Patents

Literature

105results about How to "Solve weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

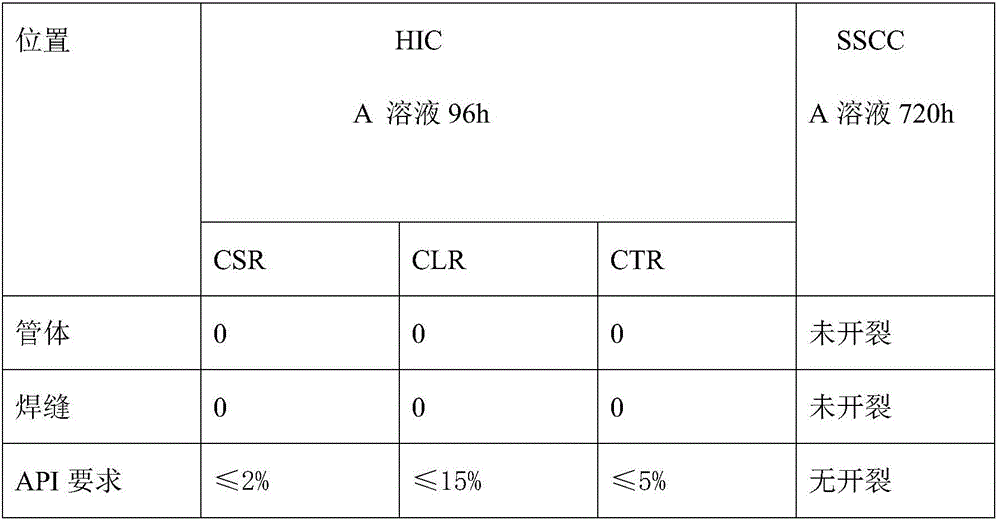

Welding method for Q420qENH coating-free weathering steel for steel bridge

InactiveCN106956064AGuaranteed compatibility of ingredientsSolve weather resistanceArc welding apparatusWelding/cutting media/materialsFillet weldWeather resistance

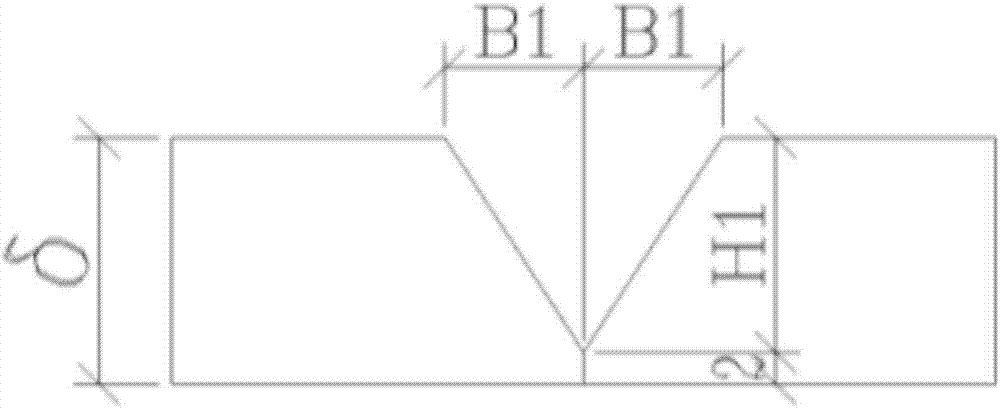

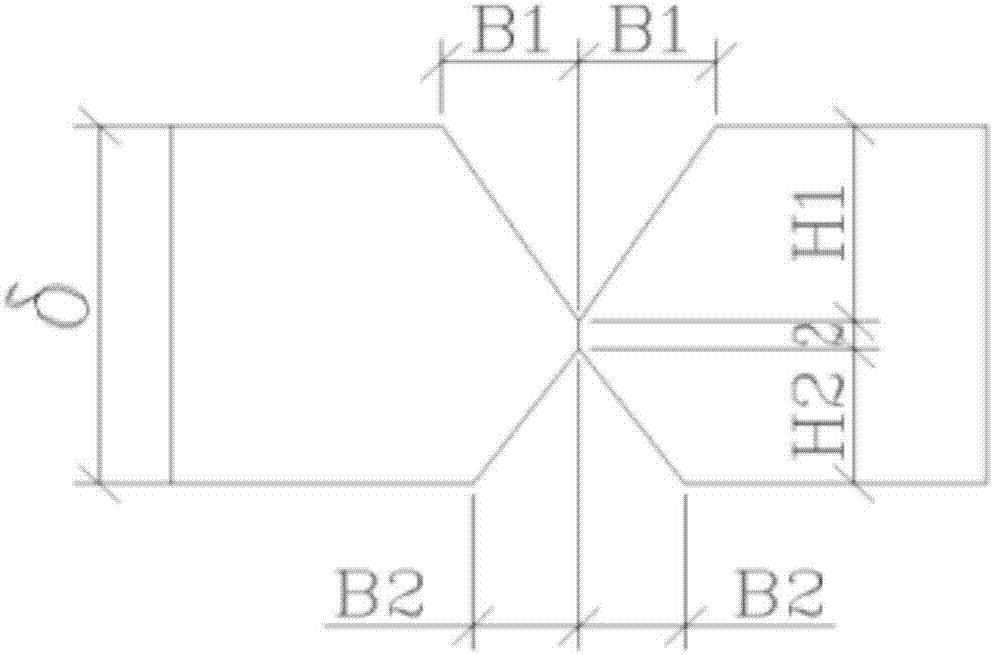

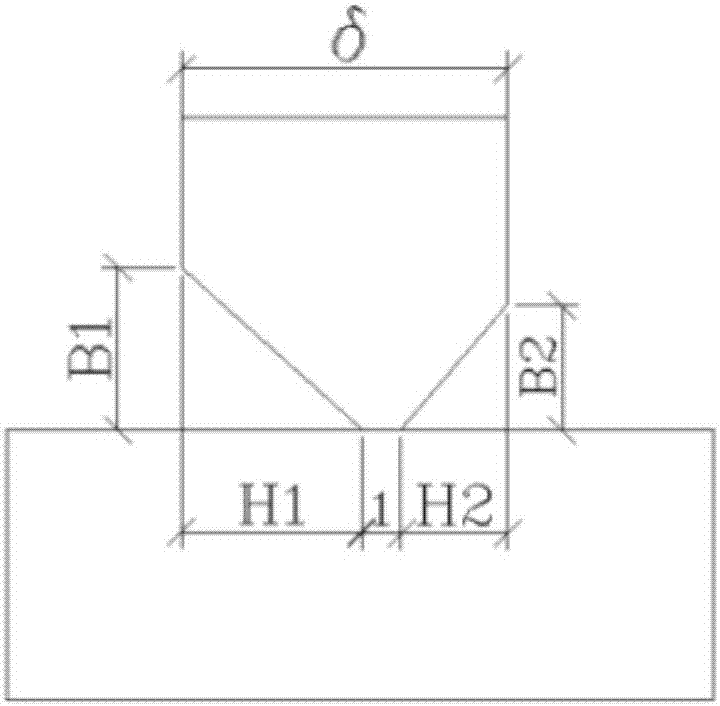

A welding method of Q420qENH coating-free weather-resistant steel for steel bridges, the Q420qENH coating-free weather-resistant steel has an atmospheric corrosion resistance index I≥6.5, a welding sensitivity index Pcm≤0.23, and when the welded joint form is a butt weld, The combined welding process of solid wire gas-shielded welding for backing and submerged arc automatic welding for filling and covering is adopted; when the welding joint form is T-shaped penetration fillet weld, the gas-shielded welding process of flux-cored welding wire is adopted; the welding joint form is single-sided bridge deck When welding double-sided formed joint welds, a combined welding process of solid wire gas shielded welding for bottoming and submerged arc automatic welding for filling and covering is used. The atmospheric corrosion resistance index I of the welding wire in the present invention is ≥ 6.5, and the relative corrosion rate of the deposited metal is ≤ 8%, which ensures that the welding seam matches the composition of the steel plate, and solves the weather resistance of the welding seam of the coating-free weather-resistant steel. Coating the weather-resistant steel bridge solved the technical bottleneck.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Fire-resistant weather-proof steel plate for 690MPa-grade building structure and manufacturing method thereof

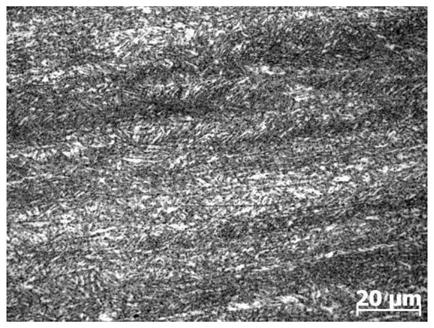

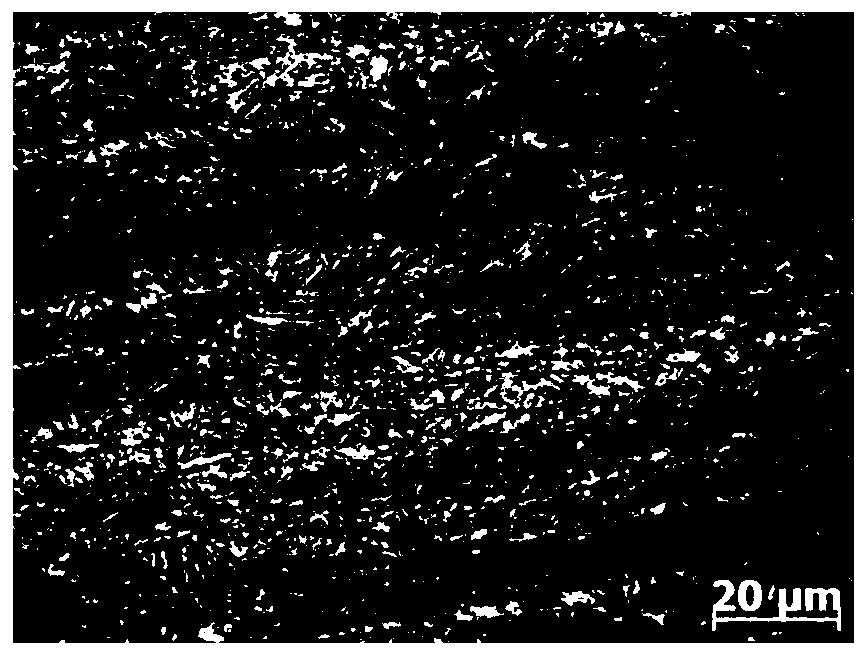

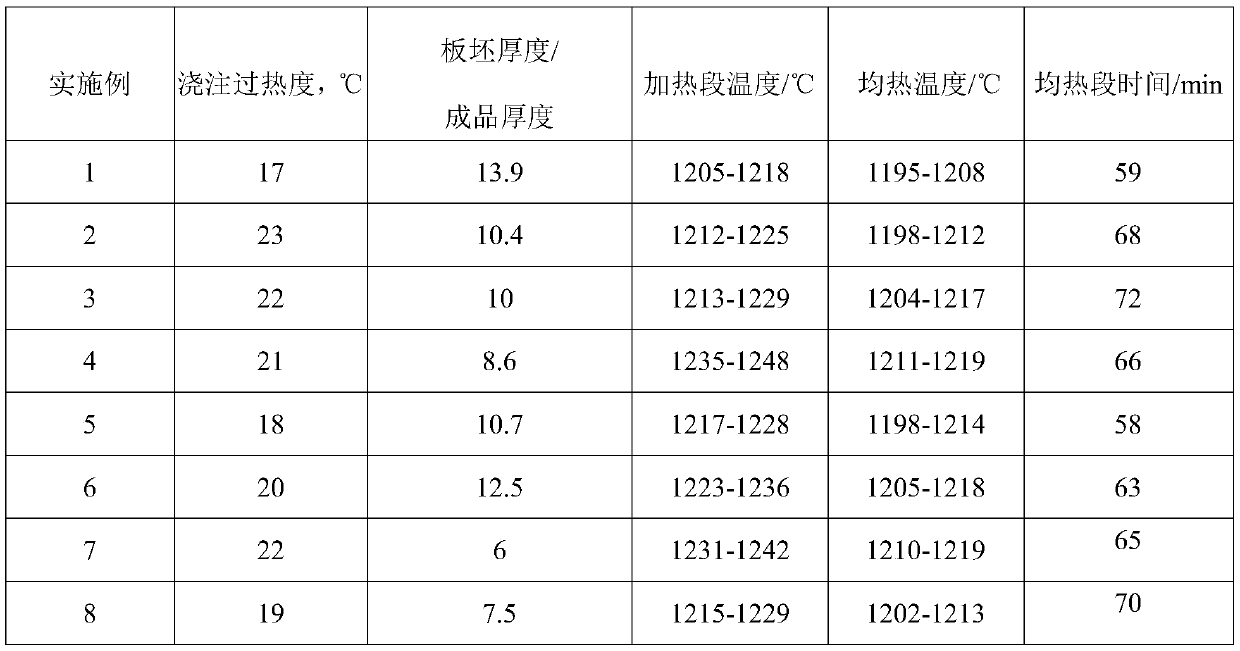

The invention relates to the technical field of fire-resistant weather-proof steel plates for building structures, in particular to a fire-resistant weather-proof steel plate for 690MPa-grade buildingstructure and a manufacturing method thereof. The steel plate consists of the following chemical components in percentage by weight: 0.05%-0.10% of C, 0.10%-0.40% of Si, 1.20%-1.80% of Mn, less thanor equal to 0.010% of P, less than or equal to 0.003% of S, 0.7%-1.1% of Ni, 0.65%-1.10% of Cu, 0.20%-0.60% of Mo, 0.07%-0.12% of Nb, 0.05%-0.075% of V, 0.02%-0.035% of Ti, less than or equal to 0.0025% of B, 0.01%-0.04% of Al, and the balance of iron and inevitable impurities. The fire-resistant weather-proof steel plate adopts a two-phase region once thermal treatment process to obtain a reversetransformed austenite structure which is proper in proportion and stable, so that a multi-phase structure which consists of tempered-state martensite, a nano precipitated phase and retained austeniteis finally obtained. A smelting and continuous-casting process scheme realizes low-phosphor low-carbon control. The product has high strength and toughness, high plasticity, a low yield ratio, and excellent fire resistance, weather resistance and lamellar tearing resistance.

Owner:ANGANG STEEL CO LTD

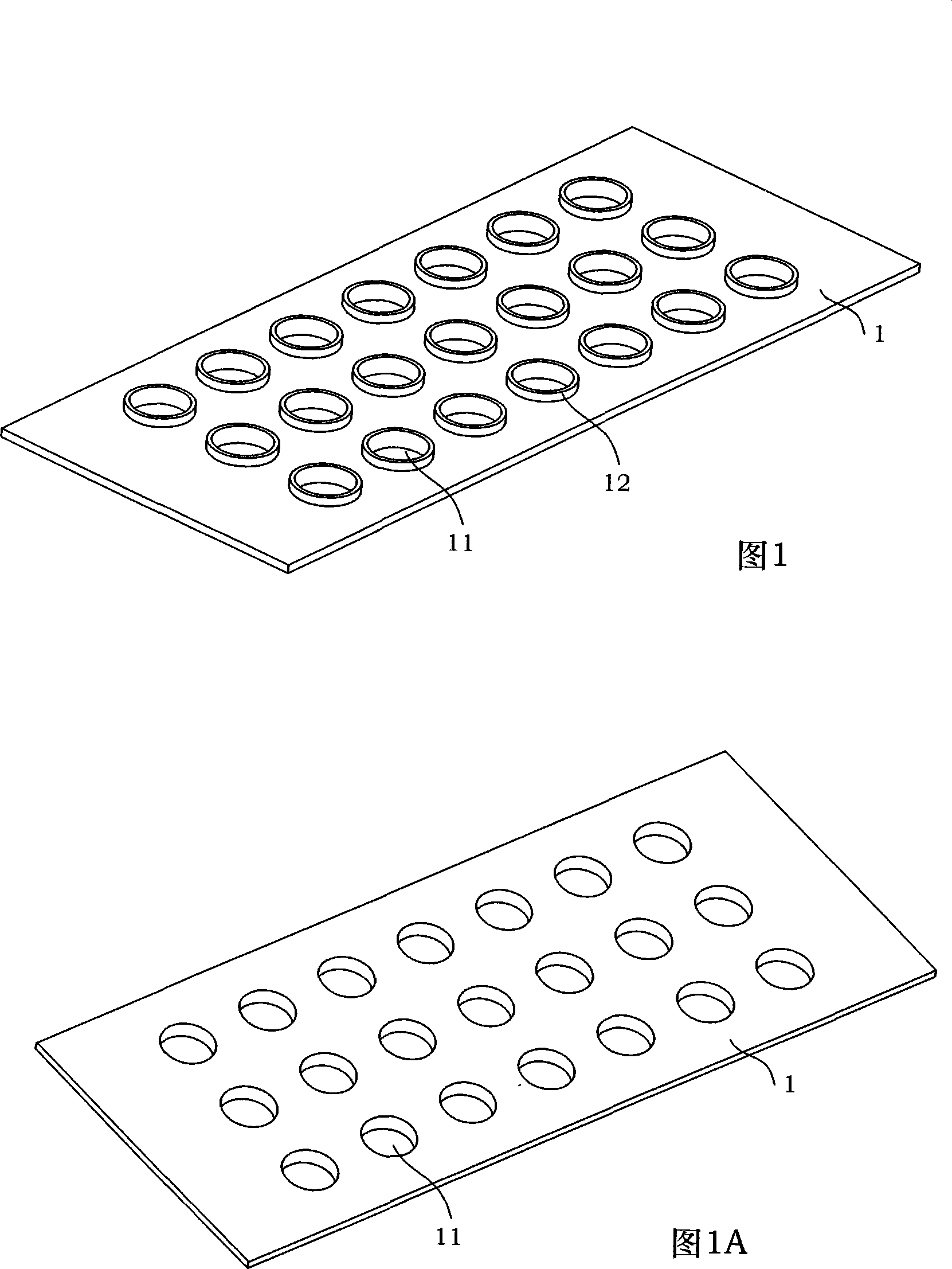

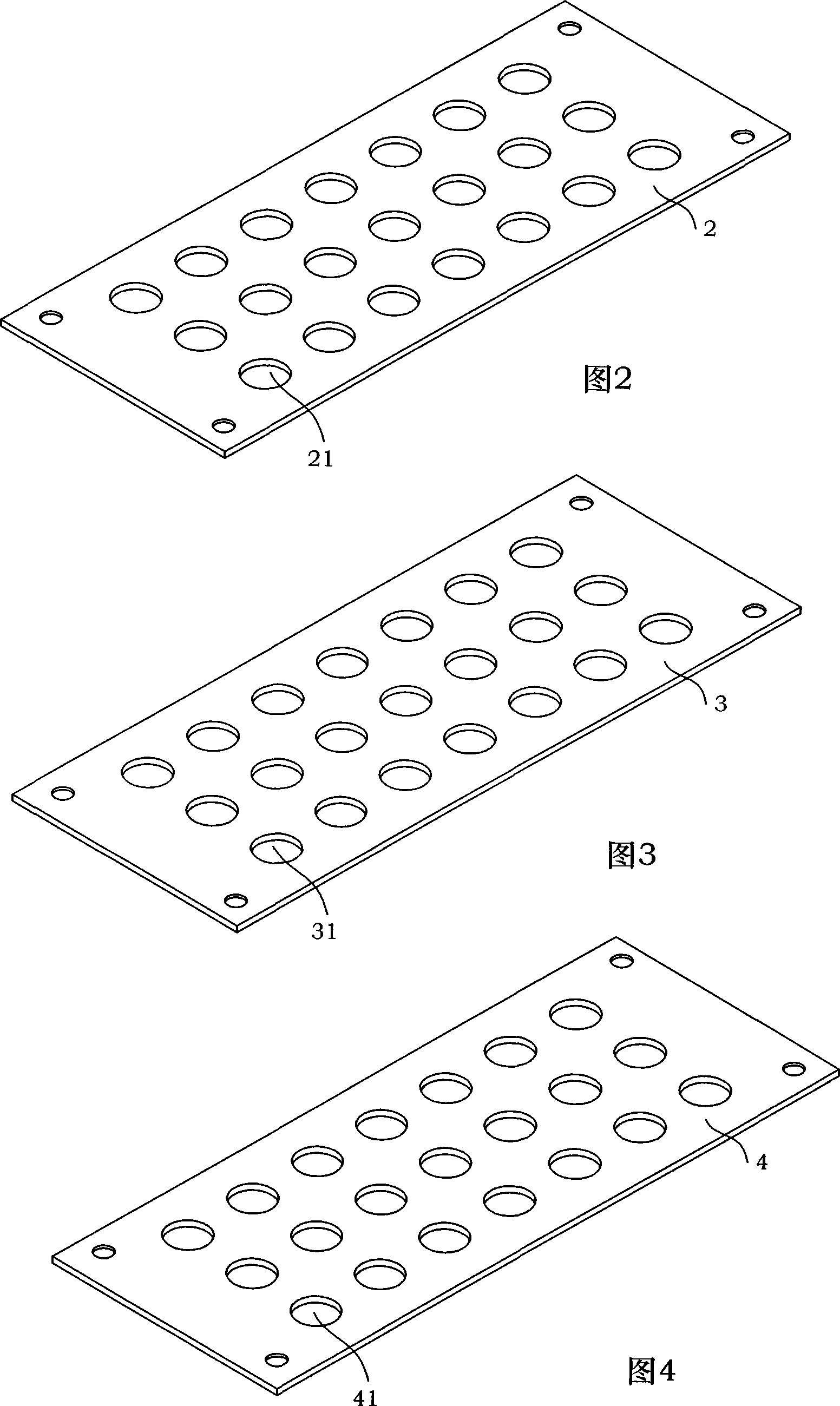

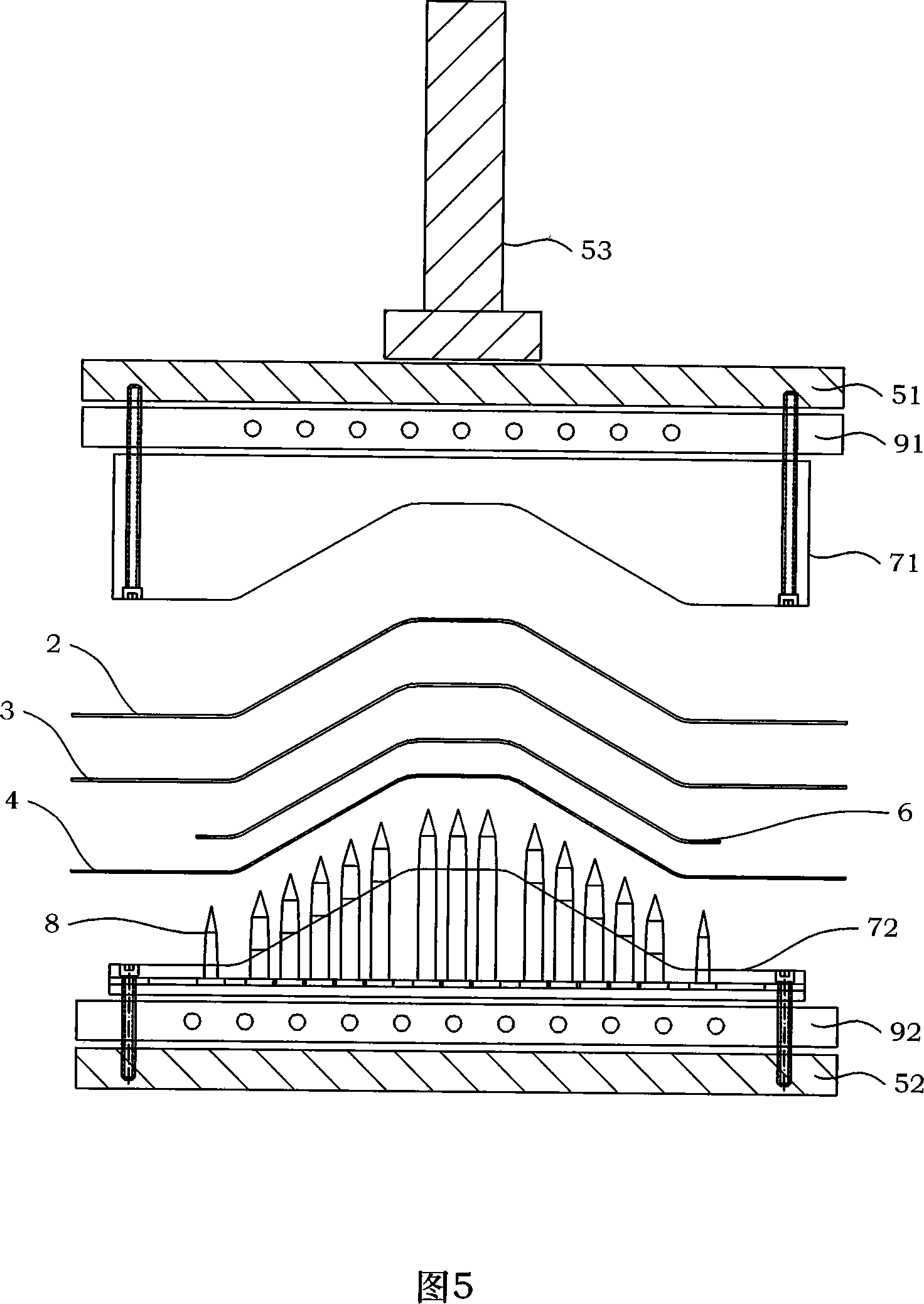

Part and through-hole one-stage forming method in resin base composite material hot-pressed formation

InactiveCN101100097AIncrease productivitySolve the mechanical propertiesResin-Based CompositeMachining

The present invention discloses one-step hot pressing process of forming composite resin material product with through hole. The process includes forming one preformed body with pre-dipped material in the pressure forming device; setting one pillar with conic tip inside the through hole of the lower mold, and mounting the upper mold on the upper heating board of the press and the lower mold on the lower heating board; setting the preformed body on the pillar with conic tip and hot pressing to form. The present invention is superior to the conventional technological process with first forming and subsequent machining through hole.

Owner:BEIHANG UNIV

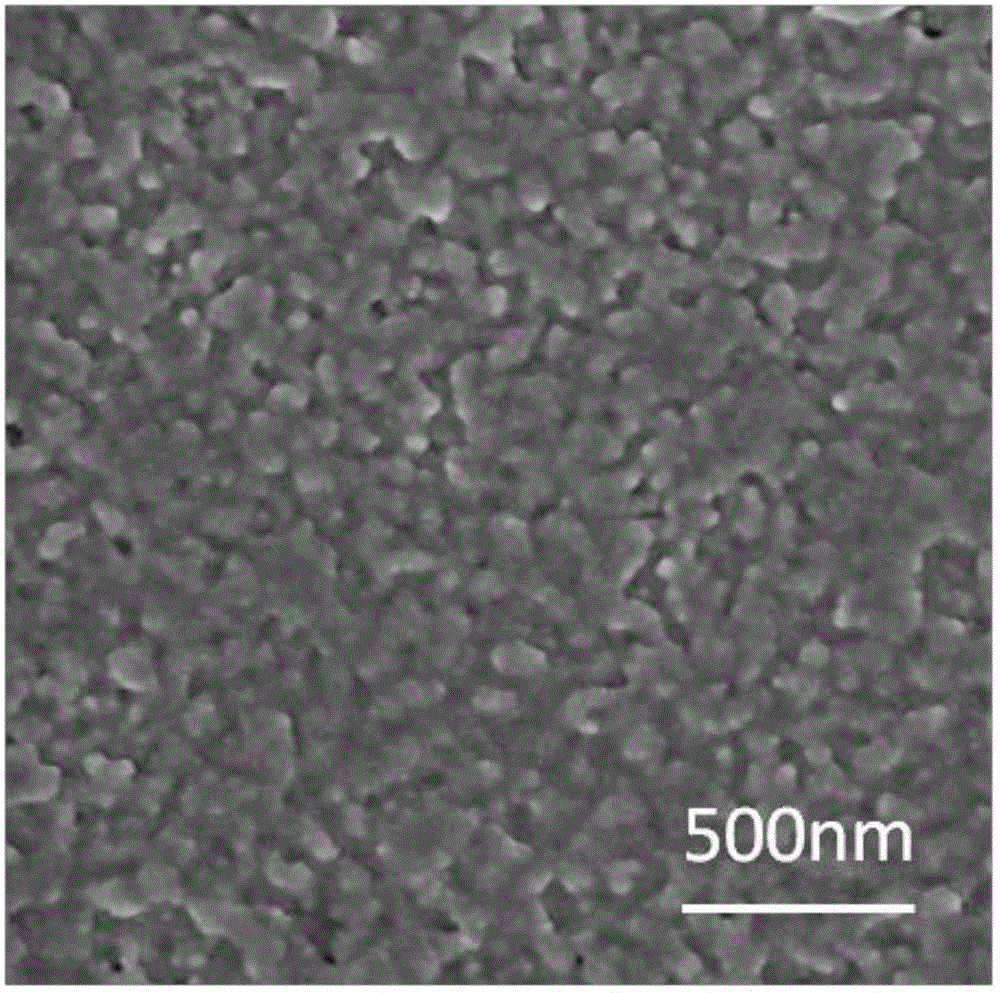

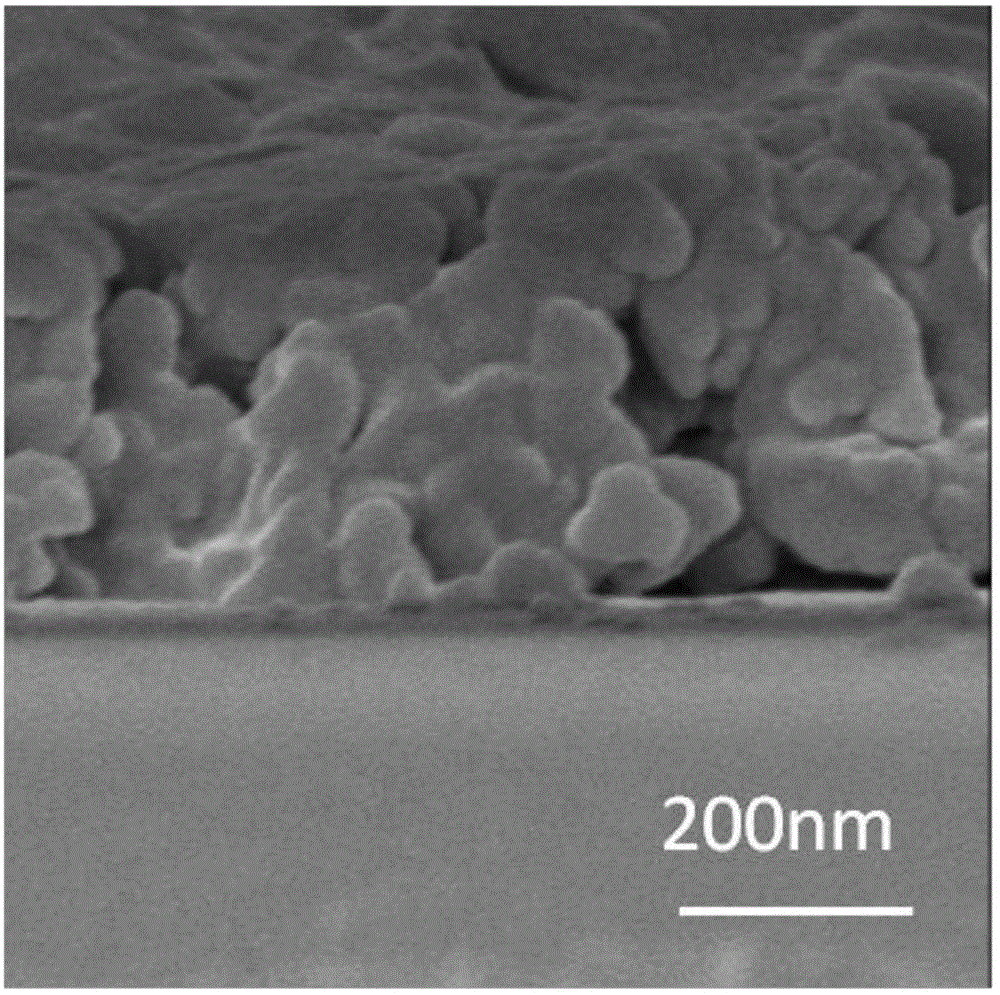

Preparation method of antibacterial metal-organic framework membrane

InactiveCN104855380ASolve associativitySolve weather resistanceBiocideDisinfectantsOrganic moleculesWeather resistance

The invention relates to a preparation method of an antibacterial metal-organic framework membrane. The technical scheme of the method is that an organic molecule modification layer is pre-grown on the surface of a carrier, such that the carrier with an organic molecule coating is obtained; the organic molecules have coordination active groups, and can induce metal ions to coordinate with them; the metal ions are further assembled with the organic ligand, such that a continuous and dense metal-organic framework membrane is formed through growth. According to the invention, the metal-organic framework membrane is grown on the organic-molecule-modified carrier, such that the problems of insufficient binding force between the membrane and the carrier, poor weather resistance and poor heat resistance can be solved. Also, with the coordination effect of the organic ligand and the metal ions, metal ion release concentration and speed can be effectively controlled, such that a long-lasting antibacterial effect can be achieved. With the method provided by the invention, the quality of the metal-organic framework membrane is improved; the preparation process is simple; and the prepared antibacterial membrane can be widely applied in the aspects of aerospace equipment, medical equipment, product packaging, anti-bacterial coating, water treatment membrane, and the like. The membrane and the preparation method have a good application prospect.

Owner:DALIAN UNIV OF TECH

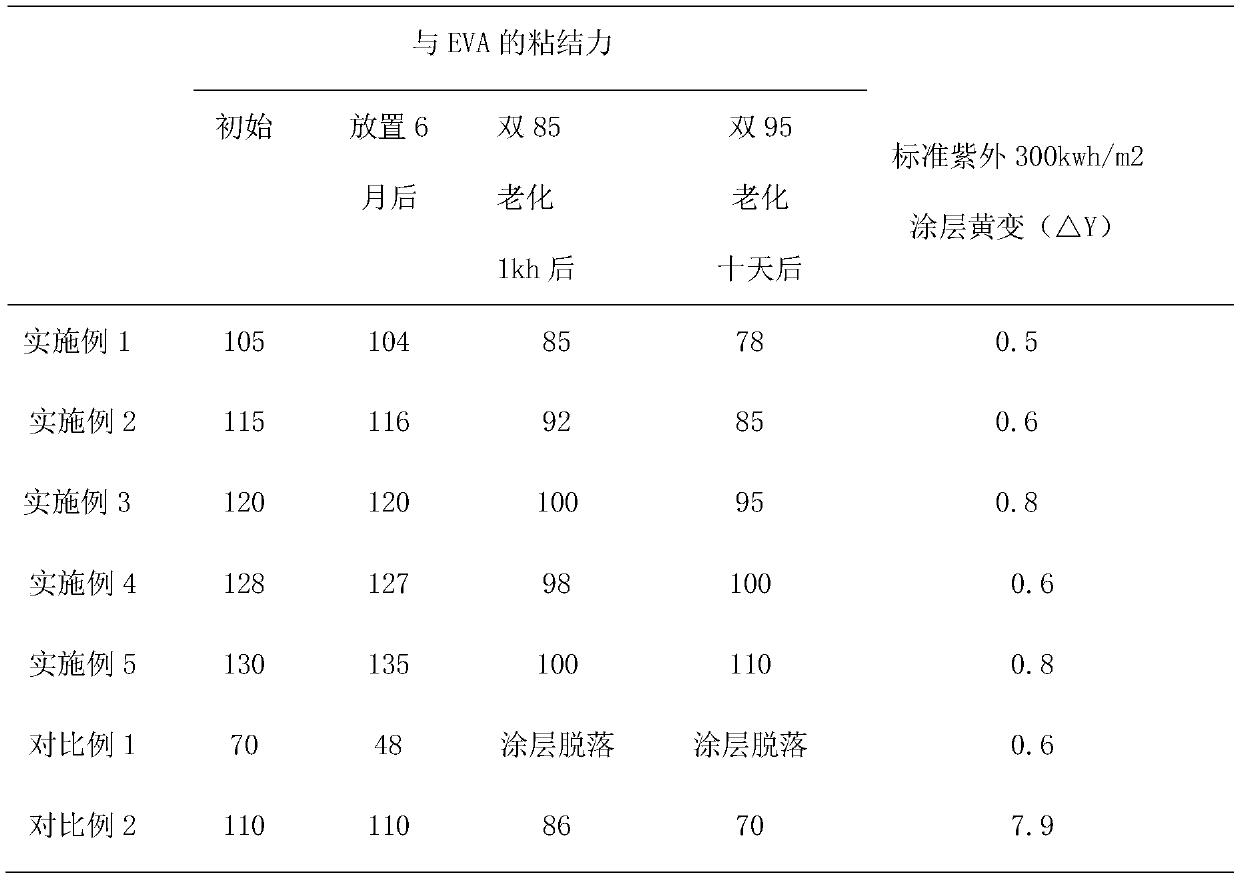

Coating for solar cell back plates

ActiveCN109735177AGood interlayer forceEasy to degradeCoatingsPhotovoltaic energy generationWeather resistanceAcrylic resin

The invention relates to coating for solar cell back plates. The coating comprises, by mass percentage, 9.2-14.4% of fluorocarbon resin, 3.6-9.2% of acrylic resin, 20.5-25.3% of pigment, 37.6-48.1% ofsolvent, 0.6-1% of auxiliaries and an isocyanate curing agent, wherein the mole ratio of hydroxyl in the fluorocarbon resin and the acrylic resin to the isocyanate in the curing agent is 0.8-1.6, andthe total mass percentage of the components is 100%. The coating has the advantages that the coating is good in interlayer performance, a coating layer after hydrothermal aging is good in bonding force with EVA, and the problem that fluorocoating cannot give consideration to both weather resistance and cohesiveness is solved.

Owner:乐凯胶片股份有限公司

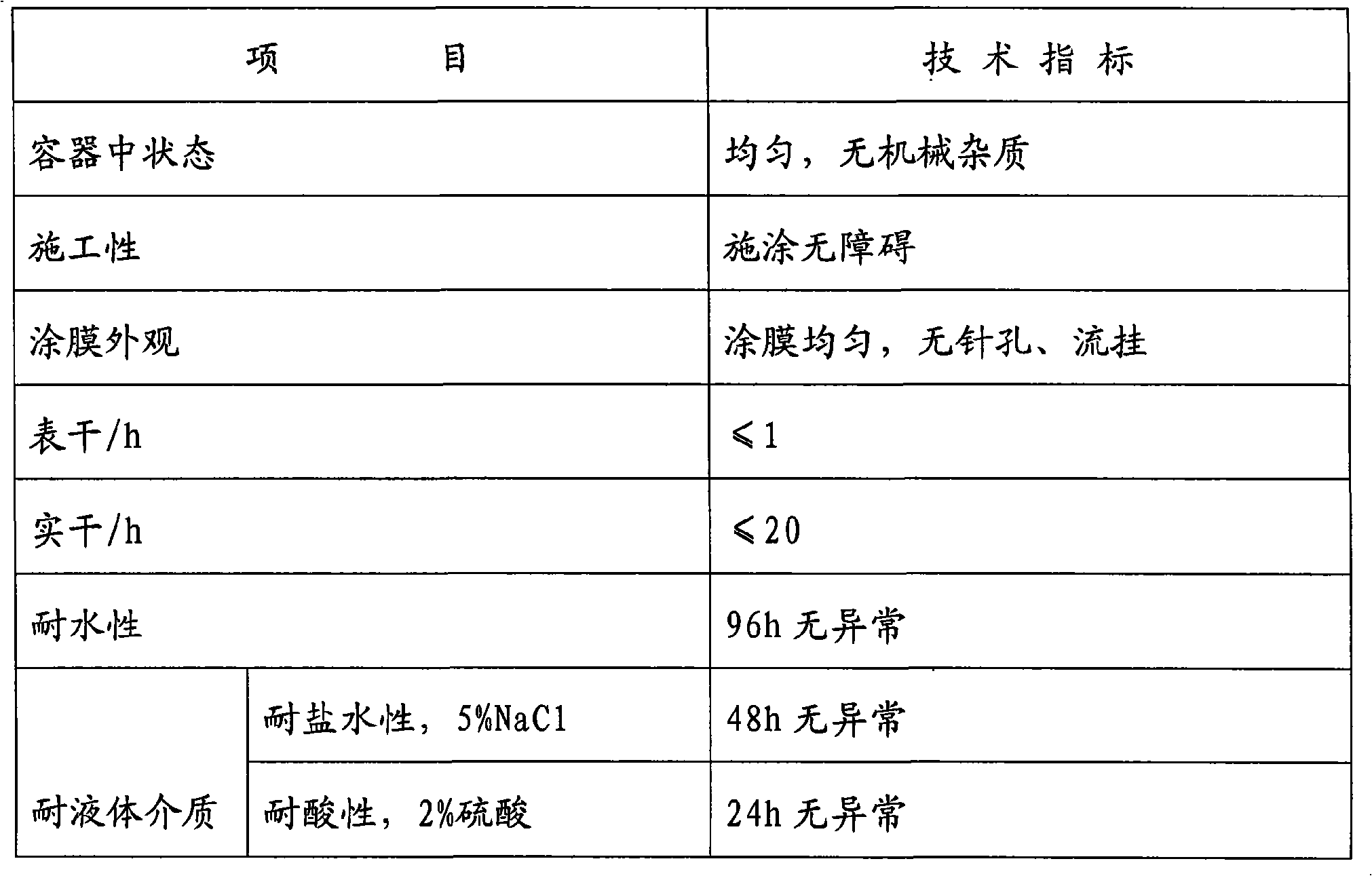

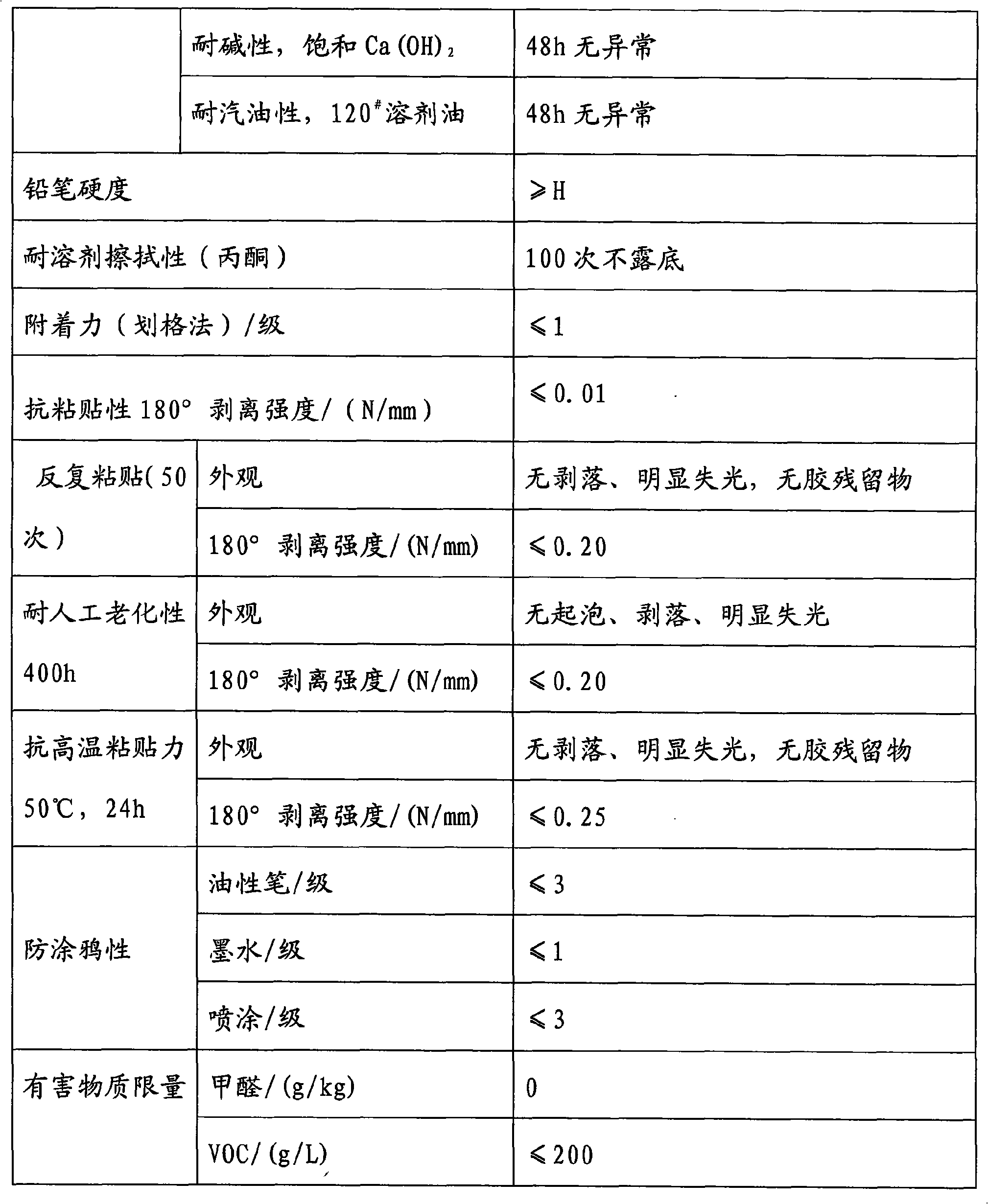

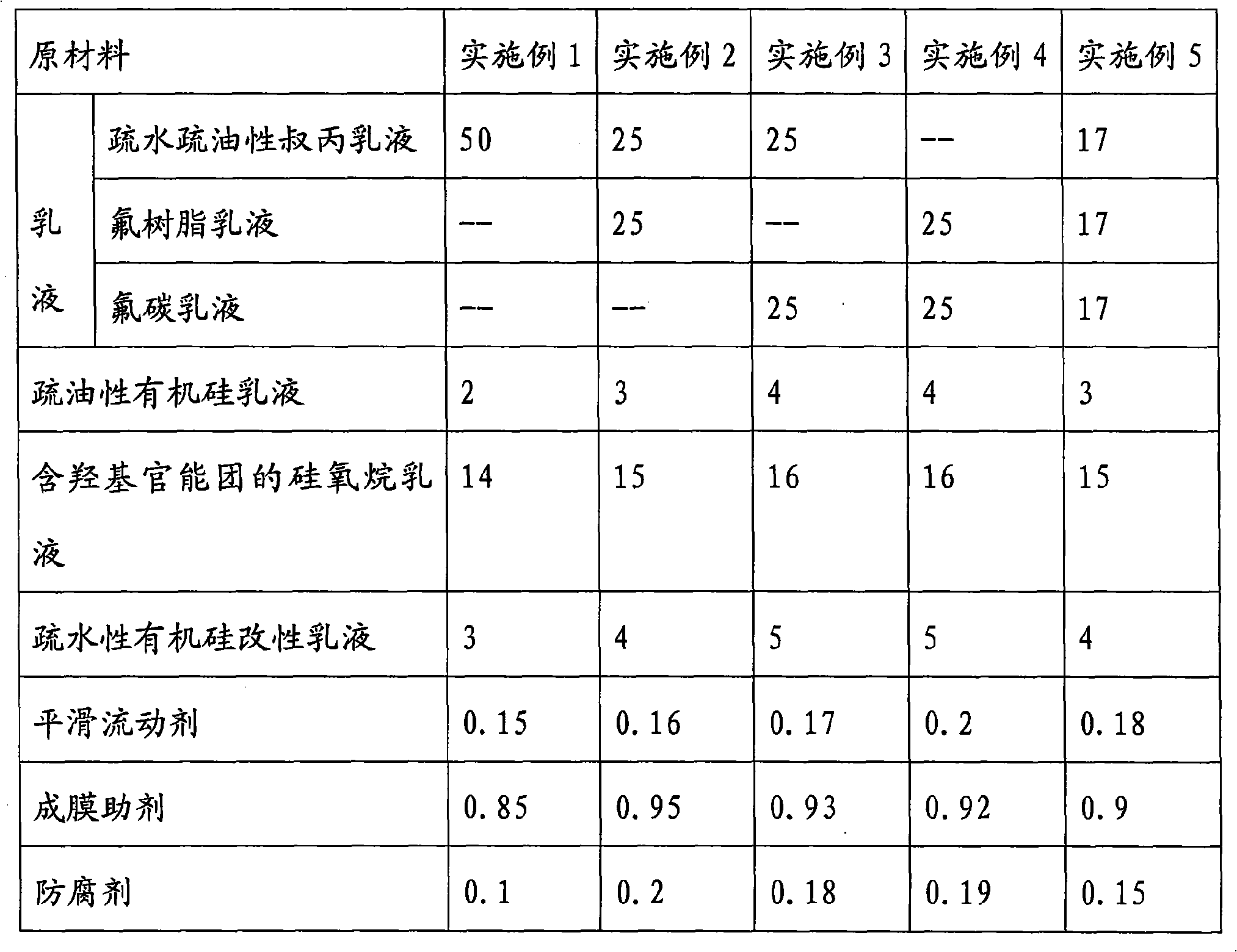

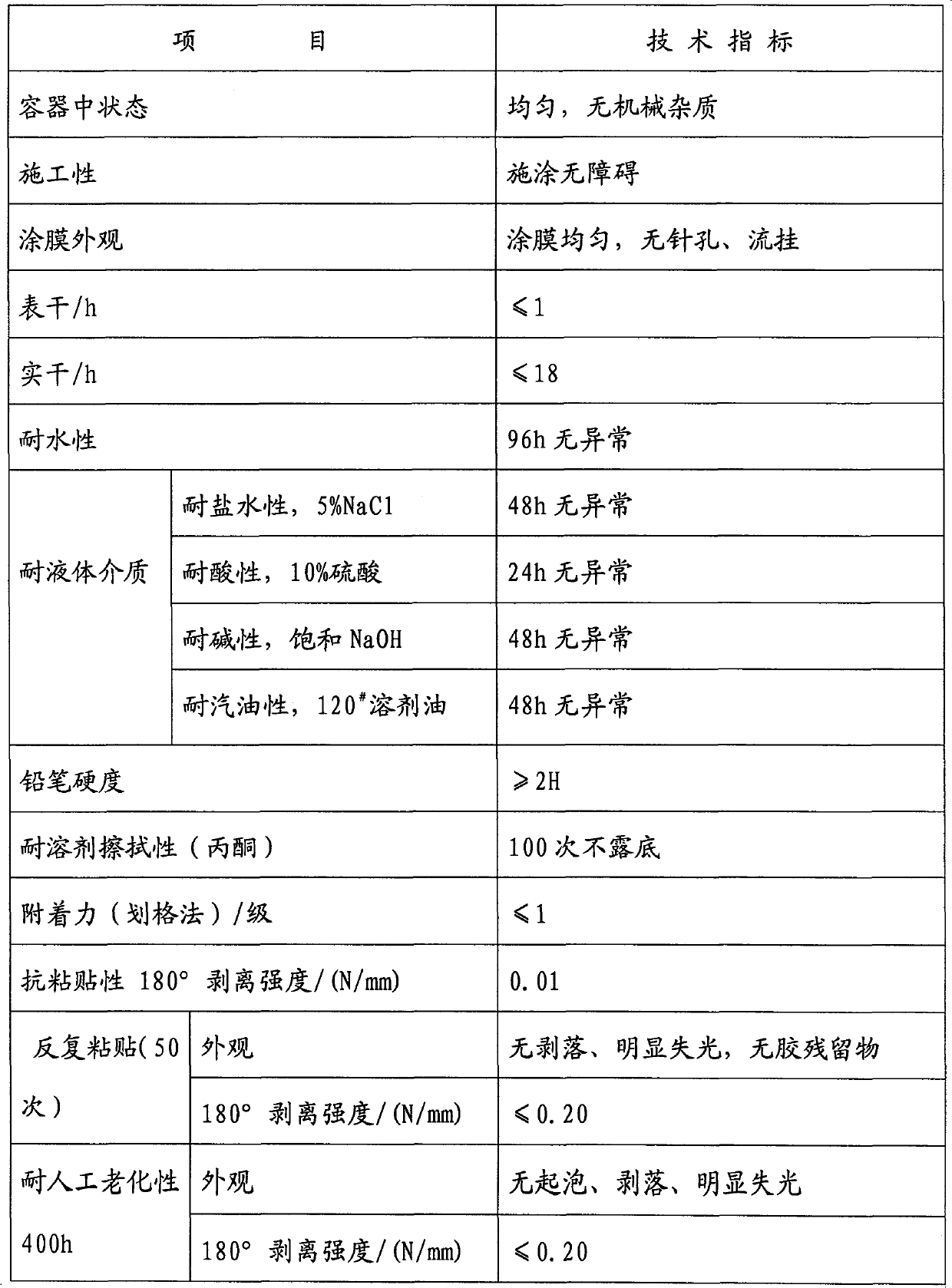

Aqueous anti-graffiti adhesion resistant paint and preparation method thereof

InactiveCN101585990AIncrease elasticityGood resistance to acid, alkali and saltCoatingsEmulsionPreservative

The invention discloses aqueous anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. The paint consists of the following components by weight portion: 50 to 55 portions of emulsion, 2 to 4 portions of organic silicon emulsion, 14 to 16 portions of siloxane emulsion containing hydroxy functional group, 3 to 5 portions of hydrophobic organic silicon modified emulsion, 0.15 to 0.2 portion of smooth flow agent, 0.85 to 0.95 portion of film forming assistant, 0.1 to 0.2 portion of preservative, 0.1 to 0.2 portion of mildew preventive, 0.8 to 1 portion of ethylene glycol, 5 to 7 portions of hydrophobic agent, 0.1 to 0.2 portion of thickening agent, and 23 to 25 portions of deionized water. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has zero formaldehyde, benzene and heavy metals, has low VOC, and is typical environment-friendly paint.

Owner:LANZHOU XUNMEI PAINT IND TECH

Permeable concrete pavement protection agent and preparation method thereof

ActiveCN106010186ASolve weather resistancePrevent ubiquinolPolyurea/polyurethane coatingsRoad surfaceBond properties

The invention provides a permeable concrete pavement protection agent and a preparation method thereof. The permeable concrete pavement protection agent contains the following components (shown in the description), can improve the bonding properties of pavement aggregates, can improve the water permeable performance of a pavement and effectively prevent concrete whiskering, can make a pavement color more uniform, brighter and more durable, and meanwhile can also slow down the carbonization and aging speed of permeable pavement concrete and improve the usage durability of ecological pavements.

Owner:上海砼仁环保技术发展有限公司

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

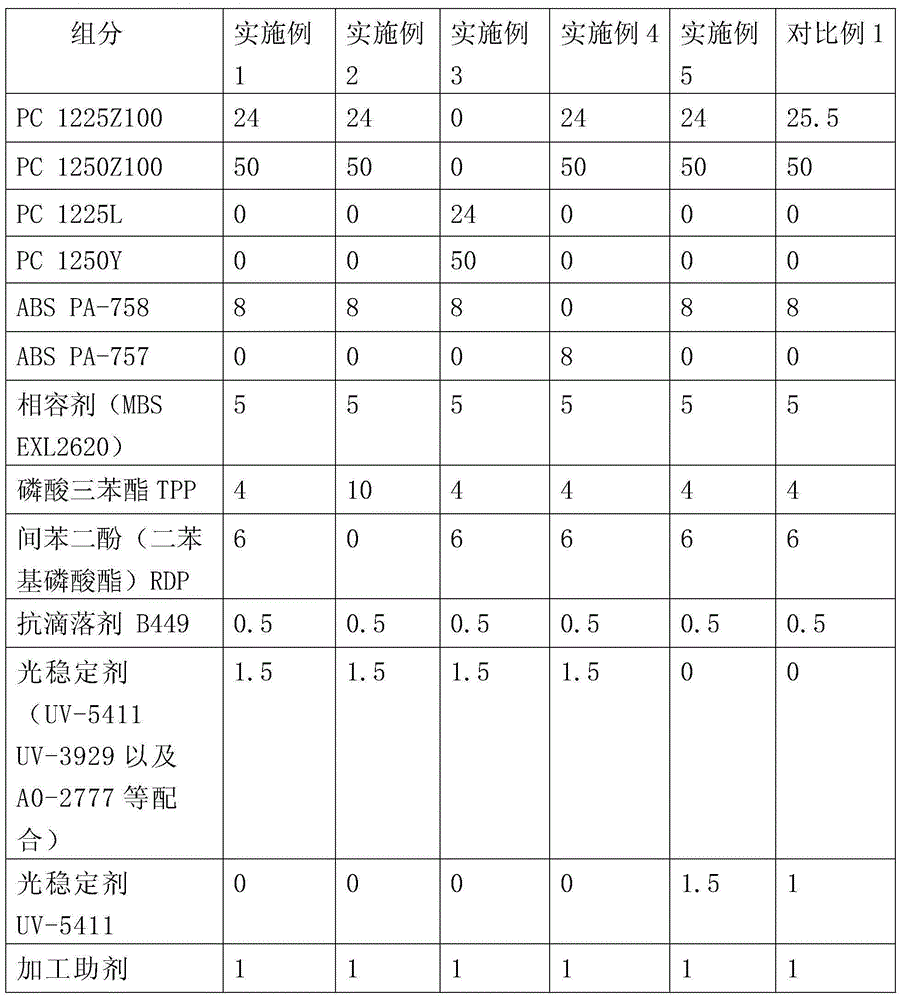

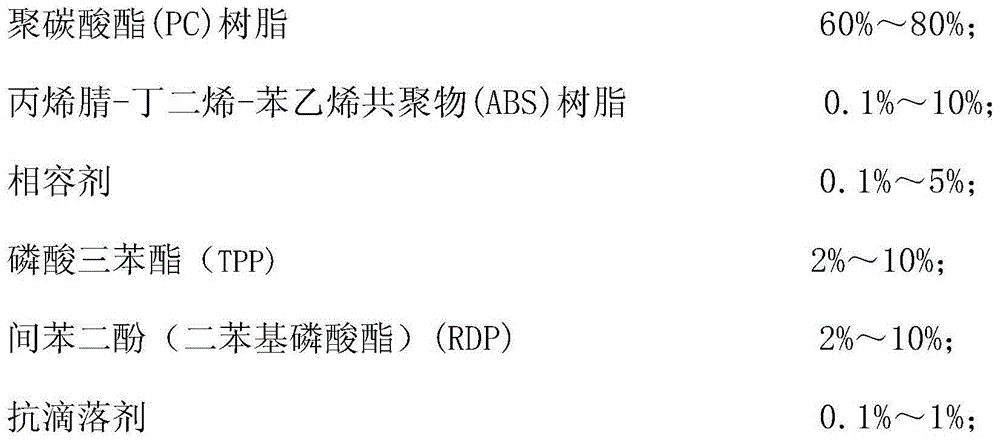

High weather resistant, halogen-free and flame retardant PC/ABS alloy material special for outdoor telecommunication box and preparation method thereof

The invention discloses a high weather resistant, halogen-free and flame retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material special for an outdoor telecommunication box and a preparation method thereof. The PC / ABS alloy material is prepared from the following raw materials by weight percentage: 60%-80% of polycarbonate resin; 0.1%-10% of acrylonitrile-butadiene-styrene resin; 0.1%-5% of a compatibilizer; 2%-10% of triphenyl phosphate; 2%-10% of resorcinol (diphenyl phosphate); 0.1%-1% of an anti-dripping agent; 0.1%-2% of a light stabilizer; and 0.1%-2% of assistants. According to the invention, the PC and ABS resin with good weather resistance are adopted as the matrix, and through synergy of the compatilizer, the halogen-free flame retardants and the light stabilizer, the halogen-free and flame retardant PC / ABS alloy material with high heat resistance and high performance can be obtained, and can be widely used in the communications industry, the automobile industry, building materials, decoration materials, cables and the electrical industry. The preparation method of the alloy material adopts existing equipment, is simple to operate, and is suitable for industrialized production.

Owner:SHANGHAI AUSELL CHEM TECH

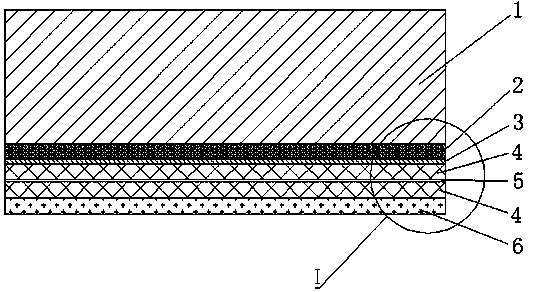

Novel photovoltaic assembly structure

InactiveCN103354249AImprove electrical insulation strengthSolve the cooling problemPhotovoltaic energy generationSemiconductor devicesPolyethylene glycolMetal sheet

The invention discloses a photovoltaic assembly structure of a photovoltaic building part. The structure successively comprises a glass layer, a solar cell and a backboard from top to bottom. A backboard material is a metal sheet, glass or composite sheet material. An insulation film layer is arranged between the solar cell and the backboard. The solar cell and the insulation film layer are connected through an EVA rubber sheet. The insulation film layer and the backboard are connected through the EVA rubber sheet or an adhesion agent. The insulation film layer is a polyimide, polyethylene glycol terephthalate and polypropylene film or an organic silicon film. By using the photovoltaic assembly structure of the photovoltaic building part of the invention, an insulating property is good, a heat dissipation effect is good and production manufacturing cost is low; structure intensity of the photovoltaic assembly is increased; simultaneously, problems that bonding of the related materials is difficult, the EVA is easy to age and weather-proof performance is poor are solved; the photovoltaic assembly structure and other materials can be combined and form the photovoltaic building part and other products.

Owner:合肥微纳电工有限公司

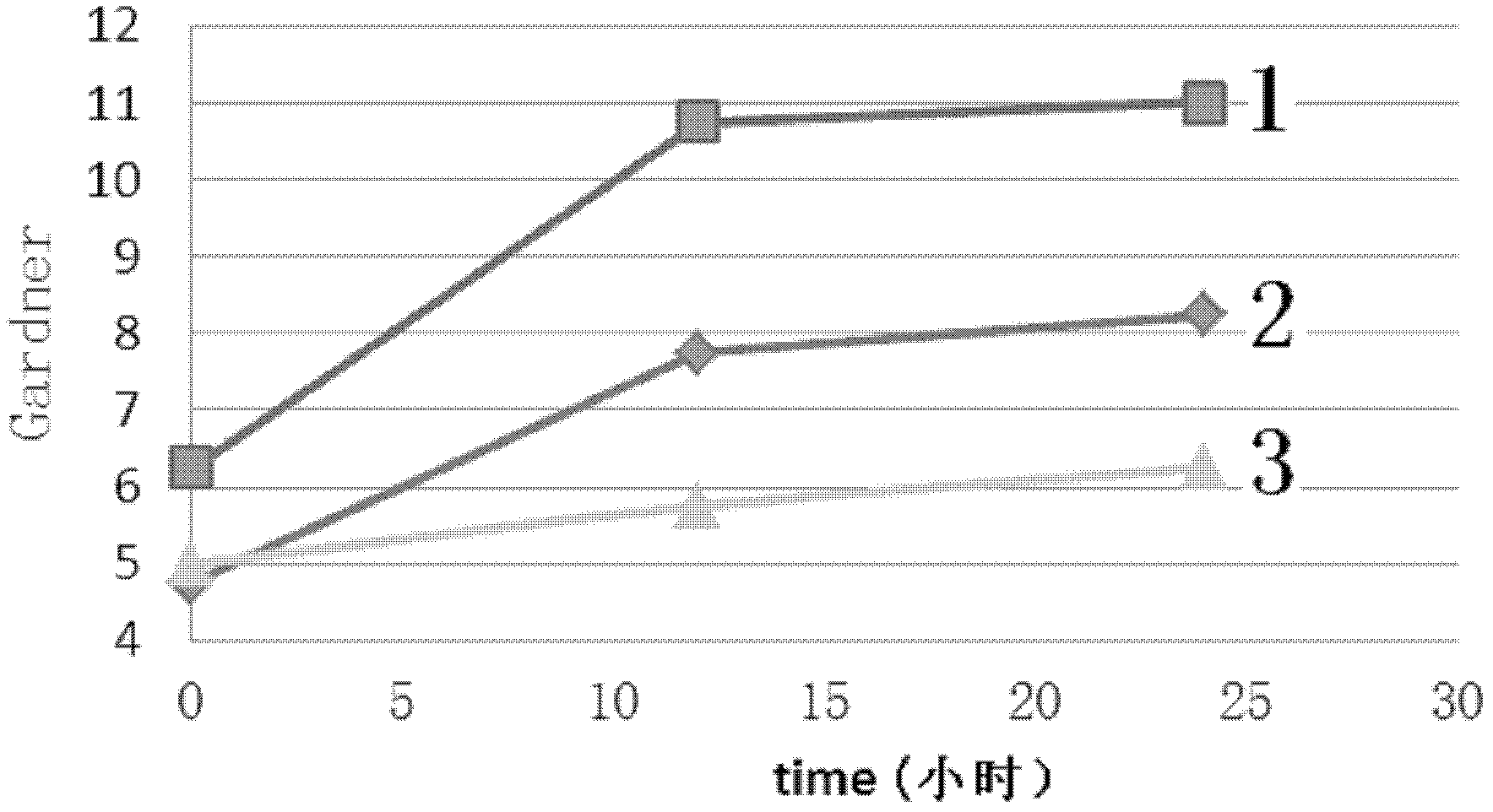

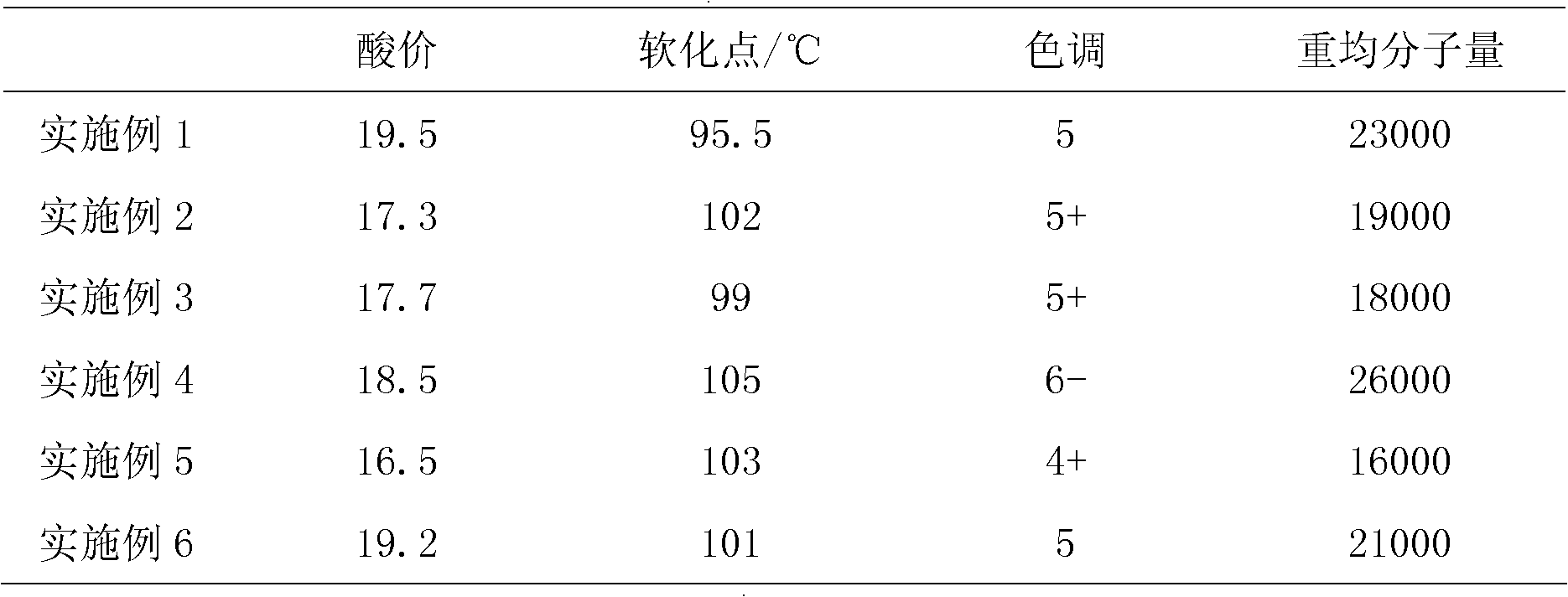

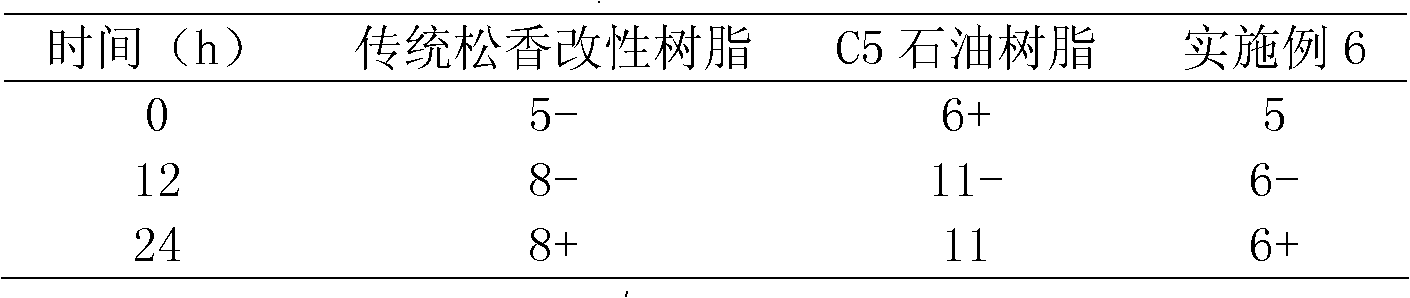

Rosin modified composite resin and preparation method

InactiveCN102532495AReduce dosageGood initial tackPolyester coatingsPolymer scienceResin-Based Composite

The invention discloses a rosin modified composite resin, which comprises the following raw materials in part by weight: 60 to 80 parts of rosin, 3 to 10 parts of conjugated polyprotic acid, conjugated polyanhydride or mixture of conjugated polyprotic acid and conjugated polyanhydride, 8 to 18 parts of polyol, 0.3 to 2 parts of pre-antioxidant, and 5 to 25 parts of vegetable oil, fatty acid or mixture of vegetable oil and fatty acid. The preparation method disclosed by the invention is to prepare rosin modified composite resin with high toughness, excellent film forming leveling property, high weather resistance and less pollution by subjecting raw materials to addition, esterification, ester exchange and other special modification reactions to increase the weather resistance and oxidation resistance of a resin structure. The preparation method can reduce production cost and environment pollution, and solve the problems of medium brittleness, poor leveling property, low weather resistance, and the like.

Owner:NANJING HALIMA CHEM

Nano polyvinyl chloride pipe and preparation method thereof

InactiveCN101157784AShorten plasticizing timeGood uniformity of plasticizationPolyvinyl chlorideResin-Based Composite

The invention relates to a nanometer polyvinyl chloride pipe and a preparation method thereof. According to weight ratio, raw materials of the nanometer polyvinyl chloride pipe comprise nanometer polyvinyl chloride resin, calcium carbonate, and PME-100 strengthening and toughening agent, etc. The preparation method is that: first, the raw materials needed are fully mixed in a high level mixing pot and a low level mixing pot; then the materials mixed are transported to an extruder production line to do extruding molding, thereby gaining the nanometer polyvinyl chloride pipe. The invention is characterized in that the invention is not only environment-friendly, but also solves the problems of insufficiency of thermal stability, initial coloring and products reddened and zinc burned, bad weather resistance and copper erosion, etc. During the mixing process of the preparation method, the plasticizing time is shortened, leading to a good plasticizing uniformity and being in favor of the basic extrusion molding process to the modification polyvinyl chloride. The mechanical property of the invention is distinctively higher than the common polyvinyl chloride resin and nanometer blending composite resin. The anti-impact performance and other performances are greatly enhanced The shock strength is two times the common resin products, and in particular the products has good shock strength in low temperature; in addition, the invention has good bending performance, thus being applied to no digging laying and repairing, etc.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK

PVC chemical leather treating agent, PVC chemical leather and method for producing the same

InactiveCN101424043ASolve the scratch resistanceSolve weather resistanceFibre treatmentWeather resistanceDrying time

The invention relates to a PVC synthetic leather treatment agent and a preparing method thereof, and also relates to PVC synthetic leather with the PVC synthetic leather treatment agent covered on the surface and a preparing method thereof. The PVC synthetic leather treatment agent is characterized in that the PVC synthetic leather treatment agent is prepared by the following raw materials in portion by weight: 30 to 40 portions of malamine resin, 10 to 20 portions of polyurethane resin, 30 to 40 portions of methylisobutylketone, 4 to 8 portions of tetrahydrofuran, 0 to 10 portions of silicon dioxide, and 3 to 8 portions of paratoluenesulfonic acid. An intaglio printing method is adopted to coat the PVC synthetic leather treatment agent on the surface of the PVC synthetic leather, and then the PVC synthetic leather is dried; a treatment wheel with 100-120 meshes is selected, and the intaglio printing method is adopted to treat; and the drying temperature is 130 DEG C, the drying time is 1min, and the treatment amount on the surface of the PVC synthetic leather is between 10 and 20g / m<2>. The PVC synthetic leather treated by the PVC synthetic leather treatment agent can prevent the fouling, is easy to clean, and also has the characteristics of scraping resistance and weather resistance.

Owner:森欧汽车内饰(上海)有限公司

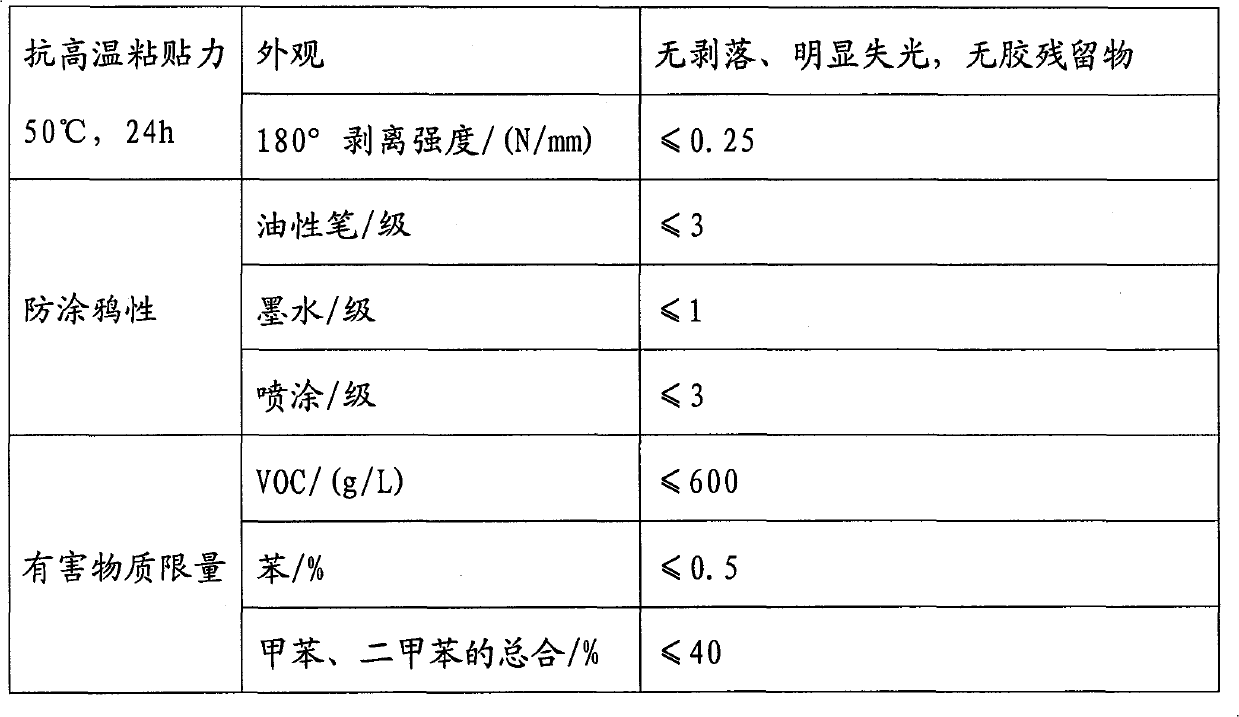

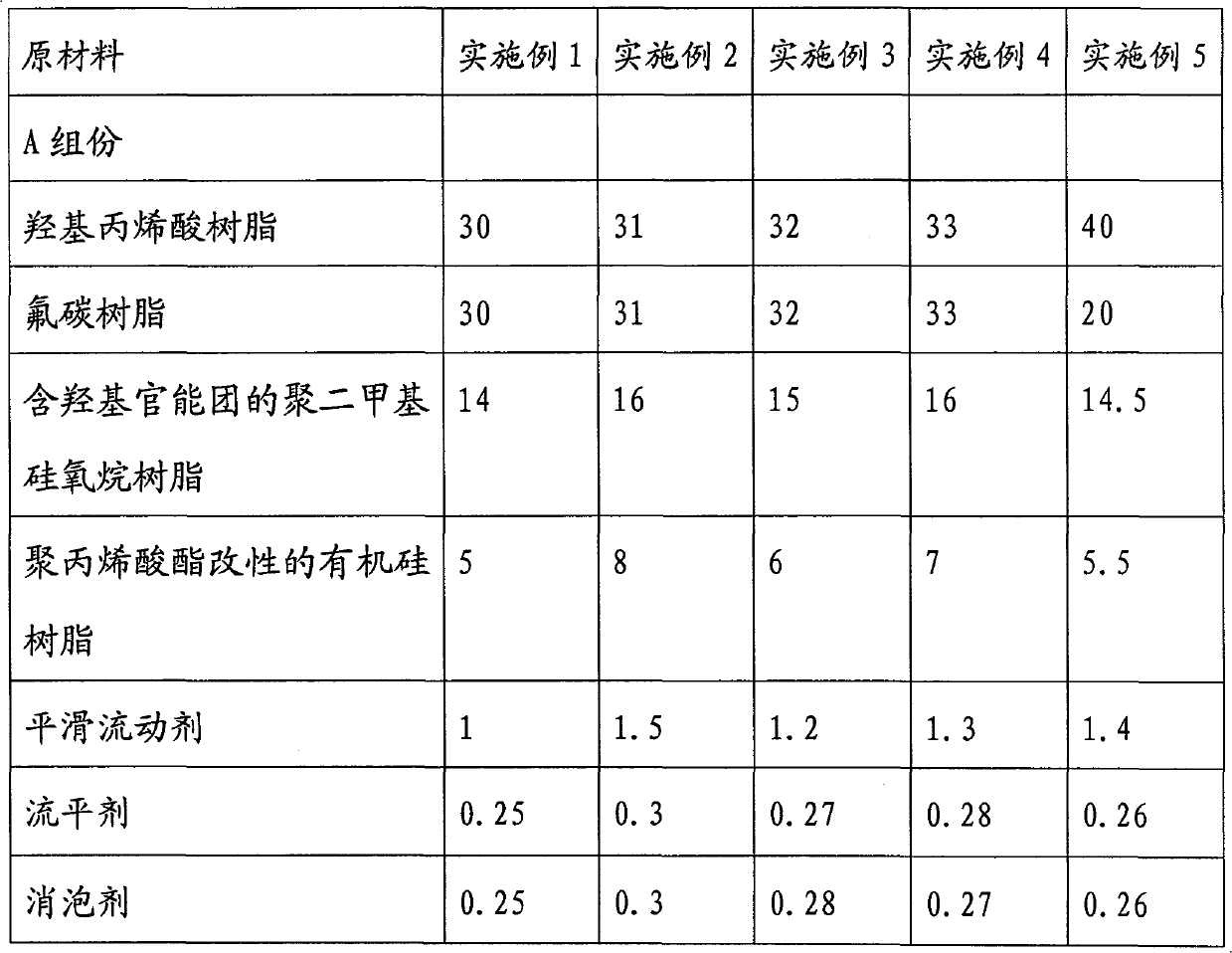

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995BHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, polydimethyl siloxane resin containing hydroxyl functional group, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easycleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

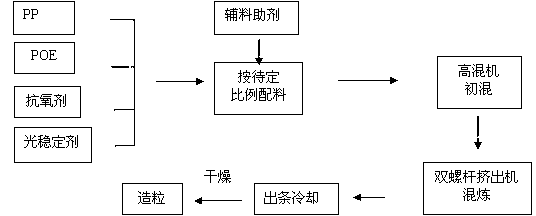

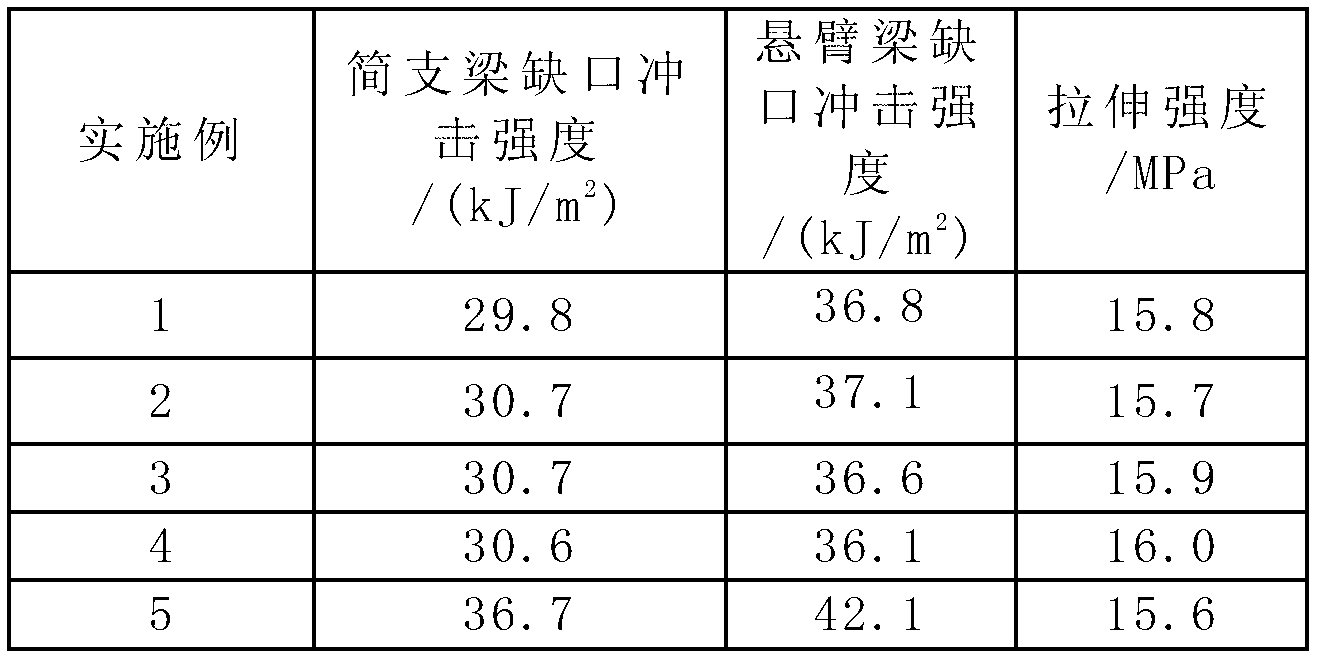

Special-purpose weather-resisting anti-shock polypropylene material for automobile bumper and preparation method

The invention provides a special-purpose weather-resisting anti-shock polypropylene material for automobile bumpers and a preparation method of the material, for solving the problems of poor anti-shock and weather resistance in the prior art. According to the technical scheme, the special-purpose material comprises the following components in part by mass: 70-80 parts of polypropylene, 2-15 parts of ethylene-octylene copolymer, 0.1-1 part of antioxidant, 0.1-1 part of light stabilizer, 10-30 parts of talcum powder, 0.1-1 part of dispersing agent and 0.08-0.12 part of nucleating agent. By improving the formula of the material, the weather-resistance of the material is improved on the premise that the influence to impact performance is reduced as much as possible, and the service life of an automobile bumper is greatly prolonged.

Owner:QINGDAO GON TECHNOLOGY CO LTD

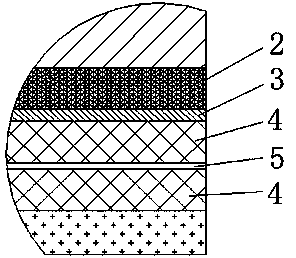

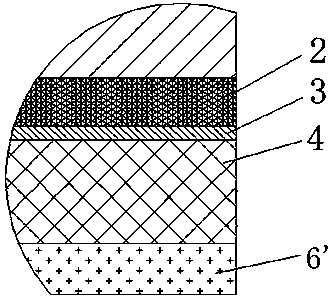

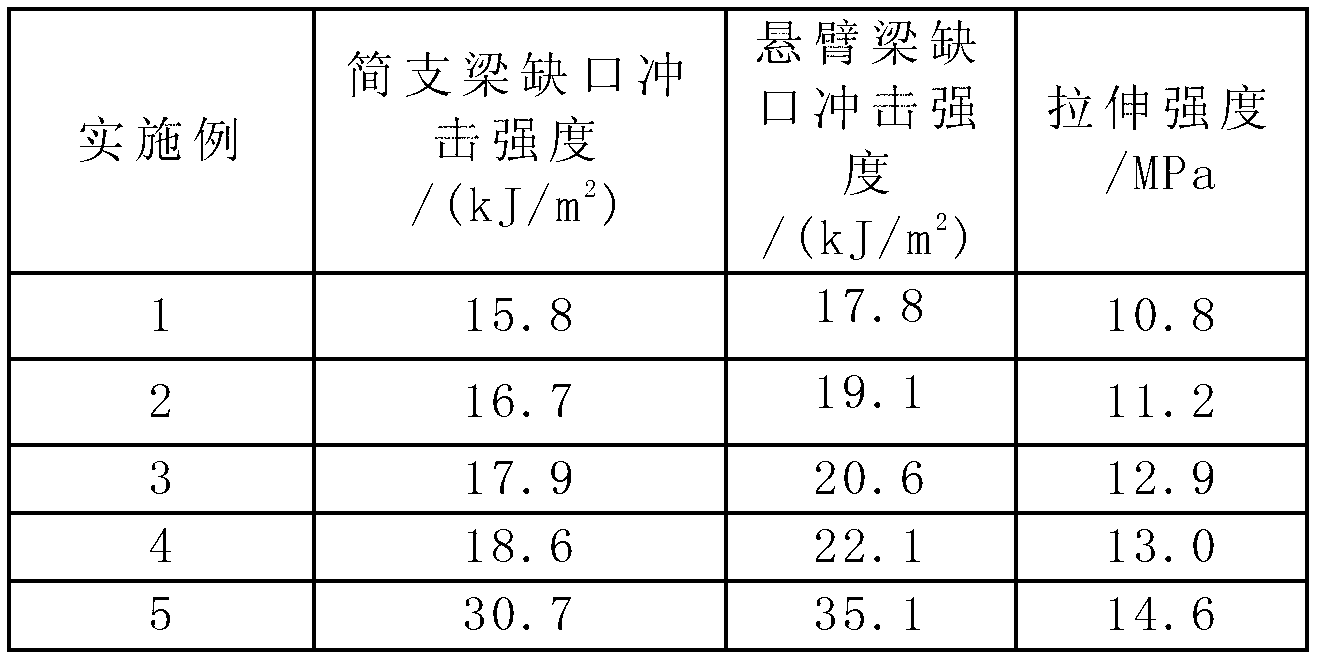

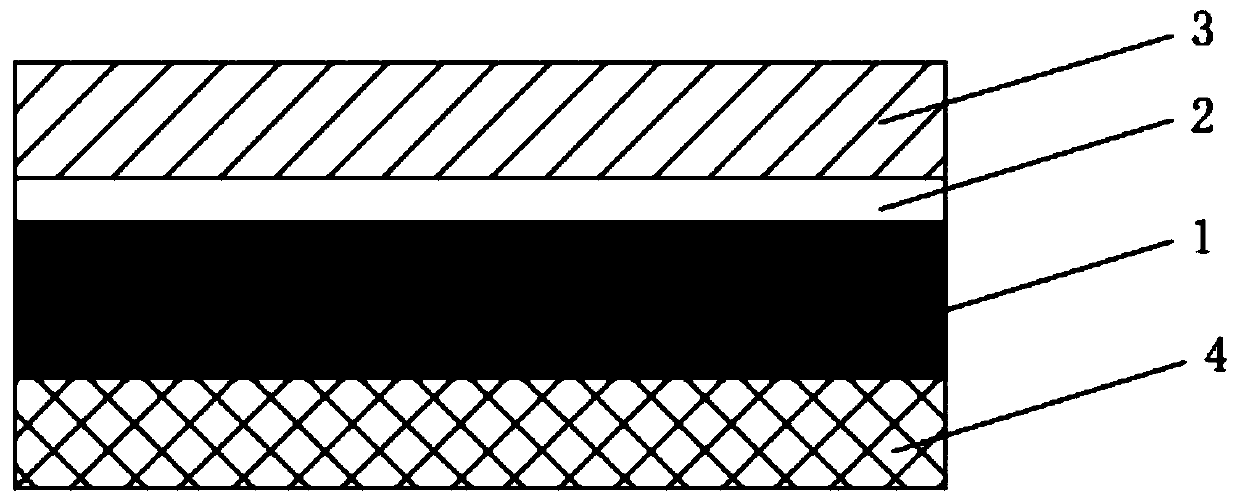

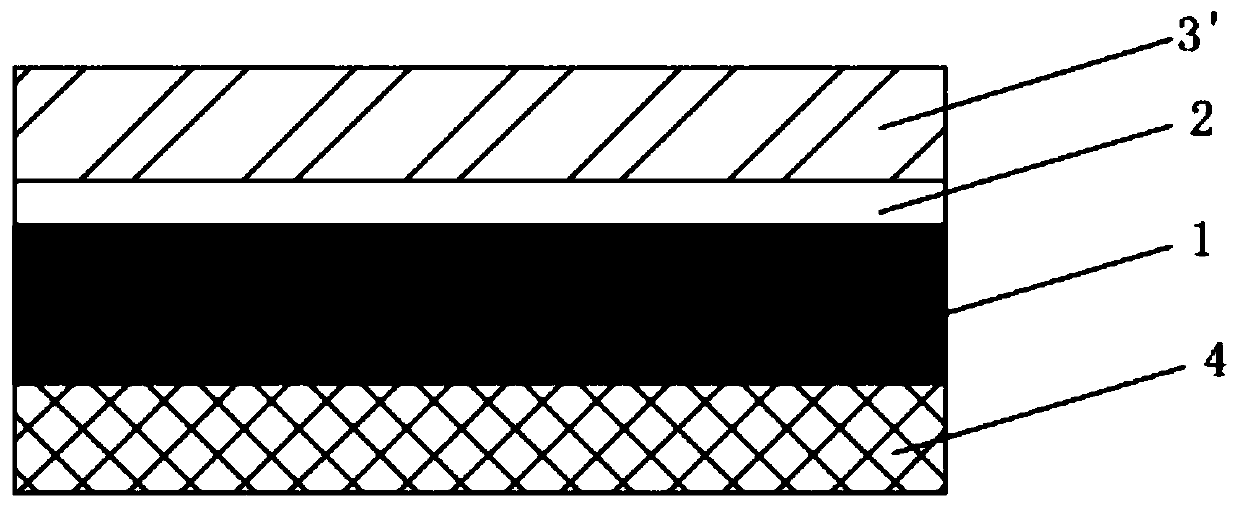

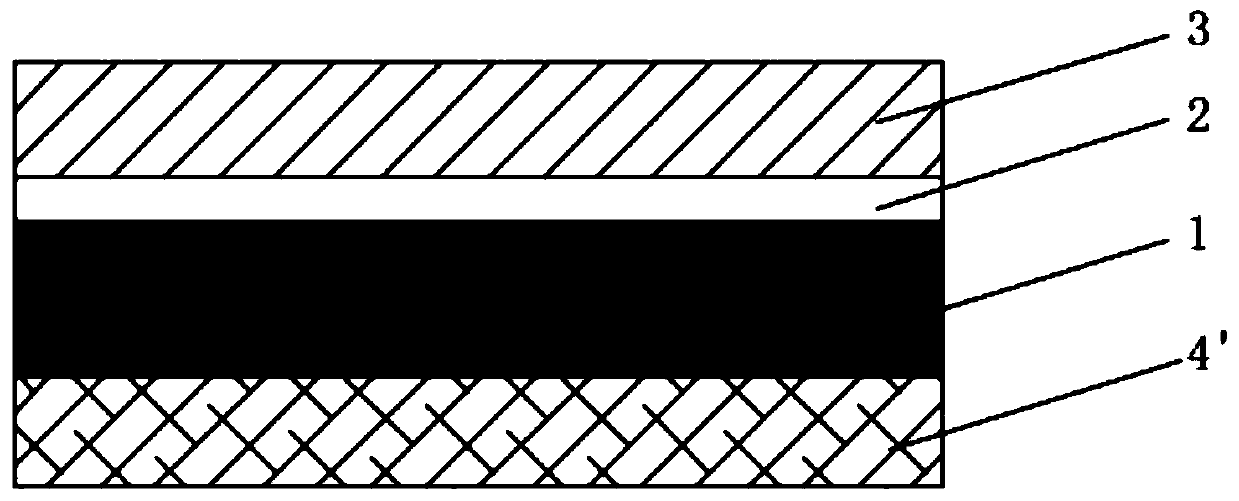

Solar cell back film with high weather resistance and high water vapor barrier property and preparation method of solar cell back film

InactiveCN110757916ANot rustedGood weather resistanceLamination ancillary operationsSynthetic resin layered productsWater vaporMetallic materials

The invention relates to a solar cell back film with high weather resistance and high water vapor barrier properties and a preparation method of the solar cell back film. The solar cell back film comprises a first weather-resistant layer, a second weather-resistant layer, a third weather-resistant layer and a supporting layer, wherein the supporting layer is arranged between the first weather-resistant layer and the second weather-resistant layer; the first weather-resistant layer is made of a weather-resistant polymer film or a weather-resistant polymer coating; the second weather-resistant layer is made of a weather-resistant metal film or a weather-resistant metal coating film; and the third weather-resistant layer is made of a weather-resistant coating for metals or a weather-resistantpolymer film for metals. The solar cell back film has the beneficial effects that a high polymer material with high weather resistance is combined with a metal material with high water vapor barrierproperties to prepare the solar cell back film with the water vapor transmittance of less than or equal to 0.01g / m<2>.d<-1> and excellent weather resistance, so that the problem that a photovoltaic module is easy to fail due to poor weather resistance of a packaging material in an outdoor use process can be effectively solved; and meanwhile, the high-weather-resistance coating can well protect themetal material from being rusted for a long time in an outdoor environment.

Owner:JOLYWOOD SUZHOU SUNWATT

Lead-acid storage battery anti-aging plastic shell material

The invention discloses a lead-acid storage battery anti-aging plastic shell material, which is prepared from the following components by weight: 40-50 parts of an ABS resin, 20-30 parts of a PVC resin, 5-10 parts of surface modified bamboo fiber, 5-10 parts of modified aluminum hydroxide, 5-10 parts of chlorinated Polyethylene, 1-3 parts of a lubricant, 3-5 parts of modified zeolite powder, 0.5-1 part of an antioxidant AT-10, 0.1-0.5 part of an antioxidant 1078, and 0.5-1 part of dibutyltin dilaurate. According to the present invention, the lead-acid storage battery anti-aging plastic shell material has advantages of reasonable and scientific formula, environmental protection, low production cost, excellent flame retardant performance, excellent mechanical property, and excellent weather resistance.

Owner:ZHEJIANG CHANGTONG SCI & TECH

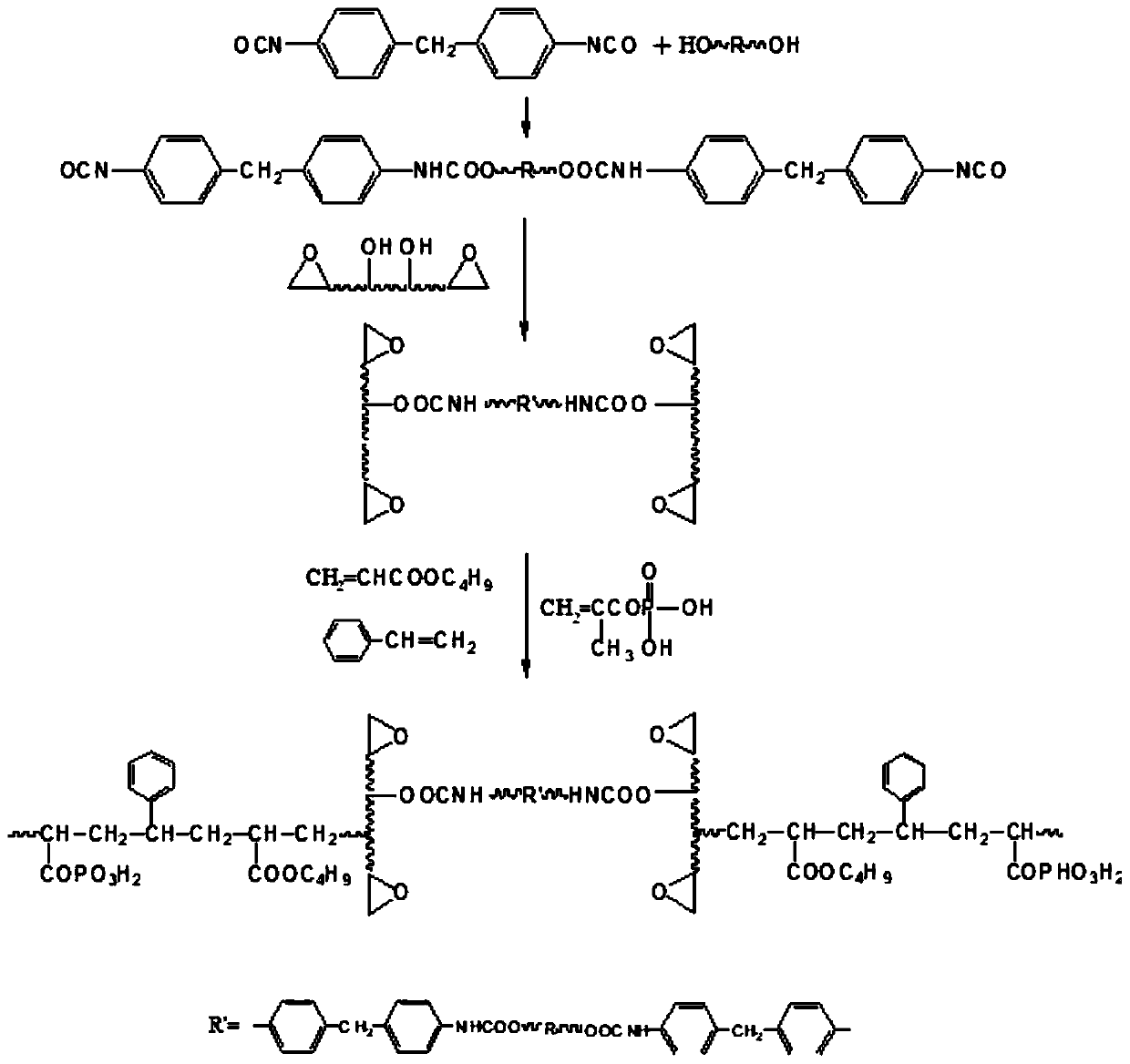

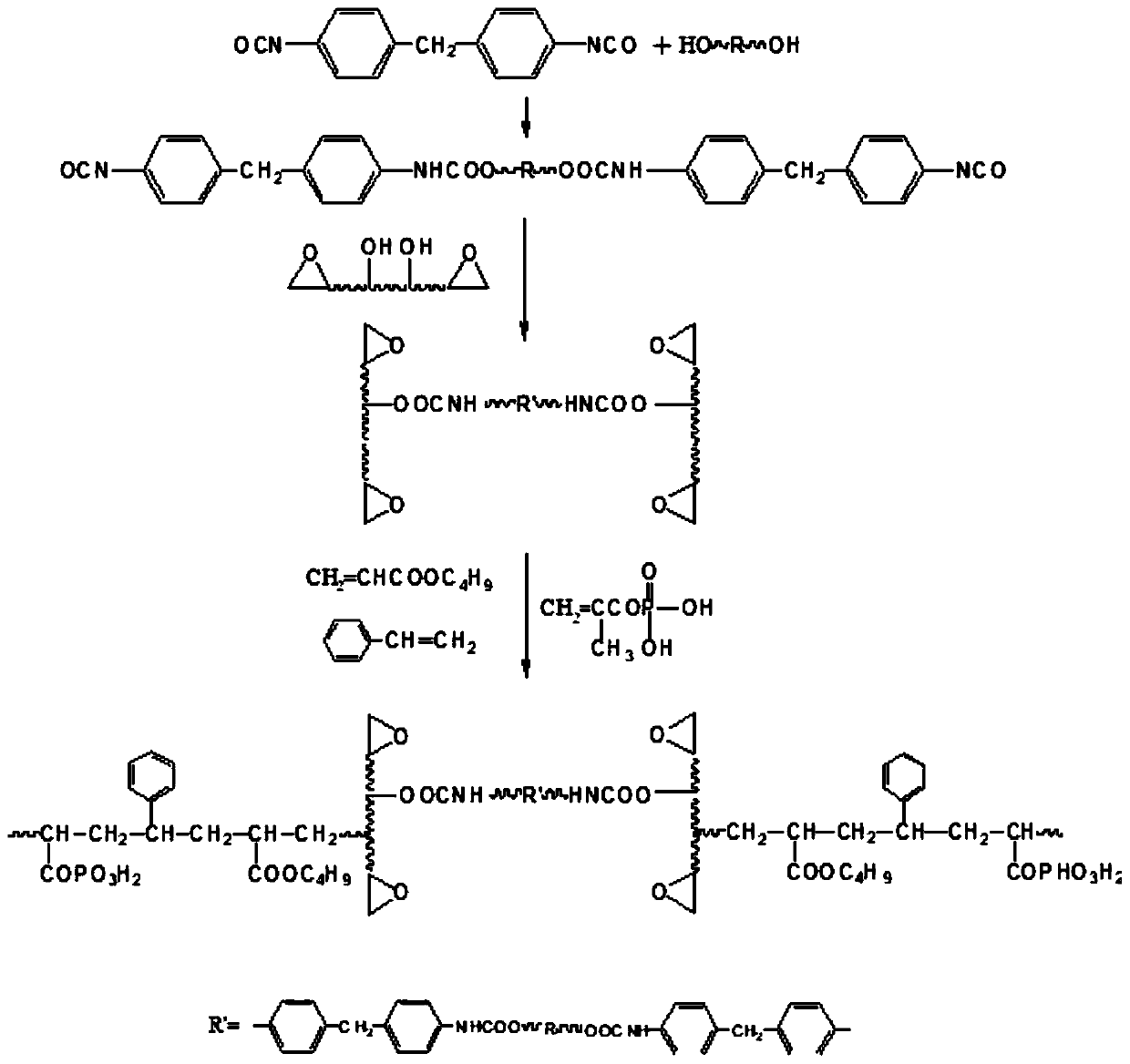

Environment-friendly acrylic acid type powder coating

InactiveCN105907211ASolve weather resistanceSolve corrosiveAnti-corrosive paintsPowdery paintsUltravioletToughening

The invention discloses an environment-friendly acrylic acid type powder coating. The environment-friendly acrylic acid type powder coating is prepared from the following raw materials in parts by weight: 85-95 parts of matrix resin, 38-48 parts of pigment filler, 12-16 parts of a curing agent, 4-5 parts of a degassing agent, 1-2 parts of a dispersing agent, 0.4-0.8 part of a hammer tone agent, 0.3-0.6 part of a toughening agent, 0.3-0.5 part of a gloss enhancer, 0.2-0.4 part of a wetting agent, 0.2-0.4 part of a preservative, 0.2-0.3 part of an antioxidant and 0.2-0.3 part of a light stabilizer; the environment-friendly acrylic acid type powder coating is obtained by mixing the raw materials, melting, tabletting, granulating and crushing. The environment-friendly acrylic acid type powder coating has weather fastness, can keep out the direct irradiation of ultraviolet ray for silver powder, has higher corrosion resistance, and is not pulverized and does not turn black after being placed under the sun for a long time, thus being widely applied to surface coating of outdoor metal such as guardrails and door industry.

Owner:张莘蔓

Single-component water-based epoxy anticorrosive primer and preparation method thereof

ActiveCN111117413AImprove water resistanceImprove anti-corrosion performanceAnti-corrosive paintsPolymer sciencePolyethylene glycol

The invention discloses a single-component water-based epoxy anticorrosive primer and a preparation method thereof. A matrix resin emulsion is synthesized by adopting a polyethylene glycol nonionic flexible chain segment through a self-emulsifying technology, and an acrylate monomer with low price is used for toughening, grafting and modifying the epoxy emulsion, so an additional curing agent is not required to participate in curing, the water resistance and the corrosion resistance are good, the drying speed is high, stability and safety are realized, the matching property with pigments and fillers is good, the problems of brittleness and weather resistance of epoxy resin are solved, and the application range is expanded.

Owner:武汉凯泽源科技有限公司

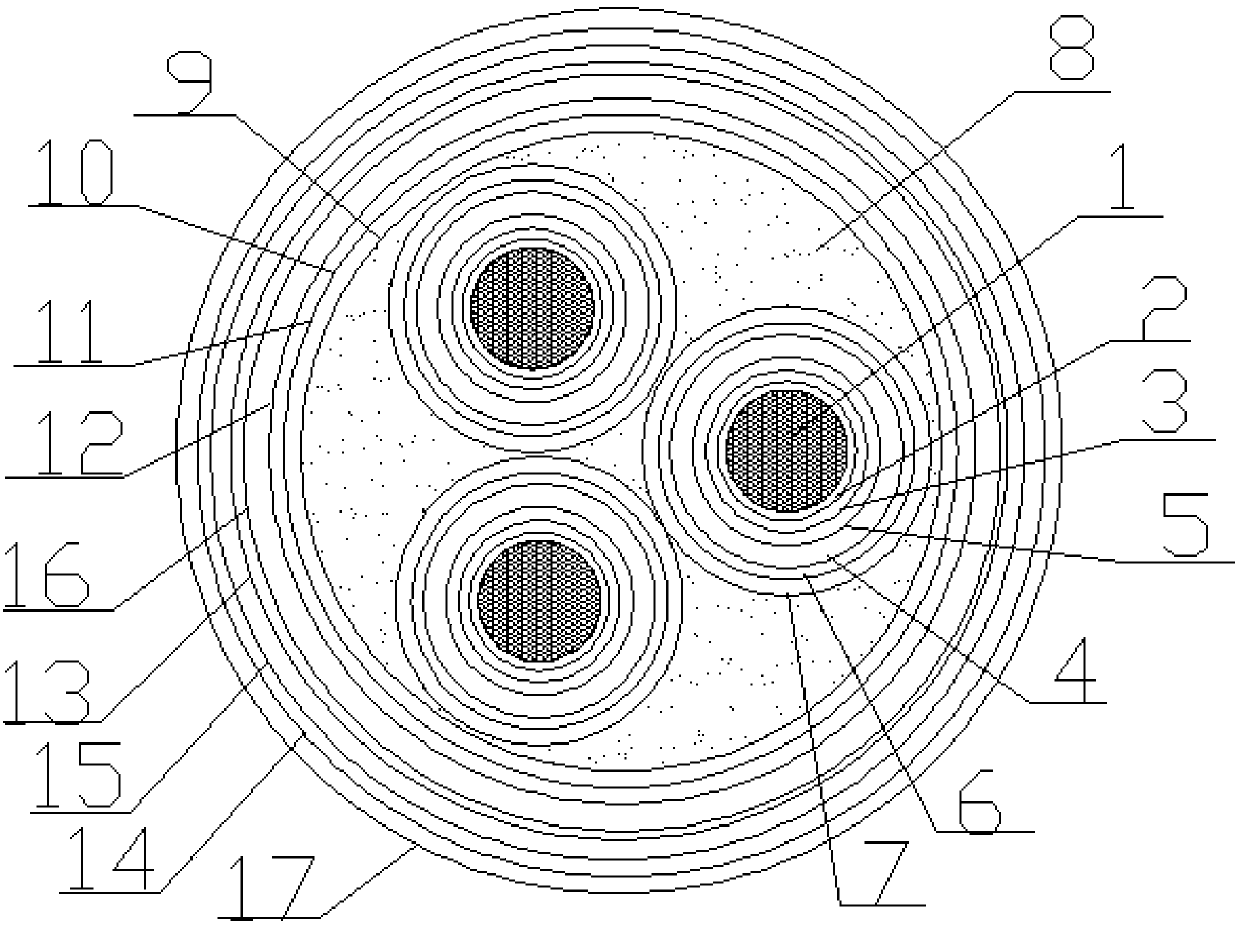

Medium-voltage fire-resistant power cable

InactiveCN107564612AExcellent flame retardantImprove fire resistancePlastic/resin/waxes insulatorsInsulated cablesFiberFirestop

The invention discloses a medium-voltage fire-resistant power cable, which comprises a cable core, wherein the cable core is formed by twisting a plurality of wire cores; each wire core comprises a conductor, a shielding layer, an insulating layer and an insulating shielding layer; the shielding layers, insulating layers and the insulating shielding layer are arranged outside the corresponding conductors; each conductor is formed by twisting a plurality of copper core conductors; a thermal insulating layer is also arranged outside each insulating layer; one insulating shielding layer is arranged outside each thermal insulating layer; a metal shielding layer wraps the outside of each insulating shielding layer; a fire-resistant layer is arranged outside each metal shielding layer; the partsamong the plurality of wire cores are filled with fillers; a ceramic fiber tape, an adiabatic cooling layer, a steel tape firestop layer, an oxygen barrier layer, an inner sheath and an outer sheathwrap the outside of the cable core; and the outer sheath wraps the inner sheath through a lubricating layer. The medium-voltage fire-resistant power cable is simple in structure, and has good flame retardant property and fire resistance; the voltage level of the cable is improved on the basis of ensuring the flexibility and the large-length processing performance of the cable; and safe and reliable operation of a power system is ensured.

Owner:JIANGSU PUCAO TECH CO LTD

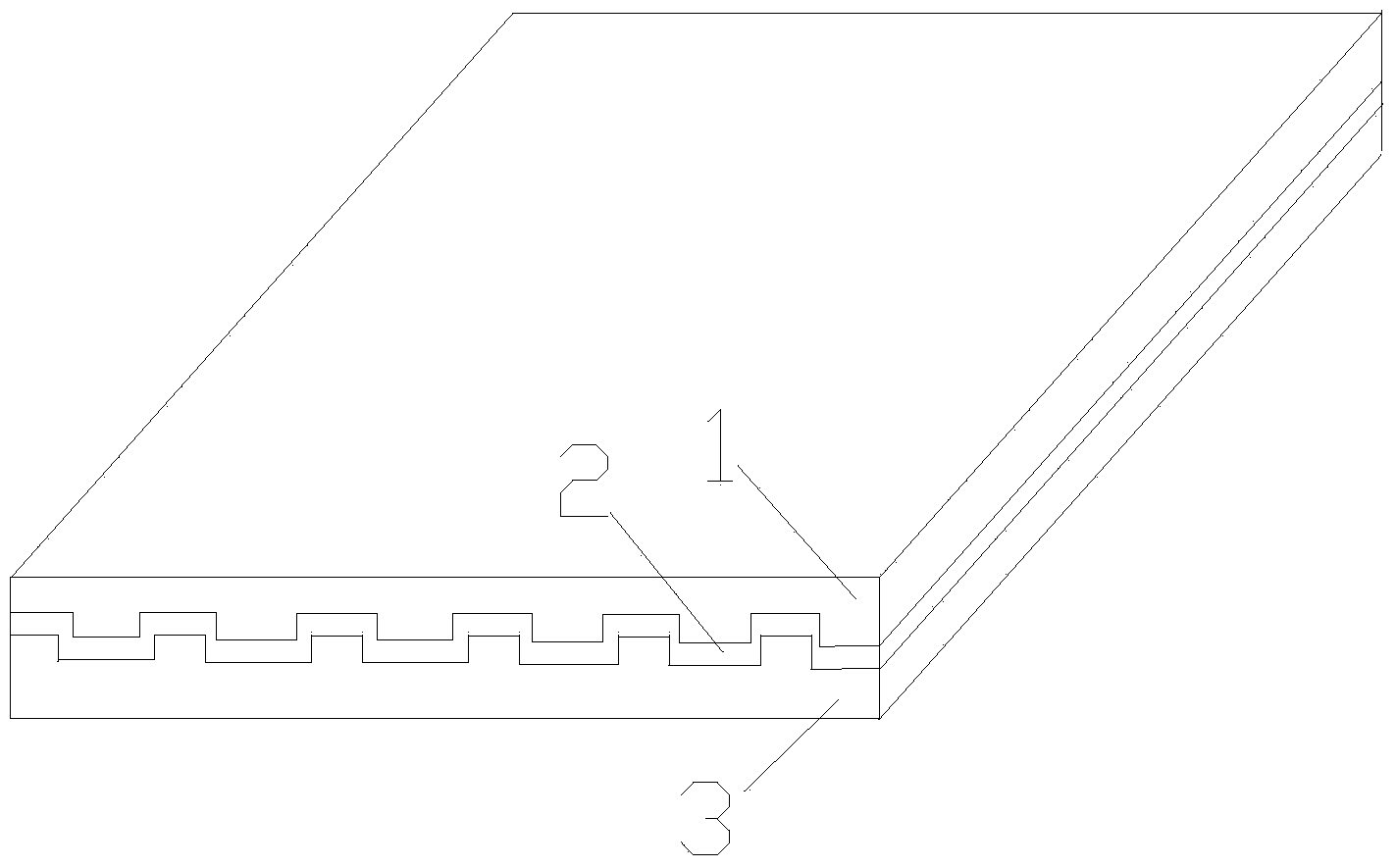

Thermal insulation composite external wall panel suitable for industrial manufacturing and environment-protecting construction and manufacturing method thereof

InactiveCN103469960AHigh strengthImprove high temperature resistanceNon-macromolecular adhesive additivesLayered productsEnvironmental resistanceFiber

The invention relates to a thermal insulation composite external wall panel suitable for industrial manufacturing and environment-protecting construction and a manufacturing method of the thermal insulation composite external wall panel. The thermal insulation composite external wall panel comprises a composite fiber pressure plate and a vermiculite base plate, and is characterized in that the composite fiber pressure plate and the vermiculite base plate are compounded through staggered grooves and bulges, wherein an energy-saving and thermal-radiation-preventing air absorbing and decomposing adhesive layer which is capable of preventing residual air at the joint face from forming local heat convection is arranged between the composite fiber pressure plate and the vermiculite base plate.

Owner:华建耐尔特(北京)低碳科技有限公司 +1

Anti-corrosion treatment process of components of assembling iron art guardrail product

InactiveCN108144824AImprove corrosion resistanceSolve corrosionPretreated surfacesCoatingsWeather resistancePunching

The invention relates to an anti-corrosion treatment process of components of an assembling iron art guardrail product. The anti-corrosion treatment process comprises the following process steps thataccording to the design requirements and the assembling structure design requirement of the guardrail product style, sectional materials are selected to carry out corresponding punching, drilling andother deep processing to be then welded to form square steel pipes and assembling connecting components, and deburring treatment and removing welding trace treatment are carried out on the deep processing parts of pipes and assembling connecting parts; then overall hot-dip galvanizing anti-corrosion treatment on the pipes and the assembling connection components are performed, and then the components are subjected to paint coating and powder coating of the single-layer powder coating which comprise primer coating, middle coating and the surface coating; the powder coating is selected to be sent into a drying room to be heated at the temperature of 180-200 DEG C; and finally, protective packaging is carrying out on pipes and assembling connecting components so as to obtain the assembling iron art guardrail product. The iron art guardrail product produced by adopting the anti-corrosion treatment process has excellent corrosion resistance, and has the advantages of being good in weather resistance, long in service life for 50 years, and excellent in quality and the like.

Owner:FOSHAN HONGTU IRON ART

Preparation method of anticorrosion coiled steel pipe for marine environment

The invention discloses a preparation method of an anticorrosion coiled steel pipe for the marine environment. The method includes the steps of firstly, detecting a plate; secondly, cutting the plate through flames and blanking, and forming grooves; thirdly, conducting coiling, wherein a polished steel plate is coiled into an O shape through a supporting type coiling technology; fourthly, conducting pairing, roundness correcting and longitudinal seam UT flaw detecting; fifthly, conducting longitudinal seam internal and external welding, wherein in the internal welding process and the external welding process, an anticorrosion welding agent are adopted, and a laser welding seam automatic tracking device with tracking precision of 0.25 mm is adopted; sixthly, conducting annular seam welding; seventhly, conducting welding seam residual height grinding, wherein seam surplus height is ground flat through a seam surplus height grinding machine; eighthly, conducting annular seam UT flaw detecting and X-ray flaw detecting; ninthly, marking the product for leaving a factory. The method is simple and solves the problems that an existing steel pipe for the marine environment is short in validity period, prone to ageing, poor in weather resistance, poor in corrosion resistance, low in size precision and the like.

Owner:HEFEI ZIKING PIPE INC

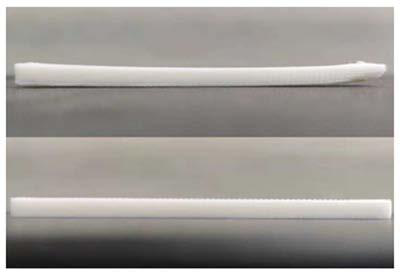

ASA 3D printing wire with low warpage at low temperature and preparation method thereof

PendingCN110330756AGood formabilityImprove continuityAdditive manufacturing apparatusElastomerWeather resistance

The invention relates to an ASA 3D printing wire with low warpage at low temperature and a preparation method thereof. According to the method, the ASA 3D printing wire with the low warpage at low temperature is prepared by taking 55-70 parts of ASA resin as a raw material adding 20-35 parts of an elastomer-aramid pulp composite, 3-12 parts of a compatibilizer, 3-8 parts of a tackifier, 0.2-1 partof an antioxidant and 0.2-1 part of paraffin oil through drying and dehumidifying, material mixing, melting blending, extrusion molding and traction winding. The wire rod does not generate shrinkageand warpage when molded under the condition of lower bottom plate temperature, has excellent mechanical property, good bonding property and excellent weather resistance, and has wide application fieldand high application value.

Owner:LIMING VOCATIONAL UNIV

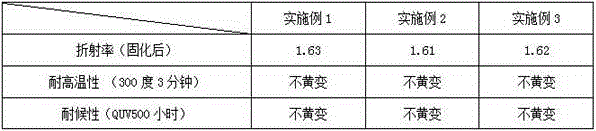

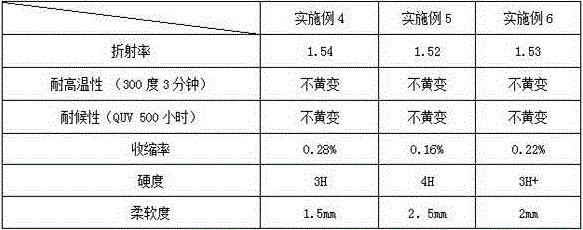

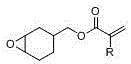

Photocured prepolymer, preparation method thereof and photocured costume jewelry molding glue prepared from photocured prepolymer

ActiveCN106588815ASolve weather resistanceSolve the problem of high-temperature yellowing that is prone to occur in over-reflow solderingOrganic chemistryNon-macromolecular adhesive additivesPolymer scienceRefractive index

The invention discloses a photocured prepolymer, a preparation method thereof and costume jewelry molding photocured glue prepared from the photocured prepolymer. The photocured prepolymer adopts a structural formula shown in the specification, wherein R1 and R2 are identical or different and are mutually independently represented as H or CH3. Cycloaliphatic epoxy groups are introduced to two ends of dimercaptothiadiazole, and the prepared photocured prepolymer has the advantages of high refractive index, good high-temperature resistance and weather fastness, low curing shrinkage rate and the like, and solves the problems of poor weather fastness and high probability of high-temperature yellowing during reflow soldering of the conventional UV curing system; by means of addition reaction synthesis of mercapto groups and cycloaliphatic epoxy groups with higher reactivity, the activity of epoxy bonds is very high, even a catalyst is not needed for the reaction, the synthetic process is simpler and consumes shorter time, energy consumption is reduced greatly, the productivity is increased, and better environment-friendliness is realized due to avoidance of solvent use.

Owner:SUMDA MATERIAL TECH CO LTD

Outdoor fitness equipment anticorrosive paint, and preparation method thereof

InactiveCN107189589AGood flexibilityImprove adhesionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses an outdoor fitness equipment anticorrosive paint. The outdoor fitness equipment anticorrosive paint comprises, by weight, 20 to 30 parts of water-based acrylic resin emulsion, 17 to 28 parts of epoxy resin, 15 to 35 parts of dicapryl phthalate, 8 to 15 parts of n-butyl acetate, 7 to 13 parts of talcum powder, 5 to 8 parts of diethylenetriamine, 1 to 2 parts of sodium dodecyl benzene sulfonate, 2 to 4 parts of polyvinyl alcohol, 1 to 2 parts of carboxymethyl chitosan, 5 to 9 parts of titanium dioxide, 2 to 3 parts of an adhesive force auxiliary agent, 1.5 to 3.5 parts of an antiseptic, 1 to 2 parts of an antifoaming agent, 2 to 3 parts of a ultraviolet ray absorber, 10 to 15 parts of dried cordate houttuynia, and 10 to 30 parts of deionized water. The outdoor fitness equipment anticorrosive paint is excellent in durability, self-drying performance, and corrosion resistance, can be used for protecting outdoor fitness equipment, and prolonging the service life of outdoor fitness equipment.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

PMMA (Polymethyl Methacrylate) type two-component road marking material and preparation method thereof

ActiveCN103254717ASolve weather resistanceSolve chronic drynessCoatingsAntioxidantPolymethyl methacrylate

The invention relates to a PMMA (Polymethyl Methacrylate) type two-component road marking material and a preparation method thereof. The PMMA type two-component road marking material is prepared from the following raw materials in percentage by mass: 40% of liquid PMMA resin, 15% of rutile titanium dioxide, 36% of 325# calcium carbonate, 0.5% of a BASF (Badische Anilin Soda Fabrik) antioxidant, 1.5% of an organic anti-settling agent, 0.5% of a BYK surface wetting agent, 2.5% of organic pigment, 0.3% of a molecular weight regulator, 1.5% of a plasticizer, 0.5% of a permeation aid, 0.2% of an acid value balancing agent and 1.5% of high-cobalt naphthenic acid-containing cobalt. The PMMA type two-component road marking material has the beneficial effects that the problems of poor weather fastness, slowly drying property and initial properties of the materials are solved; the product is green and environment-friendly material; and the PMMA type two-component road marking material as a novel material with low carbon emission is convenient to use, high in construction efficiency, simple to prepare and easy to operate.

Owner:保定市科顺达交通设施有限公司 +2

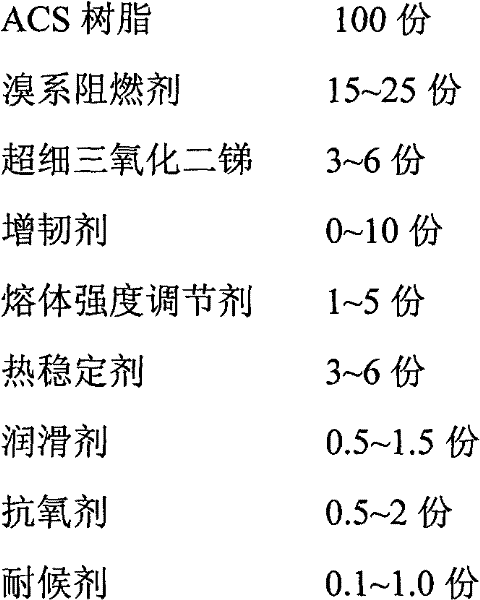

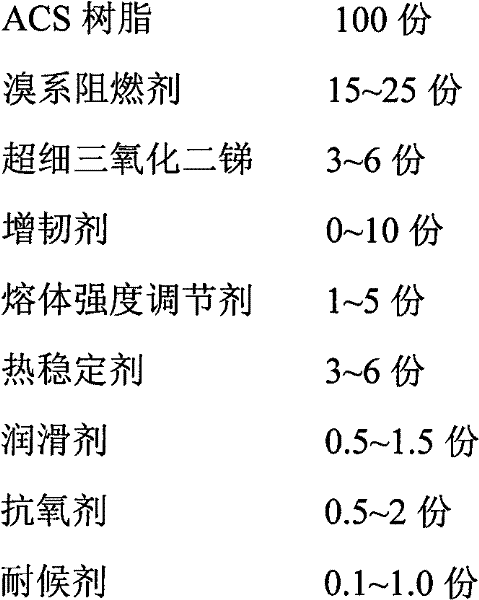

Extrusion-grade inflaming retarding ACS (acrylonitrile-chlorinated polyethylene-styrene) resin and preparation method thereof

ActiveCN102304265AGive full play to the synergistic effectAvoid color changesAntioxidantAcrylonitrile

The invention relates to an extrusion-grade inflaming retarding ACS (acrylonitrile-chlorinated polyethylene-styrene) resin. The resin is characterized by comprising the following components in parts by weight: 100 parts of ACS resin, 15-25 parts of brominated inflaming retarding agent, 3-6 parts of super-fine antimonous oxide, 0-10 parts of flexibilizer, 1-5 parts of melt strength regulator, 3-6 parts of thermal stabilizer, 0.5-1.5 parts of lubricant, 0.5-2 parts of antioxidant and 0.1-1.0 part of weather resisting agent. The extrusion-grade inflaming retarding ACS resin provided by the invention can be compounded and co-extruded with PVC (polyvinyl chloride) and has uniform coating, good surface gloss and smooth section, and the maximum processable width of the resin is greatly improved.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

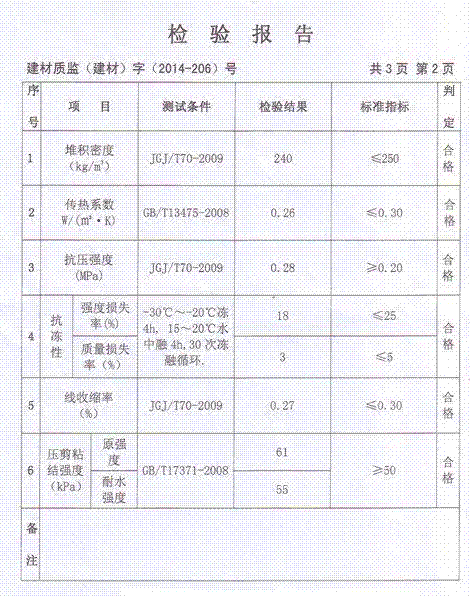

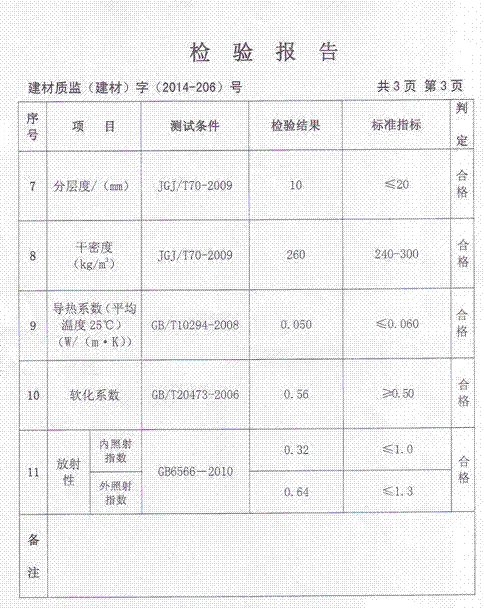

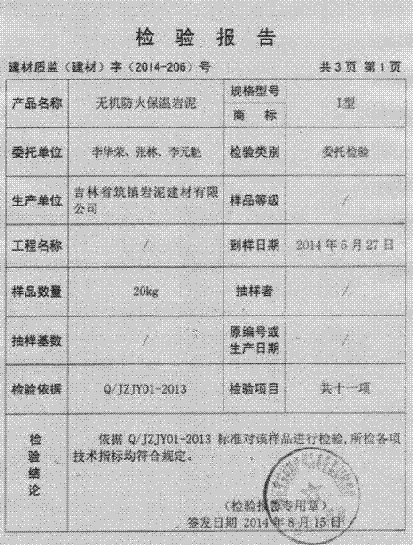

Inorganic waterproof heat insulation rock mud

The invention provides inorganic waterproof heat insulation rock mud. The rock mud comprises Portland cement, bentonite, flocculent staple iron fibers, staple glass fibers, afrodite particles, oil shale particles and hydrophobic pearlite particles. The rock mud has the beneficial effects that the rock mud is scientific in formula, has excellent properties, is used after adding water and stirring the materials uniformly, and is simple in construction process; compared with the prior art, the rock mud has the advantages that the heat conductivity ratio of the rock mud is low by 29.6% and the heat conductivity is good; the bulk density is 39.7%, so that the weight load of a wall can be effectively reduced; by adopting the rock mud, buildings have stronger waterproofing, heat insulation and sound insulation functions; the rock mud is light, has high strength, is free from cracking, hollowing, falling, molecule fission and aging and has long service life as the wall; a fiber ball netty pulling and tying structure is formed after the rock mud is formed, so that the wall is free from moisture retention, moisture condensation and mildew and then the buildings are warm in winter and cool in summer; the rock mud has good intermiscibility, flame retardance and aging resistance, can be recycled, is low in comprehensive cost and is an energy-saving and environment-friendly building material.

Owner:张林

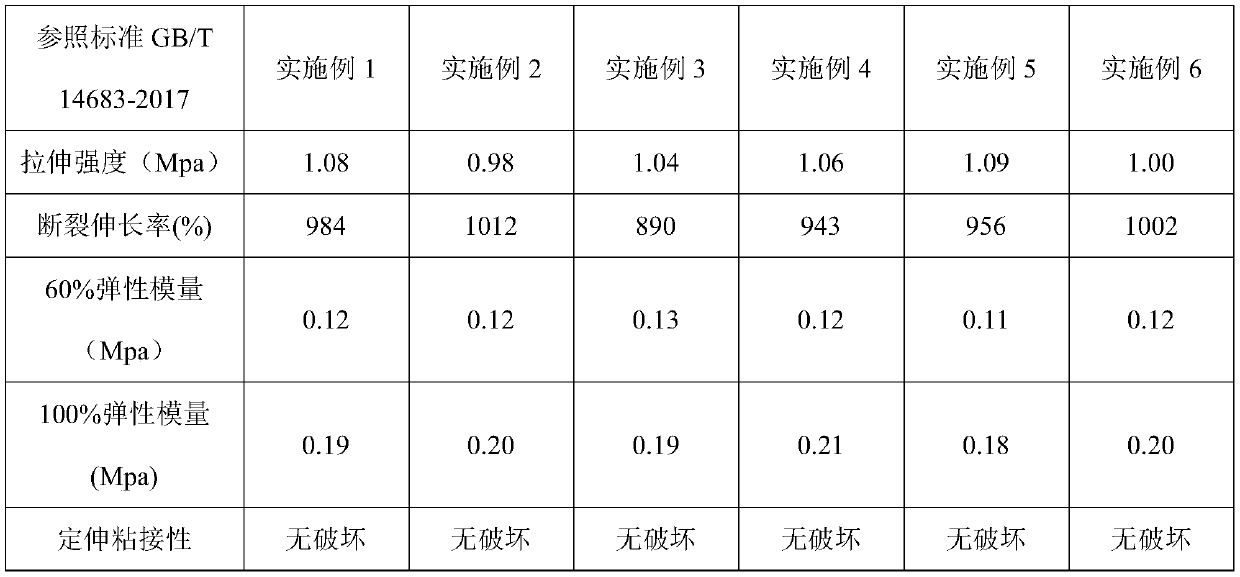

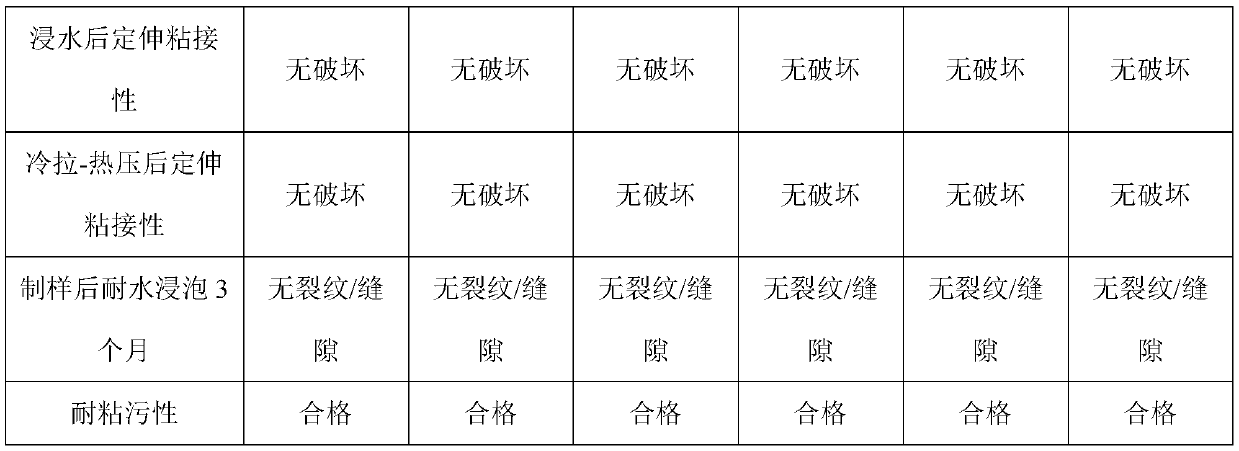

Environmentally friendly high elasticity sealant and preparation method thereof

ActiveCN109897589ASolve weather resistanceImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUltravioletSealant

The invention discloses an environmentally friendly high elasticity sealant, which is composed of a component (A) and a component (B). The component (A) is composed of silane modified polyether, a silane coupling agent, a water remover, polyether polyol, isocyanate, a plasticizer, a filling material, and an antifoaming agent. The component (B) is prepared by mixing following components: a plasticizer, nano calcium carbonate, a curing agent, a pigment, a catalyst, a thixotropic agent, a silane coupling agent, a light stabilizer, and a UV absorbent. The component (A) and the component (B) are mixed evenly according to a ratio of 10: (0.7-1.0) before using. The prepared sealant has the characteristics of environmentally friendly property, good weatherability, low cost, wide performance adjusting range, and excellent mechanical properties, and can be well adhered on various basic materials such as glass surface, cement surface, stone, and the like.

Owner:YUZHONGQING WATERPROOF MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com