Patents

Literature

71results about How to "The process principle is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nano black carbon passivator for repairing heavy metal contaminated soil

ActiveCN103084153AThe process principle is simpleReduce manufacturing costOther chemical processesContaminated soil reclamationWater bathsEconomic benefits

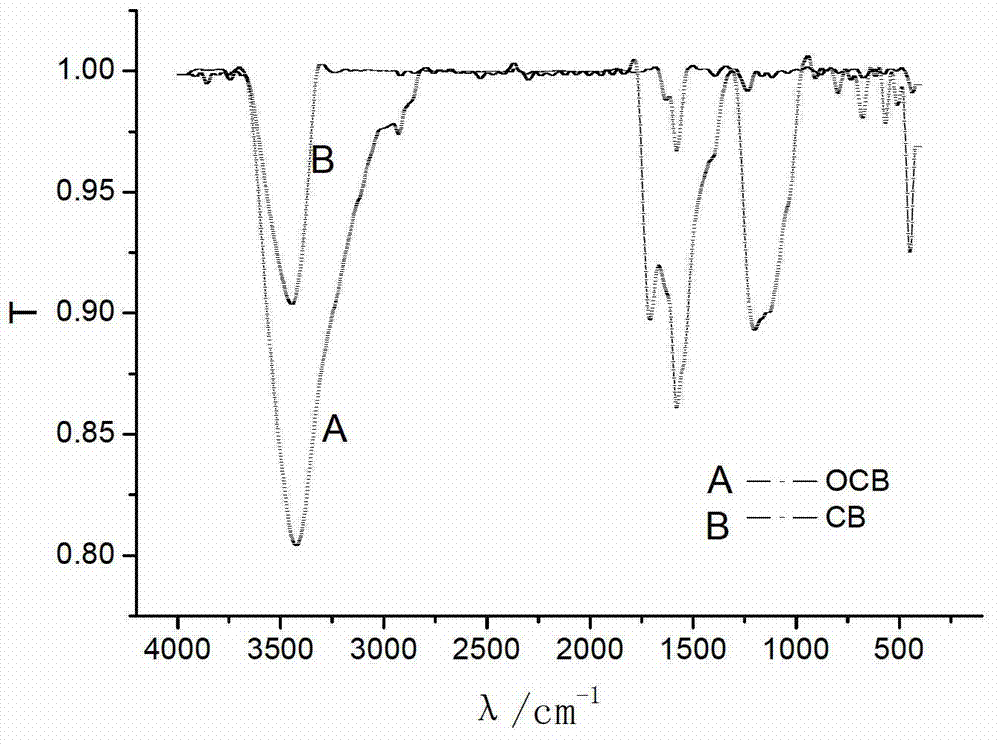

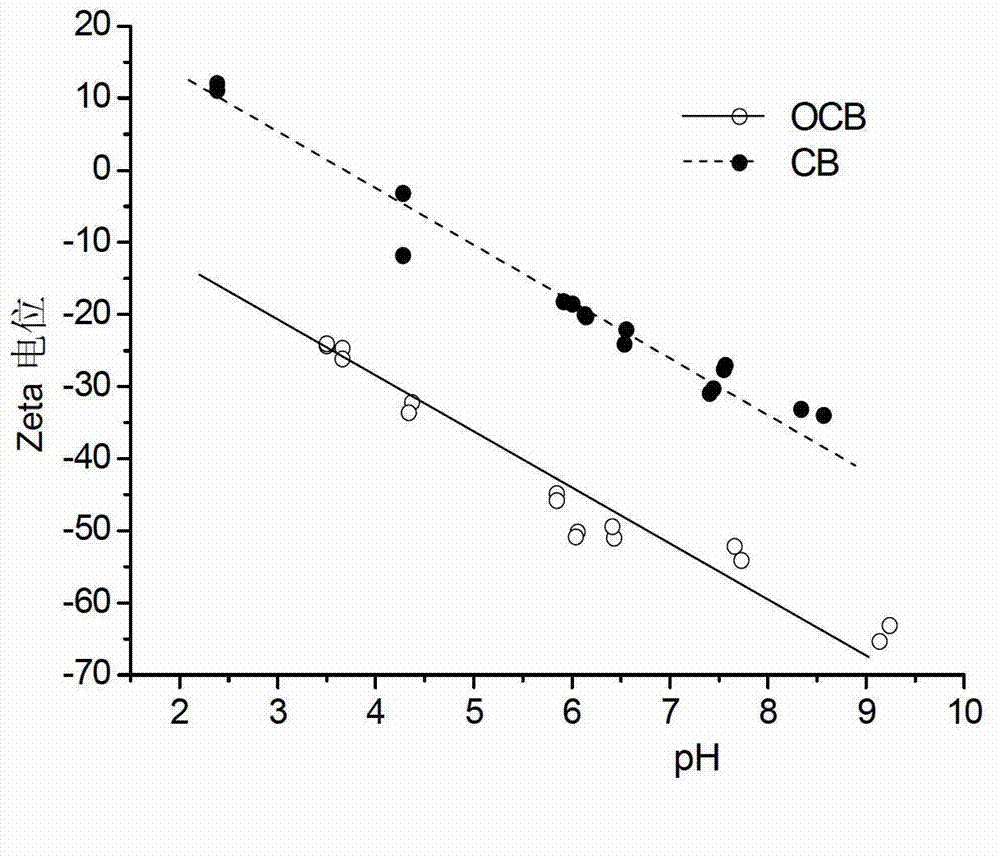

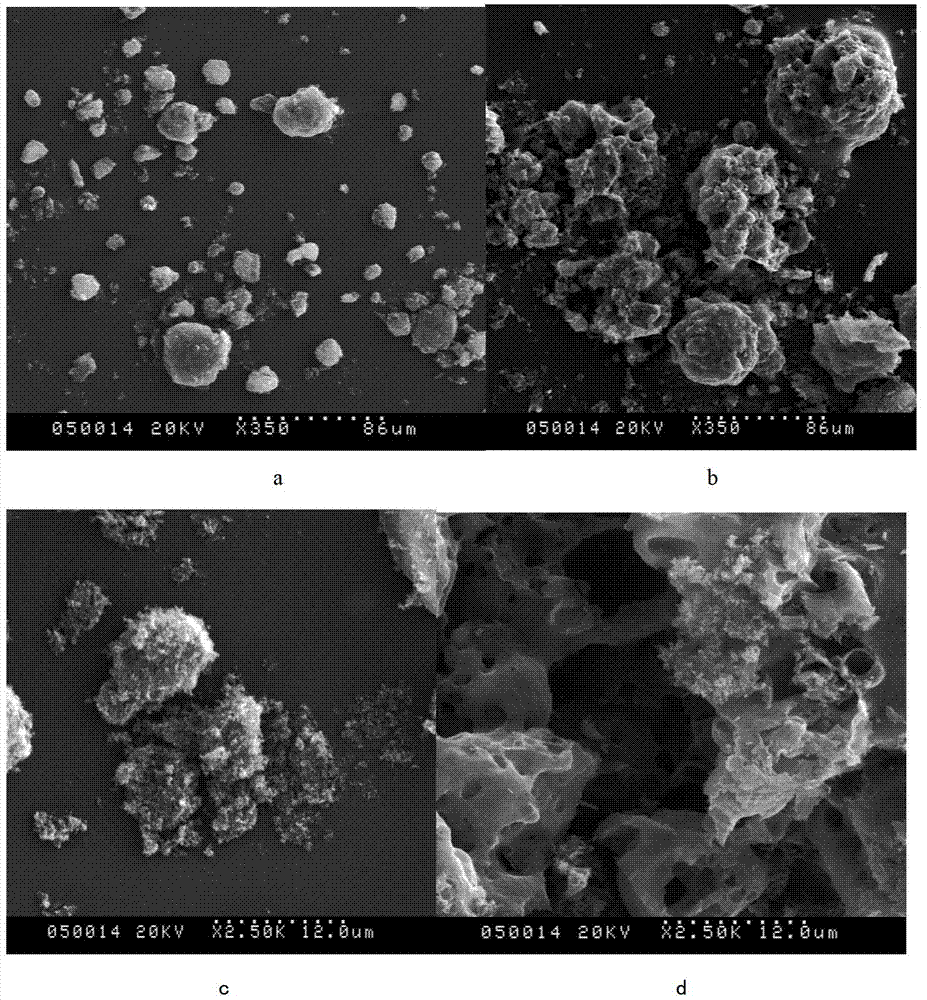

The invention belongs to the technical field of preparation of novel materials and relates to a method for preparing a nano black carbon passivator for repairing heavy metal contaminated soil. The method comprises the following steps of: weighing nano black carbon raw materials and putting the raw materials in a glass container, adding HNO3 and KMnO4, uniformly mixing so as to obtain a mixed oxidant, putting the nano black carbon and the mixed oxidant in a ventilating kitchen, and standing at room temperature so as to obtain the pre-oxidized nano black carbon; heating the pre-oxidized nano black carbon by utilizing a constant temperature water bath kettle, thus obtaining the oxidized nano black carbon; centrifuging the oxidized nano black carbon in a centrifugal machine, and pouring the supernatant; adding distilled water, and repeatedly centrifuging until the pH value of the centrifuged supernatant is more than 5.5, thus obtaining the washed modified nano black carbon; and controlling the temperature of the washed modified nano black carbon to be 105 DEG C, and drying in a dryer, thus obtaining the product. The method is simple in process principle, low in preparation cost, high in product quality, environment-friendly in production, high in economic benefits, wide in product application range and good in a using effect.

Owner:SHANDONG NORMAL UNIV

Method for preparing complex gradient material by using cold spraying technology

InactiveCN102181856AReduce porosityEasy to producePressure inorganic powder coatingPorosityGradient material

The invention relates to a method for preparing a complex gradient material by using cold spraying technology, belonging to the technical field of metal surface treatment. The method comprises the following steps: spraying first spray powder on the surface of a substrate for the first time by using a stainless steel convergent-divergent spray gun; after raising the stainless steel convergent-divergent spray gun, spraying second spray powder for the second time; and finally, spraying third spray powder for the third time by using a high-heat-resistant plastic convergent-divergent spray gun, thereby preparing the complex gradient material on the surface of the substrate. The thickness of the gradient material prepared by the method provided by the invention can be adjusted within a wide range; and meanwhile, the gradient material has the advantages of low porosity, high bonding strength and no environmental pollution.

Owner:SHANGHAI JIAO TONG UNIV

Mixed fatty acid and its prepn process and application

InactiveCN1821376ARealize rational utilizationHigh activityFatty oils/acids recovery from wasteFatty substance recoveryHeating oilMixed fatty acid

The present invention relates to a kind of mixed fatty acid and its preparation process and application. The preparation process includes the following steps: 1. heating oil leftover with steam, stirring, acidifying and hot water washing to obtain neutral acidified oil; 2. separating waste water from oil leftover and repeating the step 1; 3. separating the exhausted neutral mixture waste liquid and separating suspension acting as isolating agent; 4. mixing the separated neutral acidified oil with water and hydrolysis at 120 deg.c and 1 MPa; 5. precipitating the hydrolyte to obtain black fatty acid; 6. steam dewatering black fatty acid; and 7. negative pressure distilling black fatty acid to obtain transparent liquid mixed fatty acid. The prepared mixed fatty acid has high activity, good flexibility, high flowability and low cost, and may be used as main material for producing washing powder, and in producing oleic acid, stearic acid and other products.

Owner:杨解定

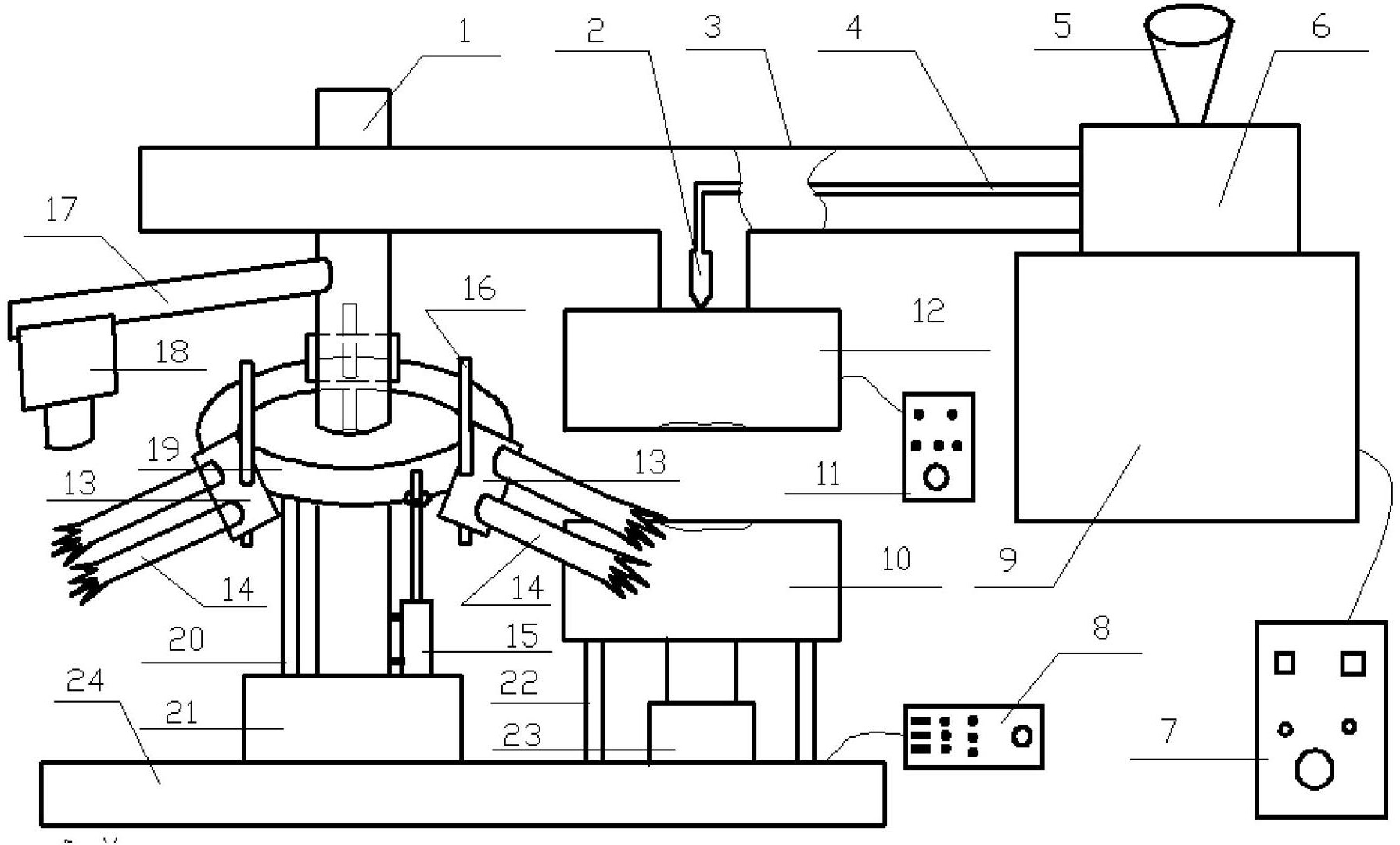

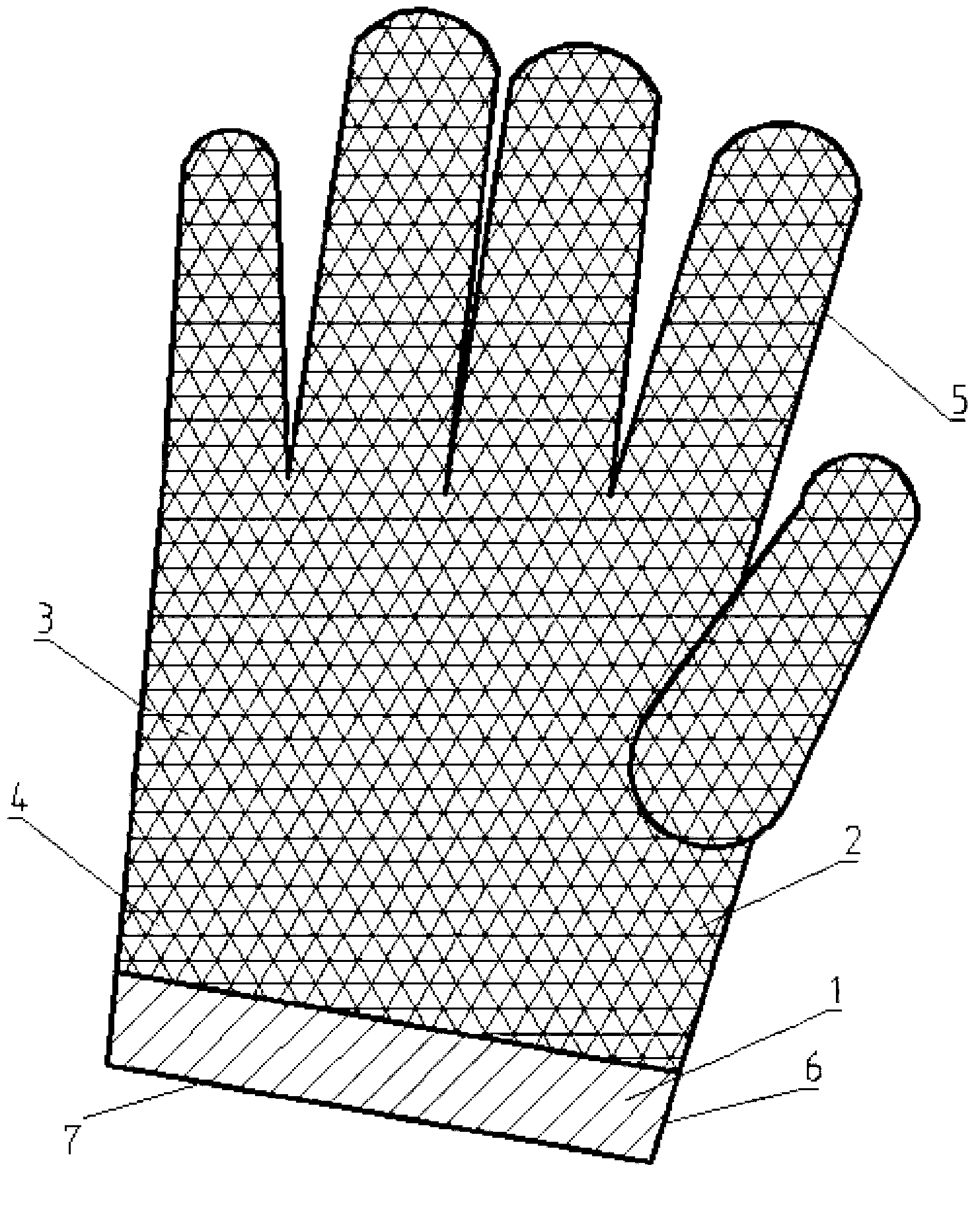

Method for producing rubber coating of protective gloves

InactiveCN102672883AThe process principle is simpleReduce processing costsDomestic articlesFiberEngineering

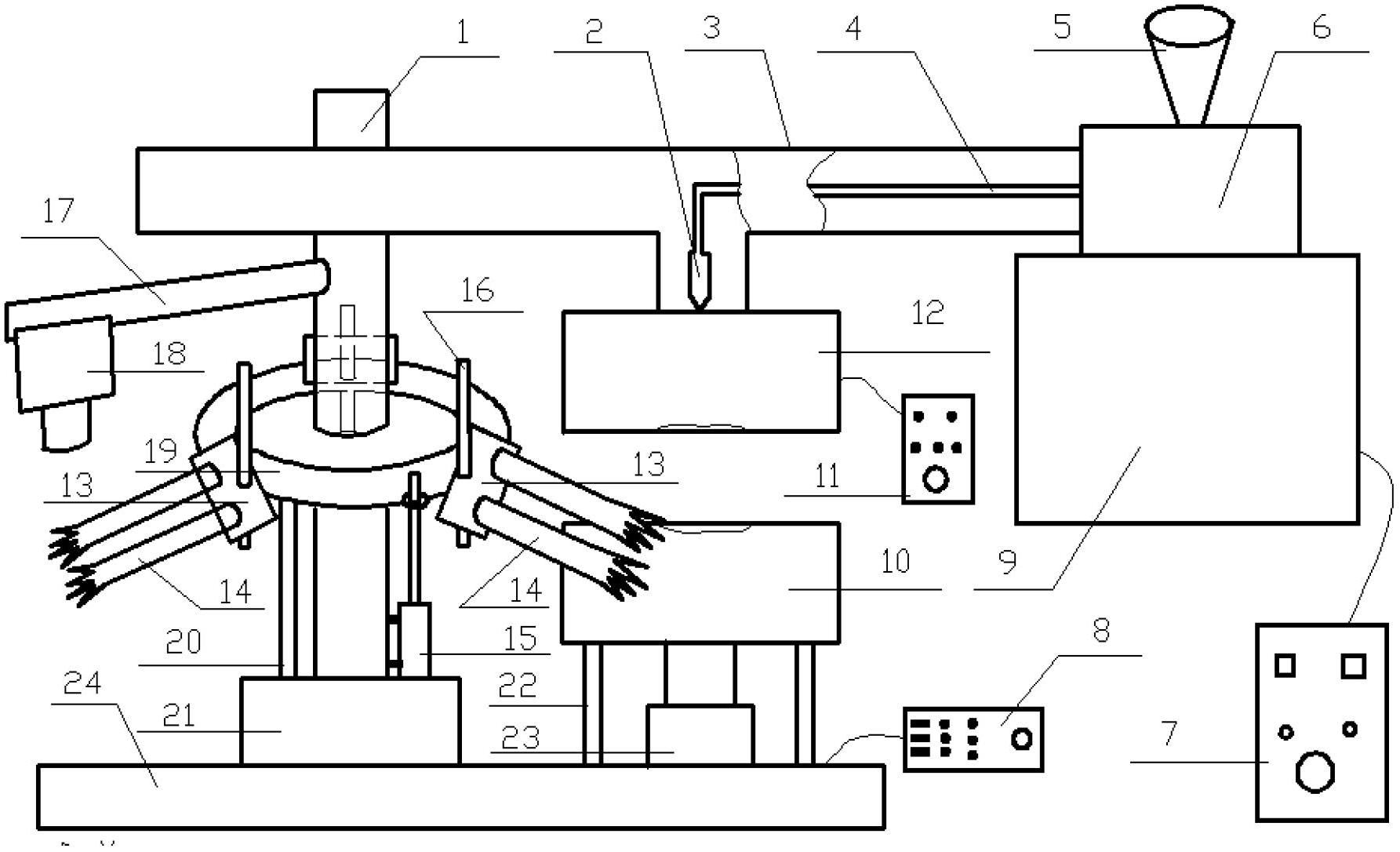

The invention belongs to the technical field of glove processing, and relates to a method for producing the rubber coating of protective gloves, which uses a rubber injection and coating device to produce the rubber coating of fiber gloves and is characterized in that the fiber gloves to be coated are firstly sheathed on hand dies, the hand dies are fixedly arranged on a sliding block of the rubber injection and coating device, a turntable is rotated so that the hand dies are embedded in the inner cavities of an upper die and a lower die which are matched with each other, the rubber injection and coating device is started, and the rubber liquid is injected into a clearance which is formed after the hand dies and the upper and lower dies are aligned through a rubber nozzle, fully filled and then cooled for 1-10 seconds to enable a rubber coating to be adhered firmly; then, the upper and lower dies are loosened, the turntable is rotated for rotating the hand dies which are coated with the rubber coating out of the inner cavities of the upper and lower dies, meanwhile, another pair of hand dies is rotated into the inner cavities of the upper and lower dies to be injected and coated with the rubber coating, the process is recirculated, so the injection and the coating of the rubber layer of the fiber gloves are completed; the coating rate of the rubber coating of a glove palm side is 100%; and the method adopts a simple principle, is low in cost, and has high product quality and a long service life.

Owner:GAOMI LICHANG LABOR PROTECTION PROD IND & TRADE

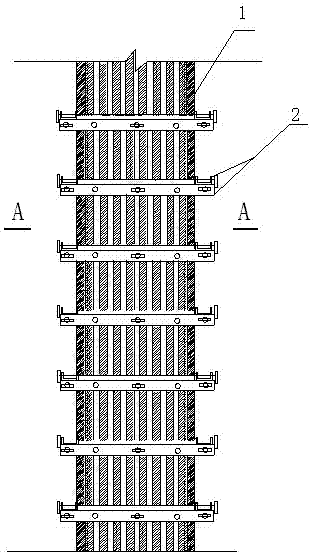

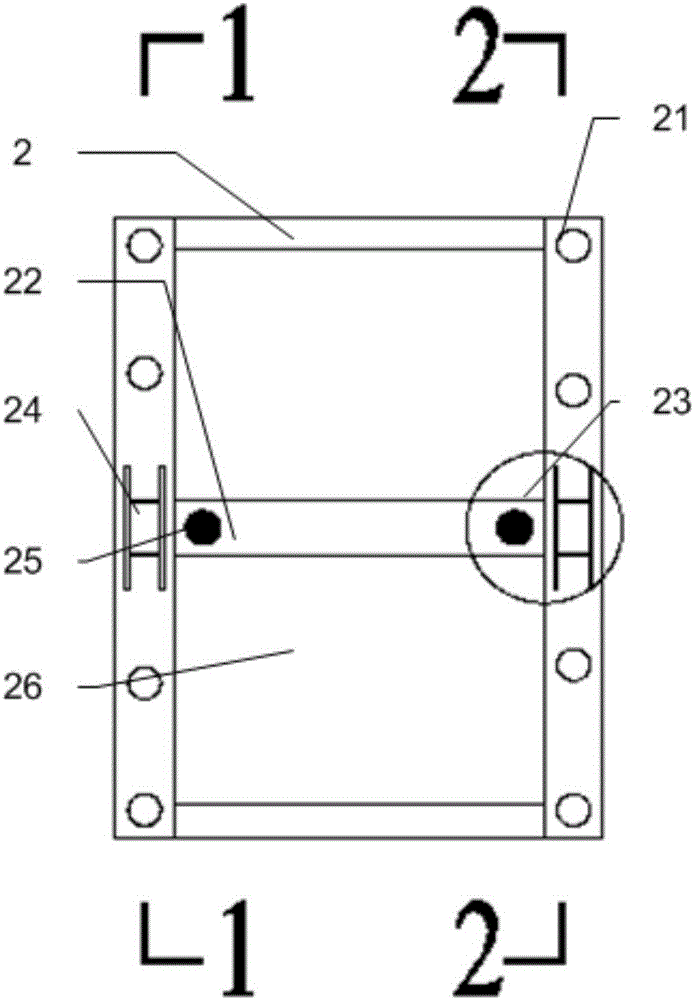

Adjustable frame column formwork back arris system

InactiveCN104295092AThe process principle is simpleEasy to operateForms/shuttering/falseworksBuilding constructionCycling

The invention relates to the field of civil engineering, in particular to an adjustable frame column formwork back arris system. The method for building the system is characterized by comprising the steps of 1, determining the number of cycling sets of black laminated timber formworks according to the type of a frame column; 2, determining the size of each steel channel back arris plate, the diameters of openings and the number of the openings according to the size and height of the section of the frame column; 3, determining the distance between vertical steel pipe back arrises according to the size of the section of the frame column; 4, arranging a pull screw with a diameter of 16 mm on each horizontal back arris of the frame column, wherein the distance between the pull screws is identical with that between steel channels; 5, installing a frame column formwork system; 6, pouring concrete onto the frame column; 7, removing the formwork system; 8, reusing the formwork after the formwork is cleaned. According to the system, the adopted technical principle is simple, and operation is convenient; the built formwork system can be reused, construction efficiency is improved, and construction cost is reduced.

Owner:CHINA MCC20 GRP CORP

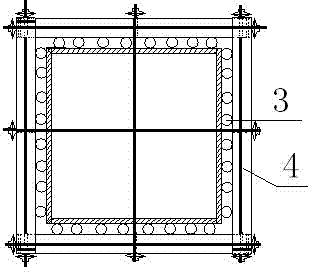

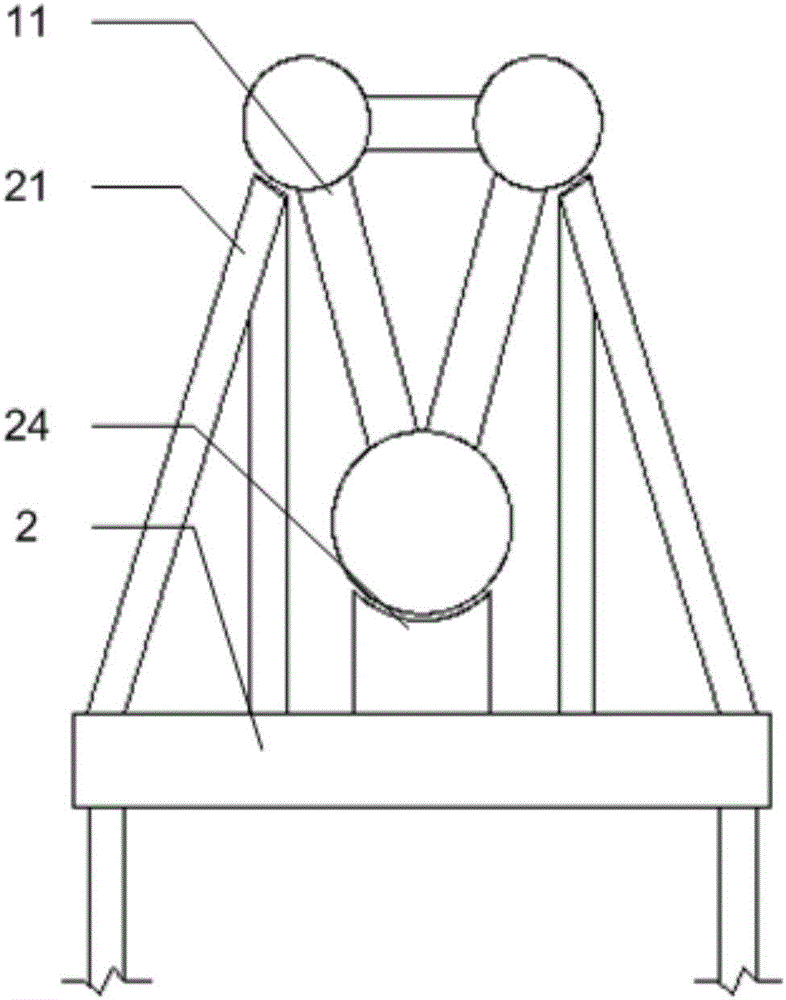

Construction method for large-span inverted-triangle-type concrete-filled steel tube arch bridge steel arch

ActiveCN107178042APrecisely adjust the elevationSave materialBridge erection/assemblyBridge strengtheningInverted triangleSpandrel

The invention provides a construction method for a large-span inverted-triangle-type concrete-filled steel tube arch bridge steel arch. The construction method is characterized in that the construction method comprises the steps that S1, segmentation is conducted on an inverted-triangle-structural-form steel arch truss according to the bearing capacity and the heavy-cargo transporting capacity of an old bridge floor; and a temporary support is arranged at each segment of joint crack, and the temporary supports are located on the old bridge floor; S2, tube holders are arranged at the junctions of the temporary supports and an upper chord as well as of the temporary supports and a lower chord correspondingly, after the steel arch truss is basically settled, loading and unloading are conducted on the steel arch truss by adopting a jack to conduct precise adjustment and elevation on the steel arch truss, and the jack is arranged on the temporary supports; S3, the steel arch truss is hoisted; S4, a steel arch tube string is connected; and S5, a cross arm is installed. According to the construction method for the large-span inverted-triangle-type concrete-filled steel tube arch bridge steel arch, a traditional installation method that a floating crane is adopted to conduct integral hoisting is replaced, operation is conducted by rationally utilizing the old bridge floor, green environmental protection is achieved, materials are saved, and the cost is saved.

Owner:CHINA MCC20 GRP CORP +1

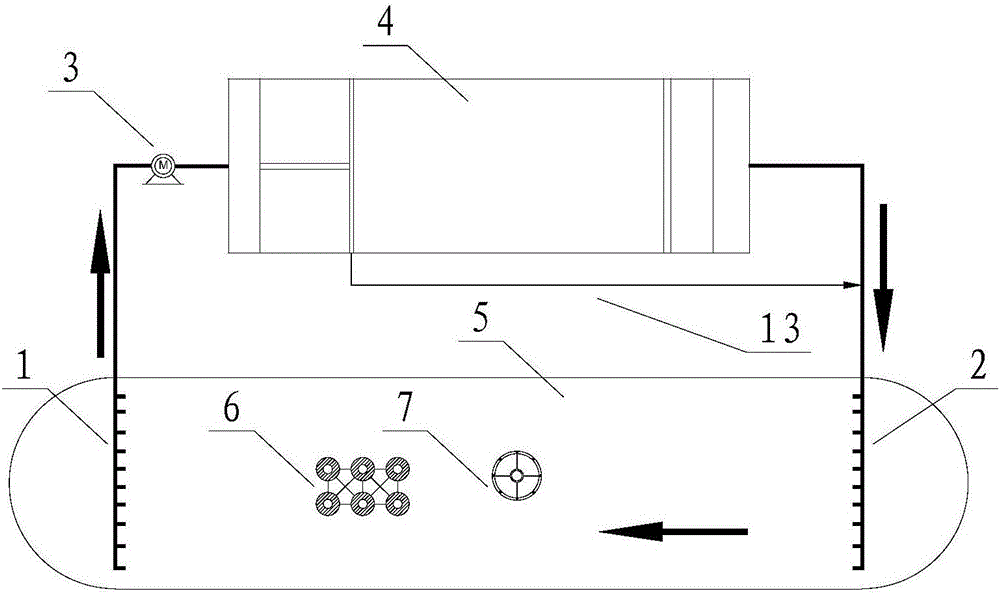

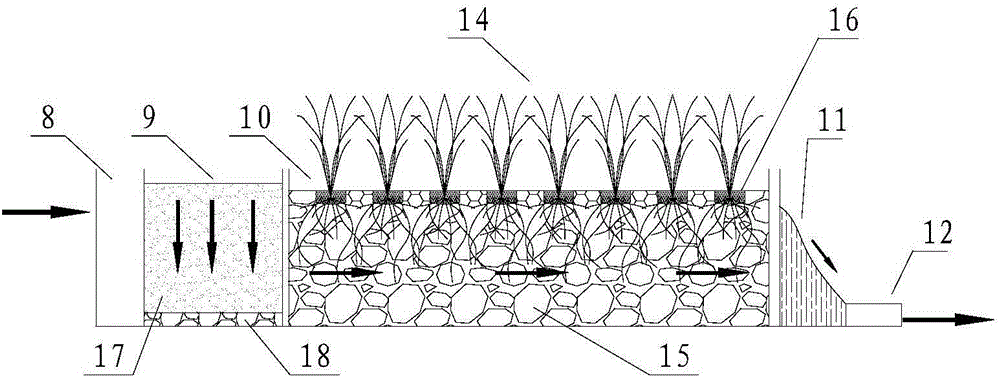

Low-pollution closed landscape water body circulating purification system

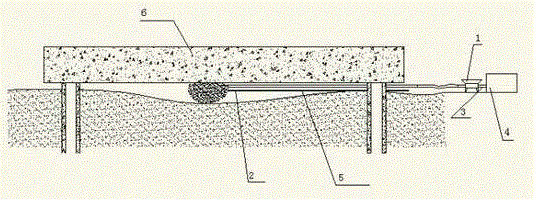

InactiveCN106396118ASpeed up the flowSimple processBiological water/sewage treatmentConstructed wetlandWater quality

The invention relates to a low-pollution closed landscape water body circulating purification system. The system comprises a landscape water body, one end of the landscape water body is connected with a water diversion tube, the water diversion tube is provided with an elevator pump, the other end of the water diversion tube is connected to the front end of a high-load undercurrent constructed wetland system, the rear end of the high-load undercurrent constructed wetland system is connected with a water supply tube, the water supply tube is connected to the other end of the landscape water body, water in the landscape water body goes through the elevator pump and the water diversion tube, enters the high-load undercurrent constructed wetland system and is purified, and purified water goes through the water supply tube and flows back to the landscape water body; and a plurality of ecological floating islands and a photovoltaic fountain are arranged in the landscape water body. The low-pollution closed landscape water body circulating purification system has the advantages of simple process flow, low running cost, excellent comprehensive effectiveness, realization of reduction of pollutants in the water body and "clear water and flowing water" dual water quality keeping function on the premise of promoting flow of the water body by adopting a water power circulating technology as a main technology and comprehensively integrating offline purification and in-situ restoration technologies, simple technologic principle and good effect.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Extraction process of acanthopanax polysaccharide

The invention discloses an extraction process of acanthopanax polysaccharide, which comprises the following steps: an orthogonal test is utilized to optimize parameters of the ultrasonic extraction process, a phenol-sulfuric acid method is utilized to determine the polysaccharide content, and an FRAP method, a pyrogallic acid autoxidation method and a DPPH method are respectively utilized to determine the antioxidation activity of the acanthopanax polysaccharide; and the optimal technological conditions are as follows: the extraction temperature is 70 DEG C, the extraction time is 9 minutes, the ultrasonic power is 500W, and the number of times of extraction is 3. The process is utilized to extract the acanthopanax polysaccharide, and has the advantages of simple principle, low cost and favorable practicality.

Owner:曾丹

Process method for sufficiently recycling precious metal from copper dross and copper matte

InactiveCN105132708AImprove production efficiencyThe process principle is simpleProcess efficiency improvementSlagReverberatory furnace

The invention relates to a process method for sufficiently recycling precious metal from copper dross and copper matte and belongs to the technical field of precious metal recycle. The process method comprises the steps that when the copper dross is smelted through a reverberatory furnace, sodium carbonate is added firstly, and the copper dross is reduced and smelted into the copper matte and wet lead; surface slags are discharged; then most wet lead is discharged; a layer of base lead is left, high-lead and low-silver lead refining slags are added for refining, and high-grade lead oxidation refining slags are obtained; and the sodium carbonate is added again, powdered coal and scrap iron are added for conducting reduction smelting, and a large amount of gold and a large amount of silver enter the base lead. By means of the process method, the content of gold and silver in the copper matte can be reduced, the precious metal is made to enter the wet lead for conducting electrolytic recovery again, and it is guaranteed that valuable metal can be recycled sufficiently by enterprises.

Owner:HUNAN JINWANG BISMUTH

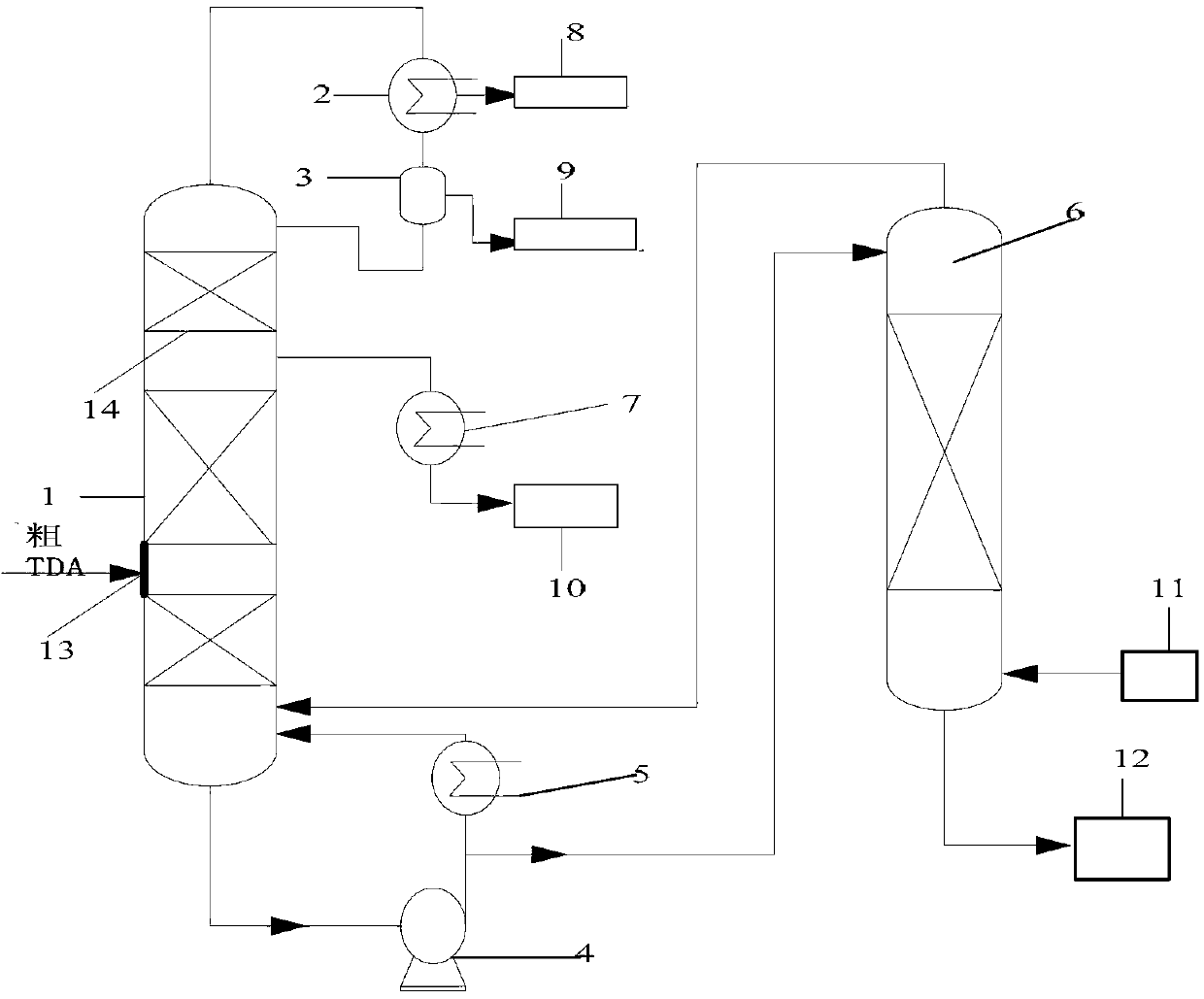

Cleaning and dehydrating method of toluenediamine

InactiveCN103012161AReduce water contentEasy to removeAmino compound purification/separationMultistage water/sewage treatmentWastewaterToluenediamine

Owner:QINGDAO UNIV OF SCI & TECH +2

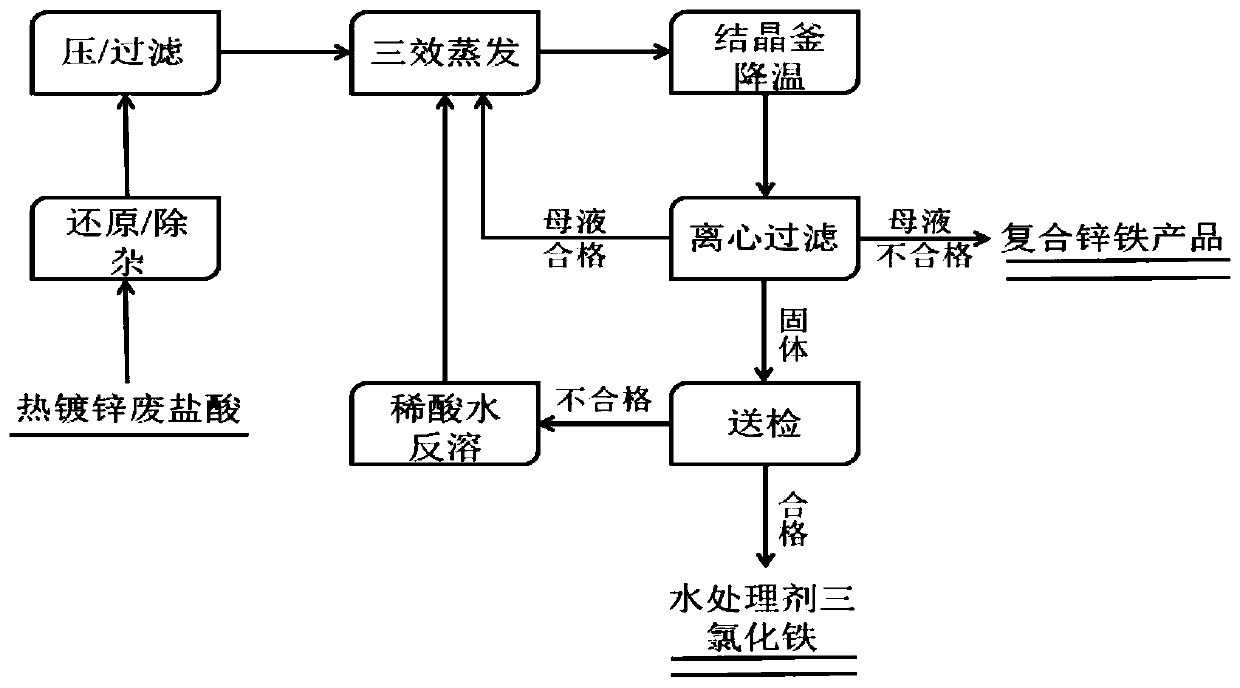

Process method for treating hot-dip galvanizing waste hydrochloric acid

InactiveCN111018001ARealize recyclingPromote resource utilizationIron halidesWater/sewage treatment by flocculation/precipitationWater chlorinationProcess engineering

The invention discloses a process method for treating hot-dip galvanizing waste hydrochloric acid, wherein the process method comprises the steps: pumping pretreated hot-dip galvanizing waste hydrochloric acid subjected to reduction and impurity removal into a triple-effect evaporation system for evaporation and concentration, cooling, and centrifugally filtering to obtain solid ferrous chloride and mother liquor. If the zinc content in the solid ferrous chloride does not exceed the control index, the solid ferrous chloride is used for producing a water treatment agent ferric trichloride product meeting the national standard requirement, otherwise, the solid ferrous chloride is dissolved with dilute acid water generated through evaporation and concentration and then recrystallized to obtain solid ferrous chloride with the zinc content meeting the control index, and then the water treatment agent ferric trichloride product meeting the national standard requirement is produced. Accordingto the technical scheme, the process is simple, the operation danger coefficient is low, secondary pollution is avoided, a new way is provided for resource utilization of the hot-dip galvanizing waste hydrochloric acid, the environmental protection pressure is effectively reduced, and meanwhile the economic benefits of enterprises are increased.

Owner:3R ENVIRONMENTAL TECH CO LTD +1

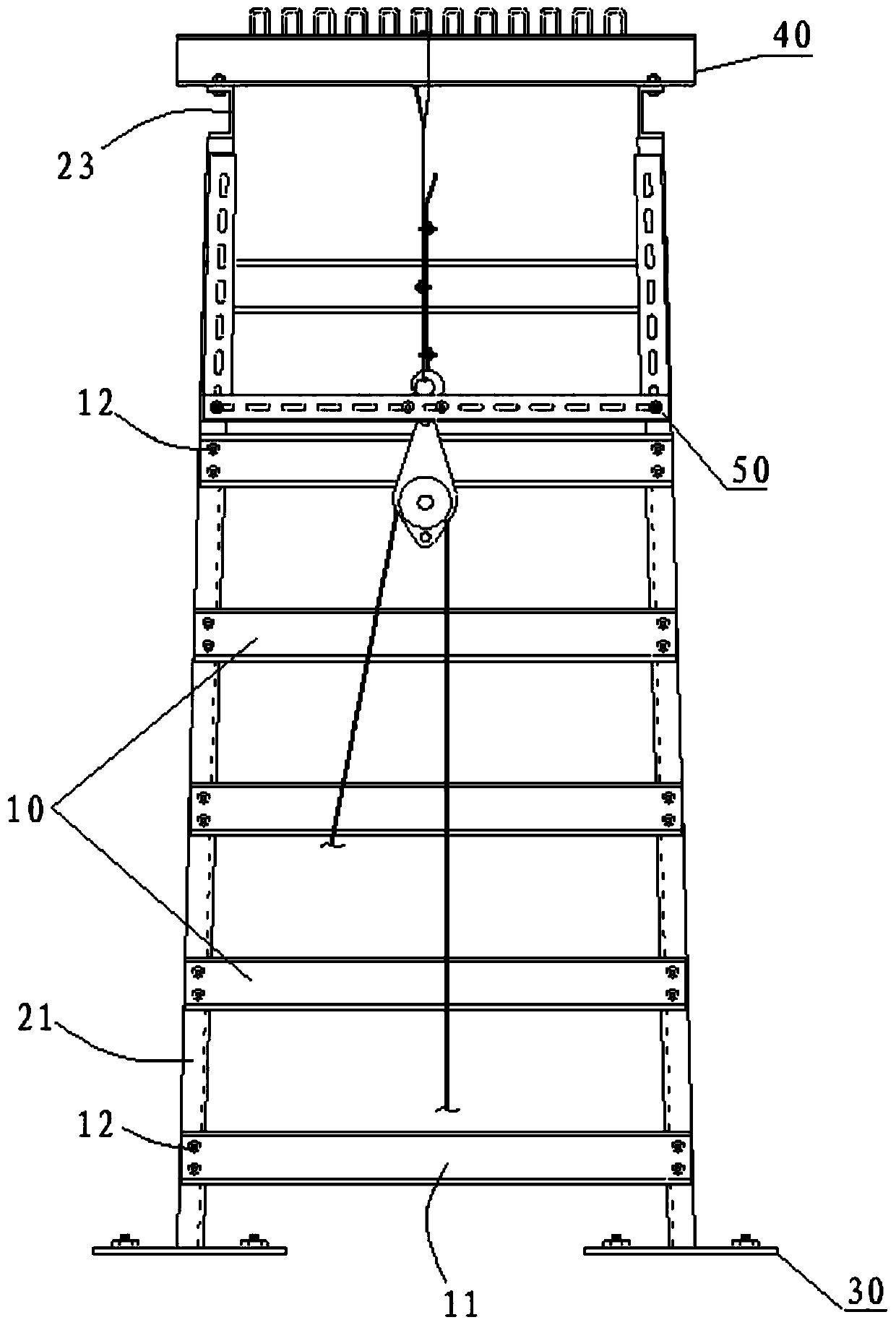

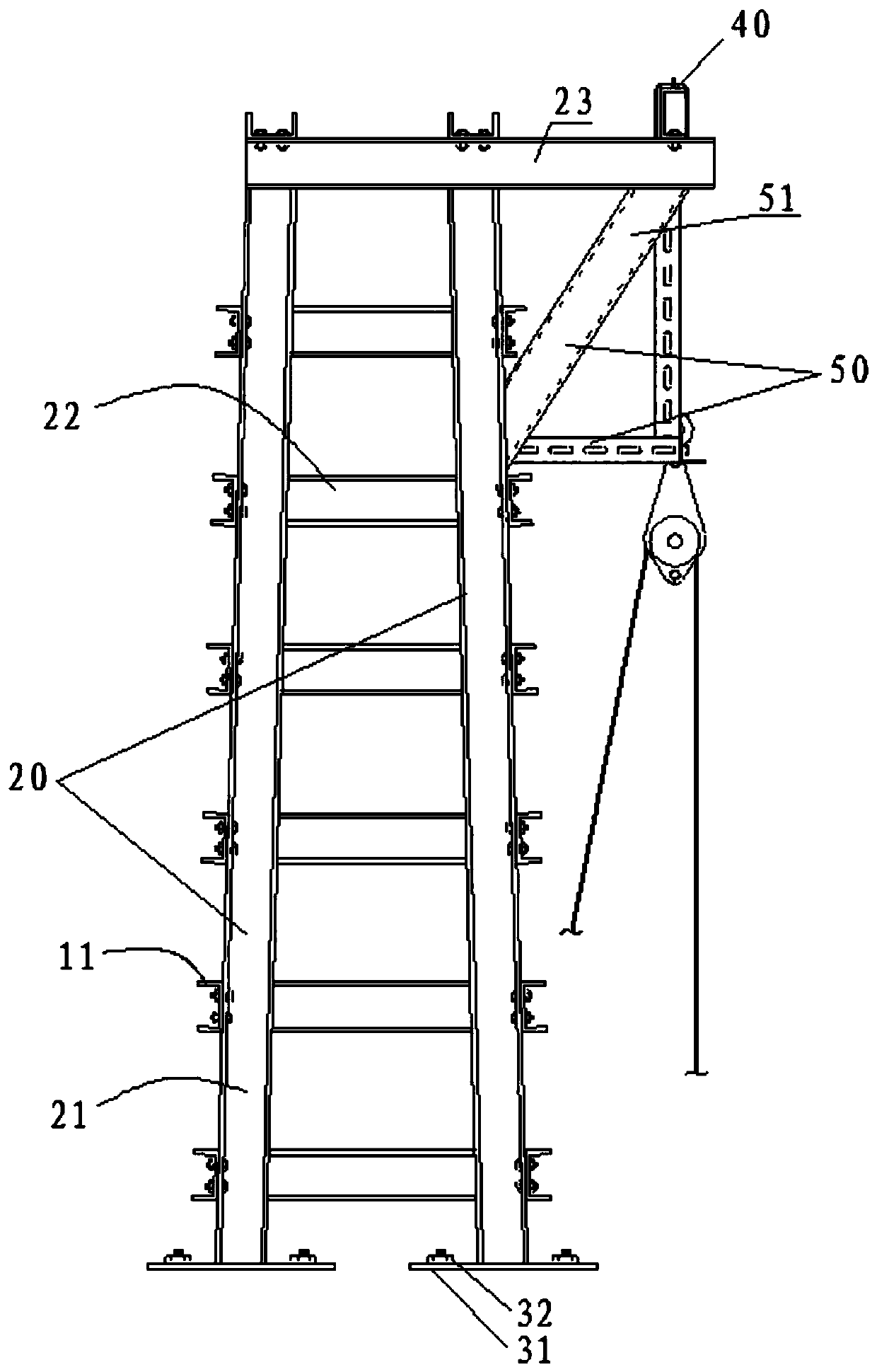

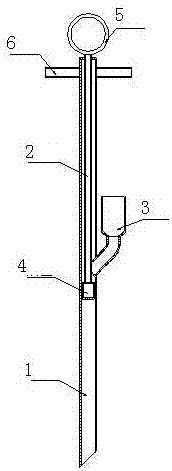

Combined cable hoisting and laying auxiliary device

ActiveCN110112681AEliminate the risk of vandalismAvoid hazards such as collapseApparatus for laying cablesPulleyBuilding construction

The invention discloses a combined cable hoisting and laying auxiliary device, which comprises a horizontal fixing component, a side fixing component, a steel cable fixing cross arm and an anti-sway fixing bracket, wherein the horizontal fixing component and the side fixing component are assembled into a trapezoidal structural frame; the anti-sway fixing bracket is fixed to the upper part of the trapezoidal structural frame and is located at one side of the side fixing component for fixing and hoisting a fixed pulley; the steel cable fixing cross arm is fixed to the top of the trapezoidal structural frame and located above the anti-sway fixing bracket for hoisting a steel cable. The combined cable hoisting and laying auxiliary device does not need the help of a ceiling structure as a fixing point, and eliminates the damage influence on a building. The hoisting frame is stable and reliable in design, can avoid hidden dangers such as collapse and the like, is not restricted by the sites,is fixed by a lateral fixing part, and is suitable for all installation sites. Regardless of a narrow cable well or an equipment-intensive equipment room, the hoisting frame is detachable and reusable, thereby reducing construction and installation cost. The combined cable hoisting and laying auxiliary device can be widely used.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL INSTALLATION

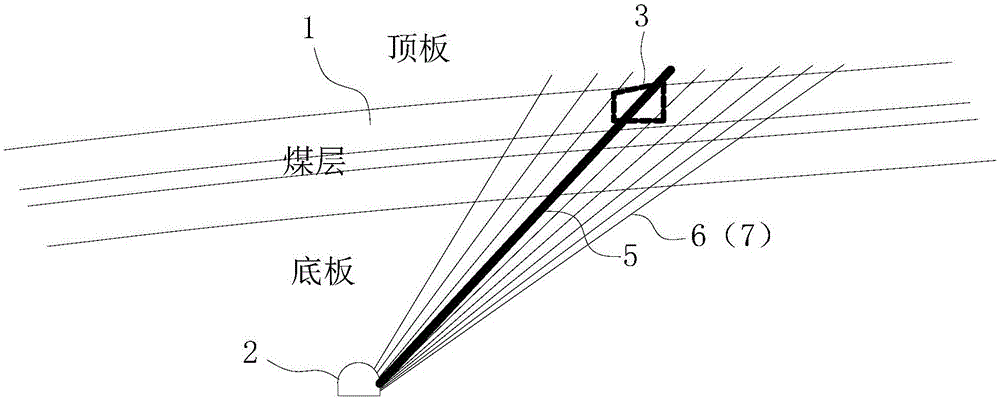

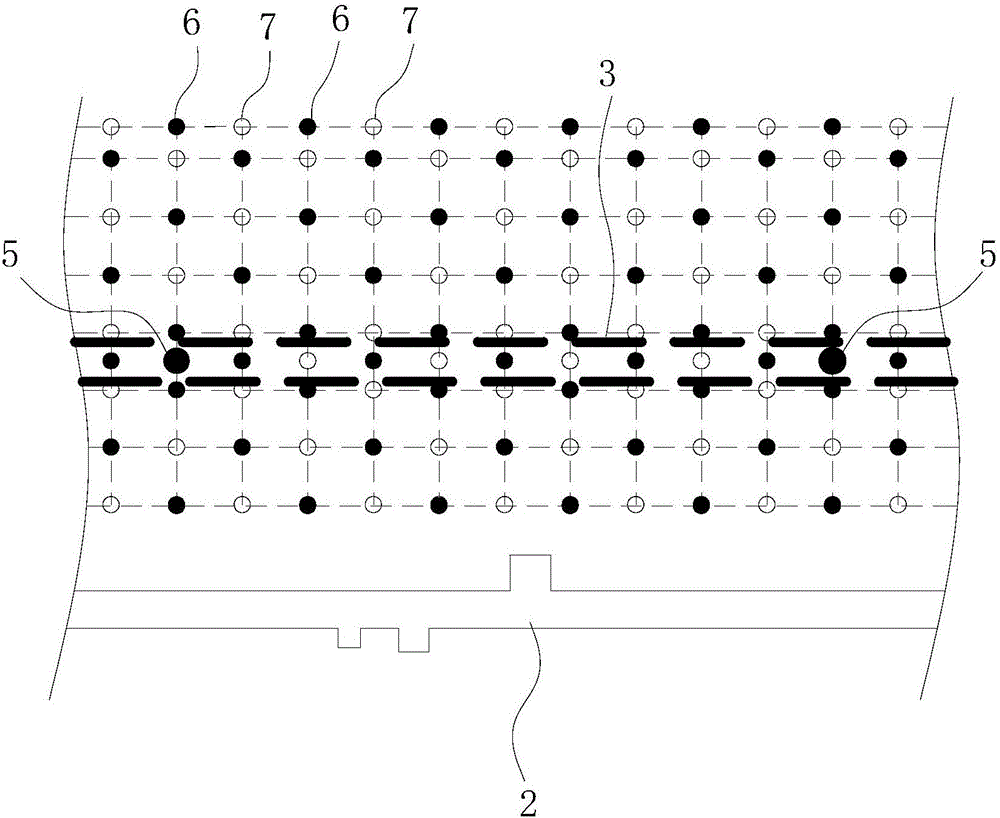

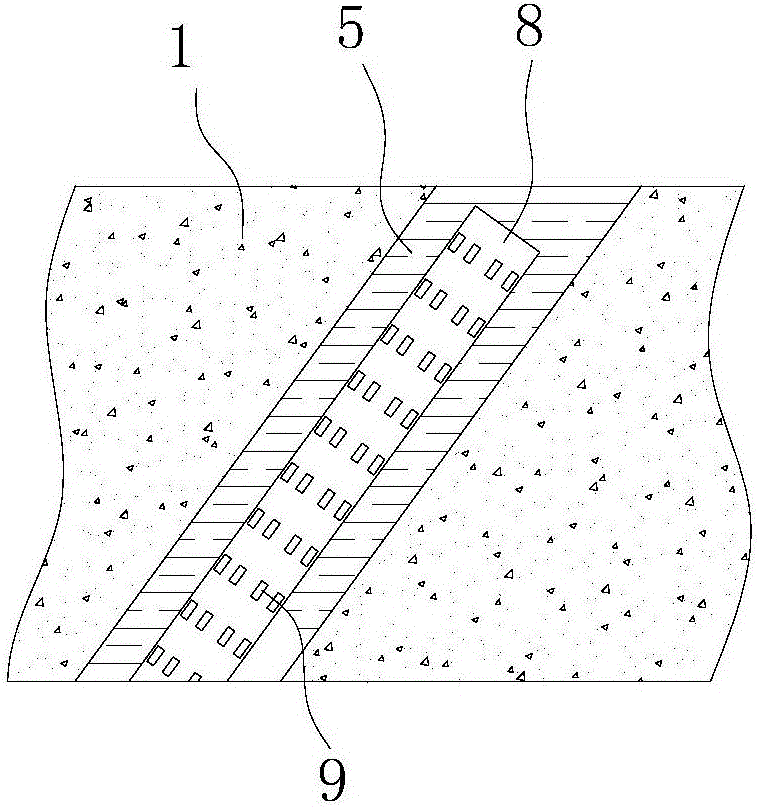

Coal seam hydraulic pressure jetting breathability-improving system and construction method thereof

InactiveCN106368730AImprove breathabilitySpeed up circulationFluid removalGas removalEngineeringHigh pressure water

The invention belongs to the technical field of coal mine safety production construction and particularly relates to a coal seam hydraulic pressure jetting breathability-improving system and a construction method thereof. The system comprises a base plate roadway located below a coal seam, and a plurality of drill holes are formed radially in the coal seam direction in the base plate roadway, a plurality of flushing holes and fracturing holes are formed between the drill holes at intervals, each fracturing hole penetrates out of a tunneling strip, and the fracturing holes are formed at interval in a - shape in the tunneling strip extending direction. The fracturing holes are sealed, high-pressure water injection devices are arranged in the fracturing holes, and flushing drill bits are arranged in the flushing holes. Hydraulic punching measures are adopted for a coal seam having undergone hydraulic fracturing, the hydraulic fracturing and hydraulic punching are optimized, the breathability of the coal seam is improved, gas circulation is accelerated, a pre-extraction effect is multiplied, a pre-extraction range is wider, gas is extracted more thoroughly, and an effect is better.

Owner:HUAINAN MINING IND GRP

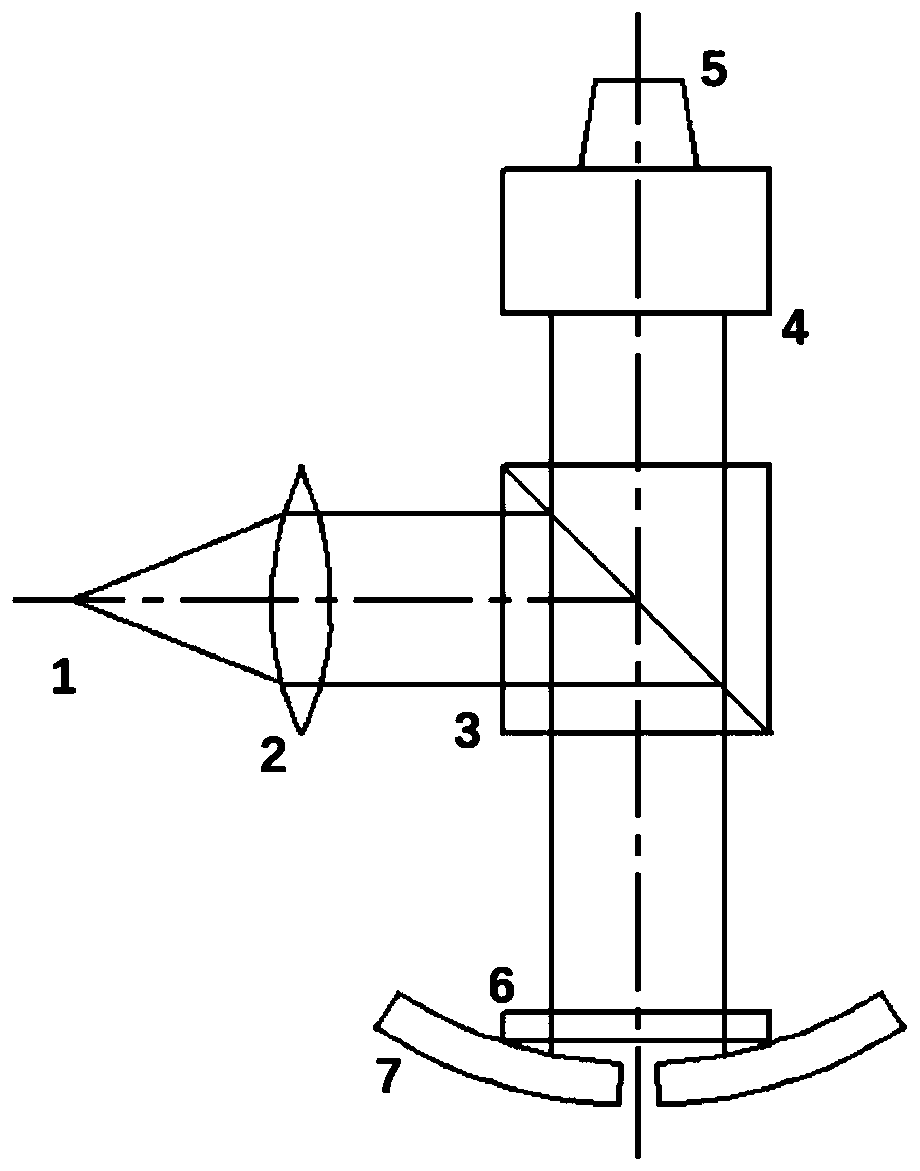

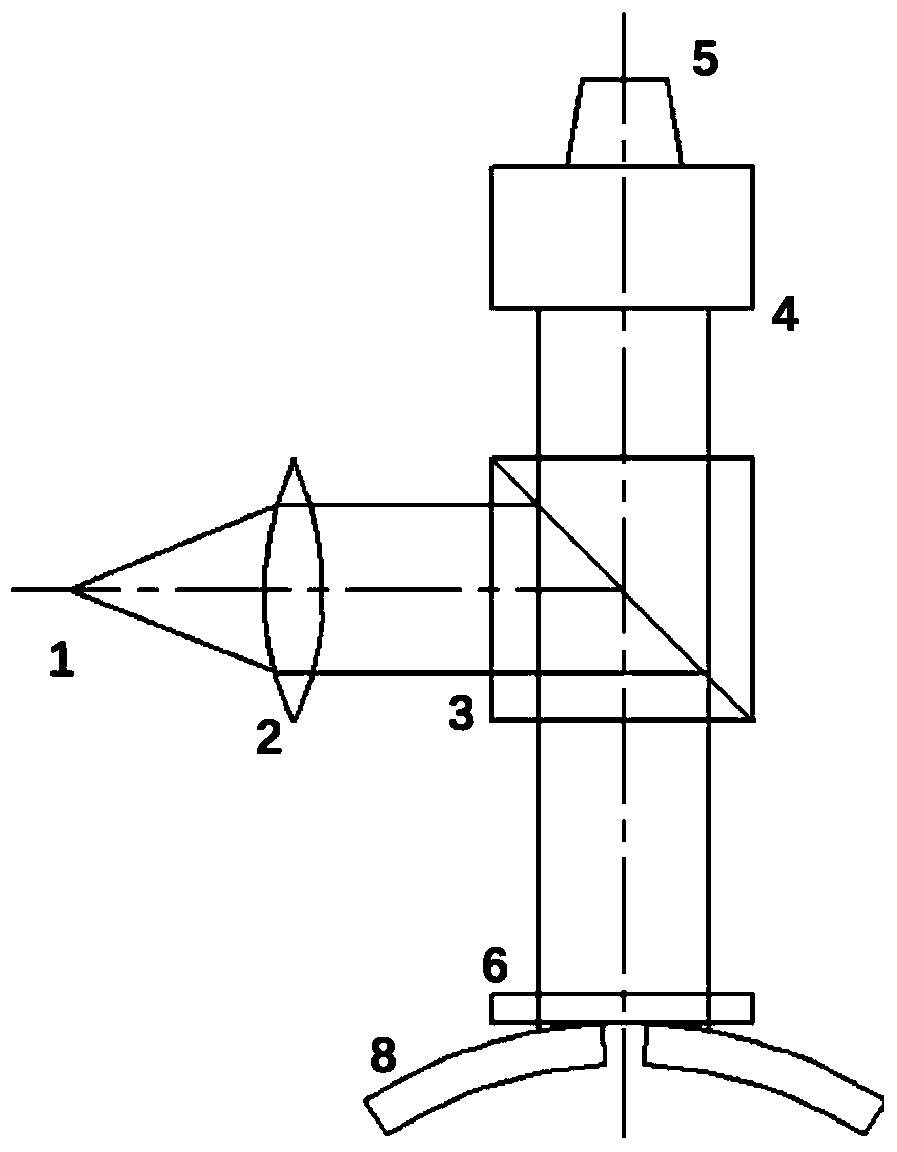

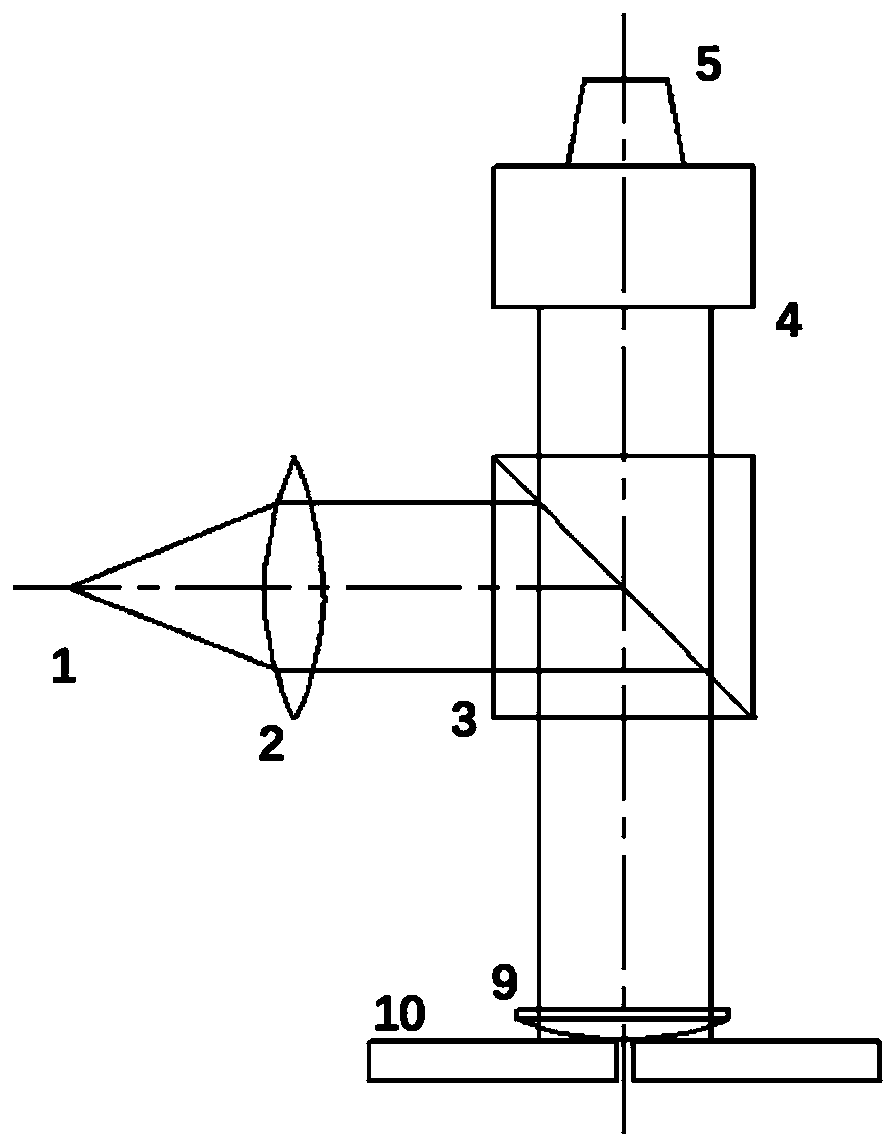

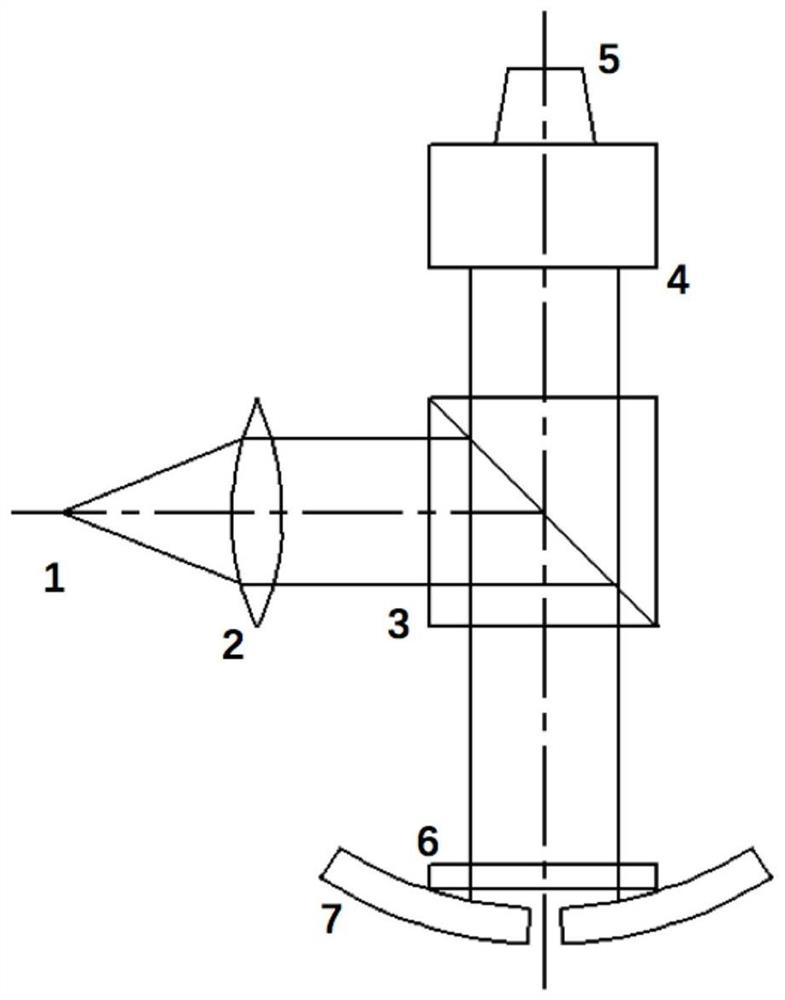

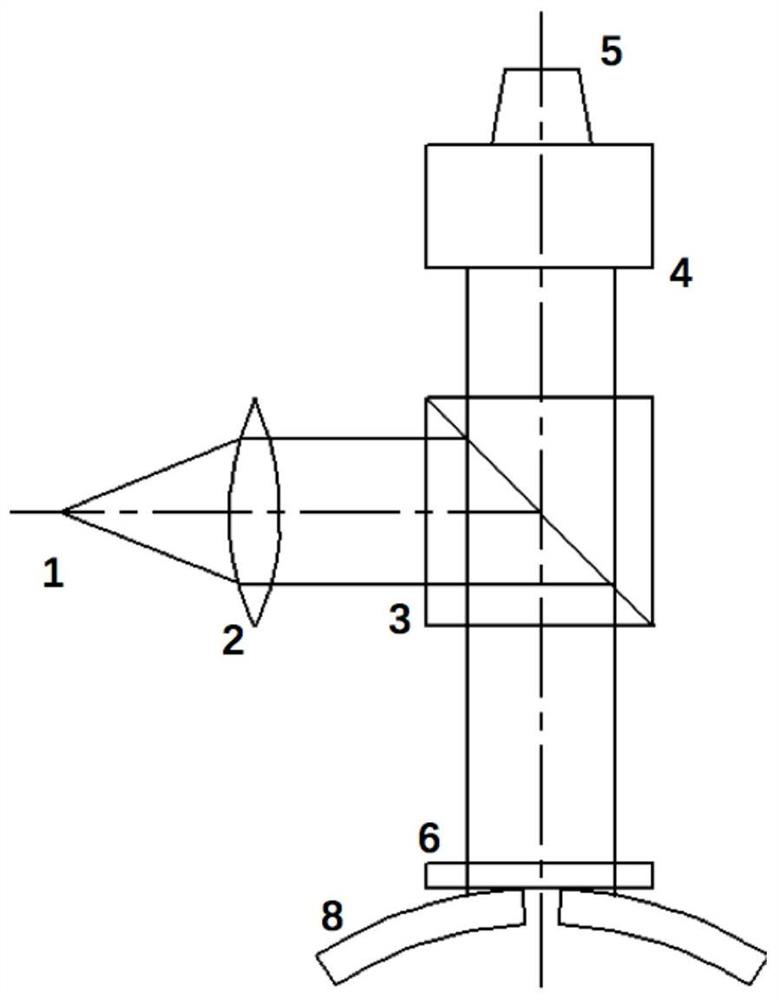

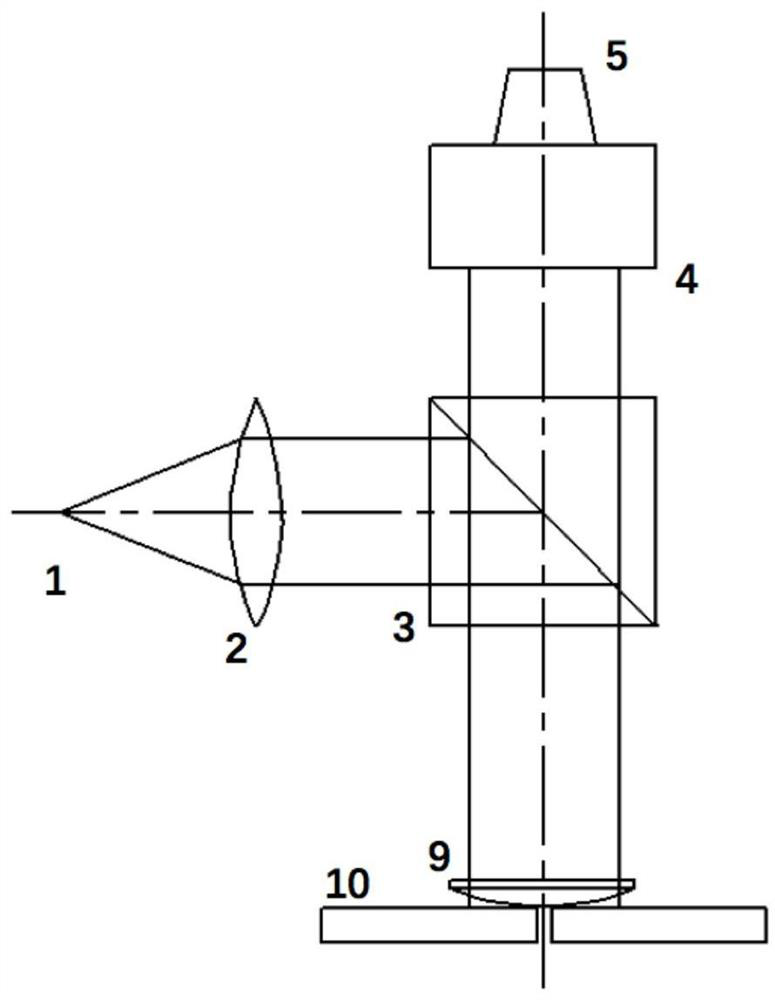

Edge sensor for segmented mirror surface based on interference principle and working method thereof

ActiveCN110779443AClear principleCompact structureUsing optical meansWavefront sensorDigital imaging

The invention discloses an edge sensor for a segmented mirror surface based on an interference principle, and a working method thereof. The edge sensor is characterized in that: an optical flat or spherical lens is placed on a sub-mirror splicing seam of a measured segmented mirror surface, the front surface of the optical flat or spherical lens is completely anti-reflection, and the rear surfaceof the optical flat or spherical lens is provided with a coating film; a parallel light source is arranged on the other side of a sub-mirror of the measured segmented mirror surface and the optical flat or spherical lens, light rays vertically enter the optical flat or spherical lens by means of a semi-reflecting and semi-transmitting prism and then part of the light beam on the surface returns, the other part is reflected by the surface of the sub-mirror along an original path, the two beams of reflected light form interference fringes, the interference fringes enter a microscopic amplification imaging system by means of the semi-reflecting and semi-transmitting prism, and target surface receiving and digital imaging are carried out by means of a CCD or CMOS detector, namely, the splicingerror of the adjacent sub-mirrors can be handled. The edge sensor prevents starlight and wavefront sensors from occupying and wasting a limited high-imaging-quality field of view of an optical system, is low in price, stable in performance and not affected by environmental factors, and is suitable for detecting the splicing errors between the adjacent sub-mirrors of various optical segmented mirror surfaces.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Injection method of rubber film layers on surfaces of cellulosic gloves

InactiveCN101966738BThe process principle is simpleReduce processing costsDomestic articlesFiberPolymer science

The invention belongs to the technical field of labor protection product processing and relates to an injection method of rubber film layers on surfaces of cellulosic gloves, which comprises: wearing the cellulosic gloves to be coated on hand mold bodies uniformly, and placing the hand mold bodies with the cellulosic gloves in mold body boxes matched with the mold bodies, wherein 0.1 to 0.5 millimeter hand back cavity type clearance layers are formed between the cellulosic surfaces of the gloves and the corresponding surfaces of the mold body boxes; closing and sealing the mold boxes, fillingup the clearance layers with liquid rubber by an injection machine through an injection hole, cooling the liquid rubber and making the liquid rubber adhere firmly; and opening the mold boxes and taking down the gloves worn on the hand mold bodies, wherein the gloves are formal products for sale. The coating rate of the rubber film layers on the palm sides of the cellulosic gloves is 100 percent, and the coating rate of the rubber film on the hand back sides of the cellulosic gloves is 0 to 100 percent; and the process principle is simple, the processing cost is low, rubber raw material is saved, the quality of the products is high, and the service life of the products is long, the labor protection effect is desirable. Thus, the method can replace the conventional processing method.

Owner:高密市德川手套有限公司

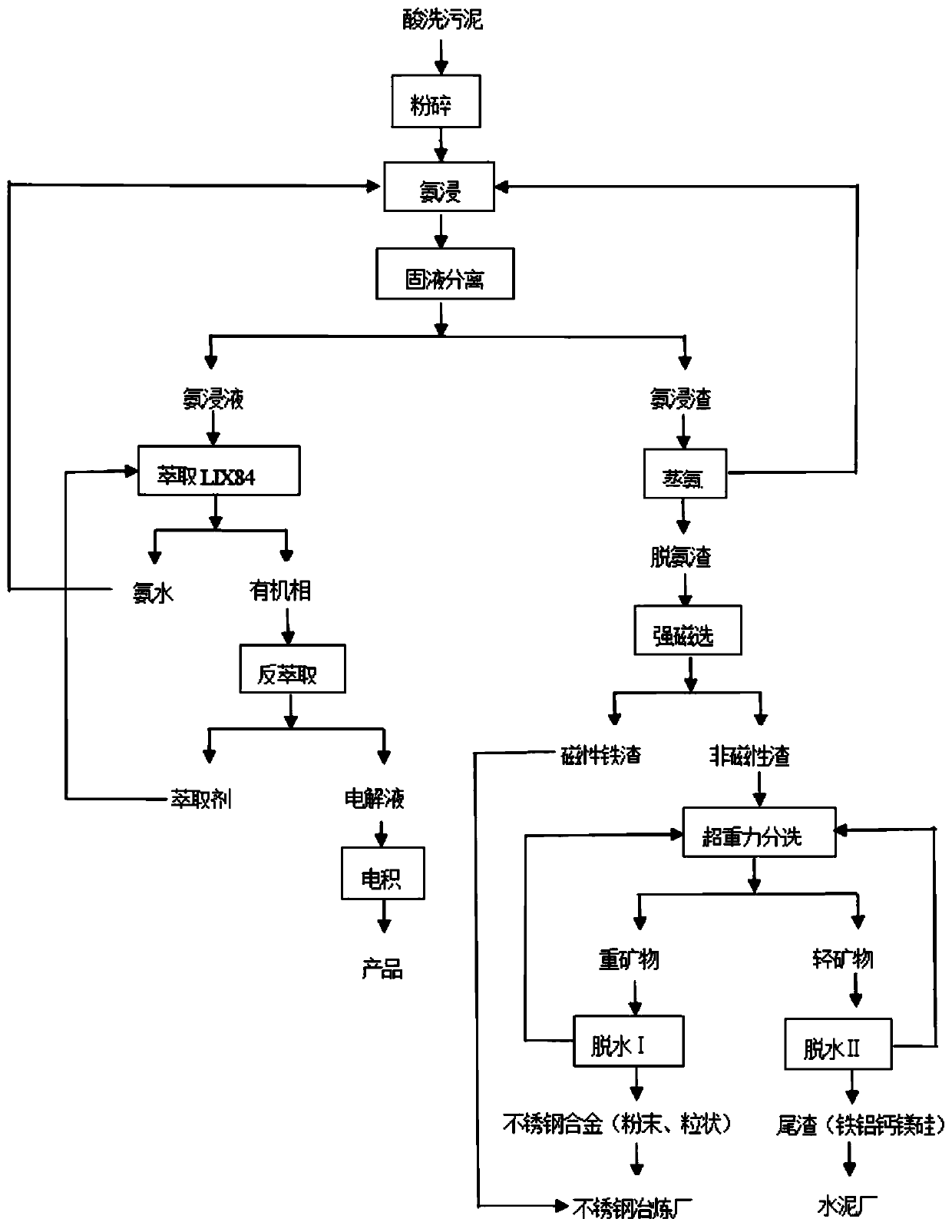

Stainless steel pickling sludge treatment method

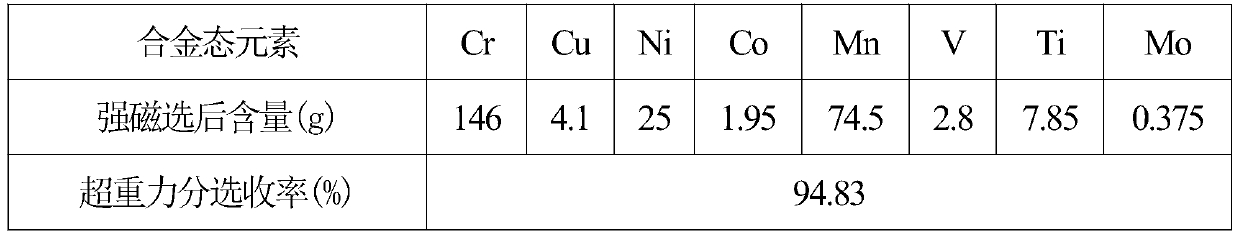

InactiveCN111560522AAchieve recyclingThe process principle is simplePhotography auxillary processesProcess efficiency improvementSludgeSS - Stainless steel

The invention discloses a stainless steel pickling sludge treatment method. The method comprises the following steps of S1, crushing; S2, ammonia leaching: S3, extraction and reextraction; S4, electrodeposition; S5, ammonia stilling; S6, strong magnetic separation; and S7, supergravity separation. According to the method, ammonia water is used for selectively leaching chromium, copper, zinc, nickel and cobalt, ammonia leaching residues are subjected to strong magnetic separation for magnetic iron residues, supergravity separation is used for selecting alloy-state heavy metal, heavy metal resources are completely recycled step by step, the process principle is simple, the technology is mature, and the method can be suitable for pickling sludge treatment of stainless steel enterprises.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

Sand-blasting reinforcing method for hanging portion of structure

InactiveCN107524179AStrong Humidification Jet AdhesionAccelerated settlementFoundation repairSand blastingEngineering

The invention relates to structures, in particular to a reinforcing method for a hanging portion of a structure. The sand-blasting reinforcing method for the hanging portion of the structure includes the steps that 1, an air compressor and a sand-blasting device are arranged around the to-be-reinforced structure, the air compressor passes through the sand-blasting device through a hose, and an outlet of the sand-blasting device communicates into the hanging portion of the structure through a sand-blasting pipe; 2, a grouting pipe is arranged according to the field; 3, sand gravel is added into the sand-blasting device, the air compressor is started, and sand-blasting is conducted; 4, the sand-blasting position is transferred, sand-blasting is conducted in the reverse direction of the original sand-blasting direction; and 5, grouting is conducted after the hanging portion of the structure is filled with sand. The sand-blasting reinforcing method provides guarantees for safety utilization of soft soil foundation structures which are liable to subside and collapse and production and operation facilities.

Owner:CHINA MCC20 GRP CORP

Labor-protecting gloves with rubber and plastic material protective coatings

InactiveCN102845873AThe process principle is simpleReduce processing costsGlovesProtective garmentThermoplasticEngineering

The invention belongs to the technical field of articles for labor protection, and relates to labor-protecting gloves with rubber and plastic material protective coatings. Existing fiber glove bodies made of mechanical fiber materials are divided into two structure parts, namely palm surfaces of the gloves and back surfaces of the gloves; the joint parts of the palm surfaces of the gloves and the back surfaces of the gloves without clear boundaries are butt edges; areas without the protective coatings are preserved at the glove edges of the fiber glove bodies and are not coated with the protective coatings; the palm surfaces of the fiber glove bodies fully cover the sealed protective coatings coated with the rubber and plastic materials; the areas on the back surfaces of the fiber glove bodies coated with protective materials are 0-100% that of the entire back surfaces of the gloves; the protective coatings on the palm surfaces and the back surfaces coated with the protective materials are fixedly coated on the outer surfaces of the fiber glove bodies, and the material of each protective coating comprises rubber, thermoplastic or mixture of rubber and plastic and an elastomer. The labor-protecting gloves are simple in principle, low in cost, high in product quality, long in service life, comfortable to wear, and good in labor protection effect, and can widely replace the existing labor-protecting gloves.

Owner:GAOMI LICHANG LABOR PROTECTION PROD IND & TRADE

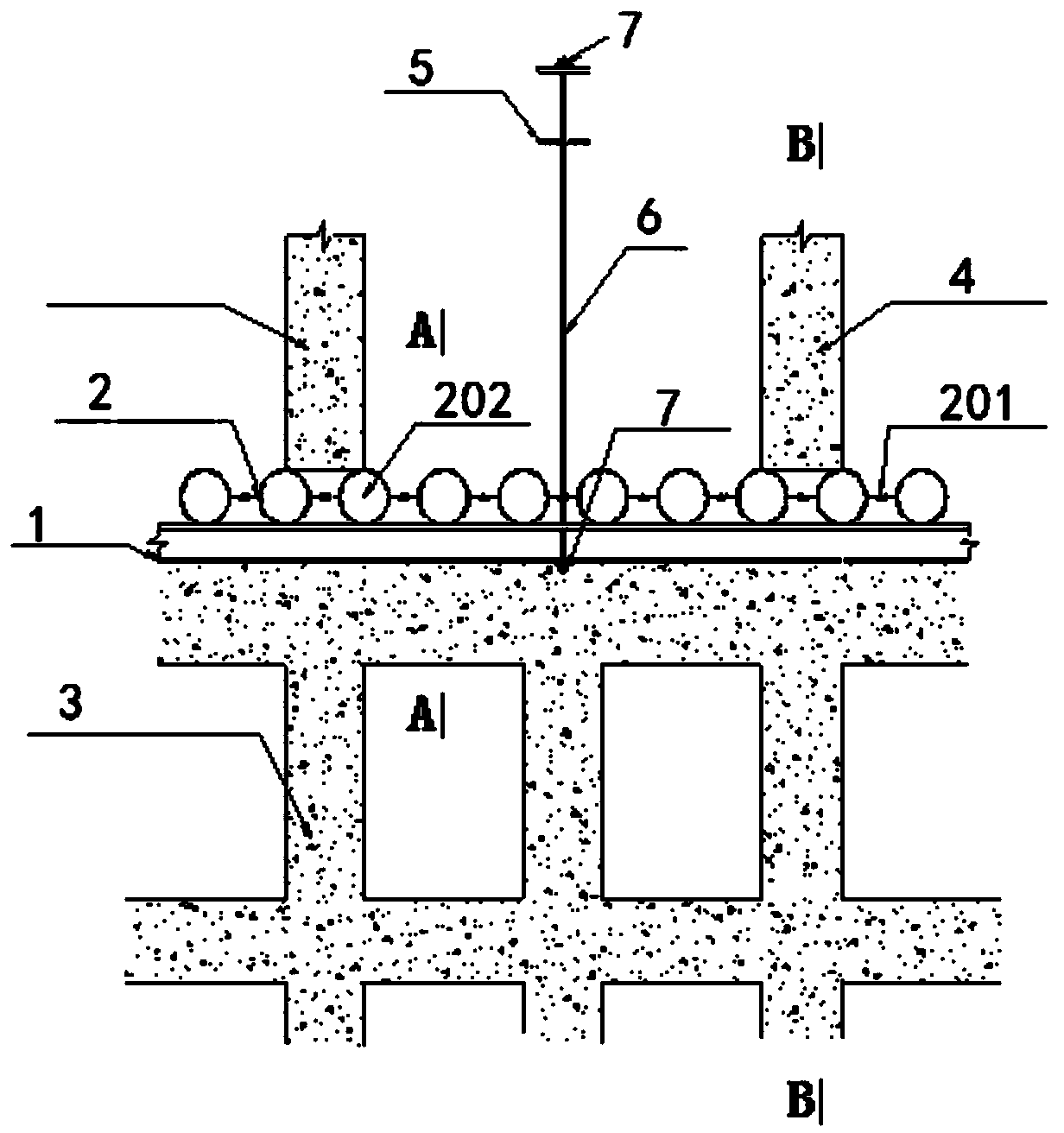

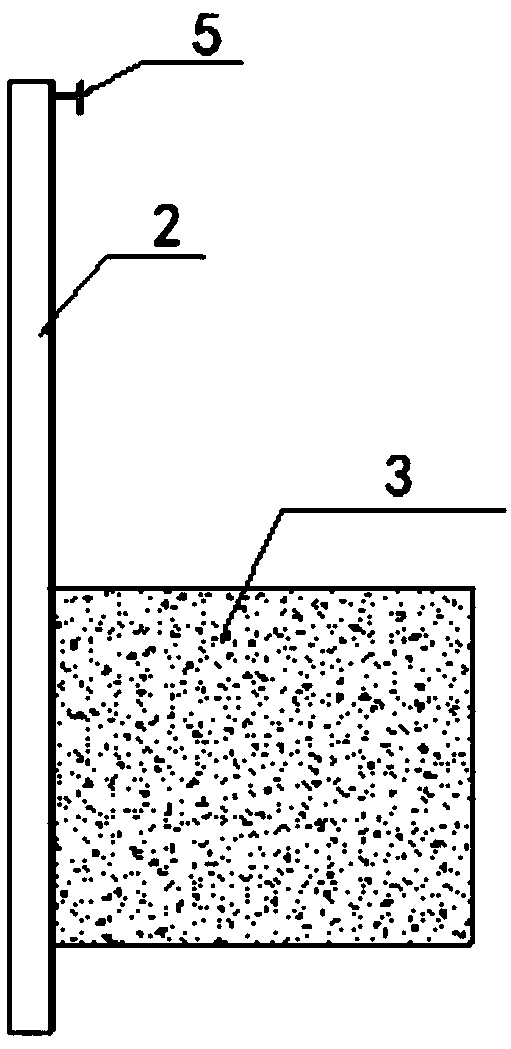

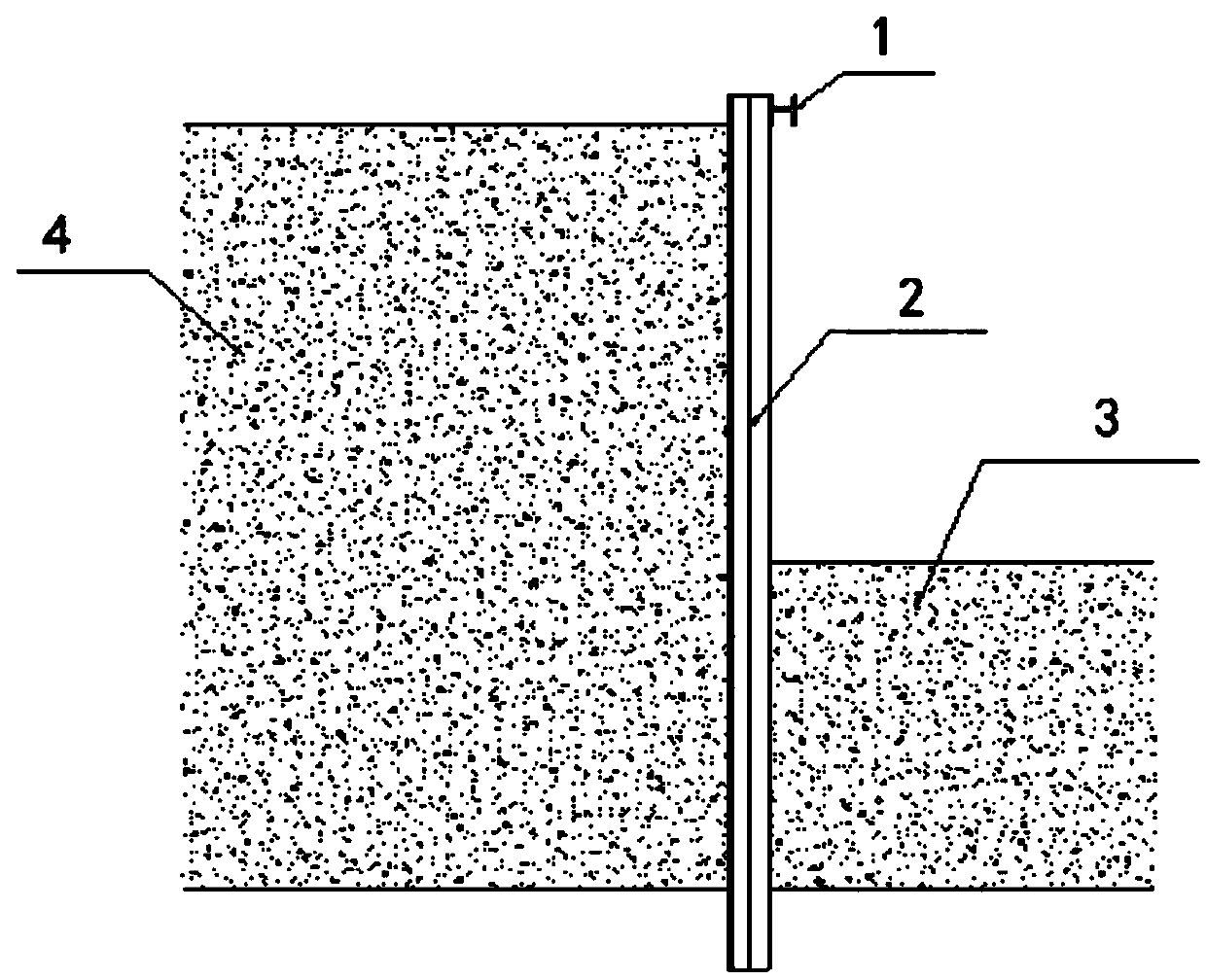

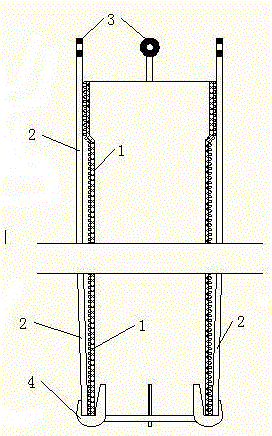

Large area silt fluid soil layer foundation pit suspension supporting comprehensive construction structure and method

PendingCN109610477AThe process principle is simpleEasy to operateExcavationsPurlinStructure of the Earth

The invention discloses a large area silt fluid soil layer foundation pit suspension supporting comprehensive construction structure and method. The large area silt fluid soil layer foundation pit suspension supporting comprehensive construction structure comprises a plurality of retaining piles arranged on the side wall around a to-be-excavated foundation pit; profile steel enclosing purlins arranged on the inner sides of the retaining piles in attaching and surrounding modes, internal pit mixing pile strengthening bodies arranged on the inner side of the to-be-excavated foundation pit, external pit mixing pile strengthening bodies arranged on the outer side of the to-be-excavated foundation pit, anchoring steel driven into a soil layer on the outer side of the to-be-excavated foundationpit, and stay cables connected between the anchoring steel and the profile steel enclosing purlins in a fastened mode; and the retaining piles are composed of pipe piles and Larsen steel sheet piles which is welded and fixed to the two sides of pipe piles in a one-broken-two mode, and the corresponding Larsen steel sheet piles on every adjacent retaining piles are connected in a mutually interlocked mode. According to the large area silt fluid soil layer foundation pit suspension supporting comprehensive construction structure and method, an overall stable silt and fluid soil layer suspensionsupporting comprehensive body can be formed, stability and safety of large area silt fluid soil layer foundation pit supporting are guaranteed, and the positive effect is achieved on surrounding environment protection under the working condition.

Owner:上海宝钢工程咨询有限公司

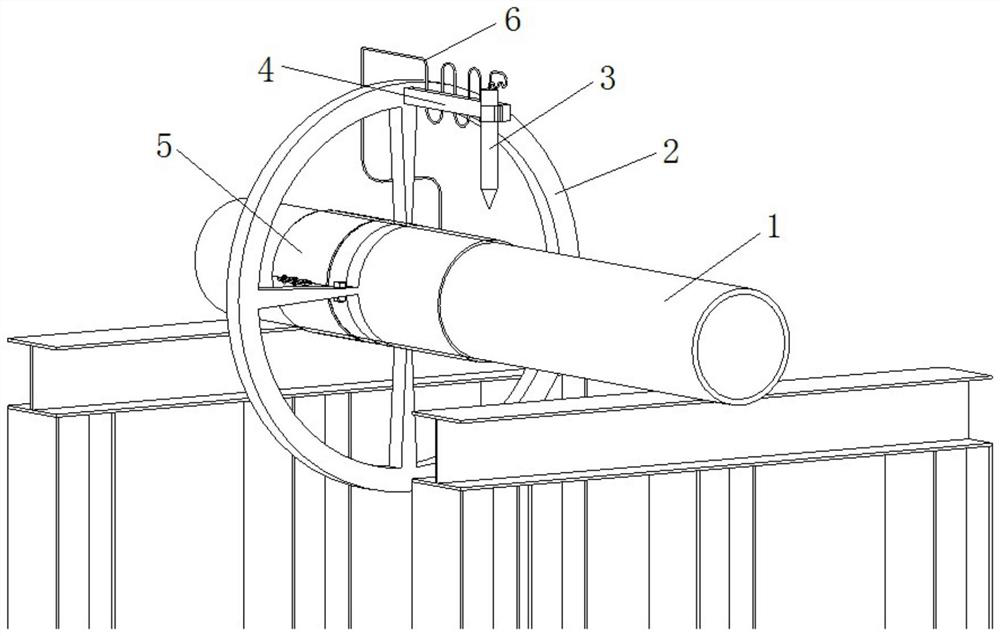

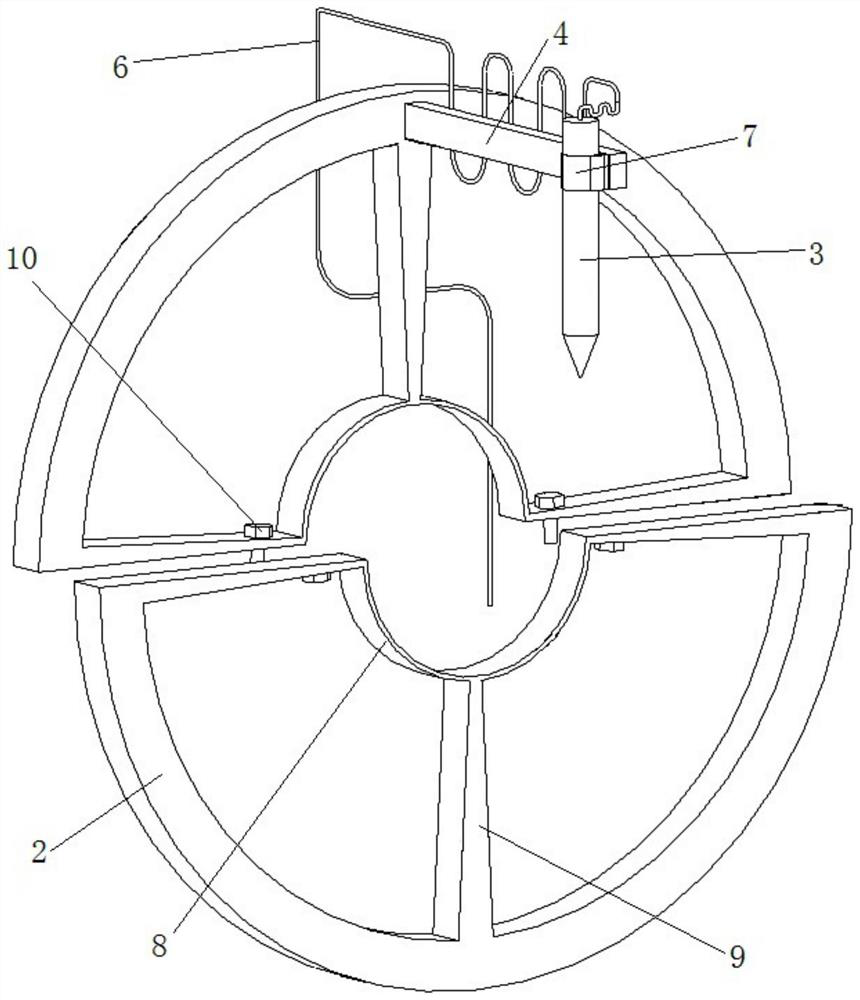

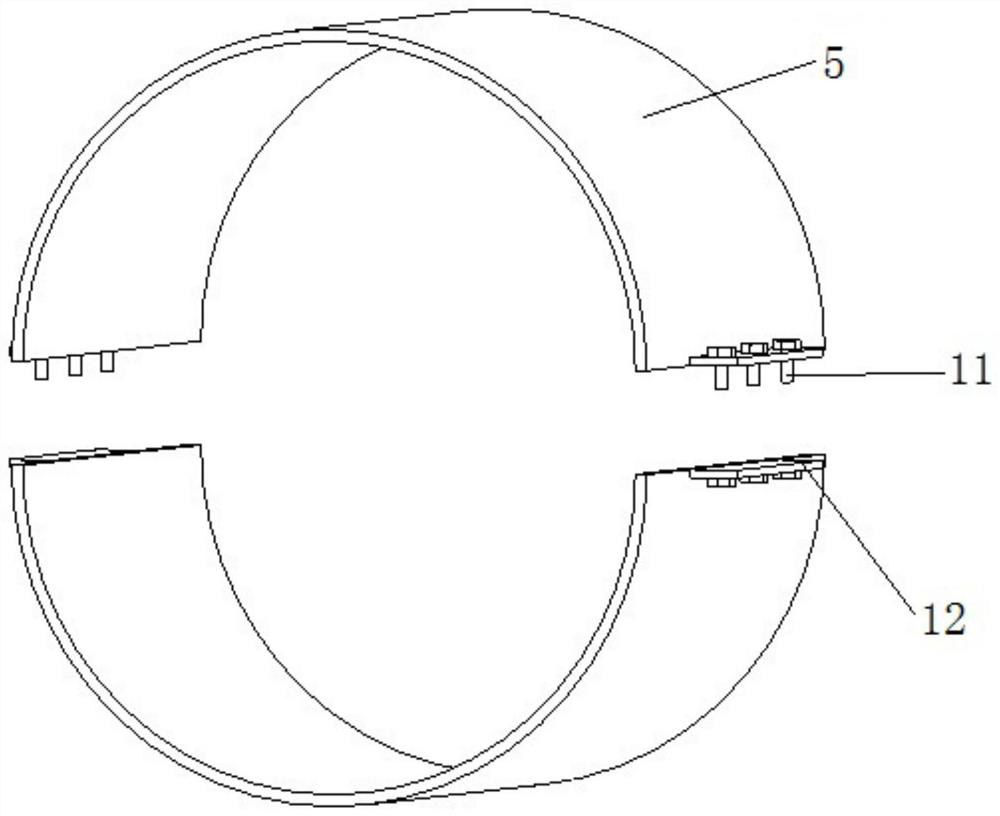

Steel pipe cutting device and method

PendingCN114012205AImproved cutting methodReduce volumeMetal working apparatusGas flame welding apparatusPipeIndustrial engineering

,The invention discloses a steel pipe cutting device and method. The steel pipe cutting device comprises a supporting frame used for horizontally erecting a steel pipe in an overhead mode and a rotary cutting frame used for fixing a cutting machine, the rotary cutting frame comprises at least two double-layer frame bodies which are detachably connected the inner rings of the at least two double-layer frame bodies are spliced to form a sleeve opening for rotationally sleeving a steel pipe, the outer rings of the at least two double-layer frame bodies are connected to the outer sides of the inner rings through fixing rods, and one of the outer rings is provided with a fixing base allowing the cutting machine to be installed. The rotary cutting frame is directly arranged on the steel pipe in a sleeving mode to fix the cutting gun, the rotary cutting frame is rotated to cut the steel pipe, and the technical problem that in the prior art, steel pipe cutting is conducted under the complex site working condition and the narrow site is solved. The device is convenient to operate, neat in notch section, high in cutting speed, straight in section, small in size of the rotary cutting frame, convenient to move, suitable for complex environments, low in site requirement and suitable for operation in the complex environments.

Owner:中建八局轨道交通建设有限公司

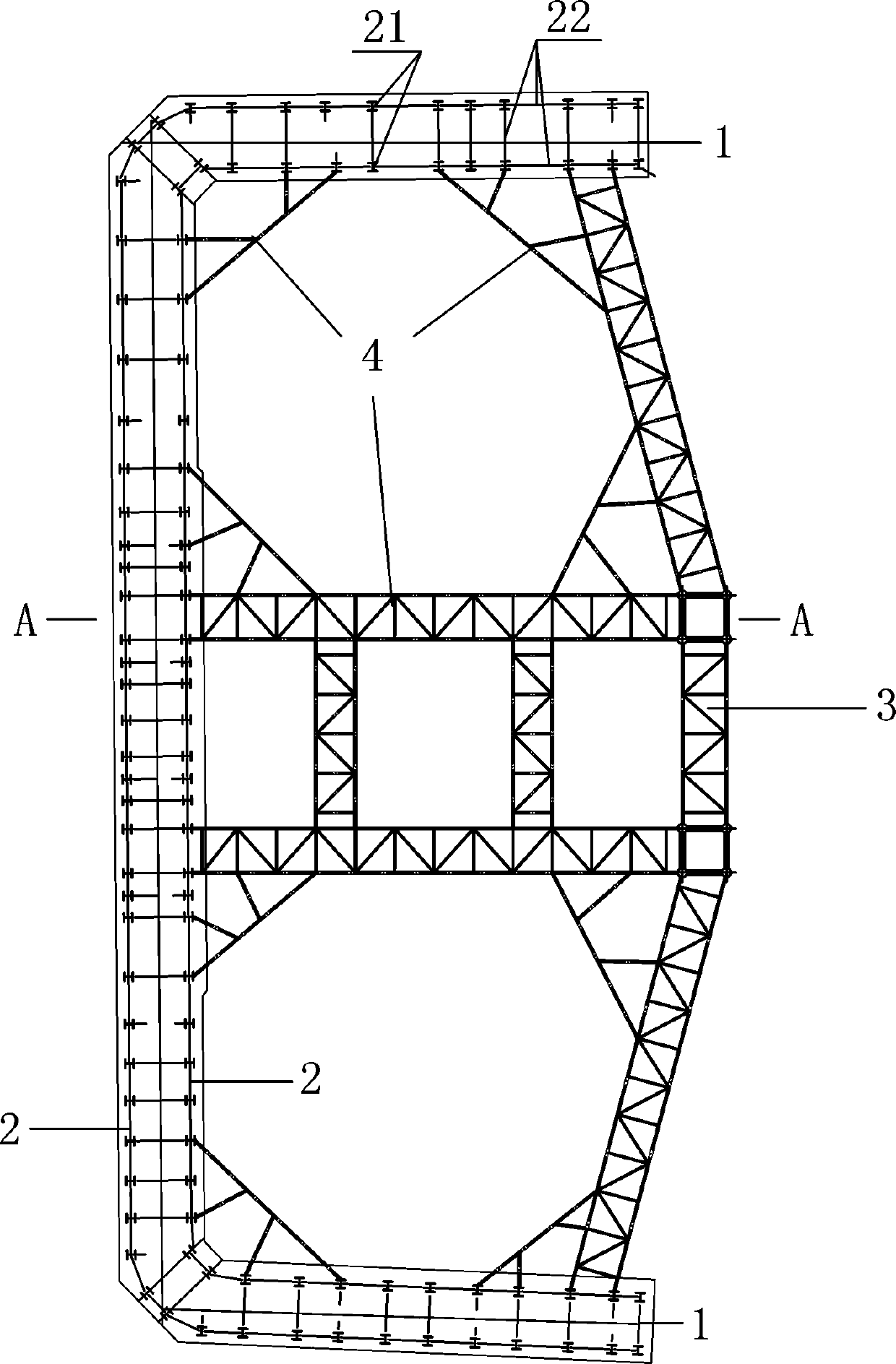

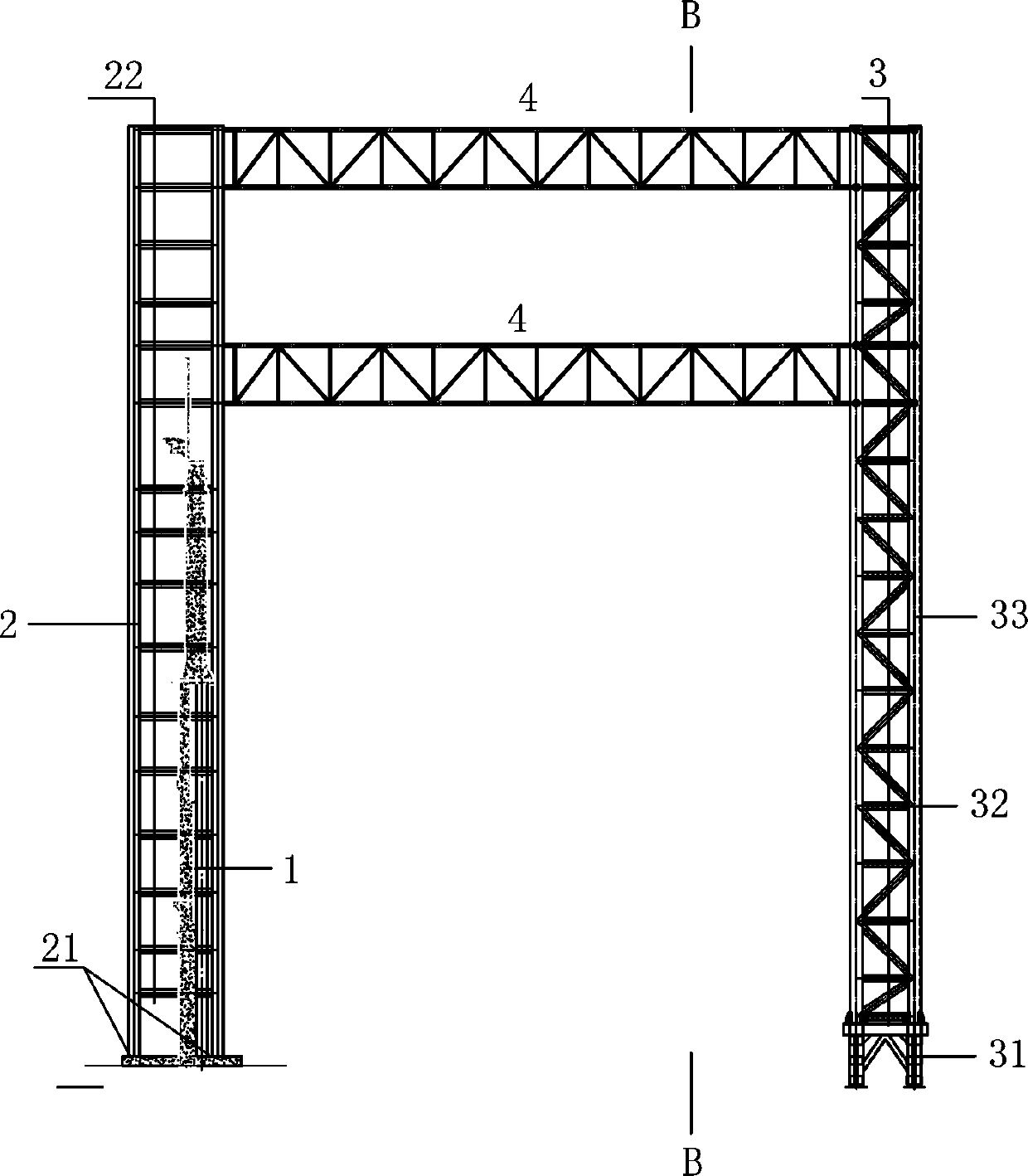

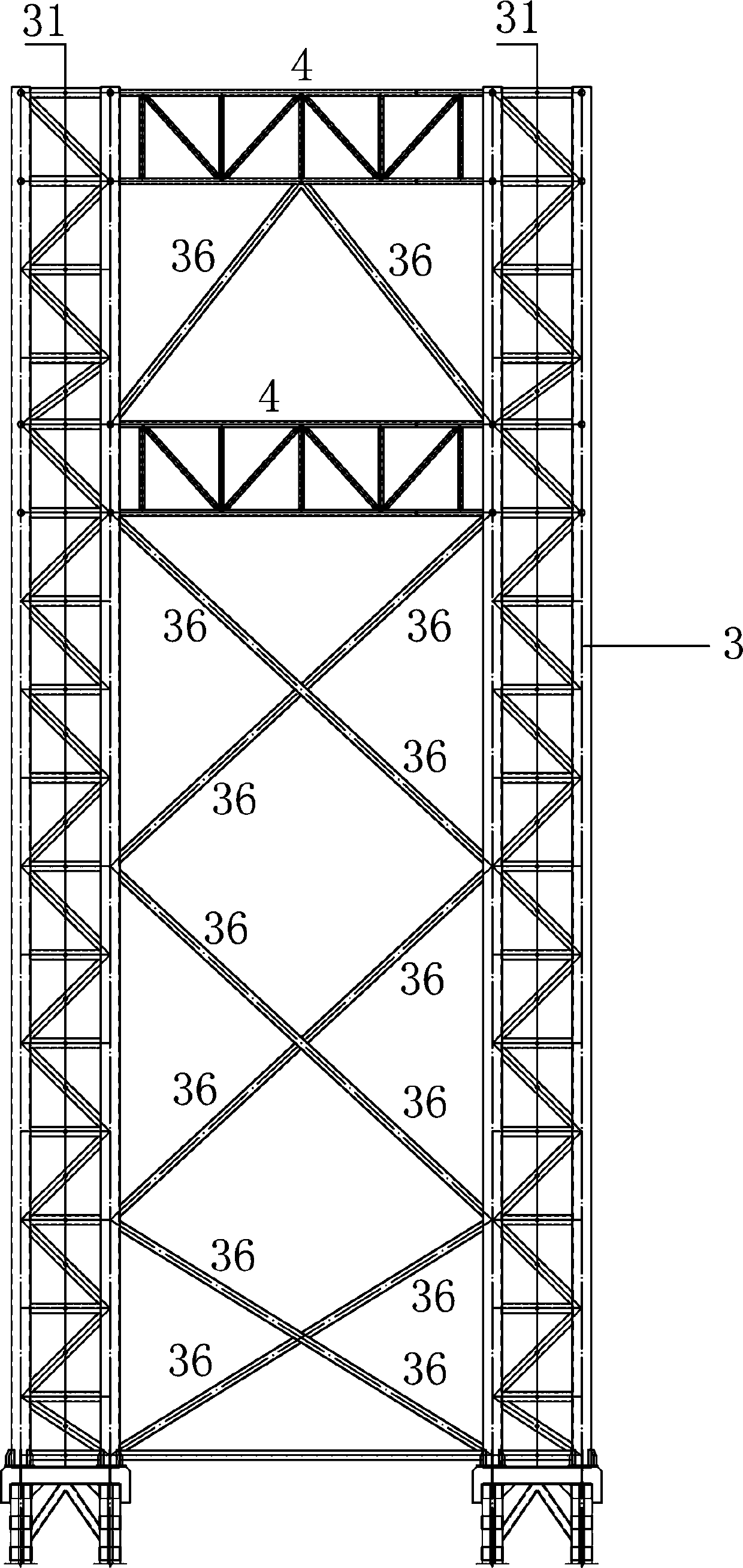

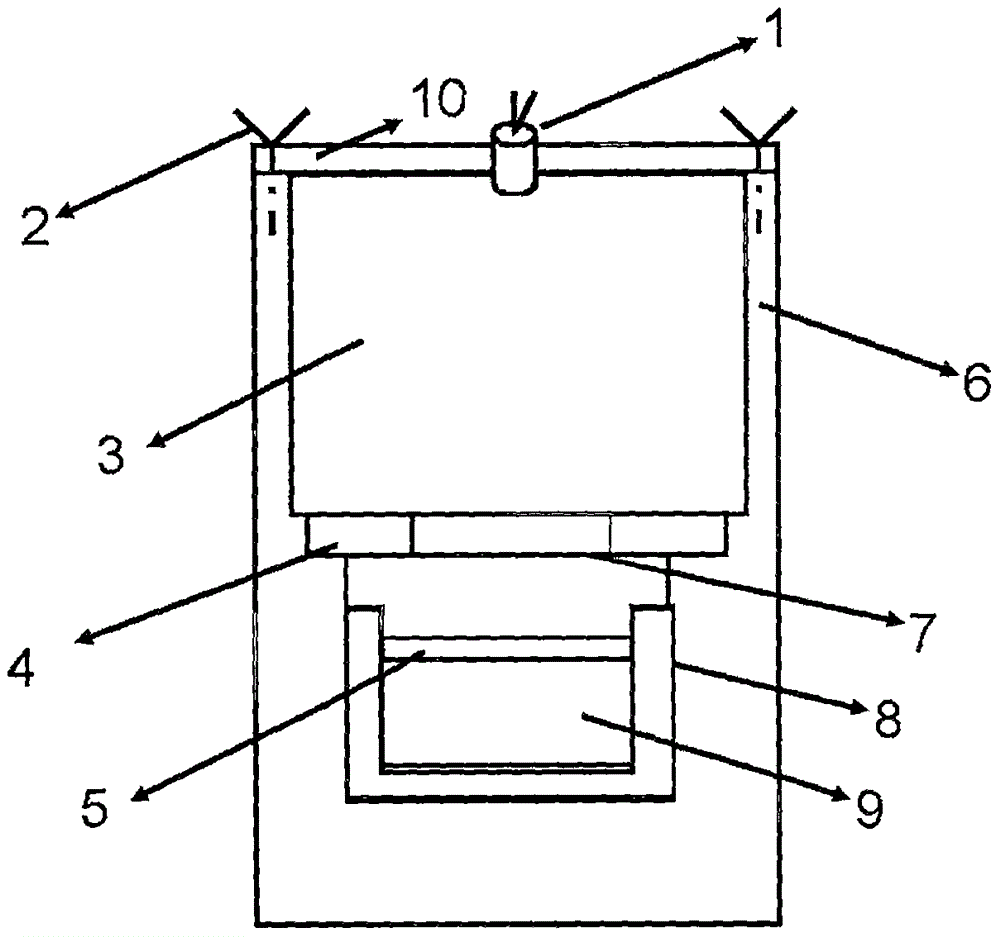

Protection device for removing interior of building and application method thereof

InactiveCN110656787AImprove protectionThe process principle is simpleBuilding repairsJoint (building)Pier

The invention relates to the field of walls of frame or pier stud structures of buildings, in particular to a protection device for removing the interior of a building and an application method thereof. The protection device for removing the interior of the building comprises wall bodies (1) vertically fixed on the ground, and is characterized by further comprising supporting frames (2), protection frames (3) and trusses (4), each supporting frame comprises supporting columns (21) and supporting beams (22), each protection frame (3) comprises bottom columns (31), connecting beams (32) and tubular columns (33), and the corners of the supporting frames (2), the corners of the protection frames (3) and the joints of the supporting frames (2) and the protection frames (3) are connected throughthe trusses (4). The application method for the protection device for removing the interior of the building is characterized by comprising the following steps in sequence that (1) the supporting frames are arranged; (2) the protection frames are arranged; and (3) the trusses are arranged. The protection device and the application method thereof have the advantages of being simple in principle, convenient in operation, safe in construction and stable in structure.

Owner:CHINA MCC20 GRP CORP

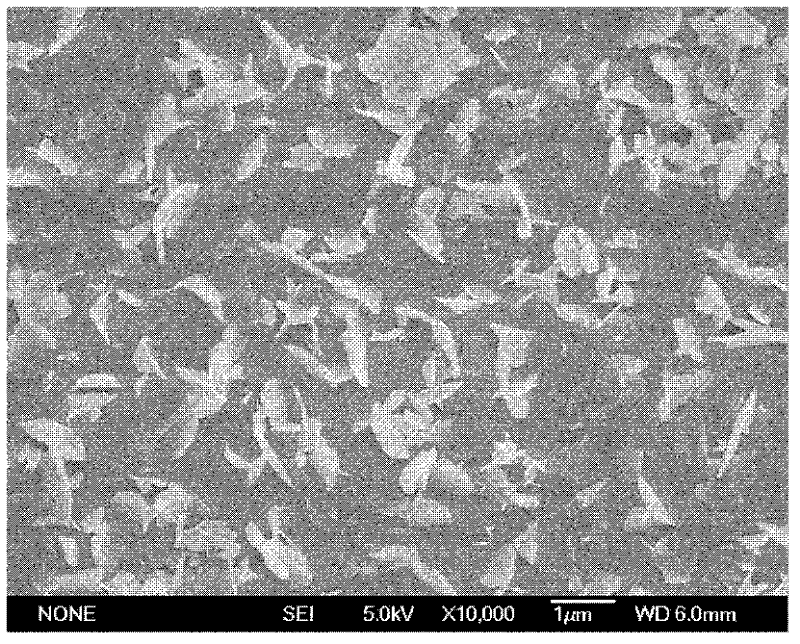

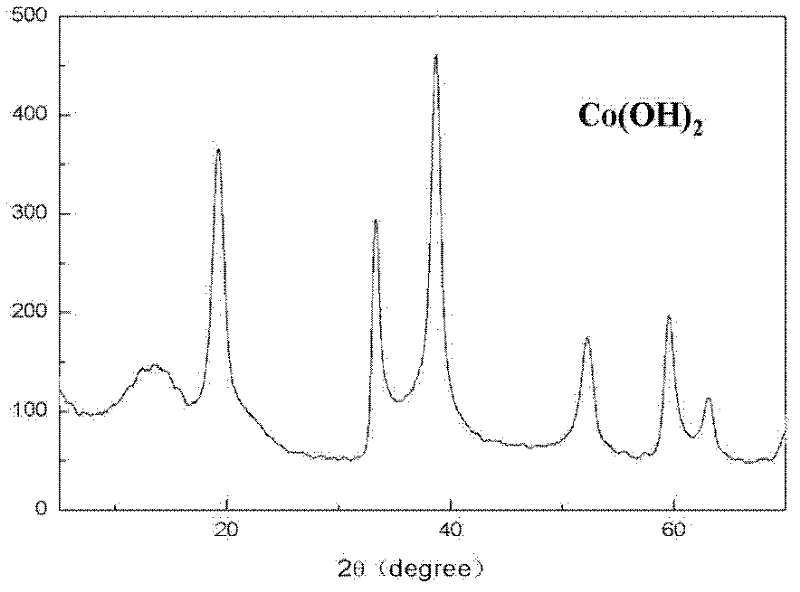

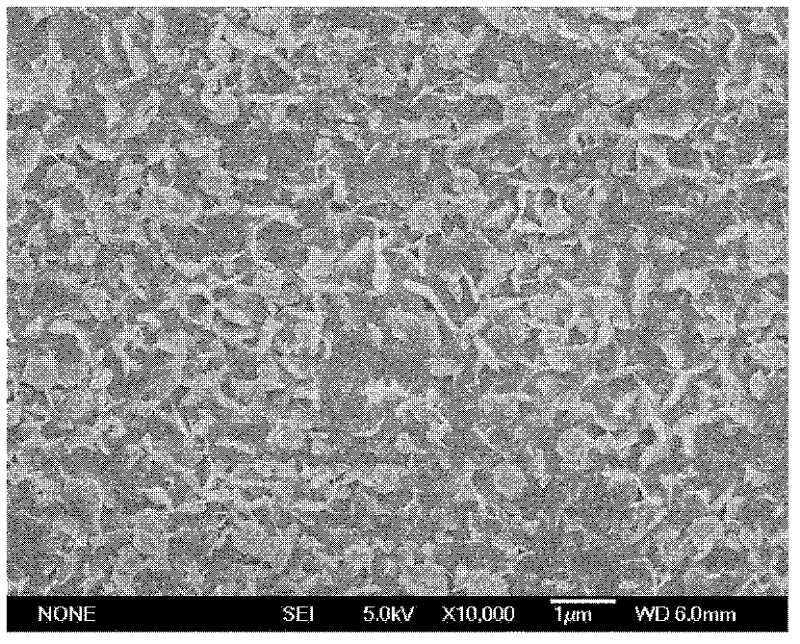

Preparation method for cobalt hydroxide film with nano-structure

InactiveCN102344254AExperimental conditions are simpleThe preparation process is easy to operateCobalt hydroxideMicrostructure

The present invention relates to a preparation method for a cobalt hydroxide film with a nano-structure, and belongs to the field of nanomaterials. The preparation method comprises the following steps: adding a coordination agent of hydrofluoric acid to a cobalt salt solution to generate [CoFx]<(x-2)->; then adding ammonia water to provide OH<-1> required by a precipitation hydrolyzing process through cobalt ions; adjusting the pH value of the solution to 8. 5-9.3; inserting a pre-treated substrate to the solution, and heating for 2-4 hours in water bath with the temperature of 50-80 DEG C; removing the film-covered substrate; carrying out treatments of washing and natural drying for the substrate to obtain the Co(OH)2 film with the nano-structure. The preparation method provided by the present invention has characteristics of simple process, high efficiency, fastness and easily-controlled reaction conditions; with adjusting the cobalt salt concentration in the reaction solution, the atom ratio of the F to the Co, the pH value of the system, the heating temperature, the reaction time, and other process parameters, the microstructure of the film can be controlled.

Owner:BEIJING UNIV OF TECH

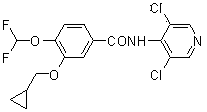

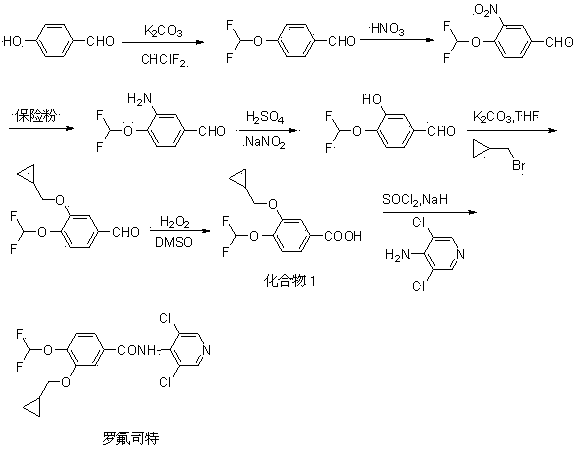

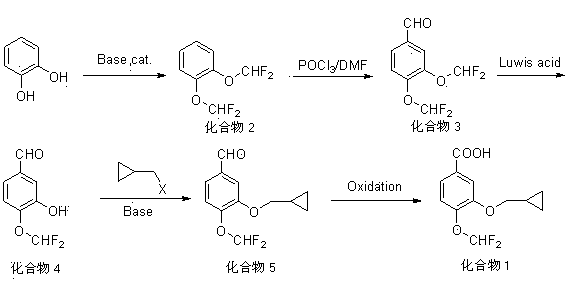

Method for synthesizing roflumilast intermediate

ActiveCN103508883AAddress reactivitySettlement yieldOrganic compound preparationCarbonyl compound preparationBenzoic acidCombinatorial chemistry

The invention discloses a method for synthesizing 3-cyclopropyl methoxyl-4difluoro methoxybenzoic acid, which can be used as an important intermediate for preparing roflumilast. 3-cyclopropyl methoxyl-4difluoro methoxybenzoic acid can be prepared by using pyrocatechin as an initial raw material, performing substitution reaction and Velsmeier reaction, selectively removing difluoro methyl, and carrying out alkylation and oxidation reaction. The method has advantages of cheap and easily available raw material, good reaction selectivity, high yield, and stable finished product quality.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

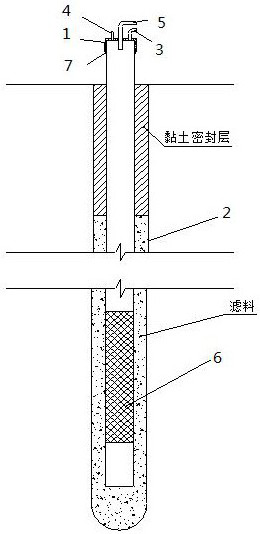

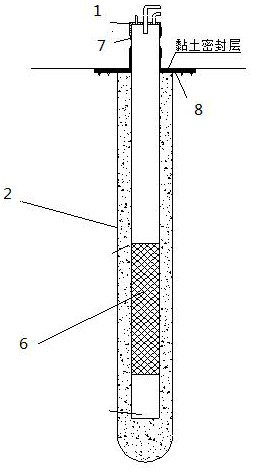

Sealing method after excavation of deep foundation pit downfall pipe well

ActiveCN108930279BGuaranteed Vacuum EfficiencyThe process principle is simpleFoundation engineeringGlass fiberPlastic film

The invention relates to deep foundation pit construction, in particular to a precipitation pipe well in a deep foundation pit. According to the method for closing a precipitation pipe well after excavating of a deep foundation pit, a closing well cap and a filter section sealing gland are included; the sealing gland is manufactured by plastic or glass fiber reinforced plastics in a shaped mode, the closing well cap is manufactured according to the diameter of the precipitation pipe well, and the filter section sealing gland is manufactured according to the diameter of the precipitation pipe well and the diameter of a borehole filter section; in the unexcavated state of earthwork, the well cap is buckled on the precipitation pipe well at the moment, and the well cap is provided with a threading pipe, a drainage pipe and a vacuum pipe; the threading pipe is connected with a water pump power source in a precipitation pipe, the drainage pipe is connected with a water pump drainage pipe inside the precipitation pipe well and a drainage pipe outside the well, and the vacuum pipe is connected with a vacuum pump outside the well; and the well cap and the precipitation pipe well are sealedin a plastic film winding mode, and the wound film is automatically adsorbed on the outer wall of the precipitation well and the outer wall of the well cap under the vacuum effect to achieve the sealing effect. According to the method for closing the precipitation pipe well after excavating of the deep foundation pit, the vacuum degree of the precipitation pipe well can be ensured, mounting and demounting are convenient, and the cost is saved.

Owner:CHINA MCC20 GRP CORP

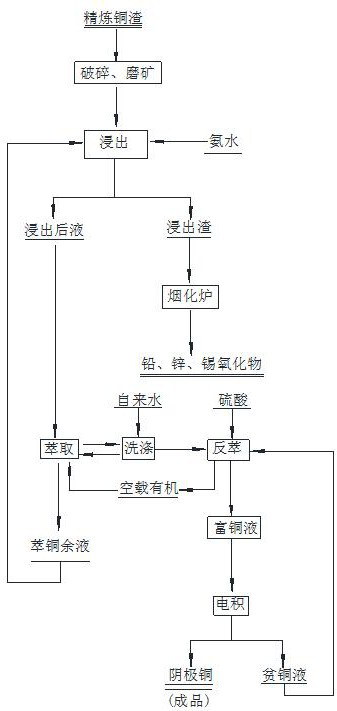

Refined copper slag wet treatment process

PendingCN114214522AReduce labor intensityThe process principle is simplePhotography auxillary processesProcess efficiency improvementAmmonium sulfateMetal leaching

The invention relates to a wet treatment process for refined copper slag. The wet treatment process comprises the following steps that S1, the refined copper slag is subjected to coarse crushing and fine crushing, and after ball milling, the granularity of the refined copper slag reaches-80--200 meshes; s2, leaching the ground refined copper slag and an ammonia water-ammonium sulfate mixed solution at normal temperature and normal pressure, and carrying out solid-liquid separation after leaching to obtain a copper ammonia complex solution and metal leaching slag; s3, the copper-ammonia complexing solution and a copper extraction agent are extracted, copper in the extracted solution is enriched in the extraction agent, and the extraction agent is subjected to reverse extraction through an electrodeposition copper-poor solution or sulfuric acid to obtain a copper-rich solution; s4, the copper-rich solution enters a copper electrodeposition system for electrodeposition, and a cathode copper finished product is separated out on the cathode; and the extracted raffinate is returned for leaching to serve as a leaching base solution. The process is simple in principle and low in energy consumption, the whole process is mechanically operated, the labor intensity of workers is low, the recovery rate of copper in the whole process is larger than or equal to 95%, and the leaching residues can return to the fuming furnace to continue to recover other metal elements in the fuming furnace.

Owner:江西自立环保科技有限公司

Edge sensor for mosaic mirror surface based on interference principle and its working method

ActiveCN110779443BClear principleCompact structureUsing optical meansWavefront sensorDigital imaging

The invention discloses an edge sensor for a segmented mirror surface based on an interference principle, and a working method thereof. The edge sensor is characterized in that: an optical flat or spherical lens is placed on a sub-mirror splicing seam of a measured segmented mirror surface, the front surface of the optical flat or spherical lens is completely anti-reflection, and the rear surfaceof the optical flat or spherical lens is provided with a coating film; a parallel light source is arranged on the other side of a sub-mirror of the measured segmented mirror surface and the optical flat or spherical lens, light rays vertically enter the optical flat or spherical lens by means of a semi-reflecting and semi-transmitting prism and then part of the light beam on the surface returns, the other part is reflected by the surface of the sub-mirror along an original path, the two beams of reflected light form interference fringes, the interference fringes enter a microscopic amplification imaging system by means of the semi-reflecting and semi-transmitting prism, and target surface receiving and digital imaging are carried out by means of a CCD or CMOS detector, namely, the splicingerror of the adjacent sub-mirrors can be handled. The edge sensor prevents starlight and wavefront sensors from occupying and wasting a limited high-imaging-quality field of view of an optical system, is low in price, stable in performance and not affected by environmental factors, and is suitable for detecting the splicing errors between the adjacent sub-mirrors of various optical segmented mirror surfaces.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Marking tool and marking method of underground pile position in engineering site

The invention relates to a pile position and an underground structure mark. An underground pile position marking tool on an engineering site, the marking tool includes a steel pipe with one end closed: a guide rod inserted from the closed end of the steel pipe with a piston, a marking material tank, which is passed into the steel pipe through a branch pipe, The outlet of the branch pipe is located at the lowest position of the piston. Use sloped steel pipes to take soil from the location to be marked underground and drill holes. After drilling, pour lime or other powdery substances into the marked material tank of the marked position marking tool. The color of the poured material should have obvious color difference from the soil of the project site. Then put the conduit of the tool into the marked hole, hold the handle with one hand, and push the bracelet up and down with the other hand, so that the powder or lime in the lime tank will be sent into the marked hole, when you find the pile position after marking Use a shovel to gently scrape off a layer of the soil surface, and the pile holes will be clearly displayed. The invention prevents pile position marks from being damaged, and prevents field marking piles from causing damage to vehicle tires.

Owner:CHINA MCC20 GRP CORP

A method for pulling upvc double-wall corrugated downpipe wells

The invention relates to tube well construction, in particular to precipitation plastic tube well construction. A method for removing a UPVC double-wall corrugated precipitation tube well comprises the steps: first four hanging bars are evenly arranged on the outer side of the UPVC double-wall corrugated precipitation tube well; the hanging bars are made of steel bars and externally wrapped with a plastic film, a cutting knife with a hook is welded to the bottom of each hanging bar, the inner side of the bottom of the hook of the cutting knife is provided with a blade, and the top of each hanging bar is provided with a hanging ring; the edge part of the cutting knife is embedded upwards into a tube well bottom cover, and a cutting edge of the cutting knife is placed at the bottommost part of the UPVC double-wall corrugated precipitation tube well; precipitation operation is performed; finally, after the precipitation operation is finished and drainage facilities in the tube well are recycled, a lifting appliance is used to pull upwards the hanging ring located on a tube well upper opening, a mode of multiple lifting or single lifting is adopted, the goal of cis-cutting is achieved, a UPVC double-wall bellows well tube divided into four pieces after the cutting is separated from a well opening and taken out manually. The method is simple and easy to operate, and environmental pollution is reduced.

Owner:CHINA MCC20 GRP CORP

Environment-friendly oil gas recycling method

InactiveCN108619753AImprove purification effectReduce the temperatureGas treatmentDispersed particle separationRecovery methodAfter treatment

The invention discloses an environment-friendly oil gas recycling method. The environment-friendly oil gas recycling method includes steps of S1, separating oil gas from air by the aid of the magnitude of adsorption force of adsorbents for oil gas / air mixed gas; S2, carrying out desorption treatment on the oil gas obtained at the step S1; S3, preferentially permeating oil gas molecules of the oilgas, which is treated at the step S2, through polymeric membranes under pushing effects of the pressures by the aid of the characteristic of preferential permeability of the special polymeric membranes for hydrocarbon, entrapping and exhausting air components and acquiring enriched oil gas; S4, sucking the enriched oil gas, which is obtained after treatment is carried out at the step S3, into pipelines by the aid of vacuum pumps, reducing the temperature of the oil gas by the aid of multilevel continuous cooling processes to condense the oil gas so as to obtain liquid and recycling the liquid.The environment-friendly oil gas recycling method has the advantages that the oil gas can be separated from the air, accordingly, the environment-friendly oil gas recycling method is high in oil gasand air separation degree, and good oil gas purification effects can be realized by the environment-friendly oil gas recycling method.

Owner:SHANDONG NEW DANENG ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of ammonium polyphosphate with high degree of polymerization and preparation method thereof

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com