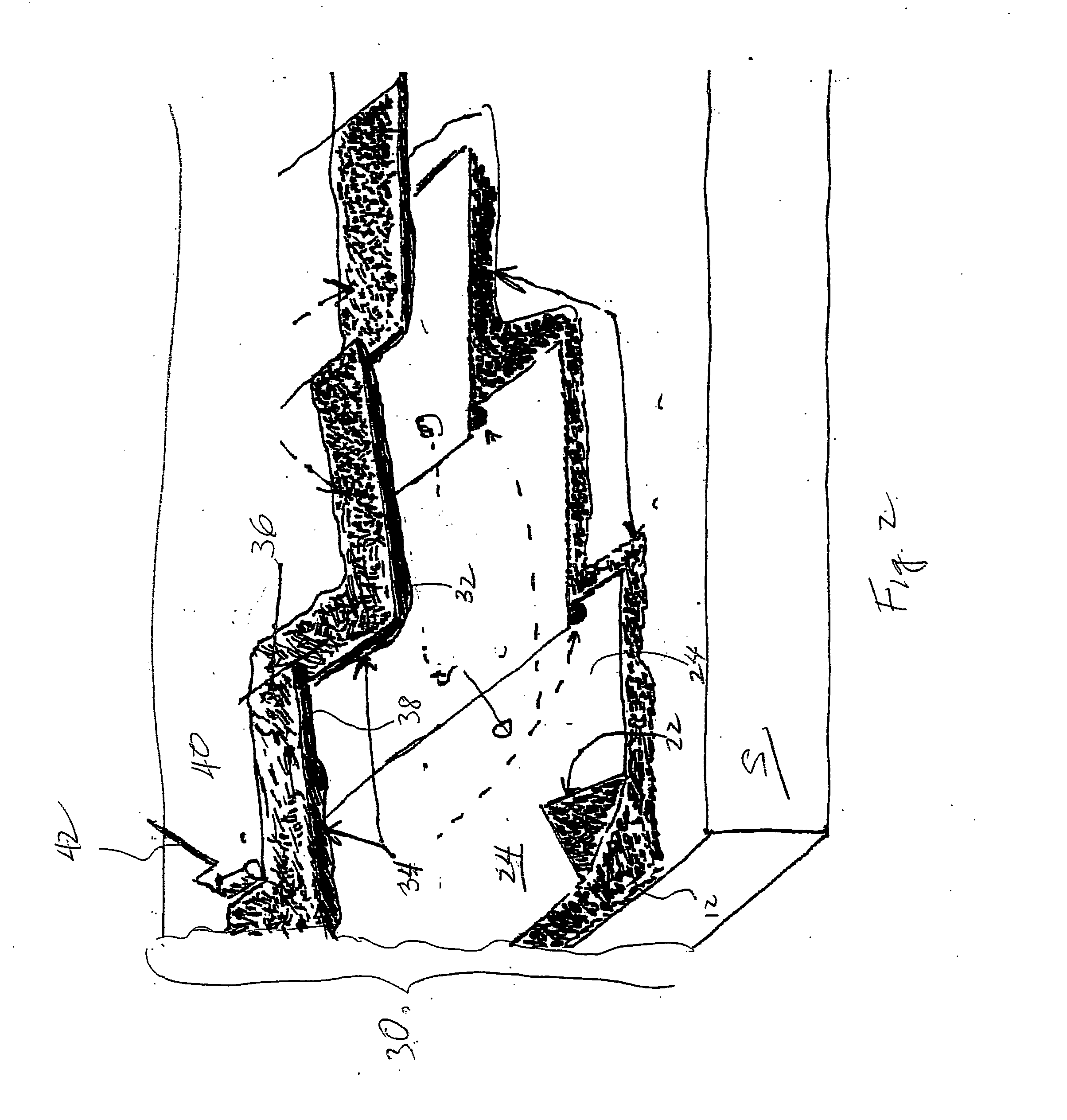

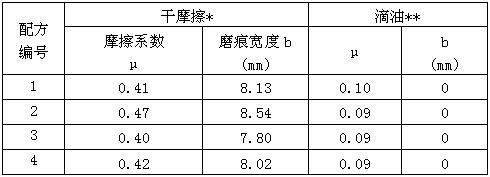

Low noise roof deck system

A low noise roof deck system eliminates the thermal expansion noises associated with metal decking and includes structural features that permit installation of composite roofing shingles directly over the deck without venting. The system includes a composite panel base layer surmounted by a layer of water resistant material, a layer of foam synthetic resin insulation and a layer of mineral board. A second layer of mineral board may be overlaid on the first mineral board layer. The system is easily installed over a system of conventional underlying supports to provide a strong, rigid deck for supporting a waterproof composite shingle roof membrane and forming a quiet weatherproof roof system. The composite base panel has a layer of synthetic resin foam insulation sandwiched between a base layer of wood fibers bonded with an inorganic cement and an upper layer of a resin bonded wood product.

Owner:BONTRAGER II ARLEY L

Roofing system

InactiveUS20070130864A1Improve wind stabilityCovering/liningsRoof covering using sealantsFiberElastomer

A roofing system includes an insulation layer and an exposed fiber surface of a sheet. A cement layer is placed intermediate therebetween. An elastomeric outer weatherproof coating overlies the sheet. A process for applying to a roofing system is provided that includes applying to a roofing substrate an insulation layer having an upper surface. Wet cement is applied on the upper surface of the insulation layer. An exposed fiber surface of a sheet is placed in contact cement. The sheet is then either directly or with intermediate layers therebetween overlayered with an elastomeric weatherproof coating. An insulation board is also provided that includes an exposed fiber backing. The exposed fiber backing accepts an overlayer of elastomer, cement, or mastic.

Owner:MOS +1

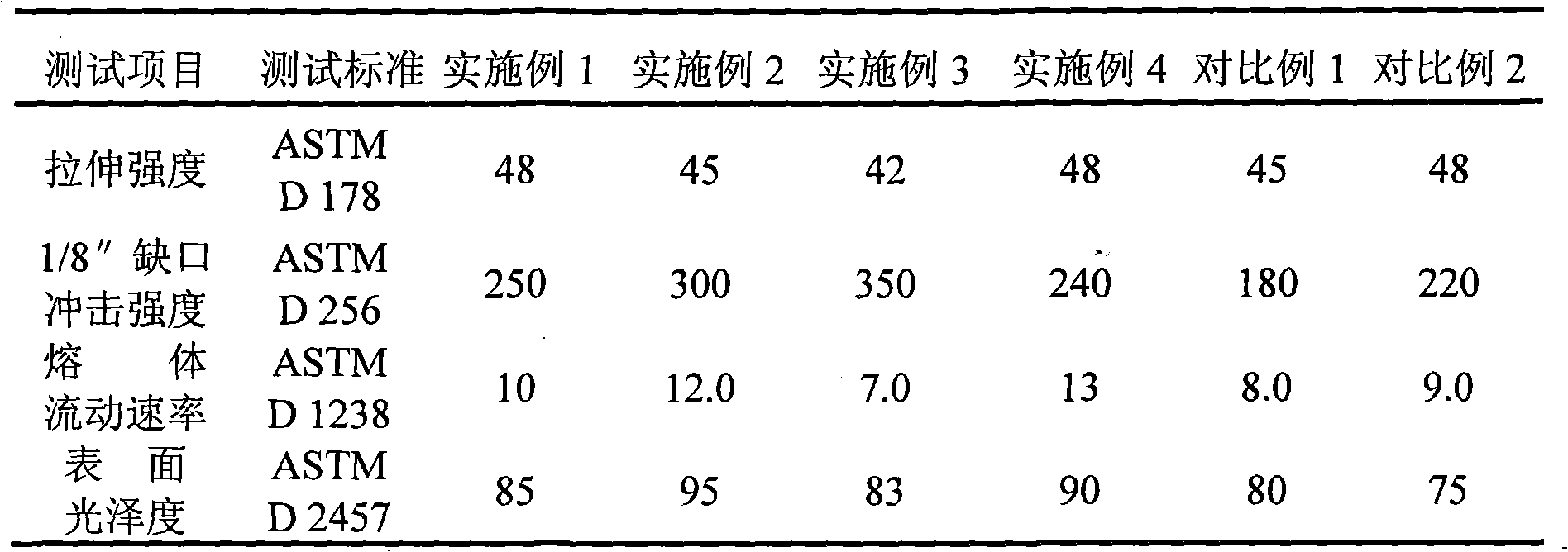

High-performance extrusion grade ASA resin composition and preparation thereof

InactiveCN101407617AGuaranteed mechanical propertiesGood weather resistancePolymer scienceWeather resistance

The invention relates to a high-performance extrusion grade ASA resin composition and a preparation method thereof. The preparation method comprises the following steps of: selecting two ASA rubber powders which have high stainability and are composited with different molecular weight and different rubber particle sizes, high molecular weight AS resin, a surface glazing agent, matching with lubricating agent, antioxidant and a weather-proofing agent simultaneously, melting in a twin-screw extruder, blending and preparing the resin composition. The ASA resin composition has high toughness, weathering resistance and surface glossness and good processing performance and is especially applicable to combining extrusion of profiled materials used for buildings of PVC doors and windows and glazed tiles and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

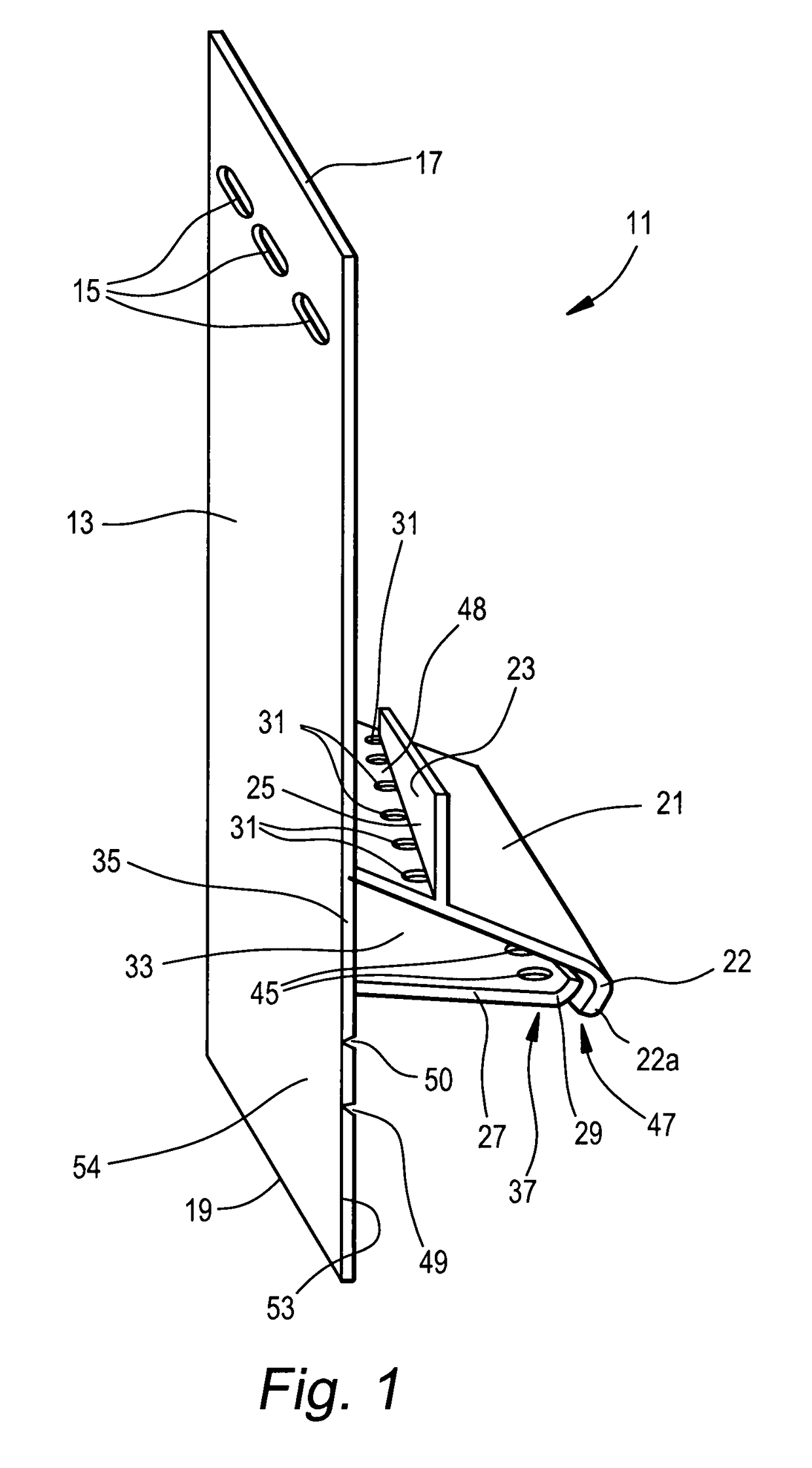

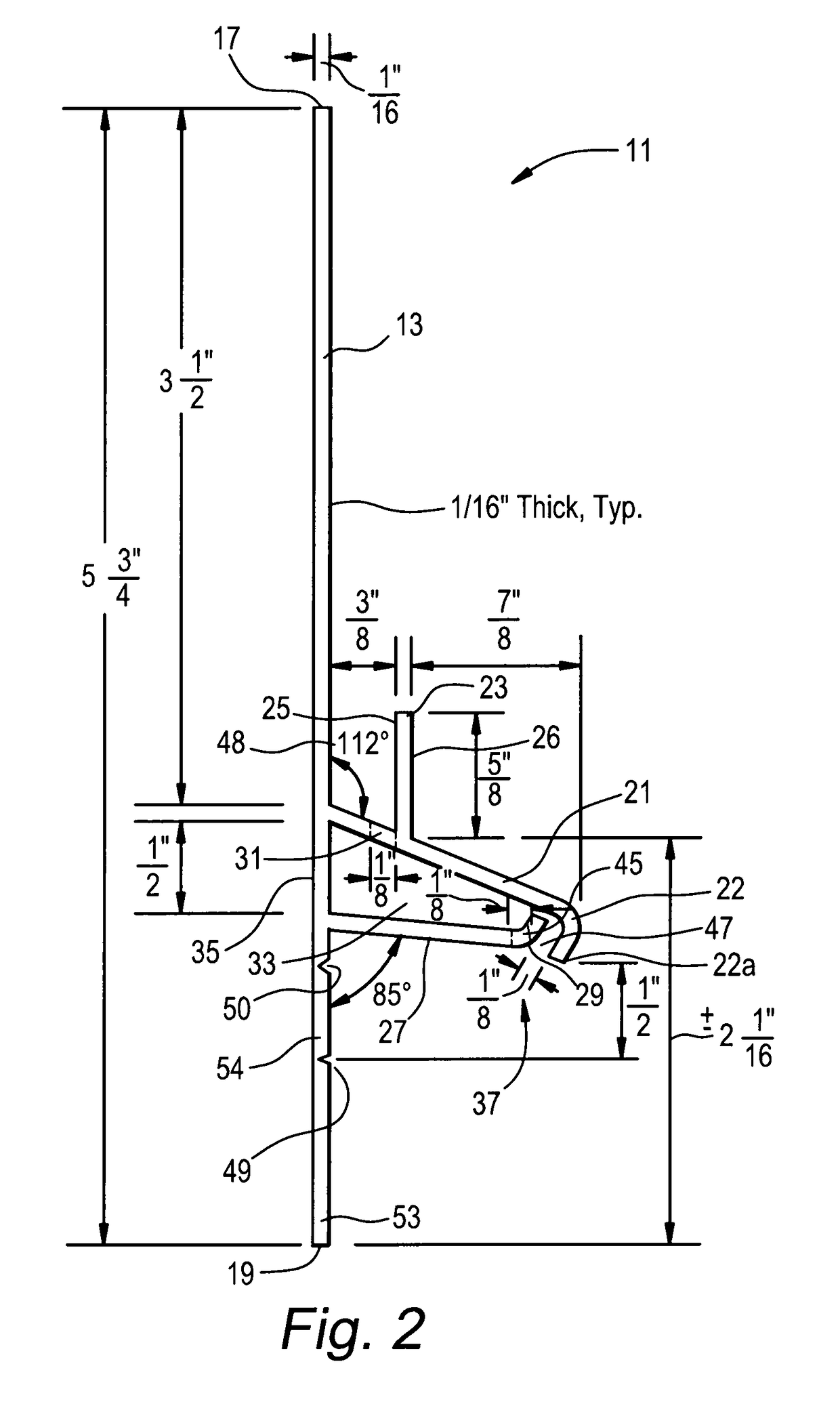

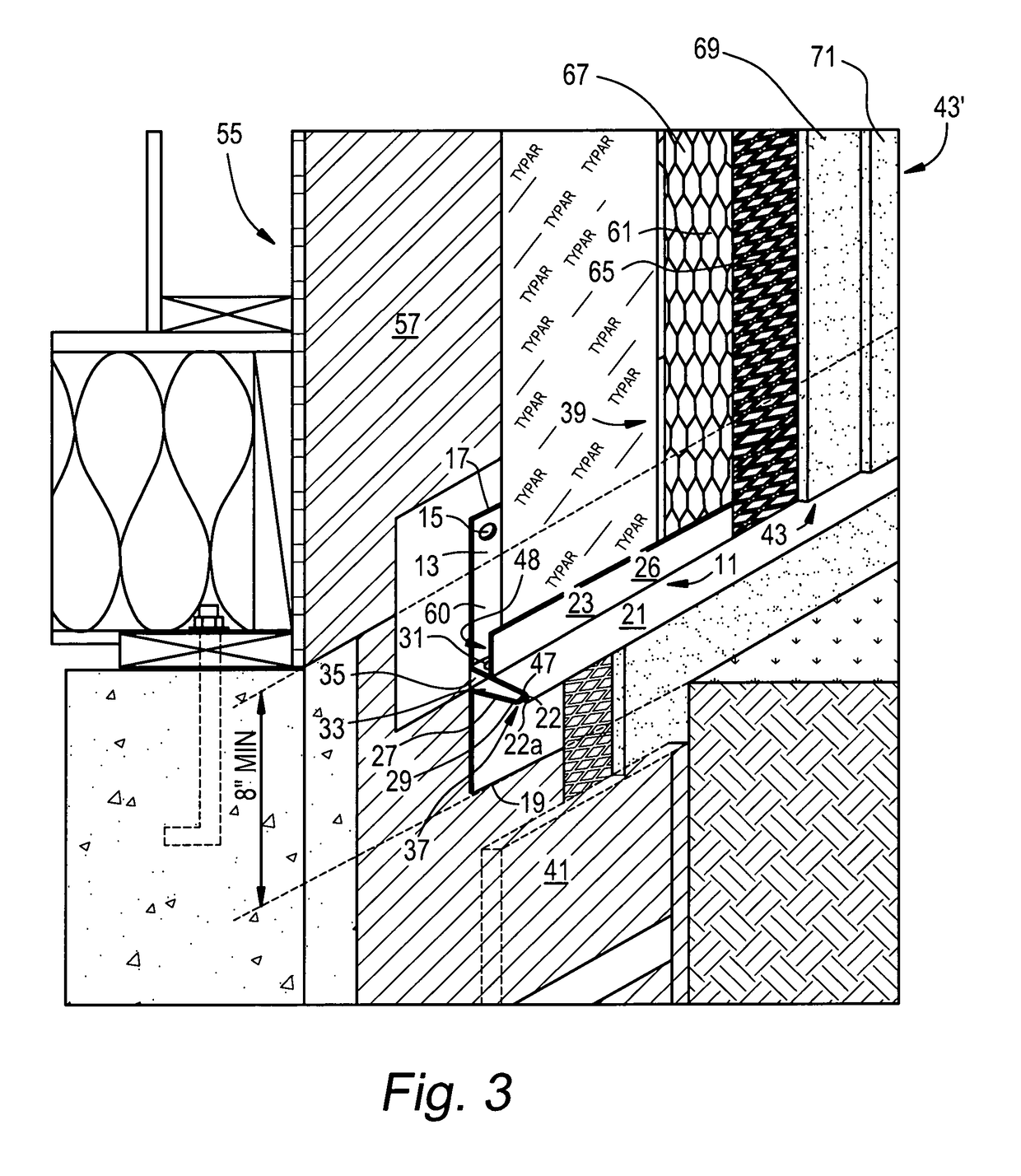

Weep screed

A convective weep screed for draining water that penetrates exterior cladding of an exterior wall of a building away from the building and for removing moisture located in the space between the weather resistant barrier of the wall and the exterior cladding and for providing ventilation to the space between the weather resistant barrier and the exterior cladding. The weep screed provides a pathway to the space between the weather resistant barrier and the exterior cladding to permit water / moisture / moisture vapor that collects there to drain therefrom and to permit air to gain access to said space, thereby providing an uninterrupted pathway for air to ventilate and dry said space.

Owner:DUFFY FRANK L +1

Slopped roof flashing system and method of use

InactiveUS20050086873A1Reduce labor costsReduce material costsRoof covering using slabs/sheetsRoof covering using tiles/slatesBrickEngineering

A flanged counter flashing unit, flashing system and method is described for weather proofing the juncture of a brick wall overlying a vertical parapet wall and the edge of a sloped roof. The one-piece counter flashing unit of the flashing system has a vertical slit into which is securely fitted the low upstanding side of a J-Channel flashing positioned at the juncture and the vertical leaf member of an L-shaped roof flashing that is flush with the outer face of the upstanding low side of the J-Channel flashing, including a flange section of the counter flashing unit that extends laterally from the top edge of the counter flashing apron and partially over the J-Channel and an apron adapted for overlying the vertical leaf member of the L-shaped flashing. The J-Channel flashing, L-shaped flashing and flanged counter flashing are included in the flashing system of the present invention. According to the method of the present invention, when the flashing system is positioned at the juncture, the brick wall is constructed from within the J-channel so that the counter flashing flange is included in the brick wall. This method eliminates the need for a separate method step of attaching counter flashing to the brick wall at an angle to the horizontal plane of the brick wall after its construction by means of a gouge cut across the brick wall for that purpose.

Owner:MARES MANUEL

All-weather enclosure for flat panel displays

ActiveUS9235232B2Improve structural rigidityTelevision system detailsCasings/cabinets/drawers detailsDisplay devicePrism

A lightweight, weatherproof, protective enclosure for flat panel displays comprising a containing element in the form of an open, shallow rectangular prism with a regular network of shallow reinforcing depressions formed in its outer surface and a substantially transparent planar viewing element hingedly connected to the containing element such that when the viewing element is closed over, and sealed to, the containing element the protective enclosure forms a lightweight, monocoque structure with enhanced structural rigidity.

Owner:PROTECTIVE ENCLOSURES CO LLC

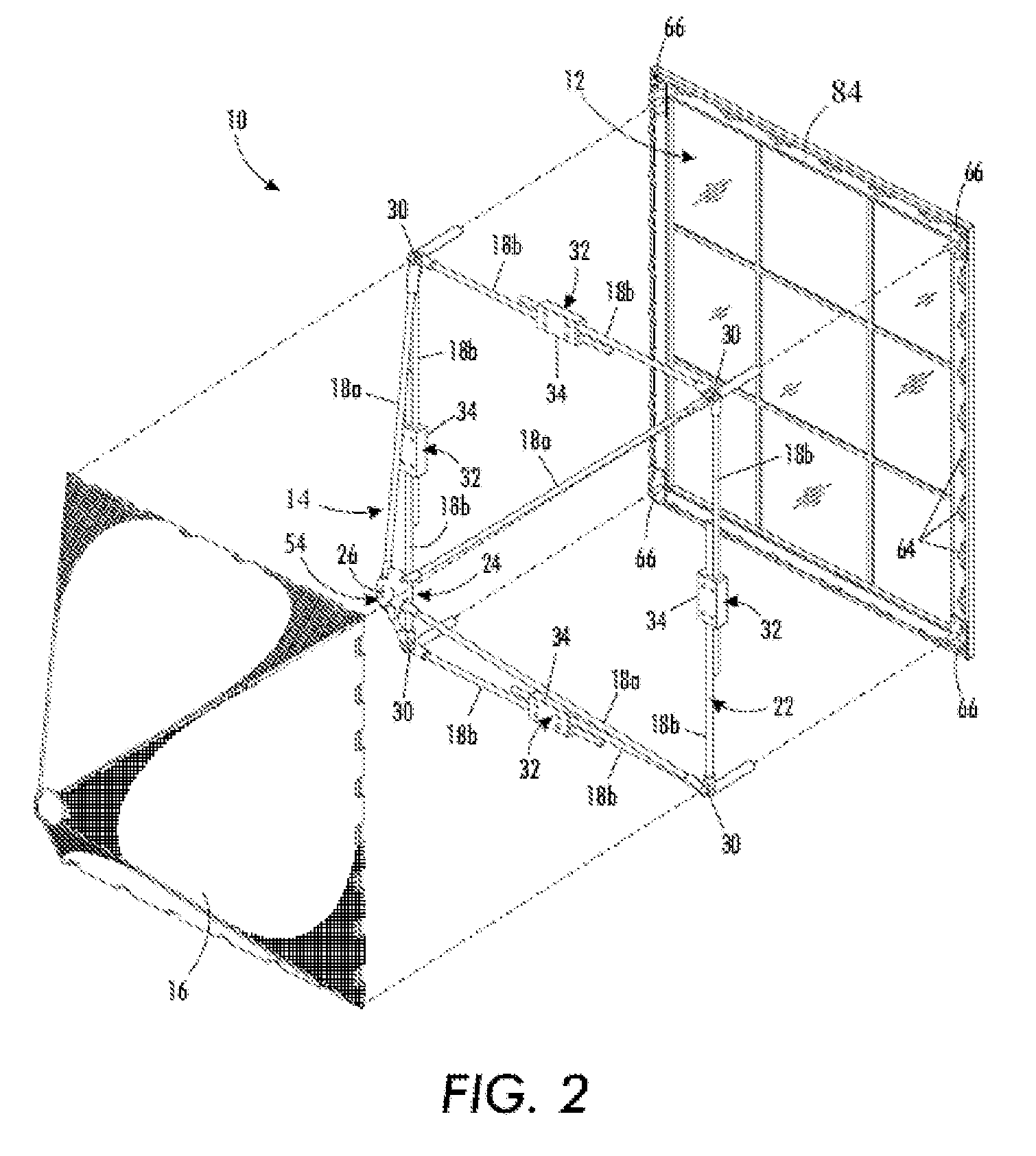

Weather protection barrier for a frangible opening of a building

Owner:STORMBLOK SYST

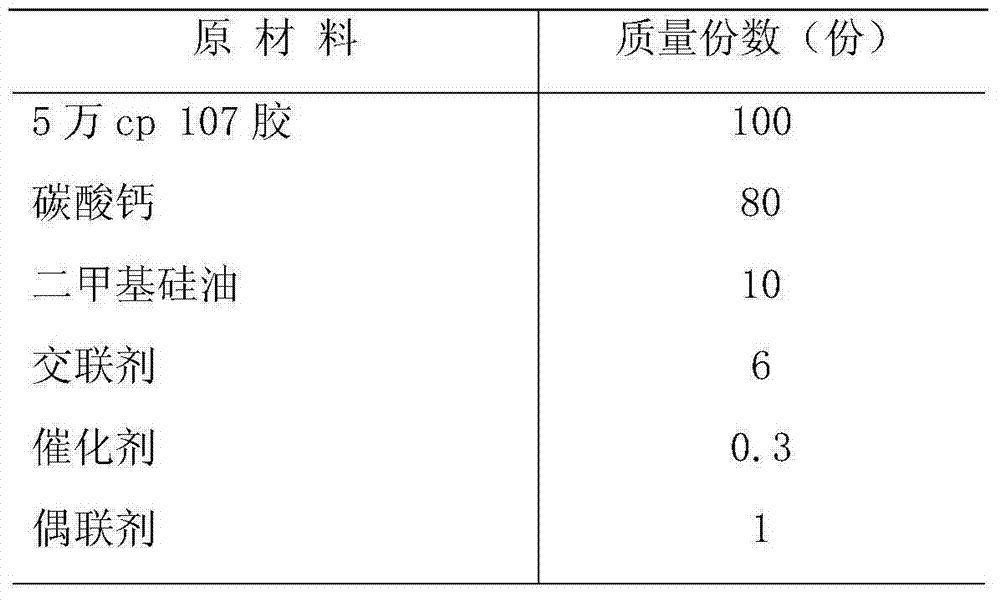

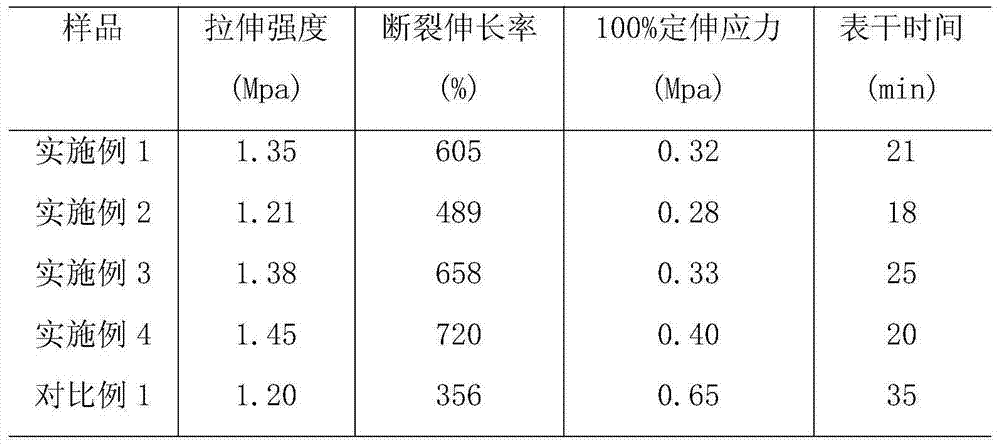

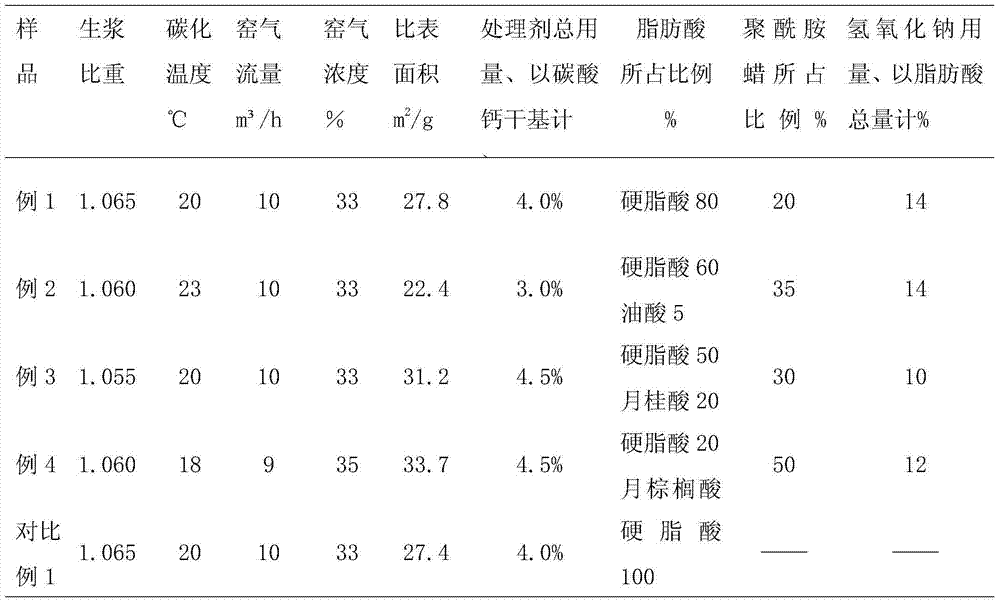

Preparation method of nano calcium carbonate used for weather proofing silicone sealant

ActiveCN104497634AShorten drying timeLow modulusNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsPolyamideDrying time

The invention discloses a preparation method of nano calcium carbonate used for a weather proofing silicone sealant, the proportion of lime milk aged for 36-72h is adjusted to 1.055-1.070, the temperature is controlled between 18 to 28 DEG C, lime kiln gas is introduced into for carbonation reaction, the lime kiln gas flow is controlled to 6-10m<3> / h, the carbon dioxide volume content is 25-40%, when the reaction solution pH is reduced to 7, the reaction solution is heated to 50 to 90 DEG C, 12-20g of fatty acid saponified solution and polyamide wax compounded surface treatment agent is added for coating, and after 60-120min of stirring, the product is obtained by completion of surface modification, dehydration, drying, crushing and grading. The nano calcium carbonate prepared by the method can significantly shorten surface drying time, reduce the curing silicone sealant modulus, and improve the filling silicone sealant thixotropy, processing and adhesion properties, and the process is easy and feasible, low in production cost, and good in economic benefit.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

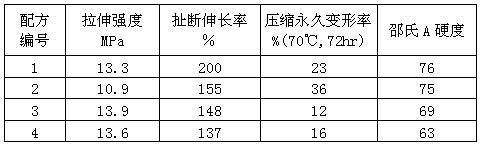

Wear-resistant modified HNBR (hydrogenated nitrile butadiene rubber), NBR (nitrile butadiene rubber) and NBR/PVC (polyvinyl chloride) dynamic sealing material adopting molybdenum disulfide solid lubricant and preparation method for same

InactiveCN102604178AImprove corrosion resistanceGood weather resistanceOther chemical processesFriction reductionVulcanization

The invention relates to a wear-resistant modified HNBR (hydrogenated nitrile butadiene rubber), NBR (nitrile butadiene rubber) and NBR / PVC (polyvinyl chloride) dynamic sealing material adopting molybdenum disulfide solid lubricant. Components of the dynamic sealing material comprise rubber matrix materials, the molybdenum disulfide solid lubricant, zinc oxide, stearic acid, anti-ageing agent, accelerator, vulcanizing agent and plasticizer. The wear-resistant modified HNBR, NBR and NBR / PVC dynamic sealing material is prepared by plastication, mixing and vulcanization molding. On the premise of maintaining original advantages of base materials such as oil resistance, corrosion resistance, weather proofing and ageing resistance, a dynamic seal ring for a high-speed running mechanical part and prepared by the three materials has more excellent friction reduction and abrasion resistance, and a certain reinforced modified effect is achieved.

Owner:SHANGHAI UNIV

Weatherproof lap siding system

InactiveUS20060260247A1Reduce maintenanceRoof covering using tiles/slatesCovering/liningsEngineeringWeather proofing

A lap siding system for use on an exterior of a building that includes a structure having a groove and a rear side for abutting the building. The groove may include a length and a contour extending along the length of the groove. The system also includes a flashing having an extension, a length, and a head. The head may be connectable to the structure so that the extension of the flashing extends from the structure generally parallel to the rear side of the structure. Additionally, a part of the head may abut and follow a portion of the contour of the groove. The lap siding system may also include a plurality of planks having a first end. The flashing may form at least part of a plank channel having a width sized to receive the first ends of the plurality of planks.

Owner:MONTEER GARY

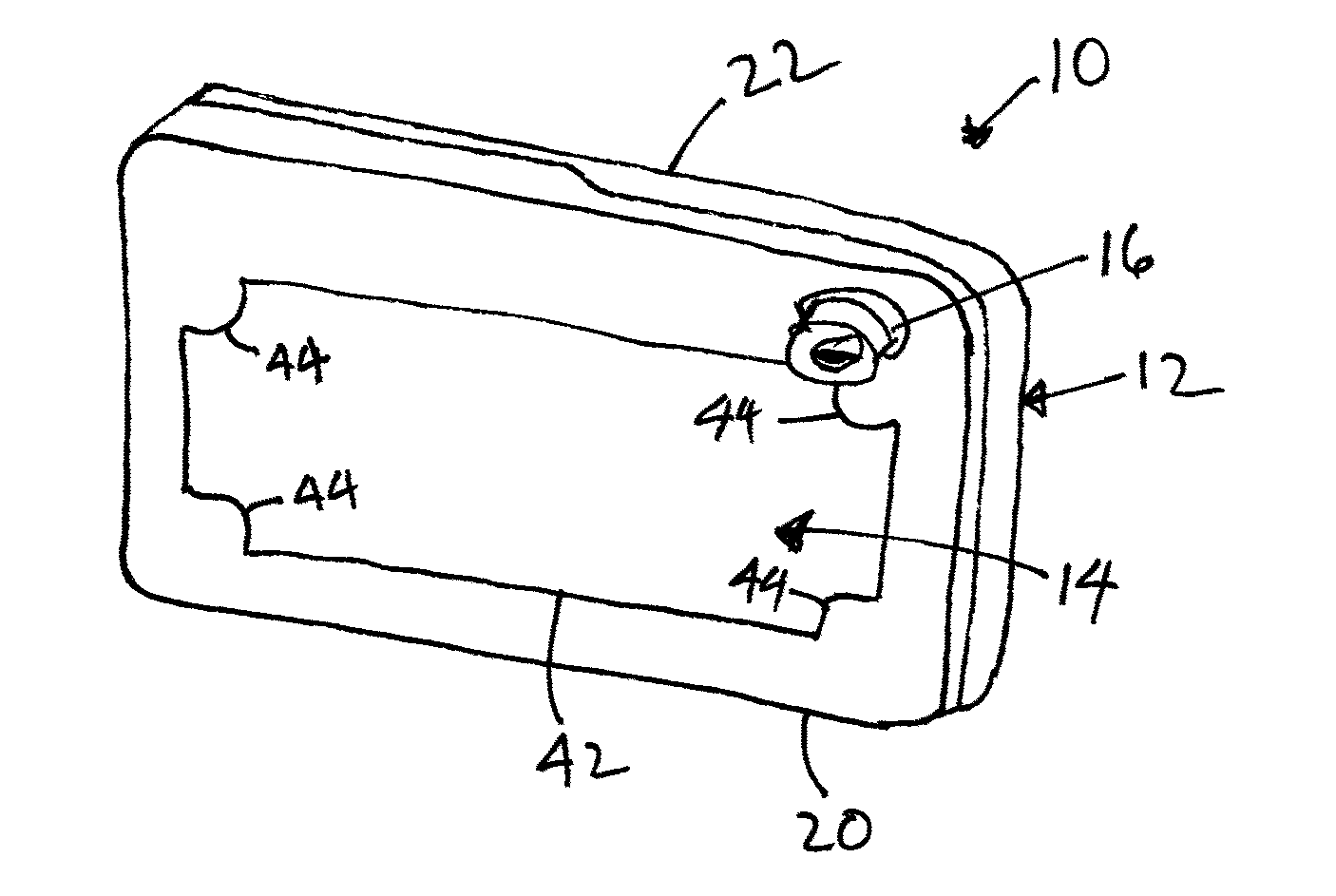

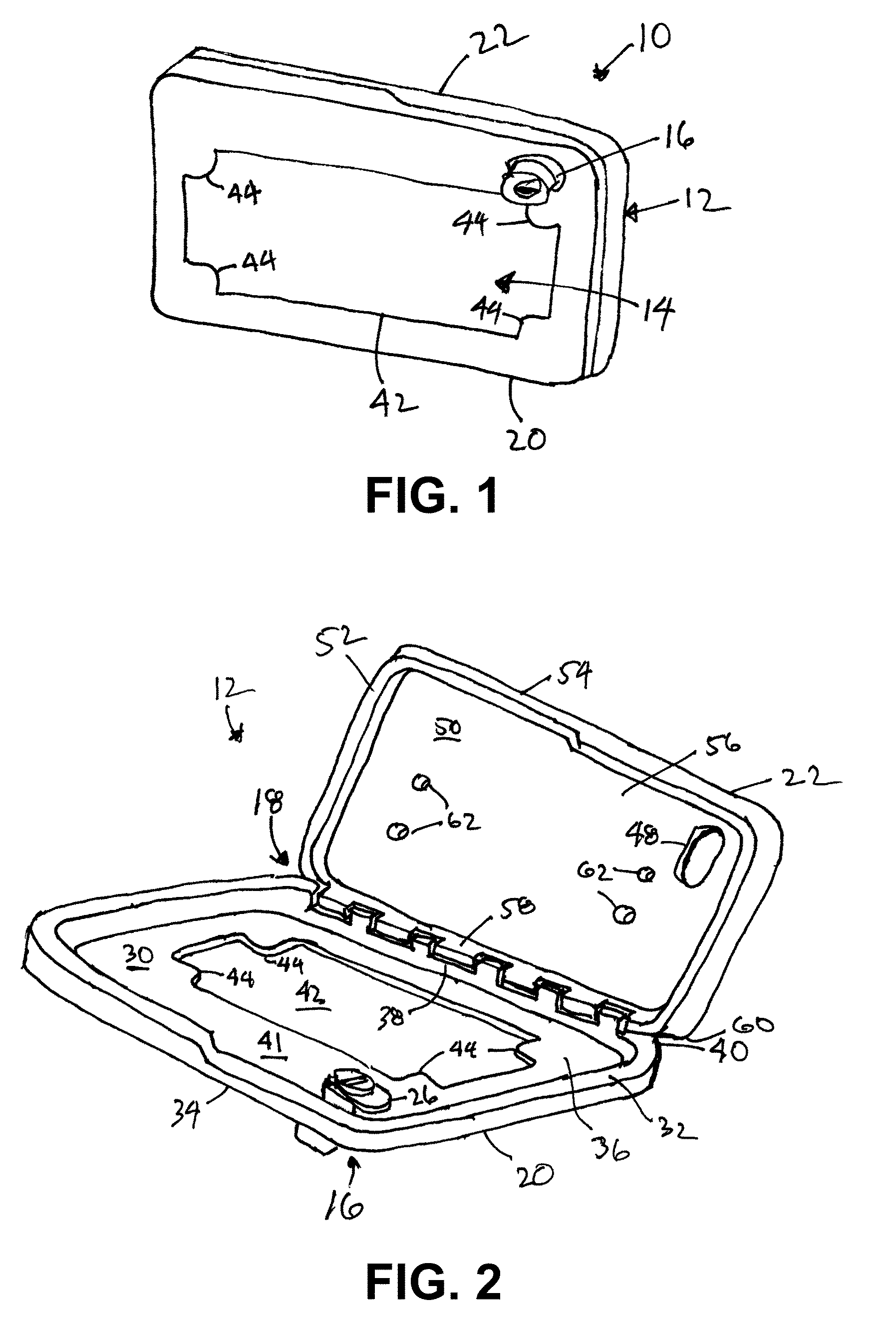

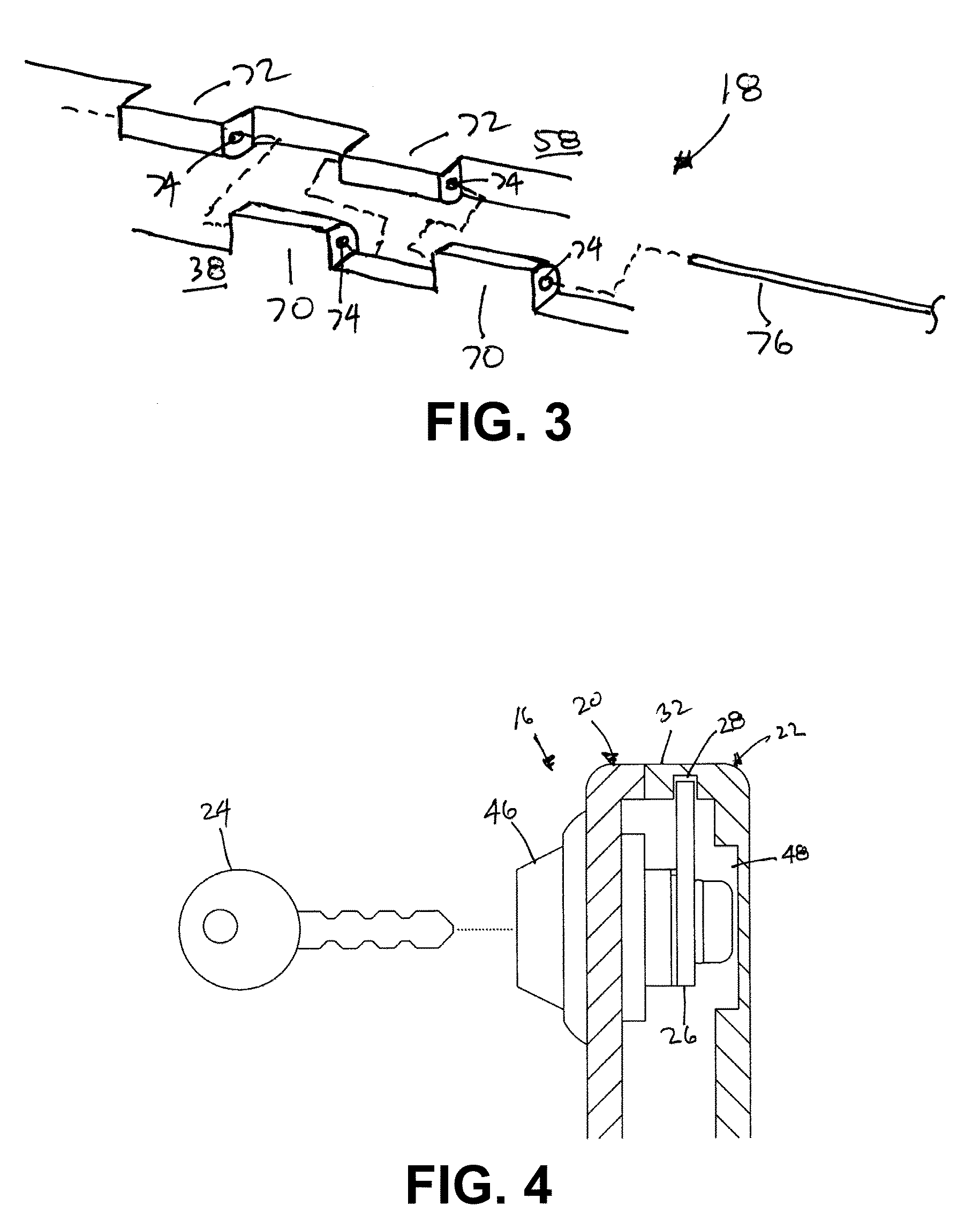

Vehicle lock box with license plate holder

A vehicle lock box with a weather-proof compartment and a license plate holder that mounts to the license plate bracket. An outer frame is comprised of a pair of hinged, rigid panels that is secured closed by the locking mechanism. Each panel has a raised lip that forms a hollow in the panel. The rear panel includes holes for mounting to the license plate bracket. The license plate is placed inside the front panel adjacent to a cutout that exposes the license plate face. The weather-proof compartment is composed of a pair of mirror image, resilient, water-impermeable sheets, each of which fits within the hollow of one of the panels. Both sheets have a raised rim that forms a depression in the sheet. The sheet in the front panel holds the license plate against the cutout. When the frame is closed, the sheet rims abut, forming a weather-tight compartment.

Owner:DOWNEY PHILIP L

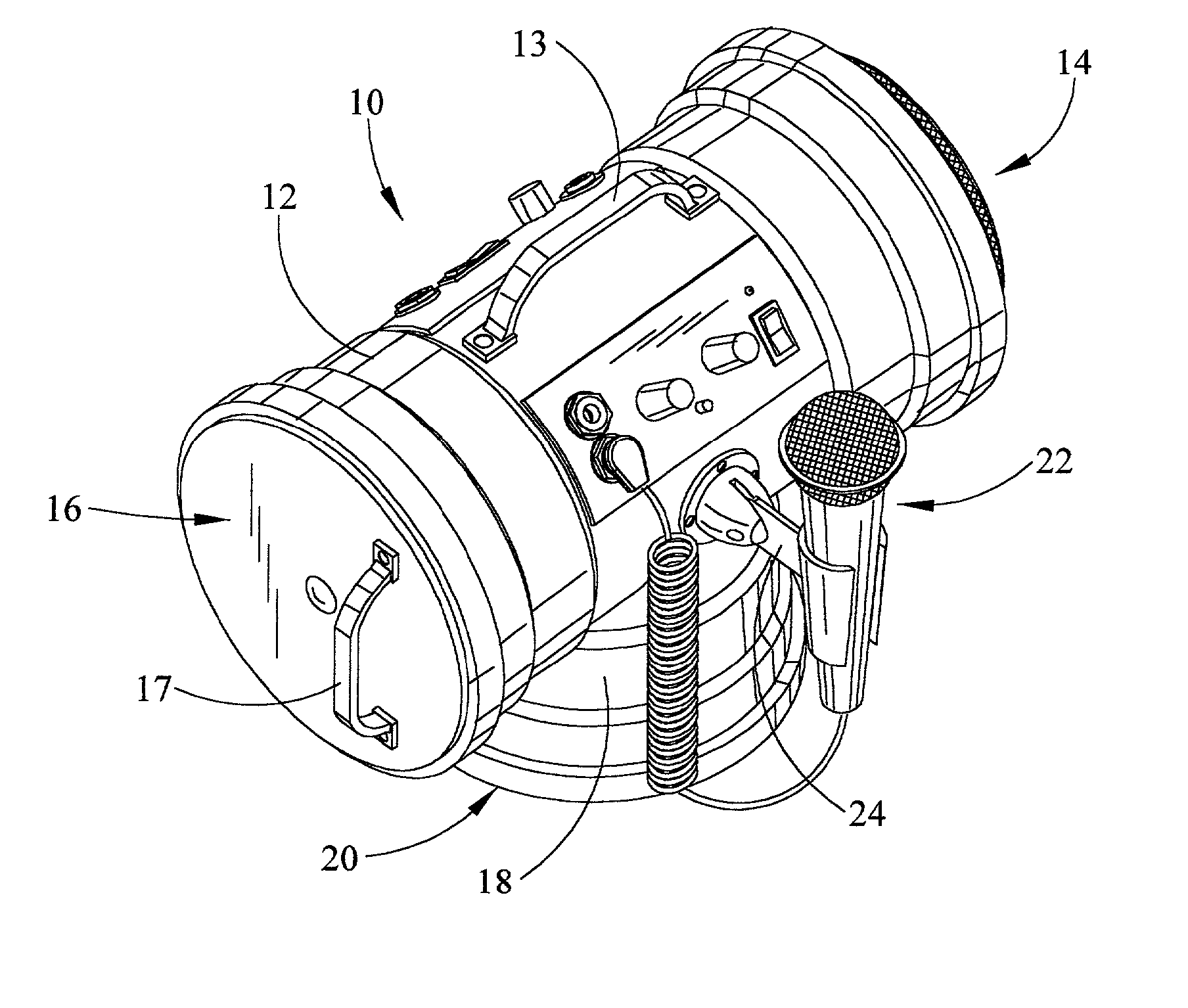

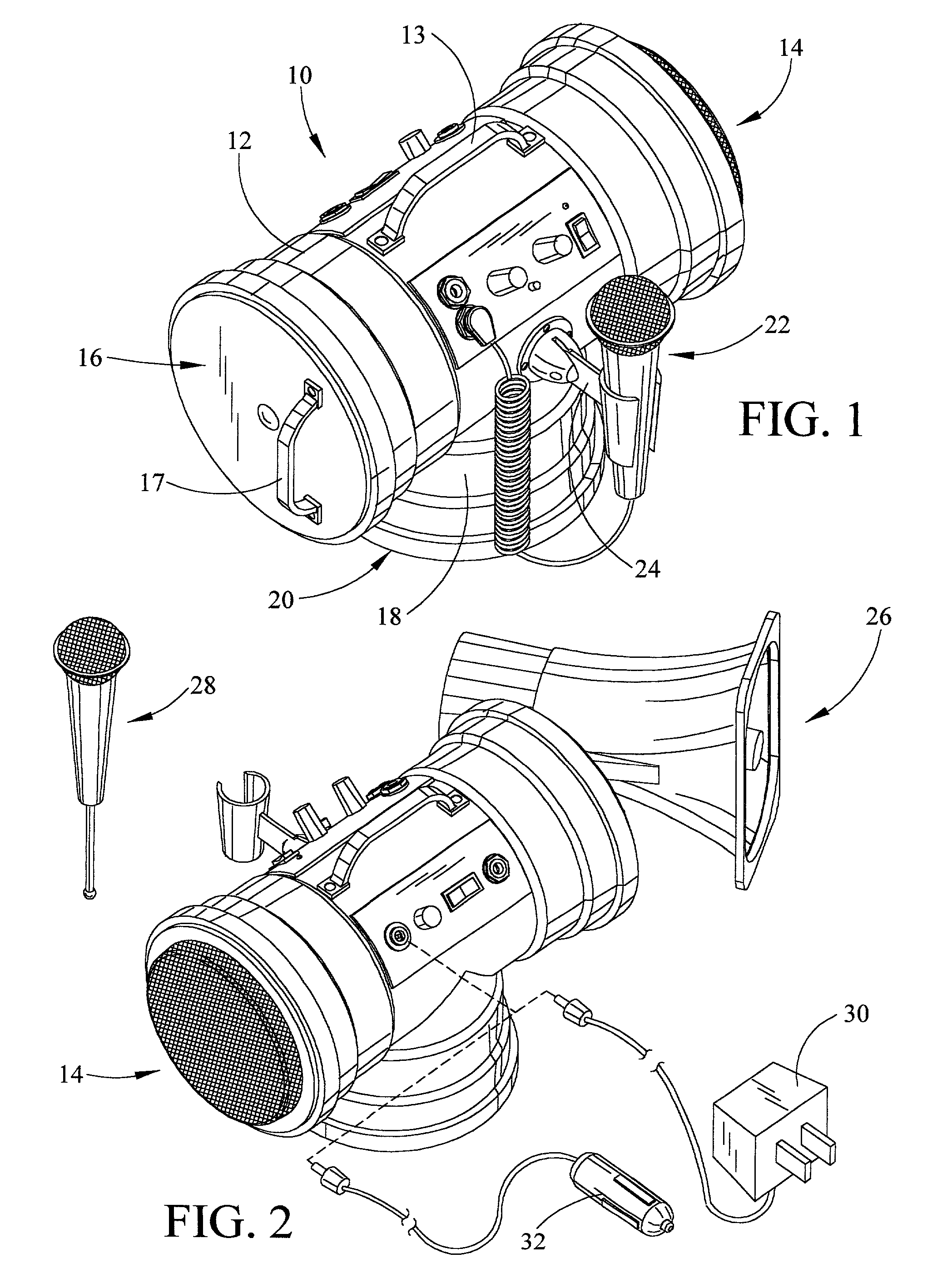

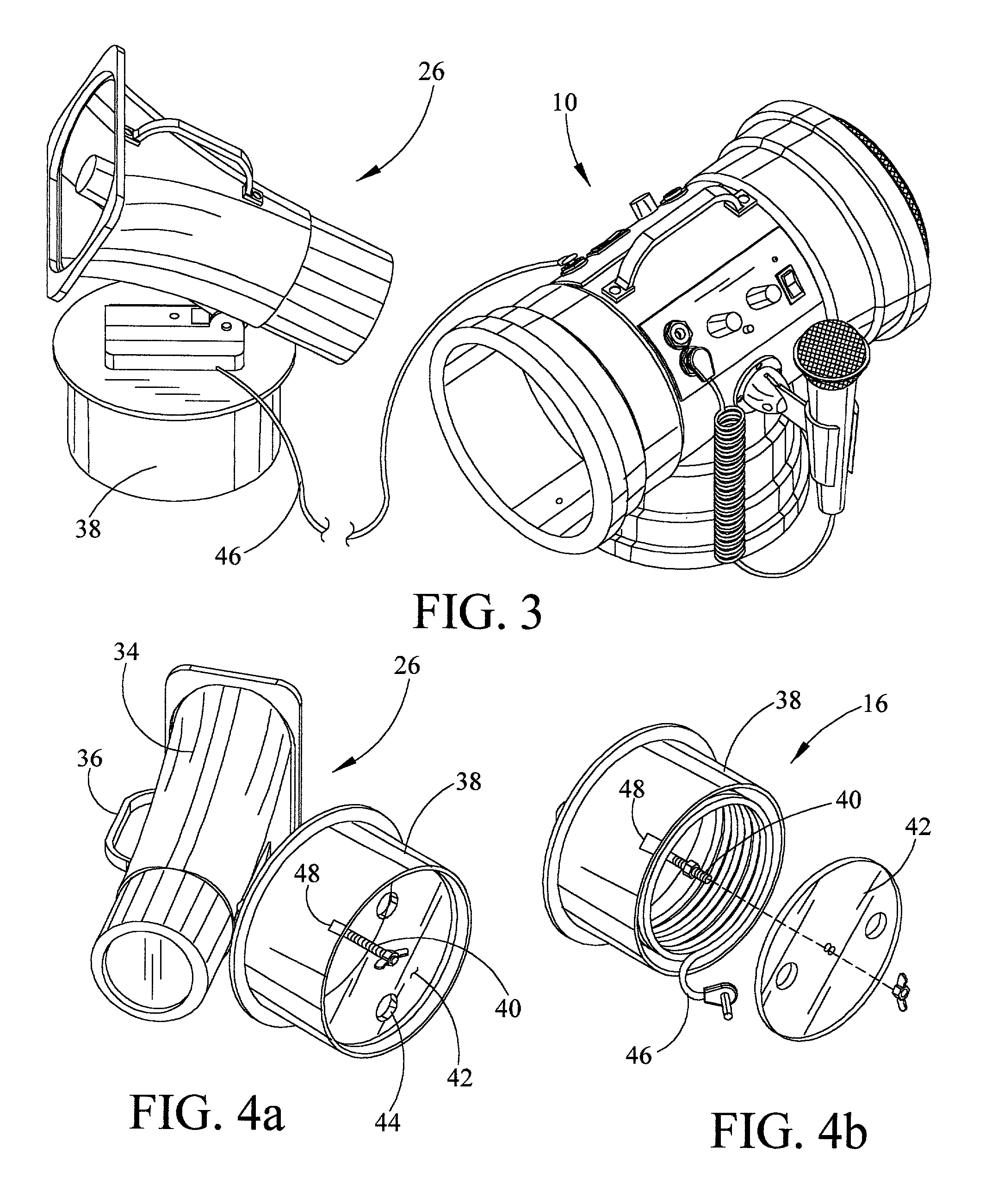

Method and apparatus for a portable public address system

InactiveUS20030063754A1Improve fidelityIncrease wattageElectric megaphonesPublic address systemWireless microphone

An improved light weight, portable public address system configured with high fidelity omni-directional and high wattage directional speakers for both indoor and outdoor use with a wide variety of sound inputs assembled in a self-contained, compact housing. Optional systems provide for the remote deployment of up to two speakers and the use of a remote wireless microphone. Improved options include a unique compact configuration that allows for modular construction of all components for plug and play operation and rapid field replacement; a weatherproof housing for operation in inclement weather, and a tape player to provide prerecorded programming.

Owner:MEARS RAYMOND L

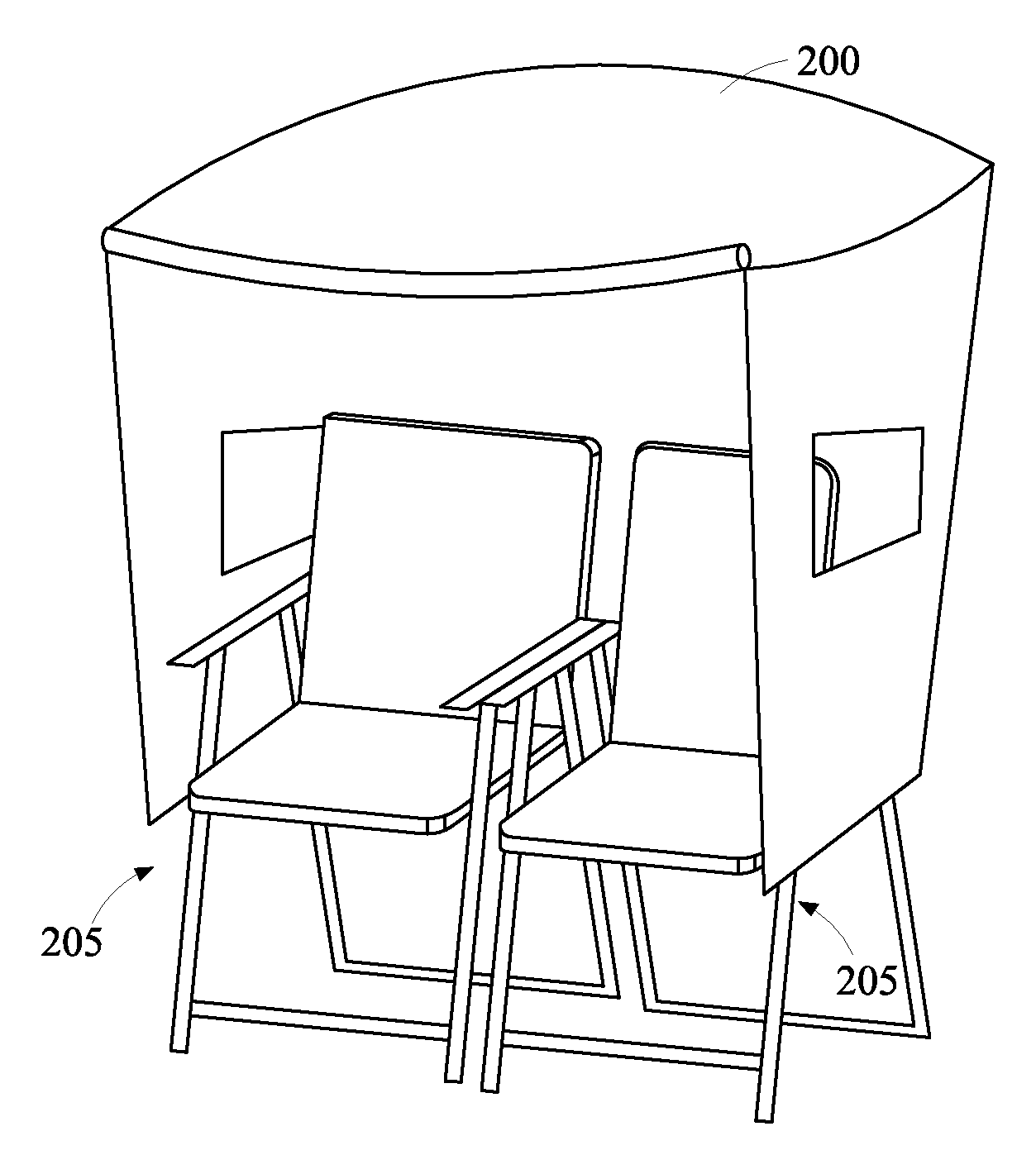

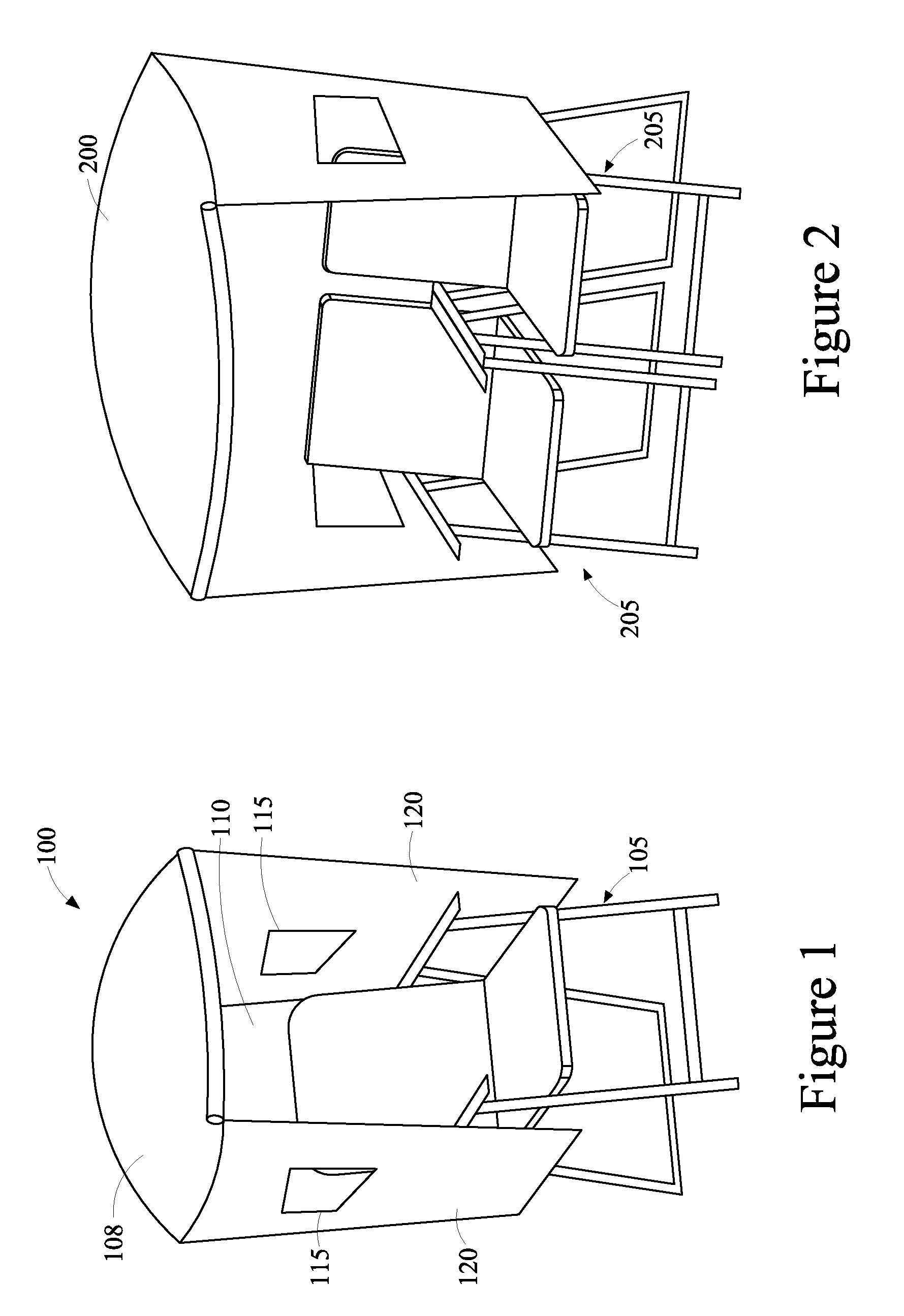

Portable weather shielding canopy

InactiveUS20090007947A1Microbiological testing/measurementMaterial analysis by electric/magnetic meansEngineeringWeather proofing

A weather shielding canopy apparatus for shielding a chair is presented. The apparatus includes a canopy that has a surface area that is sufficient to substantially cover a seating area of the chair. A tension rod frame embedded in the fabric material, maintains the canopy in an open position for covering the seating area and a closed position where the canopy retracts to fold neatly into a carrying case for portability. Side panels extending downward from a bottom side of the canopy when the canopy is in the open position at least partially shelter sides of the chair from weather. A vertical support attaches the apparatus to the chair where the top and sides of the volume are at least partially shielded from weather.

Owner:SPANGENBERG ANGELA

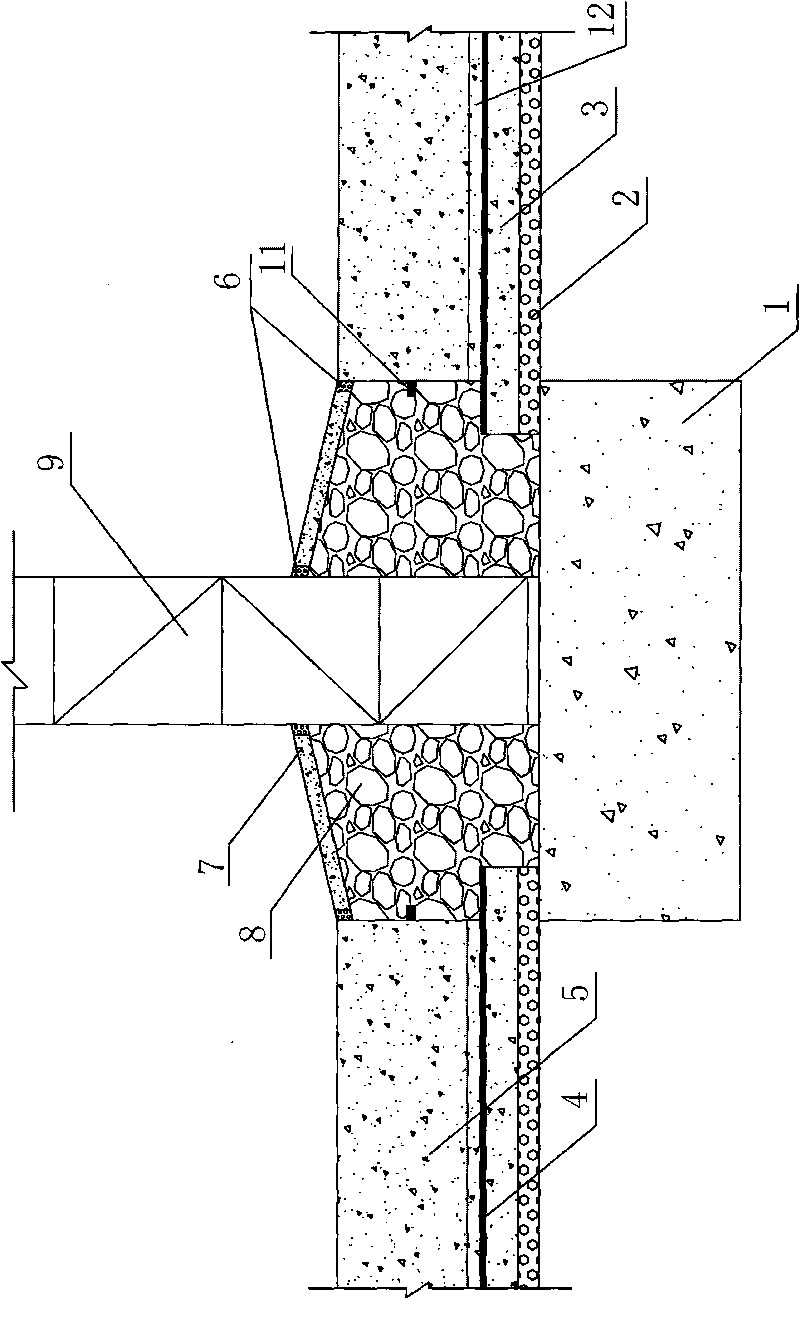

Anti-crack and anti-leak construction method of arranging tower crane foundation below waterproof baseplate

InactiveCN101761096ASolve the problem of settlement differenceSolve the problem of negative bending momentProtective foundationStress inducedPolystyrene

The invention provides an anti-crack and anti-leak construction method of arranging a tower crane foundation below a waterproof baseplate, which is characterized in that the anti-crack and anti-leak construction method adopts the following steps: 1) constructing the tower crane foundation; 2) mounting a tower crane, and then constructing a flexible mat layer, a concrete mat layer, a waterproof layer, a waterproof protective layer and the waterproof baseplate from top to bottom around the tower crane foundation, wherein the bottom surface of the flexible mat layer is leveled with the top surface of the tower crane foundation; 3) adopting pure soil for tamping and filling in the range of the tower crane foundation, then using C20 anti-leak concrete for sealing from the center of the tower crane to the periphery, carrying out calendering and anti-leak treatment, and making a 1-5% drainage slope; 4) arranging stress inducing joints of extruded polystyrene boards on the edge outside the drainage slope and the periphery of the tower crane, and further using a weather-proofing silicone sealant for tight caulking; and 5) dismantling the tower crane after completing the construction of a building, and using two layers of coiled materials for making an reinforcing waterproof layer in the range of the tower crane foundation. The anti-crack and anti-leak construction method can effectively solve the different settlement problem between the tower crane foundation and the waterproof baseplate, the problem of producing negative bending moment above the tower crane foundation, the waterproofing failure problem and the water accumulation settlement problem of the tower crane foundation.

Owner:SHANDONG WANXIN CONSTR

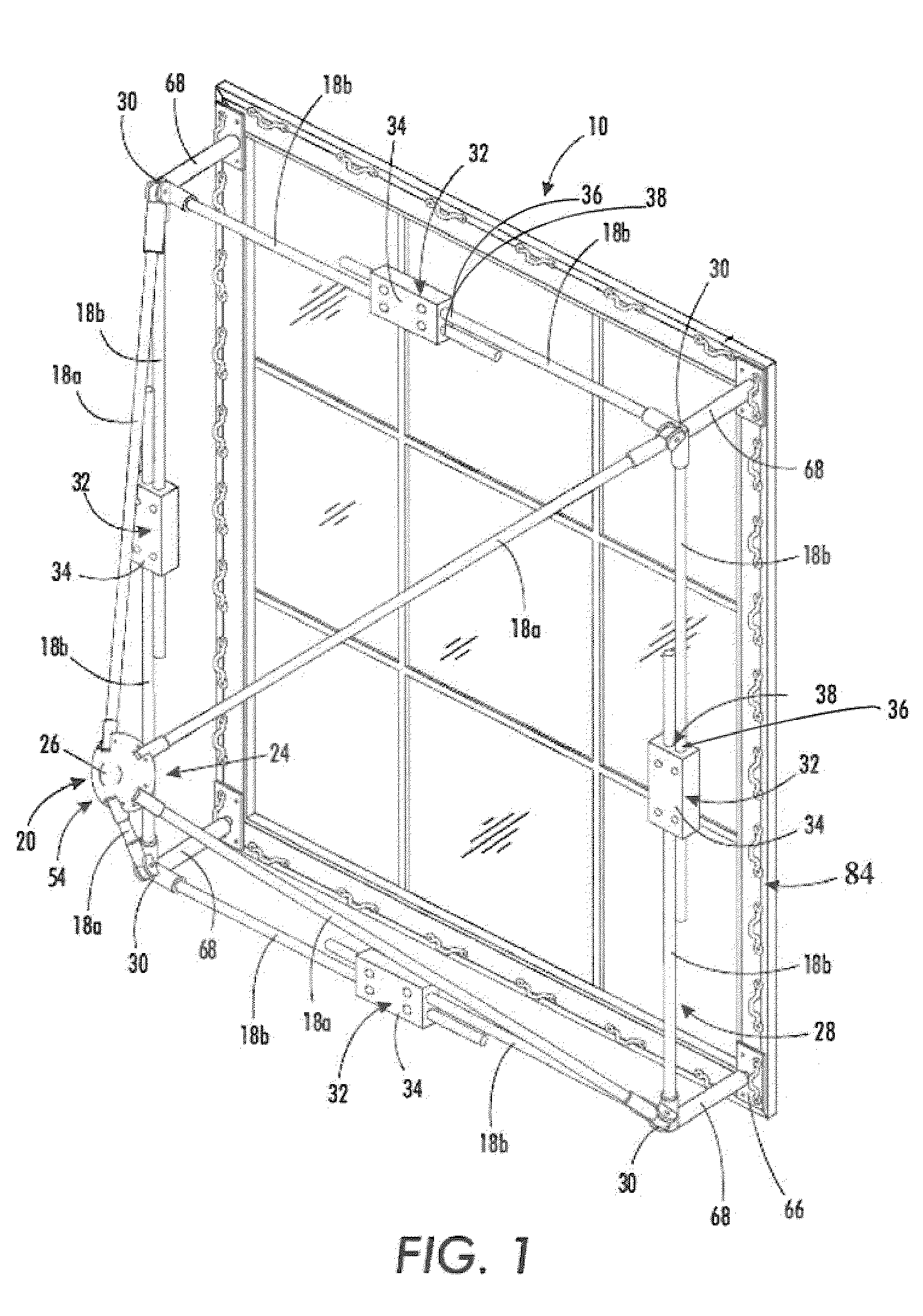

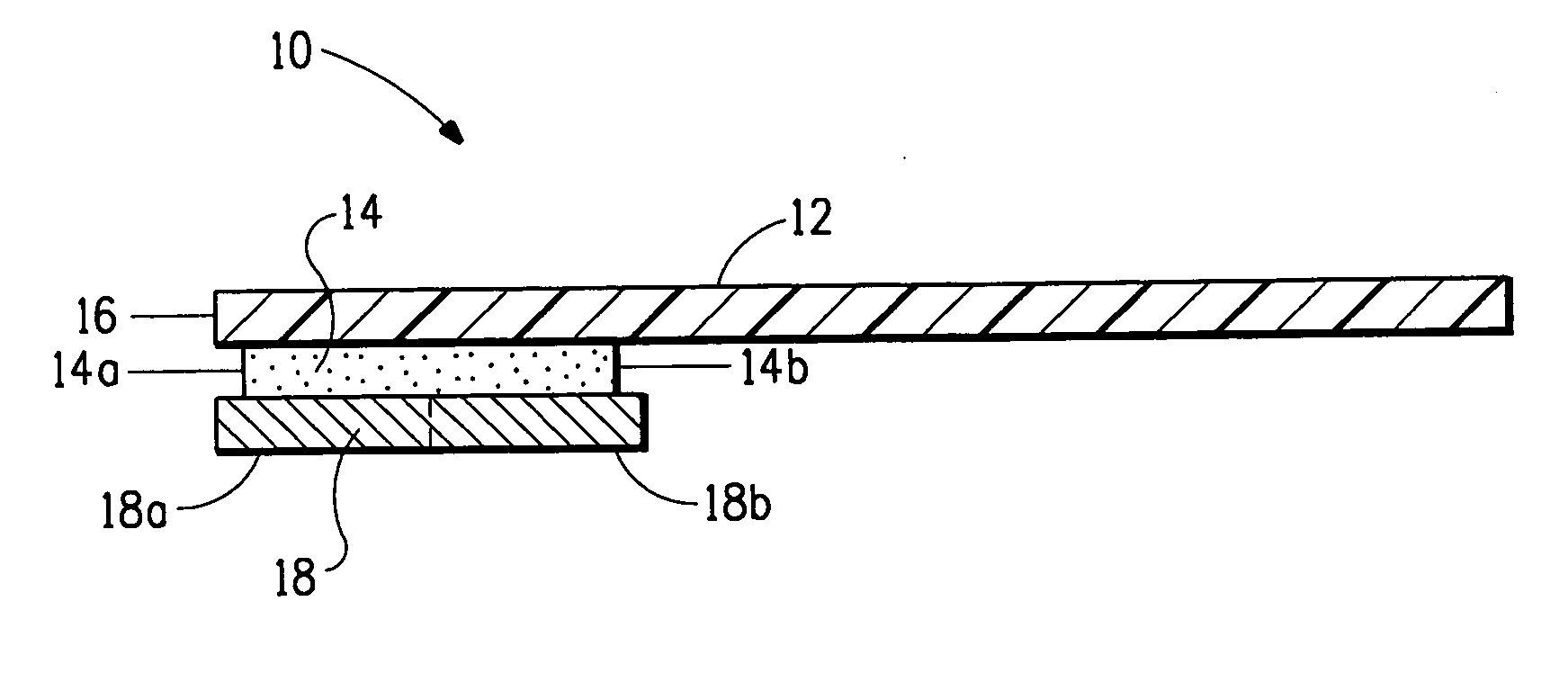

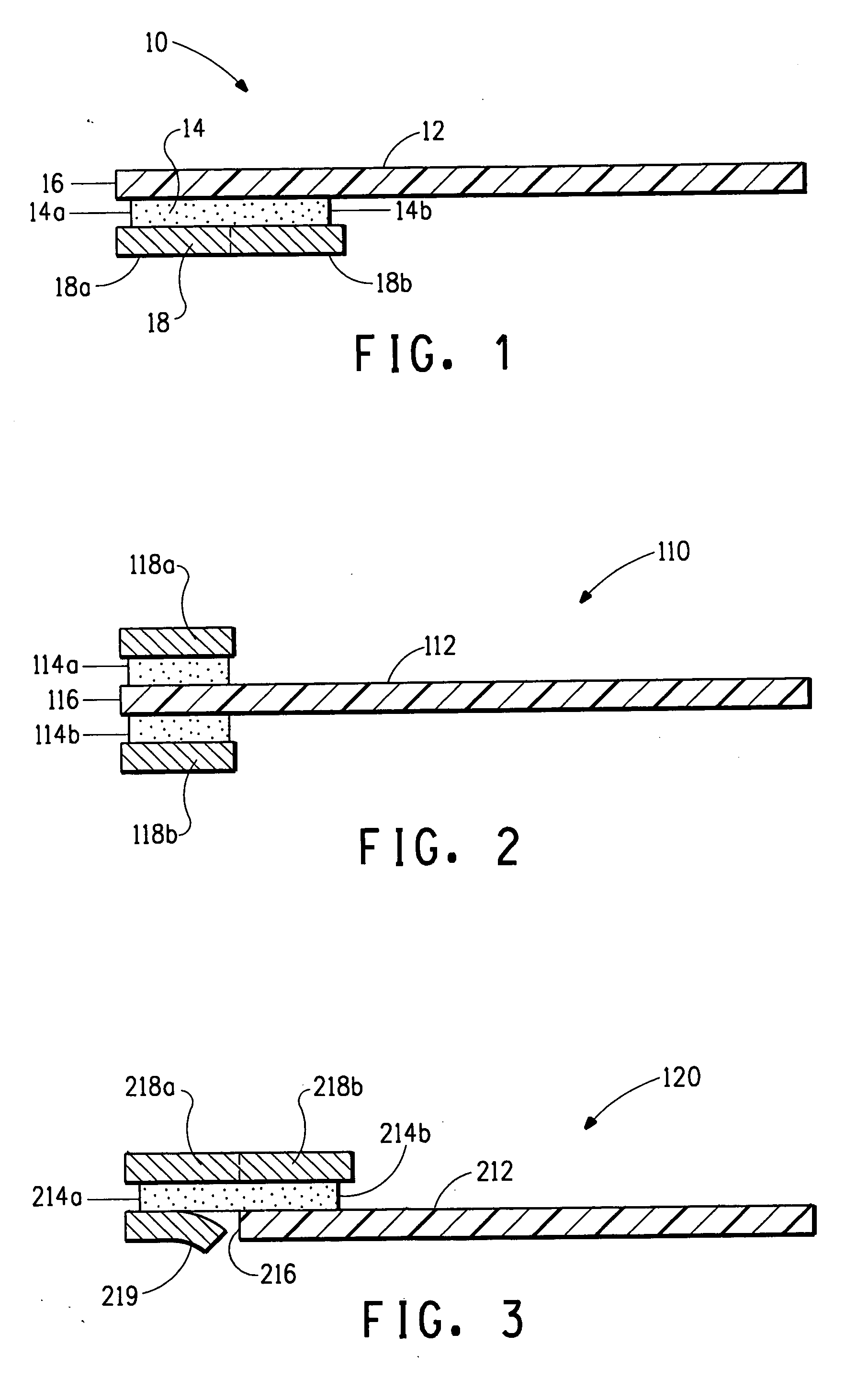

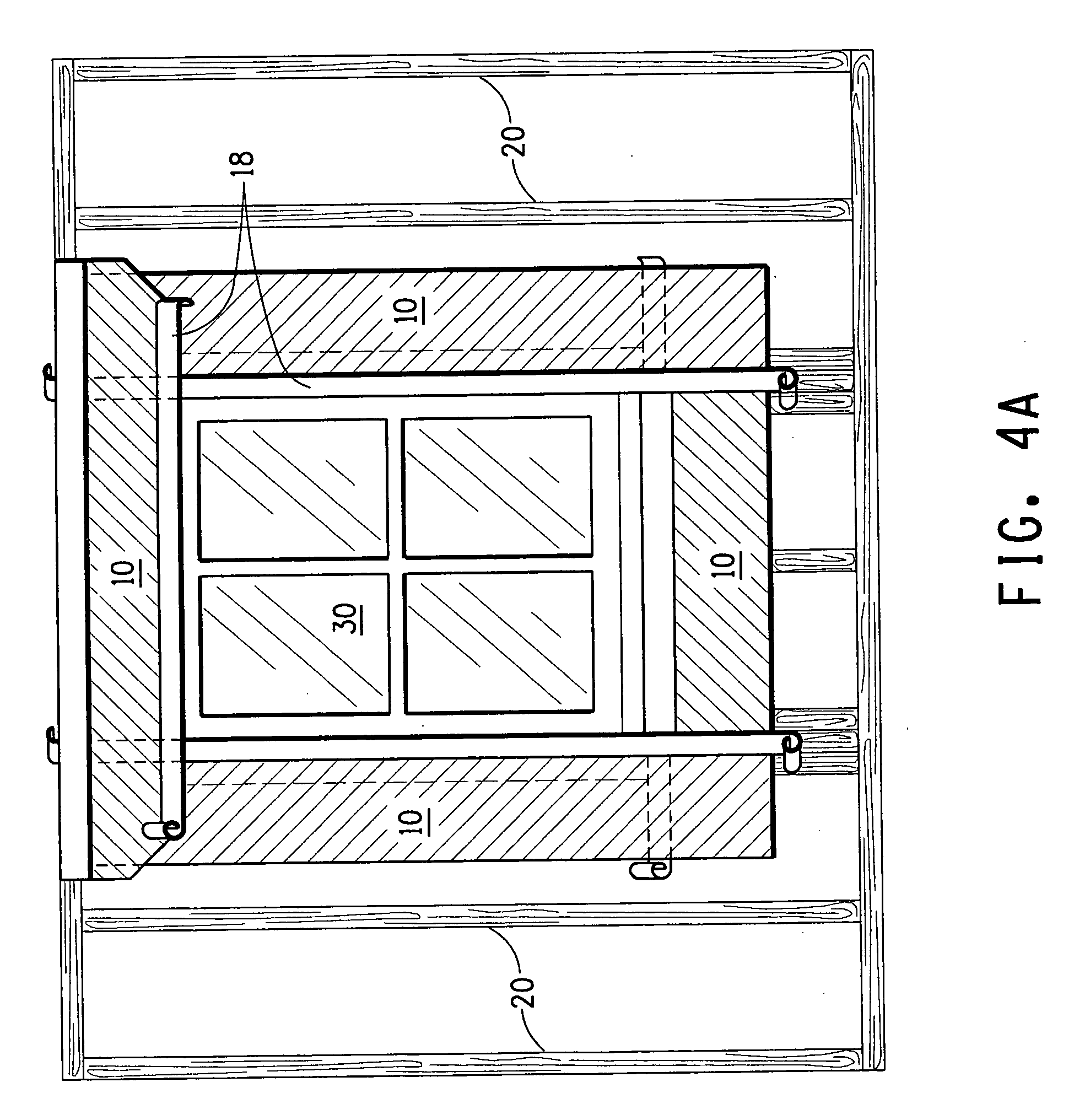

Flashing for integrating windows with weather resistant barrier

InactiveUS20080141597A1Roof covering using slabs/sheetsRoof covering using tiles/slatesResistive barrierEngineering

A self-adhesive flashing for integrating a flanged fenestration unit installed in a rough opening in a wall with a water resistive barrier where the flashing includes an elongated substrate having a pressure-sensitive adhesive layer adhered to at least one side of the substrate along a lateral edge of the substrate and methods for applying the flashing.

Owner:EI DU PONT DE NEMOURS & CO

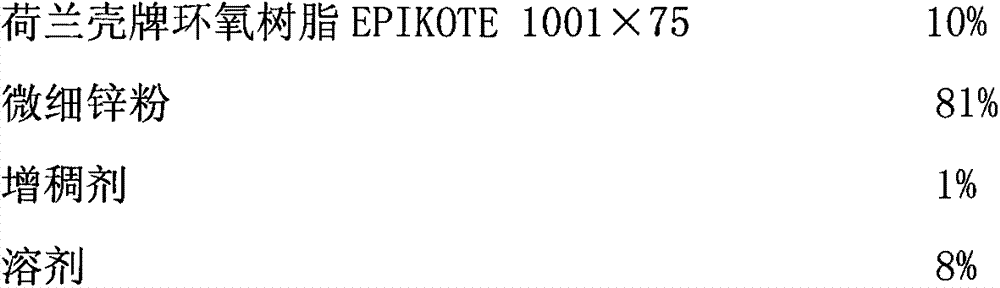

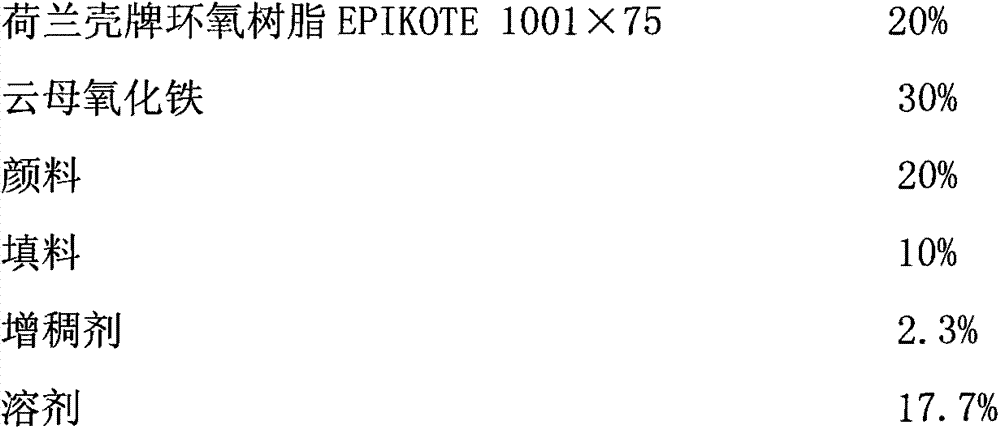

Super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system

InactiveCN103497643AHigh content of zinc dustImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsHeat conductingCoating system

The invention discloses a super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system and belongs to the technical field of chemical coatings. The super-weatherproof heavy-duty high-solid heat conductance barrier electrostatic coating system comprises a bottom coat, an intermediate coat and a surface coat, wherein the bottom coat is formed by coating an epoxy zinc rich primer, the intermediate coat is formed by coating an epoxy mica iron oxide paint and the surface coat is formed by coating a fluoro-carbon finish; the fluoro-carbon finish is added with hollow glass micro beads and a heat conducting powder. The electrostatic coating system provided by the invention is excellent in heavy duty, heat insulation and weather-proofing properties, high in electrostatic conductivity, high in solid content, low in volatilization, healthy and has environment-friendly effect, is long in system service life, and suitable for various steel structure facilities such as a gasoline can, a container, a steel pipe, a bridge, petrochemical equipment, a ship and a harbor facility.

Owner:浙江绿色德环保科技股份有限公司

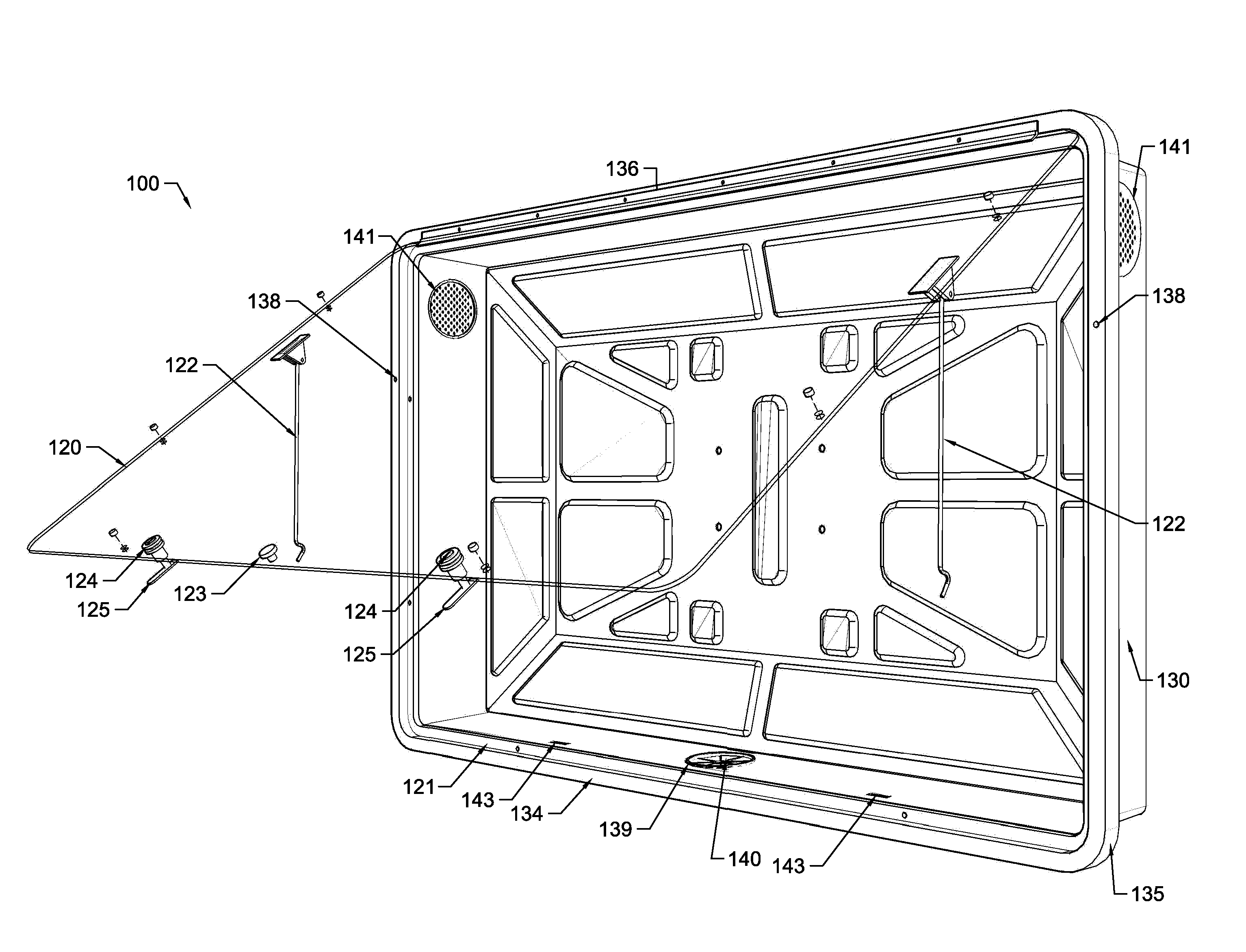

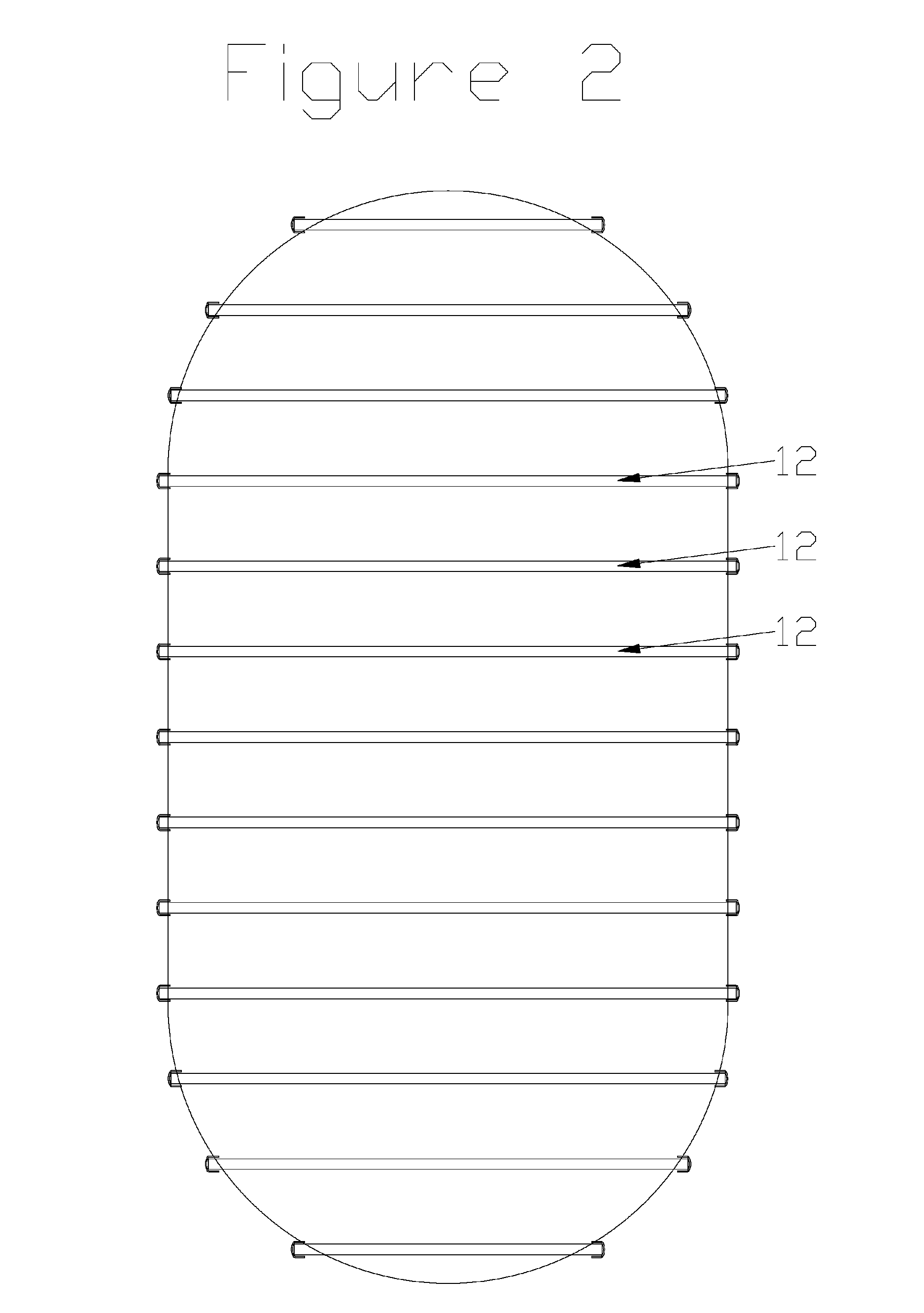

Roll-up spa and swim spa cover

ActiveUS8683621B1Improve structural strengthAccurately tailoredGymnasiumSwimming poolsGlass fiberHot spring

A spa cover constructed of layers of pliable insulation encapsulated within a weatherproof vinyl reinforced fabric or a rubber membrane which is attached to rigid square support tubes that run parallel to the short end of the spa. The encapsulated insulation is fastened to the bottom of the square support tubes with corrosion-free nylon anchors which allows the soft insulation assembly to span over the water and rest directly on the spa bartop surface sealing the heat in and keeping debris out. An arched fiberglass rod structure supports a weatherproof rainfly which is permanently affixed to the flat cover assembly to shed rain and debris. The entire assembly is held in place at each end with adjustable straps which stretch the cover from end to end keeping the rainfly taut. Removing the cover to access the spa involves undoing the straps on one end and rolling the cover assembly towards the other end until the desired amount of spa exposure is reached. Covering the spa after use is just the opposite procedure.

Owner:E2E LLC

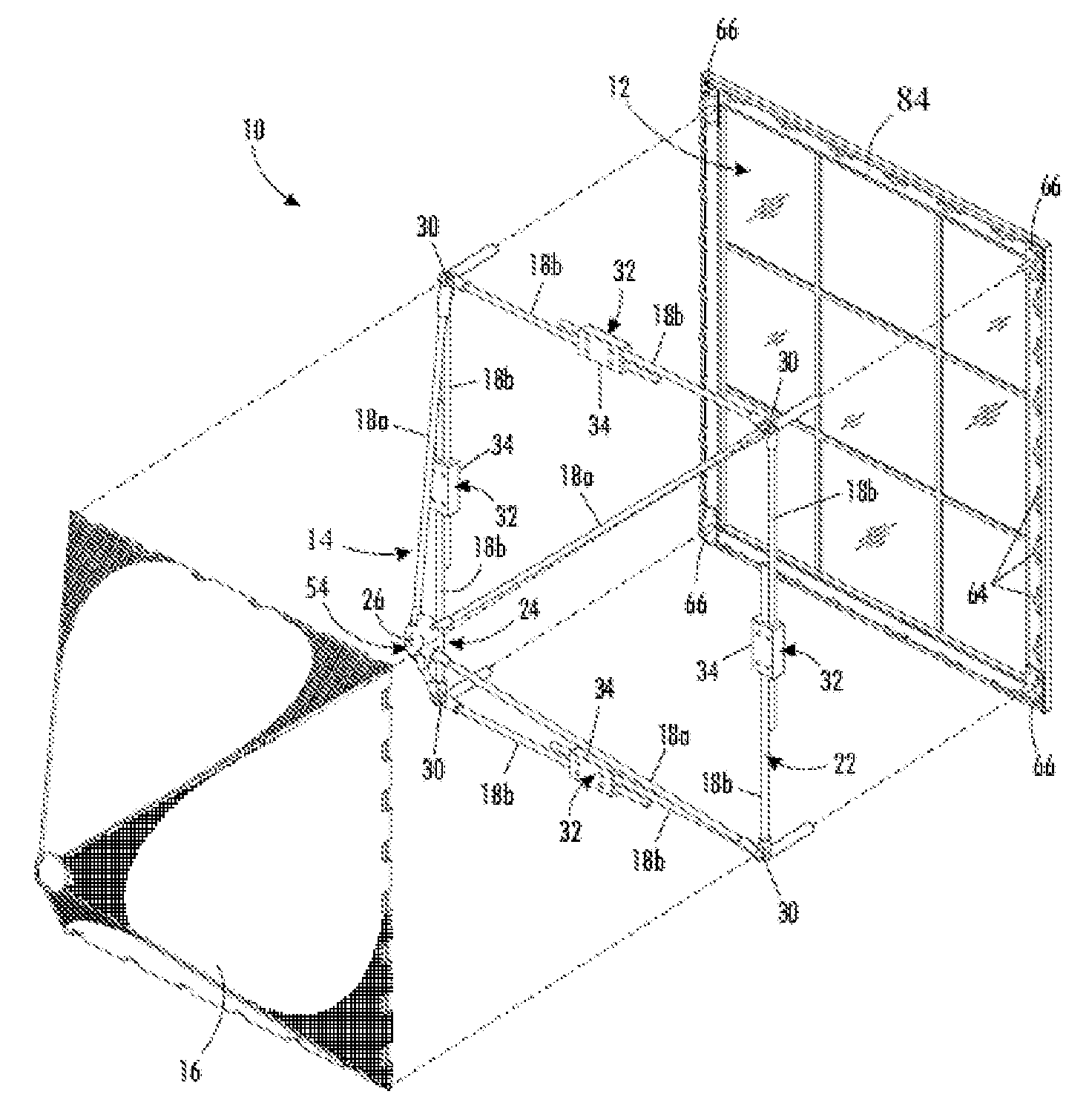

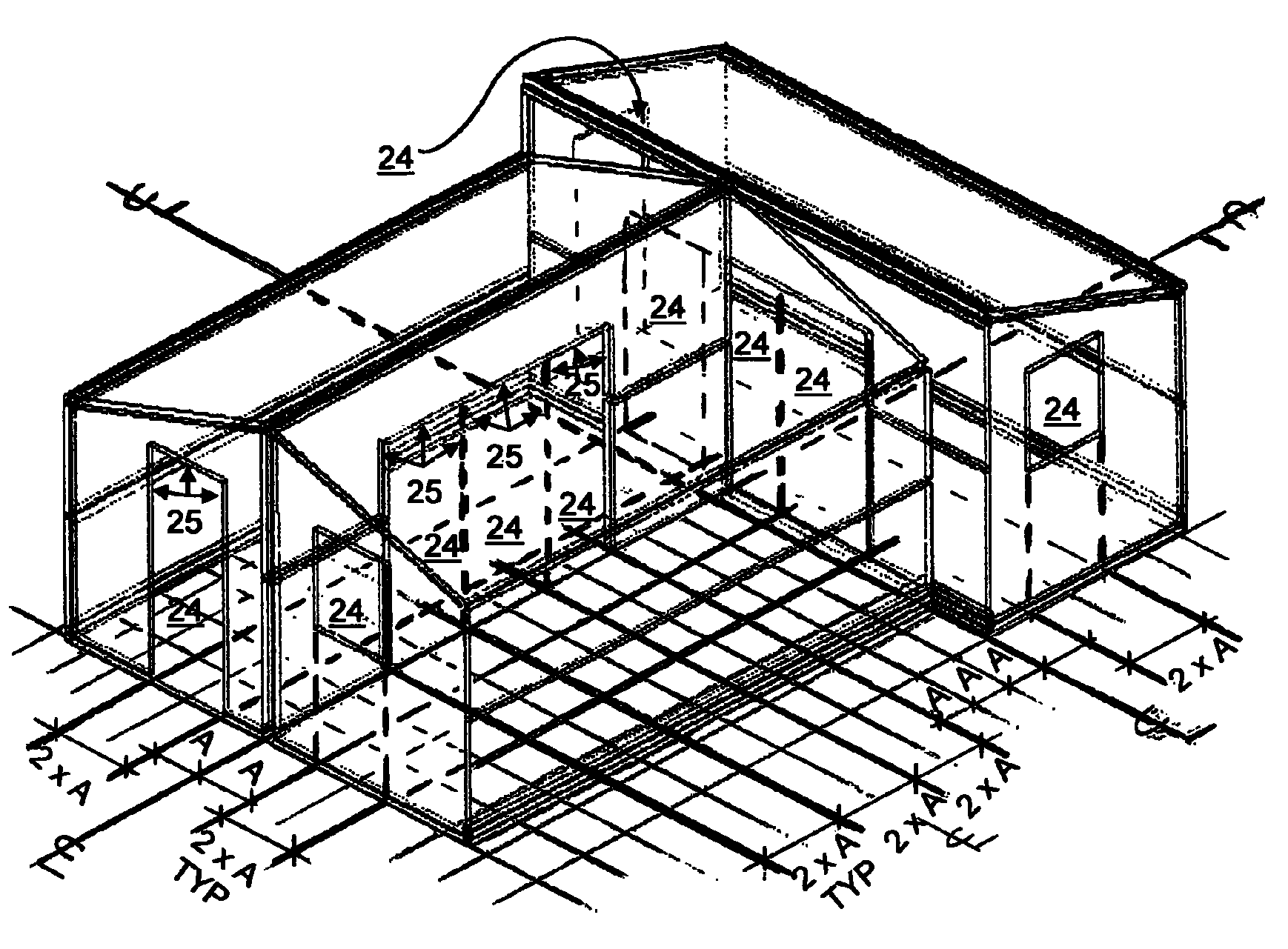

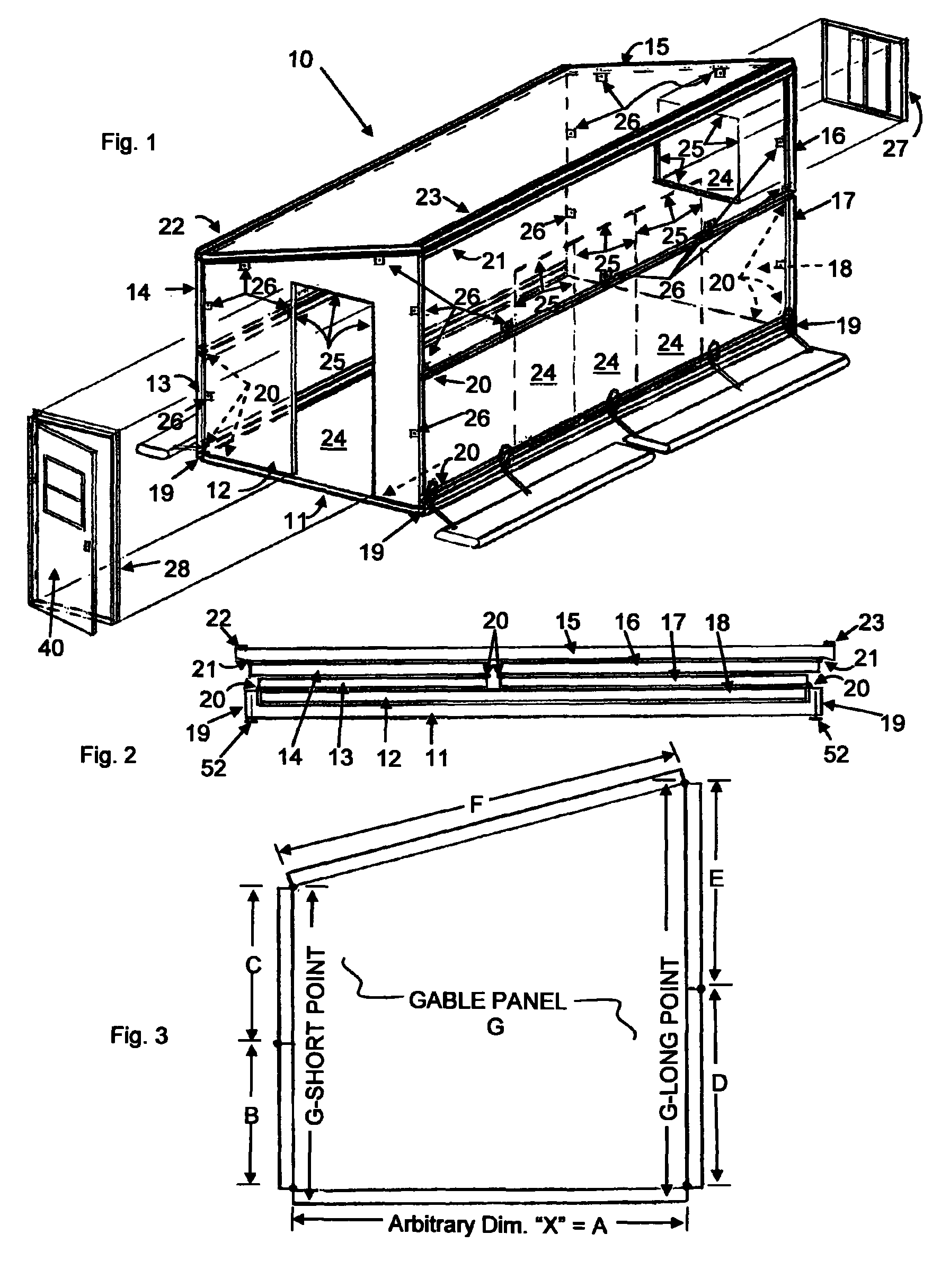

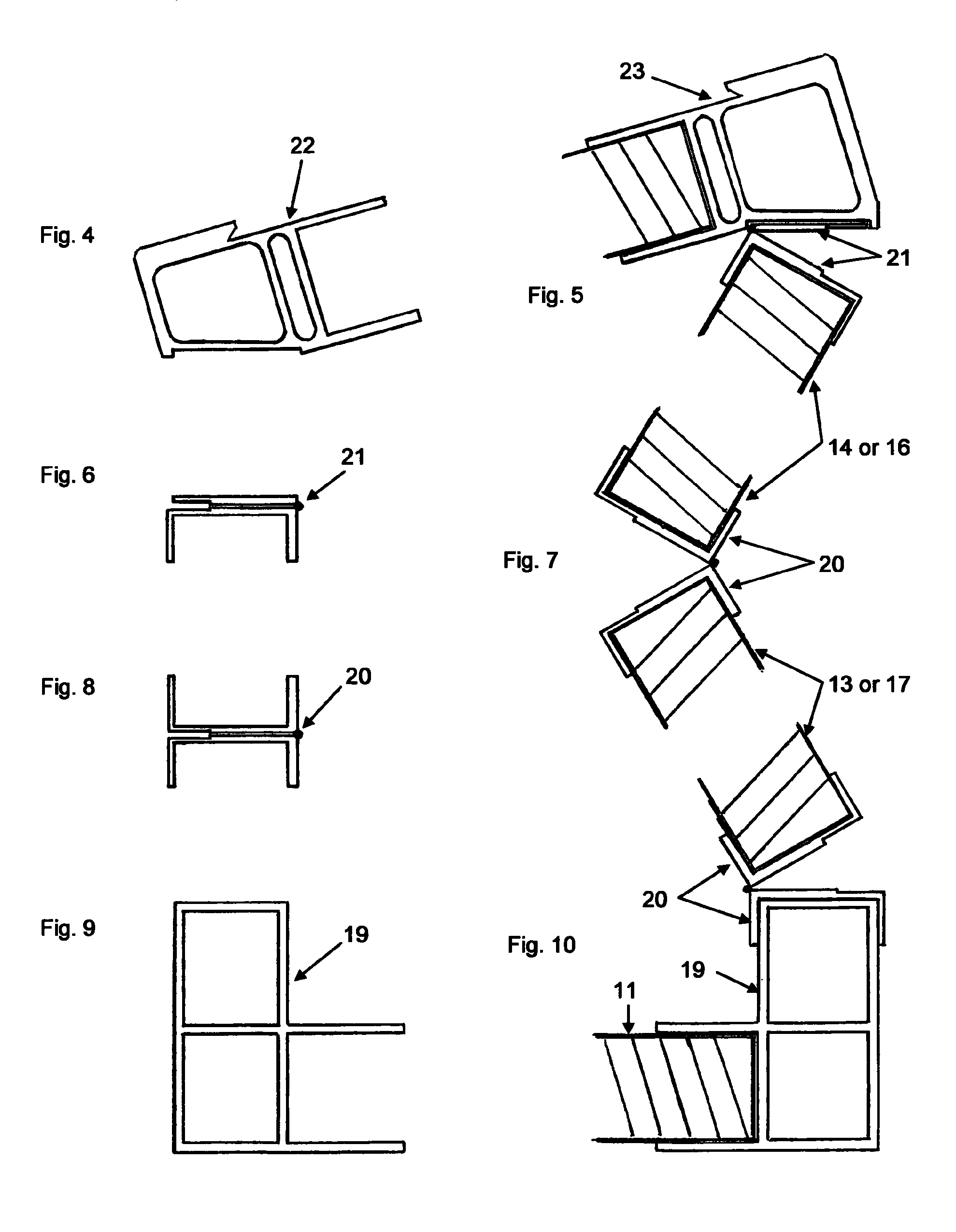

Foldable transportable structure

ActiveUS8555559B2Long-term reliabilityImprove propertiesBuilding roofsPublic buildingsWeather proofingMechanical engineering

Disclosed is a foldable transportable structure with a three dimensional rectangular shed roof shape having improved component and structural properties, and improved shipping and deployment capabilities. The integrated unique geometric folding pattern means provides enhanced folding accuracy and correct placement of interactive panels during collapse or assembly of the structure, and also greatly increases the flexibility for multiple unit combinations and component materials selection. The folding transportable structure provides a strong, safe, insulated weatherproof structure with a quick setup time, and requires NO tools or separate loose components for assembly.

Owner:DIGREGORY VINCENT J

Construction technique for novel network model glass curtain wall

ActiveCN107489215ARandom and irregular design graphicsBeautiful appearanceWallsBuilding material handlingShielded metal arc weldingArchitectural engineering

The invention discloses a construction technique for a novel network model glass curtain wall. The construction technique comprises the following steps of preparation before construction, CAD auxiliary design, piece wall positioning, surveying setting-out, embedded part mounting, steel vertical column mounting, steel beam mounting, intermediate acceptance, glass plate block and glass pressing block mounting, injection of a weather proofing sealant in glass plate blocks, cutting and mounting of aluminum alloy lines, welding and hoisting of steel net frames and clearing and completed acceptance of the glass plate blocks. According to the construction technique for the novel network model glass curtain wall, CAD auxiliary design is adopted, the relation of the drawing size and the component size is determined, on-site positioning, processing customization, numbering and mounting on the wall and finished product manufacturing are adopted, and the construction technique for the novel network model glass curtain wall is simple and convenient to operate; and when a welded joint of the steel net frame is fully welded, carbon dioxide gas protective welding is adopted, and compared with traditional shielded metal arc welding, the cost is saved by 40% or more.

Owner:WENZHOU CONSTR GROUP

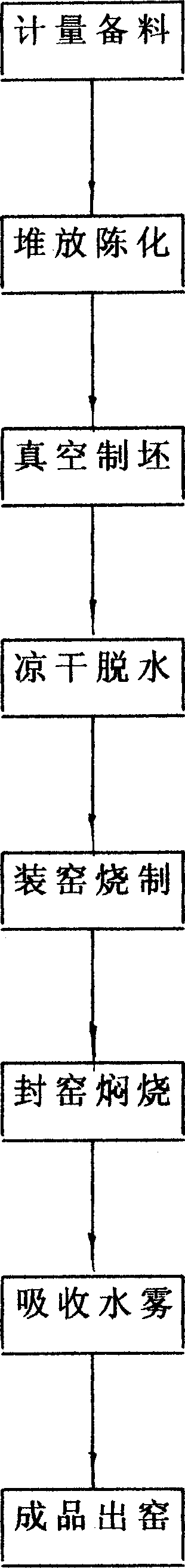

Vacuum internal-combustion type grey-brick-tile baking method using shale as raw material

InactiveCN1850695AUniform, firm and stable color quality inside and outsideSocial benefitsCombustion

The invention discloses a method for firing black tiles in vacuum internal combustion mode with shale as raw material, comprising the steps of batching, piling up and ageing, vacuum making blanks, airing and dehydrating, placing in kiln and firing, sealing kiln and smoldering, absorbing water smoke and delivering finished products, and its outstanding substantial character and remarkable advancement lie in that it uses the shale obtained by blasting for cutting a mountain to replace clay, and the black tile products have high intensity, good cold tolerance and frost resistnace, weather proofing, and osmosis proofing, and extremely large added value, and have completely remarkable economic and social benefits.

Owner:李石牛

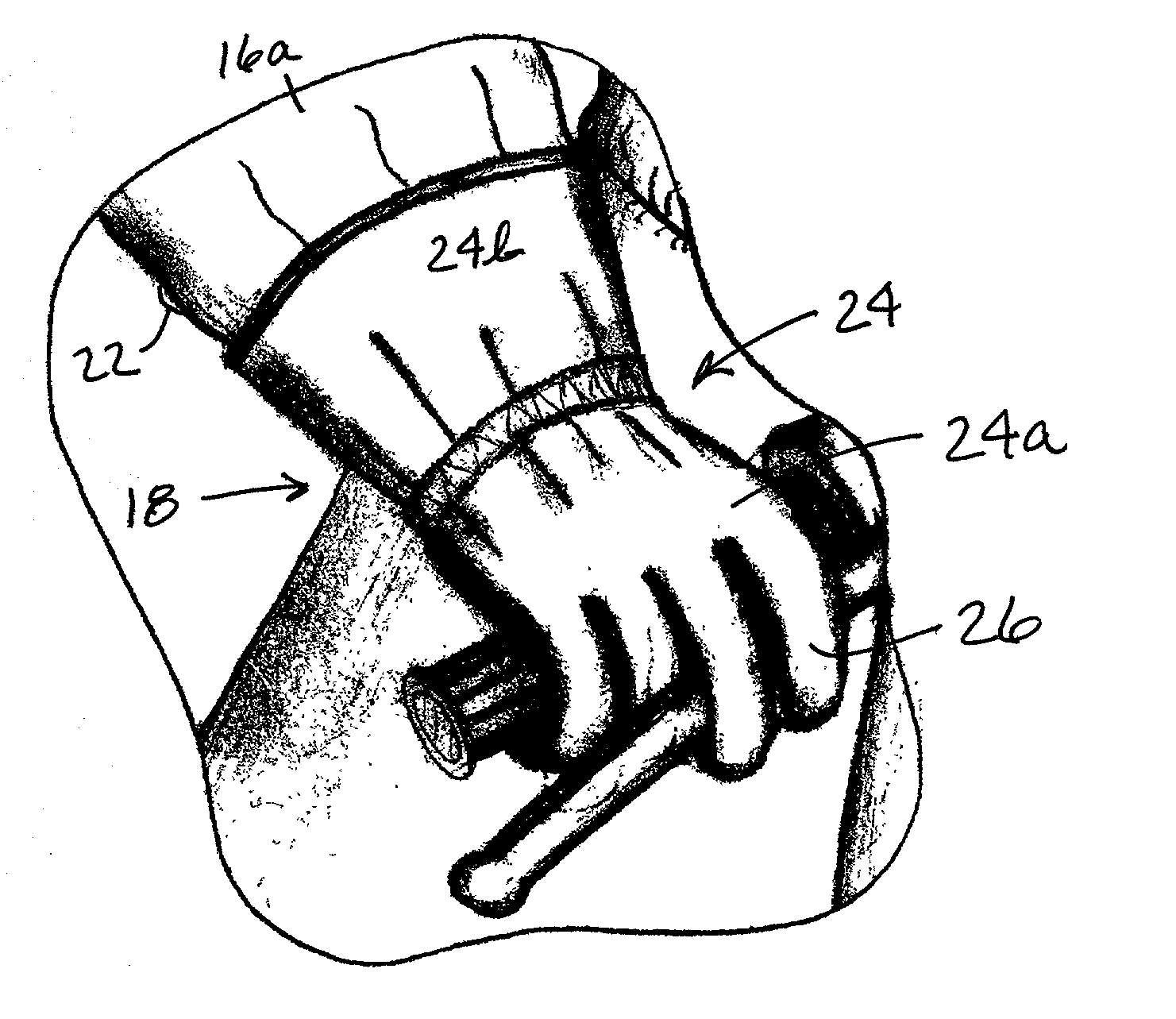

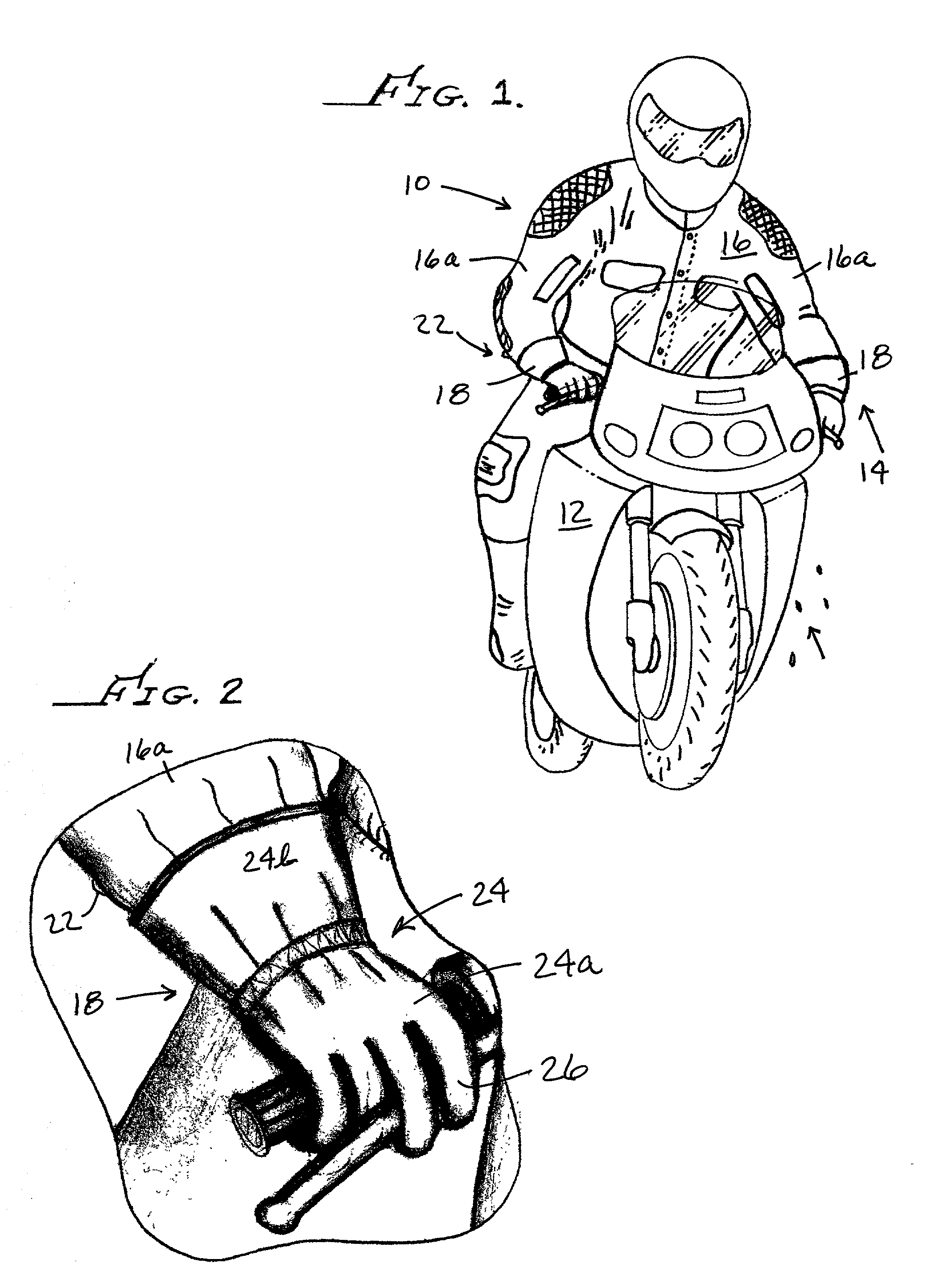

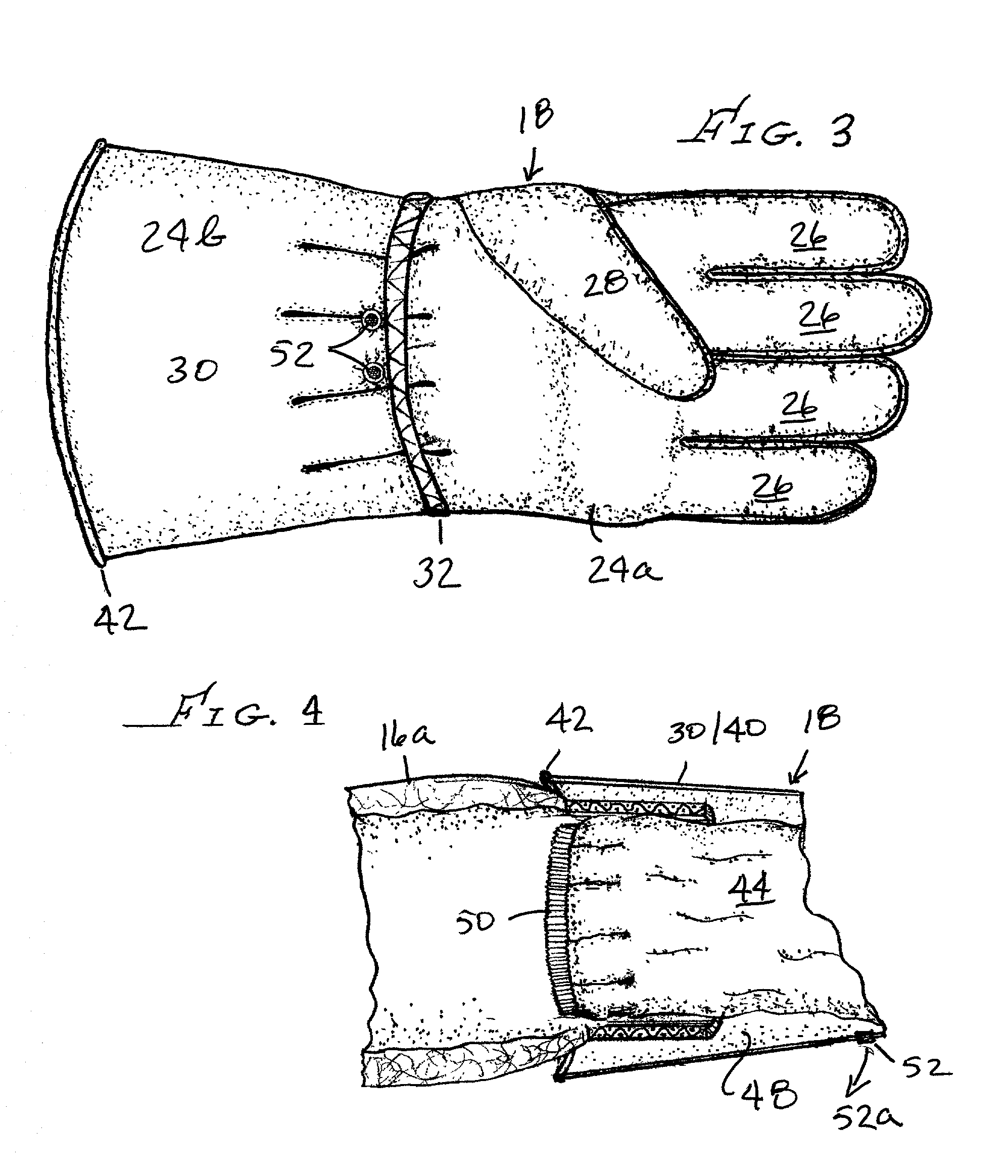

Foul-weather sport glove and method

A weather-resistant glove for wear particularly by operators and passengers of open-air sport motor vehicles includes an outer glove shell and in inner glove liner, each having an elongate gauntlet cuff portion. The gauntlet cuff portion has an inner gauntlet and an outer gauntlet cooperatively defining a water catch basin, from which a drain opens outwardly of the glove at or near the lowest point of this basin while the user's hands are in a typical downwardly angled position on the sport motor vehicle. Water dribbling along a leeward side of the user's arms and into the gauntlets of the gloves will be caught in the water catch basins and is then drained outwardly of the glove without wetting the user's hands.

Owner:INTERSPORT FASHIONS WEST

Garment made from composite fabric for weather protection

InactiveUS20050020161A1Excellent weather protectionWaterproof and breathable with stretchGarment special featuresWarp knittingFiberPolyester

A waterproof, breathable, recyclable, layered composite fabric with stretch that is especially well-suited for weather protection garments and the like, has at least one layer of a woven, knitted, or non-woven face fabric of stretch-recovery bicomponent fibers, and an elastomeric waterproof film or coating of the same polymer, and optionally a liner fabric of knitted construction. The composite fabric is recyclable using traditional techniques to recycle polyester or polyamide. Garments made from this fabric are also disclosed.

Owner:INVISTA NORTH AMERICA R L

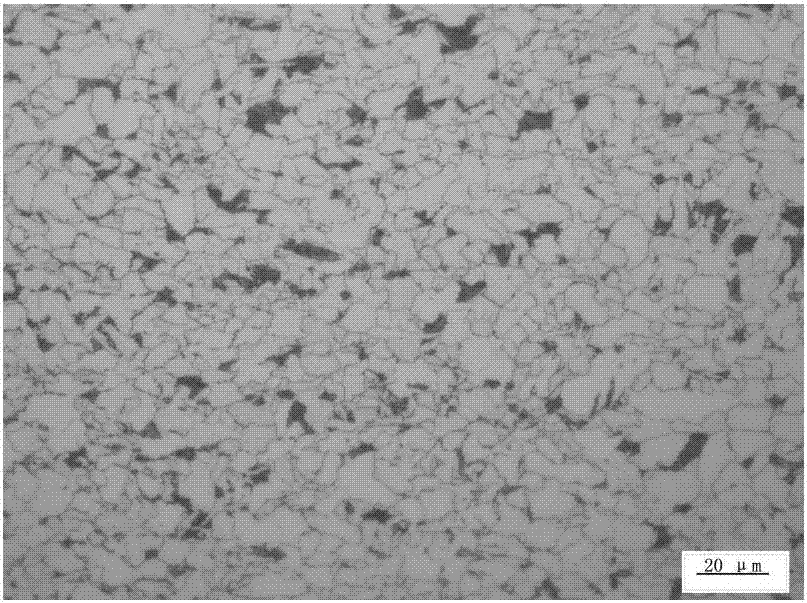

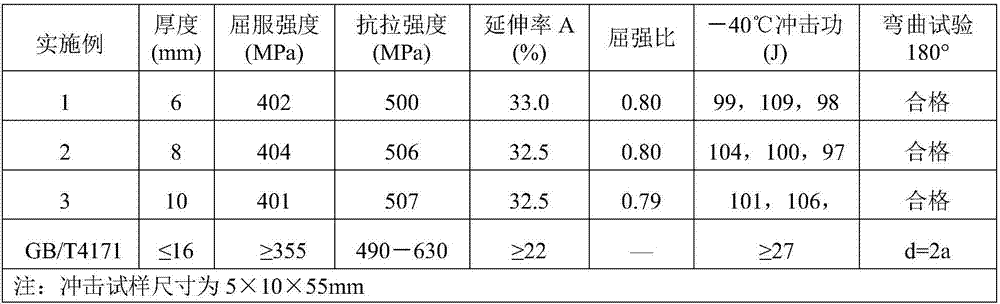

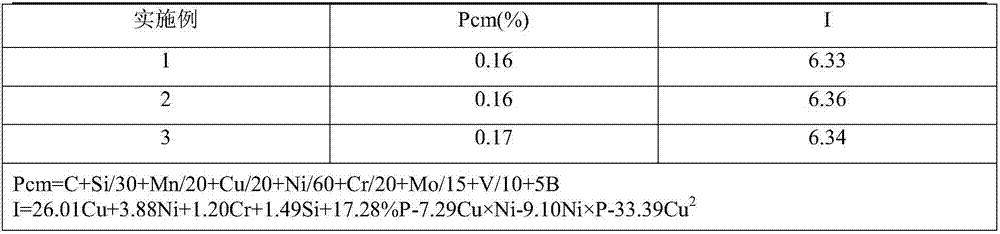

Rare-earth weather-proofing bridge steel plate with yield strength being 420MPa and production method of rare-earth weather-proofing bridge steel plate

InactiveCN107574374ASimple preparation processShorten the production cycleRare earthHeating temperature

The invention relates to a rare-earth weather-proofing bridge steel plate with the yield strength being 420MPa and a production method of the rare-earth weather-proofing bridge steel plate. The production method comprises the steps of smelting and casting, heating and rolling, and cooling. In the step of the heating and rolling, the heating temperature is 1200-1220 DEG C and the total time insidea furnace is greater than or equal to 240 min; the first stage of the rolling is carried out in an austenite recrystallization zone, the initial rolling temperature is 1130-1180 DEG C in the rolling process, the reduction rate in the first pass to the second pass shall be greater than 10%, and the reduction rate in at least 1-2 of the rest passes is controlled above 25%; and the second stage of the rolling is carried out in an austenite non-recrystallization zone, the initial rolling temperature is less than or equal to 930 DEG C, the thickness of a middle blank is 2.0-3.5 times of the thickness of a finished product, and the finish rolling temperature is 830-850 DEG C. The yield strength of the steel plate is greater than 420MPa, and has the advantages that the steel plate is low in yieldstrength ratio, and good in corrosion resistance, low temperature toughness, cold forming performance and welding performance, and can be used in a coating-free manner; a production process flow is simple; a production cycle is short; and the cost is low.

Owner:BAOTOU IRON & STEEL GRP

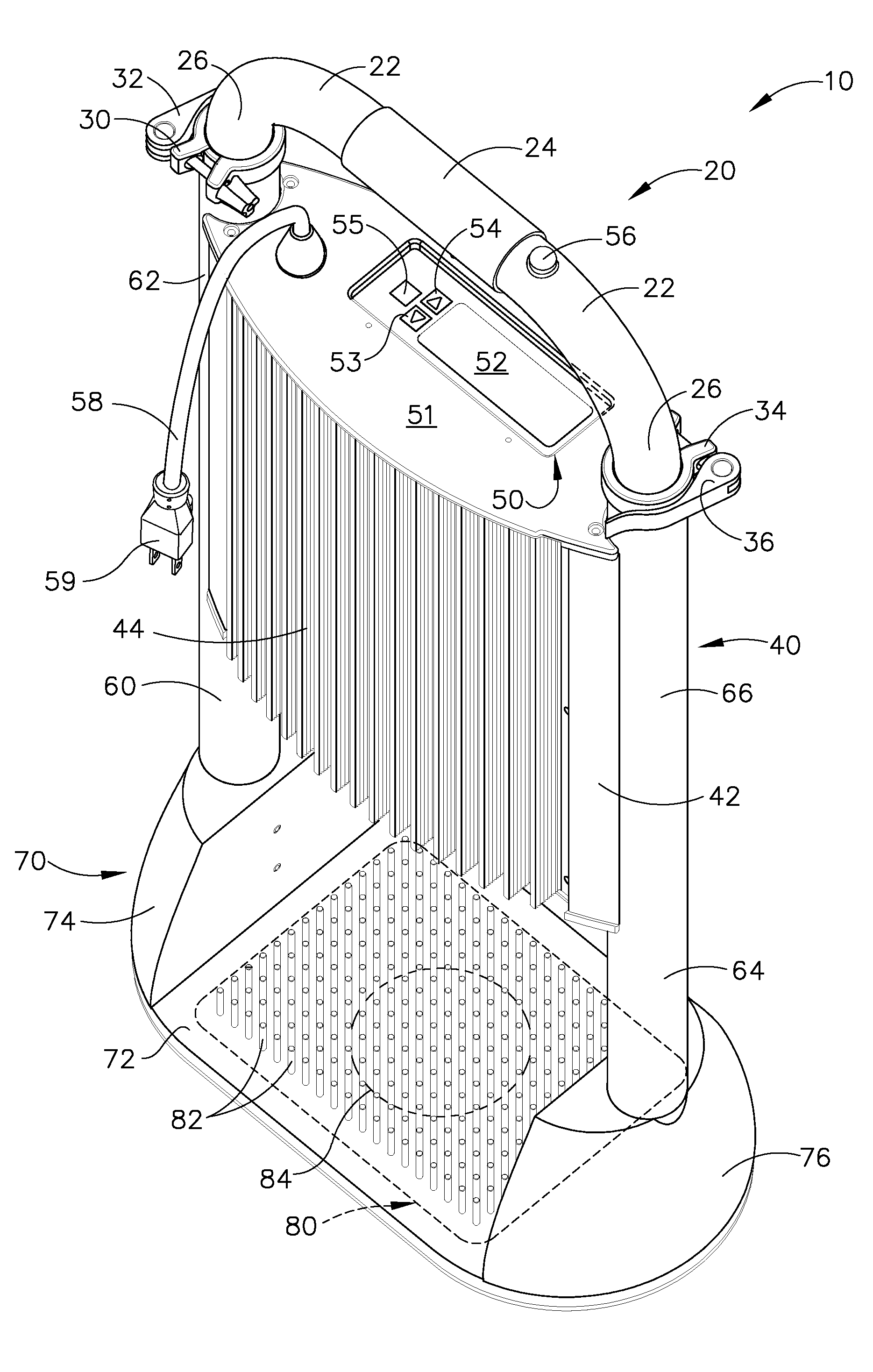

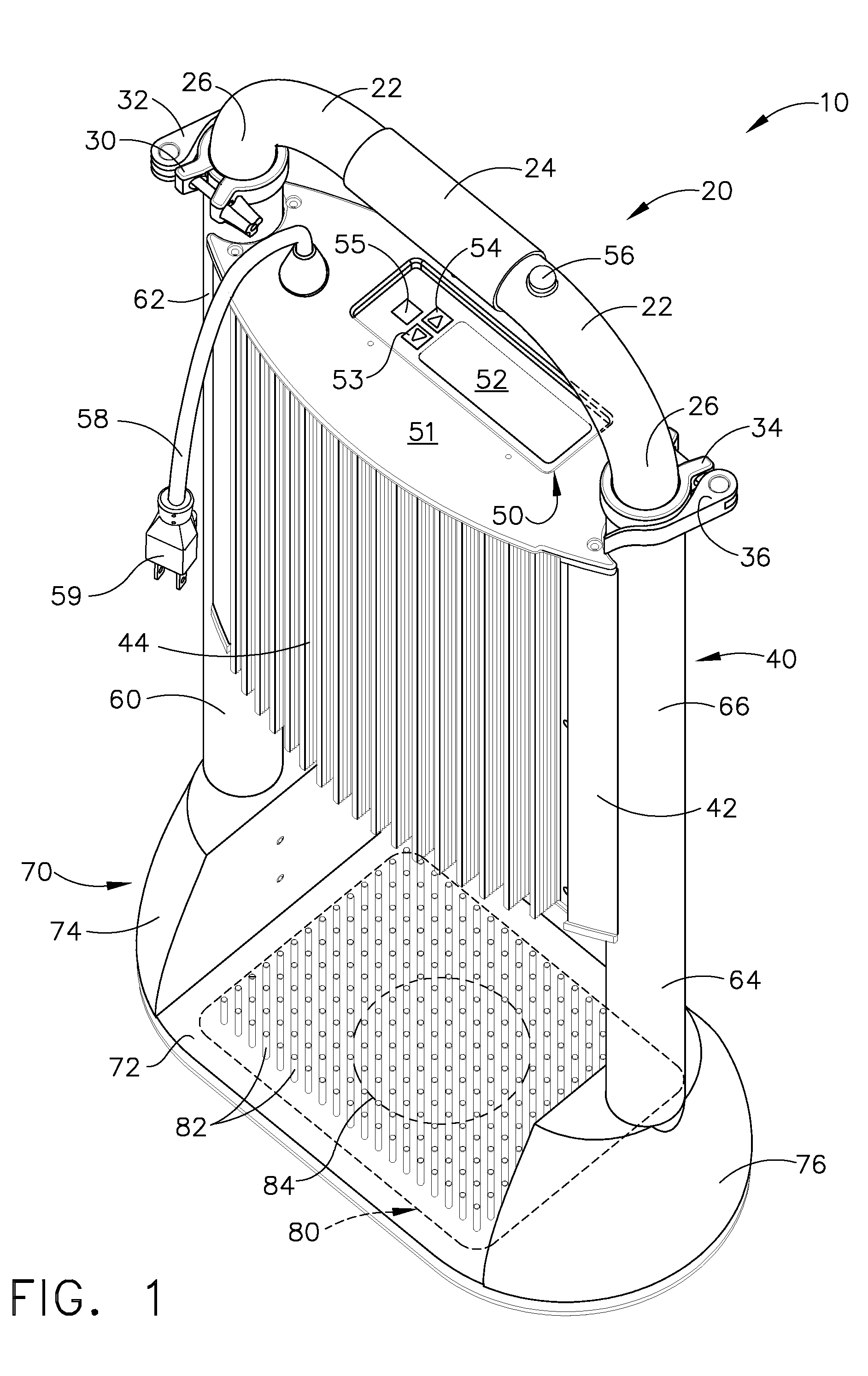

Stand-up membrane roofing induction heating tool

A portable induction heating tool is provided as a membrane roofing tool for use in sealing anchor plates with a heat-activated adhesive to a membrane roofing member. The tool uses two different audible tones so two tools can be used simultaneously on a single roof, while allowing a user to easily distinguish between the operation of both tools. The main housing containing electronics is weather-tight, and requires no forced-cooling devices. The controller automatically performs data logging functions, such as counting the number of anchor plates per job or per day that have been properly placed, counting the number of activation events for a tool's life, tracking the number of faults which occur as the tool is being used, and the controller can identify the type of fault that occurs during operation of the tool. The controller also stores energy setting changes in memory.

Owner:OMG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com