Ultrasonic welding machine for connecting pieces

A technology of ultrasonic welding and connecting pieces, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., and can solve the problems of low welding processing efficiency of connecting pieces and tabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] In the process of battery product processing, it is necessary to clamp the connecting piece on the tab and complete the welding. The connecting piece is made of two pieces of laminated objects, and it must be separated before welding before it can be clamped on the tab. In terms of processing, due to the difficulty of processing and the low efficiency of traditional processing, it is urgent to improve; in order to solve the above technical problems, this embodiment provides the following technical solutions:

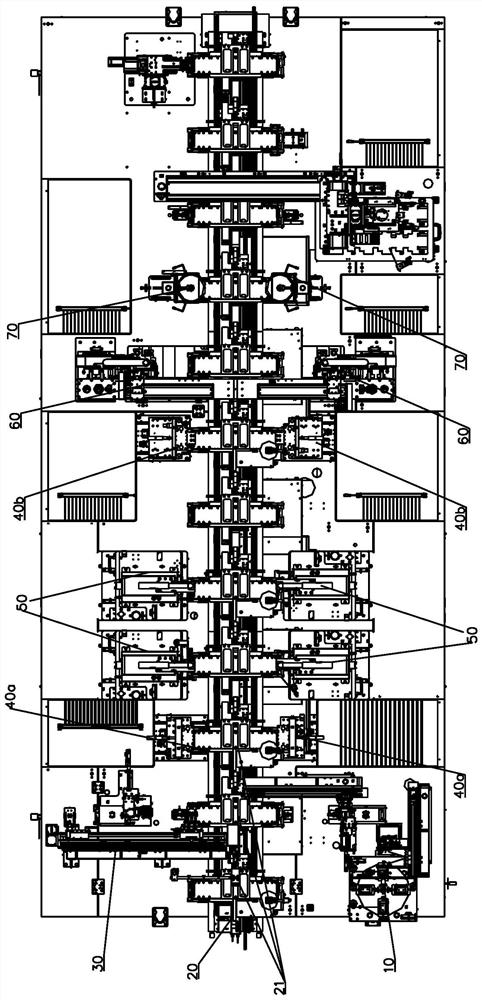

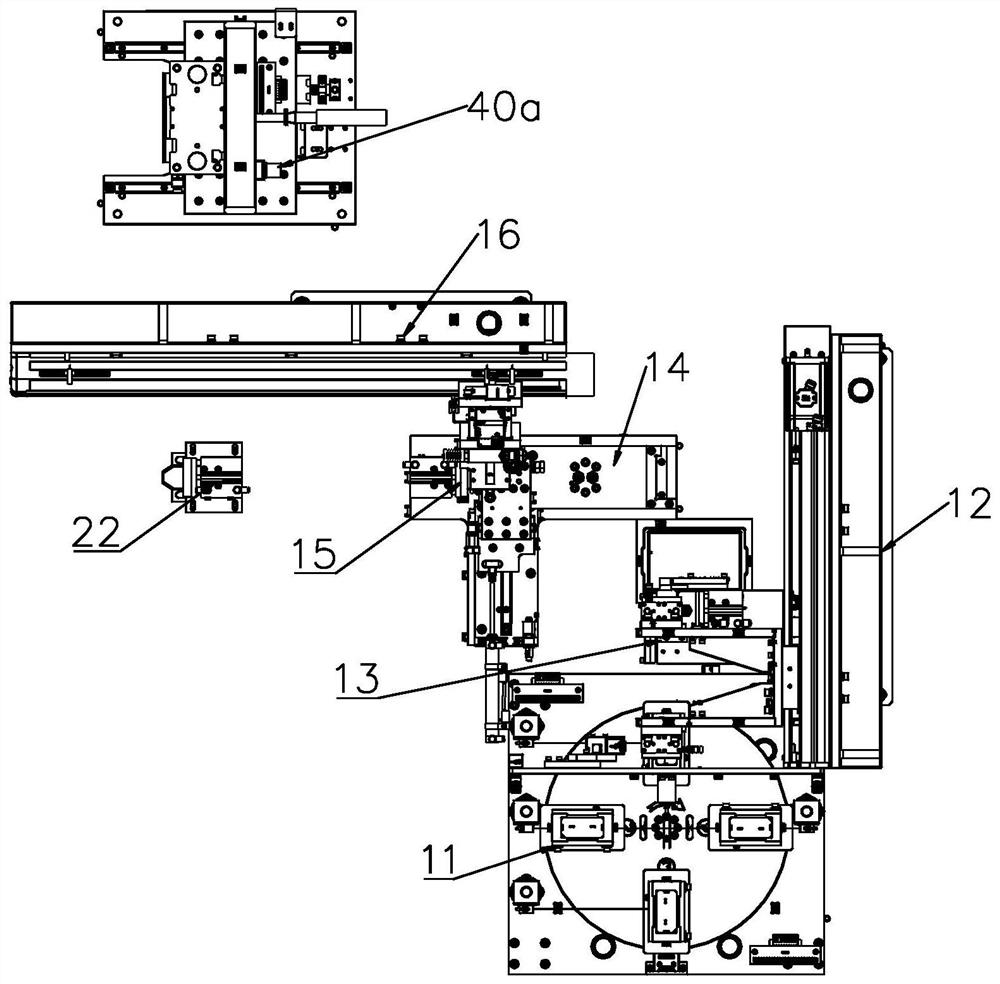

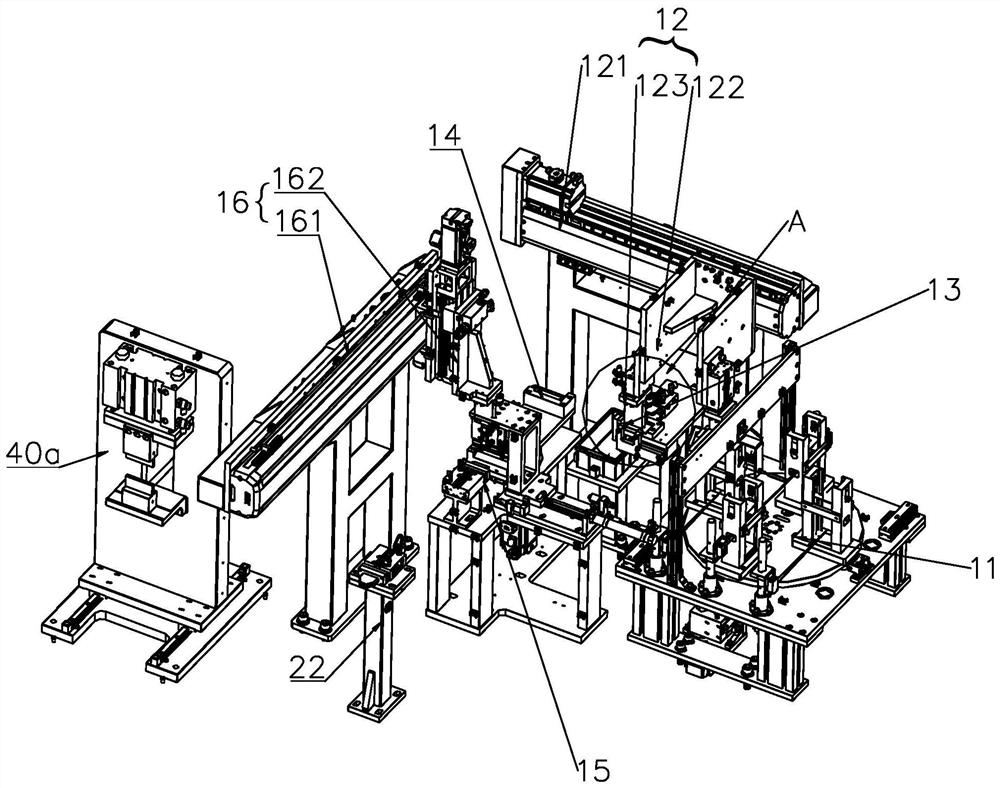

[0064] Specifically, see Figure 1-15 , this embodiment provides an ultrasonic welding machine for connecting pieces, which is used for welding connecting pieces and tabs. on both sides of the ear, and fix it by welding;

[0065] Specifically, the ultrasonic welding machine includes a jig reflow device 20 arranged along the product processing path for carrying the product; wherein, the product of this embodiment is described using a battery as an example, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com