Patents

Literature

41 results about "Pressure wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

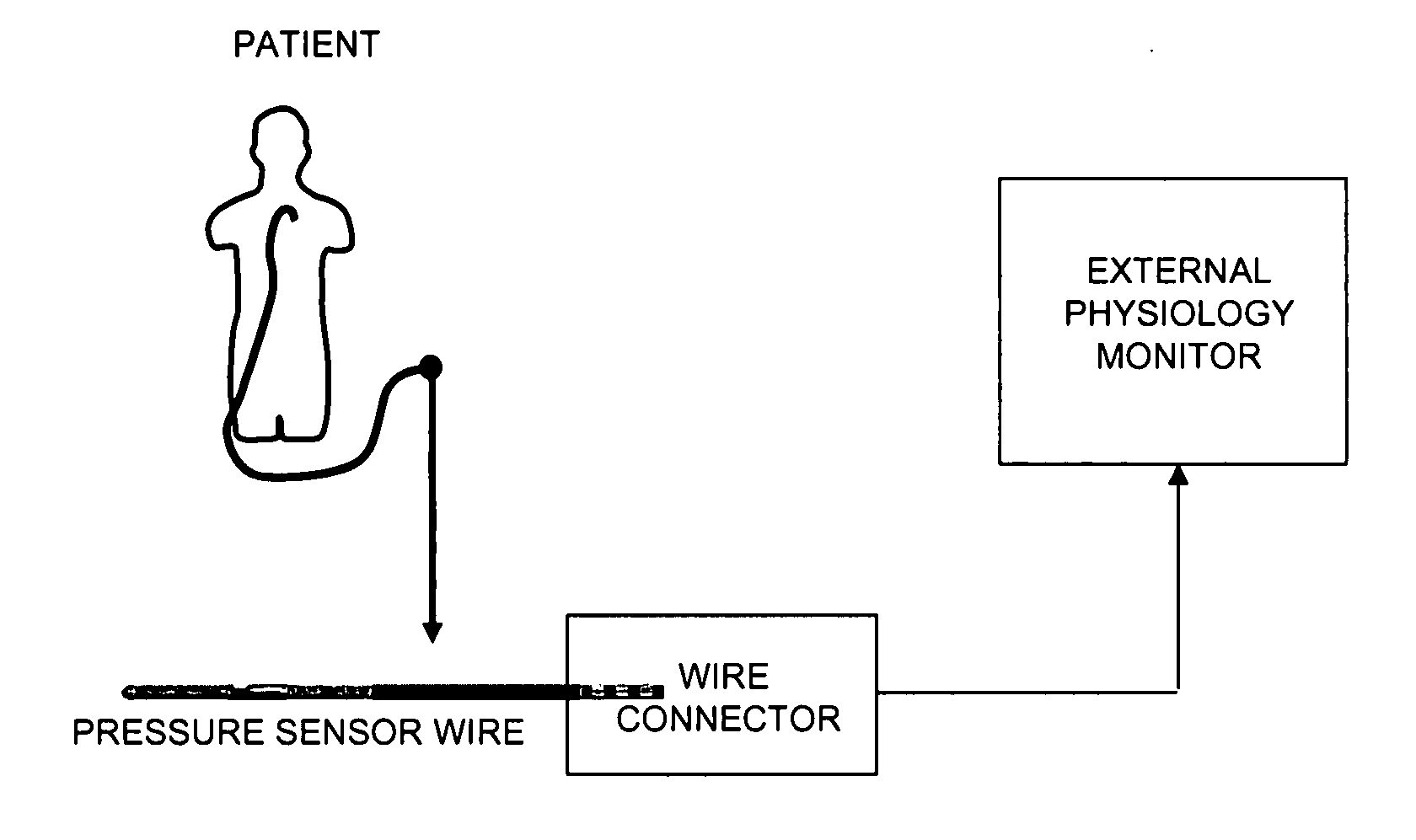

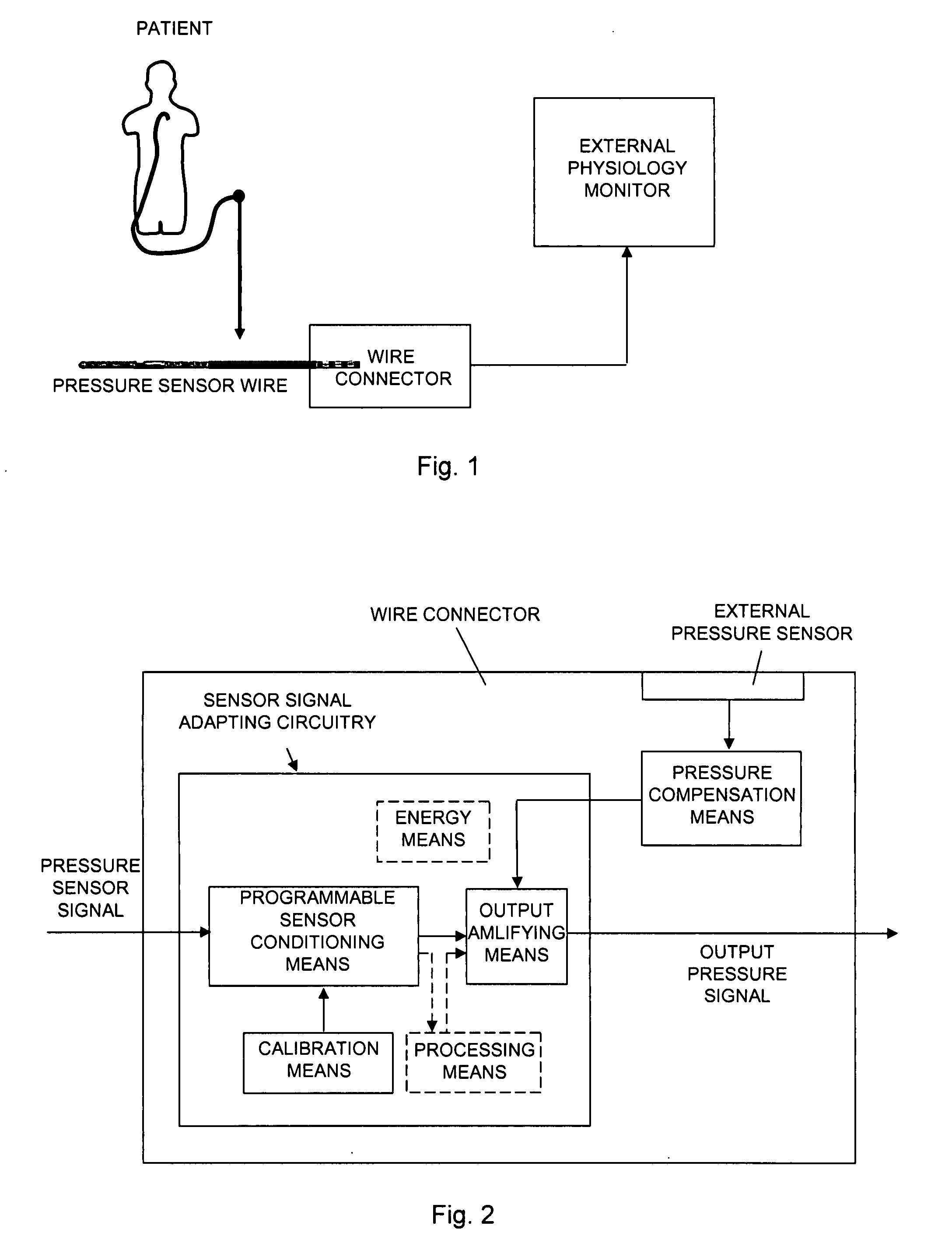

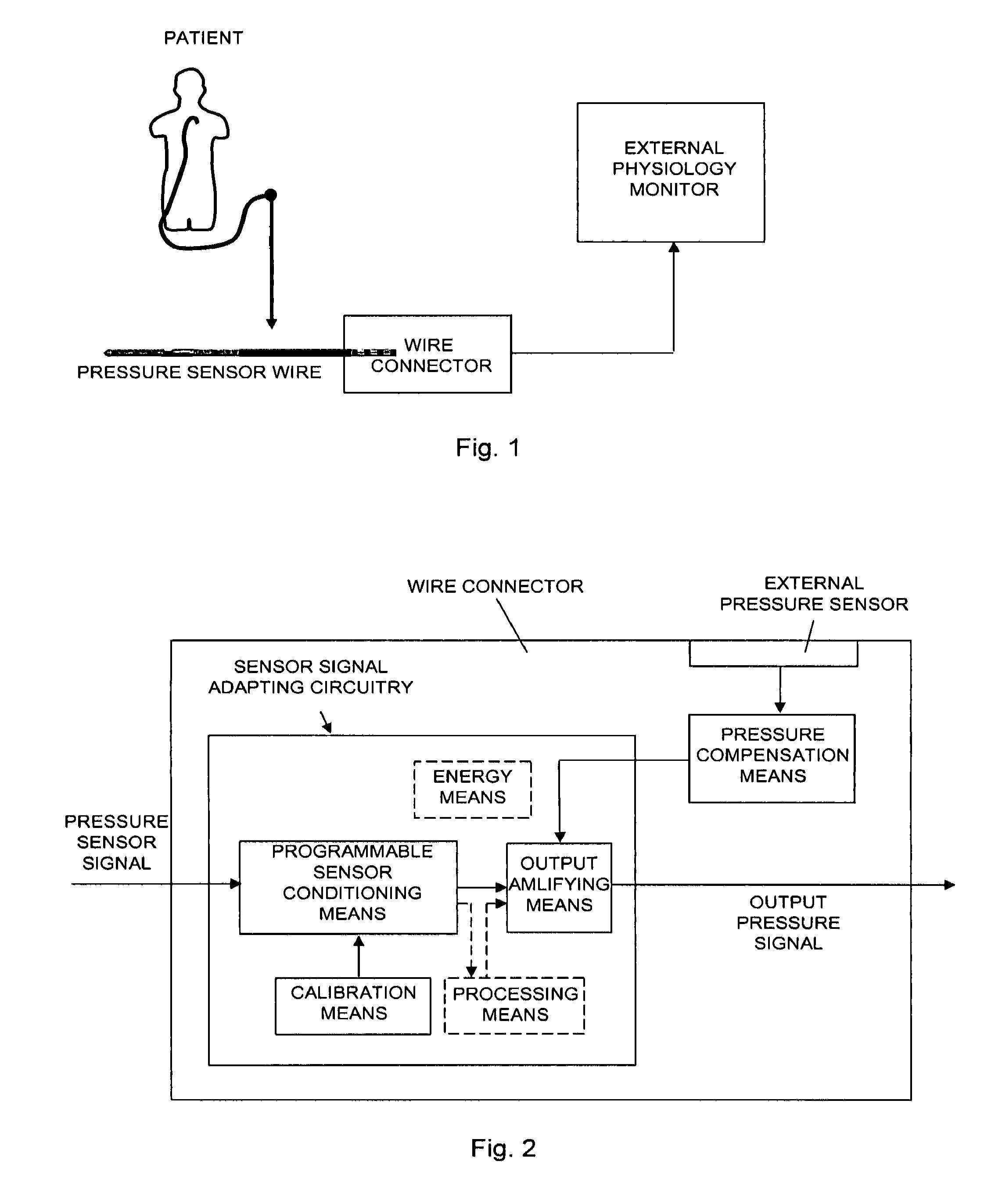

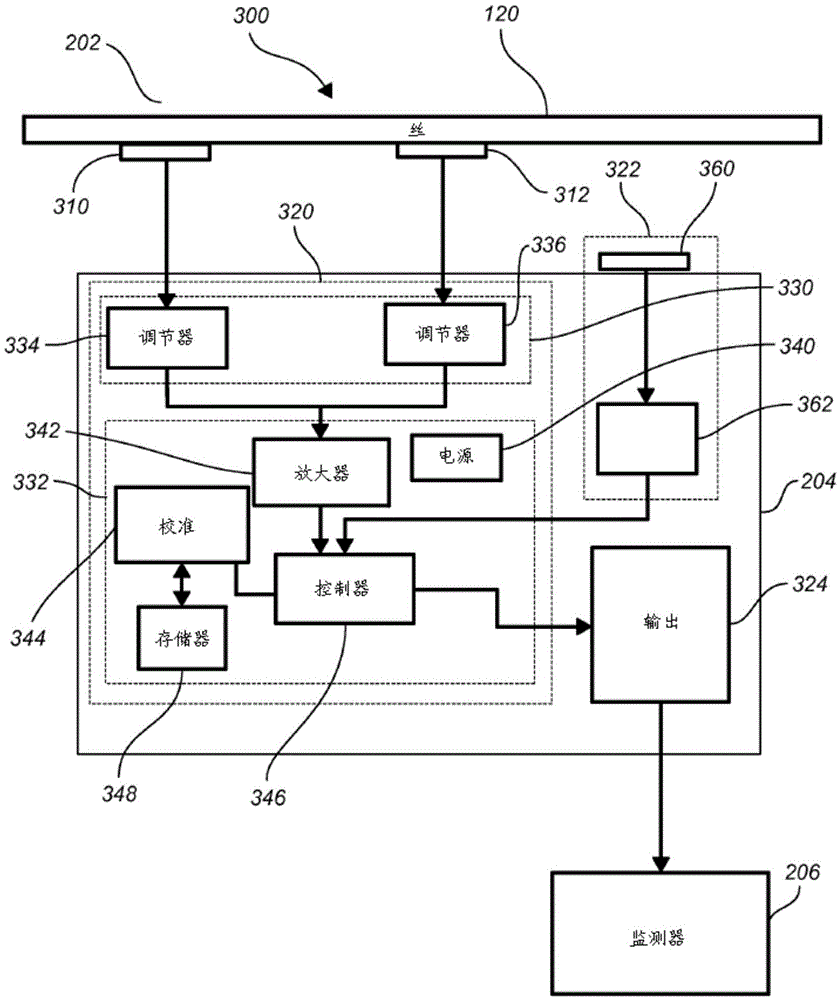

Pressure wire assembly

Pressure sensor wire assembly for measuring pressure inside a body of a patient, the assembly comprises a pressure sensor element for measuring pressure and to generate a pressure sensor signal in response of said pressure, and a pressure sensor wire having said pressure sensor element at its distal portion, and adapted to be inserted into the body in order to position the sensor element within the body. In addition is arranged a sensor signal adapting circuitry, being an integrated part of said assembly, wherein the pressure sensor signal is applied to the adapting circuitry that is adapted to automatically generate an output pressure signal, related to the sensor signal, in a standardized format such that the measured pressure is retrievable by an external physiology monitor. The assembly further comprises an external pressure sensor arranged at the assembly to measure the pressure outside the patient's body and to generate external pressure values in dependence thereto, the external pressure values are applied to a pressure compensation means, in the assembly, adapted to generate a compensation value reflecting the external pressure variation during a measurement procedure, wherein the output pressure signal is compensated by said compensation value prior to the output pressure signal being applied to the external physiology monitor.

Owner:ST JUDE MEDICAL COORDINATION CENT

Pressure wire assembly

A pressure sensor wire assembly measures pressure inside a body of a patient. The assembly comprises a pressure sensor element for measuring pressure and to generate a pressure sensor signal representative of the pressure, and a pressure sensor wire having the pressure sensor element at its distal portion, and adapted to be inserted into the body in order to position the sensor element within the body. A sensor signal adapting circuitry is an integrated part of the assembly, wherein the pressure sensor signal is applied to the adapting circuitry which is adapted to automatically generate an output pressure signal, related to the sensor signal, in a standardized format such that the measured pressure is retrievable by an external physiology monitor. The assembly further comprises an external pressure sensor to measure the pressure outside the patient's body and to generate external pressure values in dependence thereto.

Owner:ST JUDE MEDICAL COORDINATION CENT

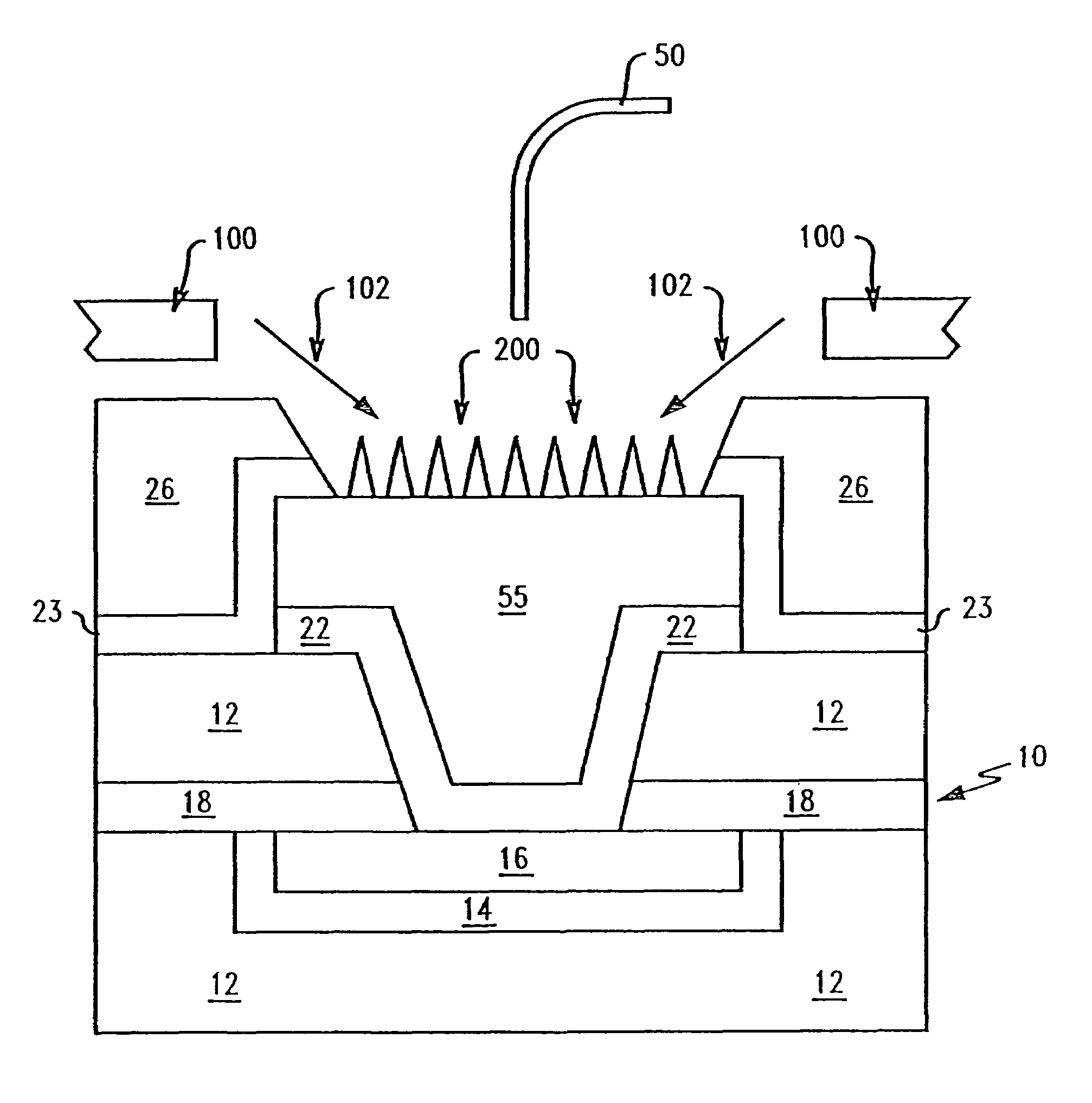

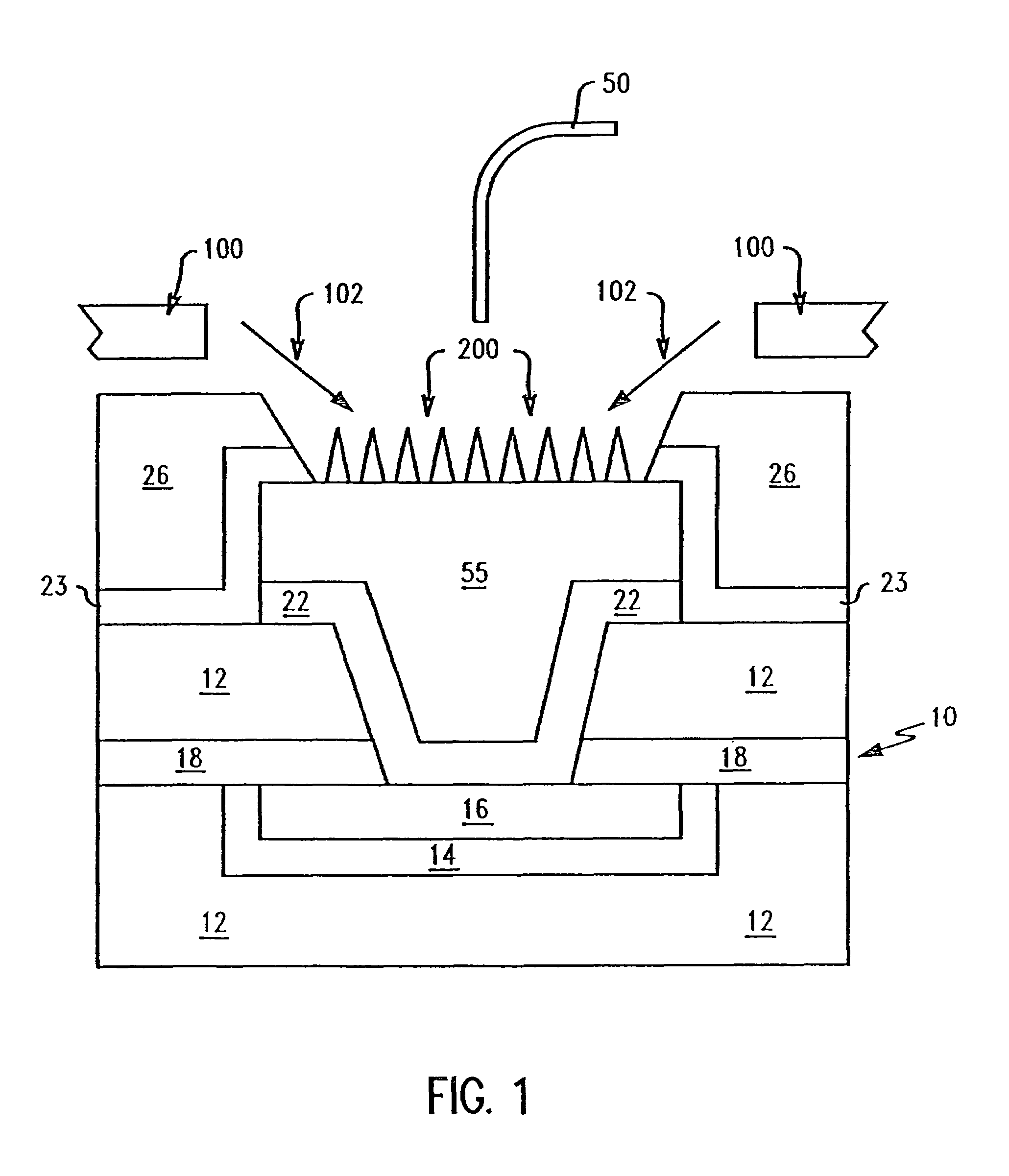

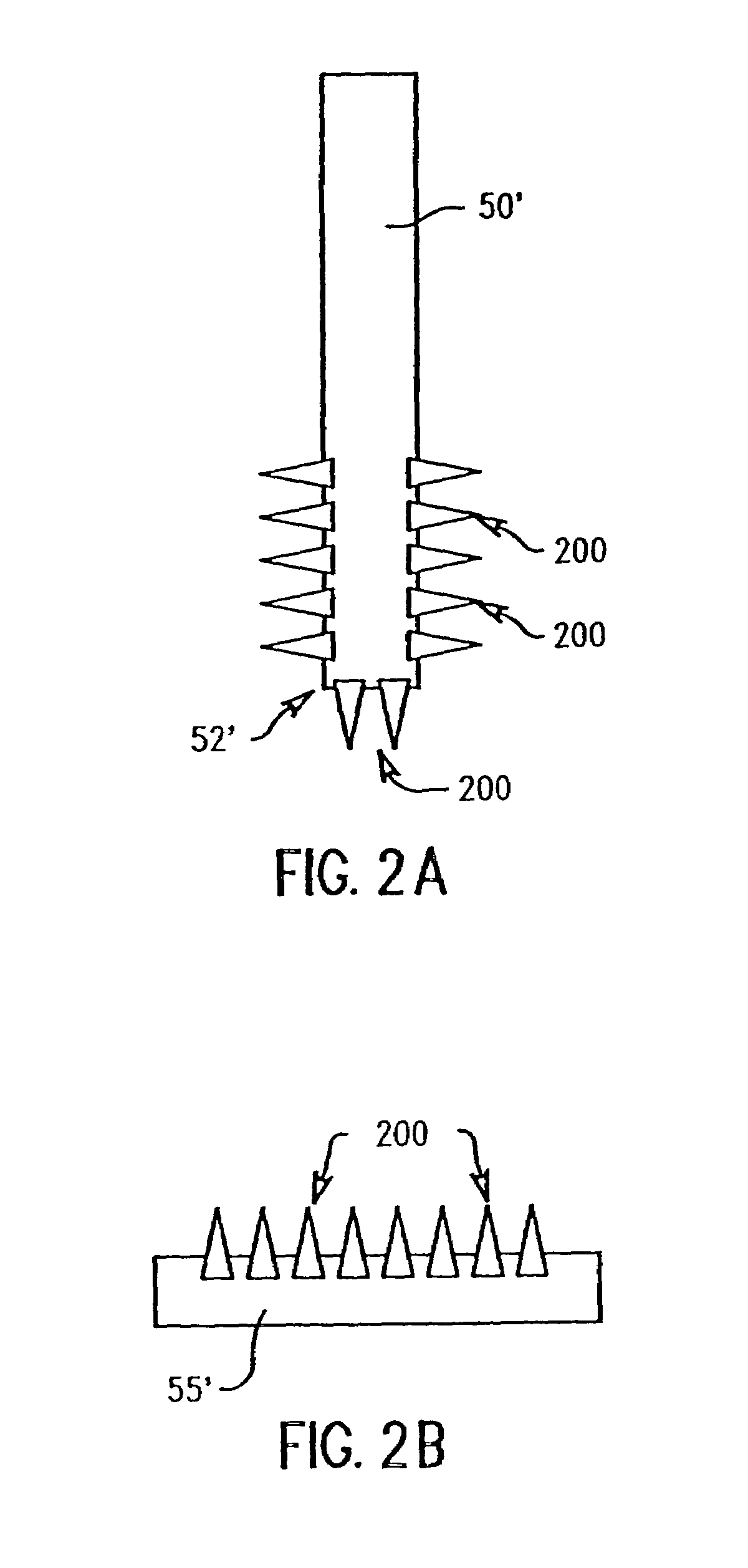

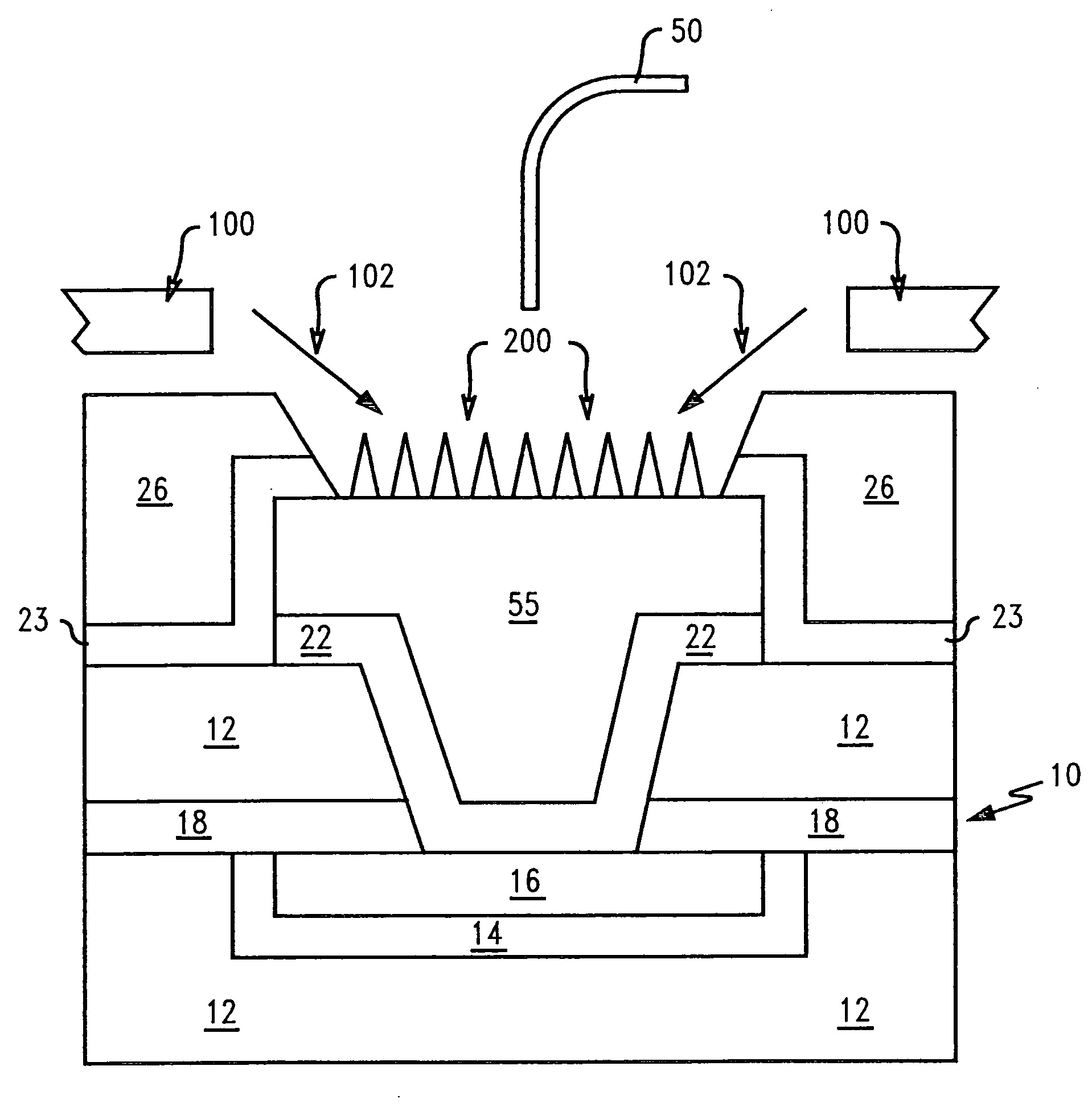

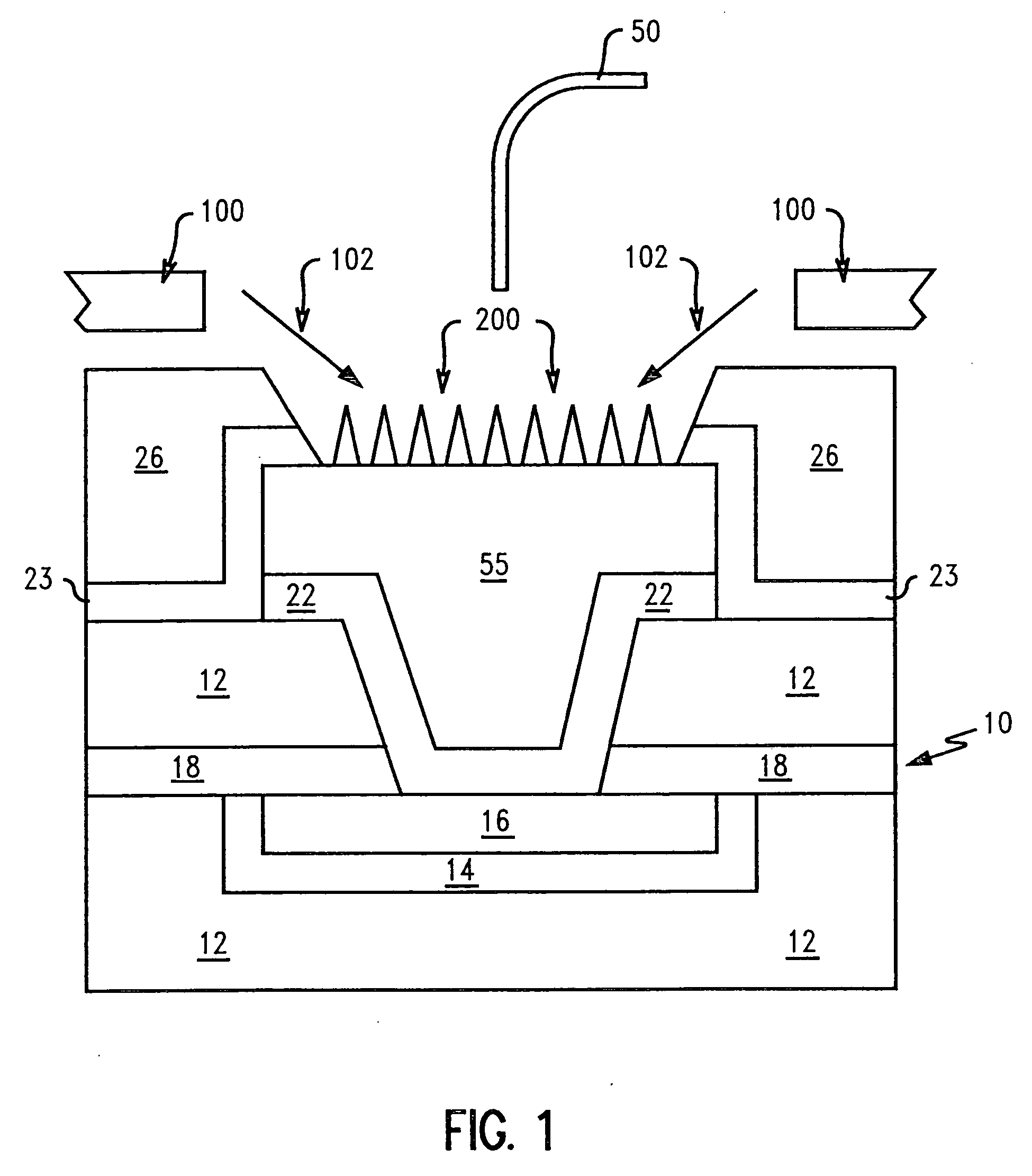

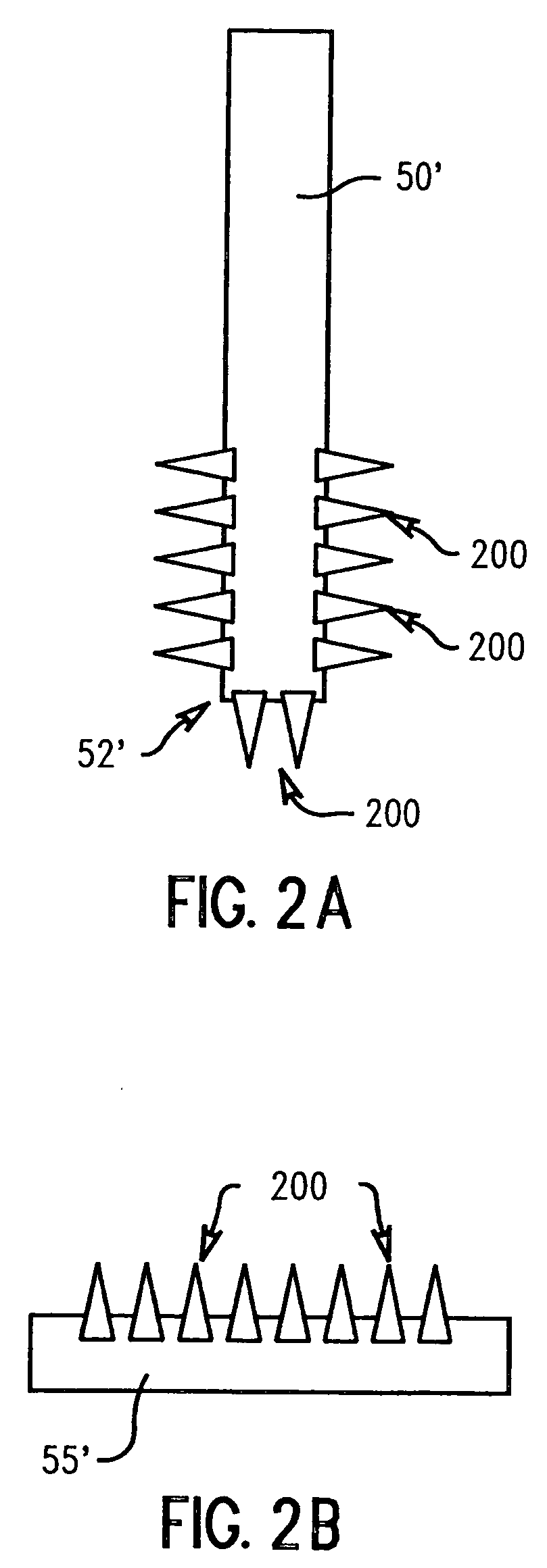

Roughened bonding pad and bonding wire surfaces for low pressure wire bonding

InactiveUS7015580B2Avoids creating any excessive force and powerStrong and reliable wire bondSemiconductor/solid-state device detailsSolid-state devicesPressure wireLead bonding

Owner:GLOBALFOUNDRIES U S INC

Roughened bonding pad and bonding wire surfaces for low pressure wire bonding

ActiveUS20050112861A1Avoids creating any excessive force and powerStrong and reliable wire bondSemiconductor/solid-state device detailsSolid-state devicesRough surfacePressure wire

An intermediate semiconductor structure and method for low-pressure wire bonding that reduces the propensity of dielectric material to mechanical failure due to any wire bonding stresses. Roughened surfaces such as metal pillars or metal dendrites are provided on a bonding pad, bonding wire or both. These roughened surfaces increase reactivity between the bond wire and the bond pad to form strong bonds. This increased activity as a result of the roughened bonding pad and / or wire surfaces reduce the amount of pressure, temperature and energy required for wire bonding, which in turn, avoids damage to the bonding pad as well as the semiconductor substrate.

Owner:GLOBALFOUNDRIES US INC

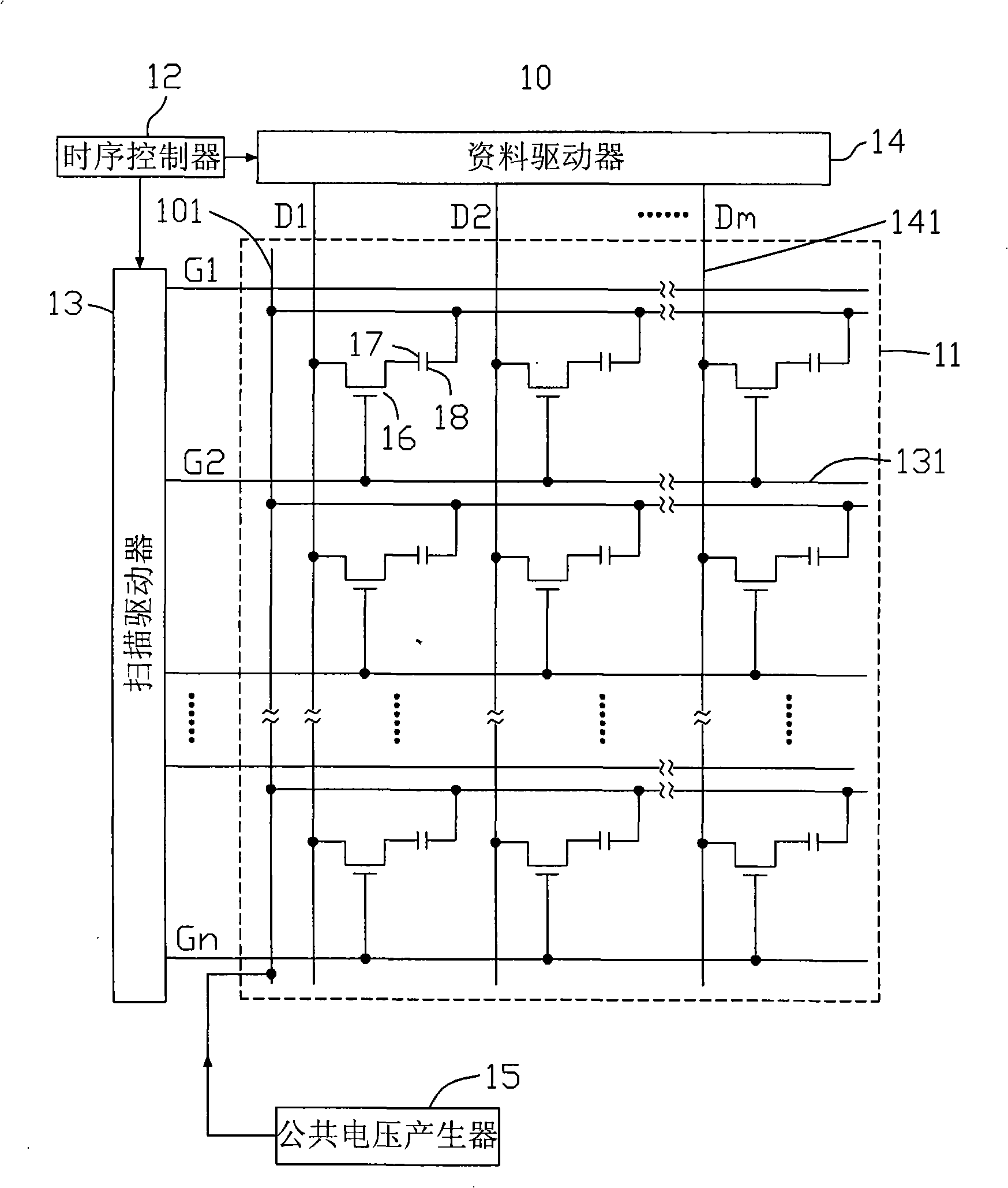

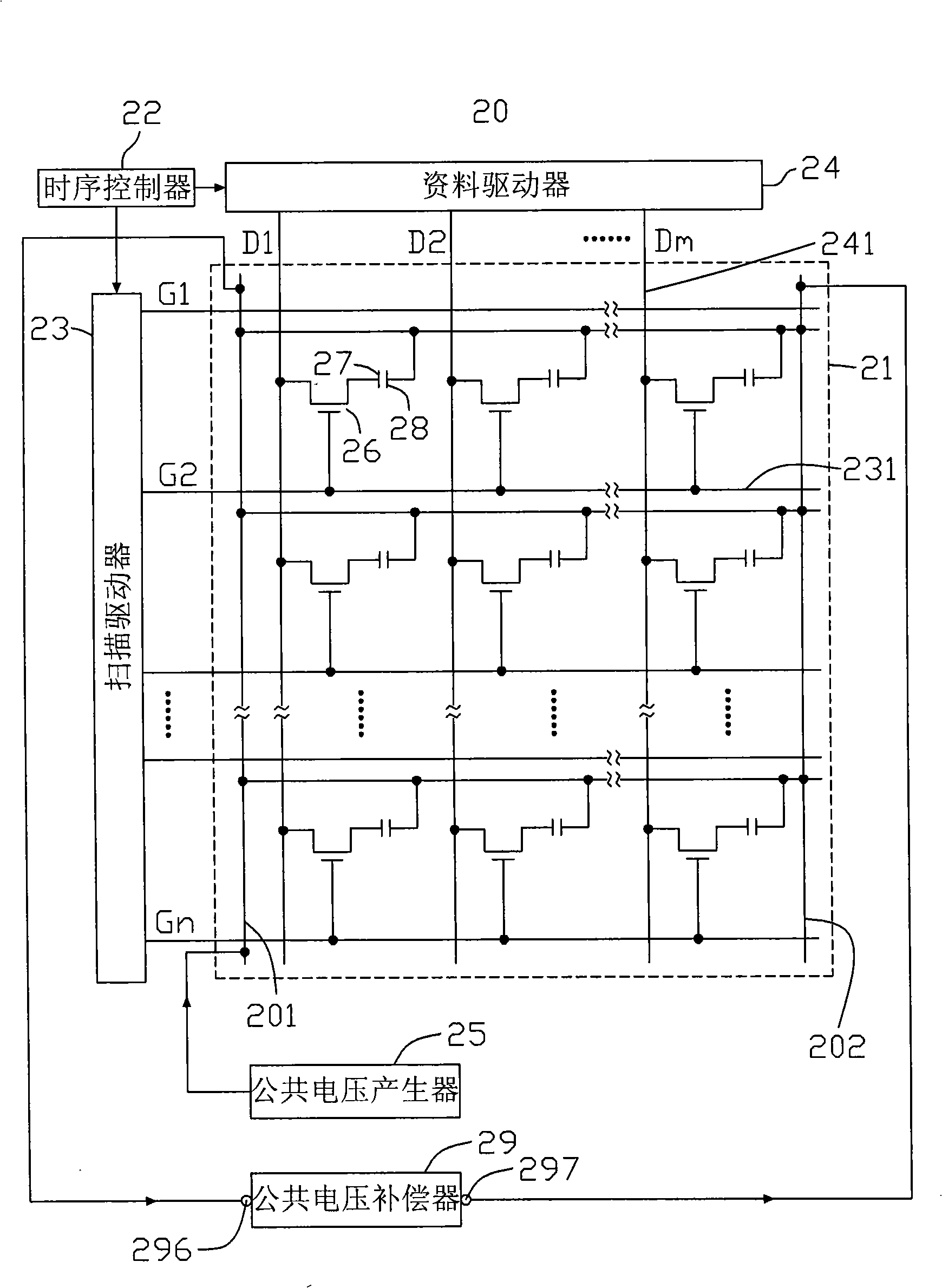

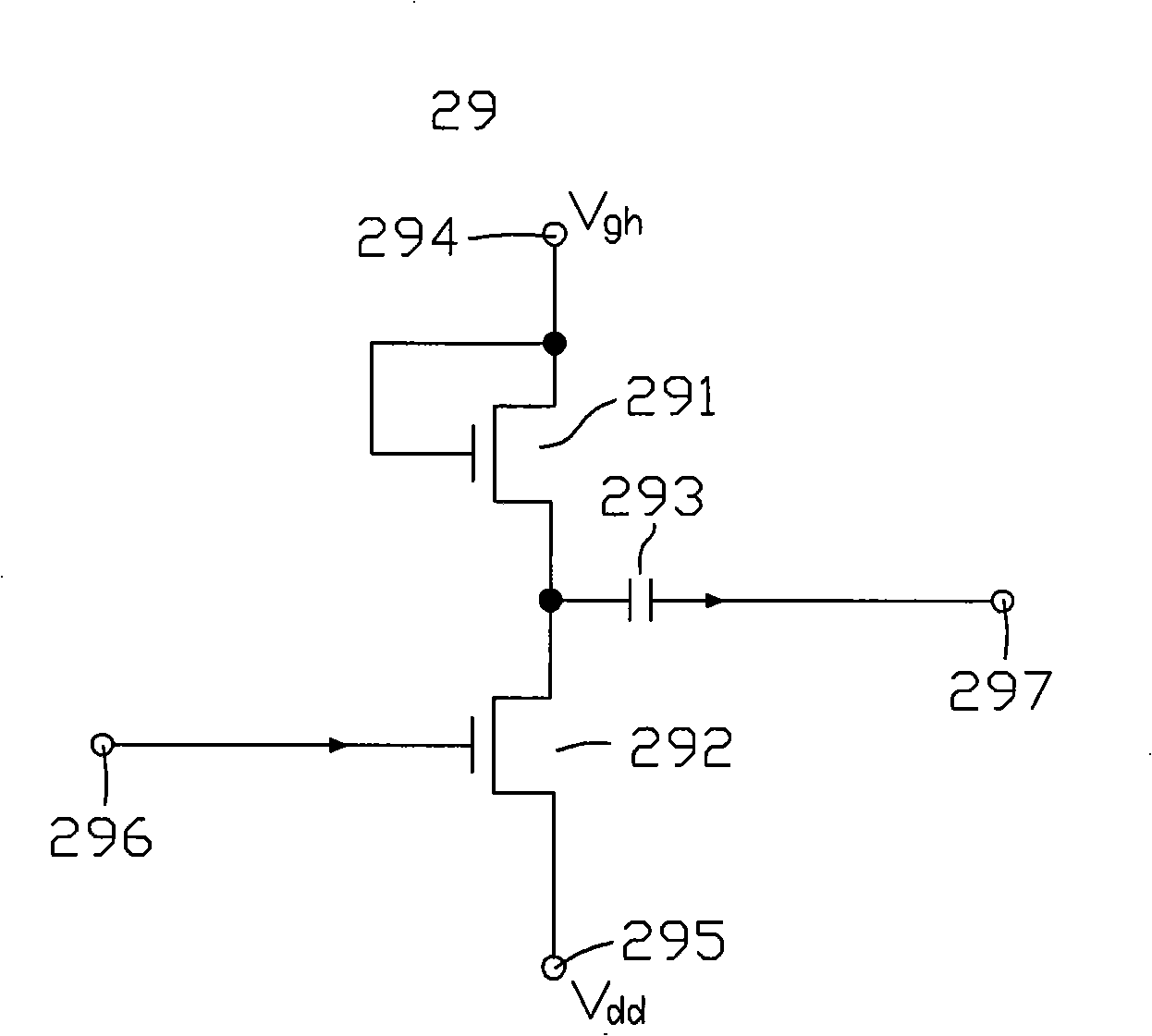

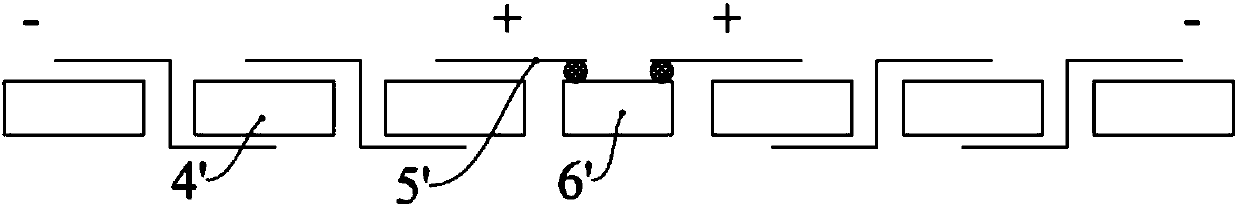

LCD device and its public voltage drive method

InactiveCN101311781ANo crosstalkPublic voltage stabilityStatic indicating devicesVoltage generatorPressure wire

The invention relates to a liquid crystal display and a drive method of public voltage of the liquid crystal display. The liquid crystal display comprises a liquid crystal display panel, a public voltage generator and a public voltage compensator. The liquid crystal display panel comprises a public electrode, a first public pressure wire and a second public pressure wire. The public voltage compensator comprises an input end and an output end. The public voltage generator is connected with the public electrode by the first public pressure wire. The public voltage compensator is connected with the public electrode by the second public pressure wire. The public voltage generator is used for providing the liquid crystal display panel with the public voltage. The public voltage compensator is used for providing the liquid crystal display panel with compensated public voltage according to the actual public voltage of the first public pressure wire.

Owner:INNOCOM TECH SHENZHEN +1

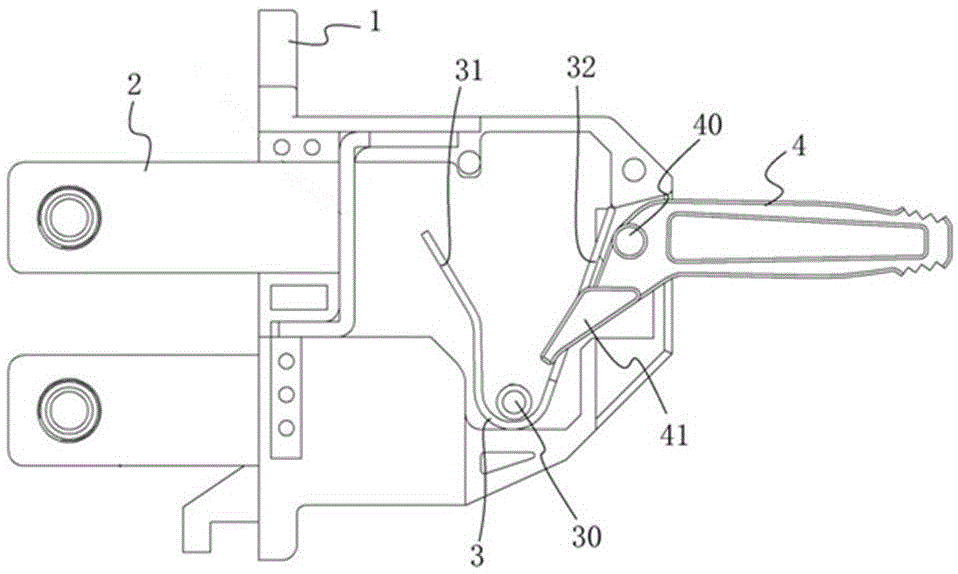

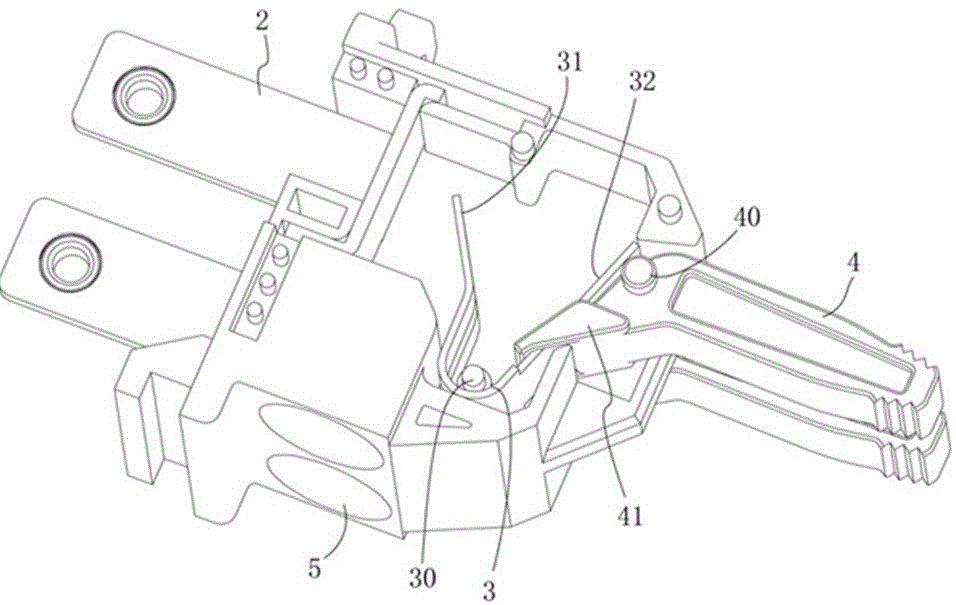

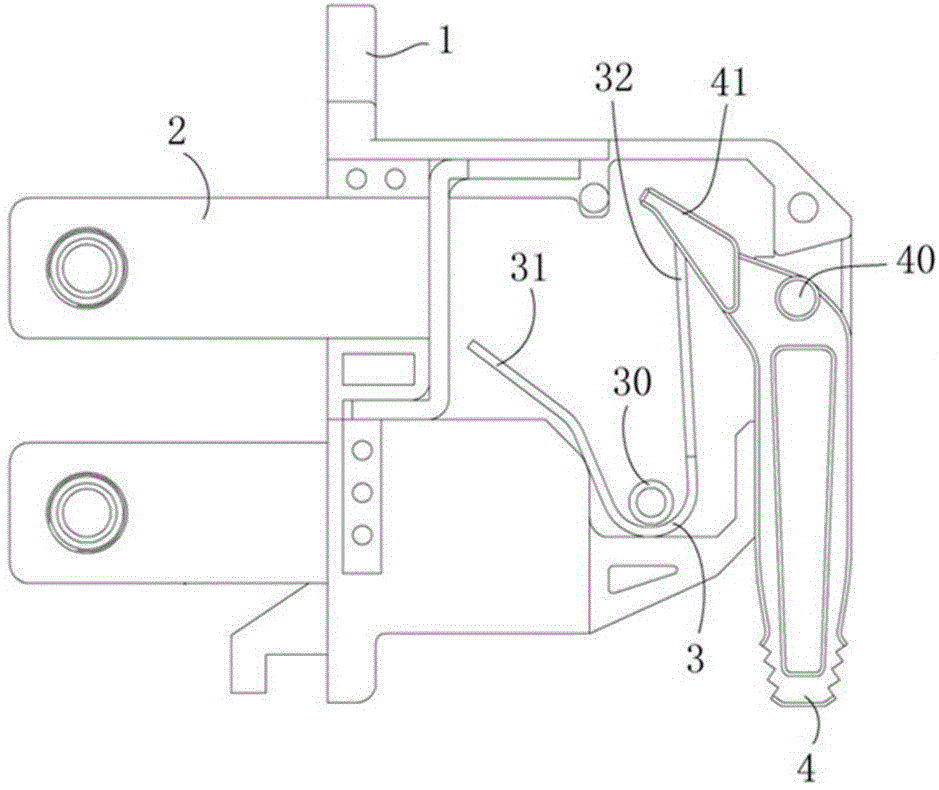

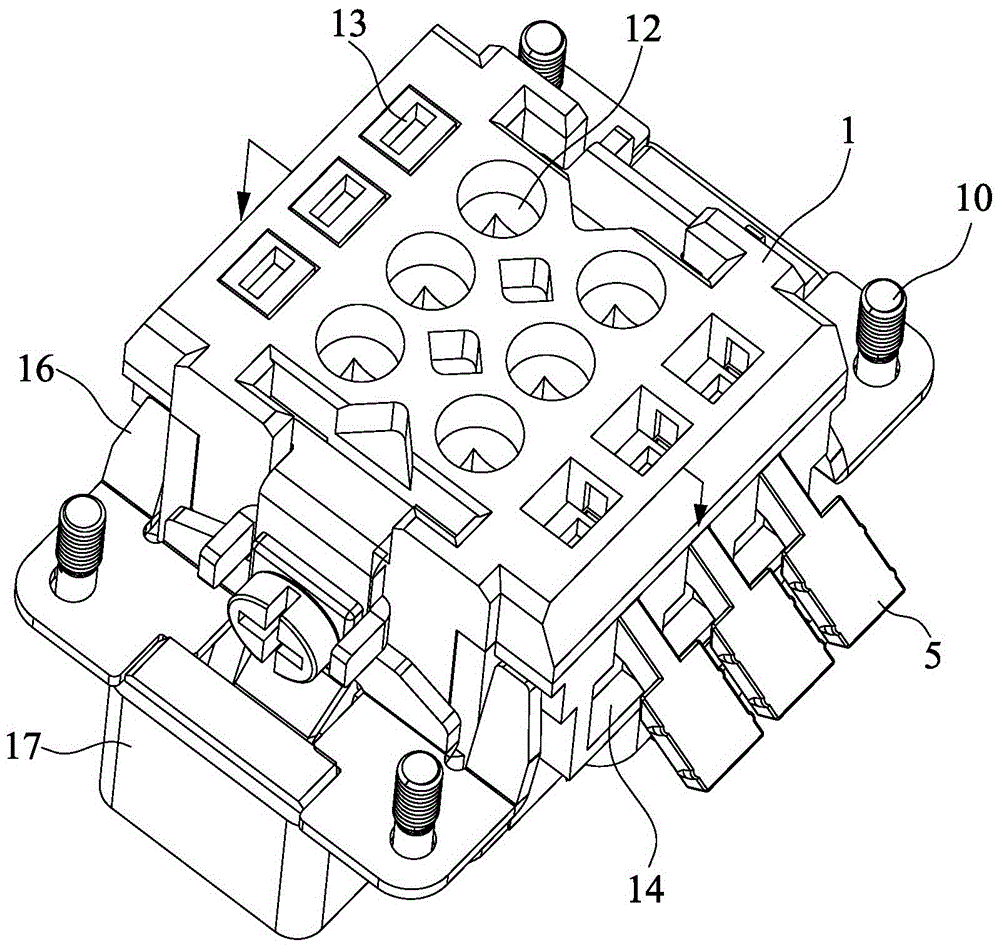

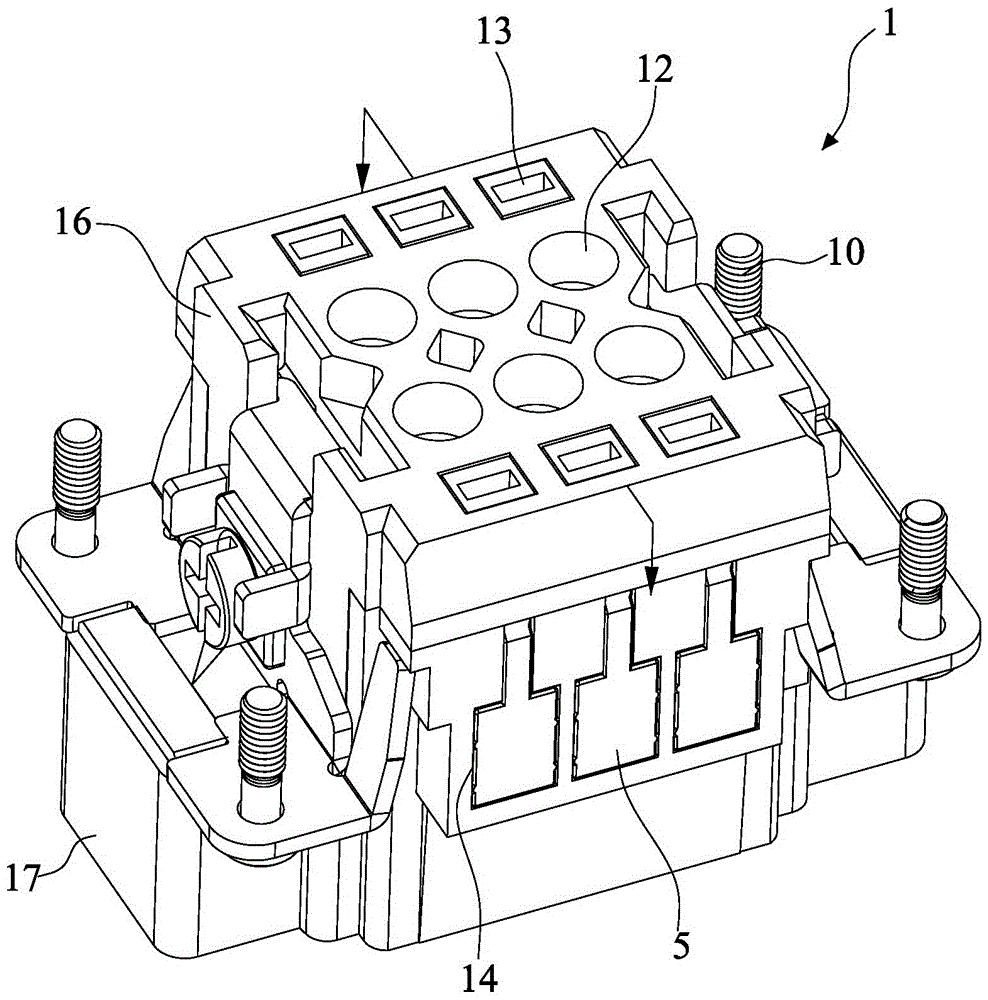

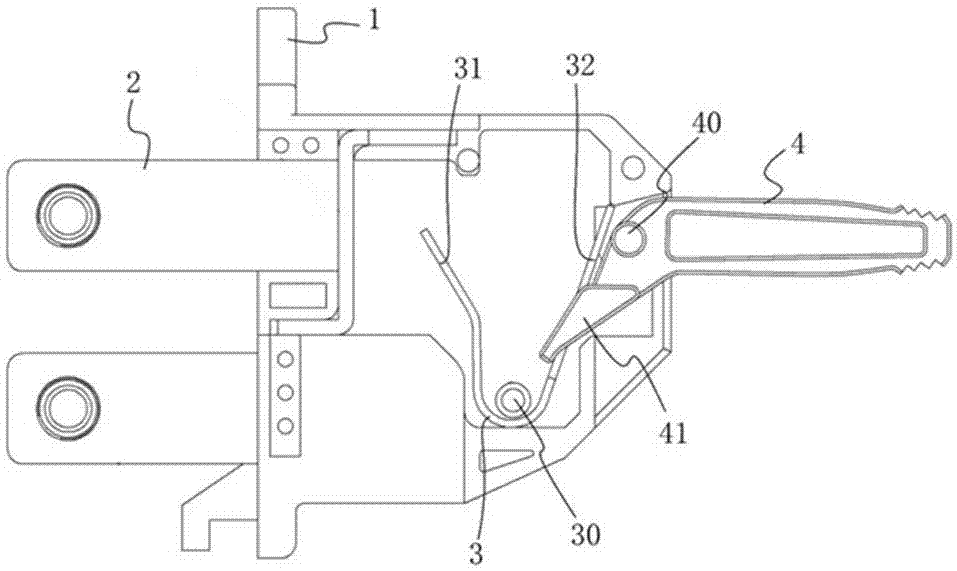

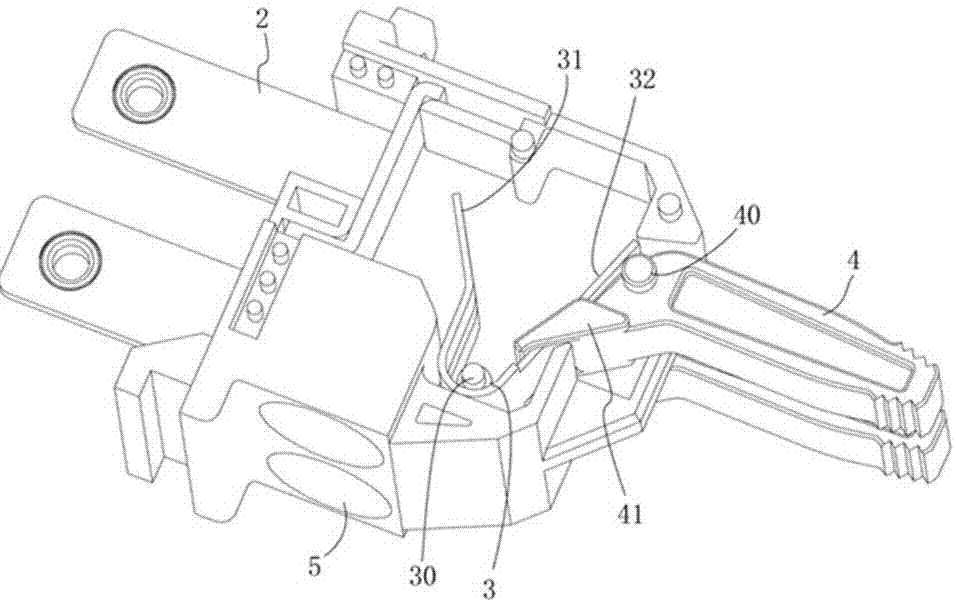

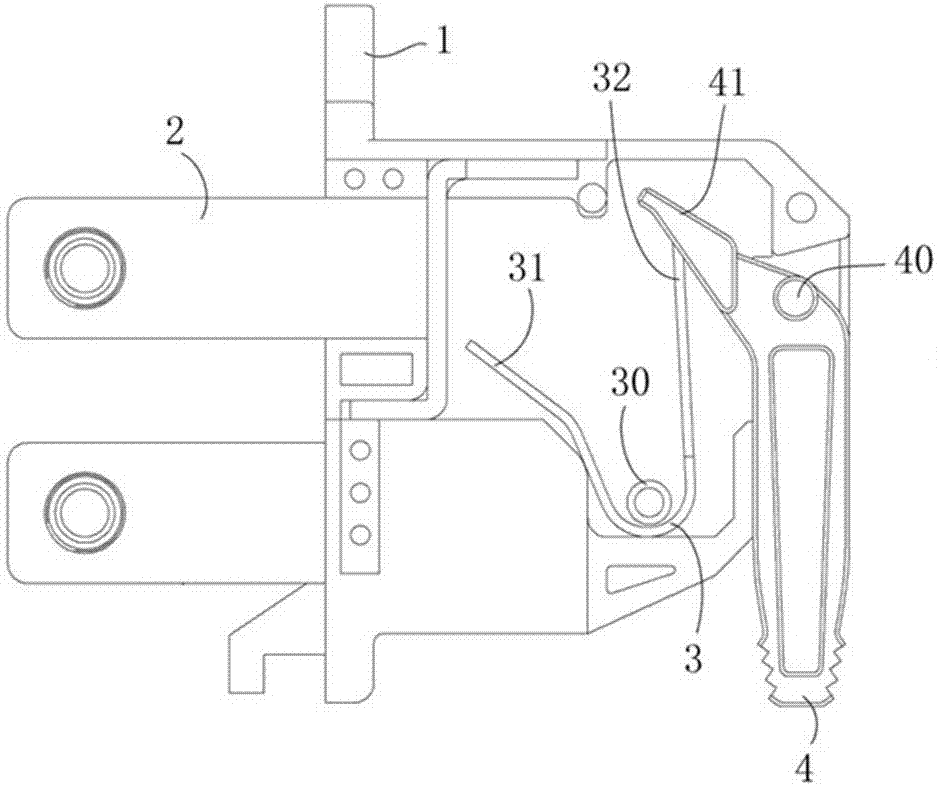

Conductive terminal

ActiveCN105428830AGuaranteed reliabilityAvoid free turningClamped/spring connectionsPressure wireEngineering

The present invention provides a conductive terminal. The terminal comprises a housing; a wire pressure reed is arranged in the housing in a manner of rotating around an axis extending front and back; the wire pressure reed is respectively provided with a wire pressure-wire end and a drive end on both sides of a rotating shaft; the housing is rotatably provided with an operating handle used for driving the wire pressure reed to rotate between a wire connection position and a wire pressure position; the operating handle is in parallel to the rotating axis of the wire pressure reed; one end of the operating handle, which is positioned inside the housing, is provided with a contact section; the contact section is provided with a reed perforated hole used for the drive end of the wire pressure reed to pass through; the reed perforated hole is provided with a right hole wall used for pushing the outer lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire pressure position when the operating handle rotates forwards; and the reed perforated hole is also provided with a left hole wall used for pulling the inner lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire connection position when the operating handle is rotated reversely. The conductive terminal disclosed by the present invention is simple in structure and very convenient to use.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

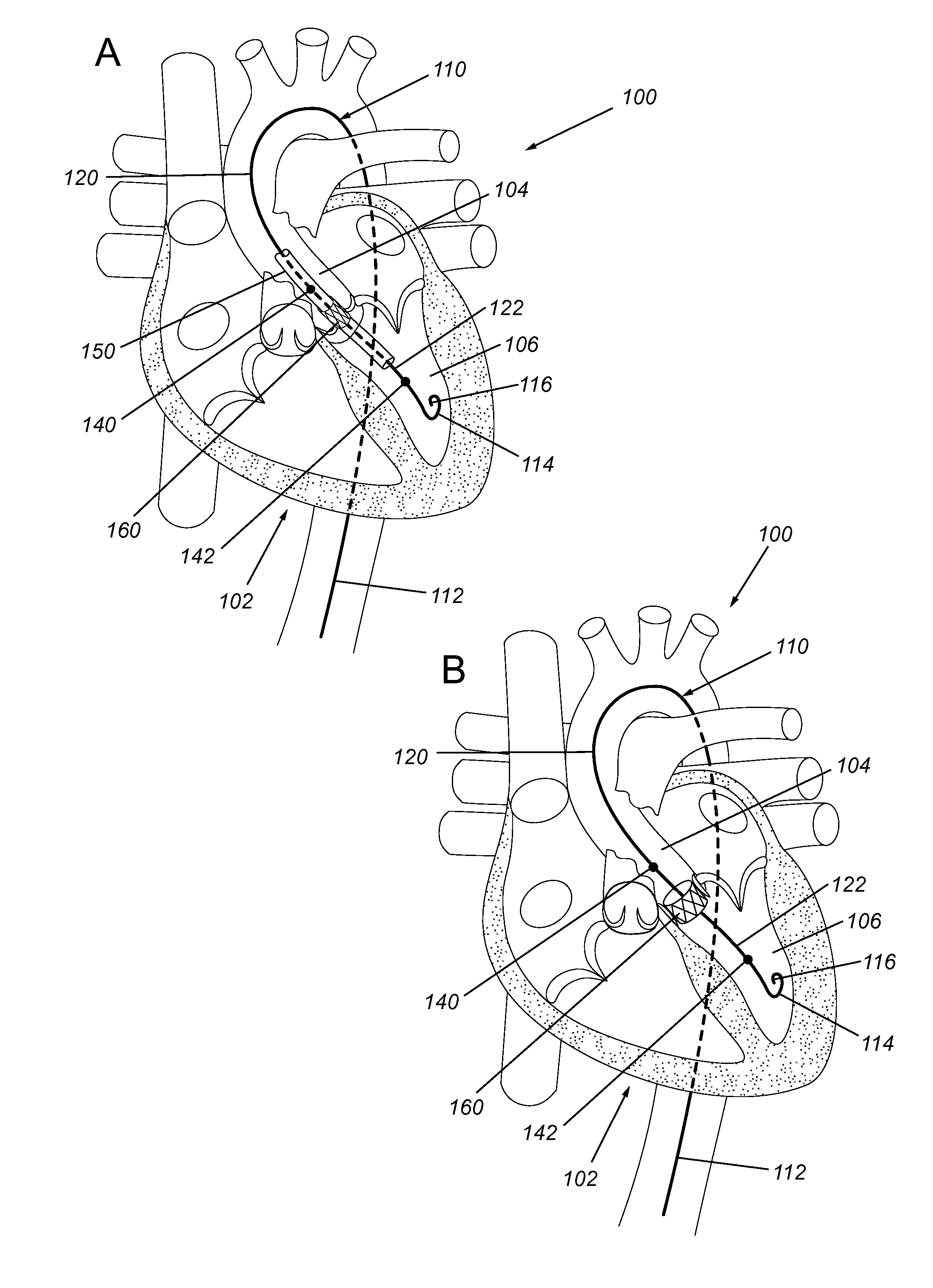

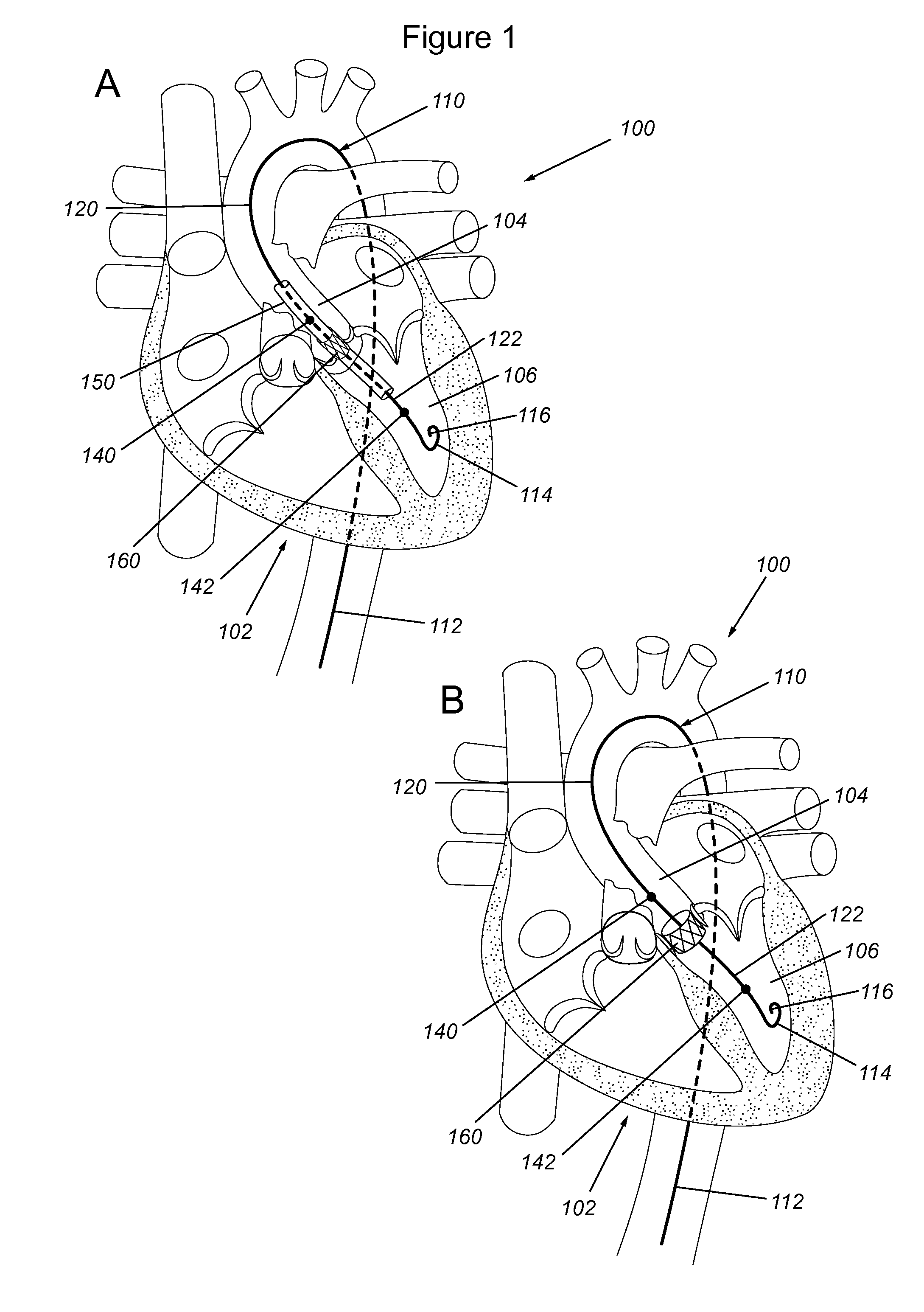

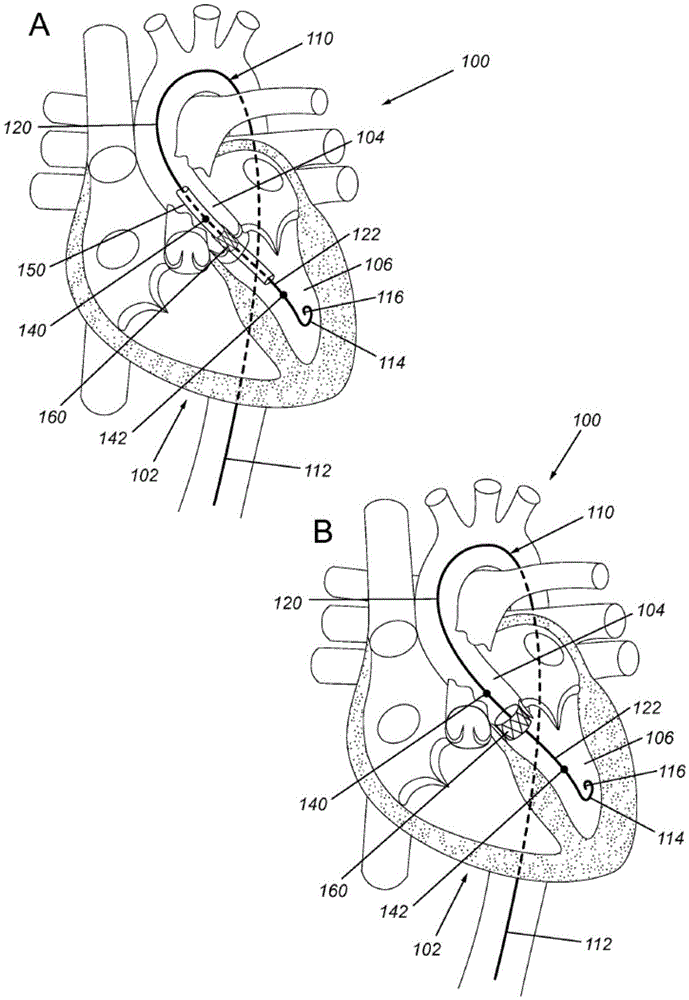

Transcatheter aortic valve implantation pressure wires and uses thereof

Described herein is a guide wire that includes one, two or multiple pressure transducers for use in TAVI. The guide wire may include an aortic pressure sensor spaced from a left ventricular pressure sensor with sufficient length to allow the aortic pressure sensor to be located in the aorta while the ventricular pressure sensor is simultaneously located in the left ventricle. The pressure readings between the left ventricle and aorta may be subtracted to determine an improved indication of the prognosis of a patient with intermediate post-TAVR aortic regurgitation after assessment with transesophageal echocardiography.

Owner:CEDARS SINAI MEDICAL CENT

Transcatheter aortic valve implantation pressure wires and uses thereof

Owner:CEDARS SINAI MEDICAL CENT

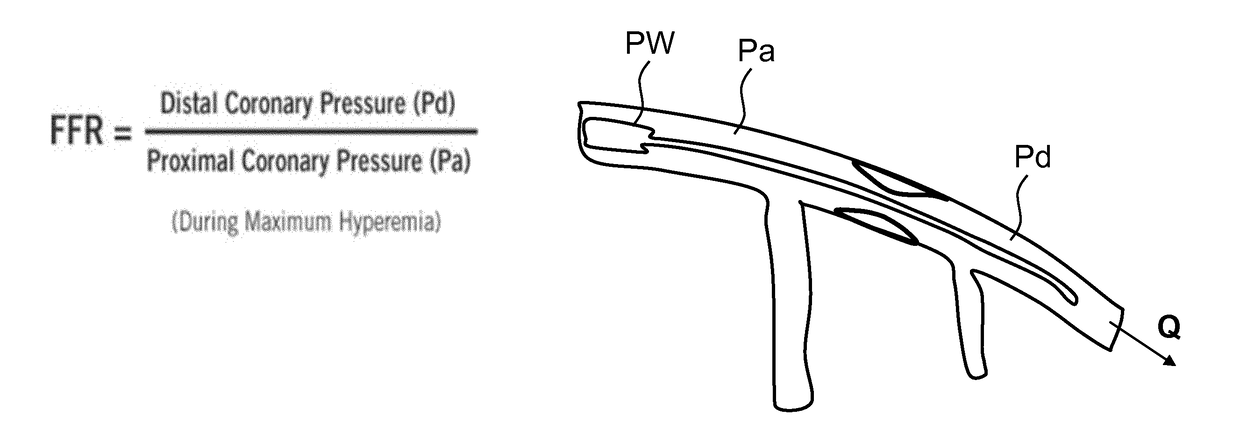

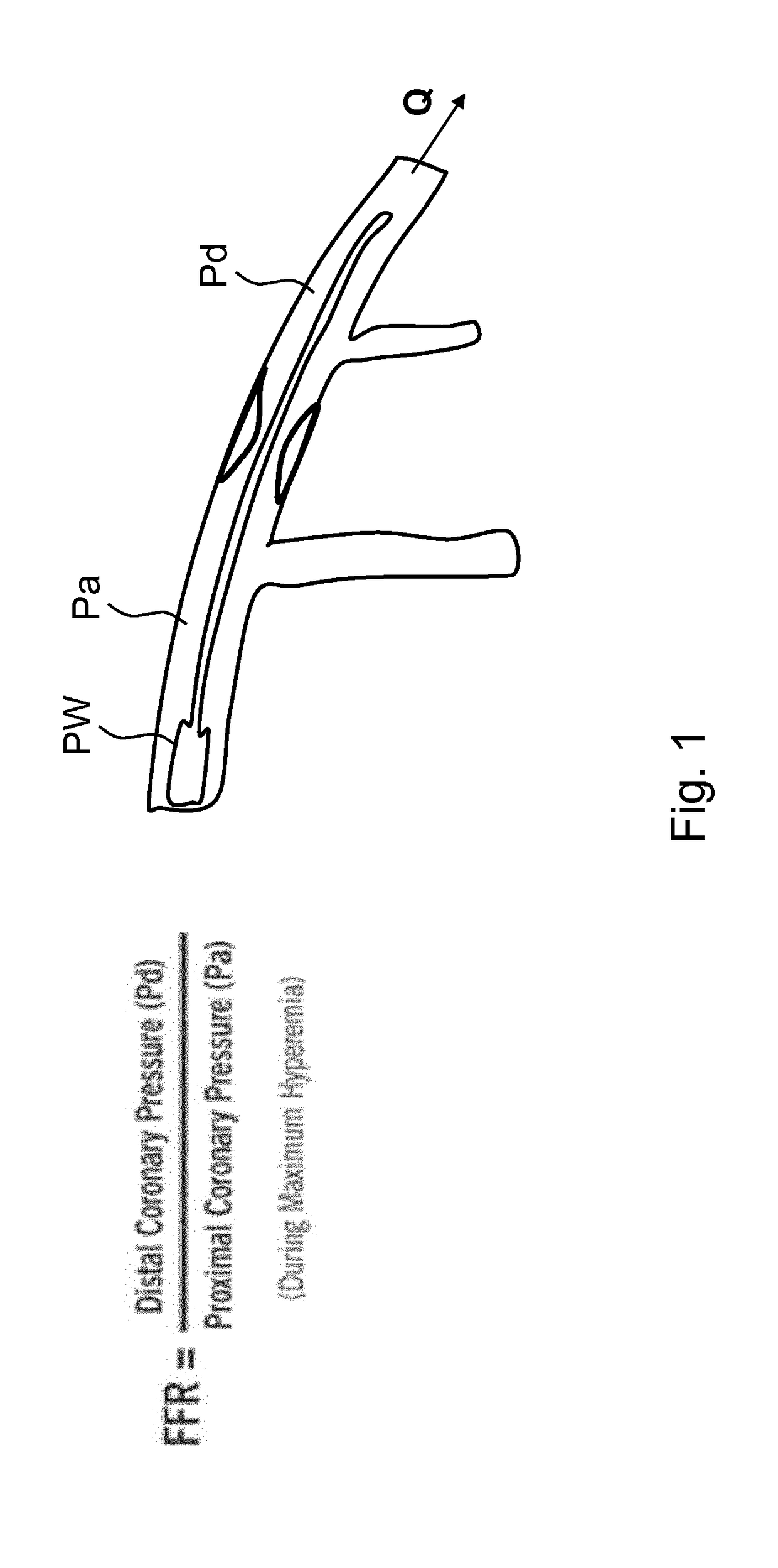

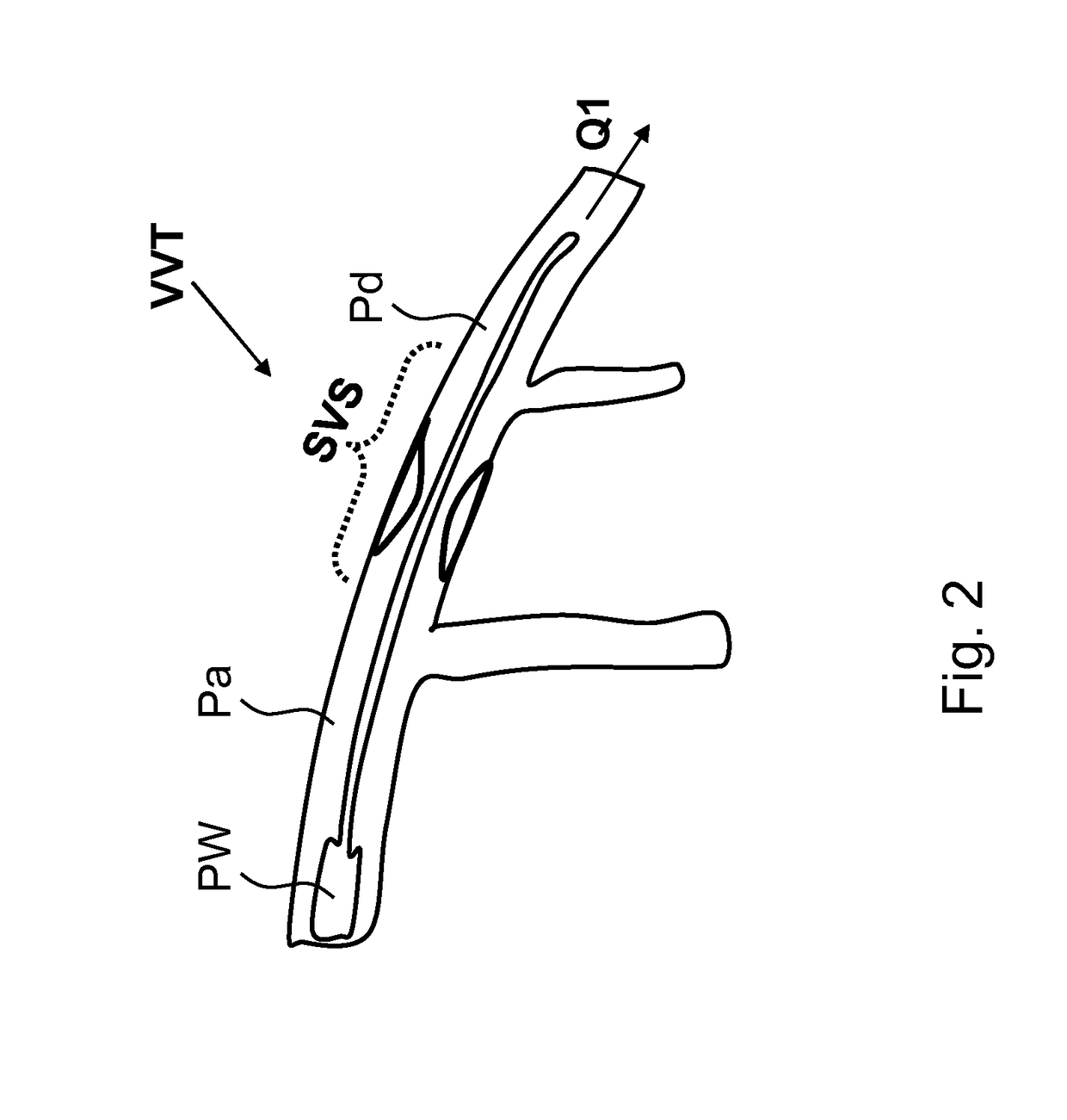

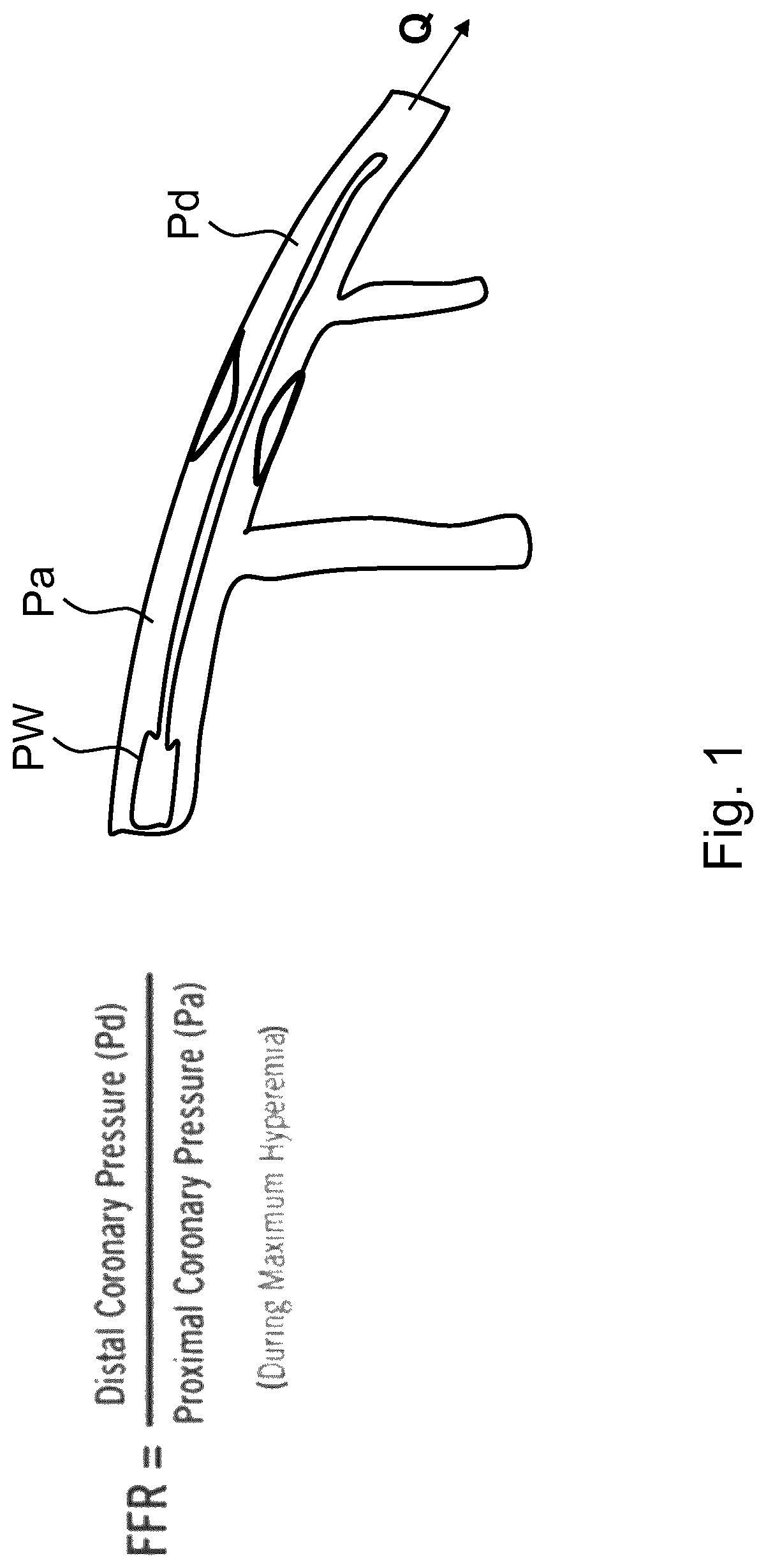

Fractional flow reserve determination

ActiveUS20180286045A1Improve simulation accuracyImprove impactImage enhancementImage analysisPressure wireRadiology

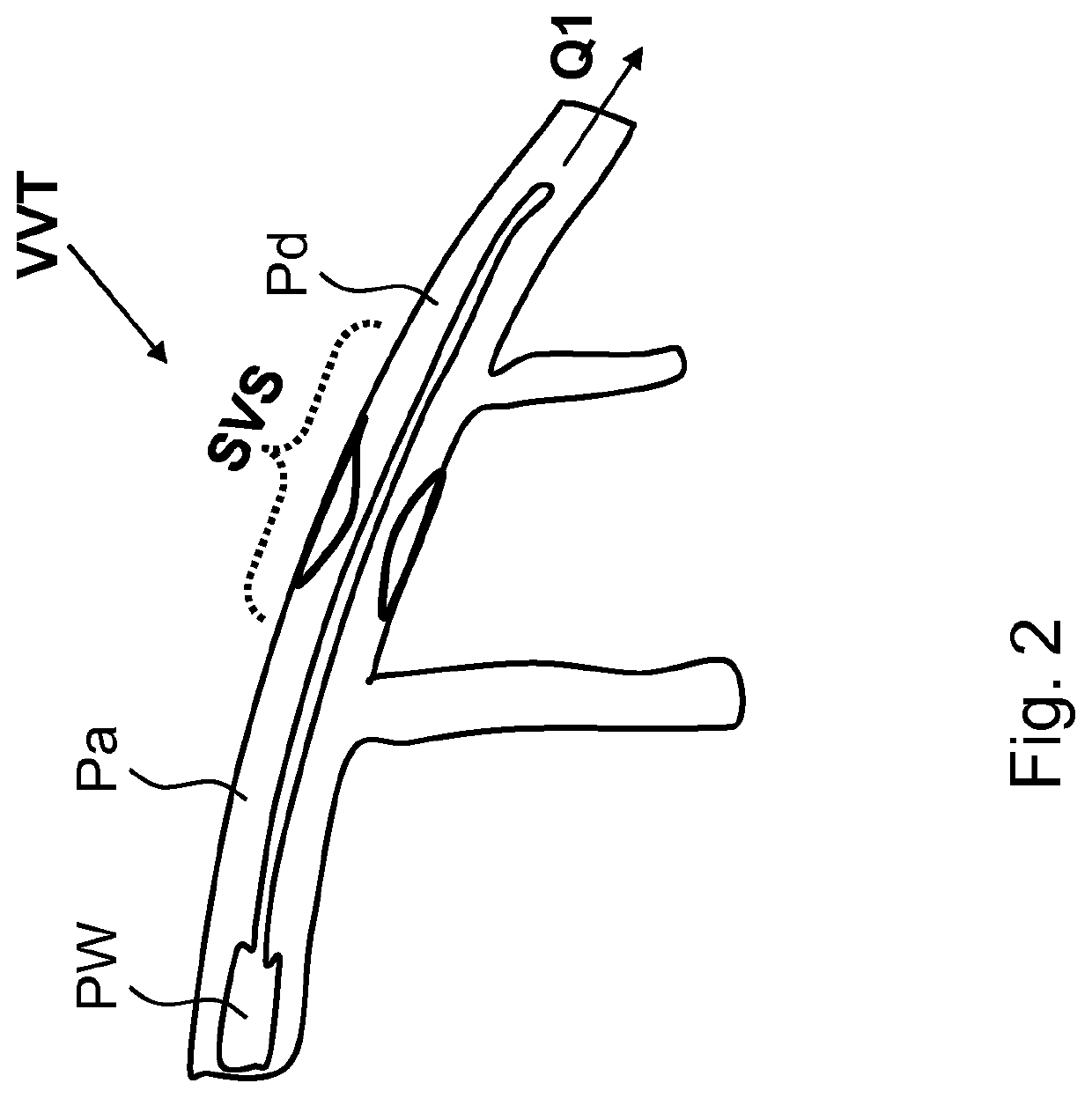

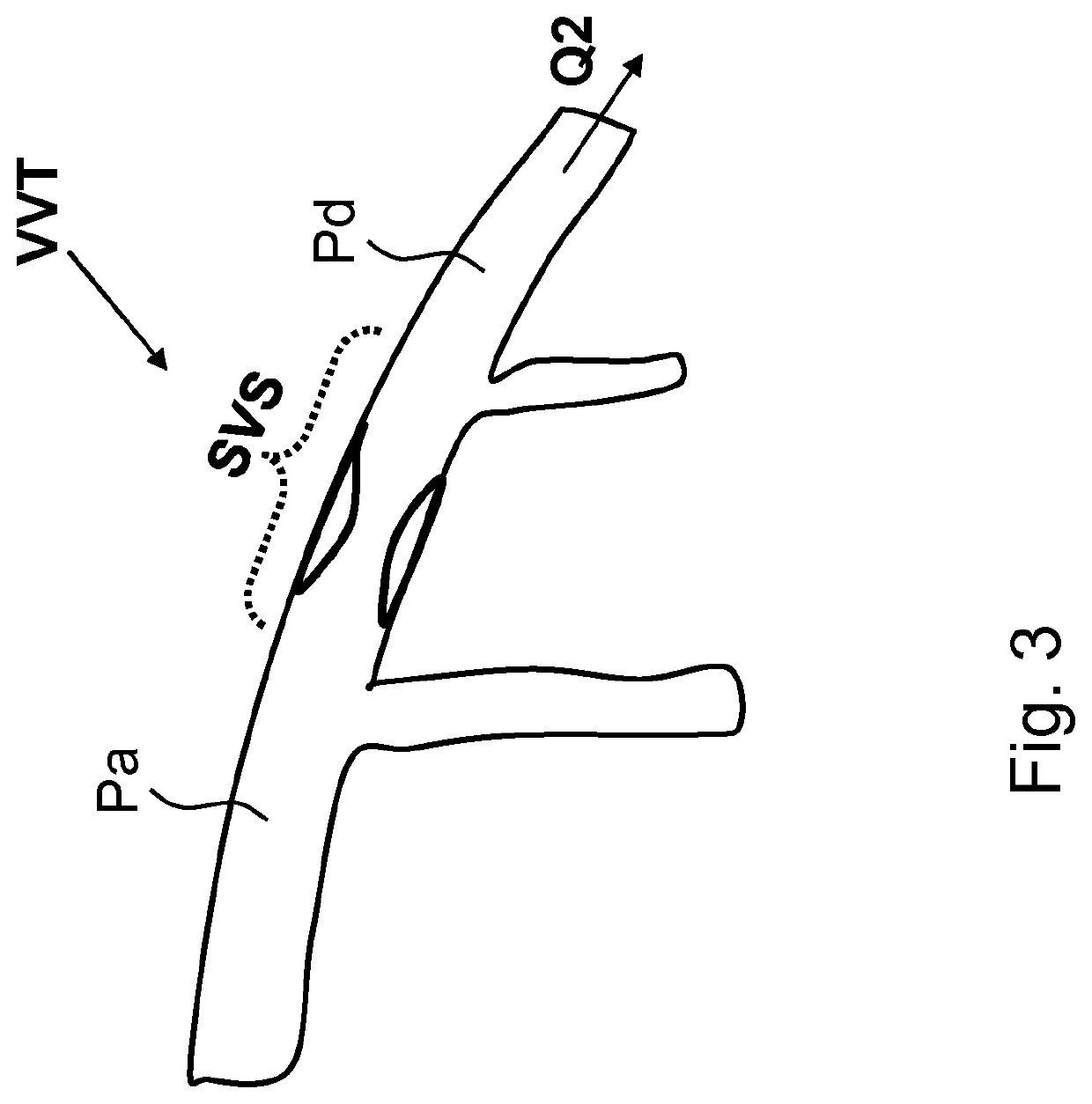

The present invention relates to a device (1) for fractional flow reserve determination, the device (1) comprising: a model source (10) configured to provide a first three-dimensional model (3DM1) of a portion of an imaged vascular vessel tree (VVT) surrounding a stenosed vessel segment (SVS) and configured to provide a second three-dimensional model (3DM2) of a pressure wire insertable into the vascular vessel tree (VVT); and a processor (20) configured to calculate a first blood flow (Q1) through the stenosed vessel segment (SVS) with the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first and the second three-dimensional model and to calculate a second blood flow (Q2) through the stenosed vessel segment (SVS) without the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first three-dimensional model (3DM1) and to determine a first fractional flow reserve value (FFR1) to be measured with the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first blood flow (Q1) and to determine a second fractional flow reserve value (FFR2) to be measured without the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the second blood flow (Q1).

Owner:KONINKLJIJKE PHILIPS NV

Body-free coaxial following synergistic perforator

The invention discloses a body-free coaxial following synergistic perforator, which comprises a body-free perforator firing mount and a body-free perforating bullet arranged on the firing mount, wherein the body-free perforating bullet comprises a cartridge case, a powder-type cover and a high explosive, the front end outer wall of the cartridge case is provided with an initiation half slot and a pressure wire, the front end inner wall of the cartridge case is provided with a booster hole, the back end of the cartridge case is provided with a fracturing powder box airtightly, and special fracturing powder is poured in the fracturing powder box and is distributed annularly along the inner wall of the fracturing powder box, wherein the special fracturing powder is prepared by evenly mixing ammonium permanganate of which the weight percentage is between 50 and 80 percent and aluminum powder of which the weight percentage is between 20 and 50 percent. The body-free coaxial following synergistic perforator has a simple structure and reliable mounting, the special fracturing powder is initiated and performs pulse fracturing on stratums directly while the powder-type cover forms high-speed jet flow to perform perforation, and the fracturing effect of the perforation is good, thus the body-free coaxial following synergistic perforator is particularly suitable for operations of high-density and low-permeability stratums.

Owner:XIAN RUITONG ENERGY TECH

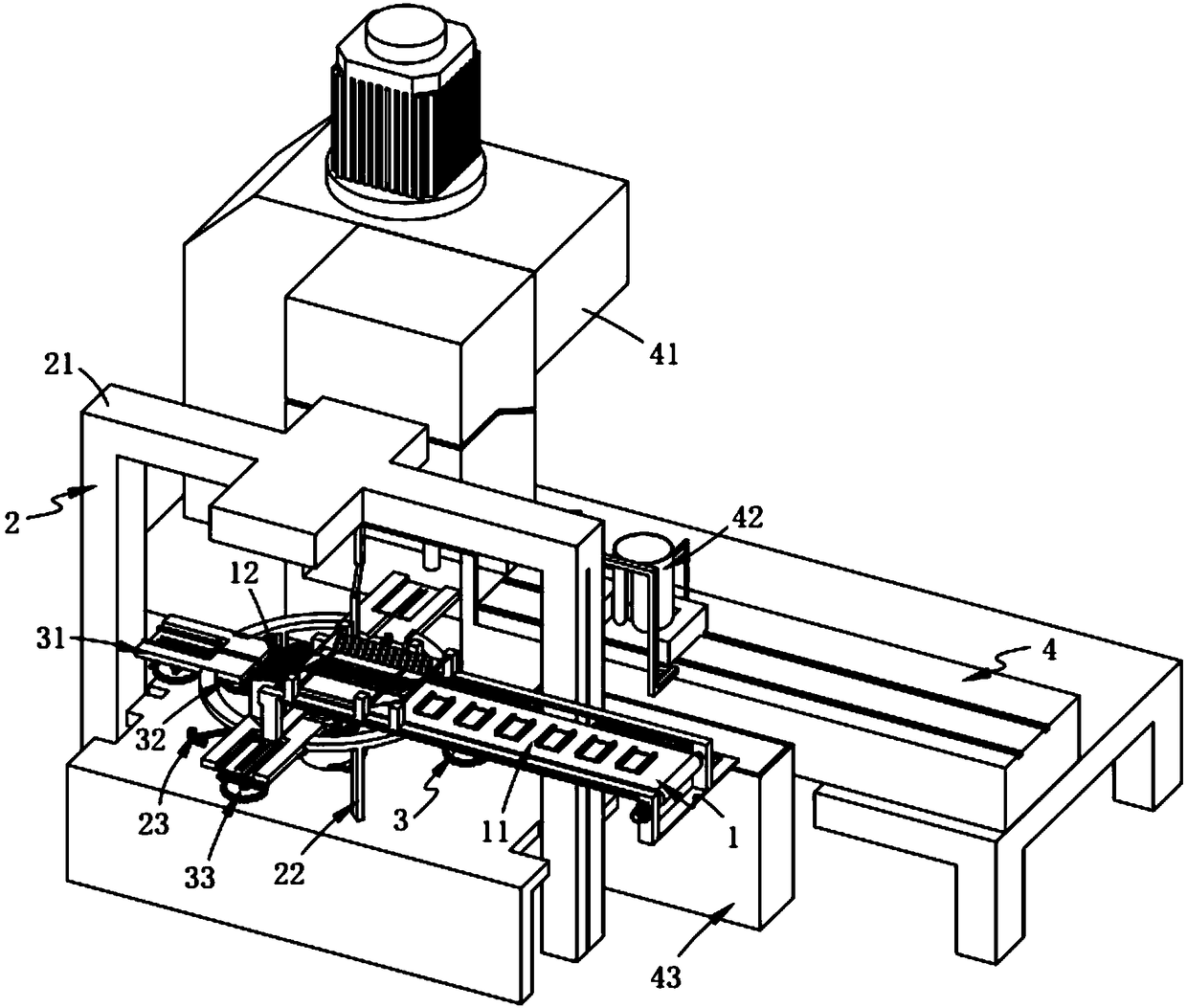

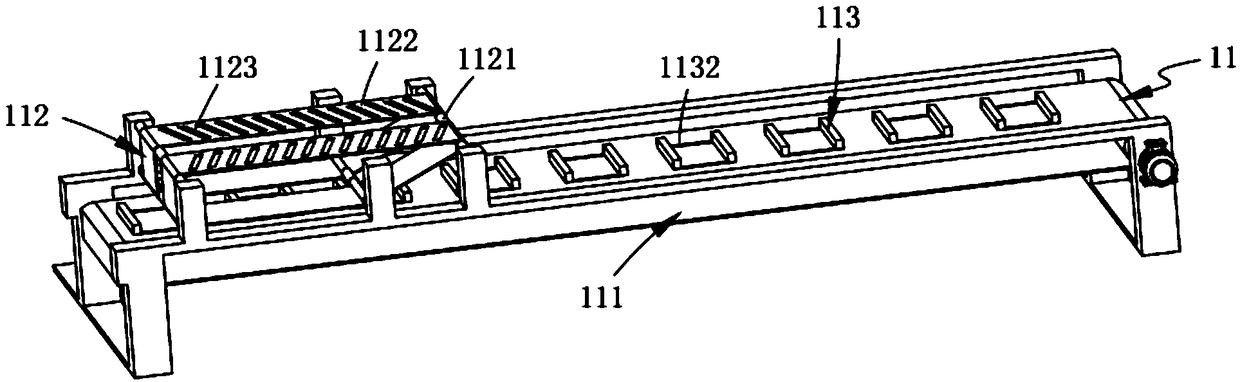

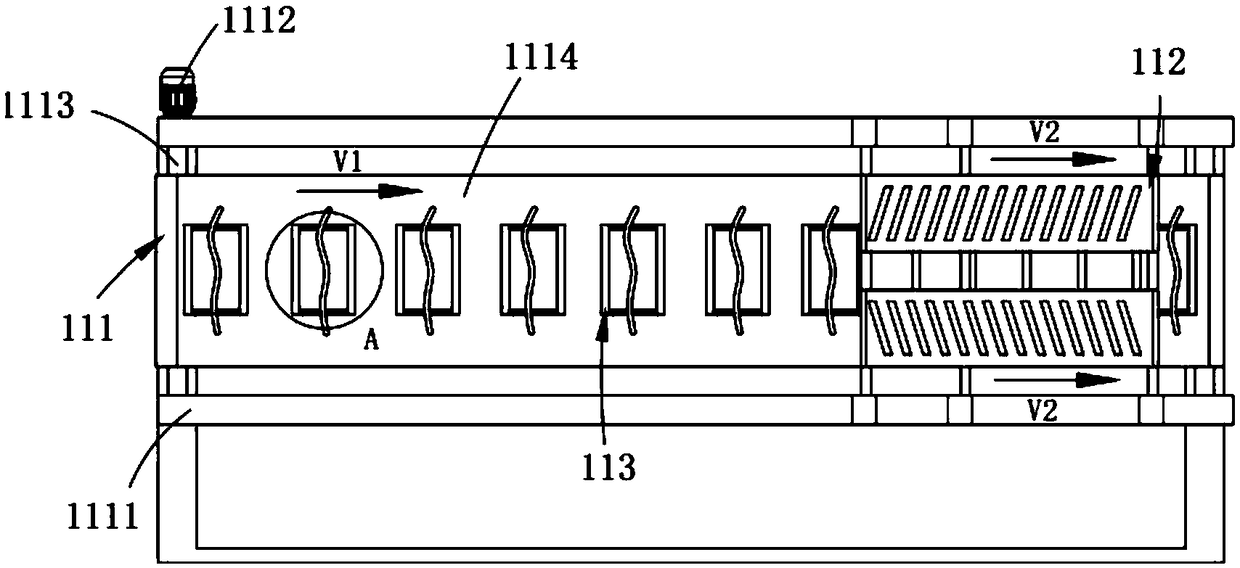

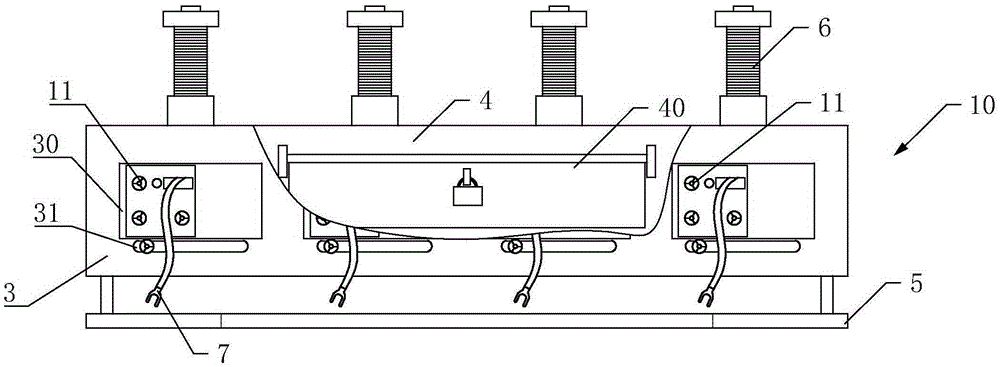

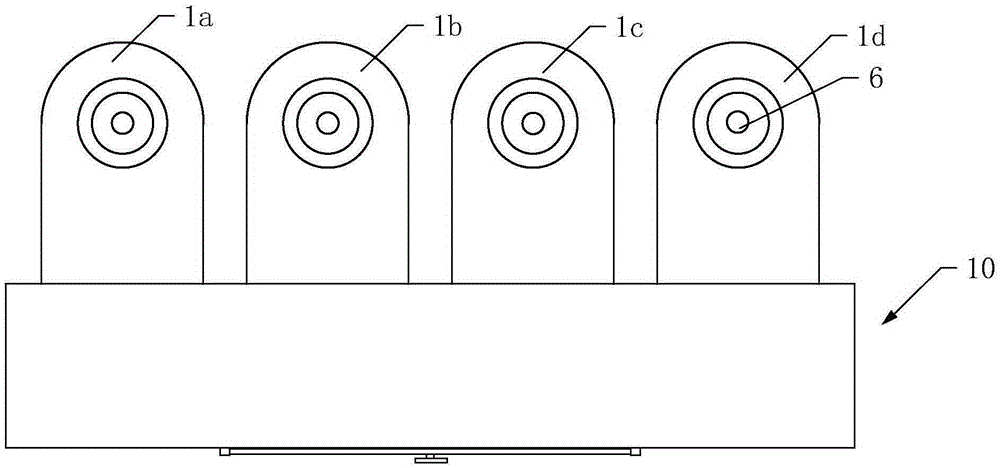

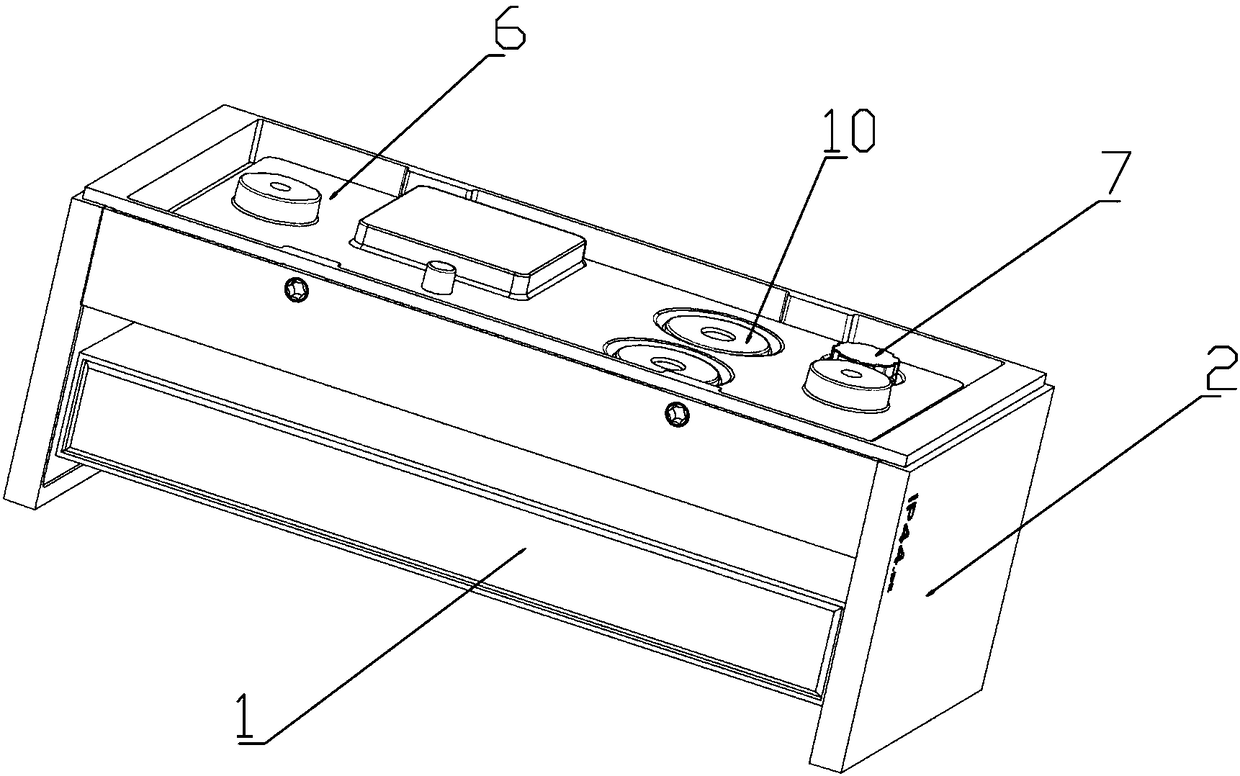

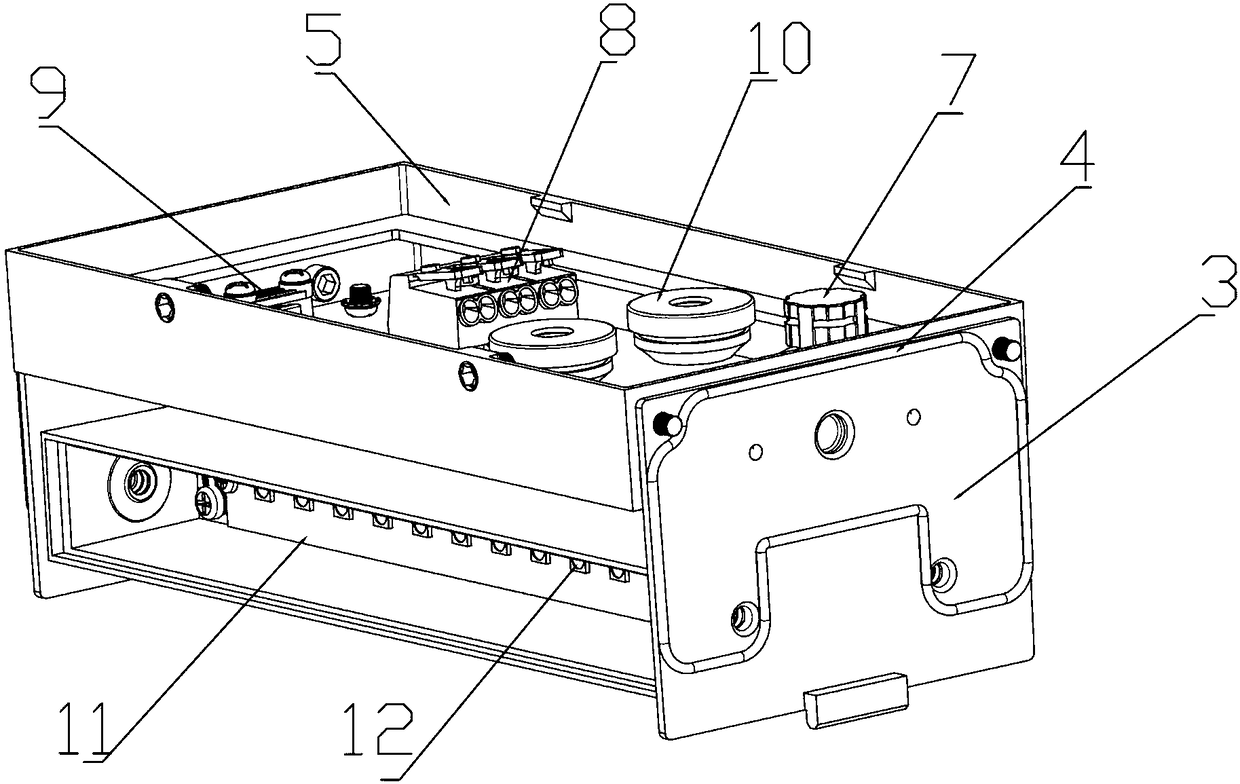

Electromagnetic clutch coil automatic assembly system for compressor

ActiveCN109360730AImprove product qualityIncrease productivityCoils manufacturePressure wireElectromagnetic clutch

The invention relates to an electromagnetic clutch coil automatic assembly system for a compressor. The system comprises a first level flattening mechanism, a turnover mechanism, a secondary level flattening mechanism and a wiring mechanism, and the first level flattening mechanism comprises a compressing straightening assembly and a wire outlet assembly at an output end of the compressing straightening assembly; the turnover mechanism comprises a frame for mounting the compressing straightening assembly, switching assemblies disposed on the frame and a driving mechanism mounted on the frame;the second level flattening mechanism circumferentially displaying on the plurality of groups of switching assemblies includes a receiving assembly mounted on the switching assemblies, a first bandingassembly arranged slidably below the receiving assembly and a second banding assembly located behind the first banding assembly, and the first banding assembly and the second banding assembly are both in cooperative drive with the drive mechanism; the wiring mechanism includes a pressure wire machine, a coil upper assembly and a reset assembly; the system solves the technical problem that a wireis twisted and pinched when the wire works, and a wire head cannot be accurately placed under the pressure wire machine every time under the automatic conveying.

Owner:赵娟

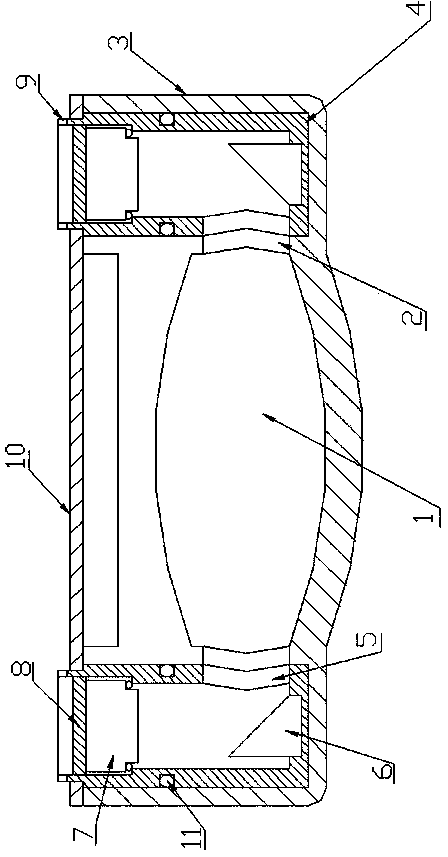

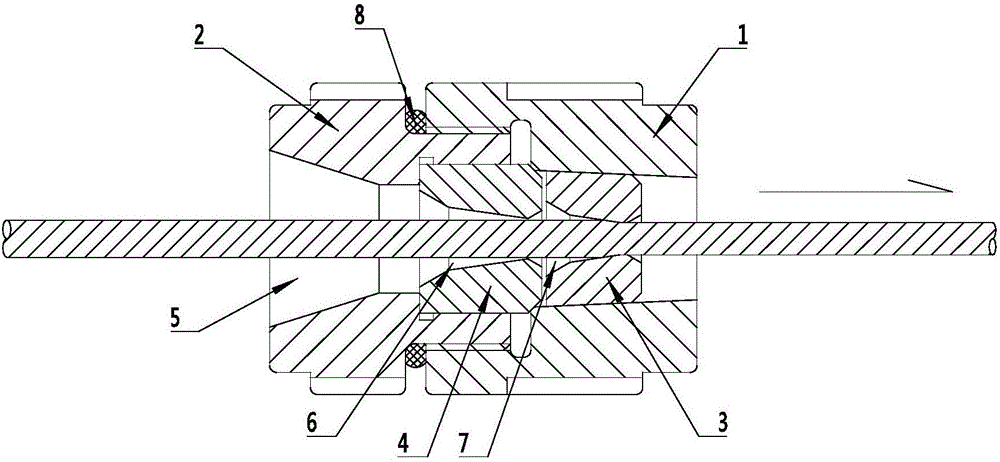

Embedded ultrasonic flowmeter

The invention relates to an embedded ultrasonic flowmeter which comprises a metering pipe, wherein metering holes are formed in two sides of the metering pipe in a staggering manner along the axis line of a pipe body; an energy conversion metering assembly is arranged outside each metering hole and comprises a fixing seat connected with the metering pipe; a rotating pipe is mounted in the fixing seat; the outer wall of the rotating pipe is in sliding fit with the inner wall of the fixing seat; reflecting holes corresponding to the metering holes in the metering pipe are formed in the side wall of the rotating pipe; reflectors corresponding to the reflecting holes are arranged in the rotating pipe; an energy converter opposite to the reflectors is arranged at the upper part of the inside of the rotating pipe; and pressure wires are arranged in the rotating pipe above the energy converter. The rotating pipe which is in sliding fit with the fixing seat is arranged, so that water in the metering pipe cannot spurt out under the control of the rotation of the rotating pipe. Thus, the energy converter and the reflectors are convenient to clean or replace. As a result, the precision of the ultrasonic flowmeter is improved and the service life of the ultrasonic flowmeter is prolonged.

Owner:连云港腾越电子科技有限公司

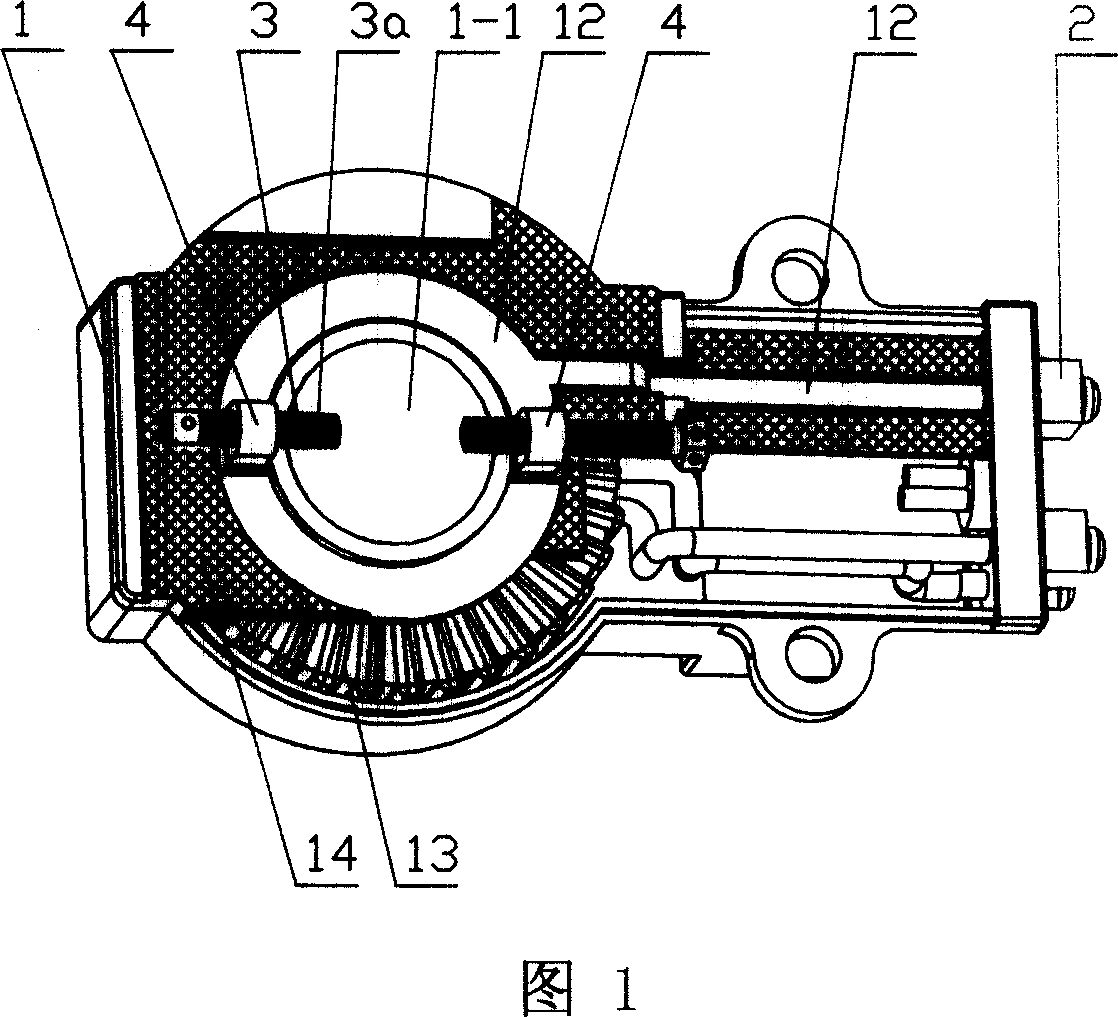

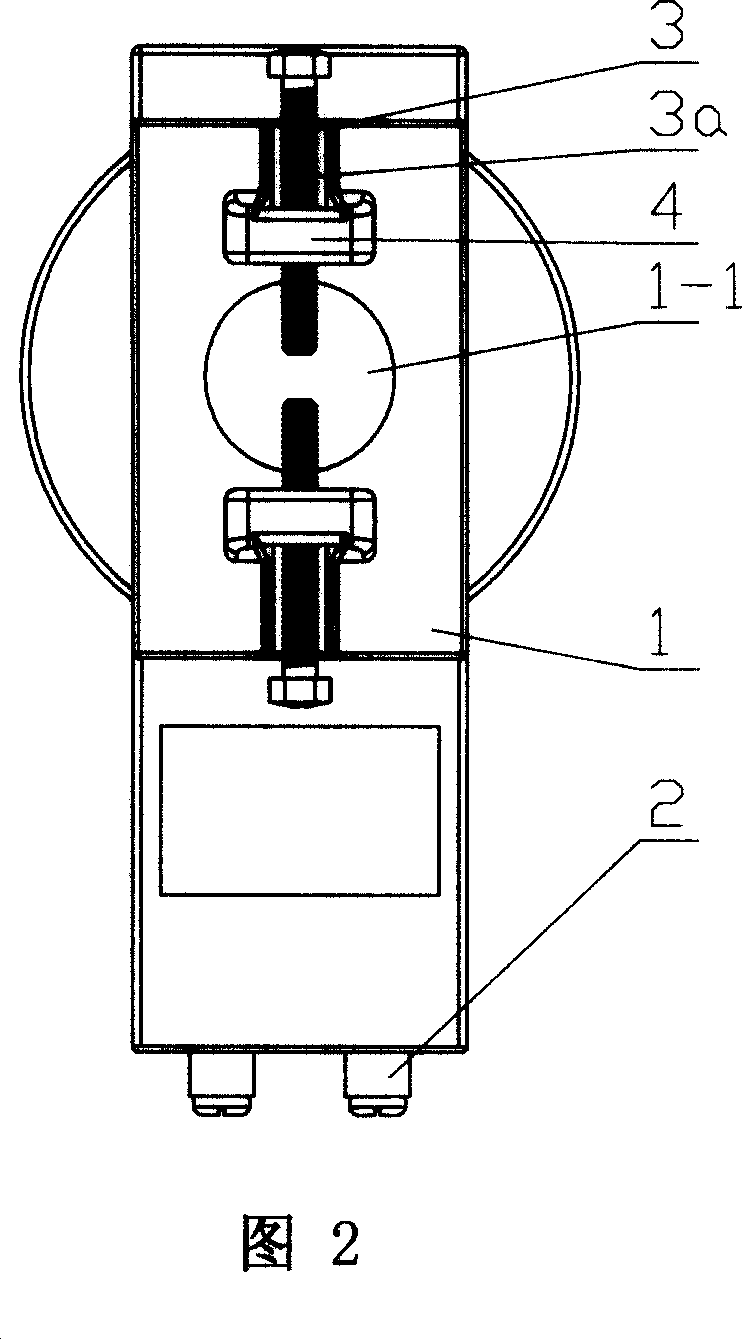

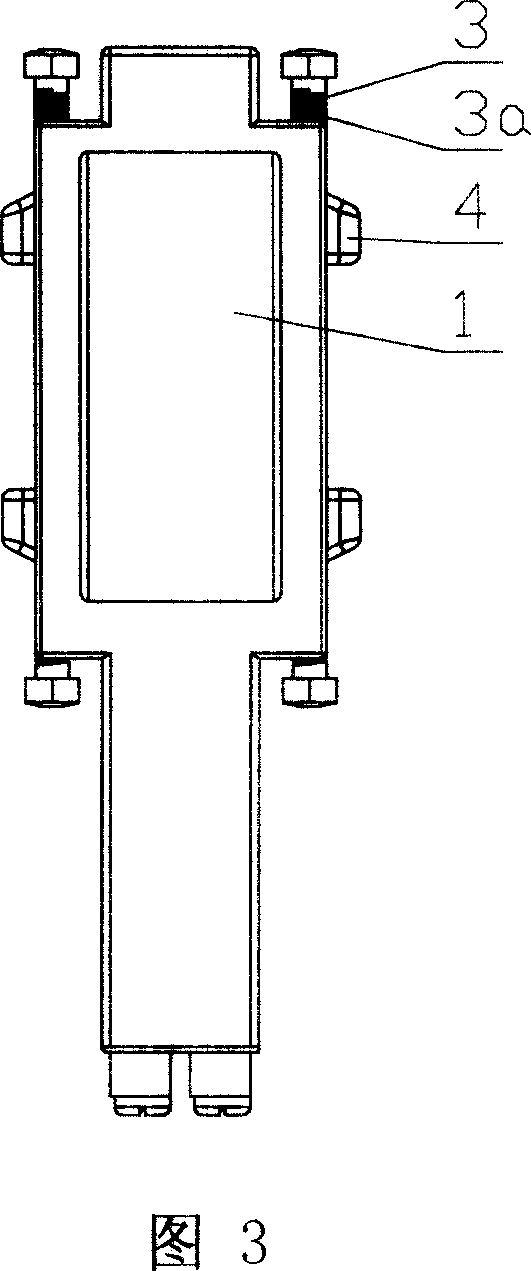

Straight-through current transformer capable of conveniently taking voltage

This invention relates to a straight-through current transformer which can take voltage easily. The invention set voltage-wire leading-out terminal (2) and voltage taking assembly ( 3) on the transformer noumenon ( 1), and each other possess electric interlock relation. The voltage taking assembly set up at one side of whole core (1-1), and can do radial movement follow hole core. This invention use existing metal embeds piece structure of current transformer, directly connect it with pressure-wire leading-out terminal, to realize purpose of taking voltage. the voltage taking mode is shortcut and not easy occur electric larceny, at the same time, the joining between stud and wire is stable.

Owner:HUBEI SHENGJIA ELECTRIC EQUIP

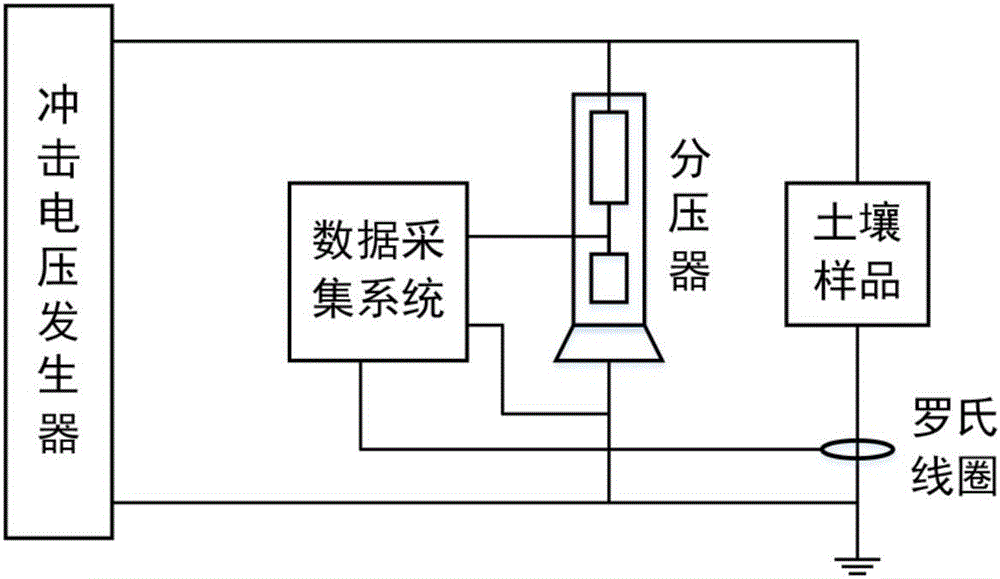

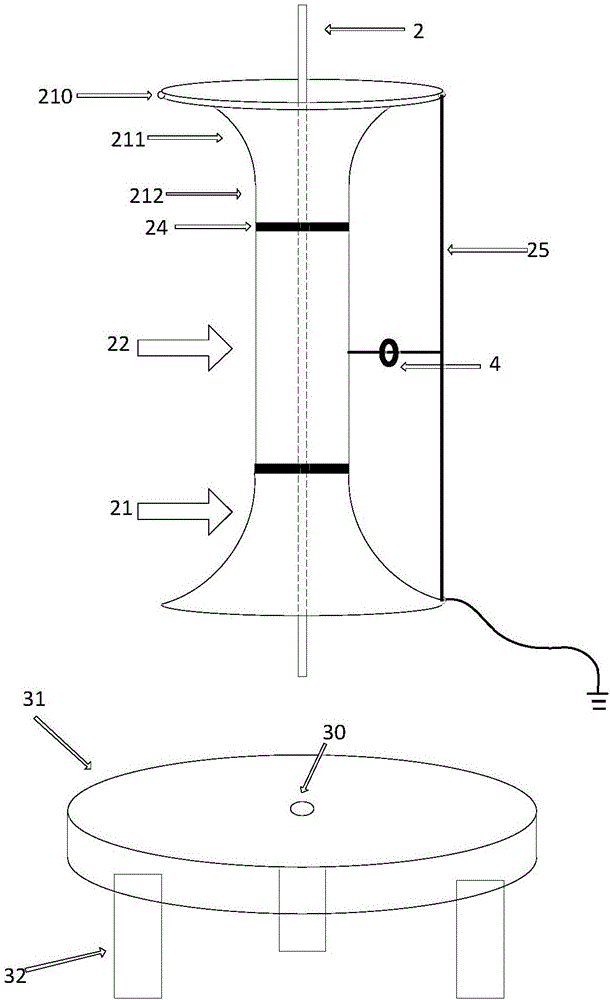

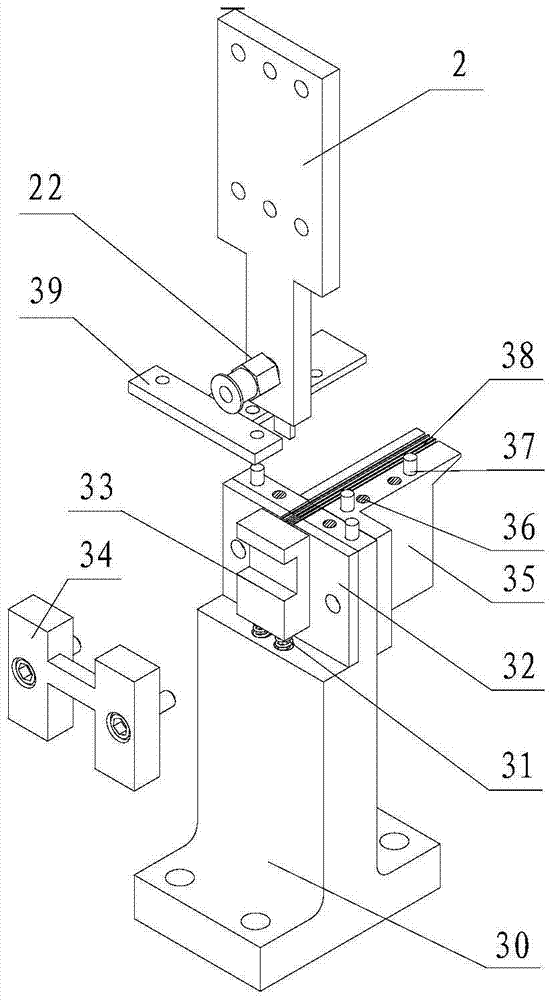

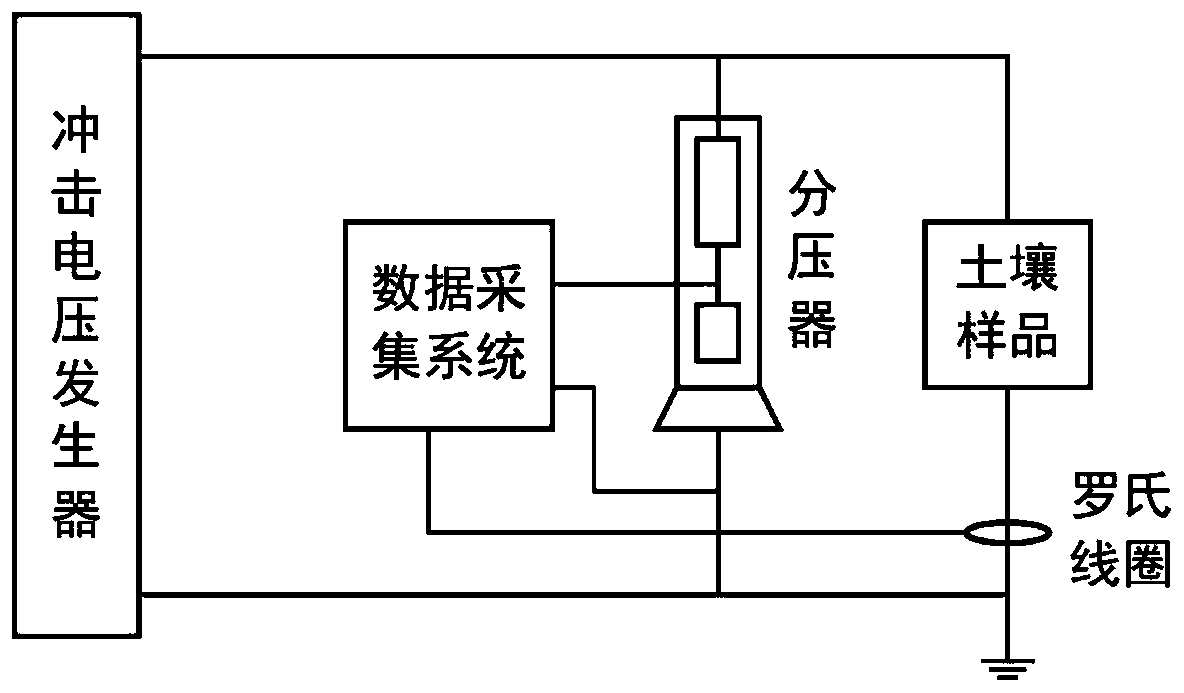

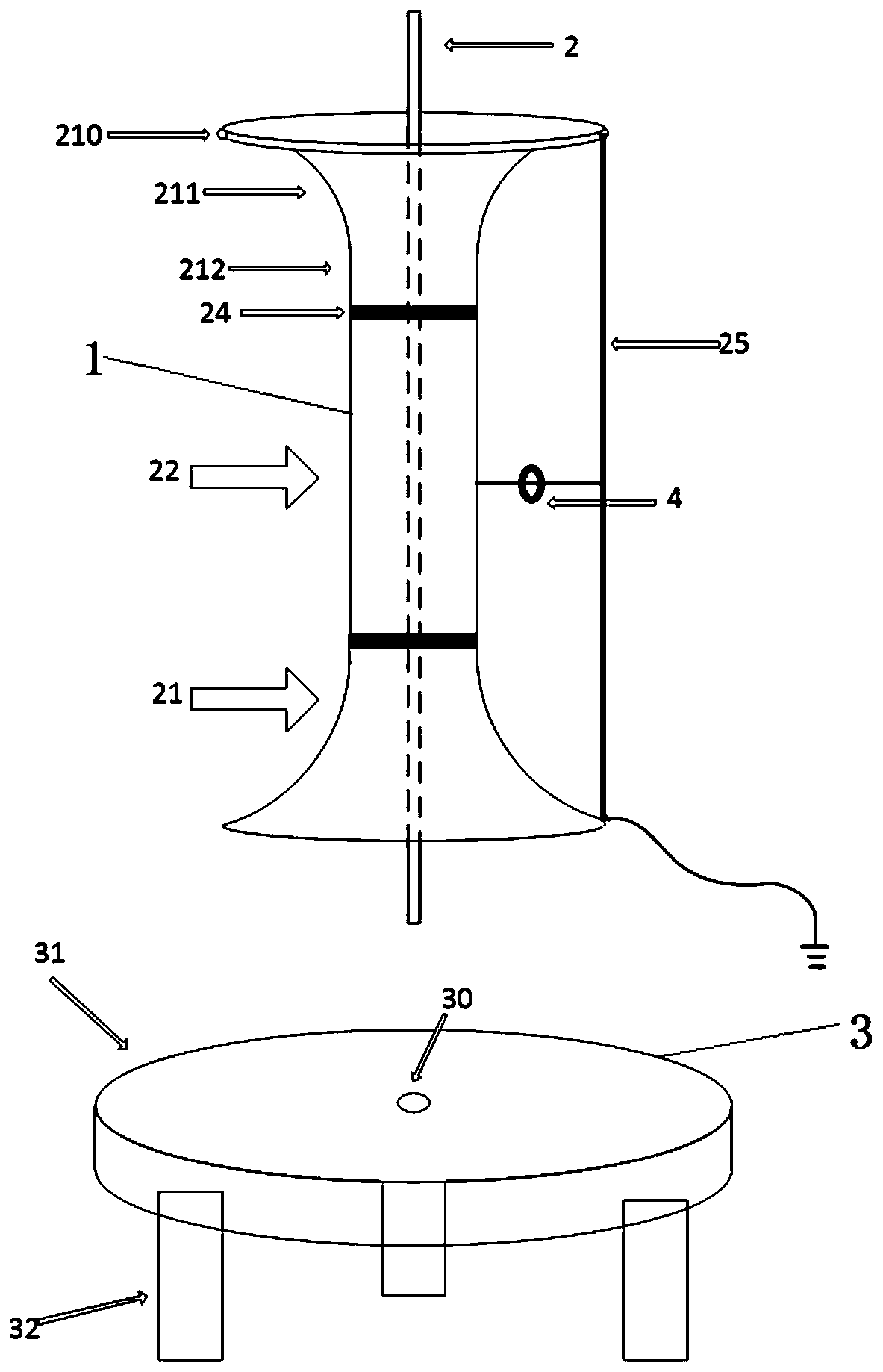

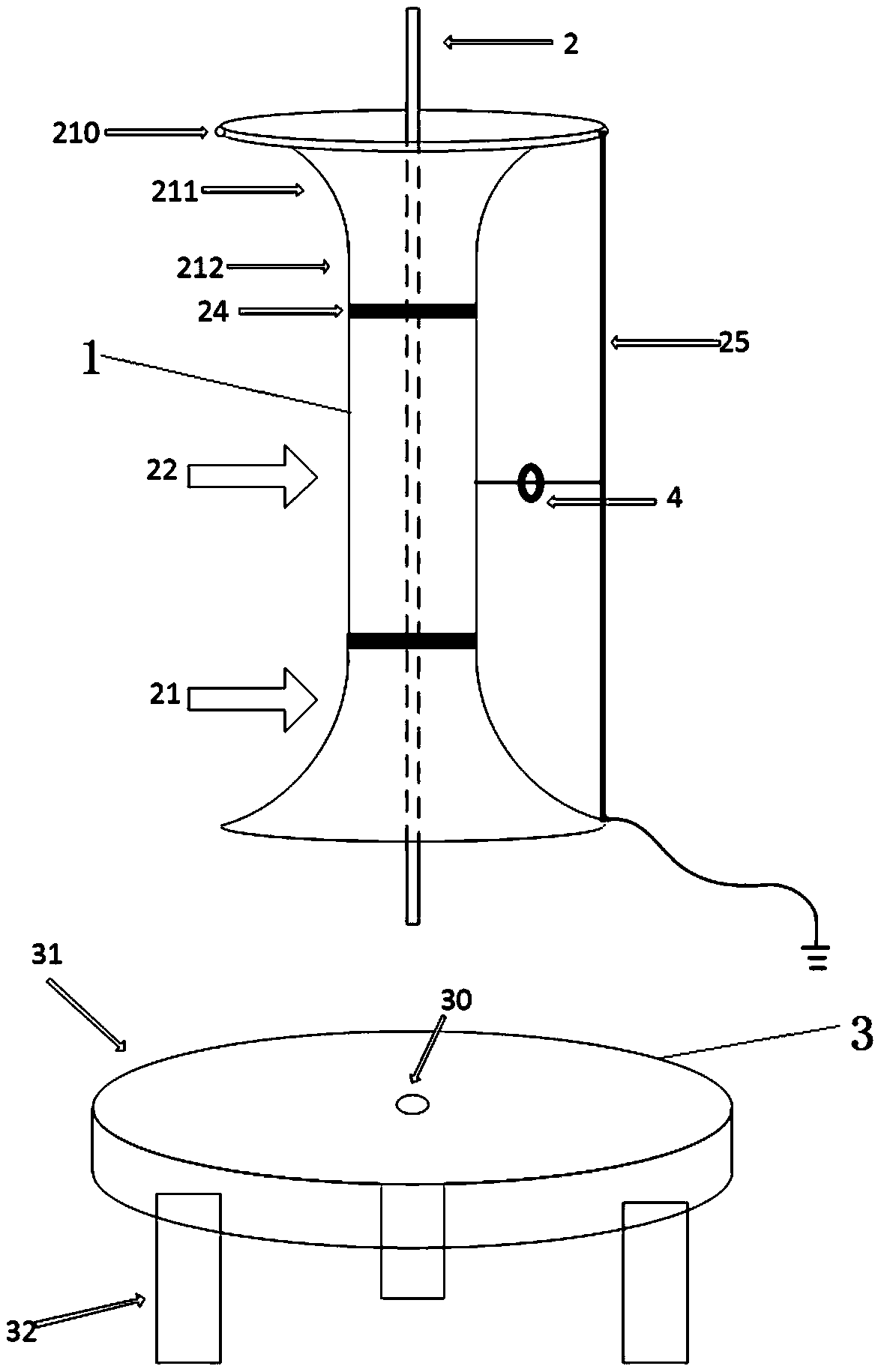

Apparatus for observing soil impact discharge characteristics of ground rods and method thereof

ActiveCN106771930AUniform electric field distributionCreeping discharge does not occurTesting dielectric strengthElectrical conductorPressure wire

The invention discloses an apparatus for observing soil impact discharge characteristics of ground rods and method thereof. The apparatus comprises a backflow electrode and a test ground rod. The backflow electrode adopts a coaxial metal cylinder structure. The backflow electrode is divided into three sections: the two ends are symmetrically arranged with equal pressure segments, and the middle straight wire segment is a test section; the equal pressure segments comprises an equal pressure ring, one fourth arc segment and an equal pressure wire segment which are connected in turn. The equal pressure wire segment and the test segment are separated from an insulated cylinder. At the center of the backflow electrode is arranged with the test ground rod. The soil was filled between the test rod and the backflow electrode. The equal pressure segment and the test segment are mutually connected by a ground wire and are connected to ground by the ground wire. The high voltage output terminal of the lightning impulse generator is connected to the grounding rod of the test case and the low voltage output is connected to the ground wire of the return electrode. The apparatus for observing soil impact discharge characteristics of ground rods can obtain the voltage and current relation of the soil central wire-neutral plate discharge, and is used to evaluate the discharge characteristics of the soil around the grounding conductor, and guide the construction of the grounding project.

Owner:STATE GRID CORP OF CHINA +4

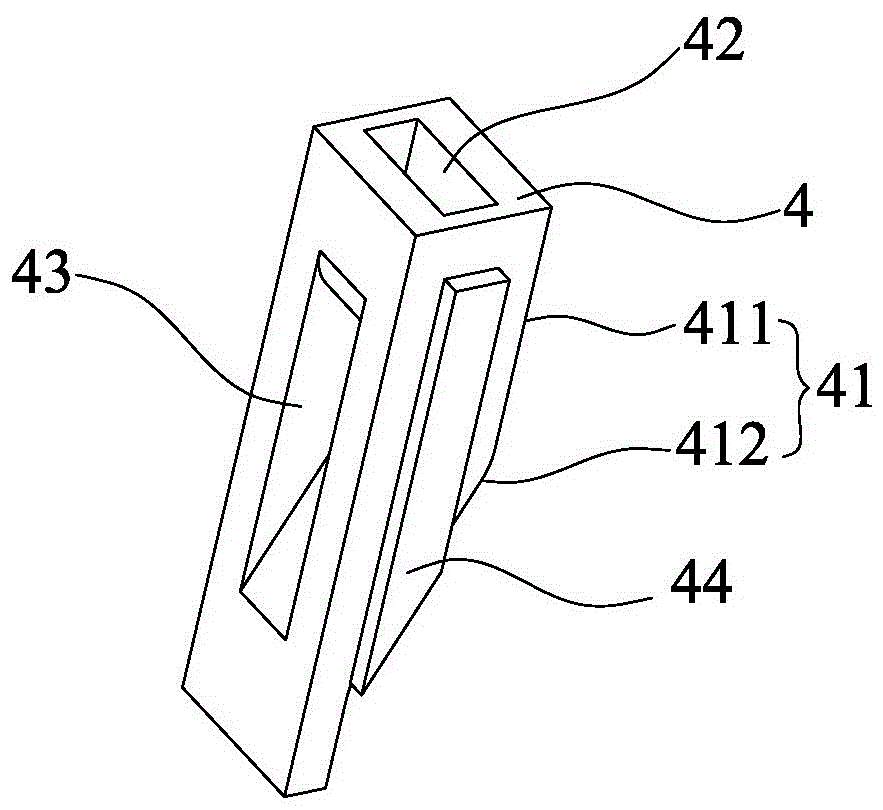

A connector that relies on ribbon-like hard metal twisted pressure wiring

ActiveCN103367935BAchieve connectionRelease the tightening effectCouplings bases/casesClamped/spring connectionsPressure wireElectrical conductor

The invention discloses a connector for wire connection by virtue of twisting pressure of strip shaped hard metal. A lower jack is formed below the middle of a base, an upper jack is formed above the middle of the base, and an upper side jack is formed above the side of the base, a side groove perforating the upper side jack is formed on the side surface, a wire connection cavity perforating the upper jack, the lower jack and the upper side jack is formed between the upper jack and the lower jack; a terminal is inserted into the lower jack, a wire connection plate of the terminal is inserted and fixed in the wire connection cavity and connected with the terminal; the strip shaped hard metal twists into a Greece letter 'Sigma' shape and is mounted in the wire connection cavity, the vertical end is connected with the wire connection plate, and a splicing hole is formed on the transverse end and sleeved on the wire connection plate; a push rod is inserted into the upper side jack in a vertically sliding way, and a pushing surface for extruding the strip shaped hard metal is formed on the inner side of the push rod corresponding to the wire connection cavity; a deflector rod is pivoted on the side groove, and a pushing deflecting structure capable of pushing the push rod upwards or the deflector to swing outwards is formed between the inner side of the deflector rod and the outer side of the push rod. A conductor is conveniently assembled and disassembled by the connector, and prevented from being contacted and furthermore electric shock is avoided.

Owner:XIAMEN WAIN ELECTRICAL

Pressure wire drawing die good in lubrication

InactiveCN106513451ASolve the problem of longevitySolve quality problemsDrawing diesPressure wireEngineering

The invention discloses a pressure wire drawing die good in lubrication. The pressure wire drawing die comprises a die base and a pressing bolt detachably arranged on the die base. A conical wire drawing die cavity is formed in the die base and internally provided with a conical wire drawing die body. The wire drawing die body is provided with a high-pressure lubrication cavity and a wire drawing hole. A pressure die is arranged in the pressing bolt and provided with a conical hole. The pressure die is arranged between the pressing bolt and the wire drawing die body. The pressing bolt is provided with a lubricating agent cavity used for containing a lubricating agent. The lubricating agent cavity communicates with the high-pressure lubricating cavity through the conical hole. According to the pressure wire drawing die good in lubrication, the steel wire surface friction force is reduced, the steel wire drawing force is reduced, and accordingly the purpose of improving the production efficiency is achieved.

Owner:鹤山恒基钢丝制品有限公司

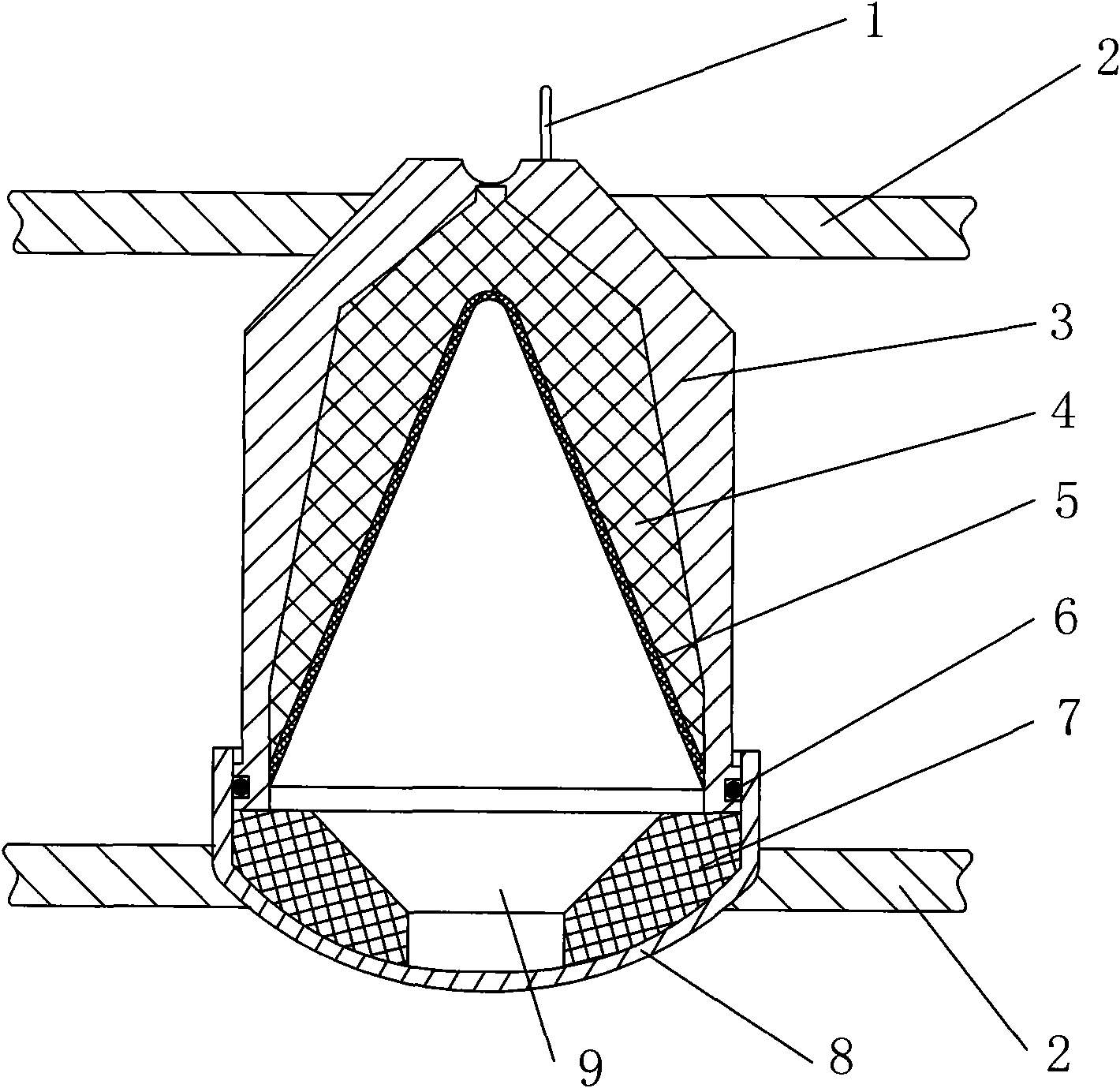

Novel tube structure of prestress ultrahigh-pressure wire winding container

ActiveCN108825777AAchieve lightweightGood preload effectPressure vesselsUltra high pressurePressure wire

The invention provides a novel tube structure of a prestress ultrahigh-pressure wire winding container. By changing the gradient of the end face of a tube, the pretightening height of a winding layeris greater than the height of a pressure-bearing surface of the inner wall of an inner tube. Under the condition that the volumes and the inner diameters of the container and the tube are fixed, a setof flat end face structure and angled end face structure models with different dimension parameters are obtained through a tube thickness and steel wire layer number adjustment and optimization trialcalculation method. ANSYS finite element modeling software is used for conducting simulation on different structures. The simulation result shows that to meet the same bearing requirements, an angledend face structure is adopted to replace a flat end face structure; compared with the flat end face, both the inner tube thickness and the steel wire layer number required for pressure bearing can bereduced, and the total mass reduction range of steel wire layers and the tube is about within 10.01%-17.77%. The changed angled end face tube structure adopts a triangular gasket and hollow metal O-ring combined hard seal and soft seal sealing structure and can both bear high pressure and ensure the good sealing performance.

Owner:CHANGZHOU UNIV

Electric larceny prevention metering device and electric larceny prevention method thereof

InactiveCN105259391AScenarios to stop power theftEasy to installTime integral measurementPressure wireElectrical conductor

The present invention discloses an electric larceny prevention metering device and an electric larceny prevention method thereof. The electric larceny prevention metering device comprises a box which is capable of closing secondary wiring of current transformers, so that electric larceny cannot occur at the position of the secondary wiring. At the same time, each current transformer sleeves an electric conductor, one end of the electric conductor is fixed to a kettle head rod of a transformer, and the electric conductor is not easy to break, so that electric larceny cannot occur at the position of primary wiring, and a pressure wire at the voltage side of the transformer can be omitted. The electric larceny prevention method of the electric larceny prevention metering device can protect the secondary wiring, the primary wiring and the current transformers, in addition, connection points of the above positions are also protected, in this way, through adoption of the electric larceny prevention metering device, the positions where electric larceny is easy to occur can be closed, thereby effectively preventing occurrence of an electric larceny condition.

Owner:国网山东潍坊市寒亭区供电公司 +1

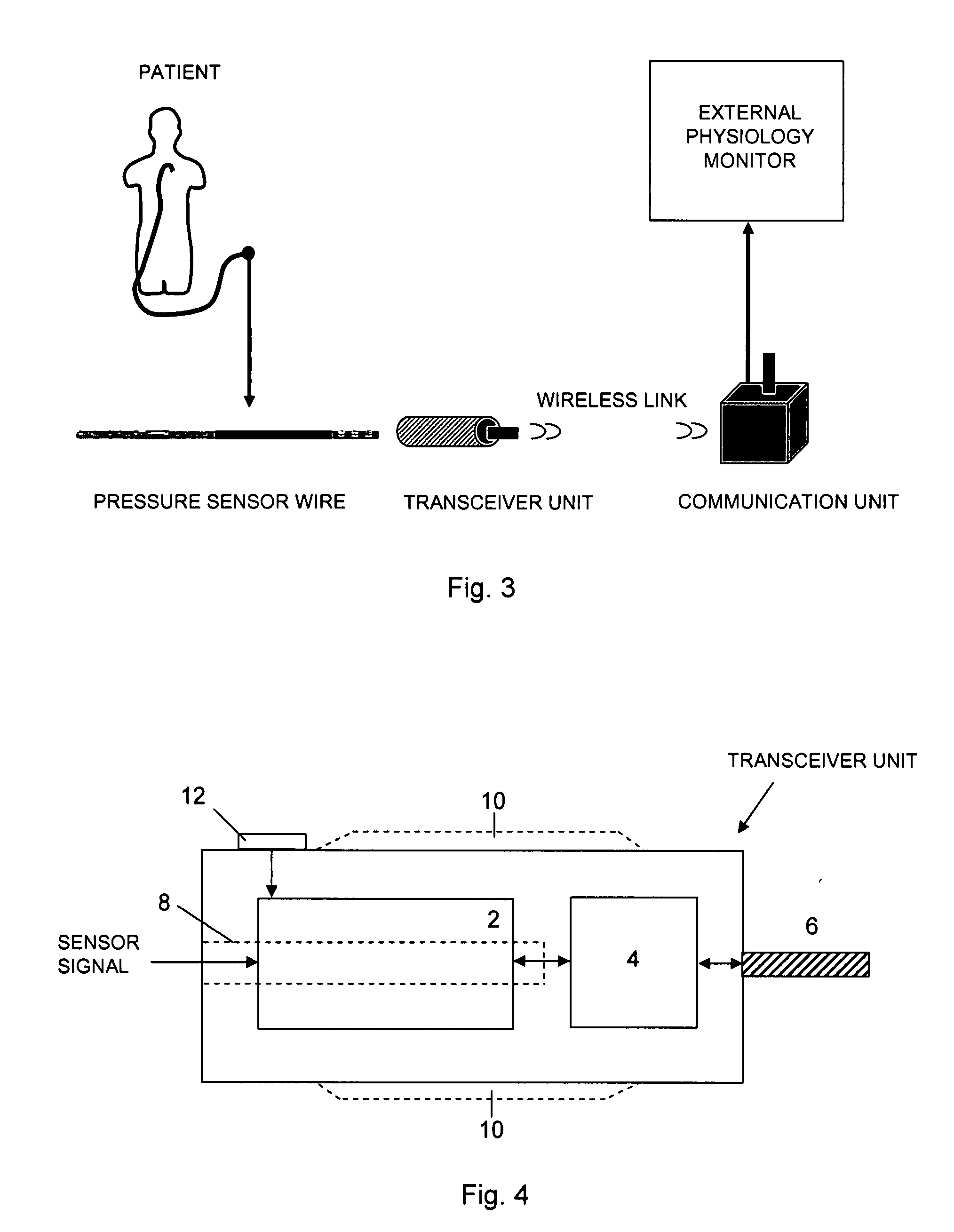

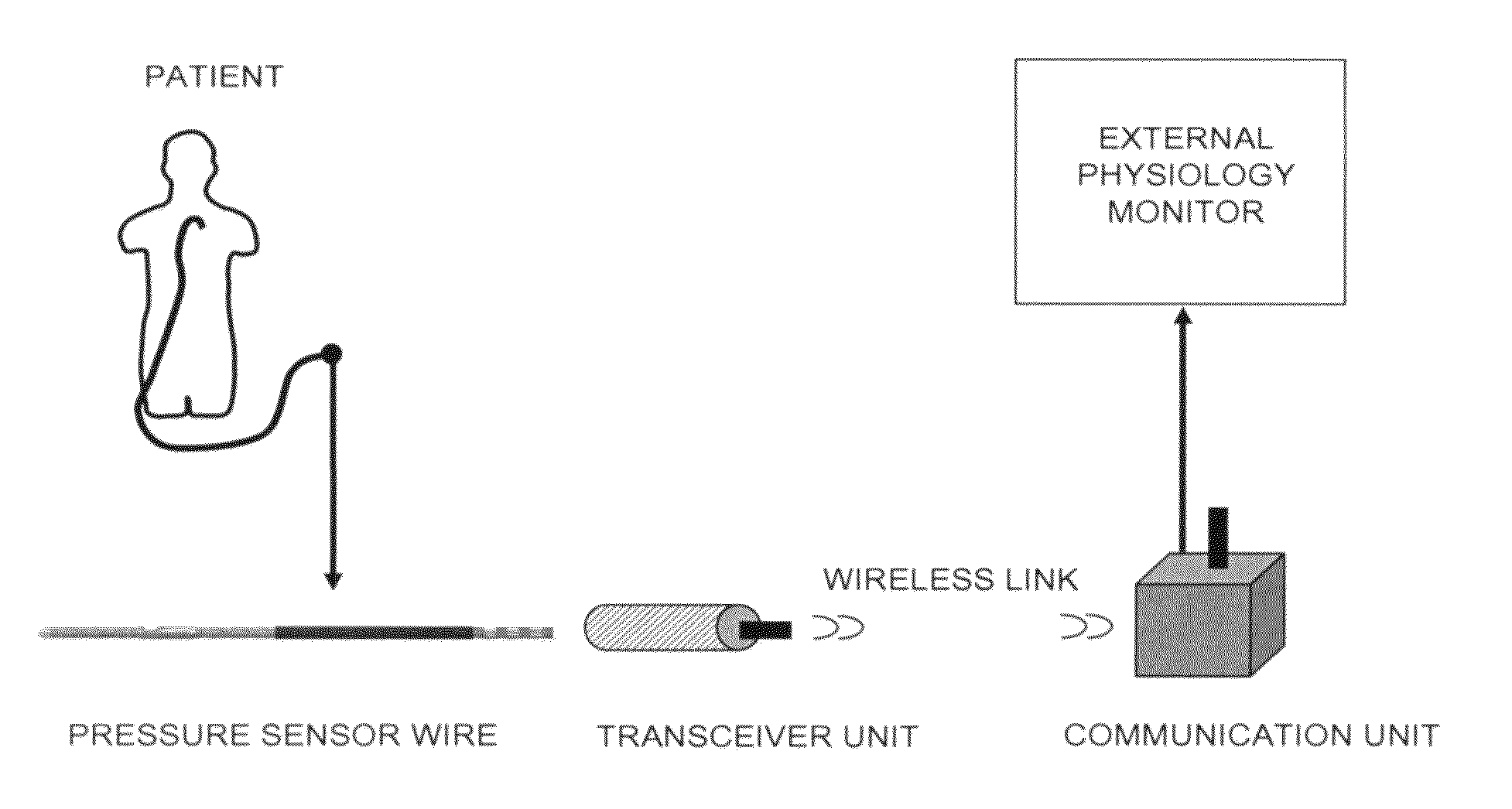

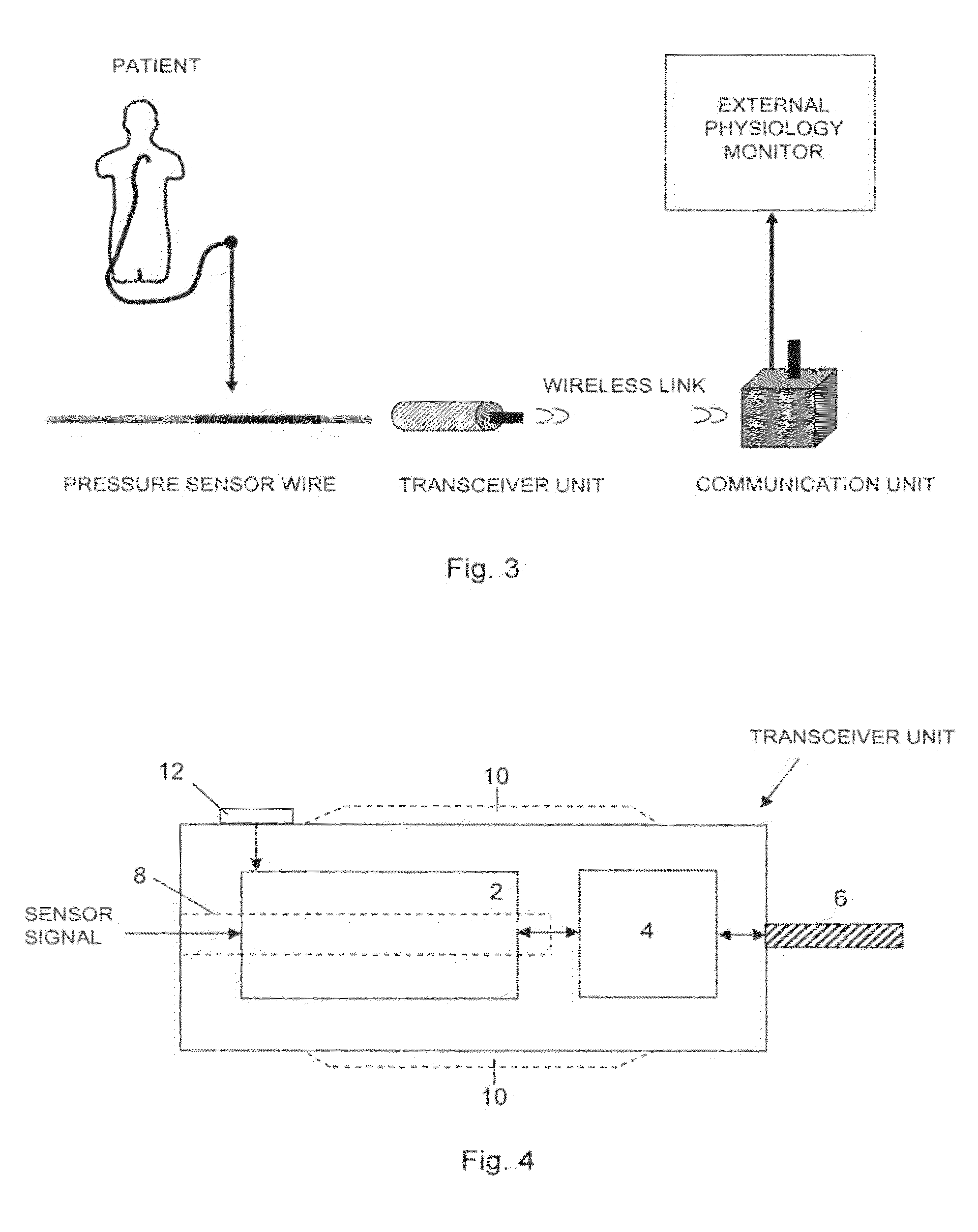

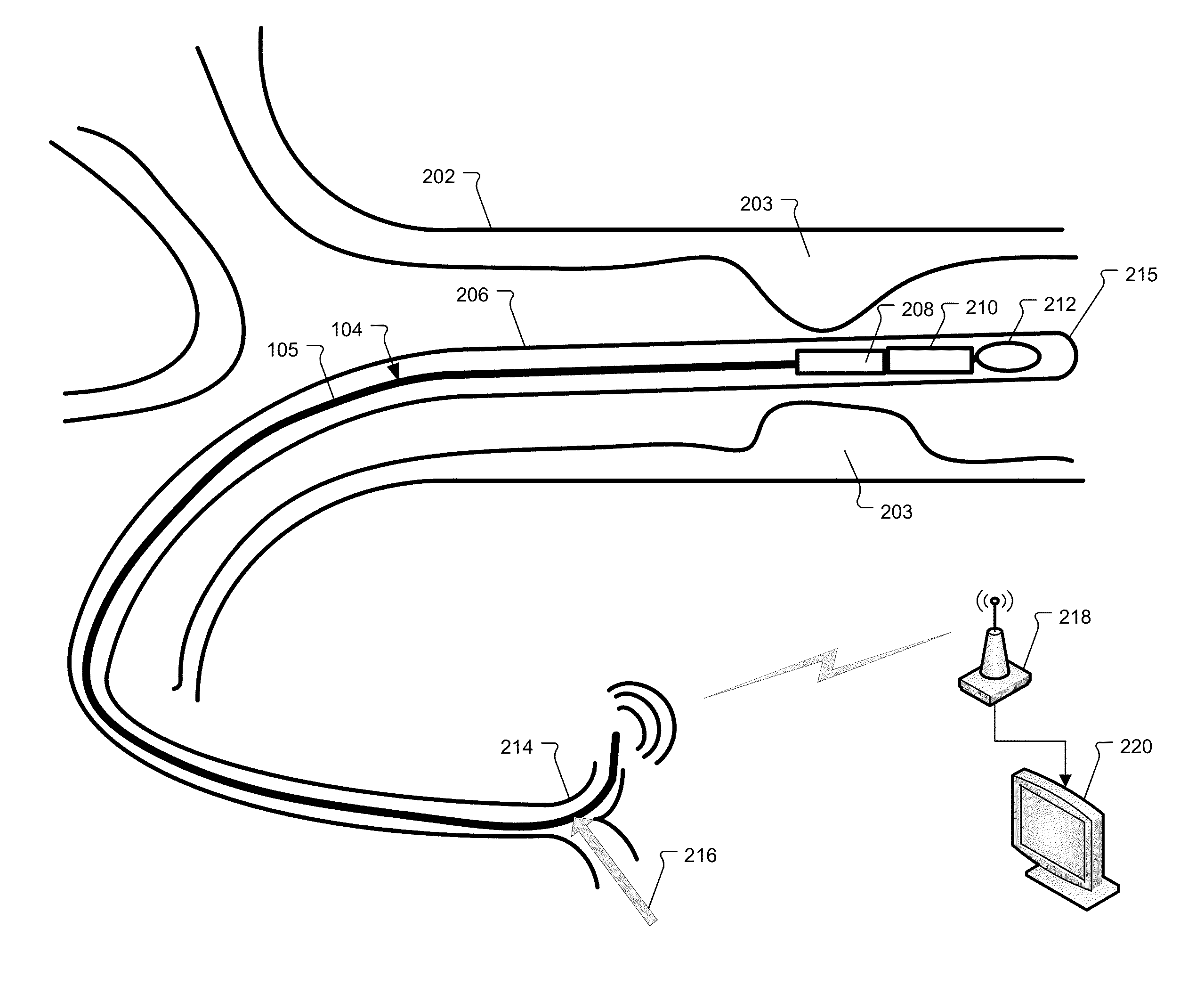

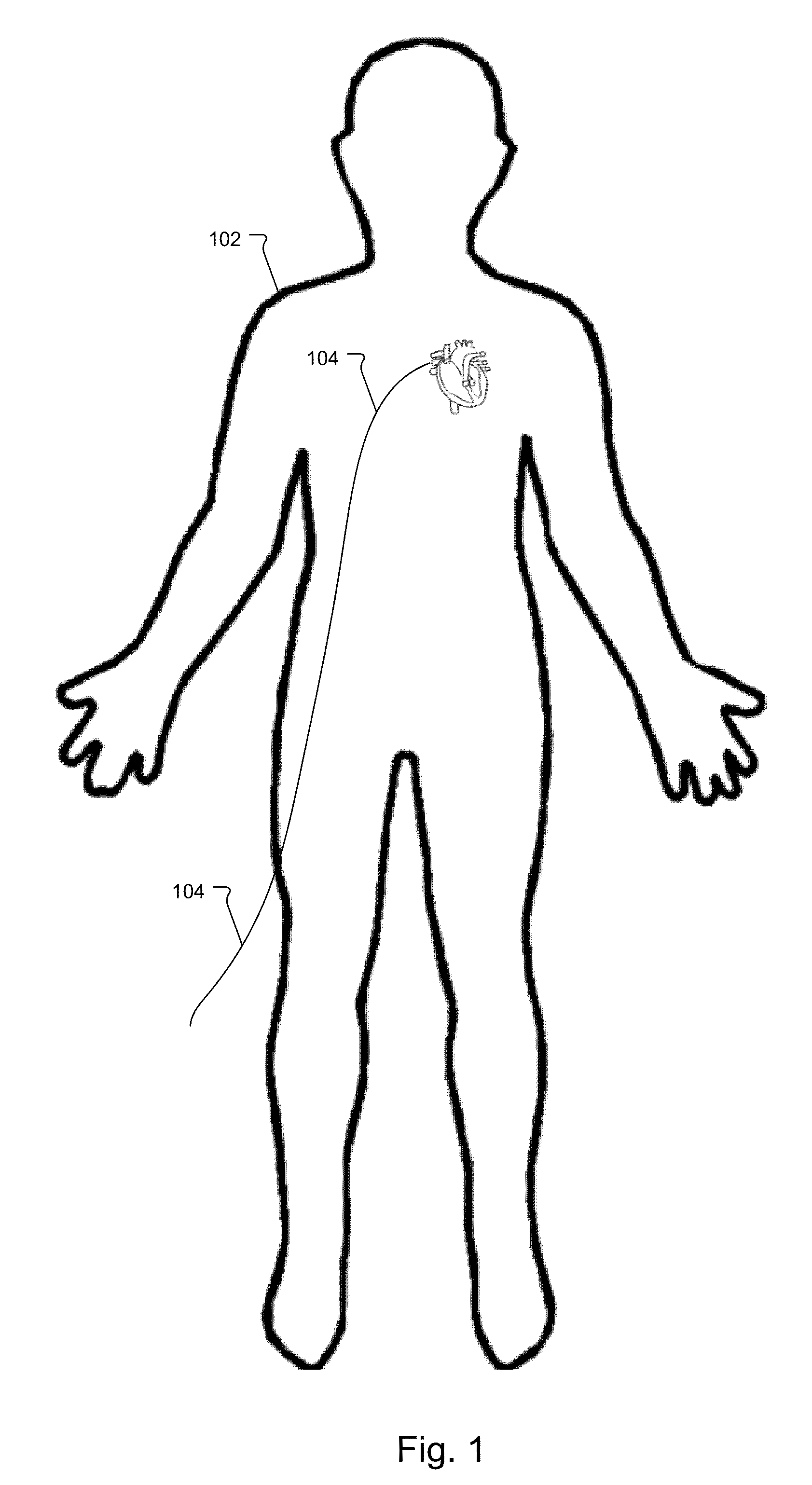

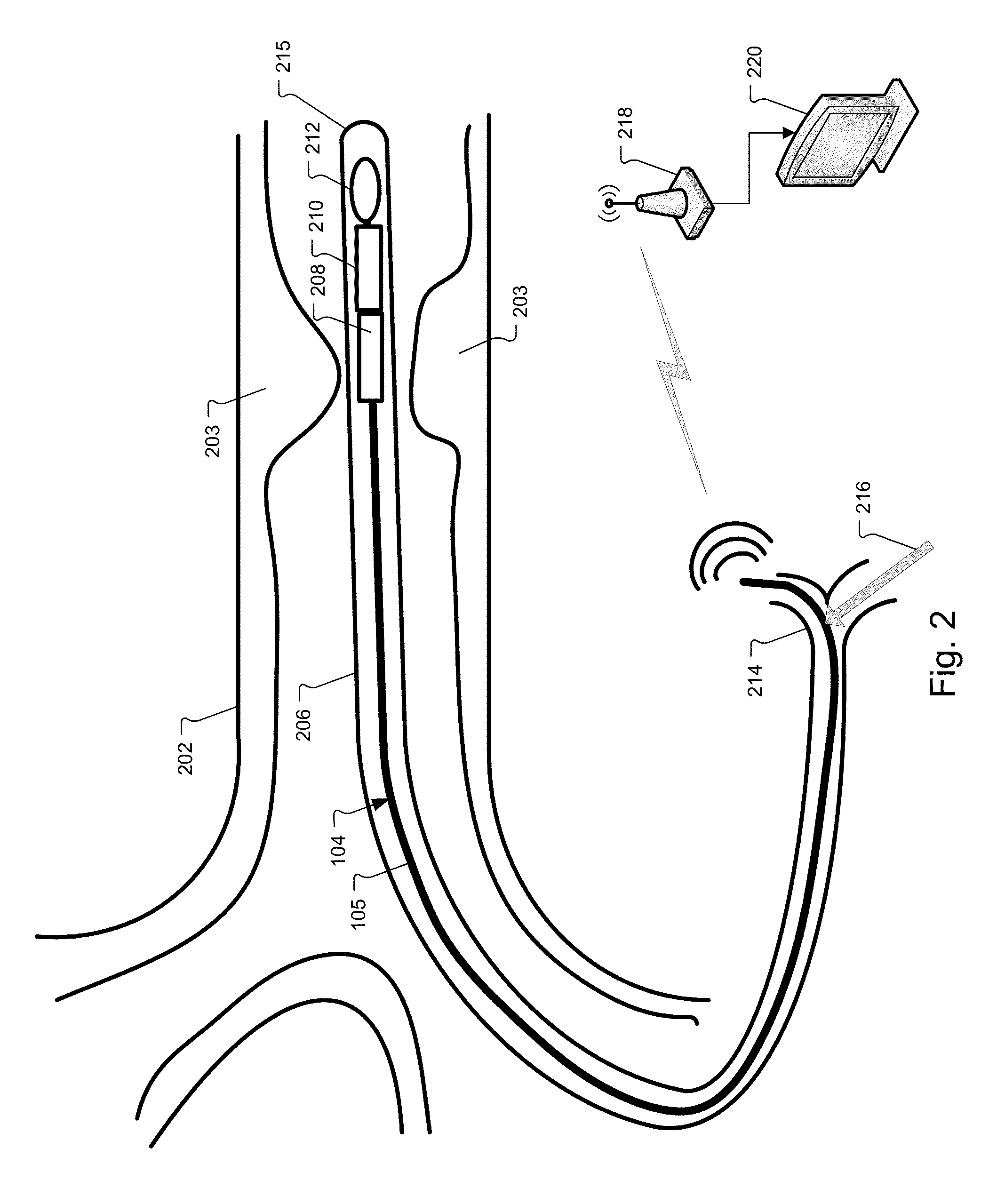

Wireless pressure wire system with integrated power

A sensor wire system with an integrated power source and wireless transmission is provided. A sensor wire includes a distal end that is inserted into a blood vessel of a patient's body. A sensor that is mounted at the distal end of the sensor wire and an electronics unit of the distal end of the sensor wire transmit information generated by the sensor to a receiver unit outside of the patient's body wirelessly. The system further includes a power source, which in one example is mounted to the distal end of the sensor wire, that supplies power to the electronics unit. Preferably the wire body functions as an antenna for the wireless broadcasting.

Owner:VOLCANO CORP

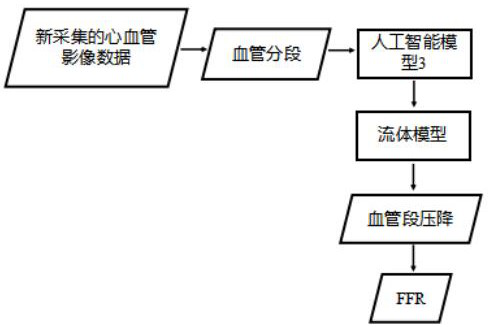

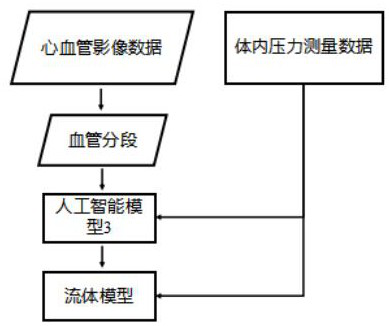

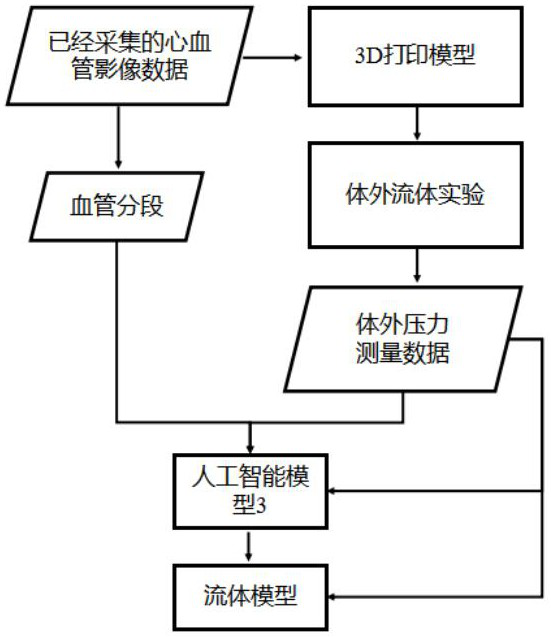

Vascular imaging based calculation method of fractional flow reserve

InactiveCN112535466AAvoid multiple intrusionsAvoid side effectsSensorsBlood flow measurementPressure wireEngineering

The invention relates to a vascular imaging based calculation method of fractional flow reserve. An artificial intelligence model 1 is utilized to automatically divide target blood vessel into multiple blood vessel segments having similar morphological features; the artificial intelligence model is also used to calculate the pressure drop of each blood vessel segments, so that the pressure distribution and FFR of the whole blood vessel can be obtained, and the use of pressure wires and the injection of vasodilators can be avoided; and the evaluation and rehearsal of vascular function recoveryafter virtual interventional surgery (such as stent placing) is performed by utilizing the pressure drop distribution information of the whole blood vessel.

Owner:成都全景恒升科技有限公司

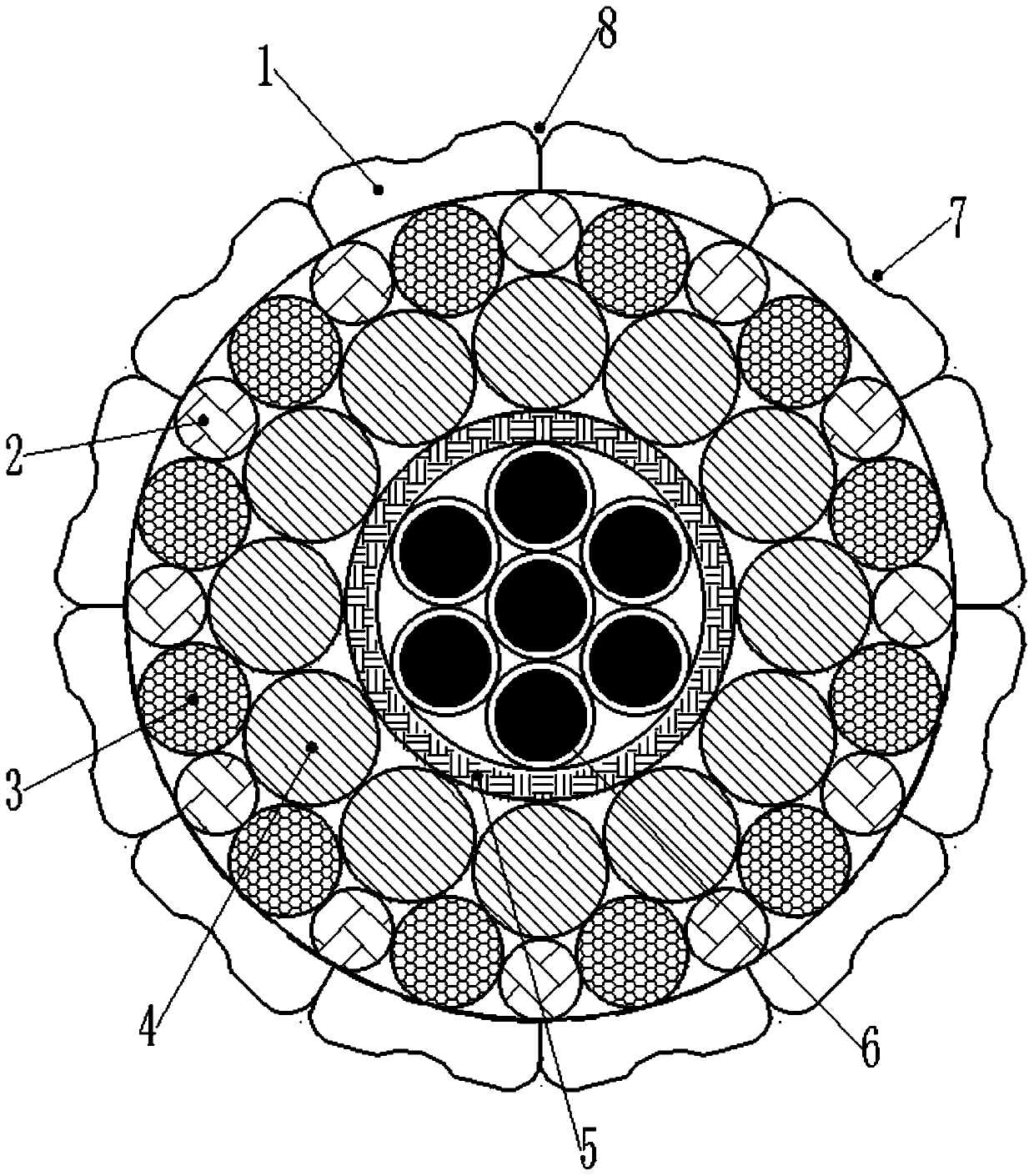

Aluminum-clad invar steel core super-heat-resistant aluminum alloy type low wind pressure wire

PendingCN110148496ACompact structureReduce wind pressureClimate change adaptationPower cables for overhead applicationPressure wireAlloy

The invention relates to an aluminum-clad invar steel core super-heat-resistant aluminum alloy type low wind pressure wire. Reinforcing cores are coated with a cladding layer, an inner conductive layer is formed by stranding a plurality of first wires, and the first wires are circumferentially distributed outside the cladding layer and are tangent to each other. A main middle conductive layer includes a plurality of second wires, the second wires are circumferentially distributed outside the inner conductive layer, the second wires are alternately distributed with the first wires, each of thesecond wires is simultaneously tangential to two adjacent first wires, and a gap is between any two adjacent second wires. An accessory middle conductive layer comprises a plurality of third wires, and each of the third wires is disposed in gaps and is simultaneously tangential to two adjacent second wires and an adjacent first wire. The outer part of the middle conductive layer is coated with anouter conductive layer which is formed by stranding a plurality of special-shaped conductive wires, a V-shaped groove is formed by any adjacent special-shaped conductive wires on the outer surface ofthe outer conductive layer, and the V-shaped groove is recessed toward the inside.

Owner:ANHUI ELECTRIC GRP SHARES

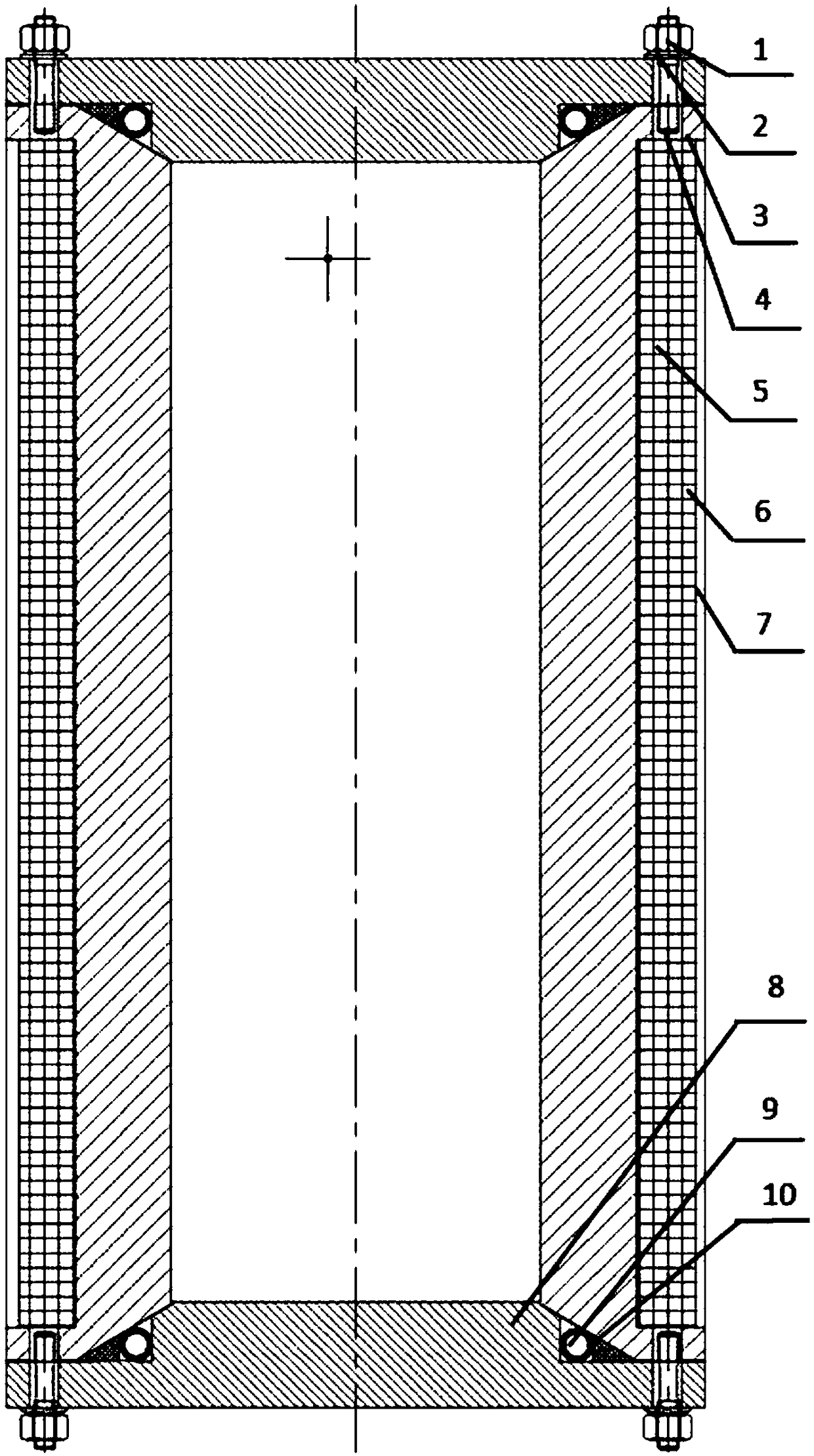

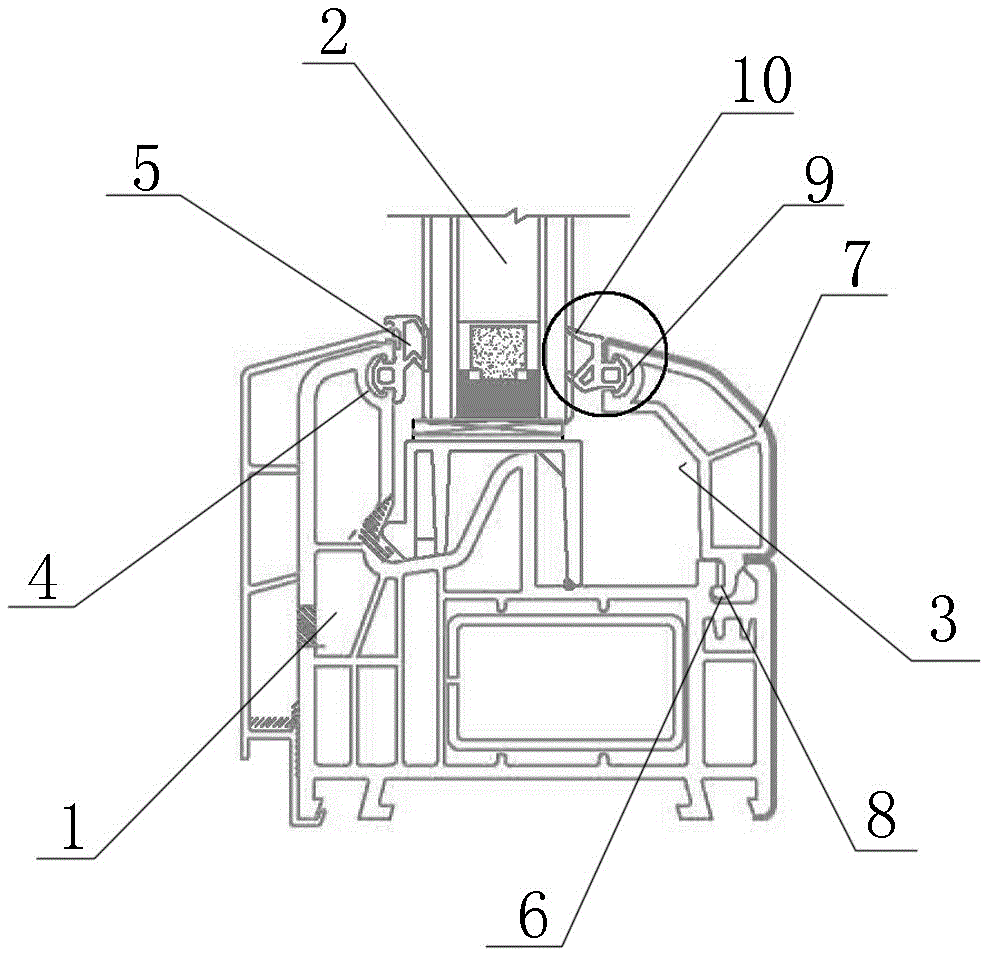

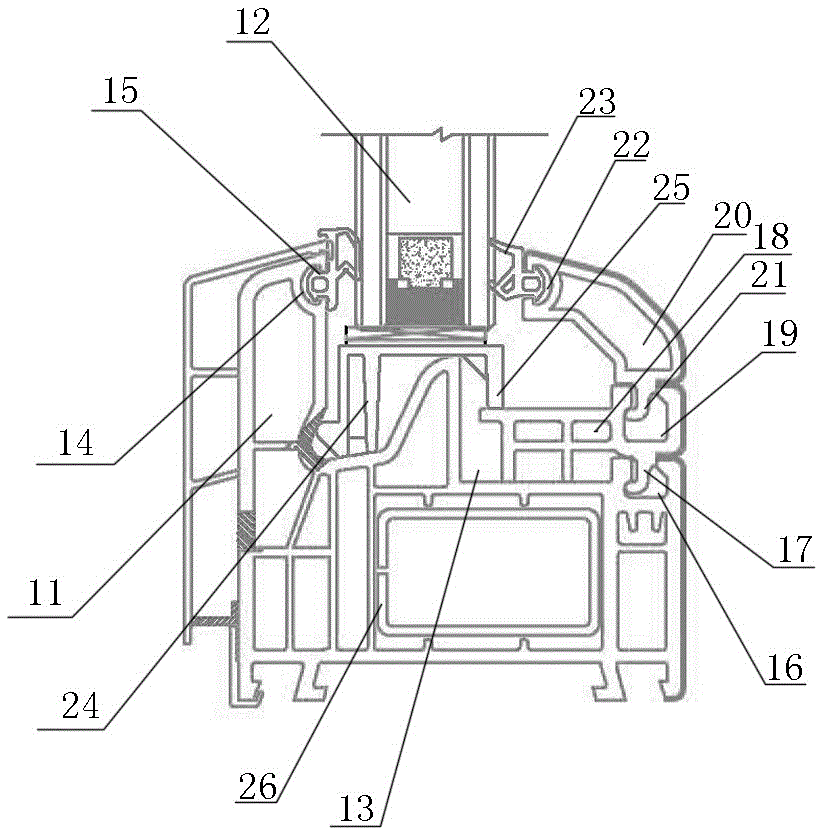

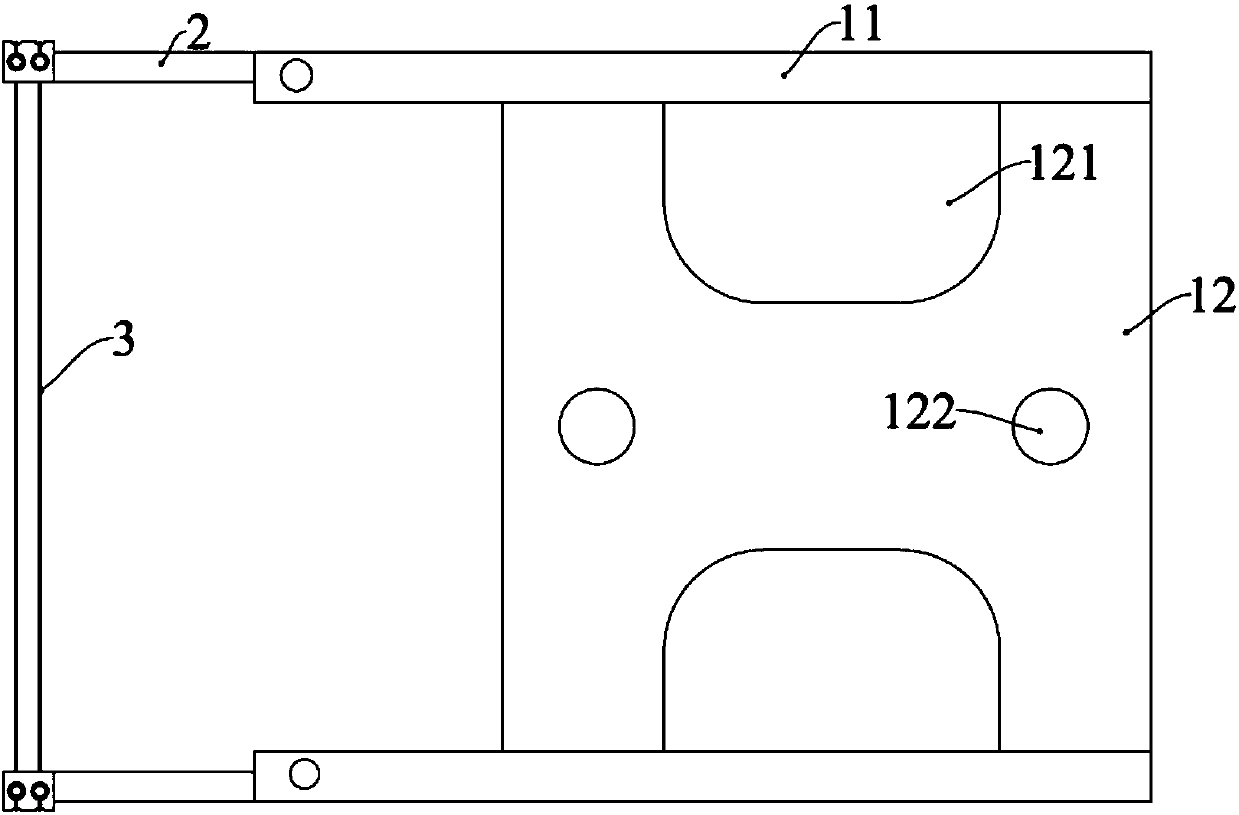

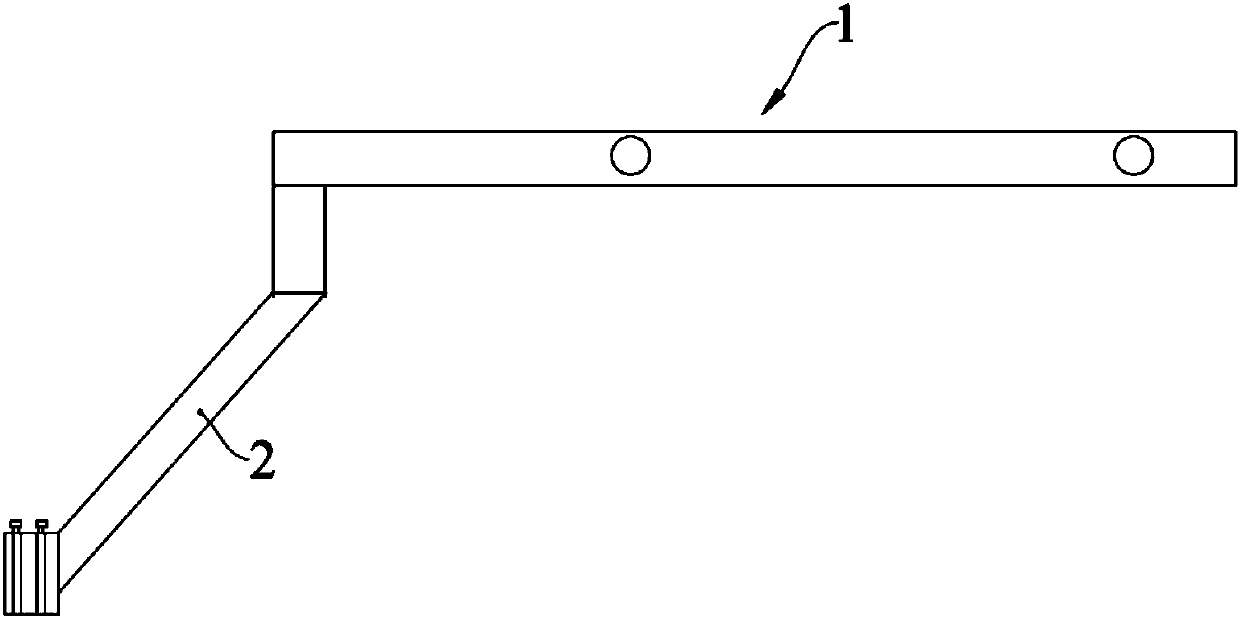

Door and window glass wire pressing mechanism with height increase material and with function of enhancing wind pressure effect

ActiveCN105756497AReduce distanceStable supportSealing arrangementsGlass pane fixingPressure wireEngineering

The invention relates to a door and window glass wire pressing mechanism with a height increase material and with the function of enhancing the wind pressure effect. The door and window glass comprises a door and window outer frame or sash, an L-shaped glass installing groove which faces the indoor side and is used for embedding and installing glass is formed in the inner end surface of a sectional material frame of the outer frame or the sash; the inner side edge of the L-shaped glass installing groove is provided with an outer glass rubber pad through a clamping groove; an indoor side clamping groove is formed in the bottom edge, near to the indoor side, of the L-shaped glass installing groove; the groove bottom of the L-shaped glass installing groove is provided with a glass supporter used for supporting and placing the glass; a pressing and connecting edge which downwards and tightly presses a height increase block extends from one side, facing the indoor side, of the upper side of the glass supporter. The door and window glass wire pressing mechanism has the characteristics that the structure is simple; the installation and the use are convenient; the support of the pressure wires on the glass can be effectively enhanced; the safety of the door and window glass is improved; the air rightness and the water tightness of the door and window glass are effectively ensured, and the like.

Owner:浙江瑞明节能门窗技术有限公司

Fractional flow reserve determination

ActiveUS10552958B2Improve simulation accuracyImprove impactImage enhancementImage analysisPressure wireBlood flow

The present invention relates to a device (1) for fractional flow reserve determination, the device (1) comprising: a model source (10) configured to provide a first three-dimensional model (3DM1) of a portion of an imaged vascular vessel tree (VVT) surrounding a stenosed vessel segment (SVS) and configured to provide a second three-dimensional model (3DM2) of a pressure wire insertable into the vascular vessel tree (VVT); and a processor (20) configured to calculate a first blood flow (Q1) through the stenosed vessel segment (SVS) with the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first and the second three-dimensional model and to calculate a second blood flow (Q2) through the stenosed vessel segment (SVS) without the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first three-dimensional model (3DM1) and to determine a first fractional flow reserve value (FFR1) to be measured with the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the first blood flow (Q1) and to determine a second fractional flow reserve value (FFR2) to be measured without the pressure wire (PW) inserted into the vascular vessel tree (VVT) based on the second blood flow (Q1).

Owner:KONINKLJIJKE PHILIPS NV

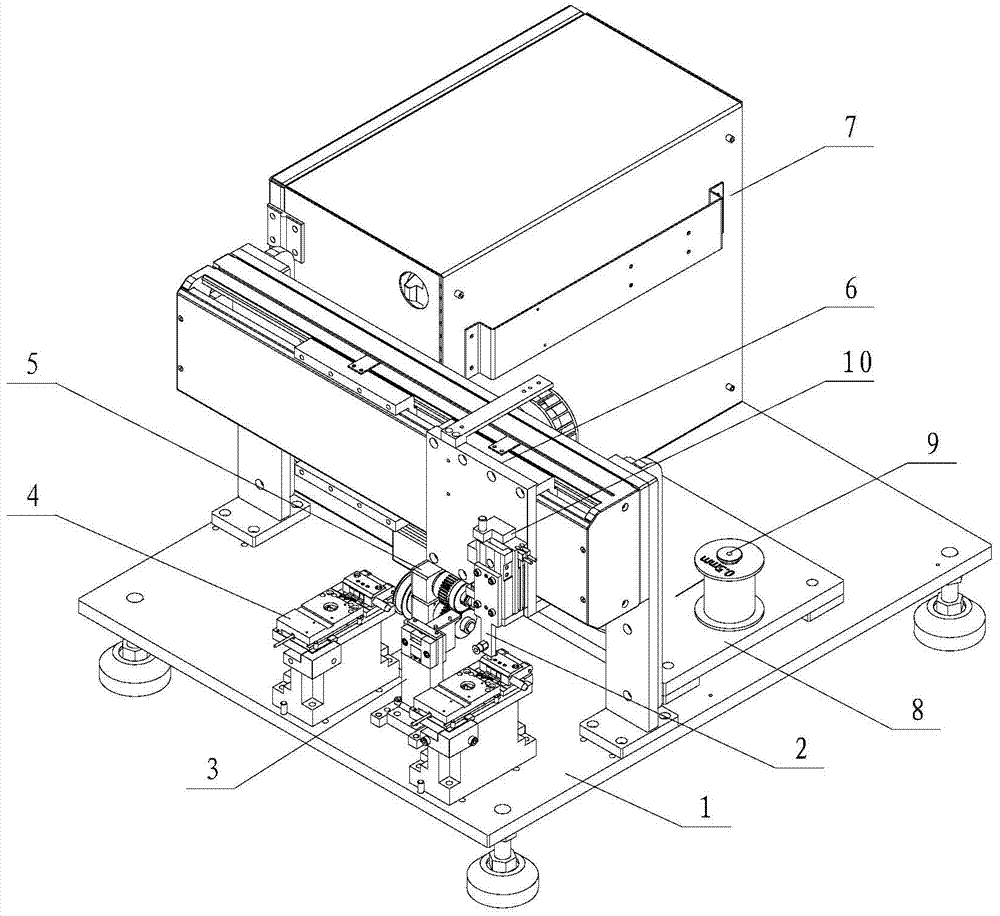

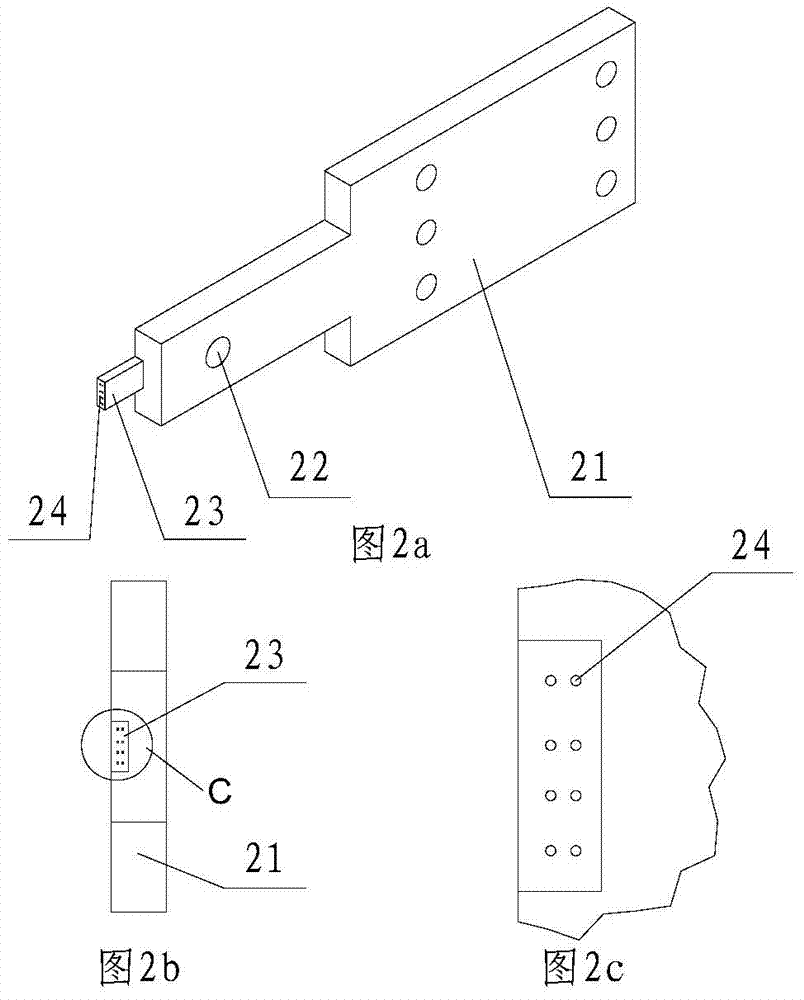

An automatic cutting and feeding mechanism for multi-station tin sheets

ActiveCN105345199BRealize automatic handlingReduce labor intensitySolder feeding devicesSoldering auxillary devicesPressure wireLaser processing

The invention relates to the technical field of laser soldering processing, and discloses an automatic cutting and feeding mechanism for multi-station tin sheets, including a base platform, a lower knife seat arranged on the base platform, a flexible wire and a pad fixing fixture and The horizontal electric platform, the downward pressure power source arranged on the horizontal electric platform, the cutter and vacuum suction cup assembly connected to the power end of the downward pressure power source, and the wire pressing and wire feeding mechanism arranged on the side of the lower knife seat, said The downward pressure power source is used to drive the cutter and vacuum suction cup assembly to cut the tin sheet after the wire pressing and feeding mechanism has been flattened. The horizontal electric platform is used to drive the cutter and vacuum suction cup assembly between the lower knife seat and the Move between flexible wire and pad holding fixtures. The invention has the advantages of being able to automatically convey, flatten, cut and transport the tin sheet.

Owner:HANS LASER TECH IND GRP CO LTD

A device and method for observing the impact discharge characteristics of soil around a ground rod

ActiveCN106771930BUniform electric field distributionCreeping discharge does not occurTesting dielectric strengthElectrical conductorPressure wire

Owner:STATE GRID CORP OF CHINA +4

A conductive terminal

ActiveCN105428830BGuaranteed reliabilityAvoid free turningClamped/spring connectionsPressure wireEngineering

The present invention provides a conductive terminal. The terminal comprises a housing; a wire pressure reed is arranged in the housing in a manner of rotating around an axis extending front and back; the wire pressure reed is respectively provided with a wire pressure-wire end and a drive end on both sides of a rotating shaft; the housing is rotatably provided with an operating handle used for driving the wire pressure reed to rotate between a wire connection position and a wire pressure position; the operating handle is in parallel to the rotating axis of the wire pressure reed; one end of the operating handle, which is positioned inside the housing, is provided with a contact section; the contact section is provided with a reed perforated hole used for the drive end of the wire pressure reed to pass through; the reed perforated hole is provided with a right hole wall used for pushing the outer lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire pressure position when the operating handle rotates forwards; and the reed perforated hole is also provided with a left hole wall used for pulling the inner lateral surface of the drive end and enabling the wire pressure reed to rotate towards the wire connection position when the operating handle is rotated reversely. The conductive terminal disclosed by the present invention is simple in structure and very convenient to use.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

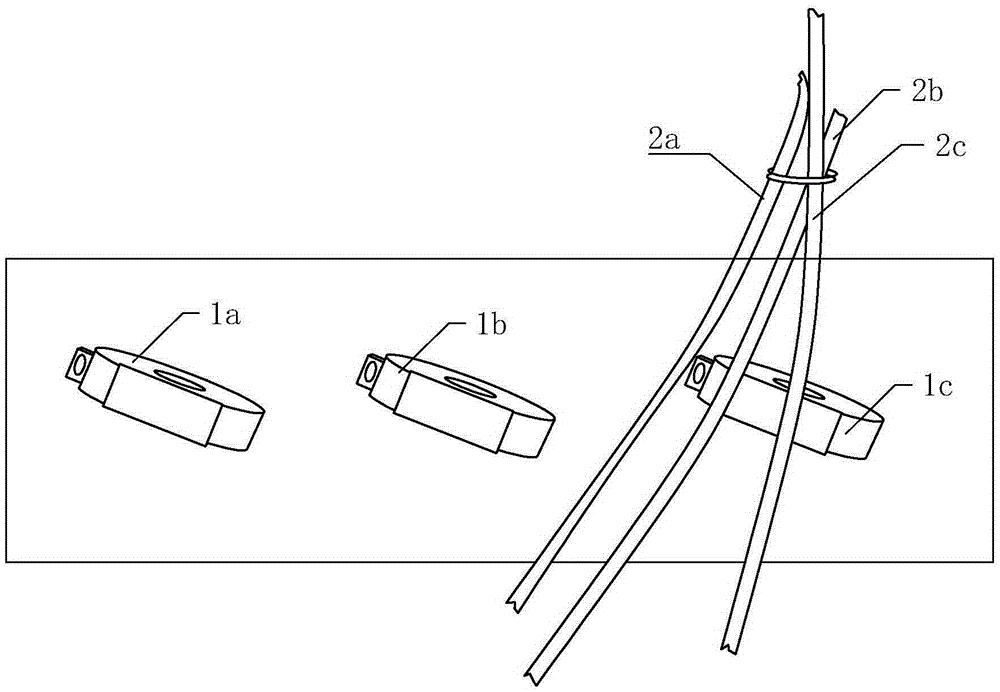

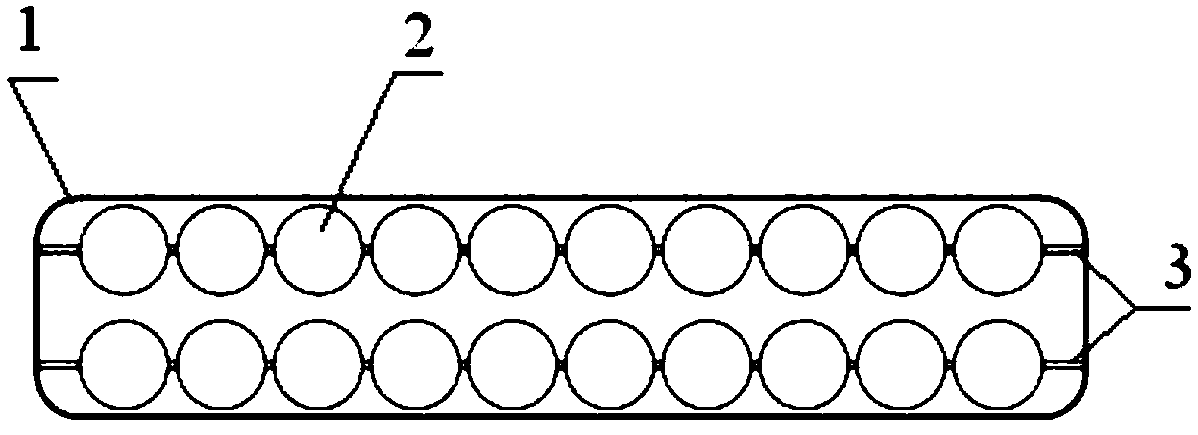

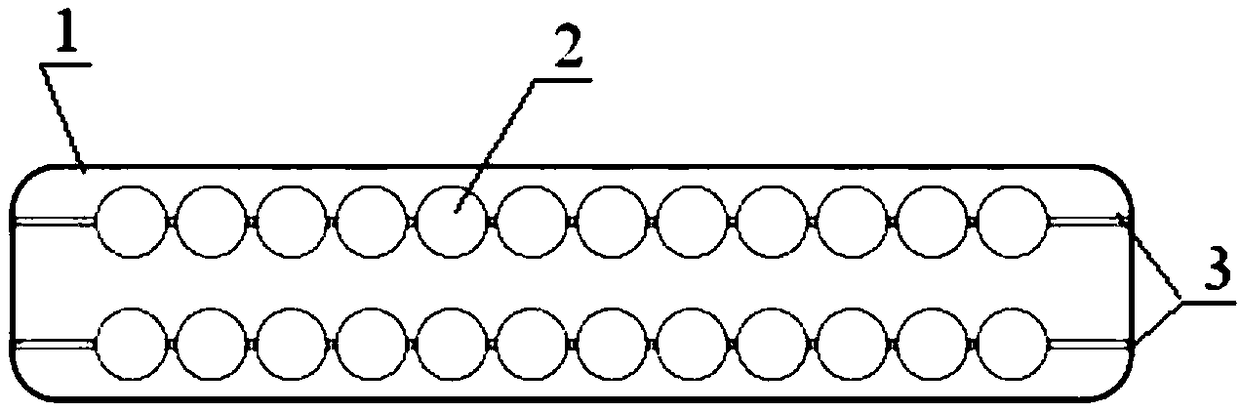

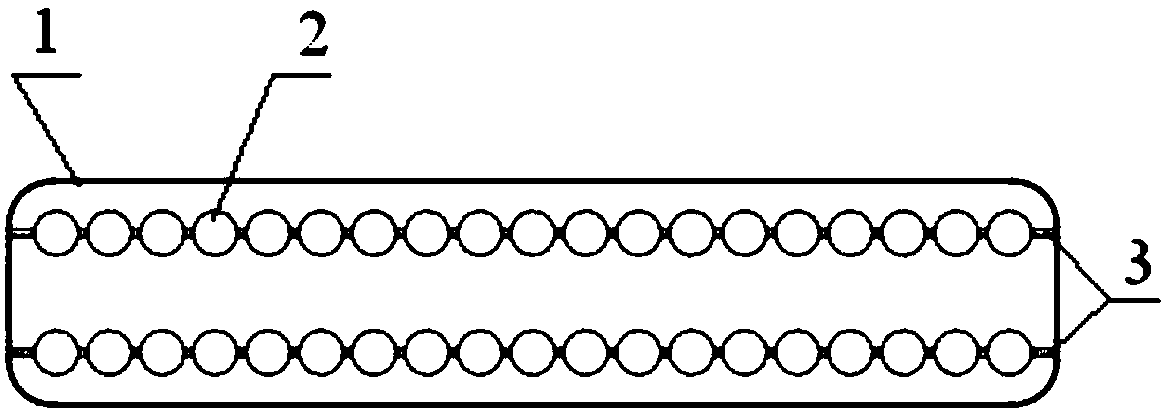

Antibiotic bone cement chain bead manufacturing device and method

The invention discloses an antibiotic bone cement chain bead manufacturing device and method. A body of the manufacturing device is of a rectangular structure, two rows of several grooves are longitudinally formed in the body, and wire grooves are formed in the portion, corresponding to the grooves, of the body. The antibiotic bone cement chain bead manufacturing method comprises the steps of 1, selecting the antibiotic bone cement chain bead manufacturing device with the matched specification according to the size of a bone cement chain bead actually required by an operation; 2, uniformly mixing antibiotics and bone cement according to the weight ratio of 1:20, and adding purified water to blend the materials into a mixture; 3, filling the grooves formed in the antibiotic bone cement chain bead manufacturing device with the mixture prepared in step 2, and then pressuring wires into the wire grooves; 4, manufacturing the bone cement chain bead. The antibiotic bone cement chain bead manufacturing device and method have the advantages that the bone cement chain bead with the corresponding specification can be implanted into any part of the body according to the demands of the operation, the bone cement chain bead is convenient to take out, the pain of a patient can be alleviated, the cost of the bone cement chain bead is lower than that of a commercialized bone cement chain bead,and more bone cement chain beads can be manufactured within an effective time.

Owner:JILIN UNIV

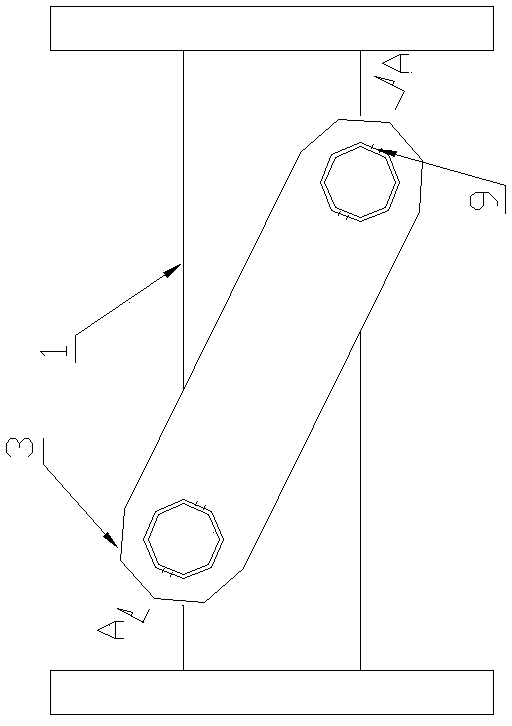

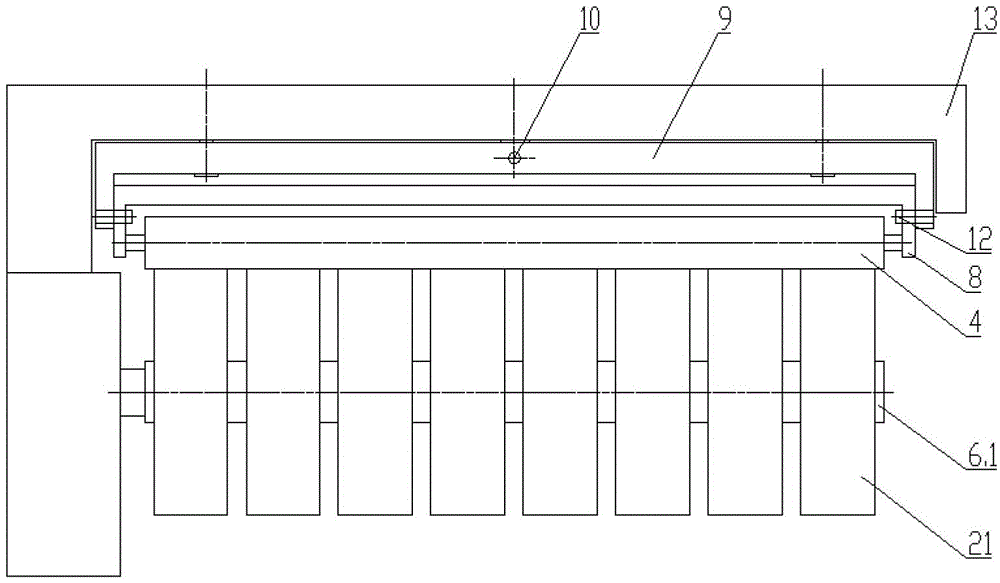

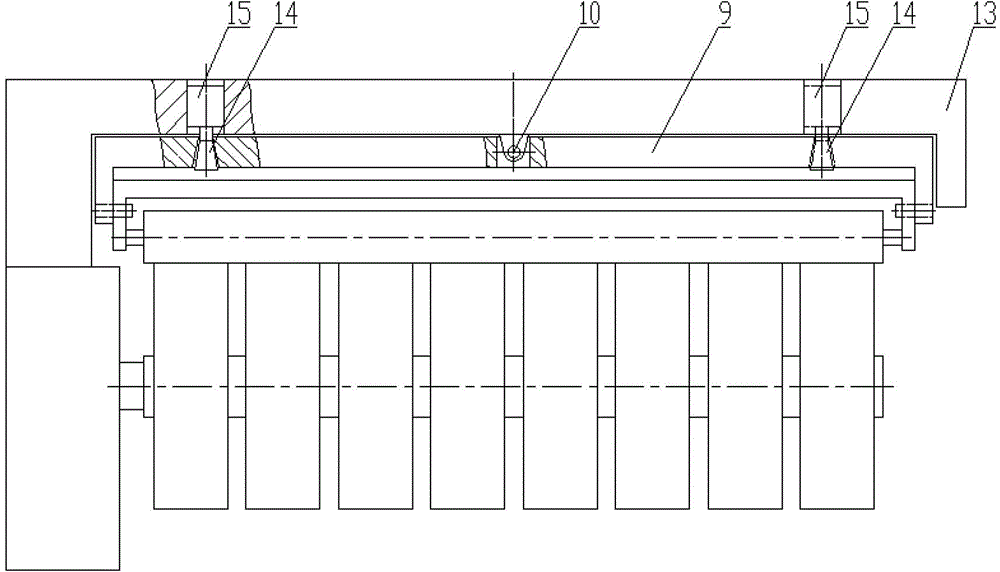

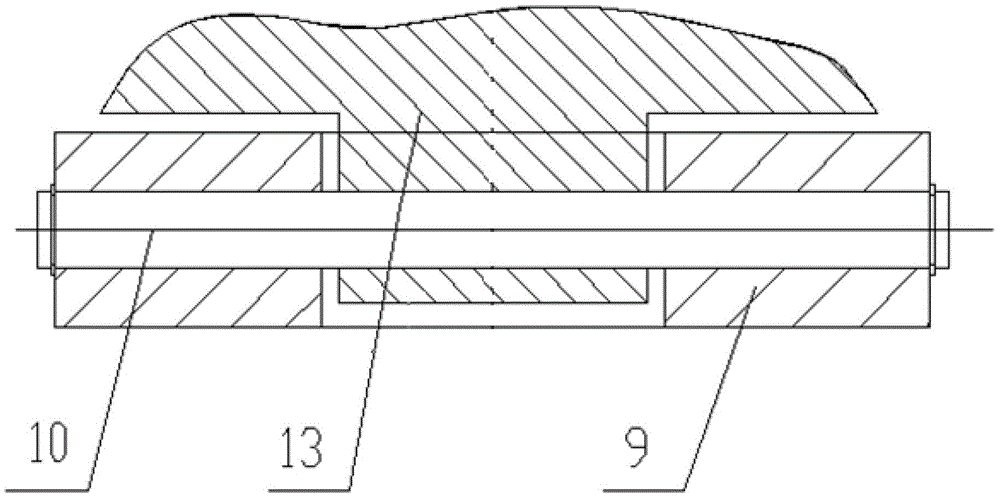

A floating pressing roller and a winding machine comprising the floating pressing roller

The invention discloses a floating pressure wire roller and a coiler containing the floating pressure wire roller. The floating pressure wire roller comprises a first support which is connected with a rack through a shaft; the connecting point of the first support and the rack is located between the left end and the right end of the first support; the first support uses the connecting point as a supporting point, and the left end and the right end of the first support can swing vertically; and the two ends of the floating pressure wire roller are movably connected with the first support. The floating pressure wire roller is connected with a second support through a bearing, the second support is connected with the first support through a pin shaft, and the first support is connected with the rack through a pivot shaft. The first support enables the left end and the right end of the pressure wire roller to swing vertically, the second support enables the pressure wire roller to swing back and forth, and therefore the pressure wire roller is automatically parallel to bobbin clamping head shafts located at the work position and pressed on the periphery of the bobbin clamping head shafts in a floating mode even though parallelism deviation of the two bobbin clamping head shafts is large, and good contact between the pressure wire roller and the bobbin clamping head shafts is kept.

Owner:BEIJING CHONGLEE MACHINERY ENG

A double-row energy-saving LED lamp

ActiveCN106287428BPrevent burstAvoid explosionMechanical apparatusOutdoor lightingInternal pressurePressure wire

The invention discloses a double-row energy-saving LED lamp which comprises lamp bodies, side seal plates, inner side plates, sealing rings, an upper frame, a cover plate, an M12 breather, a 923 wiring terminal, a pressure wire clip, wire inlet rubber jackets, an LED lamp panel and LED lamps. The double-row energy-saving LED lamp has the advantages that the double-row energy-saving LED lamp is in a double-row lamp design, and shadow generated during illumination can be reduced and even can disappear owing to the design; the double-row energy-saving LED lamp is in a sealed structural design, accordingly, the safety can be guaranteed when the double-row energy-saving LED lamp works in production environments with large quantities of flammable materials, and bursting of the double-row energy-saving LED lamp due to increase of internal pressures at the moment when the double-row energy-saving LED lamp is switched on can be solved; a breather device is further arranged on the double-row energy-saving LED lamp, accordingly, the service safety can be guaranteed, and the double-row energy-saving LED lamp can continuously work in humid environments without easy faults; the double-row energy-saving LED lamp is quite long in service life and has an extremely important application prospect in public facilities such as places where tunnel lamps need to be used for long time, and energy can be saved.

Owner:FOSHAN NANHAI KETAI INDUSTRIES LIGHTING COMPANY LIMITED

Pressure wire welding device, welding equipment and control method

PendingCN110355499AEnsure a solid weldAvoid Ribbon ArchingWelding/cutting auxillary devicesAuxillary welding devicesPressure wireEngineering

The invention discloses a pressure wire welding device, welding equipment and a control method and relates to the technical field of photovoltaic devices. The pressure wire welding device comprises amounting bracket, supporting arms and pressure wires. The two supporting arms are arranged at one end of the mounting bracket at an interval. The two sets of pressure wires are arranged in parallel between the two supporting arms, two ends of each set of pressure wires are correspondingly connected with the two supporting arms, and the distance between the two sets of pressure wires is not less than the width of a bus bar. By arranging the two sets of parallel pressure wires, the two sets of pressure wires can be correspondingly located on both sides of the bus bar before welding and abut against welding strips in overlap joint with the bus bar, so that the holding force is provided for attachment of the welding strips and the bus bar, and the problems such as bending of the welding stripsand damage of battery pieces caused by the movement of the welding strips during the pressing process of welding heads are avoided. During the welding process, the two sets of pressure wires are always located on both sides of the bus bar; the welding heads and cold press blocks can be pressed and lifted normally, and the pressure wires are continuously pressed, so that the steady and reliable welding of the welding strips and the bus bar can be ensured, and the welding is firm.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com