Extrusion-grade inflaming retarding ACS (acrylonitrile-chlorinated polyethylene-styrene) resin and preparation method thereof

An extrusion-grade and resin technology, applied in the field of extrusion-grade flame-retardant ACS resin and its preparation, can solve the problems of difficult to meet the requirements of composite co-extrusion processing, low melt strength, easy to break, etc., to improve thermal processing performance and Anti-thermal oxidation aging stability, excellent flame retardant performance, guaranteeing the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

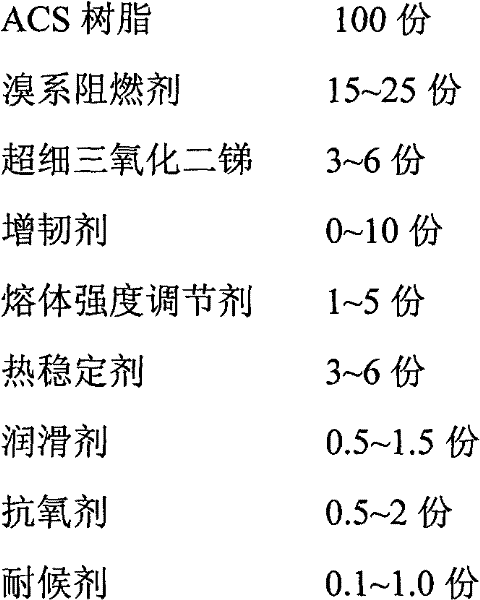

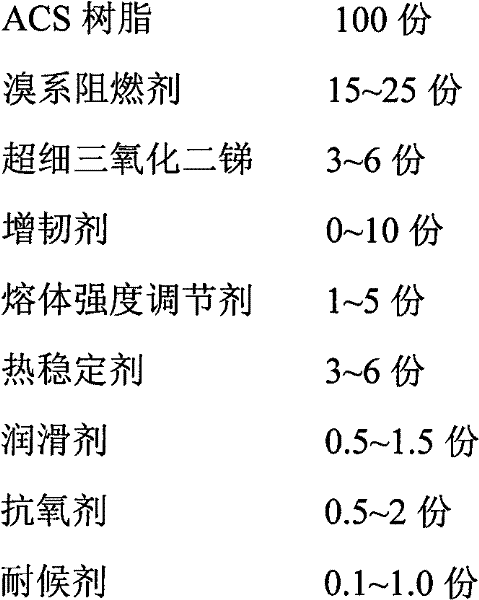

Method used

Image

Examples

Embodiment 1

[0036] 100 parts of ACS resin (produced by Ningbo Zhenyang New Material, weight average molecular weight 200,000, rubber content 30wt%), 2.0 parts of lead salt composite stabilizer (produced by Zhejiang Longhua Plastic Additives, brand LH-900), 1.0 part of calcium zinc Composite stabilizer (produced by Zhejiang Hepton Chemical, brand HCZ 1086L), 15 parts of brominated epoxy resin (produced by Shandong Haiwang Chemical, brand EP-5000), 6 parts of ultrafine antimony trioxide (particle size 0.5μm), 5 parts of ACR (manufactured by Mitsubishi Rayon, brand P-531), 0.5 part of stearic acid, 0.5 part of antioxidant 245, 0.1 part of weathering agent UV-P are added to the high-speed mixer and stirred and heated to 60℃, mixed at 1000rpm for 10 Minutes, discharge, and add the above-mentioned mixture into a twin-screw extruder for extrusion granulation to obtain an extrusion-grade flame-retardant ACS resin. The screw speed of the extruder is 100 rpm, and the temperature settings of the 10 z...

Embodiment 2

[0052] 100 parts of ACS resin (produced by Ningbo Zhenyang New Materials, weight average molecular weight 300,000, rubber content 20wt%), 2.0 parts of lead salt composite stabilizer (produced by Zhejiang Longhua Plastic Additives, brand LH-900), 1.0 part of calcium zinc Compound stabilizer (produced by Zhejiang Hepton Chemical, brand HCZ 1086L), 25 parts of brominated epoxy resin (produced by Shandong Neptune Chemical, brand EP-5000), 3 parts of ultra-fine antimony trioxide (particle size 0.5μm), 5 parts of CPE rubber (produced by Qingdao Haijinghua, grade 135A), 5 parts of ACR (produced by Mitsubishi Rayon, grade P-531), 0.5 parts of stearic acid, 0.5 parts of antioxidant TNPP, 0.3 parts of weathering agent UV-327 Add the mixture to a high-speed mixer, stir and raise the temperature to 80°C, mix at 1000 rpm for 15 minutes, and discharge, and add the above-mentioned mixture to a twin-screw extruder for extrusion granulation to obtain an extrusion-grade flame-retardant ACS resin....

Embodiment 3

[0068] 100 parts of ACS resin (produced by Ningbo Zhenyang New Materials, weight average molecular weight 300,000, rubber content 20wt%), 1.0 part of lead salt composite stabilizer (produced by Zhejiang Longhua Plastic Additives, brand LH-900), 5.0 parts of calcium zinc Compound stabilizer (produced by Zhejiang Hepton Chemical, brand HCZ 1086L), 20 parts of brominated epoxy resin (produced by Shandong Haiwang Chemical, brand EP-5000), 6 parts of ultrafine antimony trioxide (particle size 0.25μm), 5 parts of ASA high gum powder (produced by Kumho Chemical in South Korea, brand XC-500), 5 parts of ACR (produced by Mitsubishi Rayon, brand P-531), 0.5 parts of polyethylene wax, 1.0 part of antioxidant 225, 0.5 part of weather resistance Add UV-531 to a high-speed mixer, stir and heat up to 100°C, mix at 1000rpm for 15 minutes, and discharge. Add the above-mentioned mixture into a twin-screw extruder for extrusion granulation to obtain an extrusion-grade flame-retardant ACS resin. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com