River water purification treatment system and process

A technology for purification and treatment of river water, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of complex process, difficult construction, and huge system, and achieve simple and practical operation. Strong performance, solve the huge effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

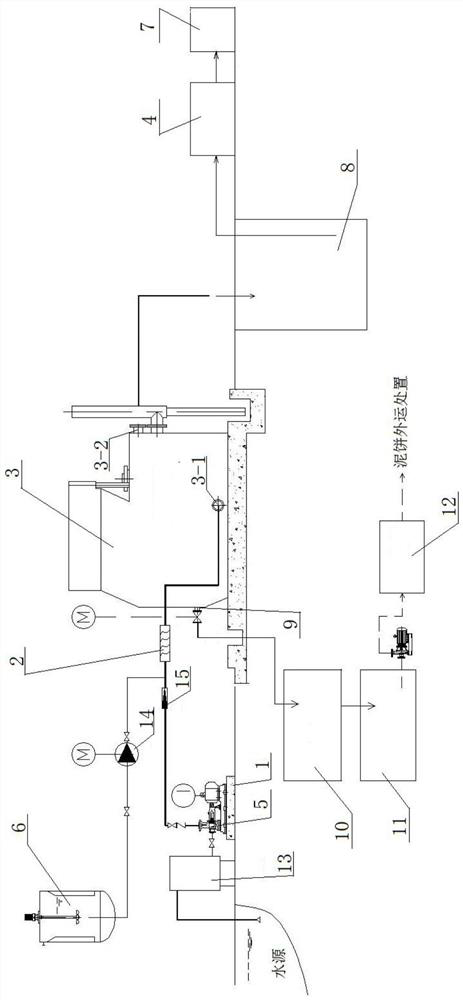

[0031] Such as figure 1 As shown, the present embodiment provides a river water purification treatment system, comprising sequentially connected water intake pumping station 1, pipeline mixer 2, FA type high-efficiency fully automatic water purifier 3 and constant pressure water supply system 4; water intake pumping station 1 is provided with The lifting pump 5 is used to lift the river water source from the river channel into the pipeline mixer 2, and a flowmeter 15 is arranged on the connecting pipeline between the lifting pump 5 and the pipeline mixer 2; the pipeline mixer 2 is connected with a dosing device 6. Introduce medicines, such as NaClO, etc. into the pipeline mixer 2 through the dosing device 6, so as to realize the disinfection and coagulation treatment of waste water, and small alum flowers are formed in the water, and the distance between the dosing device 6 and the pipeline mixer 2 A metering pump 14 is provided on the connecting pipeline to accurately control...

Embodiment 2

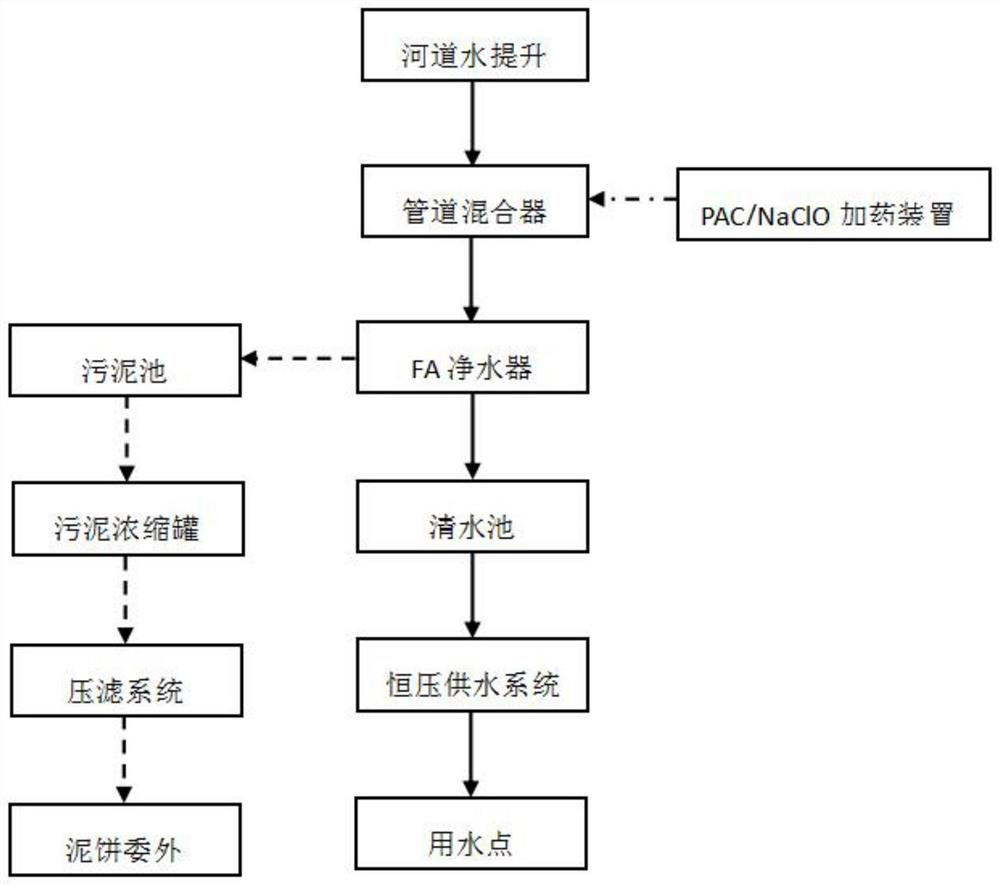

[0040] Such as figure 2 As shown, this embodiment provides a river water purification process based on the river water purification system described in Embodiment 1, which specifically includes the following steps:

[0041] Step S1: The lifting pump 5 of the water intake pump station 1 lifts the river water to the pipeline mixer 2, and adds NaClO (sodium hypochlorite) solution into the pipeline mixer 2 through the dosing device 6 to sterilize the wastewater; at the same time, through the dosing device 6 Add PAC (polyaluminum chloride) solution into the pipeline mixer 2 to carry out coagulation treatment to the wastewater, so that the suspended matter in the water body forms fine alum flowers;

[0042] Step S2: The treated river water flows into the FA type high-efficiency automatic water purifier 3 through the pipeline, and completes the flocculation, sedimentation, filtration and backwashing processes in the water purifier;

[0043] Step S3: The purified water is discharged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com