Biodegradable flame resistance material and preparation method thereof

A kind of flame retardant material, biological technology, applied in the direction of coating, etc., can solve the problems of biodegradable plastic flammability, safety and effective application, and achieve the effect of avoiding natural oxidation, improving flame retardant performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

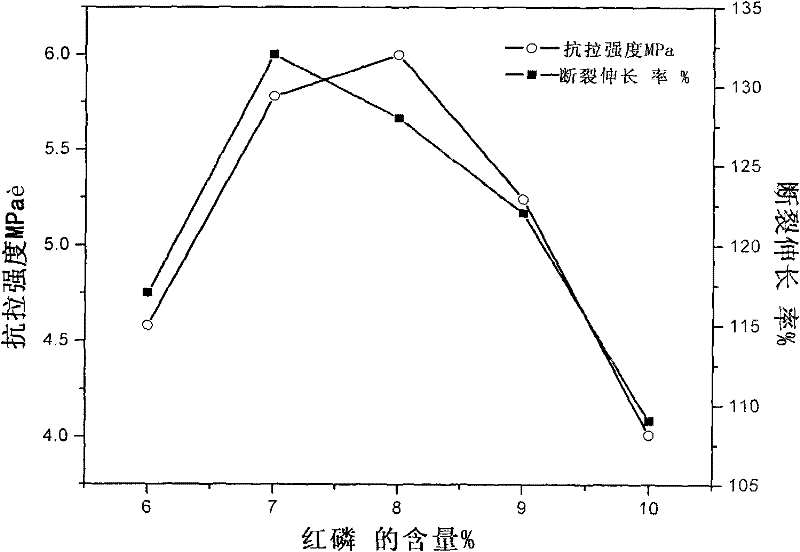

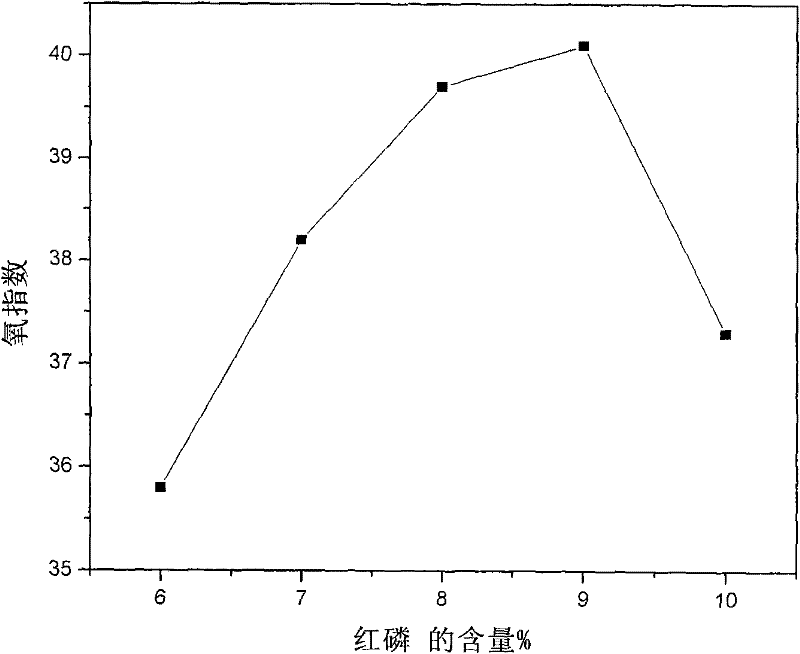

[0024] Embodiment 1, in three-necked round bottom flasks, chitosan is dissolved in 2% acetic acid (w / v) and configures 2% chitosan solution, adds the starch of chitosan quality 1.5, stirs; Add starch / Red phosphorus with 6% of the total amount of chitosan, and 35% glycerin of the total amount of starch / chitosan and deionized water with 25 times the total amount of chitosan starch were added at the same time, stirred and mixed evenly, and dispersed with 600W power ultrasonic wave for 20min, Heat to 90°C with a constant temperature heating device, and stir with a mechanical stirrer (1200r / min) for 50 minutes. Pour it into a pre-prepared mold, put it into a constant temperature drying oven, dry it at 50°C for 24 hours, and then form a film, peel off the film, and store it in a humidity box with a relative humidity of 50% for 24 hours at room temperature. Use a hot press and a cold press to vulcanize at about 120°C, make tablets, and then use conventional injection molding technol...

Embodiment 2

[0026] Embodiment 2, in three-necked round bottom flasks, chitosan is dissolved in 1.5% acetic acid (w / v) and is configured into 2% chitosan solution, adds the starch that chitosan quality 2.0 times, stirs; Add Red phosphorus with 7% of the total amount of starch / chitosan, while adding 40% of the total amount of starch / chitosan plasticizer glycerin and deionized water 30 times the total amount of chitosan / starch, stir and mix evenly, use 600W The power is ultrasonically dispersed for 20 minutes, heated to 90°C with a constant temperature heating device, and stirred with a mechanical stirrer (1200r / min) for 50 minutes. Pour it into a pre-prepared mold, put it into a constant temperature drying oven, dry it at 50°C for 24 hours, and then form a film, peel off the film, and store it in a humidity box with a relative humidity (RH) of 50% for 24 hours at room temperature. Use a hot press and a cold press to vulcanize at about 120°C, make tablets, and then use conventional injection...

Embodiment 3

[0028] Embodiment 3, in three-necked round bottom flask, chitosan is dissolved in 1.5% acetic acid (w / v) and is configured into 2% chitosan solution, adds the starch that chitosan quality 4.0 times, stirs; Add Red phosphorus with 8% of the total amount of starch / chitosan, add glycerin with 50% of the total amount of chitosan starch and deionized water with 40 times the total amount of chitosan starch at the same time, stir and mix evenly; use 600W power ultrasonic dispersion for 20min, Heat to 90°C with a constant temperature heating device, and stir with a mechanical stirrer (1200r / min) for 50 minutes. Pour it into a pre-prepared mold, put it into a constant temperature drying oven, and dry it at 50°C for 24 hours to form a film, peel off the film, and store it at room temperature in a humidity box with a relative humidity (RH) of 50%. Use a hot press and a cold press to vulcanize at about 120°C, make tablets, and then use conventional injection molding technology to inject m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com