Patents

Literature

44results about How to "High lithium ion conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

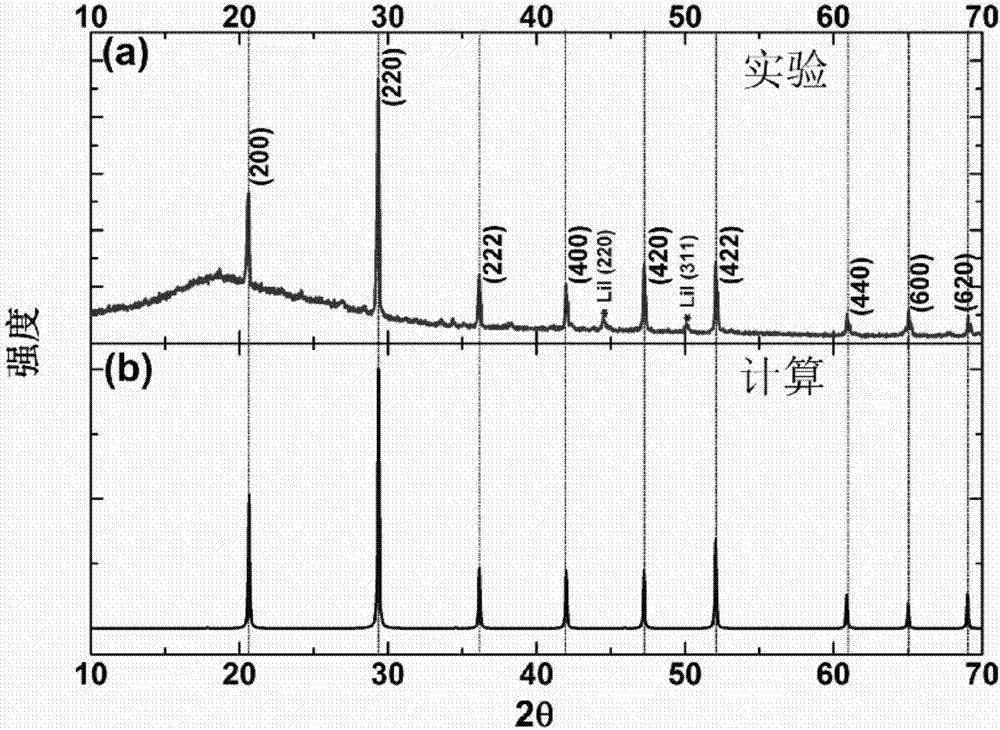

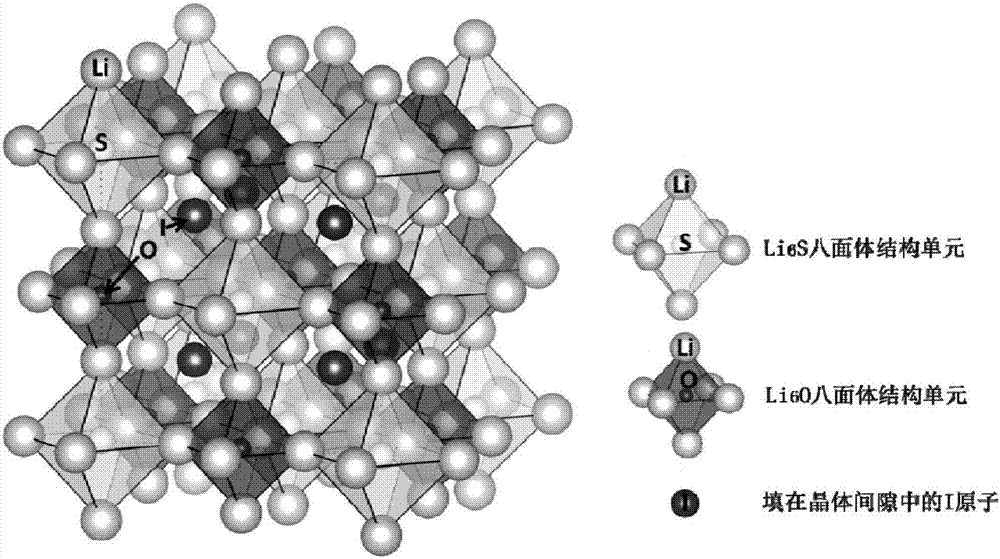

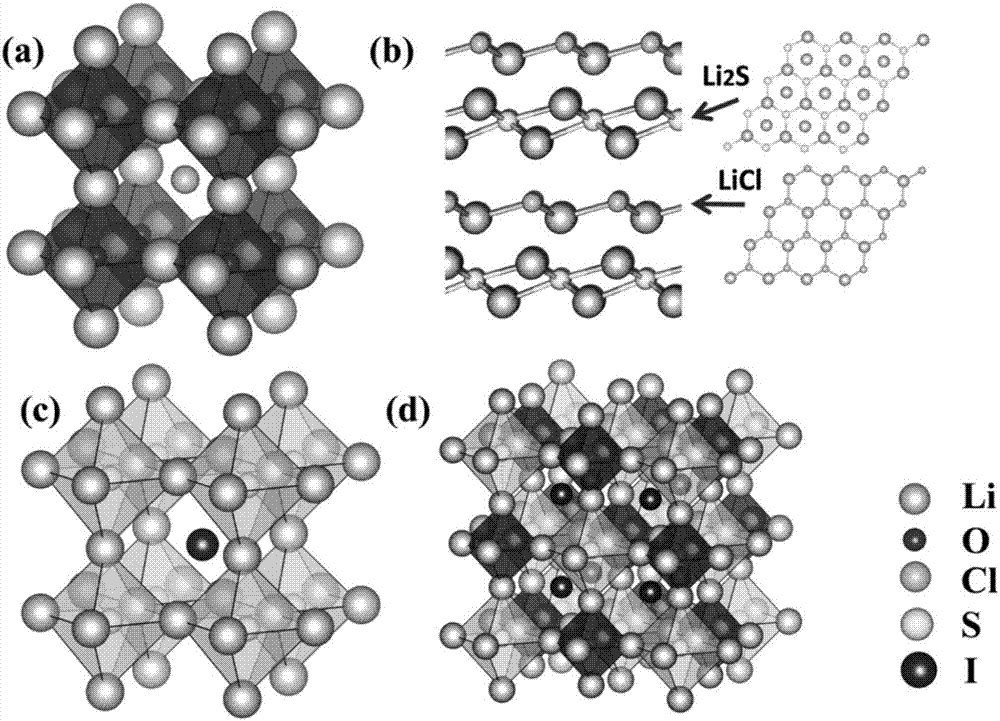

Lithium ion solid electrolyte and preparation method and application thereof

ActiveCN107425218AExcellent lithium ion conductivityHigh thermodynamic stabilityCell electrodesSecondary cellsHalogenPhysical chemistry

The invention relates to a lithium ion solid electrolyte and a preparation method application thereof, and belongs to the technical field of a lithium ion battery. The lithium ion solid electrolyte has the chemical formula shown as follows: Li<3+a>MA<m>B<n>Y<1-b>, wherein a is more than or equal to -0.25 but less than or equal to 0.25, b is more than or equal to 0 but less than or equal to 0.5, m is more than or equal to 0 but less than or equal to 1.25, n is more than or equal to 0 but less than or equal to 1.25, M is one of Ca, Ba, Mg, Al and Ti, A and B are separately selected from one of O, S, Se, Te, N, P, Si, C, Sb, Bi, F, Cl, Br and I, and Y is one of halogen, minus monovalent ionic group or vacancy. The lithium ion solid electrolyte has a stable structure and favorable lithium ion transmission performance and has favorable electrochemical performance and safety performance when used as a solid electrolyte of the lithium ion battery.

Owner:ZHENGZHOU NEW CENTURY MATERIALS GENOME INST CO LTD

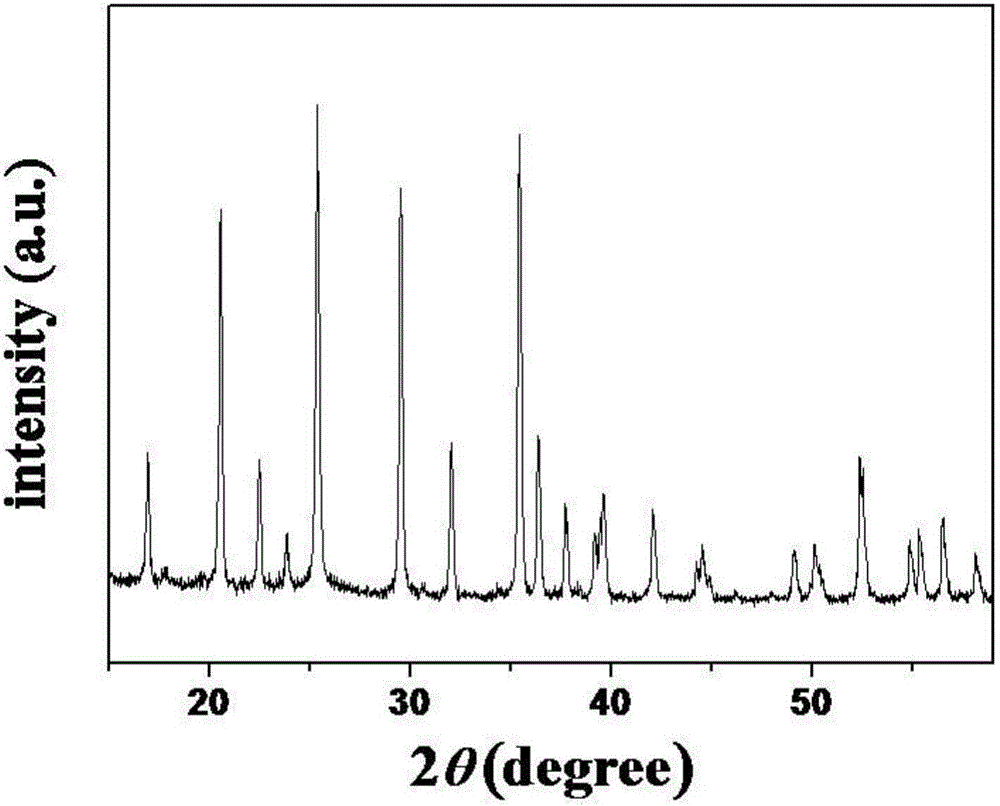

Method for preparing lithium phosphate/carbon-coated lithium iron phosphate composite material

ActiveCN103730657AImprove conductivityImprove performanceCell electrodesSecondary cellsLithium iron phosphateLITHIUM PHOSPHATE

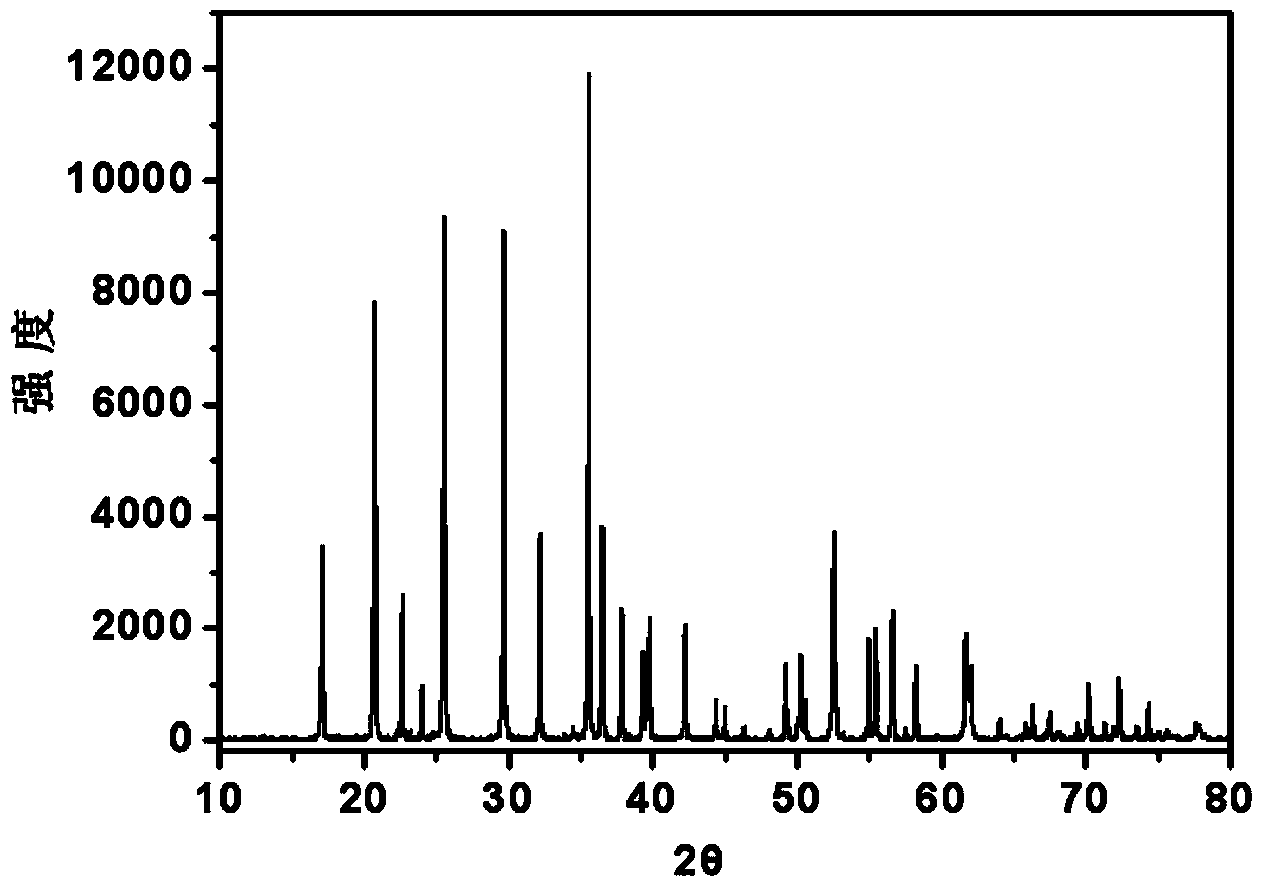

The invention discloses a method for preparing a high-performance lithium phosphate / carbon-coated lithium iron phosphate composite material. The method mainly comprises the processes of preparing lithium iron phosphate not subjected to carbon coating and preparing the lithium phosphate / carbon-coated lithium iron phosphate composite material. The method comprises the following steps: performing primary sintering to prepare lithium iron phosphate not subjected to carbon coating, and adding a certain amount of lithium phosphate and carbon source in the secondary mixing process to finally prepare the lithium phosphate / carbon-coated lithium iron phosphate composite material. The lithium phosphate is a fast ionic conductor, the aim of improving the electrical conductivity of lithium iron phosphate is achieved, and the aim of improving the overall performance of the lithium iron phosphate is also achieved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Organic/inorganic composite electrolyte and preparation method thereof

InactiveCN103515649AHigh lithium ion conductivityImprove mechanical propertiesFinal product manufactureElectrolytesPolymer electrolytesComposite electrolyte

The invention discloses an organic / inorganic composite electrolyte and a preparation method thereof. The organic / inorganic composite electrolyte is obtained by dispersing a lithium salt and a modified inorganic solid electrolyte into a polymer in a mixing manner, wherein the polymer contains an ethylene oxide repeating unit. The modification of the inorganic solid electrolyte is carried out for the first time; a polymer electrolyte and the inorganic electrolyte are effectively and evenly composited, so that the organic / inorganic composite electrolyte material is obtained. The dispersion of the inorganic solid electrolyte in the polymer is improved by the modification of the inorganic solid electrolyte, so that the adverse effect that the inorganic solid electrolyte is automatically gathered is avoided. The organic / inorganic composite electrolyte material obtained according to the preparation method has the advantages of the polymer electrolyte and the inorganic electrolyte, so that the comprehensive performance of the organic / inorganic composite electrolyte material is obviously improved. The organic / inorganic composite electrolyte material has practical value and can be popularized in lithium ion secondary batteries.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

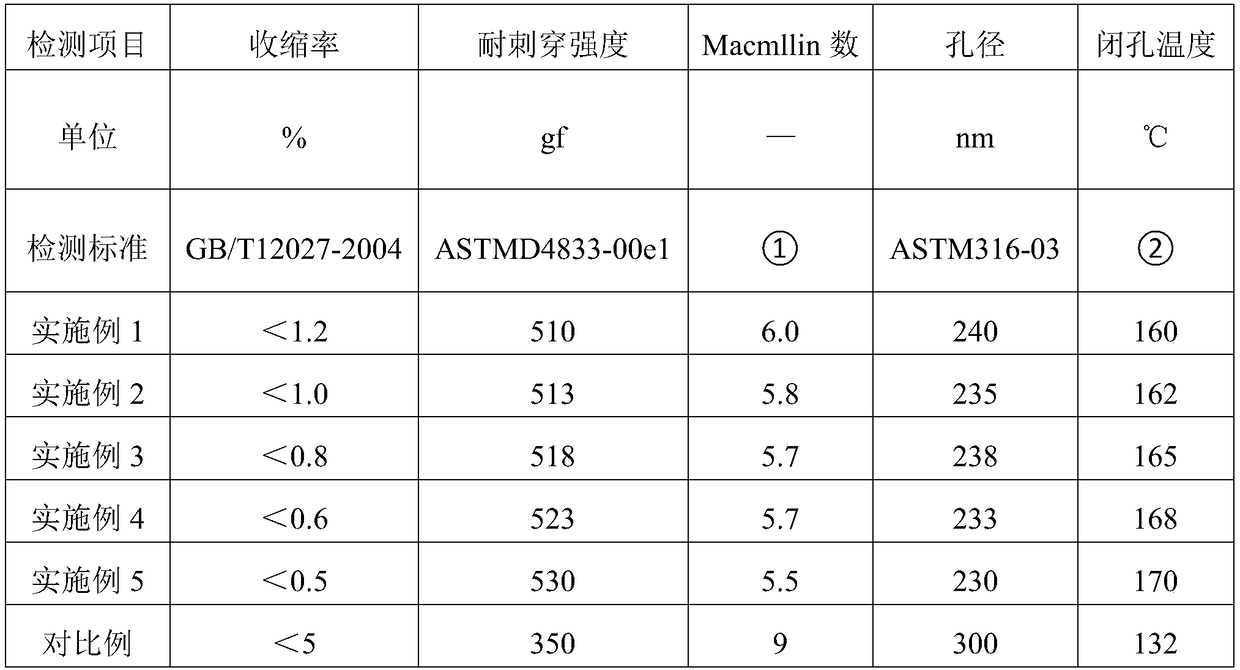

Lithium ion battery diaphragm, preparation method of the lithium ion battery diaphragm, and lithium ion battery containing the lithium ion battery diaphragm

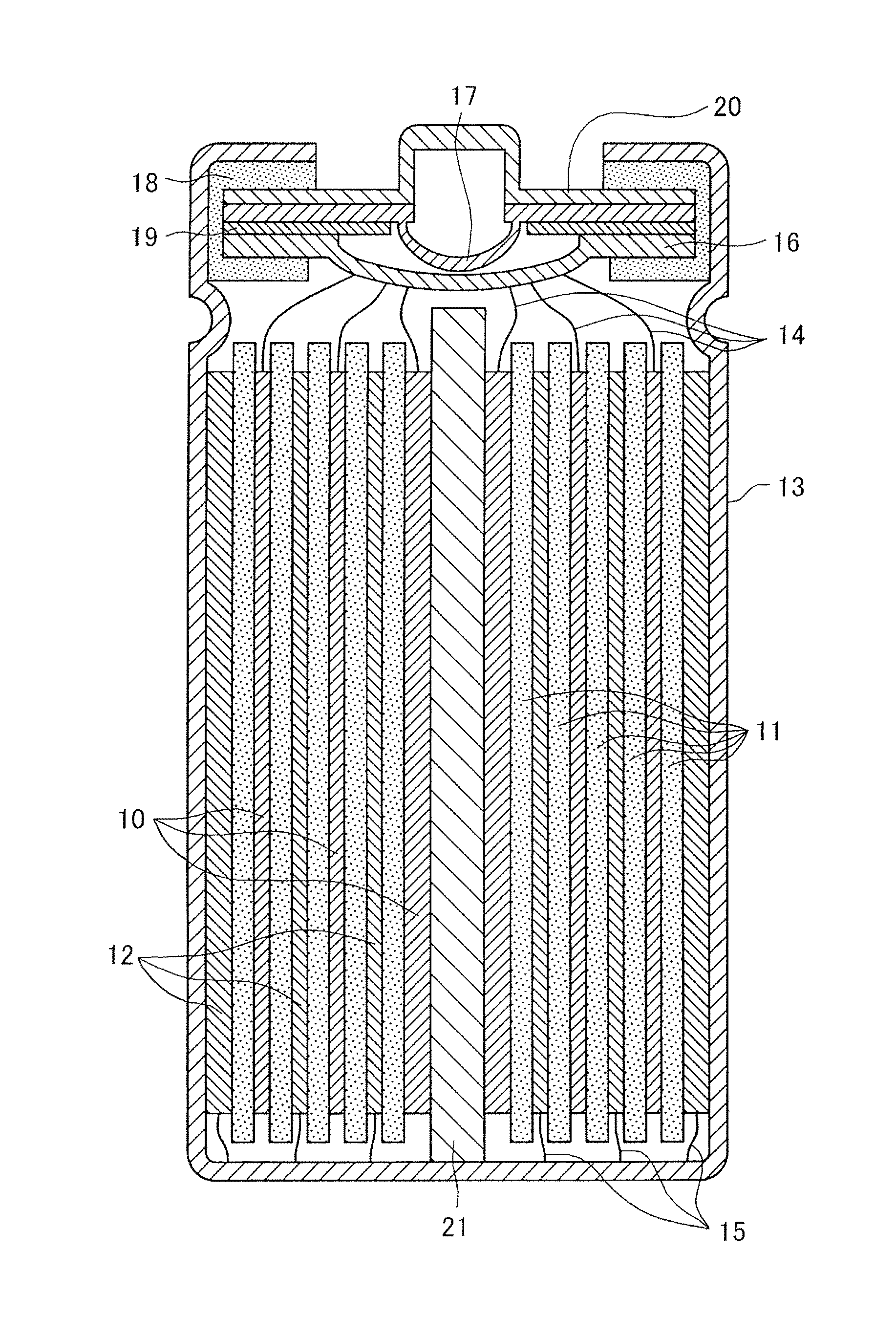

InactiveCN103137929AHigh lithium ion conductivityReduced risk of short circuitsSecondary cellsCell component detailsPhysicsLithium electrode

The invention provides a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a diaphragm base material and a solid electrolyte layer arranged on at least one surface of the diaphragm base material. The invention also provides a preparation method of the lithium ion battery diaphragm, a device adopted by the preparation method and a lithium ion battery containing the lithium ion battery diaphragm. A high rate of lithium ion transmission between positive and negative poles of the lithium ion battery containing the lithium ion battery diaphragm is kept, a risk of short circuit between the positive and negative poles is reduced, and a diaphragm heat shrinkage problem and battery safety are improved.

Owner:BYD CO LTD

Electric field activated sintering method of solid electrolyte material

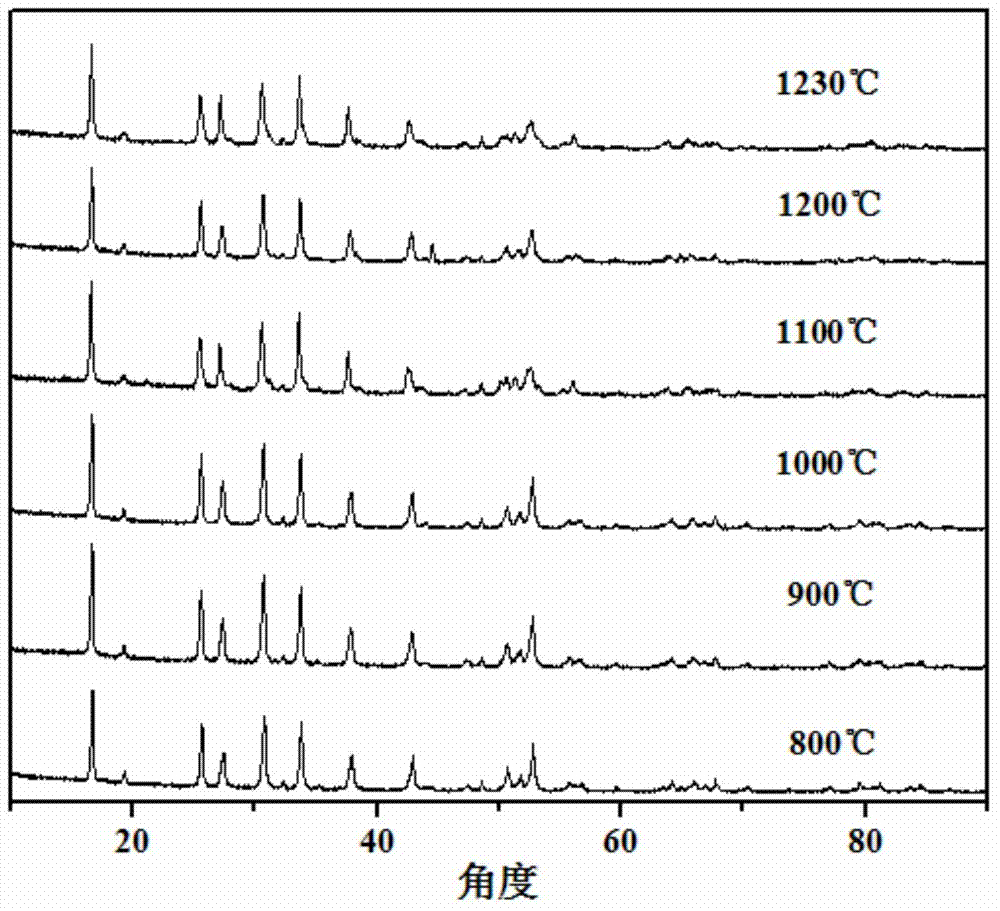

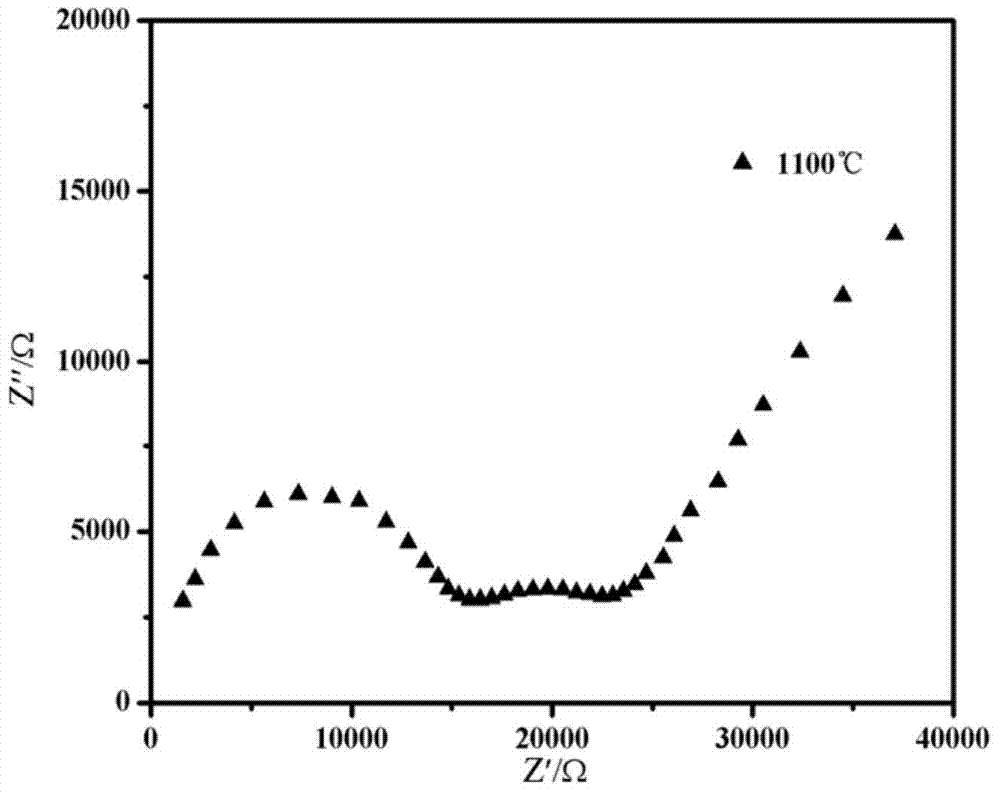

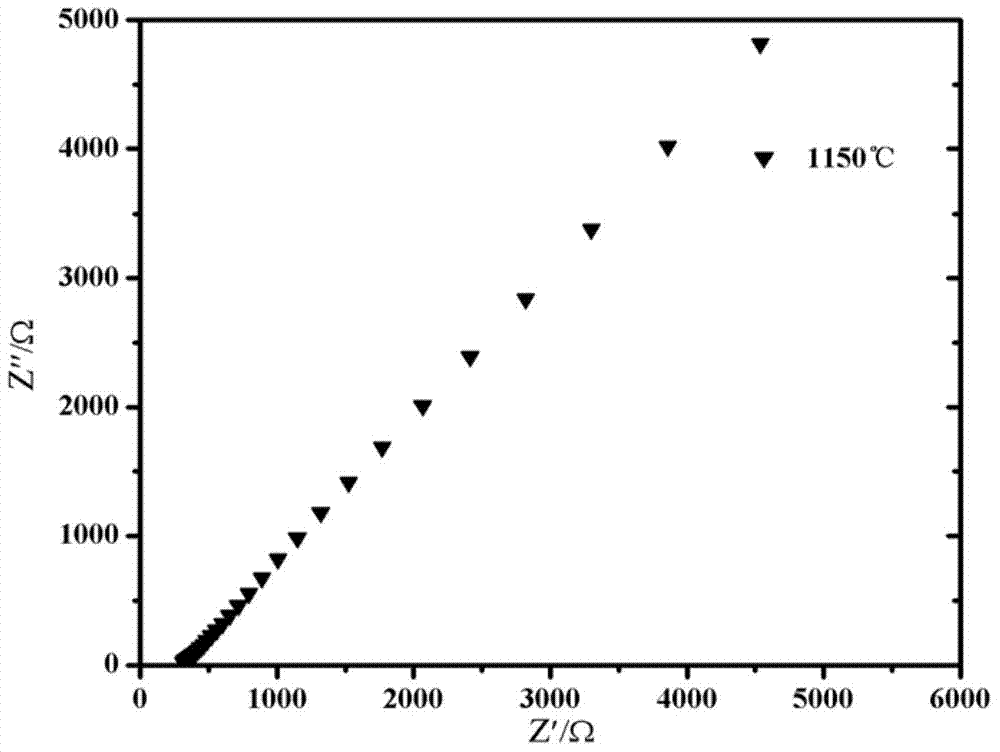

The invention provides an electric field activated sintering method of a solid electrolyte material Li7La3Zr2O12 (LLZO). The electric field activated sintering method comprises the following specific steps: ball-milling with a ball and mixing Li2O, La2O3 and ZrO2 powder, the mass percents of which are respectively 9.2-15.5%, 56.2-60.4% and 28.3-30.4%, wherein a zirconium oxide ball is used as a ball-milling medium, isopropanol is used as a solvent, and the ball-milling time is 12-36 hours; carrying out vacuum drying on ball-milling milled powder for 6-12 hours at the temperature of 80 DEG C; and carrying out electric field activated sintering, wherein the temperature is in the range from 800 to 1230 DEG C, the pressure is 0-100 MpaMPa, and a sintered sample has the room-temperature lithium-ion conductivity greater than 6*10<-4S>S / cm. Compared with a conventional solid-phase synthesis method, the electric field activated sintering method has the advantages that the synthesis reaction and the sintering compact process are completed in one step, the synthetic efficiency is improved to a large extent, the preparation technology is simplified, and the LLZO with the high lithium-ion conductivity is obtained.

Owner:WUHAN UNIV OF TECH

Solid electrolyte, all-solid-state battery including the same, and method for making solid electrolyte

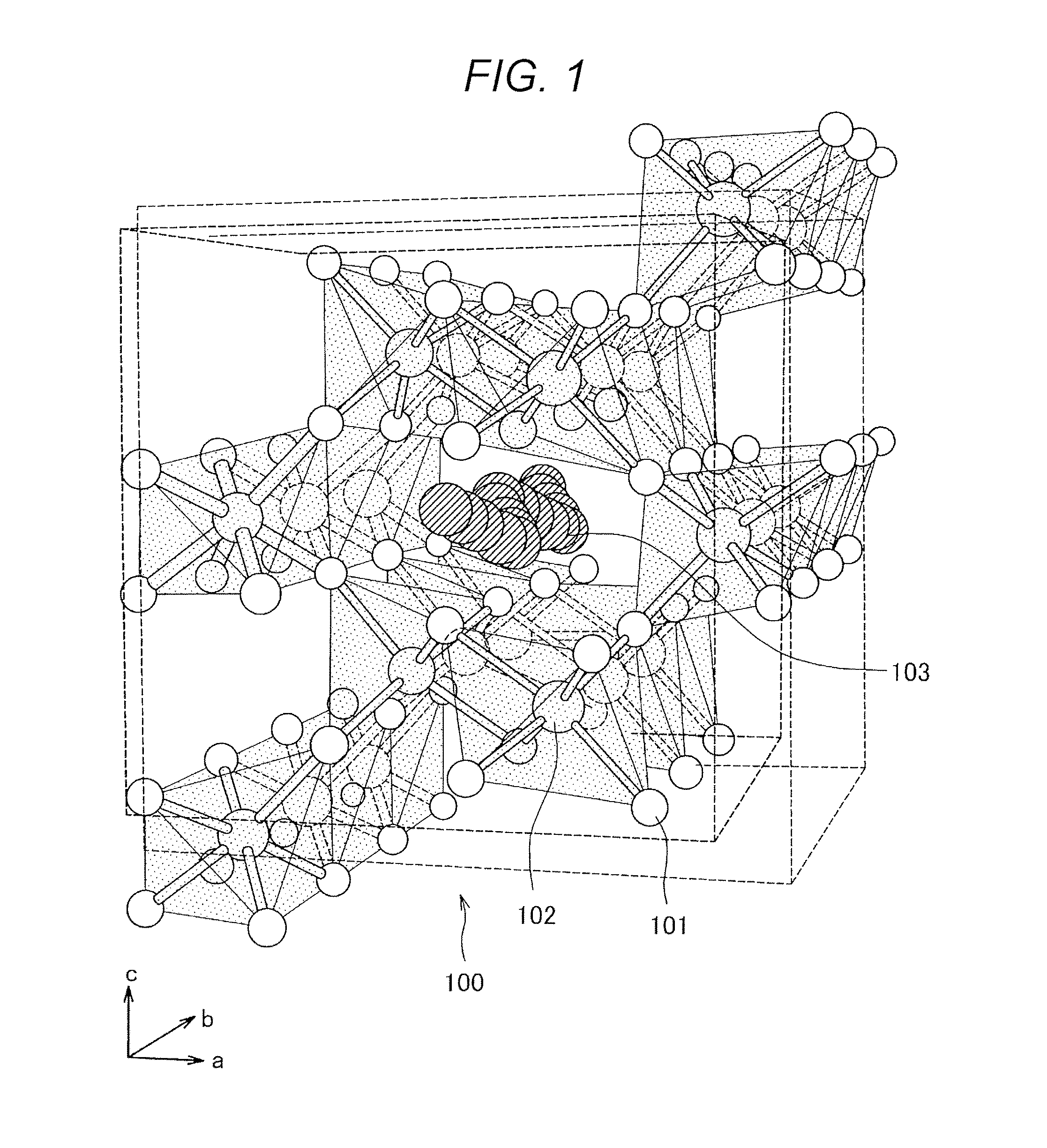

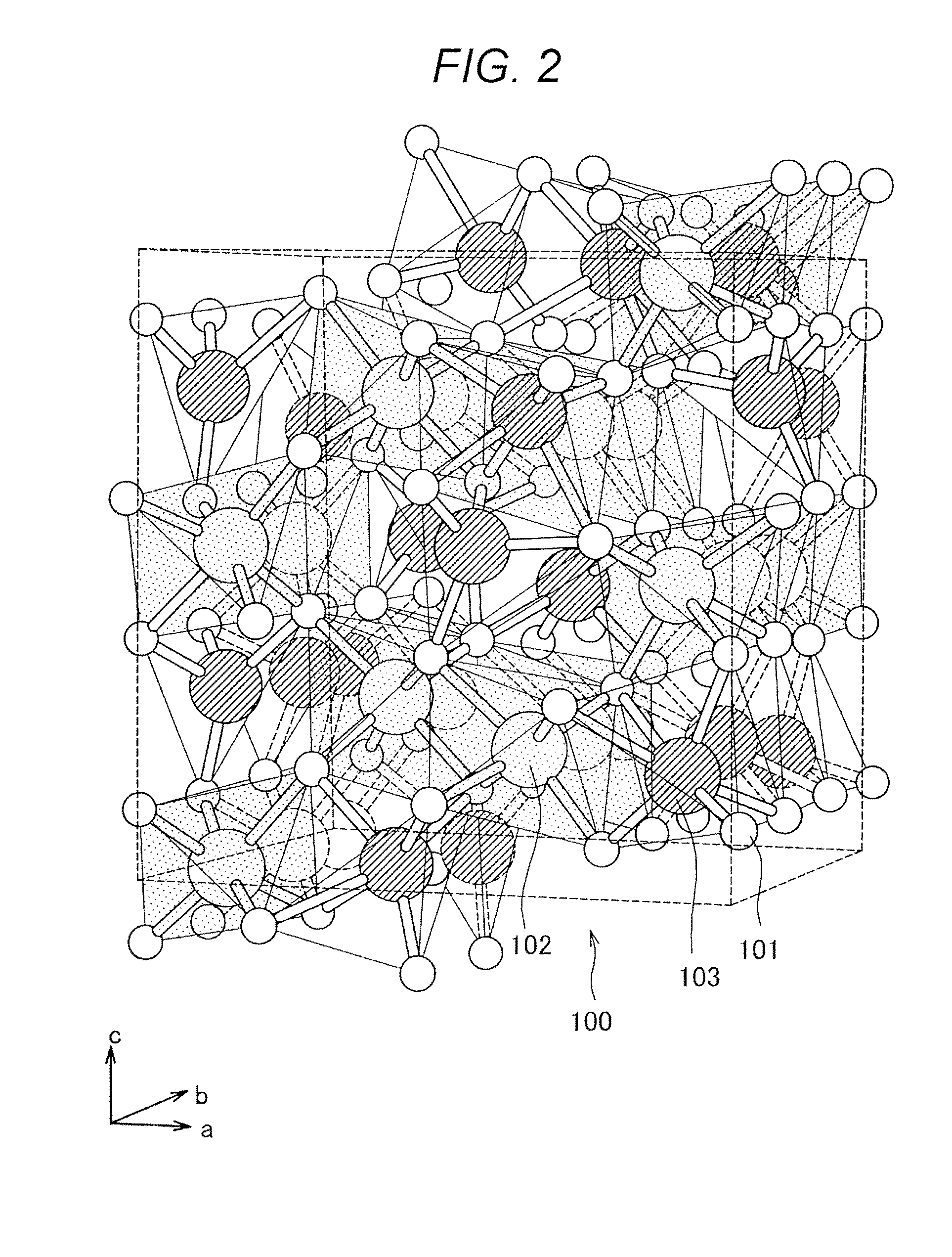

InactiveUS20160181657A1Low activation energyHigh lithium ion conductivityFinal product manufactureSecondary cellsChemistryAll solid state

A solid electrolyte comprises a ramsdellite-type crystal structure and has low activation energy of lithium ions and good lithium ion conductivity. The solid electrolyte is represented by the general formula Li4x−2a−3b−c−2dSn4−x−c−dM(II)aM(III)bM(V)cM(VI)dO8 [wherein M(II) is a divalent cation, M(III) is a trivalent cation, M(V) is a pentavalent cation, and M(VI) is a hexavalent cation, 0≦x≦1.33], wherein in the general formula, 0<a+b+c+d, 0≦a+b≦x, 0≦c+d<0.9, and 3x−a−2b−c−2d≦2. The all-solid-state battery includes the solid electrolyte in at least one layer of the positive electrode layer, negative electrode layer, and solid electrolyte layer. The method of making the solid electrolyte includes a step of preparing a mixed powder as a raw material and heating with microwave irradiation.

Owner:HITACHI LTD

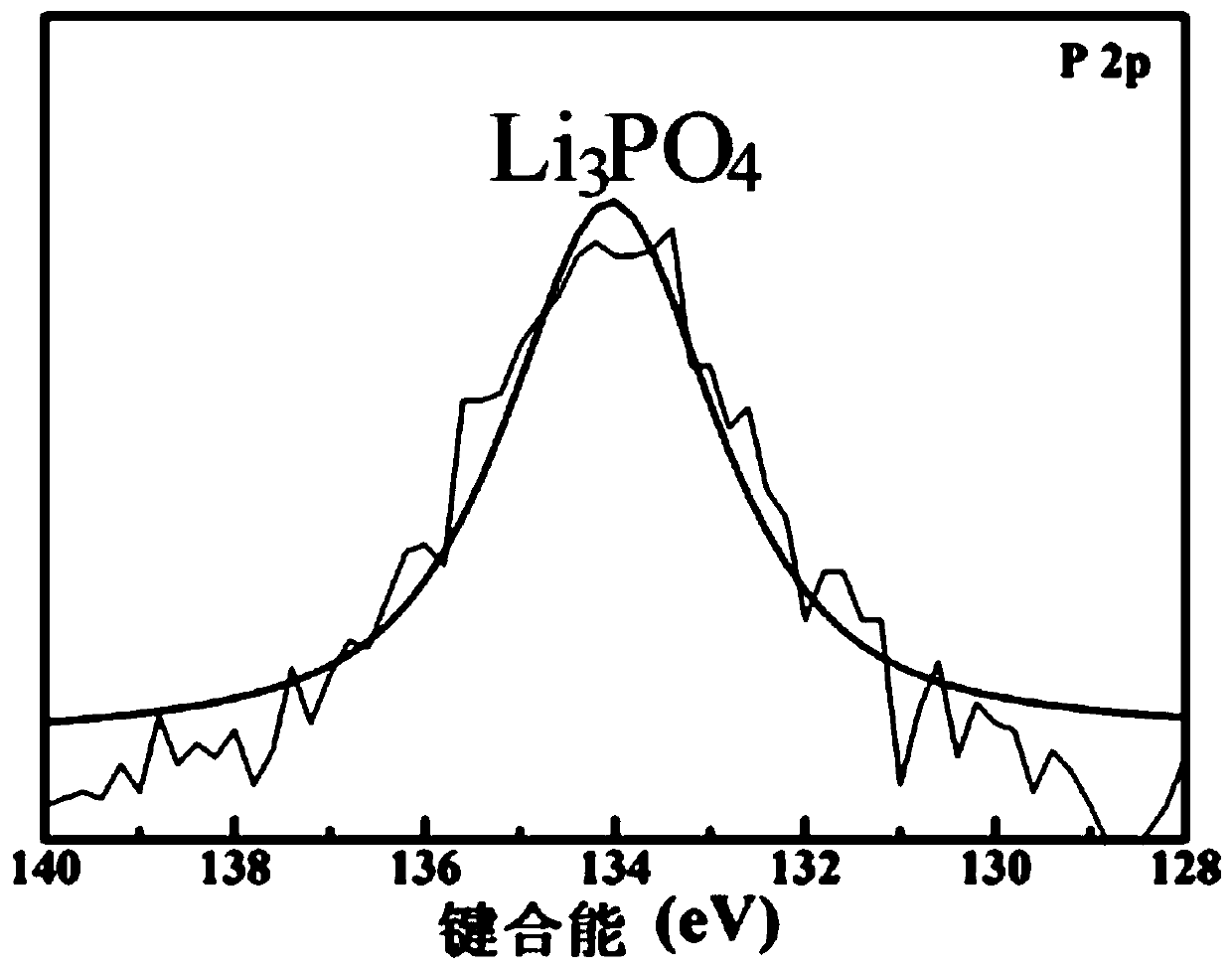

Lithium phosphate coated lithium iron phosphate electrode and preparation method thereof

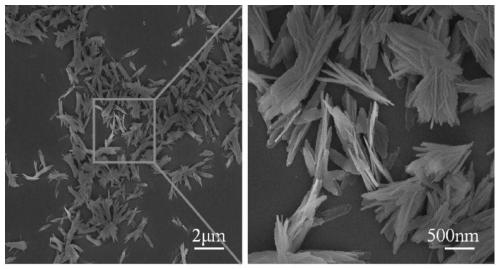

InactiveCN103151493AReduce anisotropyShorten the transmission pathMaterial nanotechnologyCell electrodesOrganic solventLithium iron phosphate

The invention relates to a lithium phosphate coated lithium iron phosphate electrode and a preparation method thereof, belonging to the technical field of electrode materials for lithium secondary batteries. The surface of the lithium iron phosphate electrode is coated with nanoscale glassy state lithium phosphate. The electrode preparation method comprises the following steps of: mixing lithium phosphate powder and an organic solvent, carrying out ball-milling on the mixture to form pulp, drying the pulp to obtain powder, compacting the powder into a lithium phosphate target precursor, and then calcining to obtain a lithium phosphate target; carrying out magnetron sputtering on lithium iron phosphate electrode (serving as substrate) and the lithium phosphate target to obtain the lithium phosphate coated lithium iron phosphate electrode, wherein the distance between the target and the substrate is 4-8cm, and the background intensity of pressure is less than or equal to 10*10<-5>Pa. The electrode has high lithium-ion conductivity, and also the capacity of the electrode is improved; the coated lithium phosphate has good chemistry and electrochemical stability and can be used for protecting the stability of the electrode structure; the preparation method is simple and low in cost; and the large-scale production is easy to realize.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Non-aqueous electrolyte and lithium ion battery

ActiveCN110911753ALower impedanceImprove power performanceSecondary cellsOrganic electrolytesHigh temperature storageElectrolytic agent

The invention provides a non-aqueous electrolyte and a lithium ion battery. The non-aqueous electrolyte comprises a solvent, an electrolyte lithium salt and a functional additive, and the functional additive comprises pentafluorophenyl vinyl sulfonate, 3-trifluoromethyl-5-methoxybenzonitrile and lithium difluorophosphate. When the electrolyte disclosed by the invention is applied to the lithium ion battery of a nickel-cobalt-manganese ternary material / graphite system, the high-voltage resistance of the lithium ion battery is improved, and the rate capability, the normal-temperature cycle, thehigh-temperature cycle and the high-temperature storage performance of the lithium ion battery are remarkably improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Full-solid electrochromic window, solid electrochromic glass and preparing method thereof

ActiveCN108254989ABoost rateImprove cycle lifeNon-linear opticsSolid state electrolyteRare-earth element

The invention relates to a solid electrolyte material. The chemical composition of the solid electrolyte material is LixSiyRezSmOn, wherein x is larger than or equal to 2 and smaller than or equal to3, y is larger than or equal to 0.5 and smaller than or equal to 2, z is larger than or equal to 0.3 and smaller than or equal to 0.6, (m+n) is larger than (x+4y+3z) / 2.1 and smaller than or equal to (x+4y+3Z) / 1.8, and Re is selected from rare earth elements Y, Gd, Gy or Sm. The solid electrolyte material is high in lithium ion conductivity, high in electron conductivity, wide in electrochemical window and high in temperature resistance. The invention further relates to a solid electrochromic device. An electrolyte is selected from the solid electrolyte material, an electrochromic layer is selected from at least one of tungsten oxide, bismuth trioxide, molybdenum trioxide or nickel oxide, and an ion storage layer is selected from at least one of lithium-embedded vanadium pentoxide, lithium-embedded titanium dioxide, lithium-embedded tungsten trioxide or lithium-embedded nickel oxide. The solid electrochromic device has the advantages of being short in color change response time and stable in performance.

Owner:NINGBO MI RUO ELECTRONICS TECH CO LTD

Quasi-solid-state lithium battery and preparation method thereof

ActiveCN110808408AImprove mechanical propertiesImprove heat resistanceSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteElectrolytic agent

The invention discloses a quasi-solid-state lithium battery and a preparation method thereof. The quasi-solid-state lithium battery comprises a negative electrode, a positive electrode and a diaphragm, and also comprises a quasi-solid-state electrolyte dispersed among the surfaces of the negative electrode, the positive electrode and the diaphragm and gaps among the negative electrode, the positive electrode and the diaphragm. The quasi-solid-state electrolyte comprises a polymer phase, and a ceramic electrolyte, a lithium salt and a flame-retardant organic solvent which are dispersed in the polymer phase, wherein the polymer phase is formed by in-situ polymerization of composite acrylate monomers; and the composite acrylate monomer comprises a star-shaped acrylate monomer and a chain-shaped acrylate monomer. According to the quasi-solid-state lithium battery disclosed by the invention, the problem that the safety of the battery is reduced by liquid electrolyte is solved, and the problem that the cycle performance of the battery is reduced due to dissolution of solid polymer electrolyte is also avoided. Therefore, the quasi-solid-state lithium battery has excellent safety performance, high conductivity and excellent cycling stability.

Owner:ZHEJIANG UNIV

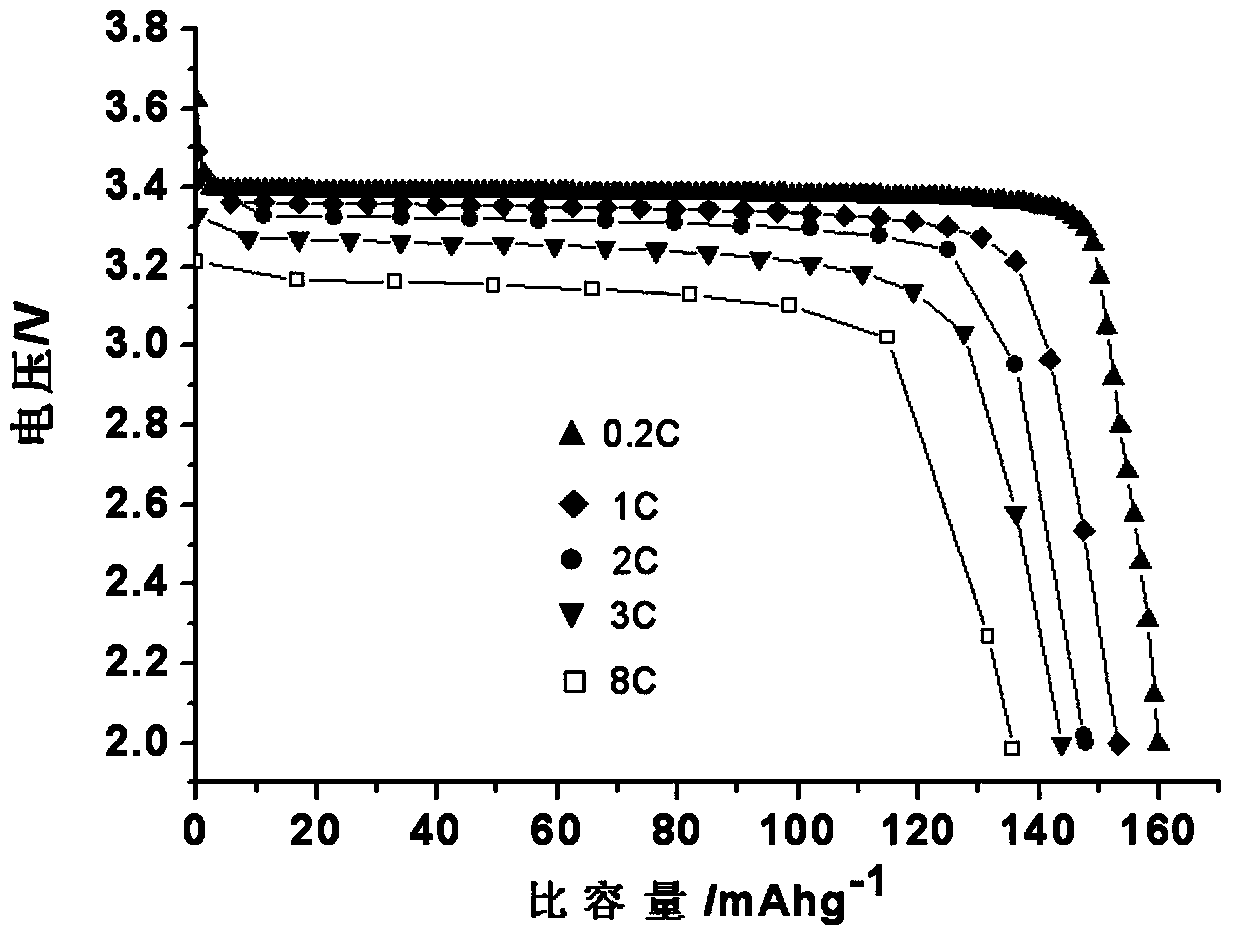

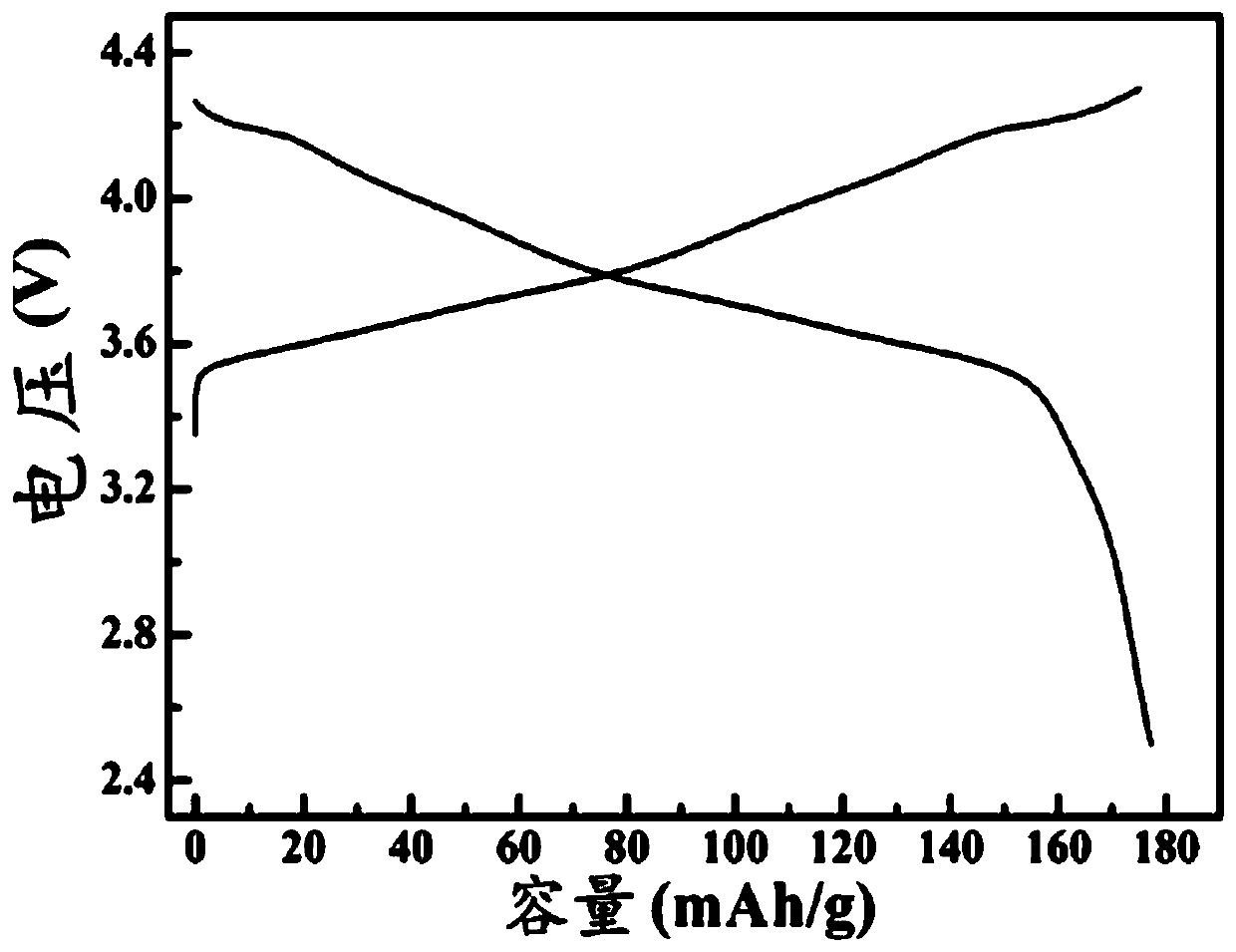

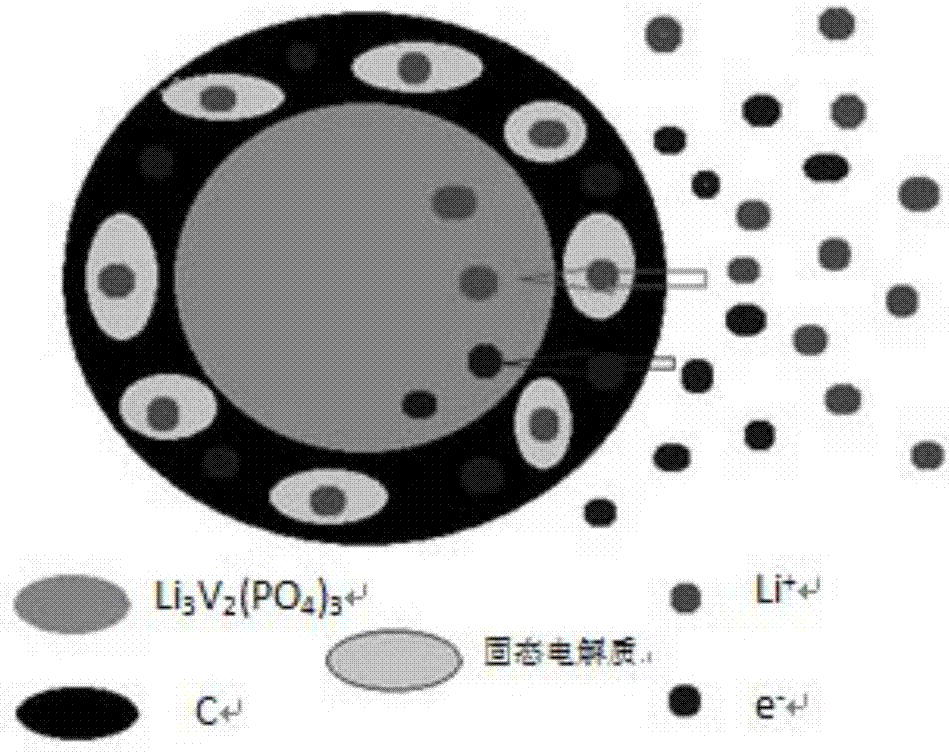

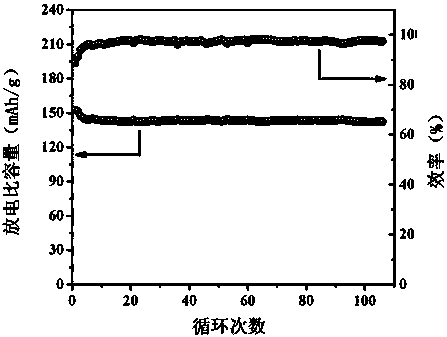

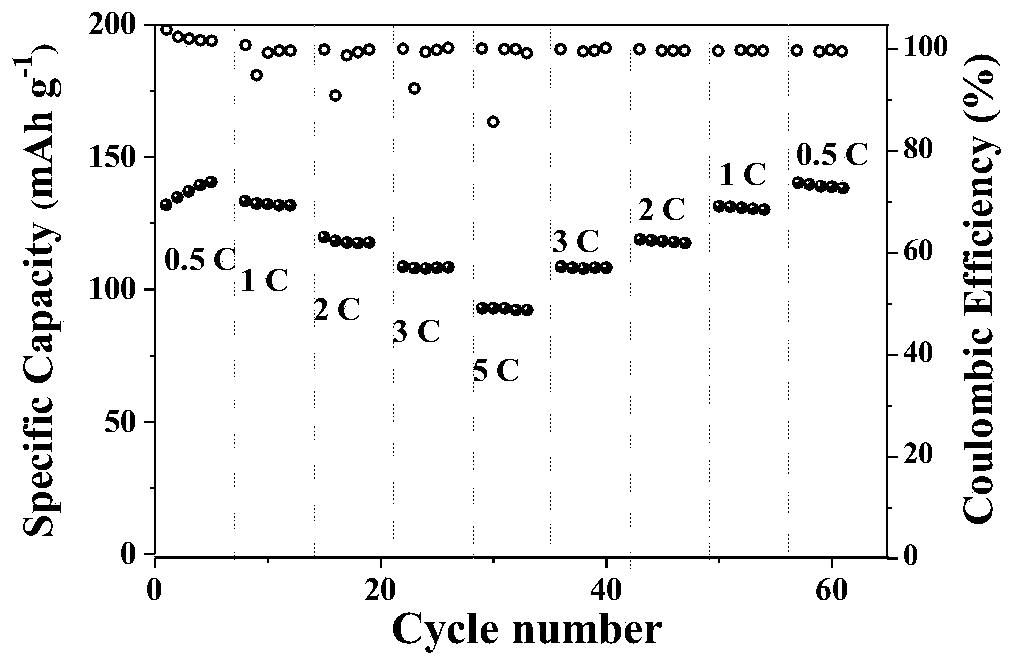

Composite cathode material for lithium ion batteries and preparation method thereof

InactiveCN107546380AImprove lithium ion conduction rateImprove electronic conductivityMaterial nanotechnologyCell electrodesLithium vanadium phosphate batteryComposite cathode

The invention relates to the field of lithium ion batteries, and specifically relates to a novel composite cathode material for lithium ion batteries. An Li3V2(PO4)3 material is taken as a core, a fast ion conductor type solid electrolyte is embedded in a carbon-coated layer, and a double coated core-shell structure is formed with carbon, the lithium ion conduction speed of the lithium vanadium phosphate material is improved in a targeted manner, the defect that the electronic conductivity of the lithium vanadium phosphate material is recovered, and the lithium ion conduction speed can also beimproved obviously, so that the performances of the lithium vanadium phosphate cathode material are improved relatively comprehensively, the impedance is reduced, the specific capacity is improved, the circulation and rate performance is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

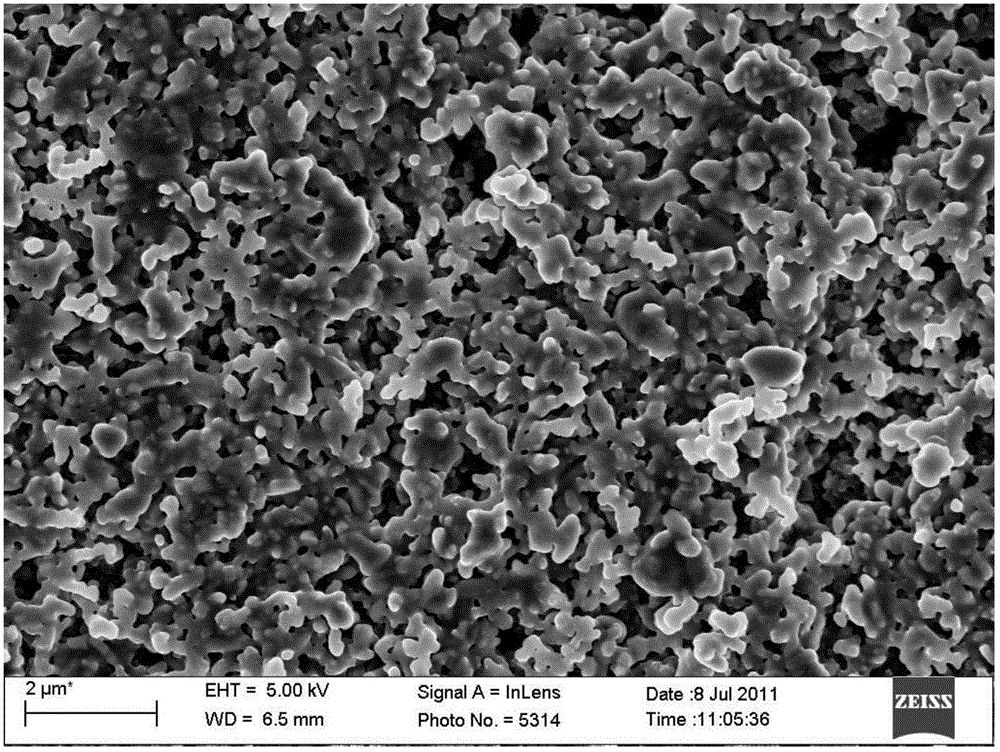

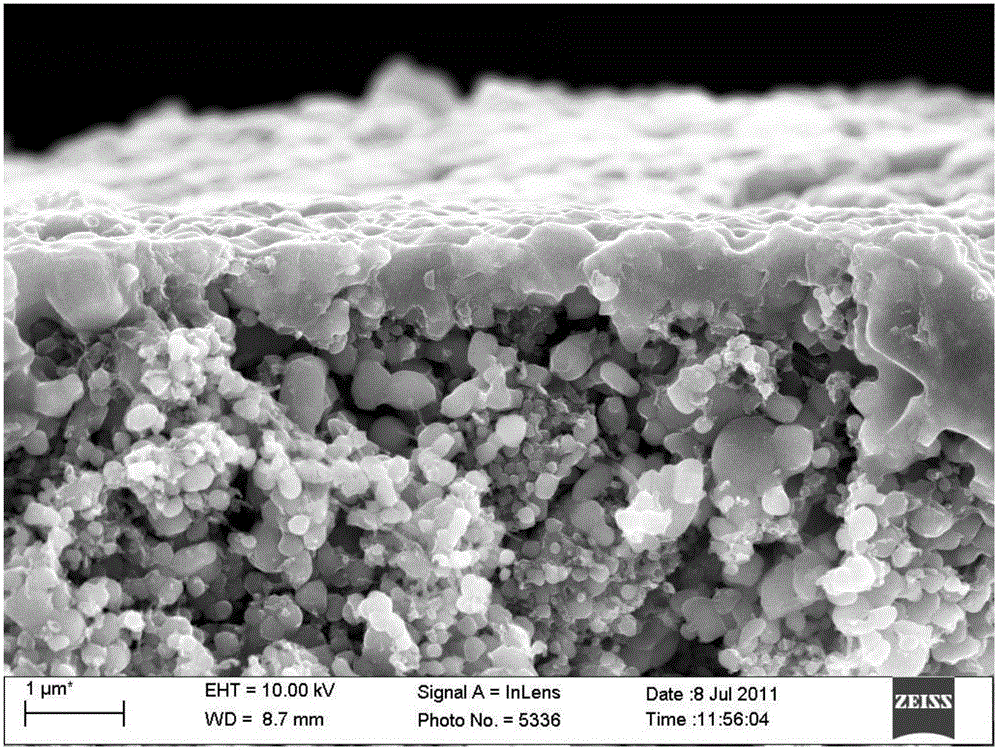

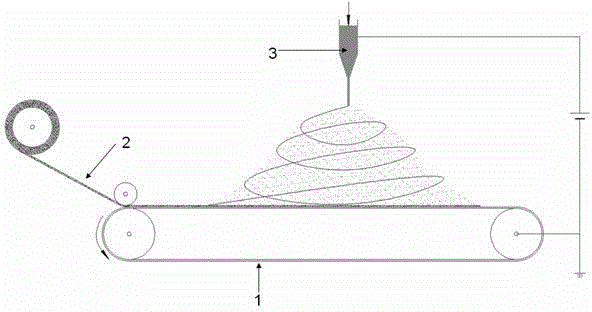

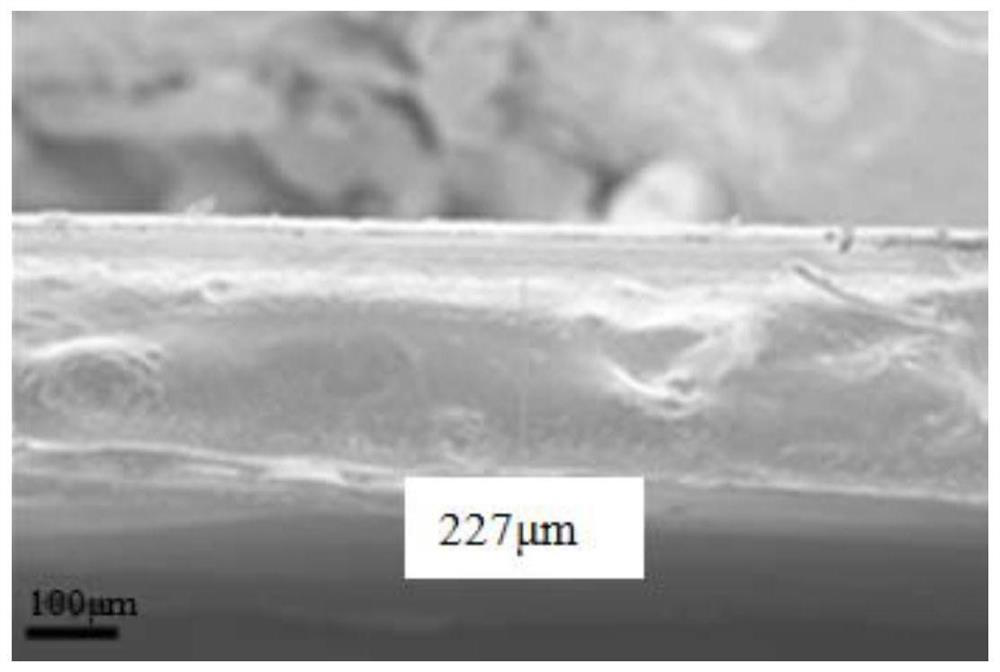

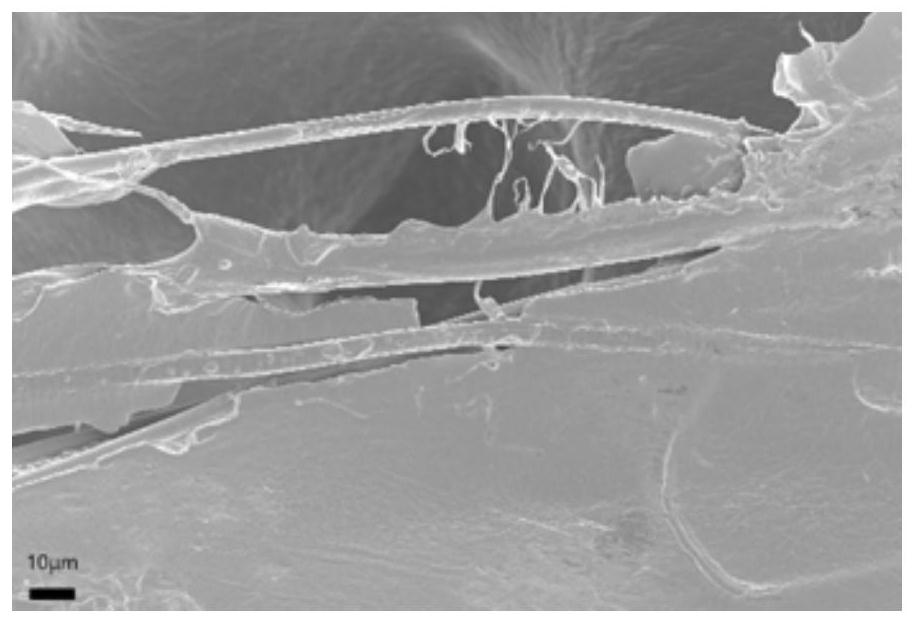

Preparation method of high-performance lithium ion conduction membrane

ActiveCN104022248AImprove securityHigh lithium ion conductivityCell component detailsSpinningOrganosolv

The invention relates to a preparation method of a high-performance lithium ion conduction membrane. The preparation method is characterized by comprising the following steps: preparing a spinning solution; dissolving commercialized Li10GeP2S12 powder with the granularity of 20nm to 200nm and organic macromolecules with certain viscosity according to the mass ratio of mLi10GeP2S12 to m macromolecules of 1 to (1-10) in an organic solvent, and adequately stirring to form turbid liquid with solid content of 30 to 95 percent; and carrying out electrostatic spinning on the mixture, and thermally rolling an electrostatic spun diaphragm through a roller-type hot press at the temperature of 60 to 85 DEG C to obtain the diaphragm with high ion conductivity. The composite diaphragm is high in safety and high in lithium ion conductivity. A lithium ion battery utilizing the diaphragm is excellent in electrochemical performance.

Owner:CHINA FIRST AUTOMOBILE

Porous film and preparation method thereof, and lithium battery

ActiveCN110391385AReduce weightImprove breathabilityLi-accumulatorsCell component detailsTemperature resistanceLithium-ion battery

The invention provides a porous film. The porous film includes a base material and a coating layer, and raw materials of the coating layer include para-aramid, meta-aramid, and polyhalogenated compounds. The porous film obtained by the invention is provided with good air permeability, high temperature resistance and lithium ion conductivity, and the lithium battery obtained by using the porous film of the invention has good safety, cycle life and rate performance.

Owner:微宏先进膜公司

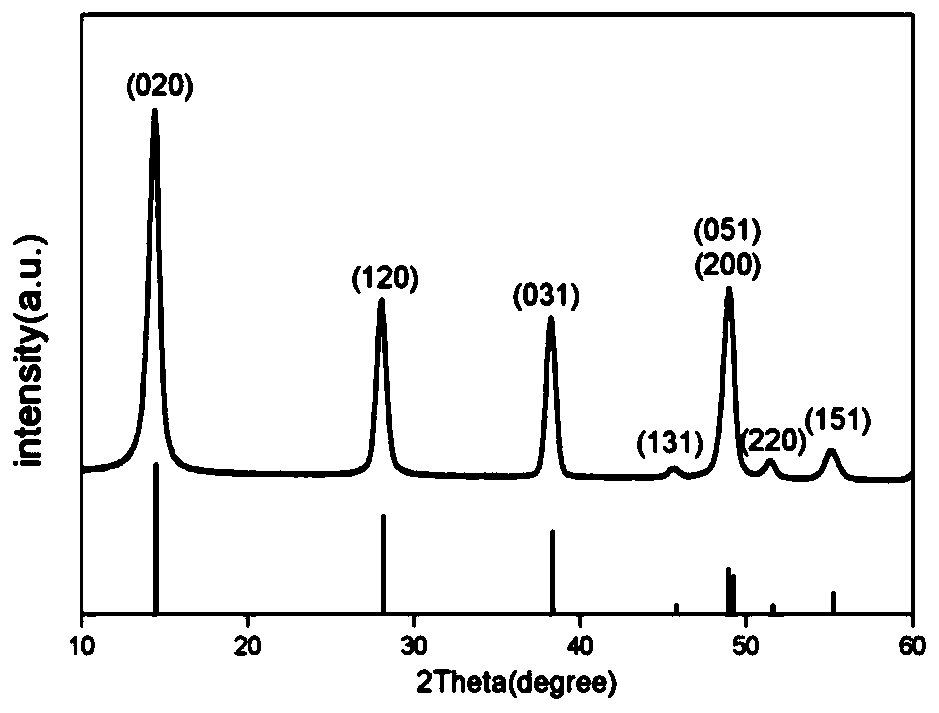

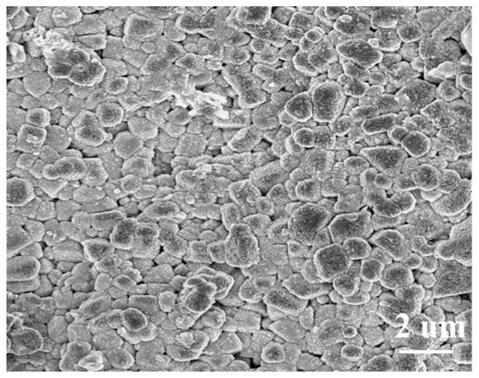

Lithium titanium aluminum phosphate solid electrolyte material and preparation method thereof

ActiveCN111233458AStop lossImprove surface activitySolid electrolytesSecondary cellsPhysical chemistryALUMINUM PHOSPHATE

The invention provides a lithium titanium aluminum phosphate solid electrolyte material and a preparation method thereof. The preparation method specifically comprises the steps that 1, soluble aluminum salt and a precipitator are mixed and dissolved in water according to the molar ratio of 1: (1.5-2), and a mixed solution is obtained; the mixed solution is placed into a reaction kettle for heating, and a product is subjected to filtering, washing and drying to obtain an AlOOH precursor; (2) the AlOOH precursor obtained in the step (1) is mixed with lithium salt, titanium salt and phosphorus salt; Li, Al, Ti and P are mixed according to a molar ratio of (1+x): x: (2-x): 3, an ethanol medium is added, ball milling is performed, and presintering and secondary molding sintering are carried out in a dry air atmosphere to obtain the lithium titanium aluminum phosphate solid electrolyte material. The method is simple in process, low in synthesis temperature and easy to implement industrially, and the prepared lithium titanium aluminum phosphate solid electrolyte material is high in purity, good in density and high in lithium ion conductivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

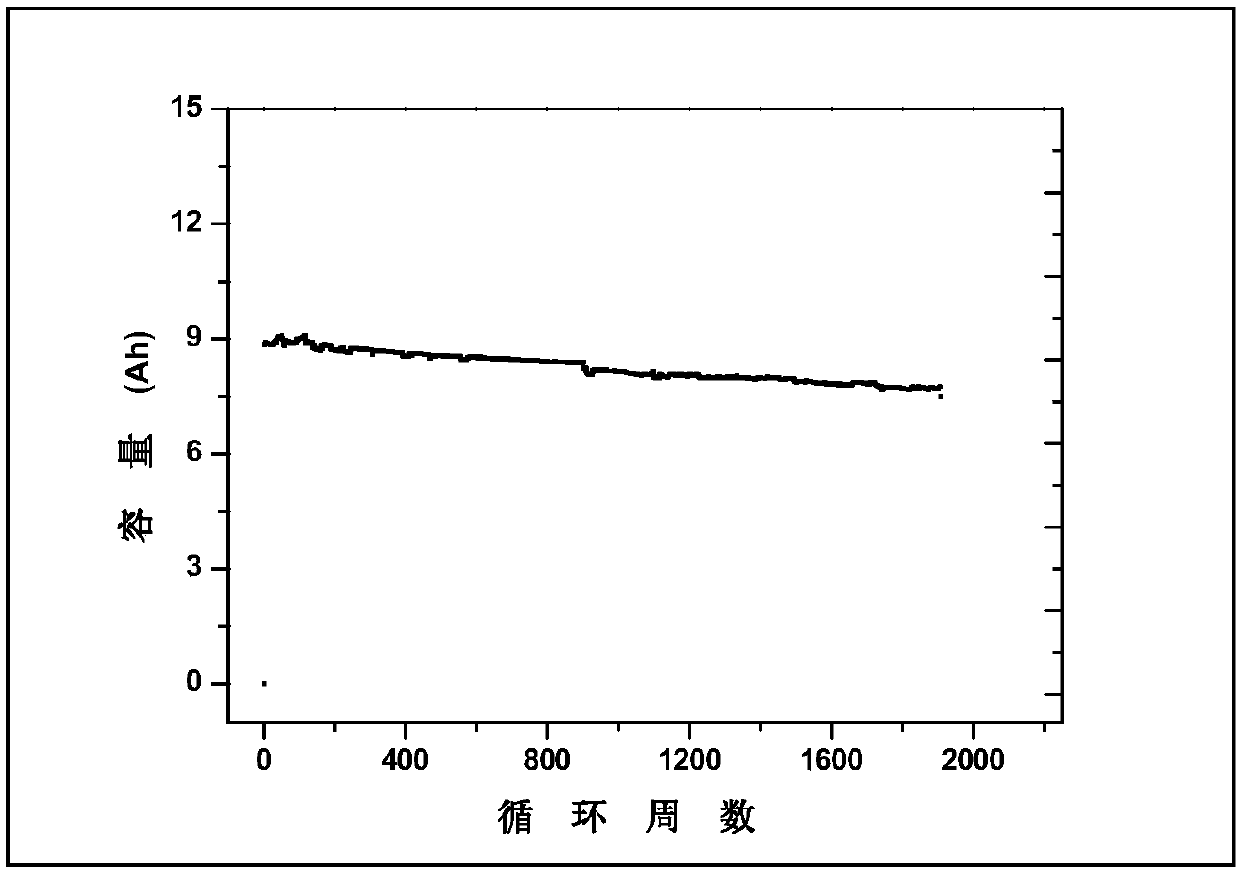

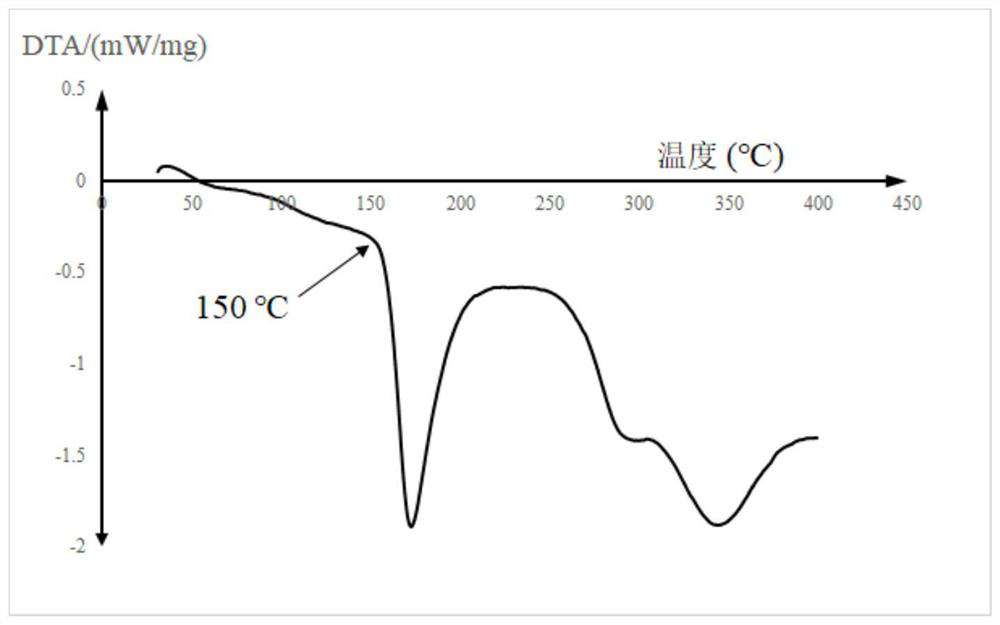

Additive for preventing thermal runaway and application of additive in secondary lithium metal battery

ActiveCN108615941AHigh lithium ion conductivityDoes not increase electrolyte resistanceLi-accumulatorsSecondary cells servicing/maintenanceCombustionLithium metal

The invention relates to an additive for preventing thermal runaway and an application of the additive in a secondary lithium metal battery. A chain end of the additive contains unsaturated double bonds and a lithium metal negative electrode interface film-forming or flame-retardant structure, and a stable SEI layer can be formed on the surface of a lithium metal negative electrode in the batterycycle process, so that, on one hand, contact of the lithium metal negative electrode and an electrolyte is improved and the lithium metal battery assembled by the lithium metal negative electrode andthe electrolyte has excellent long cycle performance; and on the other hand, the unsaturated double bonds of the additive can absorb heat to be polymerized when the battery is overheated, and the unsaturated double bonds and the contained flame-retardant group play roles in blocking combustion and preventing thermal runaway of the battery. The invention further provides an application of the additive in the lithium metal battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Polymer electrolyte of lithium ion battery and preparation method thereof

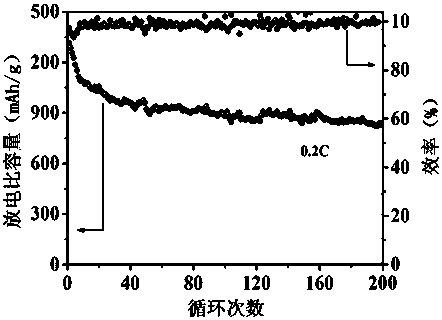

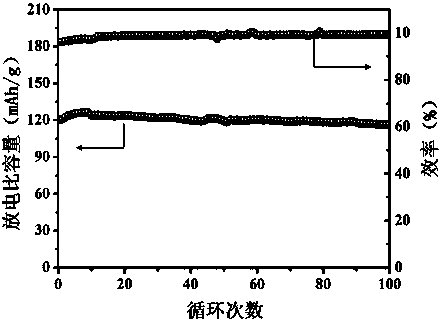

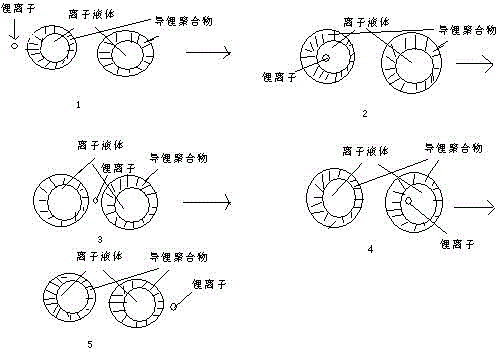

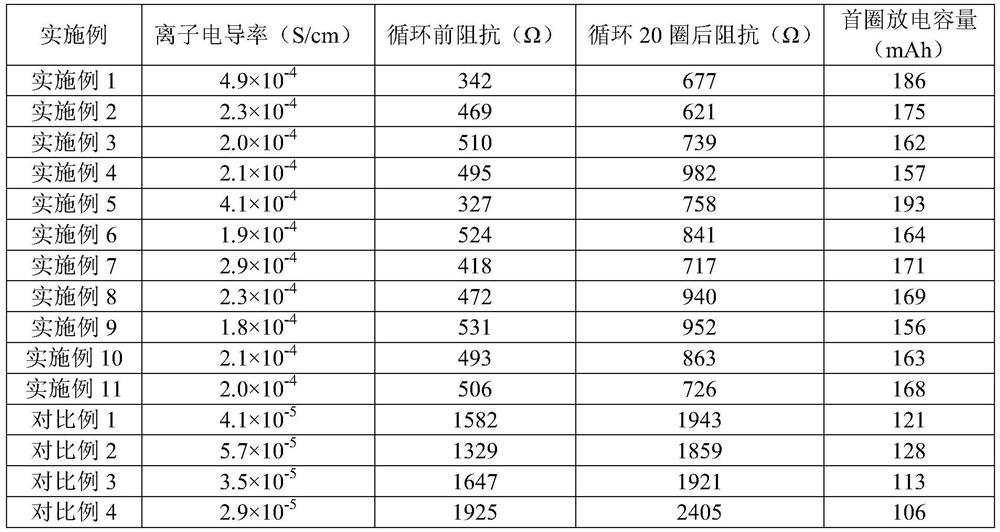

InactiveCN103915650AImprove mechanical propertiesHigh lithium ion conductivitySolid electrolytesFinal product manufactureLithium-ion batteryElectronic conductivity

The invention relates to polymer electrolyte of a lithium ion battery and a preparation method thereof. The preparation method comprises the steps of coating ion liquid with a lithium conducting polymer to form microcapsule-shaped micro particles with high lithium ion conductivity, dispersing the microcapsule-shaped micro particles into a solvent, adding lithium salt and a substrate material, and curing through coagulation bath to prepare a polymer electrolyte membrane of the lithium battery. The polymer electrolyte not only has the advantages of high ion conductivity, no liquid leakage in the application process and good mechanical property, but also is simple in preparation method, low in production cost, suitable for industrialized production and wide in application range.

Owner:LVCHI AUTO TECH SHANGHAI CO LTD

Preparation method of electrolyte of all-solid-state lithium battery

ActiveCN111446493AHigh lithium ion conductivityImprove conductivityFinal product manufactureLi-accumulatorsThermal spray coatingLithium battery

The invention discloses a preparation method of an electrolyte of an all-solid-state lithium battery. According to the invention, ball-milling mixing is combined with a low-temperature solid-phase reaction to realize the method; meanwhile, the amorphous lithium-rich anti-perovskite solid electrolyte material is prepared by means of mechanical ball milling, melting and cold quenching and the like;the prepared amorphous powder material is uniformly deposited on a selected substrate through spin coating, dipping-pulling or thermal spraying to obtain a thickness-controllable thin film, so that lithium ion conductivity test, activation energy measurement and total battery assembly can be carried out; lattice constants and anti-perovskite structure factors are regulated and controlled by dopingother halogen atoms, so that the material is more suitable for lithium ion migration; and non-stoichiometric phases are generated by volatilizing halides to construct lithium ion migration channels and shelf structures. A large number of 3D fast ion transmission channels are constructed in anti-perovskite crystal lattices through multiple means, the purpose of improving the lithium ion conductivity of the electrolyte material is achieved, and therefore the durability of the all-solid-state lithium battery is improved.

Owner:YANGDE ELECTRIC GRP CO LTD

All-solid-state lithium battery positive plate, preparation method thereof and all-solid-state lithium battery

ActiveCN112086619AImproving Li-ion Transport CapabilityHigh lithium ion conductivitySolid electrolytesCell electrodesElectrically conductivePositive current

The invention provides an all-solid-state lithium battery positive plate, a preparation method thereof and an all-solid-state lithium battery. The all-solid-state lithium battery positive plate comprises a positive current collector and a functional layer coated on the positive current collector, and the raw materials of the functional layer comprise a lithium-containing active material, a conductive agent, a solid electrolyte and a polyion liquid. The all-solid-state lithium battery positive plate provided by the invention has the characteristics of relatively high ionic conductivity and thelike, and the all-solid-state lithium battery formed by adopting the positive plate has the excellent performances of relatively high ionic conductivity, relatively low impedance, relatively high discharge capacity and the like.

Owner:ZHUHAI COSMX BATTERY CO LTD

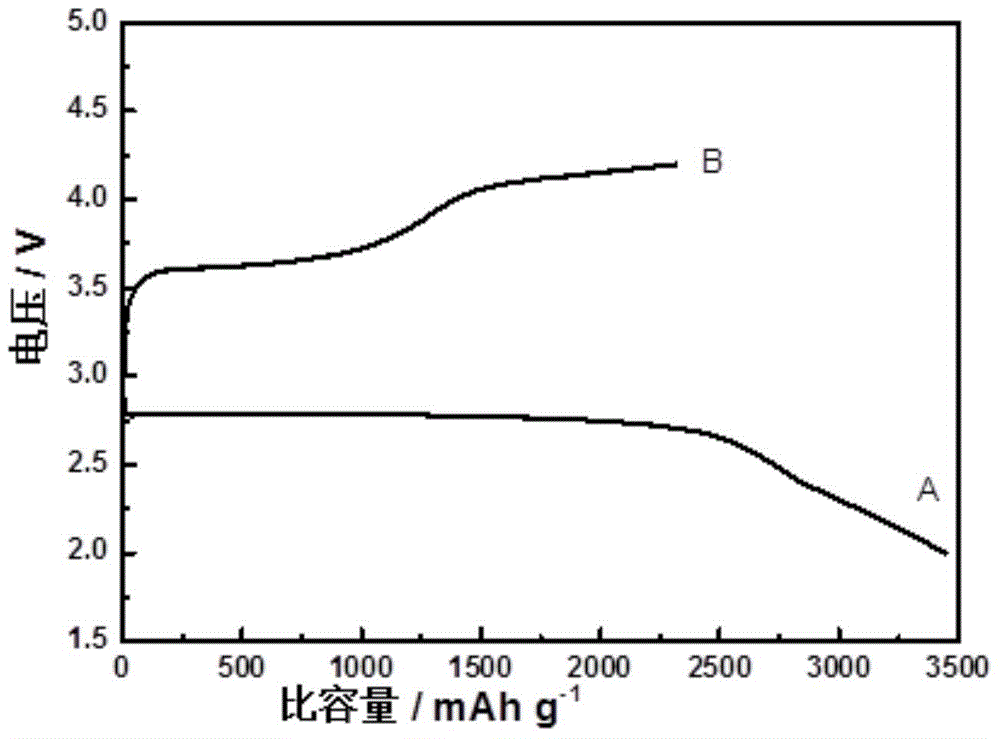

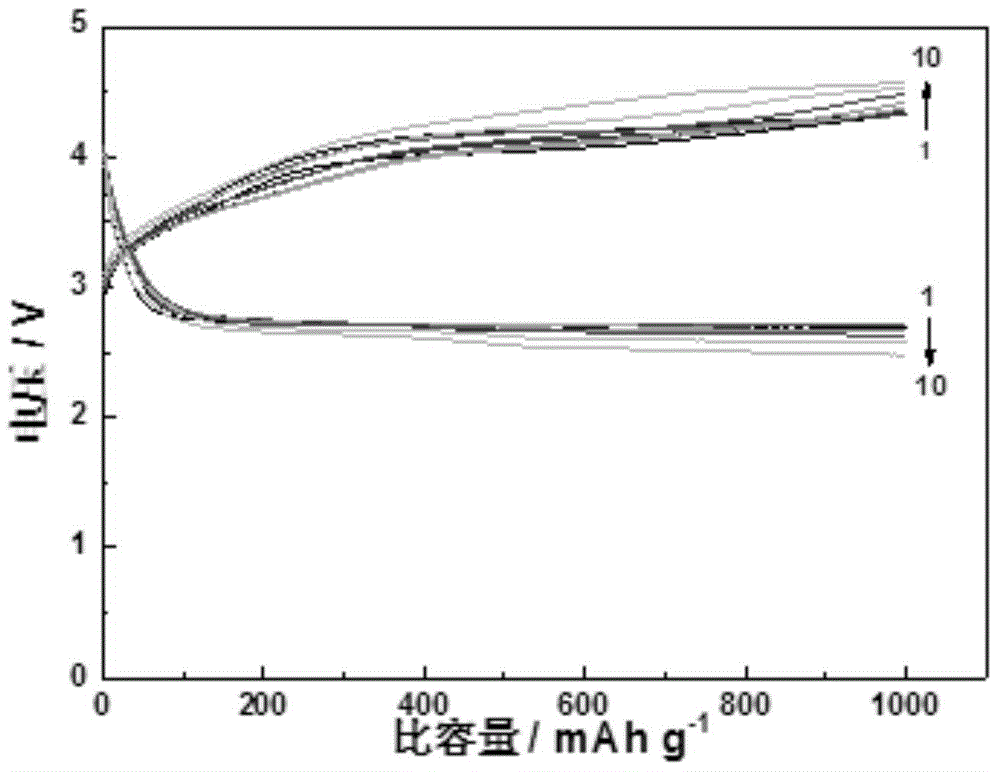

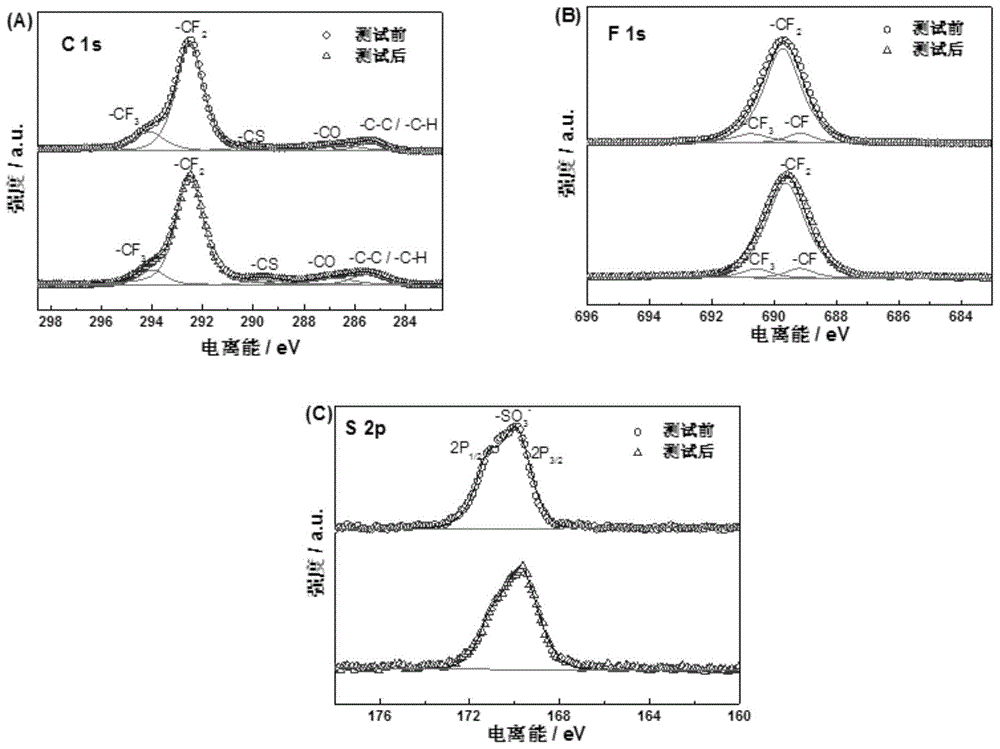

Gel polymer electrolyte for lithium-air battery and preparation method thereof

InactiveCN105006590AImprove performanceIncrease capacityFuel and secondary cellsSecondary cellsPolymer electrolytesPolymer science

The invention relates to a gel polymer electrolyte for a lithium-air battery and a preparation method thereof. The electrolyte is composed of perfluocarbon polymer electrolyte base materials with lithium ions and an electrolyte solution, wherein the perfluocarbon polymer electrolyte base materials account for 30-80% of the percentage mass content of the electrolyte; when the gel polymer electrolyte is prepared, the perfluocarbon polymer electrolyte base materials are placed in a lithium hydroxide solution to be subjected to lithiation treatment, washing is conducted, after drying is conducted, the treated perfluocarbon polymer electrolyte base materials are steeped in the electrolyte solution, full swelling is conducted, and then the gel polymer electrolyte for the lithium-air battery is prepared. Compared with the prior art, according to the gel polymer electrolyte for the lithium-air battery, prominent and excellent chemical stability can be achieved, the nucleophilic attack of superoxide ions in the lithium-air battery can be effectively resisted, and therefore prominent improvement effects on the battery capacity, the rate capacity and the cycling stability are achieved.

Owner:SHANGHAI JIAO TONG UNIV

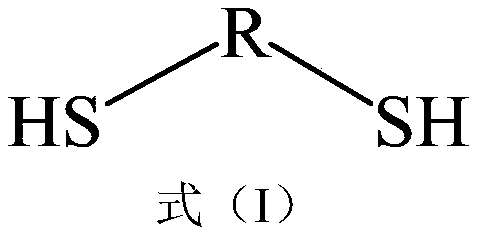

Lithium battery diaphragm and preparation method thereof

InactiveCN109449351ARaw materials are easy to getMild reaction conditionsCell component detailsMechanical propertyDithiol

The invention discloses a preparation method of a lithium battery diaphragm. The method comprises the following steps: firstly, protecting a hydroxy of dihydro-2,4,6-trioxo-1,3,5-triazine-1,3(2H,4H)-dipropionic acid, then generating a polycondensation reaction with 2,2-bi[4-(4-aminophenoxy)phenyl]hexafluoropropane, performing deprotection, then performing 3-(dimethylamino) ethyl acrylate graft modification on the obtained polycondensate, uniformly mixing the polycondensate with surface-modified nano calcium carbonate and 2,7-naphthyl dithiol, obtaining a polymer film though melting and heat setting processes, and finally forming holes. The lithium battery diaphragm prepared by the above preparation method disclosed by the invention has higher lithium ion conductivity, more excellent weather resistance, thermal stability and electrochemical stability, and maintains high wettability to the electrolyte and better mechanical properties in a repeated charge and discharge process.

Owner:孙培丽

Spherical ternary composite positive electrode material of lithium ion battery and preparation method thereof

InactiveCN112366295ACapacity impactHigh lithium ion conductivitySecondary cellsPositive electrodesSolid state electrolyteGraphite

The invention relates to the technical field of lithium ion batteries, in particular to a spherical ternary composite positive electrode material of a lithium ion battery and a preparation method thereof. The spherical ternary composite positive electrode material of the lithium ion battery is prepared from the following components in percentage by mass: 80-90% of NCM powder balls, 5-10% of solidelectrolyte LLZO and the balance of graphene. On the basis of an NCM ternary material pure sample, a layer of graphene is coated again, so that the electronic conductivity of the material can be improved, the rate capability of the material is improved, and meanwhile, the flexible graphene can slow down irreversible reduction of capacity caused by mentioned deformation in the charging and discharging process of the NCM, and the cycle performance of the material is improved.

Owner:WANXIANG 123 CO LTD

Ternary positive electrode material of lithium ion battery and preparation method of ternary positive electrode material

ActiveCN113363476AImproves the effects of reduced ionic conductivityHigh lithium ion conductivitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention discloses a ternary positive electrode material of a lithium ion battery and a preparation method of the ternary positive electrode material. The ternary positive electrode material comprises a ternary material and a coating layer coated on the surface of the ternary material, wherein the coating layer comprises a Li < 2 + x > C < 1-x > Bx O3 coating agent, and x is greater than 0 and less than 1. The preparation method comprises the steps of (1) mixing a ternary positive electrode material precursor with a lithium source and a doping agent, and carrying out primary calcination to obtain primary calcined sample powder; (2) dispersing the primary calcined sample powder into an alkaline solution, stirring to fully wet the primary calcined sample powder, performing suction filtration, drying in a vacuum environment, and performing secondary calcination to obtain secondary calcined sample powder; and (3) uniformly mixing the secondary calcined sample powder with a coating material comprising a Li < 2 + x > C < 1-x > Bx O3 coating agent, and performing tertiary calcination. By improving the coating agent and the preparation method, the surface of the ternary positive electrode material is coated with a layer of material with relatively high lithium ion conductivity, so that the capacity performance and the cycle performance of the battery are effectively improved.

Owner:WANXIANG 123 CO LTD

Preparation method of graphene/poly-anthraquinone thioether/sulphur composite cathode material

InactiveCN105702928AHigh lithium ion conductivityImprove conductivityCell electrodesLi-accumulatorsOxide compositeDissolution

The invention provides a preparation method of a graphene / poly-anthraquinone thioether / sulphur composite cathode material. The preparation method comprises the following steps: (1) dissolving sodium sulfide and elemental sulfur into distilled water to obtain an orange solution, adding Triton X-100, adding concentrated hydrochloric acid and gradually forming a yellow suspension liquid; (2) adding graphite oxide to the distilled water for ultrasonic treatment, obtaining a graphene oxide solution and adding the yellow suspension liquid to obtain dark grey sulfur graphene oxide; (3) adding a potassium iodide solution to the obtained sulfur graphene oxide composite material, and adding diluted hydrochloric acid to obtain a sulfur graphene composite material; and (4) adding the obtained sulfur graphene composite material to N-methylpyrrolidone for stirring, adding 1,5-dichloroanthraquinone for stirring, and then adding anhydrous sodium sulfide to obtain the poly-anthraquinone thioether / graphene / sulphur composite material. The sulphur in the composite material is coated with flexible graphene and poly-anthraquinone thioether, so that dissolution of a discharge product polysulfide can be inhibited; and volume expansion is relieved.

Owner:钟玲珑

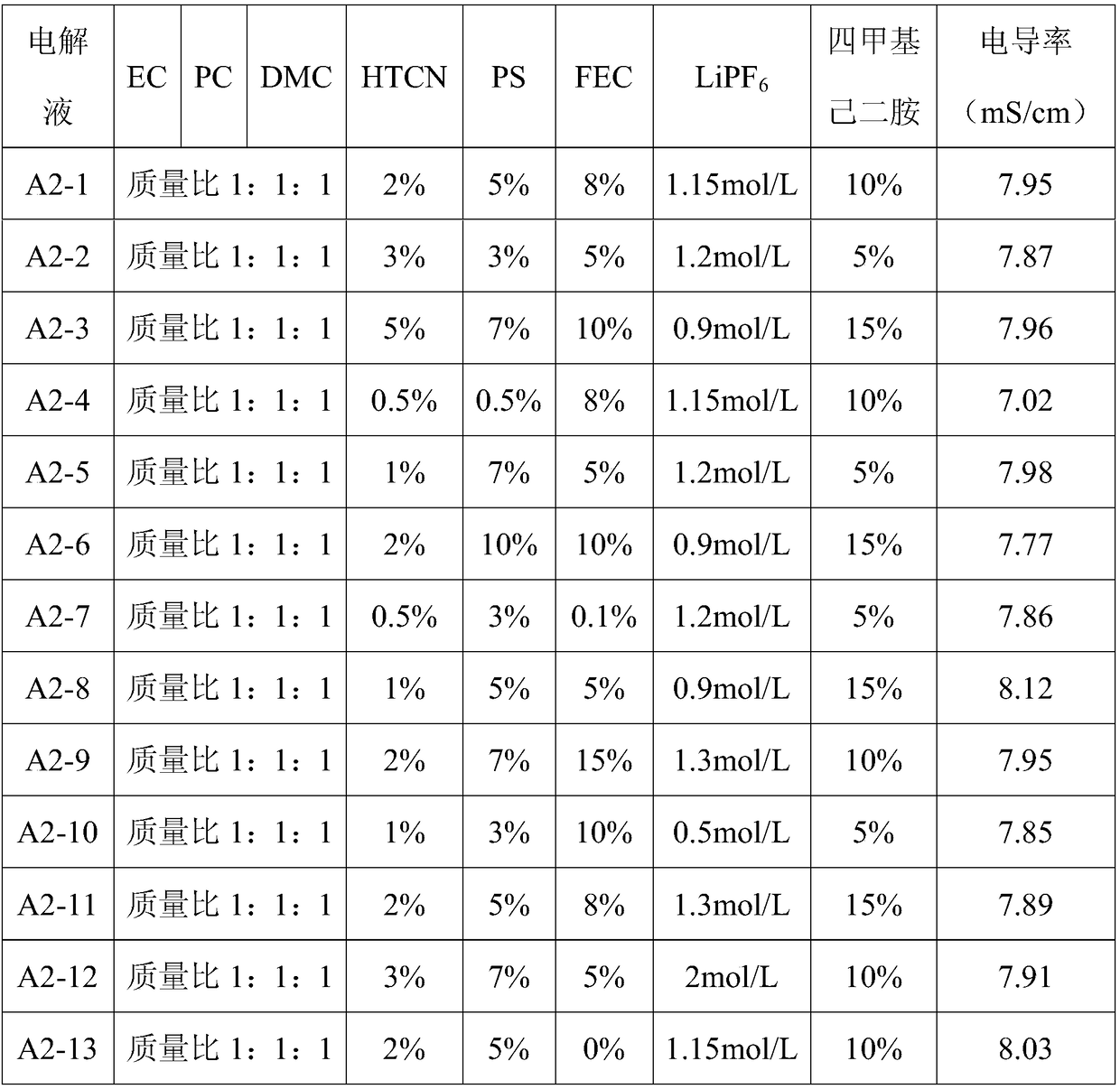

Silicon-carbon system lithium ion battery electrolyte and silicon-carbon system lithium ion battery

ActiveCN108878976AImprove stabilityImprove high and low temperature discharge performanceSecondary cellsOrganic electrolytesOrganic solventInternal resistance

The invention provides a silicon-carbon system lithium ion battery electrolyte and a silicon-carbon system lithium ion battery. The silicon-carbon system lithium ion battery electrolyte comprises an organic solvent, an electrolyte lithium salt and additives, wherein the additives include propylene sulfite and tetramethyl diamine compounds; when the electrolyte is used in the silicon-carbon systemlithium ion battery, the conductivity of the electrolyte and the stability of a negative electrode silicon carbon interface film can be improved; and meanwhile, the expansion rate of the battery is reduced, the internal resistance is lowered, and the high and low temperature discharge performance of the silicon-carbon system lithium ion battery is improved.

Owner:EVE ENERGY CO LTD

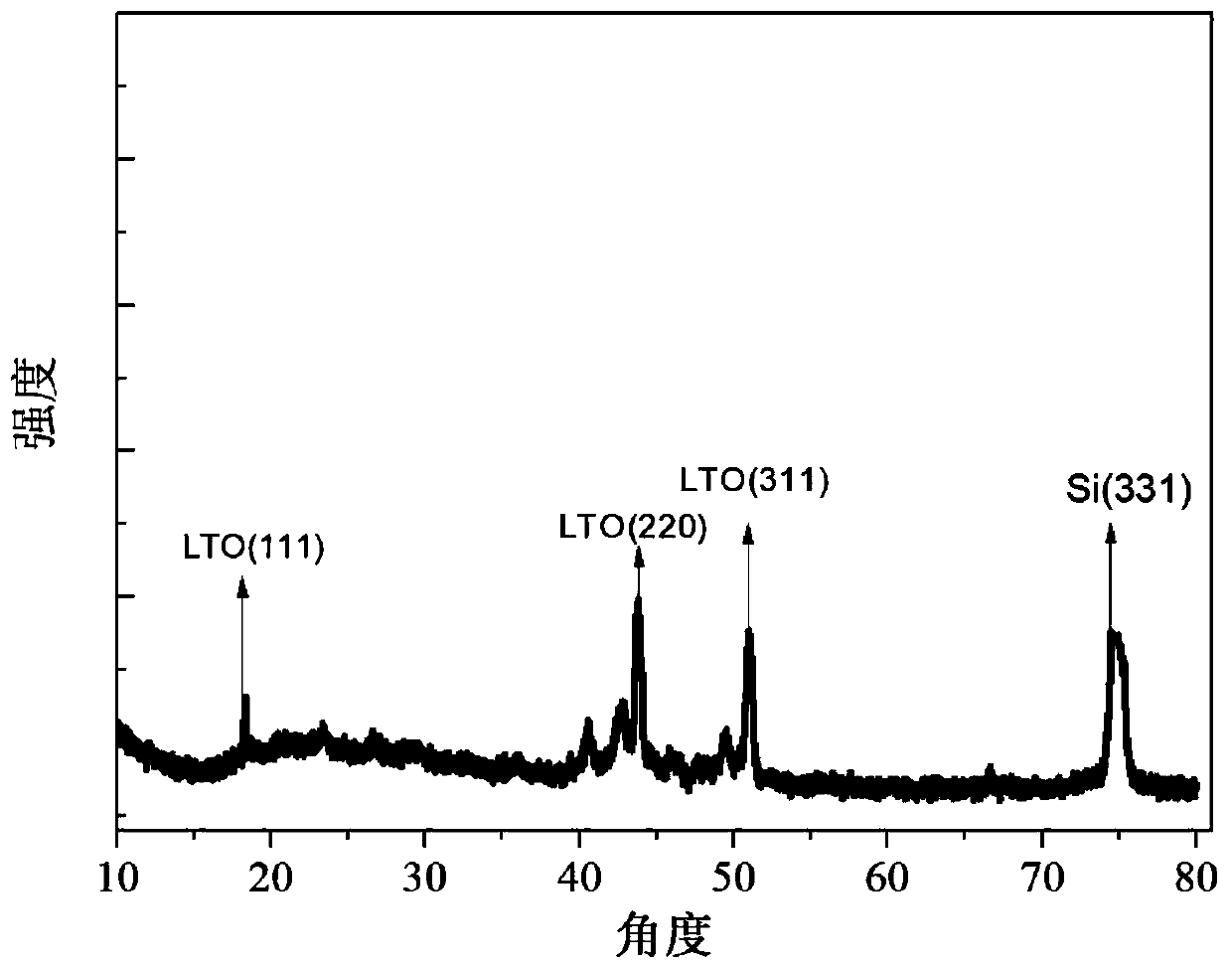

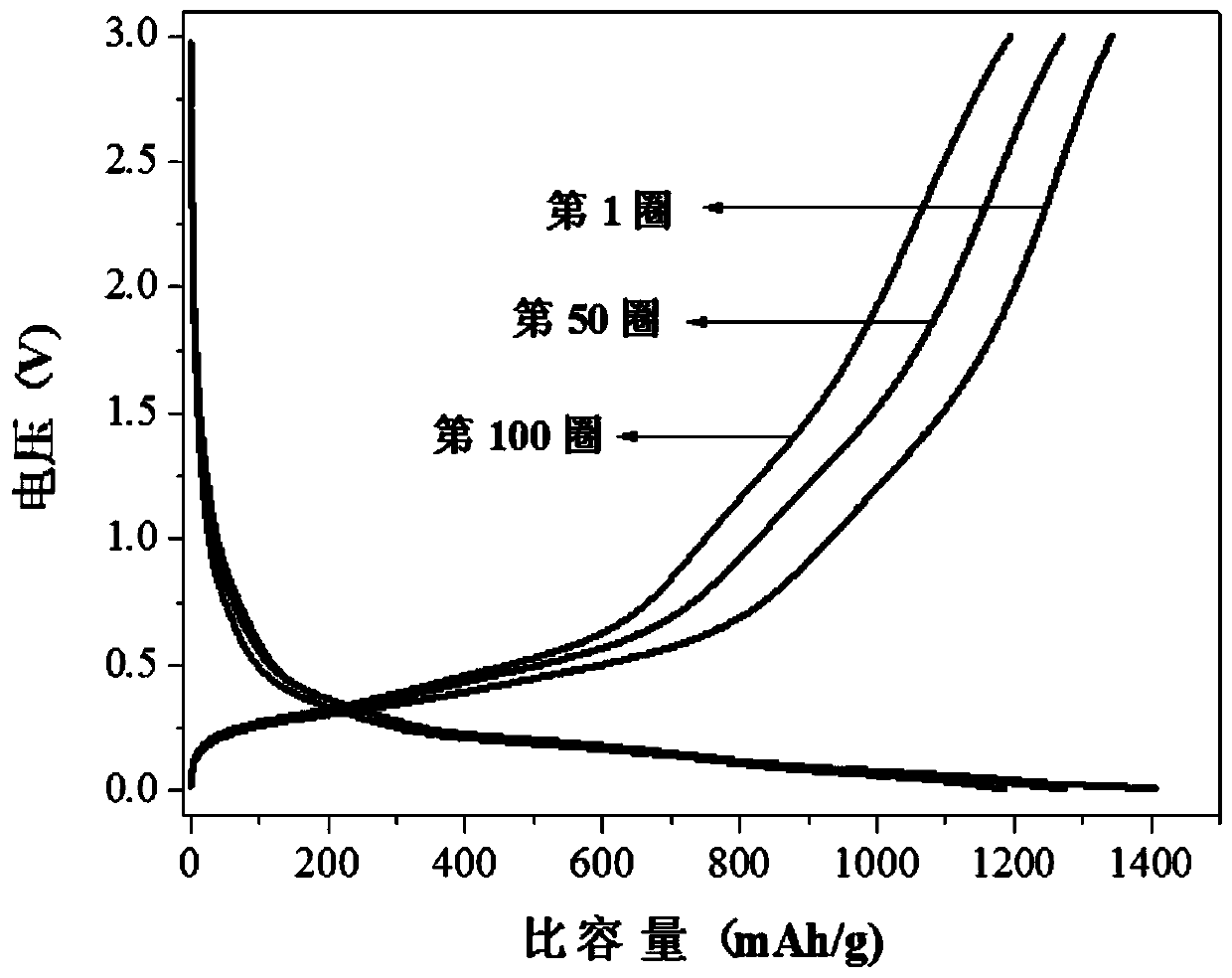

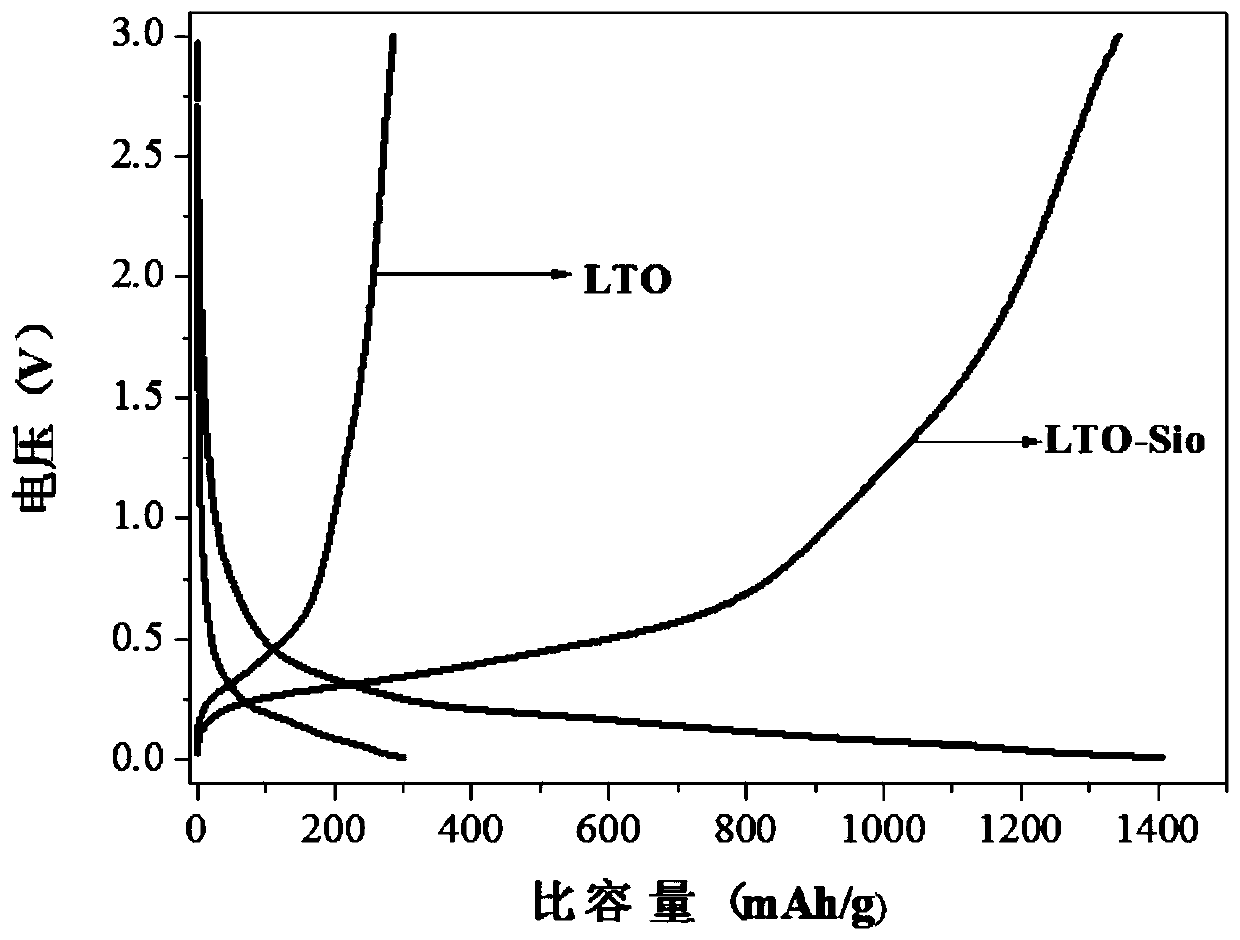

Composite lithium titanate thin film as well as preparation method and application thereof

InactiveCN110176586AImprove structural stabilityStable chemical propertiesHybrid capacitor electrodesCell electrodesLithiumSide reaction

The invention provides a composite lithium titanate thin film as well as a preparation method and an application thereof. The preparation method of the composite lithium titanate thin film comprises the following steps of carrying out co-sputtering treatment on a lithium titanate target material and an energy density contribution main body element target material in an inert atmosphere, and growing the composite lithium titanate thin film on a substrate. According to the preparation method of the composite lithium titanate thin film, the lithium titanate target material and the energy densitycontribution main body element target material are directly deposited and formed by adopting a co-sputtering method. Therefore, the grown composite lithium titanate thin film has a rich channel structure and is stable in structure, so that high lithium ion transmission rate can be provided, and high cycling reversibility and relatively high specific capacity are maintained; and meanwhile, the direct contact of an electrolyte and a nano-scale energy density contribution main body element is effectively prevented, the irreversible side reaction between the electrolyte and the energy density contribution main body can be reduced and blocked, and the generation of a solid electrolyte membrane (SEI) is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

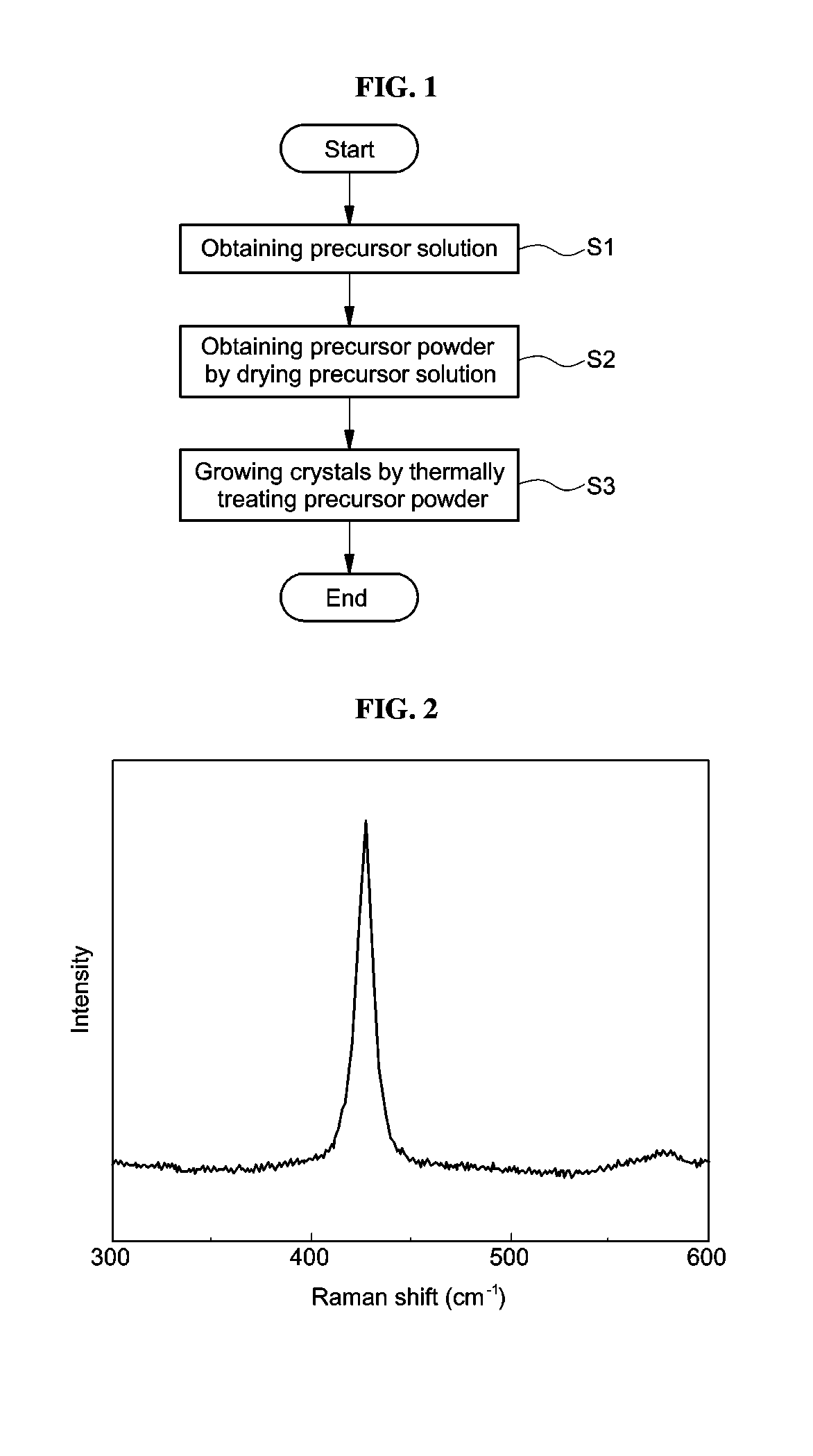

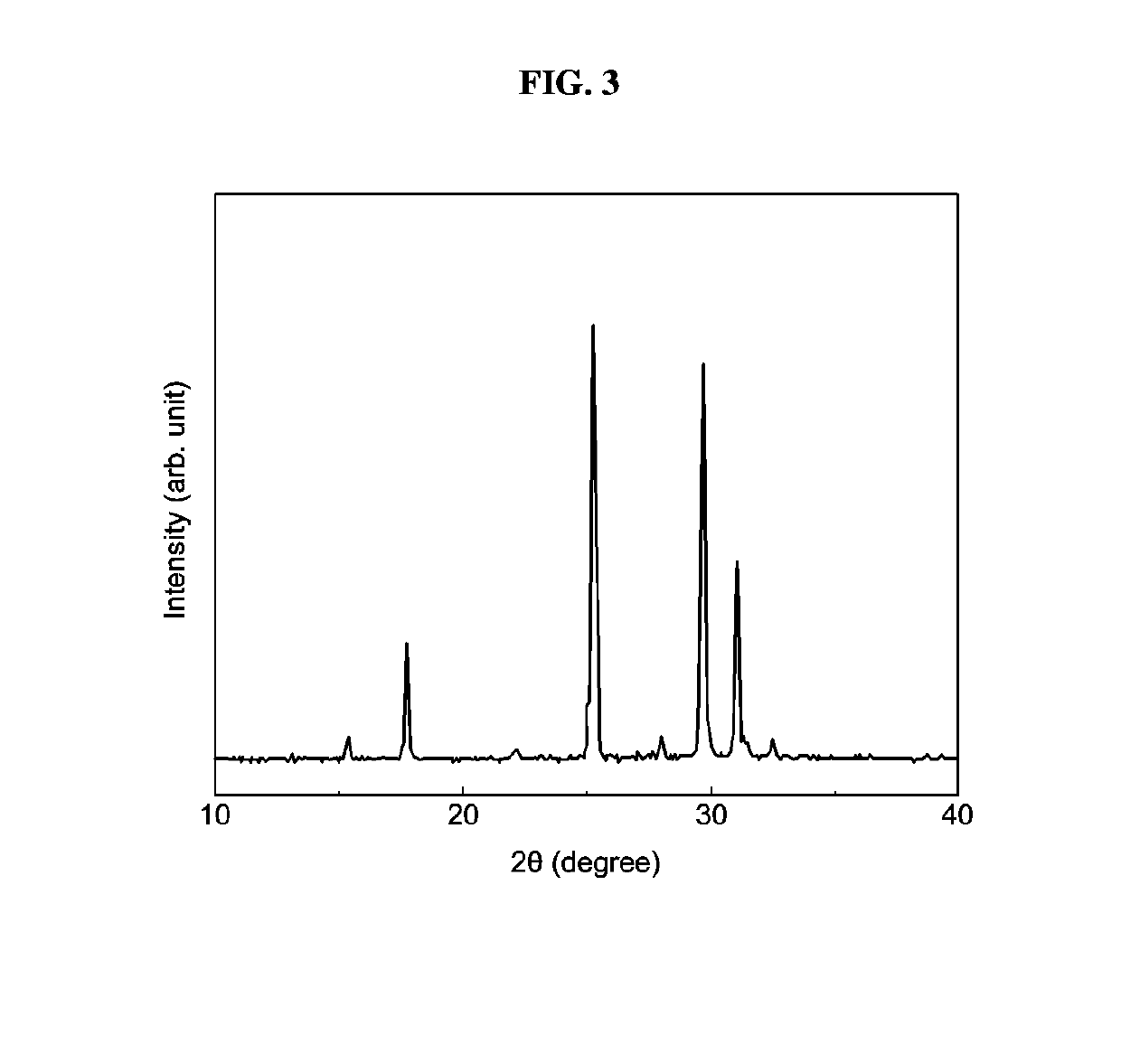

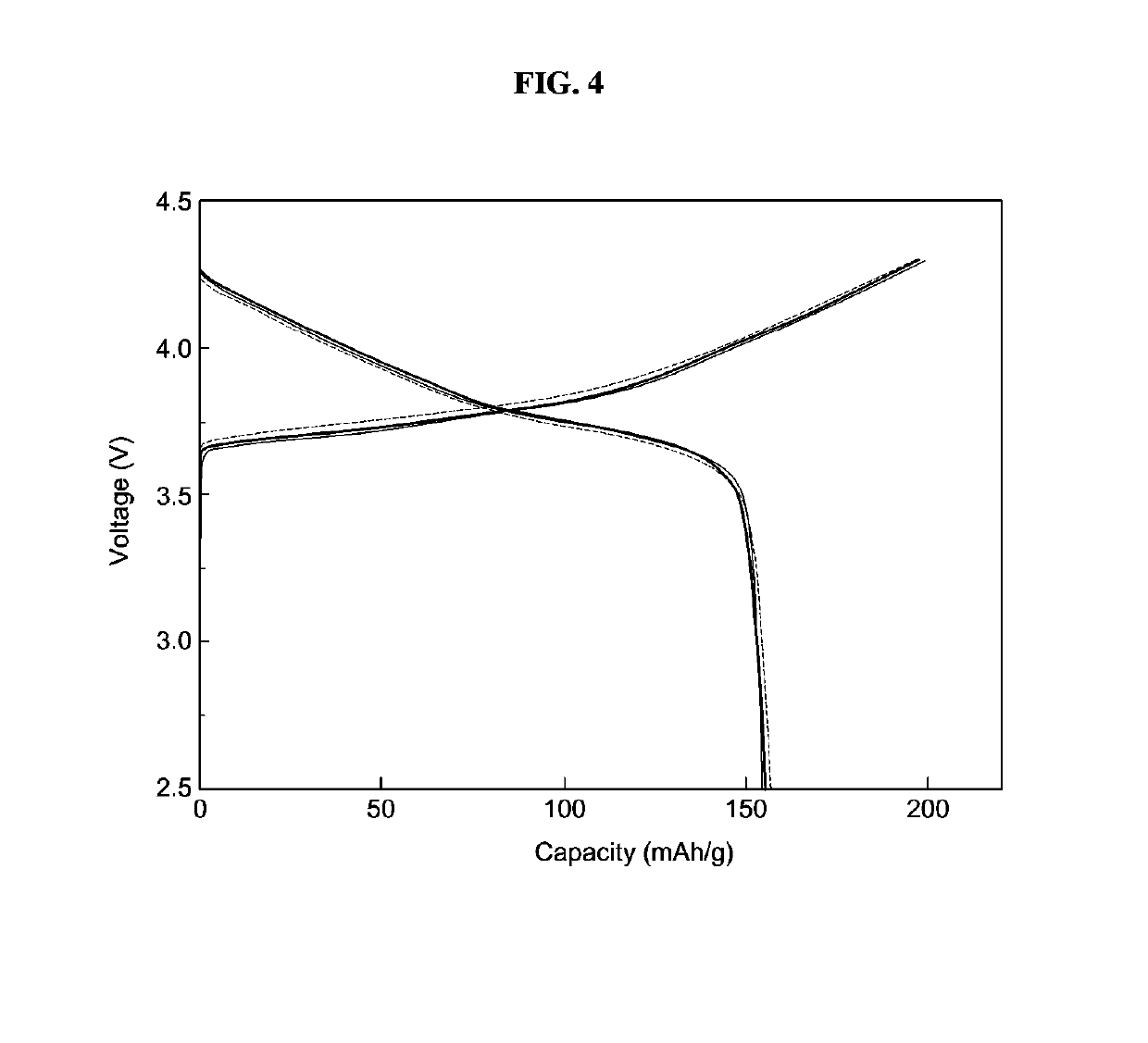

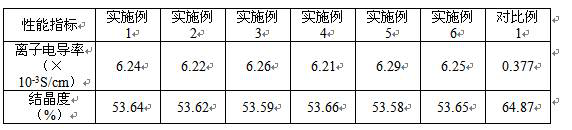

Method of preparing sulfide-based solid electrolyte for all-solid battery having argyrodite-type crystal structure

ActiveUS20190173127A1Increase price competitivenessHigh lithium ion conductivitySolid electrolytesPhosphorus sulfur/selenium/tellurium compoundsPhosphorus sulfideLithium sulfide

Disclosed is a method of preparing a sulfide-based solid electrolyte for an all-solid battery having an argyrodite-type crystal structure through a solution process. The method including obtaining a precursor solution by dissolving lithium sulfide, phosphorus sulfide and a halogen compound in a solvent, obtaining a precursor powder by removing the solvent from the precursor solution. Solid electrolyte for an all-solid battery can be produced by such method.

Owner:HYUNDAI MOTOR CO LTD +1

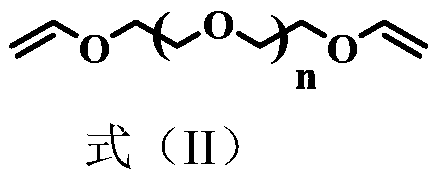

Solid-state lithium battery polymer electrolyte containing PEO side chain segment and preparation method thereof

InactiveCN111987354AGood effectImprove migration efficiencyFinal product manufactureLi-accumulatorsSide chainElectronic conductivity

The invention relates to the field of lithium battery electrolytes, and discloses a solid-state lithium battery polymer electrolyte containing a PEO side chain segment and a preparation method. The preparation method comprises the following steps: (1) adding Butanedithiol, acrylate and polyoxyethylene macromonomers into toluene, and heating and stirring to obtain a mixed material; (2) adding azodiisobutyronitrile into the mixed material obtained in the step (1), and carrying out a constant-temperature stirring reaction to obtain a PMMA-g-PEO material; and (3) firstly adding N, N-diethylethylamine for reaction, then adding a lithium salt electrolyte for mixing and centrifugal separation, and finally drying a solid product to obtain the solid-state lithium battery polymer electrolyte containing the PEO side chain segment. The solid-state lithium battery polymer electrolyte containing the PEO side chain segment has the advantages of low crystallinity, high lithium ion migration efficiency, good lithium salt adsorbability, increase of the lithium ion concentration, and substantial increase of the lithium ion conductivity of the polymer electrolyte.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

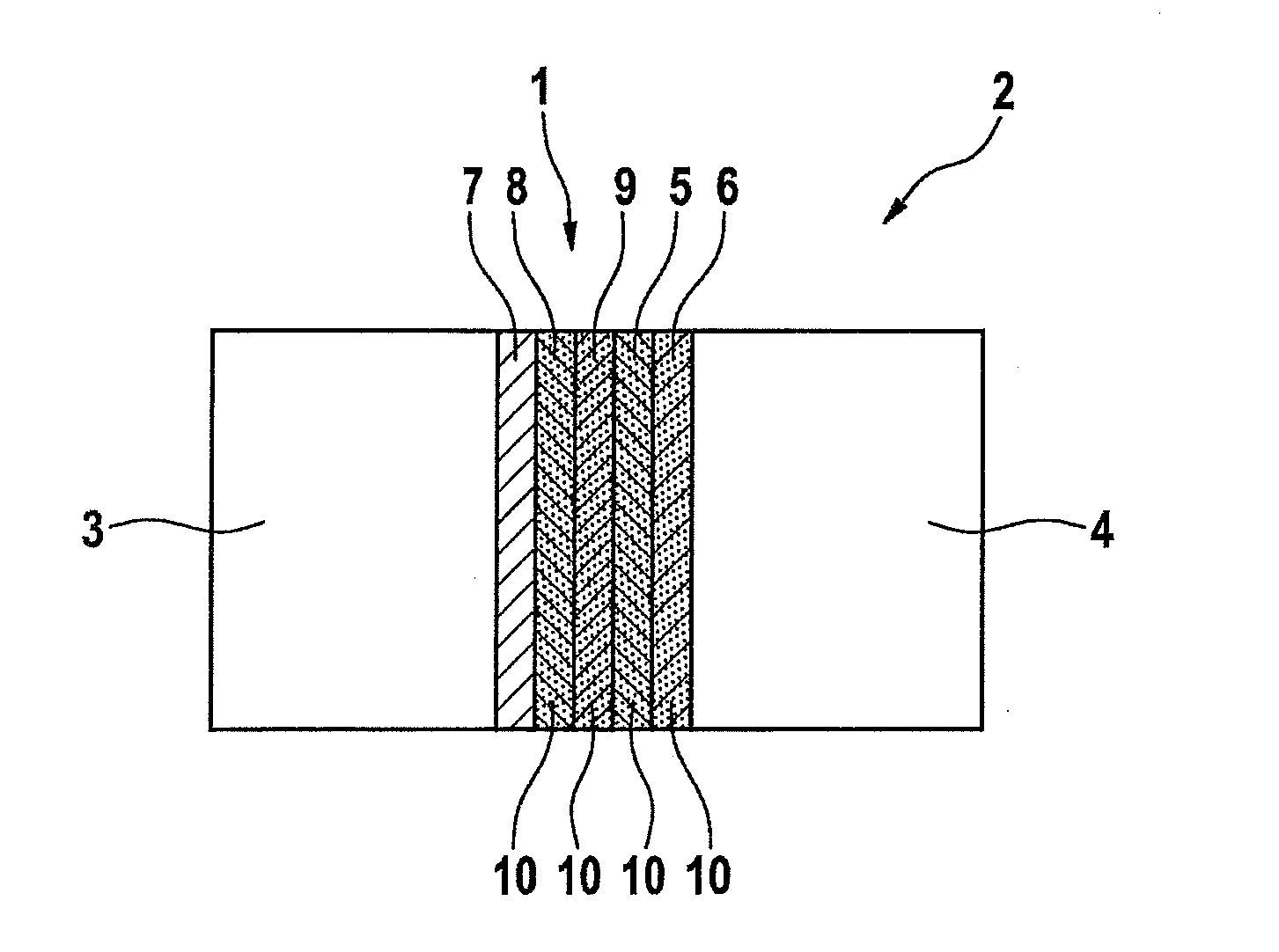

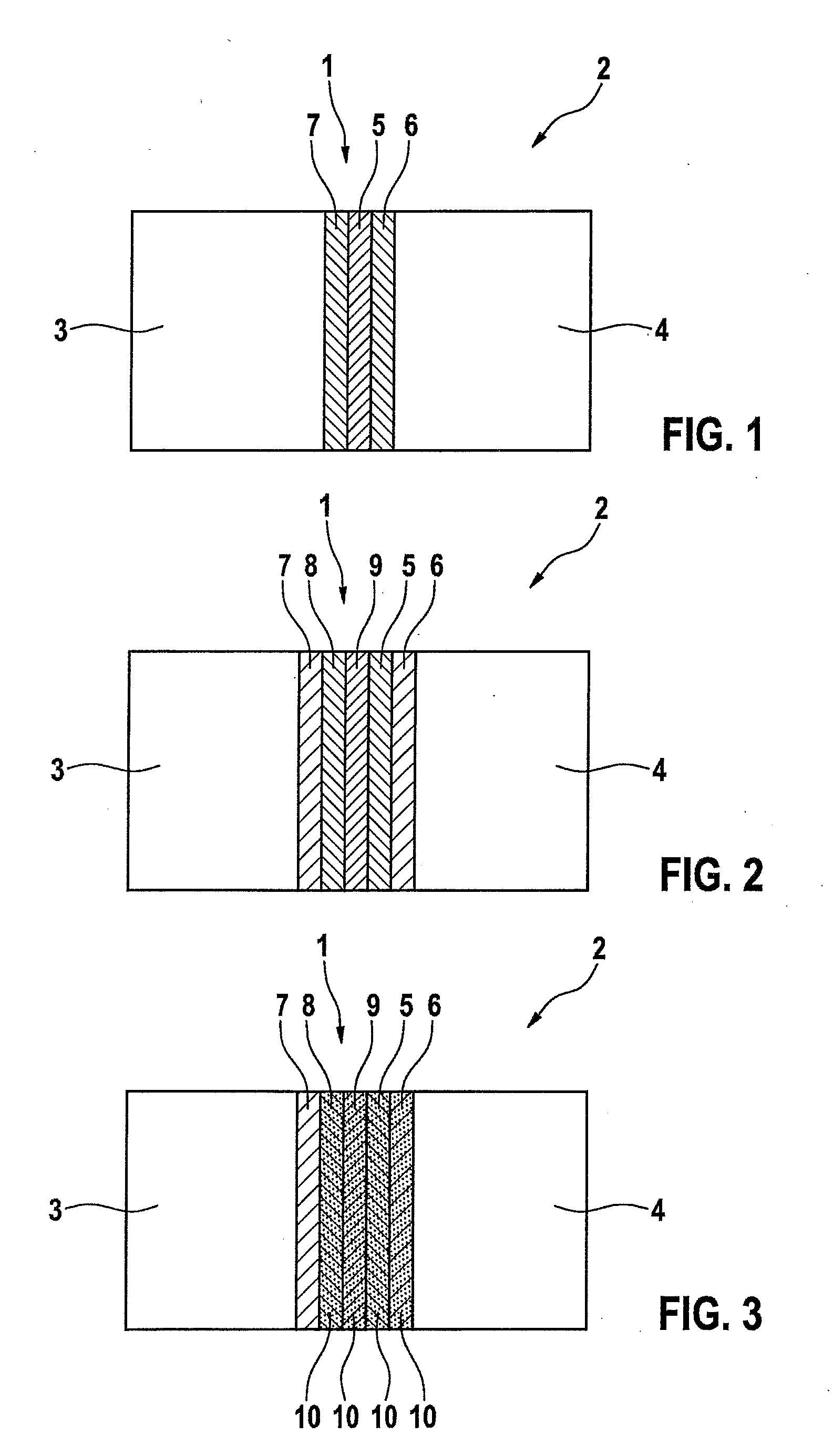

Separator for an energy store and an energy store

ActiveUS20140234692A1High lithium ion conductivityStrong affinityCell electrodesLi-accumulatorsCyclic stabilityEngineering

A separator for an energy store. The separator may be used in a lithium-sulfur battery in particular. To achieve improved cycle stability, the separator has at least one first layer and at least one second layer, the at least one first layer containing a material having an affine property with respect to at least one active electrode material, and the at least one second layer containing a material having a repellent property with respect to at least one active electrode material. The at least one first layer and the at least one second layer may be situated directly adjacent to one another. Also described is an energy store including the separator.

Owner:ROBERT BOSCH GMBH

Polymer solid electrolyte membrane as well as preparation method and application thereof

ActiveCN112670566AMinor changesSave the cost of production line transformationSecondary cellsSolid state electrolyteAll solid state

The invention provides a polymer solid electrolyte membrane as well as a preparation method and application thereof. The solid electrolyte membrane comprises a polymer matrix, a lithium salt and a plasticizer, wherein the molecular chain of the polymer matrix comprises four components: a main monomer for providing a lithium ion transmission channel, a high-pressure stabilizer for providing high-pressure stability, a softening agent for improving the flexibility of a polymer chain, and a cross-linking agent for improving the mechanical strength. The polymer solid electrolyte membrane has relatively high lithium ion conductivity, excellent high-voltage stability and cycling stability, and can be widely applied to polymer all-solid-state batteries.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Printing-like integrated all-solid-state lithium metal battery and preparation method thereof

ActiveCN111370750AHigh lithium ion conductivityImprove interface compatibilitySolid electrolytesFinal product manufacturePolymer electrolytesAll solid state

The invention discloses a printing-like integrated all-solid-state lithium metal battery and a preparation method thereof. The printing-like integrated all-solid-state lithium metal battery is formedby printing layer by layer according to the sequence of a lithium negative electrode SEI membrane, a solid polymer electrolyte membrane and a positive electrode. The printable integrated all-solid-state lithium metal battery prepared by the invention has the advantages of high lithium ion conductivity, good interface compatibility, simple preparation process, printable production, cheap and easilyavailable raw materials and the like. The printable integrated all-solid-state lithium metal battery designed by the invention is high in discharge capacity and good in cycle performance.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com