Body-free coaxial following synergistic perforator

A technology for perforating guns and gun barrels, which is applied in the field of coaxial follow-up type synergistic perforators without gun barrels, which can solve the problems of easily restricted device design, small internal space of gun barrels, and general perforation and fracturing effects. , to achieve the effects of good perforation and fracturing effects, simple structure, and less accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

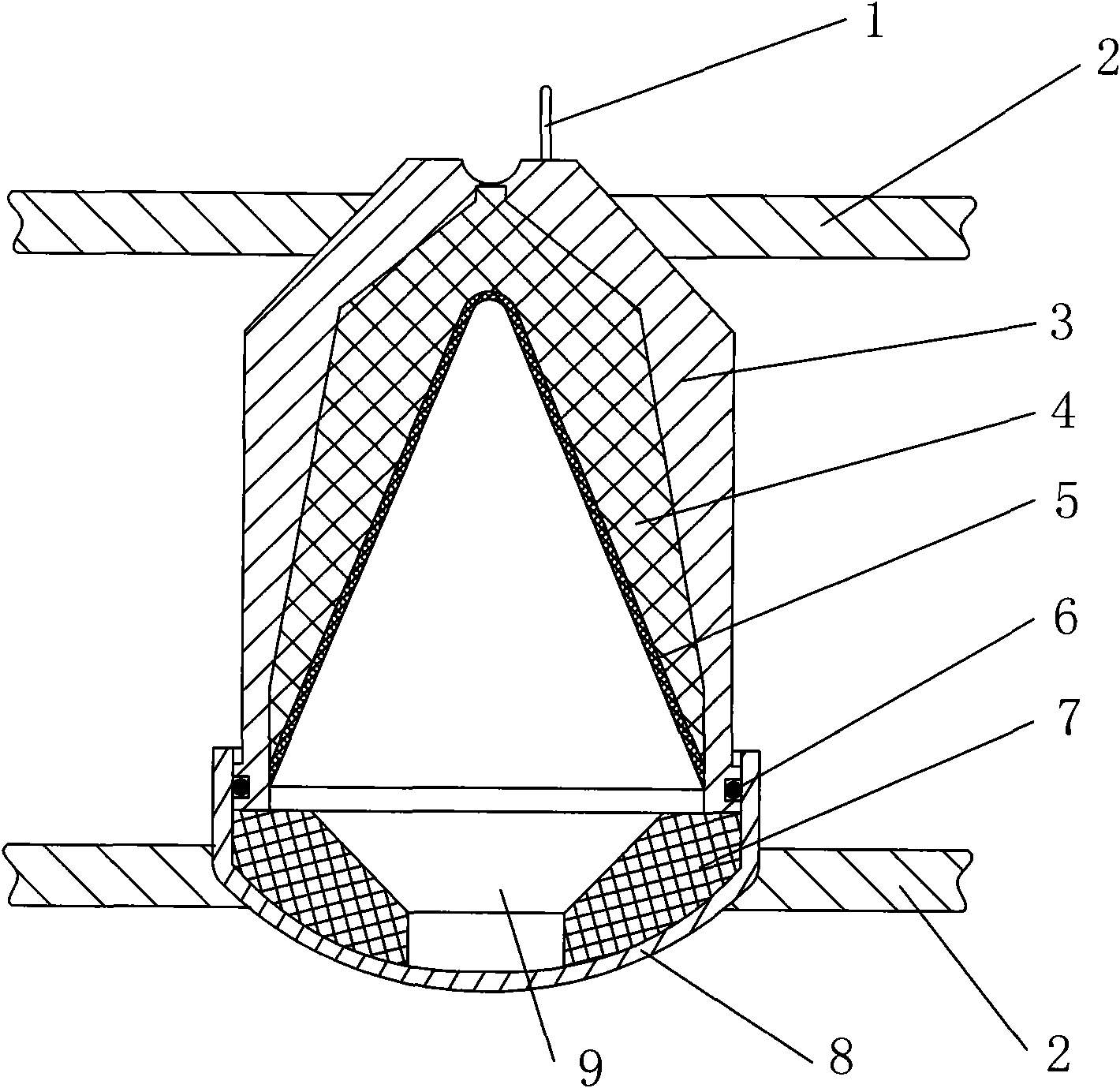

[0018] The special fracturing agent 7 is made by uniformly mixing 50% by weight of ammonium permanganate and 50% by weight of aluminum powder.

Embodiment 2

[0020] The special fracturing agent 7 is made by uniformly mixing 60% by weight of ammonium permanganate and 40% by weight of aluminum powder.

Embodiment 3

[0022] The special fracturing agent 7 is made by uniformly mixing 80% by weight of ammonium permanganate and 20% by weight of aluminum powder.

[0023] In order to ensure the sealing effect between the cartridge case 3 and the fracturing cartridge 8, an annular groove is formed on the outer surface of the annular boss of the cartridge case 3, and a sealing ring 6 is arranged in the annular groove. In this embodiment, the sealing ring 6 is made of fluorine rubber.

[0024] The barrelless perforating bullet is installed on the installation hole of the barrelless perforator bullet rack 2 through the shell case 3 and the fracturing cartridge 8 .

[0025] The working process of the non-gun body coaxial follow-up type synergistic perforator of the present invention is as follows: first, the detonating cord is placed in the detonating semicircular groove, and the detonating cord is fixed by the pressing wire 1; The detonating cord detonates and penetrates the front end wall between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com