ESD full-shielding functional foil, ESD full-shielding functional foil circuit board and manufacturing methods

A fully shielded and circuit board technology, which is applied to printed circuit components, magnetic field/electric field shielding, electrical components, etc., can solve the problems of no precise positioning requirements, increased production costs, and inability to do what one wants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

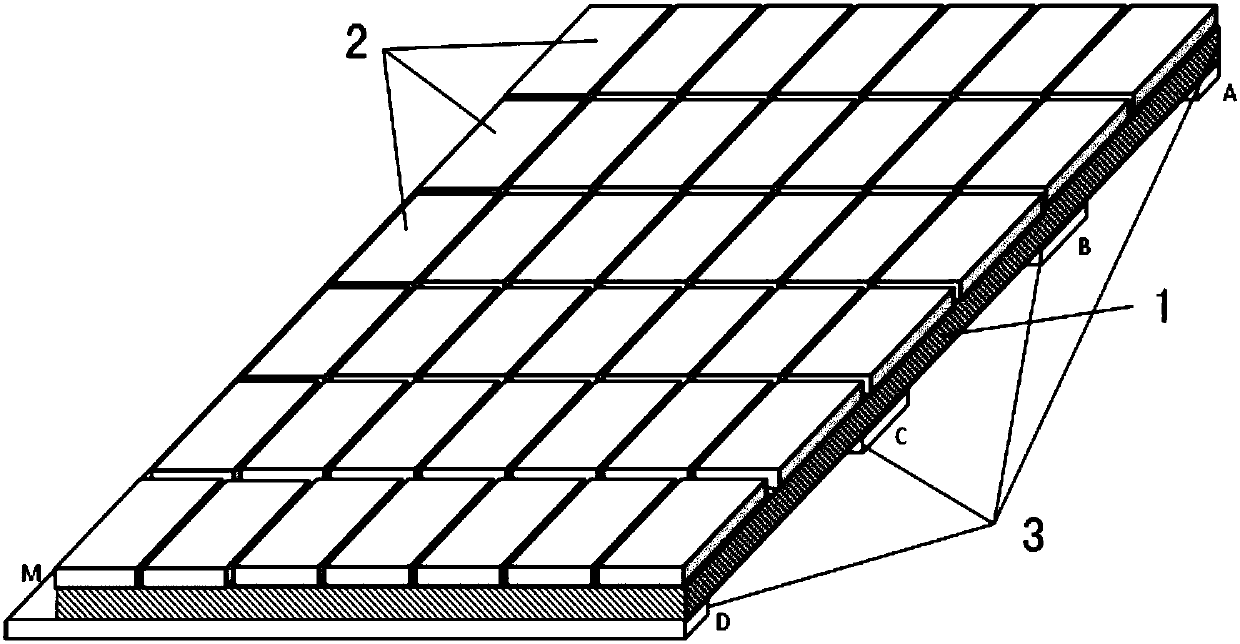

[0061] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 :

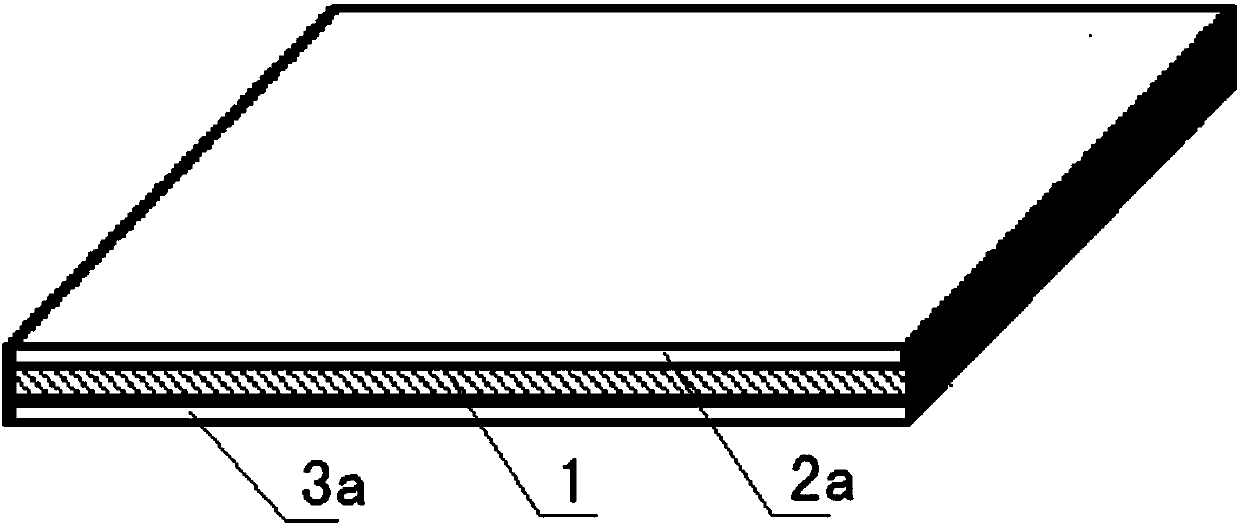

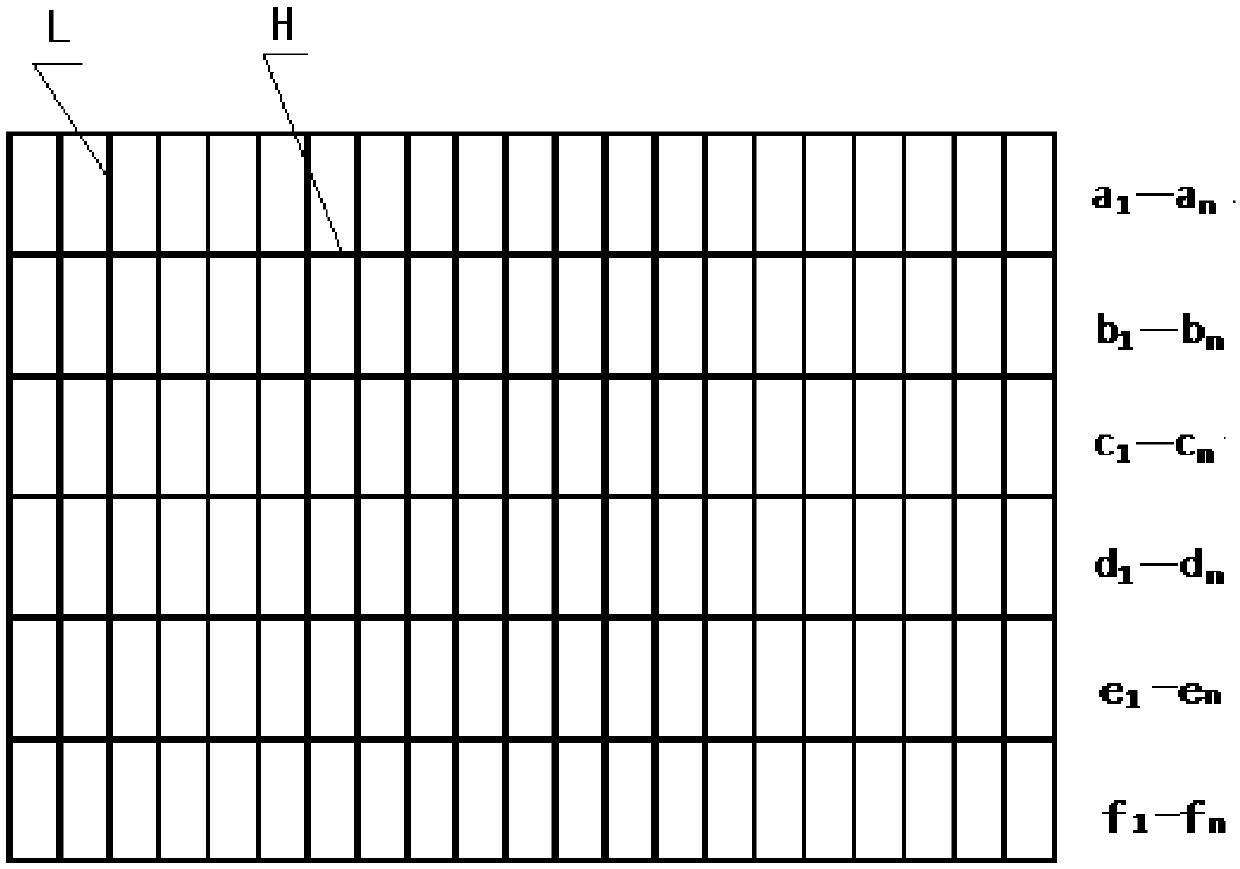

[0062]An ESD full-shielding functional foil of the present invention includes a basic functional foil, the basic functional foil has a layer of functional material layer 1 and a metal layer attached to the upper and lower surfaces of the functional material layer 1, and the upper metal layer of the functional material layer 1 is etched with multiple lines, Multiple columns of strip-shaped metal blocks form a strip-shaped metal block array. Between the rows and columns of the strip-shaped metal block array are longitudinal spacers L and horizontal spacers H. The strip-shaped metal blocks arranged at regular intervals form a strip-shaped metal block array layer 2; The lower metal layer is etched into a metal ground wire for grounding, and the metal ground wire is composed of parallel and equally spaced ground wires A, B, C, D... and M wires connecting A, B, C, D..., equally spaced The ground wires A,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com