High-performance extrusion grade ASA resin composition and preparation thereof

An ASA resin, extrusion-grade technology, applied in the field of high-performance extrusion-grade ASA resin composition and its preparation, can solve the problems of toughness, weather resistance, surface gloss and processing performance that cannot be balanced, and achieve high surface gloss degree, good fluidity, excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

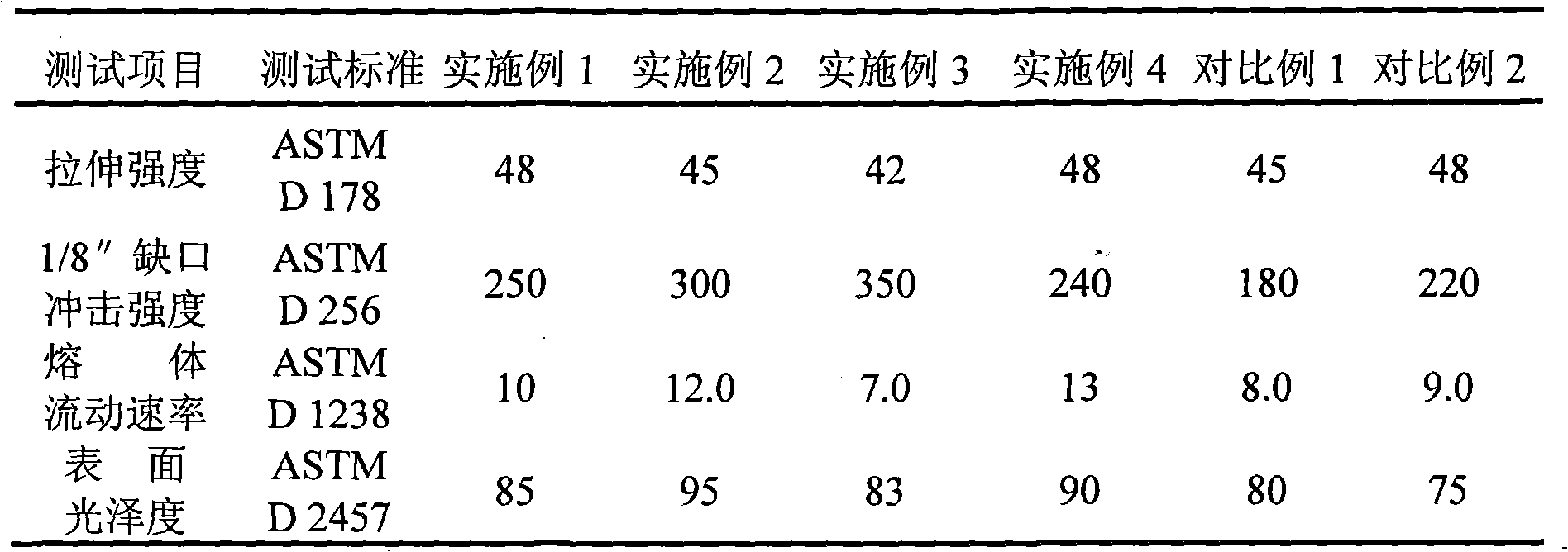

Examples

Embodiment 1

[0032] 20Kg ASA rubber powder 1, 20Kg ASA rubber powder 2, 55Kg AS resin, 5Kg graft copolymer of silicone rubber and AS, 1Kg EBS, 0.5Kg silicone oil, 0.5Kg PE wax, 0.5Kg zinc stearate, 0.2Kg bismuth Phenol A, 0.2Kg IG-168, 0.2Kg IG-245, 0.3Kg IG-770DF were added to a high-speed mixer and stirred for 20 minutes before being discharged, and then extruded in a twin-screw extruder with an aspect ratio of 36 and a diameter of 35mm For medium extrusion granulation, the barrel temperature of the extruder is 180-240°C, and the screw speed is 180-600rpm.

Embodiment 2

[0034] The purpose of this example is to compare the influence of different surface gloss agent dosages on product performance.

[0035] Select the same graft copolymer copolymer of silicone rubber and AS as the surface gloss agent for use in Example 1, and the addition amount is correspondingly changed into 20 parts from 5 parts in Example 1, and specifically made as follows: 20Kg ASA rubber powder 1, 20Kg ASA rubber powder 2, 40Kg AS resin, 20Kg graft copolymer of silicone rubber and AS, 1Kg EBS, 0.5Kg silicone oil, 0.5Kg PE wax, 0.5Kg zinc stearate, 0.2Kg bisphenol A, 0.2Kg IG- 168, 0.2Kg IG-245, 0.3Kg IG-770DF, put into a high-speed mixer and stir for 20 minutes before discharging, then extrude and granulate in a twin-screw extruder with an aspect ratio of 36 and a diameter of 35mm. The barrel temperature of the machine is 180-280°C, and the screw speed is 180-600rpm.

Embodiment 3

[0037] The purpose of this example is to compare the effects of different amounts of ASA rubber powder.

[0038] The addition amount of ASA rubber powder is changed into 60 parts by 40 parts among the embodiment 1, specifically make as follows: the graft copolymerization of 30Kg ASA rubber powder 1, 30Kg ASA rubber powder 2, 35Kg AS resin, 5Kg silicone rubber and AS Material, 1Kg EBS, 0.5Kg silicone oil, 0.5Kg PE wax, 0.5Kg zinc stearate, 0.2Kg bisphenol A, 0.2Kg IG-168, 0.2Kg IG-245, 0.3Kg IG-770DF, add to the high-speed mixer Stir in medium for 20 minutes and discharge, then extrude and granulate in a twin-screw extruder with an aspect ratio of 36 and a diameter of 35mm. The barrel temperature of the extruder is 180-280°C, and the screw speed is 180-600rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com