Pressure wire welding device, welding equipment and control method

A technology of welding equipment and control method, which is applied in the field of photovoltaic equipment, can solve the problems of welding failure, easy collapse of welding strips, virtual welding, etc., and achieves the effect of firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

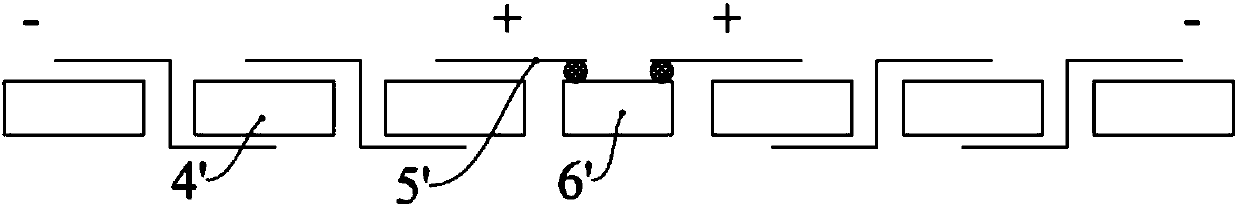

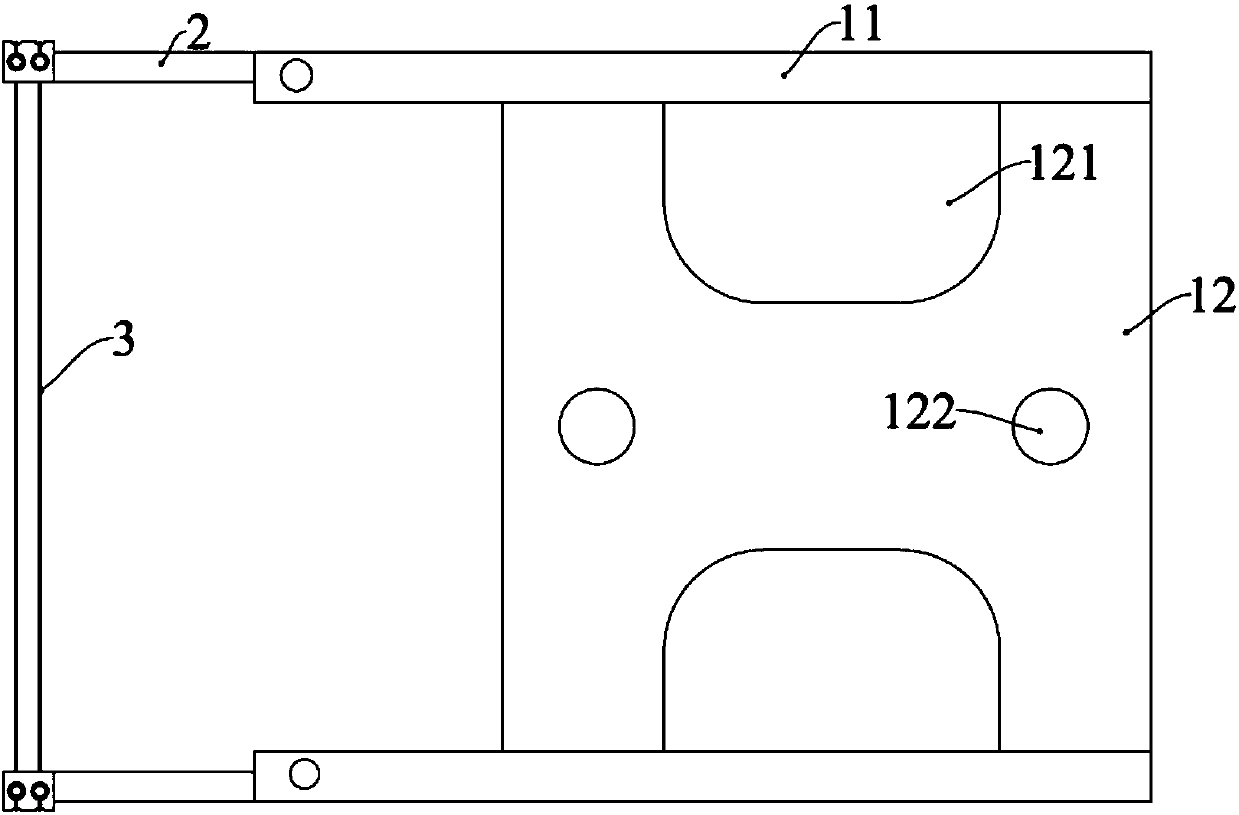

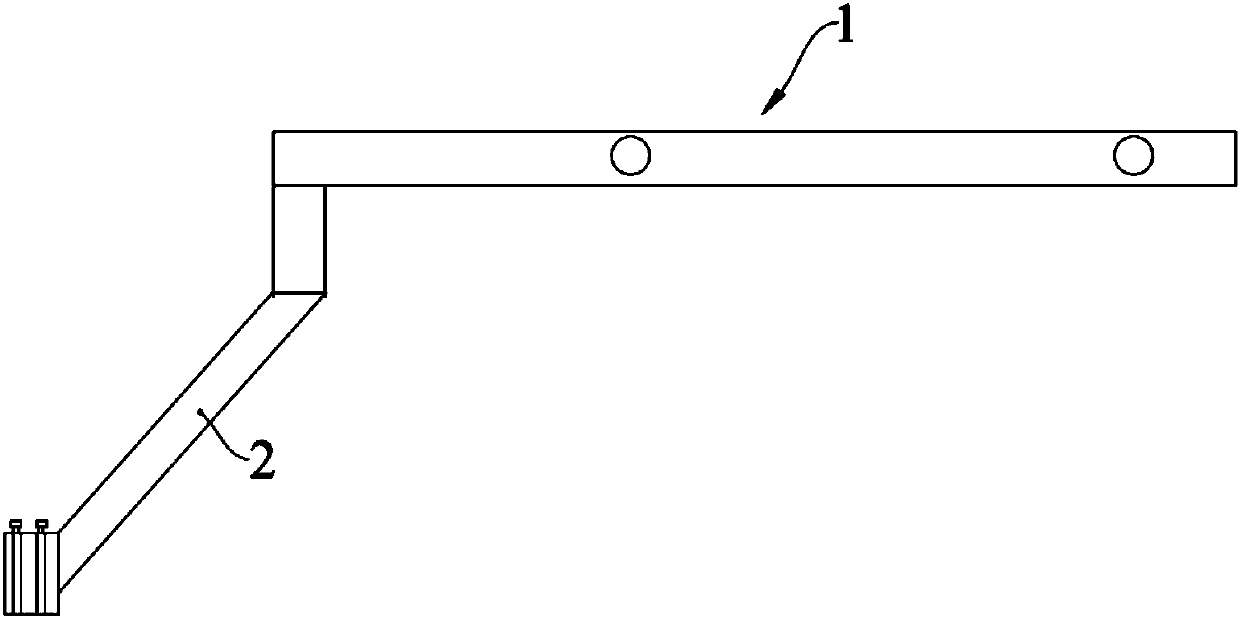

[0037] This embodiment provides a welding device that can be used for welding ribbons and bus bars in a photovoltaic module. The welding equipment includes a welding head, a cold briquetting block and a driving mechanism. The driving mechanism is respectively connected with the welding head and the cold briquetting block, and can drive the welding head and the cold briquetting block to lift or press down, so as to realize heating, melting and cooling and holding pressure.

[0038] In order to ensure that the welding strip and the bus bar are always in a compressed state, thereby improving the welding quality, the welding equipment in this embodiment is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com