Carbon composite material, and preparation method and application thereof

A technology of carbon composite materials and composite materials, applied in the field of materials, can solve problems such as the decline of electrical conductivity and mechanical properties, achieve high surface area and high conductivity, superior capacity and rate performance, and overcome the problems of high specific surface area and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

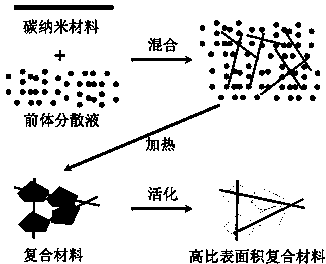

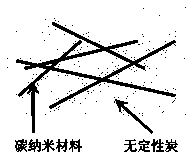

[0023] Preparation of carbon composites, such as figure 1 As indicated, weigh 4 g of polyethylene powder and disperse it in 30 ml of water. 0.34 g of carbon nanotubes were added and stirred evenly; the mixture was heated at 120° C. for 2 hours, cooled to room temperature, and the product was collected. Mix the product and sodium hydroxide uniformly at a weight ratio of 1:2, transfer to a high-temperature furnace, and under the protection of an inert gas (argon, nitrogen, and helium in any ratio), heat to 600°C and react for 2 hours; cool to room temperature , the product was rinsed with deionized water, dried for 12 hours, and set aside.

[0024] The capacity and rate performance of the composite material are obtained by cyclic voltammetry test: Take the carbon composite material, conductive carbon black and LA132 with a weight ratio of 90:5:5, stir evenly, and coat on the surface of the aluminum foil pole piece. After the pole piece is dried and rolled, the thickness is con...

Embodiment 2

[0029] Weigh 4 grams of phenolic resin powder and disperse into 30 milliliters of water. Add 0.34 g of carbon fiber and stir well. After the mixture was heated at 150°C for 2 hours, the product was collected after cooling to room temperature. The product and KOH were mixed uniformly at a weight ratio of 1:3, then transferred to a high-temperature furnace, heated to 750°C under the protection of an inert gas (argon, nitrogen, and helium in any ratio), and then reacted for 1 hour. After cooling to room temperature, the product was rinsed with deionized water and dried for 12 hours before use. The specific surface area of the composite material is 2200m 2 / g, the pore volume is higher than 0.5cm 3 / g, the conductivity is higher than 30S / cm, and the specific capacity of the product is higher than 130, 110, 90, 80, and 70F / g at 5, 10, 20, 50, and 100mV / s.

Embodiment 3

[0031] Weigh 10.625 g of sucrose powder and disperse into 30 ml of water. Add 0.34 g of carbon nanotube and graphene mixture (weight ratio 1:1) and stir evenly. After heating the mixture at 220°C for 2 hours, the product was collected after cooling to room temperature. The product and phosphoric acid (weight ratio 1:3) were evenly mixed in a weight ratio and then transferred to a high-temperature furnace, heated to 800°C under the protection of an inert gas (argon, nitrogen, and helium in any ratio) and reacted for 1 hour. After cooling to room temperature, the product was rinsed with deionized water and dried for 12 hours before use.

[0032] After testing, the specific surface area of the composite material is 2000m 2 / g, the pore volume is higher than 0.5cm 3 / g, conductivity higher than 30S / cm. The specific capacities of the composites are higher than 140, 130, 120, 110, 100, and 90 F / g at 5, 10, 20, 50, 100, and 200 mV / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com