FPC placement platform

A technology for placing platforms and platforms, applied in positioning devices, clamping, supporting and other directions, can solve problems such as difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

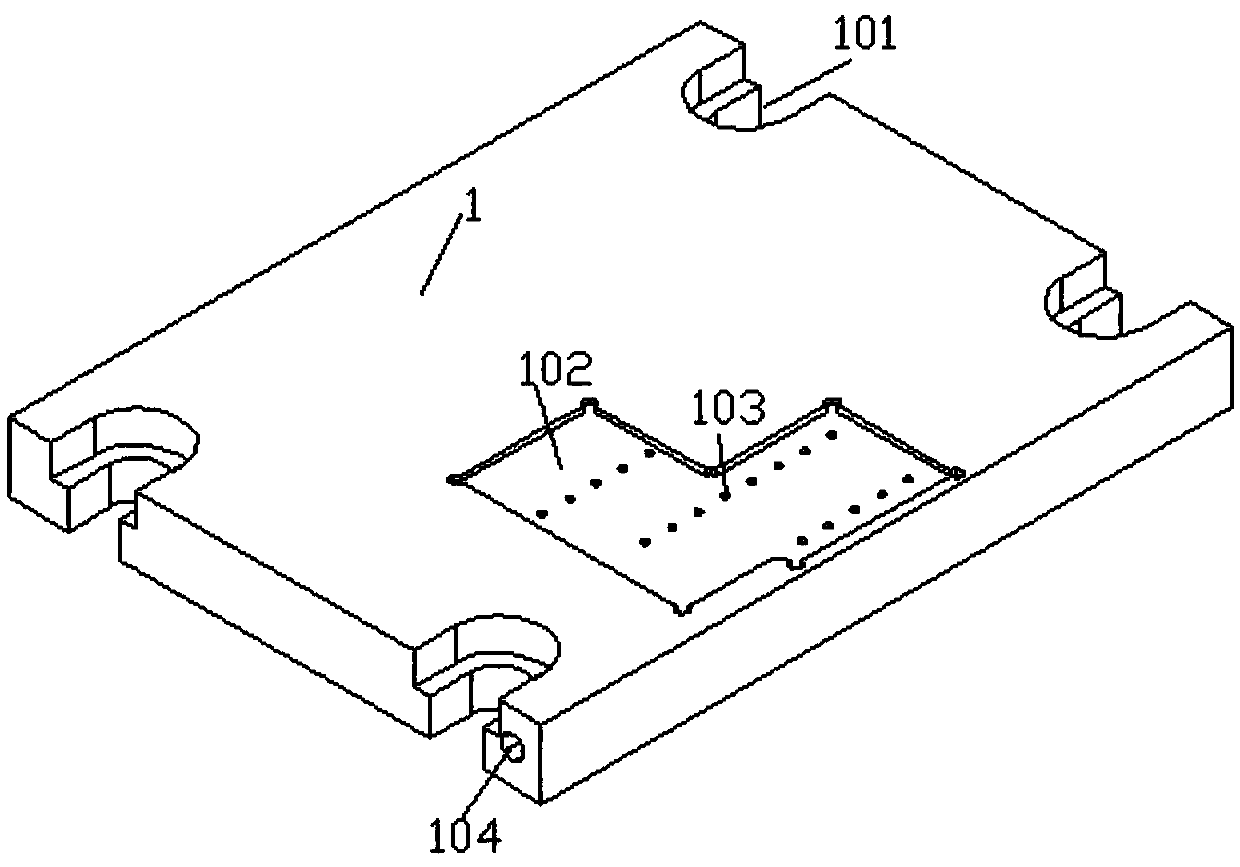

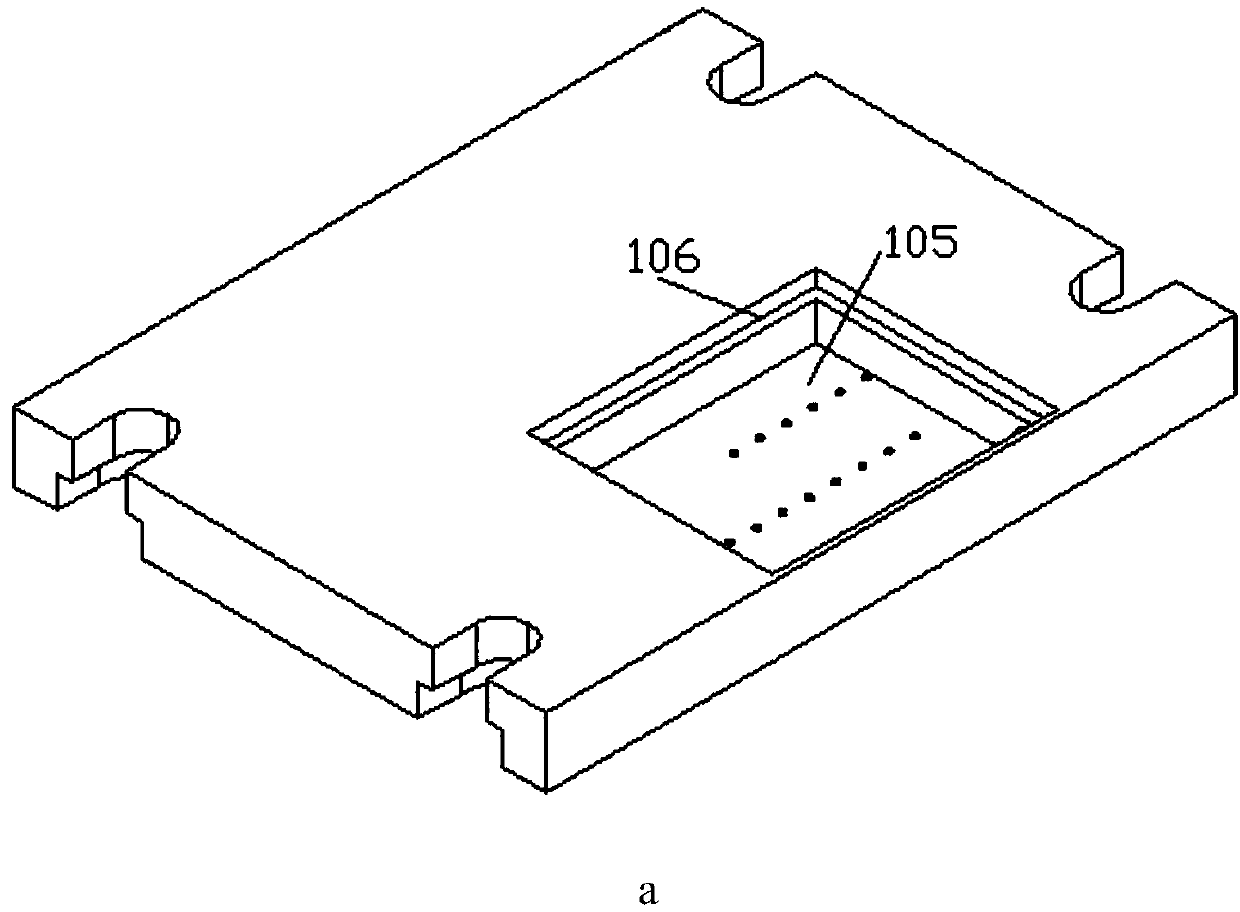

[0024] Such as Figure 1-2 As shown, what the embodiment of the present invention described is a kind of FPC placing platform, and this platform comprises:

[0025] The FPC platform main body 1 is provided with an FPC fixing slot 102 on its upper surface. The function of the FPC placement platform is mainly to play the role of FPC positioning when the FOG is pressed, and the FPC fixing slot 102 is the role of positioning the FPC. It is located on the upper surface of the FPC platform main body 1. The specific shape is Depending on the shape of the FPC in specific working conditions, the fixing effect of the FPC fixing slot 102 on the FPC can be ensured. And one FPC platform main body 1 can be provided with a plurality of FPC fixing slots 102, thereby improving work efficiency.

[0026] The vacuum groove 105 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com