A device and method for transferring graphene in batches to a grid-carrying copper substrate

A technology of copper substrate and graphene, applied in the field of graphene, can solve the problem of lack of batch transfer of graphene, etc., and achieve the effect of simple operation and simple process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

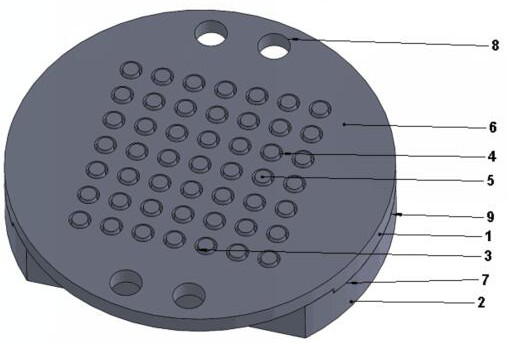

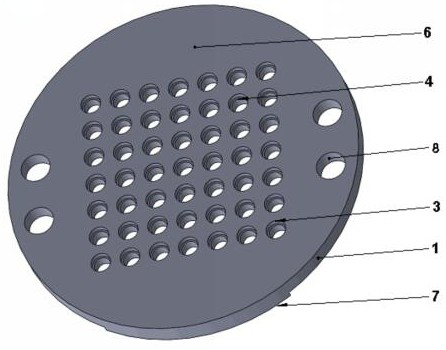

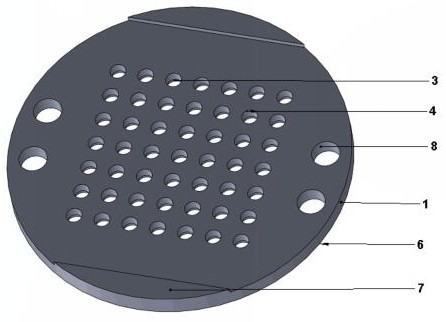

[0034] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a device for batch transferring graphene to a mesh-carrying copper substrate includes a load plate 1 and a load plate base 2 made of polytetrafluoroethylene; the load plate 1 has a matrix arrangement (linear matrix or circular matrix) Or irregularly arranged load holes 3 for the meshed copper substrate, the lower part of the load hole 3 is provided with a lead-out hole 4 that is coaxial with the load hole, has a diameter smaller than the load hole 3, and penetrates the load plate 1; the load plate The base 2 is provided with a supporting column 5 which is equal to the lead-out hole 4, coaxial and matched with each other.

[0035] When the load plate 1 is attached to the load plate base 2, the support column 5 passes through the lead-out hole 4 and the load hole 3, and the top surface of the support column 5 is 0.2mm higher than the load surface 6 of the load plate 1, which is used to push out the load hole 3 ...

Embodiment 2

[0045] like figure 1 , figure 2 , image 3 , Figure 4As shown, a device for batch transferring graphene to a mesh-carrying copper substrate includes a load plate 1 and a load plate base 2 made of quartz glass; the load plate 1 has a matrix arrangement (linear matrix or circular matrix) or no Regularly arranged load holes 3 for the meshed copper substrate, the lower part of the load holes 3 is provided with a lead-out hole 4 that is coaxial with the load holes 3, has a diameter smaller than the load holes 3, and penetrates the load plate 1; the load plate base 2 is provided with a support column 5 which is equal to the lead-out hole 4, coaxial and matched with each other.

[0046] Preferably, when the load plate 1 is attached to the load plate base 2, the support column 5 passes through the lead-out hole 4 and the load hole 3, and the top surface of the support column 5 is 0.5 mm higher than the load surface of the load plate 1. To push out the carrier copper substrate in...

Embodiment 3

[0056] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a device for batch transferring graphene to a mesh-carrying copper substrate includes a load plate 1 and a load plate base 2 made of polytetrafluoroethylene; the load plate 1 has a matrix arrangement (linear matrix or circular matrix) Or irregularly arranged load holes 3 for the meshed copper substrate, the lower part of the load hole 3 is provided with a lead-out hole 4 that is coaxial with the load hole 3, has a diameter smaller than the load hole 3, and penetrates the load plate 1; the load The disk base 2 is provided with a supporting column 5 which is equal to the lead-out hole 4, coaxial and matched with each other.

[0057] When the load plate 1 is attached to the load plate base 2, the support column 5 passes through the lead-out hole 4 and the load hole 3, and the top surface of the support column 5 is 0.3mm higher than the load surface of the load plate 1 for pushing out the load hole 3. Mesh carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com