Method for machining special-shaped hole air gage gauge head configuration

A technology of hole aerodynamic quantity and processing method, which is applied in the direction of measuring devices, instruments, and fluid devices, etc., can solve the problems of difficulty in processing the shape of the probe head of the aerodynamic gauge with special-shaped holes, and achieve the effect of solving the difficulty of processing and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

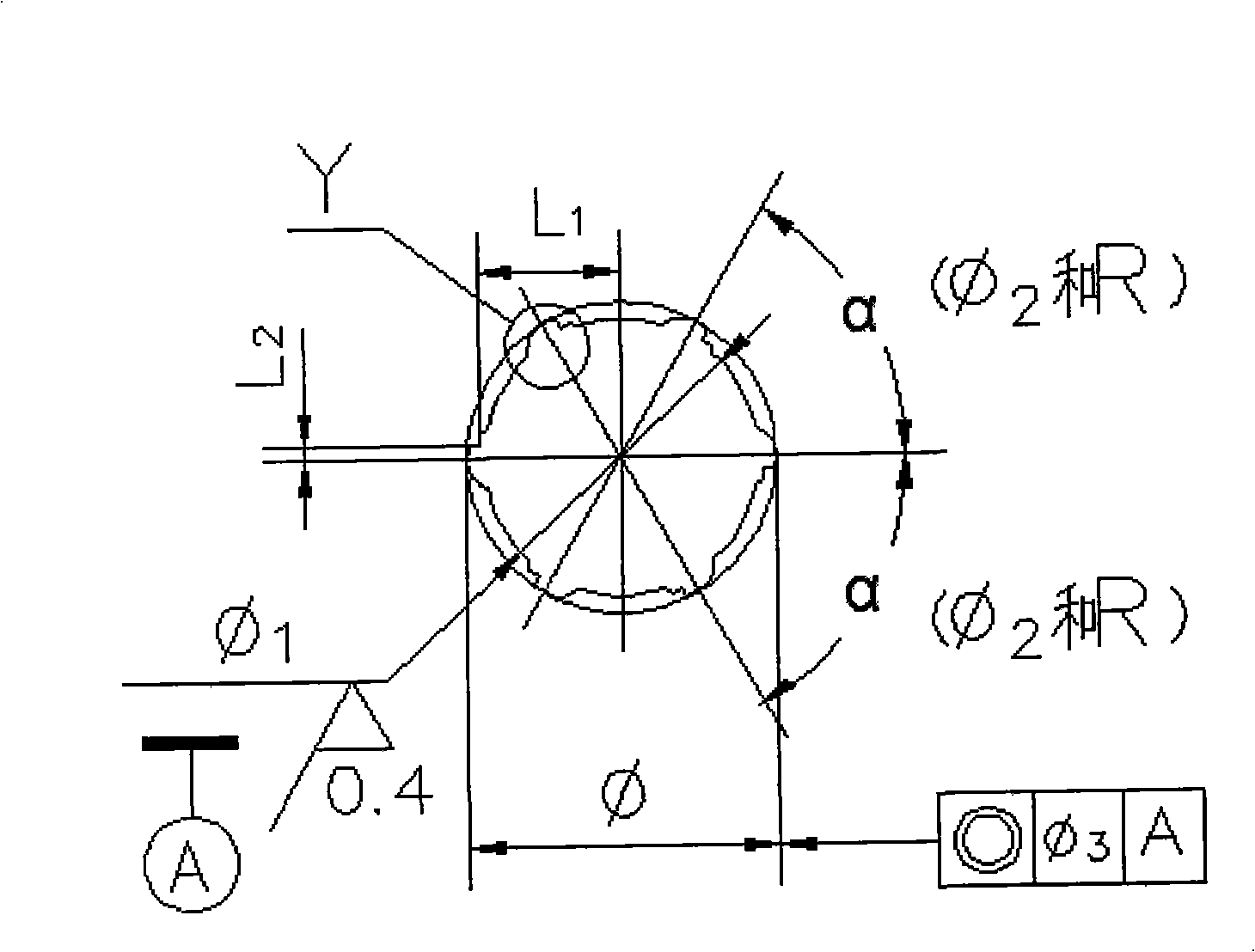

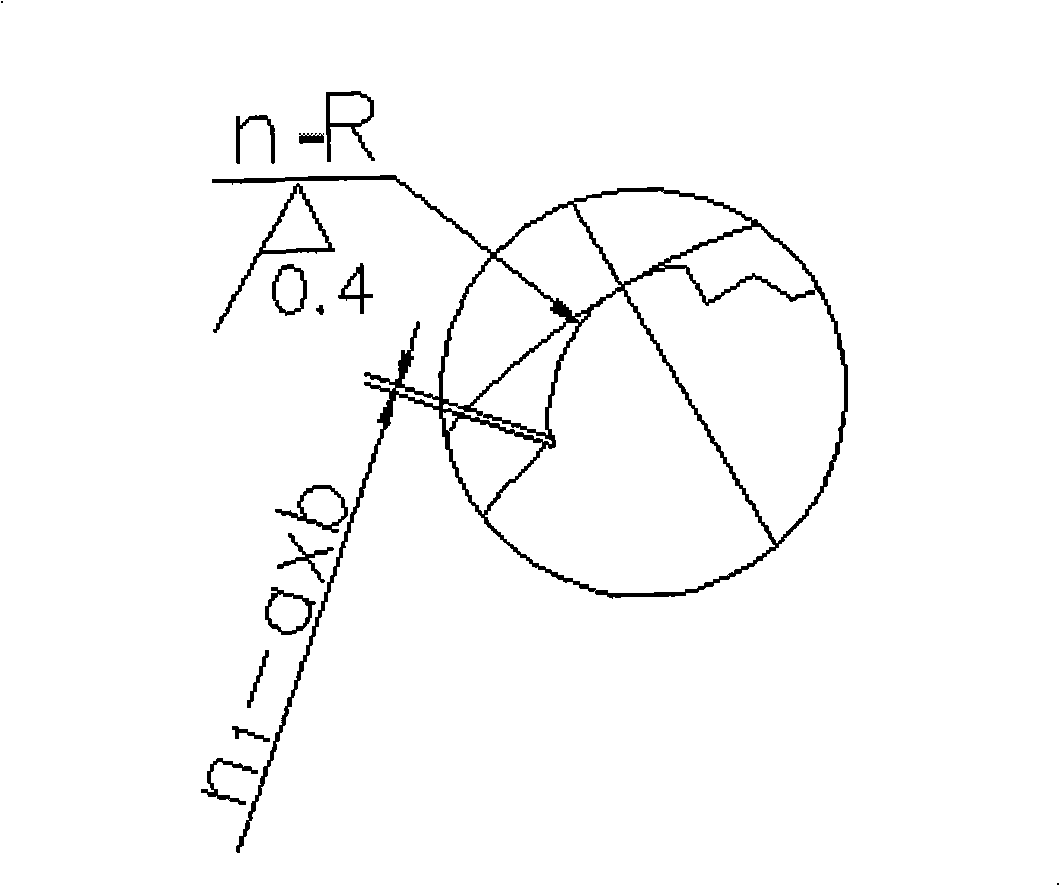

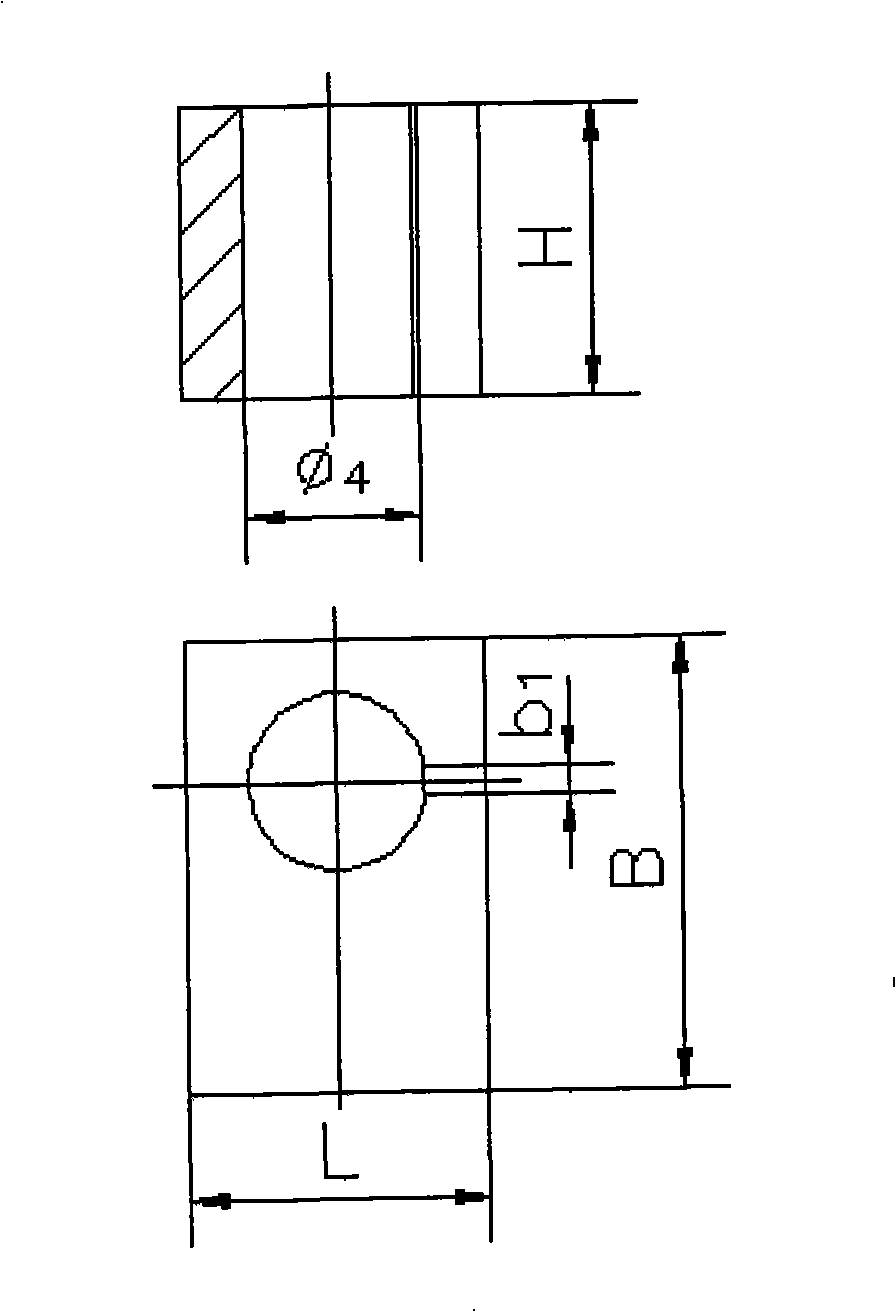

[0027] see figure 1 , figure 2 with image 3 , where, Φ-probe outer circle; Φ 1 - Probe outer circle; Φ 2 - Diameter of the air hole of the probe; Φ 3 - Outer circle Φ Outer circle Φ 1 Coaxiality; R-arc; α-each arc segment and air outlet Φ 2 position in the circumferential direction; L 1 - Dimensions of the exhaust groove on the arc segment; L 2 -The size of the exhaust groove on the arc segment; Y-local enlargement on the probe; n-R-there are n arcs on the probe; n 1 -a×b- arc and outer circle Φ 1 L-fixture length; B-fixture width; H-fixture height; Φ 4 - the diameter of the inner hole of the fixture; b 1 - Locating slot width.

[0028] The processing method of the special-shaped hole pneumatic gauge head is:

[0029] 1. Cutting material: GCr15 is used as the material.

[0030] 2. Car length: 0.50mm grinding allowance is left for the length of the measuring head.

[0031] 3. Turning outer circle: the diameter is processed according to the size of (Φ+5).

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com