Preparation method of high-performance lithium ion conduction membrane

An ion conducting membrane and conducting membrane technology, applied in the field of preparation of high-performance lithium ion conducting membrane, can solve the problems of loss and reduction of high-current charge and discharge capacity of batteries, and achieve high safety, high lithium ion conductivity, and excellent battery performance. Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

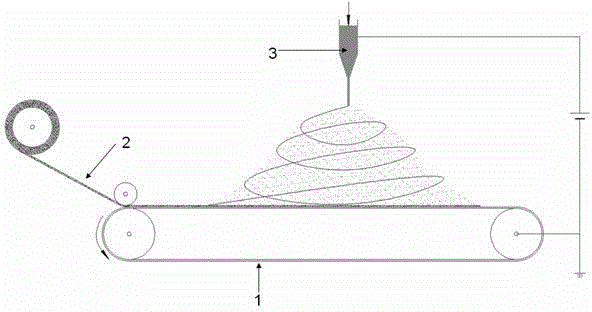

[0015] Such as figure 1 As shown, the commercialized Li with a particle size of 50 nm 10 GeP 2 S 12 Powder and PAN by mass ratio m Li10GeP2S12 :m PAN The ratio of =1:6 is dissolved in DMF organic solvent, and after fully stirring, a suspension with a solid content of 75% is formed. Put the suspension into the syringe of the electrospinning machine for electrospinning, the aperture of the spinning needle is 0.8mm, the spinning voltage is 10kV, the receiving distance is 19cm, the humidity is 30-40%, and the temperature is 30 o C, the base layer of the PP diaphragm is placed on the receiving plate of the metal foil; the static-spun diaphragm obtained above is hot-pressed by a roller-type hot press, and the hot-pressing temperature is 75 o C, A membrane with high ionic conductivity is obtained after hot pressing.

Embodiment 2

[0017] Commercialized Li with a particle size of 20 nm 10 GeP 2 S 12 Powder and PVDF by mass ratio m Li10GeP2S12 :m Pvdf =1:1 ratio is dissolved in NMP, and after fully stirring, a suspension with a solid content of 95% is formed. Put the suspension in the syringe of the electrospinning machine for electrospinning, the aperture of the spinning needle is 0.5mm, the spinning voltage is 20kV, the receiving distance is 15cm, the humidity is 25~35%, and the temperature is 20 o C, the base layer of the PE diaphragm is placed on the receiving plate of the metal foil; the above-mentioned still-spun diaphragm is hot-pressed by a roller-type hot press, and the hot-pressing temperature is 60 o C, A membrane with high ionic conductivity is obtained after hot pressing.

Embodiment 3

[0019] Commercialized Li with a particle size of 200 nm 10 GeP 2 S 12 Powder and PVDF-HFP by mass ratio m Li10GeP2S12 :m PVDF-HFP Dissolve in acetone at a ratio of 1:10, and form a suspension with a solid content of 30% after fully stirring. Put the suspension into the syringe of the electrospinning machine for electrospinning, the aperture of the spinning needle is 1.5mm, the spinning voltage is 20kV, the receiving distance is 25cm, the humidity is 30-45%, and the temperature is 40 o C, PET non-woven is arranged on the receiving plate of metal foil material; The still-spun diaphragm obtained above is hot-pressed by a drum-type hot-pressing machine, and the hot-pressing temperature is 85 o C, A membrane with high ionic conductivity is obtained after hot pressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com