Processing method for stiffening plates in reinforcing area of large-diameter tubular column

A processing method and a large-diameter technology are applied in the field of processing and manufacturing of building steel structural components, which can solve the problems of difficult processing, short service life, and complex structure of stiffeners in reinforced areas, and achieve the solution of difficult processing, long service life, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

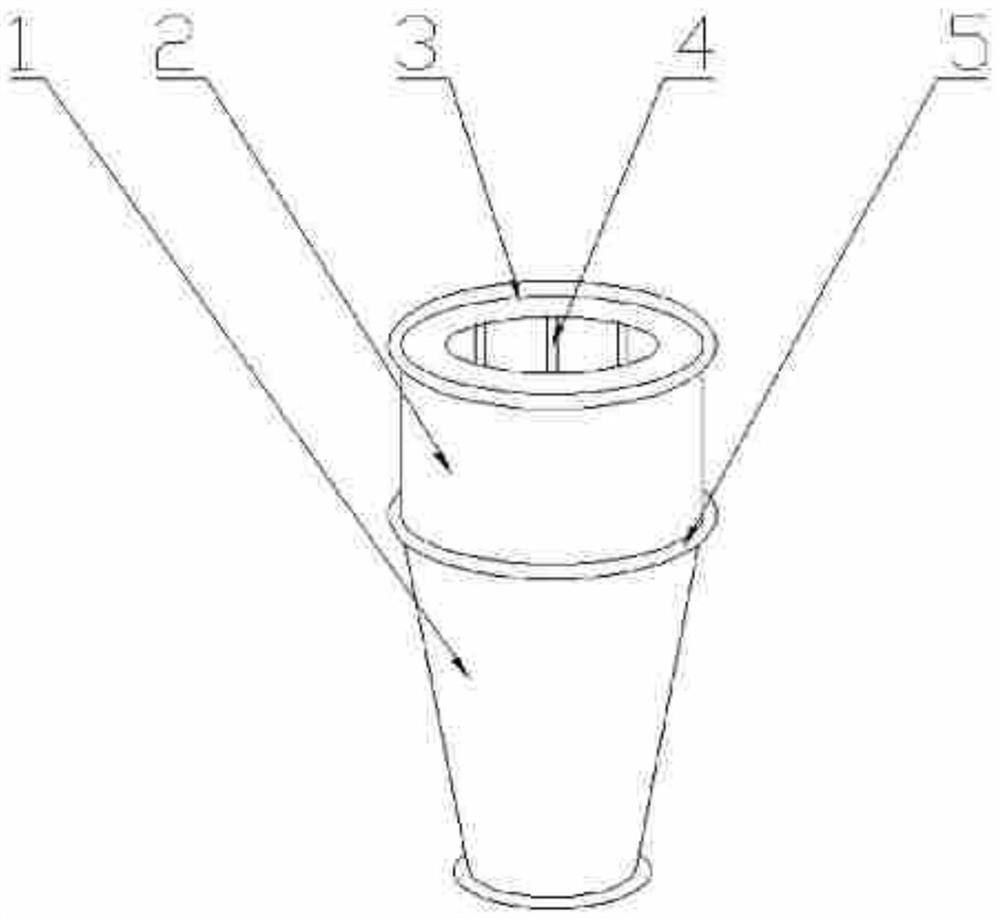

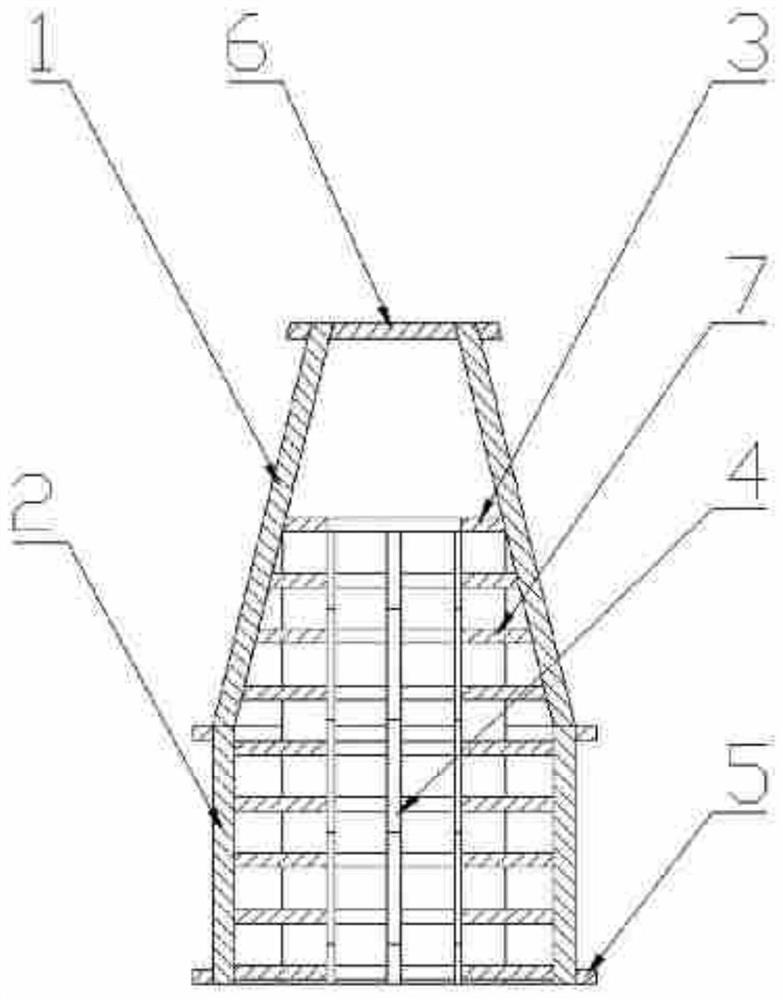

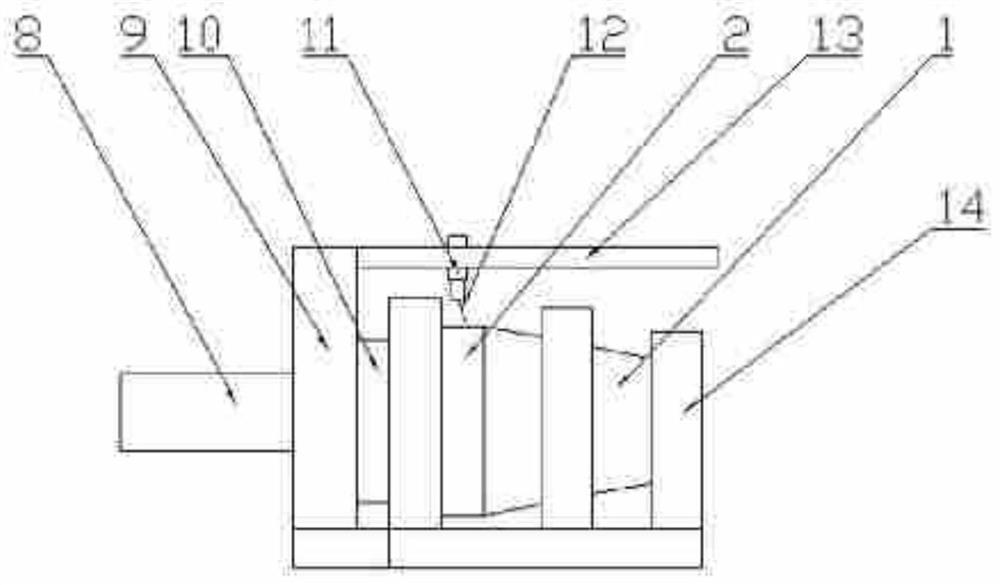

[0035] Example: such as Figure 1-5 As shown in the figure, a processing method for stiffeners in the reinforcement area of a large-diameter circular pipe column, the first step: the large-diameter circular pipe column is rolled into shape by a plate rolling machine, and when the steel plate is rolled round, the stainless steel plate template with a thickness of 3mm is continuously rolled The roundness is measured, and the longitudinal seam welding after rolling and forming adopts a combined welding method of CO2 gas shielding and submerged arc welding to form an integrated structural shape of the variable cross-section round pipe 1 and the straight section round pipe 2 .

[0036] After being rolled into shape, the large-diameter circular pipe column is placed on the welding frame 9, and the outer circular side top assembly 14 on both sides of the welding frame 9 is used to fix the large-diameter circular pipe column. 14 Use 2 compression oil cylinders 15 on the oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com