Patents

Literature

65results about How to "Solve the difficulty of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

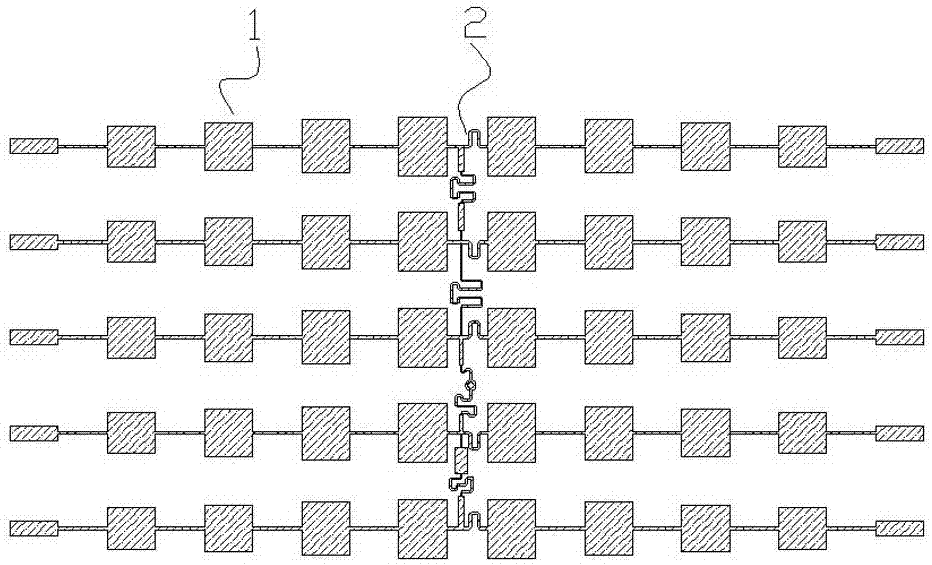

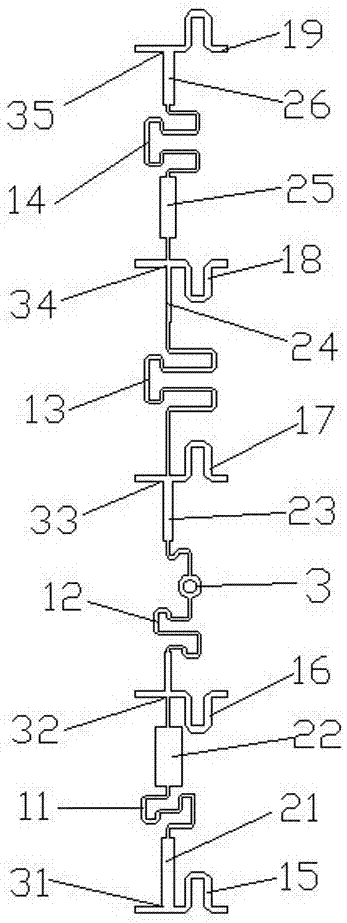

Vehicular radar array antenna

ActiveCN106972244AMeet needsReduce distractionsAntenna adaptation in movable bodiesRadiating elements structural formsImpedance matchingProduct optimization

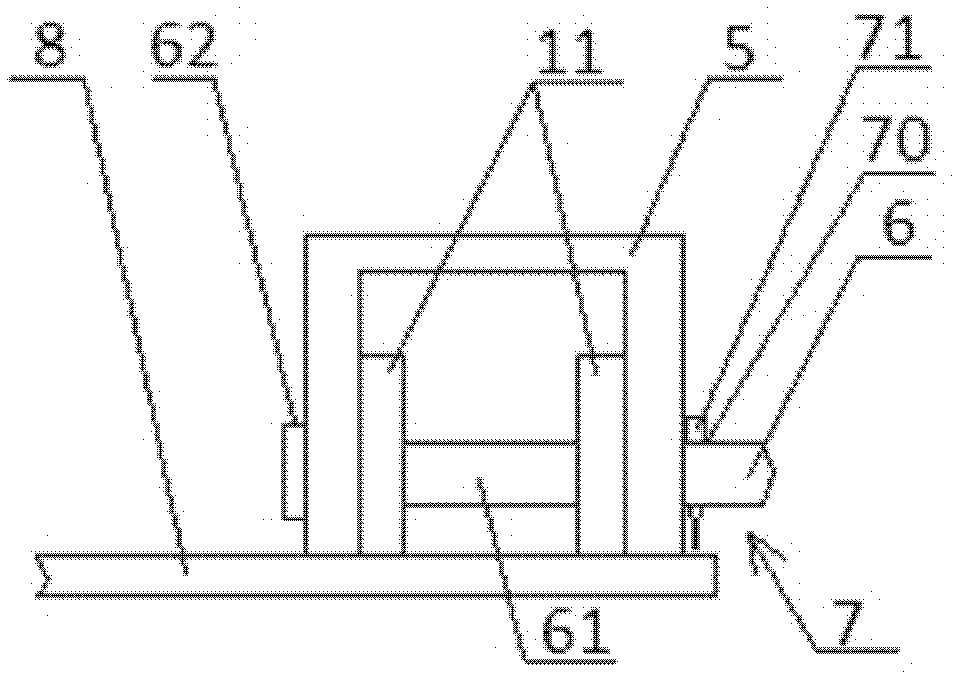

The invention provides a vehicular radar array antenna. The vehicular radar array antenna comprises a radiation fin array and an impedance matching network arranged on the same plane, and the radiation fin array is configured in a bilateral symmetry manner by taking the impedance matching network as the center axis. According to the invention, a novel feed network is employed, based on the microstrip line impedance match and phase shift principle, relevant parameter demands of the antenna radiation array are achieved by means of a simple implementation form, and furthermore product optimization is achieved. The simulation of the vehicular anticollision radar array antenna and the debugging of the antenna sample are convenient and fast, by arranging the impedance matching network and the array antenna in the same plane, the whole radar antenna profile is reduced, and the duty ratio of the antenna feed part in the whole vehicular radar is effectively reduced. By employing the novel design concept and design method, a conventional feed power splitting network structure with a complicated back side is broken through, electromagnetic interference on other radio frequency devices is effectively reduced, and the vehicular radar array antenna has a deep business application value in the actual engineering.

Owner:HUIZHOU SPEED WIRELESS TECH CO LTD

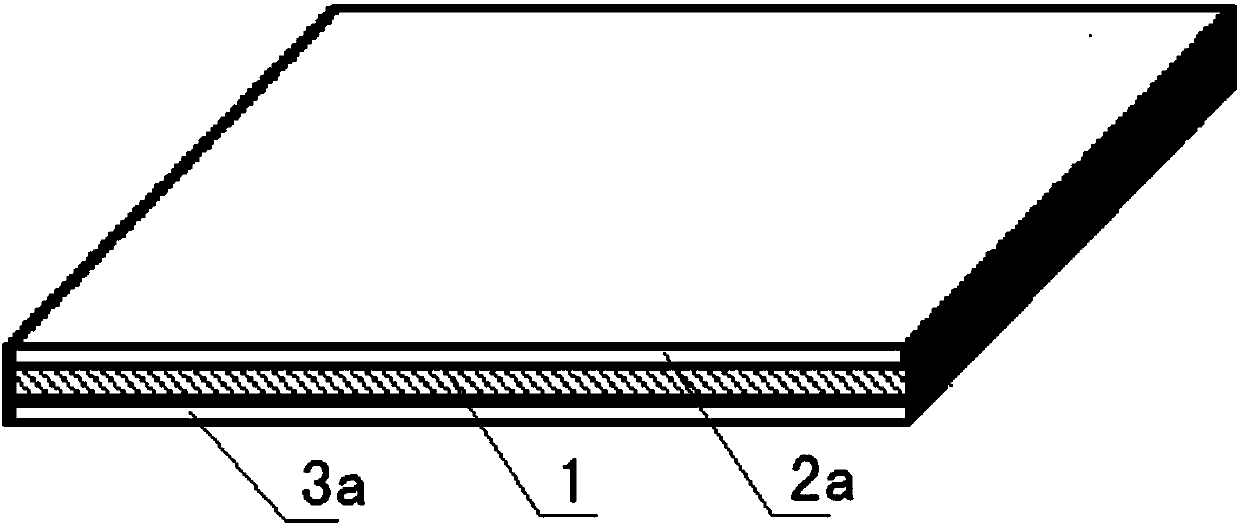

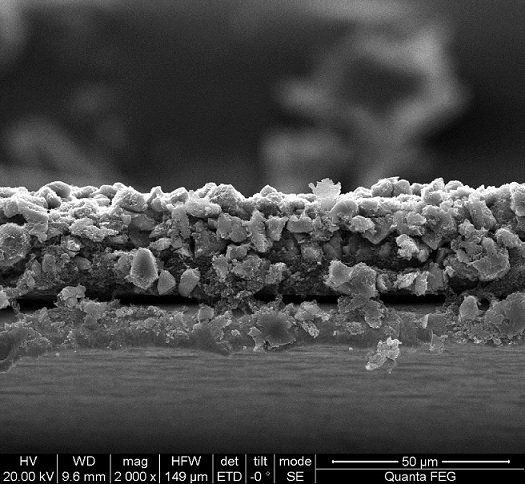

Method for preparing metal/polyaniline/plastic composite film through electrochemical in-situ polymerization

ActiveCN102876037ASolve the difficulty of processingSolve defects such as low conductivityElectrolytic organic material coatingComposite filmConductive polymer

The invention discloses a method for preparing a metal / polyaniline / plastic composite film through electrochemical in-situ polymerization. The method comprises the following steps of: 1) preparing a polyaniline / plastic conductive composite film, namely performing electrooxidation polymerization of polyaniline in an aniline-acid solution by taking a plastic microporous film as a base film to obtain the polyaniline / plastic conductive composite plastic film, wherein the electric conductivity of the polyaniline / plastic conductive composite plastic film is 1 to 59.5S.cm<-1>; and 2) preparing a polyaniline / plastic / metal conductive composite film, namely electrodepositing silver on the surface of the polyaniline / plastic conductive composite film to obtain the polyaniline / plastic / metal conductive plastic composite film, wherein the electric conductivity of the polyaniline / plastic / metal conductive plastic composite film is 10<2> to 10<4>S.cm<-1>. The conductive plastic composite film prepared by the method has high electric conductivity and thermal stability and excellent mechanical properties, is high in performance price ratio and light in mass, realizes the organic combination of conductive polymers and metal particles, overcomes the unworkability of the polyaniline, and expands the application range of the conductive polymers. The method is simple and easy; and the obtained composite film can be used as a photoelectronic device, and is used for various fields such as detection and sensing, and electromagnetic shielding.

Owner:CENT SOUTH UNIV

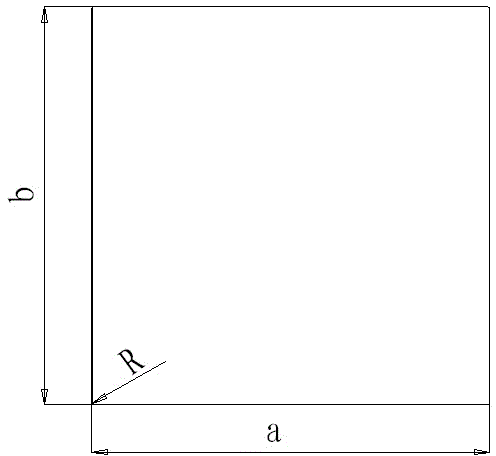

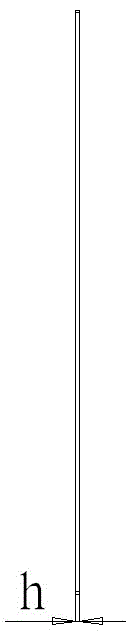

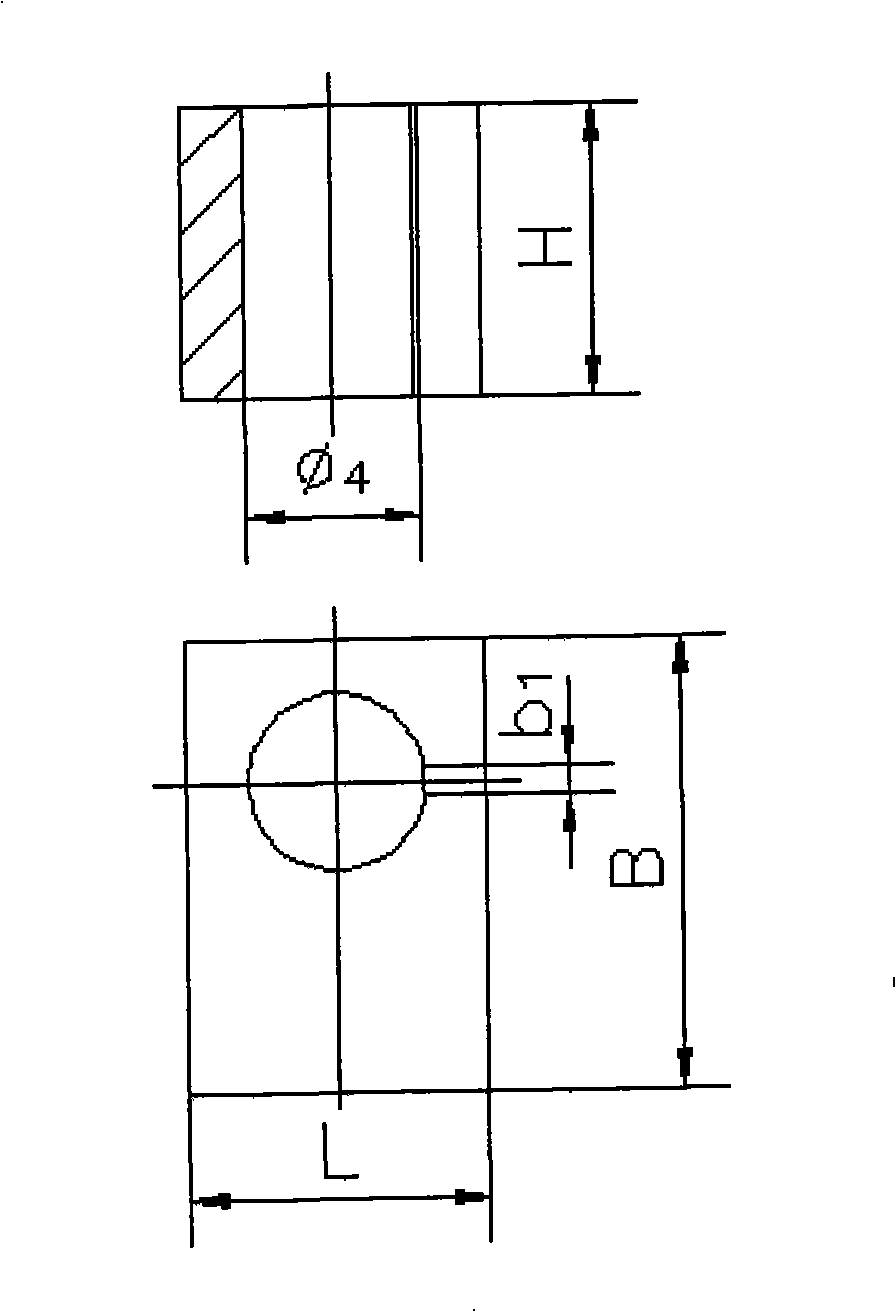

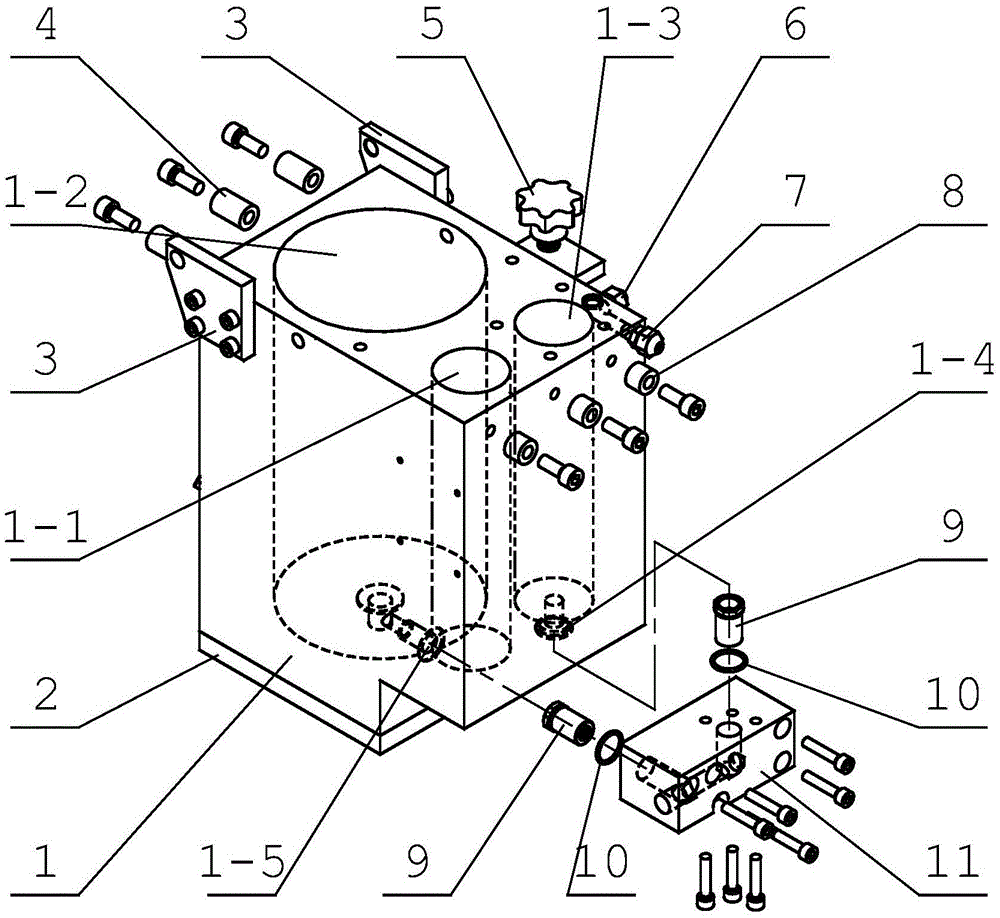

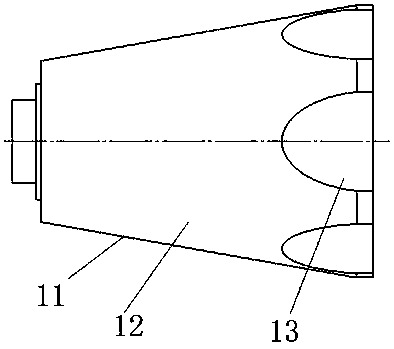

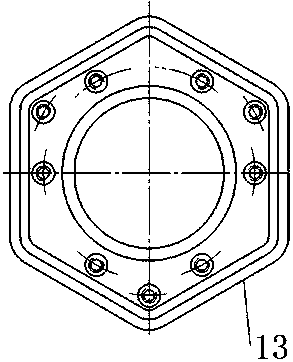

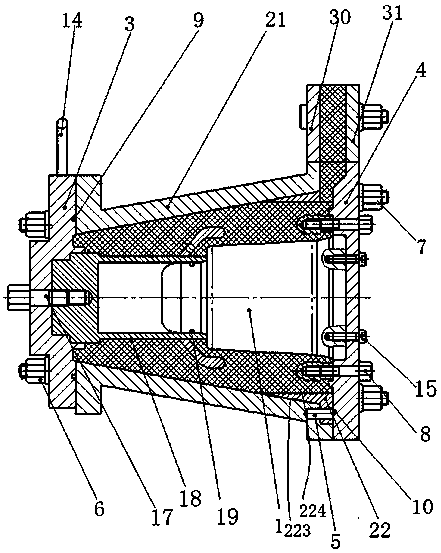

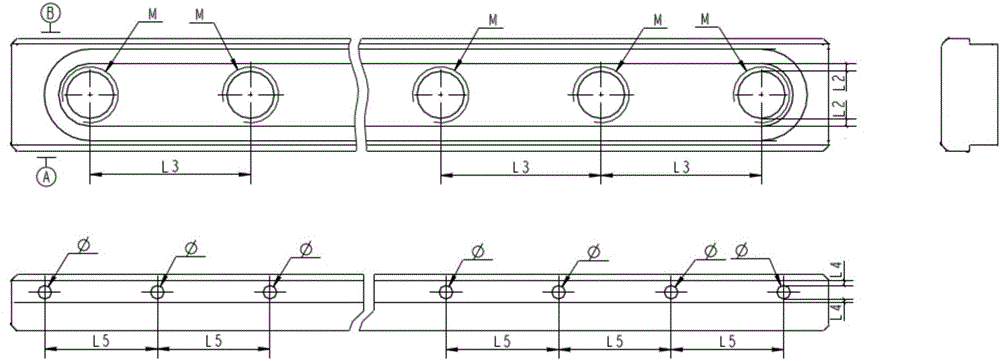

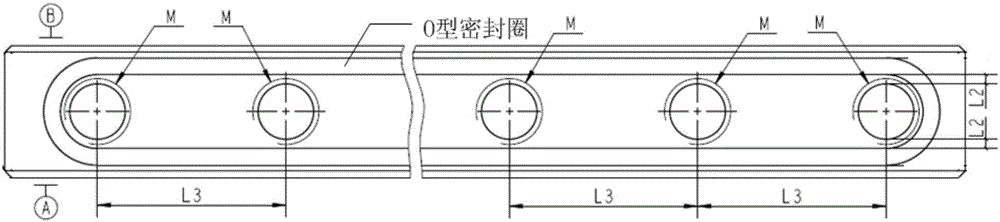

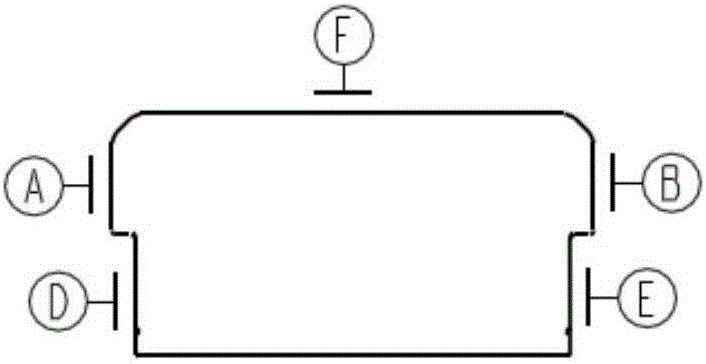

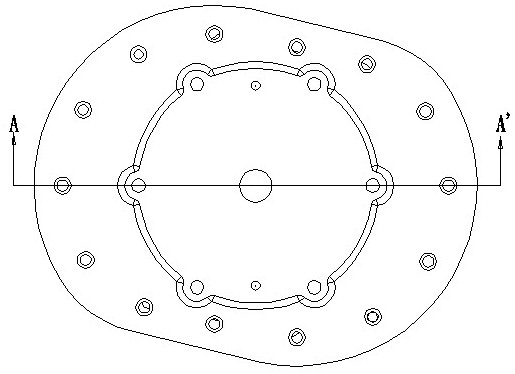

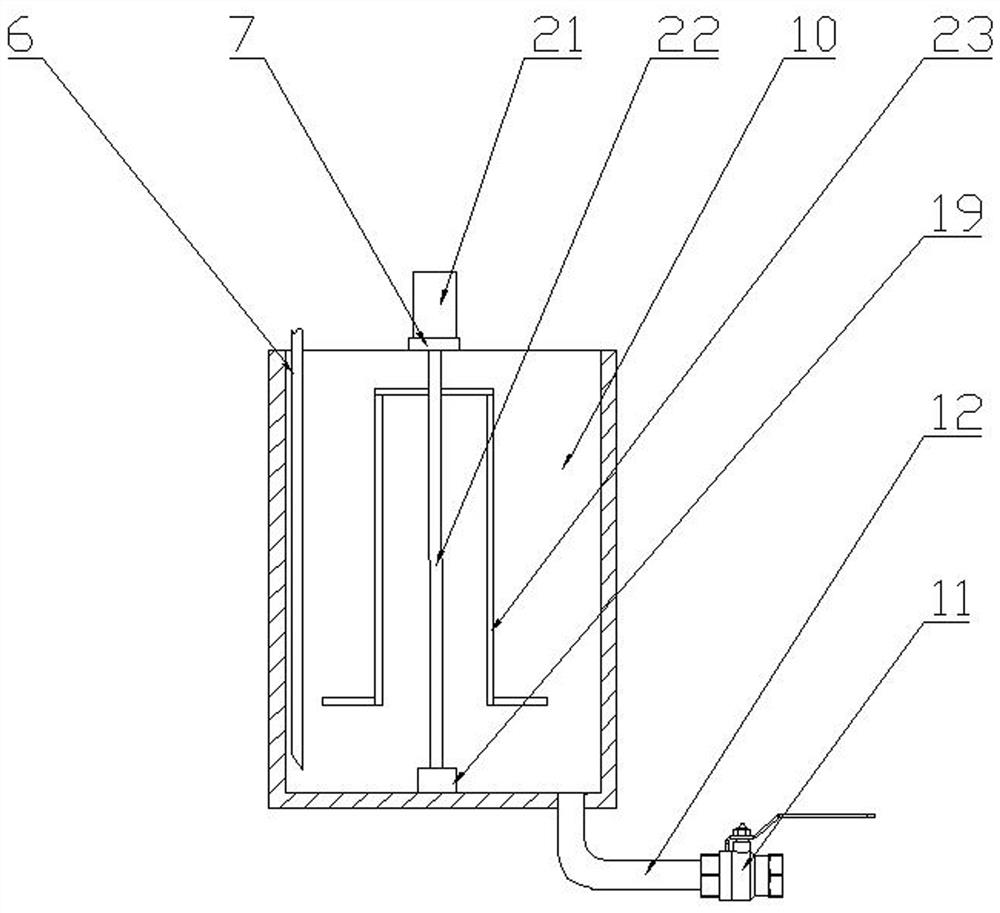

Hydraulic forming technology of tube blank of small-sized corrugated tube and forming die sheet special for tube blank of small-sized corrugated tube

InactiveCN103611768ASolve the problem that it is not easy to deform and bulgeSolve the difficulty of processingShaping toolsEngineeringHydroforming

The invention discloses a hydraulic forming technology of a tube blank of a small-sized corrugated tube. The hydraulic forming technology comprises the steps that firstly, a forming die is installed well, the forming die comprises a lower sealing cover, a forming cushion block, a forming die sheet, a forming cushion block and an upper sealing cover from bottom to top, an unformed tube blank of the small-sized corrugated tube is placed in the die, and the die is sealed; the upper sealing cover and the lower sealing cover are pressed tightly, and hydraulic oil is injected into the unformed tube blank until space defined by the upper sealing cover, the inner wall of the tube blank and the lower sealing cover is filled with the hydraulic oil; a forming press conducts pressurization continuously, the tube blank deforms and bulges due to the influence of pressure, and then pressure is released; the forming cushion block is detached, pressurization is conducted, a main oil cylinder of the forming press advances, and after the two ends of the tube blank of the corrugated tube are flanged and deformed, pressure is released; finally, the forming die sheet is replaced with a thin cushion block, pressurization is not conducted, the main oil cylinder of the forming press advances, and then deformation of the middle corrugated portion of the tube blank of the corrugated tube is completed; after the above steps are completed, the forming die is detached, and the formed tube blank of the corrugated tube is taken out.

Owner:CHONGQING FANCHENG TECH

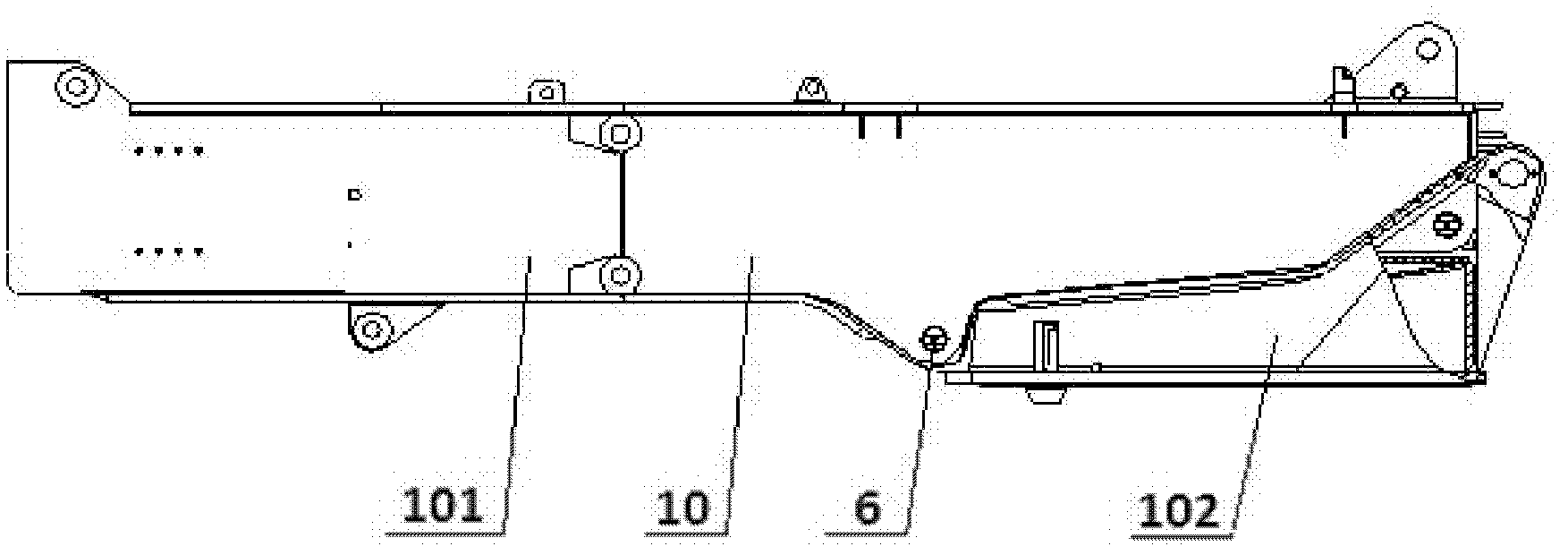

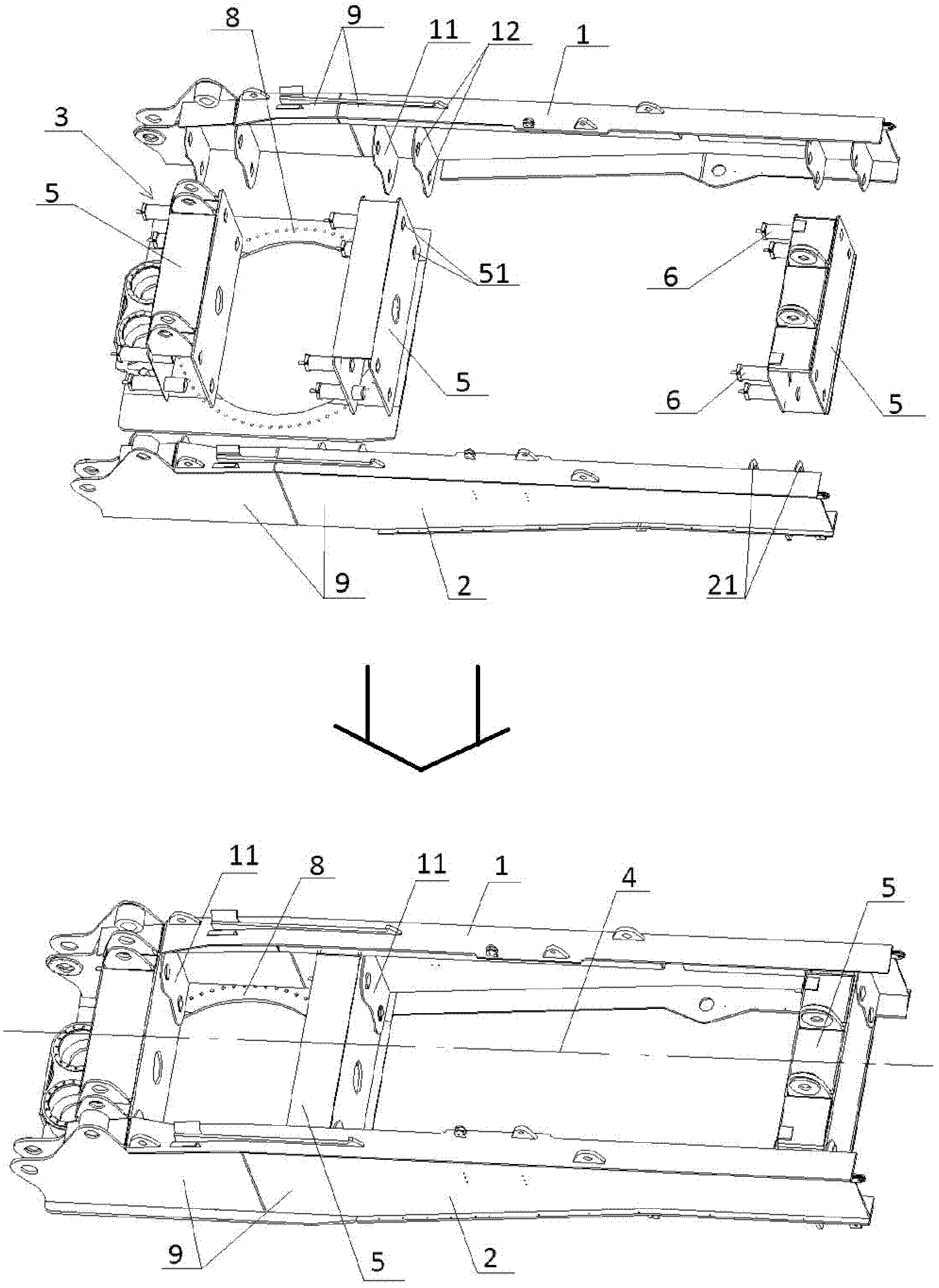

Rotary table main body structure and crane provided with same

ActiveCN102431917AReduce width sizeOvercome the defect that the width size is limited by the transportation sizeCranesSpace requirementsMechanical engineering

The embodiment of the invention discloses a rotary table main body structure and a crane provided with the same. The rotary table main body structure comprises a first assembly and a second assembly, wherein the first assembly is connected with the second assembly through a detachable connection structure; the rotary table main body structure has a length direction, a width direction and a thickness direction; and the first assembly and the second assembly are locked together by the detachable connection structure at least in the width direction of the rotary table main body structure. The crane comprises the rotary table main body structure provided by the invention, wherein at least one of a suspension arm, a swing mechanism, a winding mechanism, a power system, a hydraulic system and a swing platform of a cab is arranged on the rotary table main body structure. The rotary table main body structure disclosed by the invention can be used for overcoming the limitation, caused by the transportation clearance, on the width size of the rotary table main body structure, and can be used for solving the technical problem that the space requirements of the assembly and the maintenance of parts can not be met due to the limitation, caused by the transportation clearance, on the width size of the rotary table main body structure in the prior art.

Owner:XCMG CONSTR MACHINERY

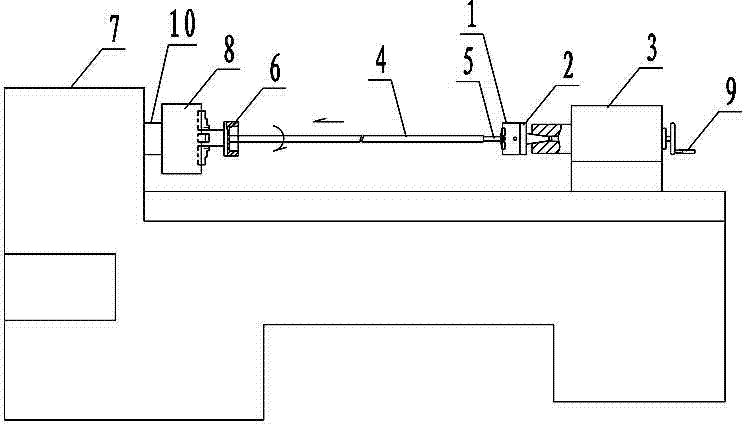

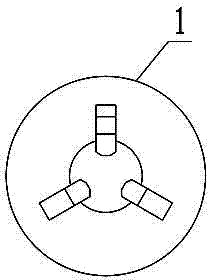

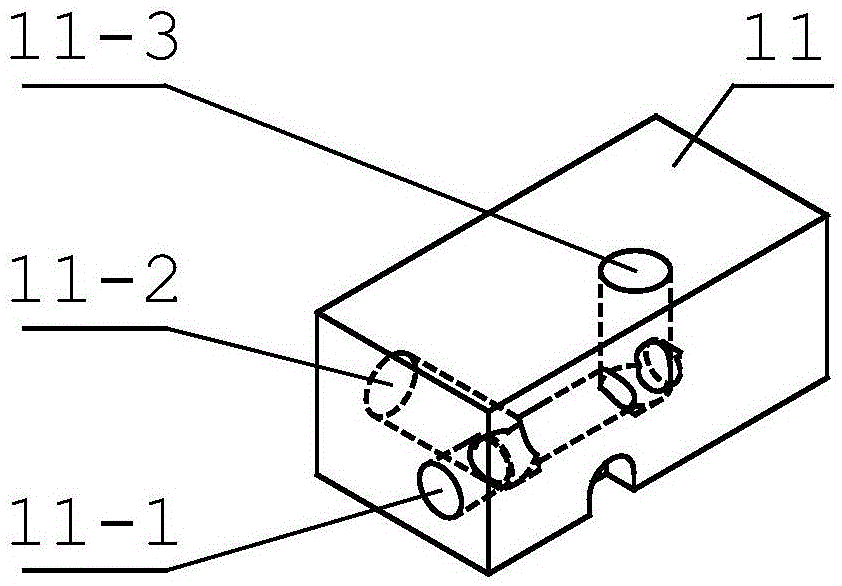

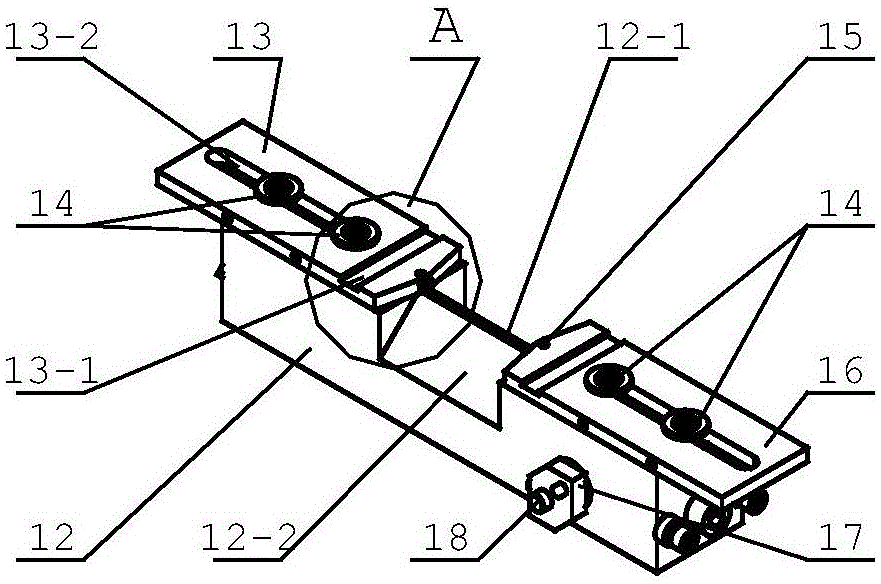

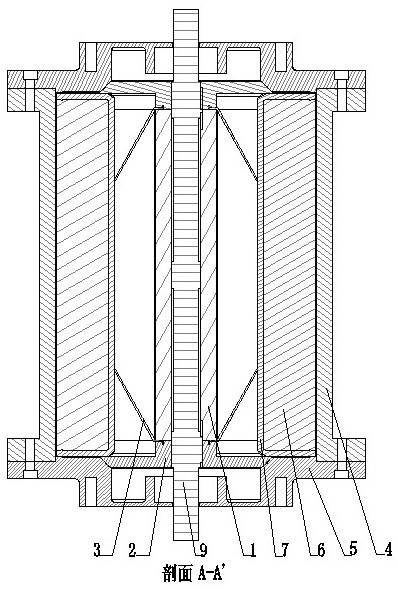

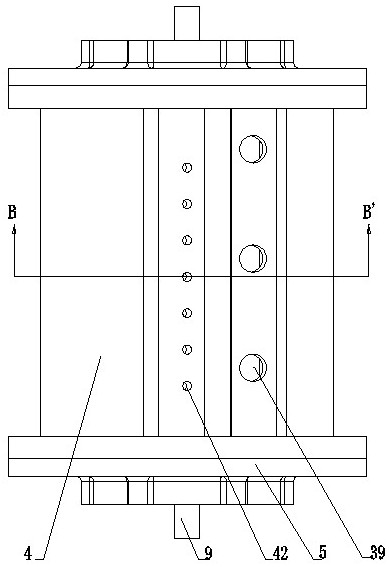

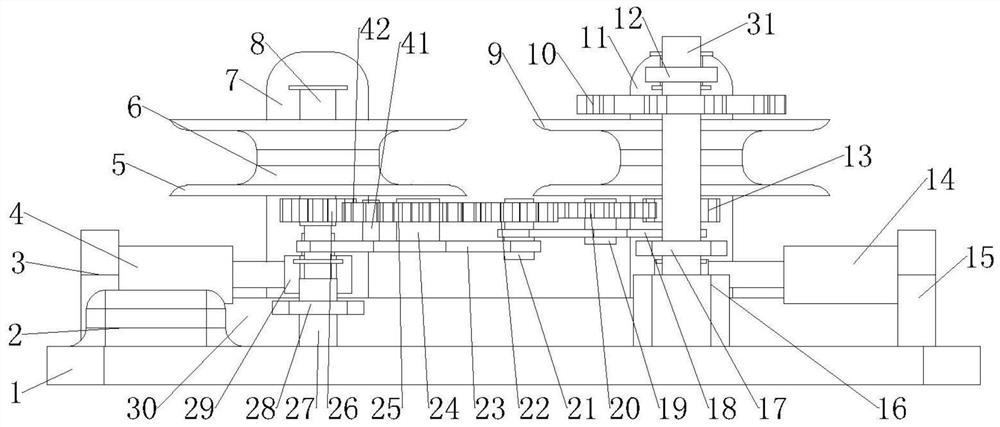

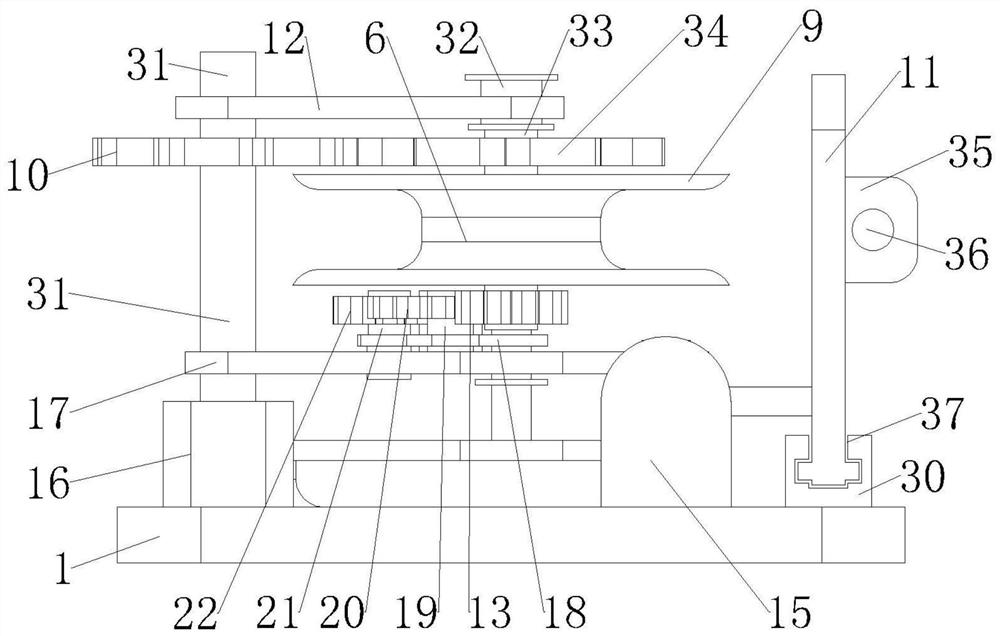

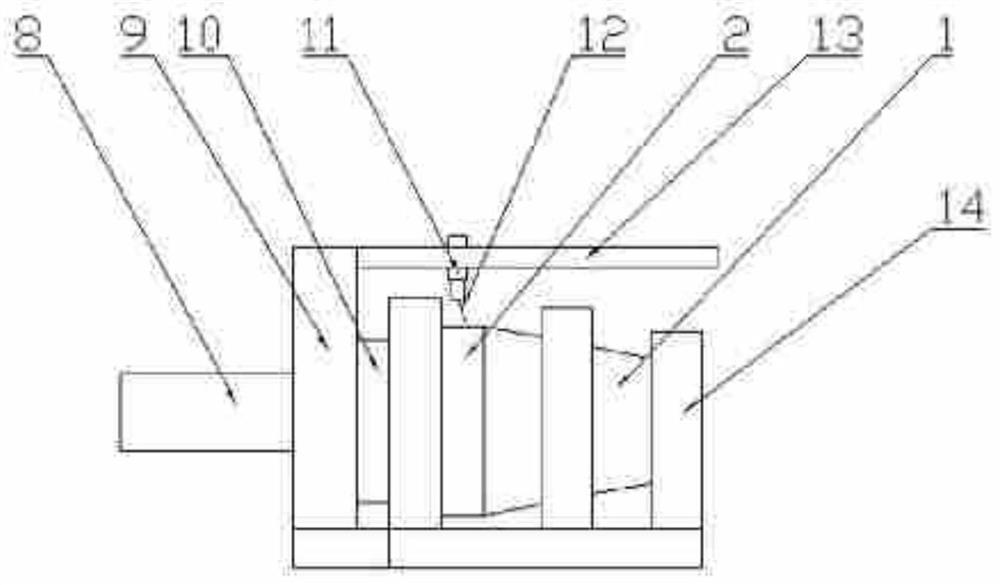

Ultra-long-stroke fast-tool servo device comprising detachable flexible leaf springs and machine tool

InactiveCN109333133AAchieve large stroke outputSolve the difficulty of processingFeeding apparatusTool holdersEngineeringMachine tool

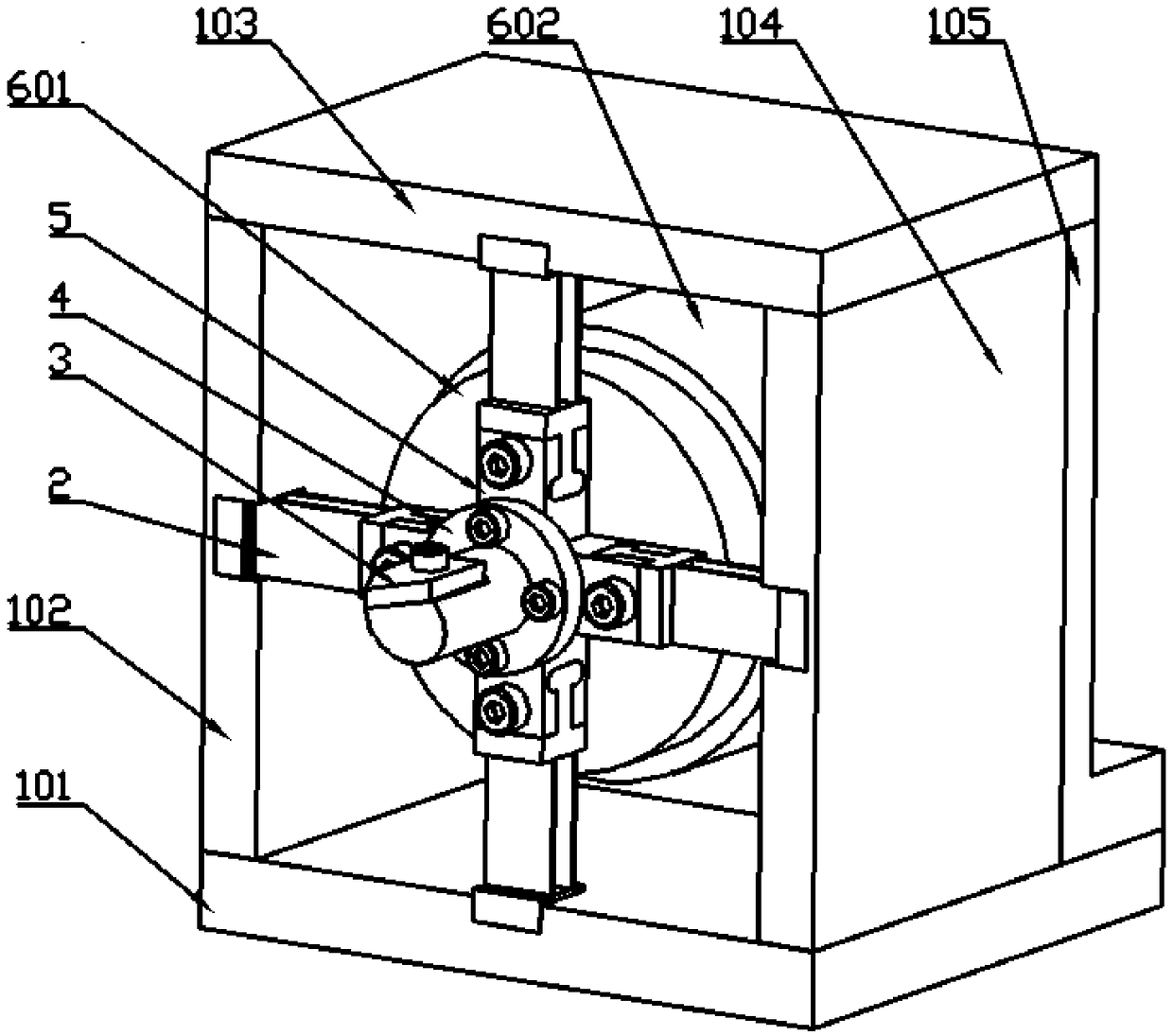

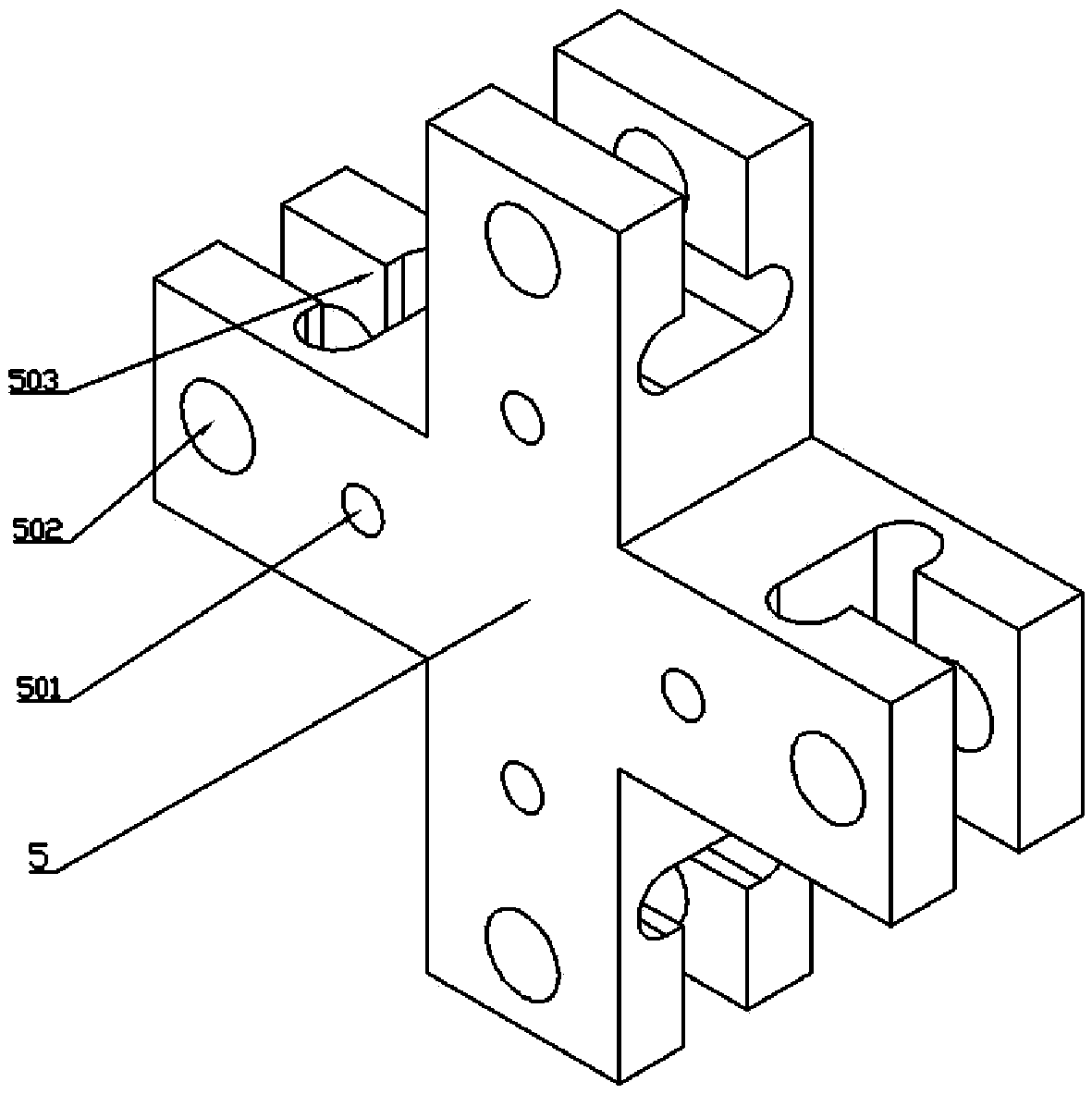

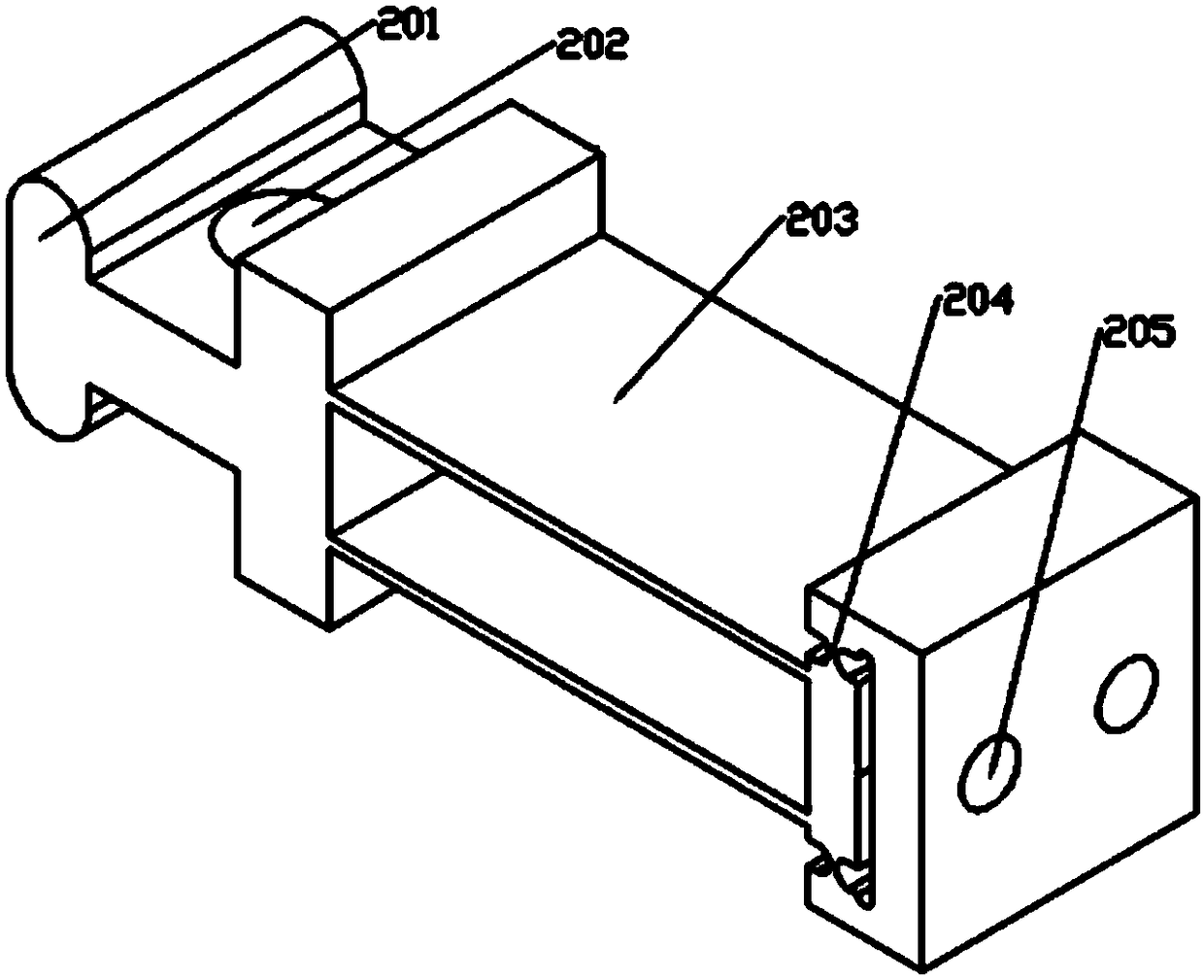

The invention discloses an ultra-long-stroke fast-tool servo device comprising detachable leaf springs. The fast-tool servo device comprises a driving mechanism, detachable flexible leaf spring mechanisms, a connecting seat and a fixing seat; one side of the connecting seat is connected with the output end of the driving mechanism; the other side of the connecting seat is connected with a tool seat; the connecting seat comprises four connecting parts in the peripheral direction; the four connecting parts are connected to the fixing seat by the aid of the four detachable flexible leaf spring mechanisms; and each detachable flexible leaf spring mechanism comprises a first connecting part and a second connecting part which are connected by the aid of one flexible leaf spring, the first connecting part is connected with the connecting seat, and the second connecting part is connected with the fixing seat. Detachable flexible leaf spring units are adopted, on the one hand, the problem of large difficulty in machining of the flexible leaf springs adopting the spatial arrangement is solved, and on the other hand, the flexible leaf springs are convenient to detach and replace, so that parameters such as the rigidity, the inherent frequency and the like of a guiding mechanism can be adjusted during practical application, and the mechanism interchangeability is realized.

Owner:SHANDONG UNIV

Processing method of main lens of large-OD (Outer Diameter) deformable mirror

ActiveCN103949952ASolve the difficulty of processingOptical surface grinding machinesWaxPlane mirror

The invention discloses a processing method of a main lens of a large-OD (Outer Diameter) deformable mirror, and belongs to the technical field of processing a deformable mirror. The processing method of the main lens of the large-OD deformable mirror comprises the steps of selecting materials; processing a first surface; adhering an upper disk by adopting bee wax, and finely grinding a second surface through an annular fine grinding mode; magnetically pressing the upper disk, and polishing the second surface through an annular polishing mode; carrying out fine polishing processing by immersing parts in polishing solution; vibrating a lower disk by ultrasonic waves. According to the processing method of the main lens of the large-OD deformable mirror, disclosed by the invention, the problem that the processing of the primary lens of the deformable mirror in large OD and thin thickness is difficult can be mainly solved, the processing method is suitable for processing the primary lens of the deformable mirror in large size and thin relative thickness, and the processing method is even suitable for processing a high-accuracy plane mirror or an optical window of which a size and thickness ratio is greater than 20 and smaller than 200.

Owner:四川欧瑞特光电科技有限公司

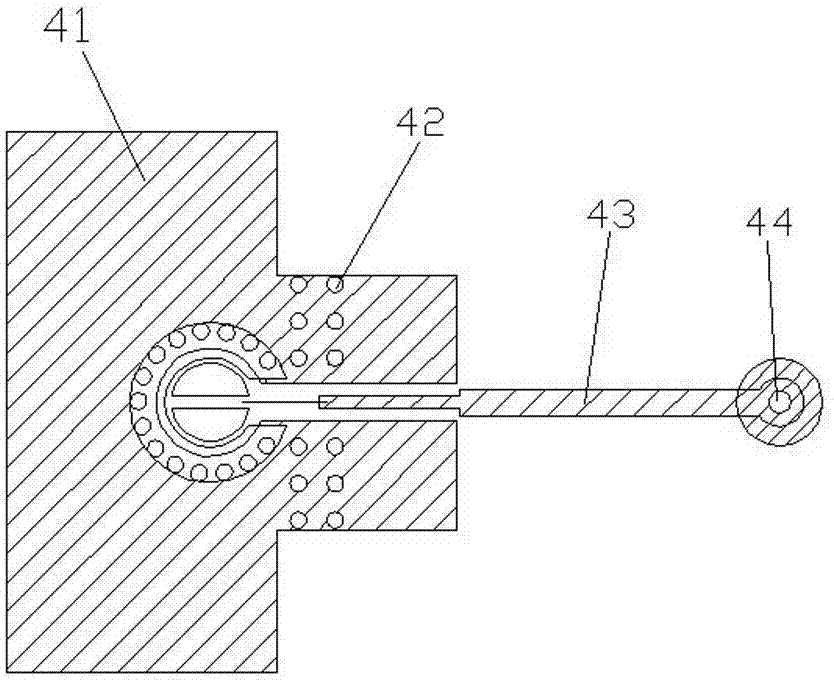

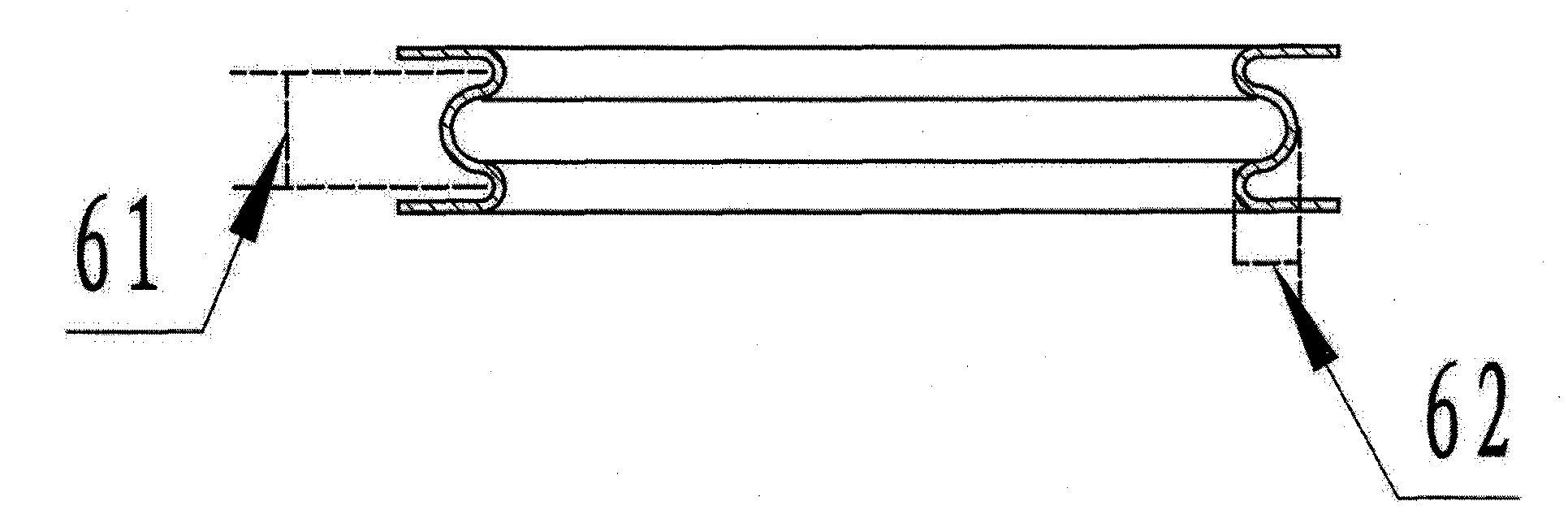

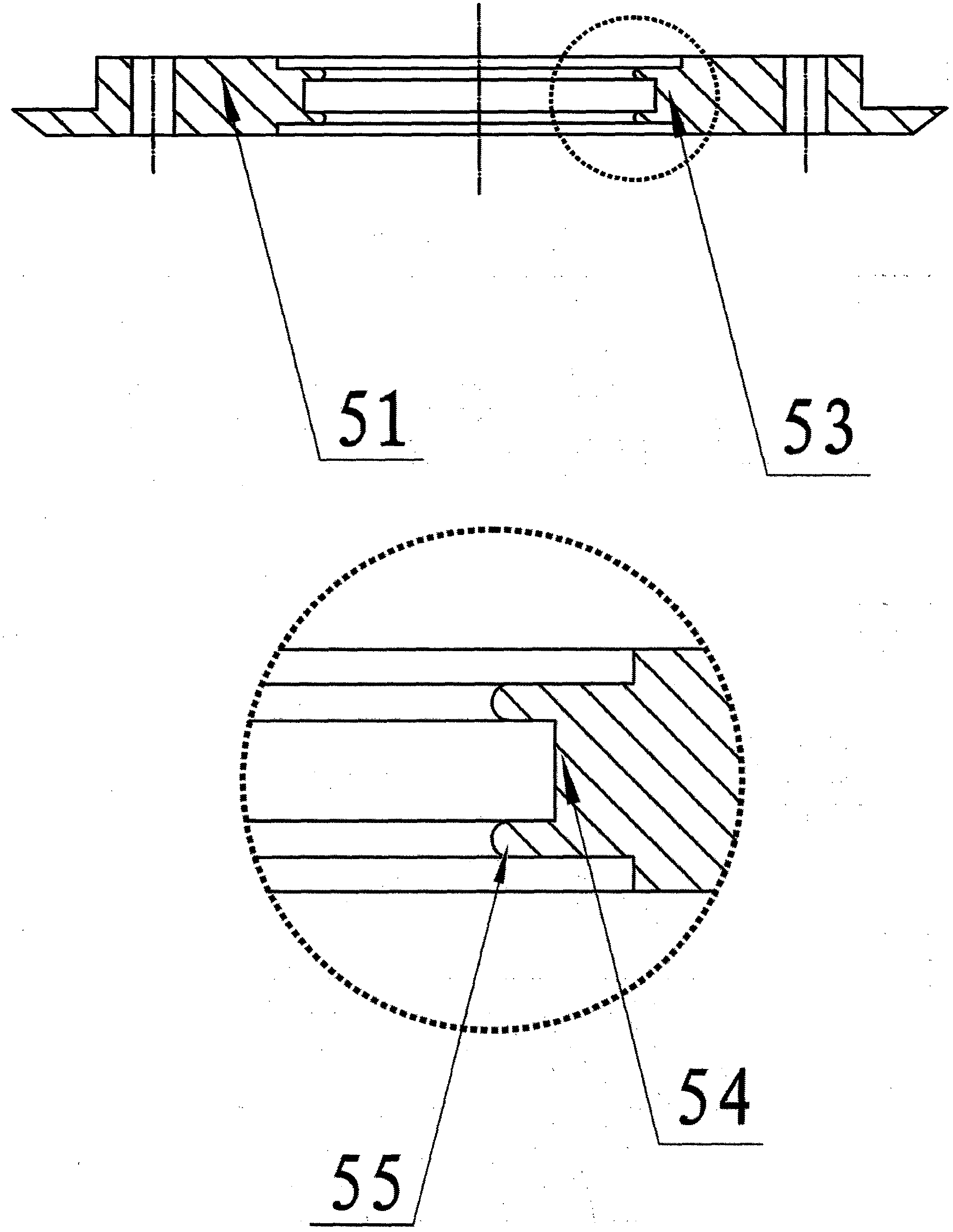

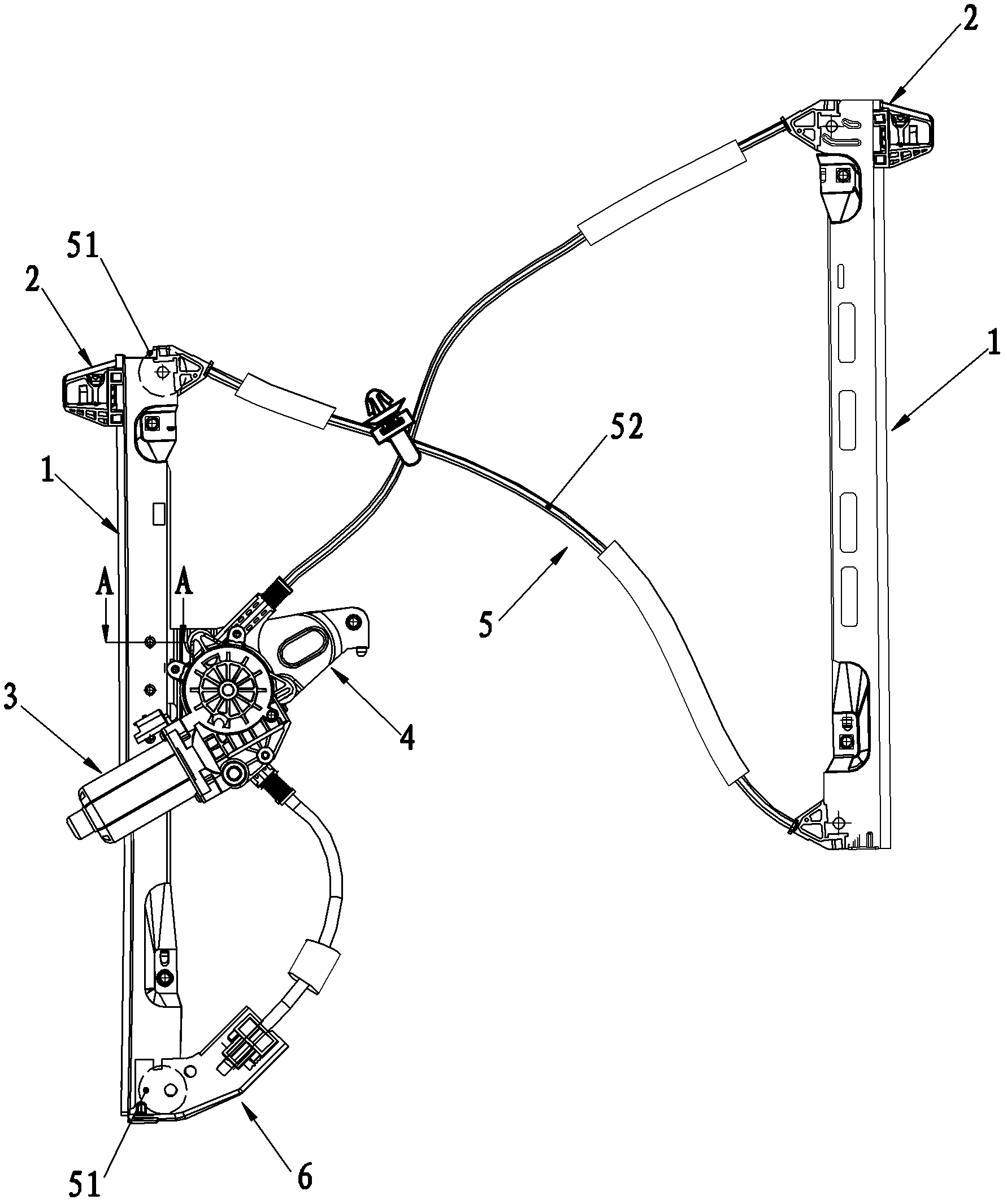

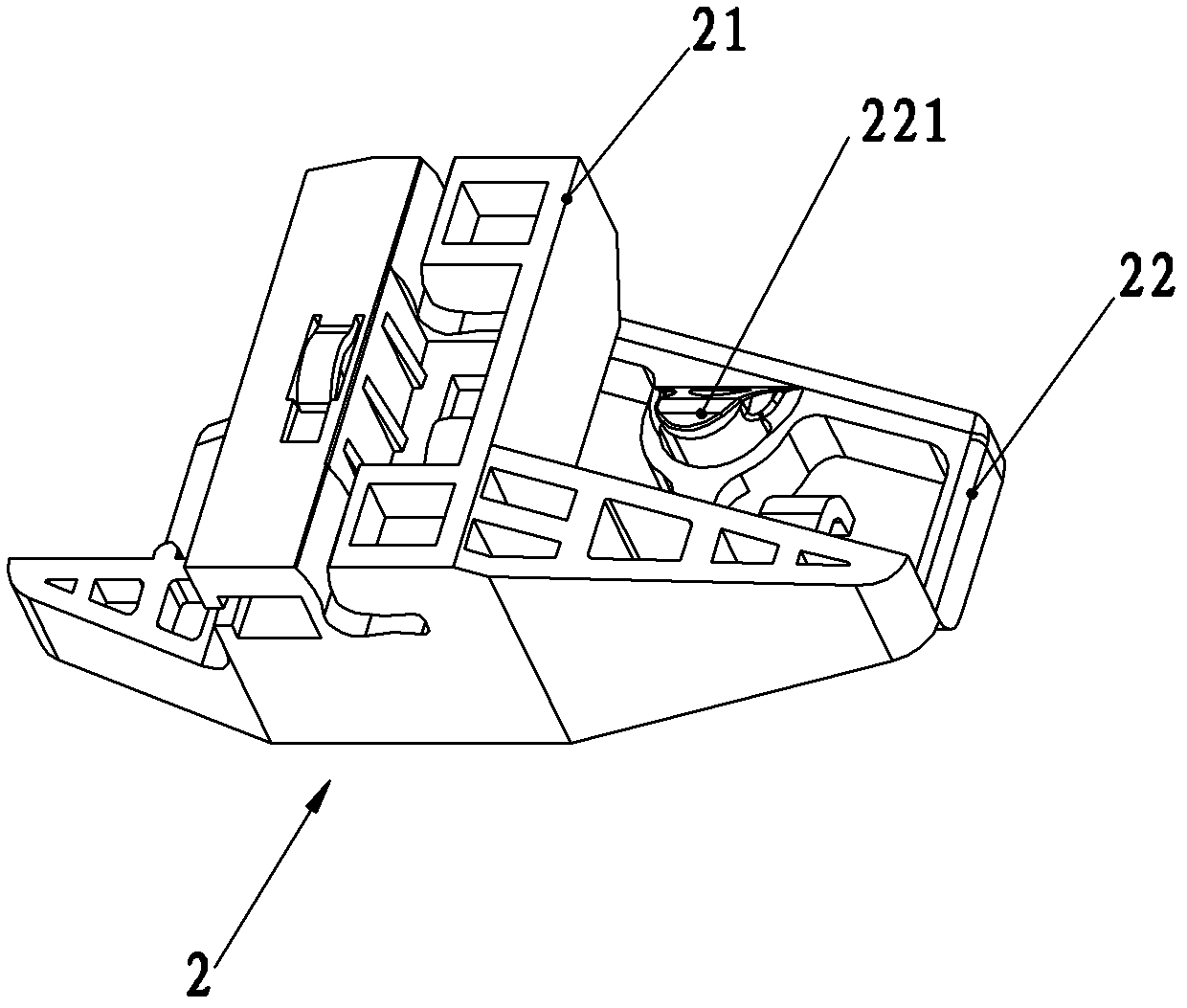

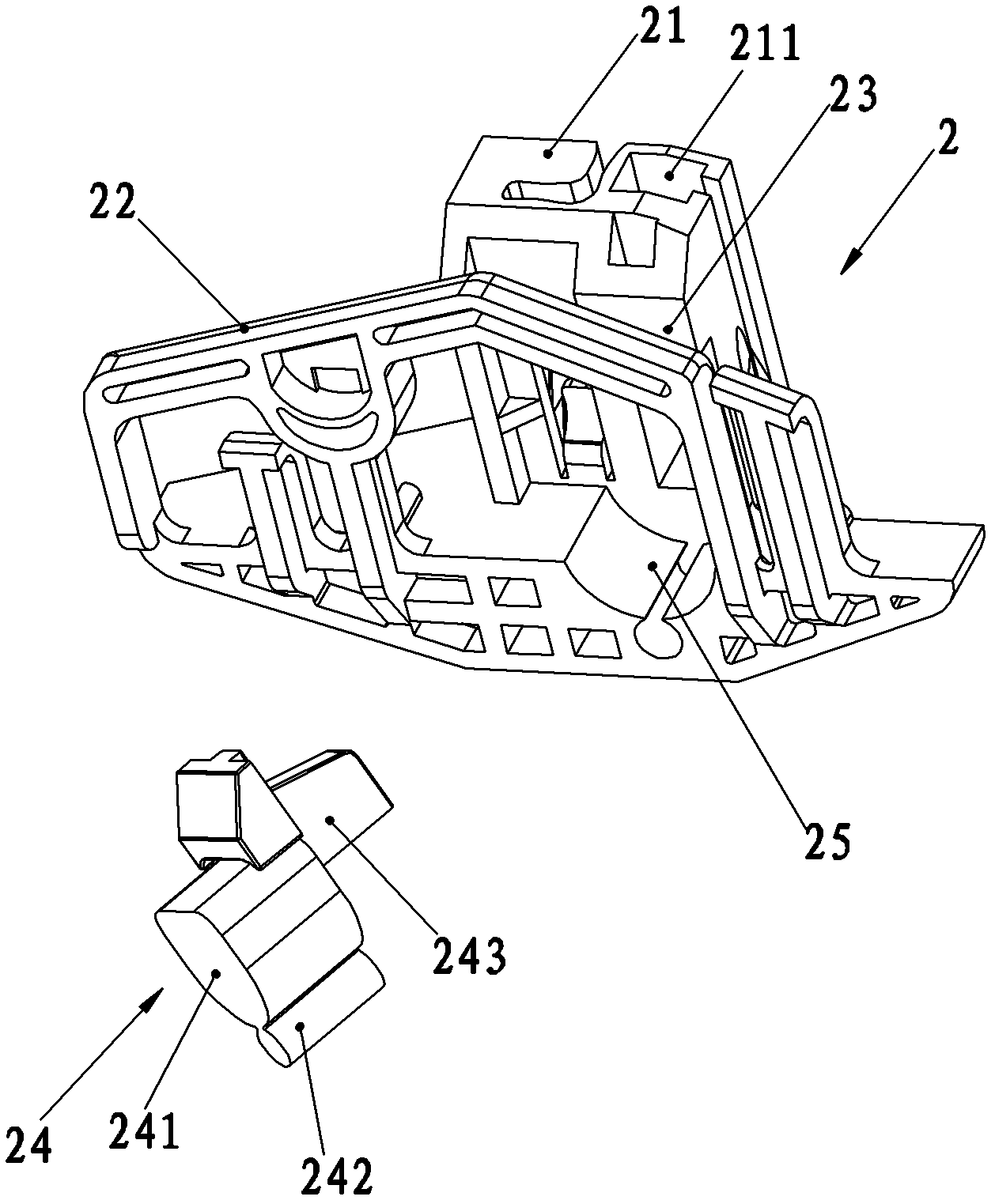

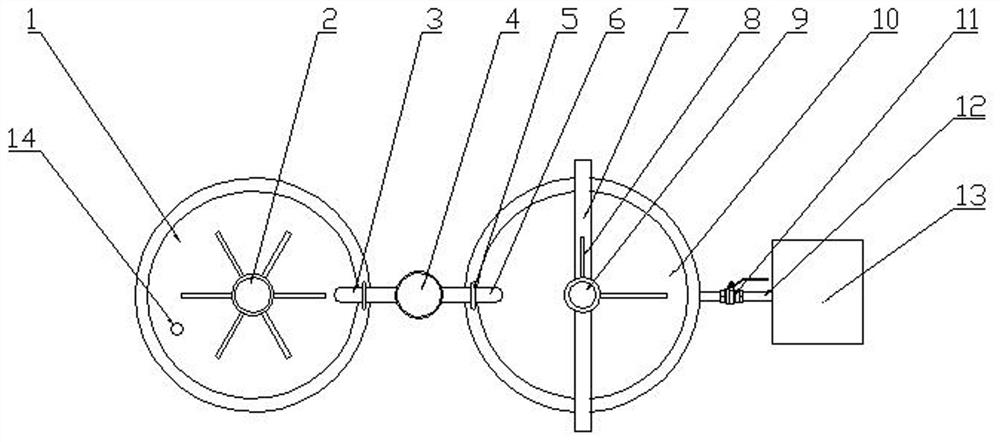

Electric glass lifter for vehicle

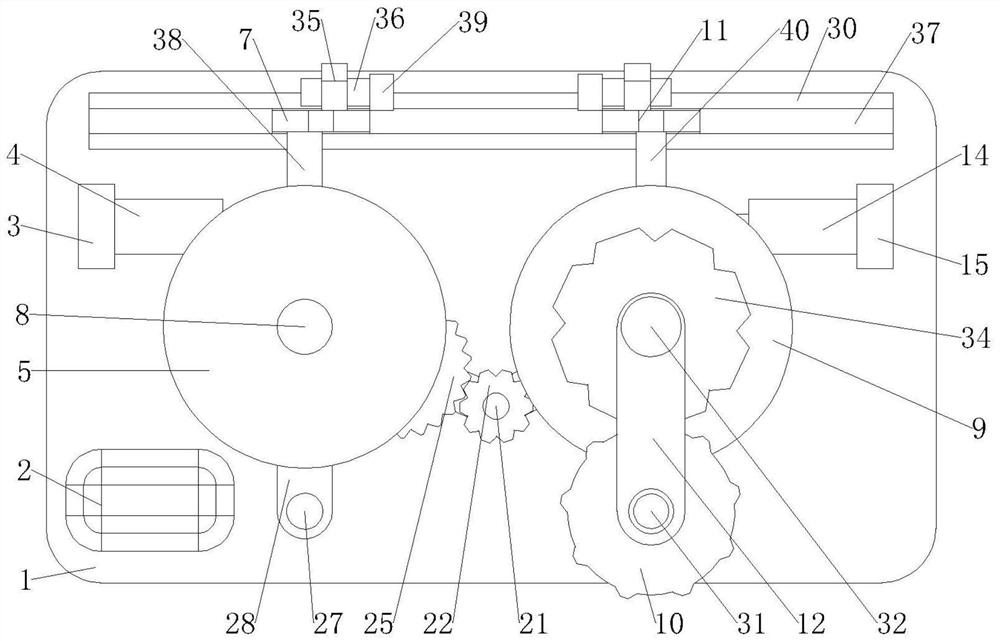

ActiveCN102606024ASolve the difficulty of processingSolve difficultyPower-operated mechanismEngineeringSlide plate

The invention relates to an accessory for a vehicle, in particular relates to an electric glass lifter for the vehicle. According to the technical scheme, the electric glass lifter for the vehicle comprises two corresponding sliding rails, sliding plates which are respectively arranged on the two sliding rails and slide along the axial directions of the sliding rails, a driving motor which is used for driving the sliding plates to slide and a transmission piece which is connected with the output end of the driving motor and the sliding plates, wherein the transmission piece comprises pulleys respectively bridged over two axial ends of each sliding rail and steel ropes which are connected with the sliding plates and the output end of the driving motor and coiled around the pulleys; each sliding plate comprises a sliding part which is arranged on each sliding rail and in sliding fit with each sliding rail, a mounting part for clamping glass and a clamping component; and a steel rope tension adjustment mechanism is arranged on the sliding rails and arranged at any pulley on the sliding rails. According to the technical scheme, the electric glass lifter for the vehicle improves the smoothness and the stability of glass motion and reduces the fault rate.

Owner:浙江瑞翔机电科技股份有限公司

Method for machining threaded rod through lathe

InactiveCN103495780ASolve the difficulty of processingHigh precisionThread cutting auxillary apparatusEngineering

The invention discloses a method for machining a threaded rod through a lathe. The method includes the steps that step 1, a three-jaw chuck is fixed to a cone-shaped die shank; step 2, a section of circular truncated cone is turned at one end of the threaded rod to be machined; step 3, a threading die is installed on a lathe head chuck, the circular truncated cone section of the threaded rod to be machined is clamped through the three-jaw chuck, the other end of the threaded rod to be machined is chamfered and then placed on a mouth of the threading die, the lathe is started, a tailstock hand shank of the lathe is shaken to enable the threaded rod to be machined to enter the threading die, at the moment, under the action of rotation of threading die screw threads, the threaded rod to be machined automatically penetrates through the threading die and enters a hollow main shaft of the lathe, and then the threaded rod machining is completed. The method for machining the threaded rod through the lathe has the advantages of solving the problem that a threaded rod with the diameter smaller than 50mm and the length larger than 1000mm is difficult to machine, according to the method, the maximum machining length of the threaded rod is the lathe bed length of the lathe, the threaded rod is not stressed by radial force in the thread machining process, and therefore precision and smooth finish of the threaded rod machining are greatly improved.

Owner:ZHENGZHOU JINTAI CANNER

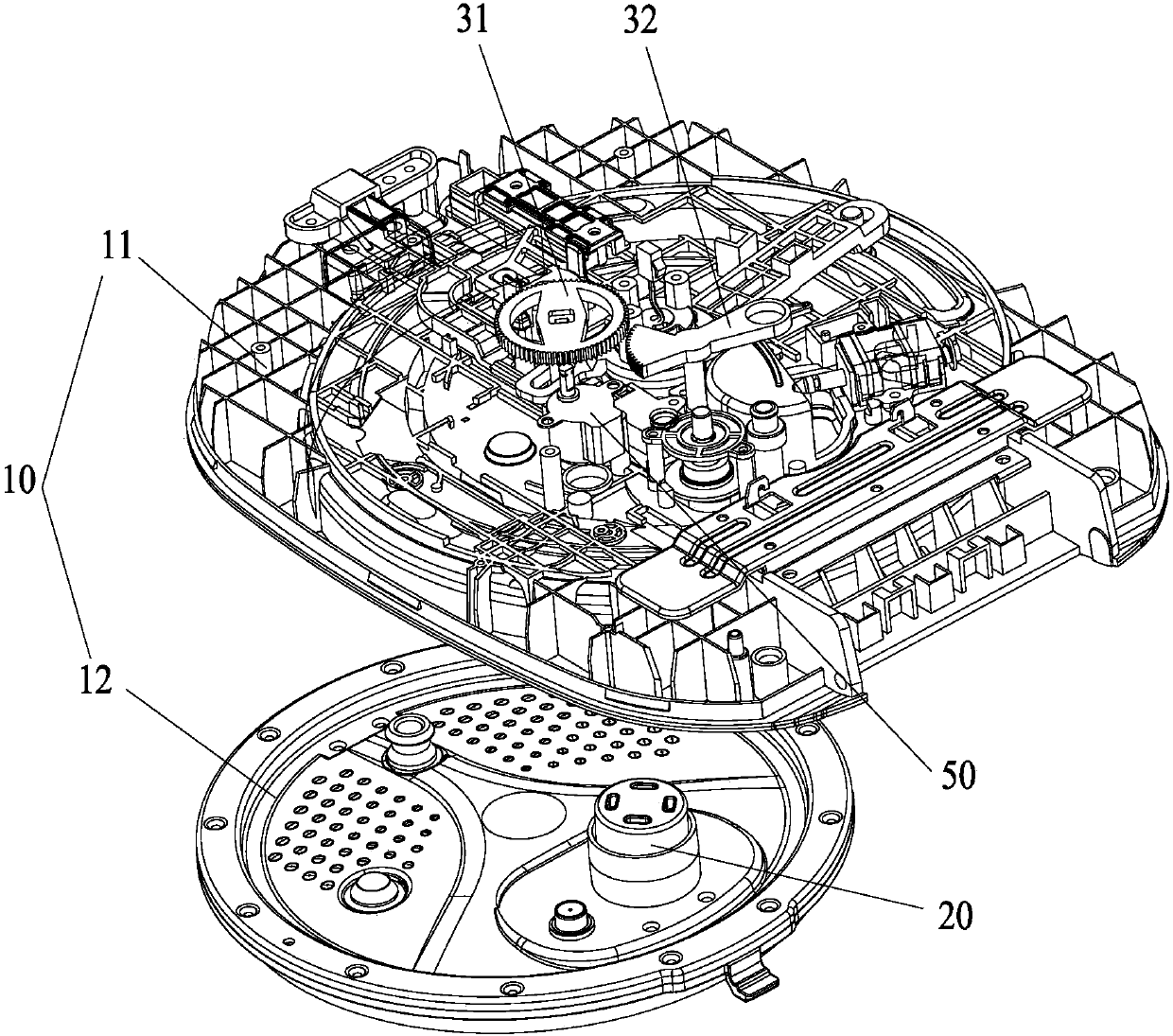

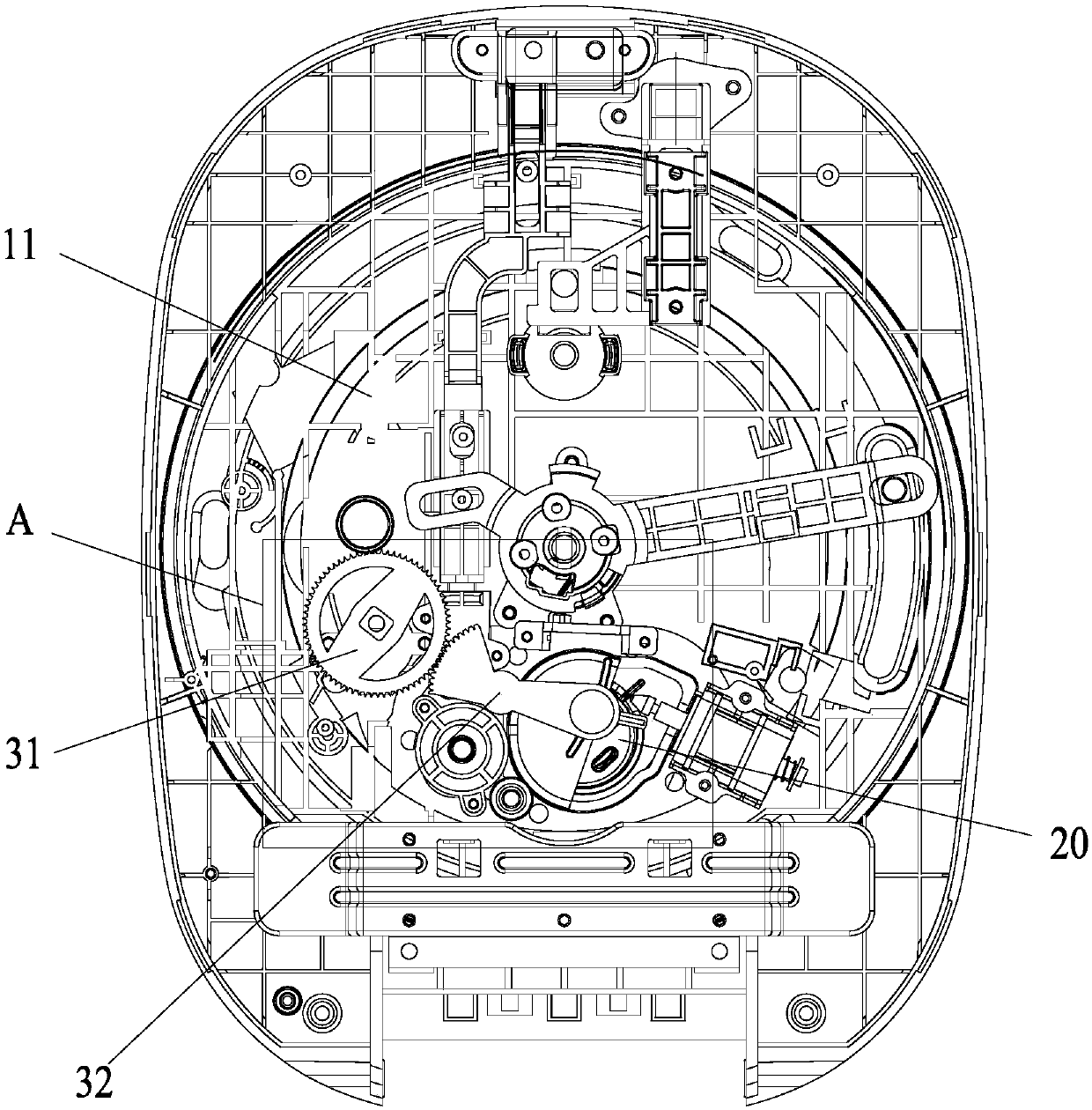

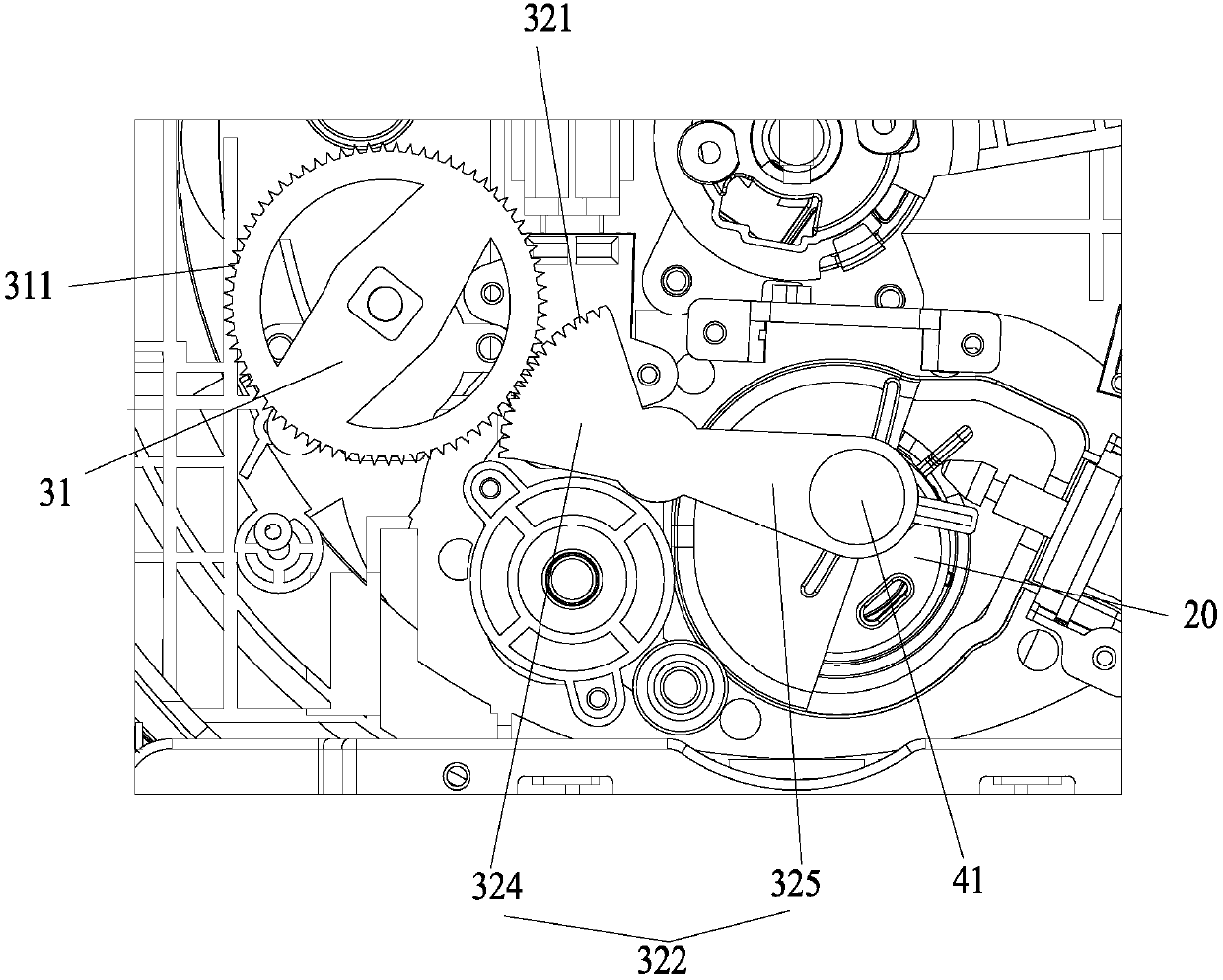

Pressure cooking appliance

The present invention provides a pressure cooking appliance. The pressure cooking appliance comprises a pot body, a pot cover, a pressure limiting valve, a first transmission piece, a second transmission piece, a driving mechanism and a magnetic mechanism, wherein the pot body is used for accommodating cooked food; the pot cover is arranged on the pot body, and an exhaust passage is formed in thepot cover; the pressure limiting valve is matched with the exhaust passage, and comprises a pressure limiting valve body and a counterweight block; the first transmission piece and the second transmission piece are matched with each other, and the second transmission piece is pivotably arranged on the pot cover; the driving mechanism drives the first transmission piece to rotate, and the second transmission piece has a first position corresponding to the pressure limiting valve and a second position away from the pressure limiting valve under the transmission of the first transmission piece; and the magnetic mechanism is arranged on the second transmission piece and / or the counterweight block, when the second transmission piece is located at the first position, the counterweight block is separated from the pressure limiting valve body under the action of magnetic attraction force, and when the first transmission piece is located at the second position, the counterweight block is pressed on the pressure limiting valve body under the action of gravity. Through the application of the technical scheme of the invention, the problem of high processing difficulty of the pressure cooking appliance in the prior art can be effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

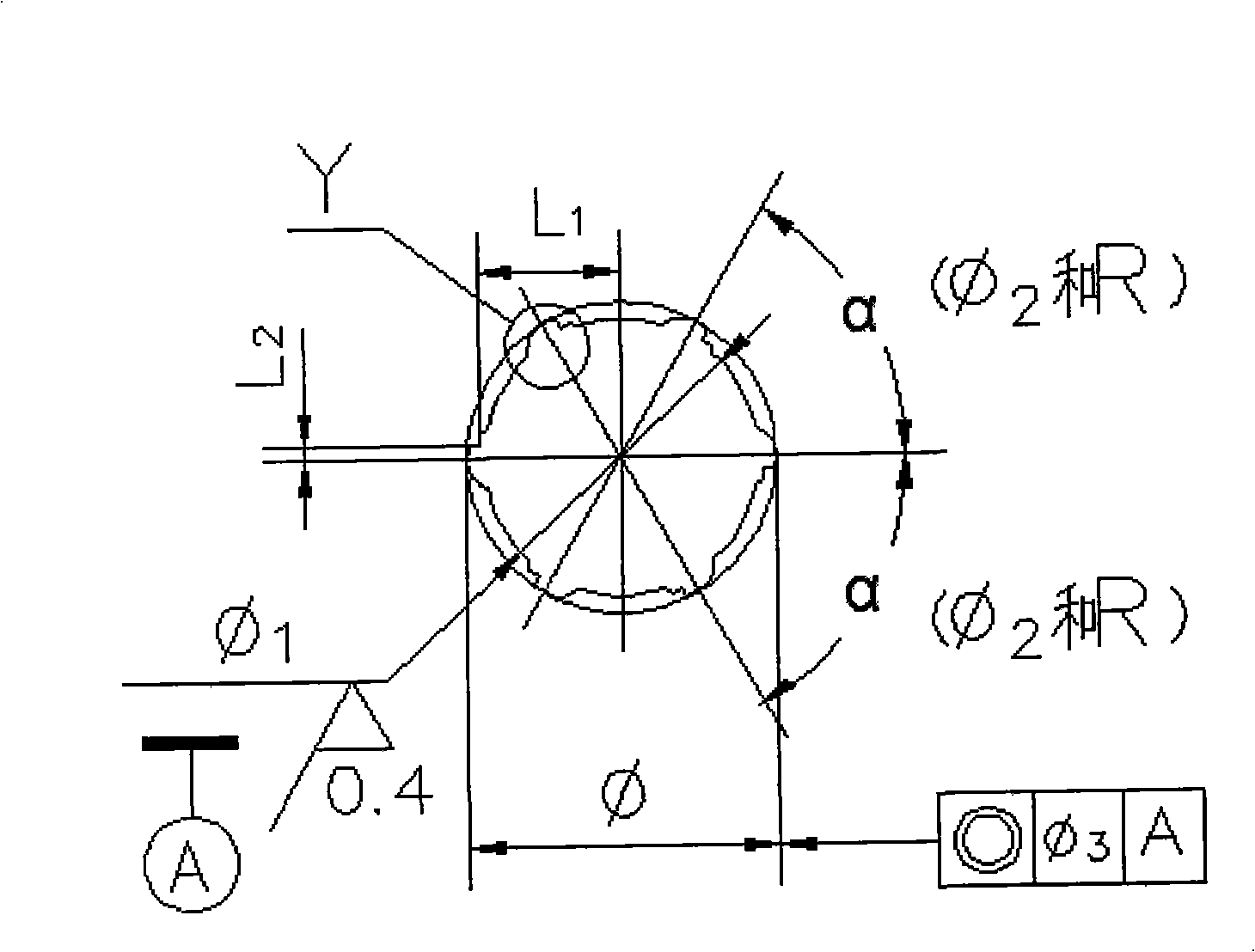

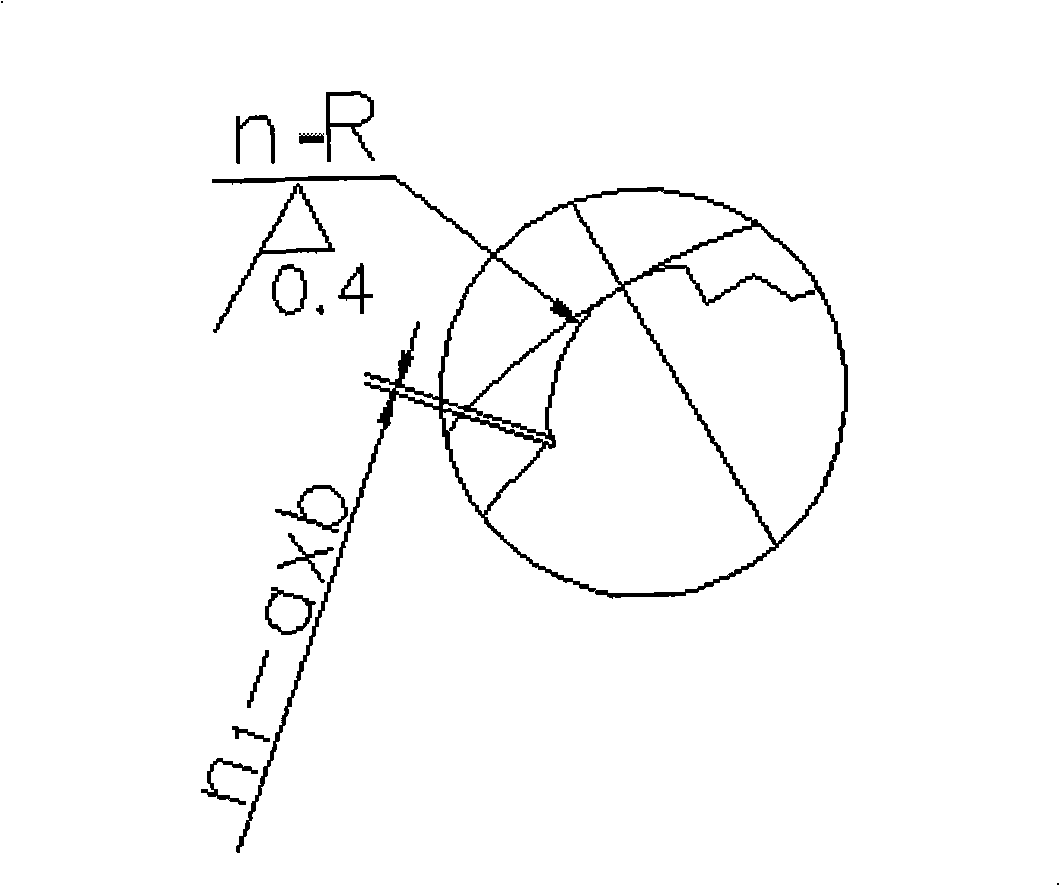

Method for machining special-shaped hole air gage gauge head configuration

InactiveCN101349552ASolve the difficulty of processingExpand the scope of processingUsing fluid meansEngineeringSurface grinding

The invention provides a processing method of a gauge head outline of a special-shaped hole air gauge, wherein the special-shaped hole air gauge head is an irregular cylinder, the outline thereof is formed by n-R arc sections, an external circle phi and an external circle phi 1, wherein the top points of n-R each arc section can form the external circle phi, and can divide the external circle phi 1 into n sections. The processing steps comprise blanking, length processing, external circle processing, external circle phi coarse grinding, end surface coarse grinding, line marking, internal boring, heat treatment, hole grinding, external circle grinding, end surface grinding, assembling and gauge head outline processing and the like. The method can solve the problem of great processing difficulty of the gauge head outline of the special-shaped hole air gauge, thereby guaranteeing the normal processing of the gauge head outline of the special-shaped hole air gauge.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

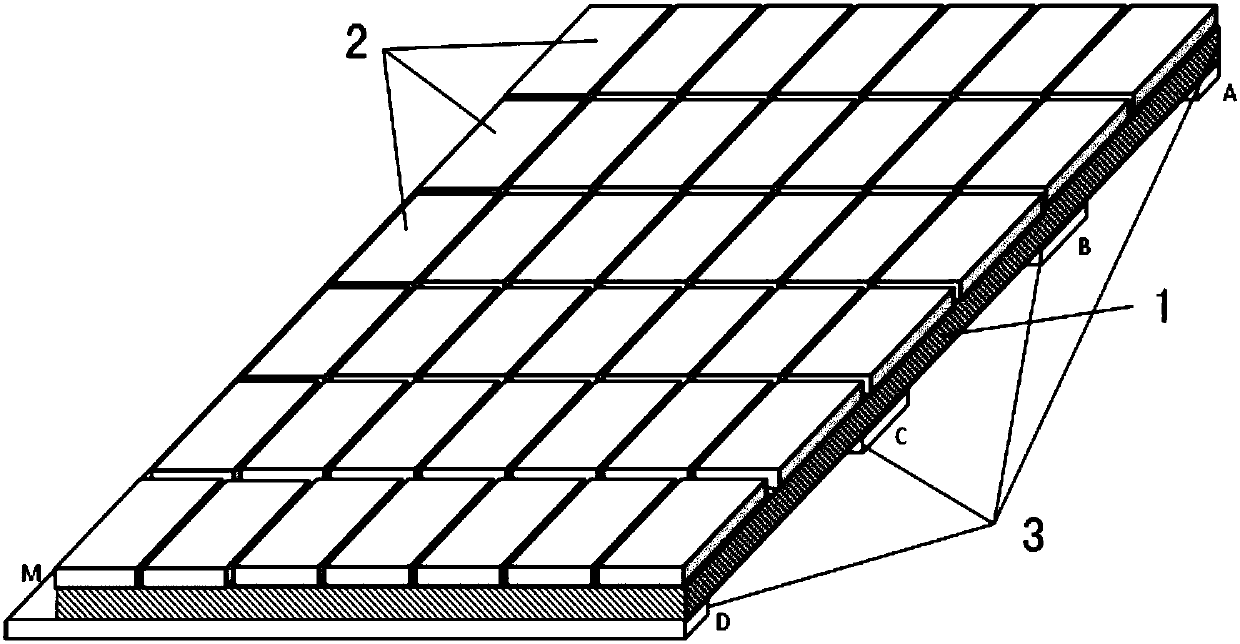

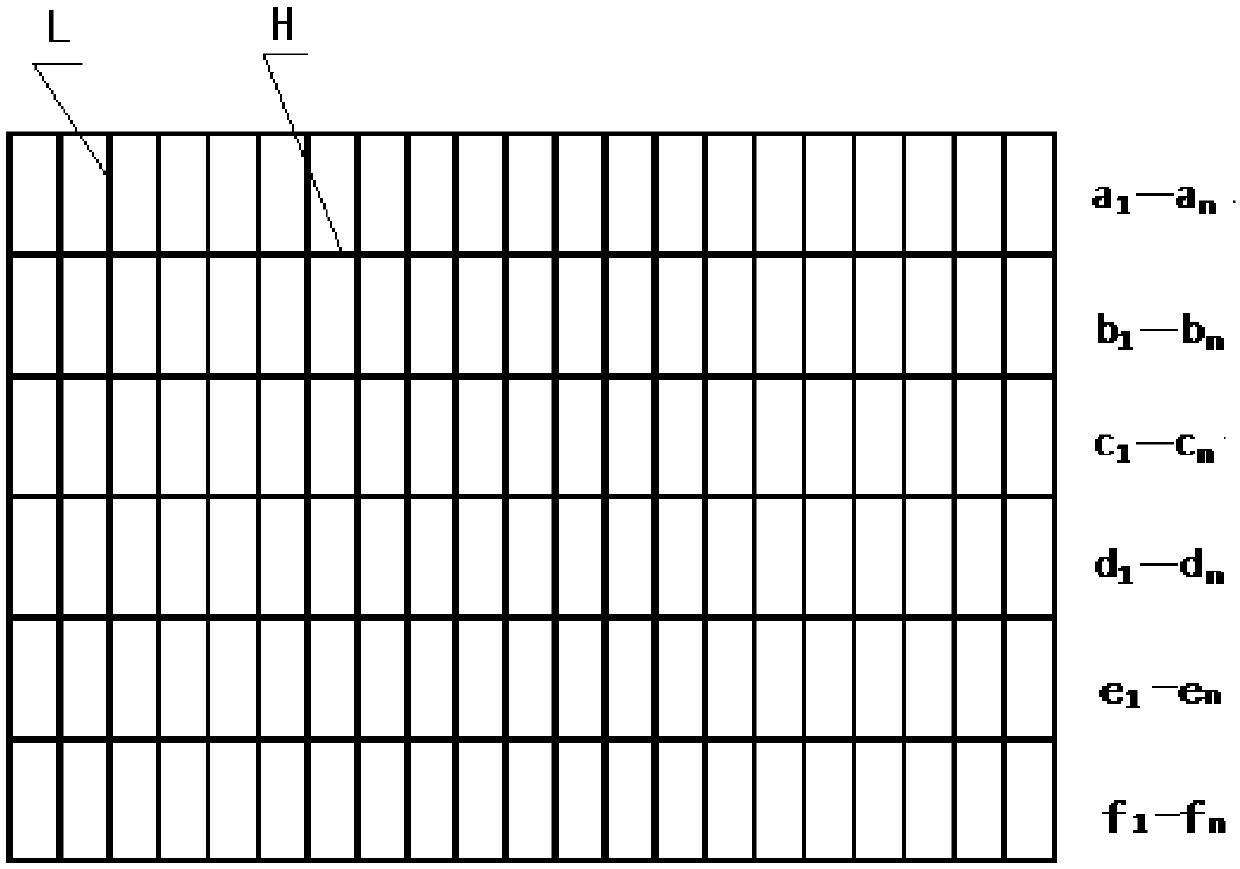

ESD full-shielding functional foil, ESD full-shielding functional foil circuit board and manufacturing methods

PendingCN107635385AAmplify flexibilitySimple preparation processPrinted circuit detailsMagnetic/electric field screeningElectricityElectrical impulse

The invention provides an ESD full-shielding functional foil, an ESD full-shielding functional foil circuit board and manufacturing methods. The core is the ESD full-shielding functional foil; the ESDfull-shielding functional foil comprises a functional material layer; multiple rows and multiple columns of bar metal blocks are etched on an upper metal layer of the functional material layer to form a bar metal block array layer; a lower metal layer is etched into a metal ground wire for grounding; the metal ground wire comprises parallel uniformly-spaced ground wires A, B, C, D ... and a lineM connecting the ground wires A, B, C, D ...; the uniformly-spaced ground wires A, B, C, D ... are located on transverse spacers of a bar metal block array, each uniformly-spaced ground wire overlapswith one end of the corresponding bar metal block, each row of bar metal blocks overlap with the corresponding ground wire, and electrostatic pulse absorption tunnels are formed at the overlapping parts. An instantaneous electric energy release network is built by putting the ESD full-shielding functional foil into any interlayer of a PCB, so that components on the circuit board generate a shielding effect on instantaneous high-voltage electric pulse energy.

Owner:WUHAN CHIP PROTECTION TECH

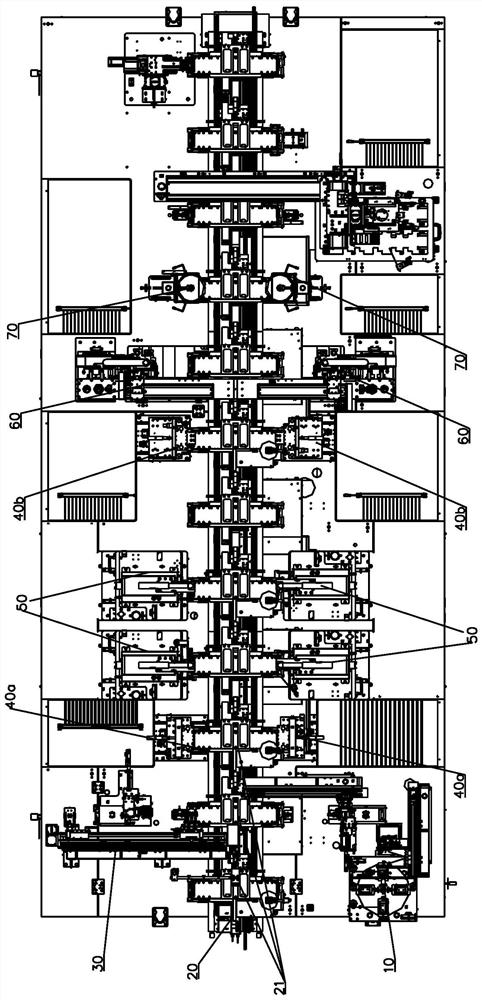

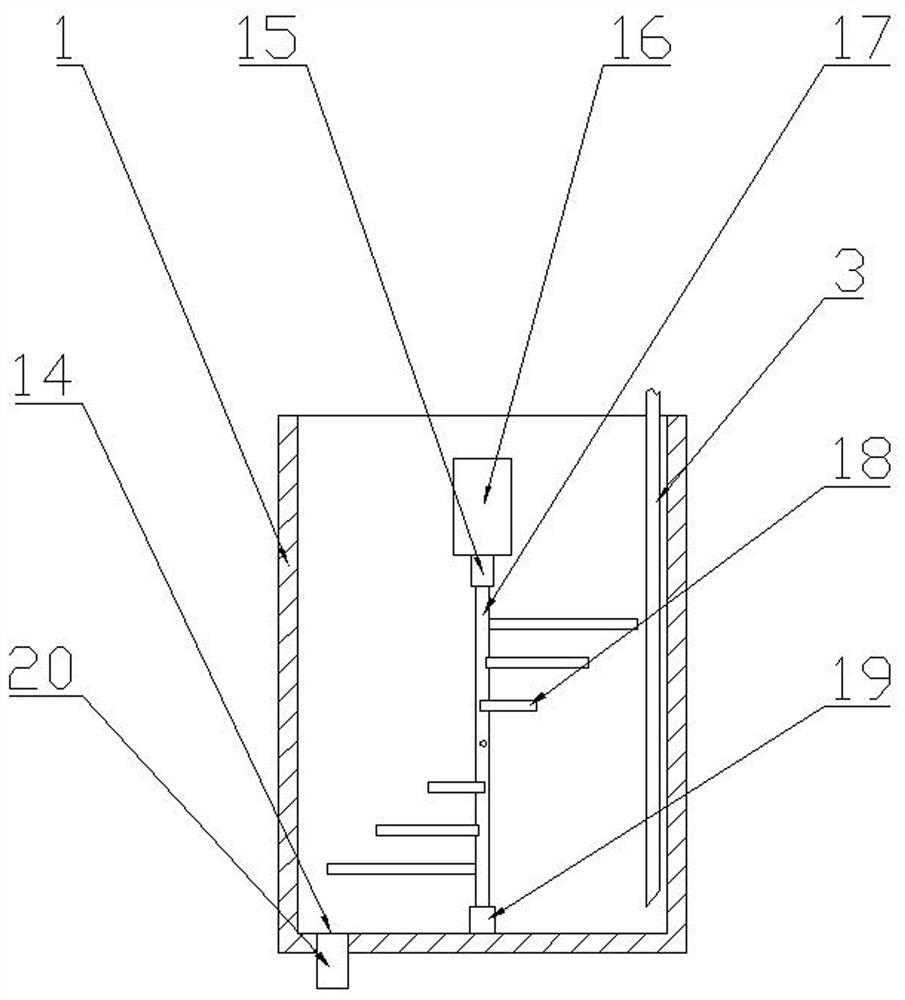

Glue binding assembly universal for ethylene vinyl acetate (EVA) glue and polyurethane rubber (PUR) glue

ActiveCN105644179ASolve the difficulty of processingSimple sealing structureBookbinding adhesiveSpray nozzleEngineering

The invention provides a glue binding assembly universal for ethylene vinyl acetate (EVA) glue and polyurethane rubber (PUR) glue. A large glue cylinder, a right small glue cylinder and a left small glue cylinder are arranged in a glue storage cylinder. Glue outlets are formed in the bottom of the large glue cylinder and the bottom of the right small glue cylinder correspondingly. The two glue outlets communicate with each other and are combined at a main glue outlet. An air inlet and an air outlet are formed in the upper portion of the large glue cylinder. A glue spray seat is provided with a glue spray pipeline and a glue spray port. The glue spray port communicates with the glue spray pipeline. The glue spray pipeline communicates with the main glue outlet. Guiding planes are arranged on the front portion and the rear portion of the glue spray seat correspondingly. A front glue baffle and a rear glue baffle are buckled the two guiding planes correspondingly. Side glue spray nozzles are formed in the front glue baffle and the rear glue baffle. A double-end lead screw is installed between a front wall board and a rear wall board in a straddling mode. A right thread sleeve and a left thread sleeve of the double-end lead screw are each connected with a driving pin. A front driving plate and a rear driving plate are connected to the left side of the front glue baffle and the left side of the rear glue baffle correspondingly. The driving pins are inserted into a backing pin part of the front driving plate and a backing pin part of the rear driving plate correspondingly. A reset tension spring is connected between the front driving plate and the rear driving plate. The glue binding assembly is used for threadless book glue binding.

Owner:HANGZHOU HUIBAO ELECTROMECHANICAL

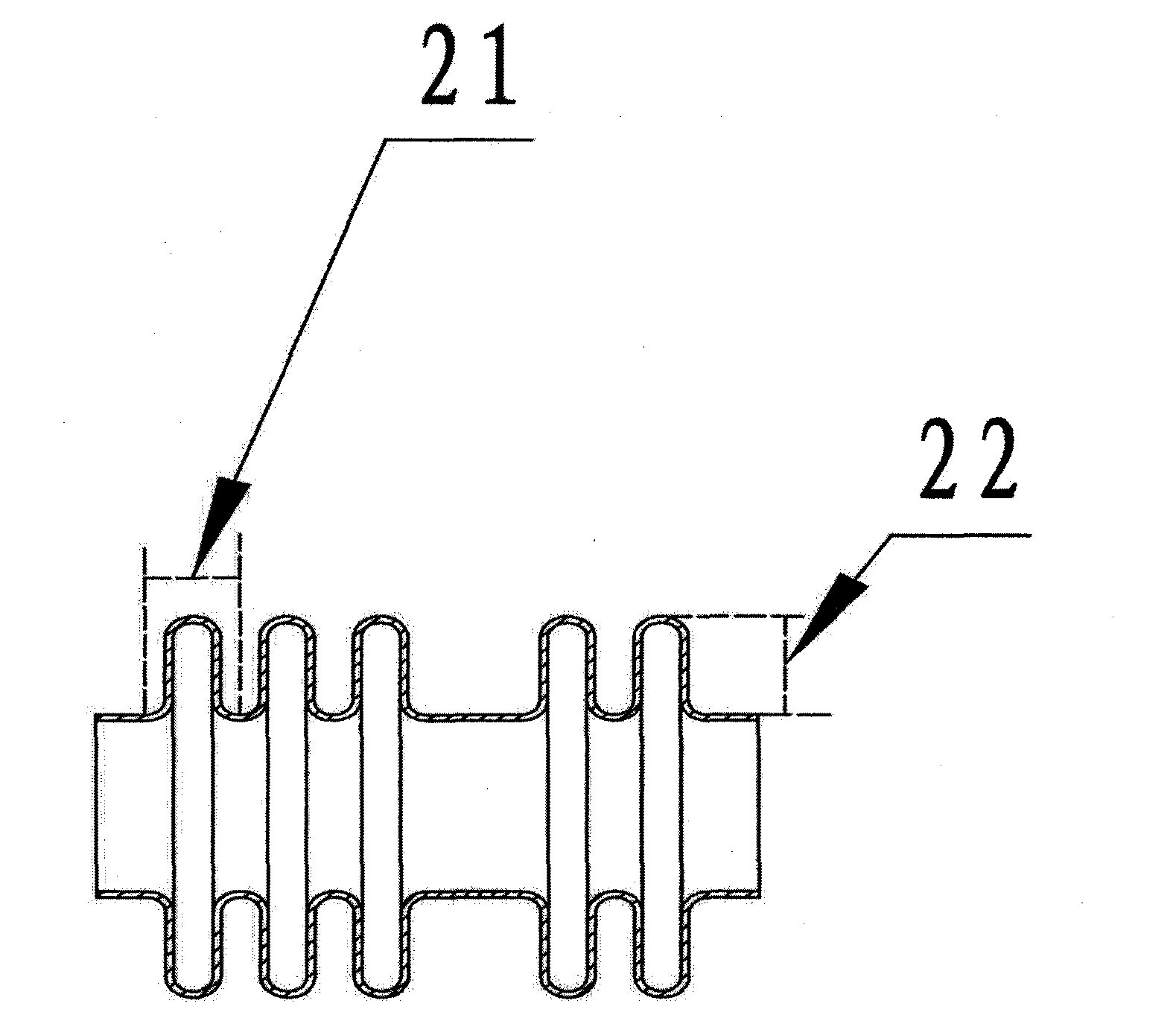

Piece type radiator welding method and tool

PendingCN111230284ANot easy to shakeFast weldingNon-electric welding apparatusFriction weldingElectric machinery

The invention relates to the technical field of radiators, and discloses a piece type radiator welding method and tool. The tool comprises a bottom plate, wherein the top of the base is fixedly connected to two motor boxes; the inner sides of the motor boxes are fixedly connected to drive motors; the output shafts of the drive motors are fixedly connected to threaded rods; the outer sides of the threaded rods are in threaded connection to slide bases; the tops of the slide bases are fixedly connected to clamping bases; and spring cavities are arranged inside the clamping bases. The piece typeradiator welding method and tool can accelerate cooling at a welding position, increases cooling speed, and improves processing efficiency; the welding tool is reasonable and reliable in design, and does not make a radiator obviously deform; a friction welding head is used for friction welding, and other materials are not added to guarantee uniform radiation of the radiator, so that the problems such as processing difficulty, easy cracking and the like are solved; the processed surface is attractive and does not generate chromatic aberration, and the tool has universality for the piece type radiator, so that the tool can be used for welding most of piece type radiators.

Owner:镇江市东亚电子散热器有限公司

Method for preparing metal/polyaniline/plastic composite film through electrochemical in-situ polymerization

ActiveCN102876037BSolve the difficulty of processingSolve defects such as low conductivityElectrolytic organic material coatingComposite filmConductive polymer

The invention discloses a method for preparing a metal / polyaniline / plastic composite film through electrochemical in-situ polymerization. The method comprises the following steps of: 1) preparing a polyaniline / plastic conductive composite film, namely performing electrooxidation polymerization of polyaniline in an aniline-acid solution by taking a plastic microporous film as a base film to obtain the polyaniline / plastic conductive composite plastic film, wherein the electric conductivity of the polyaniline / plastic conductive composite plastic film is 1 to 59.5S.cm<-1>; and 2) preparing a polyaniline / plastic / metal conductive composite film, namely electrodepositing silver on the surface of the polyaniline / plastic conductive composite film to obtain the polyaniline / plastic / metal conductive plastic composite film, wherein the electric conductivity of the polyaniline / plastic / metal conductive plastic composite film is 10<2> to 10<4>S.cm<-1>. The conductive plastic composite film prepared by the method has high electric conductivity and thermal stability and excellent mechanical properties, is high in performance price ratio and light in mass, realizes the organic combination of conductive polymers and metal particles, overcomes the unworkability of the polyaniline, and expands the application range of the conductive polymers. The method is simple and easy; and the obtained composite film can be used as a photoelectronic device, and is used for various fields such as detection and sensing, and electromagnetic shielding.

Owner:CENT SOUTH UNIV

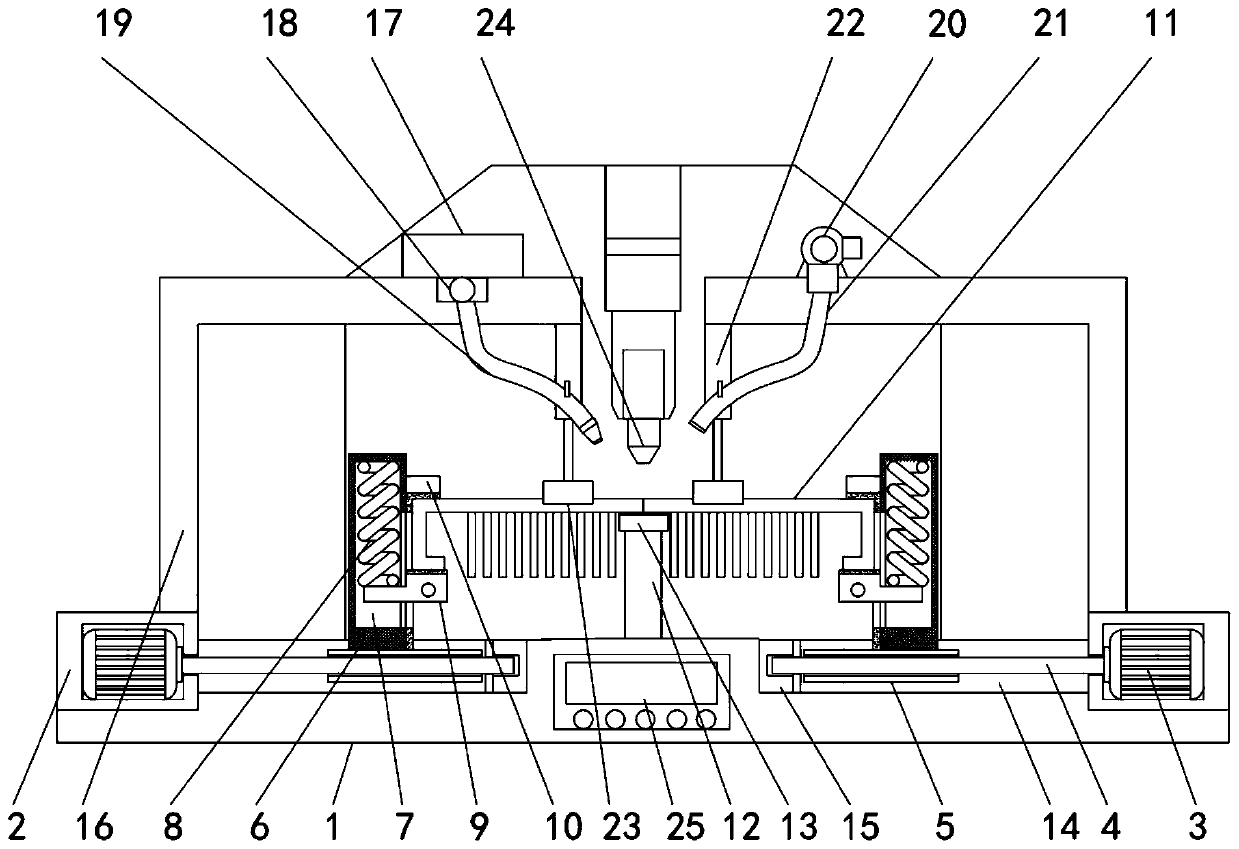

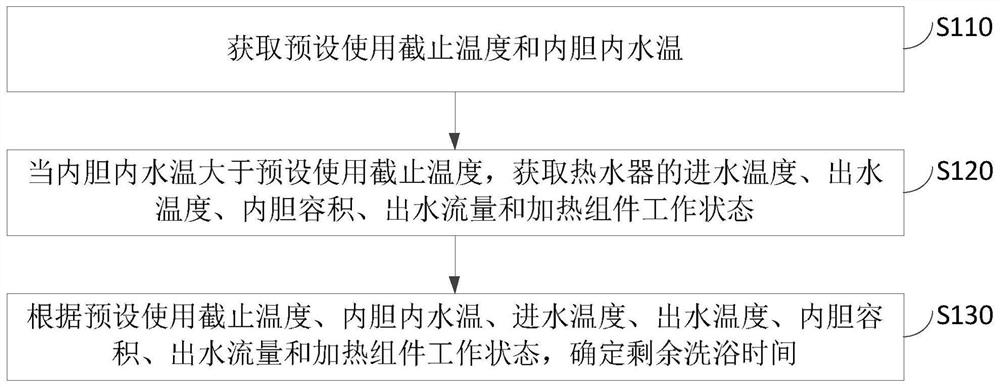

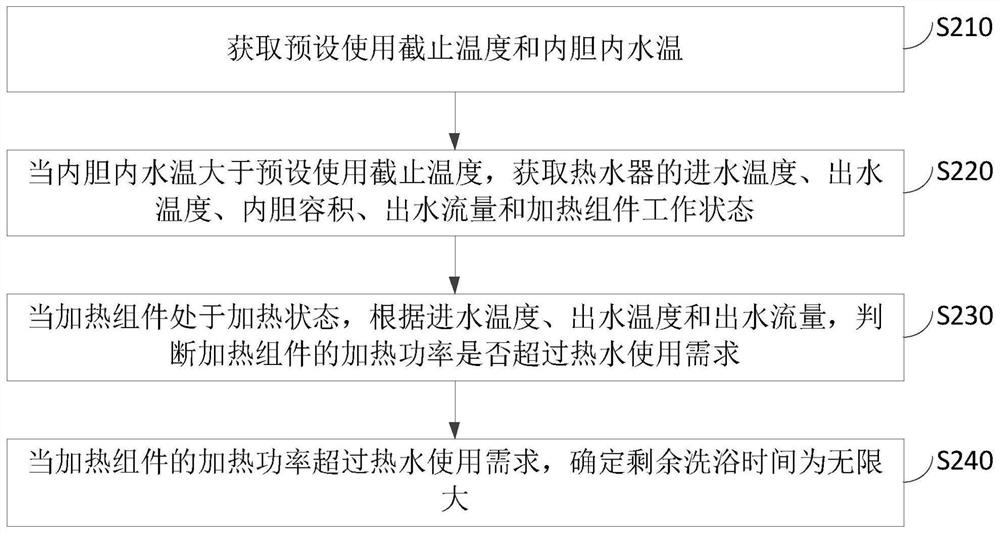

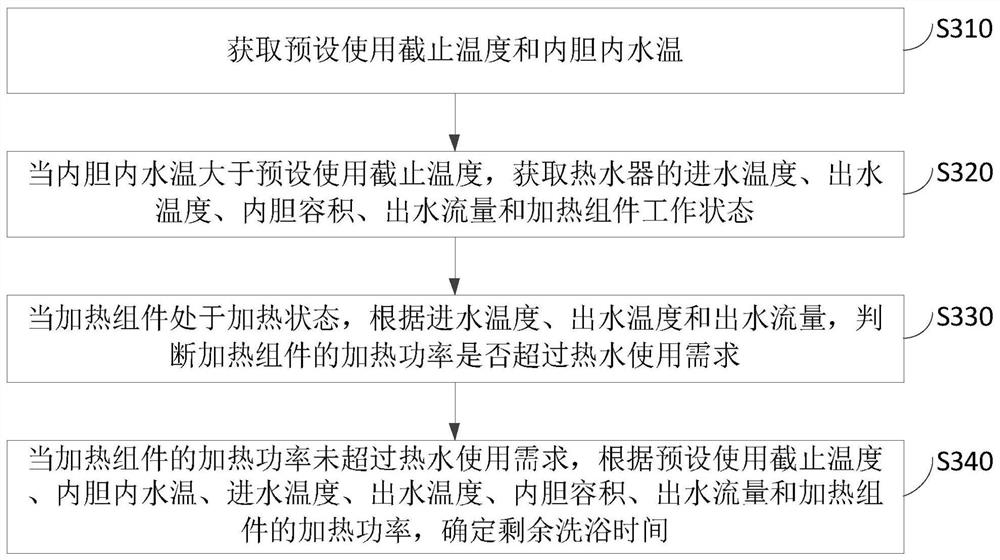

Method and device for predicting remaining bathing time of water heater, water heater and storage medium

ActiveCN112212513AImprove accuracyReduce in quantityFluid heatersForecastingThermodynamicsWater discharge

The invention discloses a method and device for predicting the remaining bathing time of a water heater, the water heater and a storage medium. The method comprises the following steps that 1, presetuse cut-off temperature and the water temperature in an inner container are obtained; 2, when the water temperature in the inner container is higher than the preset use cut-off temperature, the waterfeeding temperature, the water discharging temperature, the inner container volume, the water discharging flow and the working state of a heating assembly of the water heater are obtained, and the working state of the heating assembly comprises whether the heating assembly is in a heating state or not and heating power; and 3, according to the preset use cut-off temperature, the water temperaturein the inner container, the water feeding temperature, the water discharging temperature, the inner container volume, the water discharging flow and the working state of the heating assembly, the remaining bathing time is determined. According to the technical scheme, under the condition that the number of temperature sensors in the inner container is not increased, the accuracy of predicting theremaining bathing time of the water heater is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

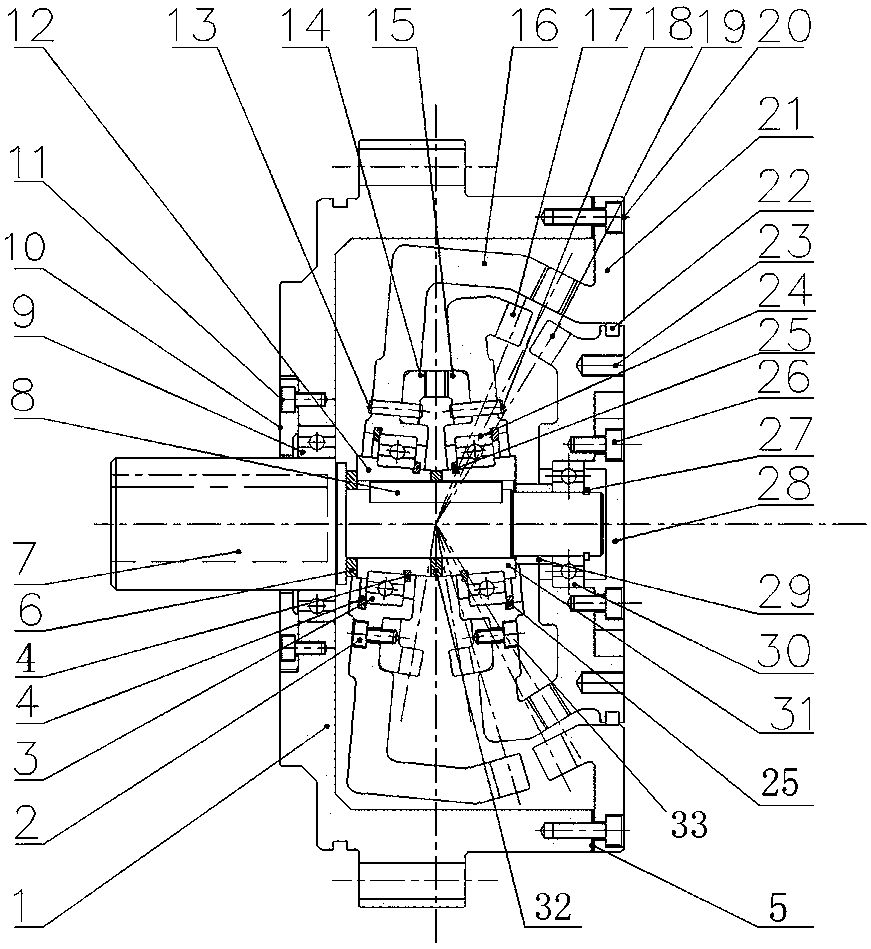

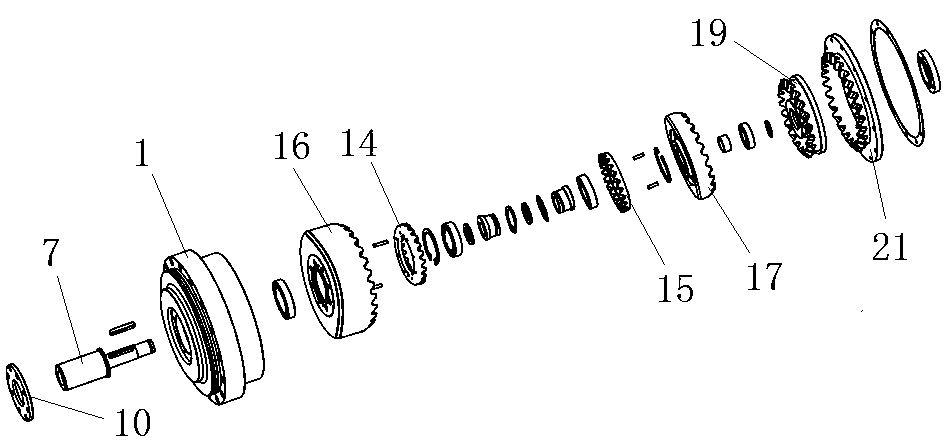

Novel double-sided meshing double-arc bevel gear nutation reducer and working method thereof

PendingCN108843743AReasonable structureReasonable speed ratioToothed gearingsGearing detailsNutationEngineering

The invention relates to a novel double-sided meshing double-arc bevel gear nutation reducer and a working method thereof. The novel double-sided meshing double-arc bevel gear nutation reducer comprises a box body, an input shaft arranged on the middle portion of one side of the box body in a penetrating mode, first nutation sleeves and second nutation sleeves, wherein the first nutation sleeves and the second nutation sleeves are oppositely arranged on the input shaft. The first nutation sleeve is rotatably connected with a first double-arc internal bevel gear, and the first double-arc internal bevel gear is fixedly connected with a first double-arc external bevel gear. The second nutation sleeve is rotatably connected with a second double-arc internal bevel gear, the second double-arc internal bevel gear is fixedly connected with a second double-arc external bevel gear, and the first double-arc external bevel gear meshes with the second double-arc external bevel gear. The novel double-sided meshing double-arc bevel gear nutation reducer further comprises a third double-arc external bevel gear and a fourth double-arc external bevel gear, the third double-arc external bevel gear isfixedly connected to the box body and meshes with the first double-arc internal bevel gear, and the fourth double-arc external bevel gear meshes with the second double-arc internal bevel gear. The novel double-sided meshing double-arc bevel gear nutation reducer is reasonable in structure and has the advantages of high speed ratio, high bearing capacity, small radial dimension, high precision, smooth transmission and the like.

Owner:FUZHOU UNIV

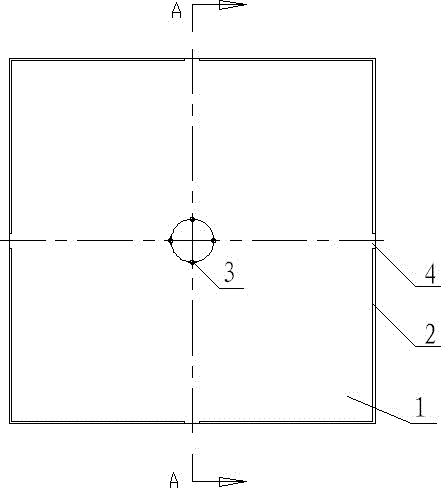

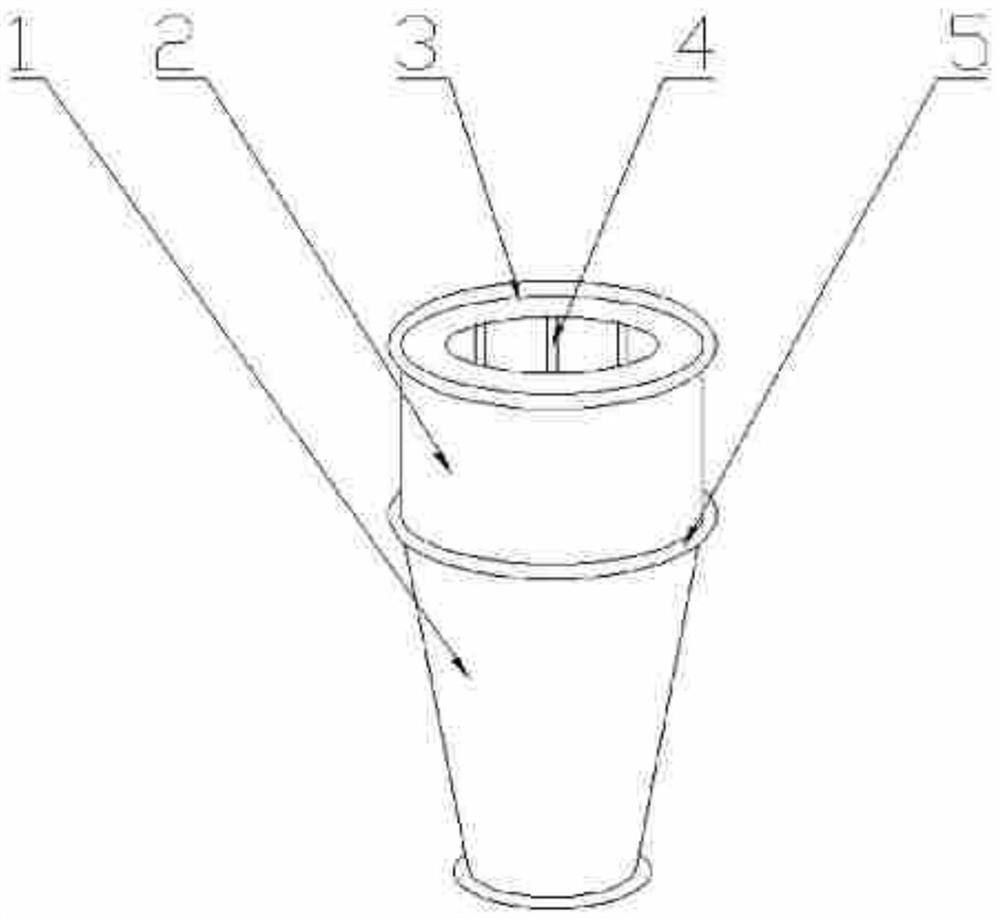

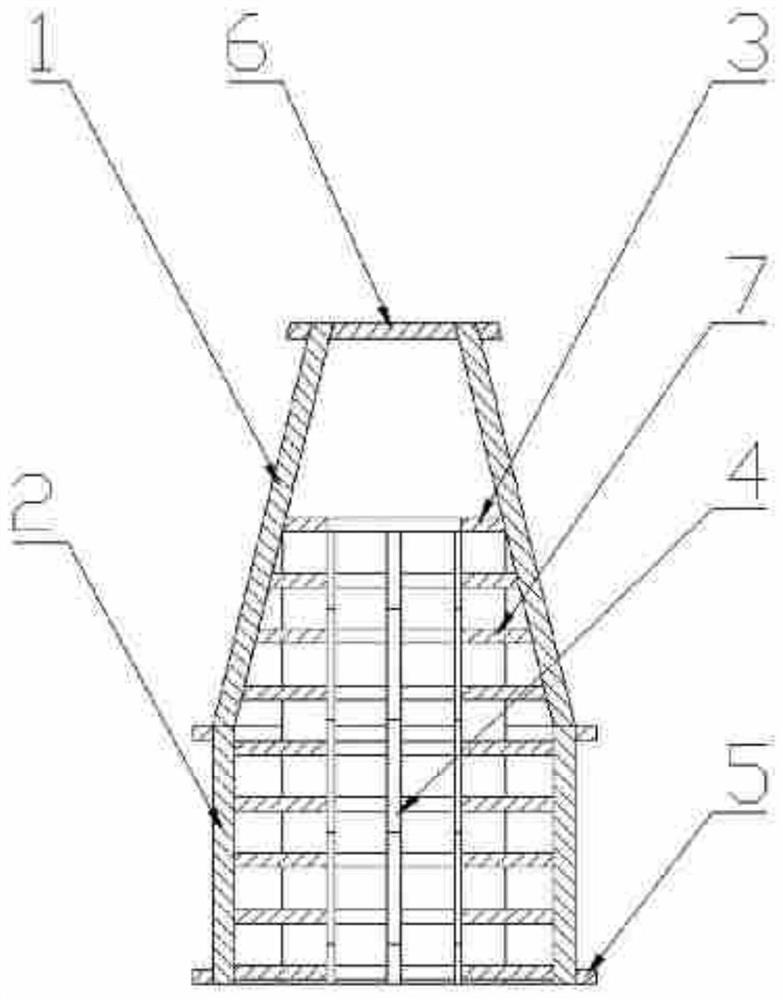

Insulator casting die, outer die thereof, and outside square shaping part

ActiveCN107856238ASolve the difficulty of processingReduce processing difficultyCircular coneMaterials science

The invention relates to an insulator casting die, an outer die thereof, and an outside square shaping part. The insulator casting die comprises an inner die and the outer die which cooperate with each other in a sleeving manner, a casting cavity for cast molding of an insulator is arranged between the outer die and the inner die, the outer die comprises the outside square shaping part and a coneshaping part which are arranged in a split manner, the axis of the cone shaping part extends along the left and right direction, the outside square molding part is inserted to the cone shaping part, the cone shaping part comprises a cone shaping part inner bore with the axis extending along the left and right direction, the cone shaping part inner bore comprises a conical hole segment having an internal diameter gradually increasing from the left to the right and used for forming the conical surface segment of the insulator, the outside square molding part comprises at least one molding sheet,and the molding sheet has a molding sheet external surface used for being laminated to the hole wall of the tapered hole segment and a molding sheet internal surface used for forming the plane of theinsulator during casting. The cone shaping part and the outside square shaping part are respectively processed, so the processing difficulty is reduced, and the precision is easily guaranteed.

Owner:HENAN PINGGAO ELECTRIC +2

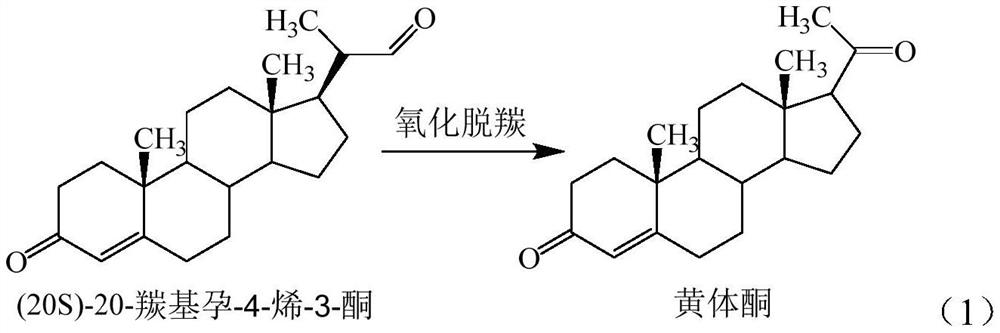

Preparation method of progesterone

ActiveCN112694512AStrong designabilityLittle green pollutionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystProgesterones

The invention discloses a preparation method of progesterone, which comprises the following steps of taking (20S)-20-hydroxymethyl pregna-4-ene-3-ketone as a raw material, and an acidic ionic liquid-based catalyst as a catalyst to react in a solvent, after the reaction is finished, separating the catalyst to obtain a reaction solution, sequentially concentrating the obtained reaction solution under normal pressure, adding water to separate out solid, filtering to obtain a progesterone crude product, and recrystallizing to obtain a progesterone fine product. The catalyst is prepared through catalysis of the acid controllable ionic liquid catalyst, the acid controllable ionic liquid catalyst has the characteristics of being high in designability, small in green pollution and the like, and when the acid controllable ionic liquid catalyst serves as the catalyst, the catalyst and a product are automatically layered after reaction; the catalyst can realize acidity controllability and regeneration through simple treatment after multiple cycles, so that the catalyst has a good application prospect.

Owner:湖北共同甾体药物研究院有限公司

Preparation method of high-purity Gd/Tb/Dy/Y rare-earth metal foil

The invention discloses a preparation method of a high-purity Gd / Tb / Dy / Y rare-earth metal foil. According to the method, rare-earth metal with the purity of not lower than 99.95% serves as a raw material, and the rare-earth metal is one of Gd, Tb, Dy and Y; and the raw material is smelted and cast to obtain a cast ingot, and the high-purity rare-earth metal foil is obtained through machining turning for skin removal, extrusion cogging, multi-pass rolling and finishing. The problems that in the prior art, the machining difficulty is large, impurities are introduced due to the fact that hot rolling is prone to oxidation, the cold rolling production period is long, the pass deformation is low, the rejection rate is high, and edge cracking and layering are likely to occur are solved, and the blank of the high-purity Gd / Tb / Dy / Y rare-earth metal foil preparation technology is filled up; the foil with high purity, clean surface, uniform grain size, small thickness deviation and good comprehensive performance can be obtained, and the preparation method is suitable for producing neutron activation detection sheets; and the preparation method has the advantages of simple process, short period, low defective rate and fund saving, and is suitable for industrial large-scale production.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

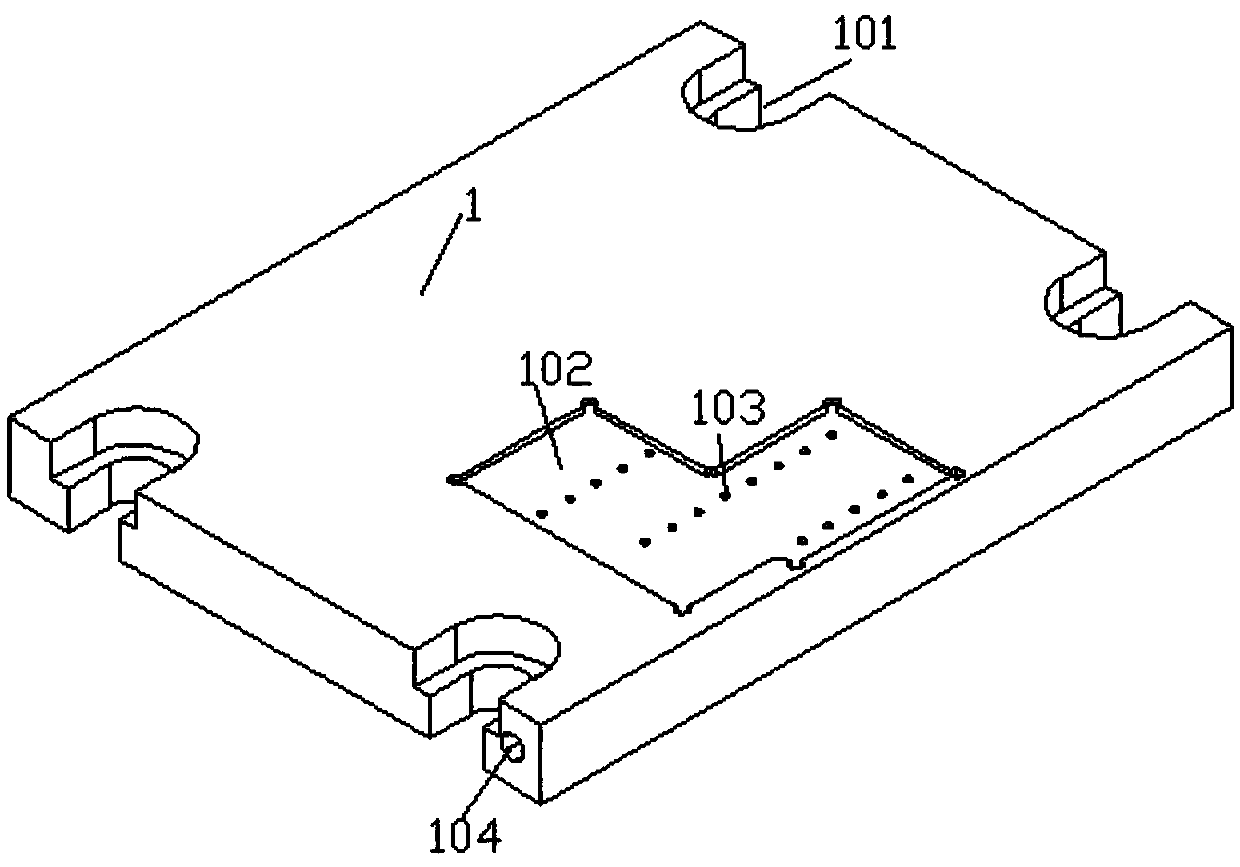

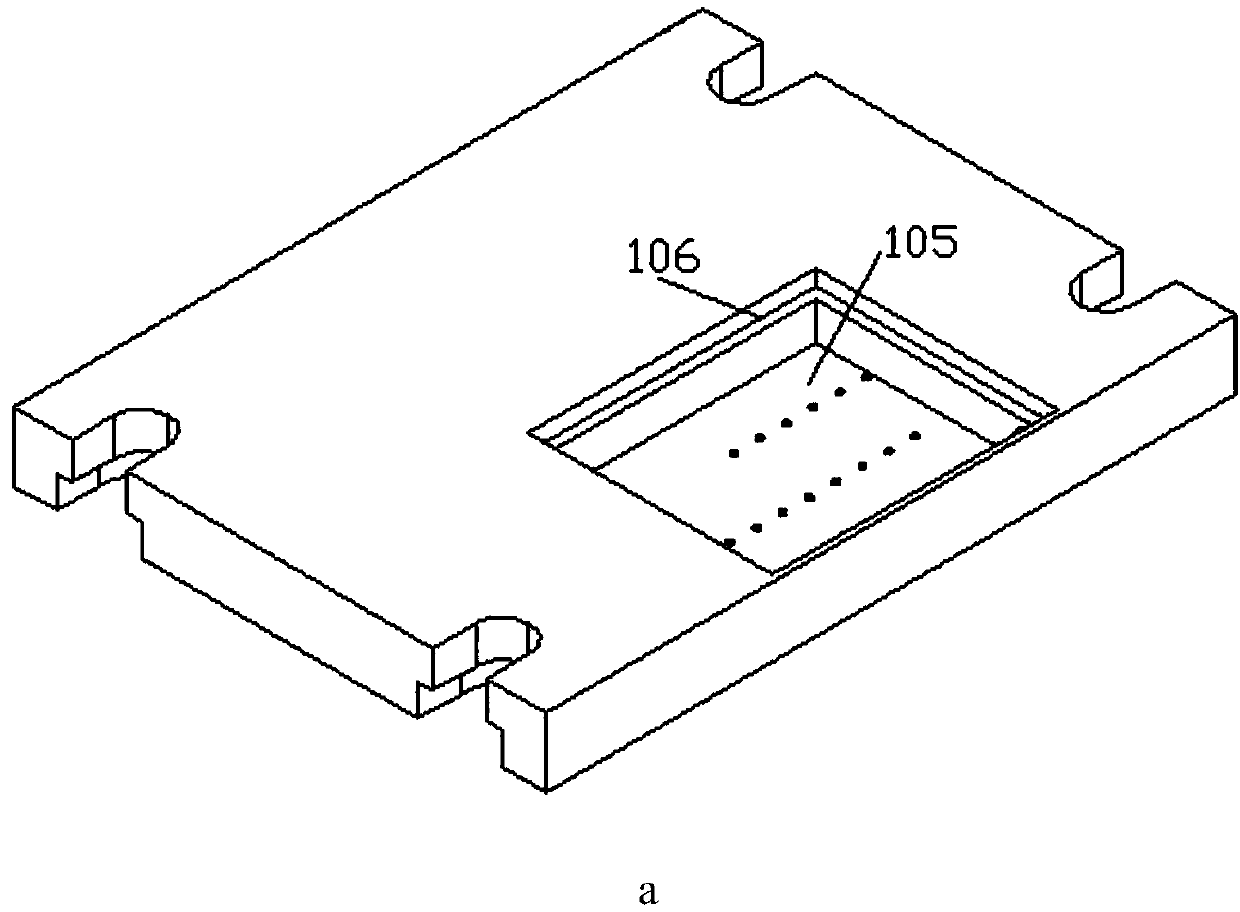

FPC placement platform

PendingCN107685240ASolve the difficulty of processingSame FOG effectPositioning apparatusNon-linear opticsInternet useEngineering

The invention discloses an FPC placement platform. The platform comprises an FPC platformbody, a vacuum groove, a sealing step, a sealing cover plate, a through hole and an air pipe jack, wherein an FPC fixing clamping groove is formed in the upper surface, the vacuum groove is formed in the lower surface of the FPC platform body and located under the FPC fixing clamping groove, the vacuum groovedoes not make contact with the FPC fixing clamping groove, the sealing step is arranged on the edge of one end of an opening of the vacuum groove, the sealing cover plate is connected with the sealingstep in a matched mode for sealing the vacuum groove, the through hole is formed in the FPC fixing clamping groove, the FPC fixing clamping groove is communicated with the vacuum groove, and the airpipe jack is arranged inside the FPC platform body and extends horizontally into the vacuum groove from the edge of one side of the FPC platform body. The FPC placement platform has the advantages that the problem that common machine tool equipment for the FPC placement platform is large in machining difficulty is solved; the FPC placement platform is not obviously different from a traditional FPCplacement platform; the FPC placement platform can achieve the identical FOG effect, and no influence is generated on products.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD +3

High-silicon-content silicon-carbon negative electrode plate and preparation method thereof

PendingCN113921756ASolve process difficulty and costAlleviate silicon anode swellingElectrode carriers/collectorsComposite materialCurrent collector

The invention provides a high-silicon-content silicon-carbon negative electrode plate, which comprises a current collector, a carbon layer formed on the surface of the current collector and a silicon material layer formed on the surface of the carbon layer, and the mass ratio of the carbon layer to the silicon material layer is 5: 95-50: 50. The surface of the current collector is coated with the carbon layer, the thickness and porosity of the current collector are controlled, silicon negative electrode expansion can be greatly relieved, and when a proper silicon negative electrode material is matched, the silicon negative electrode content of 50% or above can be achieved, and then the specific capacity of the pole piece can be greatly improved.

Owner:LANXI ZHIDE ADVANCED MATERIALS CO LTD

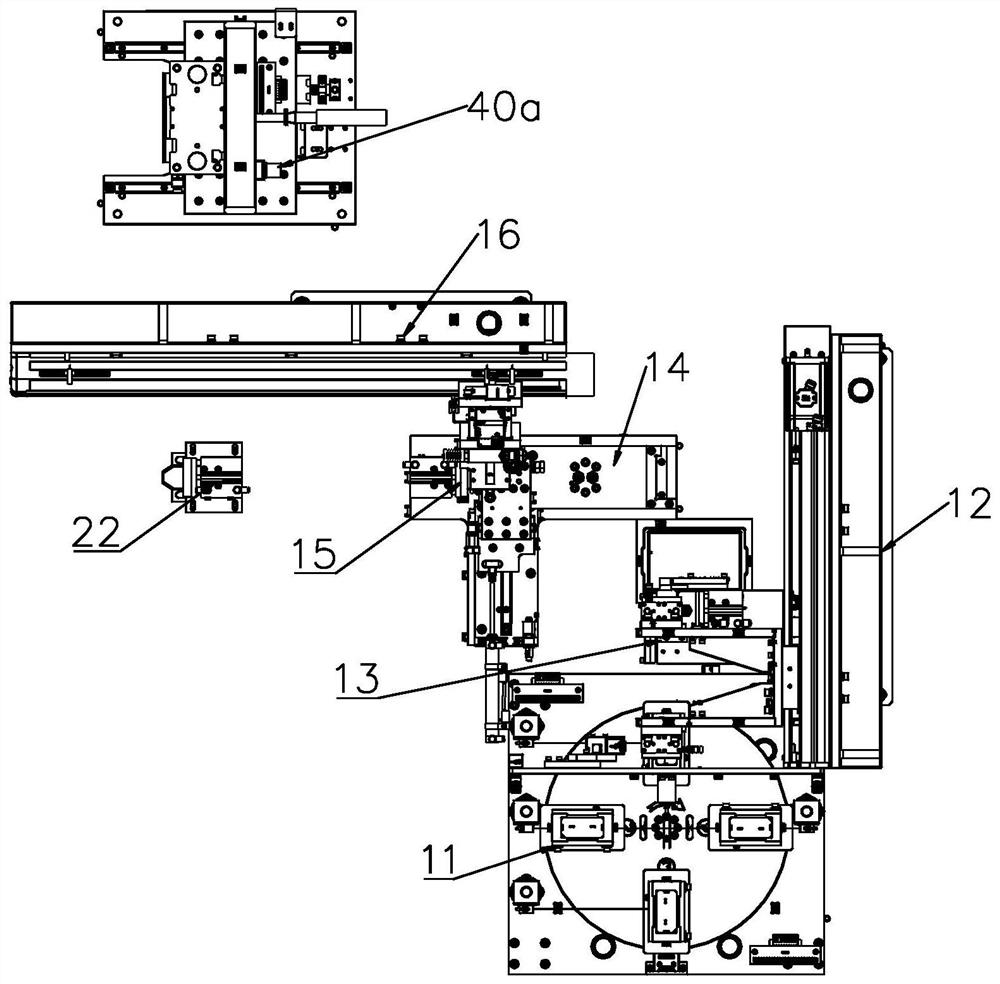

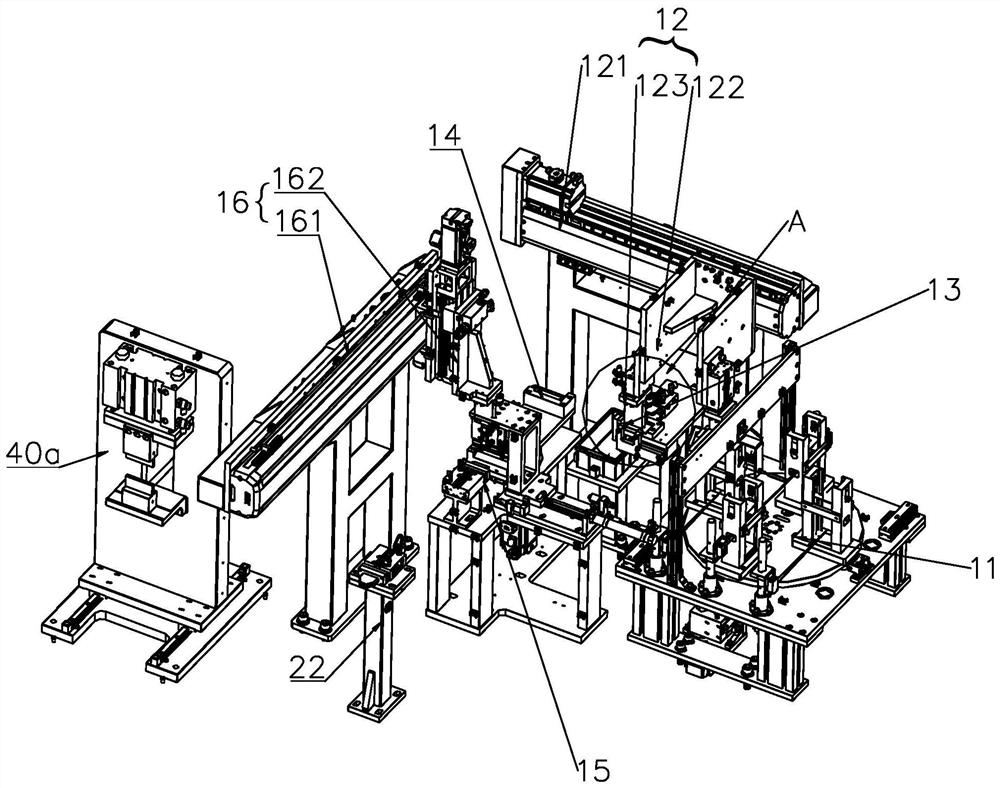

Ultrasonic welding machine for connecting pieces

ActiveCN112916997AAchieve connectionEasy to weldWelding/soldering/cutting articlesMetal working apparatusUltrasonic weldingEngineering

The invention discloses an ultrasonic welding machine for connecting pieces, and relates to the technical field of production equipment. The ultrasonic welding machine comprises a jig backflow device. A plurality of jigs used for bearing products are arranged on the jig backflow device, and a feeding device, a first shaping device, an ultrasonic welding device, a second shaping device, a gluing device and a detection device are sequentially arranged along the extending path of the jig backflow device to be used for detecting the welding and gluing conditions of the products. The feeding device comprises a connecting piece feeding device and a top cover feeding device which are arranged on the two sides of the starting end of the jig backflow device respectively. The connecting piece feeding device and the top cover feeding device each comprise a connecting piece shaping mechanism. By adoption of the technical scheme provided by the invention, the technical problem that the existing welding processing efficiency of the connecting pieces and tabs is relatively low is solved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Guide block for preventing linear displacement blocking of electromechanical actuator

ActiveCN105805254AAvoid it happening againAvoid accumulationGearingArchitectural engineeringLinear displacement

The invention discloses a guide block for preventing linear displacement blocking of an electromechanical actuator. The section of the guide block is T-shaped; the width of the narrow edge of the T-shaped section is 0.6-2mm less than the width of the wide edge; threaded holes are uniformly distributed in the guide block in the length direction; on end of the narrow edge of the T-shaped section is fixed on the inner wall of an electromechanical actuator shell through a screw to ensure that the guide block is located in a guide slot of a lead screw nut; the distance between the upper end face of the nut in the guide slot and the interface between the narrow edge and the wide edge of the T-shaped section is 0.35-0.75mm; the fit clearances between the two end faces of the wide edge of the T-shaped section and the guide slot satisfy 0.01-0.02mm, and the depth of parallelism is 0.01-0.02mm.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

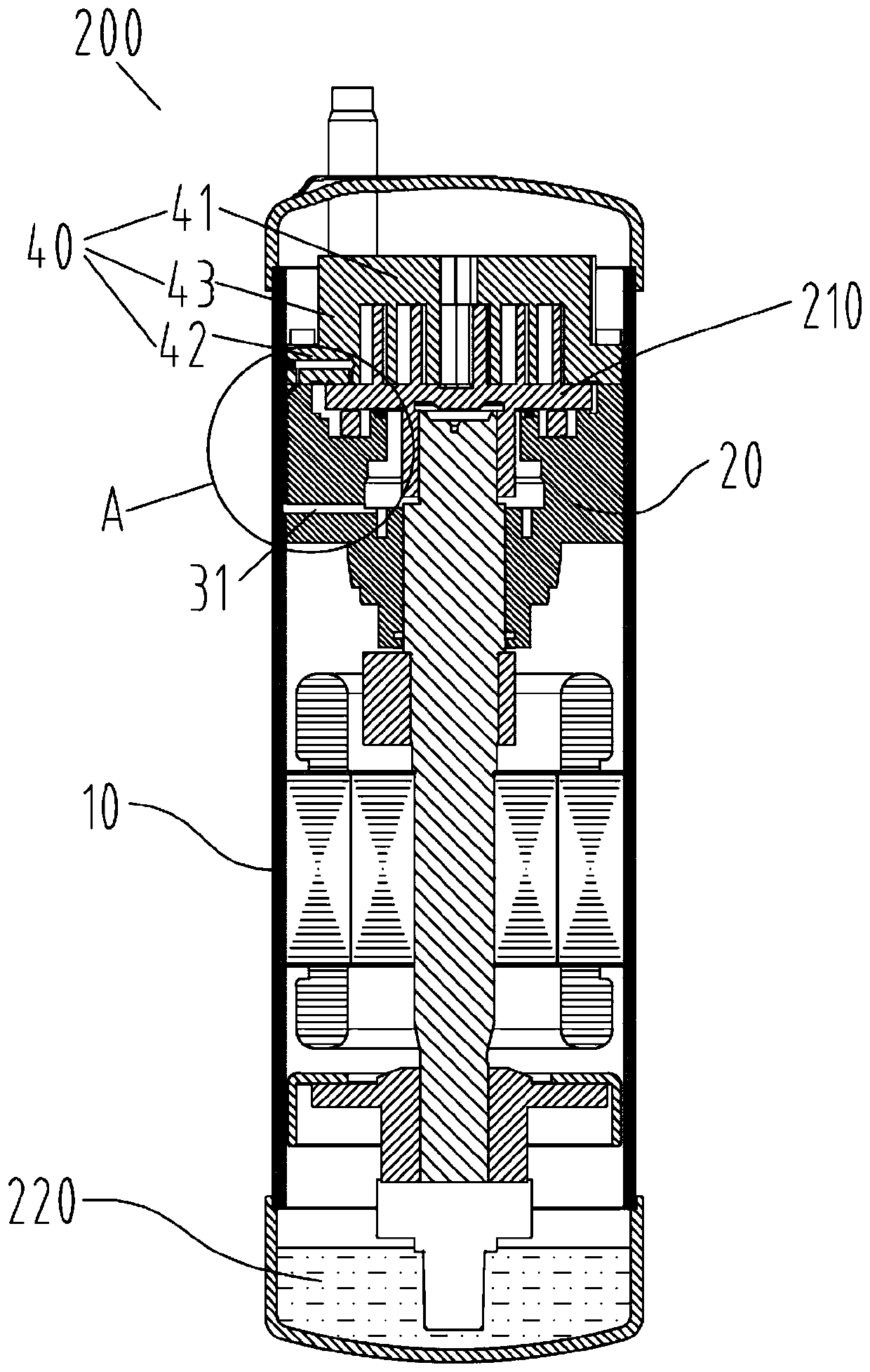

Sliding-vane type pneumatic motor as well as air compressor and internal combustion engine derived from same

PendingCN111734494ASolve the difficulty of processingImprove air tightnessInternal combustion piston enginesRotary piston pumpsCounter rotationStator

The invention relates to a sliding-vane type pneumatic motor as well as an air compressor and an internal combustion engine derived from the same. The sliding-vane type pneumatic motor consists of a rotor, a rotor end cover, a leaf spring, a stator with one or more air chambers, a stator end cover, a sliding vane and a sliding vane airtight strip. A rotor unit of the sliding-vane type pneumatic motor rotates reversely to become a sliding-vane type air compressor. The sliding-vane type pneumatic motor is connected with a middle shaft of the sliding-vane type air compressor to form a body of anengine; and the body is externally additionally provided with a supercharger to form the sliding-vane type internal combustion engine.

Owner:宋洪涛

Novel new material product round edge trimming device

InactiveCN112496925AImprove functional usabilityImproved convenience for adjustment functionalityEdge grinding machinesGrinding carriagesGear wheelElectric machinery

The invention discloses a novel new material product round edge trimming device, and relates to the technical field of material processing. The device comprises a bottom plate, and the right end of the upper side surface of the bottom plate is fixedly connected with a motor. According to the novel new material product round edge trimming device, a first gear, a seventh gear, a second supporting shaft, a second gear, a third gear, a first movable plate, a first connecting shaft, a fourth gear, a second movable plate, a second connecting shaft, a fifth gear, a third connecting shaft, an eighth gear, a fourth connecting shaft, a sixth gear and a first supporting shaft drive a first transmission wheel and a second transmission wheel to reversely and synchronously rotate, then a new material plate penetrates through two rounding cutters at the same time to complete round corner shaping of the edges and corners of the new material, and therefore the problems that most of existing new material product round edge trimming devices do not have a convenient adjusting function, consequently, most of the existing new material product round edge trimming devices can only adapt to wood plates ofcertain widths, and the machining difficulty of workers for machining new material plates of different widths is increased to a certain degree are solved.

Owner:袁博

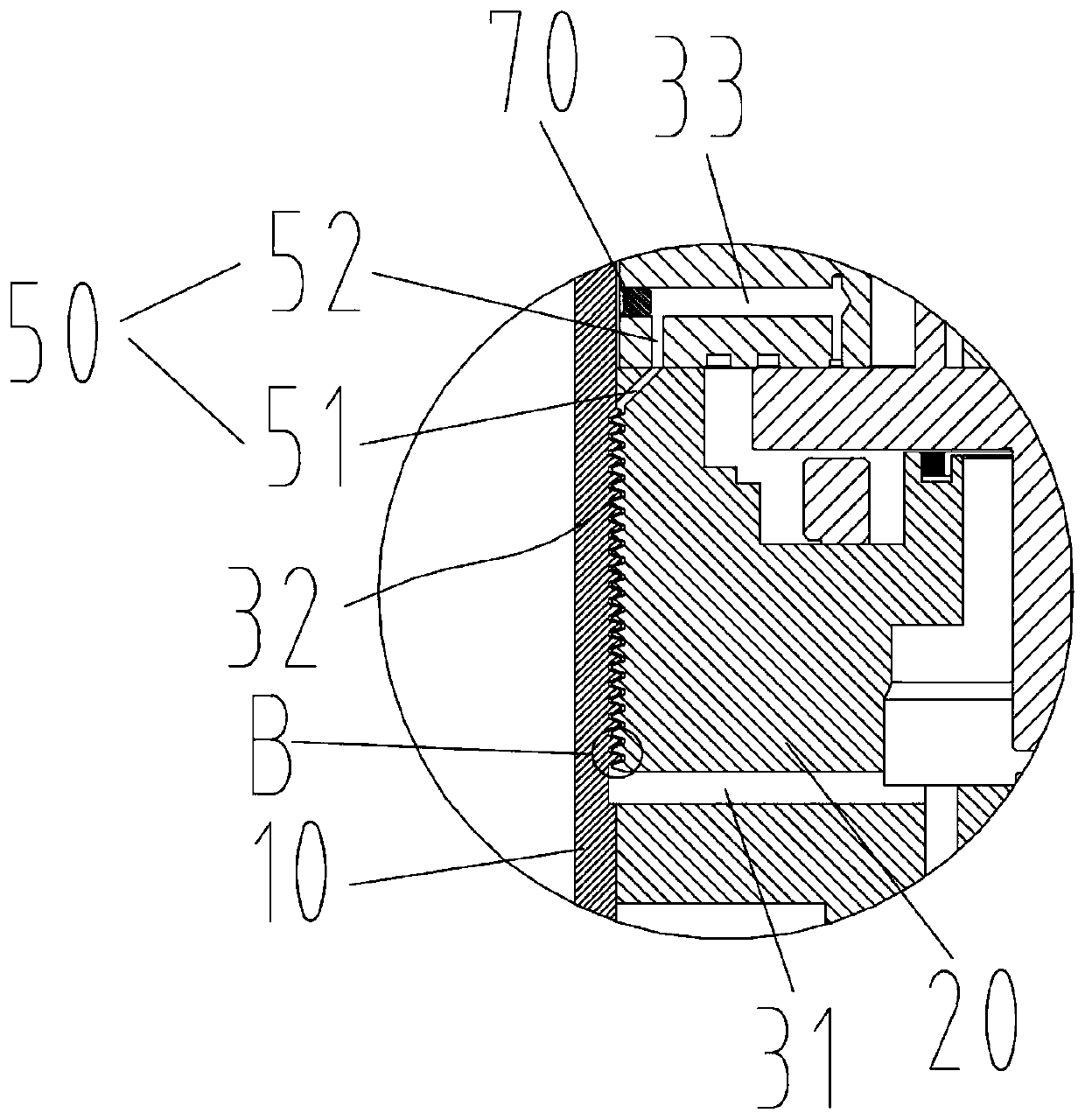

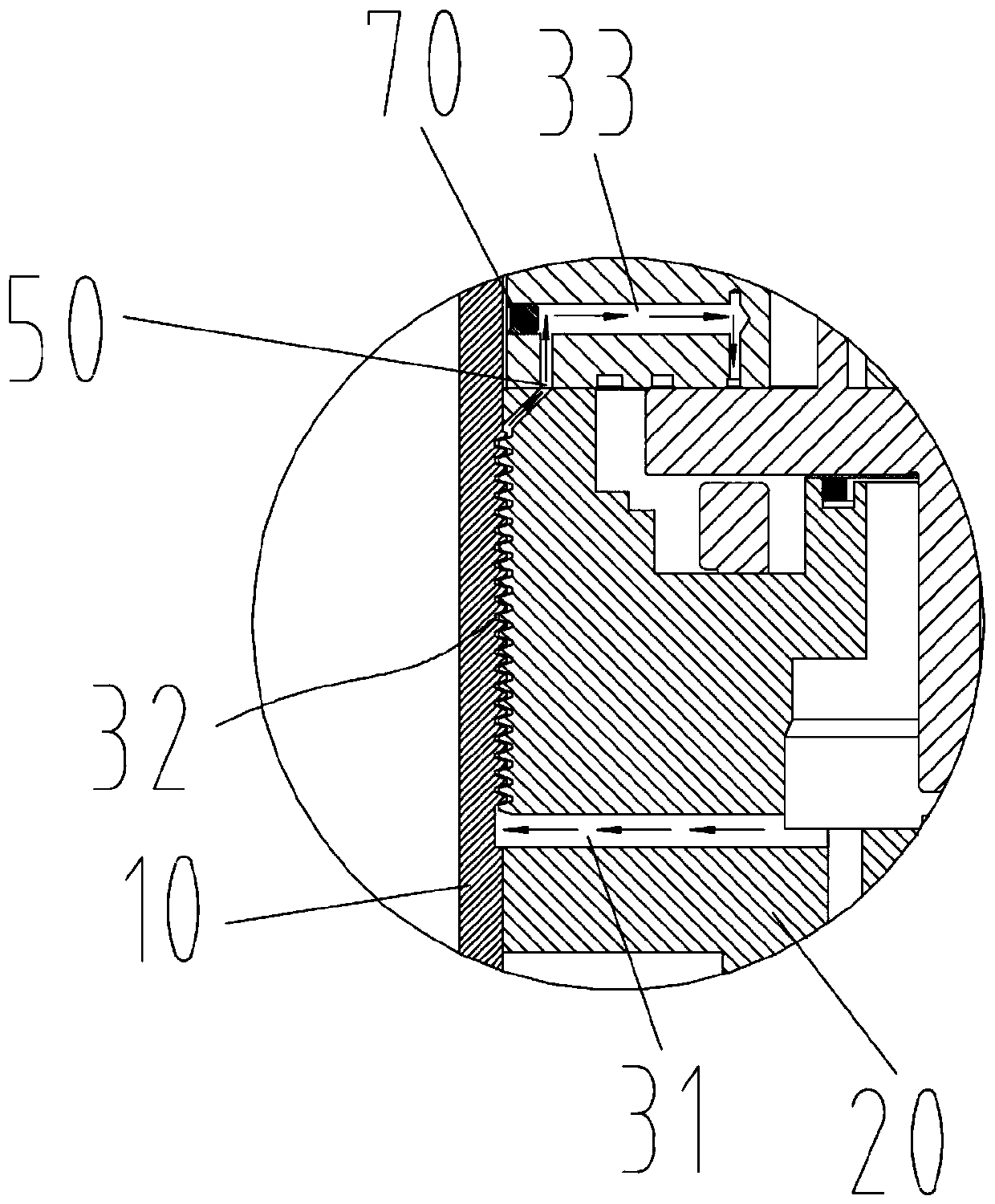

Oil way structure and compressor with same

PendingCN111173741AReduce processing difficultyAvoid enteringRotary piston pumpsRotary piston liquid enginesEngineeringStructural engineering

The invention provides an oil way structure and a compressor with the same. The oil way structure comprises a shell, a static scroll plate and an upper bracket. According to the oil way structure, a throttling channel is arranged and the fact that the throttling channel communicates with a static plate oil channel which is arranged on the static scroll plate is realized, so that lubricating oil ina throttling channel enters the static plate oil channel; moreover, the throttling channel is formed by mutual matching of a first matching part which is arranged on the upper bracket and a second matching part which is arranged on the shell, namely, under the structural matching action of the first matching part and the second matching part, the amount of oil flowing through the throttling channel can be controlled, so that the excessive lubricating oil is prevented from entering the static scroll plate; according to the mode of controlling the oil amount, the situation that a plurality of oil holes are formed in the inner part of the upper bracket and throttling screws are arranged in the oil holes is avoided, so that the machining difficulty of the upper bracket is reduced, the machining difficulty of the compressor is further reduced, and the problem that in the prior art, the machining difficulty of the compressor is large is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A die forging production method of hydraulic support connector of coal machine

InactiveCN104722688BReduce manufacturing costSmall sizeMetal-working apparatusEngineeringProjection plane

Owner:DINGXIANG COUNTY XINGHUI FORGING

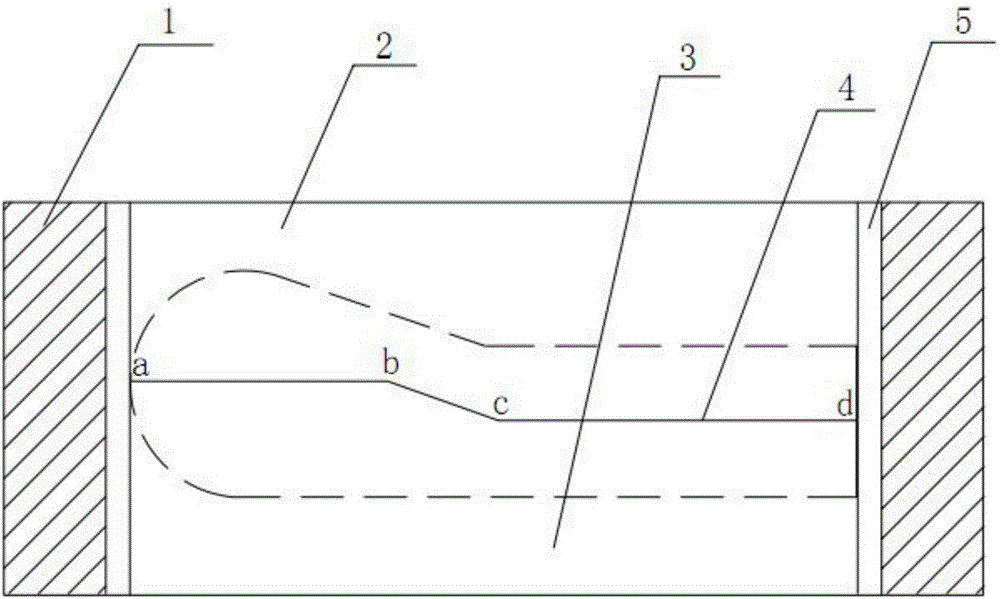

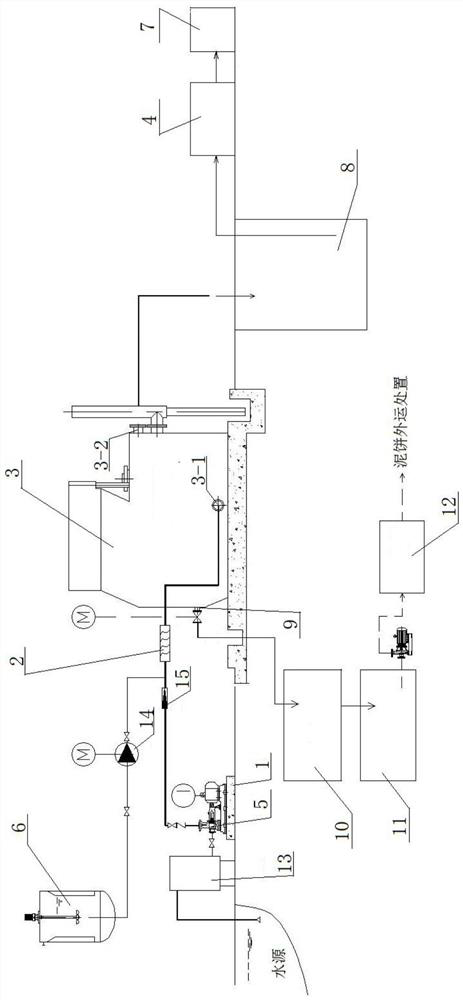

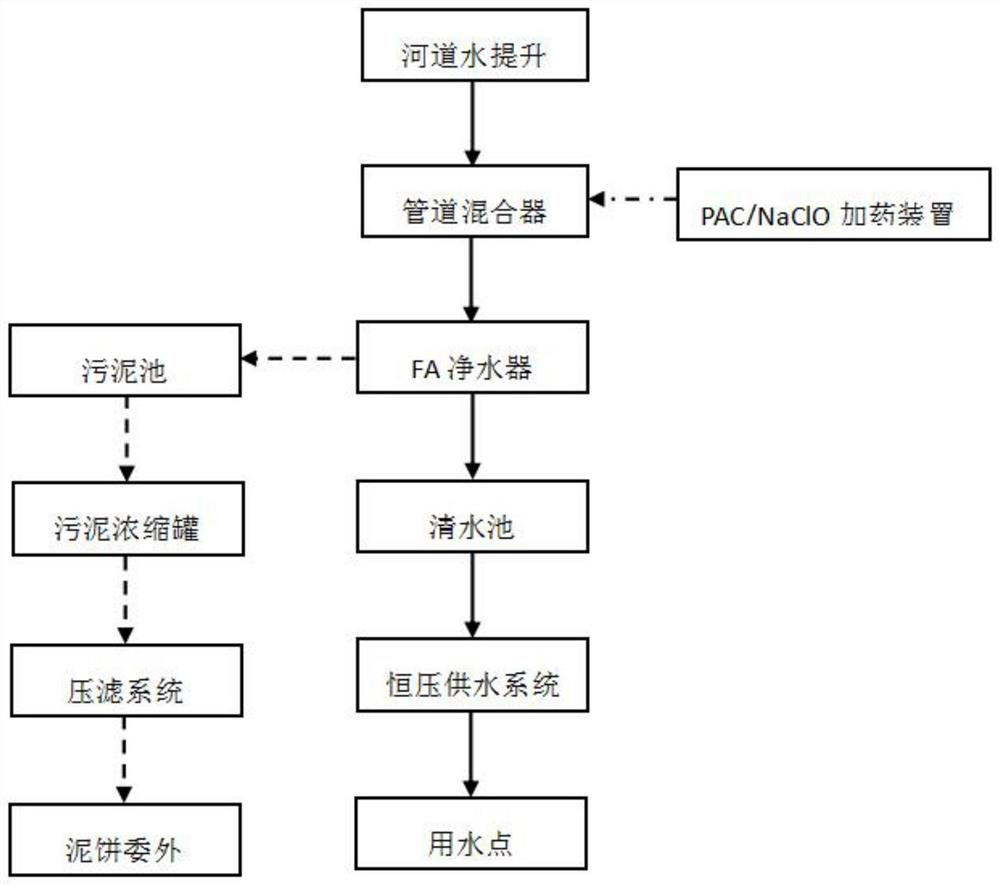

River water purification treatment system and process

PendingCN112551766AEasy to operateEasy to installSludge treatmentSpecific water treatment objectivesWater useWater saving

The invention discloses a river water purification treatment system and a process, and belongs to the technical field of water quality purification. The river water purification treatment system comprises a water taking pump station, a pipeline mixer, an FA type efficient full-automatic water purifier and a constant-pressure water supply system. The process comprises steps: lifting river water from a river channel by a water taking pump to the pipeline mixer, adding two agents of PAC and NaClO into the mixer, carrying out disinfection and coagulation treatment on wastewater, then guiding the wastewater to the FA type efficient full-automatic water purifier, and completing the processes of precipitation, filtration and the like, and conveying clear effluent to all water consumption points through the constant-pressure water supply system. According to the river water purification treatment system and the process, the purification treatment effect is good, the effluent quality is excellent, the self water consumption is low, the power consumption is reduced, the occupied area is small, water and electricity are saved, manual management is not needed, the problems that an existing river water purification system is large in investment and occupied area, complex in construction and the like are solved, and the practicability is high.

Owner:SUZHOU SUWATER ENVIRONMENTAL SCI & TECH CO LTD

Processing method for stiffening plates in reinforcing area of large-diameter tubular column

The invention relates to a processing method of stiffening plates in a reinforcing area of a large-diameter tubular column, and belongs to the technical field of processing and manufacturing of building steel structural members. The processing method comprises the following operation steps that firstly, rolling and forming are carried out on the large-diameter tubular column by adopting a plate rolling machine, and welding is carried out on longitudinal seams after rolling and forming; secondly, the surface of a longitudinal weld joint is polished to be flush with a base metal after welding; thirdly, outer ring stiffening plates are welded to the lower end of a variable-cross-section circular pipe, the upper end of a straight-section circular pipe and the position between the variable-cross-section circular pipe and the straight-section circular pipe; fourthly, an end transverse stiffening plate is welded to the middle of the variable-cross-section circular pipe, then transverse stiffening plates and vertical stiffening plates are installed and welded in the variable-cross-section circular pipe and the straight-section circular pipe, welding is conducted through a taking and retreating method, and finally the end transverse stiffening plate is welded to the end face of the straight-section circular pipe; and fifthly, an inner stiffening plate is welded to the end face of the variable-cross-section circular pipe. The processing method has the characteristics of simple structure, high efficiency and long service life. The problem of high processing difficulty of the stiffening plates in the reinforcing area is solved, and the product quality is ensured.

Owner:浙江东南网架股份有限公司

Preparation method of micro-nano vat dye suspension

The invention relates to a preparation method of micro-nano vat dye suspension, and belongs to the technical field of dye suspension manufacturing. The preparation method comprises the following operation steps that vat dye, caustic soda, sodium hydrosulfite and water are added into a chemical vat to carry out a pre-reduction process, so that the vat dye is reduced into water-soluble leuco body sodium salt; and the leuco body sodium salt is placed in a microbubble oxidation tank, a dispersion system is added at the same time, a microbubble oxidation stirring assembly is adopted to oxidize the leuco body sodium salt into water-insoluble dye particles, and therefore the micro-nano vat dye suspension is obtained. The liquid with the vat dye suspension in the microbubble oxidation tank is conveyed to a solid-liquid separation box through a liquid discharge pipe with a valve, so that the vat dye suspension is separated from the solution. Dye bath is carried out on the vat dye suspension and then the processed vat dye suspension is input into the dye vat, and a cotton cheese is dried by adopting a suspension dyeing method. The method has the characteristics of simple operation, good stability, high efficiency and short period, and the problem of high processing difficulty is solved.

Owner:SAINTYEAR HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com