Environment-friendly acrylic acid type powder coating

An acrylic powder coating technology, applied in powder coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor weather resistance and easy corrosion, and achieve the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

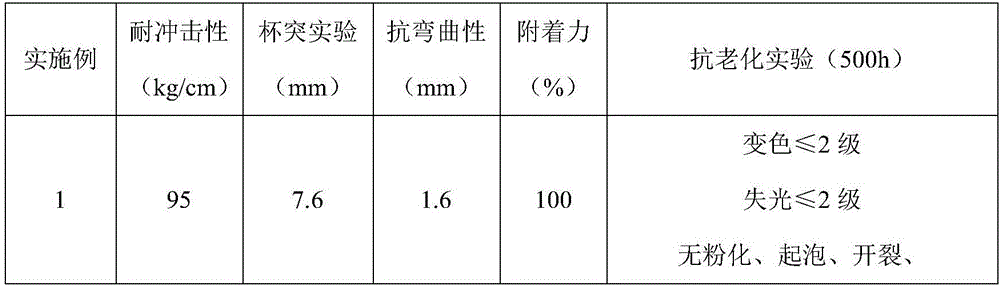

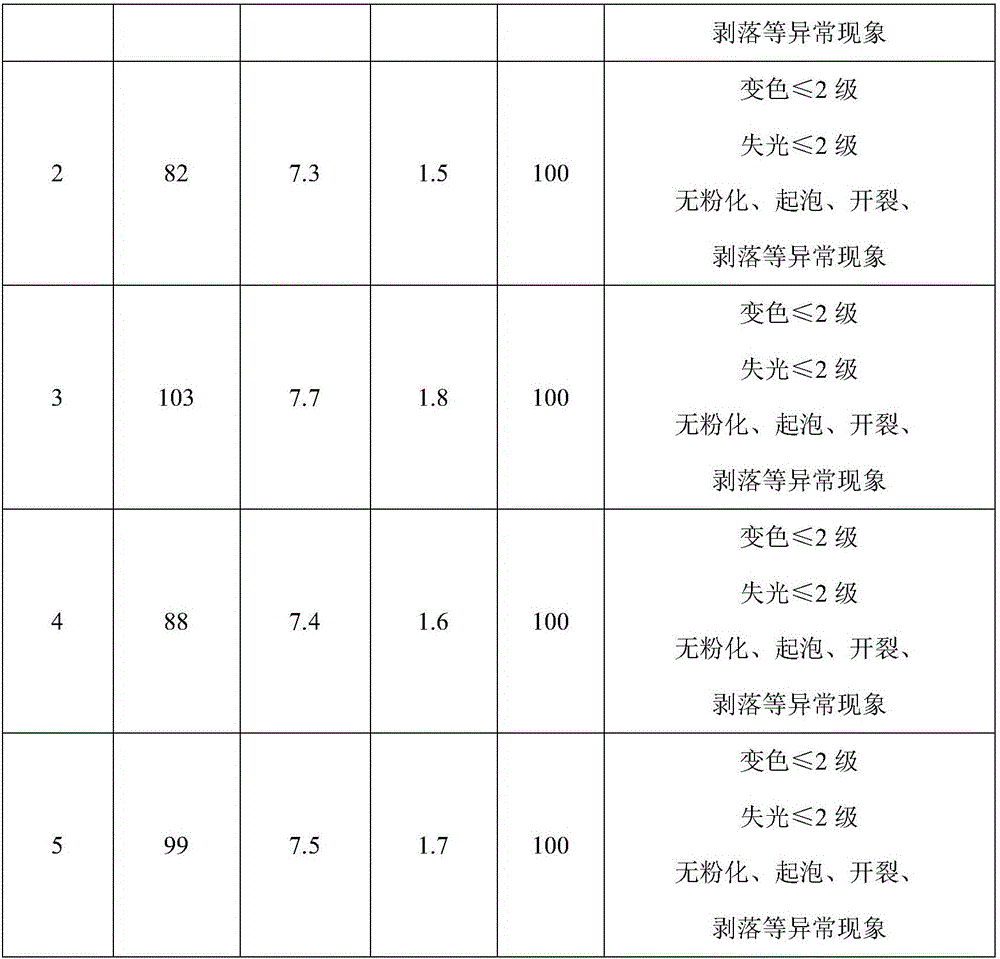

Examples

preparation example Construction

[0023] The preparation method of described environment-friendly acrylic powder coating, comprises the following steps:

[0024] S1: Put matrix resin, pigments and fillers, curing agent, degassing agent, dispersing agent, drooping agent, toughening agent, brightening agent, wetting agent, preservative, antioxidant, light stabilizer into the mixing tank Mix for 4-6min to obtain a homogeneous mixture;

[0025] S2: Melt and extrude the homogeneous mixture prepared in step S1 through an extruder at 110-114° C., and pass through a tablet crushing machine to tablet, and obtain a tablet after cooling;

[0026] S3: cutting the flakes prepared in step S2 with a cutter to obtain pellets;

[0027] S4: crush the pellets prepared in step S3 and pass through a 150-200 mesh sieve to obtain an environment-friendly acrylic powder coating.

Embodiment 1

[0029] An environment-friendly acrylic powder coating, which includes the following raw materials in units of weight: 90 parts of matrix resin, 42 parts of pigment and filler, 15 parts of curing agent, 5 parts of degassing agent, 1.5 parts of dispersant, 0.6 part of drooping agent, 0.5 parts of toughening agent, 0.4 parts of brightening agent, 0.3 parts of wetting agent, 0.3 parts of preservative, 0.2 parts of antioxidant, 0.2 part of light stabilizer; the matrix resin is acrylic resin; the pigment and filler are metal pigments and body Pigment; the metal pigment is silver powder; the extender pigment is quartz powder; the curing agent is epoxy resin; the degassing agent is stearic acid; the dispersant is dispersant nc; The agent is vertical grain agent HM-2; the toughening agent is methyl methacrylate-butadiene-styrene terpolymer; the brightening agent is brightening agent LD-608; the wetting agent is wetting agent Wet agent CF-10; the preservative is preservative N-369; the ...

Embodiment 2

[0036] An environment-friendly acrylic powder coating, including the following raw materials by weight: 85 parts of matrix resin, 38 parts of pigments and fillers, 12 parts of curing agent, 4 parts of degassing agent, 1 part of dispersant, 0.4 parts of drooping agent, 0.3 parts of toughening agent, 0.3 parts of brightening agent, 0.2 parts of wetting agent, 0.2 parts of preservative, 0.2 parts of antioxidant, 0.2 part of light stabilizer; the matrix resin is acrylic resin; the pigment and filler are metal pigments and body Pigment; the metal pigment is silver powder; the extender pigment is quartz powder; the curing agent is epoxy resin; the degassing agent is stearic acid; the dispersant is dispersant nc; The agent is vertical grain agent HM-2; the toughening agent is methyl methacrylate-butadiene-styrene terpolymer; the brightening agent is brightening agent LD-608; the wetting agent is wetting agent Wet agent CF-10; the preservative is preservative N-369; the antioxidant is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com