Quasi-solid-state lithium battery and preparation method thereof

A quasi-solid-state, lithium battery technology, used in secondary batteries, solid electrolytes, secondary battery repair/maintenance, etc., can solve the problems of battery cycle performance decline, liquid electrolyte reducing battery safety, etc., to enhance the inhibition of lithium branching. The ability to crystallize and the effect of not easy to crystallize and high lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

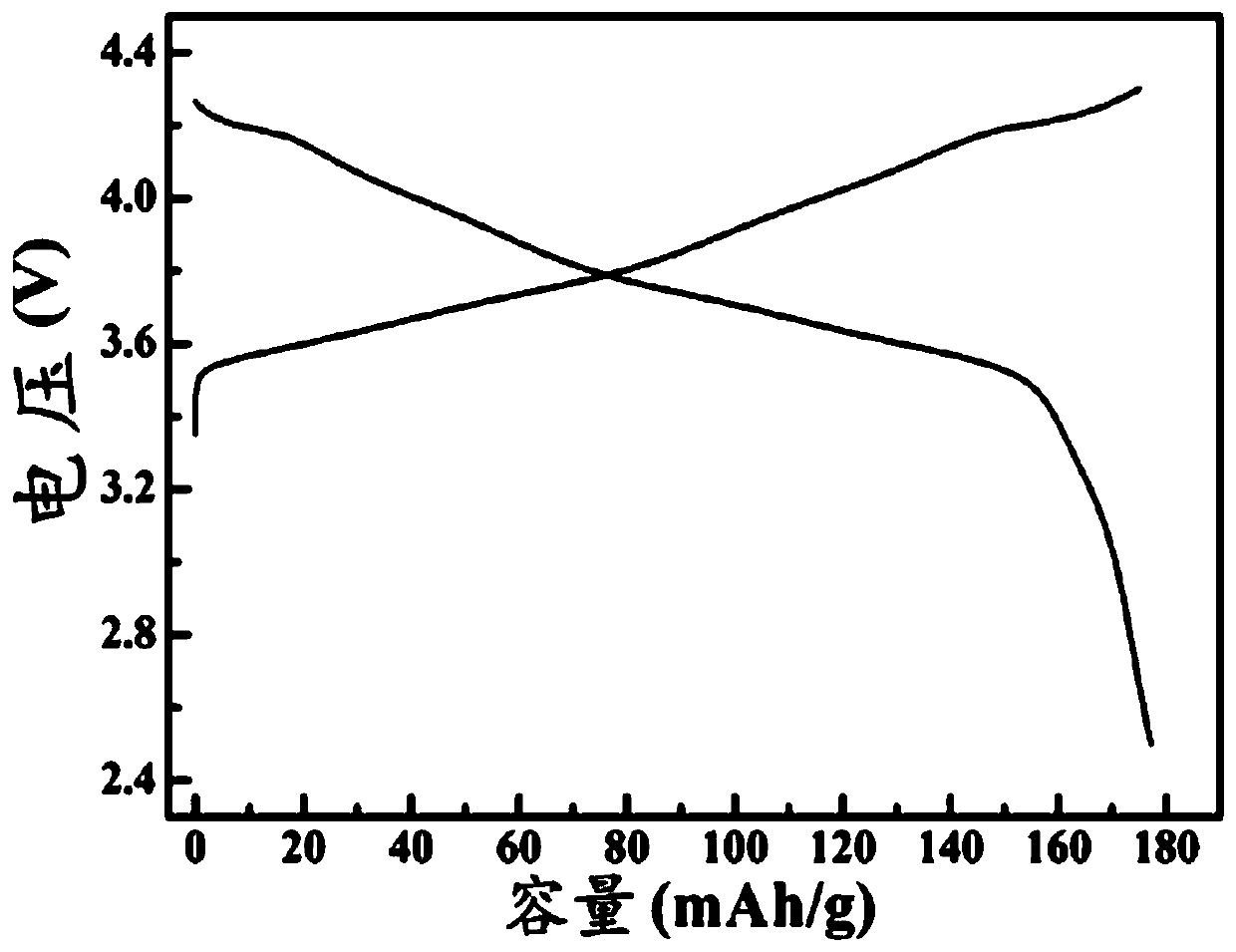

Embodiment 1

[0065] Ethoxylated trimethylolpropane triacrylate monomer and polyethylene glycol methyl ether methyl methacrylate monomer (molar ratio is 1:10, in which polyethylene glycol methyl ether methyl methacrylate monomer Body) (polyethylene glycol methyl ether methyl methacrylate monomer number average molecular weight is 500g / mol, CAS number: 26915-72-0), Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Fluoroethylene carbonate / triethyl phosphate / 1,1,2,2-tetrafluoroethylene of ceramic powder (particle size 30-50nm), 0.9mol / L lithium hexafluorophosphate and 0.1mol / L lithium difluorooxalate borate Base-2,2,2-trifluoroethyl ether (volume ratio 1:1:1) solution is mixed with liquid electrolyte (monomer, ceramic electrolyte, lithium salt weight ratio 1:0.2:0.1), and passed Stir fully and evenly to obtain a quasi-solid electrolyte precursor; combine lithium negative electrode, quasi-solid electrolyte precursor, commercial Celgard diaphragm and LiNi 0.8 co 0.1 Ni 0.1 o 2 The positive electrode is as...

Embodiment 2

[0075] The preparation of the quasi-solid-state lithium battery is similar to that of Example 1, except that the organic solvent used in the preparation of the quasi-solid-state electrolyte precursor is only fluoroethylene carbonate / triethyl phosphate (volume ratio of 1:1), without using 1, 1,2,2-Tetrafluoroethyl-2,2,2-trifluoroethyl ether. Experiments have shown that at this time in the quasi-solid electrolyte, the ceramic nanoparticles cannot be uniformly dispersed, the mechanical properties, thermal stability, and lithium ion conductivity of the quasi-solid electrolyte are not ideal, and the cross-linked structure of the polymer is not complete. After 100 cycles at 1C, the capacity retention is only 72%.

Embodiment 3

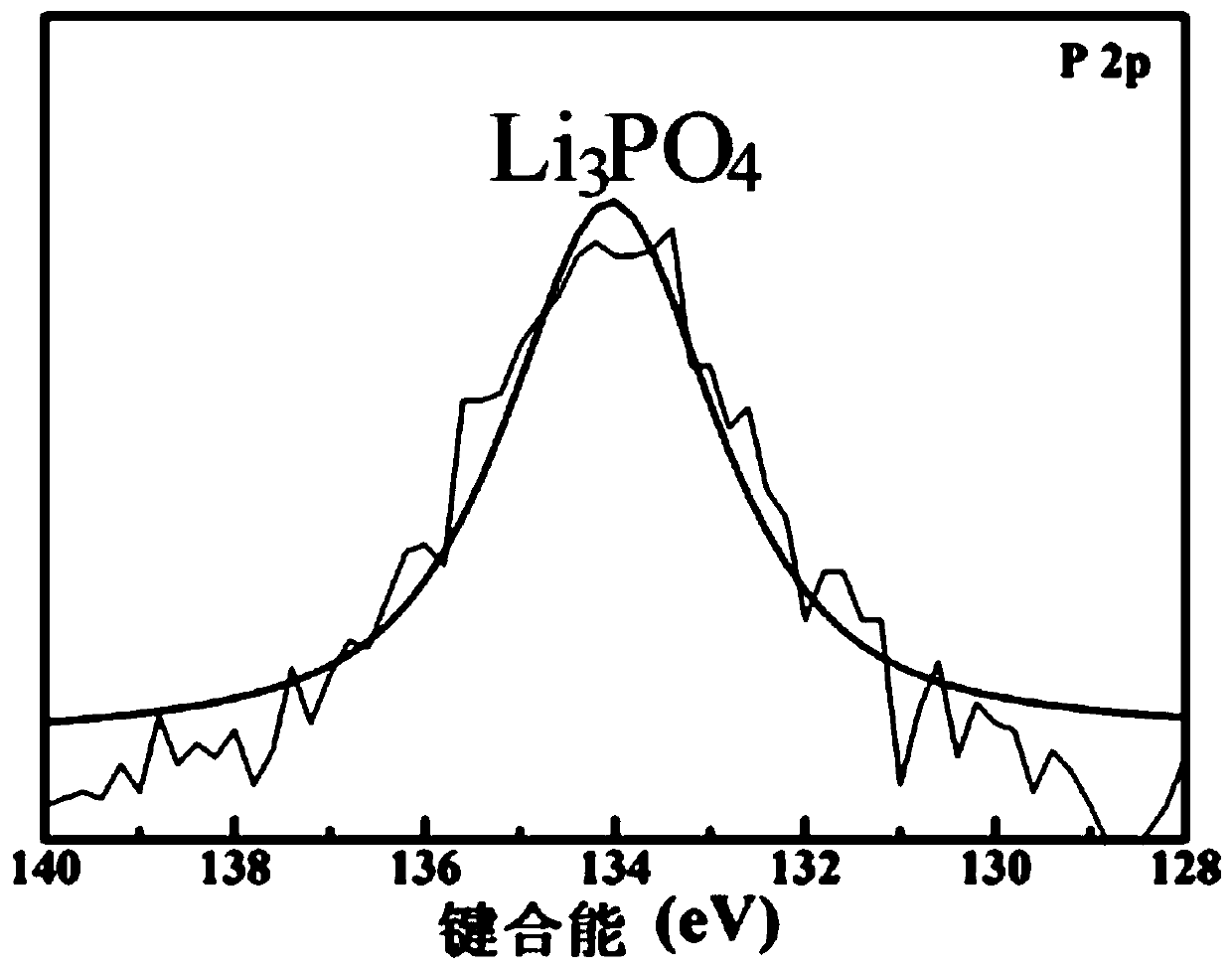

[0077] The preparation of the quasi-solid-state lithium battery is similar to that of Example 1, except that lithium hexafluorophosphate is used as the lithium salt instead of lithium difluorooxalate borate. Experiments have shown that no compound containing fluorine, phosphorus and boron is formed on the surface of the electrode, which cannot effectively protect the positive and negative electrodes. After 100 cycles at 1C, the capacity retention is only 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com