Micro light emitting diode transfer substrate and method, display panel and preparation method

A technology of micro-light-emitting diodes and transfer substrates, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve problems such as the complexity of the Micro LED device process, and achieve the effects of improving transfer yield, avoiding selection, and simplifying the transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

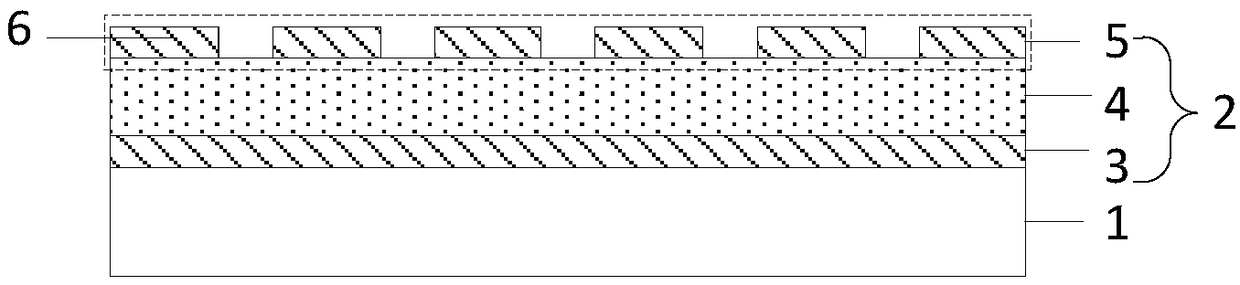

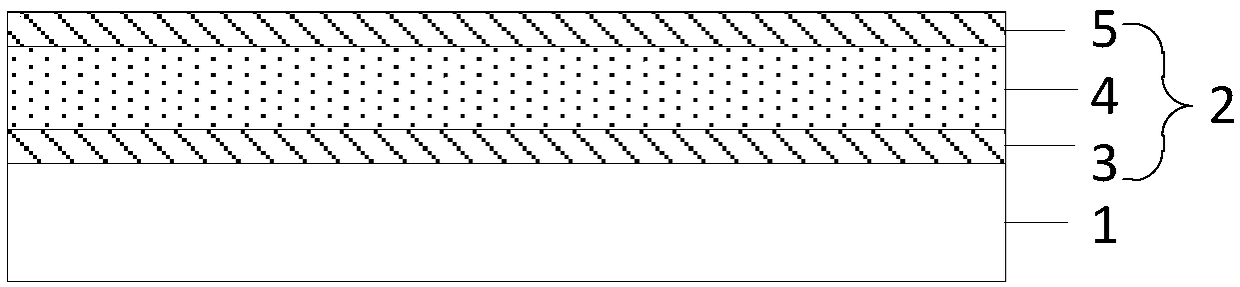

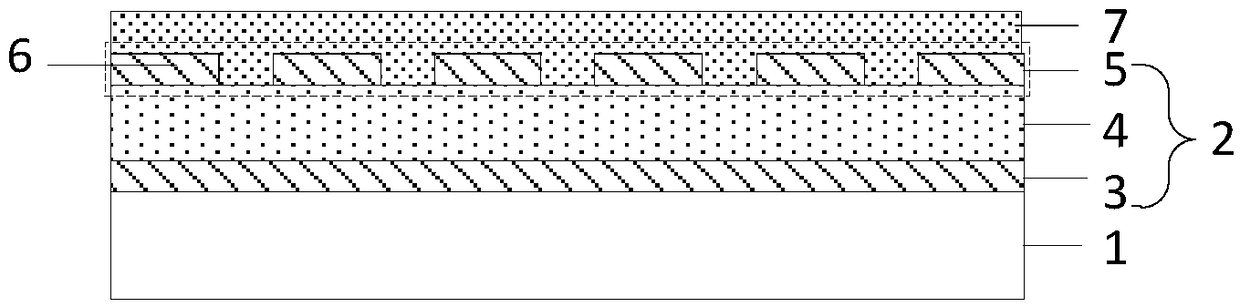

[0036] The embodiment of the present application provides a transfer substrate of a micro light emitting diode, such as figure 1 As shown, the transfer substrate includes: a first base substrate 1 and an electrostrictive layer 2 located on the first substrate substrate 1; the electrostrictive layer 2 is used to: make each transfer The thickness of the electro-deformable layer 2 in the area corresponding to the micro-light emitting diode is greater than the thickness of the electro-deformable layer 2 in the area corresponding to the micro-light-emitting diode that does not need to be transferred this time.

[0037]The transfer substrate of the micro-light-emitting diodes provided in the embodiment of the present application is equipped with an electro-deformable layer, and the height of the electro-deformable layer can be changed by applying power to the electro-deformable layer, so that the micro-light-emitting diodes that need to be transferred each time correspond to The thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com