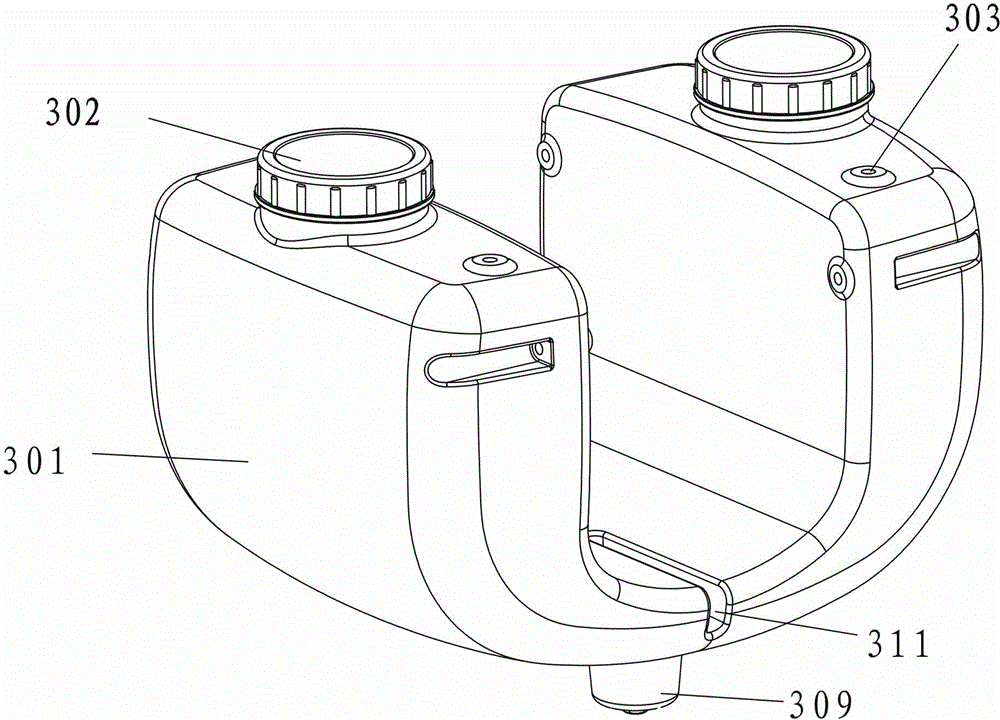

Patents

Literature

2935results about How to "Not easy to shake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

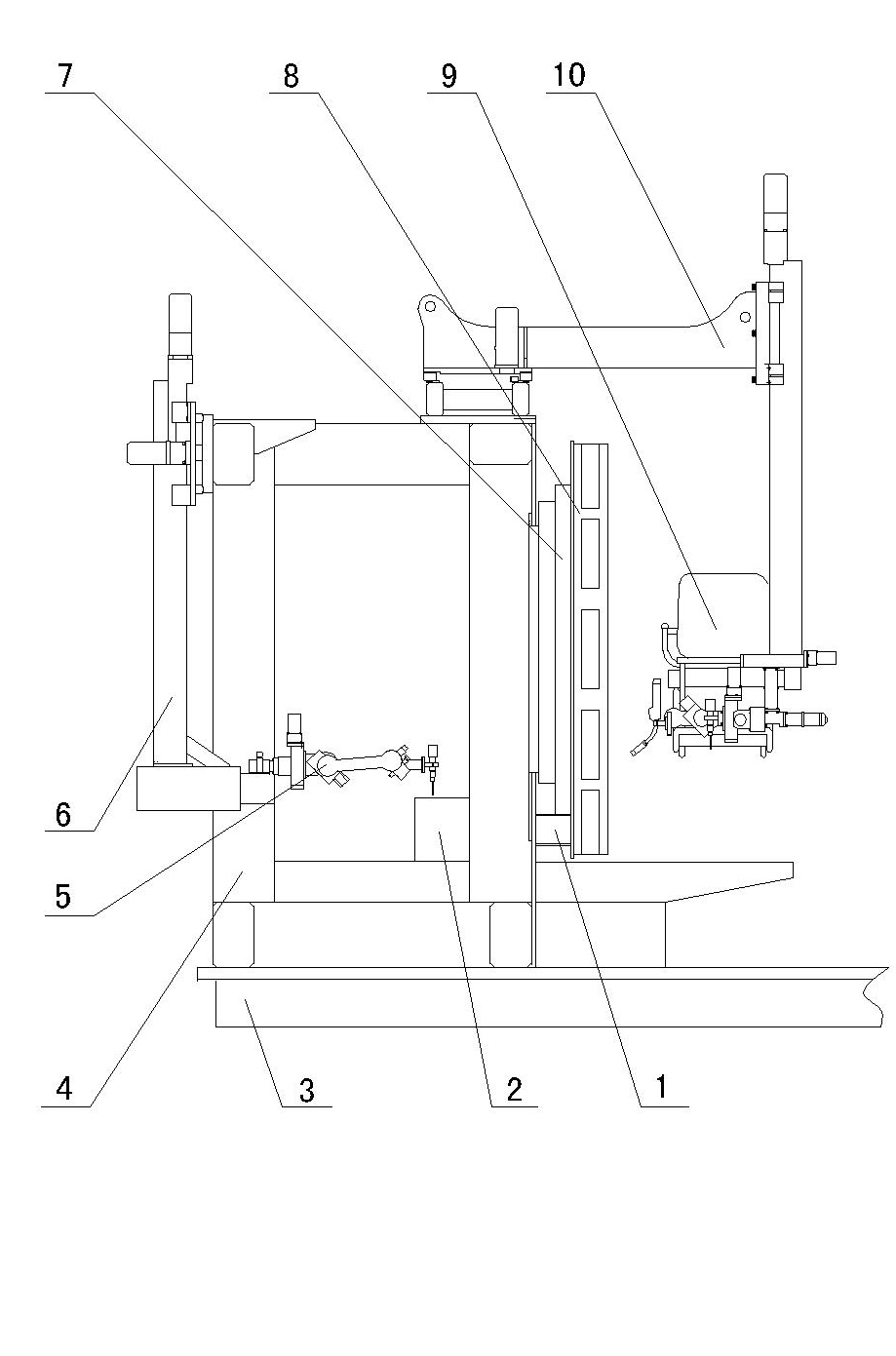

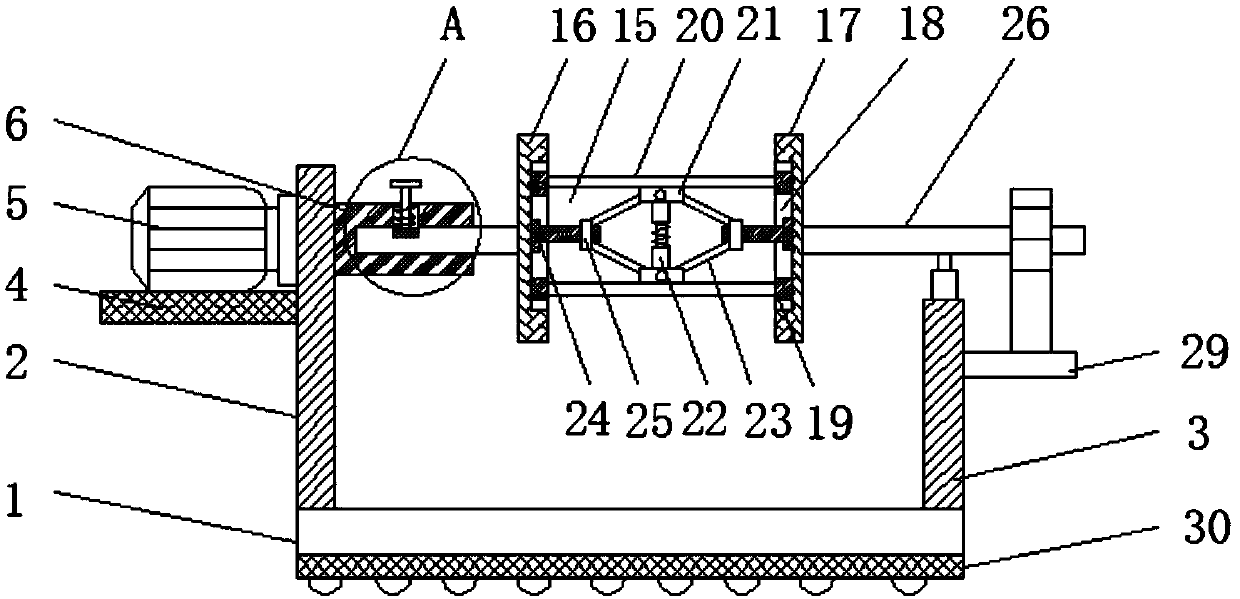

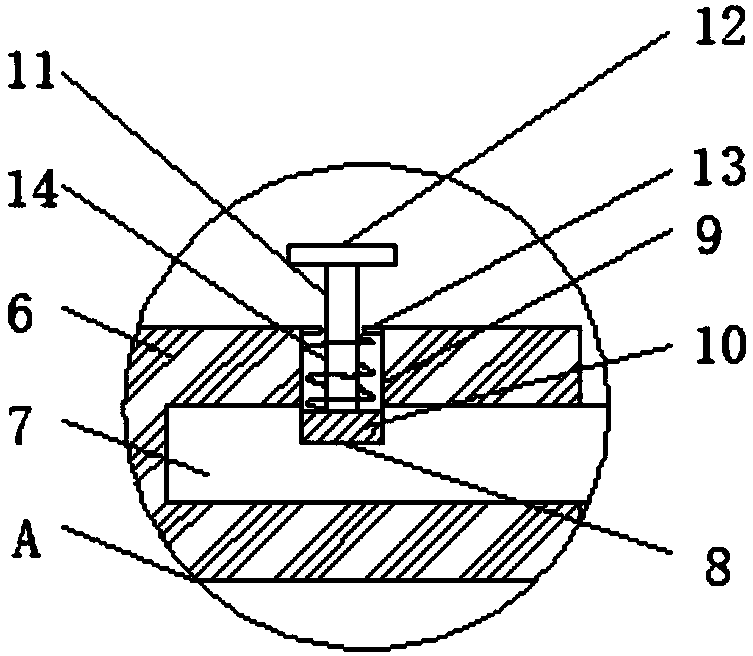

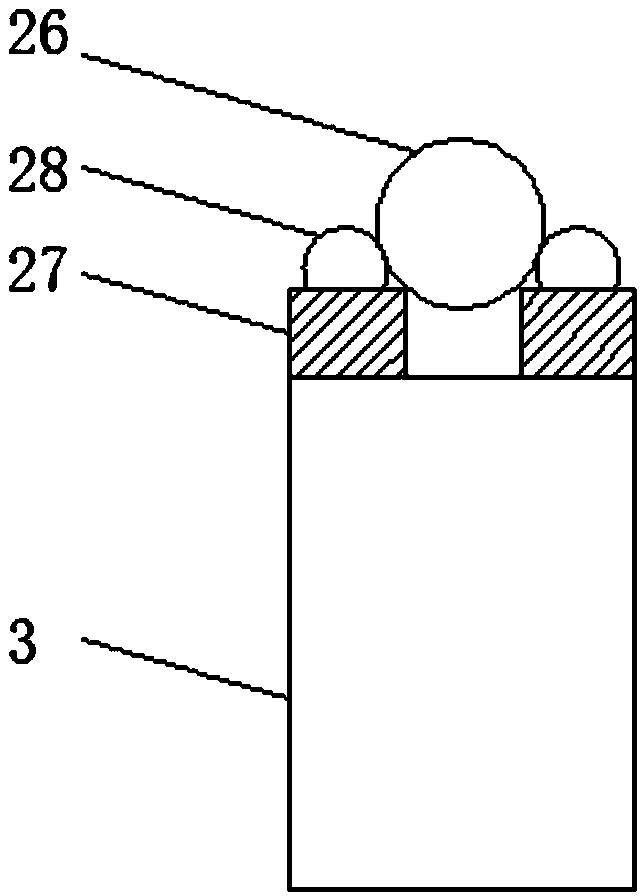

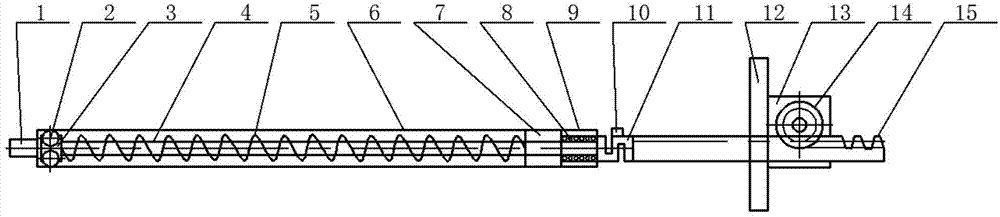

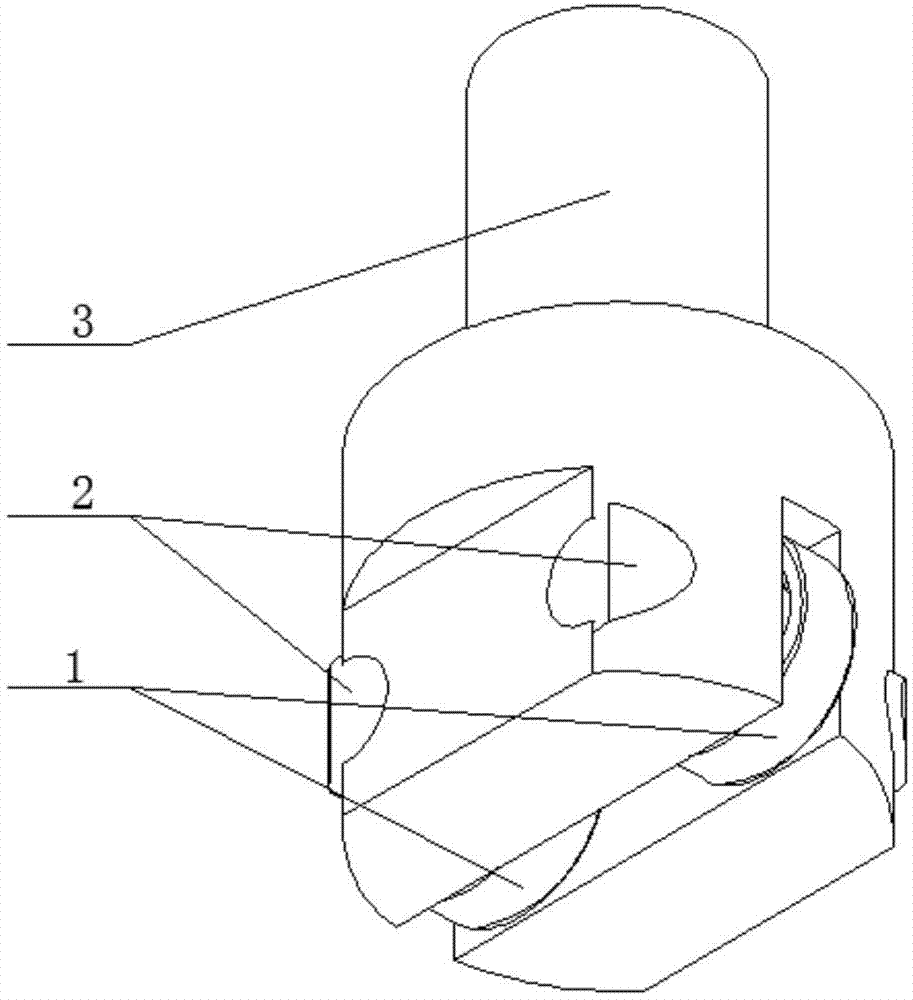

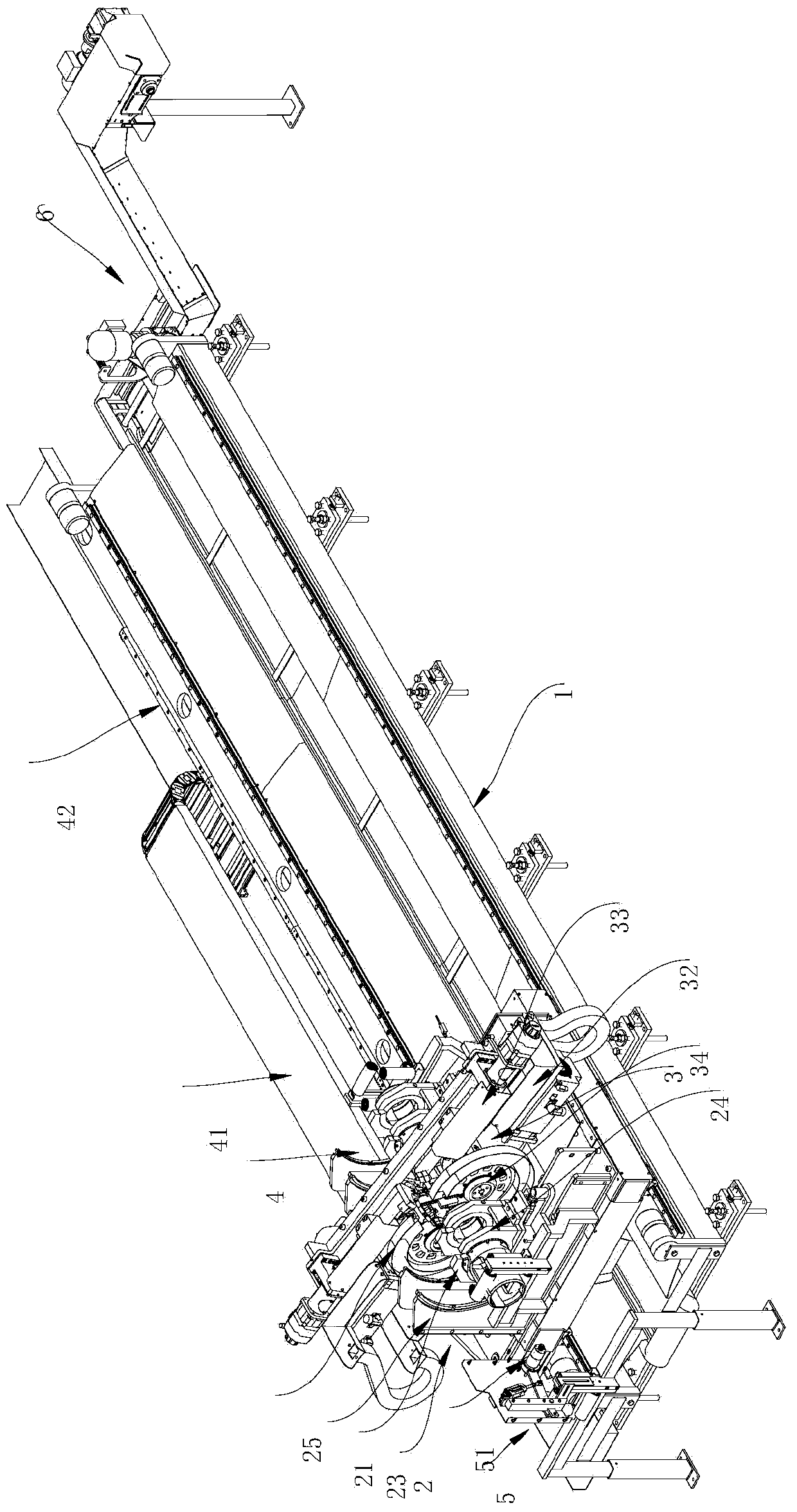

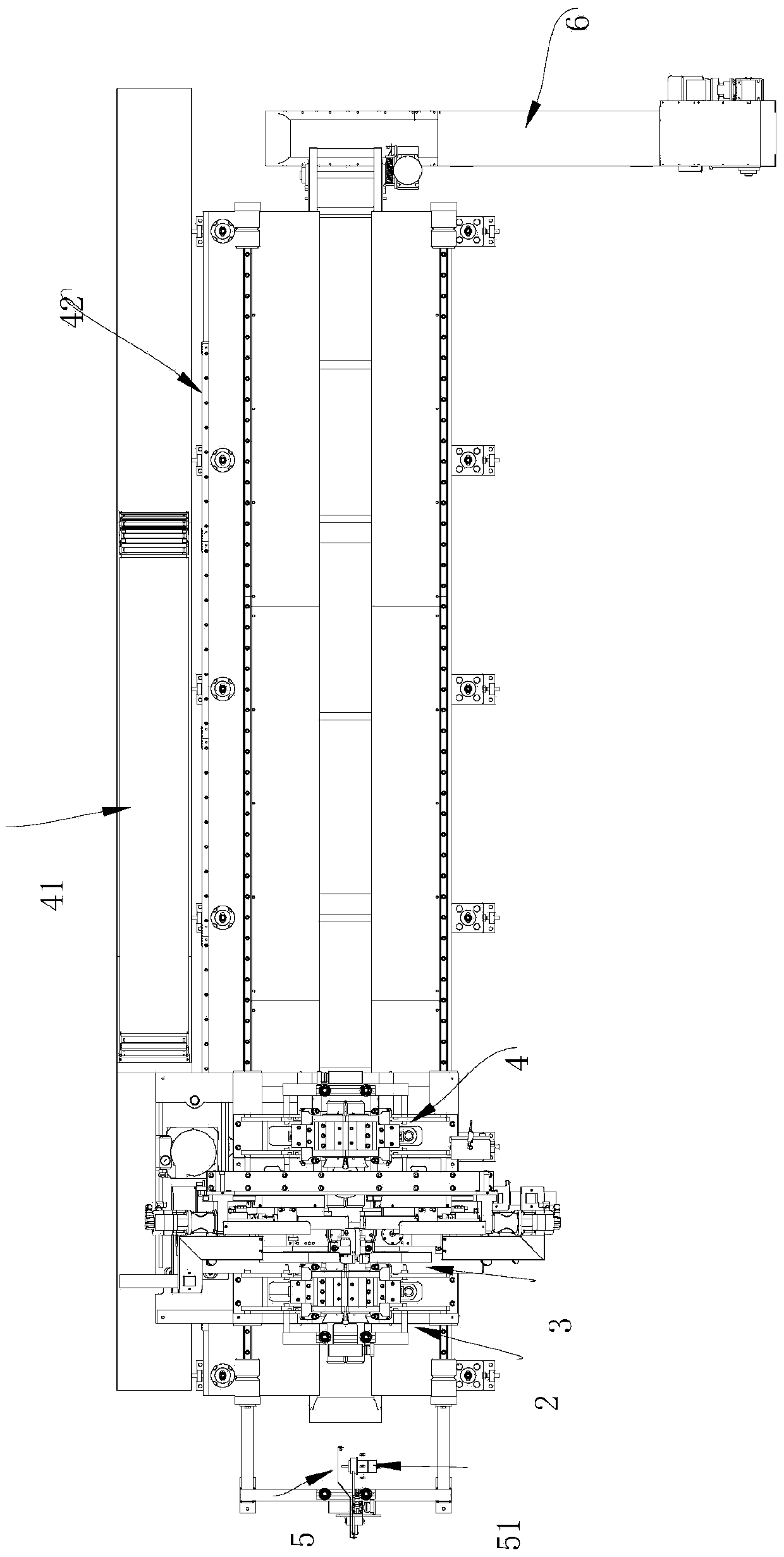

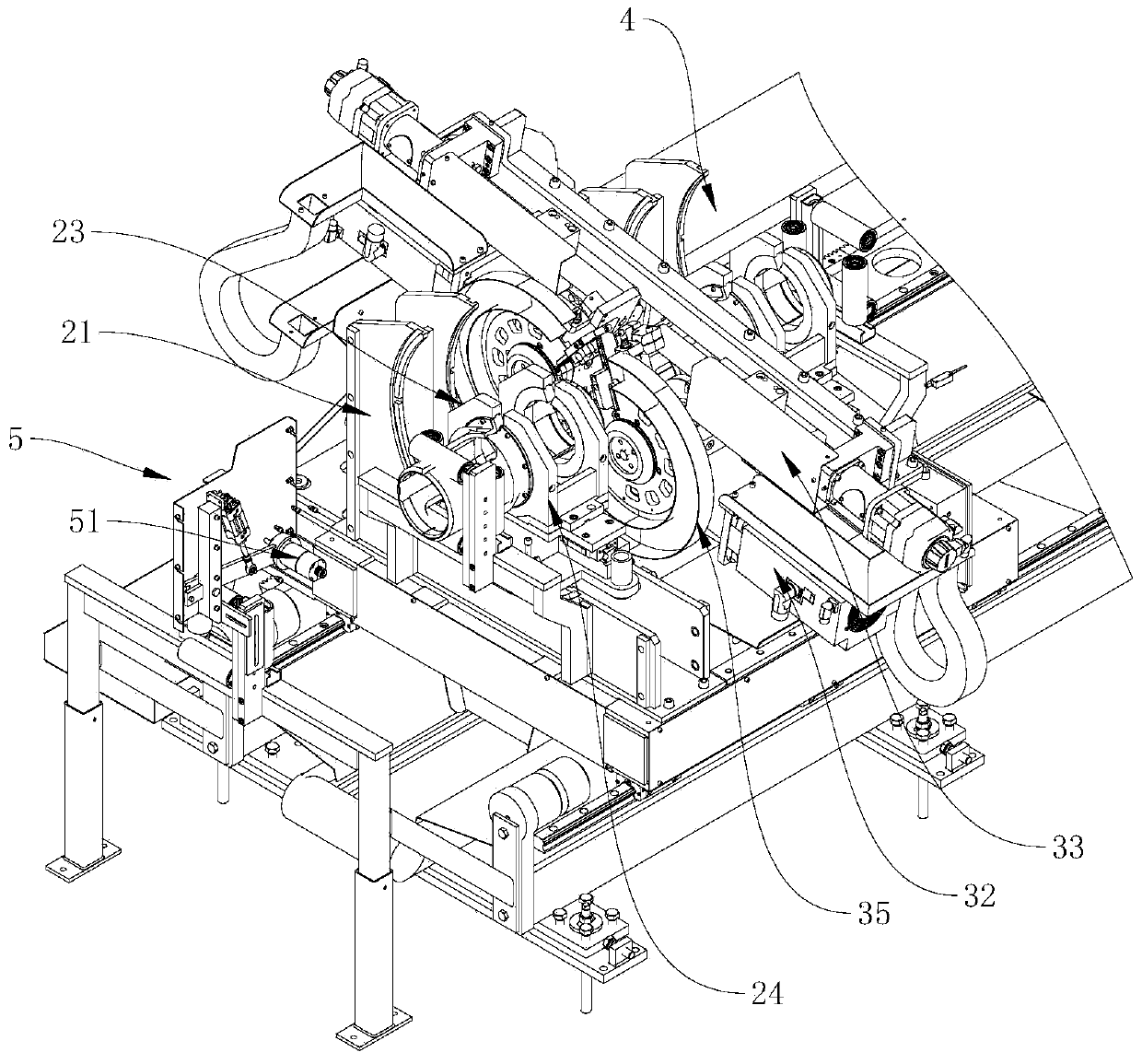

Flange welding method and welding device

ActiveCN102000921AAvoid deformationNot easy to shakeWelding/cutting auxillary devicesAuxillary welding devicesConical tubeEngineering

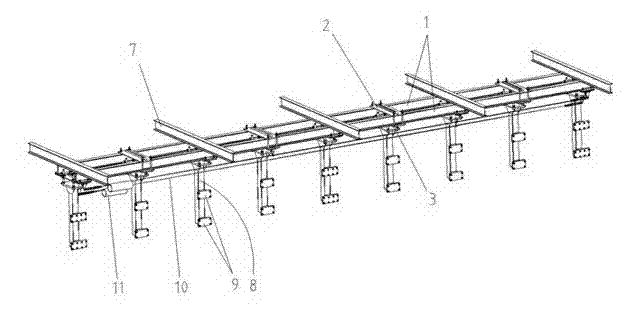

The invention discloses a flange welding method. The method comprises the following steps of: arranging chunk seats at the two ends of rails; arranging flanges on the chunk seats; placing steel tubes on automatic adjusting brackets; adjusting the positions of the steel tubes so as to butt the steel tubes with the flanges; after finishing butting, performing spot-welding on the flanges; removing the automatic adjusting brackets; driving the chunk seats to rotate by using driving devices; and simultaneously driving the flanges to rotate and welding by using welding equipment. A flange welding device comprises two rails; automatic adjusting brackets are arranged on the rails; a fixed chunk seat and a moveable chunk seat are respectively arranged at the two ends of the rails; and rotary supports, the driving devices and flexible welding equipment are arranged on the two chunk seats. The method and the device have the advantages that: the flanges can be prevented from being deforming when welding so as to ensure welding quality; and the steel tubes cannot jitter when welding seam circular tubes, polygonal tubes and conical tubes with the flanges. The horizontal movement of the steel tubes can be realized by using the automatic adjusting brackets so as to realize the accurate butt of the steel tubes and the flanges.

Owner:辽宁锦兴电力金具科技股份有限公司

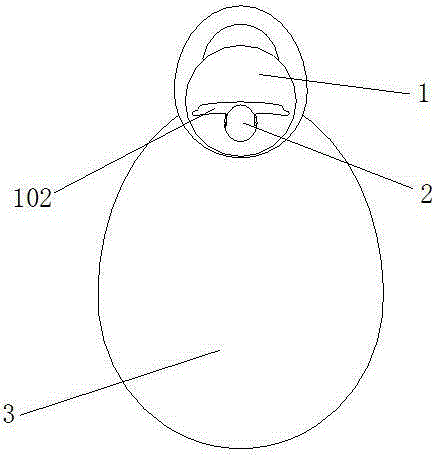

Educational toy suite

InactiveCN105194884AEasy to installEasy to disassembleDollsElectrical appliancesTablet computerEngineering

The invention relates to the technical field of computer vision recognition processing and provides an educational toy suite. The educational toy suite comprises a support, a helmet detector and a base plate, the support is installed on the base plate, and the helmet detector is installed on the support; a first groove is formed in the upper portion of the base plate; the bottom of the support is provided with a protrusion, the protrusion is installed in the first groove, a second groove and a third groove are formed in the top of the support, and the second groove is used for storing a tablet computer; the helmet detector is installed in the third groove. By means of the educational toy suite, the image acquisition scope of a camera of the tablet computer is expanded, the visual angle is enlarged, great interactivity is achieved, game experience is more vivid, the educational toy suite is helpful for alleviating asthenopia, harm to eyes is lowered, operational ability of children is improved, the children are promoted to make progress continuously, intelligence is developed, enjoyment is improved, the educational toy suite is more convenient to carry, move, install and detach, the cost is saved, and maintenance is facilitated.

Owner:SHANGHAI PUTAO TECH CO LTD

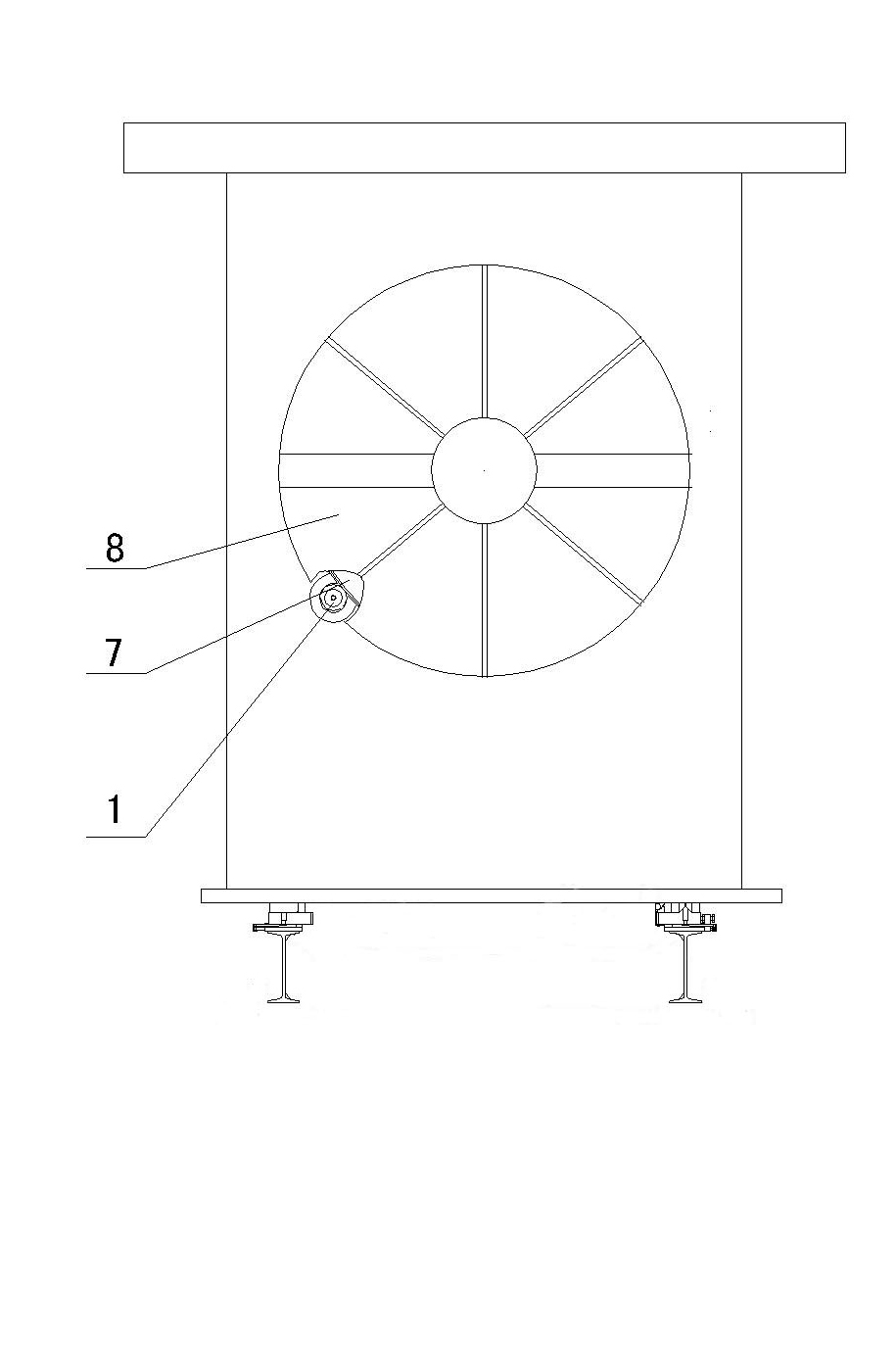

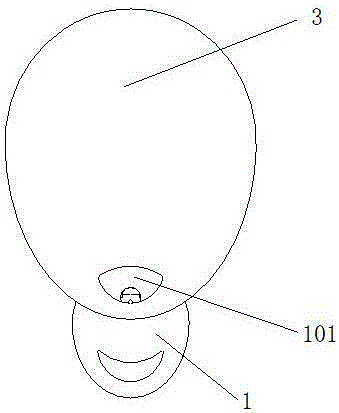

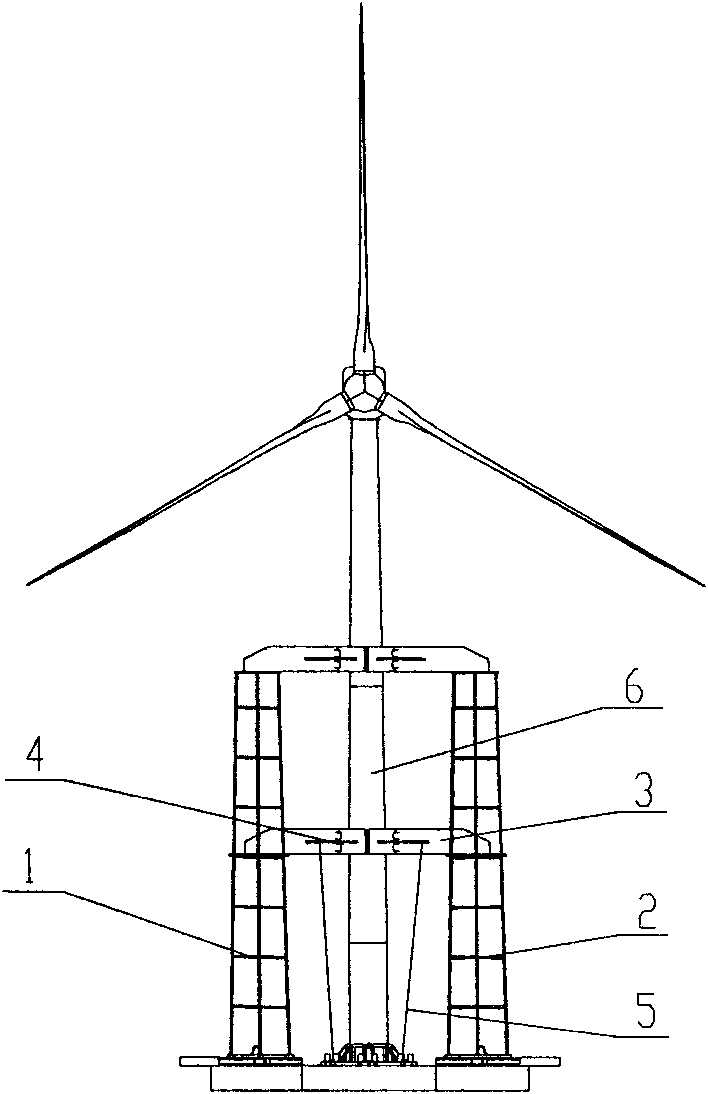

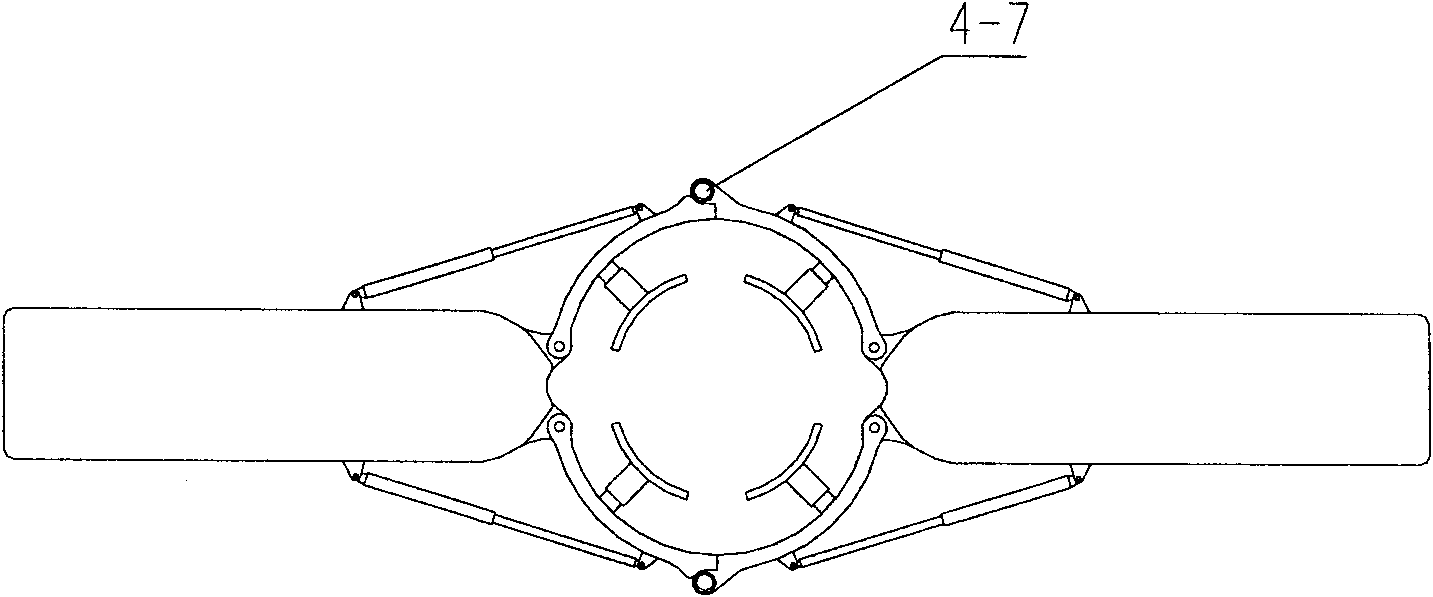

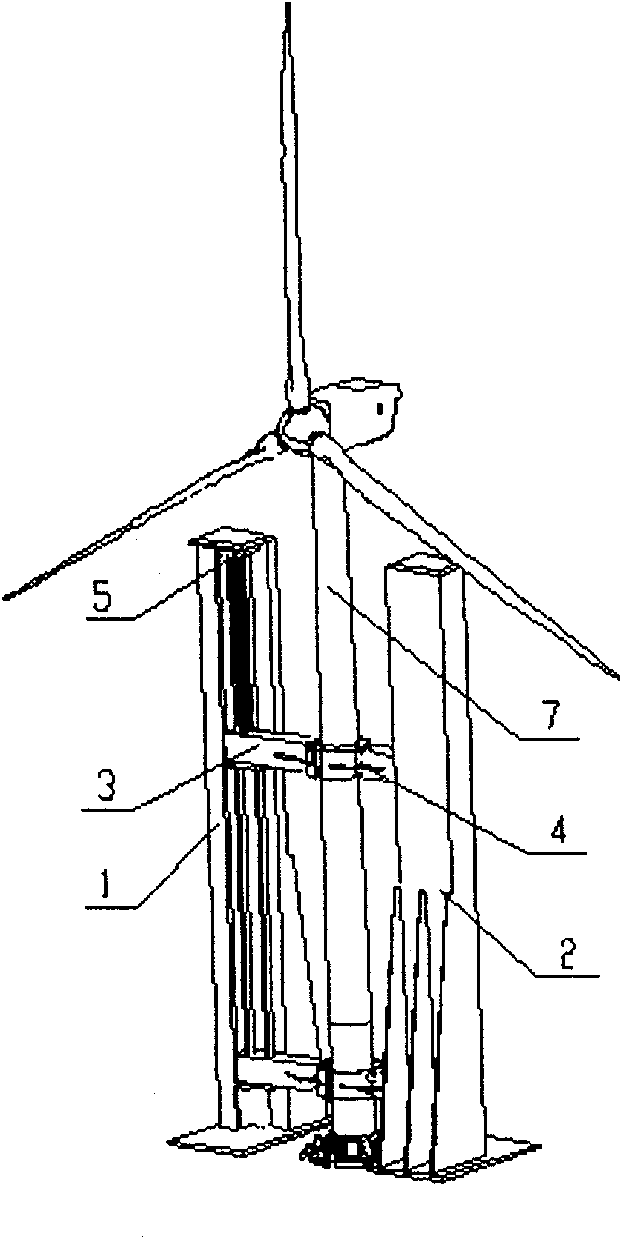

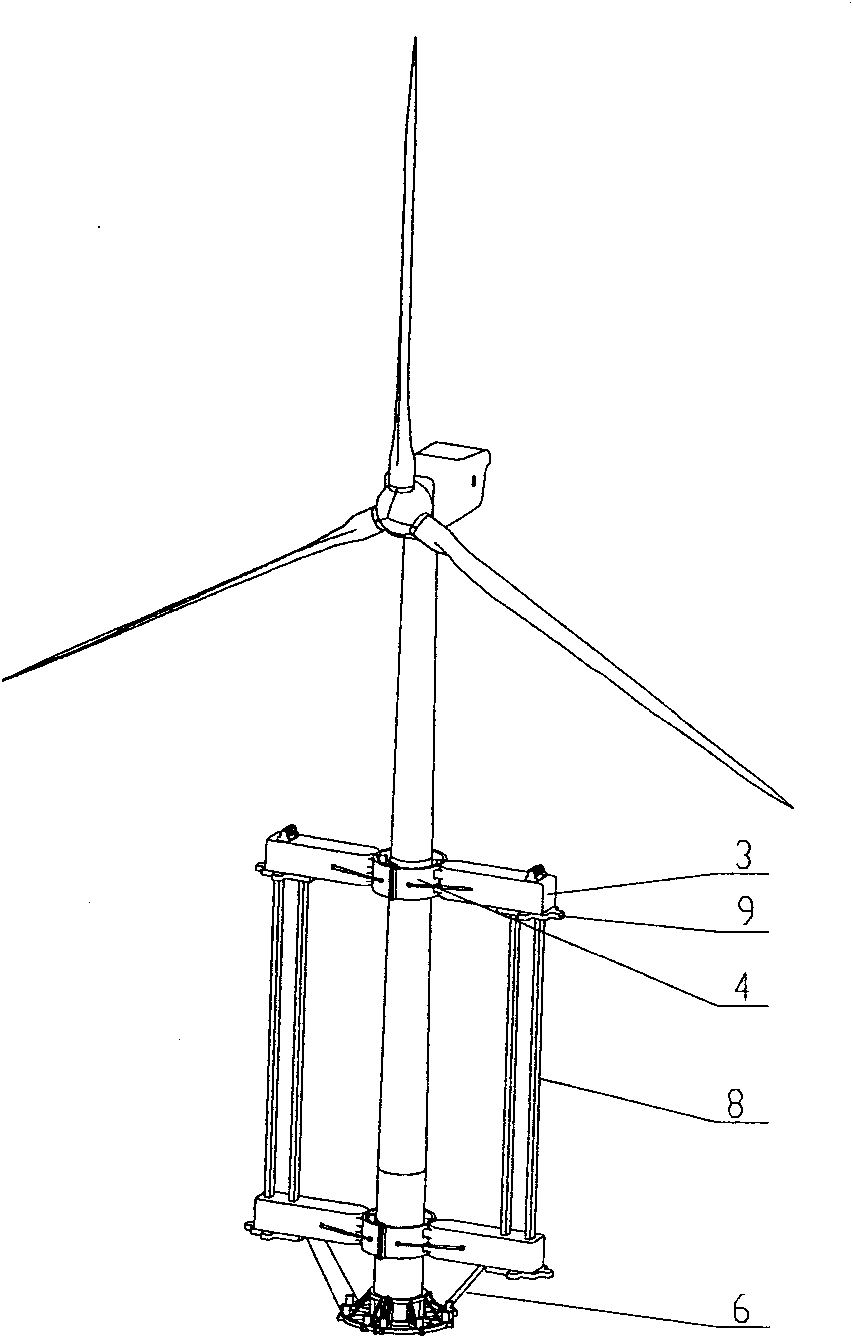

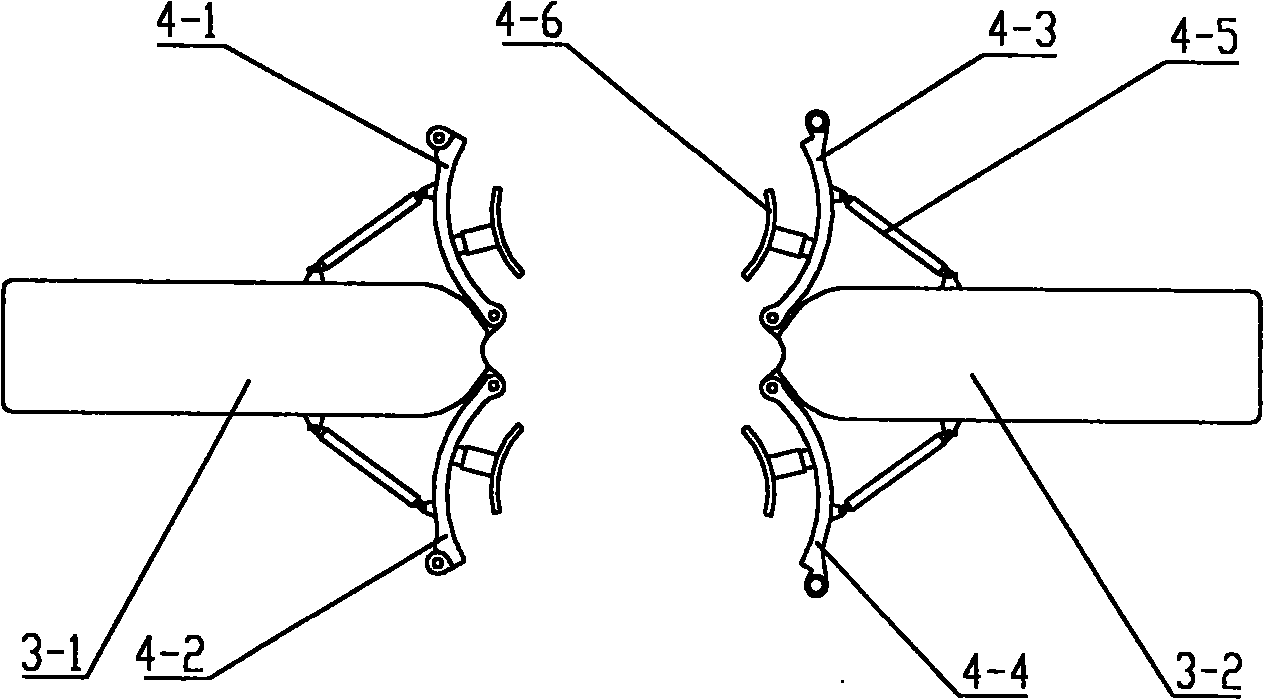

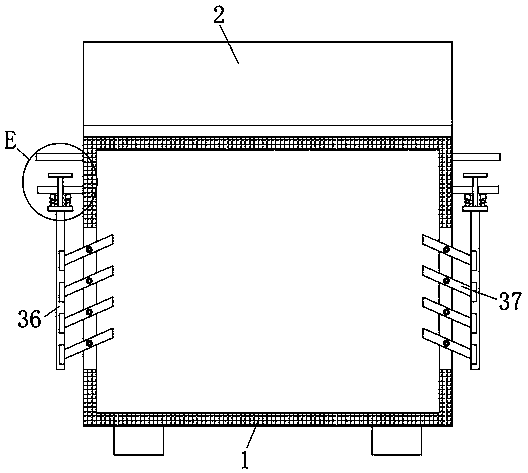

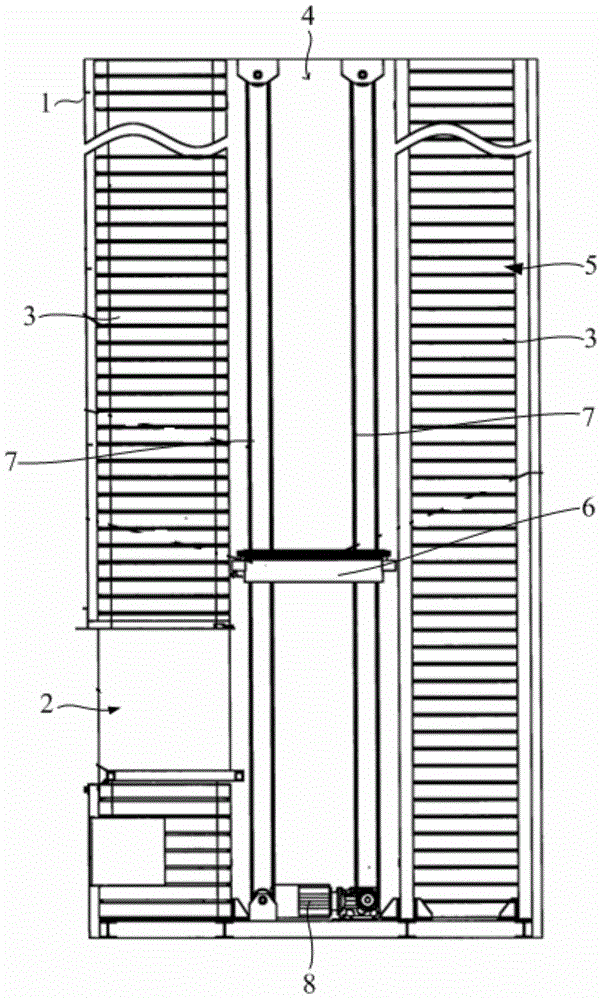

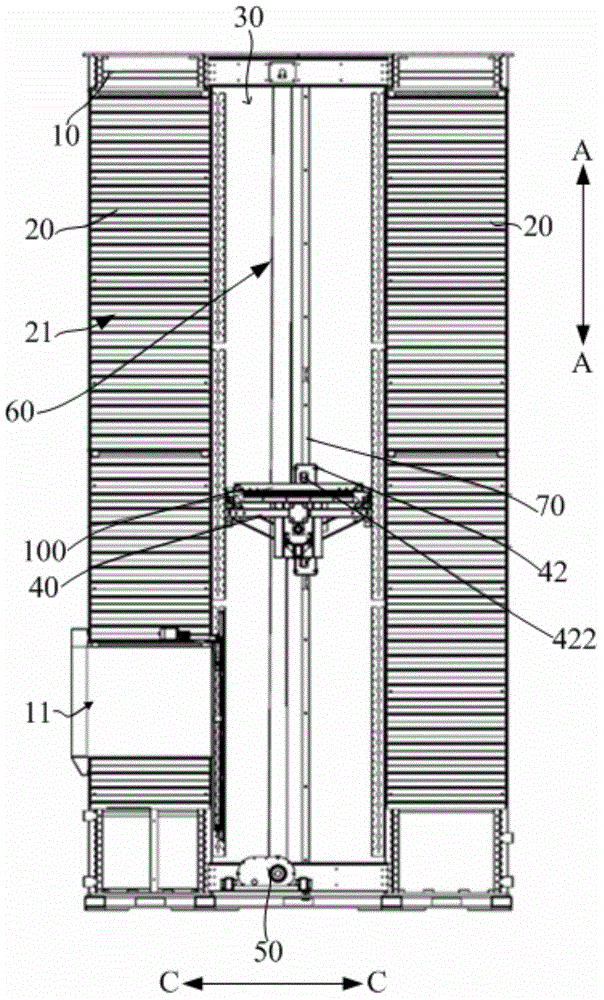

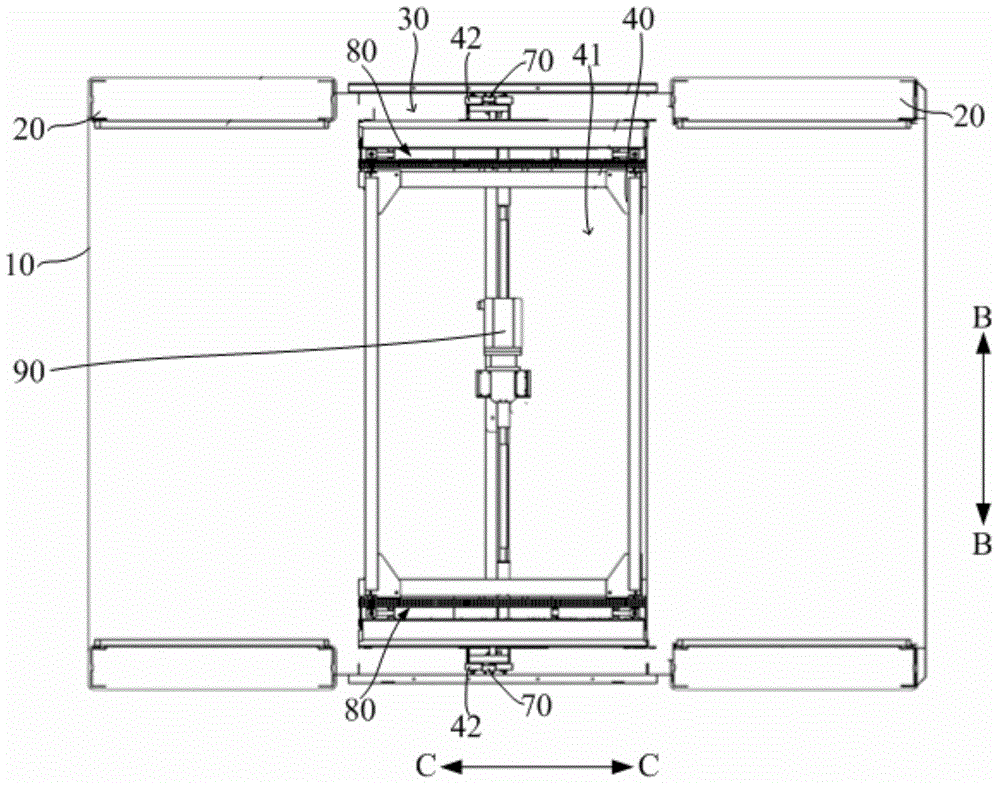

Fan holding and lifting device and mobile overwater operation platform

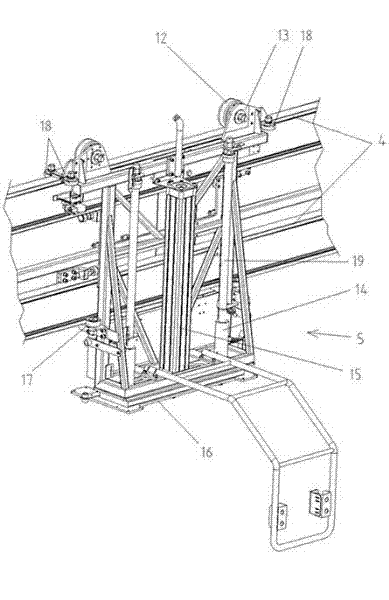

InactiveCN102079477AFixed position lowNot easy to shakeEngine manufactureFinal product manufactureEngineeringTower

The invention relates to the field of offshore fan mounting technology and discloses a fan holding and lifting device. The fan holding and lifting device is used in a mobile overwater operation platform and comprises a gate-type mounting frame, a fan lifting device and a holder for clamping a fan tower barrel, wherein the gate-type mounting frame is provided with a first support leg, a second support leg and at least one cross beam; the cross beam is fixed between the first leg and the second leg; the holder is arranged on the cross beam; the fan lifting device is fixed on the gate-type mounting frame; and a lifting end of the fan lifting device is connected with the fan tower barrel. The fan holding and lifting device of the structure can be used in the mobile overwater operation platform, the holder and the fan lifting device can completely restrain the fan, and the entire assembled fan can be fixed according to the fan mounting state. The invention also discloses a mobile overwater operation platform.

Owner:SANY ELECTRIC CO LTD

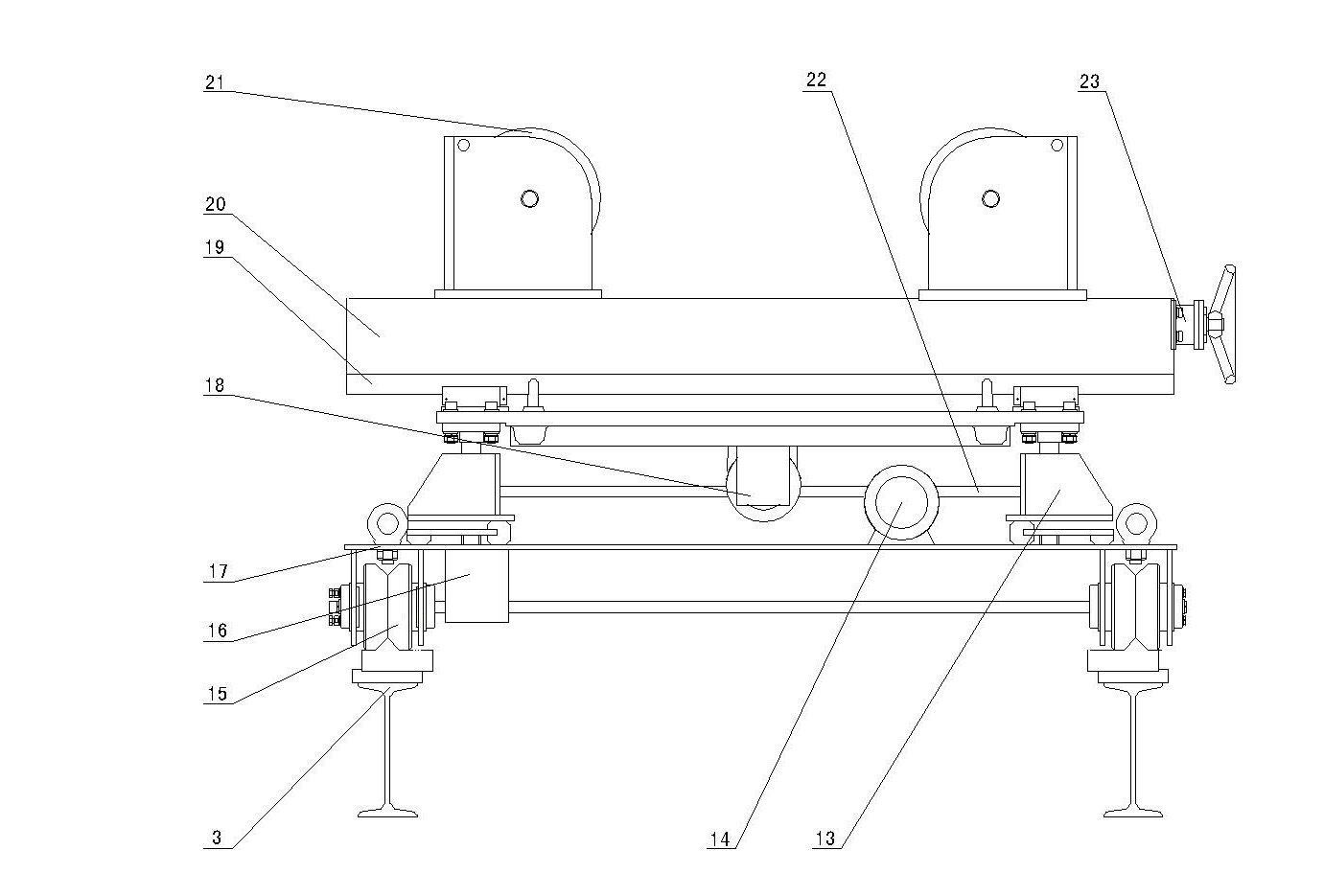

Winding device and winding method for lining cloth production

Owner:安徽恒邦新材料科技有限公司

Fan-holding equipment and mobile waterborne platform

InactiveCN102079476AReduce shakingNot easy to shakeArtificial islandsWind motor assemblyEngineeringTower

The invention relates to the technical field of installation of offshore fans and discloses fan-holding equipment. The fan-holding equipment is used on the mobile operating platform above water, including a first column, a second column, beam lifting equipment, at least one beam and a holding equipment to hold the fan tower. The first column and the second column are set side by side, and guide slots for the at least one beam to slide are arranged opposite to the first column and the second column. The holding-equipment is arranged on the at least one beam, and both ends of the at least one beam are clamped in the guide slots of the first column and the second column. The beam lifting equipment is fixed on the first column or second column, and the lifting end of the beam lifting equipment is connected to the beam. The fan-holding equipment can fix the equipped whole fan according to the fan installation status, and can realize the lifting and dropping of the fan. The invention also discloses a mobile operating platform above water.

Owner:SANY ELECTRIC CO LTD

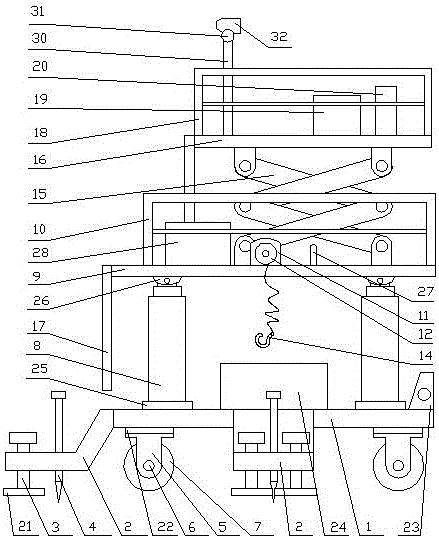

Electric power overhauling lifting platform

PendingCN106698280AThe lifting method is stable and reliableAdjustable supply voltageLighting elementsLifting framesElectric power systemEngineering

The invention discloses an electric power overhauling lifting platform which comprises a device base; supporting bases are arranged at one end of the device base and at the two sides of the device base; the supporting bases are in threaded connection with a group of supporting bolts and are equipped with a locating drill rod in a penetrating mode; a group of lifting oil cylinders is arranged on the upper part of the device base; the lifting oil cylinders are connected with a middle platform; a middle guard bar is arranged on the middle platform; a reduction motor is arranged at one side of the middle platform; the reduction motor is in key connection with a wire winding wheel; a suspender cable is wound on the wire winding wheel; a shear type lifting device is arranged on the middle platform; the top of the shear type lifting device is connected with the top platform; a top guard bar is arranged on the top platform; and a storage battery and an illuminating lamp are further arranged on the top platform. The electric power overhauling lifting platform is extremely good in stability, is stable in lifting, is not liable to shake, improves overhauling working safety, is reliable in locating, has flexible operation and also has an illuminating function.

Owner:QIXIA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

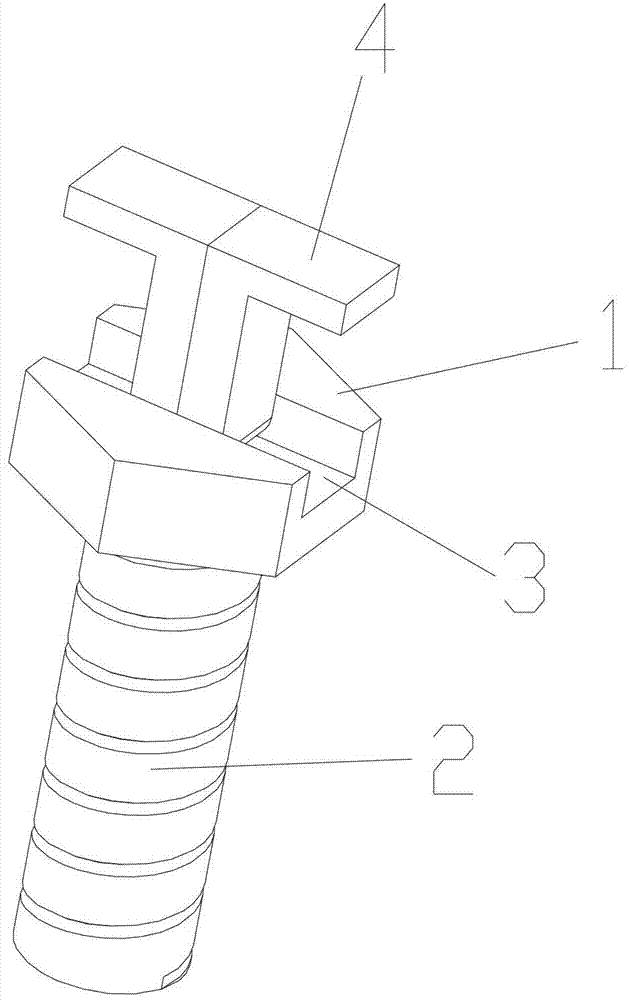

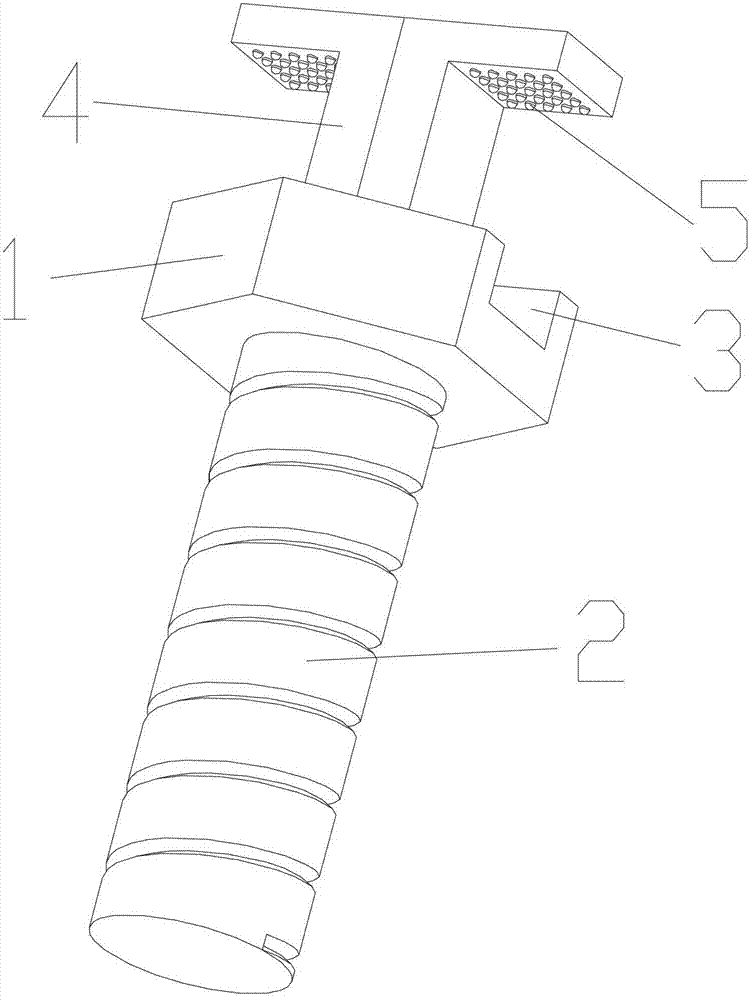

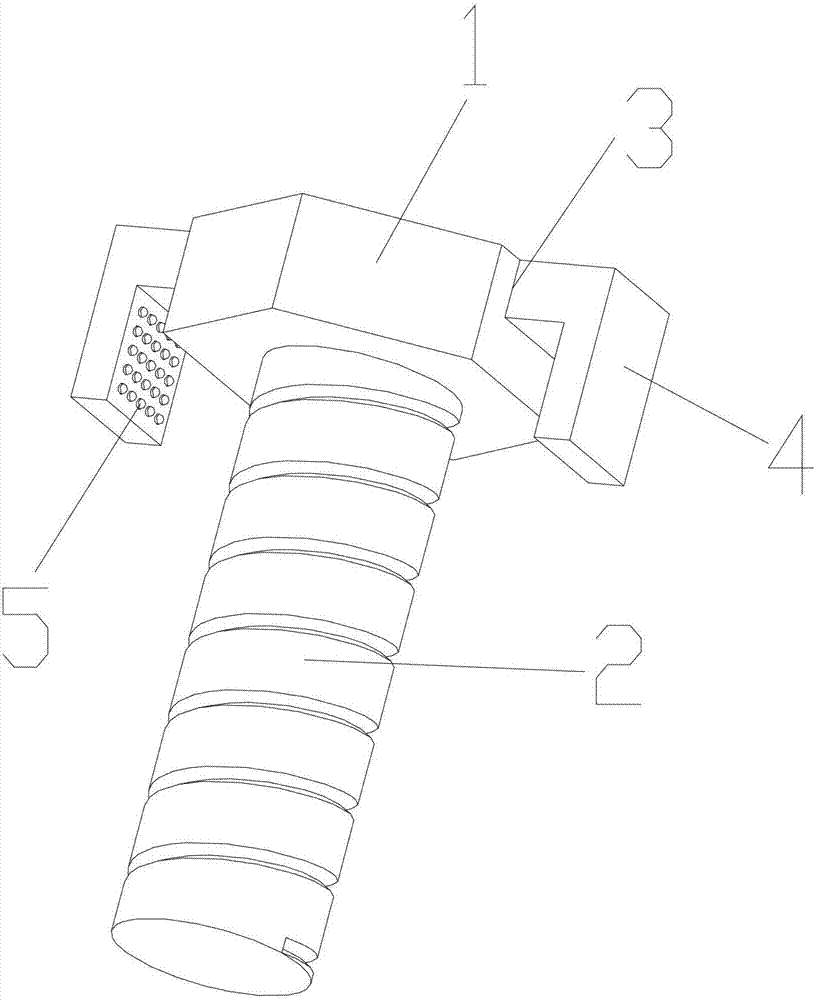

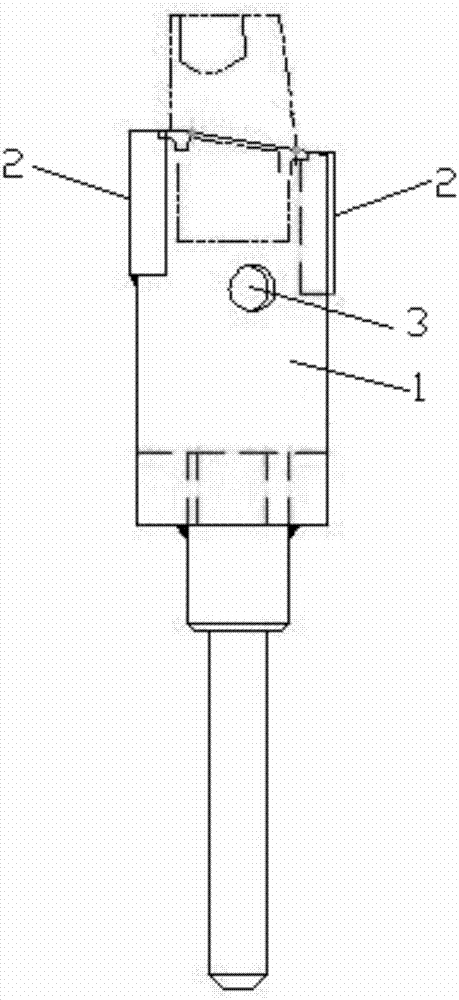

Lock bolt

The invention discloses a lock bolt. The lock bolt comprises a bolt head and screw rod, wherein the bolt head and the screw rod are connected into a whole, and a through groove is formed in the upper surface of the bolt head; two L-shaped rotating blocks are symmetrically arranged in the through groove; the top ends of I-shaped parts of the L-shaped rotating blocks are rotatably connected with a side plate of the through groove; when the I-shaped parts of the L-shaped rotating blocks are located in the through groove, transverse-line-shaped parts of the L-shaped rotating blocks face the screw rod; the thicknesses of the L-shaped rotating blocks are equal to the width of the through groove; and a plurality of bosses are arrayed on the inner end faces of the transverse-line-shaped parts of the L-shaped rotating blocks. The lock bolt provided by the invention uneasily gets loose when a mechanical device works and generate mechanical vibration, so that the thread is uneasily abraded, the fastening effect is improved, the working performance and the stability of the mechanical device are improved, specifically the machining precisions of a plurality of precision devices are guaranteed, and phenomenon that the bolt is separated from a threaded hole is further prevented.

Owner:SUZHOU DONGLI MACHINERY

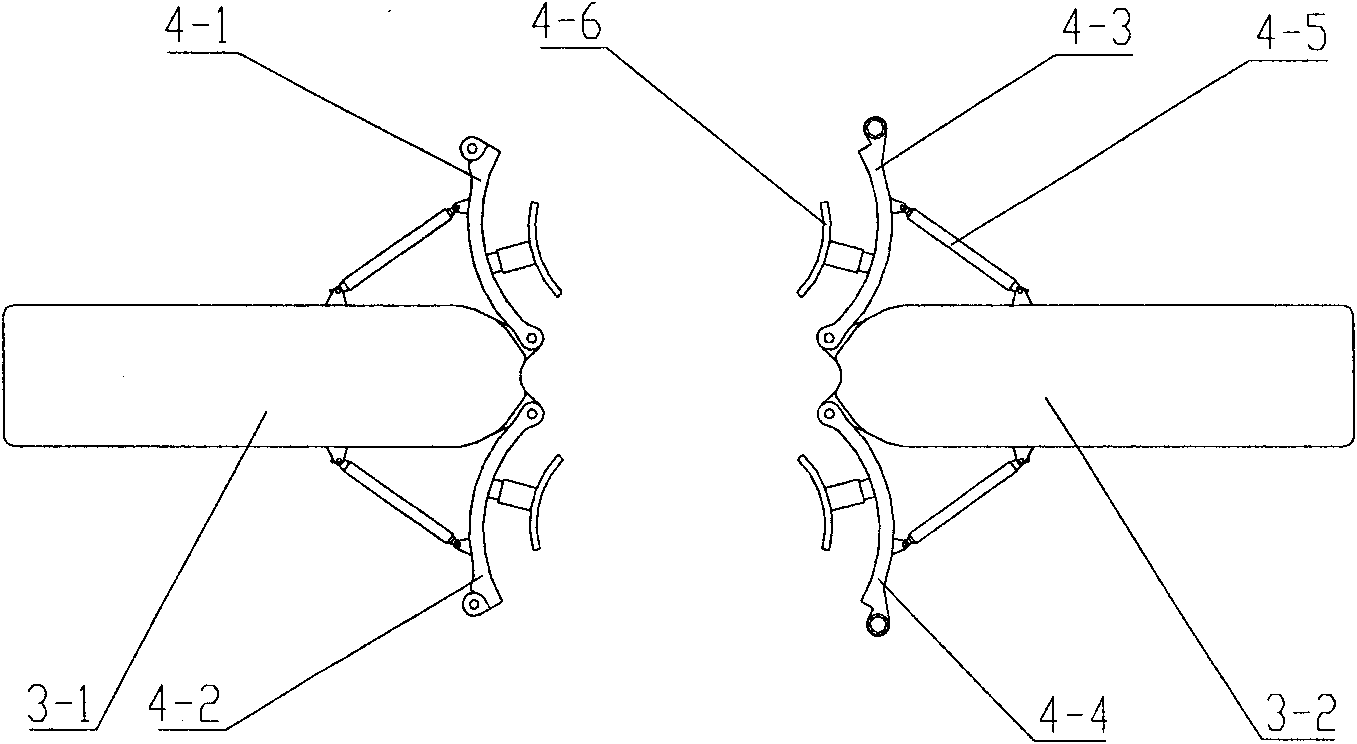

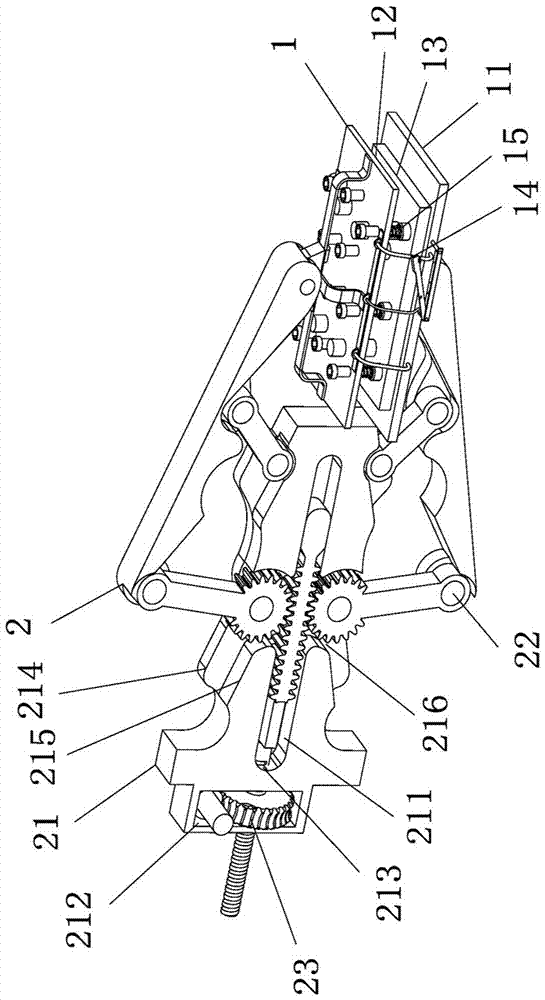

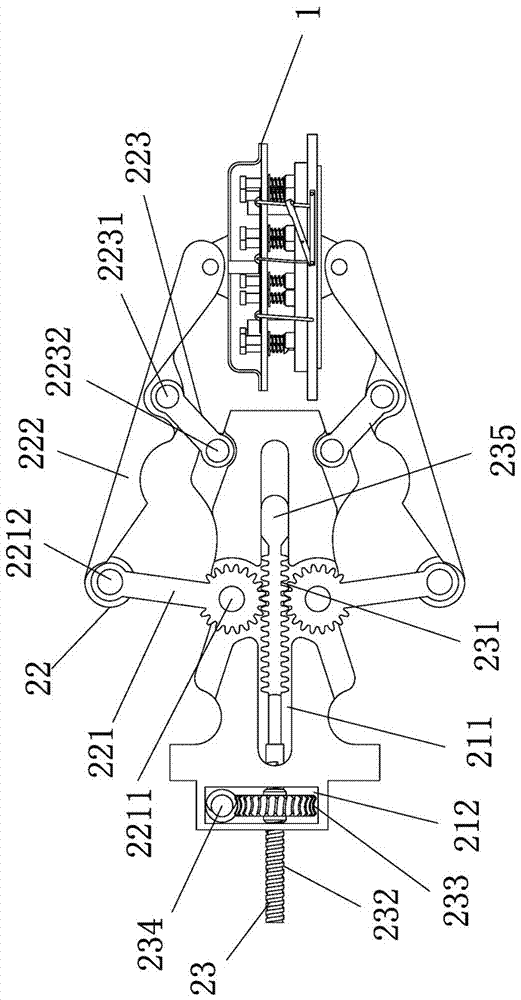

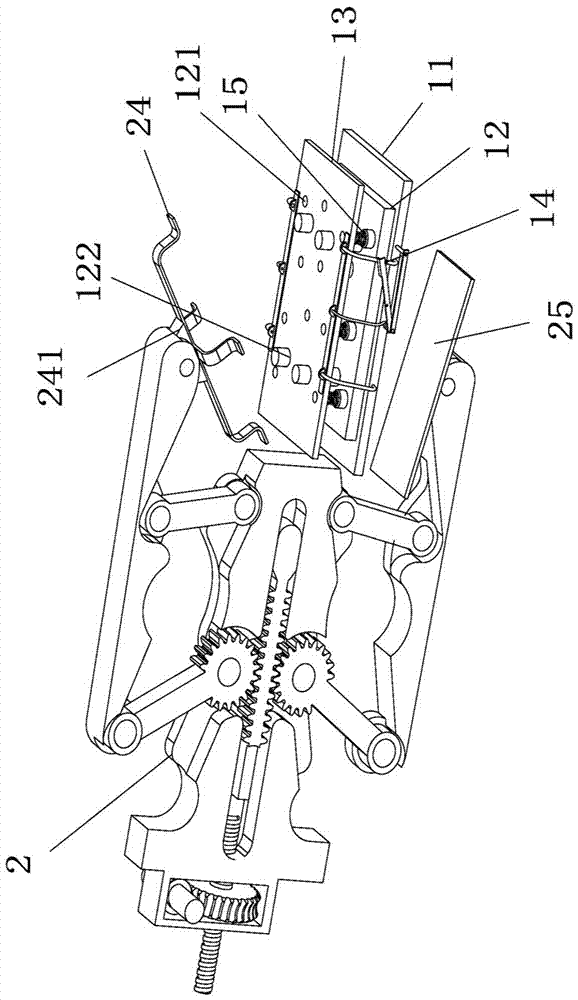

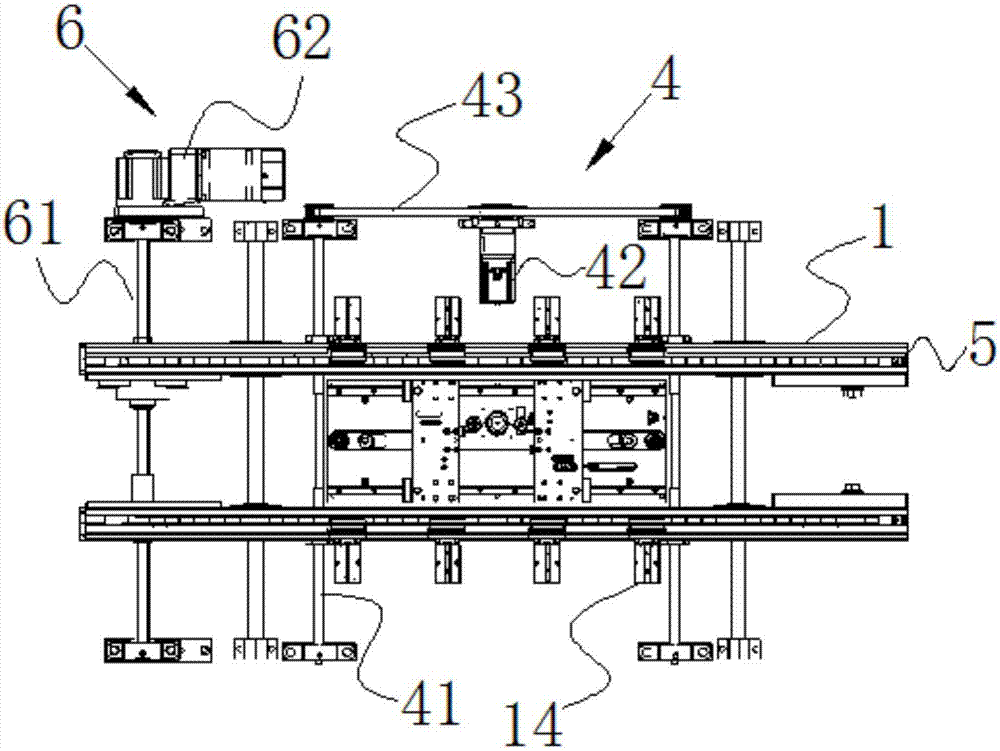

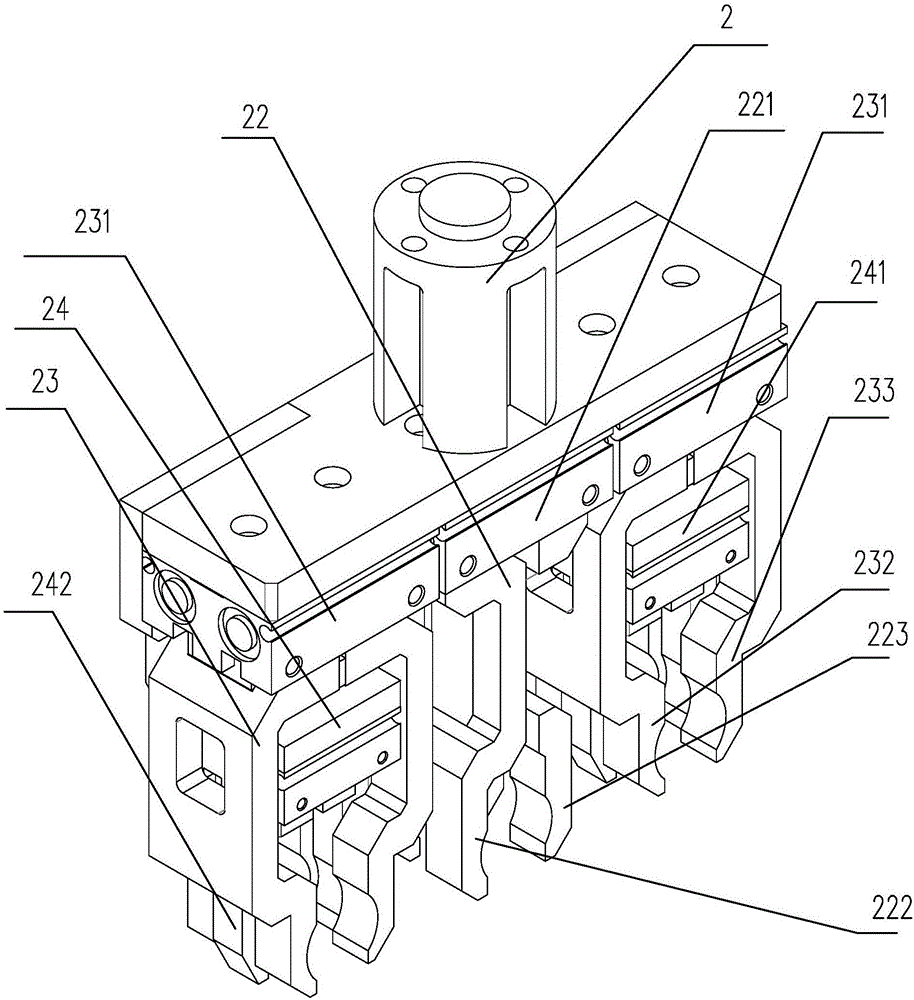

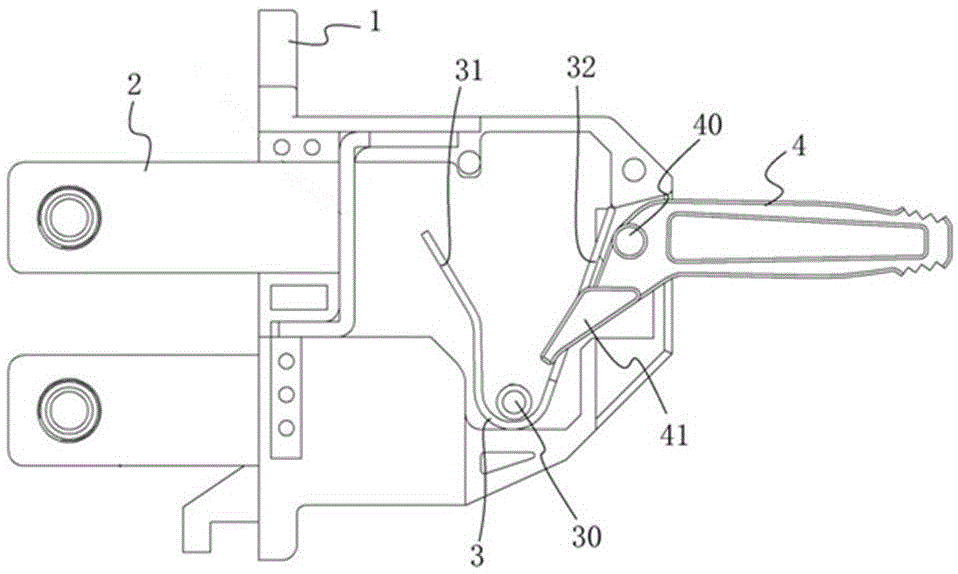

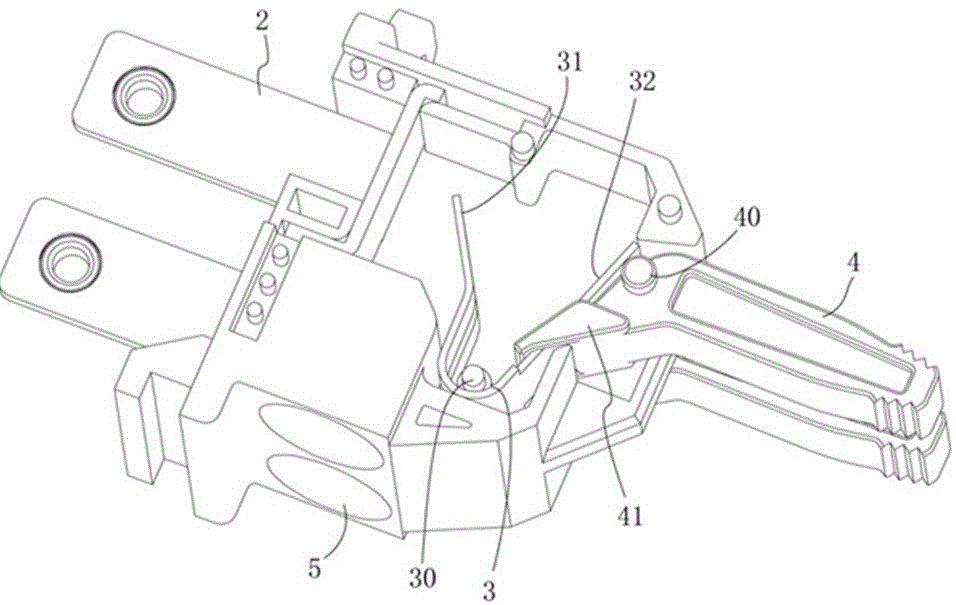

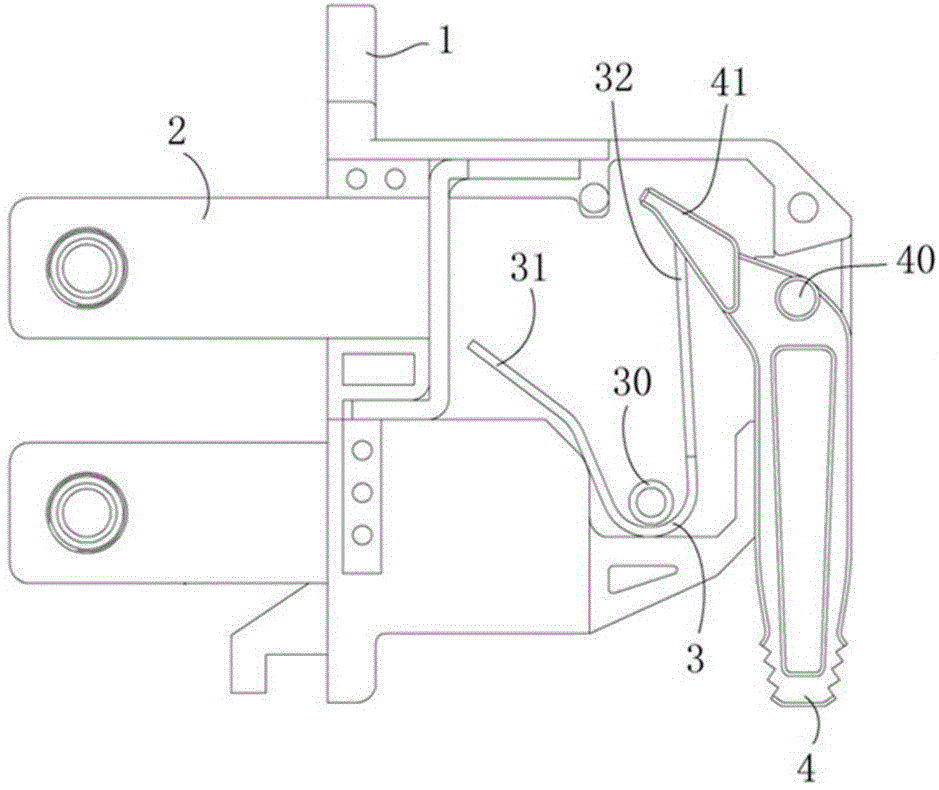

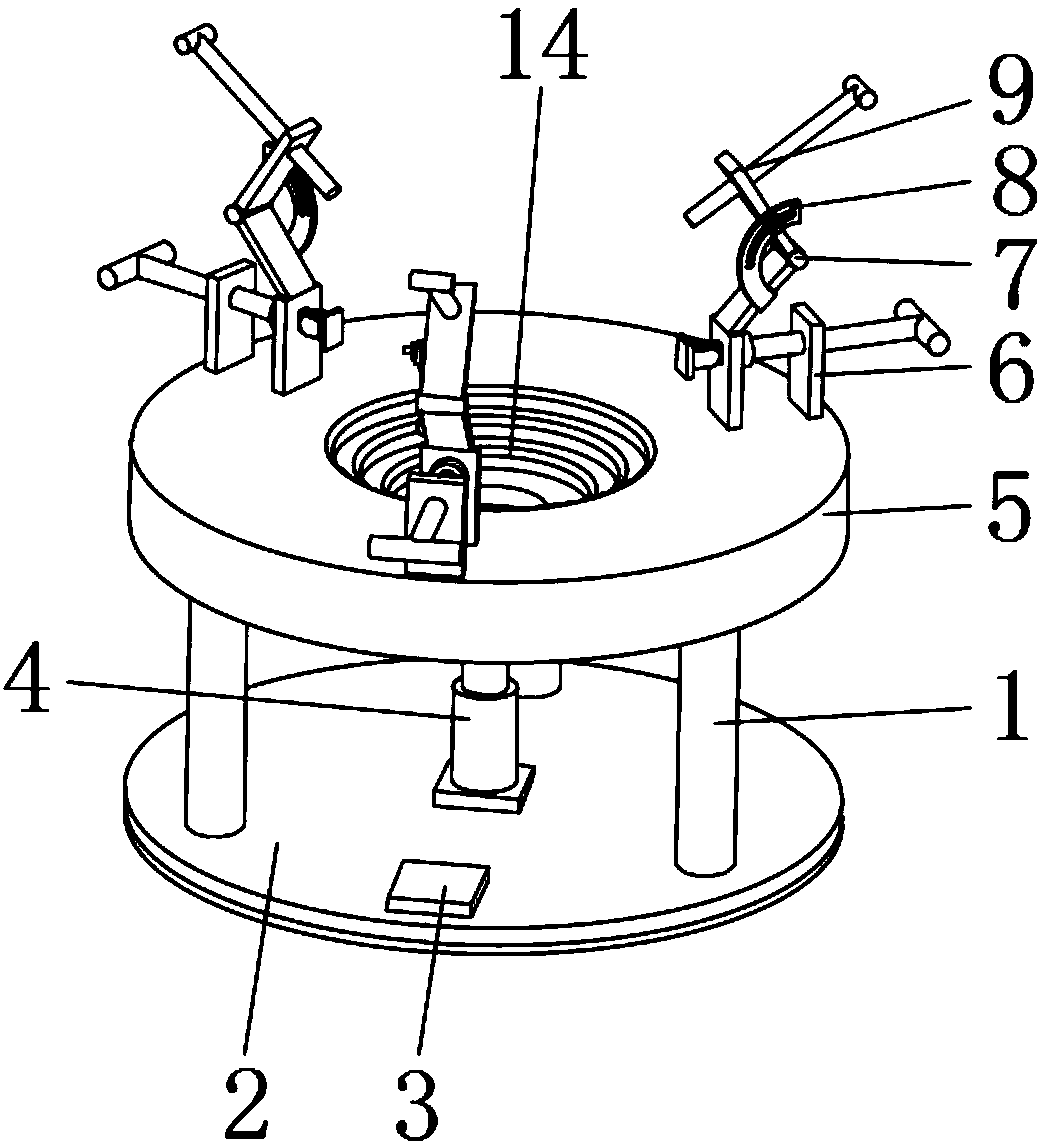

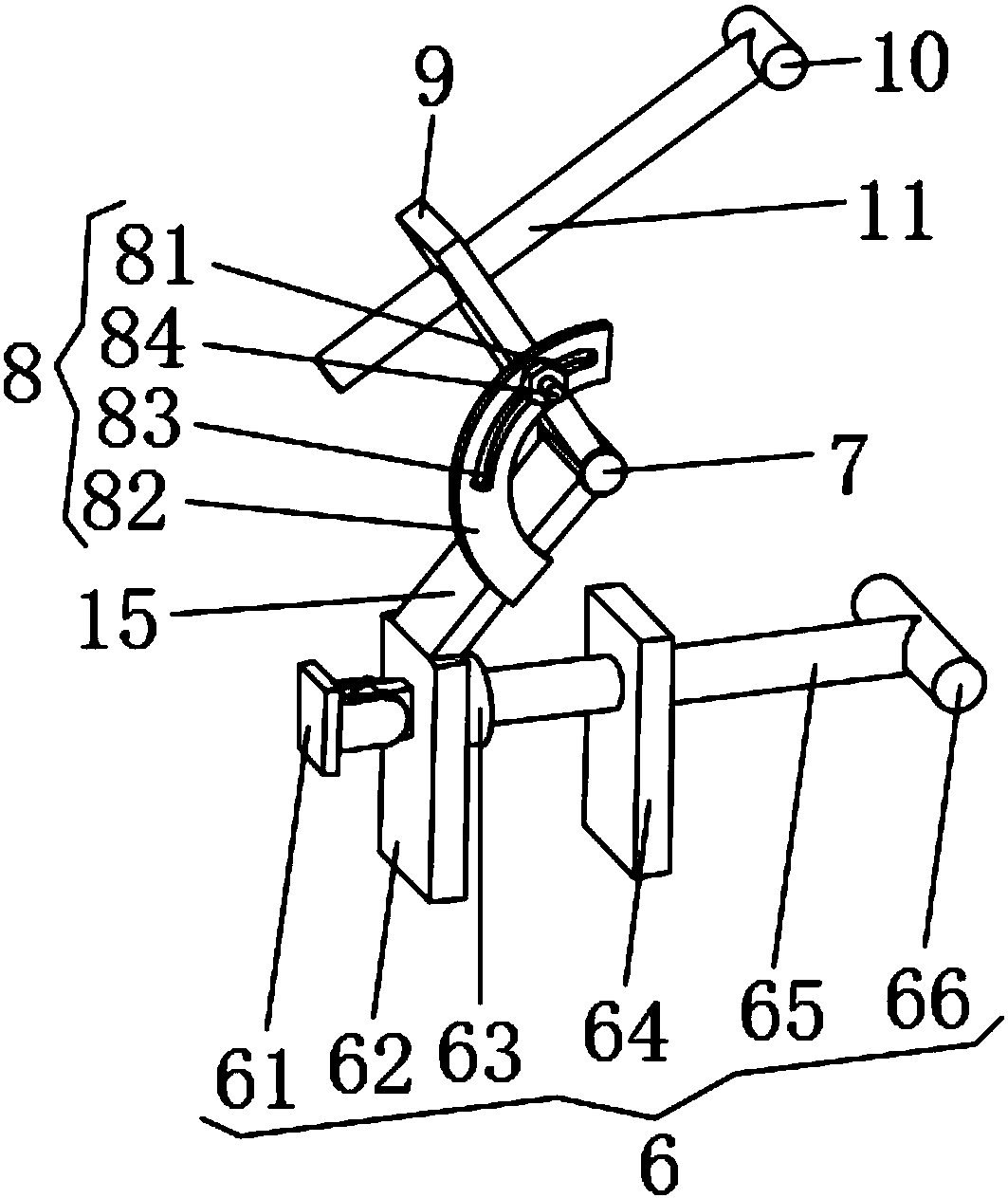

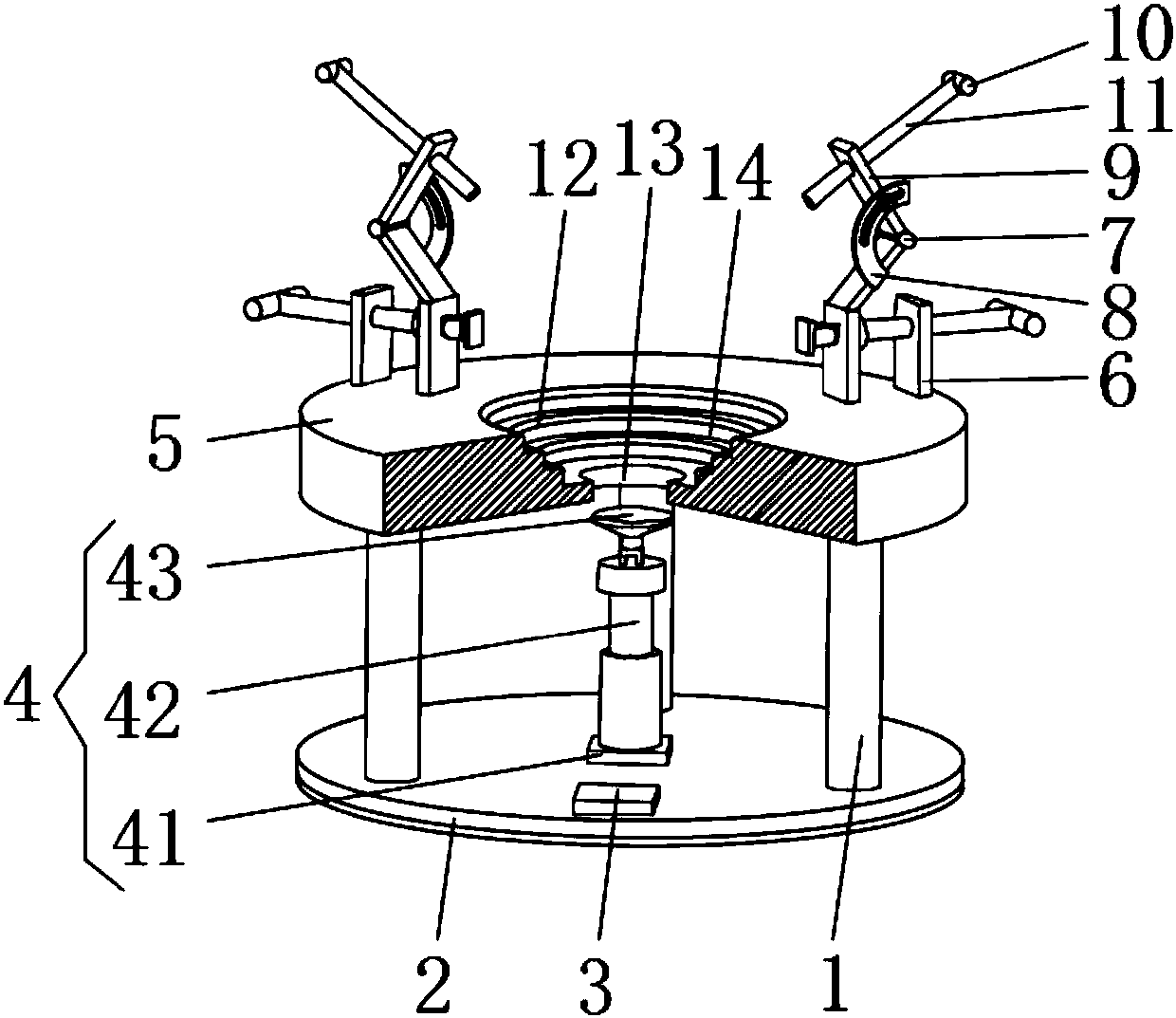

Positioning clamping system of testing machine for automatic transmission valve body assembly of automobile

PendingCN107336174ASimple structureEasy to operateWork holdersInternal combustion piston enginesEngineeringAutomotive transmission

The invention relates to the technical field of testing of automobile transmissions, and in particular relates to a positioning clamping system of a testing machine for an automatic transmission valve body assembly of an automobile. The positioning clamping system comprises a clamping mechanism for positioning and gripping a transmission valve body, and a pressing mechanism for driving the clamping mechanism to tightly press the transmission valve body. According to the system, the transmission valve body is positioned and gripped on the clamping mechanism and then is clamped by the clamping mechanism through the pressing mechanism, so that the transmission valve body is hard to shake. The system is simple in structure, convenient to operate, and accurate and quick to position and grip the transmission valve body; moreover, the transmission valve body is clamped and hard to shake. Therefore, efficiency is greatly improved; the workload of workers is decreased; and a series of disadvantages such as repeated damage and time and force waste can be completely avoided.

Owner:上海新孚美变速箱技术服务有限公司

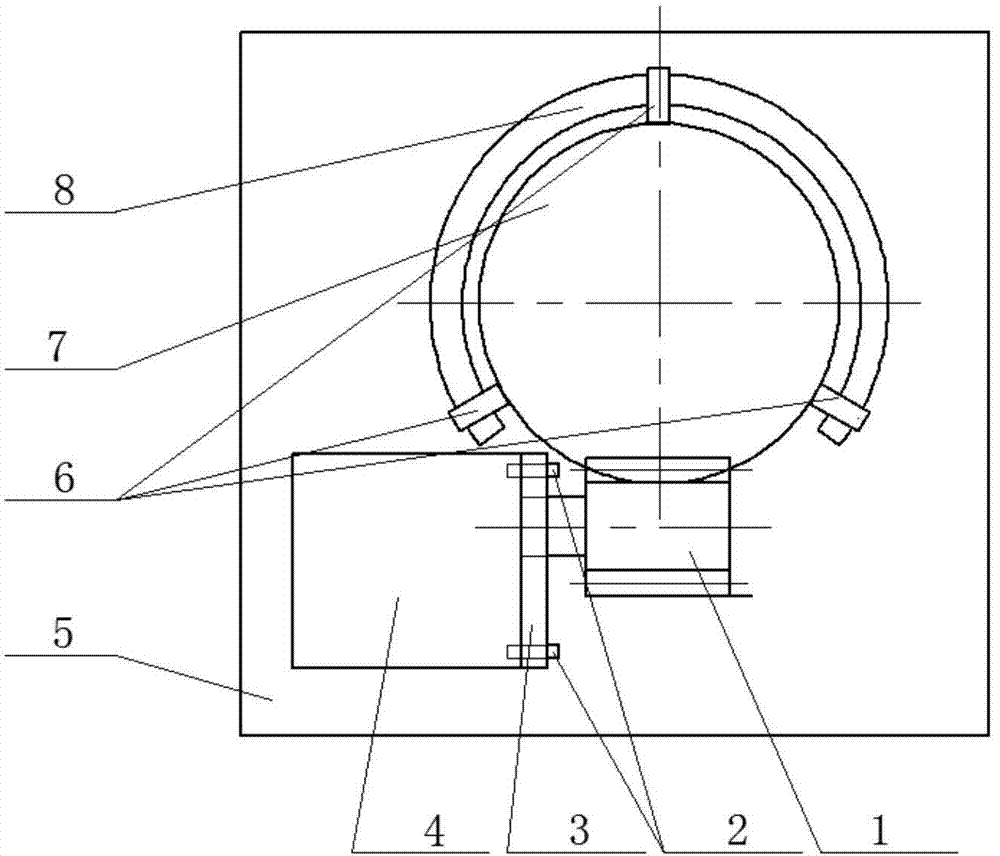

Design method for vertical constant force system

ActiveCN103879571AEasy to operateHigh precisionCosmonautic condition simulationsSystems designConstant force

The invention provides a design method for a vertical constant force system. The vertical constant force system comprises a balance point constant force spring module, a gear and rack compensation module and a data acquisition and control module and is used for compensating the gravity generated in the process of ground validation of a spacecraft. The balance point constant force spring module comprises a compressed spring, a linear guide rail, linear bearings, rolling bearings, a spring jacket and connecting parts and is used for providing constant force at a balance point. The gear and rack compensation module comprises a gear and rack set, a motor and a fixing plate. When the spacecraft deviates from the balance point, the gear and rack compensation module can drive the balance point constant force spring module arranged at the lower end of the gear and rack compensation module to do acceleration and deceleration motion or uniform motion in the vertical direction to adjust force on the compressed spring, so constant force output is guaranteed. The data acquisition and control module comprises a motor driver, a control card, a high-precision tension sensor, a displacement sensor, a data acquisition card and an upper computer PC. The vertical constant force system can be used for providing the constant force in the vertical direction and compensating the gravity of the spacecraft and has the advantages being stable in operation, not prone to external interference, high in constant force accuracy and the like.

Owner:BEIHANG UNIV

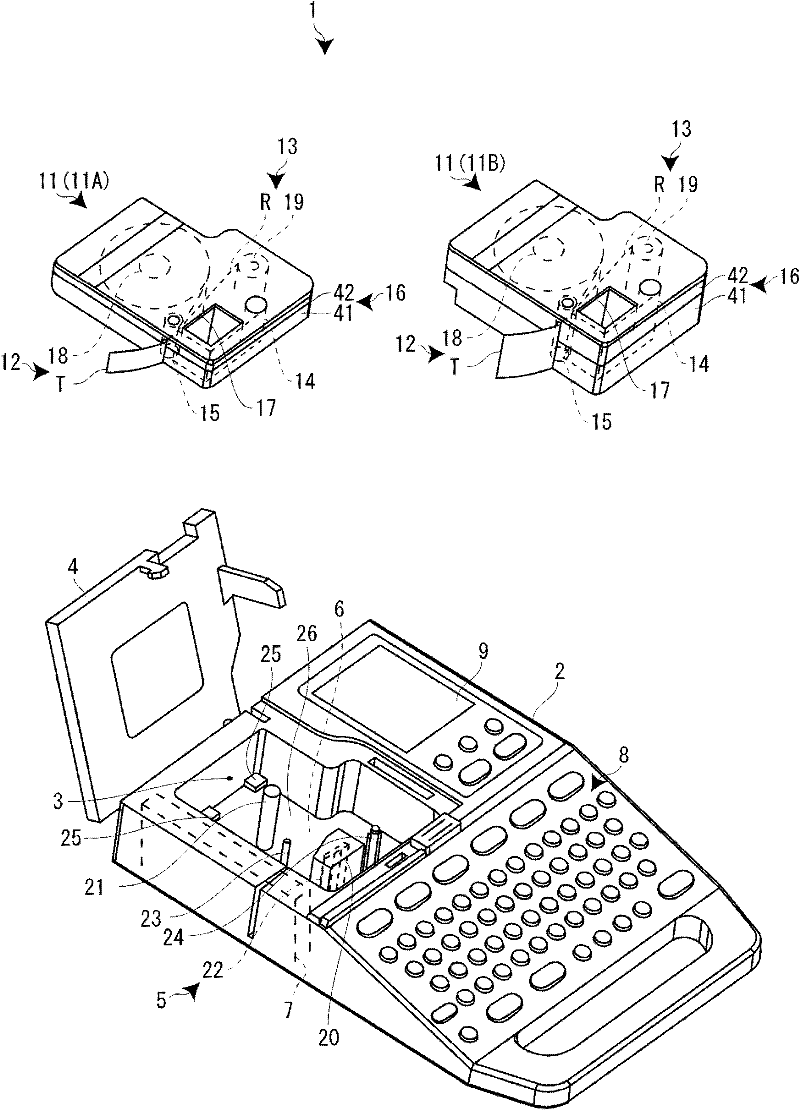

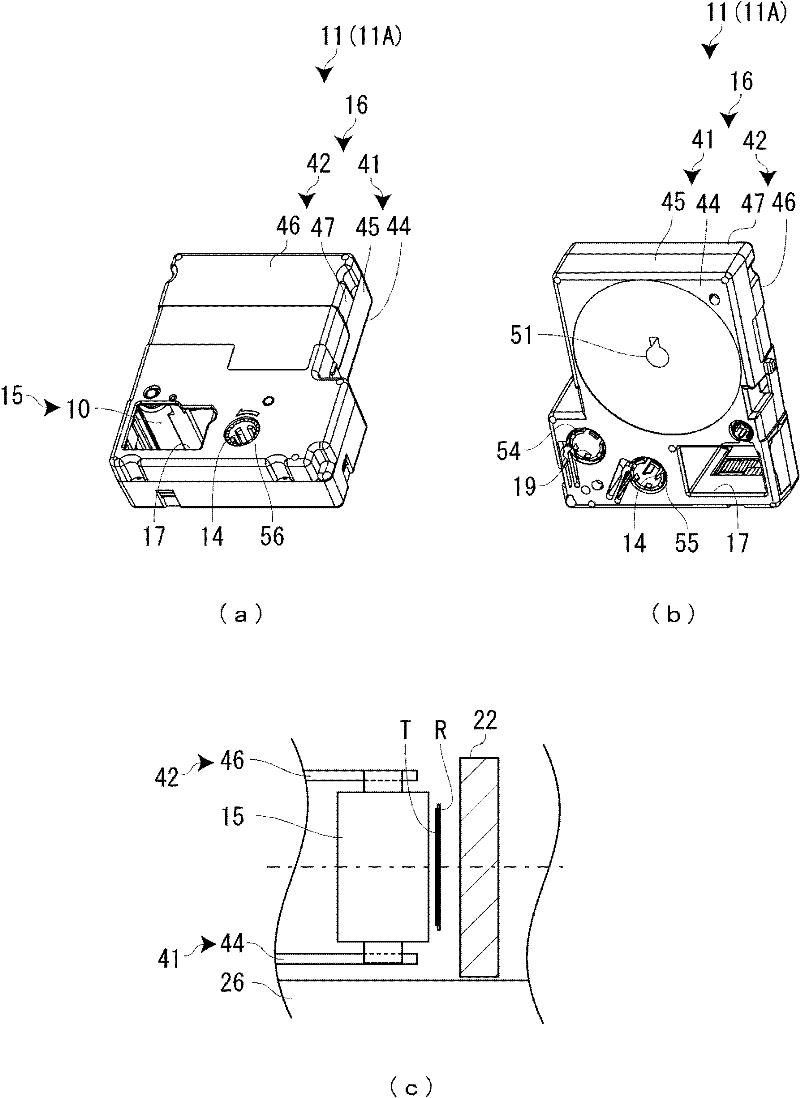

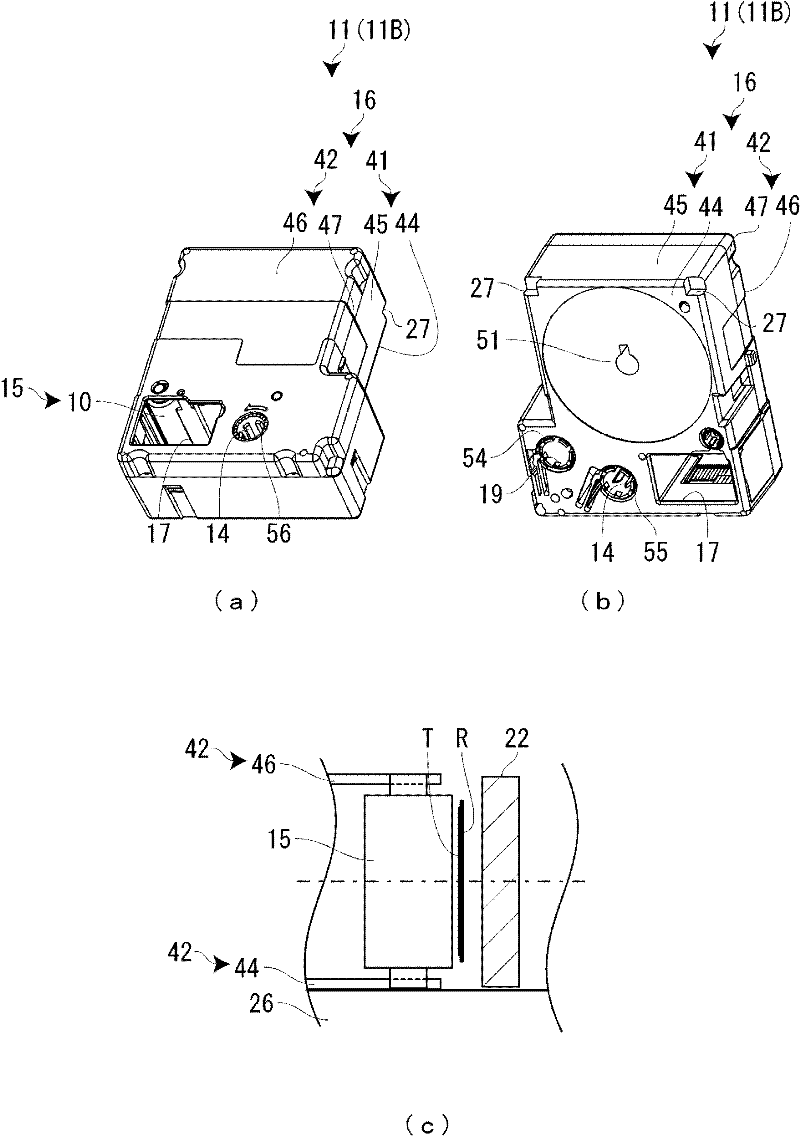

Tape cartridge and tape printer

ActiveCN102336073ANot easy to shakeNo damage to print qualityInk ribbon cartridgesTypewritersEngineeringMechanical engineering

The invention provides a tape cartridge and a tape printer, in which it is unnecessary to perform a seat-entering adjustment on a printer head relative to a lower end. The tape cartridge includes a platen roller 15, when the tape cartridge is mounted on a tape printer 1, a print head 22 of the tape printer 1 contacting the platen roller 15 with a print tape T and an ink ribbon R arranged therebetween such that the print head 22 can be separated from the platen roller 15; a cartridge case 16 that houses the print tape T, the ink ribbon R, and the platen roller 15; and an insertion opening 17 formed in the cartridge case 16, the print head 22 being inserted into the insertion opening 17. A contact portion 10 of the platen roller 15 that is brought into contact with the print head 22 protrudes relative to a head receiver 72 of the insertion opening 17 to which the print head 22 is exposed.

Owner:SEIKO EPSON CORP +1

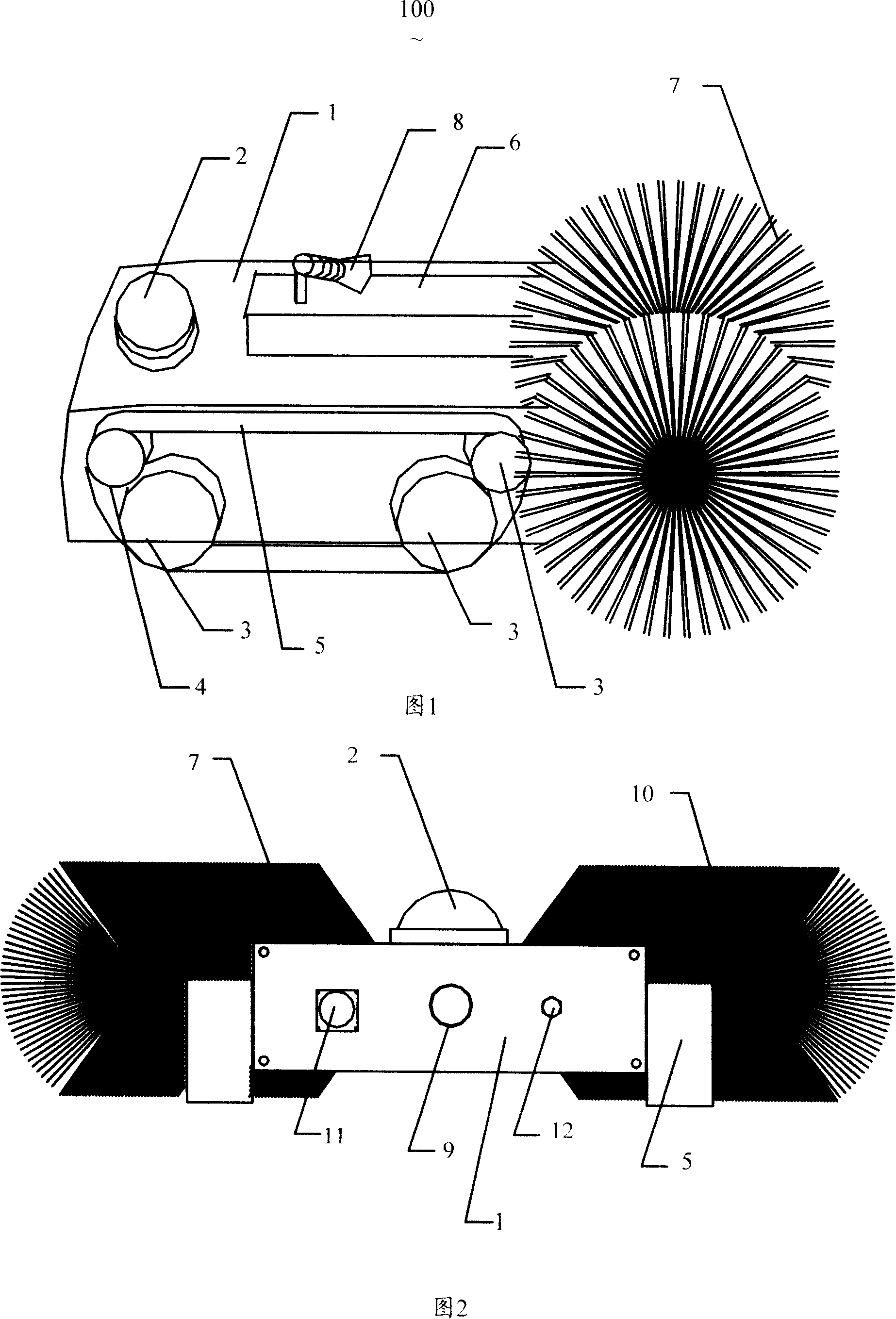

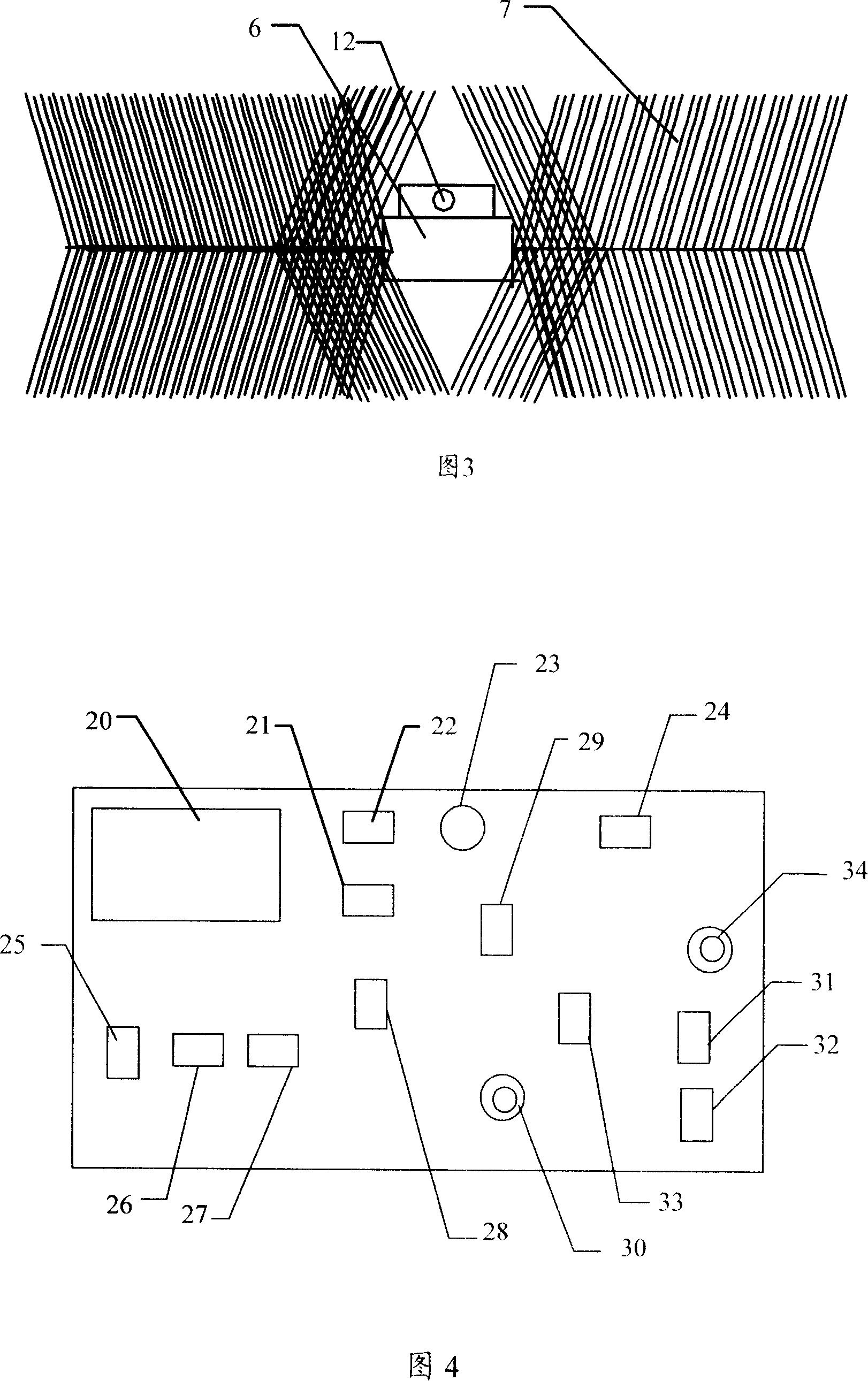

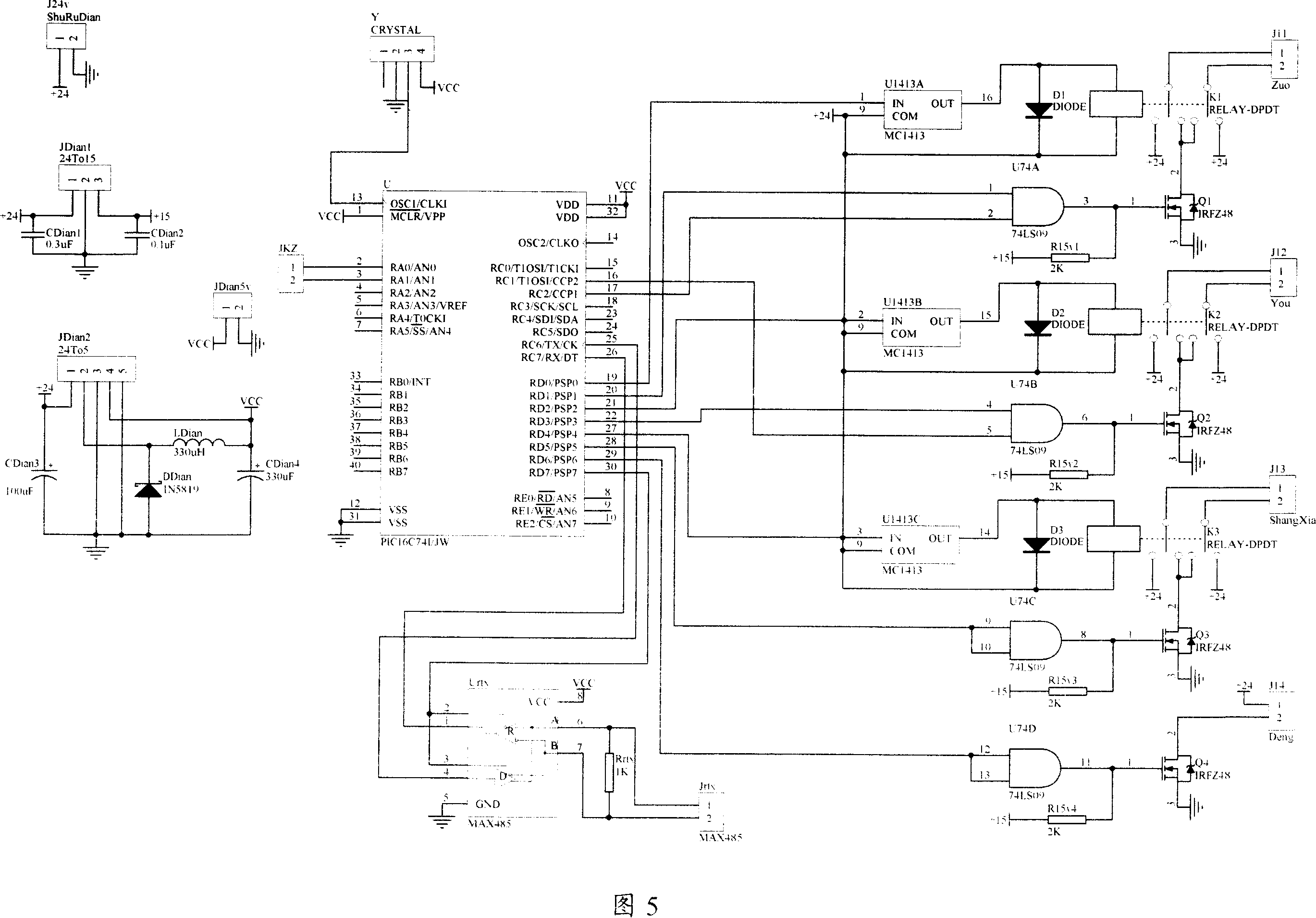

Robot for cleaning pipeline

InactiveCN101130190AIncrease contact areaModerate contact areaHollow article cleaningManipulatorCamRobot control

The invention discloses a pipe cleaning robot, which consists of robot host and robot control box, wherein the control box controls cleaning working of the robot host; the robot host contains car body, cam, wheels at two side of the car body, elevating arm on the car body, hair brush on the elevating arm, luminous tube, first motor to anchor the wheel to move forwards and backwards, turn left and right, second motor to control the up-and-down movement of the elevating arm, wherein the hair brush is pneumatically rotary hair brush, which provides dynamics for the compressed air. The invention avoids block for hair brush, which doesn't damage equipment easily with low cost.

Owner:SHENZHEN POLYTECHNIC

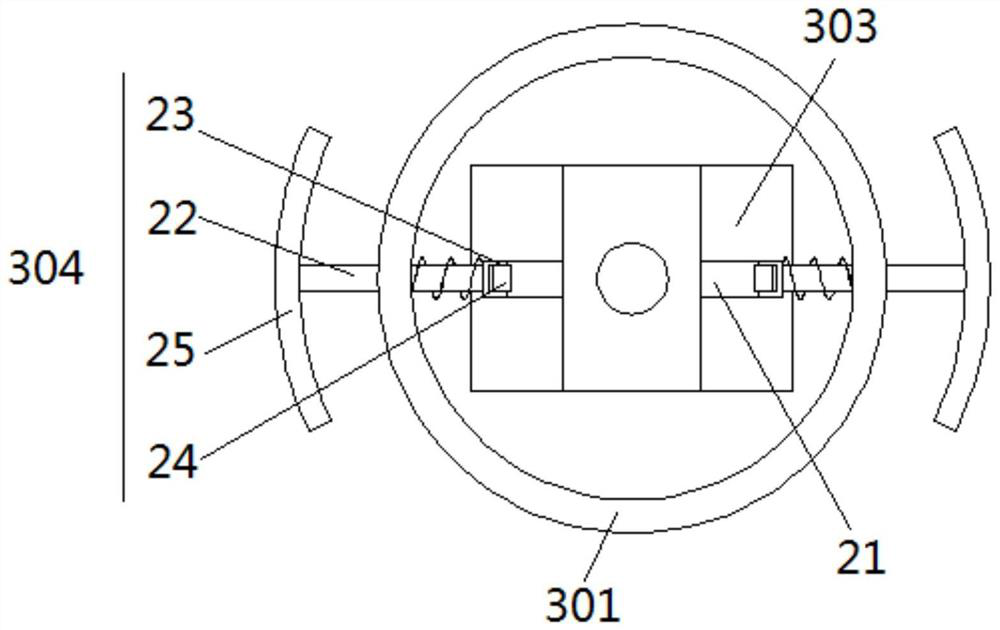

Automobile tire grinding and grooving integrated device

ActiveCN111702575AImprove efficiencyReduce the temperatureRevolution surface grinding machinesMetal working apparatusMechanical engineeringIntegrated devices

The invention provides an automobile tire grinding and grooving integrated device. The automobile tire grinding and grooving integrated device comprises a base, a rotary supporting component, a rotating shaft, and a supporting plate; the center of the top of the base is rotatably connected to the rotary supporting component; the rotary supporting component comprises the rotating shaft and the supporting plate; the top of the rotating shaft is fixedly connected with the supporting plate; the supporting plate is circular; the rotating shaft is rotatably connected to the center of the base; a mounting groove is formed in the upper end of the base and is positioned between the rotary supporting component and a supporting transmission device; a No. 1 driving device is mounted in the mounting groove; the No. 1 driving device is in transmission connection with the supporting transmission device; slots are formed in the position, positioned on the front side of the rotating device, at the upper end of the base and one side, close to the rotary supporting component, of the base; the slots are overlapped by rotating at 90 degrees; and the upper end of the rotary supporting component is horizontally clamped with a tire. The invention provides the automobile tire grinding and grooving integrated device, which solves the problems that the time and labor are wasted and the efficiency is lowwhen the tire is ground and grooves manually, the upper arc-shaped end surface and the lower arc-shaped end surface of the tire are ground unevenly by the existing mechanical grinding equipment.

Owner:庄慧明

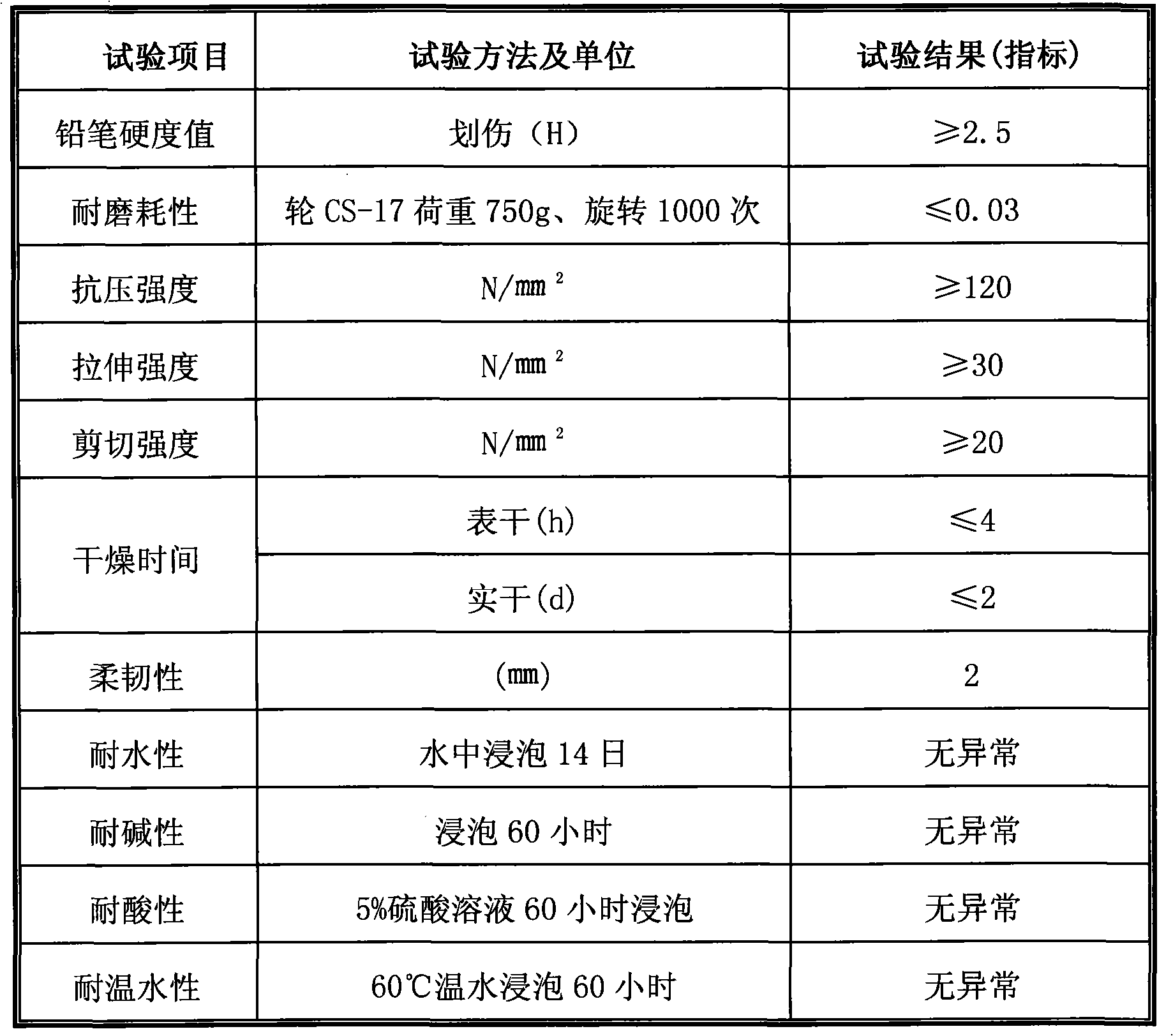

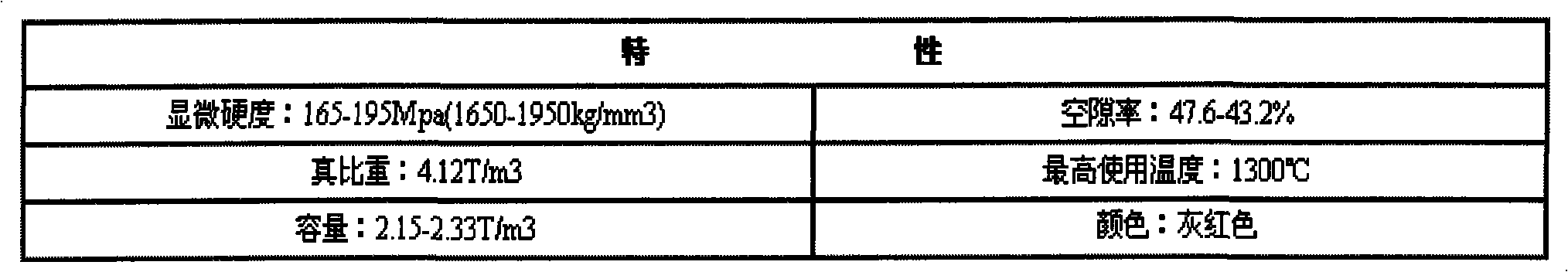

Construction method of wear-resistant non-slip ramp

InactiveCN101914886AStrong orientationReduce driving noiseIn situ pavingsClimate change adaptationWeather resistanceWear resistant

The invention discloses a construction method of a wear-resistant non-slip ramp, which comprises the following steps: clearing a concrete base, coating a base finishing agent, constructing a base coat, painting a high-strength putty layer, constructing wear-resistant non-slip size, processing a closing cover layer, constructing polished surface coating and maintaining. The ramp prepared by the invention has simple structure, convenient construction, low cost, slip prevention, wear resistance, pressure resistance, impact resistance, oil stain resistance and weather resistance.

Owner:LONGXIN CONSTR GRP

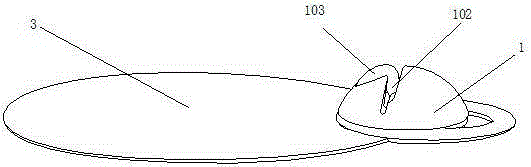

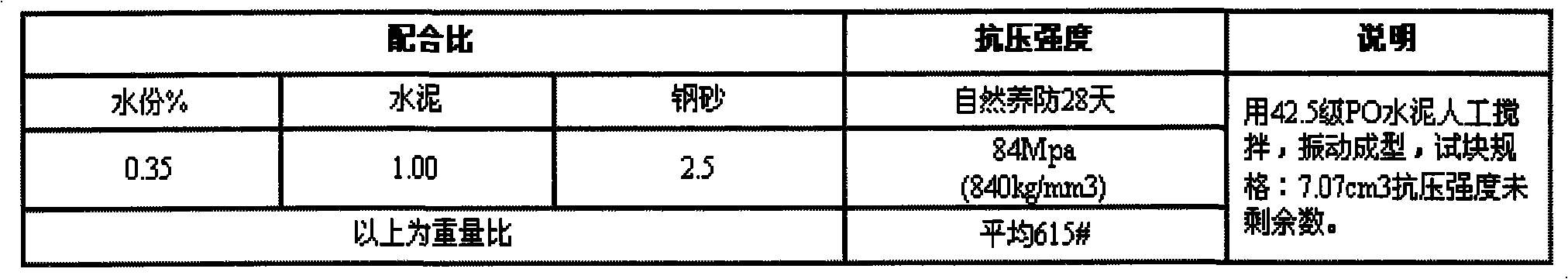

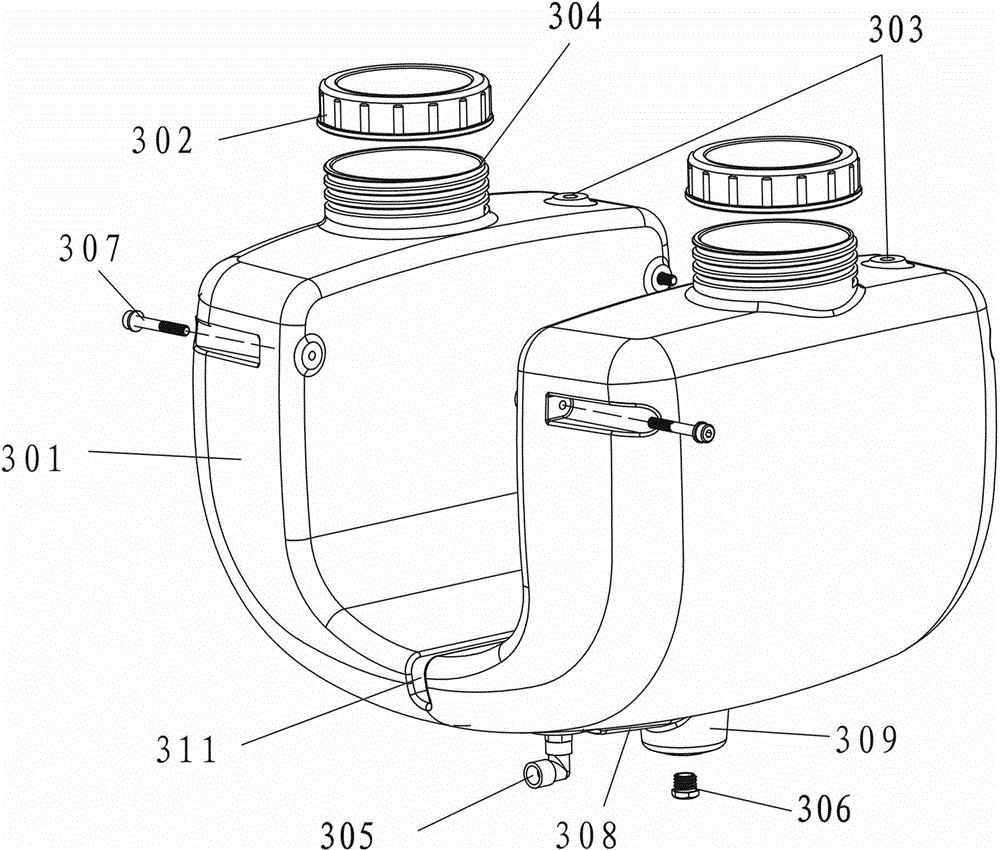

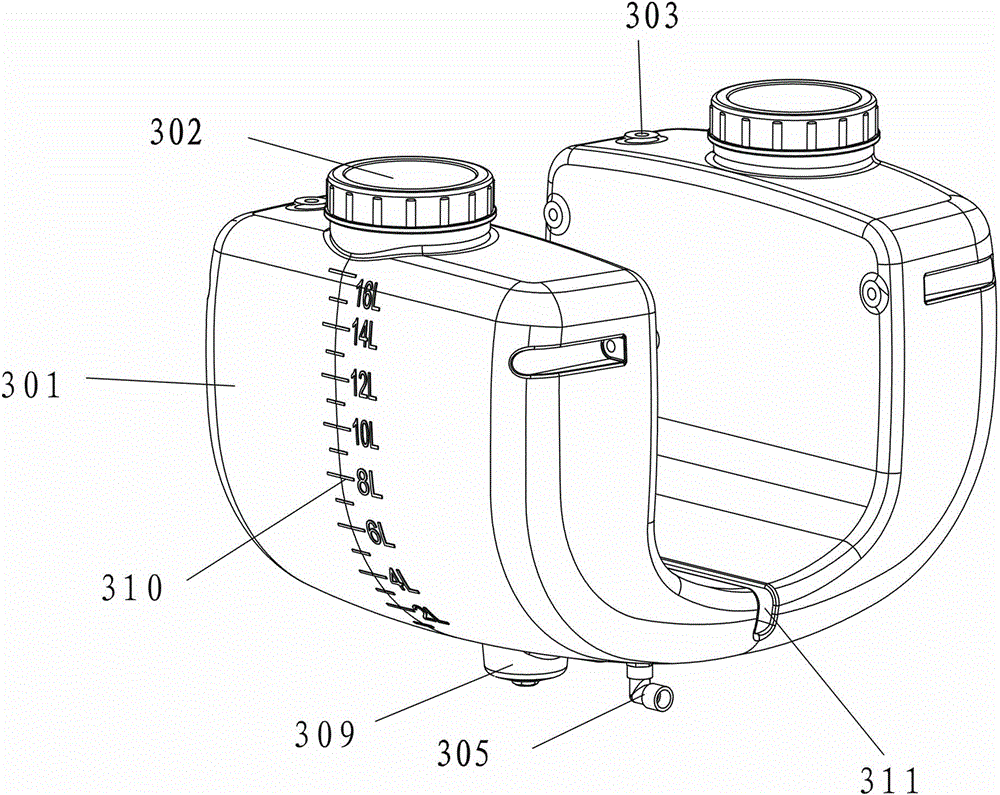

U-shaped pesticide box for agriculture unmanned helicopter

ActiveCN104354865AReduce shakingNot easy to shakeAircraft componentsLaunching weaponsEngineeringImpurity

The invention discloses an U-shaped pesticide box for an agriculture unmanned helicopter. The U-shaped pesticide box comprises a pesticide box body, wherein a groove is formed in the pesticide box body, the cross section of the pesticide box body is of an U-shaped structure, the U-shaped structure is provided with an U-shaped inside surface for forming the groove and an U-shaped outside surface for coating the U-shaped inside surface, the U-shaped inside surface and the U-shaped outside surface are smoothly connected to form the pesticide box body, the upper end surface of the pesticide box body is provided with pesticide liquid inlets, a steam hole is formed in the part near each pesticide liquid inlet, and the bottom part of the pesticide box body is provided with a pesticide liquid outlet. The U-shaped pesticide box has the advantages that the bottom part is provided with a separating plate, so the left pesticide liquid flowing position and the right pesticide liquid flowing position are reduced, and the left level and the right level of pesticide liquid of the pesticide box are consistent in the flight process; the pesticide box is arranged at the bottom part of the center of a helicopter body, so the carried pesticide liquid is mostly close to the center of gravity, the shaking of the pesticide liquid is reduced in the flight process, and the flight is more stable; meanwhile, the bottom part of the pesticide box body is provided with an impurity guide groove and an impurity storage area, so the blockage of the pesticide liquid outlet by the impurities of the pesticide liquid is avoided, and the discharge of residues is convenient.

Owner:湖南植保无人机技术有限公司

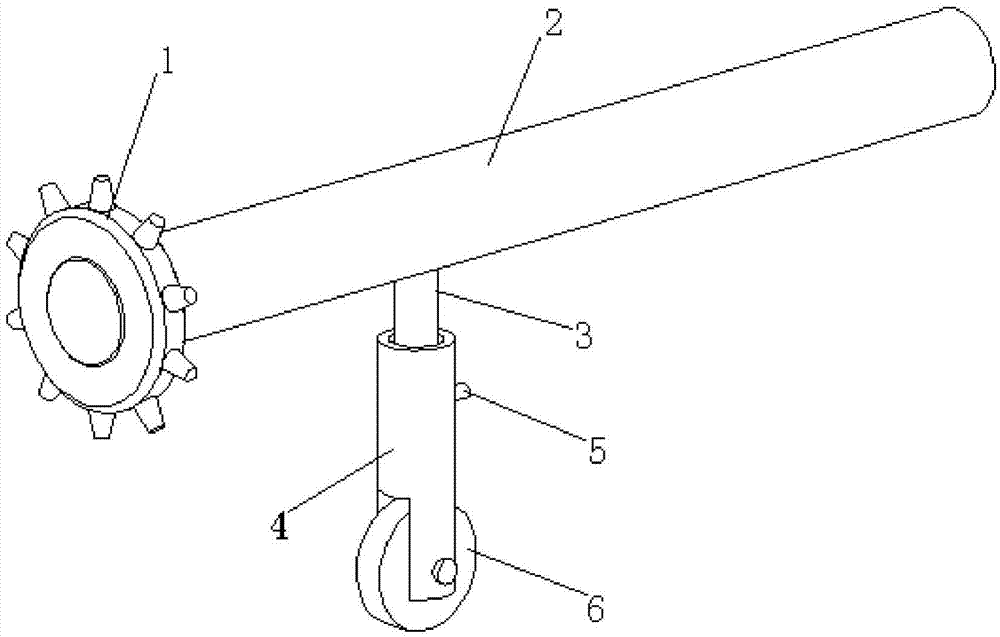

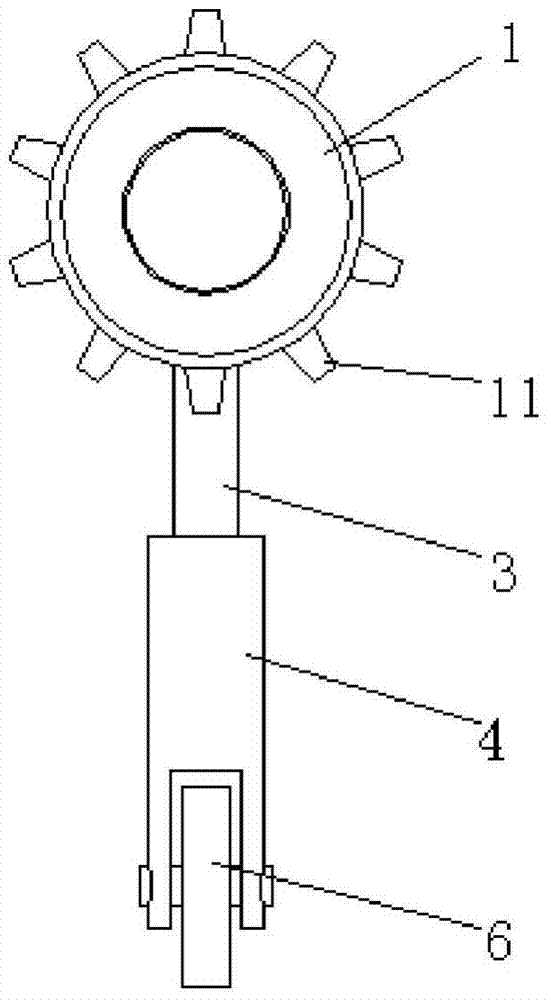

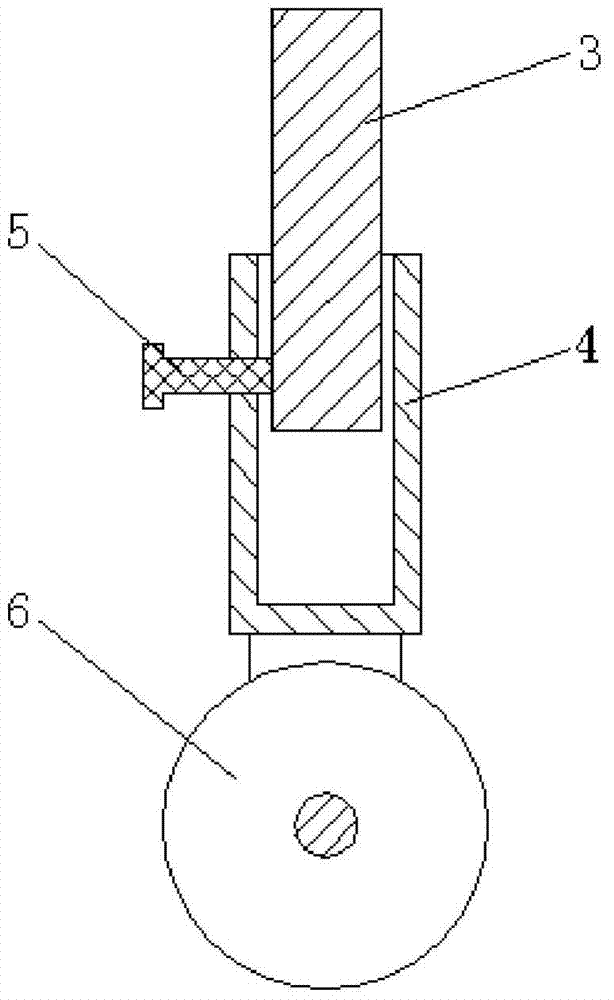

Height-adjustable pipe inner wall spraying equipment

InactiveCN104209214AImprove surface qualitySpray evenlySpraying apparatusEngineeringMechanical engineering

The invention discloses height-adjustable pipe inner wall spraying equipment and belongs to the field of spraying equipment. The height-adjustable pipe inner wall spraying equipment comprises a spraying head, a spraying pipe, a height adjusting device and a walking device, wherein the spraying head is mounted at one end of the spraying pipe and is communicated with the spraying pipe; the height adjusting device comprises a support rod, a connecting bushing and an adjusting screw; the connecting bushing is hollow inside and the side wall of the connecting bushing is provided with a thread hole; one end of the support rod extends into the connecting bushing; the adjusting screw extends into the connecting bushing via the thread hole for propping the support rod on the inner wall of the connecting bushing, and the other end of the support rod is fixedly connected to the part, near the spraying head, of the spraying pipe, and is perpendicular to the spraying pipe; the walking device is mounted at the bottom of the height adjusting device and can drive the spraying pipe to move in the axial direction of a pipe. The spraying equipment has the advantages of stable and reliable operation, good spraying effect, high efficiency and low cost and is suitable for inner walls of various small-diameter pipes, in particular for the inner walls of ultralong small-diameter pipes.

Owner:常州冯士节能环保科技有限公司

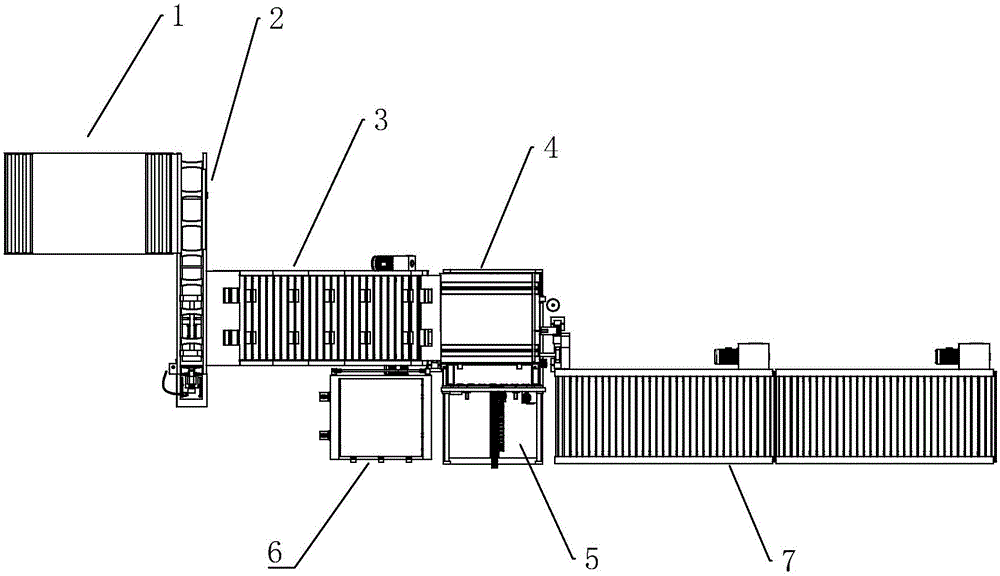

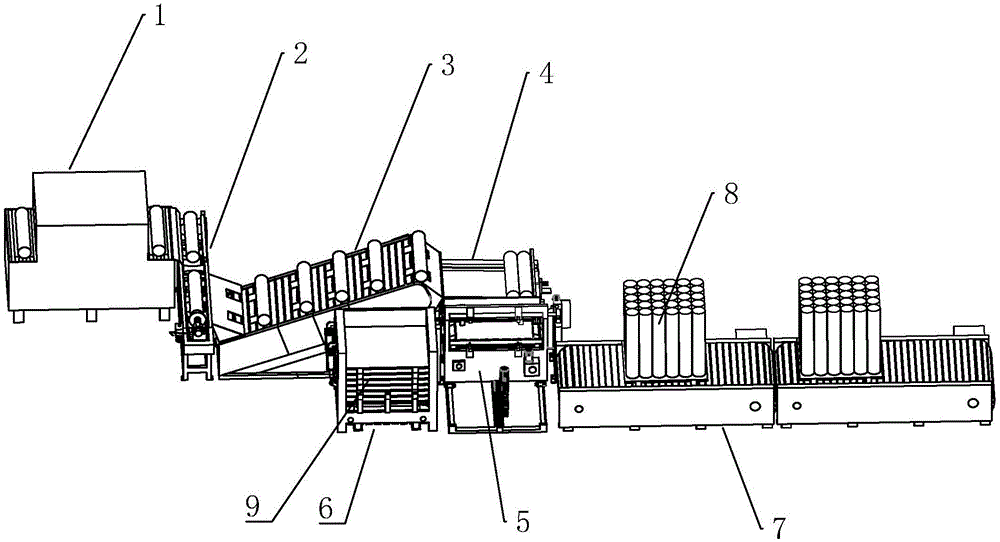

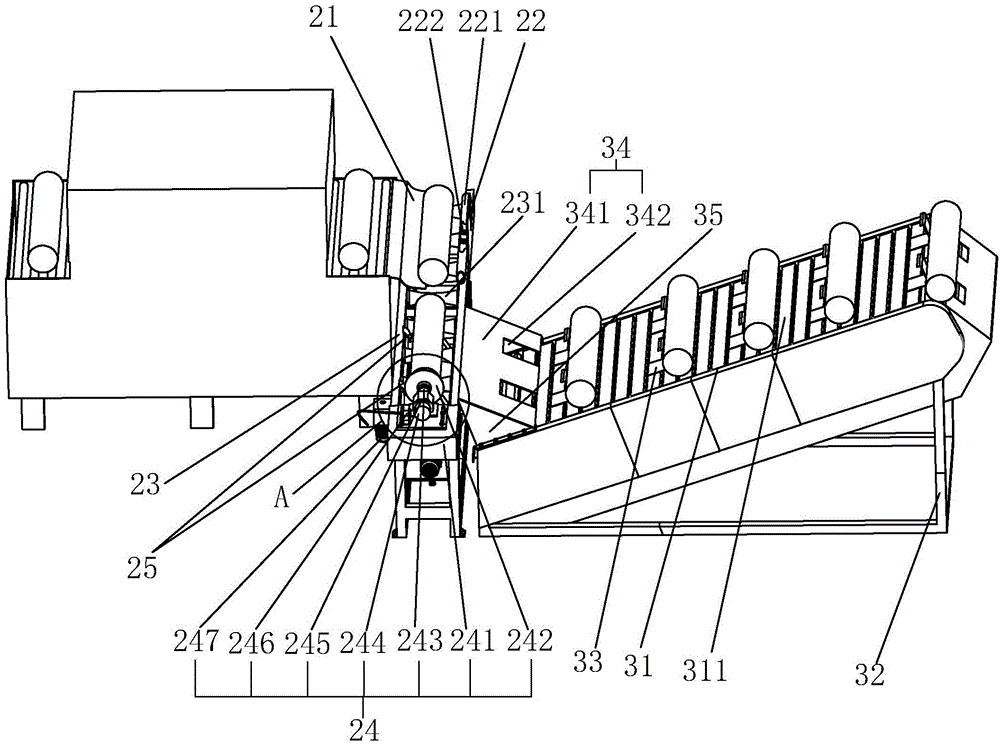

Coiled material stacking assembly line

ActiveCN106241396AStrong connectionHigh degree of automationStacking articlesConveyor partsEngineeringAssembly line

The invention discloses a coiled material stacking assembly line. The coiled material stacking assembly line comprises a film laminating mechanism which conducts film laminating outside a coiled material. The conveying tail end of the film laminating mechanism is provided with a single coiled material conveying mechanism which is perpendicular to the conveying tail end of the film laminating mechanism and used for conveying the single coiled material. The conveying tail end of the coiled material conveying mechanism is provided with a slope conveying mechanism perpendicular to the conveying tail end of the coiled material conveying mechanism. The conveying tail end of the slope conveying mechanism is provided with a turnover mechanism which receives the coiled material and vertically turns over the coiled material. A tray conveying mechanism for receiving the coiled material which is vertically turned over is arranged below the turnover mechanism. One side perpendicular to the conveying tail end of the tray conveying mechanism is provided with a tray storage mechanism for supplying trays to the tray conveying mechanism, and the other side perpendicular to the conveying tail end of the tray conveying mechanism is provided with a coiled material stacking conveying mechanism. The conveying tail end of the single coiled material conveying mechanism is provided with a switching device for controlling the subsequent processes to be continuously operated in sequence. The switching device can control starting and stopping of the follow-up series of mechanisms, real-time supervision by workers in the subsequent processes is not needed, the manpower is saved, and the efficiency is improved.

Owner:百耐尔河北建材科技有限公司

Reagent putting box difficult to shake

The invention discloses a reagent putting box difficult to shake. The box comprises a box body and a lid body rotatably connected with the box body, and the box body and the lid body are connected through an opening-closing mechanism; and the inner bottom of the box body is fixedly connected an installation cover, the upper side of the installation cover is connected with a platform plate througha plurality of first telescopic rods, the interior of the installation cover is connected with two symmetrically-arranged main drive shafts through a transmission mechanism, the upper end of each maindrive shaft passes through the top of the installation cover and is connected with one corresponding straight rack by one corresponding lifting mechanism. According to the box provided by the invention, through cooperation of the transmission mechanism and lifting mechanisms, the platform plate can be driven to move, the platform plate moves to drive circular rings to move, so that reagent bottles are conveniently taken; a reagent bottle fixing mechanism is arranged, so that the reagent bottles are difficult to shake and difficult to damage; a test tube clamping mechanism is arranged, so thattest tubes can be clamped and fixed; and a ventilation mechanism is arranged, so that ventilation in the box body is facilitated, and wetting and mildewing in the box body are prevented.

Owner:张洁

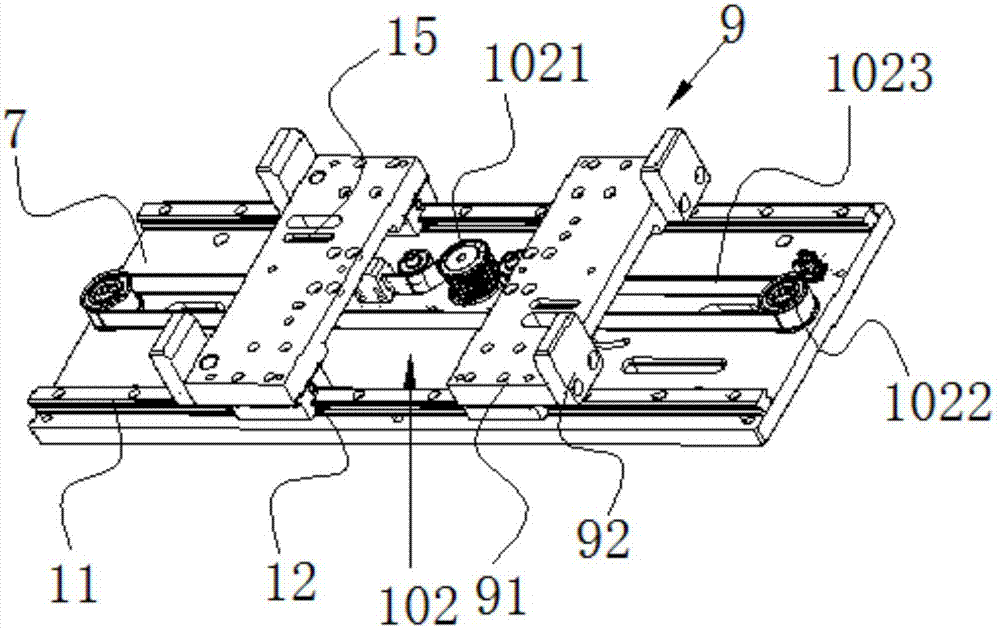

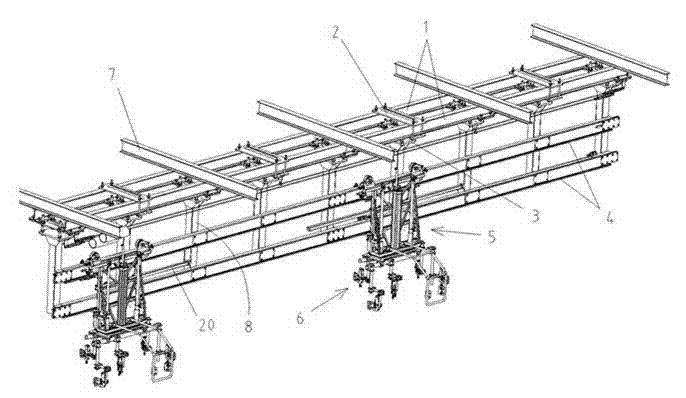

Material conveying and locating device

ActiveCN107487614AAchieve clamping and fixingIncrease productivityConveyorsFinal product manufactureAutomatic controlEngineering

The invention discloses a material conveying and locating device comprising conveying rails, a controller and a workbench. The material conveying direction is defined as the forward direction. The workbench is provided with the two forward-backward-direction conveying rails which are located on the left side and the right side of the workbench correspondingly. The conveying rails are provided with a distance-changing driving mechanism. The distance-changing driving mechanism drives the two conveying rails to go close to each other or go away from each other so as to adjust the distance between the two conveying rails. The conveying rails are provided with conveying chains, and the direction of the conveying chains is consistent with that of the conveying rails. Conveying driving mechanisms are connected to the conveying chains. A lifting plate is arranged above the workbench. A lifting driving mechanism driving the lifting plate to move up and down is arranged below the lifting plate. The lifting plate is provided with a front locating block and a rear locating block which are matched with materials front and back. The two locating blocks go close to each other or go away from each other through a front-back clamping driving mechanism so as to clamp or loosen the materials. Full-automatic control is adopted for the whole production process of the material conveying and locating device, workforce is liberated, and production efficiency is improved.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

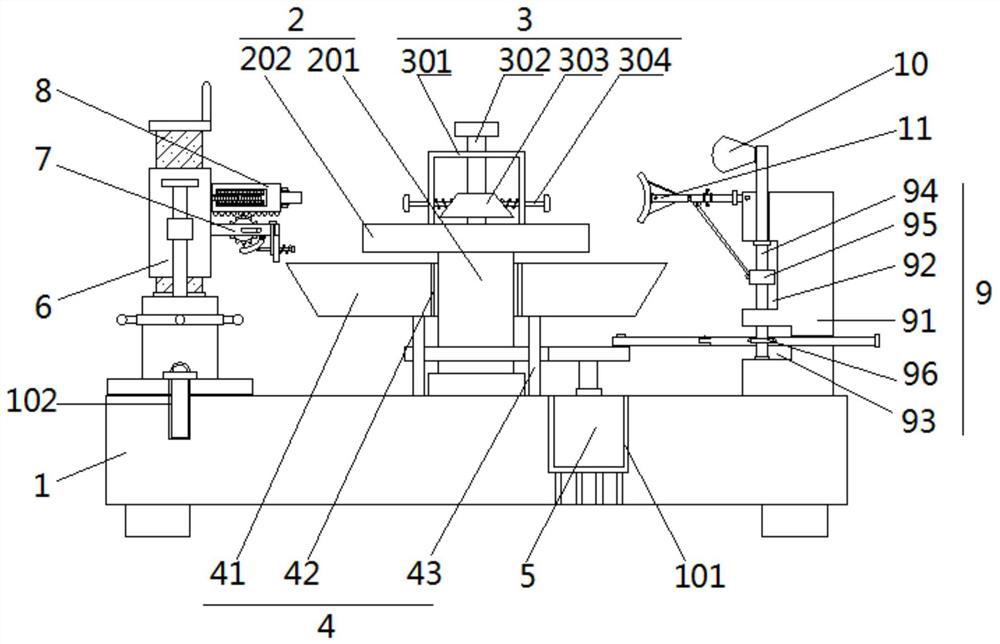

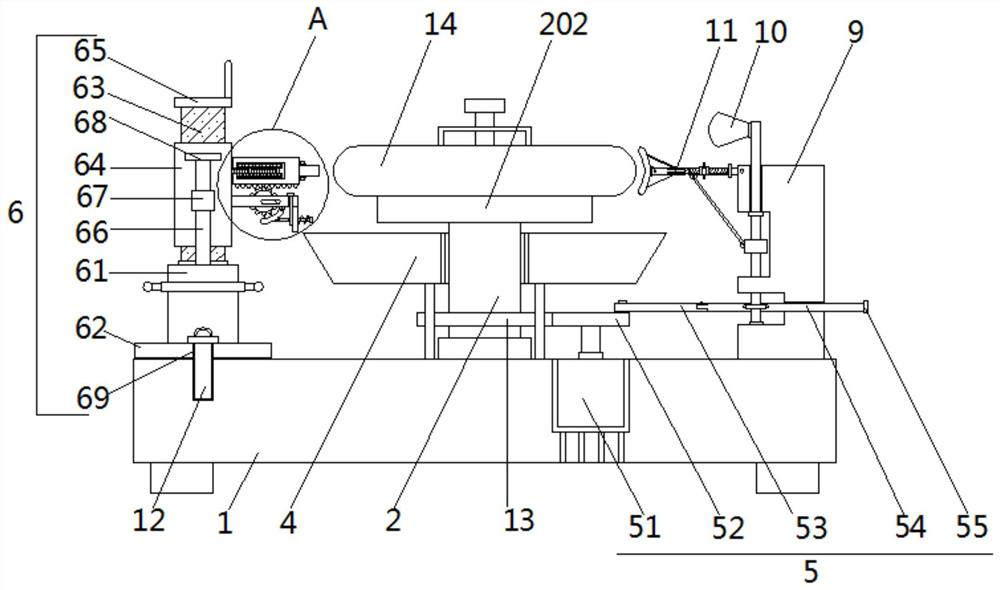

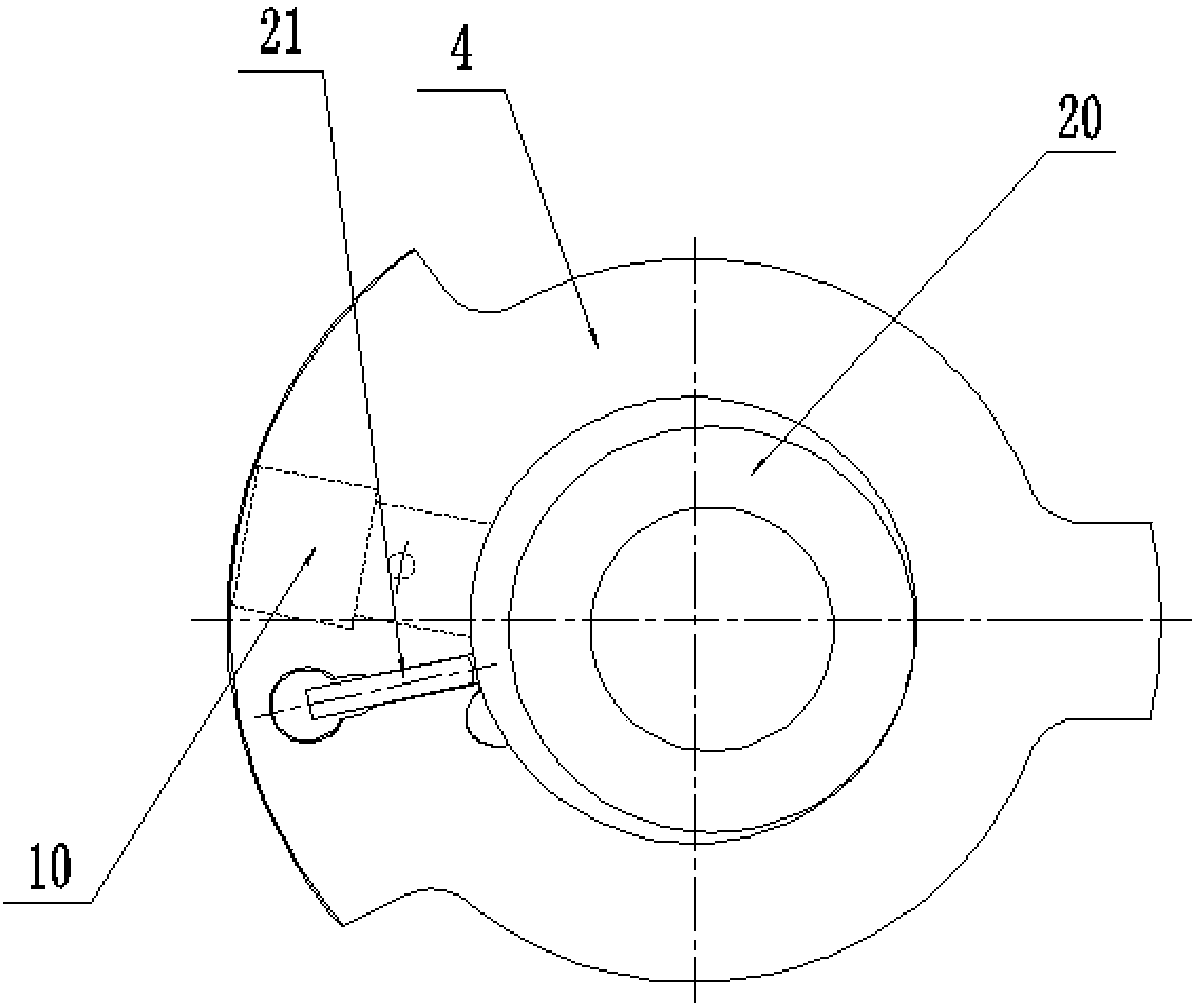

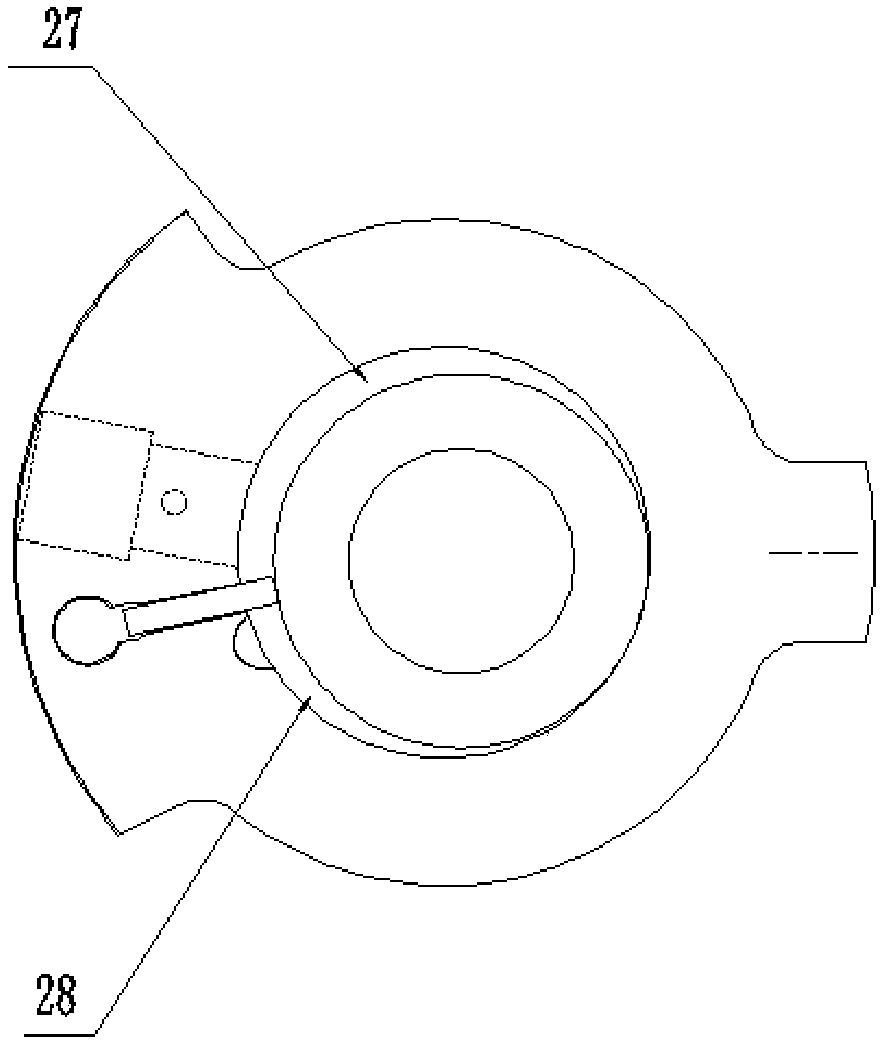

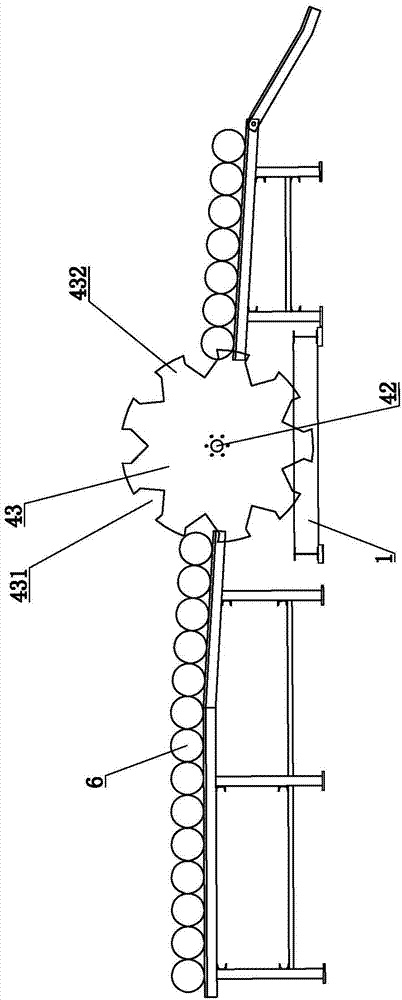

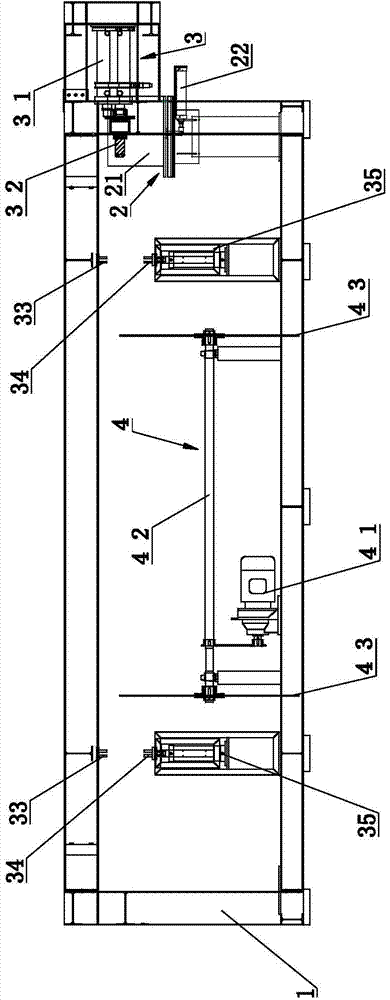

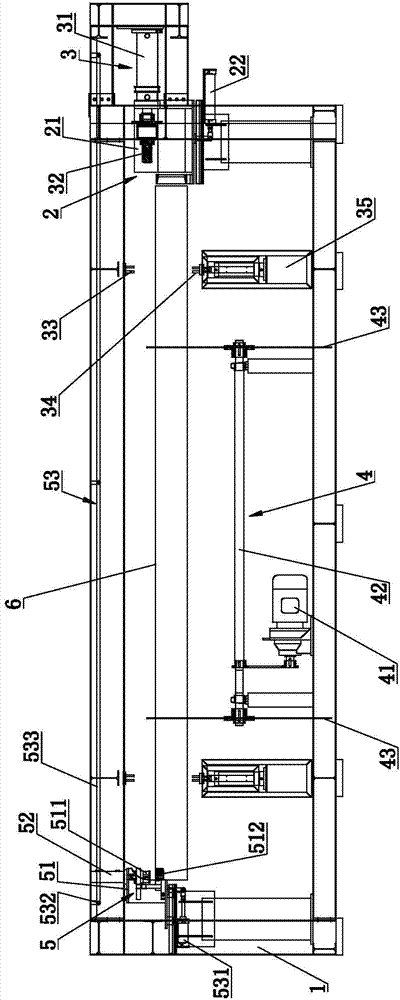

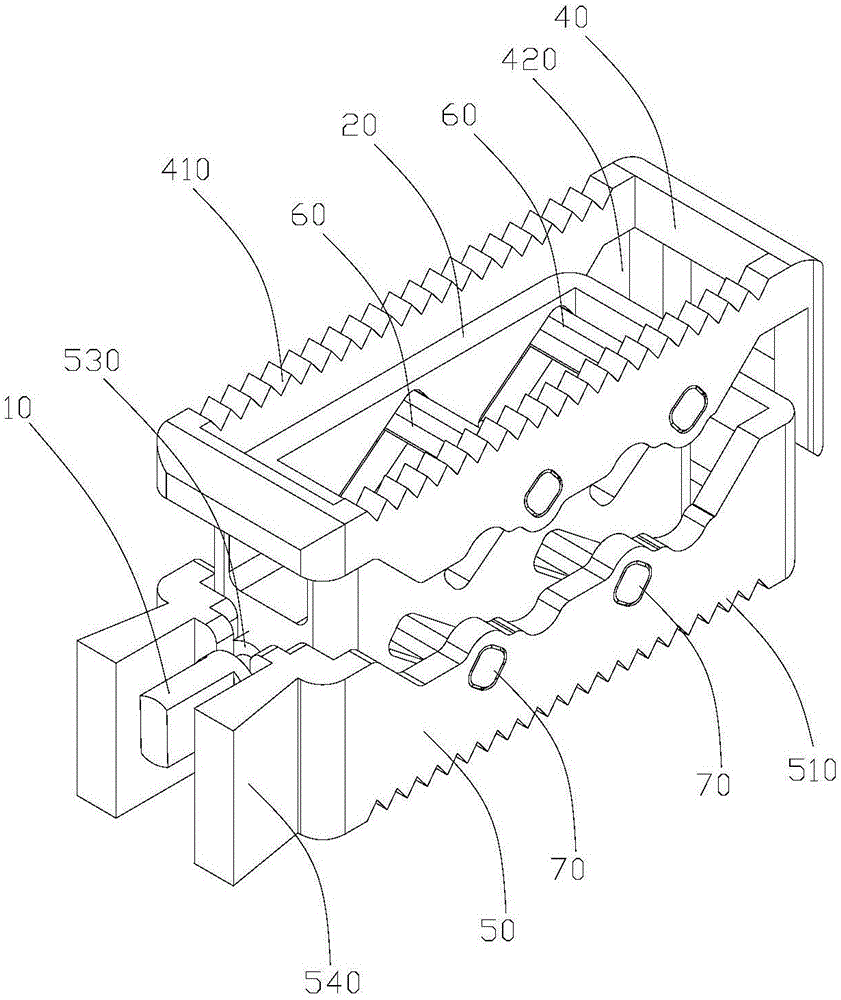

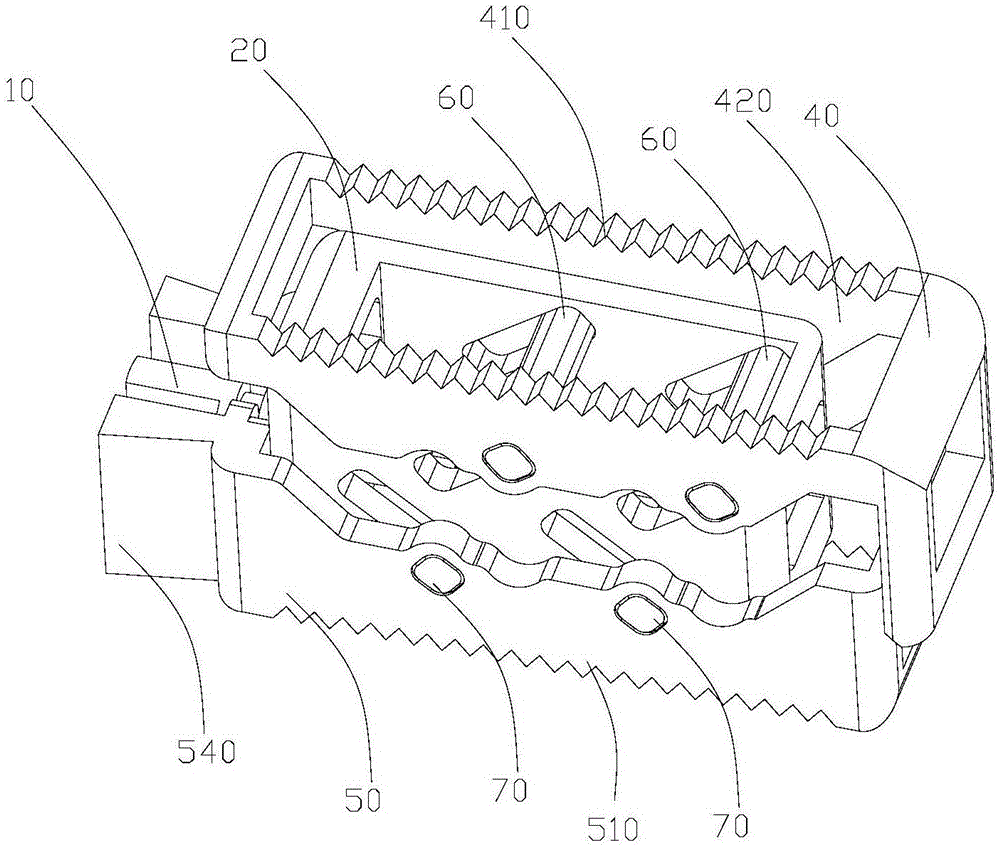

Saw cutting machine for special pipes

ActiveCN103801762ANot easy to shakeAvoid damageMetal sawing devicesEngineeringMechanical engineering

The invention discloses a saw cutting machine for special pipes. The saw cutting machine comprises a machine base, a feeding clamp assembly, a saw cutting device and a discharging clamp assembly. The saw cutting device is installed on the machine base. The feeding clamp assembly is fixed to the upstream side of the saw cutting device and comprises an arc-shaped chute base, a rotating base, a first clamp half body, a second clamp half body, a clamping power device and a locking device, wherein the arc-shaped chute base is fixed to the machine base, the rotating base is installed on the arc-shaped chute base and locked by the locking device, at least one of the first clamp half body and the second clamp half body is installed on the rotating base in a sliding mode, and the clamping power device is fixed to the rotating base to drive the first clamp half body or / and the second clamp half body to get close to each other or get away from each other in a sliding mode. The discharging clamp assembly is installed on the downstream side of the saw cutting device and driven by a discharging power device to slide. The saw cutting machine can clamp the pipes optionally in different directions, make cross sections of cut pipes neat, improve cutting quality and prevent damage to the surfaces of the pipes.

Owner:SUZHOU KINKALTECK MACHINERY TECH

Industrial part conveying device

InactiveCN102514899AImprove structural rigidityAvoid deformationMechanical conveyorsEngineeringUltimate tensile strength

The invention discloses an industrial part conveying device, which comprises part grippers. A frame consists of longitudinal main beams and horizontal crossbeams, vertical beams are connected below the frame at intervals, rails parallel to the main beams are fixed onto the vertical beams, sliding trolleys are hung on the rails, a cylinder is mounted on each sliding trolley, the tip of a piston rod matched with the corresponding cylinder is connected with a bottom plate, guide columns are connected onto each bottom plate, guide cylinders sleeved onto the guide columns are arranged on each sliding trolley, and each part gripper is mounted on the corresponding bottom plate. Compared with the prior art, the industrial part conveying device is fine in integral structure rigidity, not easy to deform, safe, reliable, low in noise in operation, high in stability and not easy to shake when hoisting workpieces for horizontal movement, and accurate in place, so that operation efficiency is improved, labor intensity of operators is reduced, and yield is high.

Owner:大连奥托股份有限公司

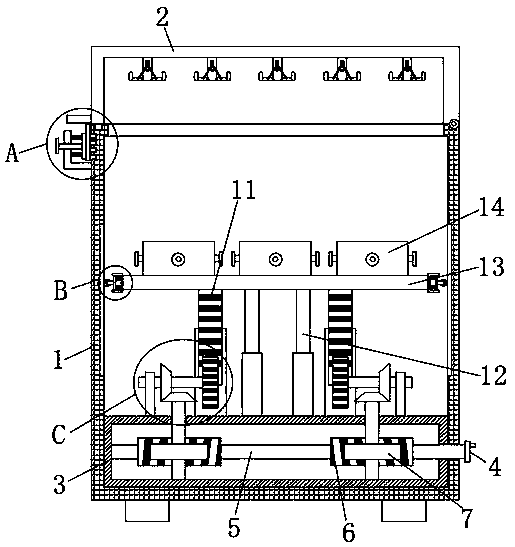

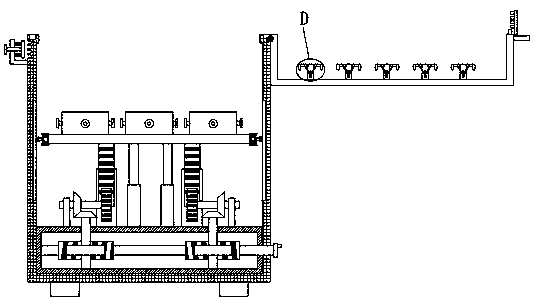

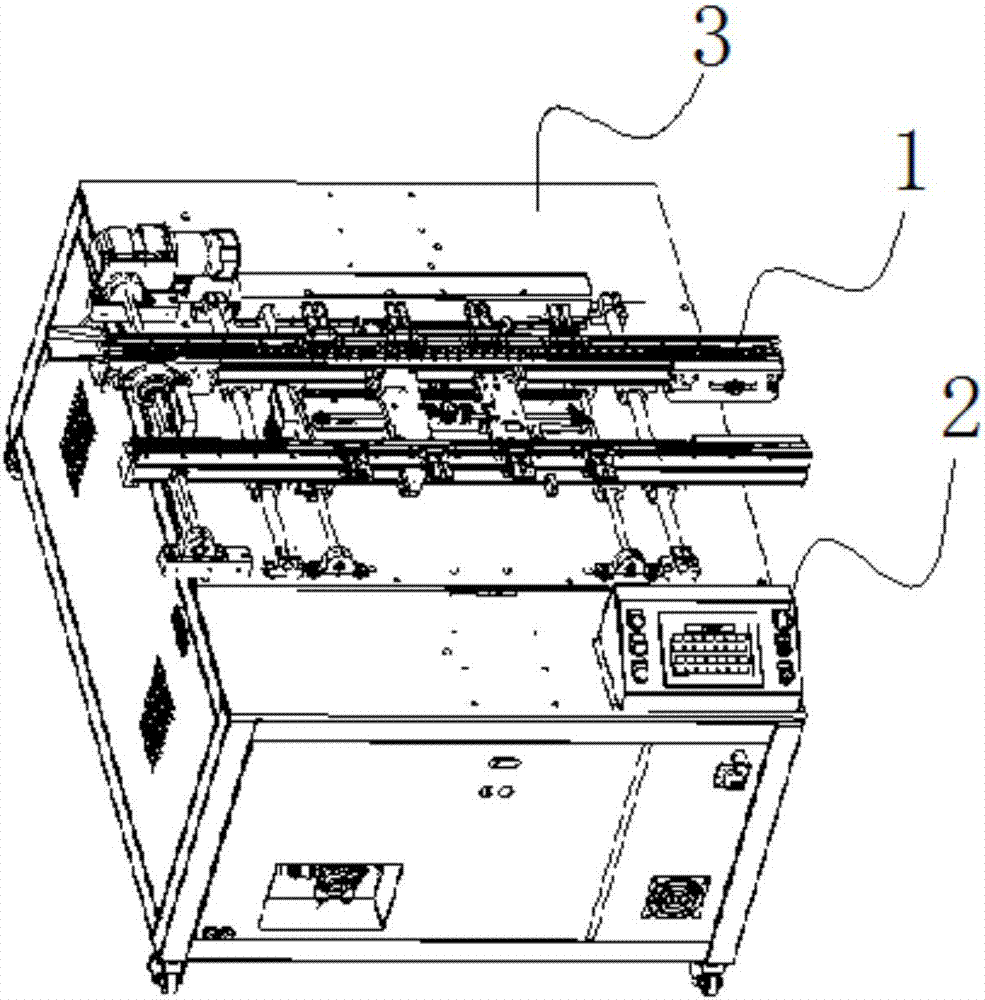

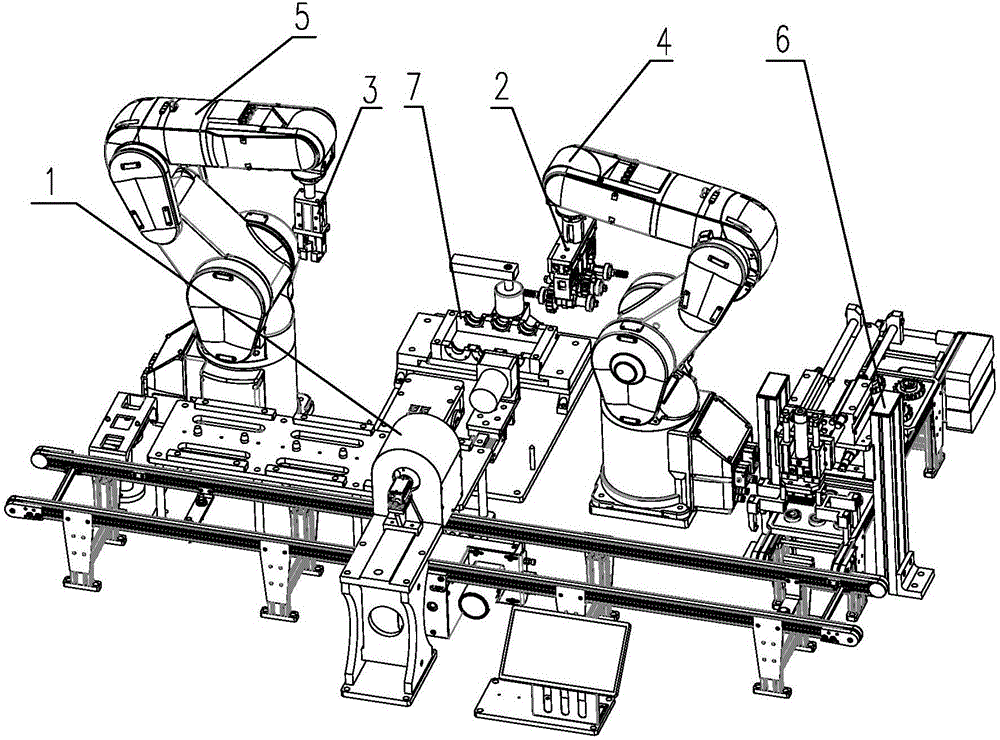

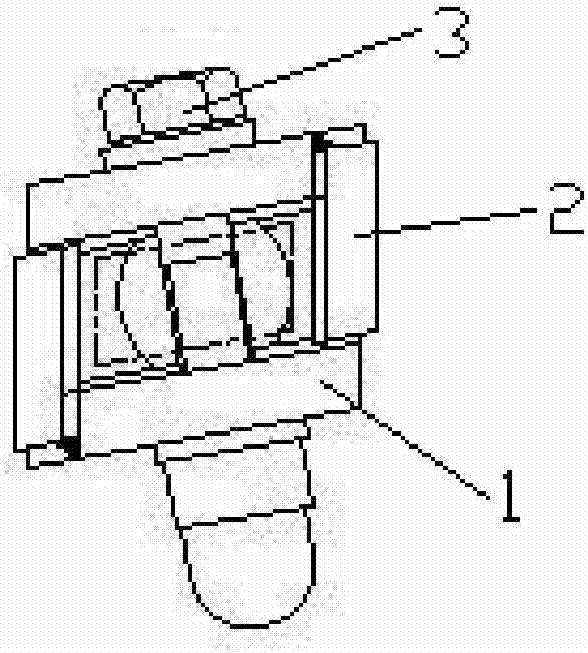

Assembling machine for assembling gears, bearings and gear shafts

Owner:YALONG INTELLIGENT EQUIP GRP CO LTD

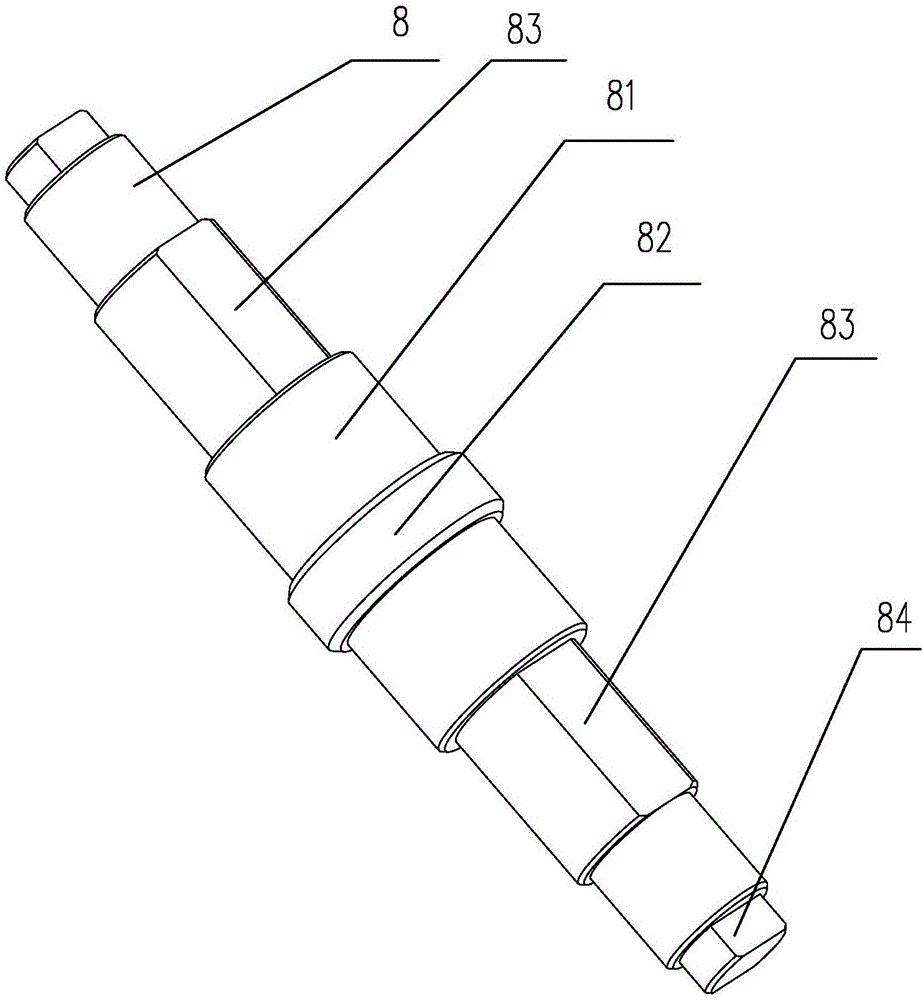

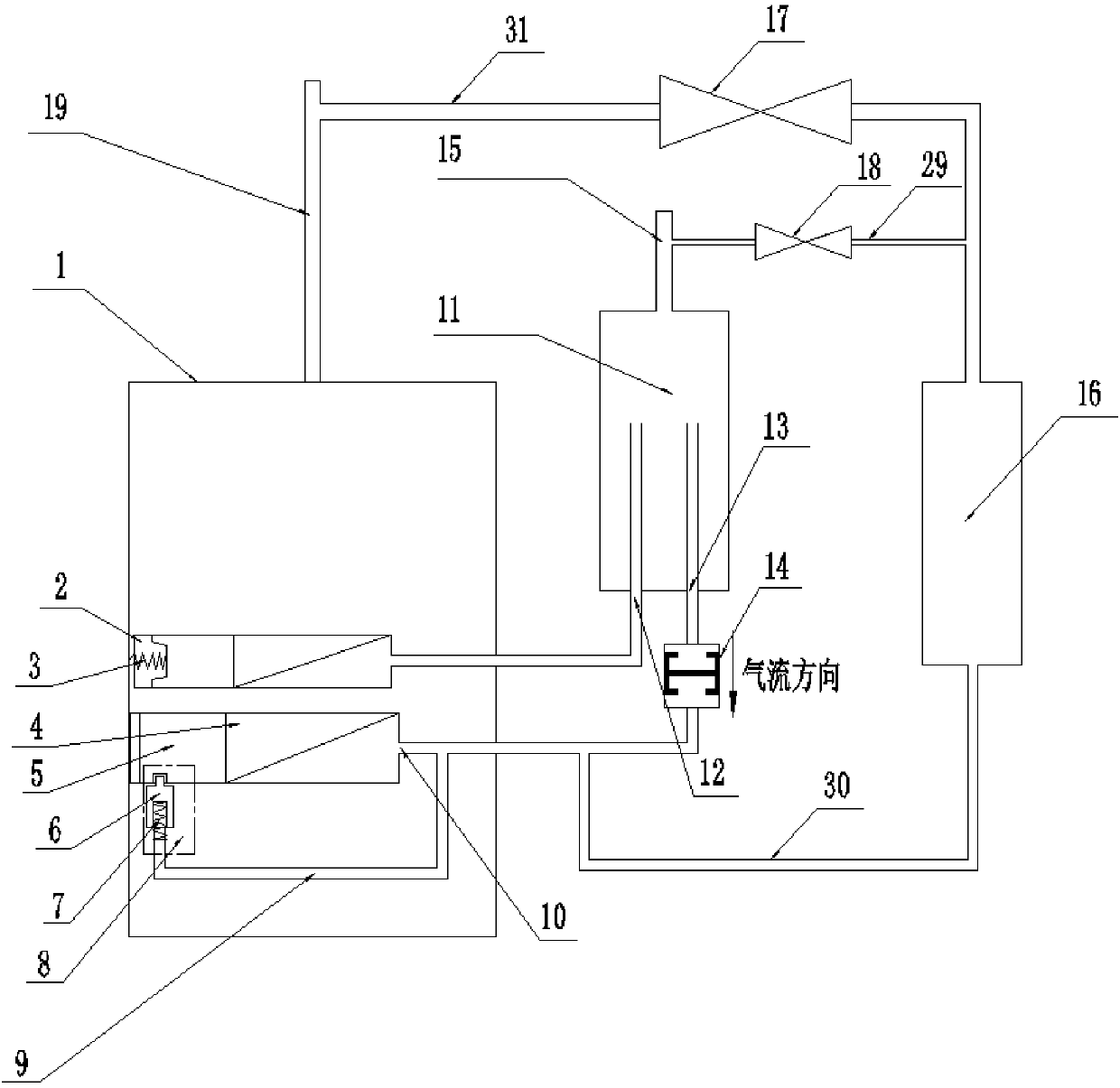

Capacitance-variable control structure, compressor and capacitance-variable control method thereof

PendingCN107917078AReduce jitterAvoid problems such as breakageRotary piston pumpsRotary piston liquid enginesCapacitanceEngineering

The invention discloses a capacitance-variable control structure, a compressor and a capacitance-variable control method thereof. The structure comprises a capacitance-variable assembly and a slidingvane restraint unit (8), wherein the capacitance-variable assembly is arranged on the outer part of a shell (1) of the compressor to which the capacitance-variable control structure belongs, and is used for acting according to a setting sequence; and the sliding vane restraint unit (8) is arranged in a pump body of the compressor, and is used for enabling a capacitance-variable cylinder assembly in the compressor to be at a working state or an idling state under the control of acting of the capacitance-variable assembly according to the setting sequence. According to the technical scheme provided by the invention, the defects such as violent shaking, easiness in machine halt and easiness in breaking a pipeline in the prior art can be overcome, and the beneficial effects on reducing shaking, preventing machine halt, and preventing the pipeline from being broken are achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Reamer

ActiveCN104492988AIncrease productivitySave energyShaping toolsMetal-working feeding devicesReamerSmall footprint

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

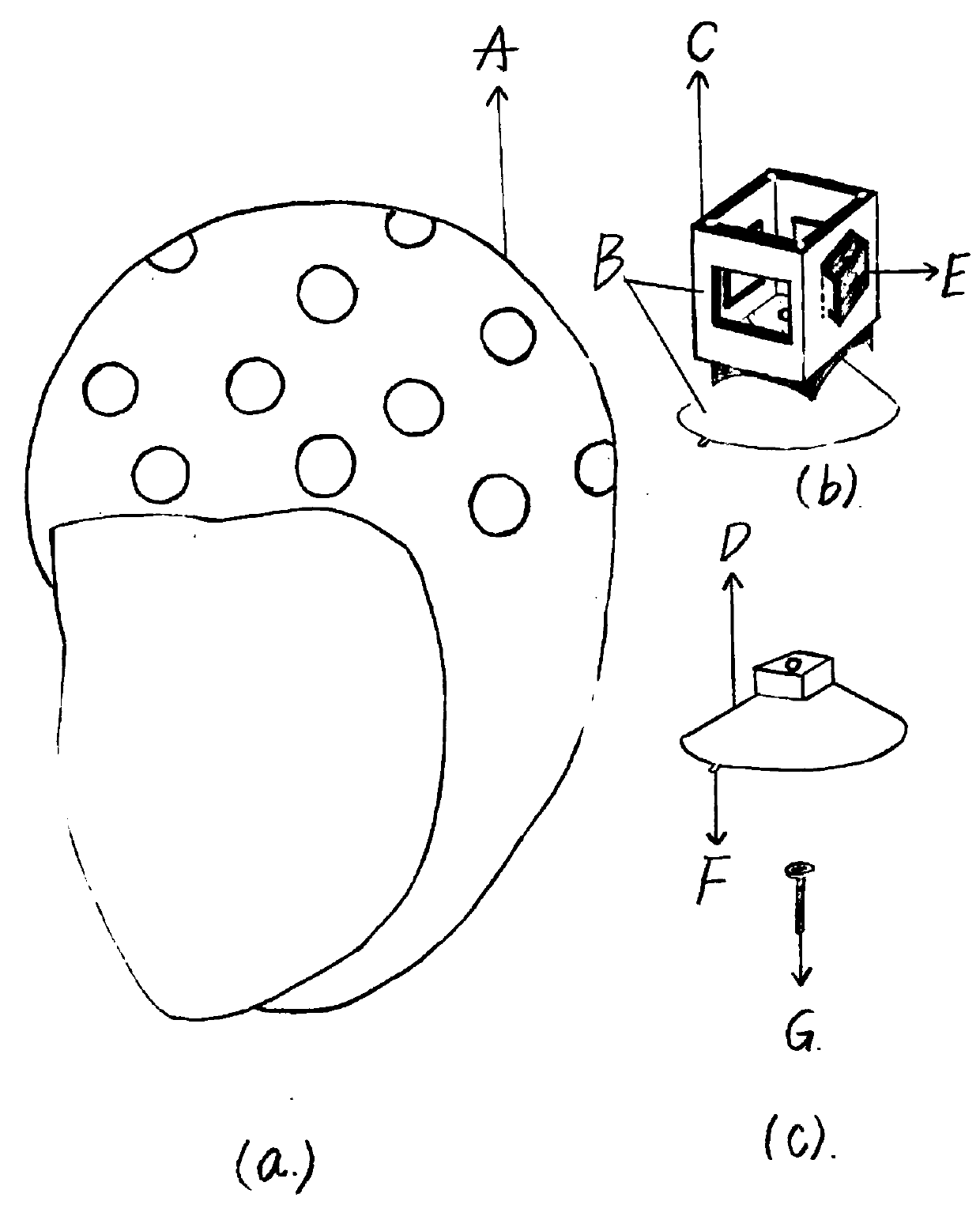

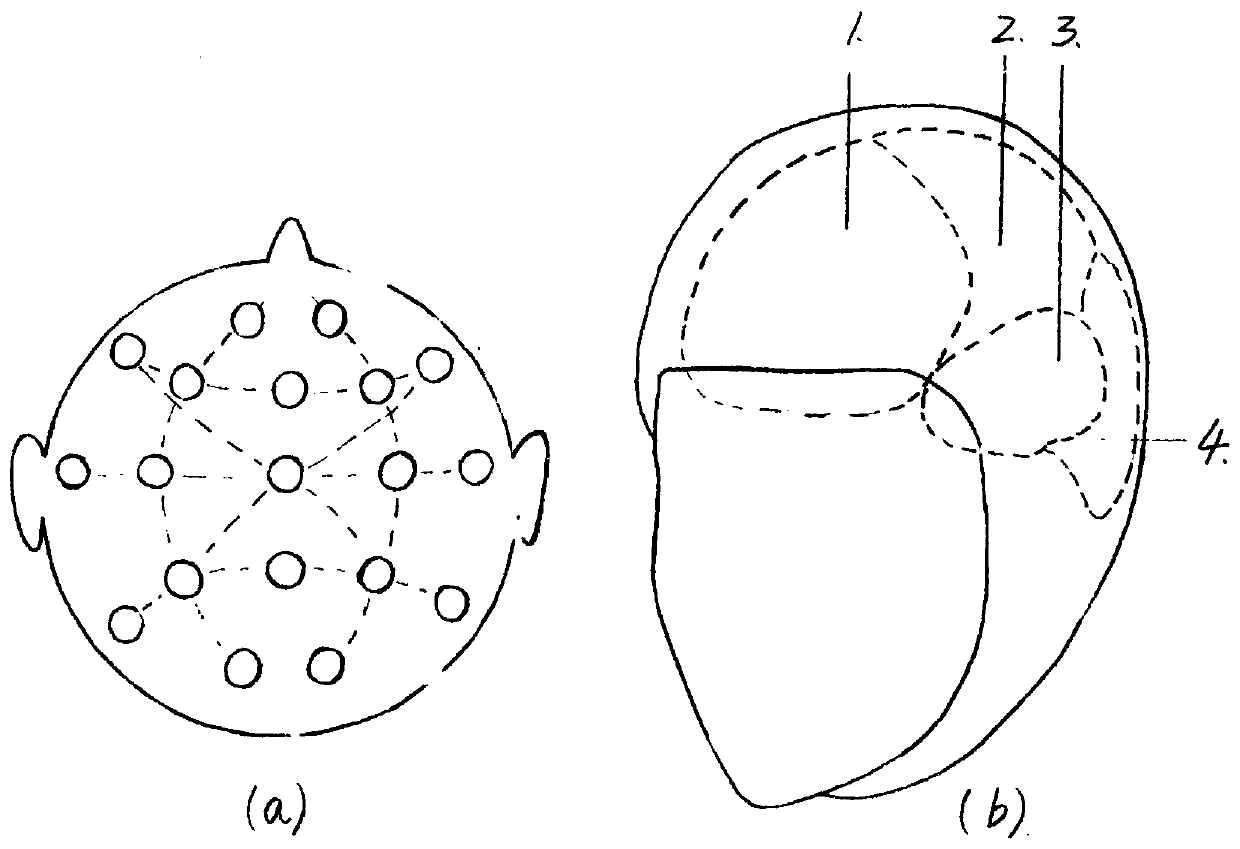

Sucked type wearable flexible MEG cap for measuring human brain magnetic field signals

ActiveCN110710966ANo shakingInsert smoothlyDiagnostic recording/measuringSensorsThermal insulationSilica gel

The invention discloses a sucked type wearable flexible MEG cap for measuring human brain magnetic field signals, belongs to the field of biomedical engineering, and relates to a medical instrument. The MEG cap consists of a flexible cap body and sucked type clamping grooves, wherein each sucked type clamping groove comprises a clamping groove, a sucker and a fixing bolt for connecting the clamping groove and the sucker; a grid MEG capable of arranging the sucked type clamping grooves in array is drawn on the surface of the flexible cap body in reference of an internationally general 10-20 standard EEG acquisition lead system and physiological construction and functional division of human brains; the flexible cap is made of a thermal insulation silicone material, can be attached to scalp of a testee closely, and guarantees the distance between low-intensity field measuring sensors inserted into the sucked type clamping grooves and the real scalp of the testee is the minimum as far as possible; and the flexible cap cooperates with the sucked type clamping grooves, can adapt any measurement positions of complex human head curved surfaces. The sucked type wearable flexible MEG cap isan MEG detection tool with higher universality, very low detection cost and reliability.

Owner:BEIHANG UNIV

Conductive terminal

ActiveCN105428830AGuaranteed reliabilityAvoid free turningClamped/spring connectionsPressure wireEngineering

The present invention provides a conductive terminal. The terminal comprises a housing; a wire pressure reed is arranged in the housing in a manner of rotating around an axis extending front and back; the wire pressure reed is respectively provided with a wire pressure-wire end and a drive end on both sides of a rotating shaft; the housing is rotatably provided with an operating handle used for driving the wire pressure reed to rotate between a wire connection position and a wire pressure position; the operating handle is in parallel to the rotating axis of the wire pressure reed; one end of the operating handle, which is positioned inside the housing, is provided with a contact section; the contact section is provided with a reed perforated hole used for the drive end of the wire pressure reed to pass through; the reed perforated hole is provided with a right hole wall used for pushing the outer lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire pressure position when the operating handle rotates forwards; and the reed perforated hole is also provided with a left hole wall used for pulling the inner lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire connection position when the operating handle is rotated reversely. The conductive terminal disclosed by the present invention is simple in structure and very convenient to use.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Blade spraying protective fixture

ActiveCN107138325AImprove spray uniformityNot prone to "collapse" phenomenonSpraying apparatusFlangeEngineering

Owner:CHINA HANGFA SOUTH IND CO LTD

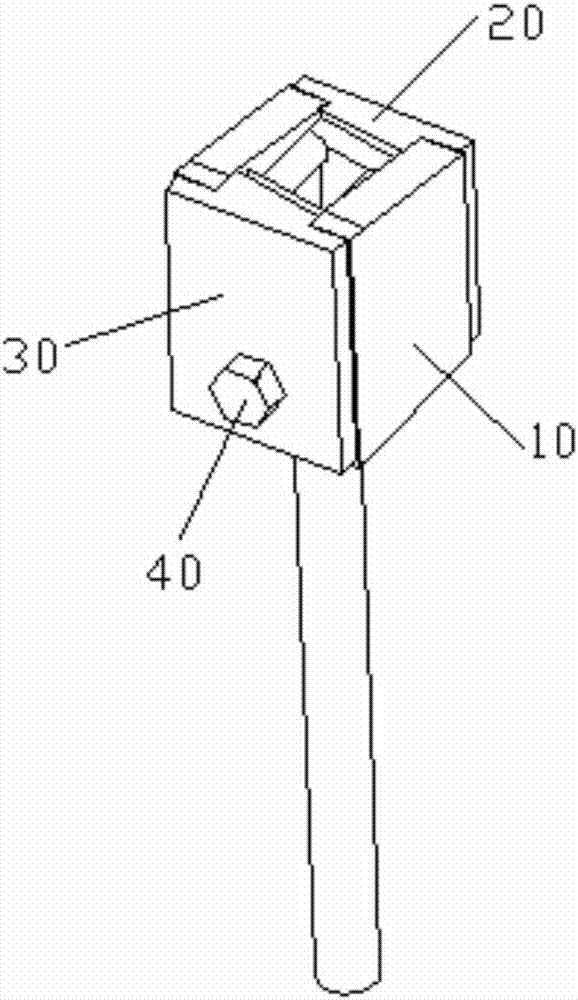

Vertical storage equipment

Owner:XUZHOU HUAHENG ROBOT SYST

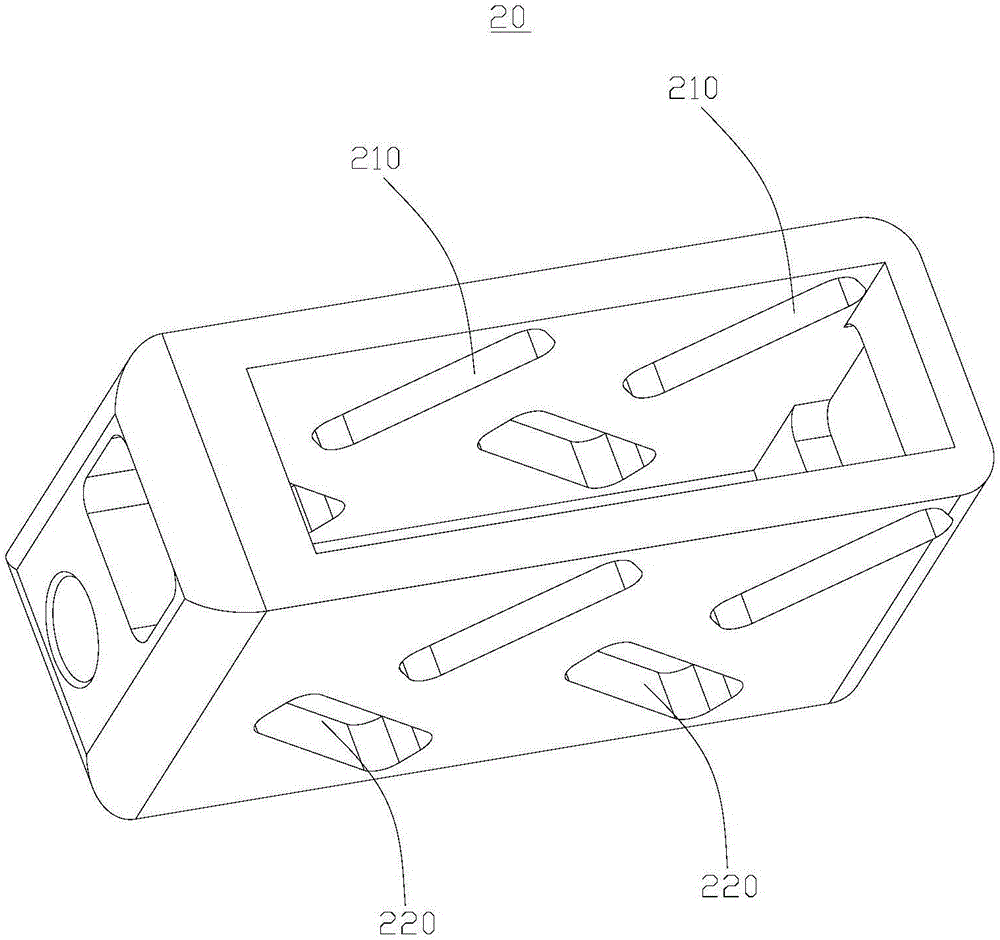

Lifting interbody fusion device and operation device for driving same

The invention relates to a lifting interbody fusion device and an operation device for driving the same. The lifting interbody fusion device comprises a screw, a middle limiting frame, an upper lifting block and a lower lifting block. The upper lifting block is arranged on the outer side of the upper portion of the middle limiting frame in a sleeving mode, the lower lifting block is arranged on the outer side of the lower portion of the middle limiting frame in a sleeving mode, at least two first inclined grooves and at least two second inclined grooves are formed in each of the two side walls of the middle limiting frame, the inclination directions of the first inclined grooves and the second inclined grooves are opposite, first bolts in sliding fit with the first inclined grooves are arranged on the slide walls of the upper lifting block, second bolts in sliding fit with the second inclined grooves are arranged on the slide walls of the lower lifting block, and the screw is connected with the middle limiting frame through threads and limited on the upper lifting block or the lower lifting block. The interbody fusion device is adjustable in height and stable in use; besides, the inner space of the interbody fusion device is large, the bone grafting space in an operation is large, the bone grafting quantity is large, and the healing success rate is high.

Owner:GUANGZHOU ARNOLD MEDICAL DEVICE CO LTD

Novel machining center fixture device applicable to polygonal part

PendingCN107900727AEasy to fixNot easy to shakePositioning apparatusMetal-working holdersEngineeringMiddle line

The invention discloses a new fixture device of a machining center suitable for polygonal parts, comprising a cylindrical workbench, the upper surface of the cylindrical workbench is fixed with three positioning devices at equal angles around its midline axis, the positioning device includes a fixing plate, a polygonal part The bottom end is located in the circular ladder, and the staff adjust the three positioning devices respectively so that the three contact plates fix the polygonal parts, the staff rotates the first handle, the first handle makes one end of the first screw contact with the polygonal parts, and the polygonal parts are fixed It is firm and not easy to shake; the electric suction cup on the adsorption device absorbs the bottom surface of polygonal parts, prevents the displacement of polygonal parts in the up and down direction, and ensures the processing accuracy and quality of parts; the annular ladder can limit the lower ends of polygonal parts of different sizes, and the The arc transitions on both sides of each step avoid damage to the surface of polygonal parts due to the design of the two sides at right angles.

Owner:韩青青

Pan-shot method and mobile terminal

ActiveCN108881733ANot easy to shakeIncrease shooting angle and image clarityTelevision system detailsColor television detailsDistinctness of imageImage stitching

The present invention provides a pan-shot method and a mobile terminal. The mobile terminal comprises a first display screen capable of folding, the first display screen comprises a first display areaand a second display area, the back surface of the first display area is provided with a first camera module, and the back surface of the second display area is provided with a second camera module.The method comprises the steps of: when a first included angle between the first display area and the second display area meets a preset condition, respectively obtaining a first image and a second image through the first camera module and the second camera module; receiving first input of a user controlling movement of the first display area to the second display area; responding to the first input, and obtaining a first image sequence through the first camera module in a process of reduction of the first included angle; and performing image stitching according to the first image, the secondimage and the first image sequence to generate a first panoramic image. The pan-shot method and the mobile terminal can improve the shooting angle and the image definition so as to improve the pan-shot effect.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com