Patents

Literature

256results about How to "Simplify the transfer process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

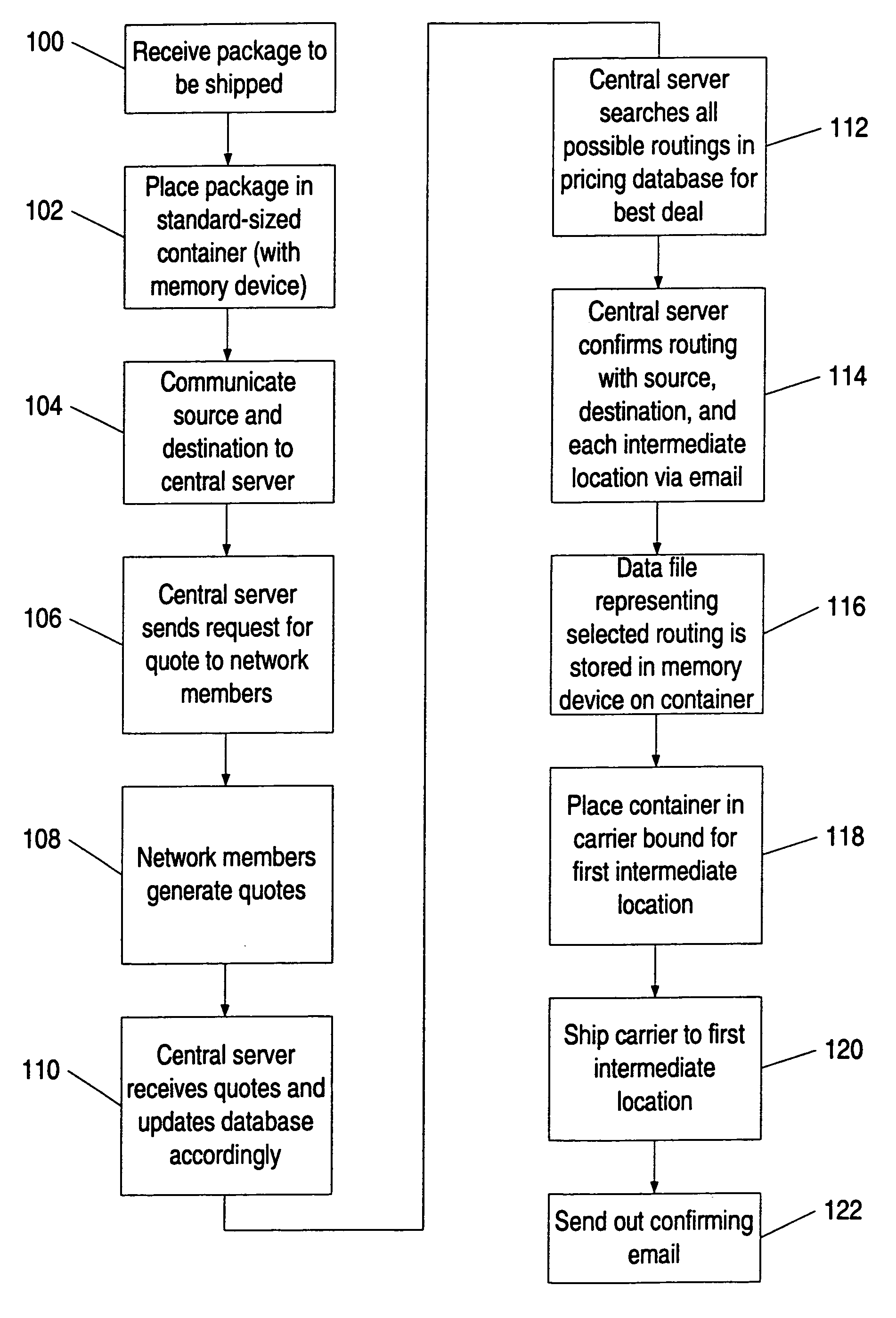

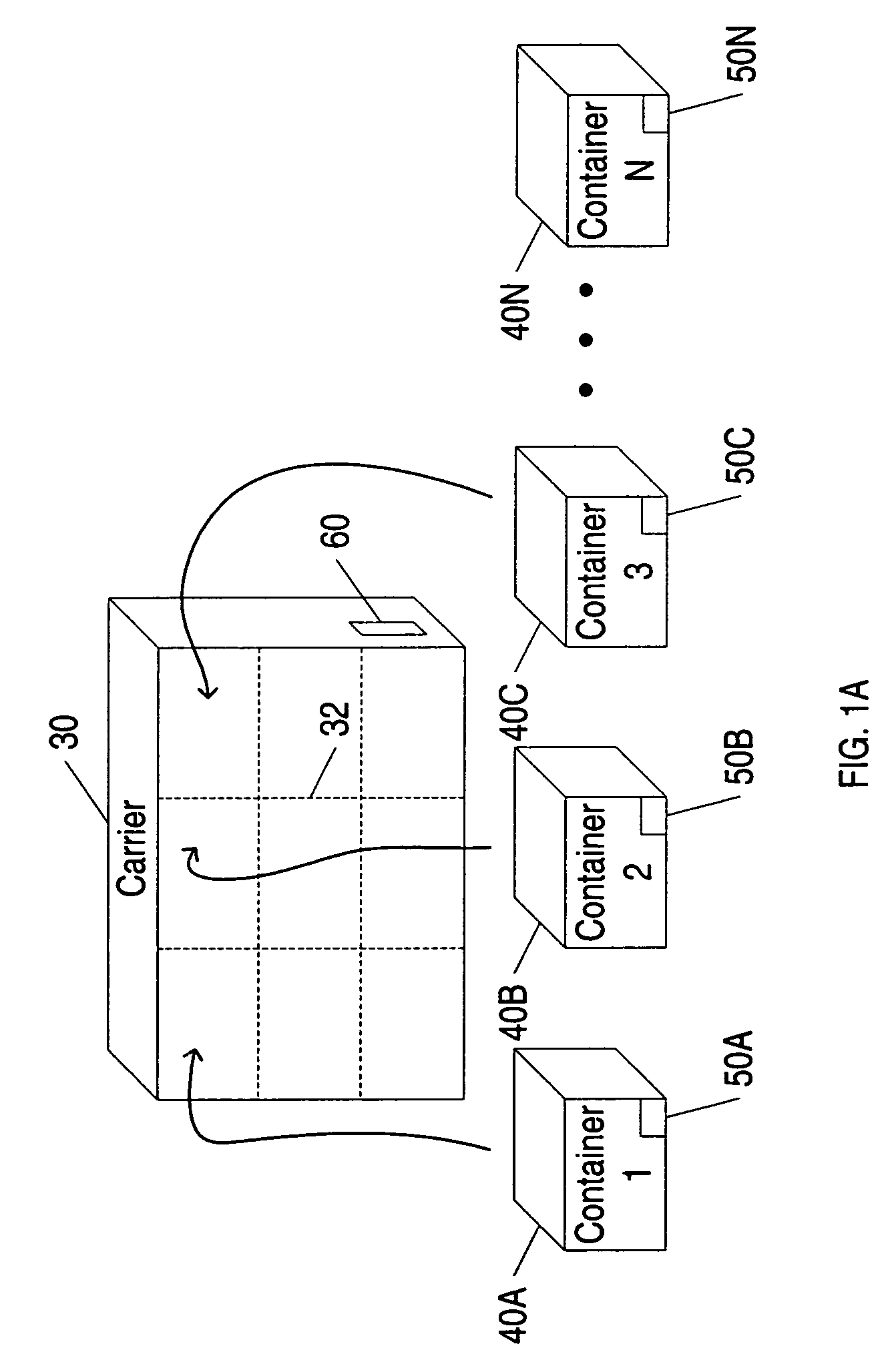

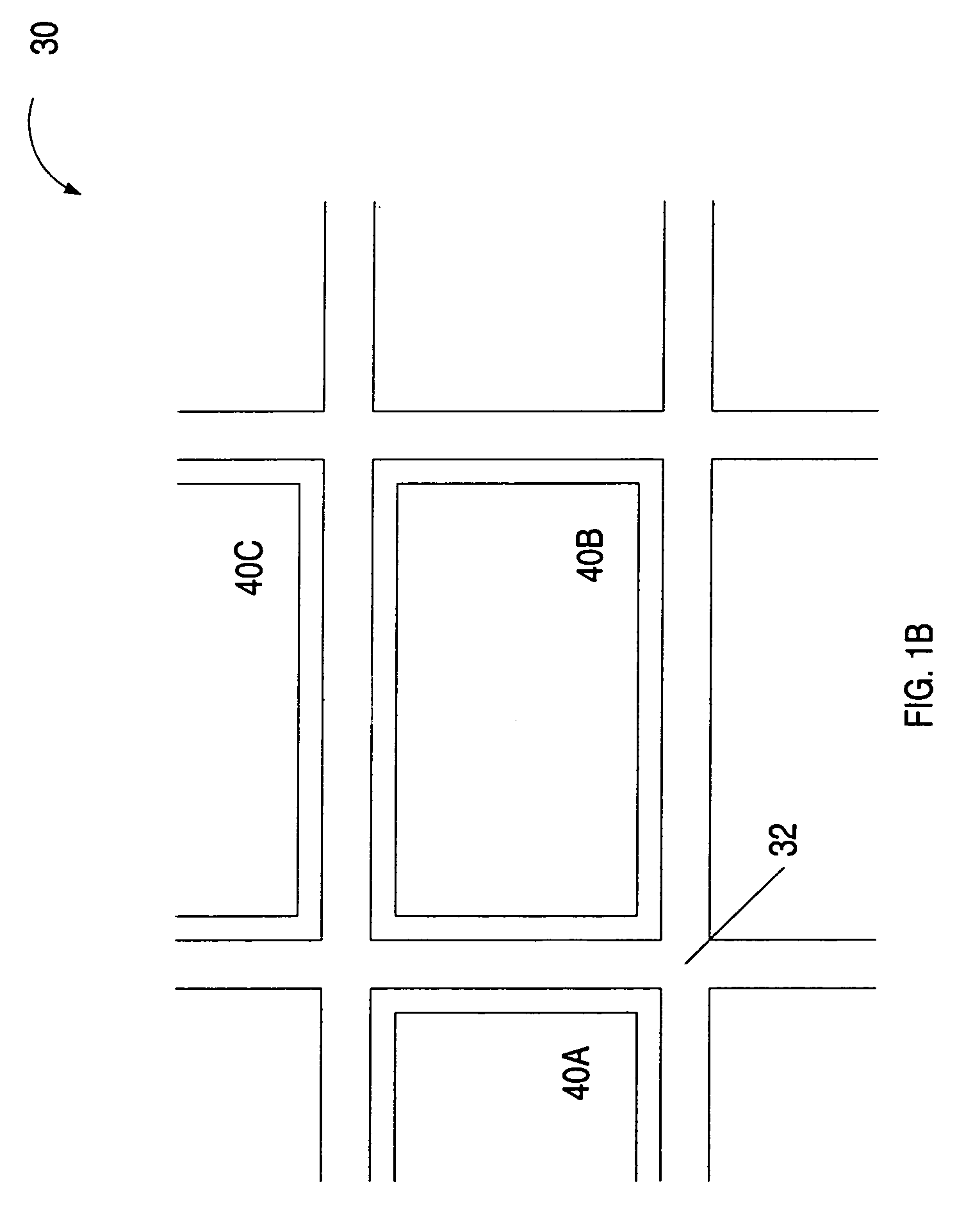

System and method for tracking and routing shipped items

InactiveUS7035856B1Simplify the shipping processSimple processContainer decorationsLevel indicationsData fileFile storage

A method and system for shipping items. A server is configured to send out requests for quotes to a number of regional shipping companies using a network. The server receives responses from the network and selects a route based on the responses. The route may include shipping the item to one or more intermediate destinations before the item arrives at the final destination. The server may create a data file reflecting the selected route. The items are packed in one or more containers, wherein each container has a memory device. At least part of the data file is then stored into the memory device. The memory device may be accessed as needed during shipping to determine where the item is going and when the item needs to arrive. Additional information may also be stored in the memory device, and the device may be updated at intermediate destinations. Each container may take a different routing, and the server may actively search for better routings as the item proceeds along the selected route. The containers may be configured to be placed within carriers that hold multiple containers, and the carriers may also be configured with memory devices.

Owner:NIHON DOT COM

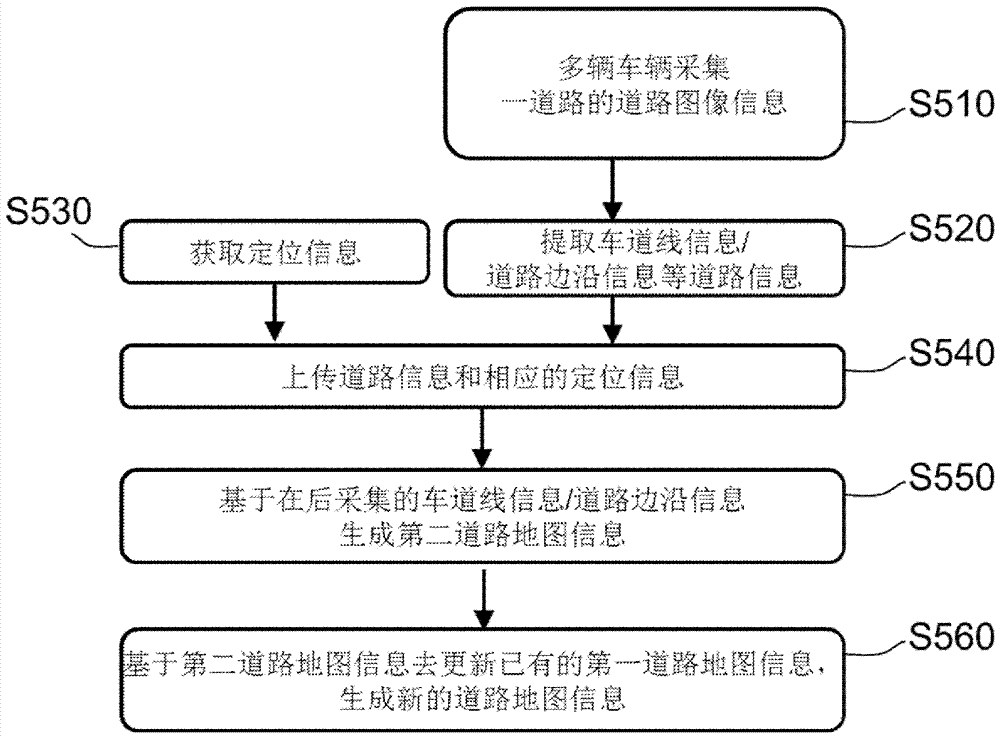

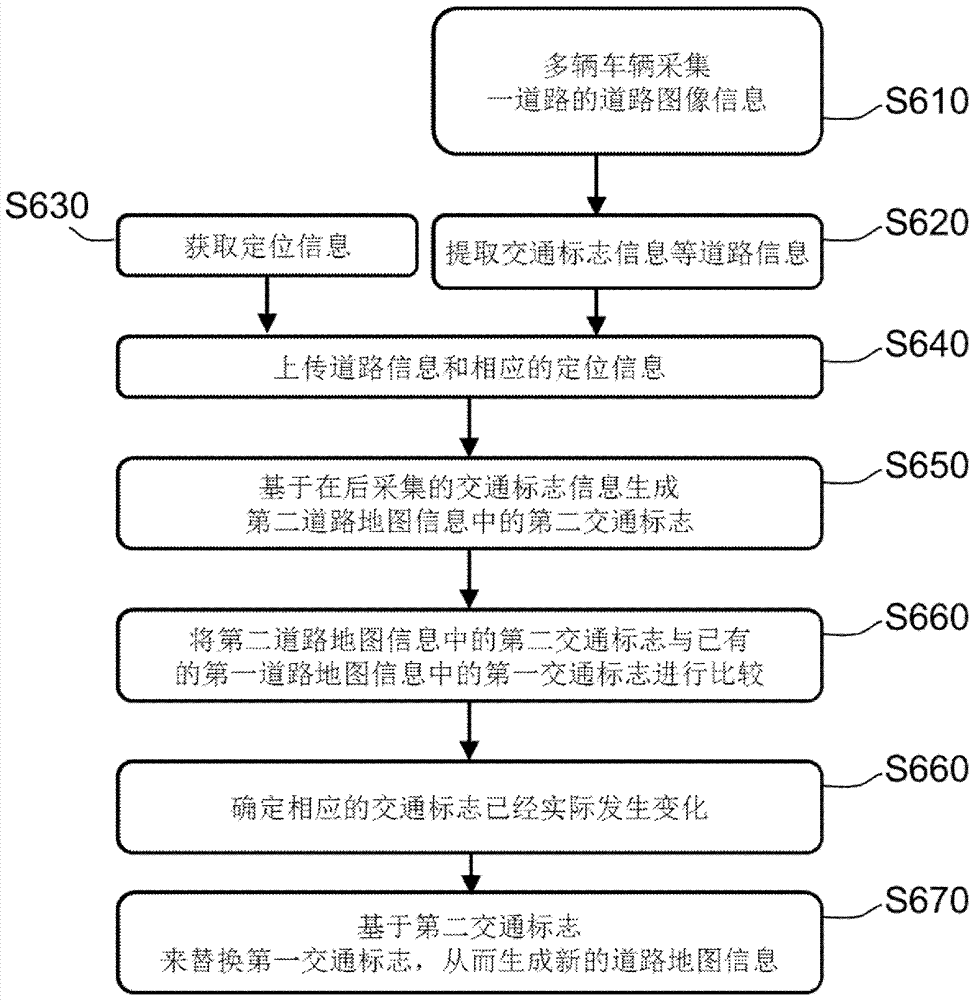

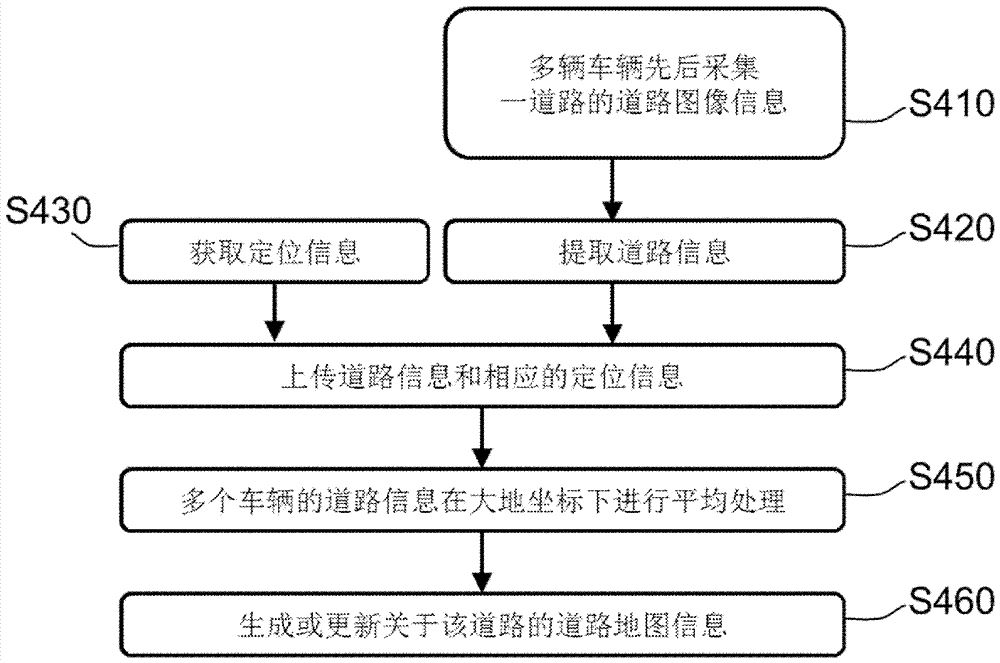

Map construction and application

InactiveCN107451526AReduce the amount of data collectedEasy to collectCharacter and pattern recognitionNavigation instrumentsRoad mapSystem construction

The invention relates to map construction and application, and belongs to the technical field of map construction. The map construction method comprises the steps of successively collecting road image information on a road by multiple vehicles running on the road, and obtaining locating information at a position point where the road image information is collected; extracting road information from the road image information; uploading the road information and the corresponding locating information obtained by the vehicles through the vehicles; and generating or updating road map information on the road based on the road information and the corresponding locating information of the vehicles.

Owner:NIO CO LTD

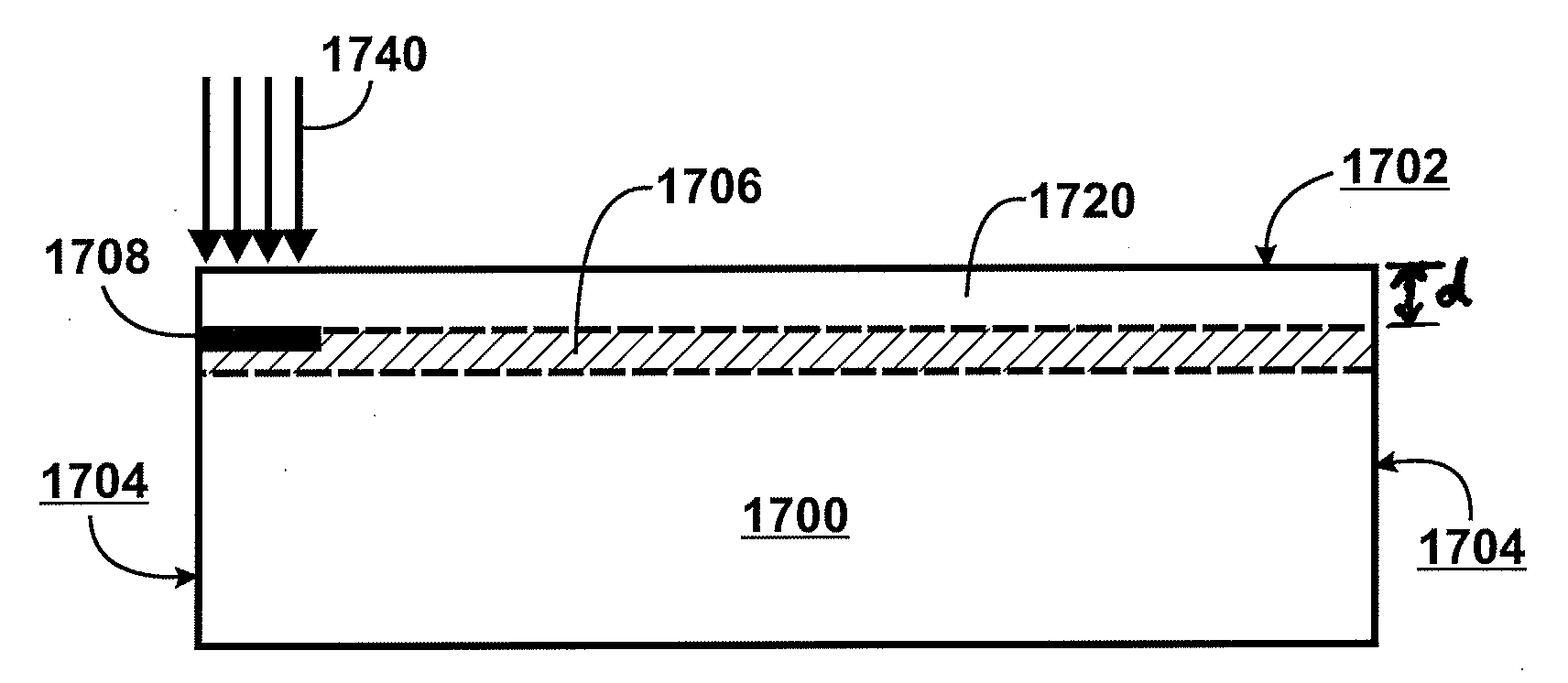

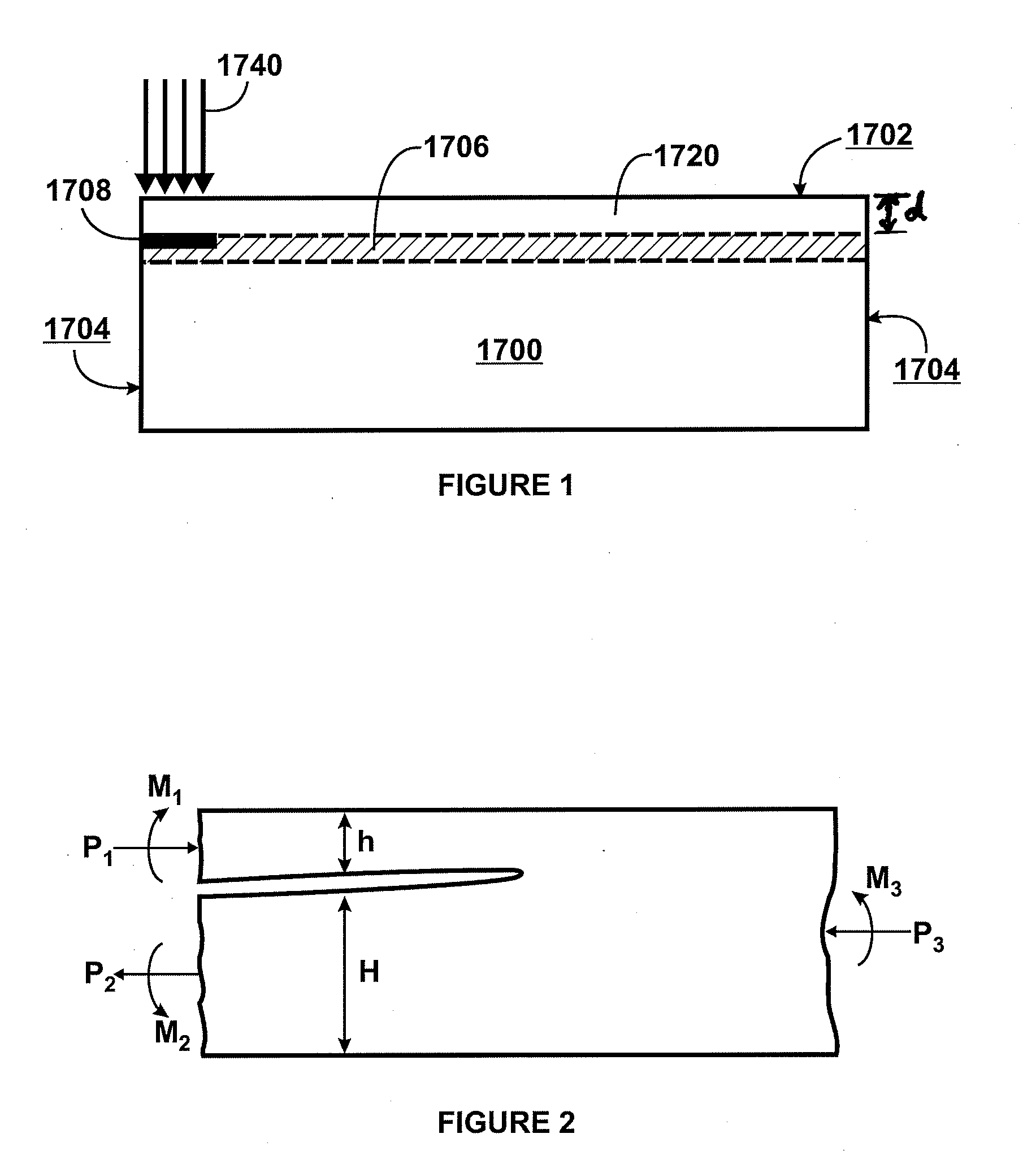

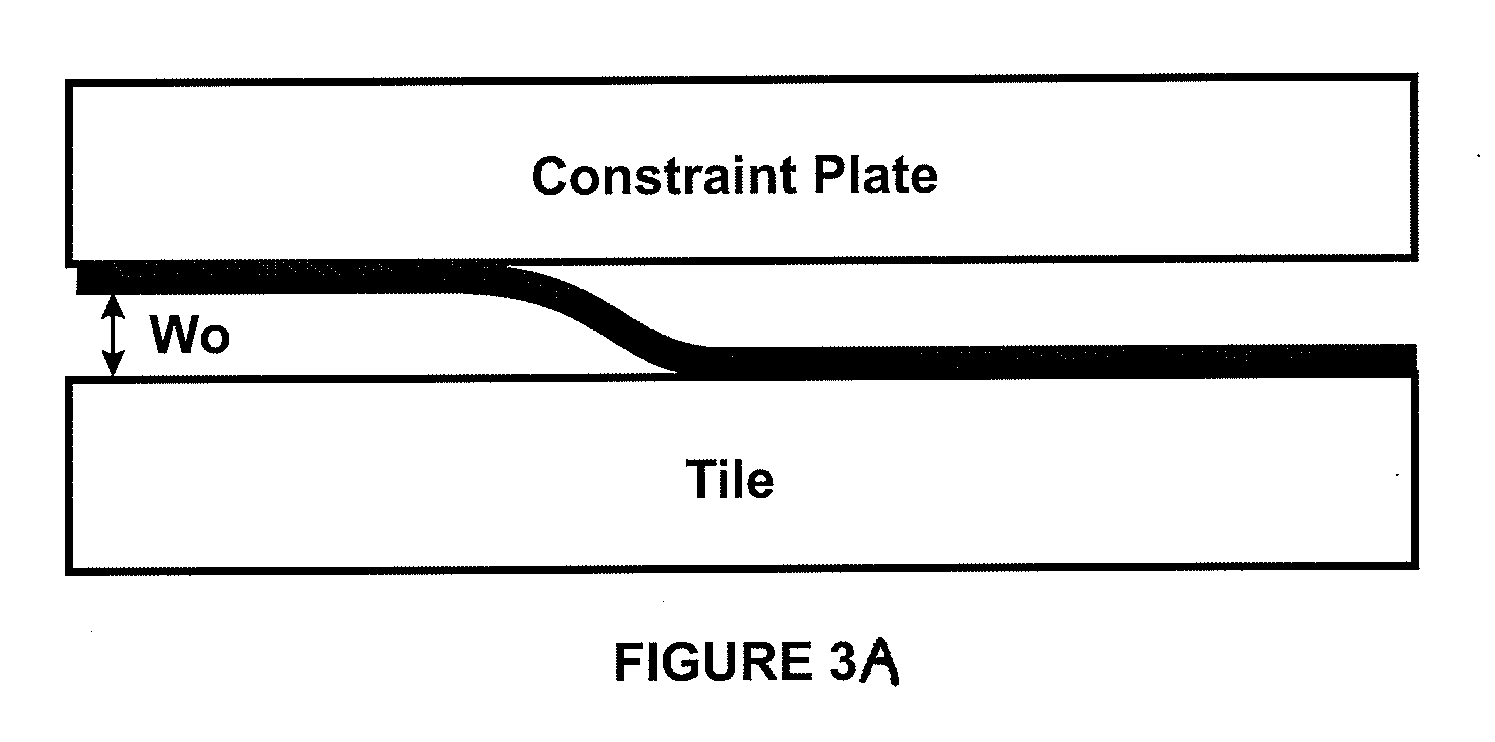

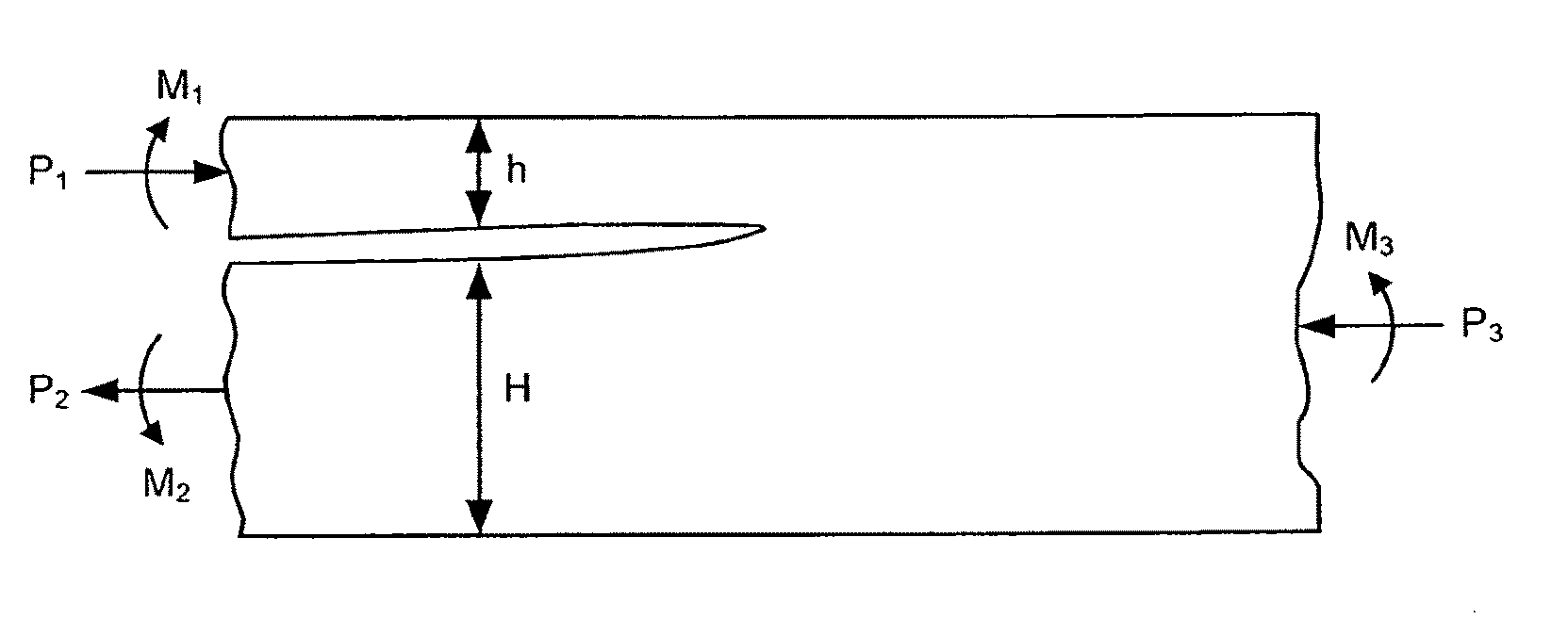

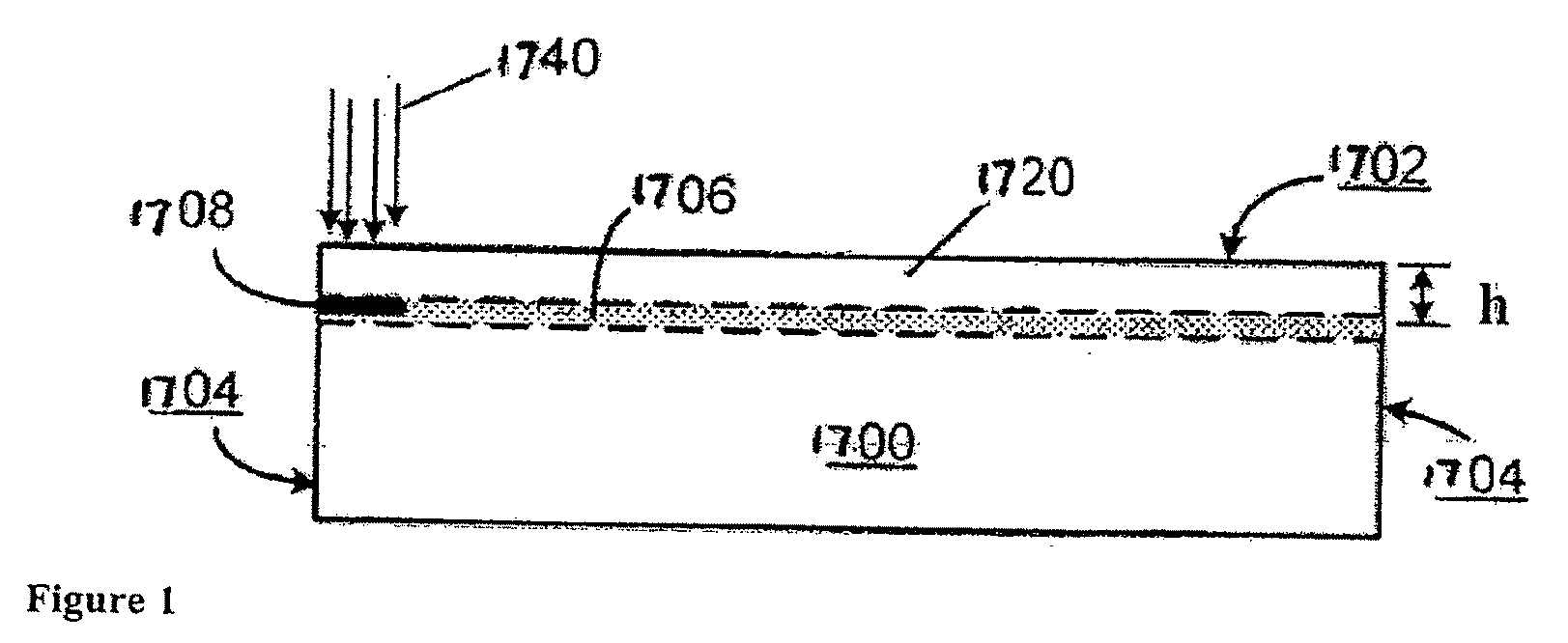

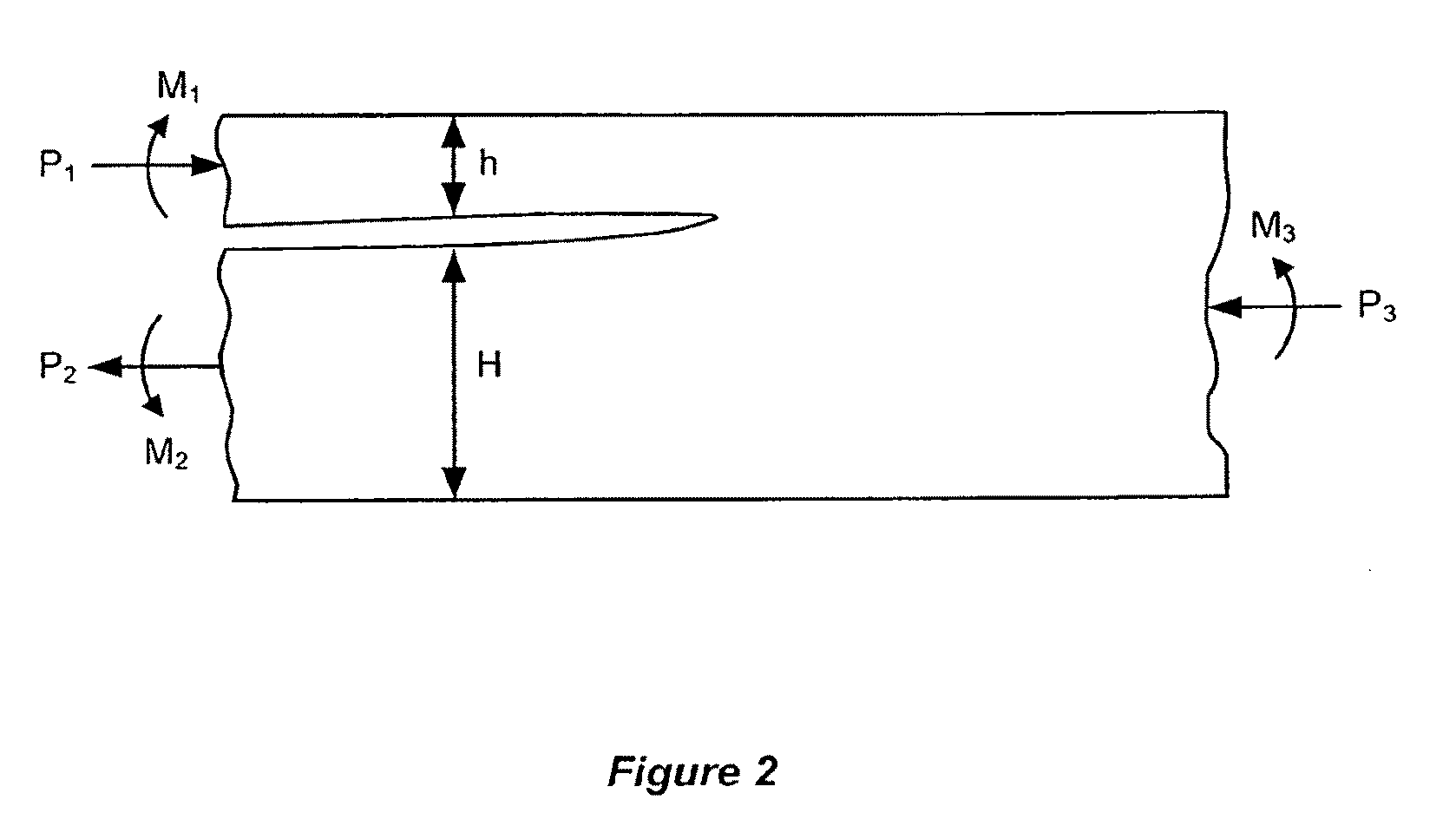

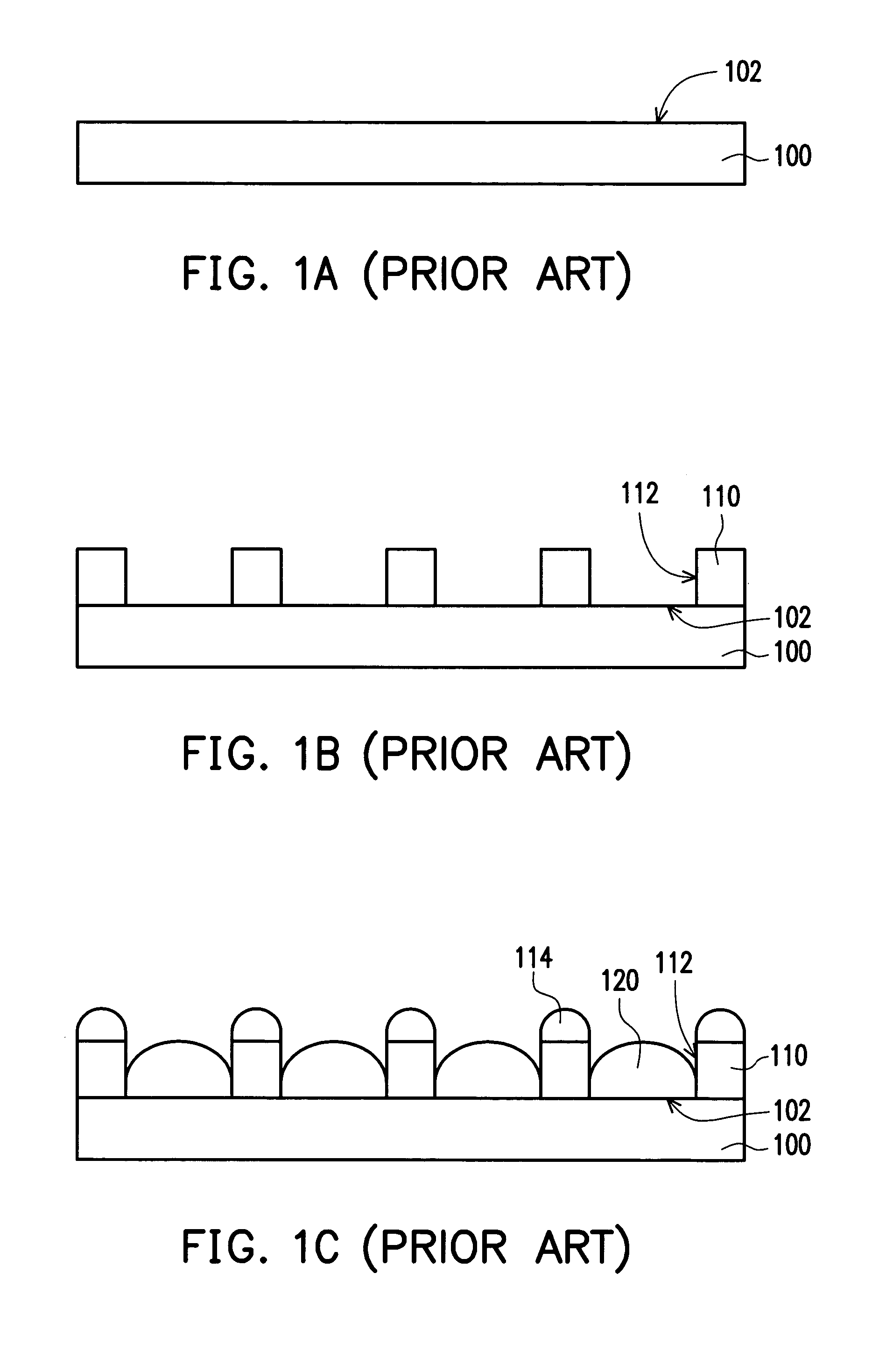

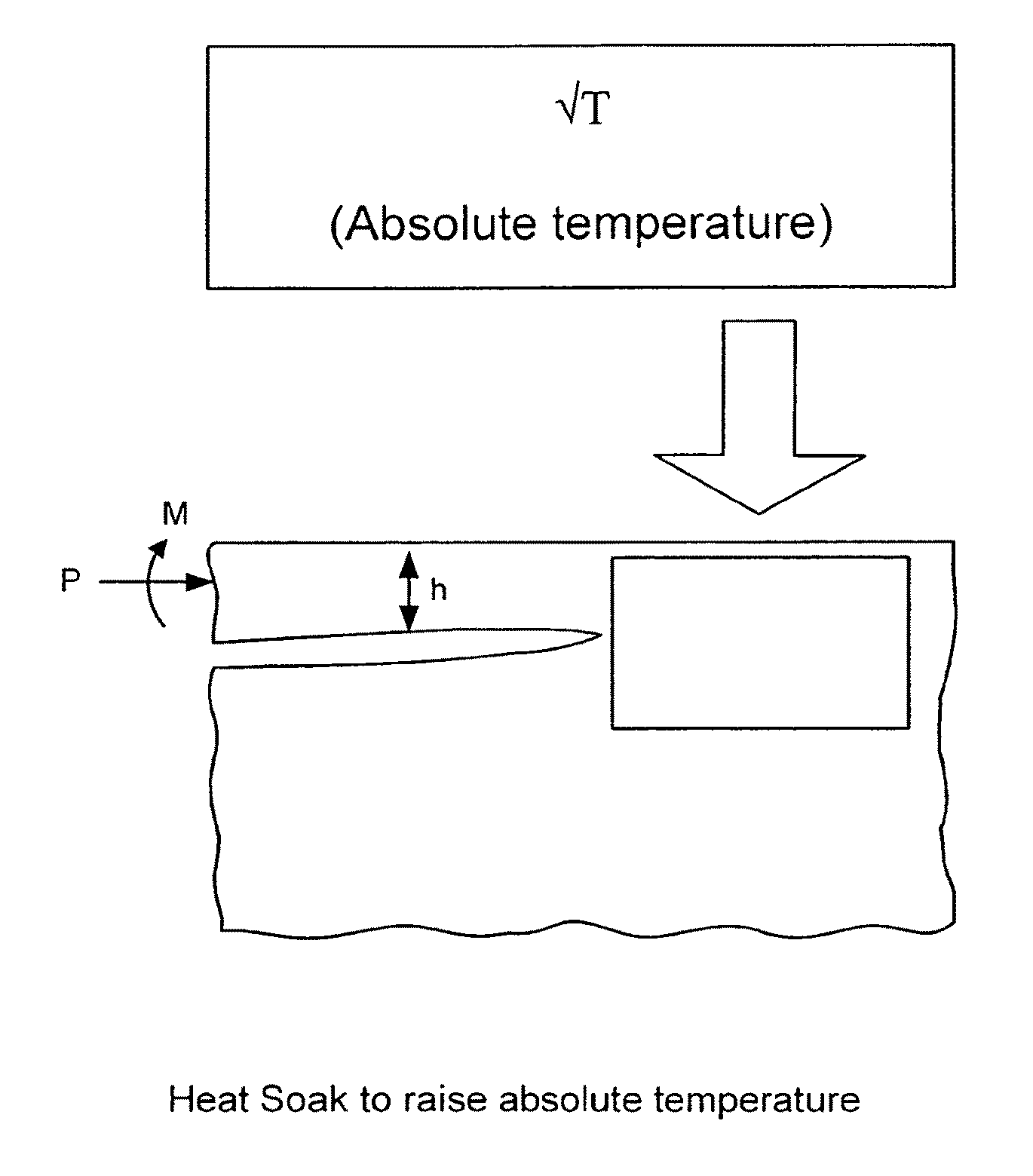

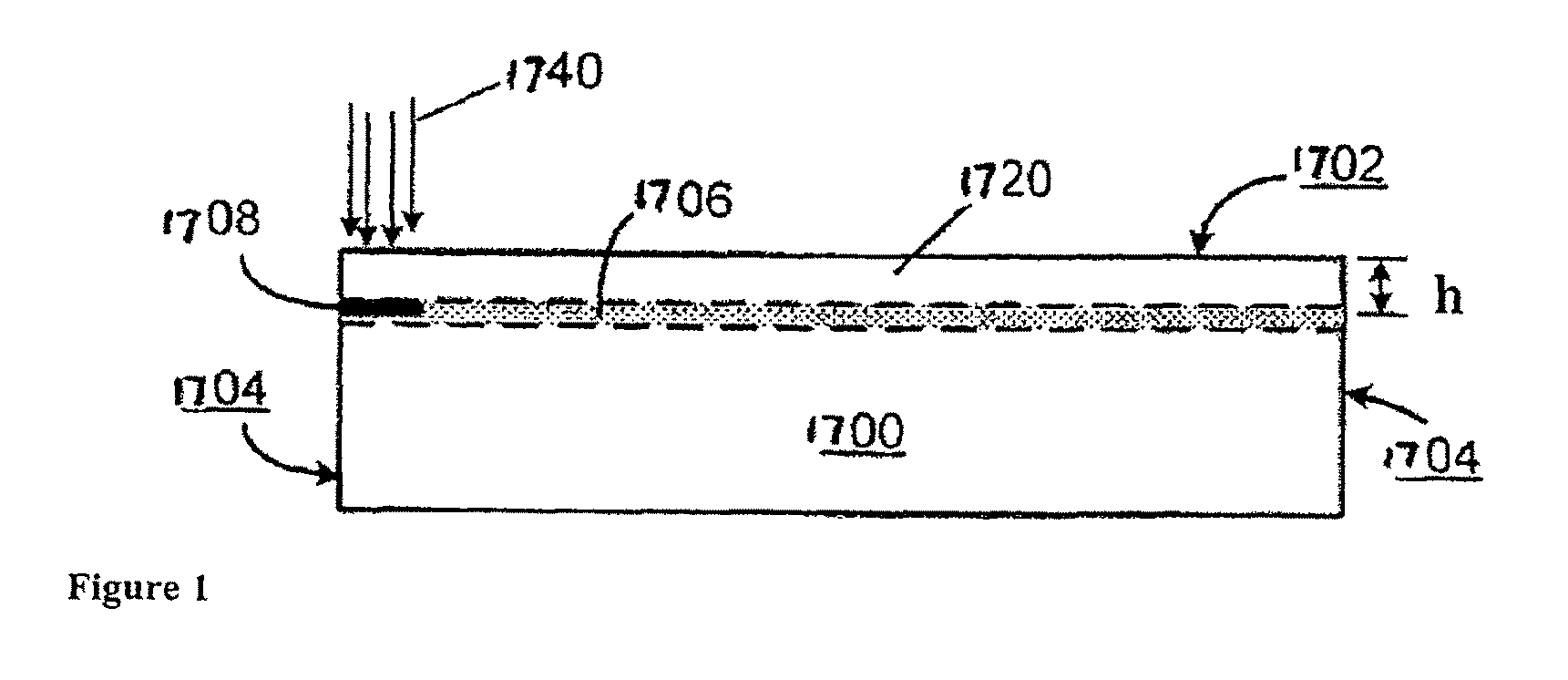

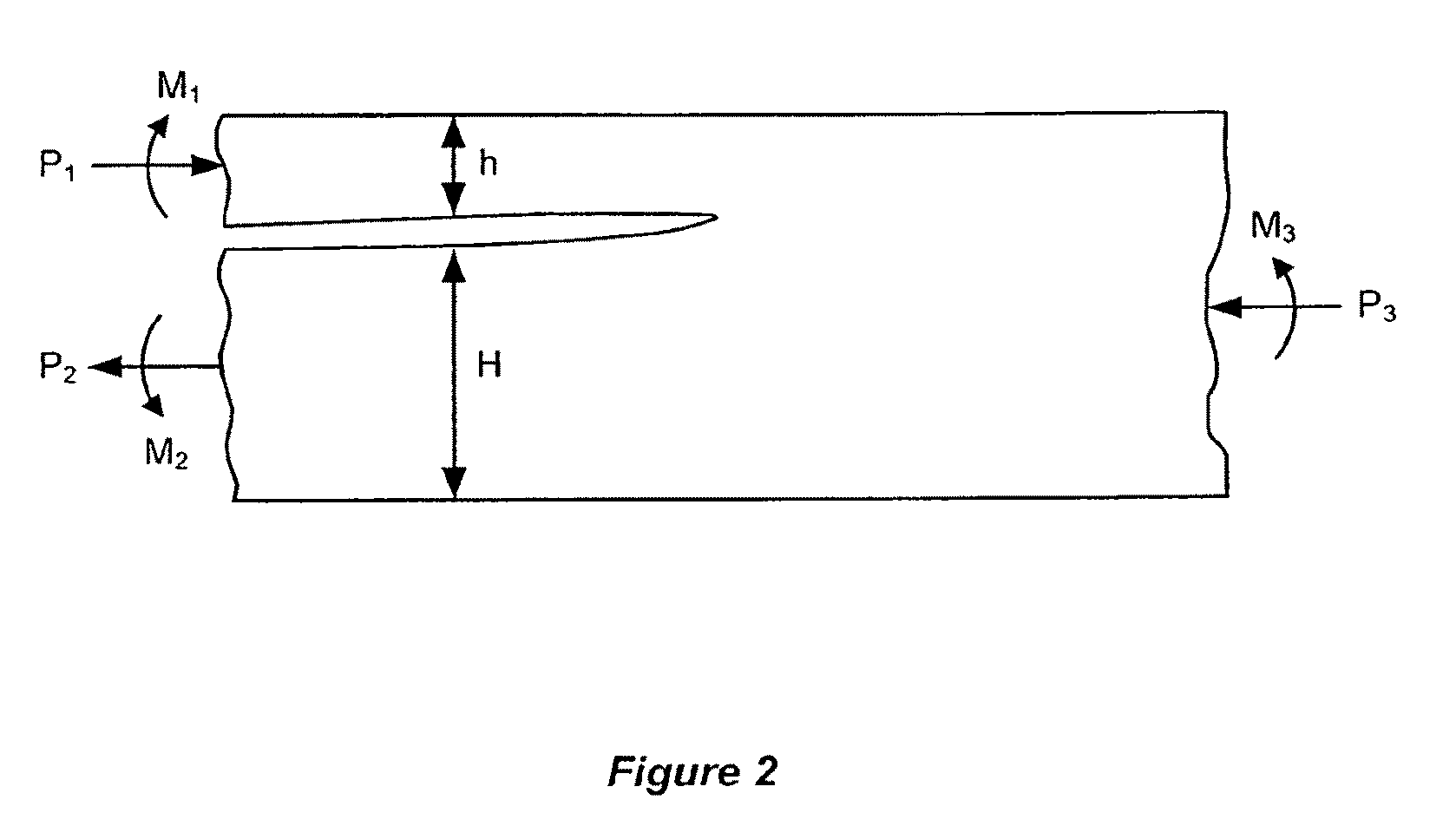

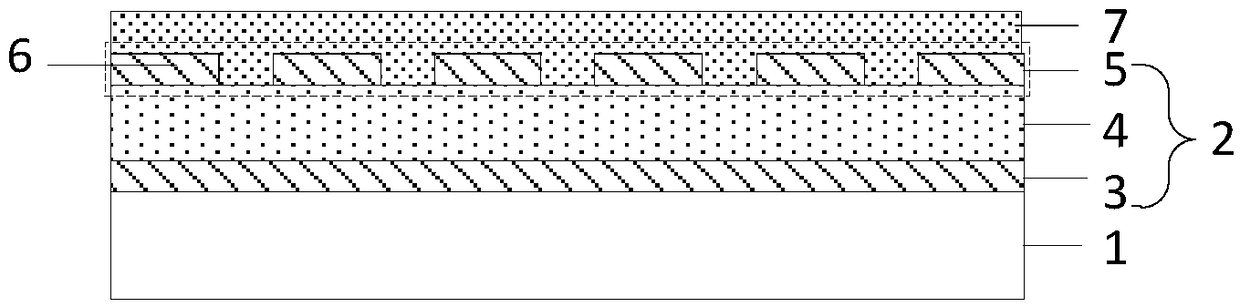

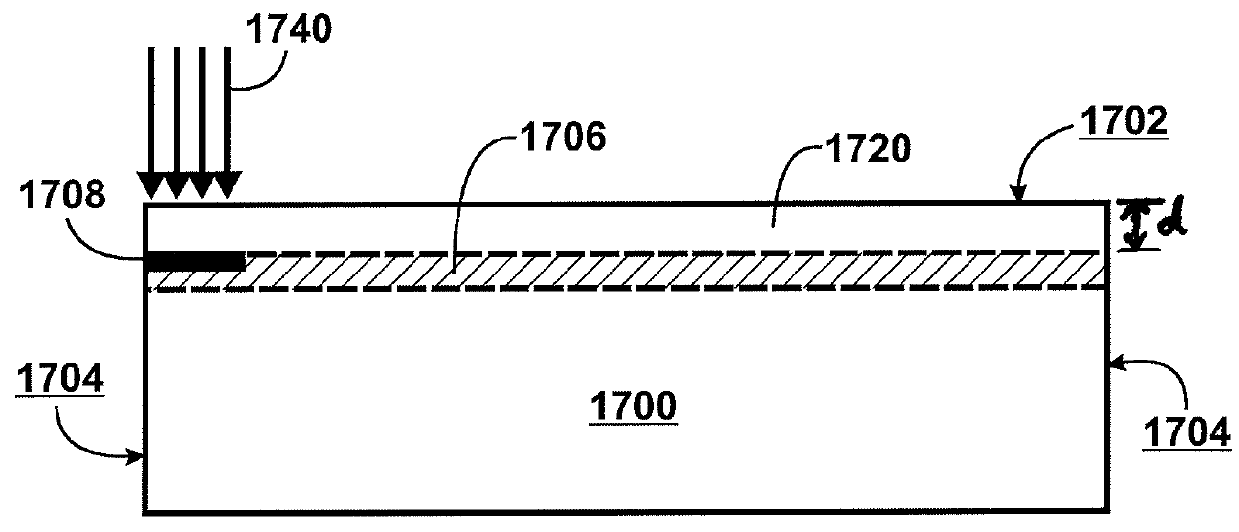

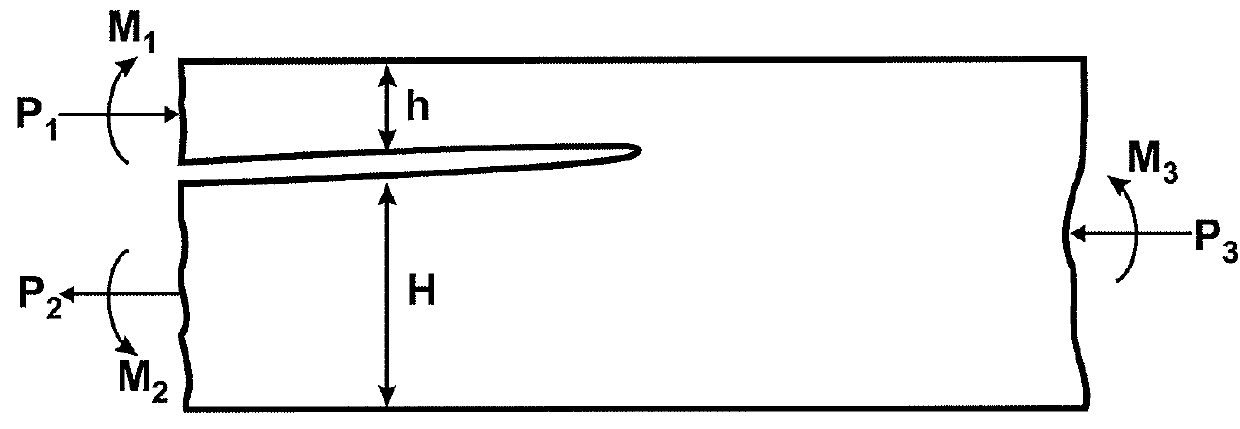

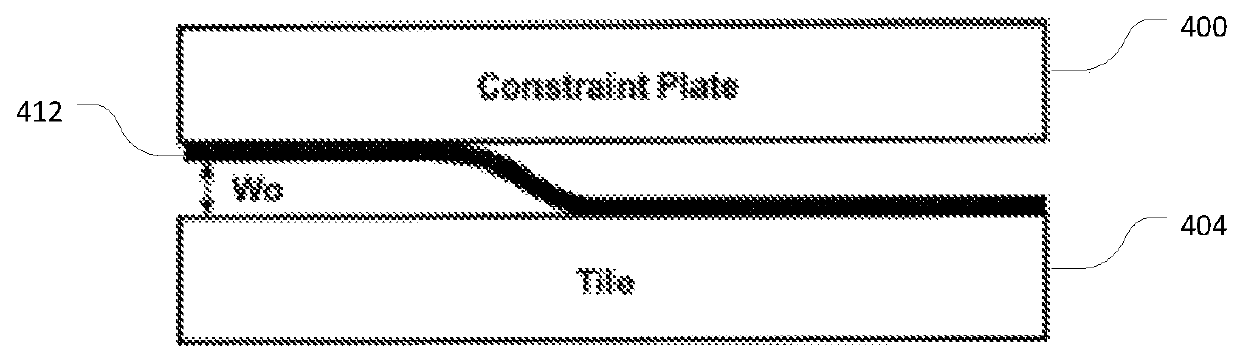

Layer transfer of films utilizing controlled shear region

ActiveUS20090277314A1Quality improvementImprove efficiencySemiconductor/solid-state device manufacturingMetal working apparatusEngineeringThermal treatment

A film of material may be formed by providing a semiconductor substrate having a surface region and a cleave region located at a predetermined depth beneath the surface region. During a process of cleaving the film from the substrate, shear in the cleave region is carefully controlled. According to certain embodiments, an in-plane shear component (KII) is maintained near zero, sandwiched between a tensile region and a compressive region. In one embodiment, cleaving can be accomplished using a plate positioned over the substrate surface. The plate serves to constrain movement of the film during cleaving, and together with a localized thermal treatment reduces shear developed during the cleaving process. According to other embodiments, the KII component is purposefully maintained at a high level and serves to guide and drive fracture propagation through the cleave sequence. In one embodiment, the high KII component is achieved by adiabatic heating of silicon through exposure to E-beam radiation, which imparts a highly abrupt thermal gradient and resulting stress at a precisely defined depth in the silicon.

Owner:SILICON GENERAL CORPORATION

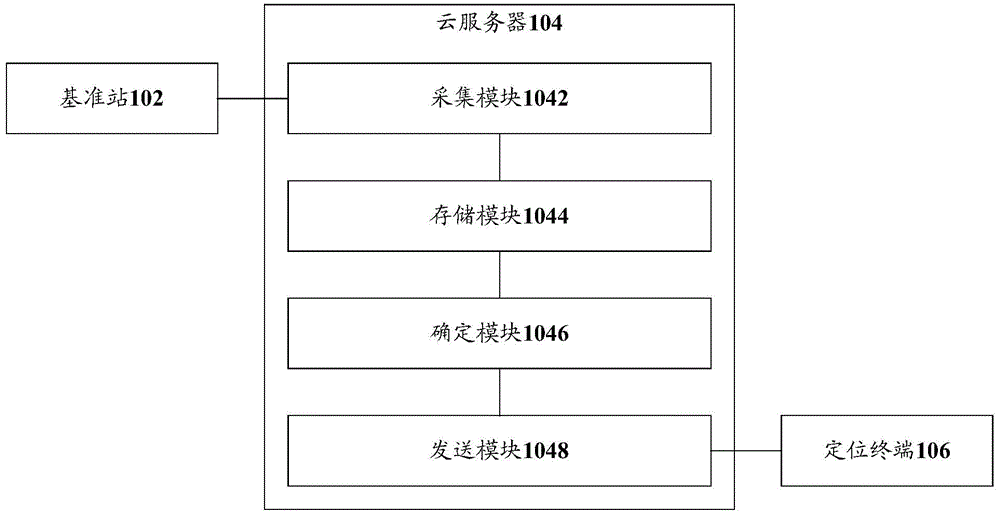

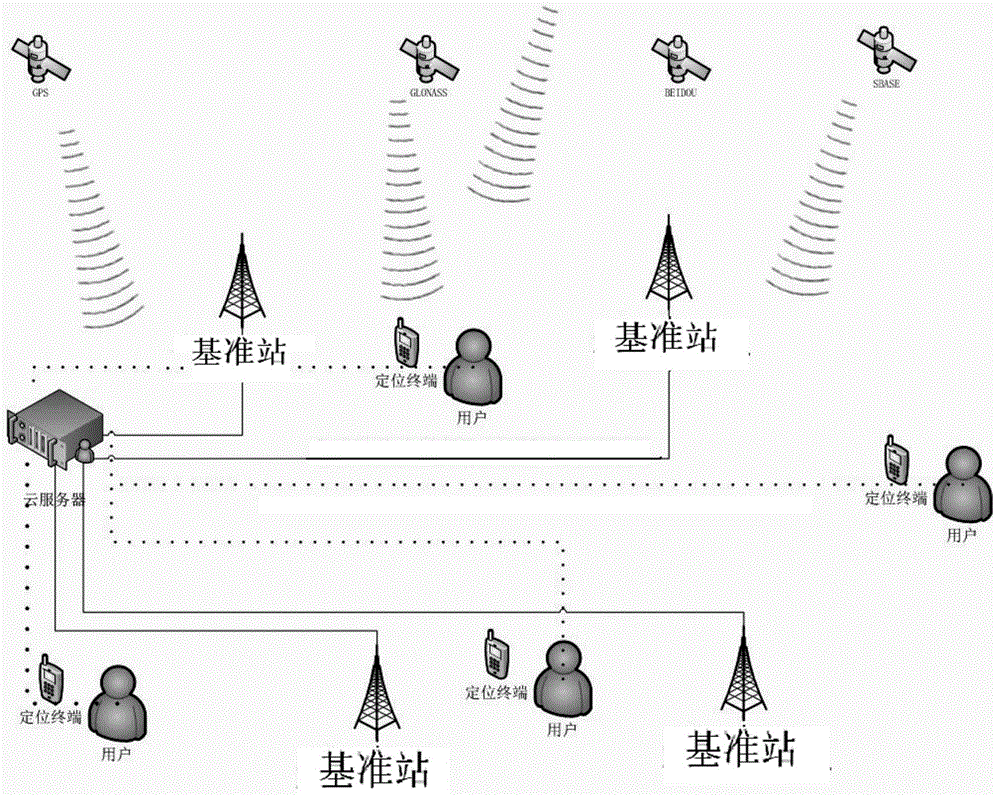

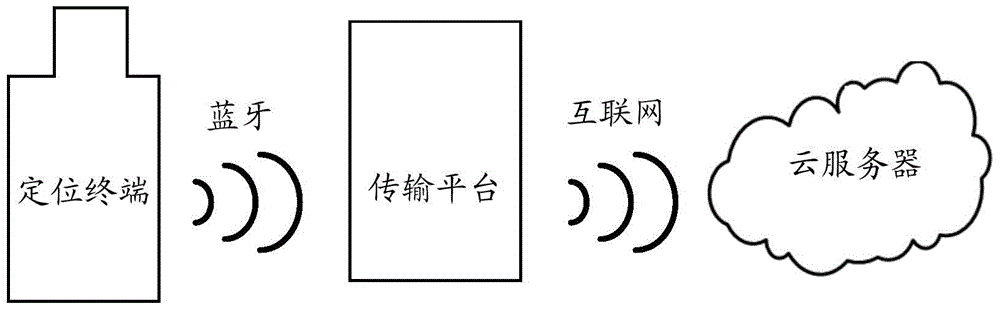

Positioning system, terminal, and positioning method

ActiveCN103823228ASimplify the management processSimplify the transfer processSatellite radio beaconingTransmissionComputer terminalPositioning system

The invention provides a positioning system, a terminal, and a positioning method. The positioning system comprises a reference station, a cloud server and a positioning terminal. The cloud server includes: an acquisition module, which is used for collecting differential data of the reference station in real time; a storage module, which is used for storing the differential data that are collected in real time and information of reference station corresponding to the differential data as well as a corresponding relation between the differential data and the reference station; a determination module, which is used for determining a reference station requested by a differential data request according to the differential data request sent by the positioning terminal; and a sending module, which is used for sending the differential data corresponding to the determined reference station according to the corresponding relation between the differential data and the reference station. According to the invention, the positioning efficiency is improved and the number of equipment used for differential positioning is reduced.

Owner:北京红旗胜利科技发展有限责任公司

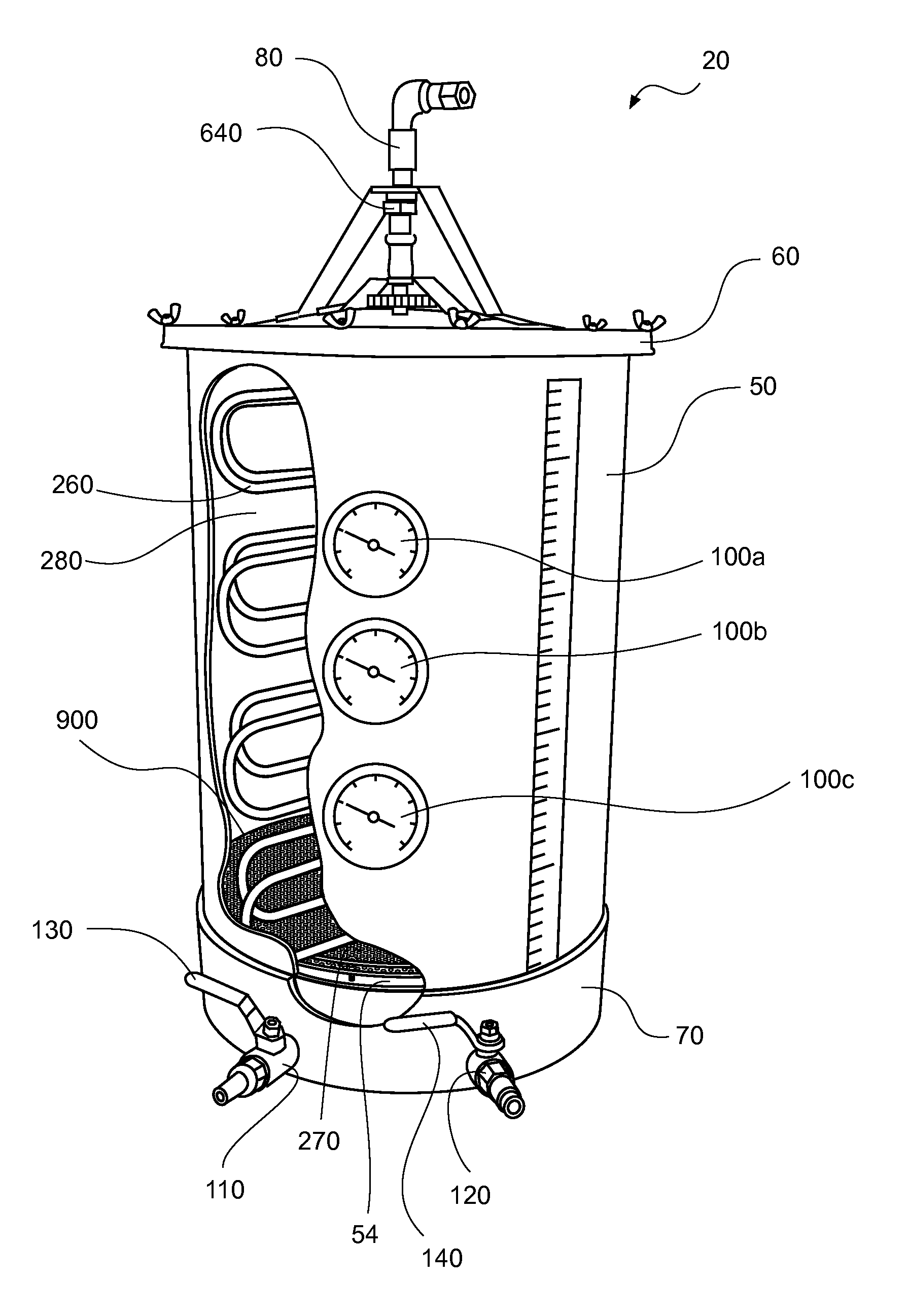

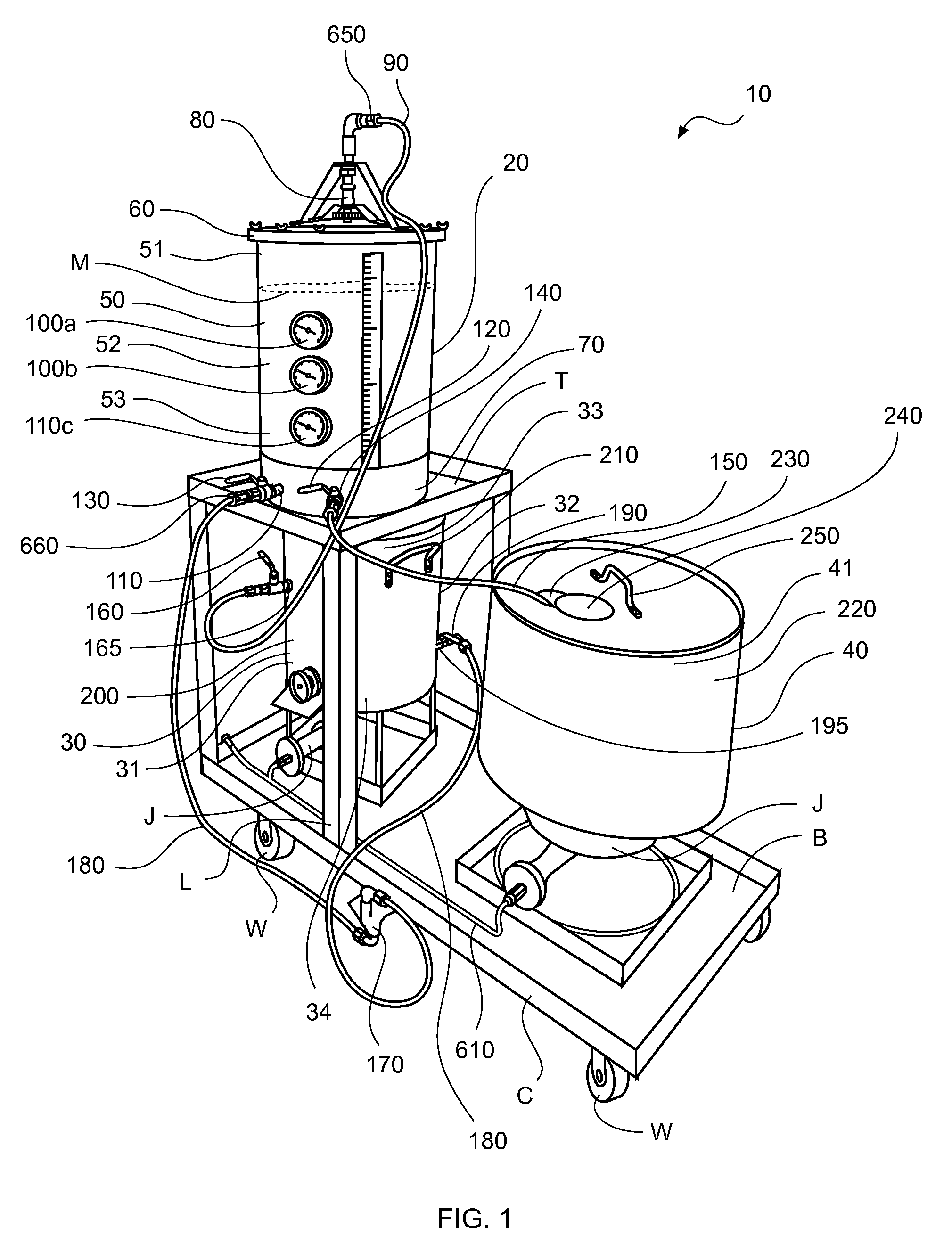

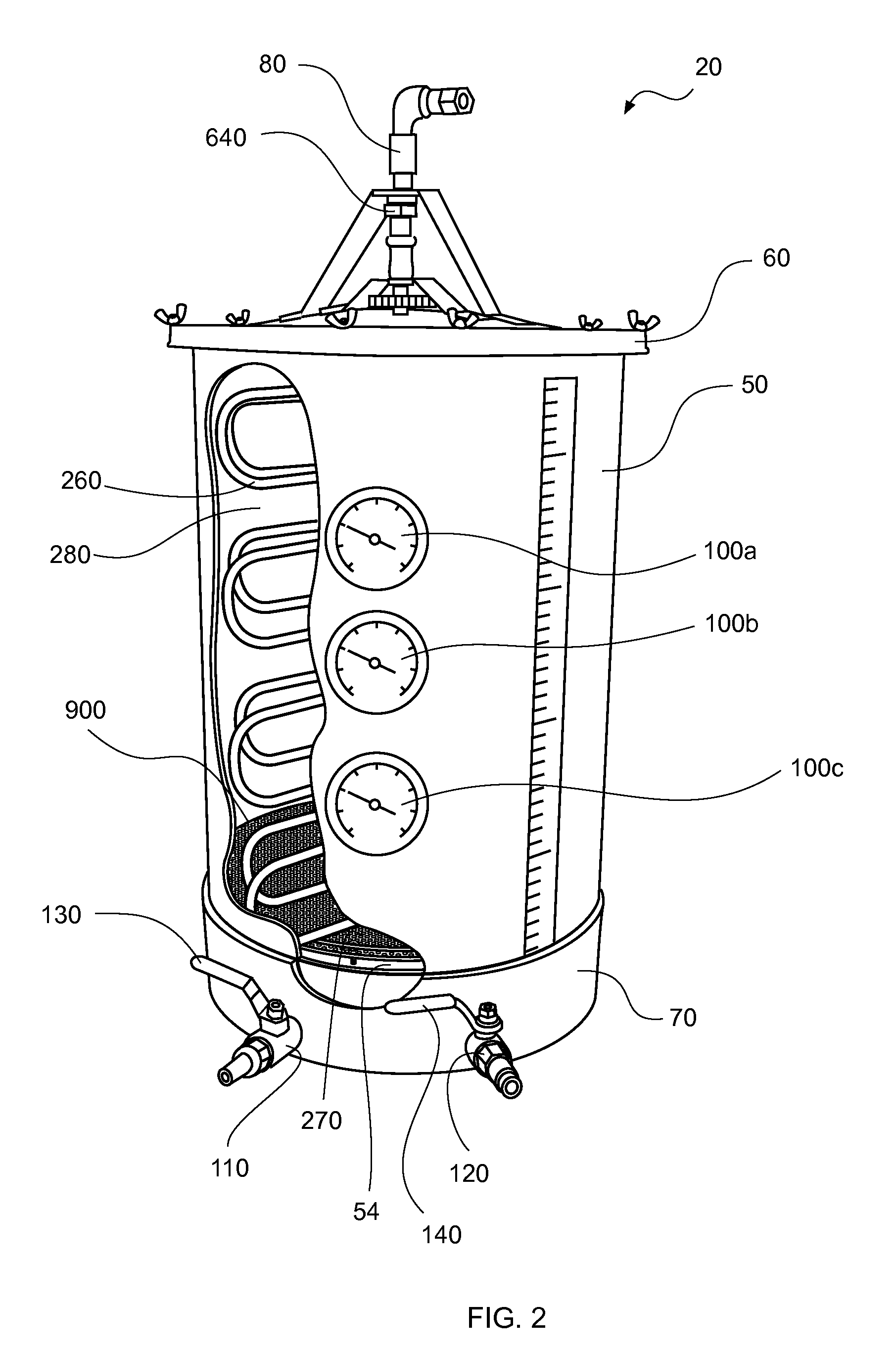

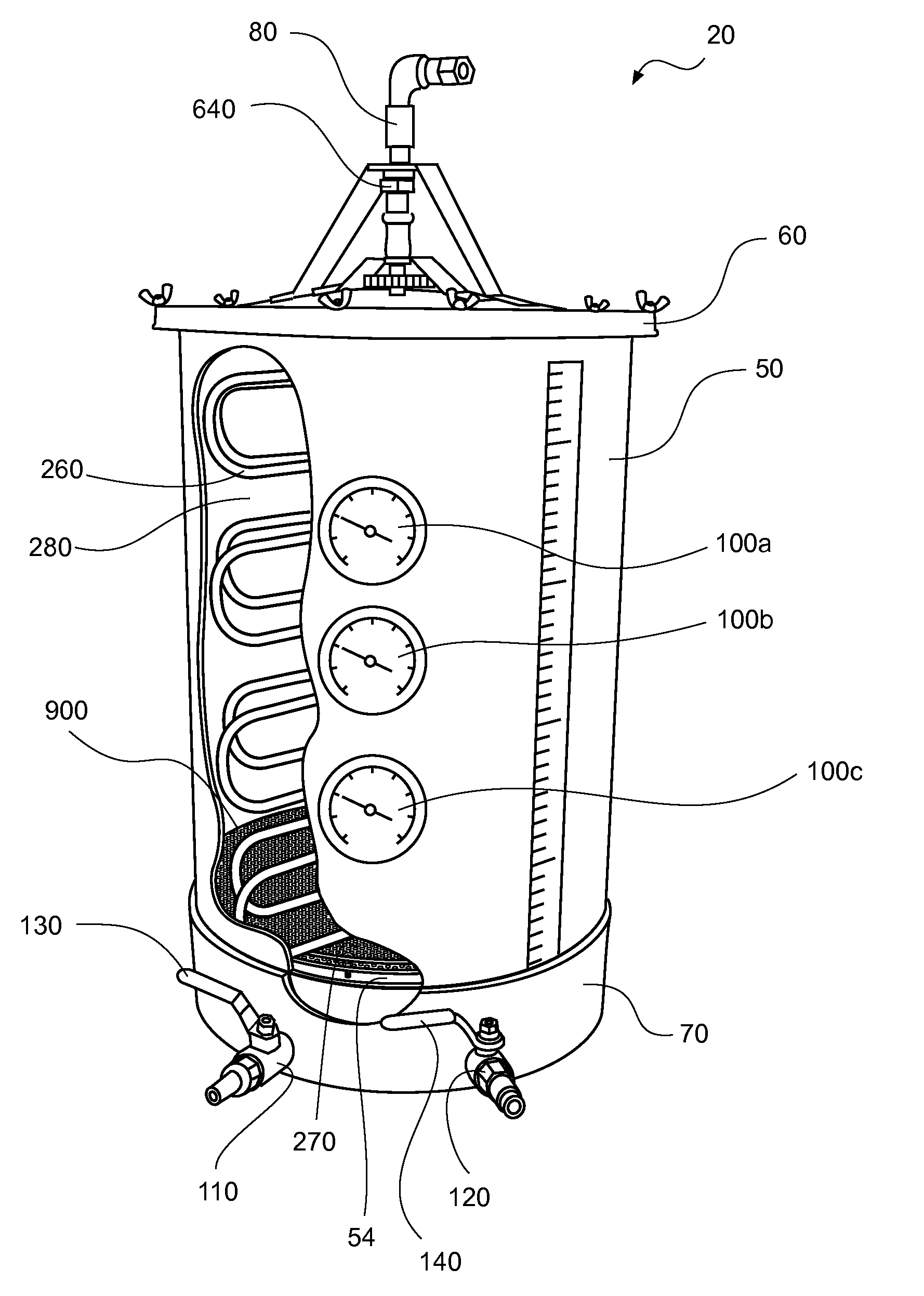

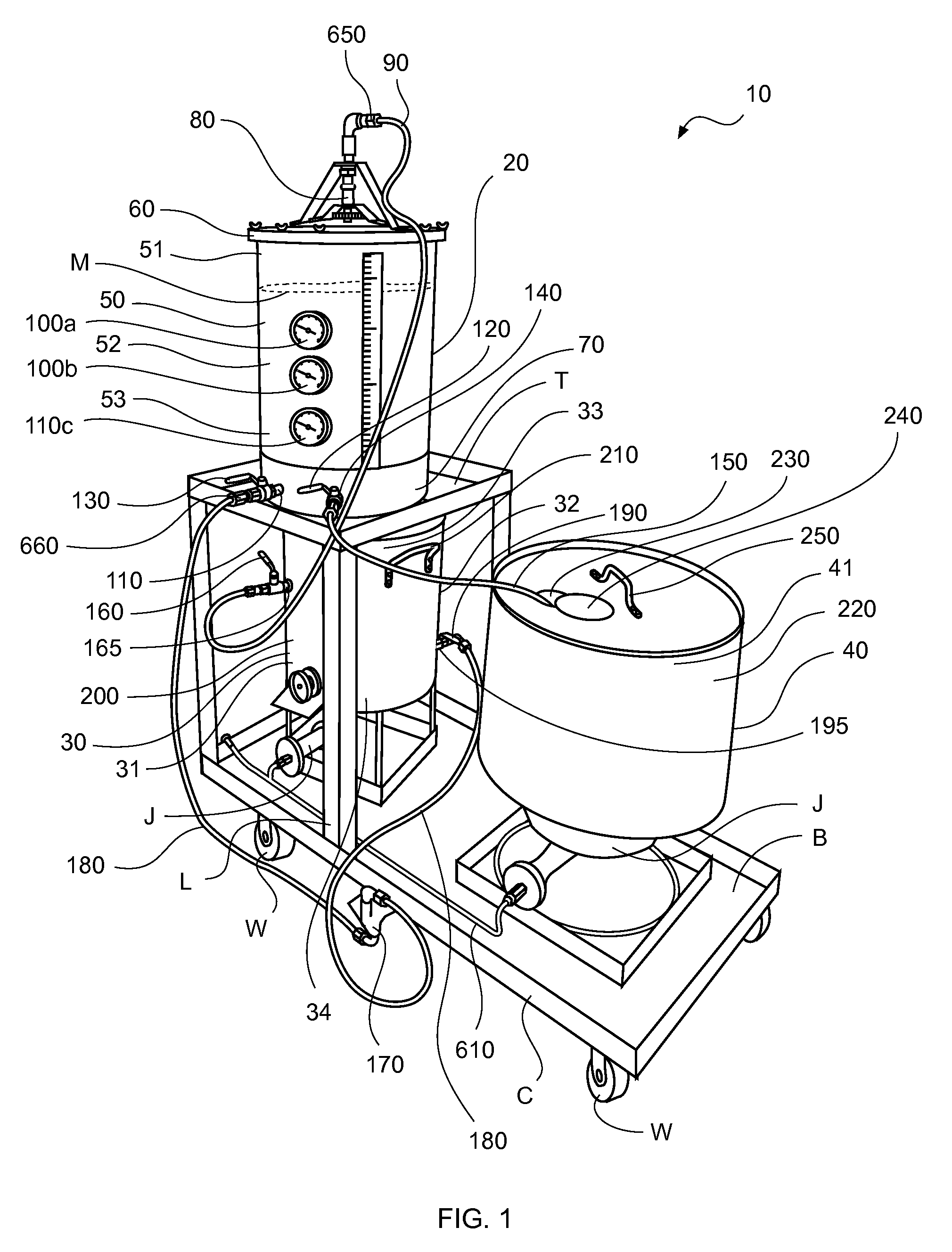

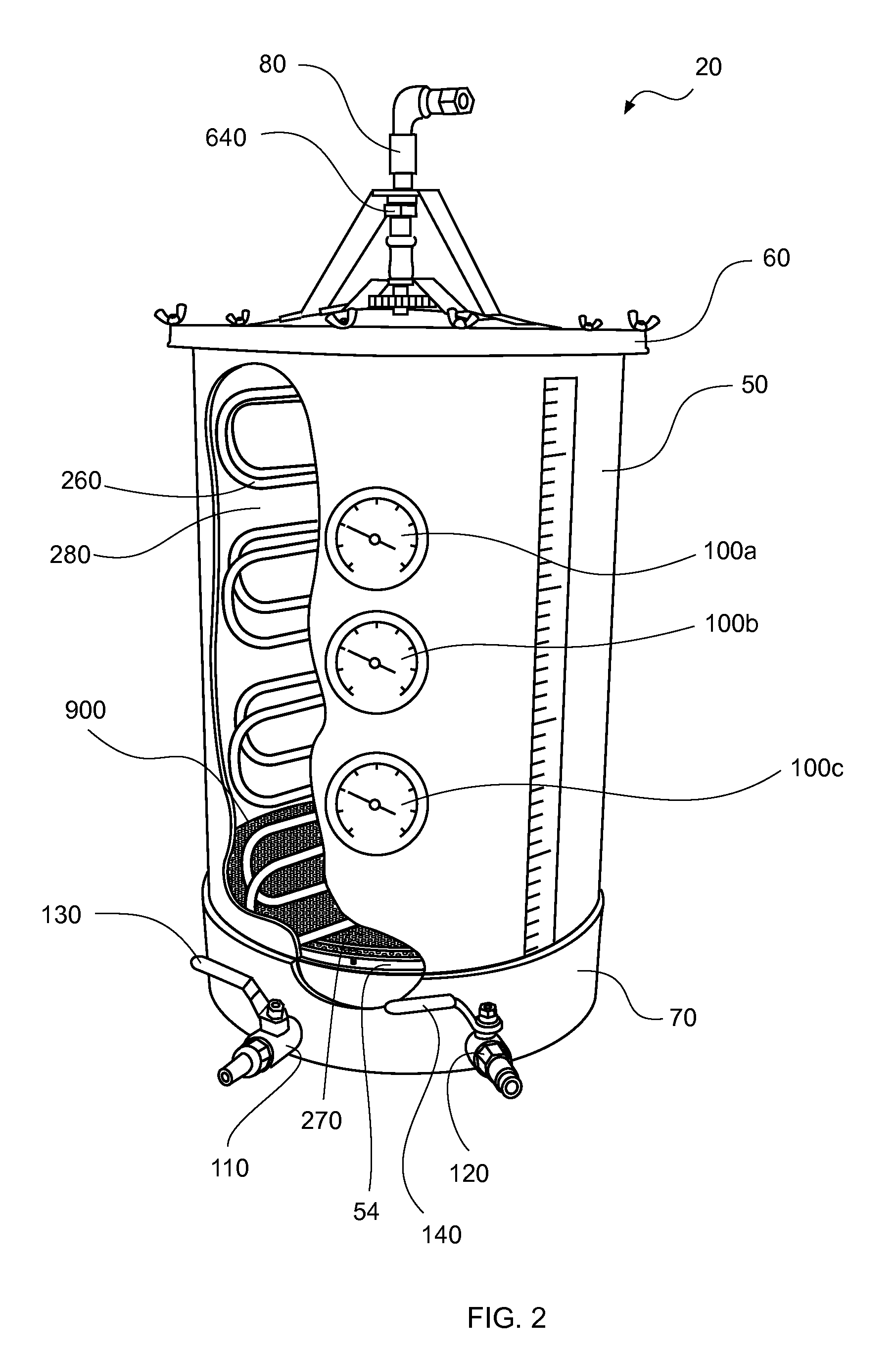

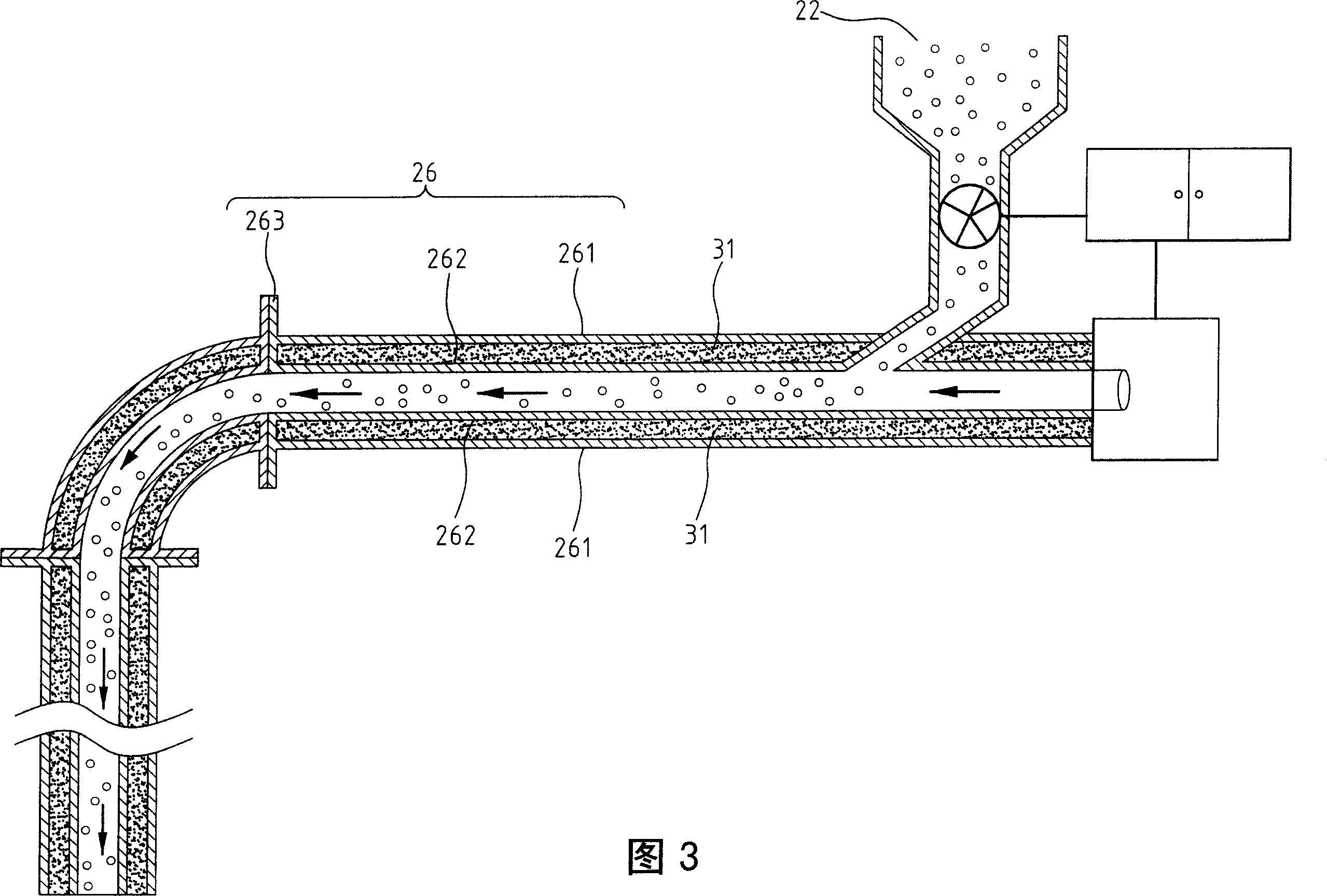

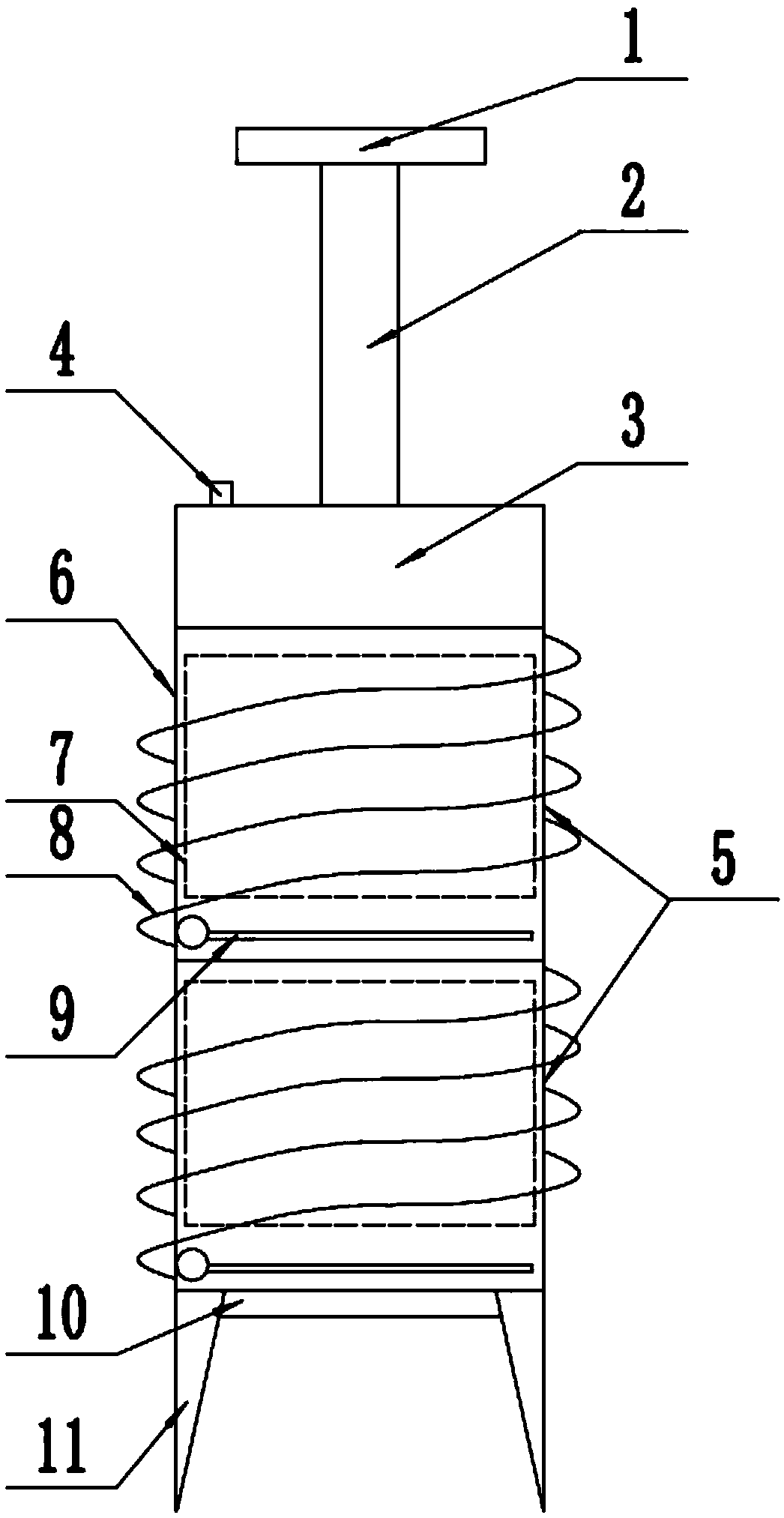

Mash/lauter tun and method of use thereof

ActiveUS20090285971A1Simplify the transfer processPromote sportsBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationVALVE PORT

A mash / lauter tun and method of converting grains to wort. The mash / lauter tun comprises a container with a double false bottom filter having two perforated plates disposed parallel with a space therebetween for receiving filtration media. The container further comprises thermometers extending to near the center of the tun and a rotating heat exchanger. In use, mash is loaded into the container and heated via the rotating heat exchanger by passing hot fluid through the rotating heat exchanger. The mash is then sparged by increasing pressure in the rotating heat exchanger above a threshold pressure via closure an outlet valve of the heat exchanger. The wort then passes through the double false bottom filter and is subsequently transferred to a brew kettle for boiling.

Owner:BRODERICK WILLIAM

Layer transfer of films utilizing controlled propagation

ActiveUS20100055874A1Quality improvementImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSilicon

A film of material may be formed by providing a semiconductor substrate having a surface region and a cleave region located at a predetermined depth beneath the surface region. During a process of cleaving the film from the substrate, shear in the cleave region is carefully controlled to achieve controlled propagation by either KII or energy propagation control. According to certain embodiments, an in-plane shear component (KII) is maintained near zero by adiabatic heating of silicon through exposure to E-beam radiation. According to other embodiments, a surface heating source in combination with an implanted layer serves to guide fracture propagation through the cleave sequence.

Owner:SILICON GENERAL CORPORATION

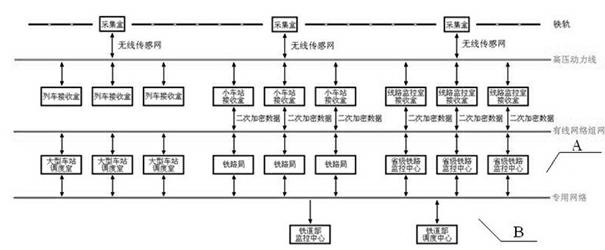

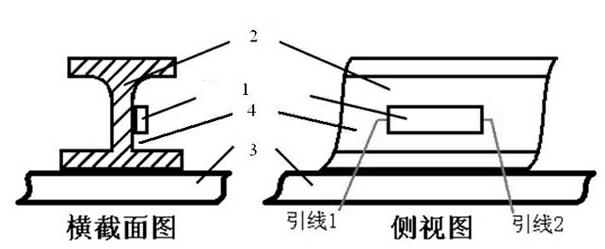

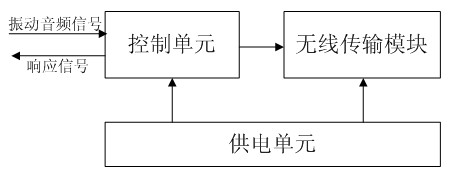

Railway track real-time monitoring system and data processing method thereof

InactiveCN102530028AEliminate monitoring blind spotsAchieve complete acquisitionElectric signal transmission systemsRailway signalling and safetyBlind zoneMonitoring system

The invention discloses a railway track real-time monitoring system and a data processing method thereof, and belongs to the filed of railway track safety. The railway track real-time monitoring system comprises a piezoelectric sensor, a collection box, a wireless sensor and a vibrator, wherein both the piezoelectric sensor and the vibrator are arranged on the railway track and connected with the collection box; the wireless sensor is arranged on a high-voltage power line; the collection box sends an encryption signal to the vibrator; the vibrator drives the railway track to generate the vibration; the piezoelectric sensor acquires a vibration audio signal on the railway track and sends the vibration audio signal to the collection box for processing; and the collection box transmits the vibration audio signal through the wireless sensor in a wireless or wired transmission way. In the invention, the vibration audio signal is taken as a data basis for analyzing the failure happening in front of a train, the monitoring blind zone of the railway track is eliminated, the integral collection of the fault analysis basis data is achieved, the failure happening in front of the train can be predicted through the data processing method, and the intelligentization and the netwoking of the monitoring system are improved greatly.

Owner:重庆安谐新能源技术有限公司

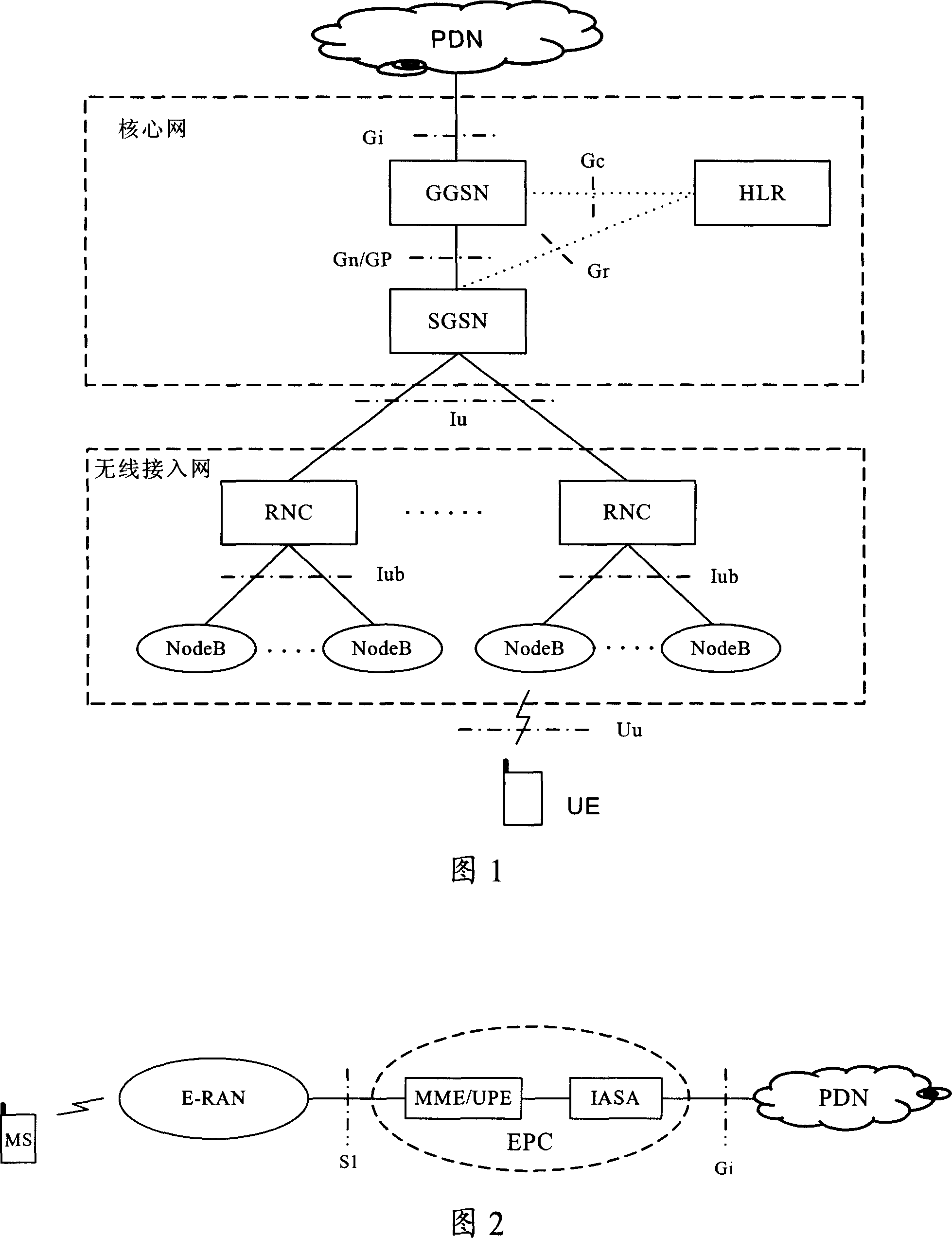

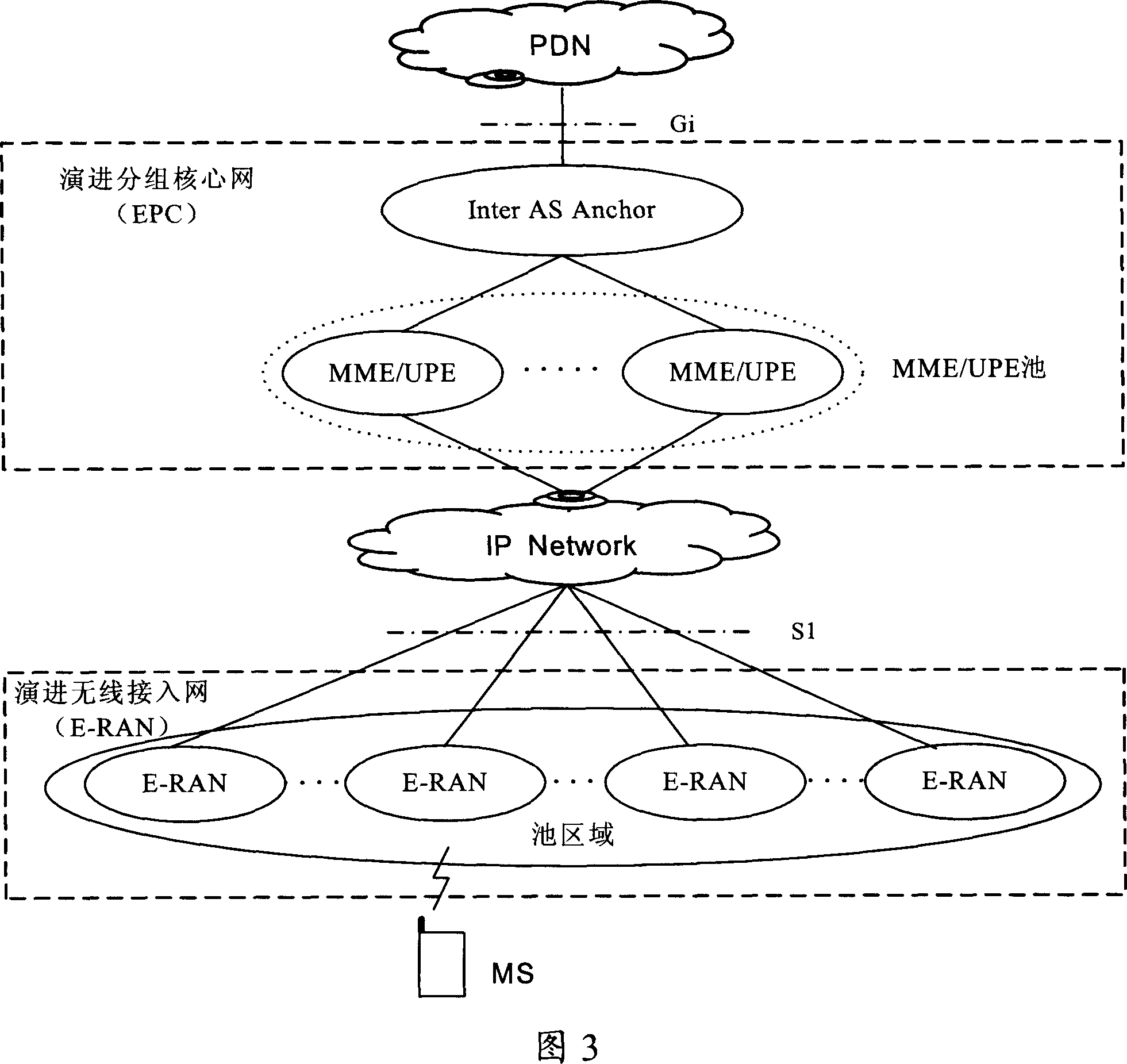

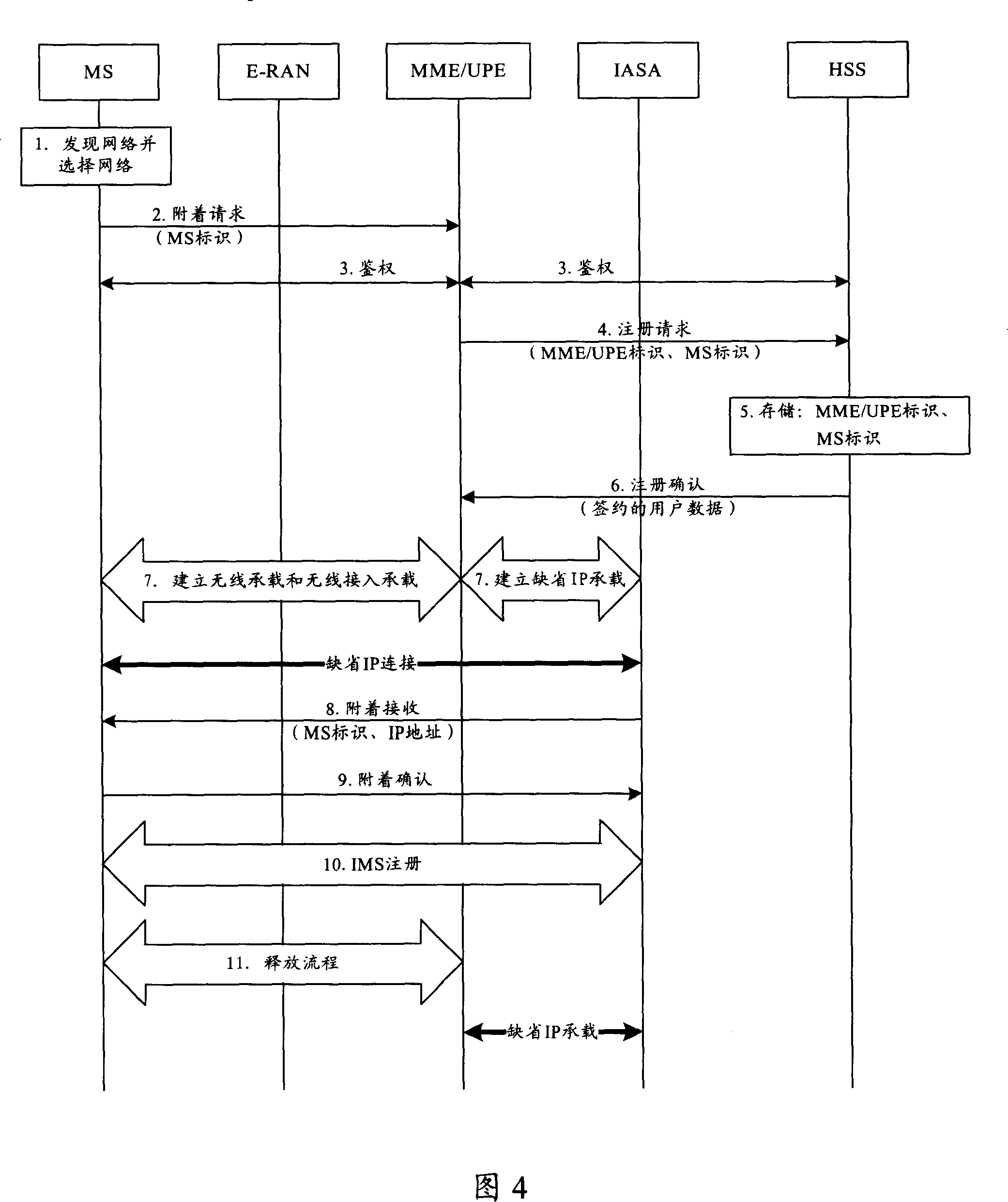

Method for transferring users among different core network equipments

InactiveCN101083830ASimplify the transfer processEfficient transferRadio/inductive link selection arrangementsWireless communicationAccess networkUser equipment

The present invention discloses a method of transferring users between different core-network equipments, and includes: a serving core network equipment transfers the attachment request from user equipment or the updating request from tracking area to an aim core-network equipment; the aim core-network equipment establishes a signaling connection with the corresponding wireless access network; the aim core-network equipment is in charge of solving the attachment request from user equipment or the updating request from tracking area. By introducing the present invention, user equipments can be transferred to aim core-network equipment through the only process of user equipment attachment or tracking area update. The process is simple, effective and rapid.

Owner:HUAWEI TECH CO LTD

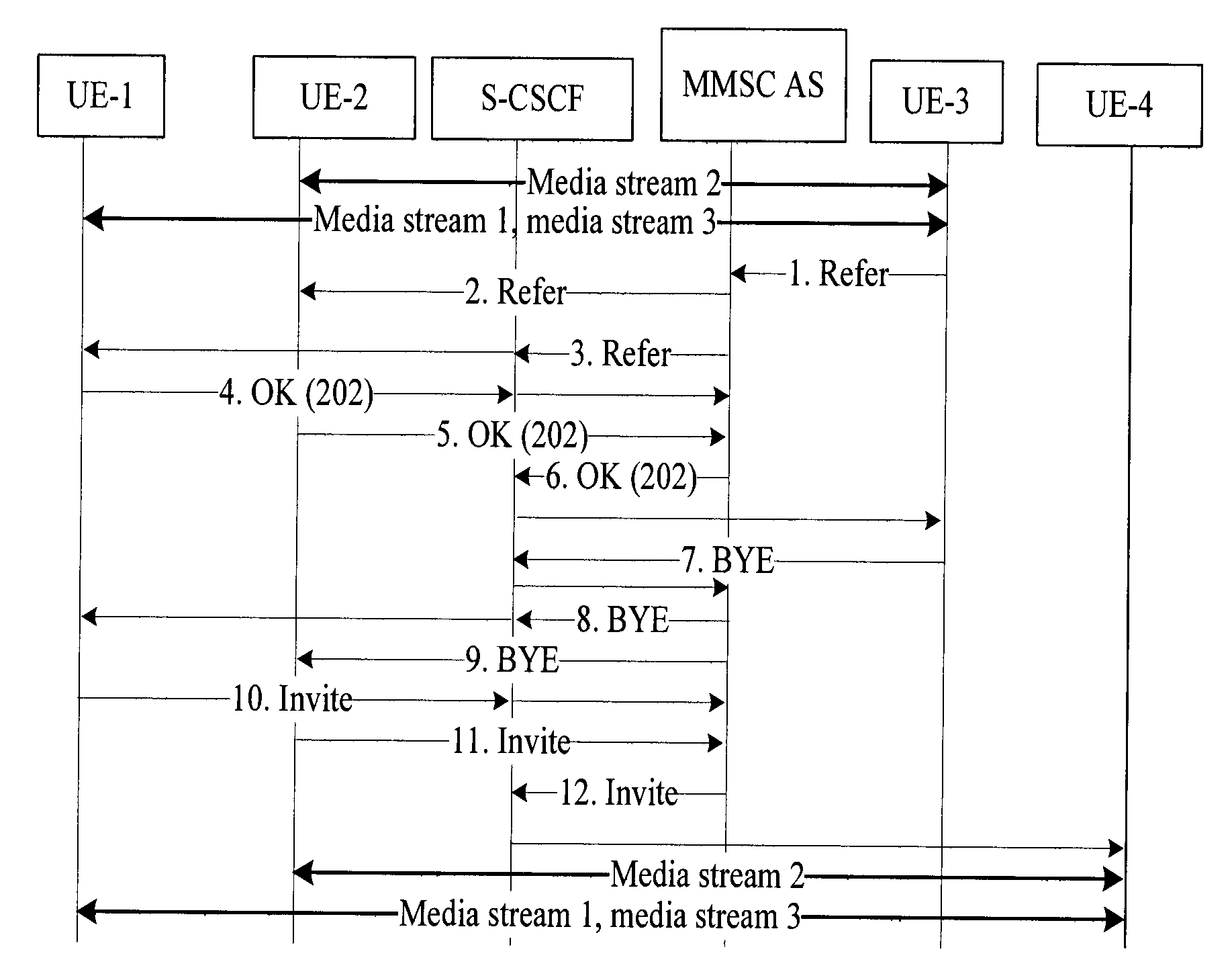

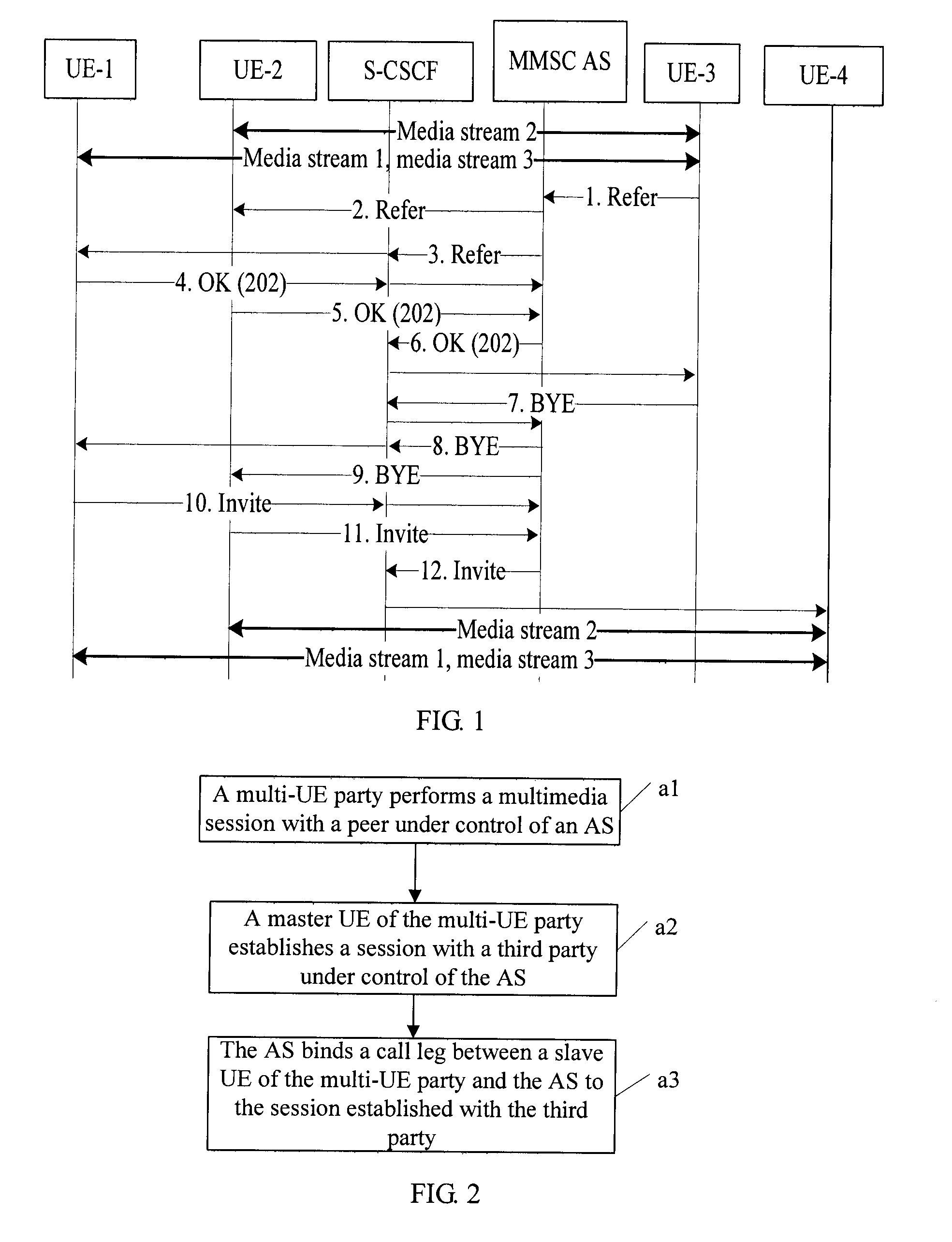

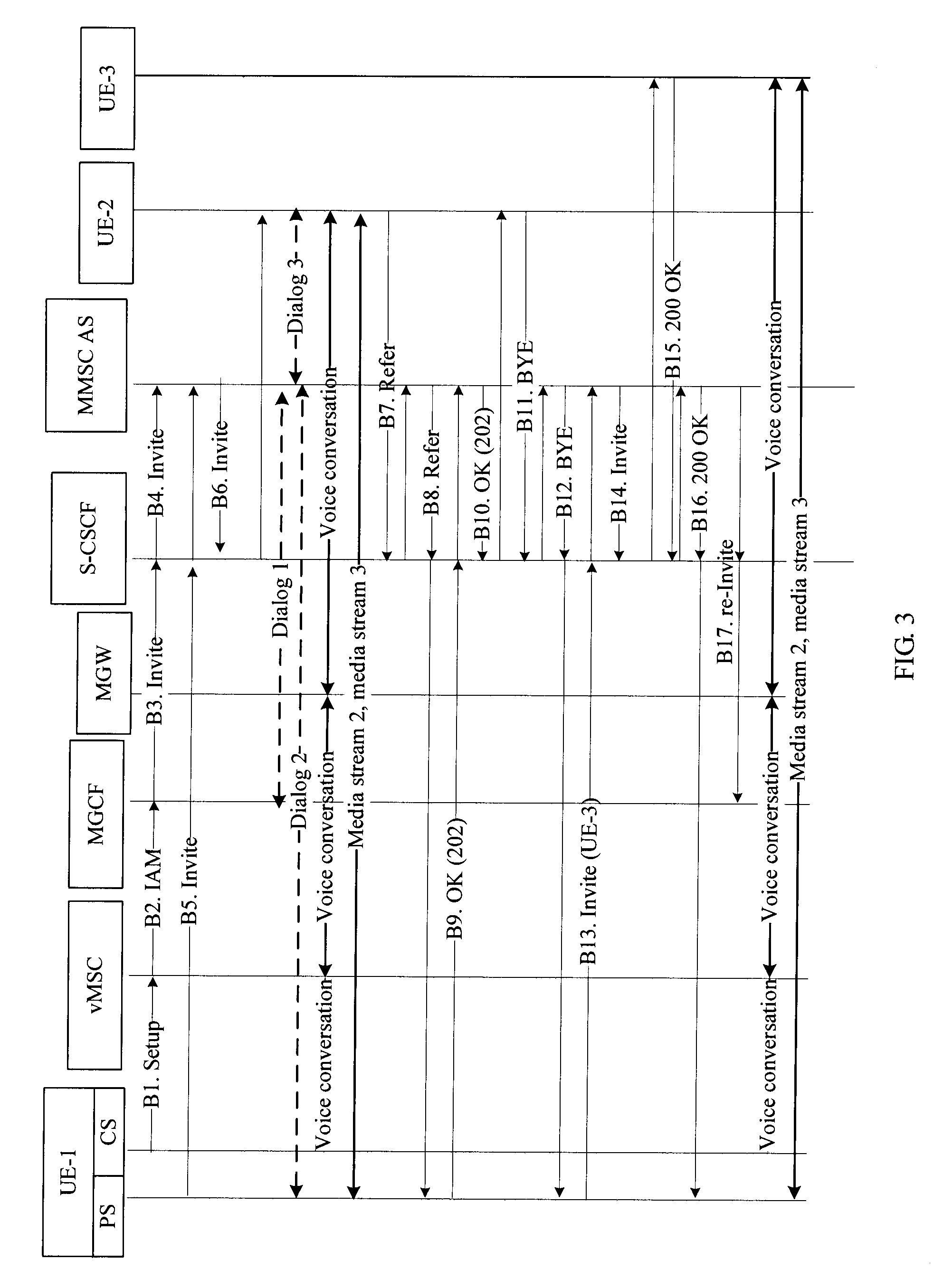

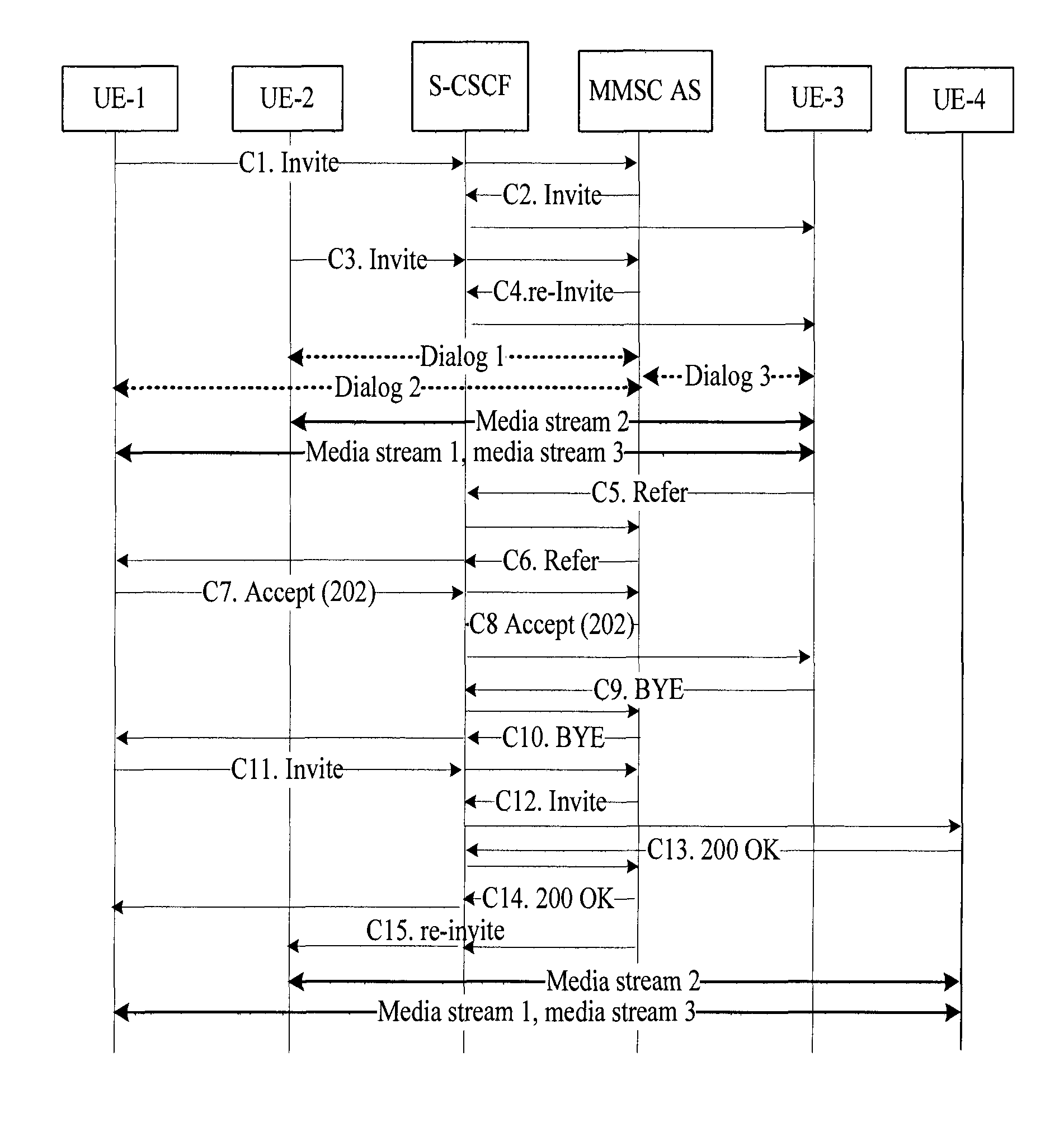

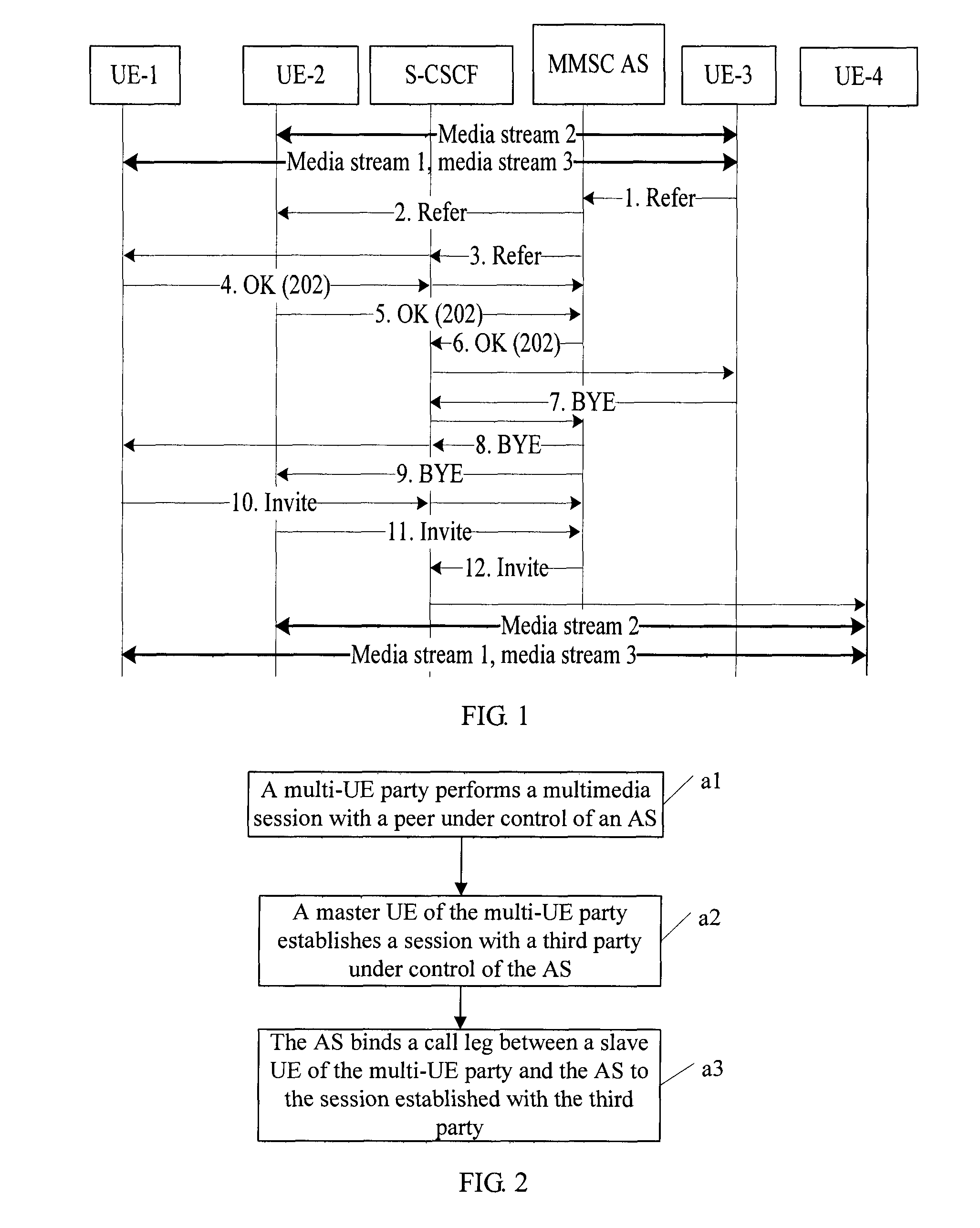

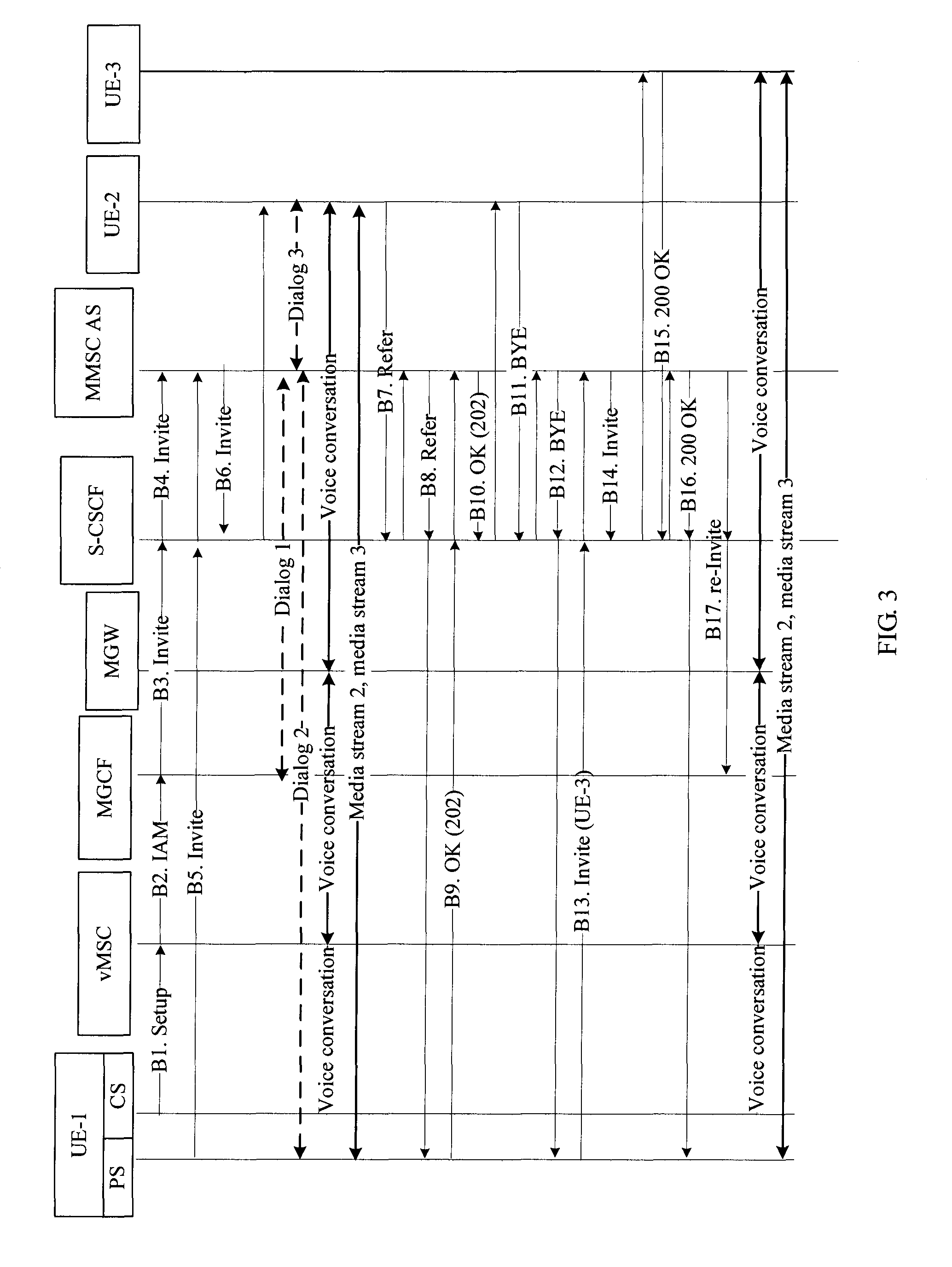

Multimedia session call control method and application server

ActiveUS20100215037A1Simplify the signaling processShorten call transfer timeNetwork connectionsThird partyApplication server

A multimedia session call control method and an Application Server (AS) are provided. The multimedia session call control method includes these steps: a multi-UE party performs a multimedia session with a peer under control of an AS; a master UE of the multi-UE party establishes a session with a third party under control of the AS; and the AS binds a call leg between a slave UE of the multi-UE party and the AS to the session established with the third party.

Owner:NOKIA TECHNOLOGLES OY

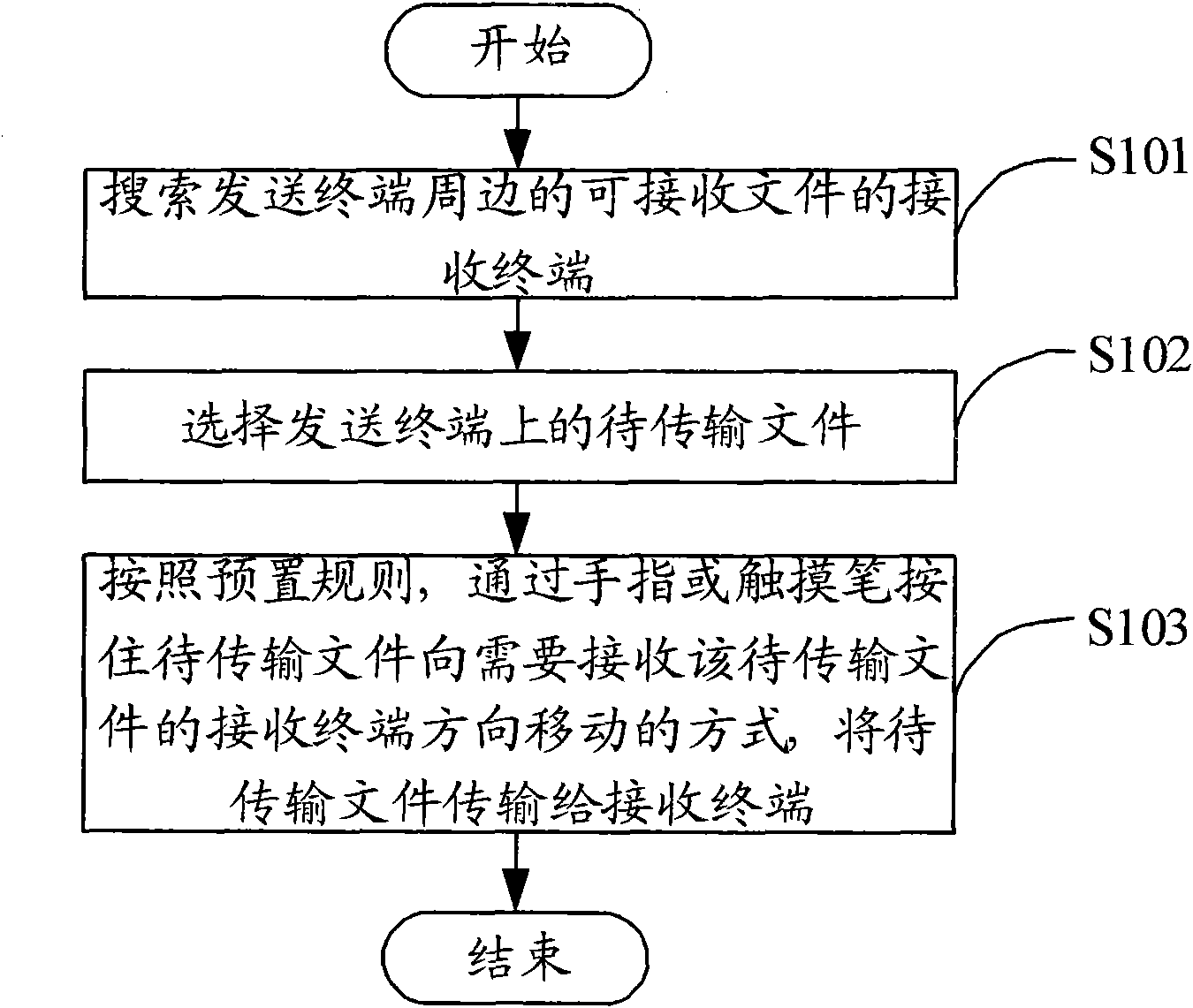

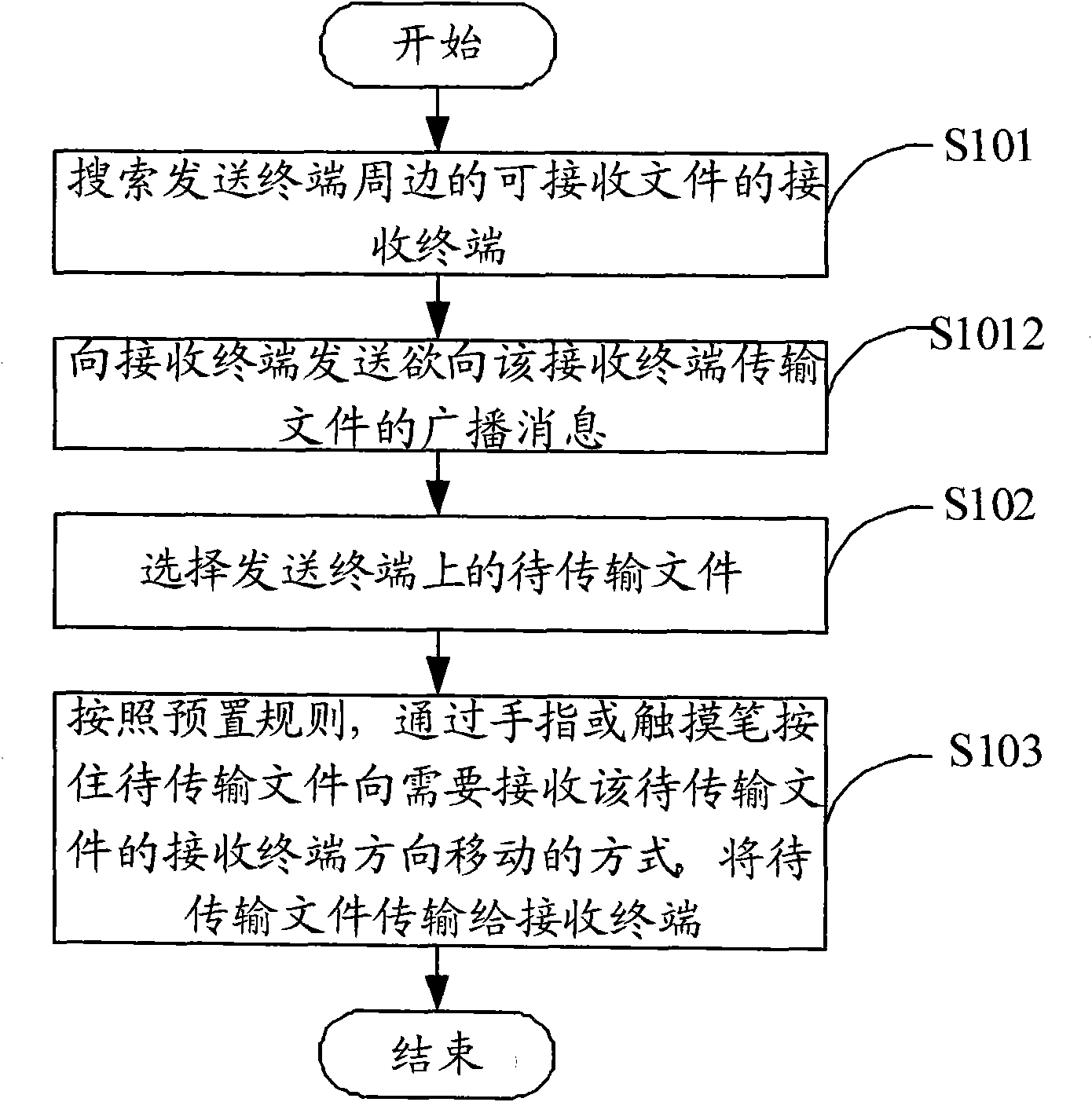

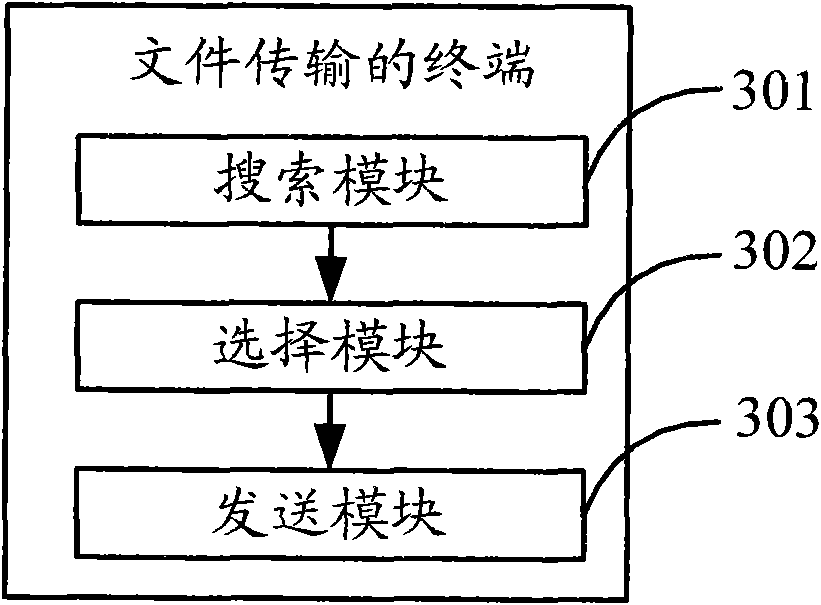

Method, terminal and system for transferring files

InactiveCN101945499ASimplify the file transfer processImprove user experience and funNear-field transmissionWireless communicationFile transferComputer terminal

The invention relates to a method, a terminal and a system for transferring files. The method comprises the following steps of: retrieving receiving terminals capable of receiving the files at the periphery of a transmitting terminal; selecting a file to be transferred on the transmitting terminal; and according to a preset rule, transferring the file to be transferred to the receiving terminal in a mode that the file to be transferred is pressed by a finger or touch pen and moved to the receiving terminal which needs to receive the file to be transferred. Through the method, the terminal and the system for transferring the files, the file to be transferred is transferred to the receiving terminal in the mode that the file to be transferred is pressed by the finger or touch pen and moved to the receiving terminal which needs to receive the file to be transferred, so that the file transfer process is simplified and user experience and interest are improved.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

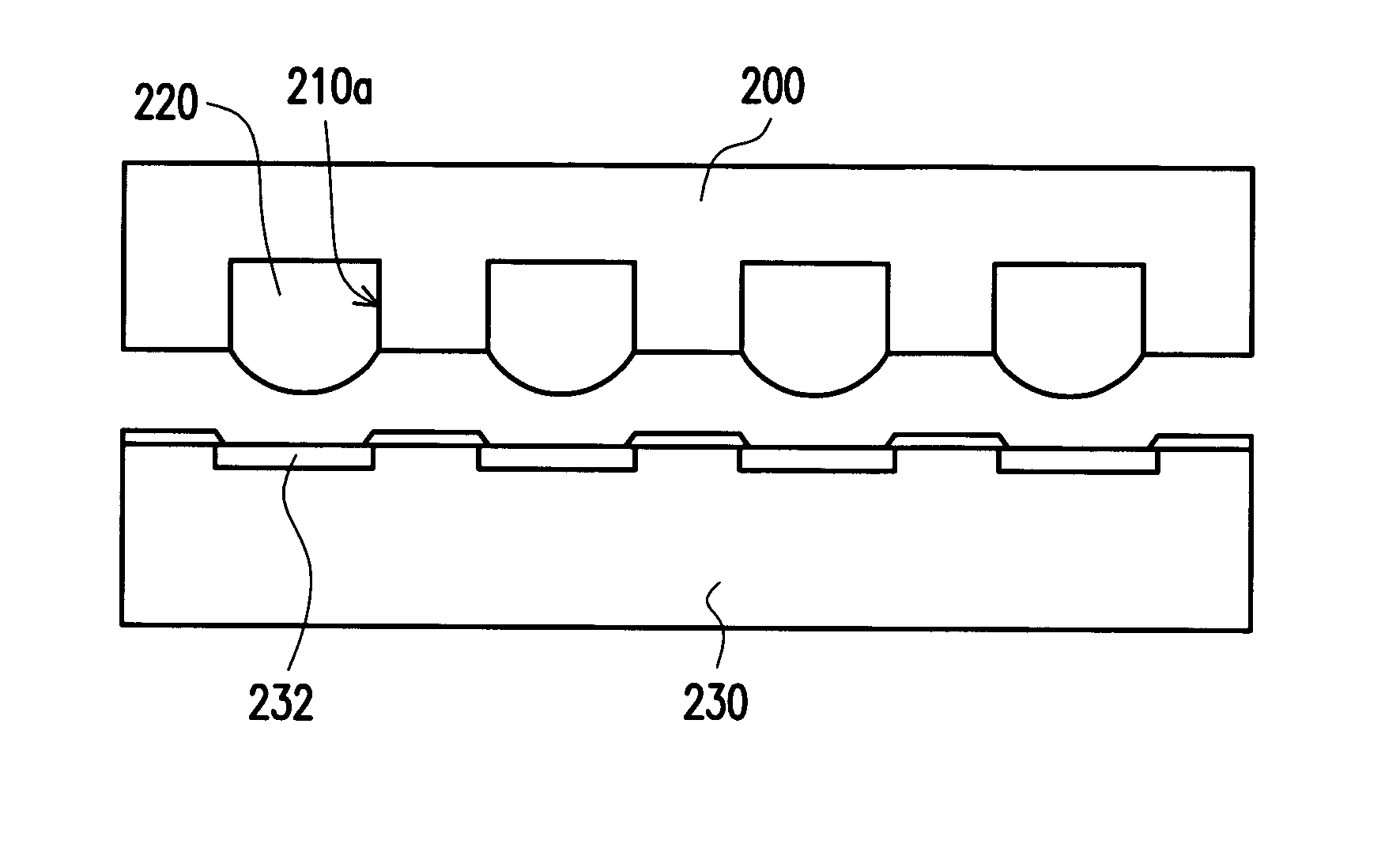

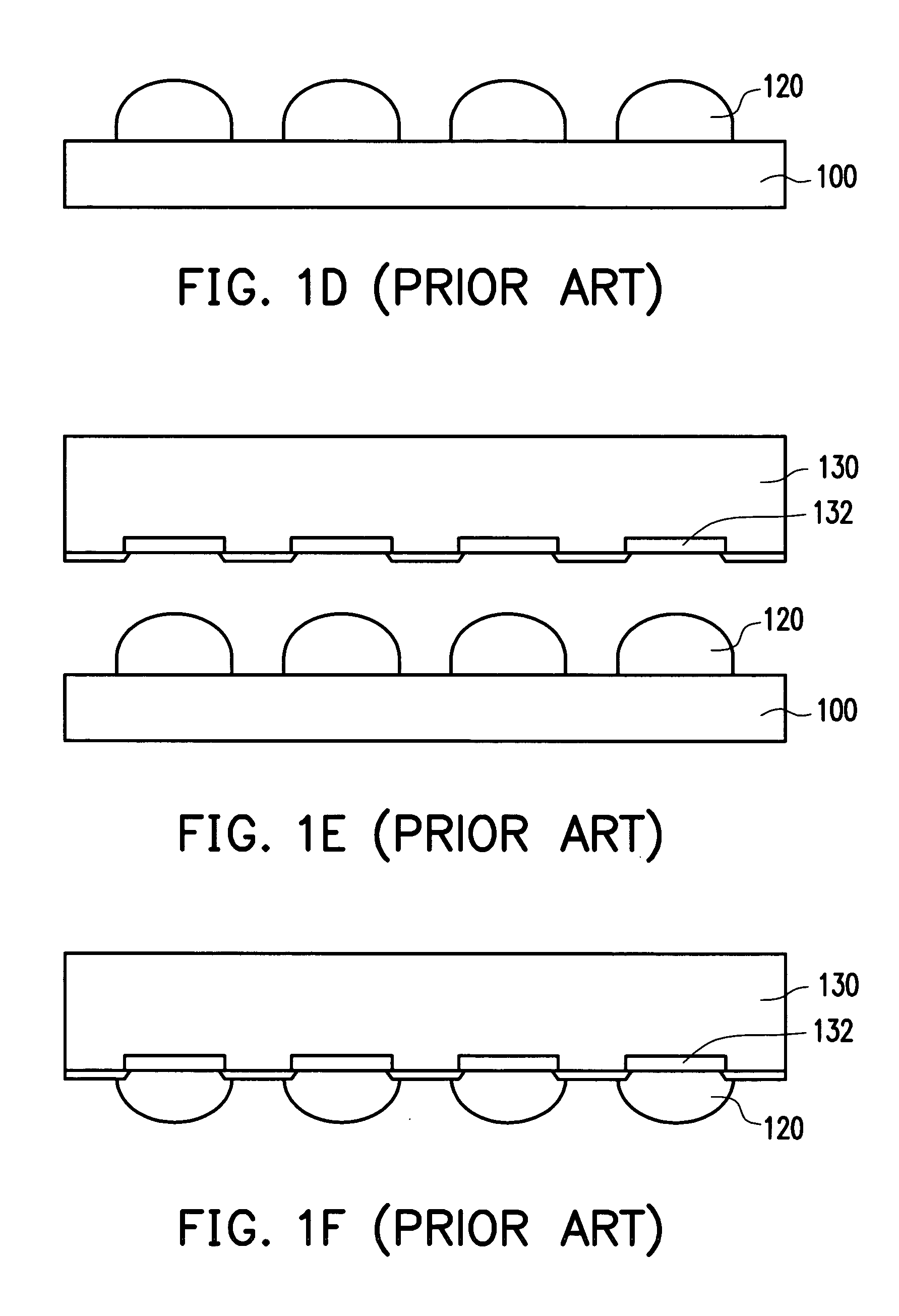

Bump transfer fixture

InactiveUS20050035453A1Simple processLow costPrinted circuit assemblingSemiconductor/solid-state device detailsConvex structureEngineering

A bump transfer fixture for accommodating a plurality of bumps is provided. The bump transfer fixture includes a transfer plate having a plurality of fix structures. The plurality of fix structures are disposed on the surface of the transfer plate. Each of the plurality of fix structures accommodates one of the bumps. The fix structures can be concave or convex structures. By using the transfer plate to form the bumps, no photolithography technology is used to form the patterned photoresist layer. Hence, the bump transfer process is much simpler and faster. Therefore, the present invention effectively reduces the cost and time for the bump transfer process.

Owner:VIA TECH INC

Mash/lauter tun and method of use thereof

ActiveUS8141477B2Simplify the transfer processPromote sportsWort preparationBeer fermentationFiltrationEngineering

A mash / lauter tun and method of converting grains to wort. The mash / lauter tun comprises a container with a double false bottom filter having two perforated plates disposed parallel with a space therebetween for receiving filtration media. The container further comprises thermometers extending to near the center of the tun and a rotating heat exchanger. In use, mash is loaded into the container and heated via the rotating heat exchanger by passing hot fluid through the rotating heat exchanger. The mash is then sparged by increasing pressure in the rotating heat exchanger above a threshold pressure via closure an outlet valve of the heat exchanger. The wort then passes through the double false bottom filter and is subsequently transferred to a brew kettle for boiling.

Owner:BRODERICK WILLIAM

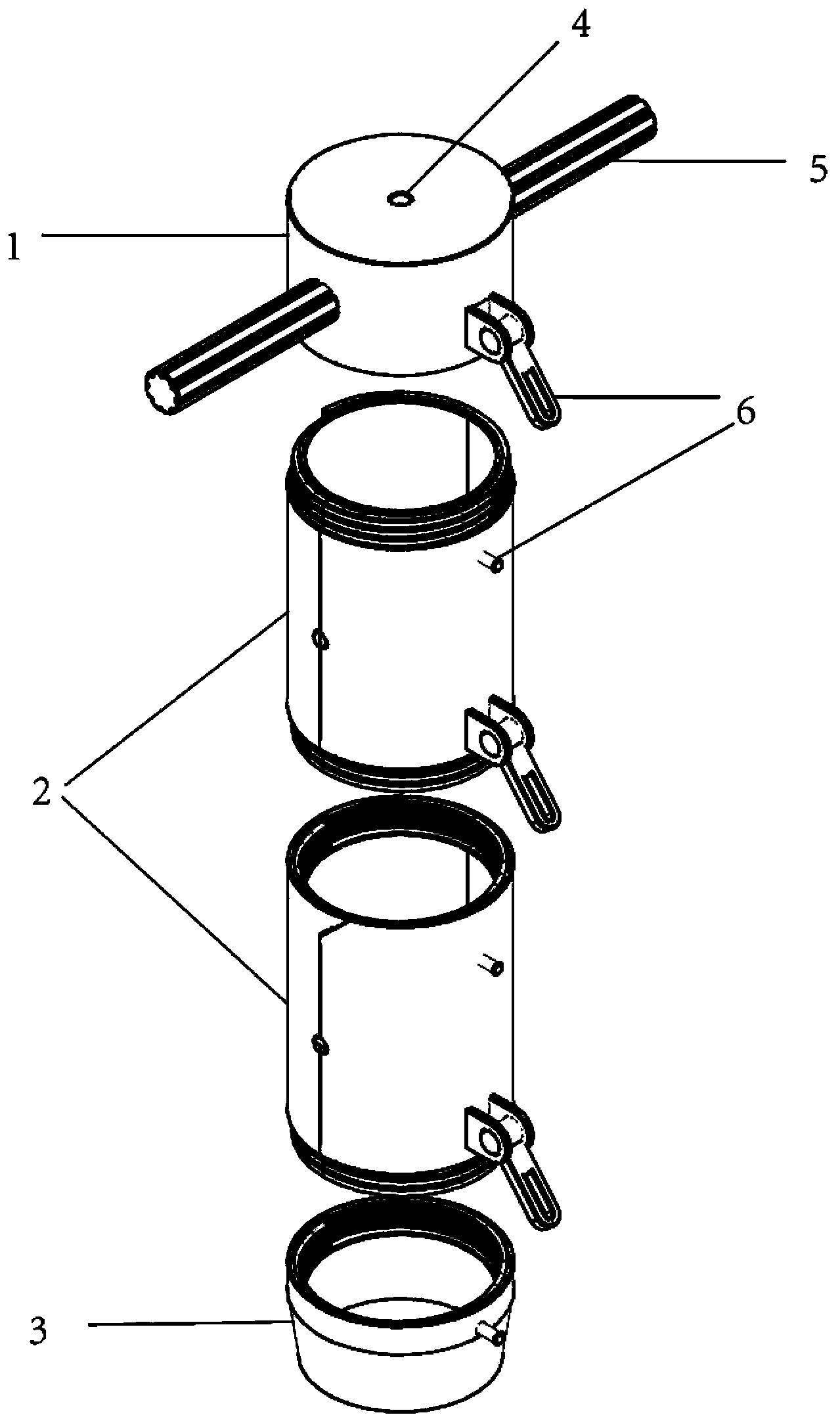

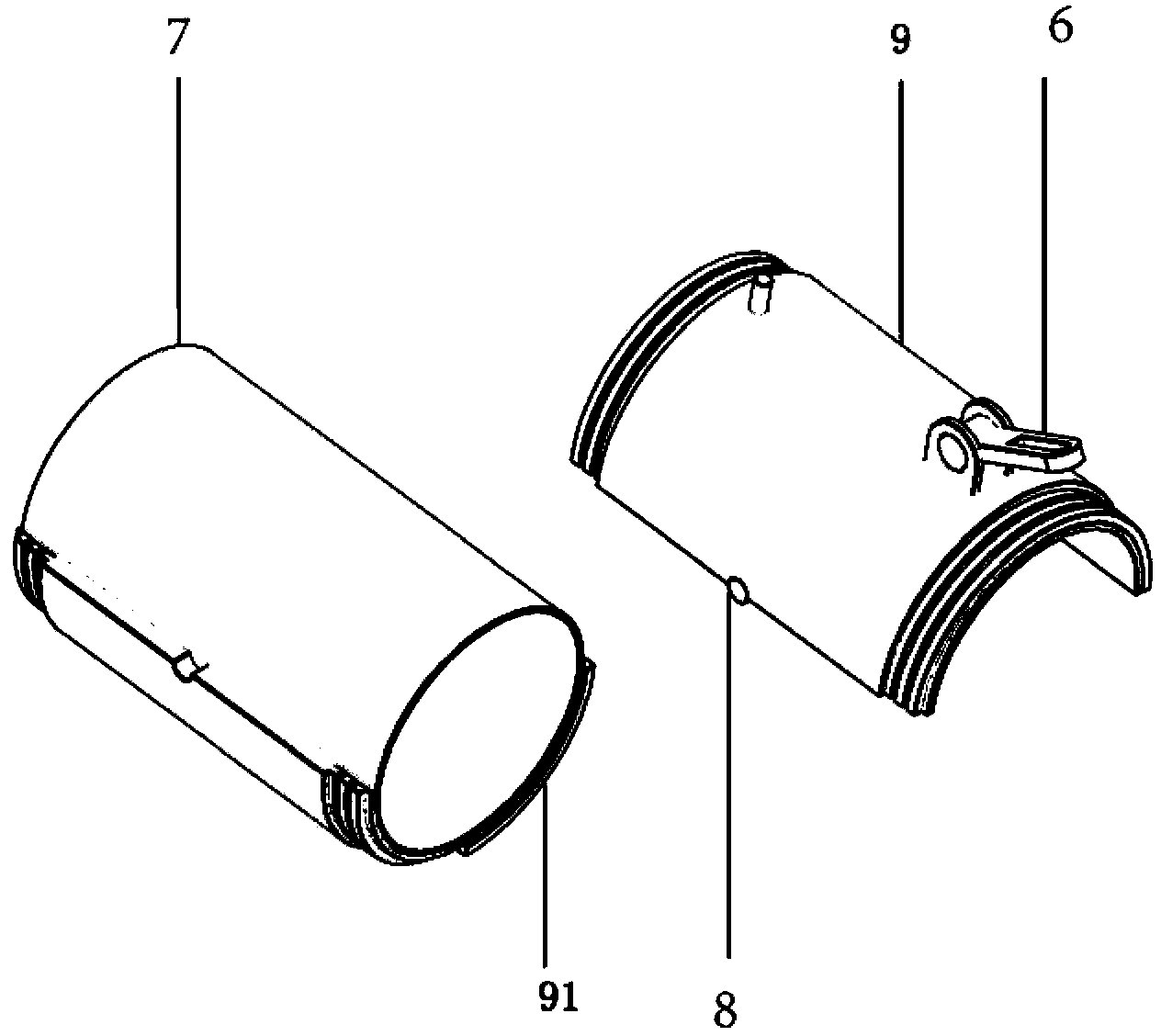

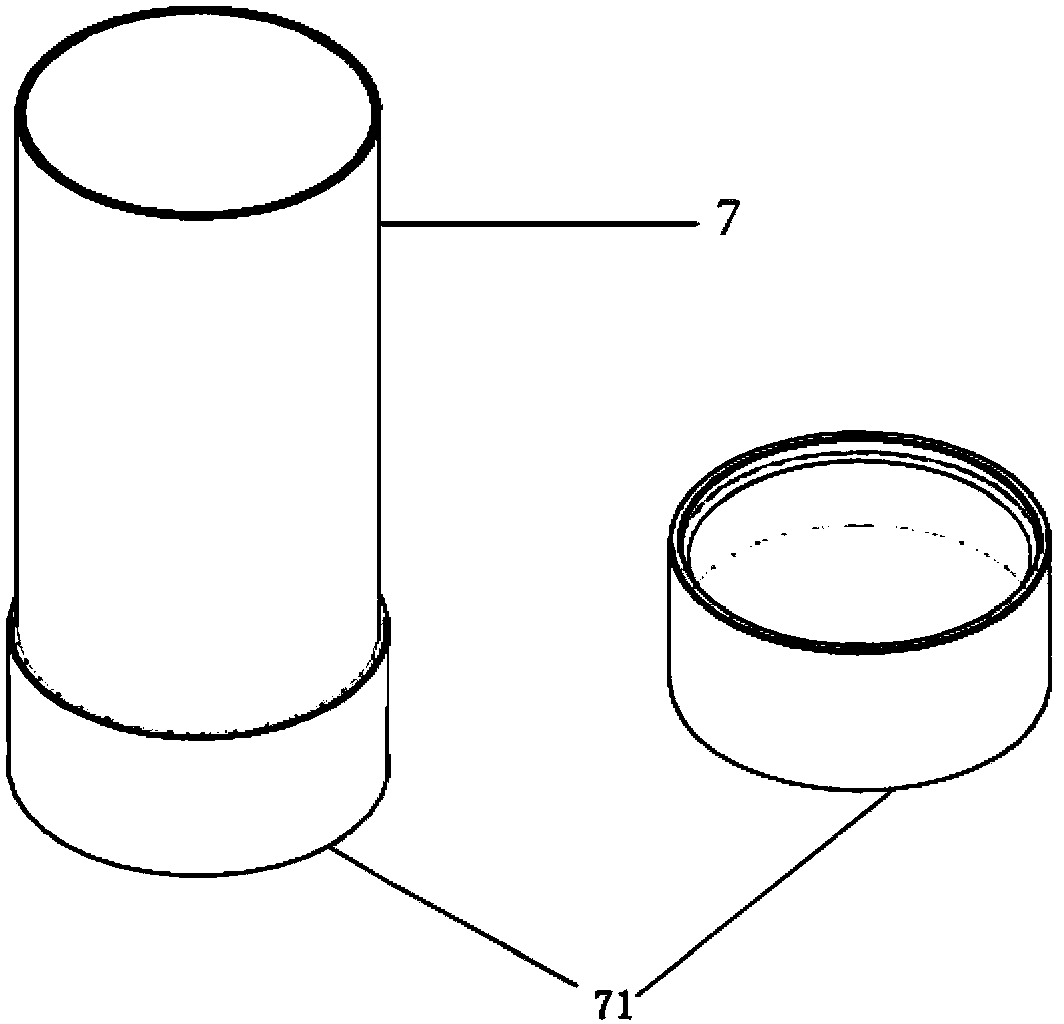

Combined soil sampler capable of sampling in layering manner

InactiveCN103364222AOvercoming diversionOvercome the Layering DifficultyWithdrawing sample devicesWhole bodyEngineering

The invention discloses a combined soil sampler capable of sampling in a layering manner. The combined soil sampler comprises a top cover, more than two cylinders and a sampling head, wherein each cylinder comprises an outer cylinder and an inner cylinder; each outer cylinder is divided into two half bodies along the middle axis; each inner cylinder is closely attached to the inner wall of the corresponding outer cylinder; each two half-bodies are connected to form a whole body through a connection clip; the top cover and the cylinders are in threaded connection; the various cylinders are in threaded connection; the cylinders and the sampling head are in threaded connection; the two parts in threaded connection are also fastened through a movable buckle; an air hole is formed in the top cover; a horizontal rotary handle is arranged on the side wall of the top cover. According to the invention, a plurality of detachable cylinders are combined, and thus pollution caused by the fact that a soil sample is in contact with a sampling cylinder during multiple times of sample collecting, and loss and pollution caused by transferring the cylinder into other containers again are avoided; in addition, because a sample is cylindrically packaged in the inner sampling cylinders, the possibility of preserving the sample for a long time and layering the sample again is realized.

Owner:SOUTH CHINA UNIV OF TECH

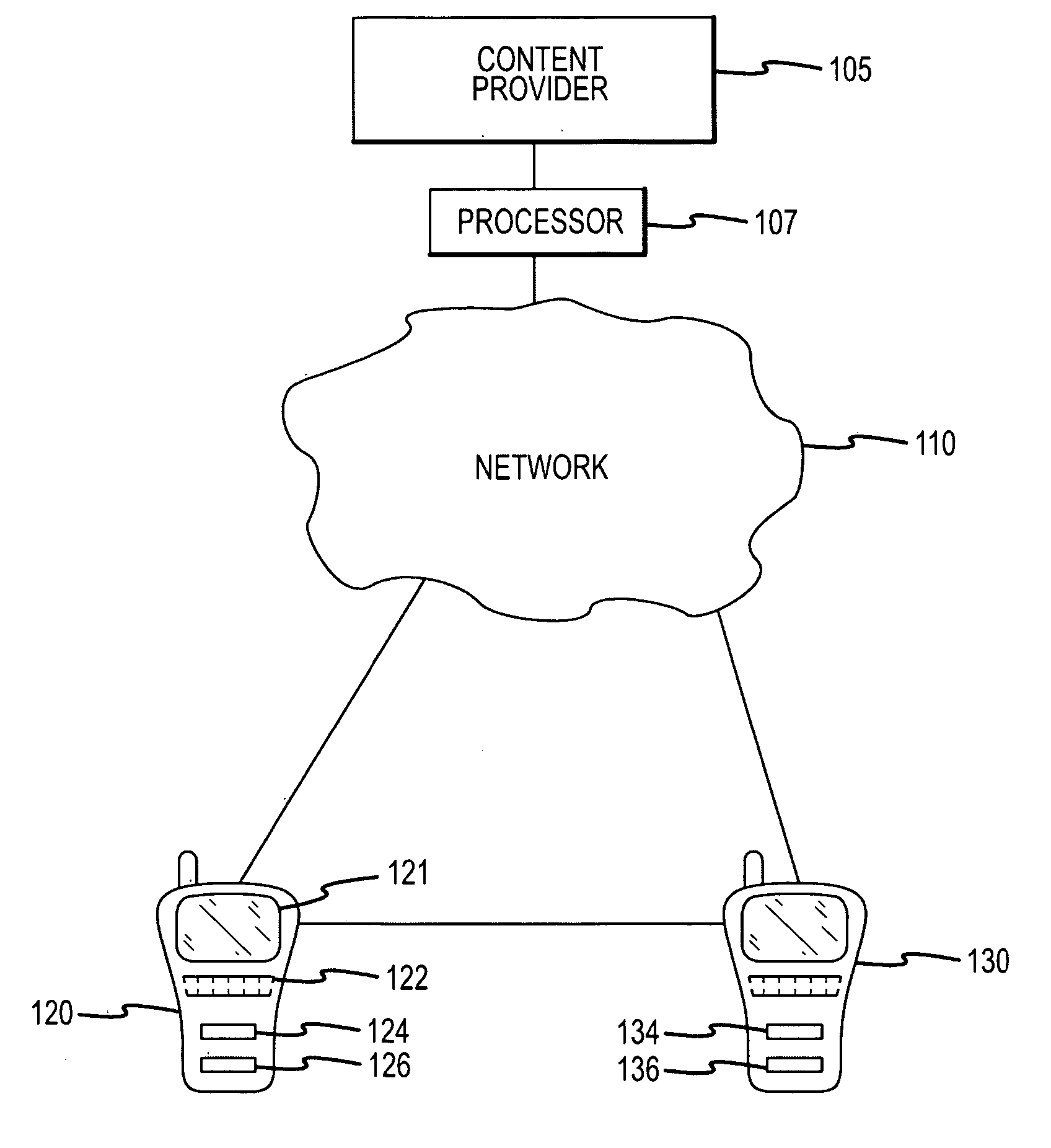

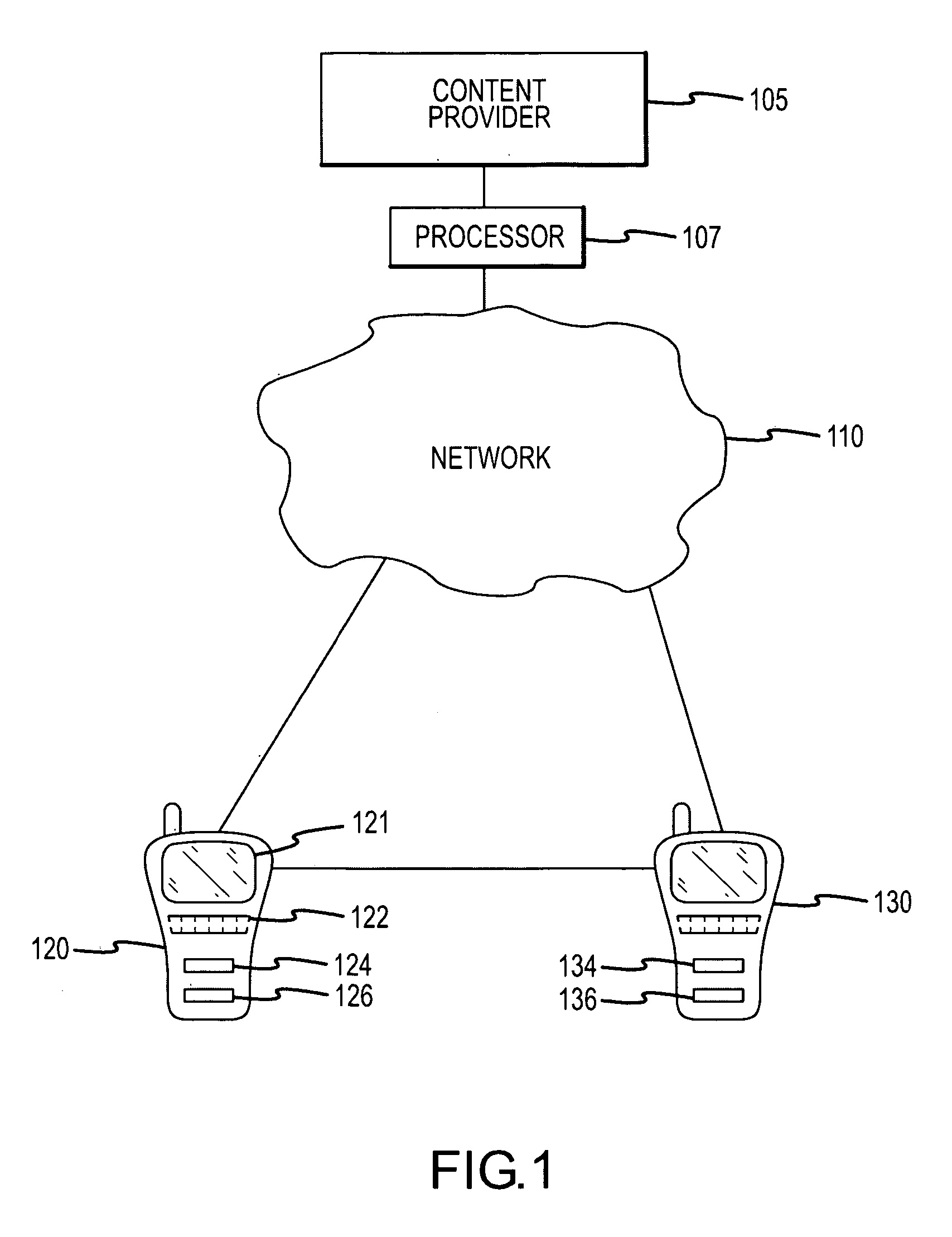

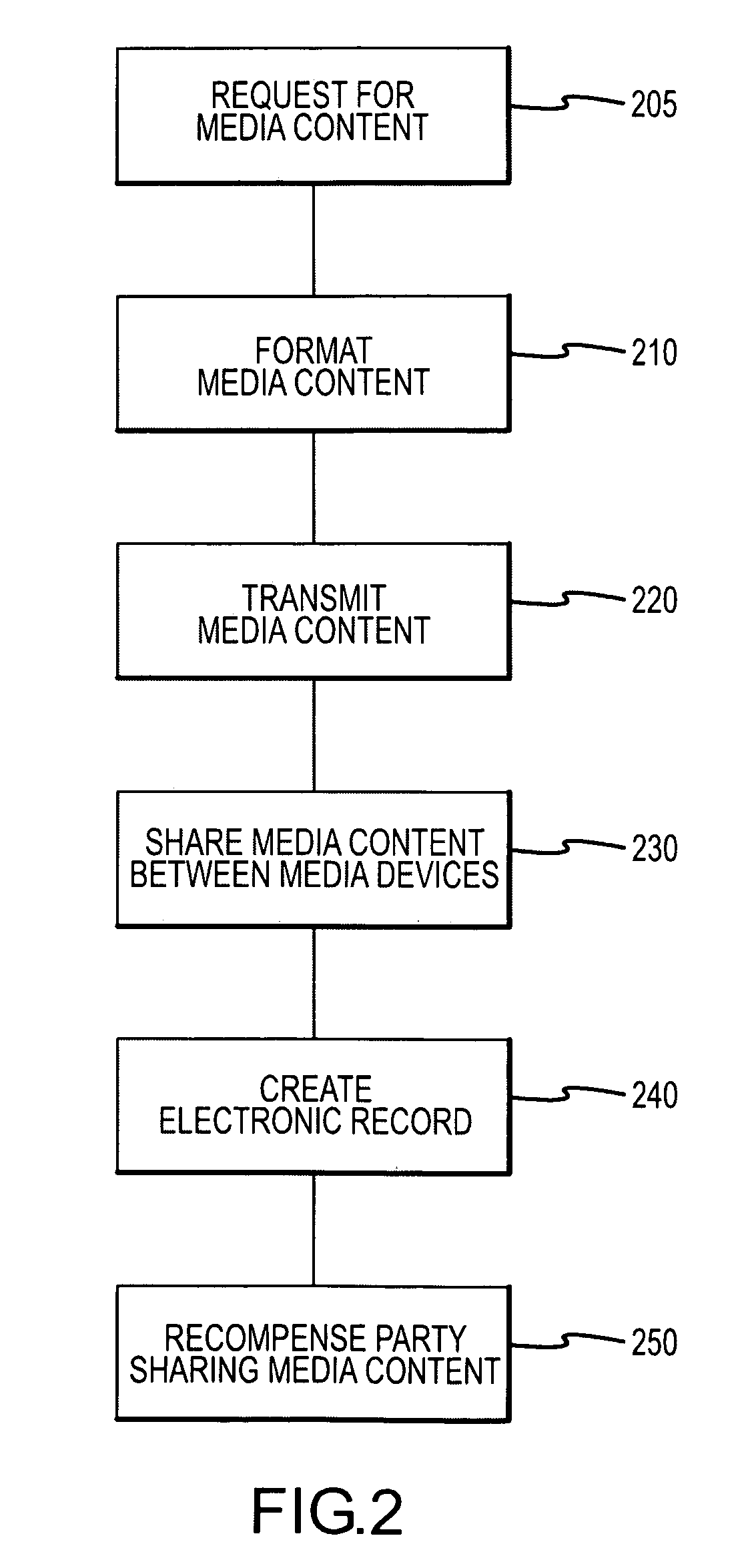

Wireless digital video recorders - content sharing systems and methods

ActiveUS20060218598A1Simplify the transfer processTelevision system detailsAnalogue secracy/subscription systemsDigital videoDigital rights management

Embodiments of the present invention provide methods for distributing media content between portable media devices with digital rights management protections. Offering several applications in the technical arts, embodiments of the present invention provide methods for managing distribution of media content between portable media devices. Further, embodiments of the present invention provide methods for easy and effective transmission of media content between portable media devices.

Owner:TIVO CORP

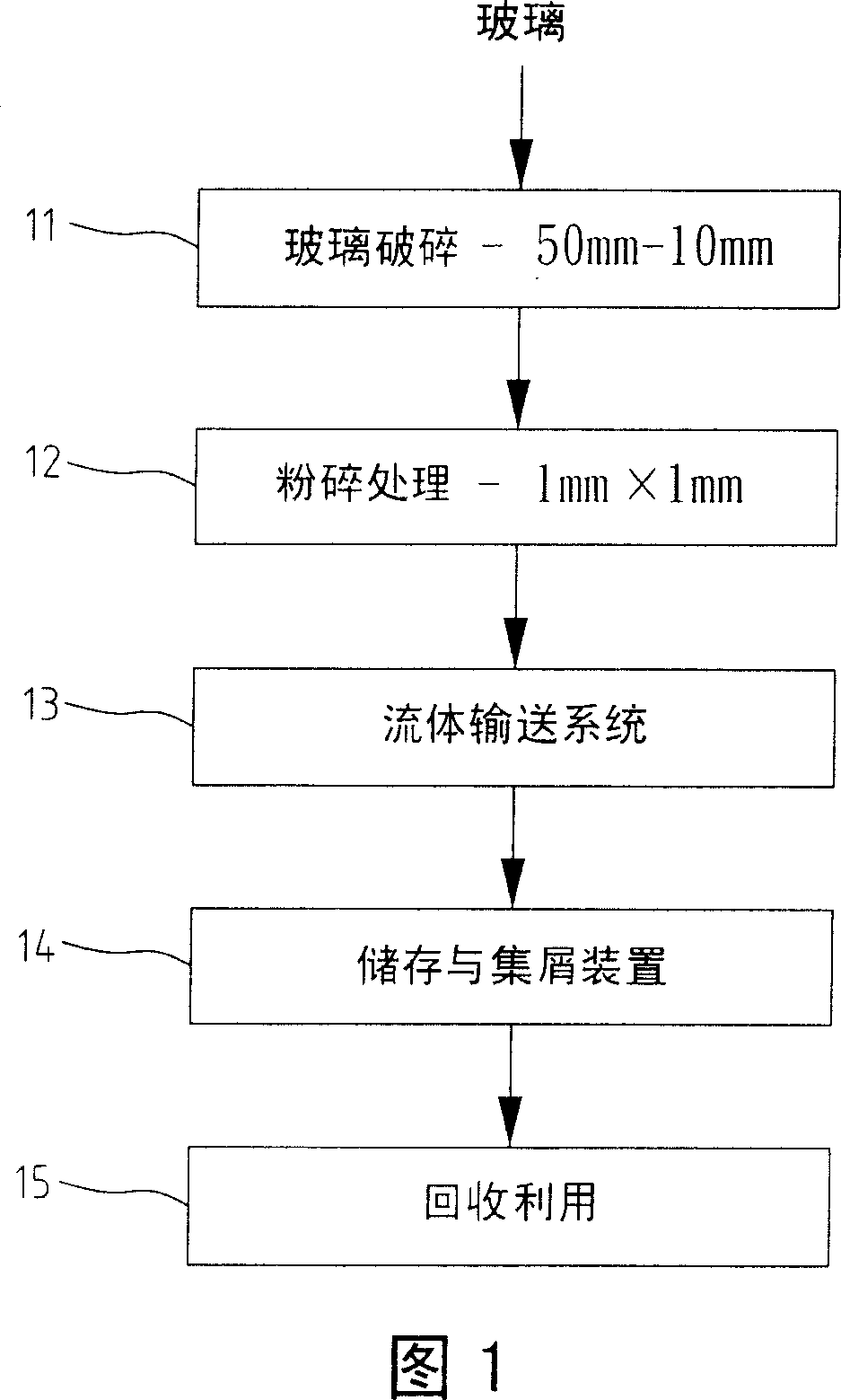

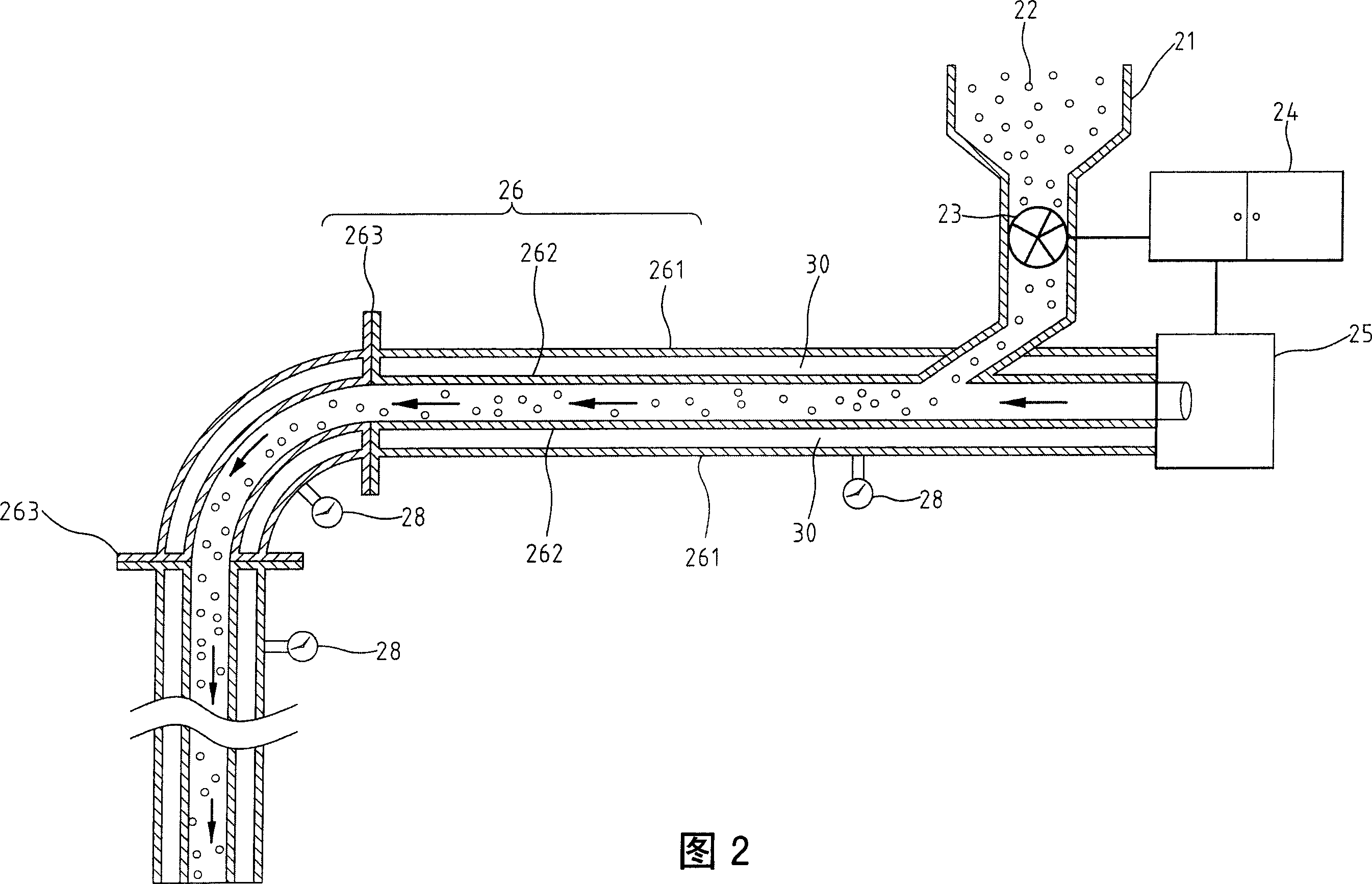

Glass waster material fluid transmission system

InactiveCN101033042ASave on shippingEasy maintenanceBulk conveyorsRigid pipesEnvironmental resistanceEngineering

This invention provides a fluid transmission system for glass wastes used in a dust-free chamber, in which, glass wastes are blown to a double-layer pipeline via a fan in low pressure and mid-speed and a pressure meter can be installed to monitor the pipeline, which is suitable for addition to current designs of workshops and is not limited by long distant pipelines or curvatures and the sealed transmission pipeline will not pollute environment.

Owner:富临科技工程股份有限公司 +1

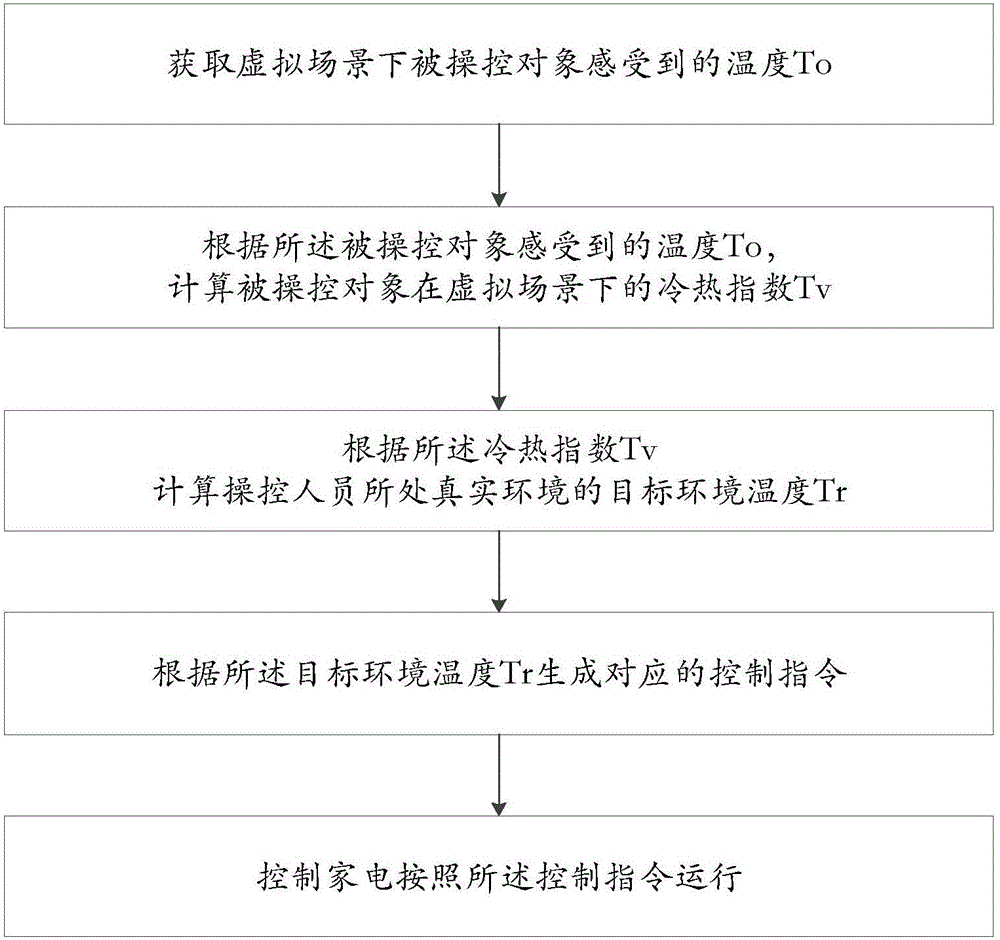

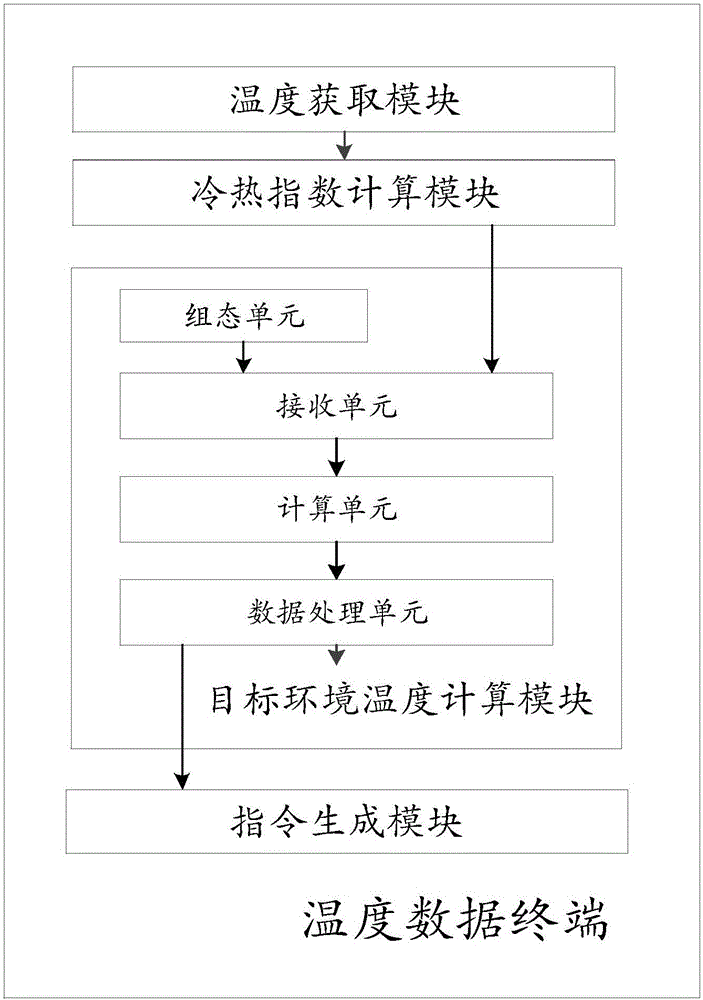

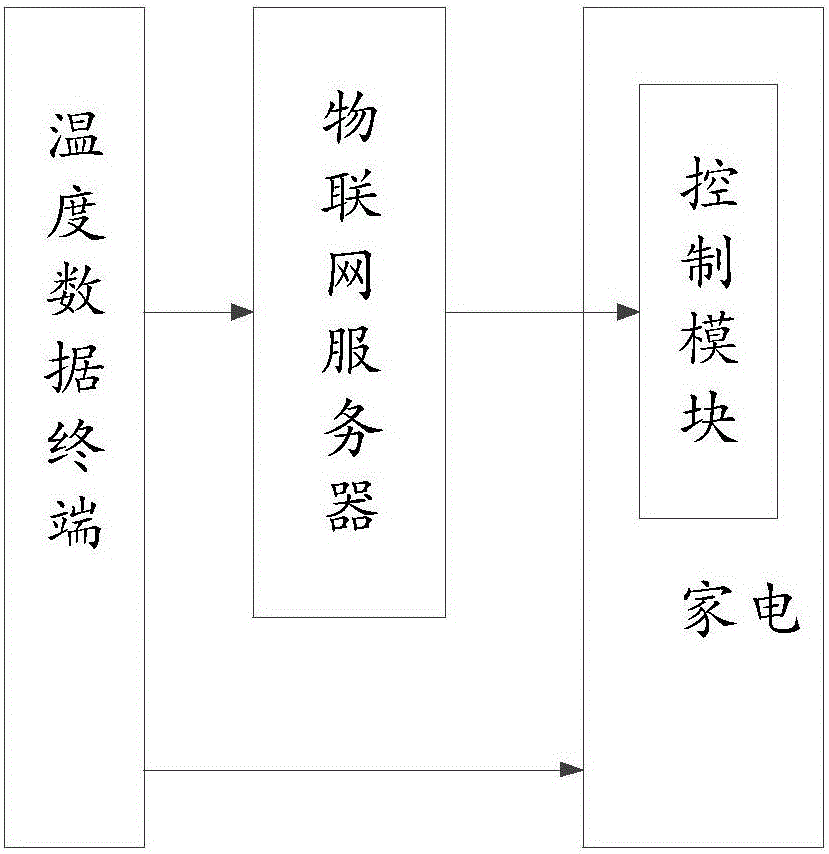

Method and system controlling environment temperature according to virtual scene and temperature data terminal

ActiveCN105843278AAdd funEasy and accurate temperature acquisitionTransmission systemsTemperature control using electric meansTemperature controlData terminal

The invention relates to a method and system controlling environment temperature according to a virtual scene and a temperature data terminal. The method includes steps of obtaining temperature To sensed by a controlled object in the virtual scene; calculating the cold and hot index Tv of the controlled object in the virtual scene according to the temperature To; calculating the target environment temperature Tr of a real environment where an operator is according to the cold and hot index Tv; generating corresponding control commands according to the target environment temperature Tr; controlling household appliances to operate according to the control commands. According to the invention, the temperature sensed by the virtual object in the virtual scene can be taken as a basis for temperature control of the household appliances, so that the household appliances create a game environment in the real environment where the user is and the user can have a feeling of being in the virtual scene. No hardware cost increase is needed and game enjoyment can be improved. At the same time, the application field of the household appliances can be expanded and a new profiting way is created for household appliance enterprises.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Layer transfer of films utilizing controlled propagation

ActiveUS8293619B2Simplify the transfer processReduce energy costsSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSilicon

A film of material may be formed by providing a semiconductor substrate having a surface region and a cleave region located at a predetermined depth beneath the surface region. During a process of cleaving the film from the substrate, shear in the cleave region is carefully controlled to achieve controlled propagation by either KII or energy propagation control. According to certain embodiments, an in-plane shear component (KII) is maintained near zero by adiabatic heating of silicon through exposure to E-beam radiation. According to other embodiments, a surface heating source in combination with an implanted layer serves to guide fracture propagation through the cleave sequence.

Owner:SILICON GENERAL CORPORATION

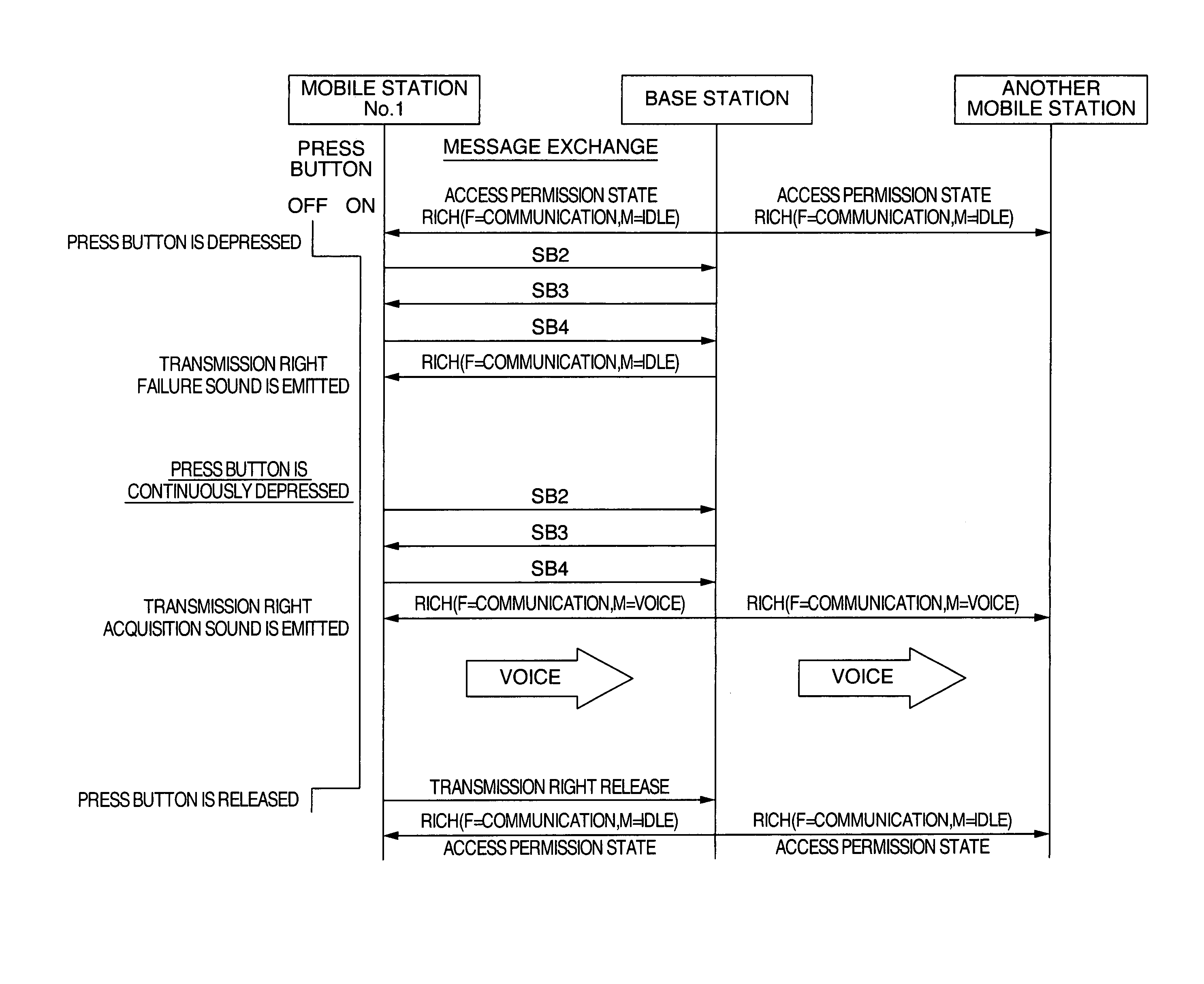

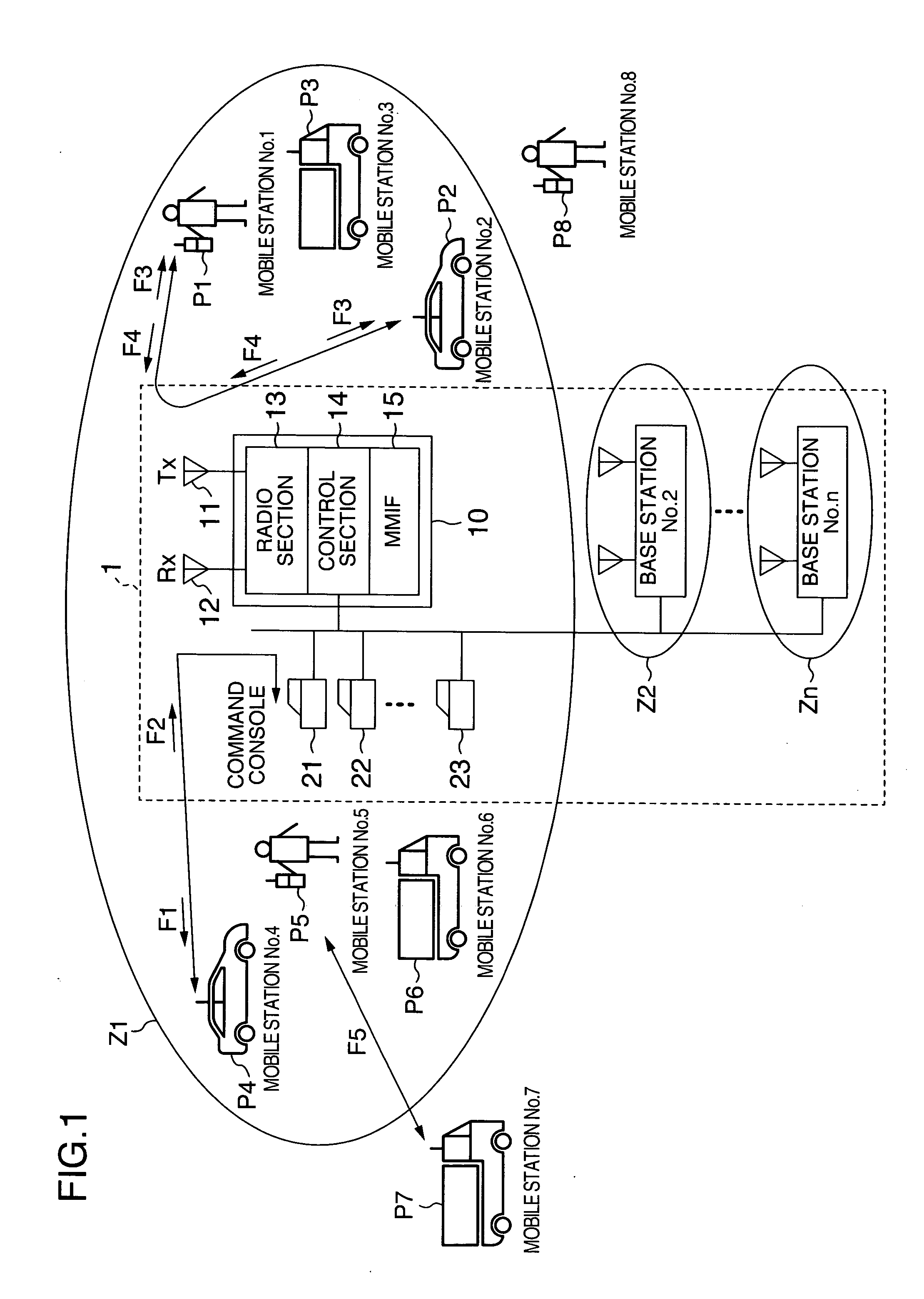

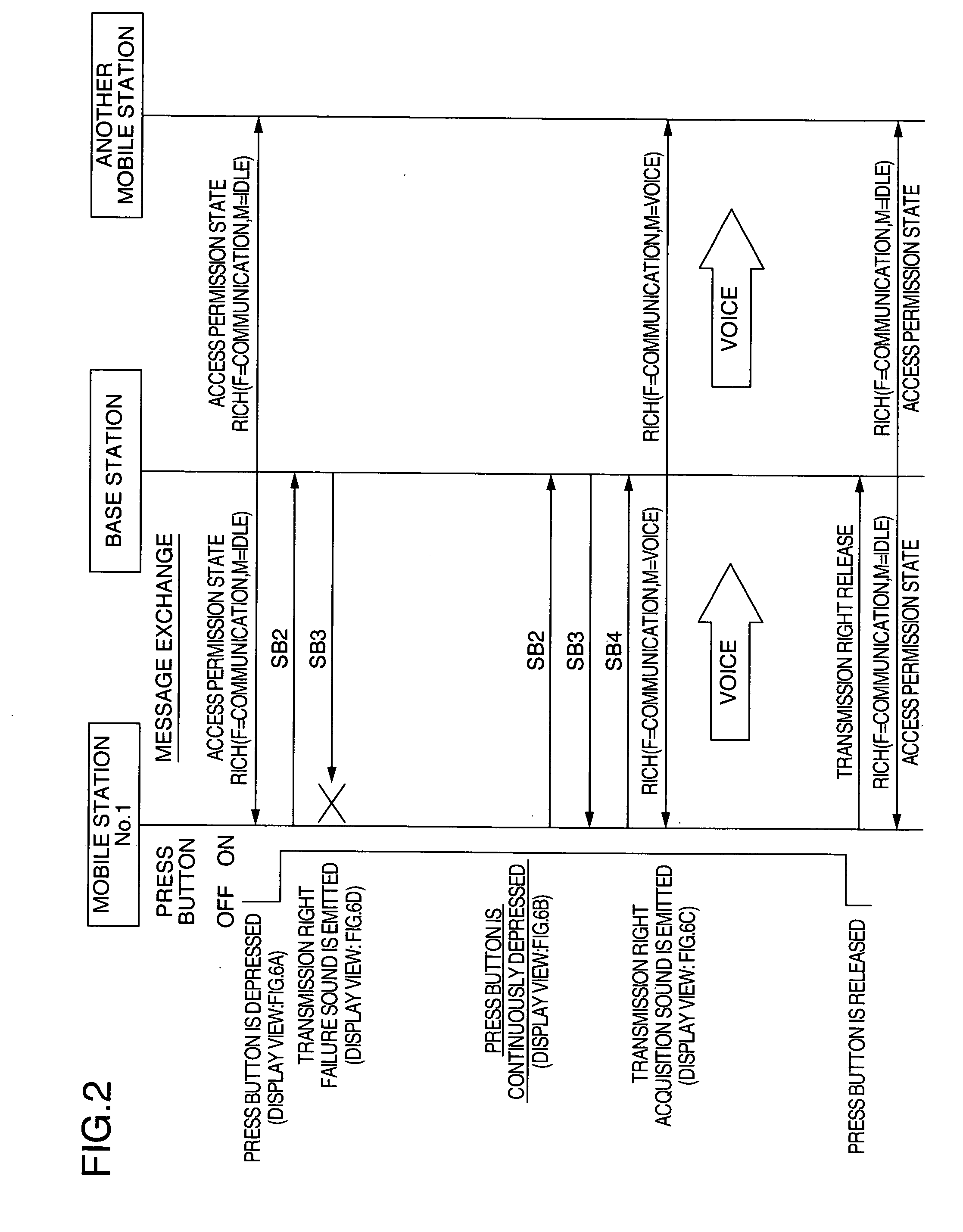

Wireless communication system and wireless communication method

InactiveUS20050220050A1Simplify the transfer processSimple transmissionTime-division multiplexConnection managementCommunications systemMobile station

A wireless communication system consisting of a base station and a plurality of mobile stations capable of conducting wireless communication with the base station. Each mobile station has a press button which accepts an order issued by an operator to execute a request for acquiring a transmission right, and a control section. The press button maintains depression electrically or mechanically. The control section in each of the mobile stations is adapted to execute a request for acquiring the transmission right, in response to acceptance of an order conducted by the press button. If the control section fails in acquiring the transmission right by executing the request, the control section is adapted to execute the request for acquiring the transmission right again.

Owner:KOKUSA ELECTRIC CO LTD +1

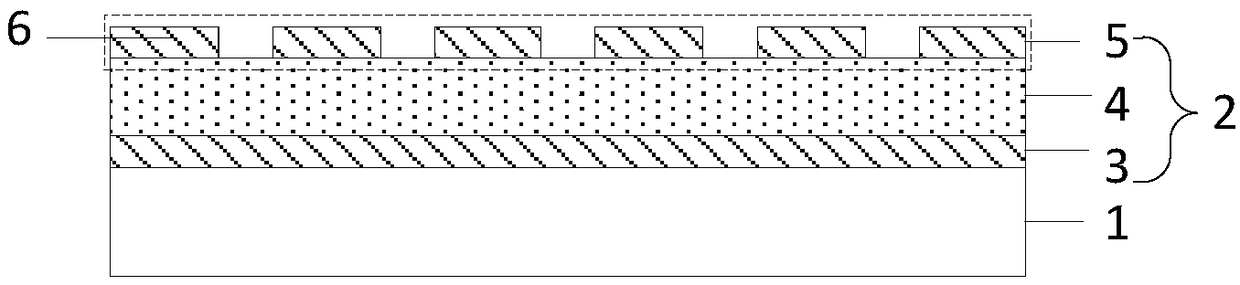

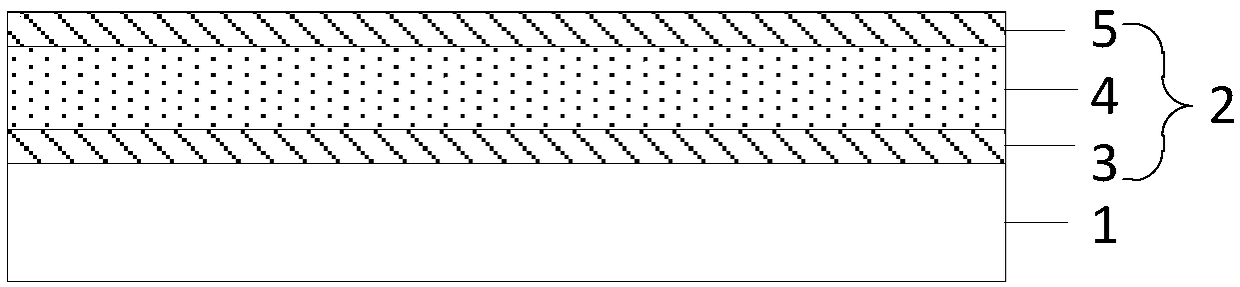

Micro light emitting diode transfer substrate and method, display panel and preparation method

ActiveCN109449260ARealize batch transferSimplify the transfer processSolid-state devicesSemiconductor devicesProcess complexityLight-emitting diode

The invention discloses a micro light emitting diode transfer substrate and method, a display panel and a preparation method, and aims at simplifying the process complexity of micro light emitting diode preparation. The micro light emitting diode transfer substrate comprises a first substrate and an electrically induced deformation layer which is located on the first substrate, wherein the electrically induced deformation layer is used for ensuring that the thickness of the electrically induced deformation layer in a to-be-transferred area of a to-be-transferred micro light emitting diode is greater than the thickness of the electrically induced deformation layer in a not-to-be-transferred area corresponding to the micro light emitting diode.

Owner:BOE TECH GRP CO LTD

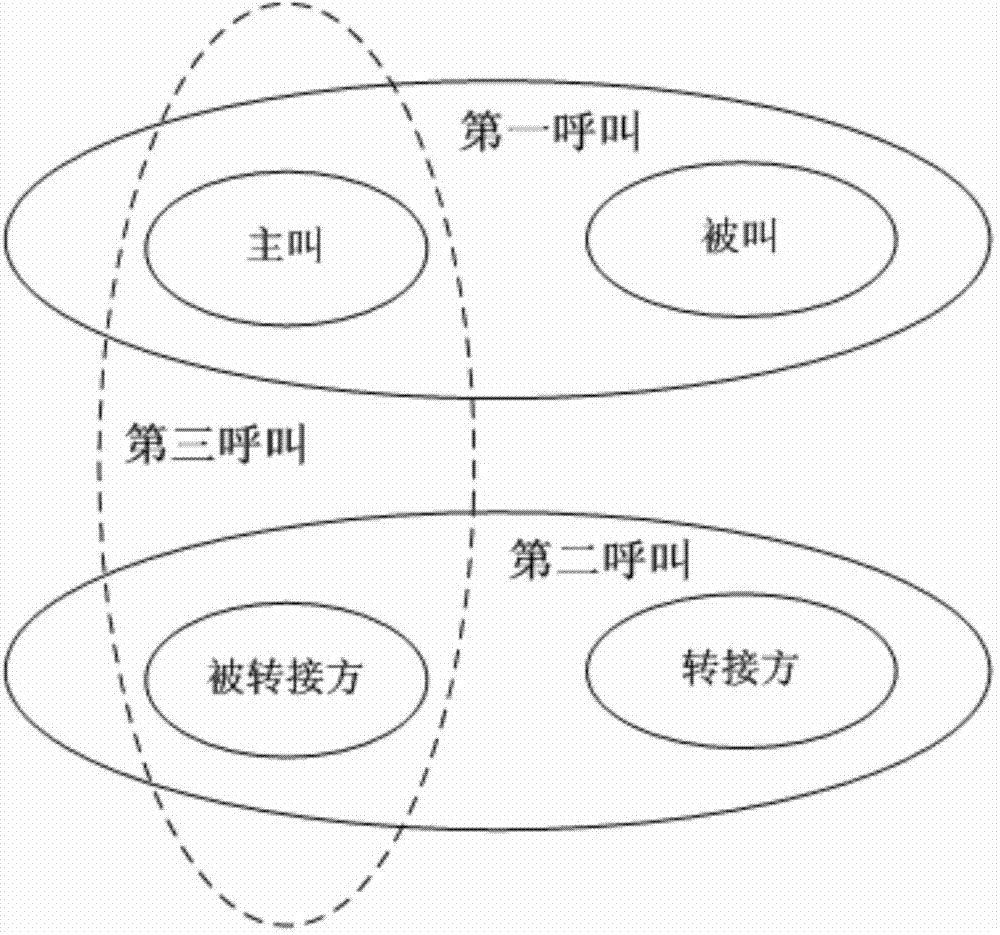

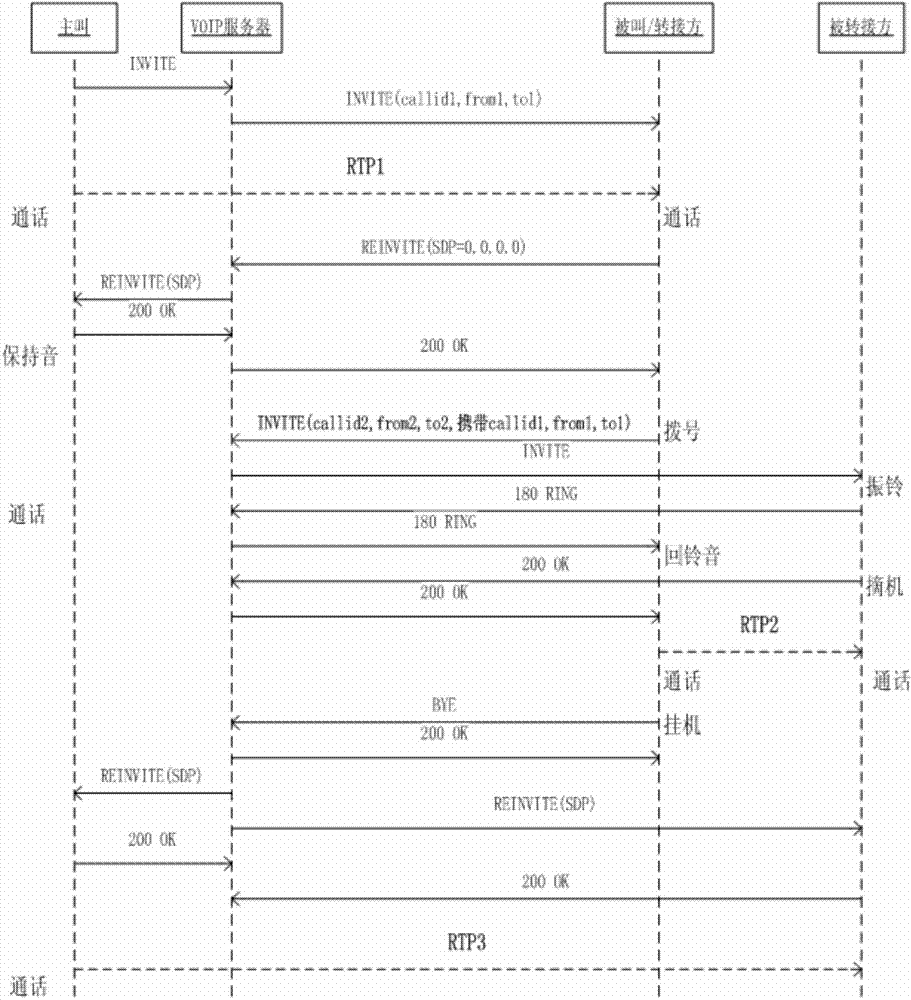

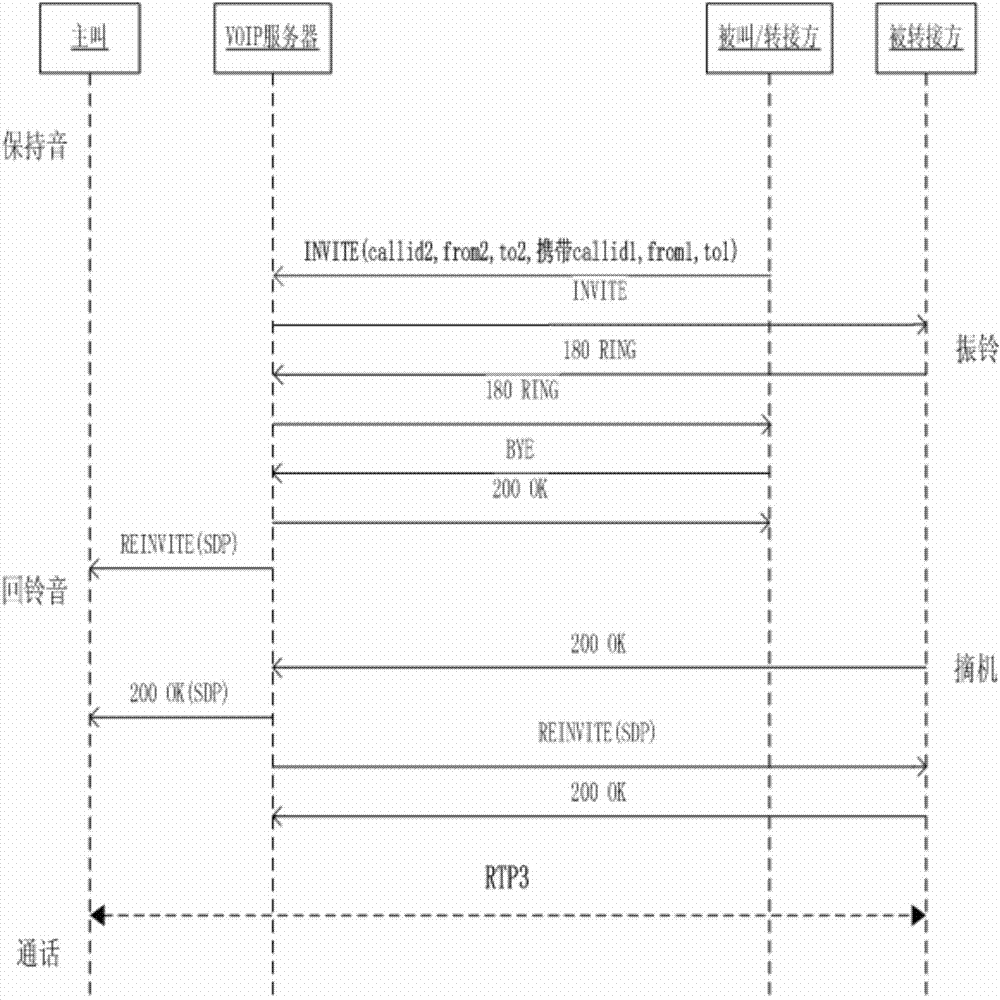

Call forwarding method under VoIP (voice over Internet protocol) of intelligent terminal

ActiveCN104506523ASimplify the transfer processSimple logicCommmunication supplementary servicesTransmissionTelephone callTelephony

The invention relates to a telephone call forwarding technology, and discloses a high-efficiency call forwarding method under the VoIP (voice over Internet protocol) of an intelligent terminal, the problems that basic call flows need to be changed, interaction signaling needs to be added, and call forwarding cannot be successfully performed under the condition that multiple calls exist simultaneously are solved by adopting the call forwarding scheme under the VoIP of the intelligent terminal in the prior art. The call forwarding method comprises the following steps: A, establishing a first call between a first terminal and a second terminal; B, when the second terminal needs to forward the call of the first terminal to a third terminal, firstly, keeping the first call, and then, sending an INVITE message of a second call to a VoIP server, wherein the INVITE message carries the relevant information of the first call; C, after the INVITE message is received by the VoIP server, establishing the second call between the second terminal and the third terminal, and associating the first call with the second call; D, after the second terminal is hung up, establishing a third call between the first terminal and the third terminal by the VoIP server. The call forwarding method disclosed by the invention is suitable for single-terminal and multi-call telephone call forwarding.

Owner:MAIPU COMM TECH CO LTD

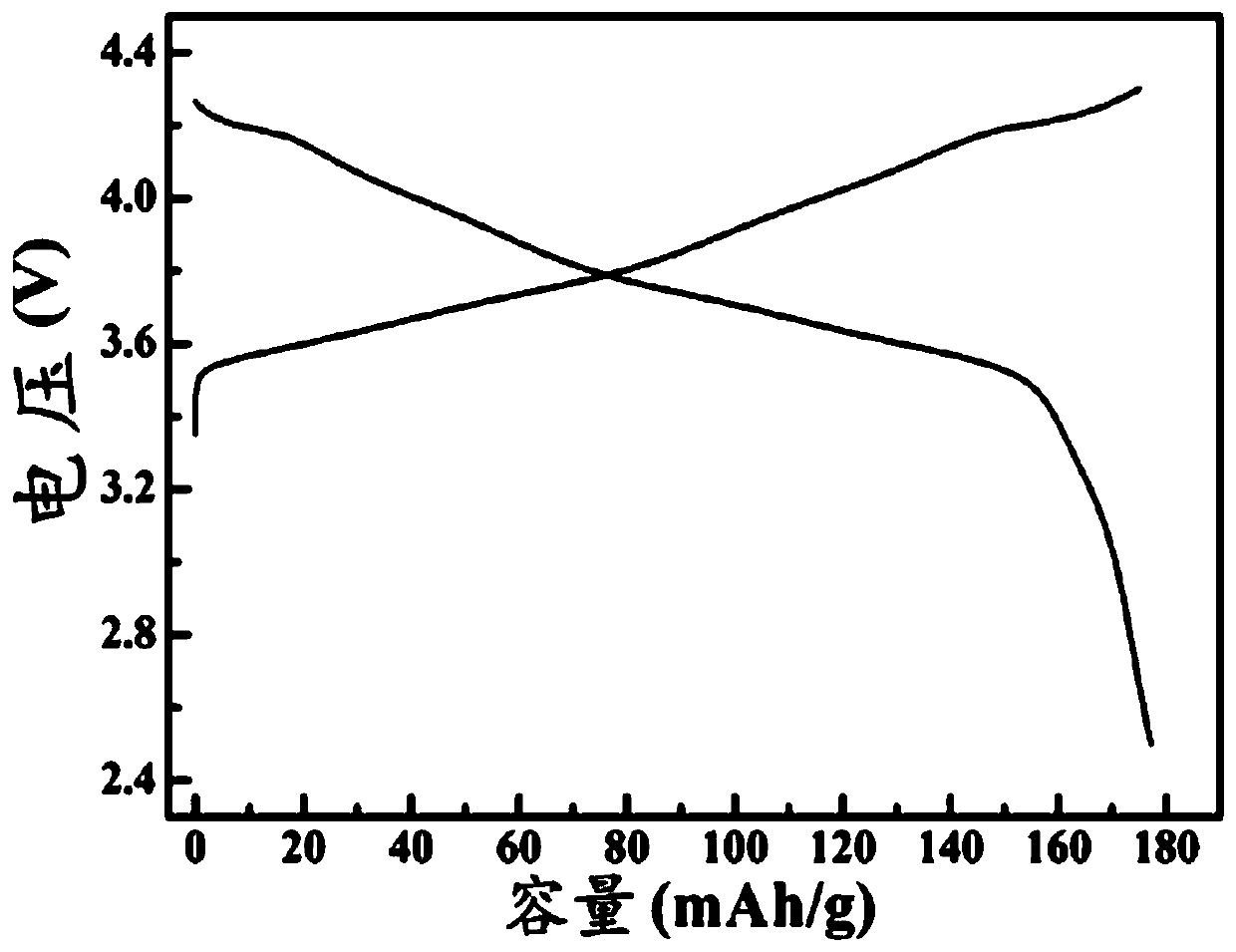

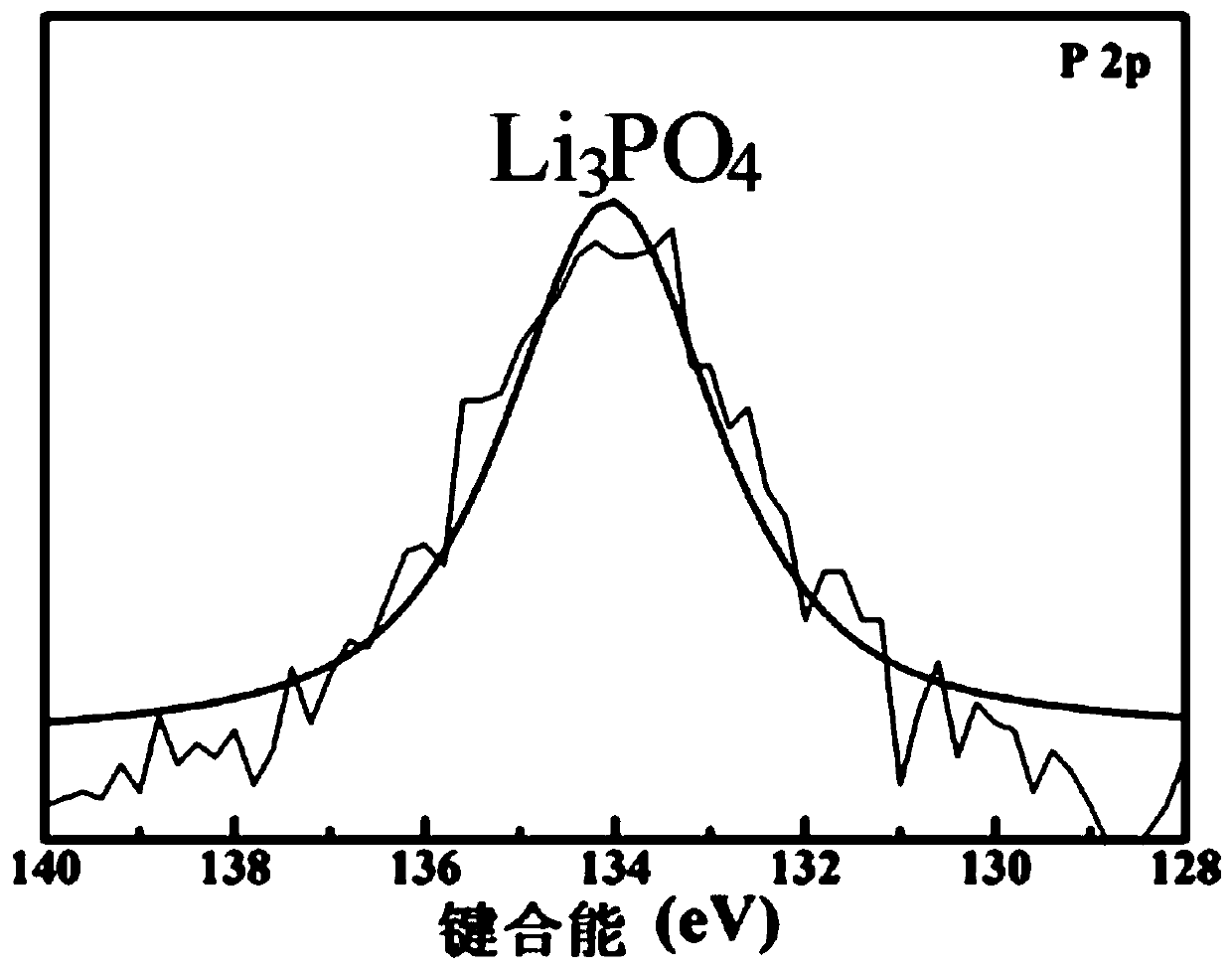

Quasi-solid-state lithium battery and preparation method thereof

ActiveCN110808408AImprove mechanical propertiesImprove heat resistanceSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteElectrolytic agent

The invention discloses a quasi-solid-state lithium battery and a preparation method thereof. The quasi-solid-state lithium battery comprises a negative electrode, a positive electrode and a diaphragm, and also comprises a quasi-solid-state electrolyte dispersed among the surfaces of the negative electrode, the positive electrode and the diaphragm and gaps among the negative electrode, the positive electrode and the diaphragm. The quasi-solid-state electrolyte comprises a polymer phase, and a ceramic electrolyte, a lithium salt and a flame-retardant organic solvent which are dispersed in the polymer phase, wherein the polymer phase is formed by in-situ polymerization of composite acrylate monomers; and the composite acrylate monomer comprises a star-shaped acrylate monomer and a chain-shaped acrylate monomer. According to the quasi-solid-state lithium battery disclosed by the invention, the problem that the safety of the battery is reduced by liquid electrolyte is solved, and the problem that the cycle performance of the battery is reduced due to dissolution of solid polymer electrolyte is also avoided. Therefore, the quasi-solid-state lithium battery has excellent safety performance, high conductivity and excellent cycling stability.

Owner:ZHEJIANG UNIV

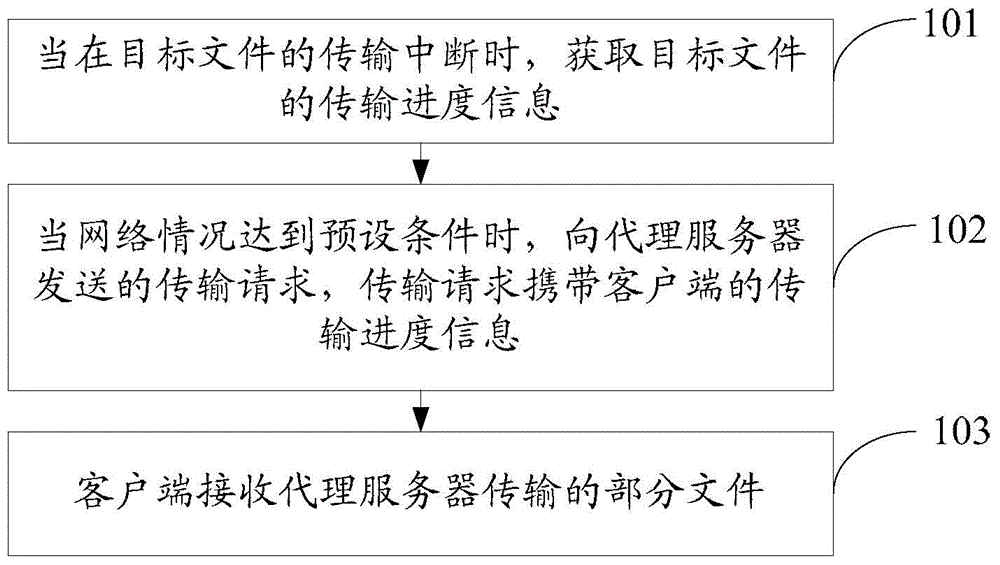

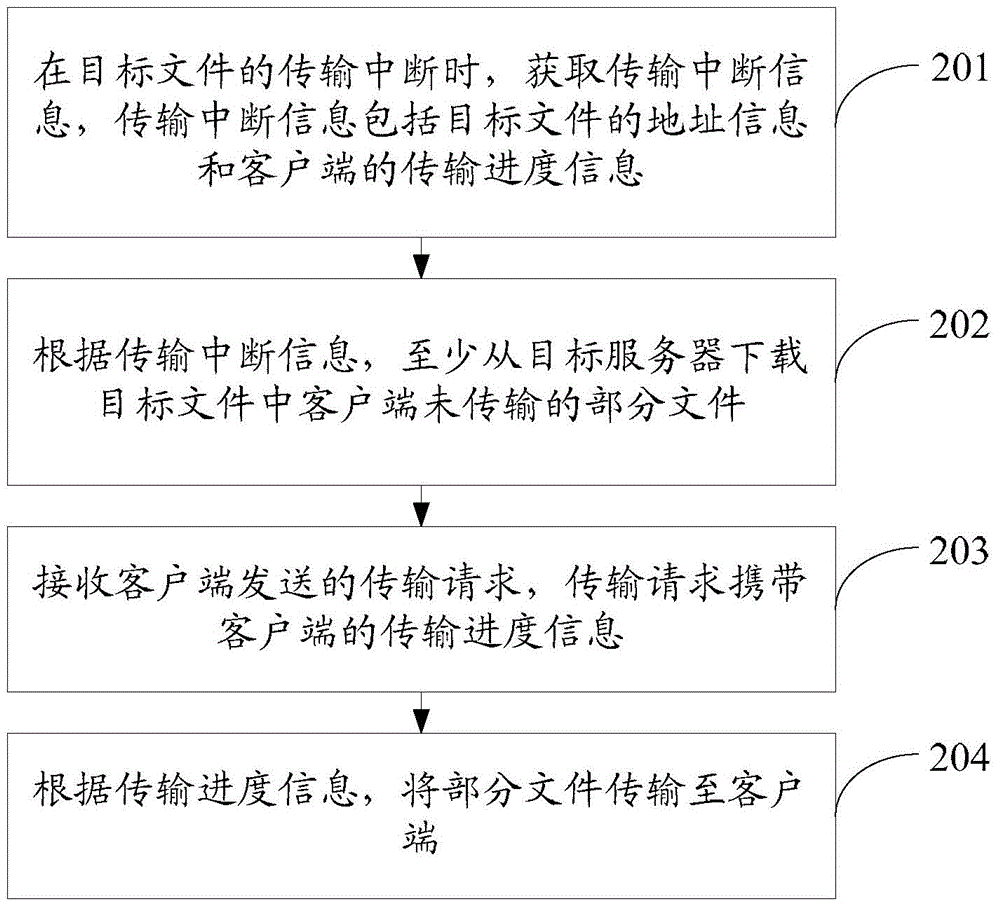

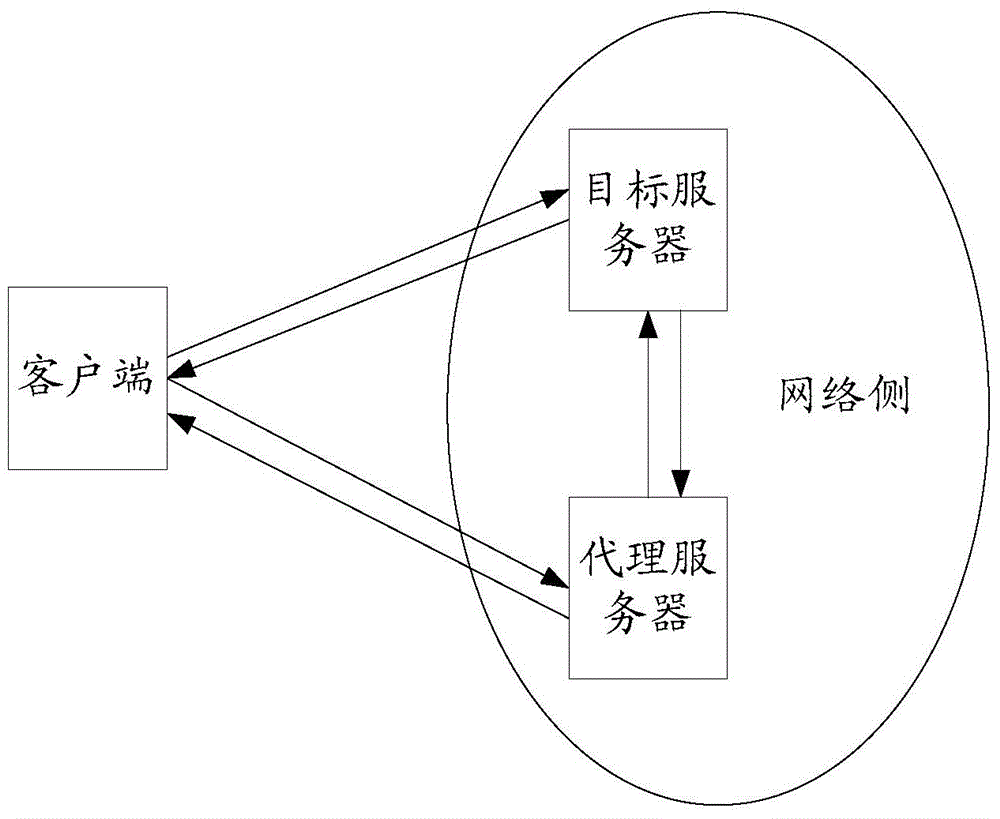

File transfer method, client and proxy server

ActiveCN104980399AAvoid cumbersome operationsSimplify the transfer processTransmissionClient-sideFile transfer

The invention discloses a file transfer method, a client and a proxy server, belonging to the field of network technologies. The method comprises the following steps that transmission progress information of a target file is obtained when transmission of the target file is interrupted; when the network conditions meet preset conditions, a transmission request is sent to the proxy server, and the transmission request carries the transmission progress information, so that after the proxy server receives the transmission request, the proxy server sends some files in the target file, which are not transmitted by the client, according to the transmission progress information; and the client receives the files, which are transmitted by the proxy server. According to the technical scheme provided by the invention, when the transmission is interrupted, the proxy server replaces the client to continue downloading the target file, and when the network recovers, the client automatically continues downloading some files in the target file, which are not transmitted, from the proxy server, so that a transmission process is simplified, and the waste of resources of the client is avoided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Sampler for undisturbed soil

InactiveCN108051242AImplement Stratified SamplingAdjustable lengthWithdrawing sample devicesProportional Stratified SamplingEngineering

The invention discloses a sampler for undisturbed soil, and belongs to the technical field of soil sampling. The sampler comprises a rotating handle, sample storage barrels and a sampling drill bit, wherein the bottom end of the rotating handle is connected with a sample storage barrel mounting base; the sample storage barrels are mounted in the sample storage barrel mounting base; the sampling drill bit is detachably connected to the bottom end of the corresponding storage sample barrel; a plurality of the sample storage barrels are arranged; the plurality of the sample storage barrels are detachably connected up and down in sequence; the sampling drill bit is arranged at the bottom end of the bottommost sample storage barrel. The plurality of the sample storage barrels are arranged; through adjusting the quantity of the sample storage barrels, a length of the whole sampler can be adjusted; the soil at a different depth can be sampled; the stratified sampling is realized; the sample storage barrels can also have different lengths; the length of the sampler can be more flexibly adjusted, and the stratified sampling can be further better realized.

Owner:GANSU DESERT CONTROL RES INST

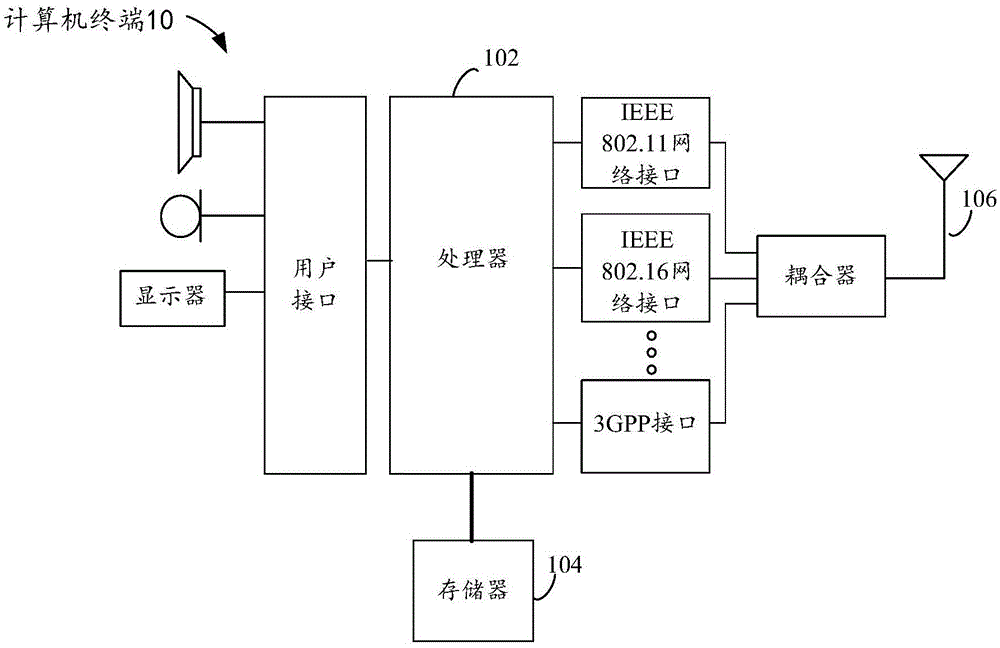

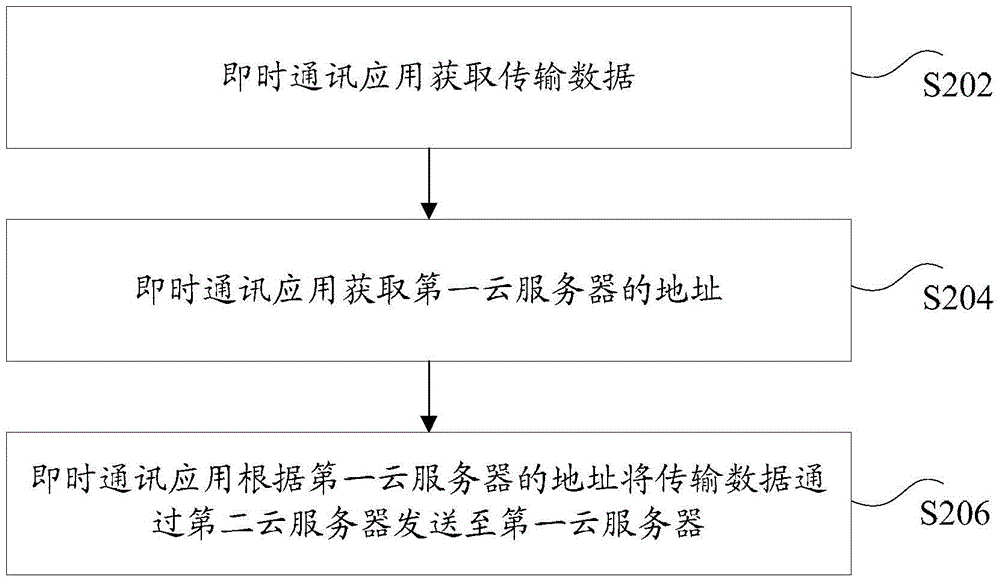

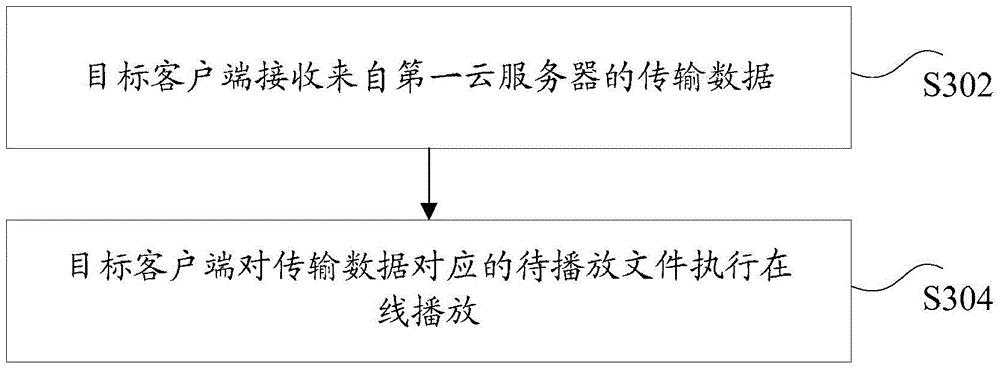

Data transmission methods and apparatuses, and vehicle-mounted terminal

InactiveCN105577818ASimplify the transfer processLong resolution processParticular environment based servicesConnection managementClient-sideData transmission

The invention discloses data transmission methods and apparatuses, and a vehicle-mounted terminal. The data transmission method comprises the steps that an instant communication application acquires transmission data, wherein the transmission data is data corresponding to a to-be-play file, and the to-be-play file is to be played at a target client; the instant communication application acquires the address of a first cloud server, wherein the first cloud server is used for providing an online play service for the target client; and the instant communication application sends the transmission data to the first cloud server through a second cloud server according to the address of the first cloud server, wherein the second cloud server is the server of the instant communication application, the first cloud server is used for sending the transmission data to the target client, and the target client is used for playing the to-be-played file corresponding to the transmission data online. According to the method, the technical problem of long data transmission process in the prior art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Multimedia session call control method and application server

ActiveUS9031057B2Simplify the transfer processShorten the timeMultiplex system selection arrangementsSpecial service provision for substationThird partyApplication server

A multimedia session call control method and an Application Server (AS) are provided. The multimedia session call control method includes these steps: a multi-UE party performs a multimedia session with a peer under control of an AS; a master UE of the multi-UE party establishes a session with a third party under control of the AS; and the AS binds a call leg between a slave UE of the multi-UE party and the AS to the session established with the third party.

Owner:NOKIA TECH OY

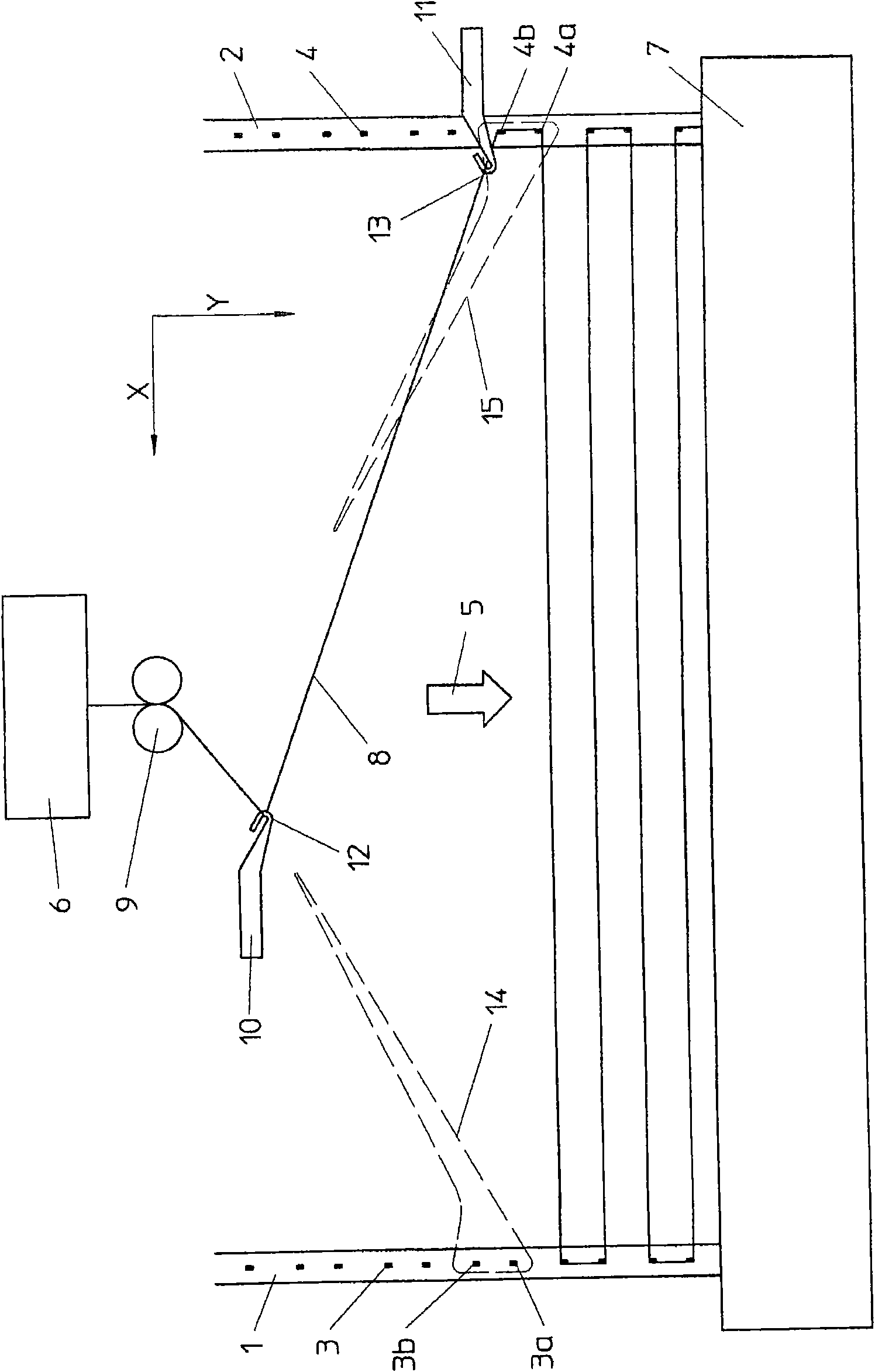

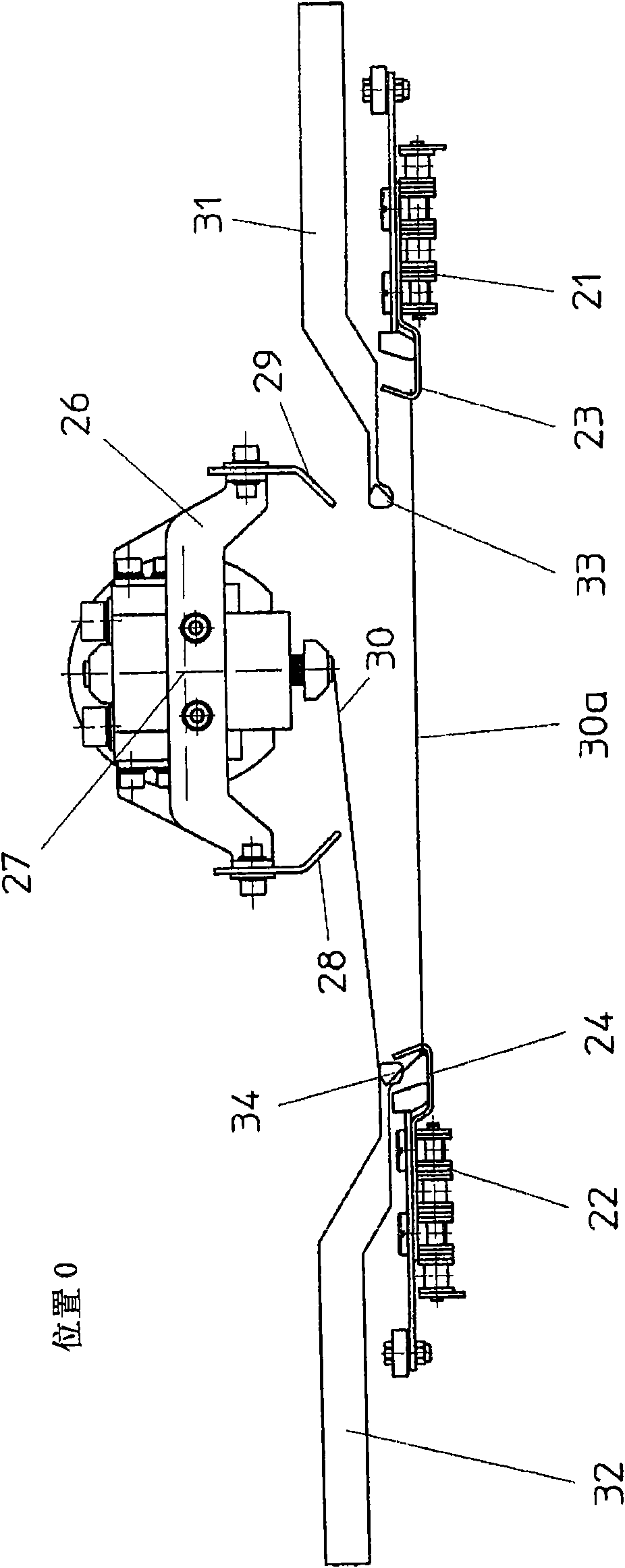

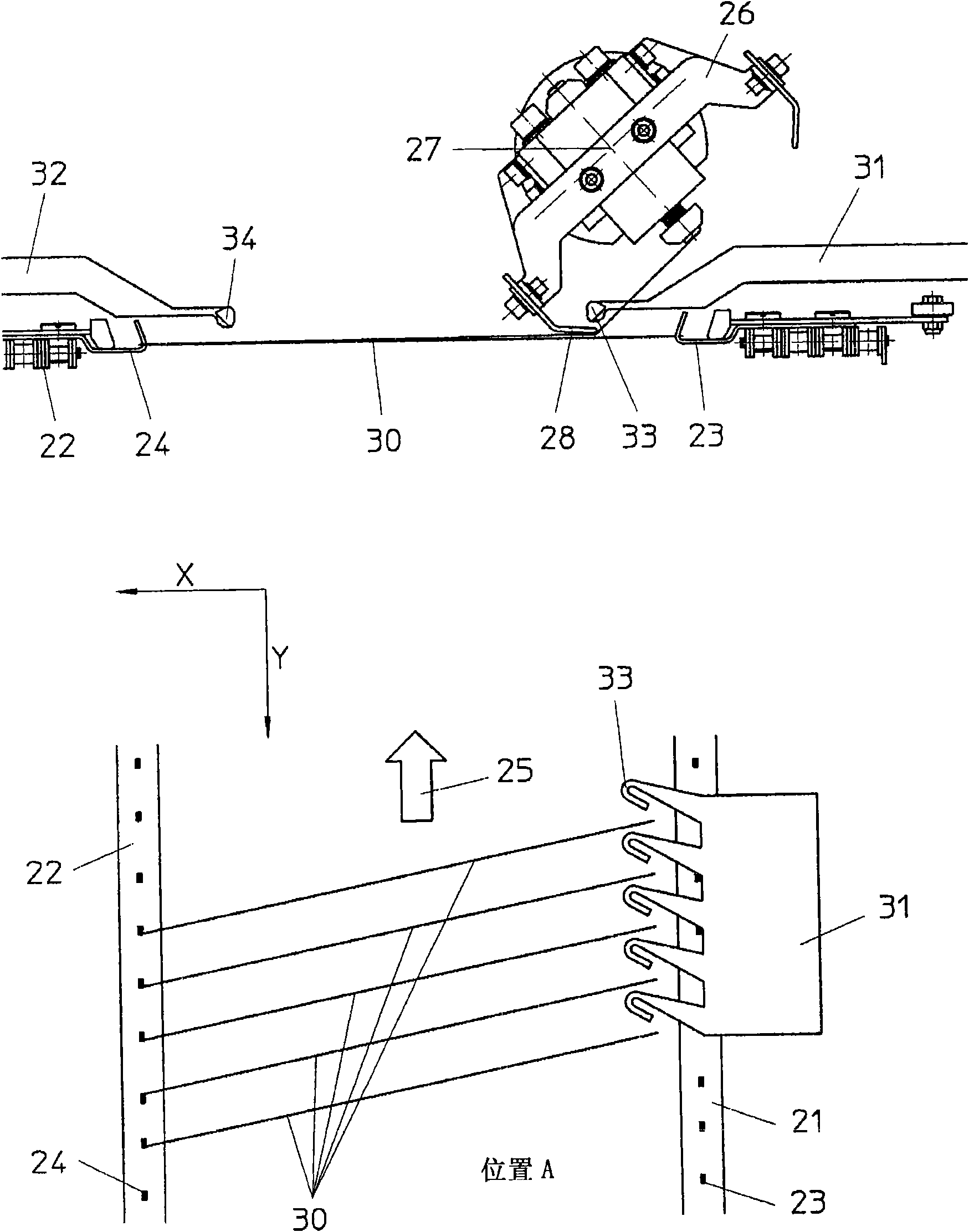

Method and device for placing a unidirectional thread layer on longitudinal conveyors, method for laying weft threads on warp knitting machines, and device to carry out said methods

InactiveCN101525809AIdeal coordination displacementHigh speedNon-woven fabricsFlat warp knitting machinesMulti axisClosed orbit

In the warp knitting machines and knitting machines for multi-axis must be one-way yarn layer (8) to mobile vertical conveyor belt installation (1,2) and hung on the conveyor belt at the vertical (1,2) on a fixed set of hooks (3 , 3a, 3b, or 4,4a, 4b) on the. Above the vertical conveyor (1,2) to send the direction (5) mobile. Described yarn (8) from the storage device (6) was extracted and transferred through the pulley off (9) transmission line to the first input device (10), referred to the input line of the device will hang the yarn to the first vertical conveyor belt (1) a fixed set of hooks (3,3a, 3b) in the. Then, the second transmission line unit (11) will be linked to the second vertical conveyor belt yarn (2) a fixed set of hooks (4,4a, 4b) in the. Described in two transmission-line device (10,11) in two mutually perpendicular extension of the direction of x axis and y-axis movement and the movement to draw a closed orbit (14 and 15). In order to grab yarn (8), referred to the input line of devices (10,11) set up branch with claws (12,13). The methods described can also be achieved through the yarn guide, which referred to the input line of devices (10,11) was designed to shift rake. Yarn made of layers is transported to a warp knitting machine knitting station (7) or knitting tools.

Owner:LIBA MASCHFAB

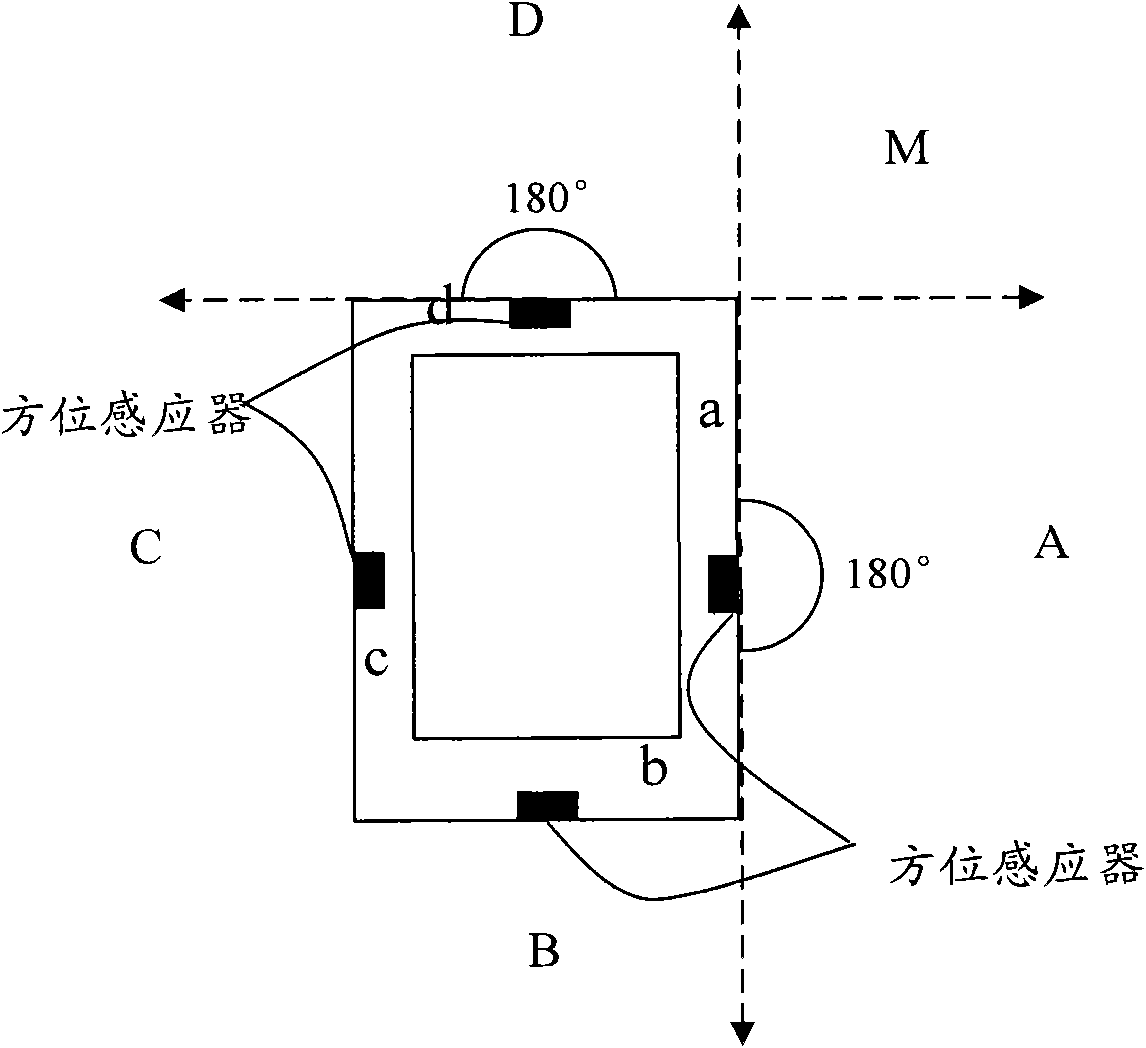

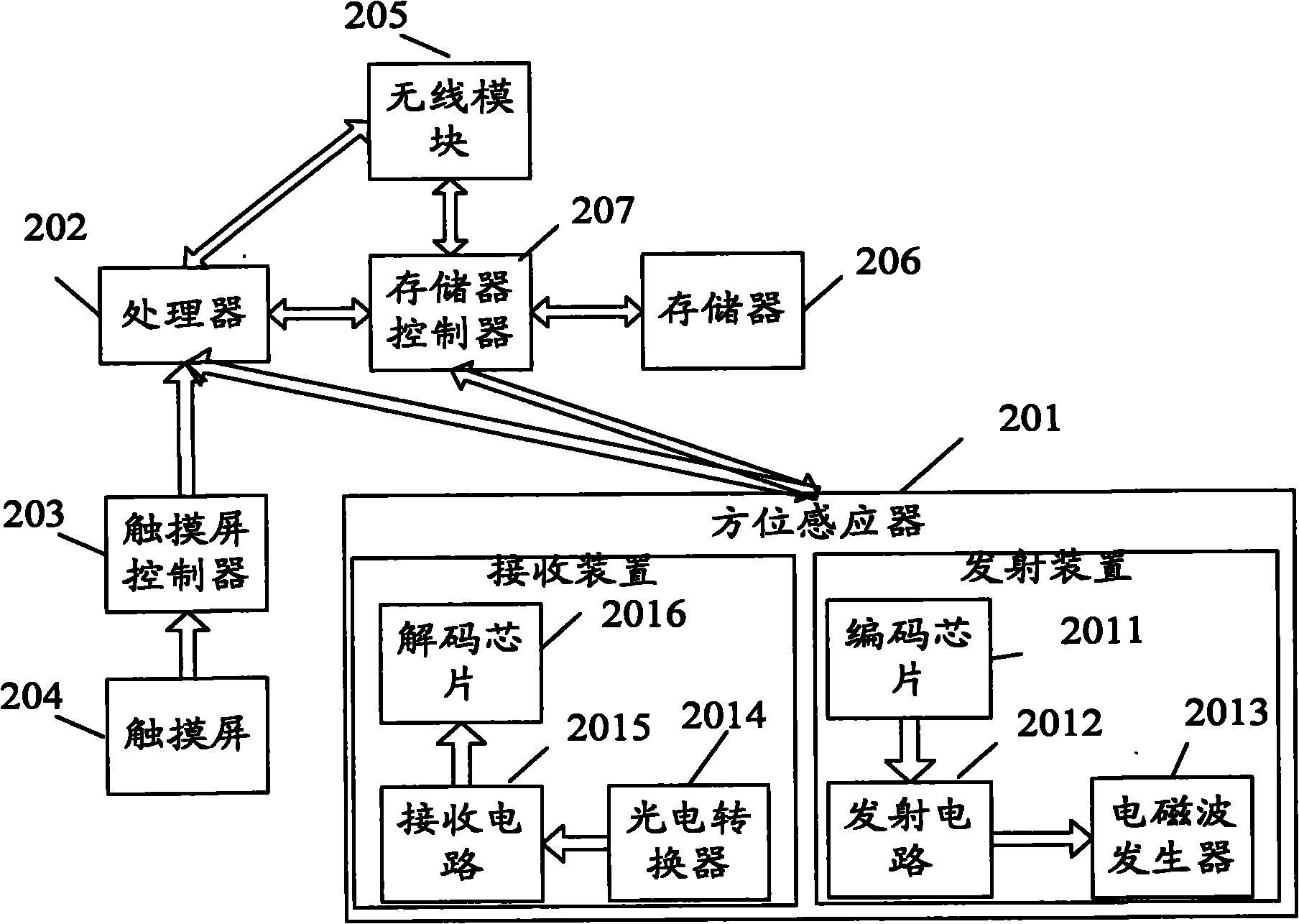

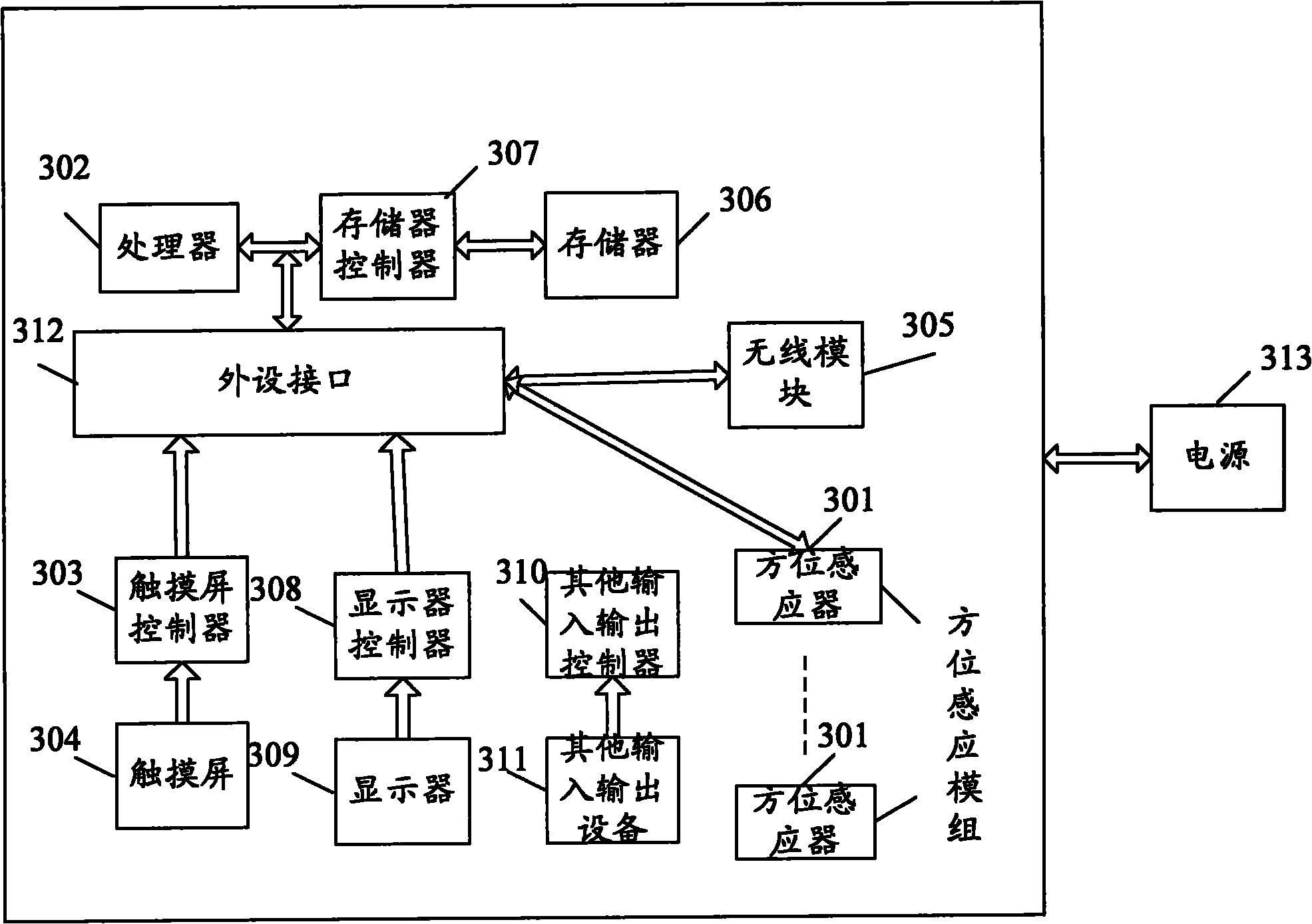

Apparatus, equipment and method for transmitting data in touch mode

InactiveCN102340332AEasy to operateSimplify the transfer processNear-field transmissionDigital data processing detailsEngineeringData transmission

The invention discloses an orientation sensor, which comprises an emitting device and a receiving device. The emitting device includes: a coding chip, which enables an equipment ID itself to be filed in a binary signal; A transmitting circuit, which is used for adjusting the binary signal into a pulse electric signal; and an electromagnetic wave generator, which is used for emitting the pulse electric signal in an electromagnetic wave mode; And the receiving device comprises: a photoelectric converter, which is used for receiving an electromagnetic wave and converting the electromagnetic wave into a pulse electric signal; a receiving circuit, which is used for converting the pulse electric signal into a binary signal and sending the binary signal to a decoding chip; and the decoding chip, which is used for reading equipment IDs of other equipment in the binary signal, obtaining an equipment ID itself, determining that the obtained equipment IDs are different from the equipment ID itself and sending the read equipment IDs and a sensor code itself. Besides, the invention discloses an apparatus, equipment and a method for transmitting data in a touch mode. According to the apparatus, the equipment and the method for transmitting data in a touch mode, the data transmission process is simple and visual; and user operation become substantially convenient.

Owner:ZTE CORP

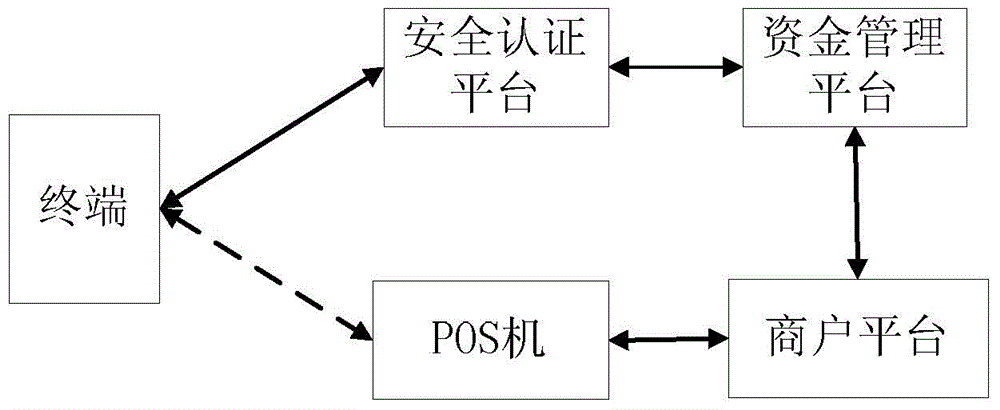

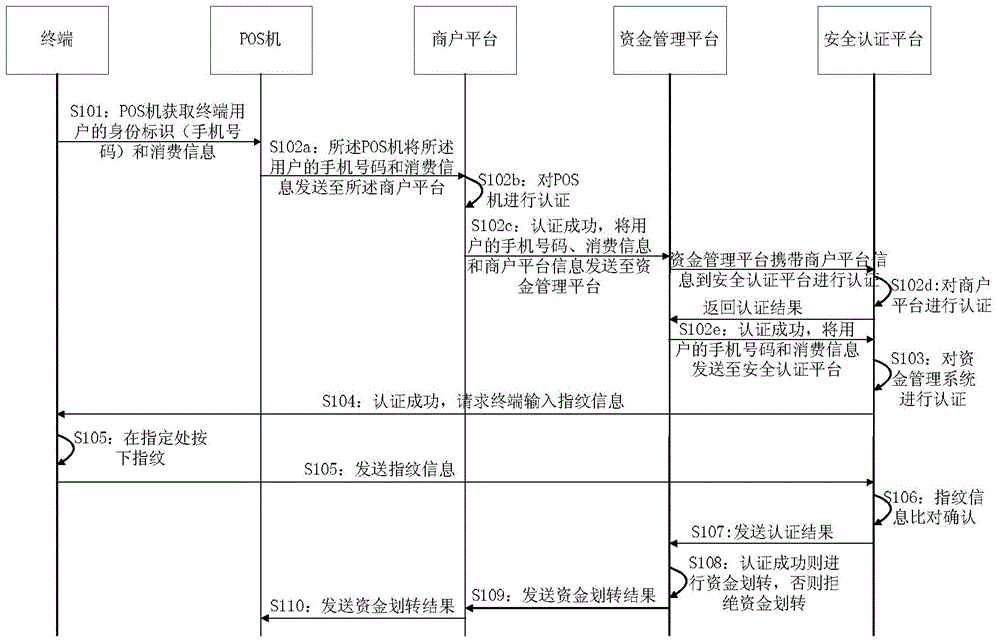

Mobile paying method and system

InactiveCN104361491AImprove securitySimplify the transfer processPoint-of-sale network systemsProtocol authorisationFingerprintManagement system

The invention discloses a mobile paying method and system. The method includes: a POS machine acquires the identity and consuming information of a terminal user, and the identify and consuming information of the user is transmitted to a safety authentication platform through a merchant platform and a fund management platform; the safety authentication platform requests the terminal user to input fingerprint information and compares the fingerprint information with the fingerprint information which corresponds to the identity and is pre-stored in the safety authentication platform, if the input fingerprint information and the pre-stored fingerprint information are consistent, fingerprint authentication succeeds, or else the fingerprint authentication fails; the fingerprint authentication result is transmitted to the fund management platform; the fund management platform performs corresponding operations of fund transfer according to the fingerprint authentication result and the consuming information. The method has the advantages that the method is suitable for a consumer who pays through the POS machine authorized by a merchant, the safety authentication platform directly transmits the authentication result to the fund management system to perform fund transfer during paying, transaction safety is increased, and the fund transfer flow is simplified.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

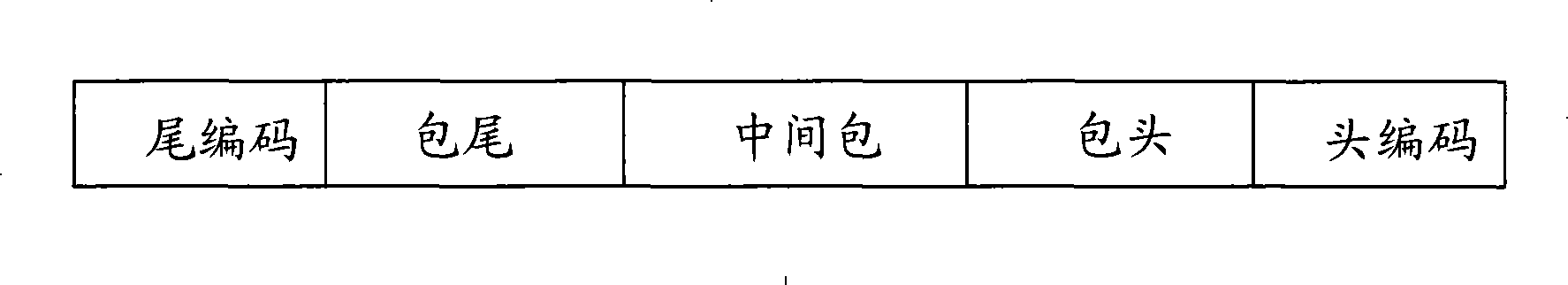

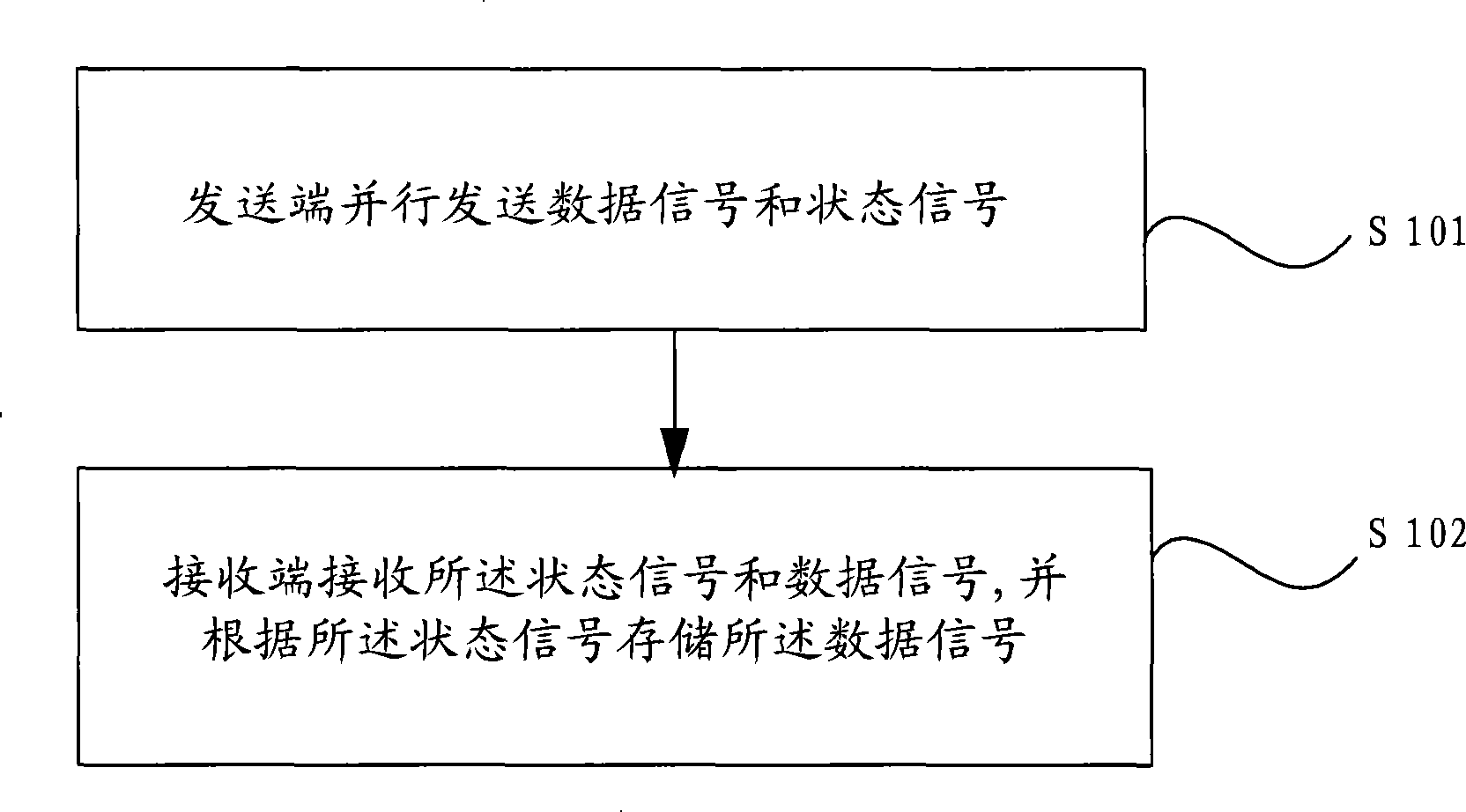

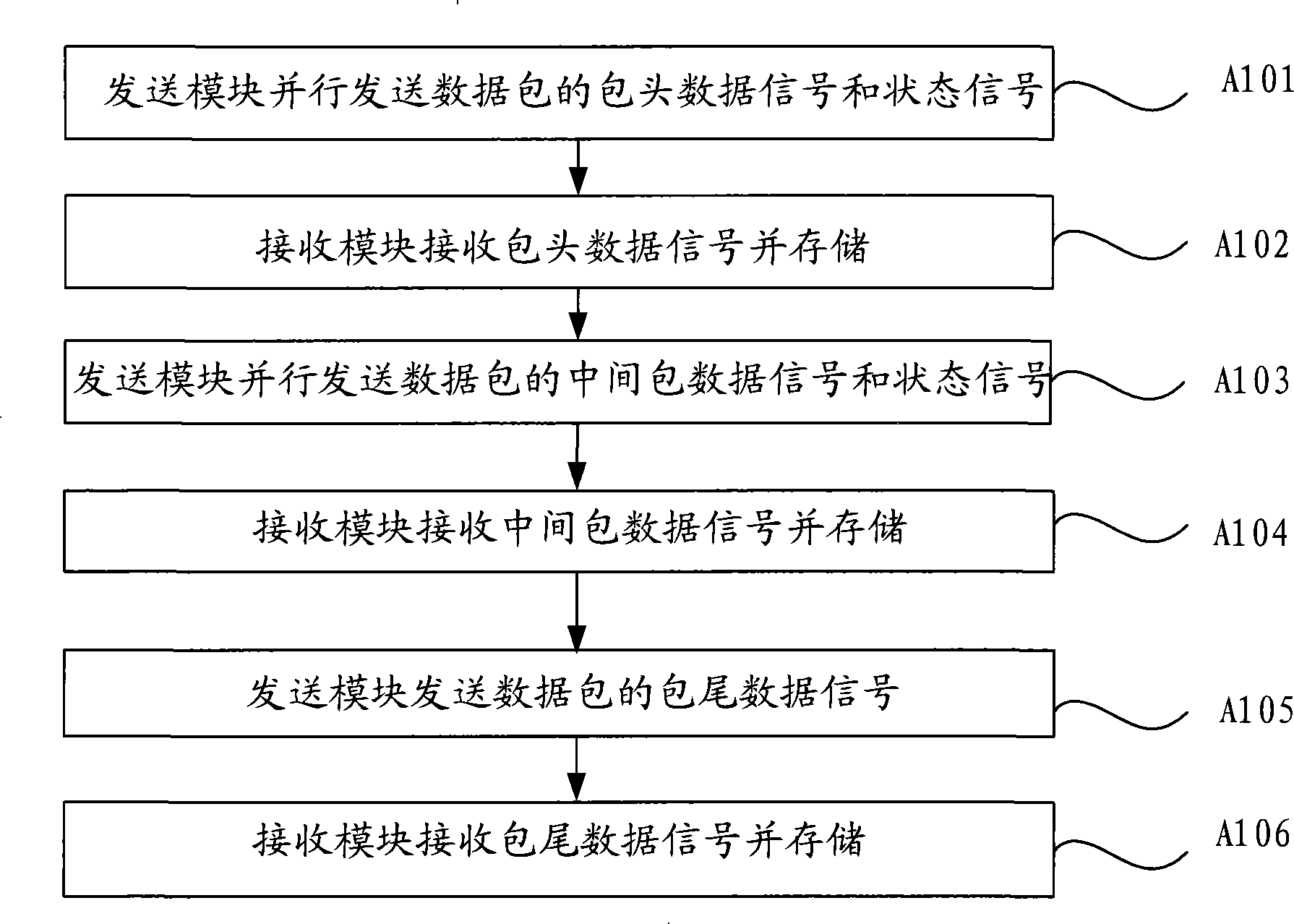

Complete package data transmission method and transmission system

InactiveCN101252415AImprove transmission efficiencySimplify the data transfer processError preventionData switching networksTransport systemData signal

The invention discloses a transmission method and a transmission system for the integral packet data, including the steps that the data signal and the state signal are transmitted in parallel by the sender; the data signal includes the data signal of the data packet; the state signal includes the state signal which indicates the transmission state of the data packet; wherein, the data signal of the data packet is transmitted at least in three times; the receiver receives the state signal and the data signal and stores the data signal according to the state signal; wherein, the receiving mode is that the data signal of the same data packet received in the continuous clock cycle is stored in the continuous storage space. In the transmission method and the transmission system for the integral packet data, the data signal and the state signal are separated for parallel transmission; thereby, the state signal can not occupy the transmission bandwidth of the data signal; otherwise, the packet reintegration is avoided in the receiver; the data signal received in the continuous clock cycle is stored in the continuous storage space in the receiver; the data transmission process is simplified and the transmission speed is improved.

Owner:THE PLA INFORMATION ENG UNIV

Layer transfer of films utilizing controlled shear region

ActiveUS9362439B2Limit regionReduce developmentSemiconductor/solid-state device manufacturingMetal working apparatusEngineeringThermal treatment

Owner:SILICON GENERAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com