Patents

Literature

75 results about "Solid sphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Solid Sphere Model was the first atomic model and was developed by John Dalton in the early 19th century. He hypothesized that an atom is a solid sphere that could not be divided into smaller particles. He came up with his theory as a result of his research into gases. He realized that certain gases only combined in specific proportions.

Porous metallic product and method for making same

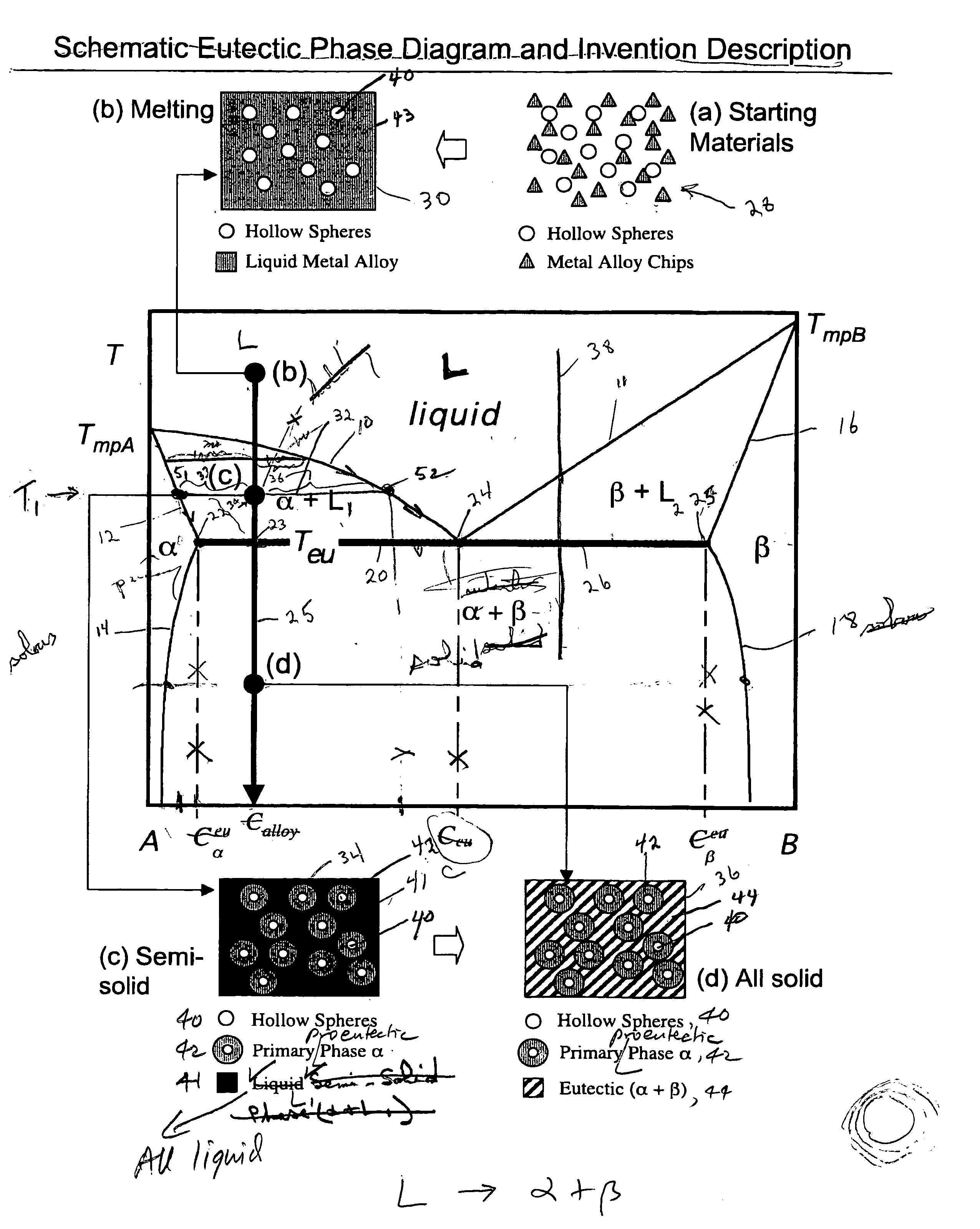

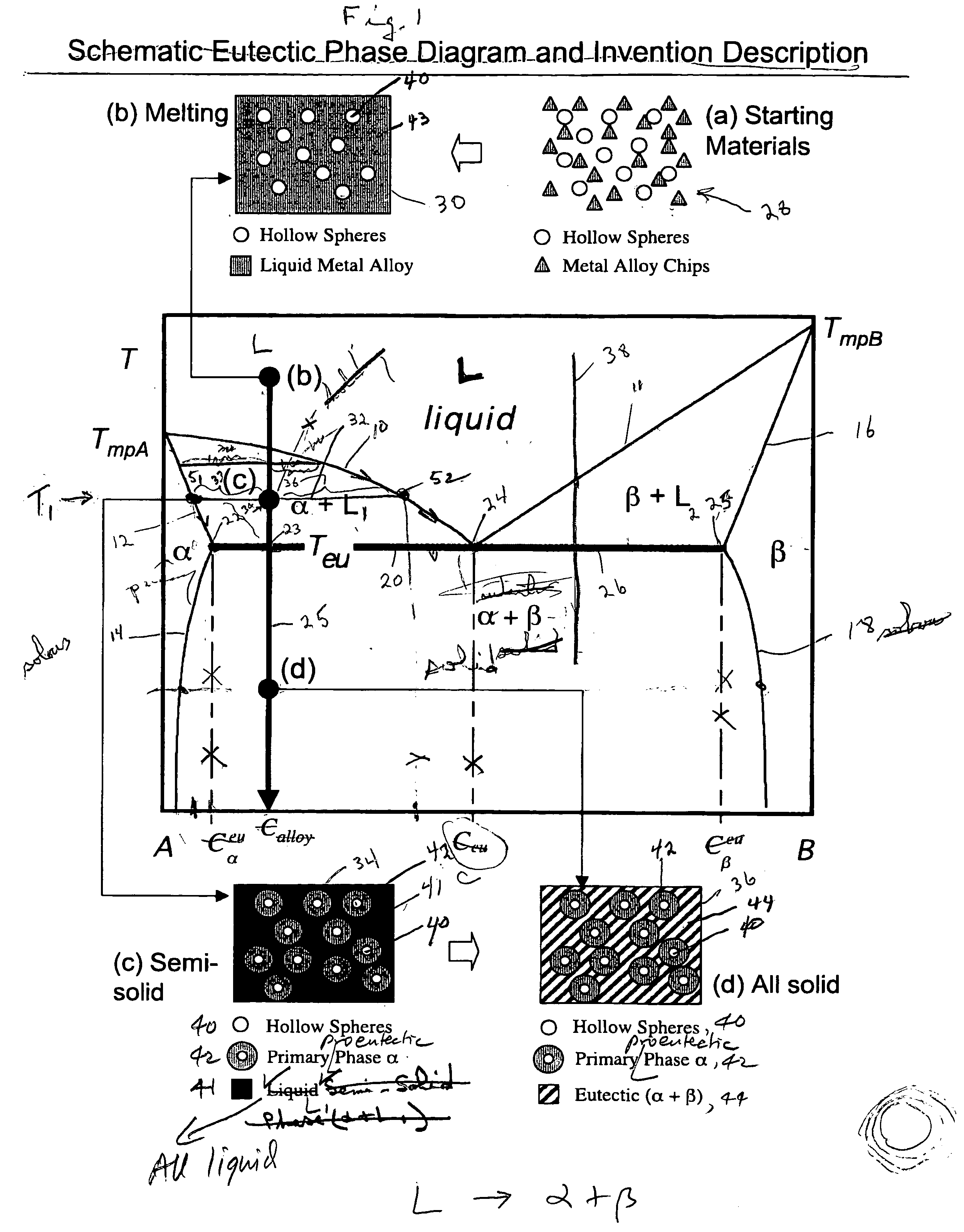

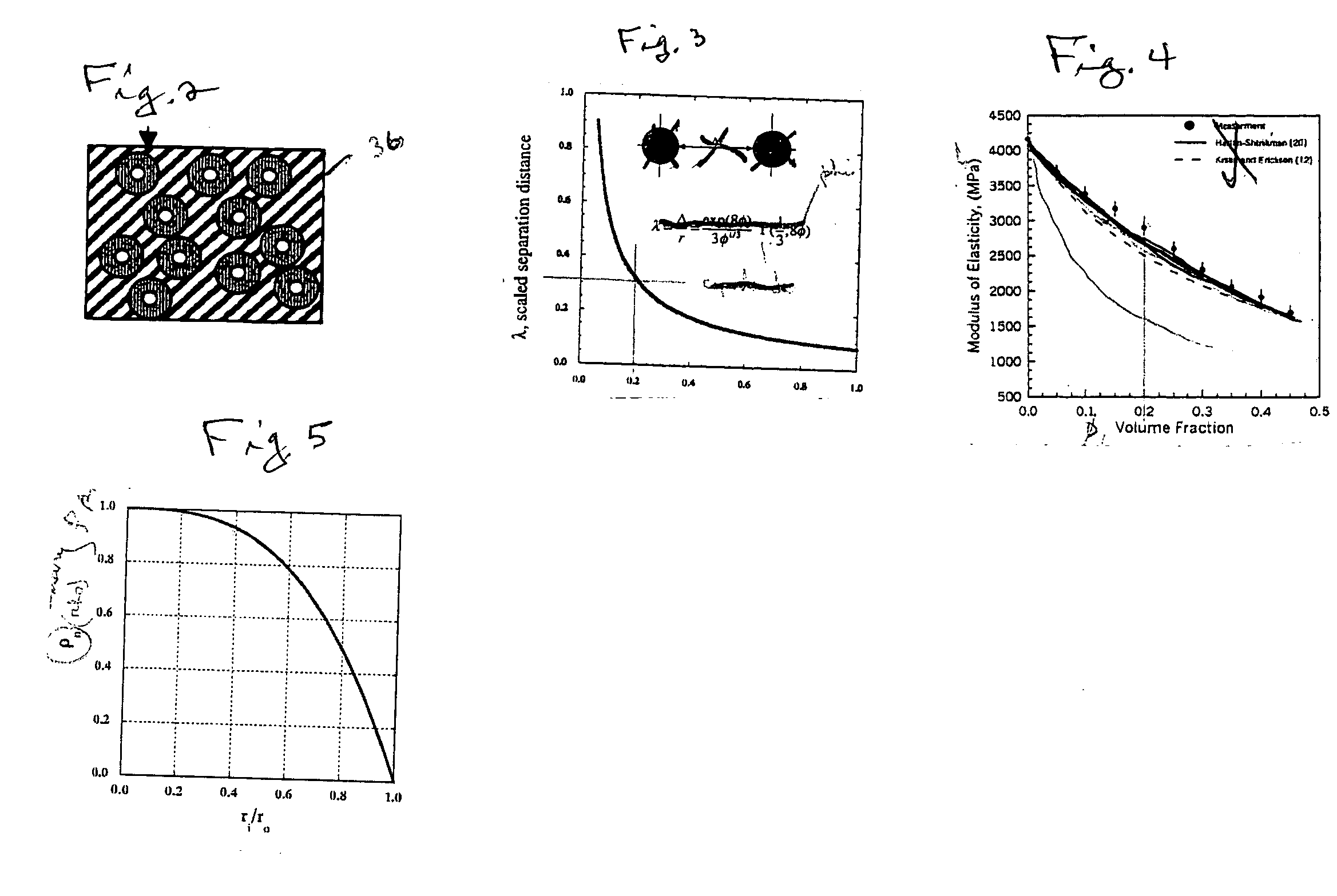

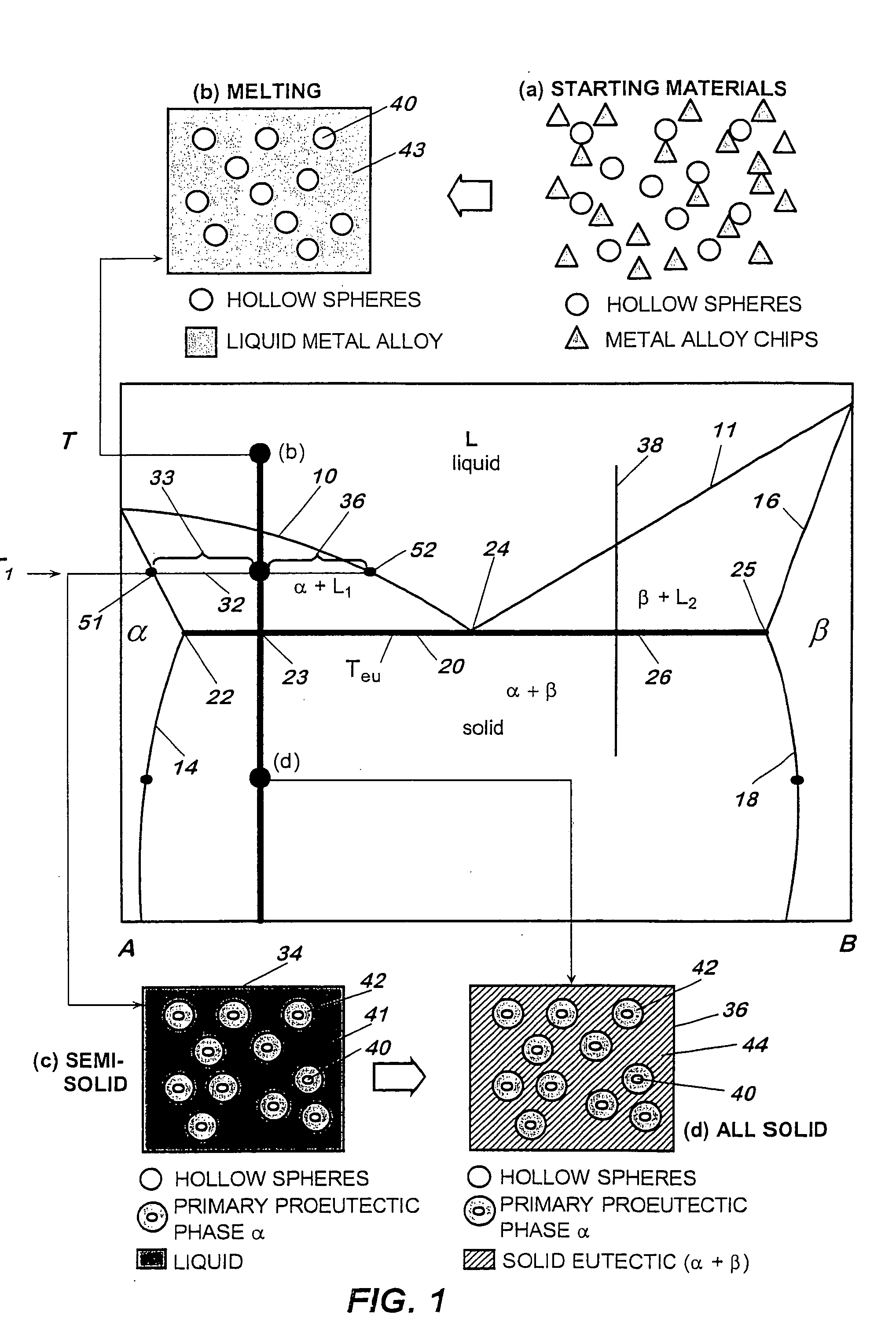

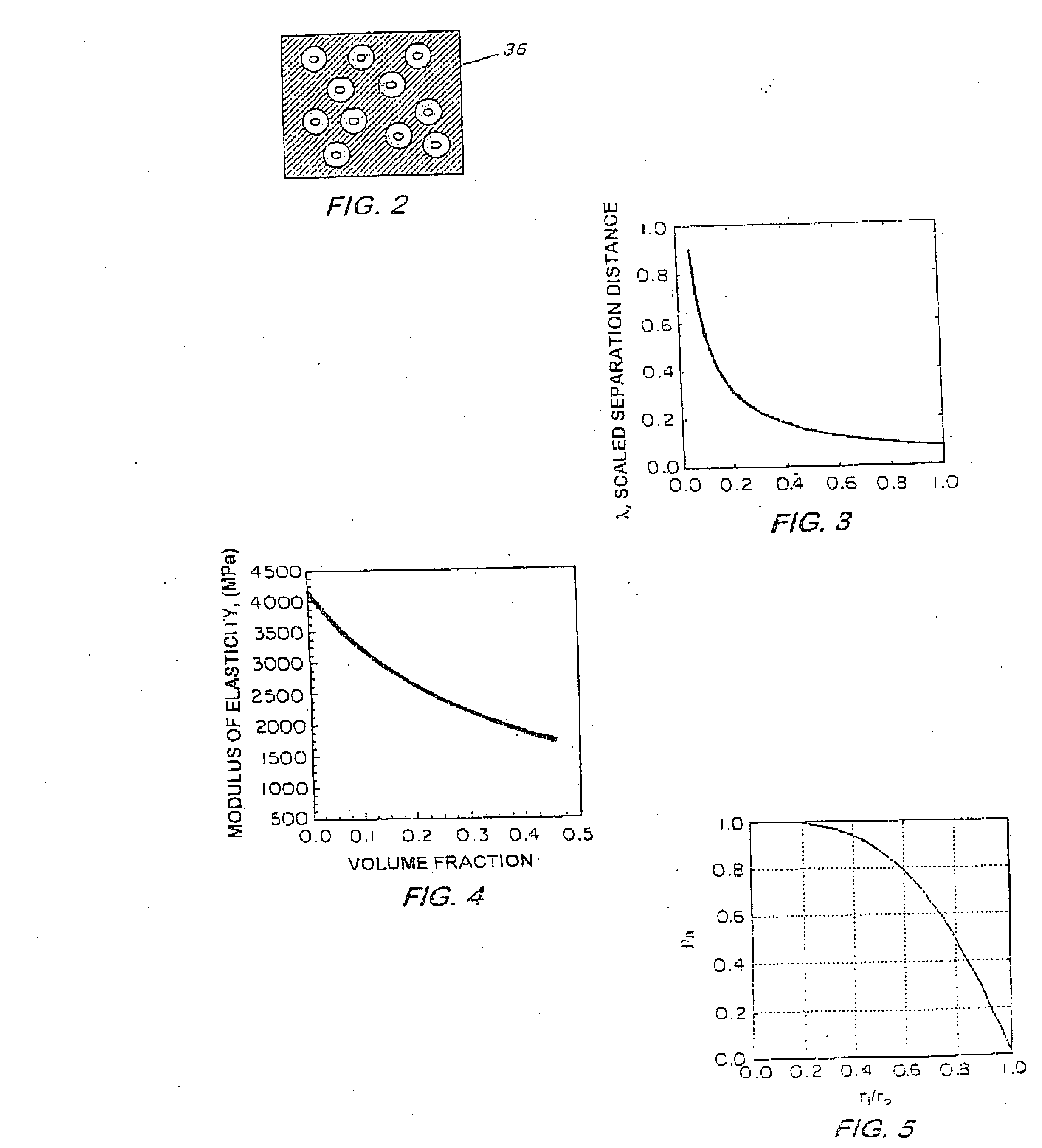

This invention pertains to a product and a method for making the product. The product is a lightweight solid porous metallic product containing small solid spheres having a coating of a primary alpha phase thereon disposed in a solid metal alloy eutectic matrix. The method includes the steps of mixing the hollow rigid spheres and a metal alloy, which metal alloy can be preheated to render it molten, in order to form a dispersion of the spheres distributed in the molten alloy; initially cooling the dispersion to render it semi-solid whereby the spheres are coated by a solid and the coated spheres are disposed in the semi-solid mixture of the solid and liquid; and finally cooling the sphere-containing semi-solid mixture to a temperature at which the sphere-containing semi-solid mixture becomes solid and the product is formed.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

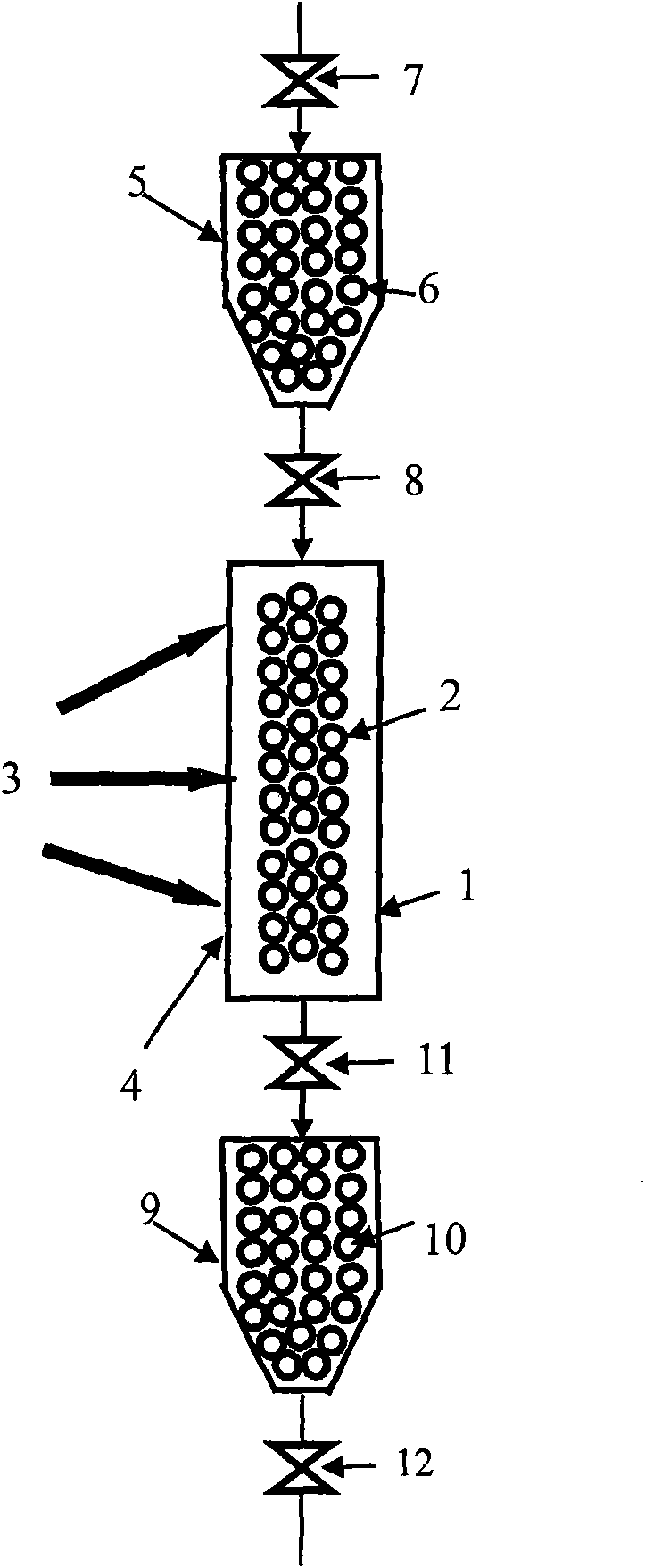

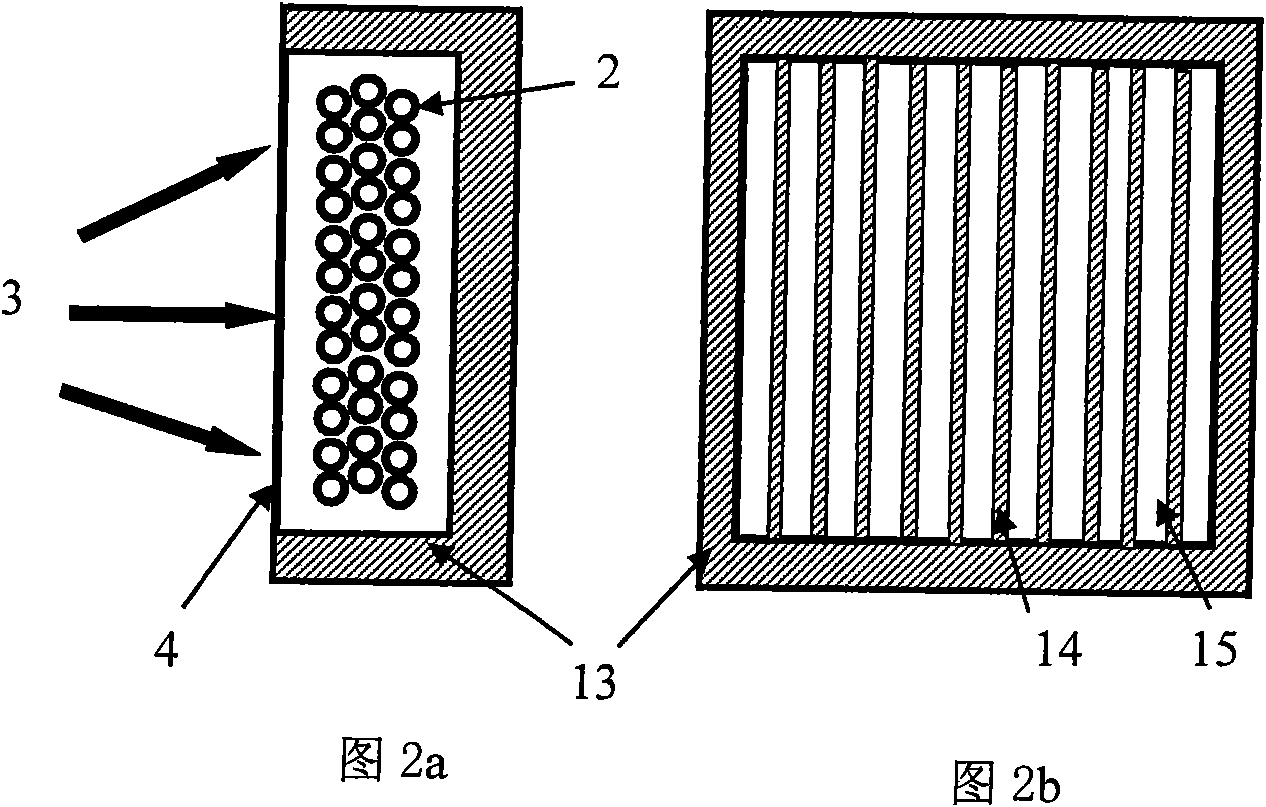

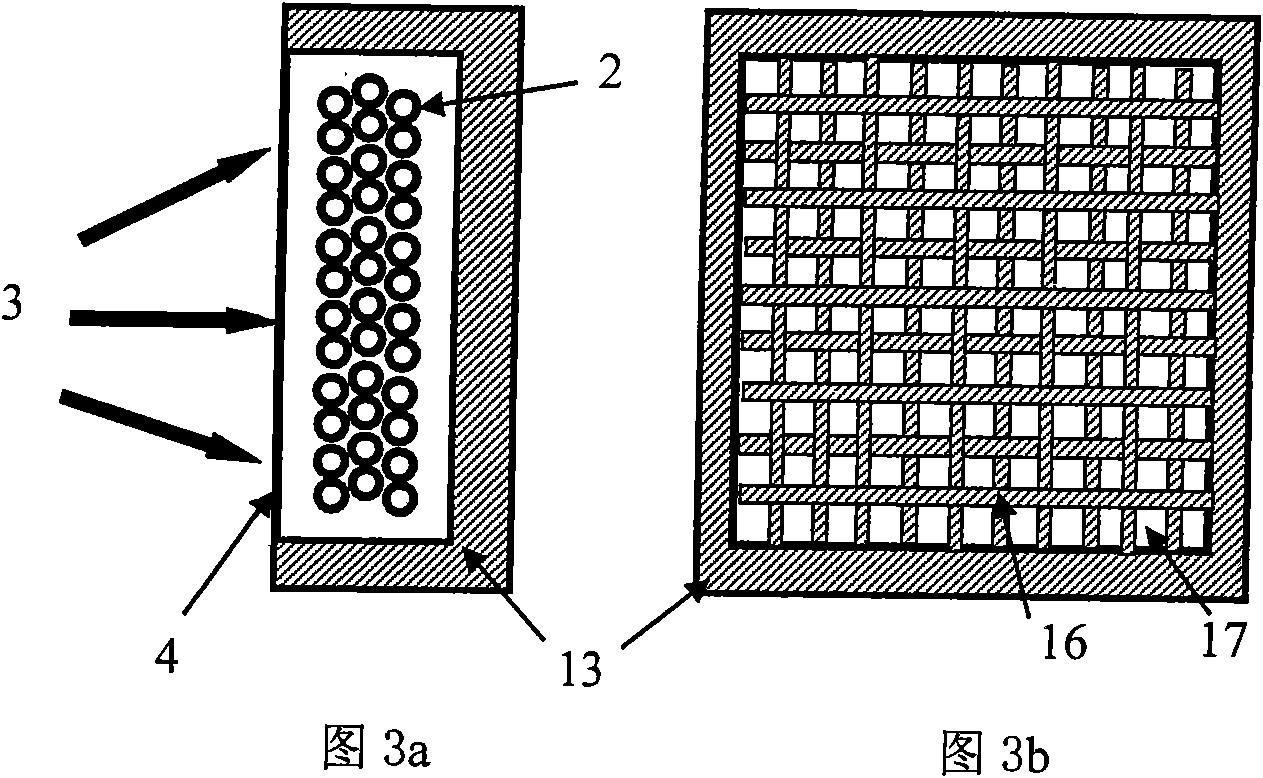

Solid sphere flux heat absorber for solar thermal power generation

InactiveCN101634490AImprove securityAvoid the risk of heatingSolar heat devicesSolar thermal energy generationSolid sphereInlet valve

The invention relates to a solid sphere flux heat absorber for solar thermal power generation, comprising a solid sphere heating absorbing device (1), a heat absorbing solid sphere (2) arranged in the solid sphere heating absorbing device (1), a lower-temperature sphere storage tank (5) arranged on the upper part of the solid sphere heating absorbing device (1), a high-temperature sphere storage tank (9) arranged on the lower part of the solid sphere heating absorbing device (1), lower-temperature sphere storage tank inlet valves (7) and (8) respectively arranged on the upper part and the lower part of the lower-temperature sphere storage tank (5), and high-temperature sphere storage tank inlet valves (11) and (12) respectively arranged on the upper part and the lower part of the high-temperature sphere storage tank (9). The solid sphere heating absorbing device (1) faces an energy flux of a radiation receiving window (4) at the throwing side of radiation energy flux (3). The lower-temperature sphere storage tank (5) is used for storing a lower-temperature solid sphere (6), and the high-temperature sphere storage tank (9) is used for storing a high-temperature solid sphere (10). The surface of the heat absorbing solid sphere (2) is black or is coated with solar selective absorption coatings.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

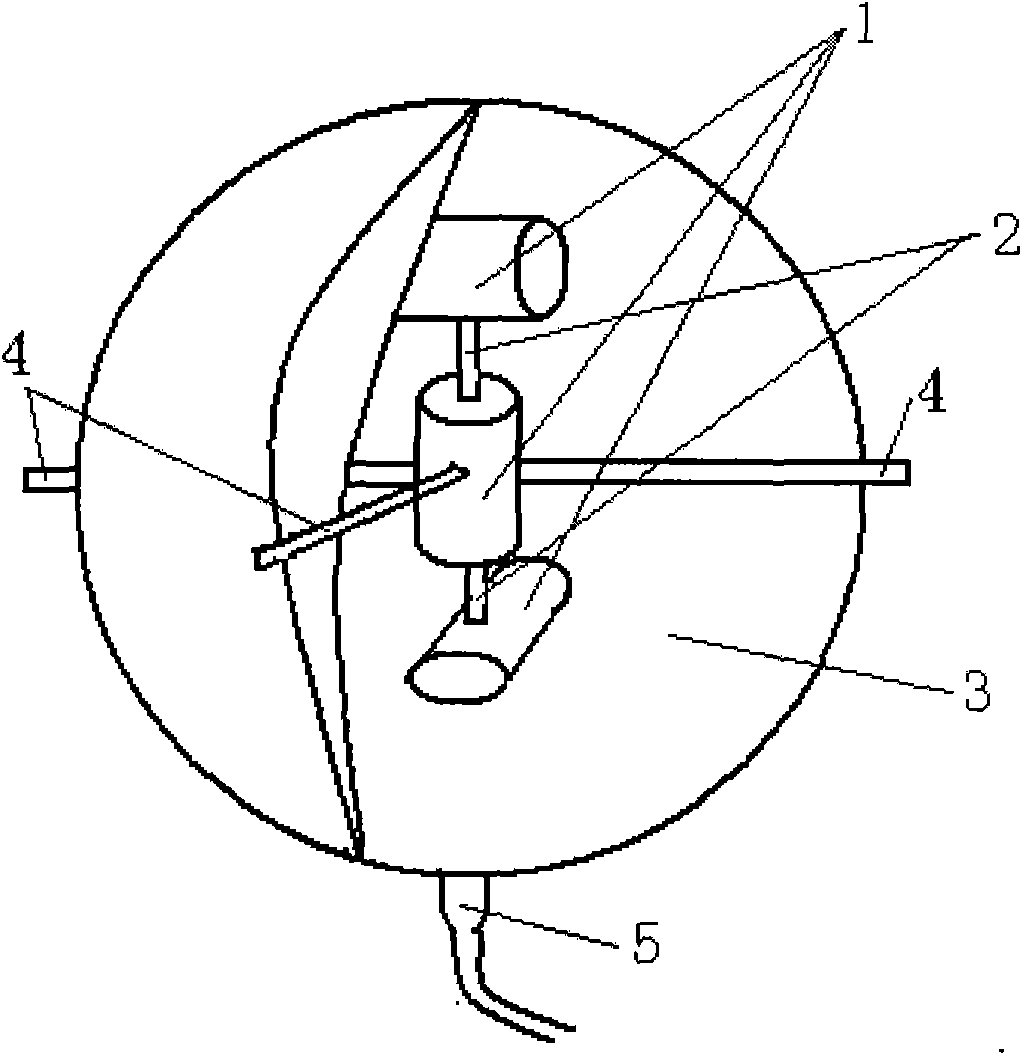

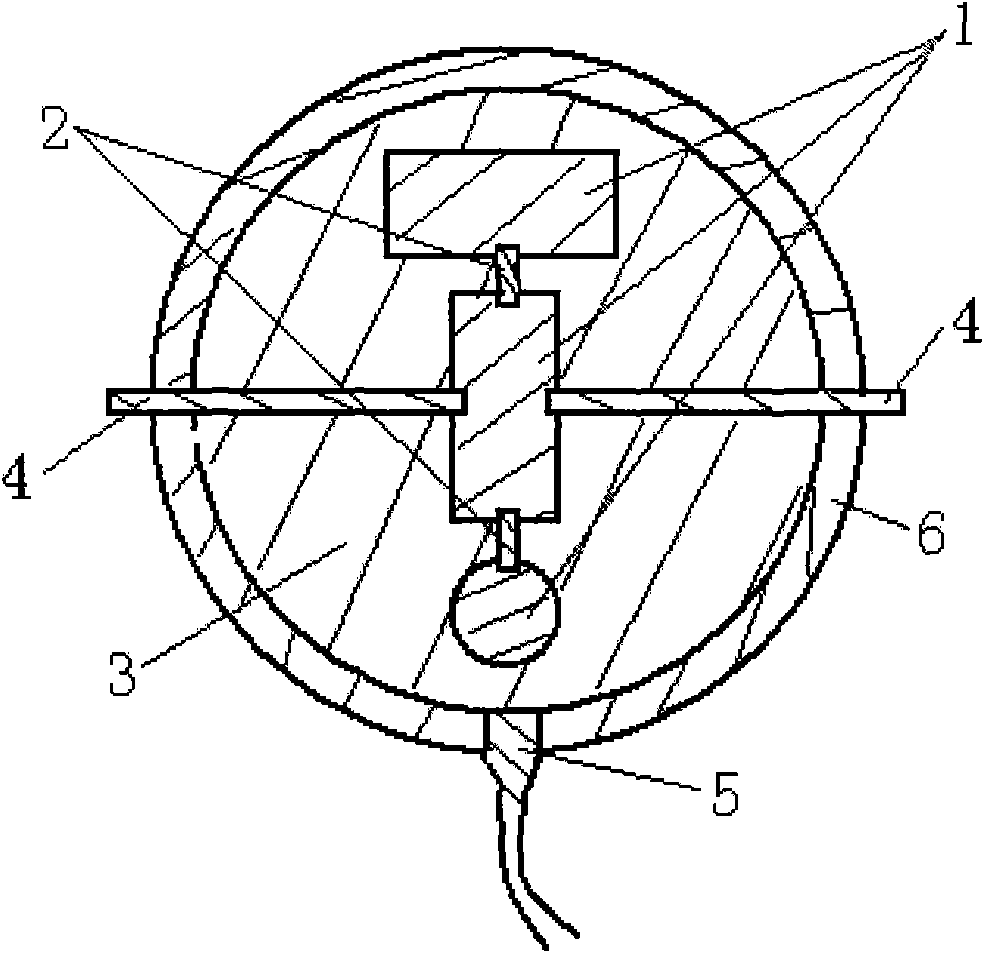

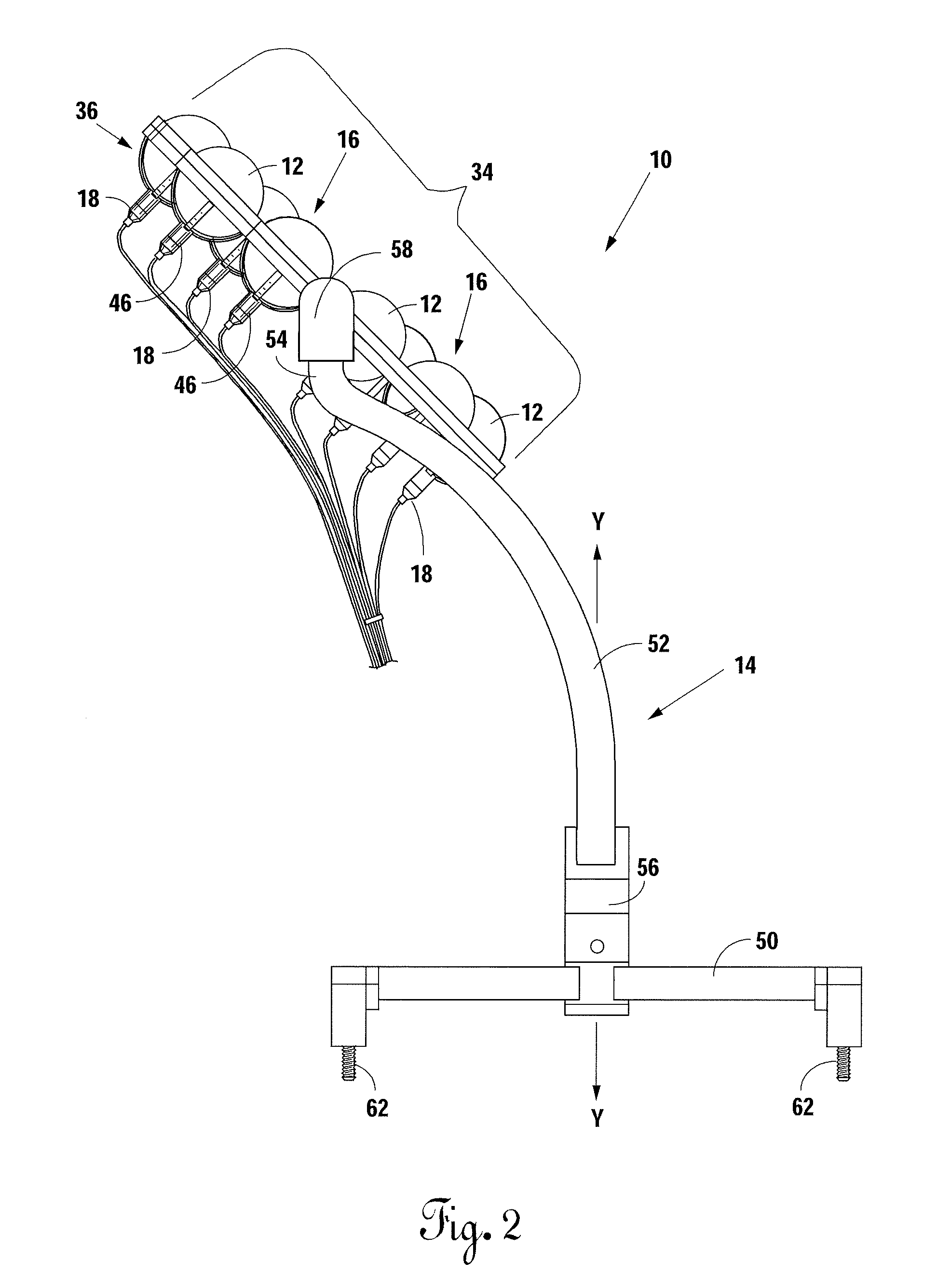

Trivector hydrophone based on piezoelectric velocity sensor

InactiveCN101561313AMeet the design requirementsSimple structureWave based measurement systemsSubsonic/sonic/ultrasonic wave measurementLow noiseHydrophone

The invention provides a trivector hydrophone based on a piezoelectric velocity sensor, which comprises a spheroid, and hanging elements, a velocity sensor and a multi-core output tape cable all arranged in the spheroid, wherein the velocity sensor comprises three piezoelectric velocity sensors which are connected in sequence through connecting rods; one end of the four hanging elements is fixed on the middle piezoelectric velocity sensor, while the other end extends out of the spheroid; and the spheroid is a solid sphere. The average density of the vector hydrophone approximates to the water medium density; the channel sensitivity is high in a working frequency band below 2,000 hz and is irrelevant to the frequency; the vector hydrophone has good cosine directivity; and the vector hydrophone is not limited by an obliquity during working. The vector hydrophone can be widely used in various fields of hydroacoustics, such as sonobuoys, low noise motion target measurement, target orientation and the like.

Owner:HARBIN ENG UNIV

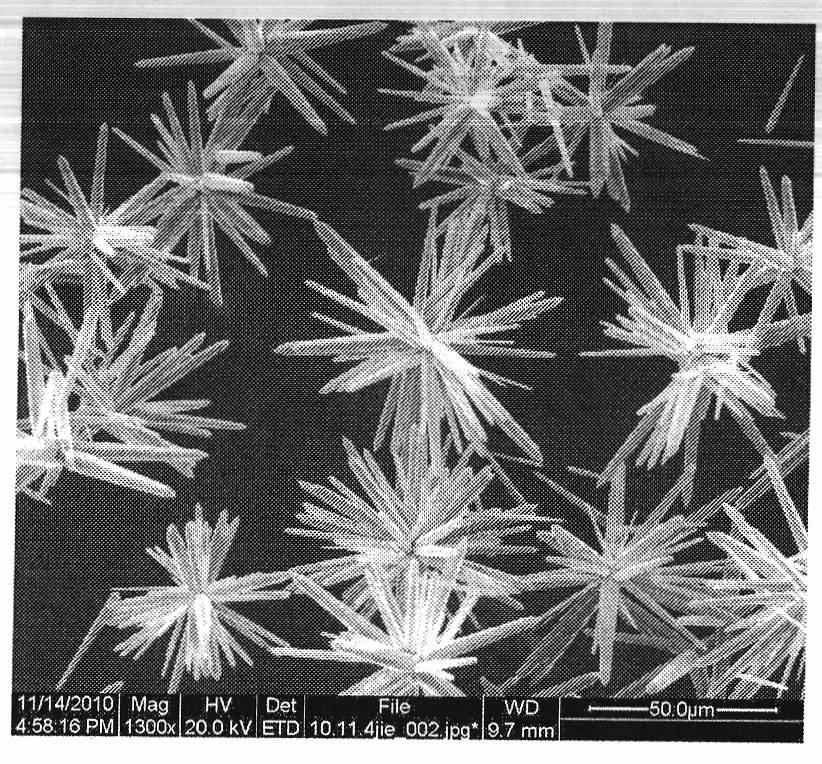

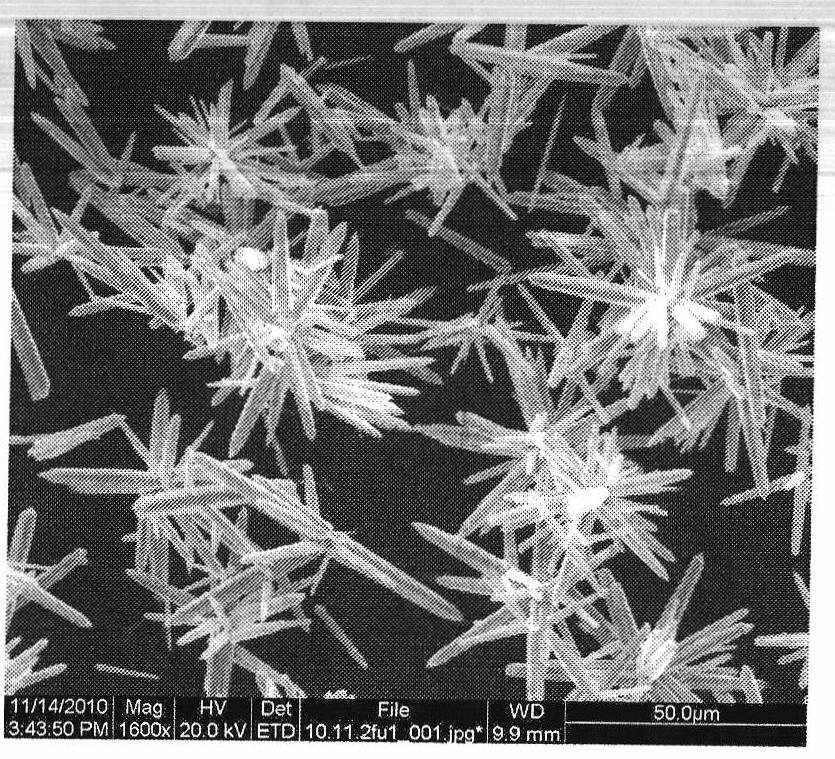

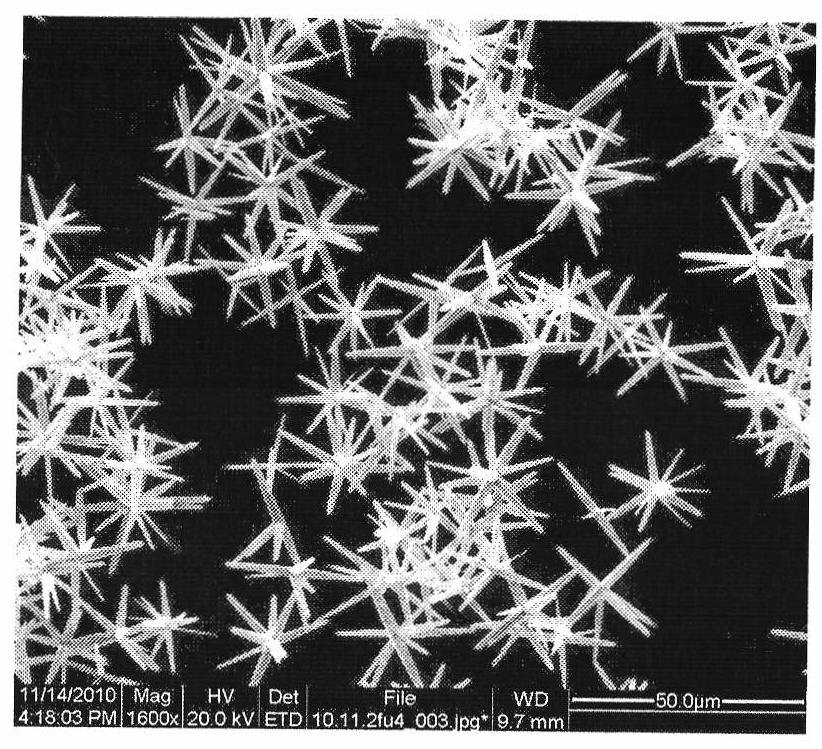

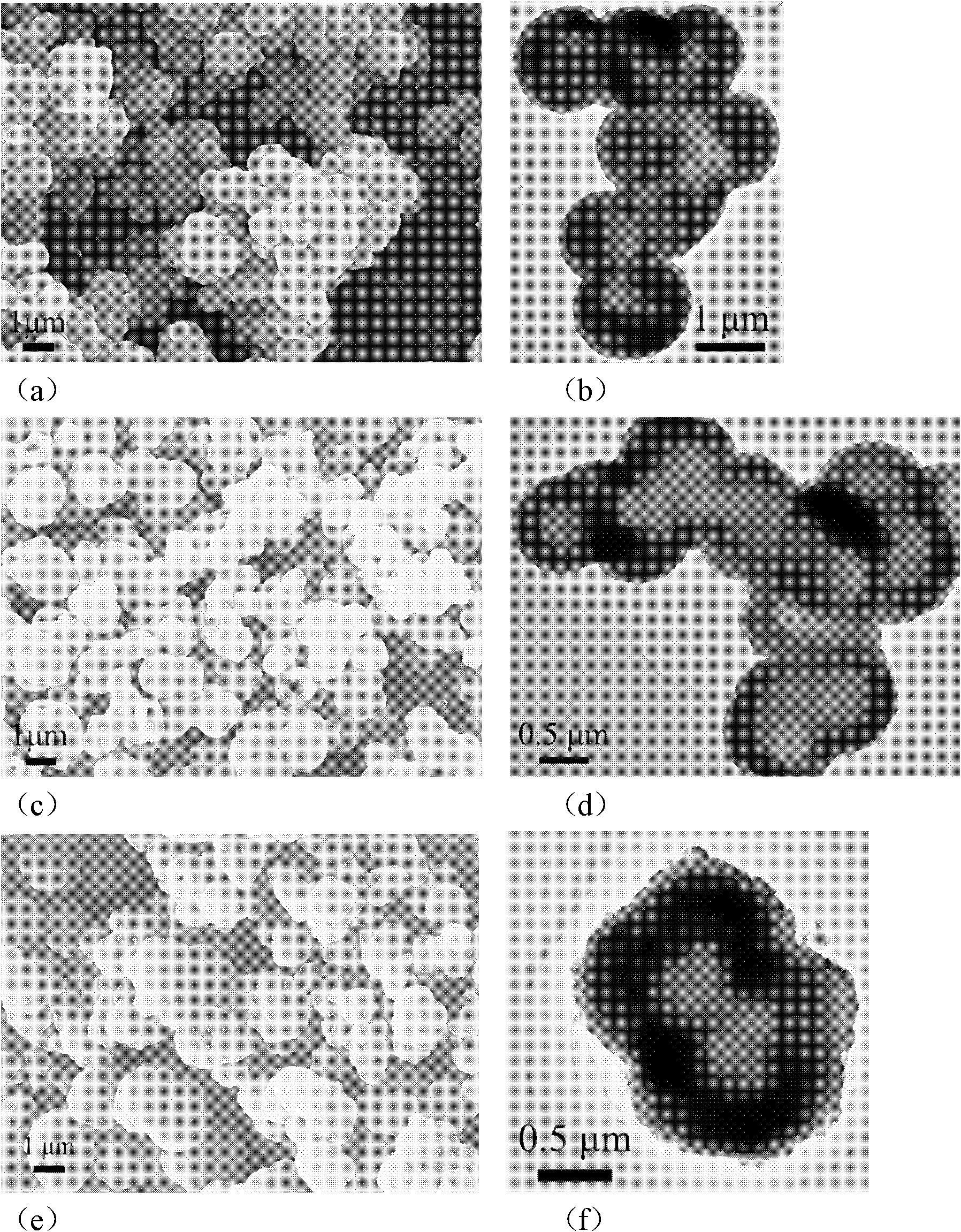

Zinc oxide based composite photocatalytic nano-material and preparation method thereof

ActiveCN103831093AImproving the Visible Light Catalytic Activity of ZnOGood chemical stabilityWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsSolid sphereMicrosphere

The invention provides a zinc oxide based composite photocatalytic nano-material, which is a material with visible light catalytic activity. The material has a sea-urchin-shaped solid sphere shape or hollow sphere shape. The preparation method comprises the following two steps: (1) putting alcohol / water solution of zinc salt into a high-pressure reaction kettle, reacting at 140-180 DEG C for 1.5-9 hours, washing the product with ethanol, and drying at 60 DEG C for 2-6 hours to obtain a sea-urchin-shaped ZnO microsphere; (2) performing ultrasonic dispersion on the sea-urchin-shaped ZnO in a ferric salt solution by utilizing a dipping-precipitation method, dripping ammonium hydroxide to react for 1-12 hours at 40 DEG C in a stirring condition, wherein the mass ratio of ferric salt to ZnO is 0.05-0.2; collecting solid, calcining at 350 DEG C for 2 hours to obtain an alpha-Fe2O3 nano-particle modified ZnO composite photocatalytic system. The material has strong light absorption and light response in the visible light range, can be used for remarkably improving the activity of visible light catalytic degraded organic dye, and can be applied to light catalytic degradation treatment of wastewater of the dye industry.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for making ultra-lightweigh structual metals

This invention pertains to a product and a method for making the product. The product is a lightweight solid porous metallic product containing small solid spheres having a coating of a primary alpha phase thereon disposed in a solid metal alloy eutectic matrix. The method includes the steps of mixing the hollow rigid spheres and a metal alloy, which metal alloy can be preheated to render it molten, in order to form a dispersion of the spheres distributed in the molten alloy; initially cooling the dispersion to render it semi-solid whereby the spheres are coated by a solid and the coated spheres are disposed in the semi-solid mixture of the solid and liquid; and finally cooling the sphere-containing semi-solid mixture to a temperature at which the sphere-containing semi-solid mixture becomes solid and the product is formed.

Owner:COOPER DR KHERSHED P +3

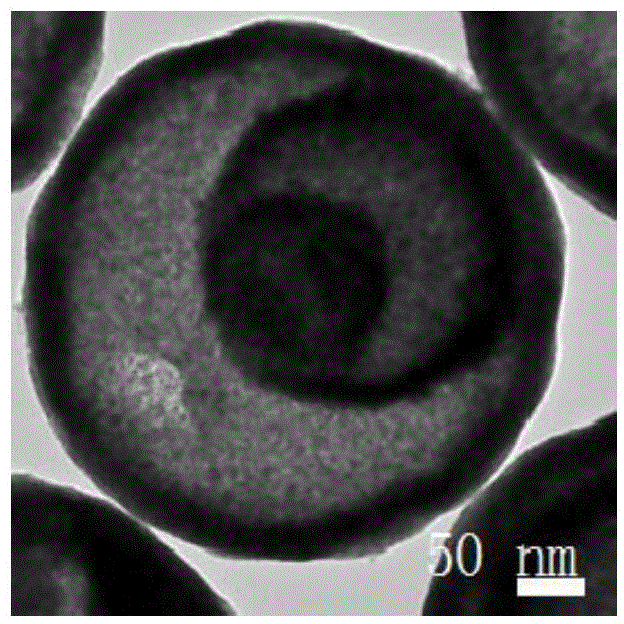

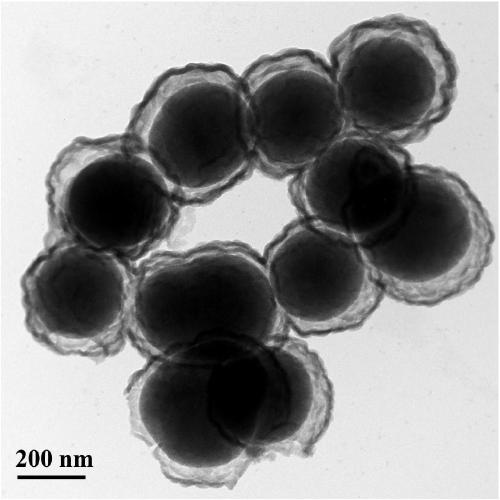

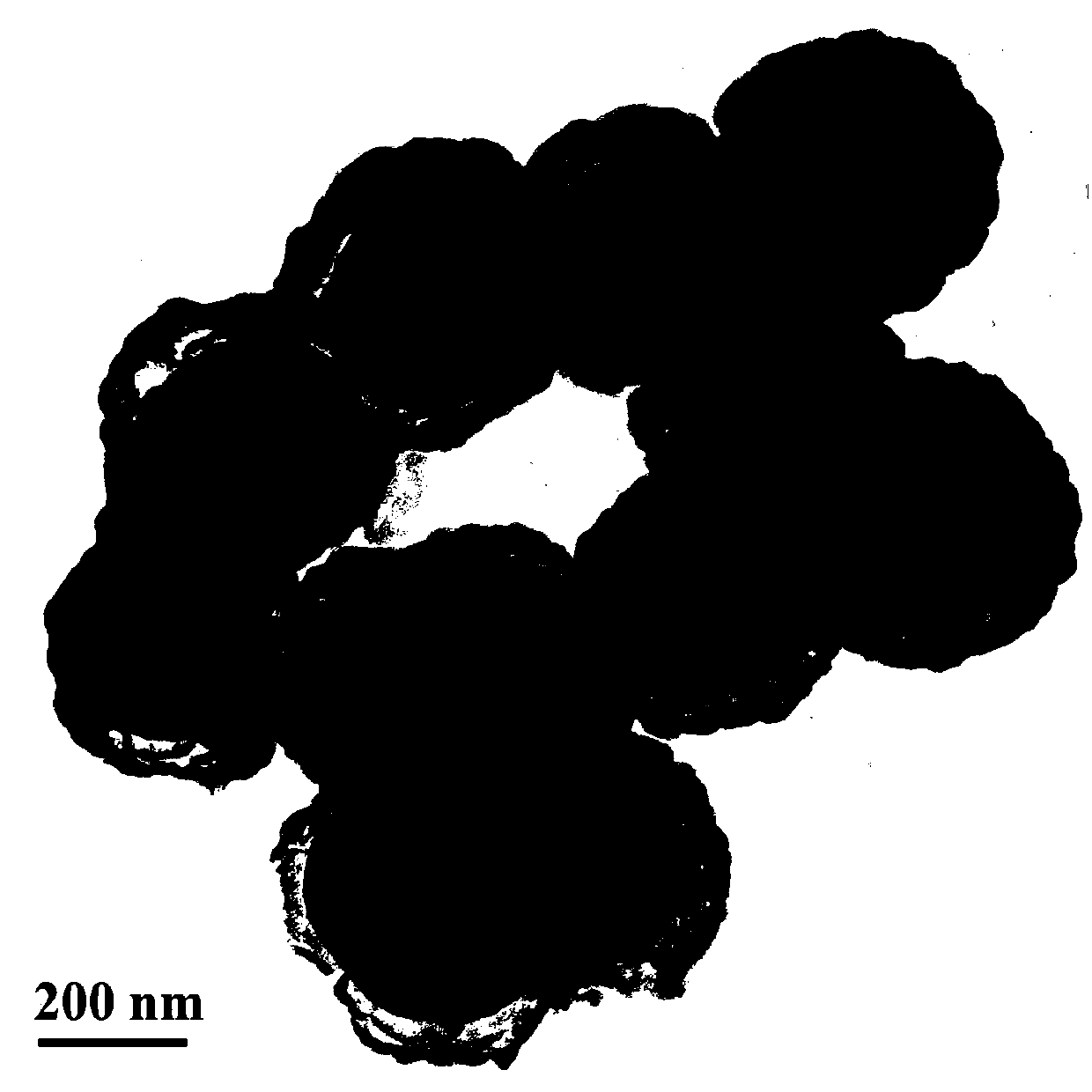

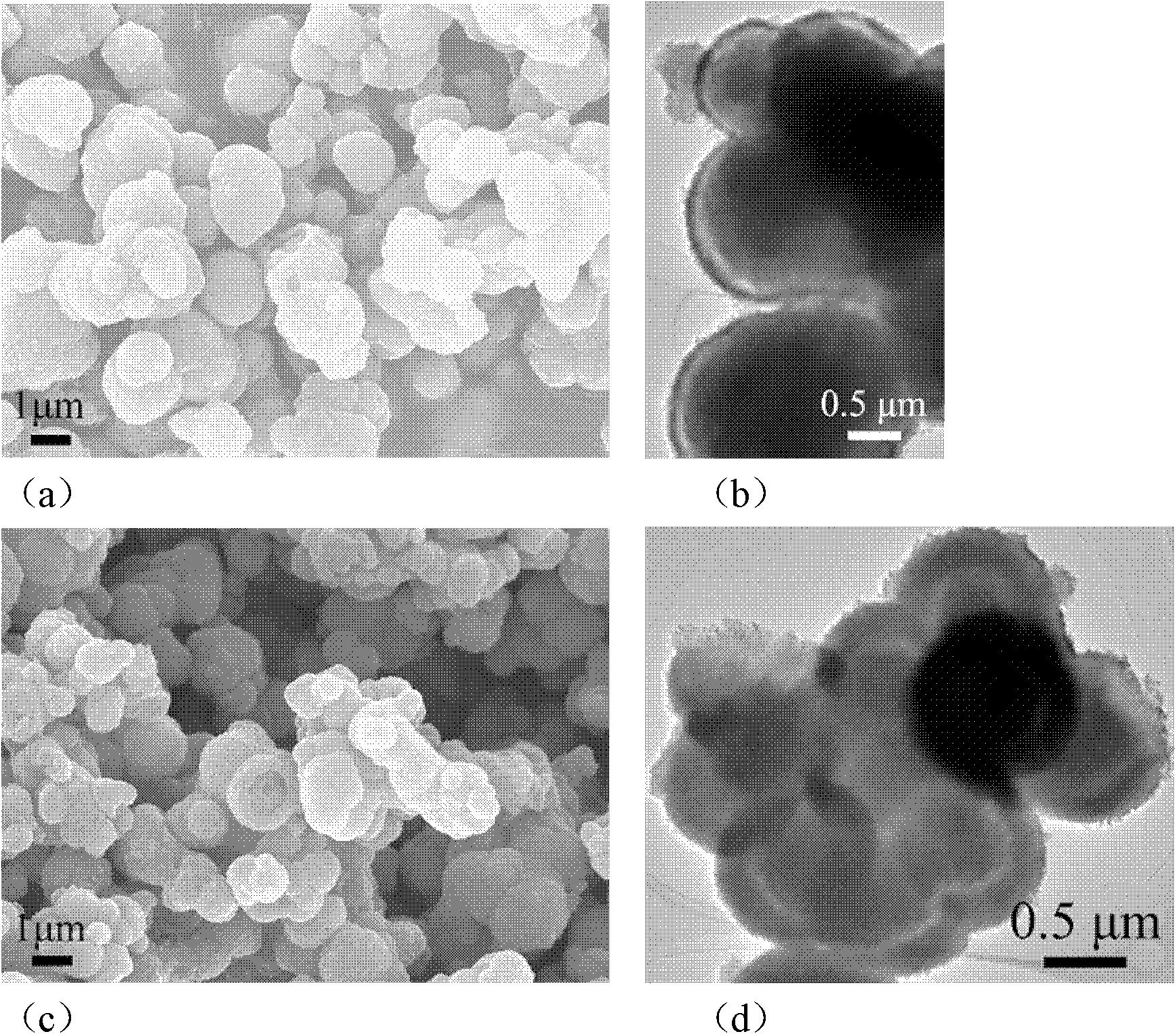

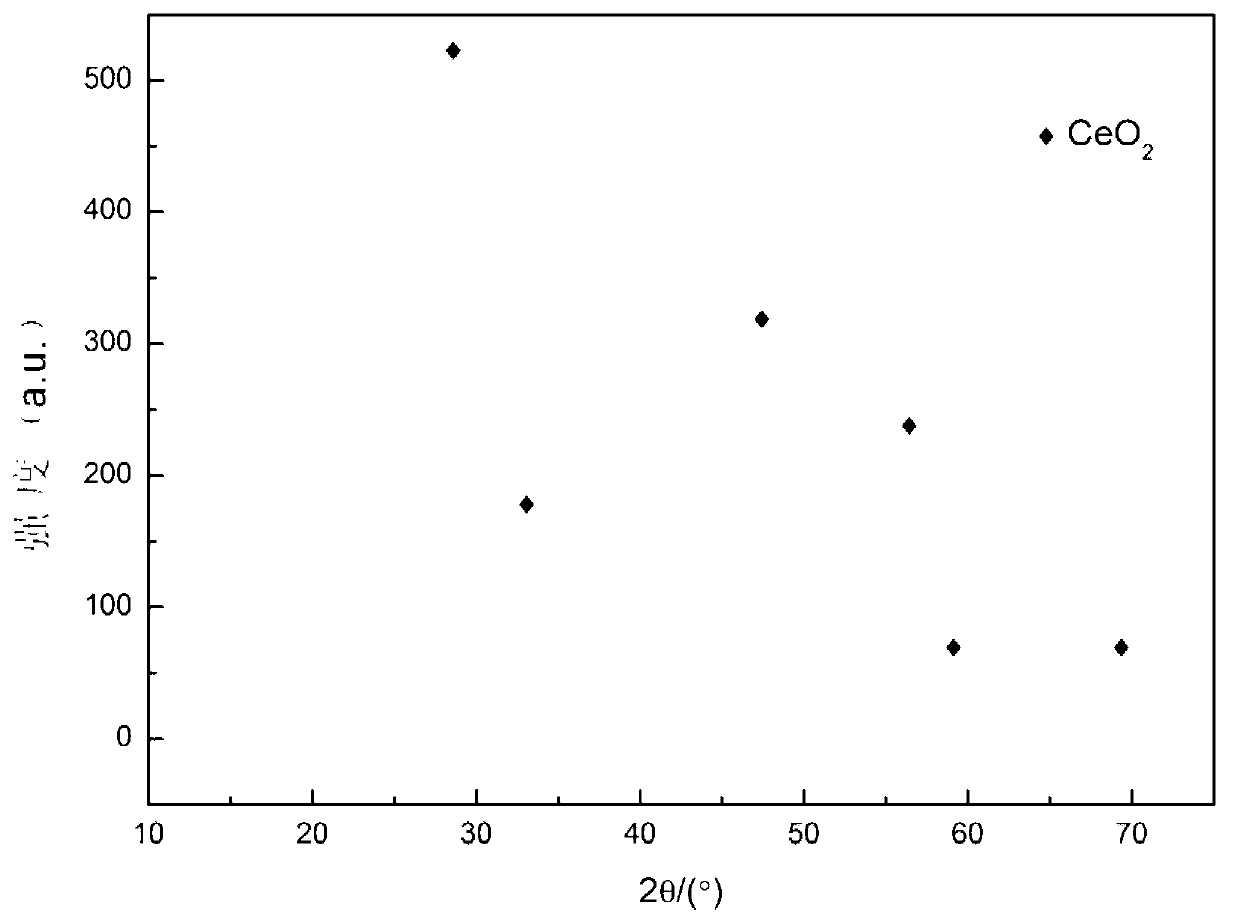

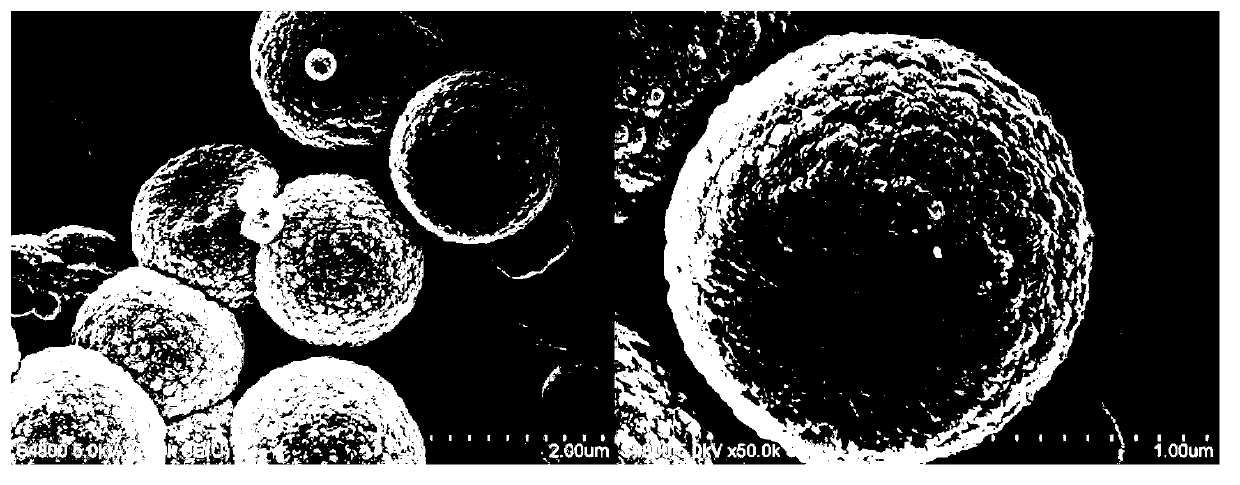

Multi-layer core shell structure CeO2 nanometer hollow sphere template-free composite method

ActiveCN104925845APrecise control of the number of core shellsPrecise thickness controlMaterial nanotechnologyRare earth metal compoundsSolid sphereCerium

The invention discloses a multi-layer core shell structure CeO2 nanometer hollow sphere template-free composite method. The method includes the steps that firstly, cerous nitrate and pyridine-2,5-dicarboxylic acid are dissolved in an absolute ethyl alcohol and DMF mixed solvent; then the mixed solution is placed in a reaction kettle, reaction is conducted for 6-12 hours at the temperature of 100 DEG C to 160 DEG C, centrifugal washing is conducted after reaction is conducted, and coordination polymer nano solid spheres of cerium are obtained after the mixture is dried at 80 DEG C; finally, the obtained dried samples are placed in a muffle furnace, roasting is conducted for 1-4 hours at the temperature of 400 DEG C to 800 DEG C, and the multi-layer core shell structure CeO2 hollow spheres are obtained after the mixture is cooled to the room temperature. The method is simple in synthesis procedures and capable of conducting accurate control over the number of core shells, the thickness and the like; the average grain size of the synthetic multi-layer core shell structure CeO2 nanometer hollow spheres is 400 nm, distribution is even, most spheres are composed of three hollow sphere shells and one hollow sphere core, and the obtained material structure is stable. The method provides a new way for synthesis of ceria of a complex core-shell structure.

Owner:JIANGXI NORMAL UNIV

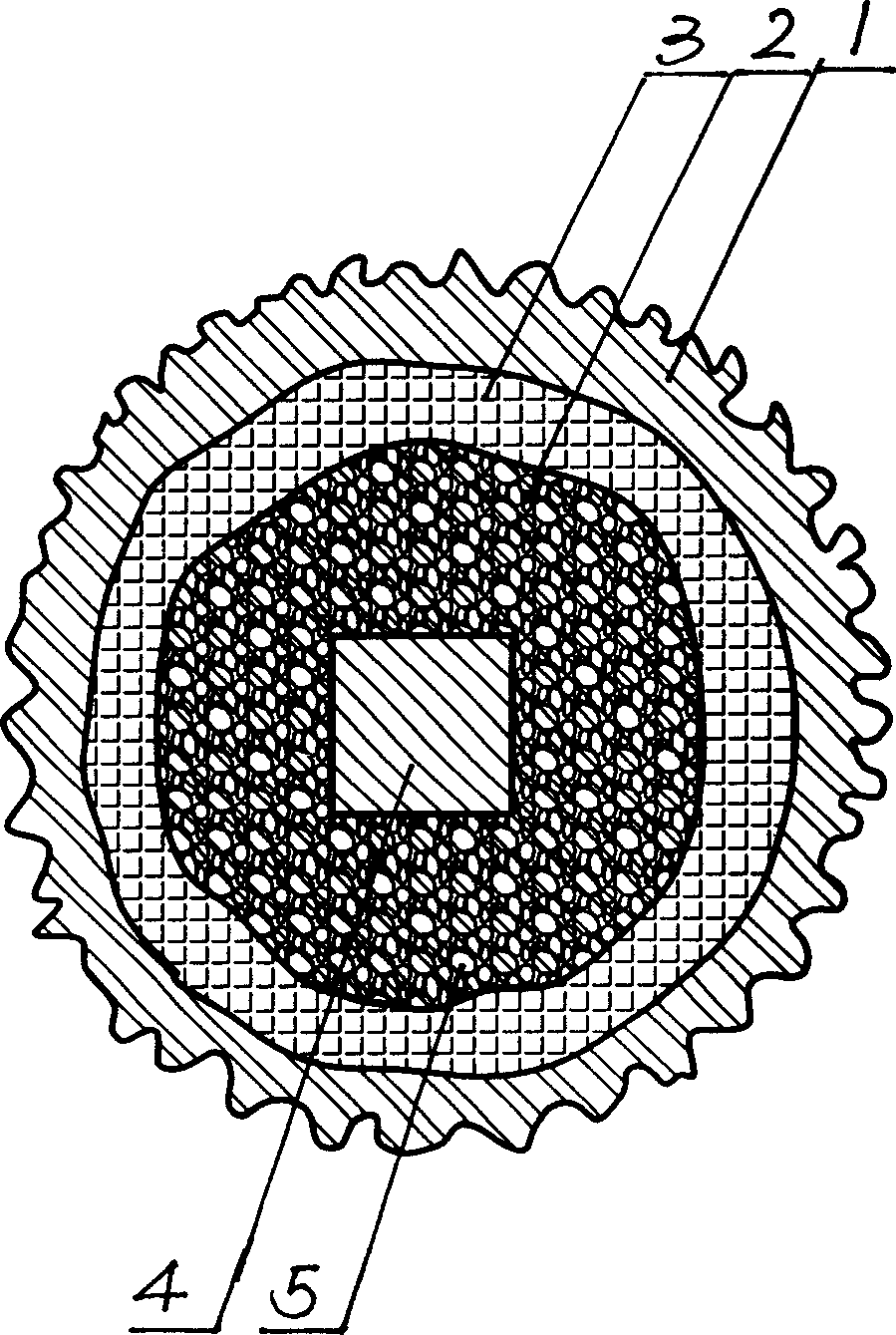

Double-layer compound biological filter material for aerated biological filter and method for preparing same

InactiveCN101759281AComponent film performance is goodLess componentsSustainable biological treatmentCeramic materials productionRough surfaceVoid ratio

The invention discloses a double-layer compound biological filter material for an aerated biological filter. The double-layer compound biological filter material is formed by combining an inner layer and an outer layer, wherein the inner layer consists of attapulgite clay and fly ash in a weight ratio of 4:6; and the outer layer consists of attapulgite clay, kieselguhr and coal dust in a weight ratio of 7-10:9-12:1. The preparation method comprises the following steps of: uniformly mixing the attapulgite clay and the fly ash, and forming inner cores of solid spheres in a granulator; uniformly mixing the attapulgite clay, the kieselguhr and the coal dust to obtain mixed powder, continuously and slowly adding the mixed powder into the granulator to coat the surfaces of the inner cores of the solid spheres for granulation to obtain the finished product spheres; and drying the finished spheres naturally for 24 hours and in a constant-temperature fan drying box at the temperature of 120 DEG C for 2 hours, taking the finished spheres out of the drying box, directly putting the finished spheres in a box-typed resistance furnace to sinter the finished spheres at the temperature of between 950 and 1.050 DEG C for 20 minutes, and naturally cooling the finished spheres to obtain the double-layer compound biological filter material. The double-layer compound biological filter material obtained by the preparation method has the advantages of rough surface, high void ratio, good wearing resistance, high strength, easy film formation and high economy and practicability.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

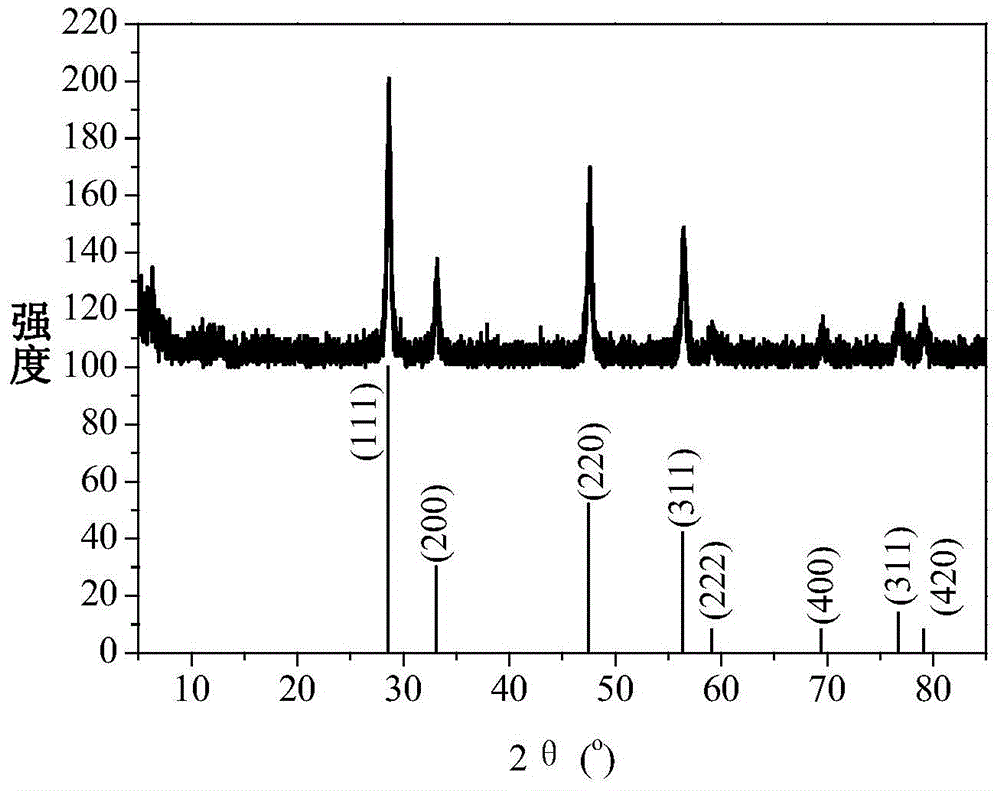

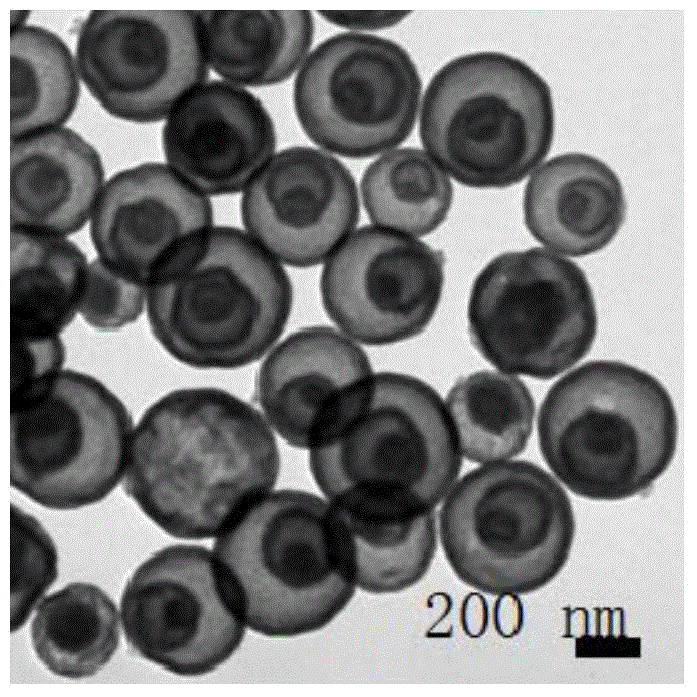

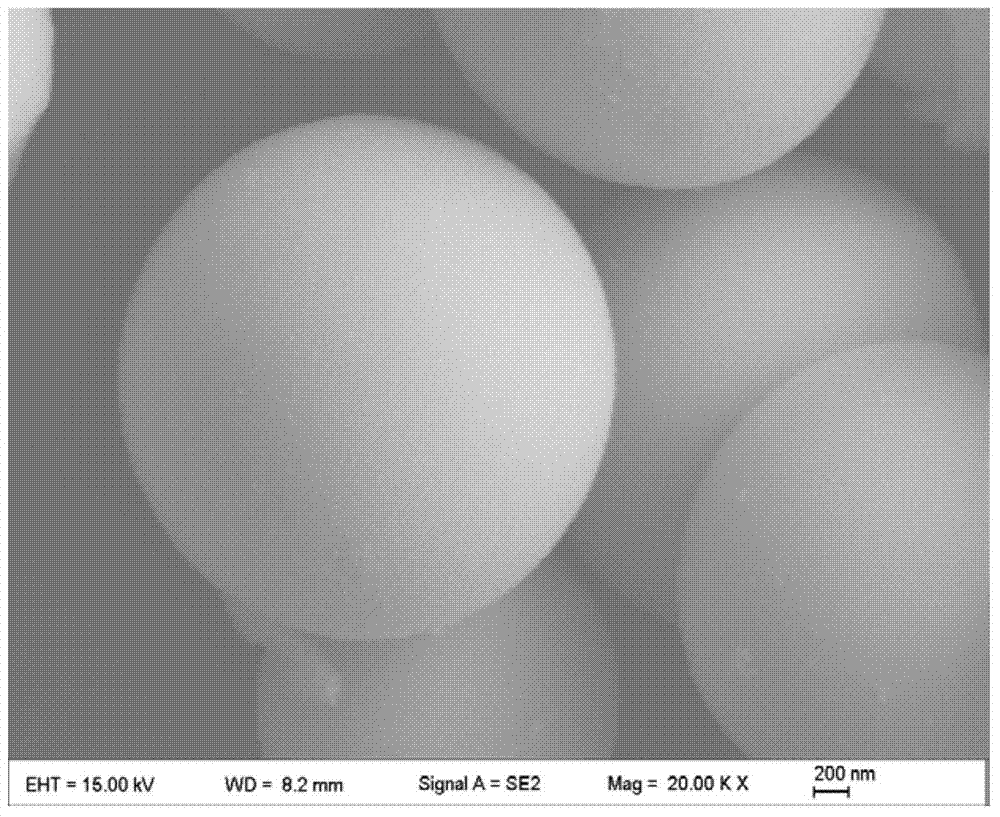

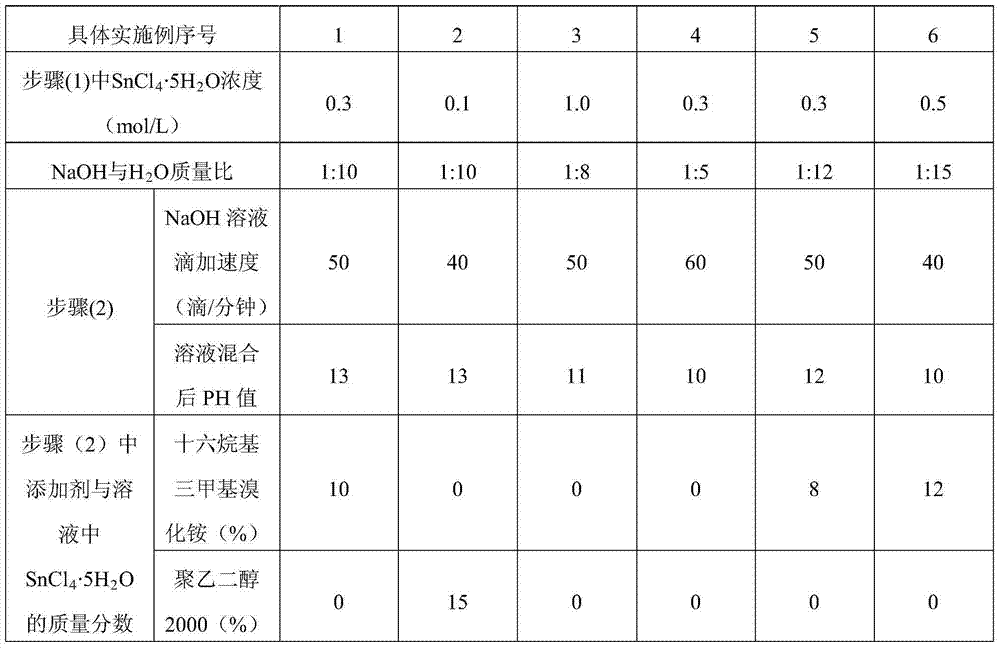

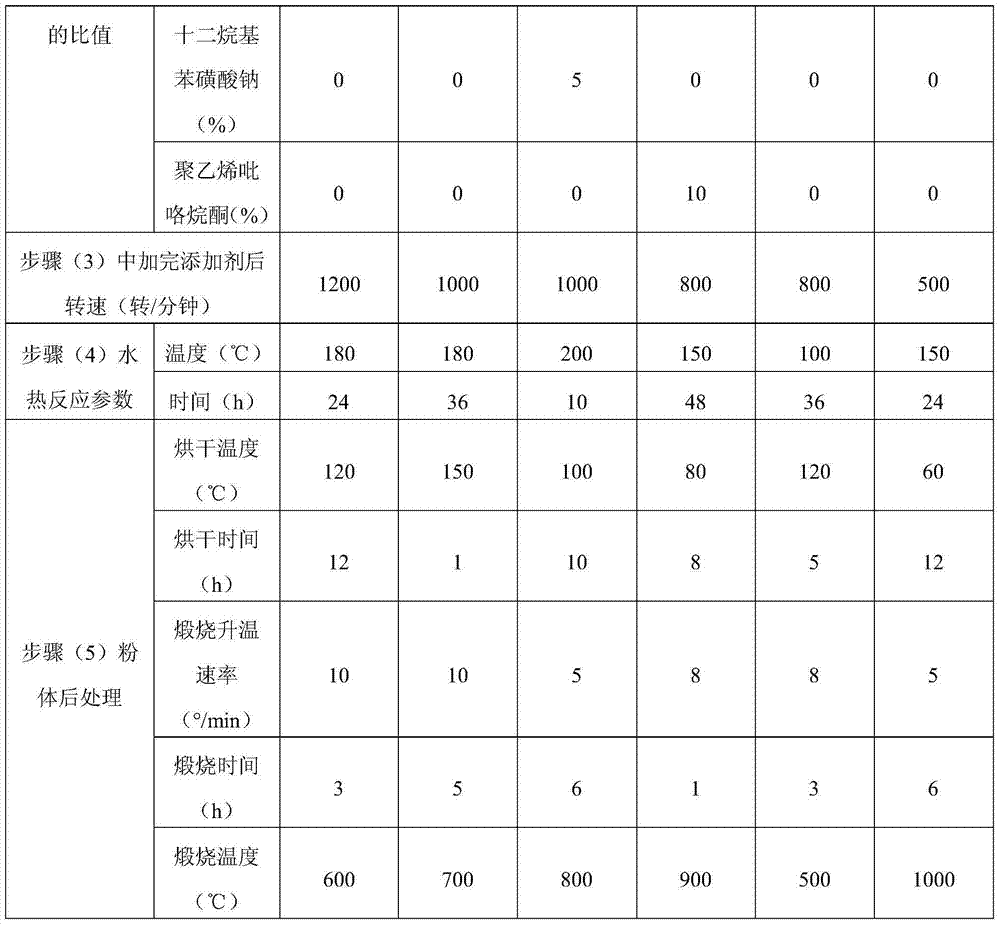

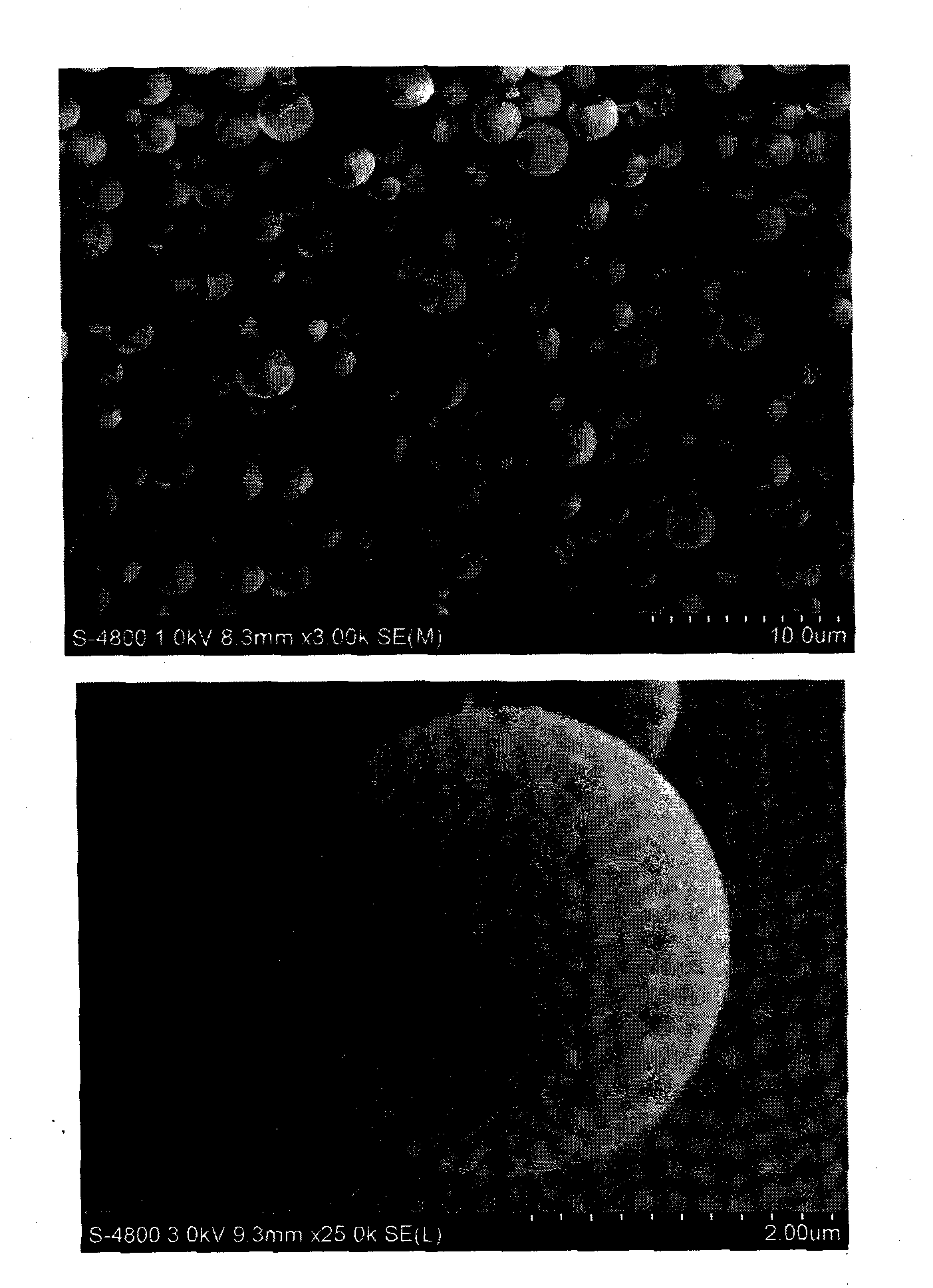

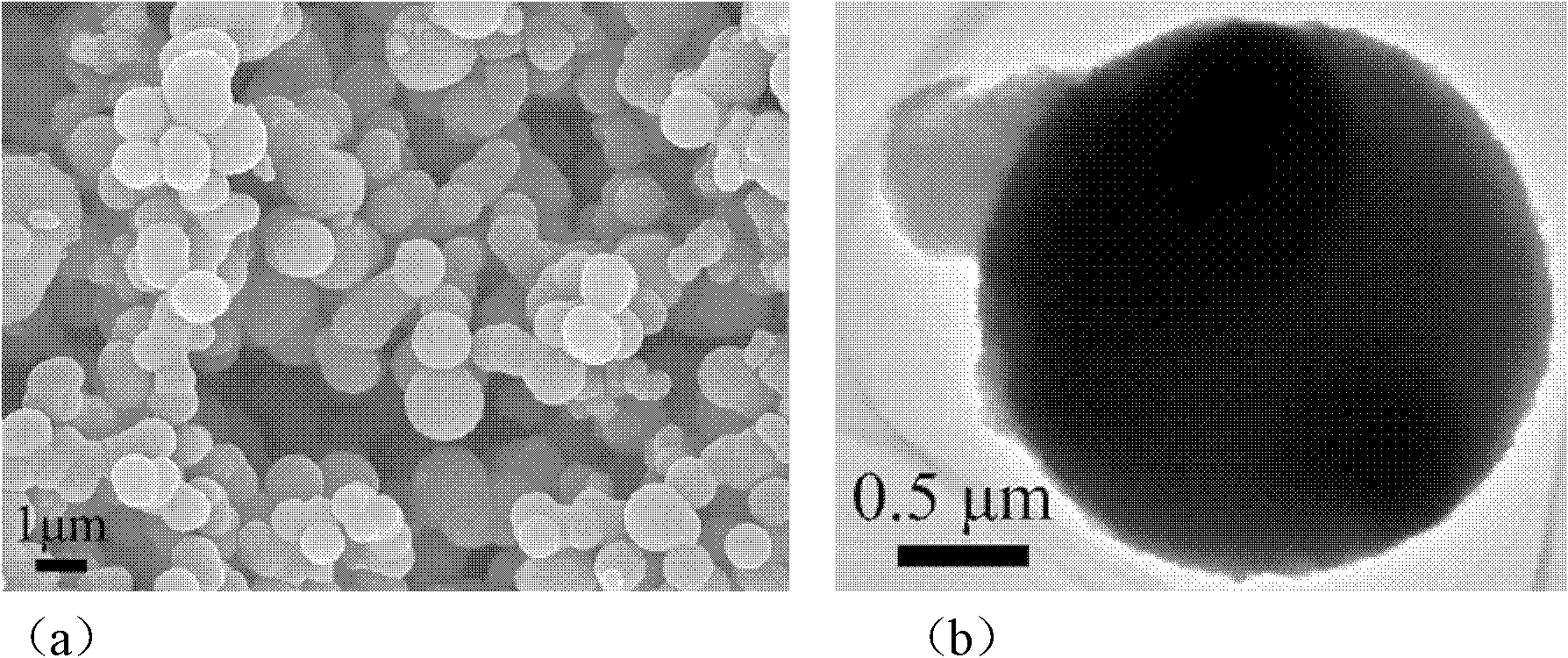

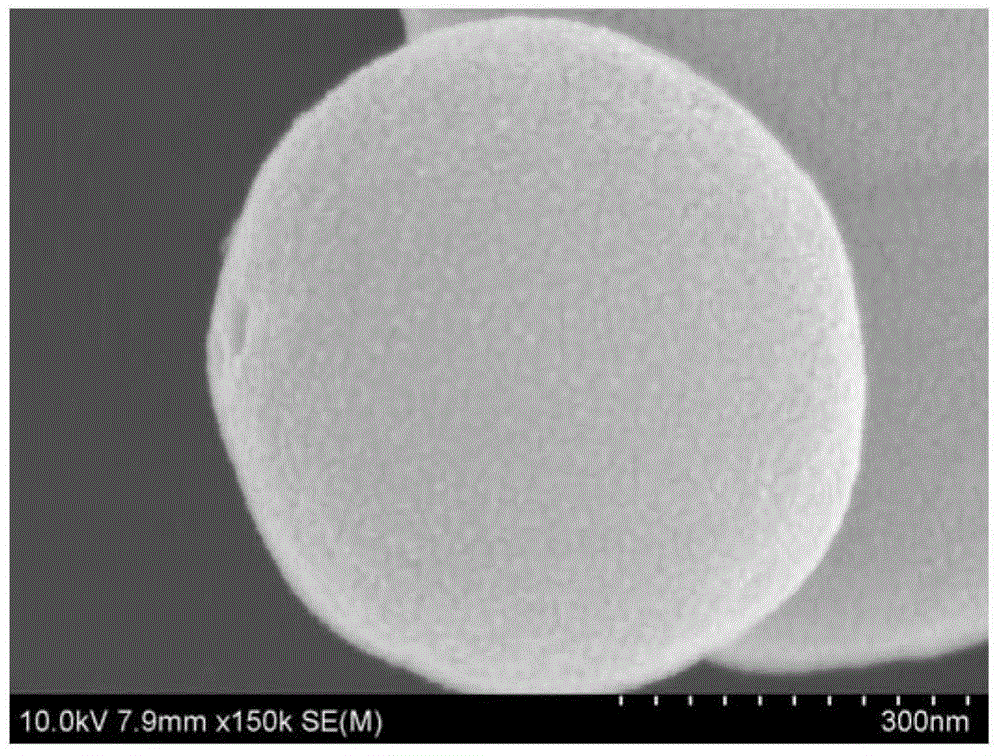

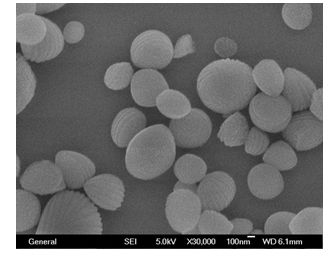

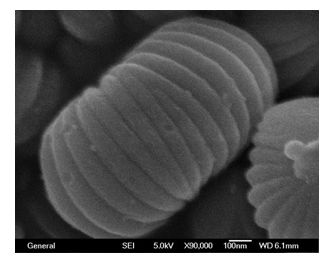

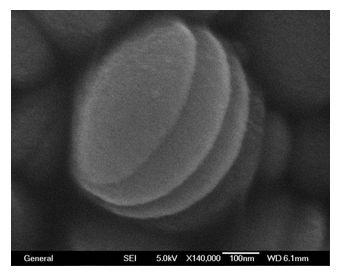

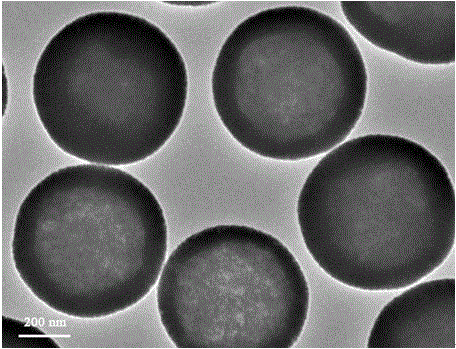

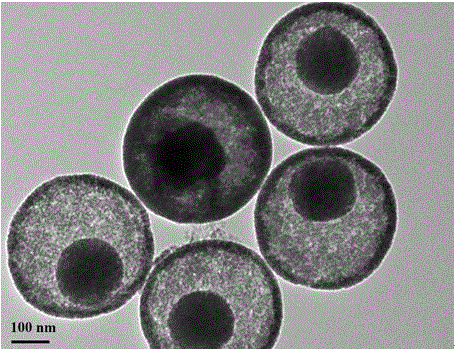

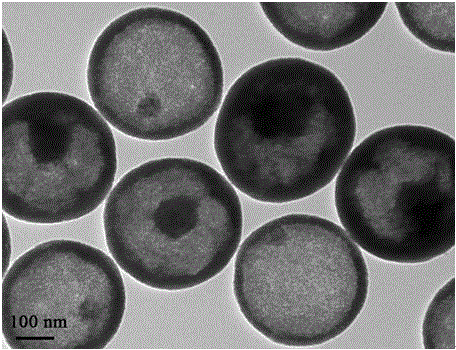

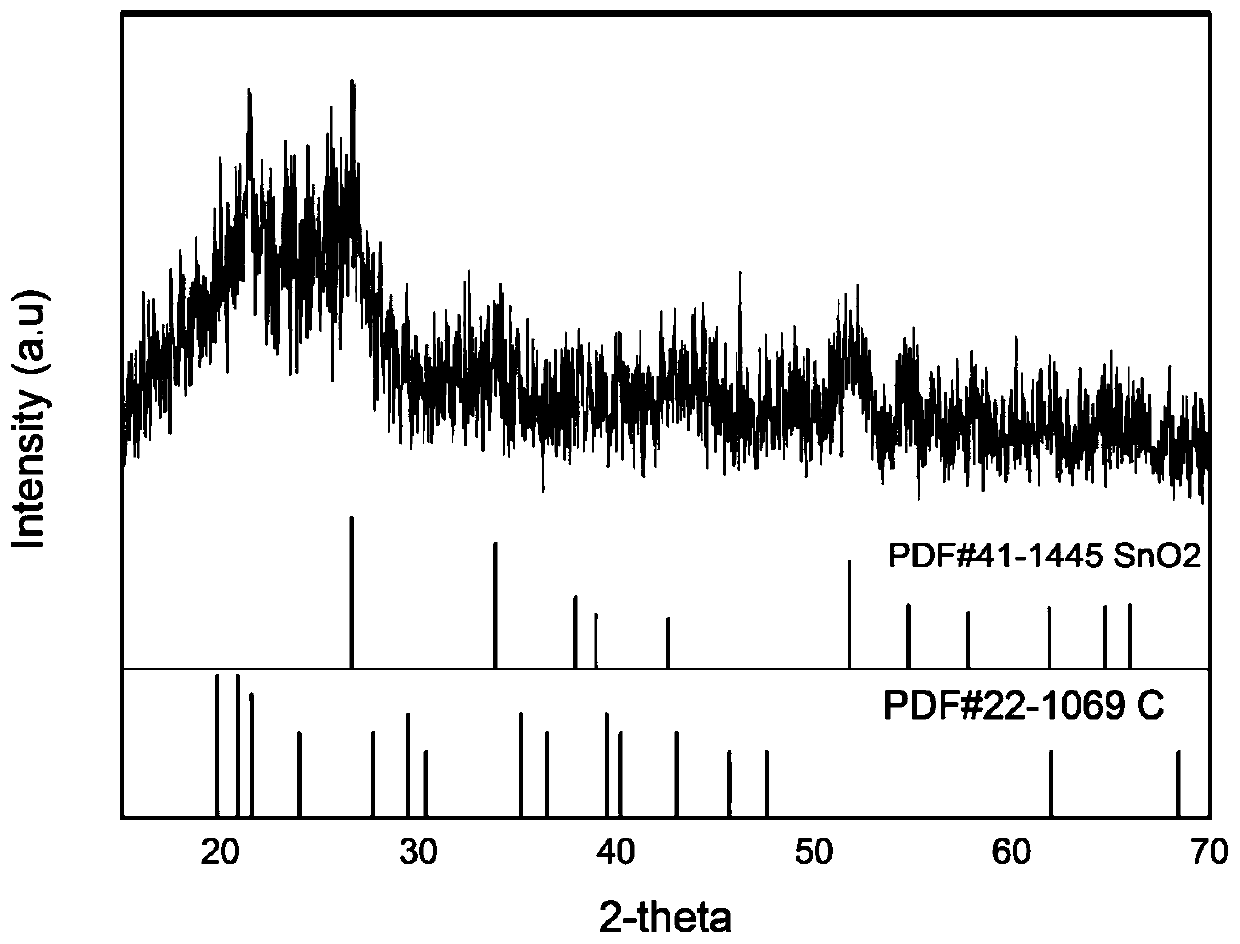

Preparation method of micro-nano tin dioxide solid spheres

The invention relates to the preparation of micro-nano materials, and aims to provide a preparation method of micro-nano tin dioxide solid spheres. The method comprises the following steps: respectively preparing a SnCl4.5H2O aqueous solution and a NaOH solution, uniformly dropwise adding the NaOH solution into the SnCl4.5H2O aqueous solution, and stirring at a high speed; transferring the mixed solution to a polytetrafluoroethylene reaction kettle, and carrying out a hydrothermal reaction on the mixed solution; carrying out centrifugal separation or filtering on the obtained product, washing the obtained object until no soluble ion exists in the solution, and drying, so that white powder is obtained; and putting the powder into a chamber electric furnace or a muffle furnace to calcine, and carrying out furnace cooling on the obtained product, so that white or light yellow powder, namely, micro-nano tin dioxide solid spheres, is obtained. Products prepared according to the preparation method disclosed by the invention are good in sphericity, smooth in surface, and uniform in size; no organic solvent as well as volatile poisonous gas and the like is used in the preparation process, so that only do sodium salts exist in products, and therefore, the product has no pollution to the environment; and no template is used, so that the method is simple in process, easily controlled in reaction process, mild in reaction condition, simple in raw material and low in cost, and therefore, the method is specially suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

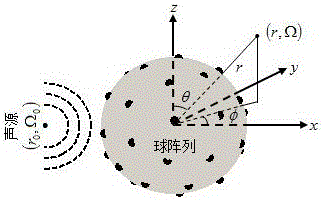

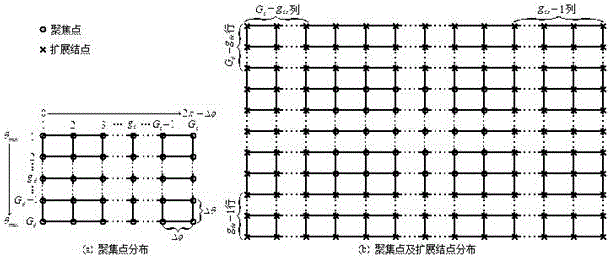

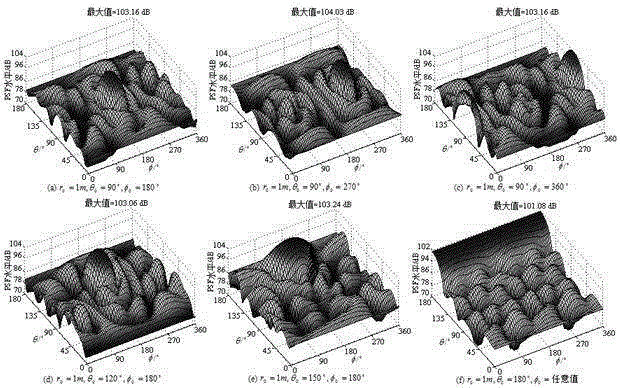

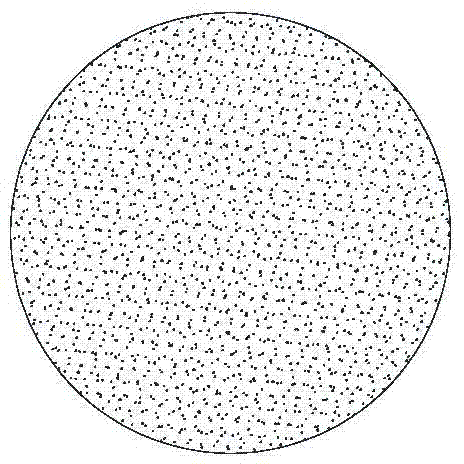

Fast deconvolution method for solid sphere array three-dimensional sound source recognition

ActiveCN106483503APrecise positioningReduce computing timePosition fixationDistribution matrixSolid sphere

The invention discloses a fast deconvolution method for solid sphere array three-dimensional sound source recognition. The method comprises the following steps: 1, a sound pressure output formula is used for calculating the sound pressure output amount of each focusing grid point; 2, an output matrix is constructed by using the output amount of each point obtained through calculation; 3; a PSF function is used for calculating a PSF matrix A-tilde at the center focusing point; and 4, a sound source strength distribution matrix S-tilde is solved iteratively. The spatial shift immovability feature is used in the fourth step, a huge A matrix does not need to be calculated, a small-dimension matrix A-tilde only needs to be calculated, A<C>-tilde is obtained through A-tilde deformation, Fourier transform is carried out on the A<C>-tilde, based on FFT acceleration, the calculation time is greatly shortened, the calculation efficiency is improved, a good spatial resolution can be kept, and each sound source can be positioned accurately.

Owner:CHONGQING UNIV

Method for preparing micro structural zinc oxide by hydrothermal method

InactiveCN102134091AHigh purityNo pollution in the processZinc oxides/hydroxidesNanotechnologyMicro structureSolid sphere

The invention discloses a method for preparing micro structural zinc oxide by a hydrothermal method. Polyvinyl pyrrolidone K-30 is used as a template, zinc acetate dihydrate is used as a zinc source, and H2O2 is used as an oxidant; and a zinc oxide material with four micro structures of sea urchin shape, taper, hexagonal prism self-assembled solid sphere and sugarcoated haw shape is prepared by controlling the reactant concentration, the hydrothermal growth time and the reaction temperature. The method is simple and has the advantages of low cost, mild condition, no environmental pollution and the like. The prepared micro zinc oxide material has high purity, regular crystal structure, good shape controllability and short production period, and has huge application prospect on the aspects of fuel cells, photoelectric conversion materials, chemical sensors and the like.

Owner:SHAANXI NORMAL UNIV

Flavone-metal complex microsphere and preparation method and application thereof

InactiveCN101891783AEasy to shapeSimple structureSugar derivativesCopper organic compoundsSolid sphereFluorescence

The invention relates to a flavone-metal complex microsphere which is in a spherical shape and in the structure of a solid sphere or a hollow sphere or a porous sphere, and the particle size of the sphere is 50nm-5000nm. The flavone-metal complex microsphere is formed by complexing flavonoid substances such as flavanol, anthocyanidin, tea polyphenol and the like with metal, and the preparation process comprises the following sequential steps: (1) preparing a flavone solution, (2) reacting and synthesizing, and (3) collecting and drying the product. In the reaction for synthesis, glycerin or glycol is used as an assistant, and the reaction temperature is 60 DEG C-70 DEG C for obtaining the solid microsphere. In the reaction for synthesis, ethyl acetate or vinyl alcohol is used as an assistant, and the reaction temperature is 90 DEG C-150 DEG C for obtaining the hollow microsphere. In the reaction for synthesis, ethanol is used as an assistant, and the reaction temperature is 70 DEG C-90 DEG C for obtaining the porous microsphere. The flavone-metal complex hollow microsphere can be used as a drug carrier or fluorescence molecular carrier for application.

Owner:SICHUAN UNIV

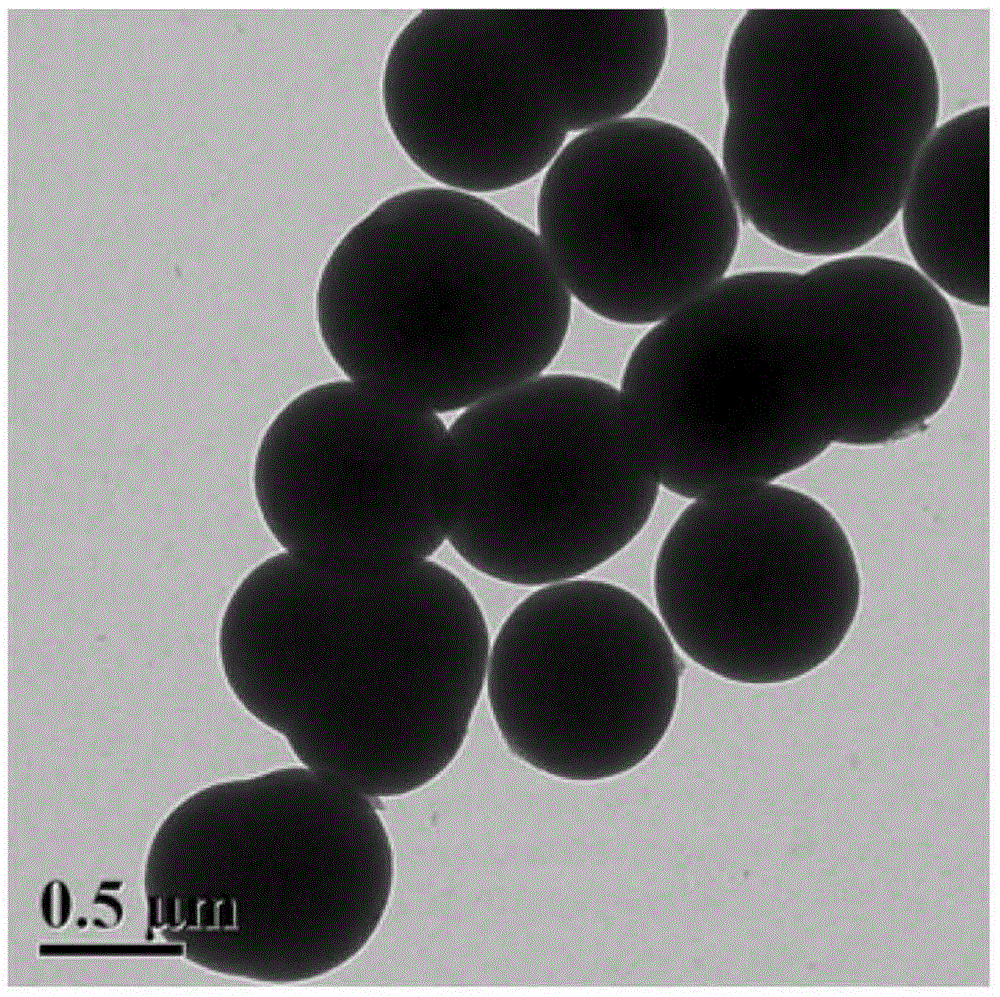

Mesoporous silicon dioxide material with eggshell-yolk structure and preparation method of mesoporous silicon dioxide material

The invention provides a mesoporous silicon dioxide material with an eggshell-yolk structure and a preparation method of the mesoporous silicon dioxide material. The material is in a spherical shape as a whole, and the specific surface area is 500-800 m<2> / g. The ''yolk'' is a silicon dioxide solid sphere with a diameter of 200-500 nm, the ''eggshell'' is a silicon dioxide hollow sphere with a thickness of 20-100 nm, the diameter of a cavity is 240-800 nm, the ''eggshell'' and the ''yolk'' have regular ordered mesopores, and the aperture is 2.5-3.5 nm. The material is prepared by adopting a simple one-pot method, a silicon source and a carbon source are added into a mixed solution of ethanol / deionized water / ammonia water / hexadecyl trimethyl ammonium bromide, a proper amount of silicon source is added after reaction for a period of time, and an obtained solid product is dried and roasted to obtain the mesoporous silicon dioxide with the eggshell-yolk structure. The invention has the beneficial effects that the provided material is regular in structure and large in specific surface area, and has good application prospects in the fields of catalysis, adsorption separation, drug sustained release and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Function type delay summation method for identifying solid sphere array three-dimensional sound source

The invention discloses a function type delay summation method for identifying a sold sphere array three-dimensional sound source, wherein a novel FDAS sound source identification method is established. In identifying incoherent sound sources in a three-dimensional space, the function type delay summation method supplies an effective approach for quickly obtaining a clean sound source imaging graph and realizes an important meaning in accurate analysis on a sound source identification result.

Owner:CHONGQING UNIV

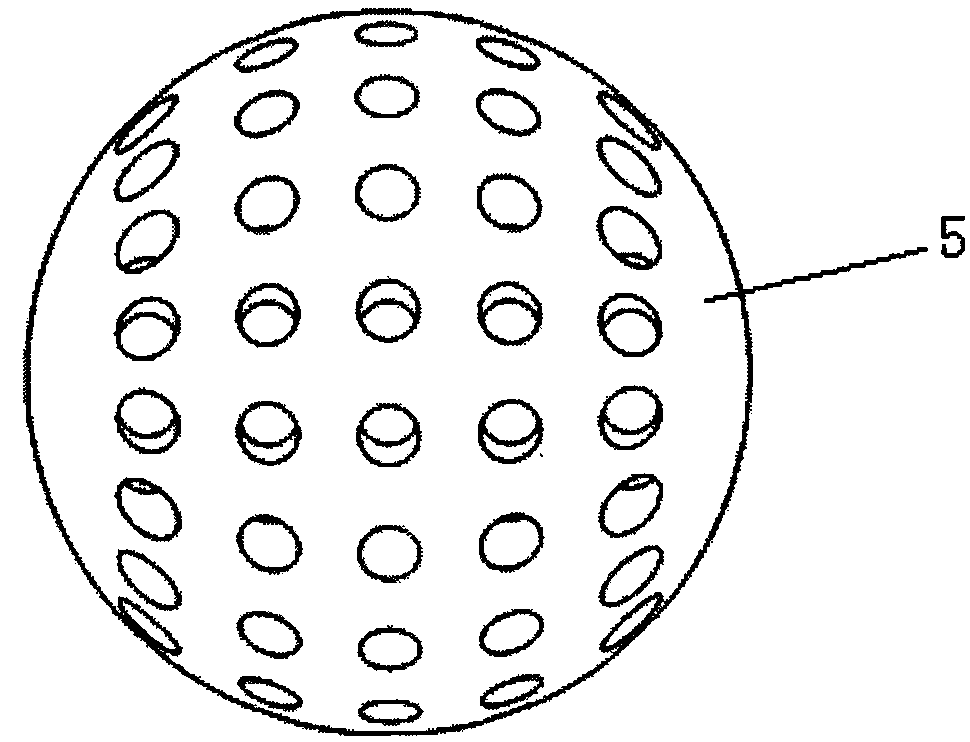

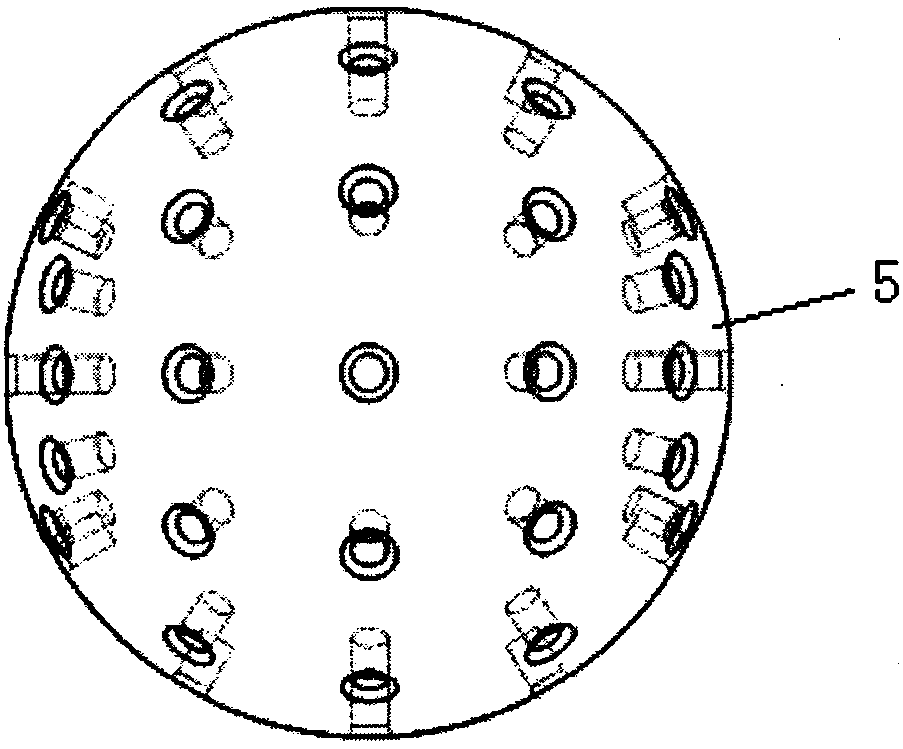

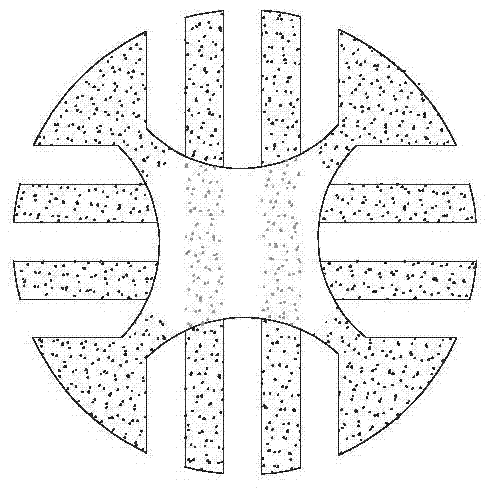

Porous spherical electrospinning nozzle and spinning method thereof

InactiveCN108411383AMulti-level distribution of diameter can be controlled and adjustedElectro-spinningPeristaltic pumpSolid sphere

The invention discloses a porous spherical electrospinning nozzle and a spinning method thereof. The porous spherical electrospinning nozzle is a solid sphere with a smooth surface, and a plurality ofholes are distributed in the spherical surface; the porous spherical electrospinning nozzle is connected to a first motor through a transmission shaft, and the lower portion of the porous spherical electrospinning nozzle is immersed in a spinning solution of a liquid storage tank. The spinning method includes the steps of opening a receiving device; opening a liquid supply device and injecting the spinning solution into the liquid storage tank through a peristaltic pump; opening the first motor, so that the porous spherical electrospinning nozzle rotates in the spinning solution, and the spinning solution forms two states of liquid films on the spherical surface and hole surfaces respectively; opening a high-voltage generator, so that the liquid films on the spherical surface and the holesurfaces generate jet flow different in fineness respectively, and the jet flow is stretched, solidified and deposited on the receiving device to form nanofibers. The nanofibers with two or more kinds of diameter distribution can be prepared under the conditions of not using a plurality of spinning solutions and not adjusting spinning parameters.

Owner:DONGHUA UNIV +1

Method for preparing anatase porous TiO2 spheres, core-shell structure and hollow spheres

InactiveCN102730753AReduce riskEasy to operatePhysical/chemical process catalystsTitanium dioxideSolid sphereTitanium

The invention belongs to the photocatalytic material field, concretely relates to a method for preparing anatase porous TiO2 spheres, a core-shell structure and hollow spheres. The method comprises the following steps: dissolving titanium salt in water, then adding a HNO3 solution and carrying out a constant temperature reaction in a reaction vessel to obtain sediments; washing by deionized water until pH value presents neutrality, and drying to obtain the TiO2 powder. The invention is characterized in that TiO2 is replaced HF for taking as a corrosive agent, the method is a fluorine-free preparation process, the TiO2 with solid spheres, the core-shell structure and hollow spheres can be prepared by controlling reaction conditions, thereby the dangerousness of the preparation process can be substantially reduced, the maneuverability is enhanced, so that the method is suitable for requirements of large-scale production and industrial application, and possesses good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

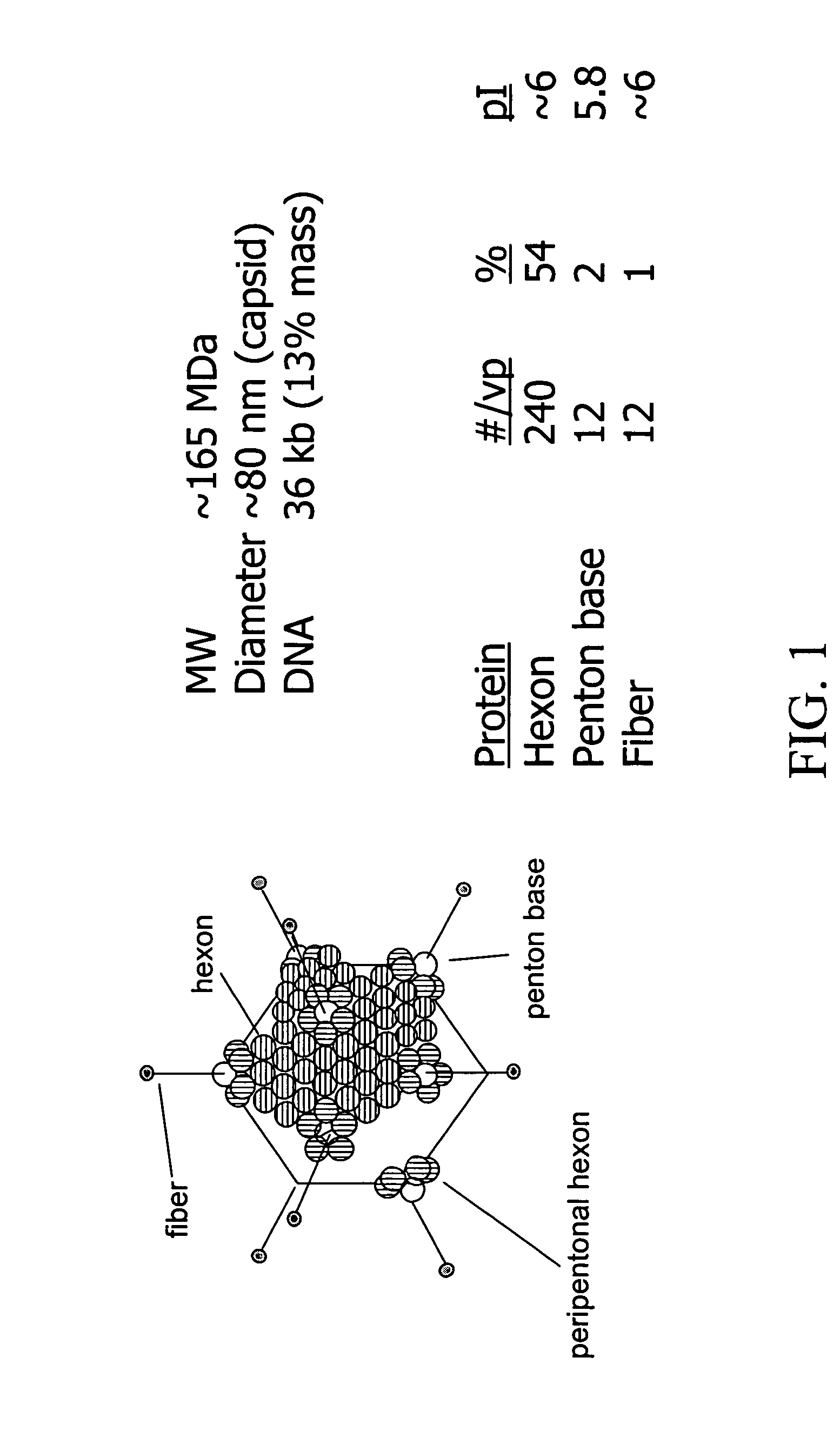

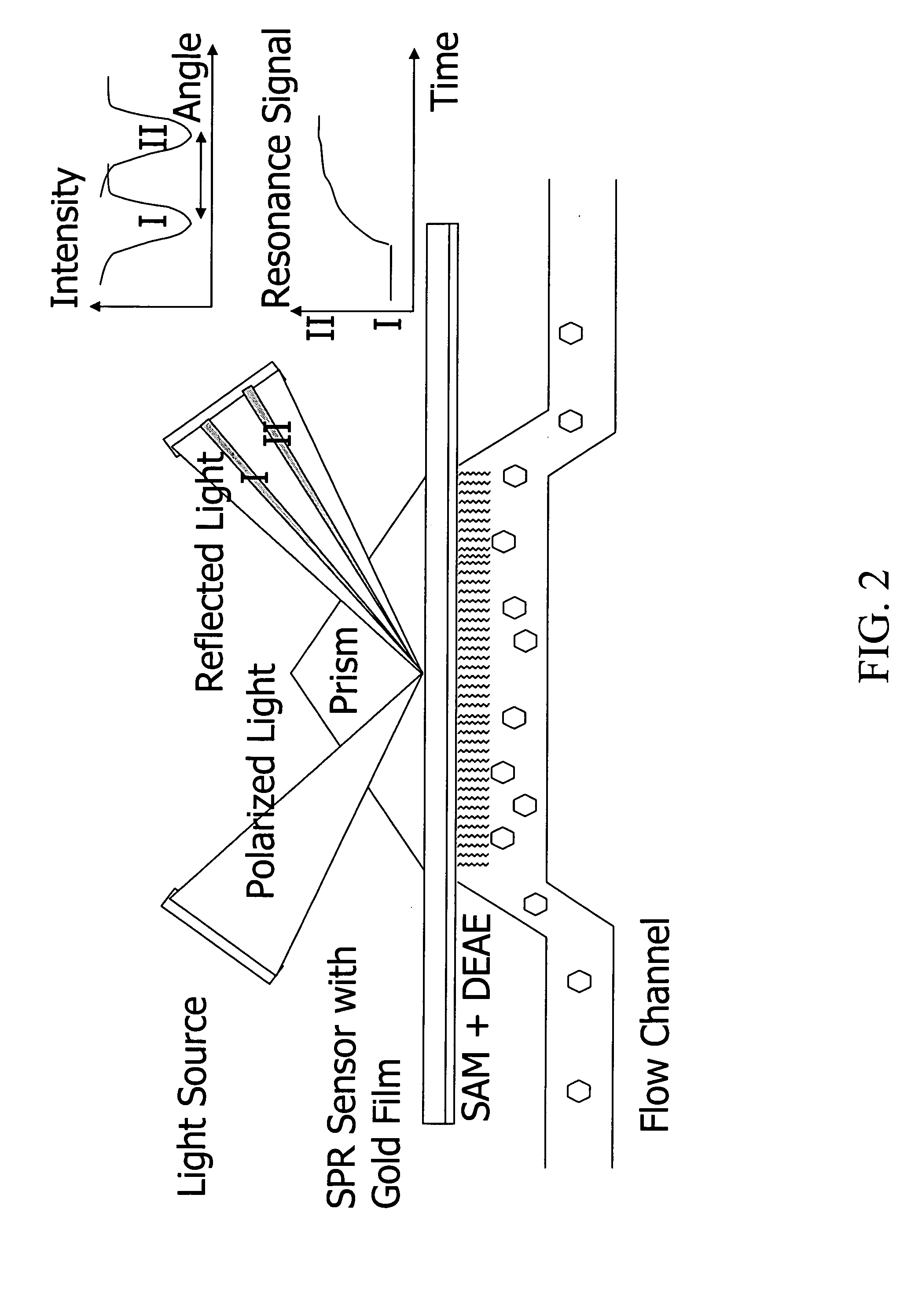

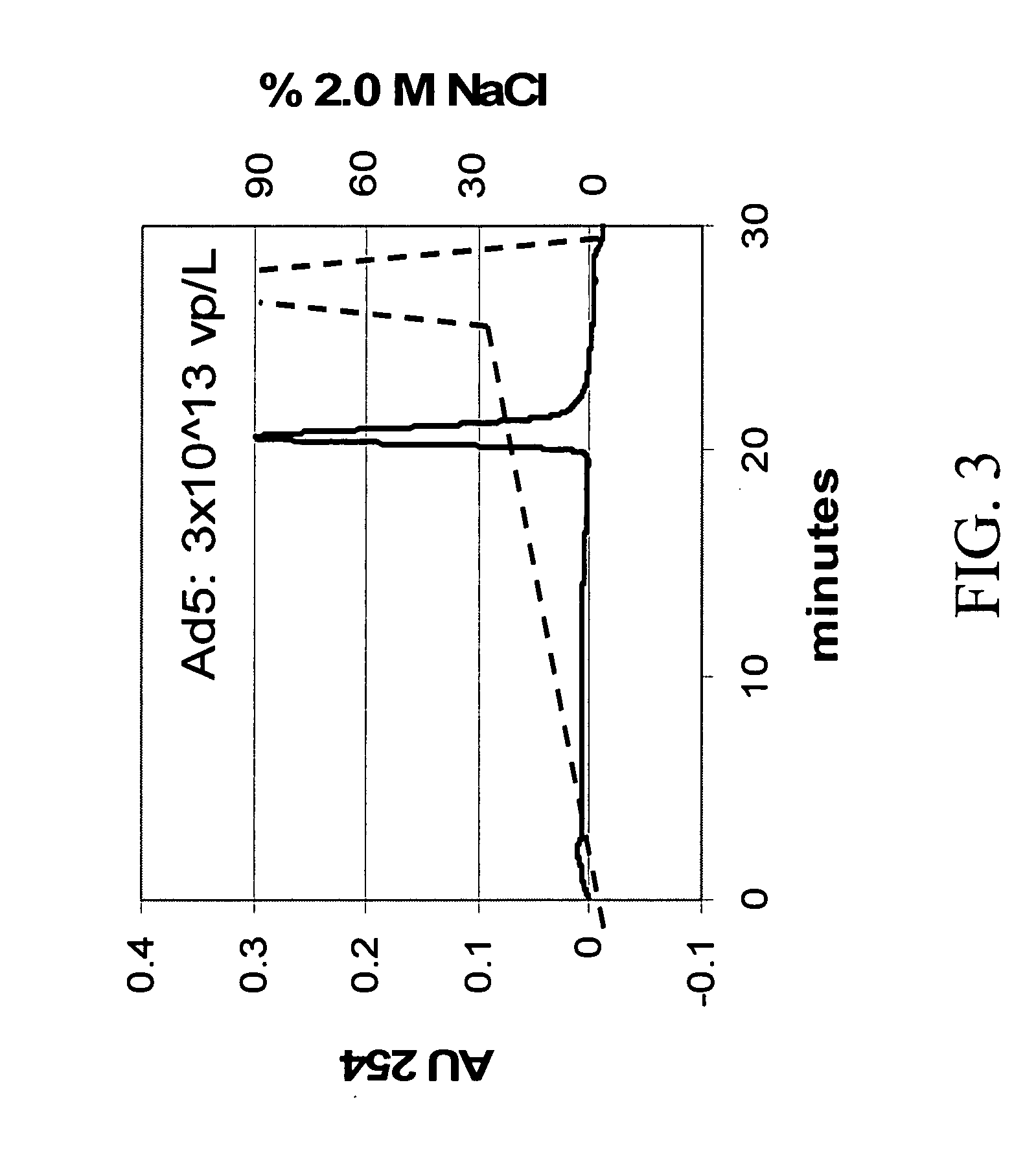

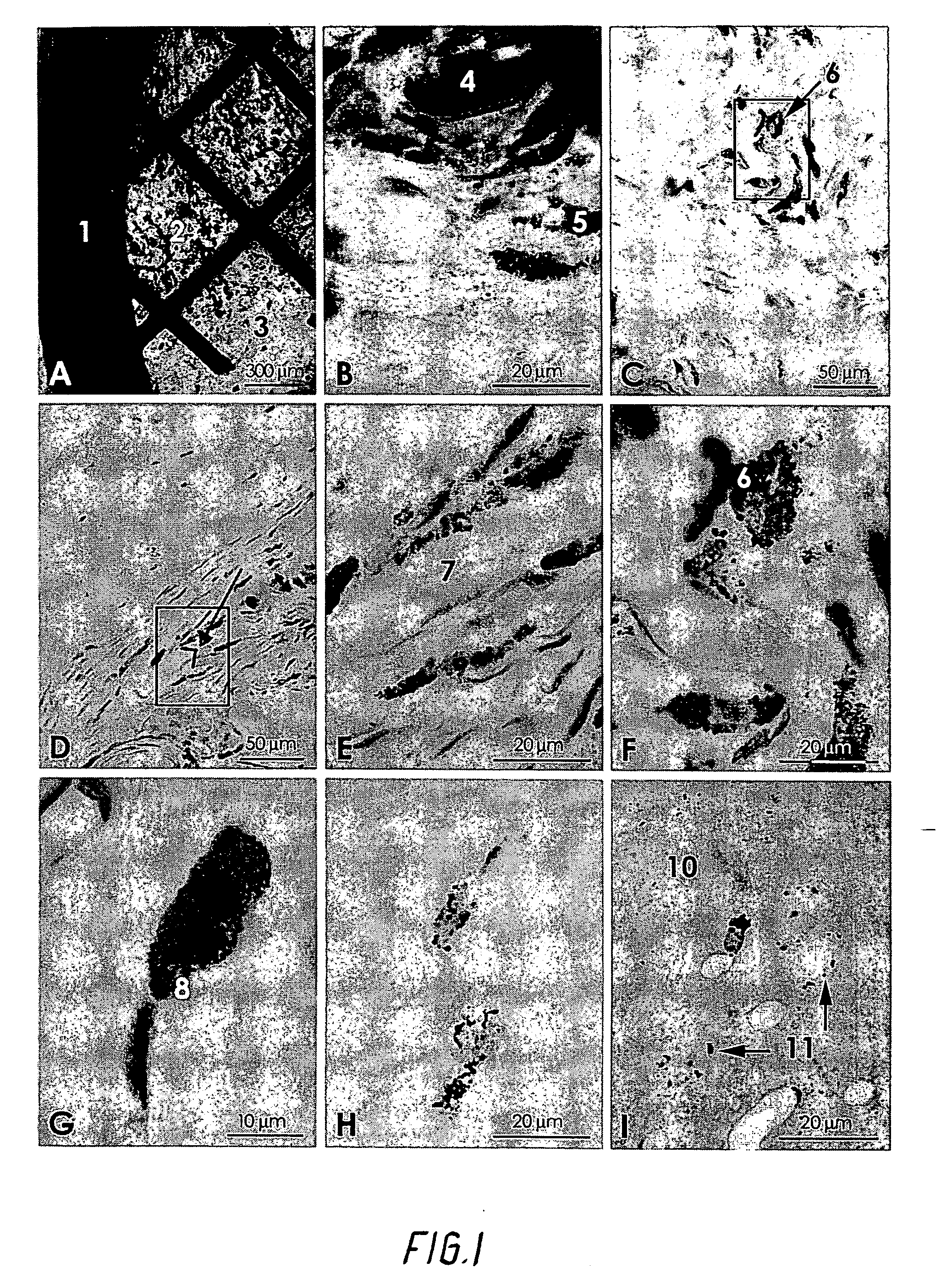

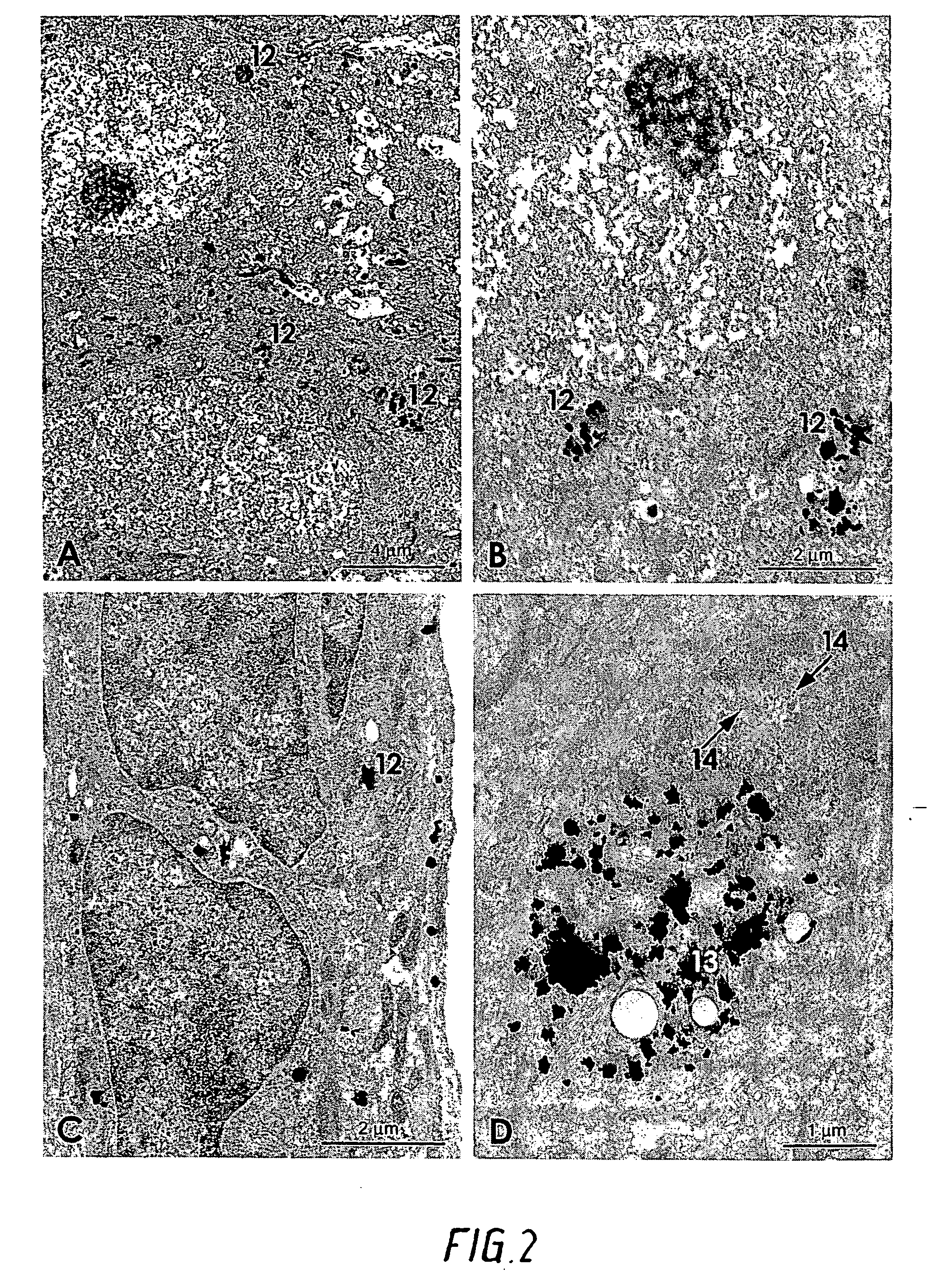

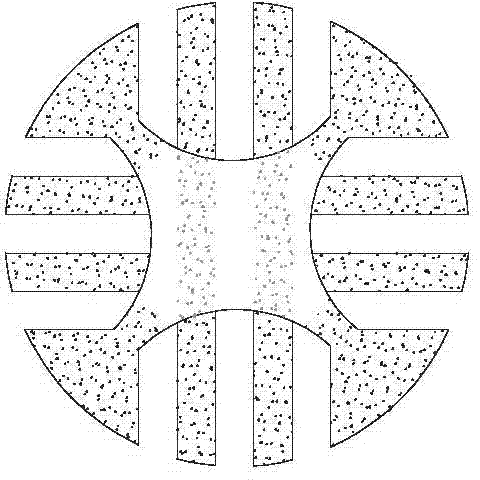

Direct measurement of sorption on three-dimensional surfaces such as resins, membranes or other preformed materials using lateral dispersion to estimate rapid sorption kinetics or high binding capacities

InactiveUS20060223053A1Accurately and directly characterizeEfficient preparationMaterial nanotechnologyBioreactor/fermenter combinationsSolid spherePorous medium

Described are methods allowing measurement of adsorption and desorption of analytes with membranes or resins directly using surface plasmon resonance (SPR). Also described are methods for assembling intact resins or membranes on SPR surfaces. Such methods provide estimates of mass-action ion-exchange adsorption and desorption rates accounting for steric (σ) and characteristic charge (ν) effects. The methods further permit accurate estimation of rate constants for uniform adsorption of a homogeneous analyte solution on homogeneous adsorptive sites distributed heterogeneously in space, relative to the planar boundary. Solutions are obtained for locally porous media and solid spheres. The methods are extendible to other media and heterogeneous adsorptive sites. The methods further provide for enhancement of lateral mass transport in such optical measurement instruments through radial hydrodynamic diffusion (radial dispersion) by, for example, incorporating porous media in flow cells of detection devices such as, but not limited to, SPR or TIRF instruments.

Owner:UNIV OF UTAH RES FOUND

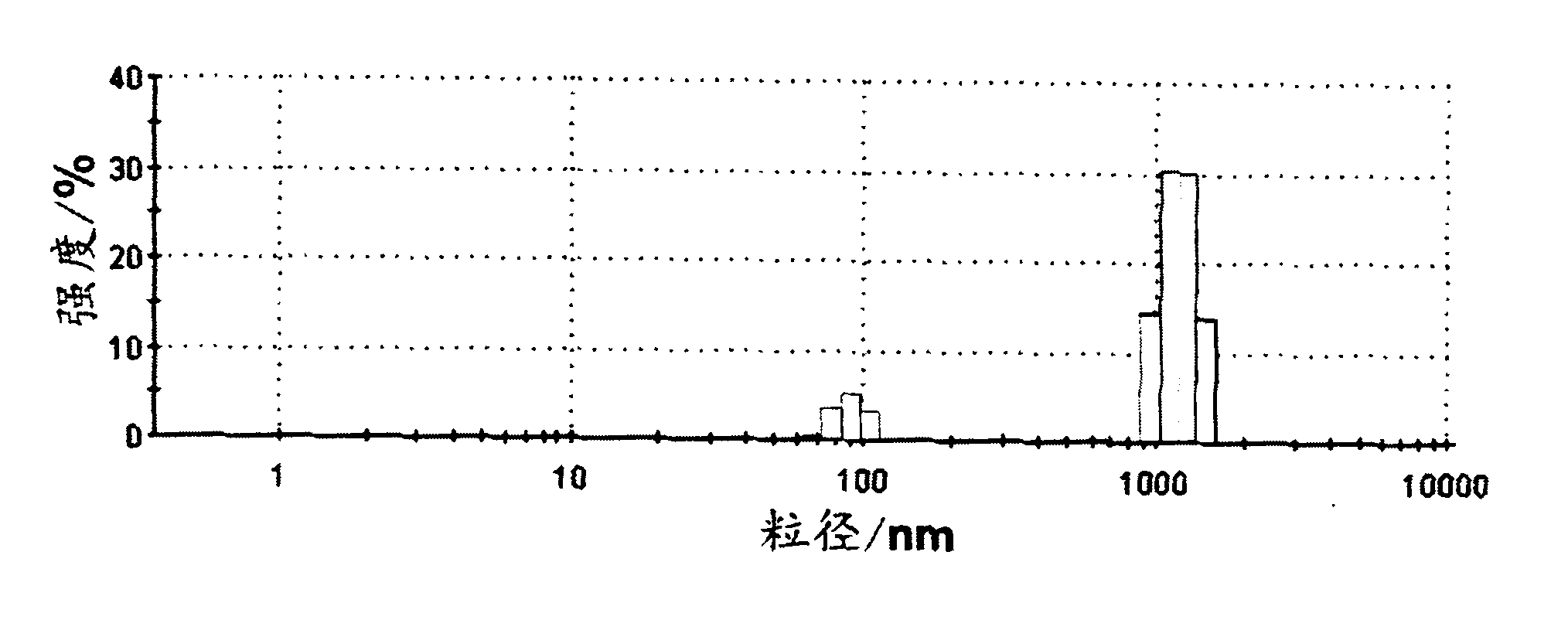

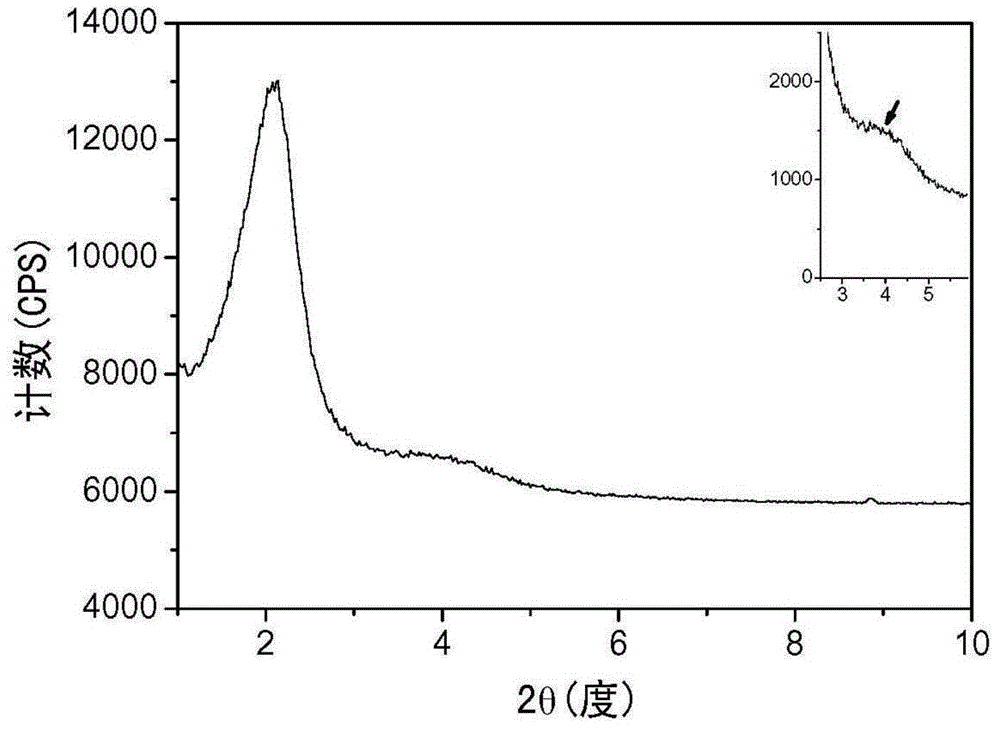

Method for preparing CeO2 nanometer solid sphere by using CTAB (Cetyltrimethyl Ammonium Bromide) as soft template

InactiveCN103101955ASave raw materialsEasy to operateMaterial nanotechnologyRare earth metal compoundsMean diameterSolid sphere

The invention discloses a method for preparing a CeO2 nanometer solid sphere by using CTAB (Cetyltrimethyl Ammonium Bromide) as a soft template. The method comprises the following steps of: dissolving Ce(NO3)3.6H2O in deionized water to obtain a Ce(NO3)3 solution; adding KBrO3 and the CTAB (Cetyltrimethyl Ammonium Bromide) into the Ce(NO3)3 solution and obtaining a mixed solution after continuous uniform stirring; and transferring the mixed solution into a reaction kettle, placing the reaction kettle in a baking oven to carry out reaction at 160-190 DEG C for 10-20hours, carrying out centrifugal washing after the reaction is finished, and drying the washed product at 80 DEG C to obtain solid sphere-like CeO2 nanometer powder. According to the preparation method disclosed by the invention, the Ce(NO3)3.6H2O, the KBrO3 and the CTAB (Cetyltrimethyl Ammonium Bromide) are used as raw materials, the nanometer solid sphere is further synthesized by taking the CATB as the soft template and by means of hydro-thermal method, mean diameter of the sphere is 1mu m, and the nanometer solid sphere is composed of a large number of fine CeO2 particles. The method has the unique advantages of relative low cost of raw materials and simple technological operation.

Owner:SHAANXI UNIV OF SCI & TECH

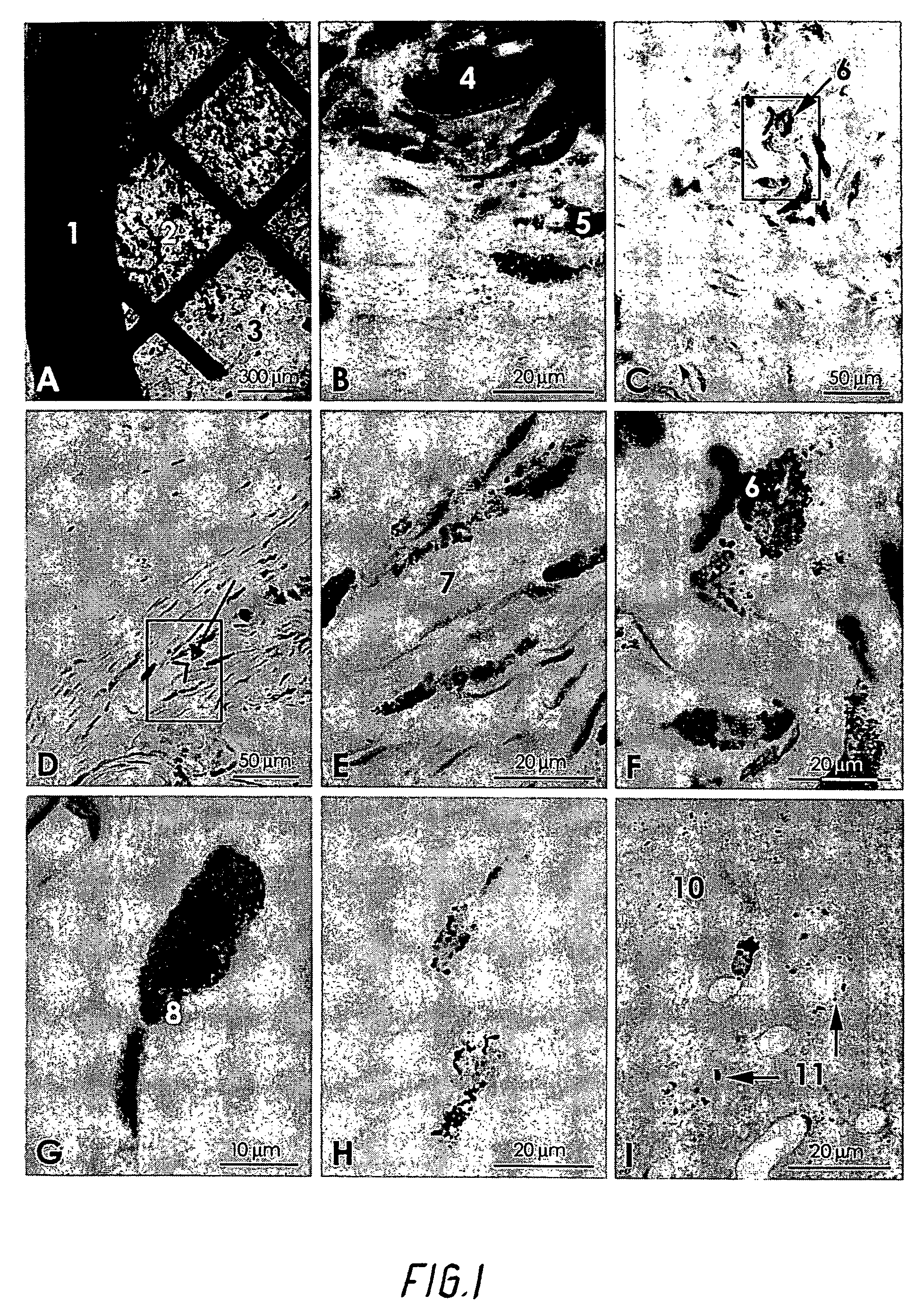

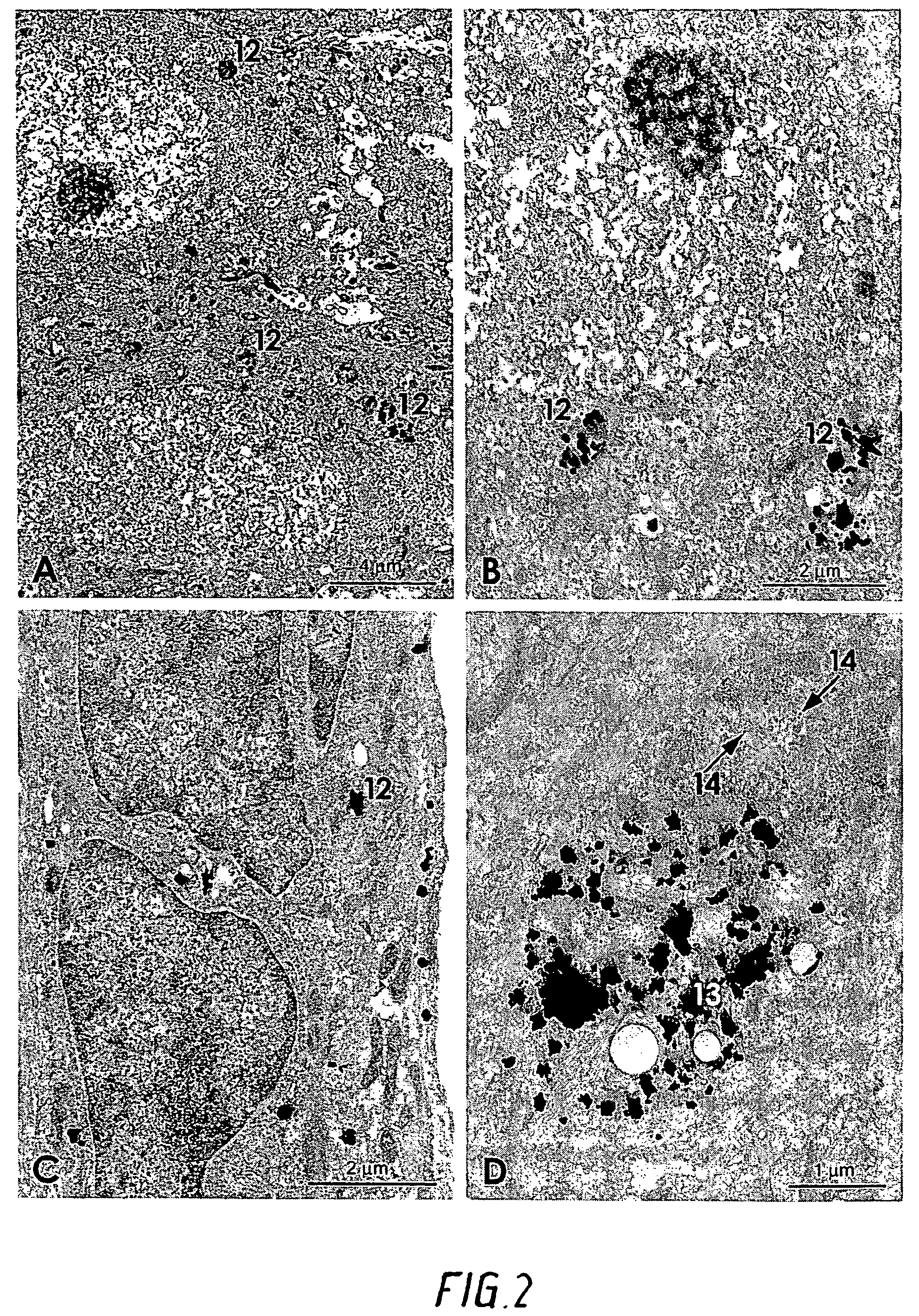

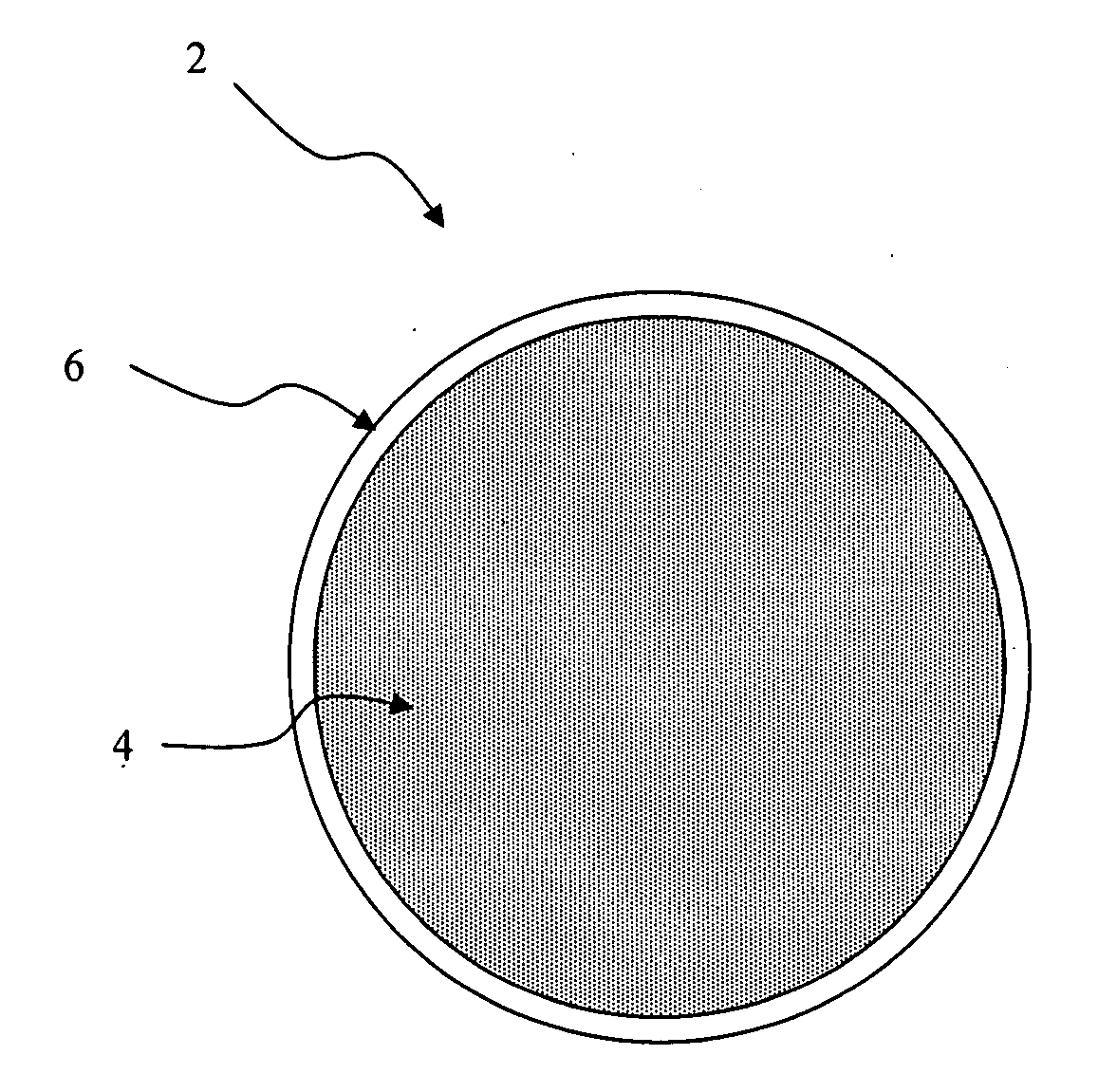

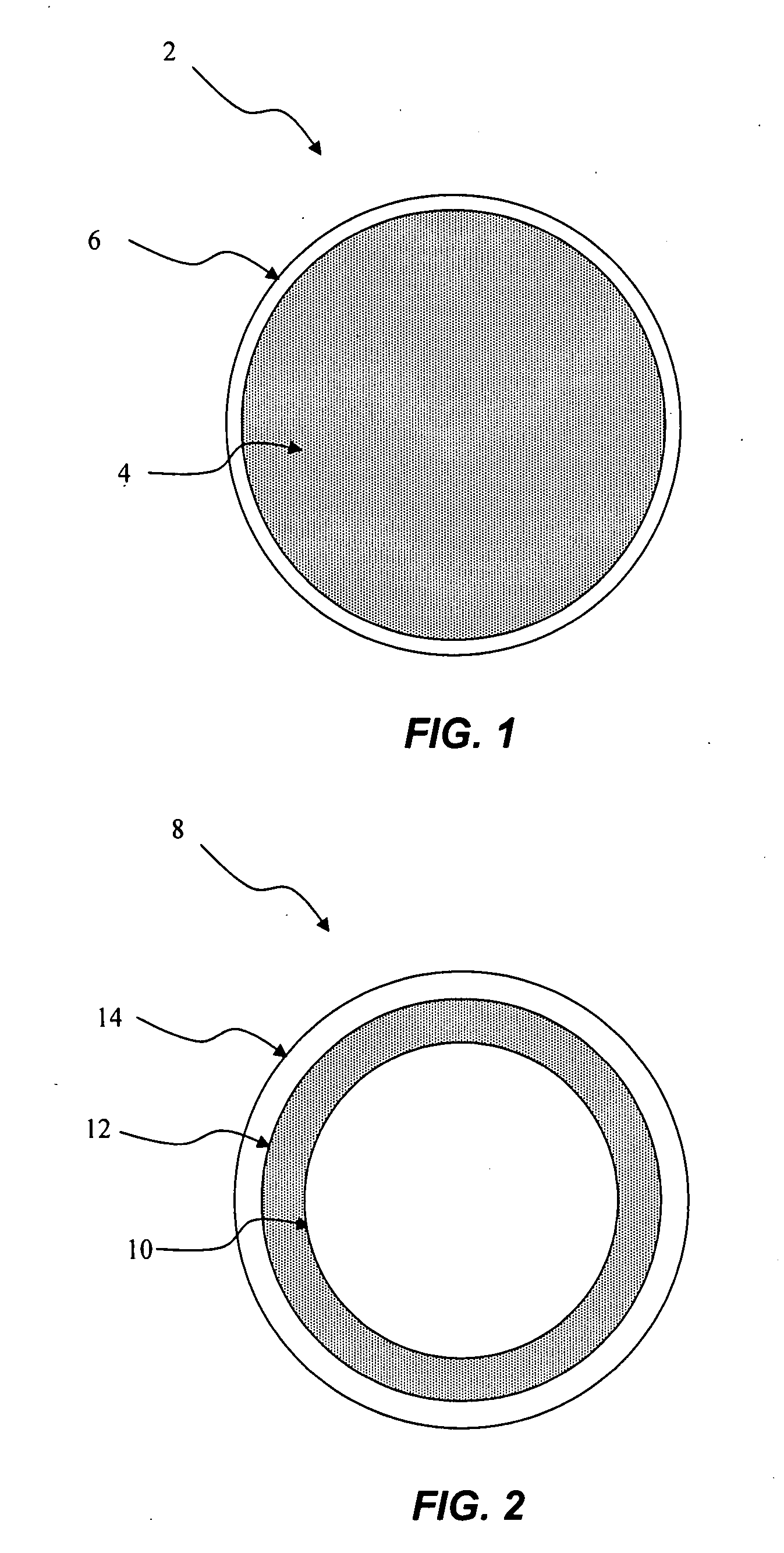

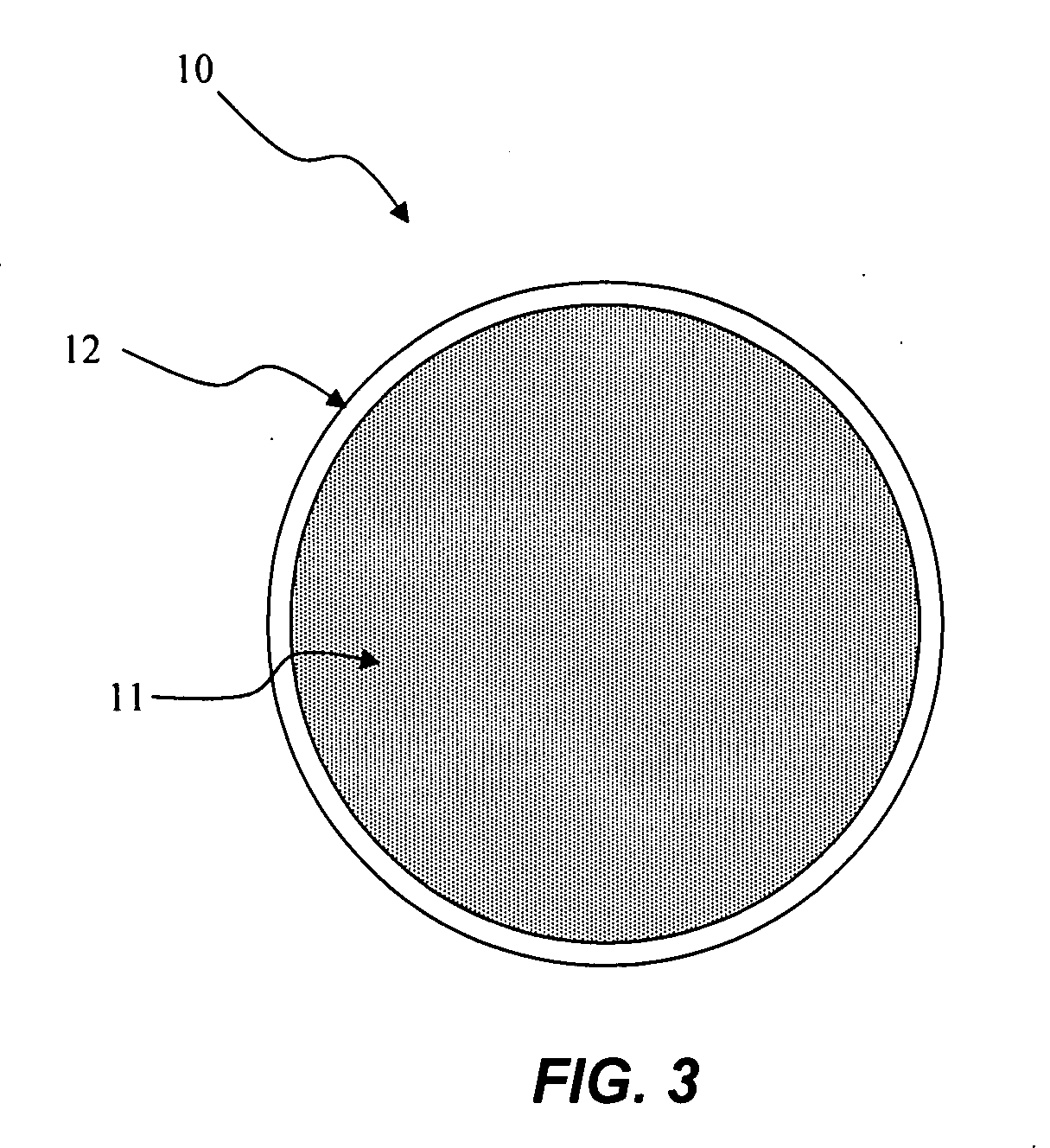

Medicament and method of treatment of patients with heavy metals

InactiveUS7655261B2The method is simple and reliableImmune reactionBiocideHeavy metal active ingredientsSolid sphereDisease patient

A method of treatment of a diseased patient in which a dose of at least one heavy metal is delivered to the patient, with a surface area which is accessible for direct contact with the patient's tissue and effects release of heavy metal ions for uptake by immuno reactive cells. The criteria to be complied with in order for the heavy metal to be effective is that the surface area is greater than the surface area of a solid sphere of the same at least one heavy metal, and that the solid sphere and dose have the same weight. In a preferred embodiment, the dose of heavy metals is delivered to the patient as very small hollow particles.

Owner:DANSCHER GORM

Preparation method of spherical meso-porous molecular sieve

The invention provides a preparation method of spherical meso-porous molecular sieve. The method comprises the following steps: mixing a cationic surfactant, ammonia water, butanone and water to obtain a mixed solution; adding tetraethyl orthosilicate, and stirring to obtain a reaction solution; filtering the reaction solution to obtain a filtered product; and calcining the filtered product to obtain the spherical meso-porous molecular sieve. The preparation method solves the defect of only synthesis of solid spheres with large particle sizes under simple synthesis step and mild synthesis conditions; butanone with a low boiling point, low polarity and low surface tension is used as a cosolvent, so the spherical meso-porous molecular sieve with small particles sizes can be conveniently and fast obtained, the synthesis time is greatly shortened, the rapid synthesis purpose is reached, and the production cost is reduced; and the spherical meso-porous molecular sieve prepared in the invention has wide practical application values in the fields of carriers in catalyst preparation, and chromatographic column filling in chromatographic separation.

Owner:LIAONING OXIRANCHEM INC

Medicament and method of treatment of patients with heavy metals

InactiveUS20060121079A1The method is simple and reliableImmune reactionHeavy metal active ingredientsAntipyreticSolid sphereDisease patient

A method of treatment of a diseased patient in which a dose of at least one heavy metal is delivered to the patient, with a surface area which is accessible for direct contact with the patient's tissue and effects release of heavy metal ions for uptake by immuno reactive cells. The criteria to be complied with in order for the heavy metal to be effective is that the surface area is greater than the surface area of a solid sphere of the same at least one heavy metal, and that the solid sphere and dose have the same weight. In a preferred embodiment, the dose of heavy metals is delivered to the patient as very small hollow particles.

Owner:DANSCHER GORM

Golf equipment formed from castable formulations with resiliency comparable to ionomer resins

Owner:ACUSHNET CO

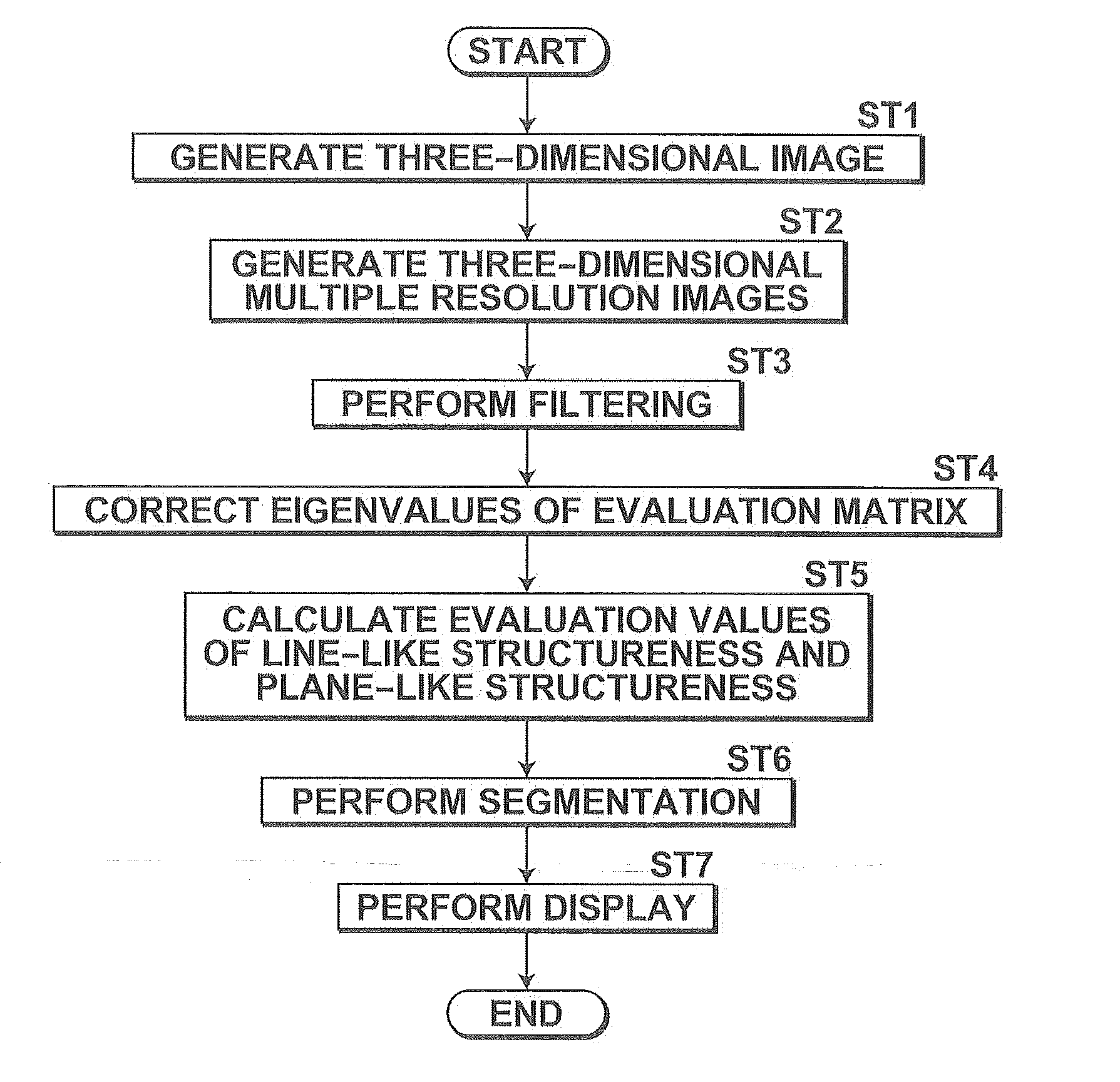

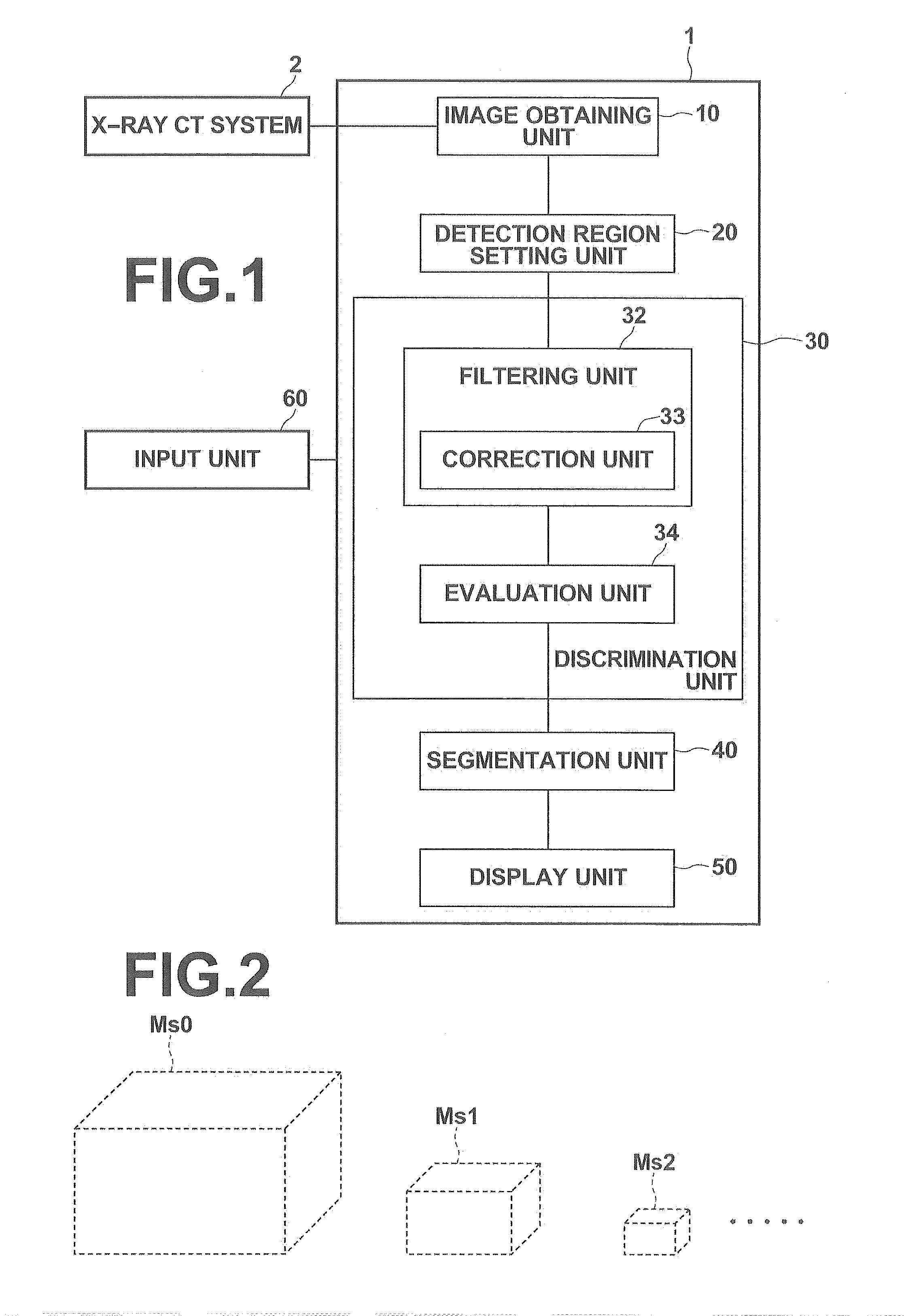

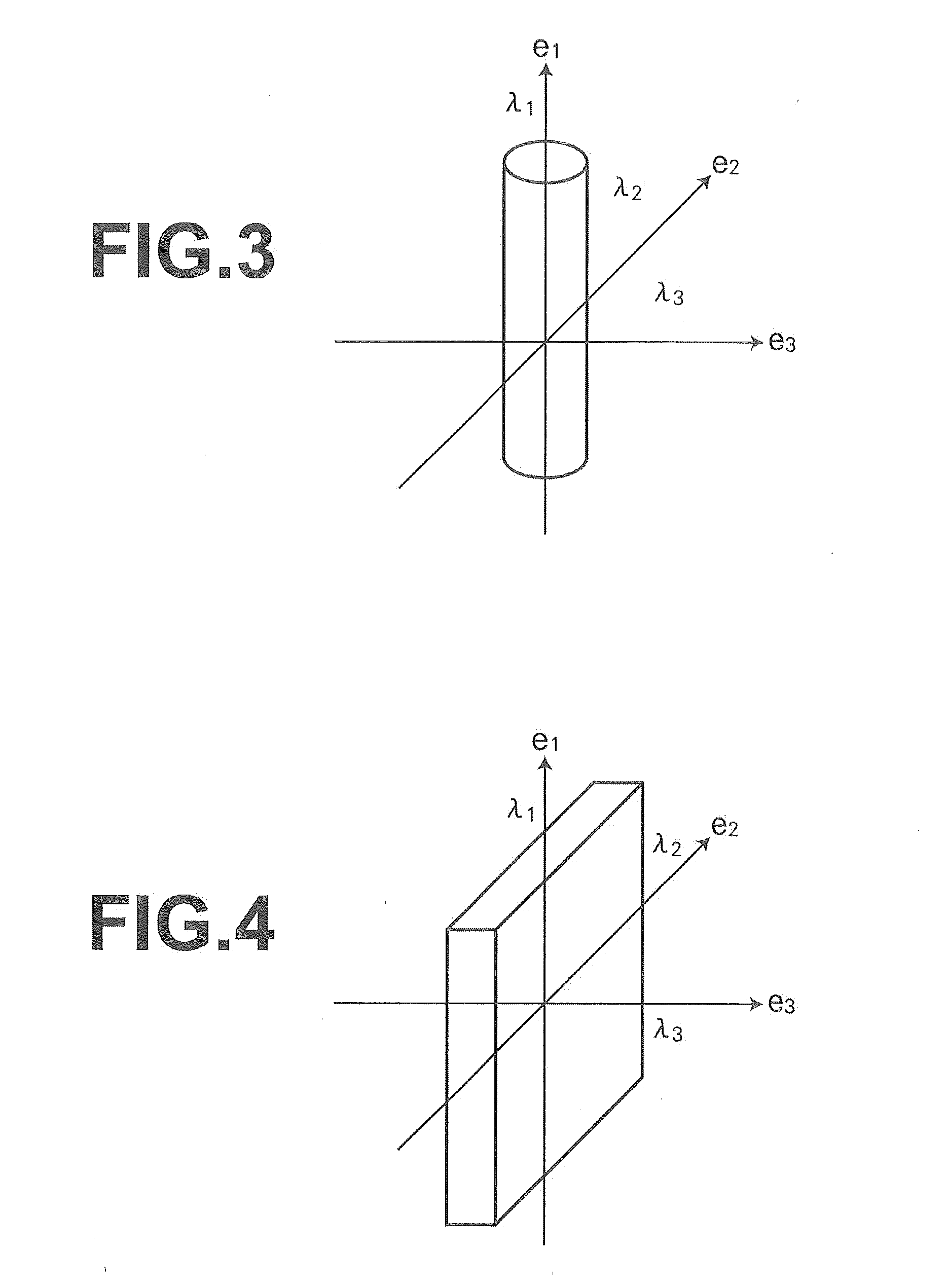

Image processing apparatus, method, and program

ActiveUS20150016686A1Inhibit discriminationImprove assessment accuracyImage enhancementMedical imagingFeature vectorImaging processing

An image processing apparatus, including a filtering unit that performs filtering on an image using a second order partial differential and calculates a Hessian matrix and an evaluation unit that discriminates a structure included in the image using eigenvalues and eigenvectors of the Hessian matrix, in which the filtering unit includes a correction unit that performs filtering on the image using a first order partial differential of a function representing a hollow sphere having the same radius as the radius of the solid sphere and obtains first order partial differential vectors, and carries out correction to cancel out one of response waveforms of the function representing the solid sphere in each direction, the response waveforms appearing at two positions symmetrically separated with respect to the center of the solid sphere, using values obtained by projecting the first order partial differential vectors onto directions of the eigenvectors.

Owner:FUJIFILM CORP

Walnut health ball and fabricating method thereof

InactiveCN1669602ARealize comprehensive utilizationGreat ornamental valueElectrotherapyGymnastic exercisingInterior spaceSolid sphere

The invention relates to the amusement gymnasium equipment played in the hands, especially a walnut ball for health and its production method. The spherical shell is made of natural walnut shell, and its inner is filled with magnetic sphere that mixed by small block-shaped permanent magnet, iron dust and adhesive agent. The magnetic sphere is full in the inner space through glass cement, and coadunited with the inner surface of the spherical shell, to form the solid sphere of natural walnut shape. The invention make the abandoned walnut shell useful, adopt the chiropractic action of the hand acupuncture points by wooden outer surface's irregular scar of the natural walnut shell, fill the magnetic substance that good for human body's health. It not only aggravates the health ball's weight, satisfies the player's hand feeling demand, but also has the effect of magnetic health care and magnetic medical treatment. The texture of the walnut shell is solid and can be played for long. The invention is difficult to break even when it is fall to the ground.

Owner:索培力

Method for preparing mesoporous nano particles with special appearance based on anion surfactant

InactiveCN102659122AEliminate non-biocompatibility factorsEasy to separateSilicaNanotechnologySolid sphereRoom temperature

The invention relates to a method for preparing mesoporous nano particles with special appearance based on an anion surfactant, and belongs to a method for preparing mesoporous nano particles. The method comprises the following steps of: dissolving 1.0 millimole of Sar-Na in 30 mL of deionized water at the temperature of between 14 and 18 DEG C, dripping 2.0 mL of 0.1 M hydrochloric acid, regulating the pH value to 6.0 to 6.8 slowly, stirring for 30 minutes, dripping 1.0 mL of tetraethyl orthosilicate (TEOS) and 0.1 mL of 3-aminopropyl trimethoxysilane (APMS), stirring a mixture at room temperature for 10 minutes, putting into a kettle, standing at the temperature of 15 DEG C for 2 hours, transferring the reaction kettle into a drying oven of 80 DEG C, and crystallizing for 20 hours; cooling to the room temperature, opening the kettle, centrifuging and washing; drying at the temperature of 40 DEG C for 48 hours; and performing reaction to generate two products, wherein one product is positioned on a solution and is named AMS-U, the other product is dispersed in a substratum solution and is named AMS-R, superstratum substances are mesoporous hollow spheres, and substratum products are solid spheres with mesoporous structures. The method has the advantages that two mesoporous nano particles are prepared in one step and are distributed in two layers, the superstratum substances are the mesoporous hollow spheres, the substratum substances are the solid spheres, and the hollow spheres and the solid spheres can be separated by a physical method.

Owner:CHINA UNIV OF MINING & TECH

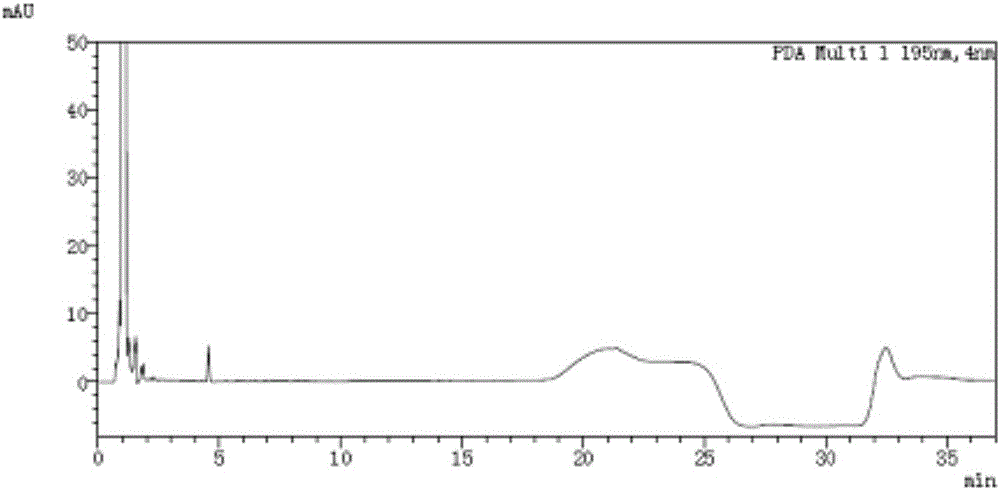

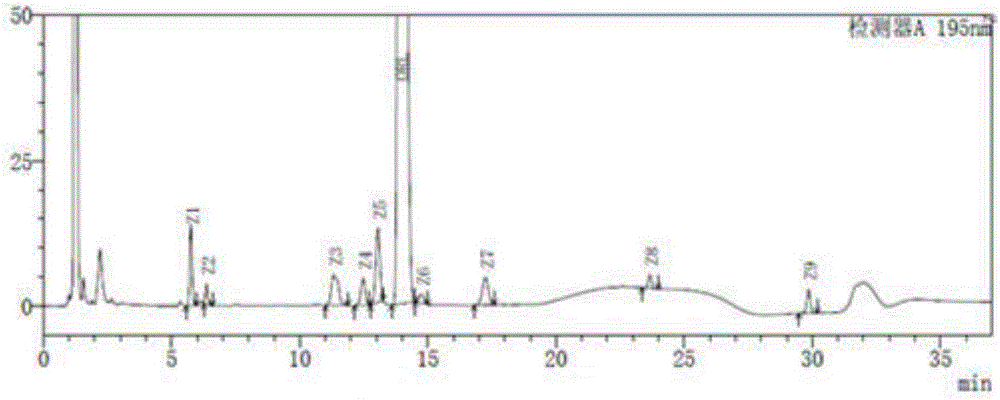

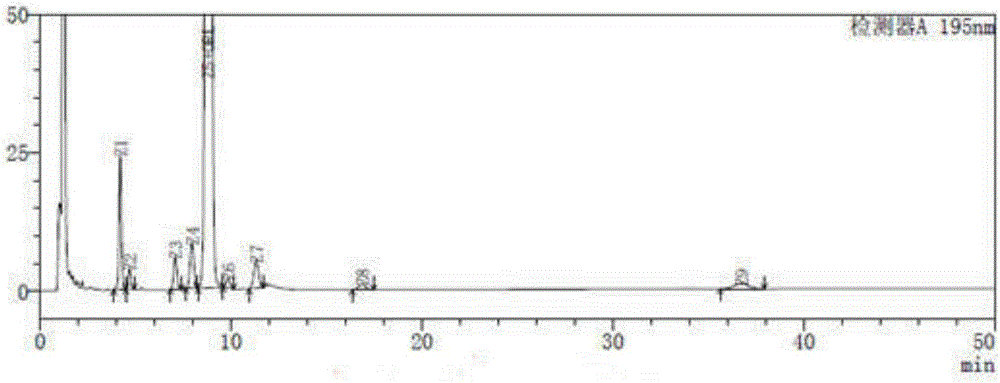

Method for measuring degraded impurities in orlistat capsules

ActiveCN105738506AEfficient detectionSolving Separation Assay ProblemsComponent separationSolid sphereGradient elution

The invention discloses a method for measuring degraded impurities in orlistat capsules and relates to the field of analytical chemistry.According to the method, a high performance liquid chromatographic method is adopted, an impurity mixed reference substance solution and a sample solution are injected in a high performance liquid chromatograph, and measurement of the degraded impurities in the orlistat capsules is completed.According to the chromatographic conditions, silica gel solid sphere particles are used as filler of a chromatographic column; a mobile phase A is an acidic water solution, a mobile phase B is an organic solvent, the sum of the percent by volume of the mobile phase A and the percent by volume of the mobile phase B is kept 100% all the time, and linear gradient elution is carried out.According to the method, the Cortecs C18 (Waters, 150 mm*4.6 mm, 2.7 micrometers) chromatographic column is adopted, and by optimizing the mobile phase gradient elution procedure, all the degraded impurities and process impurities hard to separate nearby a main peak can be separated under the same chromatographic conditions, and the degraded impurities in the orlistat capsules can be effectively detected.

Owner:ZHONGSHAN WANHAN PHARM CO LTD

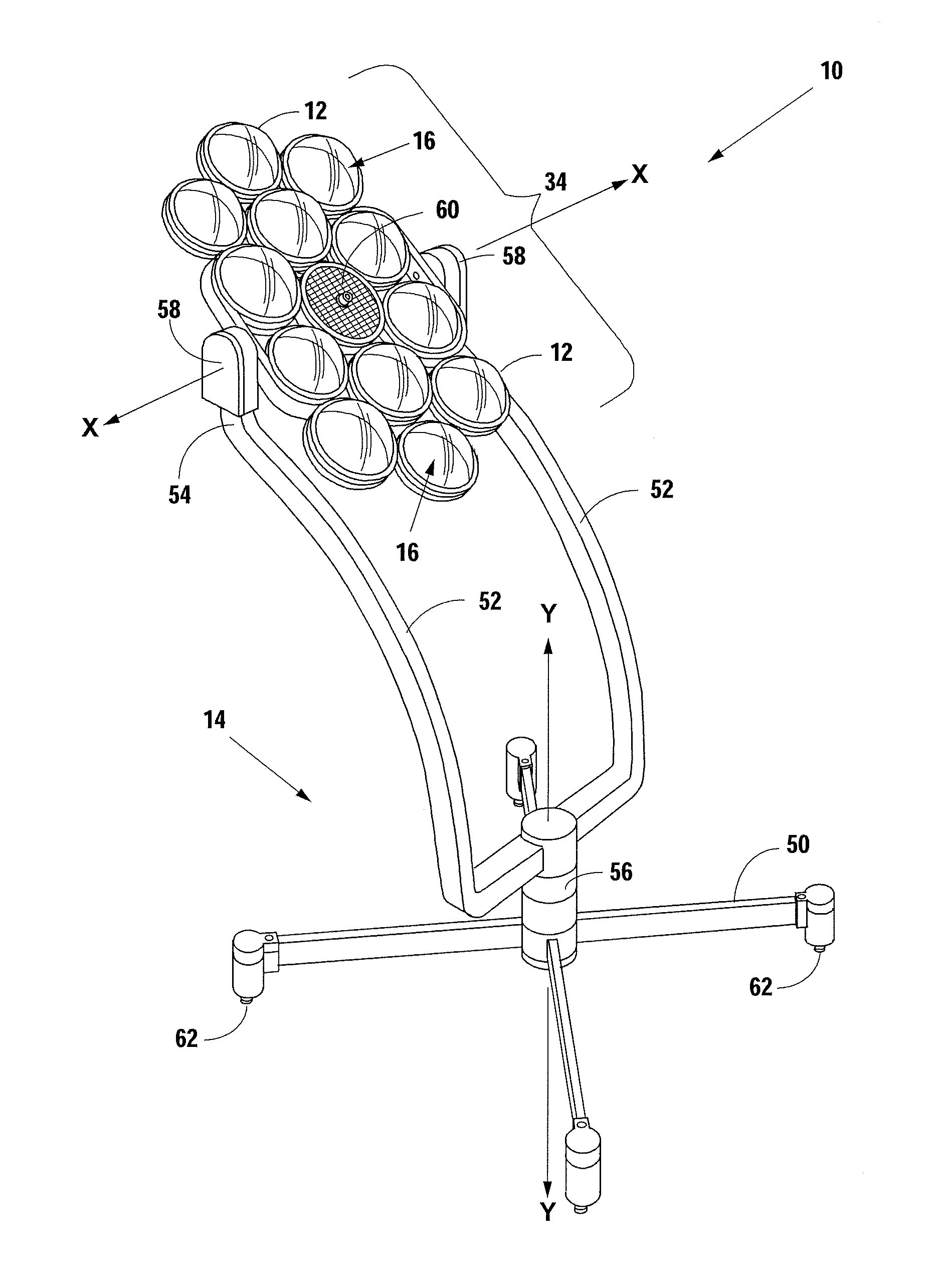

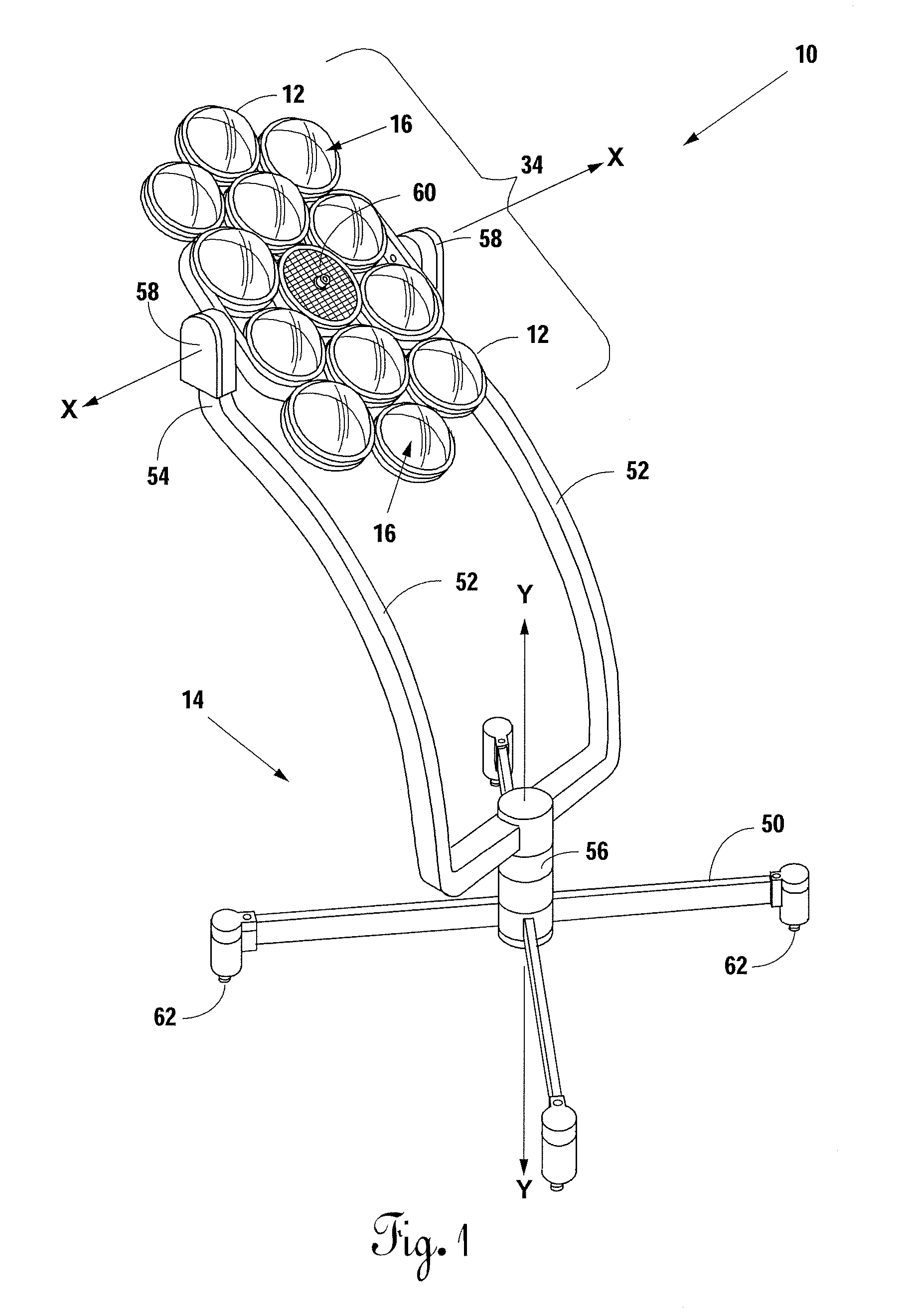

Solar energy device

ActiveUS8705917B2Improved light collectorPhotovoltaic supportsSolar heating energySolid sphereAbsorbed energy

The present invention is a solar energy device that uses an improved light collector to collect sunlight. The improved light collector is a translucent, and preferably transparent, solid sphere. The light collector transmits sunlight that is incident thereon and emits the light to a focal point on the other side of the sphere. An energy-receiving medium is located at or near the focal point of the emitted light and absorbs energy from the emitted light. The energy-receiving medium uses the energy from the emitted light in accordance with the desired function of the present invention.

Owner:GARZA JORGE A

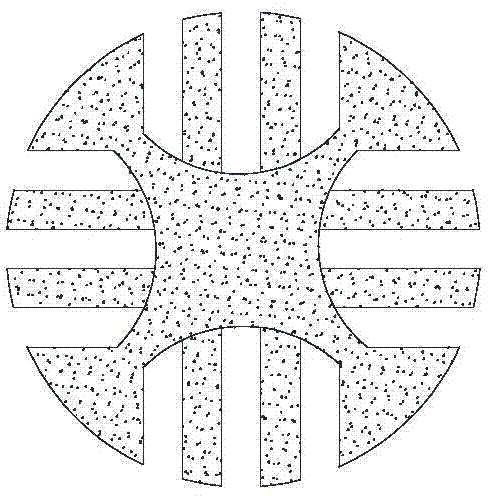

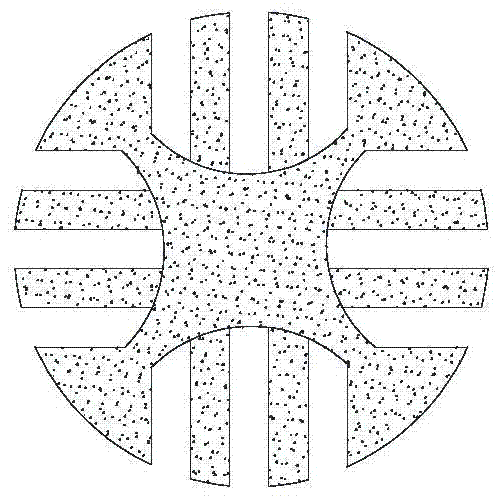

Filling material for sewage treatment and preparation method of filling material

ActiveCN104773816AImprove performanceGood exchange interfaceSustainable biological treatmentBiological water/sewage treatmentSolid sphereFilling materials

The invention discloses a filling material for sewage treatment and a preparation method of the filling material. The filling material is spherical and comprises a solid sphere in the centre, a sheet-like fan-shaped expansion area and a wool area on various surfaces, wherein the sheet-like fan-shaped expansion area and the wool area on various surfaces are arranged outside the solid sphere at intervals. The preparation method comprises the steps of manufacturing a spherical basal body, forming a fan-shaped surface in the expansion area, splitting and the like. By means of the unique structure and the process thereof, the filling material disclosed by the invention is good in oxygenizing efficiency and rapid to hang; the specific surface area of the filling material is high; attachment of microorganisms is promoted through the fan-shaped wool area; an aerobic state is formed in the sphere; an anoxic state is formed even in the spherical centre; a biological membrane has multiple varieties of the microorganisms, long food chain and higher processing capacity; the filling material is simple to install and convenient to operate and manage; the basal body shape of the filling material is a sphere; under the stirring of aerated bubbles, the filling material can rotate at high speed; therefore, the filling material is low in resistance and mould releasing and updating are easy; the filling material takes synthetic fibre polyurethane, which has good hydrophilia, as a substrate material.

Owner:四川省科学城天人环保有限公司

Double-silicon-source-oriented hollow-sandwich-hollow silicon dioxide mesoporous material and synthesizing method thereof

ActiveCN106145121AMild preparation conditionsSynthesis is simple and controllableMaterial nanotechnologySilicaHydrofluoric acidSolid sphere

The invention relates to a double-silicon-source-oriented hollow-sandwich-hollow silicon dioxide mesoporous material and a synthesizing method thereof. The synthesizing method includes the steps that ethyl alcohol serves as a solvent, and under the base catalysis effect of ammonium hydroxide, 3-(2-aminoethyl)-aminopropyl trimethoxy silane (TSD) and tetraethoxysilane (TEOS) are subjected to hydrolytic polymerization to obtain solid hybridization silicon dioxide spheres; the spheres are converted into the hollow or solid sandwich-hollow silicon dioxide mesoporous material under the etching effect of hydrofluoric acid (HF), wherein in the process of preparing the solid hybridization silicon dioxide spheres, the silicon dioxide mesoporous material of different structures can be obtained by simply adjusting the volume ratio of the two silicon sources. According to the hollow silicon dioxide mesoporous material obtained with the method, the particle size ranges from 350 nm to 420 nm, the shell thickness ranges from 30 nm to 50 nm, and the hole diameter ranges from 3 nm to 4 nm; according to the obtained sandwich-hollow silicon dioxide mesoporous material, the particle size ranges from 350 nm to 420 nm, silicon dioxide solid spheres with the particle size of 100 nm to 160 nm serve as cores, the shell thickness ranges from 30 nm to 50 nm, and the hole diameter ranges from 3 nm to 4 nm. According to the silicon dioxide mesoporous material obtained with the method, a certain amount of amino exists for modification, and the application in the fields of catalysis, biological medicine and the like is greatly expanded.

Owner:SHANGHAI UNIV

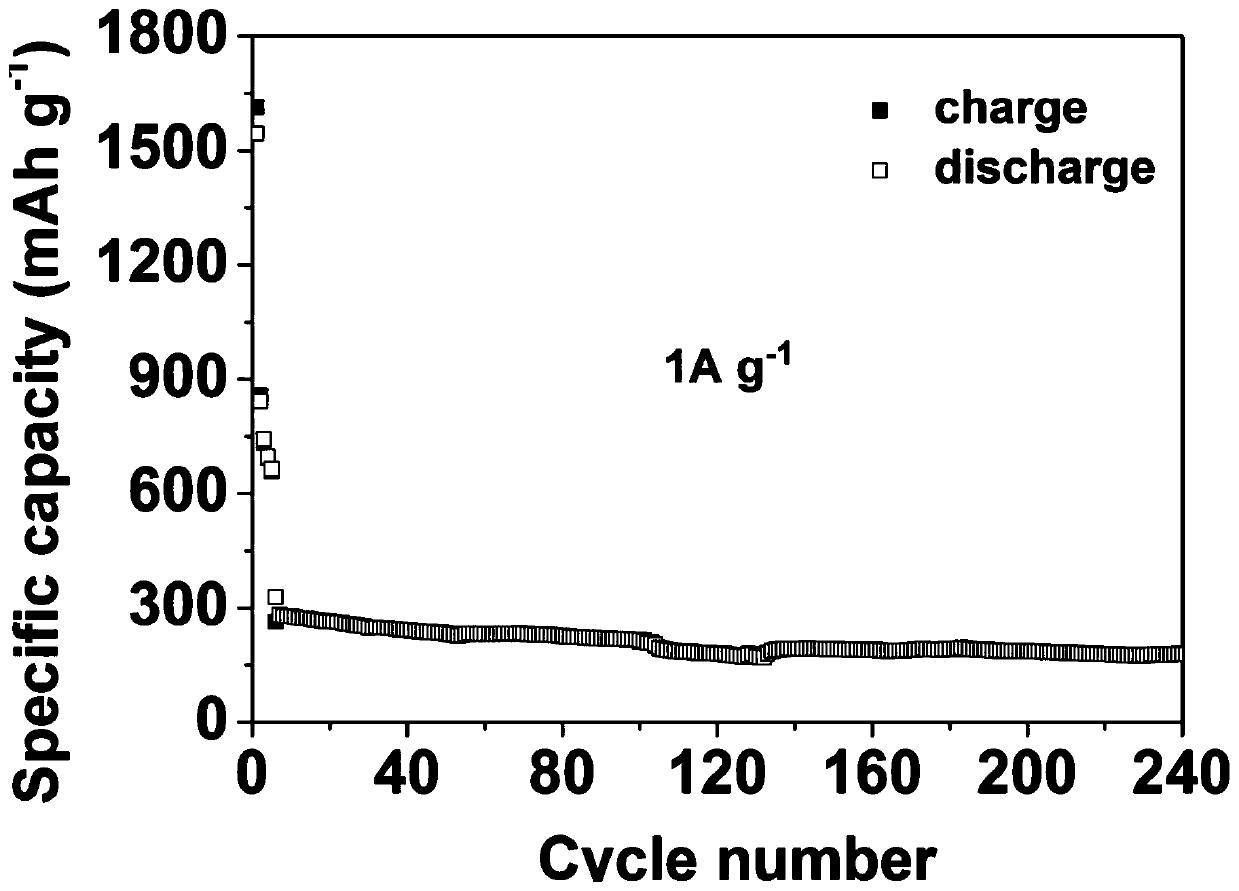

Preparation method of SnO2/carbon fabric composite material for sodium ion battery negative electrode

InactiveCN109786717AImprove conductivityIncrease the proportionElectrode carriers/collectorsSecondary cellsSolid sphereMicrometer

The invention relates to a preparation method of a SnO2 / carbon fabric composite material for a sodium ion battery negative electrode. The SnO2 / carbon fabric composite material with a grain size being0.5-1 micrometer and a uniform solid-sphere structure is prepared by taking water as a solvent and SnCl<2>.2H2O as a tin source and by a hydrothermal method, the SnO2 / carbon fabric composite materialis used as a negative electrode material to be assembled to form a sodium ion battery. Since SnO2 has relatively high theoretical capacity, the conductivity of the negative electrode material can be improved by taking a carbon fabric as a matrix; and moreover, SnO2 is directly grown on the carbon fabric, a binding agent and a conductive agent are not needed to be pasted, the active substance dutyratio is improved, the energy density is large, and thus, the SnO2 / carbon fabric composite material shows relatively good electrochemical performance. The preparation process is simple in process, theSnO2 / carbon fabric composite material low in reaction temperature, high in repeatability, short in period and low in energy consumption, is suitable for demand of large-scale production and has remarkable scientific significance to the application aspect of the sodium ion battery, and the production cost is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Filler for sewage treatment and preparation method thereof

ActiveCN104773816BImprove performanceGood exchange interfaceSustainable biological treatmentBiological water/sewage treatmentSolid sphereFood chain

The invention discloses a filling material for sewage treatment and a preparation method of the filling material. The filling material is spherical and comprises a solid sphere in the centre, a sheet-like fan-shaped expansion area and a wool area on various surfaces, wherein the sheet-like fan-shaped expansion area and the wool area on various surfaces are arranged outside the solid sphere at intervals. The preparation method comprises the steps of manufacturing a spherical basal body, forming a fan-shaped surface in the expansion area, splitting and the like. By means of the unique structure and the process thereof, the filling material disclosed by the invention is good in oxygenizing efficiency and rapid to hang; the specific surface area of the filling material is high; attachment of microorganisms is promoted through the fan-shaped wool area; an aerobic state is formed in the sphere; an anoxic state is formed even in the spherical centre; a biological membrane has multiple varieties of the microorganisms, long food chain and higher processing capacity; the filling material is simple to install and convenient to operate and manage; the basal body shape of the filling material is a sphere; under the stirring of aerated bubbles, the filling material can rotate at high speed; therefore, the filling material is low in resistance and mould releasing and updating are easy; the filling material takes synthetic fibre polyurethane, which has good hydrophilia, as a substrate material.

Owner:四川省科学城天人环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com