Patents

Literature

122results about How to "Easy to disperse evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

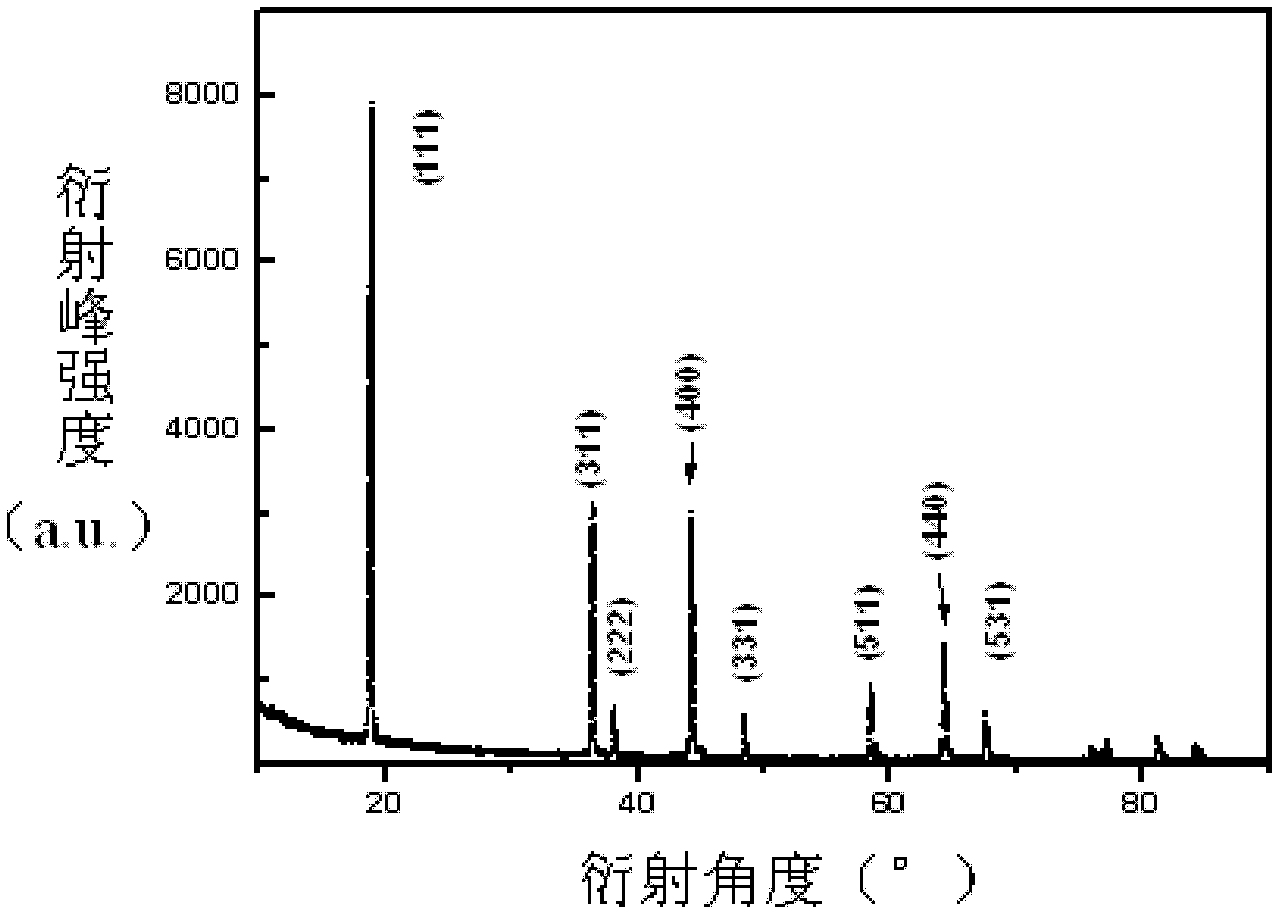

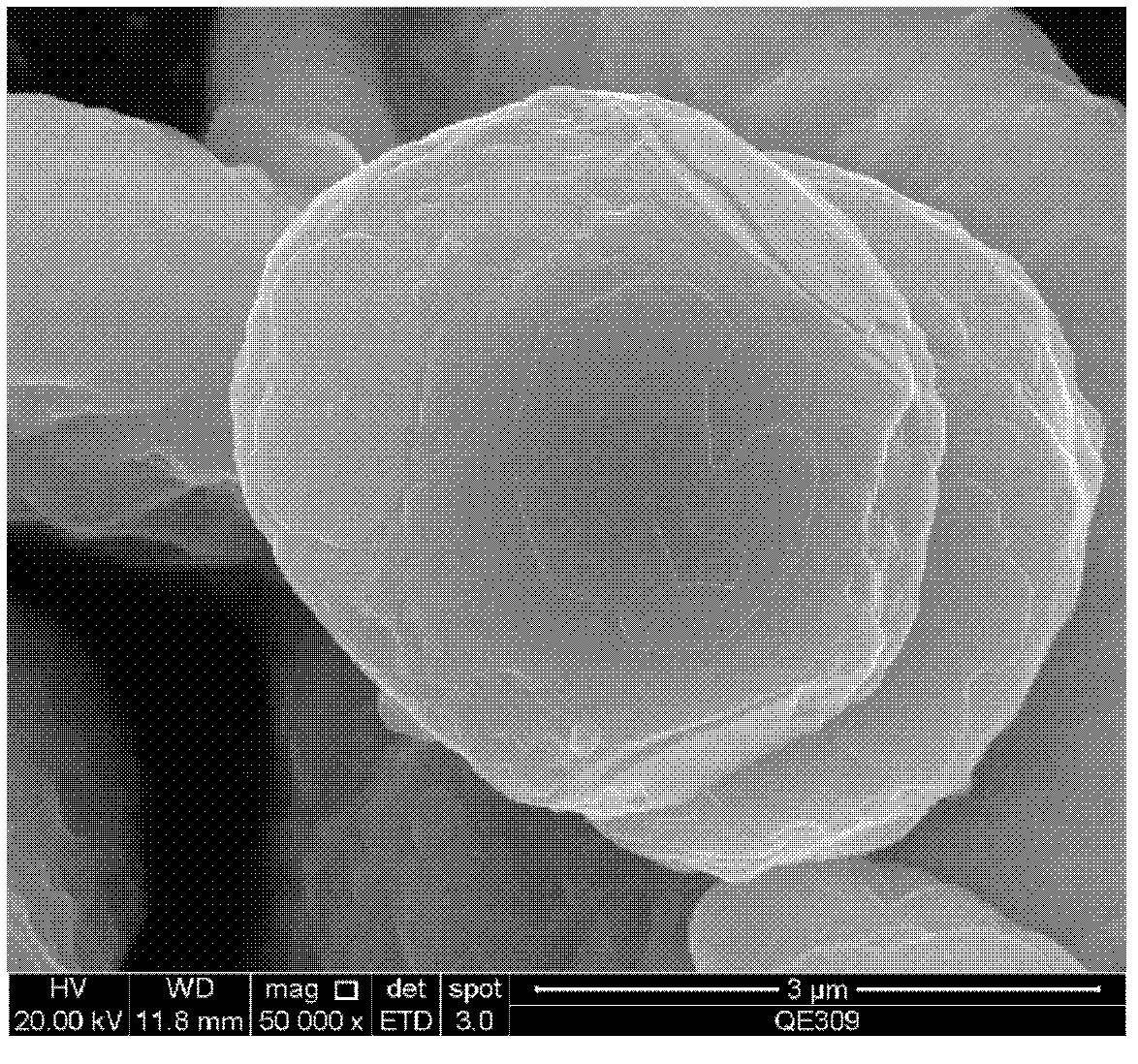

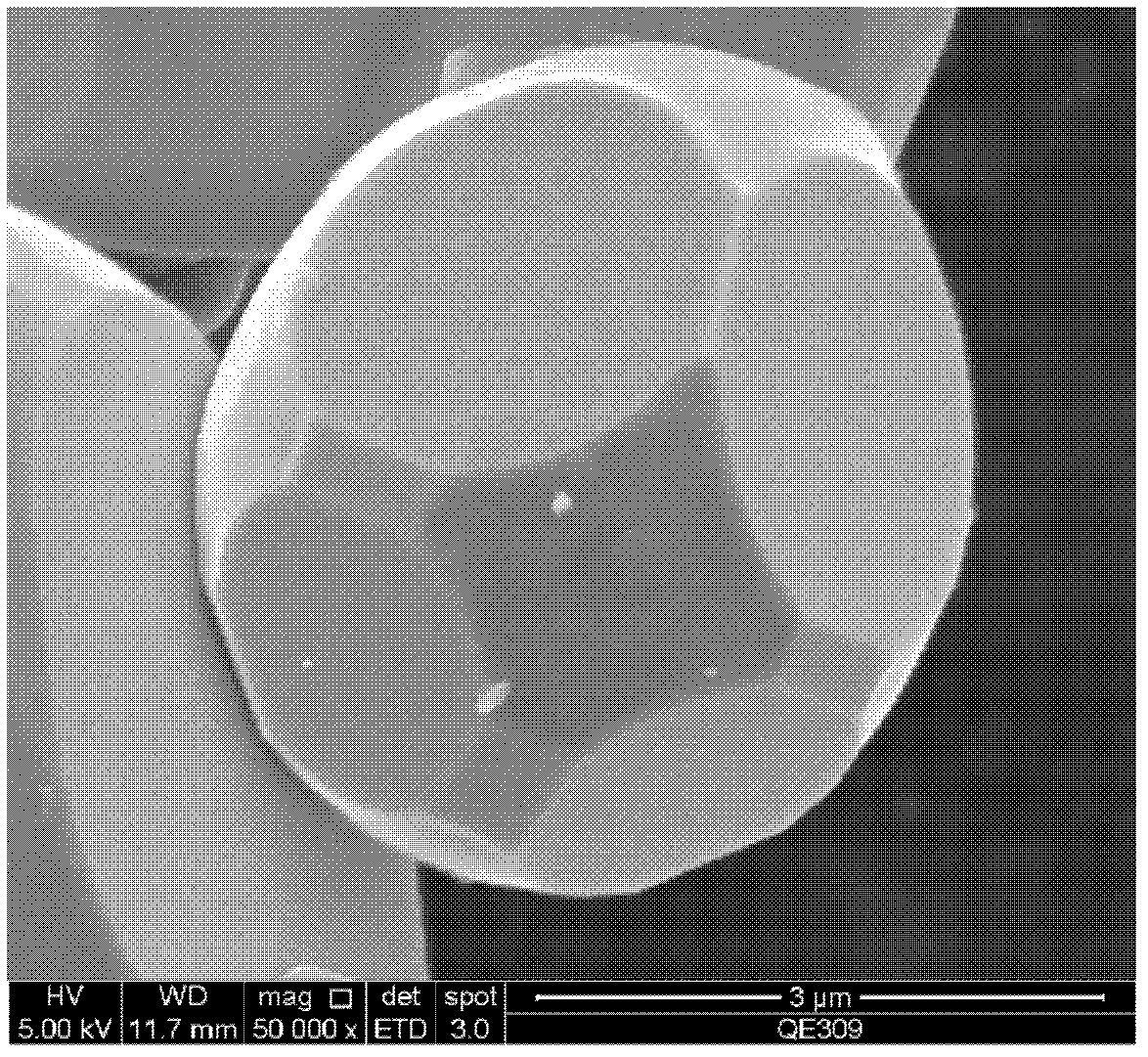

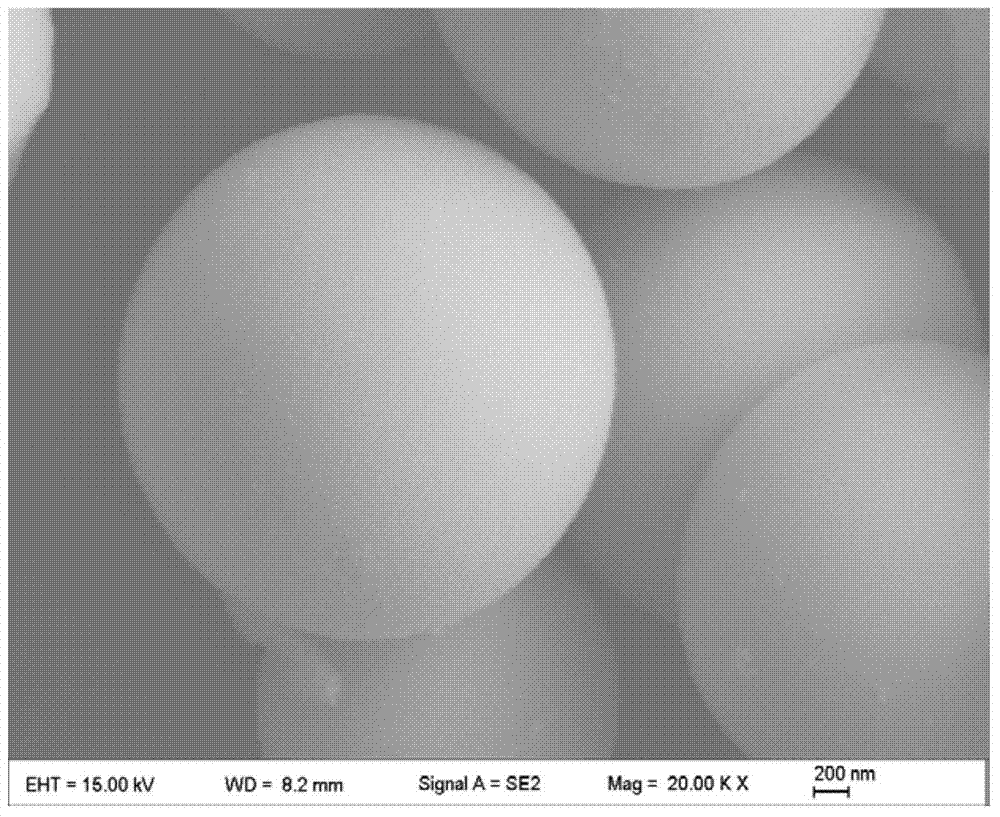

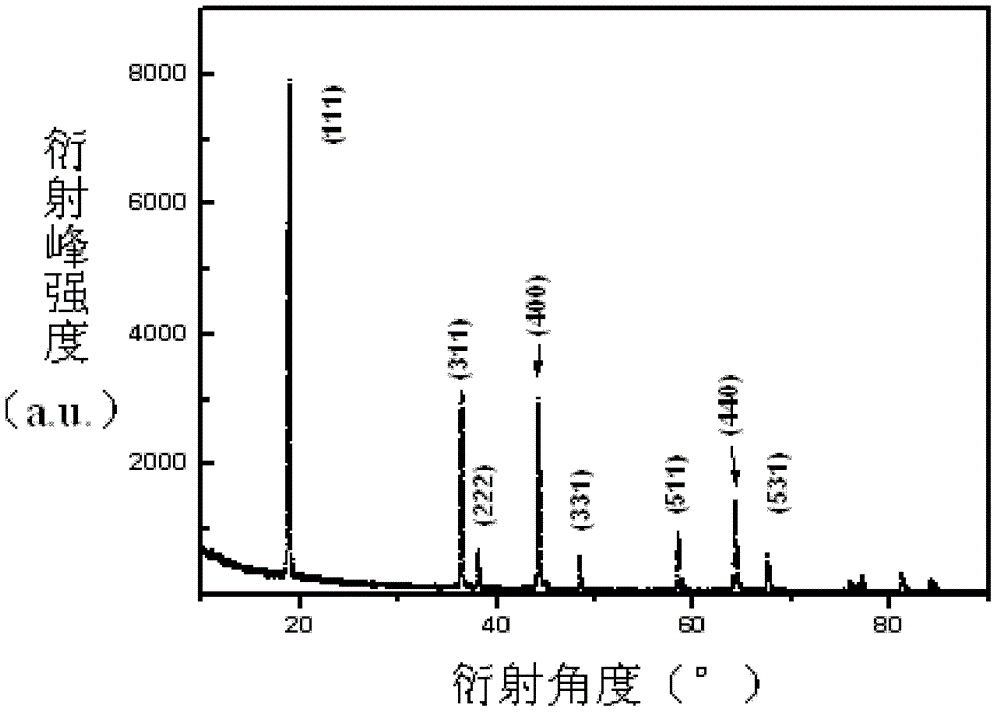

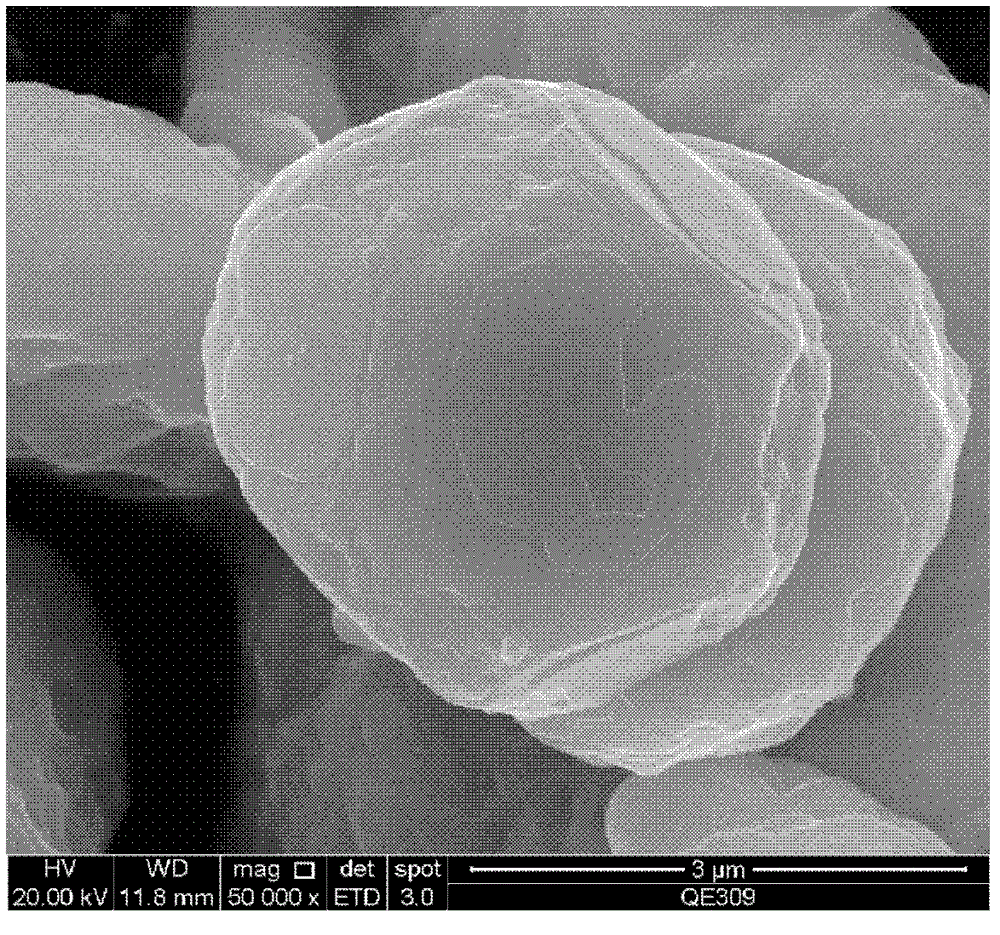

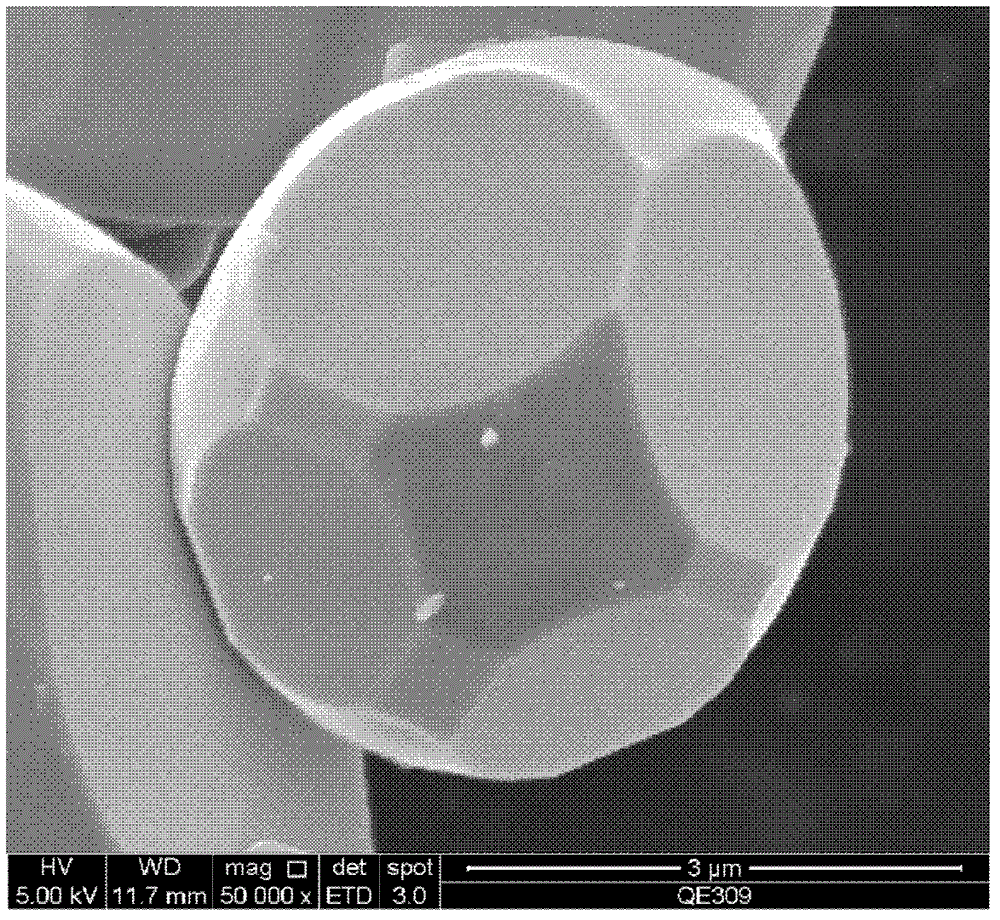

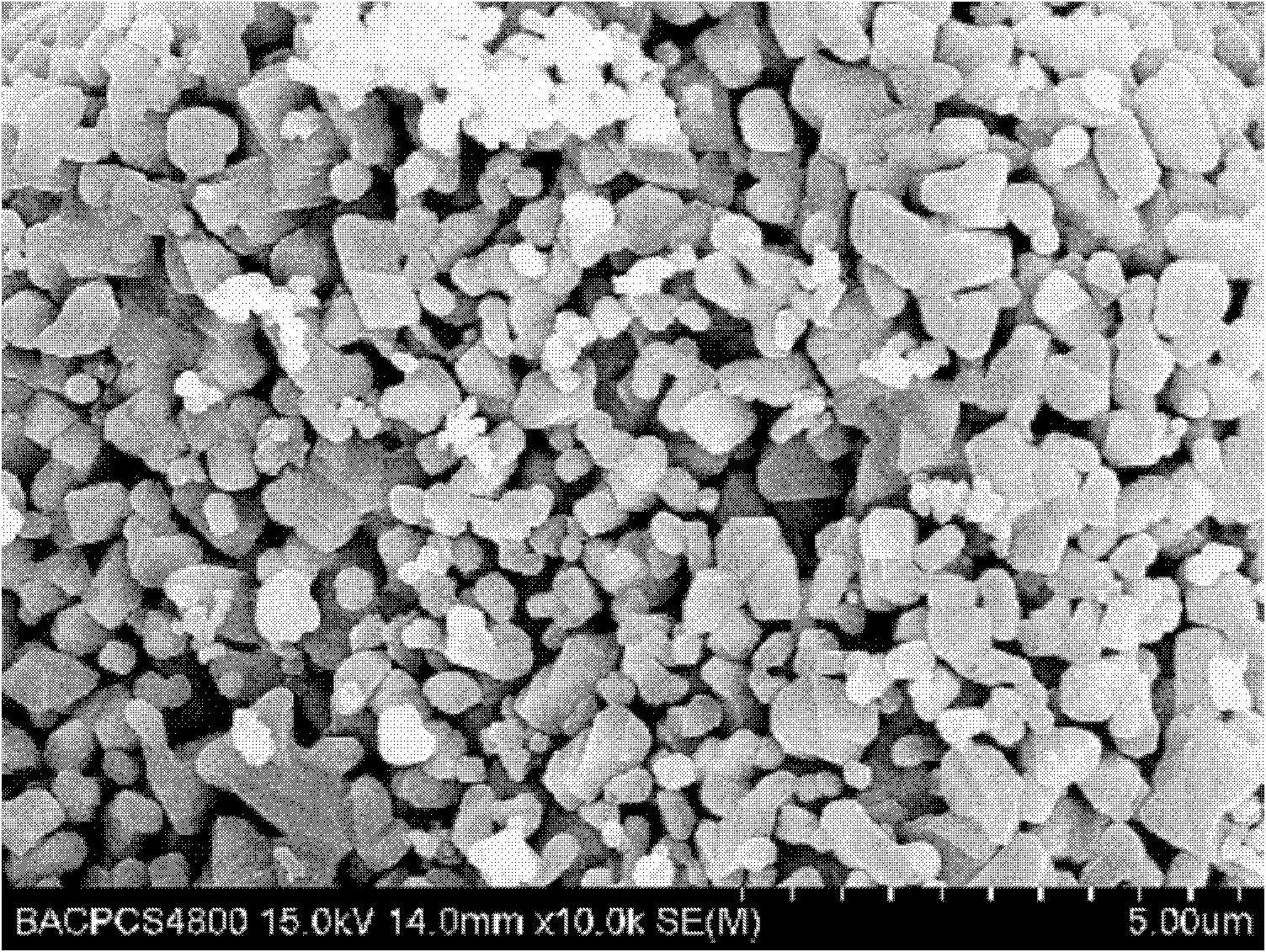

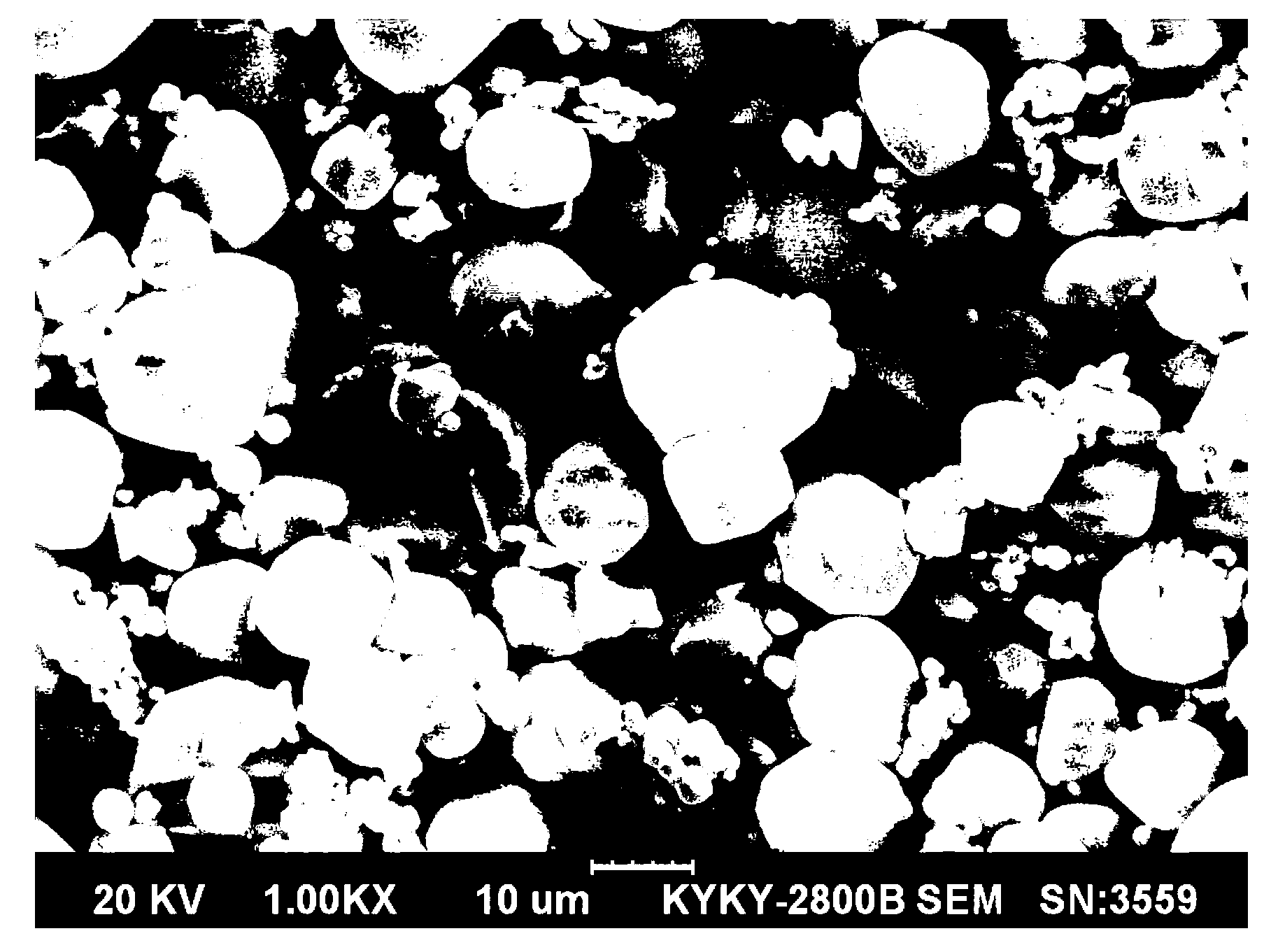

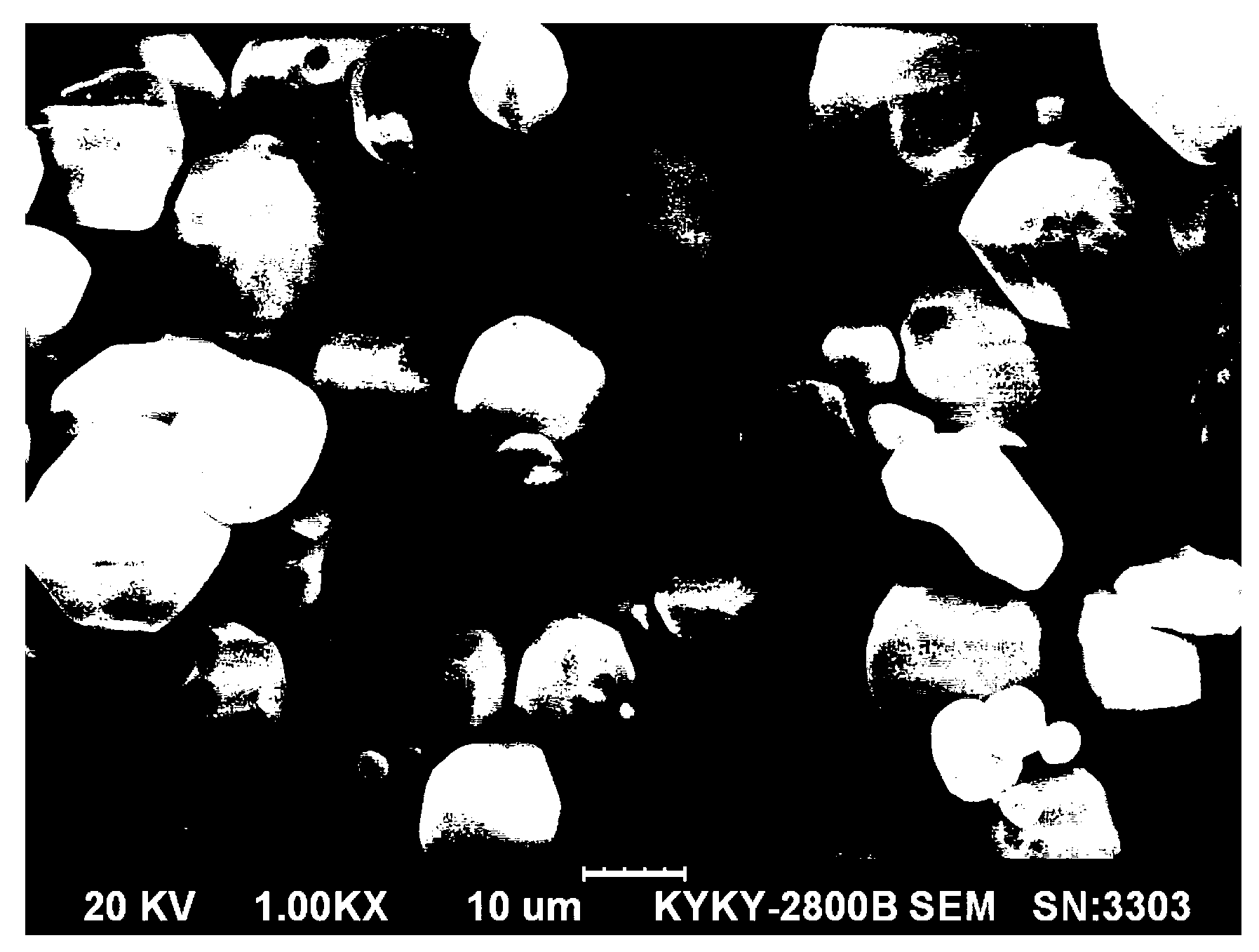

Coated-modified lithium manganese positive electrode material and preparation method thereof

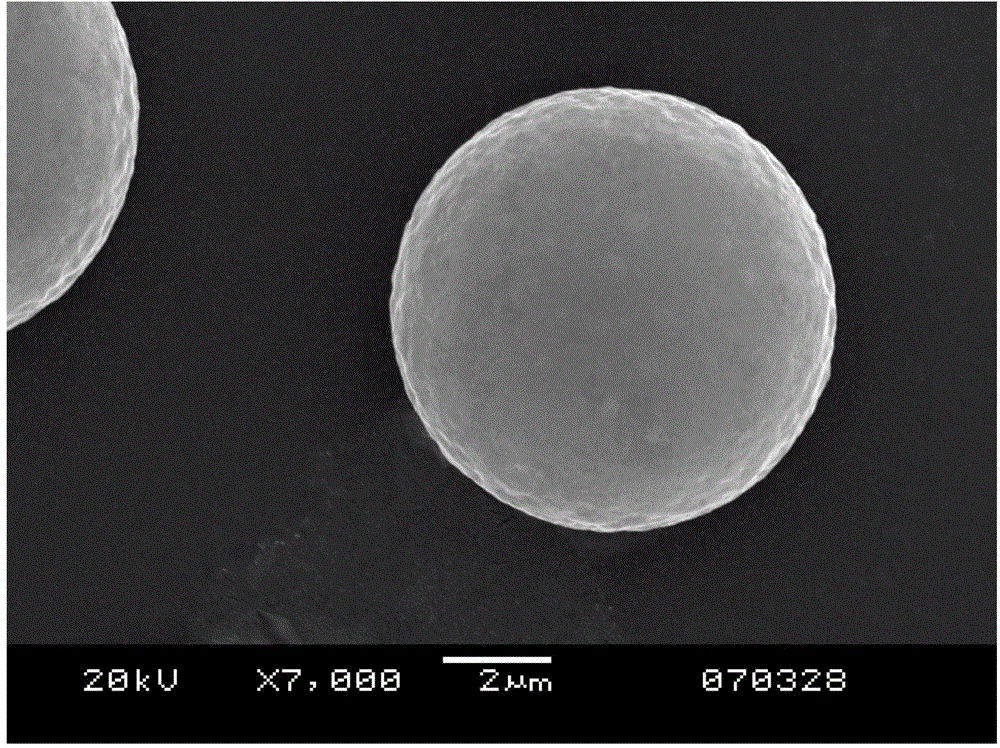

The invention discloses a coated-modified lithium manganese positive electrode material and the preparation method thereof. A manganese source compound, an M source compound and a lithium source compound are taken as raw material for preparing LiaMn2 -bMbO4 particles, and then are mixed with molten solvent and A-source compound, so as to obtain coated-modified lithium manganese positive electrode material. Compared with the prior art, the LiaMn2-bMbO4 particles are similar to spheres in shape and are in crystal face connection through curved surfaces which have no clear edges; on one hand, the LiaMn2 -bMbO4 particles have very small specific surface area, so that molten solvent and coating material are more evenly dispersed on the surfaces of the particles, and the control to average thickness of a coating is facilitated; on the other hand, the features have very small surface energy, the coating material is enabled to be more easily to be combined with the LiaMn2 -bMbO4 particles to form the coating. Therefore, the coated-modified lithium manganese positive electrode material has an excellent high temperature cycling performance.

Owner:宁波富理电池材料科技有限公司

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

Large molecular nucleating agent for poly butylenes succinate and copolyester of poly butylenes succinate and application thereof

The invention relates to a large molecular nucleating agent for poly butylenes succinate and a copolyester of the poly butylenes succinate and an application thereof. The large molecular nucleating agent is polyvinyl acetal, and the nucleating performance of the polyvinyl acetal is regulated and controlled by blending the polyvinyl acetal with the poly butylenes succinate and the copolyester of the poly butylenes succinate in an in-site polymerization way or in an adding way in a processing process. The large molecular nucleating agent is non-toxic, odorless, non-corrosive and dispersible. By taking the polyvinyl acetal as the large molecular nucleating agent, the peak crystallization temperatures of the poly butylenes succinate and the copolyester of the poly butylenes succinate can be raised remarkably, crystallization degree and crystallization speed are increased remarkably, a crystallization period is shortened remarkably, and the mechanical property of resin is enhanced remarkably.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

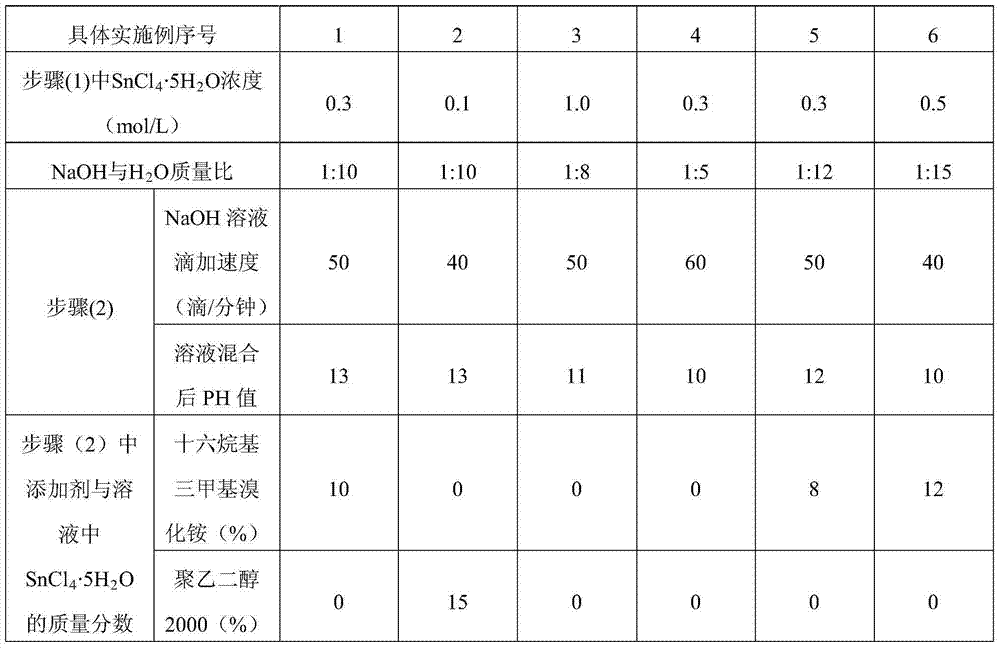

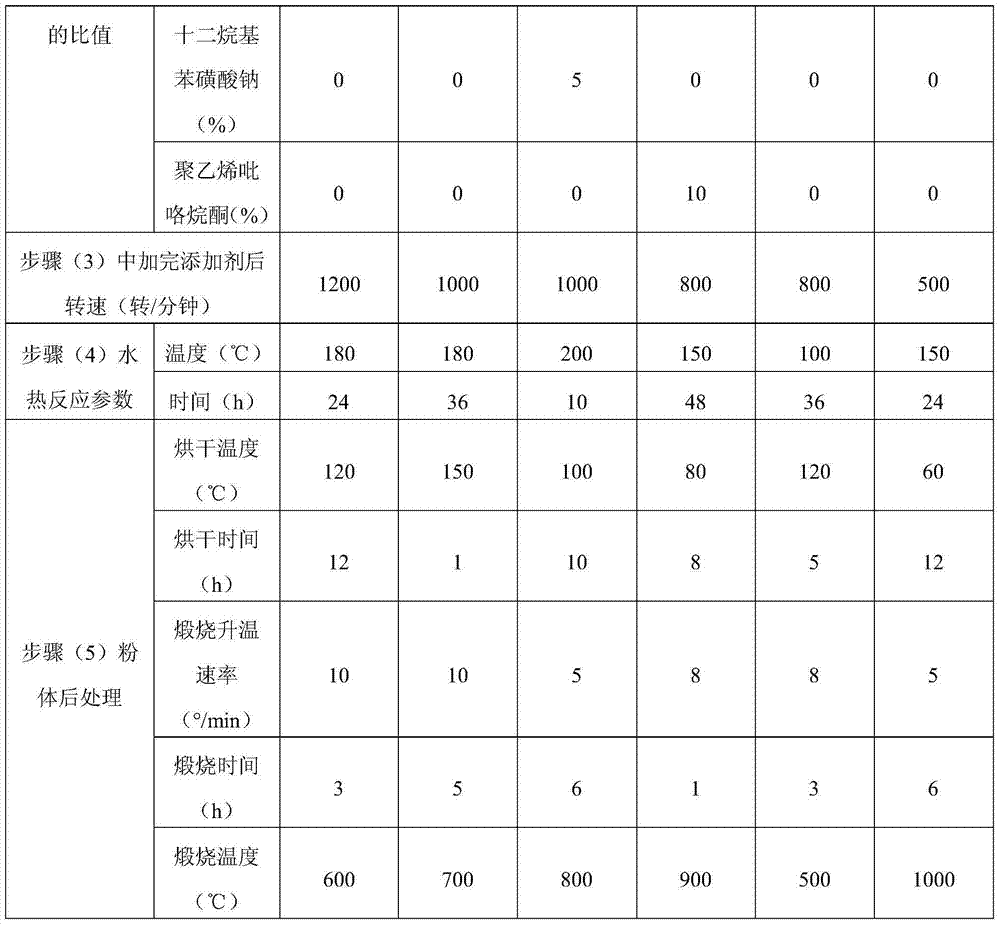

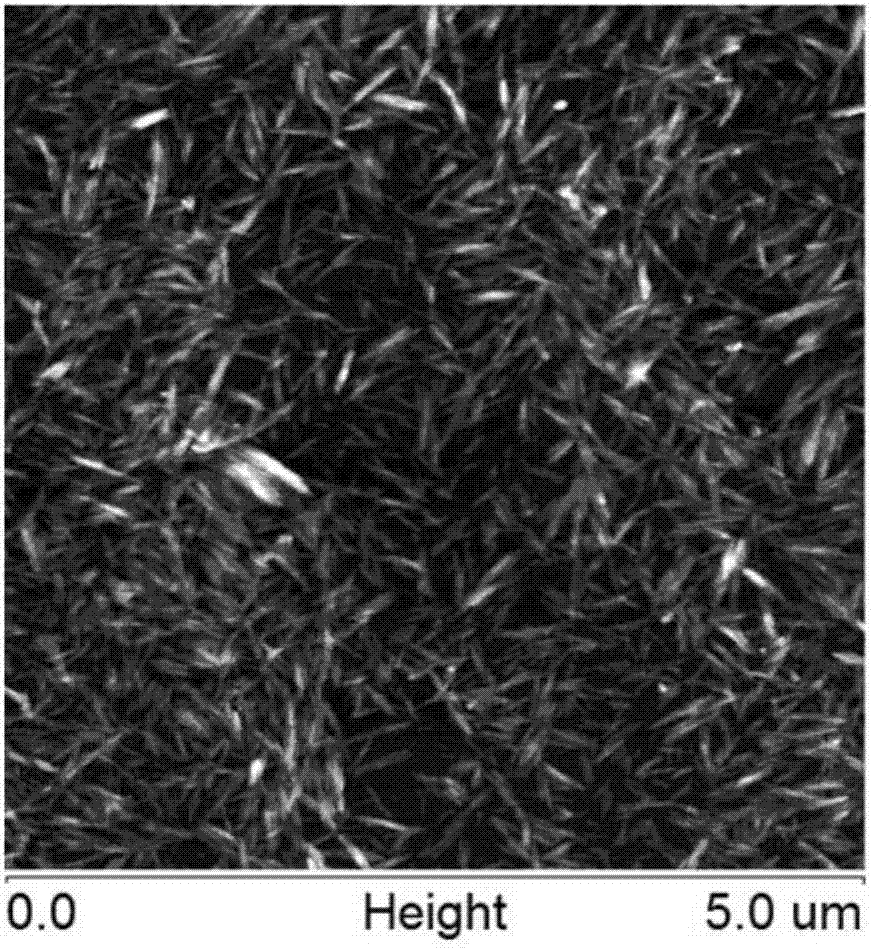

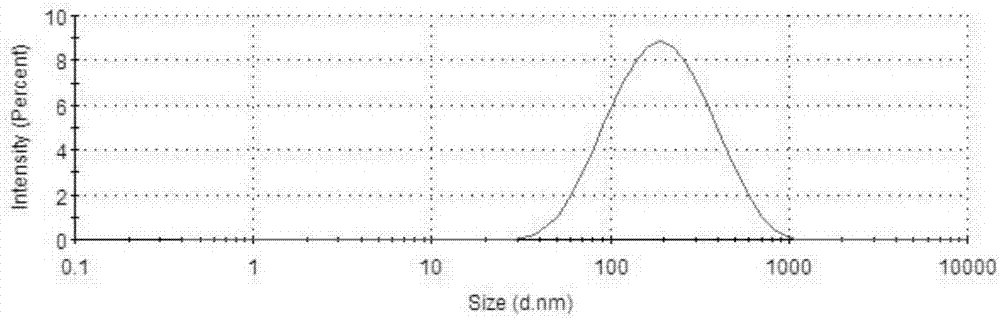

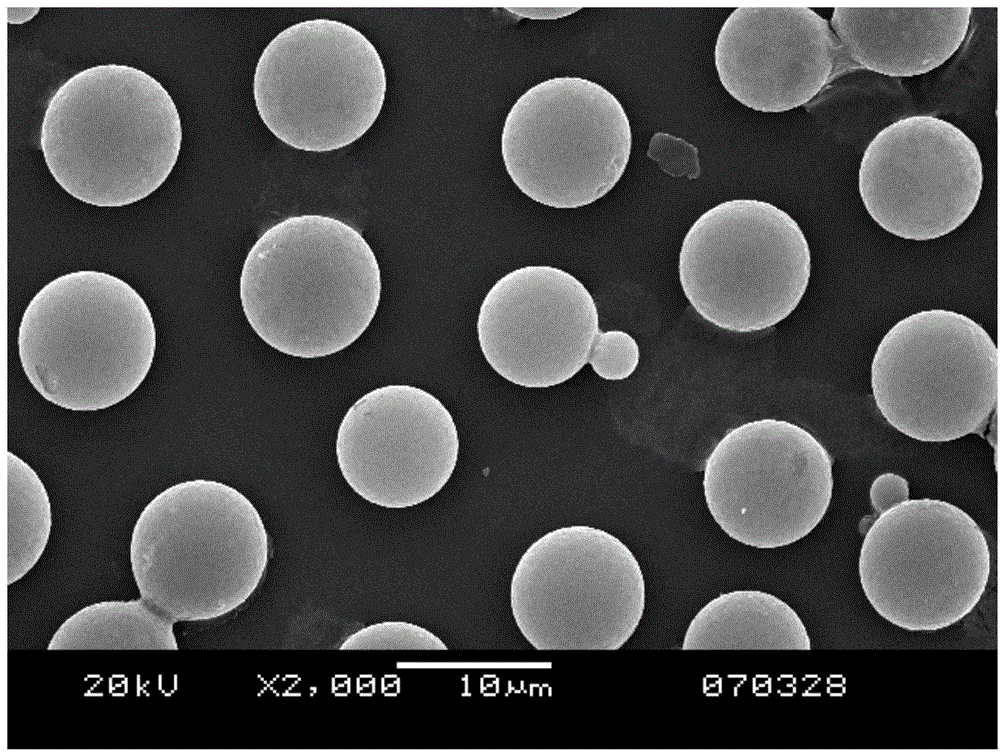

Preparation method of micro-nano tin dioxide solid spheres

The invention relates to the preparation of micro-nano materials, and aims to provide a preparation method of micro-nano tin dioxide solid spheres. The method comprises the following steps: respectively preparing a SnCl4.5H2O aqueous solution and a NaOH solution, uniformly dropwise adding the NaOH solution into the SnCl4.5H2O aqueous solution, and stirring at a high speed; transferring the mixed solution to a polytetrafluoroethylene reaction kettle, and carrying out a hydrothermal reaction on the mixed solution; carrying out centrifugal separation or filtering on the obtained product, washing the obtained object until no soluble ion exists in the solution, and drying, so that white powder is obtained; and putting the powder into a chamber electric furnace or a muffle furnace to calcine, and carrying out furnace cooling on the obtained product, so that white or light yellow powder, namely, micro-nano tin dioxide solid spheres, is obtained. Products prepared according to the preparation method disclosed by the invention are good in sphericity, smooth in surface, and uniform in size; no organic solvent as well as volatile poisonous gas and the like is used in the preparation process, so that only do sodium salts exist in products, and therefore, the product has no pollution to the environment; and no template is used, so that the method is simple in process, easily controlled in reaction process, mild in reaction condition, simple in raw material and low in cost, and therefore, the method is specially suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

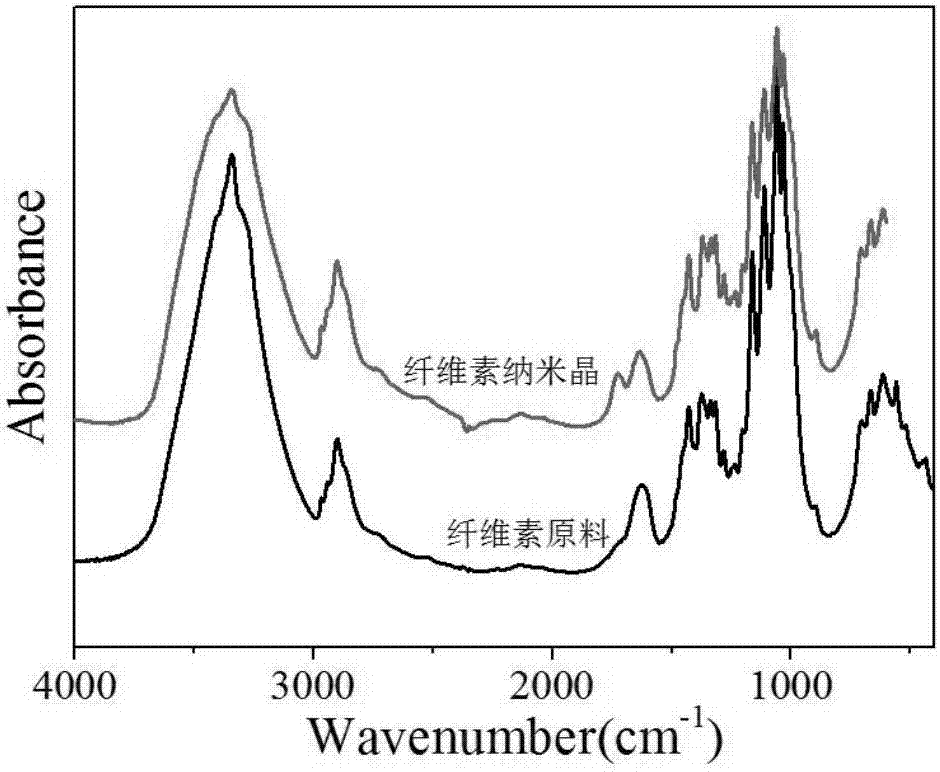

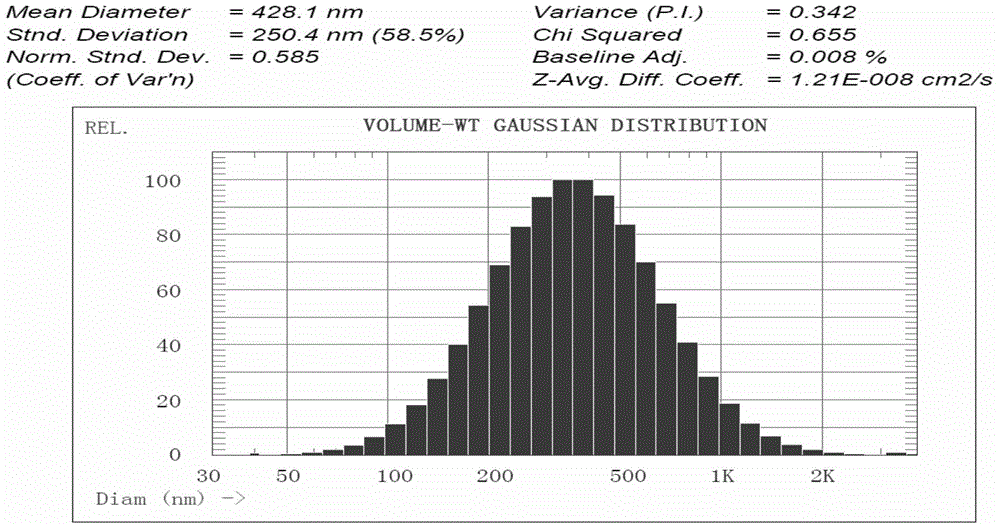

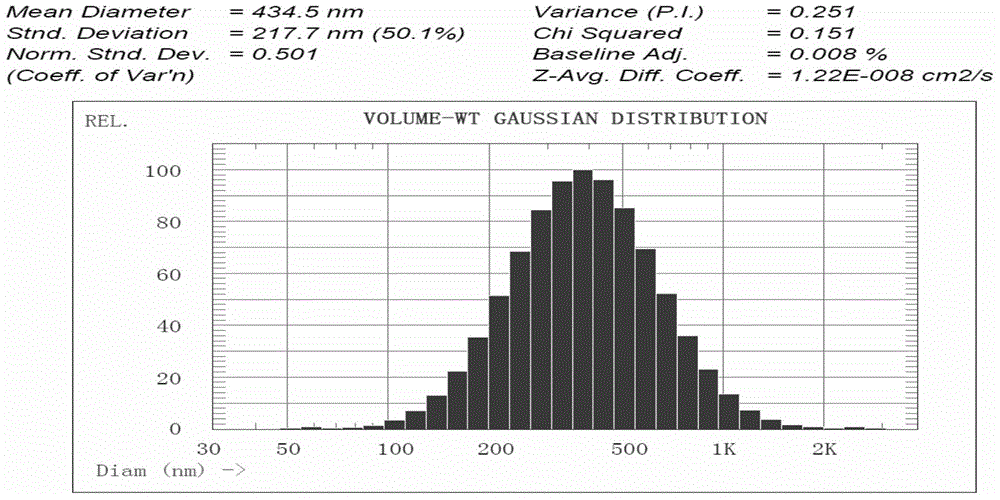

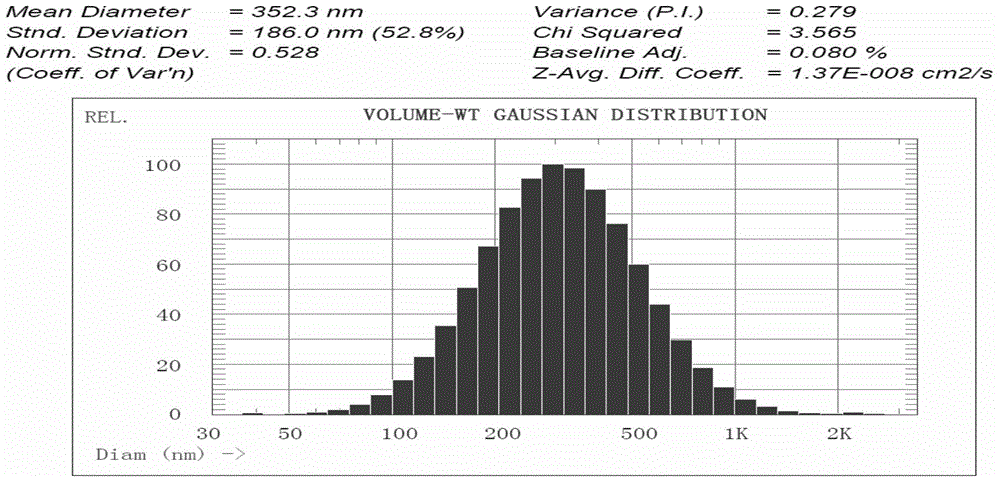

High-efficiency preparation method of cellulose nanocrystal (CNC)

The invention discloses a macroscopic preparation method of a cellulose nanocrystal (CNC), which is green and environment-friendly. Firstly, cellulose is crushed and then is pretreated; afterwards, an oxometallate solution and an organic acid are added, the oxydrolysis is carried out, and the CNC with a carboxyl group on a surface is obtained after centrifugal dialysis treatment. The yield of the preparation method can exceed 70 percent; the length of the made CNC can be adjusted in the range of 195nm to 260nm; the content of the carboxyl group on the surface can reach 50mmol / g; compared with a CNC made by a sulfuric-acid acid hydrolysis method, the CNC made by the macroscopic preparation method provided by the invention is increased by 50 to 100 DEG C in heat resistance; used oxometallate and organic acid are both green reagents and are further a few in use levels; problems that the preparation cost of the CNC is high and further the environmental pollution is easily caused, and the like, at present are solved.

Owner:QINGDAO UNIV OF SCI & TECH

Polyacrylacid ester composite emulsion with releasing anion function and preparation method and application thereof

InactiveCN101041705AGood storage stabilityEasy to disperse evenlyFibre treatmentCoatingsEmulsionPolymer science

The invention discloses a composite polyacrylacid ester emulsion with anion happening function, which comprises the following steps: adding anion particle and emulsion in the water; stirring evenly; adding acrylate, acrylic acid and acrylic nitrile; stirring to obtain emulsified monomer emulsion; adopting emulsion polymerizing method to clad anion agent in the polyacrylacid ester emulsion particle; obtaining the product; fitting for inner wall decorative paint and fabric coating agent.

Owner:ZHONGBEI UNIV

Hydrophobic modified nano cellulose preparation method

A hydrophobic modified nano cellulose preparation method includes steps: (1) using excessive sodium hydroxide solution for alkali swelling treatment of fiber materials, adding acrylamide being 5-15% of the dry weight of the fiber materials, performing reaction for 2-6h at 60-90 DEG C, washing and filtering to obtain carboxyethyl cellulose; (2) under an organic solvent system at 55-95 DEG C, subjecting the carboxyethyl cellulose and a hydrophobic compound to reaction for 2-4h to generate hydrophobic modified carboxyethyl cellulose; (3) adopting a high-pressure homogenizer for mechanical treatment of the hydrophobic modified carboxyethyl cellulose to finally obtain the hydrophobic modified nano carboxyethyl cellulose. The hydrophobic modified nano cellulose prepared according to the method is high in dispersity, transparency, compatibility and thermal stability and can be applied to industries of petroleum drilling, construction mortar, textile dyeing and printing, electronic paste, paint, ceramics, papermaking, daily chemicals and the like.

Owner:胡云

Suspension preparation of temperature change painless nano sulfadiazine metallic compound hyaluronic acid

ActiveCN104013574AStrong penetrating powerImprove bioavailabilityOrganic active ingredientsSolution deliveryCelluloseChlorhexidine

The invention discloses a suspension preparation of temperature change painless nano sulfadiazine metallic compound hyaluronic acid. The formula comprises a sulfadiazine metallic compound, a hyaluronic acid substance, an analgetic, a dispersing agent aid, a suspension aid and water, wherein the sulfadiazine metallic compound comprises sulfadiazine silver and sulfadiazine zinc; the hyaluronic acid substance is sourced from biological fermentation and animal tissue extraction and the like and can be hyaluronic acid or hyaluronate or crosslinked hyaluronic acid or crosslinked hyaluronate; the analgetic comprises ropivacaine, bupivacaine, levobupivacaine, lidocaine and other local anesthetics or combination of the local anesthetics; the dispersing agent aid comprises chlorhexidine, Tween series, oleic acid or sodium oleate; the suspension aid can comprise glycerinum, celluloses, poloxamer series and hyaluronic acid substances. The suspension preparation is mainly used for burn, scald or the surface of a wound caused by explosion or anabrosis, has the main clinical characteristics that pain is rapidly relieved, the surface of the wound is subjected to rapid film formation and rapid healing of the wound is promoted, and the conventional main administration modes refer to spraying, smearing and coating.

Owner:LIPONT PHARMA

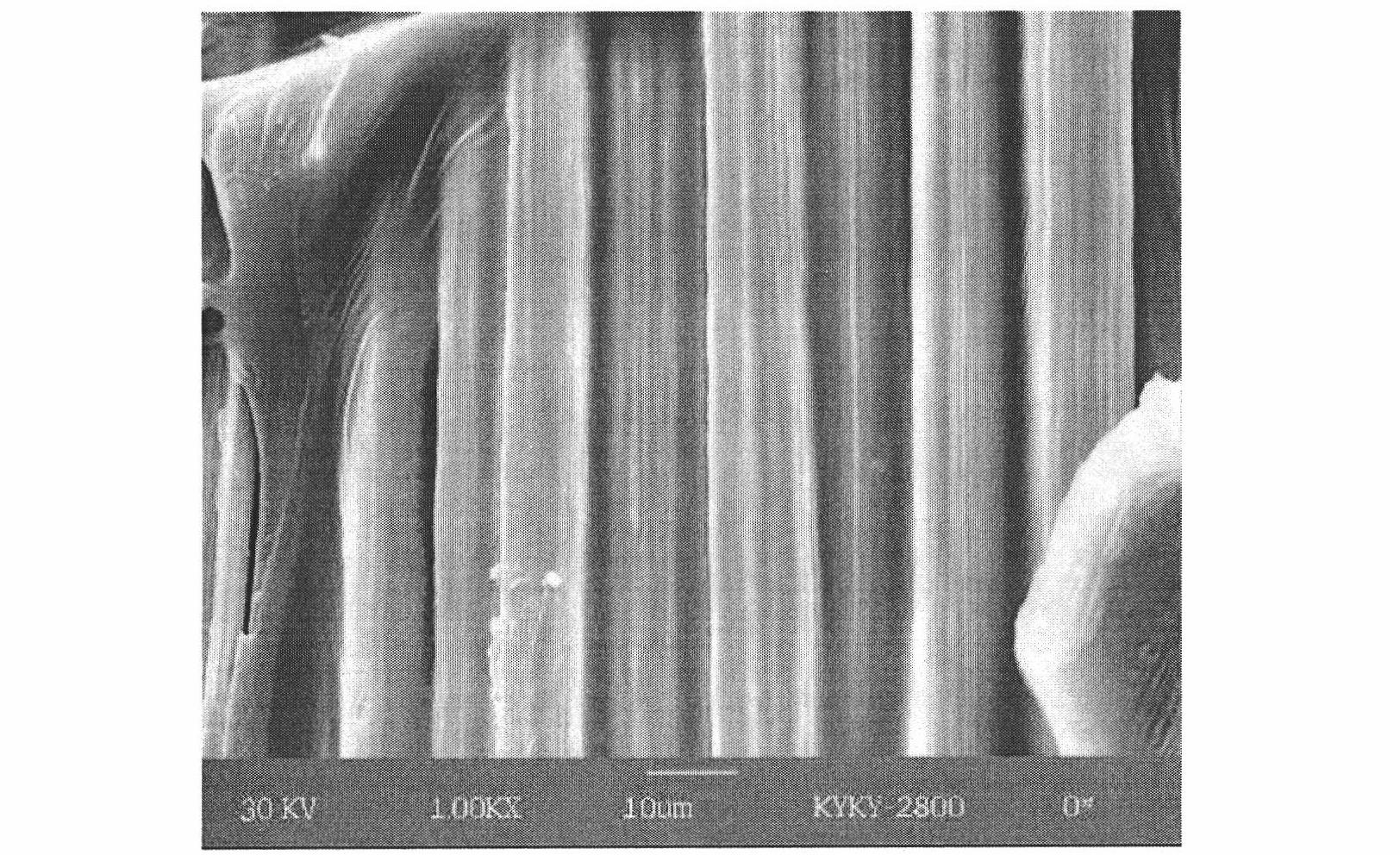

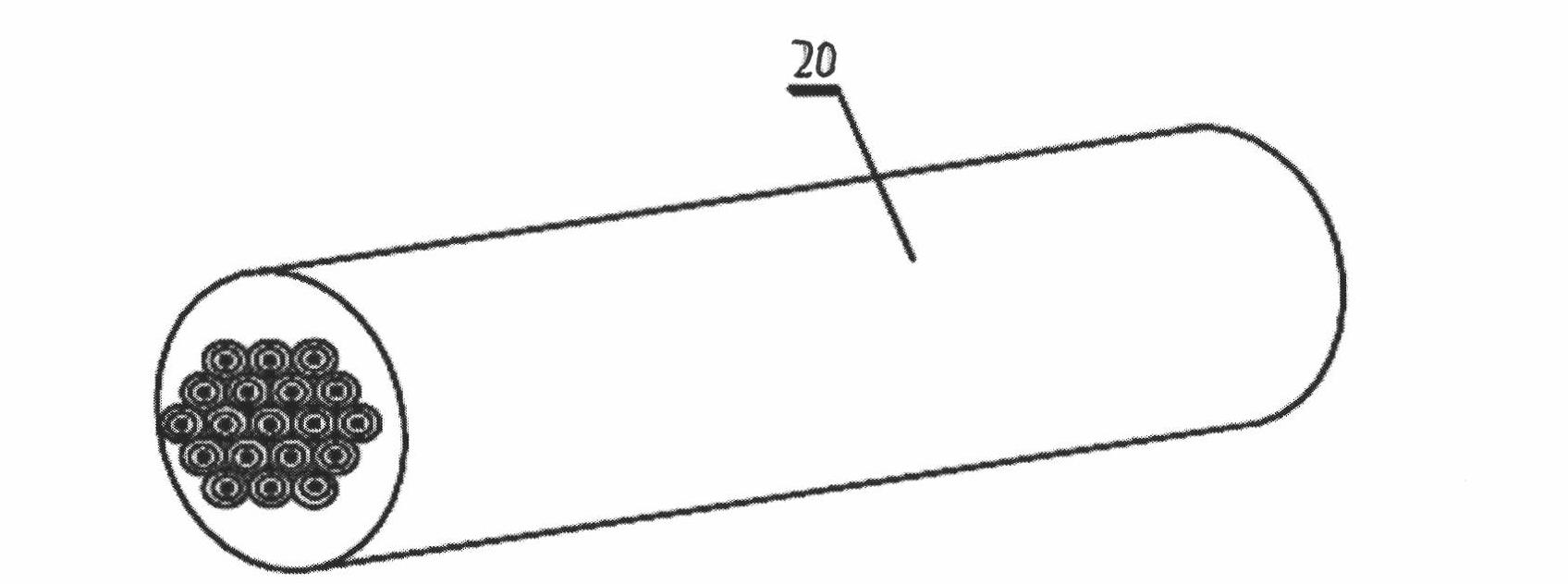

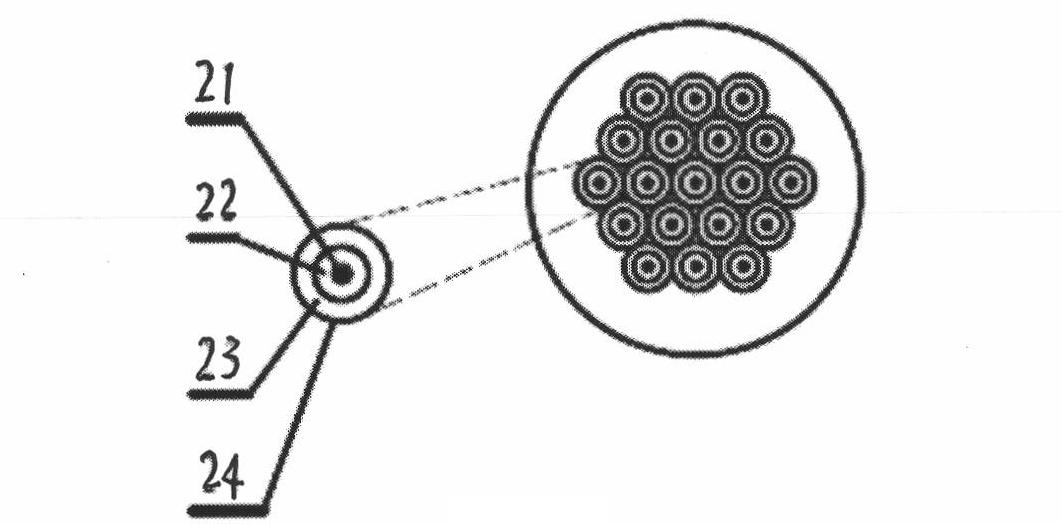

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

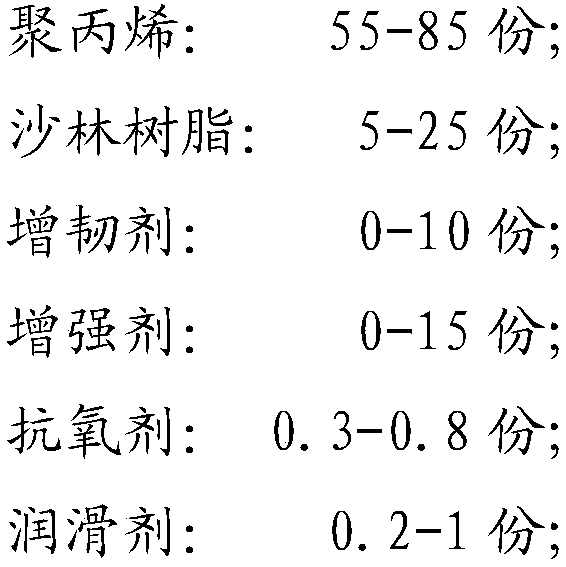

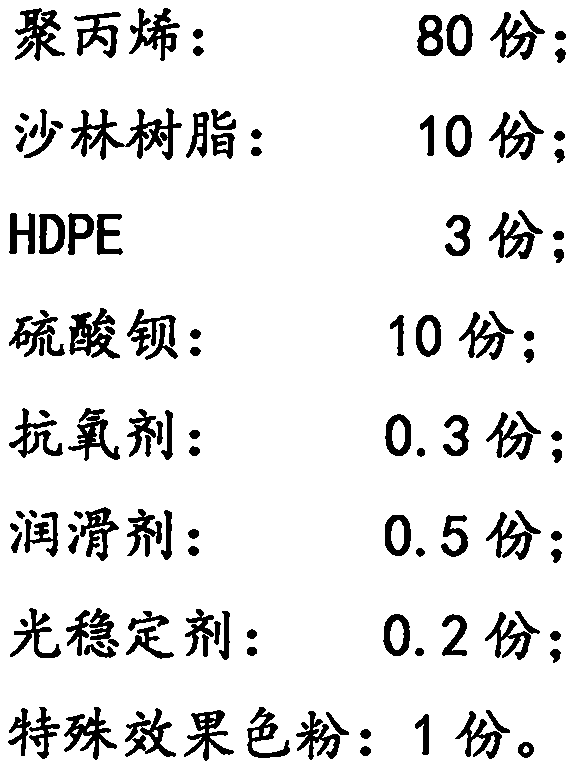

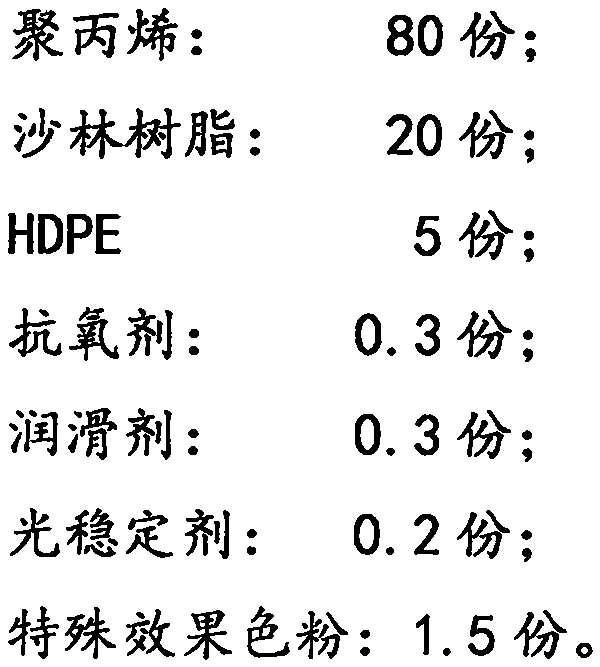

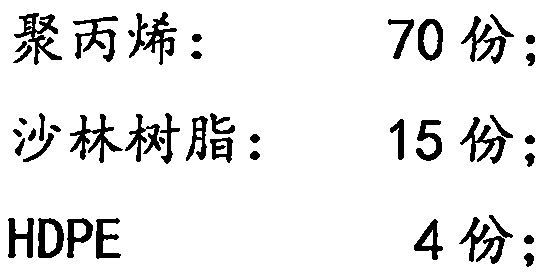

Metal appearance-imitated polypropylene-surlyn composite material and preparation method thereof

InactiveCN108342015AGood low temperature impact propertiesImprove low temperature brittlenessPolypropyleneSpecial effects

The invention relates to a metal appearance-imitated polypropylene-surlyn composite material and a preparation method thereof. The metal appearance-imitated polypropylene-surlyn composite material isprepared from the following components in parts by weight: 55-85 parts of polypropylene, 5-25 parts of surlyn, 0-10 parts of flexibilizer, 0-15 parts of enhancer, 0.3-0.8 part of antioxidant, 0.2-1 part of lubricant, 0.2-0.4 part of light stabilizer, and 1-3 parts of special effect toners. The surlyn has high low temperature impact resistance, and can remarkably improve the low temperature brittleness of a PP material after being added, the composite material has transparency and high gloss, and can remarkably improve the surface gloss of the composite material, so that the visual effect of metal is more outstanding; and the composite material has high scratch resistance, and can be remarkably improved in scratch resistance.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Micron/nano metallurgical addition agent

InactiveCN101875112APlay a role in pre-dispersionEasy to disperse evenlyProcess efficiency improvementAl powderFiber

A micron / nanometer metallurgical addition agent is prepared as the following steps: evenly mixing micron powder, nano powder and metal powder by ball milling, wherein the metal powder serves as an adhesive and is briquetted, the weight ratio of the metal powder and micron powder to nano powder is (4-10):1, and the micron powder and nano powder utilize metal oxides such as Al2O3 powder, ZrO2 powder, CaCO3 powder, CaO powder and the like, or metal nitrides such as TiN powder, AlN powder and the like, or metal powder carbides such as WC powder, SiC powder and the like, or metal power such as Ca powder, Al powder, Mg powder and the like or alloy powder, or micro / nano carbon powder, fiber powder, etc. The metal powder serving as the adhesive comprises components which are the same as or similar to the components of a product matrix, does not pollute melt and only plays a carrier role. The addition agent is rushed into melt by high temperature melt and is evenly dispersed by the impact and stirring functions of the melt, and the addition agent also can be added in the melt by an injection method or an insertion method.

Owner:佛山市微宇创展先进材料有限公司

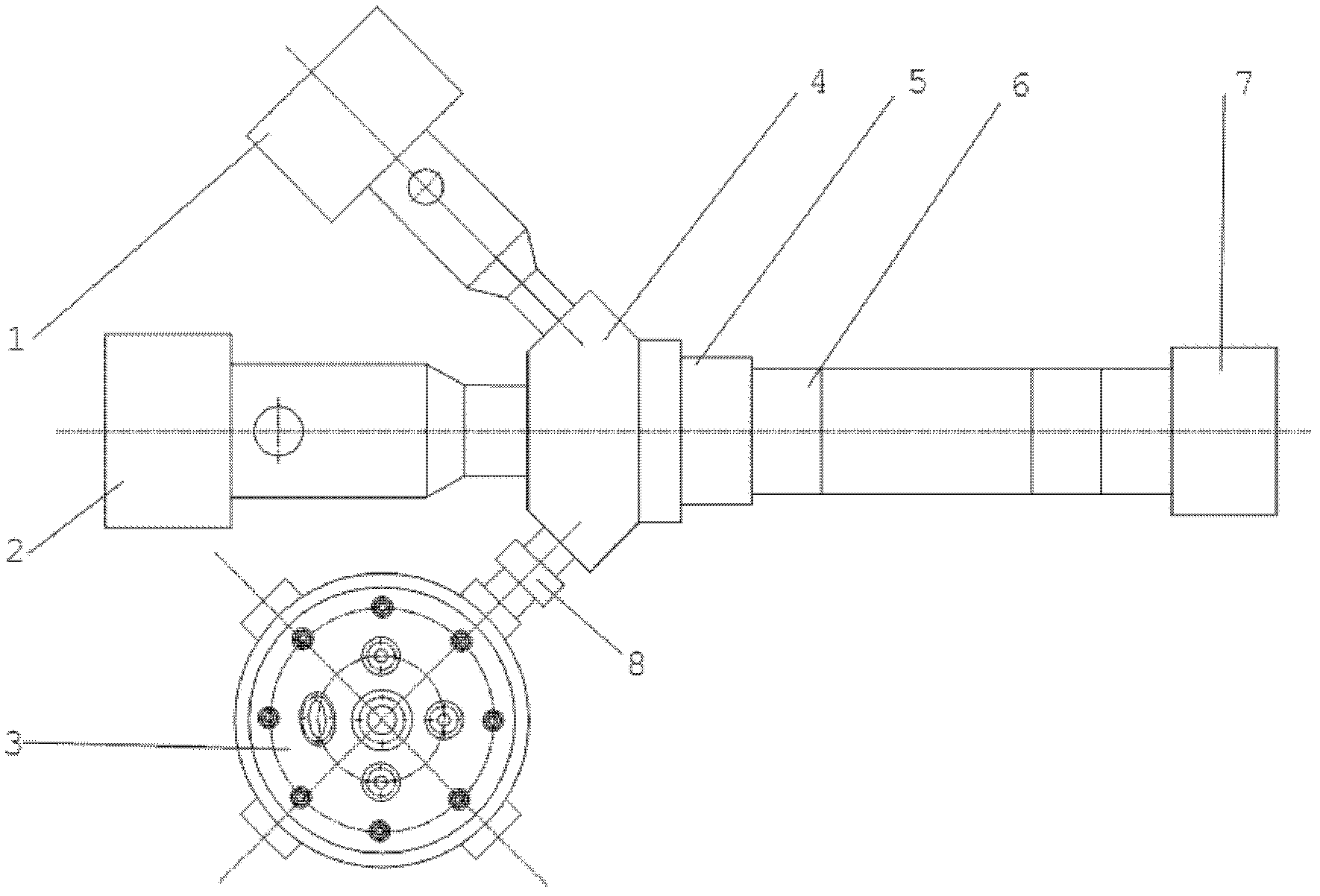

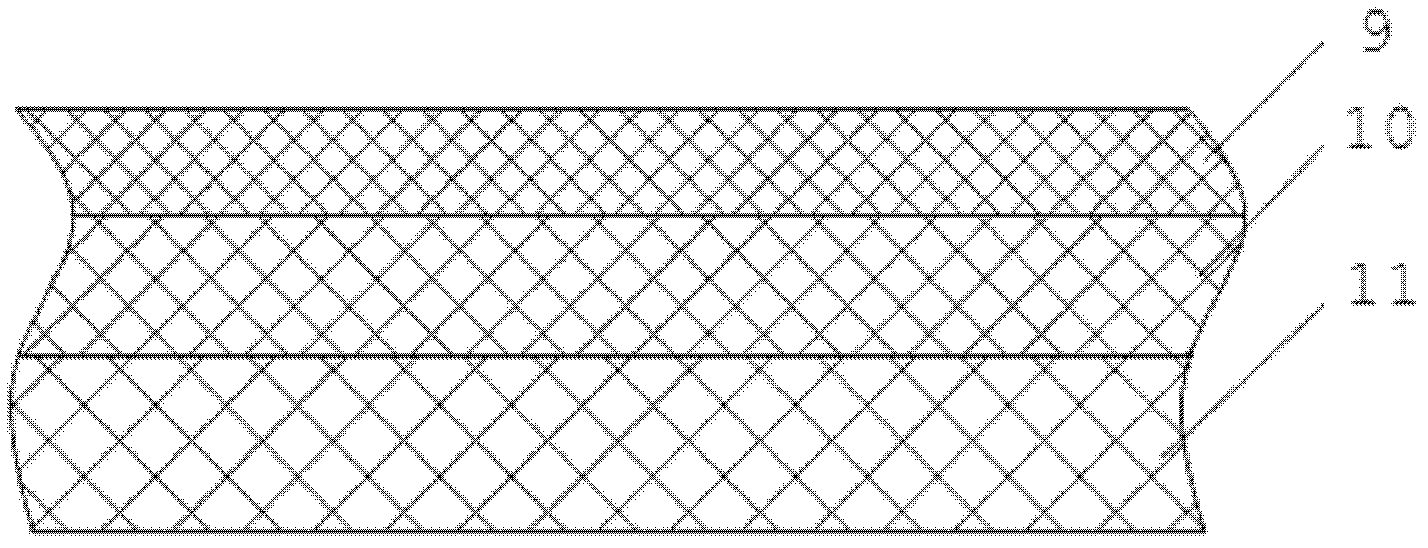

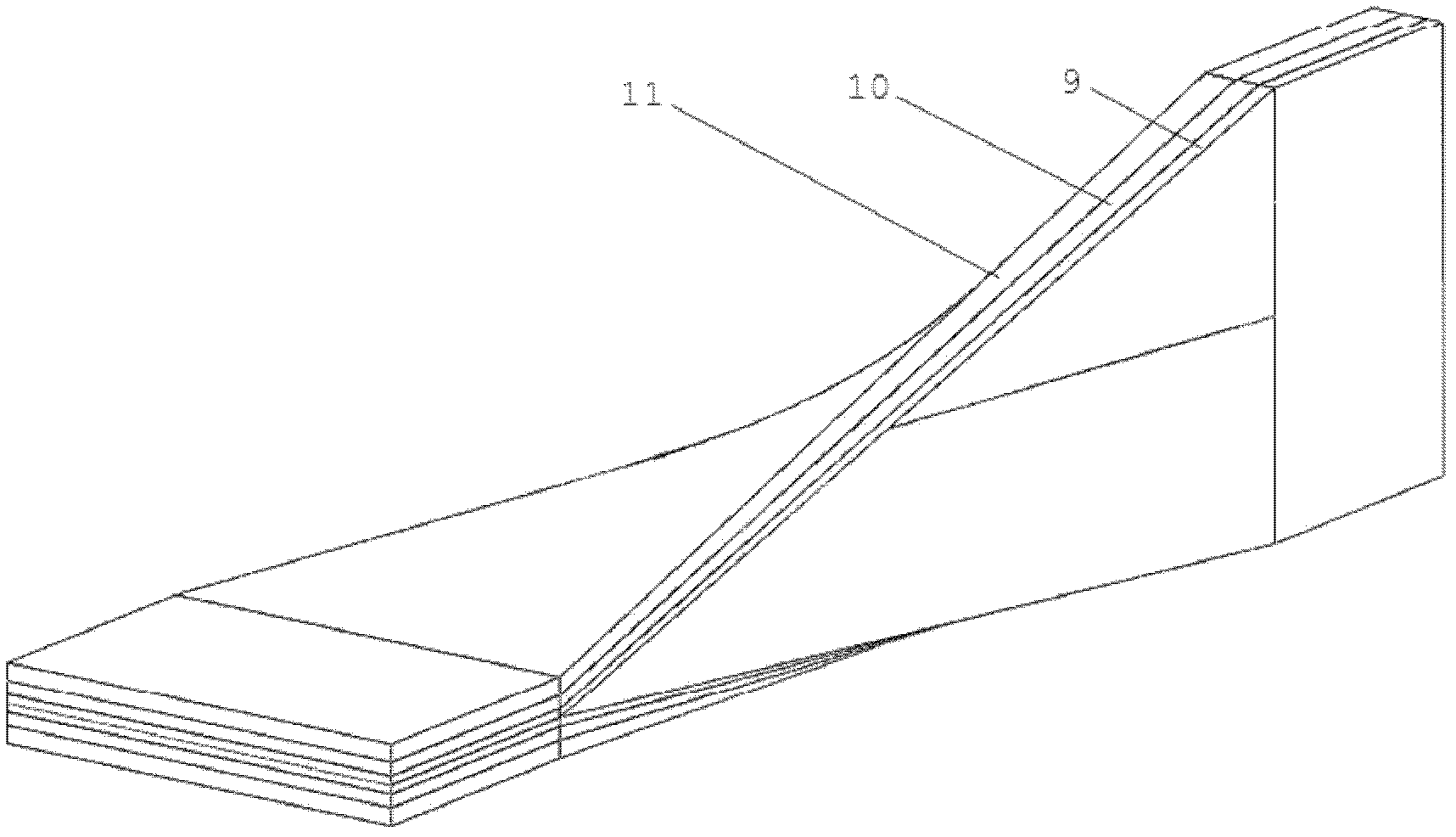

In-situ reaction forming device for differential and integral calculus laminated polymer composite material and in-situ reaction forming method

The invention relates to an in-situ reaction forming device for a differential and integral calculus laminated polymer composite material and an in-situ reaction forming method. The device comprises a plasticizing feeding device, a flow collector, a laminator and a forming device which are sequentially in series connection from front to back. Methods for processing a base layer and an adhesive layer in the differential and integral calculus laminated polymer composite material are unchanged, a functional layer is made of monomer or low polymer and the like which serve as raw materials instead of traditional high polymer, and a vacuum reactor is used as the plasticizing feeding device, so that the problem of difficulty in differential and integral calculus laminated composite of the composite material with base layer materials with low processing temperature is solved. By the aid of in-situ reaction forming technology for the functional layer, corresponding polymer modified auxiliaries can be selected according to different base materials, modifying effects are remarkable, the functional layer is thinner and even far thinner than the base layer, and raw materials are saved. Moreover, negative effects of high time consumption, degradation and the like caused by repeated hot processing are avoided as the functional layer is polymerized at one step.

Owner:BEIJING UNIV OF CHEM TECH

Polypropylene-surlyn resin composite material

The invention relates to a polypropylene-surlyn resin composite material. The composite material comprises, by weight, 55-85 parts of polypropylene, 5-25 parts of surlyn resin, 3-5 parts of HDPE, 0-10parts of a toughening agent, 0-15 parts of an enhancer, 0.3-0.8 part of an antioxidant, 0.2-1 part of a lubricant, 0.2-0.4 part of a light stabilizer and 1-3 parts of special effect color powder. Thesurlyn resin has excellent low-temperature impacting performance, the low temperature brittleness of a PP material can be significantly improved, the surlyn resin is transparent and has high glossiness, the surface gloss level of the composite material can be significantly improved after the surlyn resin is added, a metal imitation visual effect is more outstanding, the surlyn resin has higher scratching resistance, and therefore the scratching resistance of the material can be significantly improved.

Owner:严静儿

Method for preparing nickel catalyst supported on SiO2 microspheres and application of nickel catalyst

ActiveCN107899581ALarge specific surface areaHigh activityOrganic compound preparationAmino compound preparationNickel saltFiltration

A method for preparing a nickel catalyst supported on SiO2 microspheres comprises the steps of preparing a water-soluble silicon source solution A; preparing an emulsifier B; preparing an aqueous solution C of a nickel salt and an optional additive metal salt; adding the emulsifier B to the solution A, and performing stirring, suction filtration, washing and drying, so as to obtain SiO2 microspheres; and performing post-treatment on the microspheres by using dilute ammonia water, adding the solution C, and performing impregnation, rotary evaporation, microwave drying, roasting and reduction toobtain the nickel catalyst supported on the SiO2 microspheres. When the nickel catalyst is applied to catalytic hydrogenation of dinitrotoluene DNT for preparing toluene diamine TDA, the conversion rate of DNT is 100% and the selectivity of TDA is 99.9%.

Owner:WANHUA CHEM GRP CO LTD

Macromolecule nucleating agent used for polylactic acid and application method of macromolecule nucleating agent

The invention relates to a macromolecule nucleating agent used for polylactic acid and an application method. The macromolecule nucleating agent is polyvinyl acetal, and polyvinyl acetal is mixed with polylactic acid by in-situ polymerization or in an addition manner in a processing process, so as to regulate the nucleating property of polyvinyl acetal. The macromolecule nucleating agent has no toxicity or corrosivity, is odorless and is dispersed easily. Polyvinyl acetal, which serves as the macromolecule nucleating agent, can enable the peak crystallization temperature of polylactic acid to be risen obviously, so that the crystallinity and the crystallization velocity are improved remarkably, the crystallization period is shortened obviously, and the mechanical property of resin is improved more obviously.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method of nano cellulose dispersion liquid

The invention relates to the field of preparation of nano cellulose dispersion liquid, and discloses a preparation method of nano cellulose dispersion liquid. The method comprises the following steps: 1) contacting a cellulosic material and a hydrophilic solvent to obtain the wet cellulosic material; and 2) under existence of a dispersant, grinding the wet cellulosic material; wherein, the dispersant is one or more of alkylphenol polyoxyethylene, fatty alcohol polyoxyethylene ether, sodium dodecyl sulfate, sodium dodecanesulphonate, sodium dodecyl benzene sulfonate, polyethylene imidacloprid network flavanone, polyacrylamide, polysorbate, anhydrosorbitol fatty ester, cellulose sodium, 2,2,6,6-tetramethyl piperidine oxide, polyethylene glycol, a betaine-type surfactant and a quaternary ammonium salt-type cationic surfactant. The preparation method has the advantages of simple process, low preparation cost and environment protection, and the nano cellulose dispersion liquid has good dispersibility and stability.

Owner:MATERIAL & IND TECH RES INST BEIJING

Coated-modified lithium manganese positive electrode material and preparation method thereof

The invention discloses a coated-modified lithium manganese positive electrode material and the preparation method thereof. A manganese source compound, an M source compound and a lithium source compound are taken as raw material for preparing LiaMn2 -bMbO4 particles, and then are mixed with molten solvent and A-source compound, so as to obtain coated-modified lithium manganese positive electrode material. Compared with the prior art, the LiaMn2-bMbO4 particles are similar to spheres in shape and are in crystal face connection through curved surfaces which have no clear edges; on one hand, the LiaMn2 -bMbO4 particles have very small specific surface area, so that molten solvent and coating material are more evenly dispersed on the surfaces of the particles, and the control to average thickness of a coating is facilitated; on the other hand, the features have very small surface energy, the coating material is enabled to be more easily to be combined with the LiaMn2 -bMbO4 particles to form the coating. Therefore, the coated-modified lithium manganese positive electrode material has an excellent high temperature cycling performance.

Owner:宁波富理电池材料科技有限公司

Electroconductive woodceramic powder and its manufacturing method

InactiveCN102515778AWith electromagnetic shieldingChange the amount of platingCeramicwareChemical platingFiltration

Relating to woodceramic materials and their preparation methods, the invention provides electroconductive woodceramic powder and its manufacturing method, and solves the technical problems of great brittleness and easy cracking in bulk woodceramic materials. The electroconductive woodceramic powder of the takes woodceramic powder as the core, the surface of which is chemically plated with electroconductive powder of a layer of metal film, and the metal attaching amount is 1%-50% of the mass of the woodceramic powder, wherein, the metal is nickel, iron or cobalt. The preparation method consists of: subjecting the woodceramic powder to oil removal, oxidation, sensitization, activation, and dispergation, then placing the woodceramic powder into a chemical plating solution for chemical plating, and conducting filtration and washing by deionized water to neutral, then carrying out drying, thus obtaining the electroconductive woodceramic powder with volume resistivity of 4.5*10<-2>omega.cm-5.5*10<-1>omega.cm. The electroconductive woodceramic powder in the invention can be added into coatings for preparing electroconductive coatings, or the powder can be added into resin-based materialsfor preparing molding materials, thus having a wide application range. The electroconductive woodceramic powder in the invention can be used as an electromagnetic shielding material.

Owner:NORTHEAST FORESTRY UNIVERSITY

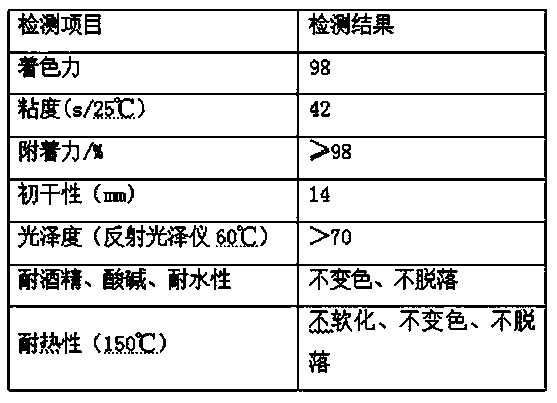

Nano barium titanate coated alkyd resin type printing ink

The invention relates to the field of printing ink, in particular to nano barium titanate coated alkyd resin type printing ink. The printing ink is prepared by raw materials in parts by weight as follows: 2-4 parts of polymethyl methacrylate, 1-3 parts of nano barium titanate, 6-10 parts of PLGA (poly(lactic-co-glycolic acid) copolymer, 1-2 parts of oleic acid, 15-20 parts of proprylene glycol monomethyl ether, 8-24 parts of alkyd resin, 10-12 parts of ethyl acetate, 4-5 parts of absolute ethyl alcohol, 2-5 parts of alumina gel, 10-15 parts of a pigment and 1-2 parts of an assistant. The printing ink takes a mixture of the alkyd resin and the PLGA copolymer as a vehicle, has excellent adhesion and is good in compatibility with all components; nano barium titanate after dispersion treatment by an alumina gel alcoholic solution is uniformly dispersed in a resin solution more easily, so that the hardness and heat resistance of a coating are improved, the wettability of the printing ink can be improved by the assistant, and coating bubbles are avoided and prevented from affecting the decoration effect; and the printing ink has good printability in an actual use process and can be prevented from decoloration and shading for a long time at higher environment temperature.

Owner:ANHUI AOYA ALLOY

Preparation method and application of Co/Ni and aluminum pyrophosphate composite hollow microsphere

ActiveCN104056646AHigh strengthSize qualityPhysical/chemical process catalystsOrganic compound preparationNickel saltMicrosphere

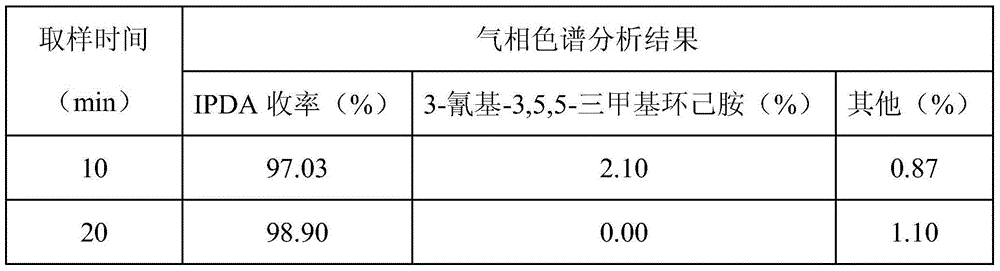

The invention relates to a preparation method of a Co / Ni and aluminum pyrophosphate composite hollow microsphere. The preparation method comprises the following steps of: preparing a mixed water solution A which contains 10wt%-25wt% of cobalt salt and 1wt%-3.5wt% of nickel salt; preparing a mixed water solution B of aluminum salt and phosphate; preparing a mixed water solution C of vinylamine and carbamide; firstly adding the mixed water solution B to a reaction kettle, then simultaneously adding the mixed water solution A and the mixed water solution C to the reaction kettle, and reacting to obtain a Co / Ni hydroxide and aluminum phosphate composite microsphere; filtering, washing, drying, and then calcinating to obtain a CoO / NiO and aluminum pyrophosphate composite hollow microspher; reducing the CoO / NiO and aluminum pyrophosphate composite hollow microspher by using H2 or CO to obtain the Co / Ni and aluminum pyrophosphate composite hollow microsphere. The whole preparation process flow is simple and can be put into industrial production easily. The prepared Co / Ni and aluminum pyrophosphate composite hollow microsphere is used for catalyzing ammoniation and hydrogenation of IPN (Interpenetrating Polymer Network) to prepare IPDA (Isophorone Diamine), is high in catalysis efficiency and has the IPDA selectivity being higher than 98%.

Owner:WANHUA CHEM GRP CO LTD +1

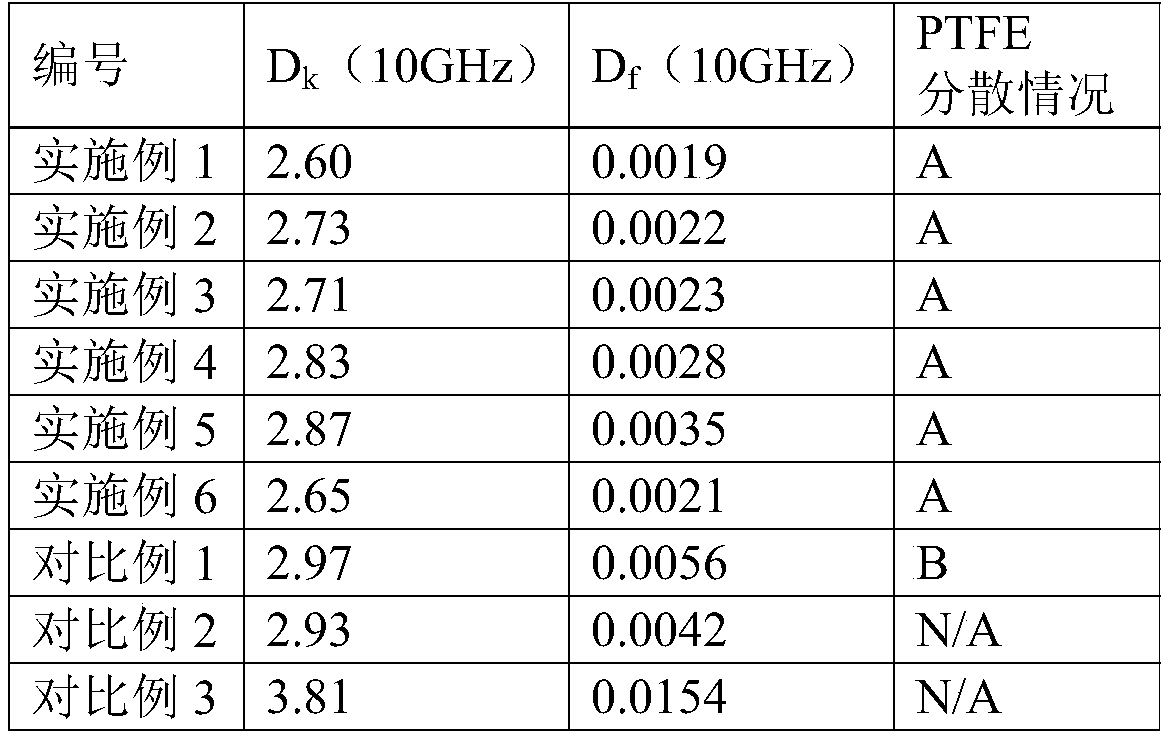

Preparation method of fluorine-containing polymer/polyimide composite film

The invention relates to a preparation method of a fluorine-containing polymer / polyimide composite film; raw materials comprise a fluorine-containing polymer, a diamine monomer, a dianhydride monomerand a fluorine-containing modifier, and the diamine monomer comprises aromatic diamine containing hydroxyl; the fluorine-containing modifier is fluorine-containing alkane containing an acyl chloride group or an anhydride group. By adopting the hydroxyl-containing aromatic diamine and the fluorine-containing modifier, the side chain of the prepared polyimide is grafted with a fluorine-containing side chain group, so that the compatibility with fluorine resin is improved, and the use of a fluorine-containing surfactant is avoided. Through the preparation method, the dielectric constant and the dielectric loss of the polyimide film are remarkably reduced.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

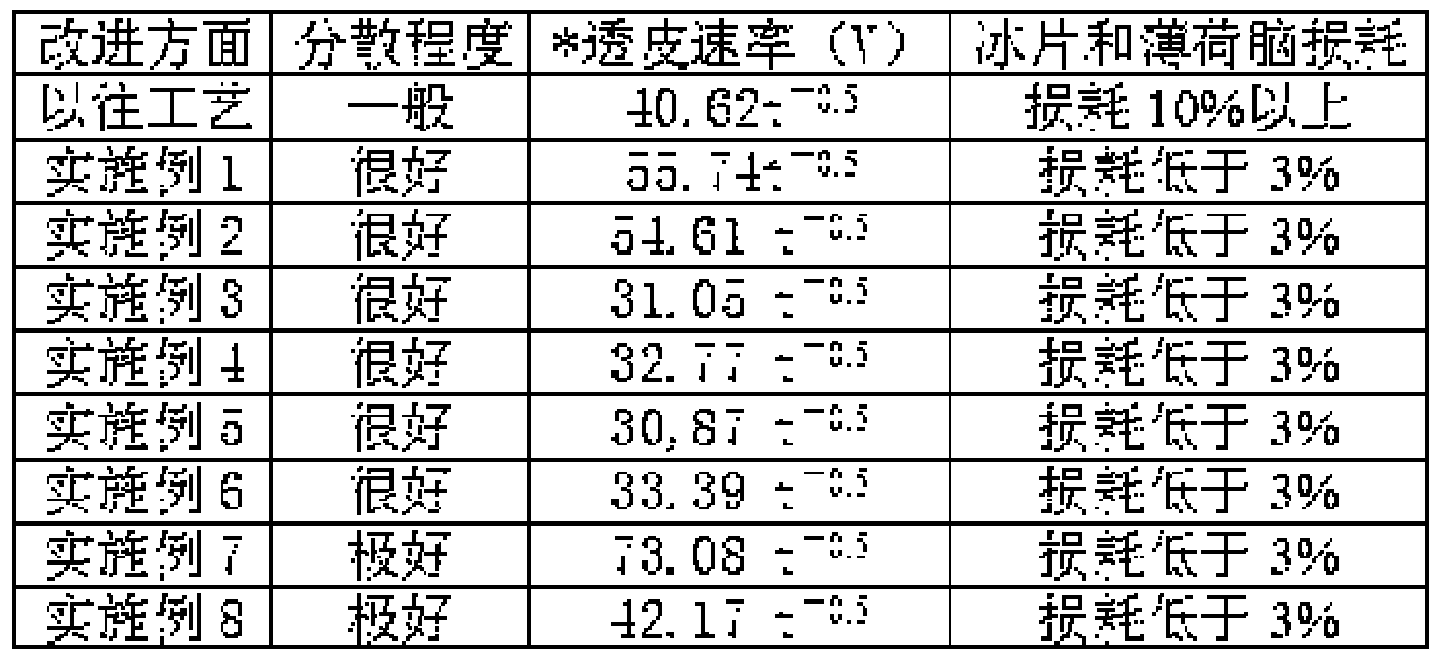

Skin external preparation with anti-inflammation, itching-relieving and disinfection and sterilization function and preparation method thereof

ActiveCN101361951AEvenly dispersedGood transdermal effectHydroxy compound active ingredientsAerosol deliveryAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a skin preparation for external application, which has remarkable efficacies of being anti-inflammatory, relieving itching and sterilizing, and can serve as a treating medicine and / or be used in different forms or different purposes of serving as a disinfector, health article, and the like, for assisting in treatment. The skin preparation aims at solving the technical problem of causing active ingredients to be evenly spread in accessorial added ingredients. The main improvement of the skin preparation for external application is that at least one of borneol and menthol is added in an accessory system in a liquid form and other active ingredients are added in the accessory system in a powder form for preparing. After improvement, the skin preparation for external application is easier to be spread evenly, also reduces material loss caused by grinding and simultaneously improves the percutaneous performance of drugs.

Owner:西藏海容唐果药业有限公司

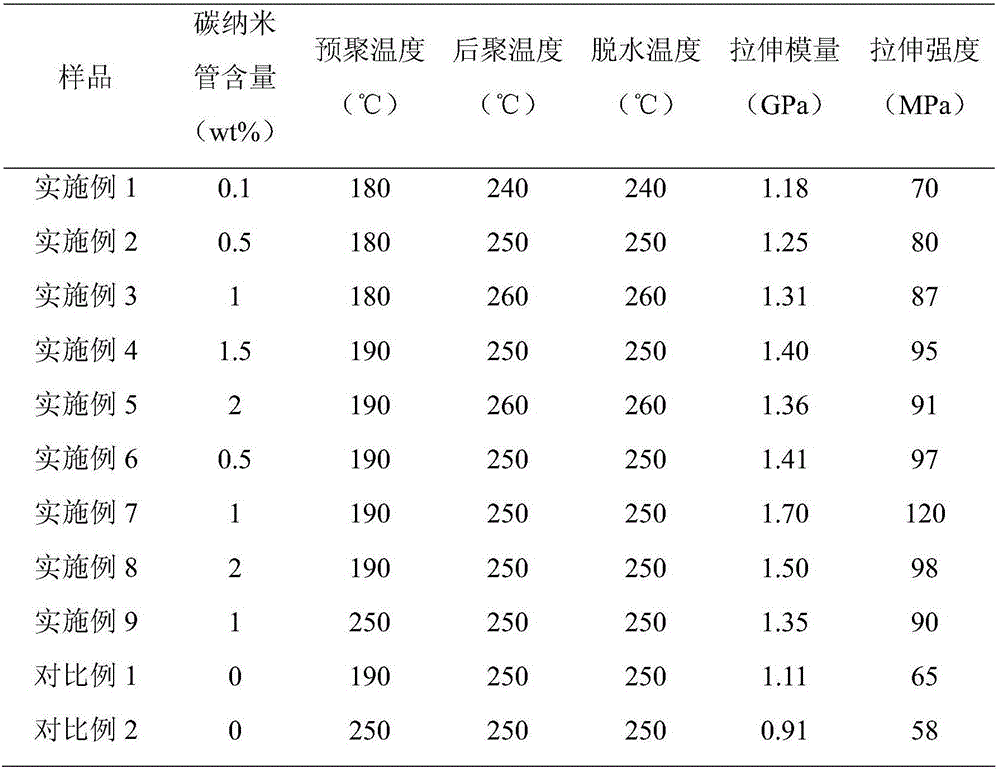

Method for preparing nylon composite modified by in-situ polymerization carbon nanotube

ActiveCN105669971AImprove mechanical propertiesImprove the lubrication effectIn situ polymerizationCarbon nanotube

The invention discloses a method for preparing a nylon composite modified by an in-situ polymerization carbon nanotube.According to the method, an MWCNTs-NH2 is prepared from the carbon nanotube, then a reaction with nylon salt is conducted, and the ammoniation multi-walled carbon nanotube composite is obtained.Compared with the prior art, the friction and wear performance, tensile strength and stability of the prepared composite are all greatly improved.

Owner:NANJING UNIV OF TECH

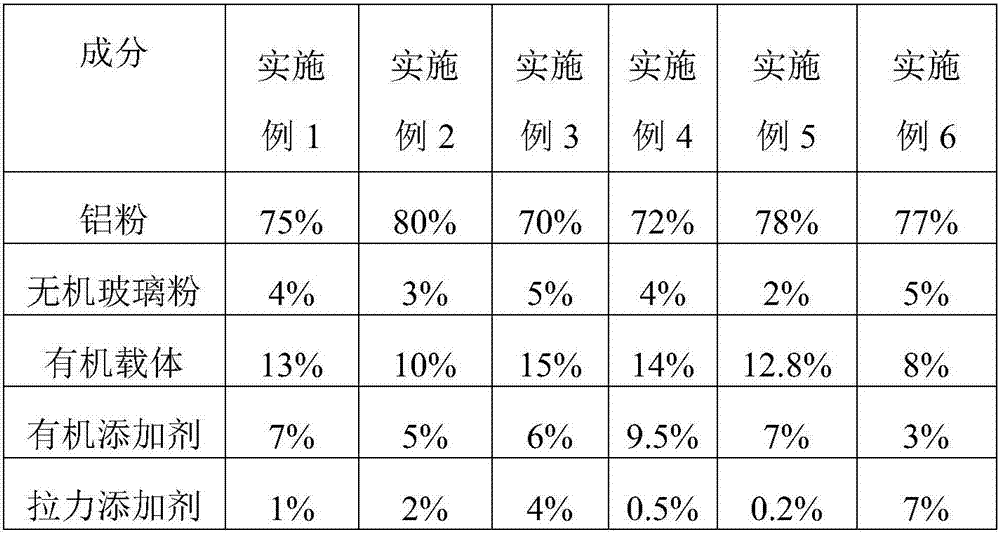

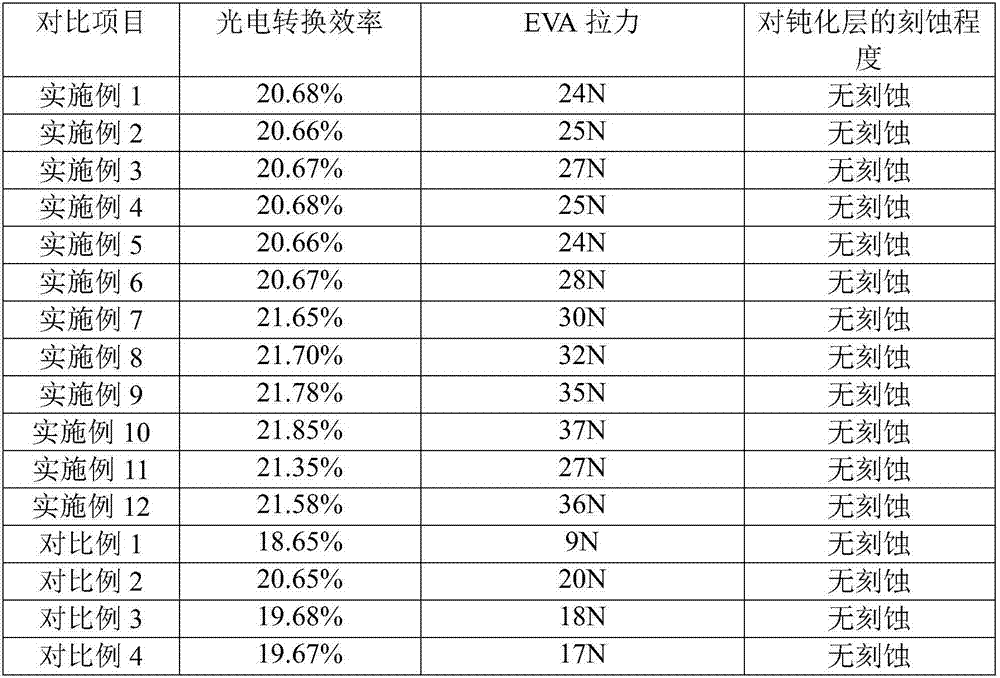

Conductive aluminum paste for back passivation solar cell and preparation method thereof

ActiveCN107331436AImprove performanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationOrganic matterUltimate tensile strength

The invention discloses a conductive aluminum paste for a back passivation solar cell. The conductive aluminum paste comprises various components having following weight percentages: 70-80% aluminum powder, 0.5-5% inorganic glass, a 1-15% organic carrier and a 0.1-10% tensile force additive. The tensile force additive is uniformly dispersed in the conductive aluminum paste, molecular bridges can be built between interfaces of inorganic and organic substances when the conductive aluminum paste is sintered, and the two kinds of materials with great disparity in nature are connected together to improve performance of a composite material and increase bonding strength, so a tensile force of the conductive aluminum paste is formed in the condition that a back field passivation layer is not damaged, the process defective rate of follow-up assemblies is reduced then, and photoelectric conversion efficiency of the cell is improved.

Owner:SICHUAN YINHE CHEM

Polyvinylidene fluoride hollow fiber porous membrane and preparation method thereof

ActiveCN101670247AImprove adsorption capacityProportionally largeSemi-permeable membranesFiberPolymer solution

The invention belongs to the technical field of polymer material preparation, relating to an increased polyvinylidene fluoride hollow fiber porous membrane and a preparation method thereof. The preparation method comprises the following steps: dispersing powdery saccharide compounds in organic solvent first and dissolving polyvinylidene fluoride with the solvent to form casting film polymer solution; and preparing a hollow fiber by a gelling phase inversion method; retaining powdery materials in a solid while using a precipitated medium to solidify polymer, and dissolving a saccharide powderymaterial by a hydrolysis method to retain a micropore structure; and controlling the molecular weight of powdery saccharide compounds and the size and quantity of powder particles to obtain films withdifferent apertures and porosity factors. The formula of polymer solution comprises the following components in percentage by weight: 15-30 percent of polyvinylidene fluoride, 40-75 percent of organic solvent and 10-30 percent of powdery saccharide compounds; and the invention has simple and easily-controllable process steps, reasonable film pore size, excellent film structure, favorable performance and low preparation cost and is suitable for industrial production.

Owner:QINGDAO SEACON WATER SERVICE TECH

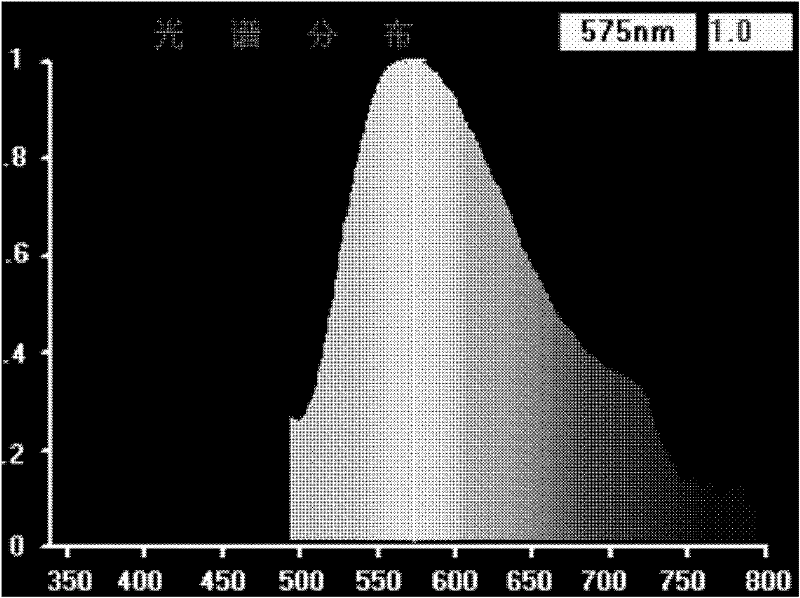

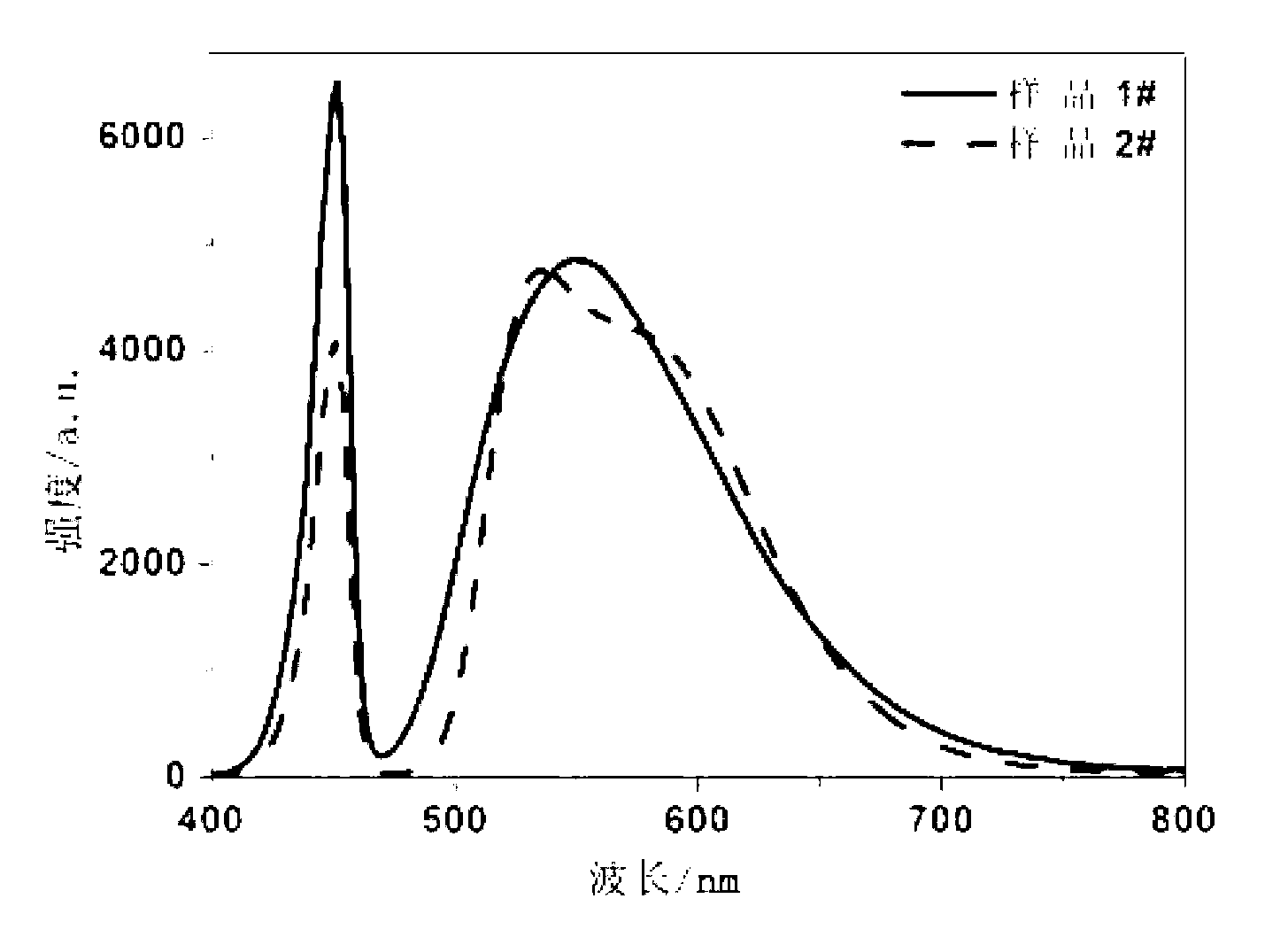

White light LED (Light Emitting Diode) fluorescent powder and preparation method thereof

InactiveCN102344809AAgglomerated particles are smallImprove spotGas discharge lamp usageLuminescent compositionsStrontium carbonateCrucible

The invention relates to white light LED (Light Emitting Diode) fluorescent powder with a chemical formula Sr(3-x)MgSiO7:xTb<3+>, wherein x is more than or equal to 0.01 and less than or equal to 0.25. The invention also provides a preparation method of the white light LED fluorescent powder. The preparation method comprises the following steps of: weighing silicon dioxide, magnesia, strontium carbonate and tetraterbium heptoxide; adding a charge compensator and a fusing assistant; mixing and grinding the raw materials; and feeding the mixture in a roasting crucible for roasting; cooling, crushing, washing and sieving to obtain the white light LED fluorescent powder. The white light LED fluorescent powder disclosed by the invention has the advantages of low price of raw materials, simple synthetic method, low loss of equipment, no need of special high-temperature equipment and the like.

Owner:IRICO

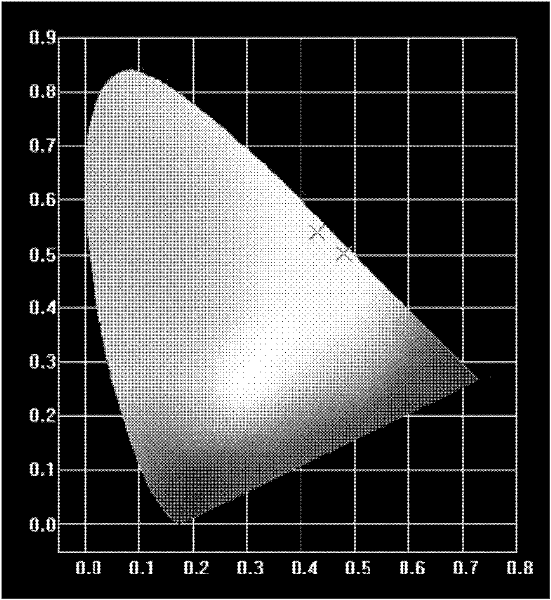

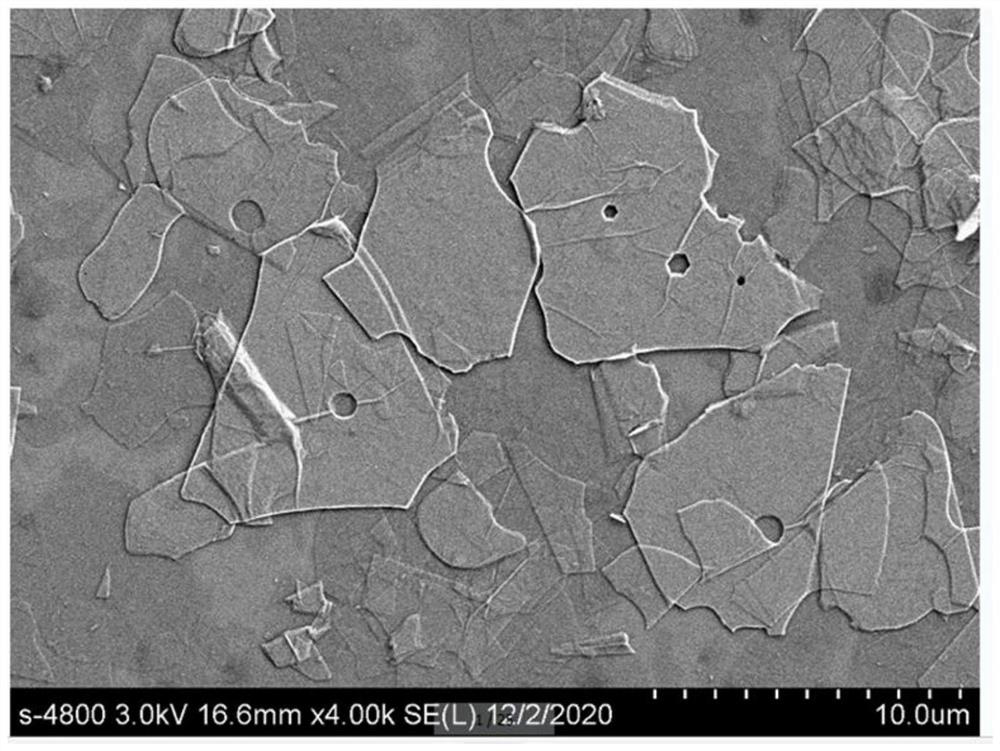

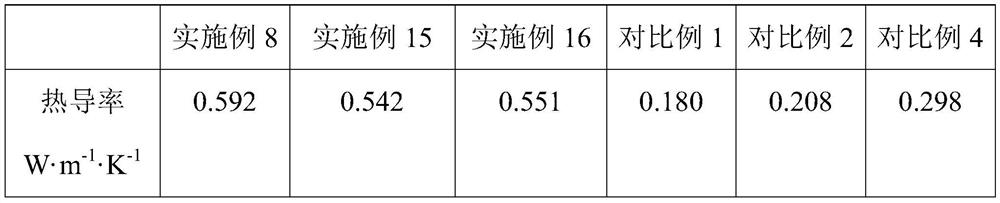

High-heat-conductivity high-molecular polymer composite heat-conducting material and preparation method thereof

ActiveCN113105735AImprove thermal conductivityEasy to evenly disperseChemical industryPrepolymerIsocyanate

The invention discloses a high-heat-conductivity high-molecular polymer composite heat-conducting material and a preparation method thereof, and relates to the technical field of heat-conducting materials, and the high-heat-conductivity high-molecular polymer composite heat-conducting material is obtained by adding an Ag / MXene sheet composite material into a high-molecular polymer heat-conducting material matrix; the invention also discloses a preparation method of the high-heat-conductivity high-molecular polymer composite heat-conducting material, which comprises the following steps: dispersing the Ag / MXene sheet composite material into an organic solvent, then adding into a polyurethane prepolymer, and heating, stirring and dispersing in a protective atmosphere; and adding polyisocyanate and a catalyst into the reaction system, heating, stirring for reaction, removing bubbles from the mixed material, pouring into a mold, and curing, thereby obtaining the product. The Ag nano particles and the two-dimensional MXene sheet material have a synergistic effect in heat conduction performance, the Ag / MXene sheet composite material is added into a high-molecular polymer heat conduction material matrix such as polyurethane, the heat conduction performance of the material can be remarkably improved, and the material can be applied to an electronic packaging material; and the preparation method is effective, controllable, economical and environment-friendly.

Owner:ANHUI UNIVERSITY

Nano fireproof material for buildings and preparation method thereof

The invention relates to a nano fireproof material for buildings and a preparation method thereof. The nano fireproof material for buildings comprises the following raw materials in parts by weight: 10-15 parts of a nano material, 10-15 parts of a graphene oxide-carbon nanotube dispersion liquid, 20-25 parts of clay, 22-35 parts of high-calcium fly ash, 18-26 parts of diatomite, 15-25 parts of vermiculite, 3-7 parts of a foaming agent, 4-10 parts of polyvinyl alcohol, 5-12 parts of zinc hydroxystannate, and 35-50 parts of water. According to the nano fireproof material for buildings, grapheneoxide and carbon nano tubes form the dispersion liquid, the dispersion liquid and the nano materials form a three-dimensional frame structure, and when the three-dimensional frame structure is matchedwith other materials in the components for action, the compatibility and dispersity of all the raw materials can be improved, the agglomeration phenomenon is effectively reduced, and finally, the toughness, the strength and the flame retardant property of the fireproof material are improved.

Owner:西安美刚达科技发展有限公司

Preparation method for LED (Light Emitting Diode) fluorescent powder

InactiveCN102329614AAgglomerated particles are smallFully absorbedLuminescent compositionsSemiconductor devicesGadolinium oxideLight-emitting diode

The invention discloses a novel preparation method for LED (Light Emitting Diode) fluorescent powder. The method comprises the following steps of: based on a chemical formula of Y4-x-yGdGa5R1-2O16:Ce<3+>xEu<2+>y, weighing yttrium oxide, gallium oxide, gadolinium oxide, alkaline earth, cerium oxide and europium oxide according to a molar ratio respectively, wherein X is equal to 0.05-0.10; Y is equal to 0.01-0.10; adding 1-8 percent of mixed fluxing agent including barium fluoride, cerium fluoride and yttrium fluoride to obtain a mixture; uniformly mixing the mixture in a mixer; filling in a baked corundum crucible; placing in a high-temperature furnace to heat; introducing nitrogen and hydrogen mixed gas or pure hydrogen as a reducing atmosphere; preserving heat; heating to bake; cooling and then crushing; and washing and then screening to obtain the LED fluorescent powder. The fluorescent powder has a wide wave spectrum range; and emission spectrum of 530-630nm can be obtained when the fluorescent powder is excited by light of 440-460nm.

Owner:IRICO

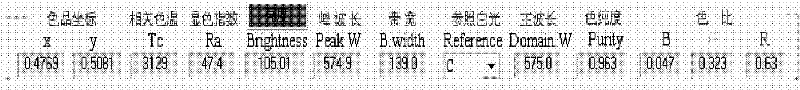

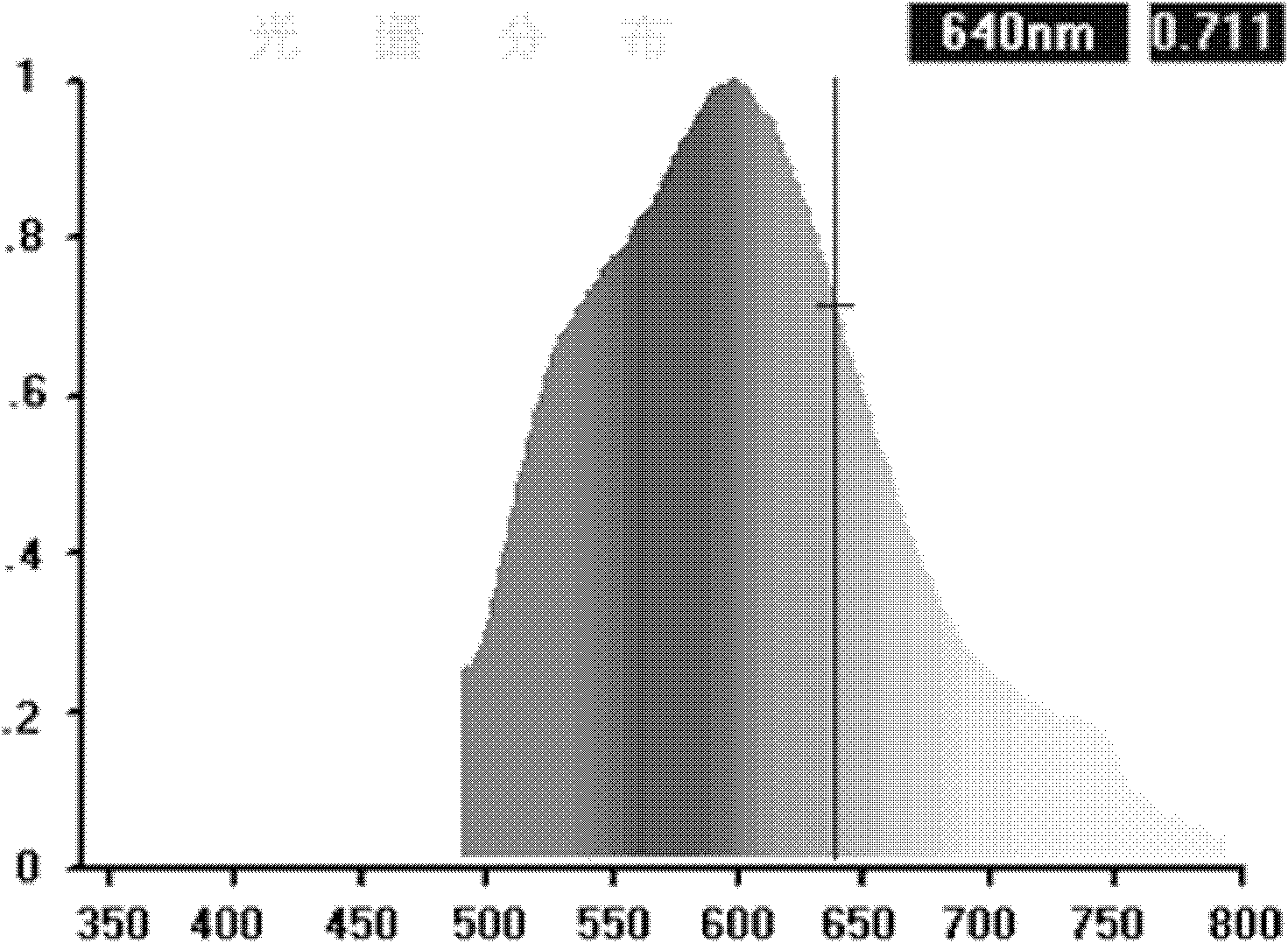

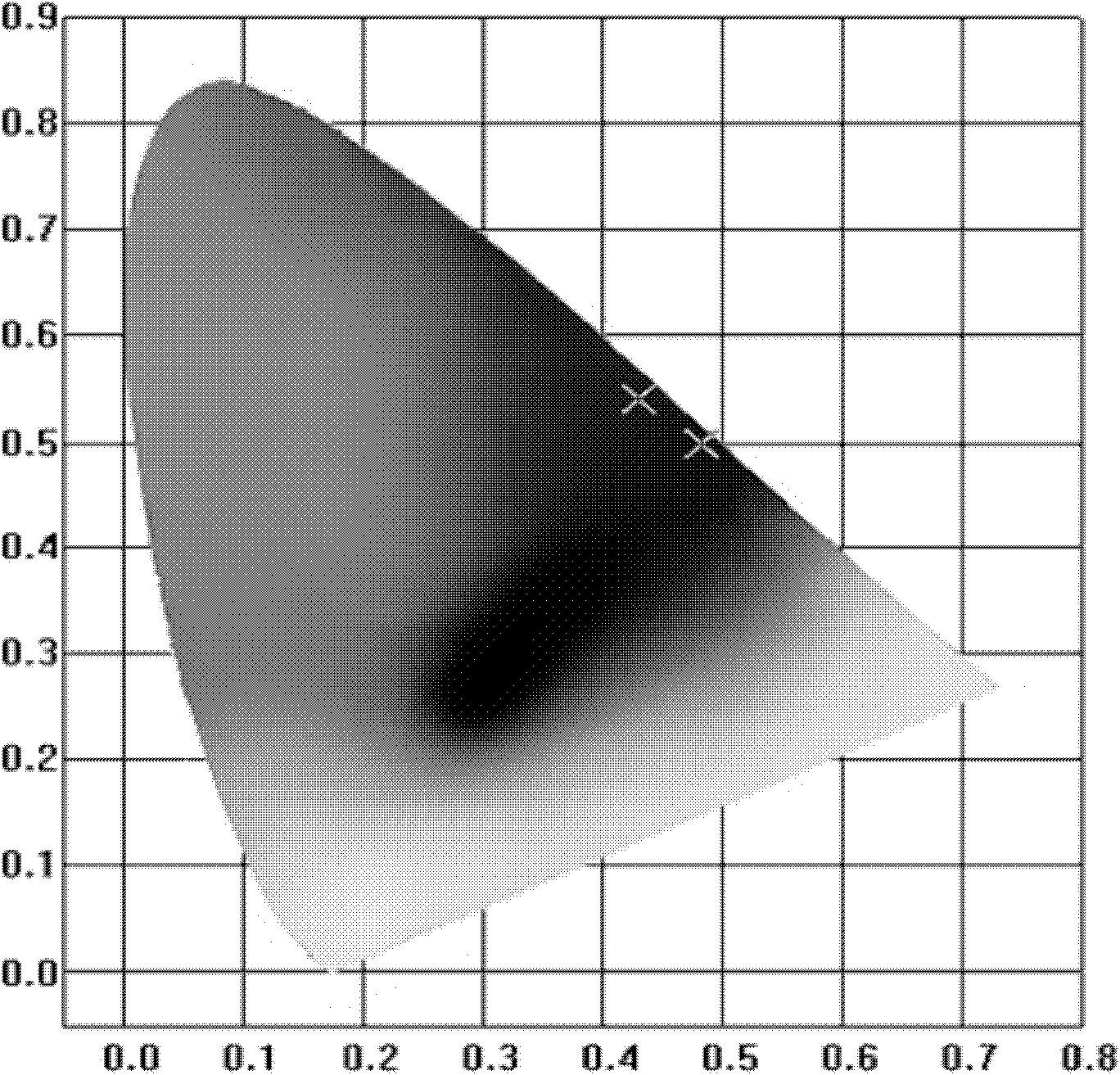

Method for increasing color saturation of yellow fluorescent powder used for LED (light-emitting diode)

ActiveCN102703075ALess agglomerated particlesAppearance rulesGas discharge lamp usageLuminescent compositionsColor saturationLight-emitting diode

The invention discloses a method for increasing color saturation of yellow fluorescent powder used for a light-emitting diode (LED) on the premise of not sharply decreasing the luminance of the fluorescent powder. The method comprises the steps of adjusting the proportion of red light components and blue light components in an emission spectrum of the yellow fluorescent powder to some extent, improving the smooth degree of the surfaces of composite powder particles, selecting raw materials, mixing, burning and crushing the selected materials, rolling the materials to powder, sieving, secondary sintering, cleaning and drying the powder, and the like. The finished product of yellow fluorescent powder used for the LED has the advantages that the appearance is regular, the surfaces of powder particles are smooth, the liquidity is good, the powder is easy to be evenly dispersed in packaging glue, and especially, the CIE (International Commission on Illumination) coordinate of the power is improved, namely the color saturation of the powder is improved.

Owner:英特美光电(苏州)有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com