Double-silicon-source-oriented hollow-sandwich-hollow silicon dioxide mesoporous material and synthesizing method thereof

A technology of silicon dioxide and mesoporous materials, applied in the fields of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome operation, time-consuming and laborious, skeleton collapse, etc., and achieve mild preparation conditions. , Expand the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Mix ethanol and ammonia water at a volume ratio of 3:1, stir for 30 minutes to make it evenly mixed; the total volume of solvent is 40mL;

[0025] b. Mix the organosilicon source 3-(2-aminoethyl)-aminopropyltrimethoxysilane (TSD) and tetraethylorthosilicate (TEOS) at a volume ratio of 1:40 and disperse them in 8 mL of ethanol , the mass ratio of the mixed silicon source and ammonia water is 1:4.5; the mixed silicon source is ultrasonicated for 5 min to make it fully uniform;

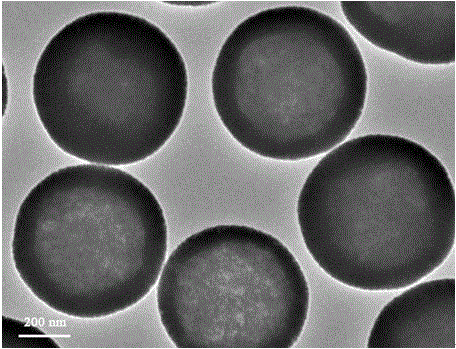

[0026] c. At room temperature, add the silicon source mixed in b to the solution in a at a constant speed. After the dropwise addition is completed, continue stirring for 2~3 h; after the reaction is completed, the reactant is centrifuged, washed with ethanol and deionized water, and dried to obtain a white powder;

[0027] d. Disperse 30 mg of the white powder obtained in step c into 10 mL of water, and sonicate for 30 minutes to obtain a white suspension;

[0028] e. Quickly drop 200 μL of ...

Embodiment 2

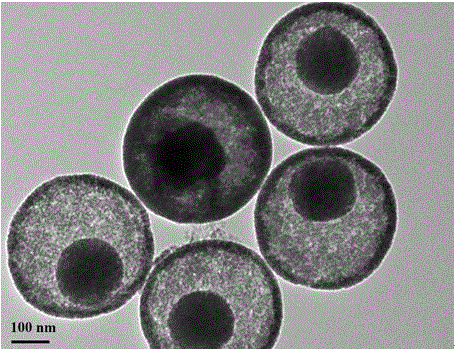

[0031] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the b step:

[0032] Mix organic silicon source 3-(2-aminoethyl)-aminopropyltrimethoxysilane (TSD) and tetraethylorthosilicate (TEOS) at a volume ratio of 1:10 and disperse them into 8 mL of ethanol;

[0033] The result obtained is quite different from the structure of Example 1. The obtained material is a sandwich hollow mesoporous silica nanosphere. There is an obvious solid silica core in the cavity of the ball. The particle size is about 150 nm, and the overall particle size is about 400 nm. , the outer shell is around 40 nm.

Embodiment 3

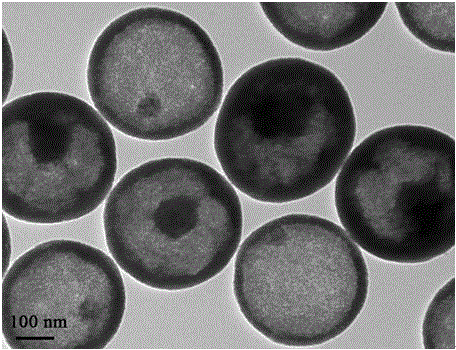

[0035] The preparation process and steps of this embodiment are basically the same as in Example 1, except that the b step:

[0036] Mix organic silicon source 3-(2-aminoethyl)-aminopropyltrimethoxysilane (TSD) and tetraethylorthosilicate (TEOS) at a volume ratio of 1:20 and disperse them into 8 mL of ethanol;

[0037] Compared with the results obtained in Examples 1 and 2, part of the obtained material is a hollow mesoporous silica sphere, and a small amount is a sandwich hollow structure. The particle size and shell thickness of the two types of silica nanospheres are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com