Sliding-vane type pneumatic motor as well as air compressor and internal combustion engine derived from same

An air motor and sliding vane technology, which is applied to internal combustion piston engines, rotary piston engines, rotary piston/oscillating piston pump components, etc., can solve the problems of small crescent air chamber, difficult processing, and large friction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

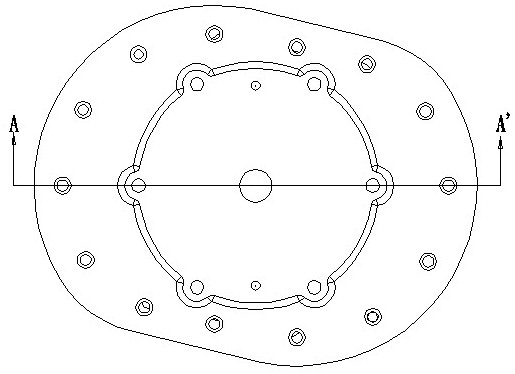

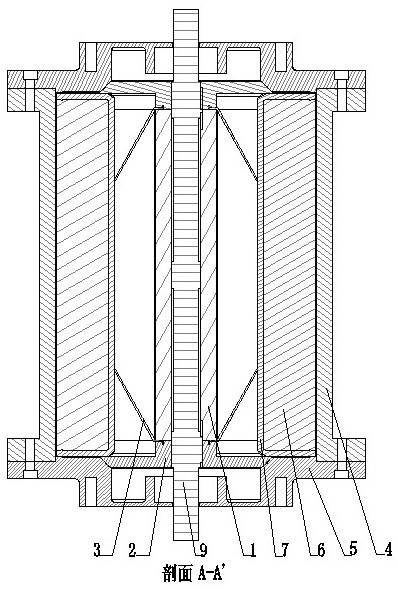

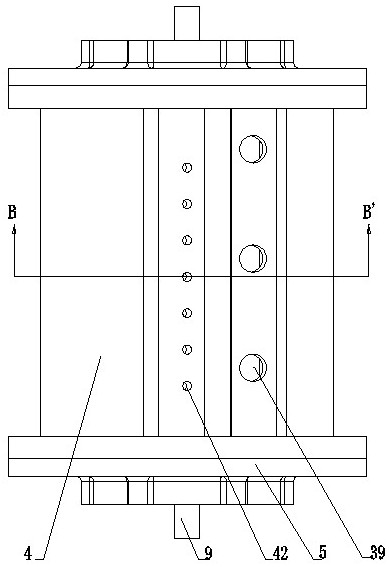

[0069] 1 All components that make up the sliding vane engine are cast, wire cut and machined. The spring leaf (3) is installed in the spring leaf groove (20) of the rotor end cover (2), the rotor end cover (2) is sealed at both ends of the rotor (1), and the slide air-tight strip (7) is sleeved on the slide The lower part and both sides of the sheet (6) form a slide group (71), and the slide group (71) is installed in the slide slot (75), and the above parts are assembled together to form a rotor group (76); the rotor group (76 ) into the cavity of the stator (4), and the stator end caps (5) are sealed at both ends of the stator (4), forming a sliding vane air motor.

[0070] 2. The rotor group (76) of the sliding vane air motor (77) rotates in reverse to form a sliding vane air compressor (78).

[0071] 3. The central axis of the sliding vane air motor (77) is connected together with the central axis of the sliding vane gas compressor (78), and the pressure combustion superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com