Patents

Literature

40results about How to "Avoid natural oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

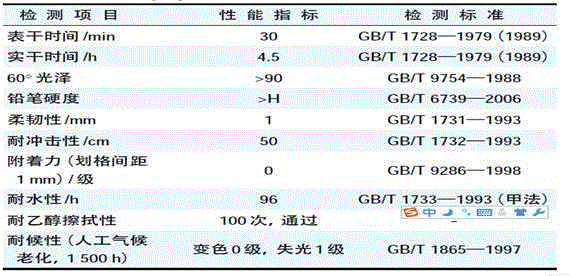

Nano flame-retardant coating

InactiveCN103540243AGood synergyLow cost of industrializationFireproof paintsAnti-corrosive paintsSodium BentoniteTalc

The invention discloses a composite type nano flame-retardant coating comprising the following raw materials in parts by weight: 22-25 parts of titanium pigment, 10-25 parts of talc powder, 10-15 parts of calcium carbonate, 5-8 parts of mica powder, 5-8 parts of bentonite, 2-8 parts of kaolin, 7-11 parts of a thickening agent solution, 1.0-1.4 parts of a dispersant, 33-40 parts of polyacrylic ester emulsion of which the mass percent is 50%, 0.05-0.2 part of an anti-mildew agent, 0.05-0.2 part of a defoaming agent, 2.1-3.1 parts of propanediol, 1-3 parts of ethanediol, 7-11 parts of purified water, 0.02 part of an initiator, 0.6 part of a leveling agent, 25 parts of a modified ammonia type curing agent, and the balance of a nano flame-retardant composite.

Owner:苏州瑞邦塑胶有限公司

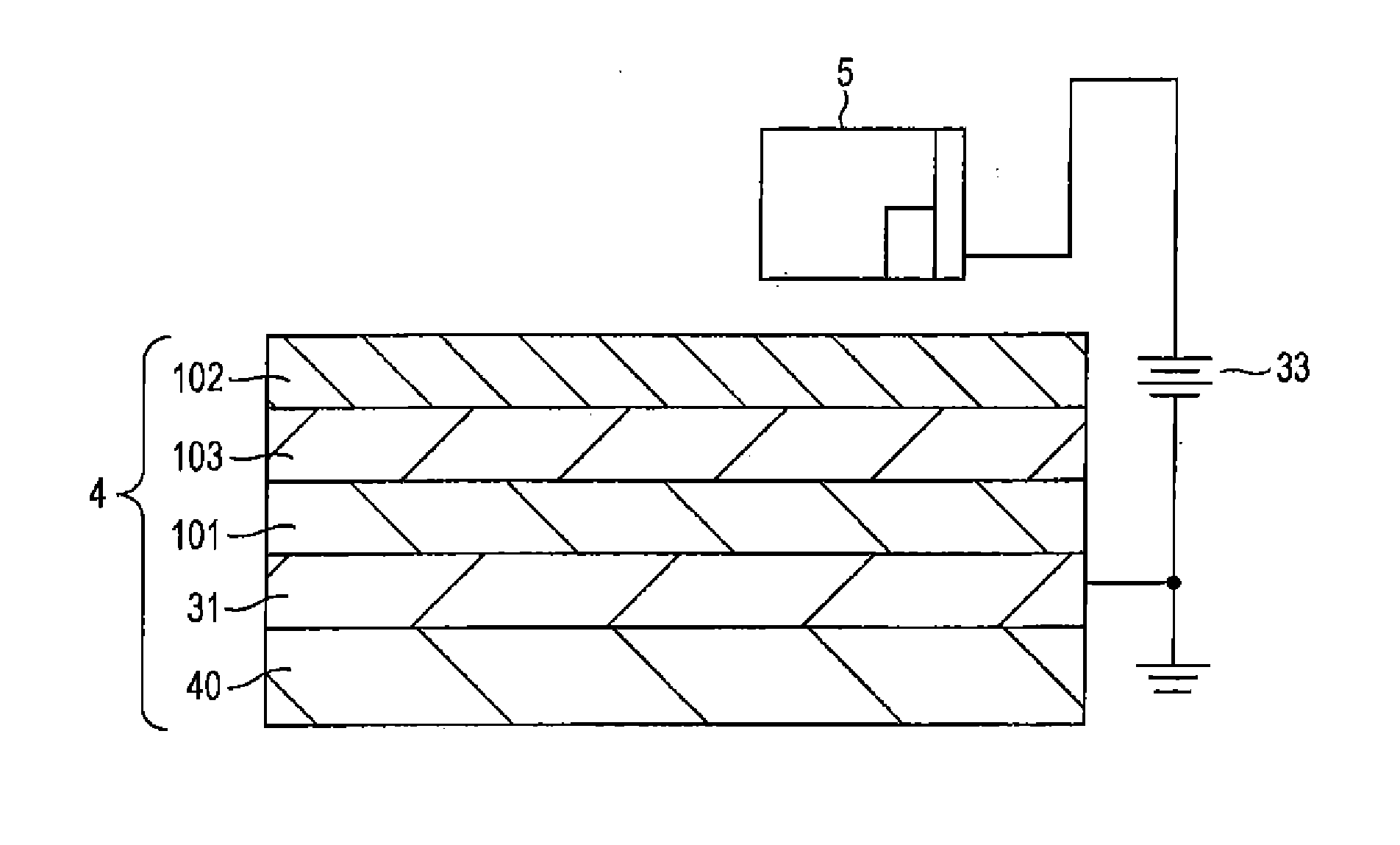

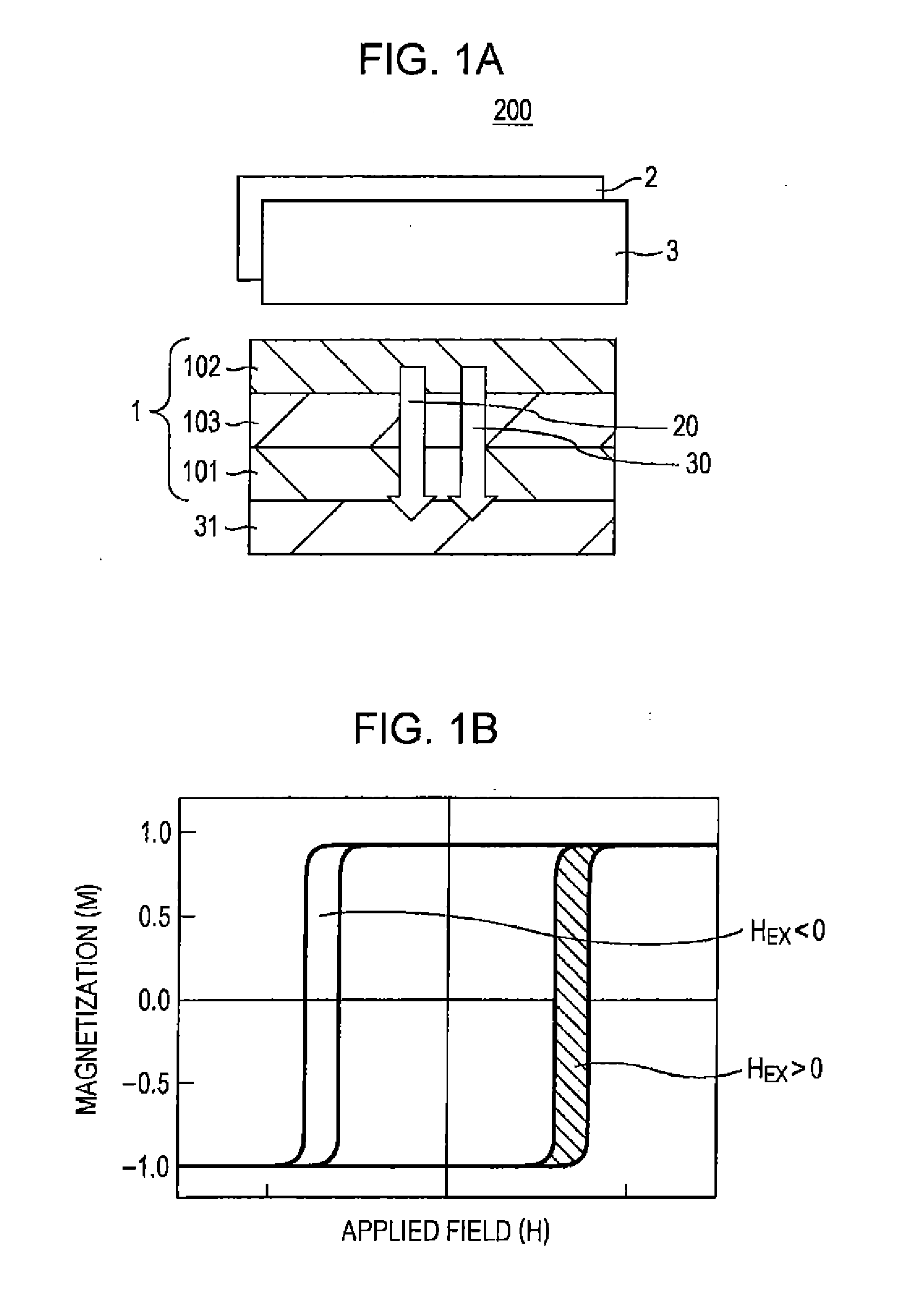

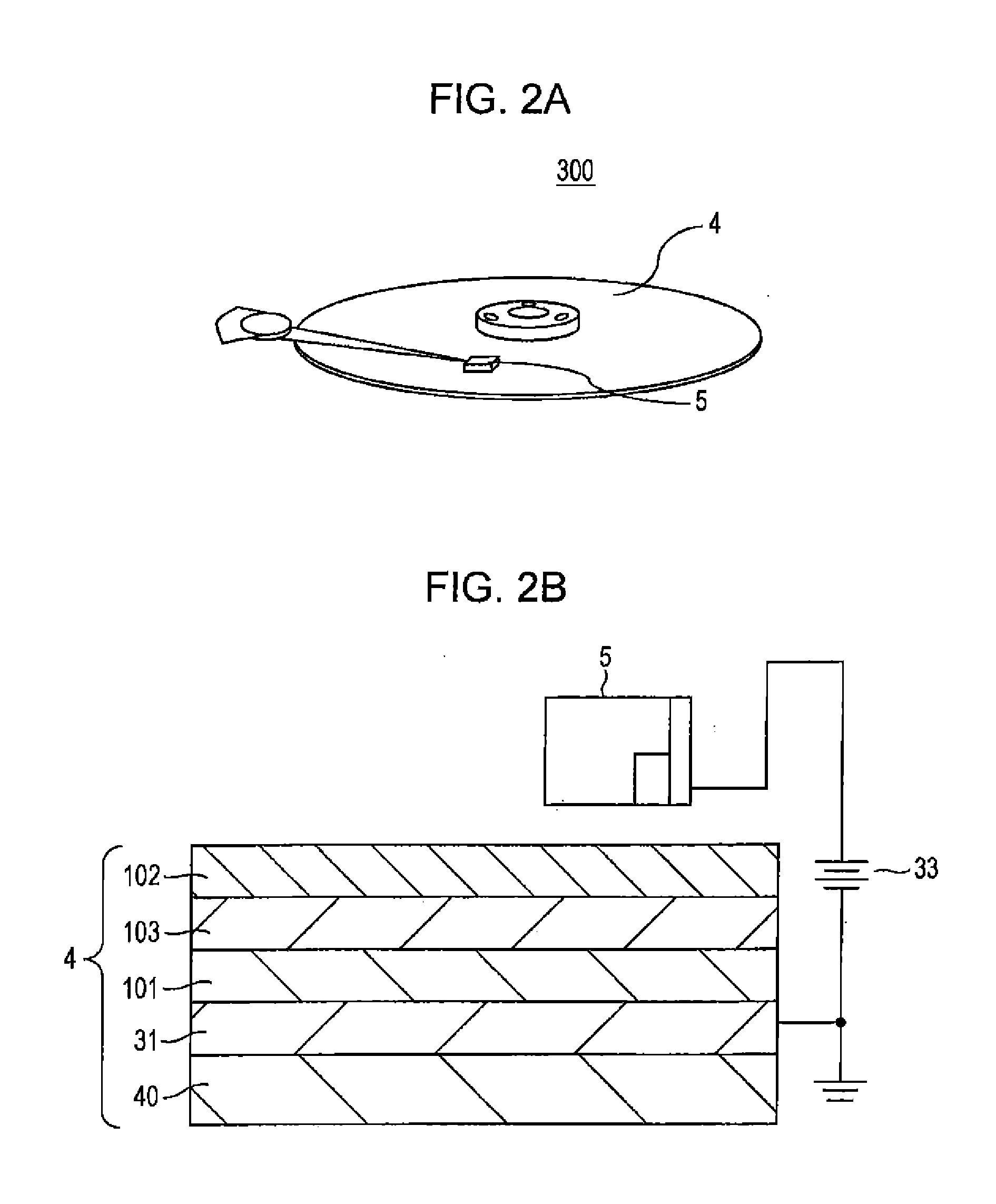

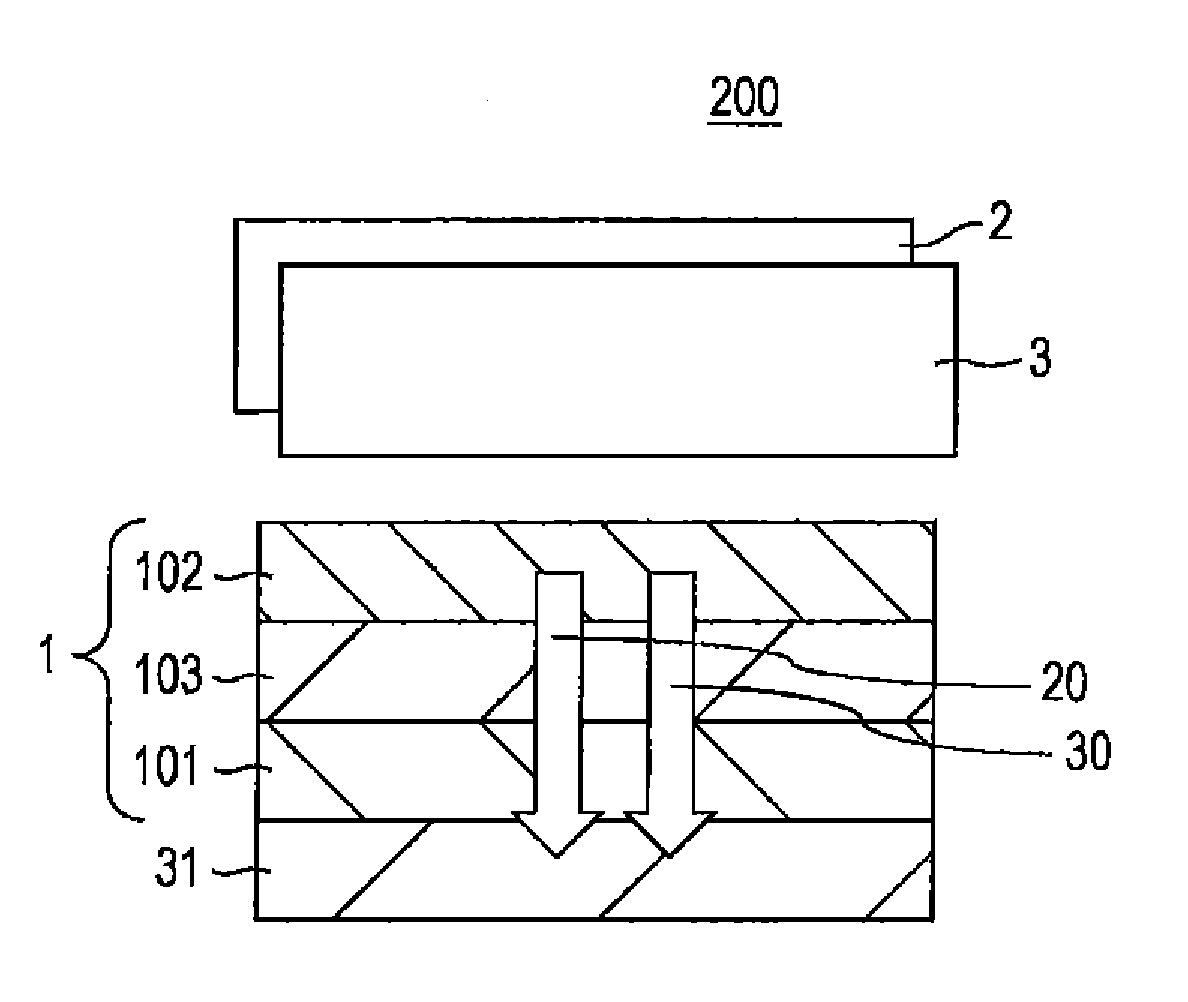

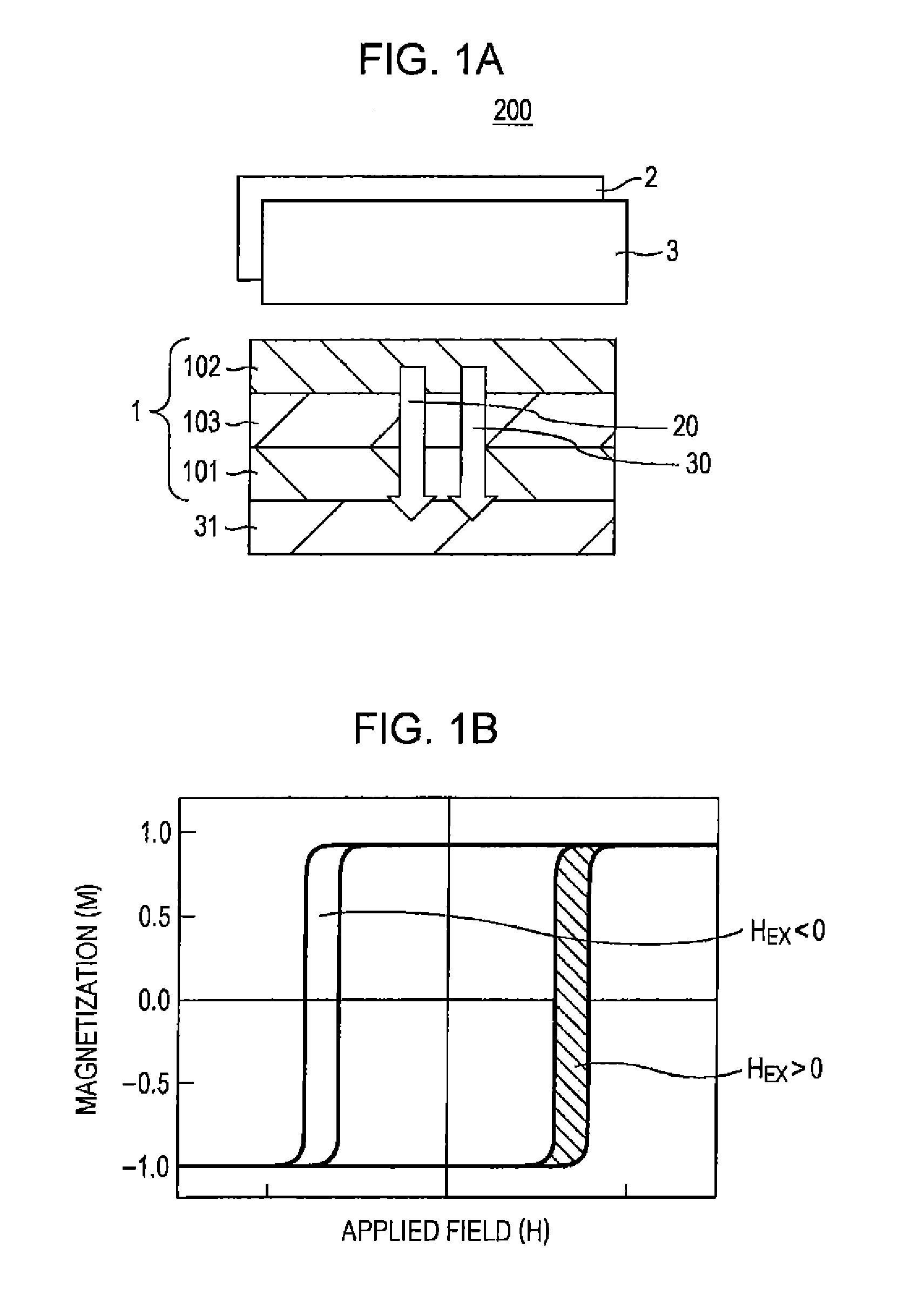

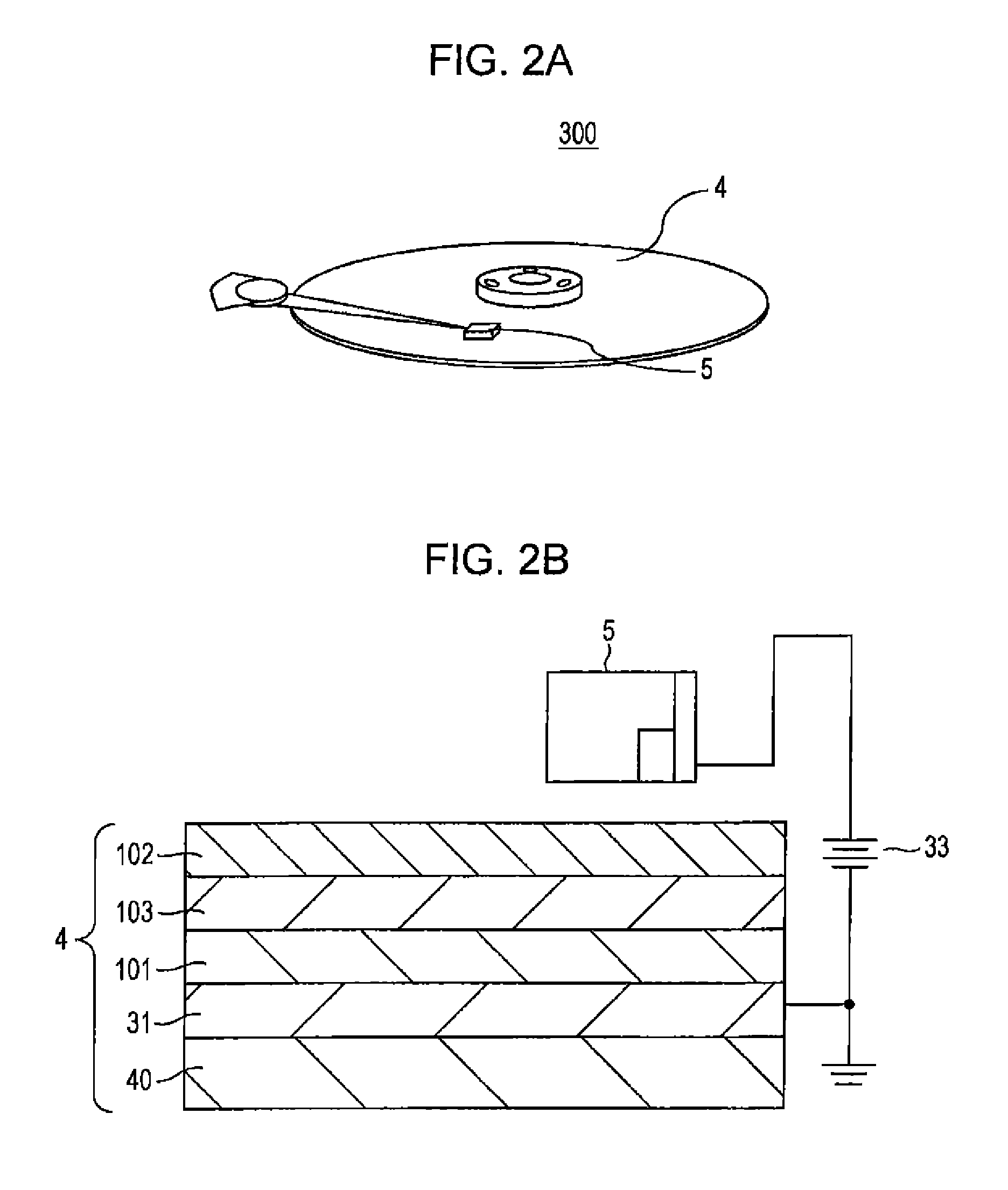

Magnetization controlling element using magnetoelectric effect

ActiveUS20150123755A1Confirm effectPrevent natural oxidationRecord information storageRecording/reproducing/erasing methodsElectric fieldNuclear magnetic resonance

A magnetization controlling element includes a ferromagnetic material layer, an exchange coupling adjustment layer, an antiferromagnetic material layer, an electrode layer, a magnetic field applying mechanism which applies a magnetic field to the antiferromagnetic material layer, and an electric field applying mechanism which applies an electric field to the antiferromagnetic material layer. The antiferromagnetic material layer contains an antiferromagnetic material or ferrimagnetic material having a magnetoelectric effect, the ferromagnetic material layer includes a perpendicular magnetization film having a magnetization component perpendicular to the film surface, the ferromagnetic material layer includes a ferromagnetic material layer that is magnetically connected, through exchange coupling, to the antiferromagnetic material layer. The exchange coupling adjustment layer has a function of adjusting exchange coupling between the ferromagnetic material layer and the antiferromagnetic material layer.

Owner:TDK CORPARATION

Nano-polypropylene flame retardant plastic

InactiveCN103467854AExcellent heat resistance and flame retardancySimple preparation processParaffin waxPolypropylene

The invention relates to a nano-polypropylene flame retardant plastic which consists of the following components in parts by weight: 60-80 parts of polypropylene, 20-50 parts of polyethylene, 20-30 parts of terpene resin, 10-30 parts of polystyrene, 10-25 parts of nitrile rubber, 5-10 parts of dibutyl sebacate, 5-10 parts of polyimide, 10-20 parts of liquid paraffin, 10-15 parts of antimonous oxide, 10-30 parts of nano-titanium oxide, 10-22 parts of zinc stearate, 20-40 parts of a flame retardant, 0.1-0.3 part of an antioxidant, 0.5-1 part of a defoamer, 1-3 parts of an assistant and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Polyurethane flame-retardant nano paint

InactiveCN103540257AGood synergyLow cost of industrializationFireproof paintsPolyurea/polyurethane coatingsEpoxyGraphite

The invention discloses a polyurethane flame-retardant nano paint. The polyurethane flame-retardant nano paint comprises following raw materials, by weight, 10 to 20 parts of graphite, 5 to 15 parts of molybdenum disulfide, 5 to 10 parts of aluminium oxide, 2 to 6 parts of xylene, 2 to 6 parts of polyurethane modified epoxy resin, 2 to 6 parts of a curing agent, 12 to 15 parts of a bonding agent, 1 to 4 parts of an auxiliary agent, 15 to 20 parts of purified water, and the like.

Owner:岳阳圣吉力高科技涂料有限公司

Biological nano plastic

The invention discloses a biological nano plastic, which is characterized in that the plastic comprises the following raw material components in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerine, 40 parts of polyethylene, 20-40 parts of a polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of additives, 5-8 parts of Pulullan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber, and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Magnetization controlling element using magnetoelectric effect

ActiveUS9520175B2Avoid natural oxidationRecord information storageRecording/reproducing/erasing methodsPerpendicular magnetizationCoupling

Owner:TDK CORPARATION

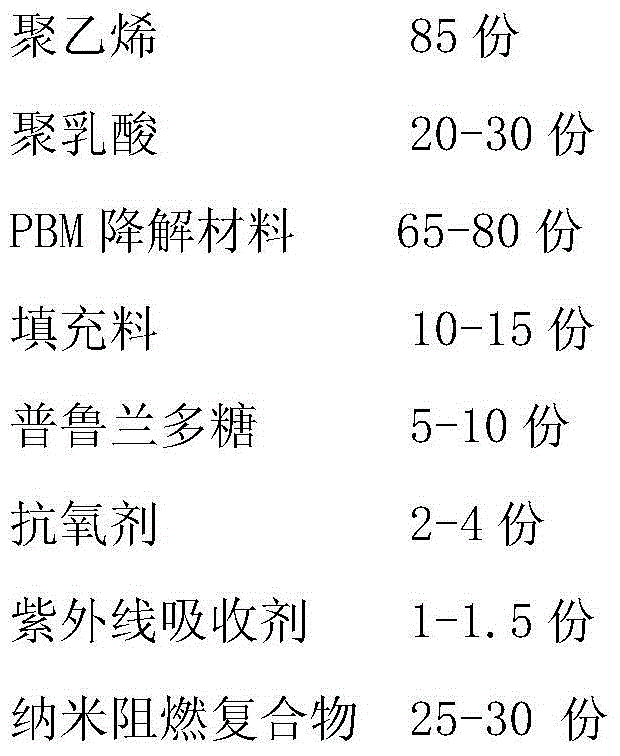

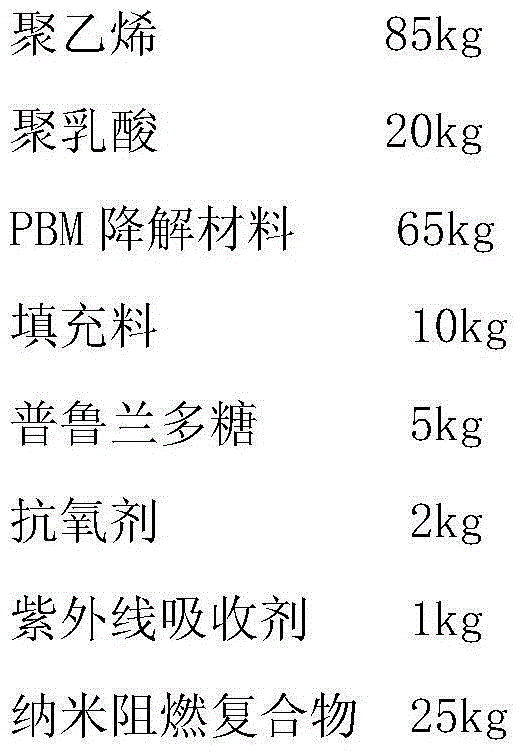

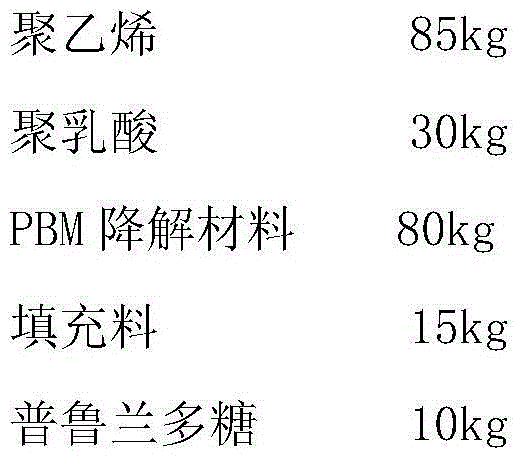

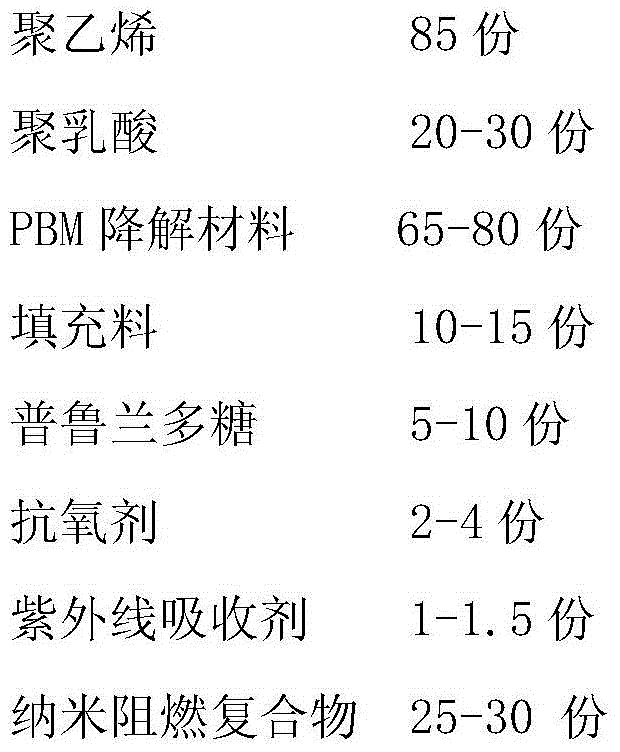

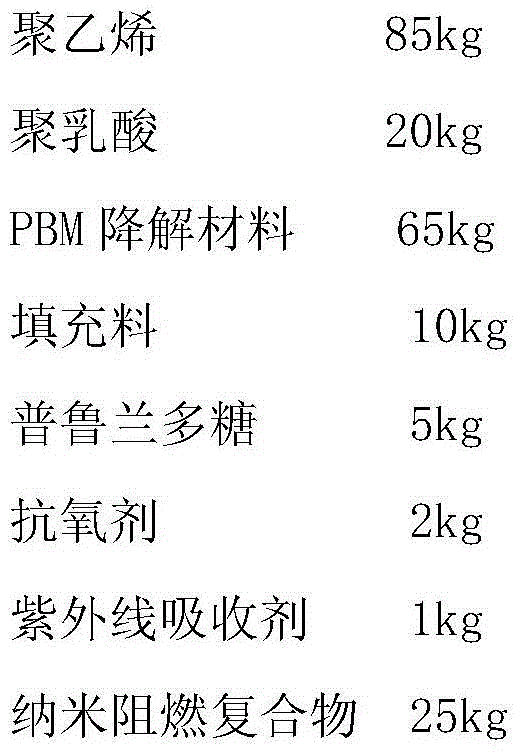

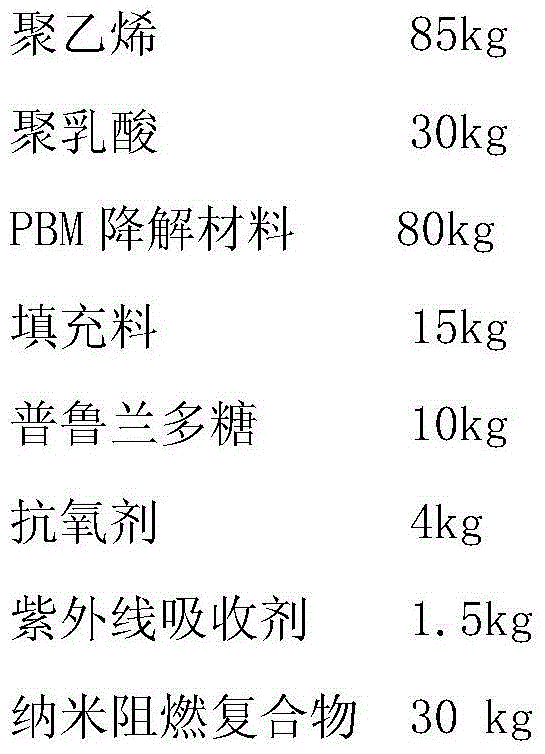

Biodegradable flame-retardant plastic film and preparation method thereof

InactiveCN104448495AGood mechanical propertiesAchieve environmental friendlinessPolymer sciencePullulan

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of the starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

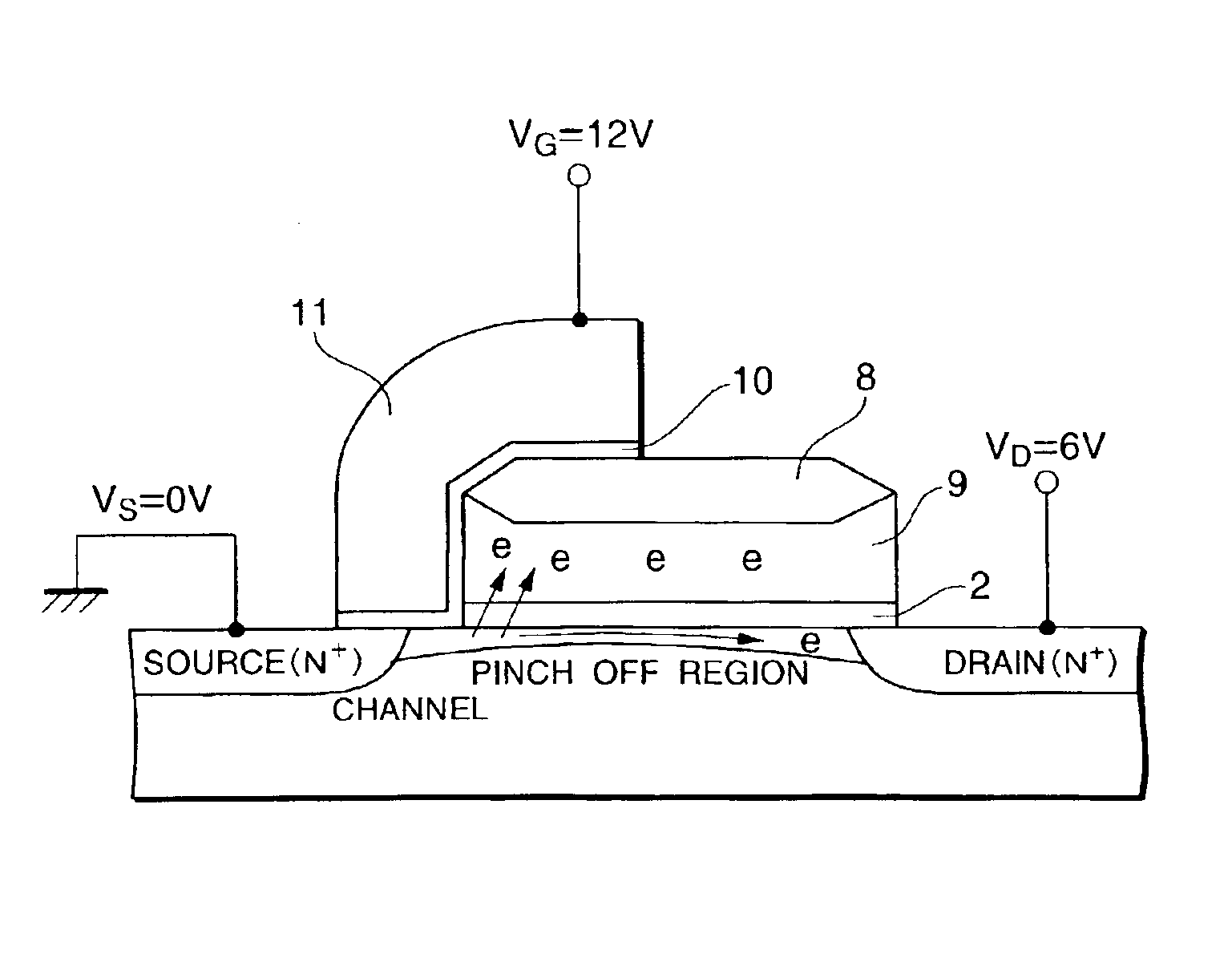

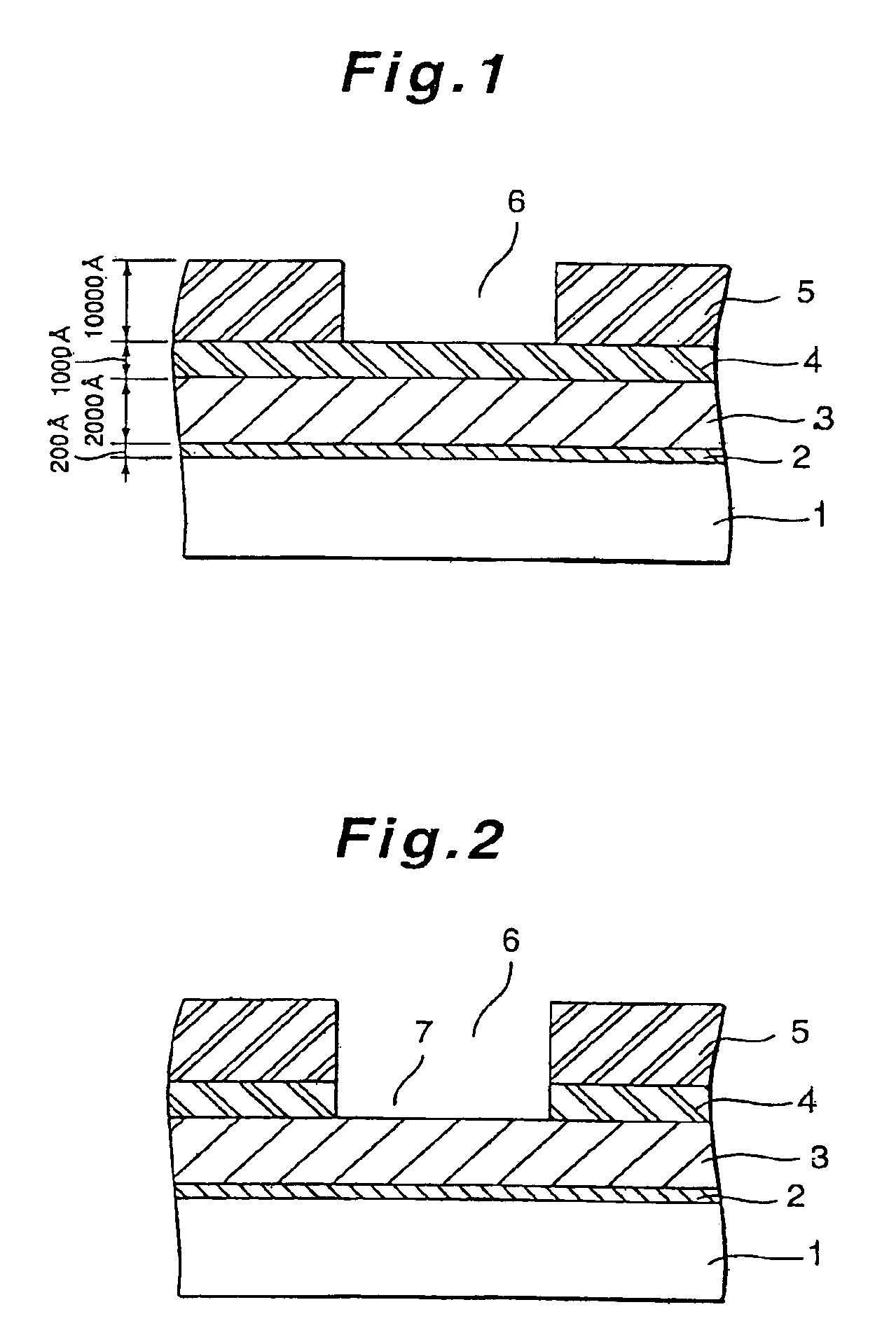

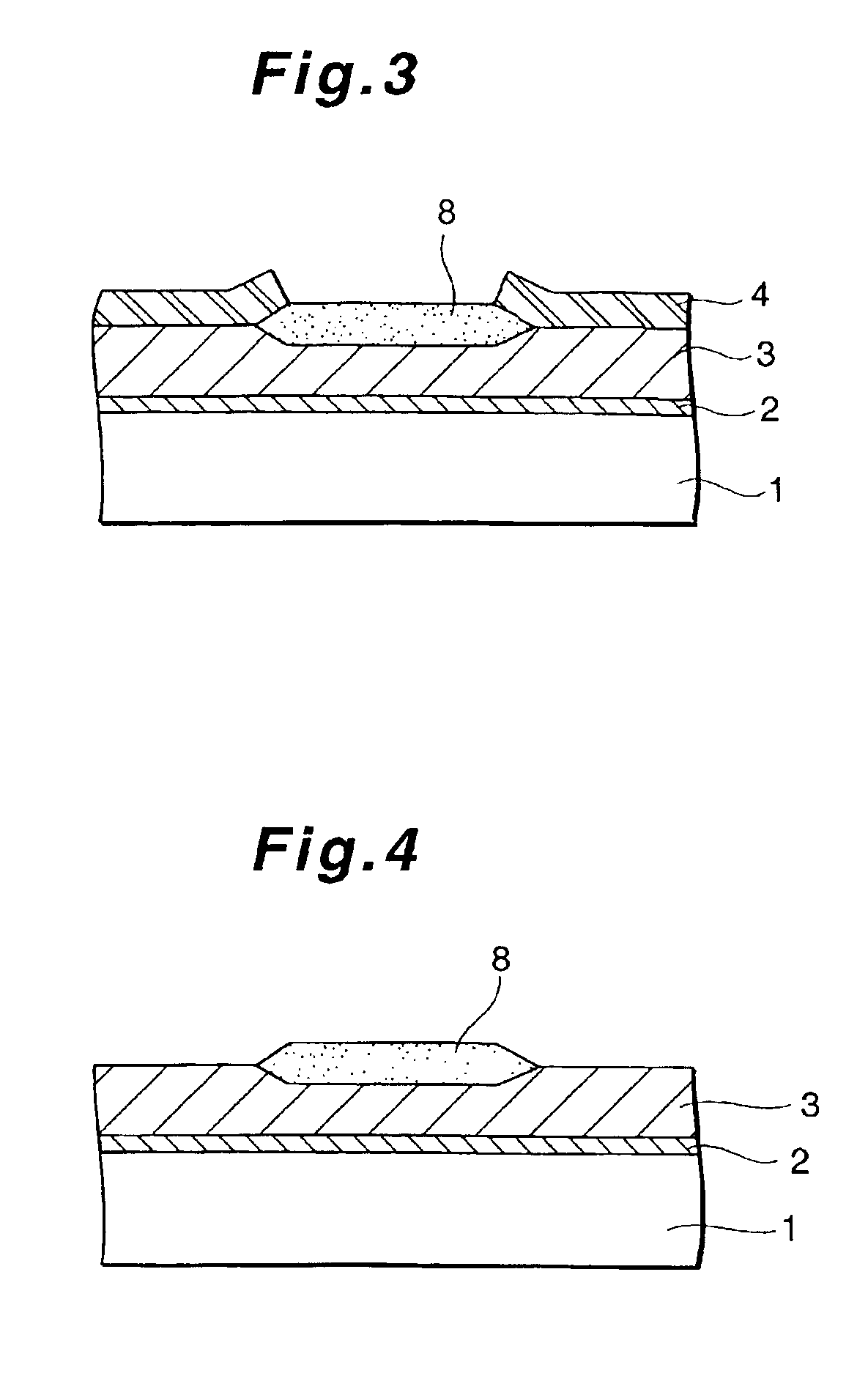

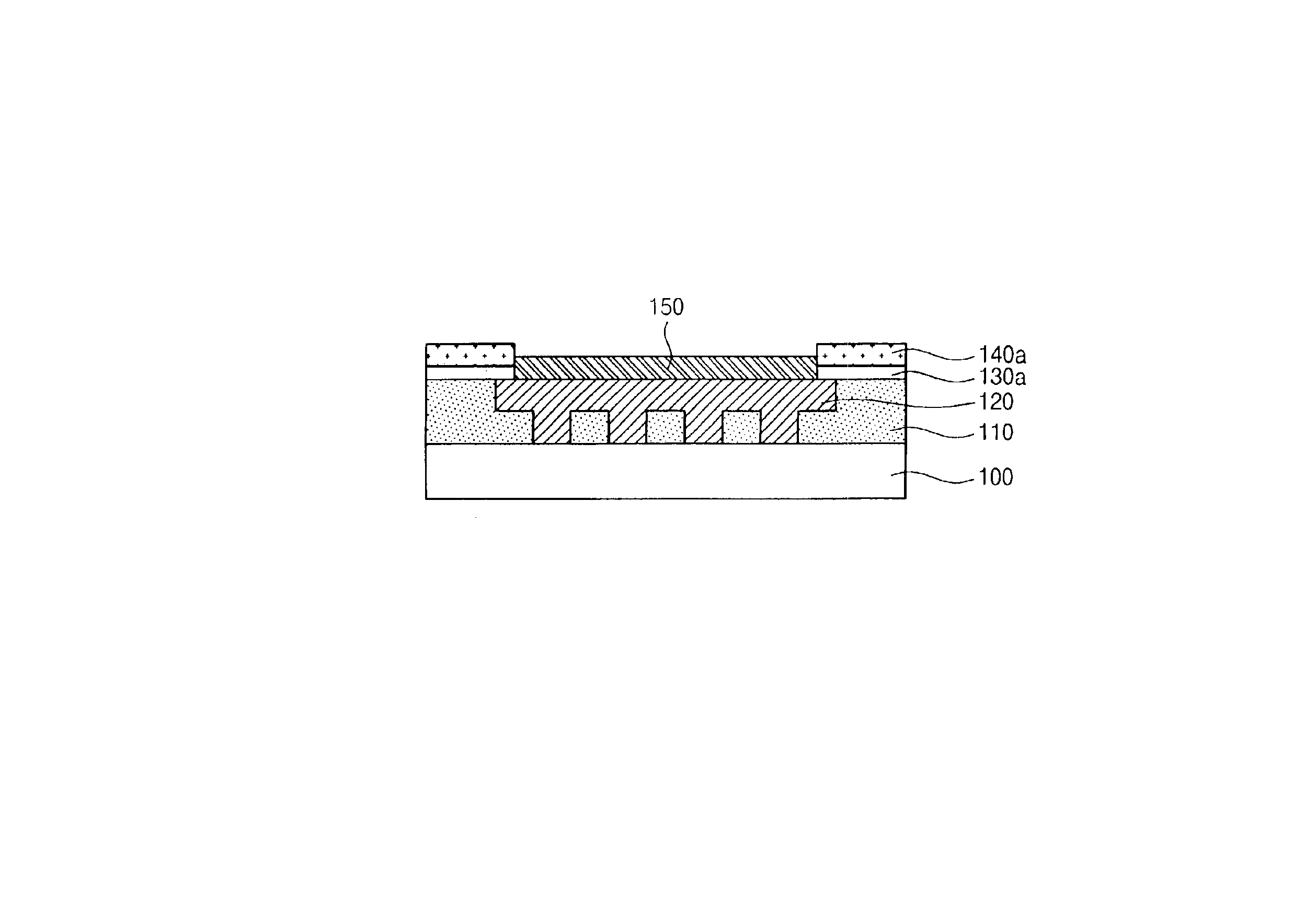

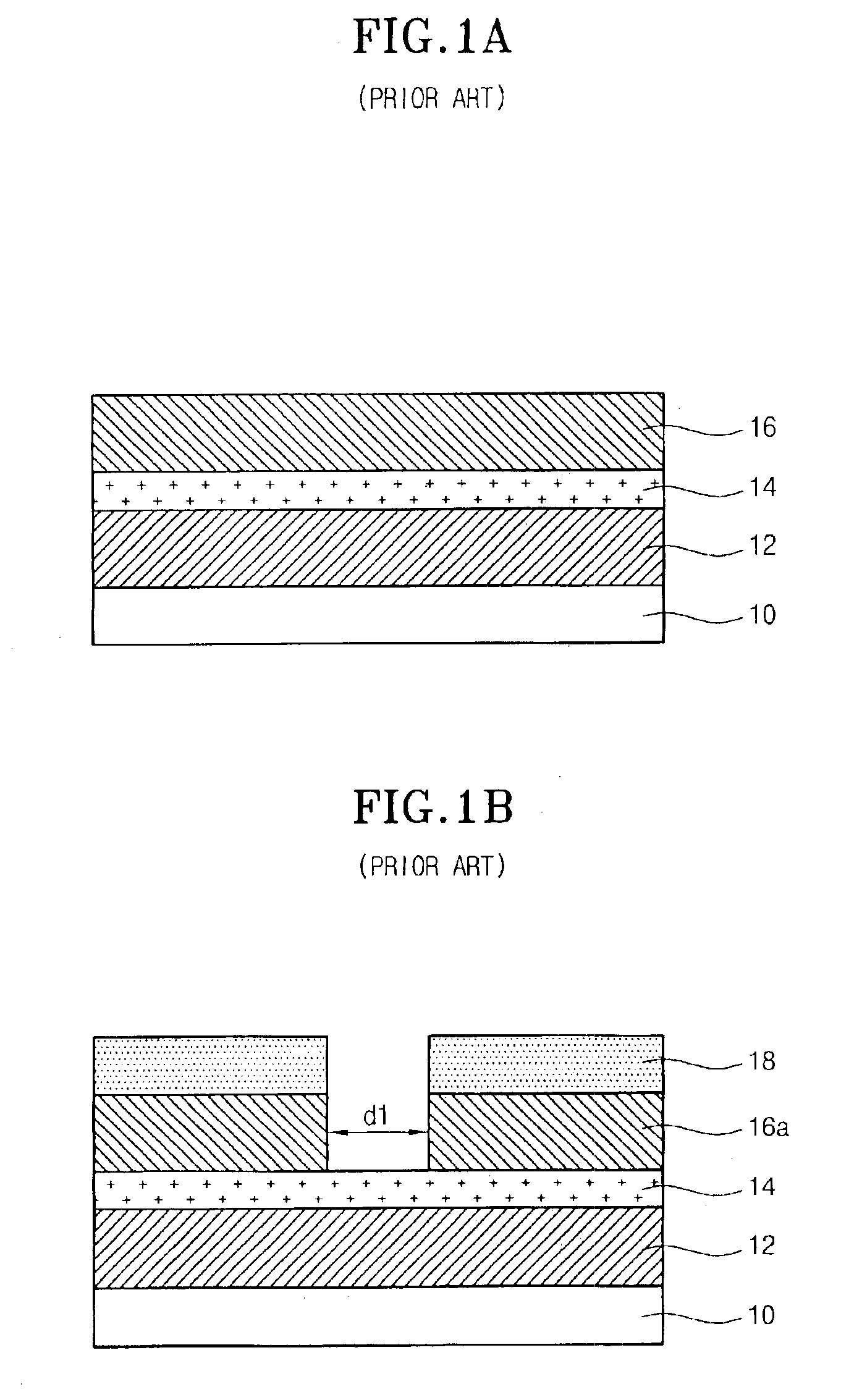

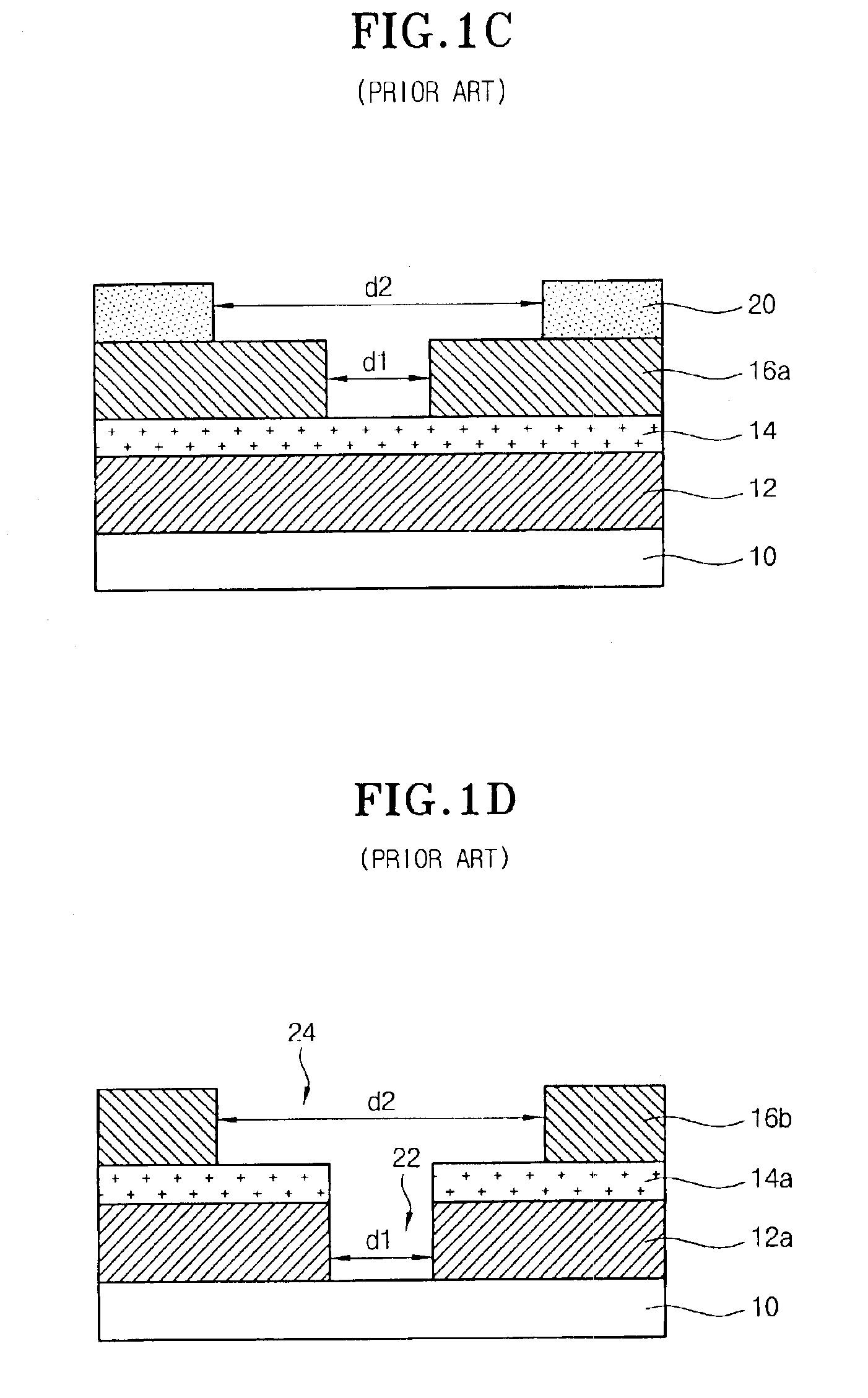

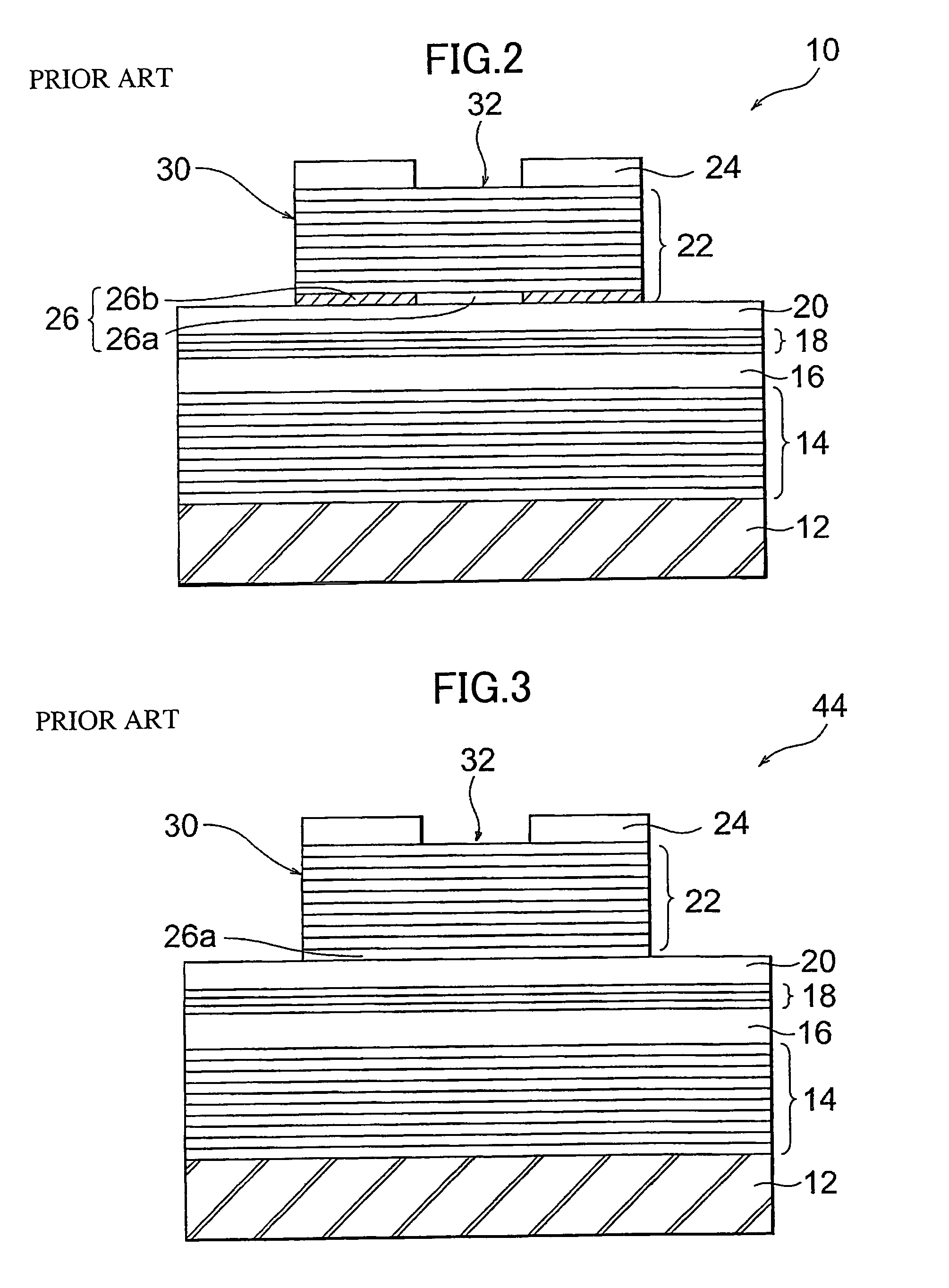

Method of producing semiconductor element and nonvolatile semiconductor memory produced by this method

InactiveUS6953966B2Avoid natural oxidationReduce defectsTransistorSolid-state devicesAutoxidationCrystallographic defect

In a first embodiment, Tetraethyl Orthosilicate Si(OC2H5)4 is used at the process temperature of 650° C.±5° C. as film forming material, to decrease crystal defects occurring during deposition. In a second embodiment, annealing is carried out in sparse oxygen gas atmosphere after deposition, to mend crystal defects that occurred during deposition. In a third embodiment, initial temperature of the CVD device is kept at about 400° C., whereby the start of natural oxidation of the deposition surface is prevented and production circumstances of the semiconductor element is not deteriorated. Then, the CVD device is heated up to CVD temperature of about 750° C. or about 650° C., to deposit oxide.

Owner:LAPIS SEMICON CO LTD

Biodegradable flame-retardant plastic film

InactiveCN104448502AImprove mechanical propertiesAchieve environmental friendlinessPullulanAntioxidant

The invention discloses a biodegradable flame-retardant plastic film, which is prepared from the following raw materials in parts by weight: 85 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of packing, 5-10 parts of pullulan, 2-4 parts of an antioxidant, 1-1.5 parts of an ultraviolet light absorber and 25-30 parts of nano flame-retardant composites. The oxygen-isolating biodegradable plastic film disclosed by the invention is prepared by blending extrusion and film blowing of mature modified starch biodegradable plastic master batches PBM and pullulan and film-grade LDPE in the market at present in the preparation method; good mechanical property of the film is ensured by using the characteristics of the LDPE; the environment friendliness of the film material is achieved by using the biodegradability of the PBM and the pullulan; the oxygen isolating property of the film material is improved by using high oxygen isolating property of the pullulan; the overall compatibility of the plastic film material is improved by using the structure similarity of starch and the pullulan as carbohydrates; and regulation and control of the oxygen isolating property, the biodegradability and the like can be achieved by controlling the blending ratio of the LDPE / PBM / Pullulan system.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Method for preparing nano-plastic by waste plastic

The invention belongs to the field of machine manufacturing, and specifically relates to a method for preparing nano-plastic by waste plastic. The method comprises the following steps: carrying out crushing, impurity removal, catalytic hydrocracking, modification, vacuum defoaming and sizing on waste plastic; adding 1-2% of a coupler, 1-2% of a compatilizer and 5-10% of inorganic filer to mix, stir and modify, wherein the coupler is amino silane, the compatilizer is maleic anhydride and the inorganic filer is superfine talcum powder; the content of the superfine talcum powder is 10-30%. After a series of treatments to thermoset waste plastic, not only are wastes recycled, but also the thermoset waste plastic is purified, thereby reducing the environmental pollution, and increasing heat resistance, wear resistance and flame resistance of reproduced plastic. The method is wide in market application.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Preparation method for regenerated nanometer flame retardant plastic

ActiveCN103483623AImprove mechanical propertiesAchieve environmental friendlinessFiberUltraviolet lights

The invention discloses a preparation method for a regenerated nanometer flame retardant plastic, wherein the regenerated nanometer flame retardant plastic is characterized by comprising the following raw materials in parts by weight: 45-60 parts of plant fiber starch, 4-6 parts of glycerinum, 40 parts of polyethylene, 20-40 parts of polylactic acid, 60-80 parts of synthetic resin, 10-15 parts of an additive, 5-8 parts of pulullan, 2-4 parts of an antioxygen agent, 1-1.5 parts of an ultraviolet light absorber and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Processing method for nano SSBR

ActiveCN103483651AGood physical and mechanical propertiesImprove heat generationAdjuvantPolymer science

The invention belongs to the field of machine manufacturing and particularly relates to a processing method for nano SSBR (Solution-polymerized Styrene Butadiene Rubber), wherein the SSBR is formed by processing a SSBR2305 base,SSBR321, new carbon black, adjuvants and a vulcanization system; the adjuvants comprise an antiager, an accelerant, a nano flame-retardant compound, nano-ZnO, A151 and Mg(OH)2; the SSBR2305 base and SSBR312 are blended, the adjuvants are added into the blended rubber and stirred for 35 min, 50 phr of new carbon black is added into the blended rubber and stirred uniformly, the blended rubber is added into the sulfur-free vulcanization system to be vulcanized for 50 min, and the temperature of the vulcanization system is 150 DEG C. The nano SSBR prepared by the method has the advantages of high production efficiency and high product percent of pass, excellent physical and mechanical properties, good low heat generation property and wide application prospect.

Owner:江苏湘园化工有限公司

A method for preparing modified nano-plastics from waste plastics

The invention belongs to the field of machine manufacturing, and specifically relates to a method for preparing nano-plastic by waste plastic. The method comprises the following steps: carrying out crushing, impurity removal, catalytic hydrocracking, modification, vacuum defoaming and sizing on waste plastic; adding 1-2% of a coupler, 1-2% of a compatilizer and 5-10% of inorganic filer to mix, stir and modify, wherein the coupler is amino silane, the compatilizer is maleic anhydride and the inorganic filer is superfine talcum powder; the content of the superfine talcum powder is 10-30%. After a series of treatments to thermoset waste plastic, not only are wastes recycled, but also the thermoset waste plastic is purified, thereby reducing the environmental pollution, and increasing heat resistance, wear resistance and flame resistance of reproduced plastic. The method is wide in market application.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

High-temperature resistant nano film and production method thereof

InactiveCN103481615AHigh surface flatnessWith coronaSynthetic resin layered productsHigh surfaceTemperature resistance

The invention relates to a high-temperature resistant nano film which comprises the following three parts in parts by weight: 40 parts of an outer layer, 20 parts of a middle layer and 40 parts of an inner layer. High-temperature resistant ingredients are added into both the inner layer and the outer layer, so that the finished product can resist to high temperature than like products. The invention further provides a production method of the film, which comprises the following steps: step 1, mixing; step 2, batching; step 3, film blowing. The film provided by the invention has the characteristics of high surface evenness, easiness for corona and compounding, high strength and high-temperature resistance and can be continuously produced by a film blowing machine in combination with batching equipment.

Owner:苏州市涵信塑业有限公司

Novel plastic film and preparation method thereof

InactiveCN109503927AImprove mechanical propertiesAchieve environmental friendlinessPullulanUltraviolet lights

The invention discloses a novel plastic film. The novel plastic film comprises the following raw material components in parts by weight: 100 parts of polyethylene, 20-30 parts of polylactic acid, 65-80 parts of a PBM degradable material, 10-15 parts of filler, 5-10 parts of lignocellulose, 3-5 parts of an anti-oxidant, 1-1.5 parts of an ultraviolet light absorber, and 25-30 parts of a nano flame retardant compound. The invention further provides a preparation method for the plastic film. According to the method, a mature modified starch degradable plastic master batch PBM in the current marketis selected to be mixed with Pullulan polysaccharide and film-level LDPE for extruding and film-blowing, with the features of the LDPE, good mechanical properties of the film is ensured; with biodegradability of the PBM and the Pullulan, environment friendliness of the film material is realized; with high oxygen insulation of the Pullulan, the oxygen insulation of the film material is improved; with similarity of the starch and the Pullulan as carbohydrates in structure, entire compatibility of the plastic film material is improved; and through controlling a blending matching ratio of a LDPE / PBM / Pullulan system, the control on the oxygen insulation and the biodegradability and the like is realized.

Owner:嘉兴市竹林塑料泡沫有限公司

High-strength nano-film and production method thereof

InactiveCN103496238AHigh surface flatnessWith coronaSynthetic resin layered productsHigh intensityHigh surface

The invention relates to a high-strength nano-film. The high-strength nano-film comprises three parts, namely an outer layer, a middle layer and an inner layer, wherein the outer layer accounts for 40% by weight, the middle layer accounts for 20% by weight, and the inner layer accounts for 40% by weight; the variety and amount of adjuvant added to the outer and inner layers are determined through tests, thus the strength of a product can be improved as much as possible on the basis that the original properties of the product are not damaged. The invention further provides a production method of the film, which comprises the steps of (1) mixing materials; (2) proportioning the materials; (3) carrying out film blowing. The film provided by the invention has the characteristics of high surface flatness, easiness in being subjected to corona, easiness in cladding and high strength, and continuous production can be realized through a film blowing machine by combining material proportioning equipment.

Owner:苏州市涵信塑业有限公司

Preparation method of plastic film

The invention relates to the technical field of plastic films, in particular to a preparation method of a plastic film. The plastic film comprises acrylic master batches, PBT master batches, an ASA antistatic agent, a light stabilizer, a plasticizer, a reinforcer, an ultraviolet light absorber and a nano flame-retardant complexing agent. The plastic film is prepared from the following components in parts by weight: 100 to 250 parts of the acrylic master batches, 100 to 250 parts of the PBT master batches, 50 to 80 parts of the ASA antistatic agent, 20 to 30 parts of the light stabilizer, 35 to 40 parts of the plasticizer, 15 to 20 parts of the reinforcer, 8 to 10 parts of the ultraviolet light absorber and 20 to 25 parts of the nano flame-retardant complexing agent. The method can effectively solve the problem that the existing plastic film is relatively poor in aesthetic property.

Owner:东阳市诰源闪光材料有限公司

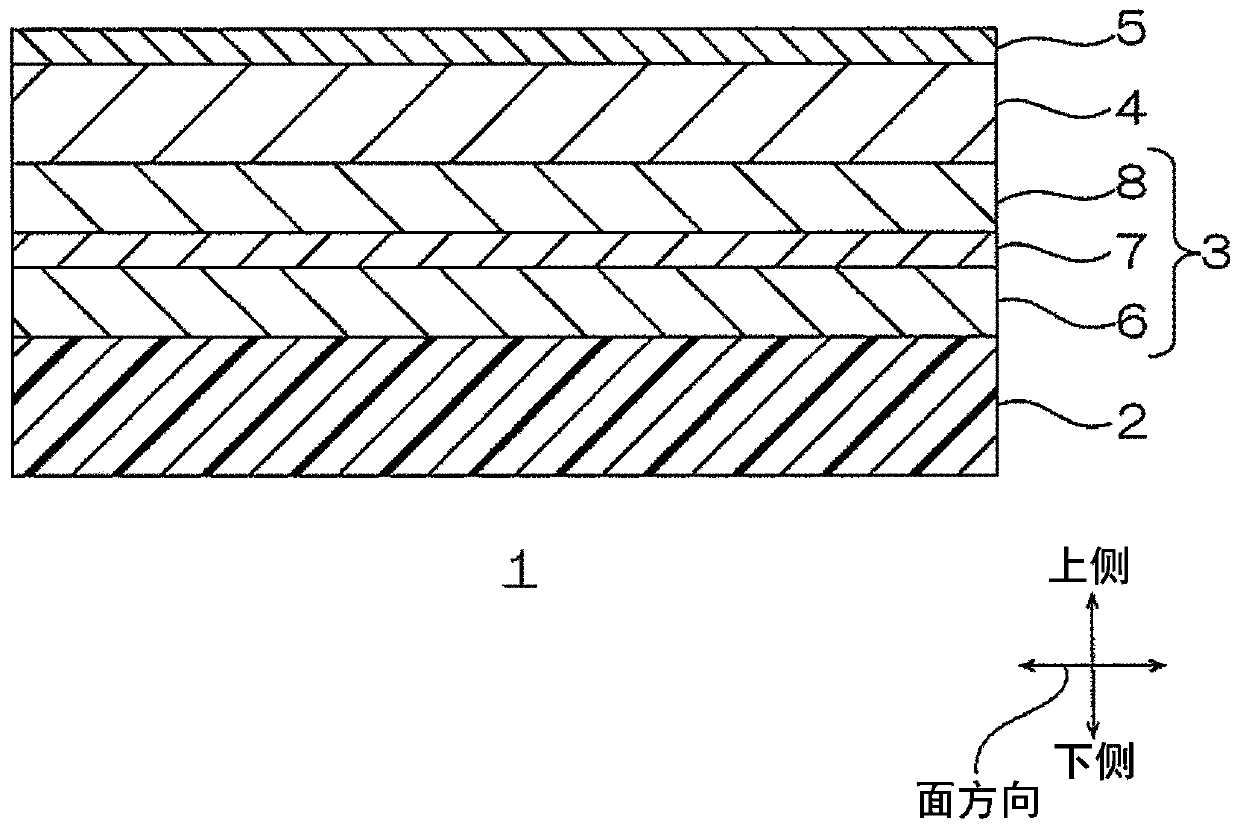

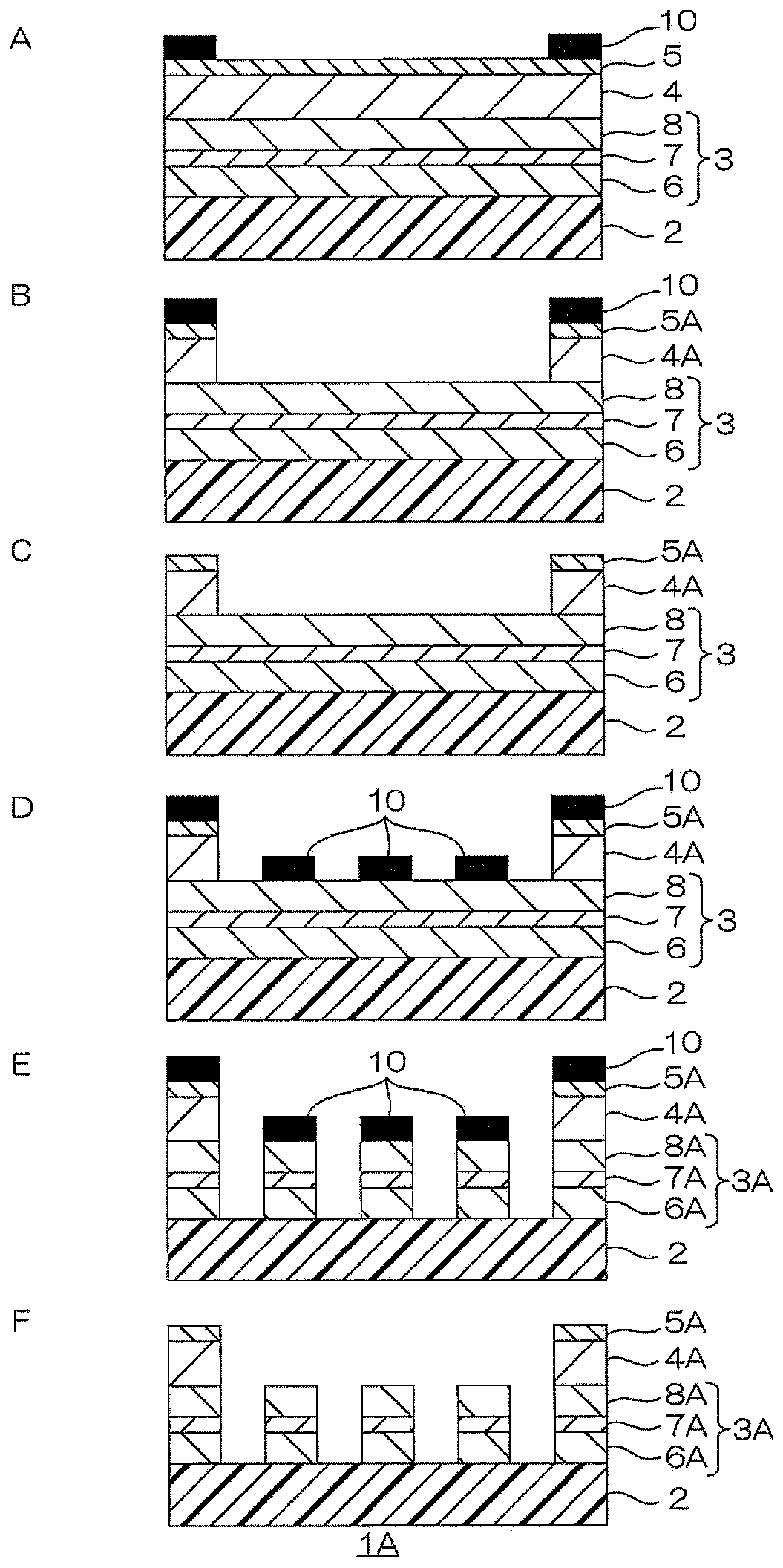

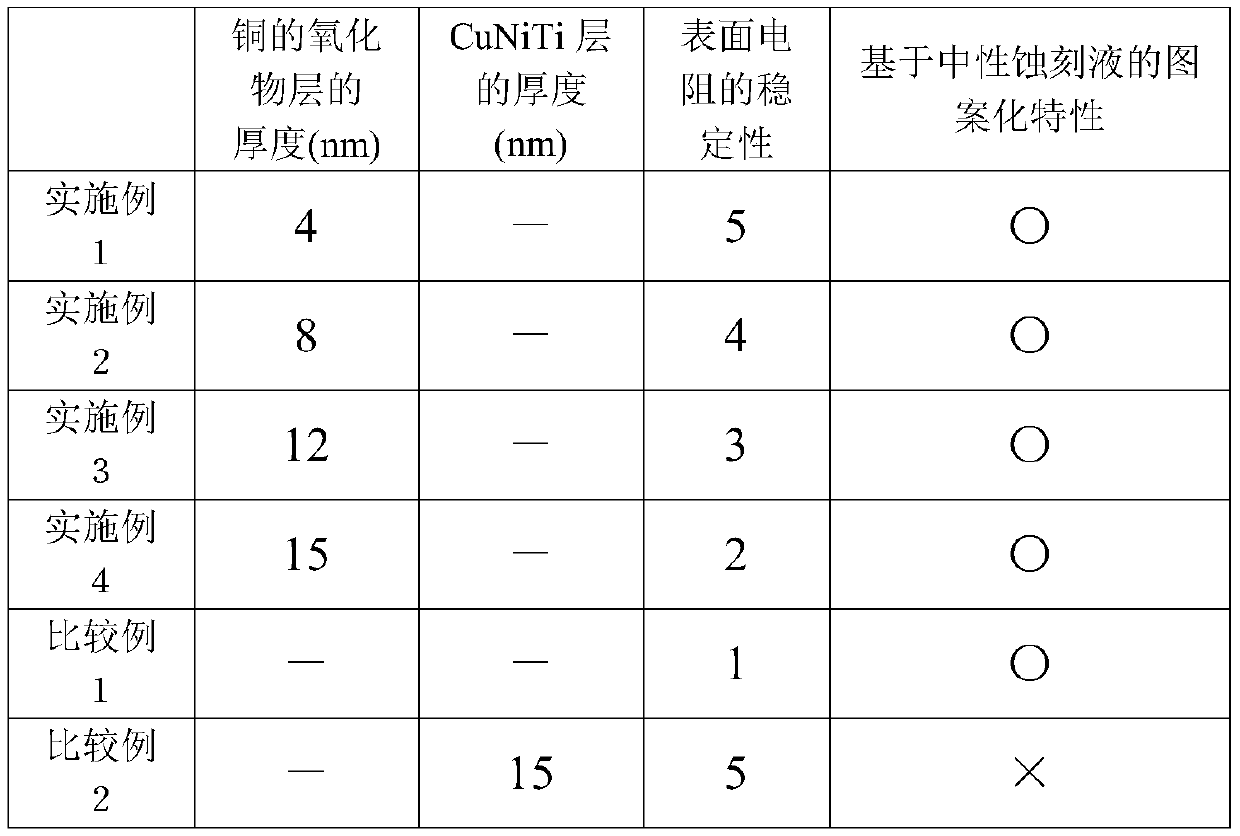

A conductive film and a patterning method thereof

PendingCN111240507AImprove conductivityAvoid natural oxidationConductive layers on insulating-supportsConductive materialThin membraneCopper oxide

The invention relates to a conductive film and a patterning method thereof. Provided are: a conductive film which has excellent copper layer stability, is capable of easily patterning a copper layer,and is capable of suppressing damage to a metal layer within a transparent conductive layer; and a patterning method therefor. A conductive film (1) is provided with: a transparent substrate (2); a transparent conductive layer (3) that is disposed on the upper side of the transparent substrate (2) and is provided with a first inorganic oxide layer (6), a metal layer (7), and a second inorganic oxide layer (8) in this order; a copper layer (4) disposed on the upper side of the transparent conductive layer (3); and a copper oxide layer (5) disposed on the upper side of the copper layer (4).

Owner:NITTO DENKO CORP

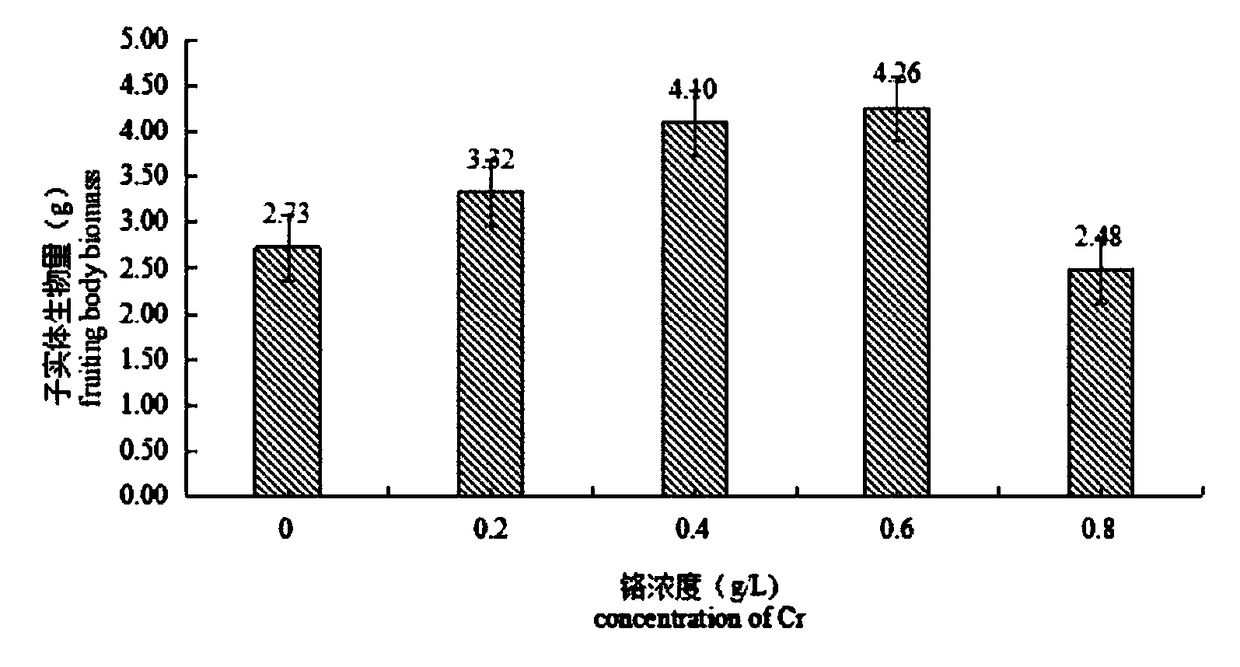

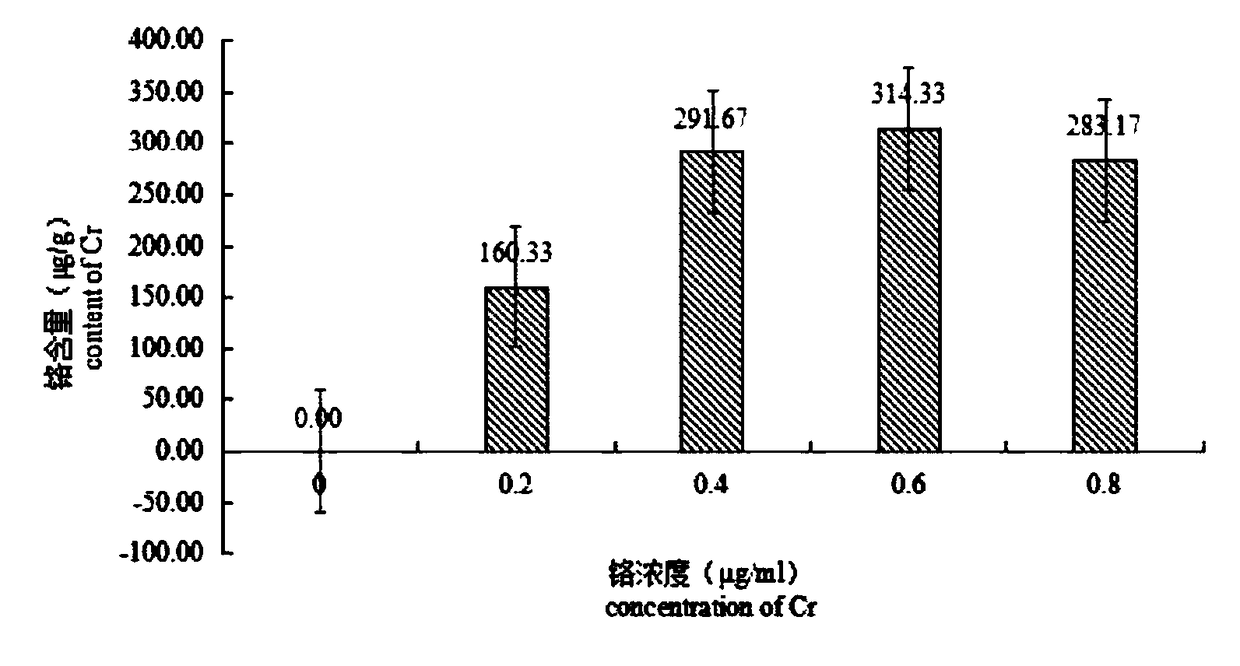

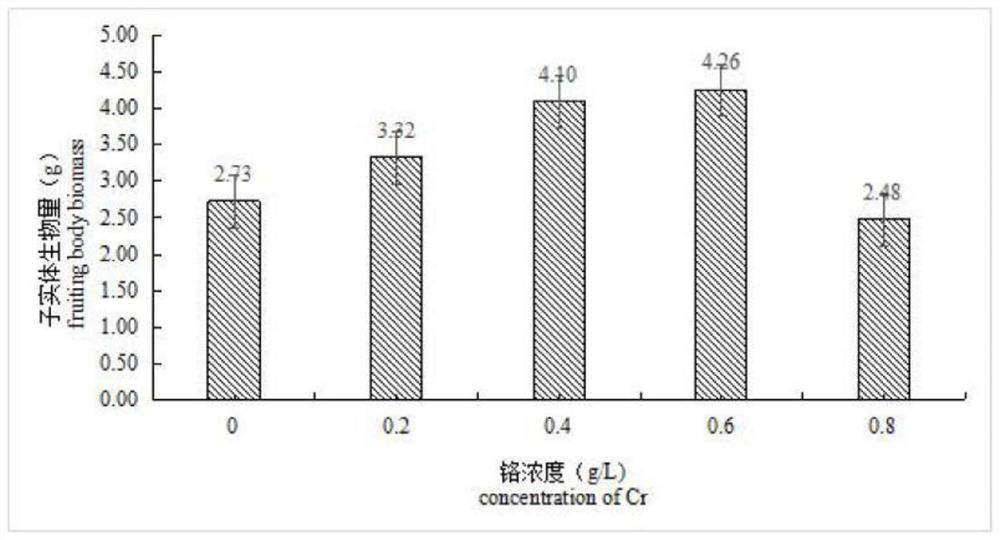

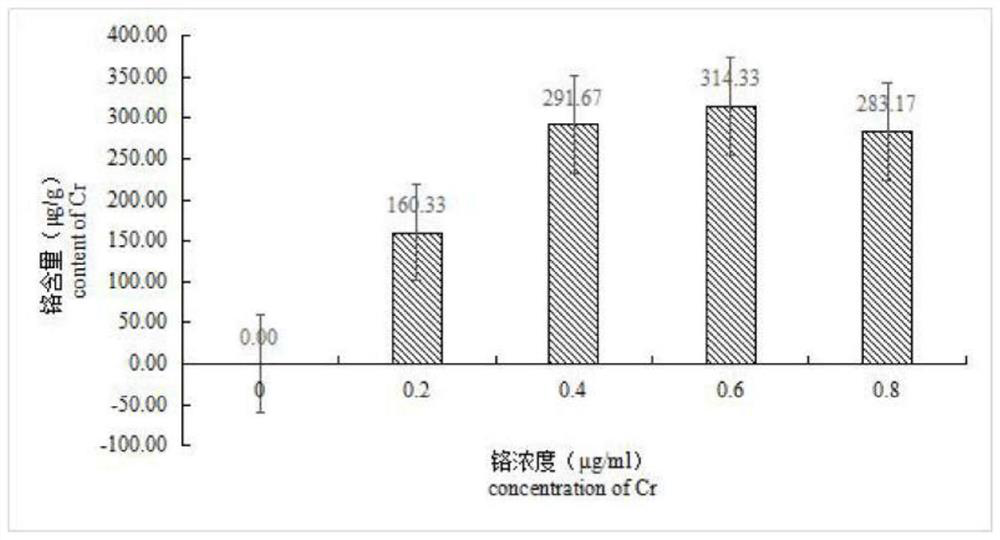

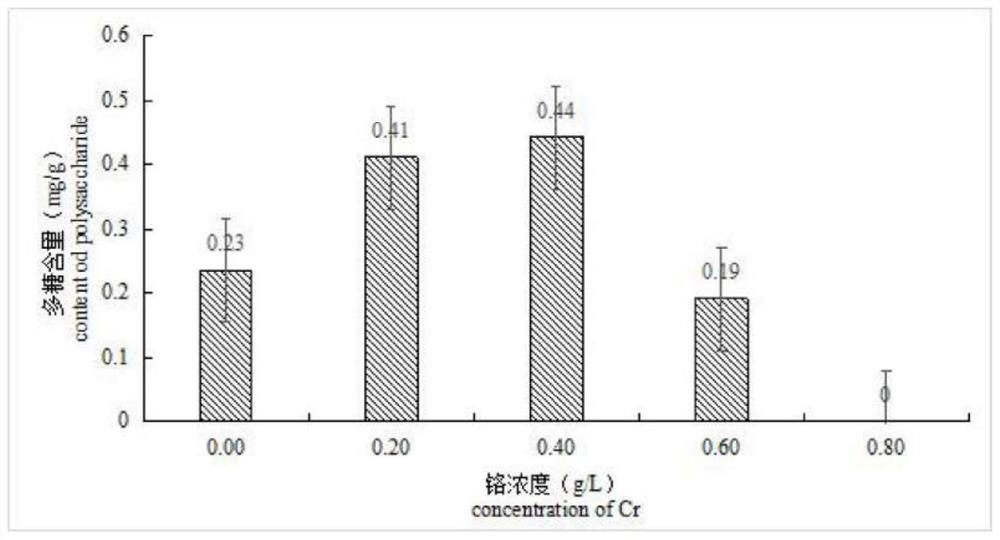

Cordyceps militaris culture method

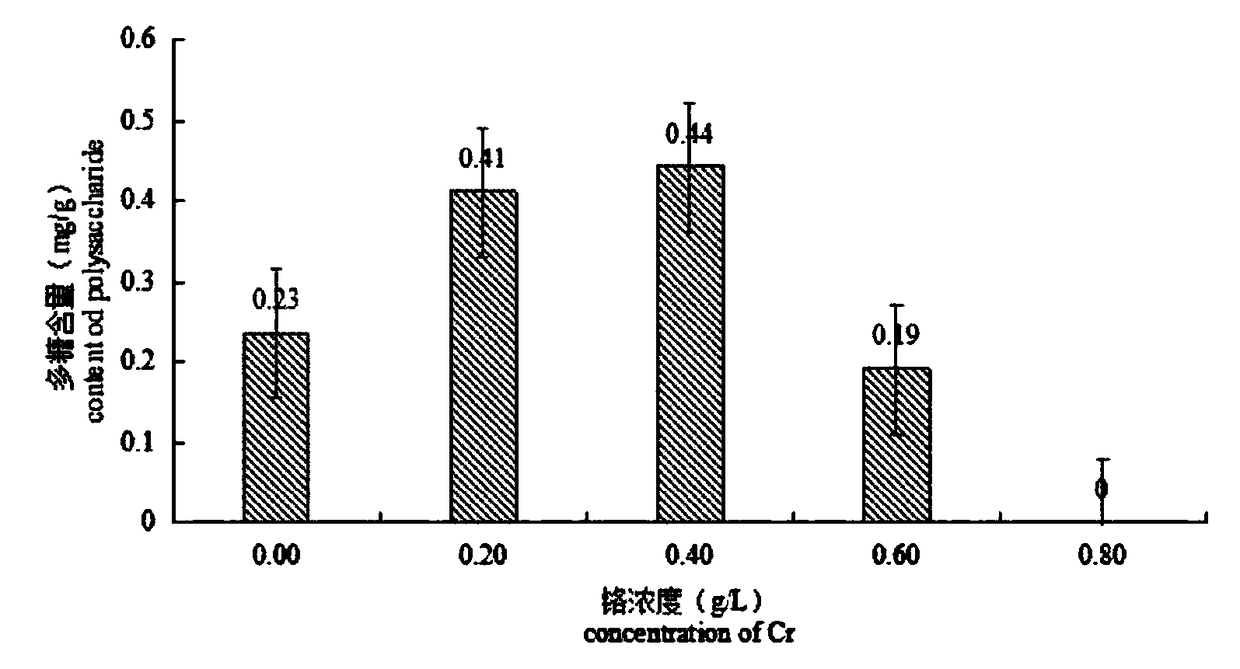

ActiveCN108812051AAvoid natural oxidationReduce harmCultivating equipmentsMushroom cultivationHuman bodyBiology

The invention discloses a cordyceps militaris culture method. According to the method, a proper culture medium and a proper culture condition are selected, and Cr<3+> of an inorganic state is converted into organic chromium through the enrichment effect of mycelia to Cr<3+>, so that the inorganic Cr<3+> is effectively prevented from being naturally oxidized to Cr<6+>, and the damage to human bodies caused by direct absorption of the metal Cr<3+> by the human bodies is reduced. The study also finds that the chromium in the cordyceps militaris also promotes the conversion of polysaccharide in the mycelia, and meanwhile, the pancreatic function of diabetic patients can be improved through the combined action of the organic chromium and cordyceps polysaccharide, so that the use of artificial insulin is reduced.

Owner:LUDONG UNIVERSITY

Method of forming copper wire on semiconductor device

InactiveUS6878617B2Avoid natural oxidationSemiconductor/solid-state device manufacturingSemiconductor devicesCopper wireProtection layer

Disclosed is a method of forming a copper wire on a semiconductor device capable of preventing the natural oxidation of copper. The method comprises the steps of: forming an insulation film pattern having vias and trenches on a semiconductor substrate; forming a copper wire by filling up the vias and the trenches with copper; successively forming a capping layer and a protective layer on the copper wire and the insulation film pattern; exposing the copper wire by selectively removing the capping layer and the protective layer; and forming an oxidation-prevention layer on the copper wire. According to the present invention, the natural oxidation of copper is avoided by selectively depositing aluminum on a copper wire pad, and therefore a dependable evaluation is possible from tests of reliability in a high temperature. Furthermore, since aluminum has a lower contact resistance compared with copper, dependable test results are obtained during tests of electrical characteristics.

Owner:CHUNG CHENG HLDG LLC

A kind of polyurethane flame retardant nano coating

InactiveCN103540257BGood synergyLow cost of industrializationFireproof paintsPolyurea/polyurethane coatingsEpoxyGraphite

The invention discloses a polyurethane flame-retardant nano paint. The polyurethane flame-retardant nano paint comprises following raw materials, by weight, 10 to 20 parts of graphite, 5 to 15 parts of molybdenum disulfide, 5 to 10 parts of aluminium oxide, 2 to 6 parts of xylene, 2 to 6 parts of polyurethane modified epoxy resin, 2 to 6 parts of a curing agent, 12 to 15 parts of a bonding agent, 1 to 4 parts of an auxiliary agent, 15 to 20 parts of purified water, and the like.

Owner:岳阳圣吉力高科技涂料有限公司

A kind of manufacturing process of crystalline nano pet plastic

ActiveCN103540108BGood physical and mechanical propertiesImprove insulation performanceShock resistanceMass content

The invention discloses a production process for crystallized nano PET (Polythylene Terephthalate) plastic. The production process comprises the following steps: (1) preparing raw materials; (2) blending: mixing terephthalic acid prepared in the step (1) with ethylene glycol (EG), wherein the mass ratio of the terephthalic acid to the ethylene glycol (EG) is 1 to (1.5-2), adding a CaCO2 organic filling agent into a mixed solution, wherein the mass content of the filling agent is 3%-5% (3) carrying out an exchange reaction; (4) carrying out a condensation polymerization reaction; (5) enhancing and modifying; and (6) crystallizing and separating. According to the production process, after the raw materials are subjected to a series of treatment, PET rubber not only has a good physical and mechanical performance, good electrical insulating property, good creep resistance, good fatigue resistance, good wear resistance and good size stability in a wide temperature range, but also has a rapid crystallization rate and is easy to mold and process; the PET rubber has the characteristics of strong shock resistance and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

A high flame retardant polyvinyl chloride plastic

A nanometer polyvinyl chloride plastic is characterized by comprises the following raw material compositions in parts by weight: 80-90 parts of polyvinyl chloride, 30-60 parts of a flame retardant plastic additive, 5-6 parts of barium stearate, 2-4 parts of calcium stearate, 4-5 parts of a brominated flame retardant, 10-15 parts of an auxiliary agent, wherein the flame retardant plastic additive comprises the following compositions in parts by weight: 25-30 parts of antimony trioxide, 15-20 parts of zinc borate, 60-80 parts of phosphotriester, 10-20 parts of tetrabromobutane, 1-5 parts of epoxy chloropropane and the like.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

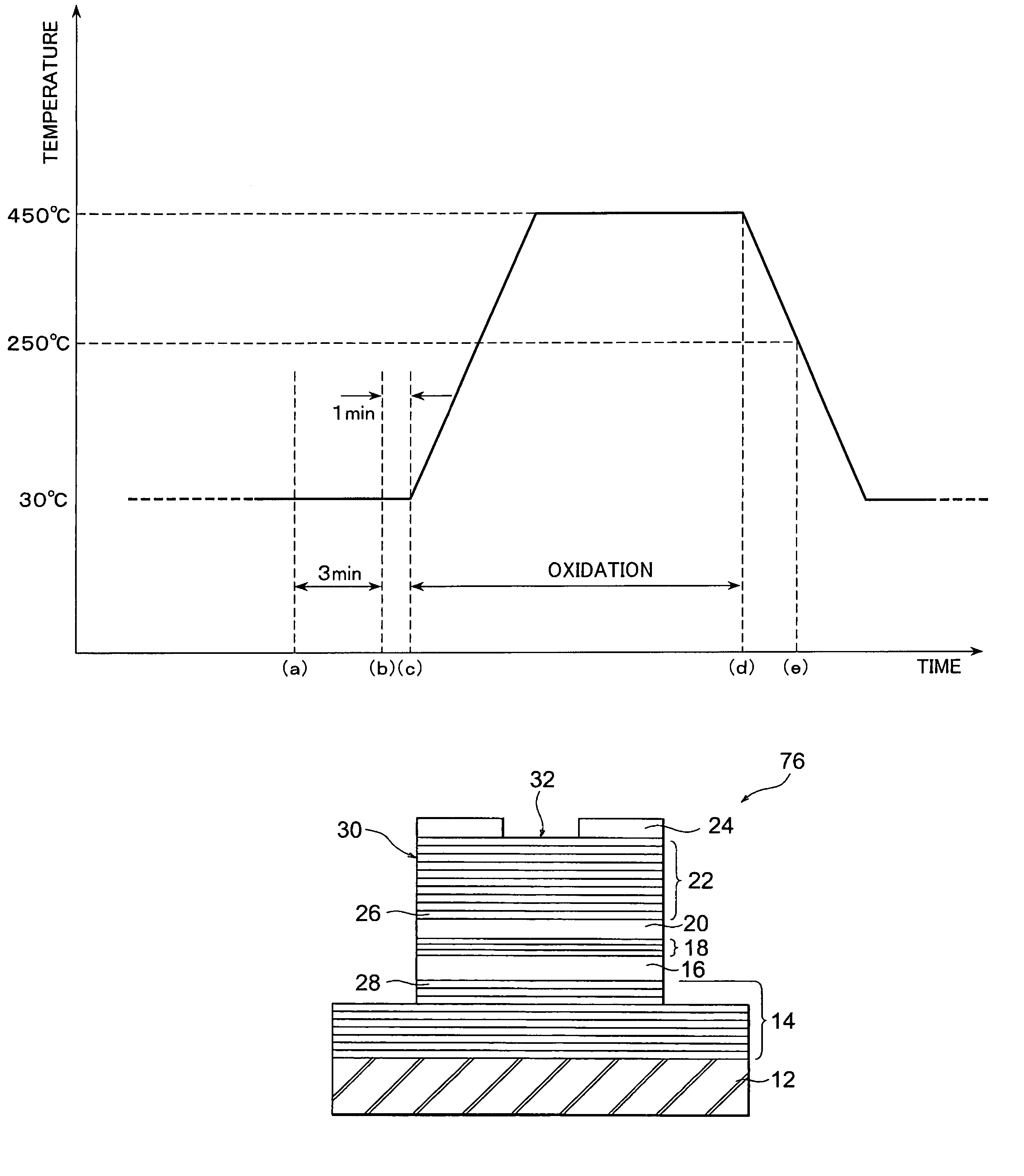

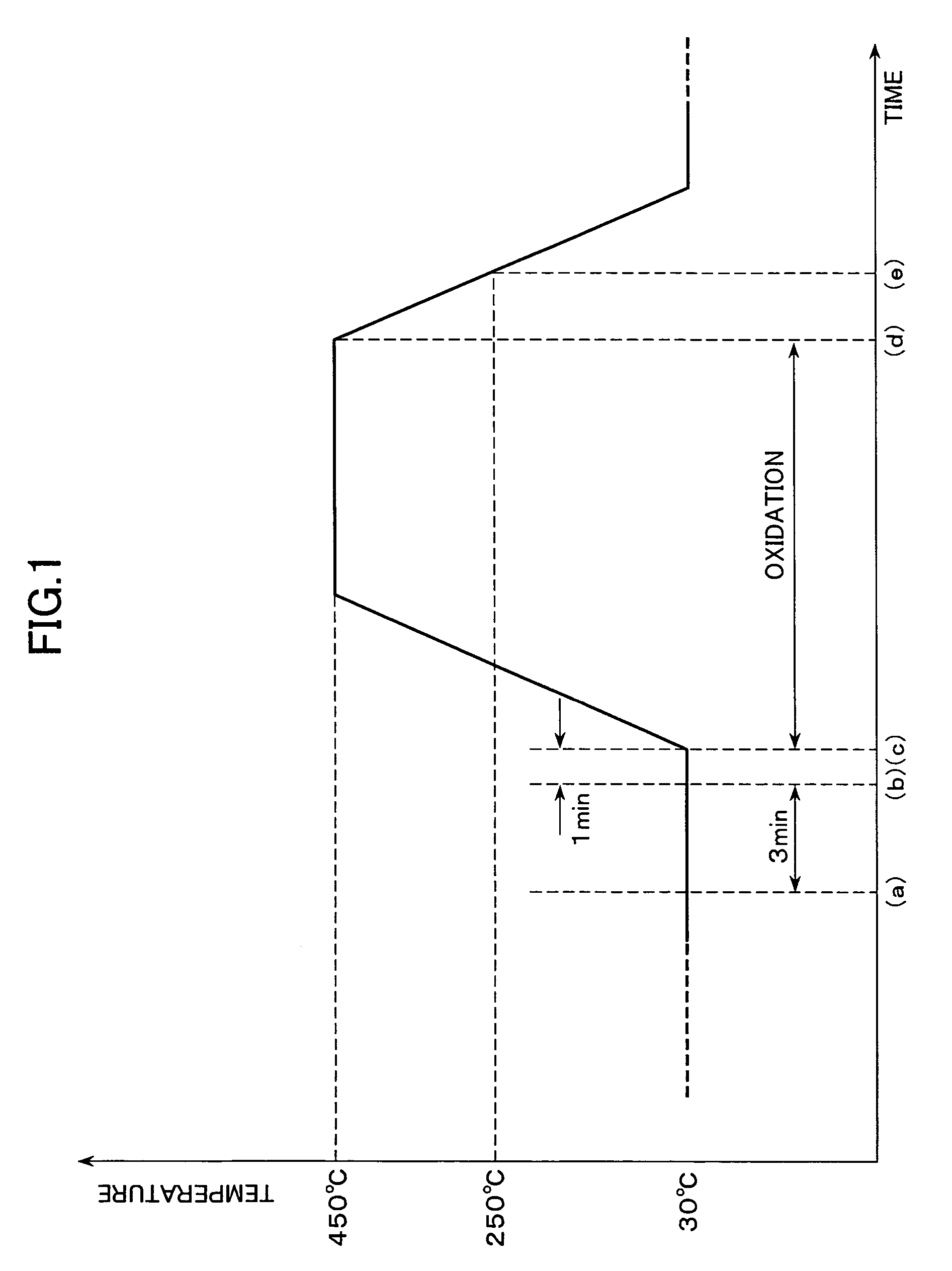

Steam oxidation method

InactiveUS7001851B2Increase temperatureAvoid natural oxidationSemiconductor/solid-state device manufacturingSolid state diffusion coatingProduct gasEngineering

This invention provides a steam oxidation method of a matter to be oxidized with proper controllability and reproducibility. It is provided a steam oxidation method, where a semiconductor substrate (a matter to be oxidized) is housed in a steam oxidation reactor and is subjected to: a first step of supplying N2 gas to the reactor housing the semiconductor substrate and substituting the inside of the reactor with N2 gas; a second step of stopping supply of the N2 gas and supplying a steam-accompanied N2 gas, in which the N2 gas is accompanied with steam, to the reactor; a third step of increasing a temperature of the semiconductor substrate to 450° C. (a steam oxidation temperature) while supplying the steam-accompanied N2 gas; and a fourth step of holding the semiconductor substrate for a predetermined time at 450° C.

Owner:SONY CORP

A kind of method that utilizes waste to prepare nano flame retardant coating

The invention discloses a method of preparing a nano fire retardant coating by using wastes. The method is characterized by comprising the following technical steps: (1) selecting the following raw materials in percentage by weight: 65% of polystyrene foam, phenolic foam plastic, waste rubber and nitryl fibers, 15% of industrial alcohol, coal tar, acetone and a hydrosolvent, 15% of pigments and fillers, and 5% of a wetting dispersing agent, a defoamer, a delustering agent and a plasticizer assistant; (2) melting and extracting; (3) pre-extracting; (4) dispersing; (5) reconciling and modulating colors; (6) filtering; and (7) packaging. The method provided by the invention is reasonable and concise in process, the process flow is greatly shortened, the raw material of the coating is wide in source, and the method belongs to waste recycle, so that the production cost is lowered. Meanwhile, coatings with various functions are conveniently prepared according to raw material ratio, so that the method is applicable to demand of production process. The inventory rating and proportioning are accurate with less inventory rating, the product quality is ensured, and the yield of enterprises is effectively improved.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

A water-based nano-coating

InactiveCN103555029BMutual synergy is goodLow cost of industrializationFireproof paintsWater dispersibleALLYL SUCROSE

The invention discloses an aqueous nano-coating. The aqueous nano-coating is characterized by being prepared from a component A and a component B, wherein the formula of the component A is as follows: 60-80 parts of hydroxyl polyacrylate dispersoid, 0.2-0.3 parts of leveling wetting agent, 12-25 parts of polyacrylic acid, and 20-30 parts of polyisocyanates; the component B comprises 6-9 parts of polyisocyanate curing agent; the aqueous nano-coating is prepared through the following steps: adding the component A to a container according to the formula, stirring at the middle speed, sequentially adding deionized water, the leveling wetting agent, a cosolvent, a defoaming agent and a thickening agent, dispersing for 20-30min at high speed, adding the water-dispersibility polyisocyanate curing agent according to the certain proportion, and fully stirring to obtain the aqueous nano-coating.

Owner:HANGZHOU FUYANG FUCHUN COATING&DECORATING

A kind of Cordyceps militaris cultivation method

ActiveCN108812051BAvoid natural oxidationReduce harmCultivating equipmentsMushroom cultivationPANCREATIC FUNCTIONSCordyceps militaris

The invention discloses a cordyceps militaris culture method. According to the method, a proper culture medium and a proper culture condition are selected, and Cr<3+> of an inorganic state is converted into organic chromium through the enrichment effect of mycelia to Cr<3+>, so that the inorganic Cr<3+> is effectively prevented from being naturally oxidized to Cr<6+>, and the damage to human bodies caused by direct absorption of the metal Cr<3+> by the human bodies is reduced. The study also finds that the chromium in the cordyceps militaris also promotes the conversion of polysaccharide in the mycelia, and meanwhile, the pancreatic function of diabetic patients can be improved through the combined action of the organic chromium and cordyceps polysaccharide, so that the use of artificial insulin is reduced.

Owner:LUDONG UNIVERSITY

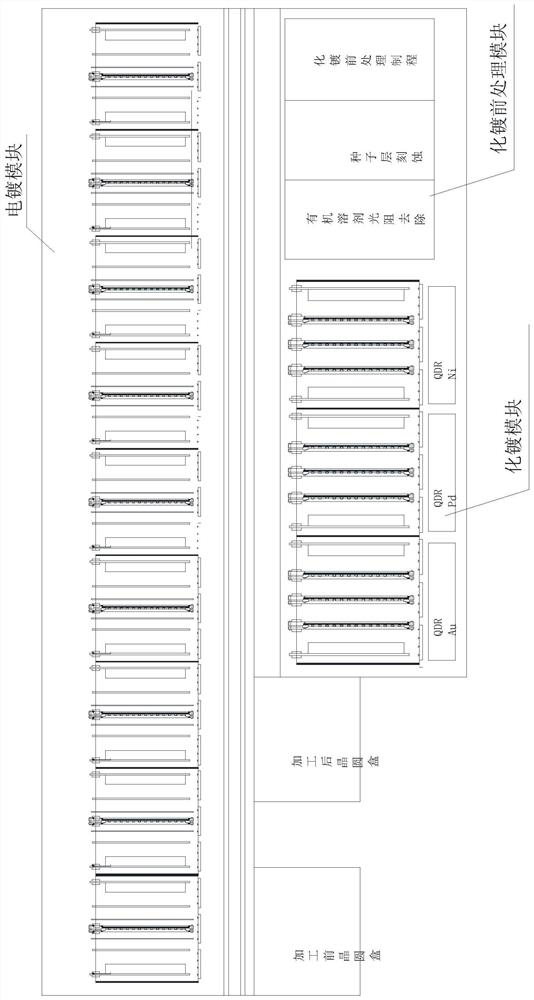

Electroplating-chemical plating integrated process for ultra-thin wafer

PendingCN112259493ABest process efficiencyReduced Risk of FragmentationSolid-state devicesSemiconductor/solid-state device manufacturingChemical platingEtching

The invention discloses an electroplating-chemical plating integrated process for an ultra-thin wafer. The process comprises the following steps: bonding an ultra-thin wafer of a glass carrier plate or an ultra-thin wafer with a gentle slope-shaped edge, jointing the ultra-thin wafer with a power supply contact point of an electroplating bath, starting an electroplating process, fixing the ultra-thin wafer into a rotary spraying cavity by an annular clamp after electroplating is finished, removing a photoresist, conducting a pretreatment process of seed layer etching and chemical plating, allowing the annular clamp to continue to fix the ultrathin wafer, enabling the clamped ultrathin wafer to enter a chemical plating tank, carrying out various metallization plating processes separately, cleaning and drying the annular clamp and the ultrathin wafer, and separating the annular clamp from the ultrathin wafer. According to the electroplating-chemical plating integrated process for the ultrathin wafer, horizontal / vertical matching, rotating and soaking matching of process equipment can be achieved to achieve optimal process efficiency, the ultrathin wafer is continuously conveyed and positioned in different types of reaction tanks to complete each process, and natural oxidation or pollution during intervals is avoided.

Owner:绍兴同芯成集成电路有限公司

Production technique of conductive nano flame-retardant rubber sheet

ActiveCN103525091AImprove mechanical propertiesReduce defective rateFlat articlesPolymer scienceStearic acid

The invention discloses a production technique of a conductive nano flame-retardant rubber sheet, which comprises the following steps: A. proportioning: mixing 65 parts by mass of silicone rubber, 35 parts by mass of copper powder, 10 parts by mass of zinc oxide, 2 parts by mass of sulfur, 5 parts by mass of stearic acid, 2.5 parts by mass of anti-aging agent and 2.5 parts by mass of anti-scorching agent together to form a conductive rubber mixture, wherein the temperature of the conductive rubber mixture is controlled at 50-90 DEG C; B. cutting; C. calendering; D. stretching; E. coating; F. heating and cooling; and G. carrying out die cutting. According to the production technique, the multiple raw materials are subjected to cutting, calendering, stretching, coating, heating, cooling, die cutting and the like to form the conductive rubber sheet while controlling the thickness at 1-3mm, so that the die cutting efficiency is enhanced, and the defective rate of the finished product is lower; and the whole production technique has the advantages of high degree of automation, low labor intensity and high production efficiency.

Owner:江苏湘园化工有限公司

Biodegradable flame resistance material and preparation method thereof

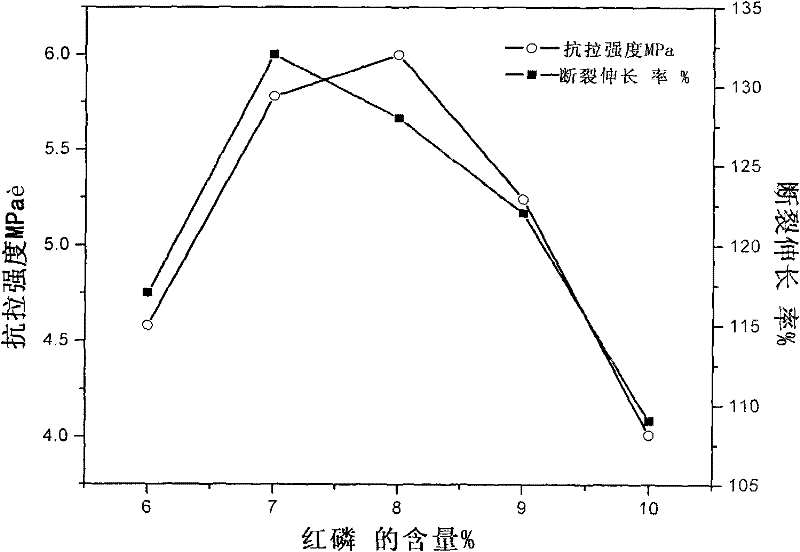

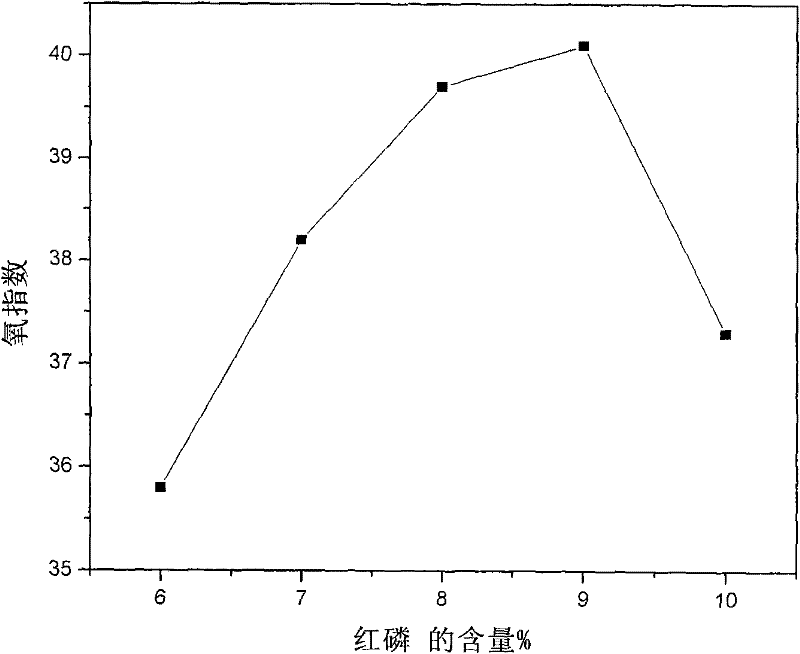

InactiveCN101665588BImprove flame retardant performanceAvoid natural oxidationCoatingsAutoxidationPolymer science

The invention provides a biodegradable flame resistance material. The flame resistance material is characterized in that starch and chitosan are used as main components, red phosphorus is used as flame resistance additive, starch / chitosan can provides a great deal of carbon, chitosan contains nitrogen element, when acid source is added in red phosphorus, the flame resistance of the biodegradable material is effectively improved and the usable range of the biodegradable composite material is expanded so that the biodegradable composite material has wider application area; the preparation method adopts solution method, ultrasonic dispersion and mechanical high-speed agitation so that red phosphorus used as fire retardant can be dispersed in solution on nano-scale and the autoxidation of thecomposite material can be effectively avoided, thus the composite material can have better mechanical performance.

Owner:余姚市环华电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com