Patents

Literature

159 results about "Autoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autoxidation is any oxidation that occurs in presence of oxygen. The term is usually used to describe the degradation of organic compounds in air (as a source of oxygen). Autoxidation produces hydroperoxides and cyclic organic peroxides. These species can react further to form many products. The process is relevant to many phenomena including aging, paint, spoilage of foods, degradation of petrochemicals, and the industrial production of chemicals. Autoxidation is important because it is a useful reaction for converting compounds to oxygenated derivatives, and also because it occurs in situations where it is not desired (as in the destructive cracking of the rubber in automobile tires or in rancidification).

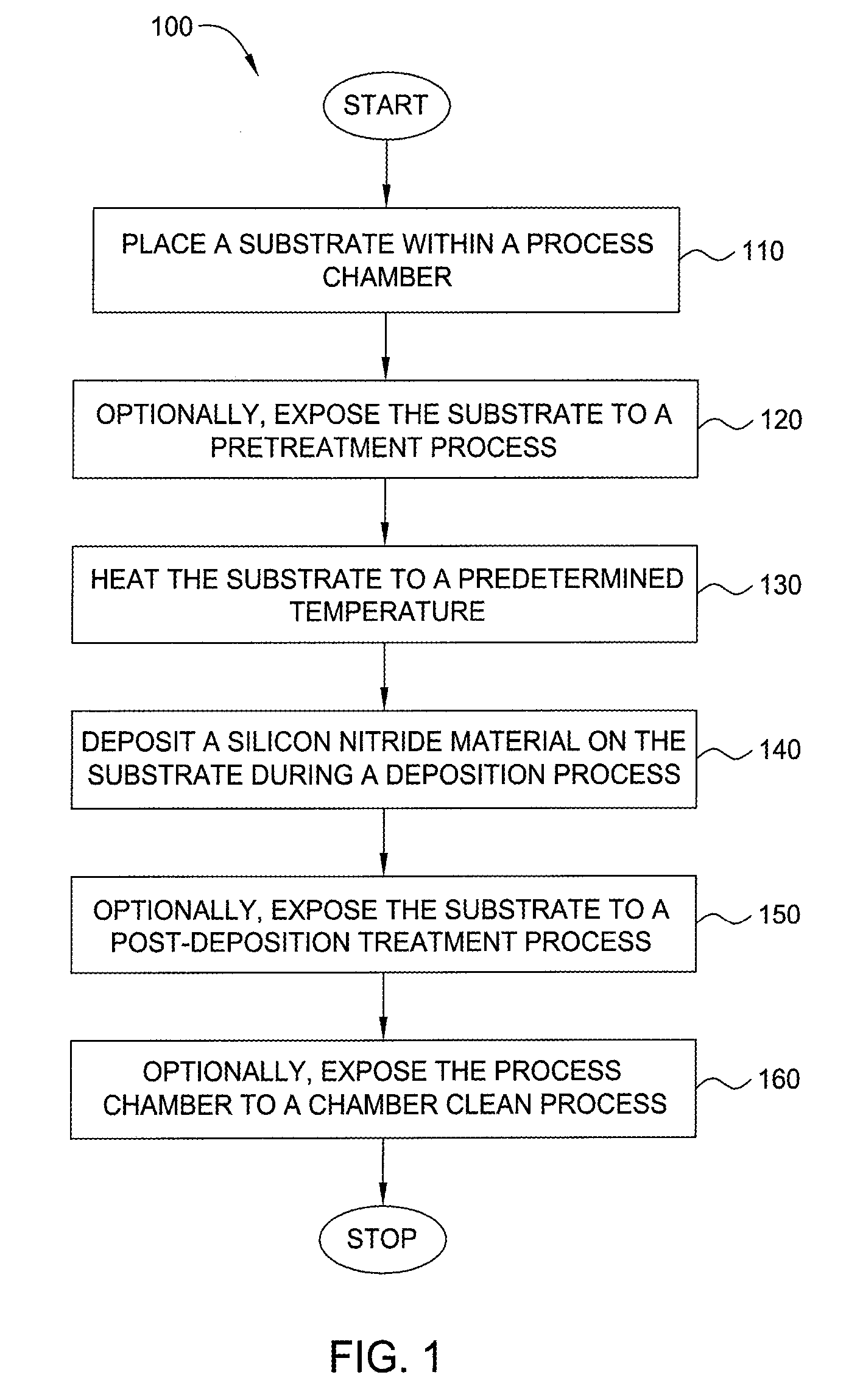

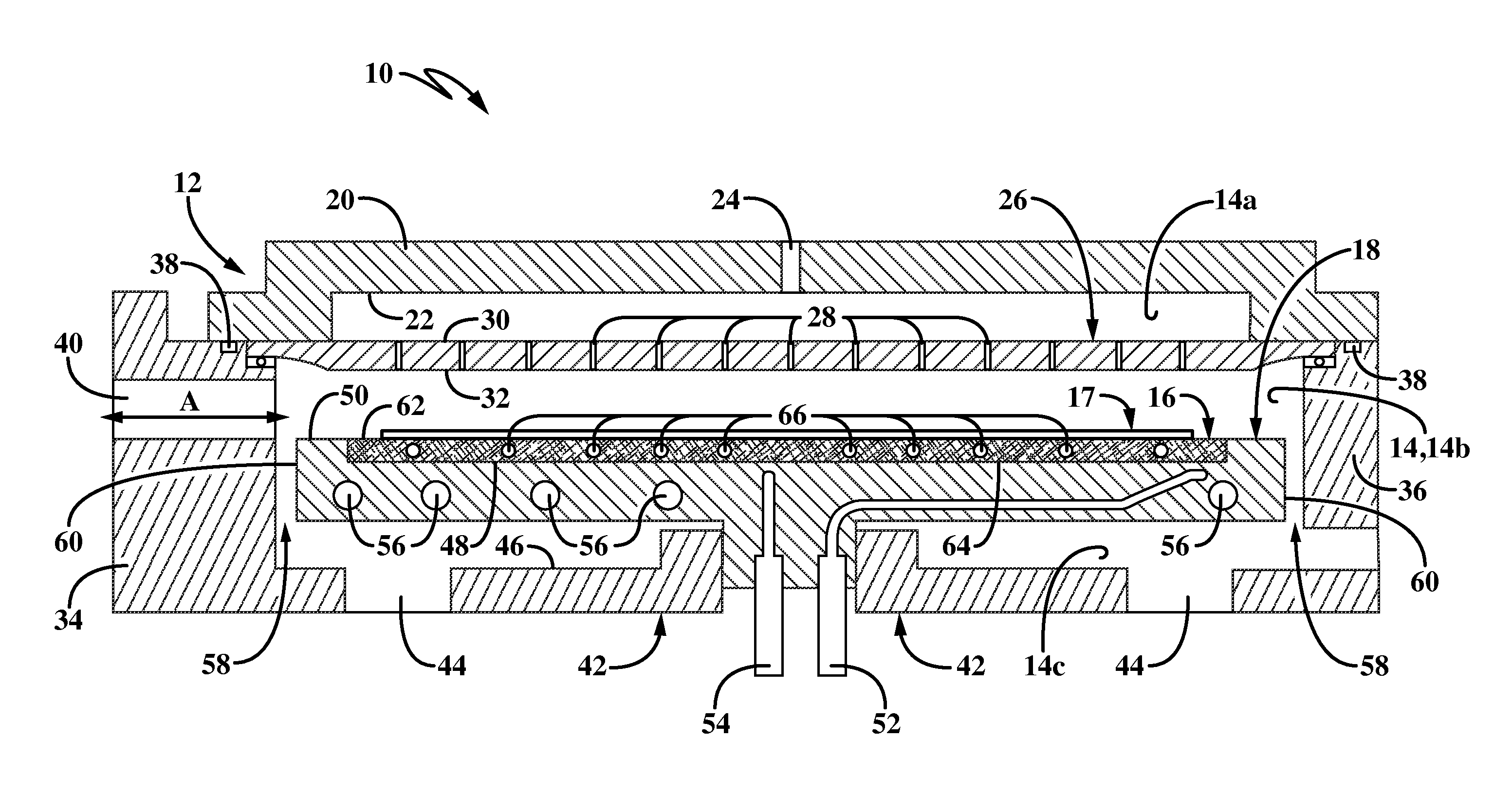

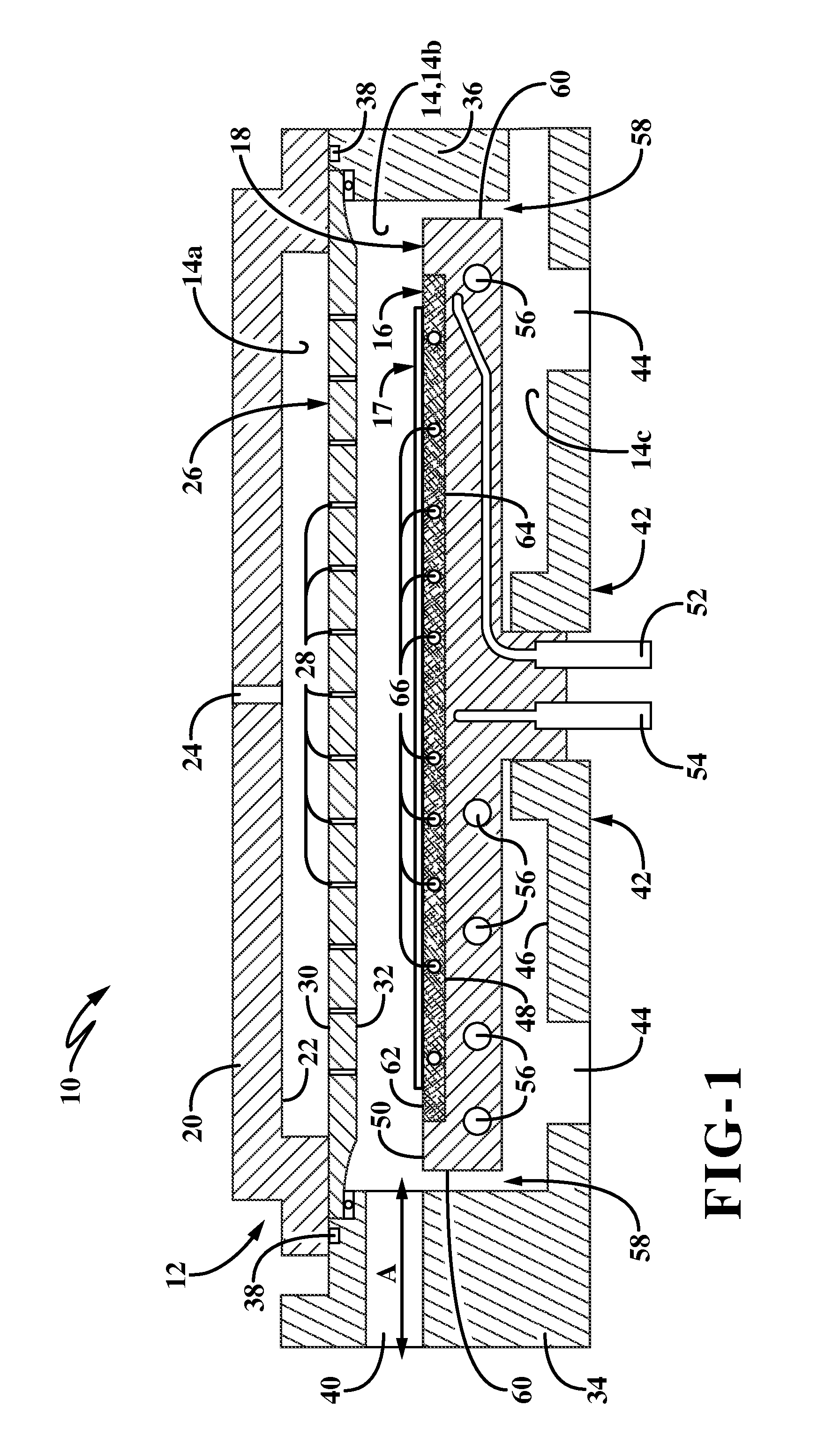

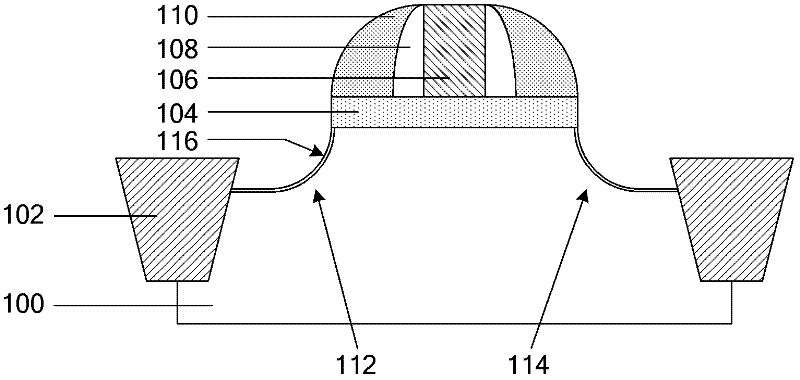

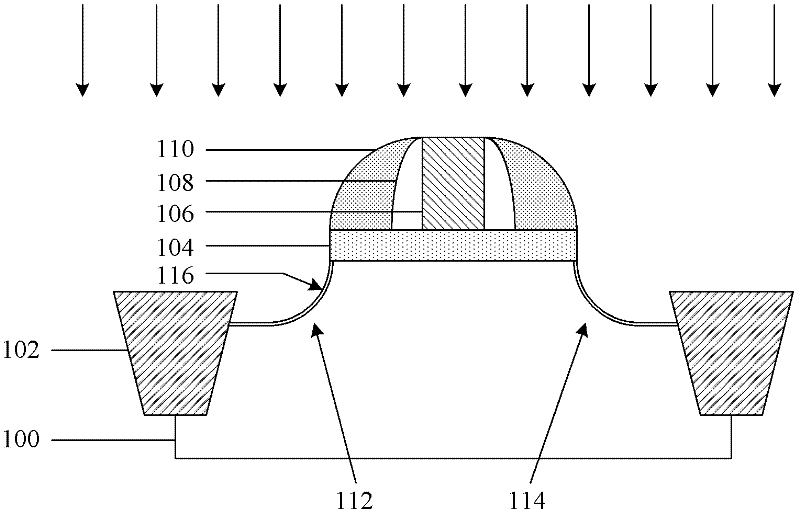

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7651955B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

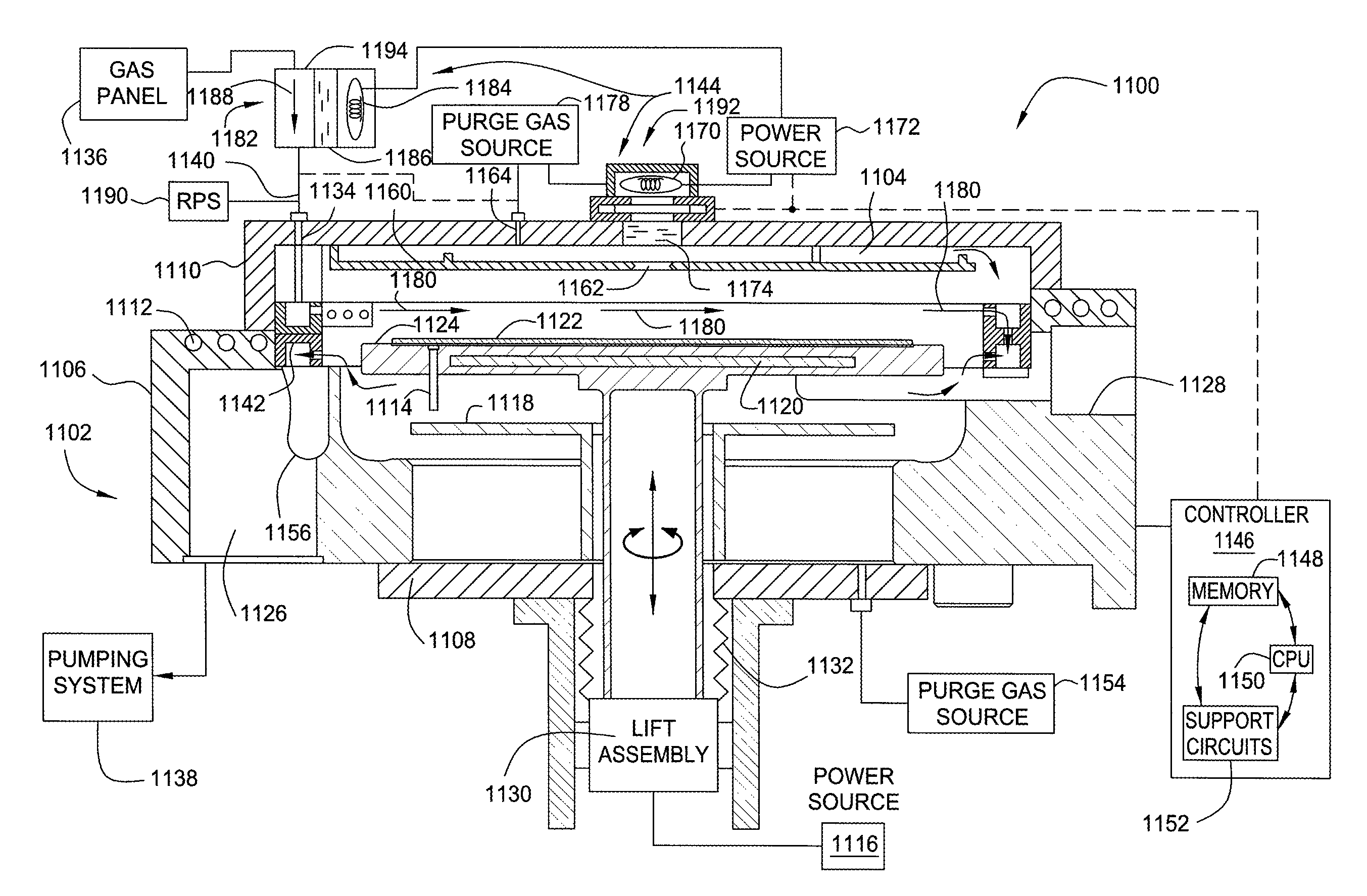

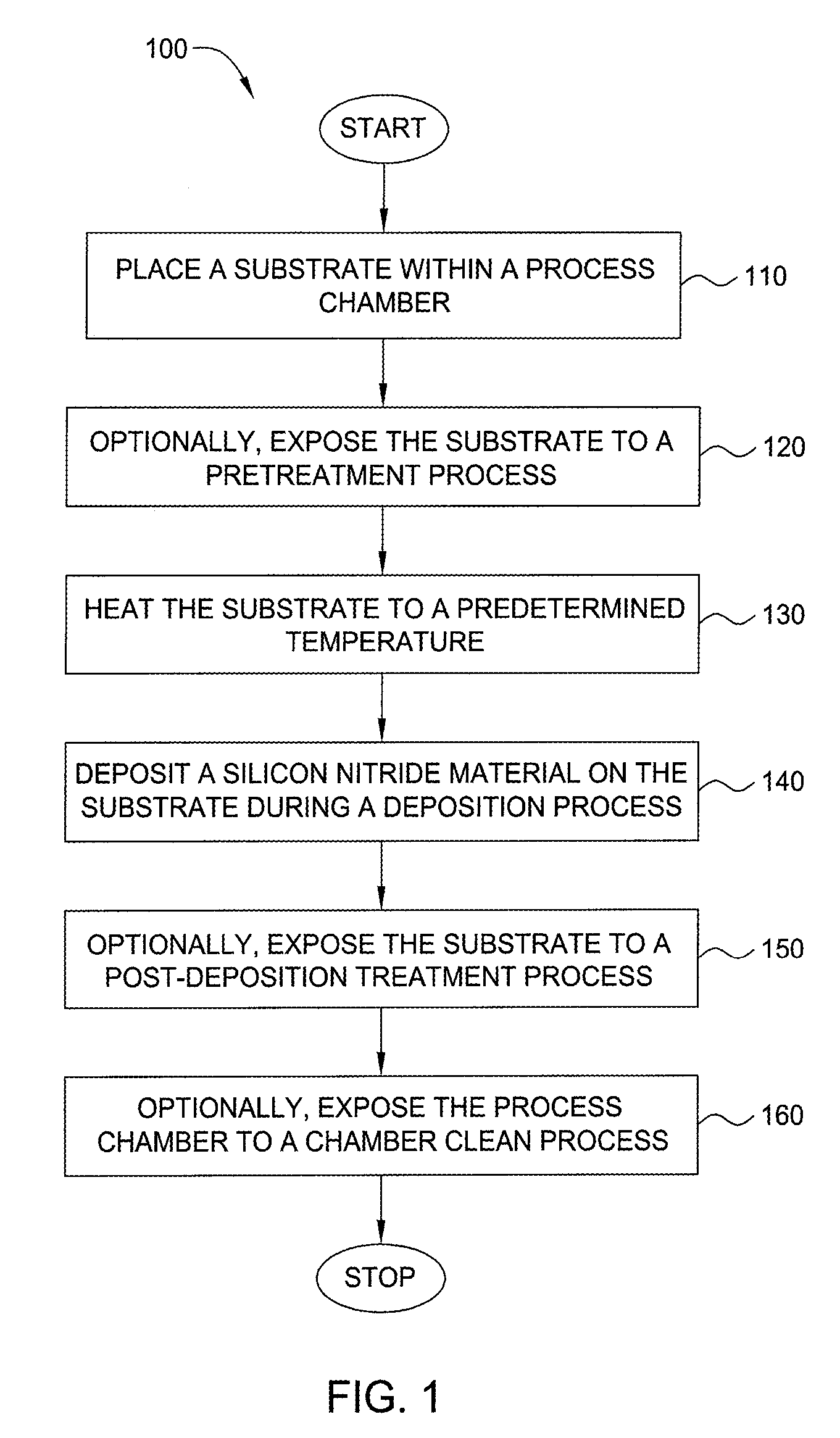

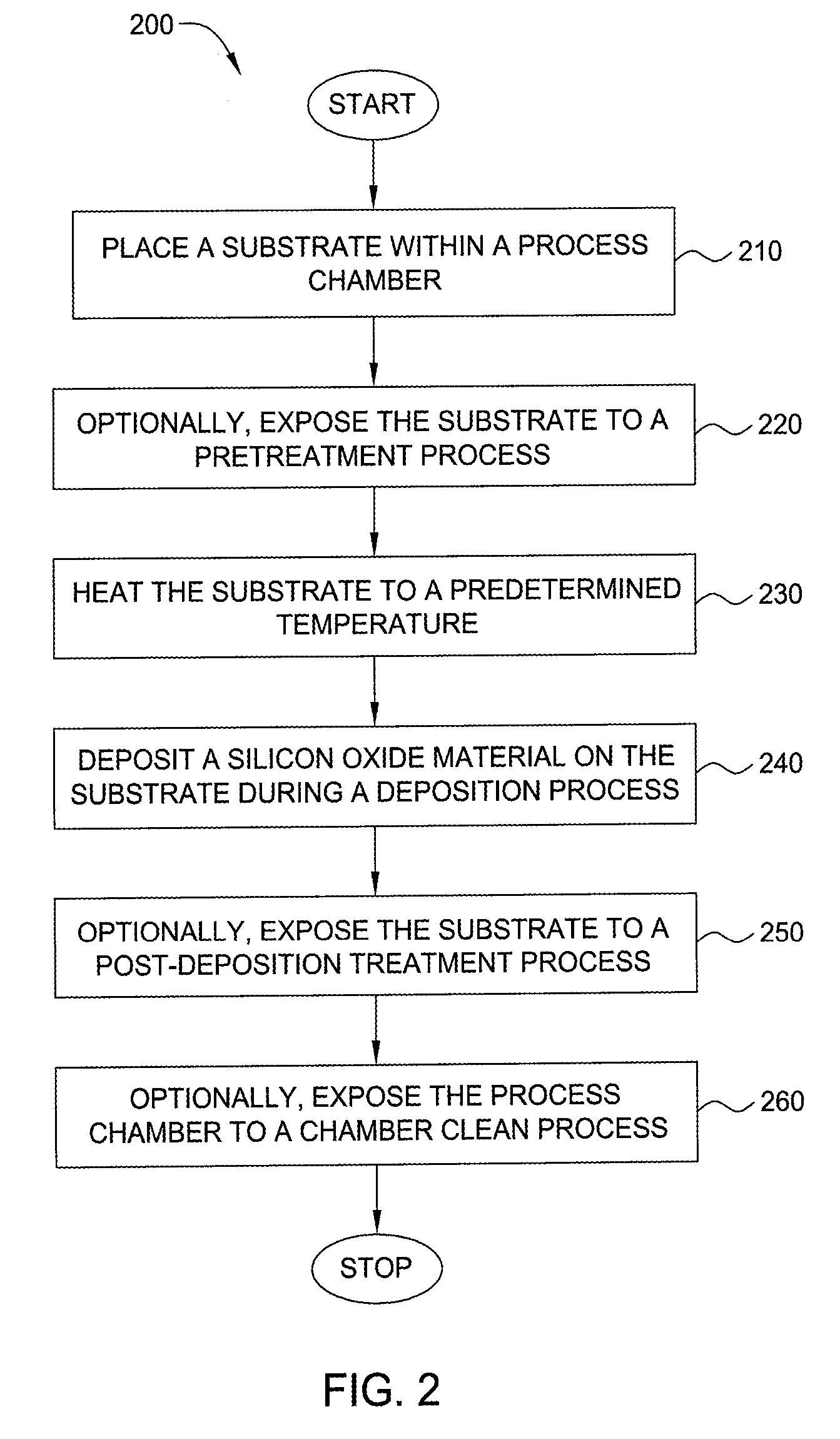

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

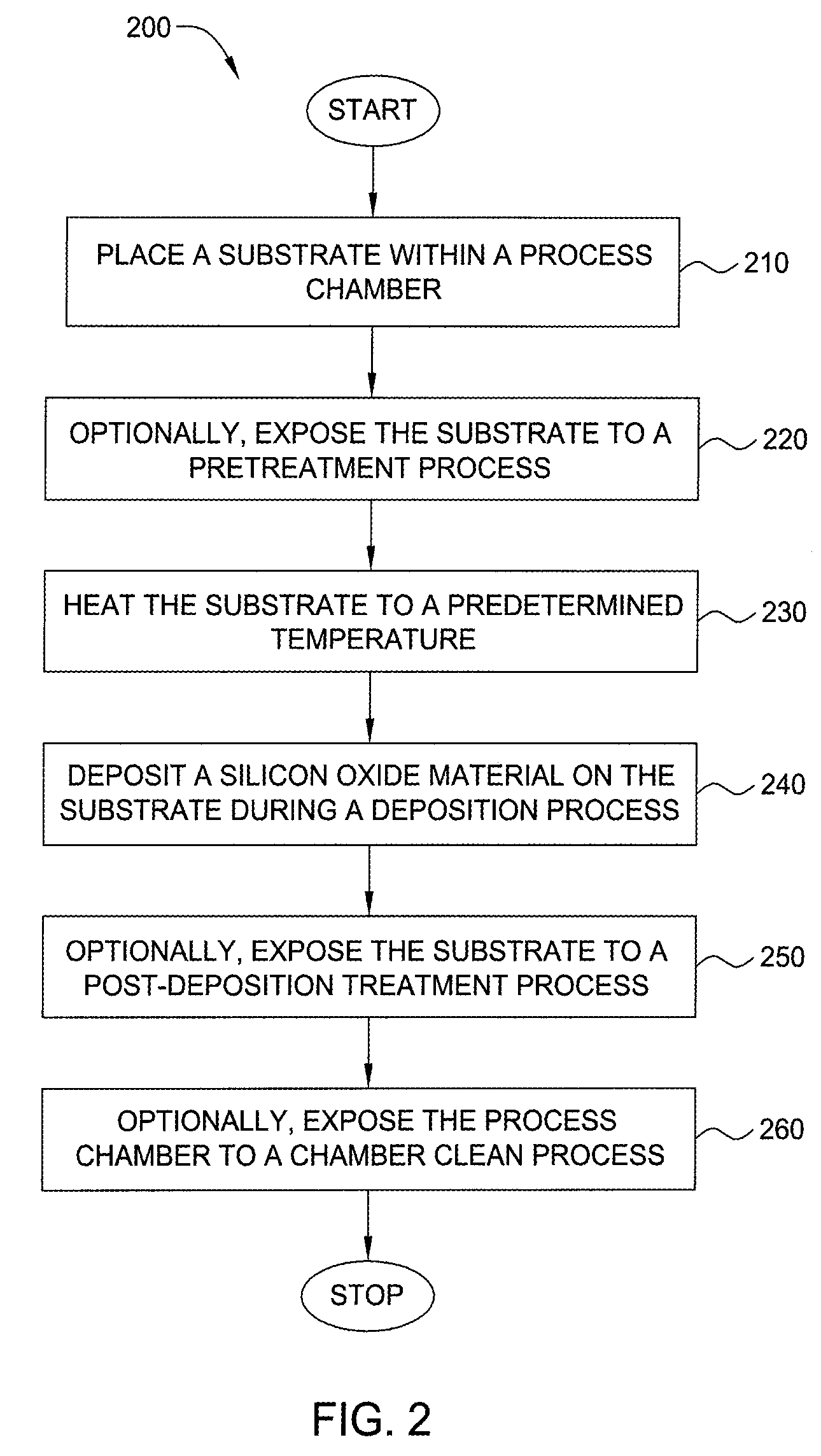

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7648927B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

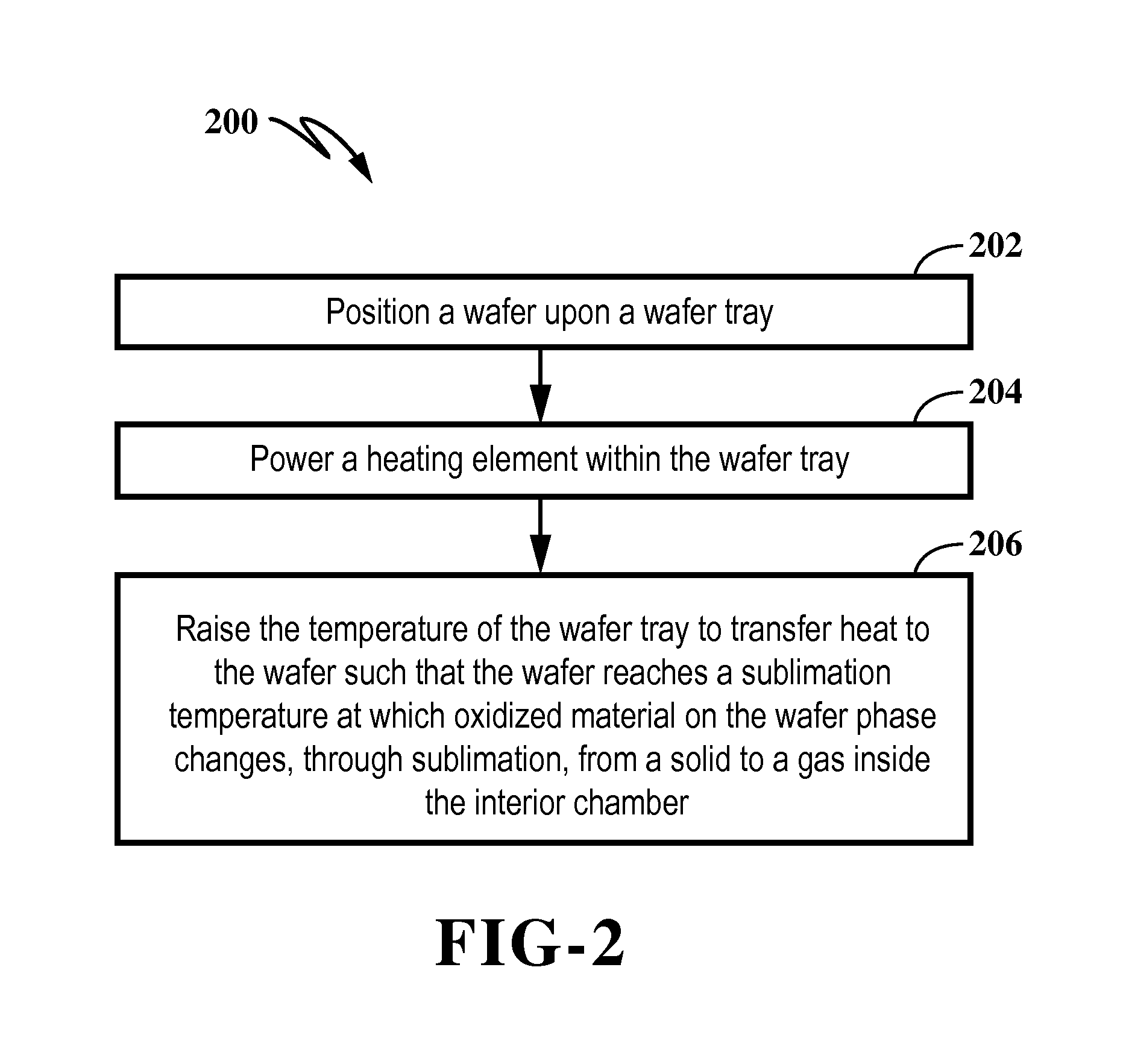

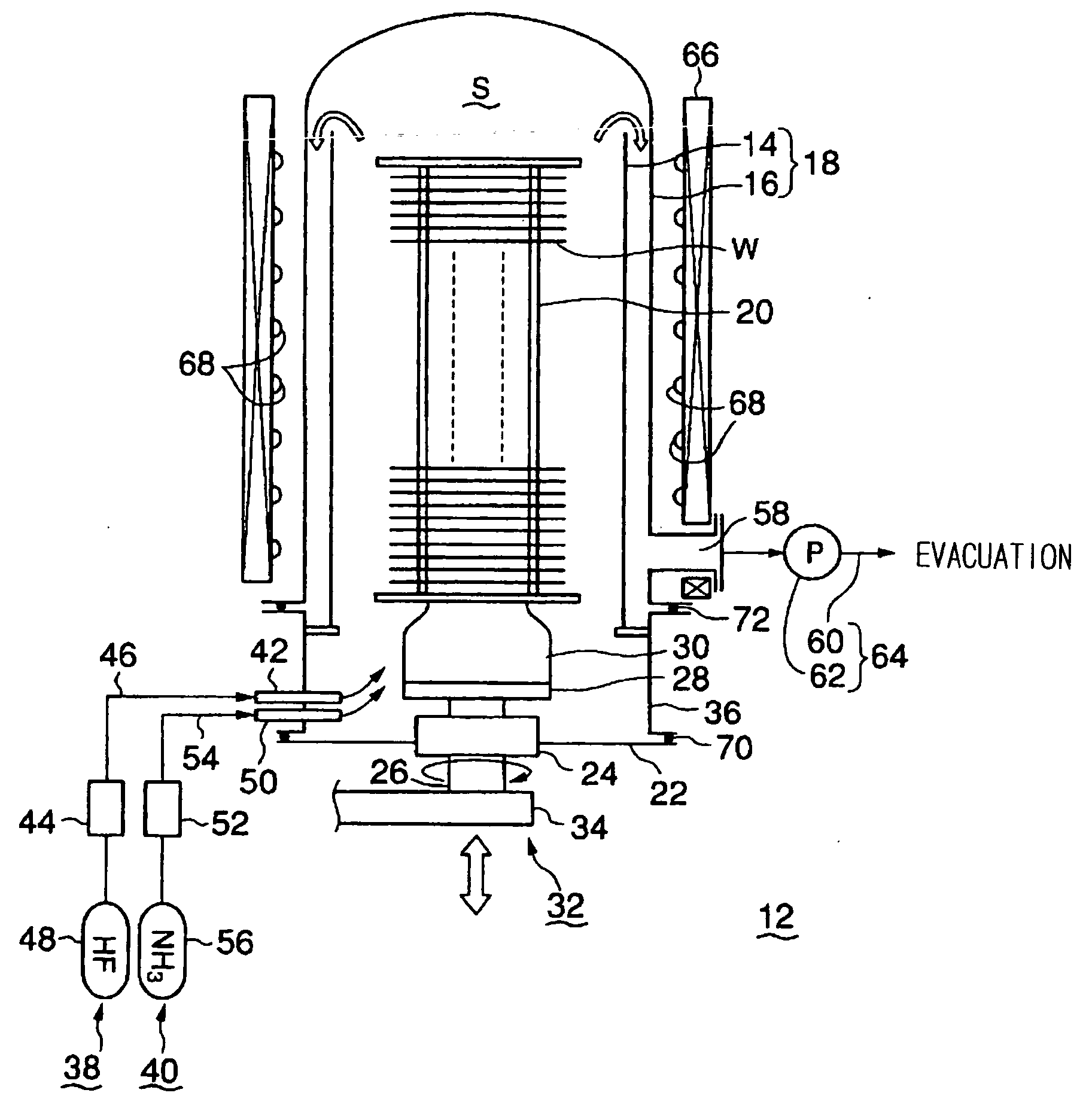

Reactor system for sublimation of pre-clean byproducts and method thereof

A reactor system and related methods are provided which may include a heating element in a wafer tray. The heating element may be used to heat the wafer tray and a substrate or wafer seated on the wafer tray within a reaction chamber assembly, and may be used to cause sublimation of a native oxide of the wafer.

Owner:ASM IP HLDG BV

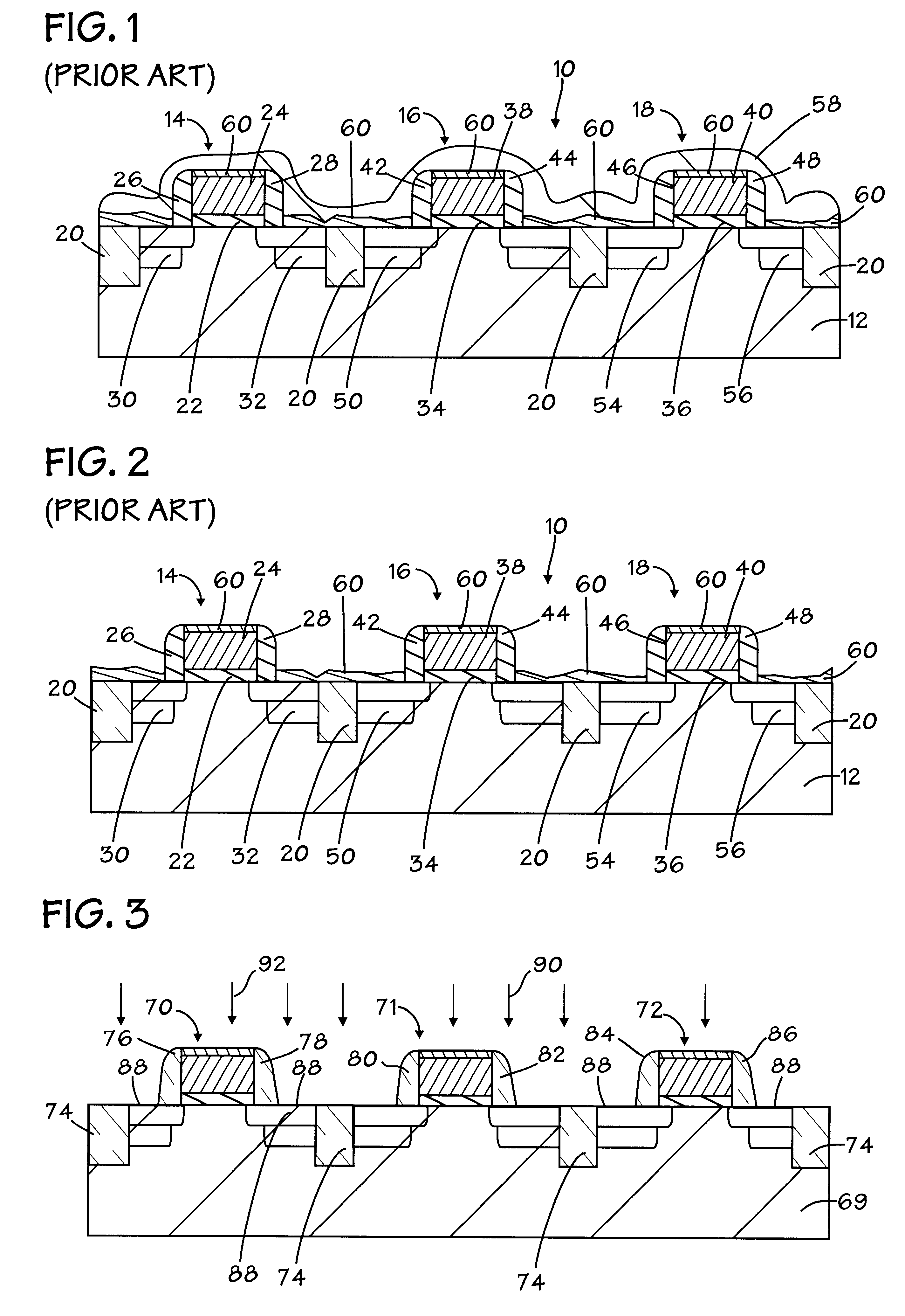

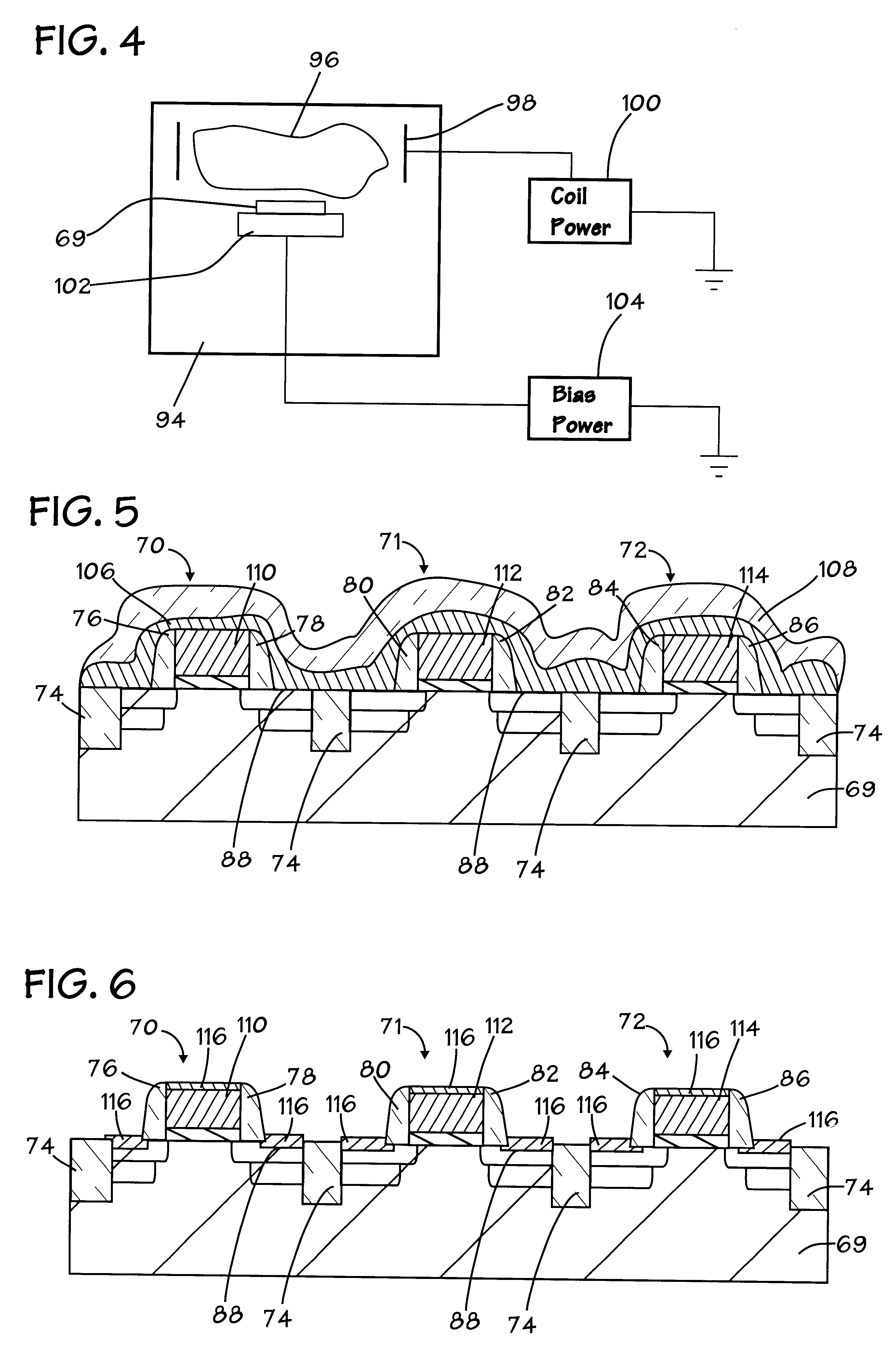

Advanced cobalt silicidation with in-situ hydrogen plasma clean

Various methods of fabricating a silicide structure are provided. In one aspect, a method of fabricating a circuit structure on a silicon surface is provided that includes exposing the silicon surface to a plasma ambient containing hydrogen and an inert gas, and depositing a metallic material capable of forming silicide on the silicon surface. The metallic material is heated to form a metal silicide on the silicon surface. The method provides for low sheet resistance silicide structures by eliminating native oxide films without the risk of spacer material backsputtering.

Owner:ADVANCED MICRO DEVICES INC

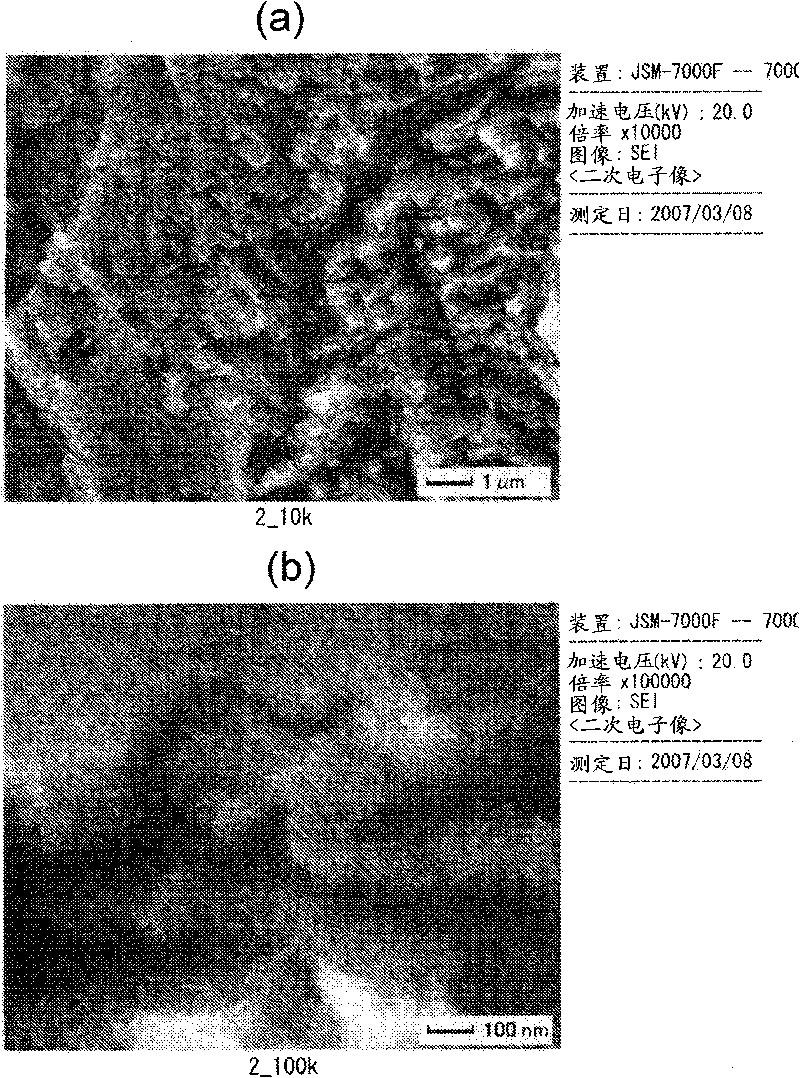

Super-hydrophobic textile prepared from modified polyester fiber based on dopamine and preparation method thereof

The invention provides a super-hydrophobic textile prepared from a modified polyester fiber based on dopamine and a preparation method thereof, the preparation method comprises the steps that a polyester fabric is soaked into different buffer solutions in sequence, nano-particles produced by dopamine polymerization are deposited on the fiber surface adhered with polydopamine, the fiber is finally treated by a low surface energy modifier to obtain the super-hydrophobic textile; the buffer solution at east comprises two kinds of different buffer solutions, namely, a phosphate buffer solution of the dopamine and a trihydroxymethyl aminomethane buffer solution of the dopamine. According to the super-hydrophobic textile prepared from the modified polyester fiber based on the dopamine and the preparation method thereof, the characteristic that the sizes of polydopamine nano particles produced by dopamine polymerization in different buffer solution systems is utilized, autoxidation polymerization of dopamine is utilized to be adhered to and deposited on the fiber surface to form a rough structure required by the super-hydrophobic surface, and the super-hydrophobic surface can be prepared after the rough structure is treated by the low surface energy; the reaction process is simple, the condition is mild; and the water drop contact angle of the super-hydrophobic surface prepared by the invention is more than 150 degree.

Owner:SHAANXI UNIV OF SCI & TECH

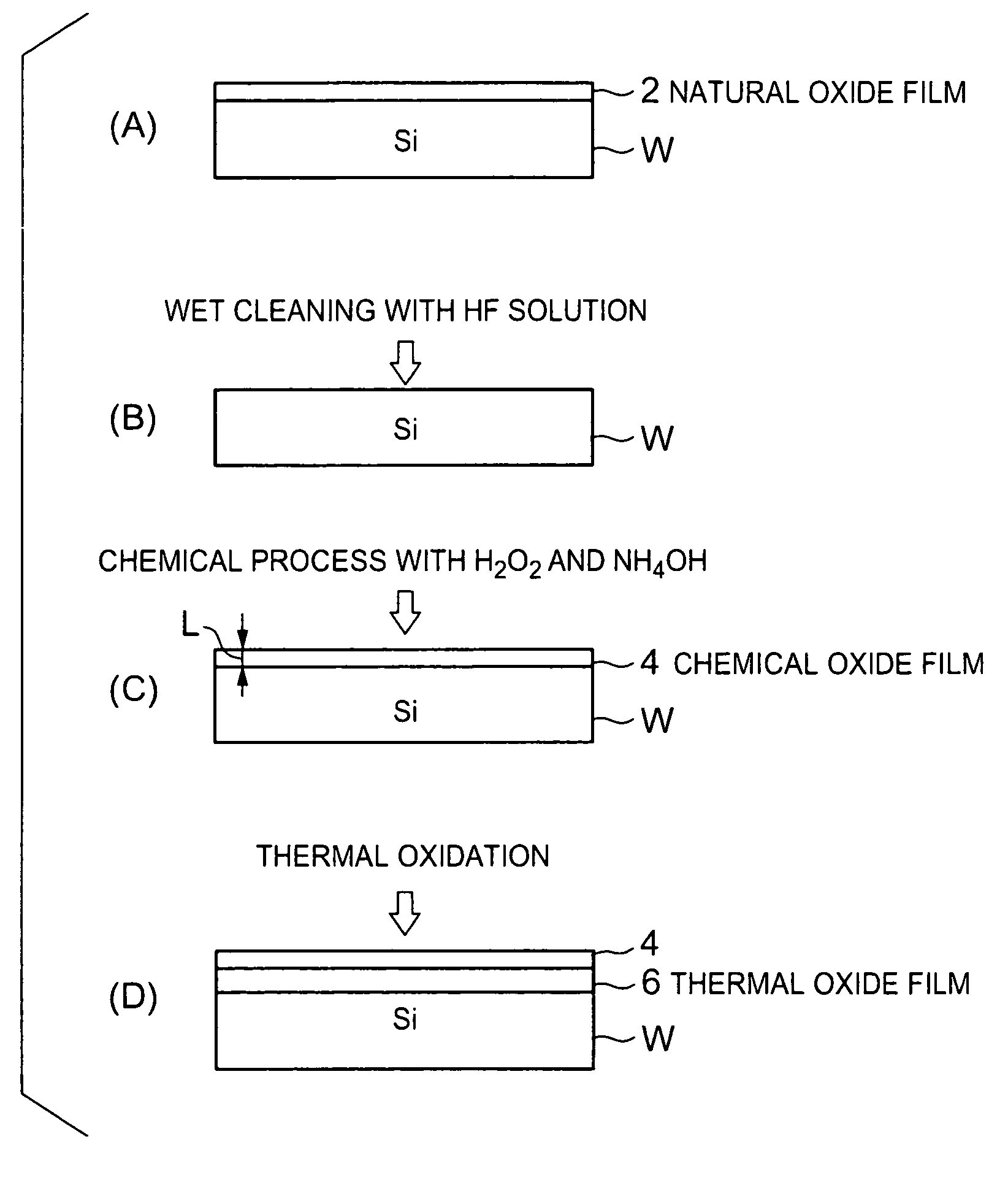

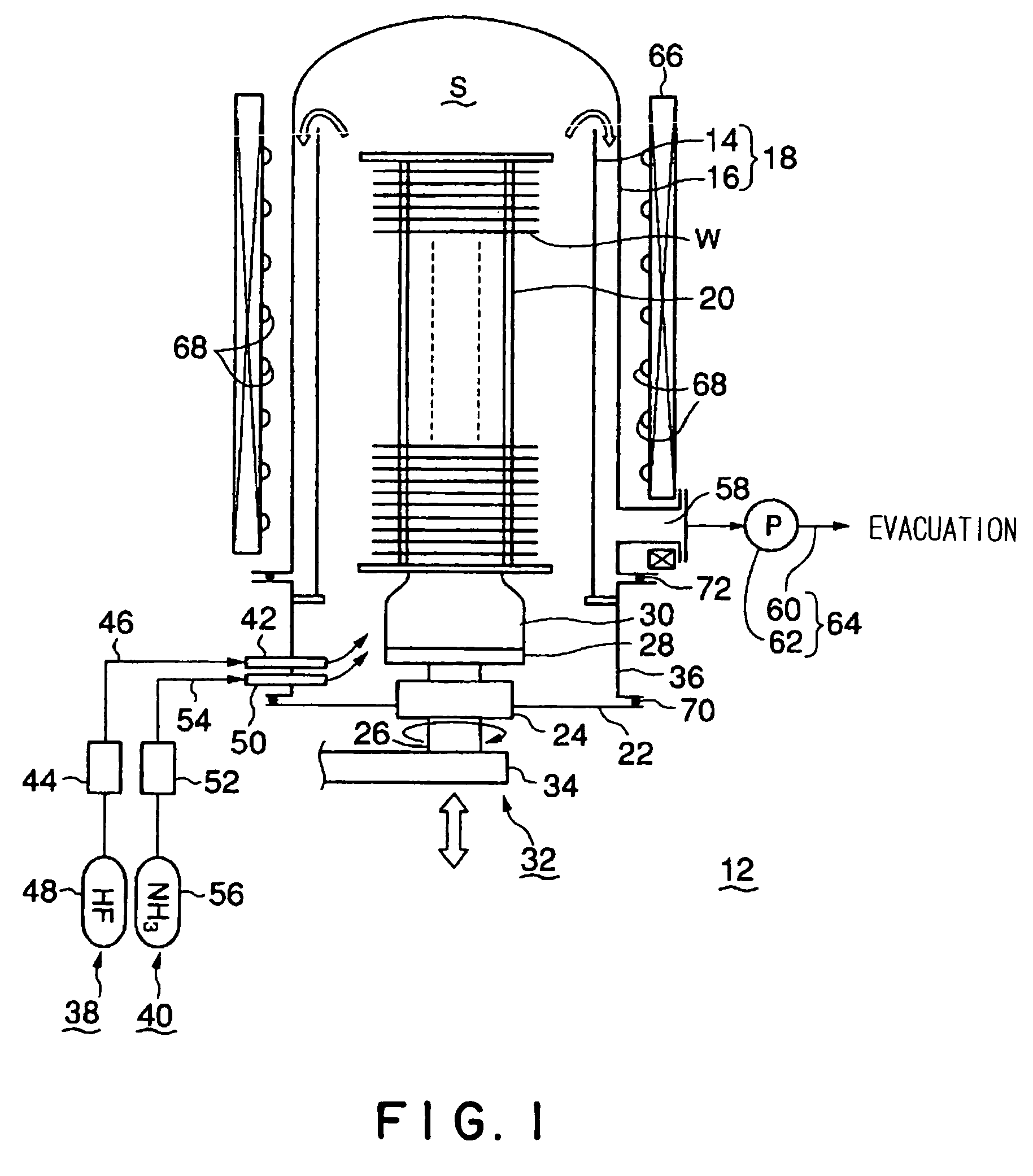

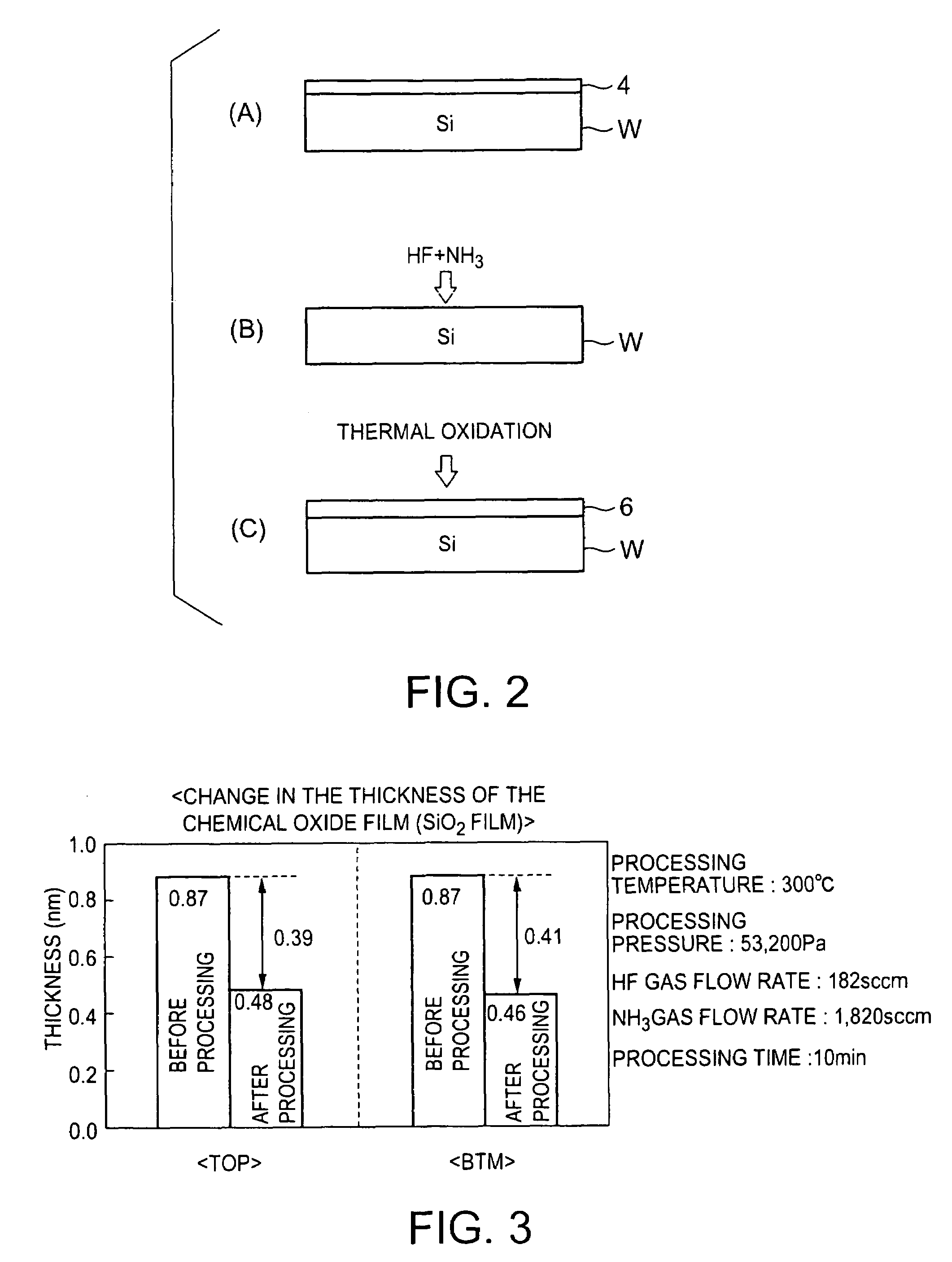

Method for removing silicon oxide film and processing apparatus

InactiveUS20060216941A1Efficient removalDecorative surface effectsSemiconductor/solid-state device manufacturingAutoxidationRoom temperature

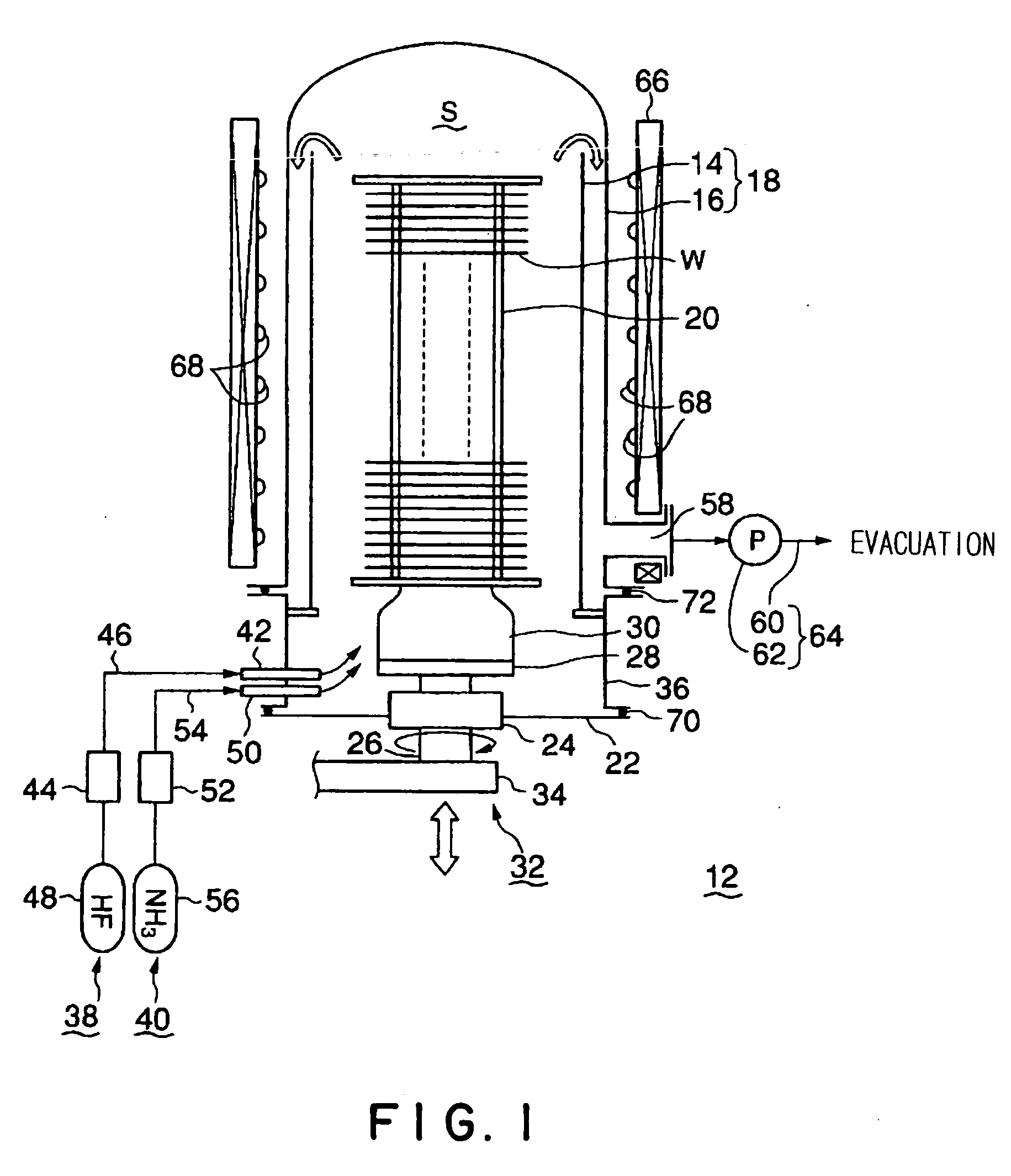

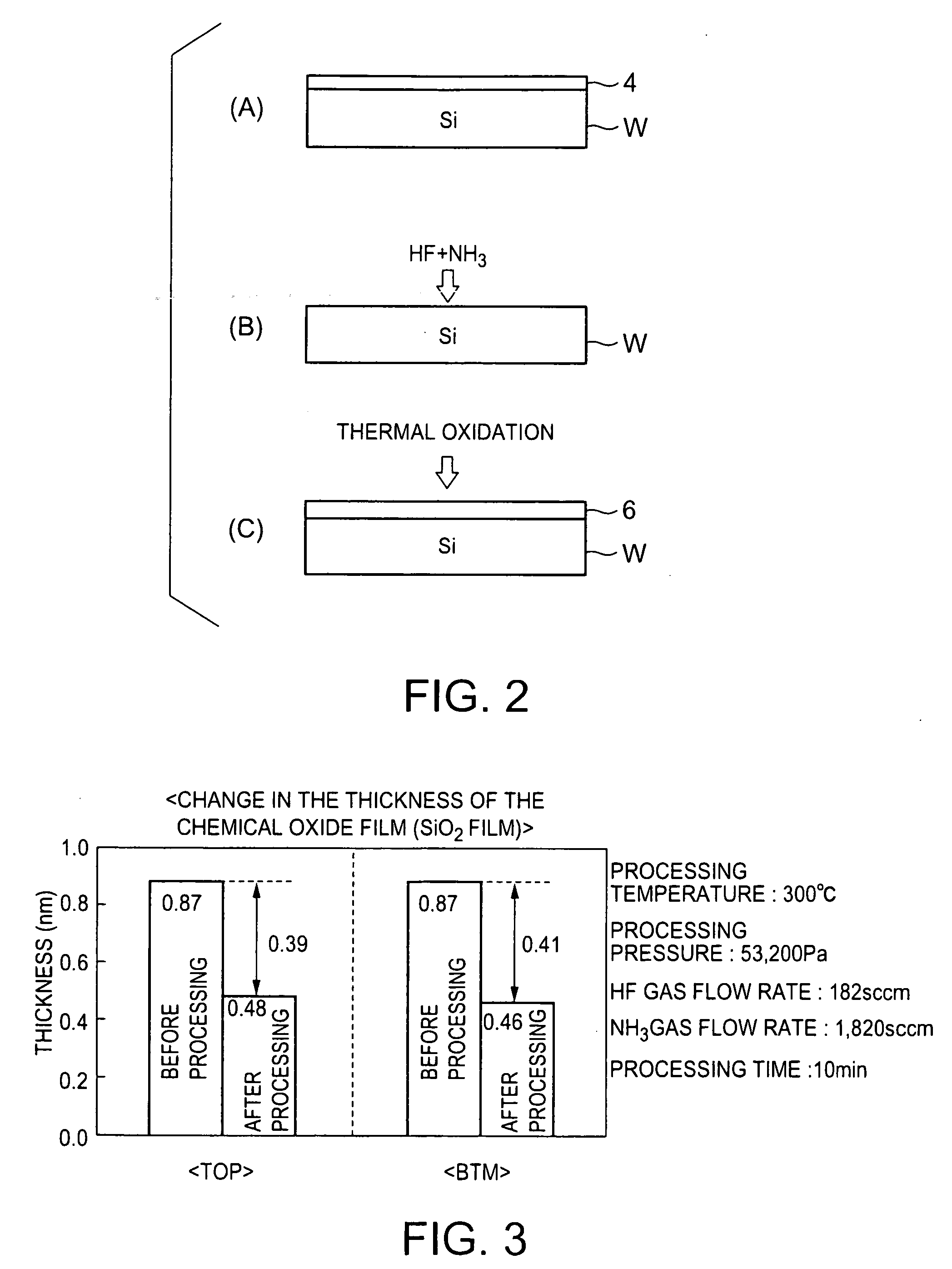

A silicon dioxide film removing method is capable of removing a silicon dioxide film, such as a natural oxide film or a chemical oxide film, at a temperature considerably higher than a room temperature. The silicon dioxide film removing method of removing a silicon dioxide film formed on a workpiece in a processing vessel 18 that can be evacuated uses a mixed gas containing HF gas and NH3 gas for removing the silicon dioxide film. The silicon dioxide film can be efficiently removed from the surface of the workpiece by using the mixed gas containing HF gas and NH3 gas.

Owner:TOKYO ELECTRON LTD

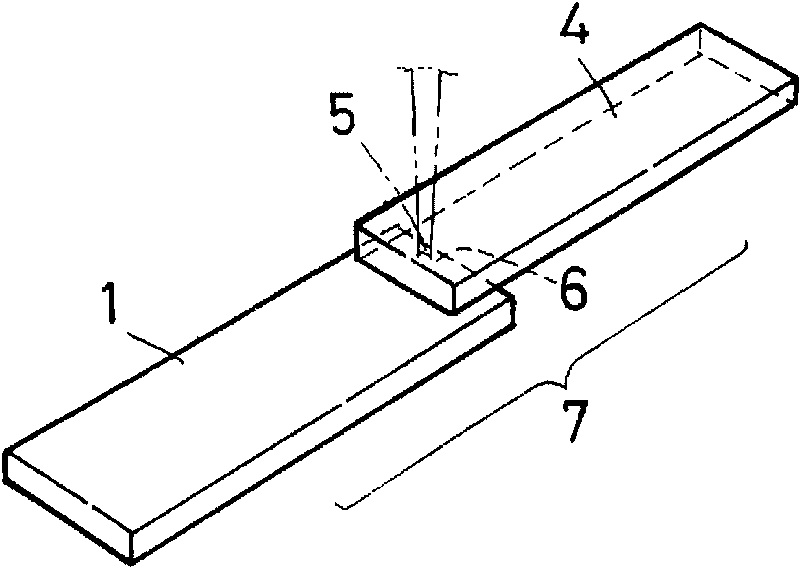

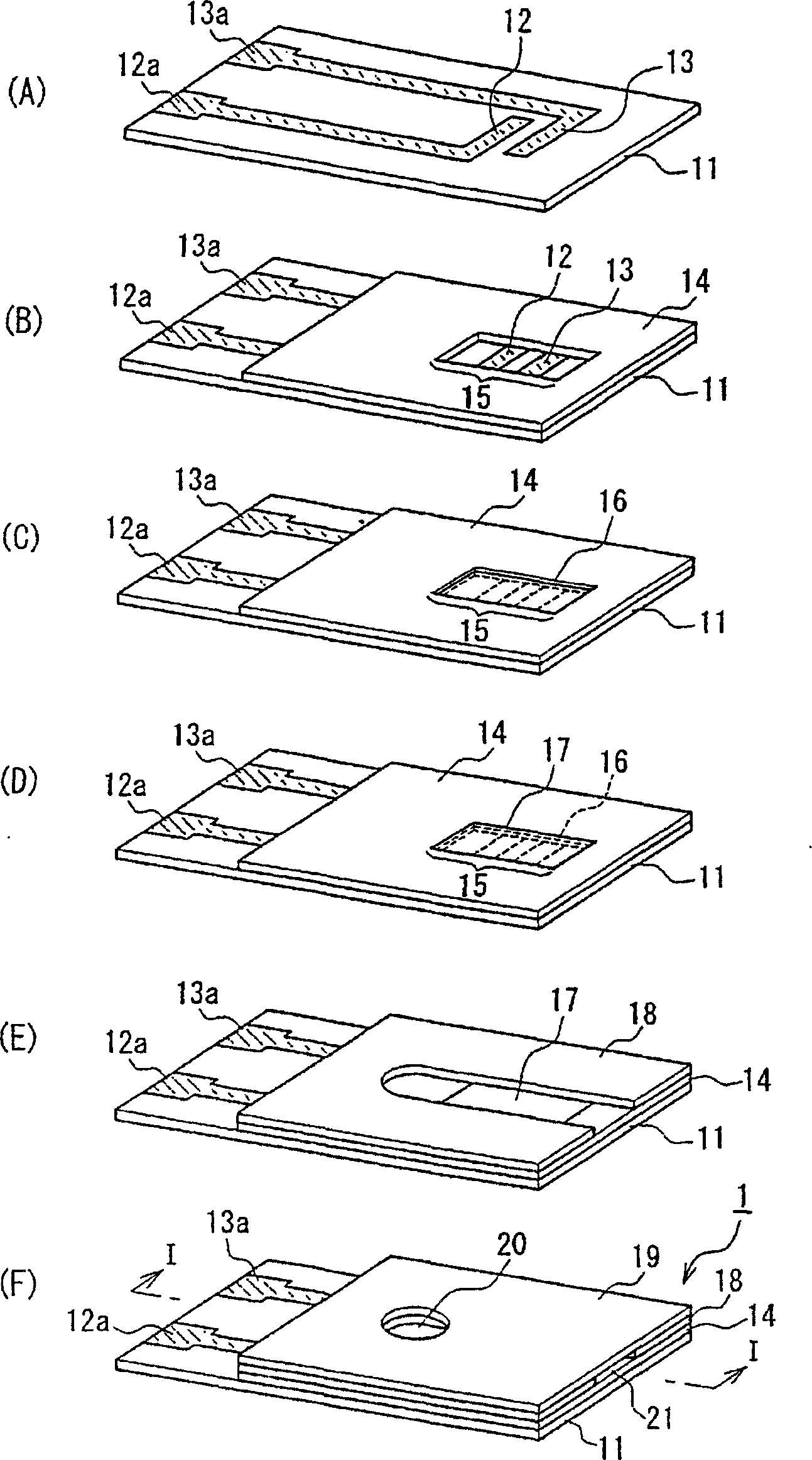

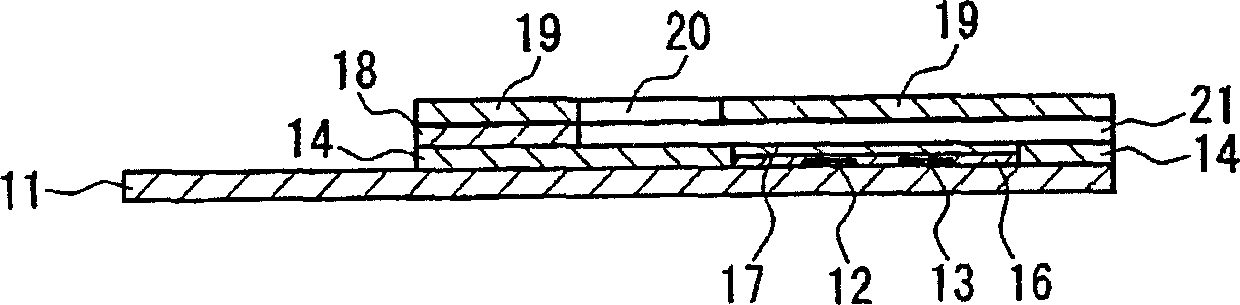

Composite of metal with resin and process for producing the same

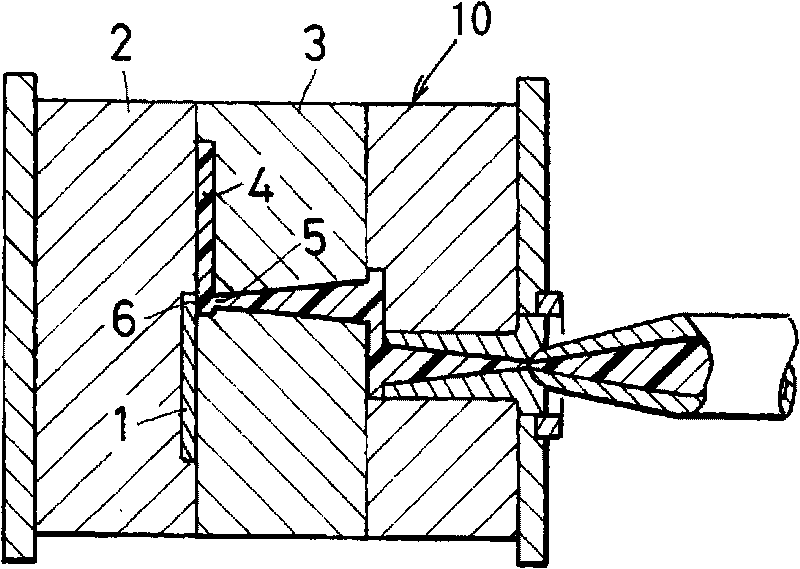

A composite of a metal with a resin in which the metal and the resin, especially a shaped base made of an ordinary steel material and a resin composition, can be tenaciously bonded and united to each other; and a process for producing the composite. A surface of a shaped ordinary steel material is treated by chemical etching or the like to form a thin iron autoxidation film layer the surface of which almost wholly has ultrafine irregularities. Hydrazine, ammonia, or a water-soluble amine is chemically adsorbed onto the treated steel material. The resultant steel material shape (1) is inserted into an injection die (10), and a specific resin composition (4) is injected thereinto. The surface of the steel material shape (1) may have a thin layer of a metal oxide or metal-phosphorus oxide. By this injection, a composite (7) is obtained in which the ordinary steel material has been tenaciously bonded and united to the resin. The resin composition (4) to be used contains a crystalline polyphenylene sulfide resin (PPS) or polybutylene terephthalate resin (PBT) as the main resin component.

Owner:TAISEI PLAS CO LTD

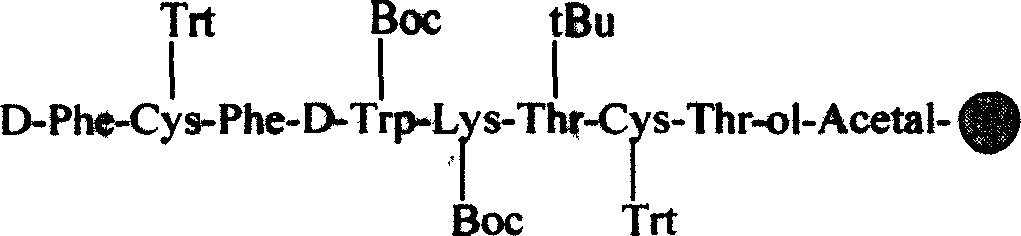

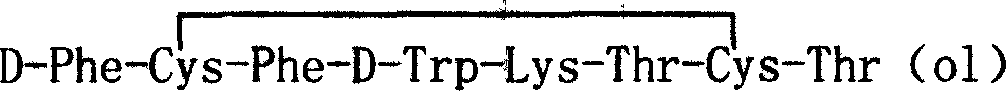

Solid-phase synthesis process of octreotide acetate

ActiveCN1569890AIncrease reaction rateRapid responsePowder deliveryPeptide/protein ingredientsAutoxidationOctreotide acetate

The invention discloses the solid-phase synthesis process of octreotide acetate which consists of, bonding acetal product with macromolecular resin, merging the bonded products with protection amino acid residue in sequence to obtain octapeptide resin, cutting the octapeptide from the resin to obtain aqueous solution, carrying out naturally oxidation in air to obtain Octreotide, charging glacial acetic acid into Octreotide aqueous solution, and freeze-drying.

Owner:SINOPHARM A THINK PHARMA

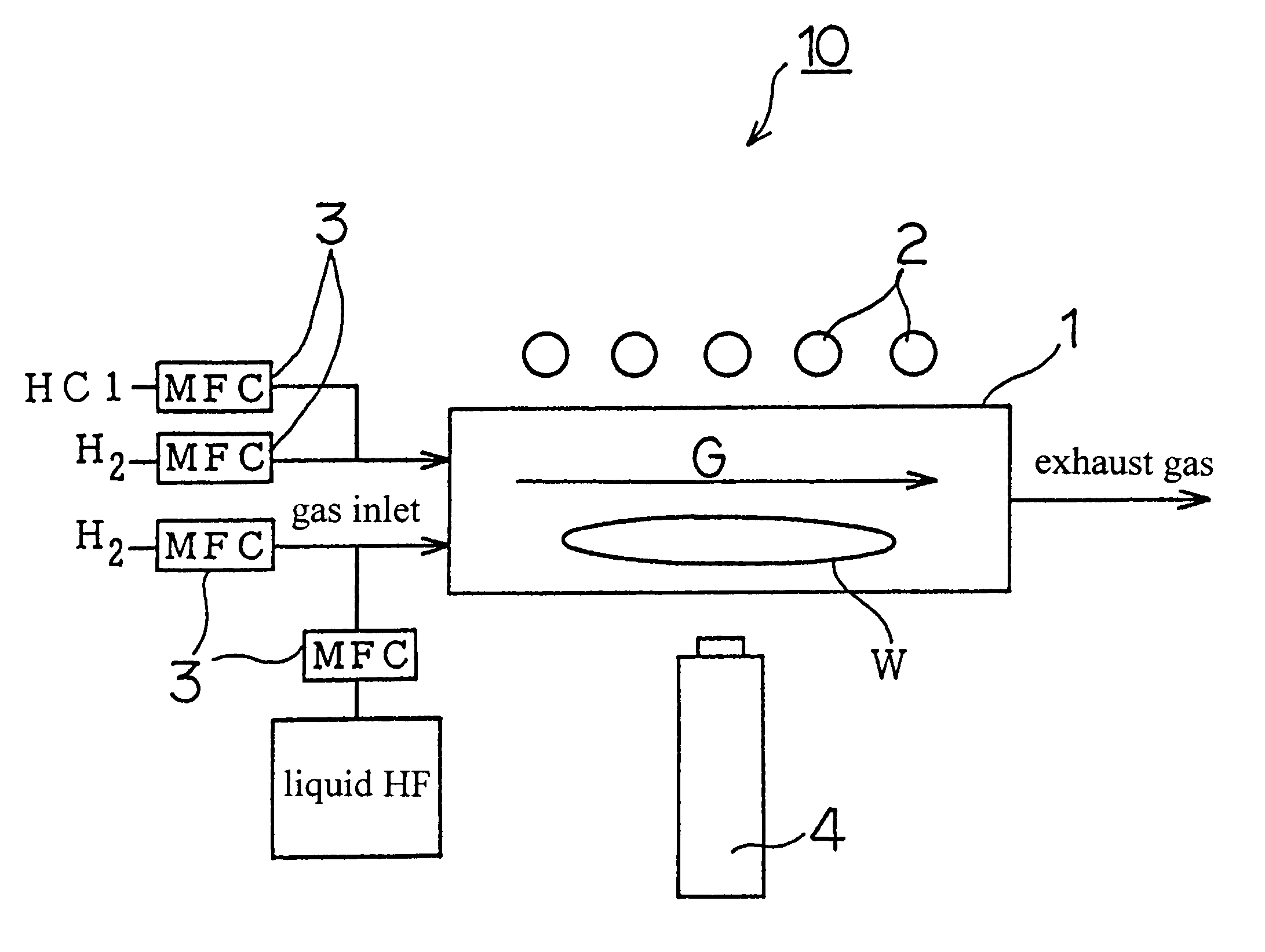

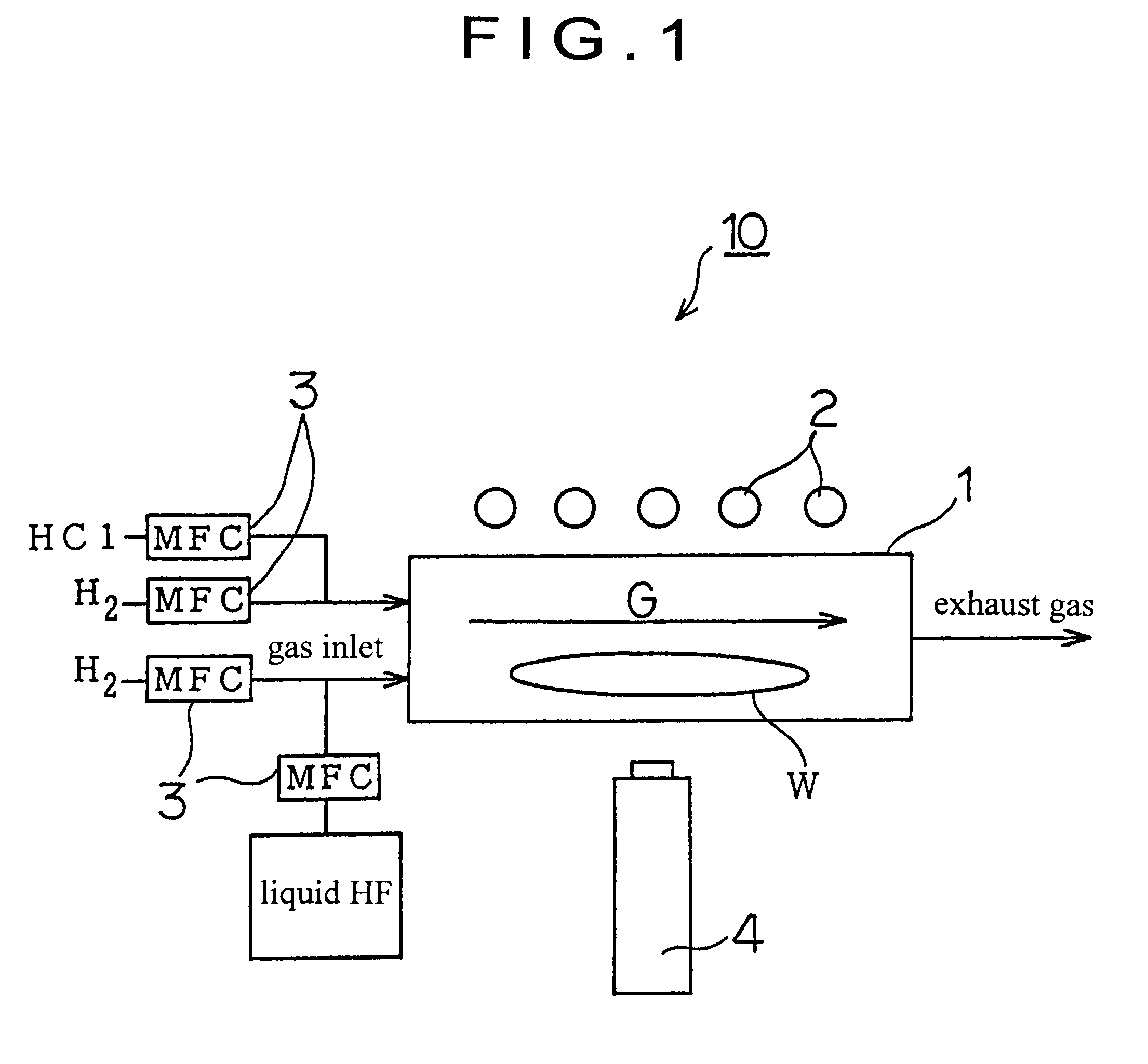

Process for cleaning silicon semiconductor substrates

InactiveUS6235645B1Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingAutoxidationMetal chloride

An object of the invention is to remove organic materials and metal impurities on a silicon-based semiconductor substrate while preventing regrowth of a natural oxide film and thermal diffusion of the metal impurities from occurring. In order to achieve the object, H2 gas that can maintain a reductive atmosphere is consistently used, as a carrier gas, through a whole process, the organic materials in attachment is decomposed by HF gas and the metal impurities are transformed into metal chlorides by HCl gas. In any of treatments, since products whose vapor pressures are higher than those of respective starting materials are obtained, the products are respectively vaporized in a H2 gas atmosphere at higher temperatures than those at which the decomposition and the transformation are performed. The whole process can be performed in a low temperature range whose upper limit is 1000° C. or lower. In a case where the impurities attach to an oxide film, the oxide film can be removed by HF gas treatment, in a preceding step of a process described above, in the temperature range of lower than 100° C. in which water adsorbed on or occluded in the oxide film can be retained, and in the case, if the HF treatment or the HCl treatment is performed from the initial stage of a process at a temperature of 100° C. or higher with no preceding step, the oxide film can be retained.

Owner:SHIN-ETSU HANDOTAI CO LTD

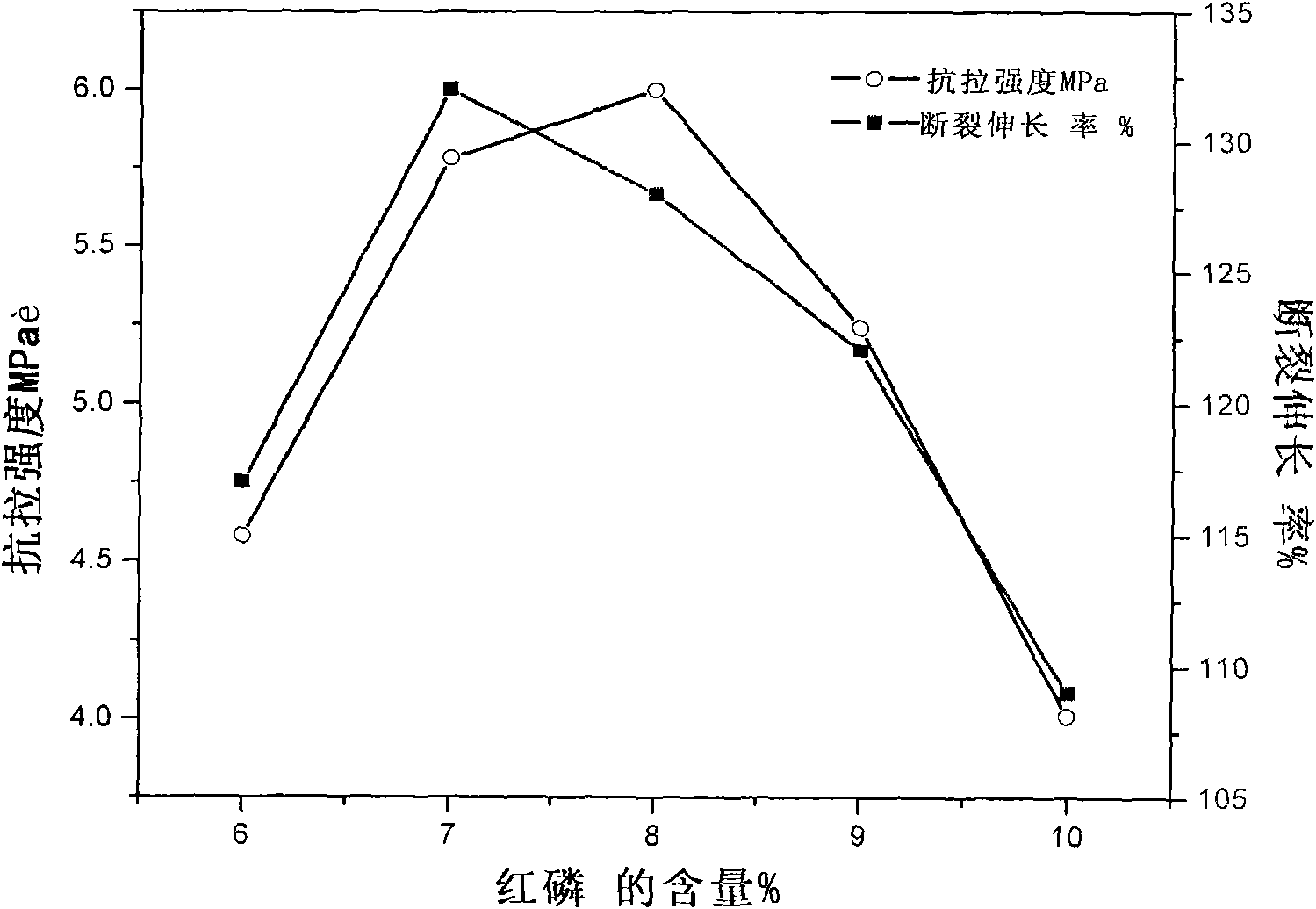

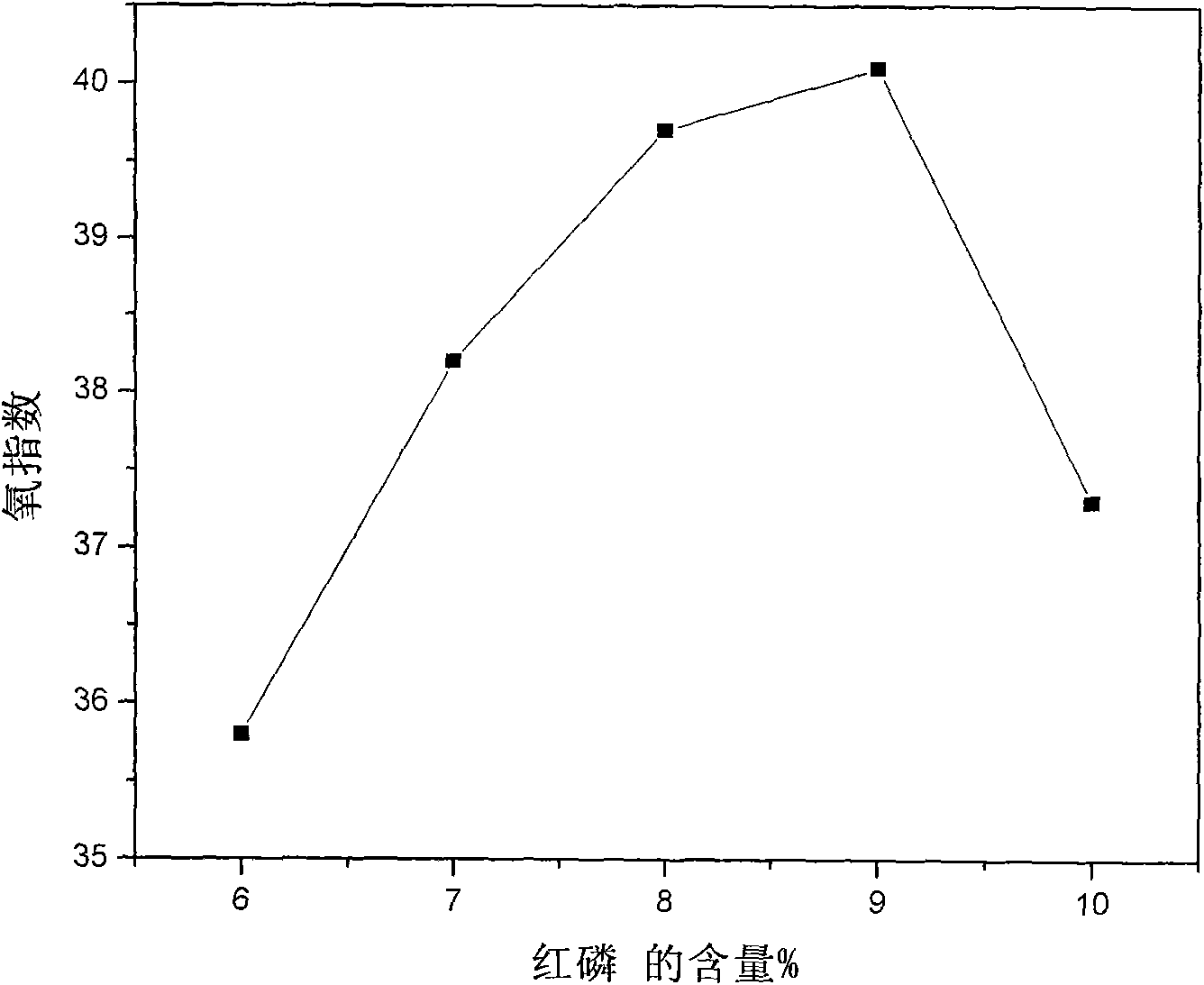

Biodegradable flame resistance material and preparation method thereof

InactiveCN101665588AImprove flame retardant performanceAvoid natural oxidationCoatingsAutoxidationPolymer science

The invention provides a biodegradable flame resistance material. The flame resistance material is characterized in that starch and chitosan are used as main components, red phosphorus is used as flame resistance additive, starch / chitosan can provides a great deal of carbon, chitosan contains nitrogen element, when acid source is added in red phosphorus, the flame resistance of the biodegradable material is effectively improved and the usable range of the biodegradable composite material is expanded so that the biodegradable composite material has wider application area; the preparation methodadopts solution method, ultrasonic dispersion and mechanical high-speed agitation so that red phosphorus used as fire retardant can be dispersed in solution on nano-scale and the autoxidation of thecomposite material can be effectively avoided, thus the composite material can have better mechanical performance.

Owner:余姚市环华电器有限公司

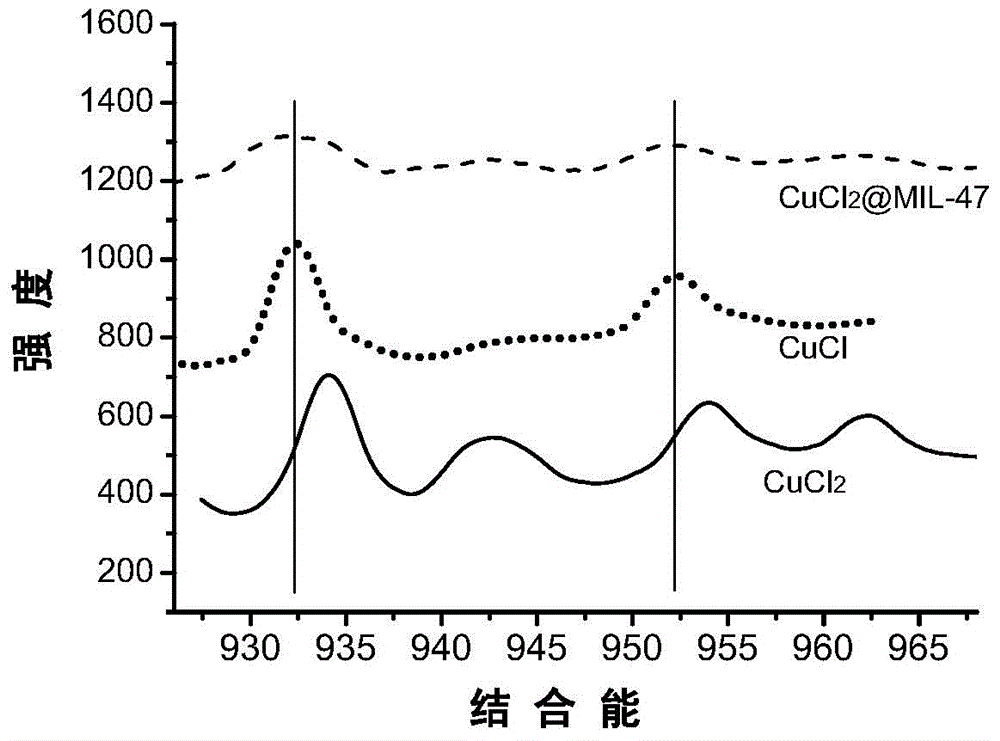

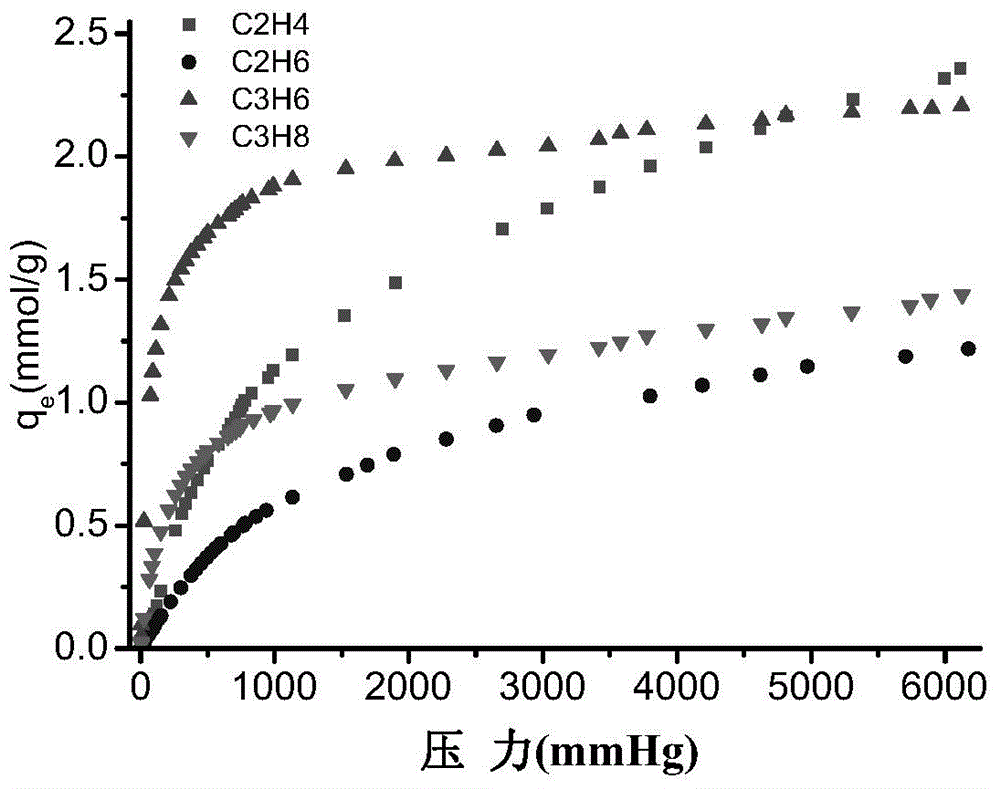

Adsorbent for olefin/alkane mixed gas separation and preparation method and application thereof

ActiveCN104525121AInhibitory concentrationAvoid the problem of being easily oxidizedOther chemical processesAdsorption purification/separationAlkaneSorbent

The invention discloses a preparation method of an adsorbent for olefin / alkane mixed gas separation. the preparation method comprises the following steps: after vanadium chloride, terephthalic acid, hydrofluoric acid and water are mixed, a hydrothermal reaction is carried out to obtain MIL-47(V<3+>) containing impurities; under the assistance of ultrasonic wave, low temperature activation treatment is carried out to remove impurities so as to obtain MIL-47(V<3+>); and by a solution impregnation method, Cu<2+> is loaded on MIL-47(V<3+>), and autoxidation-reduction is carried out to reduce the loaded Cu<2+> to Cu<+> so as to obtain the adsorbent. By using MIL-47(V<3+>) obtained by low temperature activation treatment as a carrier, Cu<2+> is firstly loaded, and then the loaded Cu<2+> is reduced to Cu<+> by the process of autoxidation-reduction. The preparation process is simple, and conditions are mild. The prepared adsorbent can be used to realize high-selective separation of olefin / alkane mixed gases.

Owner:ZHEJIANG UNIV

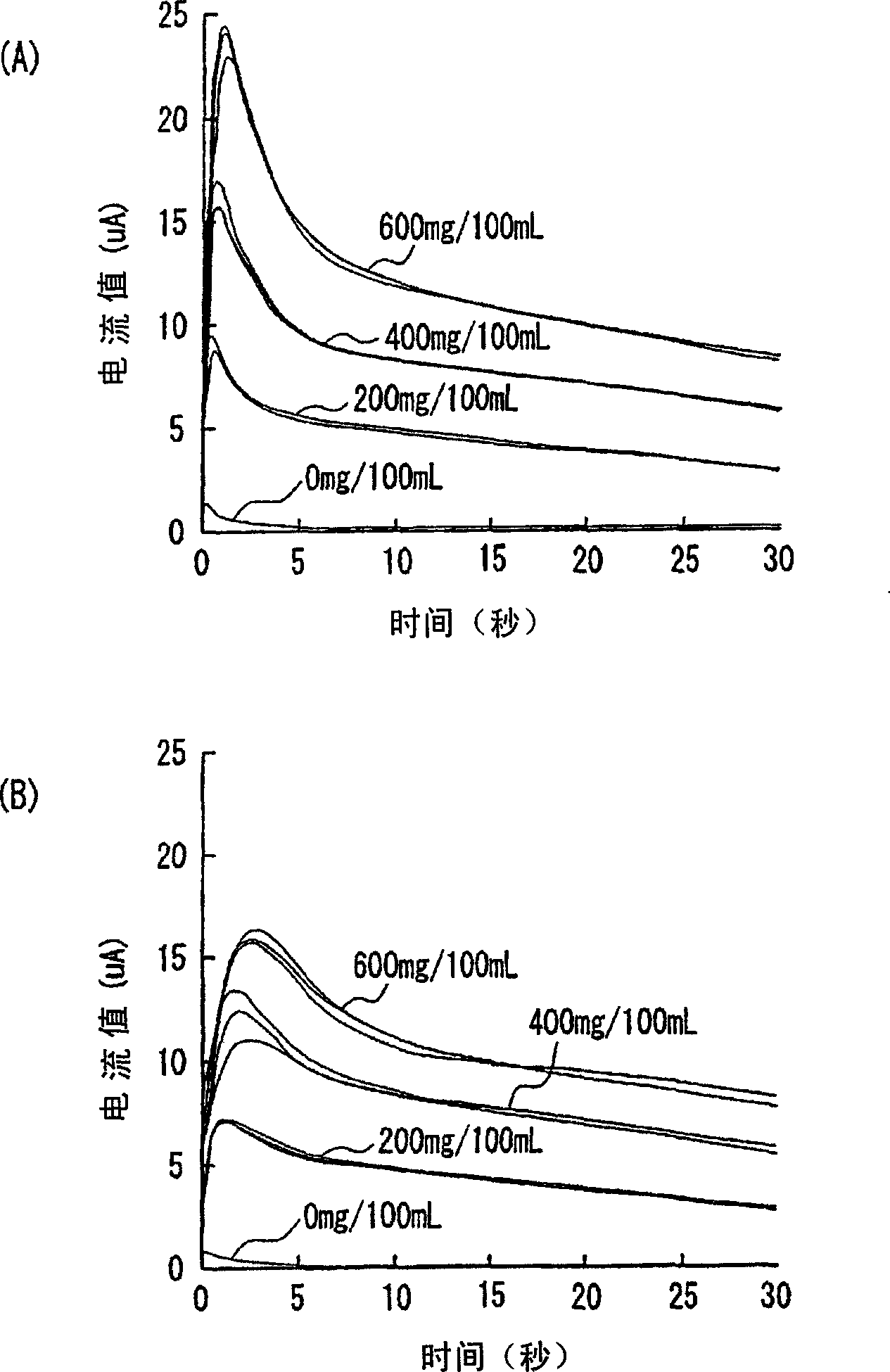

Biosensor and method for preparation thereof

ActiveCN1875265AInhibit deteriorationMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAutoxidationAnalyte

Owner:ARKRAY INC

Method for removing silicon oxide film and processing apparatus

InactiveUS7611995B2Efficient removalDecorative surface effectsSemiconductor/solid-state device manufacturingAutoxidationRoom temperature

A silicon dioxide film removing method is capable of removing a silicon dioxide film, such as a natural oxide film or a chemical oxide film, at a temperature considerably higher than a room temperature. The silicon dioxide film removing method of removing a silicon dioxide film formed on a workpiece in a processing vessel 18 that can be evacuated uses a mixed gas containing HF gas and NH3 gas for removing the silicon dioxide film. The silicon dioxide film can be efficiently removed from the surface of the workpiece by using the mixed gas containing HF gas and NH3 gas.

Owner:TOKYO ELECTRON LTD

Enhanced bonding layers on titanium materials

The present invention provides a dense-coverage, adherent phosphorous-based coating on the native oxide surface of a material. Disclosed phosphorous-based coatings include phosphate and organo-phosphonate coatings. The present invention also provides further derivatization of the phosphorous-based coatings to yield dense surface coverage of chemically reactive coatings and osteoblast adhesion-promoting and proliferation-promoting coatings on the native oxide surface of a titanium material.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Enhanced bonding layers on titanium materials

The present invention provides a dense-coverage, adherent phosphorous-based coating on the native oxide surface of a material. Disclosed phosphorous-based coatings include phosphate and organo-phosphonate coatings. The present invention also provides further derivatization of the phosphorous-based coatings to yield dense surface coverage of chemically reactive coatings and osteoblast adhesion-promoting and proliferation-promoting coatings on the native oxide surface of a titanium material.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Enhanced Bonding Layers on Native Oxide Surfaces

InactiveUS20080166470A1Enhanced interactionImprove adhesionMaterial nanotechnologyVacuum evaporation coatingAutoxidationOrganophosphorous compounds

Process for forming a coated article by (a) depositing a layer of an omega functionalized organophosphorous compound on an oxide substrate; (b) heating the substrate of step (a) to a temperature sufficient to bond the omega functionalized organophosphorous compound to the oxide substrate; (c) depositing a separate layer onto the layer produced by step (b); and (d) bonding the layers produced by steps (b) and (c) through the omega functional group.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Attapulgite-loaded zero-valent iron repair material and preparation method thereof

InactiveCN106512971AGood dispersionImprove stabilityOther chemical processesAlkali metal oxides/hydroxidesAutoxidationFerrous salts

The invention provides an attapulgite-loaded zero-valent iron repair material. The attapulgite-loaded zero-valent iron repair material uses attapulgite as a carrier; zero-valent iron is of monodisperse spherical or ellipsoidal morphology; and the average particle size of the zero-valent iron is in a range of 50 to 150 nm. A preparation method for the attapulgite-loaded zero-valent iron repair material comprises the following steps: (1) successively adding a ferric salt or / and a ferrous salt and attapulgite into oxygen-free anoxic water and carrying out stirring under the protection of inert gas so as to obtain mixed liquid; and (2) adding a reducing agent into the mixed liquid and carrying out stirring and solid-liquid separation so as to obtain a solid, i.e., attapulgite-loaded zero-valent iron. The attapulgite-loaded zero-valent iron prepared in the invention can make full use of interlayer and surface space of attapulgite, has better dispersibility and stability and more uniform particle size distribution, is not prone to particle agglomeration and autoxidation and presents better suspensibility and stability in an aqueous solution; and when applied to pollutants, the attapulgite-loaded zero-valent iron has longer reaction time and better adsorption capability.

Owner:北京德瑞科森环保科技有限公司

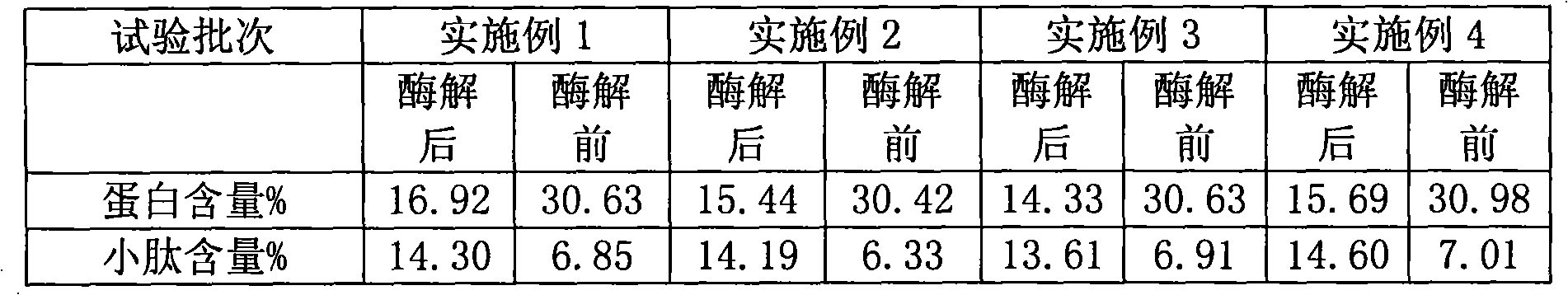

Method for extracting antioxidation activity small peptide nutrient powder from wheat embryo

InactiveCN101513218ALow costReduce manufacturing costVegetable proteins working-upFood preparationLipid formationDipeptide

The invention provides a method for extracting antioxidation activity small peptide nutrient powder from wheat embryo. The method comprises the following steps: nonprotein of the wheat embryo is removed by extraction after the wheat embryo is crushed; then, prolease and peptidase are added into the wheat embryo to obtain small peptide nutrient fluid; finally, the small peptide nutrient fluid is concentrated and dried to obtain the peptide nutrient powder. The main nutrient ingredient in the prepared small peptide nutrient powder is antioxidation activity small peptide (karnosin), wherein content of dipeptide is over 56.4 percent; and the small peptide can inhibit lipid oxidation catalyzed by iron, hemoglobin, lipid oxidase and singlet oxygen in vitro, and can reduce autoxidation rate and content of fatty hydrogen peroxide, thereby playing a role of oxidation resistance of the small peptide nutrient powder. The small peptide nutrient powder is a perfect product of resisting age and preventing obese, and is mainly used for foods and medicine additives.

Owner:周靖波 +1

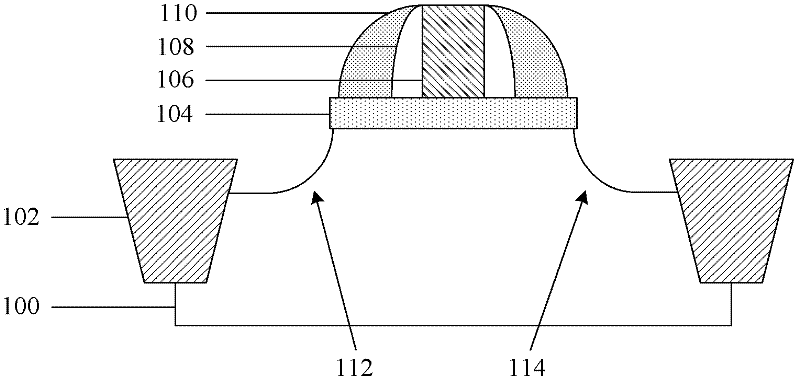

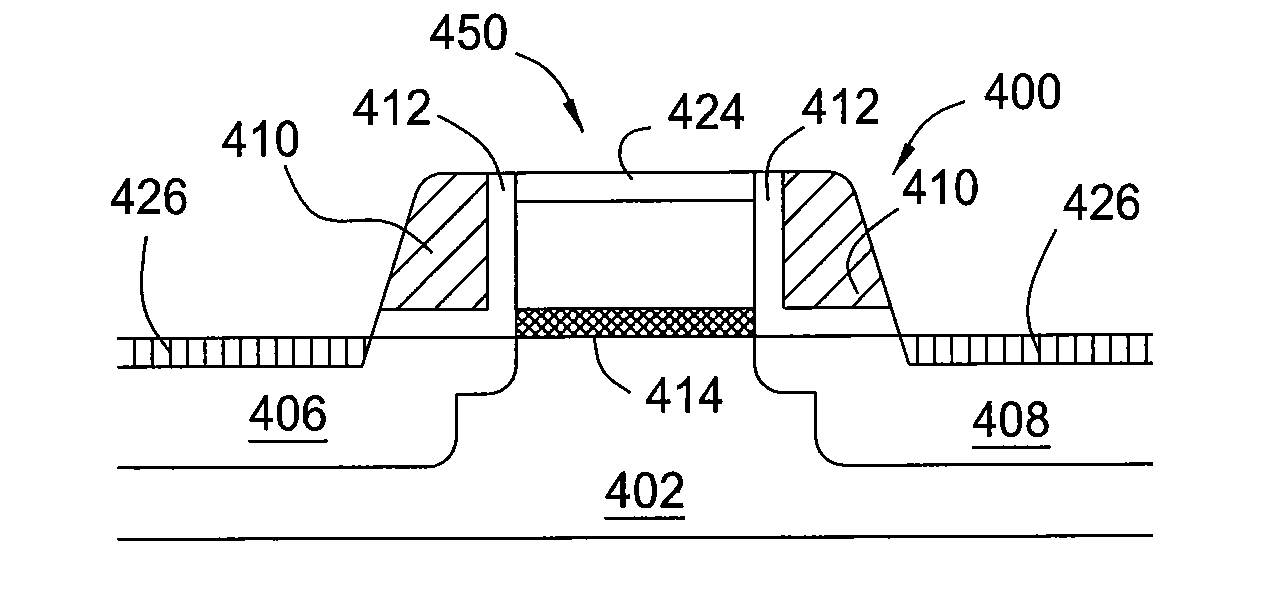

Pretreatment method for SiGe selective epitaxial growth

InactiveCN102496574ASolve the problem of critical dimension (CD) reductionPerformance is not affectedSemiconductor/solid-state device manufacturingAutoxidationChemical reaction

The invention provides a pretreatment method for SiGe selective epitaxial growth. The method comprises the following steps that: hydrogen plasma is introduced into a device in a reaction cavity; chemical reaction is carried out on a native oxide on the device and the hydrogen plasma and then steam is generated and is volatilized; and SiGe selective epitaxial growth is carried out on source / drain regions of the device. According to the above-mentioned technical scheme, etching on a side wall by the plasma during the pretreatment process can be avoided, so that the quality of SiGe film growth can be improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

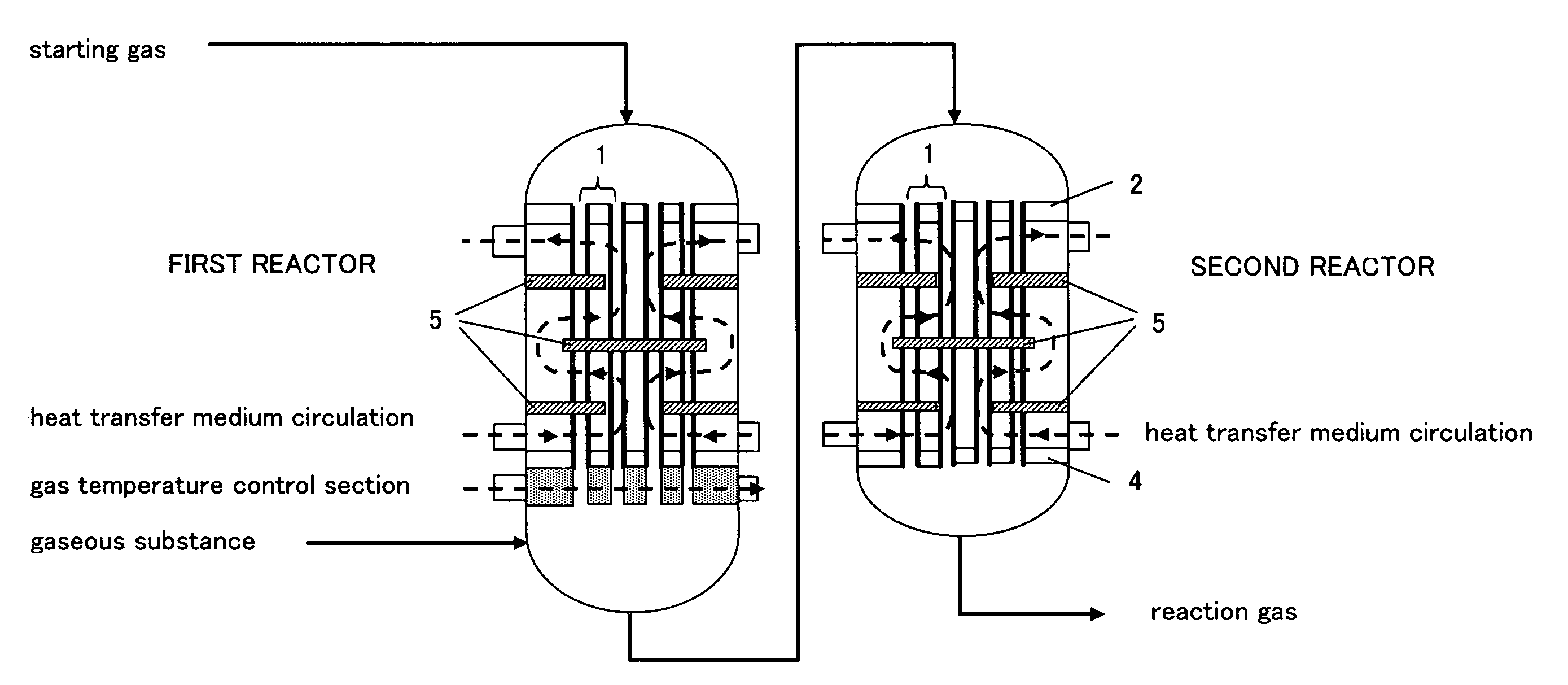

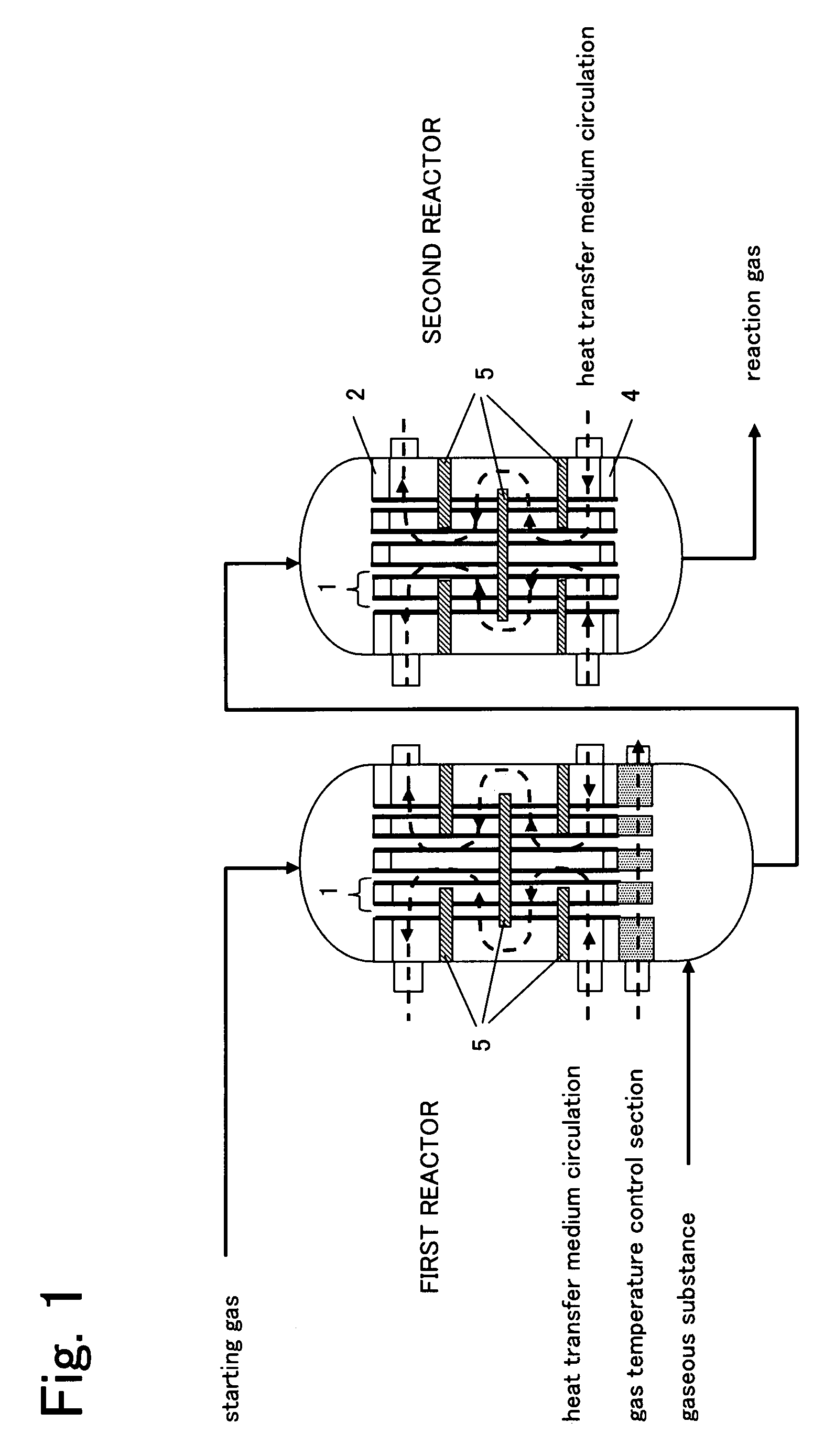

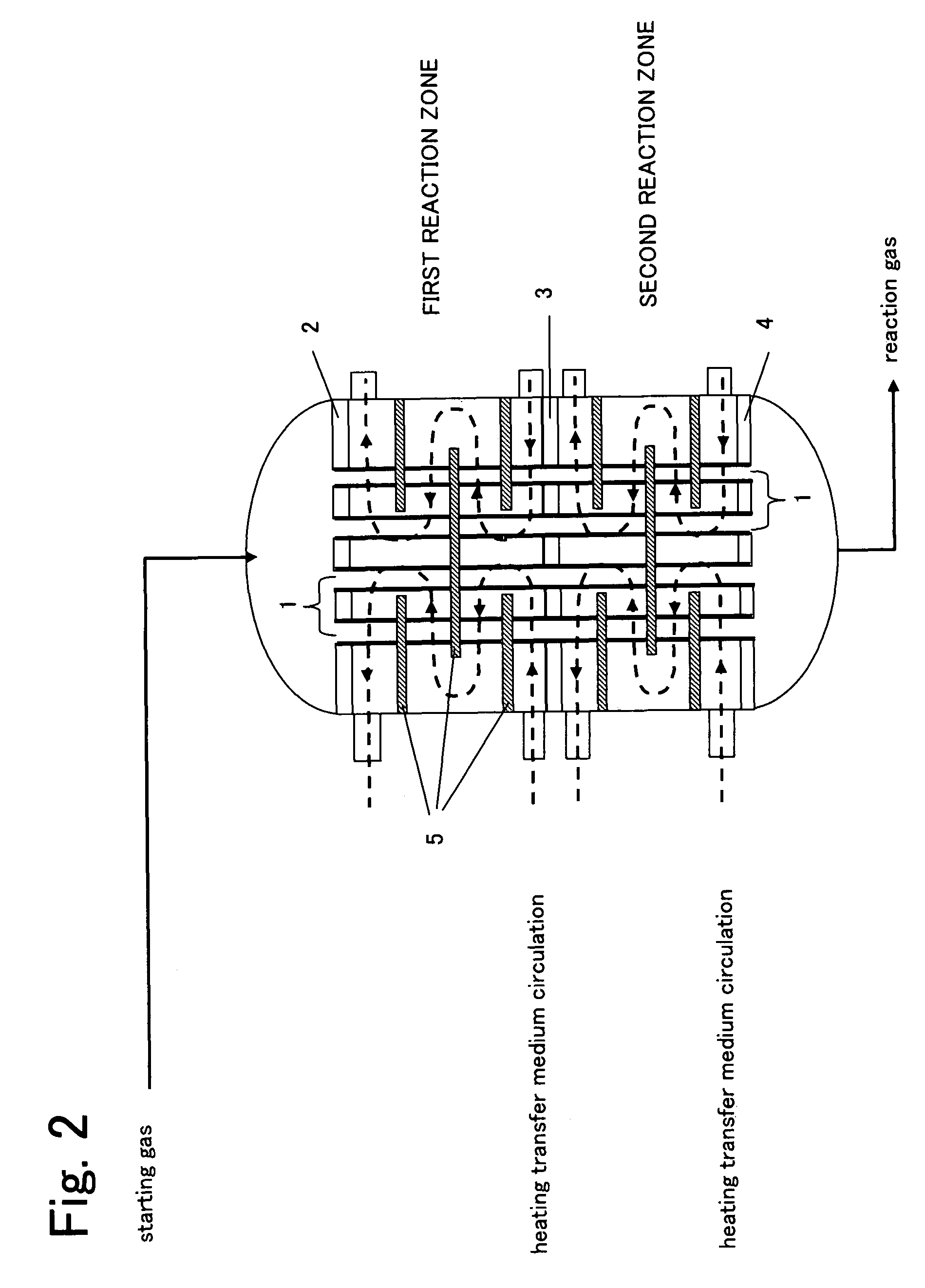

Reactor for gas phase catalytic oxidation and a process for producing acrylic acid using it

InactiveUS7897813B2Enabling changeImprove efficiencyOrganic compound preparationExhaust apparatusAutoxidationGas phase

Conventional gas-phase catalytic oxidation reaction apparatus comprising two reactors for production of acrylic acid is subject to problems of high equipment costs for the reactors and piping, necessity for wide installation area and easy accumulation of carbides generated by autoxidation of acrolein. On the other hand, conventional reaction apparatus comprising a single reactor has the drawbacks that the composition of gas in the first stage reaction and in the second stage reaction cannot be optimized independently of each other, and that the allowable concentration of starting propylene is limited because of the risk of explosion. As a reaction apparatus to solve these problems, this invention provides a fixed bed shell-and-tube reaction apparatus comprising a single reactor, characterized in that the inside of the reactor is divided into two reaction zones of the first reaction zone and the second reaction zone, and that a space equipped with a mechanism for introducing a gaseous substance from outside is provided between the two reaction zones.

Owner:NIPPON SHOKUBAI CO LTD

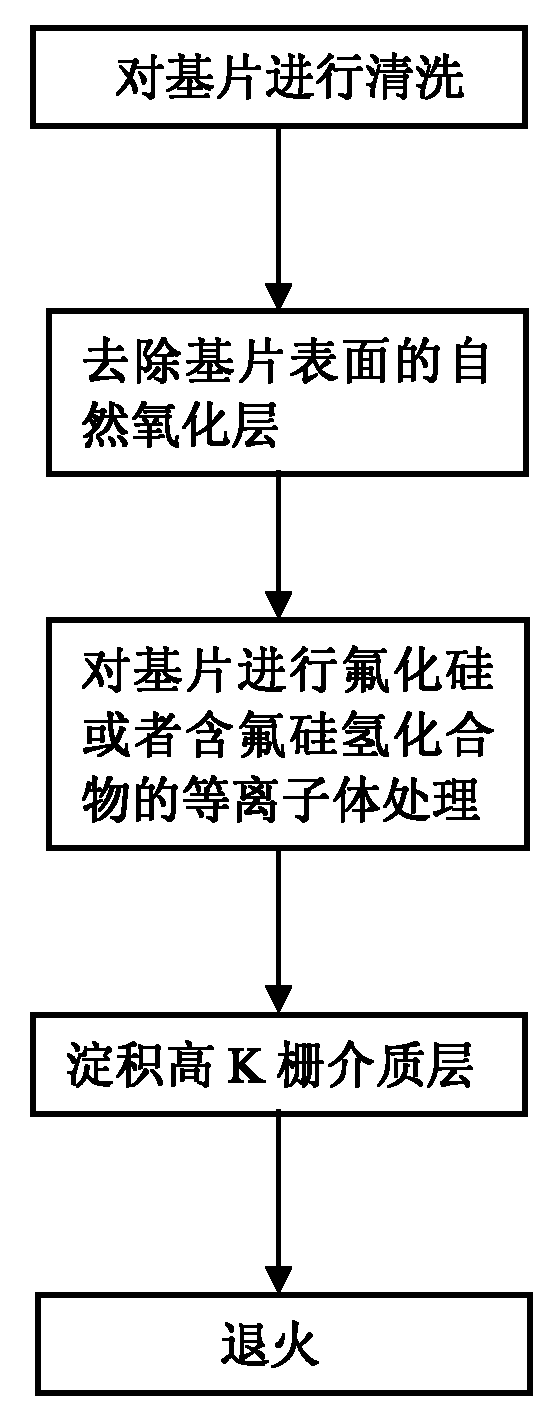

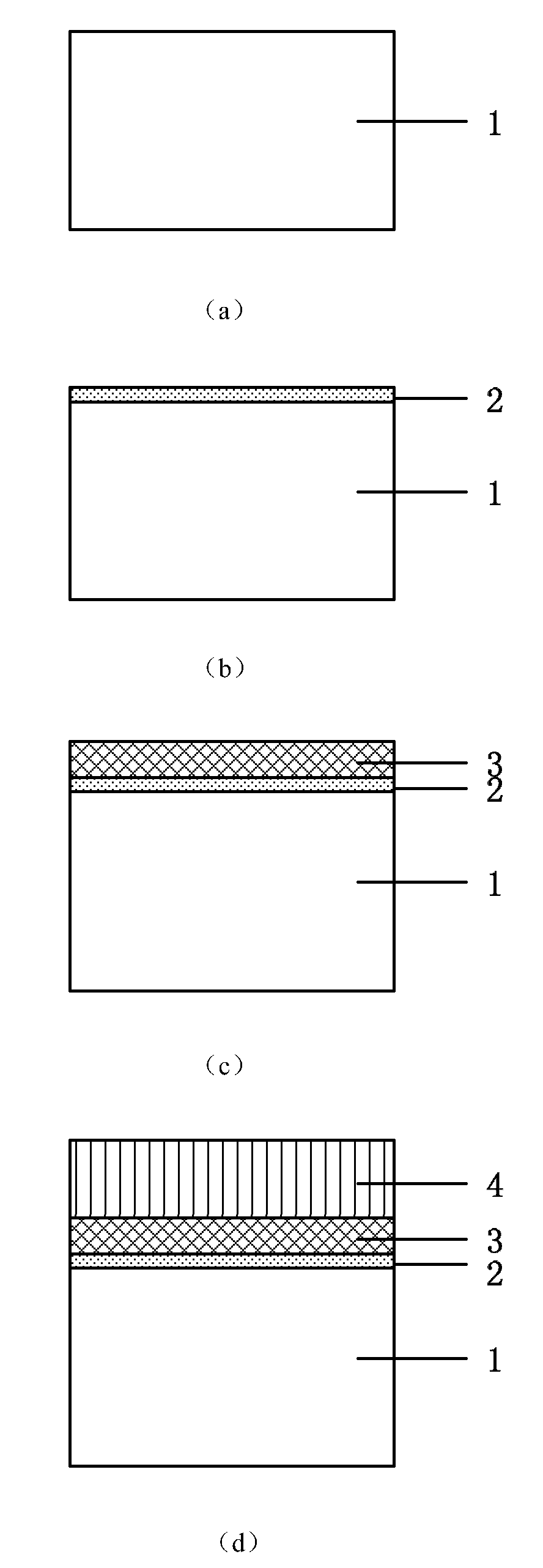

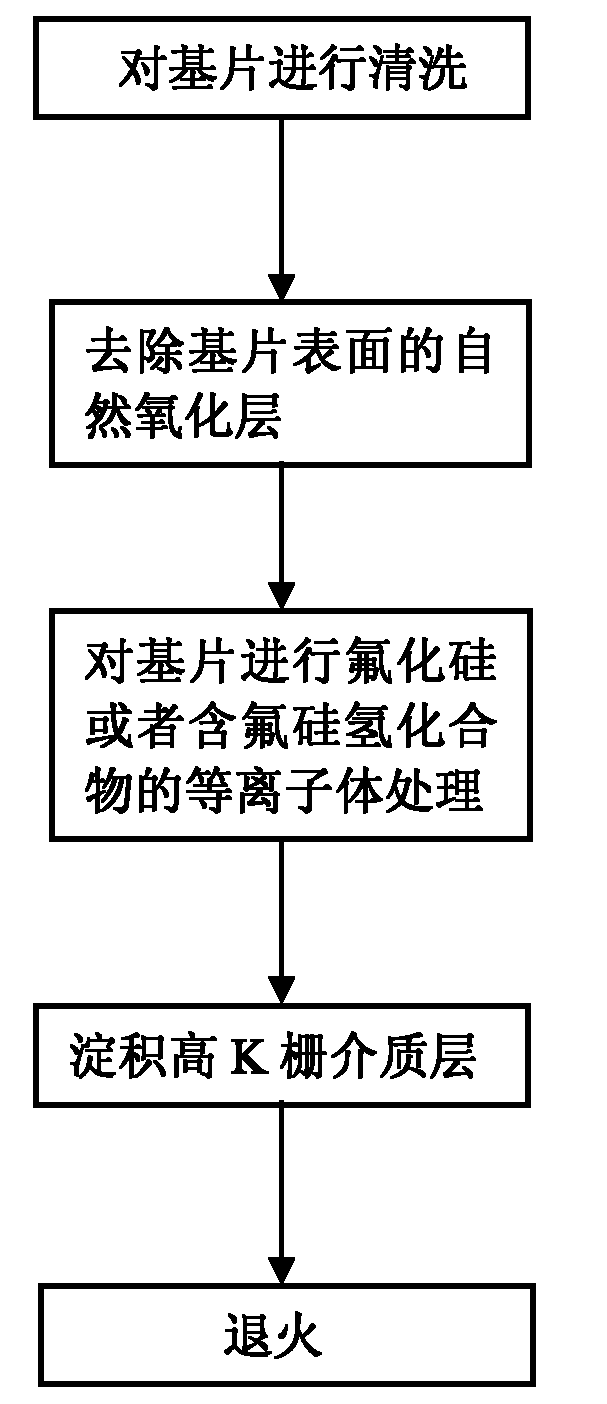

Surface passivation method for germanium-based MOS (Metal Oxide Semiconductor) device substrate

ActiveCN102206799AImprove passivation effectReduce interface state densitySemiconductor/solid-state device manufacturingSolid state diffusion coatingSemiconductor materialsGate dielectric

The invention discloses a surface passivation method for a germanium-based MOS device substrate, which belongs to the field of semiconductor material devices. The method comprises the steps of: firstly, washing a semiconductor germanium substrate which is used as a substrate for removing organic, inorganic and metallic granular contaminations on a surface and removing an autoxidation layer on thesurface of the substrate; performing plasma treatment on the substrate through use of silicon fluoride or silicone and fluorin containing hydrogen compound for depositing a silicon passivation layer on the substrate; and finally, after depositing a layer of high-k gate dielectric material, and annealing. The surface passivation method disclosed by the invention has the advantages of greatly reducing the density of an interface state between interfaces of the germanium substrate and the gate dielectric material, effectively restraining the diffusion of the germanium in the substrate into the gate dielectric material, and obviously enhancing the passivation efficiency.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Oil/fat composition

InactiveUS7090886B2Excellent visceral-fat burning propertyDough treatmentFatty acid esterificationAutoxidationFat burning

Abstract Provided is an oil / fat composition comprising 60 to 100 wt. % of a diglyceride wherein the diglyceride has, as the fatty acid constituent thereof, 15 to 90 wt. % of an ω 3-unsaturated fatty acid having less than 20 carbon atoms and a cis ω 3-unsaturated fatty acid / (cis ω 6-unsaturated fatty acid+saturated fatty acid+trans unsaturated fatty acid) at a weight ratio of 1 to 6. The composition is excellent in visceral fat burning property, body fat burning property and stability against autoxidation.

Owner:KAO CORP +1

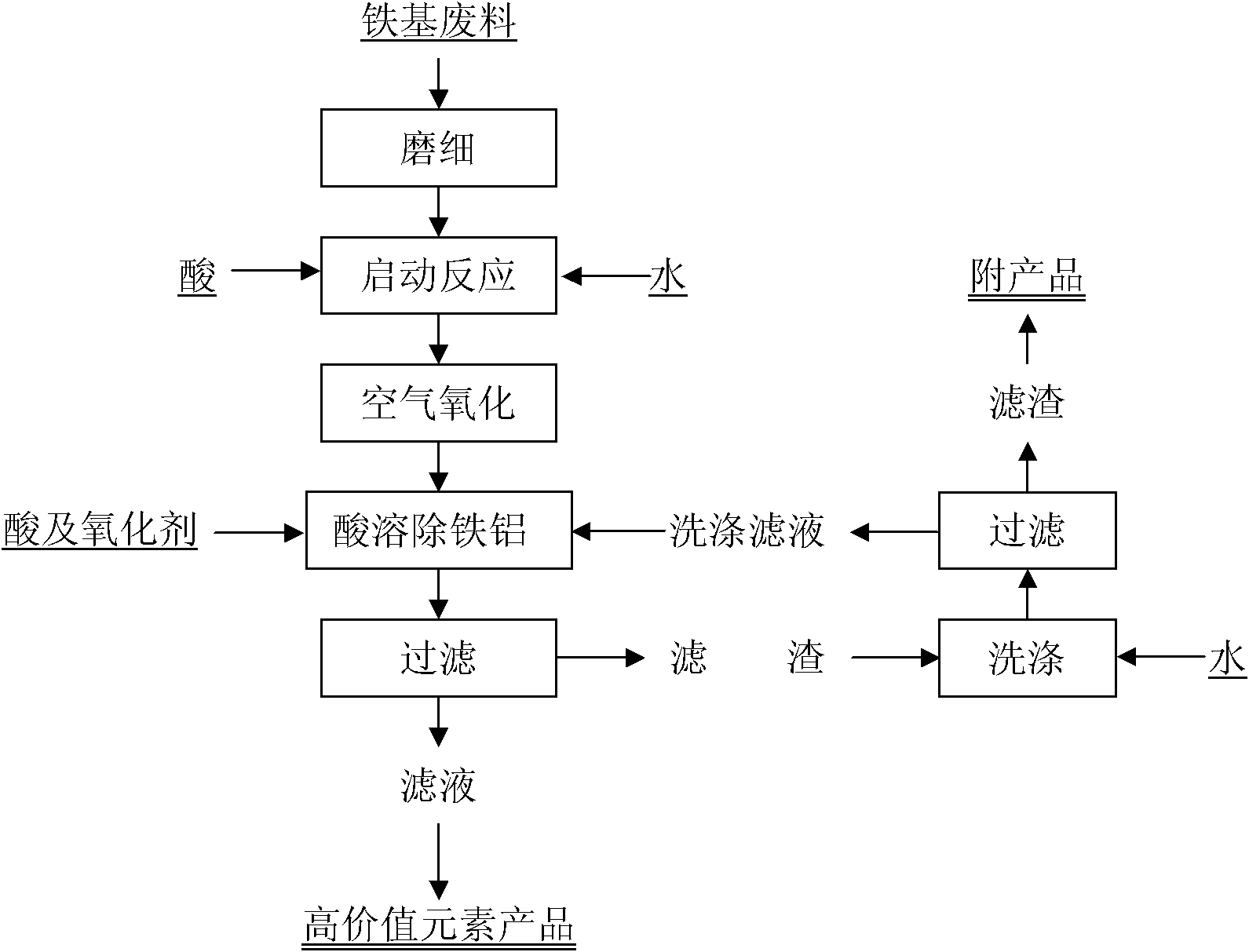

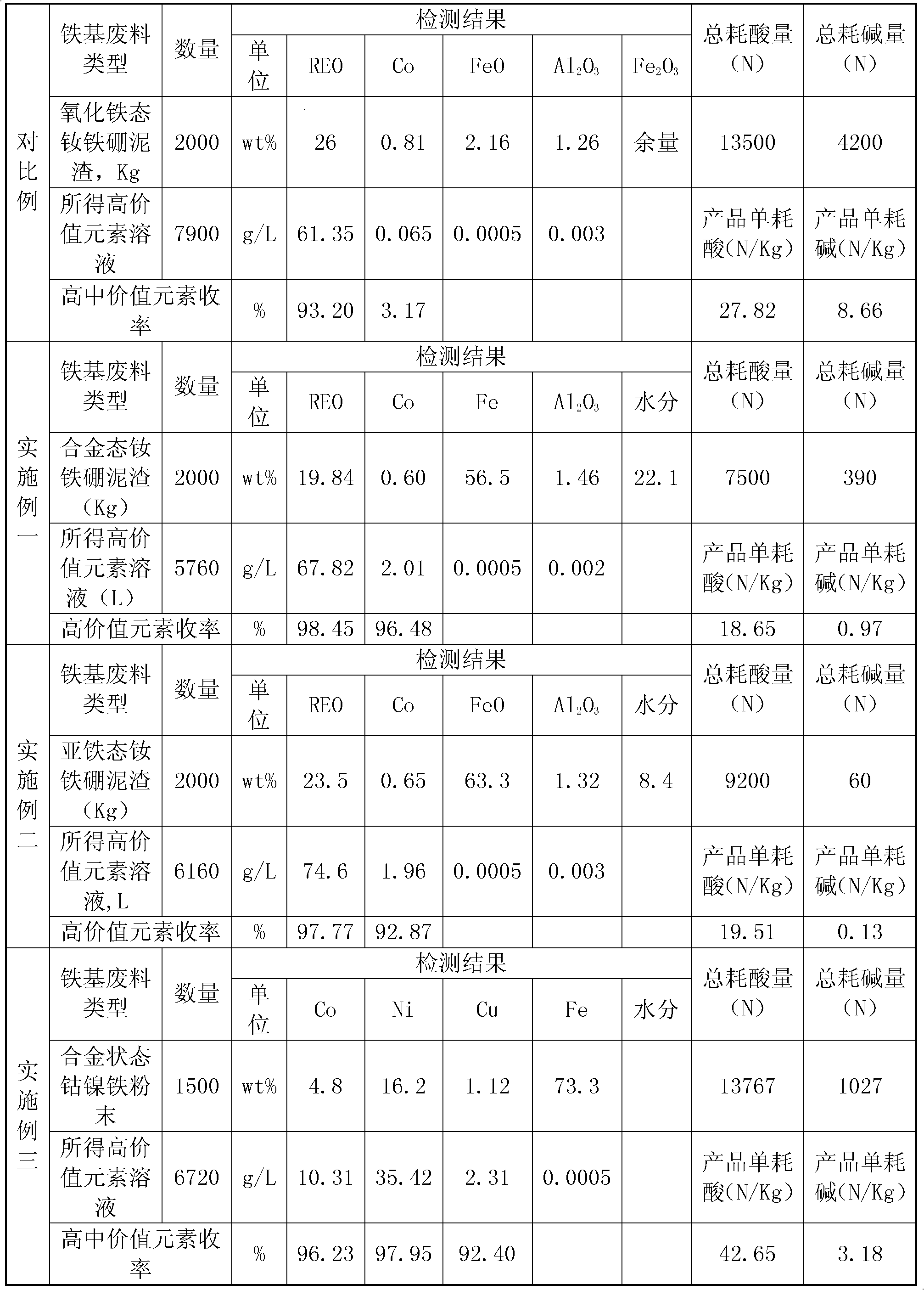

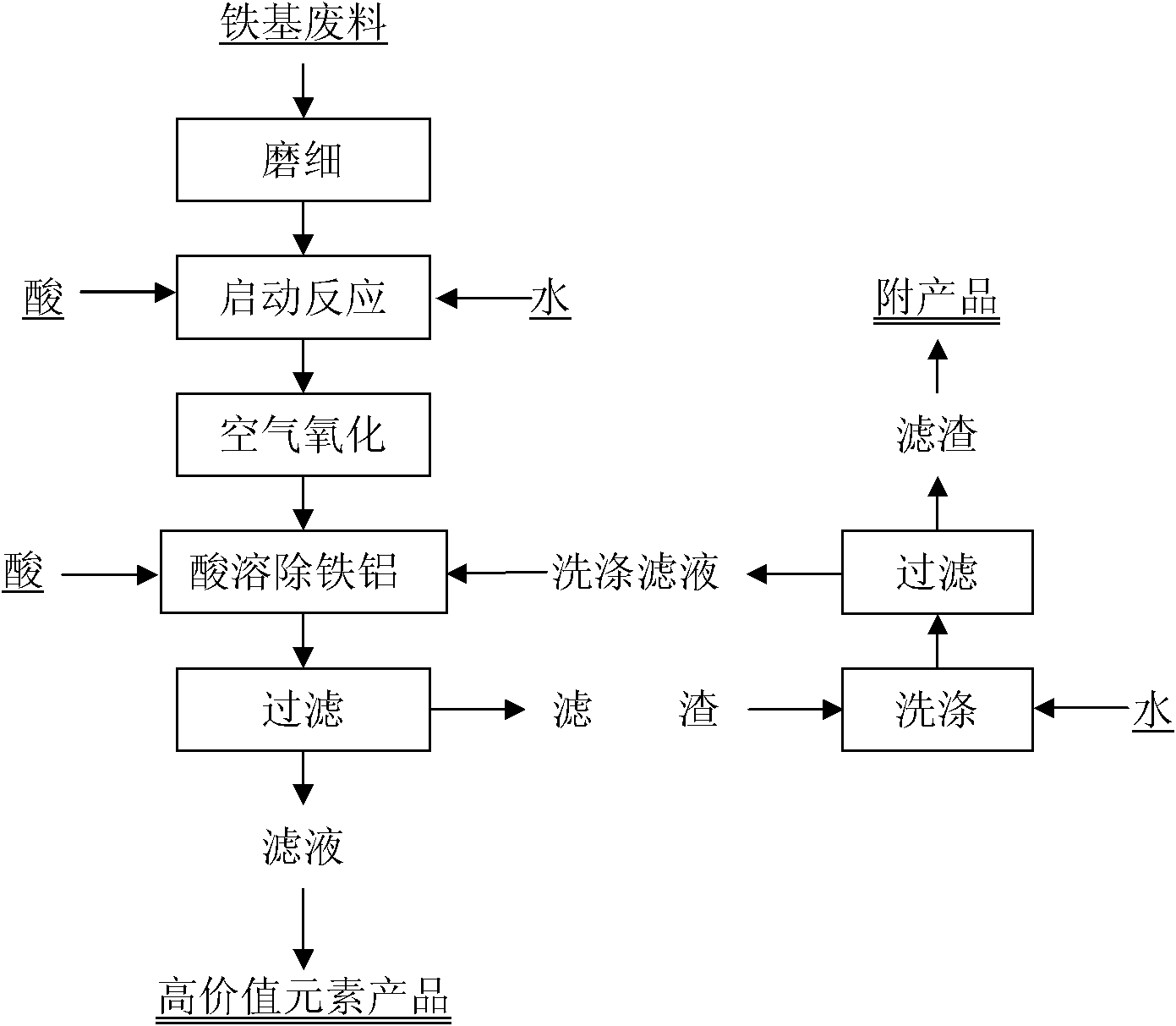

Method for removing iron and aluminum by autoxidation of iron-based waste material containing high-value elements

ActiveCN102154553AReduce consumptionHigh dissolution rateProcess efficiency improvementElectrochemical responseDissolution

The invention relates to a method for removing iron and aluminum by the autoxidation of iron-based waste material containing high-value elements. The method is characterized by comprising the following steps of: crushing the iron-based waste material, and mixing the crushed iron-based waste material, water and a small amount of acid to ensure that the iron-based waste material in air is in the humid electrolytic atmosphere, performing a series of complex oxidization reactions and electrochemical reactions, and converting simple substance iron or ferrous iron and simple substance aluminum into trivalent oxides or hydroxides; and performing processes of acid dissolving, impurity removal, filtering and the like on the material oxidized by the air to obtain solution which contains high-value elements and in which the iron and the aluminum are removed, and purifying and separating the solution further to obtain a corresponding product containing the high-value elements. The method has the advantages of short process, simple equipment, energy conservation, little using amount of industrial chemicals, high dissolution rate of the high-value elements, mild reaction condition, environment friendliness, and the like.

Owner:GANZHOU RECYCLE NEW TECH

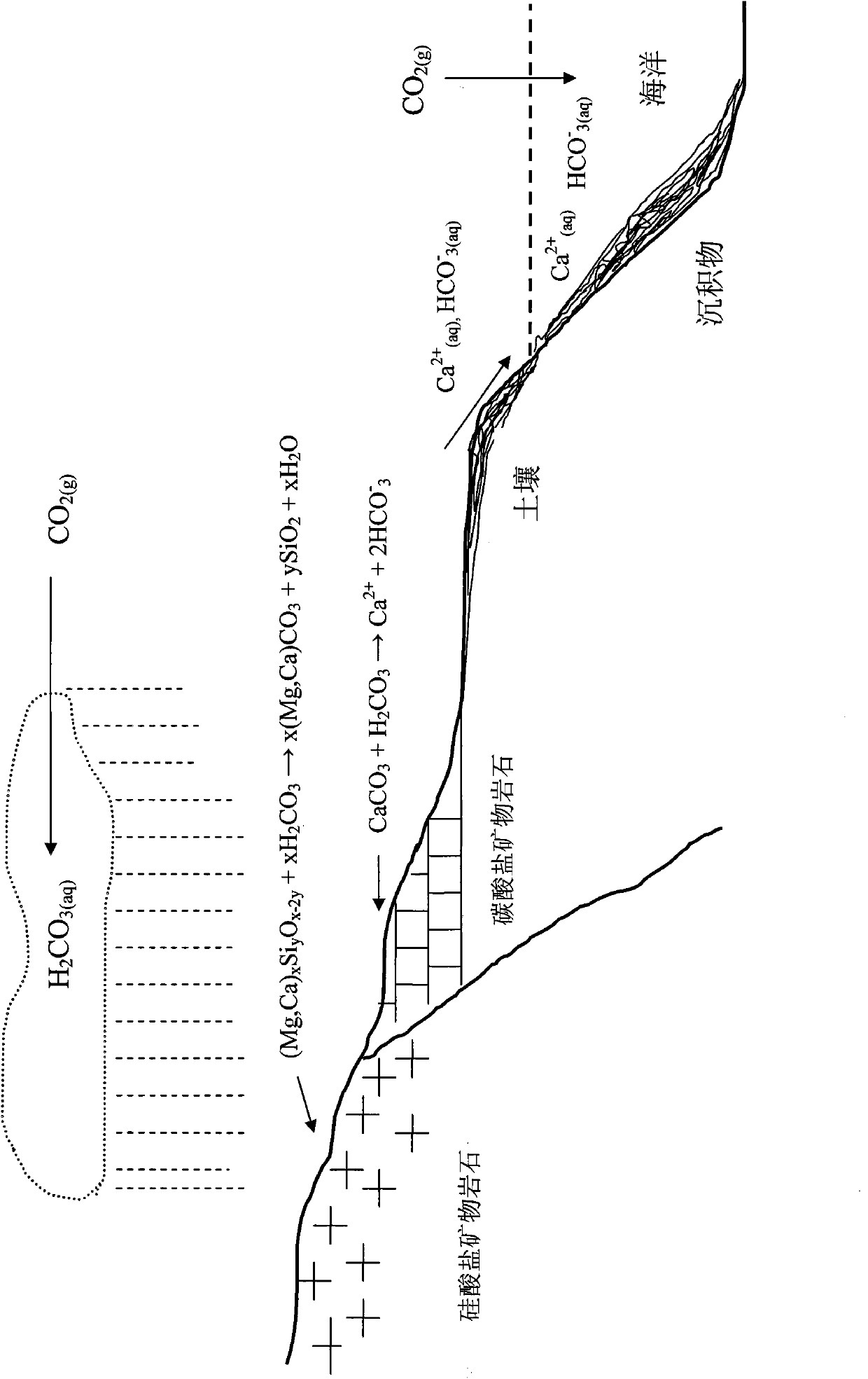

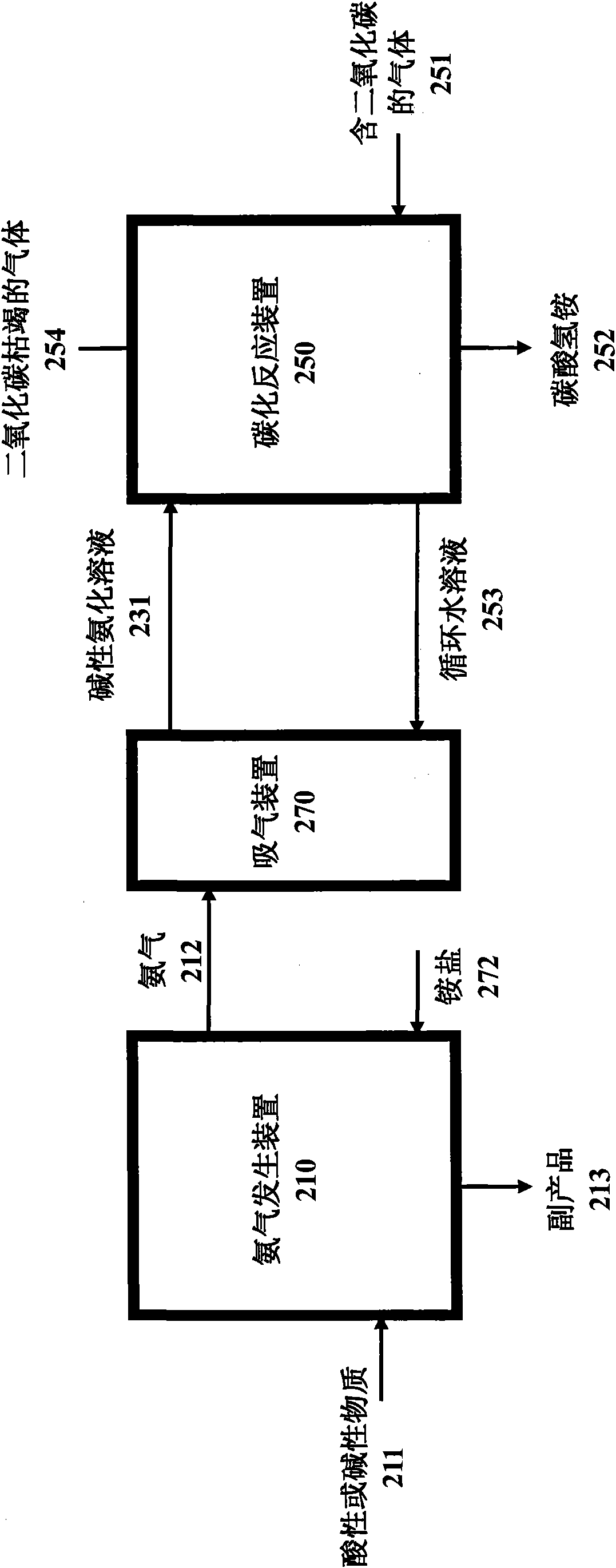

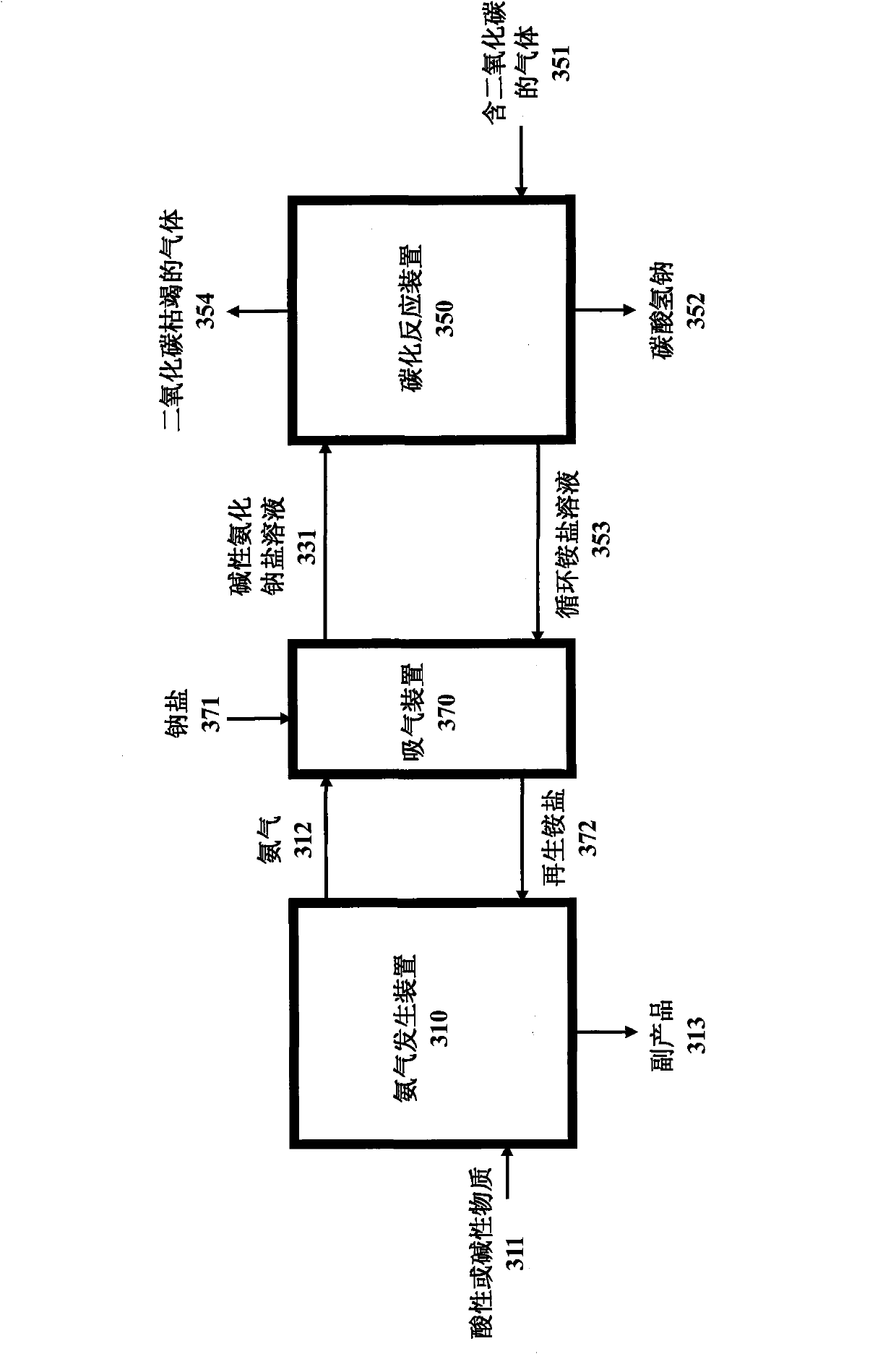

Method for sequestering carbon dioxide

InactiveCN101992015AEase acidificationPromote absorptionCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

The present invention discloses a method for sequestering carbon dioxide (CO2) that includes generating ammonia from an ammonium salt to make a basic ammoniated aqueous solution and using the solution to remove at least a portion of CO2 from a CO2-bearing gas and precipitate the removed CO2 as bicarbonate. The aqueous solution is recycled. Various valuable byproducts, including sodium bicarbonate, sodium carbonate, ammonium bicarbonate, and hydrochloric acid, are produced. Ammonia is generated by reacting an ammonium salt with either acidic or basic materials. Non-limiting examples of suitable ammonium salt include ammonium chloride, ammonium sulfate, ammonium bisulfate, and ammonia nitrate, those of the acidic material include ammonium bisulfate and sulfuric acid, and those of the basic material include calcium oxide, limestone, dolomite, cement kiln dust, calcium-rich fly ash, steel and iron slag, and silicate rocks or mining wastes that are rich in serpentine, olivine or wollastonite.

Owner:钟少军

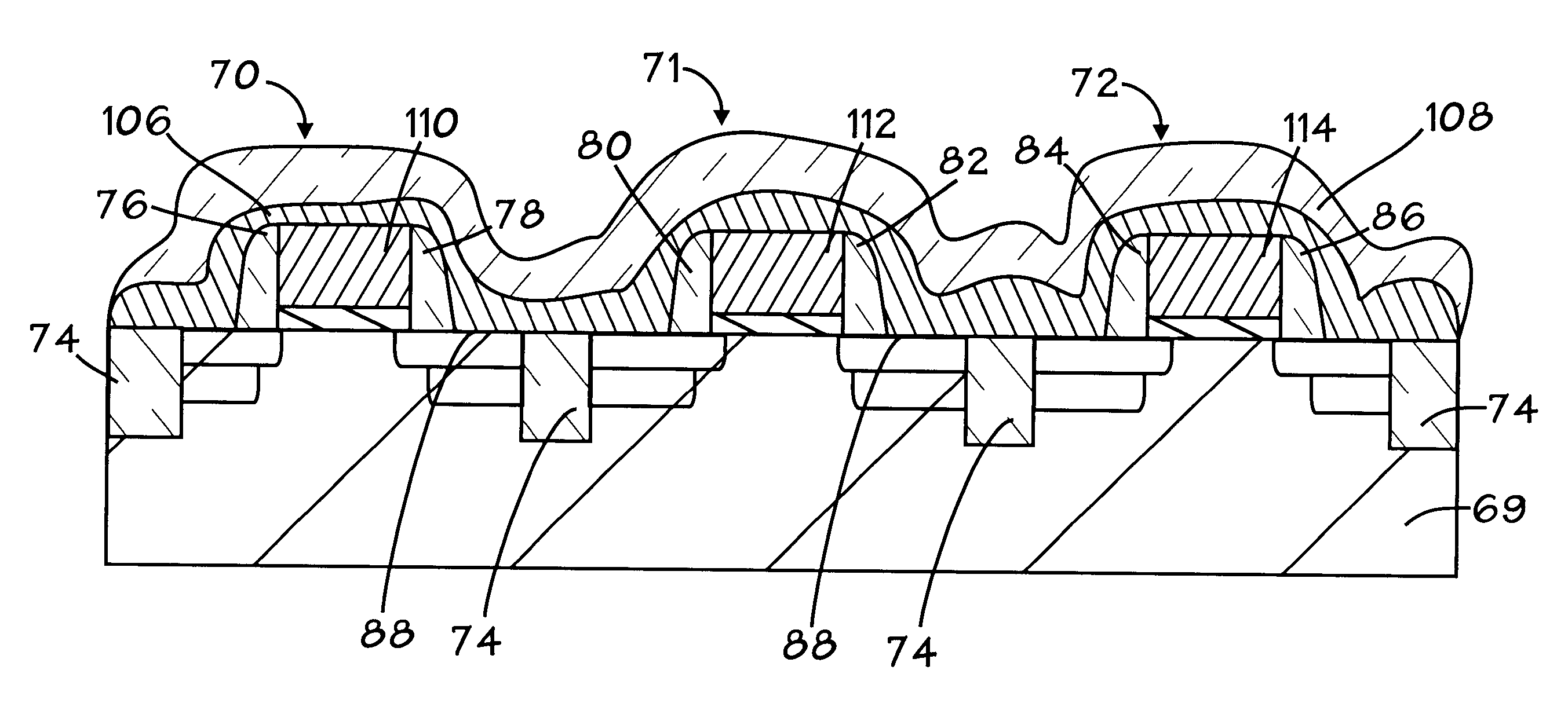

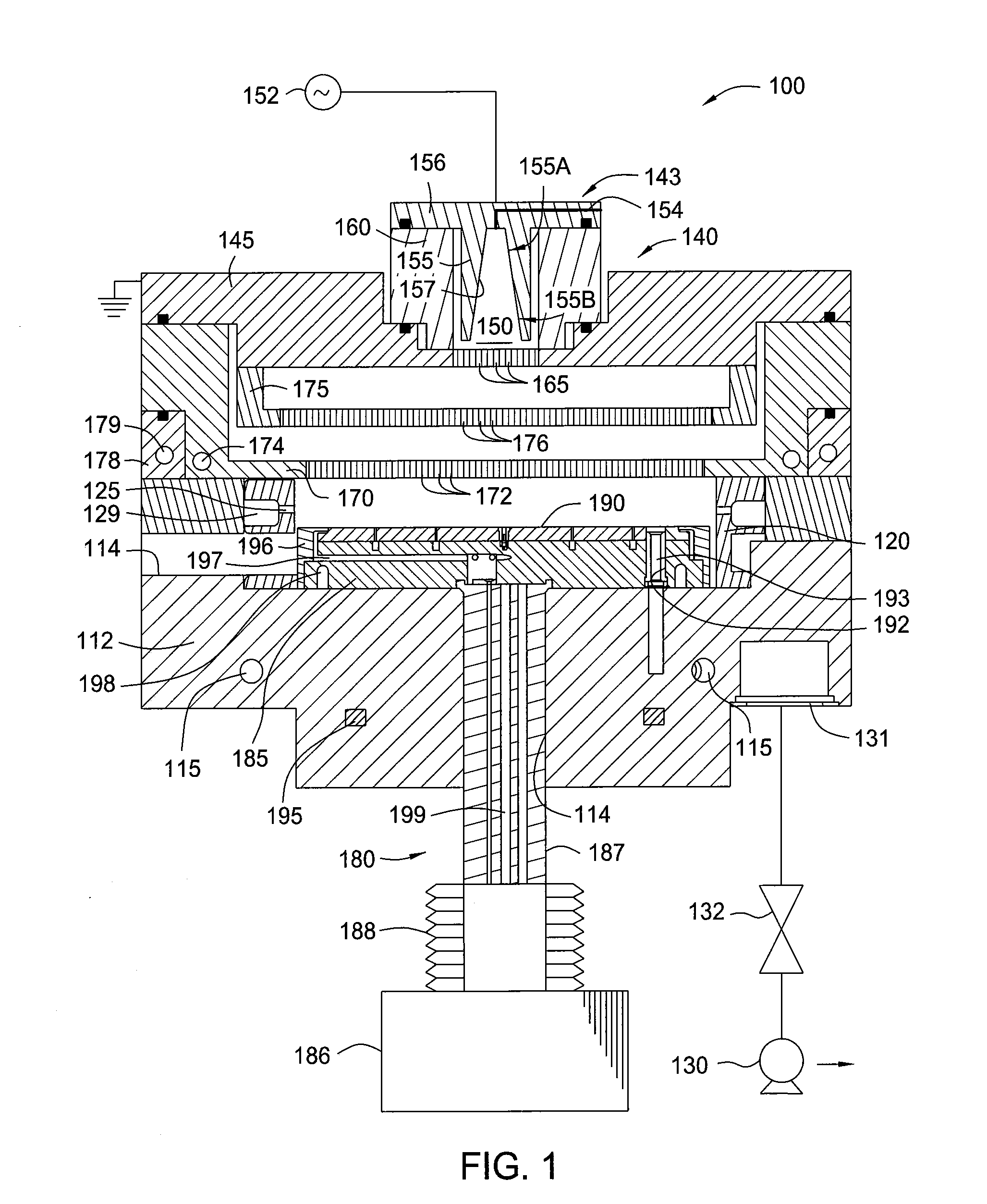

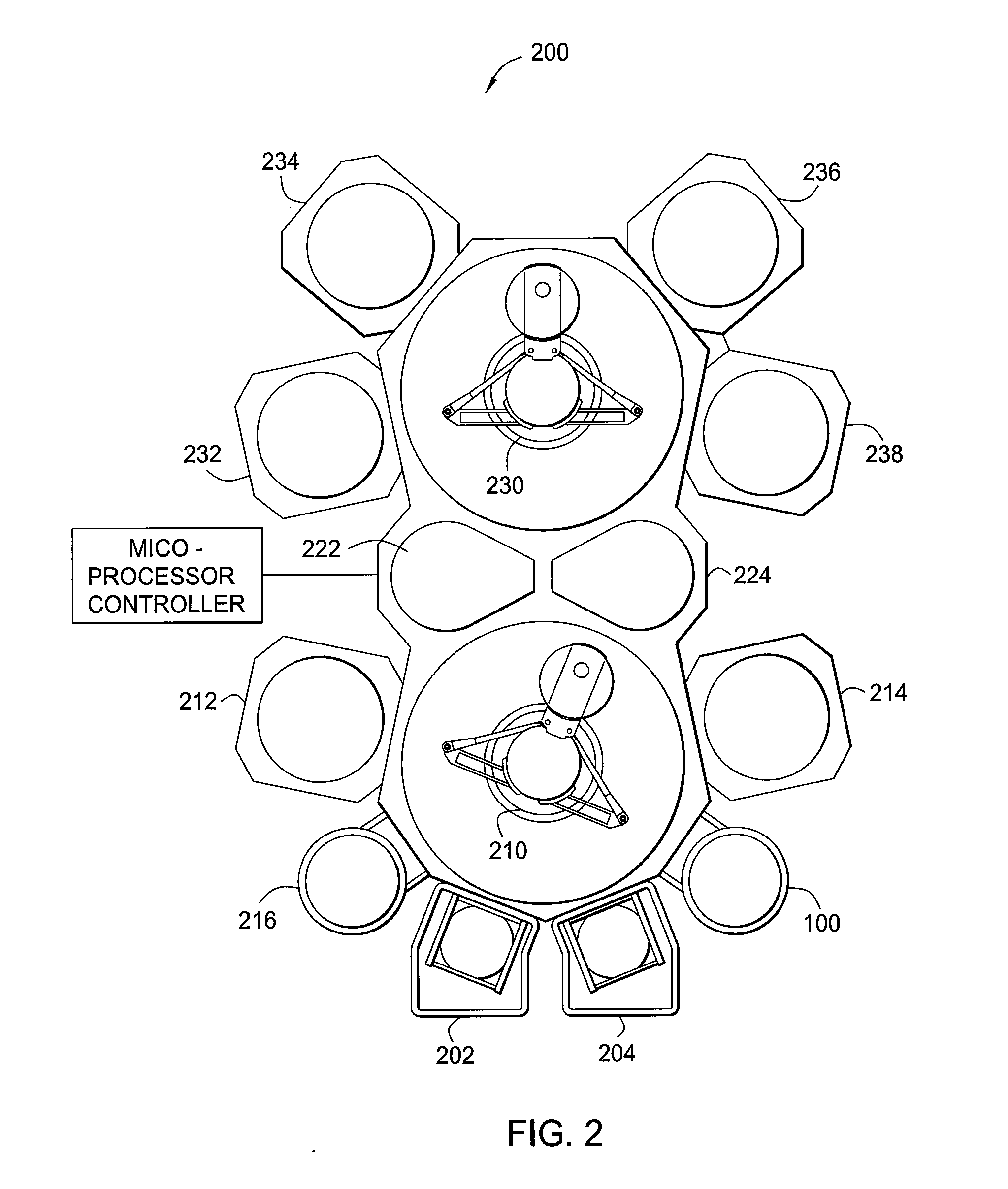

Methods for precleaning a substrate prior to metal silicide fabrication process

Methods for precleaning native oxides or other contaminants from a surface of a substrate prior to forming a metal silicide layer on the substrate. In one embodiment, a method for removing native oxides from a substrate includes transferring a substrate having an oxide layer disposed thereon into a processing chamber, performing a pretreatment process on the substrate by supplying a pretreatment gas mixture into the processing chamber, performing an oxide removal process on the substrate by supplying a cleaning gas mixture into the processing chamber, wherein the cleaning gas mixture includes at least an ammonium gas and a nitrogen trifluoride, and performing a post treatment process on the cleaned substrate by supplying a post treatment gas mixture into the processing chamber

Owner:APPLIED MATERIALS INC

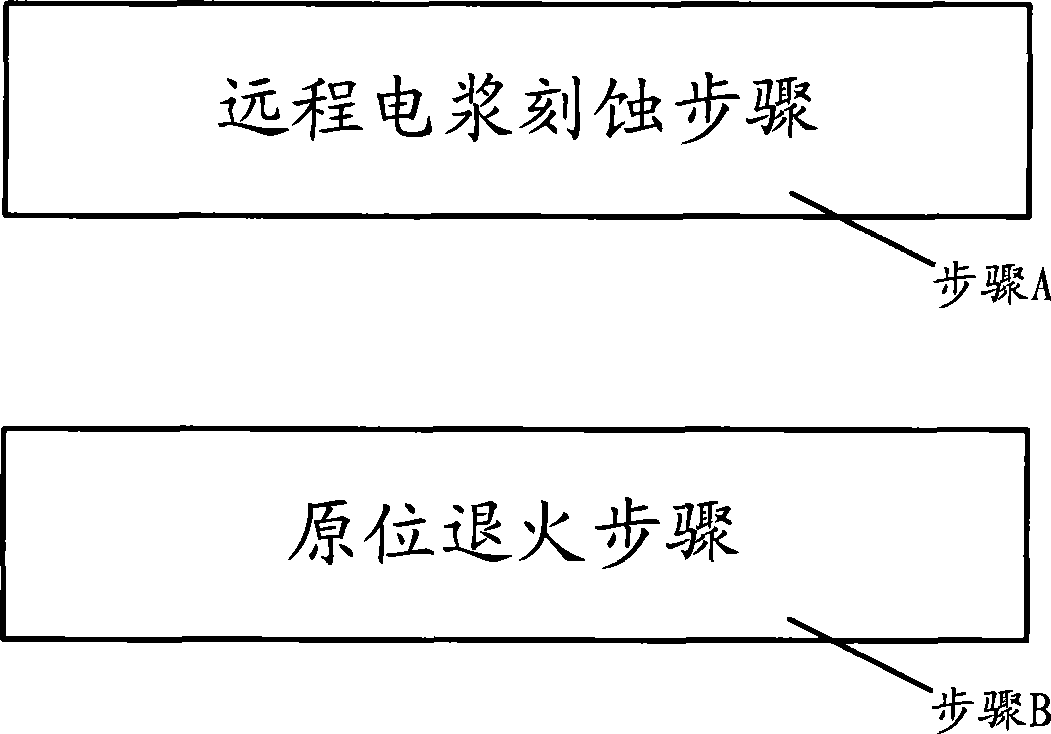

Method for precleaning thin film surface oxide before deposition

InactiveCN101440498AEfficient removalImprove performanceSemiconductor/solid-state device manufacturingAutoxidationRemote plasma

The invention provides a method for pre-cleaning oxide on the surface of a thin film before sedimentation. The pre-cleaning method adopts a dry-method chemical pre-cleaning process which mainly comprises the following steps: A, a remote plasma etching step: etching gas comprises nitrogen fluoride and ammonia gas; the nitrogen fluoride and ammonia gas are converted into fluoride through plasma with low power; and the fluoride reacts with the oxide on the surface of the thin film to generate silicate; and B, an in-situ annealing step: the silicate obtained in the step A is heated and sublimed to a gaseous state; and the gaseous silicate is pumped out. The disclosed method for pre-cleaning the oxide on the surface of the thin film before sedimentation adopts the dry-method chemical pre-cleaning process, can effectively clean the natural oxide of the bottom of a contact layer, can not degrade the performance of a device on the bottom layer and can simultaneously reduce the contact resistance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

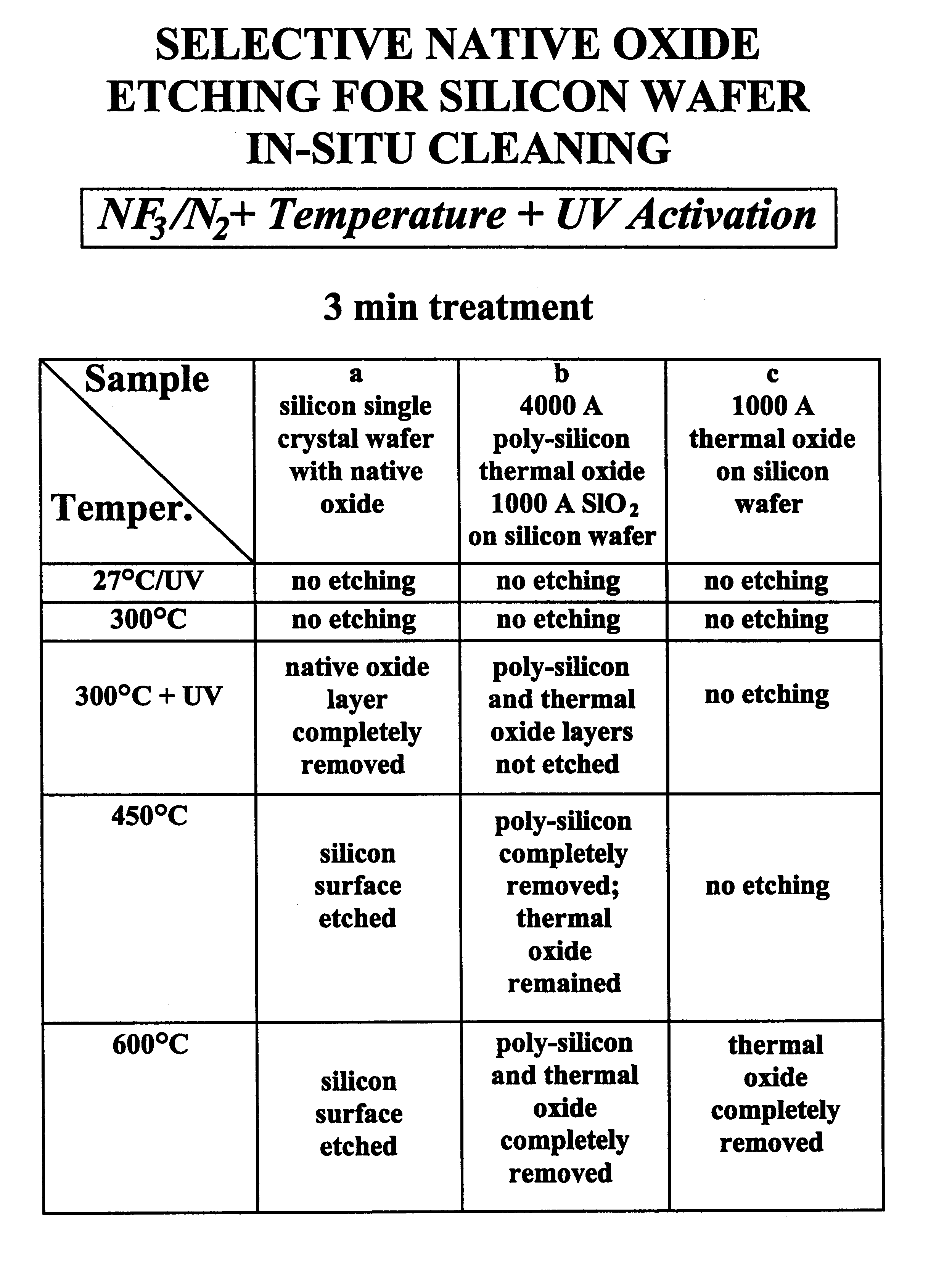

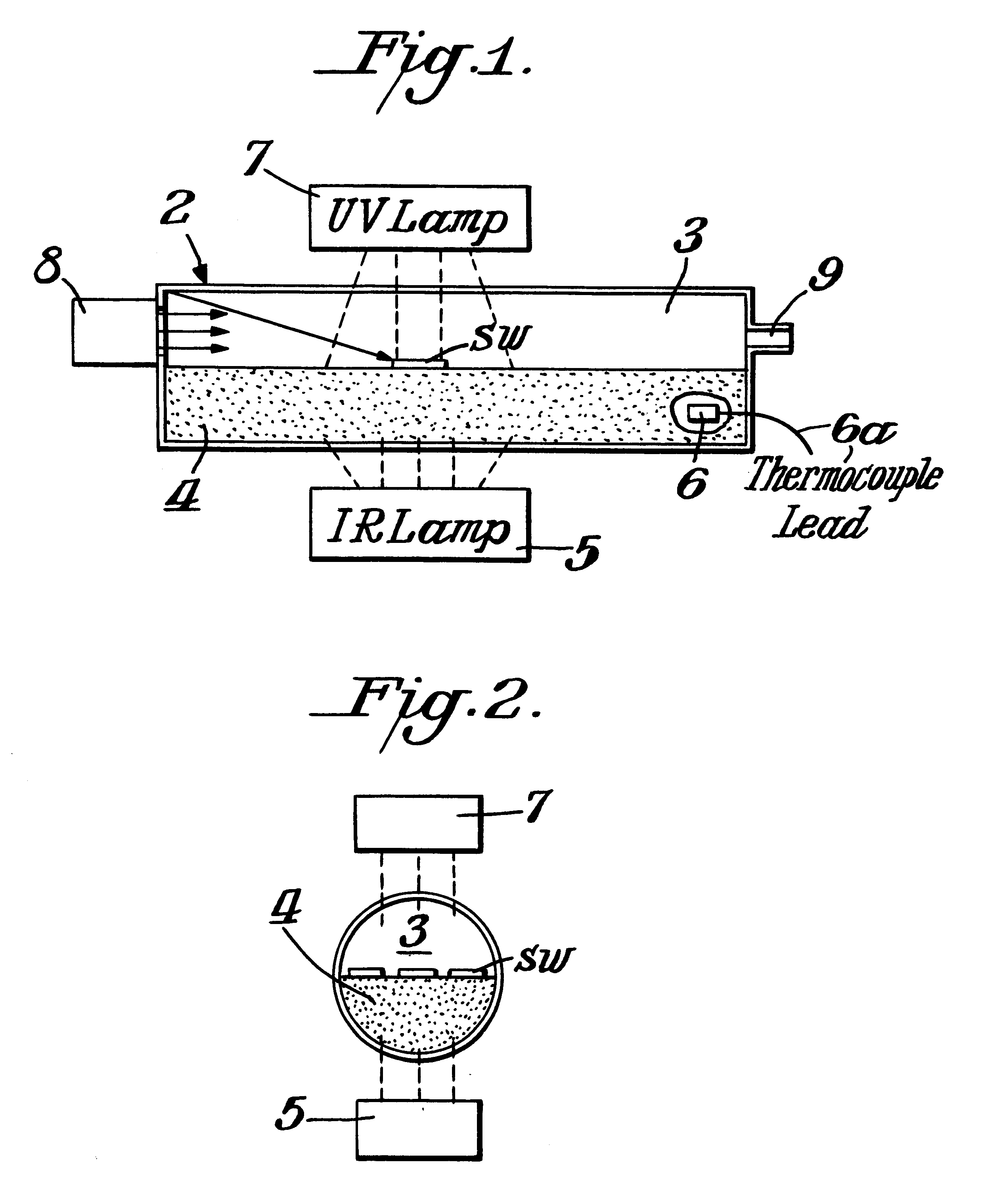

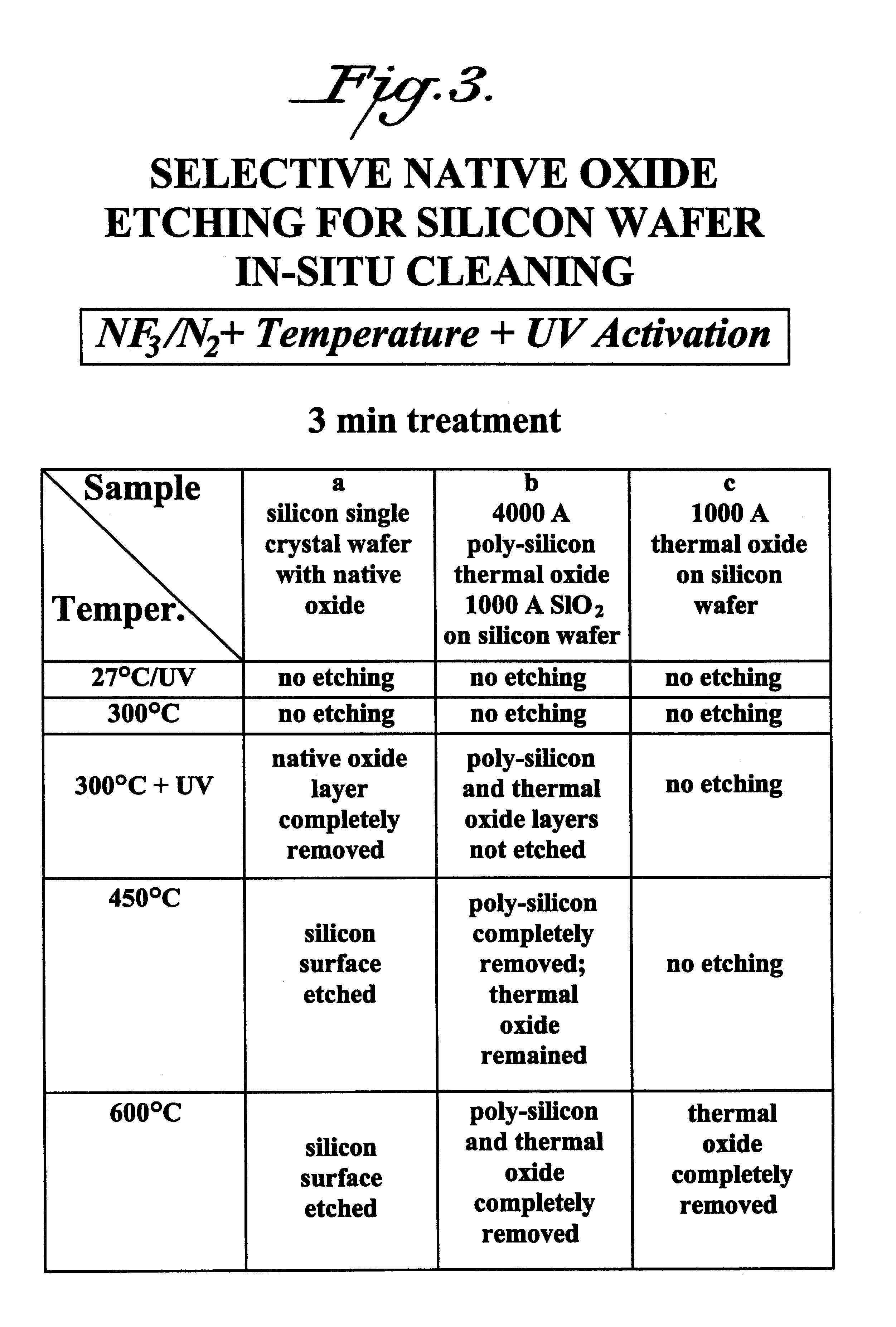

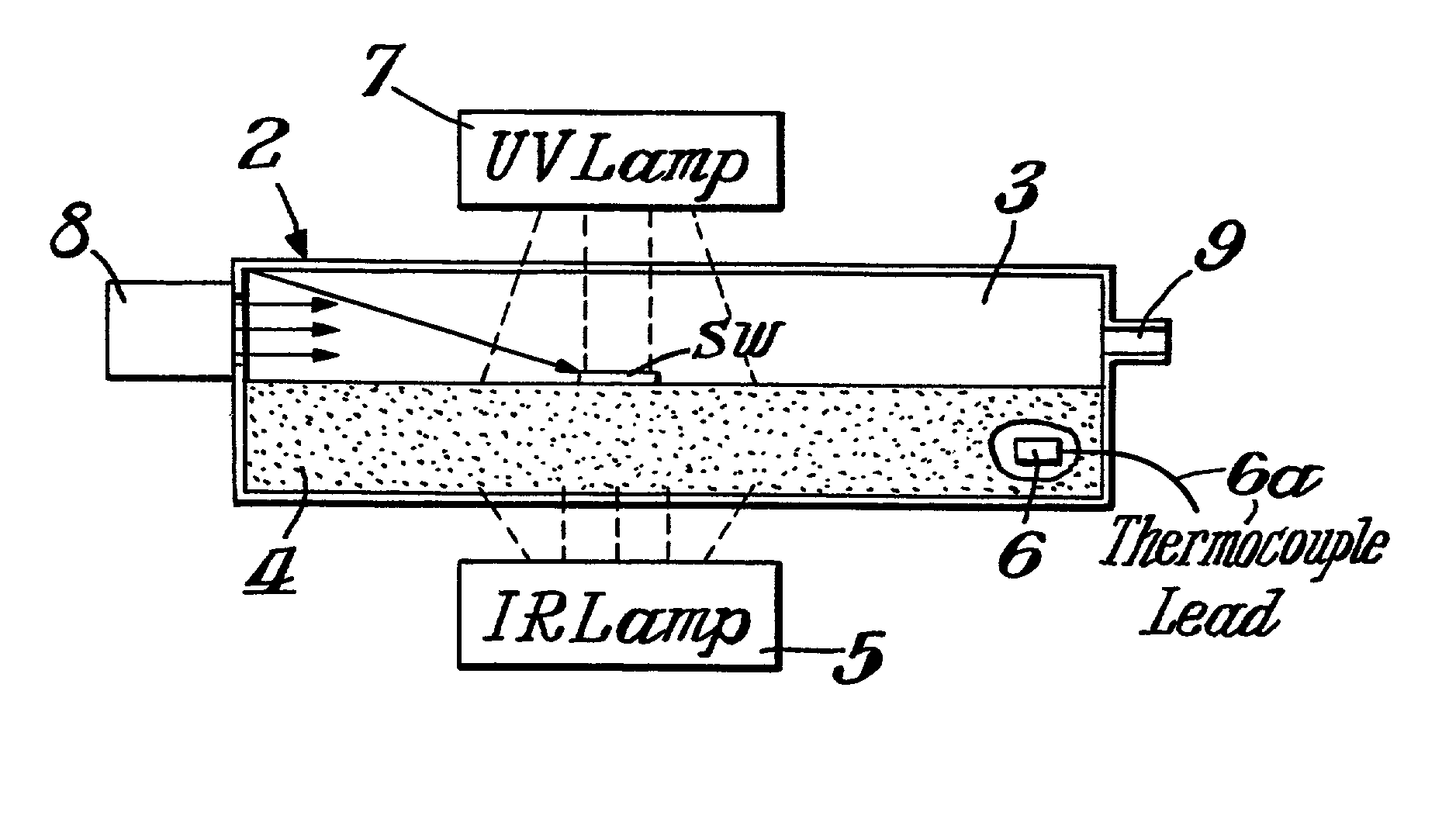

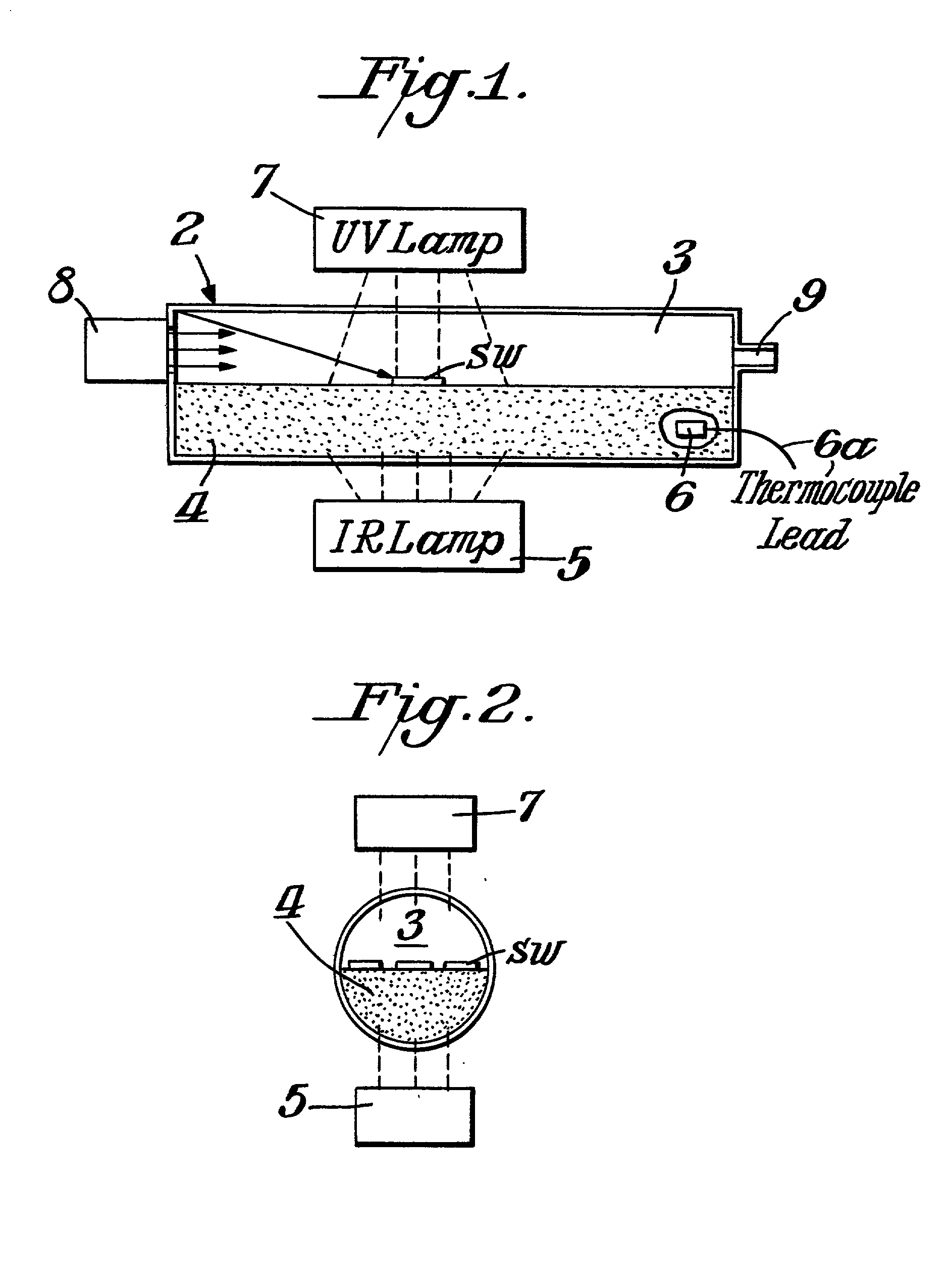

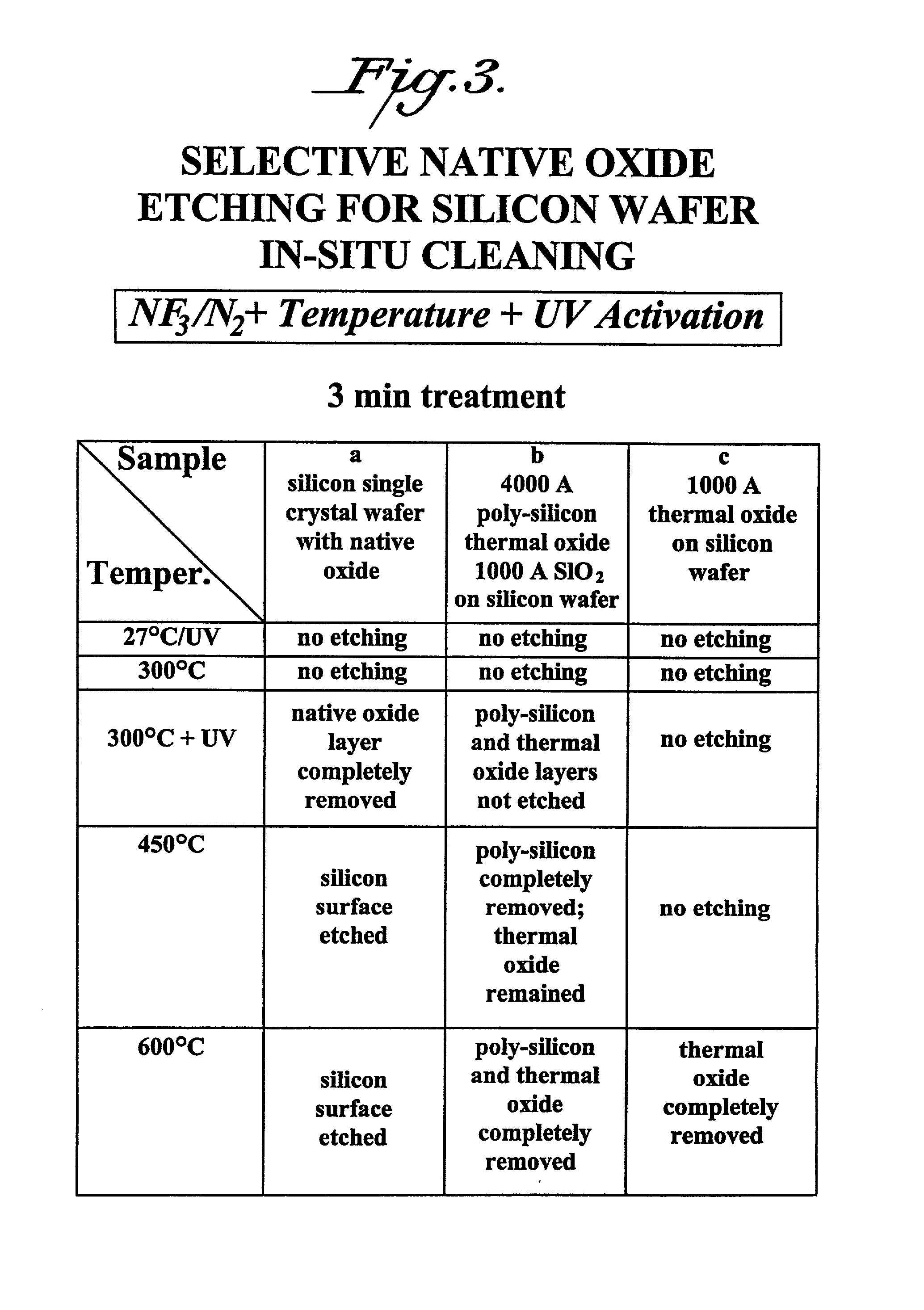

Method and apparatus for removing native oxide layers from silicon wafers

InactiveUS6395192B1Quick responseShorten the timeDecorative surface effectsSemiconductor/solid-state device manufacturingAutoxidationWafering

A method and apparatus for selectively removing a native oxide layer from a silicon wafer without significantly affecting the underlying silicon or other materials that may be thereon, by exposing the silicon wafer to an etchant gas including NF3 while simultaneously exposing the wafer to ultraviolet radiation, and heating the wafer to a temperature of 100-400° C.

Owner:STEAG C V D SYTEMS

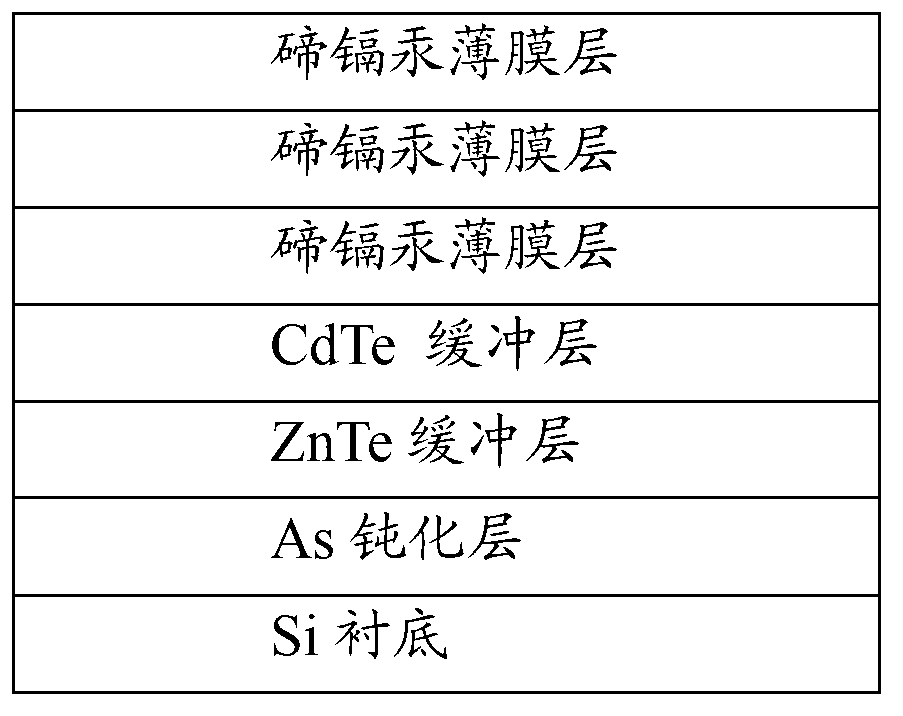

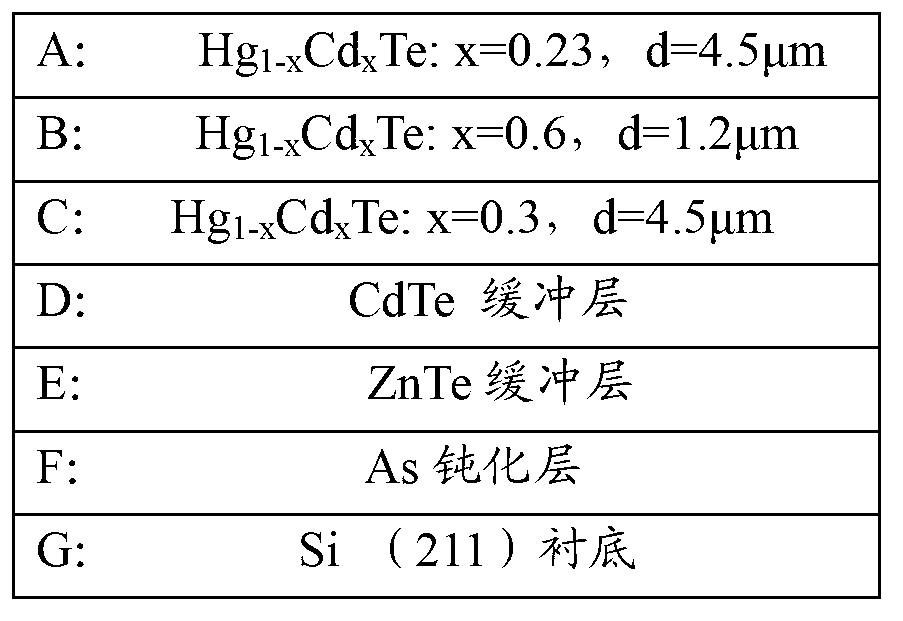

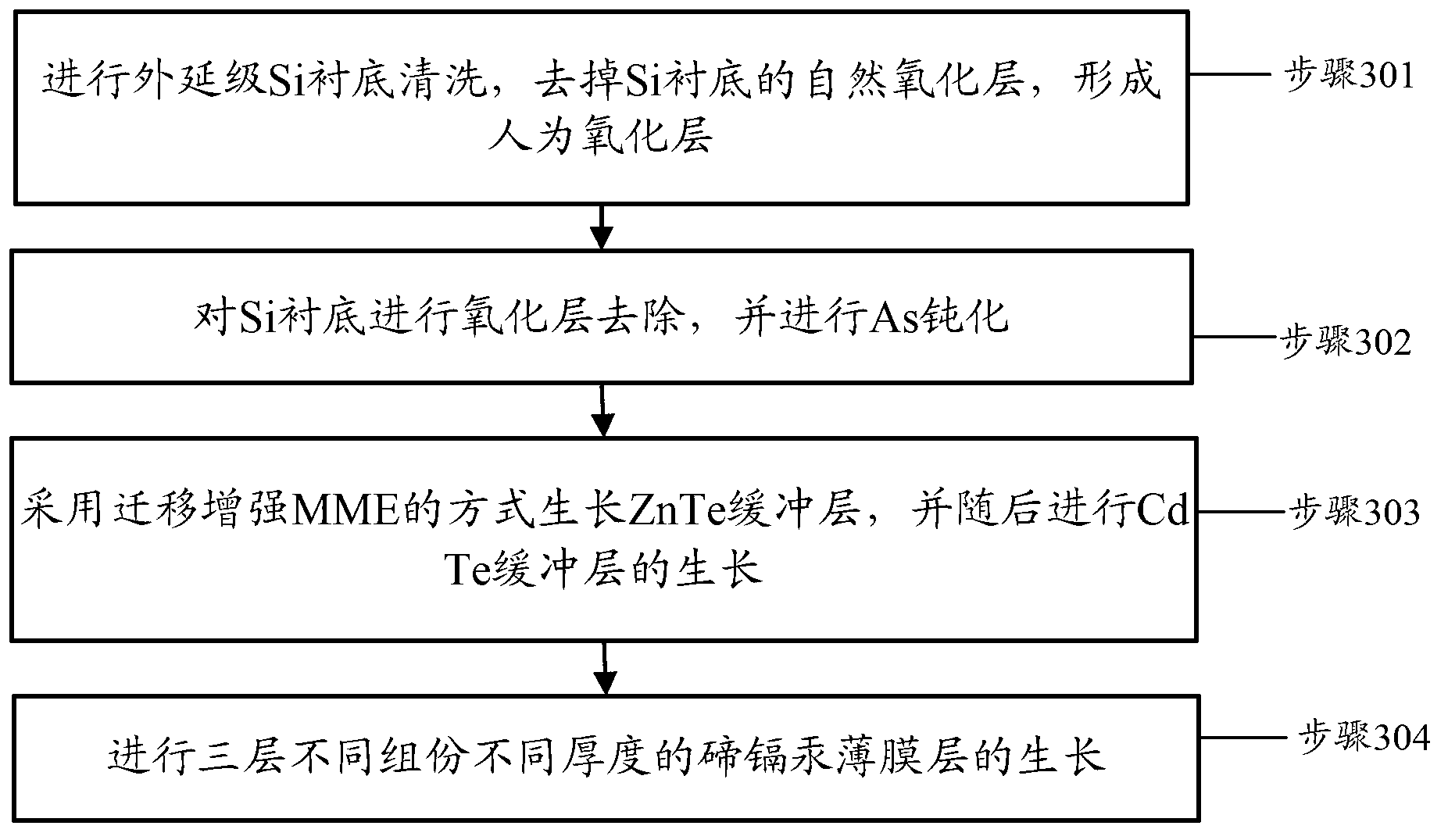

Si-substrate medium/long wave laminated bicolor HgCdTe material and preparation method thereof

ActiveCN103227217AAvoid sizeConvenient temperature controlFinal product manufactureSemiconductor devicesAutoxidationThin layer

The invention discloses an Si-substrate medium / long wave laminated bicolor HgCdTe material and a preparation method thereof. The method comprises the steps of cleaning an epitaxial-level Si substrate, removing an autoxidation layer of the Si substrate, forming an artificial oxidation layer, removing the oxidation layer of the Si substrate, conducting As passivation, allowing a ZnTe buffer layer to grow through transfer enhancement MME (melanin metabolic enzyme), allowing a CdTe buffer layer to grow, and allowing three HgCdTe thin layers with different components and thicknesses to grow.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Discarded metal sludge recovery and utilization method

InactiveCN101086035ANo regenerationAvoid Pollution HazardsOxide/hydroxide preparationSolid waste managementAutoxidationSludge

The invention relates to a method for recovering and utilizing waste metal sludge. It is characterized in that the waste metal sludge can be recycled as renewable resources, which causes no pollution and avoids the harm for water resource and human environment brought from industrial solid waste deep bury. The method comprises adding hydrogen peroxide and potassium permanganate into waste metal sludge for oxidation, which combines with autoxidation to form metal powder that is suitable for extraction.

Owner:黄丹喜

Apparatus for removing native oxide layers from silicon wafers

InactiveUS20020108930A1Quick responseExtended processing timeDecorative surface effectsSemiconductor/solid-state device manufacturingAutoxidationWafering

A method and apparatus for selectively removing a native oxide layer from a silicon wafer without significantly affecting the underlying silicon or other material, that may be thereon, by exposing the silicon wafer to an etchant gas including NF3 while simultaneously exposing the wafer to ultraviolet radiation, and heating the wafer to a temperature of 100-400° C.

Owner:STEAG C V D SYTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com