Apparatus for removing native oxide layers from silicon wafers

a technology of silicon wafers and native oxides, applied in biochemistry apparatus and processes, decorative arts, applications, etc., can solve the problems of loss of selectivity and increase the removal rate of native oxides, and achieve the effects of reducing process pressure, improving reaction rate and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

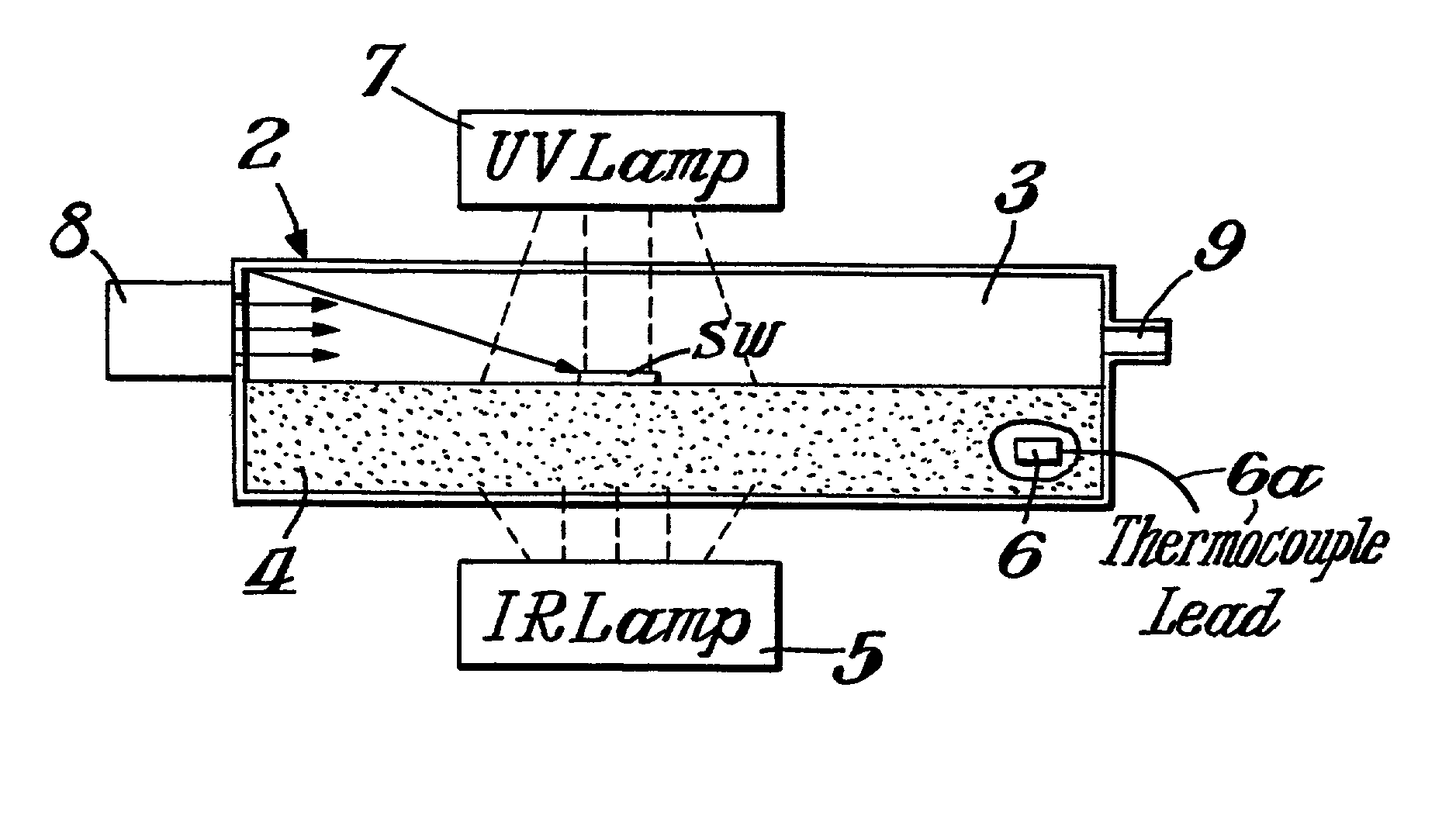

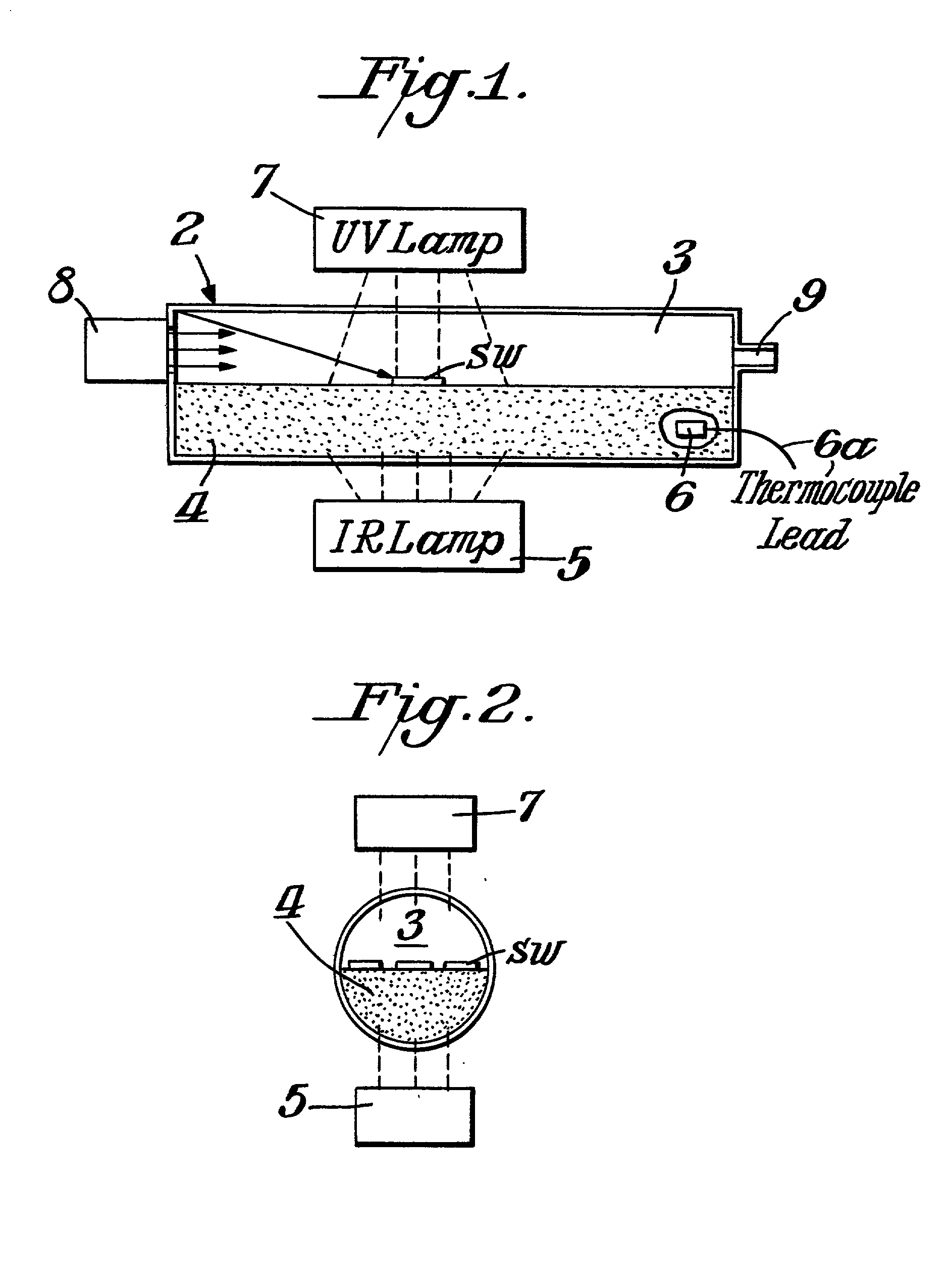

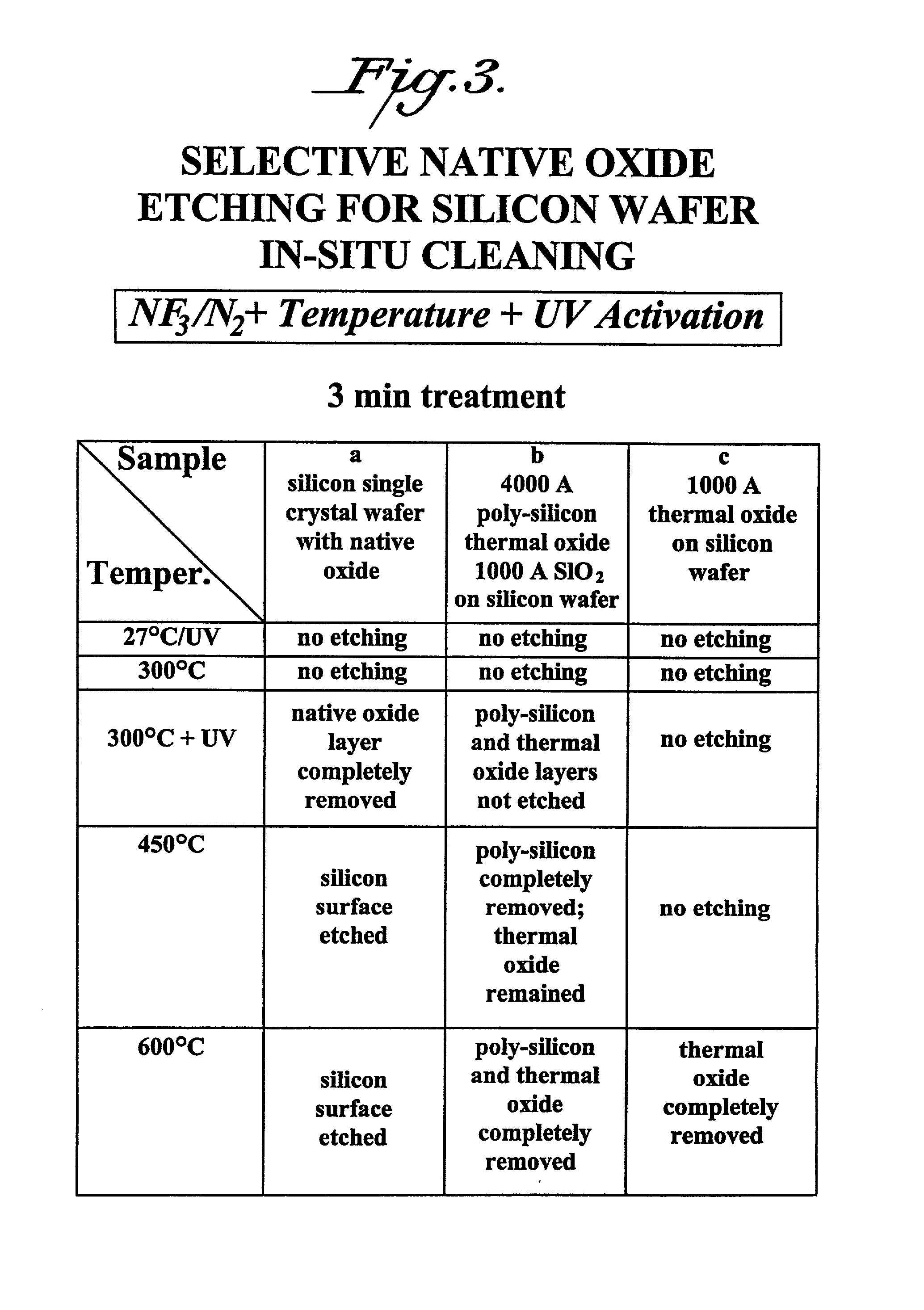

[0019] FIGS. 1 and 2 schematically illustrate one form of apparatus constructed in accordance with the present invention for cleaning silicon wafers by selectively removing a native oxide layer from the silicon wafer without significantly affecting the underlying silicon, or a polysilicon or thermal oxide deposition that may be thereon.

[0020] The apparatus illustrated in FIGS. 1 and 2 includes a reactor, generally designated 2, consisting of a horizontal quartz tube defining an internal reactor chamber 3. The horizontal quartz tube may be about 85 mm in length, about 15 mm in diameter, and about 2 mm wall thickness. The lower half of reactor chamber 3 is occupied by a half-cylinder shaped graphite susceptor 4 which supports one of more silicon wafers SW to be processed within the reactor chamber. Externally of and below reactor chamber 3 is an infrared lamp 5 which heats the graphite susceptor 4 from below. The graphite susceptor has a thermo-couple 6 embedded within it for temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com