Preparation method of micro-nano vat dye suspension

A suspension, micro-nano technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of difficult processing, poor stability, and long cycle, and achieve the effect of solving difficult processing, good stability, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

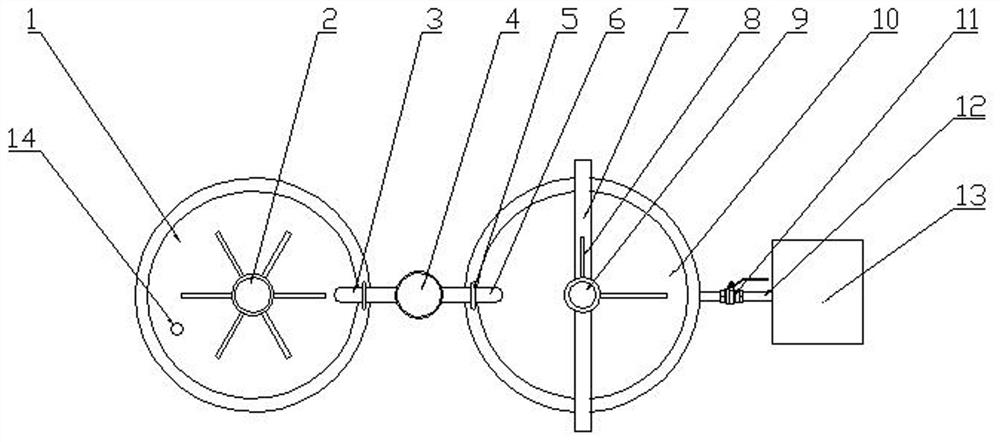

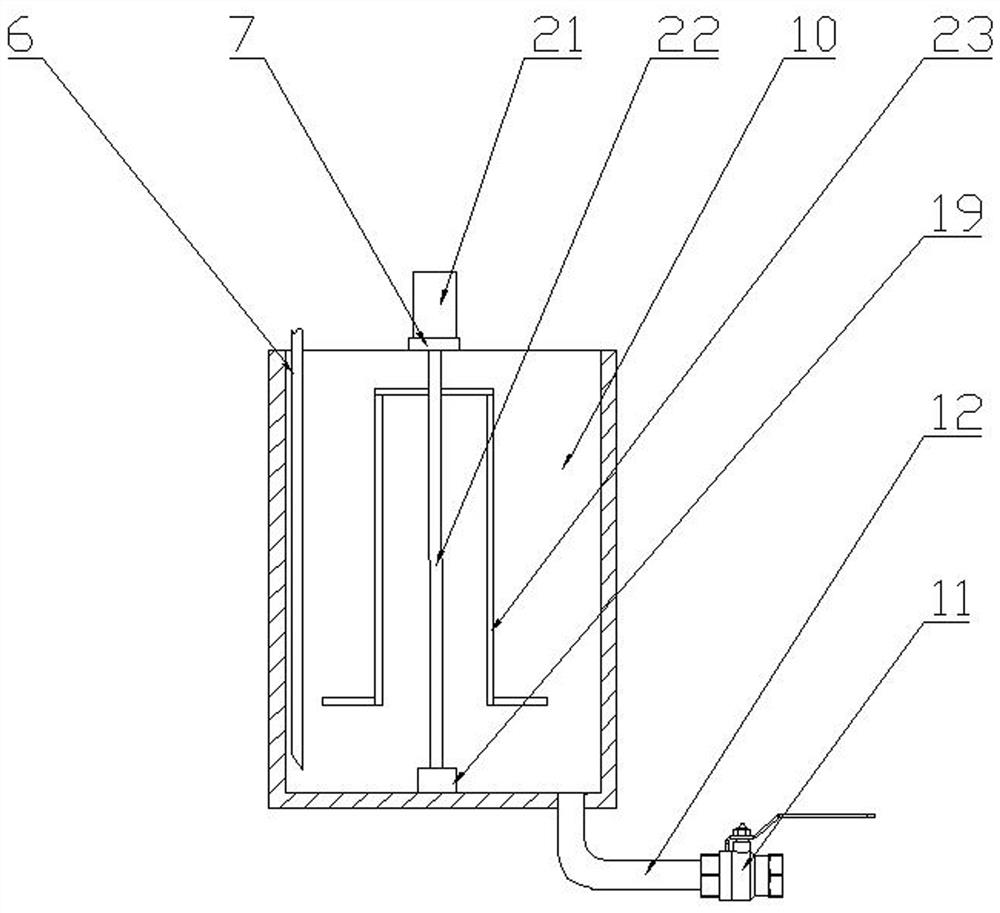

[0033] Embodiment: As shown in the figure, a preparation method of a micro-nano vat dye suspension includes the following steps:

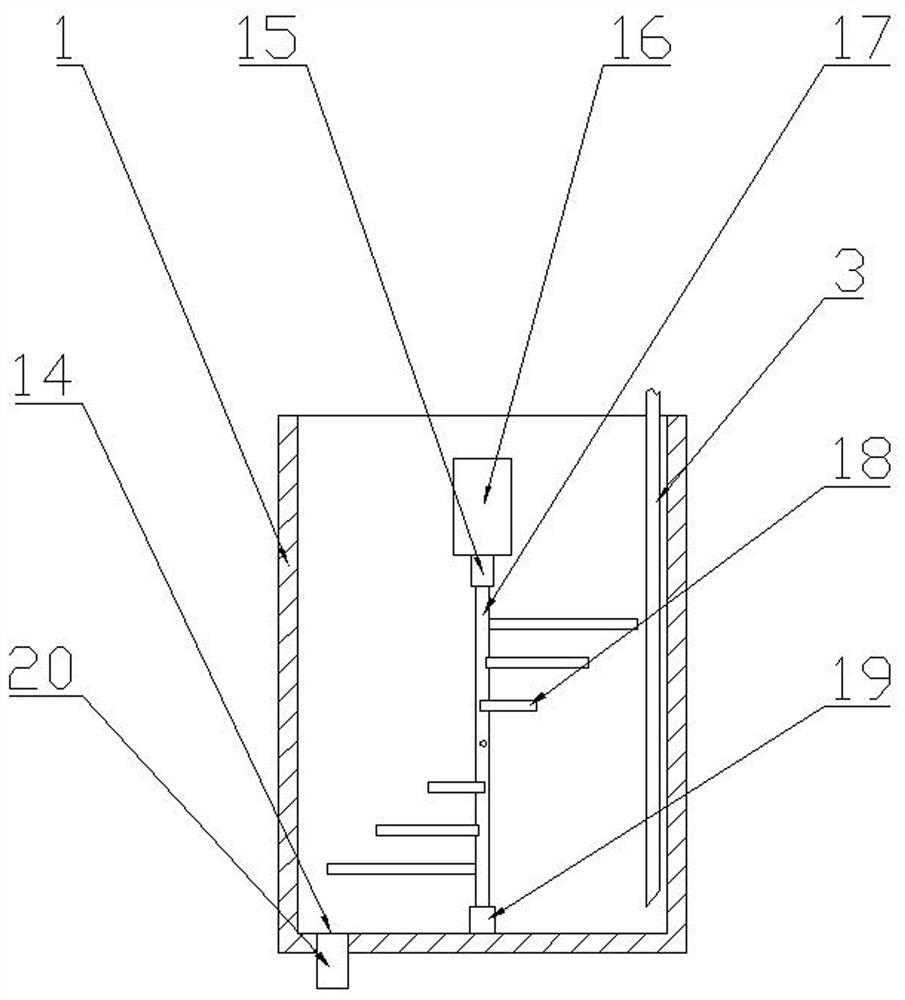

[0034] Step 1: add vat dye, caustic soda, hydrosulfite and water into chemical material tank 1 for pre-reduction process, and use stirring component 2 to reduce the vat dye to water-soluble leucochrome sodium salt. After the chemical tank 1 completes the pre-reduction process, clean water needs to be injected into the chemical tank 1 for cleaning, and the sewage is discharged through the sewage valve 20 connected to the sewage outlet 14 at the lower end of the chemical tank 1 .

[0035] The dye liquor in the chemical material tank 1 is stirred by the pre-reduction stirring rod 18 on the rotation shaft I17 driven by the pre-reduction stirring motor 16. The pre-reduction stirring rods 18 are distributed on the rotation shaft I17 in an equidistant spiral manner, and the rotation shaft I17 and the pre-reduction The reduction stirring motors 16 are conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com