Method for improving electrochemical performance of high nickel ternary cathode material through silicon dioxide/sodium collaborative modification

A synergistic modification and silicon dioxide technology, applied in the field of lithium-ion batteries, can solve the problems of limiting ternary material electrode compaction, cation mixing, lithium ion diffusion coefficient and low electronic conductivity, etc., to improve lithium ion diffusion Speed, excellent electrochemical performance, and the effect of improving the conductivity of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

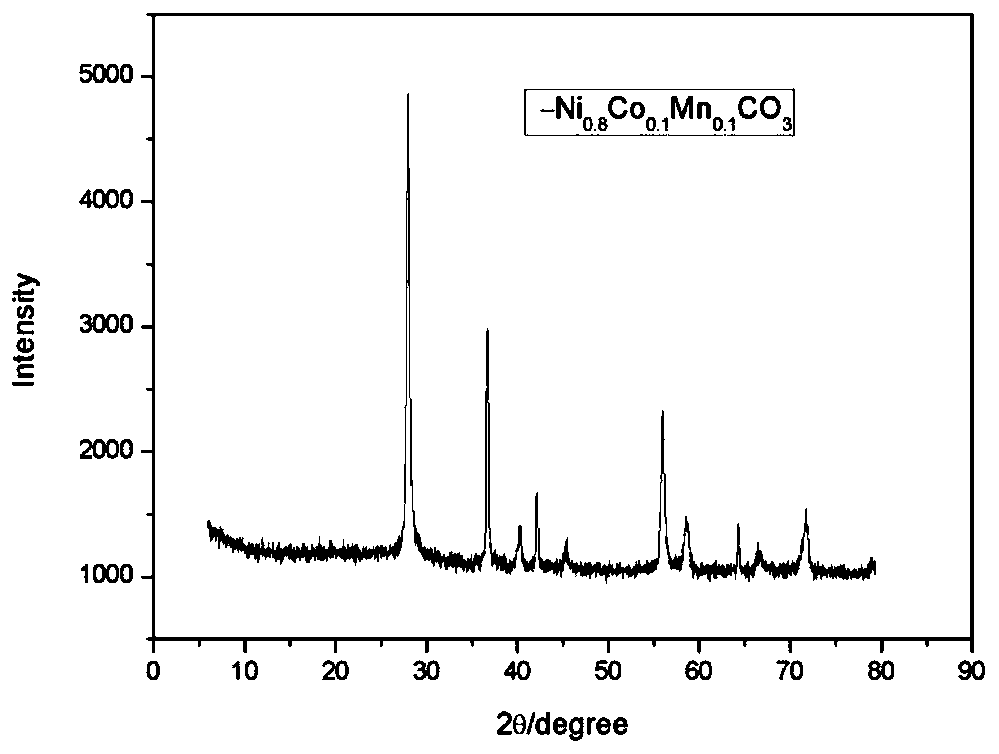

[0030] (1) Dissolve 0.0072mol nickel acetate tetrahydrate, 0.0009mol cobalt acetate tetrahydrate, 0.0009mol manganese acetate tetrahydrate and 0.027mol urea in 45mL of deionized water respectively. Mix it thoroughly with a mixer, then mix the two solutions and stir thoroughly. Then transfer the mixed solution to a 200mL polytetrafluoroethylene liner, then seal the liner into a stainless steel reaction kettle, keep it warm for 12 hours at a set temperature of 180°C, cool naturally to room temperature, filter, and store at 80°C Drying for more than 12 hours under the hood to obtain milky yellow precursor powder.

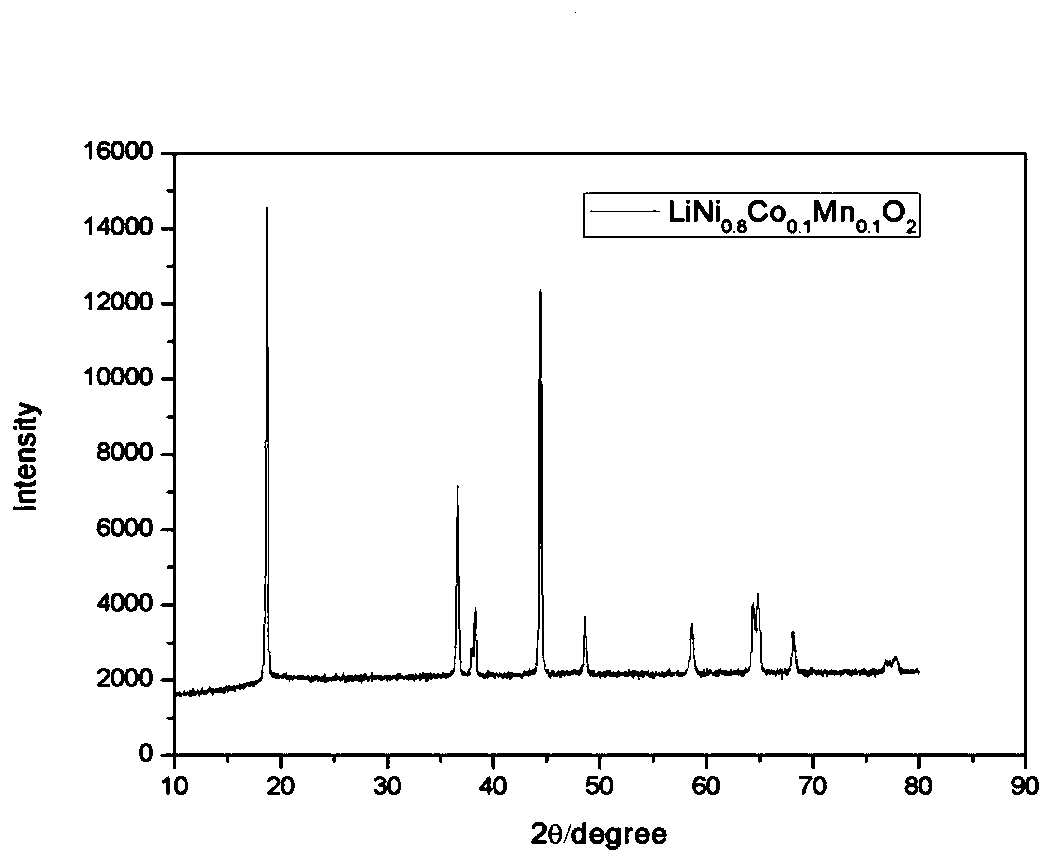

[0031] (2) Weigh 0.009mol of the precursor powder obtained in step (1), 0.00954mol of lithium hydroxide monohydrate and 0.00045mol of sodium carbonate, put the three in a beaker and add 20-30mL of absolute ethanol, and ultrasonically shake for 30min Dry in an oven at 80°C, grind in a mortar for 70 minutes, place the sample in a tube furnace, pre-sinter at 480°C for 5 ...

Embodiment example 2

[0036] (1) Dissolve 0.0288mol nickel acetate tetrahydrate, 0.0036mol cobalt acetate tetrahydrate, 0.0036mol manganese acetate tetrahydrate and 0.108mol urea in 180mL of deionized water respectively. Mix it thoroughly with a mixer, then mix the two solutions and stir thoroughly. Then transfer the mixed solution to a 200mL polytetrafluoroethylene liner, then seal the liner into a stainless steel reaction kettle, keep it warm for 12 hours at a set temperature of 180°C, cool naturally to room temperature, filter, and store at 80°C Drying for more than 12 hours under the hood to obtain milky yellow precursor powder.

[0037] (2) Weigh 0.036mol of the precursor powder obtained in step (1), 0.03816mol of lithium hydroxide monohydrate and 0.0018mol of sodium carbonate, put the three in a beaker and add 80-120mL of absolute ethanol, and ultrasonically shake for 30min Dry in an oven at 80°C, grind in a mortar for 70 minutes, place the sample in a tube furnace, pre-sinter at 480°C for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com