Electric glass lifter for vehicle

A technology of electric glass and lifter for vehicles, applied in power control mechanism, door/window fittings, construction, etc., can solve problems such as failure of electric glass lifter, loose transmission wire, motor sealing problem, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

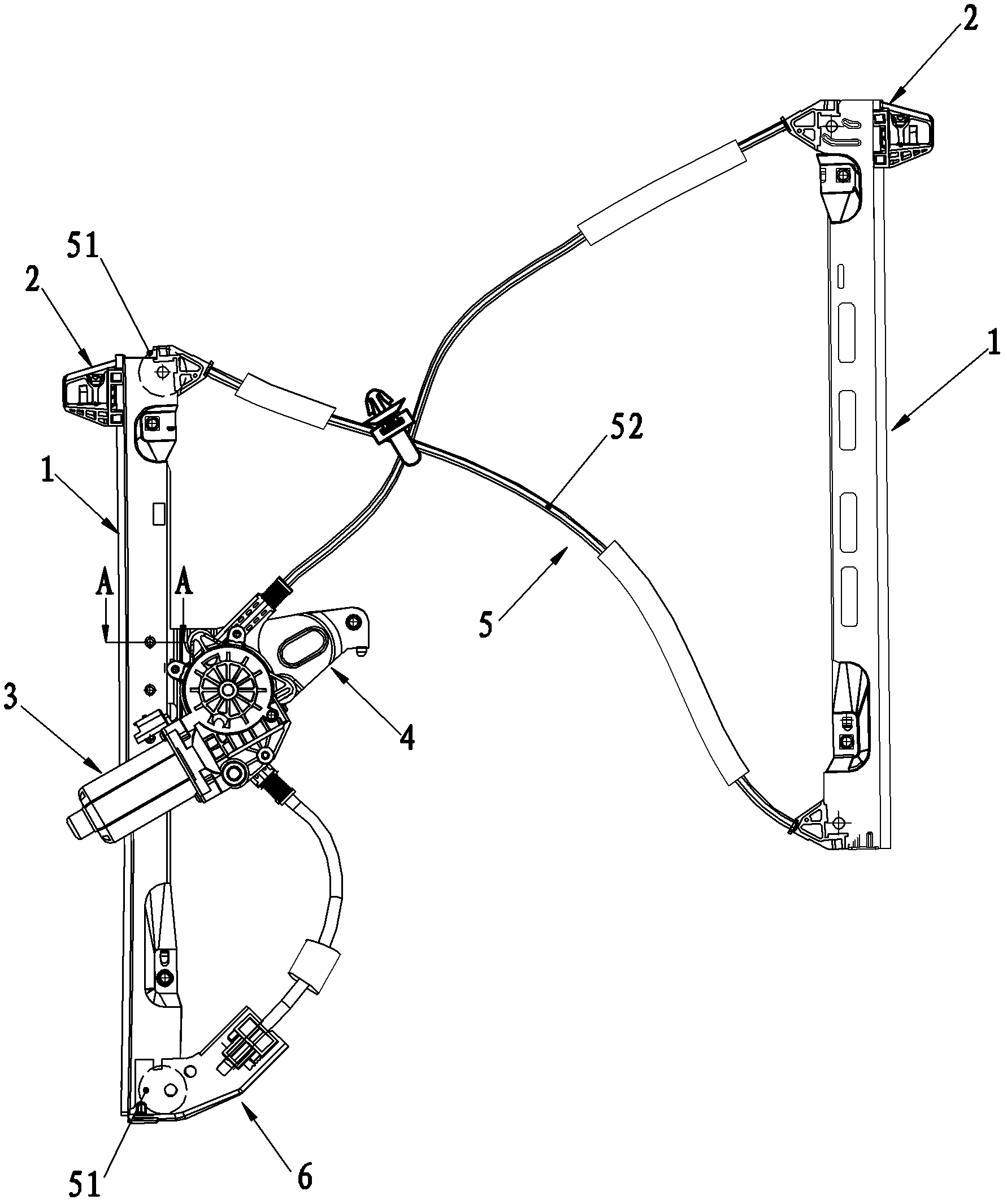

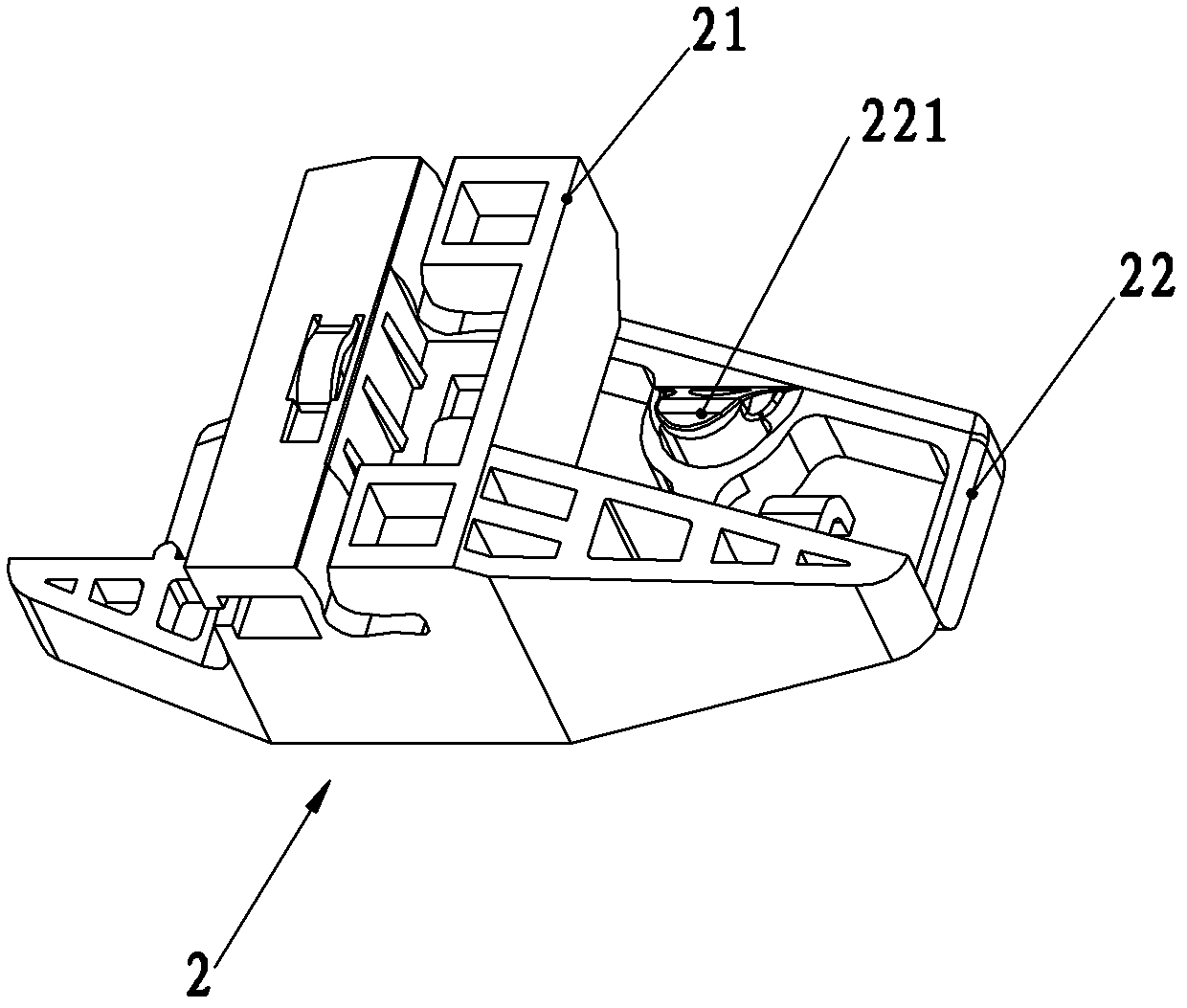

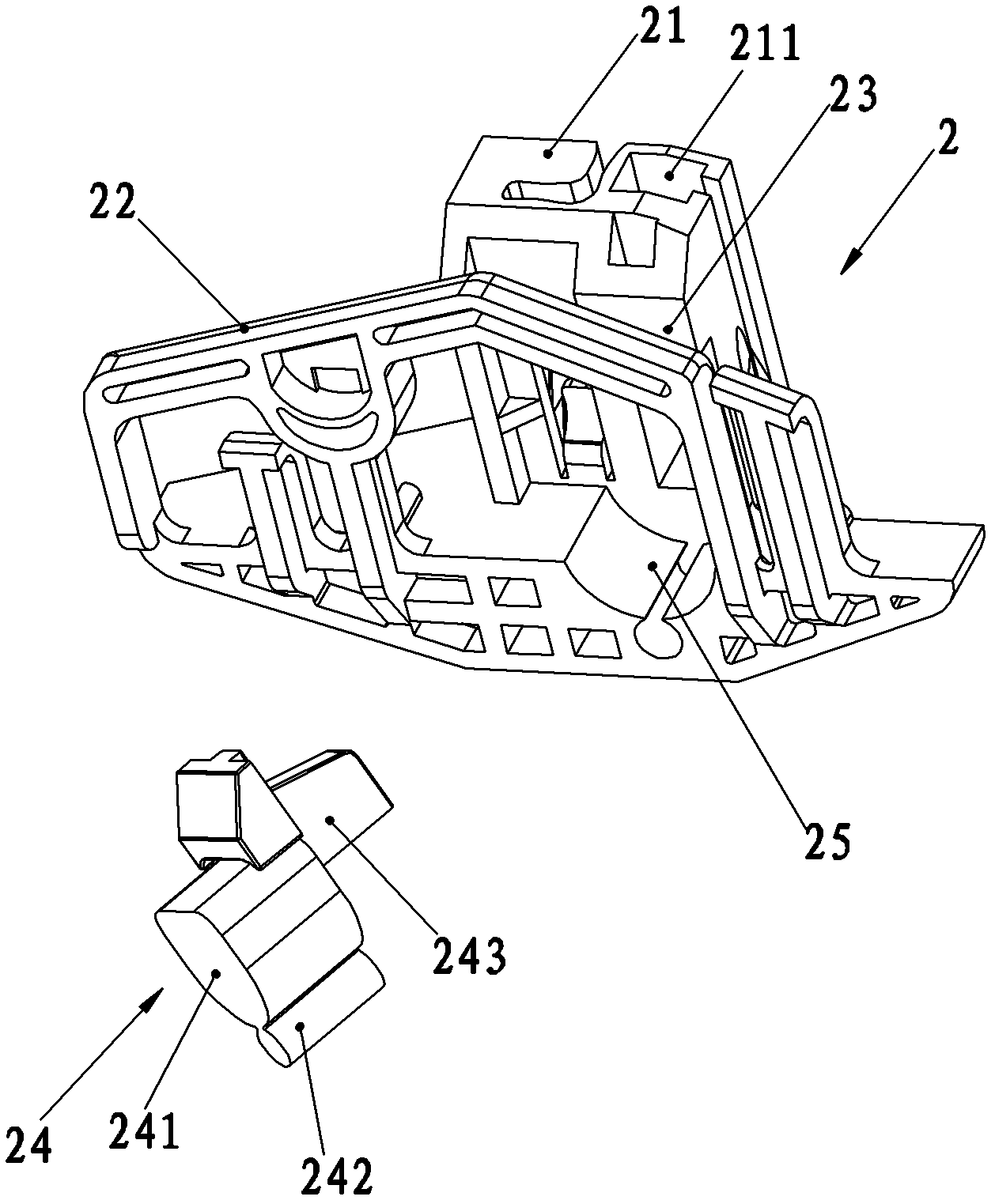

[0022] Such as figure 1 — Figure 5 The shown electric window regulator for vehicles includes two correspondingly arranged slide rails 1, a slide plate 2 respectively arranged on the two slide rails 1 and sliding axially along the slide rails 1, and driving the slide plate 2 to slide The driving motor 3 and the transmission part 5 connecting the output end of the driving motor 3 and the slide plate 2. It should be noted that the driving motor 3 is erected on the slide rail 1 through the mounting plate 4, and the mounting plate 4 is connected with the slide rail 1 by riveting. The so-called riveting connection is to use a special mold and press the slide rail 1 and the mounting plate 4 are stamped together. Such arrangement makes the driving motor 3 and the slide rail 1 connected by riveting without rivets, which changes the traditional way of separating the motor from the slide rail, and improves the efficiency of production and installation.

[0023] In the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com