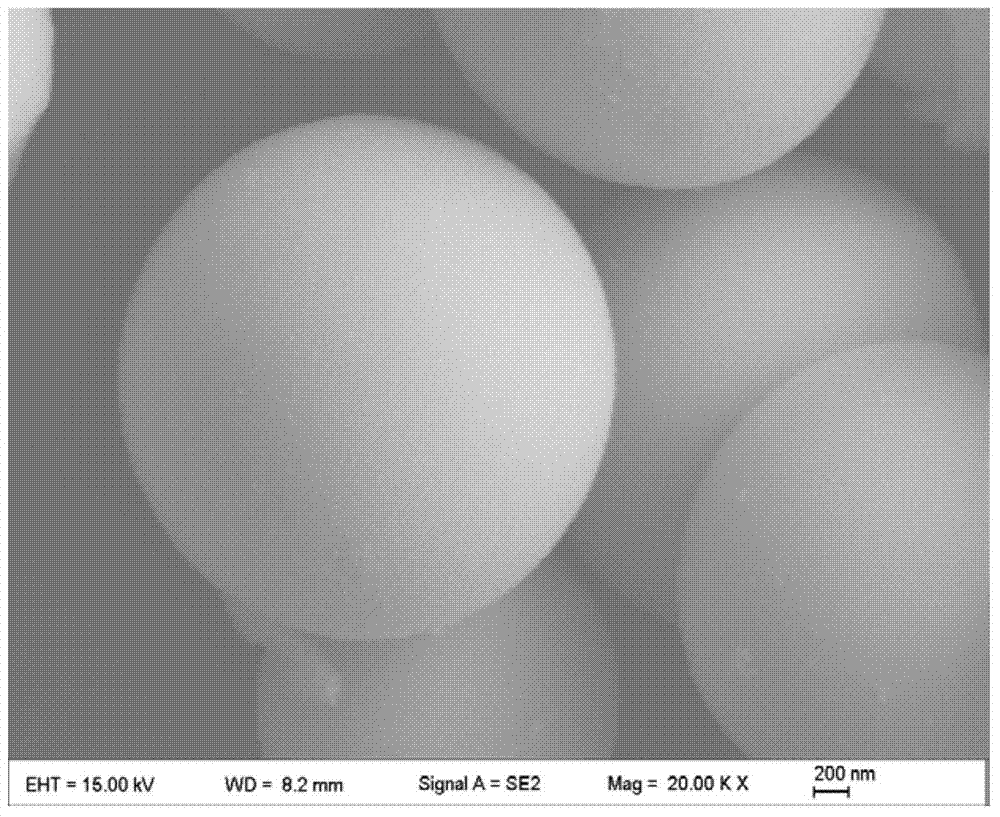

Preparation method of micro-nano tin dioxide solid spheres

A tin dioxide, solid ball technology, applied in the directions of tin oxide, nanotechnology, nanotechnology, etc., can solve the problems of low environmental protection in the preparation process, difficulty in densifying the reinforcing phase, unfavorable industrial production, etc., and is suitable for large-scale industrial production. Smooth surface and uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

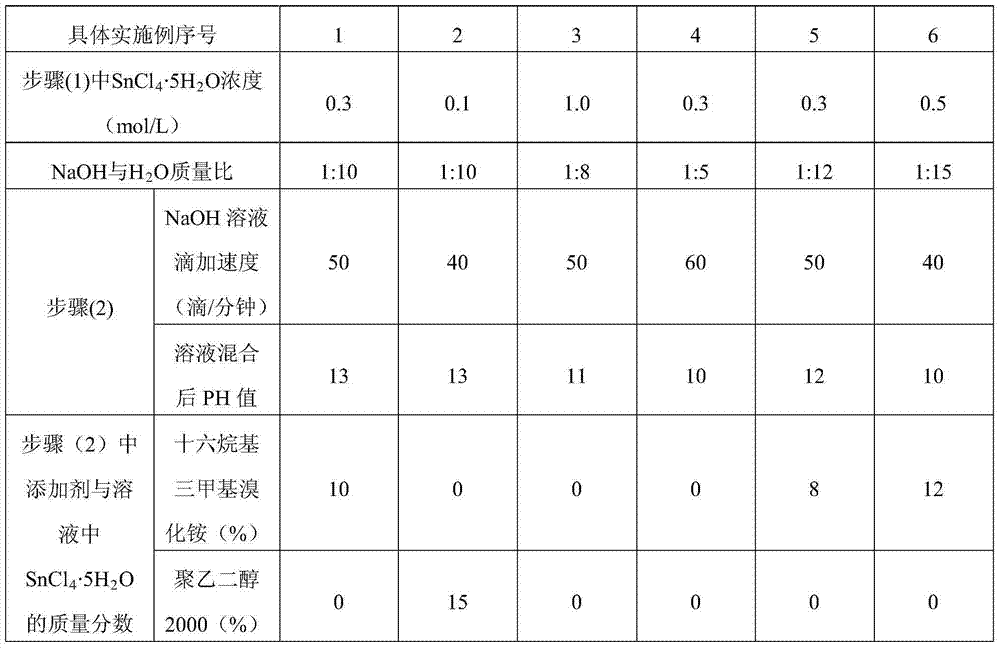

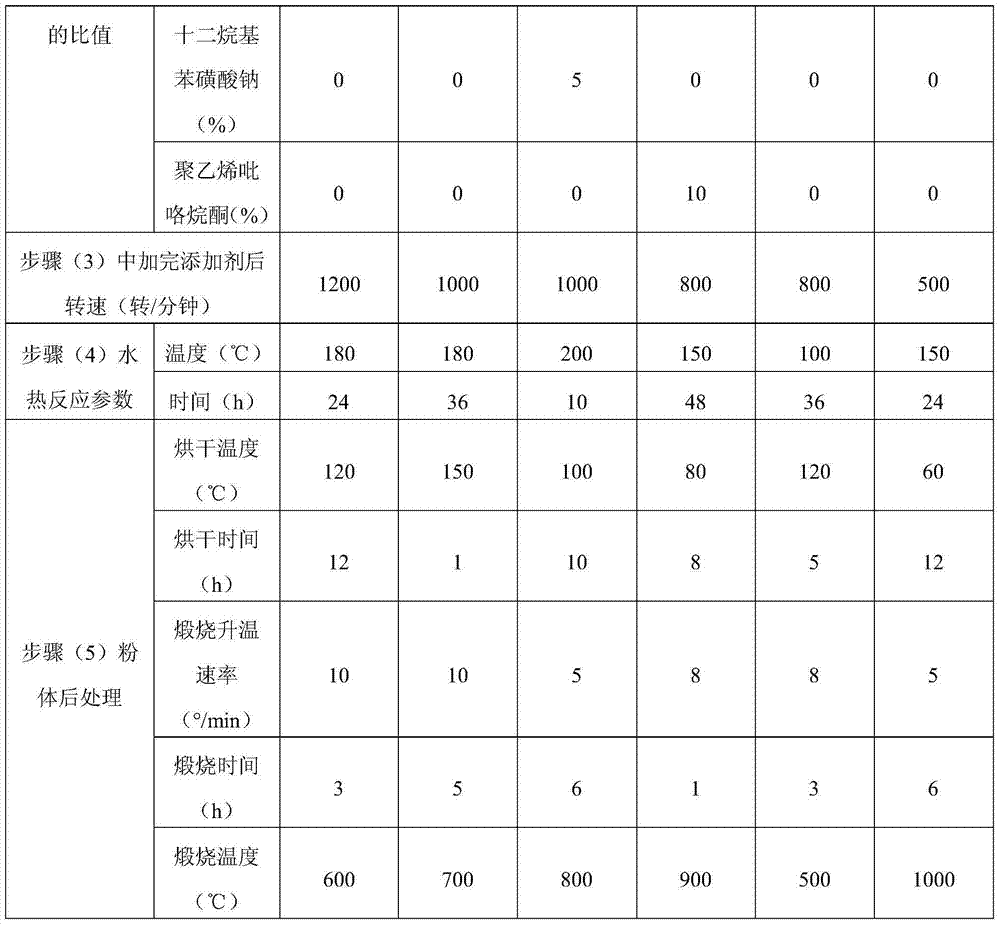

[0022] The present invention will be further described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention and should not be regarded as limiting the scope of the present invention.

[0023] The preparation method of the micro-nano tin dioxide solid ball of the present invention includes the following steps:

[0024] (1) SnCl 4 ·5H 2 O is dissolved in deionized water, and under sufficient stirring conditions, a solution with a concentration of 0.1~1.0mol / L is formed; press NaOH and H 2 The mass ratio of O is 1:5-15, the NaOH is weighed and dissolved in deionized water, and NaOH solution is obtained by stirring;

[0025] (2) Add NaOH solution uniformly to SnCl at a rate of 40-60 drops / min 4 ·5H 2 In the O solution, adjust the pH of the solution to 10-13; stir at 500-1200 revolutions per minute while dripping to obtain a uniform mixed solution;

[0026] (3) Transfer the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com